Screen printing type casting diamond dry grinding sheet and manufacturing process thereof

A manufacturing process and diamond technology, which is applied in the field of screen printing cast diamond dry grinding discs and its manufacturing process, can solve the problems of high equipment power and thermal requirements, lower grinding temperature, and unfavorable energy saving and environmental protection, etc., to achieve no power Consumption, improved heat resistance, less clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1: A kind of screen printing type casting method diamond dry grinding disc, the specific manufacturing steps are as follows:

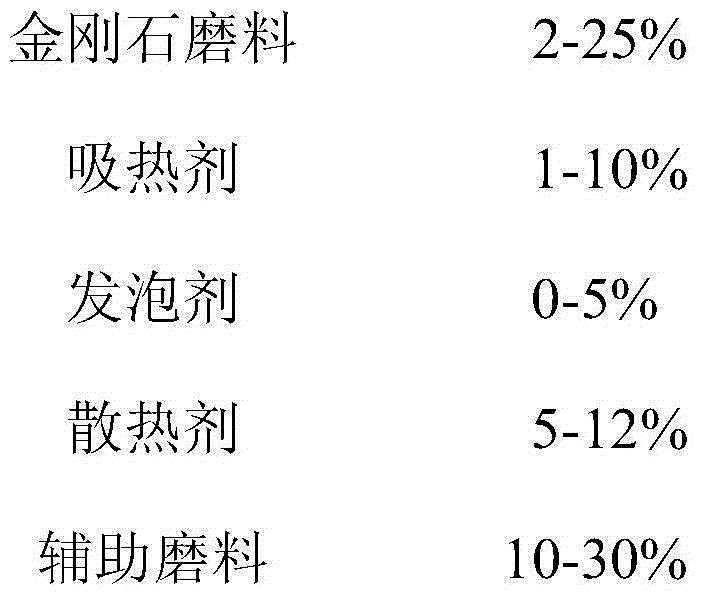

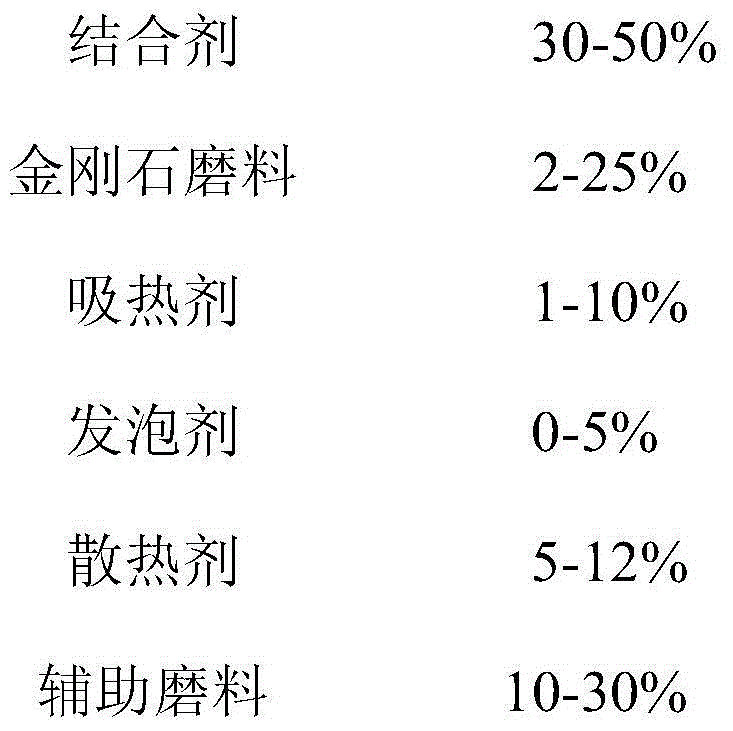

[0030] (1) Take the material of the abrasive working layer according to the following parts by volume: the liquid phenolic resin of 40% parts by volume, the liquid epoxy resin of 5% parts by volume, the diamond abrasive of 21% parts by volume, the cryolite of 2% parts by volume , the sodium lauryl sulfate of 5% parts by volume, the copper powder of 10% parts by volume, the zinc oxide of 17% parts by volume;

[0031](2) Add all the above-mentioned substances into the mixer and stir for 2 hours until fully mixed, and prepare abrasive layer slurry. After the materials of the volume fraction of the above components are mixed evenly, a suitable viscosity and natural shape can be formed. slurry;

[0032] (3) Lay the prepared cotton base layer on a flat workbench, and then select a screen printing mold that matches the design drawing to be pla...

example 2

[0035] Example 2: A kind of screen printing type casting method diamond dry grinding disc, the specific manufacturing steps are as follows:

[0036] (1) Take the material of the abrasive working layer according to the following parts by volume: the liquid epoxy resin of 32% parts by volume, the melamine formaldehyde resin of 8% parts by volume, the diamond abrasive of 15% parts by volume, the cryolite of 8% parts by volume , 12% by volume of copper powder, 15% by volume of silicon carbide; 10% by volume of zinc oxide;

[0037] (2) Add all the above-mentioned substances into the mixer and stir for 1 hour until fully mixed, and prepare the abrasive layer slurry;

[0038] (3) Lay the prepared cotton base layer on a flat workbench, and then select a screen printing mold that matches the design drawing to be placed on the surface of the textile according to the structural design drawing of the dry grinding sheet;

[0039] (4) Pour the abrasive layer slurry mixed in step (1) on the...

example 3

[0041] Example 3: A kind of screen printing type casting method diamond dry grinding disc, the specific manufacturing steps are as follows:

[0042] (1) Take the material of the abrasive working layer according to the following parts by volume: liquid phenolic formaldehyde of 30% parts by volume, polyimide of 15% parts by volume, diamond abrasive of 25% parts by volume, cryolite of 3% parts by volume; 12% by volume of aluminum powder, 10% by volume of strontium oxide; 5% by volume of aluminum oxide;

[0043] (2) Add all the above-mentioned materials into the mixer and stir for 4 hours to fully mix, and prepare the abrasive layer slurry;

[0044] (3) Lay the prepared cotton base layer on a flat workbench, and then select a screen printing mold that matches the design drawing to be placed on the surface of the textile according to the structural design drawing of the dry grinding sheet;

[0045] (4) Pour the abrasive layer slurry mixed in step (1) on the mold, and use a special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com