Full-automatic welding production line based on vision

A fully automatic welding and production line technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of increasing the assembly line, waste of resources, automatic feeding and automatic positioning of workpieces to be welded, etc., to achieve stable shape and size, improve High production efficiency and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

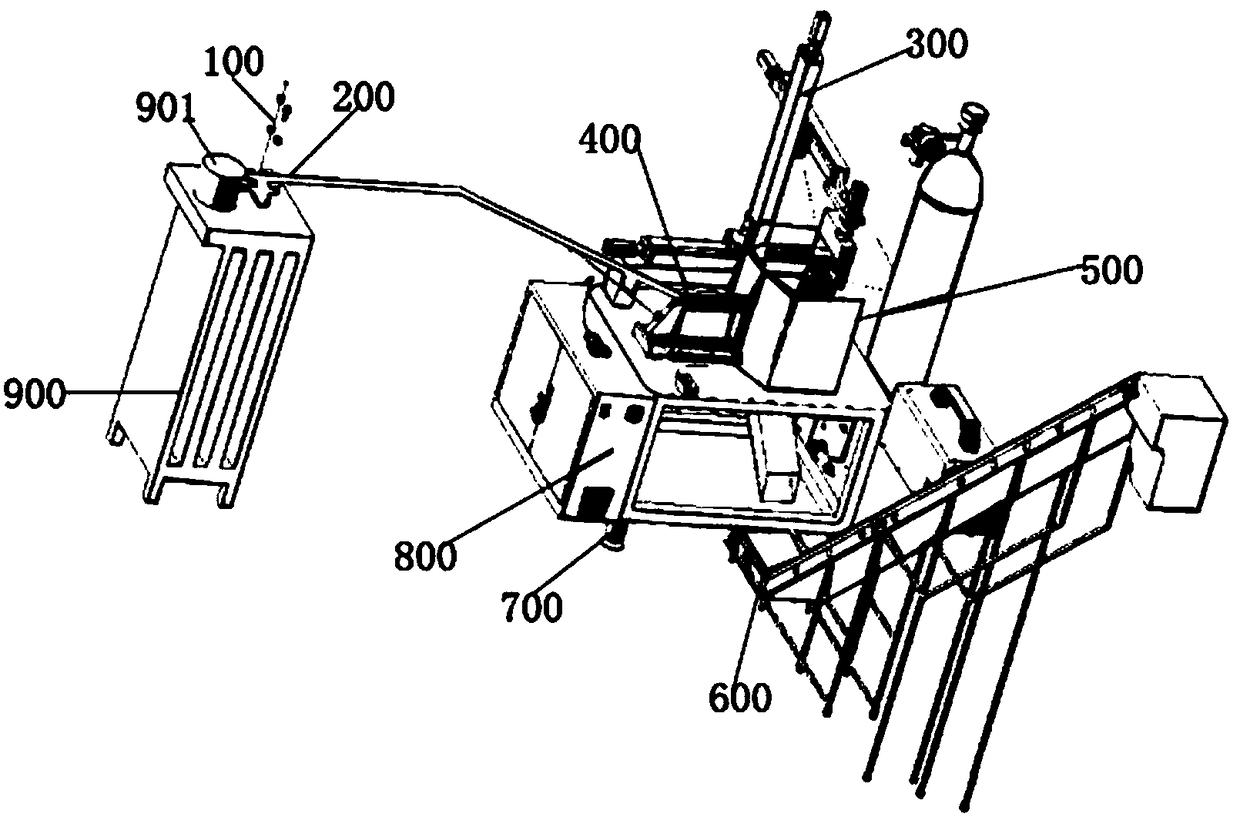

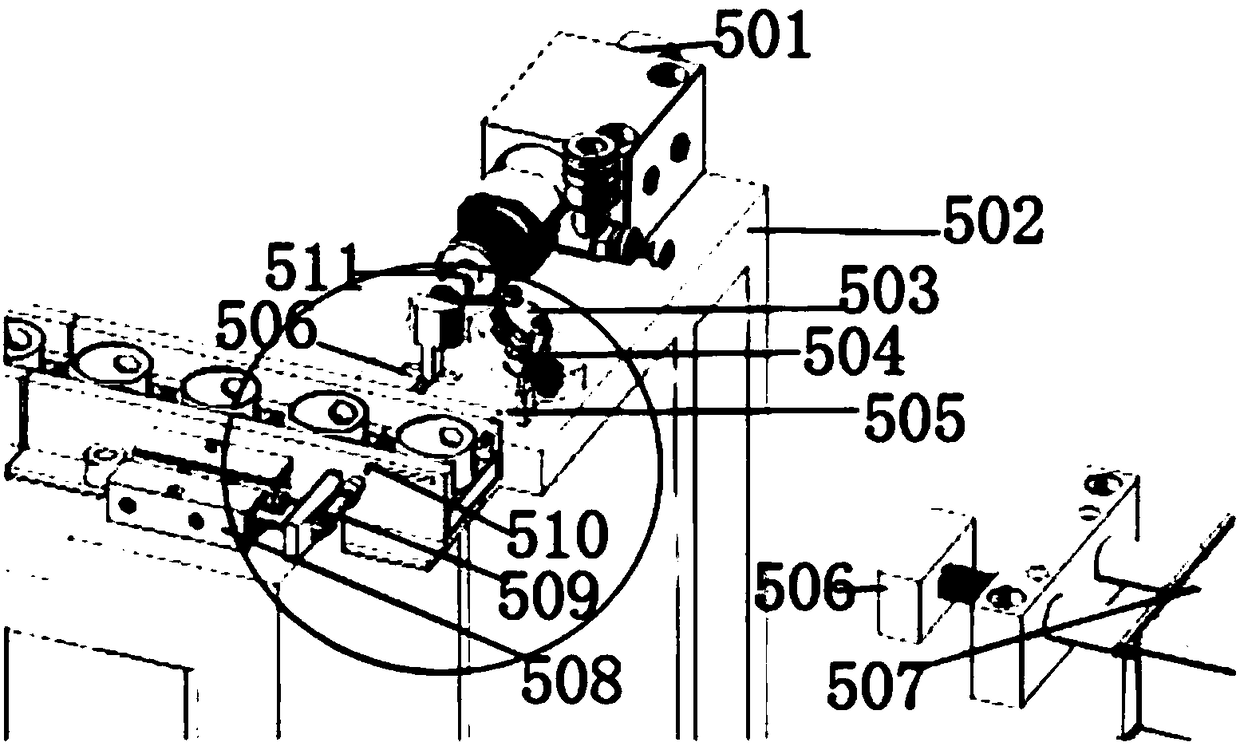

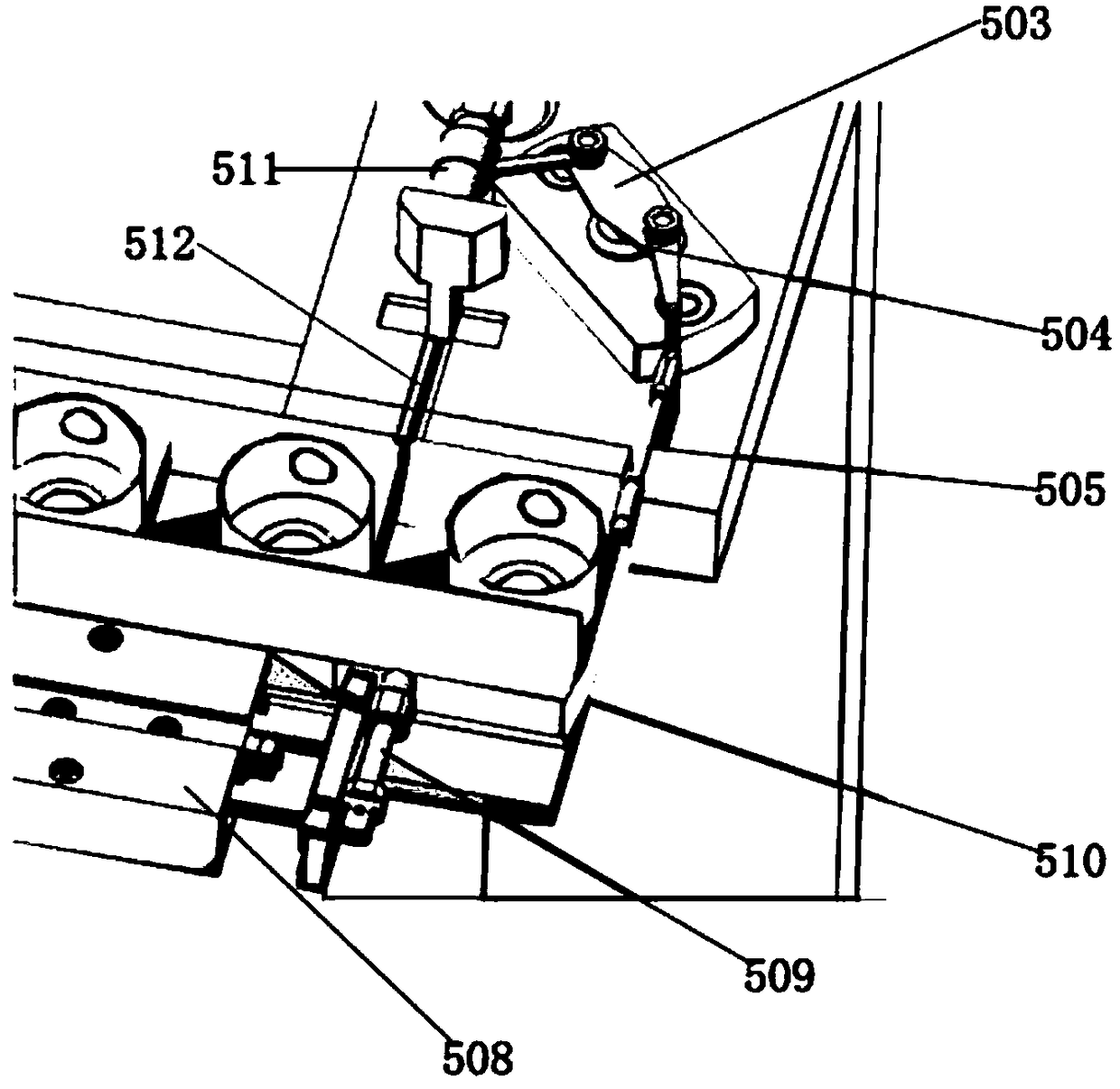

[0029] figure 1 with figure 2 A schematic diagram showing the composition of the present invention and its application to a piezoelectric valve. Such as figure 1As shown, the present invention provides a vision-based fully automatic welding production line. A vision-based fully automatic welding production line. It includes a visual detection mechanism 100, a rotating mechanism 200, a vibration mechanism 400, a welding device 300, a welding positioning device 500, a blanking device 600, a workbench 700, an electric control cabinet 800 and a vibration plate 901. The workbench 700 is provided with a vibration mechanism 400 , Welding device 300 and welding positioning device 500, with a blanking device 600 below, an electric control cabinet 800 and a vibrating plate 901 on the side, a control panel on the electrical ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com