Patents

Literature

1218results about How to "Won't burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

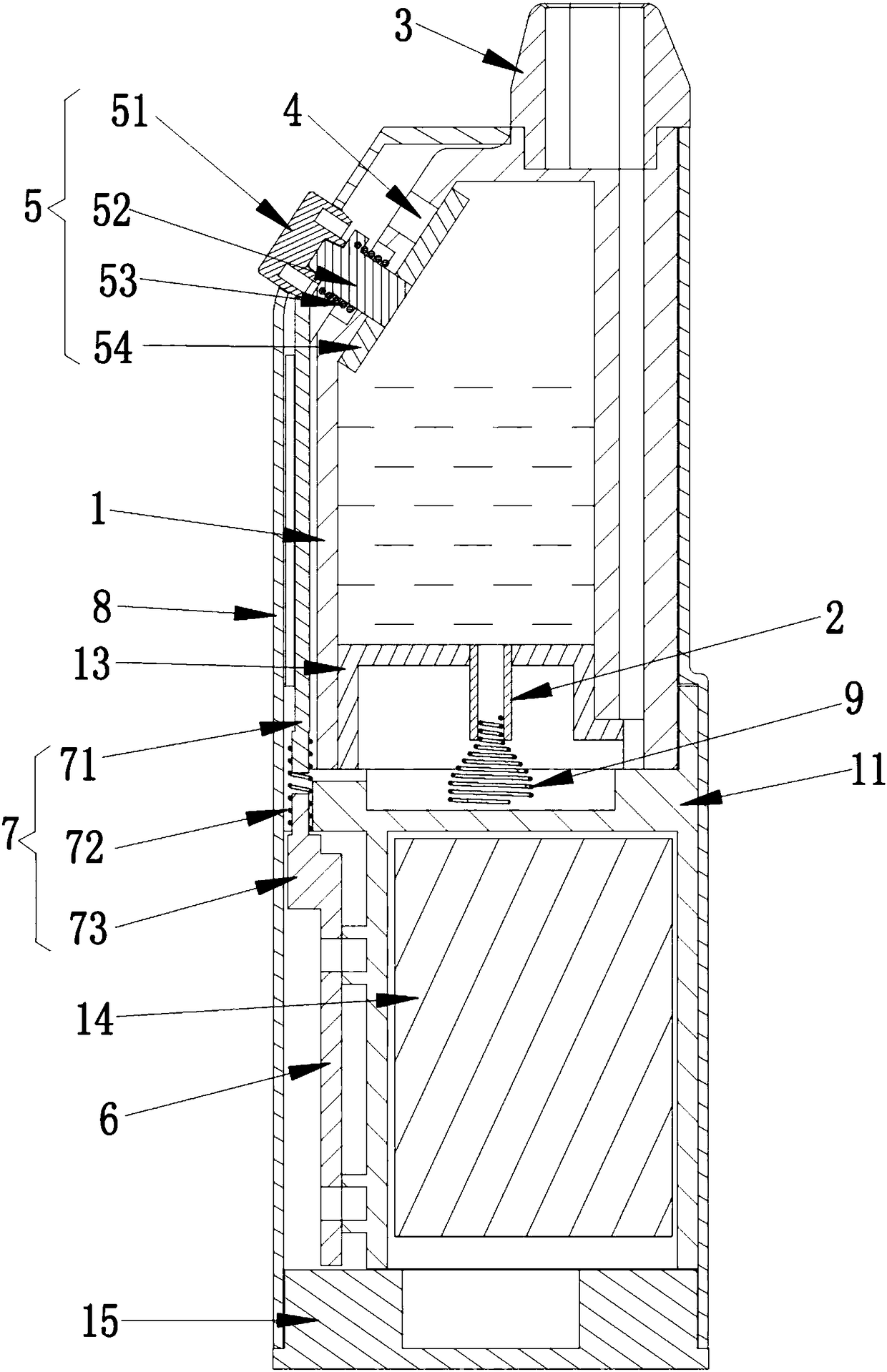

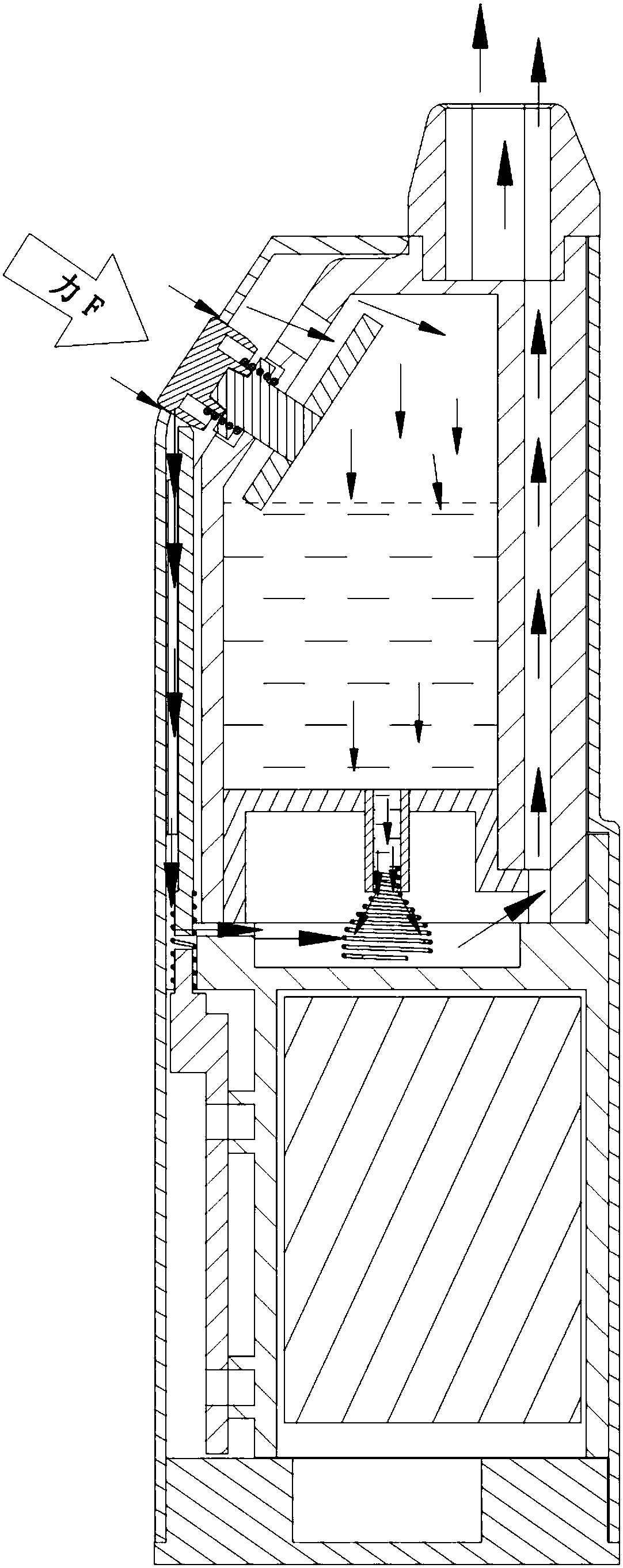

Pressure cooker

ActiveCN107048993AImprove securityPrevent togglePressure-cookersTime-controlled ignitorsEngineeringExhaust pipe

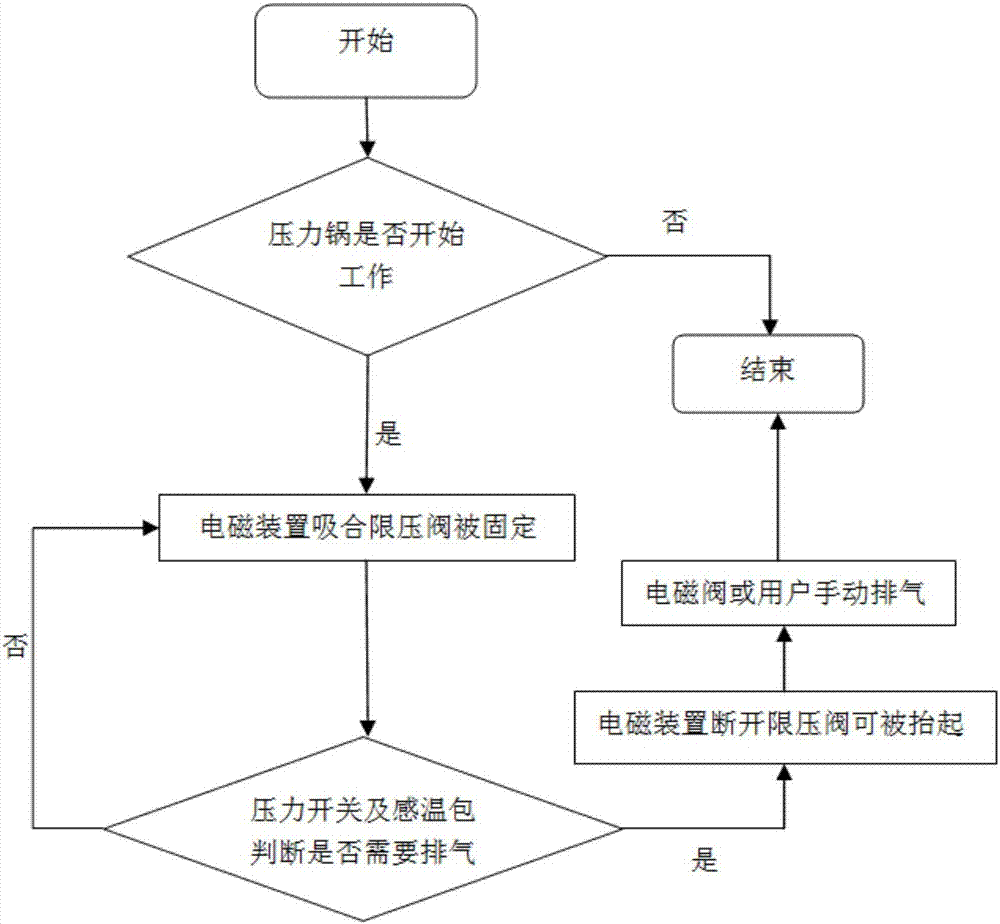

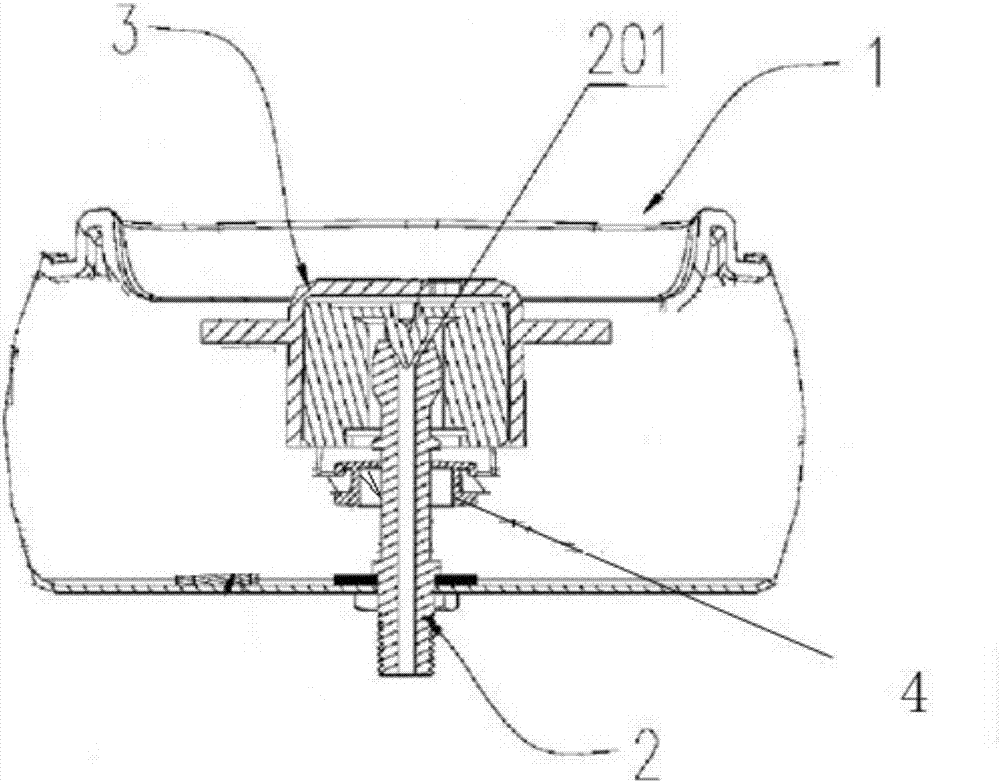

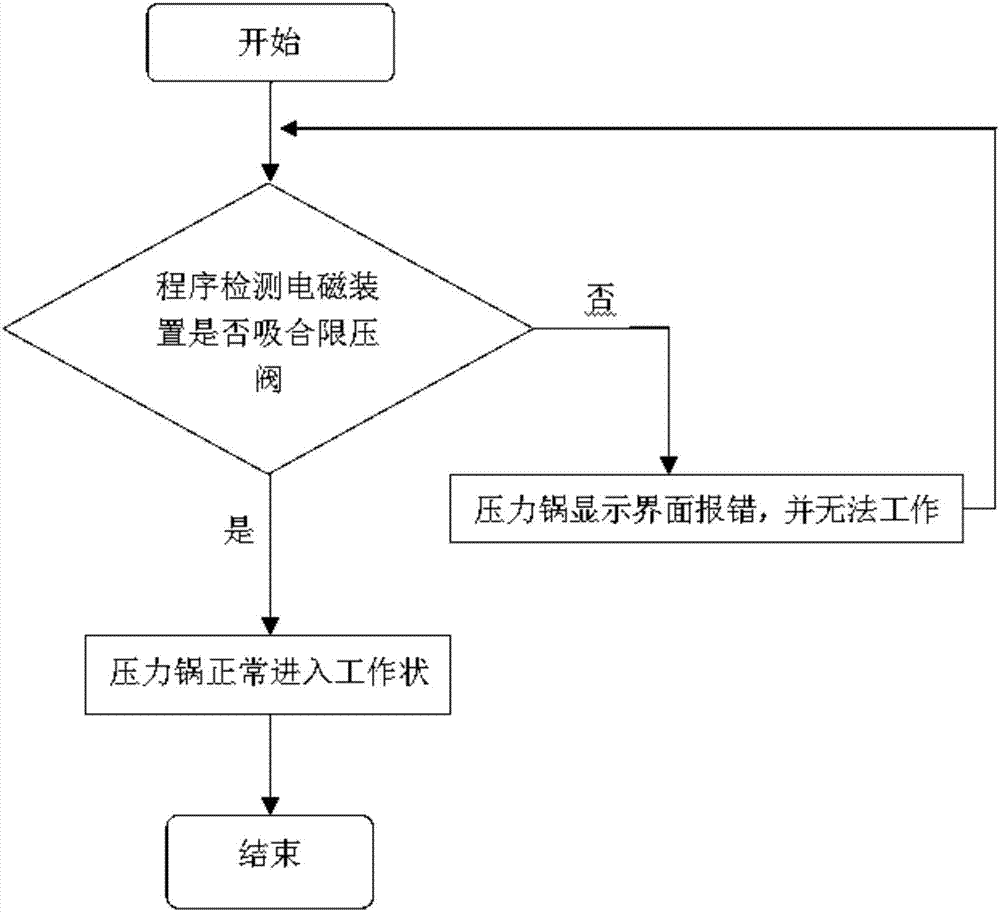

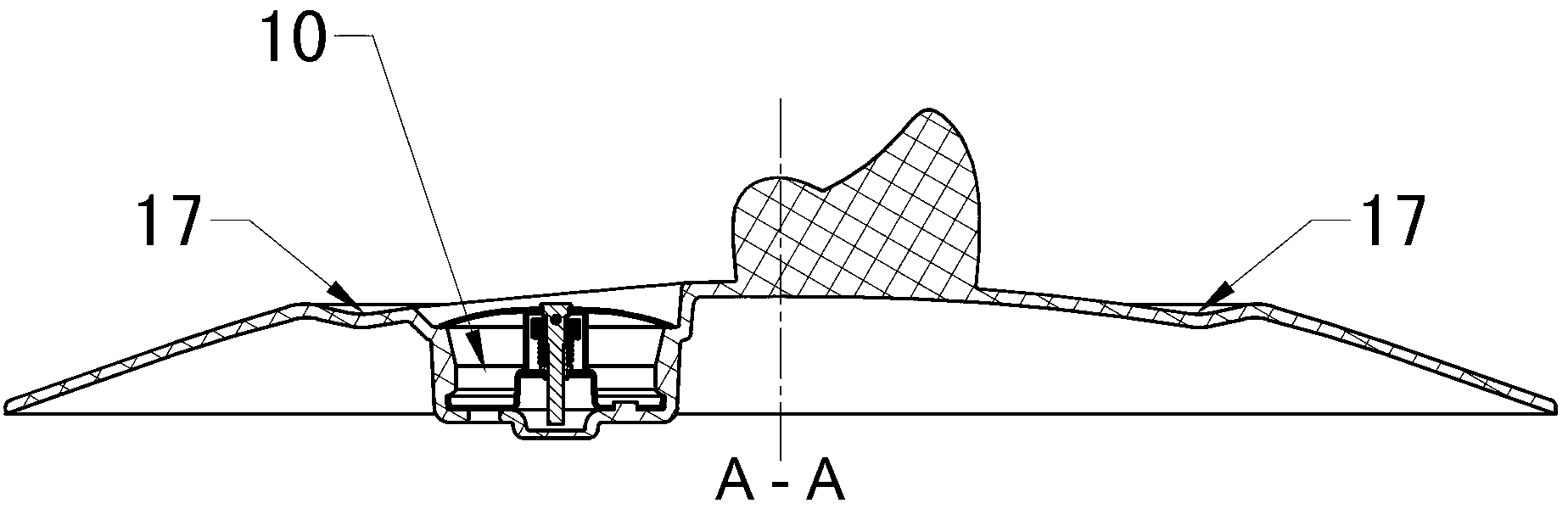

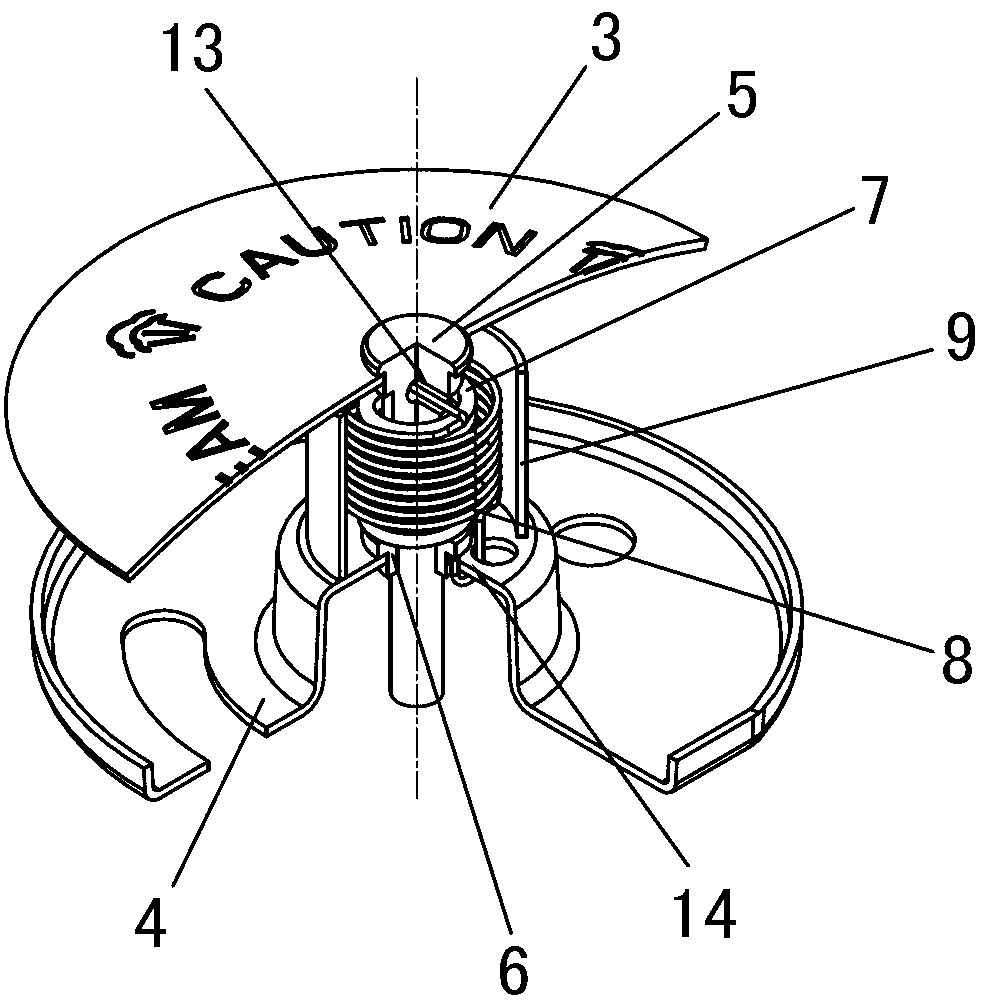

The invention provides a pressure cooker. The pressure cooker comprises a cover body, an exhaust pipe arranged on the cover body and a pressure limiting valve. The pressure limiting valve is arranged at the air exhaust opening of the exhaust pipe in a sleeving manner. The pressure cooker further comprises a limiting device used for attracting or disconnecting with the pressure limiting valve and a controller used for attracting or disconnecting with the pressure limiting valve according to the current working parameters of the pressure cooker. The pressure cooker has the following beneficial effects: a problem in the prior art is solved so that the pressure limiting valve of the pressure cooker is not wrongly operated, thereby avoiding potential safety hazards; safety of the pressure cooker is improved; and a user does not get burned during operation of the pressure cooker due to mal-operation by the user.

Owner:GREE ELECTRIC APPLIANCES INC

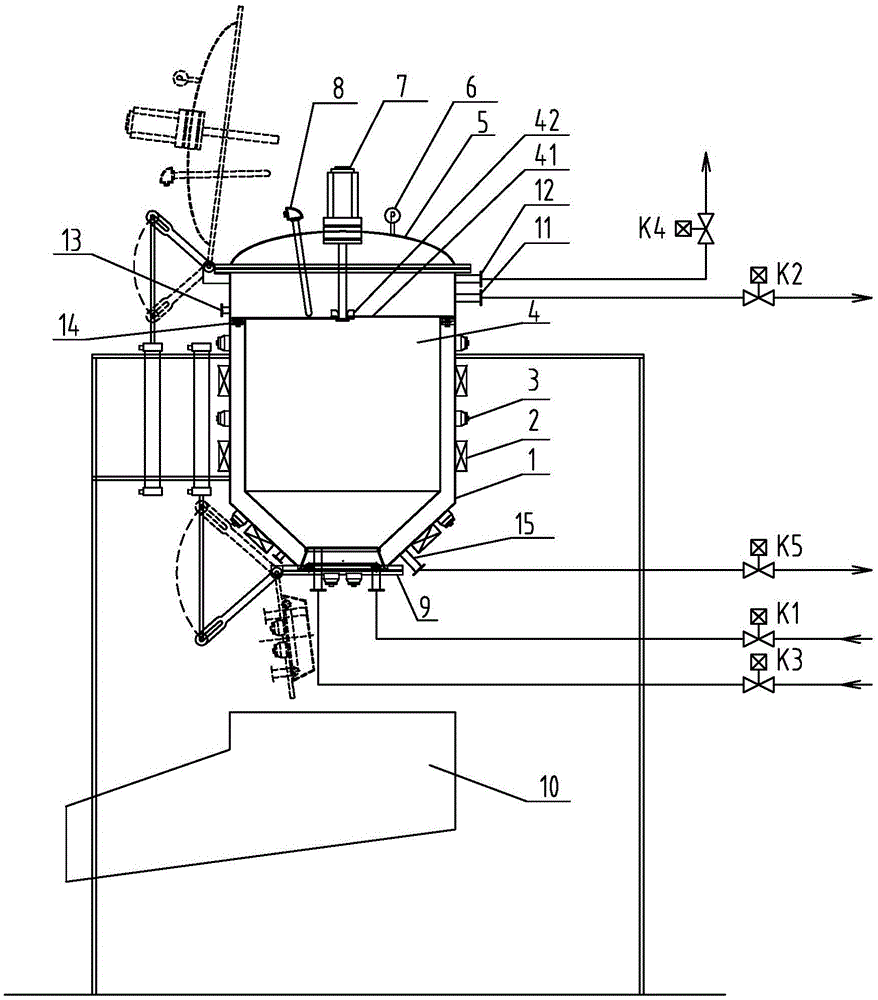

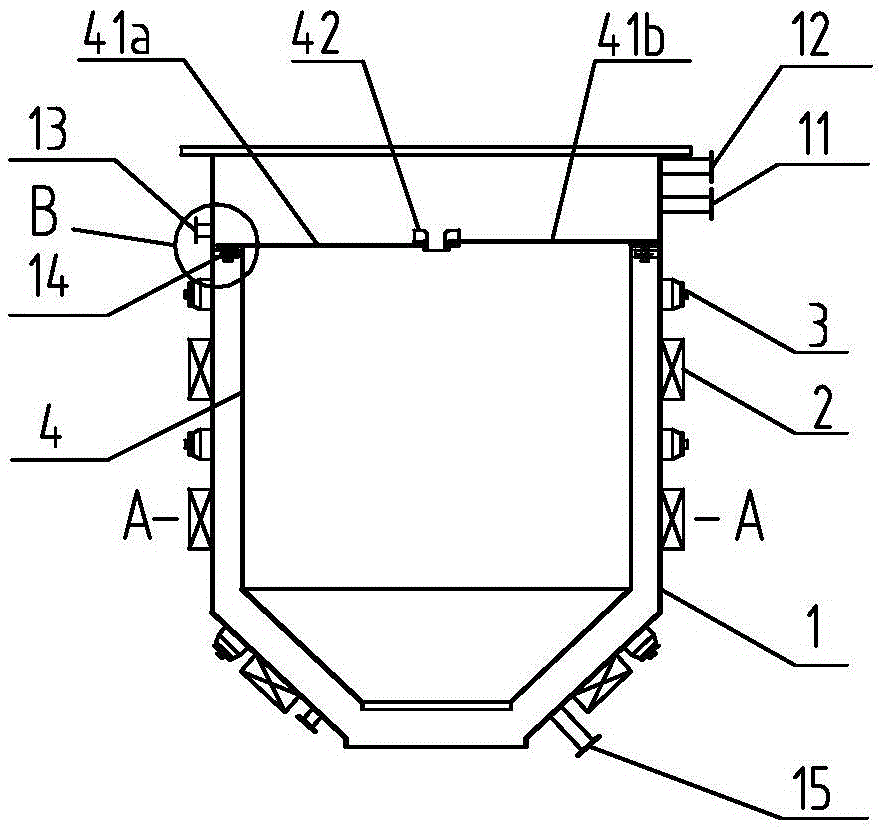

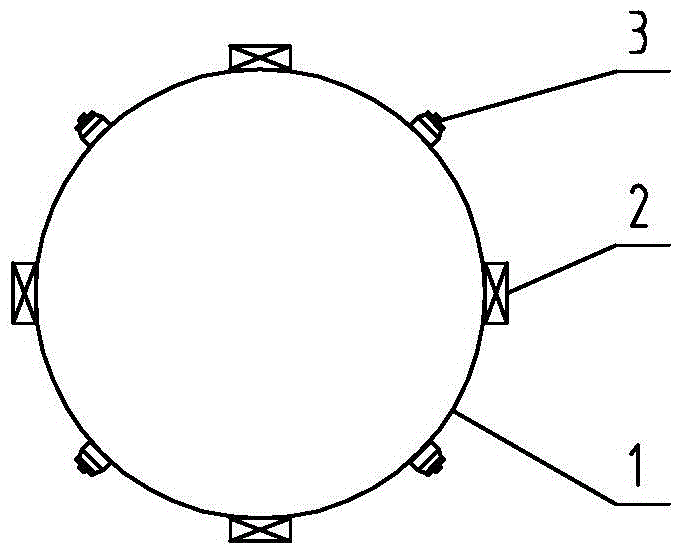

Entrained flow gasification stove, and gasification method

ActiveCN101003754ASimple structureLow construction costCombustible gas purificationCombined combustion mitigationQuenchingCoal gas

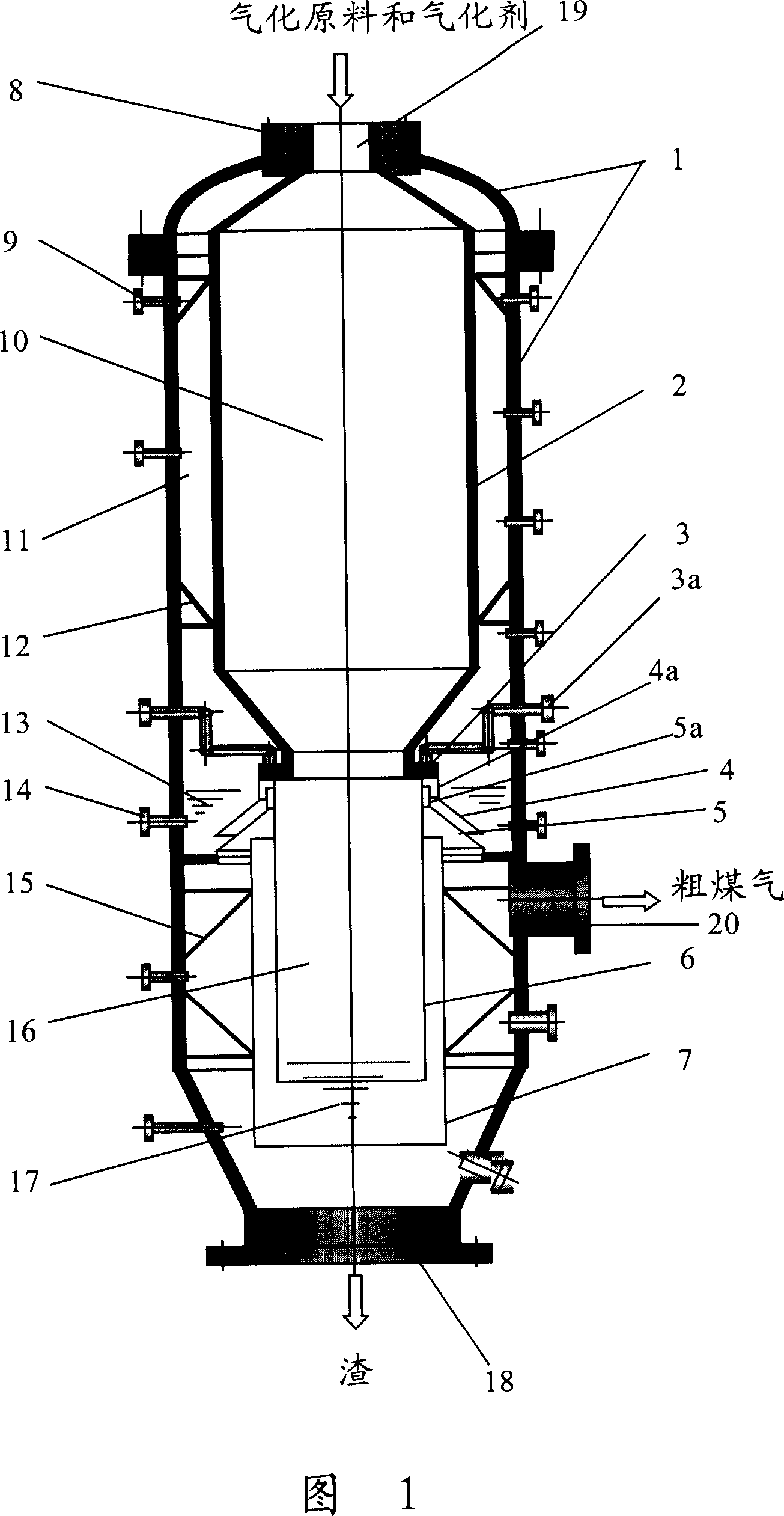

This invention discloses an entrained bed gasifier, which comprises: a shell, a jacket, a quenching ring, a water-sealing tank, a draft tube, a baffling tube, an inlet for raw materials and gasifying agent, a crude coal gas outlet, and a residue outlet. The jacket, the quenching ring, the water-sealing tank, the draft tube and the baffling tube are set inside the shell from top to bottom. The inlet for raw materials and gasifying agent is set at the top of the shell, and is connected with the jacket. The crude coal gas outlet is set below the water-sealing tank. The residue outlet is set at the bottom of the shell. A positioning support is set at the upside of the shell inner wall, and a residue outlet support is set at the bottom of the shell inner wall. This invention also provides a method for gasifying by using the entrained bed gasifier. The entrained bed gasifier has such advantages as simple structure, and convenient maintenance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

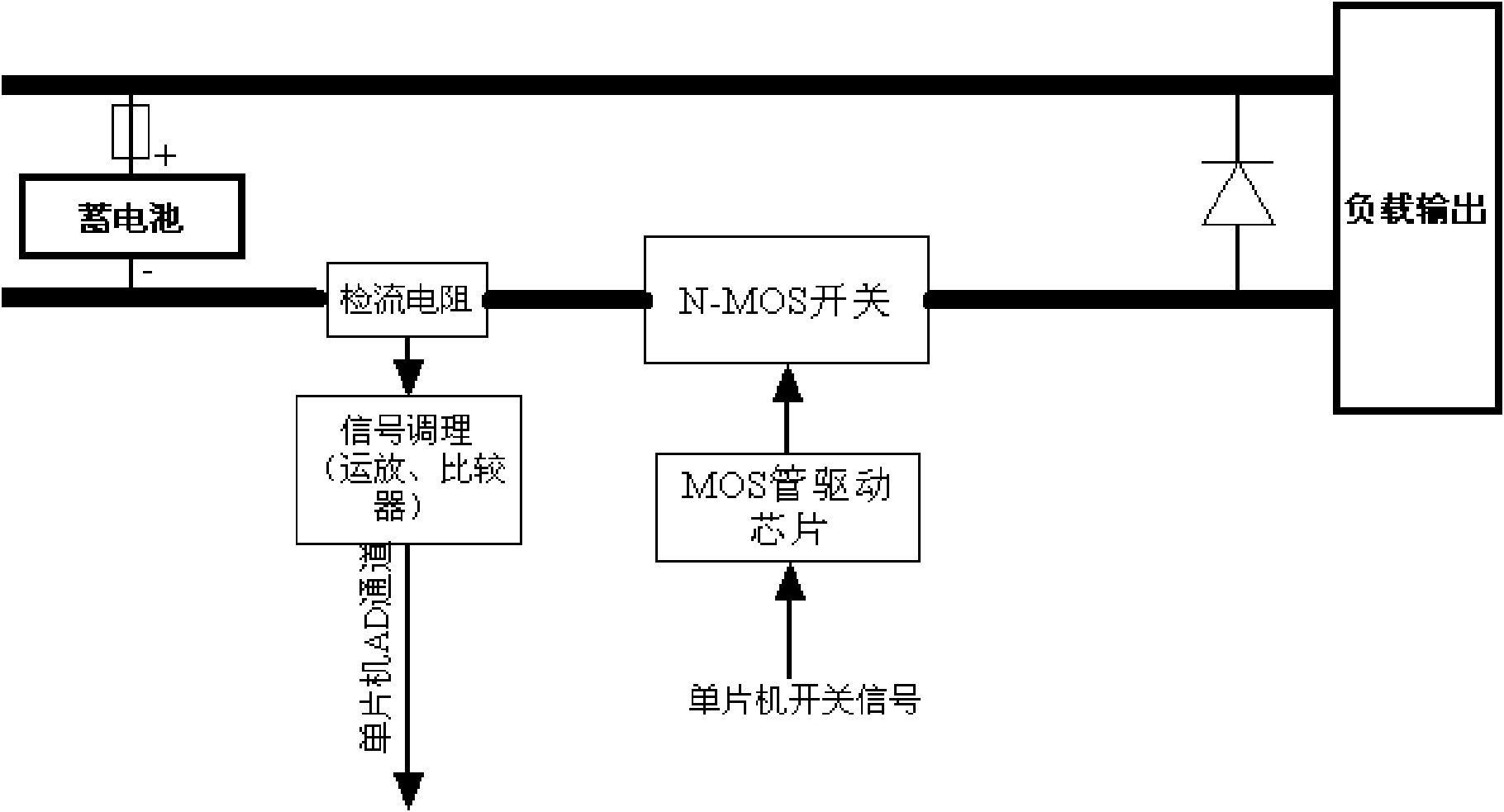

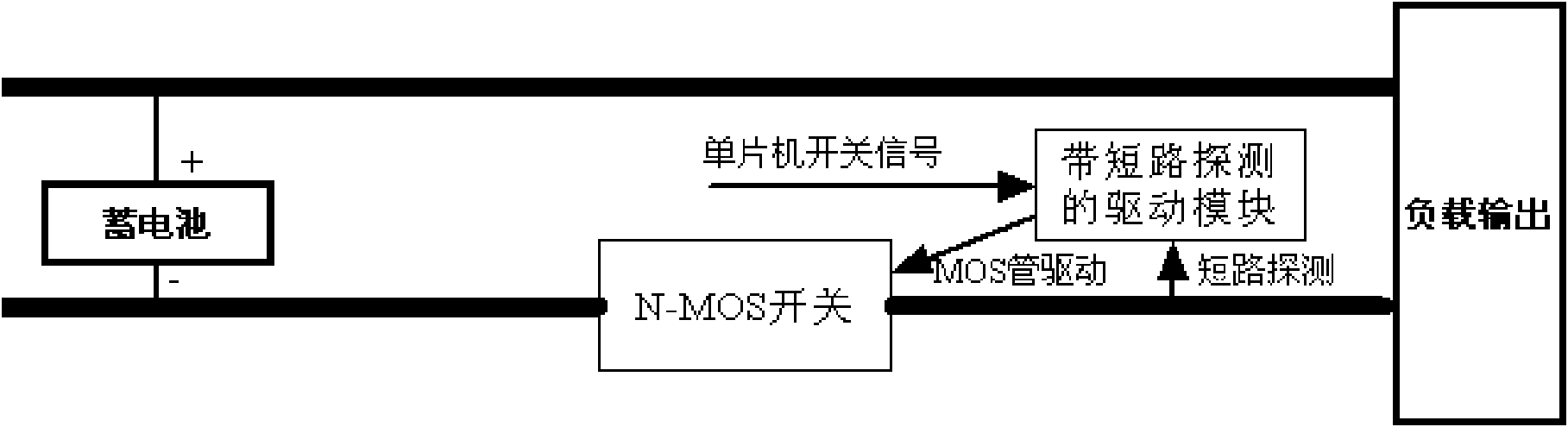

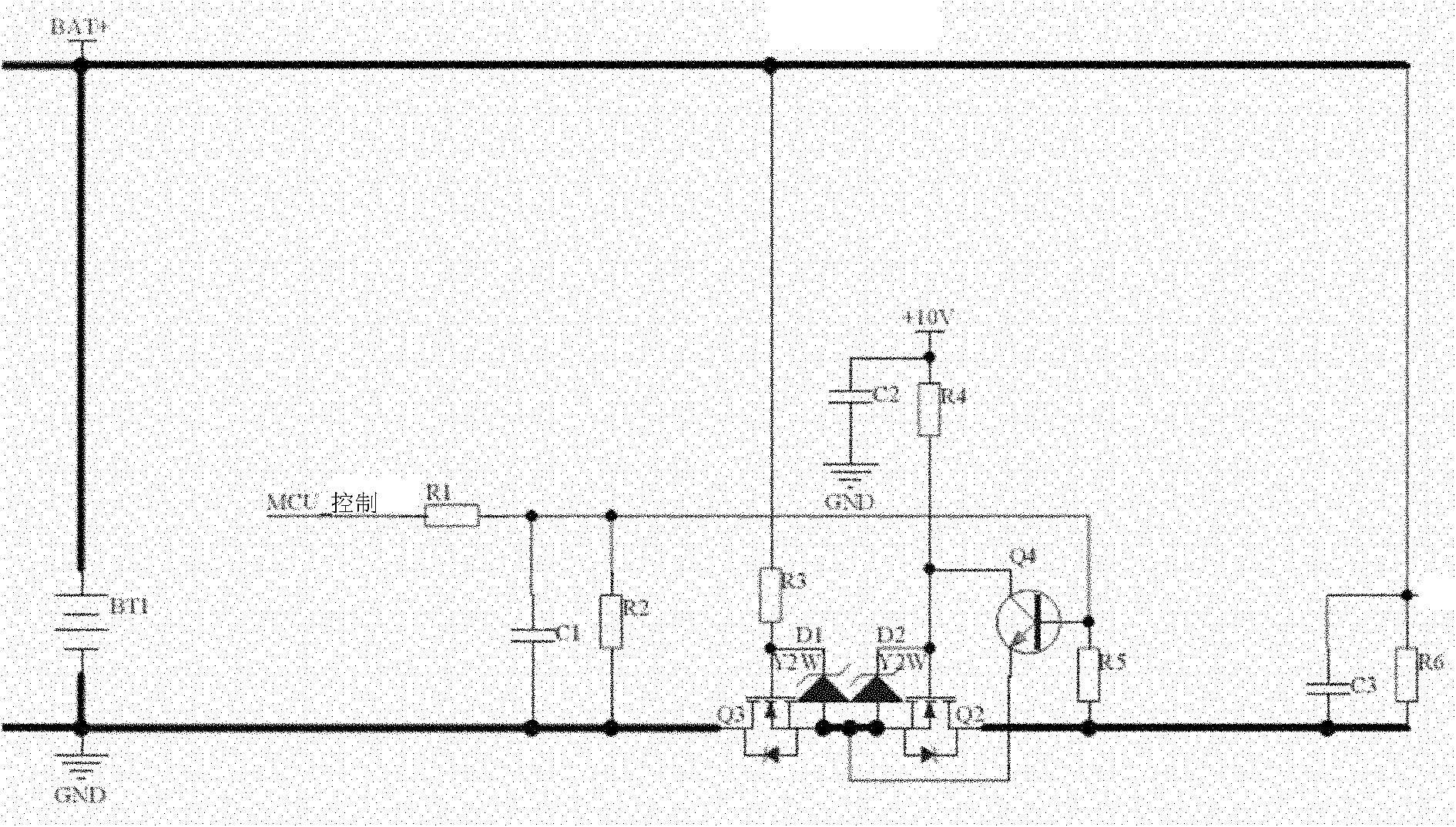

Load short-circuit protection circuit

ActiveCN101944715ALow costImpedance does not increaseArrangements responsive to excess currentEmergency protective arrangements for limiting excess voltage/currentMicrocontrollerLoad circuit

The invention relates to a load short-circuit protection circuit connected between a storage battery and a load circuit. The load short-circuit protection circuit comprises an MOS (Metal Oxide Semiconductor) tube protection circuit, a short-circuit detection circuit, a singlechip and an MOS tube switching circuit, wherein the MOS tube protection circuit is used for the reverse connection protection of the storage battery; the short-circuit detection circuit is used for detecting the short-circuit of the load circuit; the singlechip is used for sending out a switching signal according to a detection result of the short-circuit detection result; the MOS tube switching circuit is used for switching on or off the load circuit according to the switching signal; the short-circuit detection circuit comprises a comparer and a reference voltage generation circuit; the reference voltage generation circuit is connected to a first input end of the comparer; a source electrode of a first MOS tube of the MOS tube protection circuit is connected to a second input end of the comparer; and the output end of the comparer is connected to a first input end of the singlechip. The load short-circuit protection circuit is used for a load short-circuit protection circuit of a solar controller, has low cost, cannot increase the impedance of a load loop and has the function of eliminating instantaneoushigh voltage.

Owner:SHENZHEN TOPBAND CO LTD

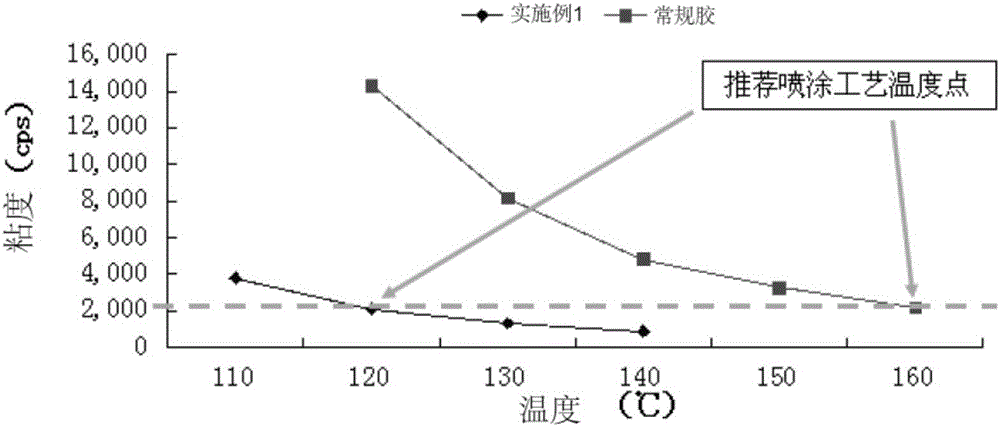

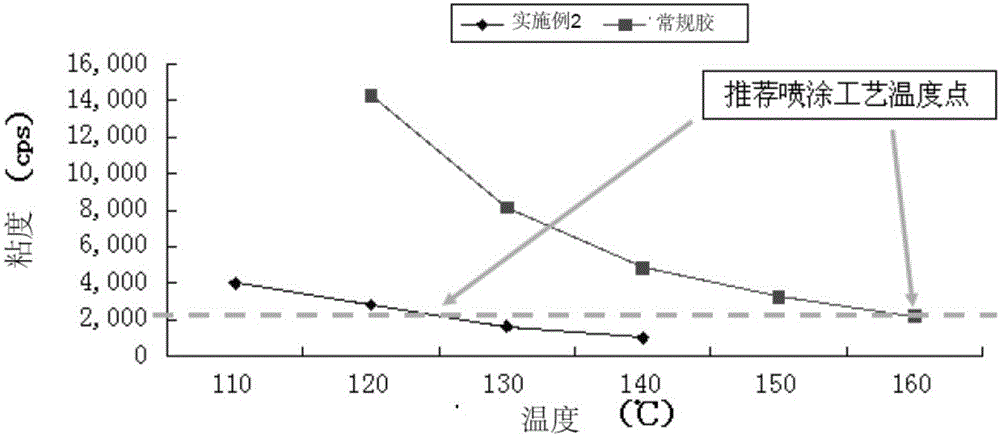

Low-temperature hot-melt pressure-sensitive adhesive for disposable hygienic product and preparation method thereof

ActiveCN106047287AReduce maintenance costsLow viscosity valueMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWaxDecomposition

The invention discloses a low-temperature hot-melt pressure-sensitive adhesive for a disposable hygienic product. The low-temperature hot-melt pressure-sensitive adhesive is prepared from 10-30wt% of styrenic thermoplastic elastomer, 40-60wt% of tackifying resin, 15-35wt% of naphthenic oil, 0.1-1.0wt% of antioxidant, and selectively 0.1-5wt% of wax. The low-temperature hot-melt pressure-sensitive adhesive has appropriate melt viscosity, good initial bonding performance, persistent bonding performance, operative weldability, heat resistance and the like within the using temperature range from 120 DEG C to 130 DEG C, carbonization is effectively reduced, the equipment failure rate is lowered, the production efficiency is improved, ageing and decomposition of the tackifying resin and the other constituents are reduced, and the environment pollution is reduced. The invention further discloses a preparation method for the hot-melt pressure-sensitive adhesive.

Owner:GUANGDONG RURGA NEW MATERIAL TECH

Biological organic fertilizer prepared by aerobic fermentation of biogas residue and preparation method thereof

InactiveCN103848698AWon't burnDecompose thoroughlyBio-organic fraction processingWaste based fuelMicrobial agentPseudomonas

The invention provides a biological organic fertilizer prepared by aerobic fermentation of a biogas residue and a preparation method thereof. The preparation method comprises the steps: mixing the biogas residue and a swelling agent to form a fermentation raw material, inoculating a compound microbial agent in the fermentation raw material, uniformly mixing for fermenting, and adding urea, diammonium phosphate, a potassium chloride inorganic salt, brown nitrogen-fixing bacteria, mycorrhiza fungi, silicate bacteria, photosynthetic bacteria acetic bacteria, bifidobacterium, and saccharomycetes after the fermentation is completed to prepare the biological organic fertilizer, wherein the compound microbial agent comprises strains of bacillus, pseudomonas, staphylococcus, streptomyces, penicillium, aspergillus and trichoderma. The compound microbial agent prepared by using the biological organic fertilizer has a pertinence to aerobic fermentation of the biogas residue, and is capable of effectively increasing the fermentation rate of the biogas residue, shortening the fermentation time and realizing high-additional value production, innocent treatment and recycling of the biogas residue; and the problem of resources and environment of villages and small towns is solved, and the rapid development of construction of new countryside and towns and cities can be promoted.

Owner:青岛福瑞斯生物能源科技开发有限公司

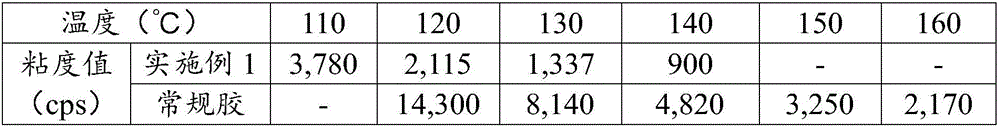

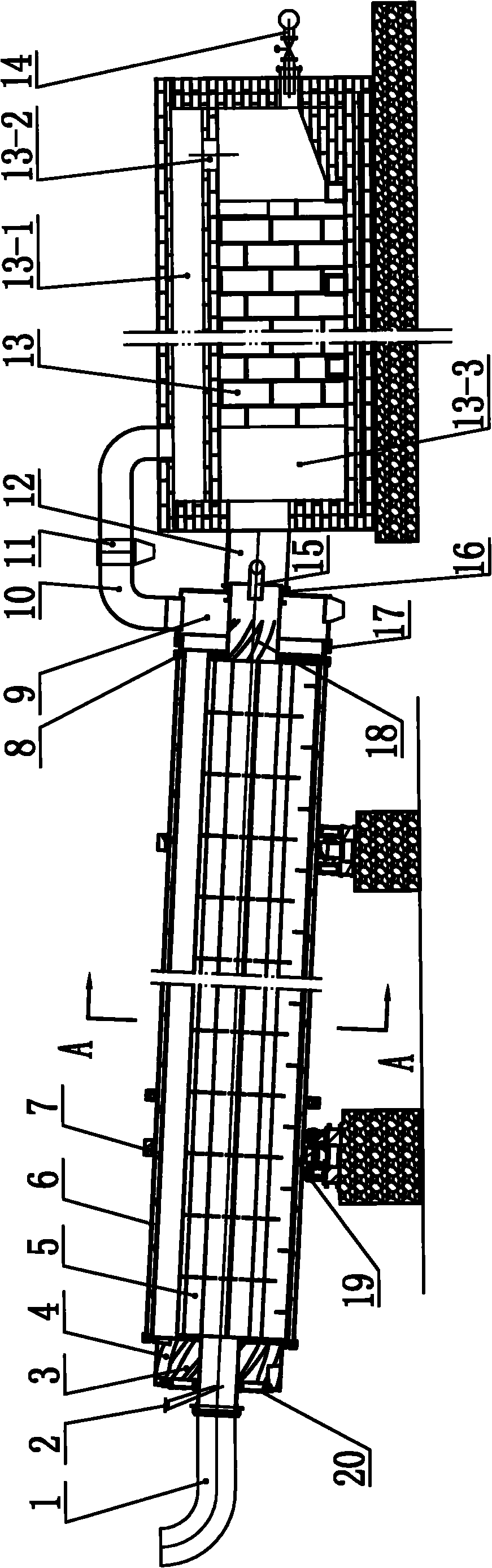

Coal underground gasification process system

InactiveCN104018820AIncrease horizontal widthIncrease widthConstructionsCoal gasificationThermodynamicsWater vapor

The invention relates to a coal underground gasification process system. The coal underground gasification process system comprises a gasification agent injection drill hole, coal gas outlet drill holes, a main gasification channel, branch gasification channels, a drill hole supporting tube, a gasification agent injection tube, a combustion agent injection tube, a sealing device and an ignition point shifter. The gasification agent injection drill hole is connected with the coal gas outlet drill holes through the main gasification channel and the branch gasification channels, and the combustion agent injection tube is sleeved with the gasification agent injection tube and is connected through the sealing device. A gasification process includes the steps of carrying out ignition, judging whether water vapor is fed into, feeding into water vapor, judging whether an ignition point is moved forward, starting the ignition point shifter and continuing to conduct combustion. The coal underground gasification process system has the advantages that the transverse gasification area and longitudinal gasification area can be enlarged, coal reserves for gasification are increased, autoignition and controllable back gas injection are achieved in a well-free coal underground gasification process, meanwhile the problem of short circuit of gasification agents in the gasification channels is solved, the probability of back mixing of product gas and the gasification agents is lowered, and safety operation of the gasification process is guaranteed.

Owner:北京中矿科能煤炭地下气化技术研究中心

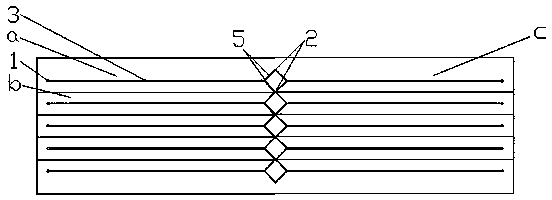

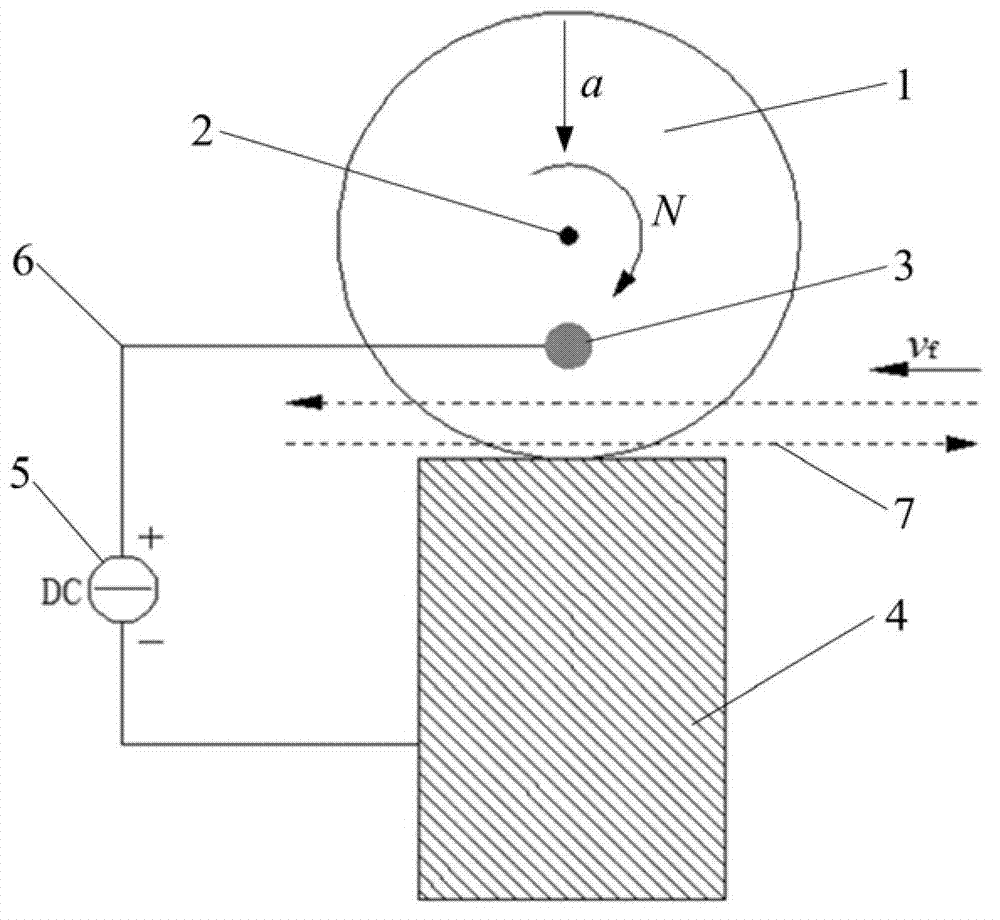

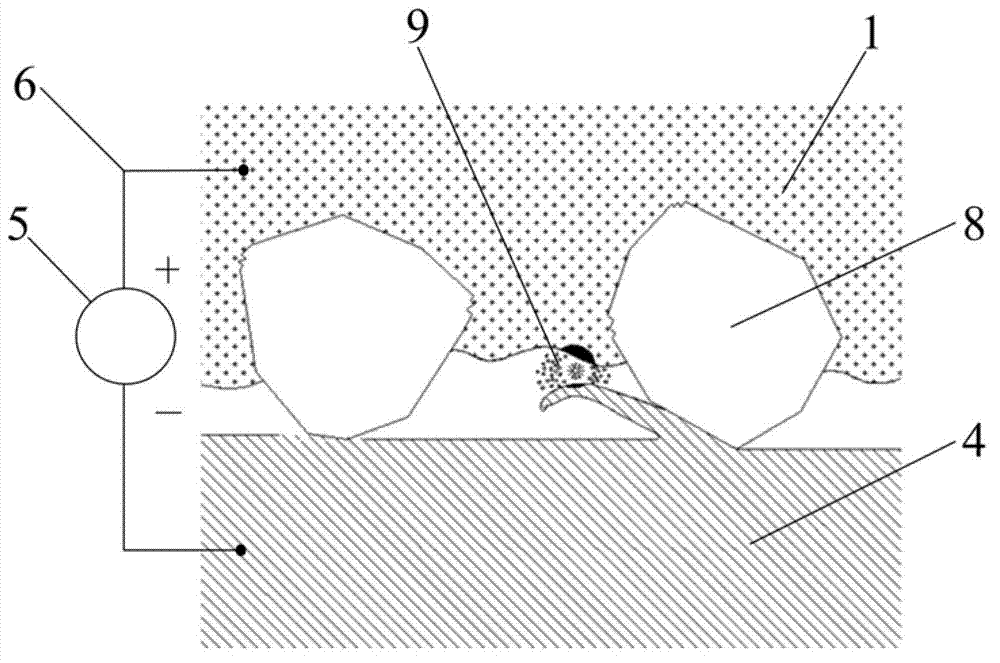

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

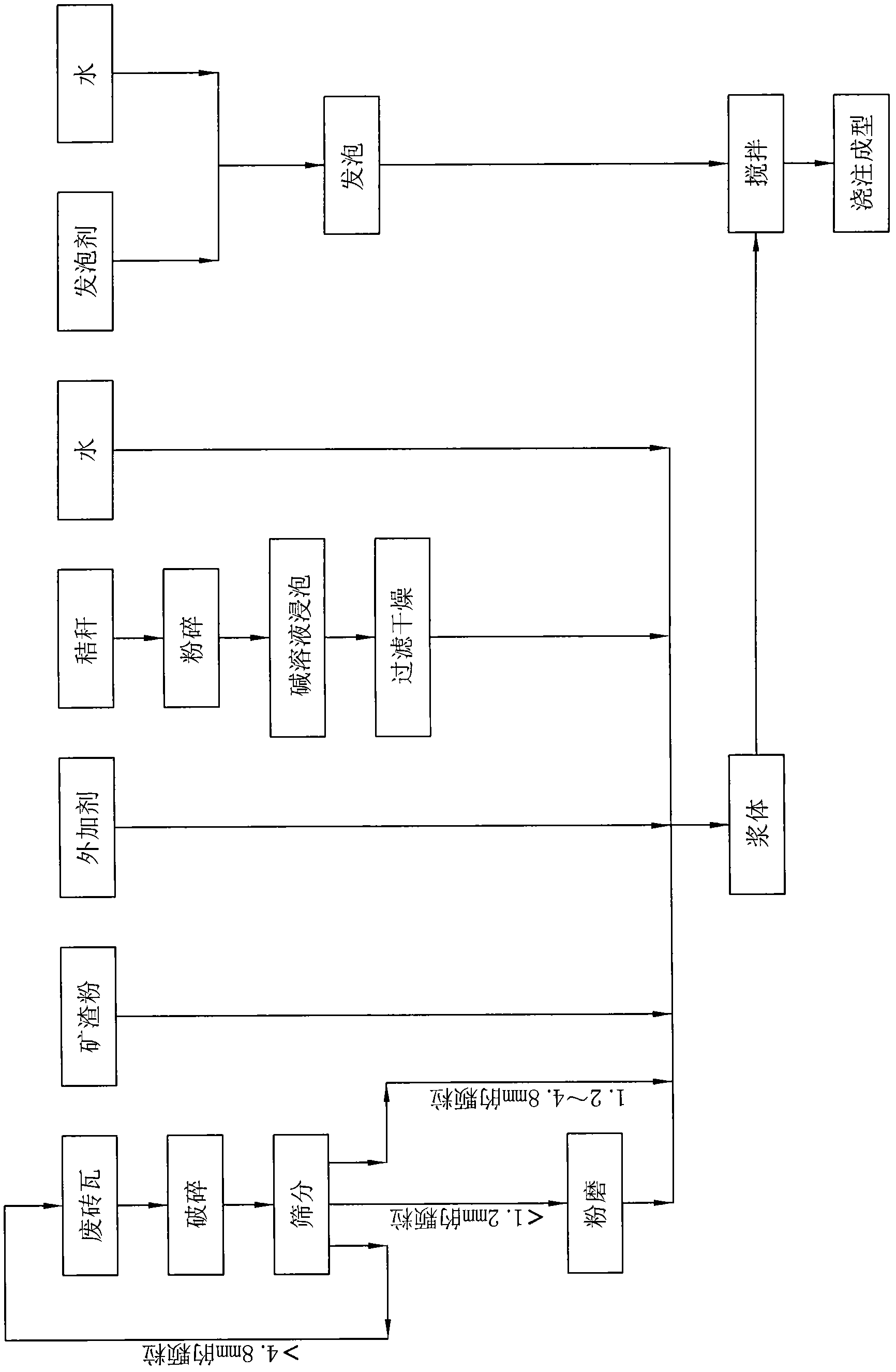

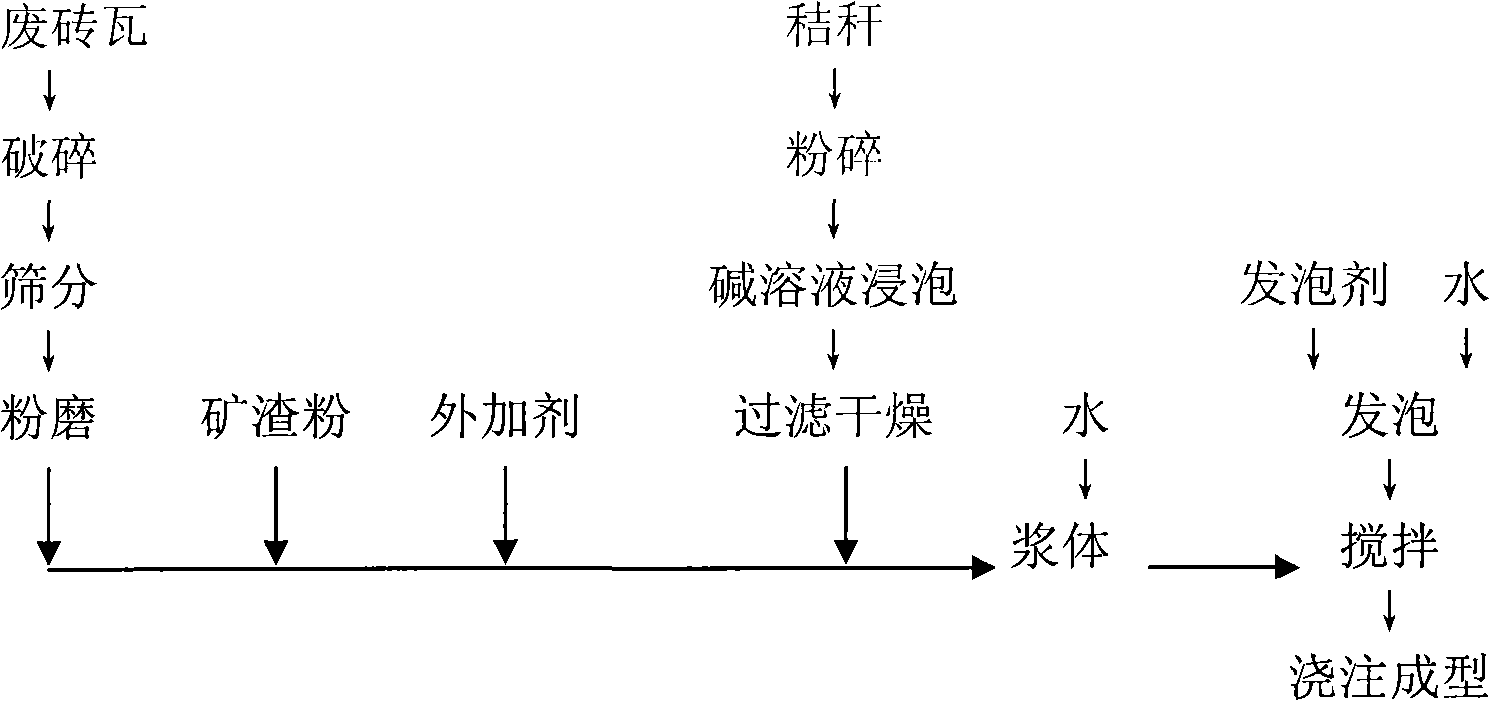

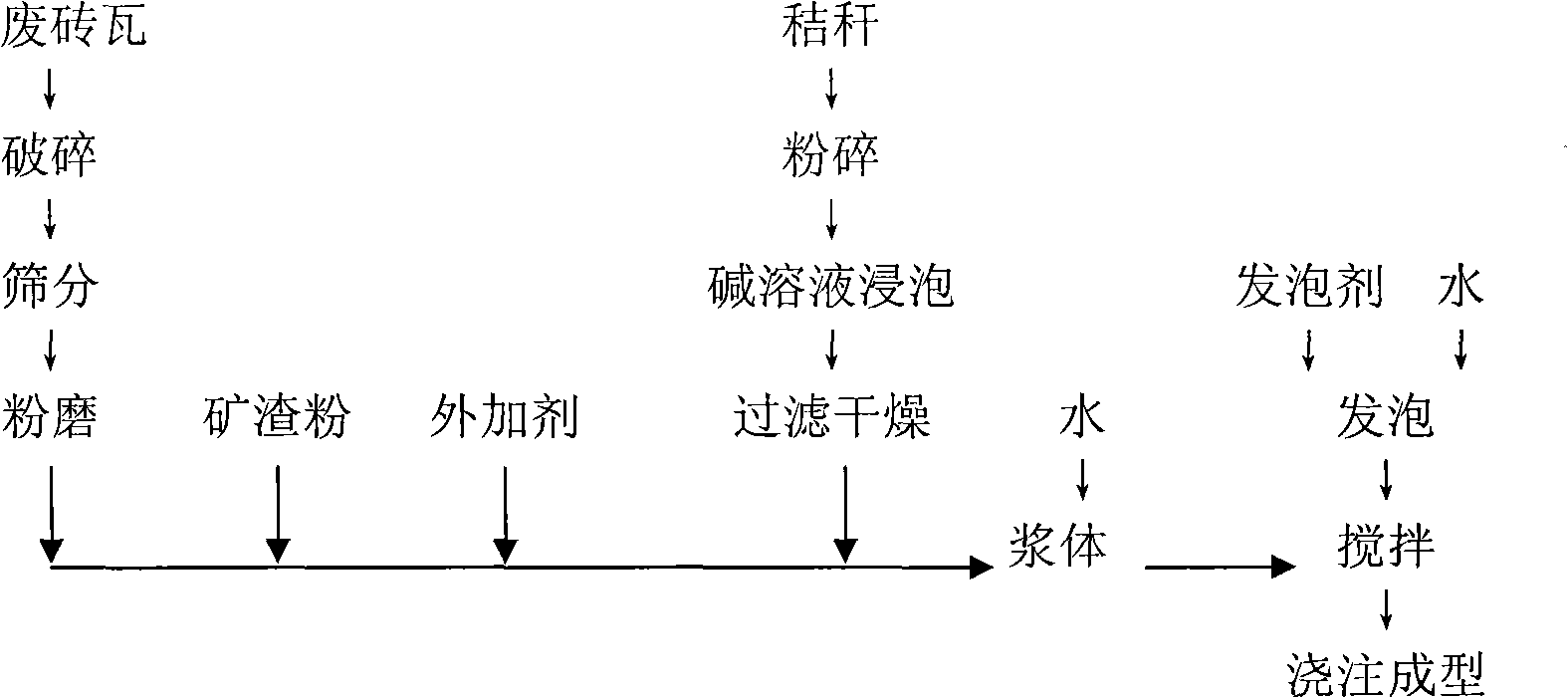

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

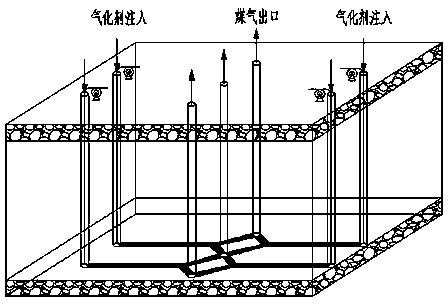

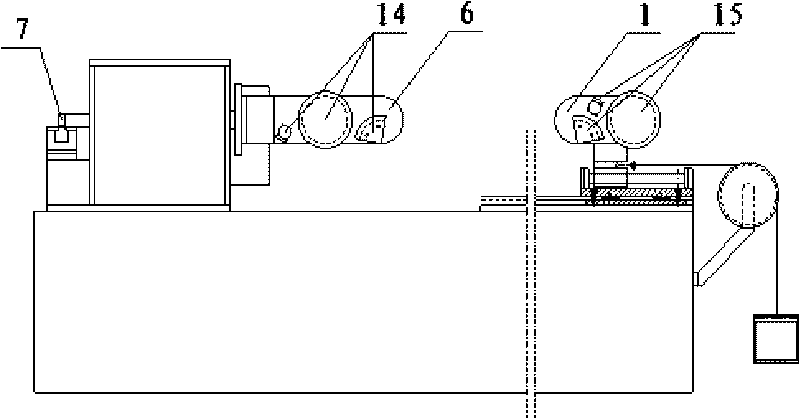

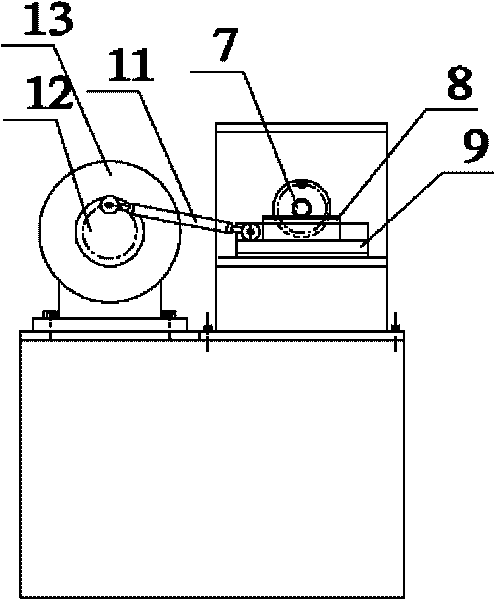

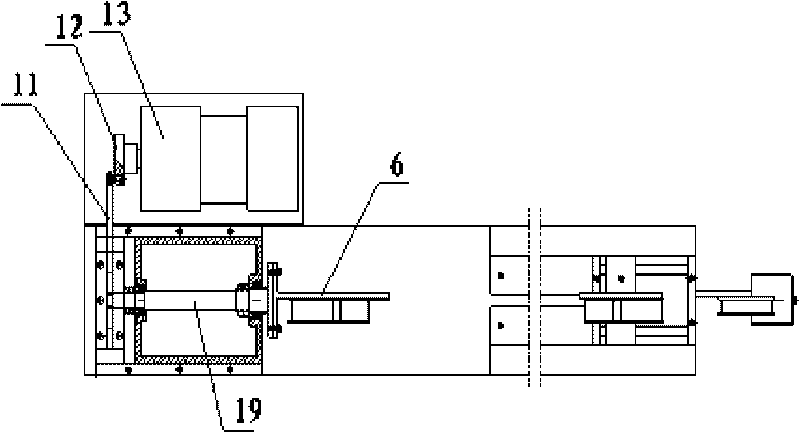

Fiber optic cable twist test equipment

InactiveCN101699260ASimple structureReliable transmissionMaterial strength using repeated/pulsating forcesLinear motionFiber

The invention relates to fiber optical cable twist test equipment. A transmission device of the fiber optical cable twist test equipment comprises a crank-slider mechanism; a slider of the crank-slider mechanism is a stick-shaped slider, and one side of the stick-shaped slider is provided with a drive gear; the toothed slider is engaged with a gear which is rotationally assembled on a machine frame to form a gear rack transmission device; and a twist arm of the fiber optical cable twist test equipment is fixed on a rotating shaft of the gear, and a rotating centre line of the twist arm and a centre line of the rotating shaft of the gear are collinear. A motor drives a crank of the crank-slider mechanism to rotate, the crank drives a connecting rod to perform planar motion, and the connecting rod drives the slider to perform reciprocating linear motion; the slider drives the gear to rotate reciprocally by the drive gear on the slider, and with the reciprocating rotation of the gear, the twist arm which is fixed at one end of the rotating shaft of the gear outputs rotation and twists and drives a fiber optical cable clamed on the twist arm to twist. The fiber optical cable twist test equipment has the advantages that: the structure is simple; the movement is reliable; and the twist arm of the motor can be twisted without rotating forward and backward.

Owner:ZHENGZHOU SHIJIA COMM TECH

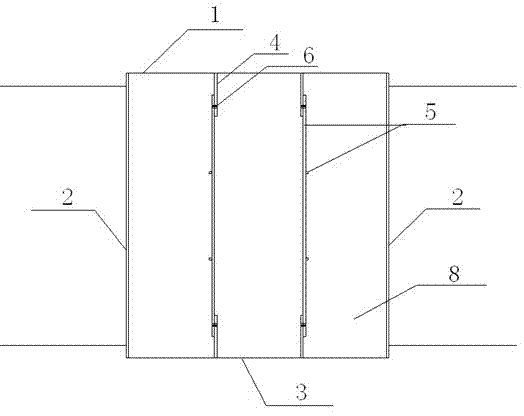

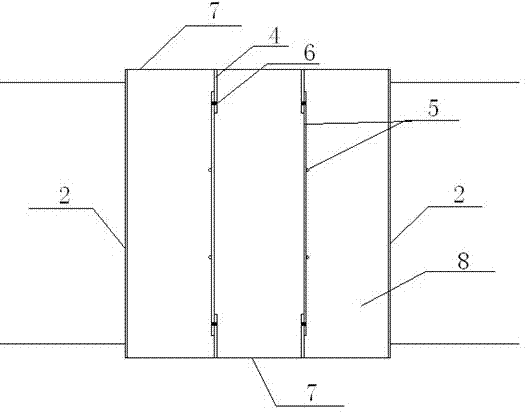

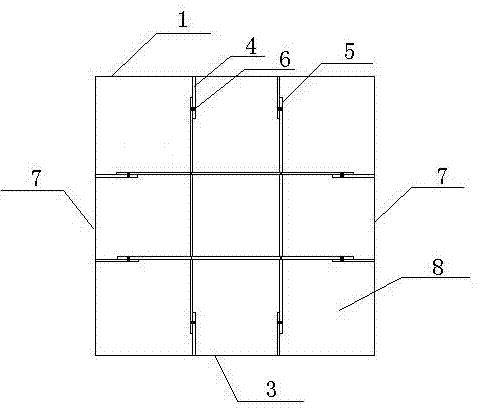

Method for constructing mining impact-resisting sealed wall

ActiveCN102777208ASimple construction processFast constructionMaterial fill-upFoam concreteImpact resistance

The invention relates to the technical field of mining security, and particularly relates to a method for constructing a mining impact-resisting sealed wall. The method adopts simpler and more convenient construction procedures, and light foam concrete is filled, so that the wall has the advantages of light weight, large bearing ability, strong flexibility, fire resistance and the like. The method is simple and convenient to construct, rapid in construction speed, good in construction effect; and the sealed wall has the advantages of good impermeability and good impact-resistance and fire-resistance.

Owner:兖矿能源集团股份有限公司 +1

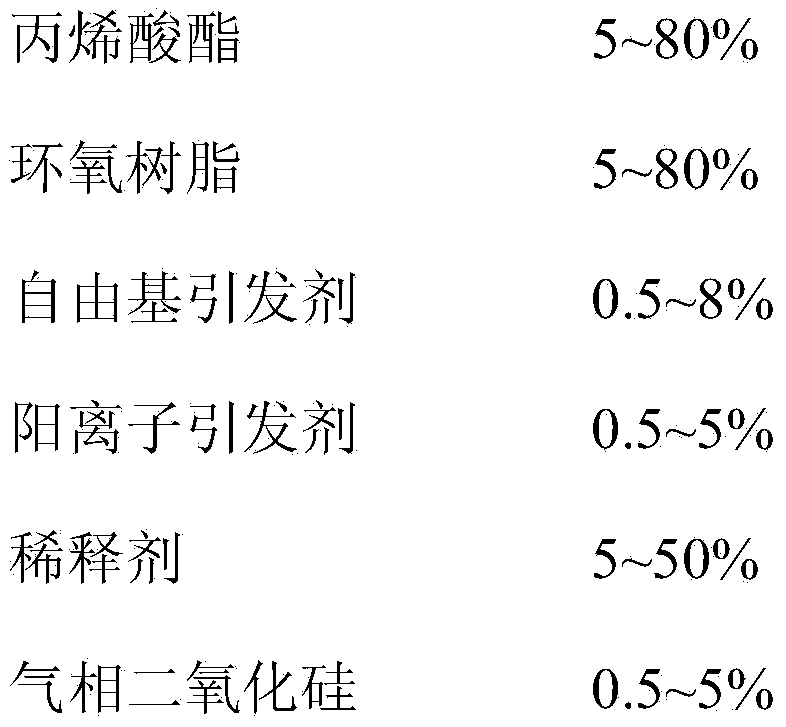

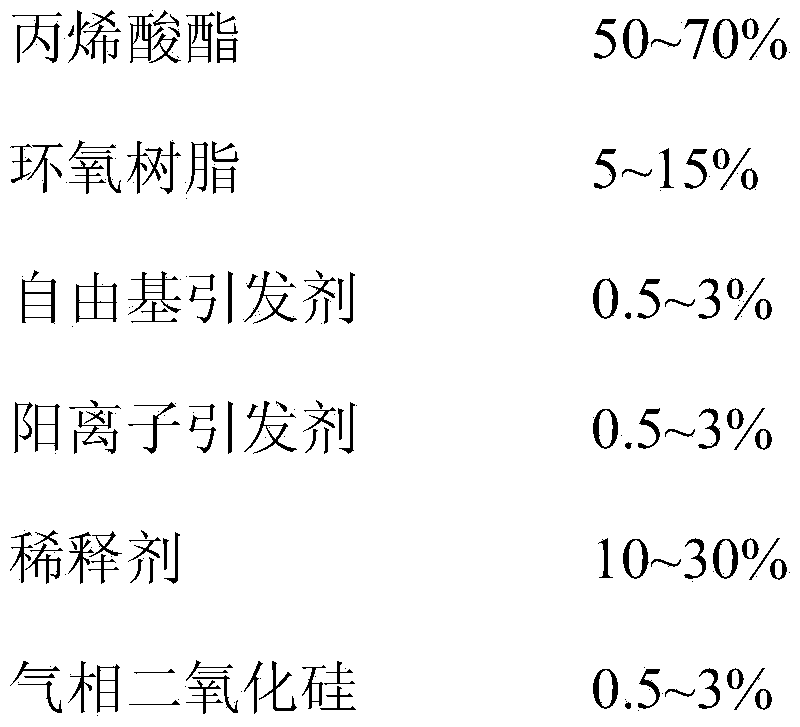

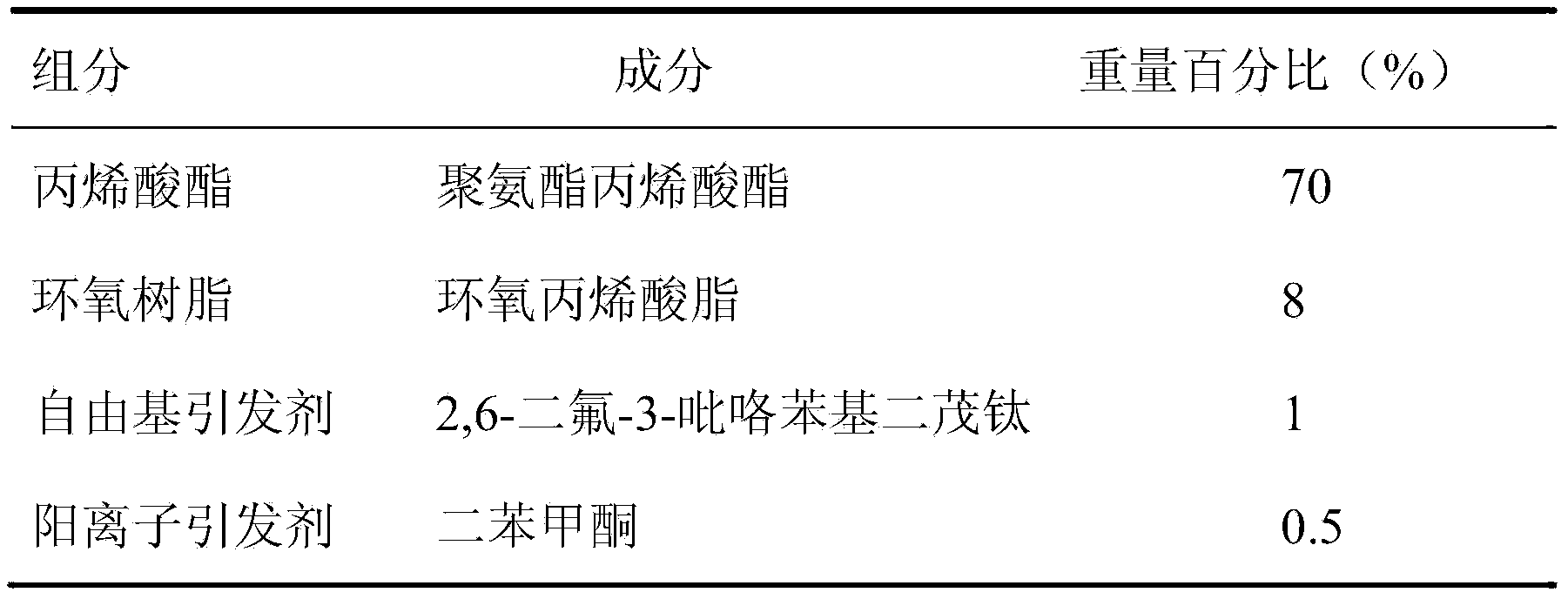

Photosensitive resin and preparation method thereof

The invention belongs to the field of novel 3D printing materials and in particular belongs to the field of photosensitive resin. The photosensitive resin is prepared from the following components in percentage by weight: 5-80% of acrylic ester, 5-80% of epoxy resin, 0.5-8% of a radical initiator, 0.5-5% of a cationic initiator, 5-50% of a diluent and 0.5-5% of gas phase silicon dioxide. Flexural modulus and tensile modulus of the photosensitive resin reach over 2000Mpa; the photosensitive resin is high in capability of resisting bending deformation stress in an elastic limit, high in strength, low in possibility of deforming and high in mechanical strength; the service life is greatly prolonged; the volume shrinkage rate is about 1.0%; the ultralow volume shrinkage rate is achieved; the industrial use requirement can be met.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

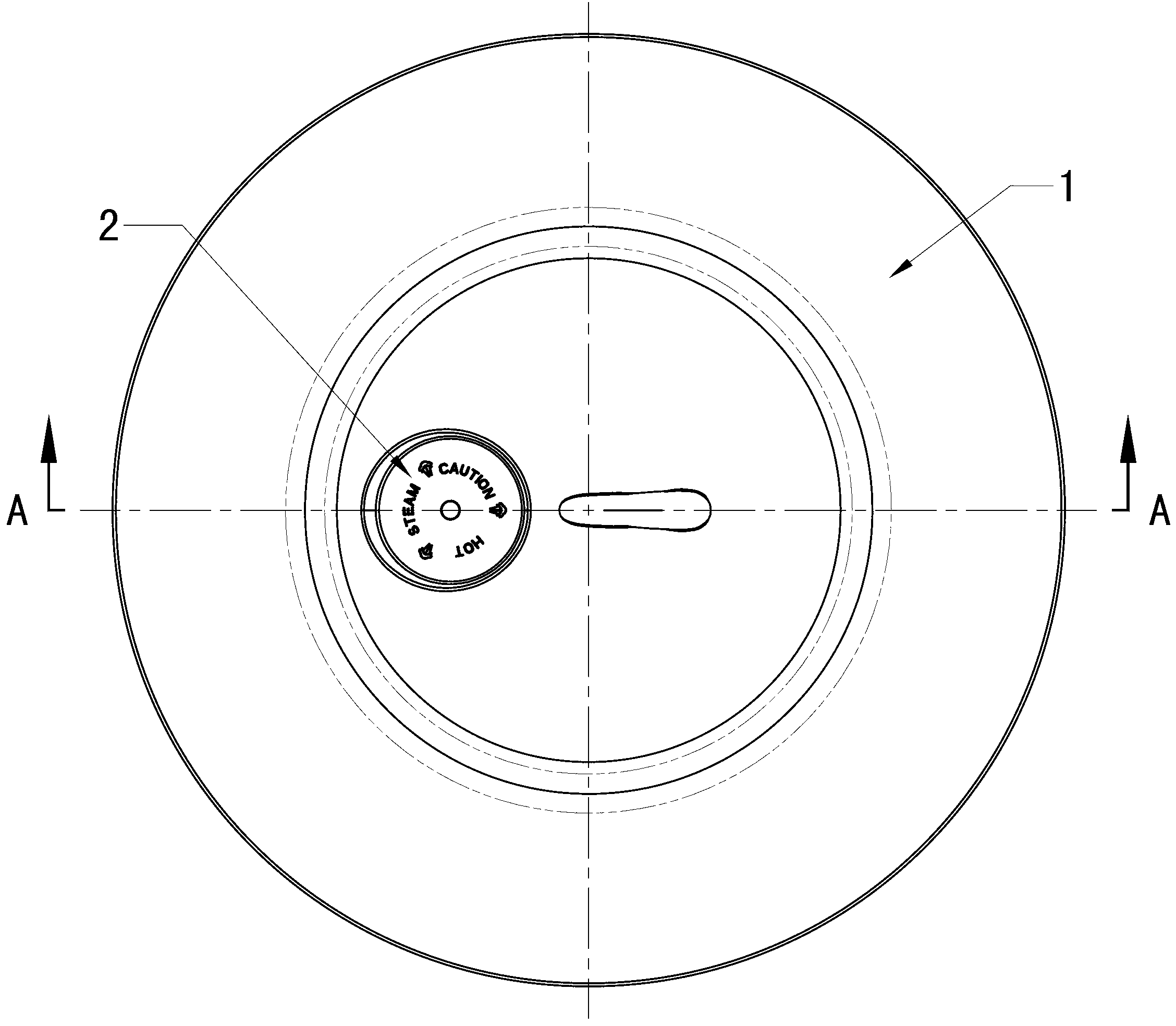

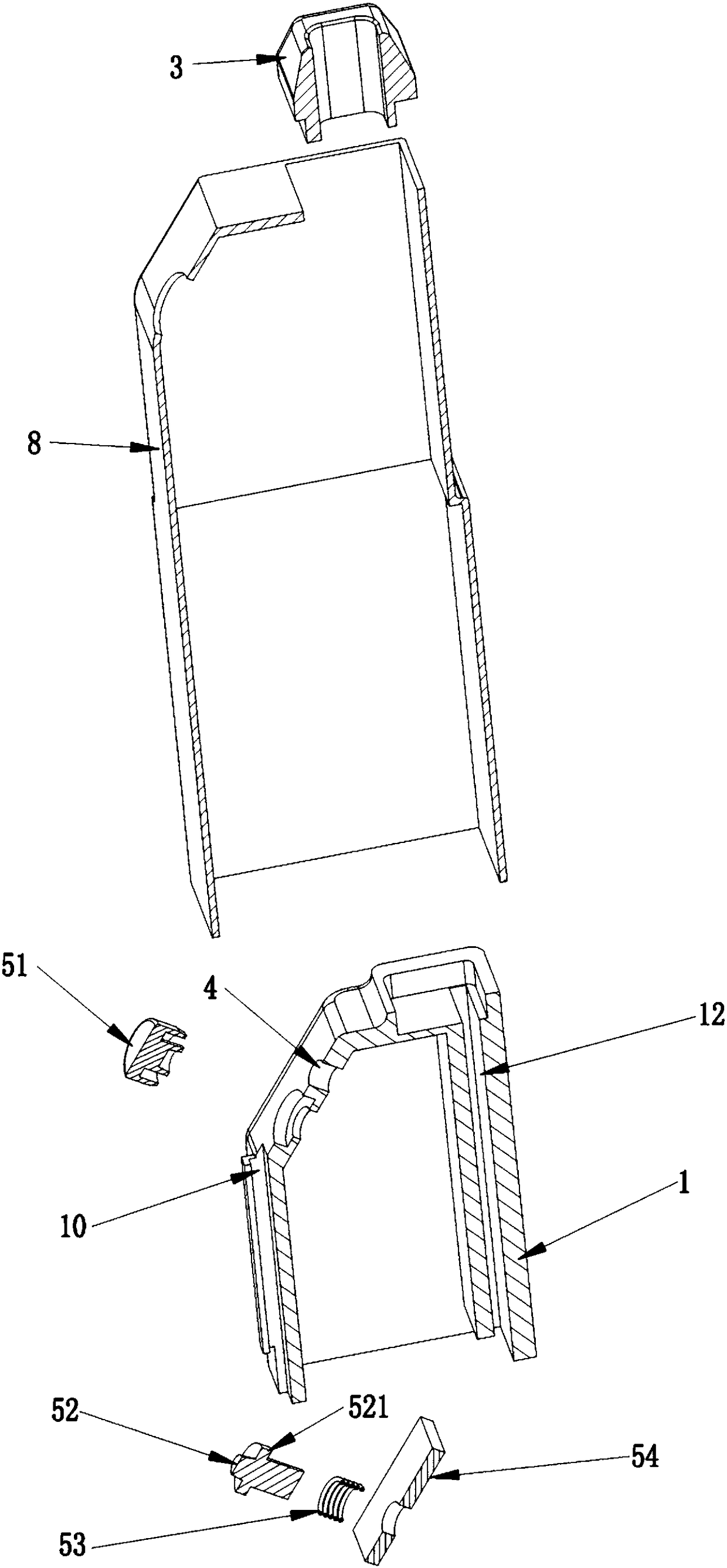

Spill-proof pot cover

InactiveCN102835904AAvoid breedingEasy to cleanBoiling over preventionCooking-vessel lids/coversArchitectural engineeringShape-memory alloy

The invention discloses a spill-proof pot cover including a pot cover and a spill-proof mechanism; the pot cover is provided with cavity for containing and enclosing the spill-proof mechanism; the spill-proof mechanism includes a top plate, a base, a sliding shaft and a flexible component; the top plate is fixed on the top of sliding shaft and covers the upper opening of the cavity, and a through hole is arranged at the bottom of the cavity; the sliding shaft penetrates the flexible component and is inserted in the base, and the base is provided with a through hole; the base is detachably embedded at the bottom of the cavity, the through hole at the bottom of the cavity is communicated with the through hole on the base. The spill-proof mechanism in the silicone pot cover is provided with a shape memorizing alloy which opens and closes a vent of the pot cover automatically based on the change of the temperature; and as the whole process is automatically finished, the spill-proof pot cover is convenient to use and saves time and energy for the users.

Owner:广州市越秀日达有限公司

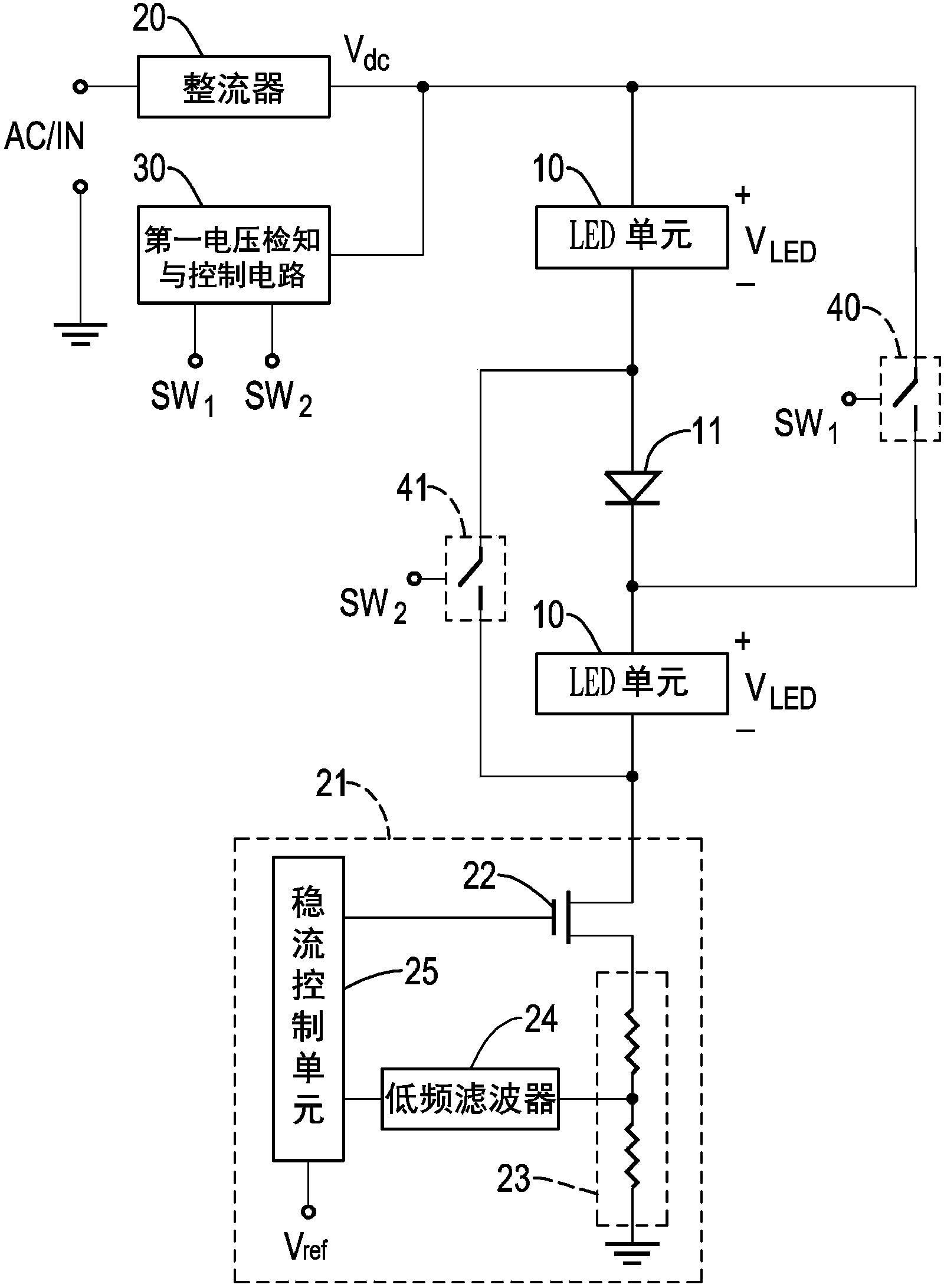

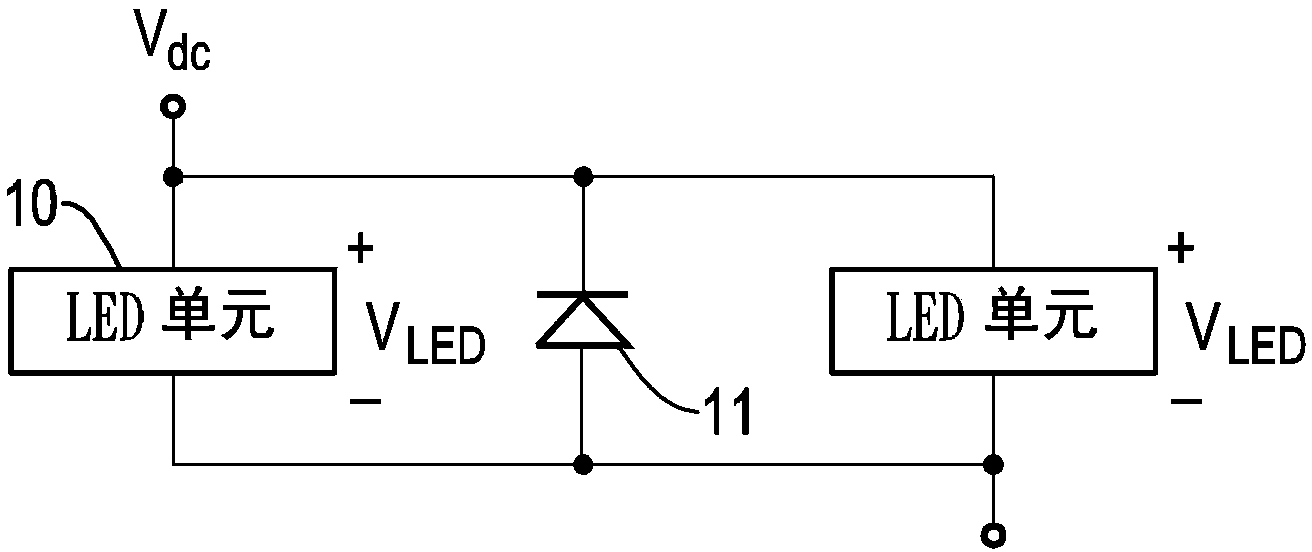

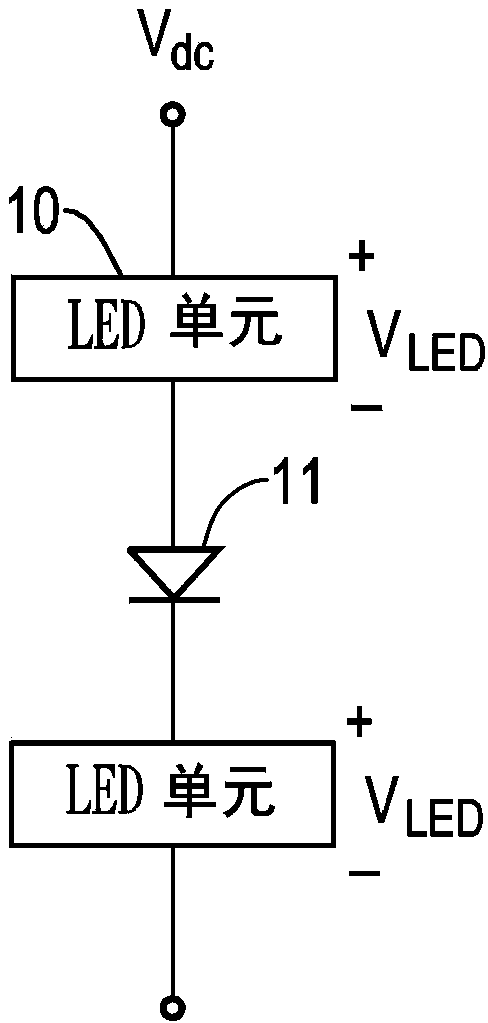

Full-voltage serial-parallel led lamp

InactiveCN103687174ALight up smoothlyWon't burnElectric light circuit arrangementLow voltageHigh pressure

Owner:LUXUL TECH

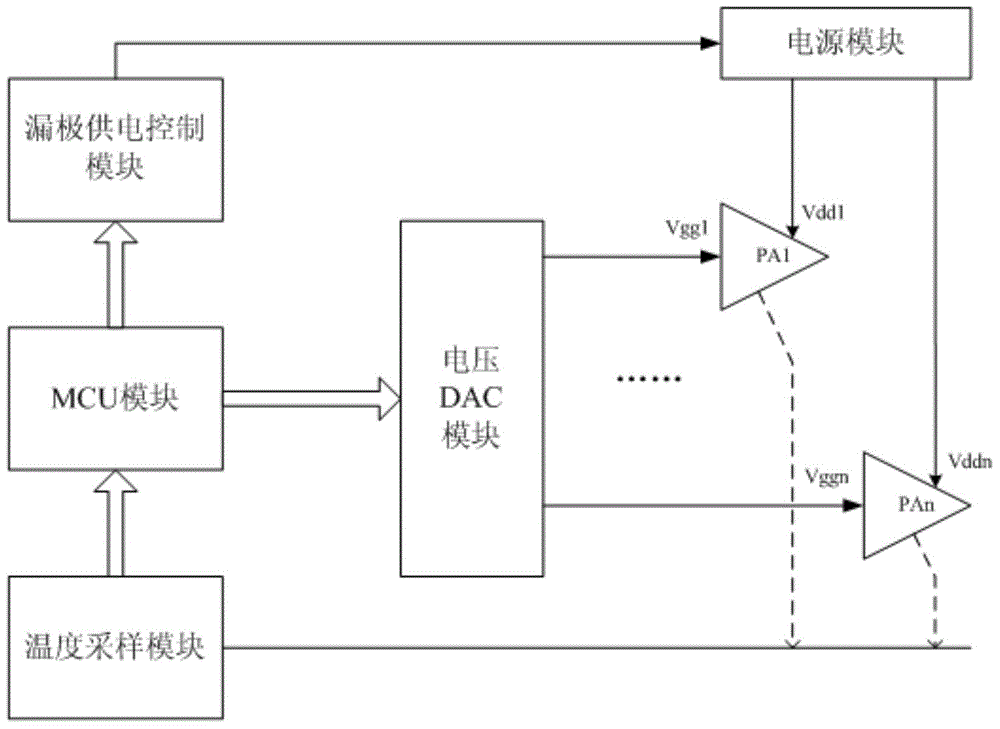

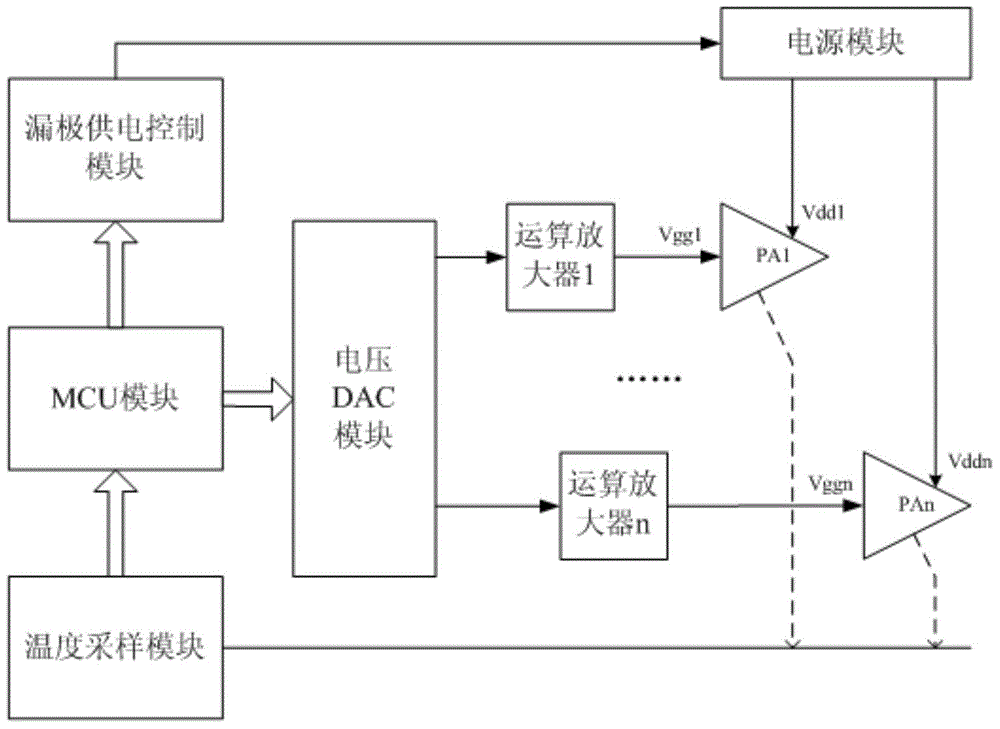

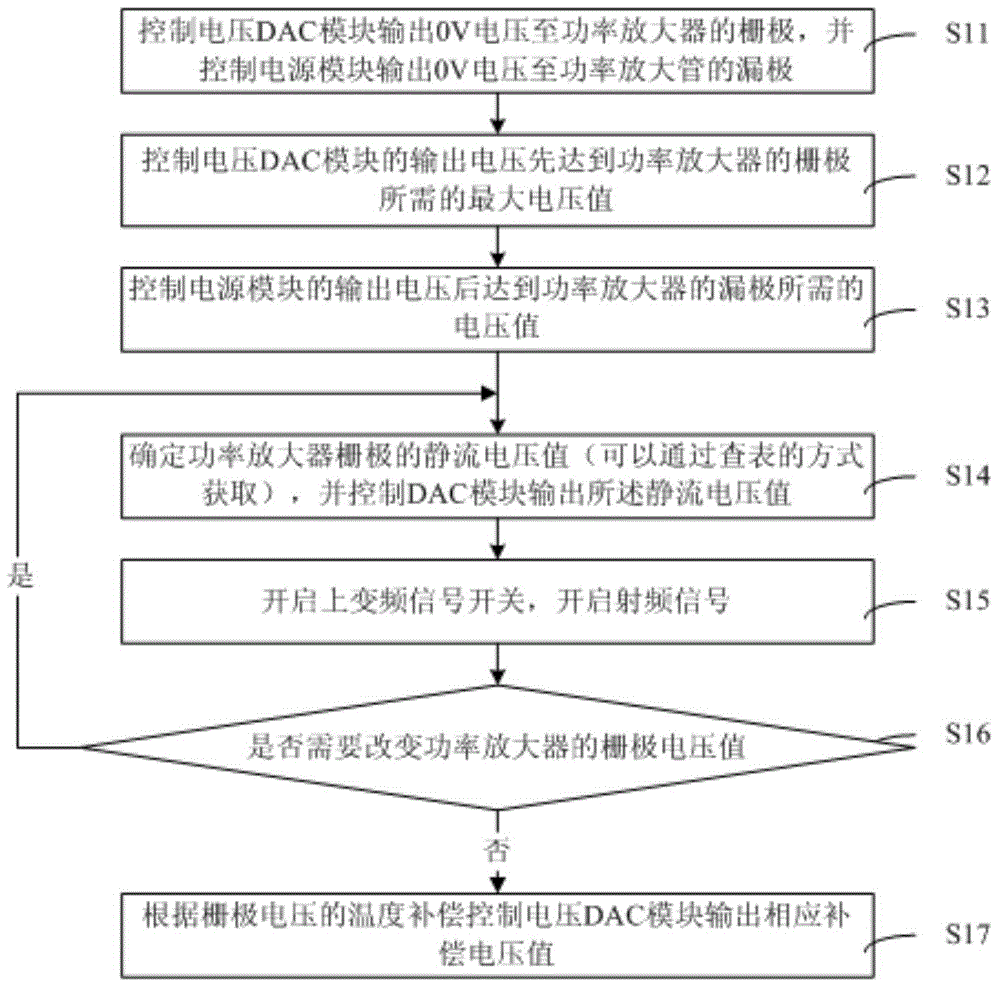

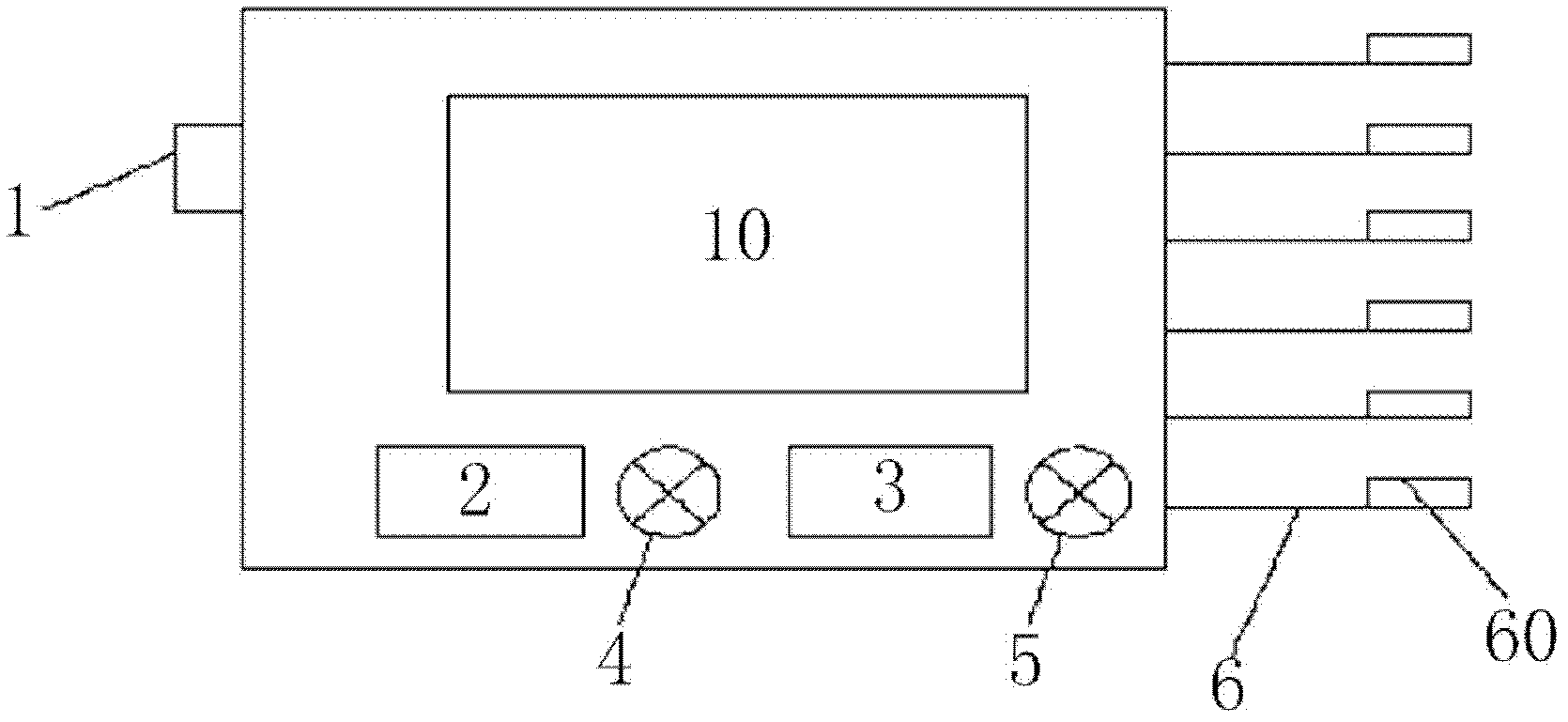

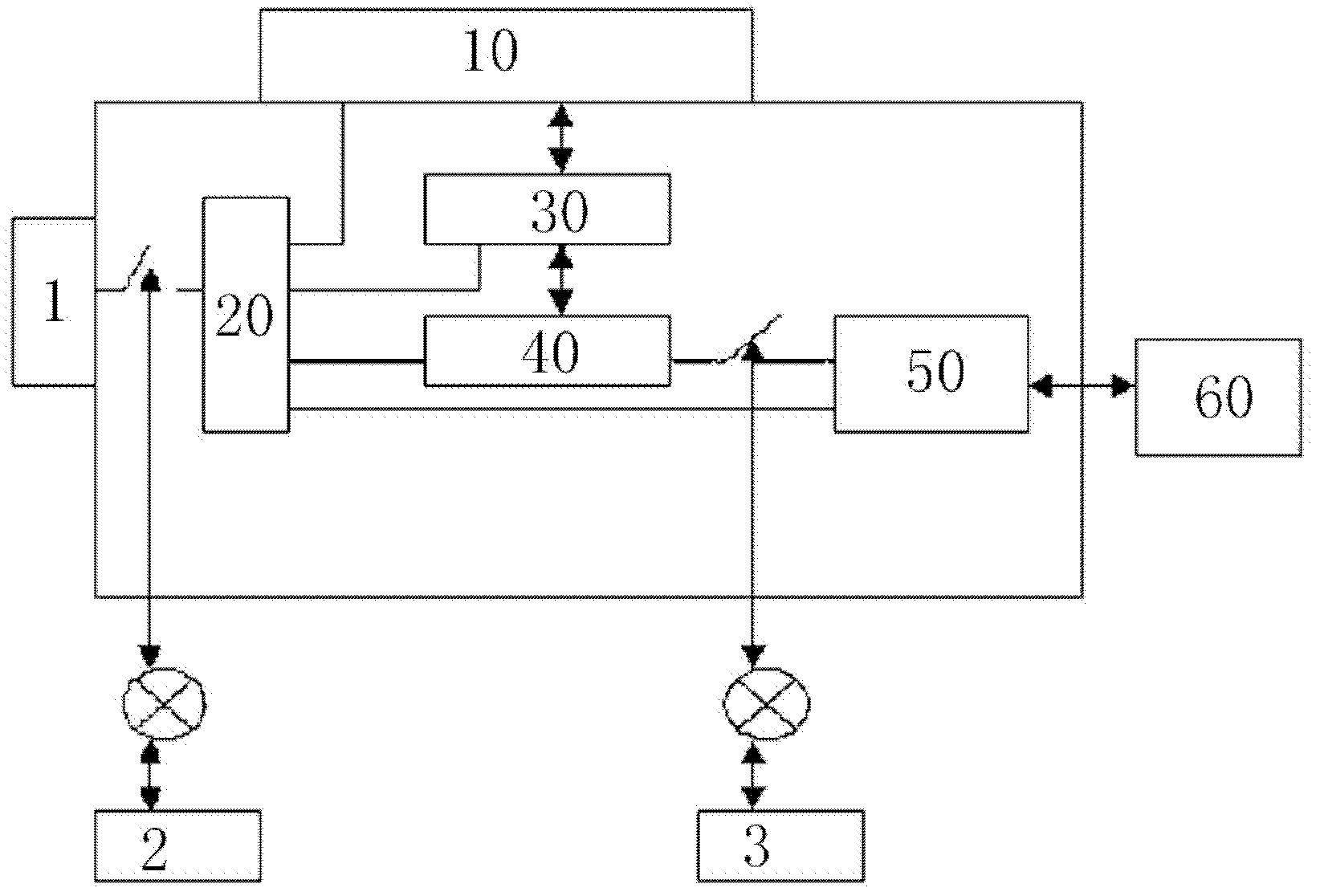

Power supply control device for power amplifier tube and power-on and power-off control method thereof

ActiveCN103956979AControl output voltageWon't burnHigh frequency amplifiersPower amplifiersSelf adaptiveDigital-to-analog converter

The invention relates to a power supply control device for a power amplifier tube and a power-on and power-off control method thereof. The device comprises an MCU (Microprogrammed Control Unit) module, a temperature sampling module, a voltage DAC (Digital to Analog Converter) module, a power supply module and a drain electrode power supply control module; the MCU module is user for controlling the drain electrode power supply of the power amplifier tube and the negative voltage power supply of a grid in a unified mode, and the grid voltage can be conveniently, quickly and dynamically adjusted through the control of the negative voltage power supply of the grid, so that self-adapted dynamic adjustment under different working temperatures is realized, and correctness and reliability for power-on and power-off sequence of the power amplifier tube are ensured through the combination of the control of the grid power supply, thus the power amplifier tube can be better protected from being burnt by incorrect power-on and power-off timing sequence, the power-on and power-off control timing sequence of the power amplifier tube is met, the power amplifier tube is always at a good working condition, and the reliability of power amplification system is promoted. According to the power supply control device for the power amplifier tube, the correctness and reliability for power-on and power-off sequence of the power amplifier tube are ensured, and the reliability of the whole power amplification system is directly promoted.

Owner:COMBA TELECOM SYST CHINA LTD

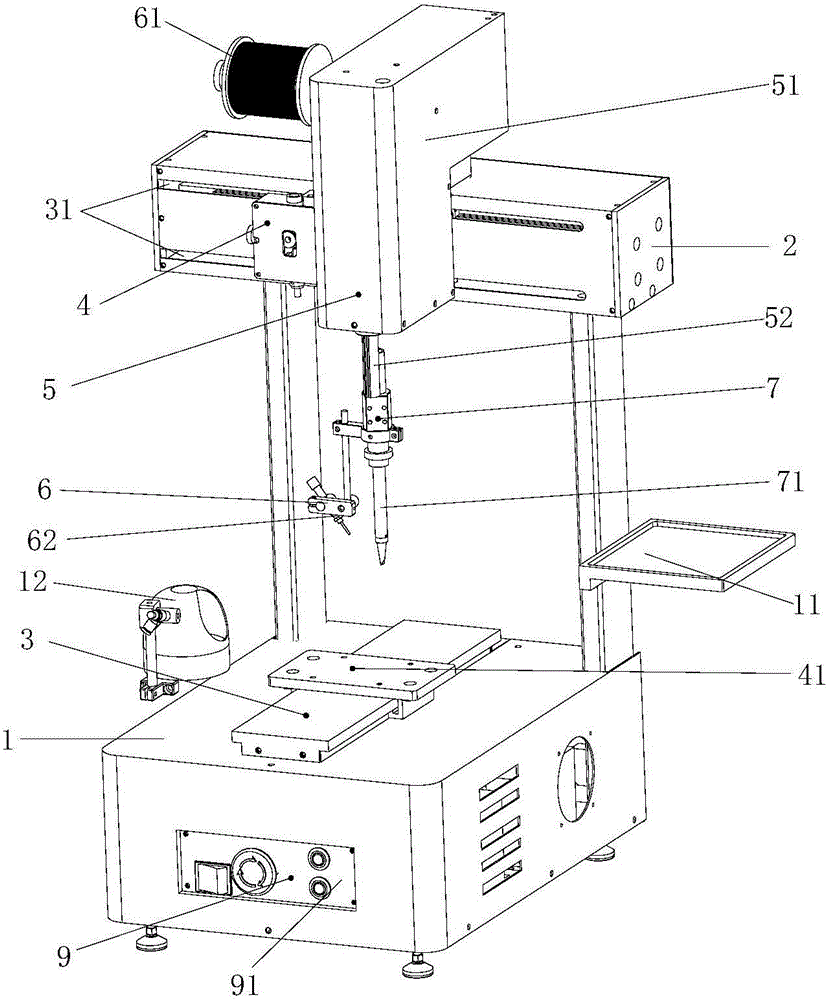

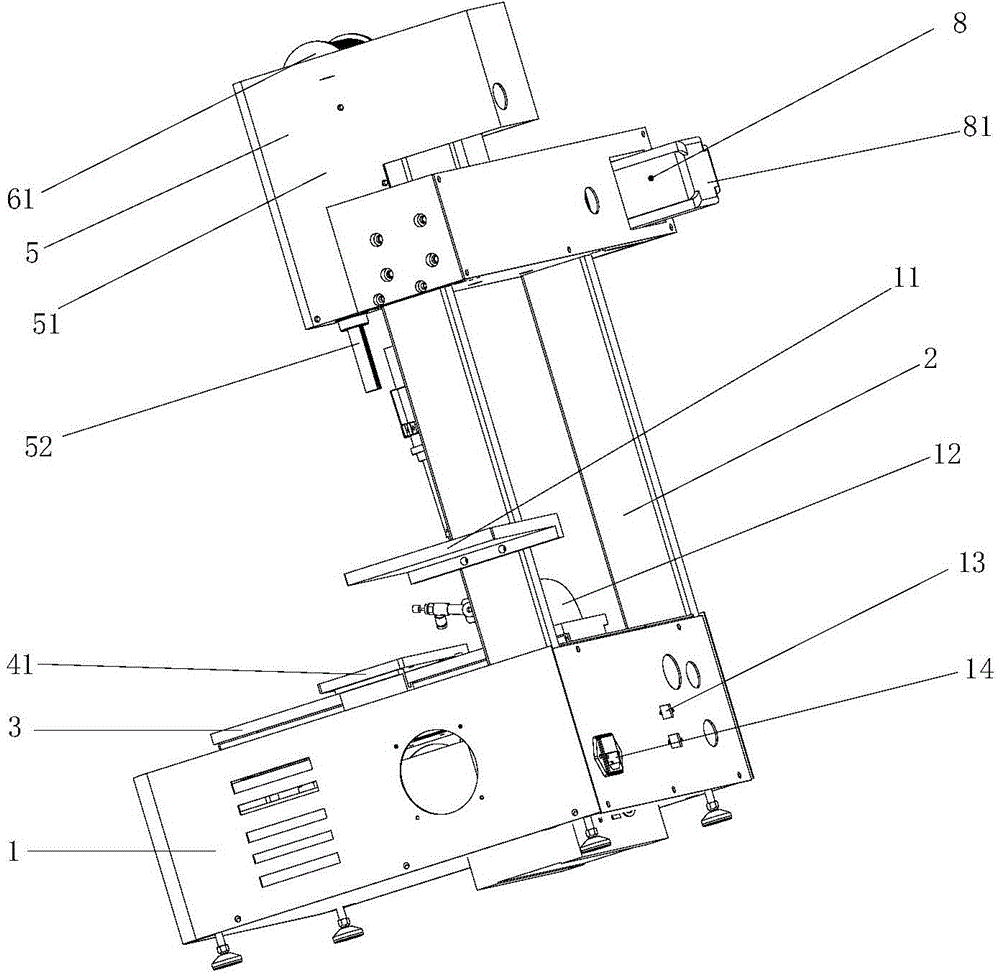

Automatic soldering tin machine

InactiveCN104439597AWon't burnAchieve free rotationWelding/cutting auxillary devicesAuxillary welding devicesElectricityEngineering

The invention relates to the technical field of machines, in particular to an automatic soldering tin machine. The automatic soldering tin machine comprises a base, and a rack, an X-axis soldering tin mechanism, a Y-axis soldering tin mechanism, a Z-axis soldering tin mechanism, an automatic tin bar feeding mechanism, a rotation mechanism, a power mechanism and a control mechanism are arranged on the base; the rack is detachably connected with the X-axis soldering tin mechanism, the Y-axis soldering tin mechanism is in screwed connection with the base, the Z-axis soldering tin mechanism is arranged on the X-axis soldering tin mechanism and detachably connected with the X-axis soldering tin mechanism, the automatic tin bar feeding mechanism and the rotation mechanism are each detachably connected with the Z-axis soldering tin mechanism, the power mechanism is electrically connected with the control mechanism, the rotation mechanism comprises a rotation head and a welding gun, and the welding gun is in screwed connection with the rotation head. The soldering tin direction and the soldering tin angle of the welding gun are adjusted through the rotation mechanism, electronic elements nearby welding points are avoided, it is guaranteed that the electronic elements nearby the welding points cannot be scalded, the production efficiency of the products is greatly improved, the product quality can be guaranteed, and the full-automatic requirement is met.

Owner:东莞市东润机电设备有限公司

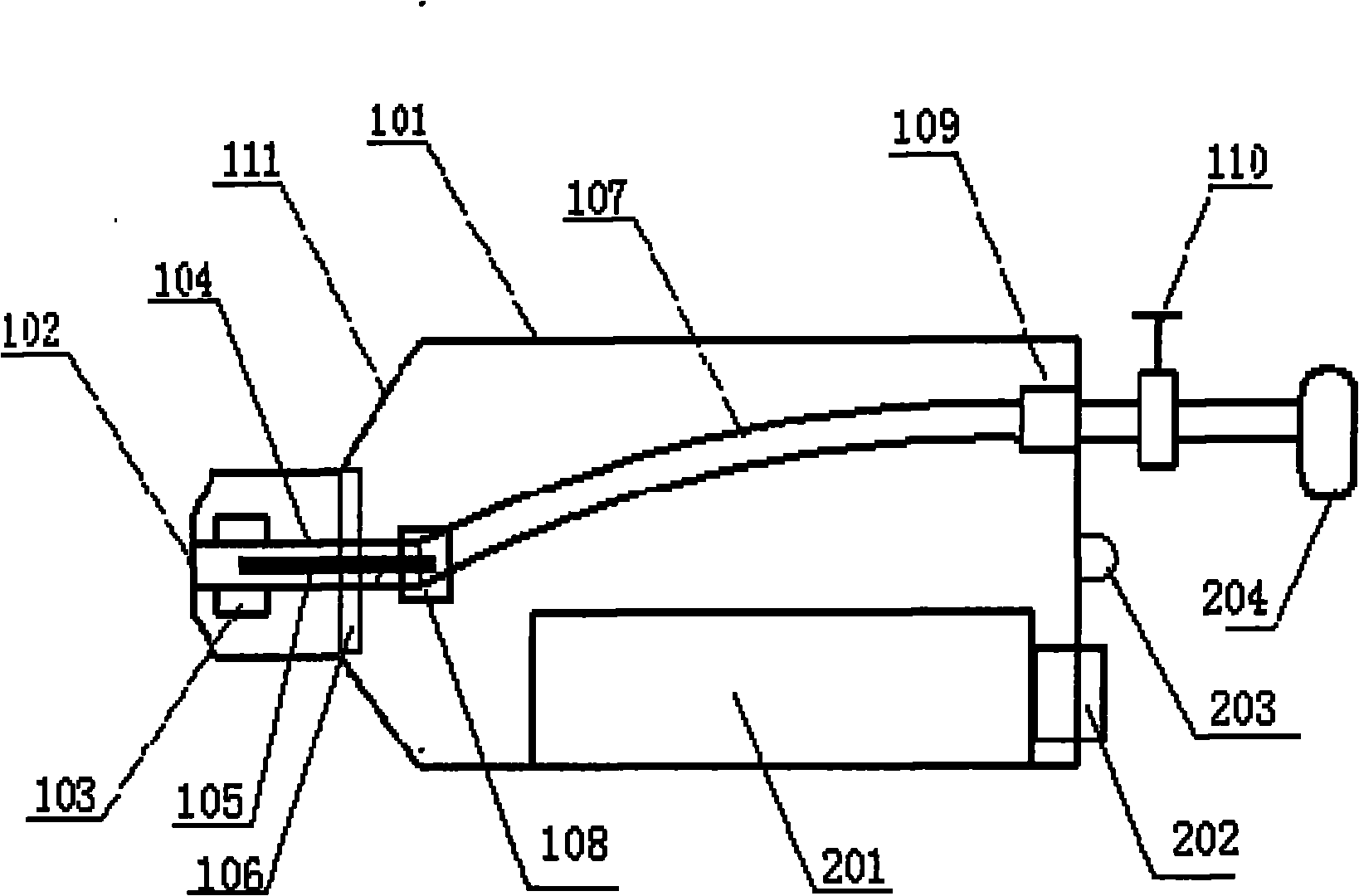

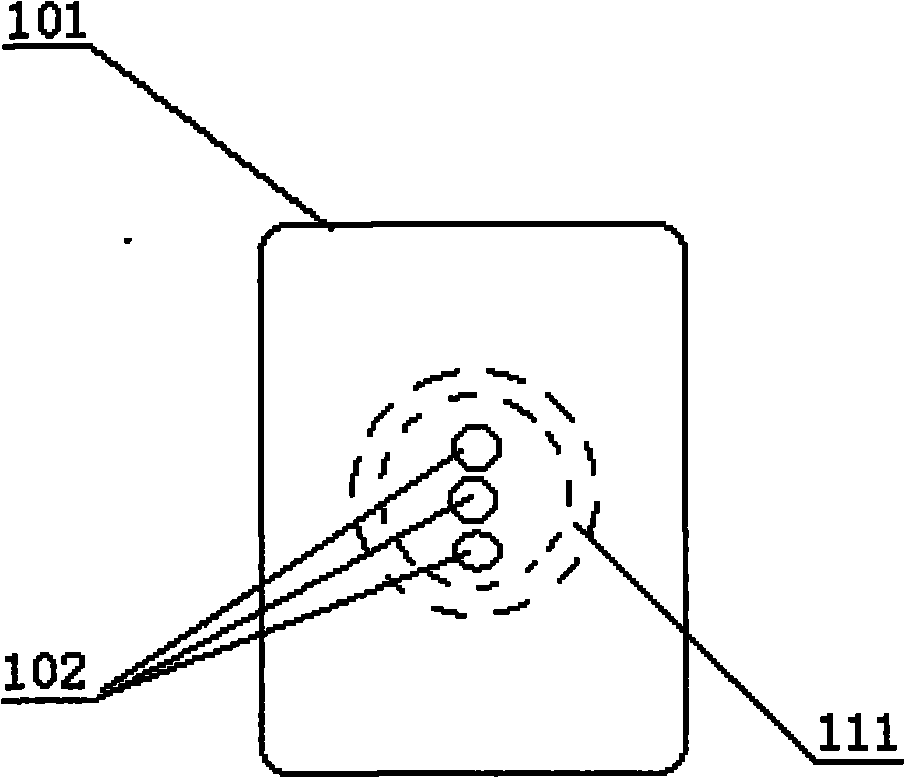

Novel plasma pen

InactiveCN101766829ALow beam temperatureWon't burnLavatory sanitoryDisinfectionIonizationRadio frequency

The invention discloses a novel plasma pen, comprising a power supply, a gas-supply source, and a novel plasma pen main body; the characteristics are as follows: the novel plasma pen main body comprises one or a plurality of insulation medium tubes, the inside and the outside of the insulation medium tube are respectively provided with an electrode which is connected with a RF (radio frequency) or a high frequency power supply, the outside of a plasma micro-beam flow is provided with a shell body, one side of the shell body is provided with one or a plurality of nozzles, the other side is provided with an air-inflow connecting port, a gas flow control valve switch and a power supply switch; when the gas in the gas-supply source flows through the clearance between the electrode inside the insulation medium tube and the electrode outside the insulation medium tube, the breakdown ionization forms the plasma to spray out of the shell body, and the sprayed plasma beam flow can be used for cleaning, disinfecting and sterilizing various surfaces.

Owner:王龙哲

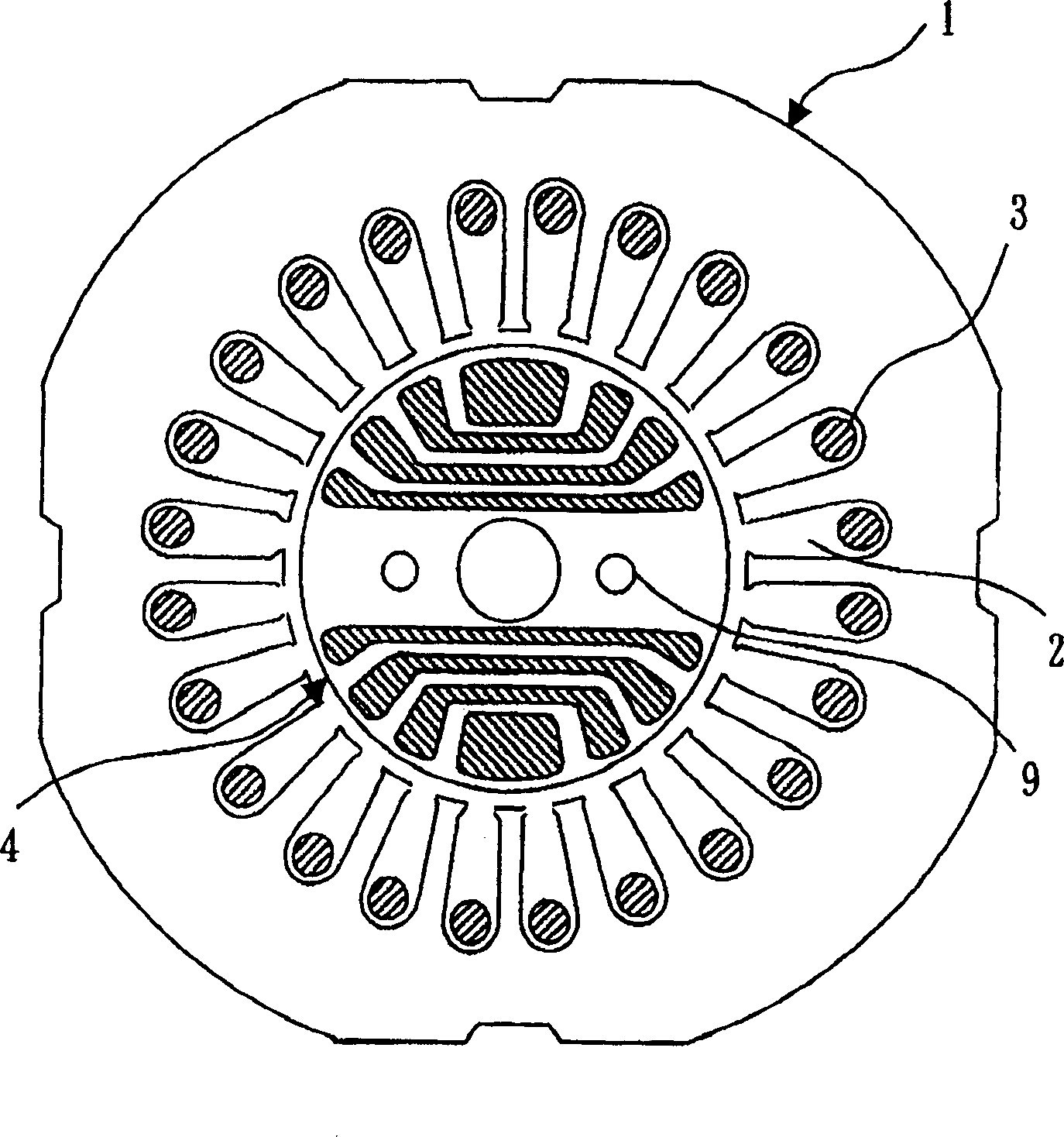

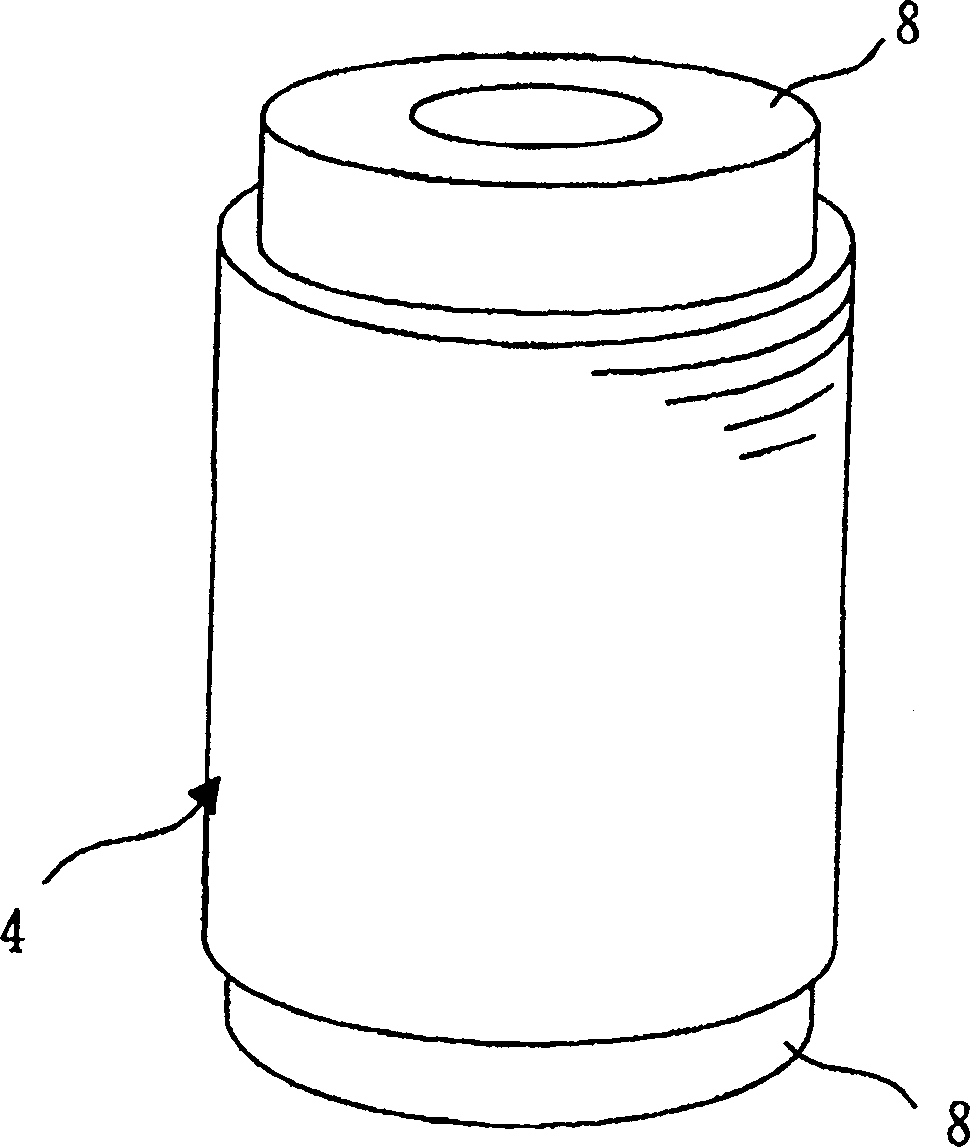

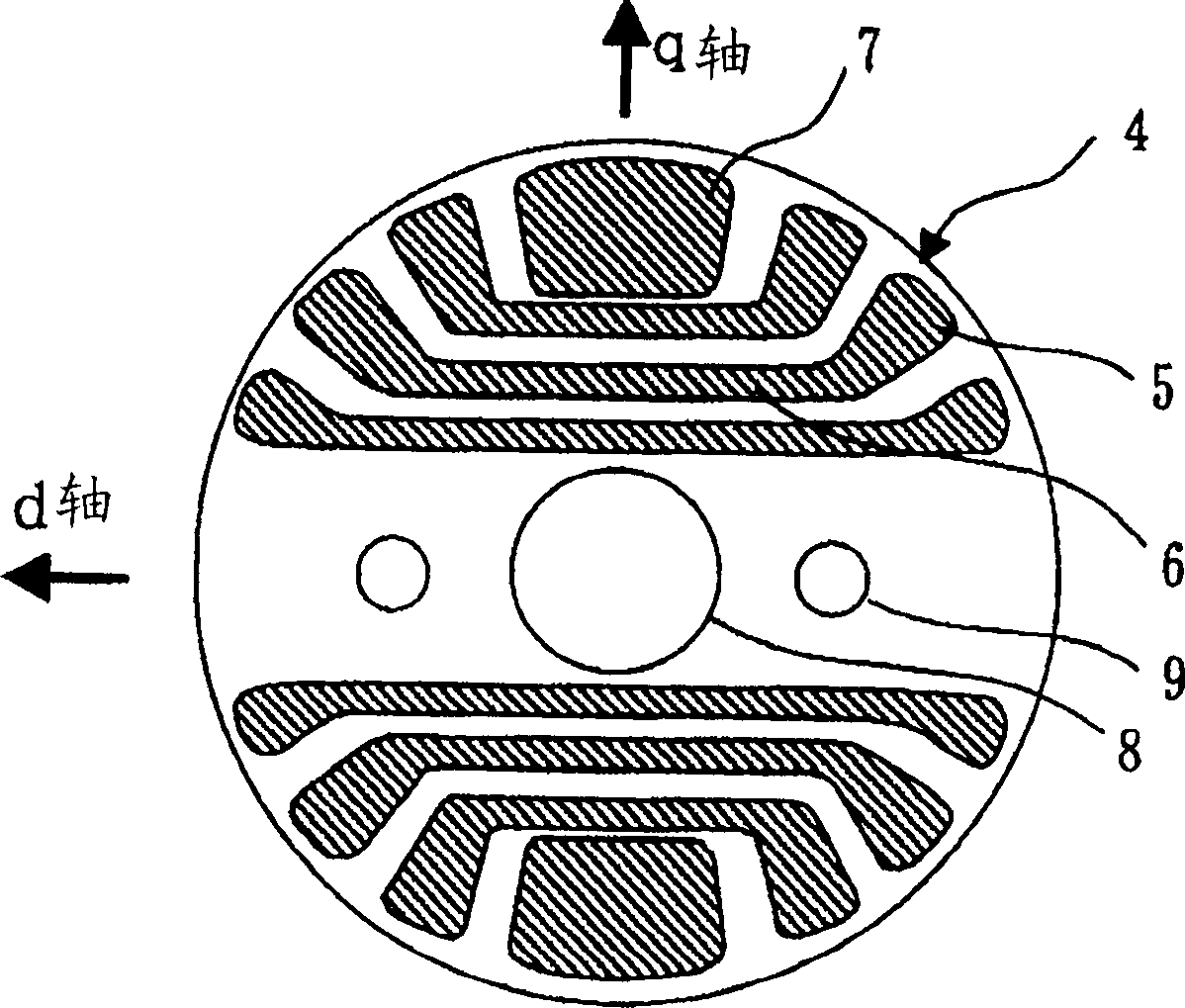

Motor rotor and its mfg. method, motor, brushless motor, compressor, refrigerator and air conditioner

InactiveCN1420606AWon't burn outReduce circulationMagnetic circuit rotating partsPositive displacement pump componentsBrushless motorsInduction motor

To provide a rotor for synchronous induction motor capable of preventing the lowering of output or efficiency due to increasing magnetic resistance even if a gas venting hole is formed for using a hermetic compressor. This rotor includes slots for generating induction torque and slits for generating reluctance torque. The slot and the slits are filled with aluminum. The filling aluminum is shorted by end ring at both ends of the rotor, and a non-filling section axially passed through the slit and not filled with aluminum is provided.

Owner:MITSUBISHI ELECTRIC CORP

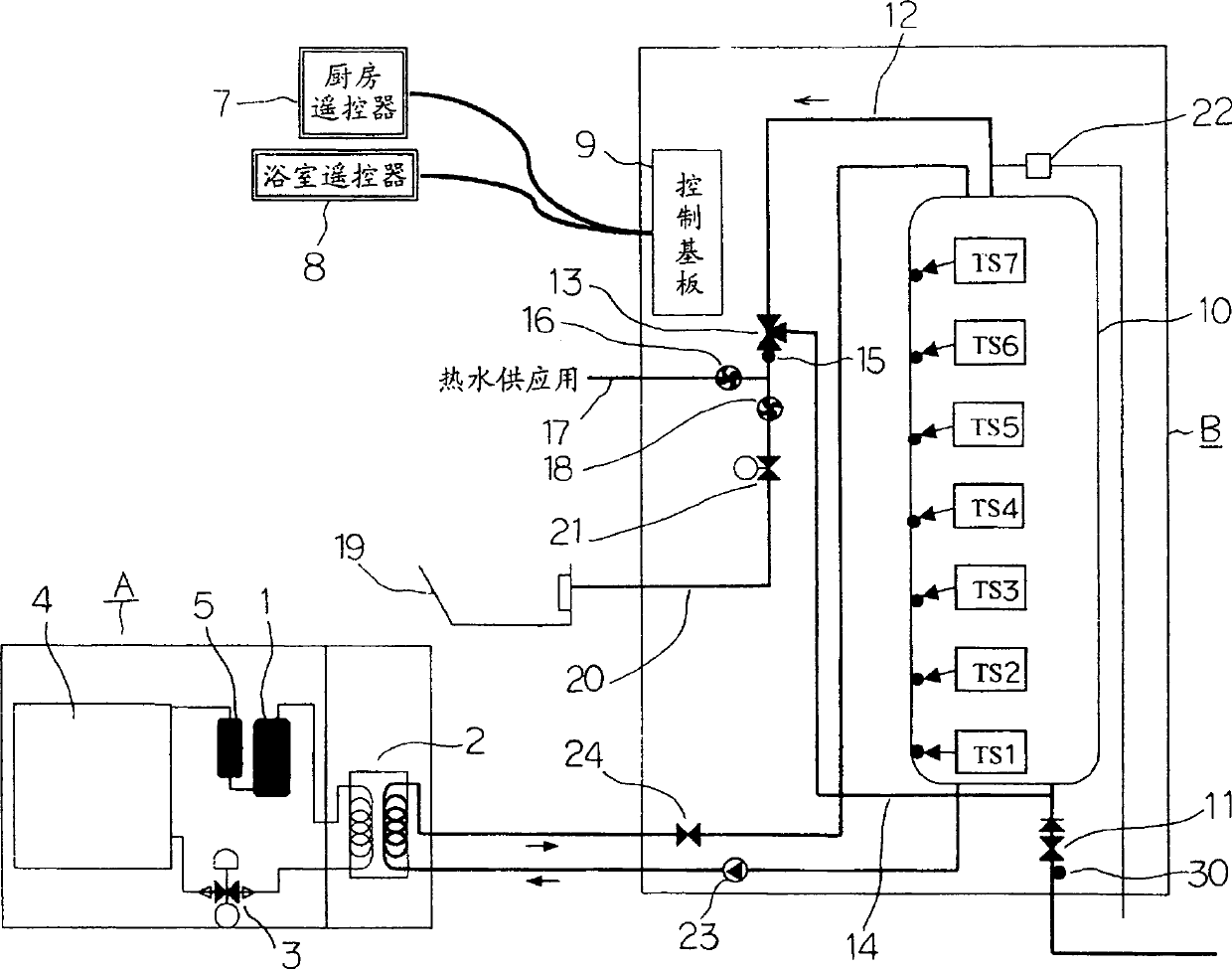

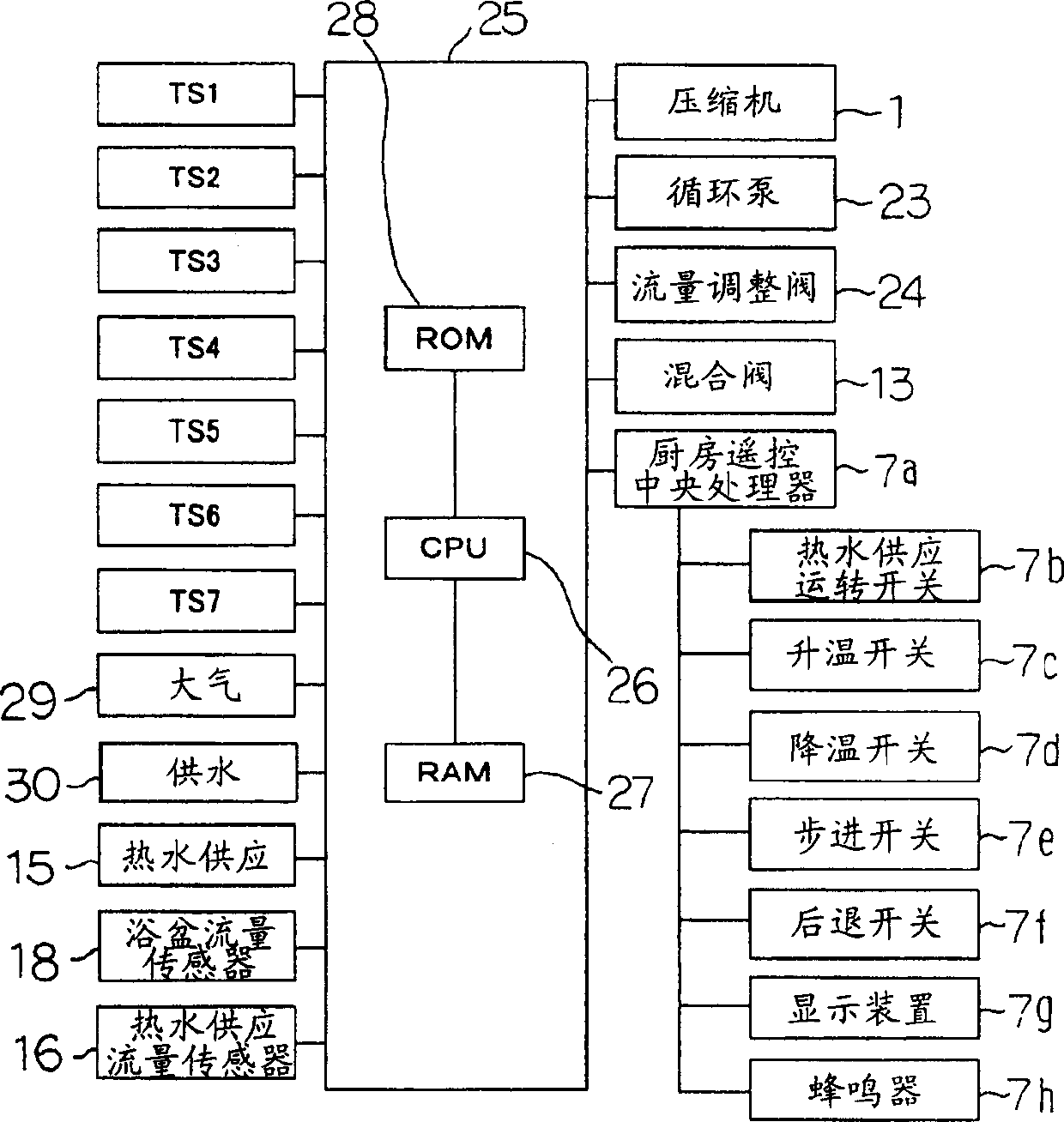

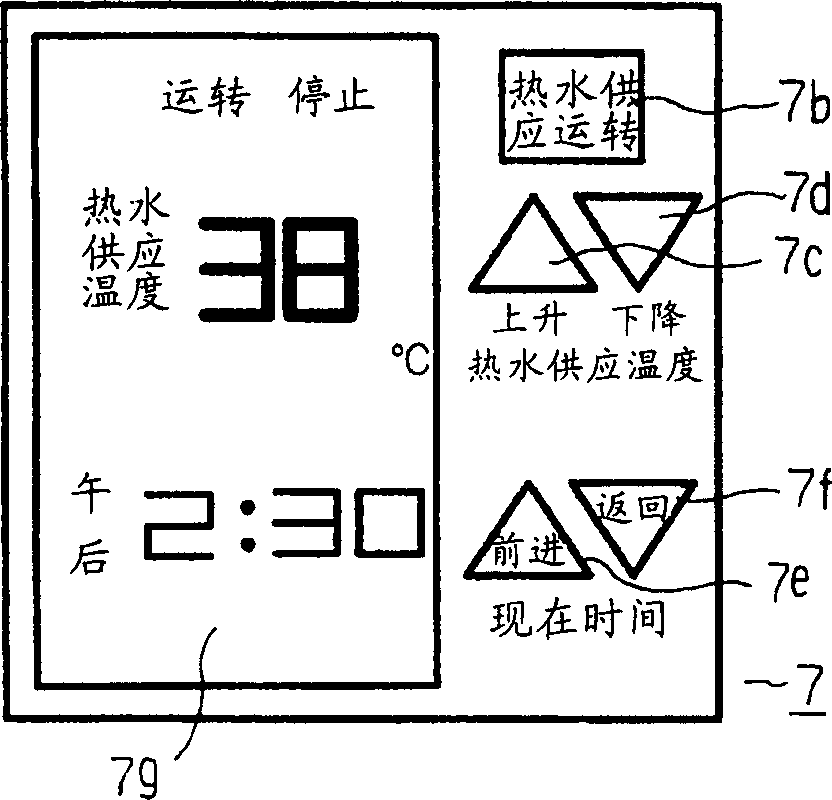

Water heater

InactiveCN1467455AWon't burnMaterial strength using steady bending forcesMaterial strength using steady torsional forcesHeat sensitiveThermistor

A water heater is safe because the hot water supply temperature detection sensor can detect the fault even if it fails, so the user will not be scalded. It includes: a heat source that heats tap water or water stored in a hot water storage tank to a set temperature; a hot water supply flow sensor that detects the amount of hot water supplied from the above heat source or hot water storage tank; The water supply temperature detection thermistor is used to detect the temperature of the hot water supply; the control device controls the heating amount of the heat source according to the temperature of the hot water supply detected by the hot water supply temperature detection thermistor. A microcomputer is provided which detects the hot water supply flow rate sensor when the hot water supply volume exceeds a prescribed amount (2 liters per minute), and continues the detection by the hot water supply temperature detection thermistor for a prescribed time (10 seconds). If the temperature is lower than the specified temperature (55°C), it is determined that the hot water supply temperature detection thermistor is abnormal.

Owner:SANYO ELECTRIC CO LTD +1

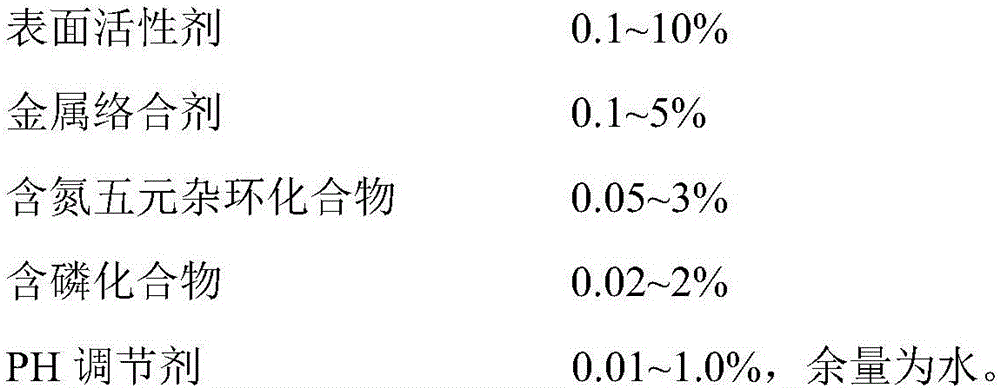

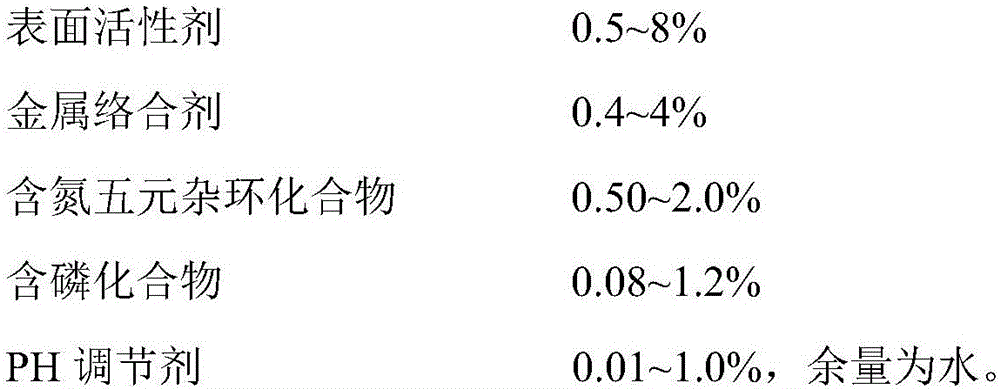

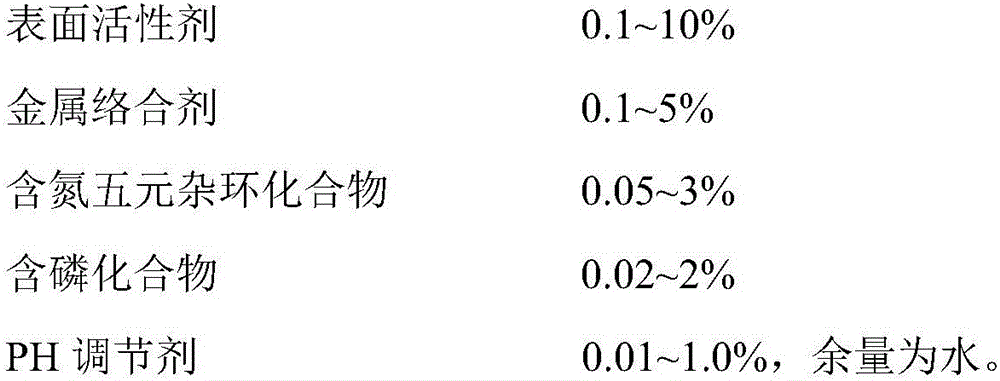

Water-based rust inhibitor for steel protection, and preparation method and application thereof

InactiveCN106756970AGuaranteed anti-rust effectSecurityMetallic material coating processesBurned skinBURNING SKIN

The invention relates to a water-based rust inhibitor for steel protection, and a preparation method and application thereof. The water-based protecting solution is a water-based mixture with the active ingredients including 0.1% to 10% of surfactants, 0.1% to 5% of metal complexing agents, 0.05% to 3% of nitrogen containing five-membered heterocyclic compounds, 0.02% to 2% of phosphorous compounds and pH regulators. A nanometer protective layer is quickly formed on the surface of steel in the water-based solution, the matrix can have excellent corrosion resistance after the nanometer protective layer is formed on the surface of the metal, the water-based rust inhibitor can be recycled without acid mist which pollutes the environment, and the water-based rust inhibitor does not burn skin in use, has no stimulation or damage to human bodies, and is safe, reliable and easy to operate.

Owner:MAANSHAN DEHONG BIOTECH +1

Intelligent temperature control acupuncture therapeutic apparatus

ActiveCN103126881AAccurate temperature controlHeating fastDevices for heating/cooling reflex pointsAcupunctureEngineeringElectrical and Electronics engineering

The invention discloses an intelligent temperature control acupuncture therapeutic apparatus. The intelligent temperature control acupuncture therapeutic apparatus comprises a power module, a liquid touch screen, a touch-screen controller, an electronic temperature control component used for simulating moxibustion temperature curve and a heating head used for being inserted into the handle portion of an acupuncture pin to conduct heating, wherein the electronic temperature control component is composed of a system control module and a heating driving module, the system control module is connected with the heating driving module in a communication mode, the system control module is connected with the power module and the touch-screen controller in a communication mode, the liquid touch screen is connected with the touch-screen controller in a communication mode and used for setting the heating time and the temperature cycle period of the heating head and displaying the temperature change and the heating time of the heating head in work, the heating head is connected with the heating driving module through a guide line, and the system control module and the heating driving module control the temperature change range of the heating head from 30 DEG C to 59 DEG C. According to the intelligent temperature control acupuncture therapeutic apparatus, moxibustion technique change and moxa-cone temperature change are effectively simulated, a continuous and variational thermal stimulus state is kept, fast - slow adaptation phenomenon caused when a human body experiences the apparatus is avoided, and clinical effect is improved.

Owner:上海中医药大学附属龙华医院浦东分院 +2

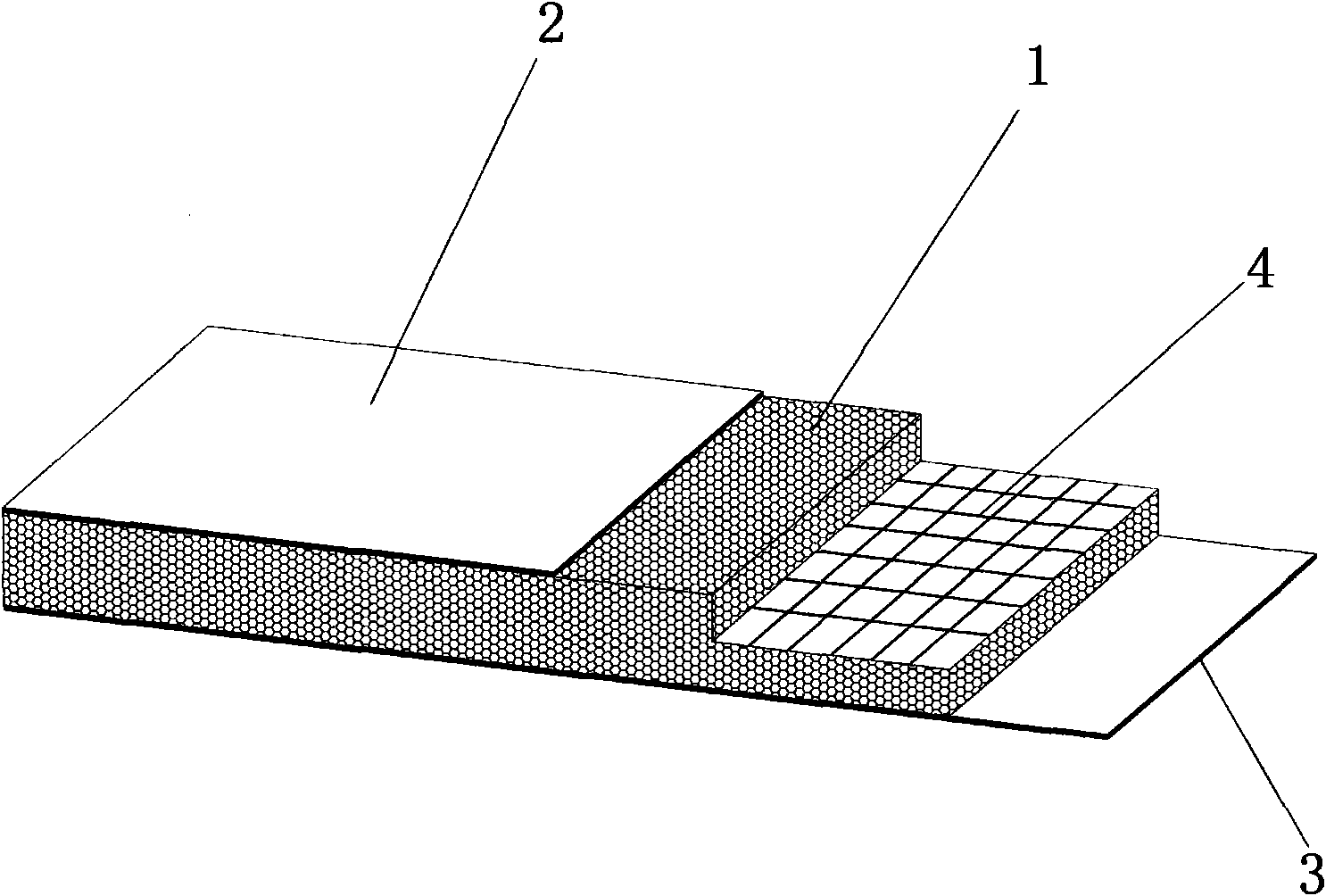

Light foaming concrete composite heat insulation plate

InactiveCN102535660ALow densityRelieve pressureHeat proofingWater-setting substance layered productPolystyreneSurface plate

The invention discloses a light foaming concrete composite heat insulation plate, which comprises an outer panel, an inner panel and a foam concrete slab heat insulation layer, wherein the foam concrete slab heat insulation layer is clamped and arranged between the outer panel and the inner panel. A foam concrete plate used as a middle heat insulation layer has the advantages and properties that the weight is light, the heat insulation and sound isolation effects are realized, the foam concrete plate does not combust, the service life is long, the intensity is high, and the like, so the light-weight foam concrete composite heat insulation plate has the advantages that the weight is light, the heat insulation performance, the sound isolation effect and the inflaming retarding and fireproof performance are good, the durability is realized, the intensity is high, the anti-impact performance is good, the construction is simple and convenient, and the like. The light-weight foam concrete composite heat insulation plate can replace color plates using high molecular materials such as polystyrene foam, polyurethane and the like as heat insulation layers, can be used as heat insulation materials for buildings, and can be particularly used as roof materials.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

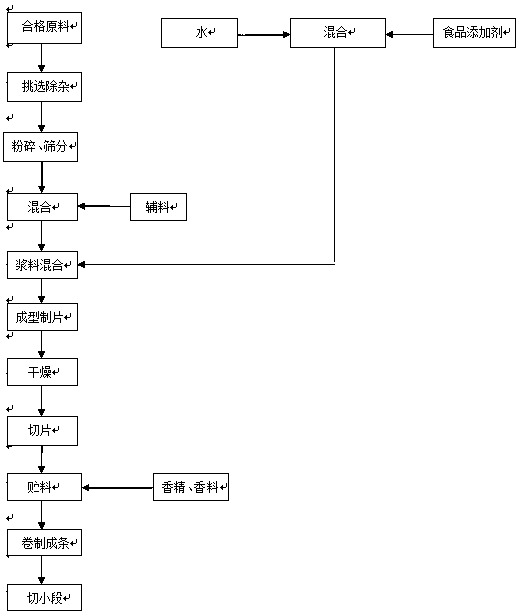

Tea healthy suction substance and preparation method of tea healthy suction substance

PendingCN108606362AAntioxidantRefreshingTobacco treatmentPre-extraction tea treatmentSmokeCatechinic acid

The invention provides a tea healthy suction substance and a preparation method of the tea healthy suction substance. The tea healthy suction substance comprises a smoke body, the smoke body comprisesexternal cigarette paper and a suction substance body arranged in the cigarette paper, the suction substance body is rolled into a cylindrical shape by a suction substance slip, the suction substanceslip comprises a plurality of connecting segments and loosening segments arranged between the connecting segments, and the connecting segments wrap the loosening segments during rolling of the connecting segments and loosening segments. The invention further provides a preparation method. The method comprises the steps that active ingredients extracted from tea slices are made into slips and assembled after being cut, the ingredients mainly comprise tea polyphenol (catechinic acid) and the like and have the effects of resisting oxidation and scavenging free radicals and the like, menthol is adopted and has the effects of cooling and refreshing and can completely replace tobacco.

Owner:东莞市香草生物工程有限公司

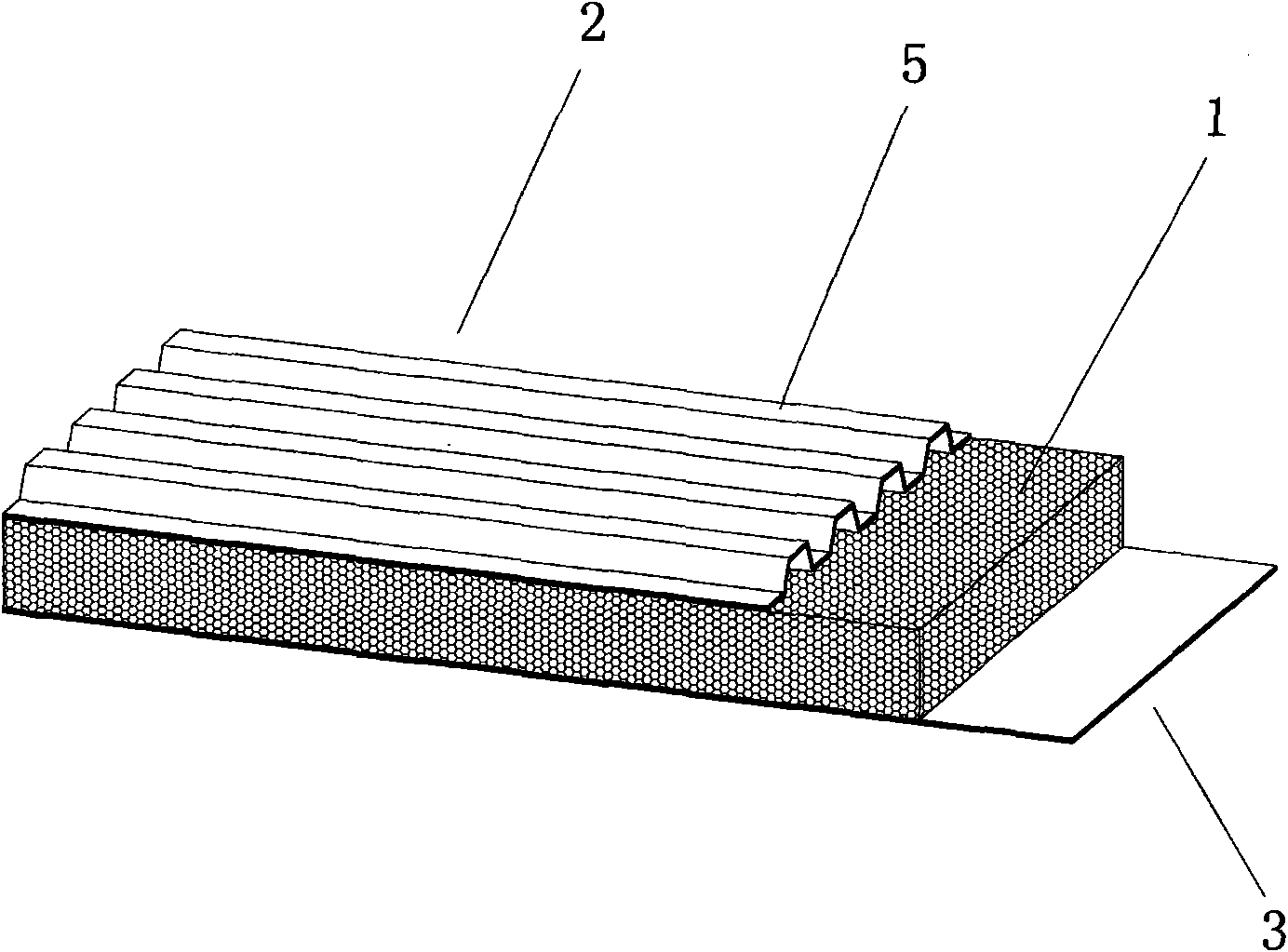

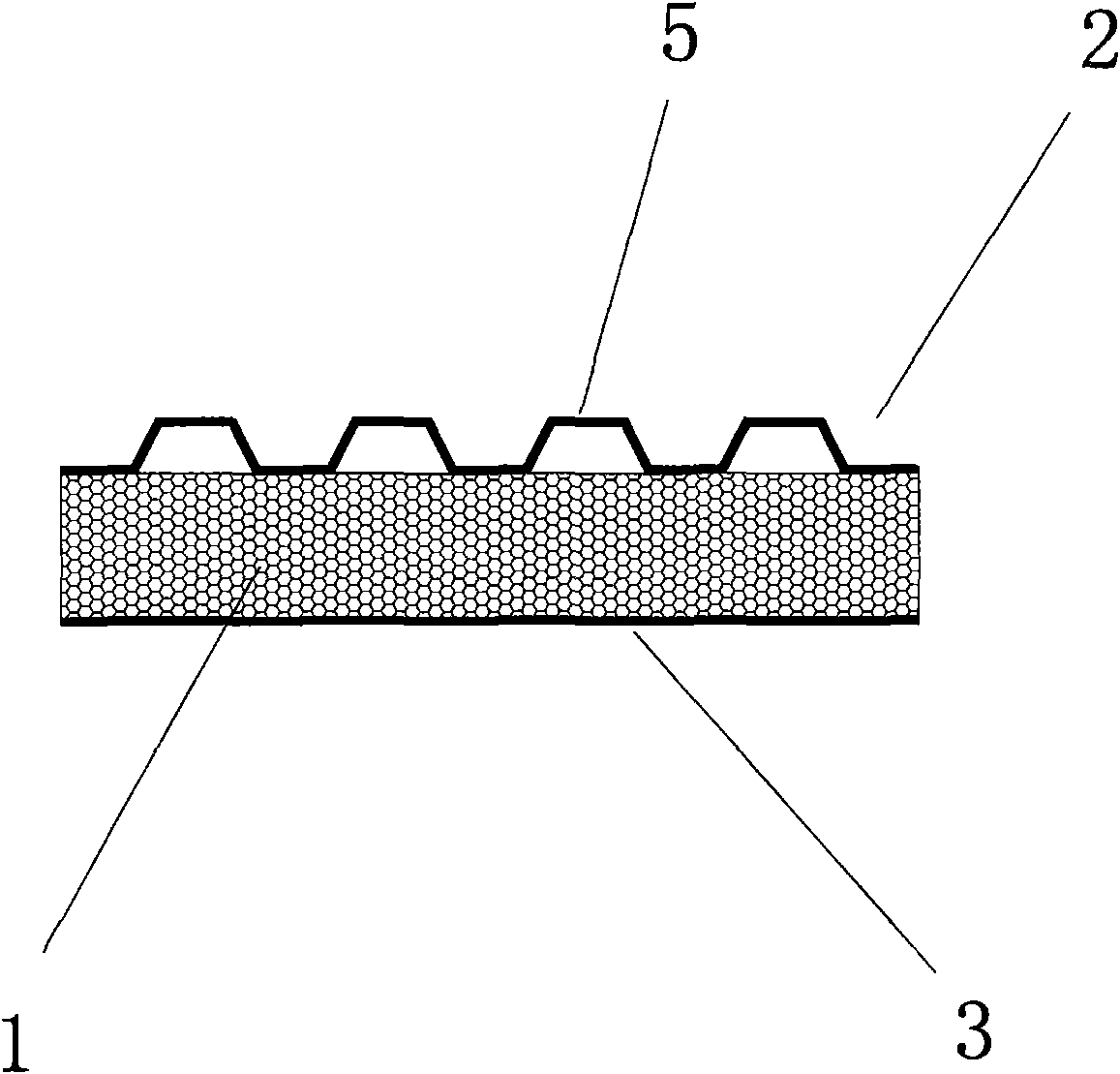

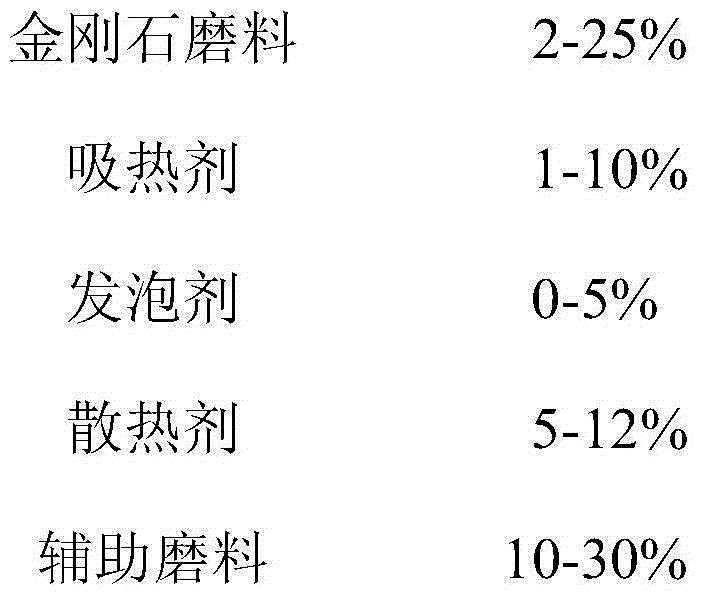

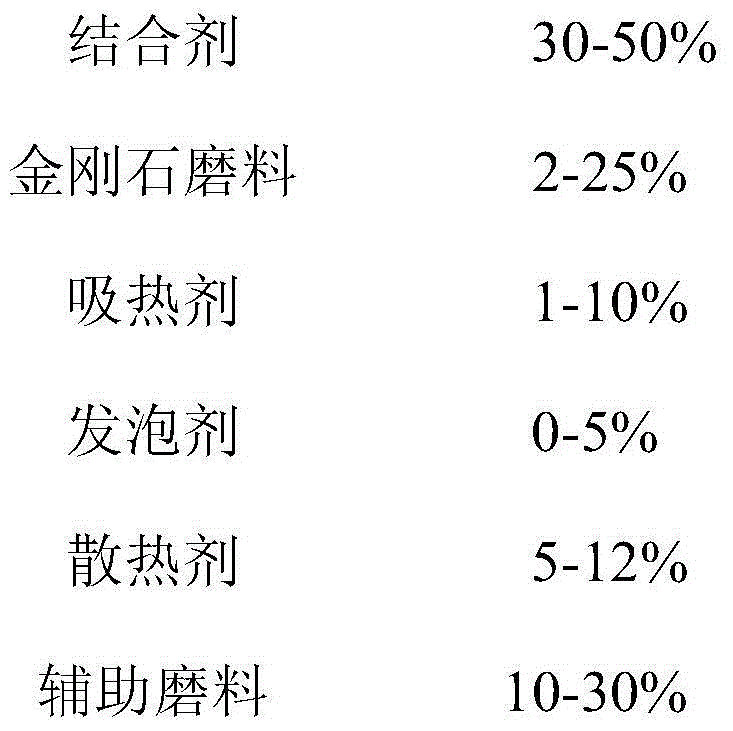

Screen printing type casting diamond dry grinding sheet and manufacturing process thereof

ActiveCN104816257AReduce the temperatureImprove protectionAbrasion apparatusGrinding devicesScreen printingPolymer adhesive

The invention provides a screen printing type casting diamond dry grinding sheet and a manufacturing process thereof. The manufacturing process comprises placing the following materials of, by volume, 30 to 50% of binding agent, 2 to 25% of diamond grinding materials, 1 to 10% of endothermic agent, 0 to 5% of foaming agent, 5 to 12% of cooling agent and 10 to 30% of grinding materials into a mixer to be mixed for 1 to 4 hours; brushing mixed paste on a textile base layer through a screen printing die; lifting up the die to be naturally solidified for 3 to 36 hours at the room temperature or placing the die into an oven to be solidified for 1 to 42 hours under the condition of 60 to 300 DEG C; adhering a layer of nylon buckle wool surface or nylon buckle hook surface onto the bottom surface of the textile base layer through a polymer adhesive; trimming the edge to obtain a dry grinding sheet finished product. According to the screen printing type casting diamond dry grinding sheet and the manufacturing process thereof, devices are simple, the process is advanced, the heat resistance of the dry grinding is improved, most of the heat generated in the grinding process can be absorbed, and the grinding temperature is directly reduced.

Owner:HUBEI LITTLE ANT DIAMOND TOOLS CO LTD

Cutting propagation method for kadsura coccinea

InactiveCN105409547AIncrease vitalityImprove survival rateFertilising methodsPlant cultivationDiseaseInsect pest

The invention discloses a cutting propagation method for kadsura coccinea. The cutting propagation method comprises the following steps: sand bed preparation: mixing river sand, vermiculite and plant ash to form a mixed matrix according to the volume ratio of 4:3:1 and establishing a sand bed; cutting slips preparation: selecting annual semi-ripe branches with complete laminas and full leaf buds and without diseases or insect pests in the initial stage or middle stage of plants of the kadsura coccinea, obliquely cutting off lower notches of the branches and flatly cutting off upper notches of the branches to obtain stems with 1-2 laminas at lower ends, and taking the stems of which each section has a corresponding leaf as a cutting slip; cutting slip pretreatment: soaking the cutting slips in a rooting agent aqueous solution for 10-30 minutes; and cutting: cutting the cutting slips on the sand bed, wherein line spacings are 10-14 cm, plant spacings are 3-4 cm, the lengths of parts, which are inserted in the sand bed, of the cutting slips are 3-5 cm, and cutting is carried out at 6 pm to 8 pm from the end of May to the beginning of July. The cutting propagation method disclosed by the invention has the advantages of high rooting rate, high seedling rate, short cultivation time and the like.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

ActiveCN105648542ASolve for uniformitySolve heatingSilk filament obtainingUltrasonic assistedCoupling

A microwave and ultrasonic wave assisted cocoon cooking device comprises a cocoon cooking barrel outer drum, a microwave generator, an ultrasonic wave generator, a cocoon cooking barrel inner drum, an upper cover of the cocoon cooking barrel outer drum, a lower cover of a cocoon cooking barrel discharge opening, and a cocoon cooking barrel; a plurality of microwave generators and ultrasonic wave generators are distributed on the outer side of the cocoon cooking barrel outer drum; the cocoon cooking barrel inner drum is made of punching hole meshes or mesh materials, and a cover of the cocoon cooking barrel inner drum consists of two semi-circular sector cover plates made of punching hole meshes or mesh materials and connected through a coupling at the circle center; the cover of the cocoon cooking barrel inner drum can be opened or closed in a rotational manner; a pressure gage and a temperature measurer are mounted on the upper cover of the cocoon cooking barrel outer drum; the lower cover of the cocoon cooking barrel discharge opening is connected with a hot water inlet pipe and is equipped with a porous steam coil and the ultrasonic wave generator; the filature cocoon cooking device has a compact and reasonable structure and is high in integration, and a cocoon cooking of the device adopts a microwave assisted direct-streaming technology and an ultrasonic wave assisted cocoon cooking technology at the same time, so that inner, middle and outer layers of cocoons are heated uniformly, the energy is saved, the consumption is reduced, and the cocoon cooking is shortened.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Method for processing non-woven wall fabrics

InactiveCN103276534AHigh vapor permeabilityAvoid condensationNon-woven fabricsPolypropylenePolyester

The invention mainly discloses a method for processing non-woven wall fabrics. The method includes steps of firstly, processing polypropylene or polyester spun-bonded non-woven fabrics; secondly, printing design patterns on the polypropylene or polyester spun-bonded non-woven fabrics; and thirdly, coating movable gum on back surfaces of the spun-bonded non-woven fabrics by a coating technique by the aid of a scraper. A technique for processing the polypropylene or polyester spun-bonded non-woven fabrics includes adding environment-friendly polypropylene flame-retardant master batches with the mass percent of 0-10% into polypropylene or polyester processed raw materials; mixing the environment-friendly polypropylene flame-retardant master batches and the polypropylene or polyester processed raw materials to obtain mixtures, and performing melt extrusion on the mixtures by a large screw; filtering the extruded mixtures by a filter which is a metal screen with 600-1200 meshes to obtain melt; quantitatively outputting the melt at the speed of 80-400 liters per hour by a metering pump; spinning the melt to obtain fibers; cooling the fibers by air; drafting the fibers by air flows; and forming nets of net curtains. The method has the advantages that new products manufactured by the method are excellent in flame-retardant effect, high in vapor permeability, convenient to assemble and disassemble and low in cost, and the like.

Owner:绍兴聚能新材料科技有限公司

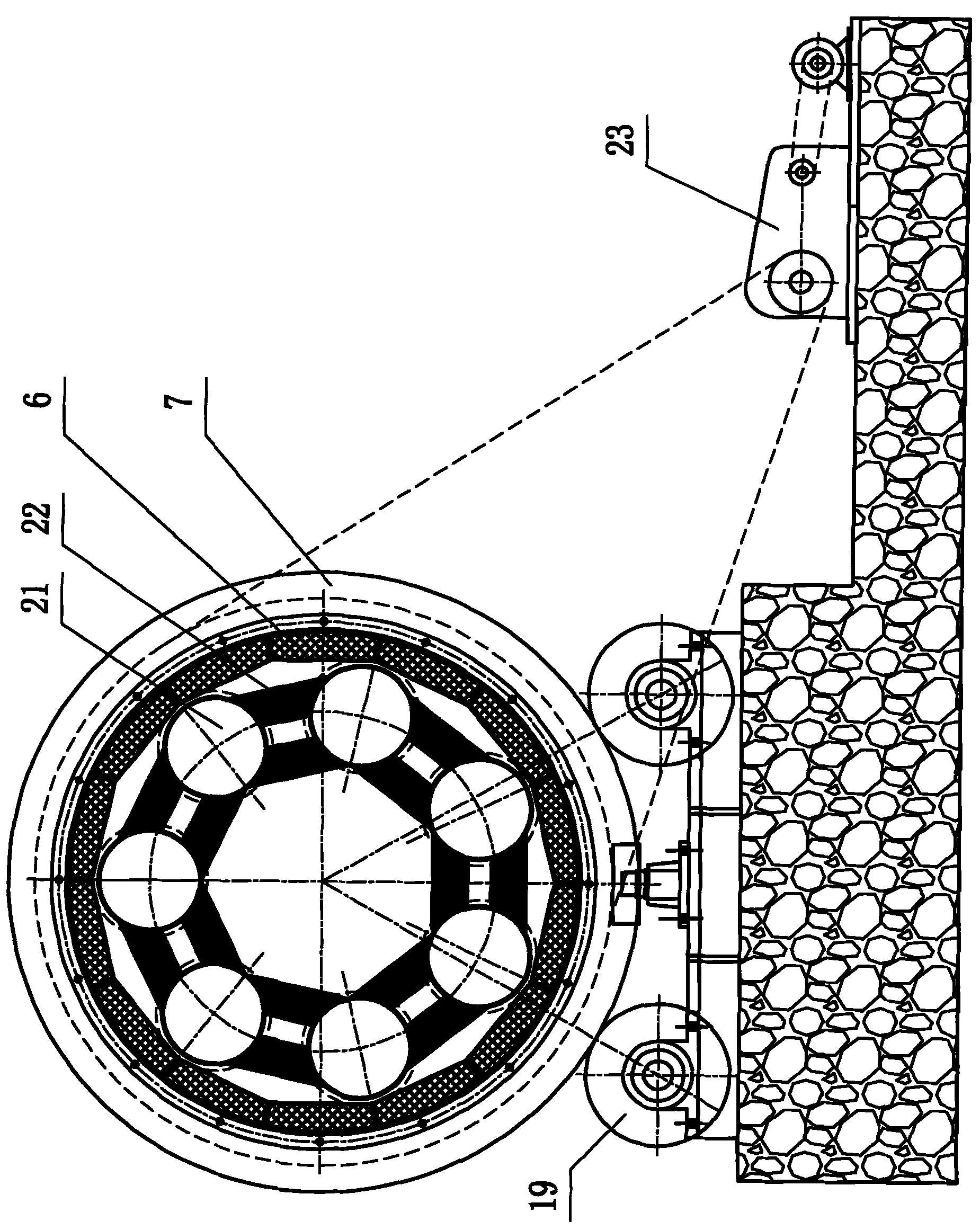

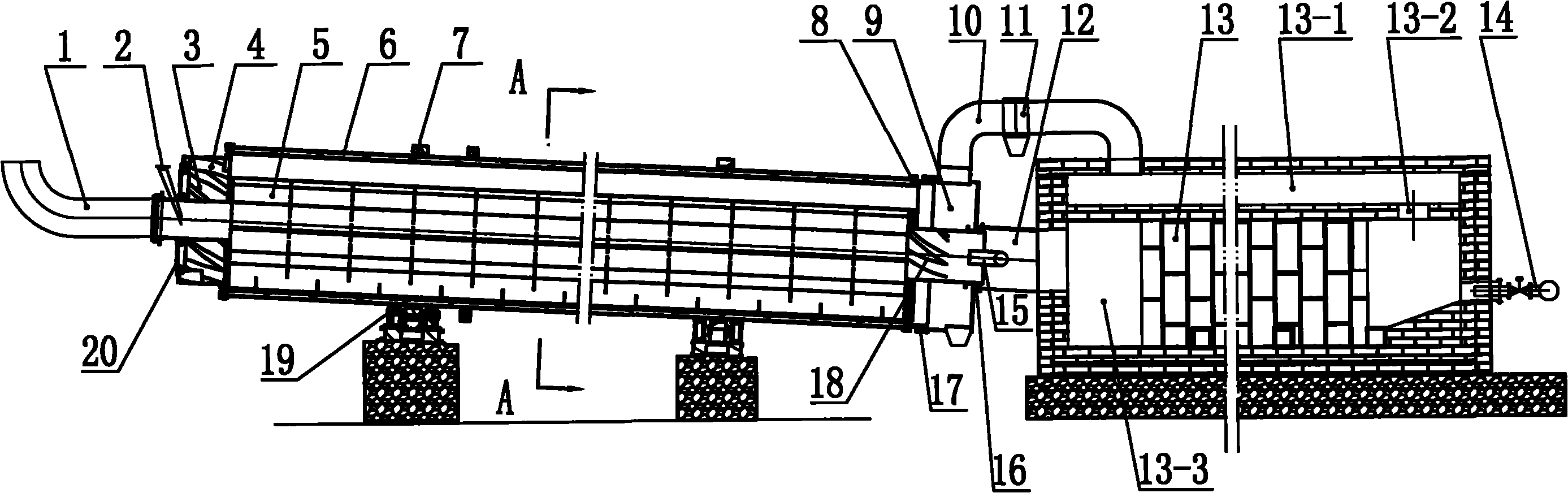

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706AImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

An electronic cigarette atomizer

The invention discloses an electronic cigarette atomizer, which comprises an oil bin, a capillary tube and a suction nozzle. The oil inlet end of the capillary tube is communicated with the oil bin inner cavity, and the oil outlet end of the capillary tube is communicated with the suction nozzle. The oil bin is provided with an air vent which communicates the oil bin inner cavity and the atmosphere, and also comprises a key assembly which can open or close the air vent. A circuit board and a circuit switch assembly for controlling whether a circuit key switch on the circuit board is turned onare also included. The key assembly and the circuit switch assembly are linked, and when the key assembly controls the air vent to open, the circuit switch assembly controls the circuit key switch toturn on; when the key assembly controls the vent to close, the circuit switch assembly controls the key switch to open. As that smoke oil can be quickly and timely supply to the heating component through the capillary tube for atomization, the us is not easy to suck large droplets, the atomization is sufficient, the smoke particles are fine and exquisite, the smoke mouthfeel is good, the smoke amount is large, the oral cavity is not scalded, and the user experience is good.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

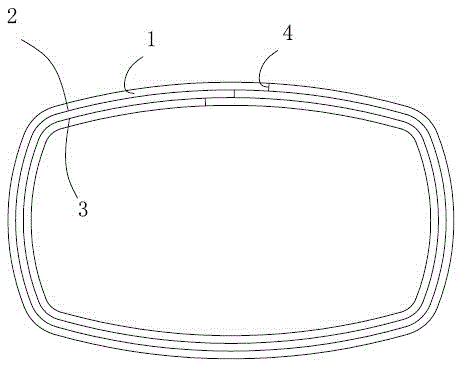

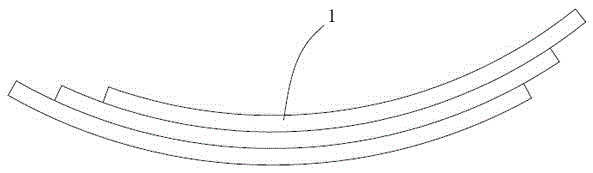

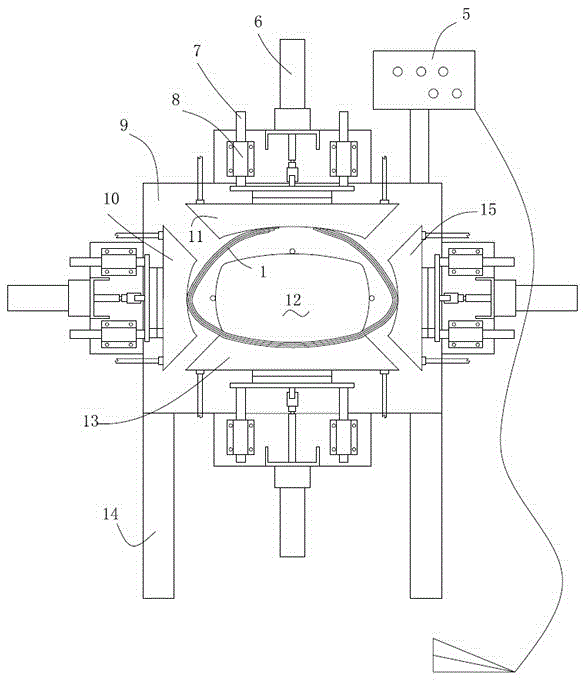

Bamboo frame forming process

ActiveCN105522634AWon't burnConvenient heating controlCane mechanical workingWood stock bendingEngineeringSoftening

The invention relates to a bamboo frame forming process which solves the defects that current bamboo frame marking-taping adopts an artificial mode, bamboo wood is required to be cut into relatively thin flat bamboo strips, processing is inconvenient, and working efficiency is low. The bamboo frame forming process comprises the following steps: firstly heating a fixed mould and a movable mould assembly to a proper temperature; preparing bamboo strips; arranging the bamboo strips; placing the bamboo strips and closing a mould; sizing; and de-molding. The bamboo frame forming process is used for heating the fixed mould and the movable mould assembly, and clamping the bamboo strips after heating, so that a heat source is not directly acted to the bamboo strips; the heating temperature of the bamboo strips can be controlled by controlling the heating temperature of the fixed mould and the movable mould assembly, so that the bamboo strips are ensured to be not burned in roasting or baking during softening, and the heating control of the fixed mould and the movable mould assembly is relatively convenient; the movable mould assembly and the fixed mould are closed for clamping the bamboo strips, so that bounce force generated by the bamboo strips can be overcome, and therefore, the thickness of the bamboo strips can be increased, the bamboo frame can be formed by making-taping with less bamboo strips, the processing efficiency is high, and all bamboo strips of the bamboo frame can be simultaneously bent and sized once.

Owner:ZHEJIANG SANJIAN IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com