Process for laminating printed circuit board (PCB) with buried/blind via structure

A PCB board and buried blind hole technology, which is applied in the lamination process of PCB boards, can solve the problems of large amount of misalignment between layers, affect welding strength, and damage the flatness of steel plates, etc., so as to reduce the amount of misalignment between layers and improve work efficiency. , Reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

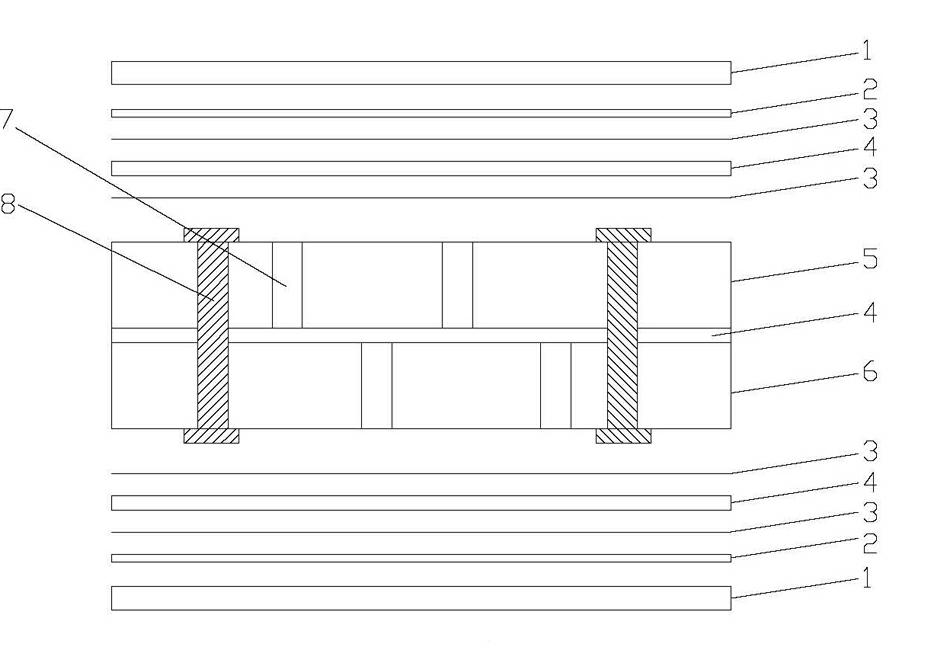

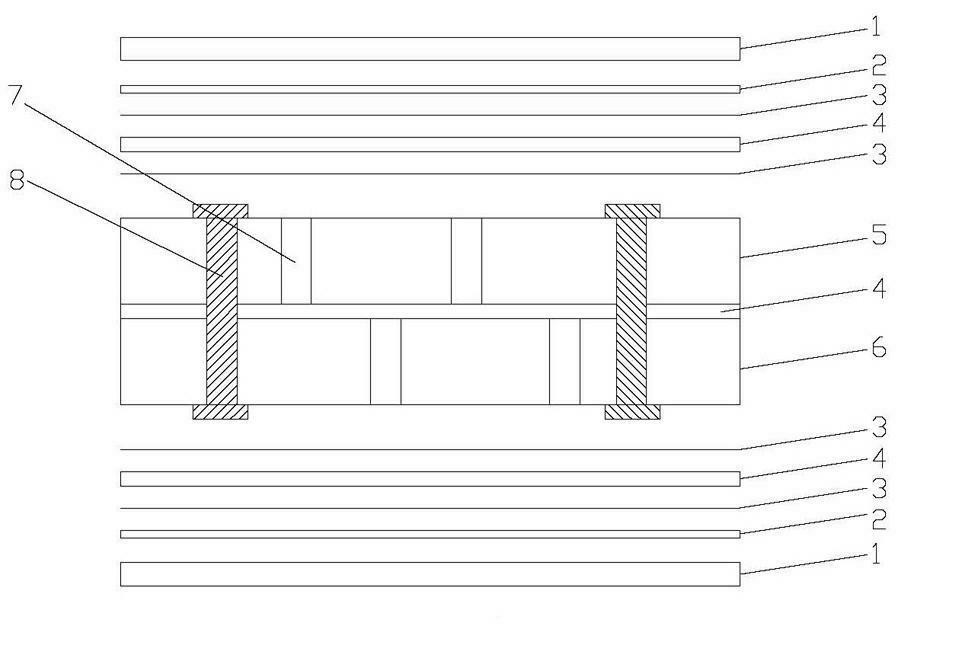

[0020] Embodiment 1, the upper core board 5 and the lower core board 6 are two-layer boards that have been drilled, electroplated and pattern transferred, and a release film 3 is sequentially laid on the upper surface of the upper core board 5 from bottom to top , a prepreg 4, a release film 3, an aluminum sheet 2, a mirror steel plate 1, a release film 3, a prepreg 4, One piece of release film 3, one piece of aluminum sheet 2, one piece of mirror steel plate 1, the thickness of release film 3 is 0.03mm, the thickness of prepreg 4 is 0.16mm, and the thickness of aluminum sheet 2 is 0.15mm. After pressing, it is For 4-layer boards, the prepreg changes from a semi-cured state to a fully cured state to become a cured sheet, remove the aluminum sheet, and remove the prepreg attached to the release film, and then undergo subsequent processing to form a 4-layer structure with buried blind holes PCB board.

Embodiment 2

[0021] Embodiment 2, the upper core board 5 and the lower core board 6 are four-layer boards that have been drilled, electroplated and pattern transferred, and a release film 3 is sequentially laid on the upper surface of the upper core board 5 from bottom to top , a prepreg 4, a release film 3, an aluminum sheet 2, a mirror steel plate 1, a release film 3, a prepreg 4, A release film 3, an aluminum sheet 2, and a mirror steel plate 1, the release film 3 has a thickness of 0.04mm, the prepreg 4 has a thickness of 0.18mm, and the aluminum sheet 2 has a thickness of 0.18mm. After pressing, it becomes an eight-layer board. The prepreg changes from a semi-cured state to a fully cured state to become a cured sheet. The aluminum sheet is removed, and the prepreg attached to the release film is removed. After subsequent processing, an eight-layer structure is formed. hole PCB board.

Embodiment 3

[0022] Embodiment 3, both the upper core board 5 and the lower core board 6 are eight-layer boards that have been drilled, electroplated and pattern transferred, and a release film 3 is sequentially laid on the upper surface of the upper core board 5 from bottom to top , a prepreg 4, a release film 3, an aluminum sheet 2, a mirror steel plate 1, a release film 3, a prepreg 4, One piece of release film 3, one piece of aluminum sheet 2, one piece of mirror steel plate 1, the thickness of release film 3 is 0.05mm, the thickness of prepreg 4 is 0.19mm, the thickness of aluminum sheet 2 is 0.20mm, after pressing For 16-layer boards, the prepreg changes from a semi-cured state to a fully cured state to become a cured sheet, remove the aluminum sheet, and remove the prepreg attached to the release film, and then undergo subsequent processing to form a 16-layer buried blind hole PCB board.

[0023] The invention utilizes aluminum sheet, prepreg and release film as auxiliary pressing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com