Phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber, preparation method therefor and application thereof

A silicone rubber raw rubber, methyl vinyl technology, applied in the field of flame retardant silicone rubber, can solve the problems of low flame retardant efficiency, mechanical properties such as tensile strength, impact strength decline, affecting the scope of use, etc., to achieve excellent flame retardant performance, good tensile and impact strength, good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of phosphorous methyl vinyl flame retardant silicone rubber raw rubber and preparation method thereof, comprises the following steps:

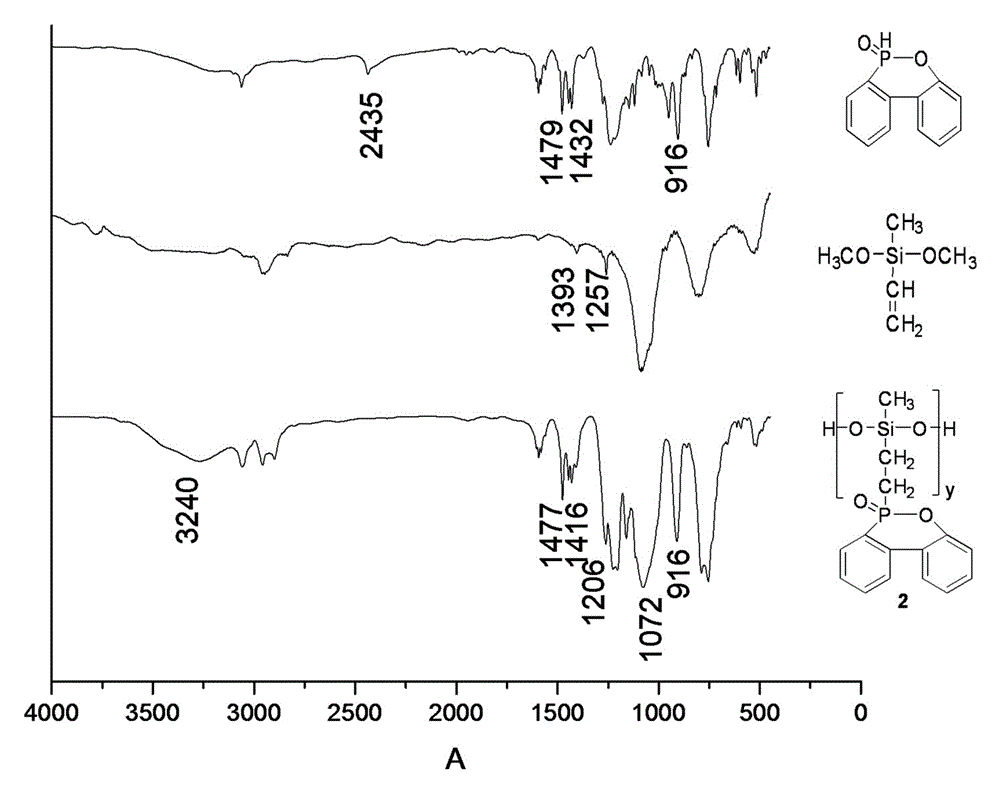

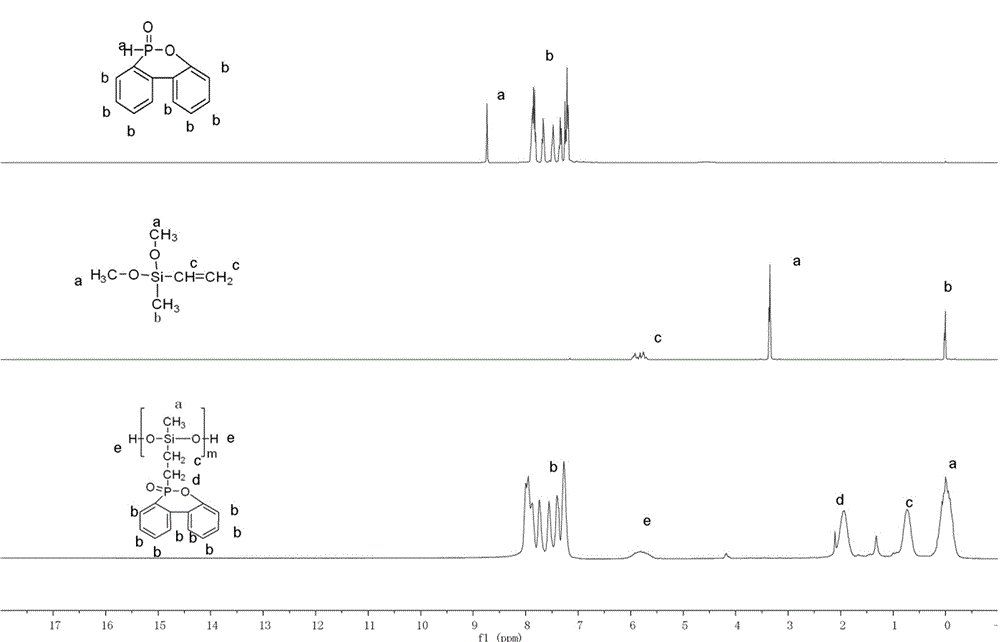

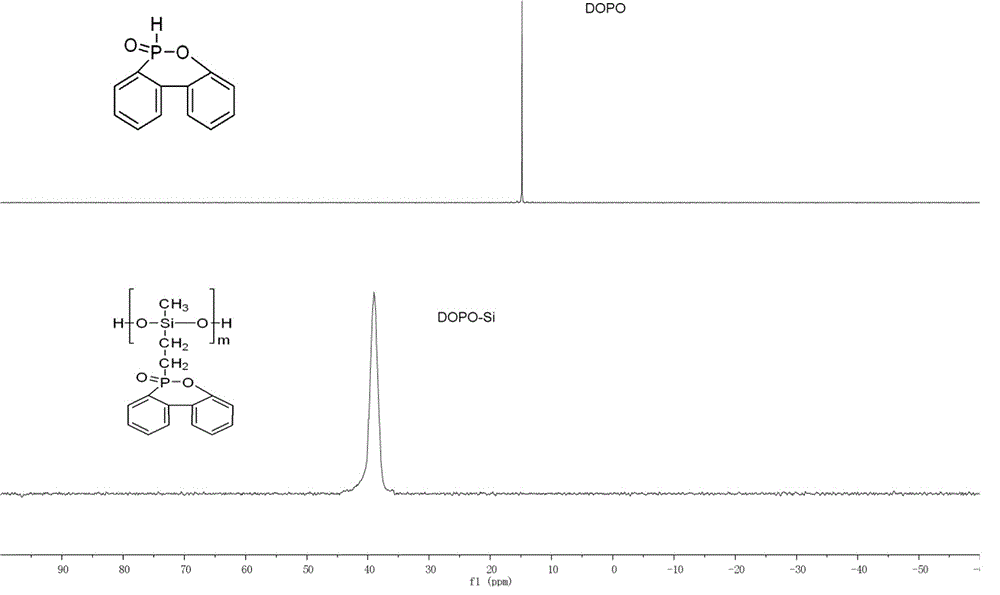

[0041] 1) Add DOPO (3.24g, 0.015mol) into a three-necked flask, under nitrogen protection, add chloroform (3mL), heat up to 65°C, after DOPO is completely dissolved in chloroform, add azobisisobutyronitrile (0.017g), then VMDMS (2.2 mL, 0.015 mol) was added dropwise and the reaction was stirred for 20 h. NaOH solution (6 wt%, 1.2 mL) was added to the product mixture, and stirring was continued at 60 °C for 2 h. Separate the liquid, extract the organic phase, and extract the aqueous phase with chloroform for 2 to 3 times, combine the organic phases, and distill under reduced pressure to obtain a viscous light yellow transparent solid, which is a phosphorus-containing silanol oligomer, with a yield of 85%. FTIR (cm -1 ,KBr):3240cm -1 (OH),3064cm -1 (C-H in phenyl group),2800-3000cm -1 (CH 2 ,CH 3 ),1595cm -1 (phenyl group),...

Embodiment 2

[0044] A kind of phosphorous methyl vinyl flame retardant silicone rubber raw rubber and preparation method thereof, comprises the following steps:

[0045] 1) Add DOPO (6.48g, 0.03mol) into a three-necked flask, under nitrogen protection, add acetonitrile (6mL), heat up to 90°C, after DOPO is completely dissolved in acetonitrile, add azobisisobutyronitrile (0.052g), and then VMDMS (5.3 mL, 0.036 mol) was added dropwise, and the reaction was stirred for 20 h. NaOH solution (5 wt%, 3 mL) was added to the product mixture, and stirring was continued at 60 °C for 2 h. Separate the liquid, extract the organic phase, extract the water phase with acetonitrile for 2 to 3 times, combine the organic phases, and distill under reduced pressure. The obtained viscous light yellow transparent solid is phosphorus-containing silanol oligomer, and the yield is about 88%.

[0046] 2) Add D to a reaction flask equipped with a thermometer and a stirring bar 4 (8g, 0.027mol), D 4 Vi (0.653g, 0...

Embodiment 3

[0048] A kind of phosphorous methyl vinyl flame retardant silicone rubber raw rubber and preparation method thereof, comprises the following steps:

[0049] 1) Add DOPO (10.83g, 0.05mol) into a three-necked flask, under nitrogen protection, add benzene (10mL), raise the temperature to 85°C, after DOPO is completely dissolved in benzene, add azobisisobutyronitrile (0.108g), then VMDMS (11.2 mL, 0.075 mol) was added dropwise and the reaction was stirred for 24 h. NaOH solution (5 wt%, 5.7 mL) was added to the product mixture, and stirring was continued at 60 °C for 2 h. Separate the liquid, extract the organic phase, extract the water phase with benzene for 2 to 3 times, combine the organic phases, and distill under reduced pressure to obtain a viscous light yellow transparent solid that is a phosphorus-containing silanol oligomer with a yield of 93%.

[0050] 2) Add D to a reaction flask equipped with a thermometer and a stirring bar 4 (15g, 0.051mol), D 4 Vi (1.09g, 0.0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com