Halogen-free flame-retardant sound-insulation composite material

A composite material and sound insulation layer technology, which is applied in synthetic resin layered products, transportation and packaging, layered products, etc. Performance is difficult to take into account and other problems, to achieve the effect of being conducive to popularization and application, easy to control, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

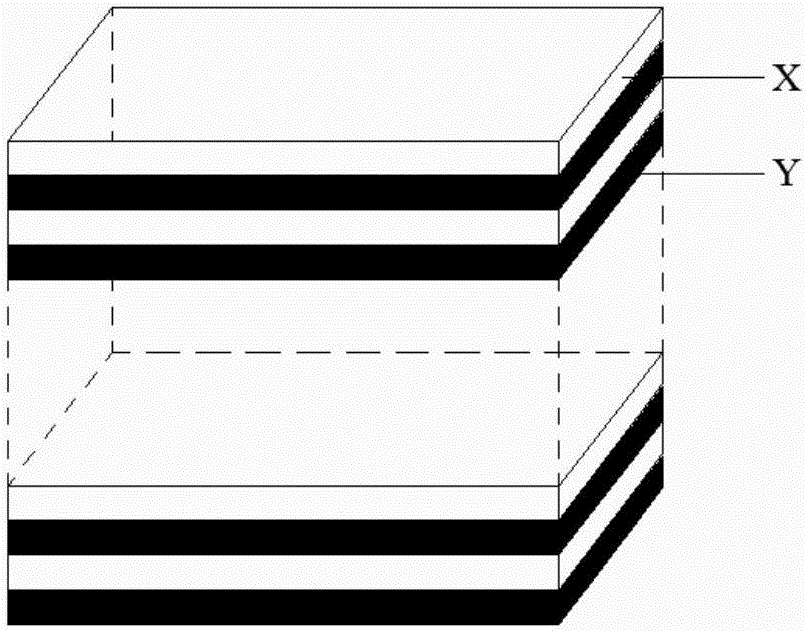

Image

Examples

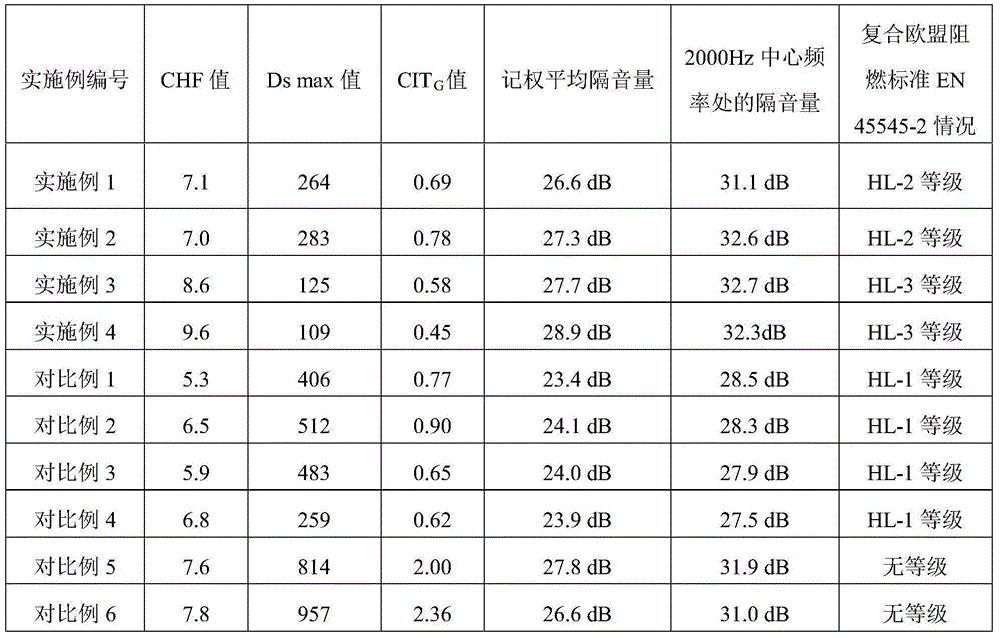

Embodiment 1

[0033] (1) Select 100 parts of ethylene-vinyl acetate copolymer particles as the base material of the sound insulation layer, add 400 parts of iron powder and 20 parts of toluene xylyl phosphate, and melt and blend through a twin-screw extruder to obtain a polymer-based sound insulation layer material particles.

[0034] (2) Select 100 parts of ethylene-vinyl acetate copolymer particles as the base material of the flame retardant layer, add 40 parts of pentaerythritol, 120 parts of ammonium polyphosphate and 6 parts of montmorillonite, and melt and blend them through a twin-screw extruder to obtain a polymer Base flame retardant layer material particles.

[0035] (3) The above two materials are put into two extruders of the micro-layer co-extrusion device respectively, and the speed ratio of the two extruders of the polymer-based sound-insulating layer and the polymer-based flame-retardant layer is adjusted to be 1:1, The temperature of each section of the extruder is set at ...

Embodiment 2

[0038] (1) Select 100 parts of thermoplastic polyurethane as the base material of the sound insulation layer, add 450 parts of barium sulfate and 40 parts of triphenyl phosphate, and melt and blend through a twin-screw extruder to obtain polymer-based sound insulation layer material particles.

[0039] (2) Select 100 parts of polyethylene as the base material of the flame retardant layer, add 30 parts of diethyl aluminum hypophosphite, 60 parts of melamine polyphosphate and 6 parts of zinc borate, and melt and blend through a twin-screw extruder to obtain a polymer Base flame retardant layer material particles.

[0040] (3) Put the above two materials into the two extruders of the micro-layer co-extrusion device respectively, adjust the speed ratio of the two extruders of the sound insulation layer and the flame retardant layer to 1.2:1, and the temperature of each section of the extruder Set at 170-190°C. After melting and plasticizing, the two melts are superimposed in the d...

Embodiment 3

[0043] (1) Select 100 parts of styrene-butadiene-styrene block copolymer as the base material of the sound insulation layer, add 500 parts of lanthanum oxide and 50 parts of tris(xylyl) phosphate, and melt blend through a twin-screw extruder A polymer-based acoustic layer material granulate is produced.

[0044] (2) Select 100 parts of polypropylene as the base material of the flame retardant layer, add 30 parts of triazine-based char-forming agent, 90 parts of ammonium polyphosphate and 5 parts of carbon nanotubes, and melt and blend the polymer through a twin-screw extruder Base flame retardant layer material particles.

[0045] (3) Put the above two materials into the two extruders of the micro-layer co-extrusion device respectively, adjust the speed ratio of the two extruders of the sound insulation layer and the flame retardant layer to 1:1.1, and the temperature of each section of the extruder Set at 180-190°C, after melting and plasticizing, the two melts are superimpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com