Mounting section structure for mounting dash silencer

A technology for cab and sound insulation board, which is applied in the direction of building structure, vehicle parts, transportation and packaging, etc., to achieve the effect of good sound insulation performance and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

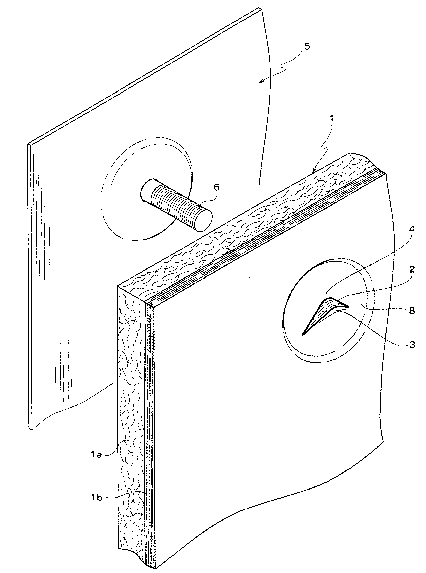

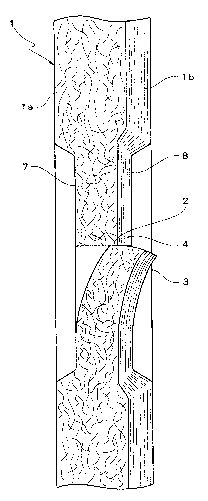

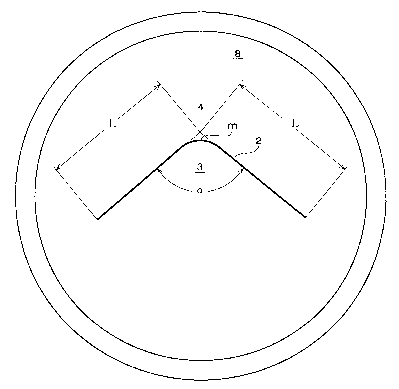

[0030] like figure 1 , figure 2 The cab acoustic panel 1 shown is a spacer of tens of millimeters consisting of a soft layer 1a and a hard layer 1b by heating and pressurizing a fibrous layer object made of thermoplastic resin fibers, cotton, natural fibers, etc. Shape, forming a mountain-shaped slender slit 2 at the position where it needs to be installed, allowing the lower edge 3 separated by the slender slit 2 to bend toward the cab side, so that the lower edge 3 is larger than the upper edge on the driver's cab side. 4 protruding, forming a height difference. which is figure 2 In the figure, the left side of the cab soundproof panel 1 is the engine room side, the right side is the cab side, and the lower edge portion 3 is formed in a shape curved toward the cab side. 5 is a vehicle body dash panel, and 6 is a stud pin with a shaft diameter of 5 to 6 mm protruding from the cab side of the vehicle body dash panel 5 . image 3 Shown is the front view of the main part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com