Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

An ultrasonic wave and cocoon cooking technology, which is applied in textiles and papermaking, silk fiber production, mechanical treatment, etc., can solve the problems of slow heat transfer, uneven cocoon cooking degree, uneven cocoon heating, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

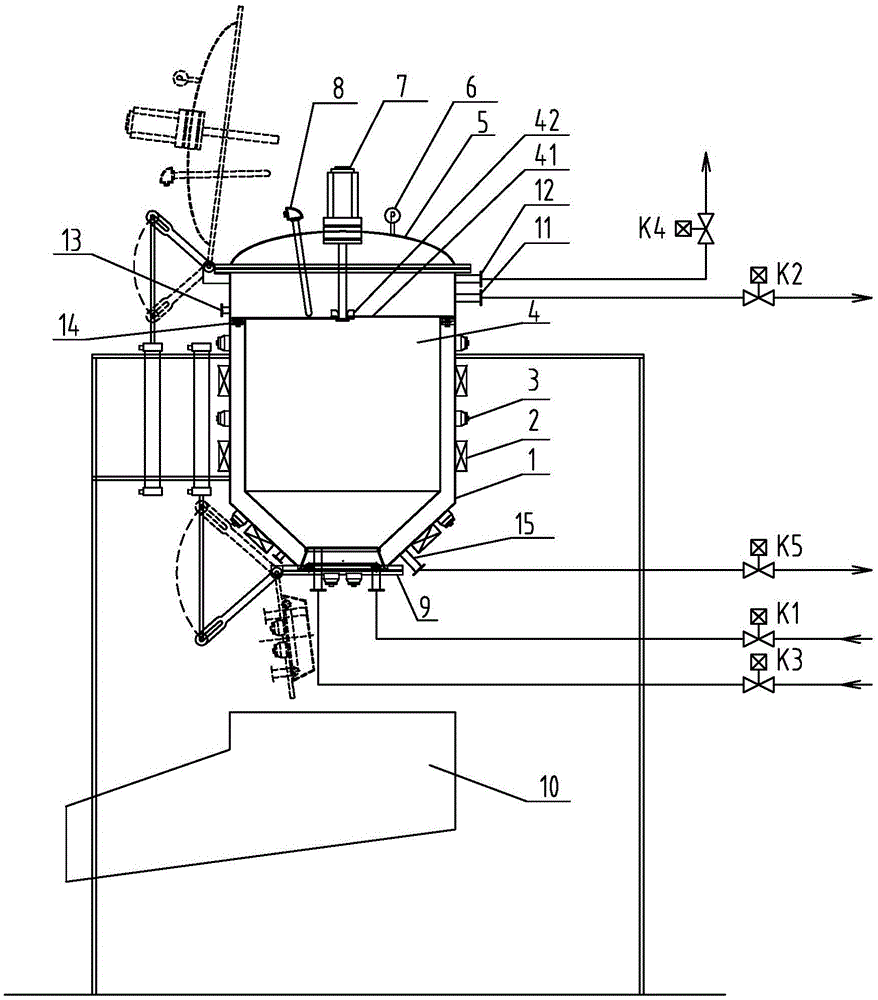

[0065] A microwave and ultrasonic assisted cocoon cooking device:

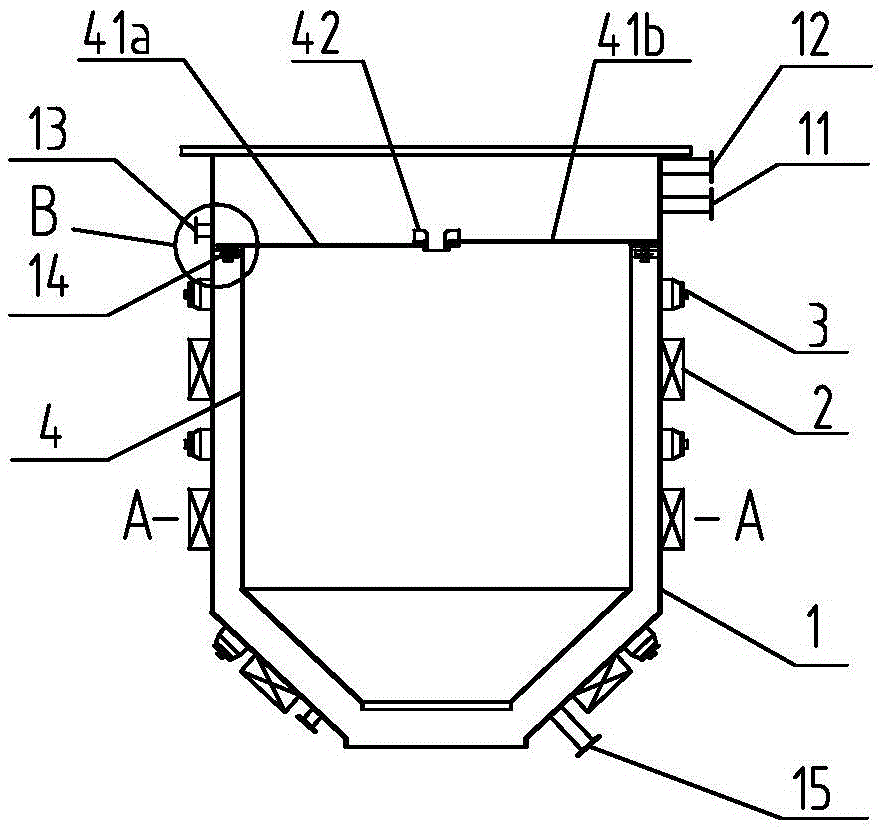

[0066] Such as figure 1 As shown, the cocoon cooking device includes an outer cocoon cooking barrel 1, a microwave generator 2, an ultrasonic generator 3, an inner barrel 4 of the cocoon cooking barrel, an upper cover 5 of the cocoon cooking barrel outer barrel, a lower cover 9 of the cocoon cooking barrel discharge opening and cocoon bucket 10;

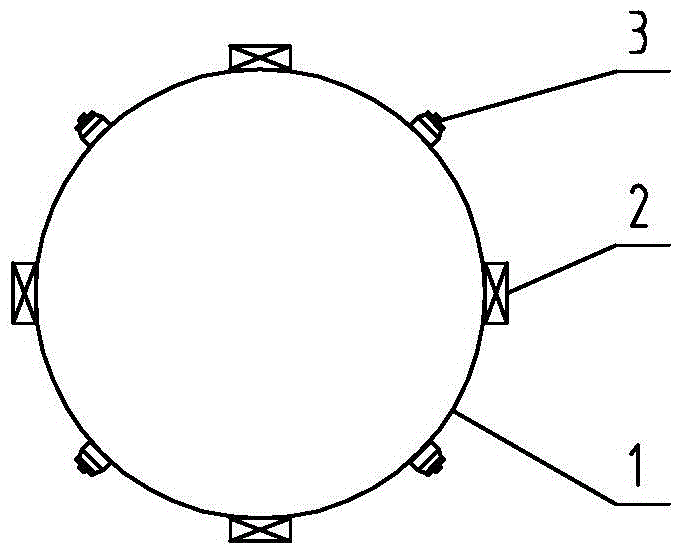

[0067] There are 3 groups of 12 microwave generators 2 and 4 groups of 16 ultrasonic generators 3 distributed outside the outer barrel 1 of the cocoon cooking barrel; (see figure 1 , diagram 2-1 , Figure 5-1 );

[0068] Such as Figure 3-1 , Figure 3-2 As shown, the inner barrel 4 of the cocoon cooking barrel is made of perforated mesh or mesh material, and the upper edge of the inner barrel can rotate along the circular guide rail 14 on the inner wall of the outer barrel. The rotation of the inner barrel of the cocoon cooking barrel is conducive to steam, m...

Embodiment 2

[0074] A method for cocoon cooking assisted by microwave and ultrasonic waves, which uses the cocoon cooking device assisted by microwave and ultrasonic waves described in Embodiment 1 and its industrial computer control system to realize the cocoon cooking assisted by microwave and ultrasonic waves, and it includes the following steps:

[0075] A. Turn on the industrial computer system, select and set the production process, device and system operation;

[0076] B. Feeding: Open the upper cover 5, add the raw material cocoon into the inner barrel 4 until it is close to the inner barrel cover 41, and cover the upper cover;

[0077] C. Start: The motor 7 is started, and the motor drives the inner barrel cover 41b to rotate 180 degrees through the inner cover coupling until the locking nail 43 closes the inner barrel cover; at the same time, the locking nail 43 drives the inner barrel to rotate;

[0078] D. Steam contact steaming: the control system opens the emptying valve K4 a...

Embodiment 3

[0089] A cocoon-cooking method assisted by microwave and ultrasonic wave, which is also a cocoon-cooking method assisted by microwave and ultrasonic wave by using the cocoon-cooking device assisted by microwave and ultrasonic wave described in Embodiment 1 and its industrial computer control system, and its basic steps are the same as those in Embodiment 2 , It differs from Example 2 in that: its D, steam contact steaming step is vacuum contact steaming, and its G, temperature rise, and temperature control steps are the G, temperature rise, temperature control step II of the steam cocoon cooking step; its specific Proceed as follows:

[0090] A. Turn on the industrial computer system, select and set the production process, device and system operation;

[0091] B. Feeding: Open the upper cover 5, add the raw material cocoon into the inner barrel 4 until it is close to the inner barrel cover 41, and cover the upper cover;

[0092] C. Start: The motor 7 is started, and the motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com