An electronic cigarette atomizer

An electronic cigarette atomizer and circuit technology, applied in the field of electronic cigarettes, can solve the problems of heavy particles, easy burns to the mouth, and small amount of smoke, and achieve the effects of fine smoke particles, good user experience, and good smoke taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

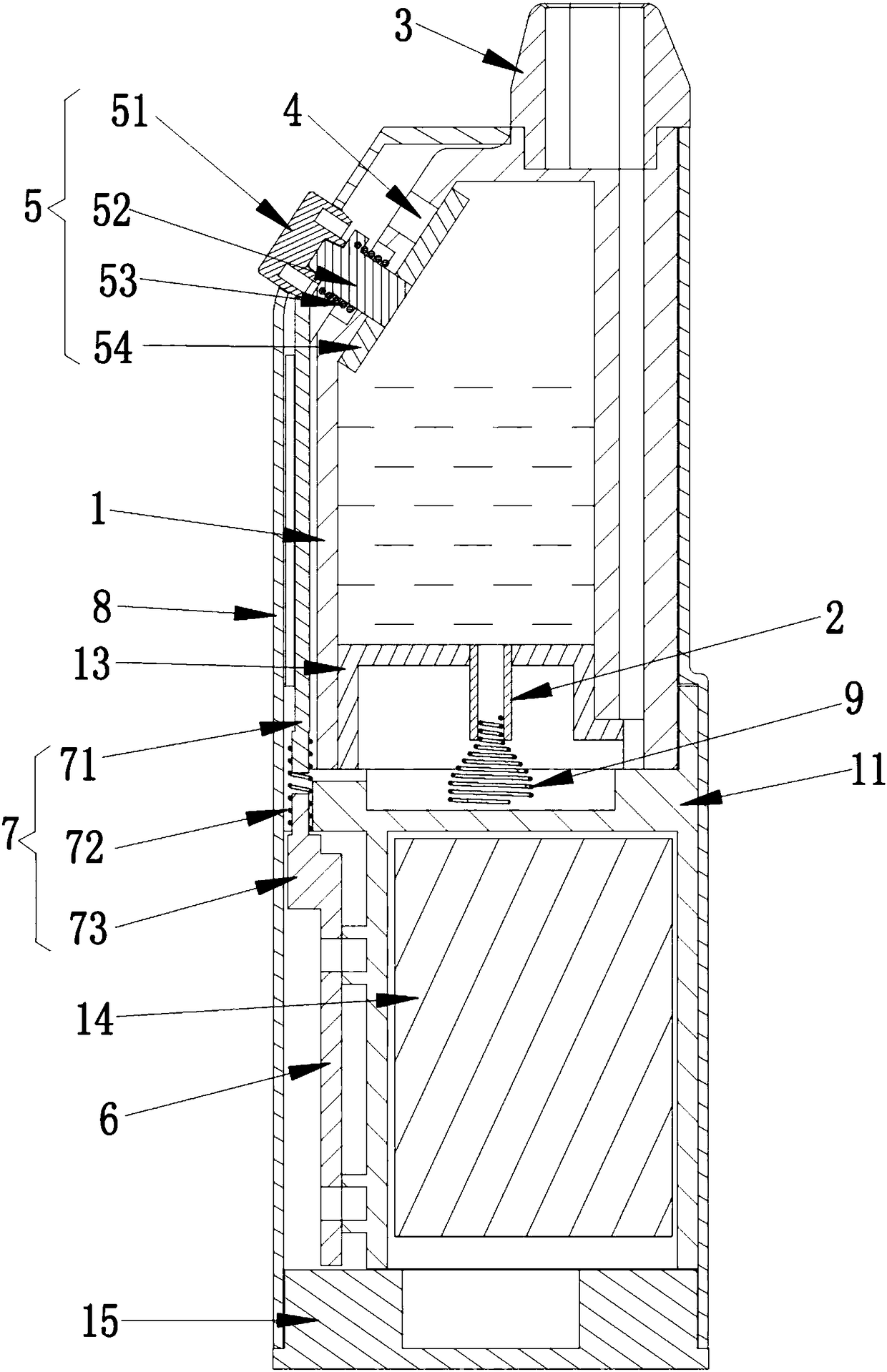

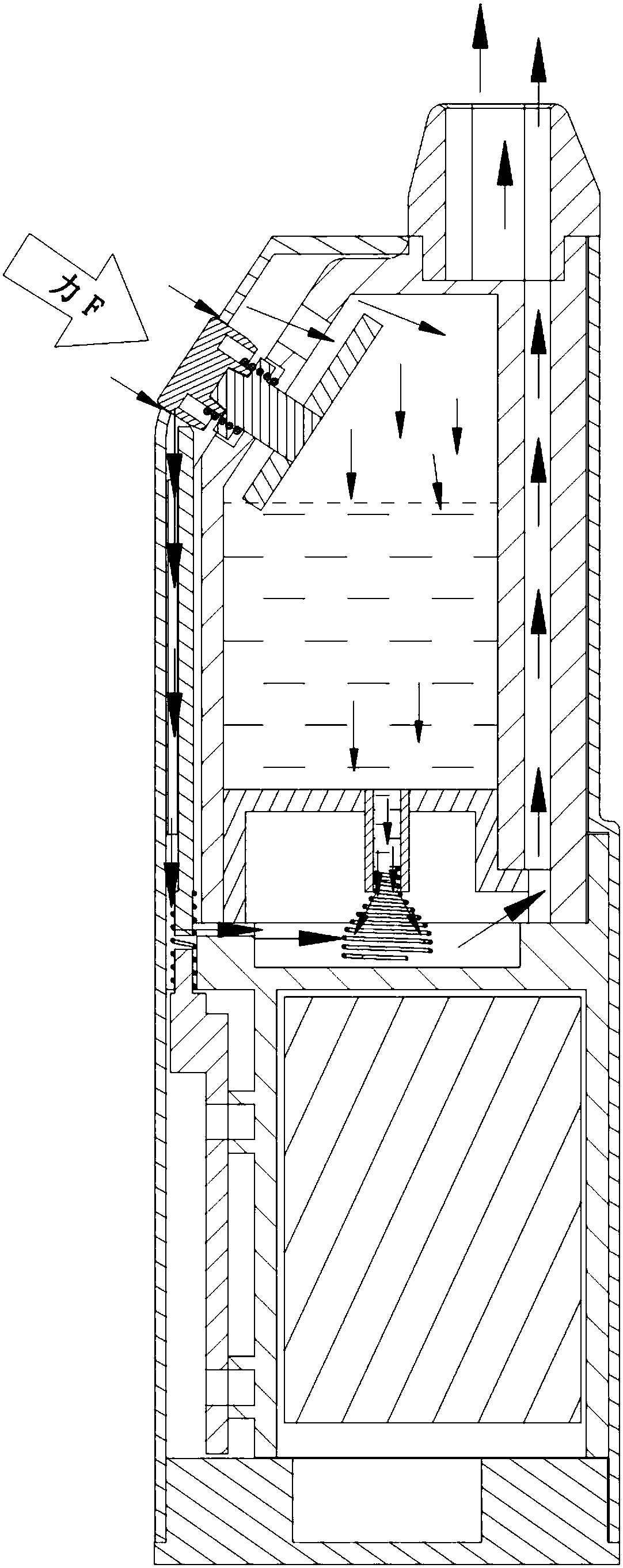

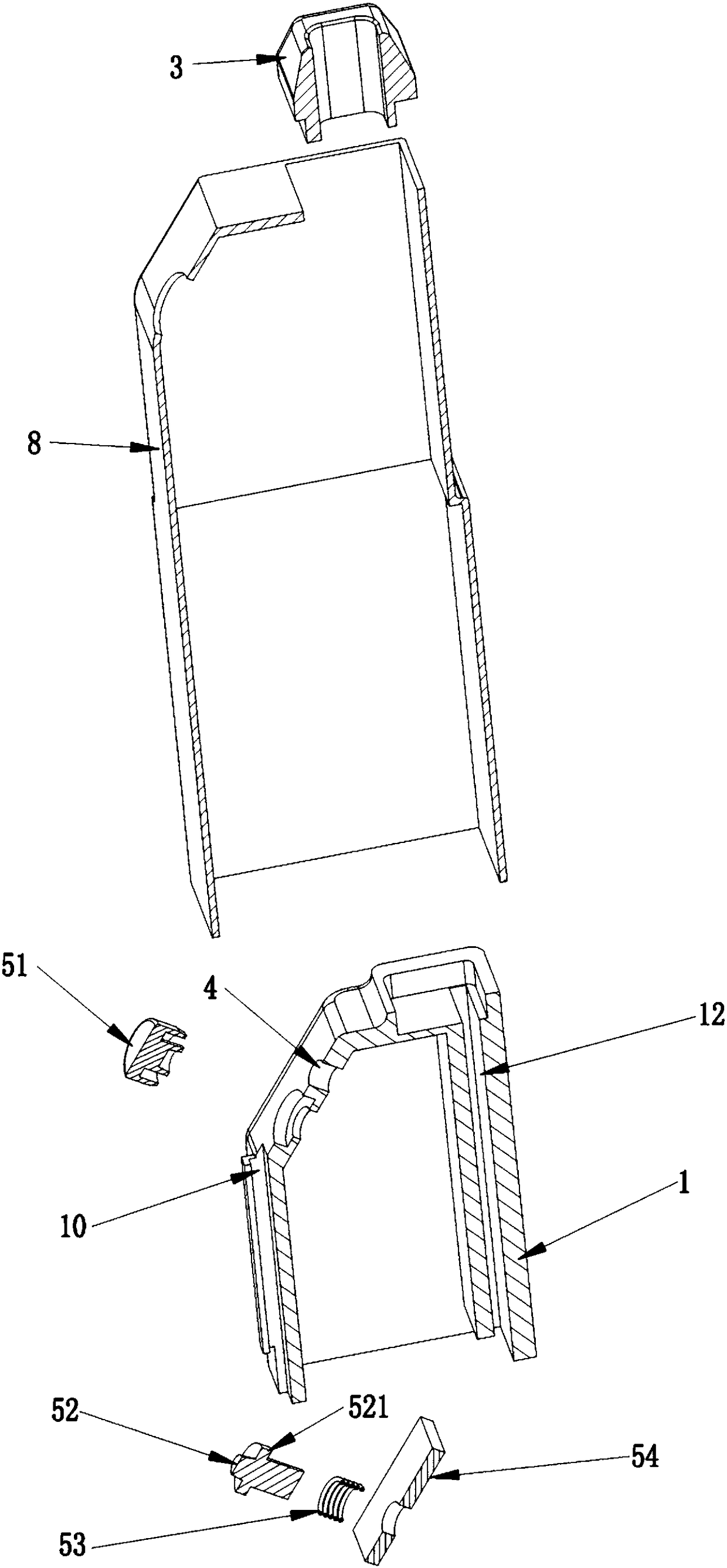

[0040] Such as Figure 1 to Figure 6 As shown, the electronic cigarette vaporizer includes an oil tank 1, a capillary tube 2 and a suction nozzle 3. The oil inlet end of the capillary tube 2 communicates with the inner cavity of the oil tank 1, and the oil outlet end of the capillary tube 2 communicates with the suction nozzle 3. The oil tank 1 is provided with a vent hole 4 that communicates the inner cavity of the oil tank 1 with the atmosphere, and also includes a button assembly 5 that can open or close the vent hole 4 . The inner diameter of the capillary 2 is 0.3-1.5 mm, preferably 0.5-0.8 mm.

[0041] The electronic cigarette atomizer also includes a circuit board 6 and a circuit switch assembly 7 for controlling whether the circuit key switch 73 on the circuit board 6 is connected; When it is turned on, the circuit switch assembly 7 controls the circuit key switch 73 to turn on; when the key assembly 5 controls the vent hole 4 to close, the circuit switch assembly 7 c...

Embodiment 2

[0056] The heating assembly 2 in Embodiment 1 and Embodiment 2 can also be replaced by Figure 8 The heating component 2 shown in the figure, in this embodiment, the heating component 9 includes a smoke oil guide part 91 extending into the oil outlet end of the capillary tube 2, a heating part 92 opposite to the outer end surface of the oil outlet end of the capillary tube 2, and the smoke oil guide part The heating part 91 is connected to the heating part 92; the heating component 9 is provided with an air passage 93 connecting the oil outlet end of the capillary 2 and the suction nozzle 3.

[0057] The heating part 92 is a cylindrical spring-type heating wire, and the e-liquid guiding part 91 includes a plurality of guide columns whose ends are fixedly connected to the heating component 9 , and the guiding columns are perpendicular to the axis of the heating part 92 .

[0058] The oil tank 1, the capillary 2, and the heating element 9 are arranged sequentially from top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com