Light foaming concrete composite heat insulation plate

A technology of foamed concrete and composite thermal insulation, which is applied in the direction of thermal insulation, hydraulically settable material layered products, building components, etc. It can solve the problems of short service life, fracture, collapse, and poor fireproof performance of the thermal insulation layer, so as to improve the service life , Density reduction, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

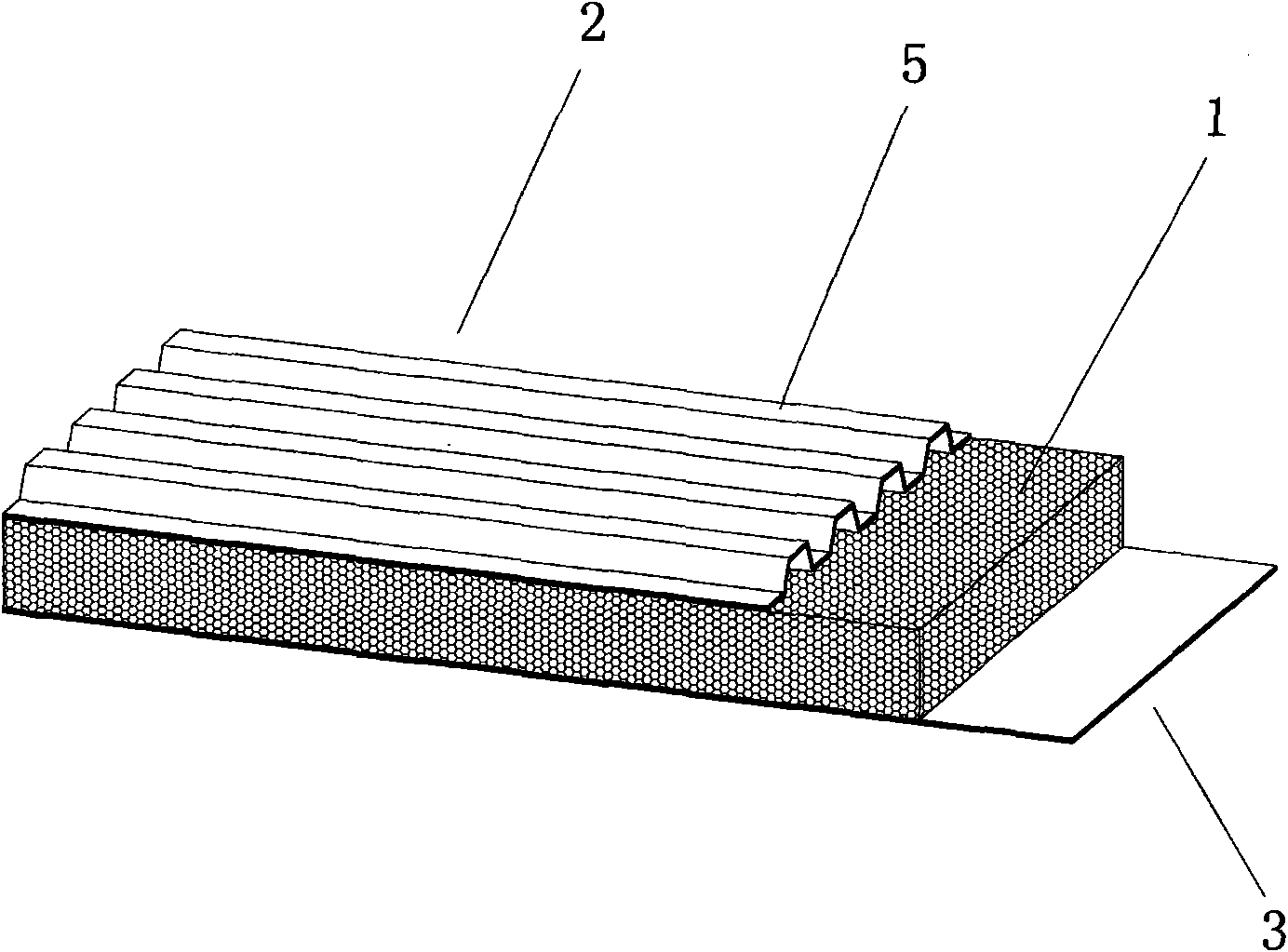

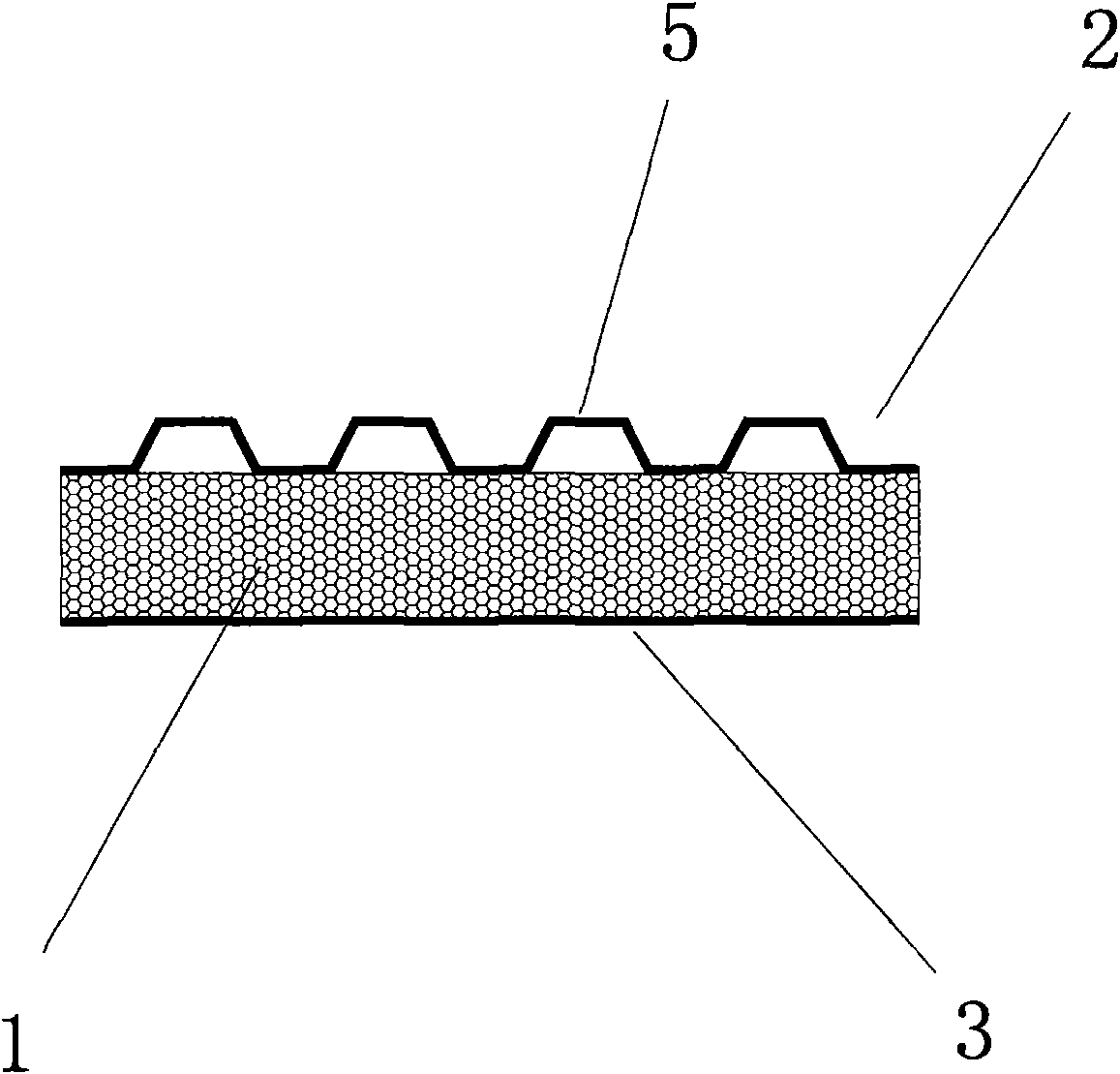

[0030] figure 1 and figure 2 It shows the structure of the lightweight foamed concrete composite insulation board of the first embodiment of the present invention. like figure 1 and figure 2As shown, the lightweight foamed concrete composite insulation board includes an outer panel 2, an insulation layer 1 and an inner panel 3, and the insulation layer 1 is a foam concrete board, and is sandwiched between the outer panel 2 and the inner panel 3 , the outer panel 2 and the inner panel 3 are both thin steel plates, and the outer panel 2 is a corrugated thin steel plate with linear corrugations 5 arranged in parallel on its outer surface. Both surfaces of the thin steel plates as the outer panel 2 and the inner panel 3 have antirust coatings which are paint layers (paint thin mold layers formed by spraying paint). The outer panel 2 and the inner panel 3 are respectively bonded to the two surfaces of the foam concrete board (insulation layer 1) by an adhesive.

[0031] The ...

Embodiment 2

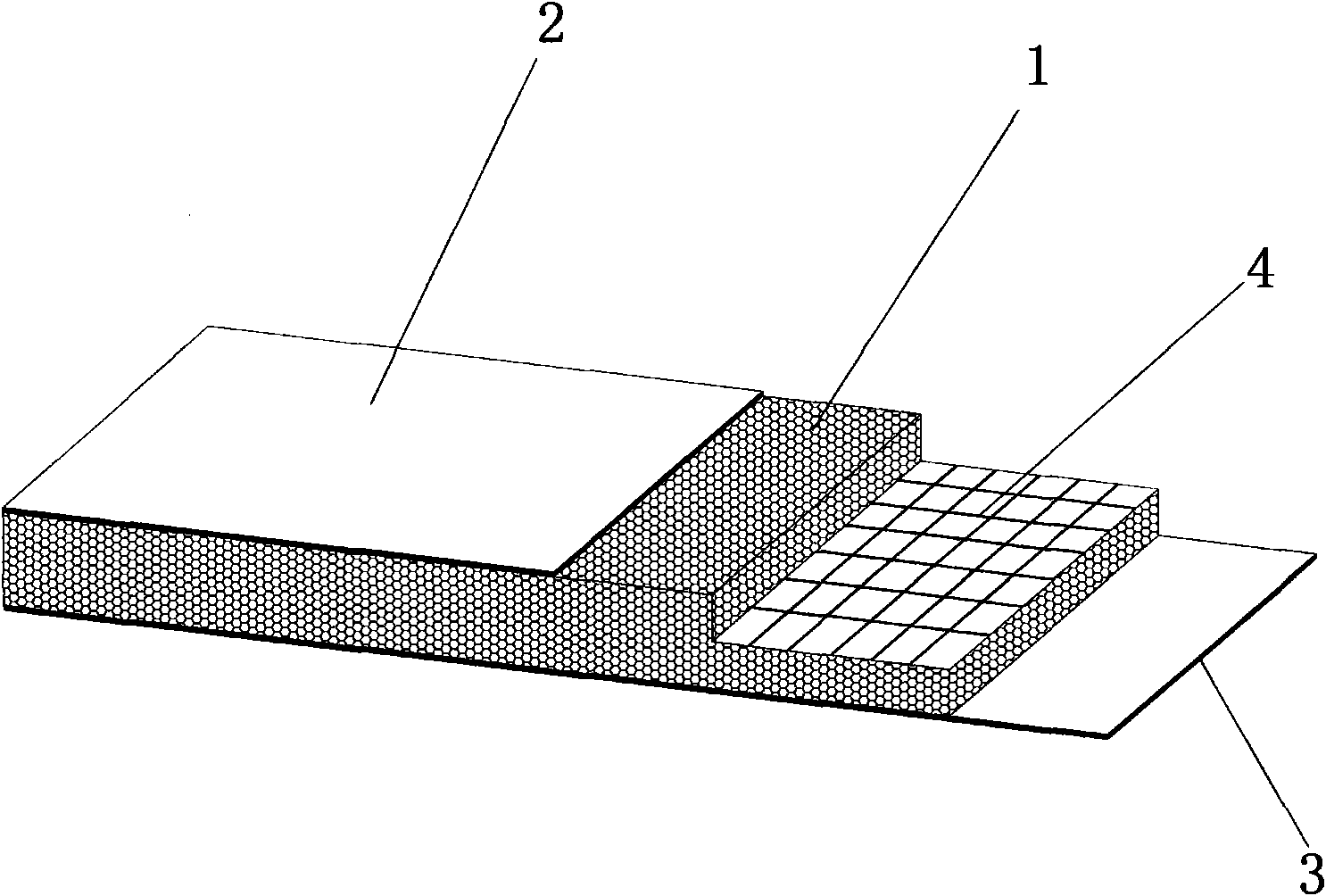

[0035] image 3 and Figure 4 It shows the structure of the lightweight foamed concrete composite insulation board of the second embodiment of the present invention. like image 3 and Figure 4 As shown, the lightweight foamed concrete composite insulation board includes an outer panel 2, an insulation layer 1 and an inner panel 3, and the insulation layer 1 is a foam concrete board, and is sandwiched between the outer panel 2 and the inner panel 3 , the outer panel 2 and the inner panel 3 are flat thin steel plates, as the two surfaces of the thin steel plates of the outer panel 2 and the inner panel 3 all have antirust coatings, and the antirust coatings are galvanized Layer (thin steel sheet with galvanized layer is essentially galvanized sheet). The outer panel 2 and the inner panel 3 are respectively bonded to the two surfaces of the foam concrete board (insulation layer 1) by an adhesive. The inside of the foam concrete slab is provided with network-shaped reinforci...

Embodiment 3

[0037] Figure 5 and Figure 6 It shows the structure of the lightweight foamed concrete composite insulation board of the third embodiment of the present invention. like Figure 5 and Figure 6 As shown, the lightweight foamed concrete composite insulation board includes an outer panel 2, an insulation layer 1 and an inner panel 3, and the insulation layer 1 is a foam concrete board, and is sandwiched between the outer panel 2 and the inner panel 3 , the outer panel 2 and the inner panel 3 are both thin steel plates, and the outer panel 2 is a corrugated thin steel plate with linear corrugations 5 arranged in parallel on its outer surface. Antirust coatings are formed by spraying paint on both surfaces of the thin steel plates as the outer panel 2 and the inner panel 3 . The outer panel 2 and the inner panel 3 are respectively bonded to the two surfaces of the foam concrete board (insulation layer 1) by an adhesive. The inside of the foamed concrete board (insulation lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com