Patents

Literature

80results about How to "Good assembly precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

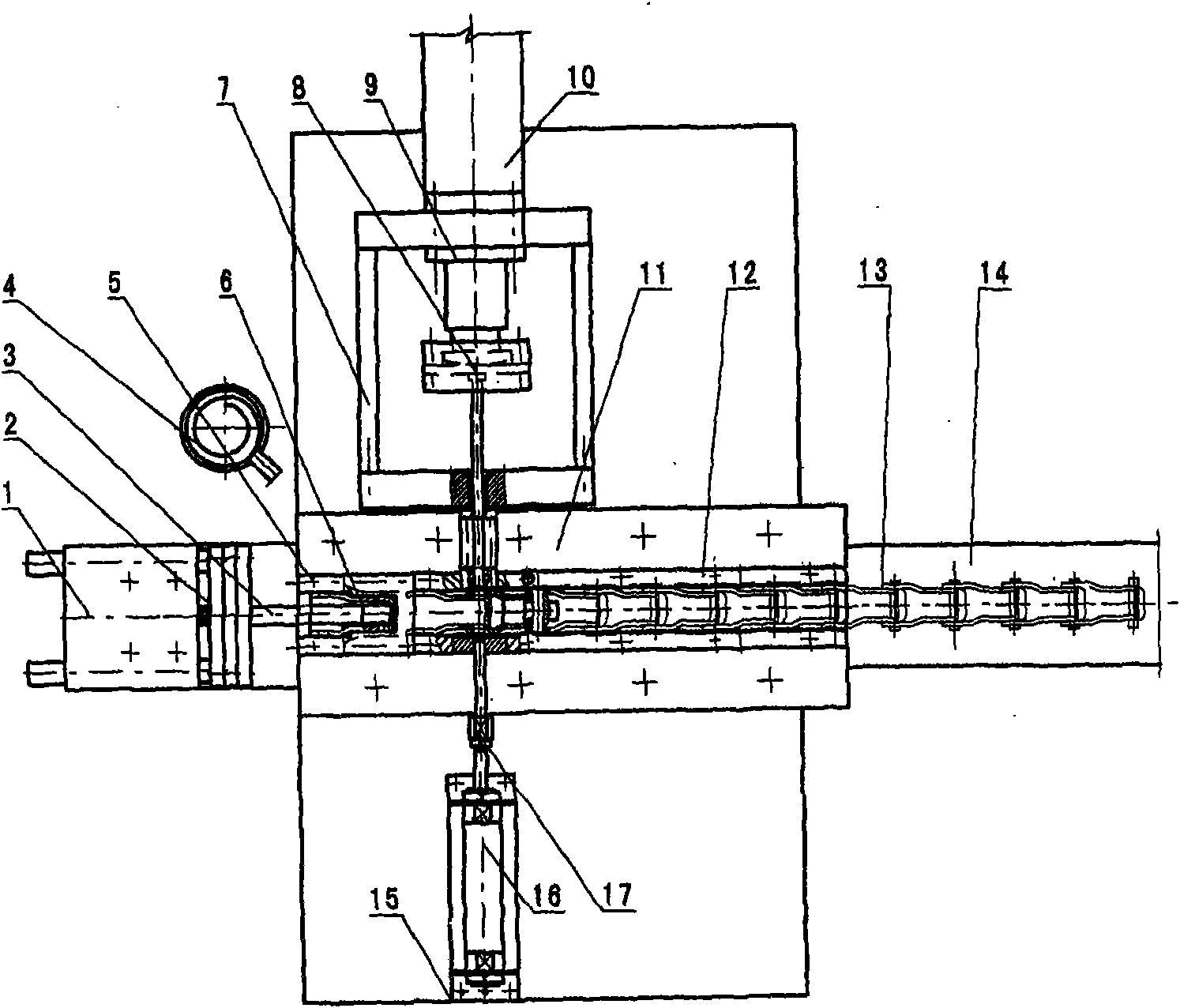

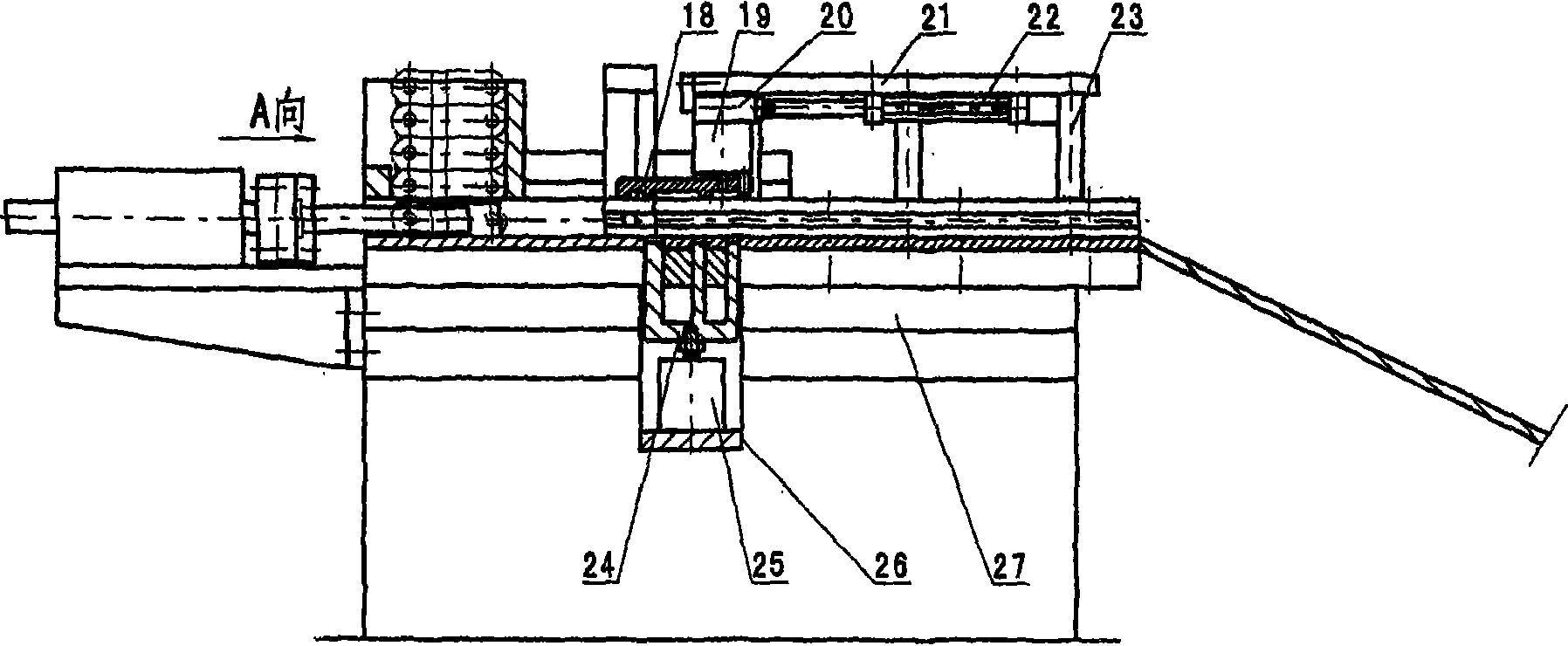

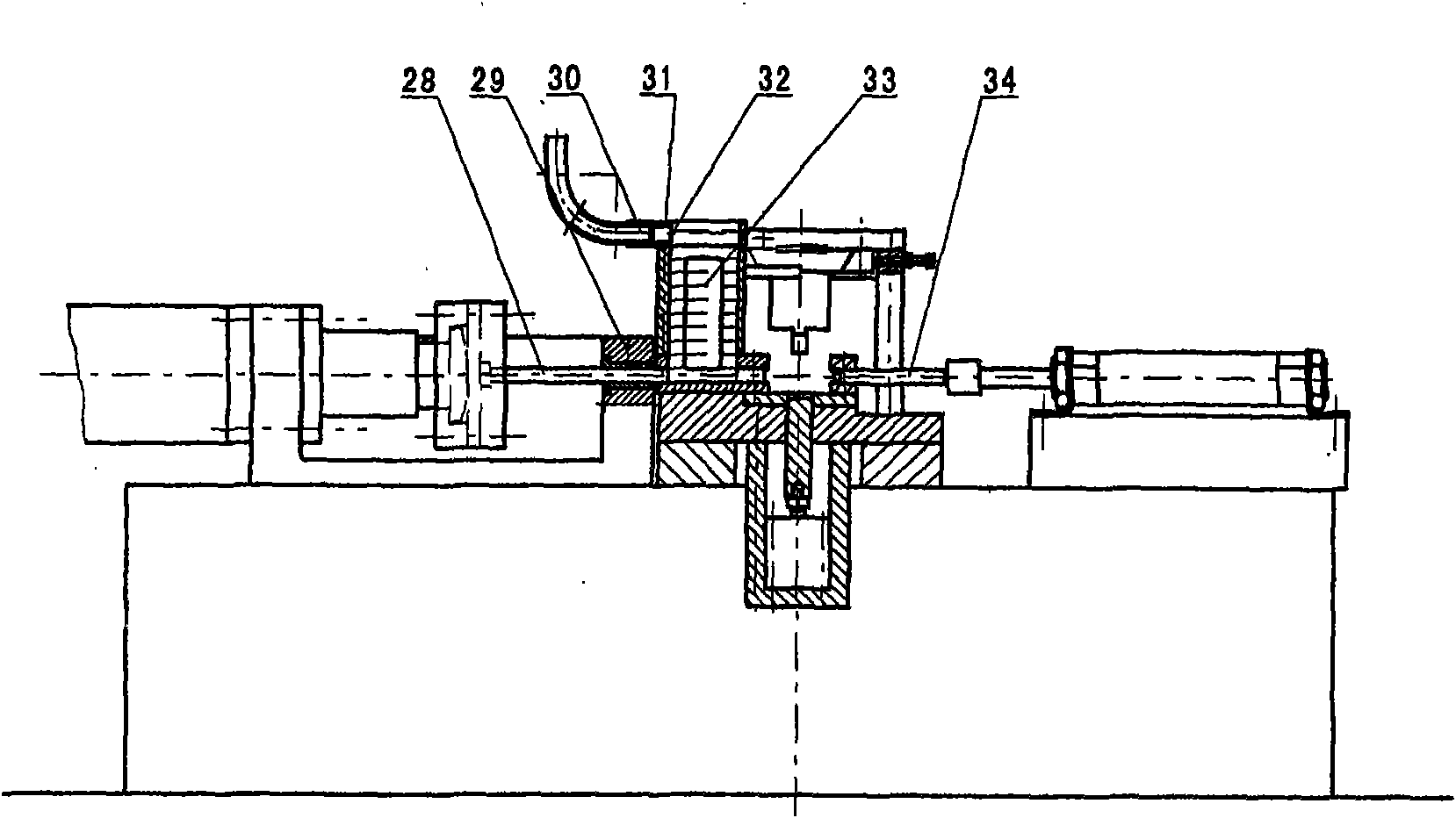

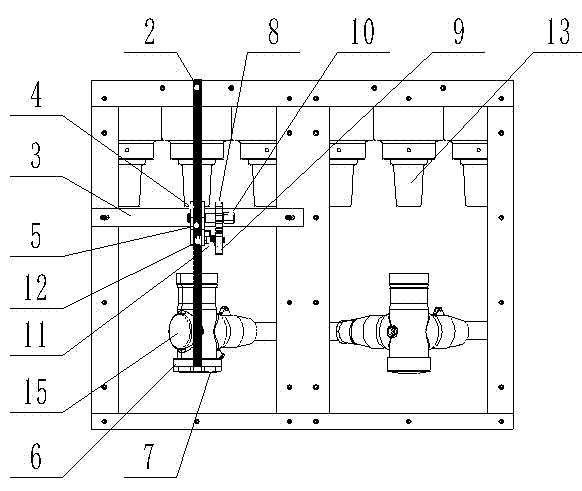

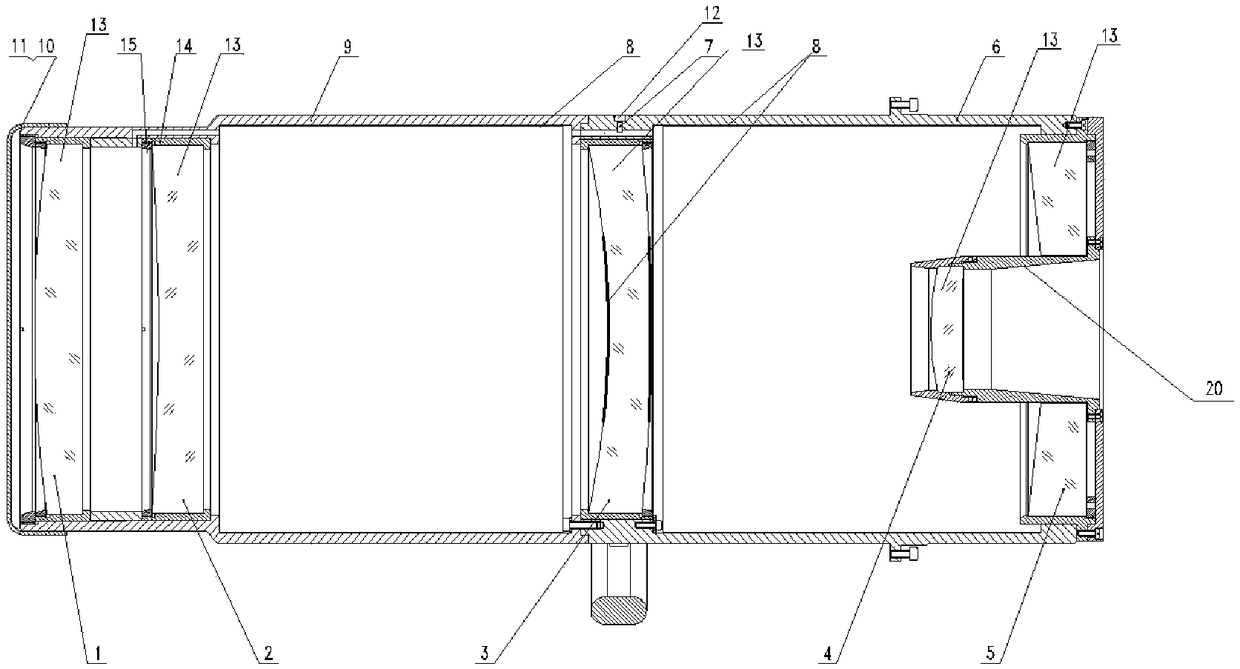

Pintle chain automatic assembly machine

InactiveCN101676049AGood assembly precisionSolve the shortcomings of manual assemblyMetal chainsControl systemEngineering

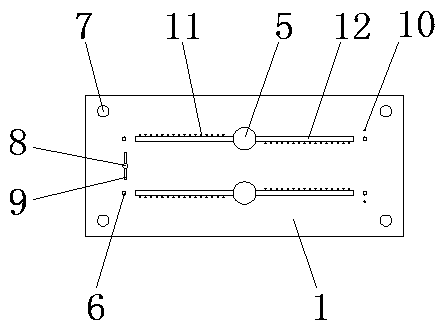

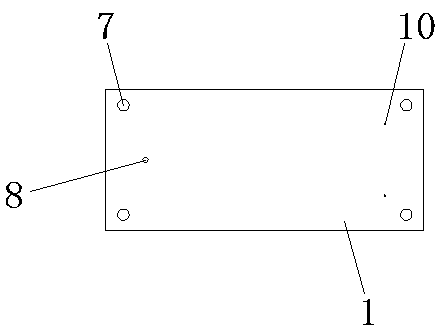

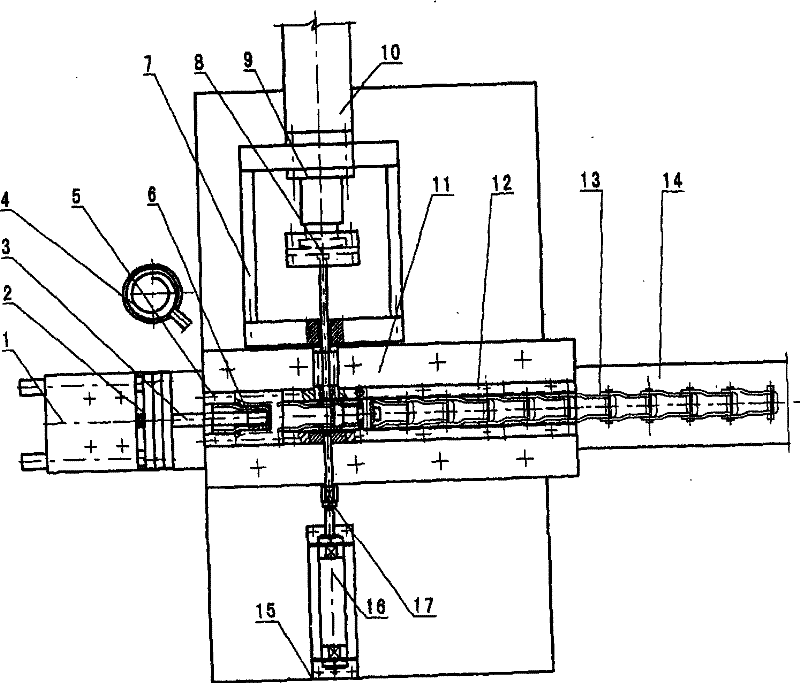

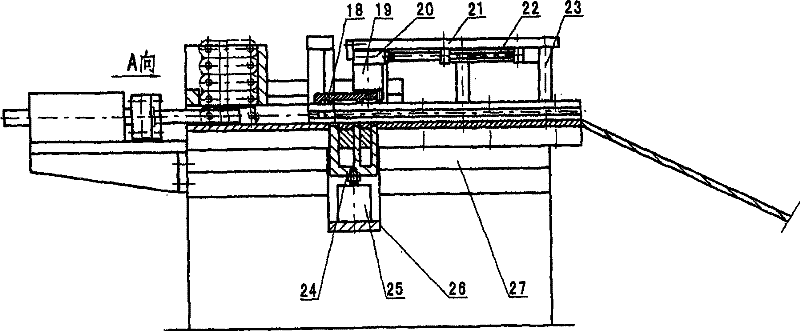

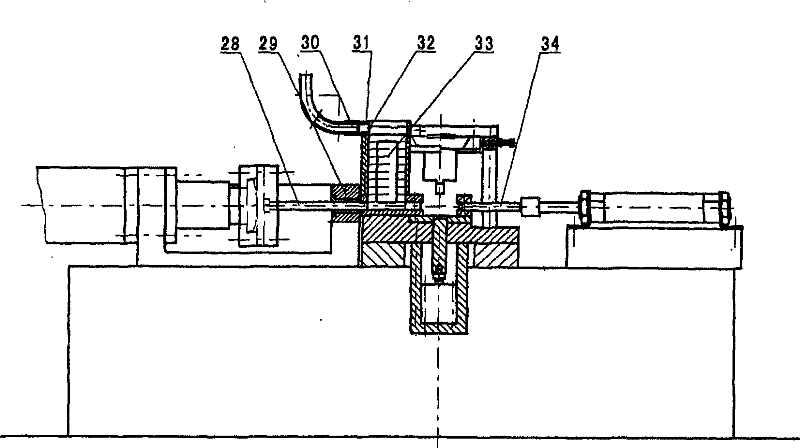

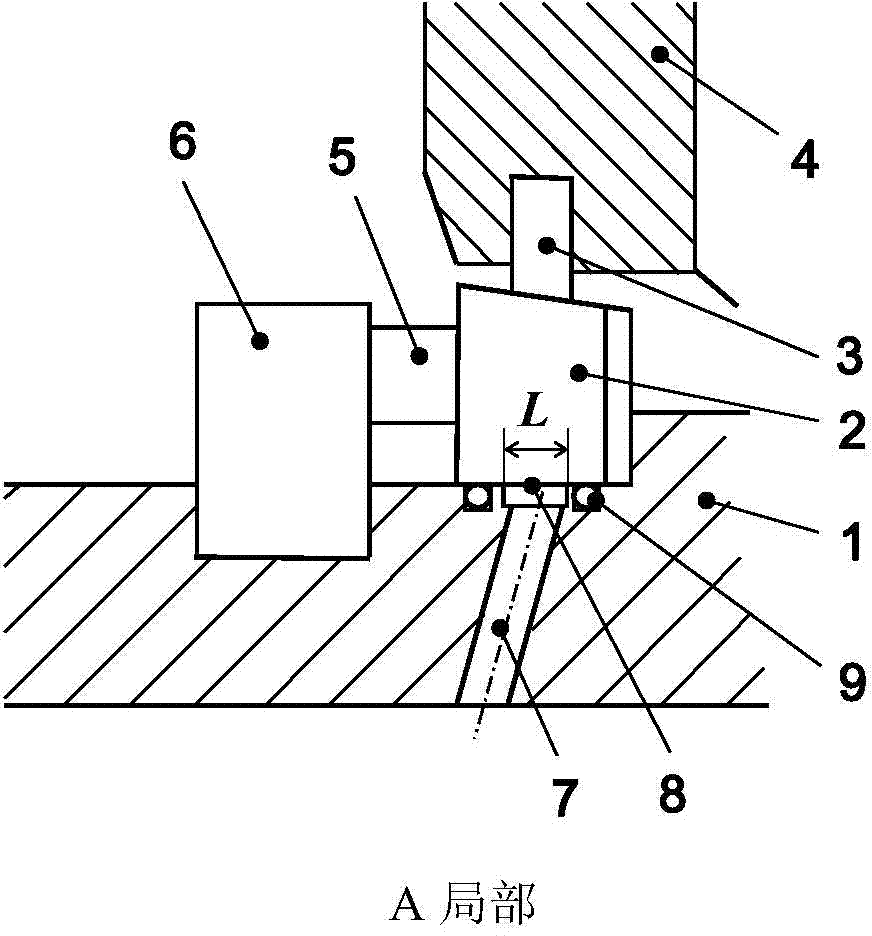

The invention relates to a pintle chain automatic assembly machine, belonging to the technical field of chain manufacturing machinery. The invention aims to provide a pintle chain automatic assembly machine which is suitable for the assembly production process of pintle chains and has good precision control and high production efficiency. The technical key of the pintle chain automatic assembly machine in that the assembly machine comprises a frame, a link plate feeding mechanism, a link plate positioning mechanism, a pin-penetrating mechanism, a chain element moving mechanism, a PLC automaticcontrol system and a discharging plate, wherein the link plate feeding mechanism comprises a double-cylinder feeding air cylinder (1) and a feeding pole (3) which are arranged in the front of the frame (27) and a link plate-feeding box (5); the link plate positioning mechanism comprises a positioning air cylinder (25) and a positioning block (24) which are arranged below the platen of the frame;the chain pin feeding and pin-penetrating mechanism comprises a pin-pressing air cylinder (10) and a pin-introducing air cylinder (16) which are arranged on the two sides of the parallel track of theplaten of the frame and a vibration pin-distributing disk (4), a pin-sending hose (30) and a pin-collecting box (32) which are arranged on the platen of the frame; the chain element moving mechanism comprises a moving air cylinder (22) and a chain element-pressing air cylinder (19) which are arranged above the platen of the frame; the discharging plate (14)is arranged on the backside of the platenof the frame.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

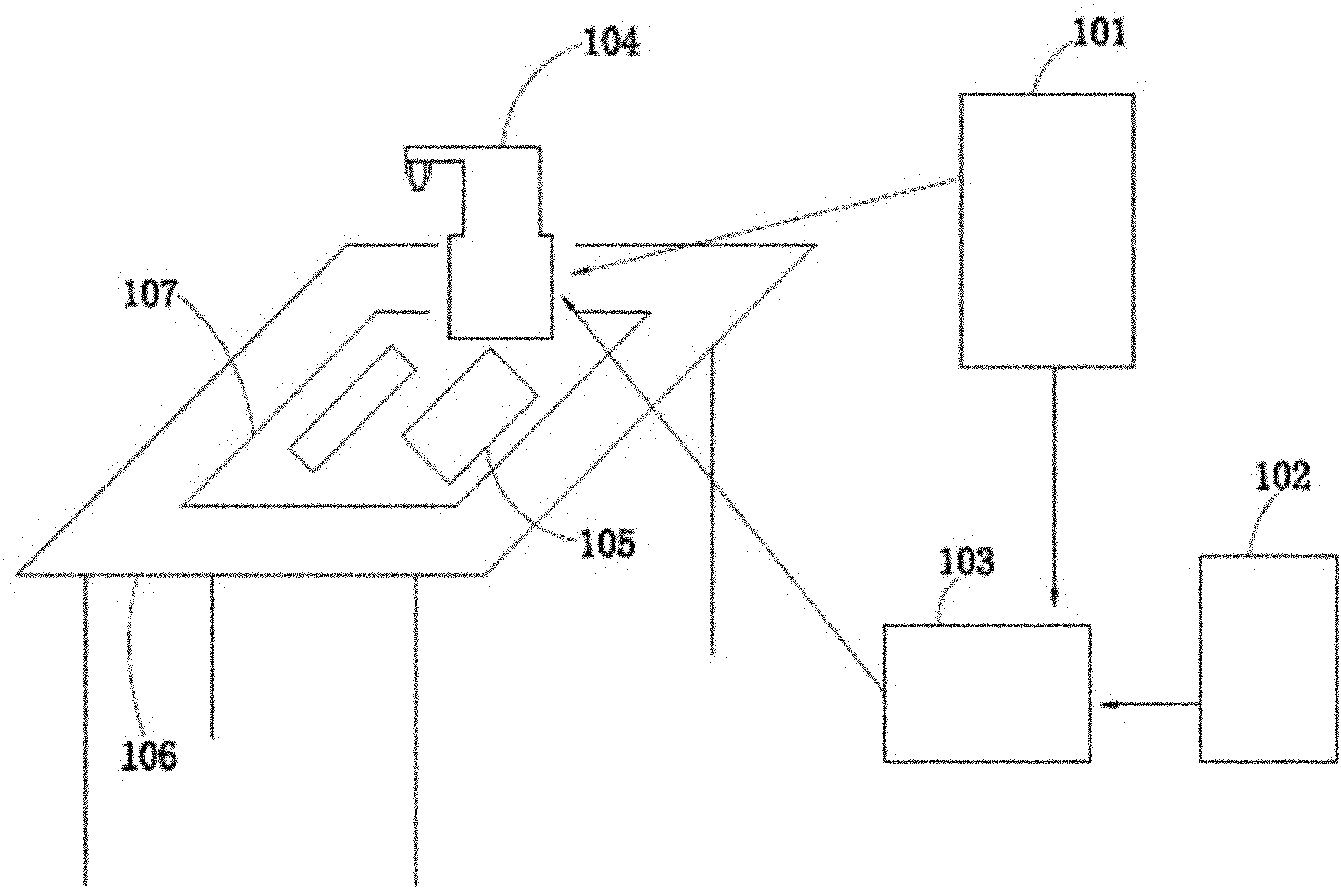

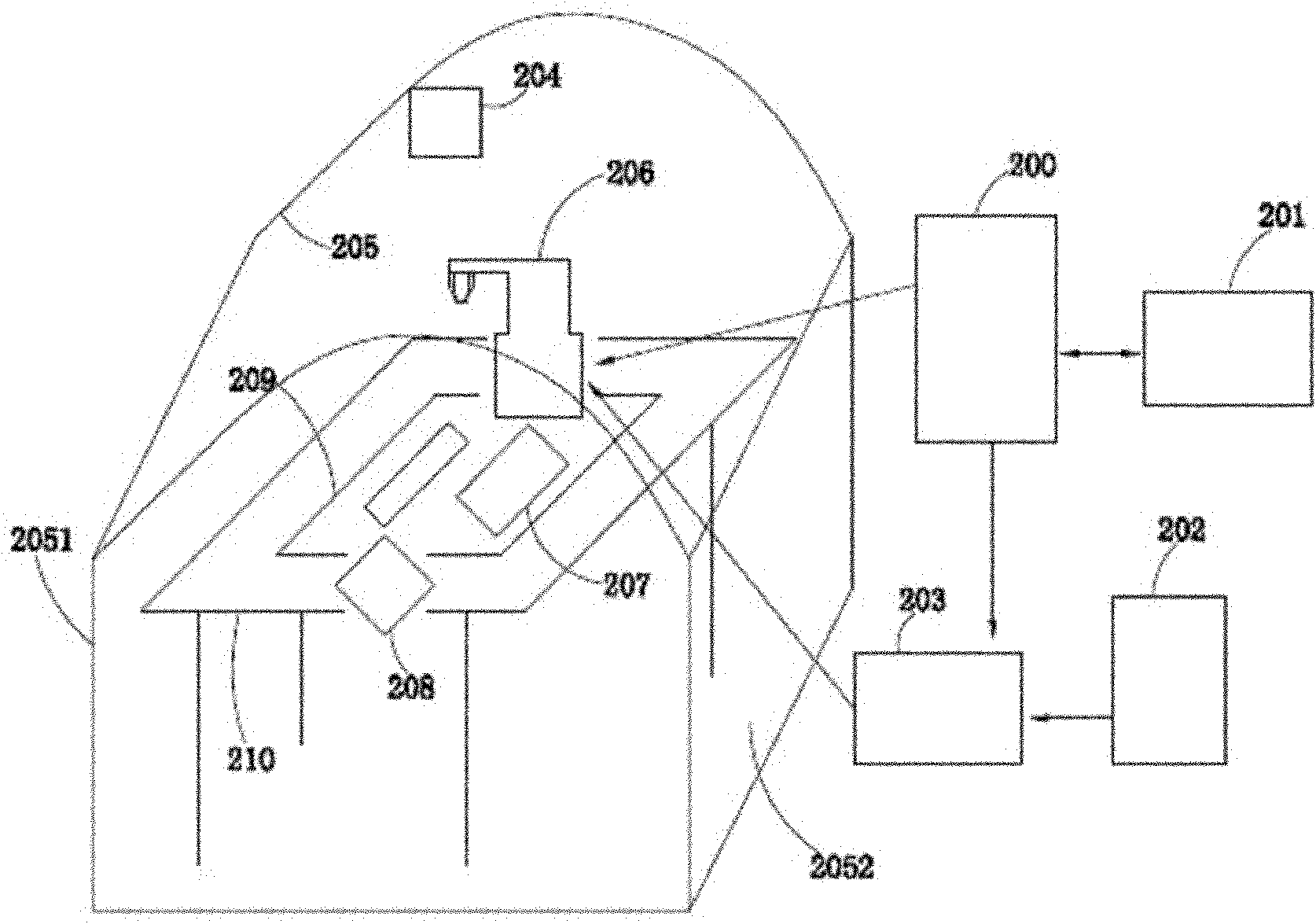

Automatic assembly method and assembly system for strain gauge

InactiveCN102085611AGood assembly precisionImprove consistencyProgramme-controlled manipulatorGripping headsSimulationPersonal computer

The invention discloses an automatic assembly method and assembly system for a strain gauge. The method comprises the following steps: automatically assembling a corresponding strain gauge with a control mechanical arm of an industrial personal computer; performing image acquisition on the suction position and placing position of the strain gauge by use of a centering camera and a bottom searching camera; calculating the central position, deflection angle and offset of the strain gauge according to the image information in the centering camera; meanwhile, calculating the type and direction of an elastic body and the central position of an assembly hole according to the image information of the elastic body for placing the strain gauge provided by the bottom searching camera; and after obtaining the information, transmitting the information to a mechanical arm control cabinet through a communication channel, wherein the mechanical arm control cabinet obtains a motion path of the mechanical arm according to the information, controls the motion track of the mechanical arm, and controls an air suction / placing controller to perform corresponding suction and placing operations. According to the invention, better assembly precision, uniformity and reliability of the strain gauge are obtained, and influence of the service life of a position sensor on the system reliability is solved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

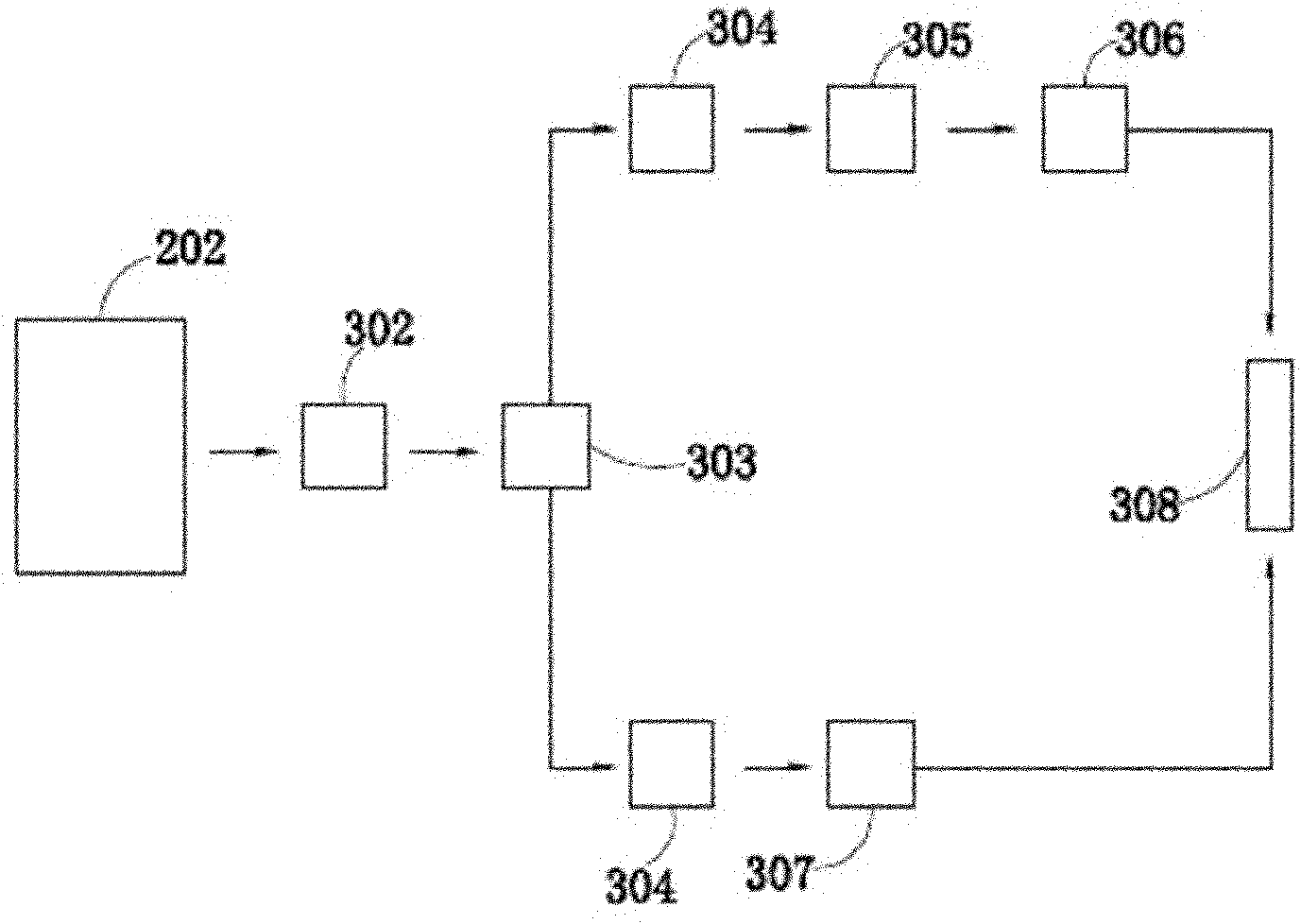

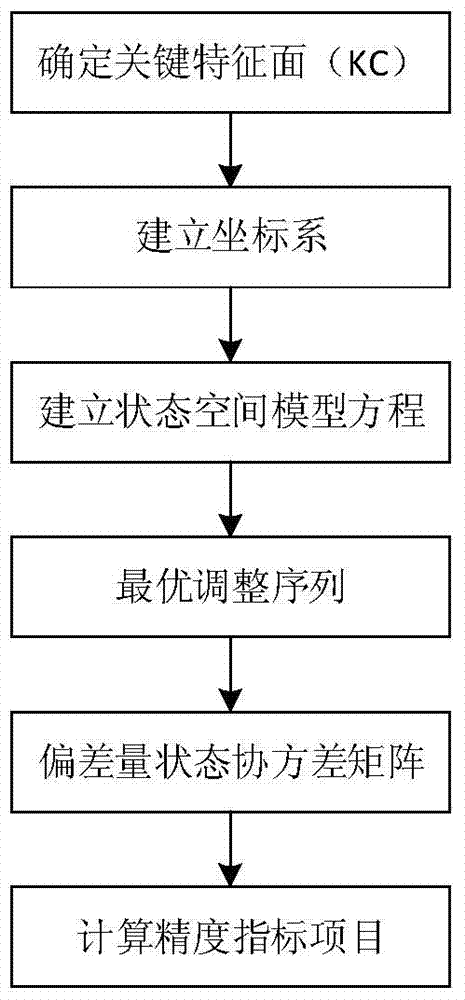

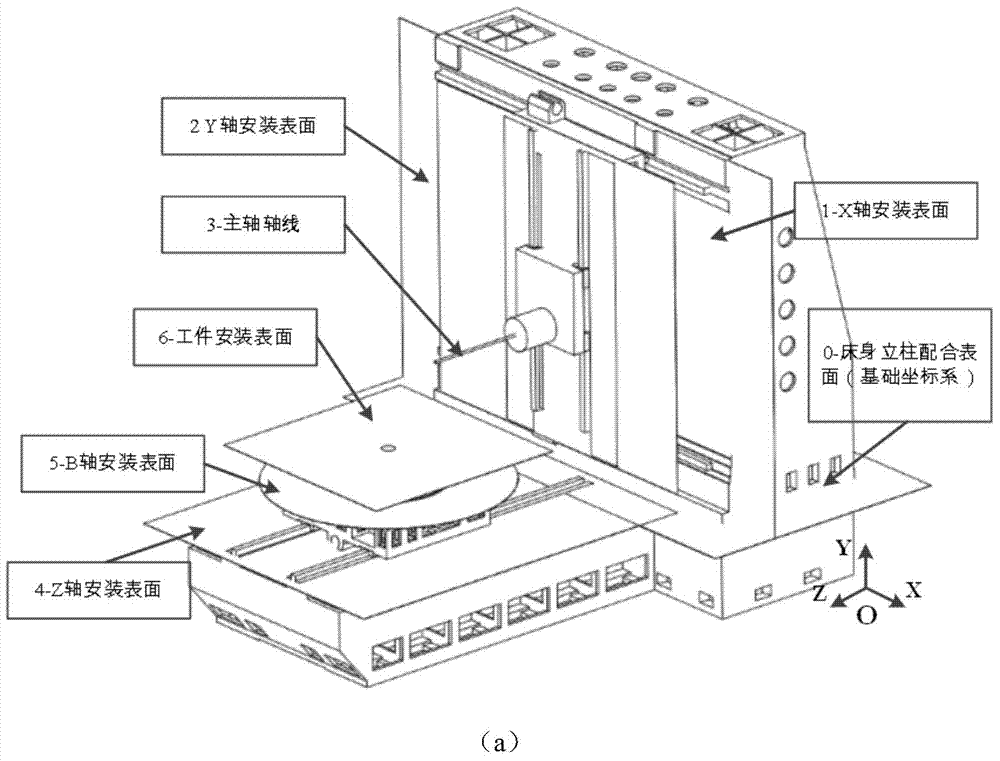

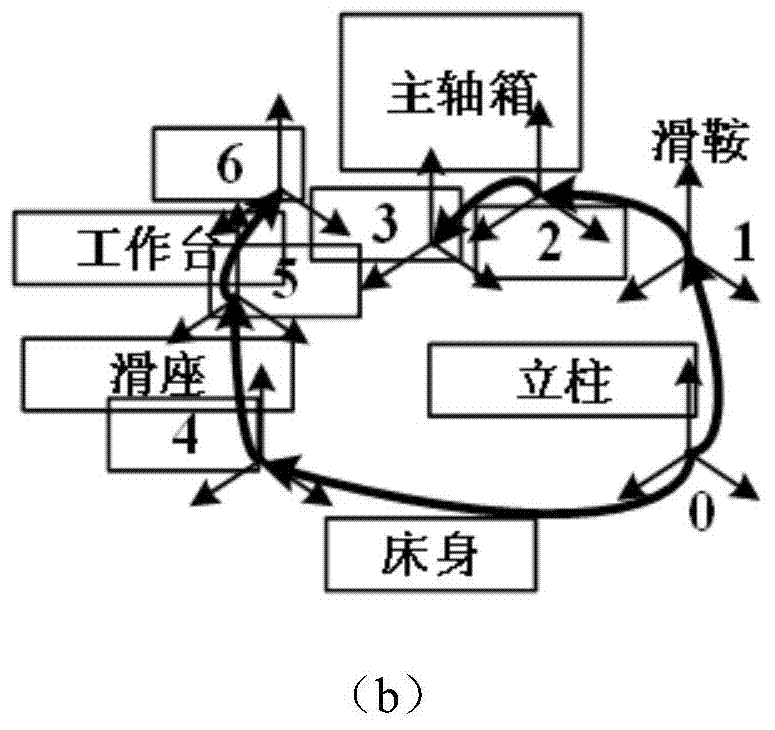

Measuring and adjusting process-considered tolerance design method of precise machine tool

ActiveCN104850698AAccurate analysisReliable analysisSpecial data processing applicationsEngineeringState space equation

The invention discloses a measuring and adjusting process-considered tolerance design method of a precise machine tool, which comprises the steps of: firstly defining a related coordination system according to a key feature plane; then determining a state space equation and a basic coefficient matrix thereof of a machine tool assembly; next, establishing a cost target function, obtaining an optimal adjustment sequence by a discrete system output regulator so as to convert the state space equation into a Gauss-Markov random process equation; then obtaining a covariance matrix, and performing iteration computation to obtain the covariance matrix after integral assembly is finished; computing a corresponding function relationship between a total precision index and a part precision index of the machine tool according to the covariance matrix after the integral assembly is finished; finally, establishing a function relation between a precision total cost and a part precision and solving to obtain an optimal part tolerance allocation result. The method can be used for accurately and reliably analyzing the tolerance of the machine tool, thus ensuring the precision performance of the machine tool.

Owner:XI AN JIAOTONG UNIV

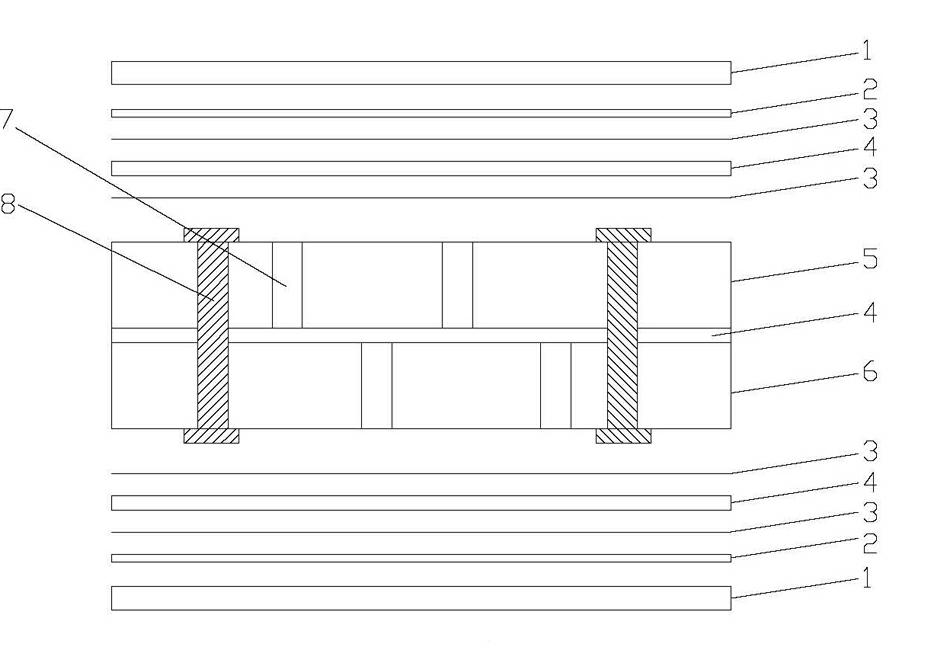

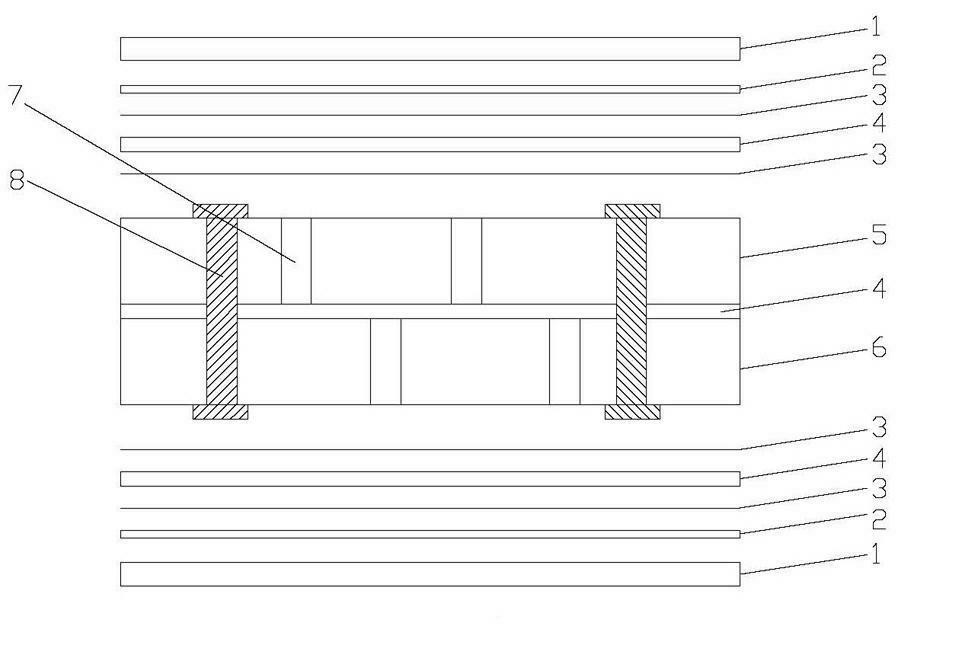

Process for laminating printed circuit board (PCB) with buried/blind via structure

InactiveCN102573339AShorten processing timeImprove work efficiencyMultilayer circuit manufacturePrinted circuit boardEngineering

The invention discloses a process for laminating a printed circuit board (PCB) with a buried / blind via structure. The process comprises the following steps of: (1) drilling via holes on an upper core board and a lower core board to be laminated, electroplating the via holes to transfer patterns, arranging a prepreg between the upper core board and the lower core board, and connecting the upper core board, the prepreg and the lower core board through rivets; (2) laying a release film, the prepreg, the release film, an aluminum sheet and laminated steel on an upper surface of the upper core board in turn from bottom to top, and laying the release film, the prepreg, the release film, the aluminum sheet and the laminated steel on a lower surface of the lower core board in turn from top to bottom; (3) laminating; and (4) removing the aluminum sheet, and detaching the prepreg to which the release film is attached so as to obtain the finished product. The process is convenient to operate, the labor cost is saved, the processing time is shortened, the working efficiency is improved, the labor intensity is reduced, and the yield of the product is improved.

Owner:SIHUI FUJI ELECTRONICS TECH

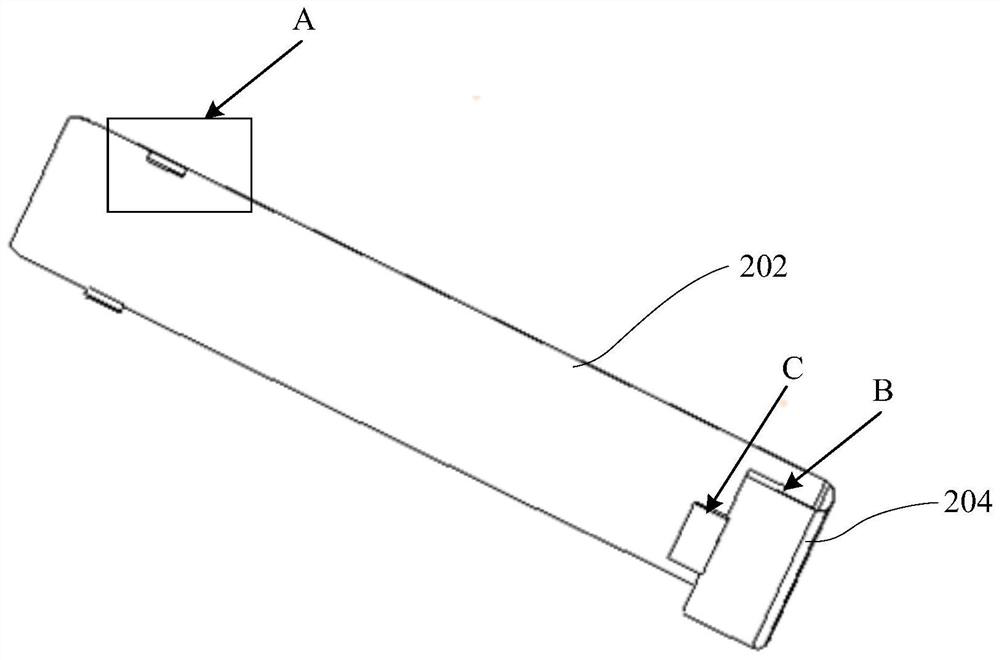

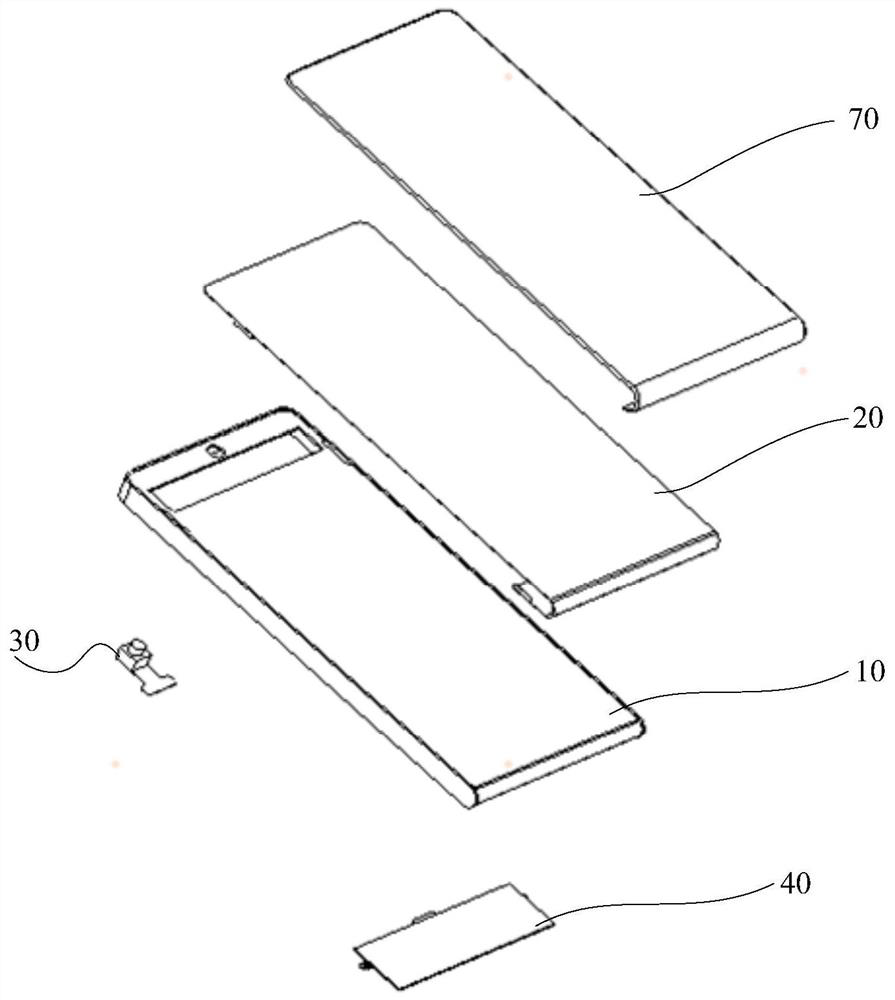

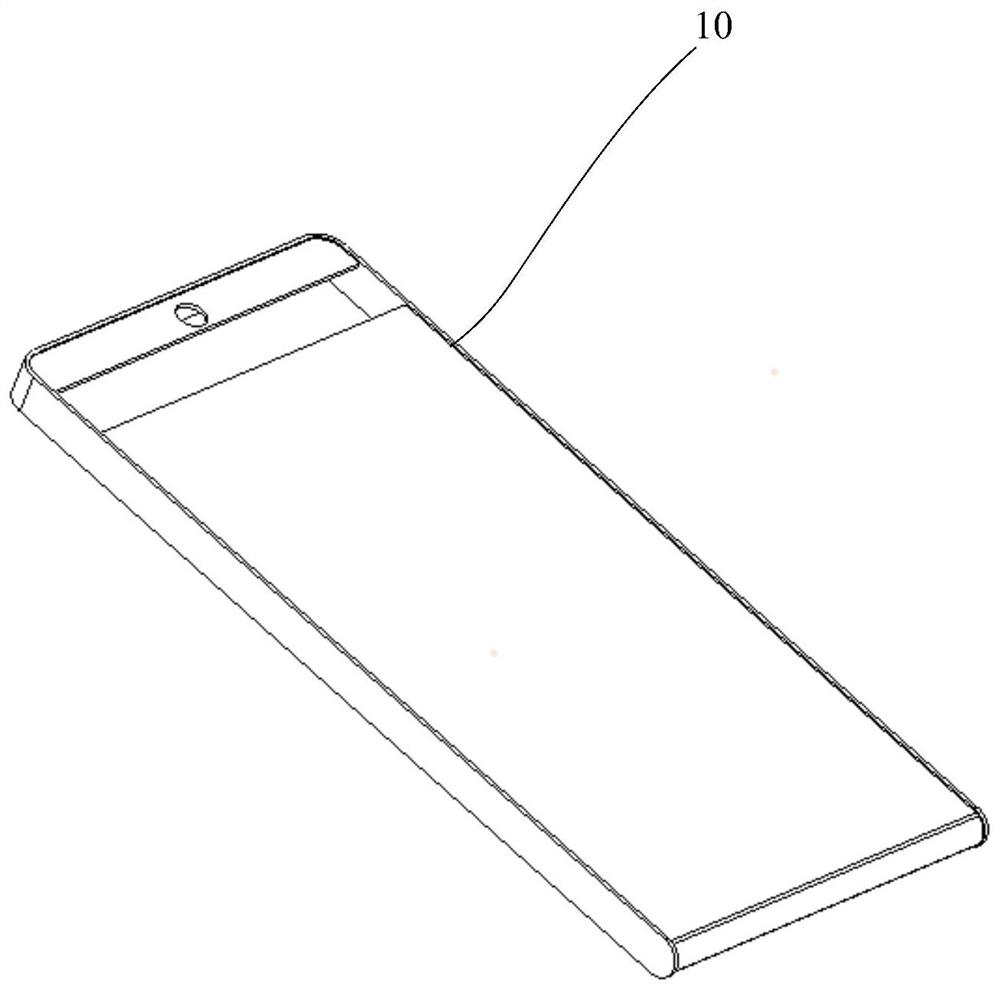

Electronic equipment

ActiveCN111970392ARealize daylightingGuaranteed to move in placeTelephone set constructionsMechanical engineeringPhysics

The invention discloses electronic equipment. The electronic equipment comprises a shell, a functional device, a flexible screen, a driving device, a first limiting structure arranged on the shell anda second limiting structure arranged on the flexible screen, wherein the functional device and the driving device are arranged in the shell; the flexible screen is movably arranged in the shell and connected with the driving device; the driving device is used for driving the flexible screen to move between a first position and a second position; the first limiting structure and the second limiting structure are used for limiting fit when the flexible screen is located at the first position and / or the second position; when the flexible screen is located at the first position, the flexible screen covers the functional device; and when the flexible screen is located at the second position, the flexible screen avoids the functional device, and the functional device is exposed out of the shell. According to the scheme, the flexible screen is driven by the driving device to be switched between the full-screen state and the state of exposing the functional devices, so that optimization of the screen-to-body ratio and the display effect and optimization of the operation effect of the functional devices such as the camera are achieved in different states.

Owner:VIVO MOBILE COMM CO LTD

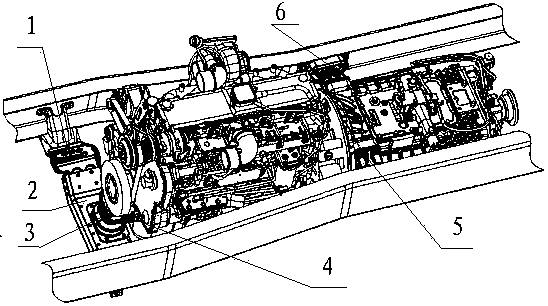

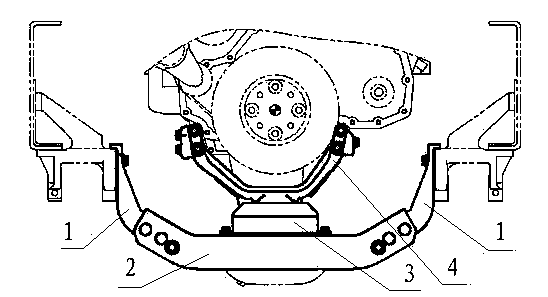

Automobile power assembly suspension device

InactiveCN104118307AStable structureImprove the vibration isolation effectJet propulsion mountingInternal combustion mountingManufacturing technologyVibration isolation

The invention discloses an automobile power assembly suspension device, and relates to the technical field of automobile making. The automobile power assembly suspension device comprises an engine suspension arranged on the front portion of an engine and two gearbox suspensions arranged on a rear gearbox of the engine. The engine suspension comprises a front suspension cylinder body support connected to the bottom of the engine, a front suspension transverse beam connected with two ends connected with a front suspension support is arranged below the front suspension cylinder body support, and the front suspension support is connected with an automobile beam. A front suspension soft cushion is arranged between the front suspension cylinder body support and the front suspension transverse beam. Each gearbox suspension comprises a rear suspension cylinder body support connected with the gearbox, wherein the rear suspension cylinder body support is connected with a rear suspension soft cushion fixed to the automobile beam. The automobile power assembly suspension device can solve the problems that a whole heavy truck is high in vibration and noise and poor in vibration isolation capacity, and consequently riding comfort of the truck is influenced.

Owner:DONGFENG LIUZHOU MOTOR

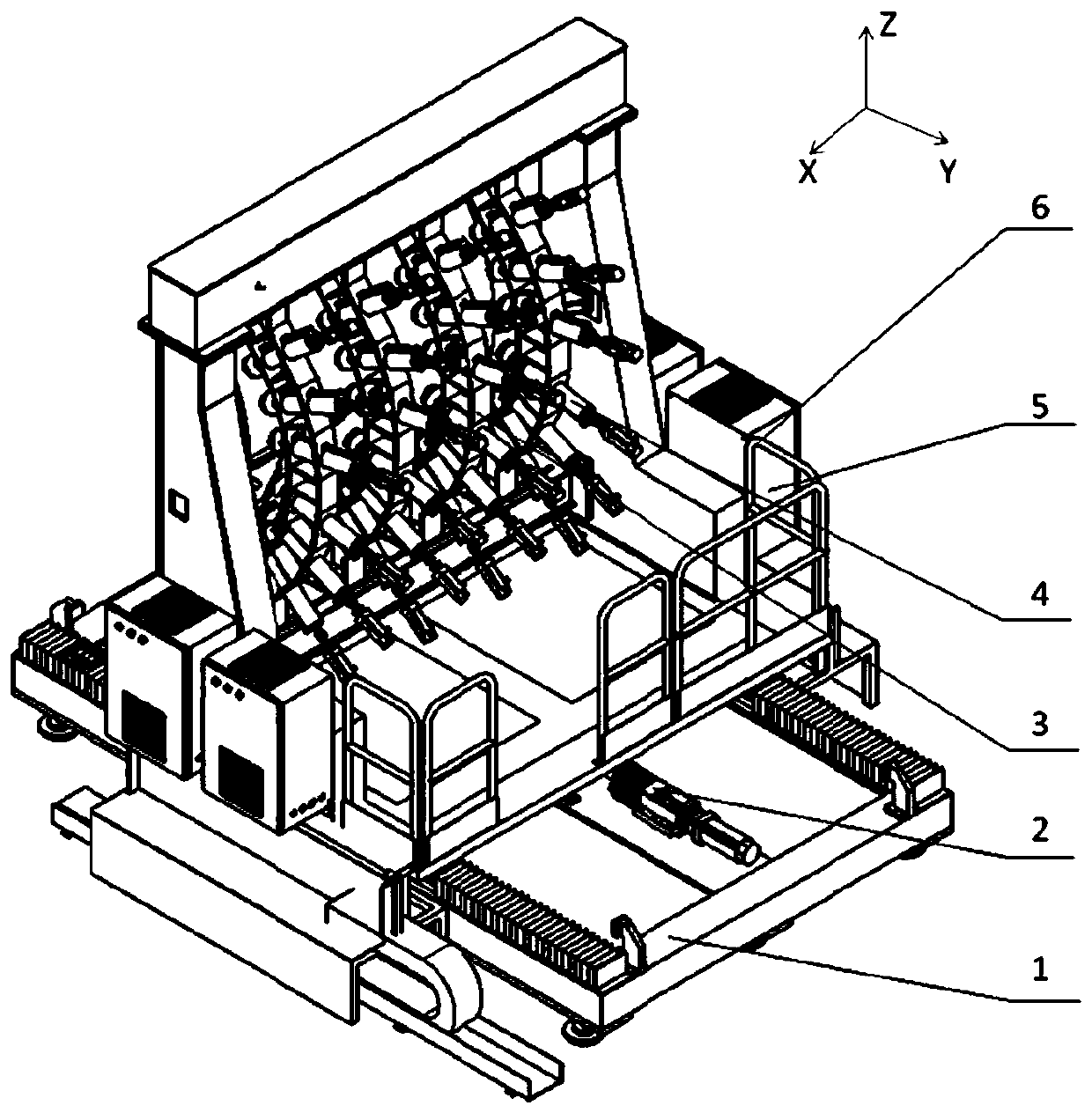

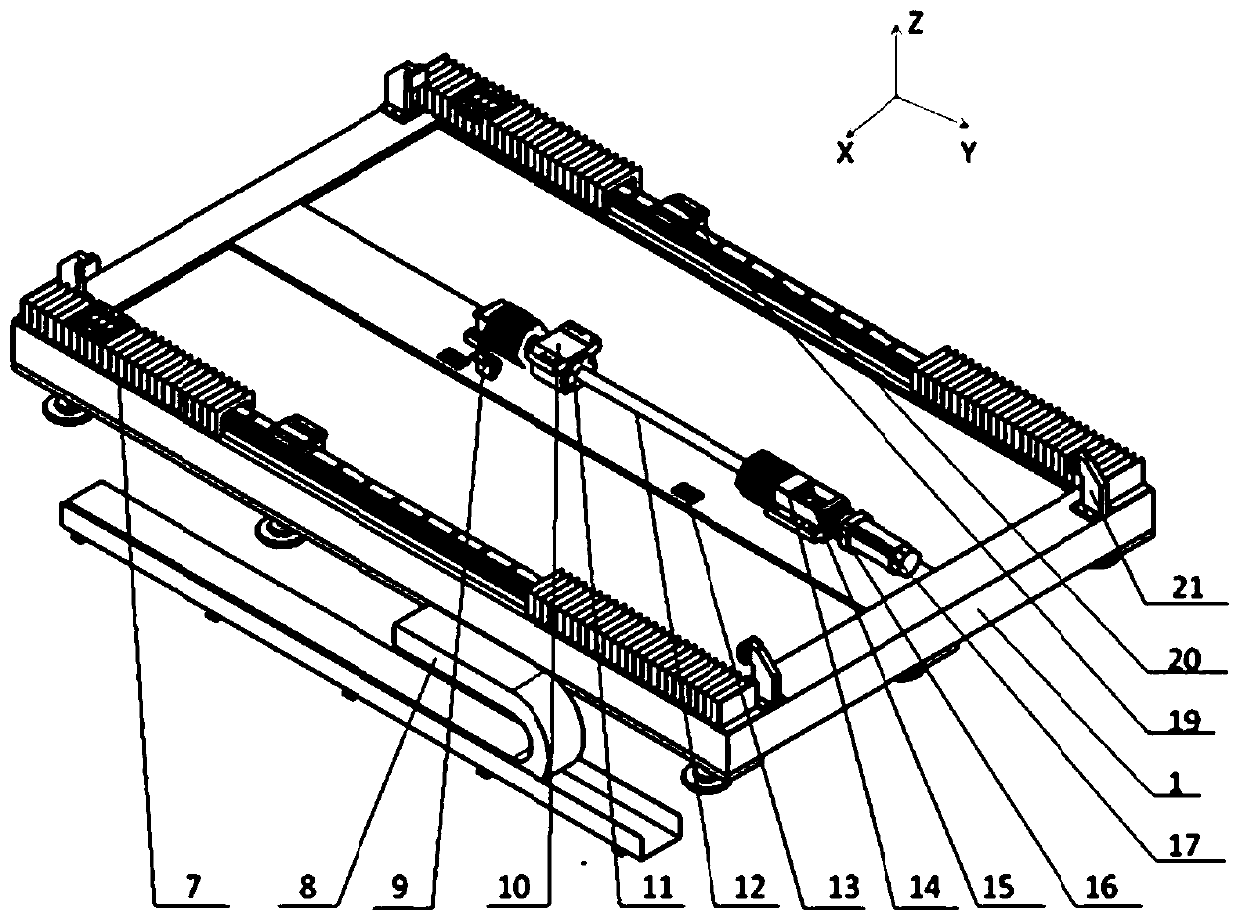

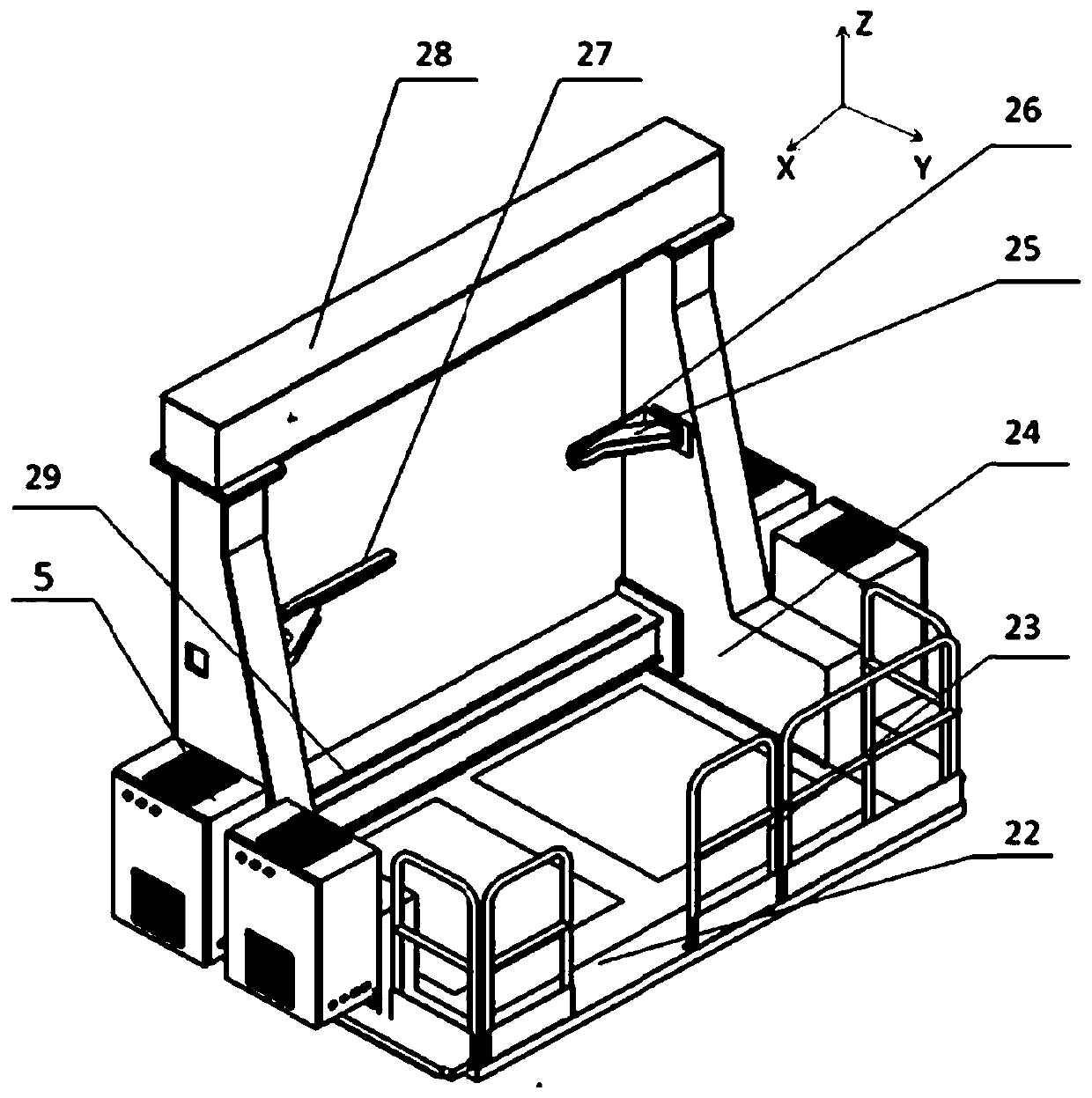

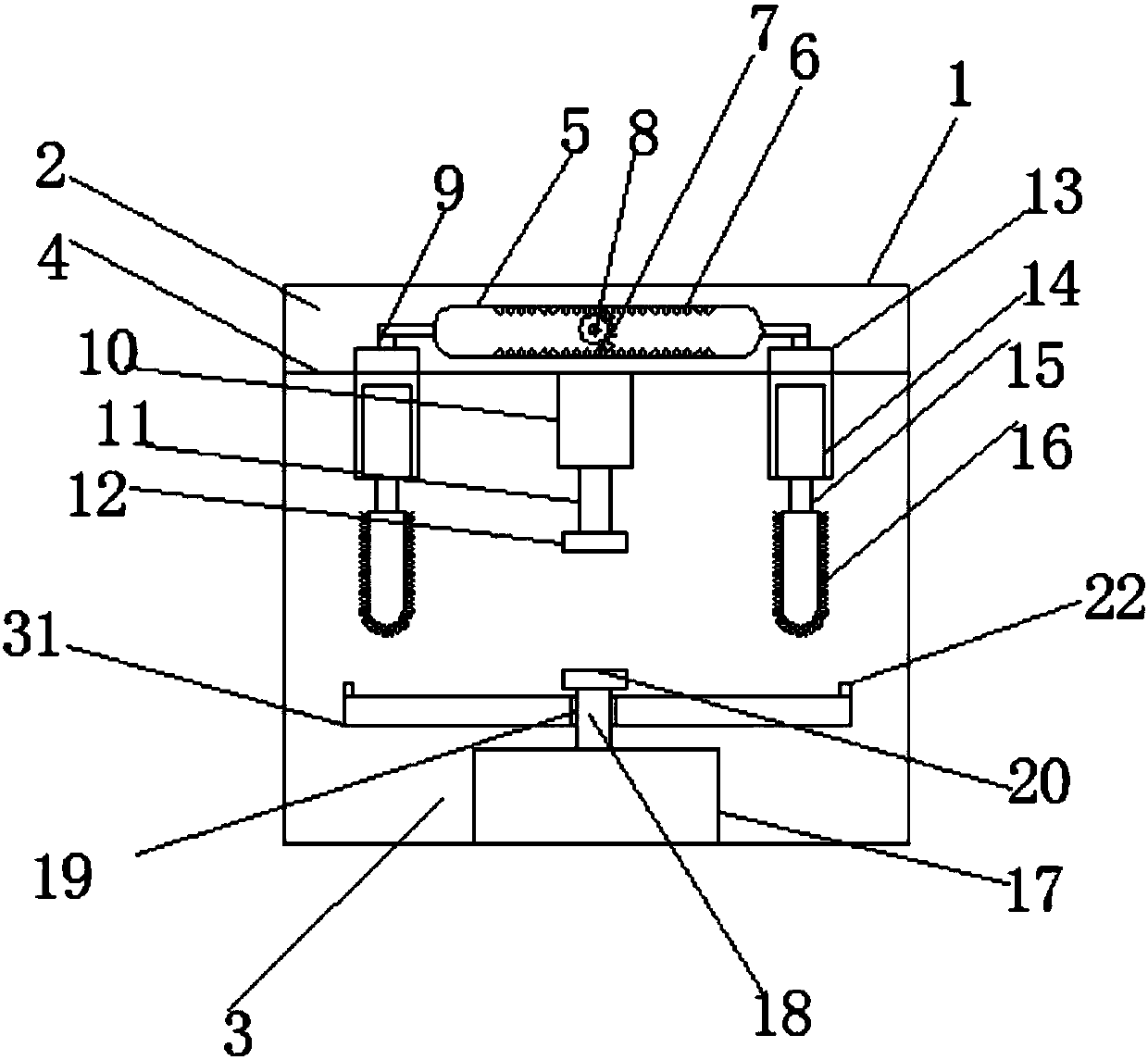

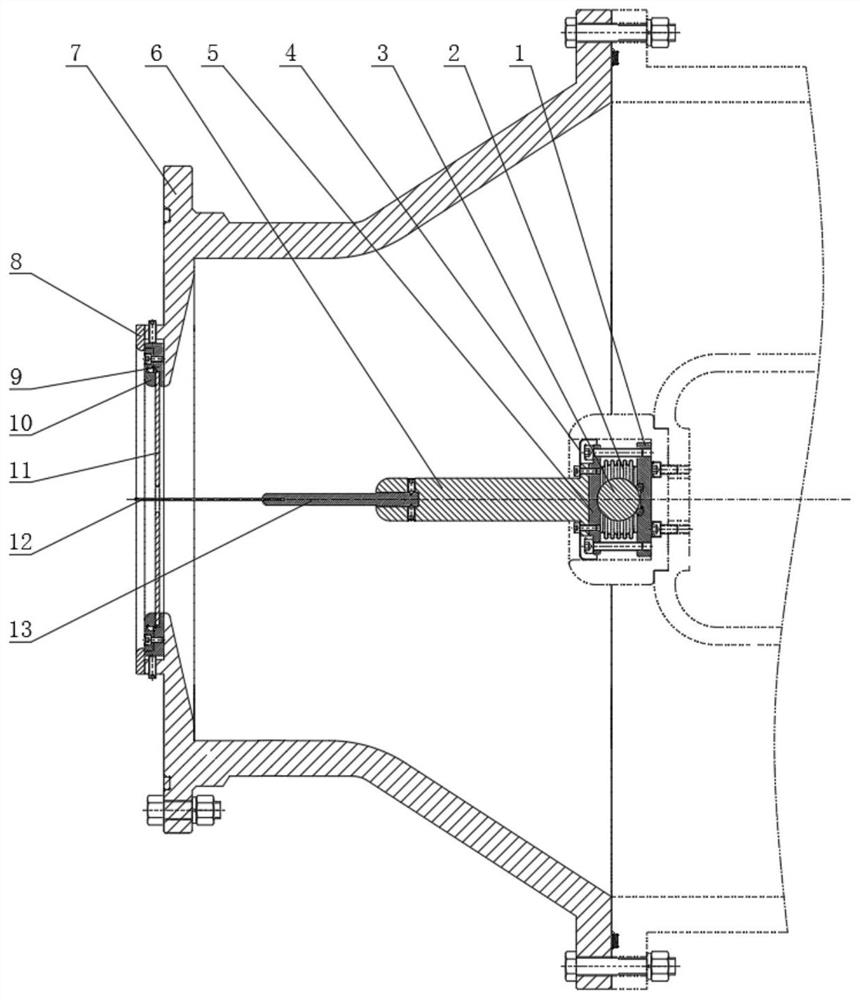

Flexible array type aircraft skin adsorption tool

InactiveCN110900481AImprove flexibilityMeet the requirements of different assembly positionsWork holdersWork benchesEngineeringStructural engineering

The invention discloses a flexible array type aircraft skin adsorption tool, which belongs to the technical field of aircraft assembly. The flexible array type aircraft skin adsorption tool comprisesa base, a movable platform and a driving mechanism, wherein the movable platform and the driving mechanism are arranged on the base. The movable platform is installed on the base, and the movable platform is equipped with a frame; the frame is internally provided with a stand column matched with the aircraft skin in shape; the stand column is provided with a plurality of vacuum adsorption units; the driving mechanism drives the movable platform to slide on the base in the Y direction, wherein the Y direction is perpendicular to the position plane where the aircraft skin is located; a Z-direction adjustable positioning stop block is arranged at the bottom end of the stand column and used for positioning the placing height of the skin in the Z direction; connecting blocks are arranged at thetwo sides of the frame, wherein the connecting block at one side is provided with a movable block capable of moving in the X direction, and the movable block and the connecting block at the other side are provided with positioning pin holes matched with positioning holes in skin lugs. A corresponding workpiece is positioned and clamped through rapid reconstruction of the vacuum adsorption units.

Owner:ZHEJIANG UNIV +1

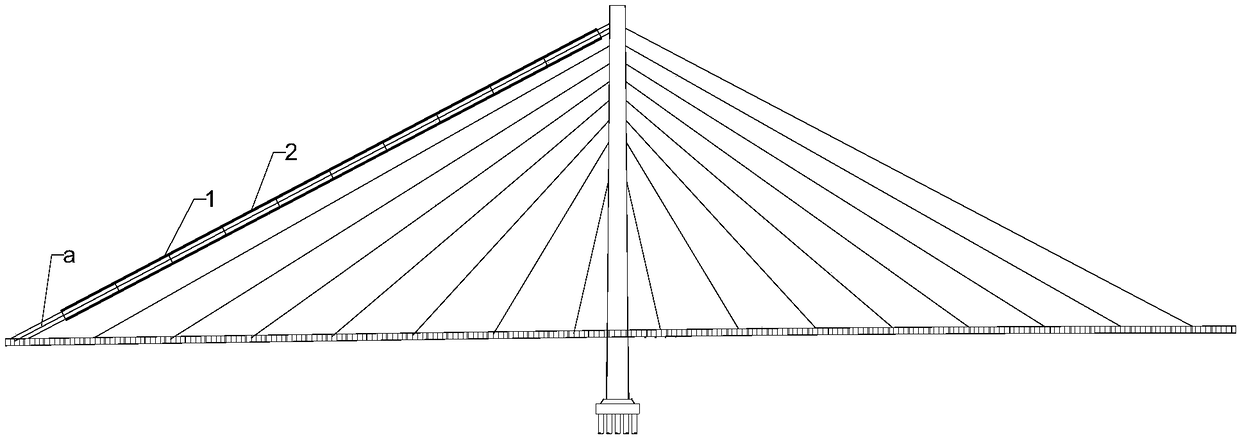

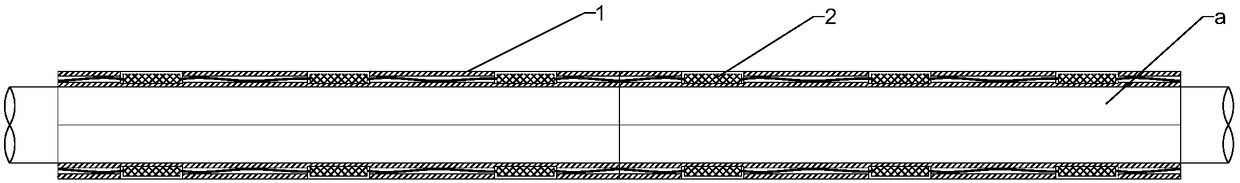

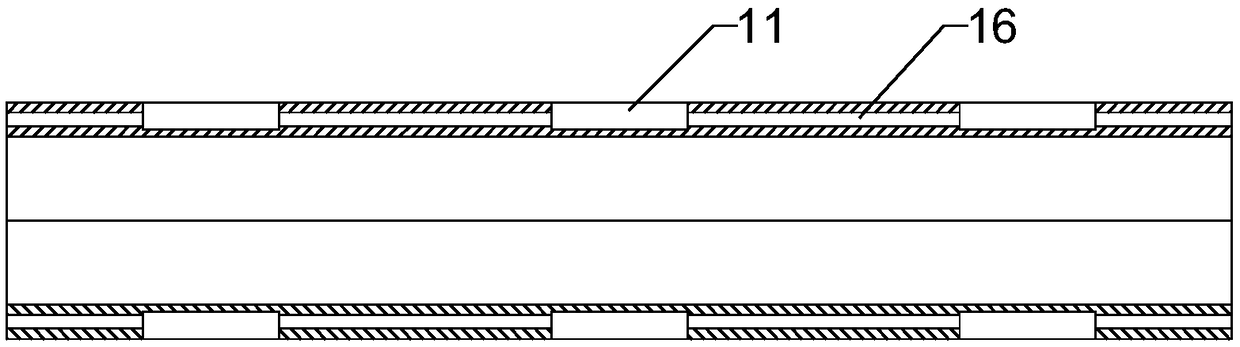

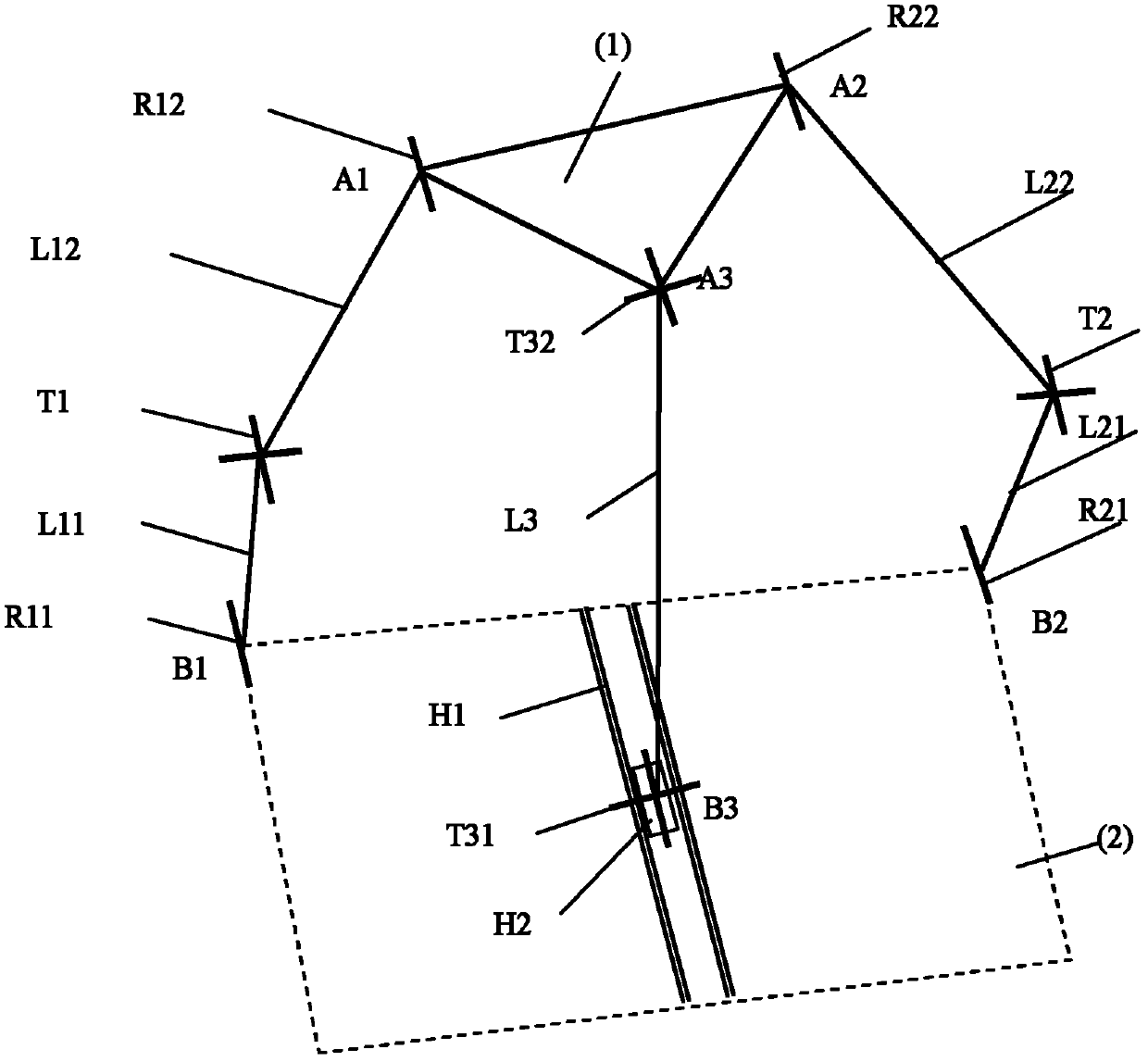

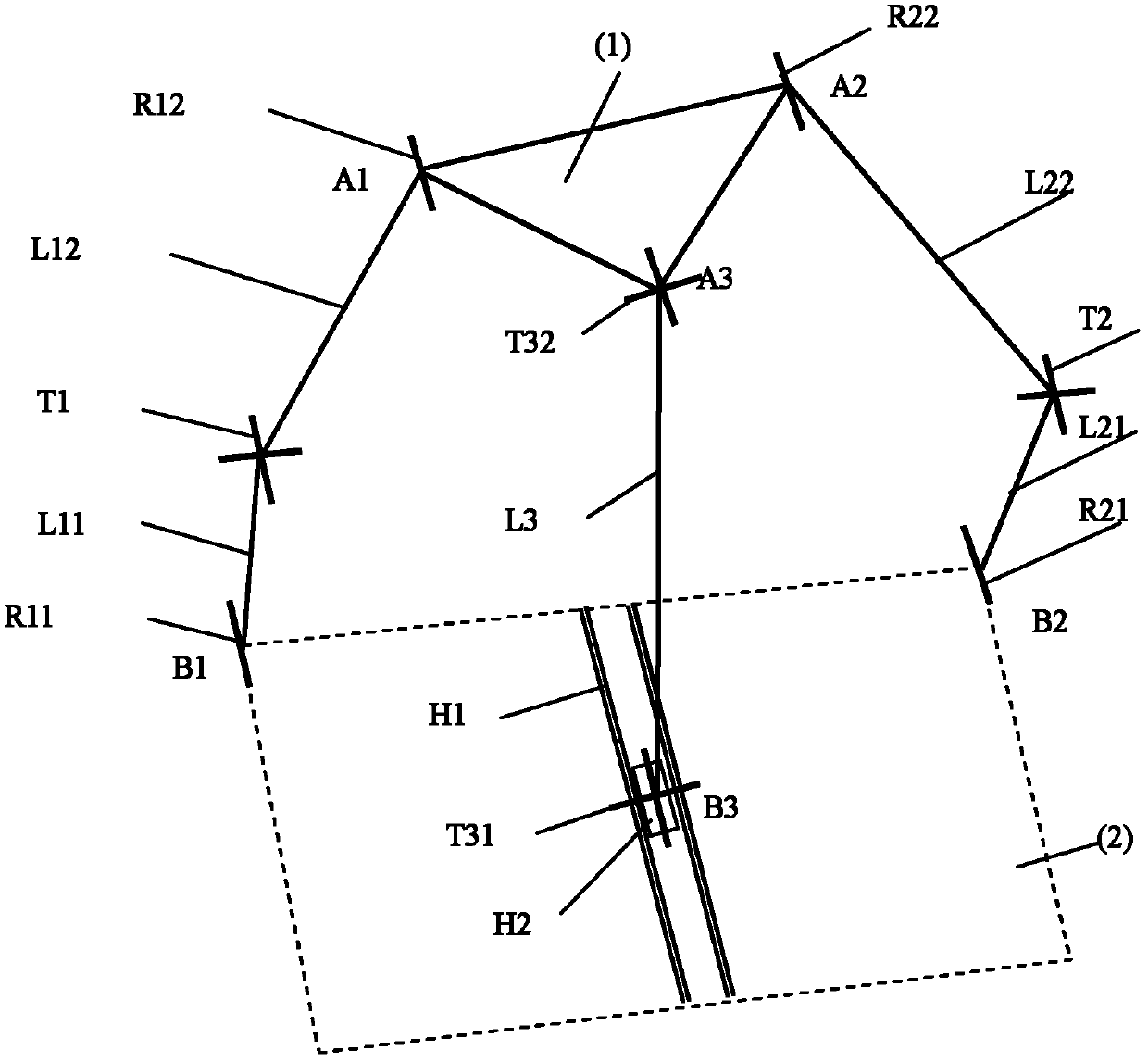

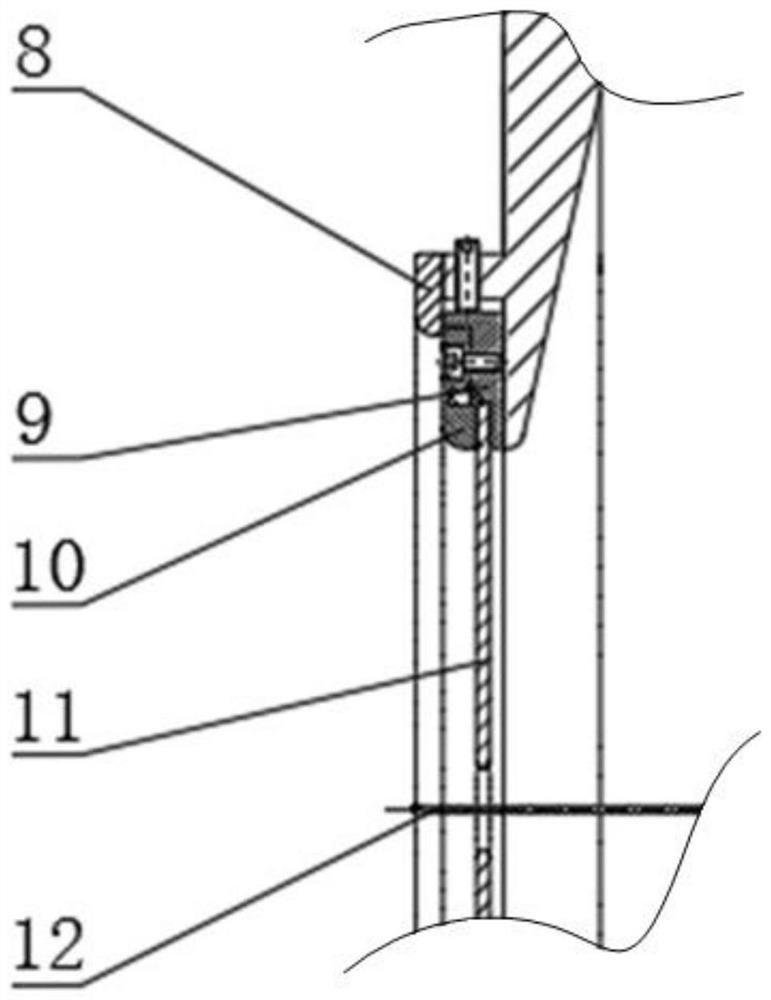

Cable pipe sleeve suitable for cable structure system, multi-functional outer casing pipe containing cable pipe sleeve and cable structure

PendingCN109403204AEasy to transportEasy to assembleBridge structural detailsTextile cablesOuter CannulaStructure system

The invention discloses a cable pipe sleeve suitable for a cable structure system, a multi-functional outer casing pipe containing the cable pipe sleeve and a cable structure. The cable pipe sleeve suitable for the cable structure system comprises a cable pipe sleeve body, the cable pipe sleeve body is spliced by a plurality of assembly units arranged in the circumferential direction of the cablepipe sleeve body,one or more installation structures for installing function units are machined on the pipe walls of one or more assembly units, and the installation structures comprise installation grooves which are formedin the axial directions of the assembly units at intervals and connecting holes for communicating the installation grooves. According to the cable pipe sleeve suitable for the cable structure system, the multi-functional outer casing pipe containing the cable pipe sleeve and the cable structure, the structure is simple, use is convenient, by designing the cable pipe sleeve body as the assembly units which can be mutually spliced in the circumferential direction and the radial direction of the cable pipe sleeve body, it is ensured that the assembly units are independent of oneanother, and thus the cable pipe sleeve is transported, assembled and replaced conveniently.

Owner:CCCC SECOND HARBOR ENG +1

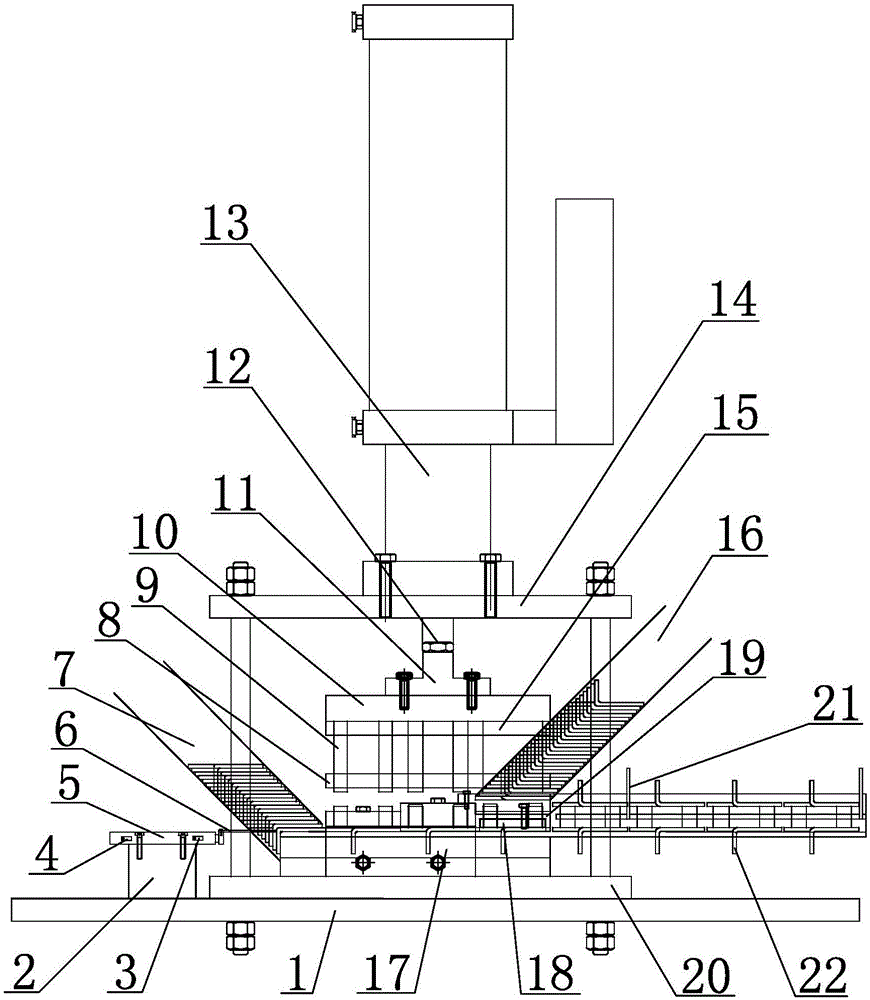

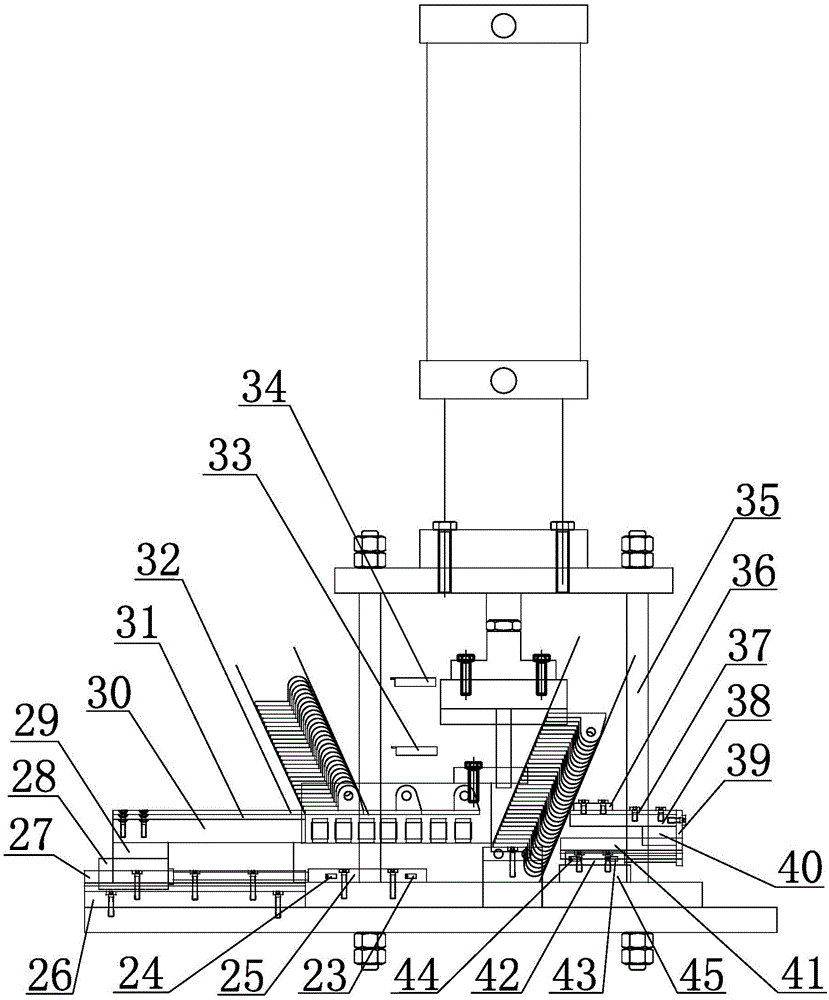

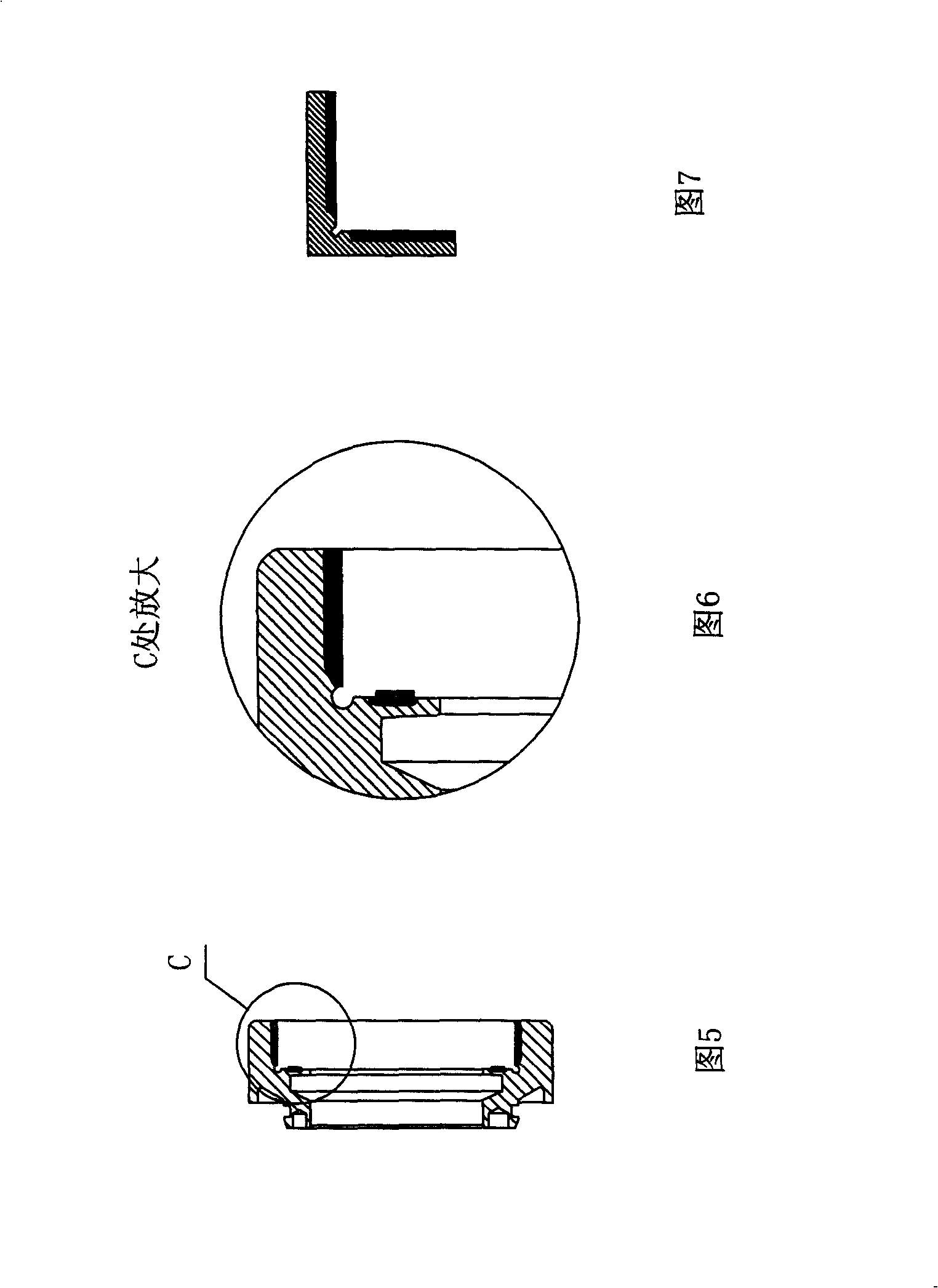

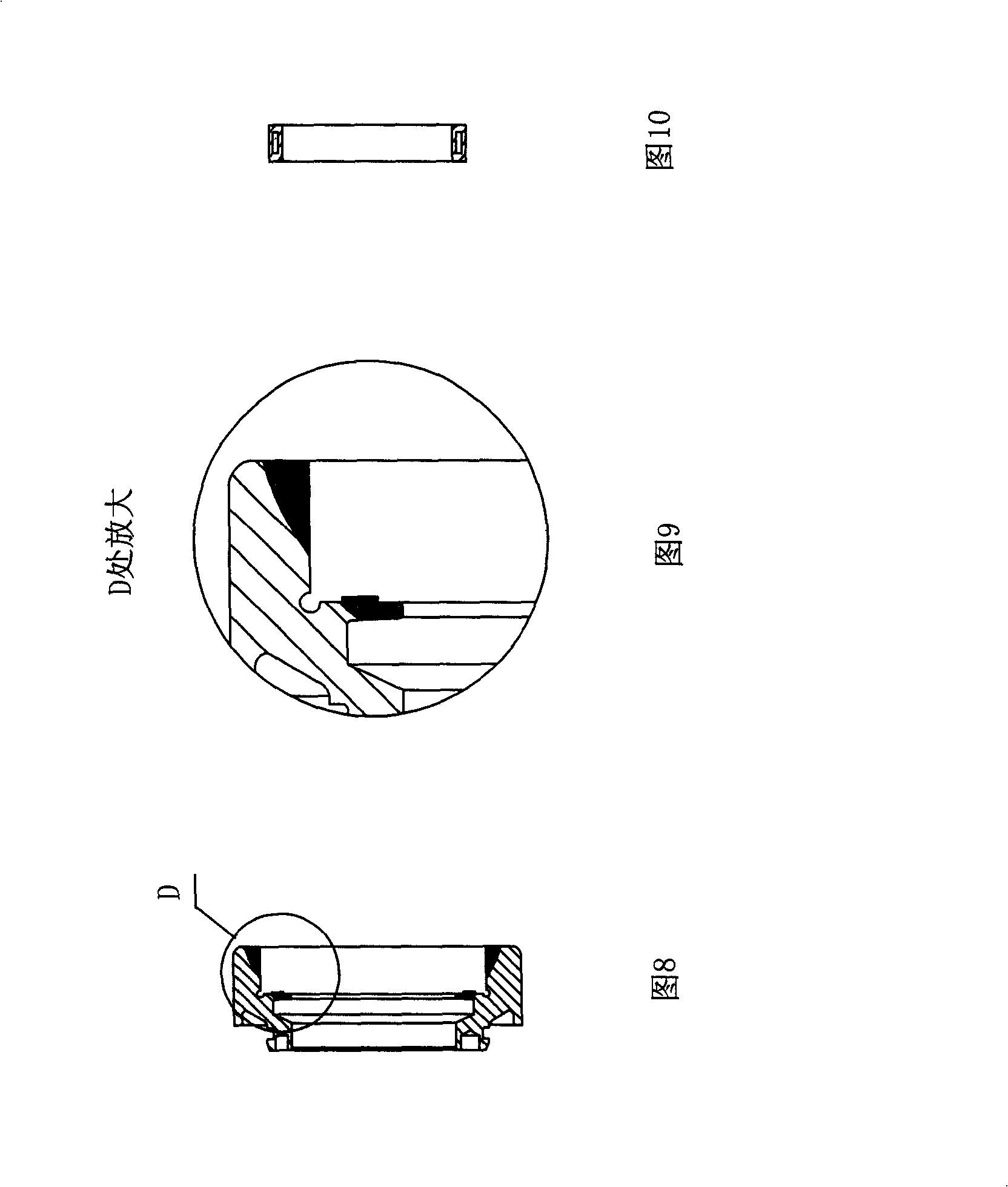

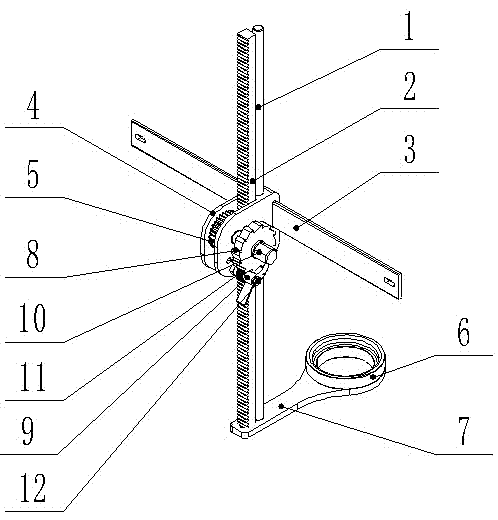

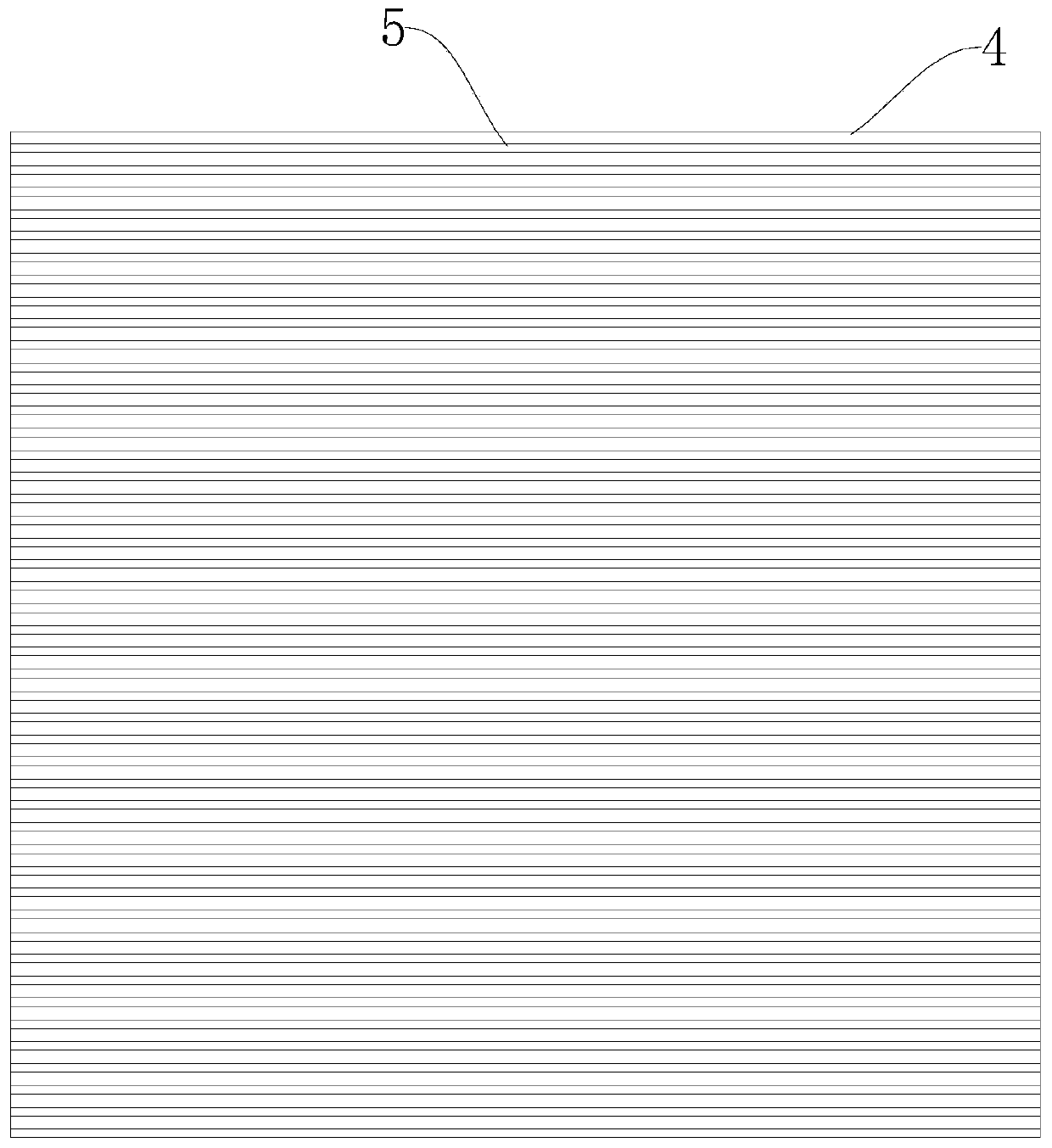

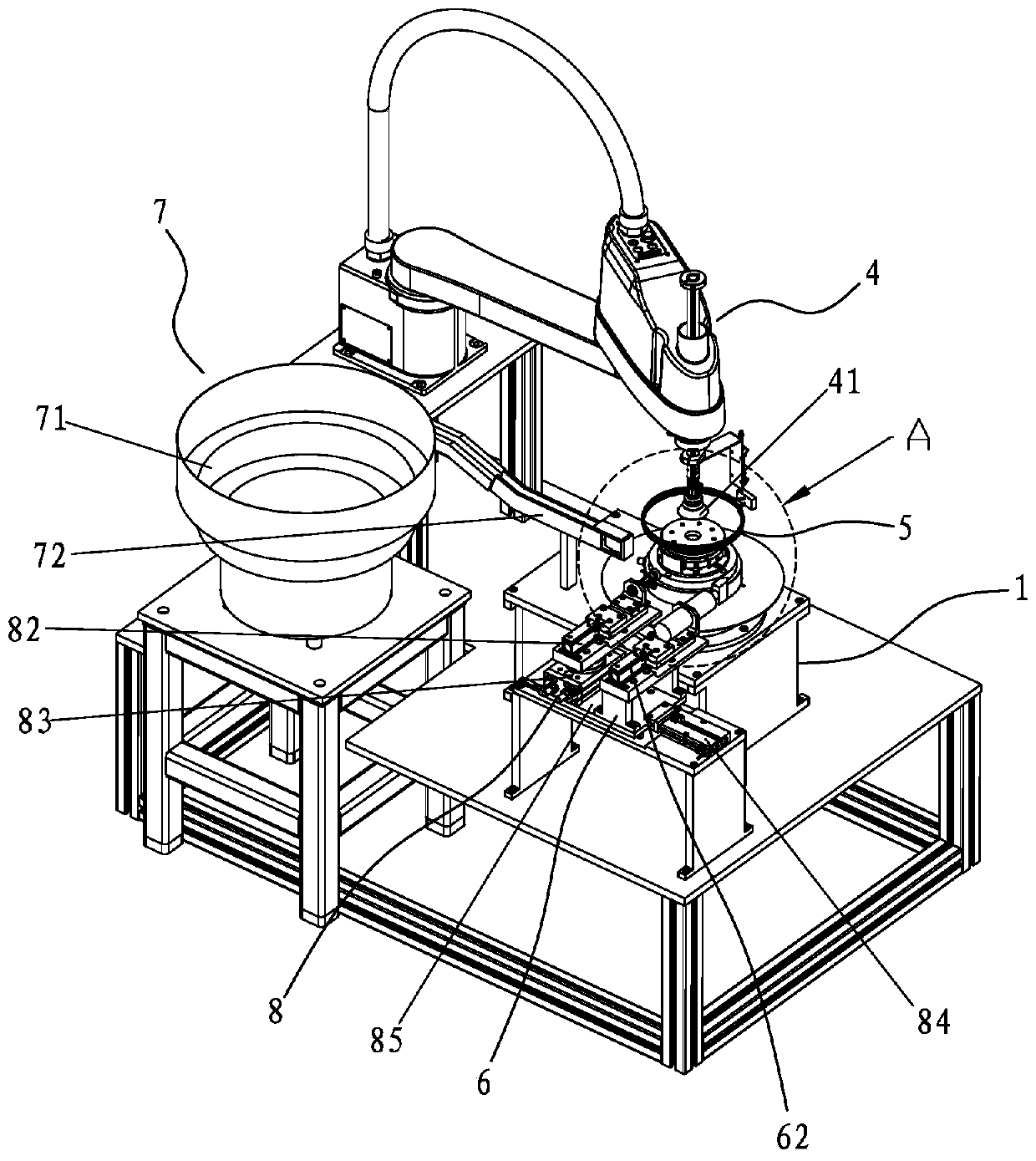

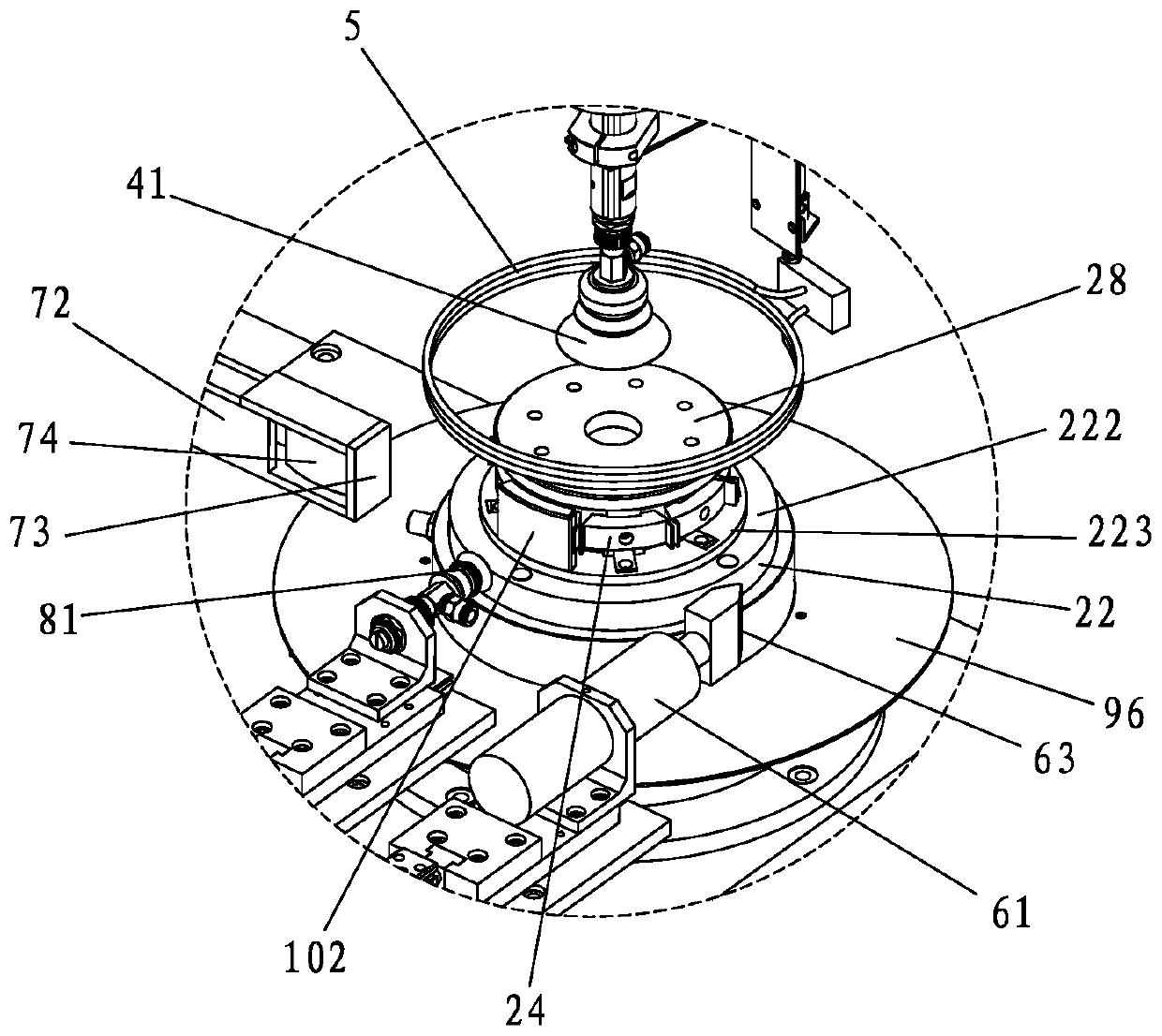

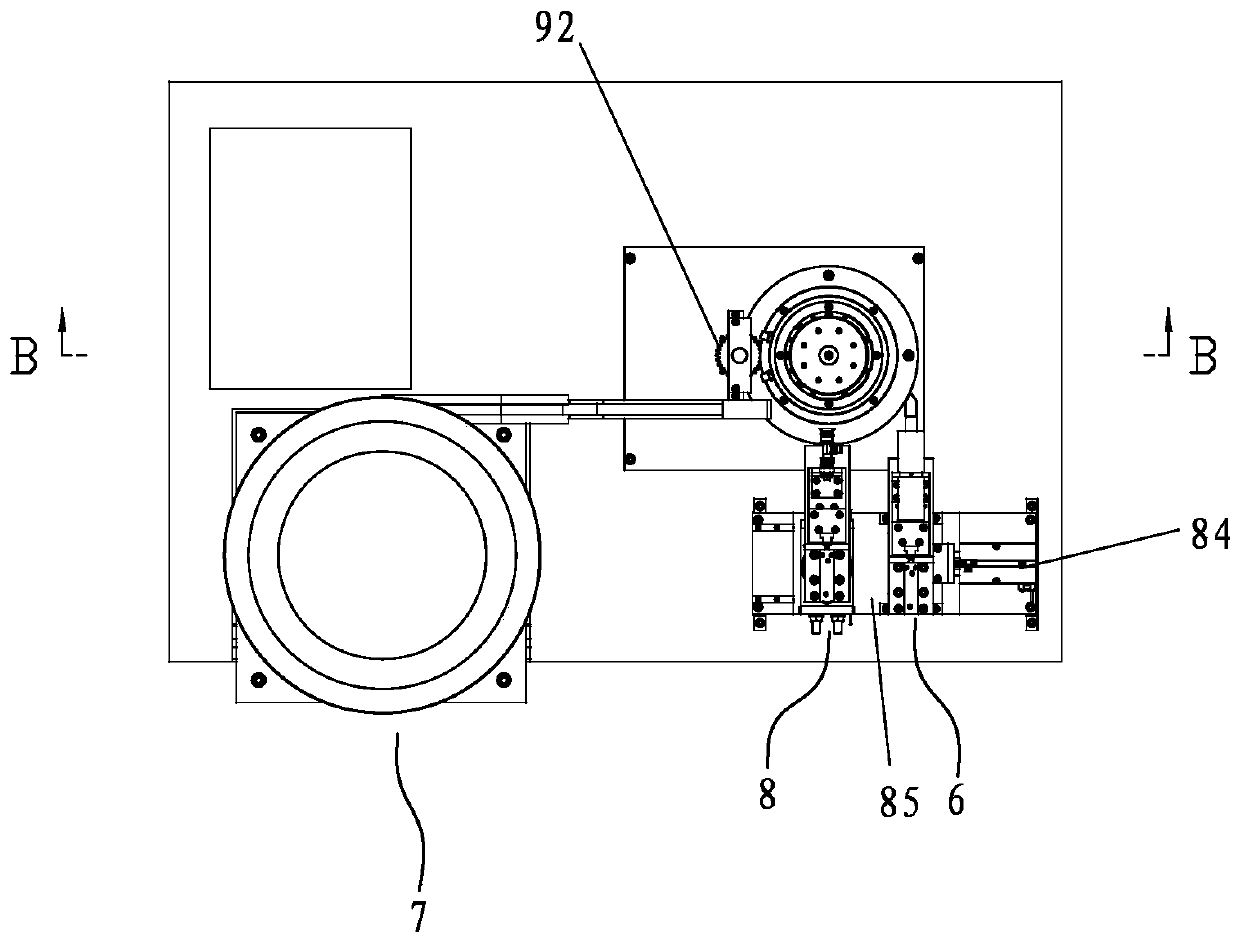

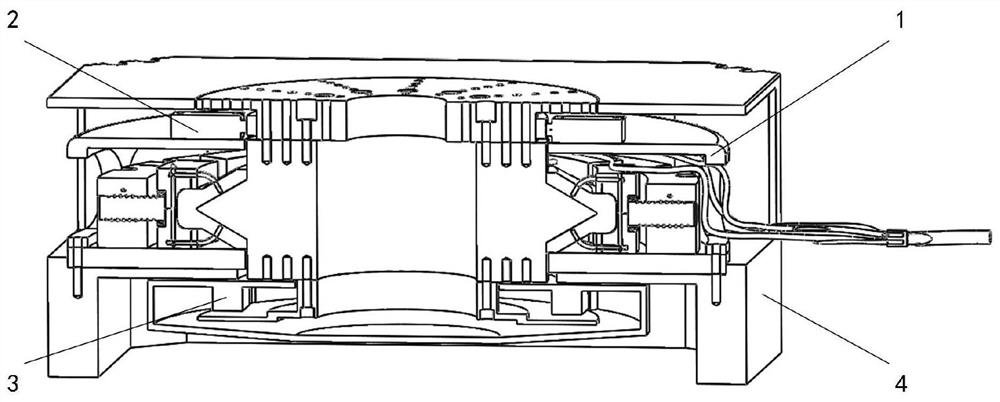

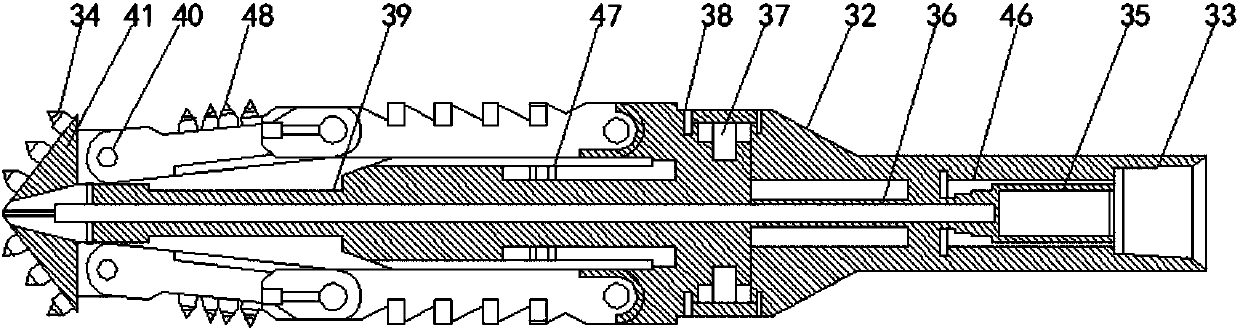

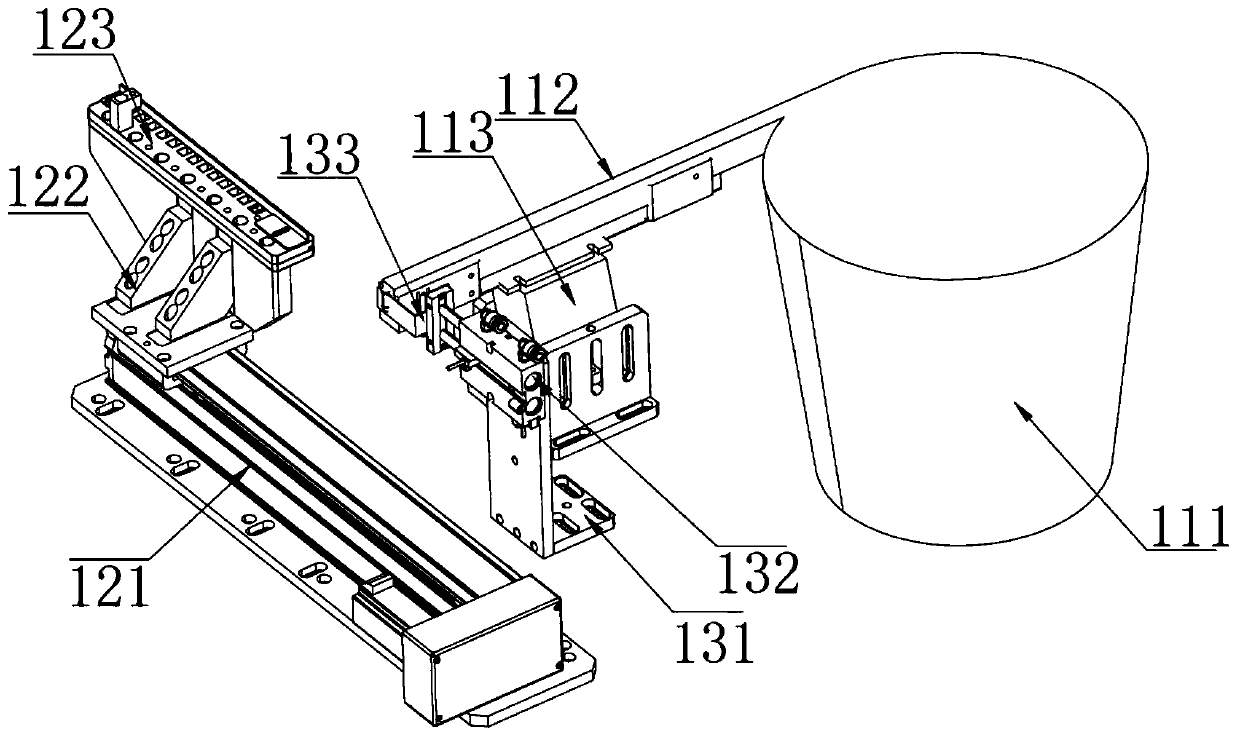

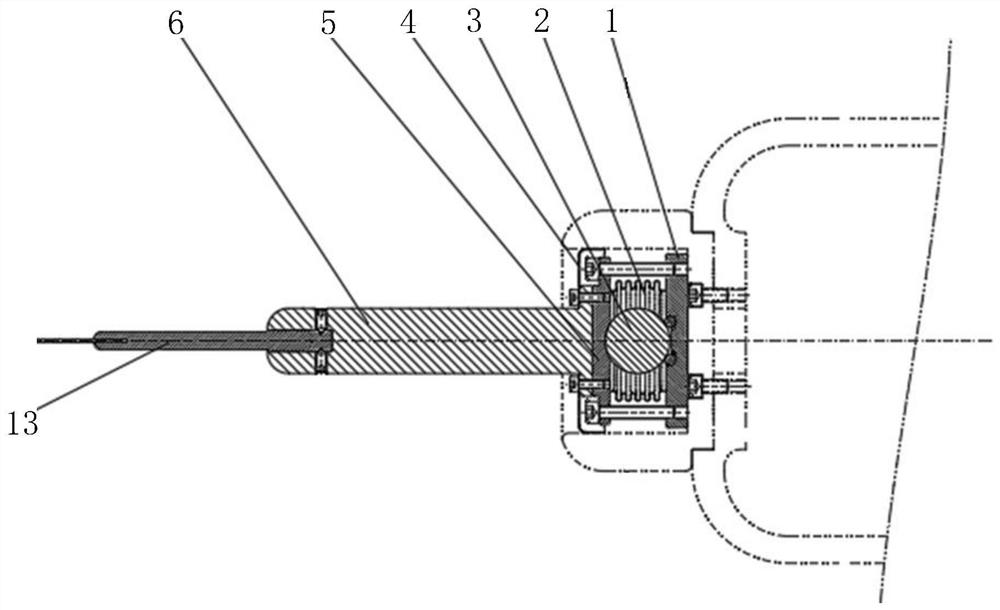

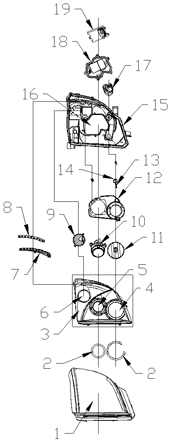

Automatic assembly machine for cranked link chain single link

ActiveCN105081769AGood assembly precisionSolve the shortcomings of manual assemblyAssembly machinesEngineeringTransfer mechanism

The invention relates to an automatic assembly machine for a cranked link chain single link. The automatic assembly machine comprises a rack, a transferring mechanism, a feeding mechanism, a positioning mechanism and a press fitting mechanism. The transferring mechanism, the feeding mechanism, the positioning mechanism and the press fitting mechanism are arranged on the rack. According to the automatic assembly machine, a left cranked link plate is pushed in place through a left cranked link plate feeding cylinder; a positioning push plate is pushed in place through a positioning cylinder; the feeding cylinder conveys a sleeve, a roller and a right cranked link plate to a positioning plate at the same time; then the press fitting mechanism performs downward pressing, and the press fitting mechanism returns after moving in place; the left cranked link plate is pushed out through the left cranked link plate feeding cylinder; and meanwhile a previous assembled single link is transferred so that assembly circulation of one single link can be completed. Due to the fact that the mechanisms move in a circulating manner, the assembly task that the link plate is pushed, positioned, fed, pressed and transferred can be completed, the defects existing in manual assembly are fundamentally overcome, mechanical, automatic and continuous cranked link chain single link production is achieved, assembly efficiency is high, assembly precision is good, and cost is low.

Owner:HANGZHOU SHIELD CHAIN

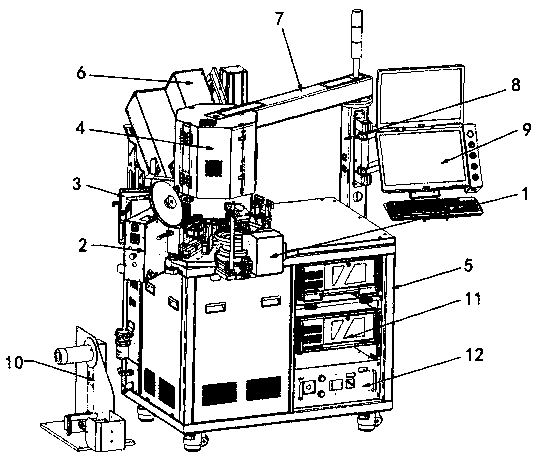

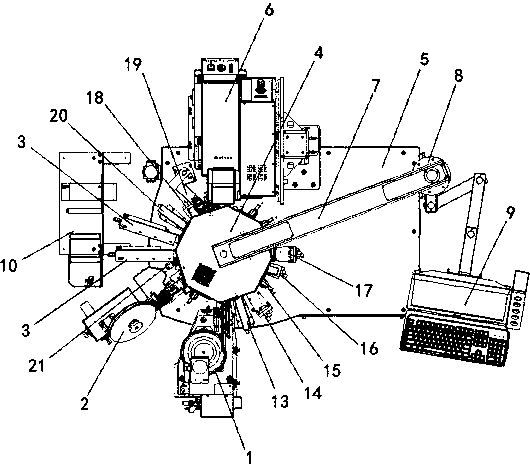

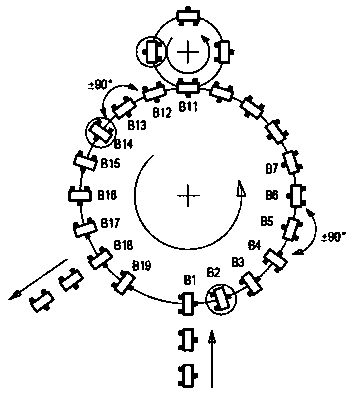

Detecting and sorting machine for SOT packaged products

PendingCN109772743AMeet diverse needsMeet the needs of various processesSemiconductor/solid-state device manufacturingSortingMaterial supplyEngineering

The invention discloses a detecting and sorting machine for SOT packaged products. The detecting and sorting machine comprises a working table, wherein an anticlockwise ring-shaped station is arrangedon the table board of the working table; functional mechanism modules such as a loading mechanism, a coding mechanism, a tri-polishing receiving mechanism and a collecting packaging mechanism are mounted on the ring-shaped station; a cantilever is arranged above the table board of the working table; one end of the cantilever is connected with a cantilever supporting column mounted on the side surface of the working table; the other end of the cantilever is connected with an absorbing and discharging rotary tower; a material supply mechanism is arranged at one side of the working table; an industrial-control computer and an electrical control module are arranged in a rack of the working table; and an equipment operating monitoring module is arranged on the cantilever supporting column. Thedetecting and sorting machine can efficiently perform checking and sorting on product pins, performance and printing effect at high speed, also very has very strong compatibility on products of different packaging types, can meet modern automatic and high-speed detecting sorting needs, and has a novel structure design much better than that of existing equipment of the market in processing and assembly precision, assembly speed and later-stage maintenance.

Owner:苏州茂特斯自动化设备有限公司

Press fitting and hammering assembling tool

ActiveCN104149069AExtend your lifeGood assembly precisionMetal-working hand toolsEngineeringMechanical engineering

The invention relates to a press fitting and hammering assembling tool which comprises an upper pressing head, a middle body and a lower pressing head. The tool is characterized in that the upper pressing head and the middle body are connected through a thread pair or a flange or a blocking opening. The middle body and the lower pressing head are connected through a thread pair or a flange or a quick-replacing mechanism. The middle body comprises a main guiding column. According to the press fitting and hammering assembling tool, upper pressing heads and lower pressing heads with different types can be selected for combining designing or mounting according to an assembled workpiece and a press fitting tool, and replacing is convenient after damaging.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

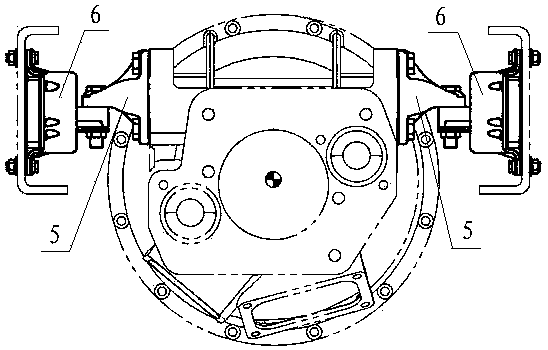

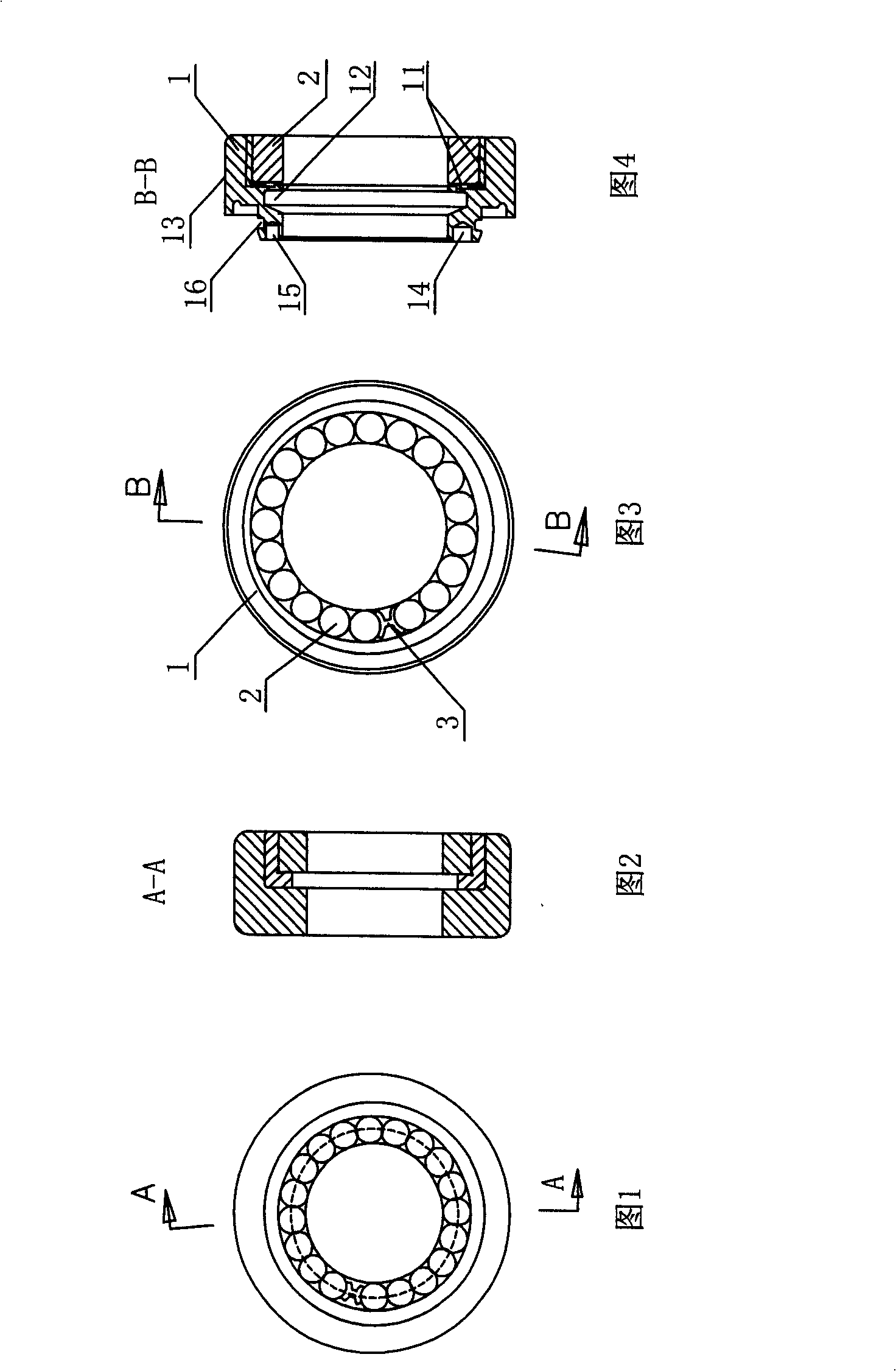

Heavy-duty car direction converter bearing and its manufacturing technique

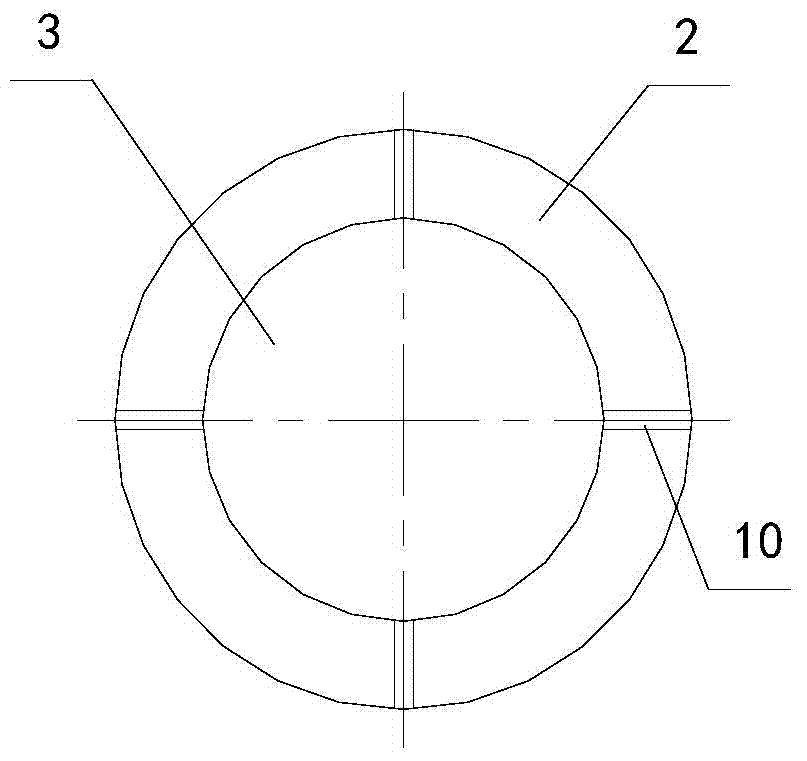

InactiveCN101245806AEasy to assembleGood assembly precisionRoller bearingsMechanical steering gearsTruckHeavy duty

The invention relates to an automobile part, in particular to a steering bearing of a heavy truck and the preparation process. An opening at one side of a bearing shell is provided with a right angle shaped internal raceway where cylindrical rollers are circularly arranged. After the rollers are closely arranged, a clamping cushion block is arranged at the clearance between a head roller and a tail roller; a pin hole is arranged on the end surface at the other side of the bearing shell; the internal ring of the bearing shell is provided with an internal sealing trough; the external ring and the internal raceway of the bearing shell are provided with eccentric structure with the eccentric direction identical to the symmetrical axis line of the pin hole on the end surface; wherein, the processing of the bearing shell comprises the processes of turning the internal hole and the end surface of the pin hole end, turning the external round and the end surface of the raceway end, coarsely turning the internal raceway, quenching and tempering and softly grinding the external round, finely turning the internal raceway, high frequency quenching, turning the internal sealing trough, grinding two external end surfaces, grinding the external round, grinding the internal hole of the pin hole end, grinding the internal raceway, reaming two pin holes, turning the eccentric external round, turning a positioning trough, chamfering a regular triangle angle, and finally grinding the external round.

Owner:杨燕敏

Hybrid input spatial 3-DOF (degree-of-freedom) parallel mechanism

InactiveCN102179811ASimple organizationLess jointsProgramme-controlled manipulatorKinematic pairEngineering

The invention relates to a hybrid input spatial 3-DOF (degree-of-freedom) parallel mechanism, relating to the technical field of robots and spatial mechanisms. The mechanism comprises a mobile platform, a fixed platform and three branched chains connecting the two platforms, wherein two branched chains comprise a rotating joint, a Hook joint and a rotating joint, as well as connecting bars therebetween, and the like. The input mode of the mechanism is of a hybrid input mode, namely the input consists of two rotating inputs and one mobile input, the mobile platform can realize movement output of one translation and two rotating; and the mechanism has fewer joints, and the total number of degrees of freedom of a kinematic pair is only 13, so that for the parallel mechanism, the component machining and whole machine assembling precision problems caused by excessive degrees of freedom of a kinematic pair can be effectively improved. Three driving pairs (including two rotating joints and one slippage pair) of the mechanism are directly connected with the fixed platform, therefore, the movement inertia of the mechanism is greatly decreased, and further the high-speed movement of the mechanism can be realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Tool for assembling flexible bus and use method of tool

PendingCN104518469ASave assembly timeEasy maintenanceBus-bar/wiring layoutsBus-bar installationDrive shaftUltimate tensile strength

The invention discloses a tool for assembling a flexible bus and a use method of the tool. The tool comprises a guide rod, a rack, a guide beam, a bracket and a supporting plate, wherein the guide rod is fixed to the rack together; the bracket penetrates through the guide rod and the rack; the bracket moves up and down along the guide rod under the meshing with the rack; a straight gear and a transmission shaft are arranged in the bracket; a ratchet wheel, a pawl, a torsional spring and a positioning rod are mounted on the side surface of the bracket; the transmission shaft penetrates through the bracket, the straight gear and the ratchet wheel; the positioning rod is fixed on the bracket; the pawl and the torsional spring are mounted on the positioning rod; the guide beam penetrates through the bracket; the bracket can move in the horizontal direction along the guide beam; two positioning holes are symmetrically formed in two ends of the guide beam; the bracket is fixed to the guide rod and the rack together; a guide sleeve is arranged on the supporting plate. According to the tool for assembling the flexible bus, the labor intensity for assembling the flexible bus on a solid insulating ring main unit can be alleviated, the precision and the efficiency of assembly are improved, the assembling time is shortened, and the production cost is reduced.

Owner:BEIHAI GALAXY SWITCH DEVICES +1

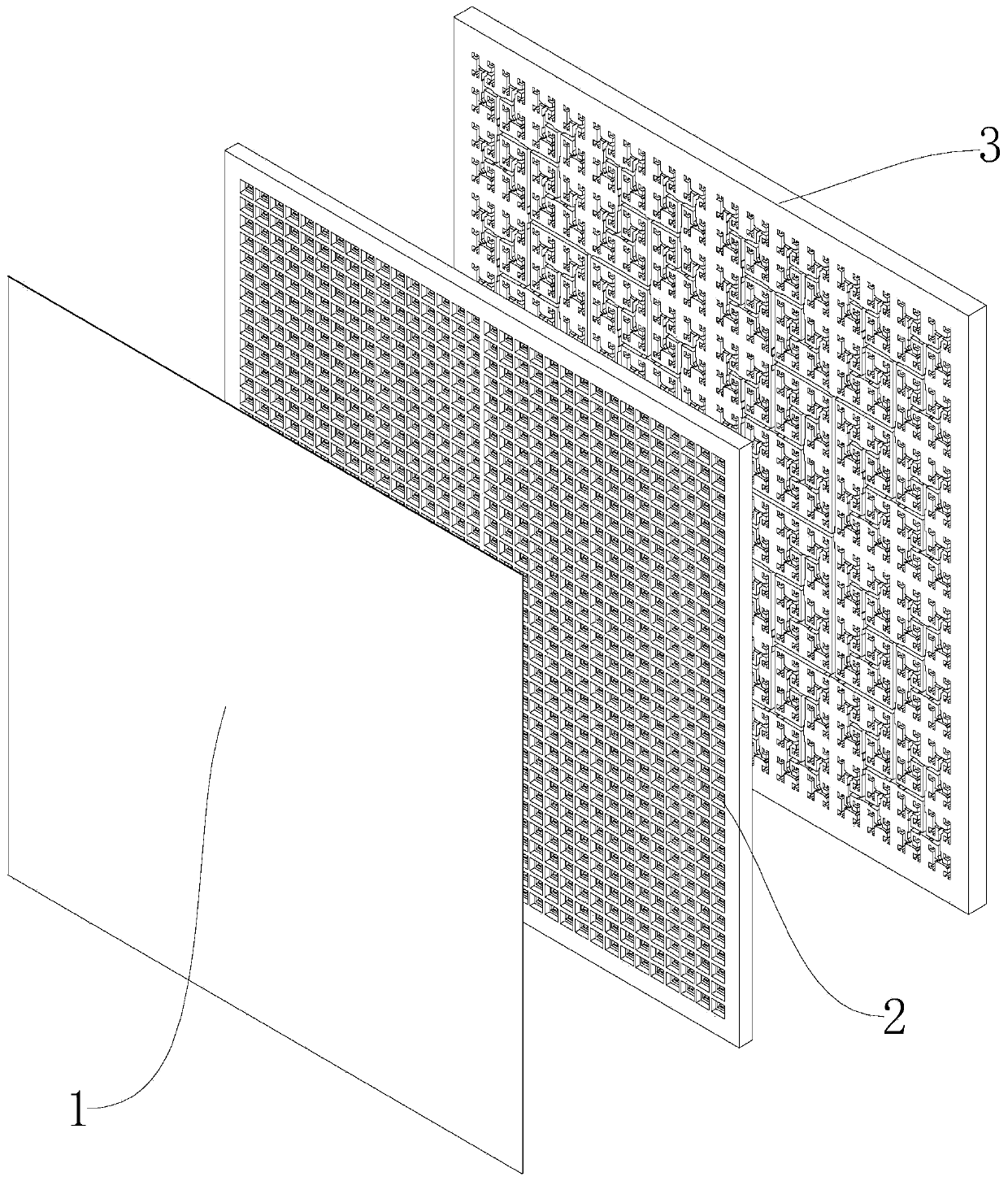

Broadband planar array antenna

ActiveCN111585050AReduce section heightHigh gainRadiating elements structural formsAntenna arrays manufactureSoftware engineeringSide lobe

The invention discloses a broadband planar array antenna, which comprises a polarization layer, a radiation layer and a feed layer which are sequentially stacked from top to bottom. The feed layer isused for converting a single TE10 mode into multiple TE10 mode signals with the same power and the same phase, and transmitting the multiple TE10 mode signals to the radiation layer; the radiation layer is used for radiating the multiple TE10 mode signals from the feed layer to a free space; and the polarization layer is used for enabling the electric field polarization direction generated by theradiation layer to rotate, so that side lobes of an E-plane directional diagram and an H-plane directional diagram are reduced. The antenna has the advantages of high gain and efficiency and low processing cost on the basis of low sidelobe.

Owner:NINGBO UNIV

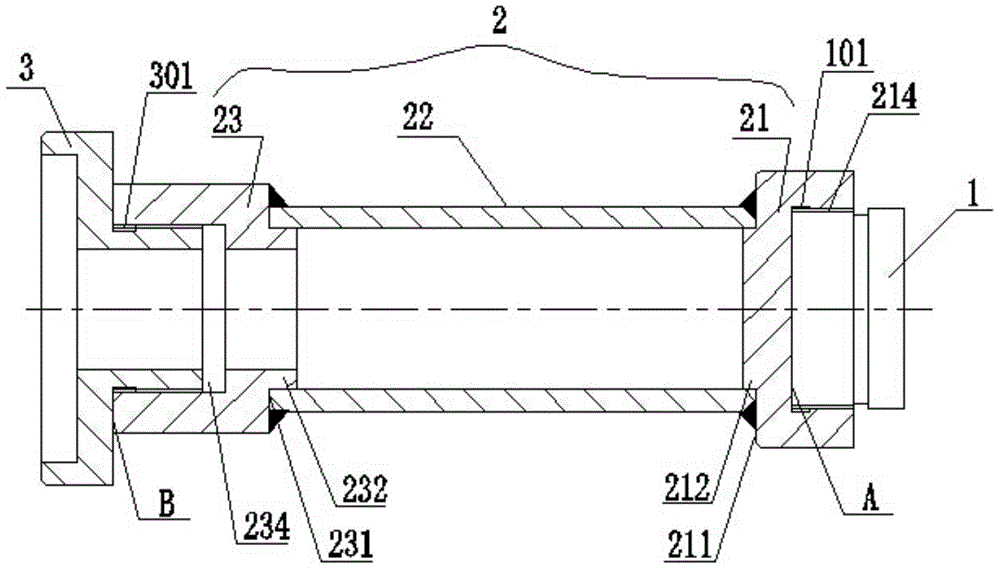

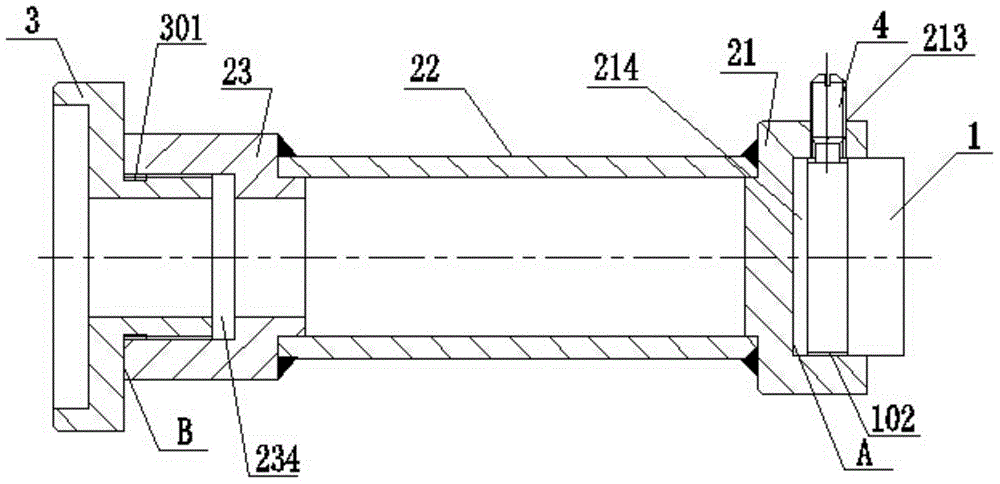

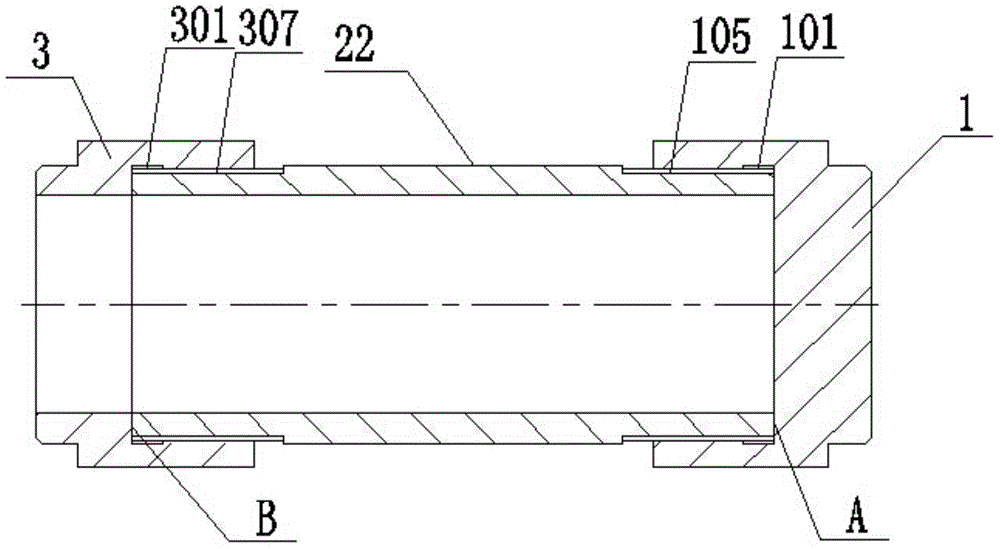

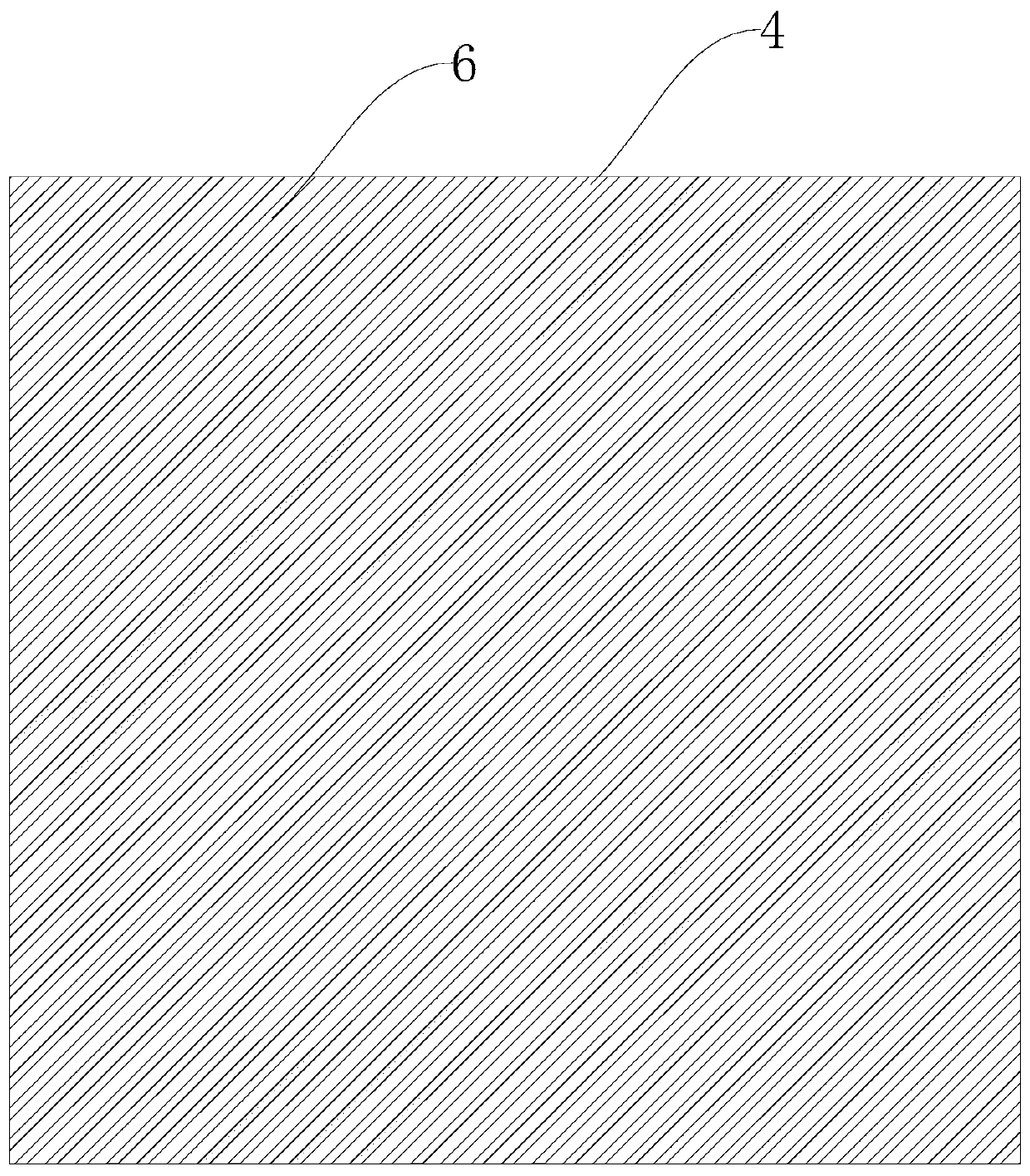

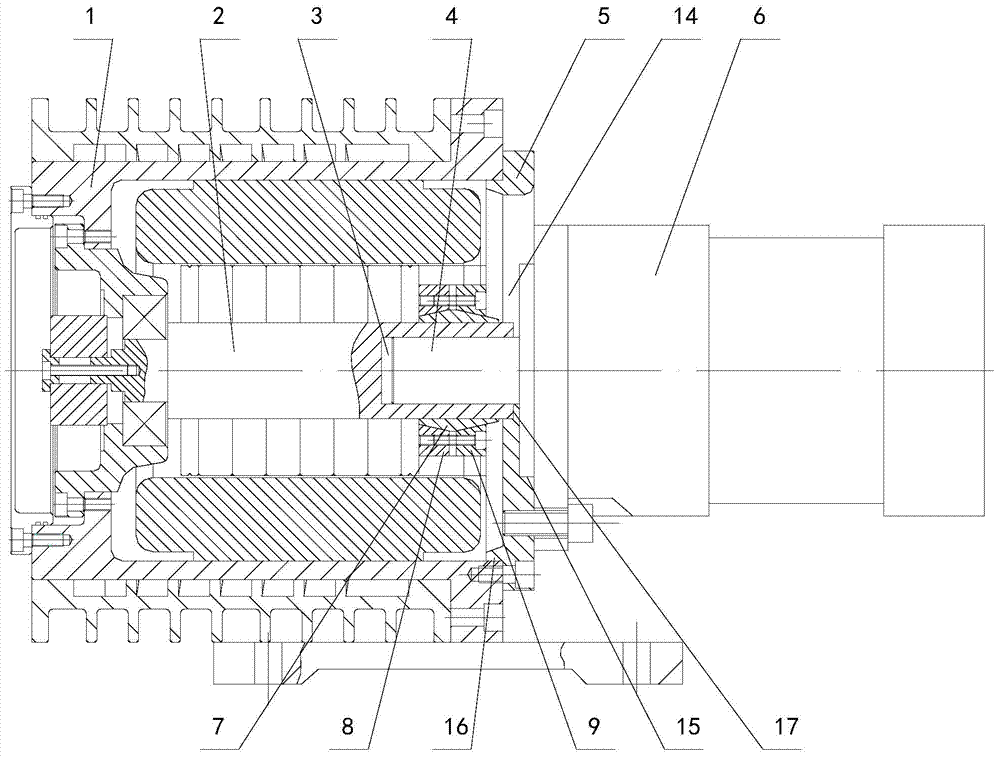

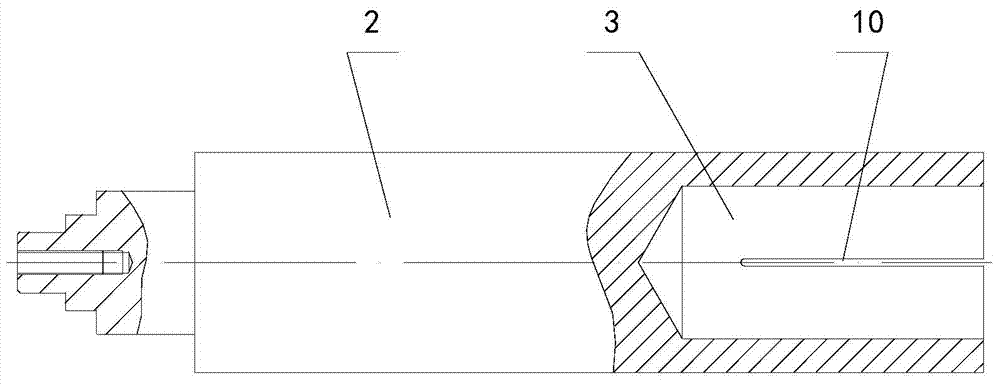

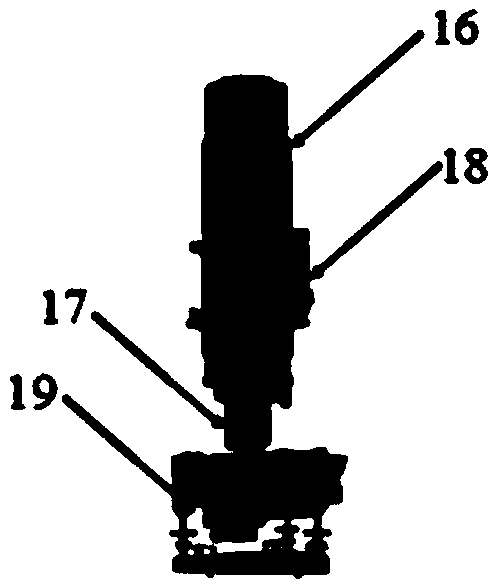

Driving connection device for motor and oil pump

ActiveCN103701257AReduce manufacturing costImprove versatilityMechanical energy handlingSupports/enclosures/casingsEngineeringUltimate tensile strength

The invention discloses a driving connection device for a motor and an oil pump. The driving connection device comprises an end cover (5) connected with the motor (1) and the oil pump (6), wherein the oil pump (6) is connected onto the end cover (5); the end cover (5) is connected onto the motor (1); the driving connection device further comprises a locking device which is located in the motor (1), close to one end of the end cover (5), and connects an output shaft (2) of the motor to a power input shaft (4) of the oil pump (6) in a locking manner; and a plug-in mounting port (14) for mounting and dismounting the locking device is formed in the end cover (5). With the adoption of the structure, the power input shaft of the oil pump is in standard delivery configuration, and is not required to be lengthened to extend into the motor, that is to say the power input shaft of the oil pump is not required to be processed and customized specially, so that the production cost is greatly lowered; the generality of the device is improved; at the same time, the rigid strength of the shaft is greatly improved; and the processing cumulative error is reduced, so that the dimensional precision of the shaft is improved.

Owner:NINGBO TENGLONG OUTDOOR IMPLEMENT

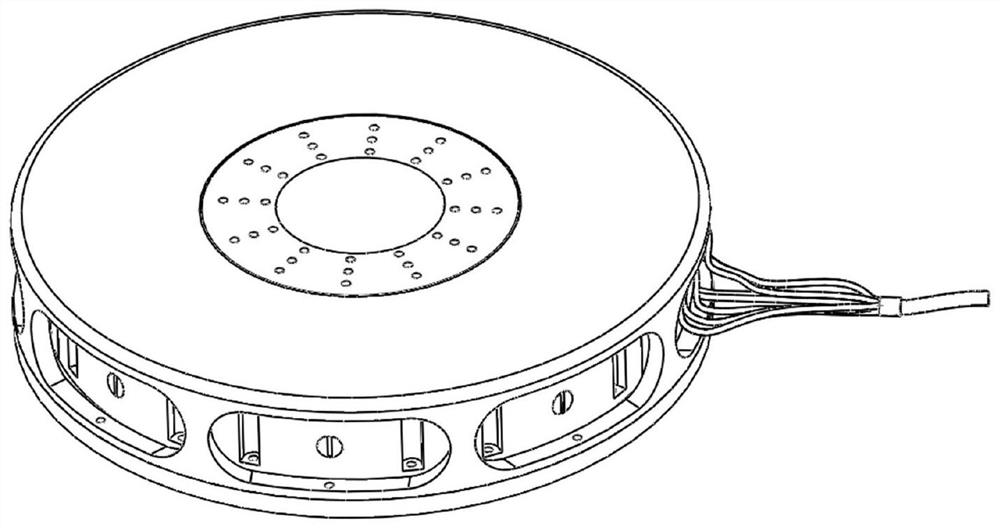

Built-in part array assembling machine and production method of motor stator using same

PendingCN110545016ARealize automated assemblySimple structureManufacturing stator/rotor bodiesEngineeringManipulator

The invention discloses a built-in part array assembling machine. Slide support blocks and clamps arranged on a positioning plate are driven to rotate by a rotating table. The rotating empty clamps are mounted on the array parts one by one by a material taking device. Glue is applied to the array parts by a glue applying device. A shell is grasped by a manipulator and buckled on the outer side ofthe assembled array parts. The slide support block is driven by the downward movement of a pressing block driven by an open cylinder to open outwardly and stick to the inner wall of the shell with thearray parts mounted on the clamps and then the glue is cured by heating through a heating ring. The opening cylinder drives the pressing block to move upward after sticking firmly, the rolling pieceon the pressing block releases the top pressure on the slide support block and the slide support block shrinks and moves inward under the action of a compression spring to drive the clamp to release the magnet piece. The automatic assembling of the built-in array parts and the shell can be realized, the structure is simple and the equipment occupation space is small. The invention also discloses aproduction method of the motor stator by using the assembling machine. The assembling efficiency is high and the quality stability is good.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

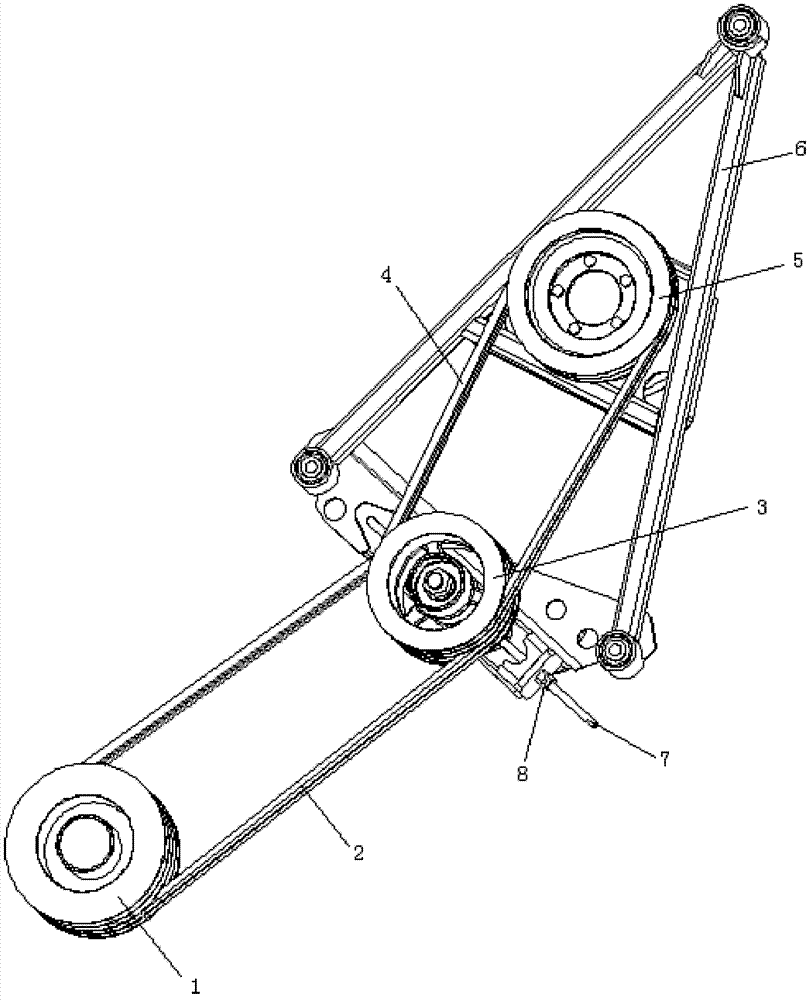

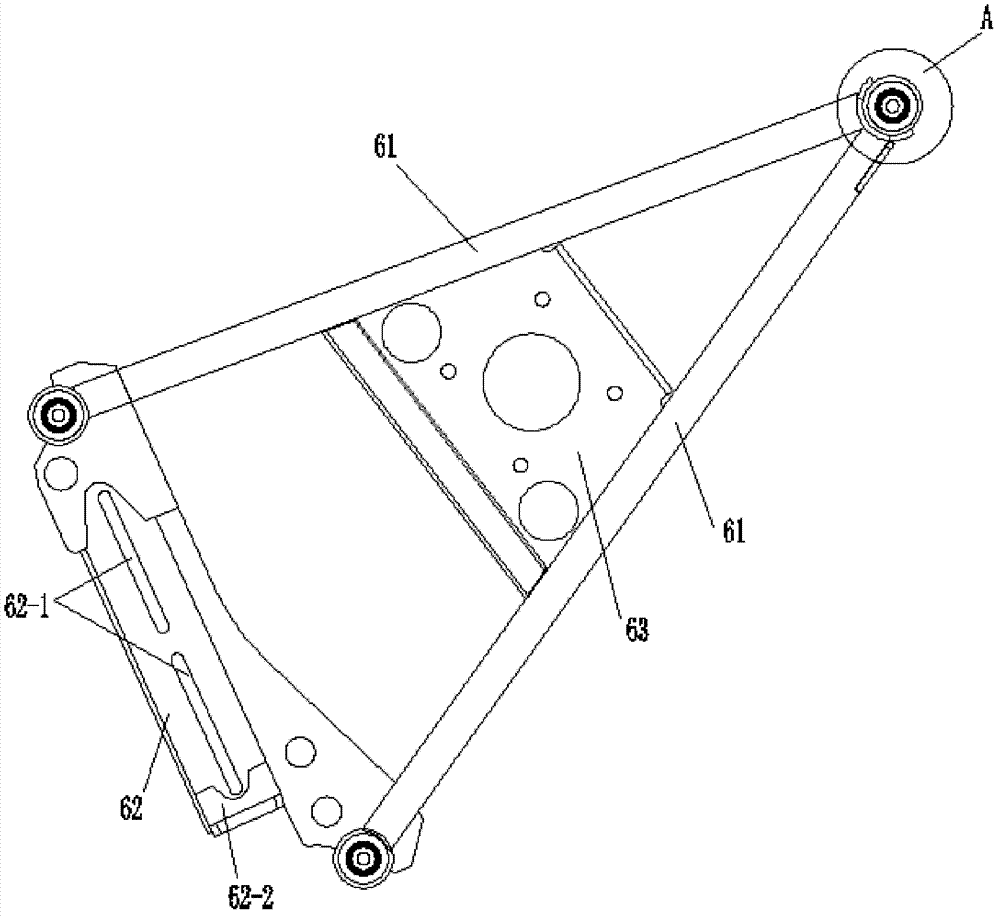

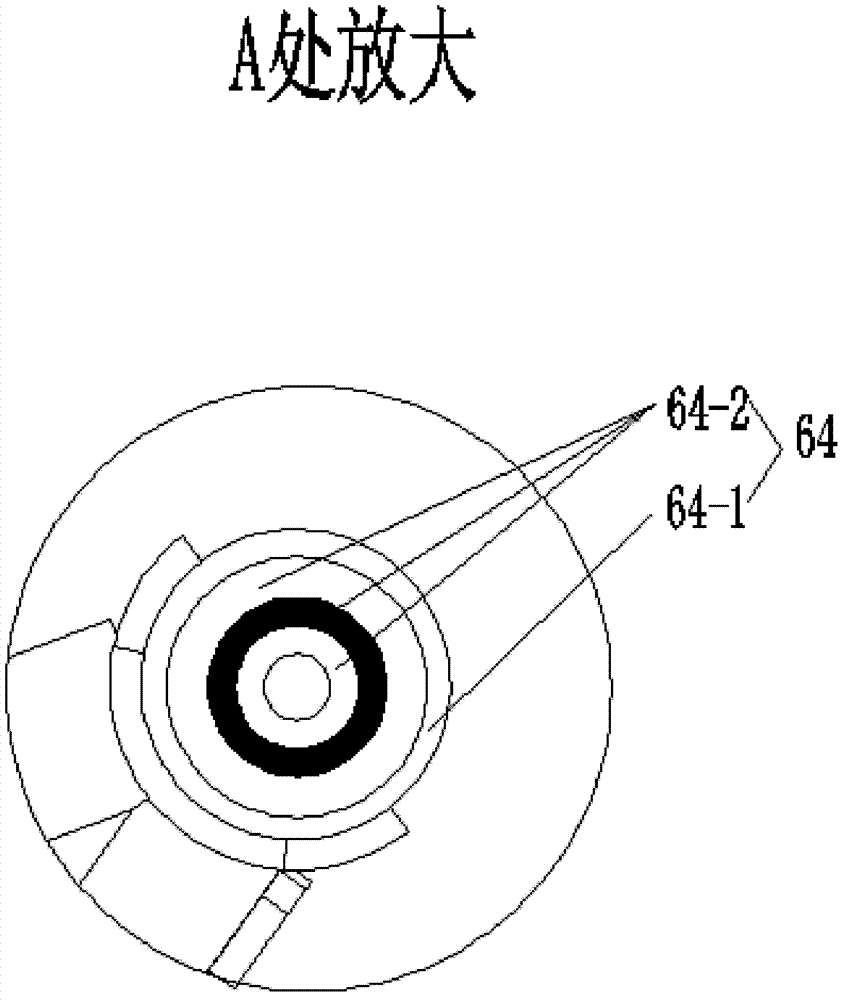

Bus fan-belt transmission mechanism

ActiveCN103089390AImprove stabilitySuitable for mass productionGearingMachines/enginesCrankshaftPulley

The invention discloses a bus fan-belt transmission mechanism which comprises a crankshaft pulley, a crankshaft belt, a central pulley assembly, a fan belt, a fan pulley assembly and a triangular frame assembly. A central pulley of the central pulley assembly is a double-layer pulley. The crankshaft belt surrounds the crankshaft pulley and a layer of the central pulley. The fan belt surrounds the other layer of the central pulley and the fan belt pulley assembly. The triangular frame assembly comprises two inclined beams, a central pulley mounting support and a fan pulley mounting support. The central pulley mounting support is taken as a base edge to form a triangle frame of the triangular frame assembly with the two cant beams. The fan pulley mounting support is mounted in the center of the triangle frame. The fan pulley mounting support and the central pulley mounting support are mounted in the triangular frame assembly, so that assembly accuracy of the fan pulley mounting support and the central pulley mounting support on the triangular frame assembly is improved, and the fan belt can be well matched with two belt grooves. The bus fan-belt transmission mechanism is simple to assemble, and structure stability thereof is improved.

Owner:北汽重型汽车有限公司

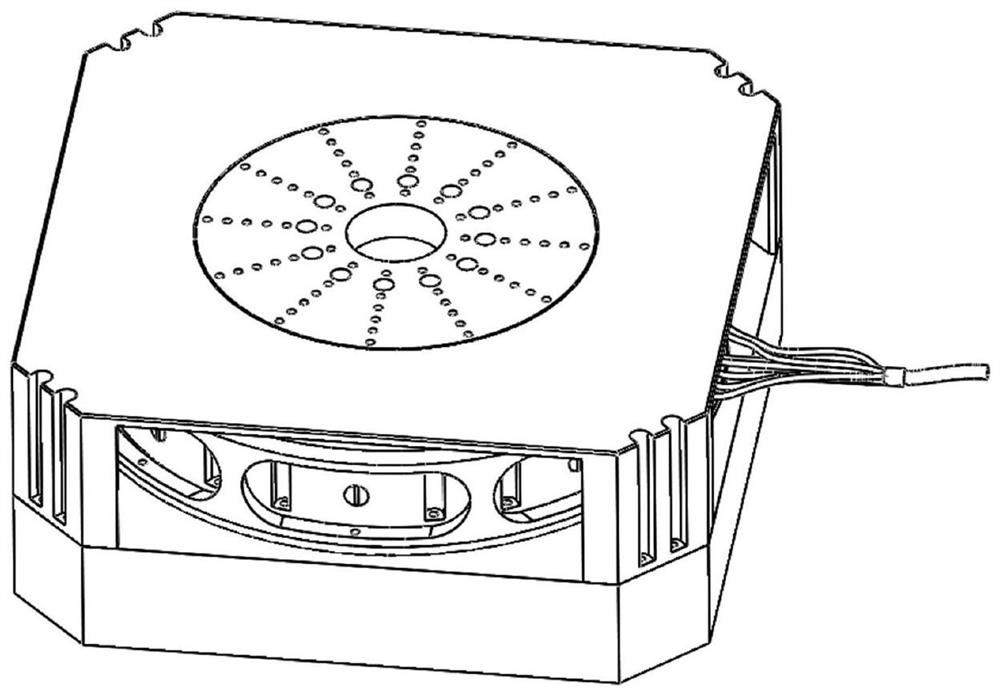

Split-type flat shaft air floating rotary table

ActiveCN113530975AIncrease flexibilityImprove machining accuracyAngles/taper measurementsBearing assemblyControl engineeringModular design

The invention discloses a split-type flat shaft air floating rotary table. The split-type flat shaft air floating rotary table comprises a split-type flat shaft air floating shaft system, a power module, an angle measurement module and a supporting protection module. According to the split-type flat shaft air floating shaft system, modular design is adopted, a closed type air floating structure is achieved through the combination of a main shaft and multiple air floating modules, the axial air floating function and the radial air floating function are integrated, the use flexibility of the air floating rotary table is improved, and the application occasion is expanded; the power module drives the rotary table to rotate; the angle measurement module measures and feeds back the actual rotation angle of the rotary table; and the supporting protection module is used for protecting the interior of the rotary table and bearing external equipment.

Owner:CHINA JILIANG UNIV

Cutting and grinding device convenient to use

InactiveCN107617941AEasy to installEasy to disassembleEdge grinding machinesGrinding drivesReciprocating motionGear wheel

The invention discloses a cutting and grinding device convenient to use. The cutting and grinding device convenient to use comprises a shell, wherein a first separation chamber, a second separation chamber and a separation plate are arranged in the shell; a reciprocating support, racks, a half tooth gear, a first motor and first fixing shafts are arranged in the first separation chamber, the racksare correspondingly arranged on the two sides of the inner wall of the reciprocating support, the half tooth gear connected with the first motor is arranged in the internal center of the reciprocating support, the half tooth gear is correspondingly meshed with the racks, and the first fixing shafts are arranged at the two ends of the reciprocating support; and a hydraulic device, a hydraulic rod,a first bearing, driving devices, driving mechanisms, driving rotating shafts, polishing brushes, a second motor, a rotating shaft, a rotating sleeve, a fixed base and a receiving plate are arrangedin the second separation chamber, and the hydraulic device is arranged in the center of the top end inside the second separation chamber. The cutting and grinding device convenient to use has the advantages that by arranging the driving mechanisms and the reciprocating support, the polishing brushes swing while rotating, so that the polishing brushes are driven to carry out left-and-right reciprocating motion to polish parts, the grinding and cutting effects of the parts are better, and the working efficiency is improved.

Owner:包晟

Catadioptric astronomical telescope and telescoping device

PendingCN108594420ASmall color differenceShorten the body lengthTelescopesBroad spectrumOptoelectronics

The invention discloses a catadioptric astronomical telescope and a telescoping device. The catadioptric astronomical telescope comprises a lens cone and lens assemblies, wherein the lens assemblies are arranged in an inner cavity of the lens cone, the lens assemblies include a first front correcting lens assembly, a second front correcting lens assembly, a catadioptric lens assembly, a rear correcting lens assembly and a main reflecting lens assembly which are arranged in the inner cavity of the lens cone sequentially, and a central axis of the lens cone is concentric with optical axes of thefirst front correcting lens assembly, the second front correcting lens assembly, the catadioptric lens assembly, the rear correcting lens assembly and the main correcting lens assembly. The catadioptric astronomical telescope and the telescoping device have the advantages that by adding appropriate number of catadioptric lenses, chromatic aberration of the telescoping device is reduced maximally,and a telescope body of the telescope can be shortened effectively; by adopting two groups correcting lens assemblies in the front and back, paraxial aberrations including coma aberration, position chromatism and the like are eliminated effectively, and good qualities of focused images in broad-spectrum bands are guaranteed.

Owner:西安航光仪器厂

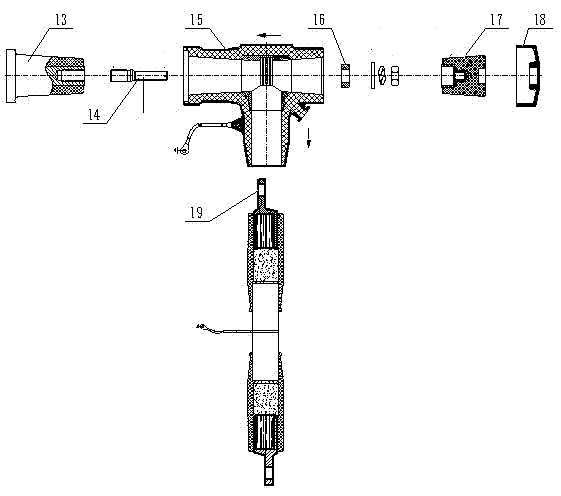

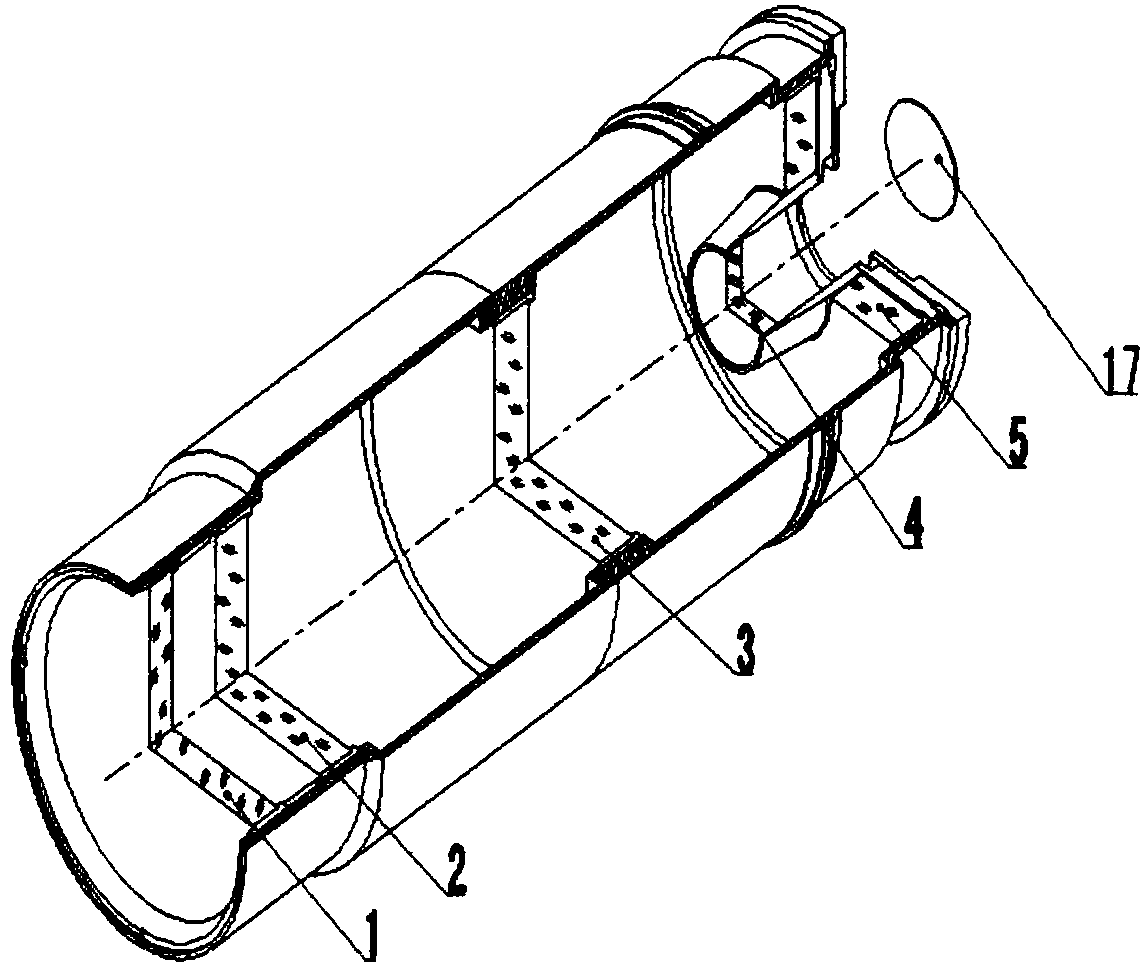

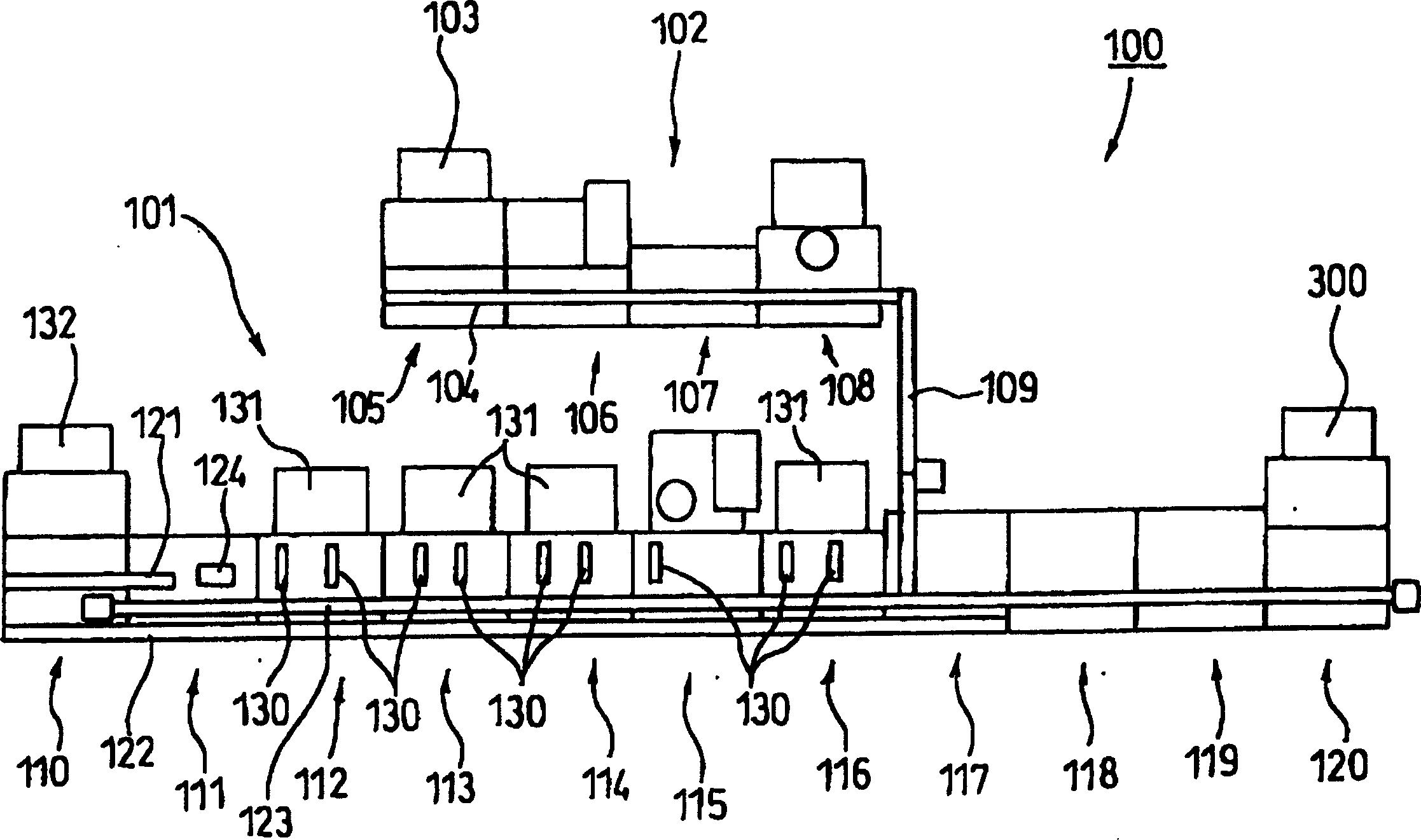

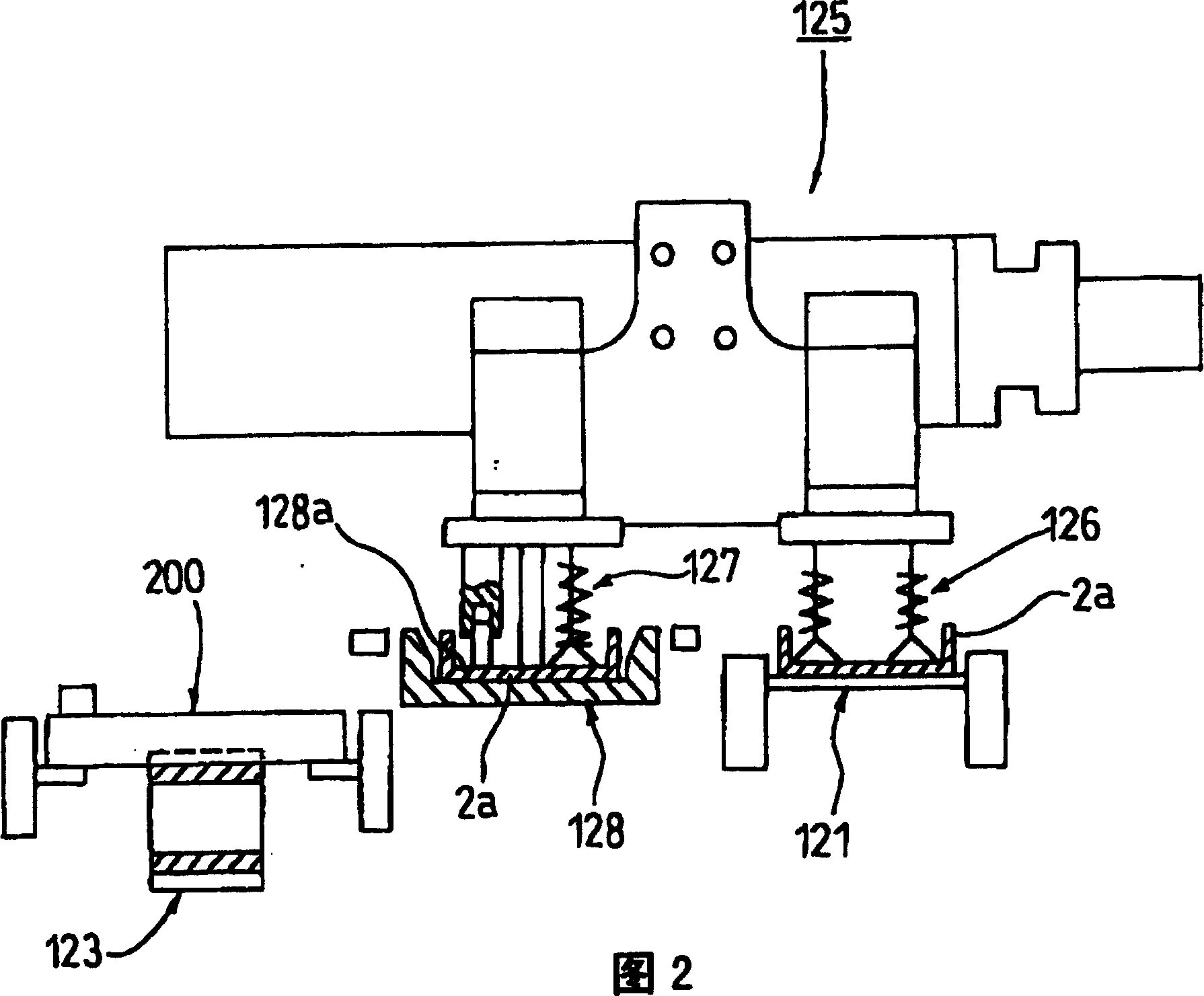

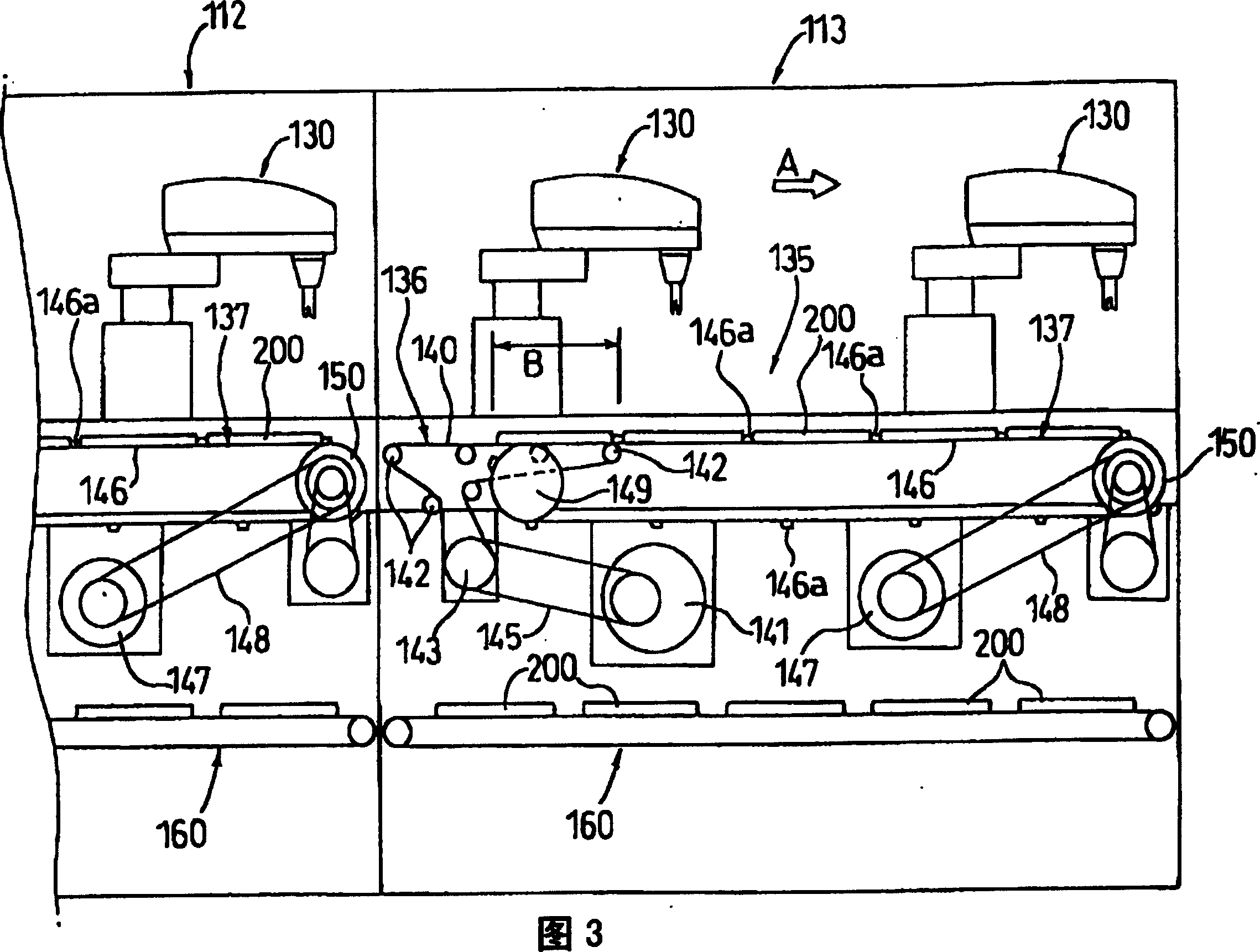

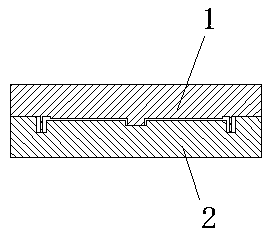

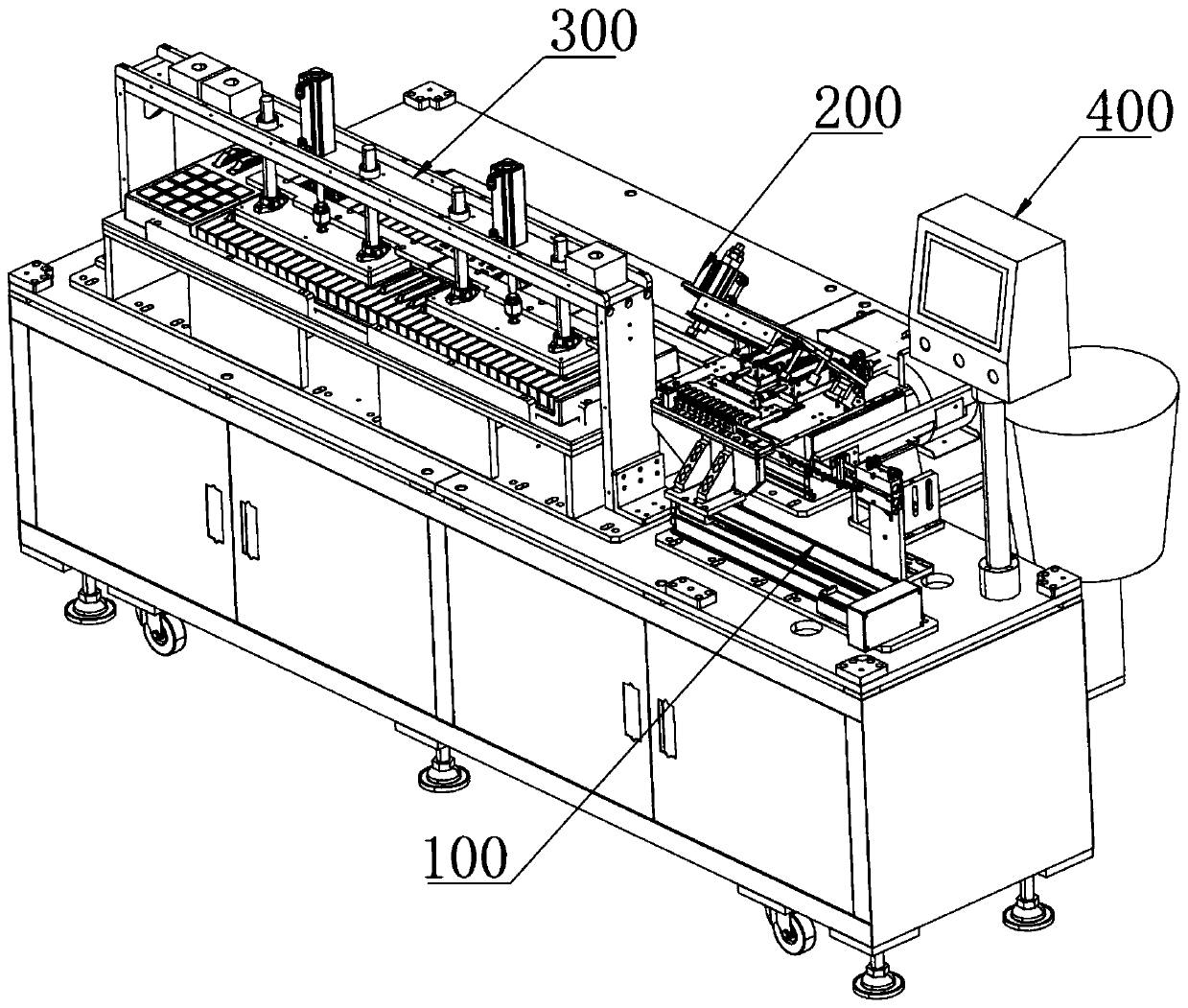

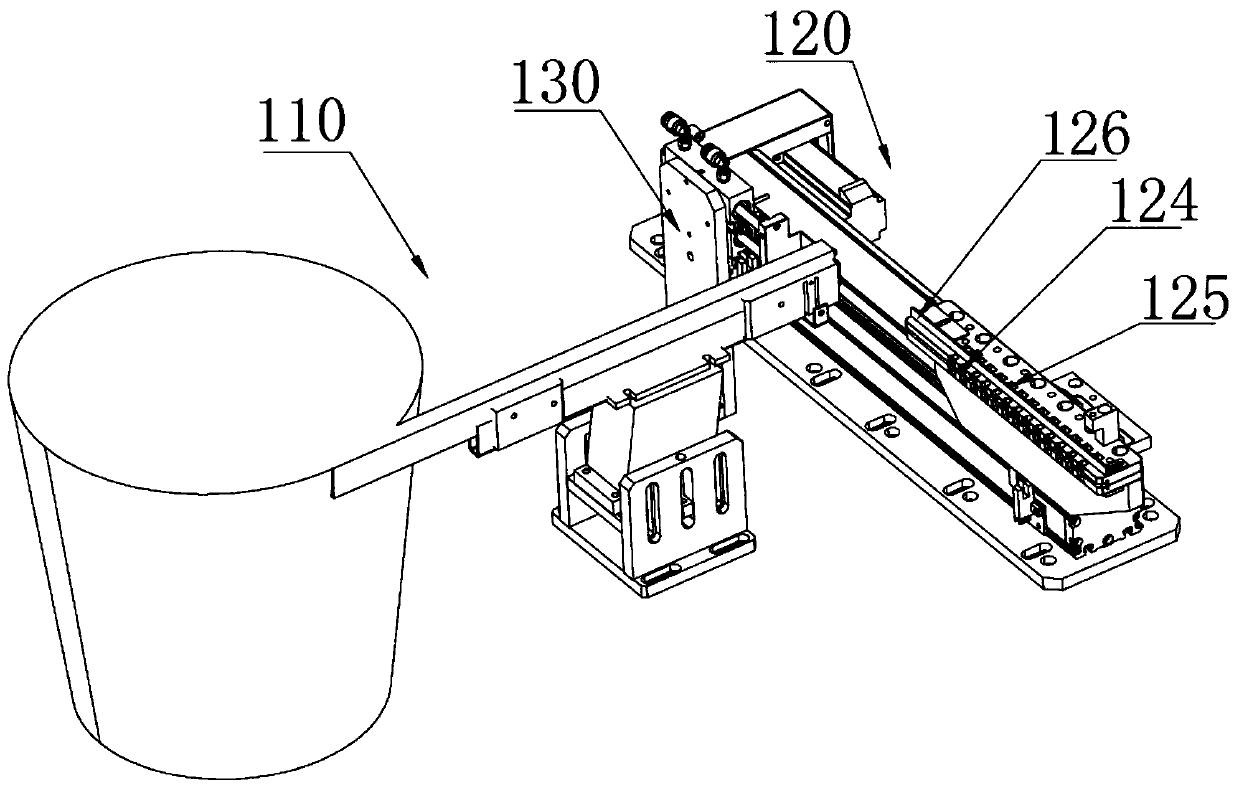

Method and apparatus for assembling magnetic tape cartridge

InactiveCN1179360CGood assembly precisionImprove productivityRecord information storageMagazine/cassette manufacturing apparatusProduction rateMagnetic tape

In the method and apparatus for assembling a magnetic tape cartridge, a plurality of assembling stations, each of which includes an assembling robot 130 for assembling the respective parts of a magnetic tape cartridge 1, respectively comprise pallet delivery mechanism 135 capable of delivering sequentially a pallet 200 on which an upper cases 2a can be placed. The pallet 200 comprises front and rear reel brake hold mechanism 210, 220 respectively capable of holding front and rear reel brakes 50, 51 against the energizing forces of brake springs 12, 13 in such a manner that the front and rear reel brakes 50, 51 retreat from the installation area of the reel 3, lid spring hold mechanism 230 capable of holding the lid engaging portion 15a of a lid spring 15 in such a manner that the lid engaging portion 15a is not in engagement with a lid 30, reel hold mechanism 240 capable of holding a reel 3 on the upper case 2a side against the energizing force of a reel spring 8, and lower case hold mechanism 250 capable of holding a lower case 2b on the upper case 2a side. Accordingly, it is possible to obtain a magnetic tape cartridge having an excellent assembling accuracy with high productivity.

Owner:FUJIFILM CORP

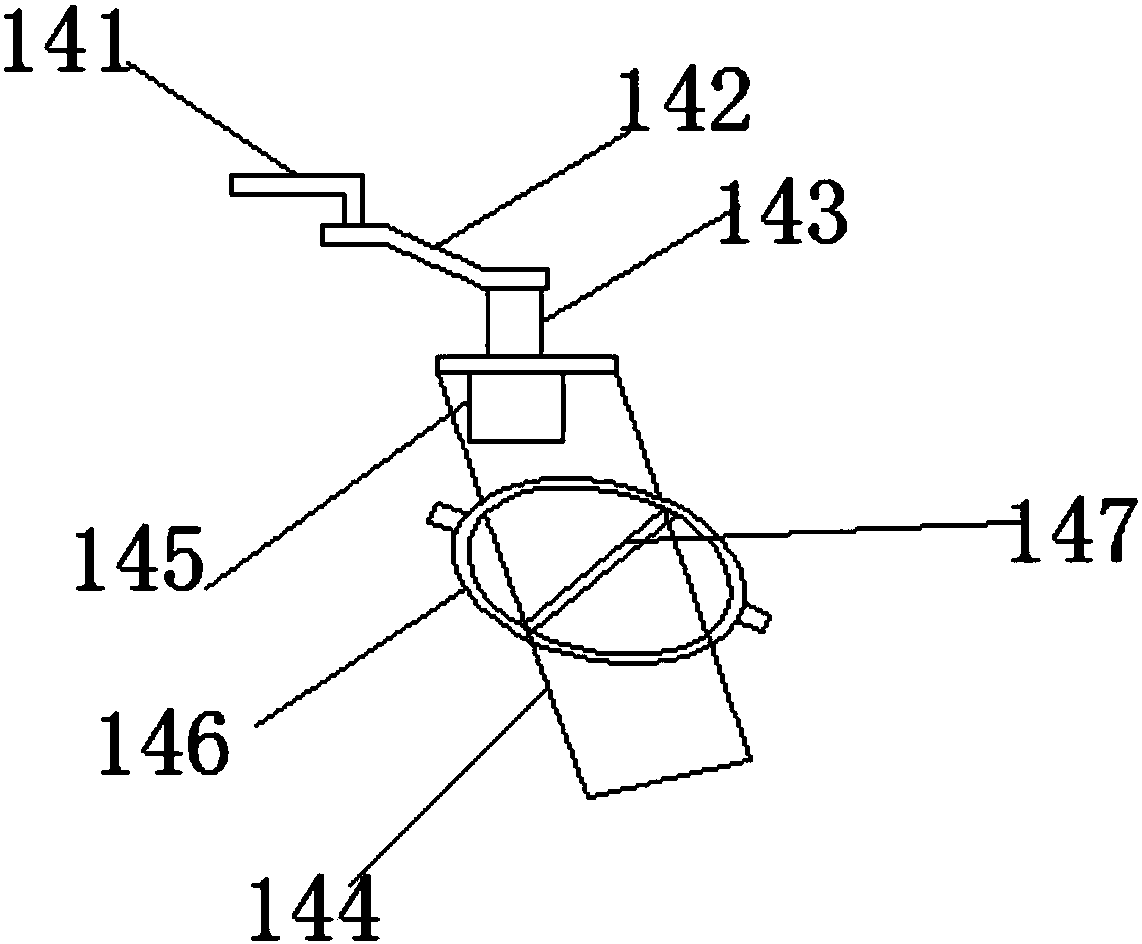

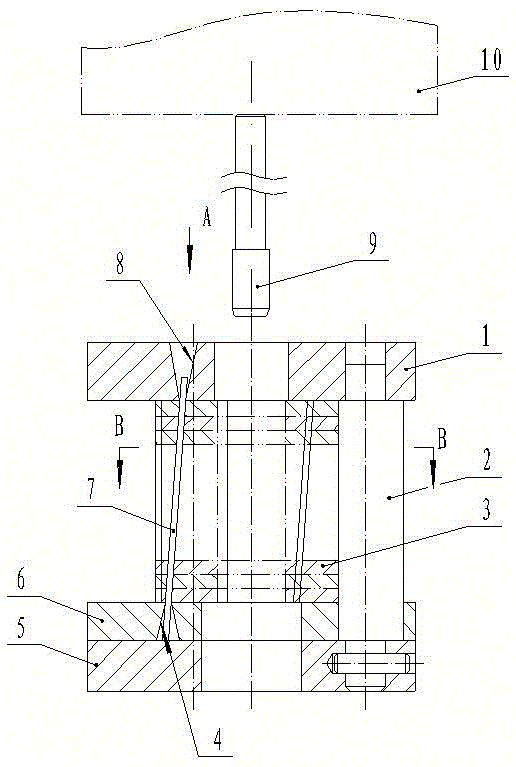

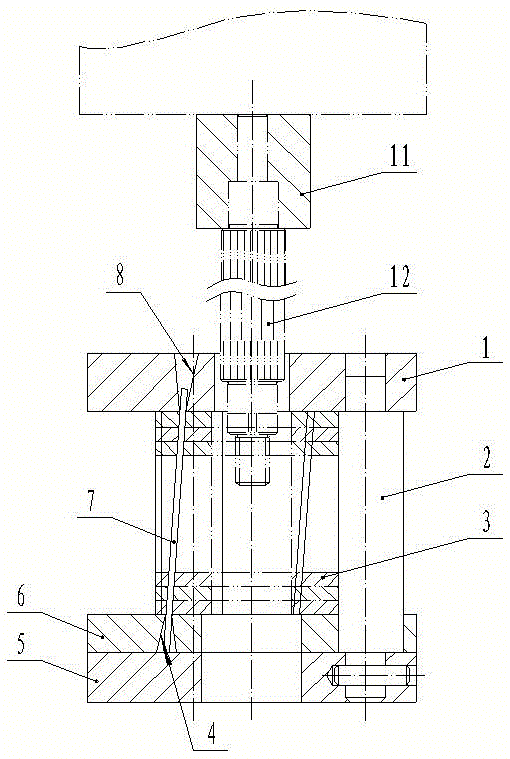

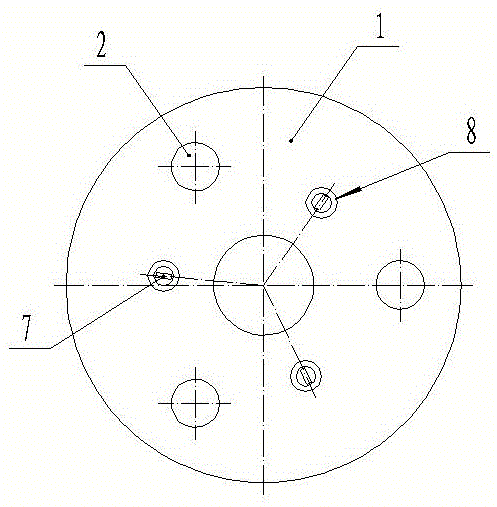

Processing die of stirrer with aeration function

PendingCN111070524ASolve processing problemsGood assembly precisionProcess engineeringMechanical equipment

The invention discloses a processing die of a stirrer with an aeration function, and belongs to the technical field of environmental protection mechanical equipment. The processing die comprises an upper die and a lower die, wherein the upper die is provided with a guide post hole and a die core; the lower die is provided with a guide post and a die cavity; the guide post hole in the upper die issleeved into the guide post on the lower die; the upper die and the lower die are closed by applying external force; a casting material is poured into a pouring hole and is injected into the die cavity through a pouring channel; and after cooling, the die is opened to take out a part. According to the processing die of the stirrer with the aeration function, parting is performed from the central position of an air nozzle, and a structure of one die and two cavities is adopted, so that the structure is novel, and later demolding is facilitated; and the die is finished in the same clamping process in the preparation process, so that the form and position errors of the two cavities are small, the part which is formed by pouring can be ensured to have high assembly accuracy, the processing problem of the stirrer can be solved, the processing die is convenient to operate, and the manufacturing efficiency can be improved.

Owner:YANGZHOU UNIV

High-efficiency electronic organ springs automatic assembly equipment

PendingCN109732326AThe overall structure is simpleImprove work efficiencyMetal working apparatusElectricityMaterial resources

The invention relates to the technical field of electronic organ assembly, in particular to high-efficiency electronic organ springs automatic assembly equipment. The high-efficiency electronic organsprings automatic assembly equipment comprises a rack, a feeding device arranged on one side of the rack and used for feeding springs, a transferring device arranged on the side, the same as the feeding device, of the rack and used for taking the springs on the feeding device, a pressing device arranged on the side, same as the transferring device, of the rack and used for fixing an electronic organ, and a control device which is electrically connected with the feeding device, the transferring device, and the pressing device. The equipment is simple in overall structure and high in working efficiency, the efficiency is greatly improved compared with a traditional manner of manual assembly, manpower and material resources are saved, and the automation degree is high.

Owner:DONGGUAN LONGJOIN ELECTRONICS

Pressing clamp for skew overlying rotor

ActiveCN105490469APrecise skew angleEasy to assembleManufacturing stator/rotor bodiesElectric machineEngineering

The invention discloses a pressing clamp for a skew overlying rotor, belongs to motor manufacturing fixtures, and aims to provide an overlying rotor assembly fixture which is good in assembly accuracy, simple in structure and convenient and efficient in demolding. The pressing clamp comprises a base, a pressing block and plug pins, wherein a base plate (6) and three positioning columns (2) are fixed on the base plate (5), and a pressing plate (1) is positioned on the positioning columns (2); three first horn holes (8) uniformly distributed by taking the center as the center of a circle are formed in the pressing plate (1), and three second horn holes (4) uniformly distributed by taking the center as the center of the circle are formed in the base plate (6); an angle is staggered between the first horn holes (8) and the corresponding second horn holes (4) by taking the center as the center of the circle; the plug pins (7) are inserted between the corresponding first horn holes (8) and second horn holes (4); and a pressing head (11) is arranged above the pressing plate (1). The pressing clamp has multiple functions in one object, and is an overlying rotor assembly clamp.

Owner:GUIYANG AVIATION MOTOR

Pintle chain automatic assembly machine

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

Concentricity adjusting mechanism, rod pinch diode, adjusting method and application

PendingCN113192812AOvercoming the effects of poor output performanceImprove stabilityCathode ray concentrating/focusing/directingEngineeringMechanical engineering

The invention discloses a concentricity adjusting mechanism, a rod pinch diode, an adjusting method and application. The concentricity adjusting mechanism comprises an anode adjusting structure, a cathode adjusting structure and an adjusting screw. The anode adjusting structure comprises a first anode adjusting seat, an adjusting corrugated pipe, an adjusting ball and a second anode adjusting seat. The adjusting corrugated pipe is arranged between the first anode adjusting seat and the second anode adjusting seat, the adjusting ball is arranged in the adjusting corrugated pipe, and the second anode adjusting seat is used for being connected with the first adjusting piece; the cathode adjusting structure comprises a first cathode disc fixing seat and a second cathode disc fixing seat; the first cathode disc fixing base and the second cathode disc fixing base are used for fixing the second adjusting piece, displacement of the second adjusting piece is achieved through the adjusting screw rod, and concentricity of the first adjusting piece is achieved. The concentricity adjusting mechanism is used for the rod pinch diode, the relative position of an X-ray focal spot can be determined, the RPD cathode and anode concentricity assembling precision can be improved, and the RPD stability is greatly improved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

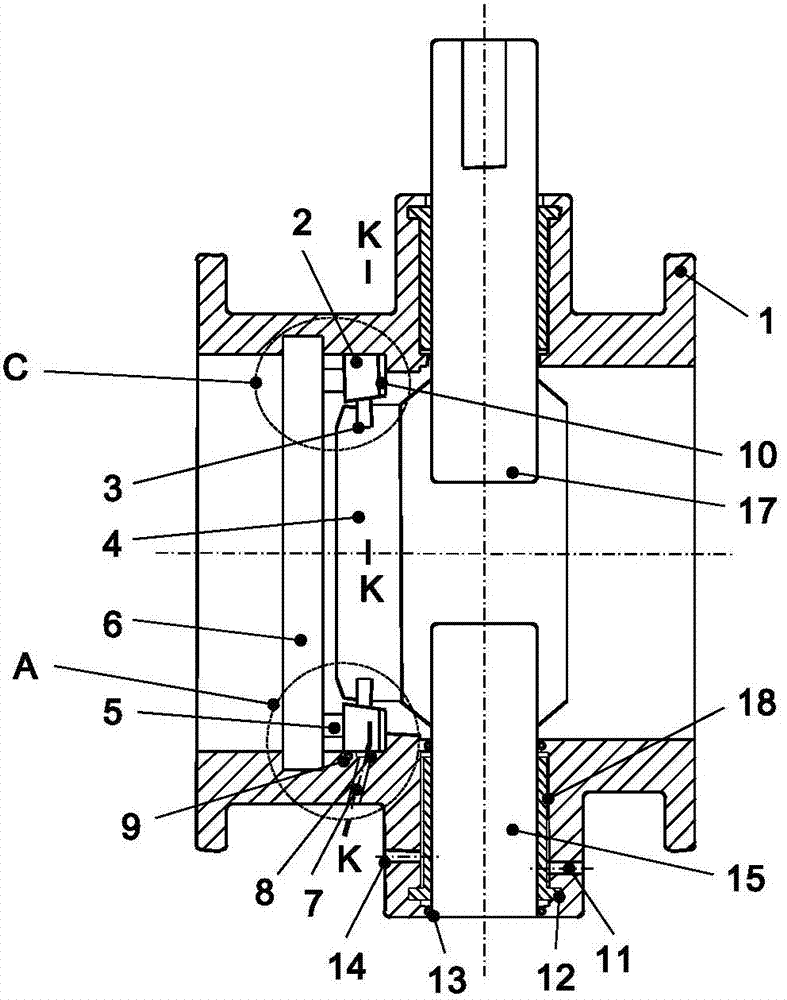

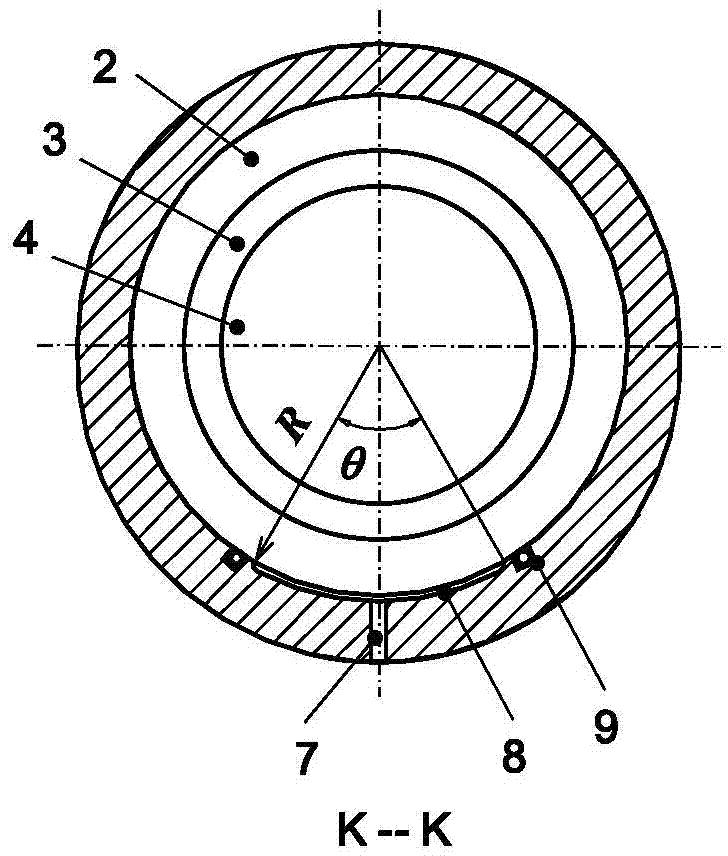

Two-way sealing butterfly valve with hydraulic-floating valve seat and sediment prevention function

ActiveCN103759024AReduce movementImprove operational performanceSpindle sealingsLift valveEngineeringWater channel

The invention discloses a two-way sealing butterfly valve with a hydraulic-floating valve seat and a sediment prevention function and relates to the two-eccentric or triple-eccentric two-way sealing butterfly valve. The technical scheme includes that a sealed water groove is arranged on the lower portion of a valve body and along the circumferential direction of the inner wall of the valve body, a first elastic sealing ring is arranged around the closed water groove on the inner wall of the valve body, and a water injection hole is formed in the closed water groove. The valve seat is capable of moving easily along the axis direction of the valve body, and operating performance of the eccentric butterfly valve in opening and closing can be obviously improved; a pressure water channel and the elastic sealing ring jointly form a sediment prevention structure, so that impurities carried along in fluid are prevented from entering fit clearance between a valve shaft and a bushing in use of the butterfly valve, abrasion can be effectively prevented, and the effect of protecting the valve shaft and the bushing can be achieved; convenience in butterfly operation under reverse pressure and reliability of sealing can be effectively improved, and range of application of the butterfly valve can be expanded.

Owner:TIELING SPECIAL VALVE +1

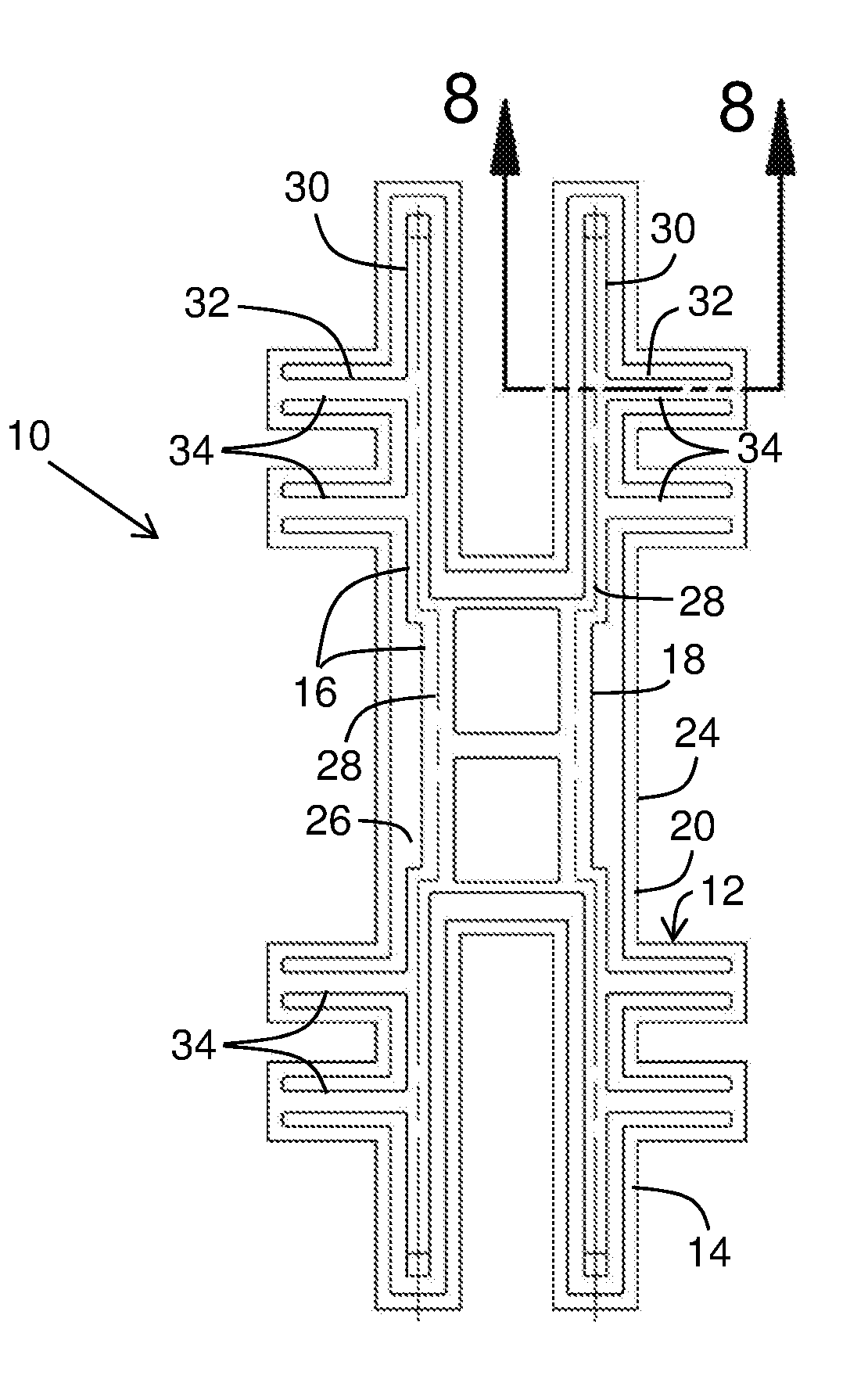

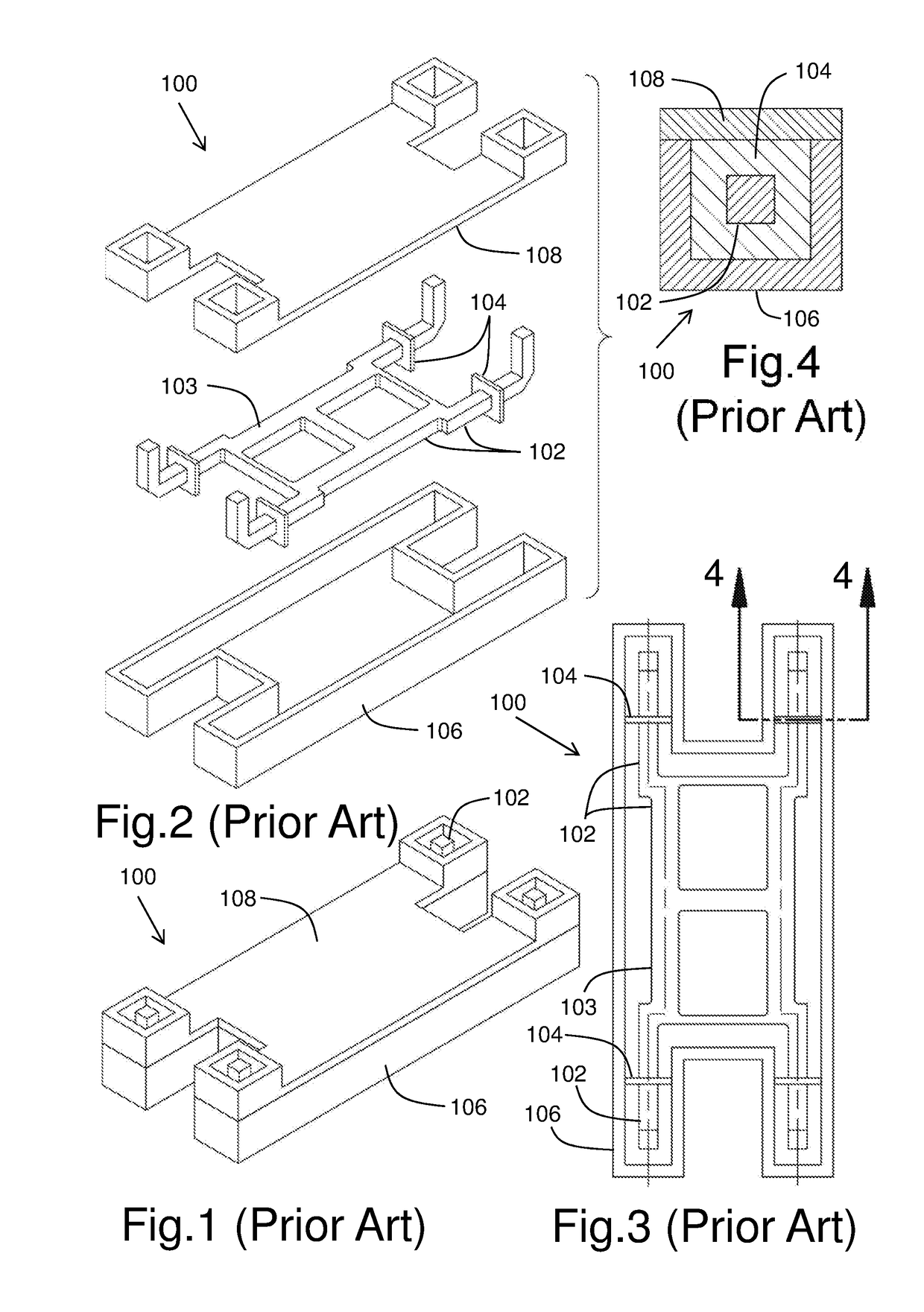

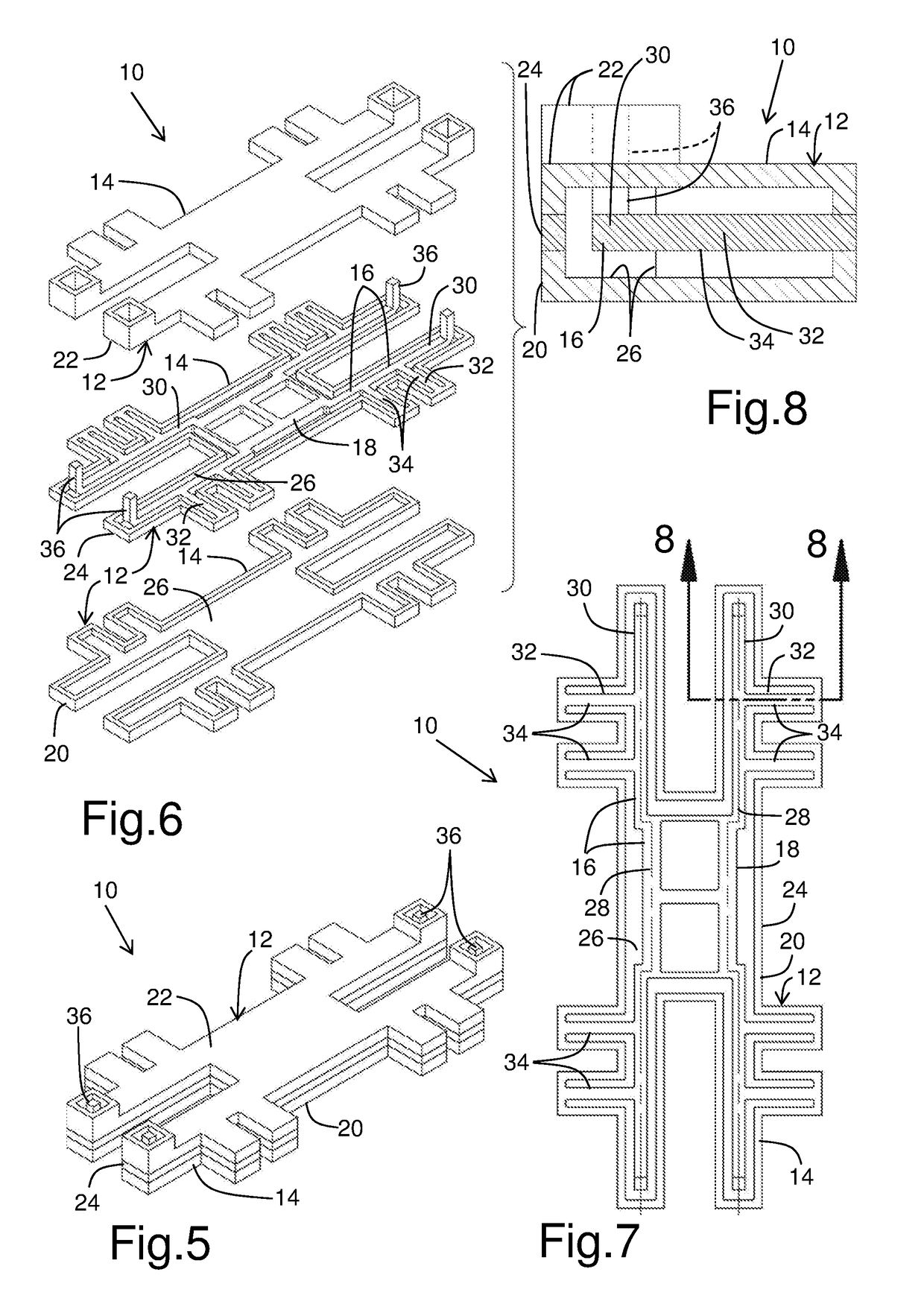

Compact and lightweight tem-line network for RF components of antenna systems

ActiveUS20170222295A1Reduce decreaseGood assembly precisionWaveguidesCoupling devicesElectrical conductorNetwork architecture

A TEM-line network architecture for RF components used in antenna system, includes an electrically conductive main body forming an outer conductor defining a signal channel, and an electrically conductive center conductor electrically grounded to the main body at predetermined locations. The center conductor is electromagnetically isolated from the outer conductor at RF frequencies while being connected and supported within the signal channel only at at least one of the predetermined locations. The outer conductor is preferably formed of three layers with the center conductor being integral with one of the layers.

Owner:MACDONALD DETTWILER & ASSOC INC

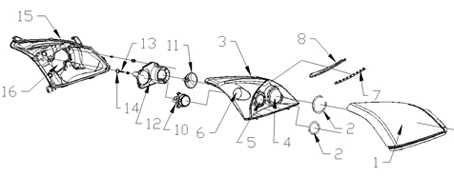

Automobile headlight

InactiveCN101893196AStructural accuracy requirements are lowEasy to producePoint-like light sourceOptical signallingEngineering

The invention discloses an automobile headlight, which solves the problems that the conventional automobile headlight has monotonous luminous mode and cannot well meet the requirement of pursuing fashion. The invention adopts the technical measures that the automobile headlight comprises a transparent lampshade, a bracket and a base, wherein the bracket is positioned between the base and the lampshade, the bracket is provided with a lens hole and a reflector hole which are communicated, a lens group with lenses is arranged in the lens hole, and a bowl reflector is arranged in the reflector hole. The automobile headlight is characterized in that a luminous ring is arranged at the outer edge ports of the lens hole and the reflector hole of the bracket respectively. The lens group and the bowl reflector can be preassembled on a plate lamp frame so as to realize quick assembly of the automobile headlight.

Owner:浙江龙鼎车业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com