Patents

Literature

42results about How to "Avoid gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

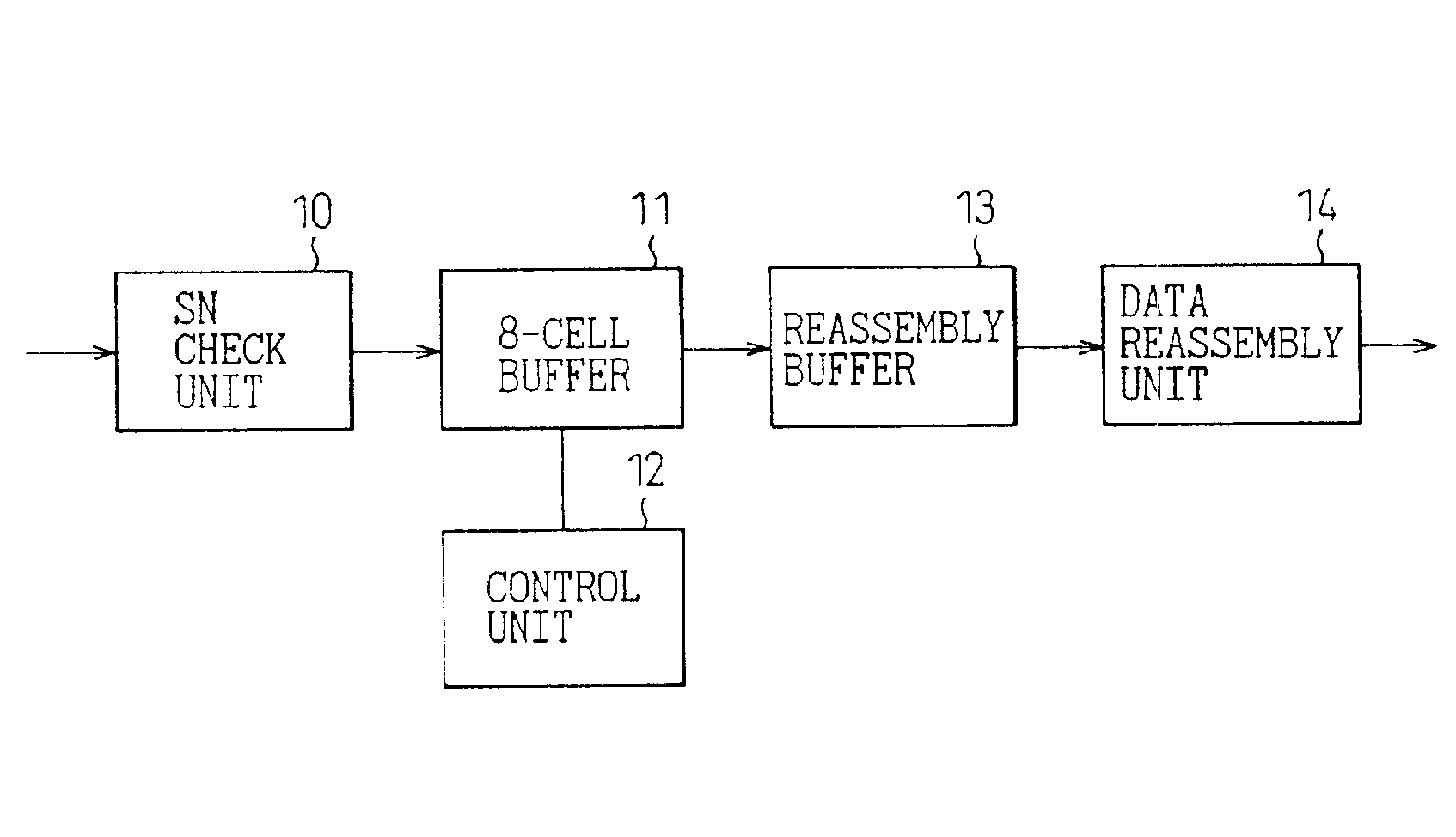

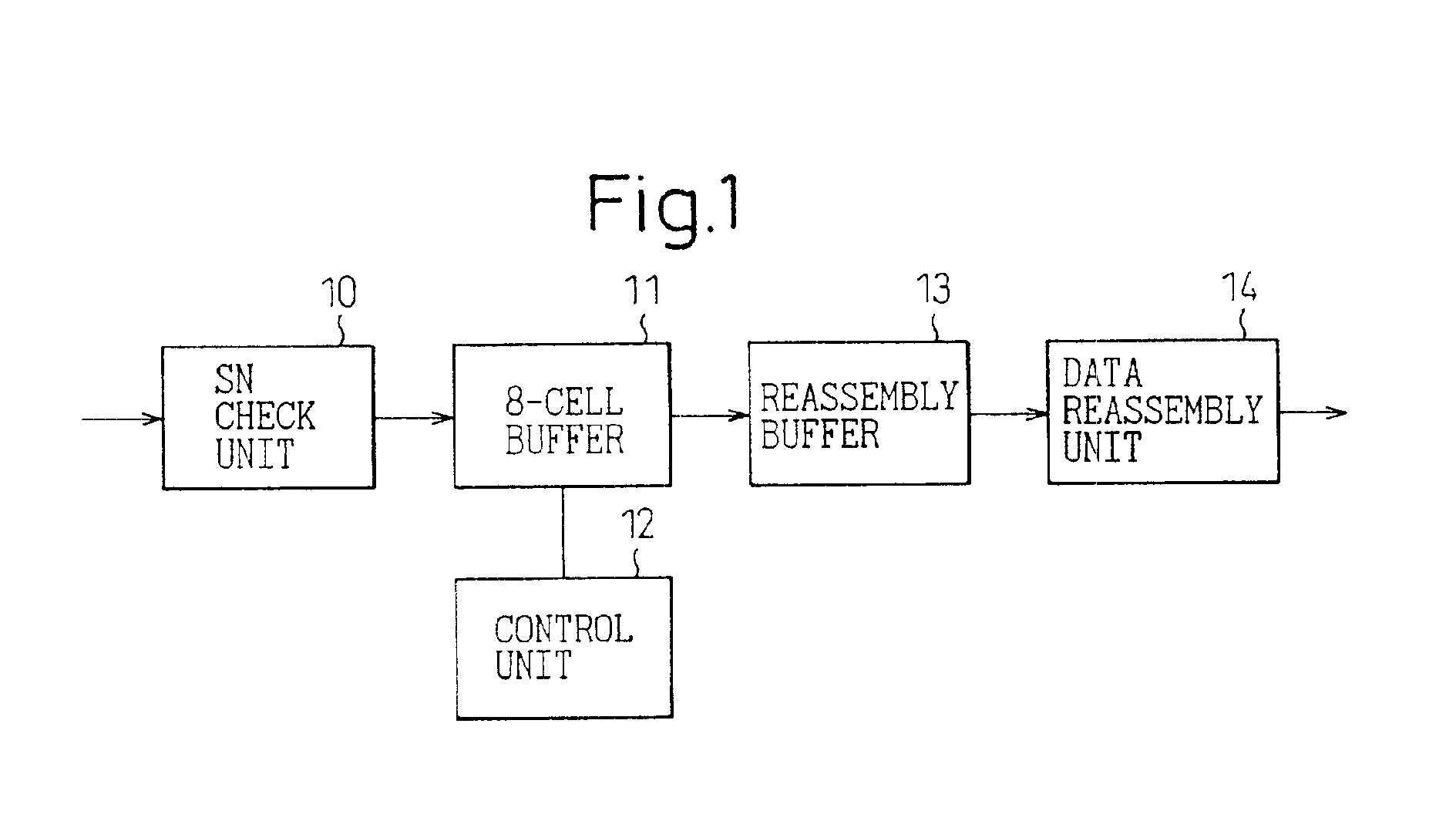

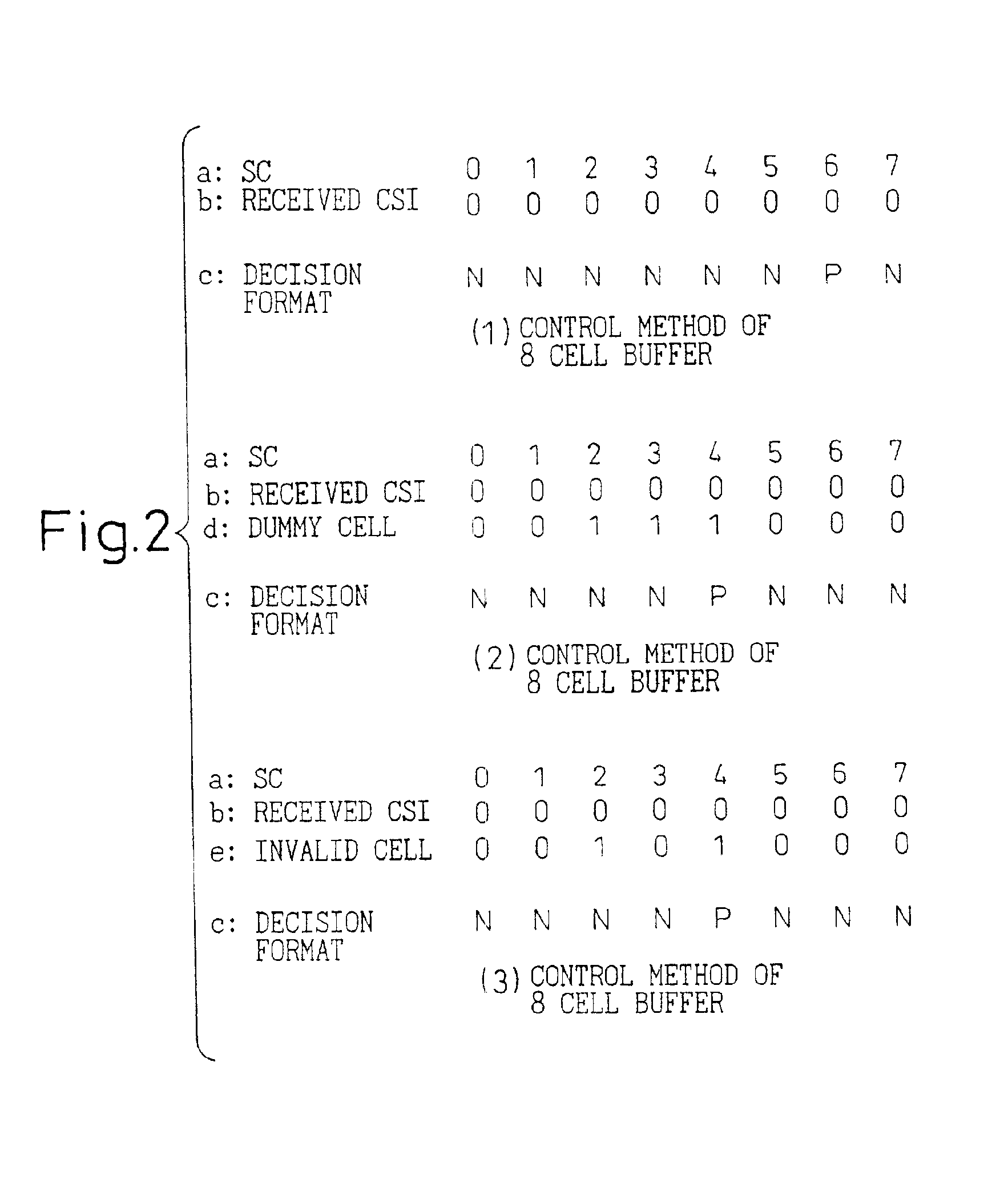

System for controlling AAL1 cell bandwidth

InactiveUS6873621B2Avoid gapsAccurate determinationTime-division multiplexData switching by path configurationData bufferControl unit

A system for controlling a bandwidth when receiving and reassembling a consecutive data stream transferred while segmented by AAL1 format cells which enables correct determination of non-P and P formats and reassembly of cells even when error arises in multiple bits including the CSI bit of an AAL1 cell or when adding dummy cells and thereby enabling prevention of a gap in data in a frame, comprising, in a data reassembly unit which reassembles received cells, an 8-cell buffer for storing 8 cells of a cycle of a sequence count (SC) of 0 to 7 and sending the cells out to a later stage after a check unit of a sequence number (SN) field confirms normalcy of the cells and a control unit for control so that the number of P format cells stored in the 8-cell buffer becomes 1 cell when 8 cells are stored in the 8-cell buffer.

Owner:FUJITSU LTD

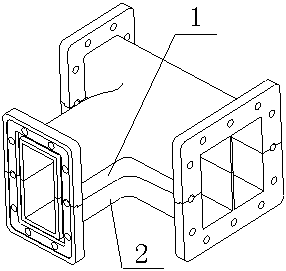

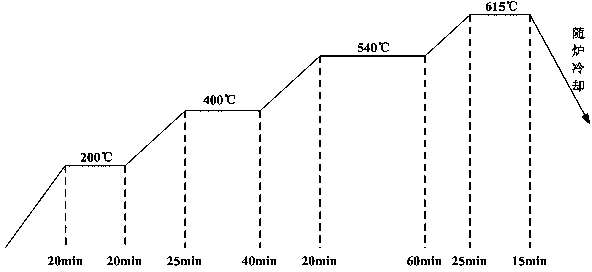

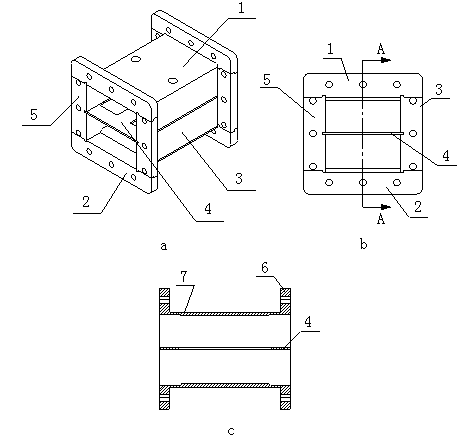

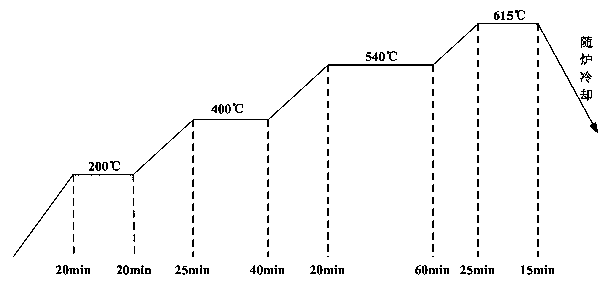

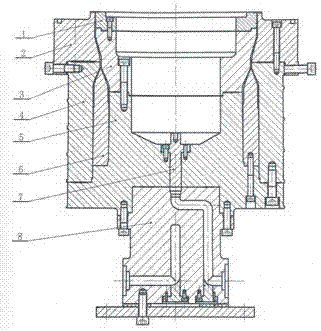

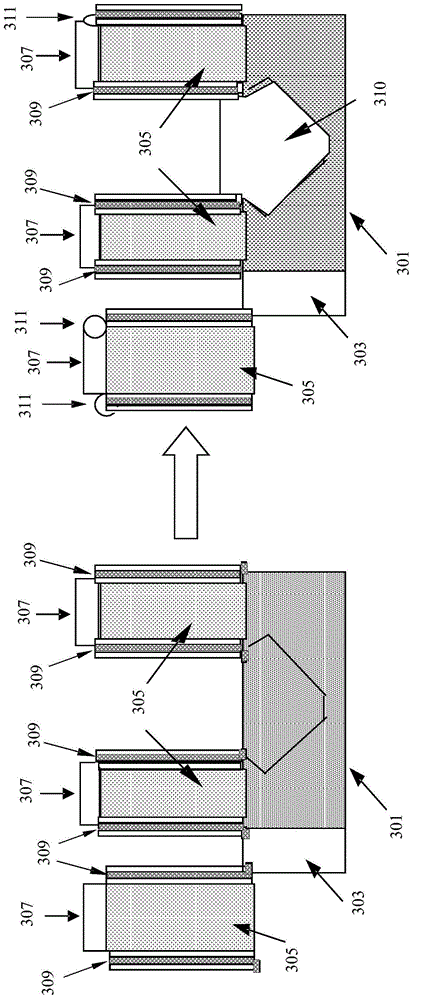

Self-positioning vacuum brazing technique for multi-cavity electrical bridge waveguide

The invention relates to a self-positioning vacuum brazing technique for a multi-cavity electrical bridge waveguide. The self-positioning vacuum brazing technique comprises the following steps of preparing materials and finishing the machining of an upper part and a lower part of the waveguide; respectively carrying out surface treatment on the machined upper and lower parts of the waveguide; producing brazing filler metals according to overall dimensions of the upper part and the lower part of the waveguide and assembling the upper part and the lower part of the waveguide and the brazing filler metals; matching the assembled electrical bridge waveguide with a work fixture and placing the assembled electrical bridge waveguide and the work fixture into a vacuum aluminum brazing furnace; carrying out vacuum brazing on the multi-cavity electrical bridge waveguide according to a vacuum brazing temperature process curve; carrying out numerical control machining on the shape of the waveguide and a ring flange; drilling and carrying out electrochemical treatment. According to the self-positioning vacuum brazing technique disclosed by the invention, the ring flange and a waveguide tube are integrally formed at one time, so that the processing work procedures are simplified, and the production period is short; a groove and a shoulder are arranged, so that self positioning is realized, combined times are reduced, and the assembly precision is high; one-time welding forming is realized by adopting vacuum brazing, and thus the deformation of cavities caused by multiple times of welding is avoided; in addition, no brazing flux is needed, and thus the corrosion of the brazing flux to the cavities is avoided, and the service life of the multi-cavity electrical bridge waveguide is prolonged.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

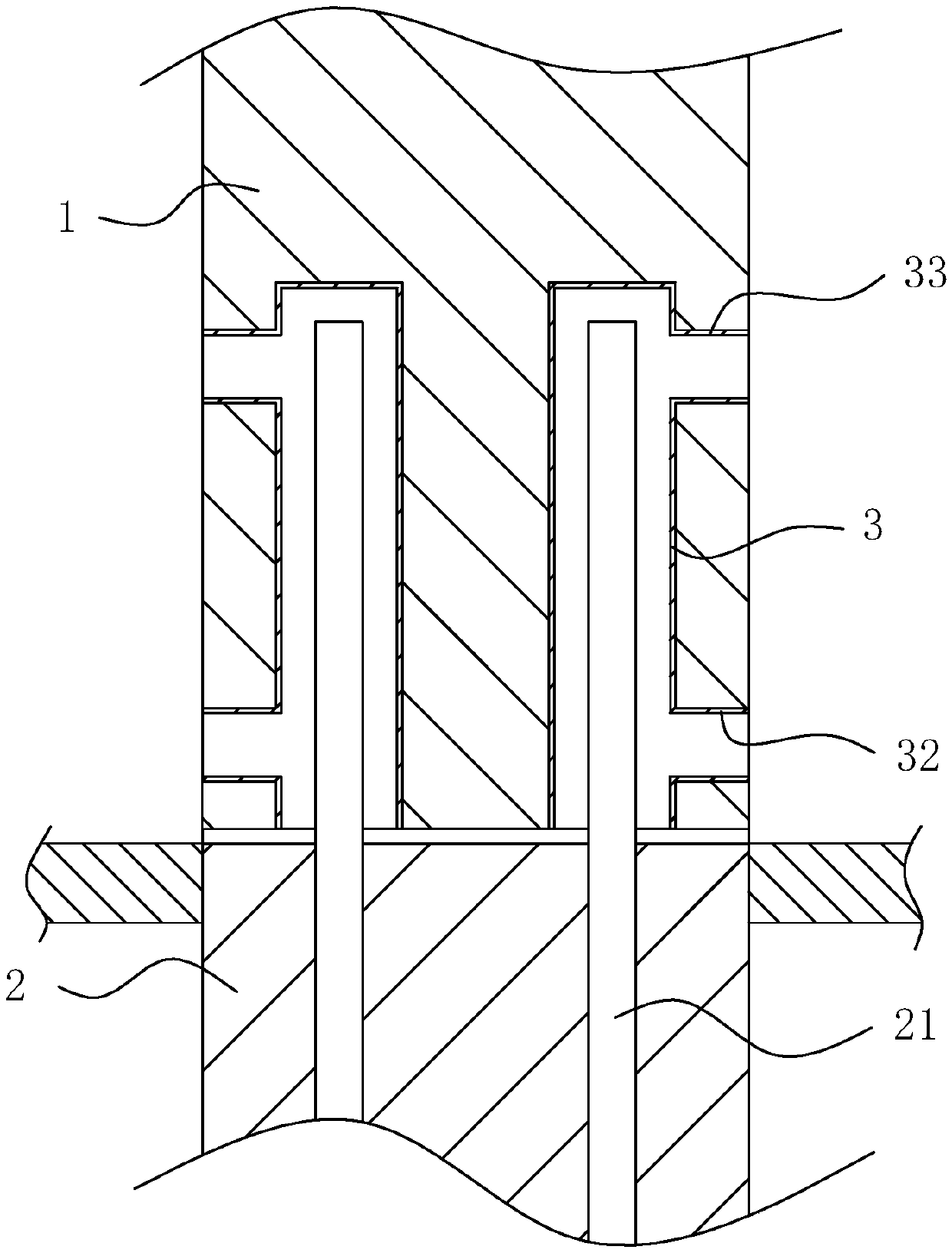

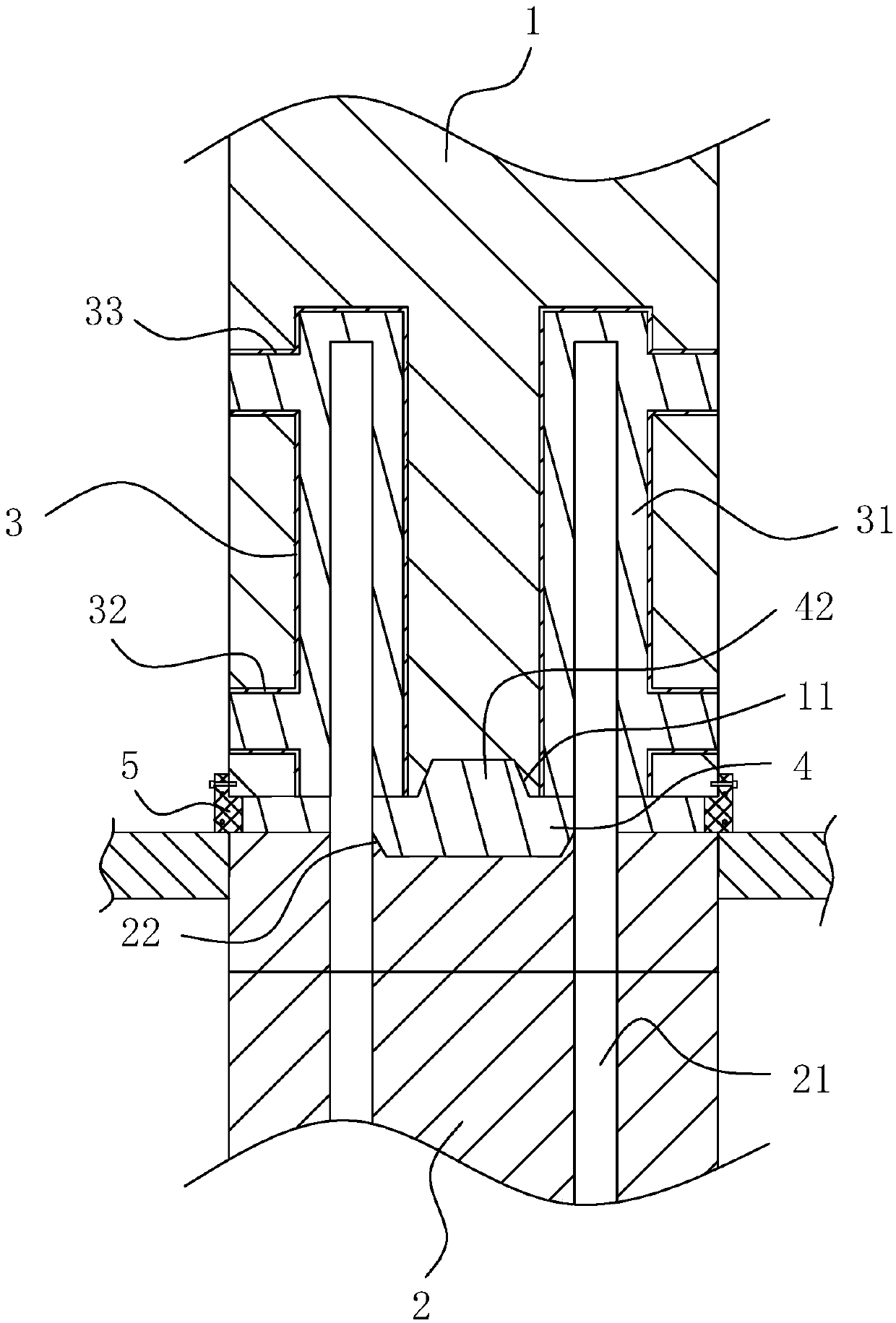

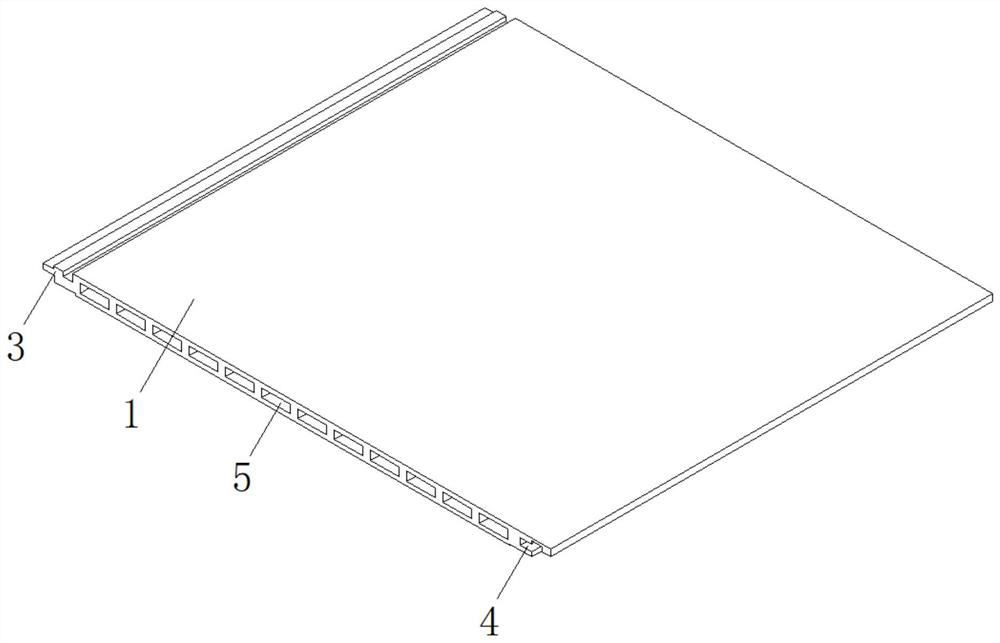

Shear wall connection structure and construction process thereof

The invention discloses a shear wall connection structure and a construction process thereof, and relates to the technical field of prefabricated shear wall design. A gap exists between the lower endwall of an upper wall body and the upper end wall of a lower wall body. The shear wall connection structure is characterized in that the upper end face of the lower wall body is provided with a slurrypassing groove in the length direction of the upper end face of the lower wall body, and the slurry passing groove communicates with all grouting sleeves; sleeve interior slurry blocks are arranged in the grouting sleeves, and the slurry passing groove is internally provided with a grouting joint filling block which is integrally formed with the sleeve interior slurry blocks; and concrete is injected into the grouting sleeves through a grouting pipe, because of the gravity effect, the concrete downwards flows into the slurry passing groove and forms the grouting joint filling block after being solidified, thus the gap between the upper wall body and the lower wall body is fully filled, and the phenomenon that the gap exists between the upper wall boy and the lower wall body is effectivelyavoided.

Owner:南通市建筑设计研究院有限公司

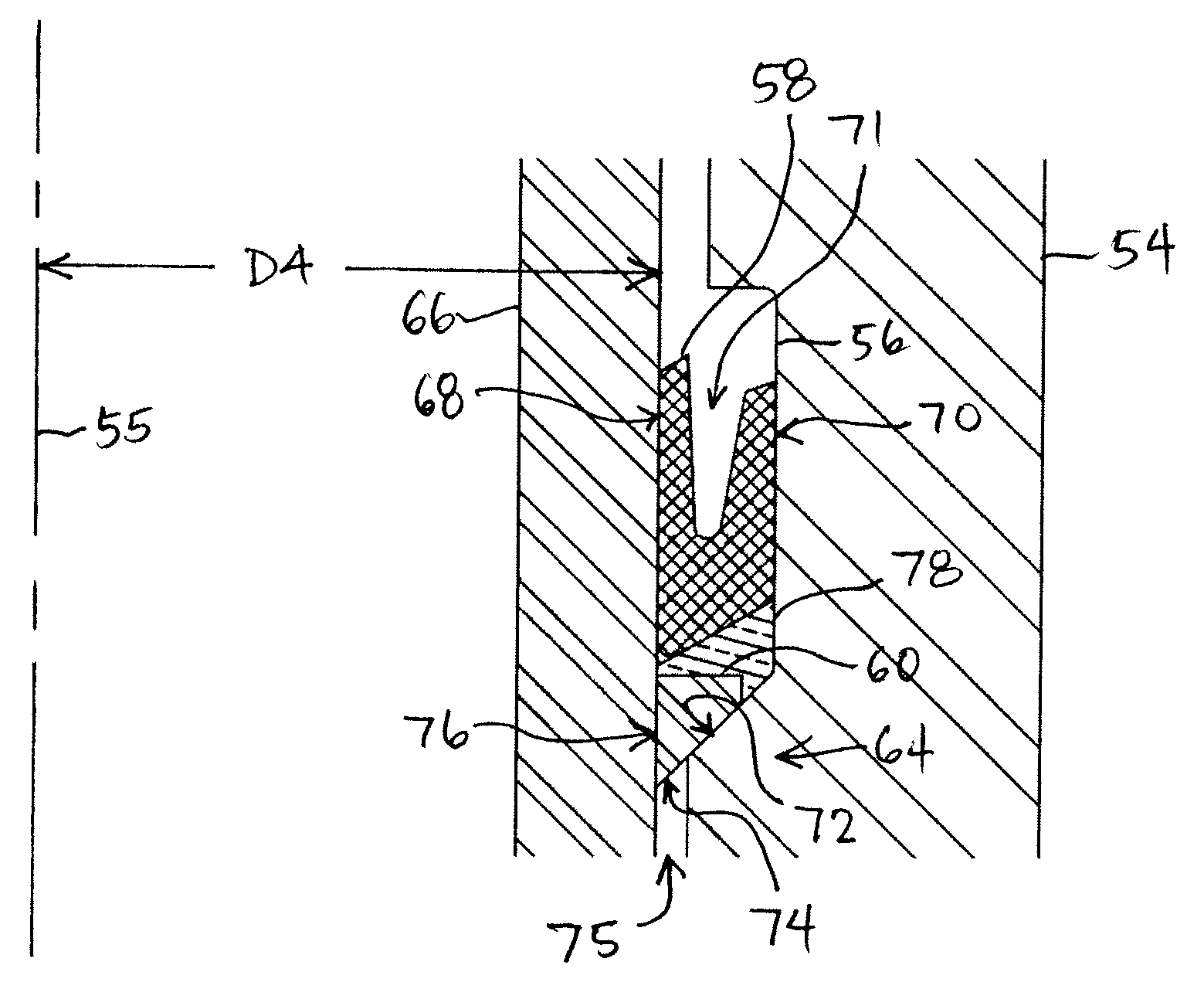

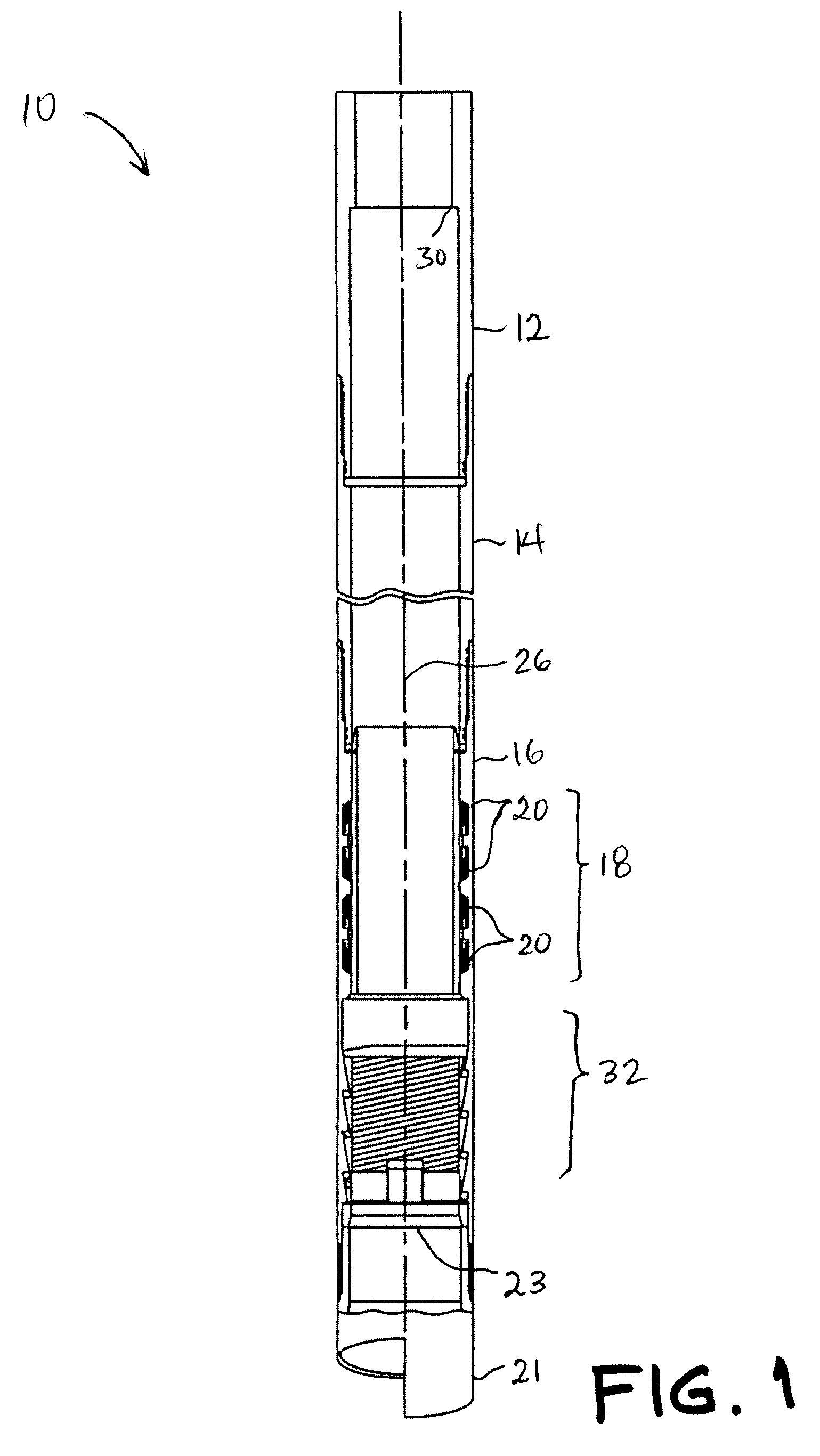

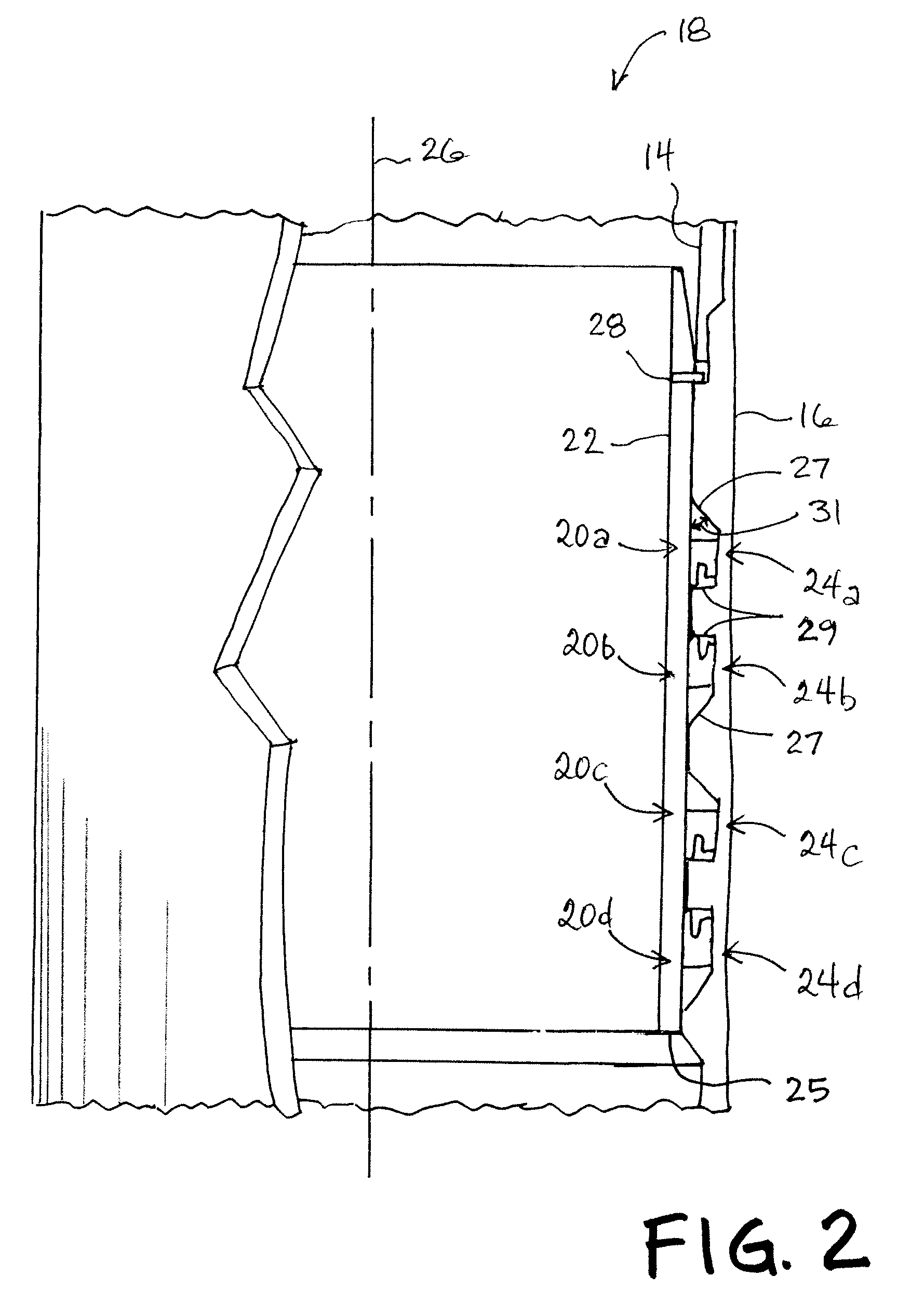

Casing Patch and Seal

A casing patch assembly may include a patch seal having two ring-type seals with different performance characteristics. A first ring seals against a casing patch and a casing stub. A second ring self-adjusts to the size of the casing stub and is located so that it blocks the first seal, which may be softer material than the second ring, from being squeezed into an annular gap between the casing patch and the casing stub. The second ring may include a split feature to allow for the self-adjustment. Optionally, a third ring made of a malleable material may be located between the first and second rings to protect the first ring from being damaged by movement of the split feature.

Owner:LOGAN OIL TOOLS

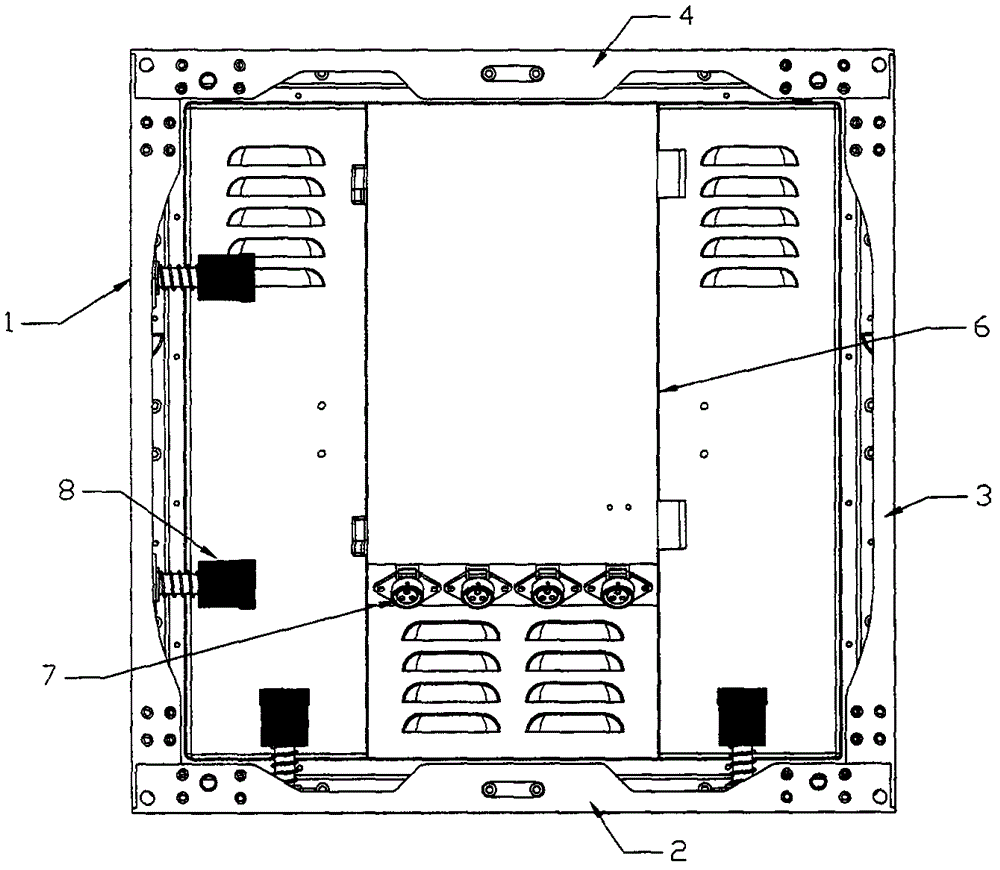

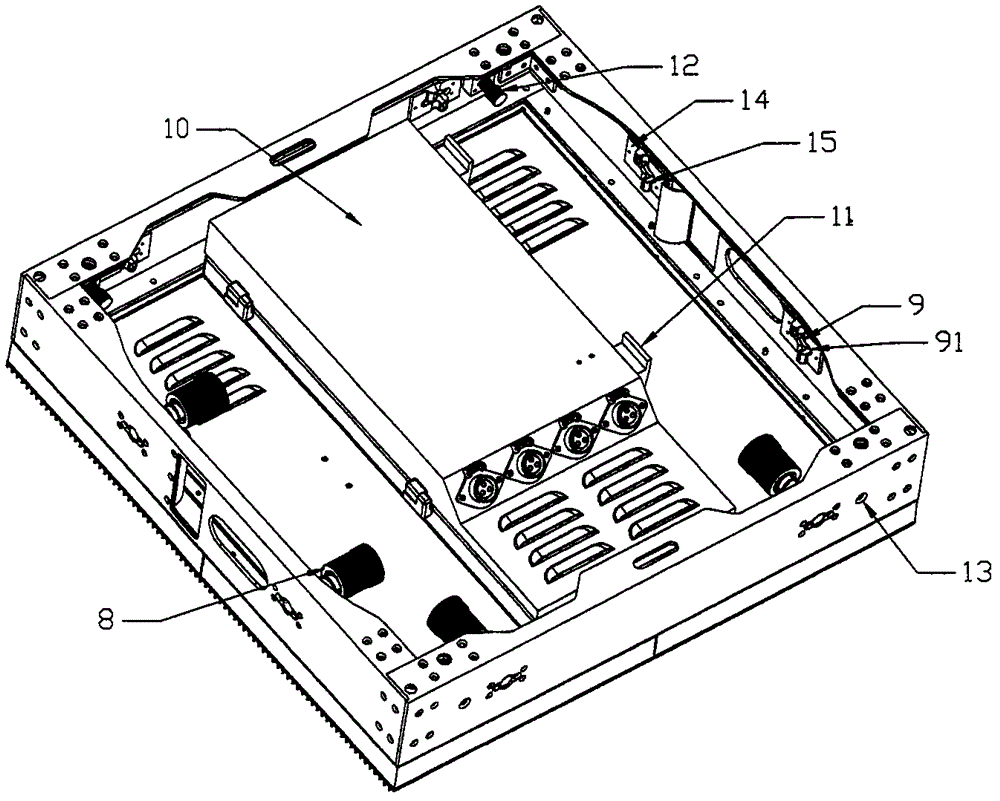

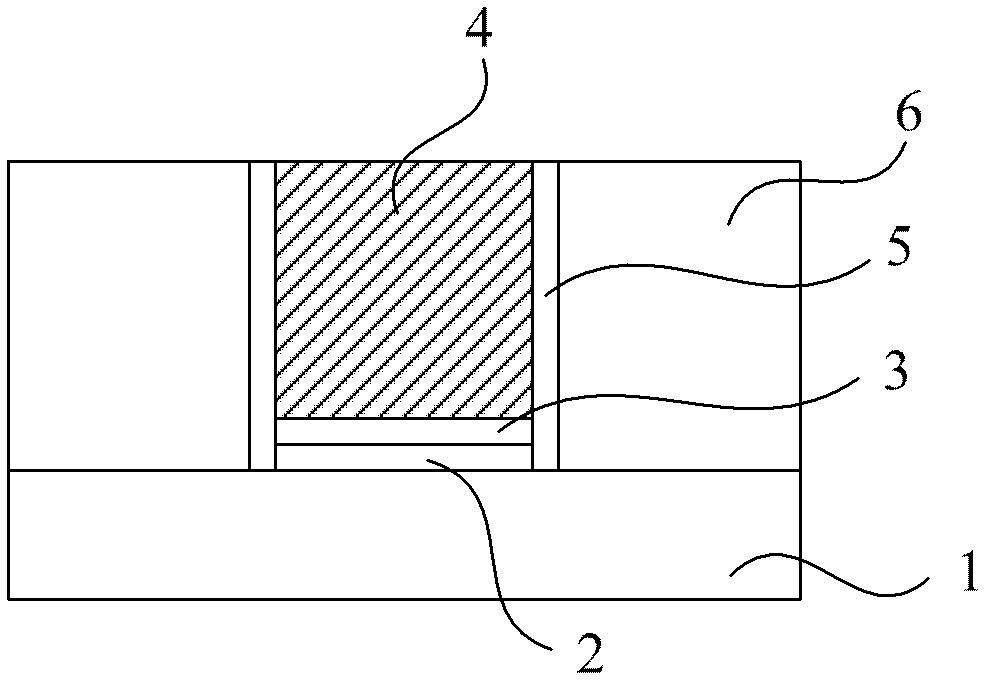

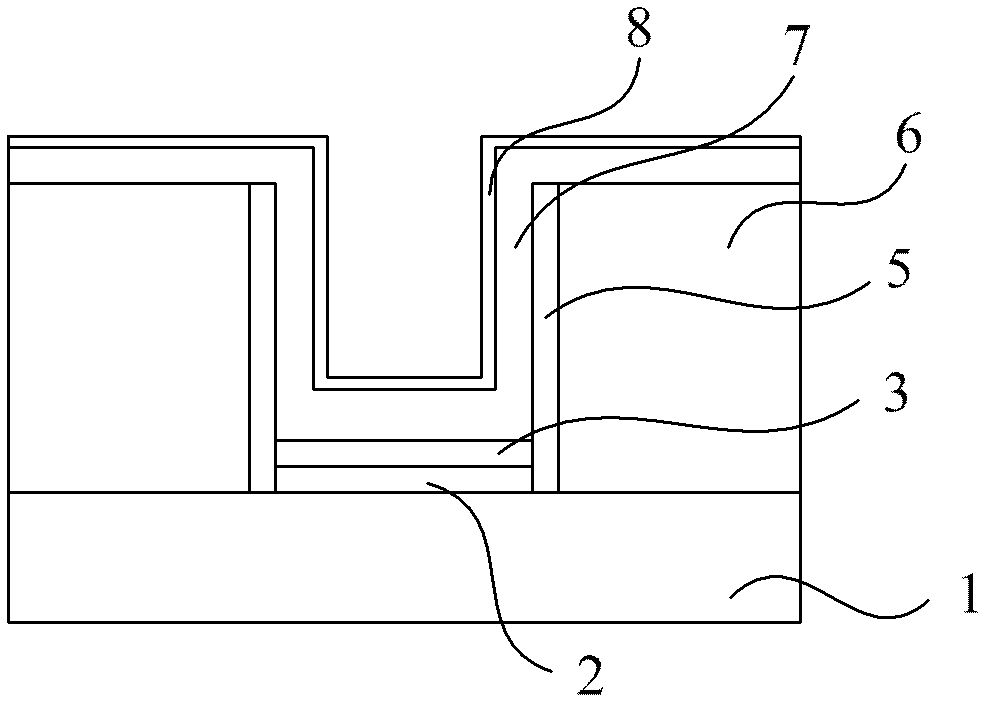

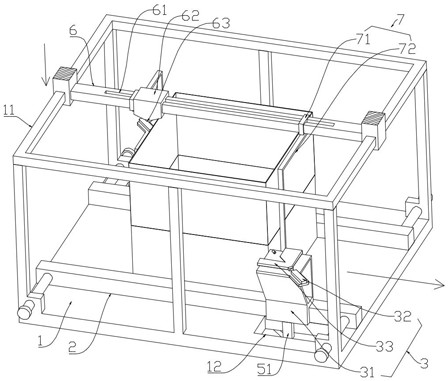

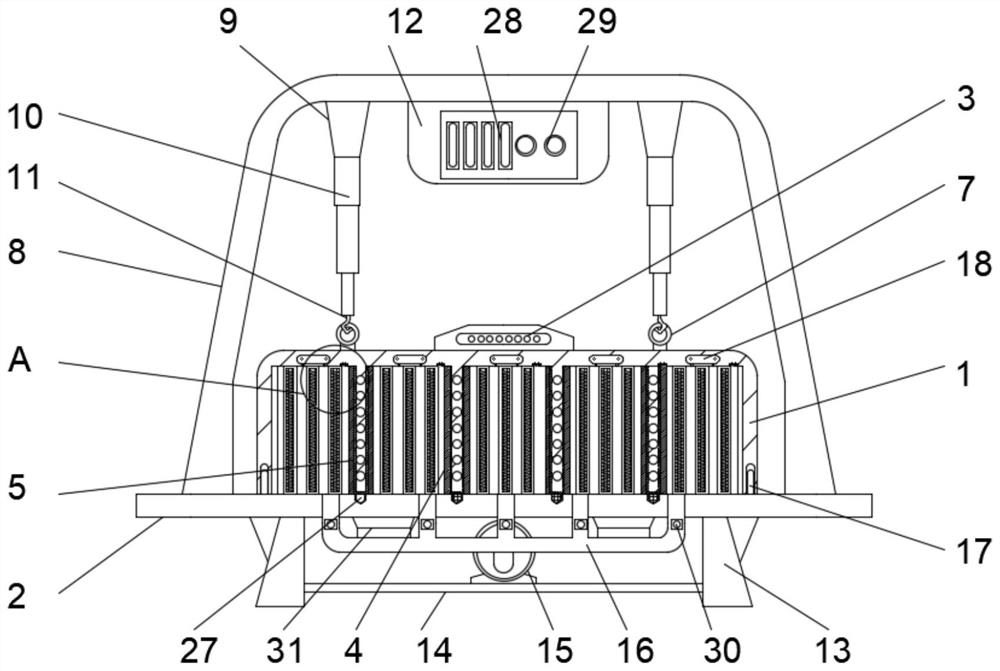

Light-emitting diode (LED) tiled screen module box

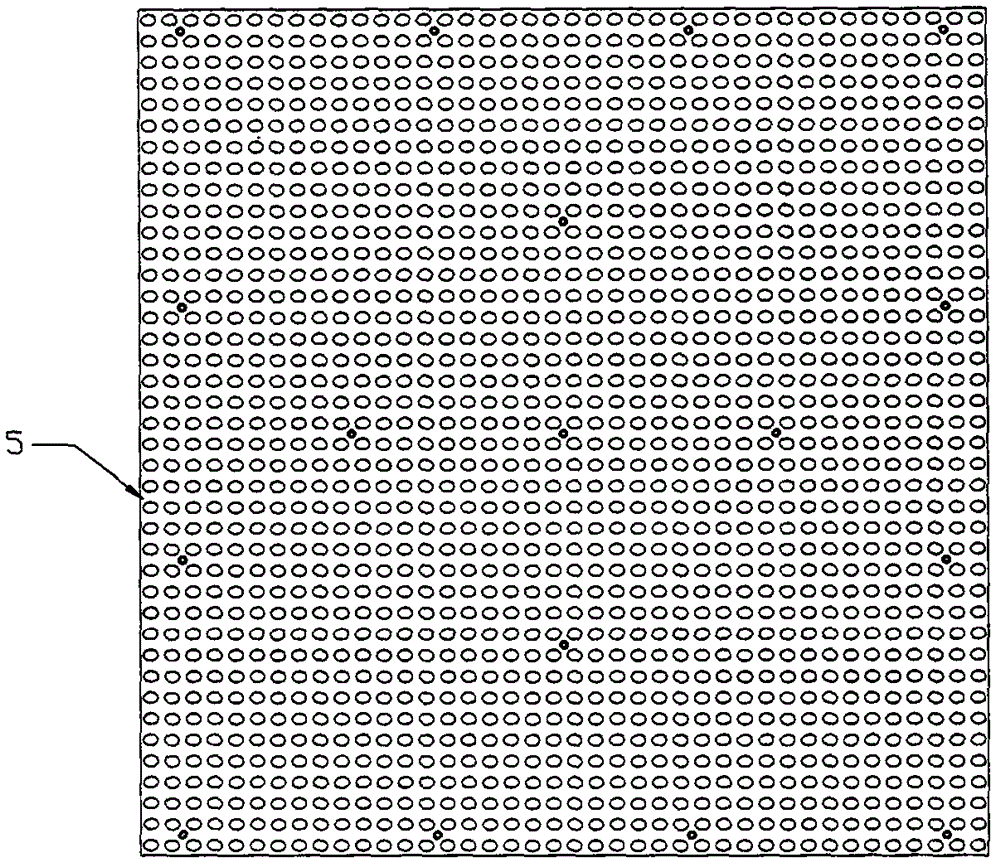

InactiveCN103065554AEasy installationAvoid gapsCasings/cabinets/drawers detailsIdentification meansLight sourceDot matrix

The invention relates to the field of a light-emitting diode (LED) tiled screen, in particular to an LED tiled screen module box. The LED tiled screen module box comprises a square module frame which is formed by four section bar boarders. LED light sources arranged in a dot matrix mode are arranged on the front side of the module frame, and a place in the module frame and located on the back of the LED sources is provided with a module power source box which is provided with a power source and a circuit board. A connection terminal is arranged outside the power source box, and at least two rapid locking rods are arranged on two section bar boarders which are vertical to each other. The rest two section bar boarders which are vertical to each other are provided with locking holes corresponding to the positions of the locking rods. The LED tiled screen module box splices LED tiled screen module boxes through the rapid locking rods, so that not only is installation speed fast, but also the phenomenon that gaps are generated between the module boxes under the condition of being hung for a long time is avoided. Accordingly, the stable using time of the LED tiled screen is prolonged, and the phenomenon that maintenance is needed usually is avoided.

Owner:CREATELED ELECTRONICS

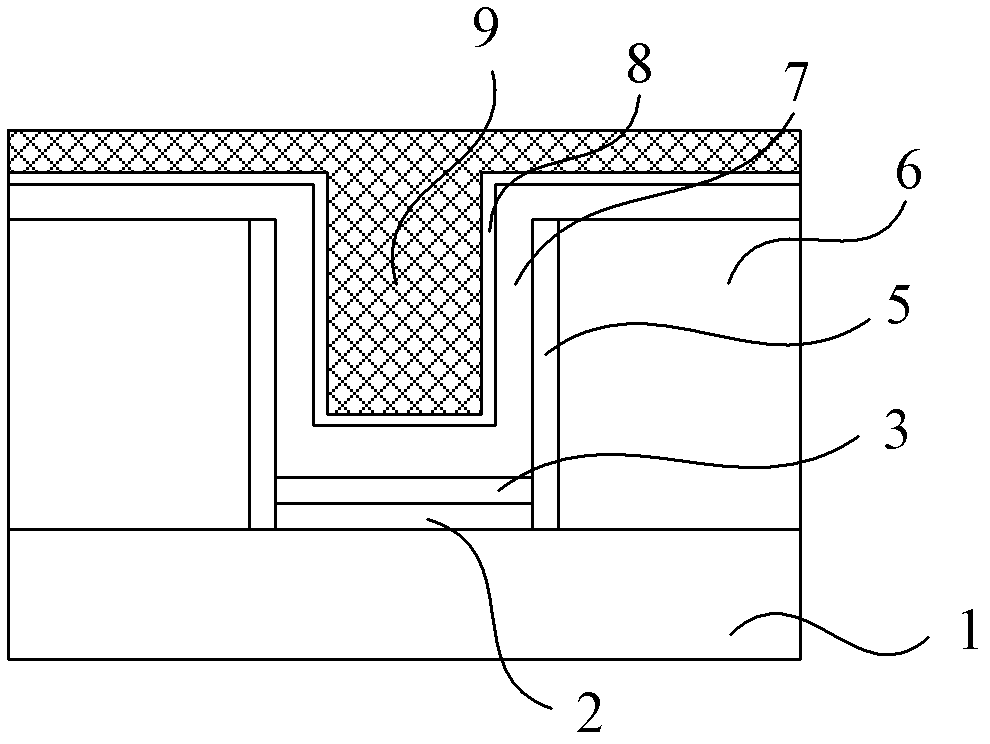

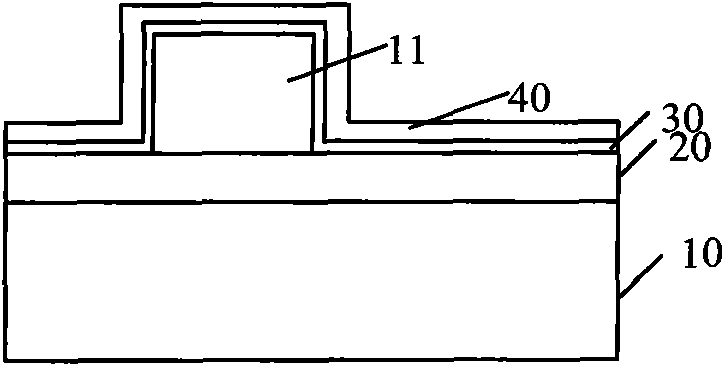

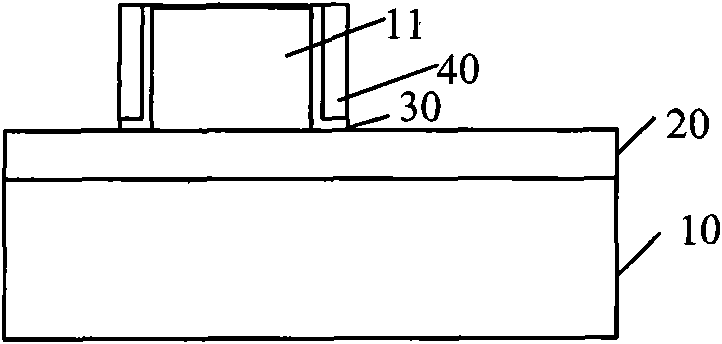

Metal grid electrode manufacturing method and CMOS manufacturing method

InactiveCN103377899AAvoid gapsPrevent performance degradationSemiconductor/solid-state device manufacturingSemiconductor devicesMetal gridCMOS

The invention discloses a metal grid electrode manufacturing method and a CMOS manufacturing method based on the metal grid electrode manufacturing method. The metal grid electrode manufacturing method includes the steps of providing a substrate which is provided with a pseudo grid structure, removing a pseudo polycrystalline silicon grid electrode to form a groove, sequentially depositing a metal work function layer and an isolating layer in the groove, depositing a polycrystalline silicon layer, filling the groove with the polycrystalline silicon layer, depositing an A1 metal layer on the polycrystalline silicon layer, conducting thermal annealing treatment so that the A1 metal layer and the polycrystalline silicon layer can be interchangeable and an A1 electrode can be formed, and removing the replaced polycrystalline silicon layer and A1 metal located outside the groove so that a metal grid electrode can be formed. According to the metal grid electrode manufacturing method and the CMOS manufacturing method, in the manufacturing process of smaller than 32nm, gaps in the A1 electrode can be prevented, and further the performance of semiconductor devices is prevented from being lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP

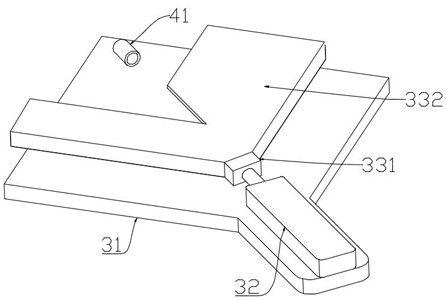

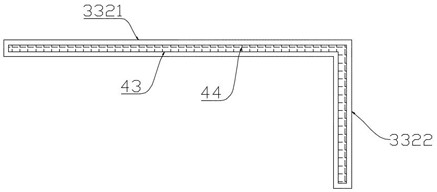

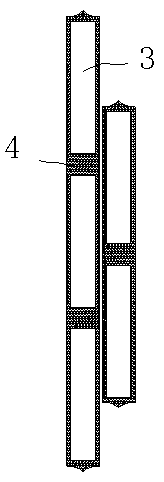

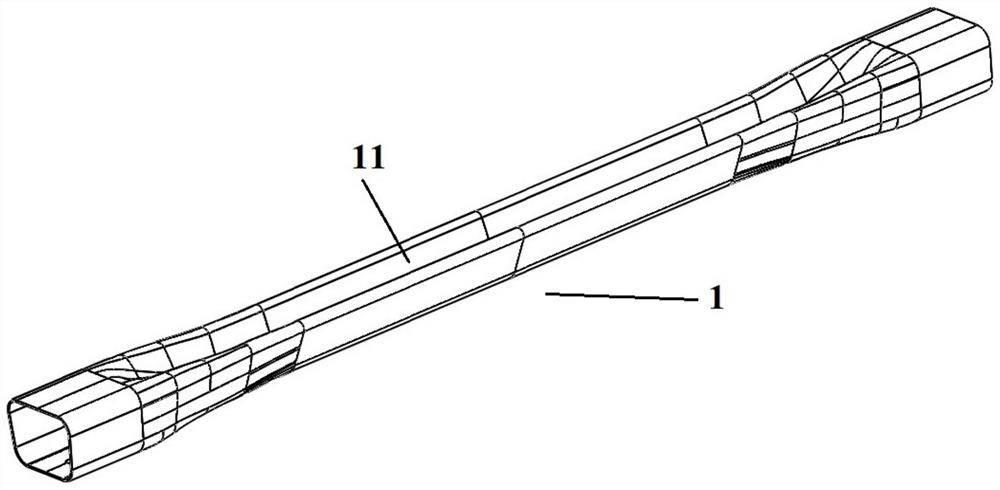

Self-positioning process of plate-type electric bridge waveguide

InactiveCN103394915AReduce assembly processHigh combination precisionSoldering apparatusAssembly machinesControl mannerEngineering

The invention relates to a self-positioning process of plate-type electric bridge waveguide, which comprises the following steps: preparing material to complete preliminary processing of each part of the plate-type electric bridge waveguide; conducting surface treatment on each processed part, so as to remove oil stain, impurities and the like on the surface of the part; assembling a left wallboard, a right wallboard, an upper end plate, a lower end plate, a partition board and brazing alloy; placing the assembled plate-type electric bridge waveguide into a vacuum aluminum soldering stove under the matched use of a tooling clamp; conducting vacuum brazing on the plate-type electric bridge waveguide; machining the shape of the plate-type electric bridge waveguide and a flange plate in a numerically controlled manner; drilling through machining; reaming on the flange plate; carrying out electrochemical treatment; rigging. According to the invention, the flange plate is divided into four parts which are formed on the upper end plate, the lower end plate, the left wallboard and the right wallboard respectively, so that the assembly process of the flange plate is eliminated, and the production efficiency is improved; grooves and convex shoulders, which correspond to each other, are formed on the end plates and the wallboards, so that self-positioning assembly is realized, and the cavity assembling precision of the electric bridge waveguide is high; as vacuum brazing is adopted, brazing flux is not required, which avoids corrosion of brazing flux on a cavity, and prolongs the service life of a product.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

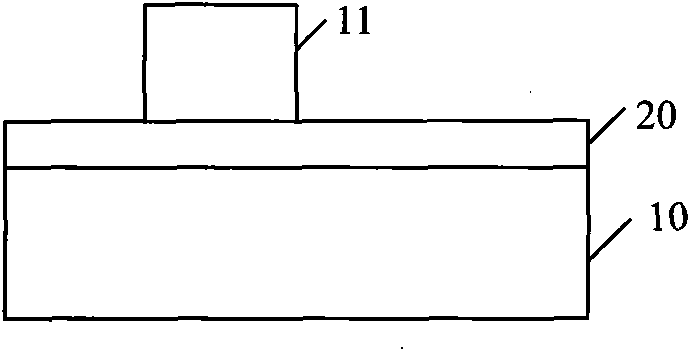

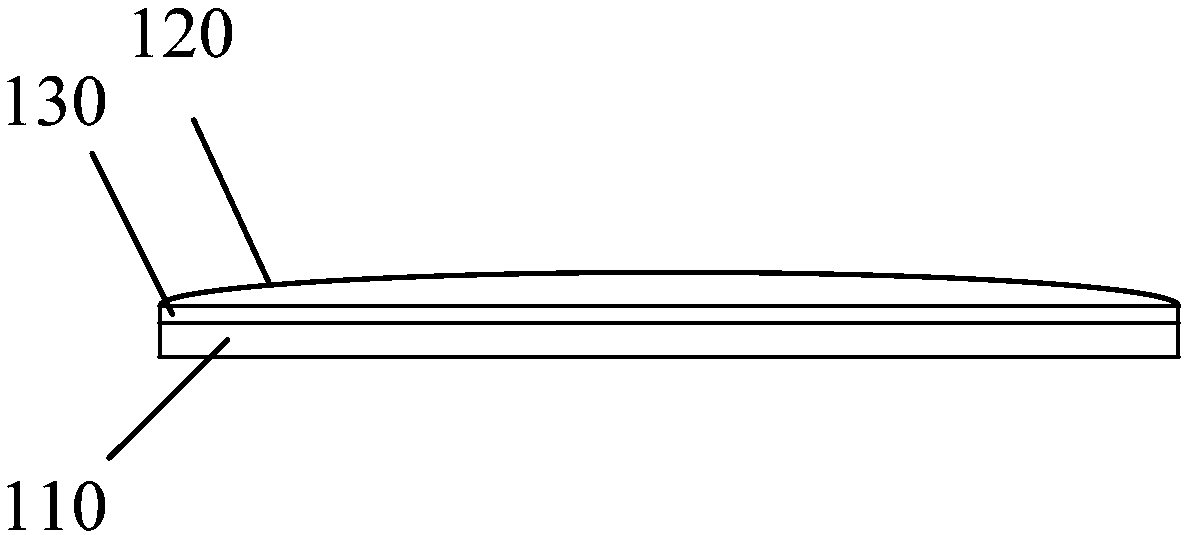

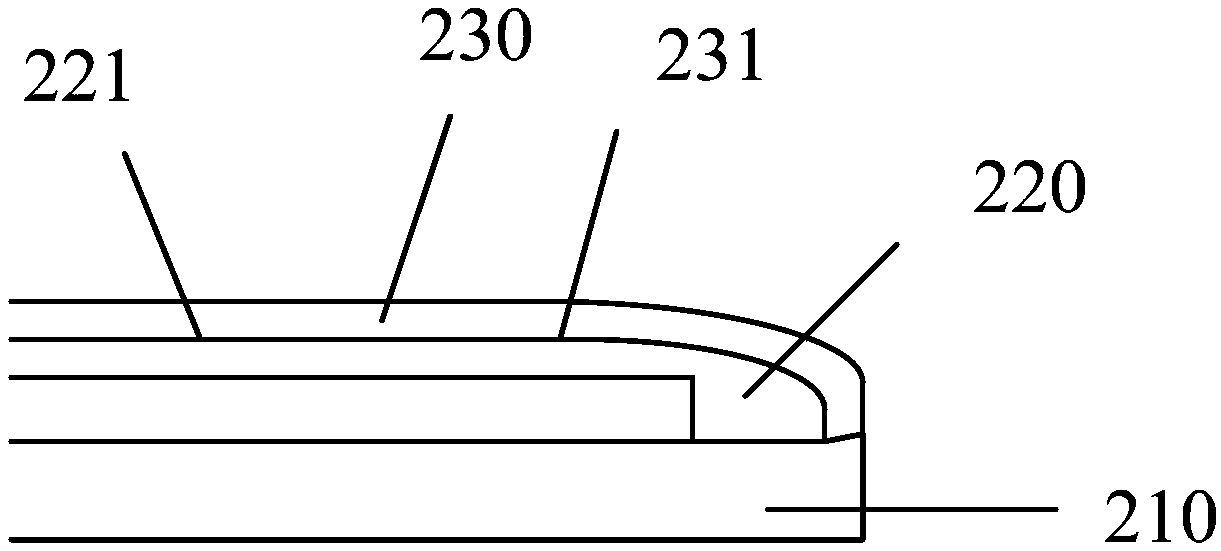

Method for preventing gap below side wall barrier layer during self-aligning silicide process

InactiveCN101826465AAvoid gapsCreate a gapSemiconductor/solid-state device manufacturingComposite materialSalicide

The invention discloses a method for a part to prevent a gap below a side wall barrier layer during a self-aligning silicide process. The part comprises a bedding oxidation film which covers a part underlayer and a grid which is formed on the bedding oxidation film. The method comprises the following steps that: after a sacrificial layer TEOS is deposited, the sacrificial layer and the bedding oxidation film covering the part underlayer are etched until the surface of the part underalyer and the grid top part; and during the manufacturing process of the side wall barrier layer of the grid, by utilizing the self-aligning silicide way, the thickness of the oxidation layer which is deposited on the part underlayer which is etched in a wet way is more than or equal to 100 angstroms and is less than 200 angstroms. The method can prevent the gap below the barrier layer during the self-aligning process of silicide.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Mobile terminal

Owner:NUBIA TECHNOLOGY CO LTD

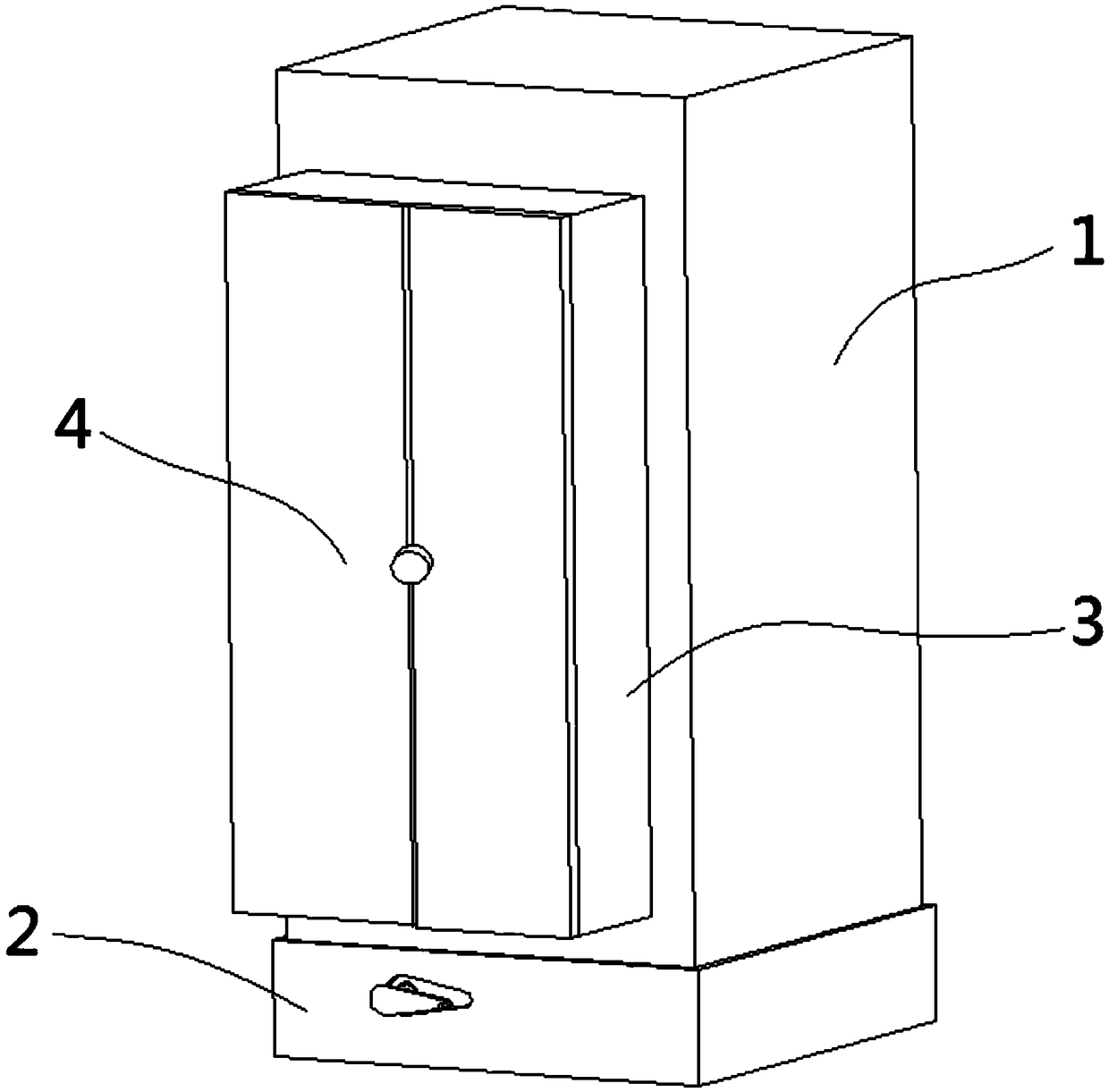

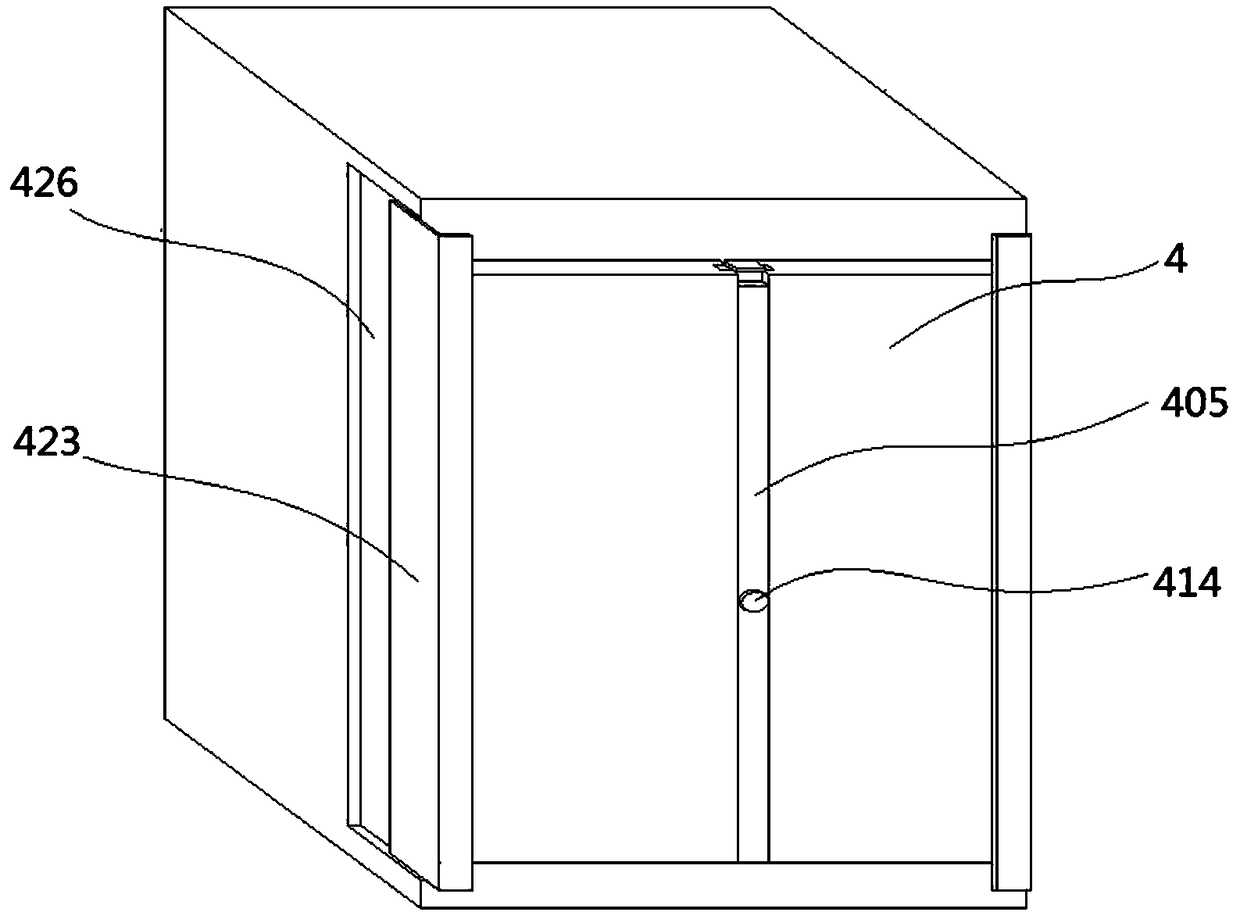

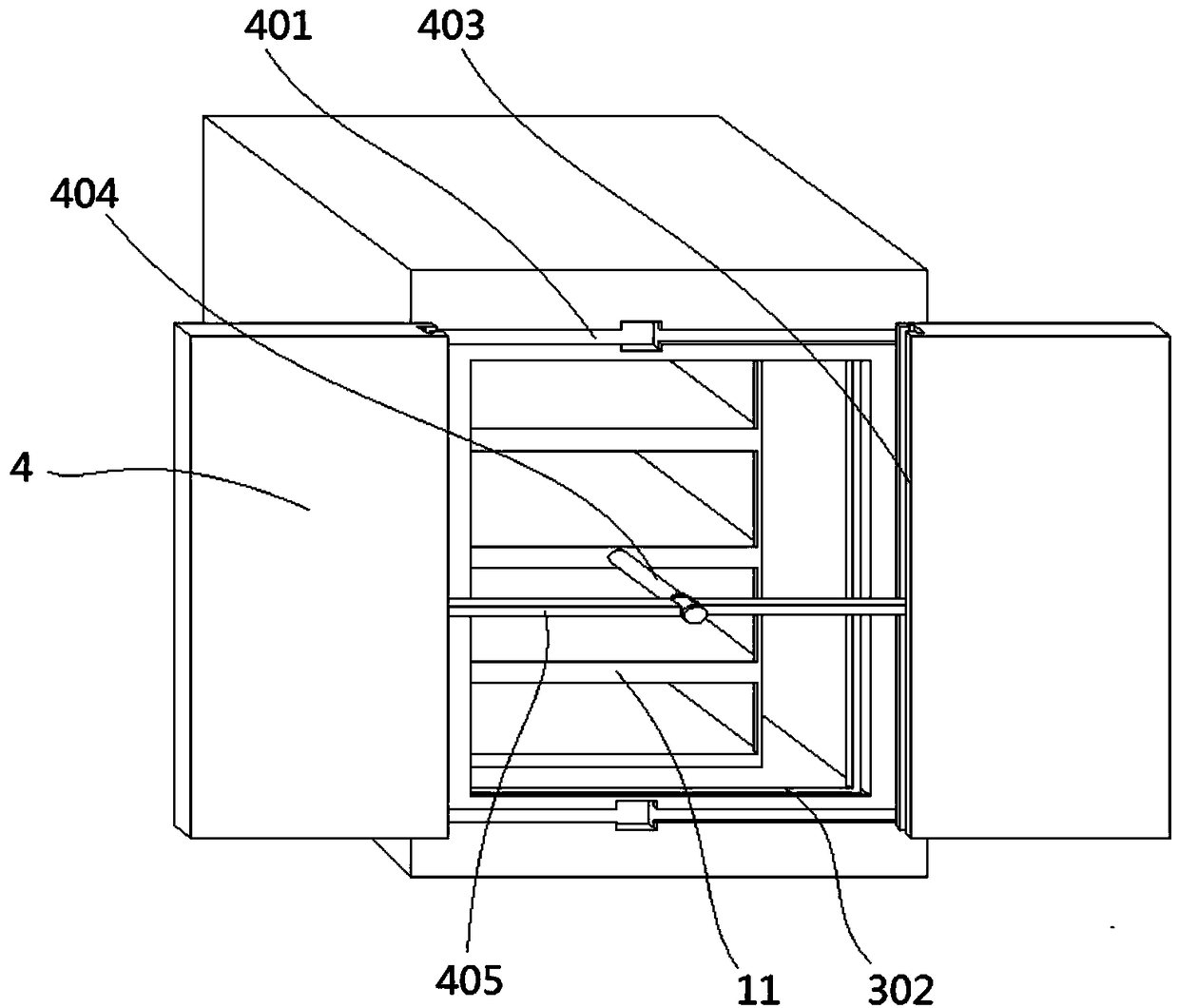

Electrical equipment box door convenient to open and close and electrical equipment box with cabinet door

ActiveCN109413909AEnsure structural stability and safety performanceAvoid gapsCasings/cabinets/drawers detailsPush and pullReciprocating motion

The invention relates to electrical equipment, and discloses an electrical equipment box door convenient to open and close and an electrical equipment box with the cabinet door. The electrical equipment box door comprises a left door body and a right door body which are located on the same vertical plane, wherein the two door bodies are arranged oppositely and can do linear reciprocating motion inthe relative directions; through grooves which extend from the upper end surfaces of the door bodies to the lower end surfaces of the door bodies in the length direction are formed in the opposite side surfaces of the two door bodies respectively; the electrical equipment box door further comprises a rod assembly used for opening the two door bodies; the rod assembly comprises a fixed rod which is transversely arranged and is perpendicular to the front end surfaces of the door bodies, and a rotating rod which is connected to the end, close to the door bodies, of the fixed rod and can rotate around the fixed rod; and the middle of the rotating rod is connected to the fixed rod, and the two ends of the rotating rod can be inserted into the through grooves in the side surfaces of the door bodies respectively. The electric equipment box door is designed to be in the form of pushing and pulling on the two sides, and the door bodies can be pushed and pulled through the rod assembly with therotating rod and a knob, so that the operation is very convenient.

Owner:博控电气有限公司

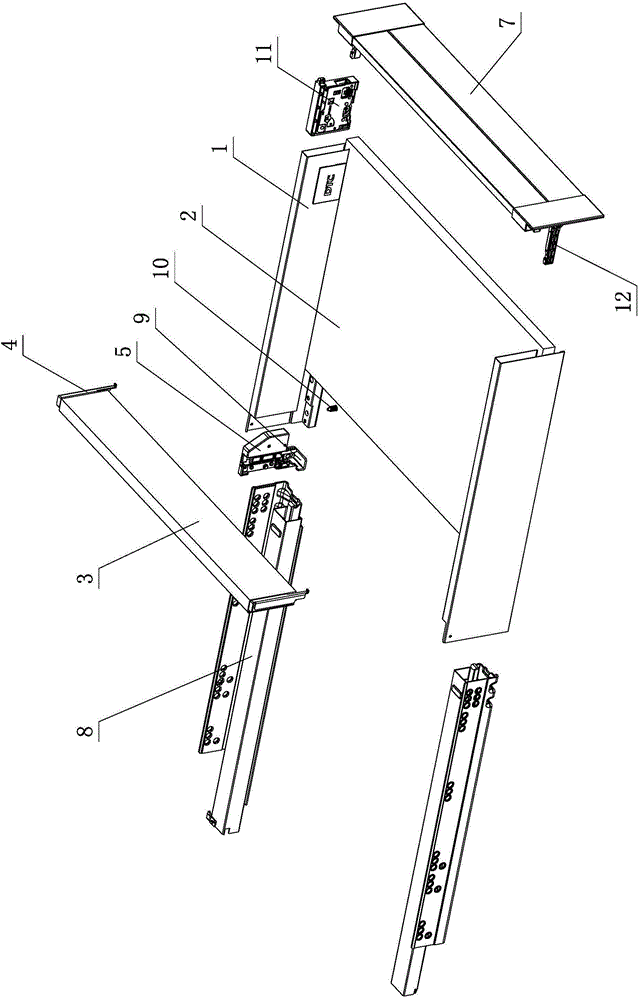

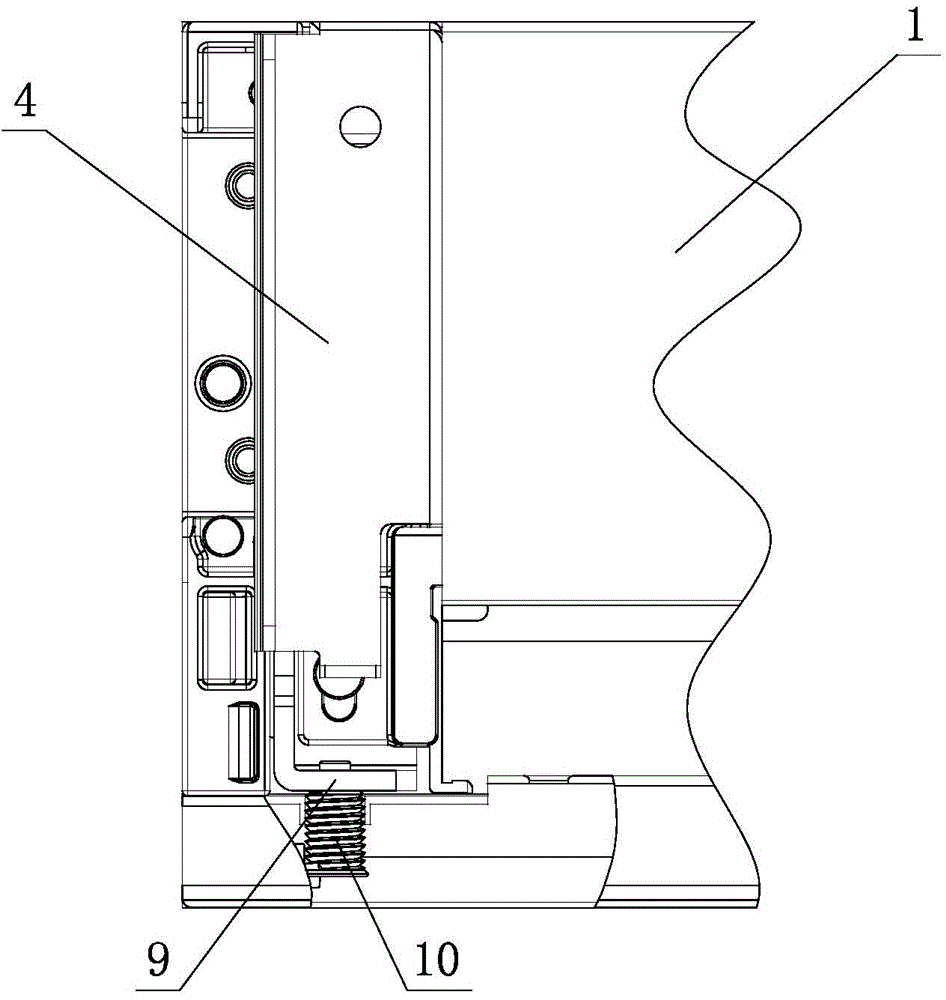

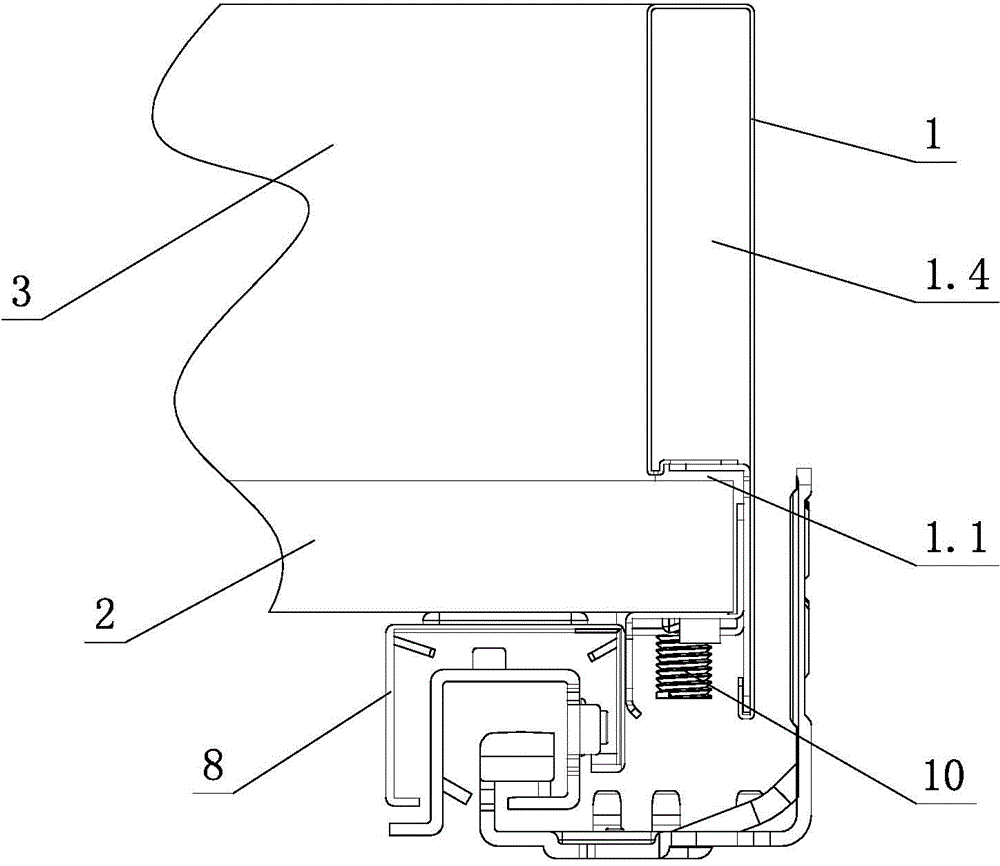

Leaning mechanism for drawer back plate

The invention relates to a leaning mechanism for a drawer back plate. The leaning mechanism comprises side plates, a bottom plate, a front surface plate, a back plate and a slide rail assembly, wherein the back plate consists of a back plate part and a connecting piece, the back plate part is made of wood material, the connecting piece is tightened to the two ends of the back plate part, the back plate is matched and connected with the side plates through the connecting piece, a cavity is formed in each side plate, a fixing device is arranged in the cavities, a connecting part is arranged on the fixing device, at least one part of the inner side of each side plate is vertically arranged, the back plate is connected with the connecting part through the connecting piece, and the back plate part of the back plate is leaned against the vertical surfaces of the inner sides of the side plates. By improving the structure, the leaning mechanism has the characteristics that the structure is simple and reasonable, the property is reliable, the detachment and installation are quick and convenient, the appearance is regular and attractive, the manufacturing cost is low, and the practicality is high.

Owner:伍志勇

Carton packaging machine with pneumatic automatic cover sealing function

ActiveCN113501154AAvoid affecting the sealing effectAvoid creasesWrapper twisting/gatheringVertical edgeCarton

The invention discloses a carton packaging machine with a pneumatic automatic cover sealing function, and relates to the technical field of packaging machines. The carton packaging machine comprises a workbench, wherein a conveying device is arranged on the workbench, the conveying device conveys cartons placed on the conveying device in a gap mode, limiting frames are fixedly connected to the two sides of the workbench, the cartons to be sealed are placed in the two limiting frames, a cover sealing mechanism is connected to the two limiting frames, the cover sealing mechanism comprises a mounting frame, a driving air cylinder and a cover sealing block, and the mounting frame is connected to the limiting frames in a sliding mode. According to the carton packaging machine, when the cartons are sealed, two driving mechanisms are started, the output ends of the driving mechanisms extend to push the cover sealing block to get close to the two vertical edges of the cartons, and are in contact with carton covers on the four sides of the cartons in sequence, so that the cartons are folded and kept in a folded state; and compared with a traditional mode that the carton covers are folded through guide rods, the situation that the carton covers are folded and folded marks are generated due to the fact that the carton covers rebound after being bent can be avoided, so that the sealing effect of the cartons is prevented from being influenced.

Owner:南通市通州区茂润包装制品有限公司

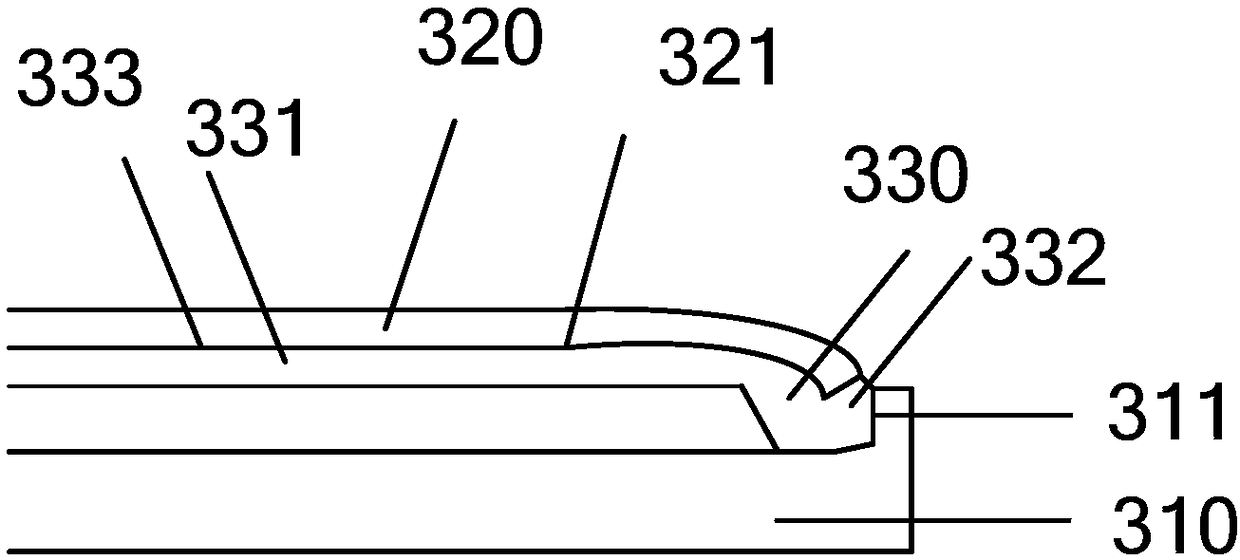

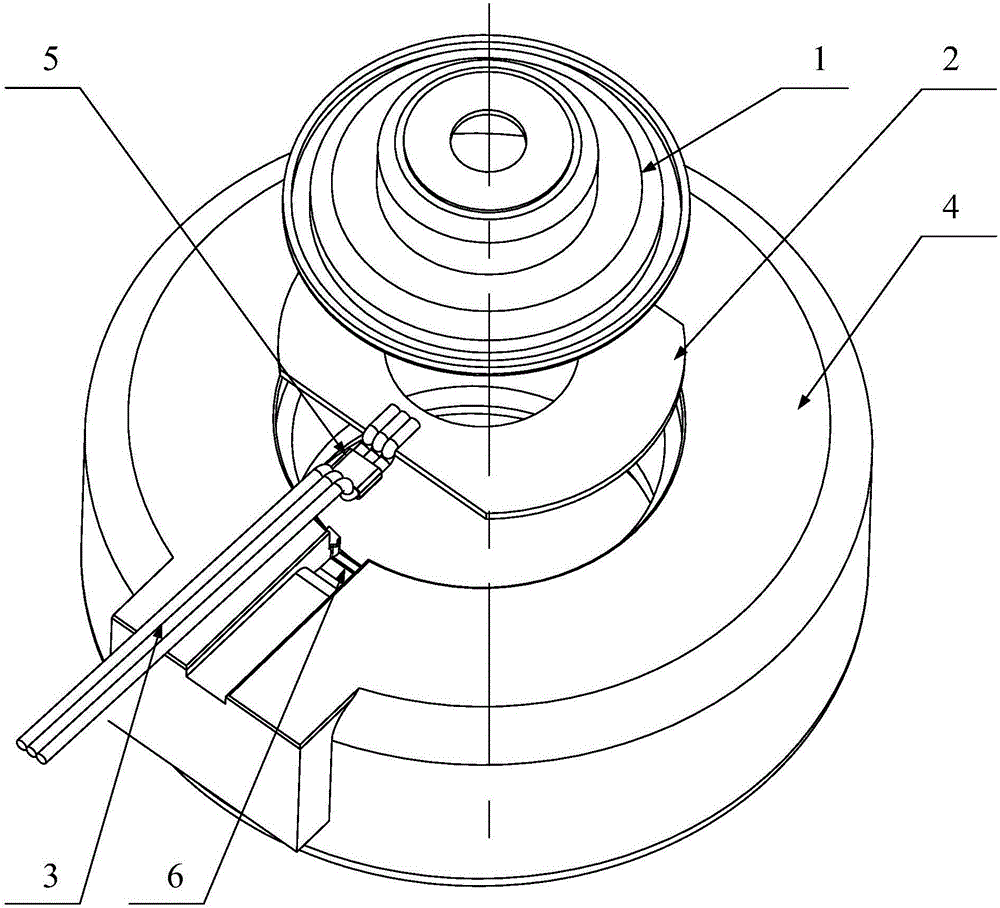

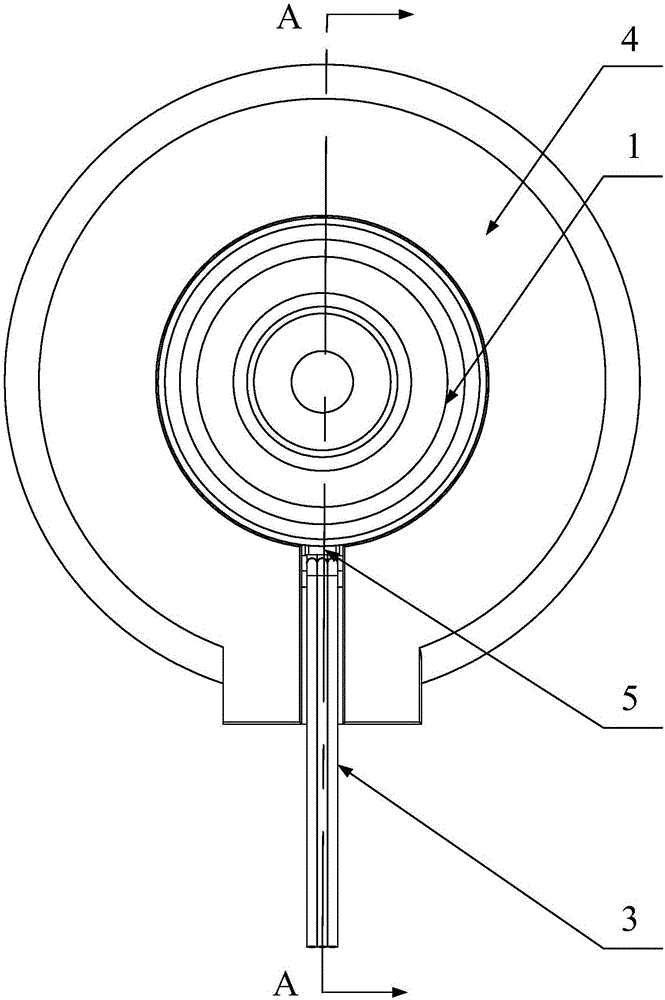

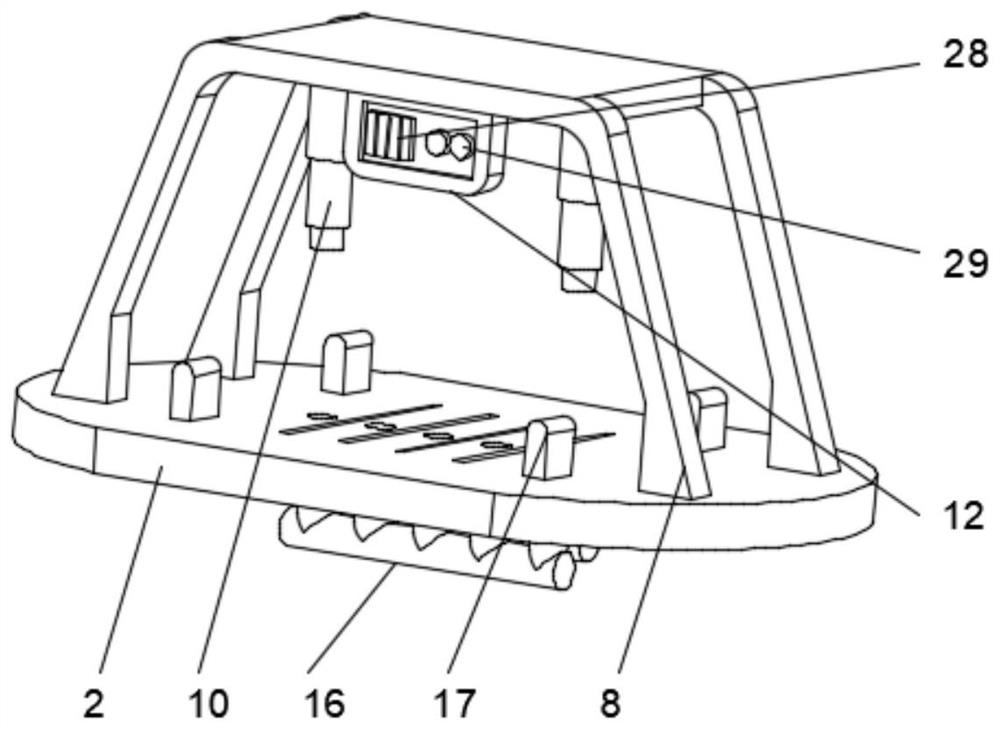

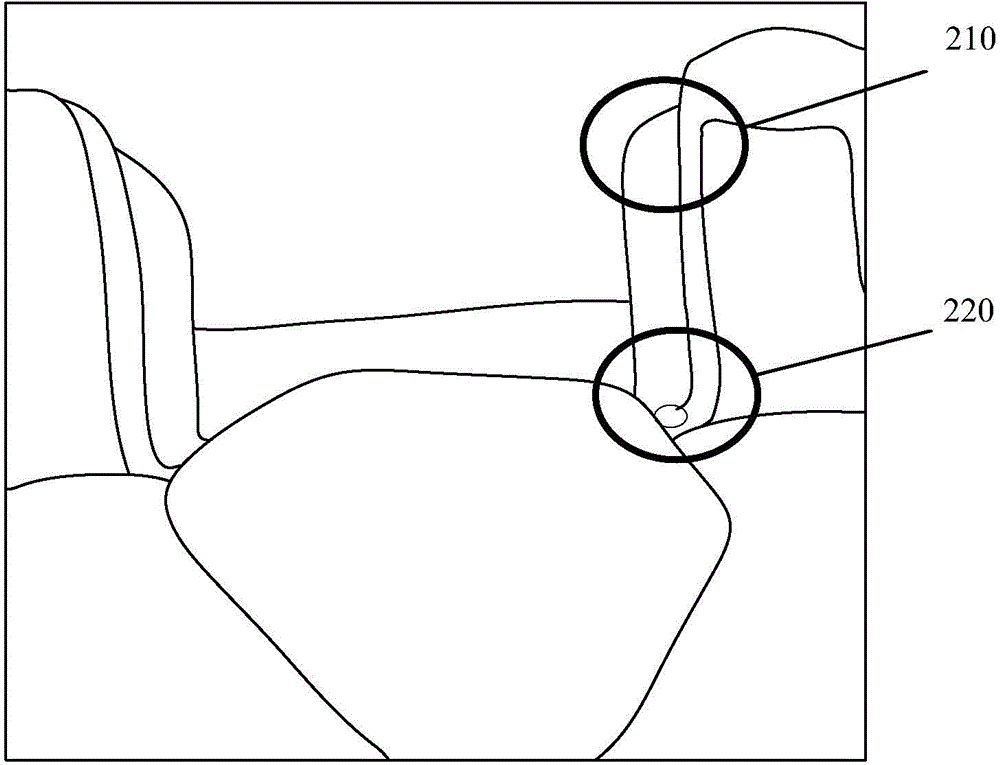

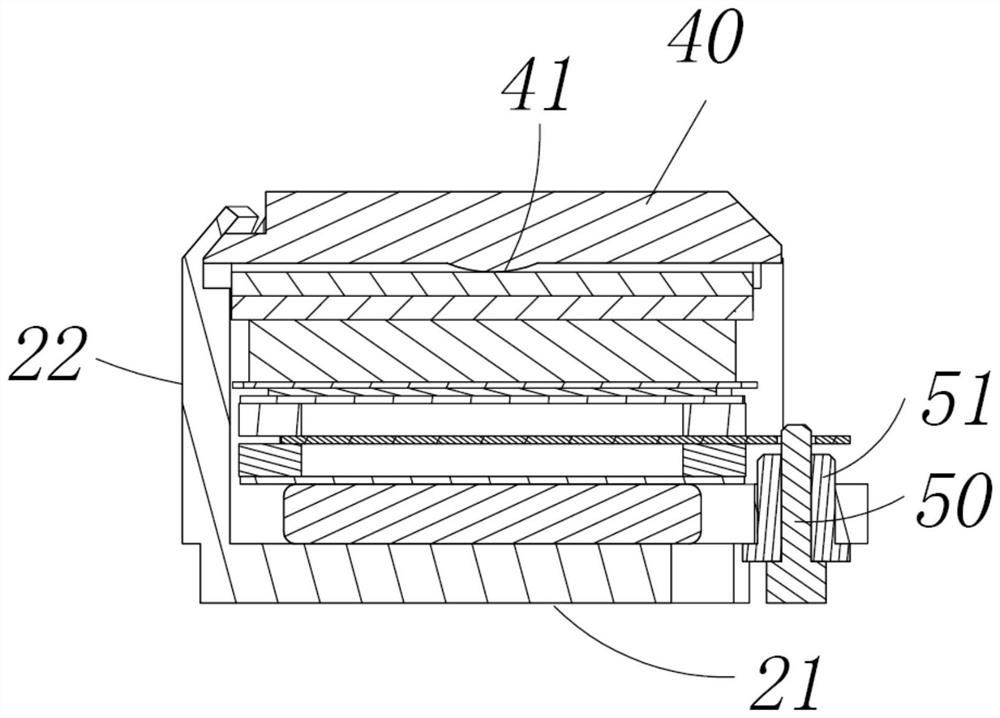

Plastic package motor and stator assembly thereof

PendingCN106849395AAvoid gapsAvoid uneven air gap and stuckAssociation with control/drive circuitsMagnetic circuit stationary partsStructural engineeringElectrical and Electronics engineering

The invention discloses a plastic package motor and a stator assembly thereof. The stator assembly comprises a stator (4), a cover plate (1) and a circuit board (2), a groove (6) is formed in the stator (4), a power line (3) of the circuit board (2) is located in the groove (6) and makes contact with the inner side face of the cover plate (1); seal ribs abutting against the power line (3) are arranged in the groove (6). According to the stator assembly, by means of the arrangement, the power line, the cover plate and the groove are in close fit under the action of contact force between the seal ribs and the power line, pressure exerted on the power line by the cover plate and own tension of the power line, gaps are avoided, it is avoided that ants and other tiny organisms enter the motor and the motor is uneven in air gap and is stuck, the normal work performance of the motor is improved, and the service life of the motor is prolonged.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

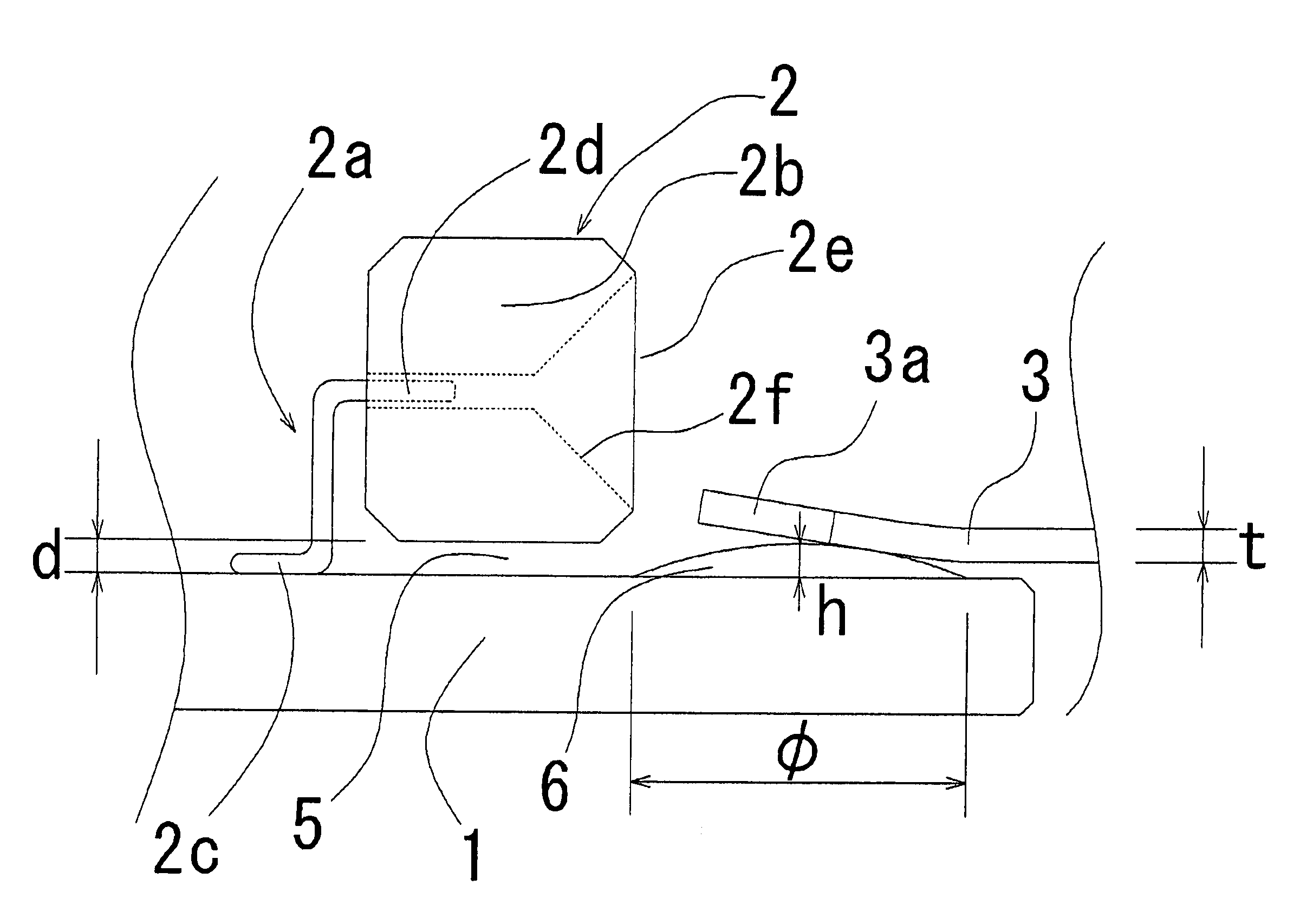

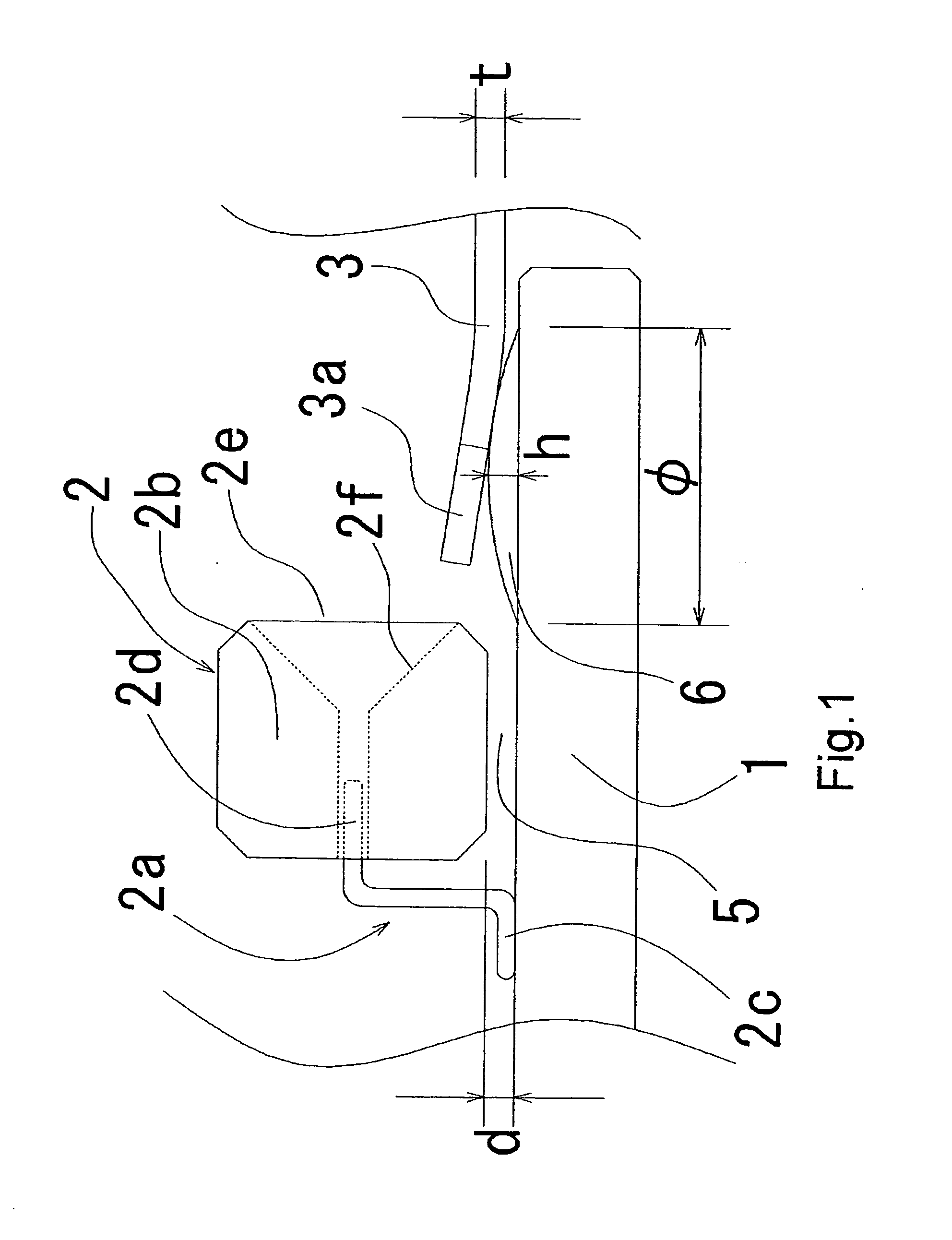

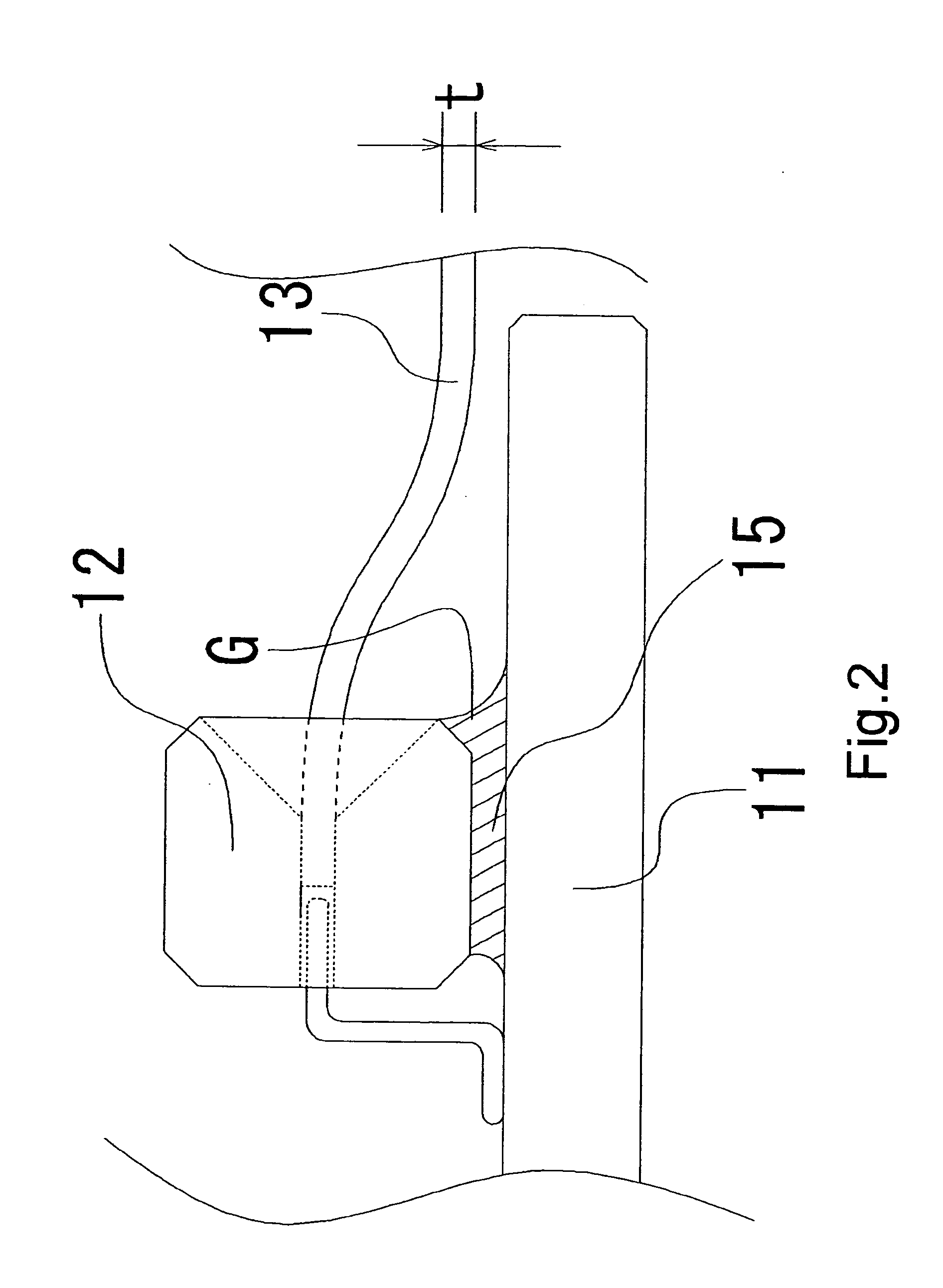

Electric equipment

InactiveUS20060057870A1Avoid gapsGood connectionEngagement/disengagement of coupling partsIncorrect coupling preventionPrinted circuit boardElectronic equipment

In order to prevent any erroneous insertion of a thin circuit board 3 into a gap 5 formed between a main circuit board 1 and a connector 2 when the thin circuit board 3 is inserted into an inserting port 2e formed at the connector 2 fixed at a mounting surface of the main circuit board 1 by electric connection, a guide 6 is formed by applying solder onto the mounting surface of the main circuit board 1 and in the vicinity of the inserting port 2e. The guide 6 can prevent any insertion of the thin circuit board 3 into the gap 5.

Owner:NIDEC CORP

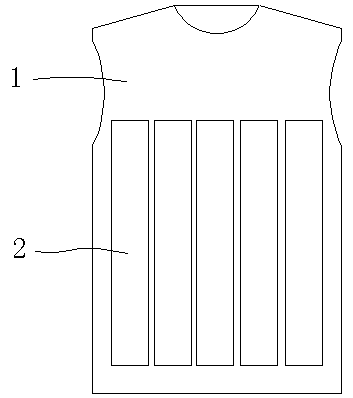

Virus penetrating blocking film for operating gown and preparation method of film

The invention discloses a virus penetrating blocking film for an operating gown and a preparation method of the film. The virus penetrating blocking film is prepared from components in percentage by mass as follows: 94%-95% of thermoplastic polyurethane, 0.5%-1.5% of ABS (acrylonitrile butadiene styrene) resin, 4%-6% of silicon dioxide and 0.1%-0.3% of an antioxidant, wherein the thermoplastic polyurethane is prepared from raw materials as follows: 40-50 parts of polyester polyol, 15-20 parts of aromatic isocyanate, 18-22 parts of propylene glycol and 4-8 parts of dibutyltin dilaurate. By means of the scheme, the virus penetrating blocking rate of the polyurethane film can be increased, the preparation process is simple and easy to control, and the prepared film has good uniformity and high qualification rate.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

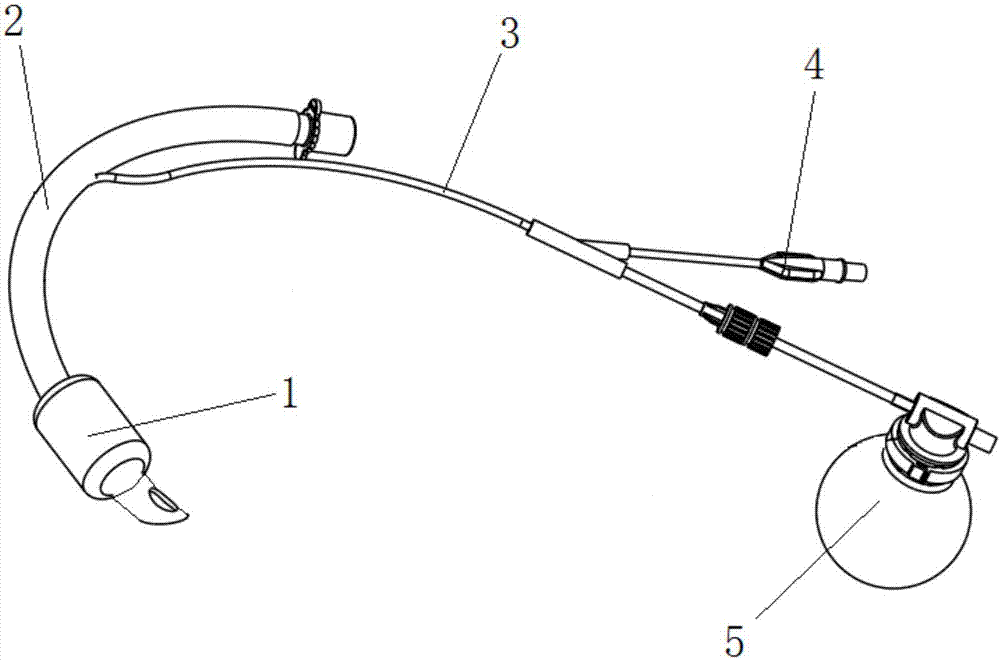

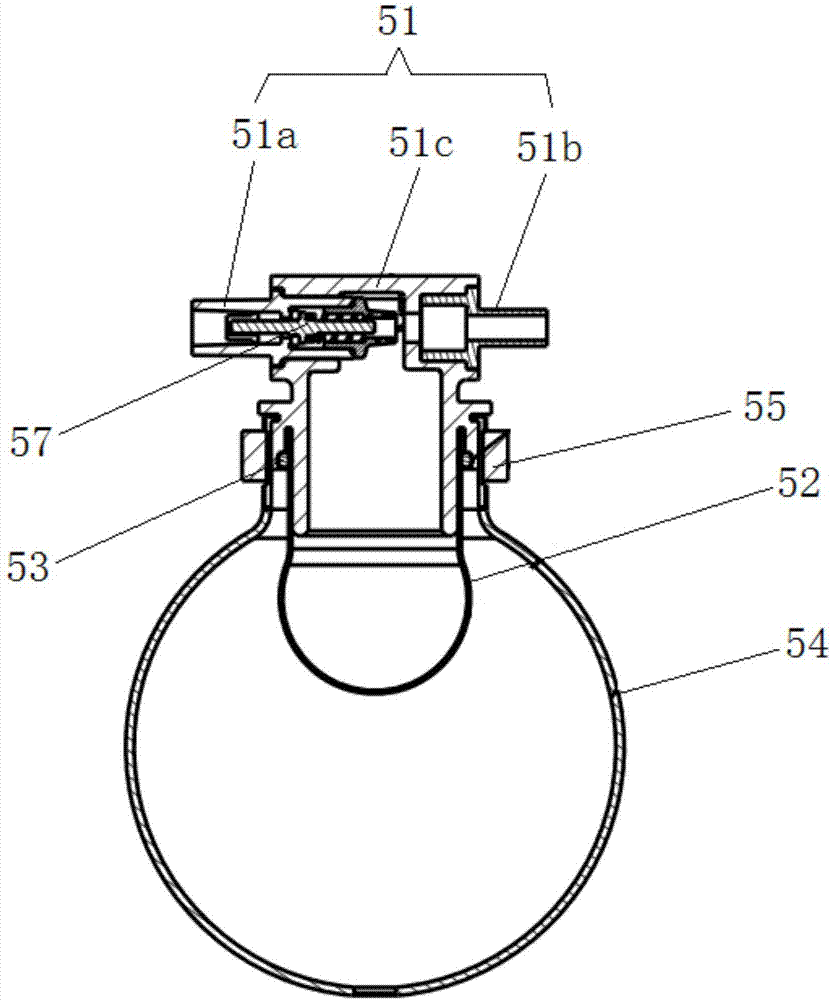

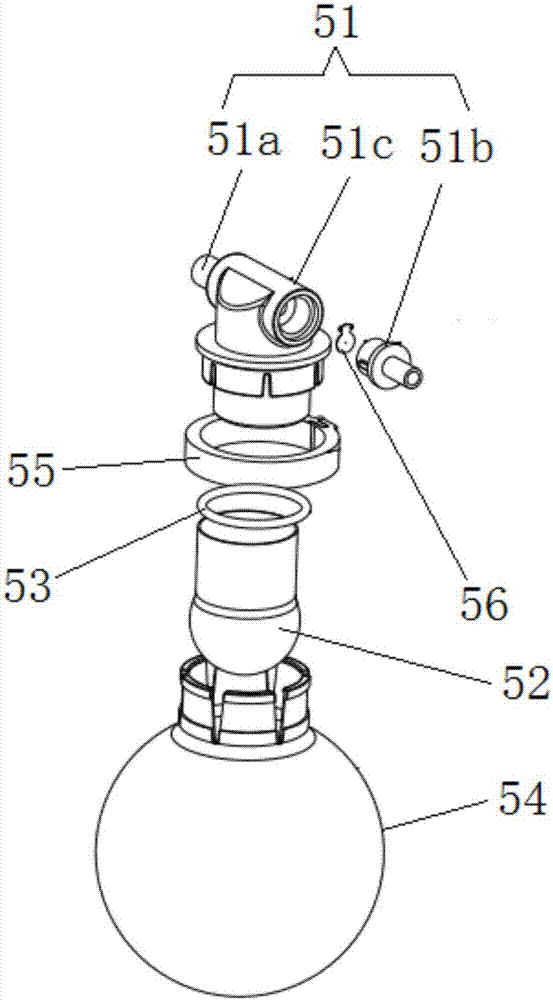

Cuff tracheal intubation device with automatic pressure stabilizing function

PendingCN107961425AEnsure life safetyAvoid gapsTracheal tubesBalloon catheterTrach tubeEndotracheal intubation

The invention discloses a cuff tracheal intubation device with an automatic pressure stabilizing function. The cuff tracheal intubation device comprises a tracheal cannula with a cannula cuff. A sleeve which is communicated with the cannula cuff is arranged on the tracheal cannula, an air supply assembly which is communicated with the sleeve is arranged in the middle of the sleeve, the cannula cuff can be inflated by the air supply assembly, a pressure stabilizing system is further arranged at the tail end of the sleeve, air can be automatically supplied for the cannula cuff by the pressure stabilizing system, or air can be sucked from the cannula cuff by the pressure stabilizing system, so that the pressures of the cannula cuff can keep balanced. The cuff tracheal intubation device with the automatic pressure stabilizing function has the advantages that the pressures of the cannula cuff can be maintained in the tolerant ranges of human bodies by the pressure stabilizing system, the cannula cuff always clings to the walls of the tracheas of patients, accordingly, the cuff tracheal intubation device is applicable to the patients with long-time intubation requirements due to long surgery time, and the life safety of the surgery patients can be guaranteed.

Owner:GUANGZHOU WELLLEAD MEDICAL EQUIP CO LTD

Elastic body armor

Owner:CHONGQING SHIELD KING IND

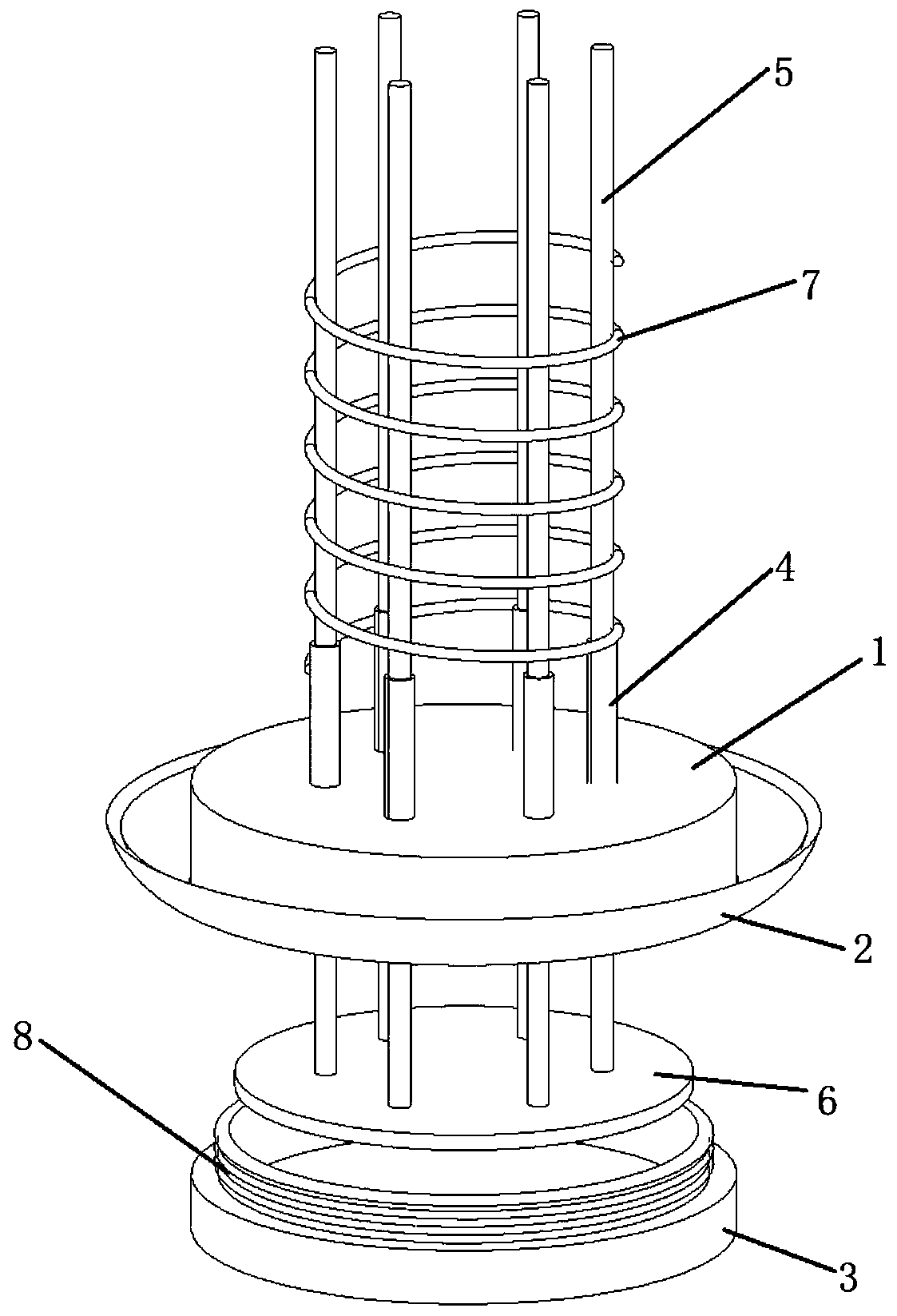

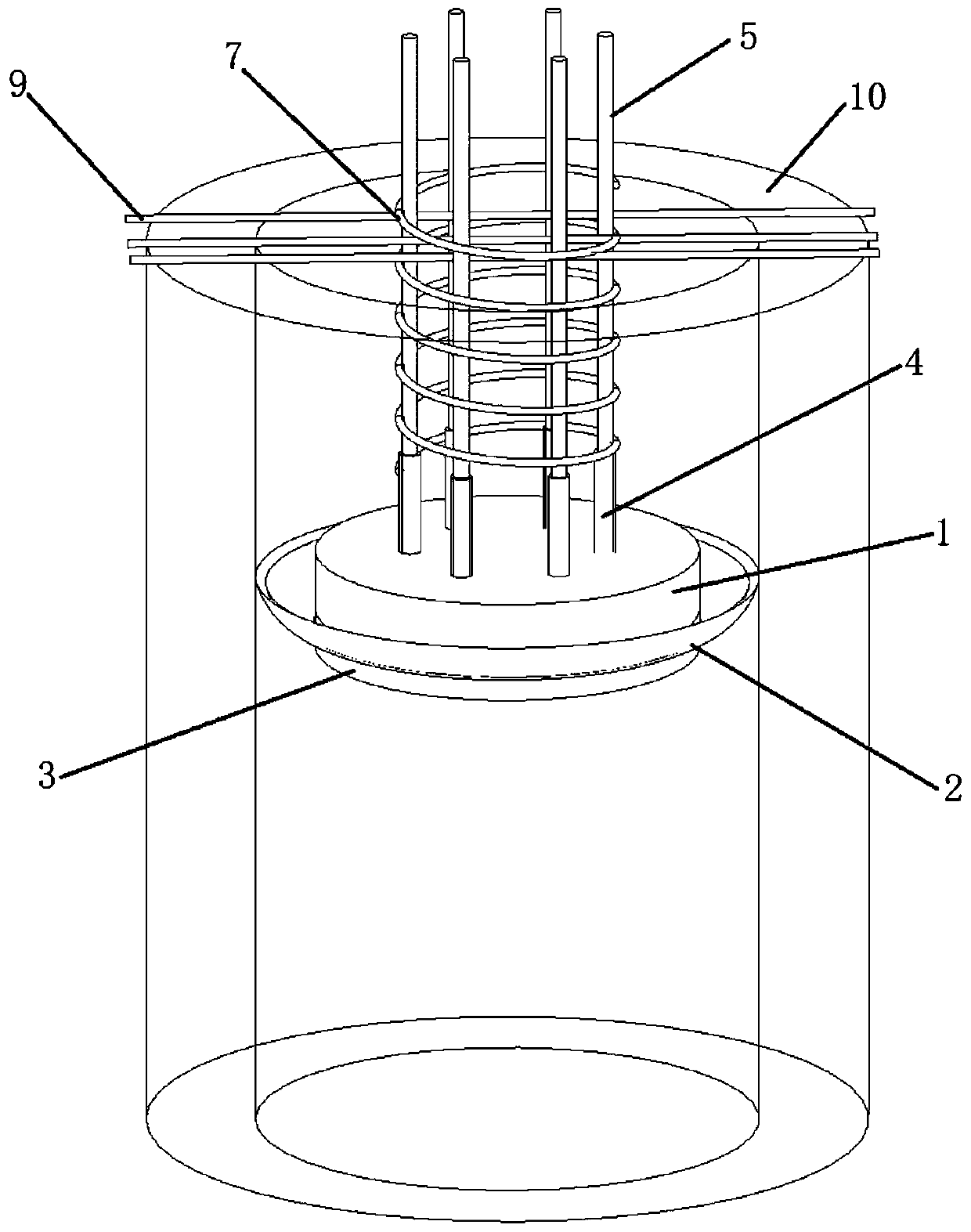

Prestressed pipe pile reinforcement cage support plate blockage device

The invention provides a prestressed pipe pile reinforcement cage support plate blockage device. The device comprises a pipe pile, a ring main body, a blockage ring, a reinforcement cage support plateand a bottom tray; the ring main body, the blockage ring, the reinforcement cage support plate and the bottom tray are arranged in the pipe pile; the bottom tray is of a cylindrical cavity structureopened at the top; a spiral projection is arranged on the outer side surface of the bottom tray; the reinforcement cage support plate is of a disc structure, and is annularly arrayed with multiple longitudinal reinforcements extending up; the ring main body is of a cylindrical cavity structure opened at the bottom; a spiral groove matched with the spiral projection is formed in the inner side surface of the ring main body; multiple holes are annularly arranged at the top of the ring main body; the holes are adapted to the longitudinal reinforcements in position; and the blockage ring is of a horn structure and arranged on the outer side of the ring main body for preventing formation of a gap with a certain width between the inner wall of the pipe pile and the reinforcement cage support plate to prevent leakage of core filling concrete during casting.

Owner:CHINA FIRST METALLURGICAL GROUP

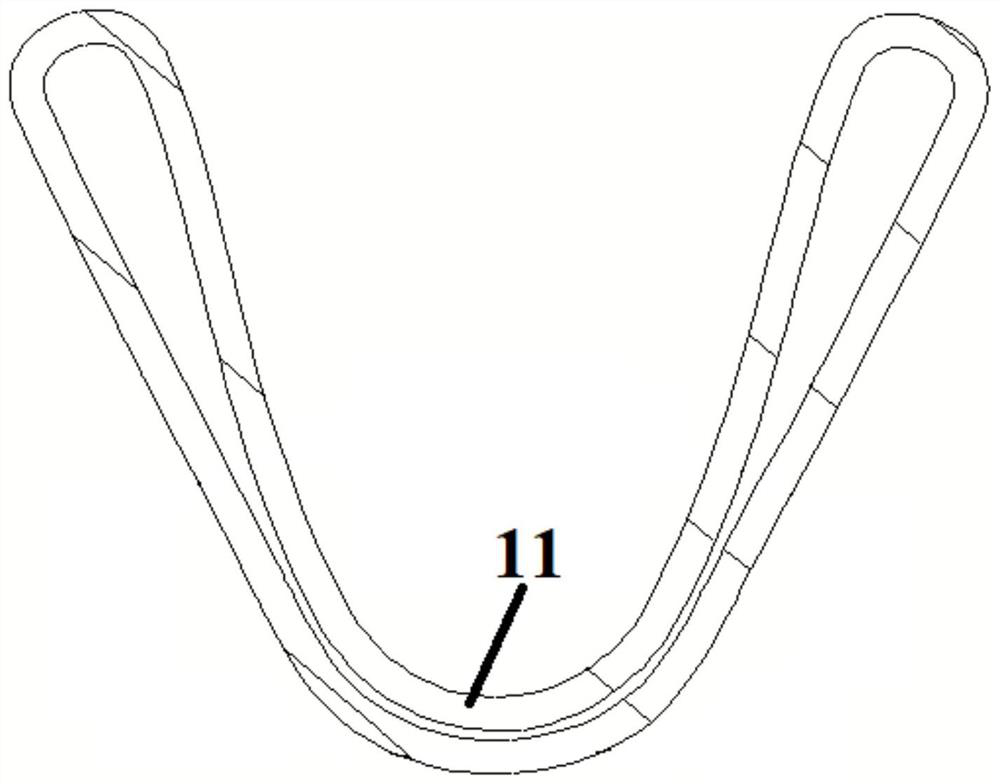

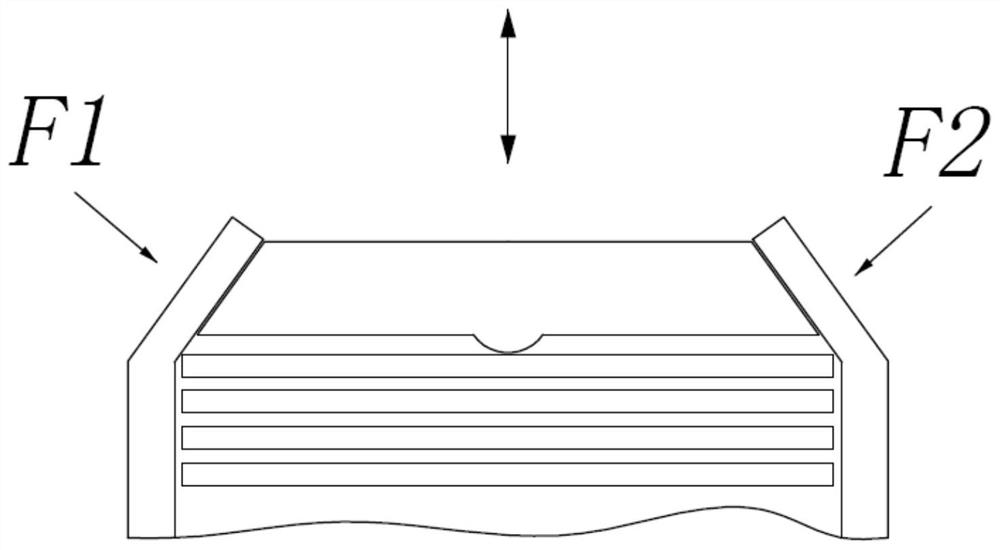

Torsion beam high-frequency quenching method capable of eliminating abnormal sound

ActiveCN113684347AAvoid deformationAvoid gapsFurnace typesIncreasing energy efficiencyEngineeringMechanical engineering

The invention provides a torsion beam high-frequency quenching method capable of eliminating the abnormal sound, stress borne by all parts of a torsion beam under the real road condition is analyzed through analogue simulation and is compared with the strength of the torsion beam in the non-quenched state, quenching treatment is conducted on the non-attached areas, bearing high stress, of the two ends, and the attached area bearing low stress is not subjected to quenching treatment. The torsion beam high-frequency quenching method has the advantages that the real stress condition of the torsion beam is analyzed through analogue simulation, so that the bearing capacity requirement of each part of the torsion beam is determined, heat treatment quenching is only conducted on the two non-attached ends of the torsion beam, heat treatment is not conducted on the middle V-shaped area formed by attachment, the attached area is prevented from deforming in heat treatment, and gaps are avoided, so that the abnormal sound caused by friction due to the gaps is avoided.

Owner:BAOLONG ANHUI AUTO PARTS

Concrete hollow brick blank making mold made of concrete

PendingCN112549261AEasy to disassemble and save timeAvoid gapsCeramic shaping mandrelsCeramic shaping coresMagnetorheological fluidHydraulic pressure

Owner:郑州坤泽商品混凝土有限公司

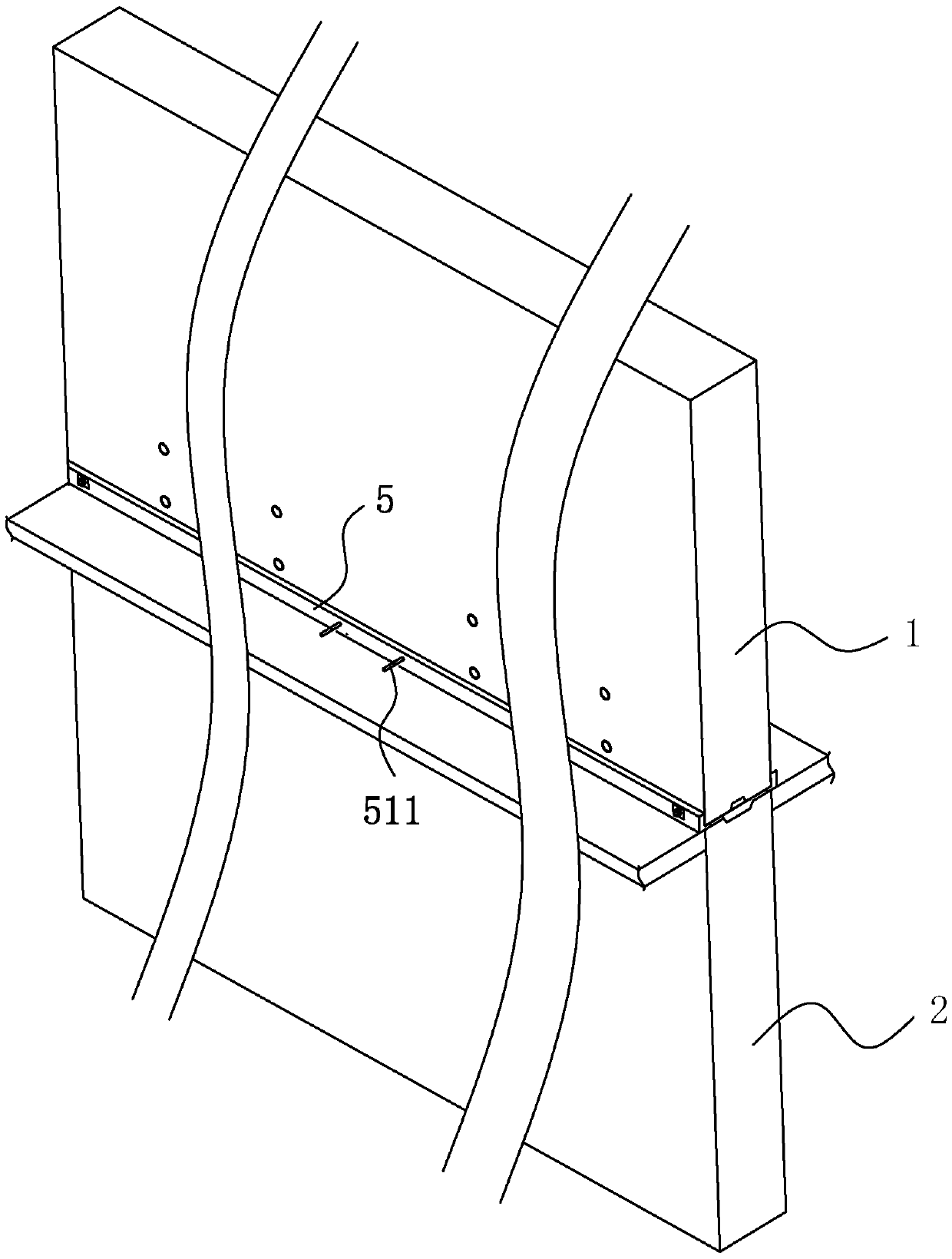

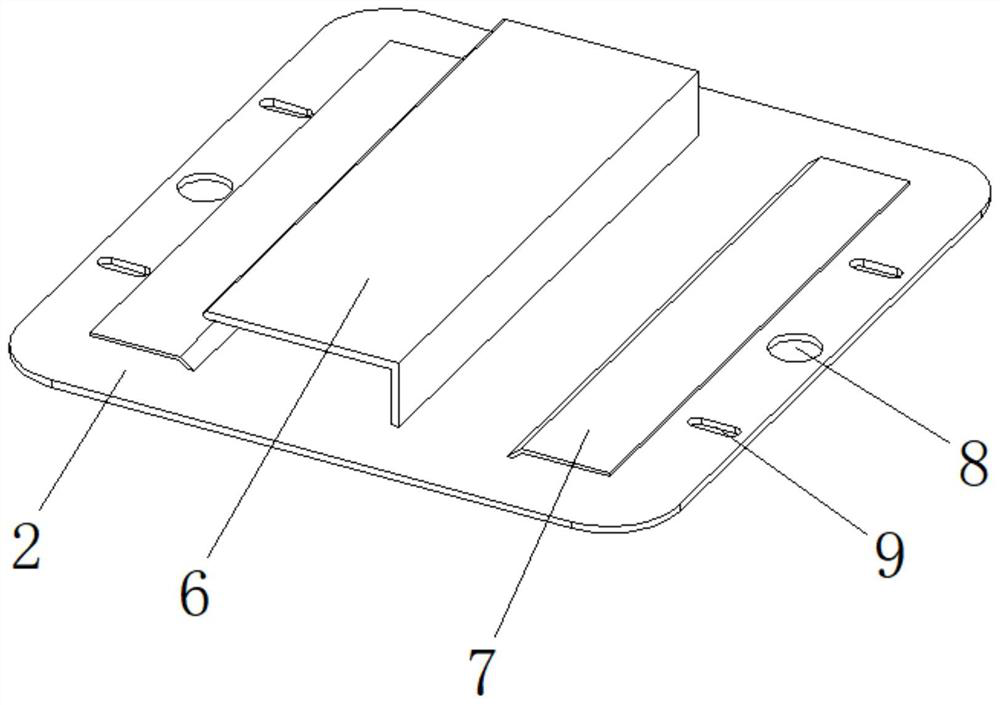

Installation method of seamlessly-spliced integrated wallboard

The invention discloses an installation method of a seamlessly-spliced integrated wallboard, and relates to the technical field of integrated wallboards, in particular to the seamlessly-spliced integrated wallboard. The wallboard comprises an integrated wallboard body and a metal fastener, a tenon is arranged on the left side of the integrated wallboard body, a clamping groove is formed in the right side of the integrated wallboard body, and a through hole is formed in the integrated wallboard body. A buckle is fixedly connected to the top of the metal fastener, and metal elastic pieces located on the two sides of the buckle are fixedly connected to the top of the metal fastener. The integrated wallboard body and the metal fastener are used in cooperation, the metal fastener is connected to the joint of the tenon and the clamping groove in a clamped mode, the tilted metal elastic pieces are used for providing certain elastic force for the tenon and the clamping groove, and due to the fact that the middle joint of the tenon and the clamping groove is fixed through the buckle, the two sides of the tenon and the two sides of the clamping groove tend to be extruded inwards; and therefore, the joint is more compact, a larger gap is avoided, and the installation is more convenient and faster.

Owner:HUNAN HENGXIN NEW BUILDING MATERIALS CO LTD

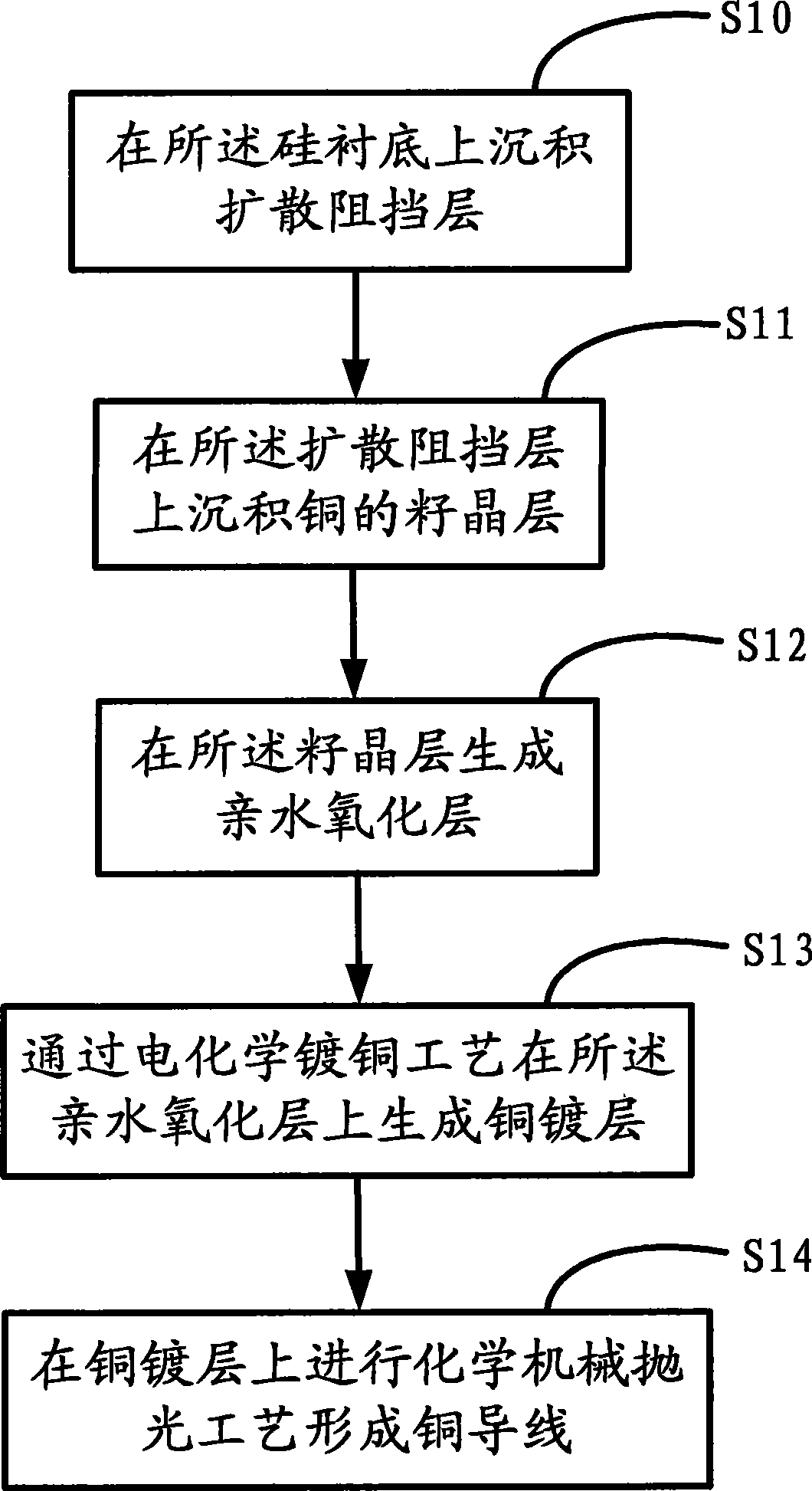

Method for manufacturing copper conductor with improvable quality

InactiveCN101442022AAvoid gapsQuality improvementSemiconductor/solid-state device manufacturingCopper platingOxide

The invention provides a copper conductor manufacturing method capable of improving quality, which is used for manufacturing a copper conductor on a silicon substrate. The prior art carries out a copper electrochemical plating process on an seed layer directly and part of the seed layer can not be plated with copper due to the poorer hydrophilic performance of the seed layer, so the manufactured copper conductor has notches and the quality of the copper conductor is seriously affected. The copper conductor manufacturing method capable of improving quality comprises the following steps: firstly, depositing a diffusion barrier layer on the silicon substrate; secondly, depositing a copper seed layer on the diffusion barrier layer; thirdly, generating a hydrophilic oxide layer on the seed layer; fourthly, generating a copper plating layer on the hydrophilic oxide layer through a copper electrochemical plating process; and finally, carrying out a chemical and mechanical polishing process on the copper plating layer to make the copper conductor. The method can avoid that part of the seed layer is not plated with copper to cause the notches on the copper conductor, and can greatly improve the quality of the copper conductor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Surface treatment method of insert in vacuum casting and APG processes

The invention relates to a surface treatment method of an insert in vacuum casting and APG processes, which is realized by the following steps: preparing adhesive: mixing 100 parts of epoxy resin, 50 parts of phenolic resin, 175-200 parts of toluene and 175-200 parts of butanone, and stirring the mixture for 2-2.5 hours at the normal temperature; adding 1.5 parts of 2-ethyl-4-methylimidazole and stirring for 0.4-0.6 hour at the normal temperature; adding 8-10 parts of QS toughening agent and stirring for 0.4-0.6 hour; standing for 12-24 hours; cleaning the insert; airing; sealing insert: sealing the non-adhesive part with a transparent adhesive tape according to the pattern requirement, and tearing the transparent adhesive tape after the adhesive is solidified; gluing for 2-4 times at the normal temperature, wherein after the glue coated in the previous gluing process is aired, the next gluing process is carried out; preheating the glued insert, wherein the preheating temperature is 135-145 DEG C, and the preheating time is 1-1.5 hours; and taking out the insert and reserving the insert by covering for later user. The invention has the beneficial effect that because a buffer layer is additionally arranged between the insert and an epoxy material, the invention prevents gaps from occurring between the insert and the epoxy material because of larger difference of thermal expansion coefficients.

Owner:SHANGHAI ROX ELECTRIC

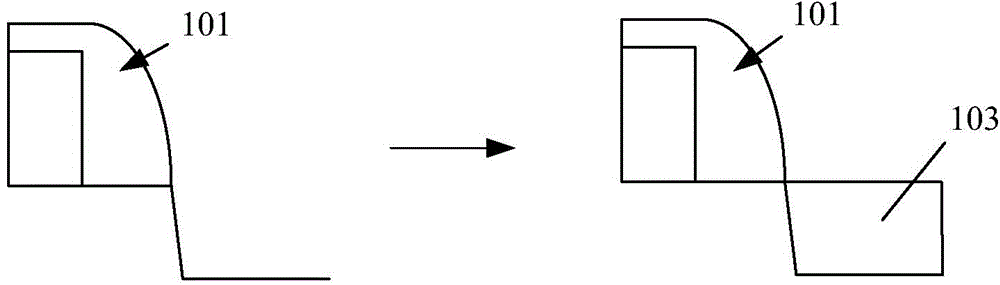

Method for forming embedded silicon germanium

ActiveCN105304491ASuppression of shoulder defectsAvoid gapsSemiconductor/solid-state device manufacturingCarbon dopedSilicon nitride

The invention discloses a method for forming embedded silicon germanium. The method comprises the following steps: providing a front-end device structure, wherein the front-end device structure comprises a semiconductor substrate and a gate structure arranged on the semiconductor substrate; depositing a carbon-doped silicon nitride layer on the surface of the front-end device structure; forming a silicon nitride film on the surface of the carbon-doped silicon nitride layer; carrying out photoetching and etching process, and forming sunken areas in the positions where a source electrode and a drain electrode are to be formed in the semiconductor substrate; and epitaxially growing the embedded silicon germanium in the sunken areas.

Owner:SEMICON MFG INT (SHANGHAI) CORP

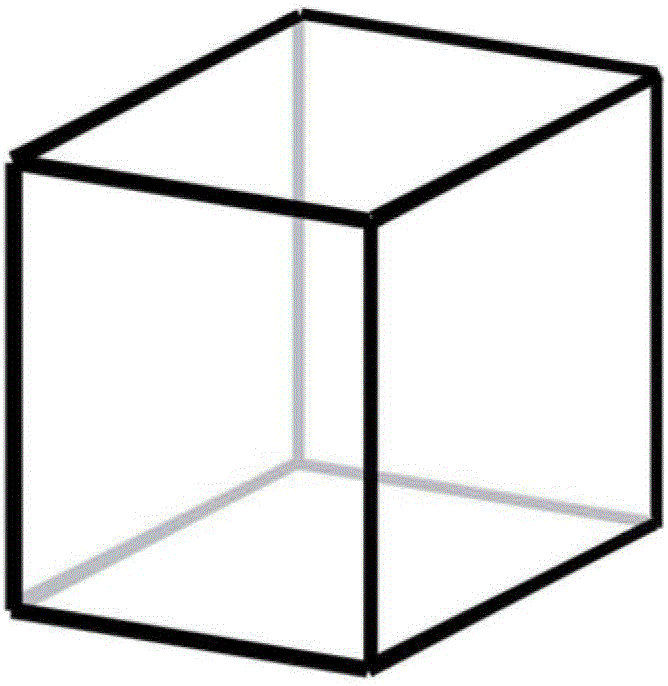

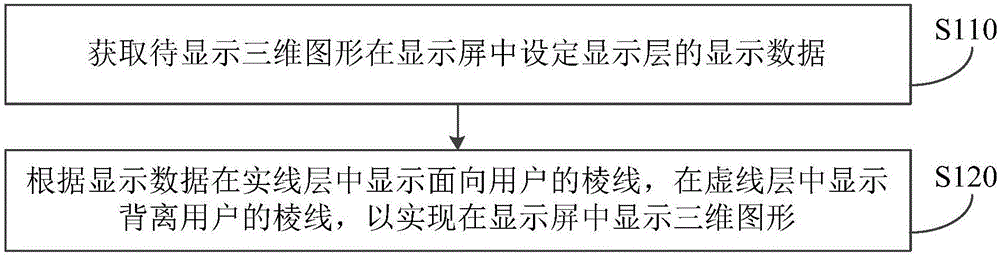

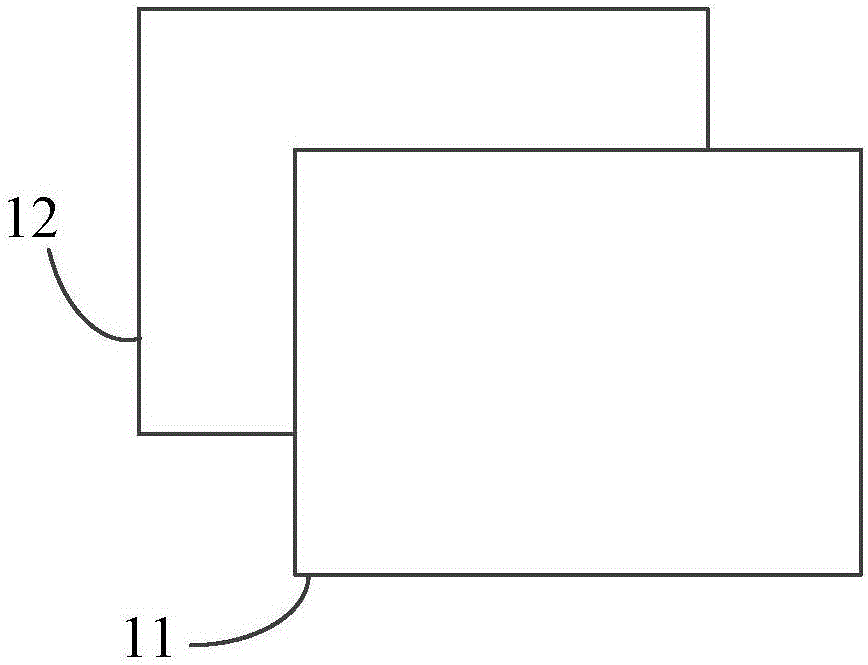

Three-dimensional graph display method and apparatus, device and storage medium

ActiveCN107526563AGuaranteed display accuracyAvoid gapsDigital output to display deviceThree-dimensional graphGraphics

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

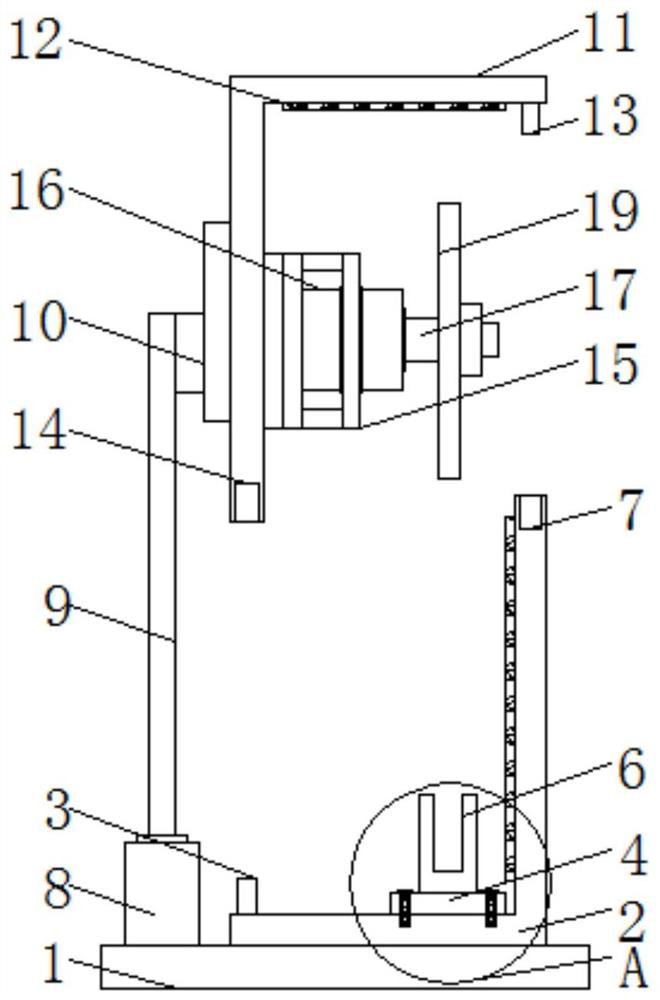

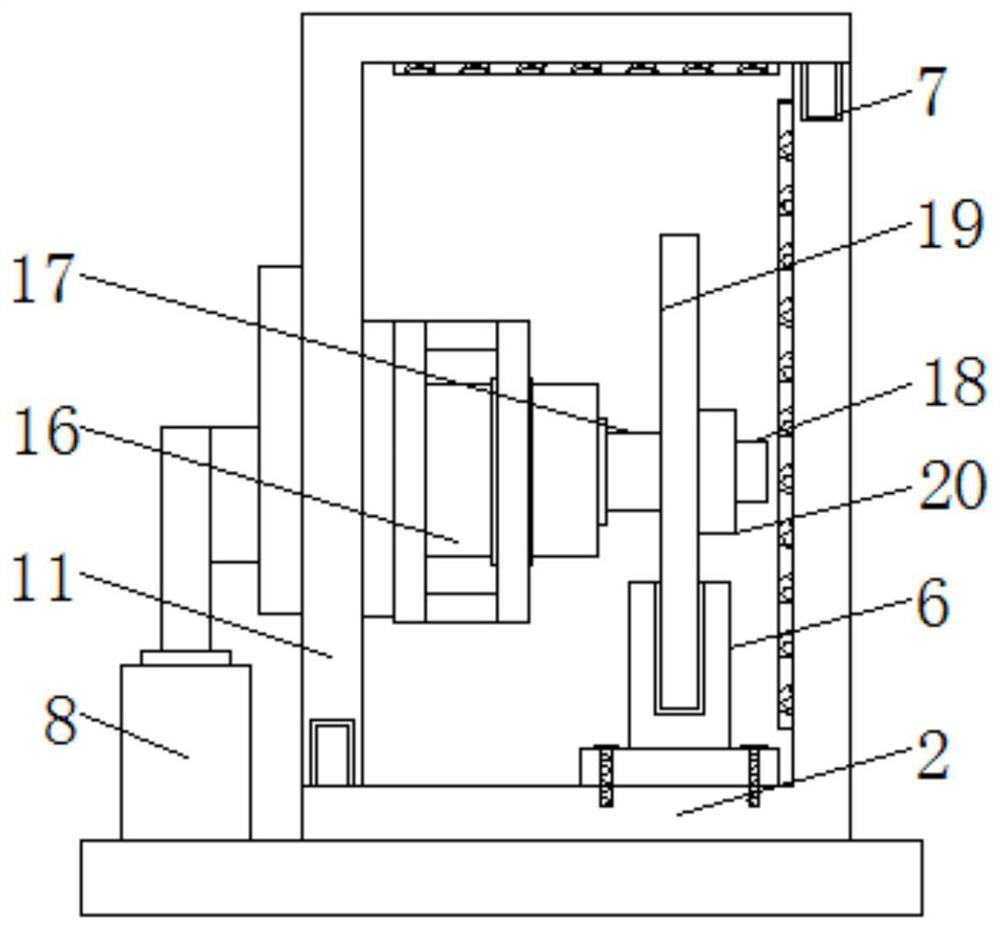

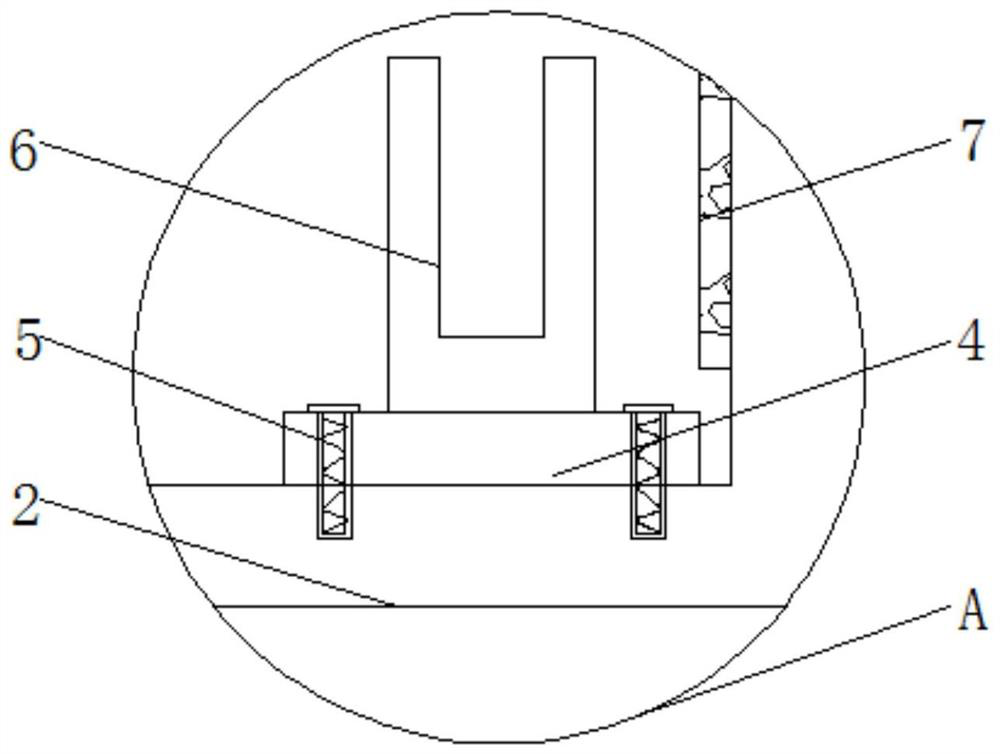

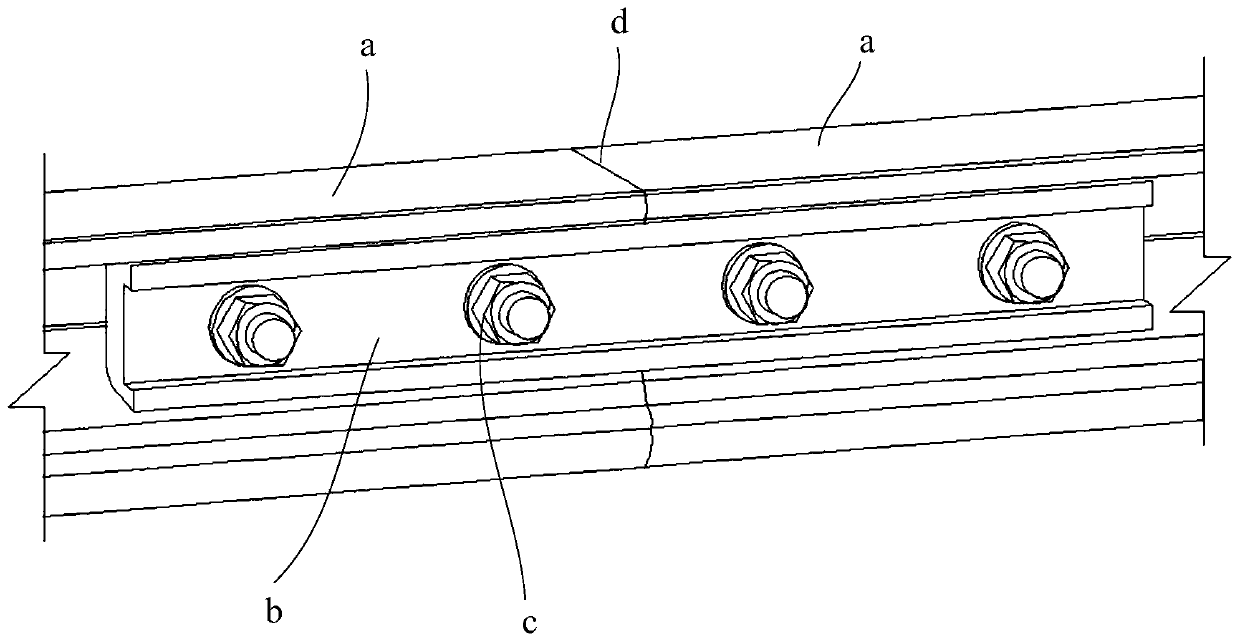

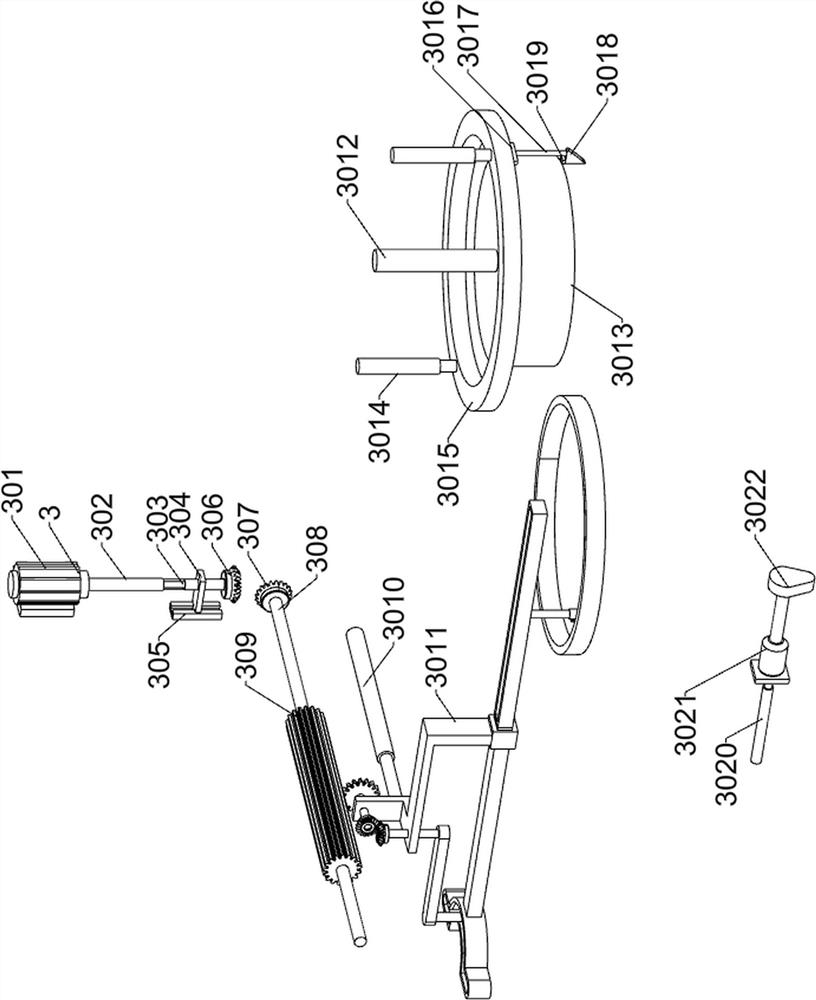

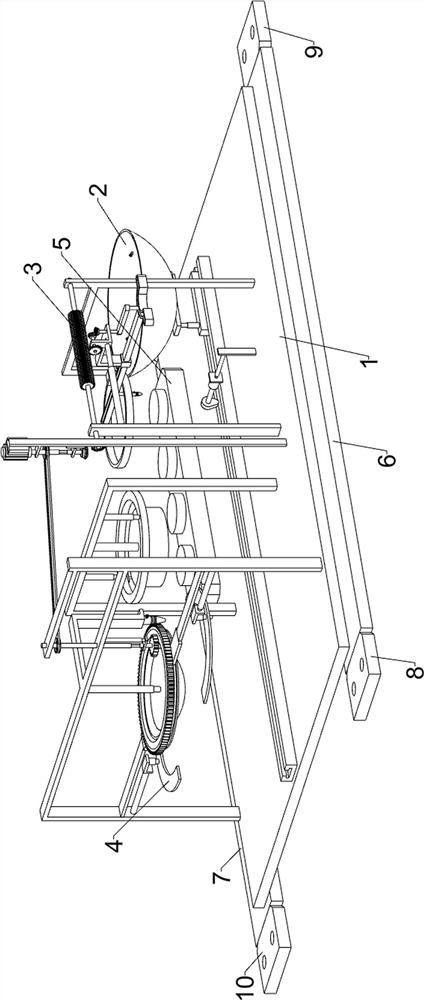

Grinding wheel dressing mechanism

PendingCN113770919AAvoid connection misalignmentAvoid gapsAbrasive surface conditioning devicesSound producing devicesPhysicsNoise pollution

The invention discloses a grinding wheel dressing mechanism. The grinding wheel dressing mechanism comprises a base, an upper fixing table and a fixing rack, a lower fixing table is installed on the upper surface of the base, a bottom plate is arranged on the upper surface of the lower fixing table, a grinding plate is installed at the upper end of the bottom plate, a first limiting groove is formed in the upper surface of the right end of the lower fixing table, an electric push rod is arranged on the left side of a first limiting column, the upper end of a piston rod is connected with one end of a connecting rod, the upper fixing table is located at the other end of the connecting rod, and the fixing rack is located in the upper fixing table. According to the grinding wheel dressing mechanism, through limiting connection among a second limiting column, a second limiting groove, the first limiting column and the first limiting groove, stable lifting of the upper fixing table can be kept, the phenomenon of connection dislocation of the upper fixing table and the lower fixing table is avoided, sound insulation pads are arranged on the inner walls of the lower fixing table and the upper fixing table, and the sound insulation pads can absorb part of noise, so that noise pollution generated in the working state of the mechanism is reduced.

Owner:无锡钦盈机械有限公司

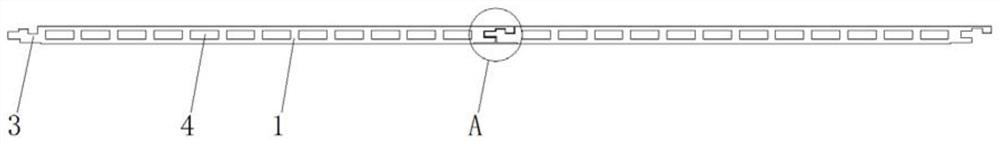

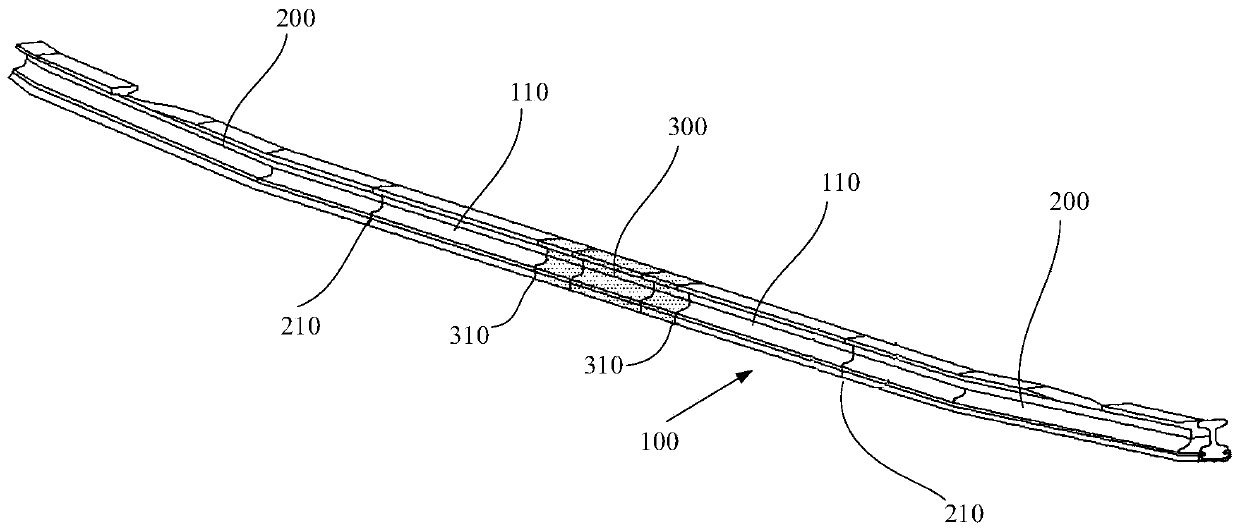

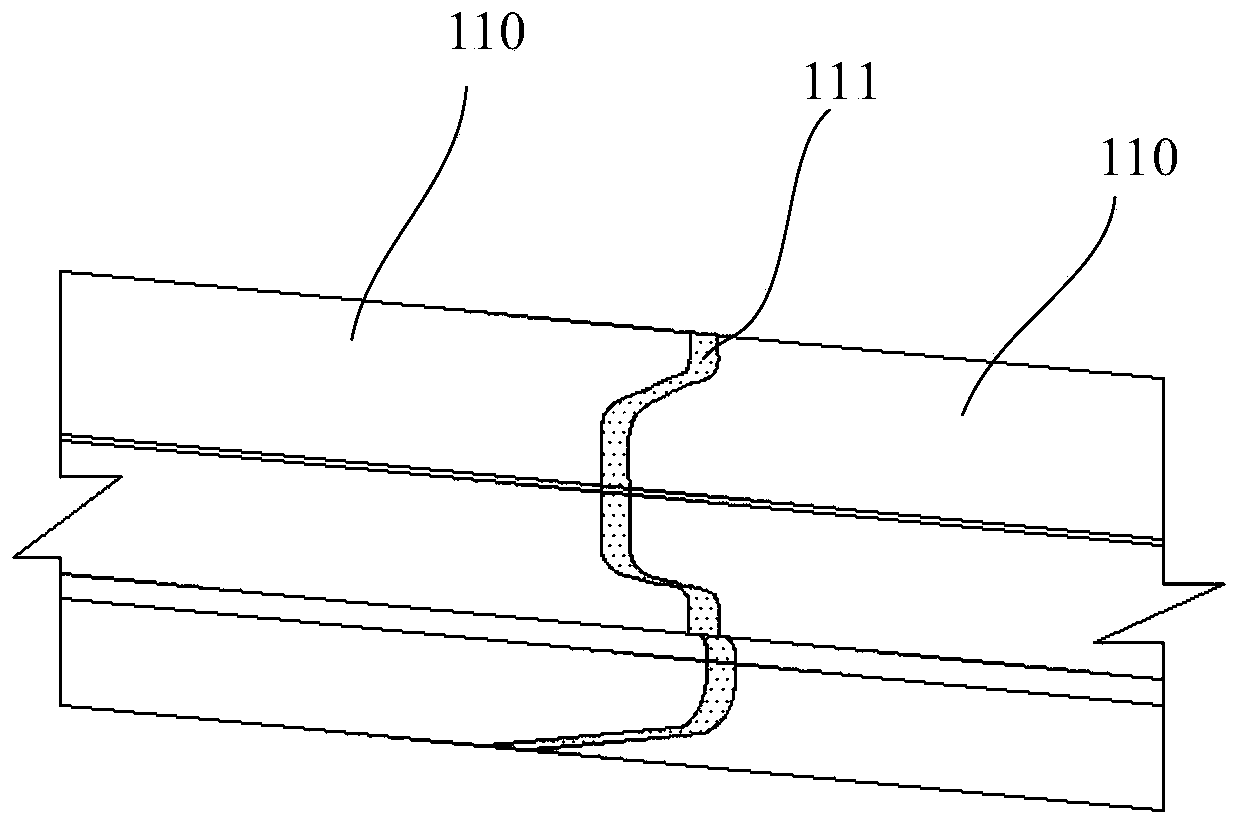

Seamless contact rail system and connecting method of contact rail system

PendingCN110626218AAvoid gapsReduce operational workloadRail devicesPower railsEngineeringMechanical joint

The invention discloses a seamless contact rail system and a connecting method of the contact rail system. The seamless contact rail system comprises multiple anchoring sections arranged in the line direction; each anchoring section comprises at least two current-carrying parts with current-carrying demands; and the two adjacent current-carrying parts are seamlessly connected with each other. According to the technical scheme of the embodiment of the invention, the use of a mechanical joint is avoided, and the operation workload is reduced. The integrity and smoothness of a contact rail are also improved, the dynamic characteristic between a collector shoe and the contact rail is improved, and the system and the method are beneficial for improving the current supplying quality and enhancing the adaptability to higher speed target value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

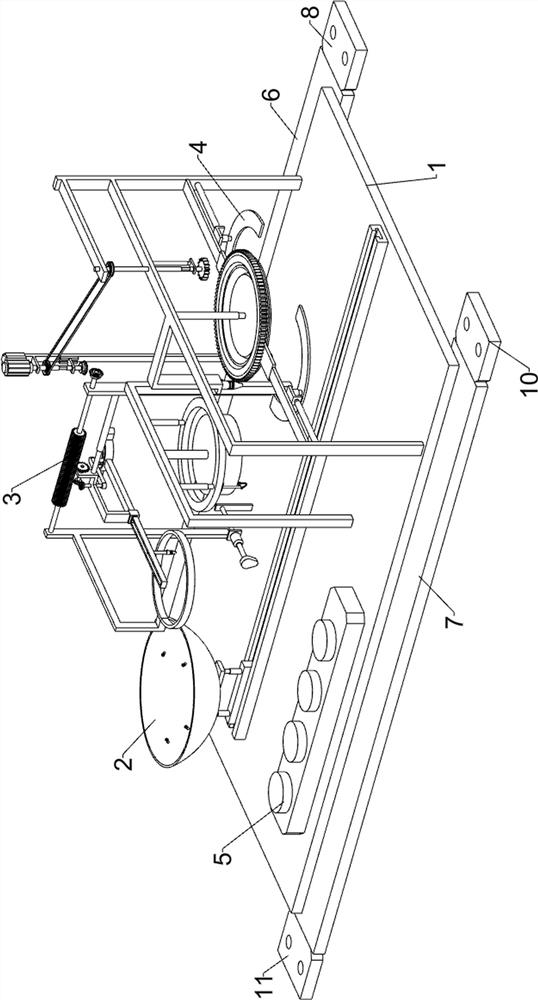

Knee pad forming device capable of eliminating bubbles for AR equipment

The invention relates to the field of AR equipment, in particular to a knee pad forming device capable of eliminating bubbles for AR equipment. The technical purpose to be achieved by the invention is to provide a knee pad forming device capable of eliminating bubbles for AR equipment. According to the technical scheme, the knee pad forming device capable of eliminating bubbles for AR equipment comprises a chassis, a transportation assembly, an upper silica gel assembly, a forming assembly and the like; and the upper silica gel assembly is connected with the forming assembly. When the knee pad forming device is used, silica gel is automatically injected into a groove of an EVA composite shell layer by layer, so that the silica gel has sufficient time to flow into a small groove in the EVA composite shell; meanwhile, each layer of silica gel is circular, so that the silica gel is uniformly distributed; meanwhile, the upper surface of the silica gel layer is flat through vibration, and glue marks on the inner wall of the groove are removed completely; and the groove of the EVA composite shell is automatically extended and supplemented with polyurethane foaming colloid for forming operation, so that the notch phenomenon of a formed sponge body is avoided.

Owner:汤水霞

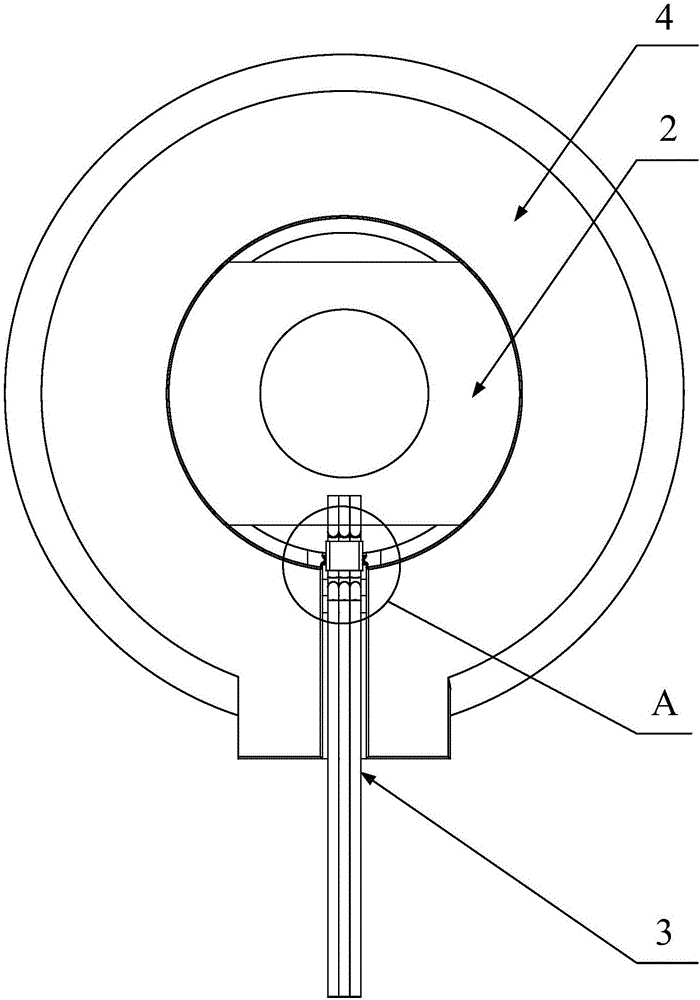

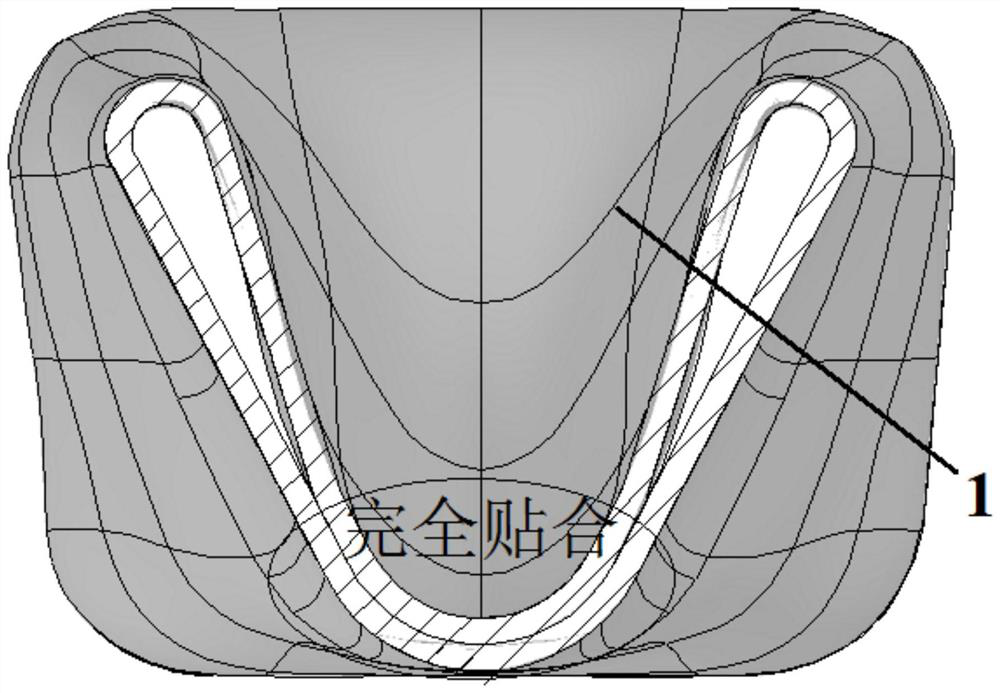

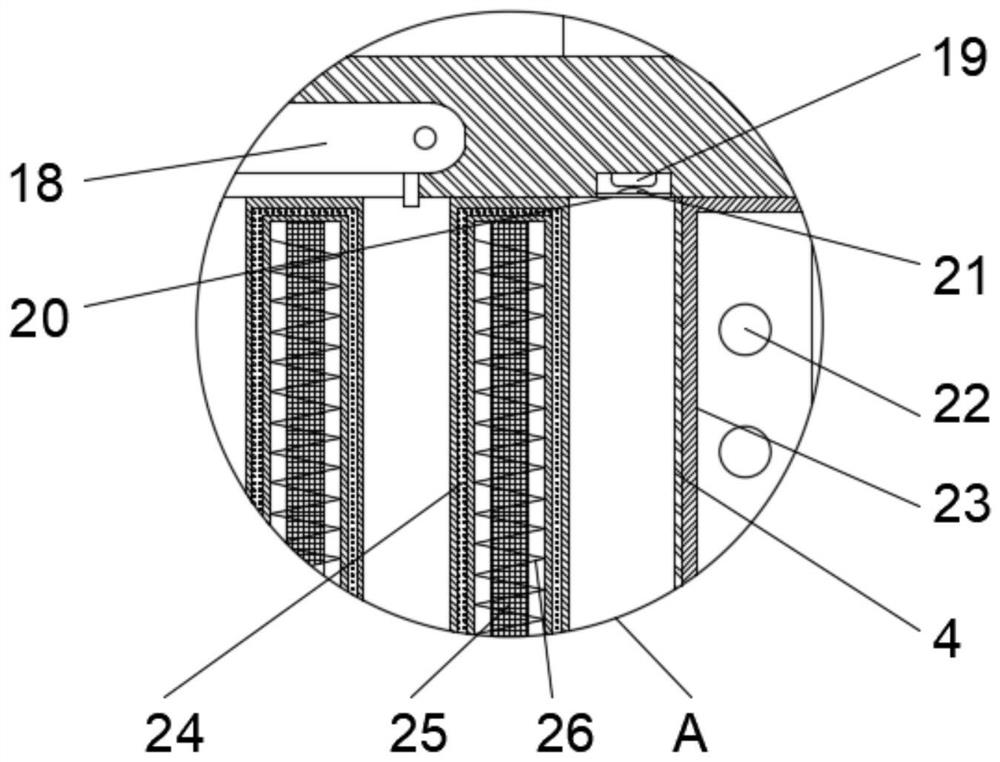

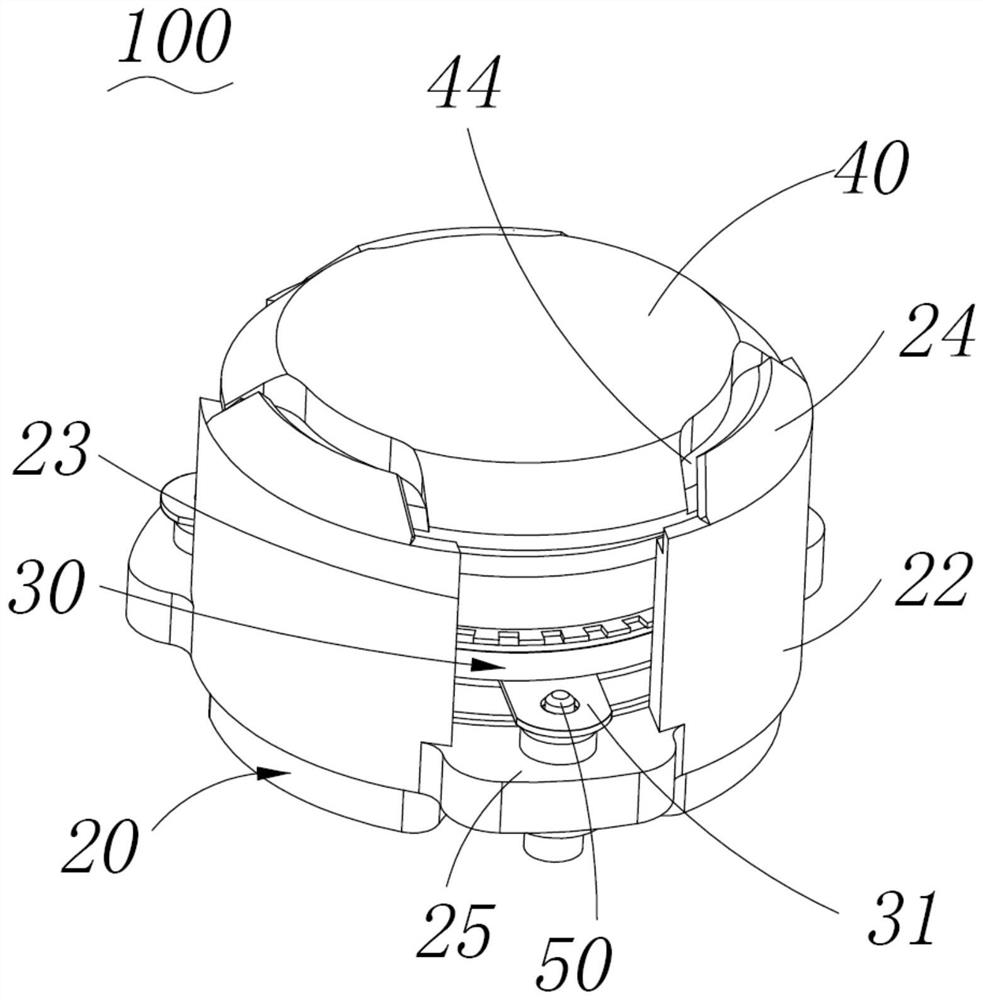

Circulator

PendingCN111682295AAvoid gapsThere will be no warpingWaveguide type devicesStructural engineeringCirculator

The invention provides a circulator, which comprises a shell, an in-cavity assembly accommodated in the shell, and a cover plate for packaging the in-cavity assembly in the shell, wherein the shell comprises a bottom wall and a side wall extending upwards from the periphery of the bottom wall, a cavity is defined by the side wall and the bottom wall, the side wall is provided with a plurality of notches from top to bottom, the in-cavity assembly is provided with a plurality of pins used for being connected to a mainboard of communication equipment, the pins straightly extend outwards from thecorresponding notches, a protruding part is formed on the side, facing the in-cavity assembly, of the cover plate, and the protruding part abuts against the top of the in-cavity assembly. According tothe invention, by arranging the protruding part, the sheet materials can be prevented from tilting to form gaps, so that the sheet materials are perfectly attached, and the circulator is reliable inthe using process.

Owner:SUZHOU IND PARK KAYMAX PRECISION ENG

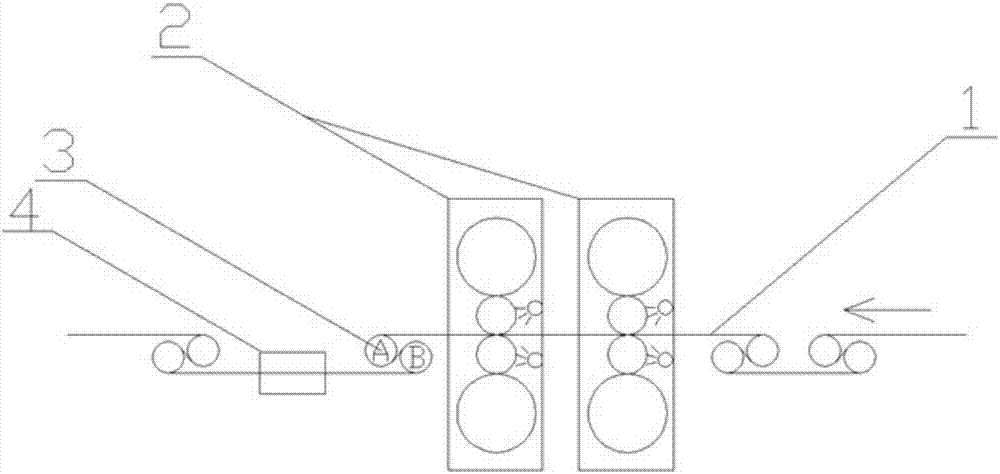

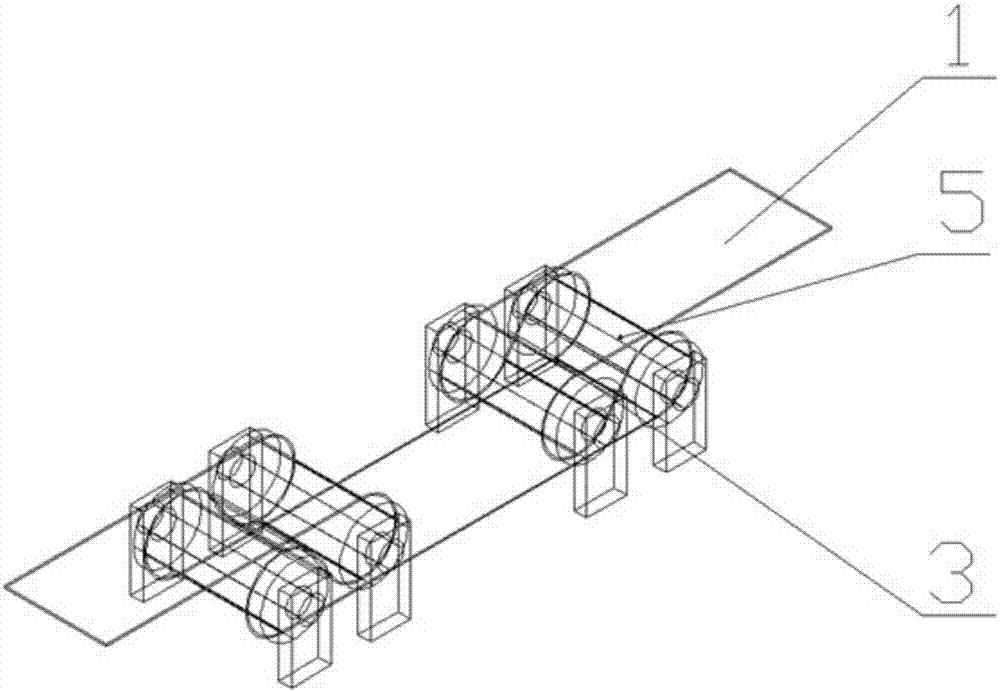

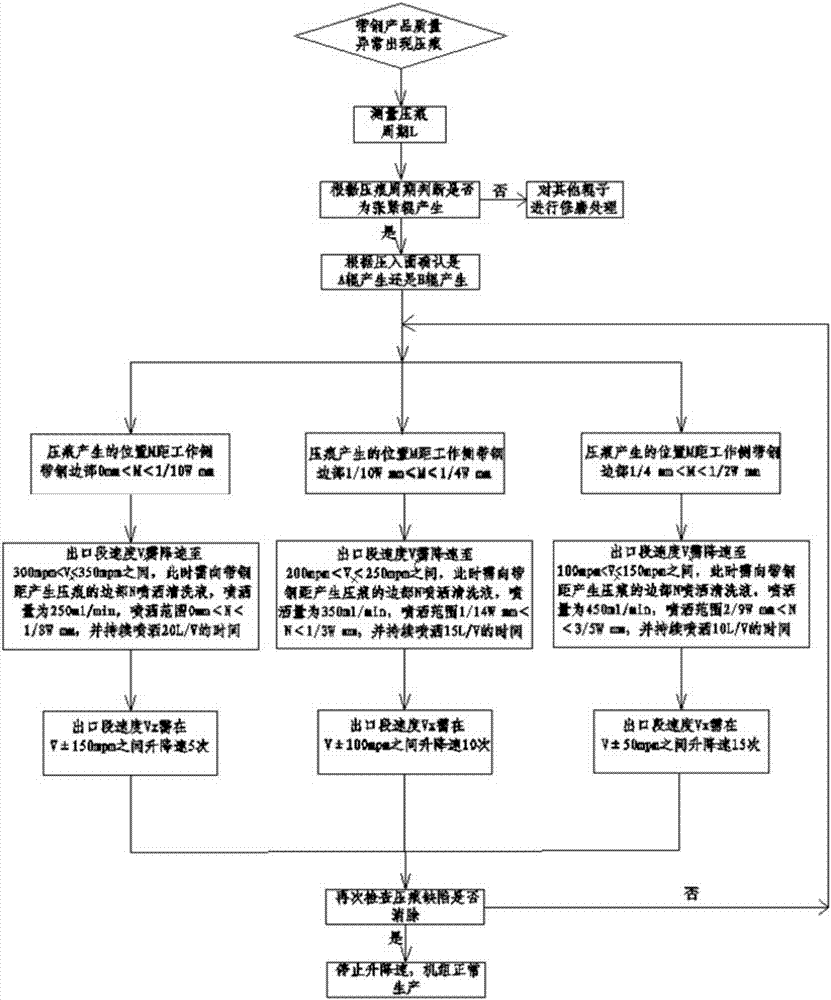

On-line control method for removing foreign matters adhered to the roll surface

ActiveCN105458010BGuaranteed outputAvoid gapsRolling equipment maintainenceRoll mill control devicesEngineeringForeign matter

The invention provides a control method for removing foreign matter adhered to a roll surface on-line. The method of the present invention includes the following steps: (1) determine the specific tension roller that produces the indentation by sampling the defective sample, (2) spray cleaning liquid according to the position of the indentation and the width of the strip steel, (3) According to the spraying range, spraying amount and unit speed V of the cleaning liquid, different speed changes are used to perform different times of speed up and down operations to further improve the effect of repeated grinding of foreign objects; (4) Hot air drying. The present invention achieves the purpose of on-line removal of foreign matters adhered to tension rollers under the condition of utilizing existing equipment and without affecting the operation of the unit.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com