Bamboo frame forming process

A molding process, bamboo frame technology, applied in the direction of manufacturing tools, wood processing utensils, sugarcane machining, etc., can solve the problems of high processing efficiency, inconvenient processing, low processing efficiency, etc., achieve high processing efficiency, save processing time, The effect of convenient heating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

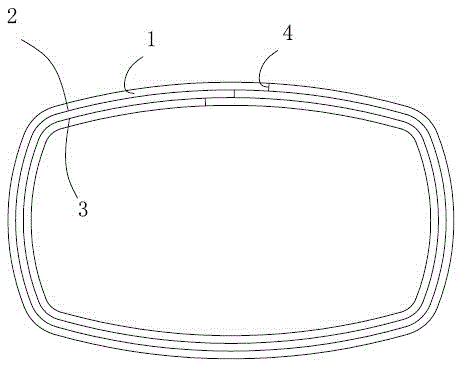

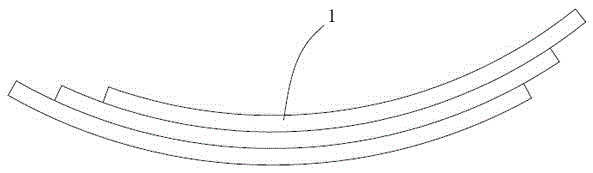

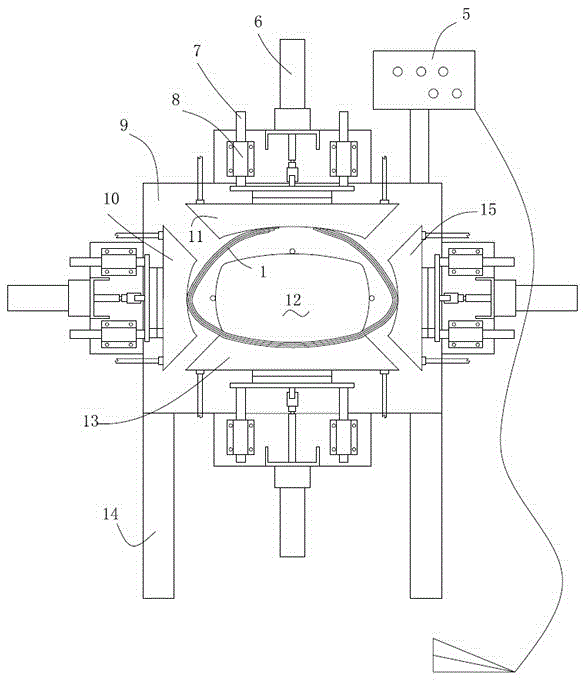

[0031] Embodiment: a kind of bamboo frame molding process, uses bamboo frame molding die, and bamboo frame molding die comprises frame, and frame comprises a frame body 14 and the mounting plate 9 that is fixed on the frame body, and mounting plate is inclined shape, and mounting plate is provided with a forming die (see image 3 ).

[0032] The forming mold includes a fixed mold 12 and four movable mold assemblies, the fixed mold is fixed in the middle of the mounting plate, and the four movable mold assemblies are arranged around the fixed mold in four directions, namely the upper movable mold assembly 11 , The left side moving die assembly 10, the lower side moving die assembly 13 and the right moving die assembly 15. The forming mold is inclined equally with the mounting plate, and the outer side of the fixed mold and the side of the movable mold towards the fixed mold form a bamboo frame molding area, and the movable mold assembly is movably connected with respect to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com