Elastic fiber fabric and preparation method thereof

An elastic fiber and fabric technology, applied in the field of elastic fiber fabric and its preparation, can solve the problems of poor quality in dyeing and finishing process, easy pilling and weaving, dry and rough hand feeling of finished products, etc., so as to improve the differentiation of chemical fibers and improve pilling , The scientific and reasonable effect of the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

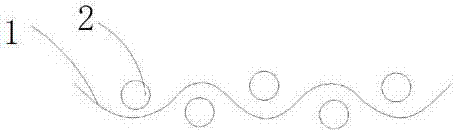

[0045] Example 1: as figure 1 As shown in the figure, an elastic fiber fabric is formed by interweaving warp 1 and weft 2, characterized in that the warp 1 and weft 2 are respectively 150D or 75D PTS elastic yarn. The warp thread 1 accounts for 50% of the fabric percentage, the weft thread 2 accounts for 50% of the fabric percentage, the twist of the warp thread 1 is 5 twists / cm, and the twist of the warp thread 1 is 5 twists / cm. The direction is the Z twist direction. The elastic shrinkage rate of the fabric is 20%, the specification of the PTS elastic yarn is 150D / 48F, and the twist direction of the PTS elastic yarn is the S twist direction.

[0046] A preparation method of elastic fiber fabric is characterized in that carrying out by the following steps:

[0047] (1), winding wire:

[0048] Load 500 raw material bobbins on the winding machine, lead out the wire ends from the raw material bobbins and pass them into the guide wire bobbins respectively, adjust t...

Embodiment 2

[0076] Embodiment 2: An elastic fabric, the fabric is interwoven by warp 1 and weft 2, characterized in that the warp 1 and weft 2 are respectively 150D or 75D PTS elastic yarn. The warp thread 1 accounts for 60% of the fabric percentage, the weft thread 2 accounts for 40% of the fabric percentage, the twist of the warp thread 1 is 8 twists / cm, and the twist of the warp thread 1 is 8 twists / cm. The direction is the S twist direction. The elastic shrinkage rate of the fabric is 30%, the specification of the PTS elastic yarn is 75D / 24F, and the twist direction of the PTS elastic yarn is the Z twist direction.

[0077] A preparation method of elastic fabric is carried out according to the following steps:

[0078] (1), winding wire:

[0079] Load 505 raw material bobbins on the winding machine, lead out the silk heads from the raw material bobbins and pass them into the guide wire bobbins respectively, adjust the unwinding tension disc to 12 grams according to the thi...

Embodiment 3

[0107] Embodiment 3: an elastic fabric, the fabric is interwoven by warp 1 and weft 2, characterized in that the warp 1 and weft 2 are respectively 150D or 75D PTS elastic yarn. The warp thread 1 accounts for 70% of the fabric percentage, the weft thread 2 accounts for 30% of the fabric percentage, the twist of the warp thread 1 is 12 twists / cm, and the twist of the warp thread 1 is 12 twists / cm. The direction is the Z twist direction. The elastic shrinkage rate of the fabric is 40%, the specification of the PTS elastic yarn is 150D / 48F, and the twist direction of the PTS elastic yarn is the Z twist direction.

[0108] A preparation method of elastic fabric is carried out according to the following steps:

[0109] (1), winding wire:

[0110] Load 512 raw material bobbins on the winding machine, draw the wire ends from the raw material bobbins and pass them into the guide wire bobbins respectively, adjust the unwinding tension disc to 16 grams according to the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com