Tool for assembling flexible bus and use method of tool

A flexible busbar and tooling technology, applied in busbar installation, busbar/line layout, cable installation, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing production cost, labor intensity and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

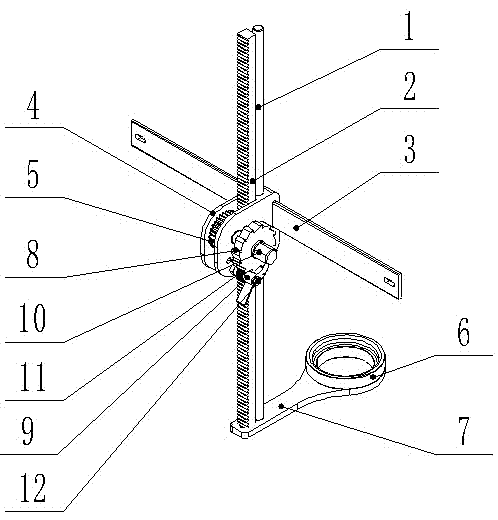

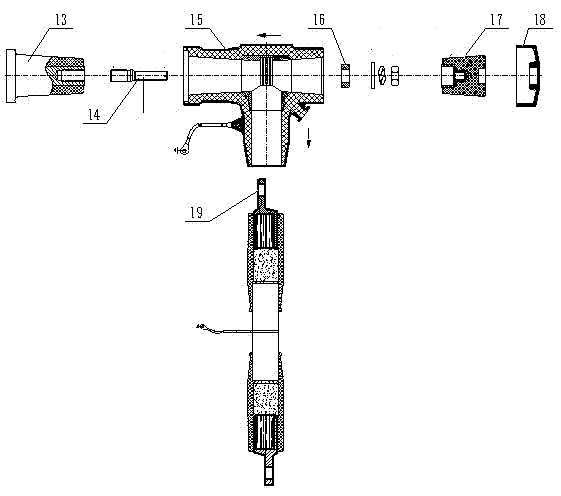

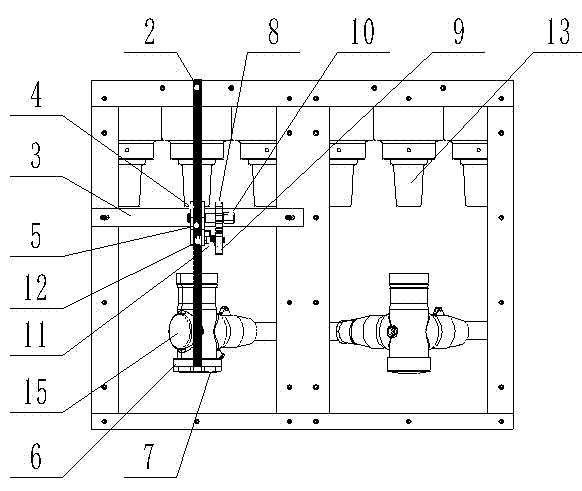

[0012] Such as figure 1 As shown, a flexible busbar assembly tool for a solid insulated ring network cabinet includes a guide rod 1, a rack 2, a guide beam 3, a bracket 4, and a support plate 7. The guide rod 1 and the rack 2 are fixed together; the bracket 4 passes through The guide rod 1 and the rack 2, the bracket 4 moves up and down along the guide rod through the engagement with the rack; the bracket 4 has a spur gear 5, a transmission shaft 10, and the side of the bracket 4 is equipped with a ratchet 8, a pawl 9, and a torsion spring 11 And positioning rod 12, transmission shaft 10 passes through bracket 4, spur gear 5 and ratchet 8; positioning rod 12 is fixed on the bracket 4, ratchet 9, torsion spring 11 is installed on the positioning rod 12; , the bracket 4 can move horizontally along the guide beam 3, and two positioning holes are symmetrically opened at both ends of the guide beam 3; There is an annular platform at the bottom of the support plate 7 and the gu...

Embodiment 2

[0023] Add a DC 24V motor on the bracket 4 to drive the spur gear 5 to move up and down. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com