Patents

Literature

267results about How to "Good flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveCN1847352AGood flame retardant performanceImprove flame retardant performanceFilm/foil adhesivesLaminationChemistryCopper foil

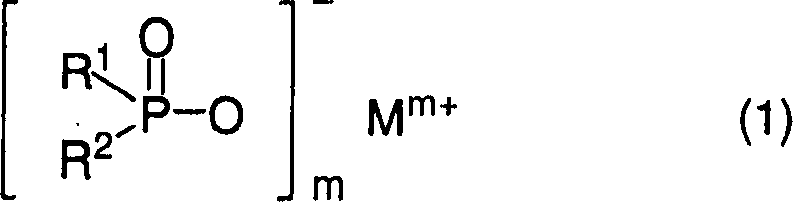

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) an organophosphinate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

High-flame-retardant polypropylene material and preparation method thereof

InactiveCN105385028AGood flame retardant performanceGood self-extinguishingPolypropyleneBrominated flame retardant

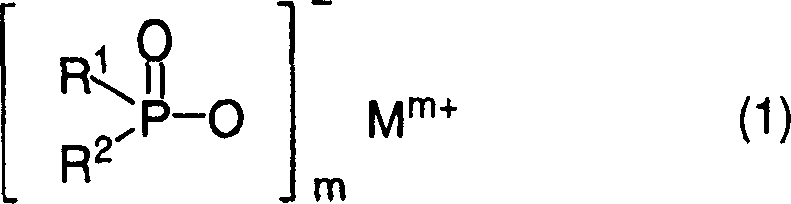

The invention discloses a high-flame-retardant polypropylene material and a preparation method thereof. The material is composed of the following raw materials in parts by mass: 60-75 parts of homo-polypropylene aggregates, 5-15 parts of homo-polypropylene powder, 10-20 parts of a brominated flame retardant, 3-8 parts of an antimony flame retardant, 1-3 parts of a flame retardant synergist, 0-10 parts of a cooling master batch, 0-3 parts of a flexibilizer, 0-1 part of a lubricant, 0-1 part of an ultraviolet light absorber, and 0-1 part of an antioxidant. The preparation method of the material comprises the following steps: 1) uniformly mixing all materials in certain proportion; and 2) adding the obtained mixture into a twin-screw extruder, carrying out high-temperature mixing and shearing, and after the obtained object is subjected to water cooling, sequentially carrying out bracing and grain-sized dicing, so that the high-flame-retardant polypropylene material is obtained. The high-flame-retardant polypropylene material disclosed by the invention is excellent in flame resistance, good in self-extinguishment, excellent in aging resistance, good in insulating property and heat resistance, not easy to deform by heating, excellent in processing fluidity, and easy to shape.

Owner:GUANGDONG JUSHI CHEM CO LTD

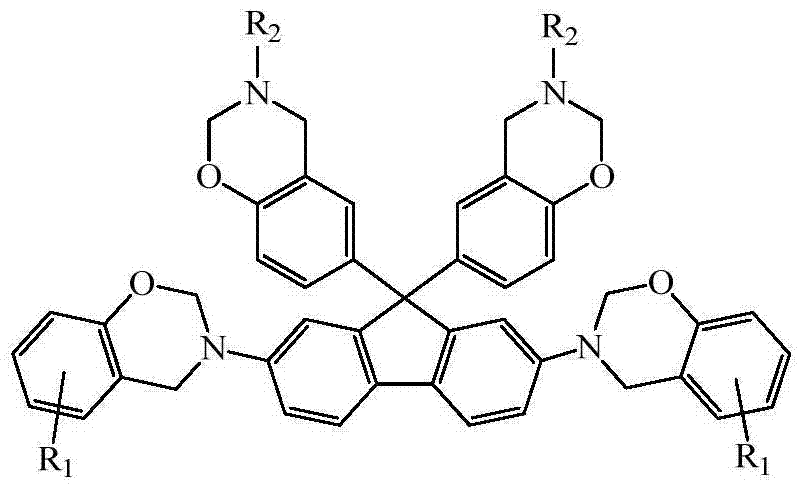

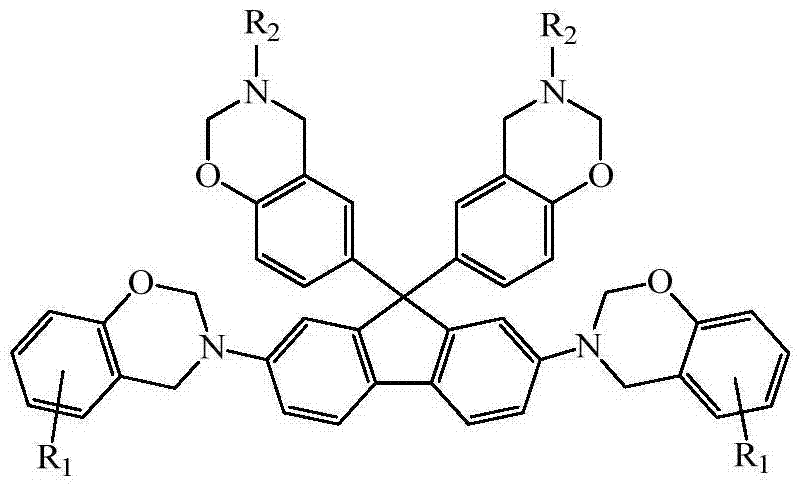

N-semi aromatic hydrocarbyl diamine-bisphenol tetrafunctional fluorene-based benzoxazine and preparation method thereof

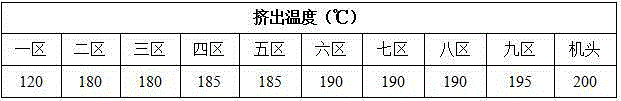

InactiveCN103936686AGood flame retardant performanceImprove crosslink density and toughnessOrganic chemistryDiamineParaformaldehyde

The invention provides N-semi aromatic hydrocarbyl diamine-bisphenol tetrafunctional fluorene-based benzoxazine and a preparation method thereof. A N-semi aromatic hydrocarbyl diamine-bisphenol tetrafunctional benzoxazine monomer is obtained by the following steps: reacting substituted or unsubstituted salicylaldehyde with 2, 7-diamido-9, 9-bis-(4-hydroxy phenyl) fluorene, using sodium borohydride for reduction to obtain substituted or unsubstituted 2-hydroxy benzylamino bisphenol fluorene, and performing a one step Mannich condensation reaction of the substituted or unsubstituted 2-hydroxy benzylamino bisphenol fluorene and aliphatic amine and paraformaldehyde. The reaction process is simplified, the total product yield is increased; by adjusting of rigid and flexible groups in the aliphatic amine and the substituted or unsubstituted salicylaldehyde compound, the melting point of the benzoxazine monomer is improved, the crosslinking density and toughness of polybenzoxazine are improved, and the problems that fluorene-based benzoxazine with a structure with larger steric hindrance is small in molecular weight, low in crosslinking density, and poor in toughness and thermal performance reduction caused by the introduction of flexible groups can be solved.

Owner:HARBIN ENG UNIV

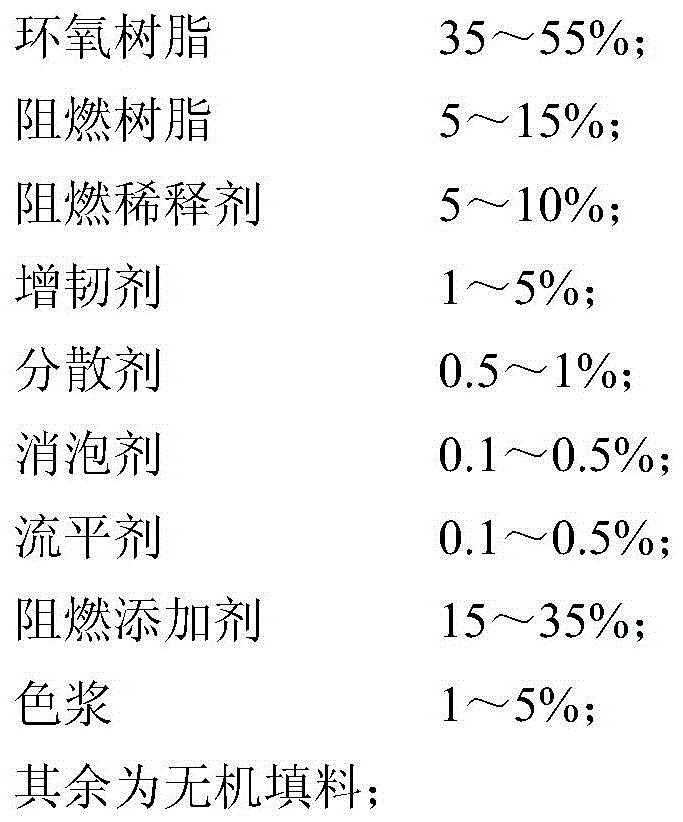

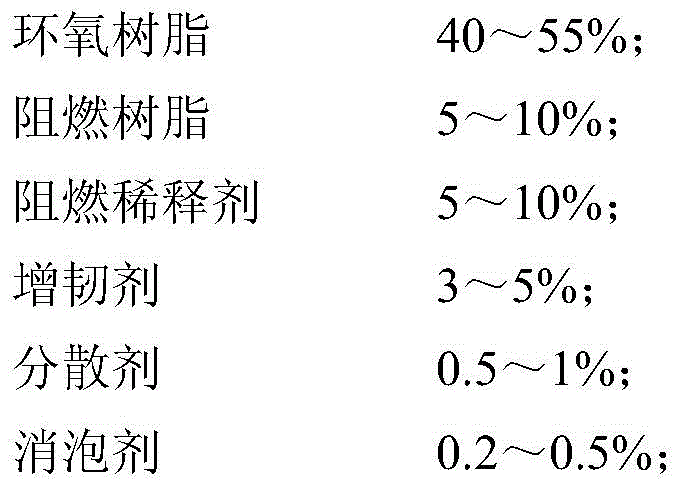

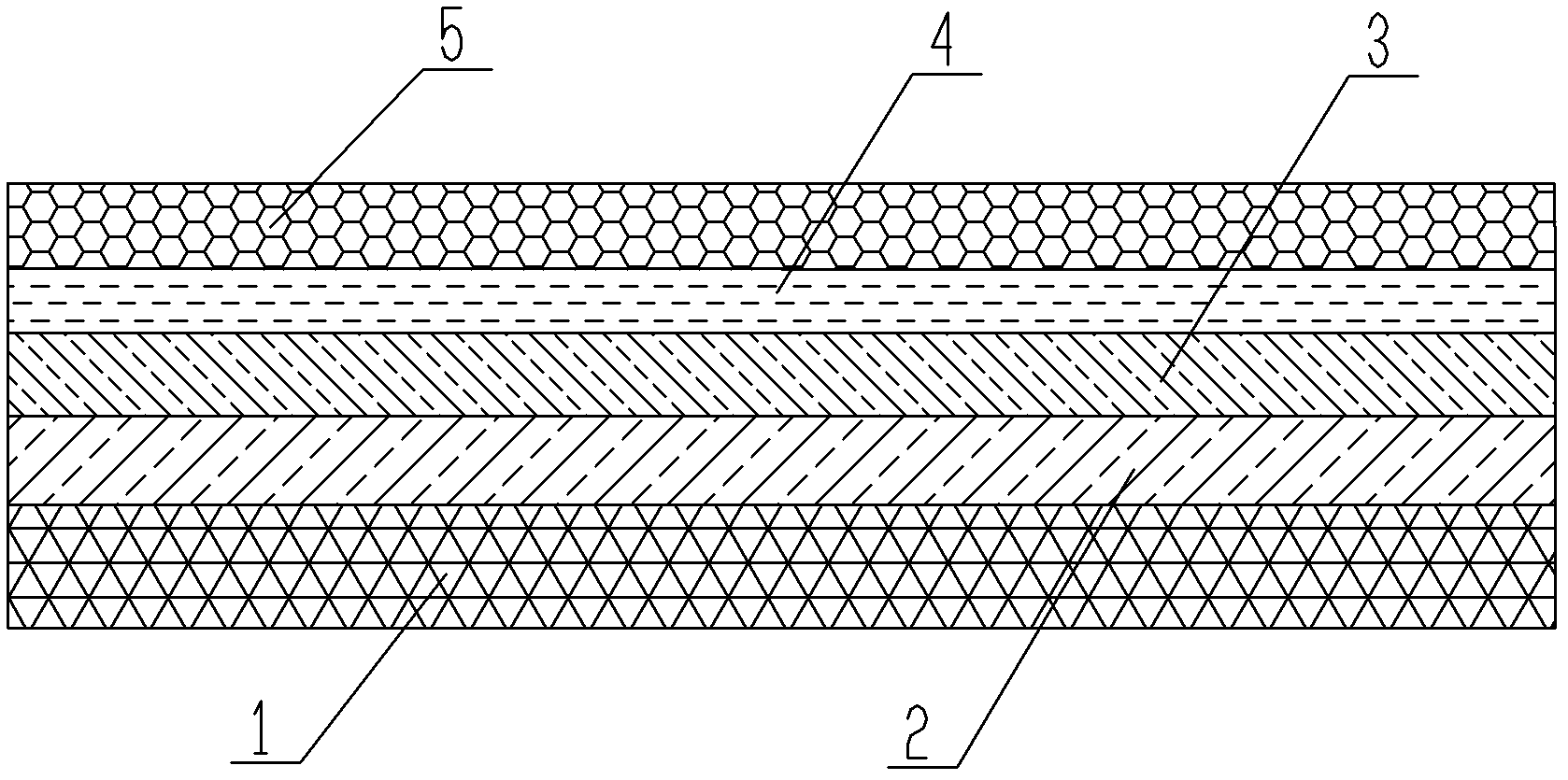

Flame-retardant coiled material and preparation method thereof

ActiveCN105694665AImprove flame retardancyGood flame retardant performanceFireproof paintsEpoxy resin coatingsChemistryMagnesium

The invention discloses a flame-retardant coiled material and a preparation method thereof. The flame-retardant coiled material is a laminated structure which is formed by bonding a flame-retardant surface layer and a chopped fiber layer by a flame-retardant paint and carrying out curing. The flame-retardant paint is composed of a component A and a component B in a weight ratio of 10:(2-5). The component A comprises the following ingredients in percentage by mass: an epoxy resin, a flame-retardant resin, a flame-retardant diluter, a toughener, a dispersing agent, a defoaming agent, a leveling agent, a flame-retardant additive, a color paste and the balance of inorganic filler. The component B comprises a curing agent and the balance of curing accelerator. The flame-retardant additive comprises at least one of antimony trioxide, aluminum hydroxide, magnesium hydroxide, melamine cyanurate, chlorinated paraffin, tri(2-chloropropyl) phosphate and dimethyl methylphosphate. The epoxy resin, flame-retardant resin, flame-retardant diluter and flame-retardant additive are utilized to form the compound system, thereby fully displaying the synergistic effects of the components, and greatly enhancing the flame retardancy of the flame-retardant paint.

Owner:浙江港流高分子科技股份有限公司

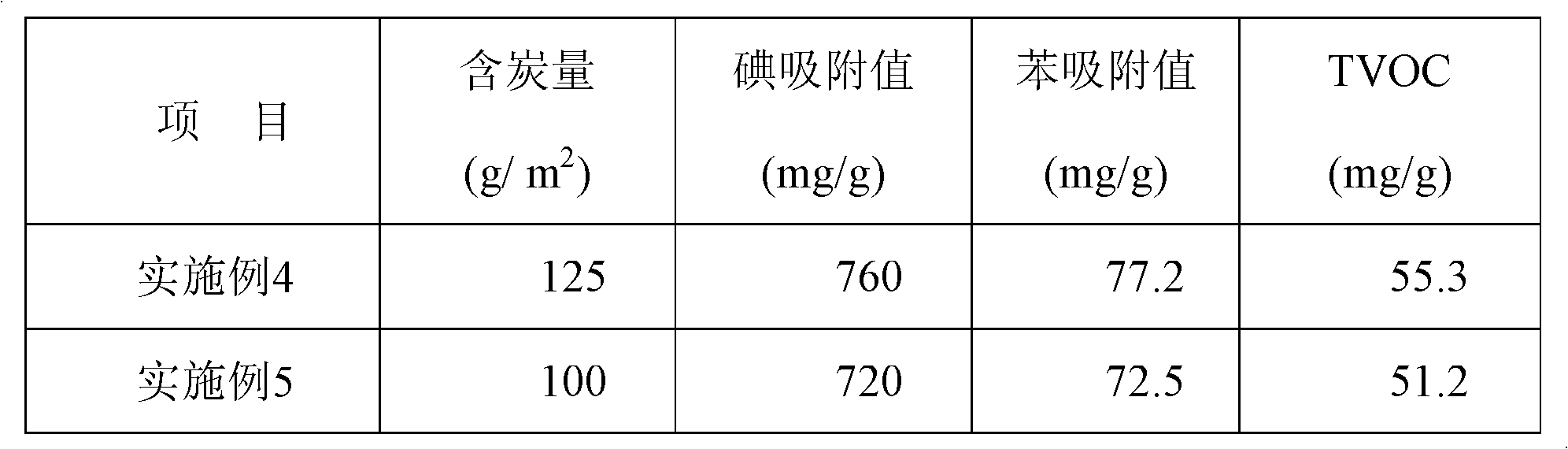

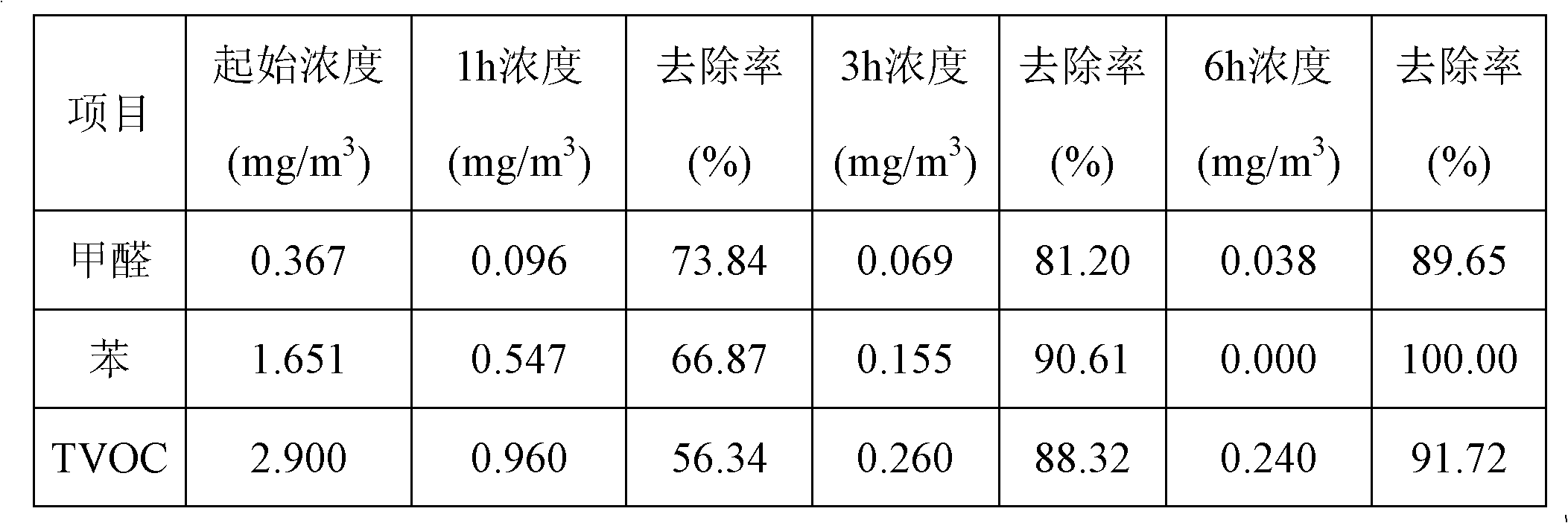

Flame-retardant activated carbon fabric and preparation method thereof

ActiveCN102529254ASimple processGood flame retardant performanceSynthetic resin layered productsActivated carbonChemistry

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

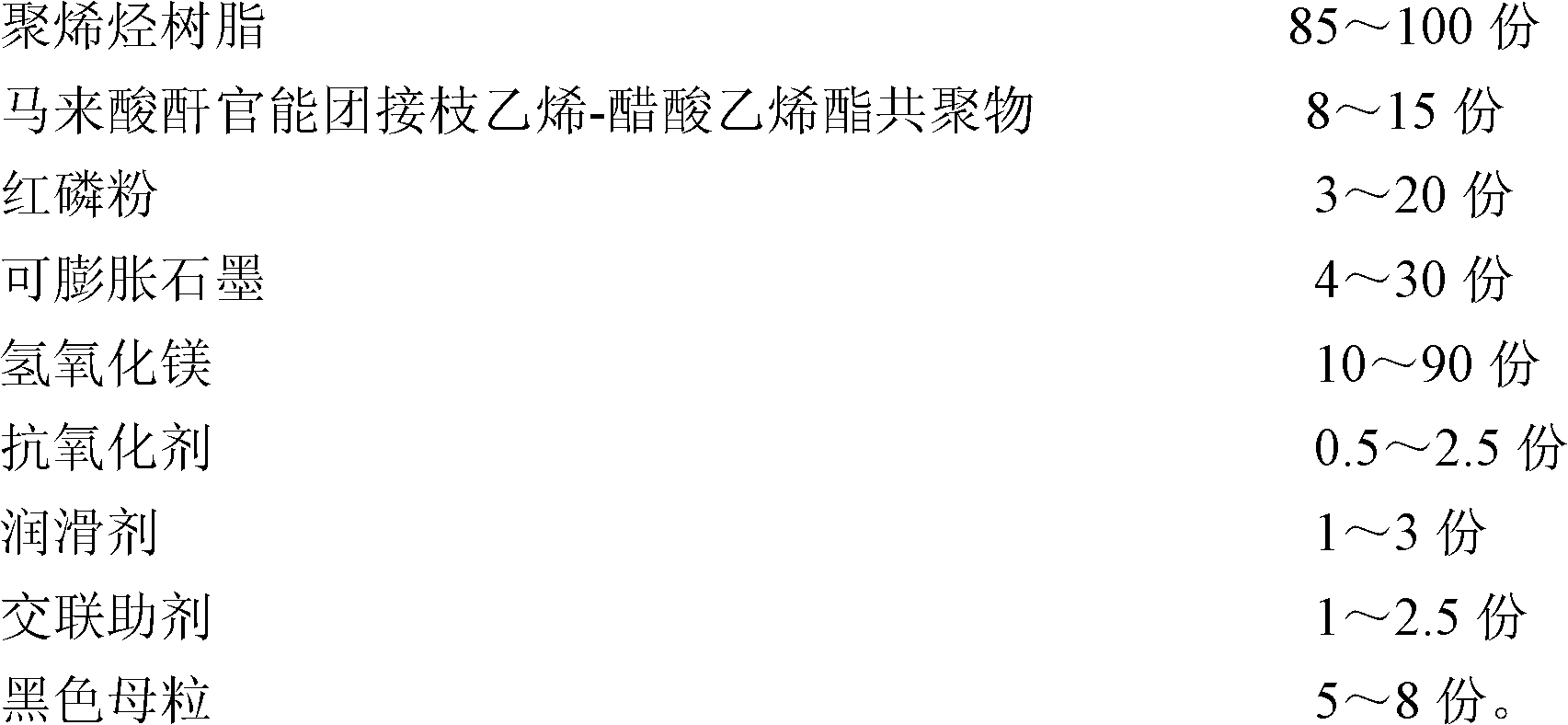

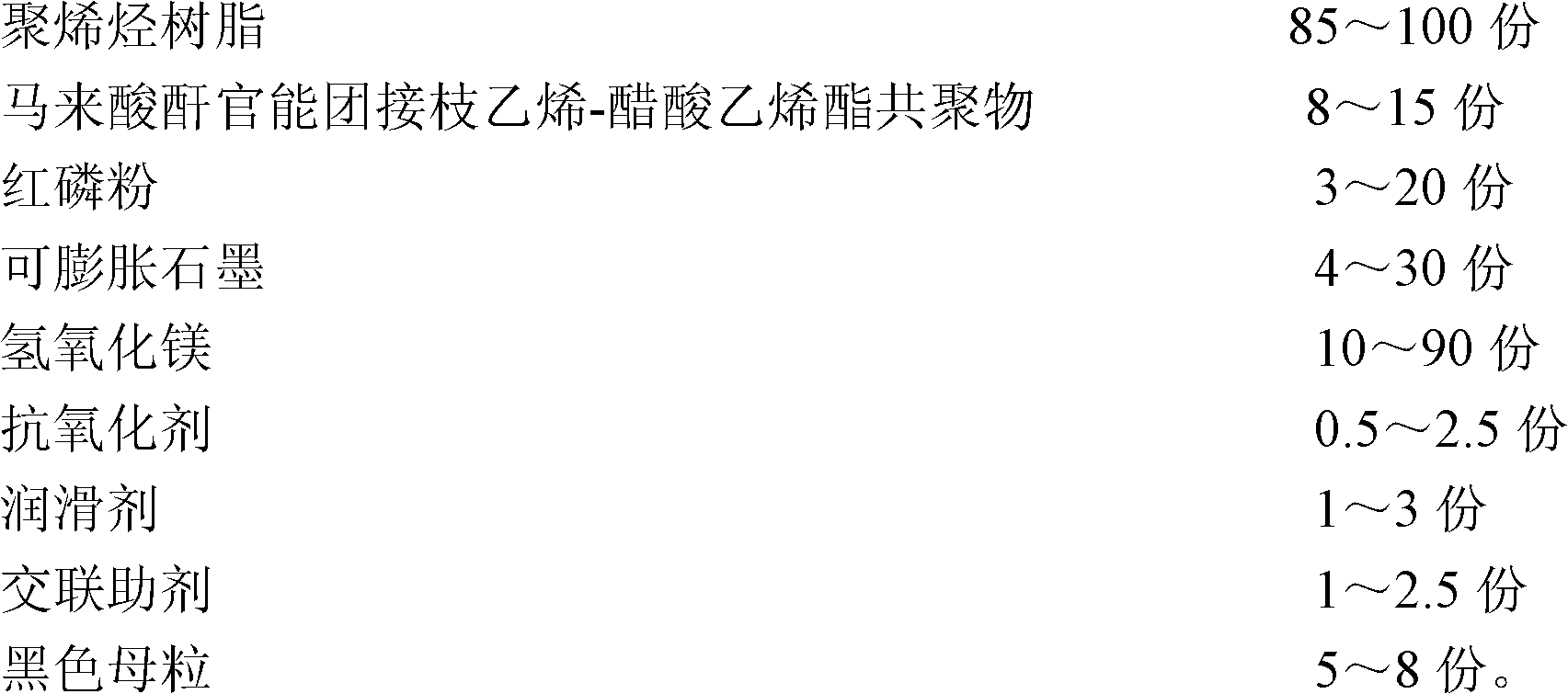

Low smoke zero halogen flame-retardant mould shrinkage sleeve and preparation method as well as application thereof

ActiveCN102321295AGood flame retardant performanceLow smoke productionConnection insulationMaleic anhydrideChemistry

The invention discloses a low smoke zero halogen flame-retardant mould shrinkage sleeve and a preparation method as well as application thereof. The low smoke zero halogen flame-retardant mould shrinkage sleeve comprises the following raw materials in parts by weight: 85-100 parts of polyolefine resin, 8-15 parts of maleic anhydride functional group-grafted ethylene-vinyl acetate copolymer, 3-20 parts of red phosphorus powder, 4-30 parts of expandable graphite, 10-90 parts of magnesium hydroxide, 0.5-2.5 parts of antioxidant, 1-3 parts of lubricant, 1-2.5 parts of cross-linking auxiliary agent and 5-8 parts of black master batch. The preparation method comprises the following steps of: uniformly mixing the raw materials; extruding by using a double-screw extruder at the temperature of 100-160 DEG C; performing wire drawing, air cooling and granulation; injecting the granular material formed by granulation into the mould shrinkage sleeve; performing irradiation at the dosage of 8-12Mrad; and then extending and drawing the mould shrinkage sleeve, which is subjected to irradiation cross-linking, at the temperature of 140-160 DEG C and cooling and forming to obtain the low smoke zero halogen flame-retardant mould shrinkage sleeve. The preparation method is simple; an obtained product has superior flame retardant performance and low smoke formation; meanwhile, superior mechanical property, electrical insulation performance and thermal resistance performance are kept.

Owner:广州凯恒科塑有限公司

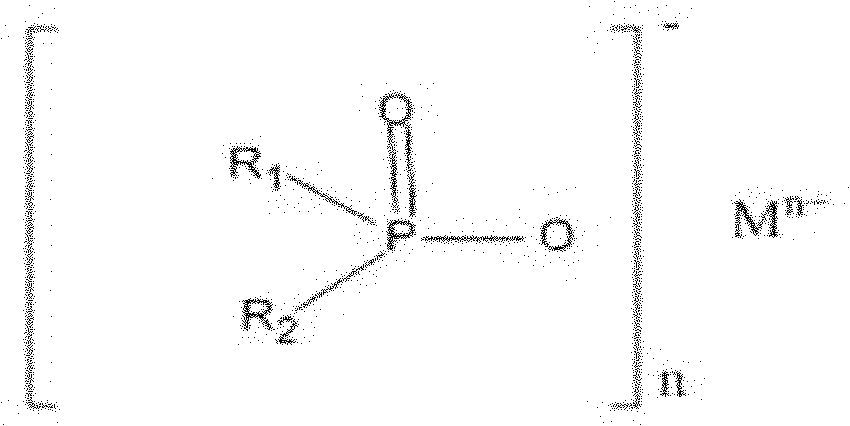

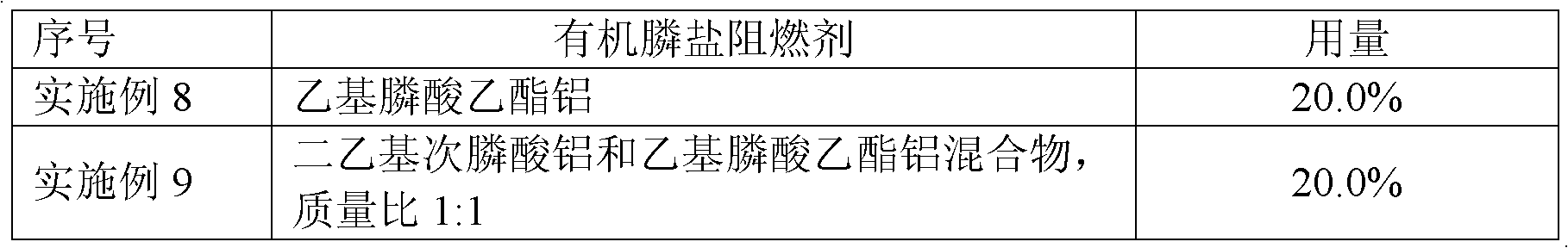

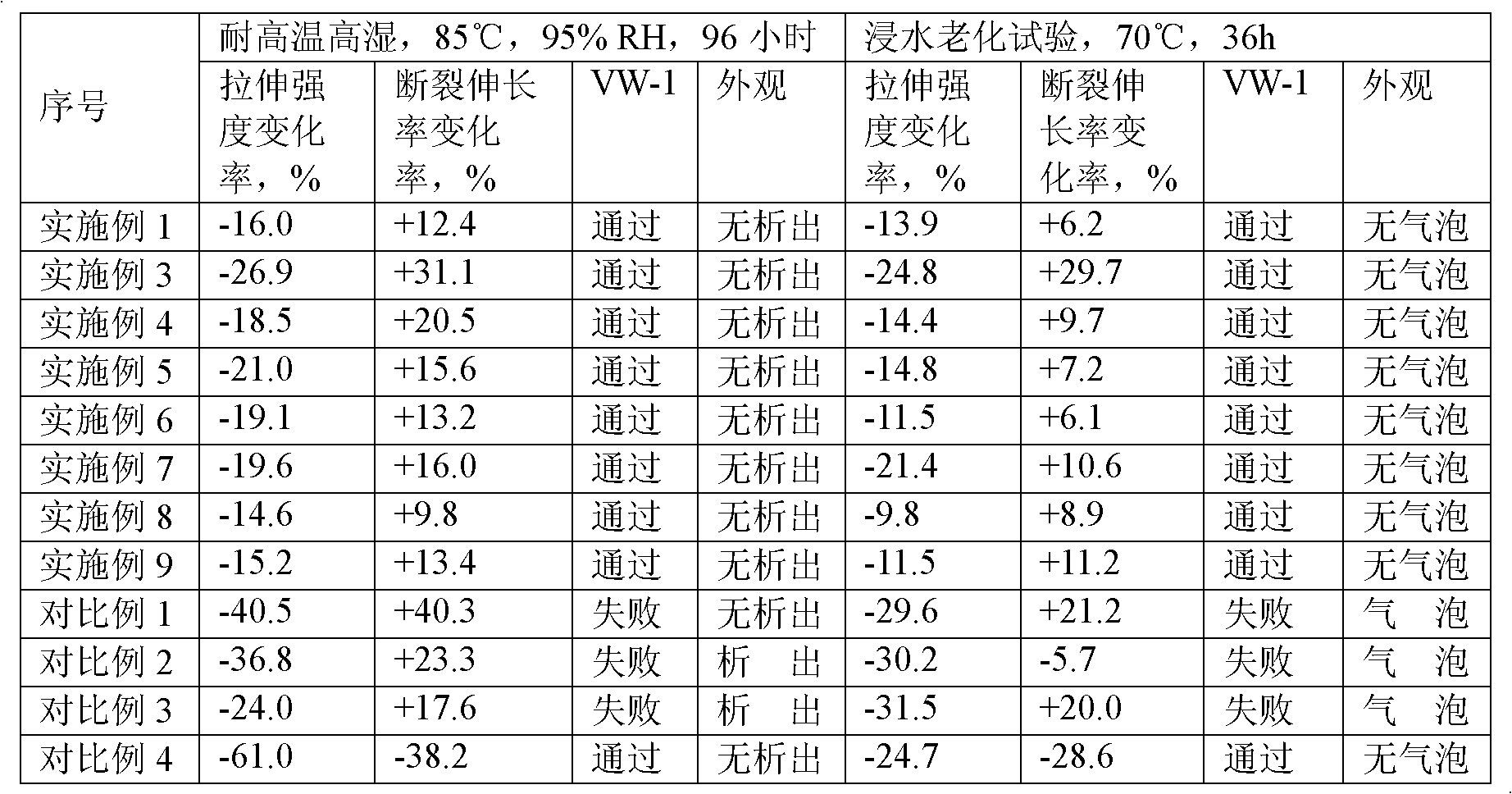

High-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition

ActiveCN102120875AImprove high temperature and high humidity precipitation performanceGood flame retardant performanceInsulated cablesInsulated conductorsHalogenChemistry

The invention relates to a high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition. The invention aims to solve the technical problem of precipitation of the halogen-free flame-retardant polyester type polyurethane elastomer in a high-temperature high-moisture environment, maintain the softness and mechanical strength of the elastomer and conform to the RoHS instruction, thereby satisfying the requirements for high-performance electronic / electric appliance materials and the development characteristics of no halogen and flame retardancy. The invention is characterized in that the high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester type polyurethane thermoplastic elastomer composition is prepared from the following components in percentage by weight: 5.0-40.0% of organic phosphonate flame retardant, 0.0-15.0% of nitrogen-containing compound, 1.0-15.0% of viscosity modifier, 0.1-1.5% of antioxidant and ultraviolet absorbent, and the balance of polyether type polyurethane thermoplastic elastomer. The components are premixed, extruded and granulated to obtain the product.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

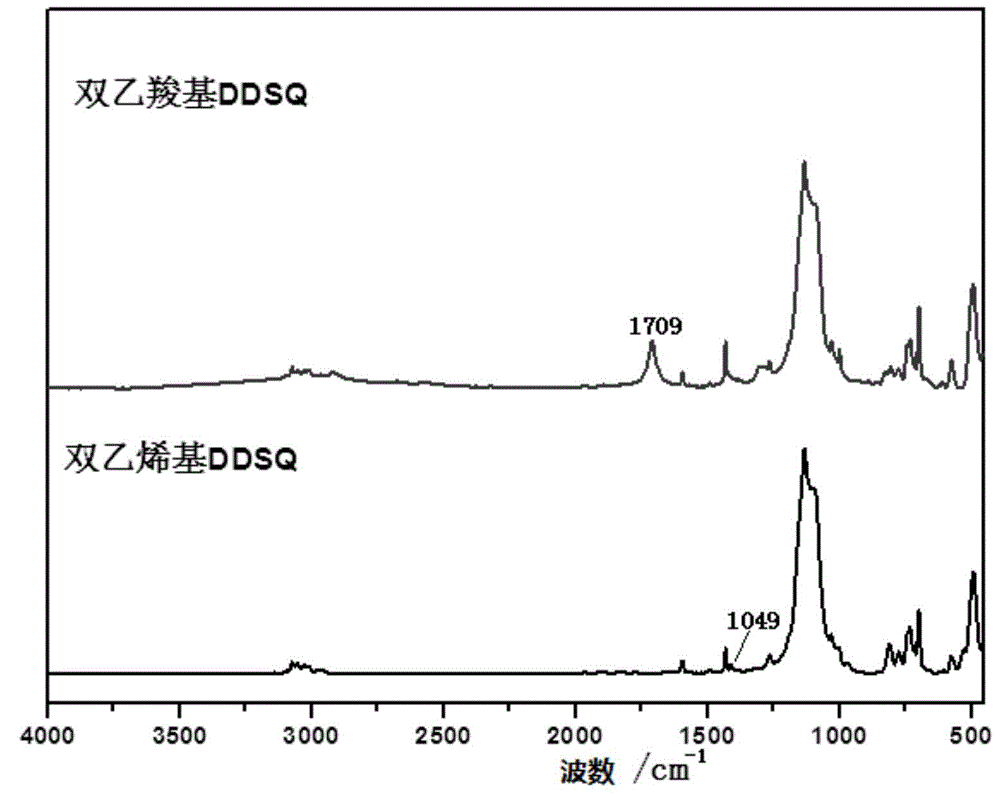

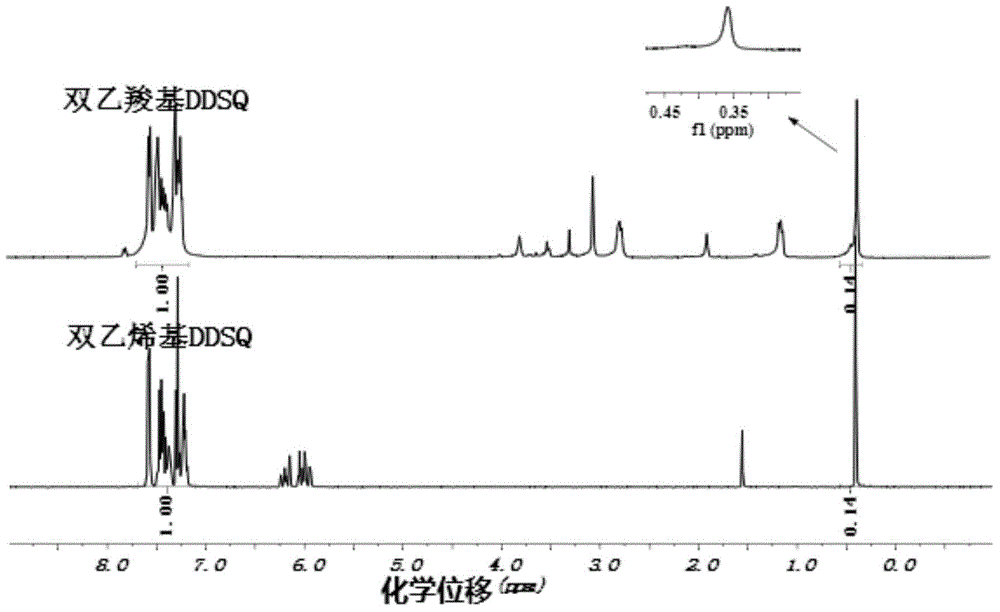

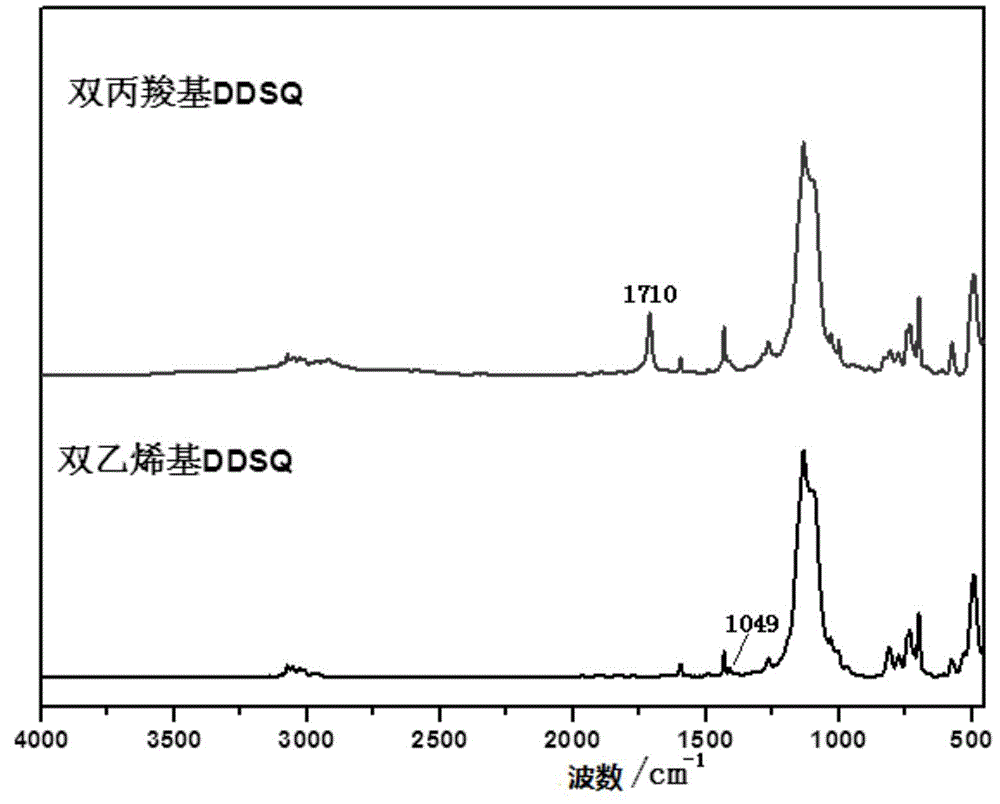

Functionalized double tower-type polyhedron oligomeric silsesquioxane and preparation method thereof

ActiveCN105198916AGood high temperature resistanceGood flame retardant performanceSilicon organic compoundsChemistryAddition reaction

The invention discloses functionalized double tower-type polyhedron oligomeric silsesquioxane. The functionalized double tower-type polyhedron oligomeric silsesquioxane can be widely used in special structure double tower-type polyhedron polysilsesquioxane preparation, polymer modification and polymer synthesis, and can be used in biomedical and photoelectric functional materials. The oligomeric silsesquioxane is obtained by a mercapto-olefin addition reaction of divinyl-containing double tower-type polyhedron oligomeric silsesquioxane, mercapto-terminated carboxylic acid, alcohol and amine. The preparation method has the advantages of control and operation easiness, short reaction time, high yield and purification easiness.

Owner:BEIJING UNIV OF CHEM TECH

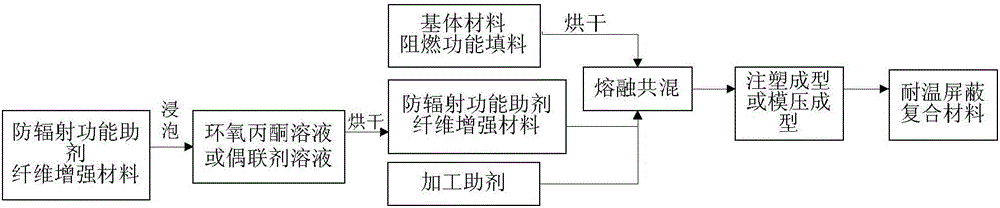

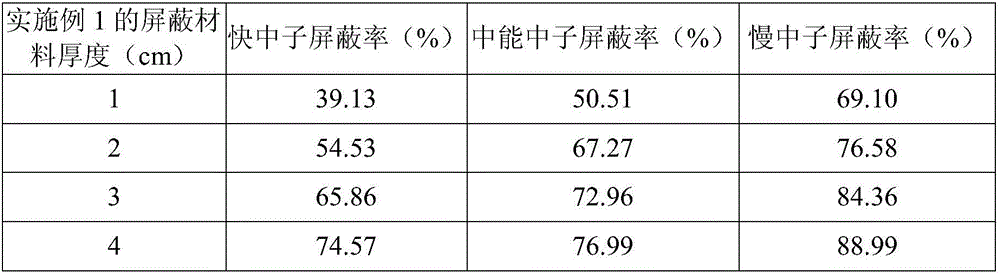

High-temperature-resistant neutron and Upsilon-ray shielding composite and preparation method thereof

InactiveCN106280461AGood neutron and gamma ray shielding propertiesGood flame retardant performanceShieldingFibre reinforcementRadiation

The invention provides a high-temperature-resistant neutron and Upsilon-ray shielding composite and a preparation method thereof. The high-temperature-resistant neutron and Upsilon-ray shielding composite is made from, by weight, 20-200 parts of a base material, 100-800 parts of an anti-radiation functional aid, 5-100 parts of a fiber reinforced material, 50-150 parts of a flame-retardant functional filling material, and 1-10 parts of a processing aid. The high-temperature-resistant neutron and Upsilon-ray shielding composite prepared herein has good neutron and Upsilon-ray shielding performance and good flame retardance, may operate normally in the temperature range of 150-260 DEG C, has excellent resistance to high temperature, and has low average linear expansion coefficient; it is indicated that the material has good size stability, and stability of neutron and Upsilon-ray shielding performance can be guaranteed; the high-temperature-resistant neutron and Upsilon-ray shielding composite is suitable for use as a radiation-protective material in a high-temperature environment.

Owner:BEIJING RADIATION APPL RES CENT

Flame-retardant roll type curtain and production process thereof

InactiveCN102078132AGood flame retardant performanceSimple processFibre treatmentCurtainsSolventAlkylphenol

The invention relates to a flame-retardant material and a production process thereof, in particular to a flame-retardant roll type curtain and a production process thereof. Both the front and the back of the curtain fabric of the flame-retardant roll type curtain have a colorless and transparent flame-retardant coating. Slurry for the flame-retardant coating comprises the following components in percentage by mass: 10 to 40 percent of environmentally-friendly flame-retardant agent, 10 to 45 percent of environmentally-friendly nanometer adhesive, 2 to 5 percent of thickener and 45 to 78 percent of water. The roll type curtain has an excellent flame-retardant property, and a GB5455 vertical burning method is adopted for an flame-retardant test, and the flame-retardant property of the roll type curtain reaches above B2 level when assessed according to 6817591; the curtain is free of solvent volatilization pollution, formaldehyde, alkylphenol ethoxylates (APEO), or toxic gas released in the process of burning; the production process is simple, can realize continuous production without any special equipment, and also can be combined with other processes for one-step implementation.

Owner:CHANGZHOU UNIV +1

Seaweed fiber blending flame-retardant garment plus material and production method

InactiveCN102505270AGood flame retardant performanceImprove safety performanceBiochemical fibre treatmentFibre typesElectrically conductiveDyeing

The invention relates to a seaweed fiber blending flame-retardant garment plus material, which is characterized in that the seaweed fiber blending flame-retardant garment plus material is formed through blending and weaving the following ingredients in percentage by weight: 30 to 50 of seaweed fibers, 20 to 40 of aramid fibers, 25 to 30 of chinlon and 1 to 10 of conductive fibers. A production method comprises four major production process steps of spinning, weaving, dyeing and later-period sorting. The characteristics of the seaweed fiber, the chinlon and the aramid fiber are utilized, in addition, the conductive fibers are added for eliminating the static influence on the plus material, the flame-retardant performance of the seaweed fiber blending flame-retardant garment plus material is good, the safety performance is high, the elasticity is good, wear resistance, moisture absorption, breathability, softness and comfort are realized, the static is avoided, and the seaweed fiber blending flame-retardant garment plus material is particularly suitable for garment plus materials for better meeting the requirements of people.

Owner:山东奈琦尔海洋科技有限公司 +1

Mute environment-friendly paint and preparation method thereof

The invention relates to mute environment-friendly paint and a preparation method thereof. The mute environment-friendly paint consists of filler, an odor-eliminating latex, an assistant, pigment, a flame retardant and water, wherein the filler comprises a wood fiber, diatomite, expanded perlite and hollow glass microspheres; the expanded perlite is open pore expanded perlite with 14-120 meshes; and the average grain diameter of the odor-eliminating latex is 0.15-0.5mu m. The preparation method of the mute environment-friendly paint comprises three steps of premixing, dispersing and grinding and adjusting paint. The prepared mute environment-friendly paint has the advantages of favorable mute effect, safety, environmental protection, capability of adjusting the indoor air temperature, simple and convenient construction, favorable decorative effect and the like as well as favorable market prospect.

Owner:中科力川(北京)建设工程有限公司

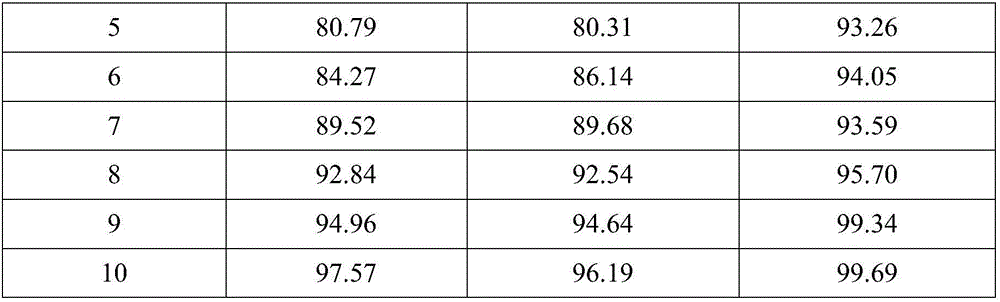

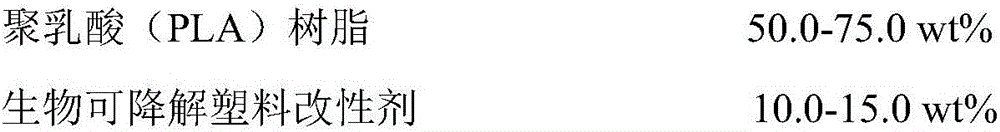

Halogen-free flame retardant polylactic acid toughening modification composite material and preparing method thereof

InactiveCN105694405AGood flame retardant performanceExcellent toughness and elongation at breakBiodegradable plasticAntioxidant

The invention discloses a halogen-free flame retardant polylactic acid toughening modification composite material.The composite material is mainly composed of 50.0-80 wt% of polylactic acid, 5.0-20.0 wt% of biodegradable plastic, 10.0-20.0 wt% of phosphorus based flame retardant, 0.5-20.0 wt% of reactive compatibilizer and 0.2-1.0 wt% of antioxidant.Hypophosphite and phosphonate with different ratios are taken as the flame retardant to achieve flame retarding of polylactic acid, polylactic acid is toughened through a bio-based elastomer, a reactive polymer is added to serve as the reactive compatibilizer, and the halogen-free flame retardant biodegradable polylactic acid toughening modification composite material is prepared through melting reaction and blending.The composite material has excellent flame retarding property, elongation at break and toughness.The biodegradable halogen-free flame retardant polylactic acid toughening modification composite material is efficient and low in toxicity and is an environment-friendly biodegradable flame retardant plastic.The composite material has excellent flame retarding property and mechanical property and can be used in the fields such as packaging, film, textile and automobiles.

Owner:QINGDAO UNIV OF SCI & TECH

High-gloss scratch-resistant ABS/PVC (acrylonitrile-butadiene-styrene/polyvinyl chloride) alloy and preparation method thereof

ActiveCN102875920AMechanical properties and easy processingGood flame retardant performancePolymer chemistryStyrene

The invention discloses a high-gloss scratch-resistant ABS / PVC (acrylonitrile-butadiene-styrene / polyvinyl chloride) alloy and a preparation method thereof. The alloy comprises ABS, PVC, PMMA (polymethyl methacrylate), toughening agent, assistant, stabilizer, lubricant and antioxidant. The ABS / PVC alloy is balance in mechanical property, excellent in flame retardancy, easy to machine, low in cost, easy to color, scratch-resistant, high in surface hardness, and is applicable to high-gloss and scratch-resistant products such as electronic appliances, automobiles and machinery.

Owner:HEFEI GENIUS NEW MATERIALS

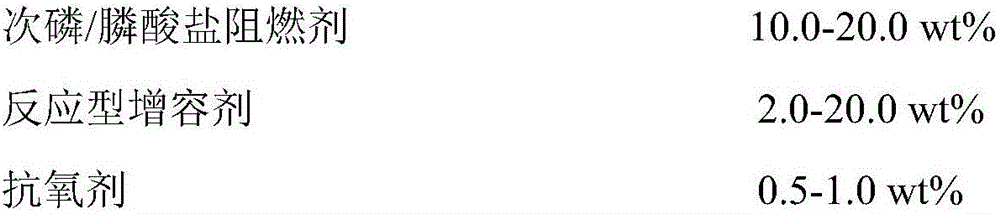

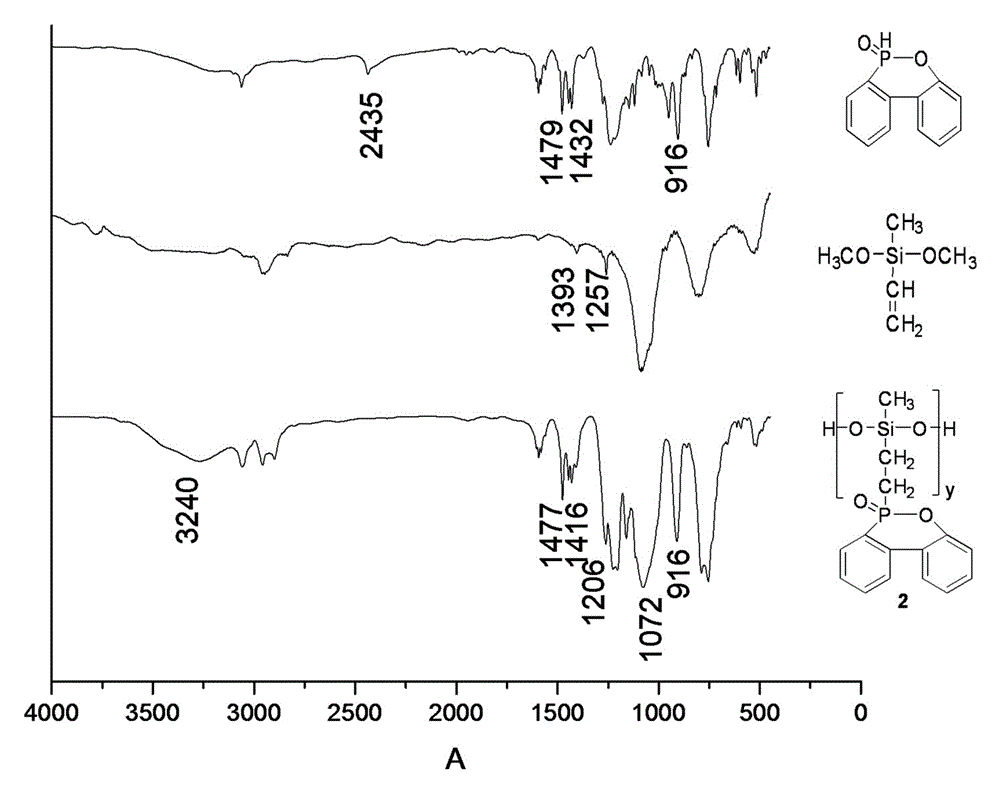

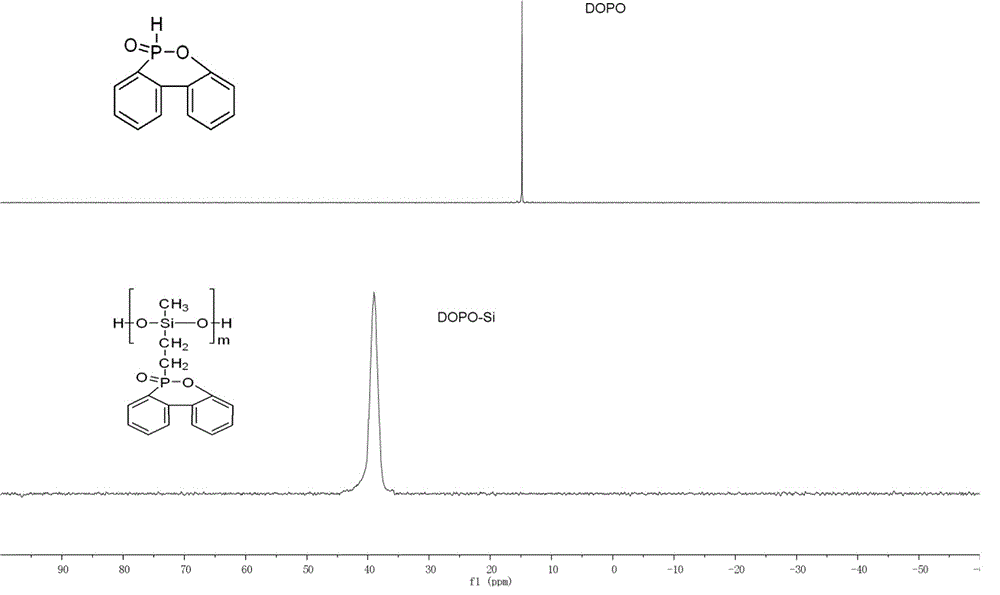

Phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber, preparation method therefor and application thereof

The invention discloses phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber, a preparation method therefor and an application thereof. The material has a following structural unit: FORMULA as shown in the specification, wherein X is 2-4, y is 3-6, z is 300-325 and Mw is equal to 18900-27600. The invention further discloses the preparation method for the phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber; linear methyl vinyl phosphorus-containing silicone rubber crude rubber with a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide structure in a side chain is obtained; compared with conventional addition methyl vinyl flame-retardant silicone rubber, the phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber disclosed by the invention has better flame resistance; and problems of high filling volume and low flame resistance efficiency in a conventional flame-retardant rubber blending process are overcome; and physical characteristics such as good tensile strength, good impact strength and the like of the silicone rubber are kept.

Owner:湖北省兴发磷化工研究院有限公司 +1

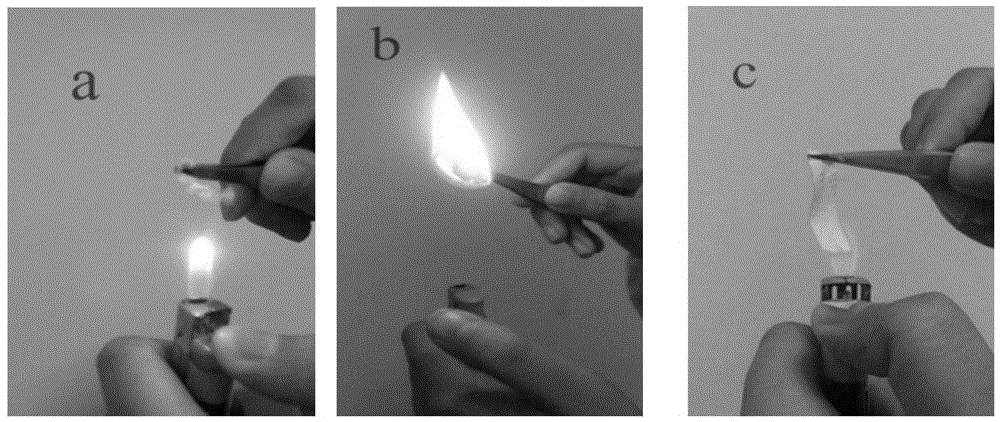

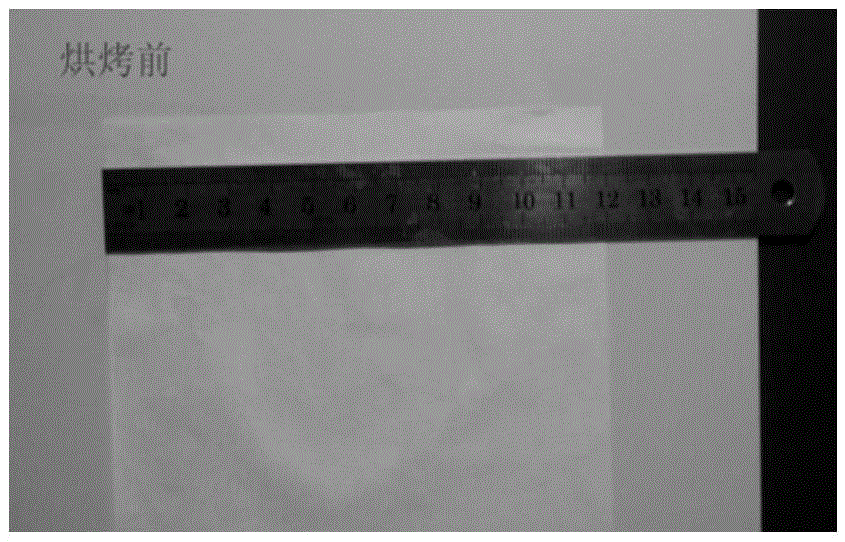

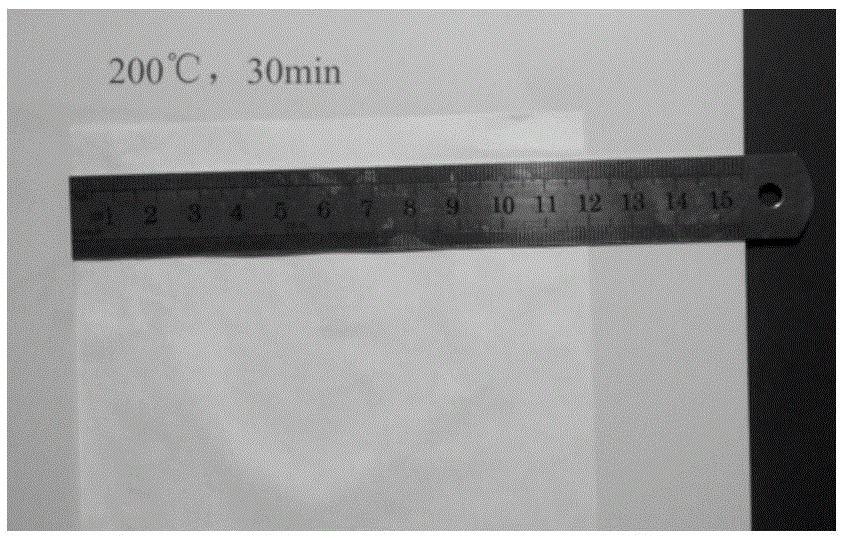

Composite nanofiber diaphragm for electrochemical element, preparation method and energy storage device

InactiveCN105655526AGood flame retardant performanceAvoid explosionCell component detailsNon-woven fabricsElectrochemistryLimiting oxygen index

The invention provides a composite nanofiber diaphragm for an electrochemical element, a preparation method and an energy storage device. The diaphragm is prepared from high-temperature-resistant nanofibers, low-melting-point polymer nanofibers and a flame-retardant material through self-assembly crosslinking with a wet-process production method. The diaphragm is 10-80 mu m thick, the porosity is 40%-90%, the size shrinkage rate is 0-5% when the diaphragm is put in the environment with the temperature of 200 DEG C for 30 min, the LOI (limit oxygen index) is 20%-65%, the breathability index Gurley value is 5-300 s / 100cc, the absorption rate of an electrolyte solution is 150%-500%, the mechanical stretching strength is 10-100 MPa. The diaphragm has excellent high-temperature resistance and flame retardancy, the preparation process is simple, and the cost is low.

Owner:NINGBO ATMK LITHIUM ION TECH INC

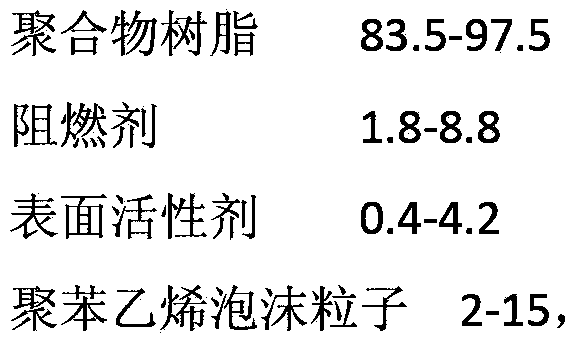

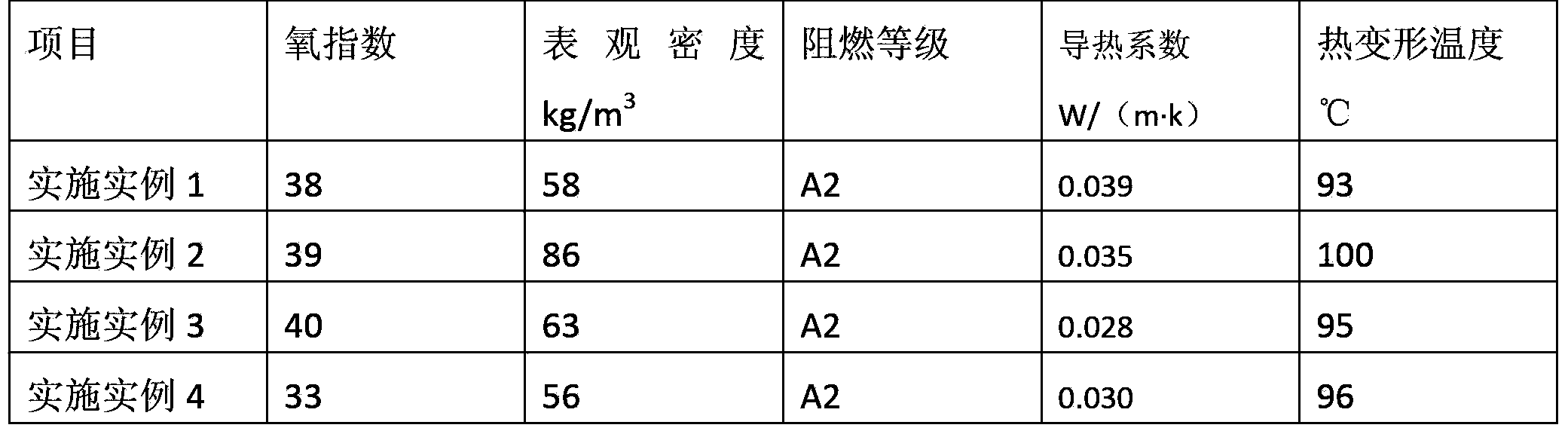

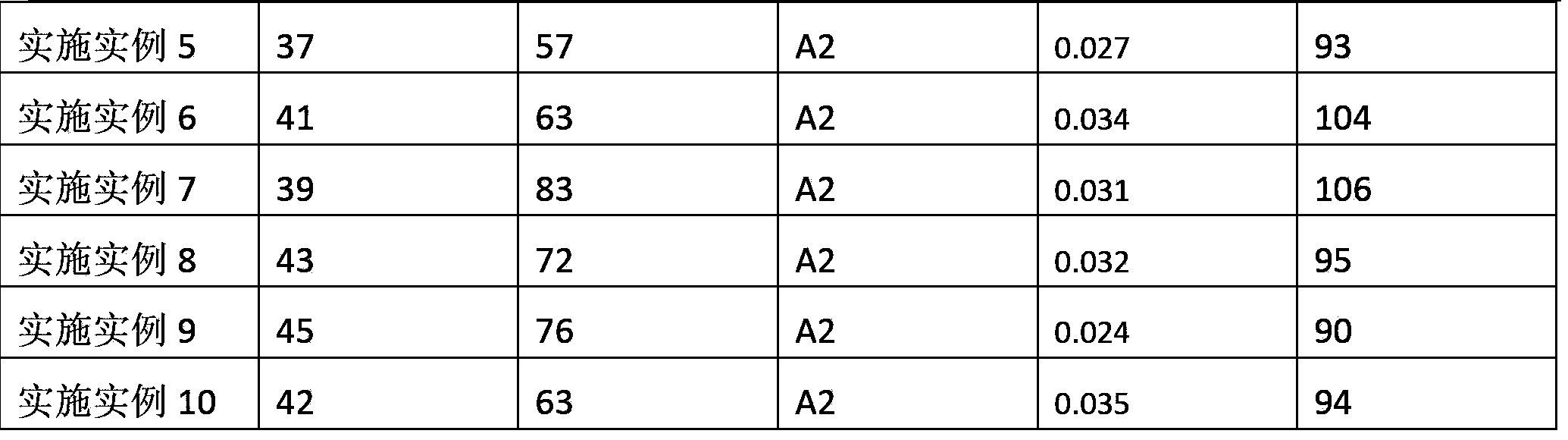

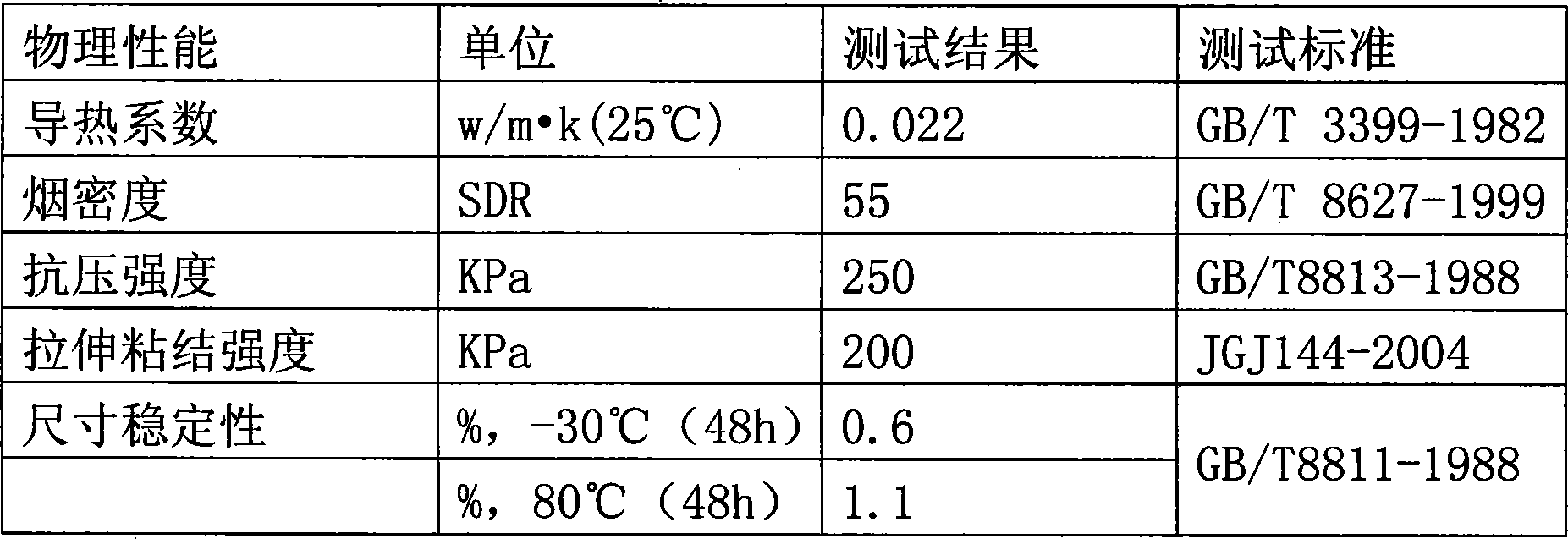

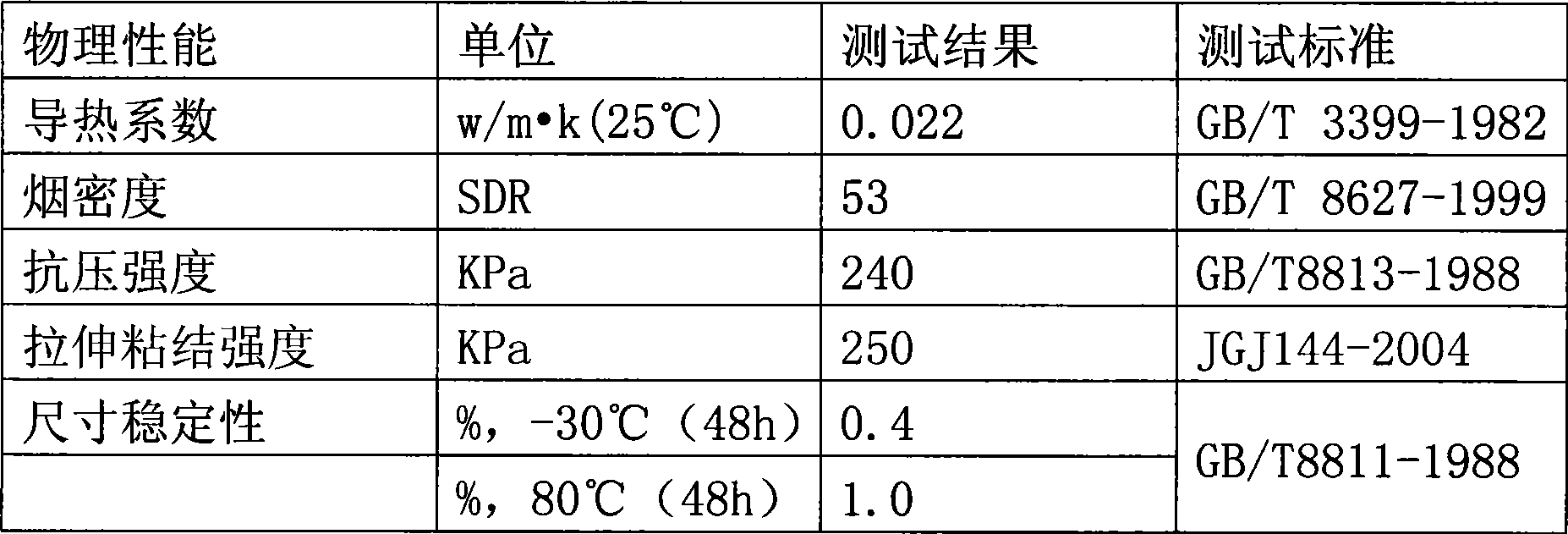

High-molecular flame-retardant foam material and preparation method thereof

InactiveCN103408891ALow thermal conductivityGood flame retardant performanceThermal insulationSurface-active agents

The invention provides a high-molecular flame-retardant foam material which is prepared by mixing the following components in parts by weight: 83.5 to 97.5 parts of polymer resin, 1.8 to 8.8 parts of flame retardant, 0.4 to 4.2 parts of surface active agent and 2 to 15 parts of polystyrene foam particles. The preparation method of the high-molecular flame-retardant foaming heat insulating material comprises the following steps: the polymer resin, the flame retardant and the surface active agent are mixed uniformly to prepare a high-molecular organic flame-retardant adhesive, then after being mixed, the high-molecular organic flame-retardant adhesive and a curing agent are added into the polystyrene foam particles, and the high-molecular flame-retardant foaming heat insulating material can be formed quickly through hot pressing. The high-molecular flame-retardant foam material provided by the invention synthesizes the characteristic of low heat conductivity coefficient of the foam particles and efficient flame-retardant effect of the high-molecular organic flame-retardant adhesive, really achives integration of flame retardance and heat preservation, and uses various flame-retardant compounds for mixing to form the flame retardant, and the prepared high-molecular flame-retardant foaming heat insulating material is better in flame retardant property, better in thermal insulation effect, and higher in oxygen indexes.

Owner:南通南京大学材料工程技术研究院

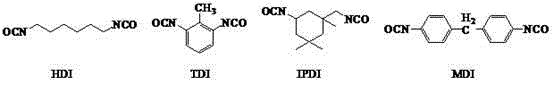

Spray finishing polyurethane rigid foam raw material and foam produced thereof

The invention relates to a sprayed rigid polyurethane foam raw material and foam produced therefrom. The sprayed rigid polyurethane insulation foam raw material comprises an isocyanate component and a polyol component, and can be used in various insulating fields. The sprayed rigid polyurethane foam raw material comprises component A and component B, the volume ratio of the component A to the Component B ranges from 1:1 to 1.5:1; the component A is of isocyanate and the component B is of polylol and various additives, and the optional additives comprise a catalyst, a foam stabilizer, a flame retardant and a foaming agent. The sprayed rigid polyurethane foam raw material is characterized in that the foaming agent comprises a chemical foaming agent and a physical foaming agent, the chemical foaming agent is of water, and the physical foaming agent comprises a main foaming agent accounting for 0.1%-30% of the component B and other physical foaming agents based on mass percentage. Products constructed with the foam raw material have good adhesive force and flame retardance, low thermal conductivity and good dimensional stability. The raw material can be conveniently used for rigid polyurethane foam construction in the insulation fields including external wall insulation of buildings.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

Covering rubber and usage thereof

ActiveCN103304861AGood flame retardant performanceExcellent low temperature and cold resistanceConveyorsChemistryNatural rubber

The invention discloses covering rubber which is characterized by being prepared by the following formula: 15-20phr of natural rubber, 80-85phr of butadiene rubber and butadiene styrene rubber, 5phr of zinc oxide, 2-3phr of stearic acid, 45-46phr of reinforcing filler, 35-45phr of a fire retardant, 4-6phr of a plasticizer, 4phr of an anti-aging agent, 2phr of a vulcanizing accelerator and 3phr of sulphur. The invention also discloses the usage of the covering rubber in the production of a steel wire rope conveyer belt. The covering rubber not only has good flame retardant property and bonding force, but also has excellent low temperature resistance and cold resistance; after the covering rubber is used for producing the steel wire rope conveyer belt, the steel wire rope conveyer belt is not hardened, does not slide and crack, is not broken and the like due to the very low temperature in winter when being used in the severe cold low-temperature area.

Owner:青岛福凯橡塑新材料有限公司

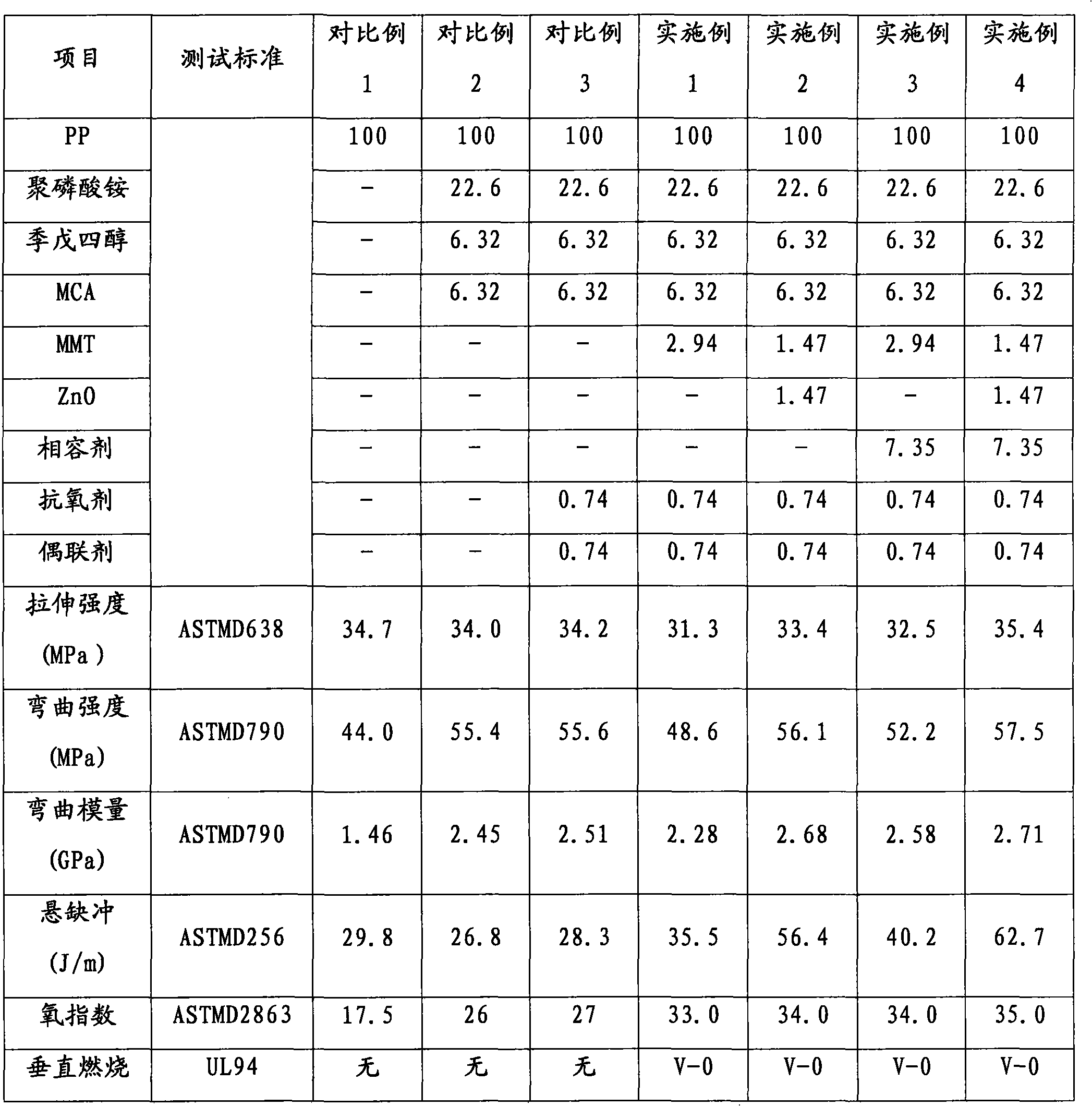

Expanded carbon flame-proof polypropelene composition and preparation method thereof

ActiveCN101293984AThe preparation method is simple and reliableGood flame retardant performanceAmmonium polyphosphateChemistry

The invention relates to an expansive char-forming flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 2.8-8.3 weight parts of pentaerythritol, 2.8-8.3 weight parts of melamine cyanurate and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning all components (including polypropylene, ammonium polyphosphate, pentaerythritol, melamine cyanurate and montmorillonite) at the given ratios, melting, mixing, extruding and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paligorskite ethene-vinyl acetate composite flame-proof material

InactiveCN1737045AStable performanceGood flame retardant performanceFireproof paintsAttapulgus clayVinyl acetate

The invention provides a composite flame-proof material of paligorskite ethane-vinyl acetate. Wherein, mechanical mixing the natural paligorskite powder of smashed 100-5000 items and polyphosphoric acid amine and / or pentaerythrite with given proportion to form composite flame-proof agent then, mixing and the refining said agent and ethane-vinyl acetate copolymer; the latter is one of most important ethene copolymer with well performance and wide application. The product has stable performance and well flame-proof effect and low cost, and accompanies with functions of flame-proof, smoke suppression and decreasing toxic gas.

Owner:NORTHWEST NORMAL UNIVERSITY

Unsaturated polyester resin composite material for furniture and preparation method thereof

ActiveCN104045986AImprove the overall mechanical propertiesGood flame retardant performanceDefoaming AgentsResin composite

The invention relates to an unsaturated polyester resin composite material for furniture. The composite material is characterized by comprising the following components in parts by weight: 100 parts of unsaturated polyester resin, 20 to 40 parts of modified bamboo fibers, 20 to 50 parts of flame retardant, 0.5 to 3 parts of accelerant, 0.8 to 2 parts of initiating agent, 0.5 to 2 parts of defoaming agent and 1 to 10 parts of coupling agent. The invention further provides a preparation method of the unsaturated polyester resin composite material for furniture. The composite material is good in overall mechanical property and flame retardant property as well as excellent in comprehensive property, and can be used for replacing log materials and can be directly molded in a room-temperature curing manner. Thus, the composite material is simple to prepare and easy for scale production, and meets the modern environmental friendliness requirement. As a result, the composite material provided by the invention is especially suitable for the mass manufacturing of the furniture, especially classical furniture.

Owner:VESACH FURNITURE & DECORATION

Magnesium and magnesium alloy composite protection fire-proof covering flux and its production method

InactiveCN1570162AGood flame retardant performanceImprove the protection effectFire retardantFluoride calcium

A magnesium and magnesium alloy composite protection fire-retardant covering flux and its manufacturing method are provided. The chemical components of the covering flux are as follows (by weight): 50% to 70% of magnesium chloride, 8% to 18% of potassium chloride, 7% to 16% of sodium chloride, 1% to 8% of calcium chloride,1% to 8% of calcium fluoride,1% to 7% of magnesia, 1% to 5% of fluxing medium cryolite, 0.5% to 6% of carbonate foaming agent, 0.5% to 4% of beryllide fire retardant. The flux provided by the invention has excellent flame retardant property.

Owner:SHANGHAI AIERSI LIGHT ALLOY

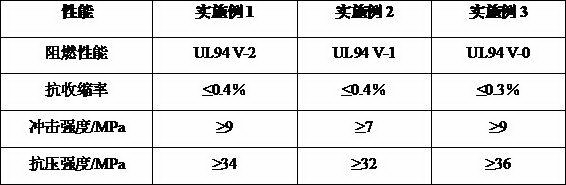

Halogen-free low-smoke flame-retardant polypropylene/polyamide composite material and preparation method

The invention relates to a halogen-free low-smoke flame-retardant polypropylene / polyamide composite material, which is prepared by the following raw materials in parts by weight: 100 parts of polypropylene, 30-50 parts of polyamide, 20-50 parts of thermoplastic elastomer, 30-50 parts of halogen-free low-smoke flame-retardant agent, 10-20 parts of high molecular compatilizer, 1-5 parts of dispersing agent and 1-5 parts of antioxidant. After the raw materials are weighed according to the weight parts, the raw materials are evenly mixed and are fused and extruded through a double-screw extruder and are granulated. The method has the advantages that the process is simple, the cost is low, the weight of the obtained composite material is light, no halogen is contained and the smoke is low, the flame-retardant performance is good, the aging resistance is high and the surface is bright and smooth.

Owner:ANHUI KEJU NEW MATERIALS

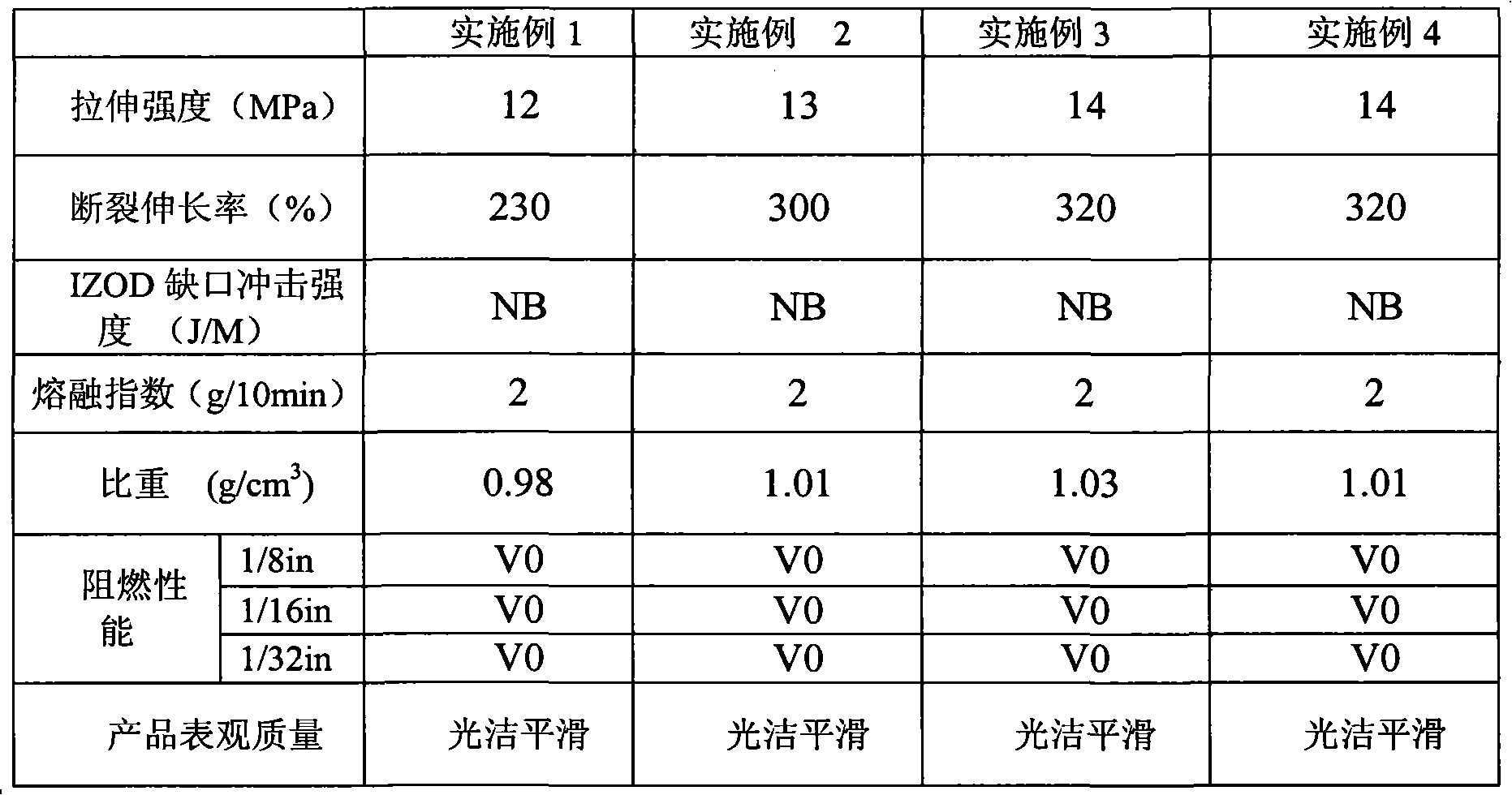

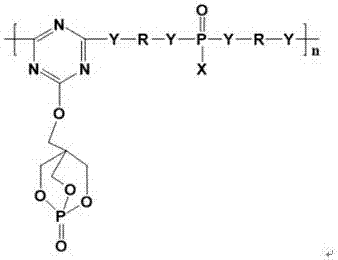

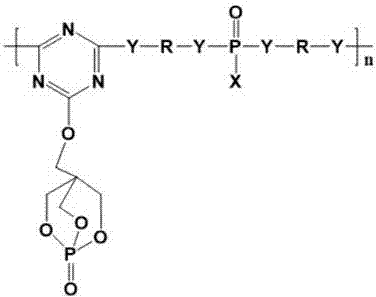

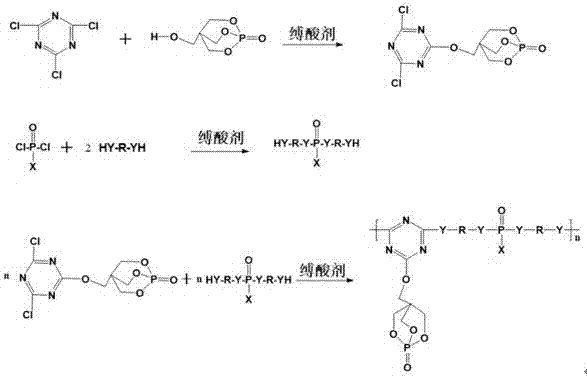

Trine expansion type flame retardant and synthetic method thereof

ActiveCN107118347AGood char formation and thermal stabilityGood flame retardant performanceSolventDiamine

The invention relates to a trine expansion type flame retardant and a synthetic method thereof. The synthetic method is characterized by comprising the following steps: adding a solvent into a container, adding cyanuric chloride and 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo[2.2.2] octane into the container, cooling to 0-45 DEG C in water bath or oil bath and stirring and dispersing, dropwise adding an acid-binding agent to react step by step, thereby obtaining unary substitute; adding matters containing aliphatic diamine or aliphatic dihydric alcohol and a mixture of the solvent and the acid-binding agent into another container, cooling to -10 to 10 DEG C in ice bath or a freezing reactor, slowly dropwise adding a phosphorus-containing compound to react, thereby obtaining phosphorus-containing intermediate; adding the obtained unary substitute (CNC-PEPA) and the obtained phosphorus-containing intermediate into a reaction container with the solvent, dropwise adding the acid-binding agent, heating to 80-130 DEG C to react, cooling, washing and drying to obtain powder solid, namely the trine expansion type flame retardant. The trine expansion type flame retardant has the advantages of being great in molecular weight, relatively moderate in proportion of an acid source, a carbon source and a gas source in a molecular structure, relatively high in char forming content, relatively good in thermal stability and the like.

Owner:蕉岭金鹏精细化工有限公司

Double-coated microencapsulation expansion flame retardant natural rubber and preparation method thereof

InactiveCN103087360AImprove heat stabilityGood flame retardant performanceMicroballoon preparationMicrocapsule preparationAmmonium polyphosphateDouble coating

The invention discloses double-coated microencapsulation expansion flame retardant natural rubber and a preparation method thereof and relates to rubber and a preparation method thereof. The method comprises the following steps of: sequentially mixing a rubber matrix, stearic acid, zinc oxide, an accelerant, an anti-aging agent, carbon black, paraffin, double-coated microencapsulation ammonium polyphosphate / mesoporous molecular sieve MCM-41, pentaerythritol, ammonium polyphosphate and sulfur in an open mill, and performing microencapsulation on the ammonium polyphosphate and mesoporous molecular sieve MCM-41 by employing melamine resin-zinc borate double coating, so that the thermal stability of the rubber matrix is improved. The coating defect of the melamine resin layer can be filled through the outer zinc borate layer, so that the microencapsulation coating is complete. The outer zinc borate layer is a flame retardant and an inorganic matter, and the flame retardant property and the mechanical property are effectively improved. In addition, the mesoporous molecular sieve MCM-41 has the special catalysis and adsorption functions and is synergistic with the expansion type flame retardant, so that the flame retardant property and carbon layer stability of the composite material are further improved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

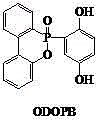

Epoxy powder for packaging medium-low-voltage bus bar

InactiveCN104356602AGood flame retardant performanceGood electrical performanceSilicone resinChemistry

The invention discloses epoxy powder for packaging a medium-low-voltage bus bar and belongs to the technical field of epoxy powder coating. The epoxy powder comprises common epoxy resin, phosphorus-containing and silicon-containing polyurethane-type epoxy resin, a curing agent, silica micro-powder, an outer flame retardant, a toughening agent, a curing accelerator, a pigment and other substances. According to the epoxy powder, the phosphorus-containing and silicon-containing polyurethane-type epoxy resin is synthesized by isocyanate, a reactive phosphorus-containing compound and organic silicone resin and applied on epoxy powder so as to solve the problems of environmental friendliness and flame retardancy. The epoxy powder prepared by the invention has the characteristics of fast curing and excellent thermal cycle impact resistance, voltage resistance and insulation property and has broad application prospects in the field of medium-low-voltage bus bar packaging.

Owner:JIANGSU ZHONGPENG NEW MATERIAL

Flame-retardant master batch for nylon carrier and preparation method thereof

The invention discloses a flame-retardant master batch for a nylon carrier and a preparation method thereof. The flame-retardant master batch comprises the following components in percentage by weight: 9.4-49.6 percent of polycaprolactam powder, 50-90 percent of MCA (Melamine Cyanurate) and 0.4-0.6 percent of antioxidant. The preparation method comprises the following steps: weighting the components according to the weight percent; adding the weighted components into a high-speed mixer, mixing for 20-30 minutes and controlling a temperature in a range of 160-180 DEG C; and cooling the mixed components, adding the cooled components into a hopper of a double-screw extruder, performing fusion reaction, extruding and pelletizing. The flame-retardant master batch for the nylon carrier prepared according to the preparation method is excellent in flame-retardant property; the additive amount of the MCA in nylon is increased; and the production cost is reduced.

Owner:SHENZHEN KEJU NEW MATERIAL

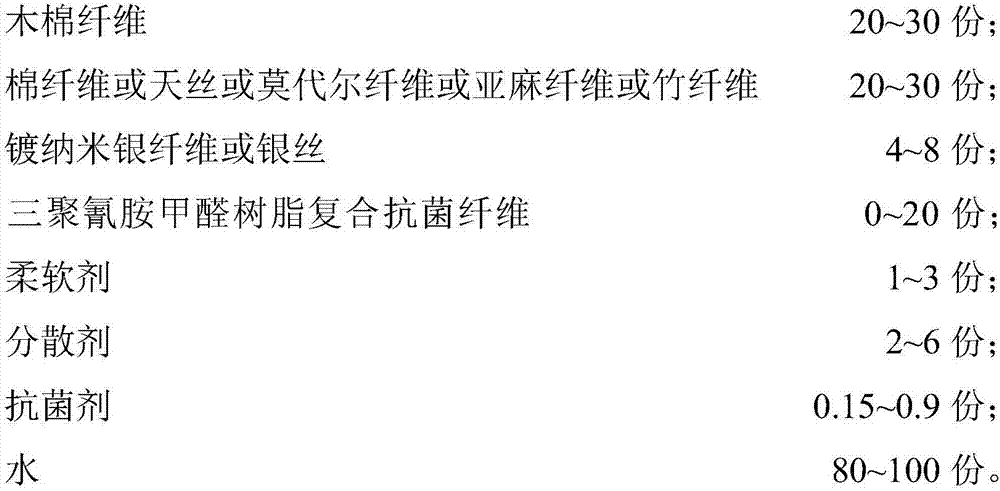

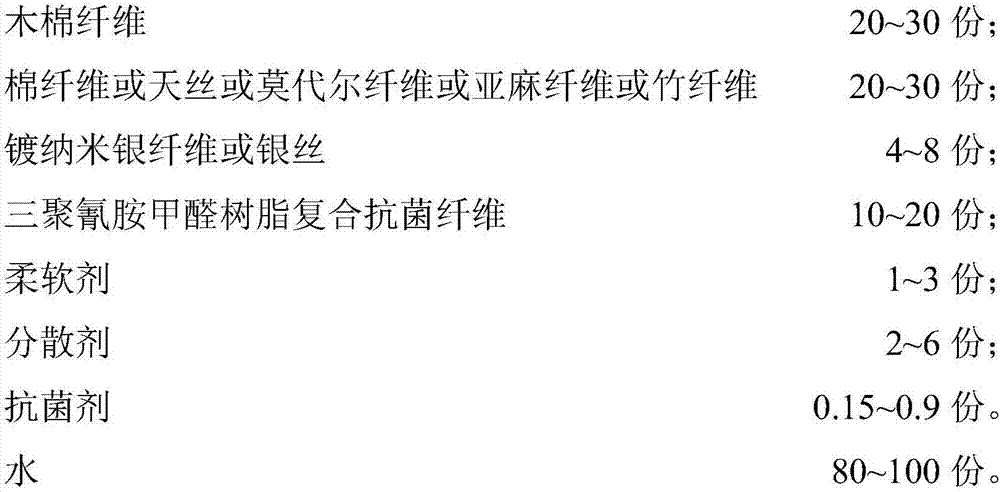

Antibacterial fabric and preparation method thereof

InactiveCN107475857AGood antibacterial propertiesGood flame retardant performanceBiochemical fibre treatmentHeat resistant fibresAnti bacterialKapok fiber

The invention discloses an antibacterial fabric and a preparation method thereof. Raw materials of the antibacterial fabric comprise spandex, kapok fibers, cotton fibers or tencel or modal fibers or linen fibers or bamboo fibers, melamine formaldehyde resin composite anti-bacterial fibers, nano silver coated fibers or silver silk, softener, a dispersing agent and an antibacterial agent. The invention further discloses a preparation method of the antibacterial fabric. Compared with the prior art, the antibacterial fabric obtained through adding and preparing has not only good antibacterial performance, but also good antiflamming performance.

Owner:储旭

Halogen-free flame-retardant sound-insulation composite material

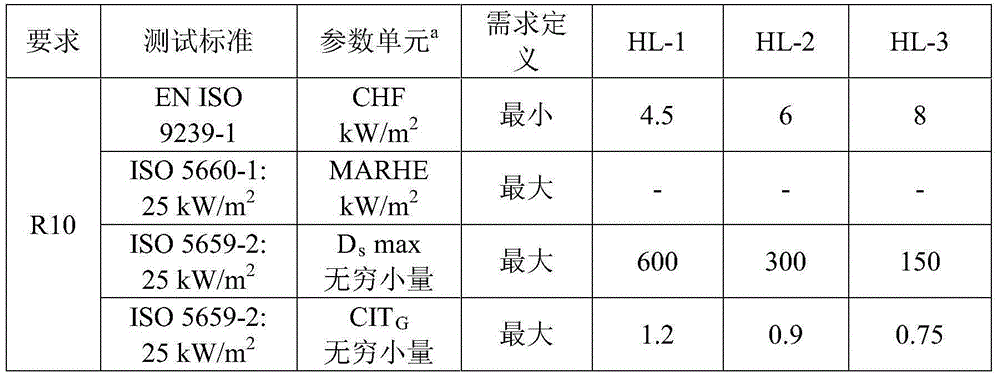

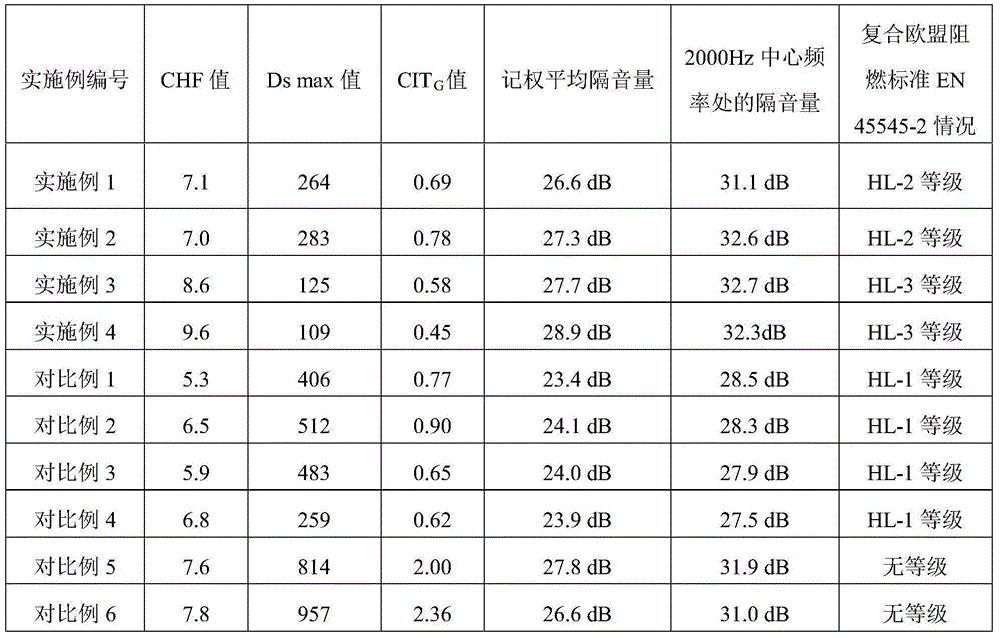

ActiveCN105034509AGood sound insulationGood flame retardant performanceSynthetic resin layered productsVehicle componentsInsulation layerMaterials science

The invention discloses a halogen-free flame-retardant sound-insulation composite material. The halogen-free flame-retardant sound-insulation composite material provided by the invention is a multi-layer polymer composite material formed by alternately superosing polymer-matrix sound-insulation layers and polymer-matrix halogen-free flame-retardant layers. The halogen-free flame-retardant sound-insulation composite material is endowed with flame-retardant performance by virtue of the flame-retardant layers and endowed with sound-insulation performance by virtue of the sound insulation layers; not only can the overall sound insulation performance of the composite material be obviously improved, but also the HL-3 grade (R10) in the newest European Union flame-retardant standard EN45545-2 can be met.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com