Integrated building method of shipboard subsection in shipbuilding process

A construction method and broadside technology, applied in ship construction, ship parts, ships, etc., can solve the problems of consuming a lot of manpower, time cost, and a lot of time, so as to save assembly and welding time, save grinding, and improve the quality of parts. The effect of segment integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

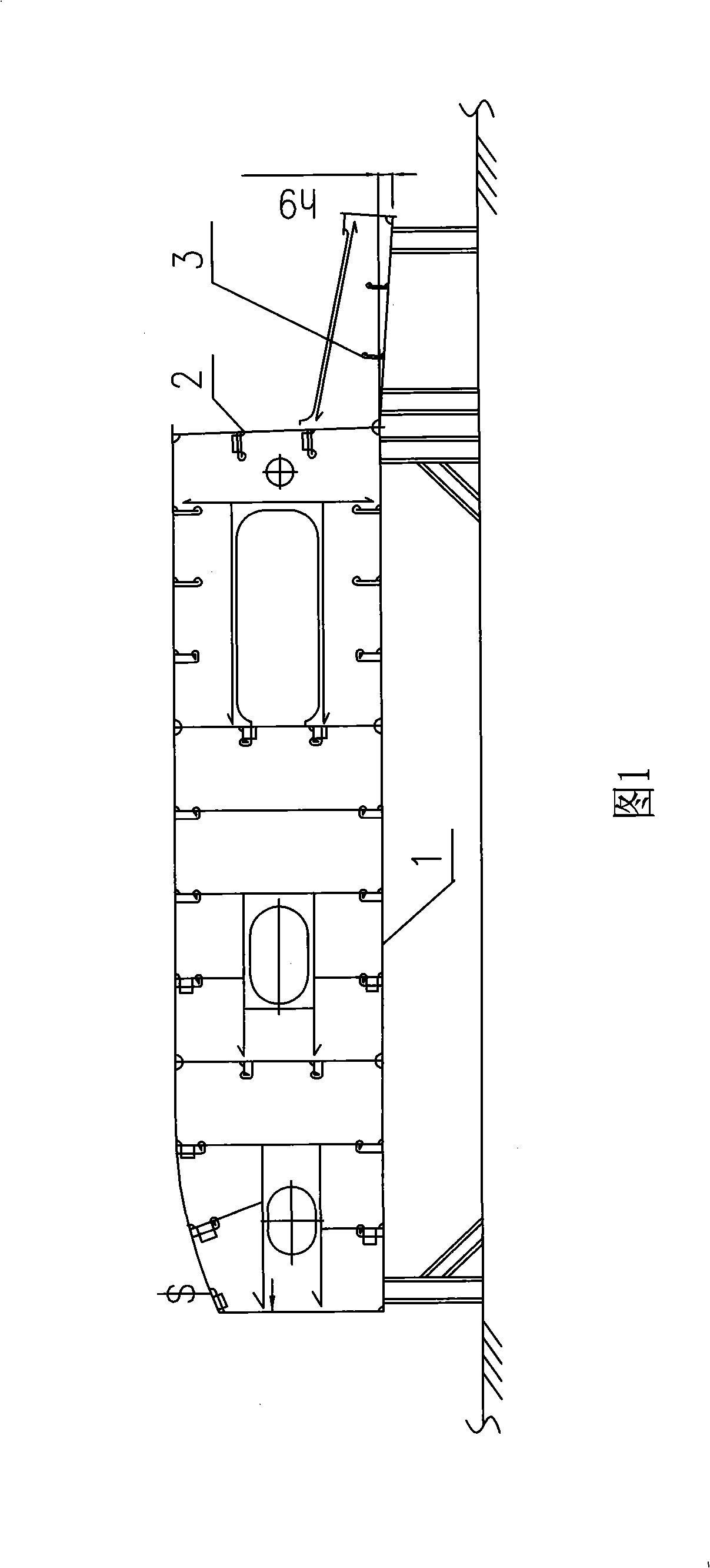

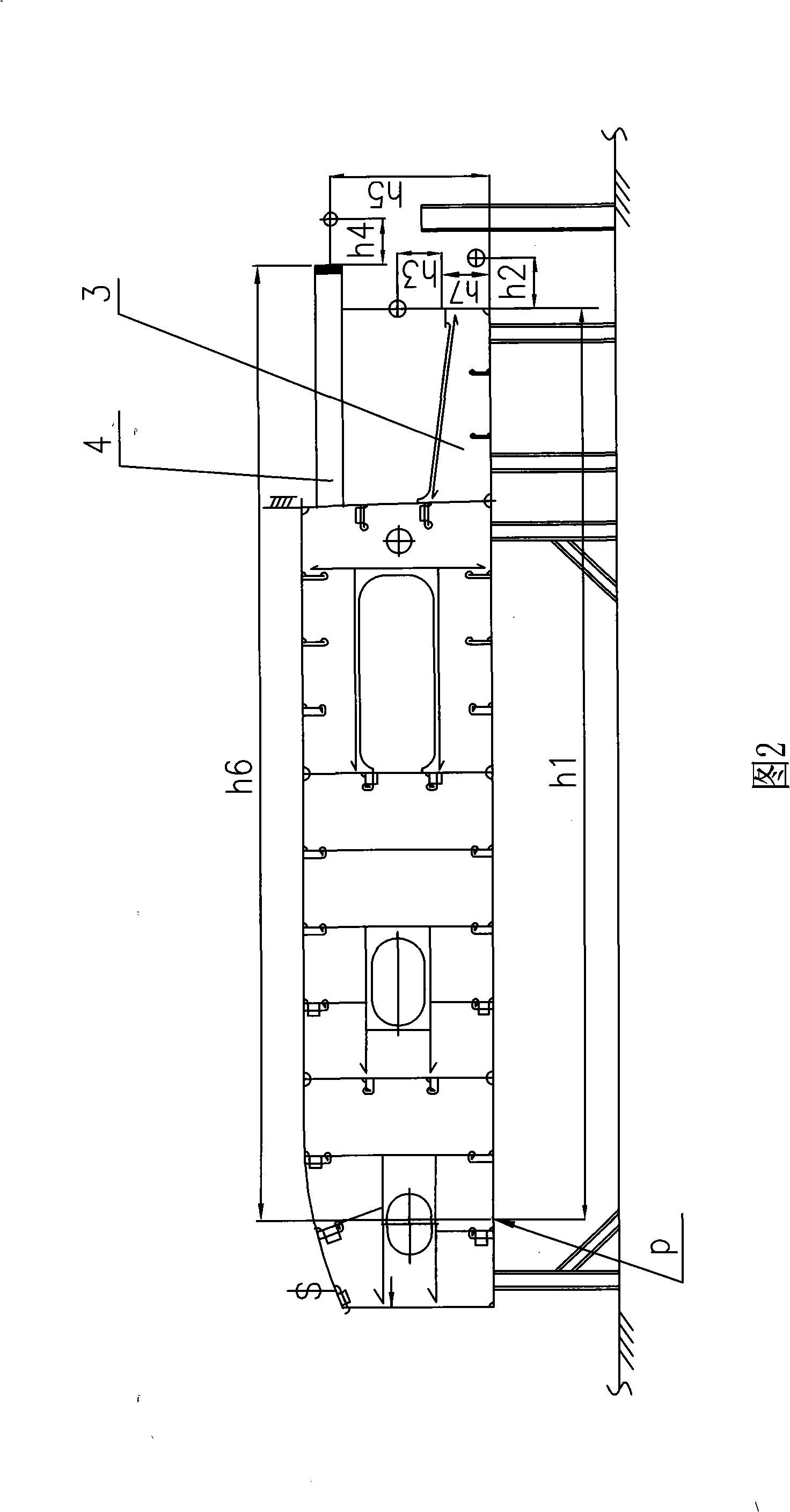

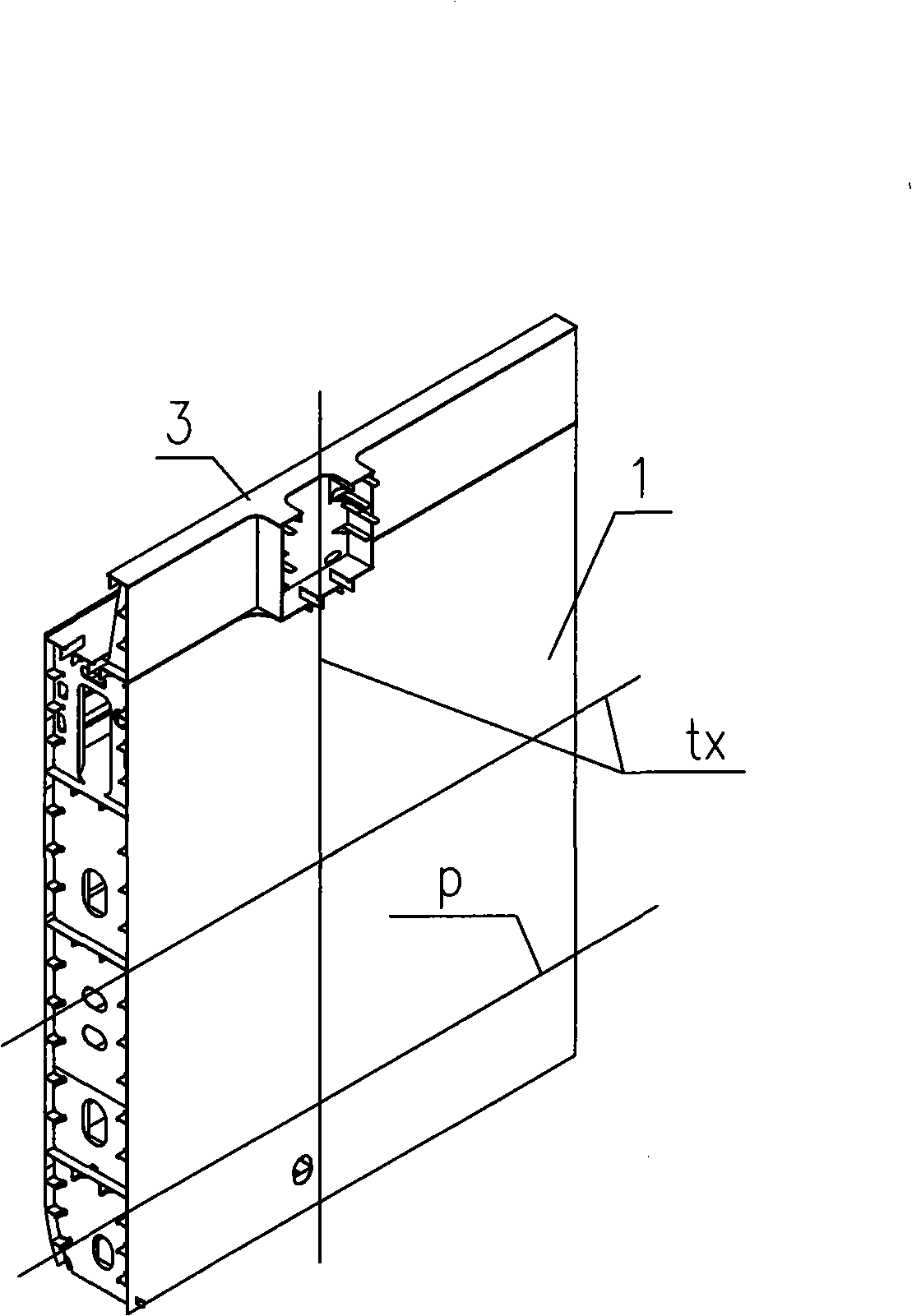

[0013] The present invention changes the construction method of the lower side section of the existing shipbuilding technology, such as Figure 4 Comparing with Fig. 2, it can be seen that the present invention pre-installs the longitudinal hatch coaming 3 and the side stand column 4 in advance in the stage of subsection construction of the side of the ship. So as to achieve the purpose of improving the overall shipbuilding efficiency. In order to achieve the above object, it is necessary to strictly control the assembly accuracy of the longitudinal hatch coaming and the side stand column, for this reason the present invention provides the following scheme:

[0014] First of all, as shown in Figure 1, when the tire frame is manufactured (before welding and assembly), anti-deformation is added to the longitudinal hatch coaming 3 to control the welding deformation, so that the hatch coaming is in a horizontal state after welding, so as to ensure the level degree, straightness. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com