Patents

Literature

243results about How to "Shorten processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

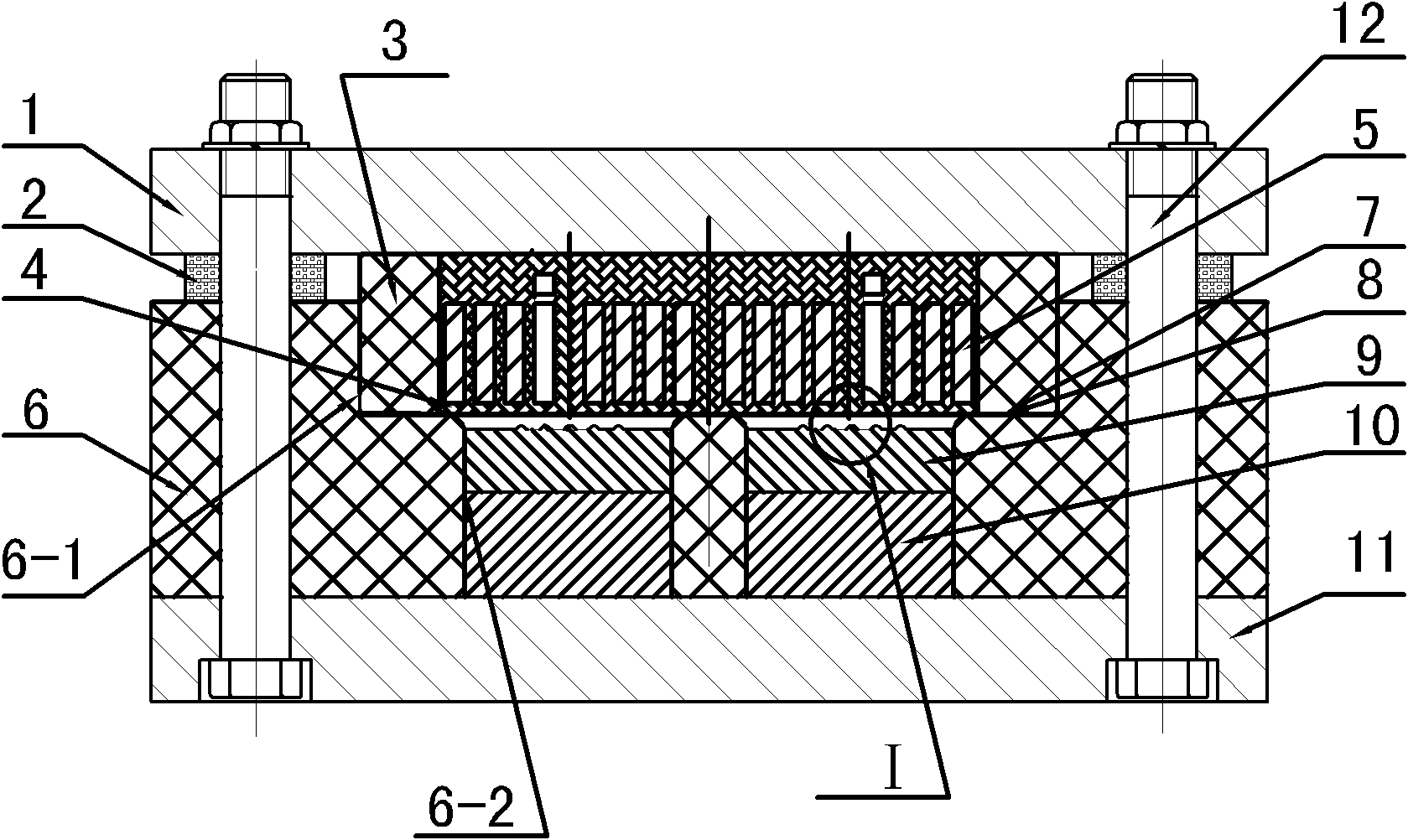

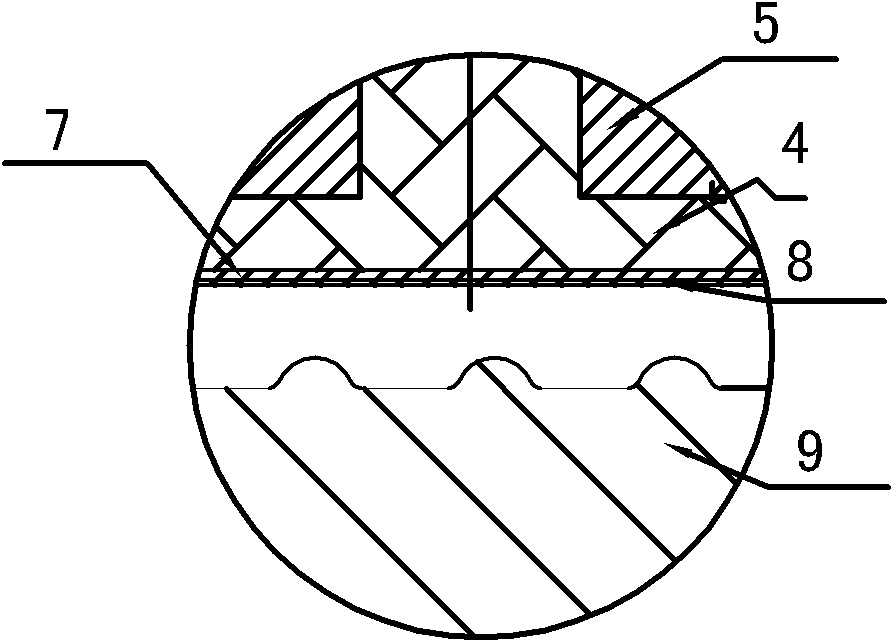

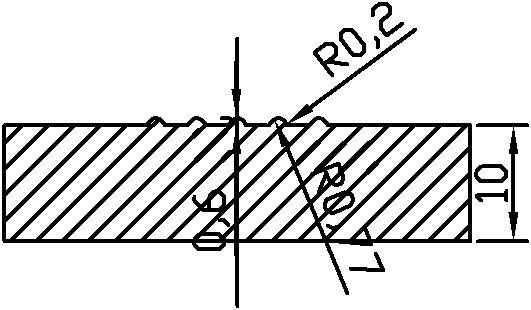

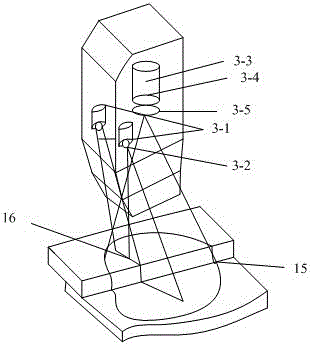

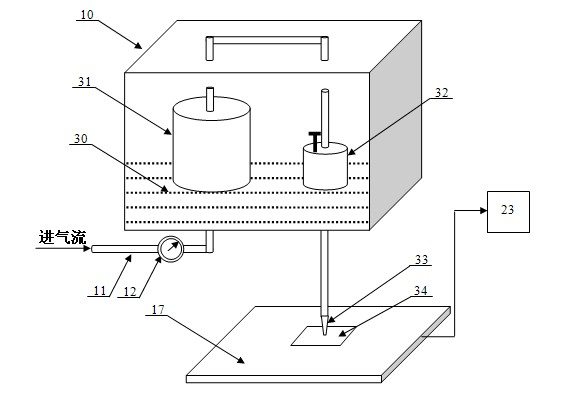

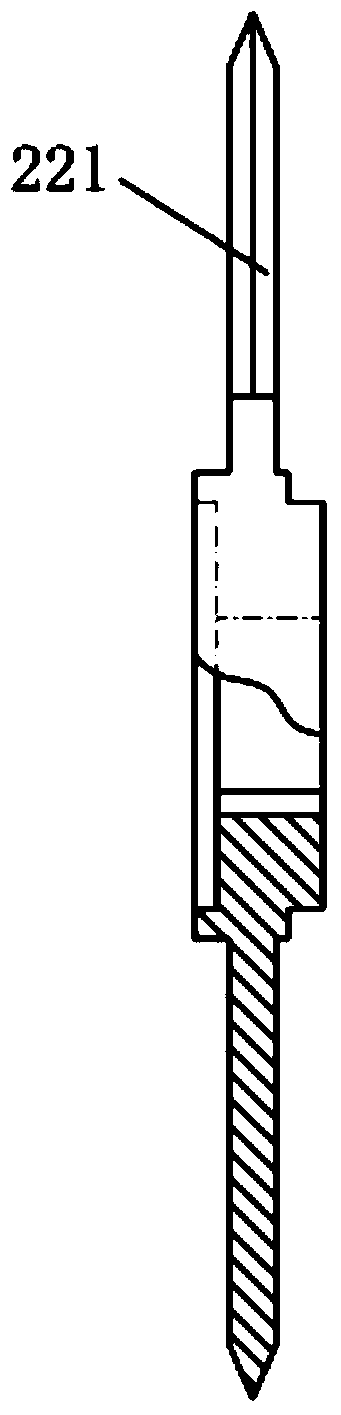

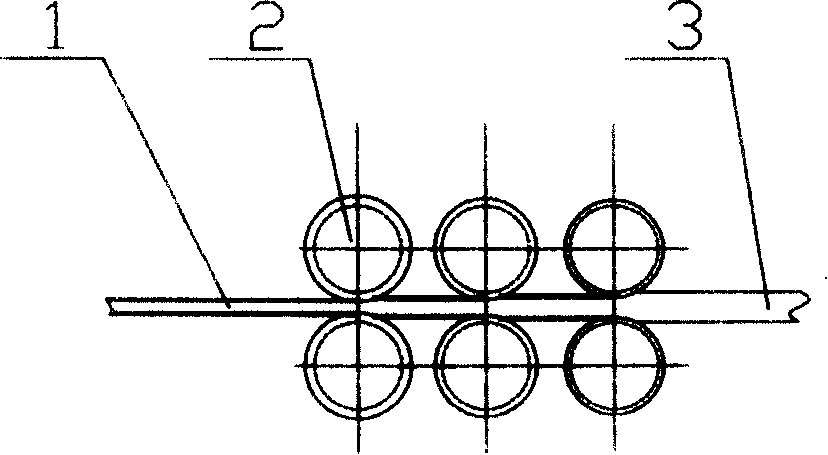

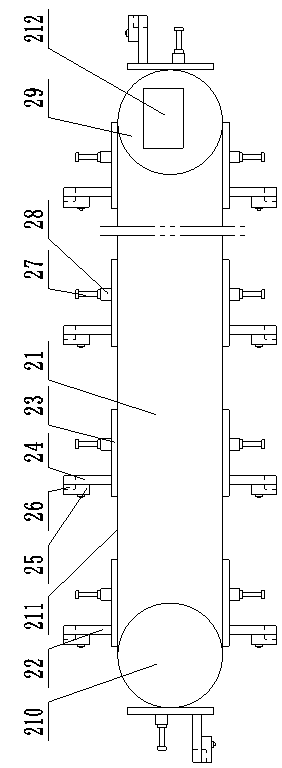

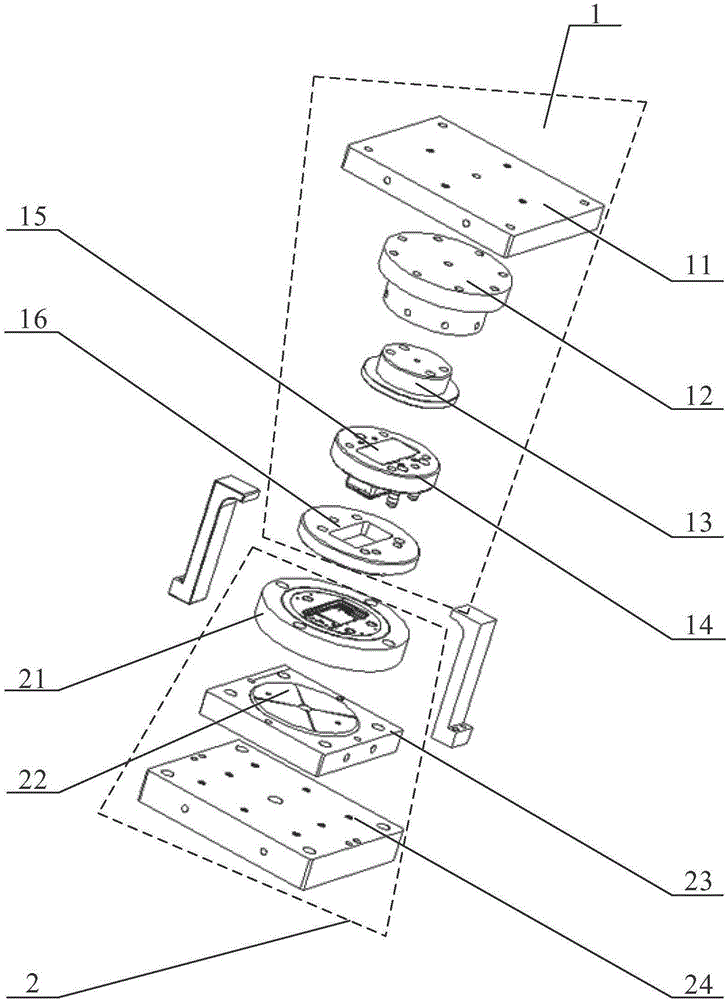

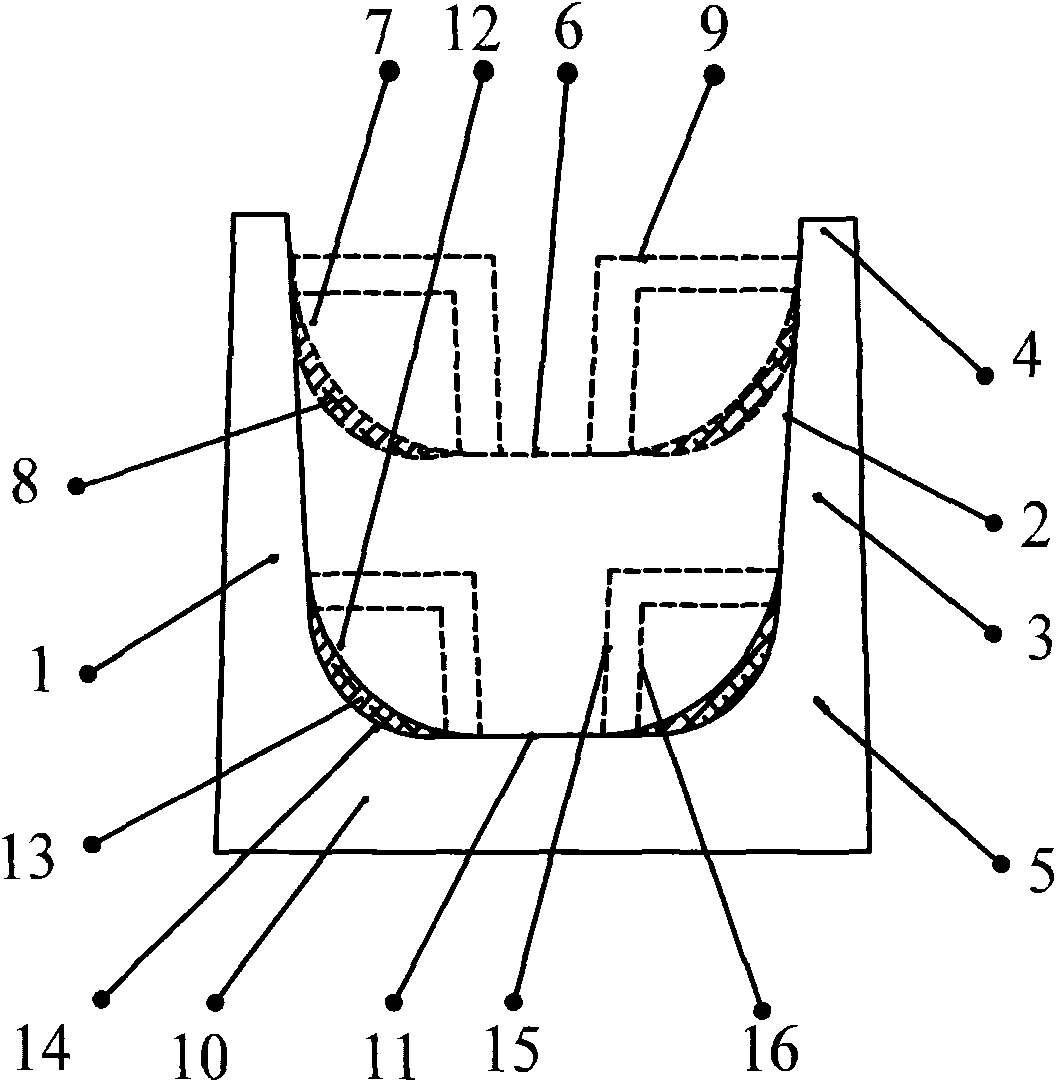

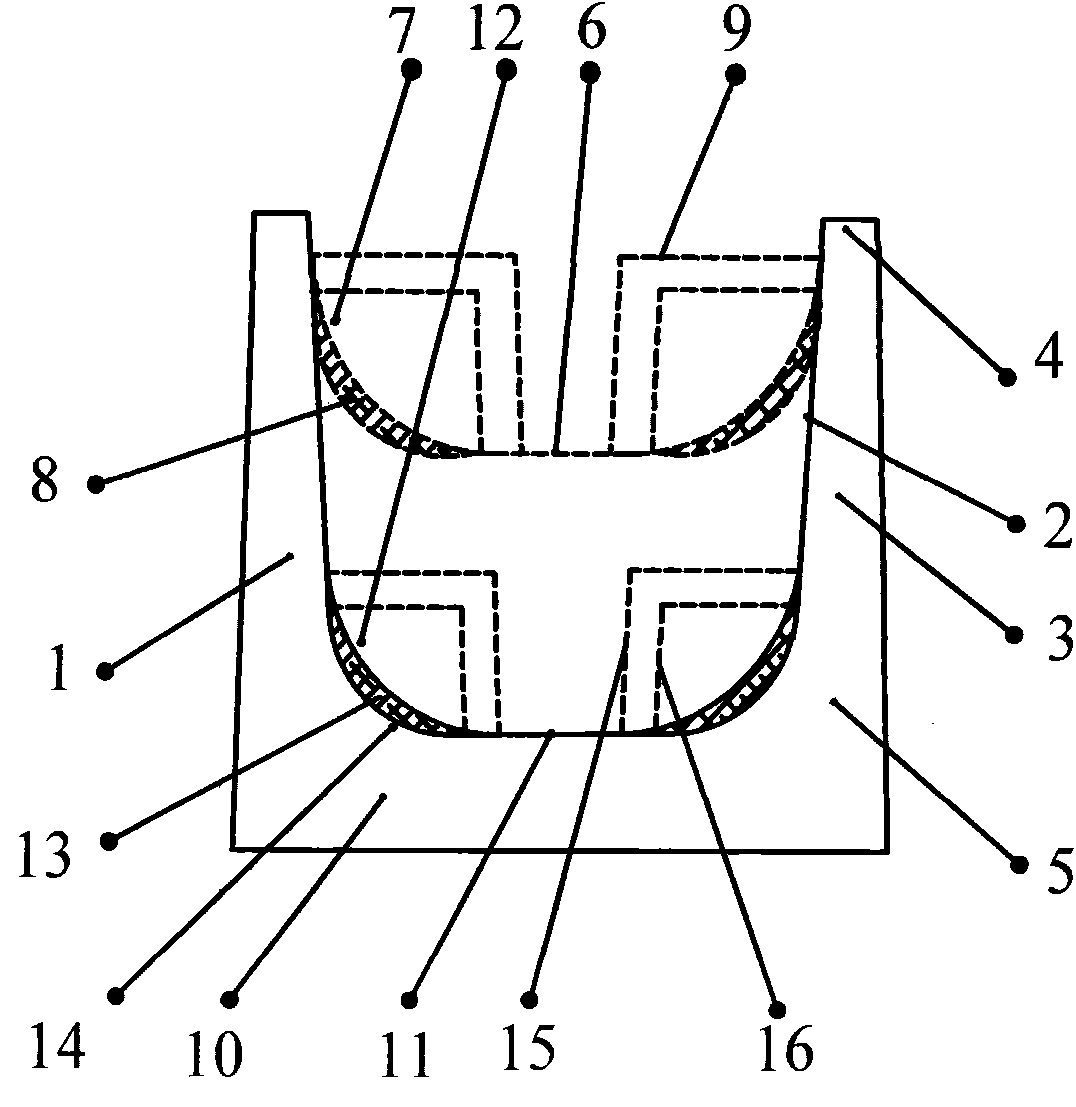

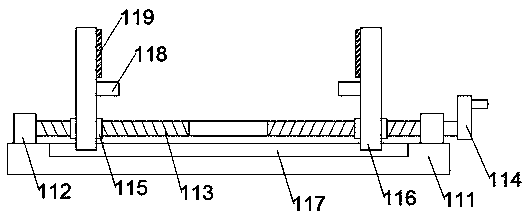

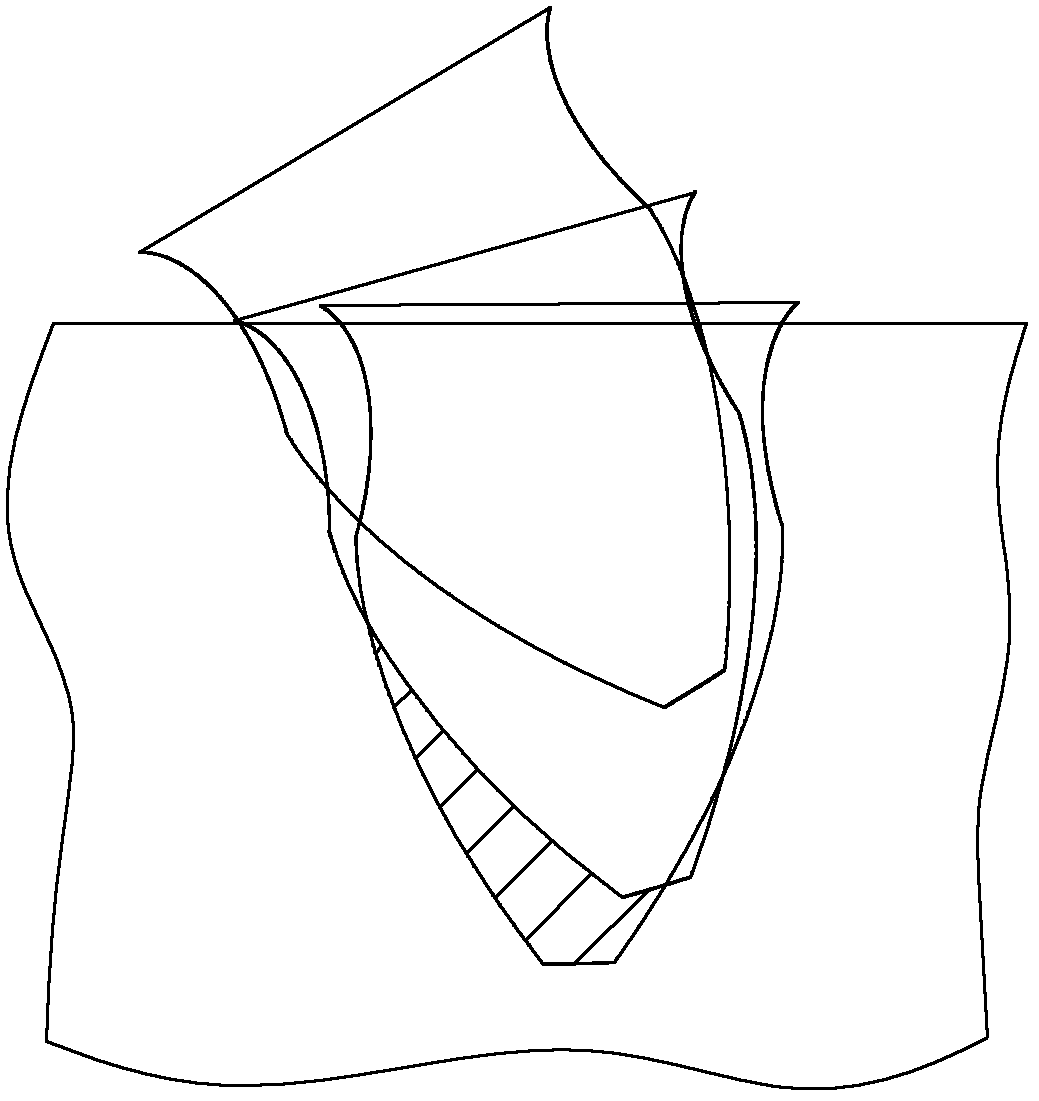

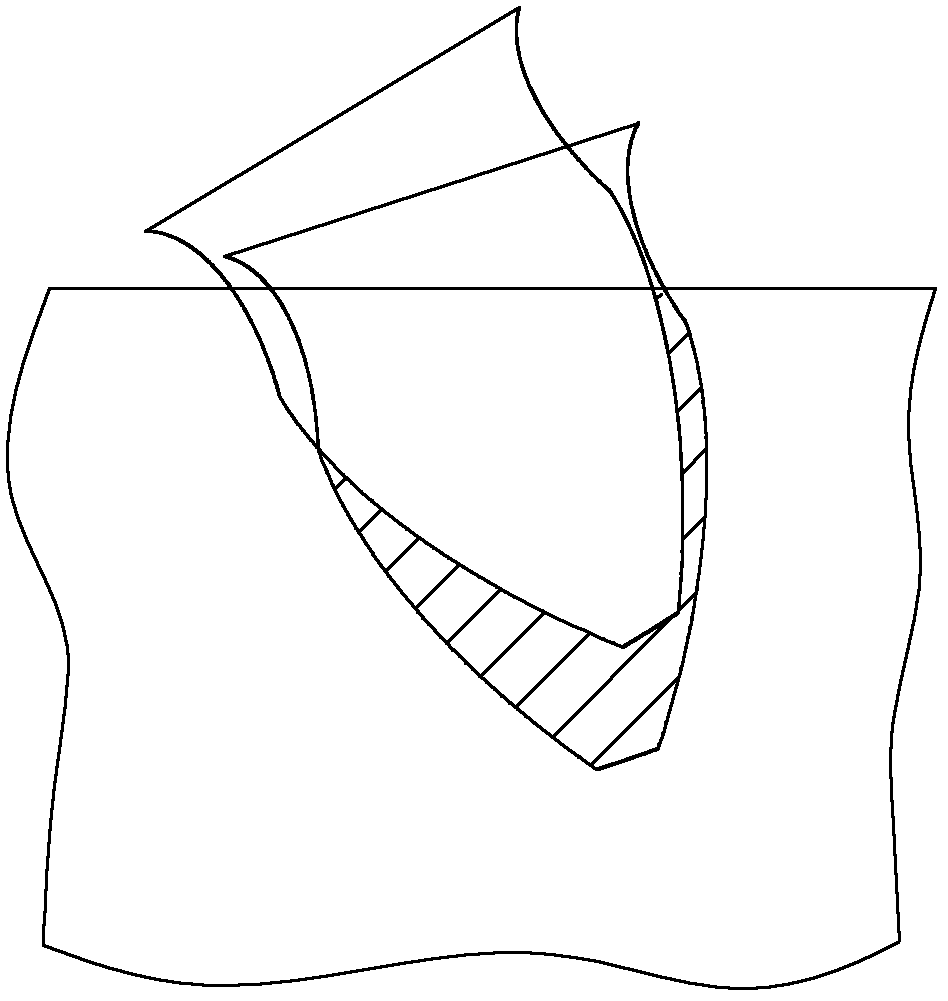

Electromagnetic forming device and method for micro fuel cell metal bipolar plate microchannel

The invention discloses an electromagnetic forming device and an electromagnetic forming method for a micro fuel cell metal bipolar plate microchannel, and relates to a micro fuel cell metal bipolar plate microchannel forming device and a micro fuel cell metal bipolar plate microchannel forming method so as to solve the problem of matching difficulty between micro male and female dies in the process of forming a microstructure on a metal thin plate based on stamping and other conventional plastic deformation means. The device comprises an upper template, a coil, a driving sheet, a die, a lower template and a fastening bolt; a groove is formed on the surface of a supporting frame so as to accommodate the coil; a circular through hole is formed in the center of the bottom of the groove so as to accommodate the die; the driving sheet is arranged above the die; and an axial lead of the coil is in upper and lower directions. The method comprises the following steps of: discharging to the coil to excite a strong pulsed magnetic field; generating induced eddy on the surface of the driving sheet so as to generate a magnetic field opposite to the magnetic field of the coil in the transient strong pulsed magnetic field; and driving a plate blank to make die attaching motion by using the driving sheet under repellent applied force between the magnetic fields. The invention is used for micro-forming.

Owner:HARBIN INST OF TECH

Preparation method of particle-reinforced metal matrix composite

ActiveCN106541129AHigh strengthShorten processing timeAdditive manufacturing apparatusTransportation and packagingThree dimensional modelPhotoinitiator

The invention discloses a preparation method of a particle-reinforced metal matrix composite. The preparation method comprises the steps that reinforcement powder, metal powder and a dispersing agent are added into a ball grinder to be subjected to ball grinding and mixing, and uniformly-mixed solid powder is obtained; the solid powder obtained after ball grinding is added into a photocuring monomer, then a dispersing agent, a defoaming agent and an anti-settling agent are added, a photoinitiator is added under the dark condition, stirring is carried out, and slurry is obtained; a part three-dimensional model is guided into data processing software for data processing, then the slurry is contained in photocuring equipment, printing parameters are set, and by means of ultraviolet light beams, layer-by-layer printing is carried out according to a design model to prepare a particle-reinforced metal matrix composite part blank; and an organic binder of the cured and formed blank is removed through low-temperature sintering, and then a composite part is formed through sintering. According to the preparation method, the complex part can be formed, dependency on molds can be eliminated, the manufacturing cost can be reduced, the machining duration can be shortened, and the forming efficiency can be improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

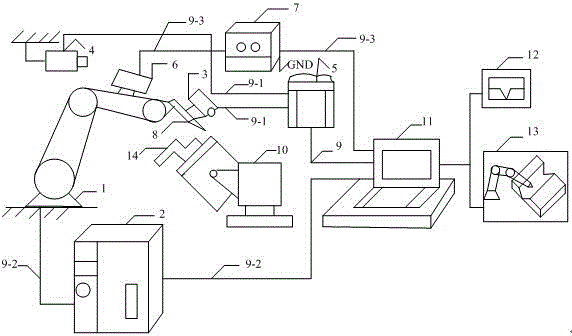

Automated welding machining system for non-standard components based on structural light vision

PendingCN106238969AShorten processing timeImprove labor productivityWelding/cutting auxillary devicesAuxillary welding devicesSix degrees of freedomStructure based

The invention provides an automated welding machining system for non-standard components based on structural light vision. The automated welding machining system comprises a weld joint visual detection system, a welding executing system, a communication and control system, a robot controller and a welder controller, wherein the weld joint visual detection system is used for recognizing weld joints, detecting positions, monitoring progress and transmitting images to the communication and control system; the welding executing system is used for executing welding action, and comprises a six-degree-of-freedom industrial robot, a welder and a welding gun; the communication and control system is used for realizing communication and process control, uses an industrial control computer as main control equipment and finishes the functions of displaying a welding process, processing the images, carrying out data operation and sending instructions; the robot controller receives instruction signals from the industrial control computer and controls the joint movement of the six-degree-of-freedom industrial robot so as to adjust the pose of the welding gun; and the welder controller receives the instruction signals from the industrial control computer and controls welding parameters, such as welding current and wire feed speed. The automated welding machining system can accurately detect and recognize features, such as weld joint types, positions and shapes, stably improve the welding machining quality of the non-standard components and greatly increase the production efficiency.

Owner:NANJING CHINA CONSTR CHEM EQUIP MFG +3

Flower cake stuffing and preparation process thereof

The invention belongs to the technical field of food processing, and in particular relates to a flower cake stuffing and a production process thereof. The stuffing comprises flower sauce and other auxiliary materials, and is characterized by comprising the following components in part by weight: 40 to 45 parts of rose sauce, 20 to 25 parts of candied wax gourd, 5 to 10 parts of cooked powder and 10 to 15 parts of honey. By optimizing the formula of the traditional cake stuffing and the processing technology, the flavor of the cake is improved, the processing time is shortened, and the white granulated sugar content is reduced, so the cost is reduced, the ratio of the rose sauce to the candied wax gourd in the stuffing is optimized, the stuffing preparation process is improved, mechanical quantitative stuffing preparation is realized on the premise of ensuring the viscosity and mouthfeel of the stuffing, the production efficiency is improved, pollution caused by manual stuffing preparation is reduced, the shelf life of the cake foods is prolonged, and a new field is opened for the cake industry.

Owner:高厚基

Application of solid microbe fermentation technology in processing Puer tea

InactiveCN1930995AShorten processing timeReduce manufacturing costPre-extraction tea treatmentChemistrySaccharomyces cerevisiae

The present invention is application of solid microbe fermentation technology in processing Puer tea, and belongs to the field of biotechnology. The application method is to add beneficial strain of aspergillus oryzae, aspergillus niger or Saccharomyces cerevisiae or their mixture in the ratio of 1 to 1 to 1 or 1 to 2 to 1 into Puer tea producing process, with the added amount being 0.01-0.05 wt% of the Puer tea. The present invention has the advantages of controllability of the contents of tea polyphenol, tea brown pigment, tea polysaccharide and other functional matters, shortened processing period of Puer tea, lowered production cost and raised quality of Puer tea.

Owner:秘鸣

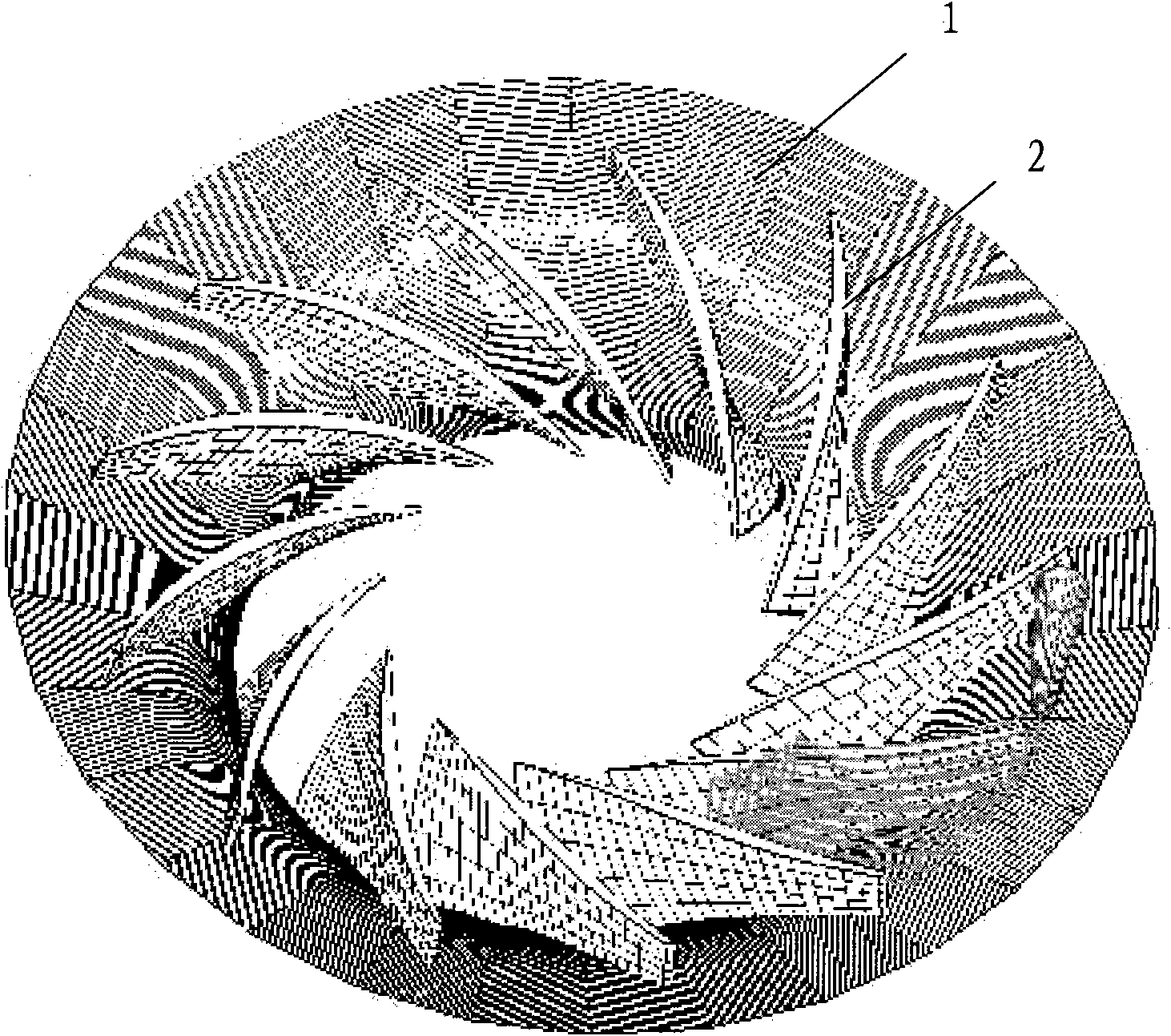

Milling method for ternary impeller with large diameter

ActiveCN102107295AShorten processing timeReduce tool costsMilling equipment detailsImpellerEngineering

The invention relates to a manufacturing method for a ternary impeller of a compressor, in particular to a milling method for a ternary impeller with large diameter. The method comprises the following steps: generating a data file from the blade type and hub data of the calculated ternary impeller with large diameter, and inputting the data file into an operation platform; defining the rotating direction of blades, the quantity of the blades, a blade fillet and a blade round head manner; carrying out three-dimensional entity modeling by using the existing operation platform to generate an impeller ternary model file; clamping an impeller blank on a work table of a five-axle numerical control manufacturing center; linking three linear axles and fixing two rotating axles; firstly milling the welding line of the slot body of the short blade, and welding the short blade; after vacuum stress relieving, milling the welding line of the slot body of the long blade; and welding the welding line of the slot body of the long blade and milling the welding line. In the invention, the process time of the impeller is shortened; and compared with the traditional processing method, the process time can be shortened by more than twice, the cost of the cutter is reduced by eight folds, and the service life of machine tool is greatly prolonged.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

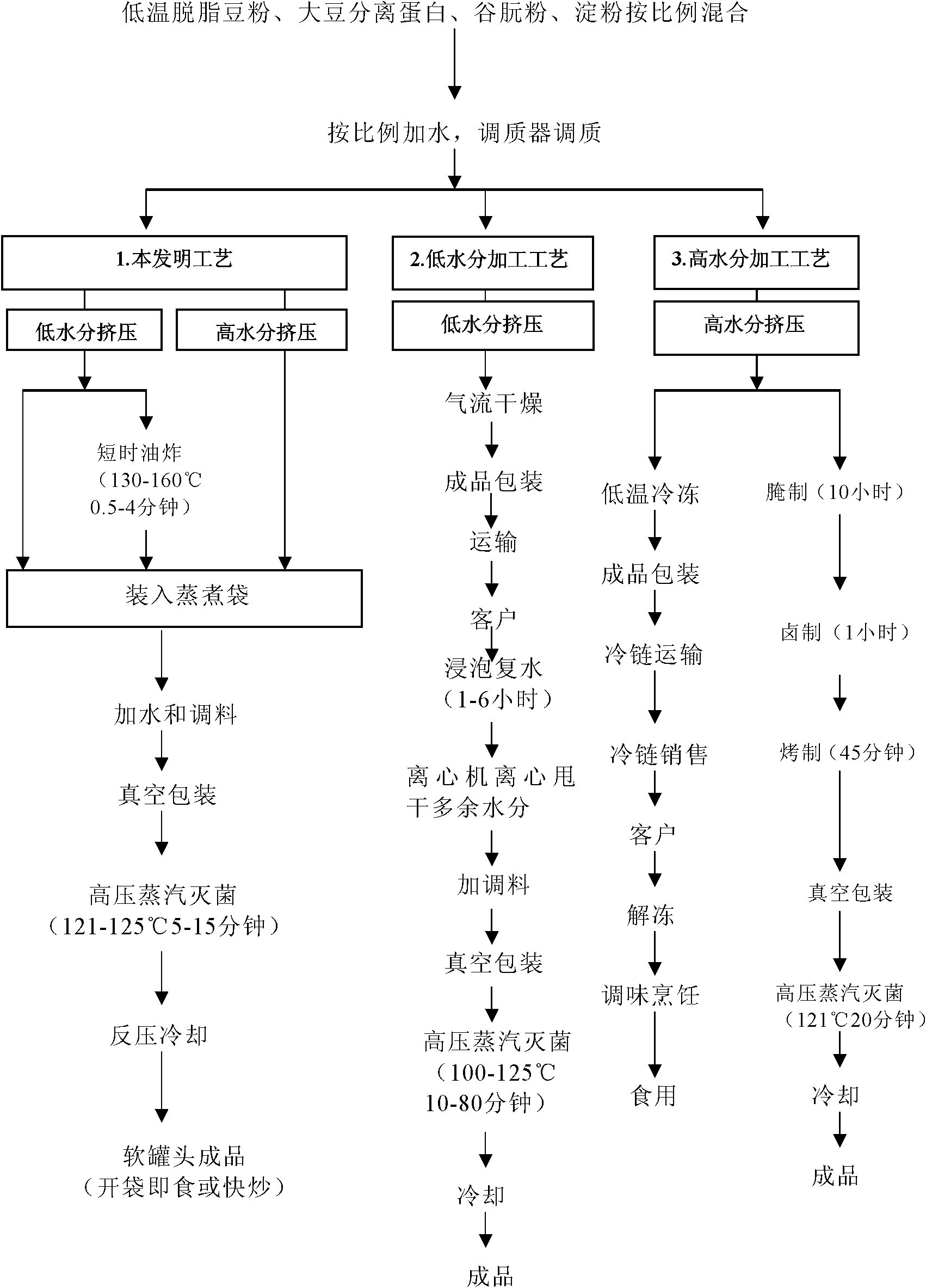

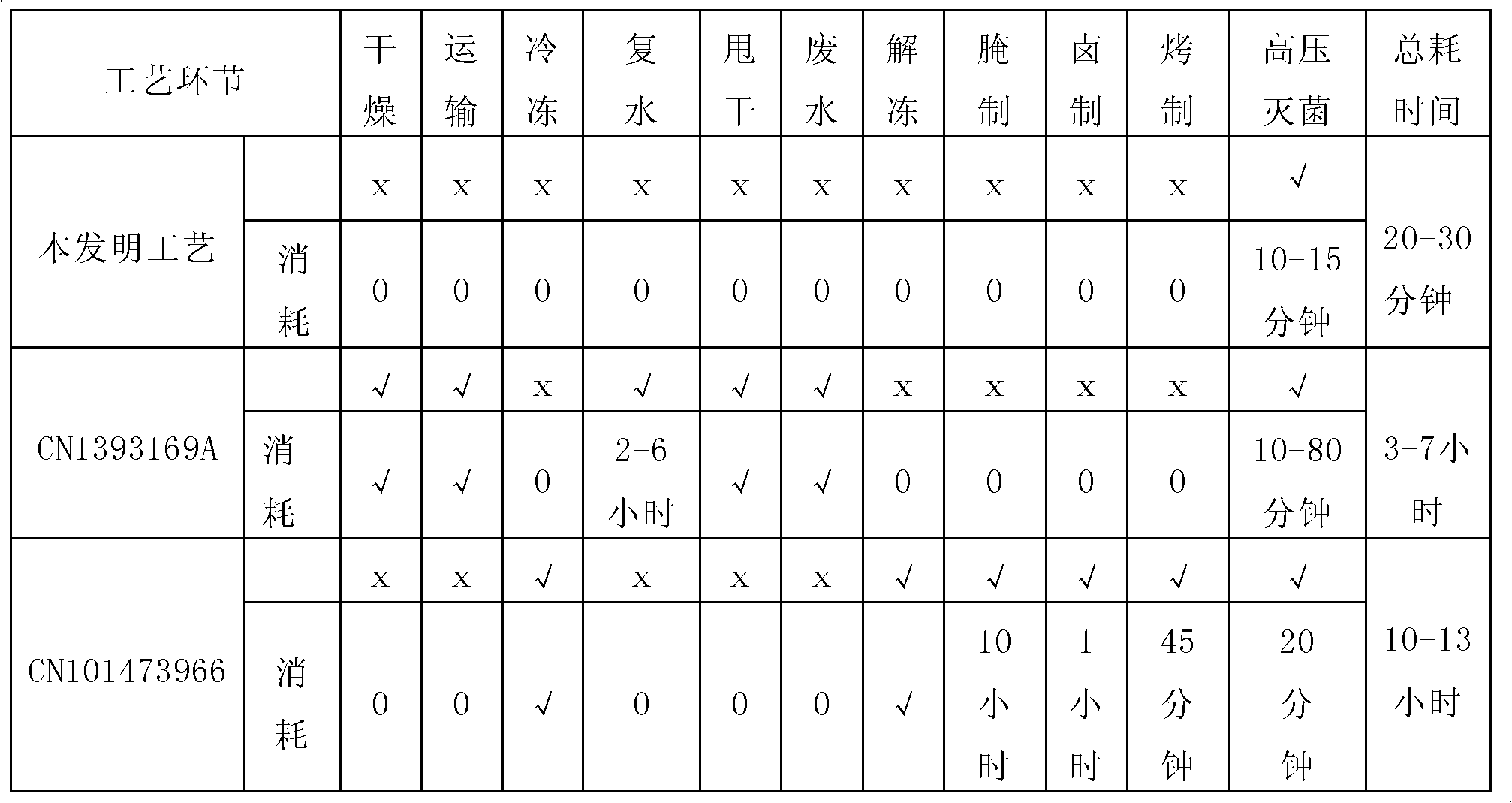

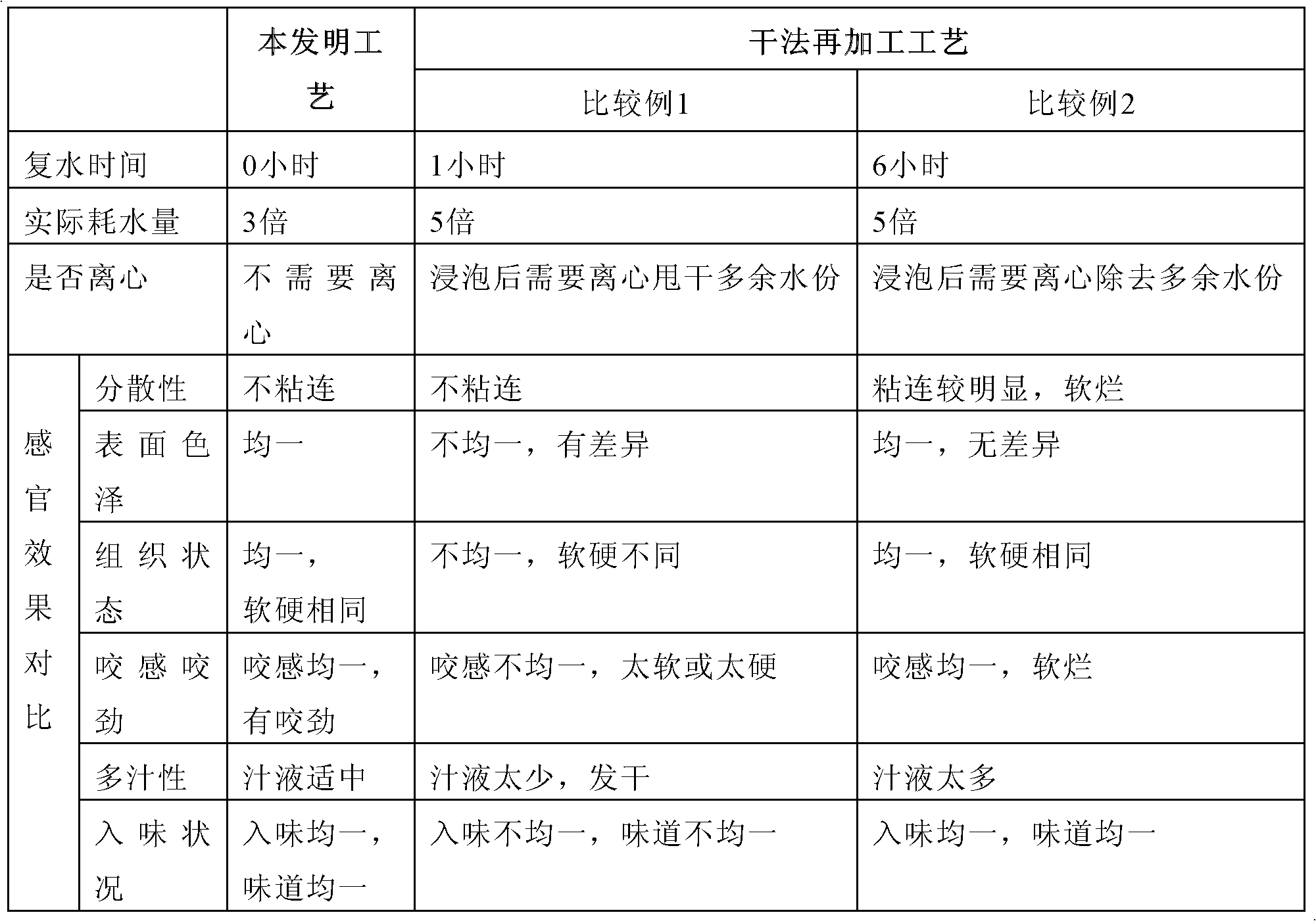

Method for continuous production of tissue protein food

InactiveCN102461726AShorten processing timeReduced risk of microbial contaminationVegetable proteins working-upFlavorTissue protein

The present invention relates to a method for continuous production of a tissue protein food, tissue protein, and a food containing the tissue protein or a food prepared by the method. According to the present invention, the method of the present invention has characteristics of convenience, rapidness and energy saving; the produced food does not has bean state and beany flavor, and has characteristics of good taste, tissue structure similar to meat, good toughness, elasticity, high protein, low fat, nutrition and health. In addition, the food can be eaten after package opening, rapid stir-frying or instant cooking, and is convenient to eat, and the guarantee period at the room temperature is long.

Owner:秦皇岛金海食品工业有限公司

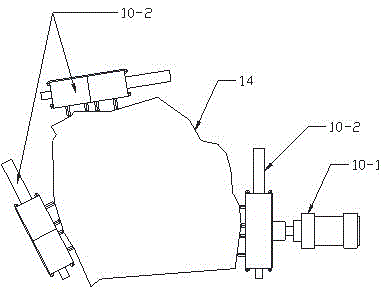

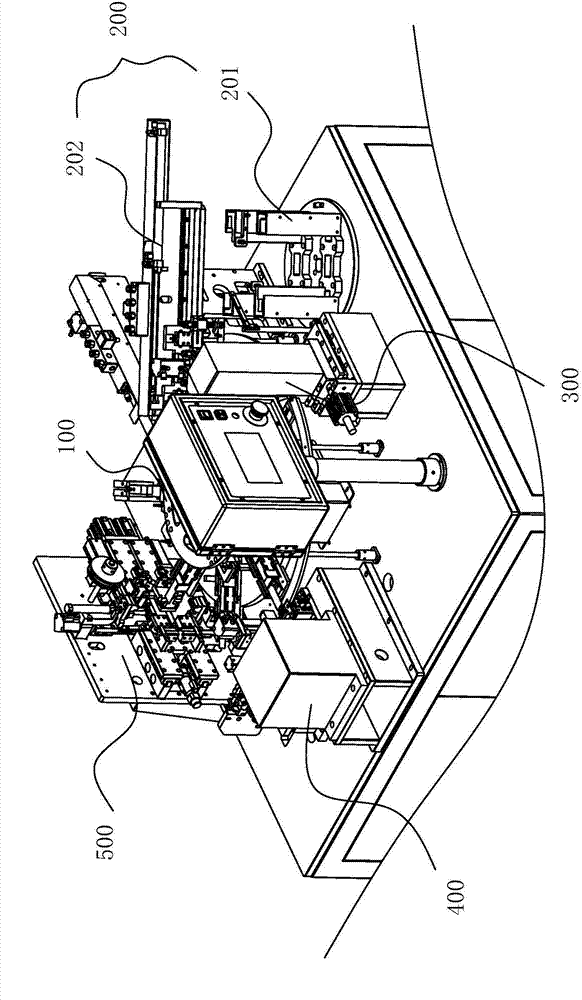

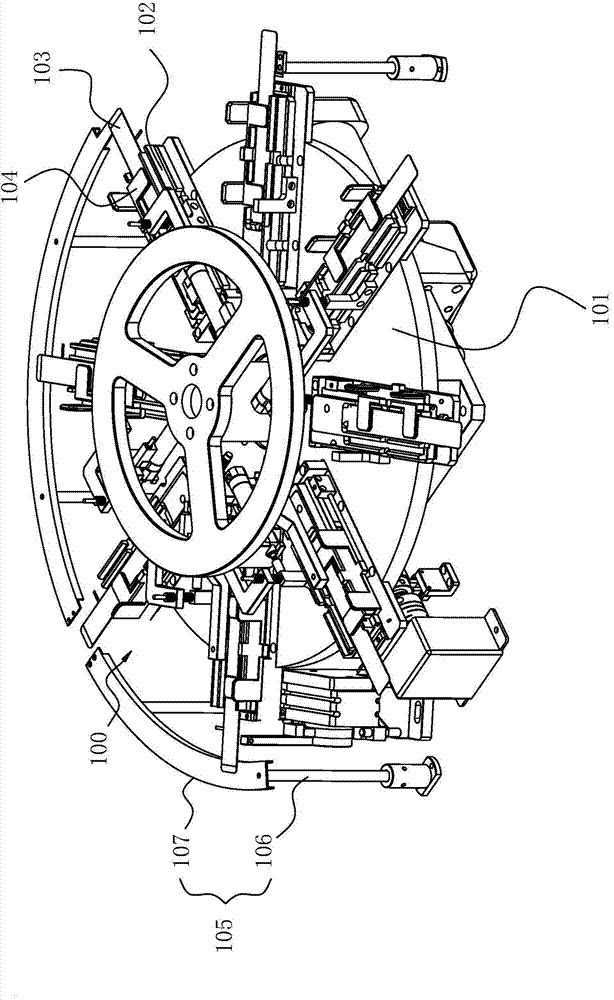

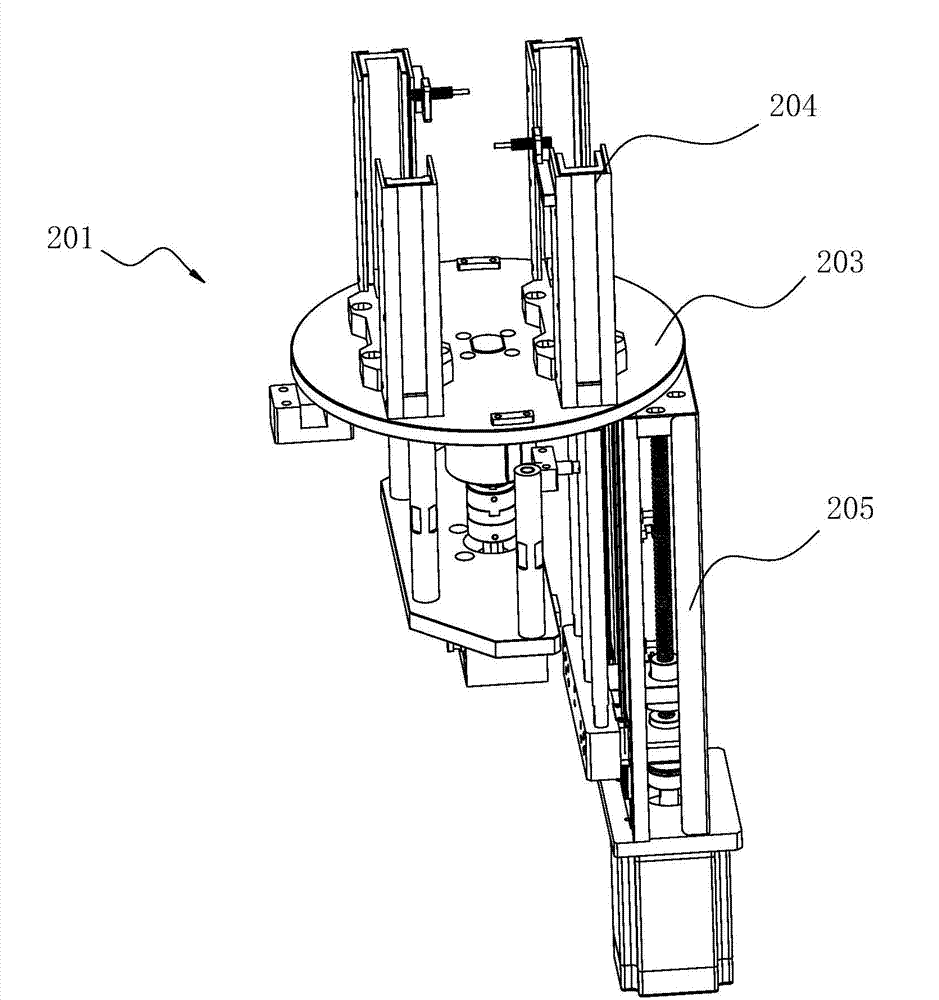

Automatic electrode slice current-collection and conductive tab welding equipment

ActiveCN104332580AShorten processing timeImprove work efficiencyCell component detailsNon-electric welding apparatusEngineeringElectrical and Electronics engineering

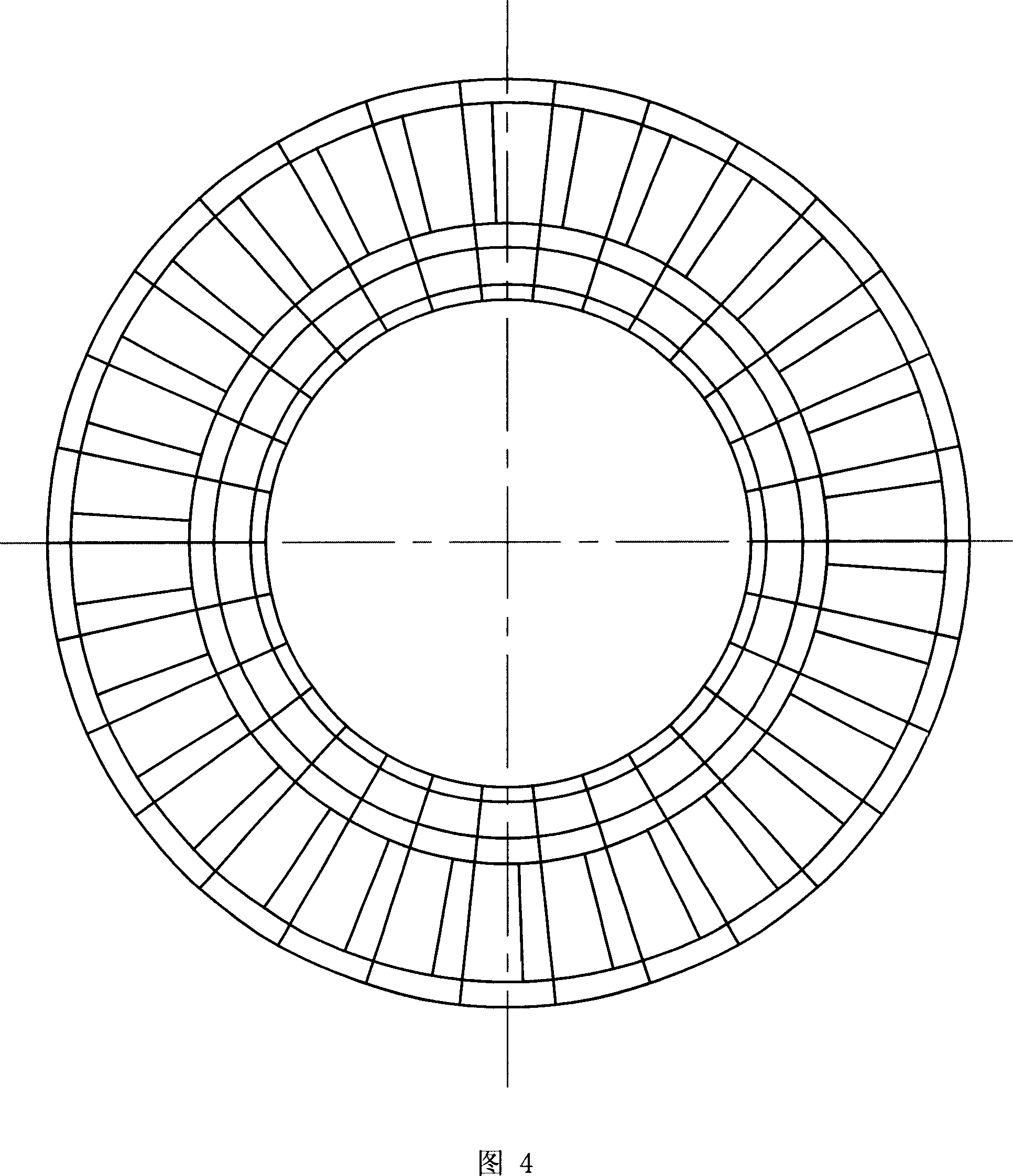

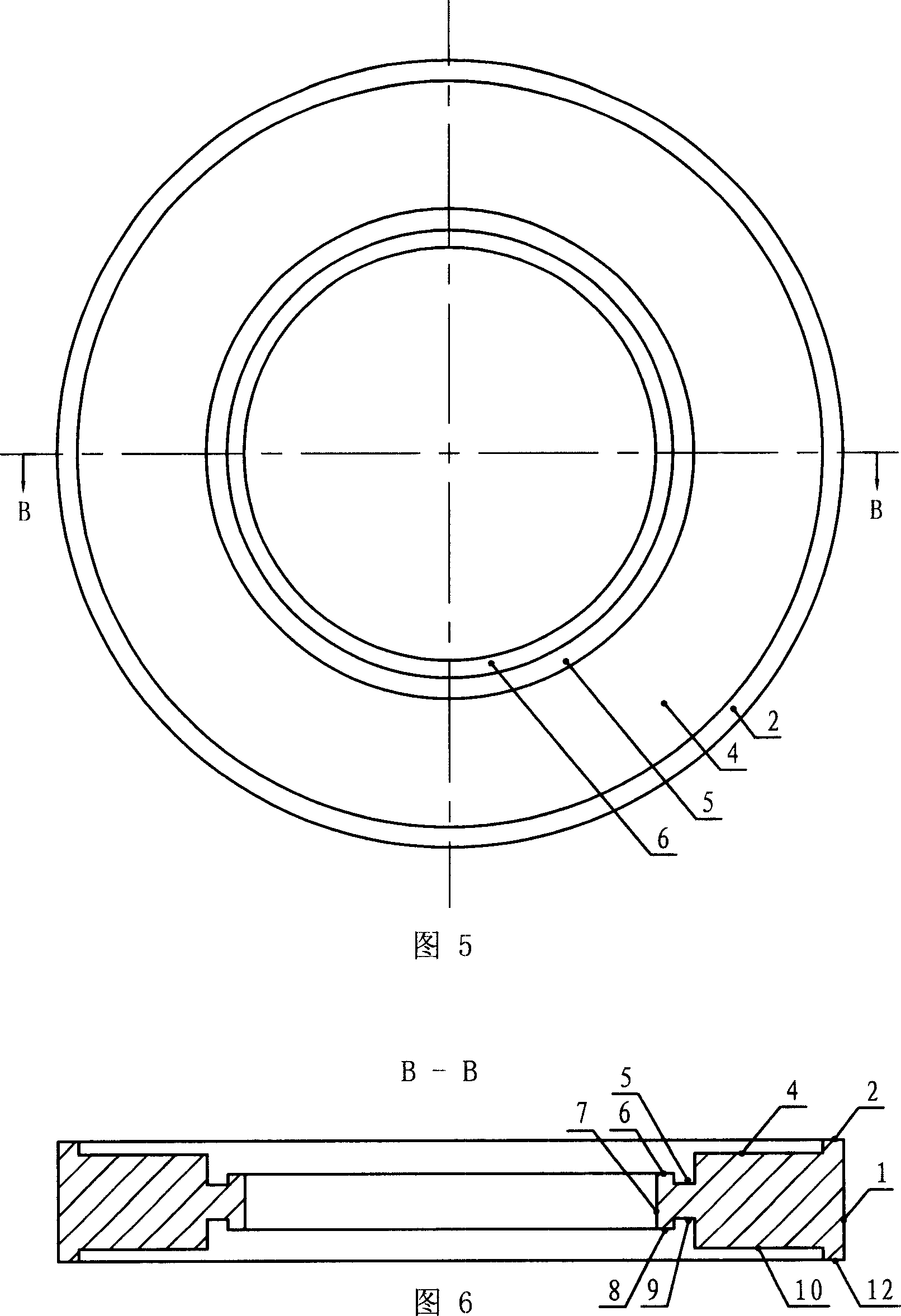

The invention discloses automatic electrode slice current-collection and conductive tab welding equipment. The automatic electrode slice current-collection and conductive tab welding equipment comprises a rotary worktable for conveying an electrode slice, wherein the periphery of the rotary worktable is sequentially provided with a feeding device for conveying the electrode slice to the rotary worktable, a powder cleaning device for cleaning powder at the position in which a current-collection and conductive tab is welded on the electrode slice, a spot welding device for welding the current-collection and conductive tab on the electrode slice, and a rubberizing device for rubberizing the welded electrode slice; the rotary worktable can rotate along the distribution direction of the feeding device, the powder cleaning device, the spot welding device and the rubberizing device, and corresponding machining is carried out on the feeding device, the powder cleaning device, the spot welding device and the rubberizing device; powder cleaning, spot welding and rubberizing operation are carried out on the electrode slice can be finished by one set of equipment; feeding and discharging do not need to be repeatedly carried out in the process so that the machining time is saved and the working efficiency is improved; the automatic operation is realized in the whole process and the manpower cost is saved; and hands are prevented from being in contact with the electrode slice, and the quality of a product can be effectively guaranteed.

Owner:EVE ENERGY CO LTD

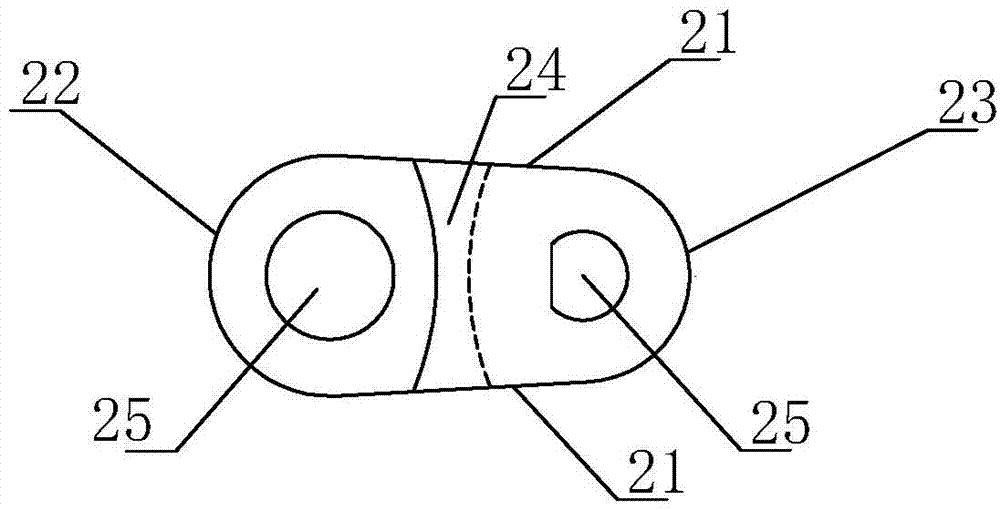

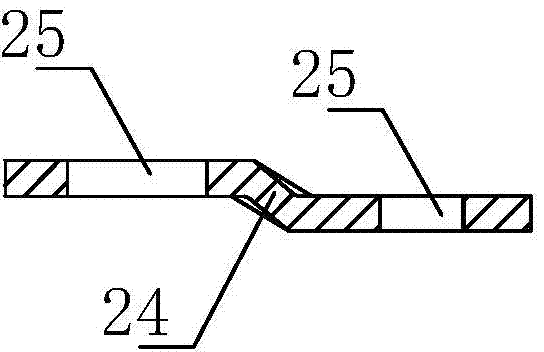

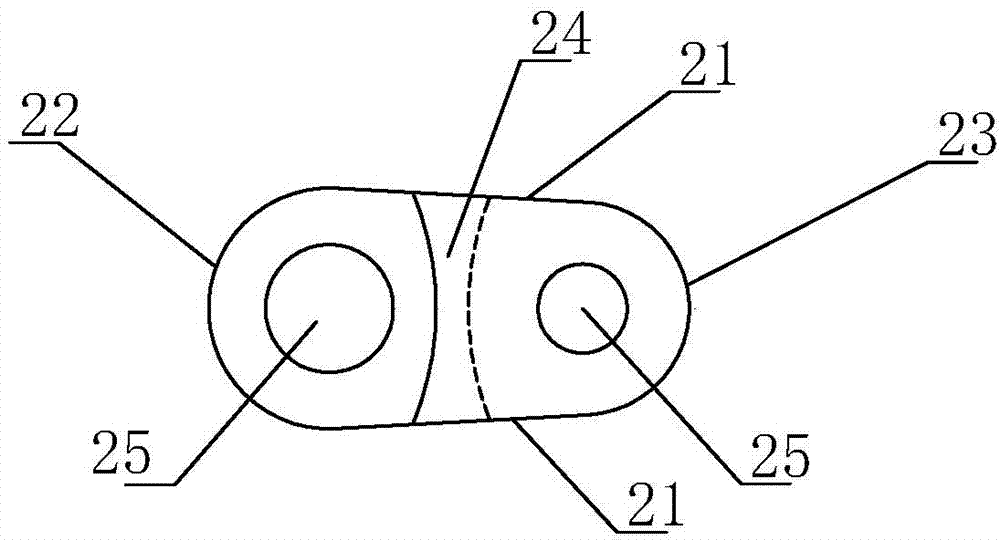

Chain, chain transition chain plate and automatic chain transition chain plate integration punch forming technology

ActiveCN104259377AShorten processing timeImprove efficiencyChain linksMetal chainsEngineeringSteel belt

The invention discloses an automatic chain transition chain plate integration punch forming technology and a chain and a chain transition chain plate manufactured by same. The automatic chain transition chain plate integration punch forming technology comprises automatically achieving positioning hole punching and trimming of a transition chain plate, trimming, primary bending, bending and finishing, pre-punching, fine punching, blanking and the like through a progressive die on a punching machine during an advancing process of a steel belt. According to the automatic chain transition chain plate integration punch forming technology, automatic machine operation replaces traditional manual operation, production efficiency of products is improved, the forming process is achieved through primary bending and bending and finishing, cracks caused at the bending positions can be reduced, and accordingly the smoothness of the transition chain plate is guaranteed; the hole size accuracy and shape accuracy and the hoe diameter euphotic belt quality are guaranteed due to the pre-punching and the fine punching; machining is performed based on the same positioning reference, the product size accuracy and the product identity are guaranteed, the product quality is improved, and the unaccepted product rate is reduced.

Owner:HANGZHOU DONGHUA CHAIN GRP

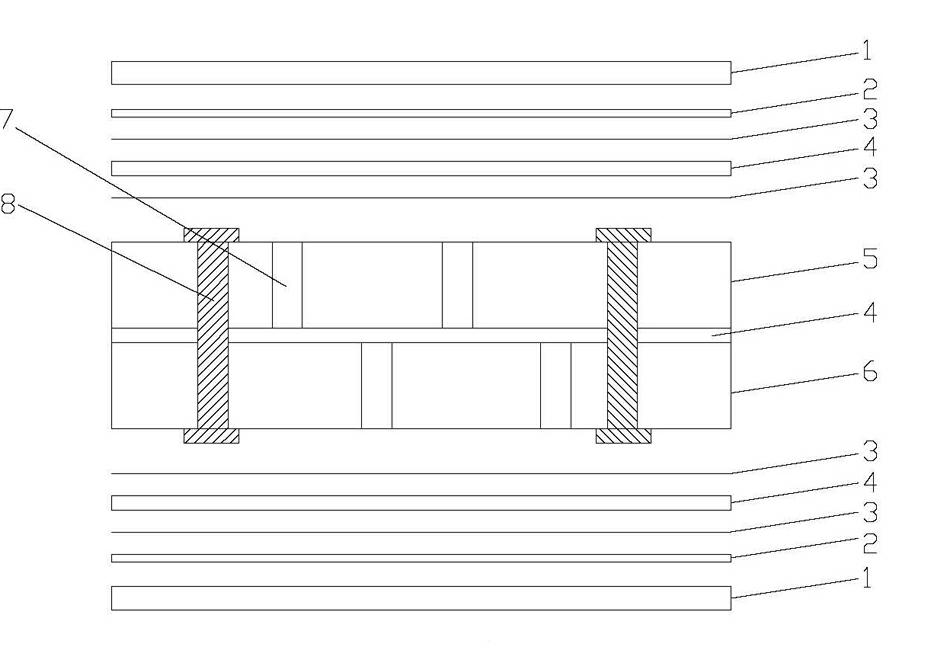

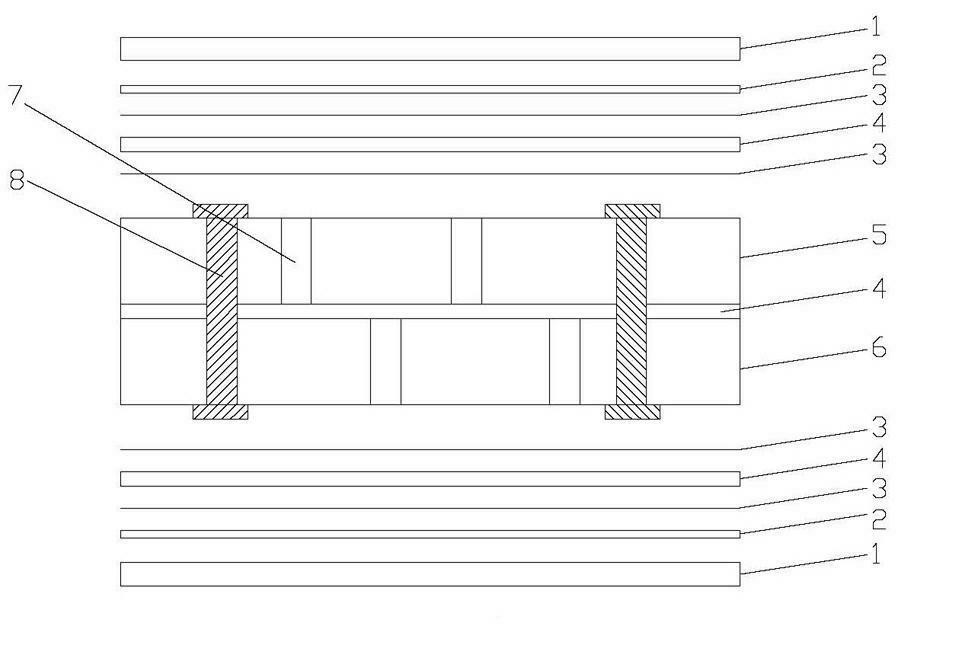

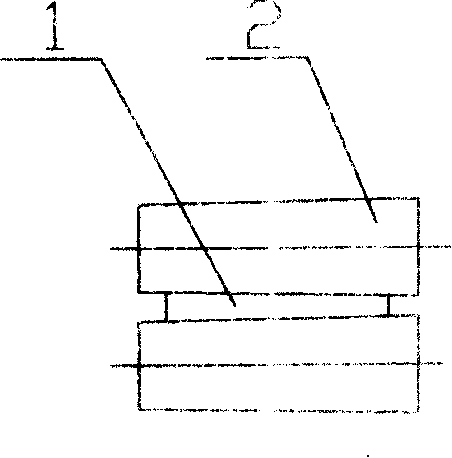

Process for laminating printed circuit board (PCB) with buried/blind via structure

InactiveCN102573339AShorten processing timeImprove work efficiencyMultilayer circuit manufacturePrinted circuit boardEngineering

The invention discloses a process for laminating a printed circuit board (PCB) with a buried / blind via structure. The process comprises the following steps of: (1) drilling via holes on an upper core board and a lower core board to be laminated, electroplating the via holes to transfer patterns, arranging a prepreg between the upper core board and the lower core board, and connecting the upper core board, the prepreg and the lower core board through rivets; (2) laying a release film, the prepreg, the release film, an aluminum sheet and laminated steel on an upper surface of the upper core board in turn from bottom to top, and laying the release film, the prepreg, the release film, the aluminum sheet and the laminated steel on a lower surface of the lower core board in turn from top to bottom; (3) laminating; and (4) removing the aluminum sheet, and detaching the prepreg to which the release film is attached so as to obtain the finished product. The process is convenient to operate, the labor cost is saved, the processing time is shortened, the working efficiency is improved, the labor intensity is reduced, and the yield of the product is improved.

Owner:SIHUI FUJI ELECTRONICS TECH

Aspergillus niger fungus and its application in production of Pu'er tea

InactiveCN1752202AImprove qualityShorten processing timeFungiPre-extraction tea treatmentCulture mediumsAspergillus niger

Owner:秘鸣

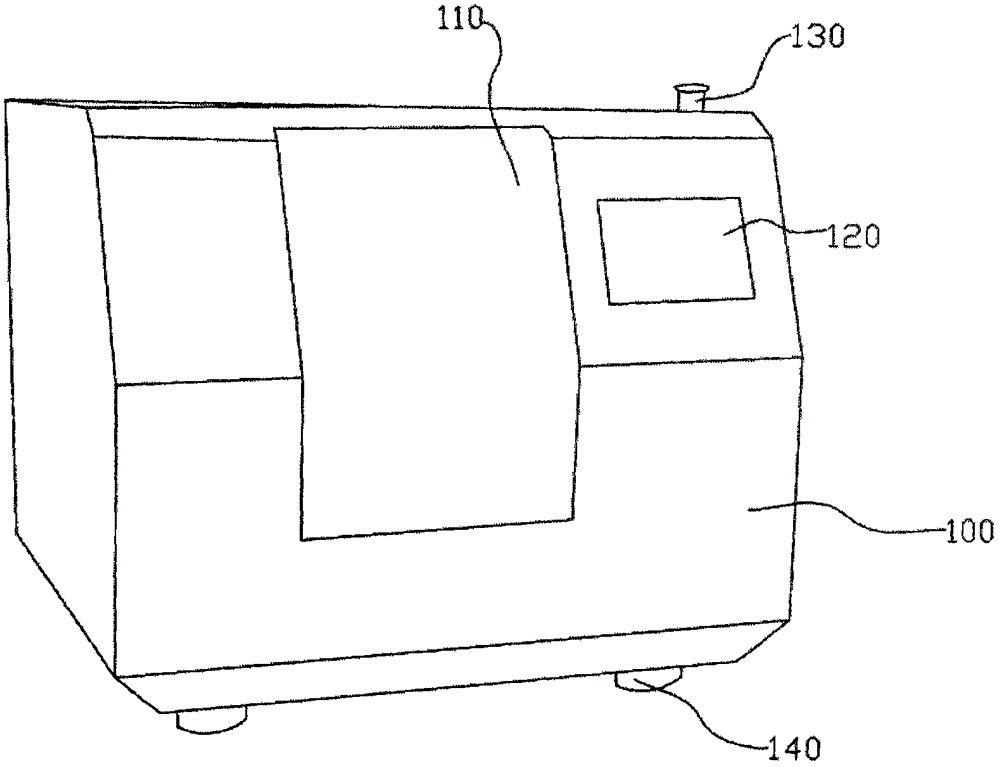

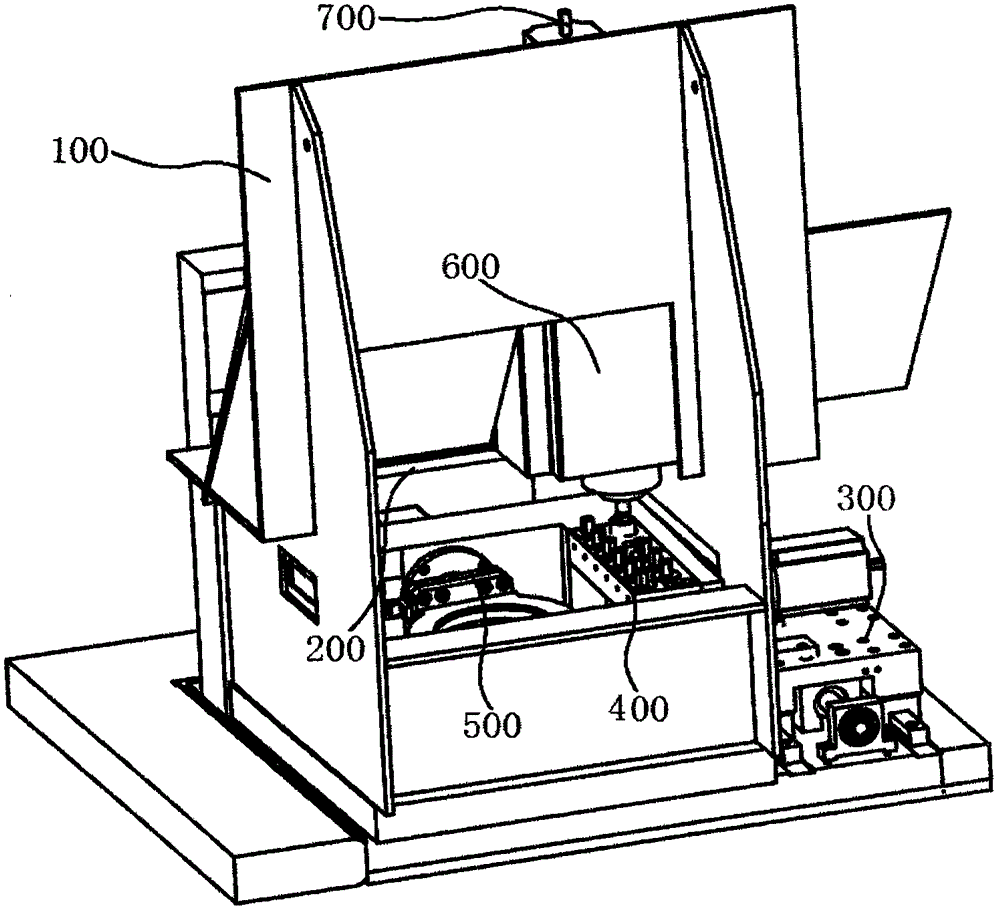

Full-automatic five-axis false tooth processing equipment

The invention discloses full-automatic five-axis false tooth processing equipment which comprises a machine cover, wherein the machine cover is internally in a hollow structure, and the machine cover internally comprises an X-axis motion platform, a Y-axis motion platform and a Z-axis motion platform which are respectively provided with a basic axis; an A-axis inclined device is arranged on a position which is overturned around the X-axis motion platform, and a B-axis overturning device is arranged on a position which is overturned around the Y-axis motion platform; and the A-axis inclined device and the B-axis overturning device are both arranged on an L-shaped support frame of the Y-axis motion platform. The full-automatic five-axis false tooth processing equipment disclosed by the invention can be used for processing pure titanium, zirconium oxide and a wax type material, and processing relatively multiple varieties of false tooth materials through one equipment, is capable of operating a complex processing path, greatly reducing the thickness of a material block needed by a long bridge, and can be used for machining special angles and inverted recesses inside a material disc, supporting the normal mode processing, achieving a individual base station and the bridge body milling, supporting the grinding of a glass ceramic tooth, a beautifying patch and an inlay and fast completing a workpiece, is good in practicability and novel in design, is a very good innovation scheme and has great market popularization prospect.

Owner:SHANGHAI VULTURE NC MACHINERY

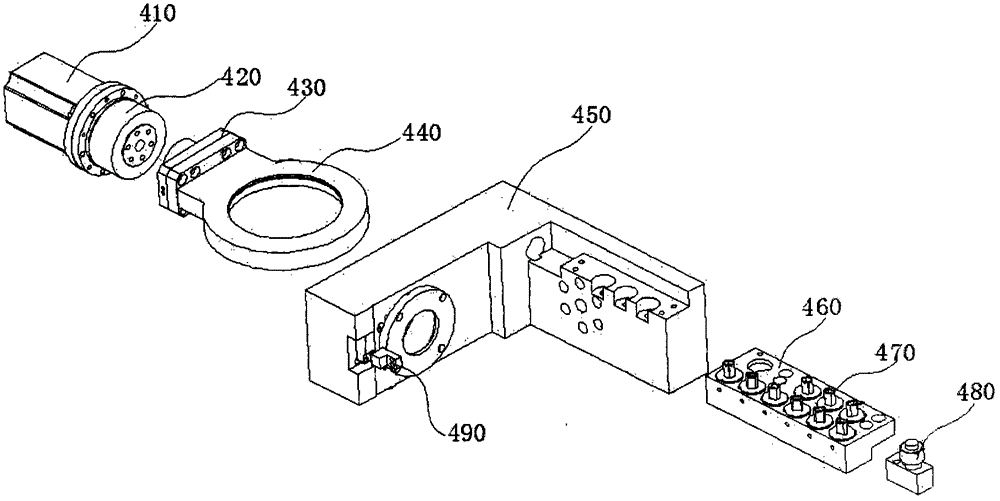

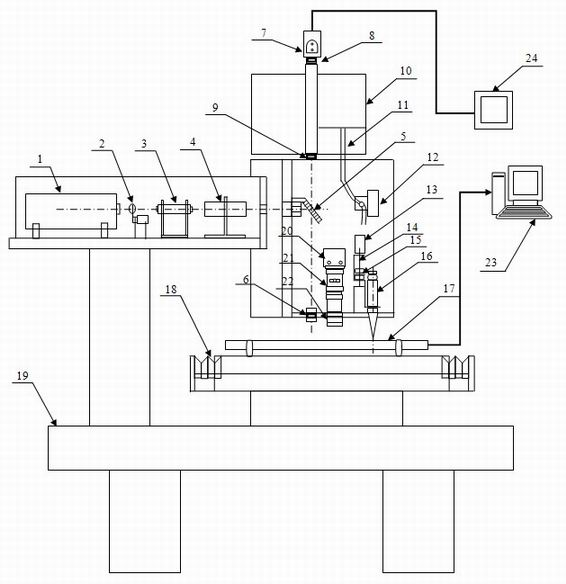

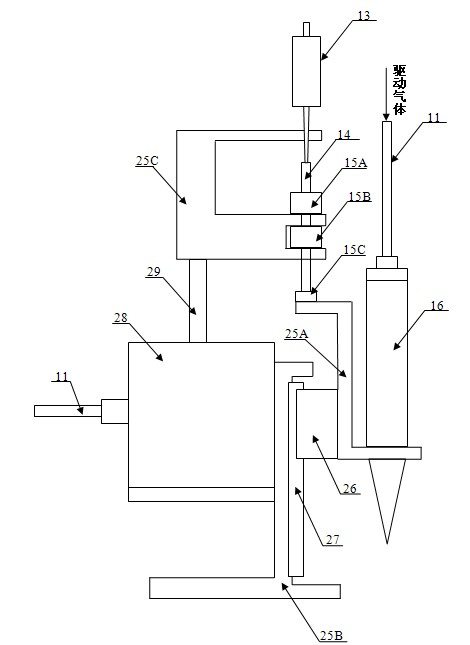

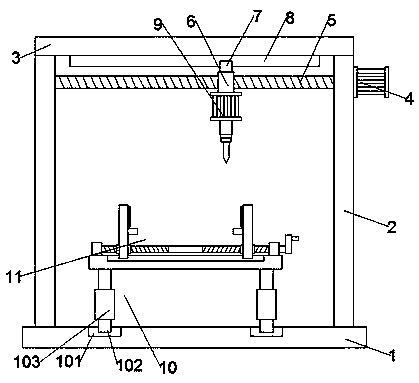

Special equipment for laser micro-cladding

ActiveCN102011123AShorten processing timeGuaranteed accuracyMetallic material coating processesLaser beam welding apparatusOptical pathPhysics

The invention discloses special equipment for laser mirco-cladding. The equipment comprises a workbench, a laser processing system and a control system, and is characterized by also comprising a charge coupled device (CCD) monitoring and positioning system and a direct writing system, wherein the CCD monitoring and positioning system comprises a coaxial CCD sensor, a paraxial CCD sensor, a zoom lens, an imaging eye lens, a zoom optical system, a paraxial imaging object lens and an external monitor; the direct writing system comprises a micro-pen direct writing device and a micro-jet direct writing device; the micro-pen direct writing device comprises a support, a guide rail, a cylinder, a slider, a piston rod, a dial gauge, a micro adjustment nut and a micropen; and the micro-jet direct writing device comprises a water bath kettle, a gas-guide tube, a micro-pressure gauge and a micro-jet tool. In respect of the equipment, a laser optical path and the installation stations and working modes of the micro-jet direct writing device and the micropen are reasonably designed, and laser processing, the micropen and the micro-jet direct writing system are integrated on the same working platform, thereby realizing advantage complementation of various processing methods.

Owner:HUAZHONG UNIV OF SCI & TECH

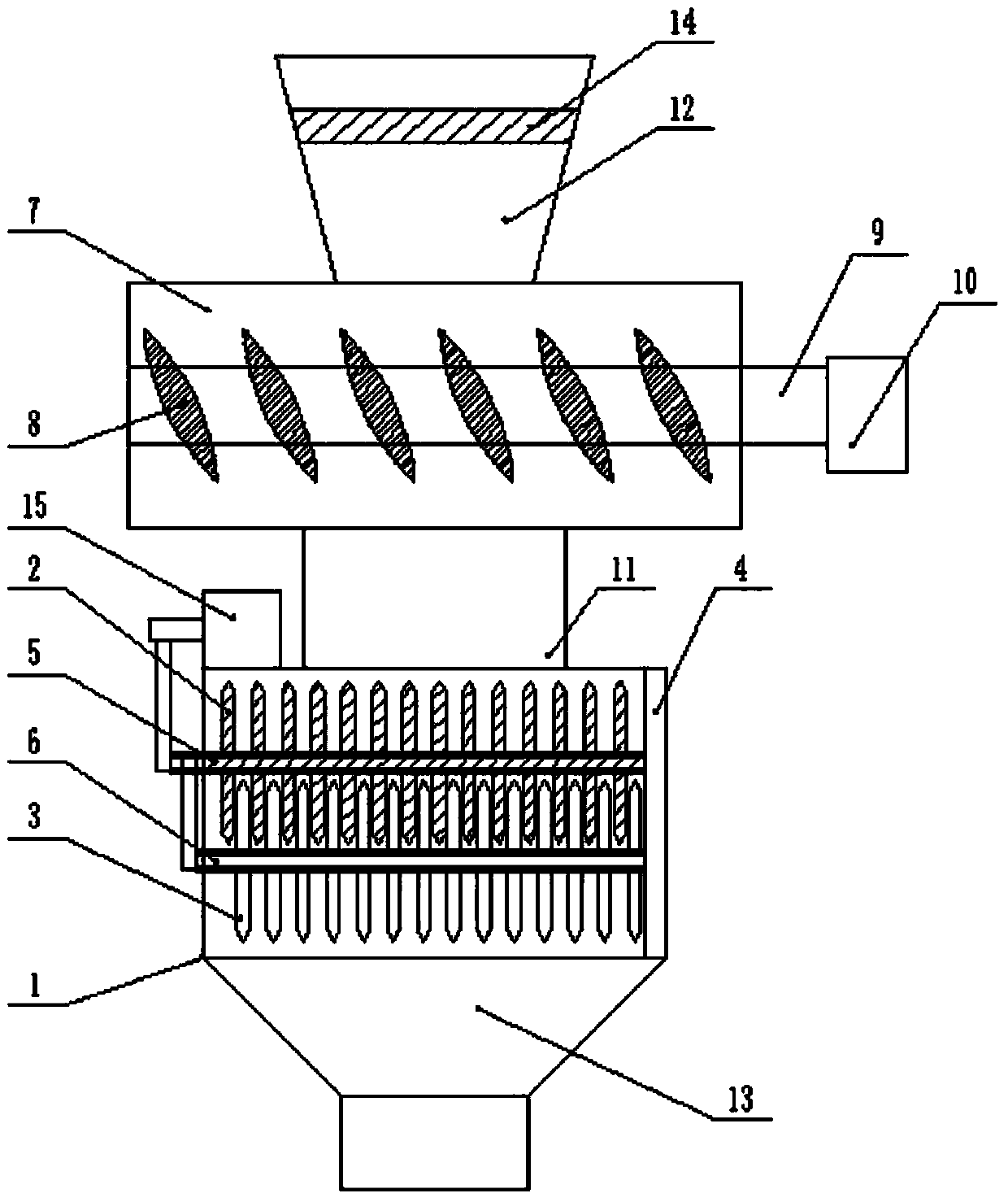

Novel two-stage crusher

InactiveCN104084281AShorten processing timeImprove work efficiencyGrain treatmentsPulverizerEngineering

The invention discloses a novel two-stage crusher. The novel two-stage crusher comprises a primary crushing device, a secondary crushing device and a connecting pipe, wherein a feeding hole is formed in the primary crushing device; blades connected with a shaft are arranged in the primary crushing device, the shaft is driven by a first motor, and the blades are obliquely arranged on the shaft; the primary crushing device is connected with the secondary crushing device through the connecting pipe; the secondary crushing device comprises driving blades, driven blades and an end cover, and the driving blades and the driven blades are arranged in the secondary crushing device; a cone-shaped discharging hole is formed in the bottom of the secondary crushing device. The novel secondary crusher has the beneficial effects that by virtue of a secondary crushing structure, a primary crushing process and a secondary precise crushing process are continuously carried out, so that the machining time is shortened, and the working efficiency is improved; as the driven blades can overtake the driving blades, a strong crushing region is formed during the secondary crushing; the total crushing effect is good, the total crushing efficiency is high, the structure is simple, and the service life is long.

Owner:SUZHOU CHUANGWEISHENG AUTOMATION SCI & TECH

Deformation processing method for optical aspheric element

ActiveCN104759964AImprove processing efficiencyShorten processing timeOptical surface grinding machinesGrinding feed controlEngineeringSurface shape

The invention claims a deformation processing method for an optical aspheric element, relates to the optical manufacture field and solves the problems of the existing optical aspheric element processing method that the processing time is long and the cost is low. Specially-made vacuum fixture is designed for the optical aspheric element to be processed, the vacuum card mounting mode is adopted, the surface of the optical aspheric element has certain deformation under the vacuum card mounting state, the processing method for the optical aspheric element is adopted for processing, the concrete mode is the grinding and forming mode, accurate grinding mode and polishing mode; the vacuum fixture is taken off after processing, and the surface shape error of the optical aspheric element meets the technology design requirement under the non card mounting state. The processing of the surface of the optical aspheric element can be realized through deformation card mounting operation; the aspheric optical element processing mode is used for correcting partial diaphragm, the processing efficiency of the surface of the optical aspheric element is effectively improved, the processing time is greatly shortened, the processing cost is reduced and the processing precision is improved.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

High-content and high-elasticity special modifier for asphalt, and preparation method thereof

ActiveCN106700578AShorten processing timeImprove high temperature stabilityBuilding insulationsChemistryButadiene-styrene rubber

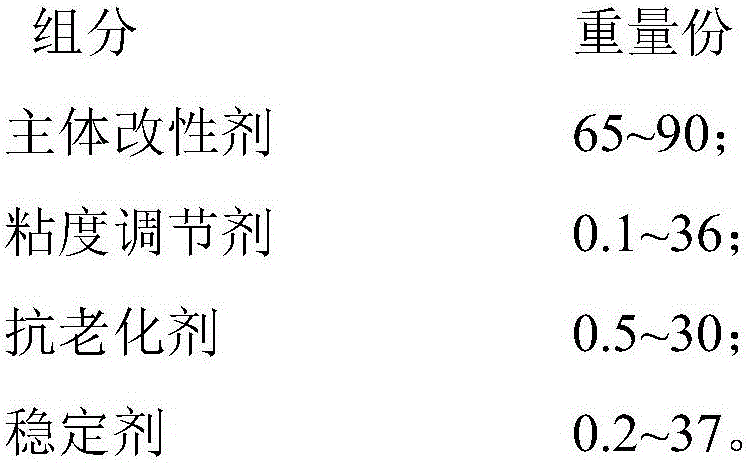

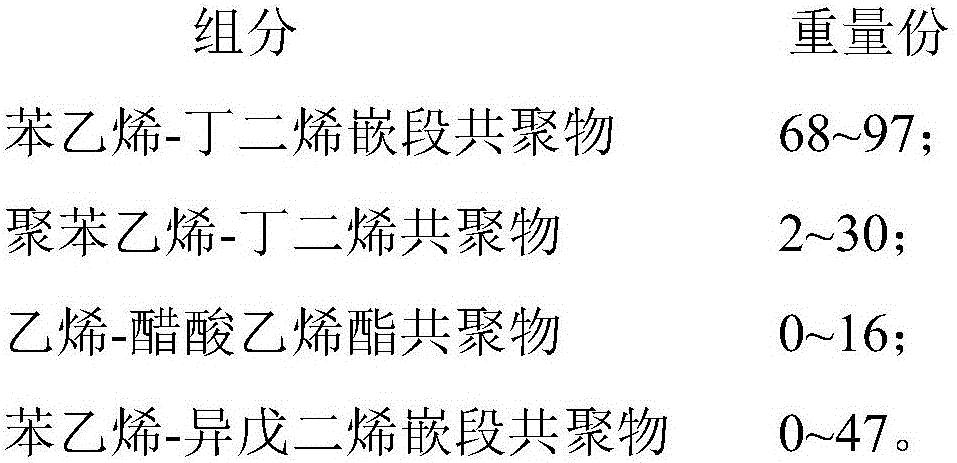

The invention belongs to the technical field of asphalt modifiers, and relates to a high-content and high-elasticity special modifier for asphalt, and a preparation method thereof. The modifier comprises, by weight, 65-90 parts of a main body modifier, 0.1-36 parts of a viscosity regulator, 0.5-30 parts of an antioxidant and 0.2-37 parts of a stabilizer. The preparation method comprises the following steps: crushing the main body modifier, the viscosity regulator, the antioxidant and the stabilizer at -10-5 DEG C by a crusher, and screening the crushed materials by a 60-150 mesh sieve to obtain the high-content and high-elasticity special modifier for asphalt. Compared with modifiers in the prior art, the special modifier substantially improves the high temperature stability, the low temperature crack resistance, the ageing resistance and the elasticity recovery performance of asphalt, and solves the problems of difficulty processing and long processing time of present styrene-butadiene-styrene block copolymer modifiers at high content.

Owner:SHANGHAI RES INST OF CHEM IND +1

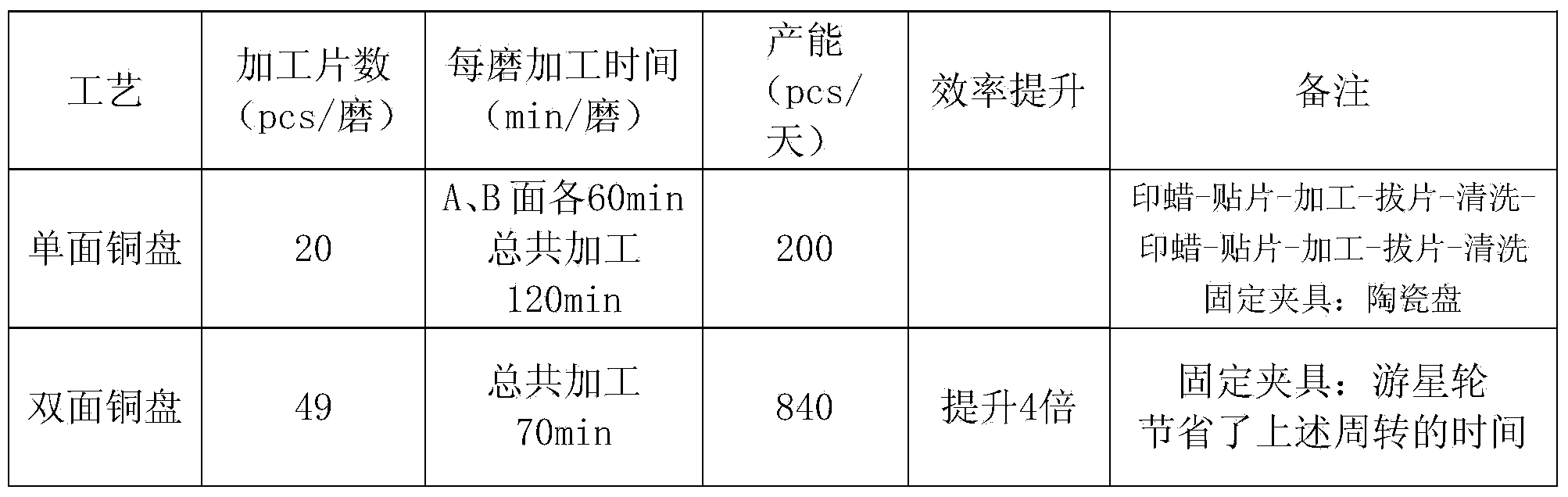

Double-sided copper disc grinding process for sapphire panel

InactiveCN104015122AShorten processing timeSimple processing stepsLapping machinesLapping toolsProduct processingSapphire

The invention discloses a double-sided copper disc grinding process for a sapphire panel. The double-sided copper disc grinding process comprises the first step of placing the sapphire product into a wandering star wheel mold cavity of a double-sided copper disc grinder and smearing grinding and cutting fluid on the upper surface and the lower surface of the sapphire product, wherein a tooth ring and a sun wheel of the double-sided copper disc grinder are respectively meshed with wheel teeth on the wandering star wheel, the second step of controlling an upper copper disc of the double-sided copper disc grinder to move downwards until the upper copper disc and a lower copper disc make contact with the upper surface and the lower surface of the sapphire product respectively, and the third step of performing pressurization on the upper copper disc and meanwhile controlling the upper copper disc and the lower copper disc to rotate reversely so that the upper surface and the lower surface of the sapphire product can be ground. According to the double-sided copper disc grinding process for the sapphire panel, the two surfaces of the sapphire panel are ground at a time, so that the machining time of the grinding process is shortened, the machining process steps are simplified, production cost is lowered, and production efficiency is enhanced; meanwhile, as the synthetic resin copper grinding discs are adopted for grinding, the grinding process has the advantages of high accuracy and high grinding efficiency, thereby enhancing the machining yield of the product.

Owner:LENS TECH

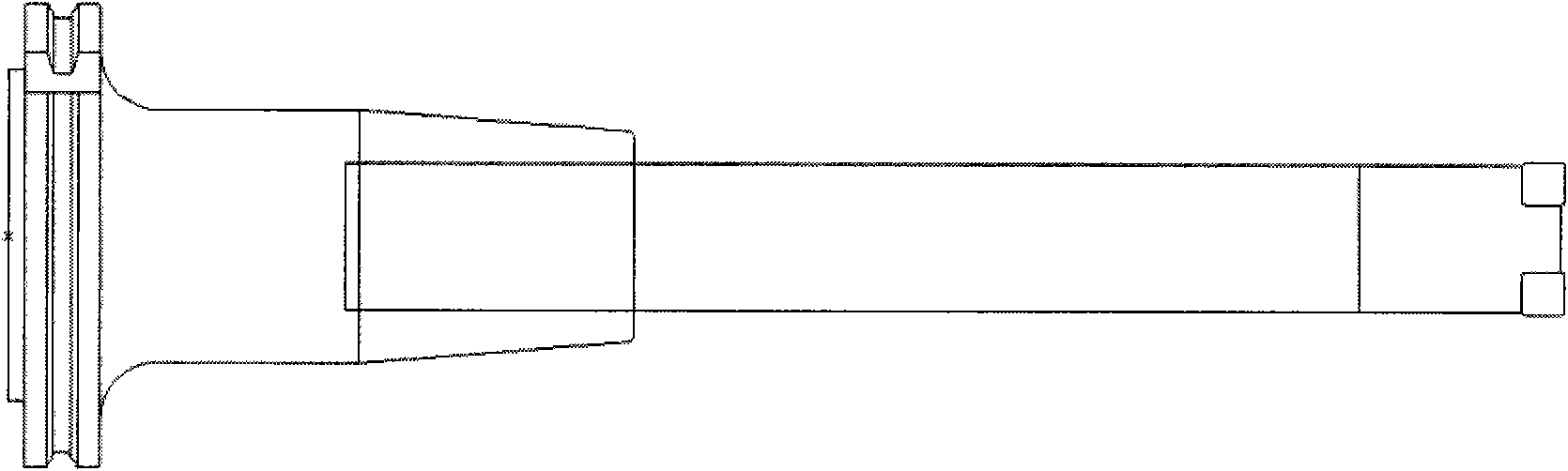

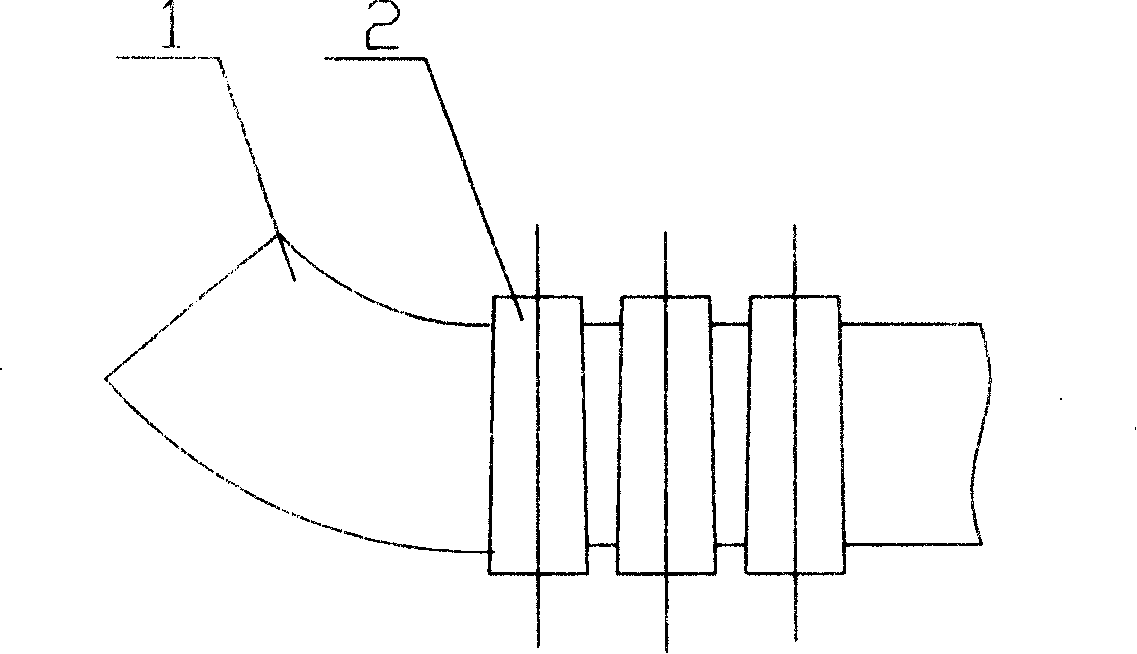

Process method and special device of helical blade

InactiveCN101204771AShorten processing timeImprove efficiencyShaping toolsExtrusion diesWinding machineHelical blade

The invention relates to a processing method and a specific device for a spiral blade. The processing method of the invention essentially adopts strip shaped materials to form through binding and enwinding. The specific device of the invention consists of a taper roller extruding press and a drag winding machine. An outlet of the taper roller extruding press is arranged correspondingly to an inlet of the drag winding machine. The taper roller extruding press comprises a frame, at least one pair of taper rollers ad a drive device. The conicity of the taper roller is 1 to 15 degrees. Two taper rollers are arranged in the same direction and the axes are in an included angle of 1 to 10 degrees. The bigger head parts of the rollers have a small gap and the drive device is connected with the rollers. The drag winding machine comprises a frame, a rotary shaft, three drag rollers uniformly arranged at the circumferential direction of the rotary shaft and a drive device. The drag rollers are provided with V-shaped slot. The axes of the three drag rollers are parallel to the rotary shaft and arranged in an equal distance on height. The rotating directions of the rotary shaft and the three drag rollers are opposite. The invention omits a plurality of working procedures, improving the efficiency and has a high product precision.

Owner:王琪

Method for processing blade form work piece and fittings dedicated therefor

InactiveCN1962145AReduce processing stepsShorten processing timePositioning apparatusMetal-working holdersWork in processEngineering

The invention relates to a method for processing blade work piece, wherein it comprises 1, machining annular blank; 2, fixing the blank on special device, sing digit-control machine to process the semi product of single blade work piece; 3, milling inner and outer arc surfaces of semi product on milling machine. The inventive special device is formed by base, transmission axle, several bearings, axial sheath, and mounting disc and positioning pin; one end of transmission axle is connected to the center of mounting disc in cam ring; the protrusion part at the middle of mounting disc can match the blank. The invention has wide application.

Owner:胡梁发

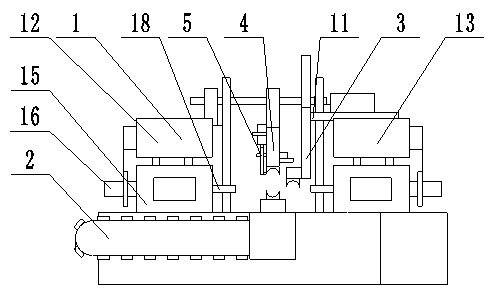

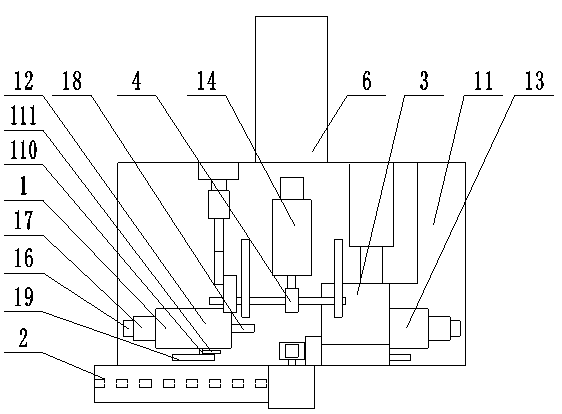

Automatic pipe end flattening machine

ActiveCN103008790AShorten processing timeImprove work efficiencyMetal working apparatusPositioning apparatusEngineeringMechanical engineering

The invention relates to an automatic pipe end flattening machine, which belongs to the technical field of an end flattening machine. The invention provides an automatic pipe end flattening machine capable of machining a workpiece in one step as long as the workpiece is arranged on a feeding device and stable in machining quality. In order to solve the technical problems, the invention adopts the technical scheme as follows: the automatic pipe end flattening machine comprises a power head assembly, a stander, an automatic feeding device, an automatic grabbing device, an automatic clamping device, an automatic unloading device and an automatic collecting device, the power head assembly is installed on the stander, the stander on one side of the power head assembly is provided with the automatic feeding device, the stander on the other side of the power head assembly is provided with the automatic collecting device, the stander on the tail end of the automatic feeding device is provided with the automatic grabbing device, and the automatic clamping device which is arranged on the top of the stander fixes the workpiece into a working area of the power head assembly. The automatic pipe end flattening machine is used for flattening ends of a pipe.

Owner:TAIGU COUNTY XINKA NAIFU PLUMBING EQUIP CO LTD +1

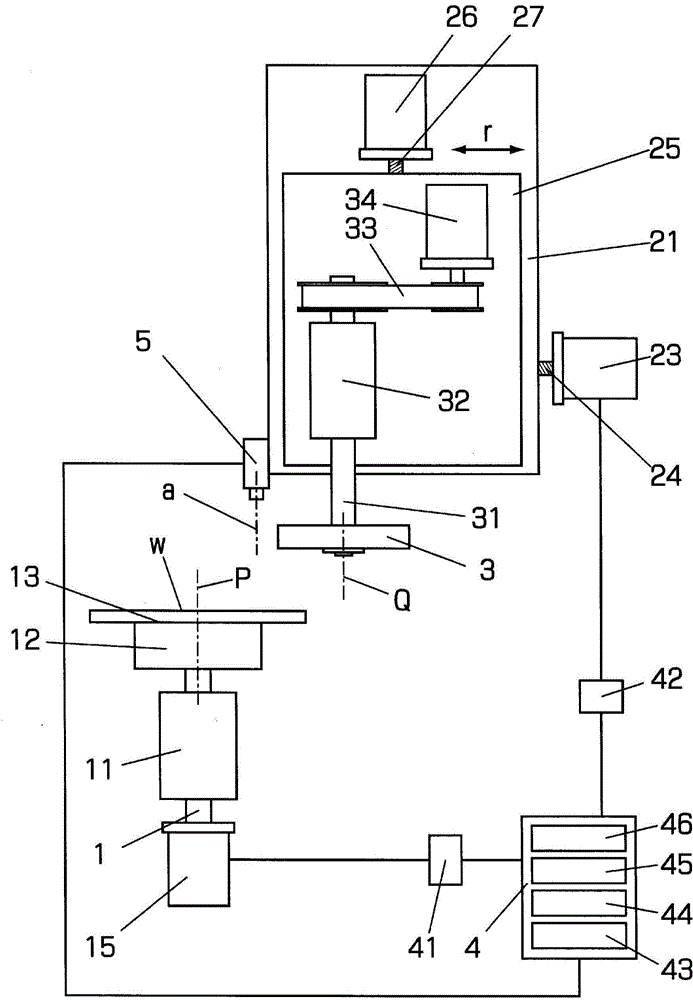

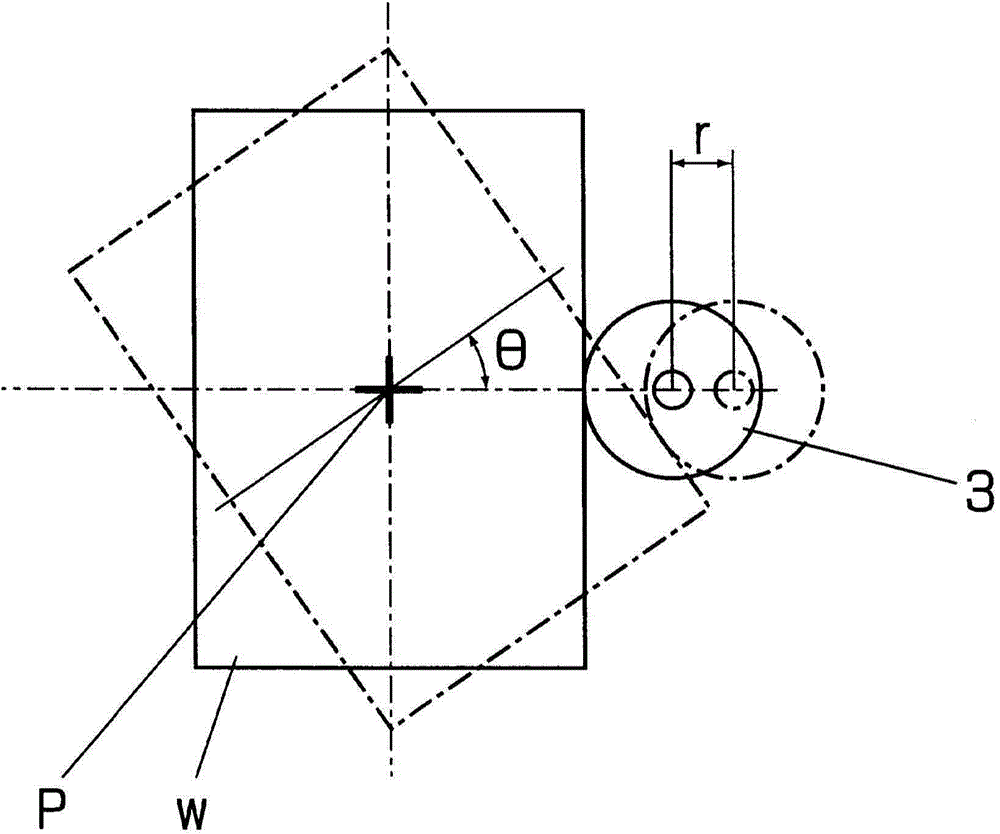

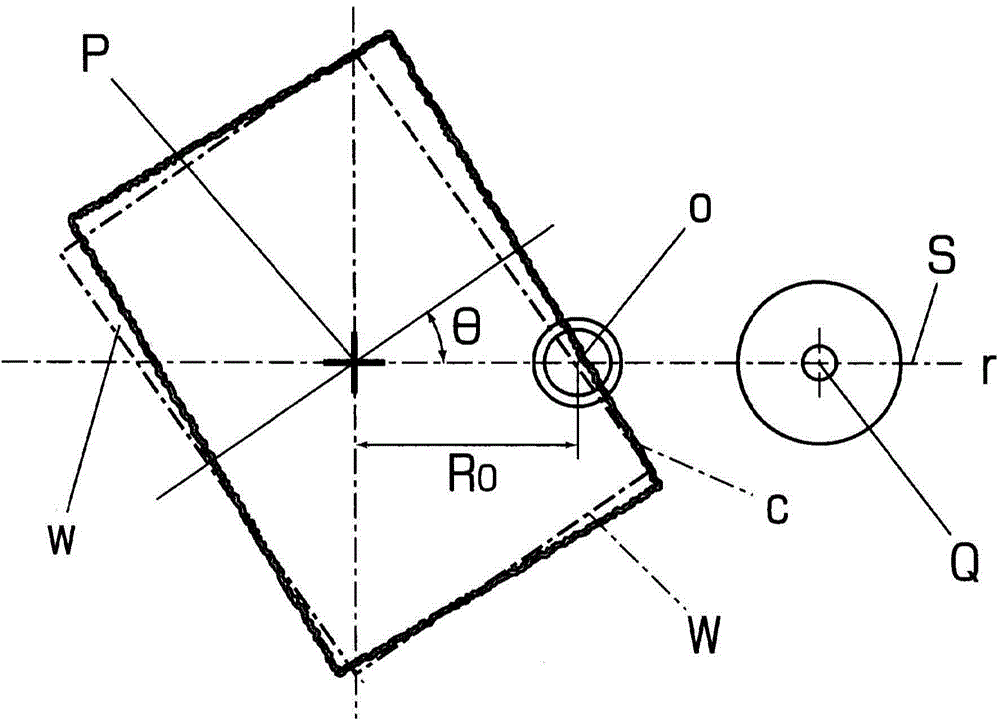

Apparatus for circumference grinding of workpiece

InactiveCN104070613AShorten processing timeExtend tool lifeEdge grinding machinesGrinding feed controlMachining timeNotching

The invention provides an apparatus for circumference grinding of a workpiece, which is suitable for performing circumference grinding fine-machining on a glass plate. The apparatus can perform optimal circumference machining on a blank with a gap or crinkle on the circumference and has functions of: reducing cutting allowance of the workpiece, and realizing machining time shortening and workpiece wear reduction. Furthermore the apparatus can perform quality inspection on the blank. The apparatus performs continuous photographing on the whole circumference or a plurality of circumference areas of the blank which is fed to the apparatus, and detects the inner edge of the circumference of the workpiece according to an image. A correction operating unit operates a correction value according to a derivation (offset) between the circumference of the blank and a product in a product machining manner that the cutting allowance is unified in the whole circumference of the workpiece and the cutting allowance is minimized and defects of a gap or crinkle, etc. can be cut when the defect is detected on the circumference of the workpiece.

Owner:NAKAMURATOME SEIMITSU IND

Processing system of mobile equipment shells

InactiveCN106734842AShorten processing timeMeet product appearance and size performance requirementsForging/hammering/pressing machinesEngine componentsMachine toolMachining time

The invention discloses a processing system of mobile equipment shells. The processing system comprises a forging mould and a numerically-controlled machine tool, wherein the forging mould is used for roughly machining a preprocessed plate to obtain a rough base with the size being larger than the preset allowance of a product, the forging mould comprises an upper mould component and a lower mould component, a mould core for forging the plate is mounted on the upper mould component, and the lower mould component is provided with a cavity allowing the plate to be placed in; the numerically-controlled machine tool used for finely machining the rough base to remove the preset allowance to obtain the product. The processing system has the advantages that the plate can be roughly machined by the forging mould before the numerically-controlled machining to form the rough base, the machining quantity of the numerically-controlled machining is reduced, only the preset allowance needs to be removed, about half of CNC machining time can be reduced, the product structure and product size cannot be changed, product machining efficiency can be increased effectively, product machining cost and company resource cost are lowered evidently, and product appearance, size and performance requirements are satisfied.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

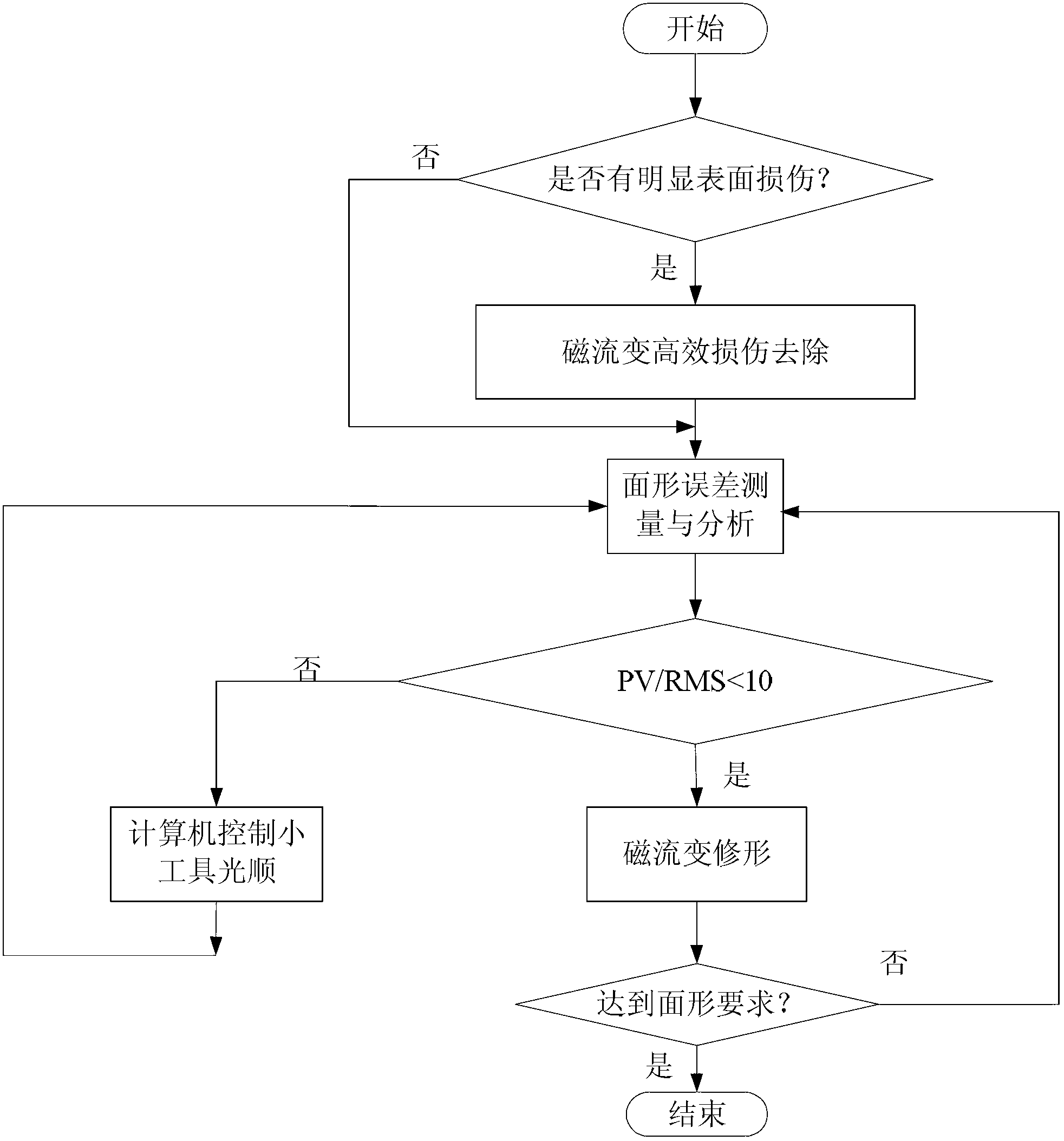

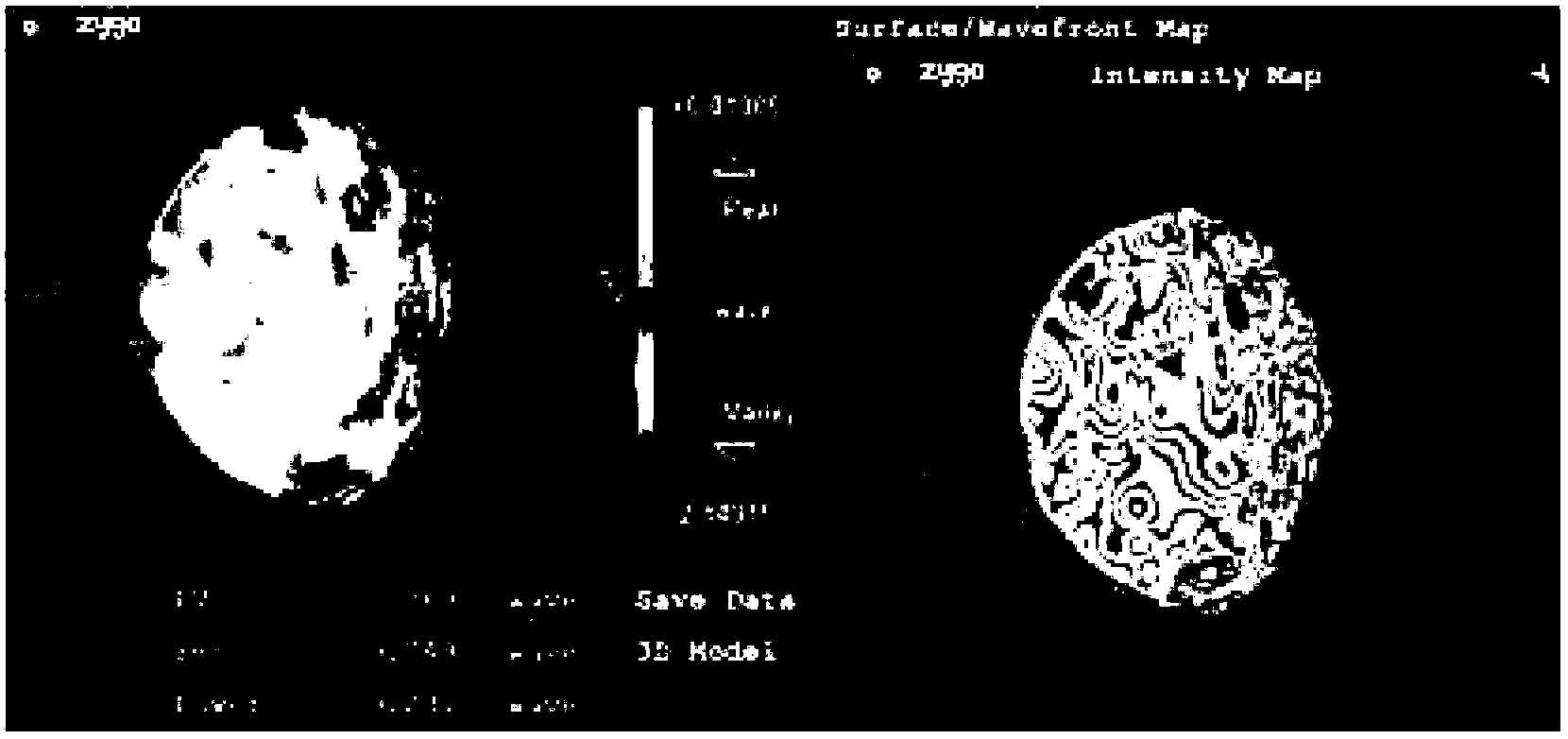

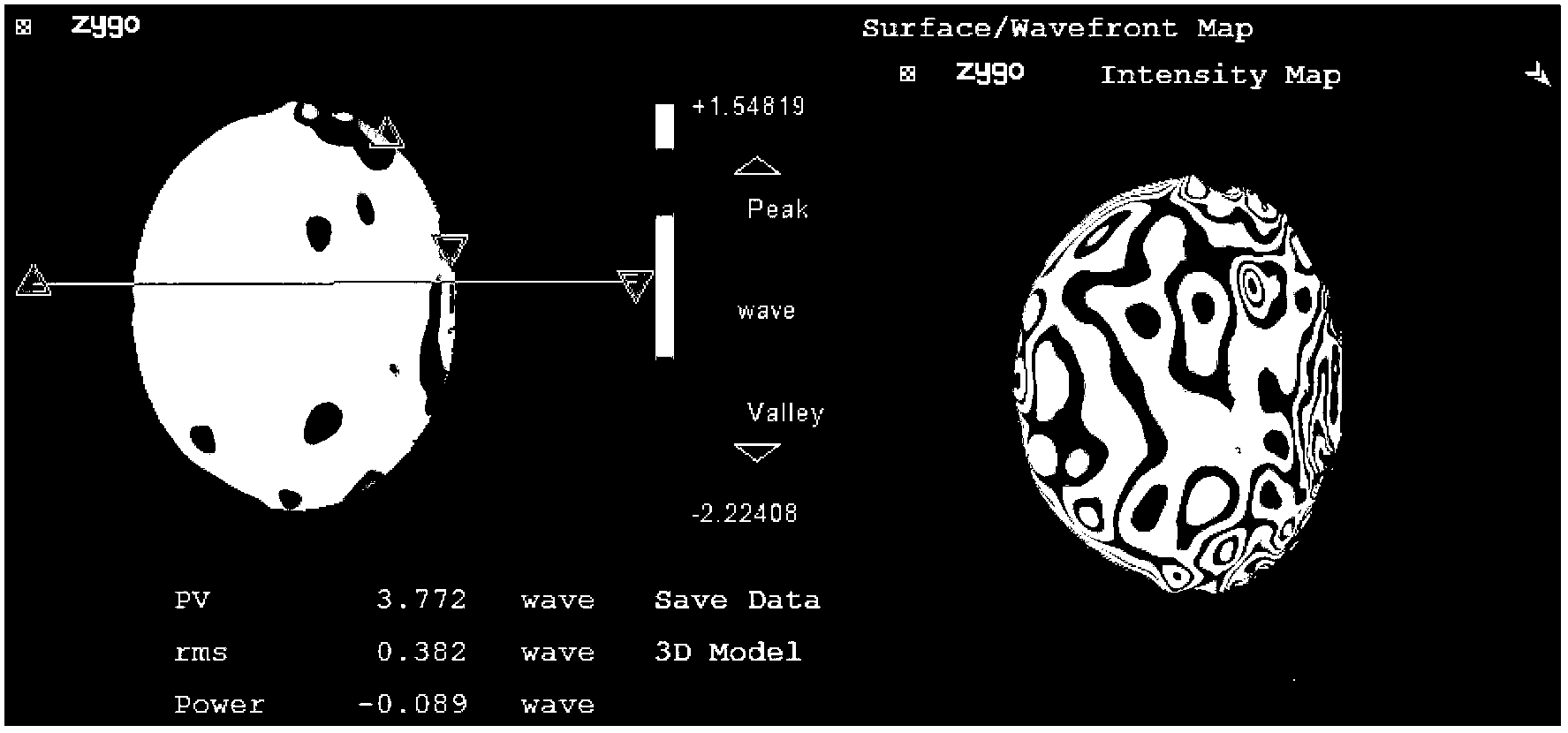

Short flow processing method of aspheric optical element

The invention discloses a short flow processing method of an aspheric optical element. The short flow processing method comprises the following steps: firstly carrying out grinding and rough polishing on the aspheric optical element, and carrying out damage removing by magnetorheology according to the requirement; carrying out judging by a ratio of a surface-shape error peak-valley value obtained by surface-shape error measurement and a surface-shape error root-mean-square value, if the ratio is less than 10, entering a magnetorheology shape modification iteration processing step to eliminate a low-frequency surface-shape error, and finishing processing until reaching the surface precision requirement; and otherwise, adopting a computer to control a gadget fairing iteration processing step to remove the middle-frequency and the high-frequency surface-shape errors until the surface-shape error measurement and analysis result shows that the ratio of the surface-shape error peak-valley value and the surface-shape error root-mean-square value is less than 10, and entering the magnetorheology shape modification iteration processing step to eliminate the low-frequency surface-shape error until the surface precision satisfies the requirement. The short flow processing method provided by the invention has the advantages of high efficiency and high precision.

Owner:NAT UNIV OF DEFENSE TECH

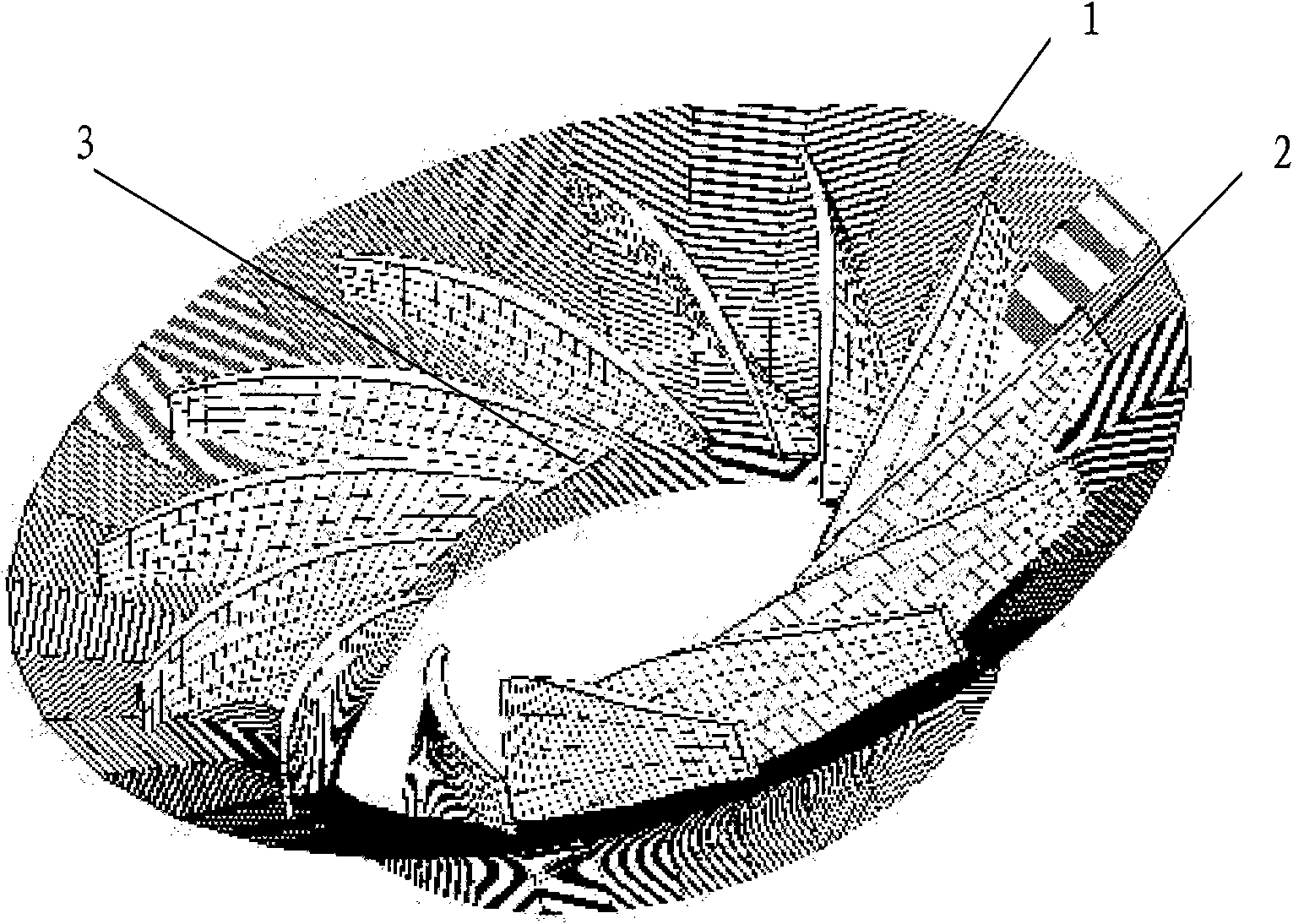

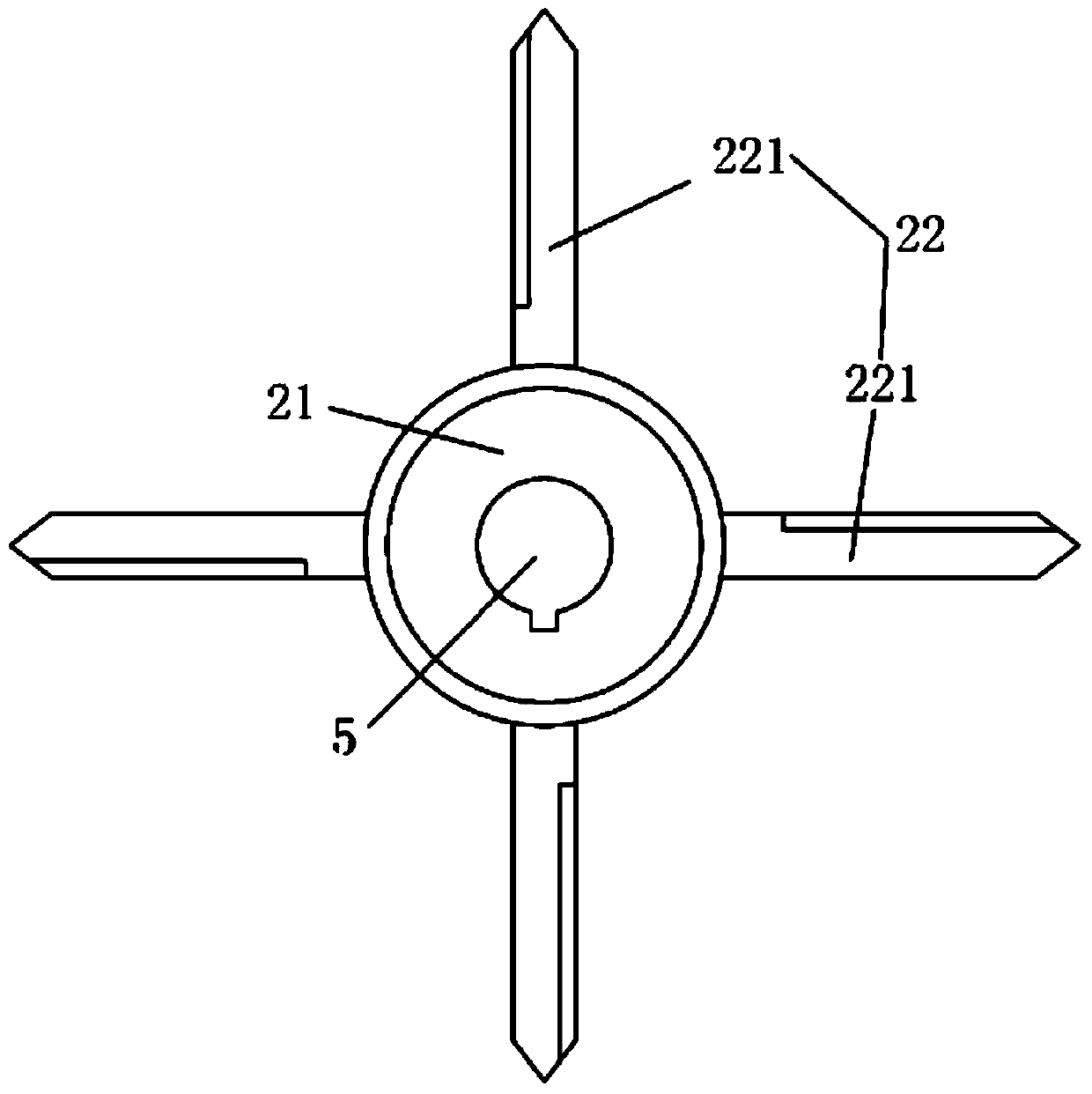

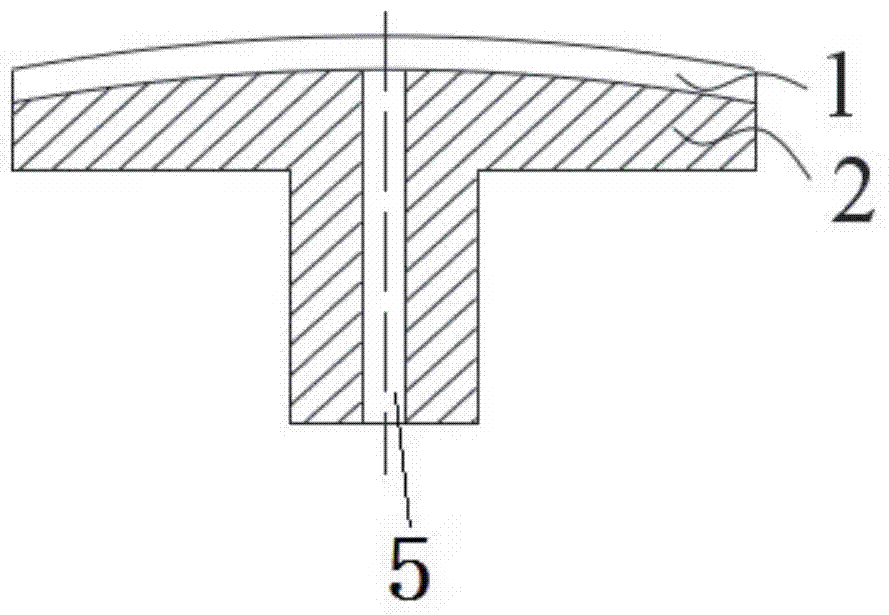

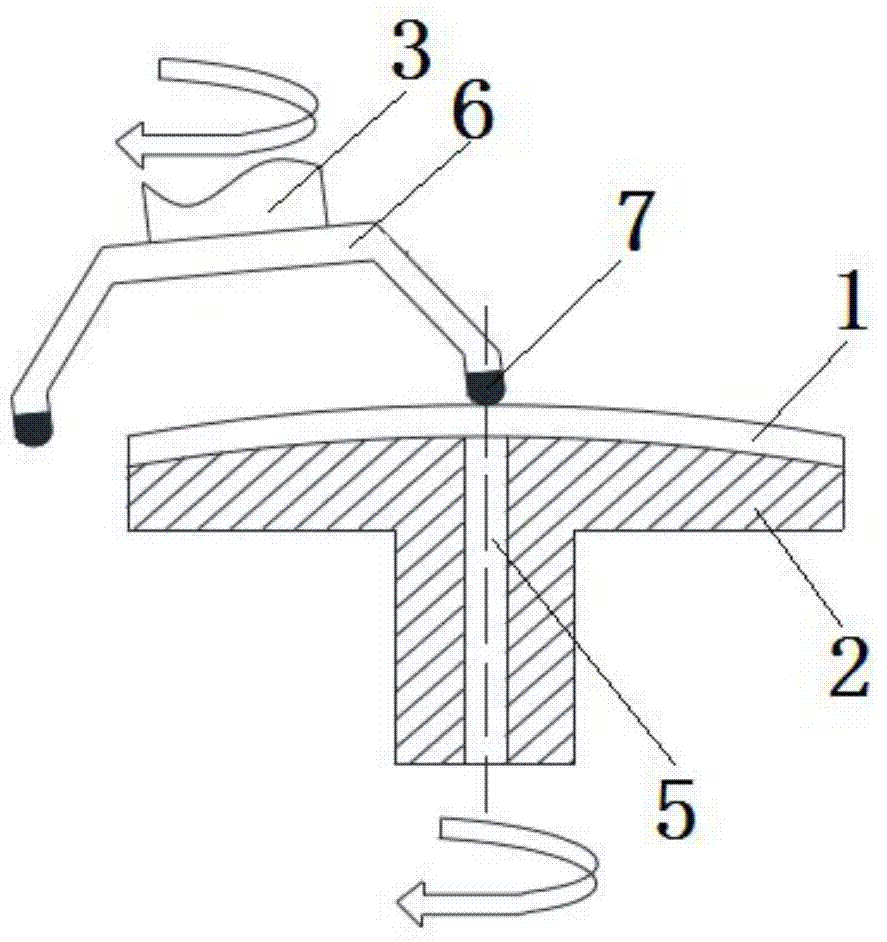

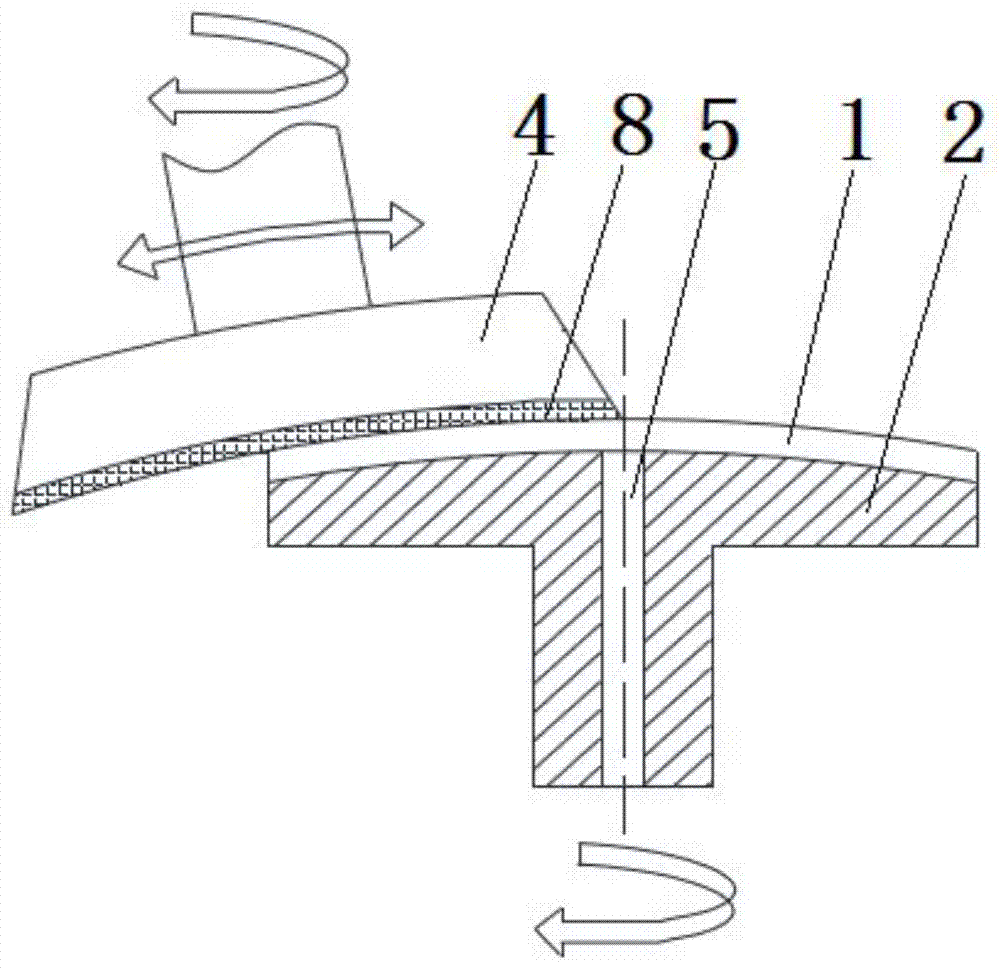

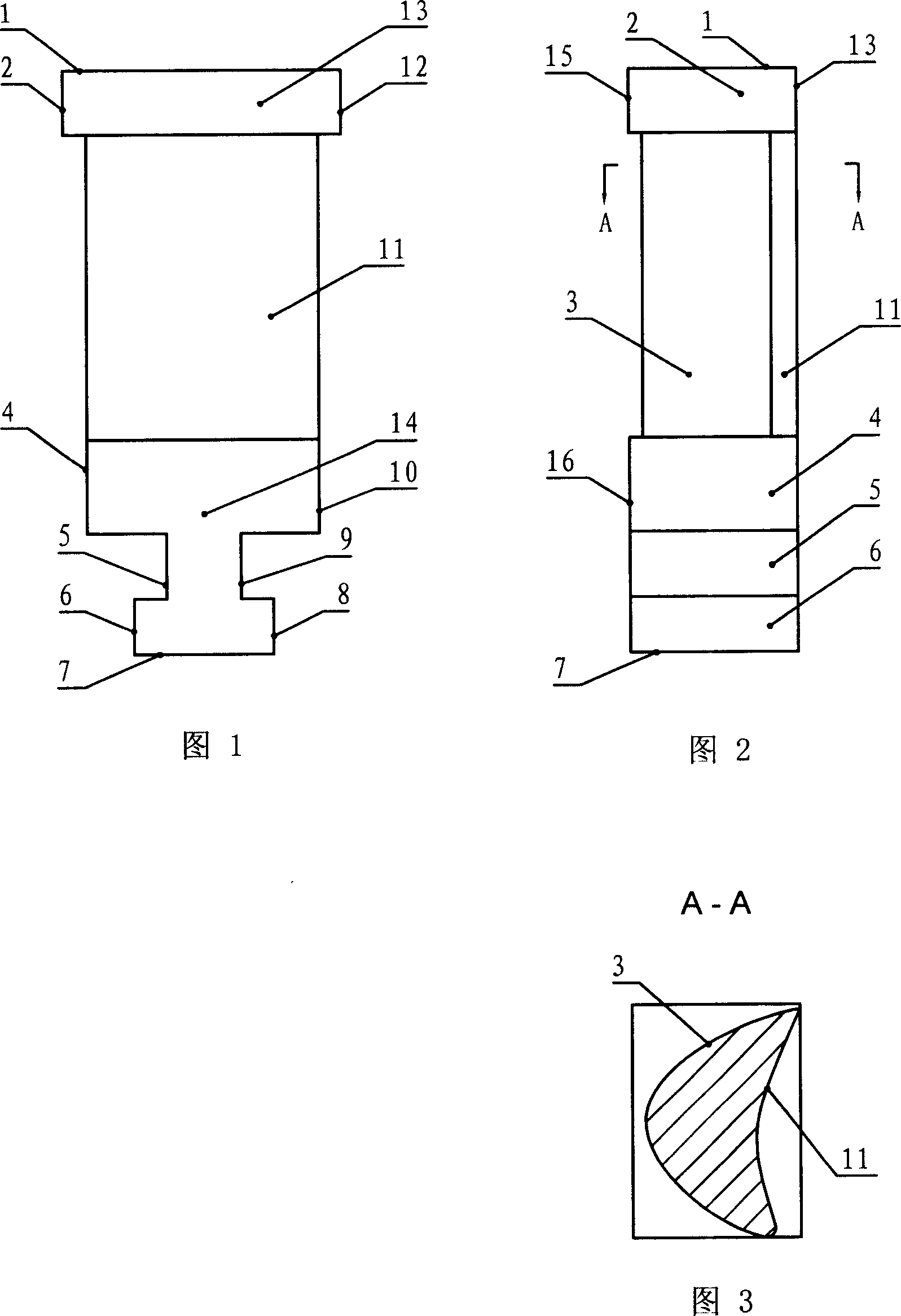

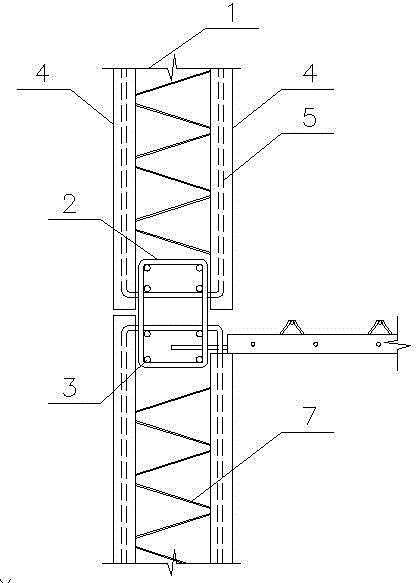

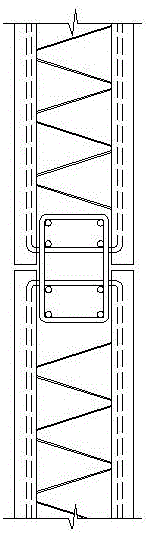

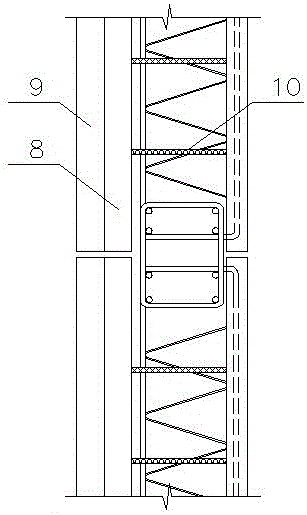

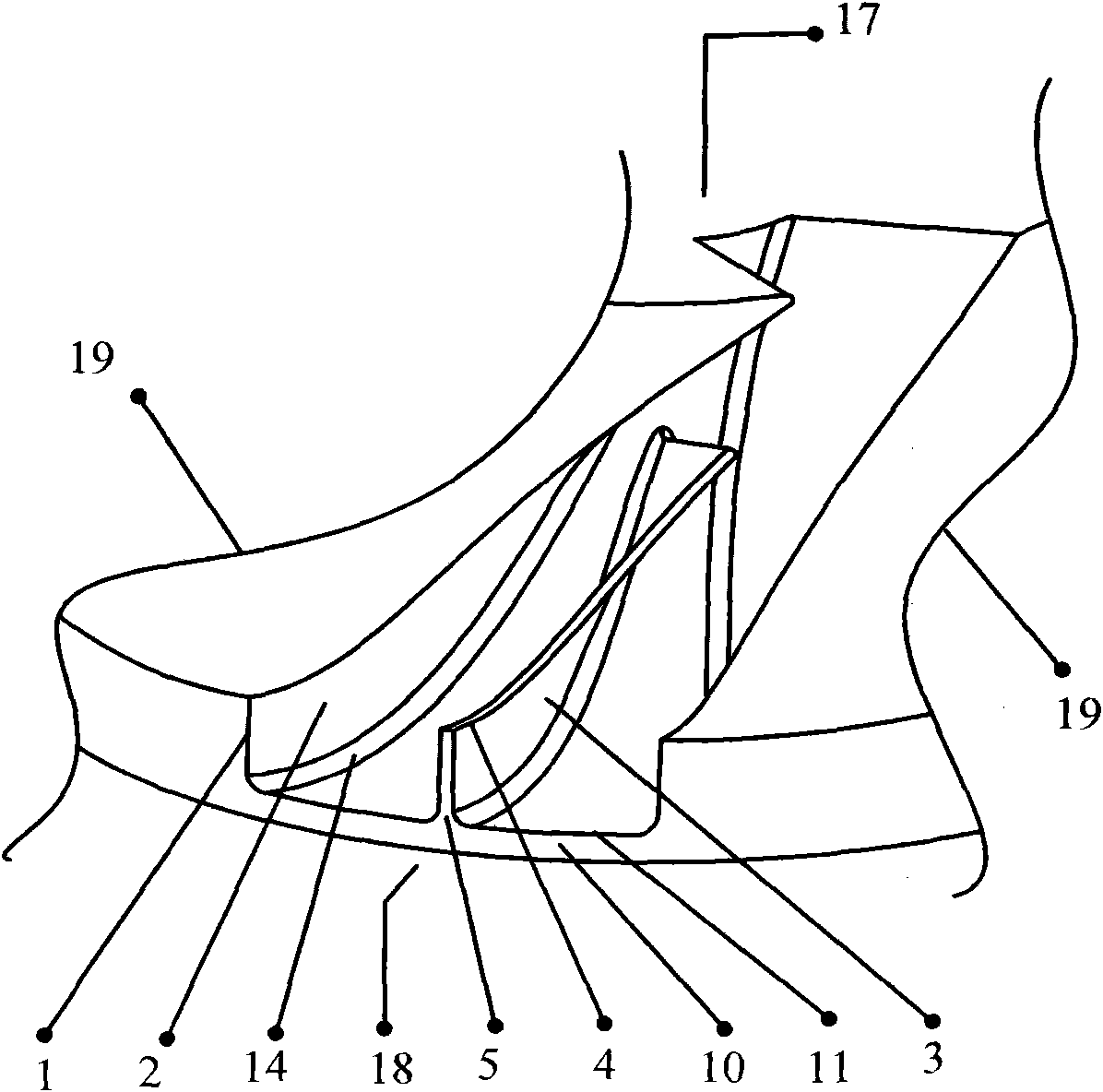

Longitudinal connection structure for superimposed slab concrete shear walls and connection method

The invention provides a longitudinal connection structure for superimposed slab concrete shear walls and a connection method, and solves the problems of a traditional longitudinal connection method for prefabricated part walls that the prefabricated part production process is complicated, field hole aligning is difficult, the loss of a grouting material during field mixing is huge, the grouting material is quick in setting and hardening, and the mixing qualities are much different during mixing. The longitudinal connection structure comprises a closed ring-shaped connecting stirrup (2), the connecting stirrup extends into an upper superimposed slab concrete shear wall (1) and a lower superimposed slab concrete shear wall (1) which are mutually connected to form a transition space together with ring-shaped longitudinal bars (5) of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall, pin joint longitudinal bars (3) penetrate into the transition space in a manner of being perpendicular to the plane where the connecting stirrup is positioned, and the ring-shaped longitudinal bars of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall are integrated with the pin joint longitudinal bars. The connection method is applied to the longitudinal connection structure for the superimposed slab concrete shear walls.

Owner:HUBEI YUHUI NEW BUILDING MATERIAL

Rough machining method of integrated three-dimensional flow blade wheel

ActiveCN102126042AImprove efficiencyShorten processing timeMilling equipment detailsEngineeringAlloy steel

The invention provides a rough machining method of an integrated three-dimensional flow blade wheel. Materials in runners between every two blades are milled and removed by a ball cutter, milling is performed from a blade wheel cover side to a blade hub side gradually, and the specification of the ball cutter is gradually varied from large to small; the milling is performed in a certain layer by the ball cutter of the largest specification which is allowed to be used in the runner space, a ball head radius of the milling cutter of the certain layer is set to be Ra, an arc bevel A is left beside the blade after the milling, and the redundancy of the arc bevel left in the milling process of the certain layer is milled in a mode of rough opening in a full-length direction of the blade; and the processes are repeated, so that a predesigned arc bevel r is finally obtained. Related data and processes can be programmed, and the milling is performed by a numerical control milling machine or anumerical control machining center. A cleaning mode has high efficiency, machining time is shortened by 5 to 20 percent, and the rough machining method is particularly suitable for the rough machining of the large integrated three-dimensional flow blade wheel made of stainless steel, alloy steel and titanium alloy materials.

Owner:JIN TONG LING TECH GRP CO LTD

Flange processing drilling device and method used for electric vehicle rear axle

InactiveCN109202128AImprove efficiencyShorten processing timePositioning apparatusBoring/drilling componentsDrive motorElectric vehicle

The invention relates to the technical field of flange processing used for an electric vehicle rear axle and especially relates to a flange processing drilling device and method used for the electricvehicle rear axle. The device comprises a bottom plate, side plates and a top plate. The left and right sides of the top of the bottom plate are symmetrically provided with the side plates. The upperends of the side plates are provided with the top plate. The upper portion of the right side wall of the side plate located on the right side is provided with a driving motor. The output end of the driving motor is provided with a first lead screw. The left end of the first lead screw passes through the right side plate and is rotatably connected to the left side plate. The thread portion of the first lead screw is cooperatively provided with a first nut. The top of the first nut is provided with a first slide block. In the invention, the functions of the drilling and clamping and positioningof flanges with different specifications used for the electric vehicle rear axle can be simultaneously realized, drilling efficiency is increased and processing time is saved. The structure is novel,the design is reasonable, the usage is convenient, and the device and the method have a high popularization value.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

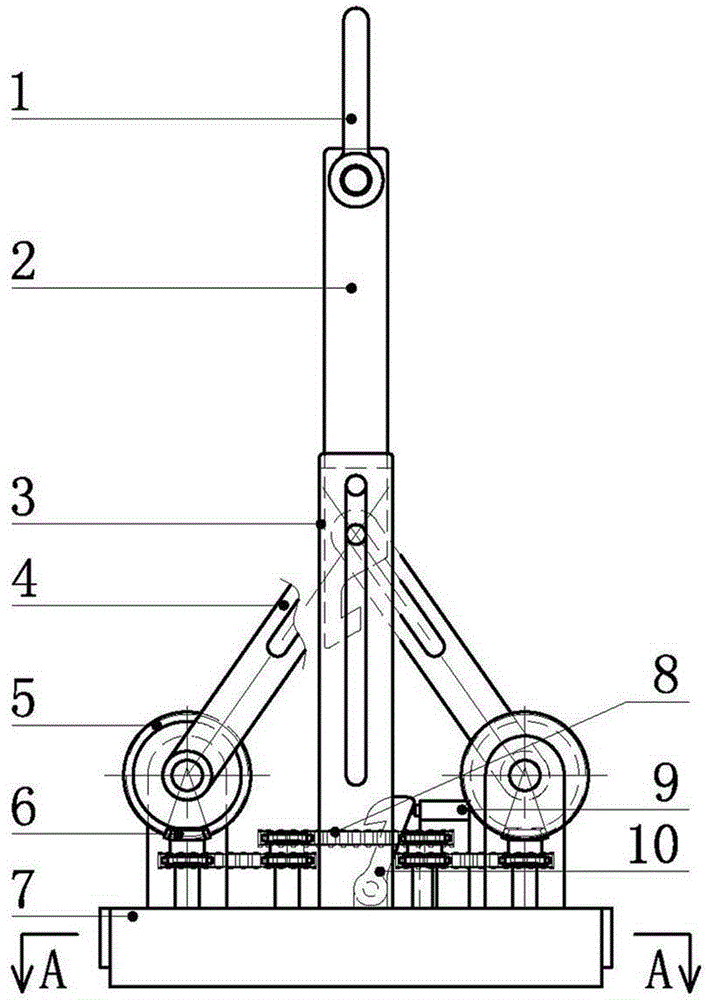

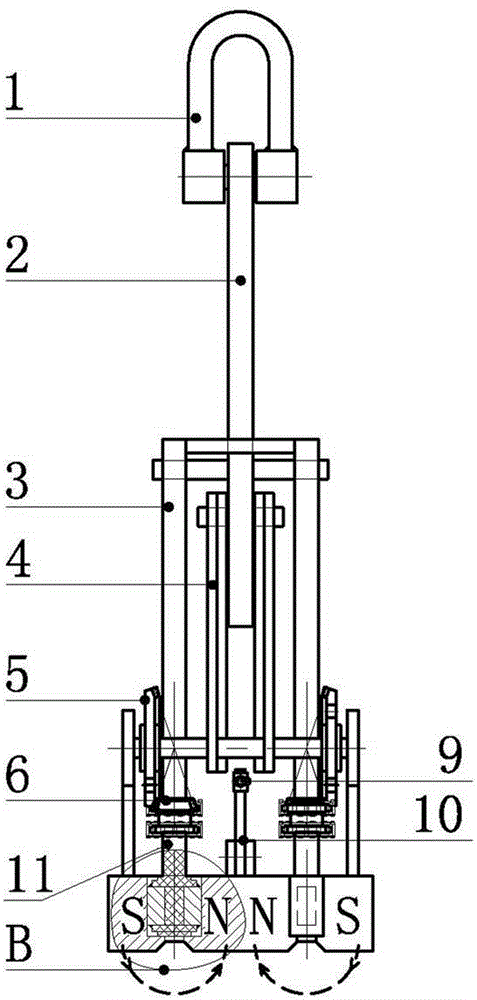

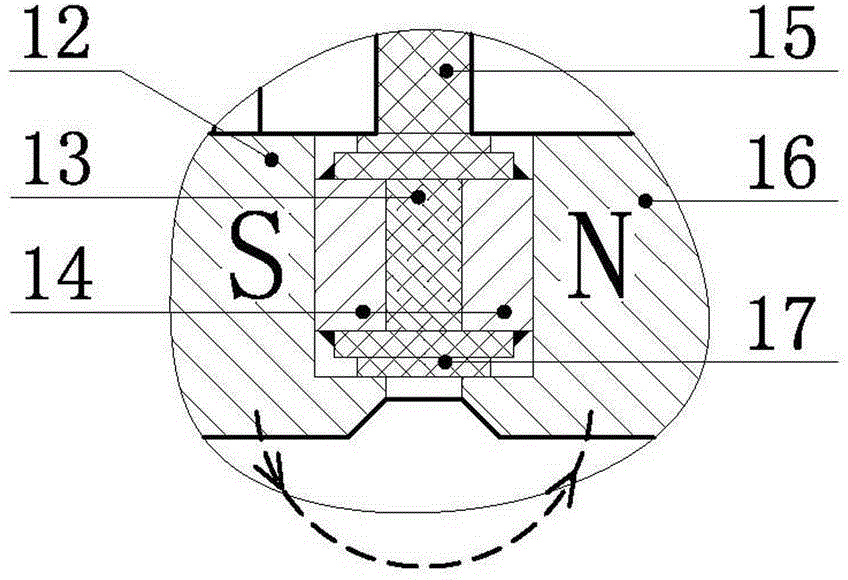

Magnetic path horizontal rotary type hoisting permanent magnet

ActiveCN104310192AShorten processing timeReduce processing difficultyLoad-engaging elementsEngineeringHooking

The invention provides a magnetic path horizontal rotary type hoisting permanent magnet. The magnetic path horizontal rotary type hoisting permanent magnet is mainly composed of three parts, namely a mechanical rotation part, a magnetic system body and a control device, and is characterized in that a lifting ring of the mechanical rotation part is arranged on a lifting rod with a hook; when the lifting rod with the hook slides in a lifting rod slide rail, left and right lifting bars and large bevel gears are driven to rotate, then small bevel gears are driven to horizontally rotate, and finally, a plurality of rotary magnetic shafts in the magnetic system body are driven to rotate by a roller chain so as to change a magnetic path; and each lifting or descending of the lifting rod with the hook is used for controlling the unhooking or the hooking of the hook, so that the rotary angles of the magnetic shafts in the magnetic system body are controlled to control the circulation of two states, namely iron suction and iron releasing, of the hoisting permanent magnet; and a ratchet wheel is not used so that the problems of an old type hoisting permanent magnet that the iron suction is not synchronous, the machining is difficult and the like are completely overcome.

Owner:雷艳

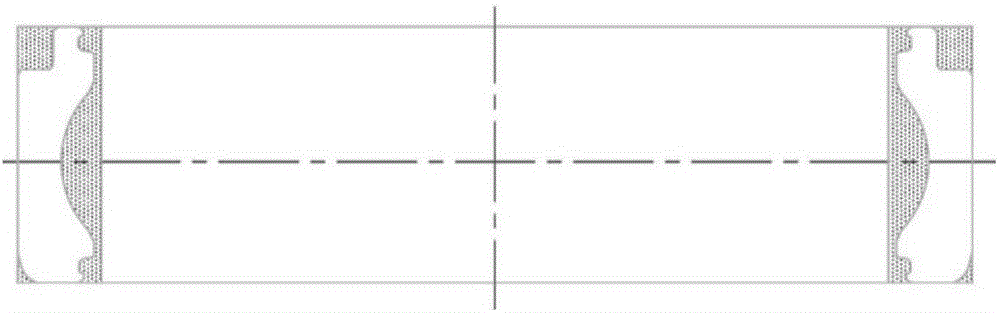

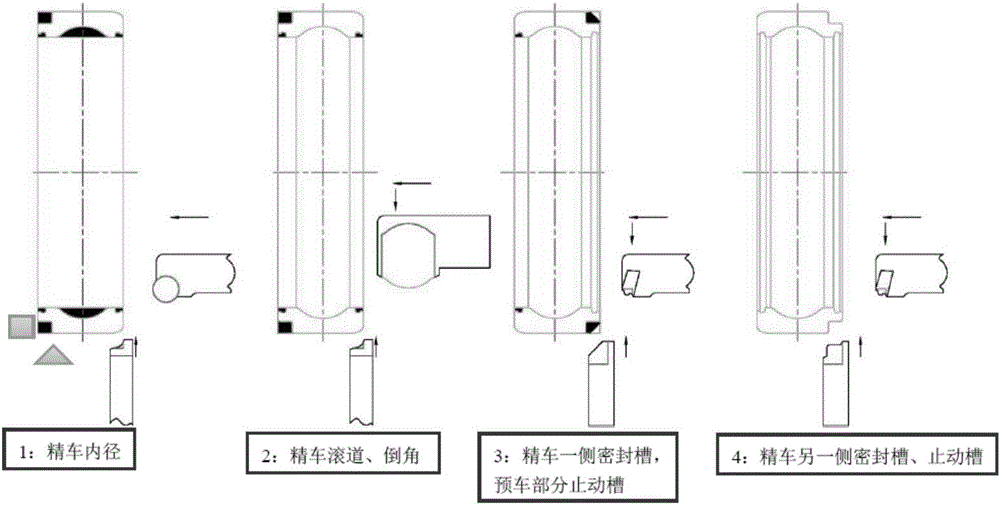

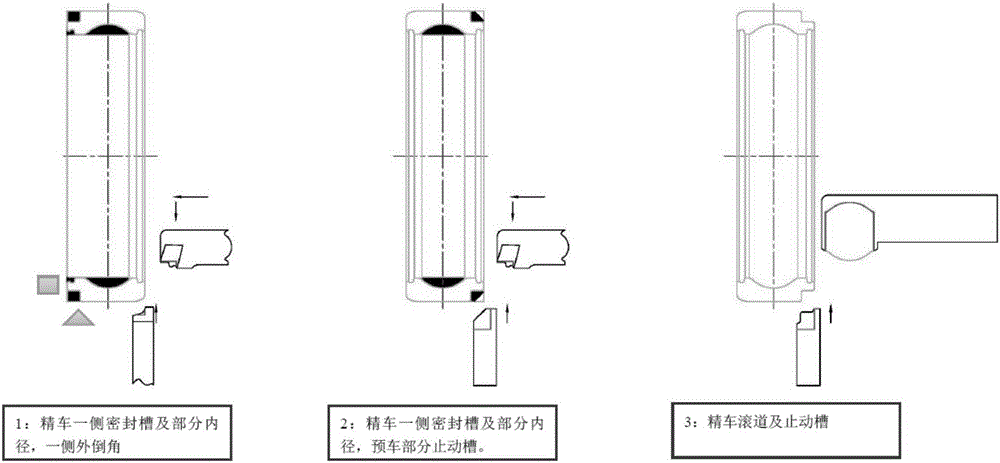

Novel technology for turning bearing outer ring connecting line

InactiveCN105081356ALow costShorten processing timeBearing componentsTurning machinesEngineeringMachining time

The invention provides a novel technology for turning a bearing outer ring connecting line. Three single machines are adopted for connecting line machining, and the technology comprises the following steps that 1, the first single machine is adopted for finish turning of the inner diameter and a chamfer of one side of an outer ring or cutting of a sealing groove or cutting of an outer chamfer; 2, the second single machine is adopted for finish turning of the inner diameter and a chamfer of the other side of the outer ring or cutting of the sealing groove or cutting of the outer chamfer and pre-turning of a part of a locking groove; and 3, the third single machine is adopted for finish turning of an outer ring roller path and cutting of the outer ring roller path and the locking groove. Compared with existing four-machine connecting line machining technology, the novel technology has the beneficial effects that one machine tool is directly omitted, and the cost of a production line is greatly lowered; meanwhile, the machining time is saved, and the machining efficiency of the production line is greatly improved; and the novel technology is the innovative connecting line machining mode.

Owner:黄石哈特贝尔精密锻造有限公司

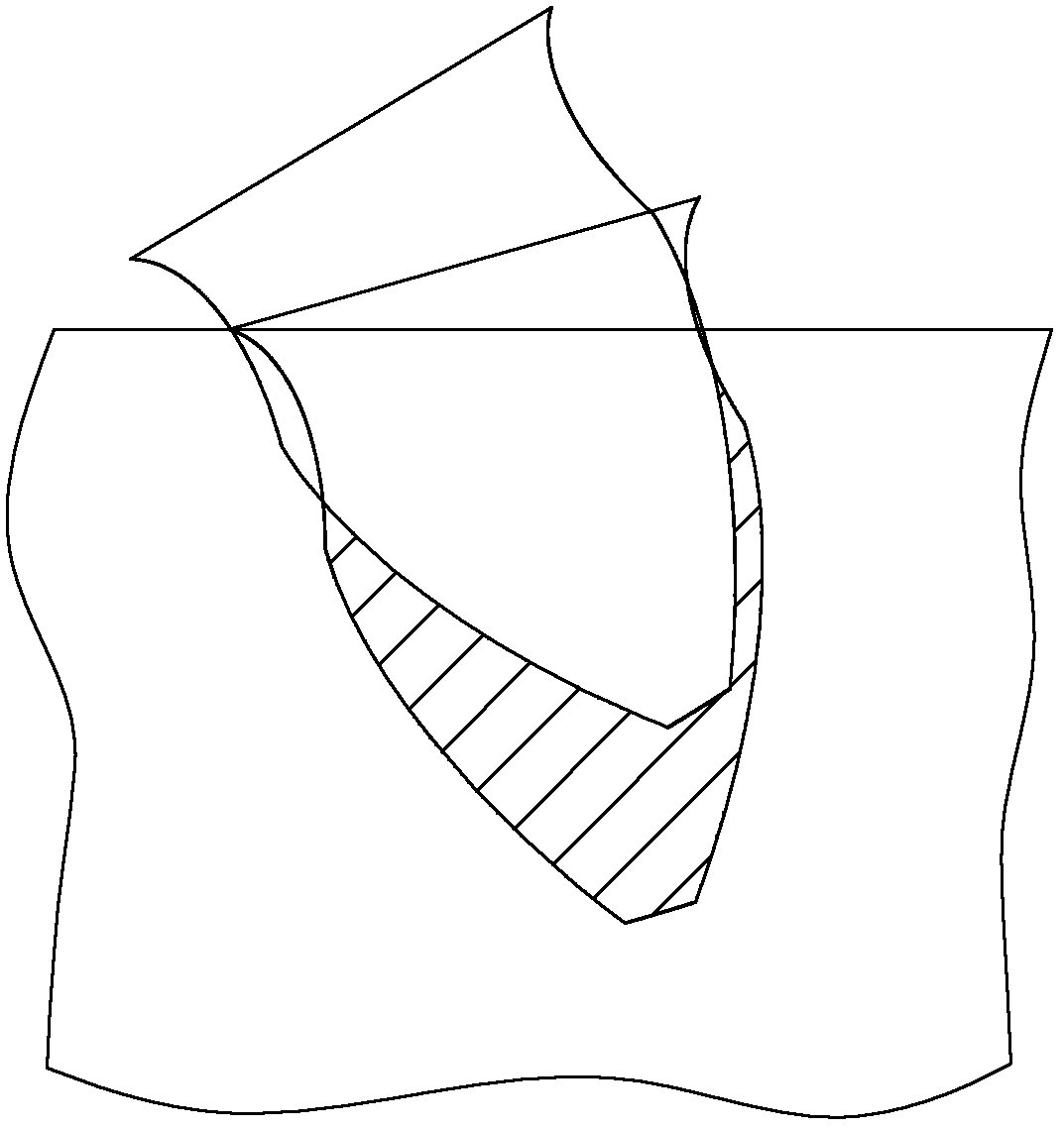

Gear shaping method based on equal cutting area

ActiveCN102581384ASlow down jerky vibrationsShorten processing timeSpecial data processing applicationsGear teethInstabilityEngineering

The invention relates to a gear shaping method based on the equal cutting area, which is characterized in that gear shaping of a gear aims to realize shaping with equal cutting force by means of gear shaping with equal cutting area. The gear shaping method has the advantages that the method can be used only by adding corresponding numerical control codes without changing a main structure of a machine tool, main driving force of the machine tool can be fully used in a rough shaping phase, instability of the machine tool is reduced, shaping time is shortened, shaping cost is reduced, and shaping efficiency is improved.

Owner:天津第一机床有限公司

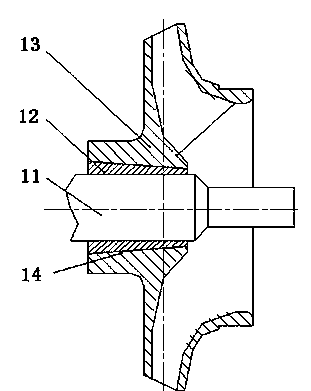

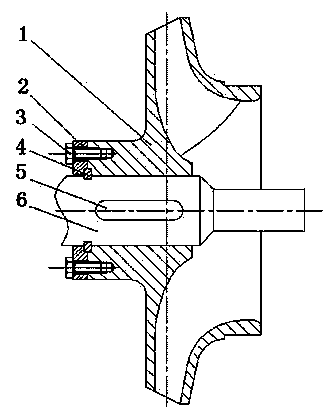

Impeller positioning structure

The invention relates to an impeller positioning structure. The impeller positioning structure comprises a pump shaft, a positioning shaft sleeve sleeving the pump shaft and an impeller sleeving the positioning shaft sleeve; the match surface of the impeller and the positioning shaft sleeve is of an inclined surface; the inclined surface is upwards inclined along the water inlet direction of the impeller. The impeller positioning structure has the advantages that the structure is simple, the processing steps are simplified, the machining time is saved, the assembly and maintenance are facilitated and the impeller is not easily damaged.

Owner:SHANGHAI LIANCHENG(GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com