Servo electrohydraulic composite pressure method and press machine thereof

A servo electric and press technology, applied in the field of presses, can solve the problems of simultaneous pressing, stretching, demoulding, high manufacturing cost, and low control accuracy, and achieve shortened work cycle, low manufacturing cost, and high control accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

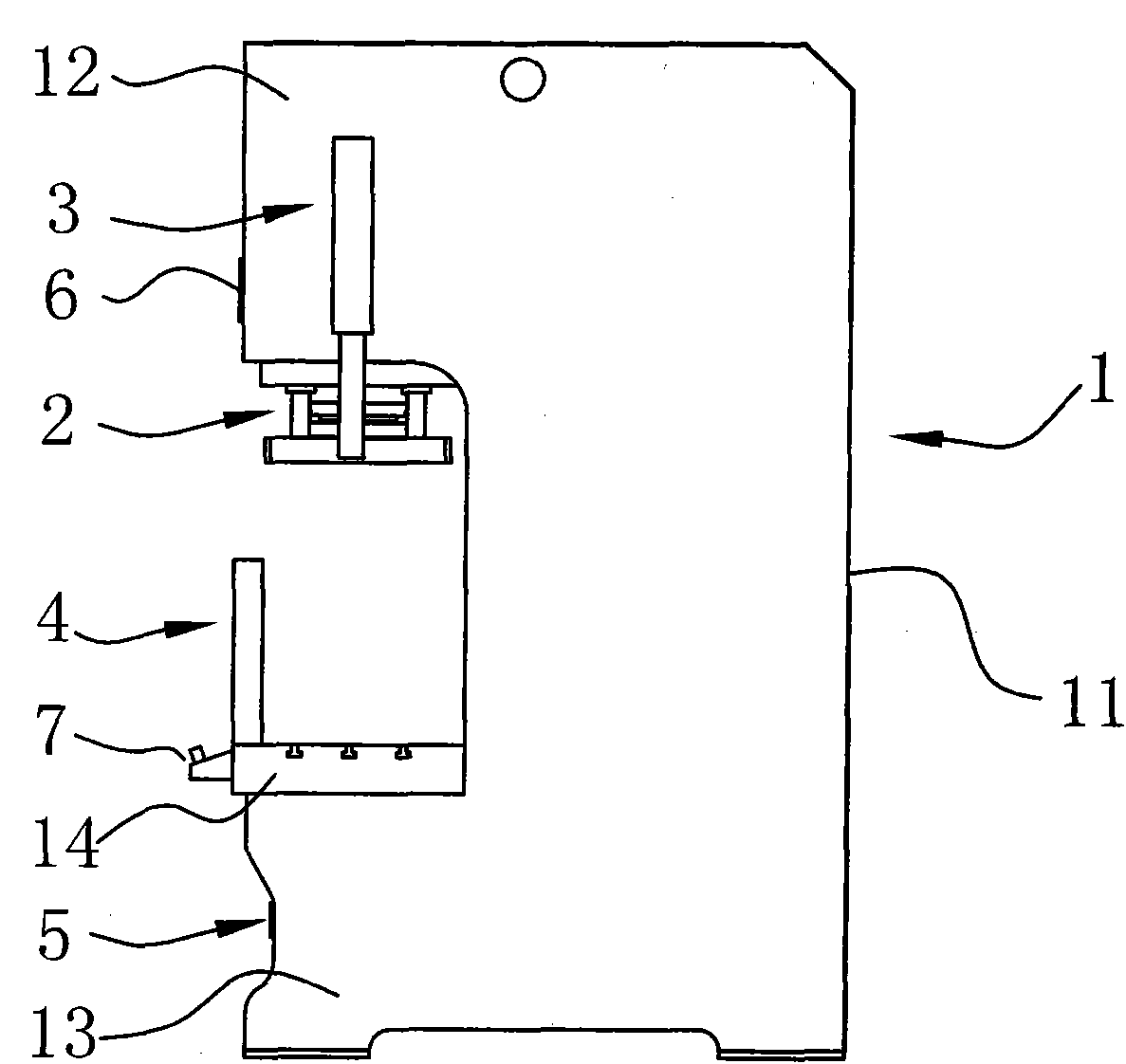

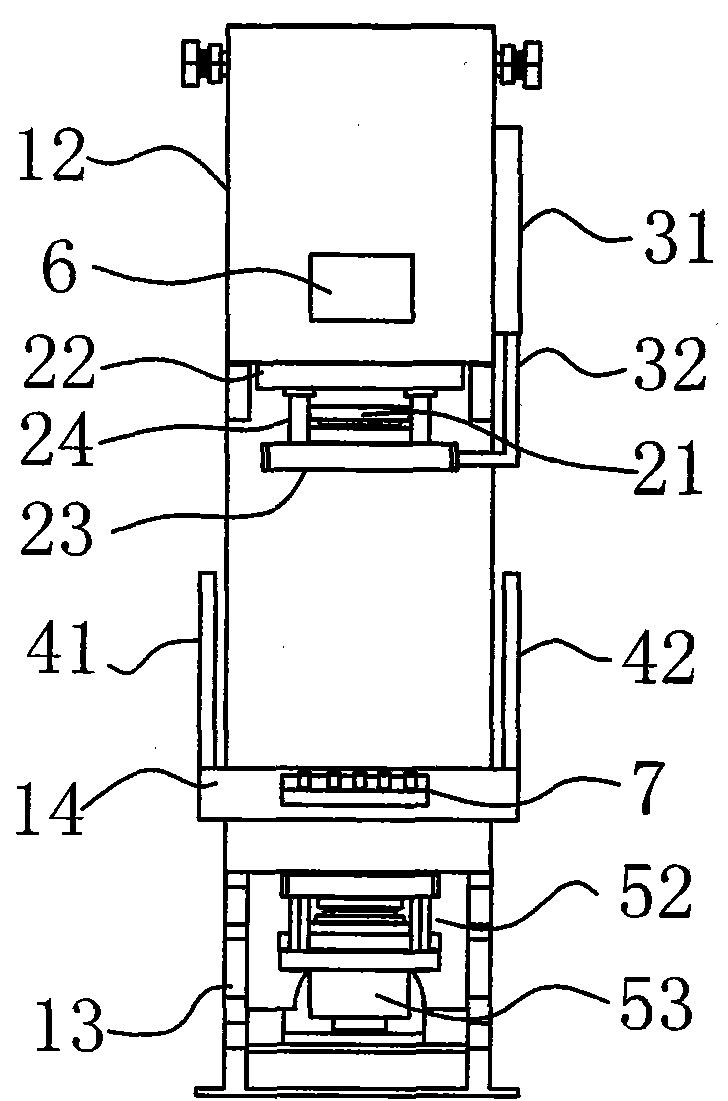

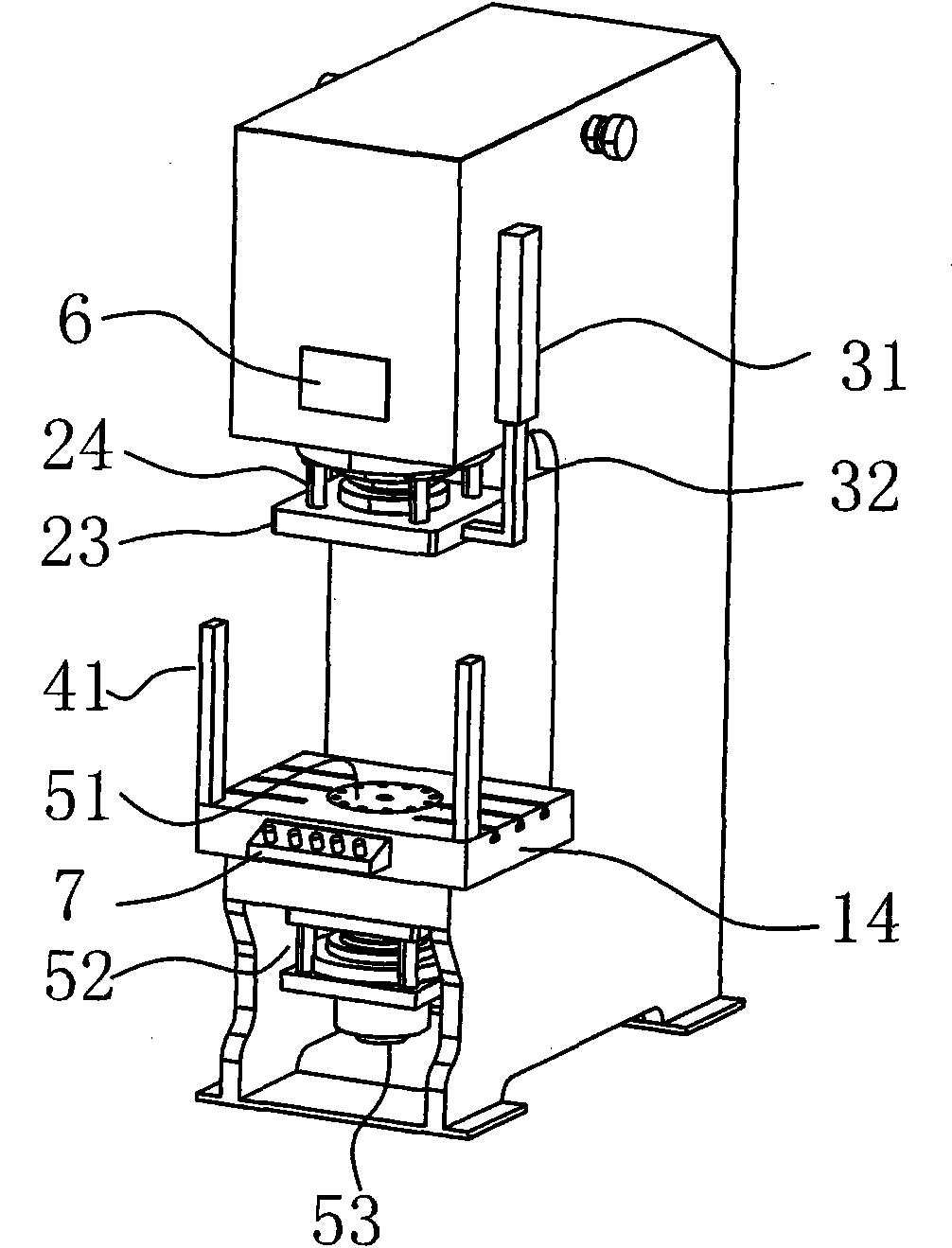

[0042] Example: see Figure 1 to Figure 4 , the present embodiment provides a servo electro-hydraulic composite pressure method, which includes the following steps:

[0043] (1) A frame 1 is set, and the frame 1 includes a support portion 11 and an upper convex portion 12 symmetrically arranged on the top of the support portion 11, and a lower convex portion 13 at the bottom, wherein the upper convex portion 12 and the lower convex portion 13 protrudes to the same side, and the overall outline is a "]" shape, the overall structure is ingeniously designed, the structure is strong, it is beneficial to improve stability, the volume is small, and the manufacturing cost is low; the protruding part of the lower convex part 13 A workbench 14 is provided on the upper surface;

[0044] (2) An upper hydraulic device 2 is arranged on the protruding position of the upper convex part 12 of the frame 1, and the upper hydraulic device 2 faces the direction of the workbench 14 to provide dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com