Patents

Literature

53results about How to "Good connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

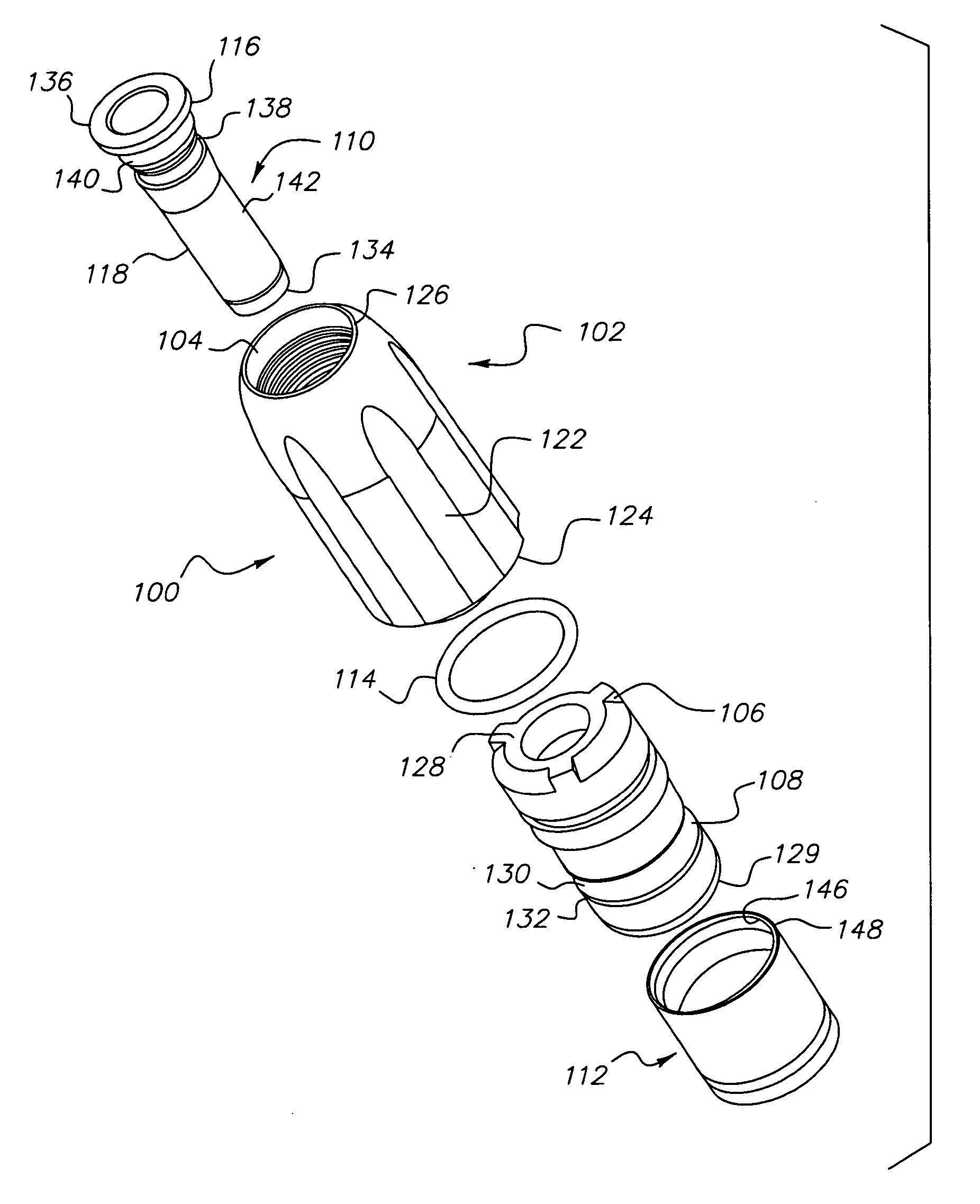

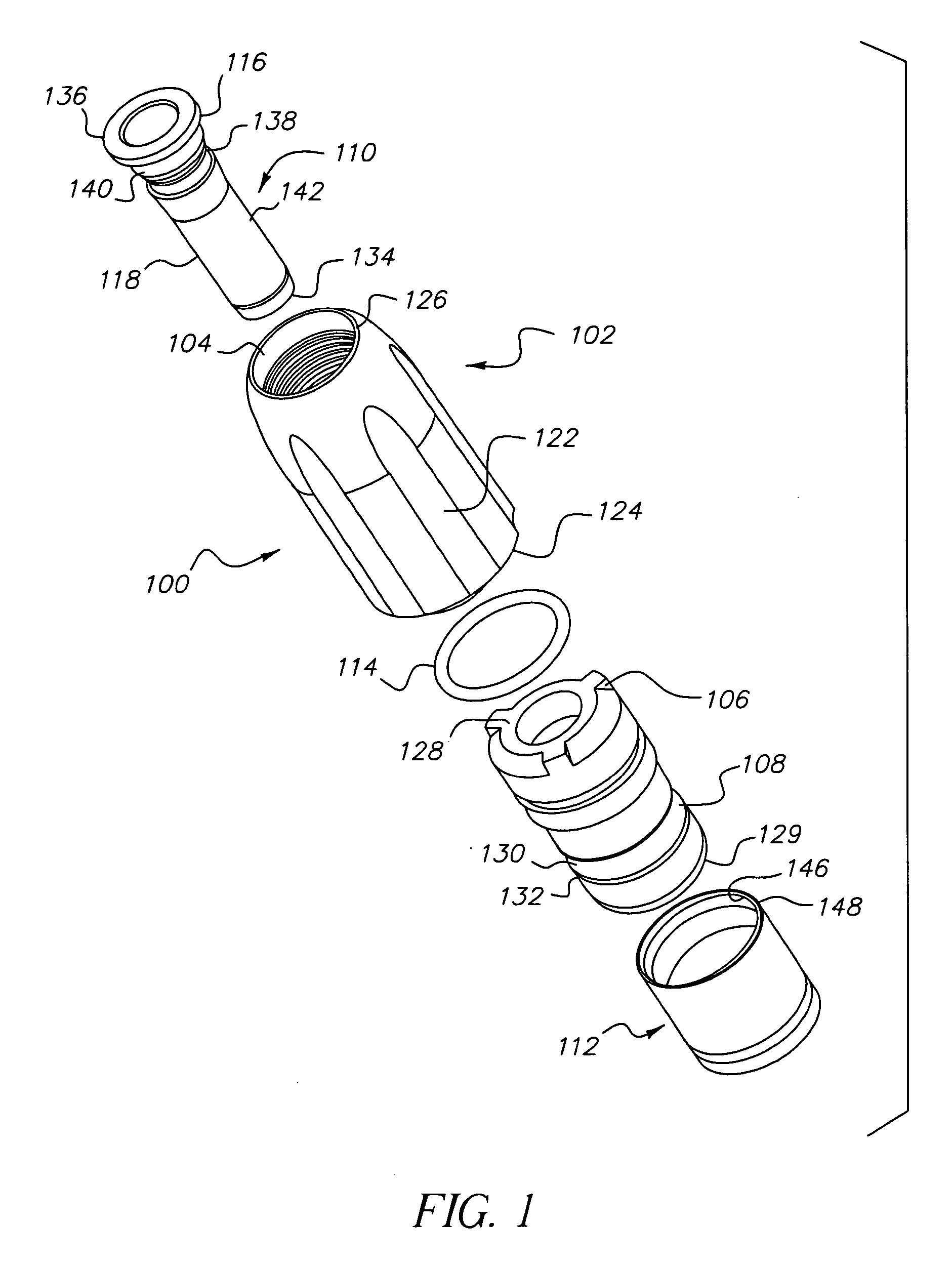

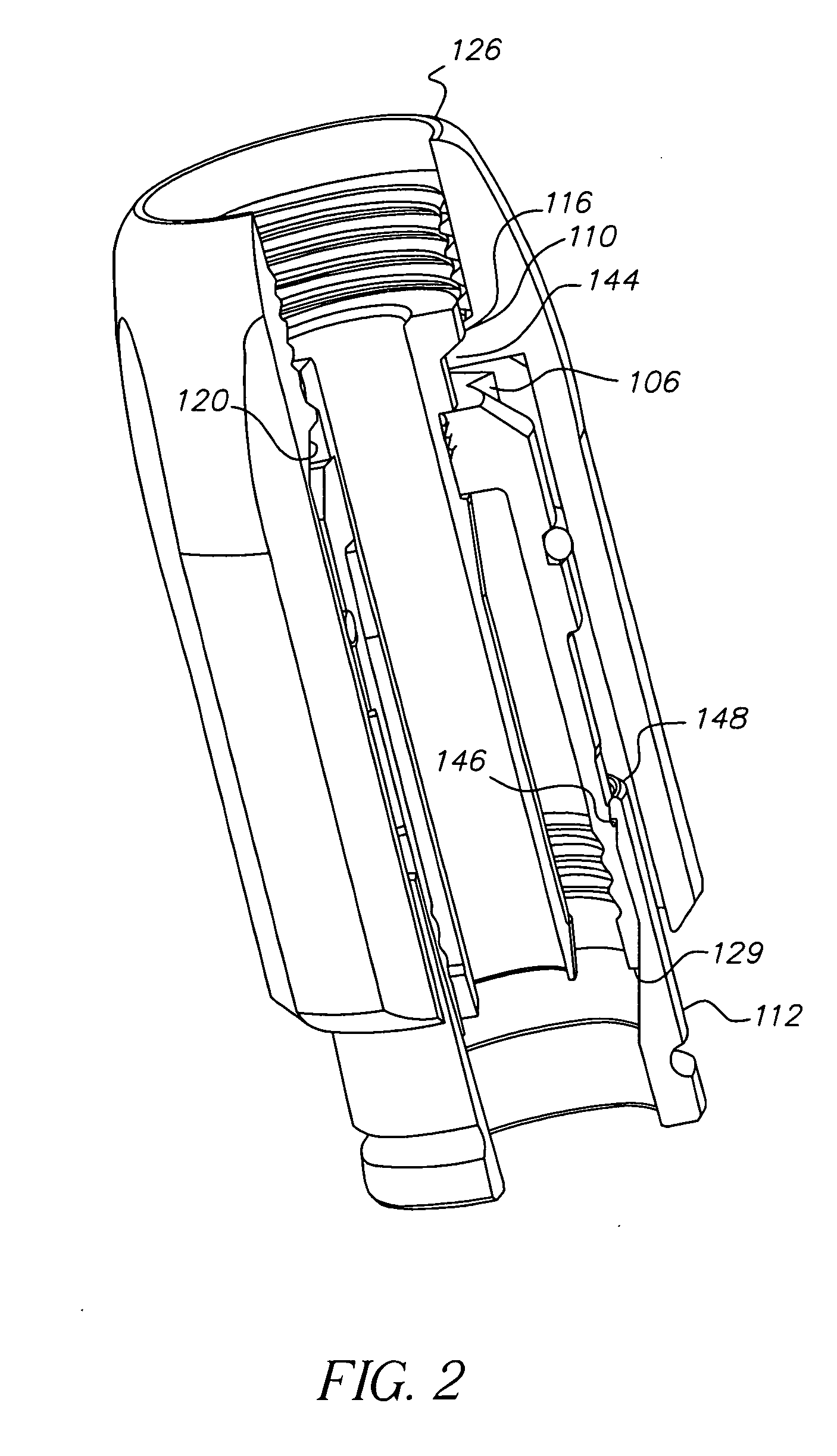

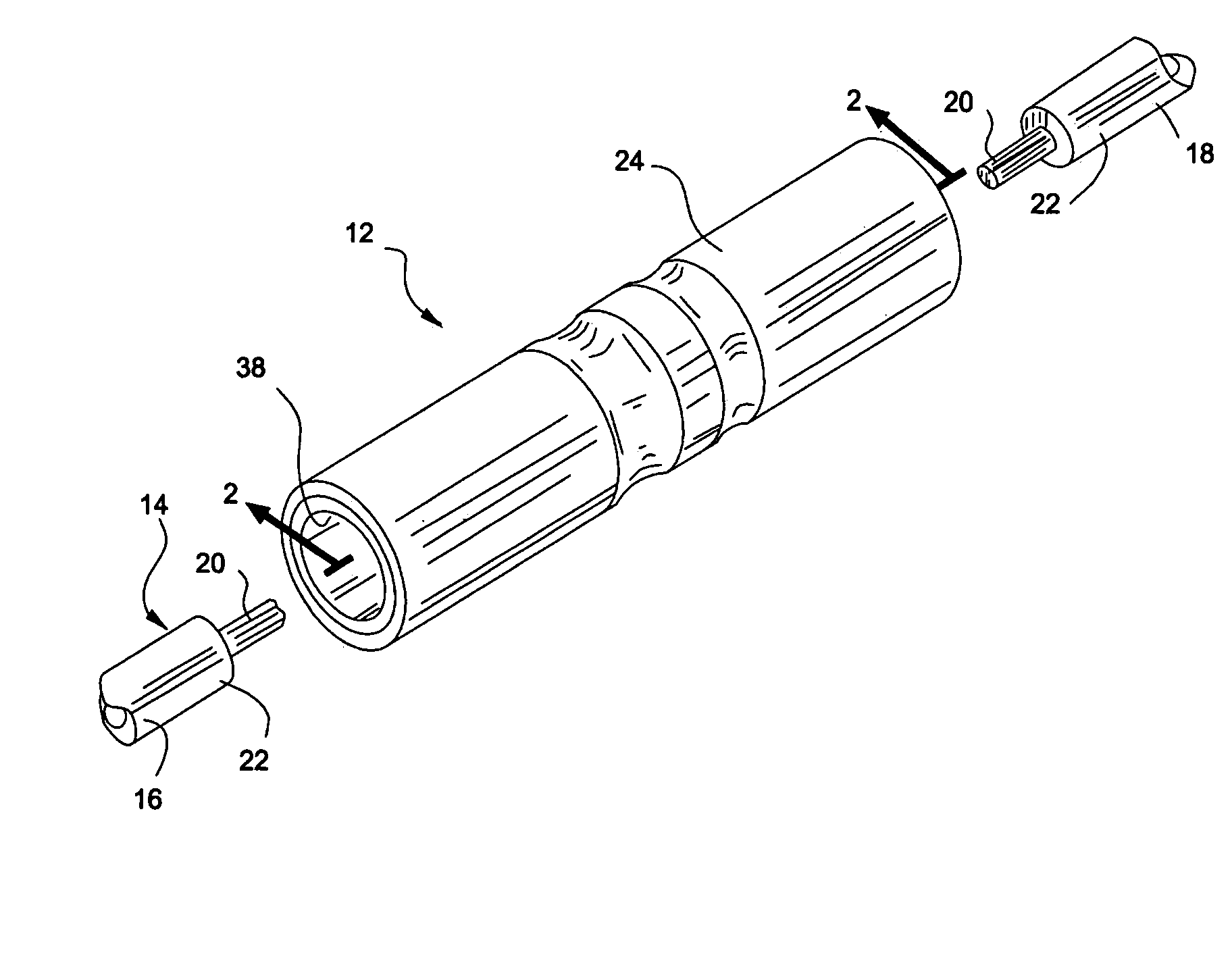

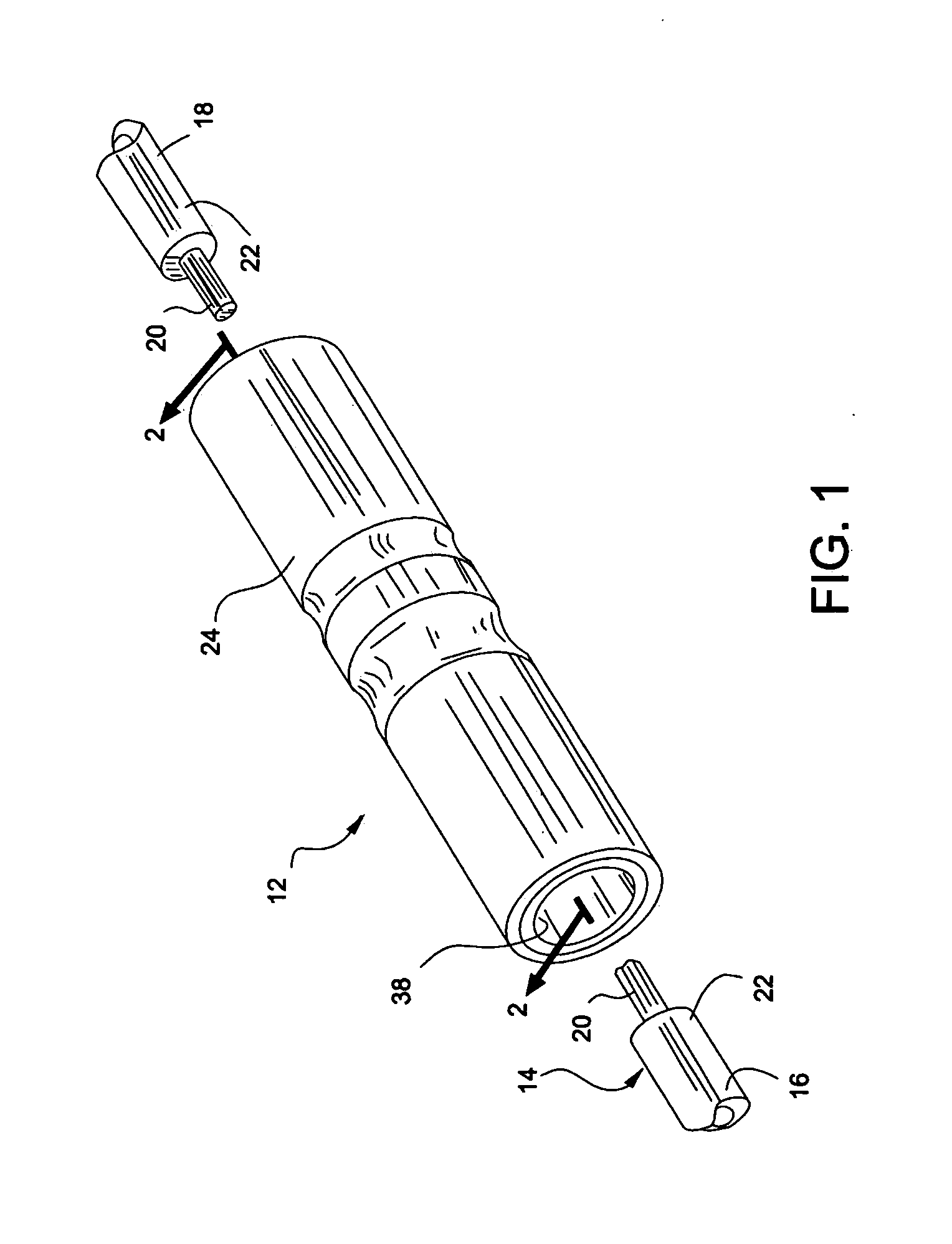

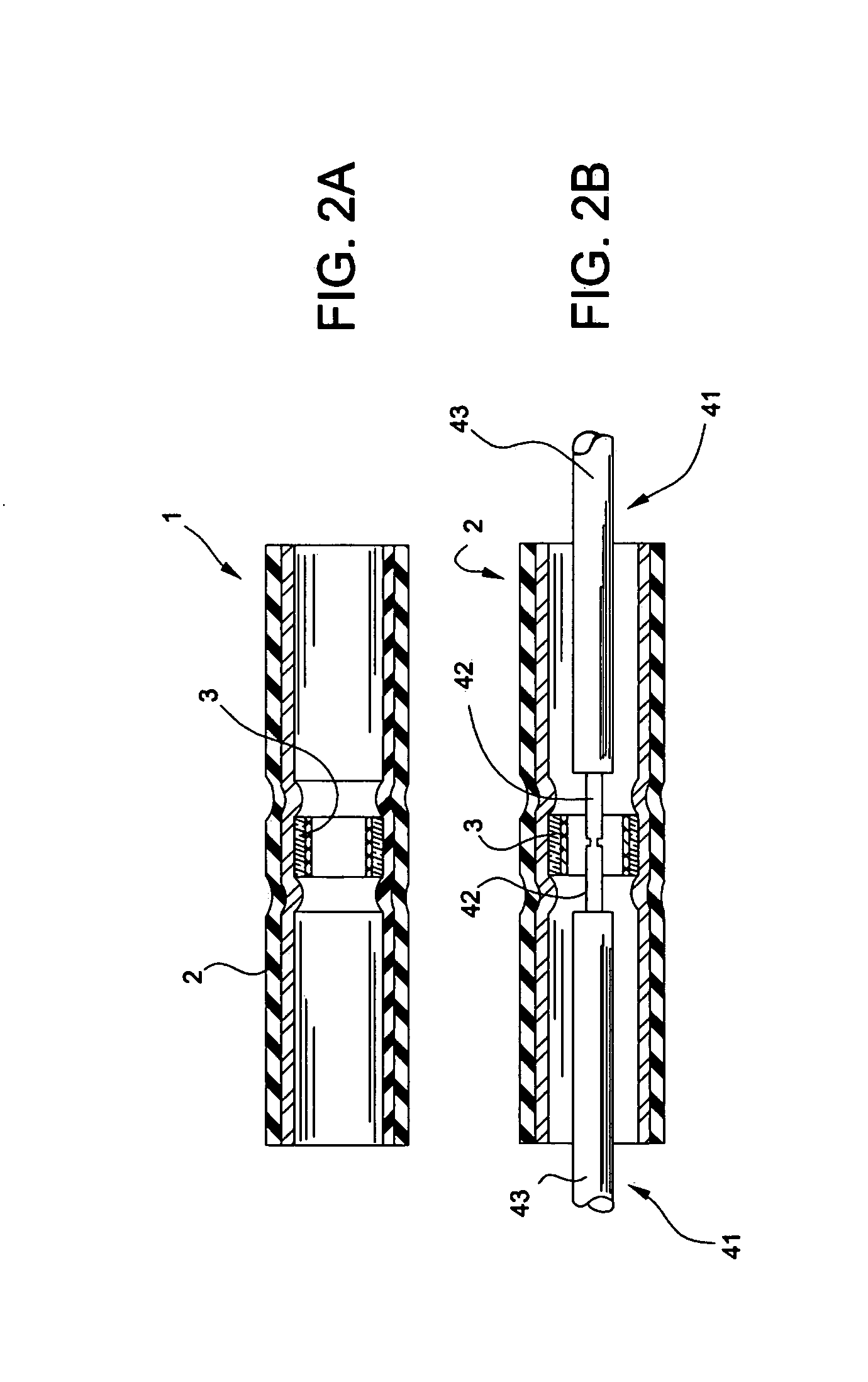

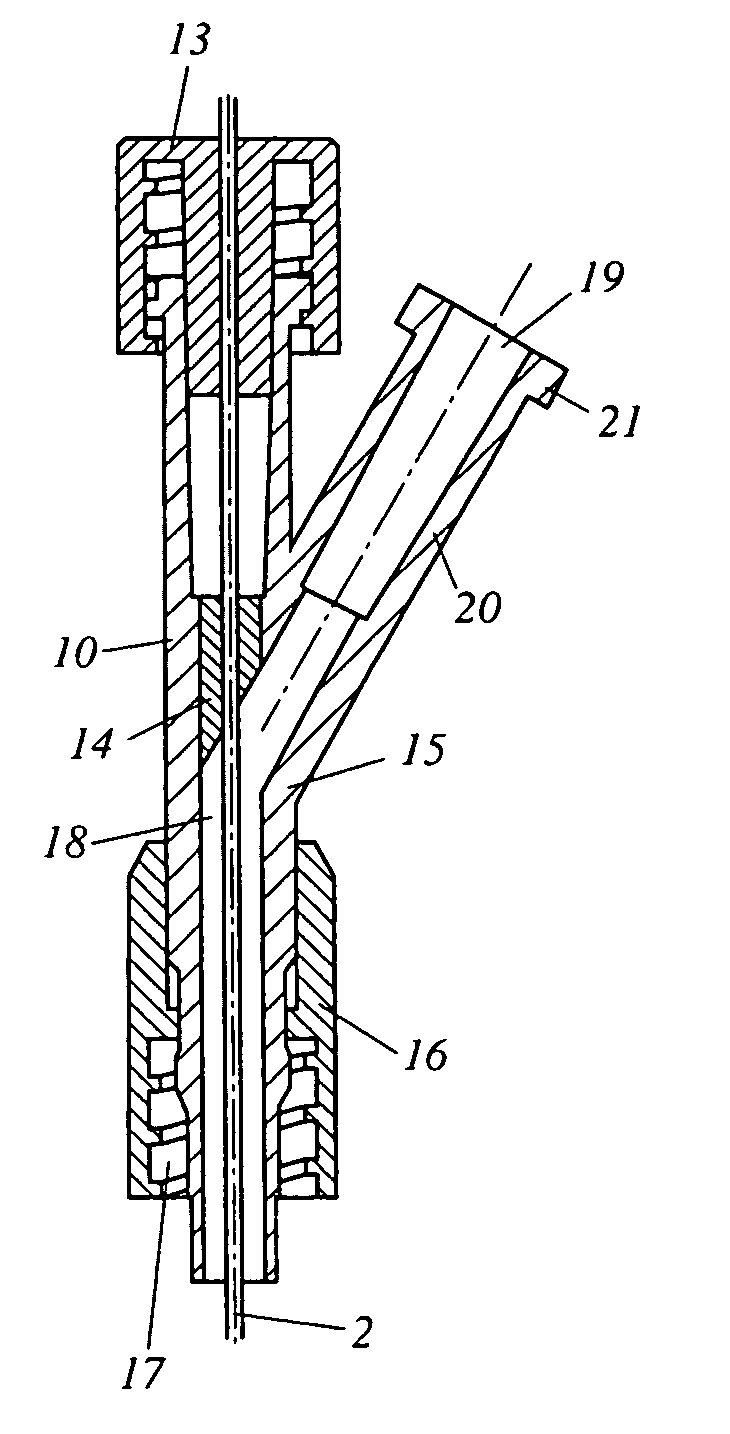

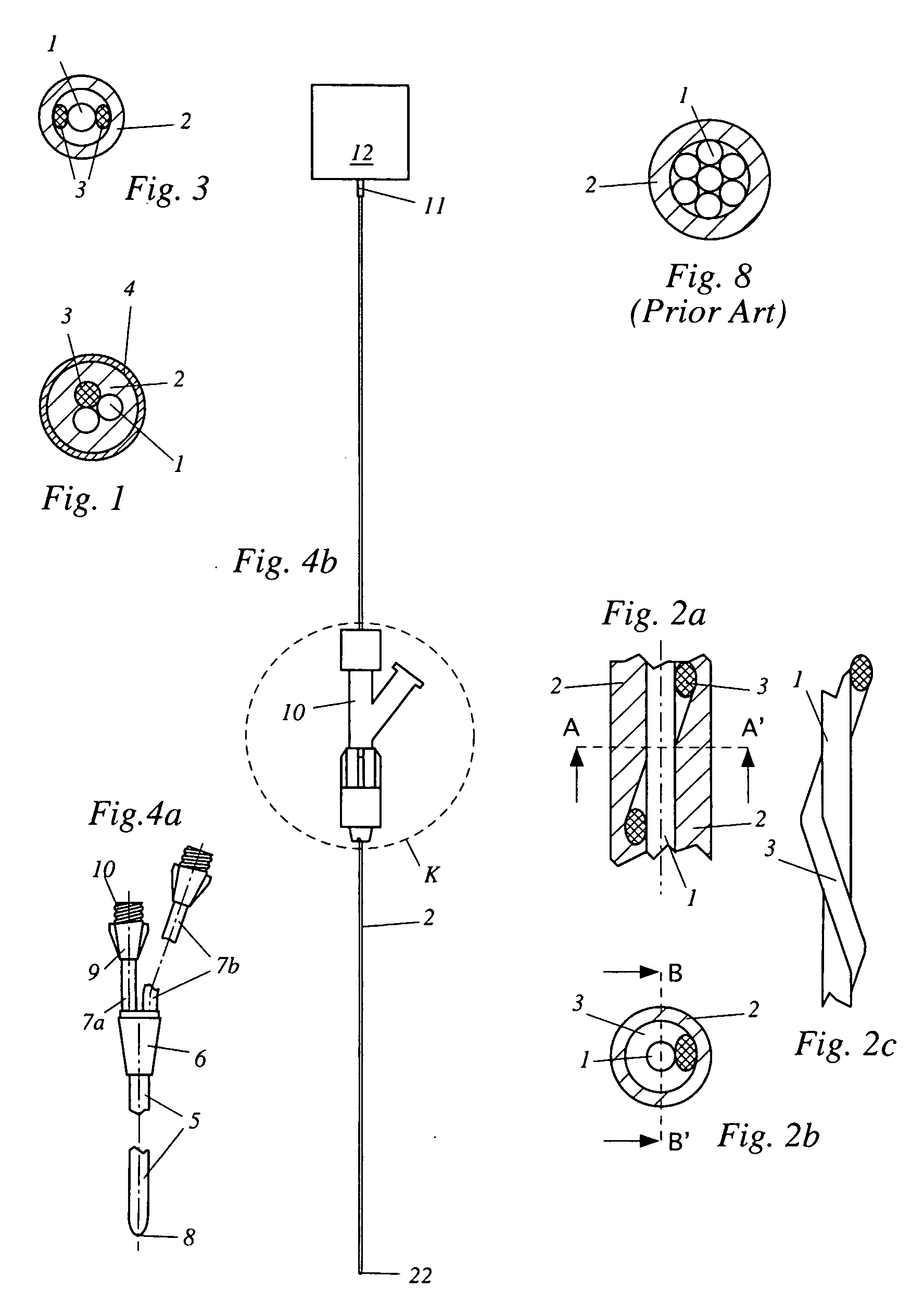

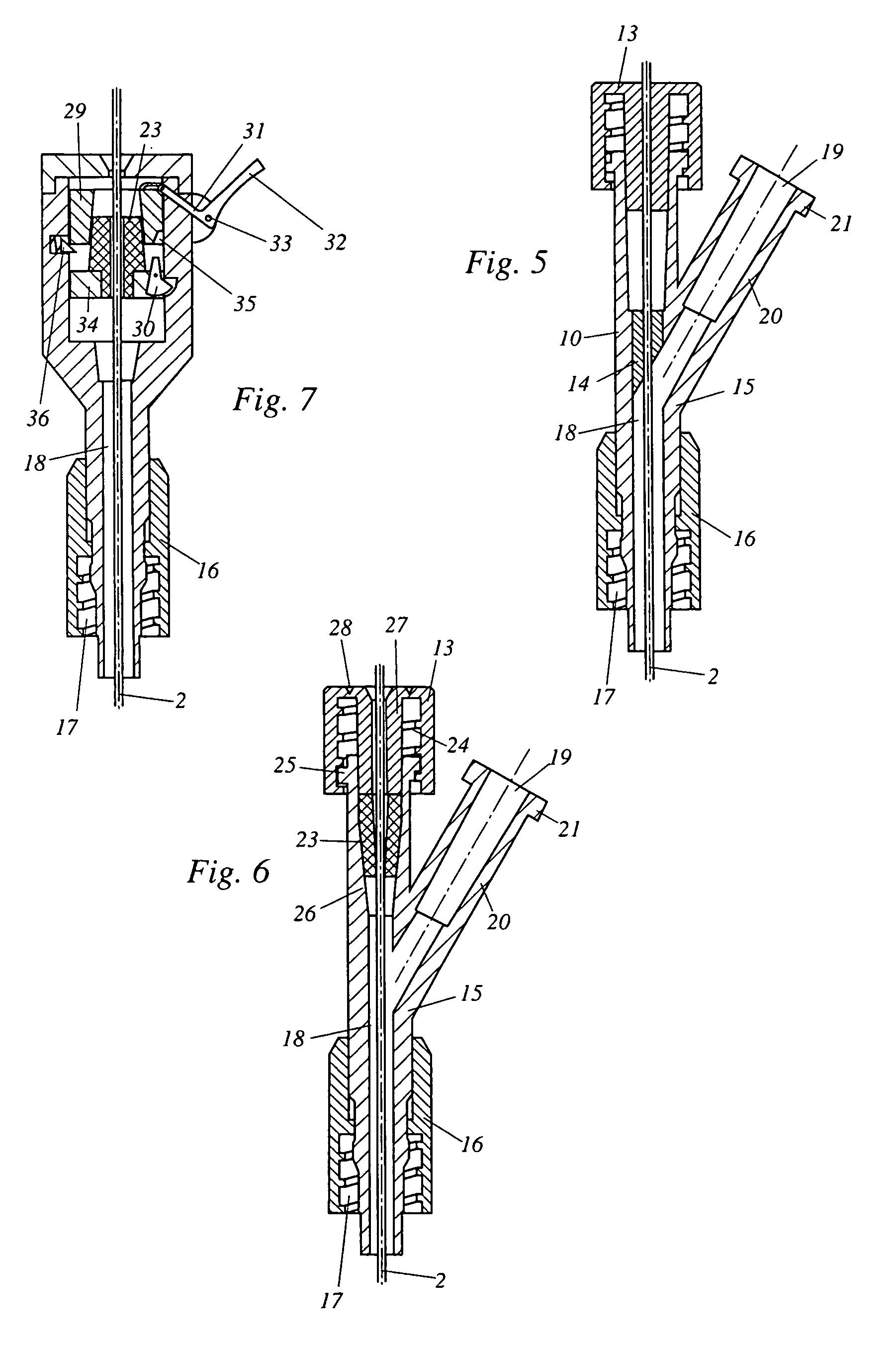

Coax connector having clutching mechanism

InactiveUS20060240709A1Good connectionGenerate more torqueElectrically conductive connectionsTwo pole connectionsClutchInternal standard

The invention is directed to a clutching mechanism for a coax connector. The device comprises an extended nut having a standard connector contained within. The extended nut comprises internal threads and a first clutch face and the internal standard connector comprises a connector body having a second clutch face. In operation, the first clutch face and the second clutch face are engaged by forcing the nut toward the connector body / cable, thereby serving as an interlocking mechanism. The device further comprises a compression sleeve between the nut and the connector body, serving to secure the cable to the connector.

Owner:PPC BROADBAND INC

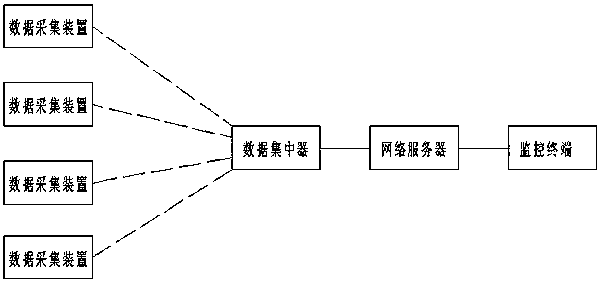

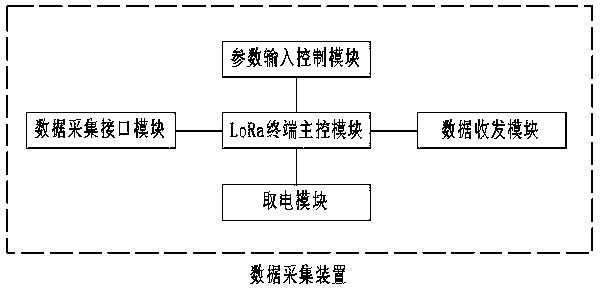

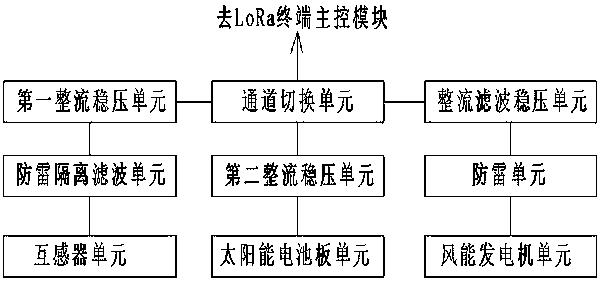

LoRa-based power distribution terminal communication system

PendingCN107682756AReduce energy consumptionGood connectionSub-station arrangementsTransmission systemsPower gridAutomatic tuning

The invention discloses a LoRa-based power distribution terminal communication system, and relates to the communication field of power distribution networks. The power distribution terminal communication system herein is proposed in order to address the technical problems of wireless communication used by current power distribution networks, such as poor matching among transmission power consumption, transmission velocity, transmission data volume and transmission distance, and high construction cost due to the fact that most reply on infrastructure to provide communication support. The systemherein includes a data acquiring apparatus, a data concentrator, a network server and a monitoring terminal. The data acquiring apparatus is connected to the data concentrator in a wireless manner. The data concentrator is connected to the network server through a network. The network server and the monitoring terminal are connected. According to the invention, the system herein, based on the characteristics of the LoRa technology, such as low energy consumption, long transmission distance and no need for support from a base station, can acquire power from solar energy, wind energy, voltage transformers and on-site inspection devices and can automatically adjust work modes to adapt to energy consumption. Therefore, the system herein can ensure long-term and efficient communication of a power grid.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST

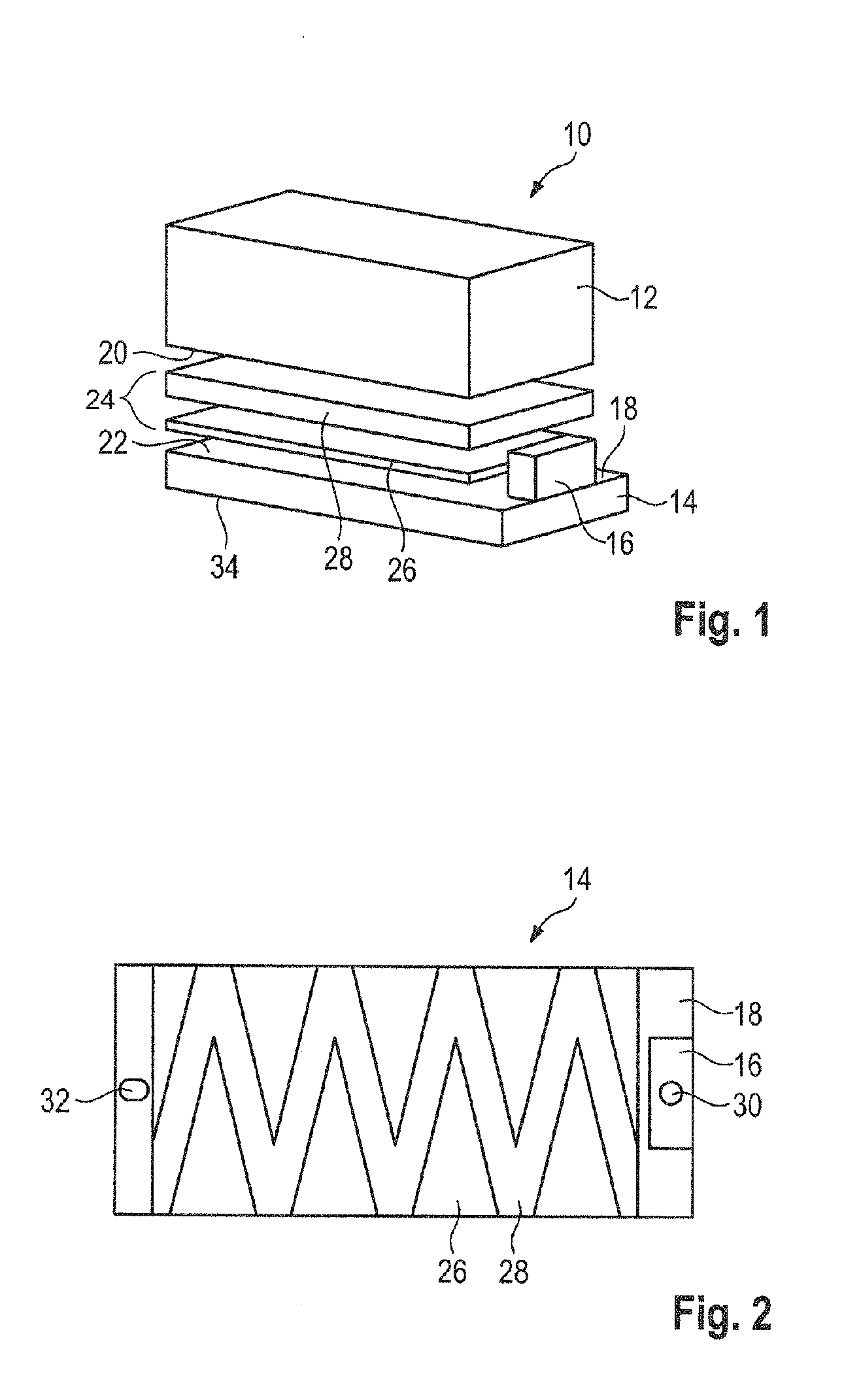

Wire connector and method of fabricating the same

InactiveUS20080009202A1Well connect effectGood connectionElectric connection structural associationsSolderingElectrical and Electronics engineering

This invention relates to a wire connector and method of fabricating the same. The wire connector assembled by an insulating tube and a soldering sleeve is used to connect a plurality of conducting wires which are made of conducting cores and insulating claddings surrounding the conducting cores. The insulating tube with the melting point at the second temperature is shrinking to deform when heated to the first temperature. The soldering sleeve with corrugated surface is placed in the insulating tube. The melting point of the soldering sleeve is the third temperature which is between the first temperature and the second temperature. When heating the external part of the insulating tube where corresponding to the soldering sleeve by the temperature between the first temperature and the third temperature, the insulating tube will shrink to lodge the corrugated surface of the soldering sleeve, and the wire connector is assembled.

Owner:KS TERMINALS INC

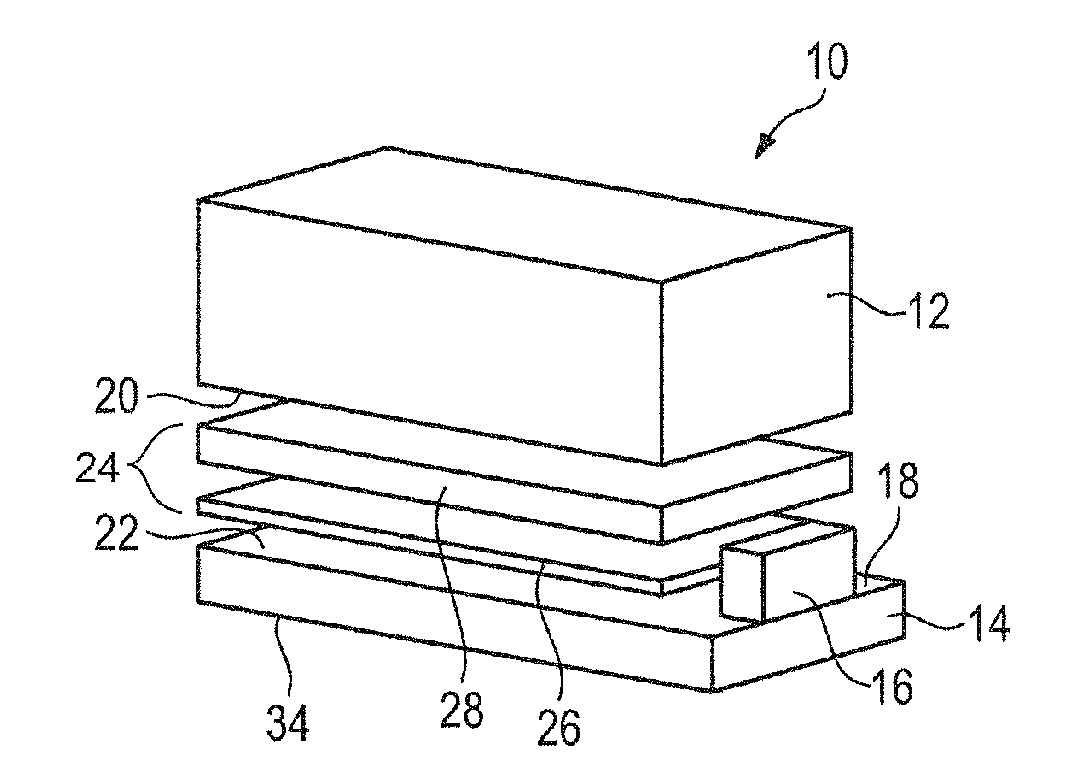

Method for Producing an Assembly from an Energy Storage Module, and a Cooling Element and Assembly

ActiveUS20160322679A1Improve adhesionGood connectionBattery isolationSecondary cellsSupply energyStructural unit

Owner:BAYERISCHE MOTOREN WERKE AG

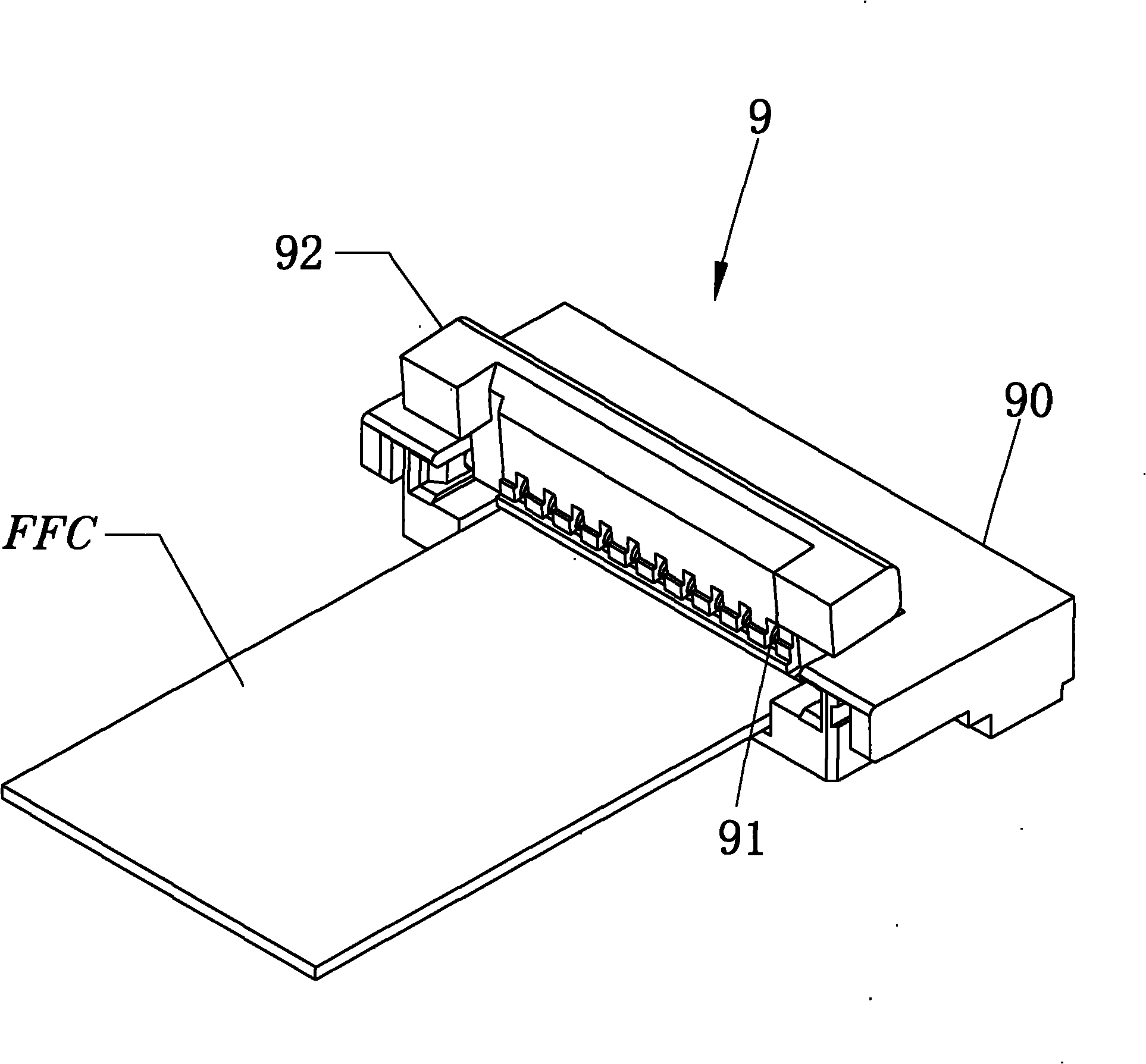

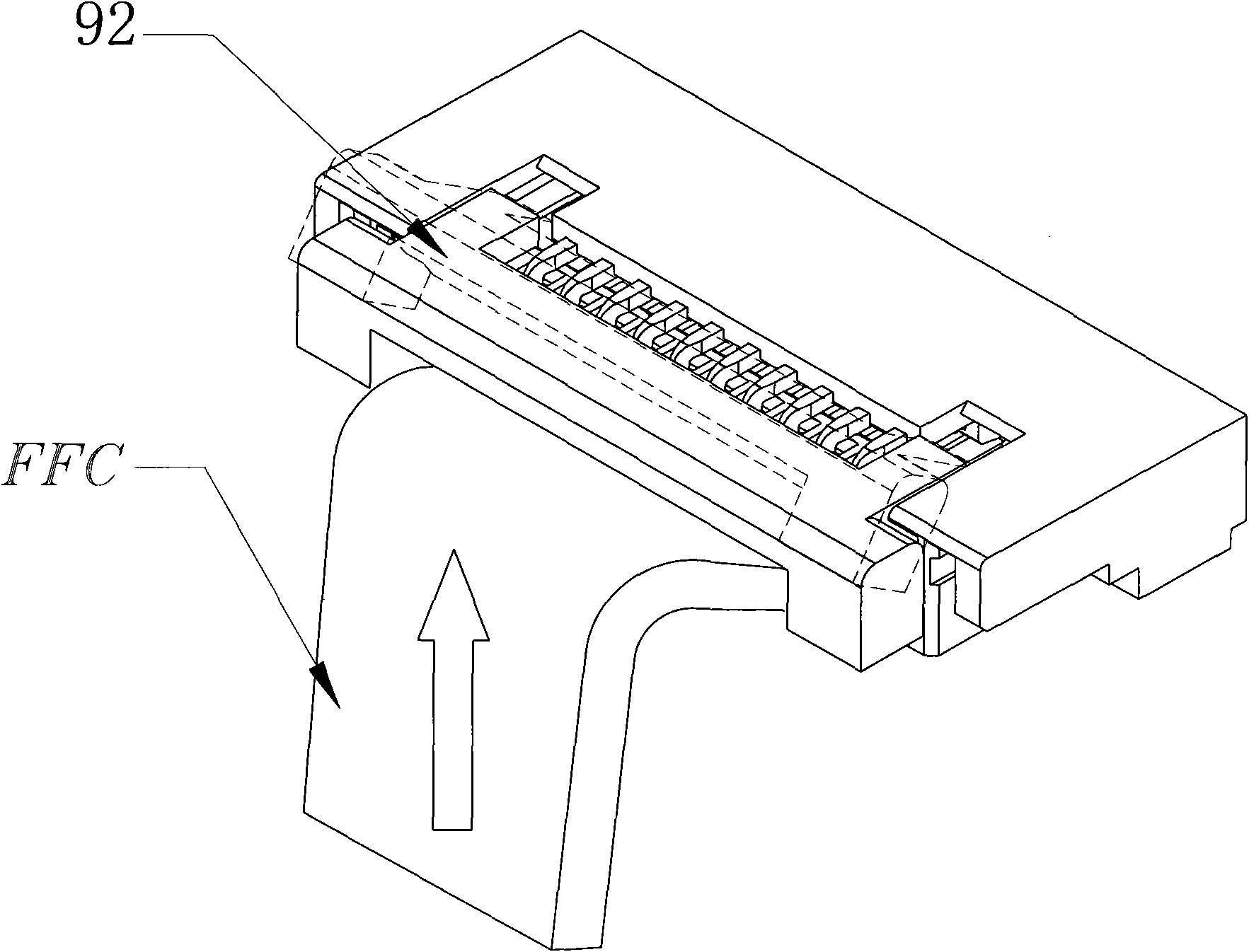

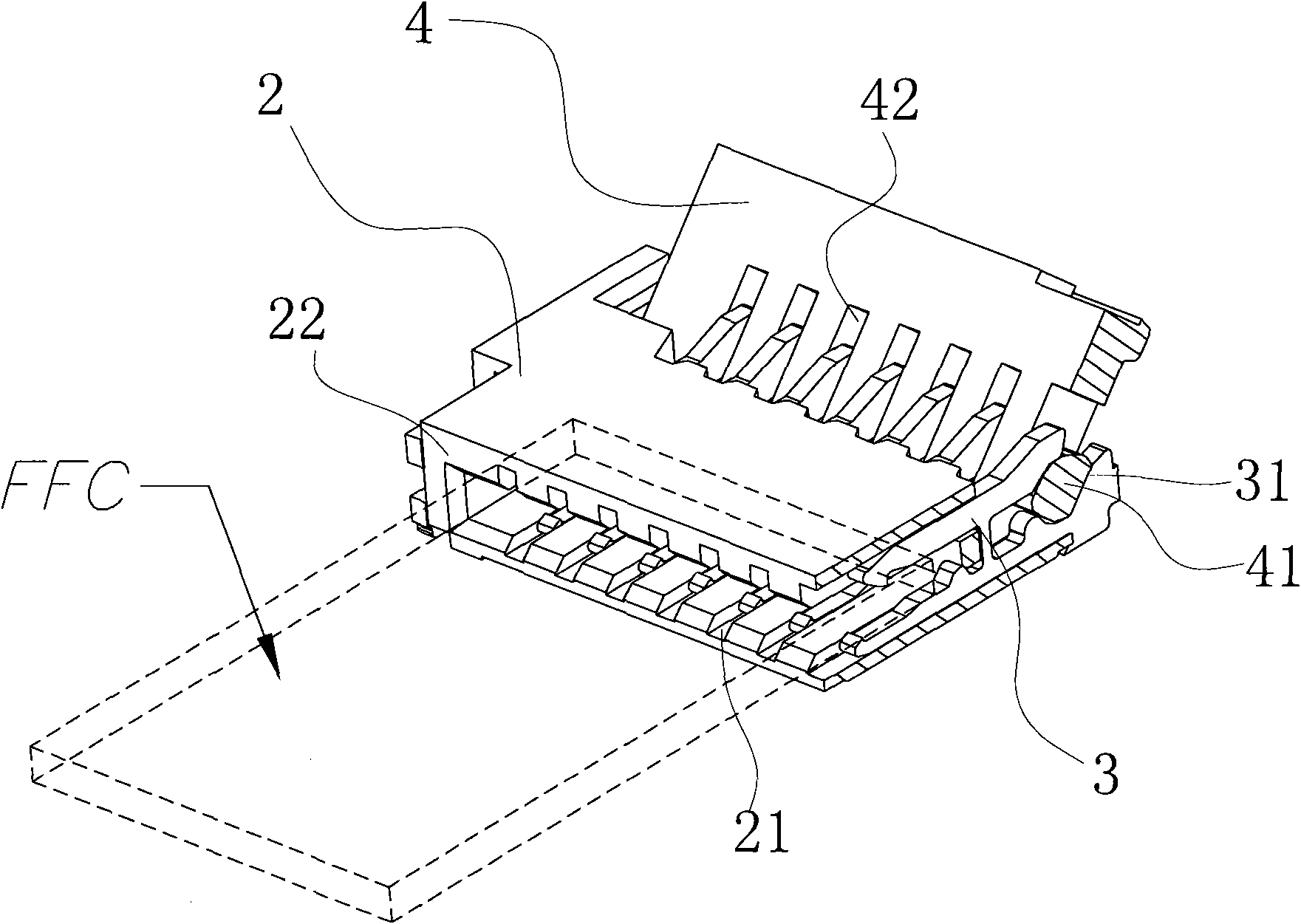

FPC (Flexible Printed Circuit) connector

InactiveCN101867107AGood connectionAccurate connectionCoupling contact membersCouplings bases/casesEngineering

Owner:昆山捷讯腾精密电子科技有限公司

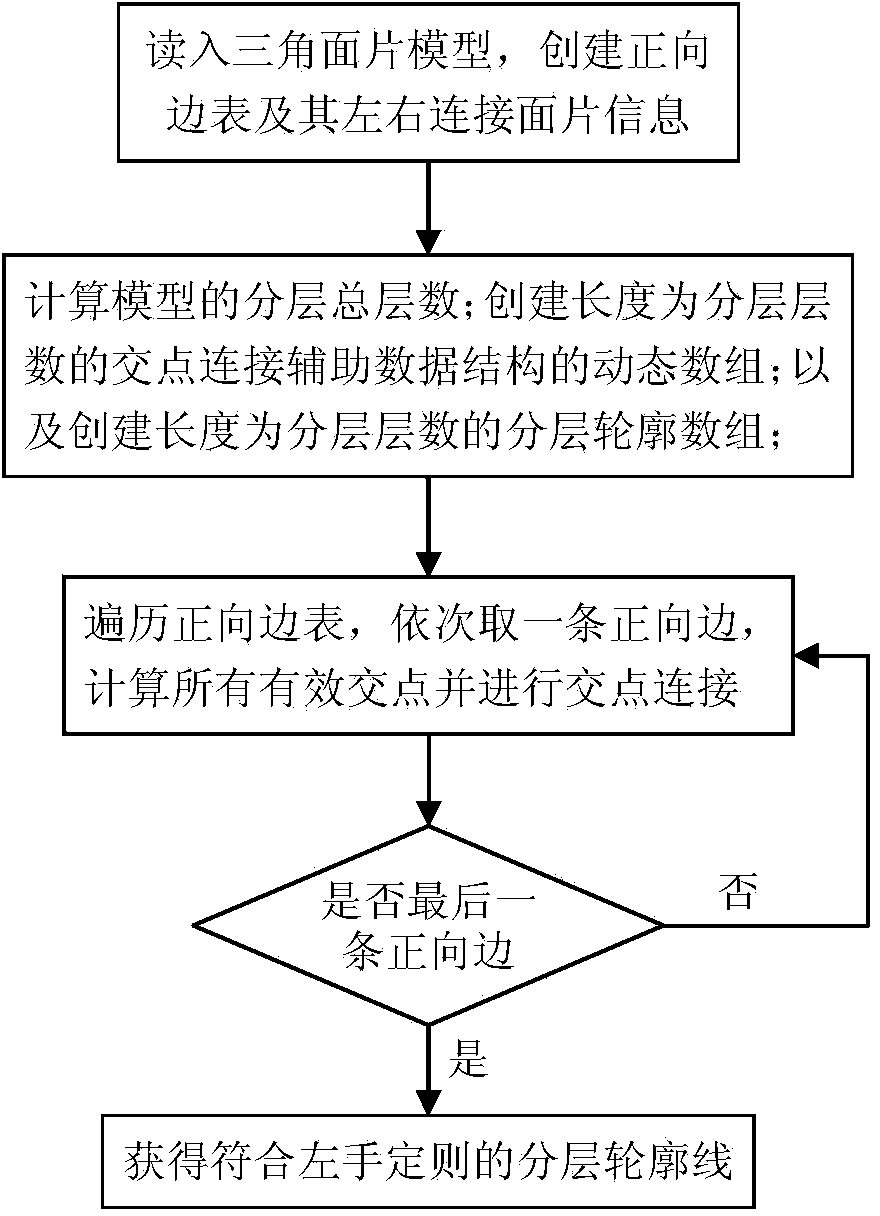

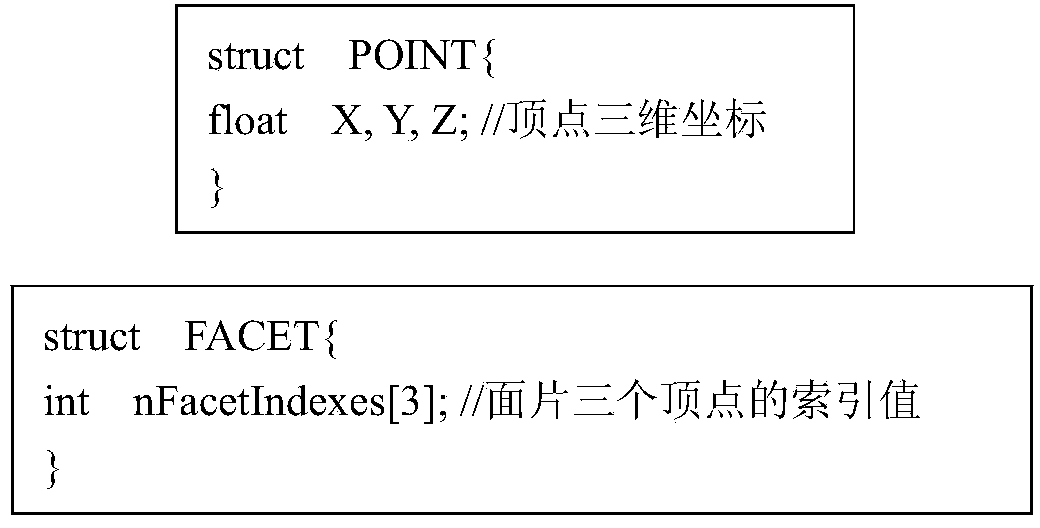

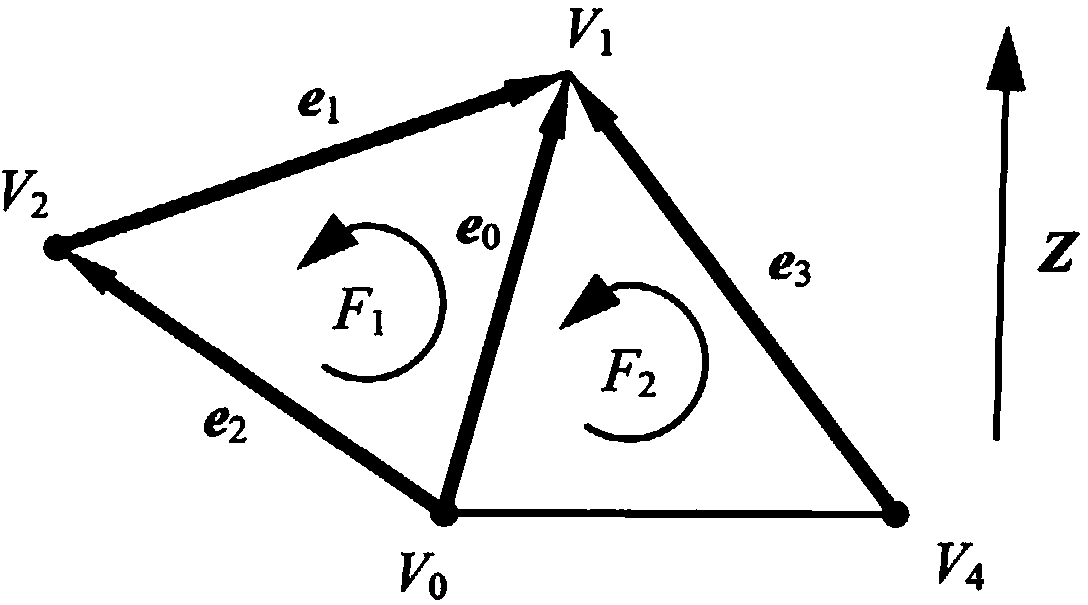

Edge-by-edge layering method of triangular patch model in rapid forming

ActiveCN103970949AImprove Layering EfficiencyGood connectionSpecial data processing applicationsInteraction pointArray data structure

The invention discloses an edge-by-edge layering method of a triangular patch model in rapid forming. The method comprises the steps: firstly, removing redundant points based on triangular patch model data read into an internal storage, and establishing a forward edge table, information of a left connection patch of the forward edge table and information of a right connection patch of the forward edge table; then, traversing the model to acquire the maximum Z value and the minimum Z value in the layering direction, and working out the total number N of layers of the model according to a preset layer thickness; establishing a dynamic array with an intersection point connection auxiliary data structure, and a layering contour array, wherein both the length of the dynamic array and the length of the layering contour array are equal to number N of the layers; thirdly, traversing the forward edge table, selecting forward edges sequentially, working out the intersection points of the edges and an intersection layering plane sequentially based on the geometric continuity of the edges, and executing the intersection point connection algorithm immediately every time when one effective interaction point is worked out; finally, processing all the forward edges to obtain a layering contour line with the contour line direction meeting the left-hand rule. By means of the method, the layering efficiency can be effectively improved.

Owner:HUAQIAO UNIVERSITY

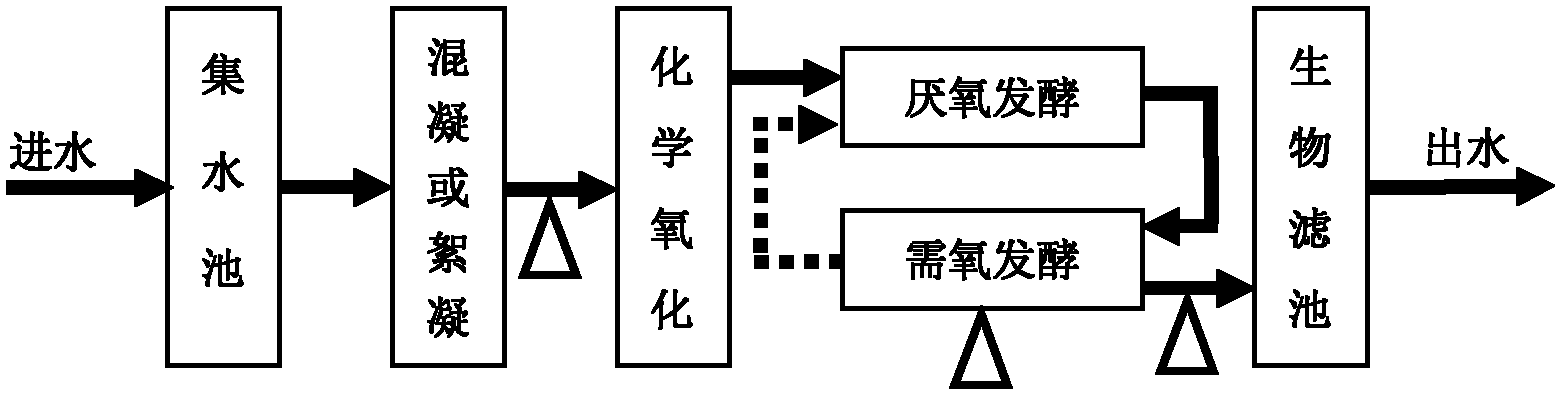

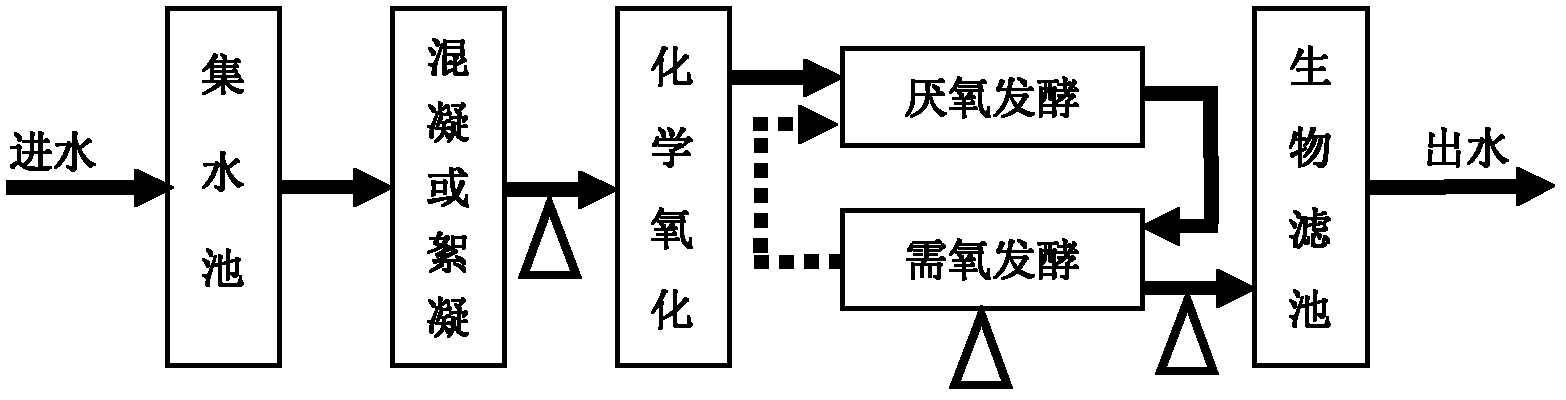

Harmless treatment method of coffeine-containing waste water and bacterium used in harmless treatment method

ActiveCN102604865AGood connectionRemove completelyTreatment using aerobic processesBacteriaLaboratory cultureCaffeine

The invention discloses pseudomonas putida CT2025 with preservation department of CGMCC (China General Microbiological Culture Collection Center) and preservation address of No.3, No.1 Institution, Beichen West Road, Chaoyang District, Beijing, Chinese Academy of Sciences Institute of Microbiology, and preservation date of February 17th, 2012 and preservation number of CGMCC No.5767. The invention also discloses a harmless treatment method of coffeine-containing waste water. The method comprises the following steps of: inoculating 0.8-1.2kg of pseudomonas putida in every 100ton of caffeine-containing waste water, and intervening and applying in any one of the following waste water treatment stages: aerobic treatment stage after anaerobic fermentation and application after the aerobic treatment on the waste water is finished.

Owner:ZHEJIANG UNIV

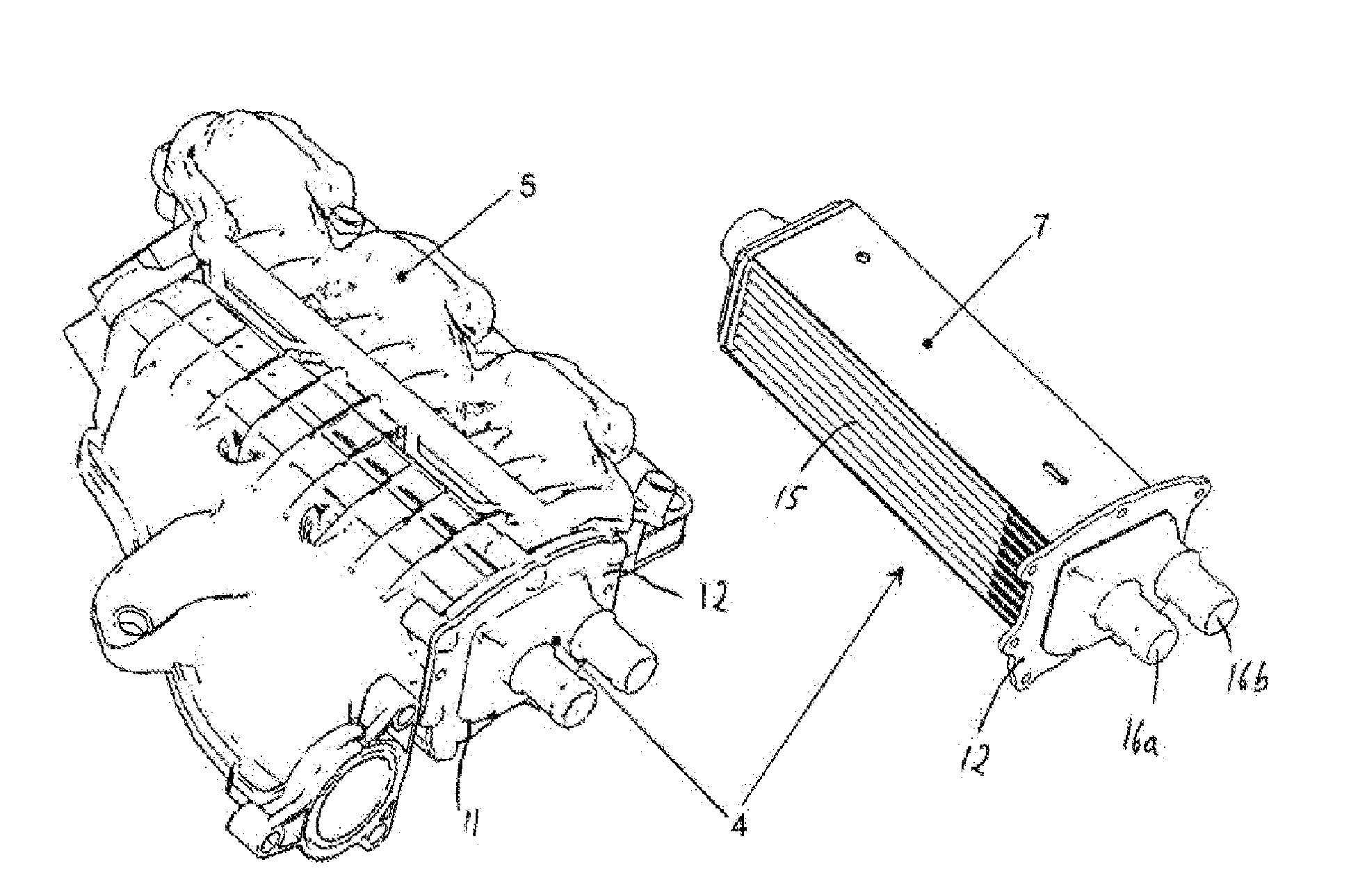

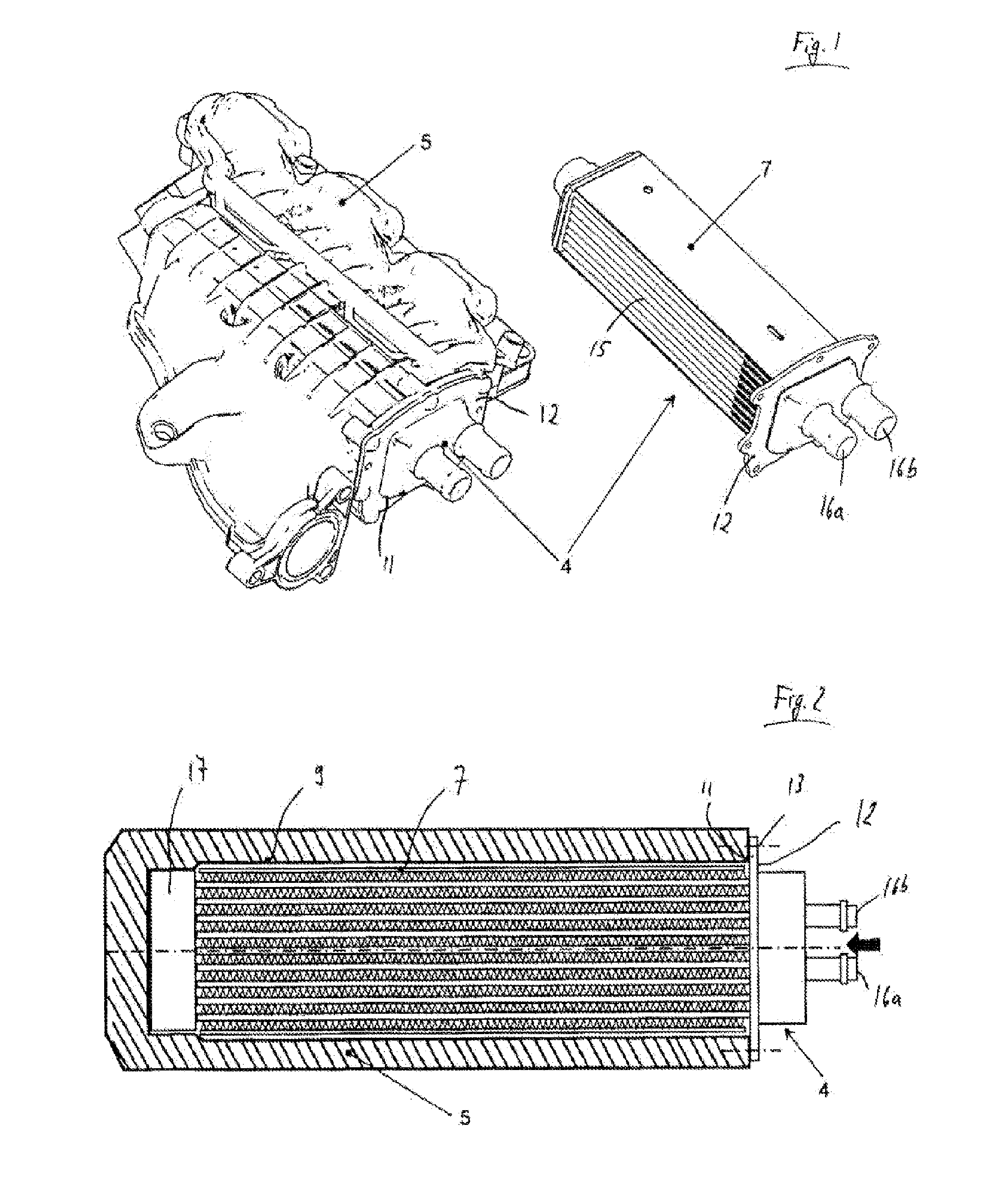

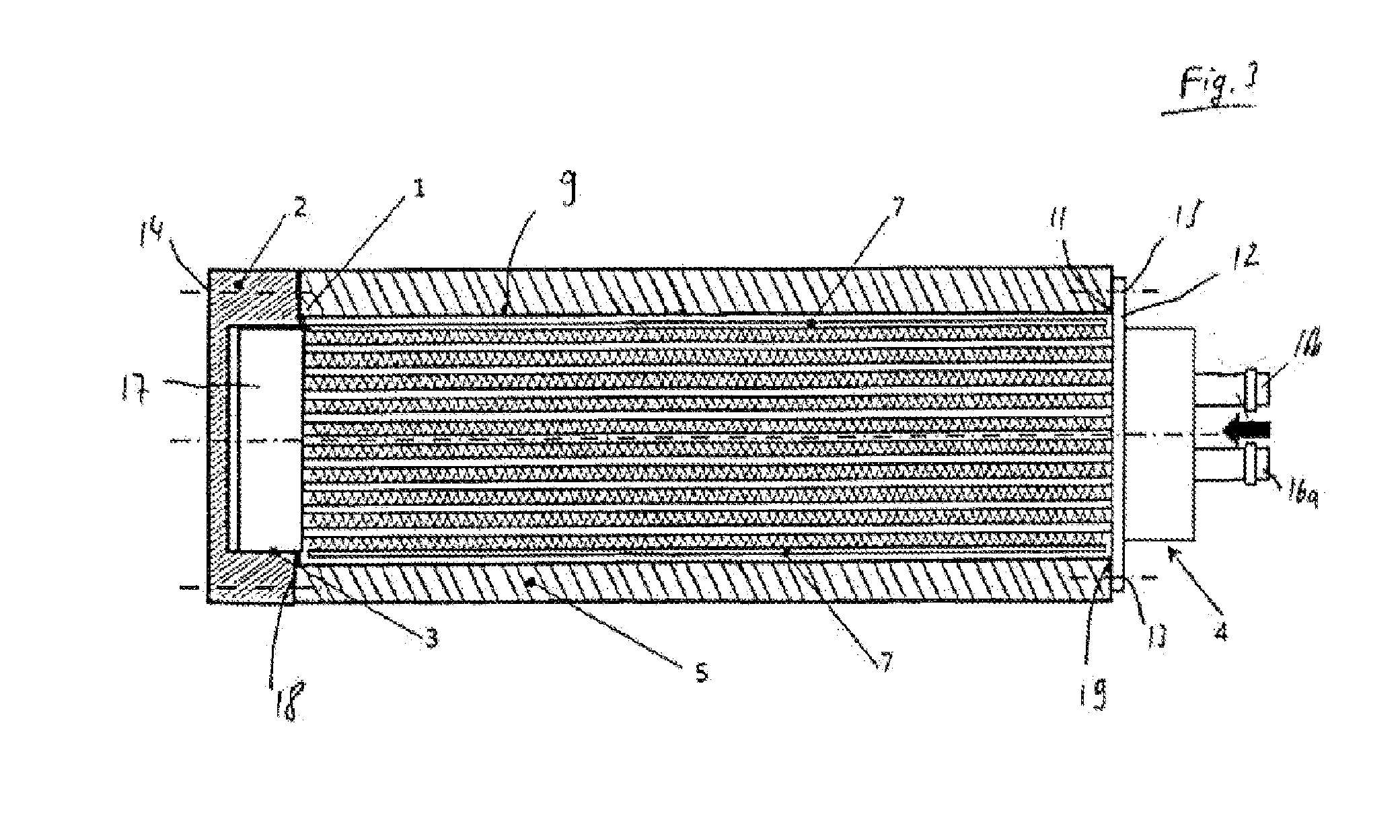

Arrangement of an intercooler in an intake pipe

InactiveUS20150059336A1Good connectionSimple and safe processInternal combustion piston enginesIntercoolerEngineering

Arrangement of an intercooler in an intake pipe, wherein the intercooler has a cooler block through which charge air can flow and a first opening through the intake pipe, through which the intercooler can be inserted into the intake pipe, wherein the intake pipe has a second opening, which is arranged substantially opposite the first opening and can be closed by means of a housing part.

Owner:BEHR GMBH & CO KG

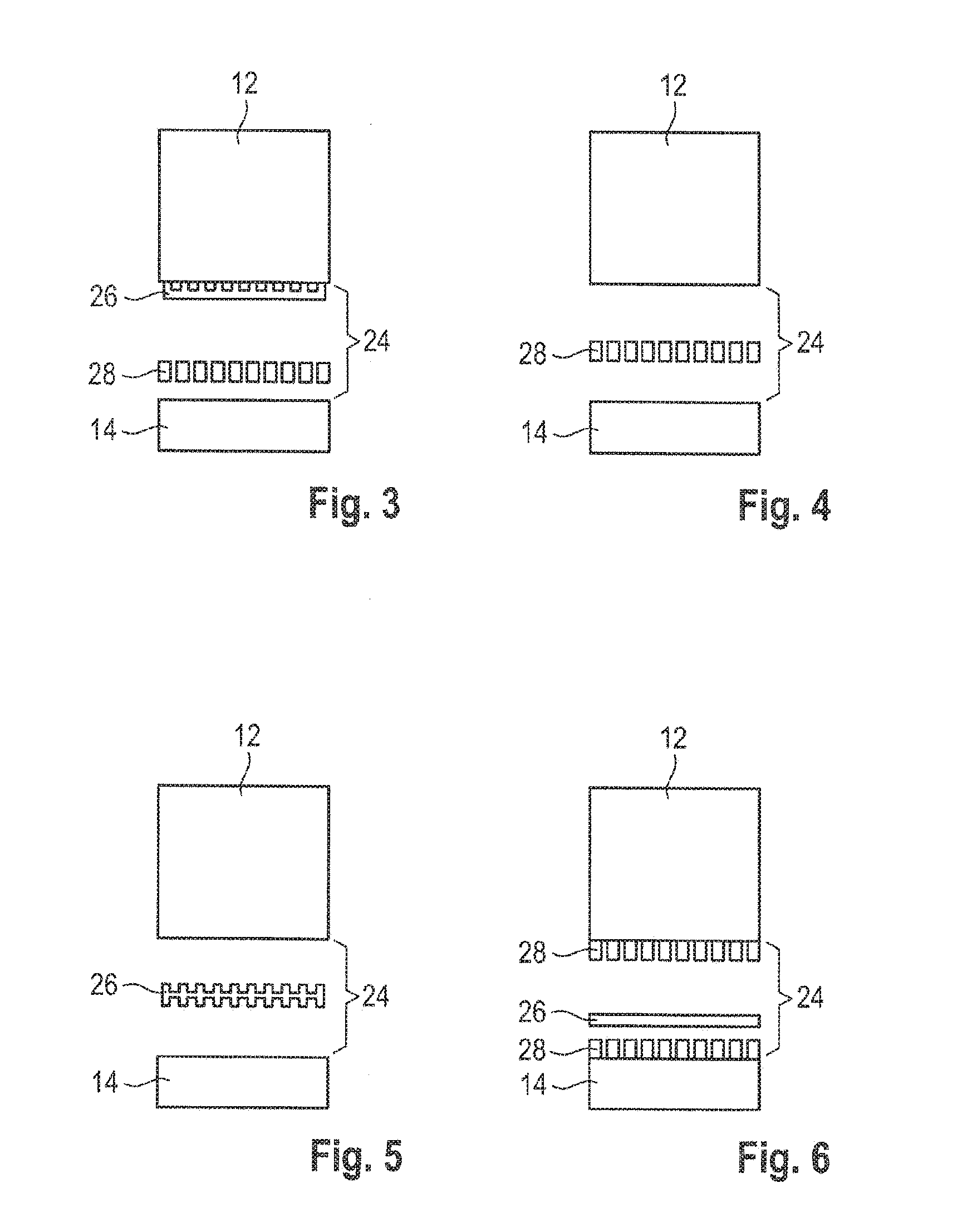

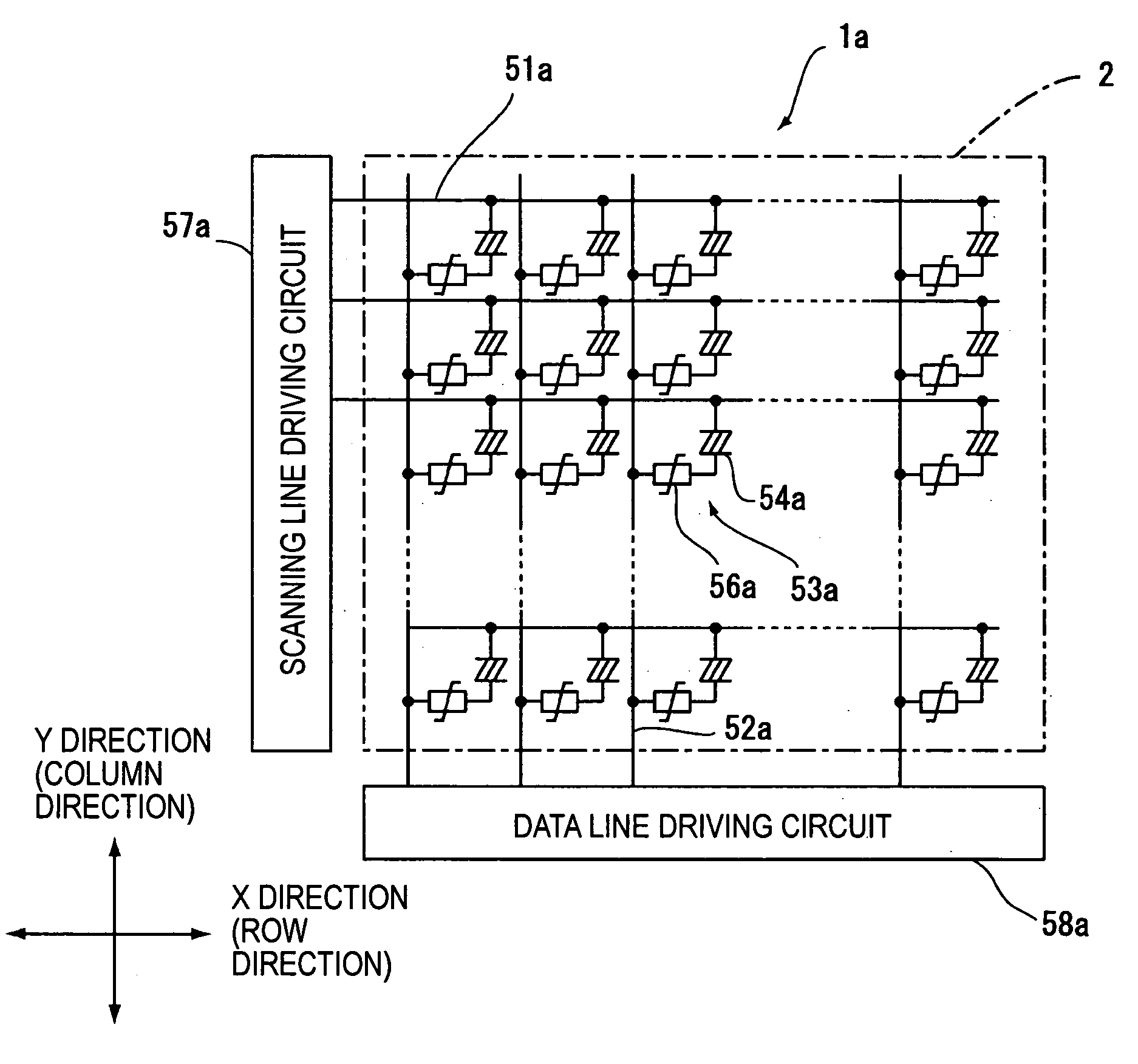

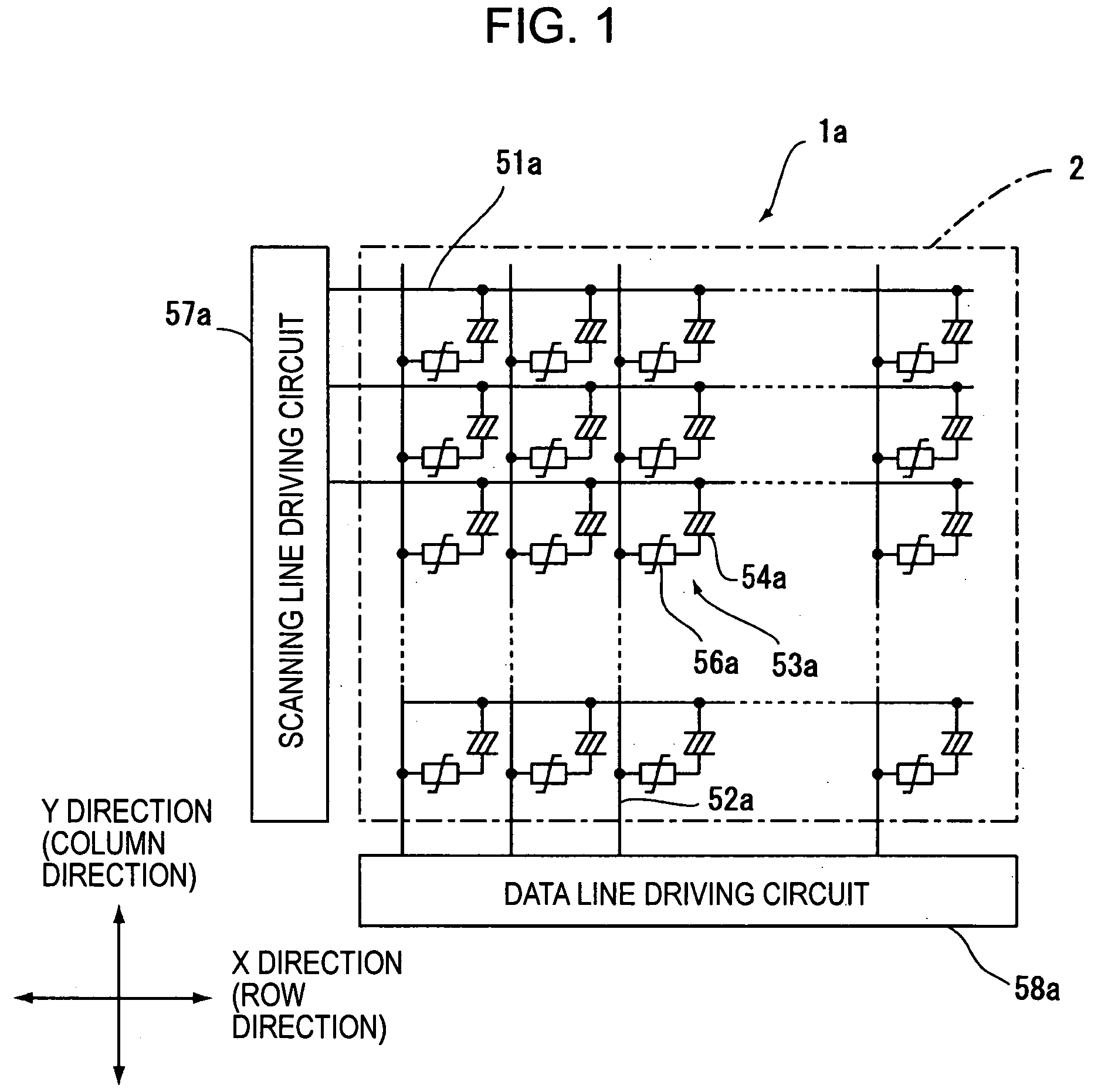

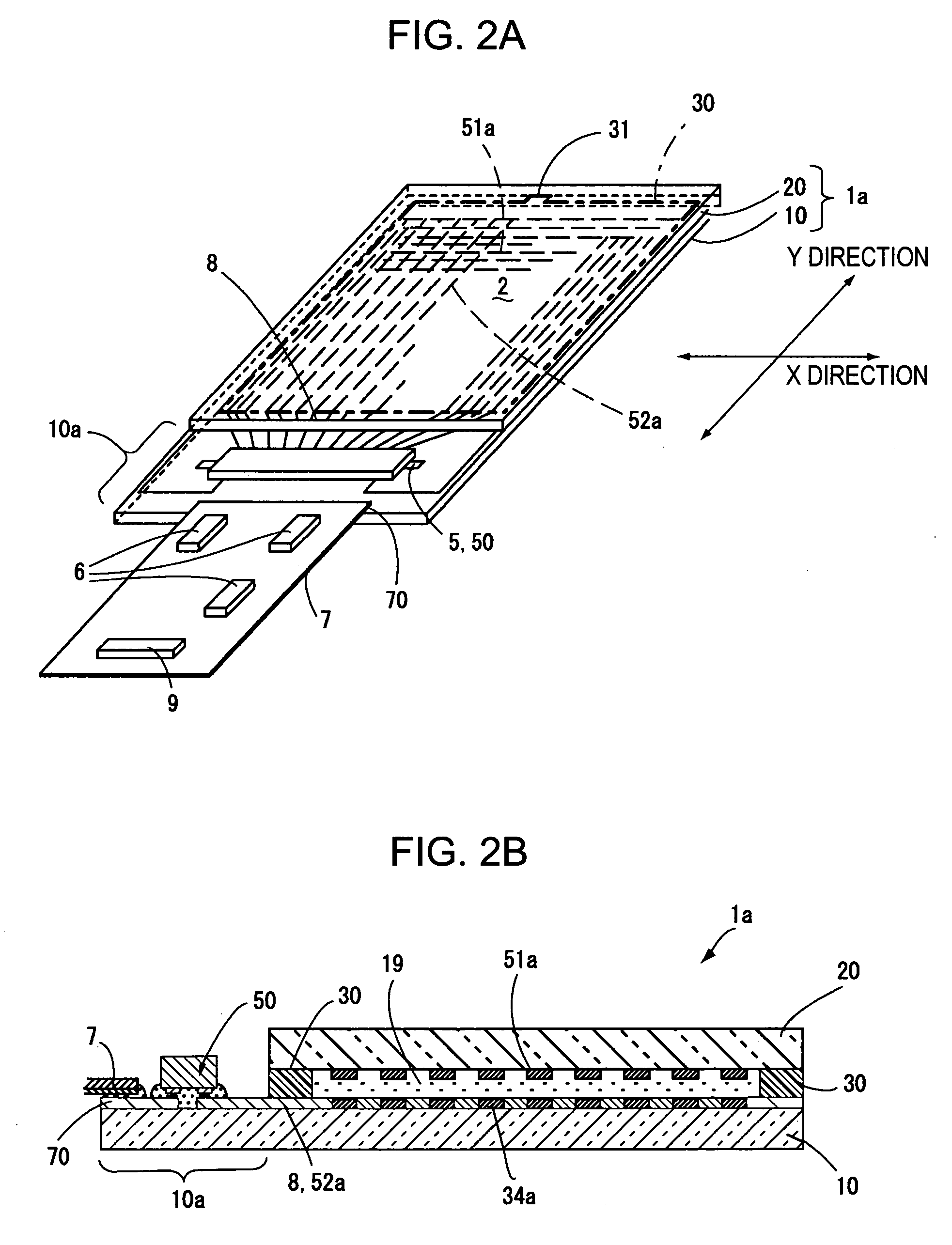

Electro-optical device, electronic apparatus, and mounting structure

ActiveUS20060020656A1Easily detectGood connectionComputing operations for integration/differentiationNon-linear opticsElectricityEngineering

Owner:BOE TECH GRP CO LTD

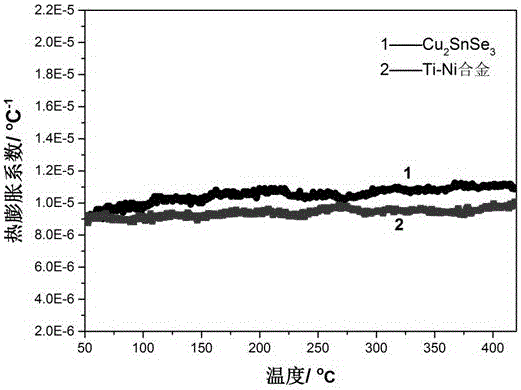

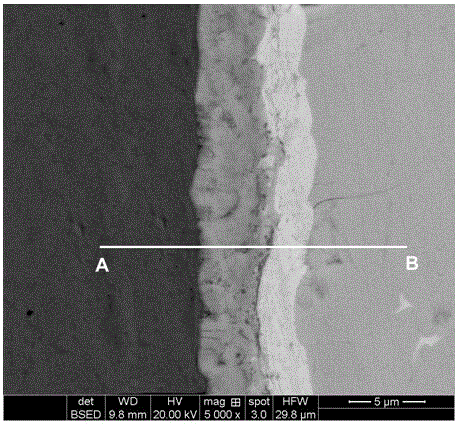

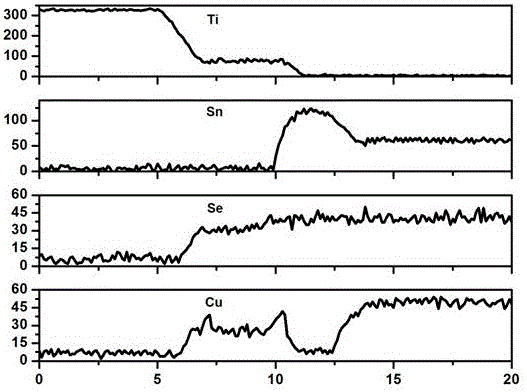

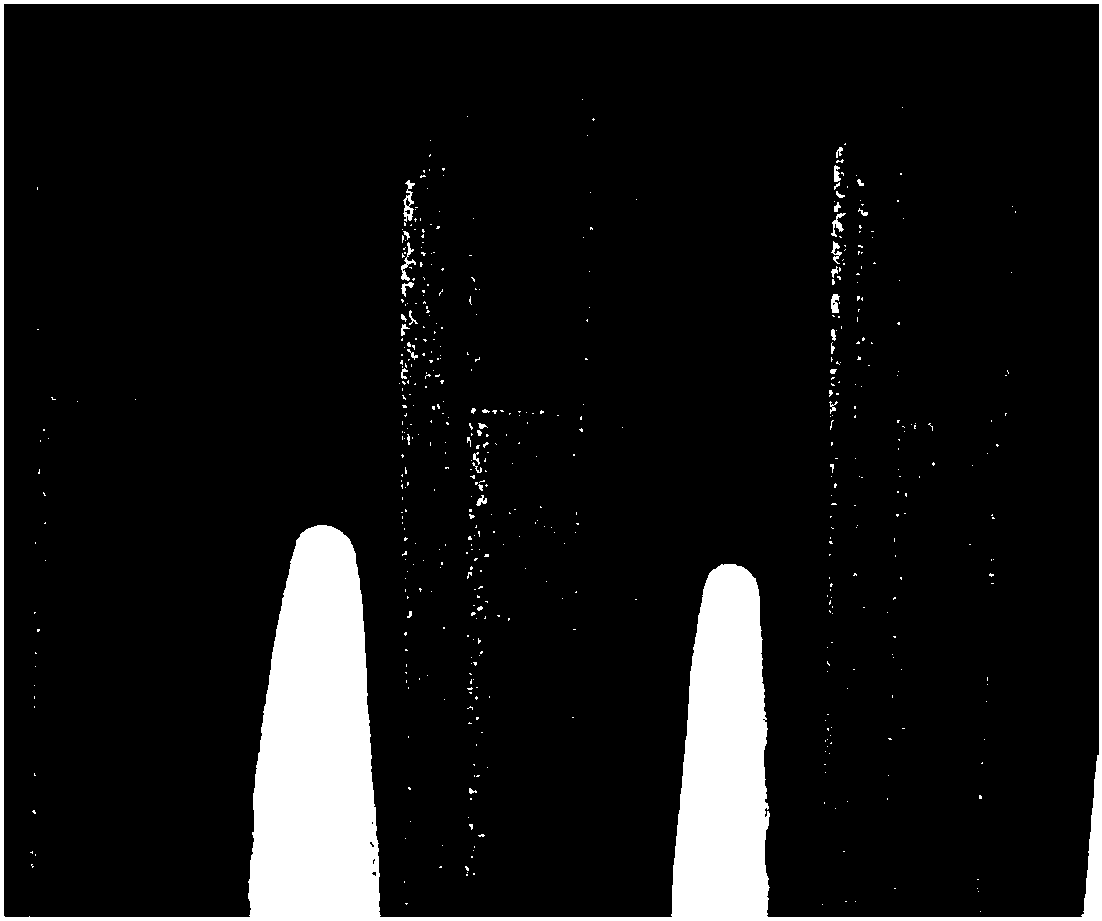

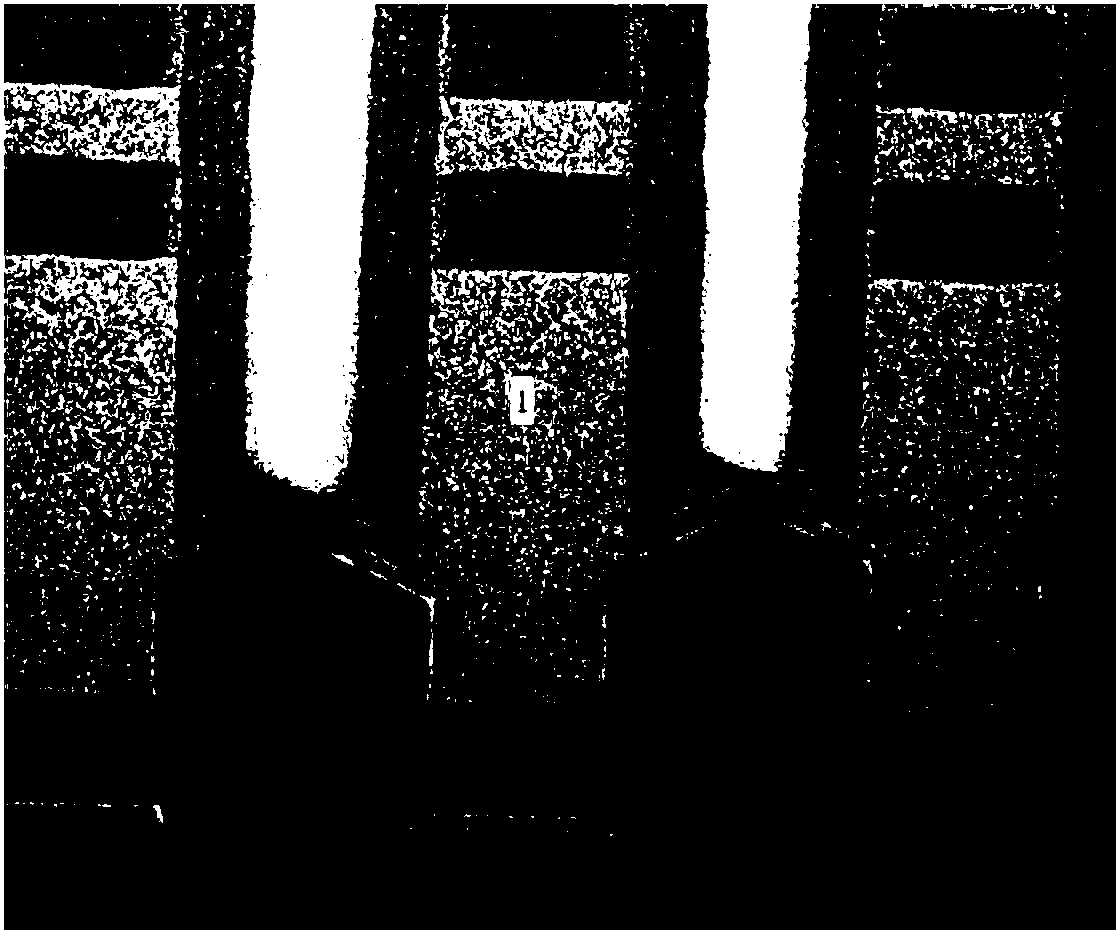

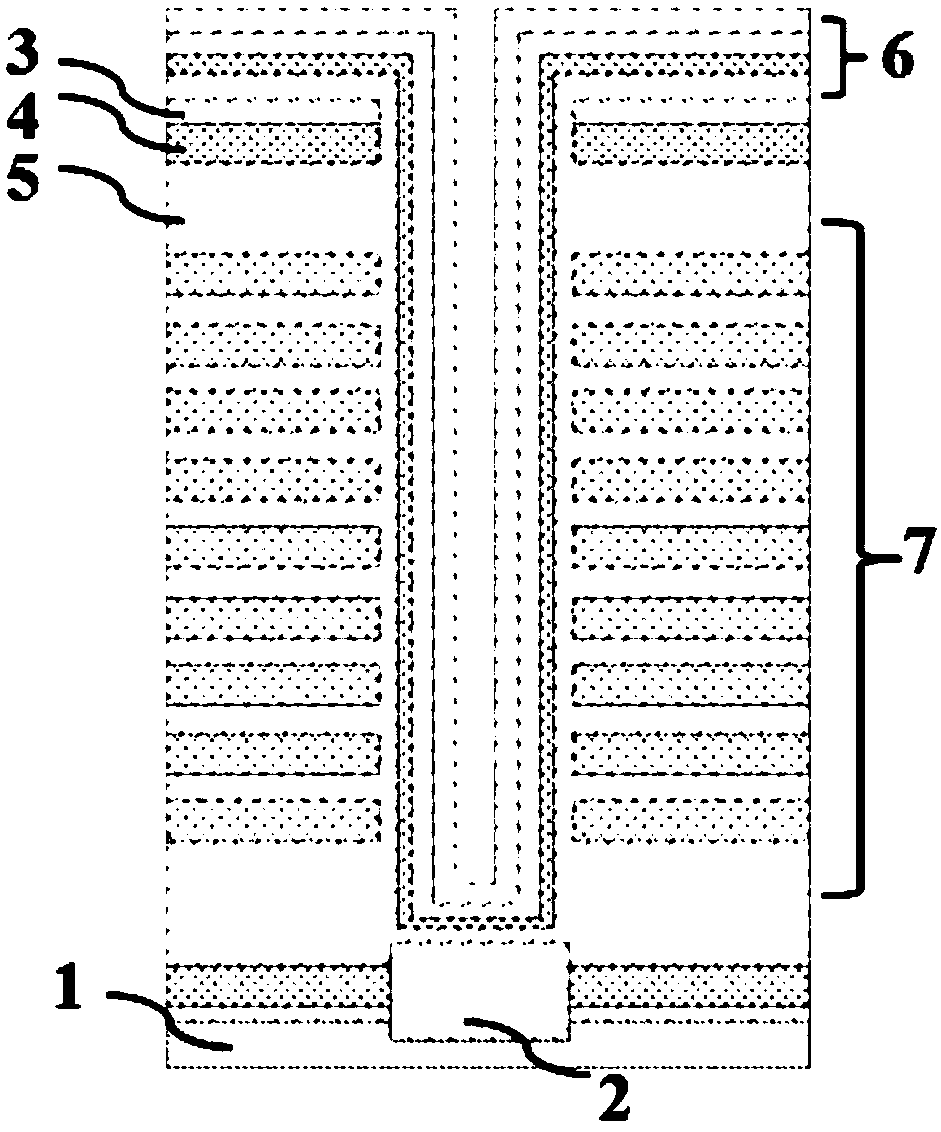

Alloy electrode suitable for Cu<2>SnSe<3>-based thermoelectric element and preparation technology of thermoelectric element

ActiveCN105679928AGood connectionWell combinedThermoelectric device manufacture/treatmentThermoelectric device detailsElectrode interfaceThermoelectric element

The invention relates to an alloy electrode matched with a p-type Cu<2>SnSe<3>-based thermoelectric material and a preparation technology of a Cu<2>SnSe<3>-based thermoelectric element. The alloy electrode is a Ti-Ni alloy, and has high electric conductivity and thermal conductivity. The Ti-Ni alloy provided by the invention has a coefficient of thermal expansion, which is very similar to that of the Cu<2>SnSe<3>-based thermoelectric material. According to preparation of the Cu<2>SnSe<3>-based thermoelectric element, the Cu<2>SnSe<3>-based thermoelectric element is formed by directly sintering the Cu<2>SnSe<3>-based thermoelectric material on the Ti-Ni alloy electrode by an (RHPS) technology; and an intermediate transition connection layer is not needed. The sintered electrode interface bonding is very stable; and the Cu<2>SnSe<3> / electrode interface is free of obvious resistance transition. The preparation technology is simple, is very suitable for preparation of the Cu<2>SnSe<3>-based thermoelectric element and can be applied to large-scale production and preparation.

Owner:UNIV OF JINAN

SONO etching technology with ultrahigh depth-to-width radio

ActiveCN107731750AGood connectionIncreased process windowSolid-state devicesSemiconductor/solid-state device manufacturingSilicon nitrideTwo step

The invention provides a SONO etching technology. According to the technology, by changing the structure of a film layer in the prior art on one hand and optimizing a conventional single-step etchingtechnology to the two-step etching technology on the other hand, it is ensured that all SONO holes are opened in an etching process, so that good connection among the channel holes and epitaxial silicon on the bottom is achieved; meanwhile, it is guaranteed that hard-mask silicon nitride on the side walls of the channel holes is not damaged, the technology window of a subsequent manufacturing procedure is increased, and then the performance of a product is improved.

Owner:YANGTZE MEMORY TECH CO LTD

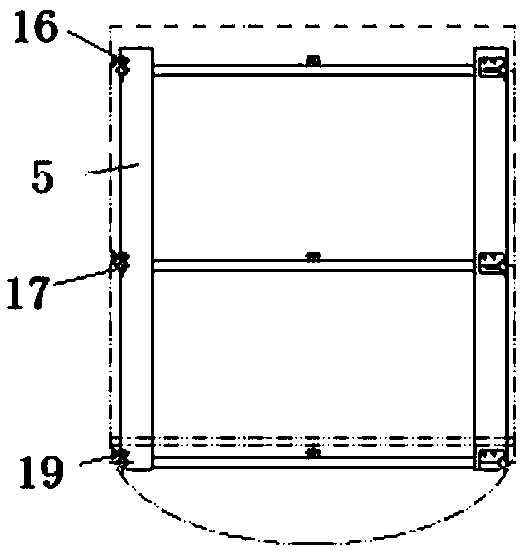

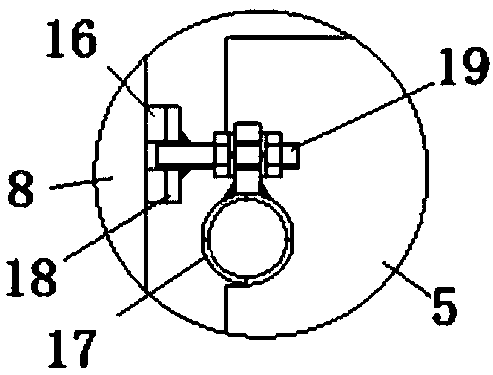

Prefabricated energy pipe pile joint

PendingCN109083142AGood connectionReasonable structural designBulkheads/pilesEngineeringStructural engineering

The invention relates to a prefabricated energy pipe pile joint. The pipe pile joint comprises a hook part arranged on an upper pile section and a slot part arranged on a lower pile section, wherein the hook part comprises a plurality of hook bodies arranged on the lower end face of the upper pile section at intervals; the top ends of main bodies of the hook bodies can be arranged on the upper pile section in an axial up and down movement manner; the bottom ends of the main bodies extend downwards vertically and are bent upwards to form hooks; the slot part comprises a plurality of notches formed in the lower pile section; the notches correspond to the hook bodies one to one; a plurality of upper openings penetrating in an axial direction of the upper pile section are formed in the upper pile section; a plurality of lower openings penetrating in an axial direction of the lower pile section are formed in the lower pile section; the upper openings correspond to the lower openings one toone; and one upper opening and one corresponding lower opening penetrate vertically to form a channel allowing a pipeline to pass through. According to the joint, a pipe pile is connected by a mechanical connecting structure; and the joint is not influenced by worker operation, and has the advantages of convenience and good connecting effect.

Owner:ZHEJIANG UNIV OF TECH

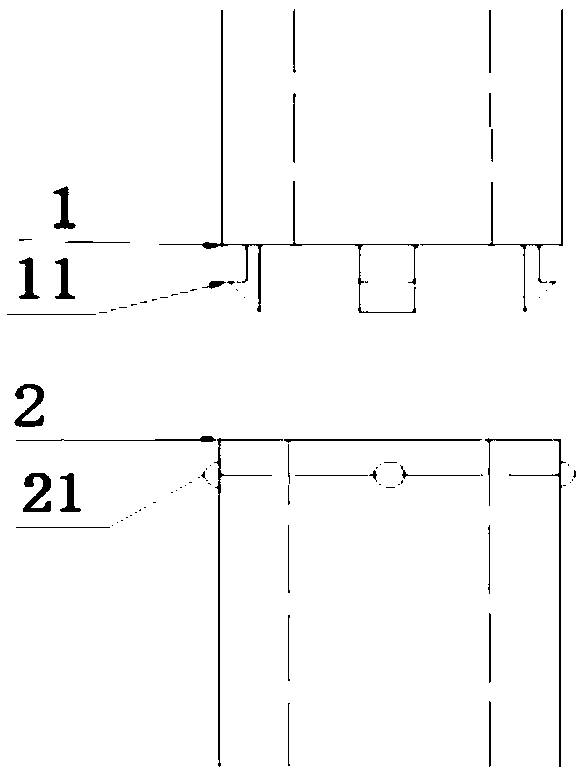

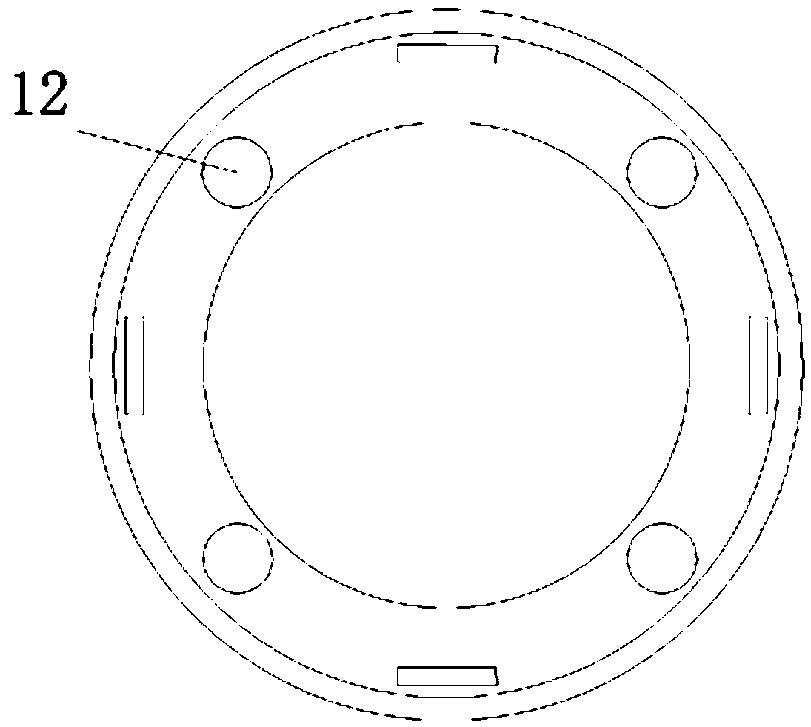

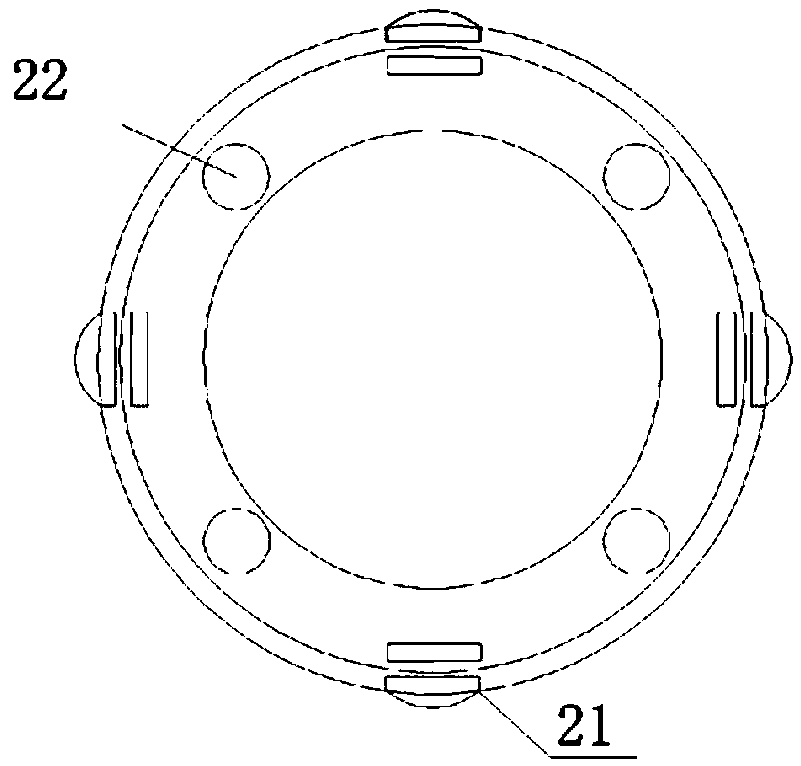

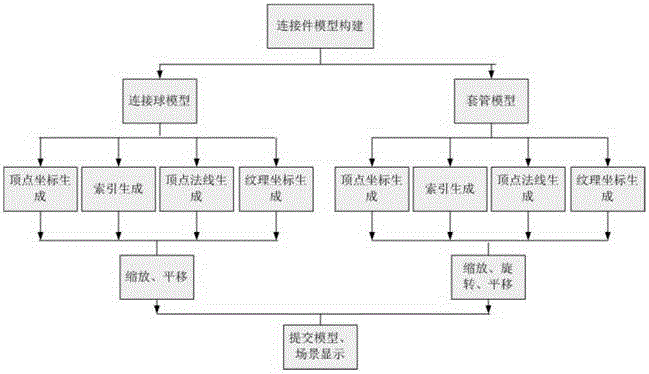

Constructing method for three-dimensional pipeline model connecting piece model

InactiveCN106469466AThe pipeline connection is beautifulGood connectionDetails involving 3D image data3D-image renderingInformation systemEngineering

The invention relates to the space information system technology field and discloses a constructing method for three-dimensional pipeline model connecting piece model. The method comprises the following steps: 1) constructing a connecting piece model in which a connecting ball model is created and a sleeve tube model is created; 2) controlling the position and the shape of the connecting piece model in which operations are made to the connecting ball model and the sleeve tube model; and 3) controlling the appearance attributes of the connecting piece model. The invention is used for smoothing process to package a pipeline mouth at the starting terminal or the ending terminal of the pipeline where a connecting ball or a sleeve tube are used. When two pipelines are aligned with an angle of 180 degrees at the aligning position, the sleeve tube can completely wrap the connecting ball and realize the smooth alignment of the two pipelines, making the pipelines connected with better looking. When the pipelines are aligned with an angle of other degrees, the connecting ball is apparently visible from the outer side of the bended point so that the two pipelines can transit naturally. When three or more pipelines are connected, the sleeve component of the invention can achieve a good connection effect.

Owner:ZHEJIANG KELAN INFORMATION TECH CO LTD

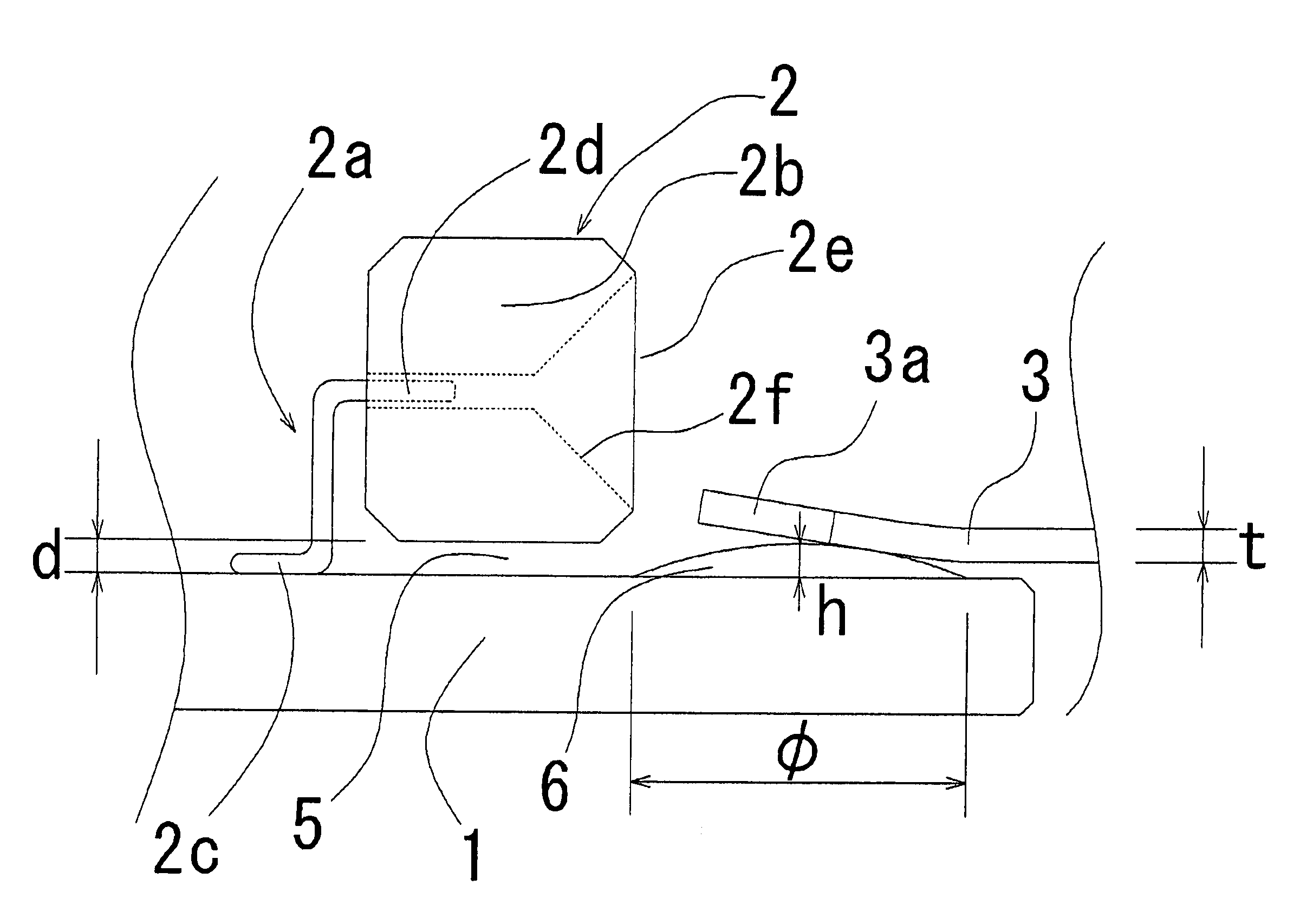

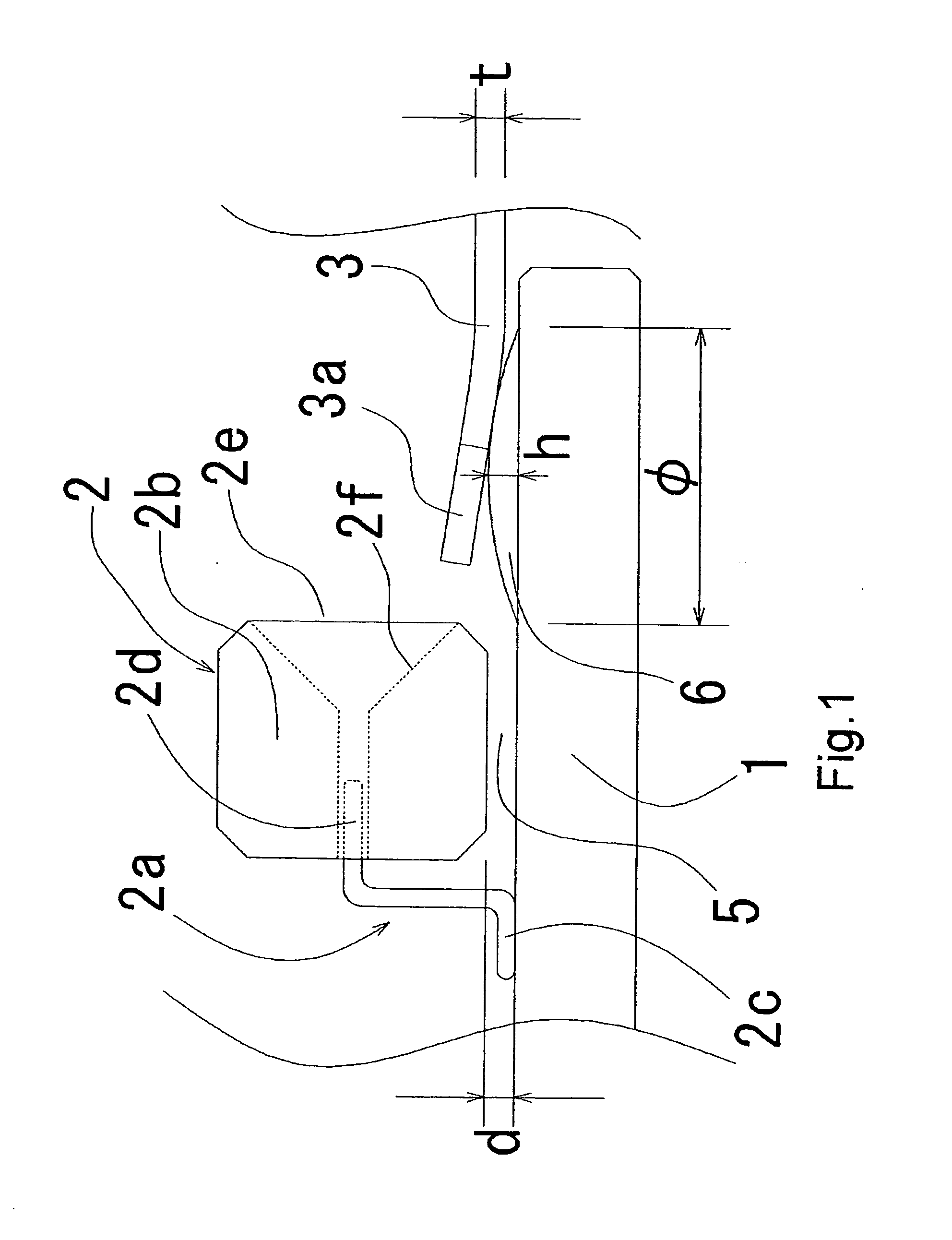

Electric equipment

InactiveUS20060057870A1Avoid gapsGood connectionEngagement/disengagement of coupling partsIncorrect coupling preventionPrinted circuit boardElectronic equipment

In order to prevent any erroneous insertion of a thin circuit board 3 into a gap 5 formed between a main circuit board 1 and a connector 2 when the thin circuit board 3 is inserted into an inserting port 2e formed at the connector 2 fixed at a mounting surface of the main circuit board 1 by electric connection, a guide 6 is formed by applying solder onto the mounting surface of the main circuit board 1 and in the vicinity of the inserting port 2e. The guide 6 can prevent any insertion of the thin circuit board 3 into the gap 5.

Owner:NIDEC CORP

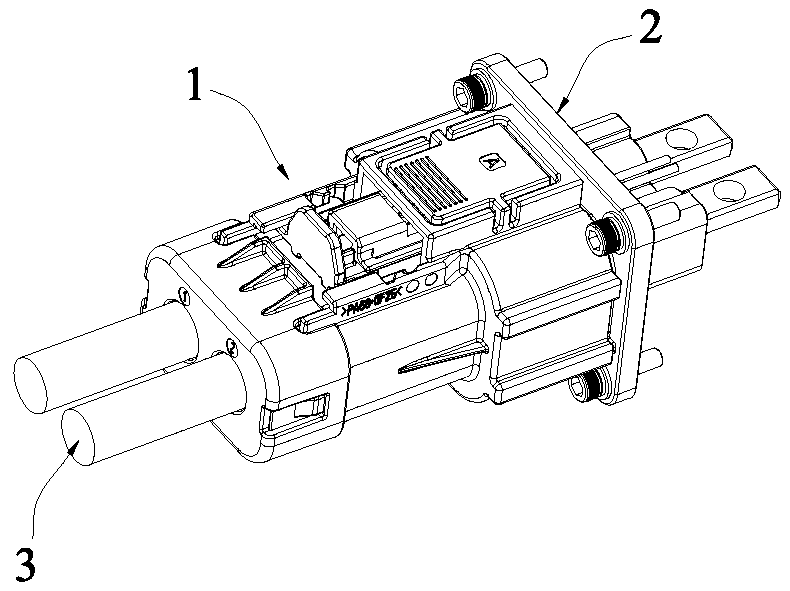

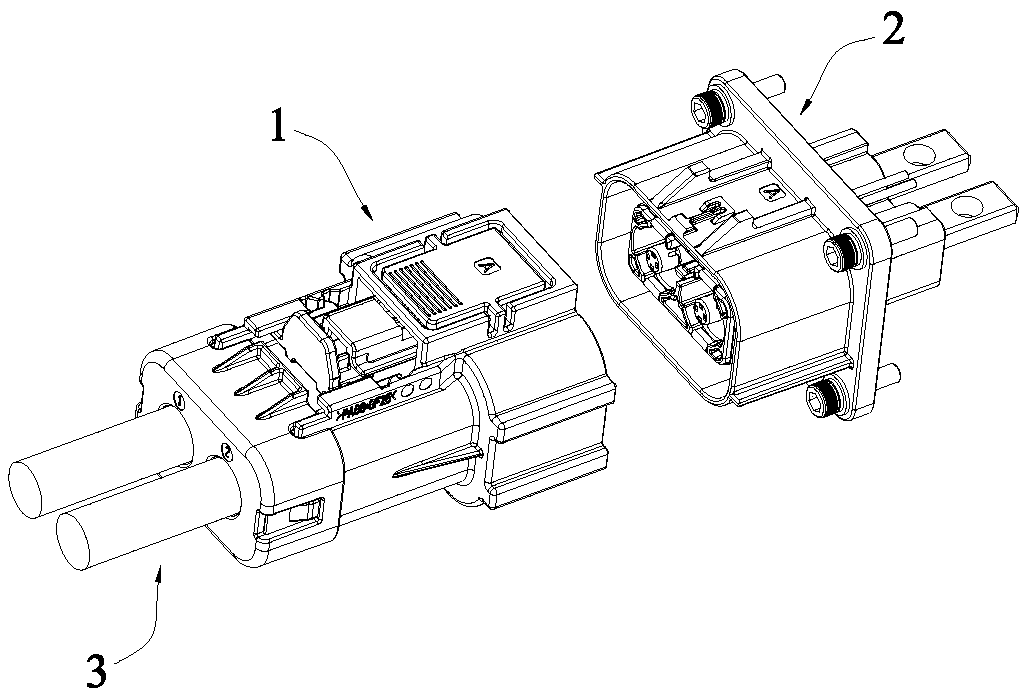

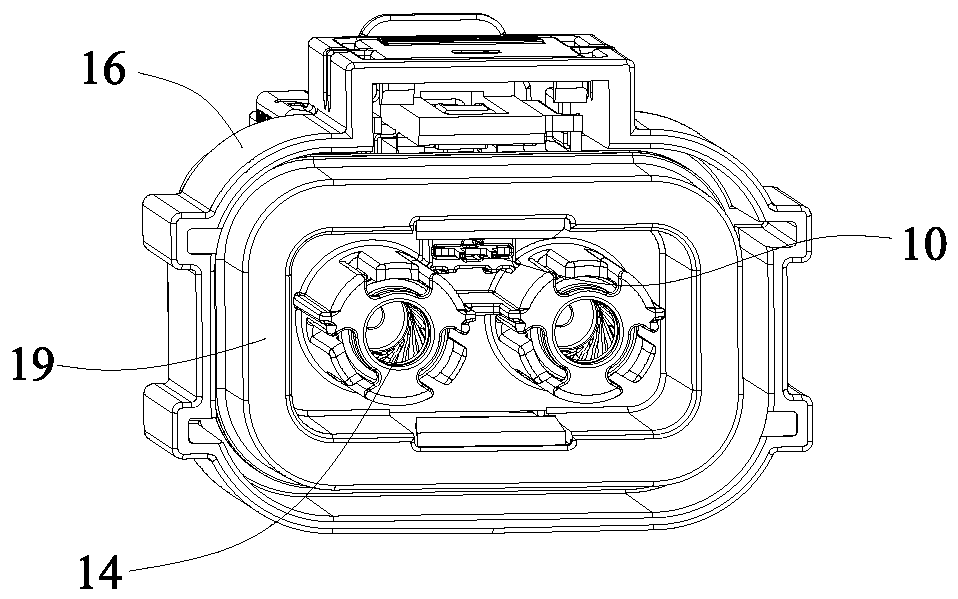

Plastic straight-head high-voltage connector

PendingCN108933351AIngenious structural designGood connectionVehicle connectorsIncorrect coupling preventionEngineeringHigh pressure

The invention discloses a plastic straight-head high-voltage connector, which comprises a plug assembly and a socket assembly, wherein the plug assembly comprises a tail cover, a cable waterproof ring, shielding rings, jack sleeves, a position guaranteeing part, a plug shell, a head waterproof ring, a plug shielding cover, a plug rubber core and signal pins; and the socket assembly comprises a socket shell, a signal jack piece, a socket waterproof ring and a socket shielding cover. As the position guaranteeing part is arranged reasonably, accurate abut joint between the plug assembly and the socket assembly can be ensured, and the connection effects are good; through match between a positioning slot and an external sleeve part and match between a connector and an internal sleeve part, thecoupling is tighter, falling is not easy, and the match stability is enhanced; the shielding effects are good, external interference is reduced, the sealing effects are good, the possibility of entering of water and dust is thus reduced, the working reliability is effectively ensured, the service life is long, and besides, a man hand can be prevented from touching the jack sleeve or the connectionpin due to error operation, the use safety is greatly improved, and wide promotion and application are facilitated.

Owner:广州连捷新能源科技有限公司

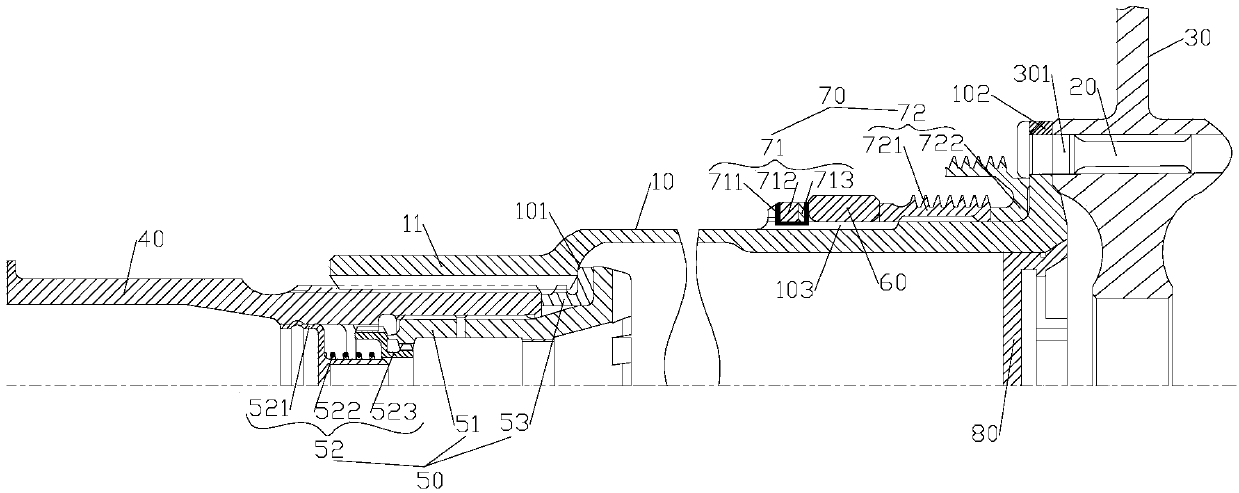

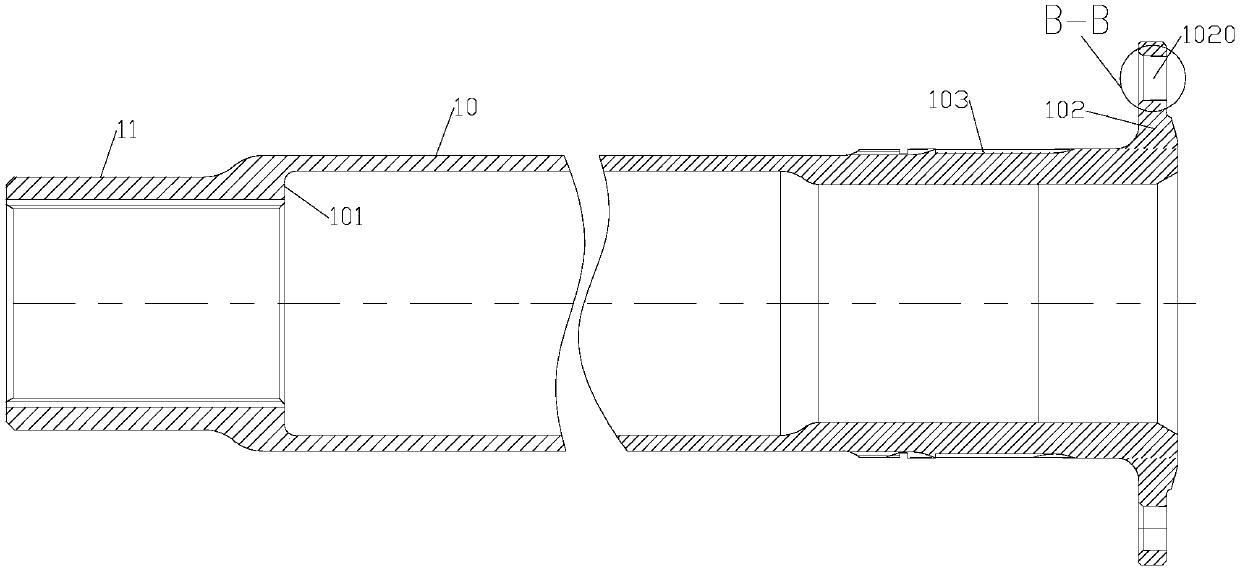

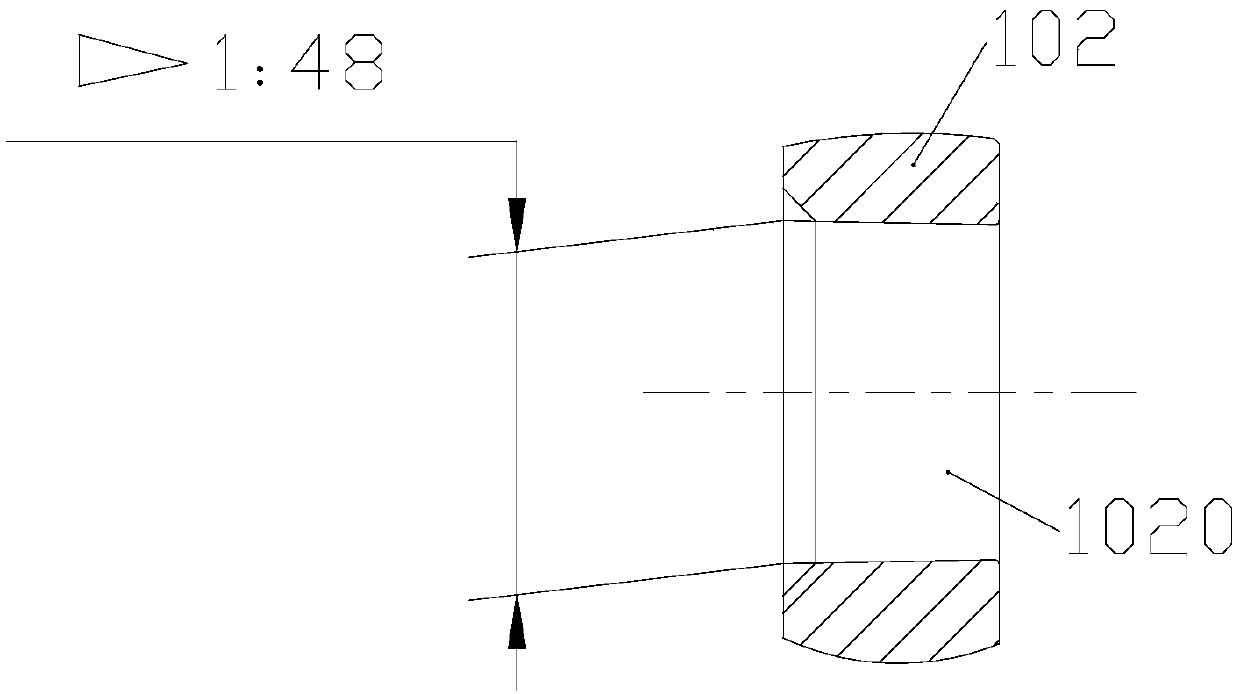

Fiber-optic probe

InactiveUS20100049019A1Limiting force exertedGood connectionCatheterDiagnostic recording/measuringOxygen Saturation MeasurementBiomedical engineering

In a fiber-optic probe for intravascular measurements, e.g. oxygen saturation measurements, the fiber-optical core has only two fibers. A single fiber core is also possible. A reinforcement fiber improves stiffness, kink resistance and overall strength of the probe. The reinforcement fiber is arranged essentially parallel to the core fibers. The reinforcement fiber may also be wound around the core in a helical manner thus improving the mechanical properties to an even higher degree. The outside of the sheath is coated with an antithrombogenic coating for reducing the danger of clots forming at the surface. The reinforcement fiber may be made of carbon, metal, ceramics or aramide.

Owner:PULSION MEDICAL SYSTEMS SE

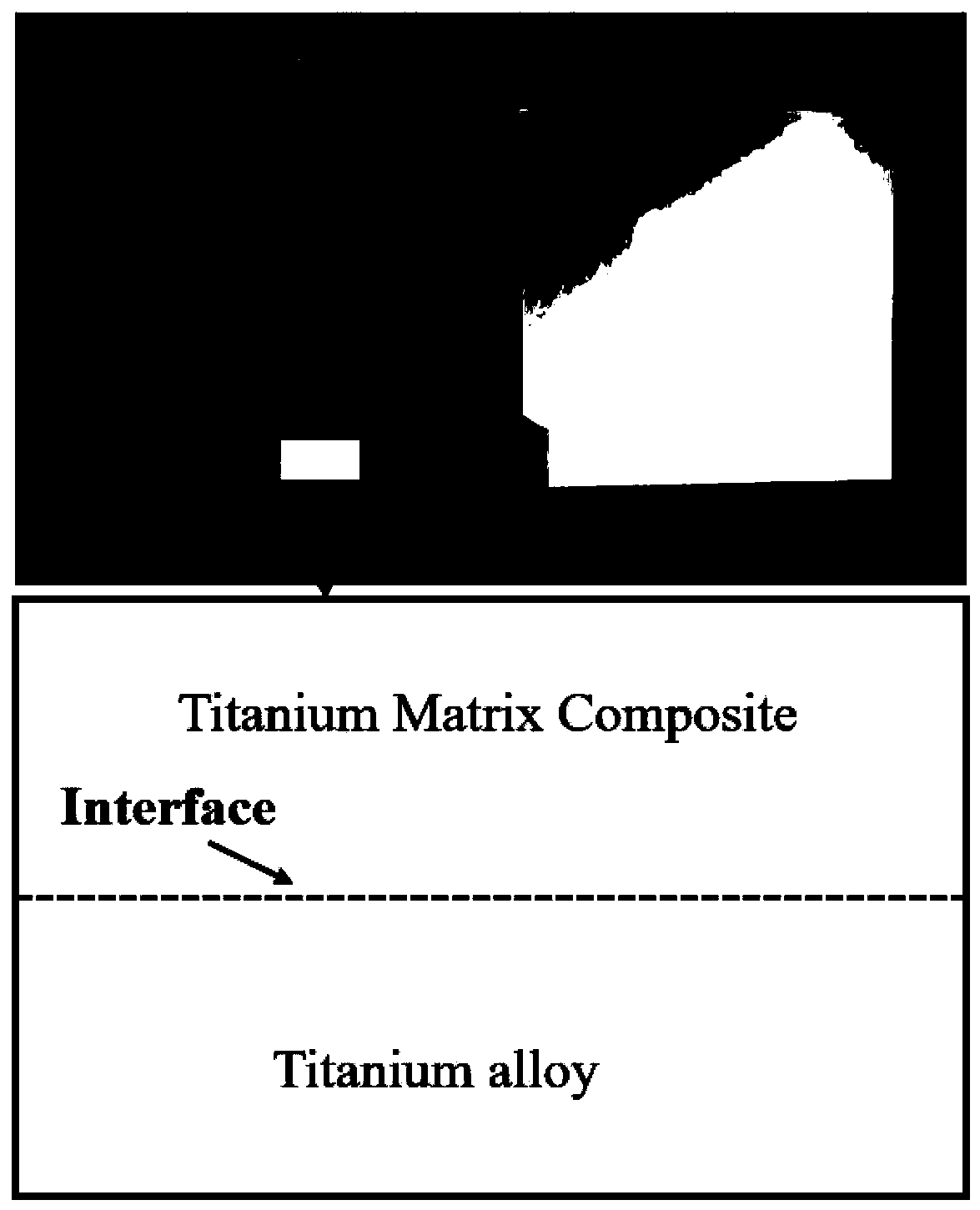

In-situ synthesized titanium-based composite material composite laminated component, and preparation method and application thereof

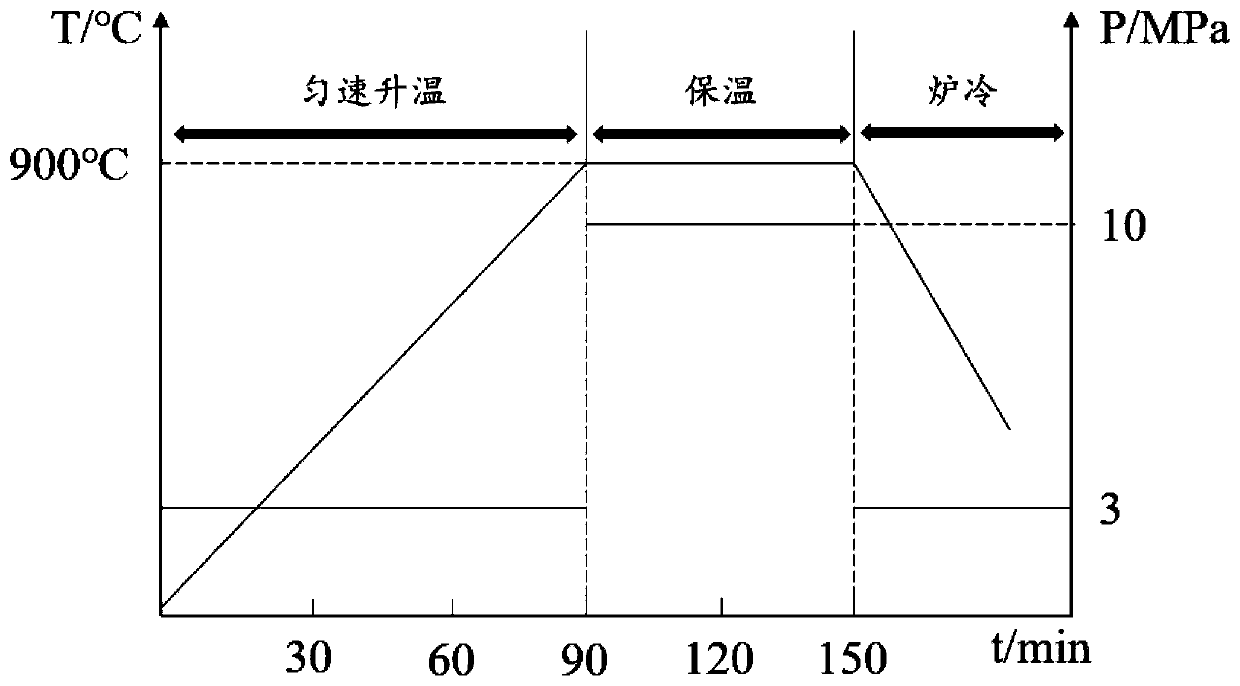

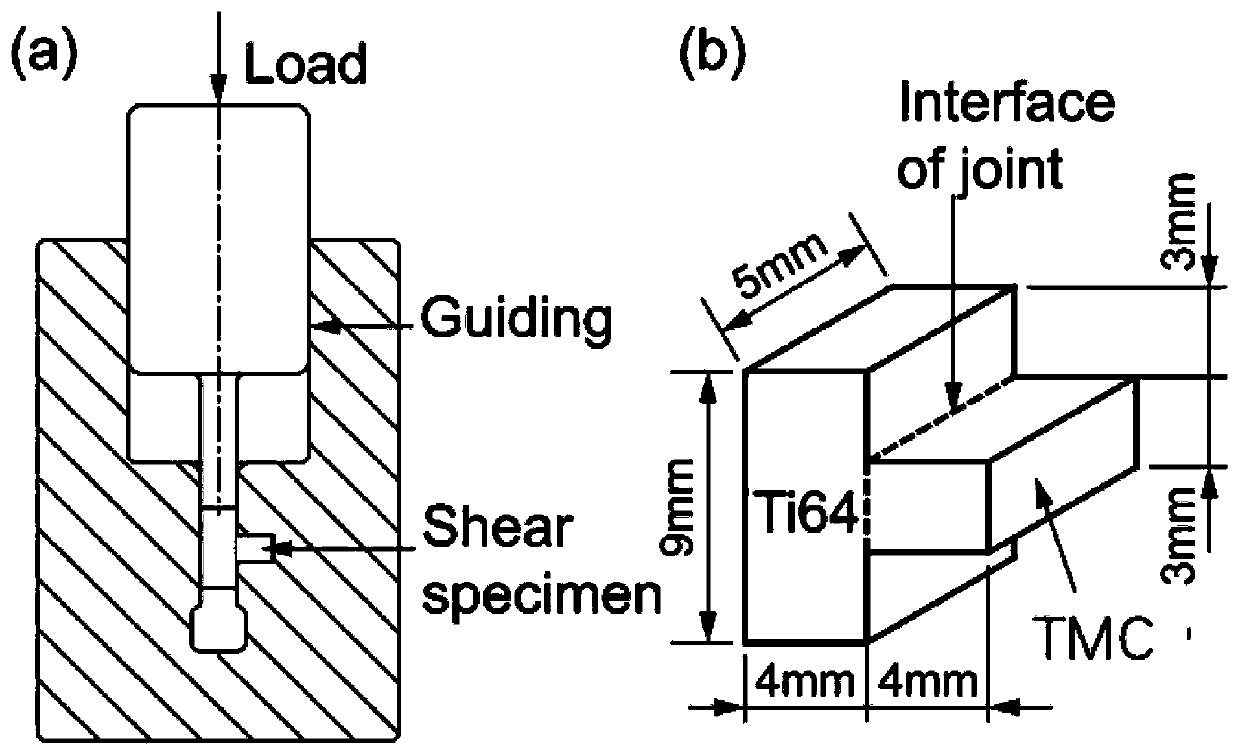

ActiveCN111590997AReduce oxidationGood connectionLamination ancillary operationsLaminationPlastic propertySurface preparation

The invention discloses a preparation method of an in-situ synthesized titanium-based composite material composite laminated component, and relates to the field of metal-based composite materials. Themethod comprises the following steps: A, carrying out linear cutting machining on a titanium alloy base material and a titanium-based composite material plate sample; B, performing surface treatmenton the plate sample; C, tightly attaching at least one layer of the titanium alloy base material and at least one layer of the titanium-based composite material plate sample to obtain a composite plate component, and coating the surface of the composite plate component with a BN solution, putting the coated component into a pressure mold, and fixing; and D, carrying out heat insulation on the composite board component at 850-950 DEG C under 5-15 MPa for 0.5-1.5 h to obtain the titanium-based composite material double-layer board or multi-layer board component without the interface cavity defect. The interface shear strength of the composite component is 640-670 MPa, the composite component has good strength and plasticity, a new solution is provided for machining of the high-strength-and-toughness titanium-based composite component, and the composite component has far-reaching strategic significance in preparation of the ultrahigh-strength multi-layer composite component.

Owner:SHANGHAI JIAO TONG UNIV

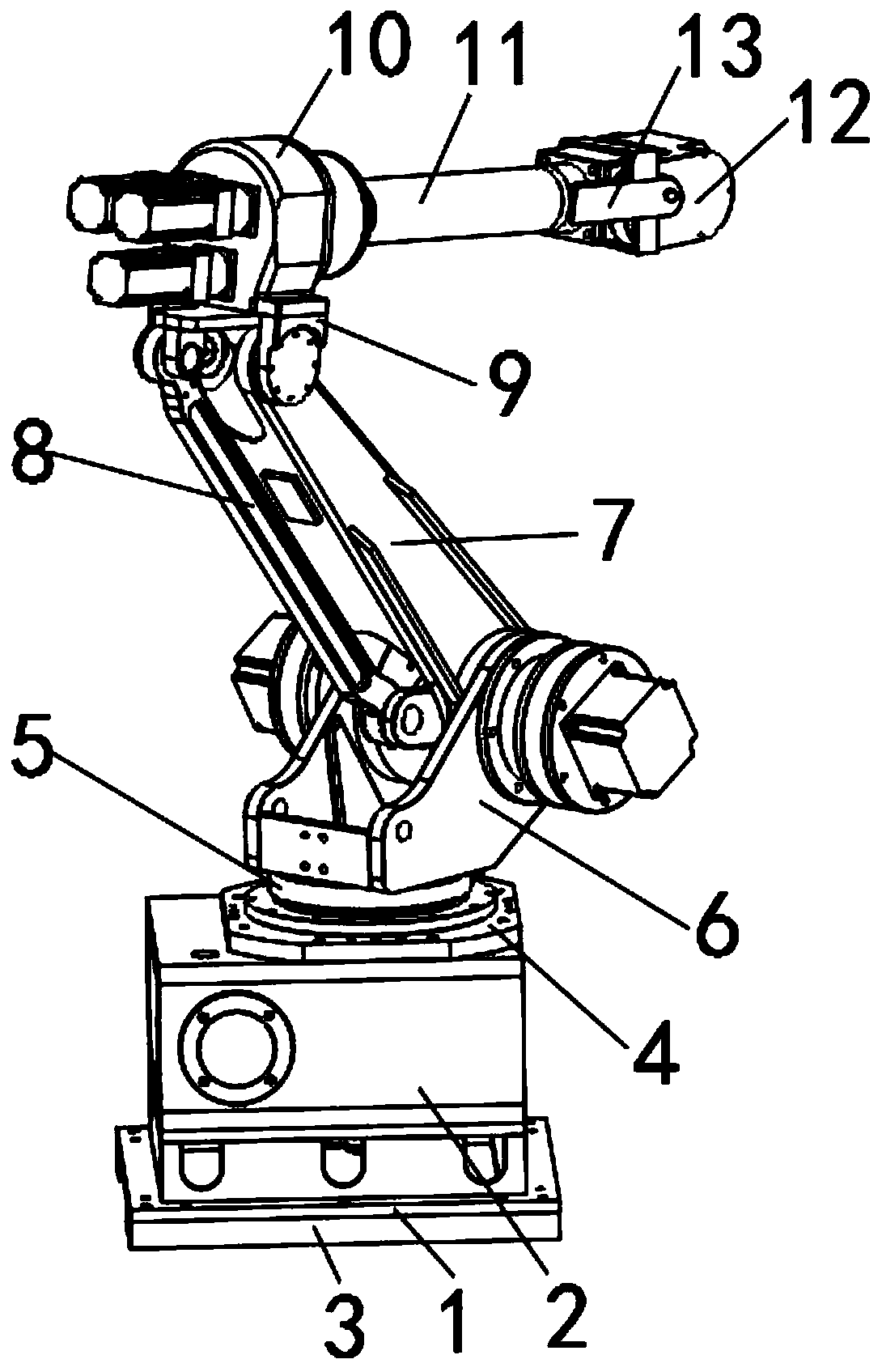

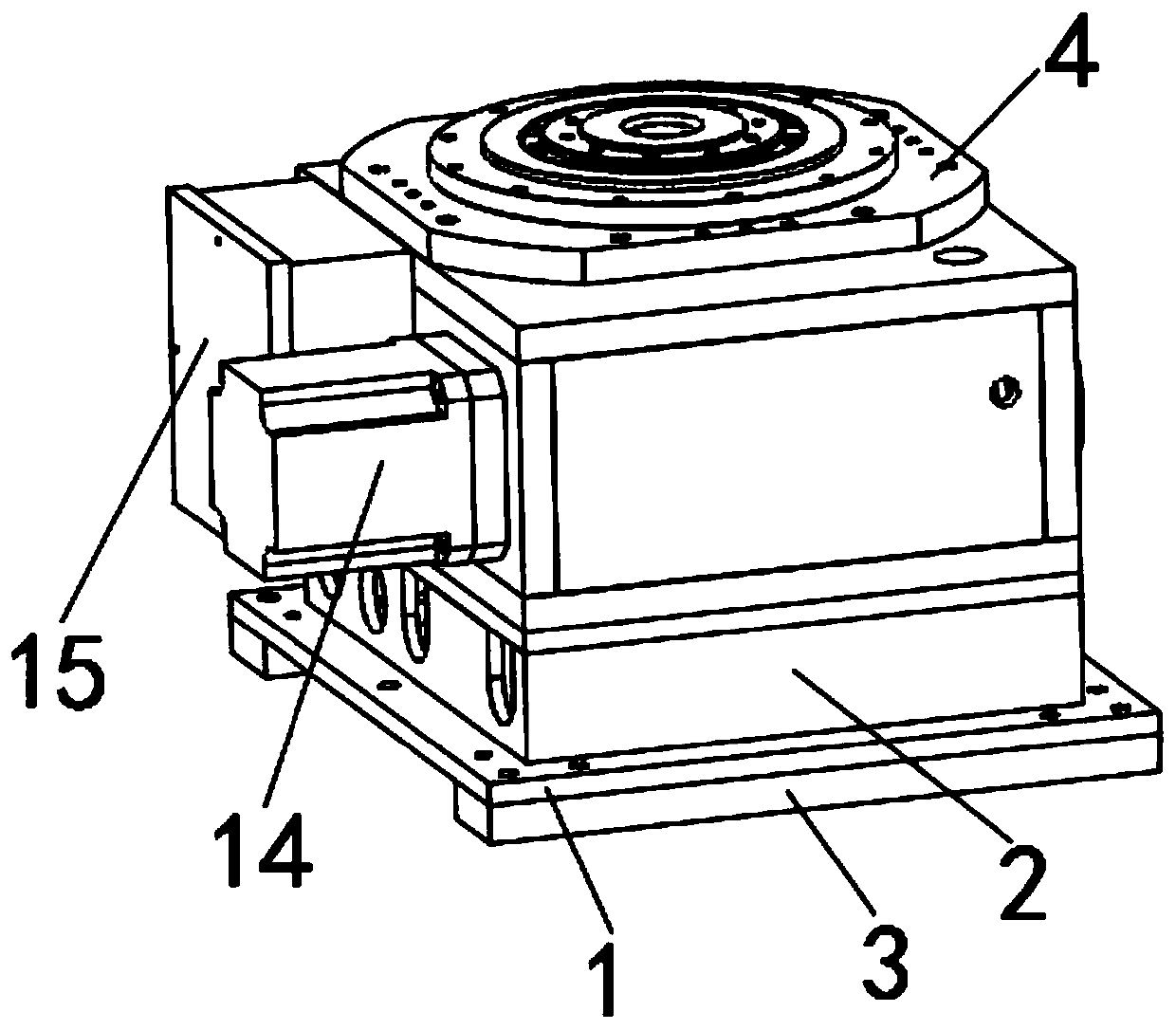

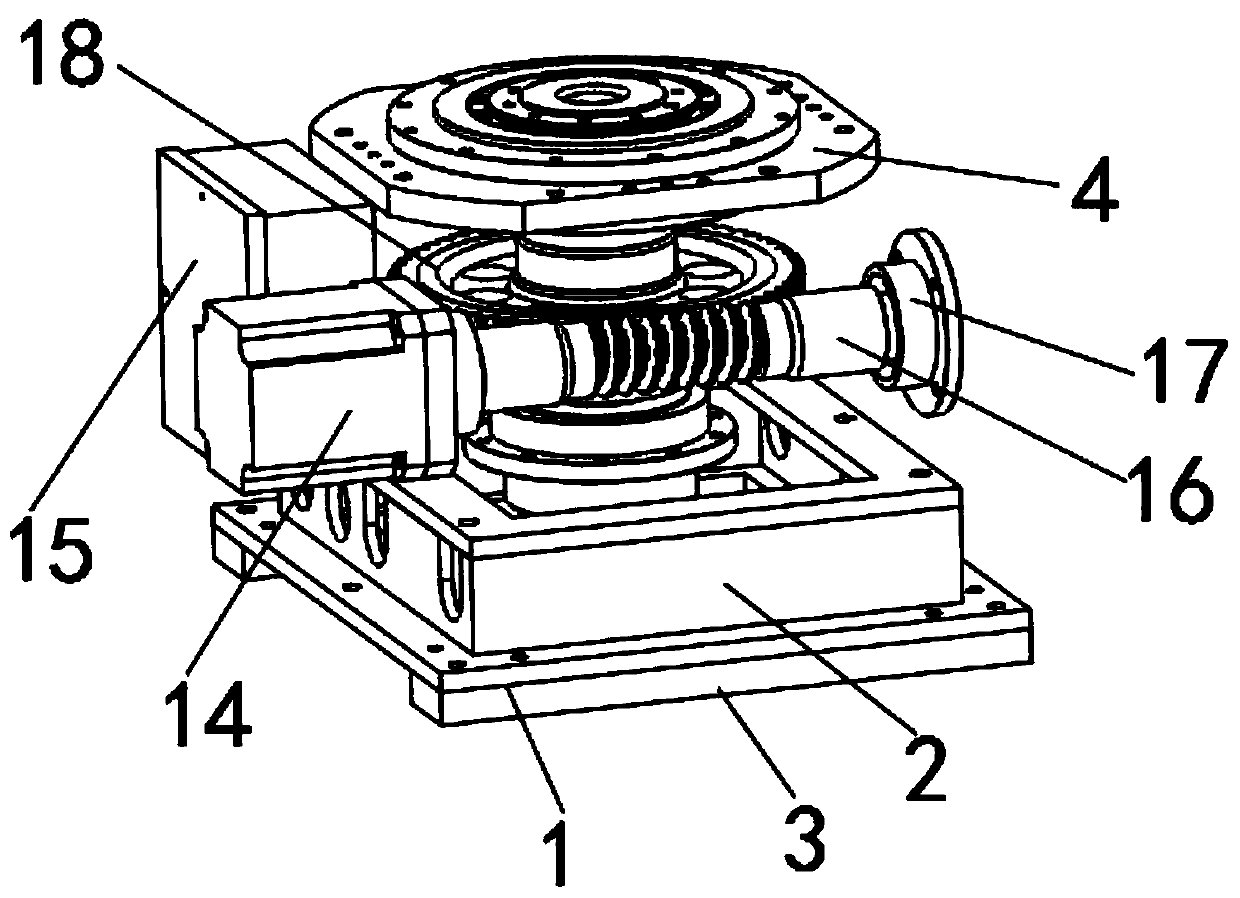

Mechanical arm assembly used for automated production

ActiveCN109760037AGood solid performanceGood connectionProgramme-controlled manipulatorJointsEngineering

The invention discloses a mechanical arm assembly used for automated production. The mechanical arm assembly comprises a bottom plate. A box body is fixedly installed on the upper surface of the bottom plate. A horizontal movement frame is fixedly installed on the lower surface of the bottom plate. A fixed plate is arranged on the upper surface of the box body. The upper surface of the fixed plateis connected with a drive plate. The upper portion of the drive plate is connected with a short arm. A supporting arm is connected to the inner side of the short arm. A connection arm is arranged onone side of the supporting arm. The invention discloses the mechanical arm assembly used for automated production. By means of the mechanical arm assembly, after the mechanical arm assembly is installed and fixed, the transverse position of the mechanical arm assembly can be adjusted, and the mechanical arm assembly can conveniently adapt to different work areas; when an arm end joint clamps an object, the pressure borne by the arm end joint can be effectively reduced, and a good protection effect is achieved; and the supporting arm and an arm rod can also be reinforced, and therefore the firmness degree between the supporting arm and the arm rod can be better, and the situation that the supporting arm and the arm rod loose is effectively avoided.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

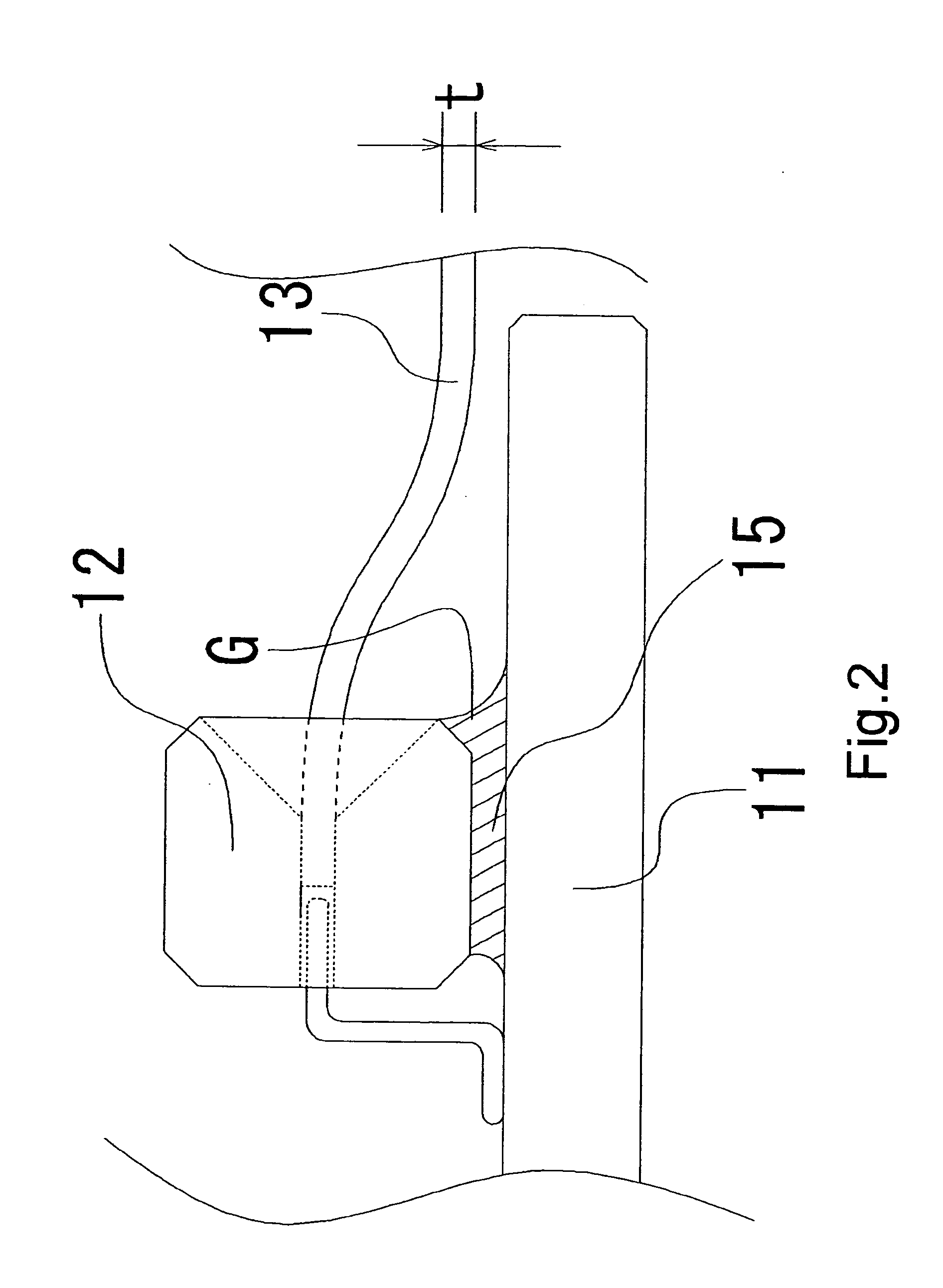

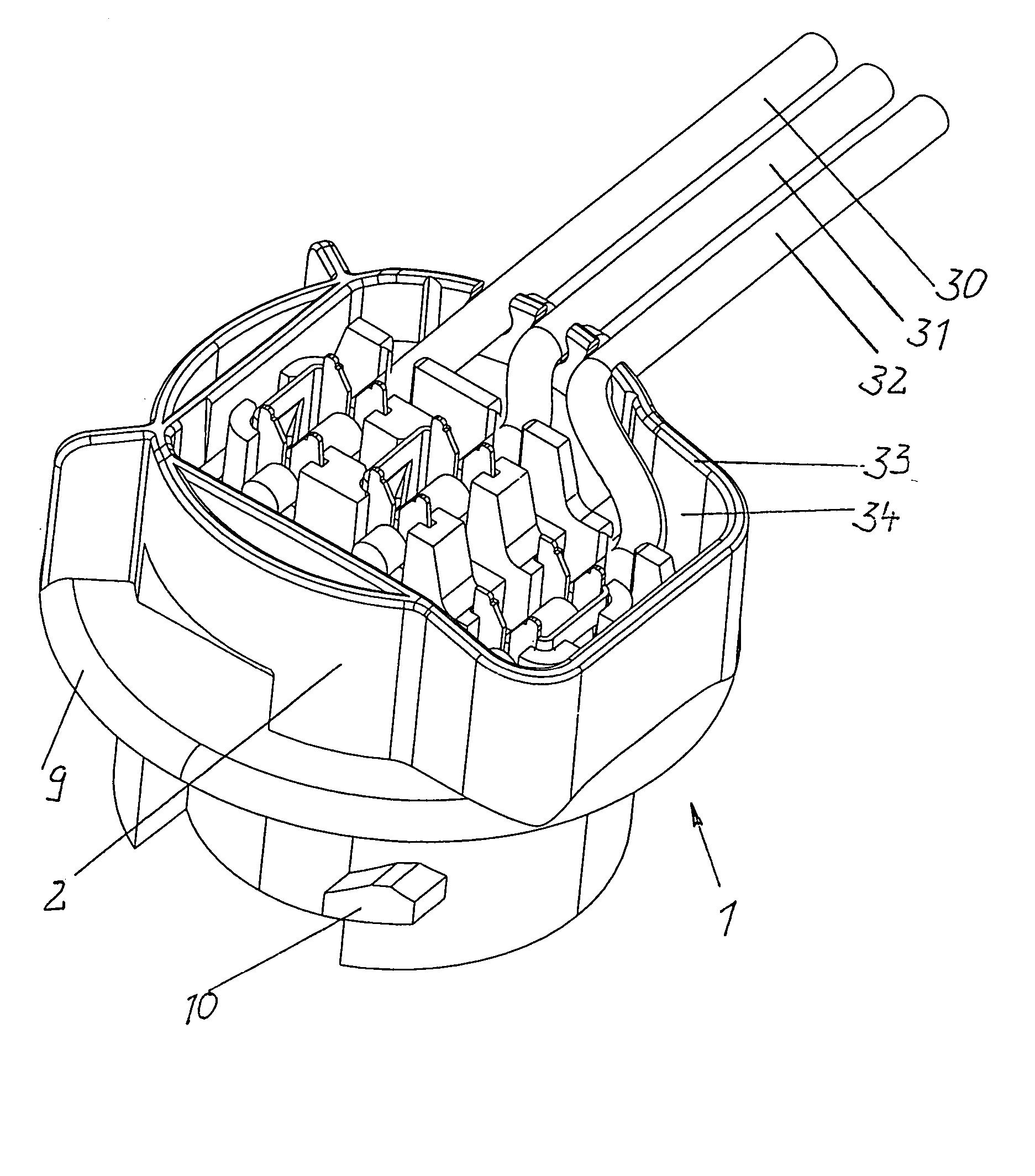

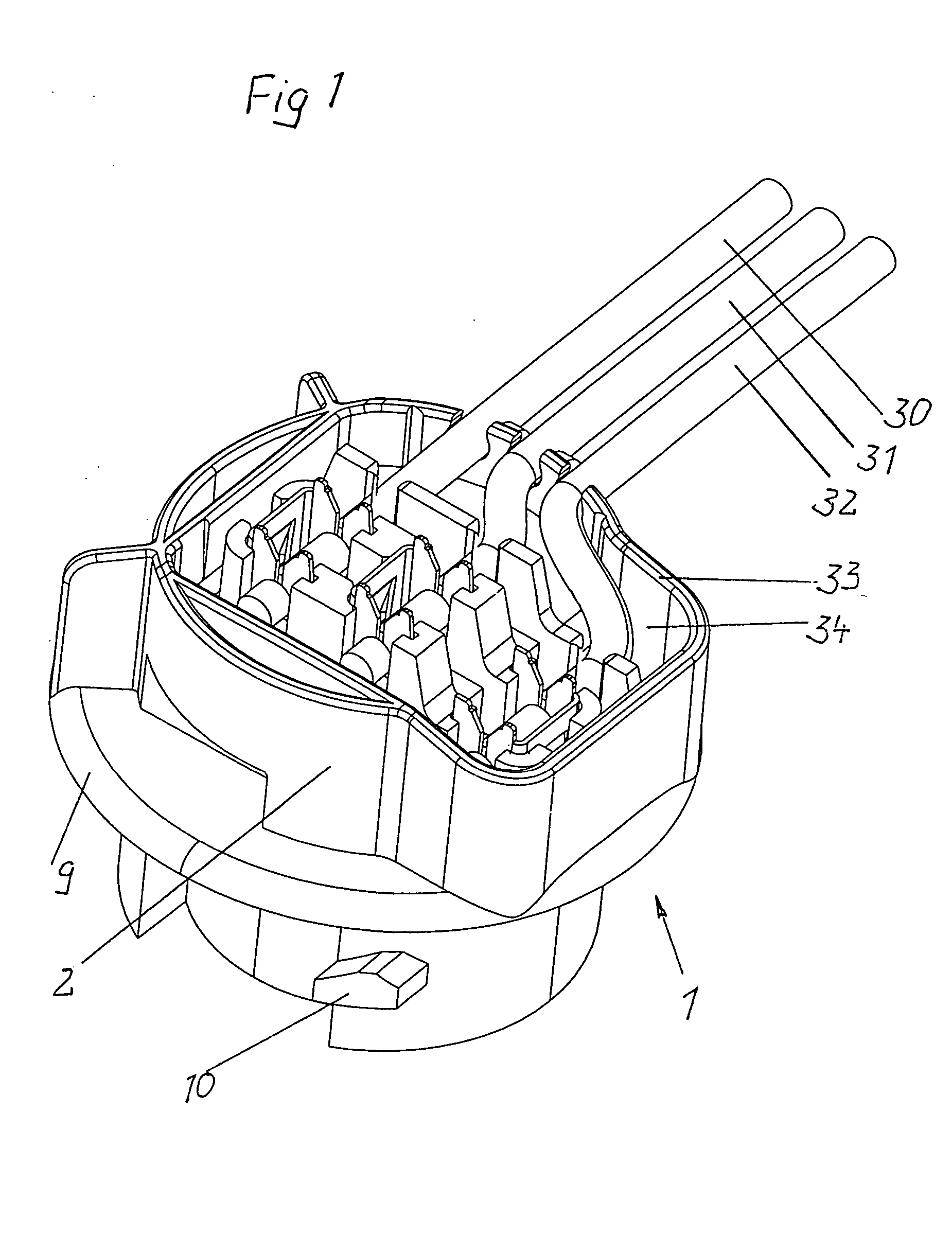

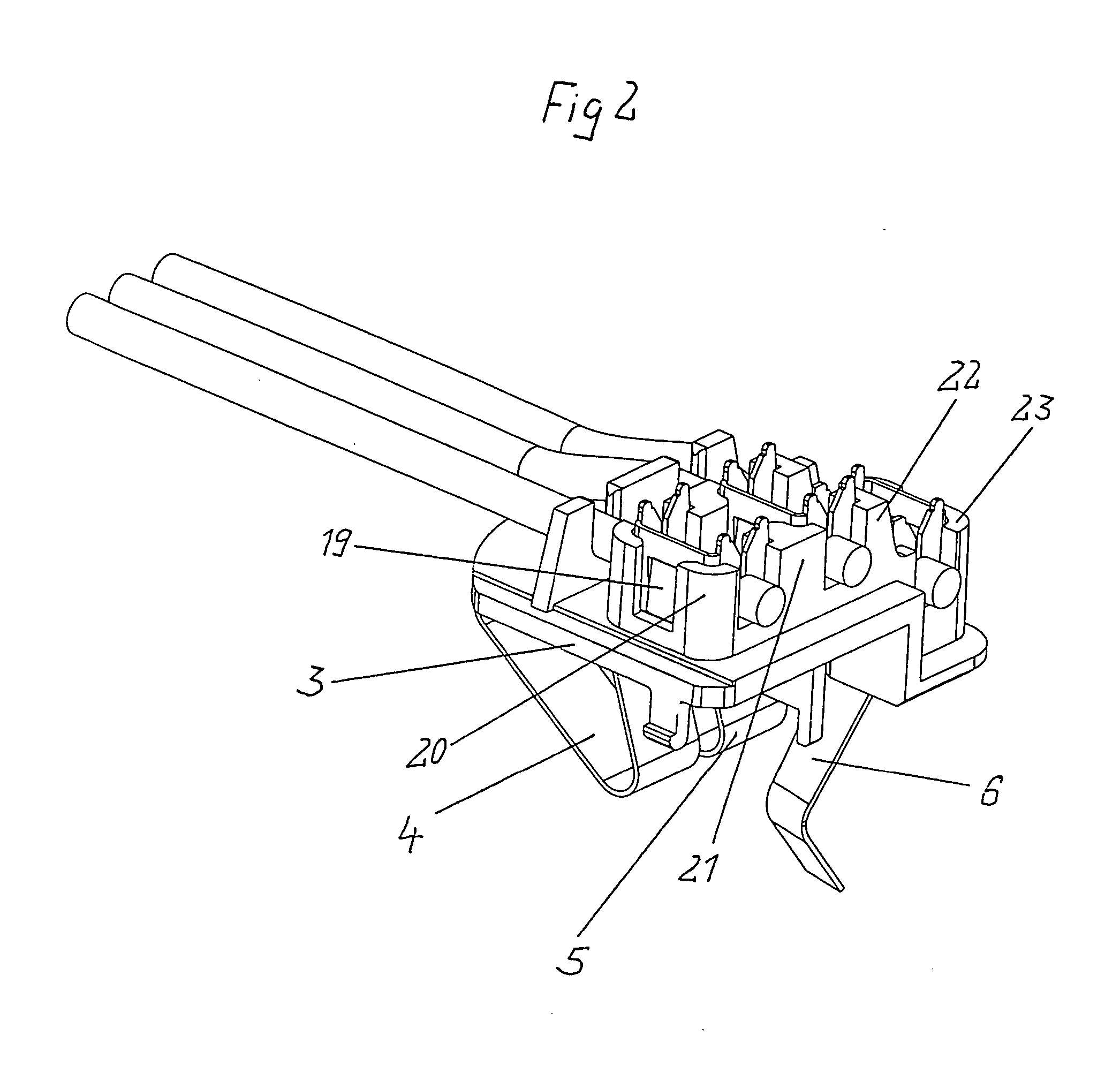

Light bulb socket for motor vehicle lamps

InactiveUS20050095895A1Good connectionReduction of movement playVehicle connectorsCoupling contact membersMechanical engineeringMotorized vehicle

A light bulb socket for a motor vehicle lamp has a hull-shaped socket body formed of a cylindrically-shaped part and a separate plate for receiving contact springs. For stabilizing a seating of the contact springs, the plate has rearwardly directed protrusions that snugly enclose cross-sectional U-shaped end portions of the contact springs. Legs of the U-shaped end portions of the contact springs form a double contact bond to power lead cables with insulation-displacement connections.

Owner:BERNHARD JURGENHAKE FUR KABELKONFEKTION & METALLVERARBEITUNG MBH

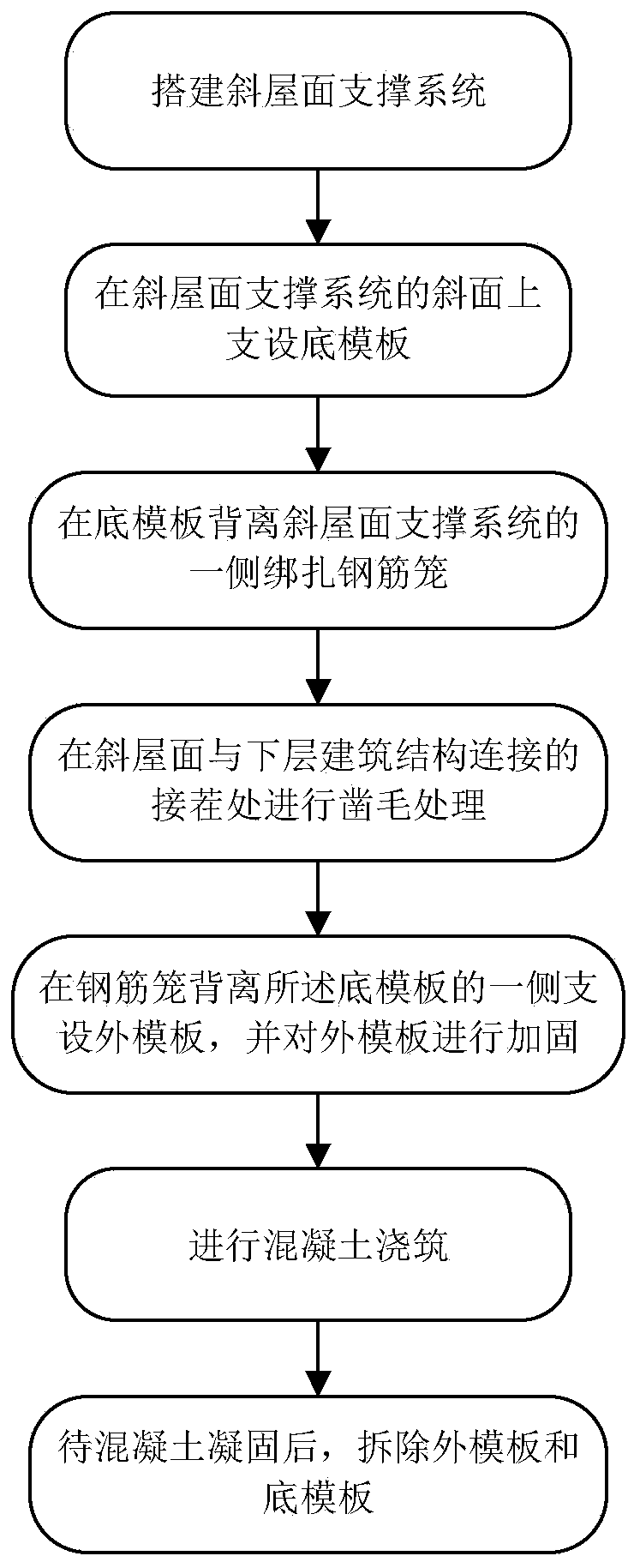

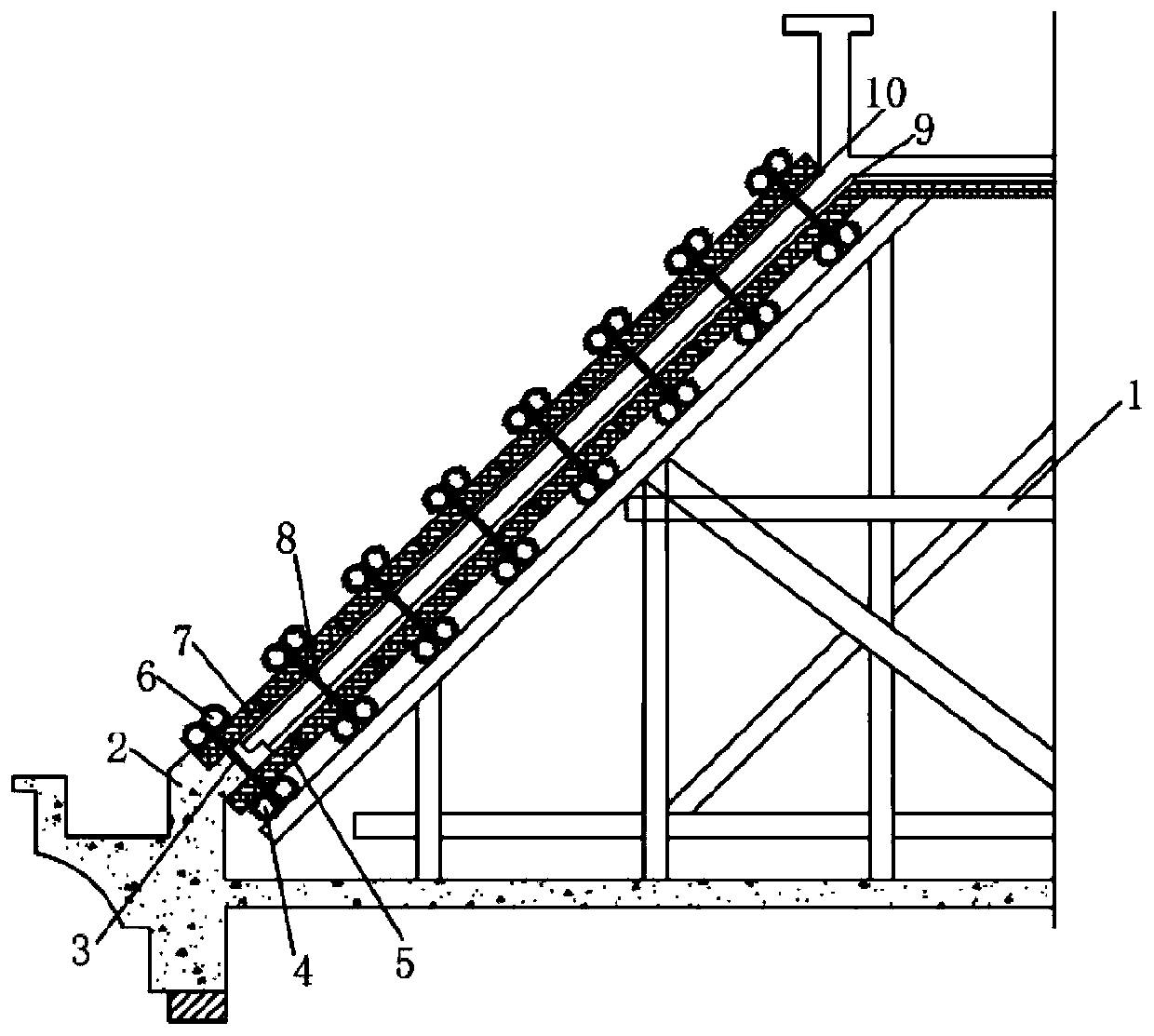

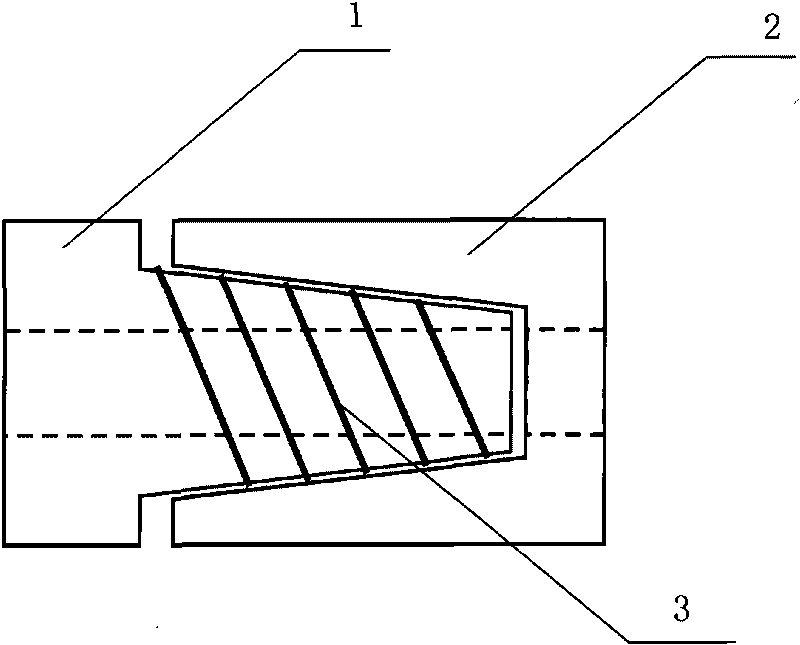

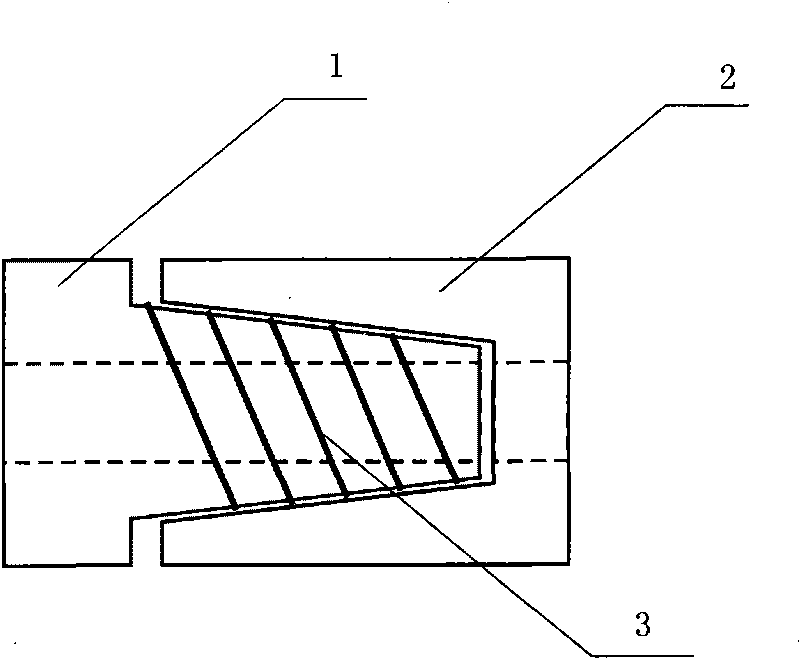

Construction method of sloping roof concrete structure

InactiveCN110424640AGood flatnessGood connectionBuilding roofsRoof covering using sealantsSupport systemBuilding construction

The invention relates to the technical field of building construction, and in particular to a construction method of a sloping roof concrete structure. The construction method comprises the followingsteps of S1, building a sloping roof support system; S2, erecting a bottom template on the slope of the sloping roof support system; S3, binding a reinforcement cage on the side, deviating from the sloping roof support system, of the bottom template; S4, carrying out scabbling treatment at the connection place of a sloping roof and a lower building structure; S5, erecting an outer template on theside, deviating from the bottom template, of the reinforcement cage and reinforcing the outer template; S6, carrying out concrete pouring; and S7, after concrete setting, dismounting the outer template and the bottom template. According to the construction method, a double-template structure is adopted, so that the flatness of the sloping roof boards formed by pouring is relatively good after concrete pouring, no voids and pits phenomenon exists and the connection at the connection places is favorable.

Owner:BEIJING CHONGJIAN ENG

Tube head connecting piece

InactiveCN101761715AGood connectionEasy to disassembleScrew threaded jointsBiomedical engineeringHeat spreader

Owner:天津吉鑫达商贸营销有限公司

High-voltage winding middle inlet wire structure K wire lead cold pressing technology

InactiveCN103531350AGood connectionShorten processing timeConnections effected by permanent deformationCable junctionsEngineeringHigh pressure

The invention discloses a high-voltage winding middle inlet wire structure K wire lead cold pressing technology. To solve the problems that many defects exist and difficulty is large when a K wire is connected through flame welding, the technical scheme is put forward. According to the technical scheme, the technology adopted to connect the K wire comprises the steps of selecting a connecting pipe, improving the connecting pipe, preprocessing a cable and carrying out cold welding. By means of the technology, the connecting effect is good, the processing time is shortened, product quality is improved, the potential safety hazards brought by the defects of the original technology are eliminated, and meanwhile labor intensity is reduced.

Owner:洛阳华明变压器有限公司

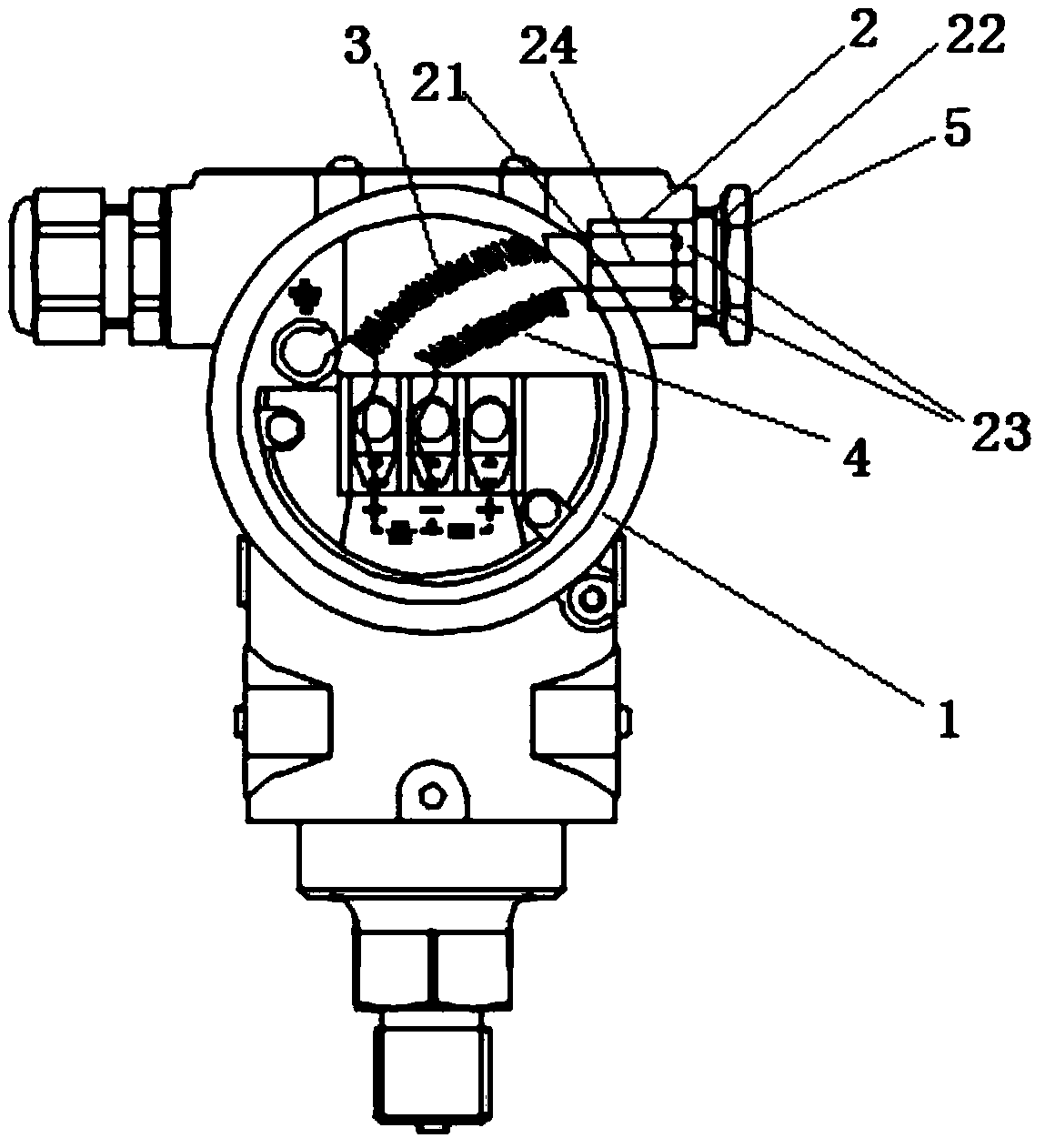

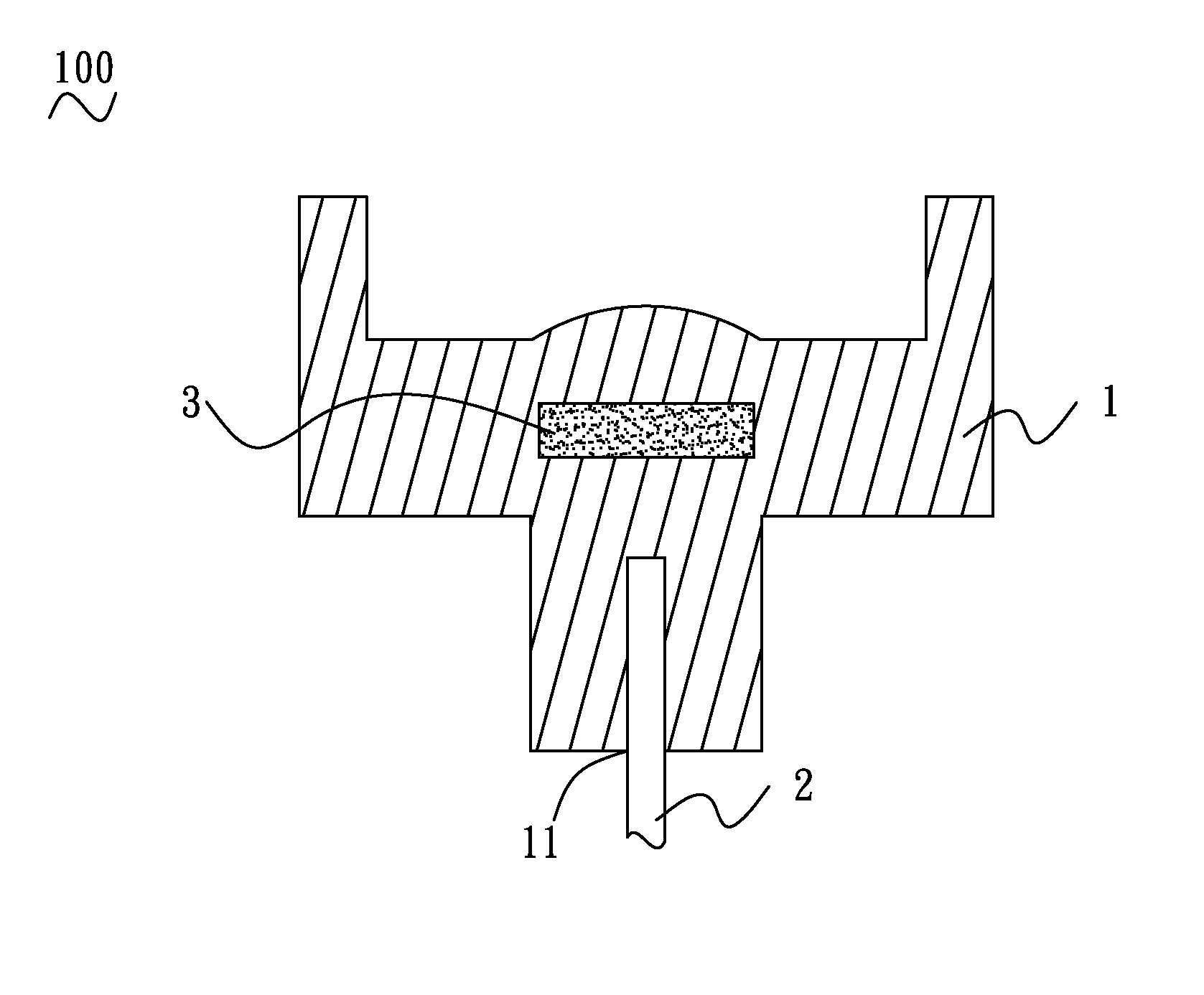

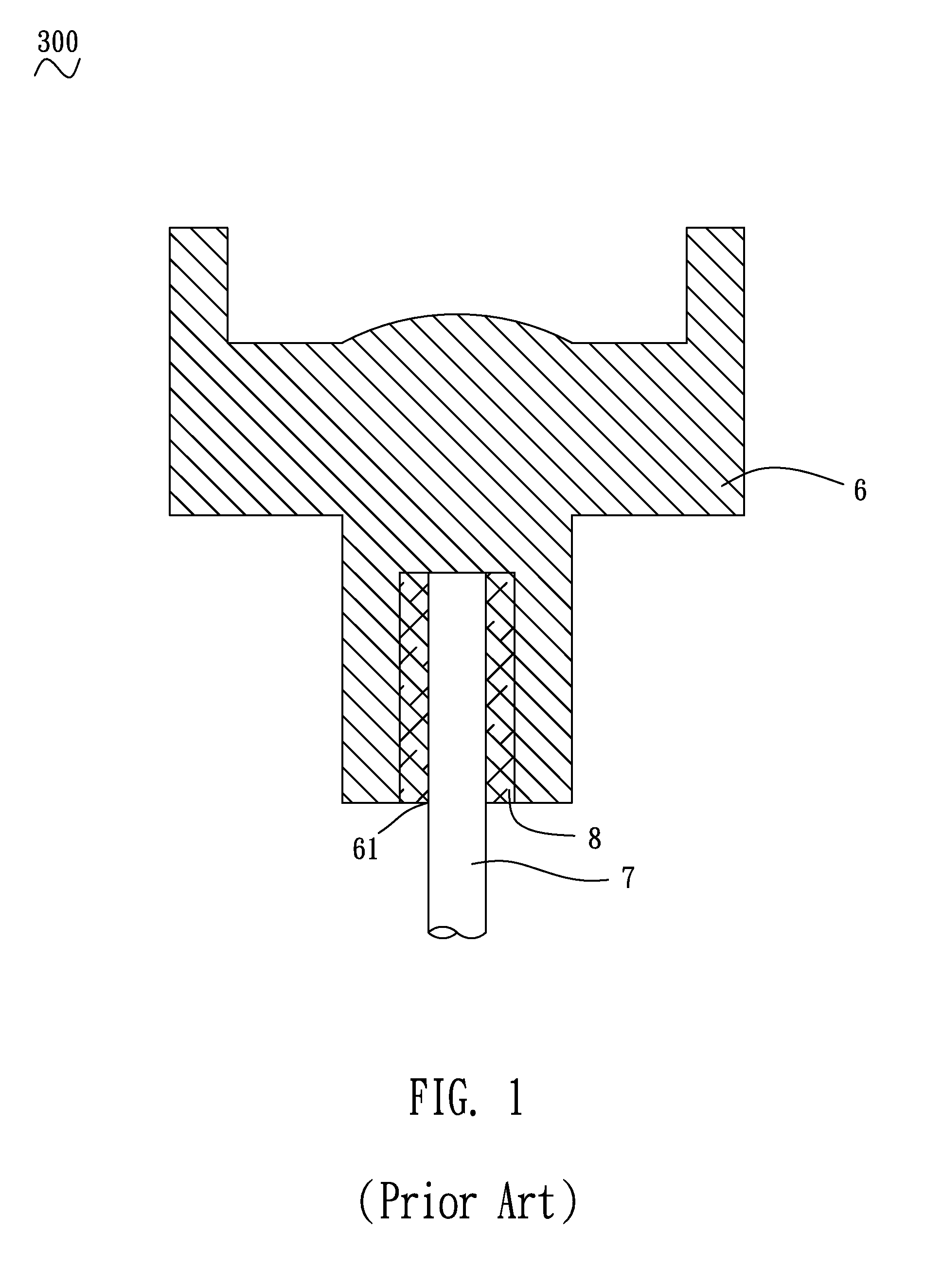

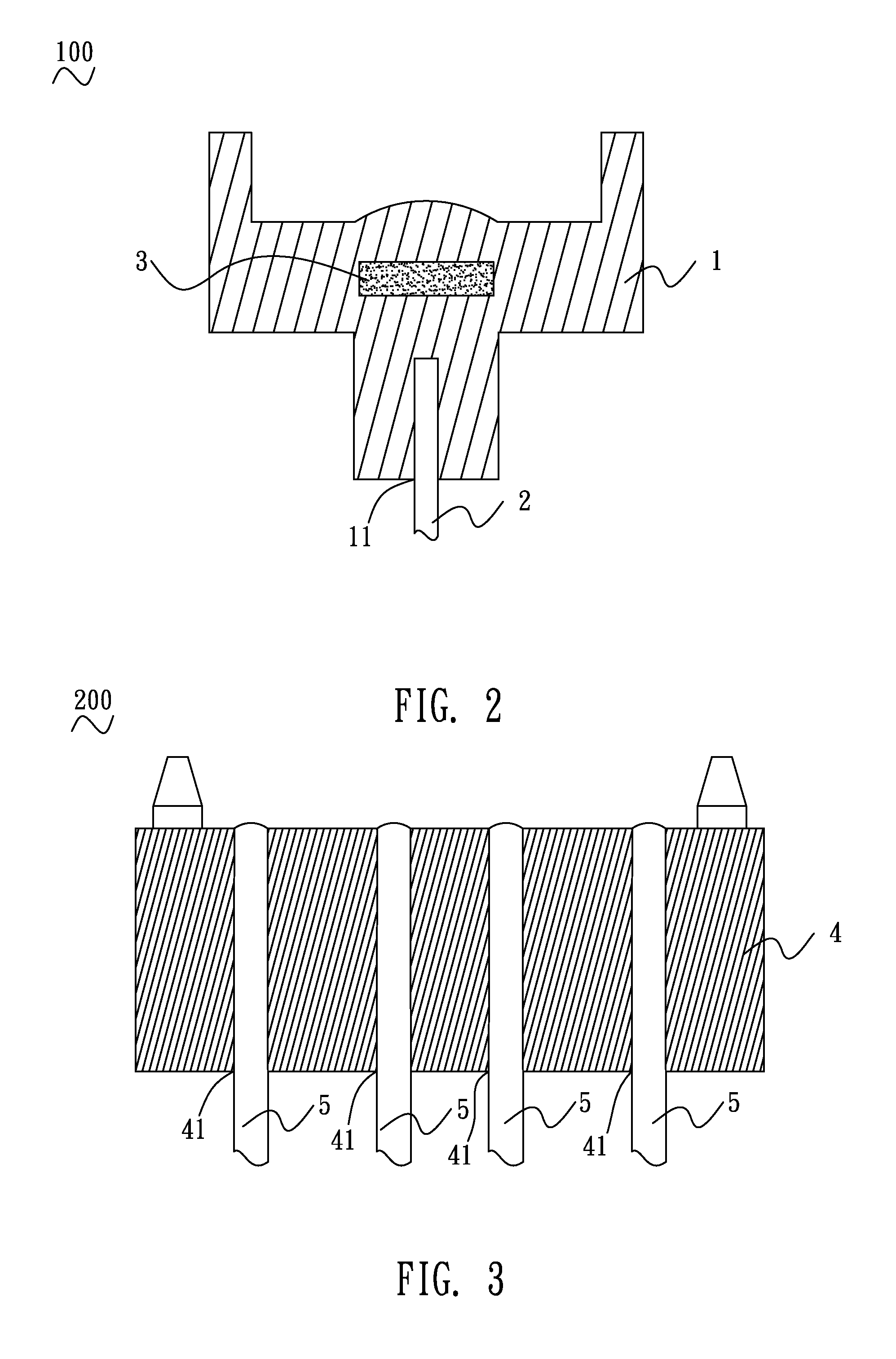

Pressure transmitter device

The invention discloses a pressure transmitter device, and the device comprises a pressure transmitter and a lead wire mechanism. The lead wire mechanism comprises a hollow insulating cylinder, a positive lead wire and a negative lead wire; the hollow insulating cylinder is fixed with the pressure transmitter, and the two sides of the hollow insulating cylinder are respectively an inlet end and anoutlet end of the opening; a bolt cover is mounted at the outlet end of the hollow insulating column body, and two insulating hanging rods are arranged on the inner wall of one side of the outlet end; one end of the anode lead and one end of the cathode lead are respectively connected with a power supply wiring terminal of the pressure transmitter, and the other ends of the anode lead and the cathode lead extend into the hollow insulating column body from the inlet end and are respectively connected to the two insulating hanging rods. According to the invention, the connection between the pressure transmitter and the manual operator can be efficiently realized, and the working efficiency of the debugging process of the transmitter is improved.

Owner:SHANGHAI FL AUTOMATION

Quick-drying environment-friendly special alcohol acid iron red antirust coating for steel structures

InactiveCN106479331AGood adhesionGood connectionAnti-corrosive paintsPolyester coatingsSolventBrown iron oxide

The invention discloses quick-drying environment-friendly special alcohol acid iron red antirust coating for steel structures. The quick-drying environment-friendly special alcohol acid iron red antirust coating comprises, by weight, 15%-50% of special plant-oil-modified resin for antirust paint, 10%-25% of environment-friendly No.200 solvents, 0.1%-0.5% of dispersing agents, 10%-30% of iron oxide red, 5%-30% of zinc phosphate, 0.5%-1% of organic bentonite, 0.1%-0.3% of methyl ethyl ketoxime and 0.5%-1% of efficient drying catalysts. The quick-drying environment-friendly special alcohol acid iron red antirust coating has the advantages that the quick-drying environment-friendly special alcohol acid iron red antirust coating is applicable to metal surfaces of the large steel structures and is generally used as antirust paint; the quick-drying environment-friendly special alcohol acid iron red antirust coating is good in adhesion, moisture resistance and priming and finish paint junction property and is particularly adaptable to atmospheric corrosion resistance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Optical fiber connector and method of manufacturing the same

InactiveUS20120163756A1Decrease of deviationGood connectionOptical articlesCoupling light guidesOptical fiber connectorEngineering

An optical fiber connector includes an insulating housing, an optical fiber and a transparent hetero substrate. The optical fiber is exposed outside the insulating housing with one end portion molded in the insulating housing. The transparent hetero substrate is molded inside the insulating housing. The transparent hetero substrate is substantially perpendicular to the end portion of the optical fiber and spaced from an end edge of the end portion of the optical fiber. A middle of the transparent hetero substrate is substantially in alignment with the end portion of the optical fiber. The method of manufacturing the above-mentioned optical fiber connector is described hereinafter. Firstly, set an end portion of the optical fiber and a transparent hetero substrate in a mold. Secondly, inject molten materials into the mold. Thirdly, separate the mold and then take out the optical fiber connector from the mold when the mold is cooled.

Owner:GLORY SCI

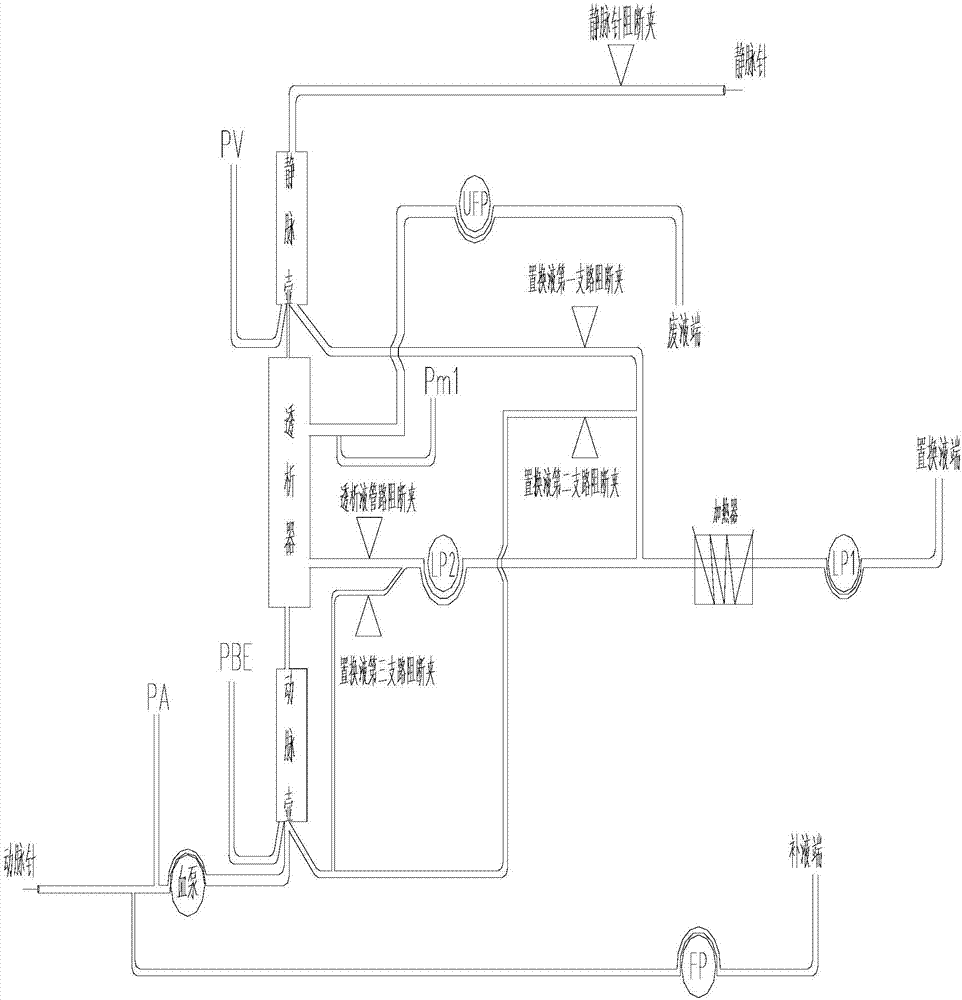

Blood purification system and pipe pre-filling control method of blood purification system

PendingCN107485742AGood connectionRealize full automation and intelligenceOther blood circulation devicesDialysis systemsDialysis fluidEngineering

The invention discloses a blood purification system and a pipe pre-filling control method of the blood purification system. The system comprises a blood pump, a waste liquid pump, a replacement liquid pump and a flow division pump and / or a liquid supplying pump; the flow division pump is arranged between the dialysis fluid inlet of a dialyzer and the outlet of the replacement liquid pump; the liquid supplying pump is arranged between a liquid supplying end and the inlet of the blood pump. According to the blood purification system and the pipe pre-filling control method of the blood purification system, automation and intelligence without artificial interference of the full pipe pre-filling process are achieved, automatic pressing and sealing tests can be conducted in the pre-filling process so that it can be guaranteed that the pipe connectors are connected well, and the blood purification system can automatically prompt a user to conduct the next step of operation in a sound-light alarm mode after passing the sealing tests.

Owner:SWS HEMODIALYSIS CARE CO LTD

Shaft connection structure

ActiveCN109595265AIncreased connection contact areaGood connectionCouplings for rigid shaftsEngineeringRelative motion

The invention discloses a shaft connection structure. The shaft connection structure comprises a connecting shaft, wherein the connecting shaft is hollow, and two ends of the connecting shaft are in communication; the input end of the connecting shaft is detachably and fixedly connected with a turbine disk of a turbine component through a fixed connecting piece, so that relative motion between theconnecting shaft and the turbine disk is avoided; a limiting step which is protruded facing the center of a shaft hole is arranged in the shaft hole of the output end of the connecting shaft; the output end of the connecting shaft is connected with a gas compressor rear shaft journal of the gas compressor component through an internal and external spline structure; an axial limiting member is fixedly mounted in the shaft hole of the gas compressor rear shaft journal, and is used for propping the limiting step to enable the connecting shaft to be in rigidity connection with the gas compressorrear shaft journal, then the power transmitted by the turbine disk to the connecting shaft is smoothly transmitted to the gas compressor rear shaft journal, and besides, the axial limiting member andthe propping limiting step are also used for preventing the connecting shaft to slide towards the turbine disk in the axial direction. According to the shaft connection structure disclosed by the invention, the power can be smoothly transmitted to the gas compressor rear shaft journal by the connecting shaft, and the power transferring quality is good.

Owner:CHINA HANGFA SOUTH IND CO LTD

Novel electronic connector

PendingCN109449665AGood connectionThe connection effect is not easy to looseCouplings bases/casesElectrical and Electronics engineeringButt joint

The invention provides a novel electronic connector comprising a connection end and a butt-joint end. A but-joint conductive core sleeve is arranged in the butt-joint end; the connection end comprisesa connection shell, a connector, a connection rod and a knob handle; a butt-joint slot and a connection cavity are arranged in the connection shell; the connector comprises a fixing block, a connection block and a pin; a guiding block is arranged on the connection block; multiple guide rails are arranged in the connection cavity; and a protection sleeve is sleeved on the outer periphery of the butt-joint end. The device provided by the invention is simple and reasonable in structure; the guiding block and the guide rails are arranged in the connector, so that the connector can be connected quickly.

Owner:ZHENJIANG KEMAO ELECTRONICS CO LTD

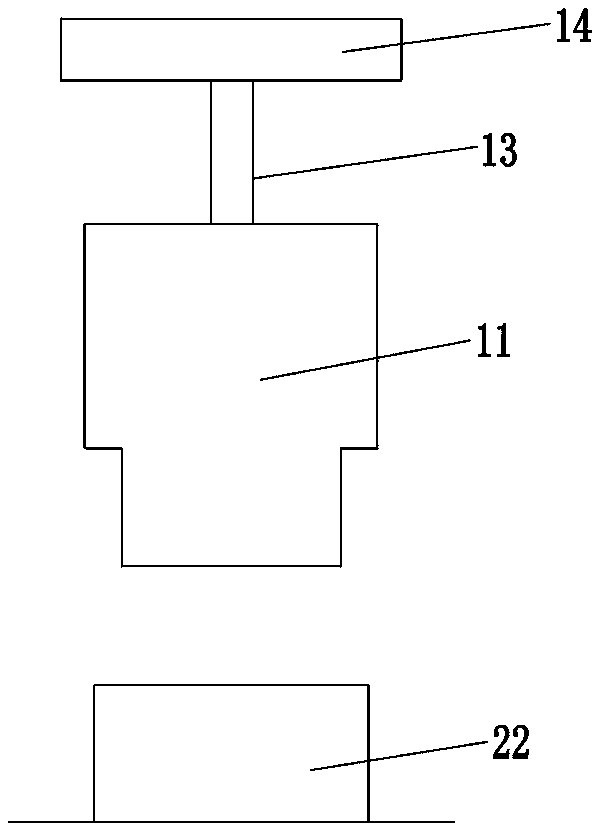

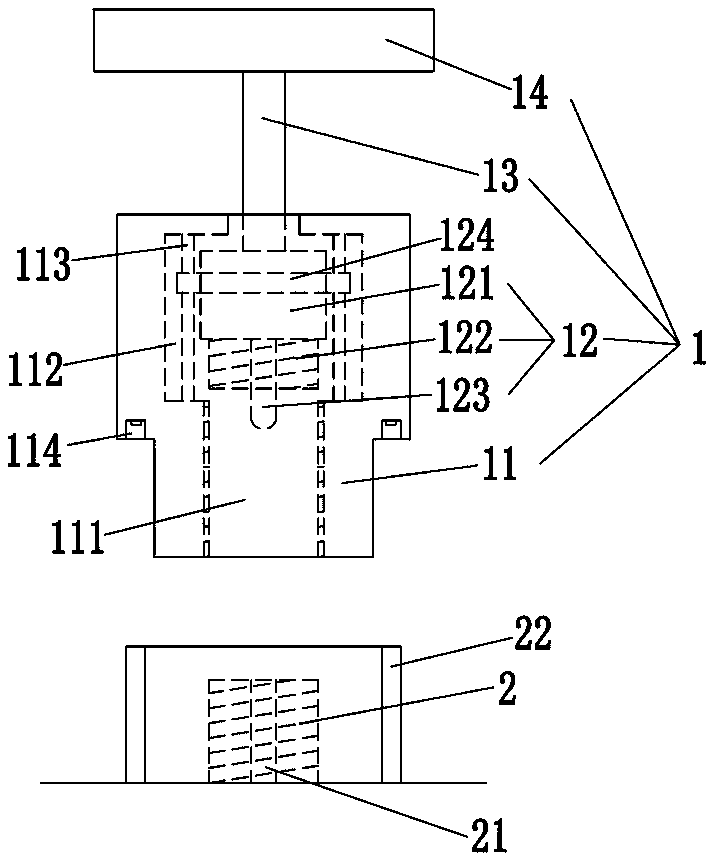

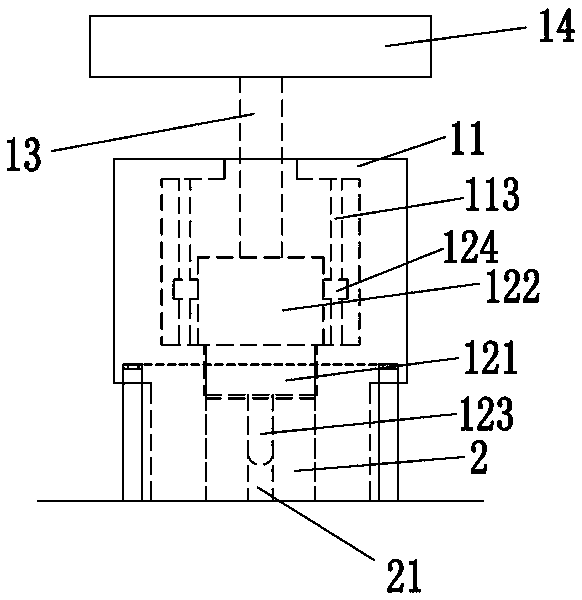

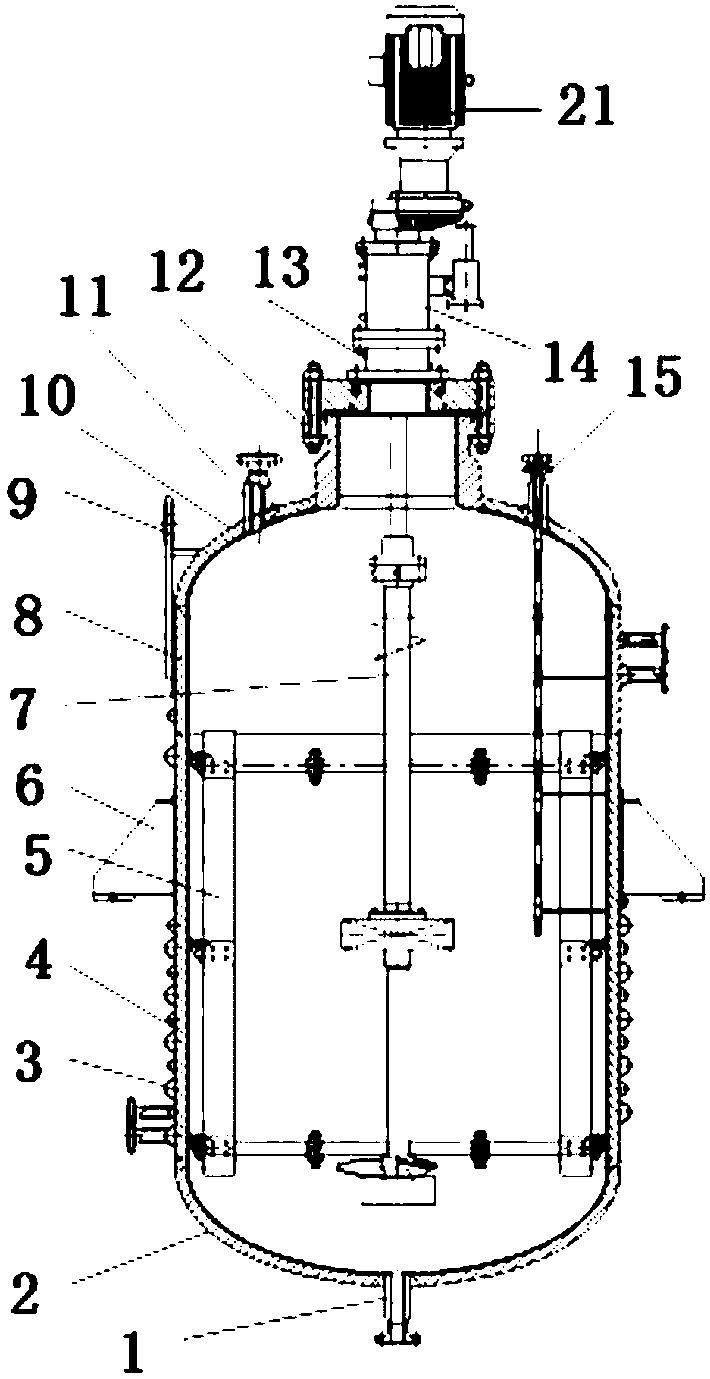

Reaction kettle prepared from active tantalum metal, active zirconium metal, active titanium metal and low-alloy-steel composite plate

InactiveCN109621861AReduce manufacturing costGood connectionChemical/physical/physico-chemical stationary reactorsTitanium metalTitanium

The invention discloses a reaction kettle prepared from active tantalum metal, active zirconium metal, active titanium metal and a low-alloy-steel composite plate. The reaction kettle comprises a first cylinder body, wherein the top of the first cylinder body is fixedly connected with an upper seal head, the left side of the top of the upper seal head is communicated with a material inlet, the interior of a stirring port is rotatably communicated with a transmission device, and a shaft seal device is fixedly connected in the stirring port; the inner wall of the shaft seal device is rotatably connected with the transmission device. According to the reaction kettle prepared from the active tantalum metal, the active zirconium metal, the active titanium metal and the low-alloy-steel compositeplate, zonal corrosion resistance is effectively achieved, the cost is reduced, the integral use effect of equipment is ensured, and effective zonal material selection is achieved; a zirconium material is applied to a contact medium part of a stirring device according to medium corrosion properties and the corrosion resistance requirements of materials, a baffle assembly is used as the main partof the stirring device, and a supporting-type stirring design structure is selected, so that the reaction effectiveness of each section is ensured, and the effective and reliable reaction functions ofa reactor are guaranteed.

Owner:NANJING BAOSE

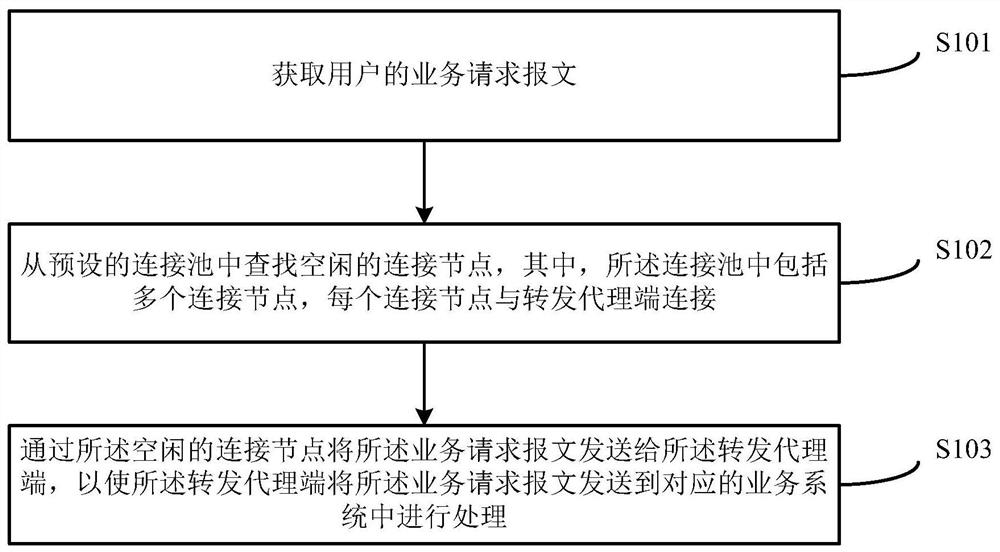

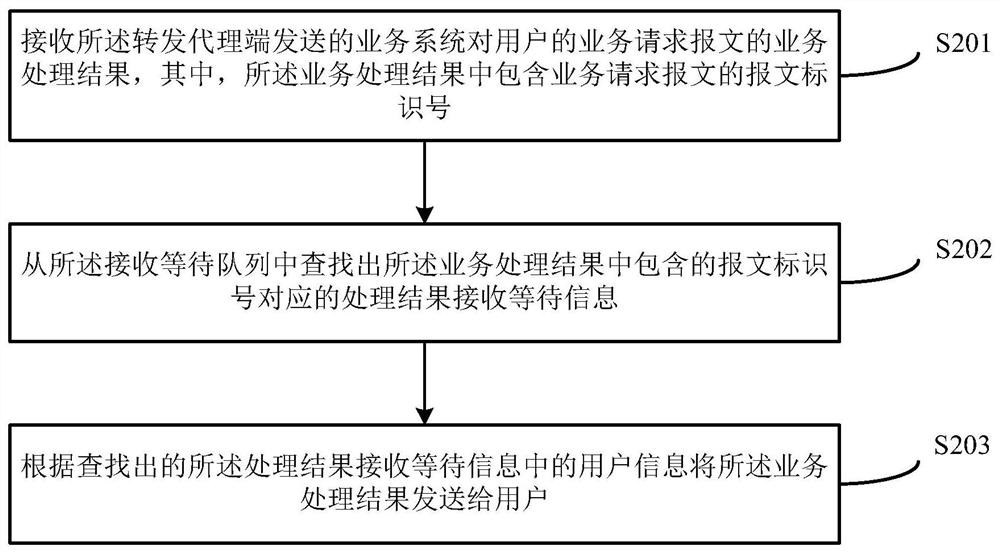

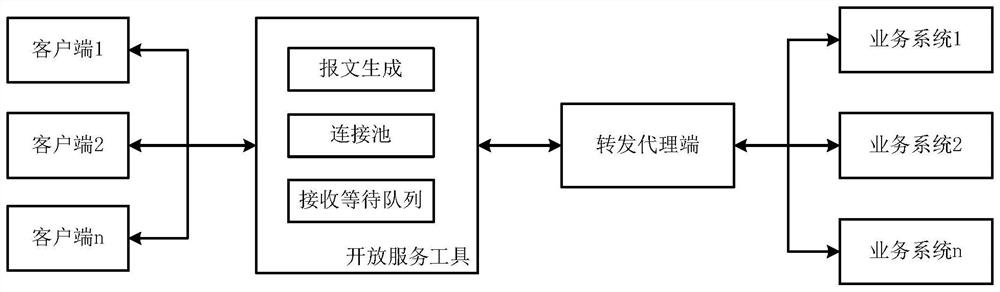

Service request processing method and device

ActiveCN113301136AAvoid processing inefficienciesGood connectionTransmissionService systemEngineering

The invention discloses a service request processing method and device. The method comprises the following steps: acquiring a service request message of a user; searching idle connection nodes from a preset connection pool, wherein the connection pool comprises a plurality of connection nodes, and each connection node is connected with a forwarding agent end; and sending the service request message to the forwarding agent end through the idle connection node, so that the forwarding agent end sends the service request message to a corresponding service system for processing. According to the invention, by setting and maintaining the connection pool and the receiving waiting queue, the service processing is more efficient.

Owner:银清科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com