Method for processing blade form work piece and fittings dedicated therefor

A processing method and blade-shaped technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of labor-intensive material utilization, time-consuming, etc., to reduce the number of processing times, reduce processing procedures, and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

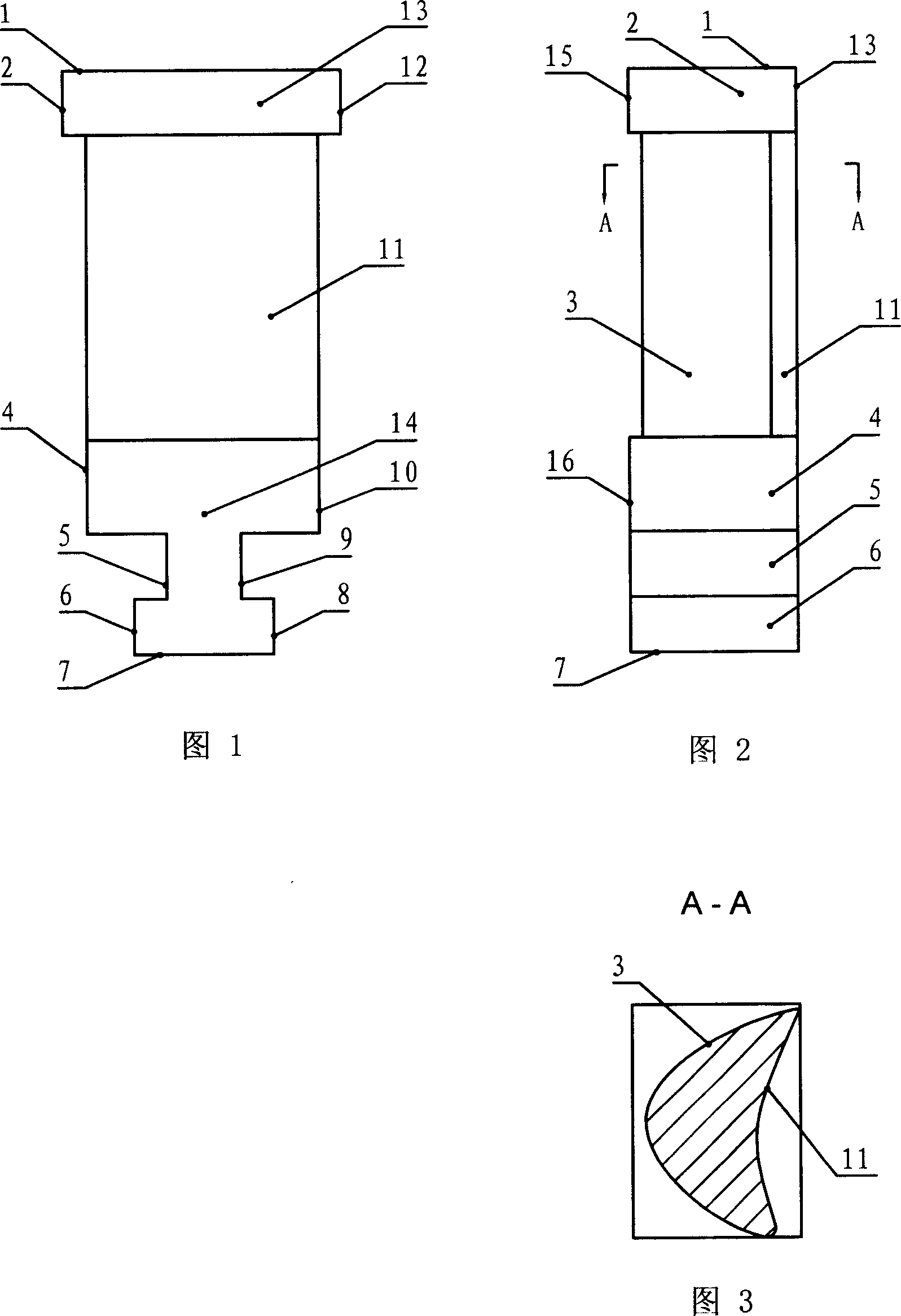

[0010] Specific embodiment one: referring to Fig. 1 to Fig. 10 to illustrate this embodiment, the processing steps of the blade-shaped workpiece of this embodiment are:

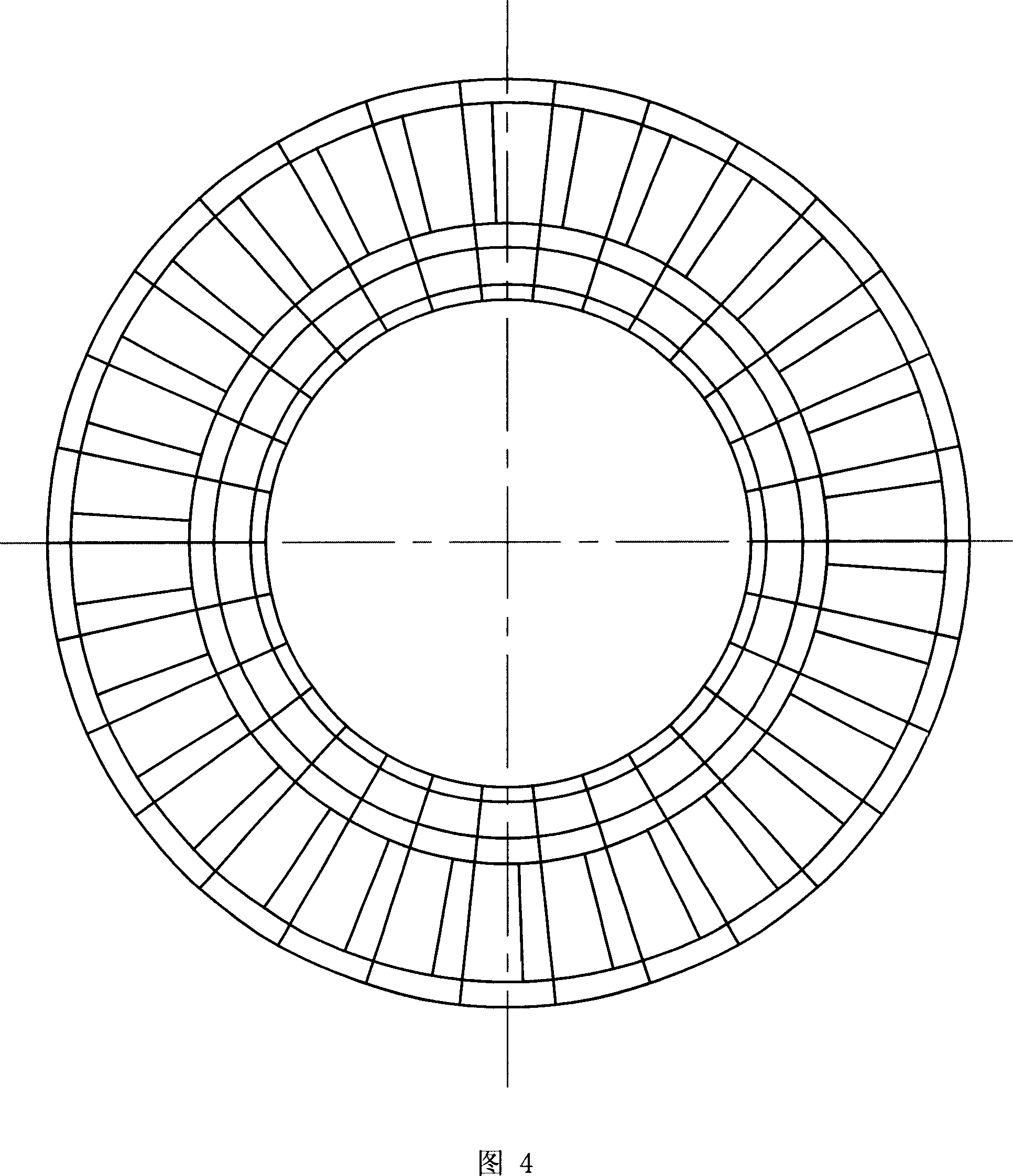

[0011] 1. Use a lathe to turn the ring-shaped blank, and turn each side of the blade-shaped workpiece on the two planes of the disc-shaped blank successively, and process the first plane 1 and the second plane of the blade-shaped workpiece 2. The fourth plane 4, the first groove 5, the sixth plane 6, the seventh plane 7, the twelfth plane 12, the tenth plane 10, the second groove 9, and the eighth plane 8.

[0012] The ring-shaped rough blank described in this step is made according to the shape of the ring formed after several blade-shaped workpieces are installed on the impeller. Fig. 1 to Fig. 3 are the schematic diagrams of the structure of the blade-shaped workpiece. When the impeller is filled with the blade-shaped workpiece, the shape is shown in Fig. 4, and the thirteenth plane 13 and the fourteenth p...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that after Step 3, Step 4 is added. Step 4 is: polishing the milled inner arc surface 11 and outer arc surface 3 .

specific Embodiment approach 3

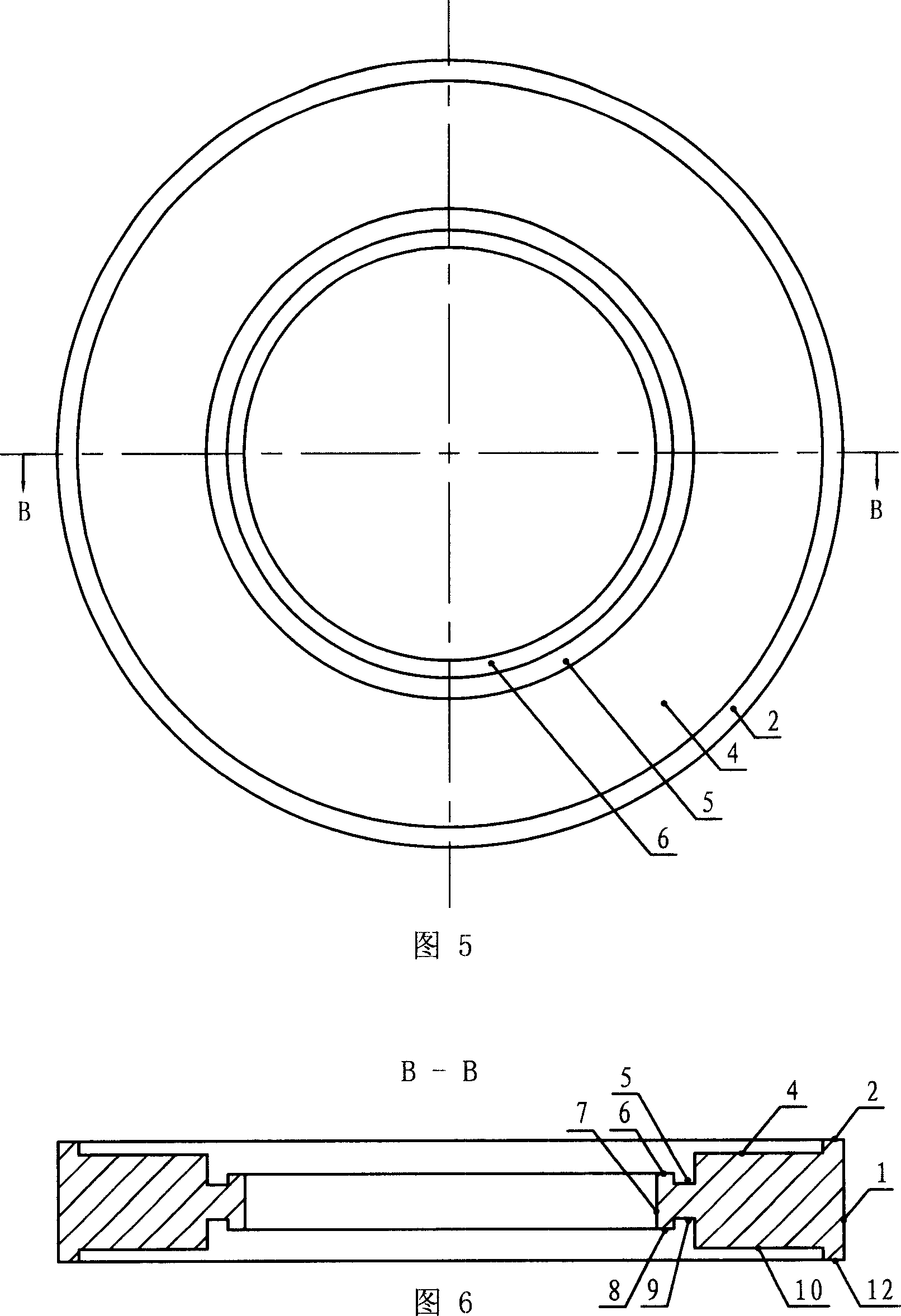

[0024] Specific embodiment three: refer to FIG. 11 . The special tooling for processing blade-shaped workpieces of the present invention is composed of a base 20, a drive shaft 22, several bearings 23, a shaft sleeve 24, a mounting plate 25, and positioning pins 27. The base 20 is a fixed support for the special tooling. The side 20-1 of the installation and processing workpiece of 20 has a positioning hole 28, the positioning hole 28 can fit with the positioning pin 27 clearance, one end of the transmission shaft 22 is fixedly connected to the center position of the mounting plate 25, and the plurality of bearings 23 Fixed between the drive shaft 22 and the shaft sleeve 24, the mounting disc 25 is a circular ring with a "convex" cross-section, and the raised part 25-1 in the middle of the mounting disc 25 can be aligned with the circular ring-shaped blank 30 to be processed. Clearance fit.

[0025] Before carrying out the wire cutting process, earlier according to the quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com