Irregular brick and wall body structure made from same

A technology of wall structure and special-shaped bricks, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of poor seismic performance, poor leak-proof performance, and no function of permeable soil retention, etc., and achieve good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

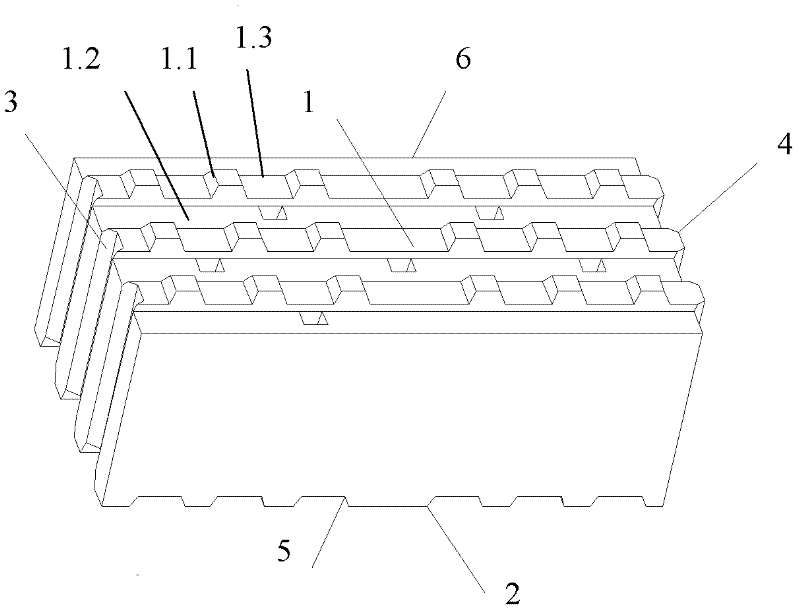

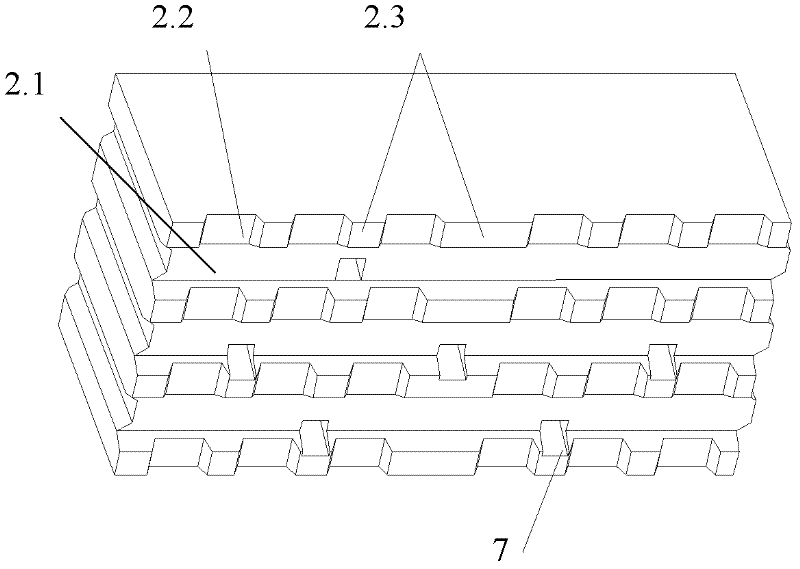

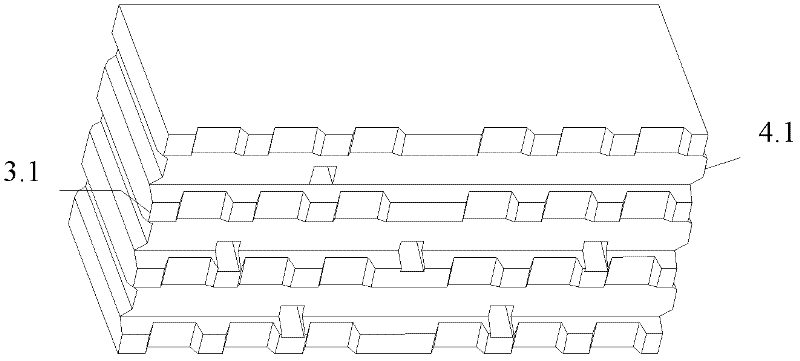

[0041] refer to Figure 1 to Figure 8, a special-shaped brick, the brick is a longitudinal profile, including: a top surface 1, a bottom surface 2, two end surfaces 5, 6 and two side surfaces 3, 4, the top surface 1 of the brick is provided with at least two horizontal Upper corrugations 1.1, the horizontal upper corrugations 1.1 are arranged in parallel longitudinally, between adjacent horizontal upper corrugations 1.1 is a horizontal upper groove 1.2, the bottom surface of the brick is provided with at least two horizontal lower grooves 2.1, the The horizontal upper corrugation 1.1 matches the horizontal lower groove 2.1, the number of the horizontal upper corrugation 1.1 is equal to the number of the horizontal lower groove 2.1; one side of the brick is provided with at least two vertical corrugations 3.1, The vertical ribs 3.1 are vertically arranged in parallel, and the other side of the brick is provided with at least two vertical grooves 4.1, the vertical ribs 3.1 match...

Embodiment 2

[0060] refer to Figure 9 ~ Figure 13 , a wall structure formed of special-shaped bricks, the wall includes a wall layer formed by the longitudinal connection of the bricks, the wall layers are stacked layer by layer, and the bricks of adjacent wall layers are arranged in a staggered manner, The brick is a longitudinal profile, comprising: a top surface 1, a bottom surface 2, two end surfaces 5, 6 and two side surfaces 3, 4, the top surface 1 of the brick is provided with at least two horizontal corrugations 1.1, the The horizontal upper corrugations 1.1 are vertically arranged in parallel, and between adjacent horizontal upper corrugations 1.1 is a horizontal upper groove 1.2, and the bottom surface of the brick is provided with at least two horizontal lower grooves 2.1, and the horizontal upper corrugations 1.1 and The horizontal lower grooves 2.1 are matched, and the number of the horizontal upper grooves 1.1 is equal to the number of the horizontal lower grooves 2.1; one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com