In-situ synthesized titanium-based composite material composite laminated component, and preparation method and application thereof

A titanium-based composite material, an in-situ self-generating technology, which is applied in the field of in-situ self-generating titanium-based composite material composite laminated components and their preparation, and the field of pressure diffusion connection preparation of in-situ titanium-based composite material composite laminated components, which can solve the problem of In the aerospace field, the application prospect is small, the plate connection cannot be realized, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

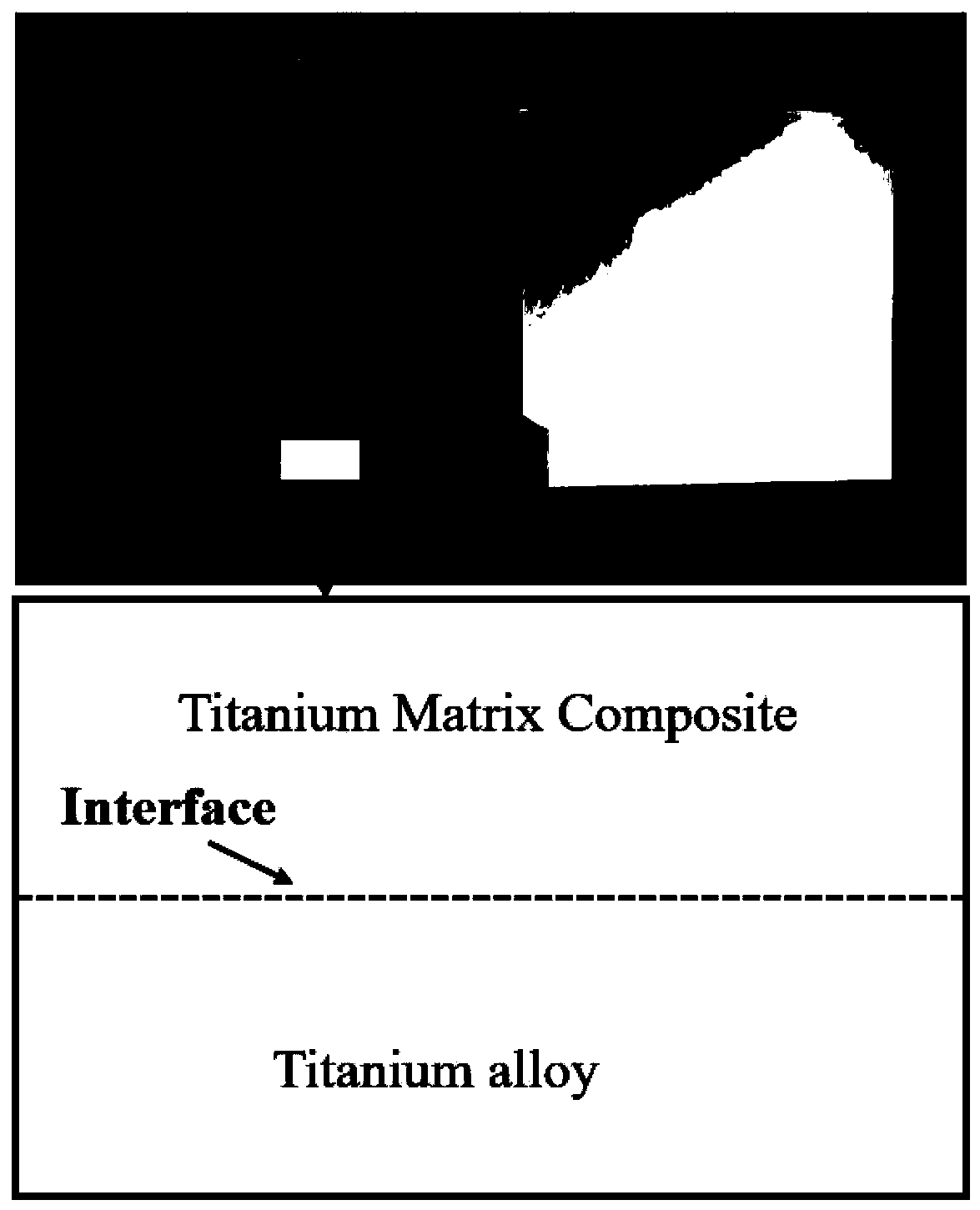

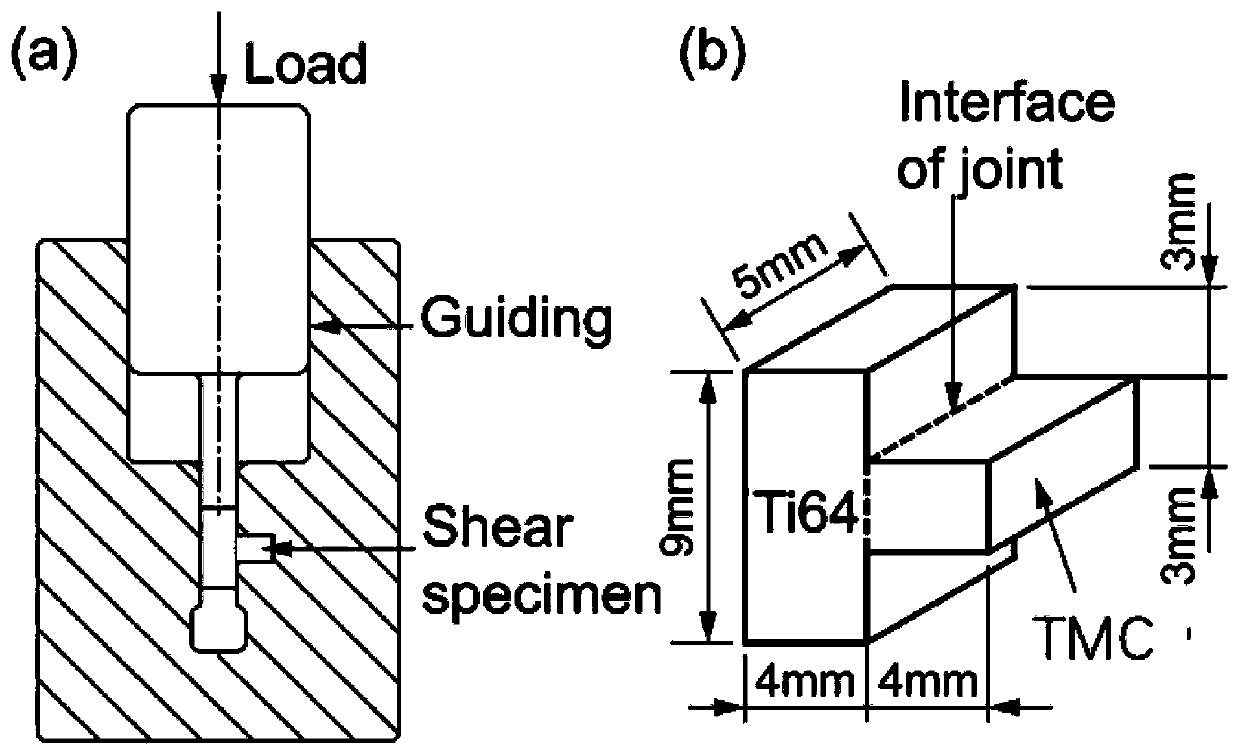

[0042] A method for preparing an in-situ self-generated titanium-based composite material composite laminated component, comprising the following steps:

[0043] A. Use wire cutting to process titanium-based composite materials and titanium alloy plate samples with the same size and uniform thickness. The specific size: 50mm×50mm×4mm, and the titanium alloy plate is Ti 6 Al 4 V titanium alloy, in-situ self-generated reinforcements in titanium matrix composites include TiB and TiC, the volume content of reinforcements is 5%, and the volume content of TiB and TiC reinforcements is 1:1;

[0044] B. Clean the surface of each plate sample, and then use 200#, 400#, 600#, 800#, 1000#, 2000# metallographic sandpaper to polish the surface of the sample step by step, and then put the polished sample plate Put it into acetone solution and clean it with ultrasonic waves. After cleaning, it can be packed in a sealed bag to ensure the integrity of the surface of the sample;

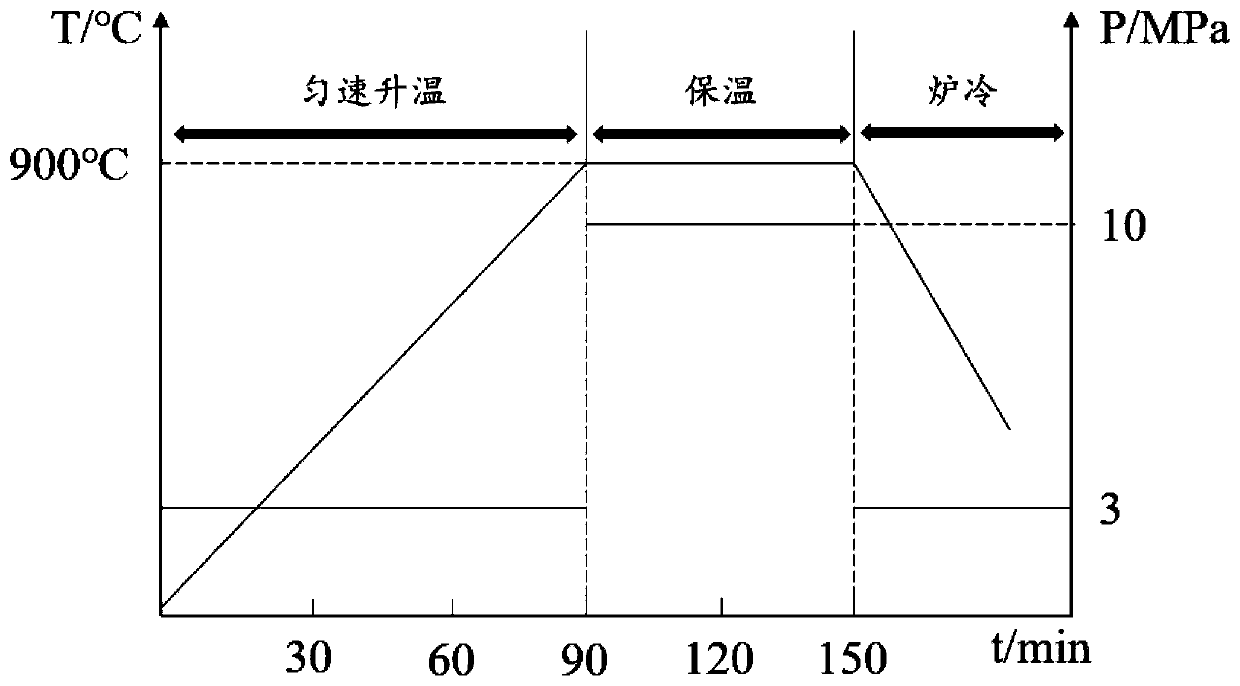

[0045] C. Ap...

Embodiment 2

[0054] A method for preparing an in-situ self-generated titanium-based composite material composite laminated component, comprising the following steps:

[0055] A. Wire cutting to cut titanium-based composites (Ti 6 Al 4 V-TiB) and pure titanium plates, cut into 50mm×50mm×4mm samples, the volume content ratio of TiB reinforcement is 3%;

[0056] B. Clean the surface of the titanium-based composite material and titanium alloy plate, first use a grinder to smooth it, and then use a relatively fine sandpaper to polish it to the surface roughness of 2000# sandpaper, and then put the polished sample plate into Use ultrasonic cleaning in acetone solution. After cleaning, it can be packed in a sealed bag to ensure the integrity of the surface of the sample;

[0057] C. Apply BN solution on the upper and lower surfaces of the plates in contact with the pressure mold, stick to each plate, and fix the four corners of the sample by spot welding, and then place it in a vacuum hot press...

Embodiment 3

[0061] A method for preparing an in-situ self-generated titanium-based composite material composite laminated component, comprising the following steps:

[0062] A. Wire cutting to cut titanium-based composites (Ti 6 Al 4 V-TiB / TiC) and titanium alloy (Ti 6 Al 4 V) plates, cut into 50mm×50mm×4mm samples, where TiB:TiC=1:1, and the total volume content ratio of the reinforcement is 10%;

[0063] B. Clean the surface of the titanium-based composite material and titanium alloy plate, first use a grinder to smooth it, and then use a relatively fine sandpaper to polish it to the surface roughness of 2000# sandpaper, and then put the polished sample plate Put it into acetone solution and use ultrasonic cleaning, after cleaning, it can be packed in a sealed bag to ensure the integrity of the surface of the sample;

[0064] C. Apply BN solution on the upper and lower surfaces of the plates in contact with the pressure mold, stick to each plate, and fix the four corners of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com