Automatically continuous carbon fiber winding device

A carbon fiber, automatic technology, used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of low degree of automation and affect the efficiency of wire collection, and achieve ingenious structural design, cost reduction, continuous collection. The effect of wire and coil change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

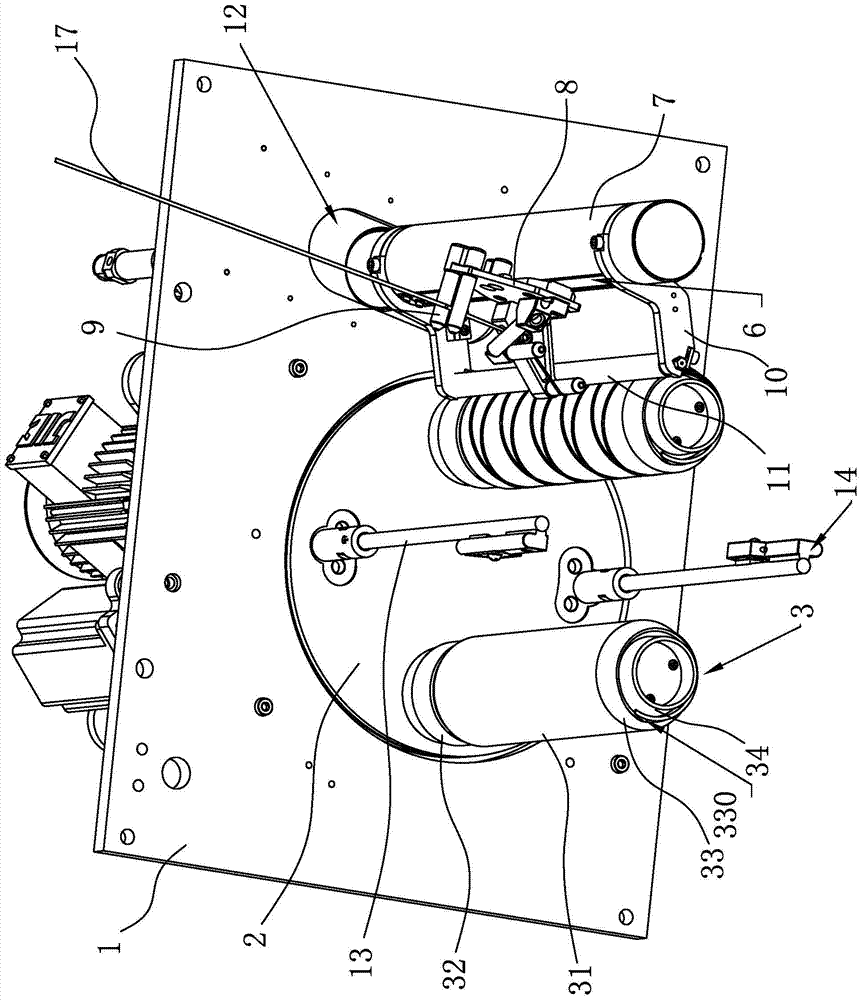

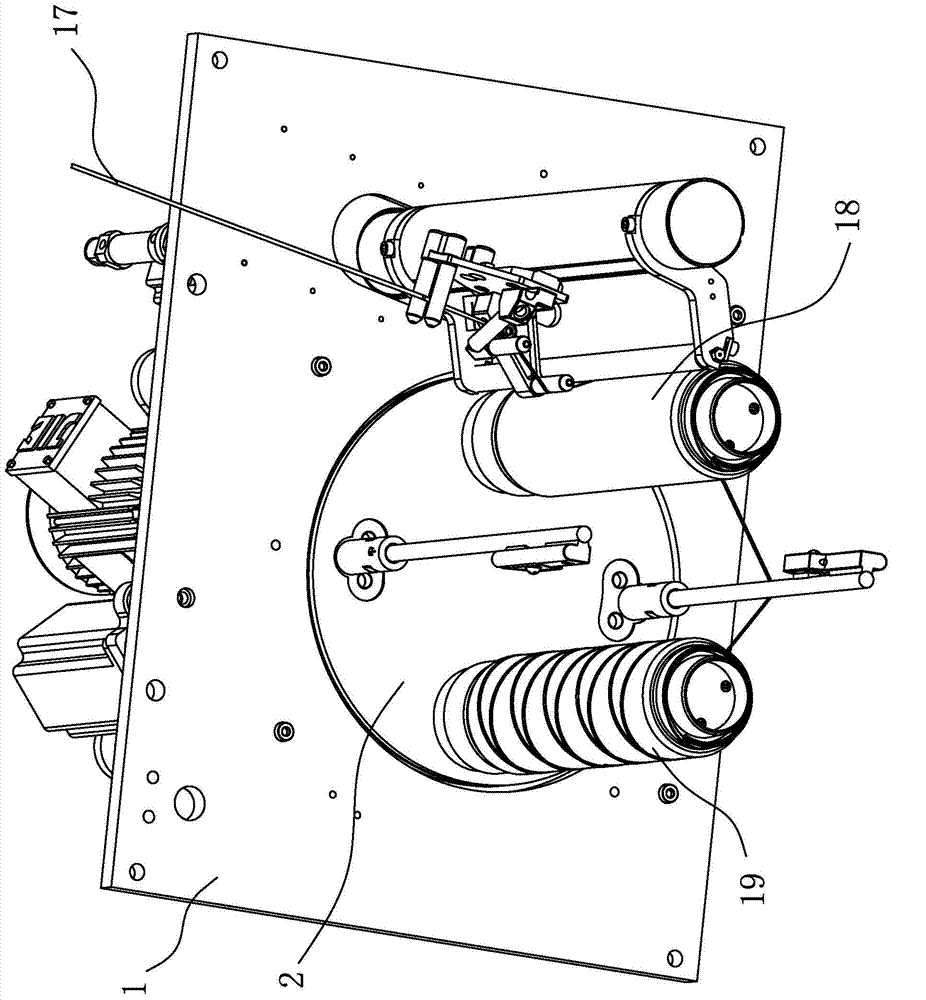

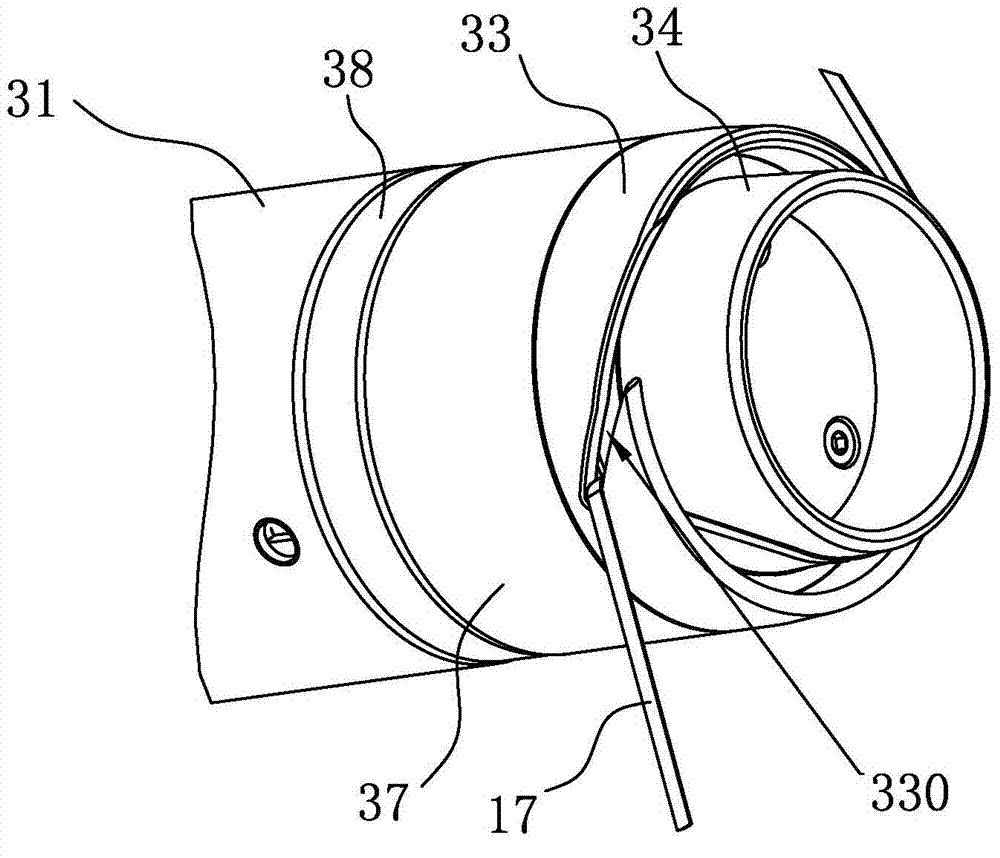

[0020] Embodiment: carbon fiber automatic continuous winding wire collection device, such as Figure 1-5 As shown, it includes a base 1, a wire guiding mechanism arranged on the base 1, a wire receiving replacement seat 2 provided with a reel seat, and a driving wire receiving replacement seat to replace the reel seat to make it alternately with the guide wire The mechanism is correspondingly provided with a reel changing drive mechanism, which drives the reel seat to rotate and winds and rewinds; the reel seat is fixedly connected with at least two reel seats 3 and each pair of reel seats. The seat is correspondingly provided with a wire cutting mechanism, and the wire guide mechanism, the roll changing drive mechanism and the winding and winding drive mechanism are all connected with an automatic control system signal.

[0021] The rewinding replacement seat 2 is disc-shaped, which is pivotally connected with the base 1, and each reel seat 3 is respectively connected to a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com