Plastic straight-head high-voltage connector

A high-voltage connector and straight head technology, which is applied in the direction of vehicle connectors, connections, parts of connection devices, etc., can solve the problems of abnormal use interruption of connectors, unsatisfactory waterproof effect, and accidental pull-out, etc. Achieve the effect of reducing the possibility of water and dust entry, increasing the stability of coordination, and reducing external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

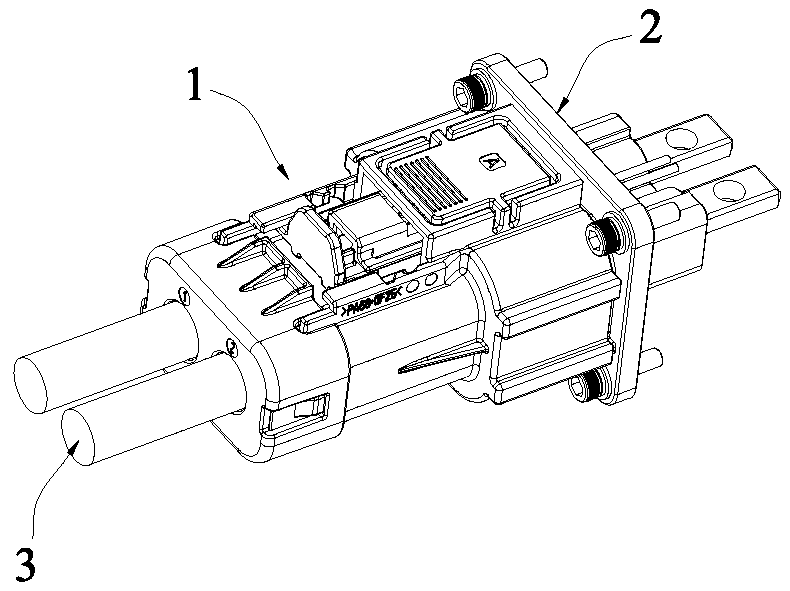

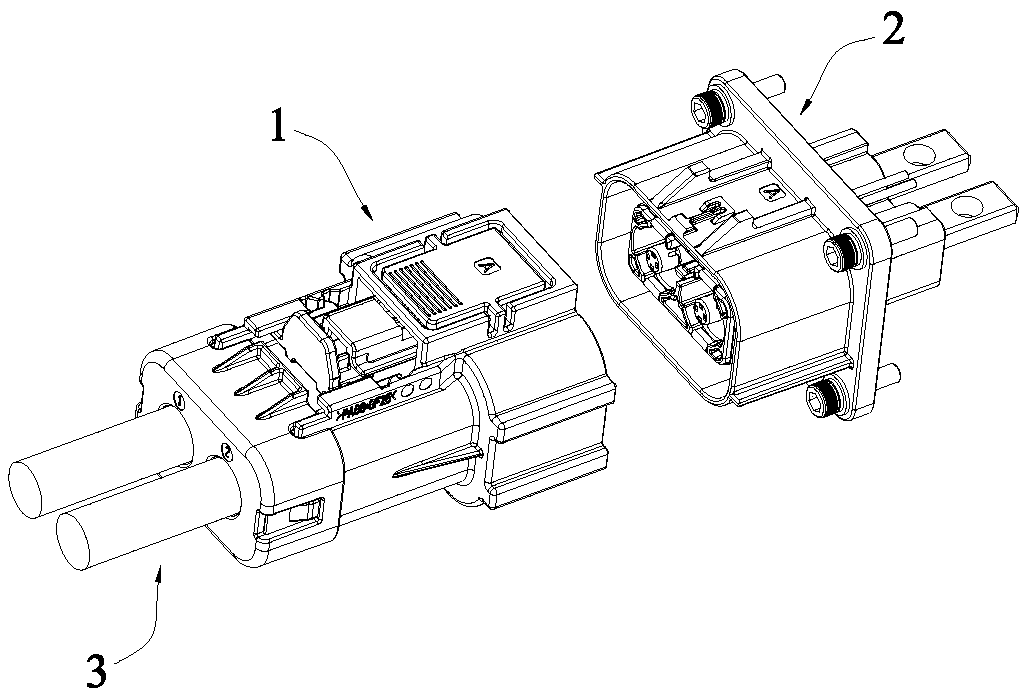

[0032] Example: see figure 1 and figure 2 , the present embodiment provides a plastic straight high-voltage connector, which includes a plug assembly 1 and a socket assembly 2 adapted to the plug assembly 1 .

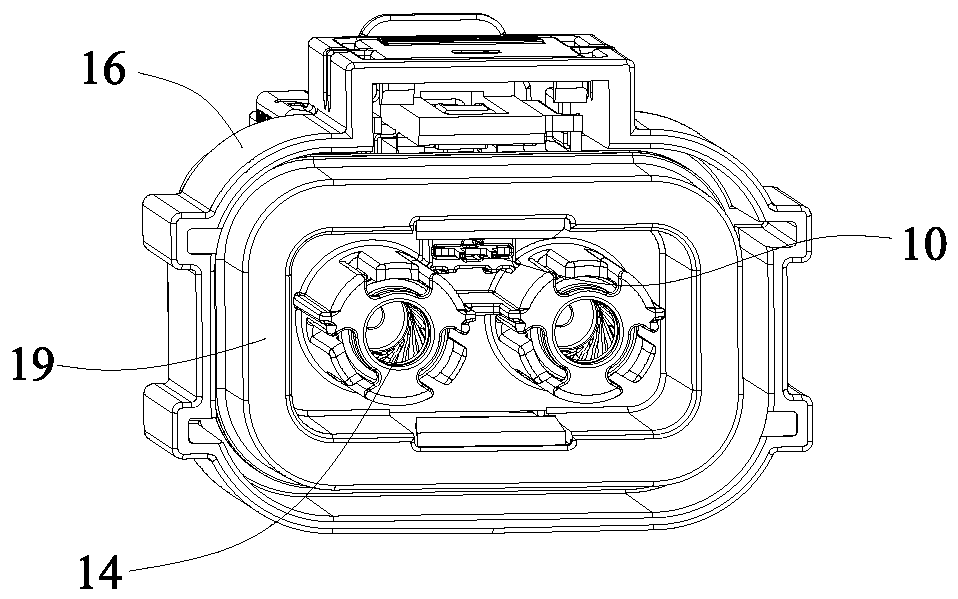

[0033] see Figure 3 to Figure 10 , the plug assembly 1 includes a tail cover 11, a cable waterproof ring 12, a shielding ring 13, a jack sleeve 14, a position ensuring part 15, a plug housing 16, a head waterproof ring 17, a plug shield 18, and a plug rubber core 19 and signal pin 10. The head of the plug rubber core 19 is provided with a connector 191, and the tail is provided with a connector 192. One end of the jack sleeve 14 is arranged in the connector 191, and the other end extends to the connector 192, and the cable is inserted into the connector. 192 and is connected with the jack sleeve 14, the signal pin 10 is set on one side of the connector 191, the plug shield 18 is covered on the connection part 192, and the plug shield 18 is provided with a cable 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com