Patents

Literature

52results about How to "Shorten the shipbuilding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

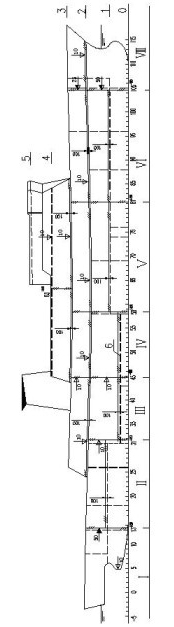

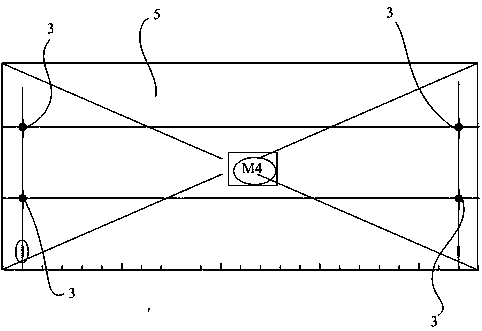

Shipbuilding method

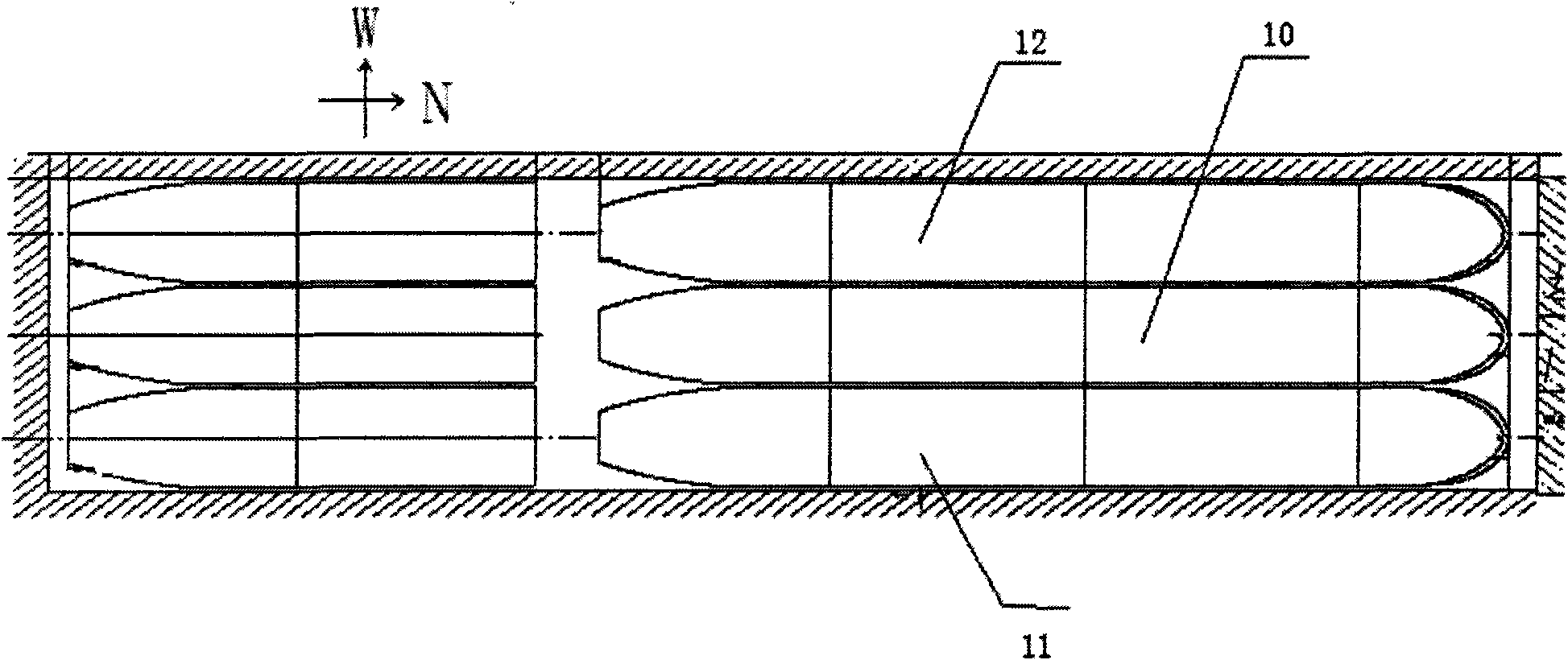

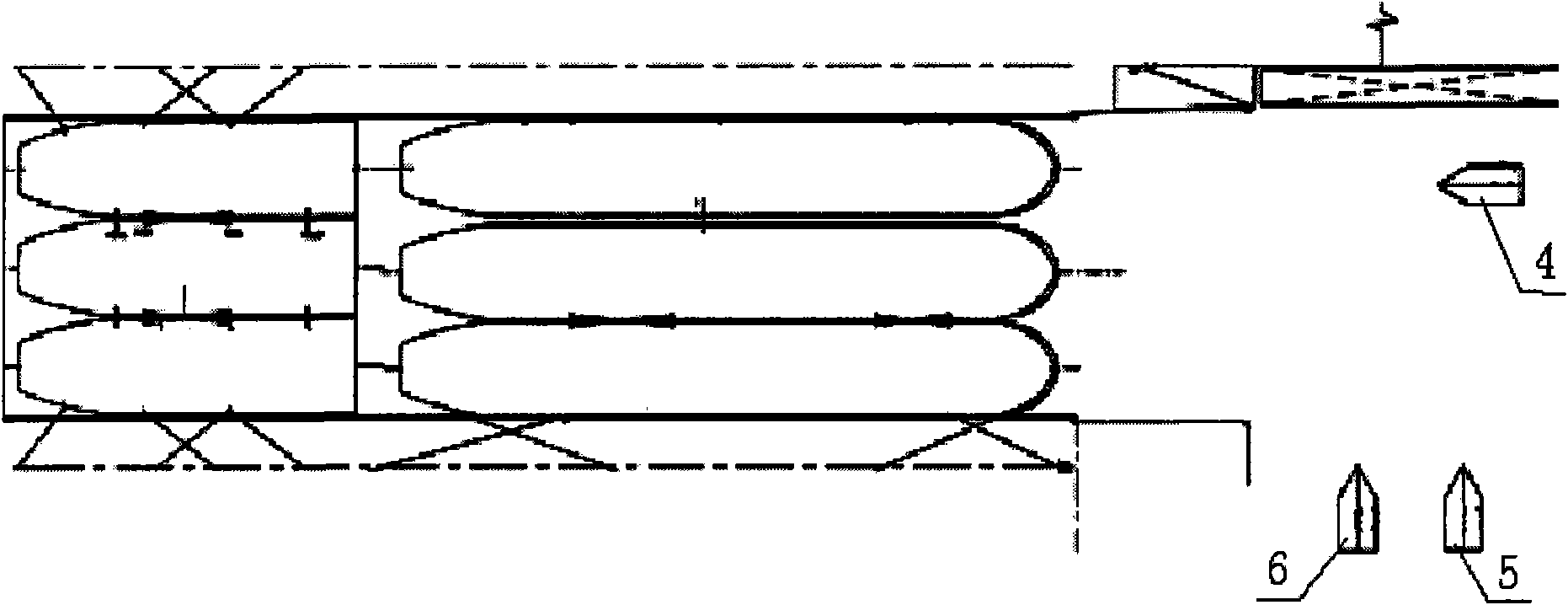

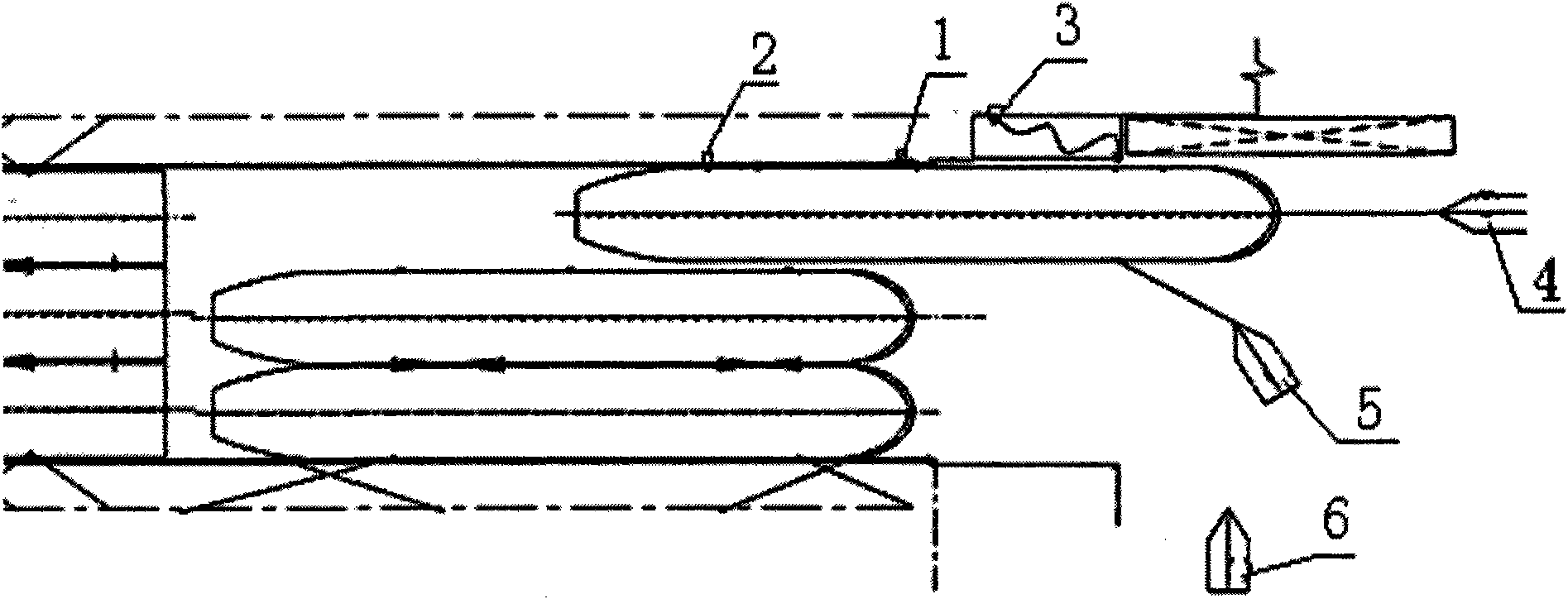

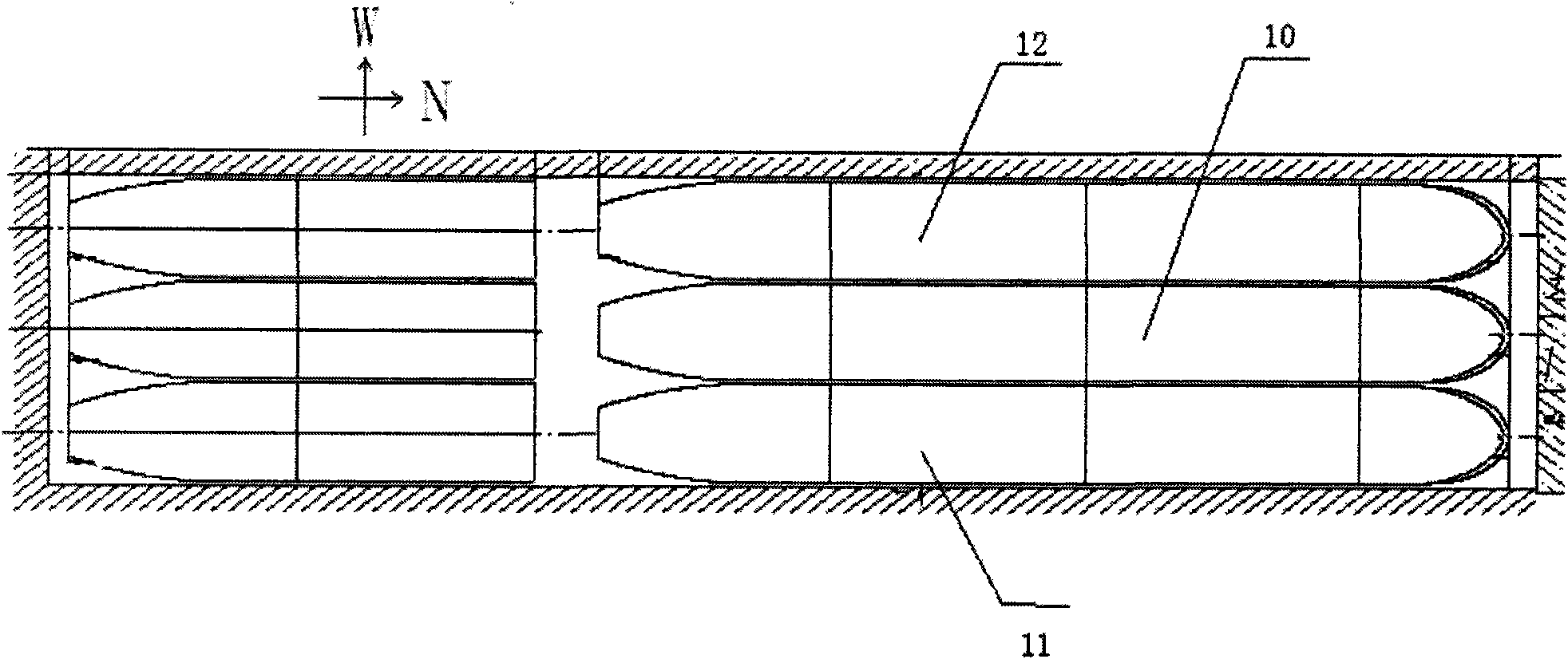

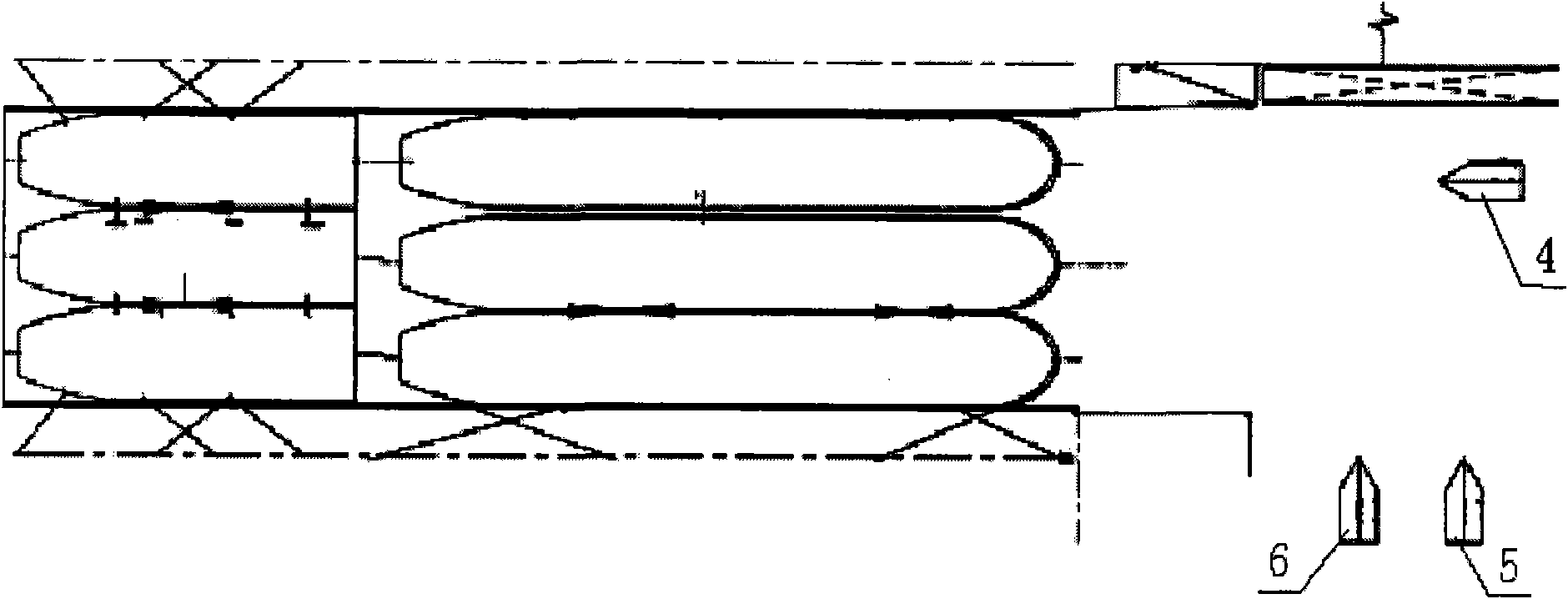

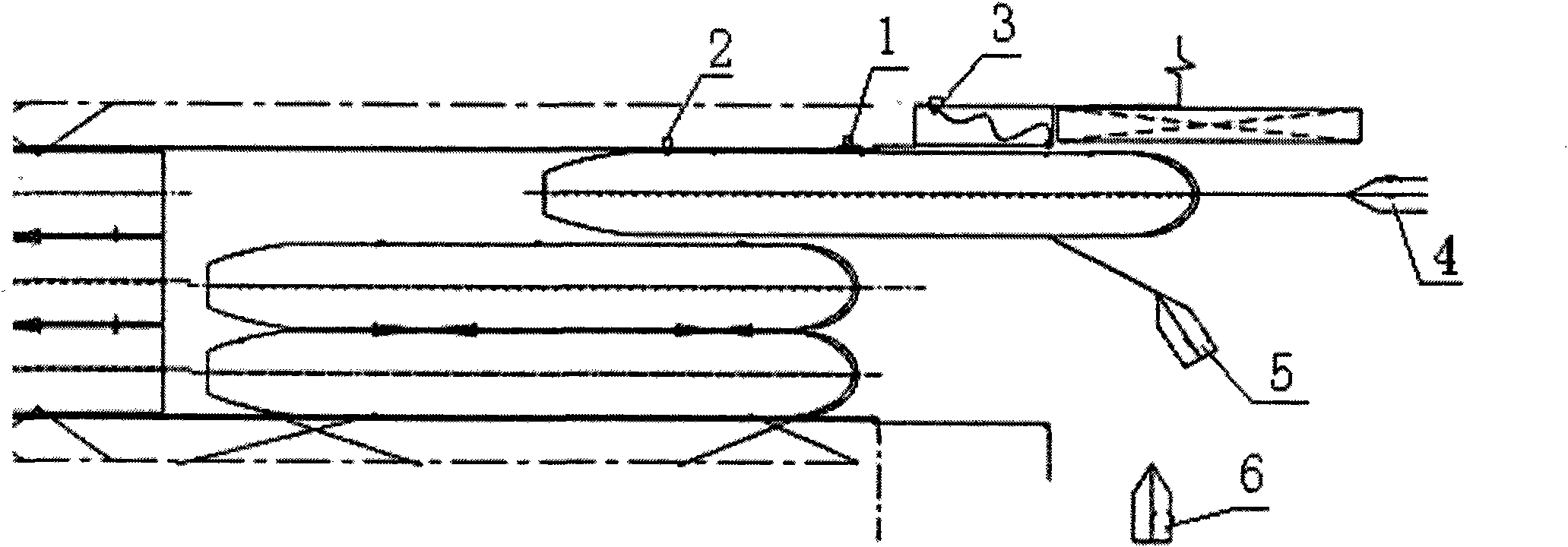

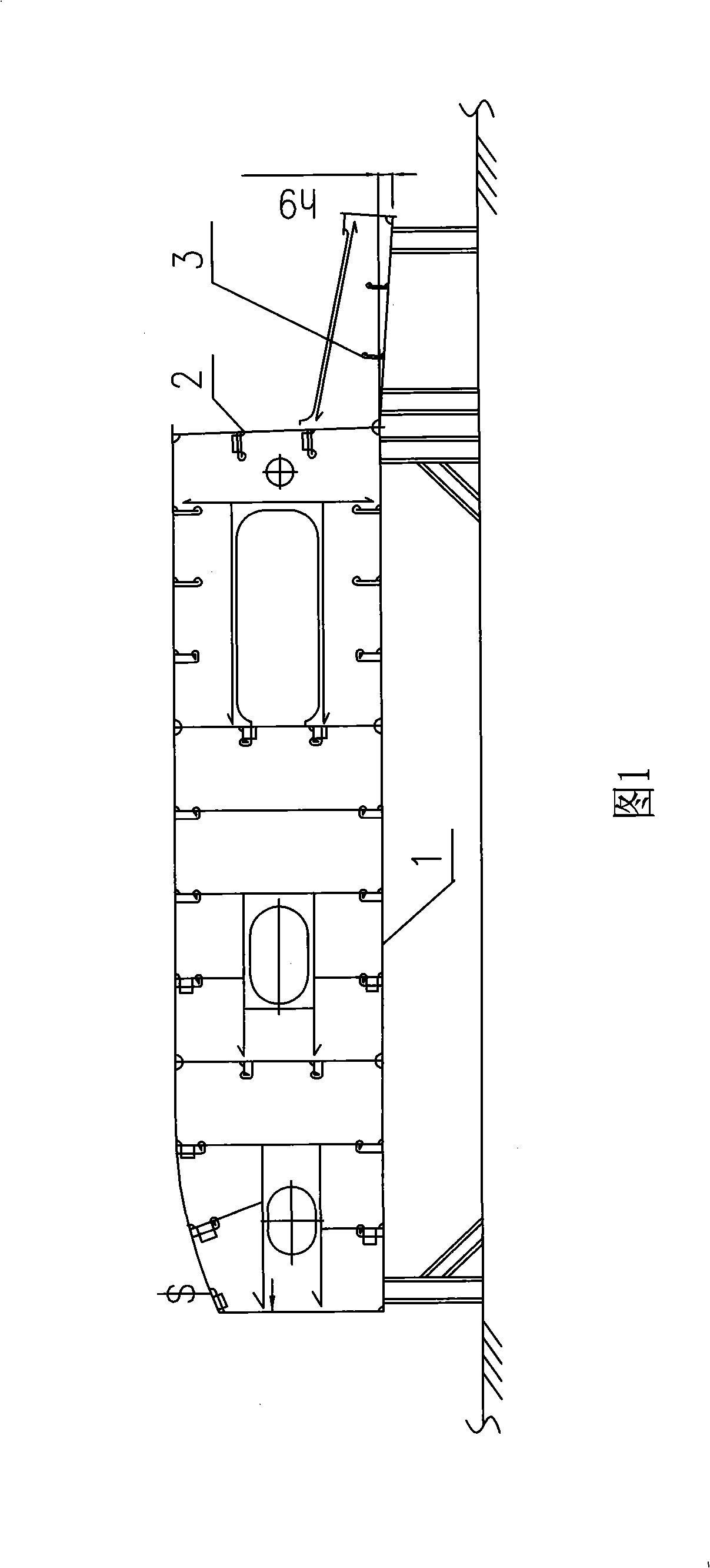

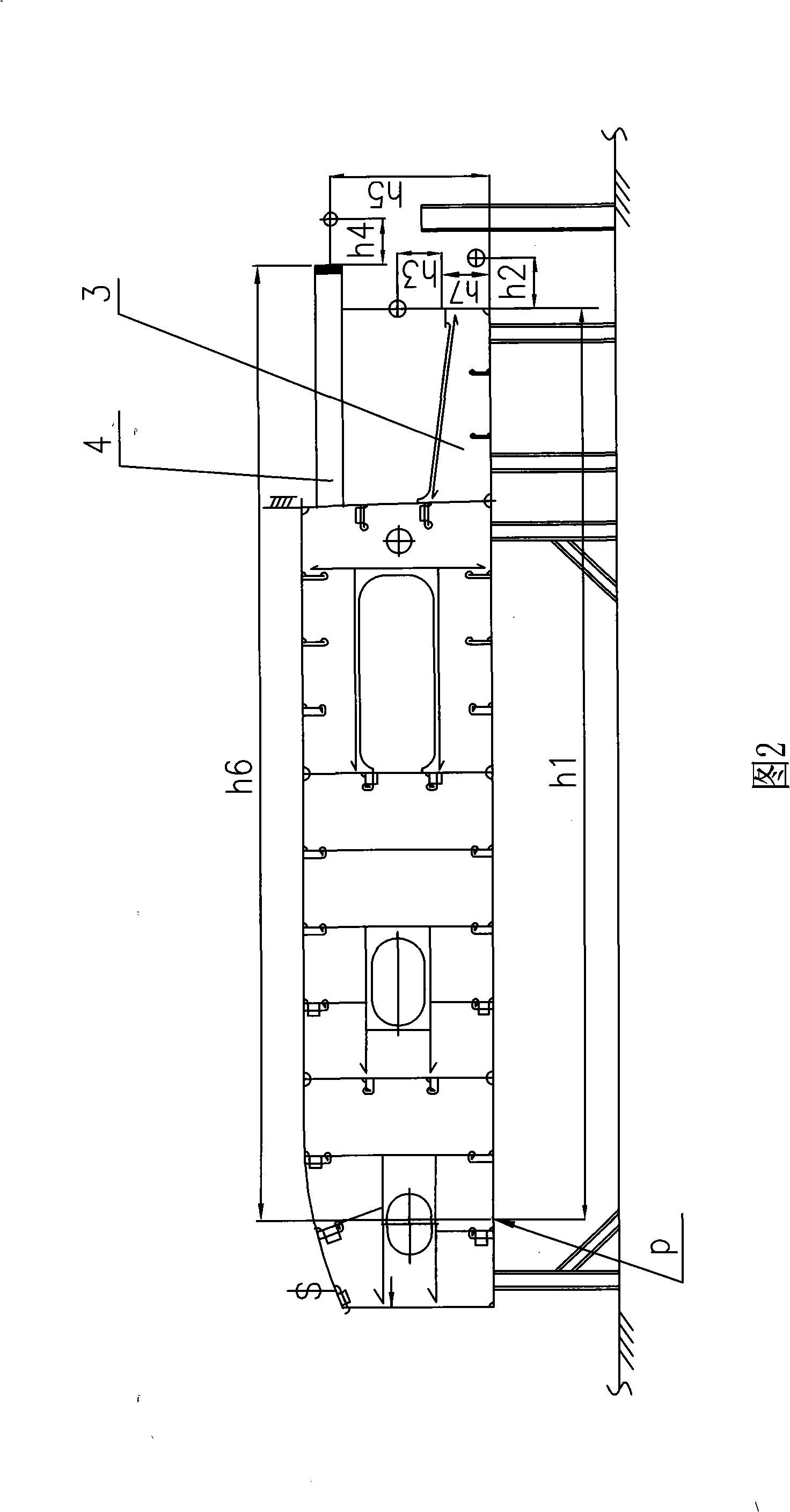

The invention relates to a shipbuilding method, in particular being applied to building a Panama bulk freighter in a dock, and belonging to the technical field of shipbuilding methods. The shipbuilding method comprises the following steps: simultaneously building three whole ships at the front of the dock, wherein the mutual interval among the three ships is 1.2m; simultaneously building three after semi-ships at the back of the dock, wherein the mutual interval among the three semi-ships is 1.2m; folding the three whole ships, driving out of the dock for entering the water, and carrying out underwater operation; after the three whole ships are in the water, moving the three after semi-ships to the front of the dock and keep 1.2m at intervals; and at that time, turning to a building stageof the three whole ships for the three after semi-ships, and carrying out new building of three after semi-ships at the back of the dock. The invention belongs to a 3+3 building method, which furthest utilizes dock resources, improves use ratio of the dock and shortens shipbuilding period in the dock.

Owner:蓬莱中柏京鲁船业有限公司

Method for undock ballasting in ship building

ActiveCN101920771AEffectively expandAchieve precision controlSlipwaysSecondary stageMarine engineering

The invention relates to a method for undock ballasting in ship building, which is particularly applicable to the building of Panamax bulk carrier in a dock and belongs to the technical field of dock building methods. The method is characterized in that: before large dock water injection, first-stage ballasting which comprises tail half ship ballasting and entire ship ballasting by three identical ships is performed; after the large dock water injection, second-stage ballasting which consists of primary large dock water injection, secondary large dock water injection, tertiary large dock water injection and quaternary large dock water injection is performed; and after ship ballasting is finished completely, water is injected into a large dock again till the water is 4.6 to 4.8 meters deep. The undock ballasting method is used in a '3+3 building method', realizes maximum utilization of dock resources, improves the utilization rate of docks and reduces an in-dock ship building period.

Owner:蓬莱中柏京鲁船业有限公司

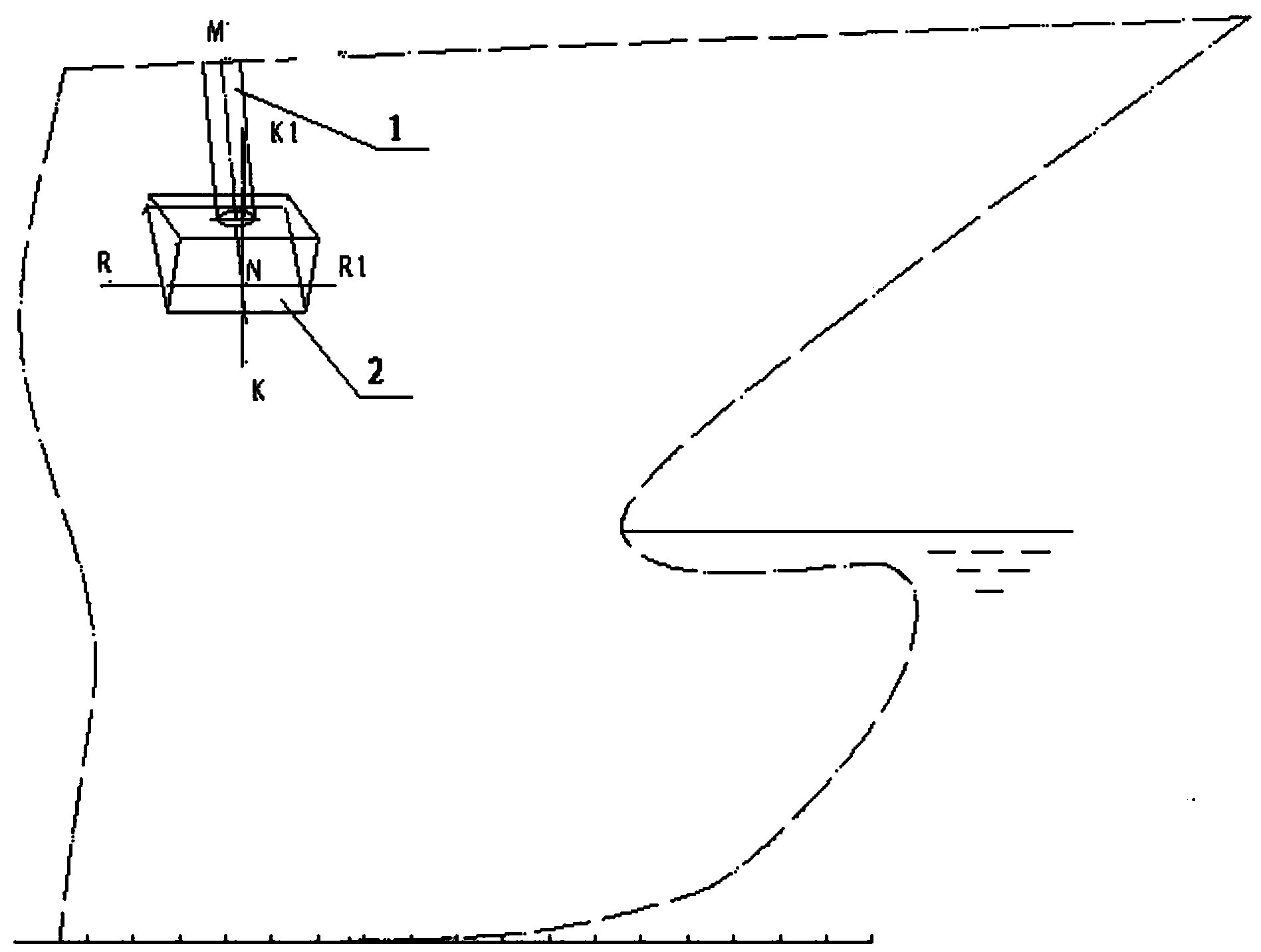

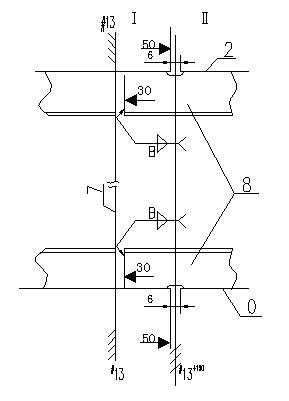

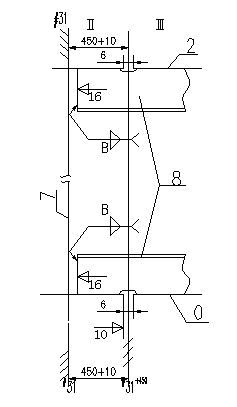

Hidden anchor recess and manufacturing installation technology

InactiveCN103523174ABreakthrough installation accuracy is not highHigh precisionVessel partsMarine engineeringReturned Amount

The invention relates to a hidden anchor recess. Sides of a first elbow plate and a second elbow plate are symmetrically welded at the two sides of an anchor recess side plate. Bottom plates of the first elbow plate and the second elbow plate are welded to an outer plate respectively. One side of a third elbow plate is welded to an anchor recess top plate and the other side of the third elbow plate is welded to the inner side of an anchor chain tube. The first side of a fourth elbow plate is welded to the outer side of the anchor chain tube, the second side of the fourth elbow plate is welded to the anchor recess top plate and the third side of the fourth elbow plate is welded to the outer plate. One side of a fifth elbow plate is welded to an anchor recess bottom plate and the other side of the fifth elbow plate is welded to the outer plate. In an inner field stage, all parts of the hidden anchor recess and the five elbow plates are welded and assembled and the hidden anchor recess is welded to the outer plate at one time in a slipway stage. According to the hidden anchor recess, a plurality of elbow plates are added on the outer side of the anchor recess and the included angles between the anchor recess and other devices are fixed, the sizes of parts are determined at one time and precision of manufacturing the parts is improved. Work of the anchor recess is completed in the inner field in advance instead of being performed in the slipway. Work loads and the waste and return amount of the slipway are reduced, the period of shipbuilding is shortened and shipbuilding cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

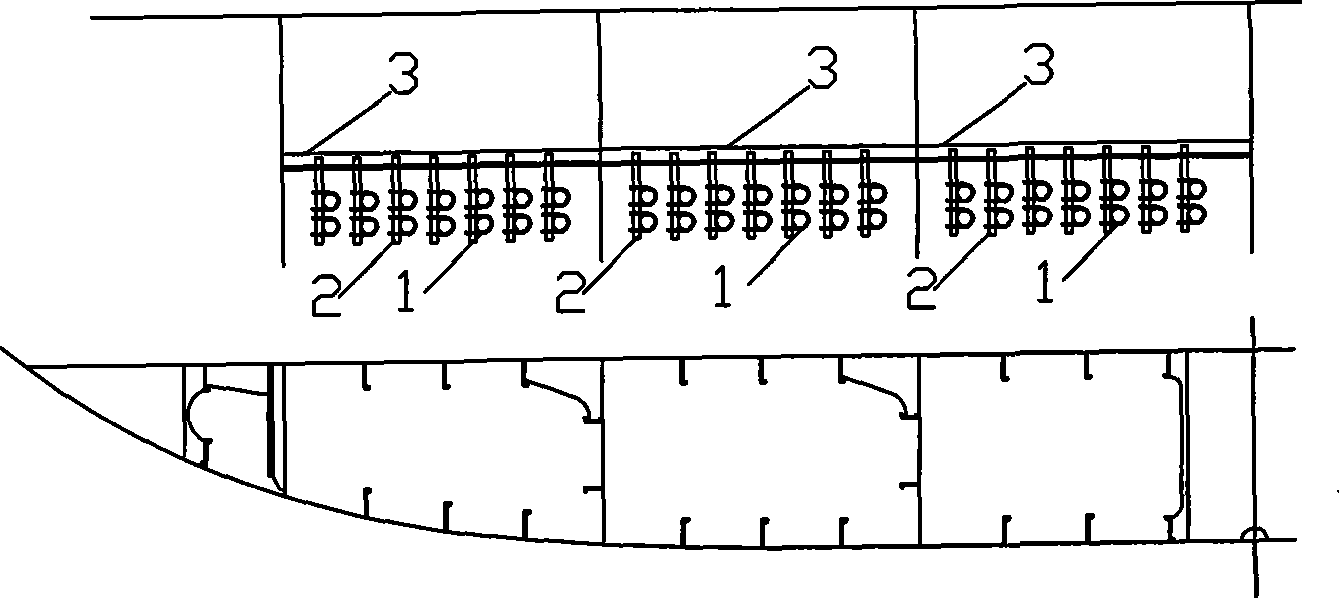

Integrated building method of shipboard subsection in shipbuilding process

ActiveCN101407248ASave assembly timeSave welding timeVessel partsStructural engineeringIntegrated manufacturing

The invention relates to the field of marine engineering, and discloses an integrated manufacturing method for a shipboard segment in shipbuilding. At the stage of manufacturing the shipboard segment, longitudinal hatch coamings and shipboard standing poles are fixed on the shipboard segment by welding respectively. Particularly, before the erecting welding, the longitudinal hatch coamings are reserved with inverse deformation, and the inverse deformation value is 0 to 10mm deviation of the end parts of the longitudinal hatch coamings relative to the vertical wall plane of the inner shell. Therefore, in the method, the longitudinal hatch coamings and the shipboard standing poles are mounted at the stage of manufacturing the shipboard segment, and the method for controlling the mounting accuracy is also provided. Compared with the prior shipbuilding method, the method has the advantages of improving the segmentation integrity, saving the assembling and welding time of the longitudinal hatch coamings and the shipboard standing poles at the building berth (dock) stage and simultaneously saving polishing and painting time.

Owner:DALIAN SHIPBUILDING IND

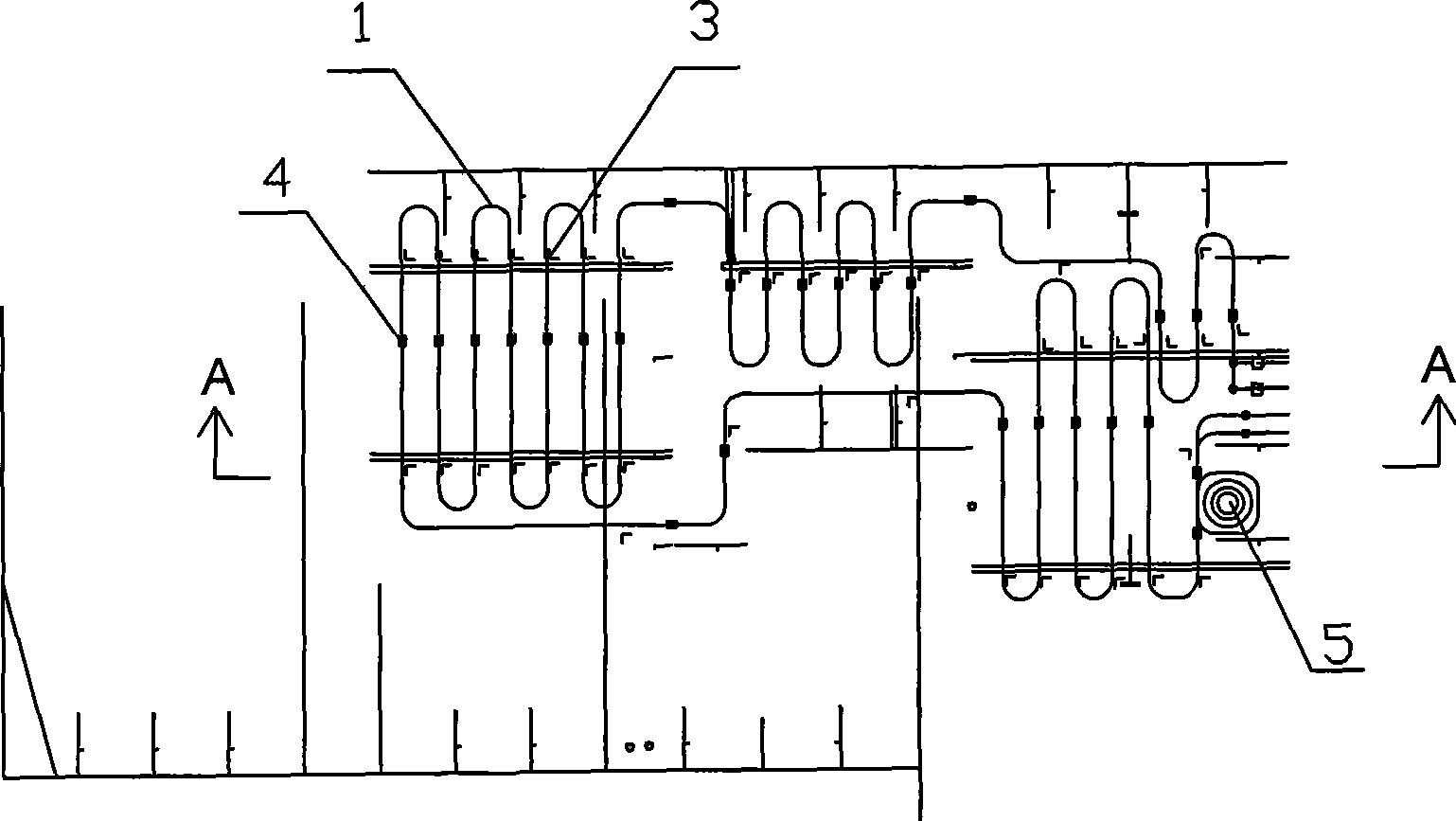

Installation method of steam heating coil for ship oil tanks

InactiveCN101362509AShorten the construction periodSolve the problem of construction weldingAuxillariesVessel ventillation/heating/coolingEconomic benefitsEngineering

The invention discloses an installation method of an oil compartment steam heating coil pipe used for a ship. After the segmenting forming is carried out to the oil compartment, the oil compartment steam heating coil pipe is started to be installed; then the position of a pipe bracket is determined according to the installation coordinate of the oil compartment steam heating coil pipe in a drawing, and the pipe bracket is installed on a special large angle bar for the oil compartment steam heating coil pipe to be preassembled; then a first oil compartment steam heating coil pipe is fixed on the pipe bracket according to the installation coordinate in the drawing, then one end of the second oil compartment steam heating coil pipe is inserted into the connecting sleeve of the first oil compartment steam heating coil pipe and the second oil compartment steam heating coil pipe is fixed on the pipe bracket according to the coordinate, the positioned and installed oil compartment steam heating coil pipes are fixed on the connecting piece of the connecting sleeve by dot welding, and the other oil compartment steam heating coil pipes are installed in sequence; and finally the pipe bracket and the connecting sleeve are welded. The installation method has the advantages of regular and artistic appearance, convenient installation and inspection, environmental protection, and good economic benefit.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

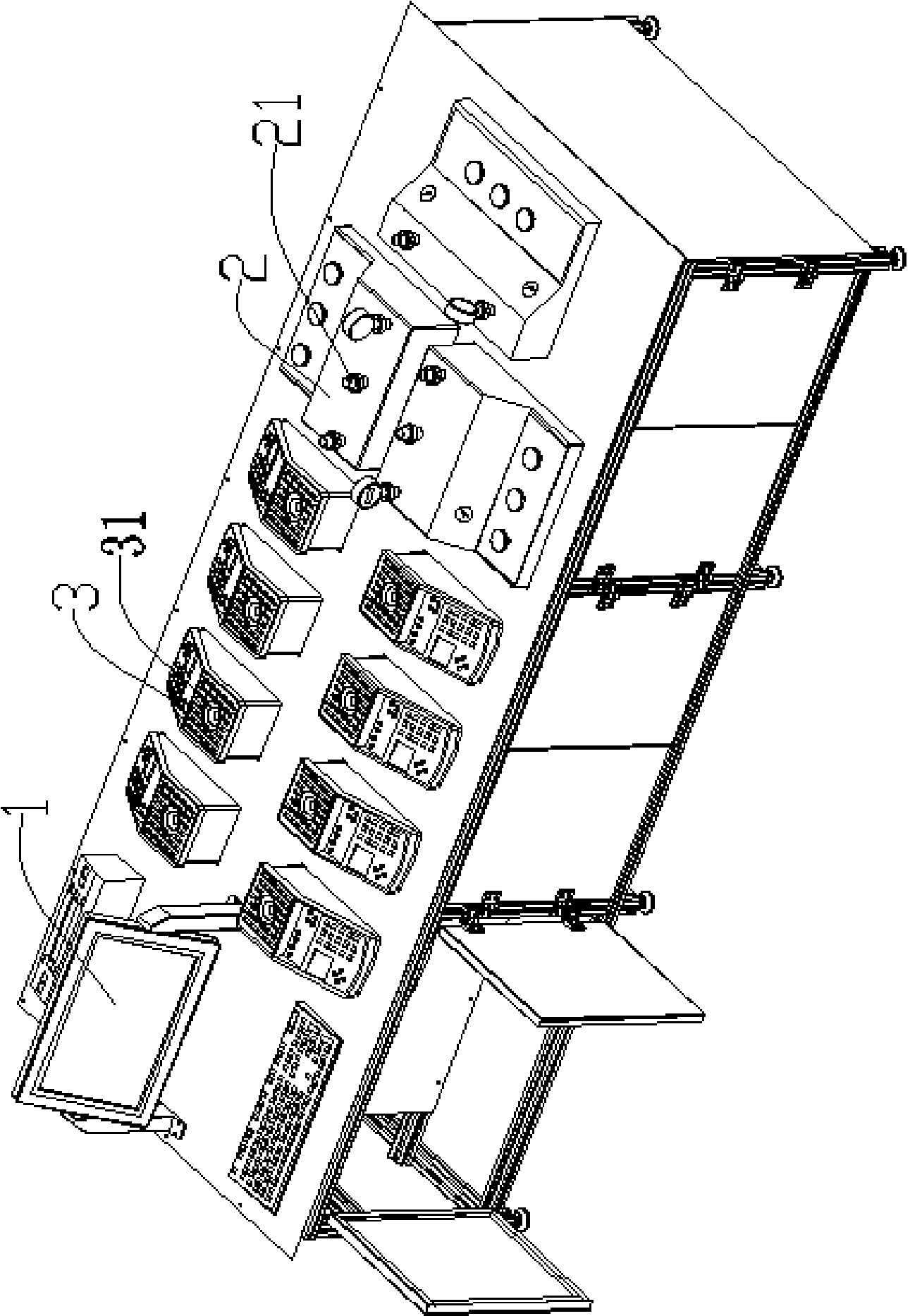

Comprehensive test-bed

ActiveCN101545820AImprove the operating environmentImprove verification efficiencyTesting/calibration apparatusFluid pressure measurementElectrical resistance and conductanceTransducer

A comprehensive test-bed comprises a computer which is connected with a pressure check meter and a temperature checking groove through the serial / parallel port of a multi-serial card and connected with a PLC controller through a data line. The PLC controller comprises a digital quantity input module, a current analog input module, a thermo-electric couple input module, a thermal resistor input module and a controller, checks a pressure transmitter, a level transducer, a thermo-electric couple sensor, a thermal resistor sensor, an switching value pressure sensor and an switching value temperature sensor and checks out the plural sensors in batch with high checking efficiency and good operation environment.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Technology for reducing allowance cutting during ship building

The invention relates to a technology for reducing allowance cutting during ship building. In the technology, a hull is firstly divided into a plurality of general sections for building; and the general sections are gathered up. The invention is characterized in that in the step of lofting and baiting of parts, section allowance, slipway allowance, compensation dosage and material cutting are additionally and respectively placed once on a deck, a strake, a longitudinal bone, a rib, an enforced bone, a wall plate and other structures of each typical node according to section splicing or section butt joint and other different forms; in the step of the whole building of the general sections, when the joint of one of two general sections is provided with a transversal bulkhead, the two general sections adopt a splicing form, and the general section without the transversal bulkhead is inserted with the general section with the transversal bulkhead for carrying out sintered ceramsite liner welding; and when the joint of the two general sections are not provided with the transversal bulkhead, the two general sections adopt a sintered ceramsite liner welding butt joint form. The invention can determine the size of parts once, and improve the precision of parts manufacturing, thereby avoiding on-site secondary cutting quantity, and providing guarantee for general section construction; and the procedures are shifted forward, thus reducing slipway working capacity and waste backflow volume, shortening building ship period and reducing building ship cost.

Owner:WUCHANG SHIPBUILDING IND

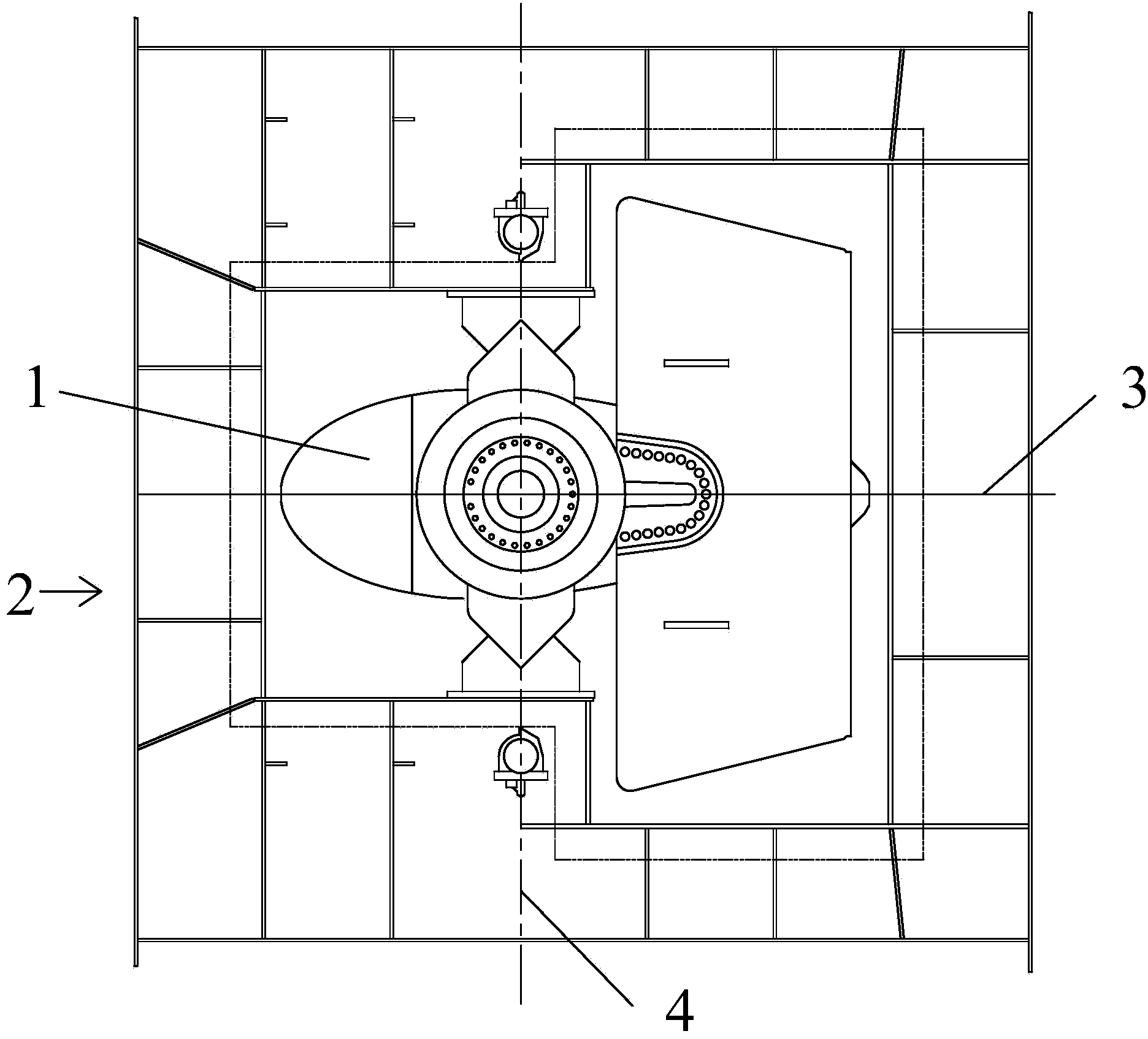

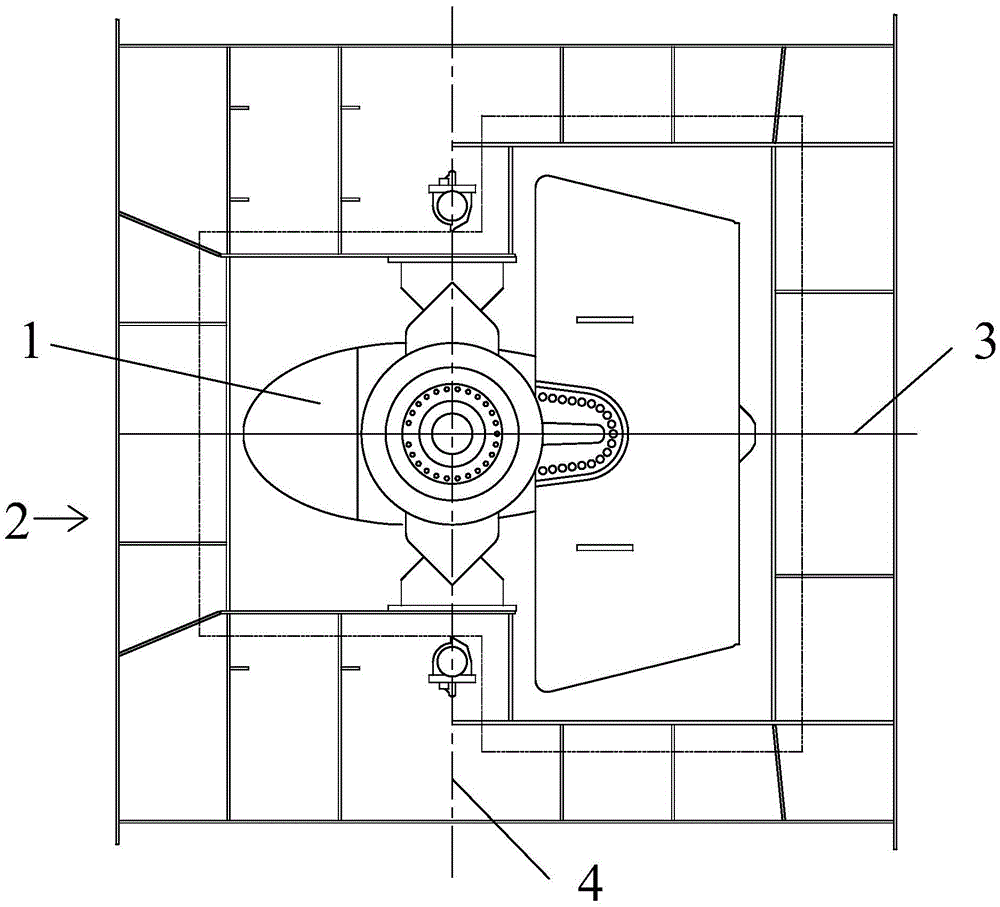

Method for installing telescopic full-rotation auxiliary thruster

InactiveCN103963919AShorten the shipbuilding cycleImprove build qualityVessel partsAerospace engineeringPosition line

The invention discloses a method for installing a telescopic full-rotation auxiliary thruster. The method includes the following steps of firstly, fixing a ship body in a segmented mode, drawing out a midship line and a rib position line, and removing obstacles; secondly, hanging the thruster to the installation position so that the distance between the bottom of the thruster and the plane of a base at the installation position can range from 30 mm to 35 mm; thirdly, adjusting the levelness and perpendicularity of the thruster and fixing the thruster; fourthly, fixing a guide part so that the numerical value of a gap between a guide frame of the thruster and the guide part can be smaller than 1mm; fifthly, marking the installation position with a positioning mark, recording positioning data, and then hanging the thruster away; sixthly, installing accessories at the installation position; seventhly, hanging the thruster to the installation position again, and fixing the thruster according to the positioning data. According to the method, the segmented internal pre-assembly and two-time installation method is adopted, the ship manufacturing cycle is shortened, installation accuracy of the thruster is ensured, the use requirement of the thruster is met, and ship building quality is improved.

Owner:SHANGHAI SHIPYARD

On-sea alignment and assembly method for huge blocks of hull

InactiveCN108557007ASolve the problem that the large size cannot be folded and carriedSave resourcesVessel designingKeelEngineering

The invention provides an on-sea alignment and assembly method for huge blocks of a hull. The method includes the steps of carrying out simulated assembly of the huge blocks; setting assembly locatingreferences on the huge blocks; carrying out floating-state adjustment on each huge block, wherein the draft of each huge block is adjusted to make the drafts of the huge blocks nearly uniform; carrying out on-sea alignment and assembly, wherein with one huge block as a reference block, one huge block is drawn towards the reference block, the huge block and the reference block are located throughlocating assemblies arranged on the huge block and the reference block, the assembly precision is detected through a detector, an underwater welding seam between the huge block and the reference blockis inspected at the same time, and on-water parts of the huge block and the reference block are welded after the huge block and the reference block are located; carrying out docking, wherein the assembled block is pulled into a dock through a pulling device, and after draining, lying on a keel block and locating, underwater remaining parts are assembled and welded. The method solves the problem that due to the large size of existing huge blocks, the huge blocks cannot be assembled in the same factory.

Owner:QINGDAO SHIPYARD

Method for designing asymmetric hull outer panel tyre frame

ActiveCN107985503AAvoid negligenceAvoid the build processVessel designingEngineeringBuilding construction

The invention discloses a method for designing an asymmetric hull outer panel tyre frame. The method includes the steps of S10, establishing models of a left outer panel seam and a left frame materialof an asymmetrical molded line area of a segment respectively to obtain a left outer panel seam model and a left frame material model, and establishing models of a right outer panel seam and a rightframe material of the asymmetrical molded line area respectively to obtain a right outer panel seam model and a right frame material model; S20, generating a left outer panel model according to the left outer panel seam model and a left outer panel molded line respectively, combining the left outer panel model and the left frame material model to obtain a left outer panel frame model, generating aright outer panel model according to the right outer panel seam model and a right outer panel molded line respectively, and combining the right outer panel model and the right frame material model toobtain a right outer panel frame model; S30, obtaining a left tyre frame model and a right outer panel tyre frame model according to the left outer panel frame model and the right outer panel frame model respectively. The method can be applied to the construction of the asymmetric hull outer panel tyre frame.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Integrated land leveling construction method for translation type hatch cover system of large ocean-going bulk cargo ship

InactiveCN110877677AImprove work efficiencyMeet the requirementsWaterborne vesselsBulk cargoLine tubing

The invention discloses an integrated leveling construction method for a translation type hatch cover system of a large ocean-going bulk cargo ship. The integrated leveling construction method comprises the following steps: 1, manufacturing a special jig frame on a foundation flat ground; 2, splicing a hatch coaming steel structure on the special jig frame, 3, pre-assembling a hydraulic power pipeline and a cable system on the foundation flat ground, 4, installing the hatch cover on the hatch cover steel structure; 5, installing a reinforcing plate on the hatch cover system, hoisting the hatchcover system to a deck to be assembled, assembled and welded, and fixing a pre-assembled hydraulic power pipeline and a cable system to the hatch cover system and the deck through clamping sleeves. The construction environment coefficient, the construction safety coefficient, the construction production efficiency and the productivity are all improved. A great effect is achieved on preassembly maximization of modern shipbuilding enterprises, the shipbuilding period is shortened, the process precision is guaranteed, and the requirements of ship inspection and shipowners are met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

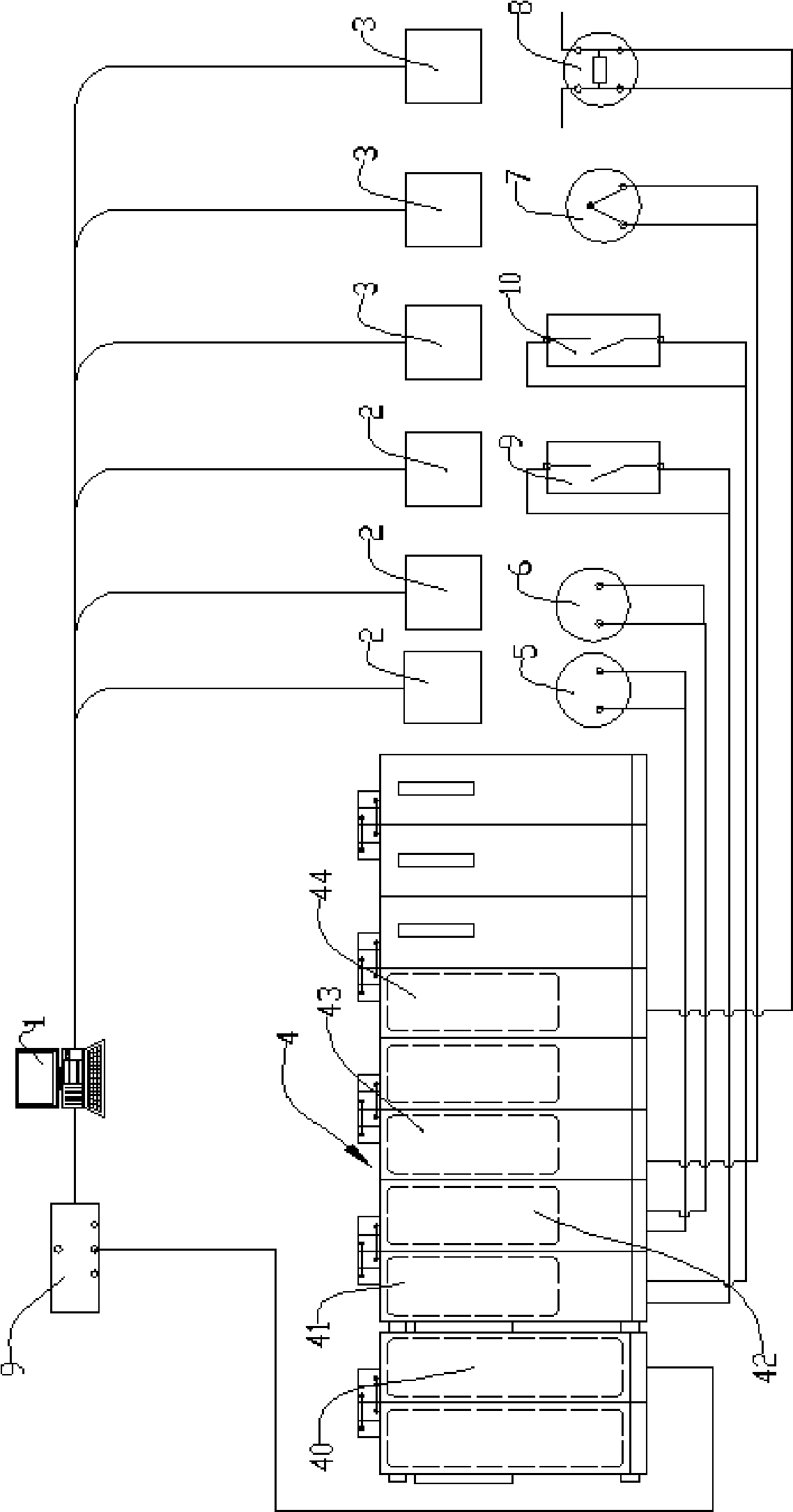

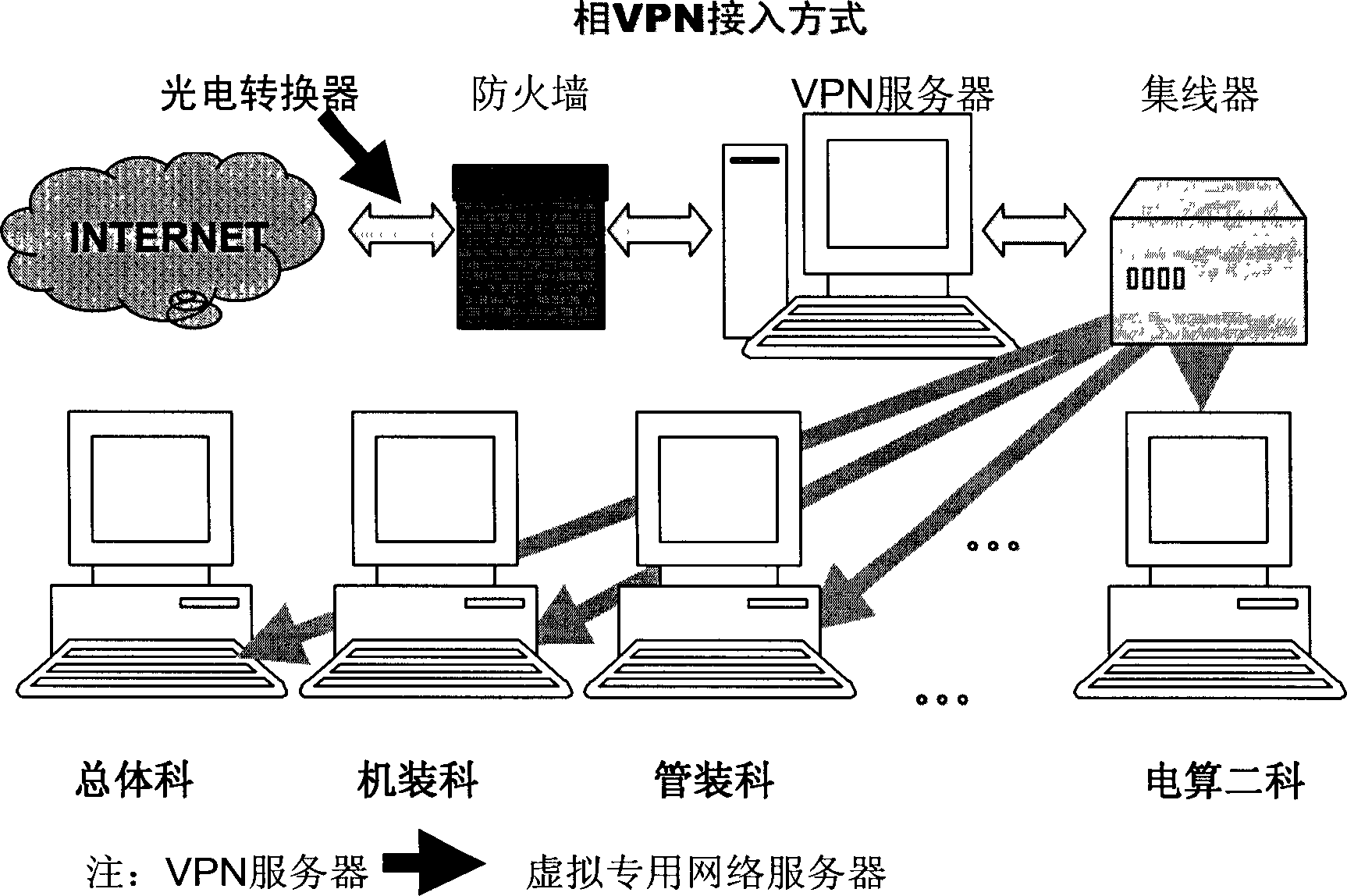

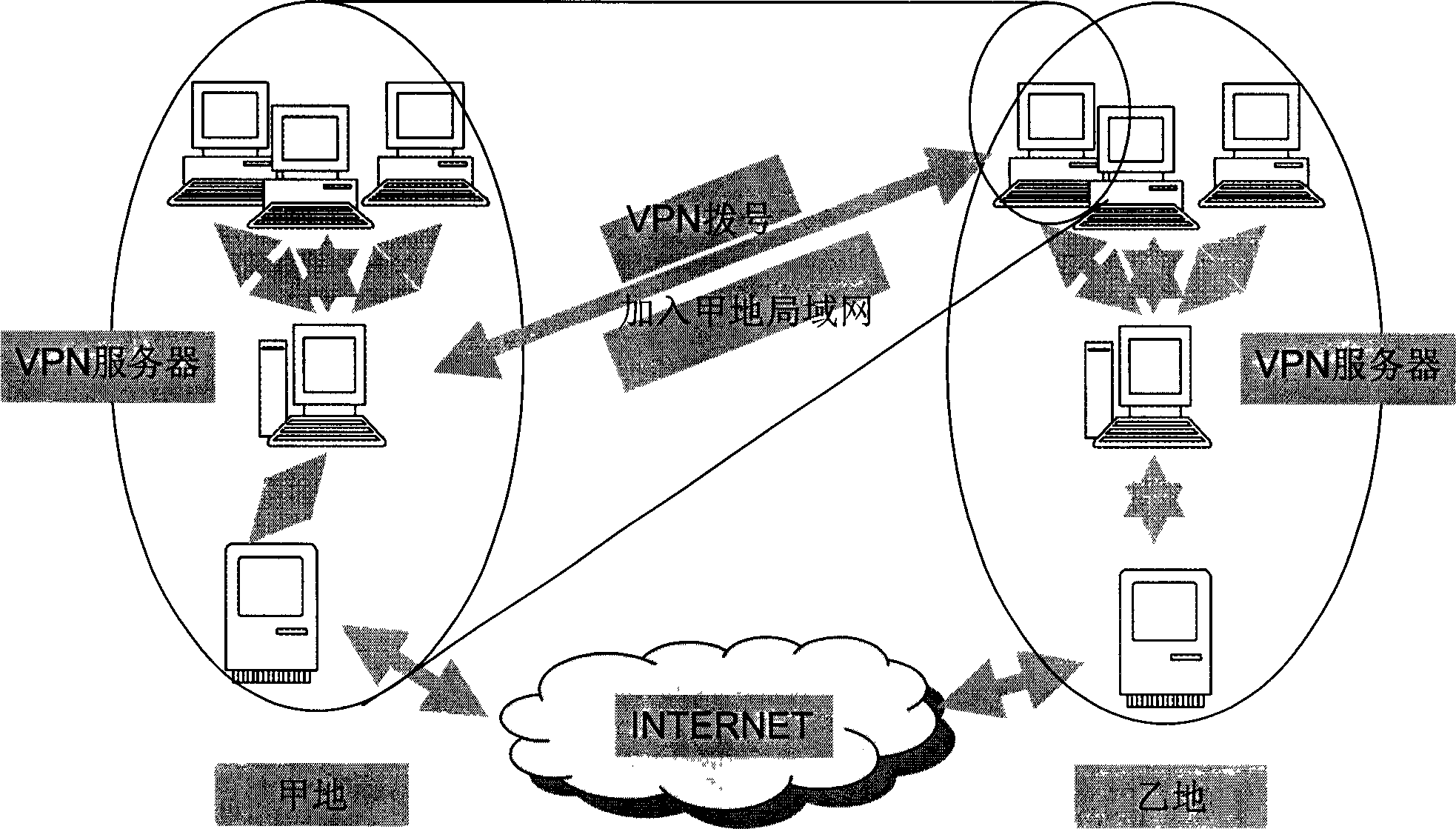

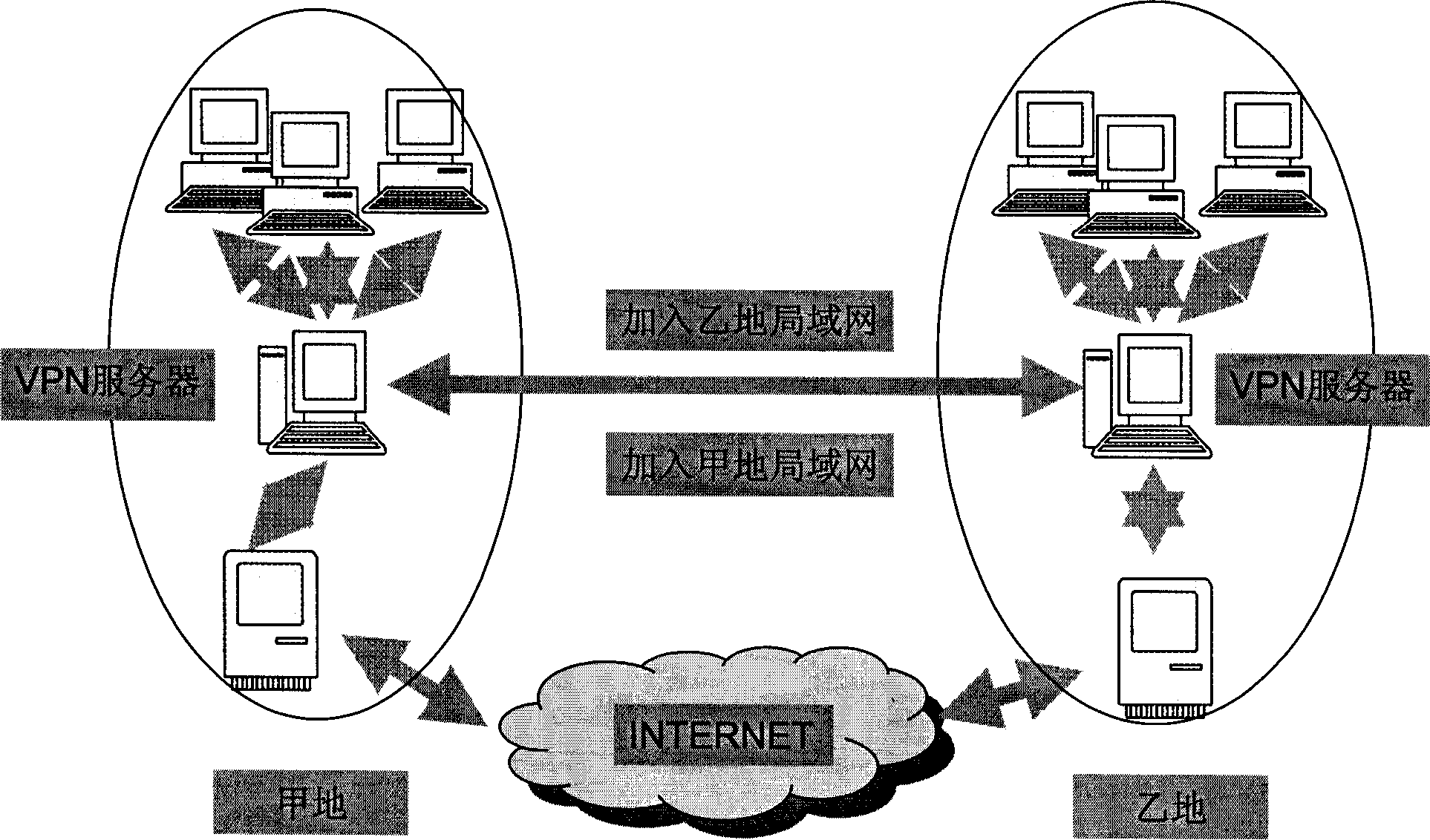

Remote cooperation design technique for civil ship

InactiveCN1629846AShare human resourcesShorten the shipbuilding cycleSpecial service provision for substationNetworks interconnectionDesign technologyShort-SHIP

Civil ship for distance associated design technology characterizes in solving the design of resource allocation first, two-way usage of database, namely, share of license is realized by setting up VPN, setting up agent servers, allocating network virtual server VPN and far distance LAN to reach the aim of entering into Internet, sharing of database and accessing far distance database and coordinating design contents and programs. The advantage is: 1, sharing hardware and software resources, 2, sharing man power resources 3, shorting ship-making period, 4, increasing design quality.

Owner:BOHAI SHIP HEAVY IND CO LTD

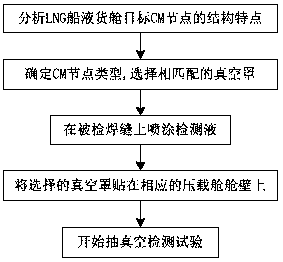

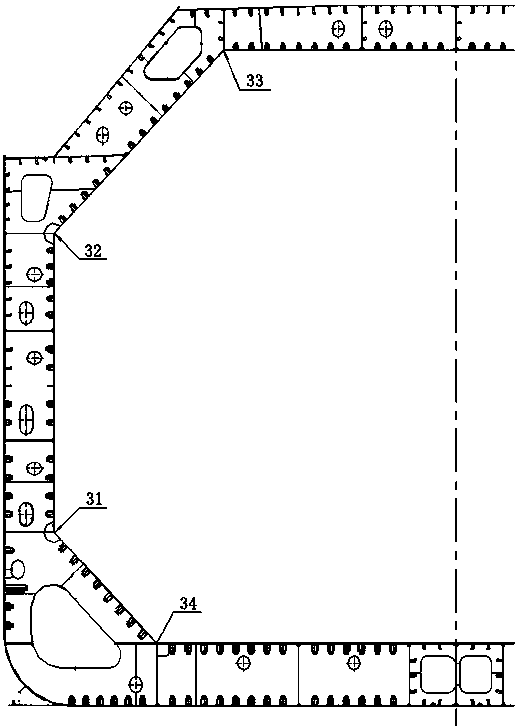

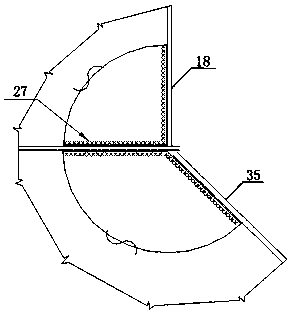

Airtightness detection method of CM node area of liquid cargo tank of LNG ship

InactiveCN108020380AFast tightness testConvenient and effective leak detectionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateMarine engineeringBallast tank

The invention discloses an airtightness detection method of a CM node area of a liquid cargo tank of an LNG ship. The method comprises: a structural characteristic of a target CM node of a liquid cargo tank of an LNG ship is analyzed; on the basis of the structural characteristic of the target CM node, a CM node type is determined and a matched vacuum cover is selected based on the CM node type; and detection liquid is sprayed on a detected weld joint, the selected vacuum cover is in close contact with a corresponding ballast tank wall, and then vacuumization detection is started. According tothe invention, while related ship structures of the ballast tank do not form a complete tank, airtightness detection is carried out on the CM node area quickly and conveniently, so that time is earned for follow-up construction of the LNG ship containment system and the construction period of the LNG ship is shortened. Moreover, the CM node can be detected at the forming process of any construction stage like the segmentation stage and the main stage and restrictions on the construction state, the segmentation placing state, and the welding mode are eliminated.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

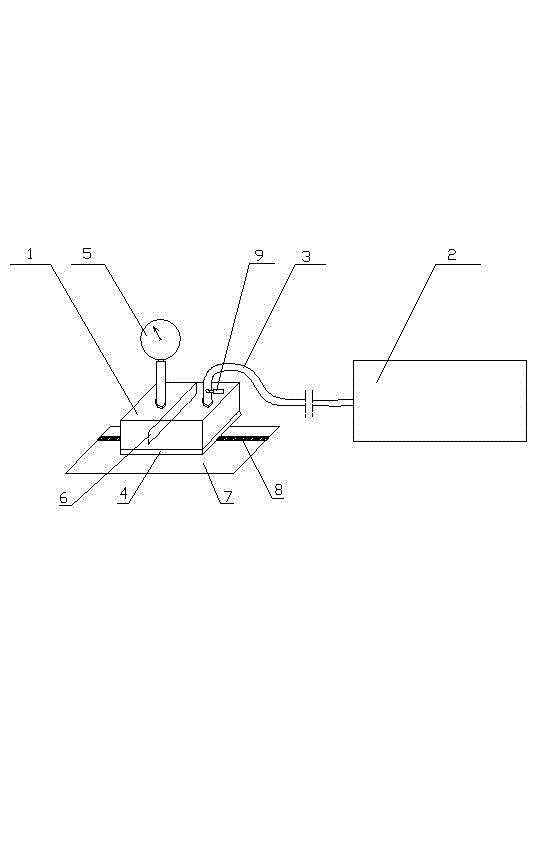

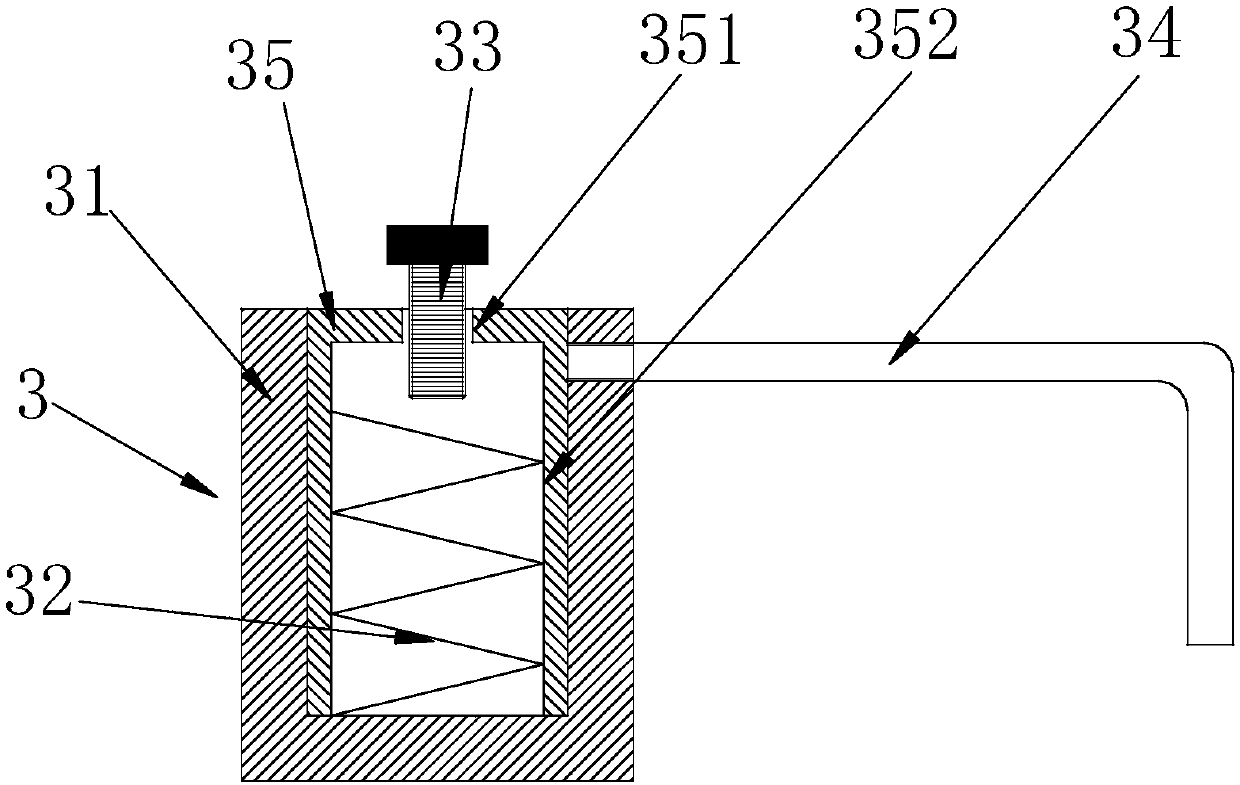

Weld joint tightness detecting device for ship under construction

InactiveCN102721513AFew stepsUndamagedDetection of fluid at leakage pointTime-ConsumingBuilding construction

The invention relates to shipbuilding, and provides a weld joint tightness detecting device for a ship under construction. The weld joint tightness detecting device aims to solve technical problems that an existing weld joint tightness detecting mode for a ship under construction is labor-consuming and time-consuming, and production cycle of the ship is prolonged. The weld joint tightness detecting device for the ship under construction comprises a weld joint covering box and a vacuumizing device which are connected by a pipeline. The weld joint tightness detecting device is characterized in that the weld joint covering box consists of a cover plate and at least two welded surface support plates fixedly connected to edges of the back of the cover plate, the welded surface support plates are arranged on the back of the cover plate, and a sealed space is formed by the cover plate, welded surfaces and the welded surface support plates after the cover plate and the welded surface support plates contact with the welded surfaces with a weld joint. The weld joint tightness detecting device is reasonable in structure and convenient to use, and can test tightness of weld joints which have different shapes and are located at different positions.

Owner:HUANGHAI SHIPBUILDING

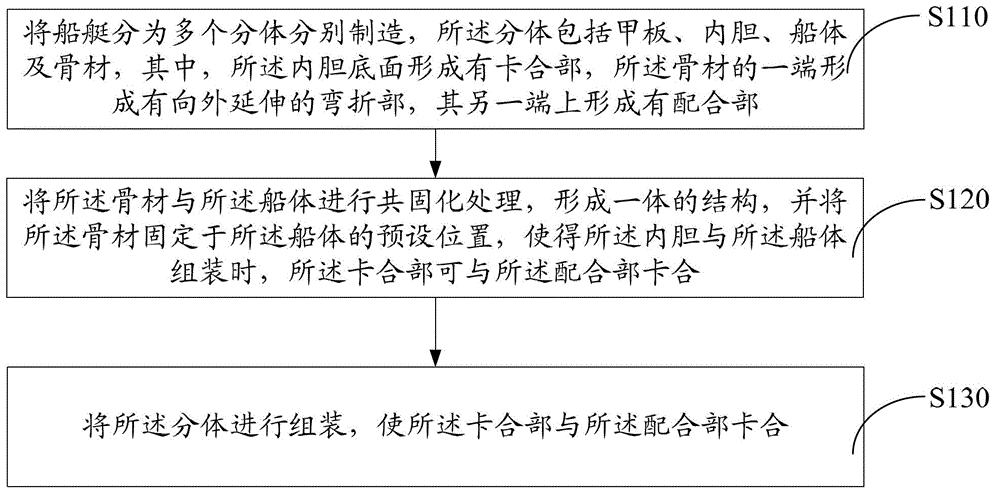

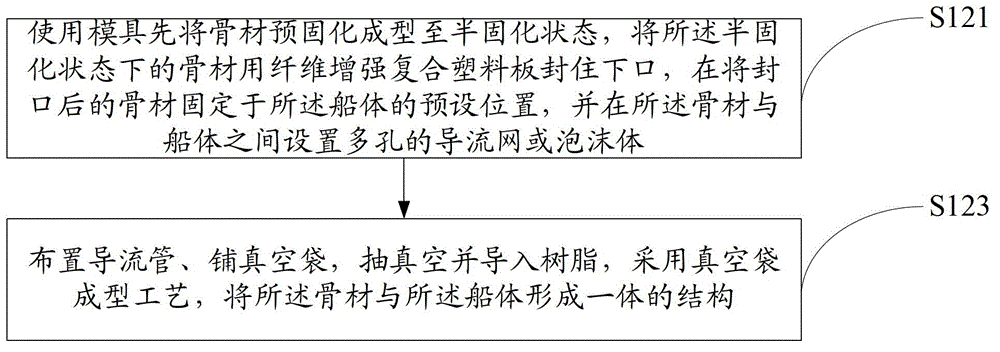

Manufacturing method of ship and ship manufactured by using same

The invention discloses a manufacturing method of a ship. The ship is manufactured by respectively a plurality of split bodies, each split body comprises a deck, an inner container, a ship body and a skeleton, wherein a clamping part is formed on the bottom surface of the inner container; a bending part which extends outwards is formed at one end of the skeleton; a matching part is formed at the other end of the skeleton; the skeleton is commonly cured at a preset position of the ship body, so that the clamping part can be clamped with the matching part when the inner container and the ship body are assembled; and the split bodies are assembled to clamp the clamping part and the matching part. Because the position of the skeleton on the ship body is determined based on the calculation, only the clamping part is clamped with the matching part when the inner container and the ship body are assembled, and the complicated manual positioning is avoided. In addition, when the skeleton and the ship body are cured together, the contact area of the skeleton and the ship body is increased by the bending part. By adopting the manufacturing method of the ship, the shipbuilding efficiency can be improved, the shipbuilding period is shortened, and the structure strength of the ships can be enhanced; and in addition, the invention also provides the ship manufactured by using the method.

Owner:SHENZHEN HISPEED BOATS TECH

Rudder propeller double-layer damping device and design method thereof

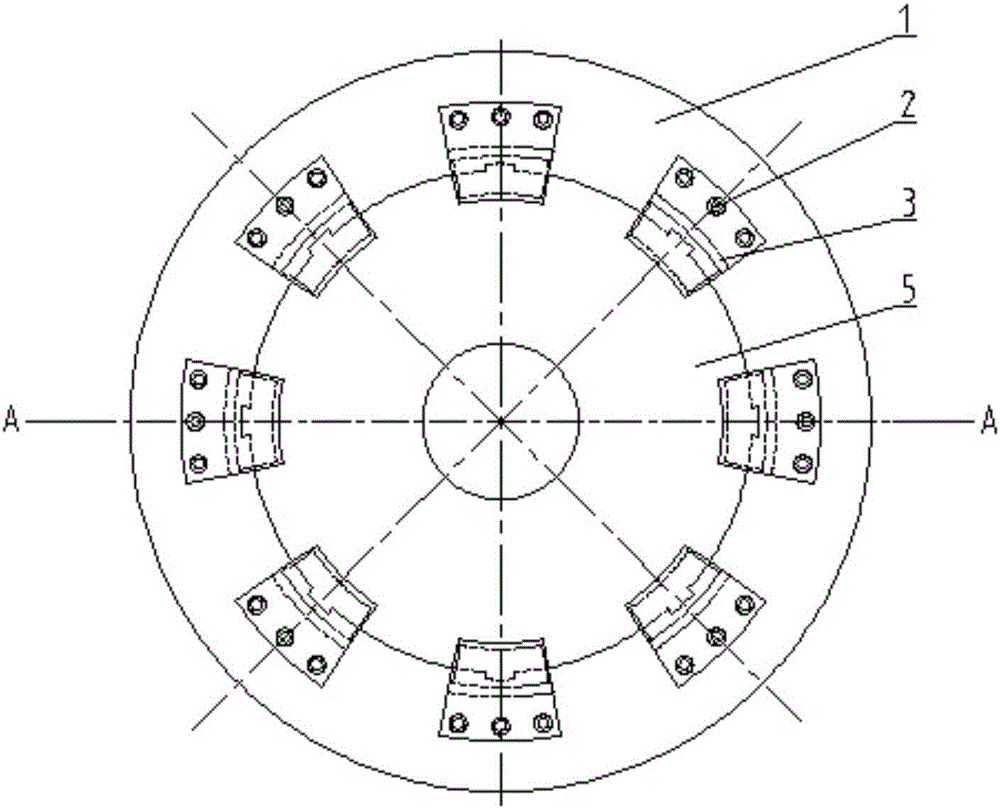

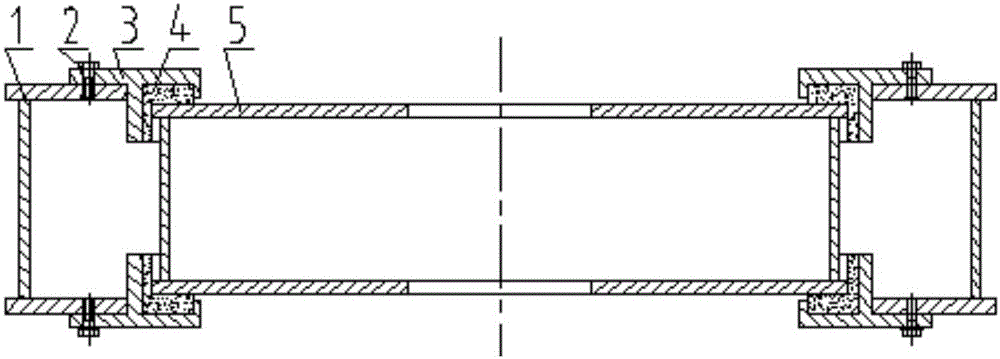

ActiveCN106114797ASmall amount of deformationLower natural frequencyPropulsion power plantsVessel designingPropellerEngineering

The invention discloses a rudder propeller double-layer damping device. The rudder propeller double-layer damping device comprises an installation rack of the rudder propeller device, a plurality of damping blocks which have three-way stiffness and are uniformly arranged along the periphery of an upper panel and the periphery of a lower panel of the installation rack, damping block cover shells which are used for fixing the damping blocks and achieving a limiting effect on the rudder propeller device, a base structure for installing the damping block cover shells and the like. According to the rudder propeller double-layer damping device, vibration in the perpendicular direction, vibration in the transverse direction, vibration in the longitudinal direction, vibration in the torsional direction and coupled vibration in the perpendicular direction, the transverse direction, the longitudinal direction and the torsional direction of the rudder propeller device can be effectively damped at the same time; due to the fact that the multiple damping blocks are uniformly arranged along the periphery of the installation rack in an up-down layer mode, damping block deformation under the action of the input shaft torque and the propeller propelling force can be effectively controlled at the same time; the dynamic deformation problem of an input shaft of the rudder propeller device is solved; vibration transmitted from the rudder propeller device to a stern structure is reduced; and thus, the operation stability is improved, meanwhile, the shipbuilding cost can be reduced, and the shipbuilding time can be saved. The invention further discloses a design method of the rudder propeller double-layer damping device.

Owner:JIANGSU UNIV OF SCI & TECH

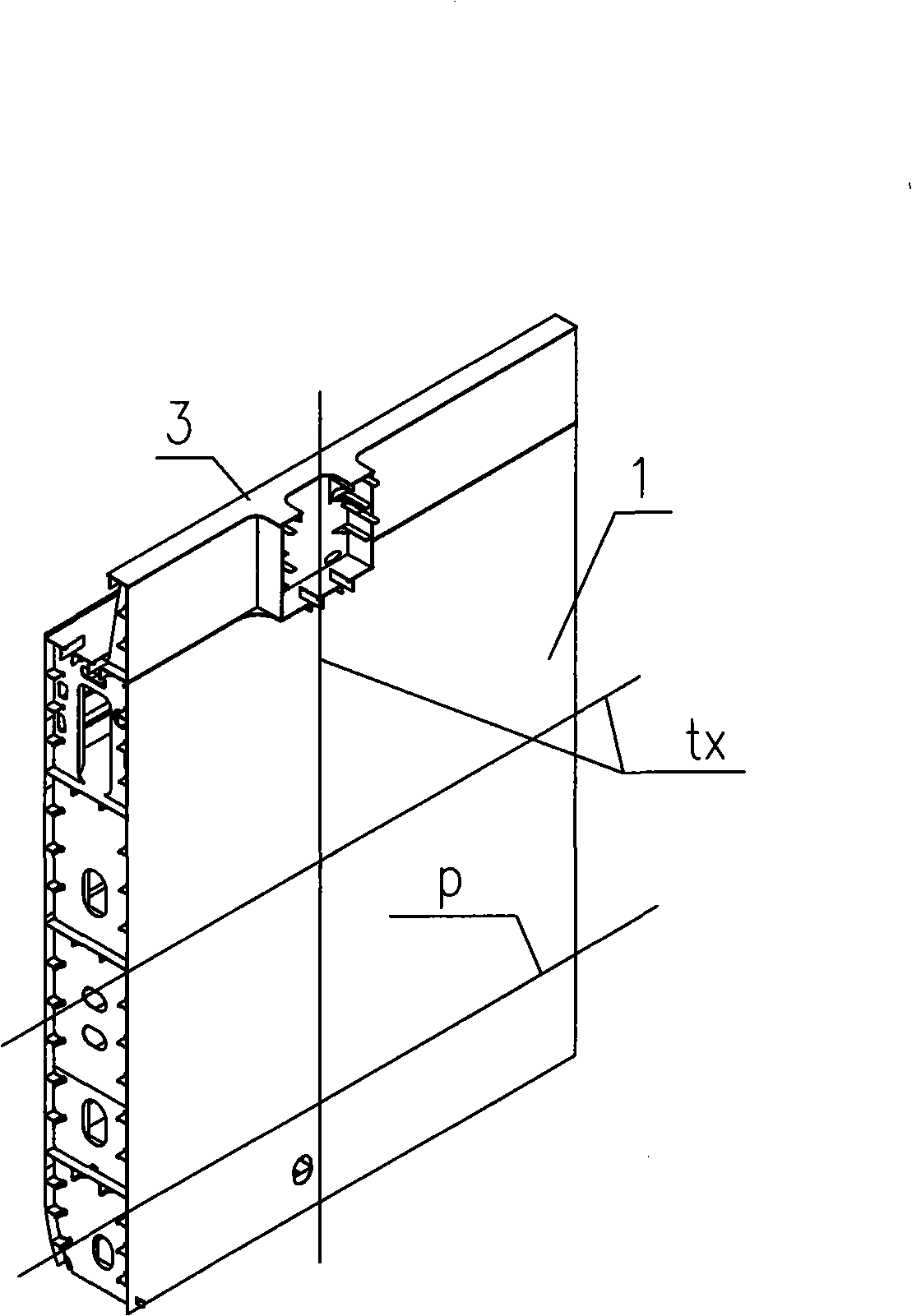

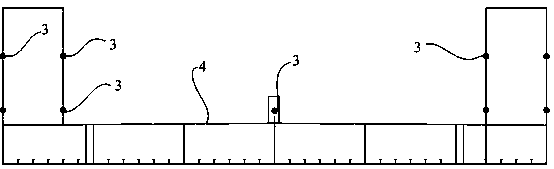

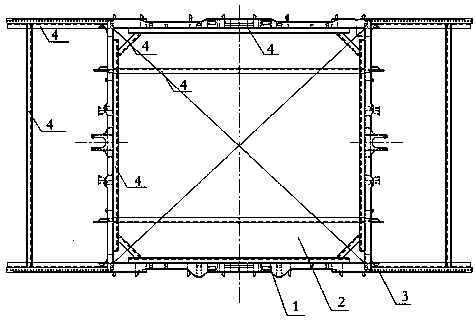

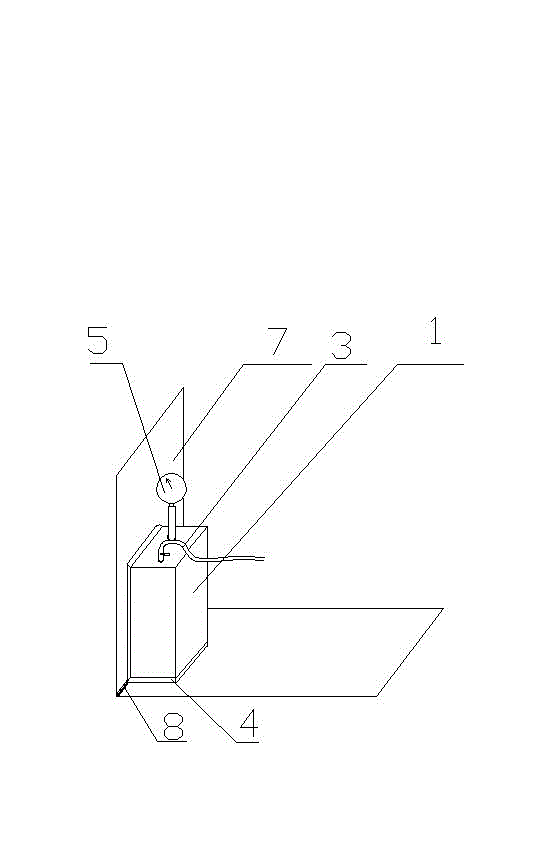

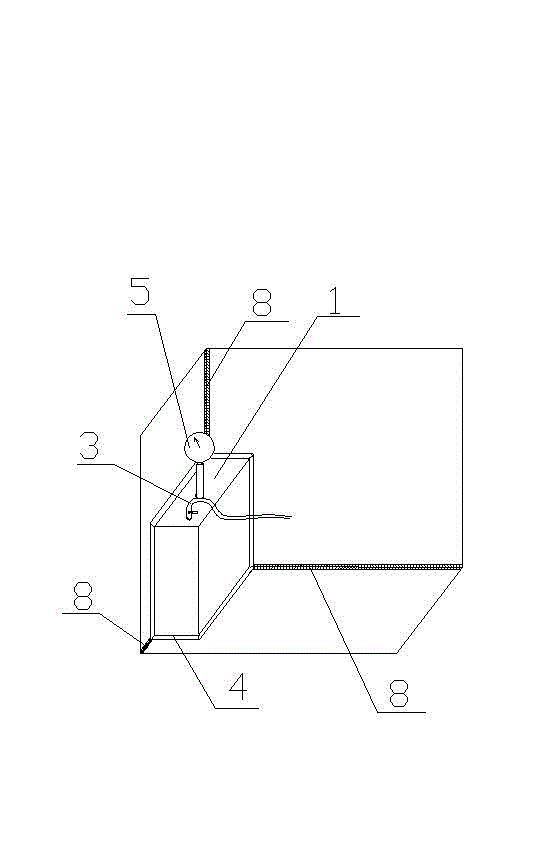

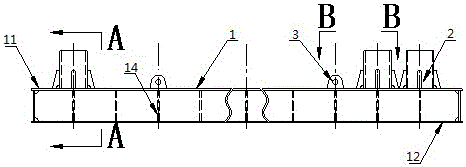

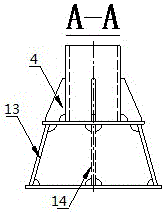

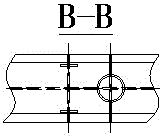

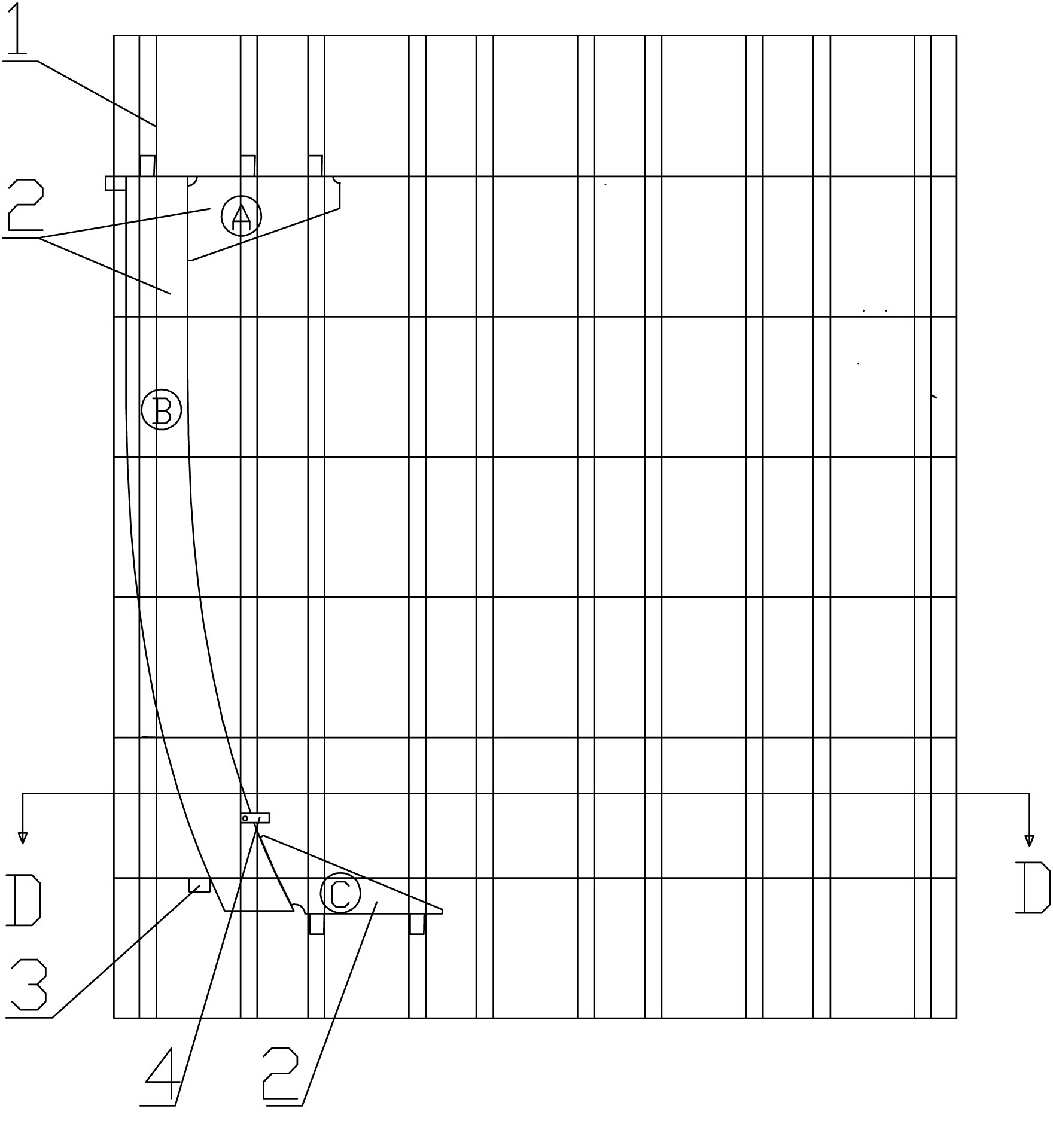

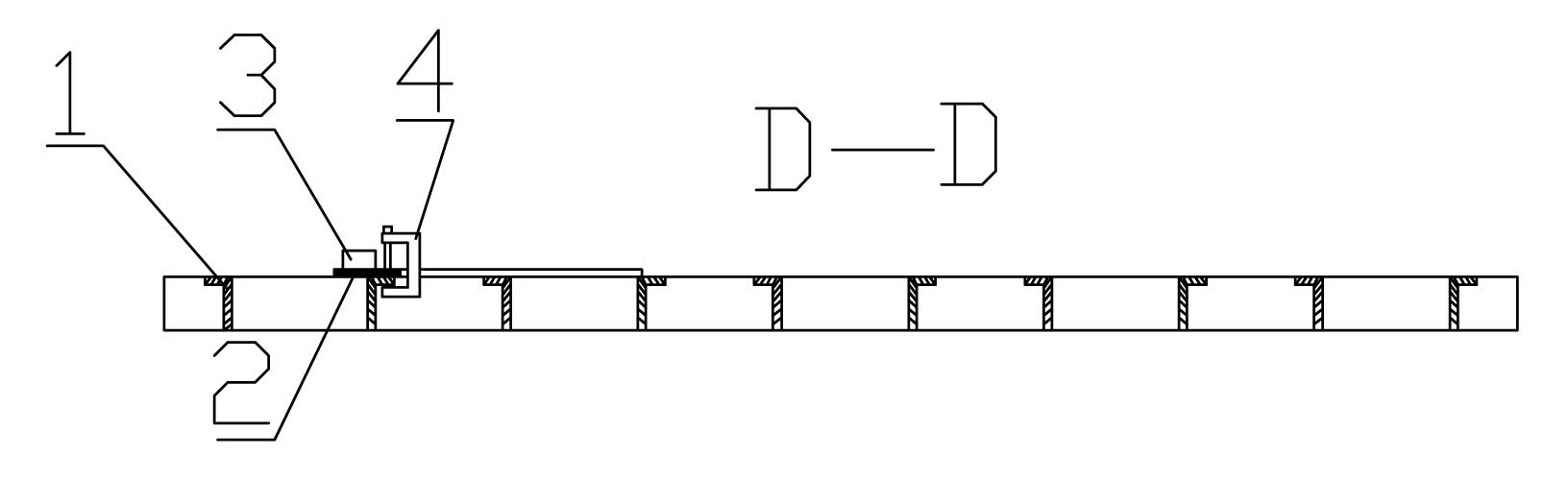

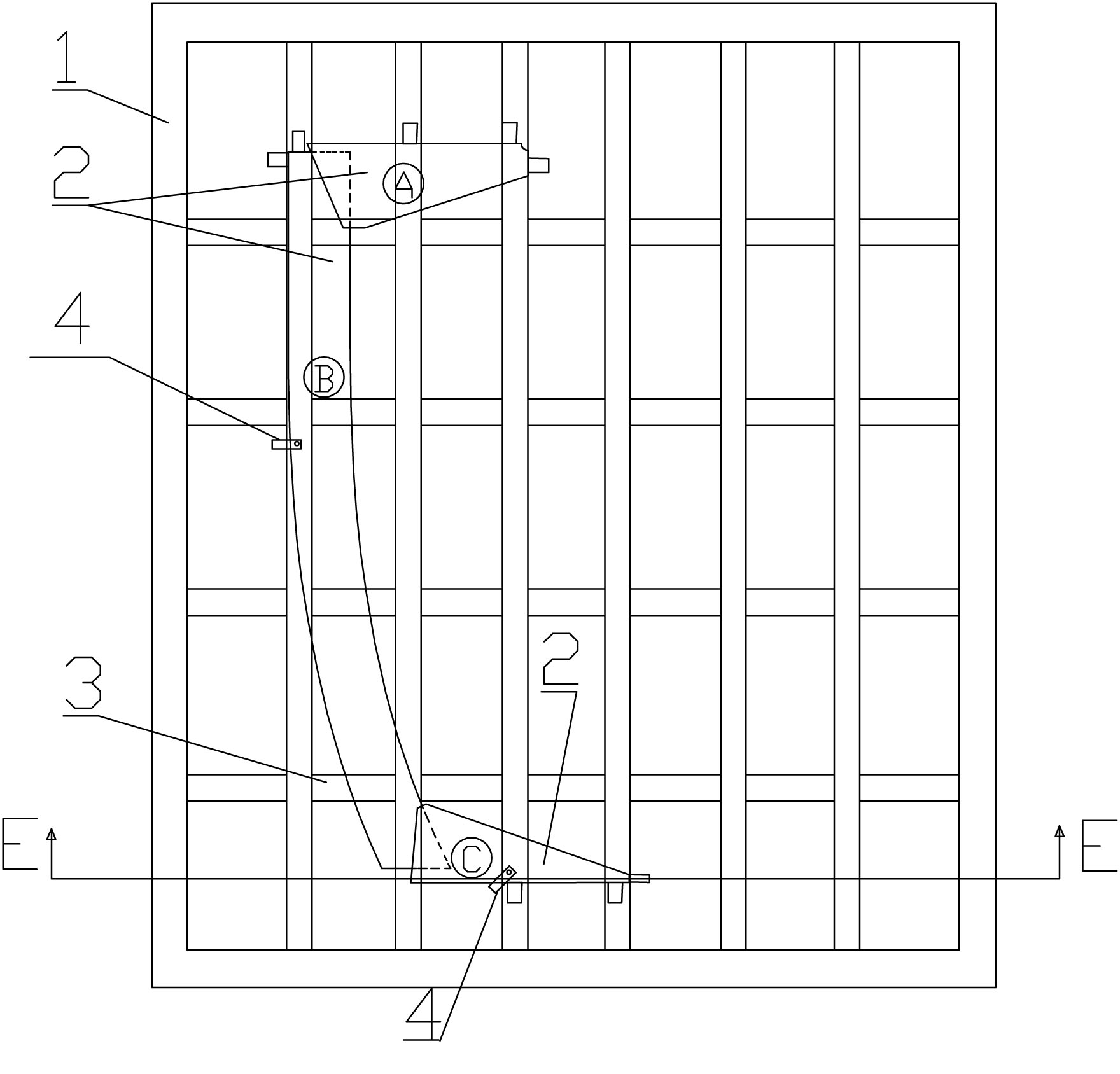

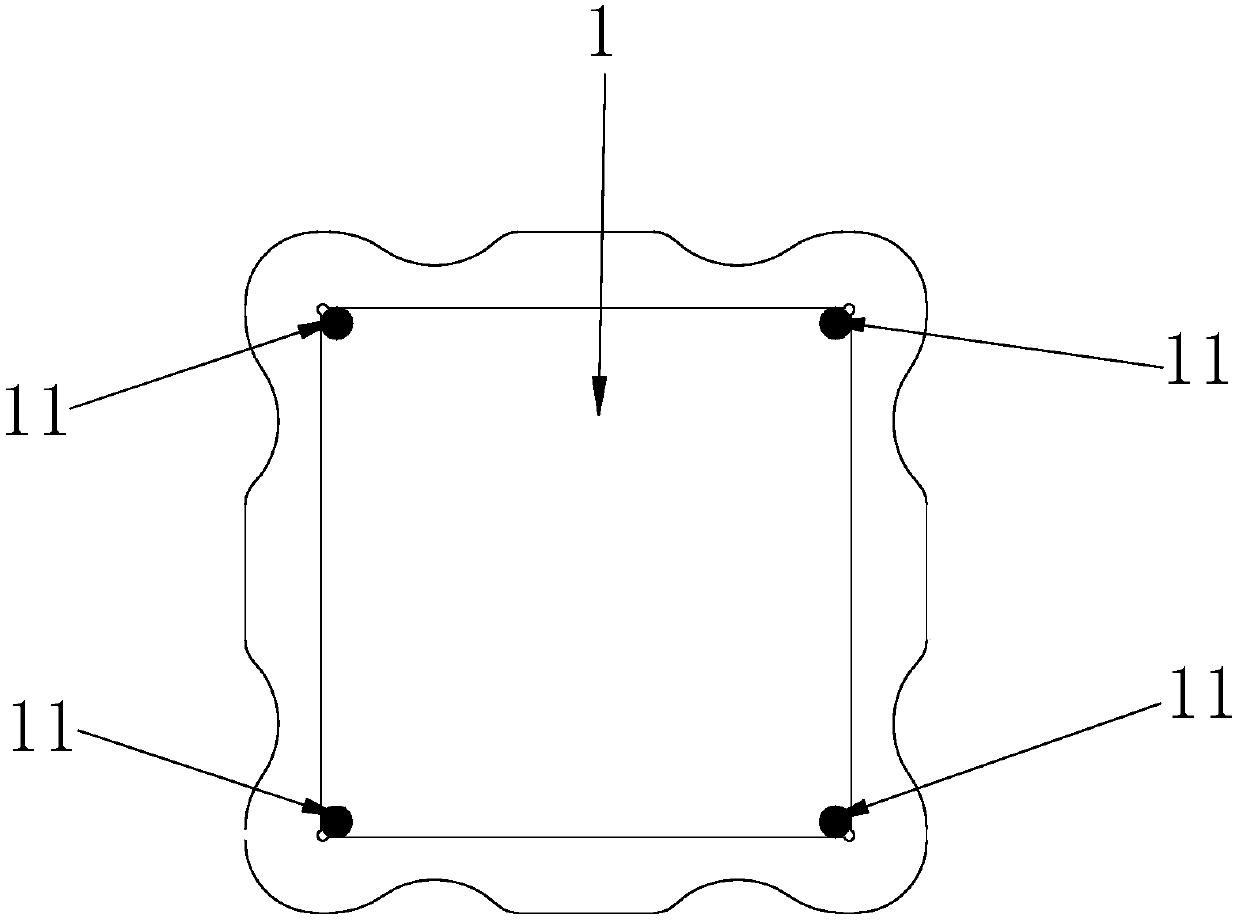

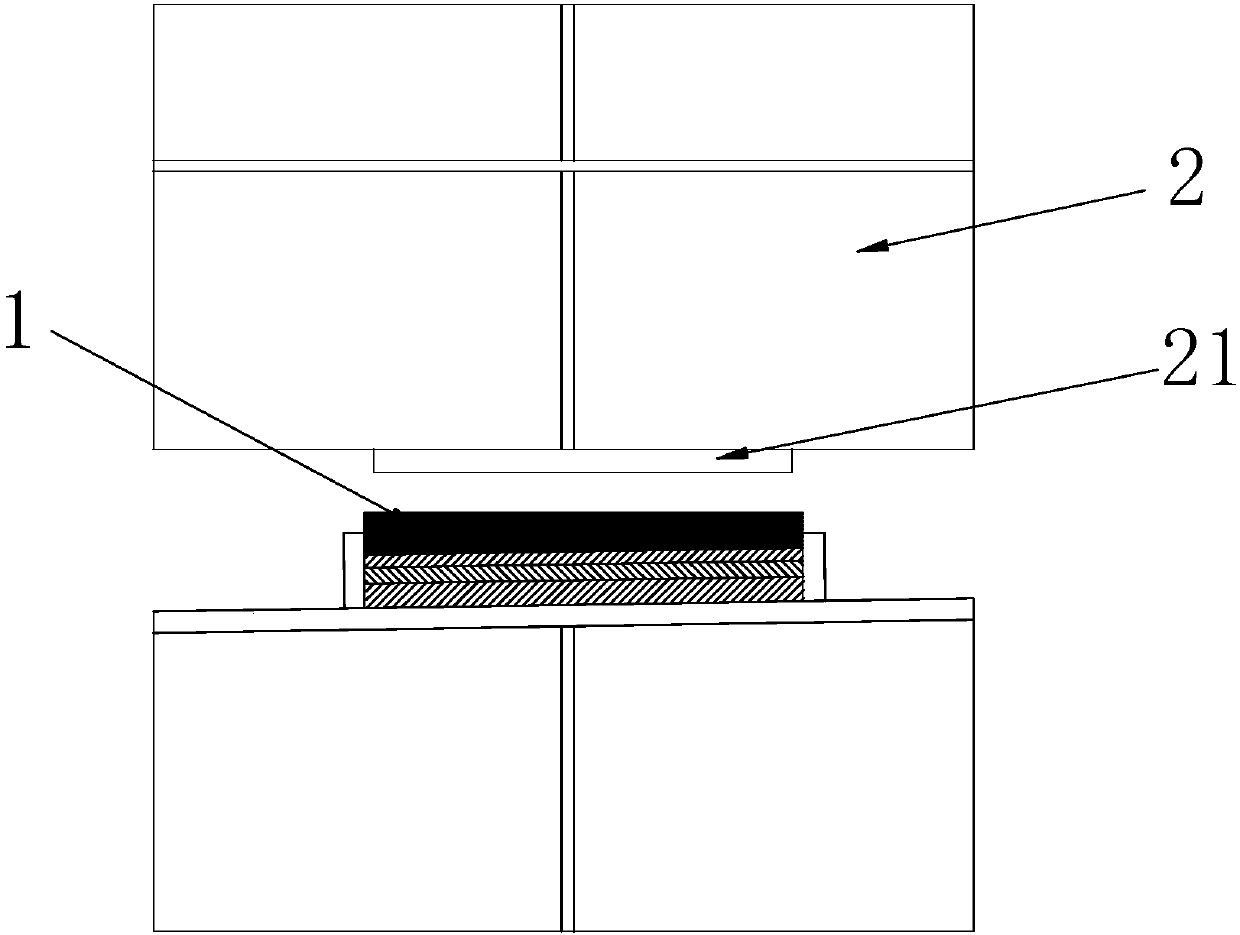

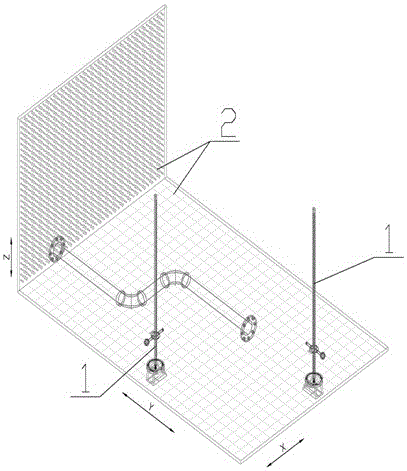

Supporting method and device used for assembling ship broadside curved sections

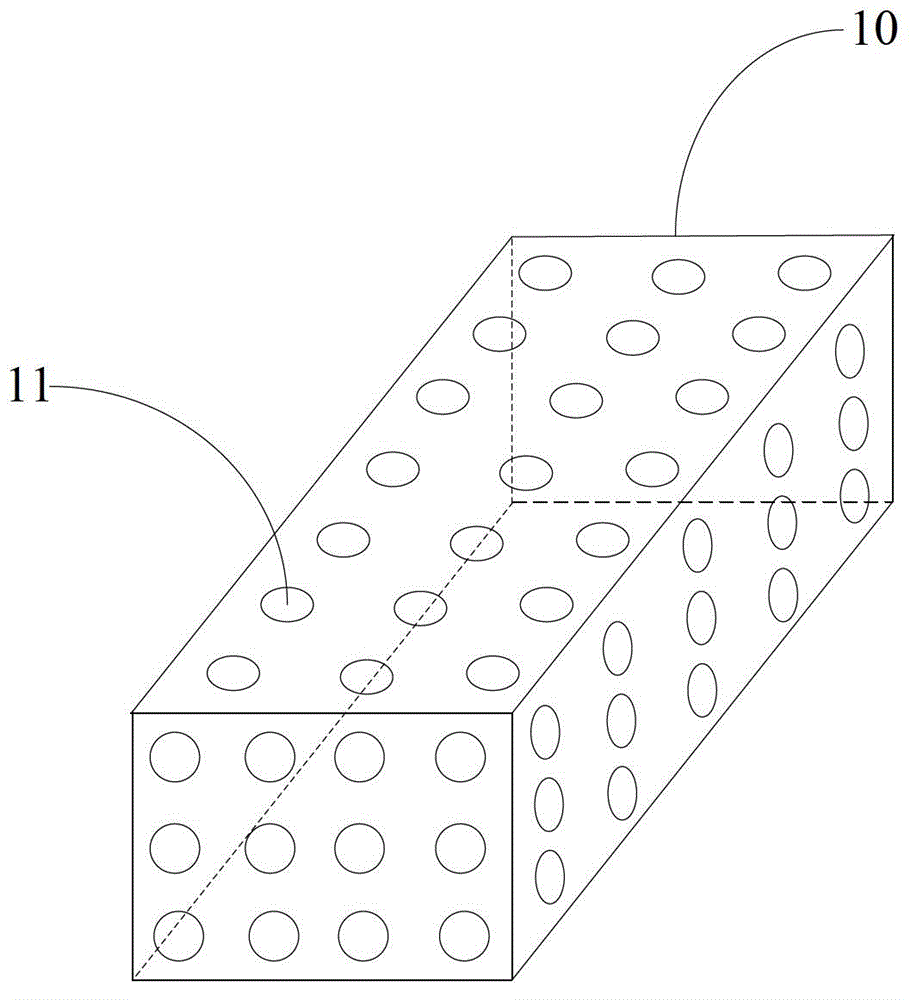

The invention relates to a supporting method used for assembling ship broadside curved sections. The method comprises the steps of drawing an assembling process chart, placing a base (1), installing supporting legs (2), welding reinforcing ribs (4), trimming the supporting legs (2), assembling the curved sections (5) and storing for standby use. The invention further relates to a supporting device used for assembling the ship broadside curved sections. The device comprises the base (1), the supporting legs (2) and hangers (3). The base (1) is of a long-strip-shaped framework structure and comprises an upper plate (11) and a lower plate (12). Two side plates (13) are arranged between the upper plate (11) and the lower plate (12) which are arranged on the left side and the right side of the base (1). The upper ends and the lower ends of the side plates (13) are welded to the lower end face of the upper plate (11) and the upper end face of the lower plate (12) correspondingly. At least two supporting legs (2) are welded on the upper plate (11). At least one hanger (3) is welded on the upper plate (11). The supporting method and device used for assembling the ship broadside curved sections have the advantages that the use is convenient and the safety performance is high.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

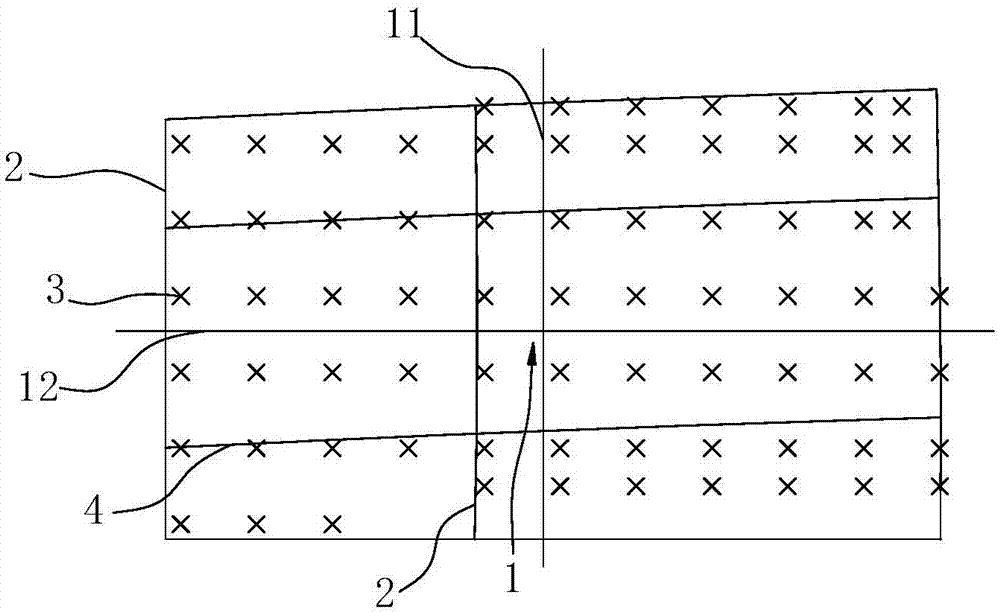

Bottom template for ship frame and method for processing same

InactiveCN102059495AHigh precision requirementsEasy clampingWelding/cutting auxillary devicesVessel partsMarine engineeringEconomic benefits

The invention relates to a bottom template for a ship frame. Profiles with reverted L-shaped and [-shaped cross sections are welded together to form a template frame. The template frame is provided with a plurality of limiting blocks, a plurality of clamps and a gasket block. Because the template frame is formed by welding the profiles with reverted L-shaped and [-shaped cross sections, and the upper plane of the template frame has the tolerance of + / -1 mm, the template frame has qualified planeness and support stiffness and is convenient for clamping by the clamps. The template frame can meet the high-precision requirement of zero-allowance ship building for the ship frame and has the tolerance ranging from -2 mm to 0 mm. The speed of producing the bottom template for the ship frame by using the method is four times as fast as the speed of producing the bottom template for the ship frame by using the original method, and the land occupied to produce the bottom template for the ship frame by using the method is 30 percent of that occupied to produce the bottom template for the ship frame by using the original method. All the work can be finished by only one electric welder by adopting the method for producing the bottom template for the ship frame, and the method for producing the bottom template for the ship frame is convenient and rapid to operate, improves the product quality and the economic benefit, shortens the ship building period and increases the ship building capacity of the same plant area.

Owner:长航集团宜昌船厂有限公司

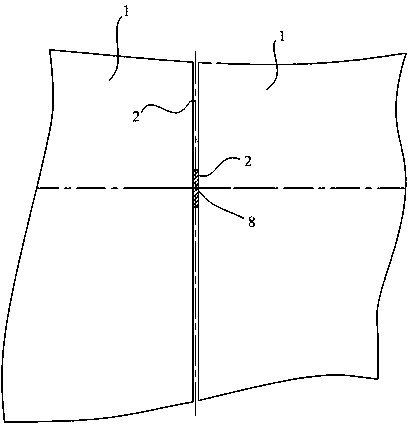

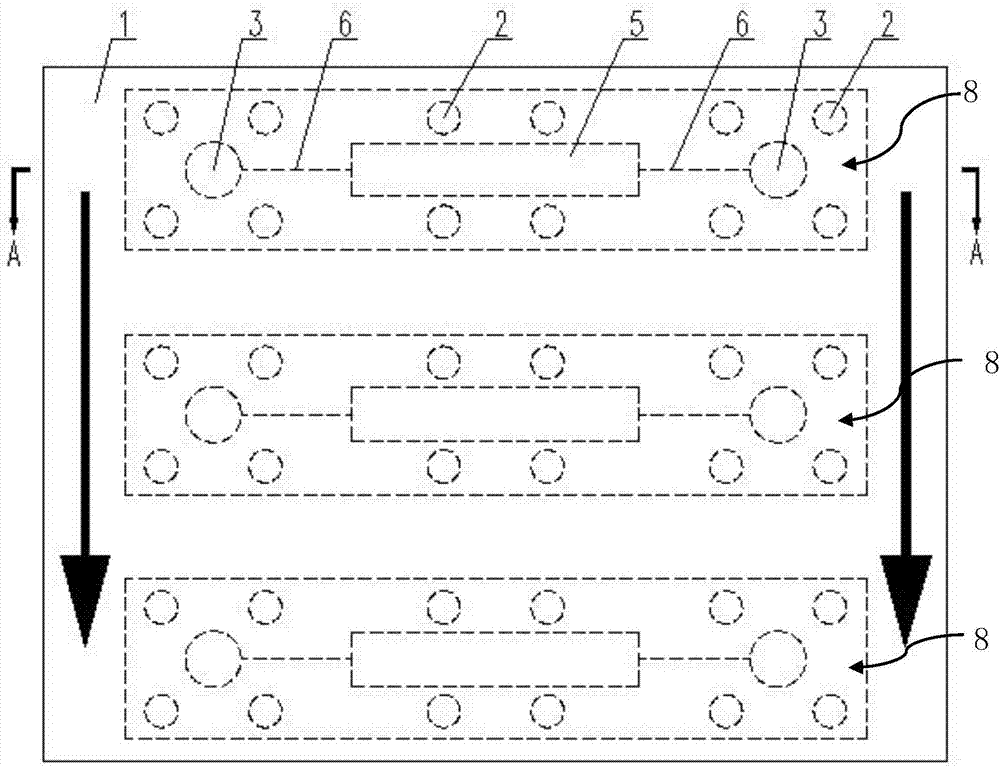

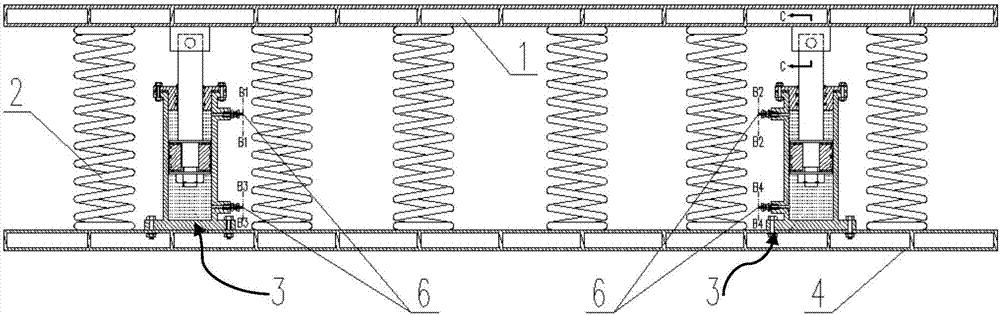

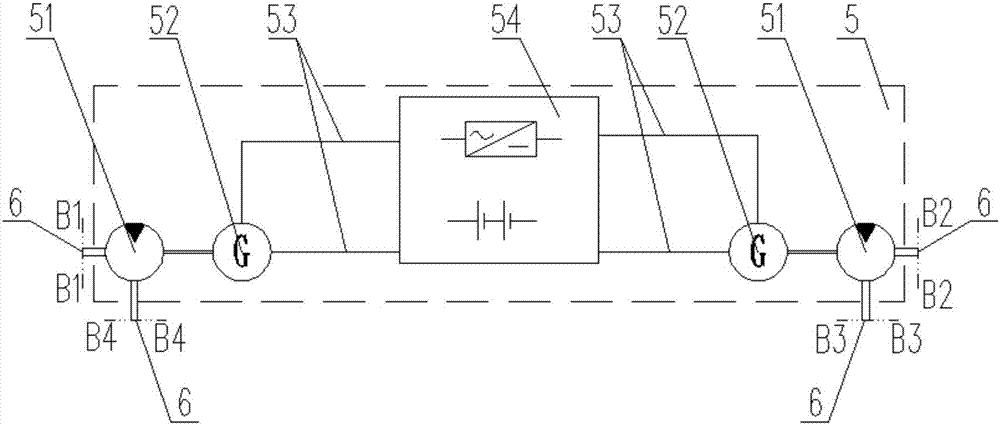

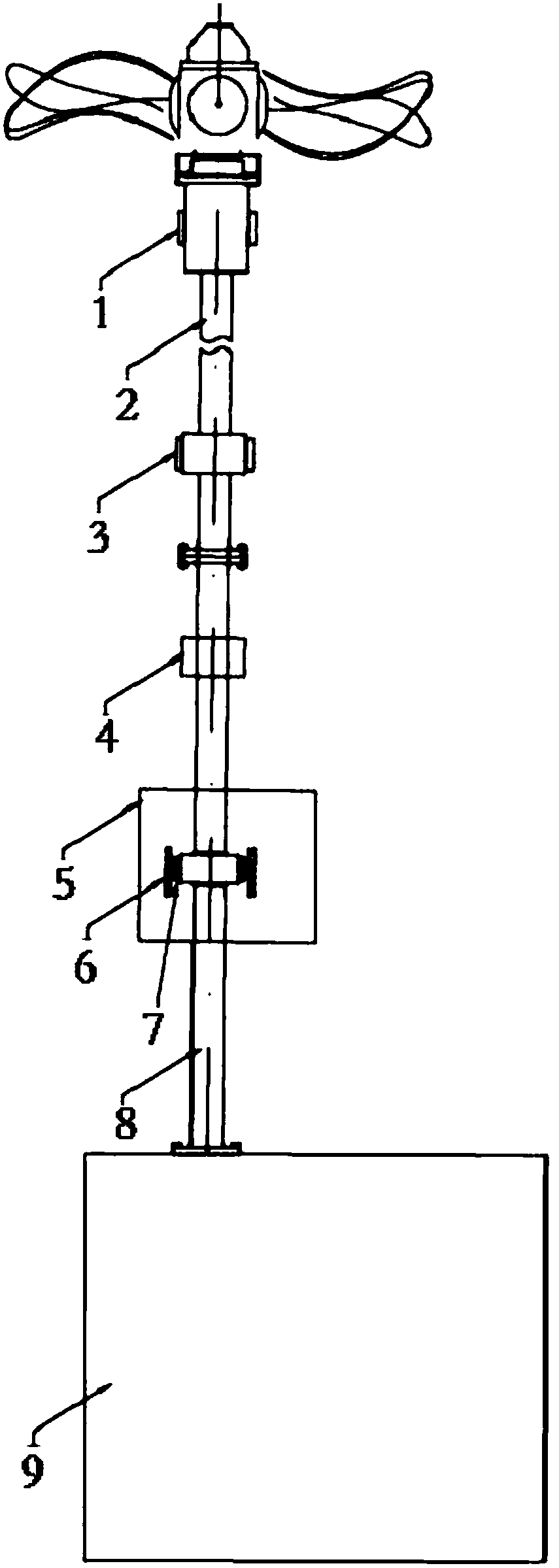

Shake and vibration reducing electricity generating ship under frame

InactiveCN107226176AReduce vibrationReduce swingShip vibration reductionMovement controllersElectricityEngineering

The invention provides an anti-rolling and vibration-reducing underframe of a power generation ship, which comprises an upper support frame (1), a spring (2), a lower support frame (4) and a functional component (8). The upper supporting frame (1) is fixed on the ship cabin, and the lower supporting frame (4) is fixed on the splint. The upper supporting frame (1) is connected with the lower supporting frame (4) through a spring (2). A functional component (8) is provided between the upper supporting frame (1) and the lower supporting frame (4), and the functional component (8) includes a hydraulic component (3) and a power generation and energy storage component (5). When the ship vibrates, the underframe weakens the vibration through the spring (2); when the ship sways, the underframe improves the torsional stiffness of the ship through the flow of the hydraulic medium (315) inside the hydraulic assembly (3) and reduces shaking, and the hydraulic assembly The circulation of the internal medium (315) in (3) enables the power generation and energy storage component (5) to generate electricity.

Owner:JIANGSU UNIV OF SCI & TECH

Precision control method for container ship lashing system without real ship box test

ActiveCN110182312AWill not cause interferenceAvoid real ship lashing testsAccommodation for deck loadsVessel designingSimulation

The invention discloses a precision control method for a container ship binding system without a real ship box test. According to the method, after precision control production of hatch covers, a hatch coamings and lashing bridges according to the design drawing, the theoretical distance between box feet in the hatch covers and the lashing hole plates in the corresponding lashing bridges is compared with the measuring distance, actual allowance values of the lashing pieces in the real ship are obtained through calculation, and the actual allowance values of the lashing pieces are controlled tobe always larger than the allowable minimum allowance values, so that positions of all the lashing hole plates on the ship meet the requirements, the interference among the adjacent lashing pieces isavoided, and then the real ship lashing test can be effectively avoided, the shipbuilding cost can be reduced, and the shipbuilding period can be shortened.

Owner:DALIAN COSCO KHI SHIP ENG

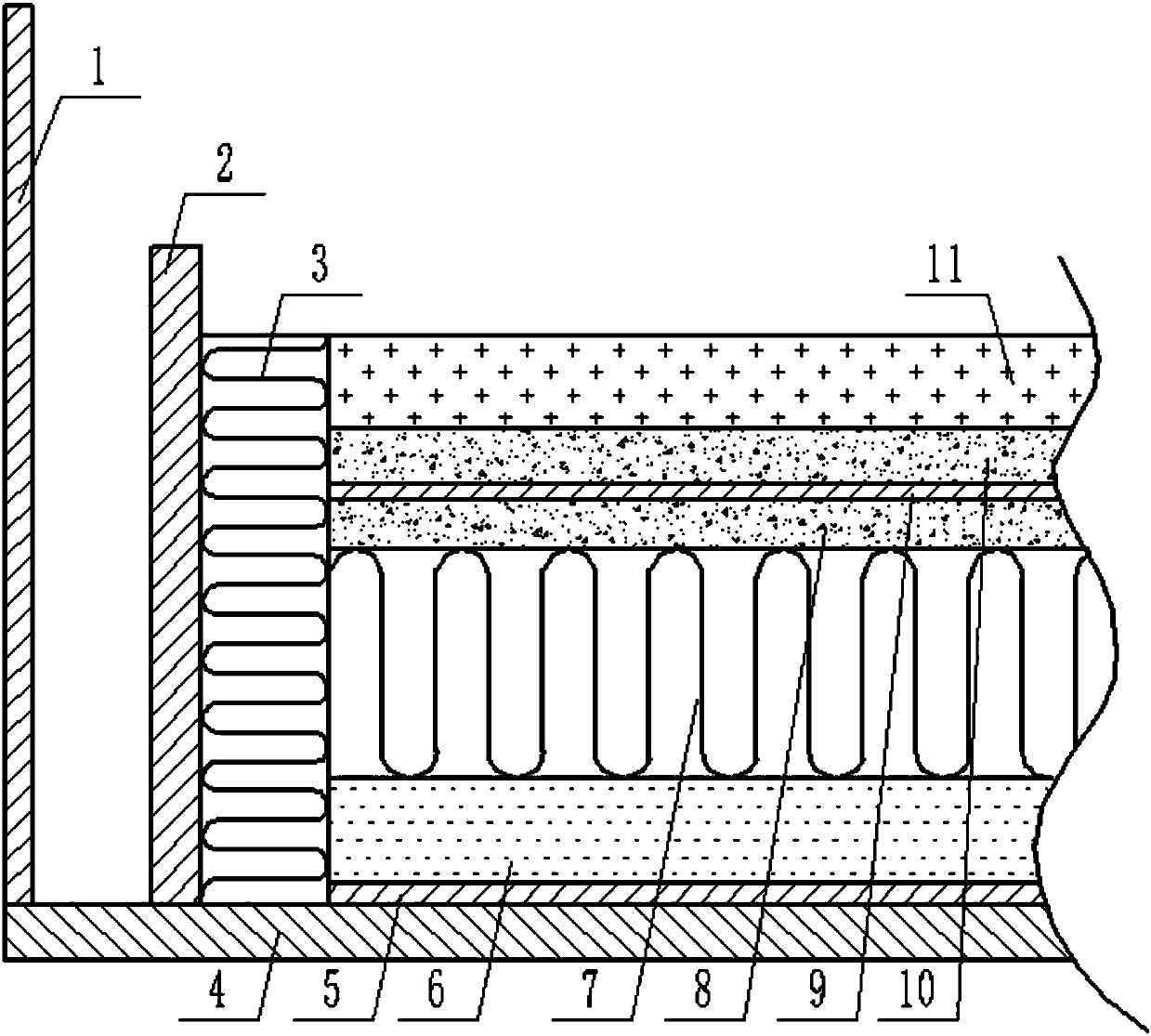

Floating floor

InactiveCN107933820ASimple designEasy constructionHull decksVehicle componentsNoise levelEngineering

The invention relates to the technical field of shock and noise reduction for ships, and more specifically, a floating floor, which is simple in design, convenient in construction, effectively shortens the shipbuilding cycle, and has various technical indicators that fully meet various indicators such as ship vibration and noise reduction, fire prevention, etc. Requirements: The noise index of the crew cabin and working area is lower than the maximum allowable noise level, the vibration is lower than the maximum allowable vibration level, the comfort level can reach the first grade, and the surface material meets the requirements of the SOLAS international convention for low flame spread, According to the special requirements of different parts of the ship, the fire rating can reach A60. On the deck, there are damping layer, constraining layer, rock wool II, galvanized steel plate I, damping layer, galvanized steel plate II and base dressing in order from bottom to top; Above, rock wool I is in contact with the damping layer, constraining layer, rock wool II, galvanized steel plate I, damping layer, galvanized steel plate II and the base dressing, and the water-blocking flat steel is in contact with rock wool I.

Owner:麻城市通达阻尼材料股份有限公司

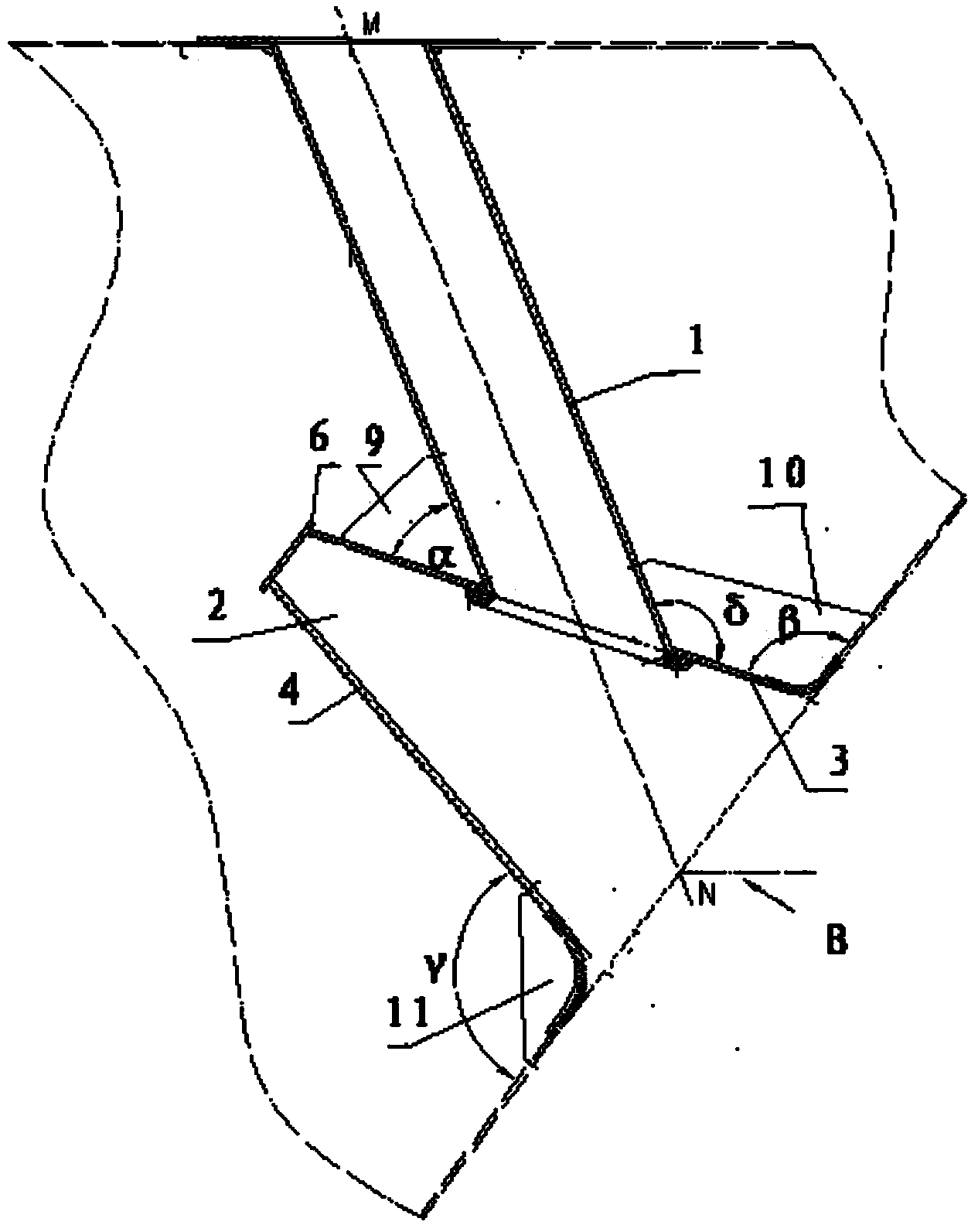

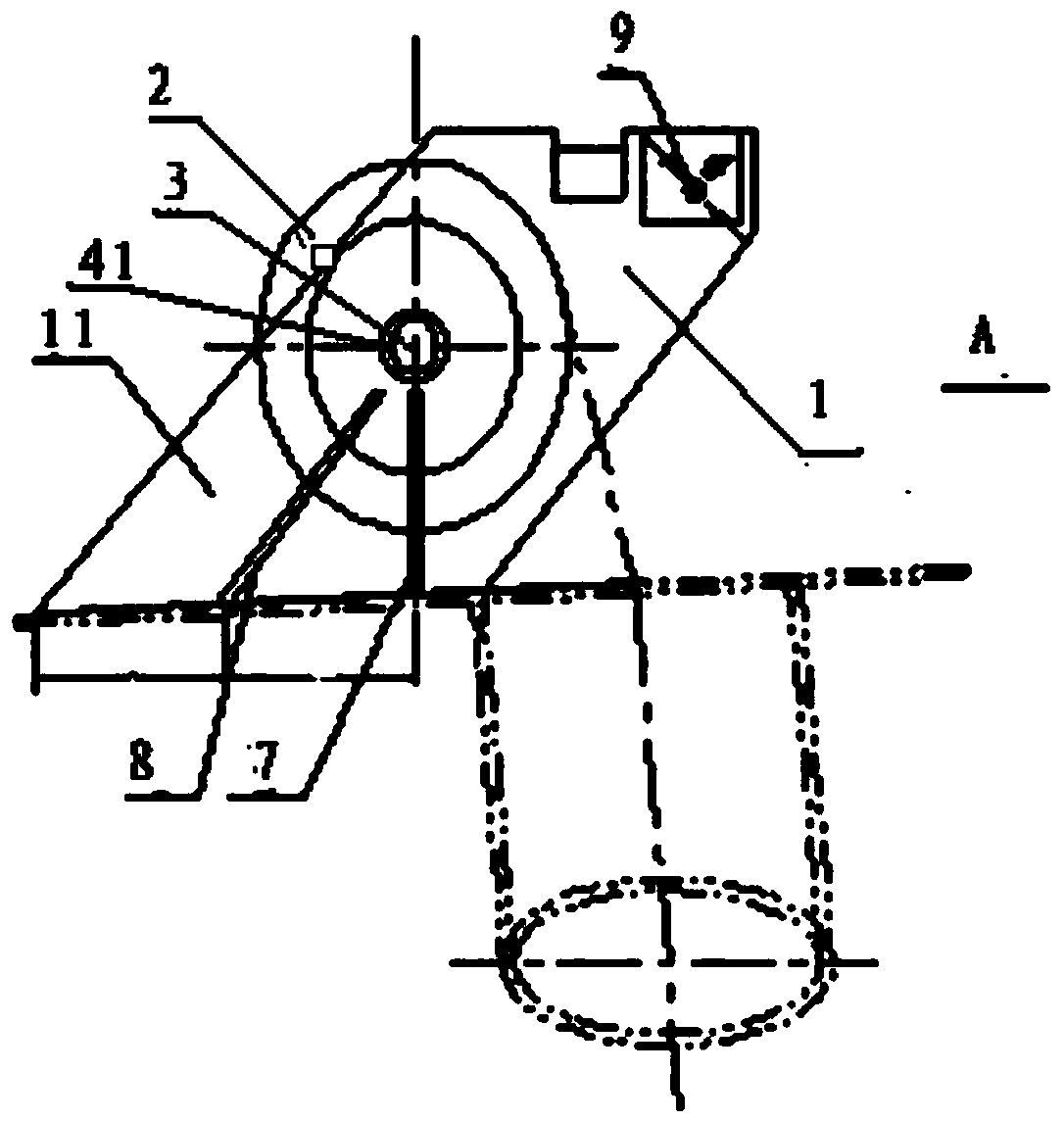

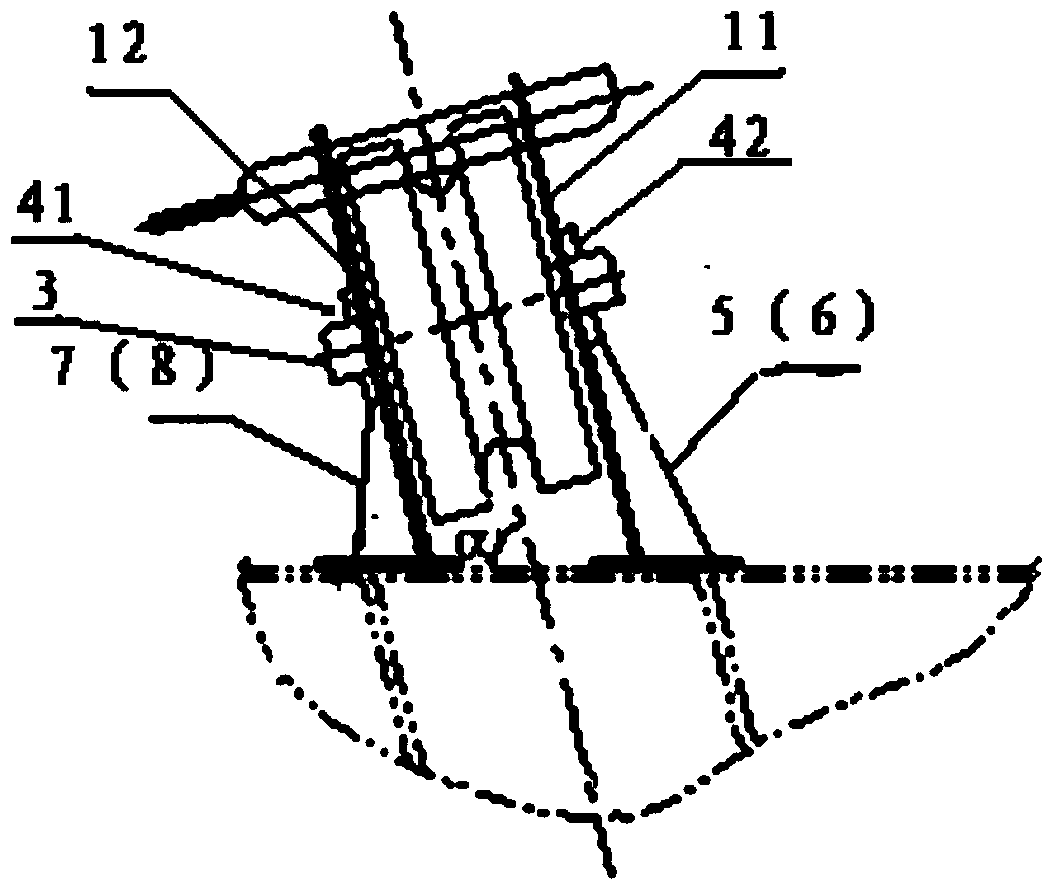

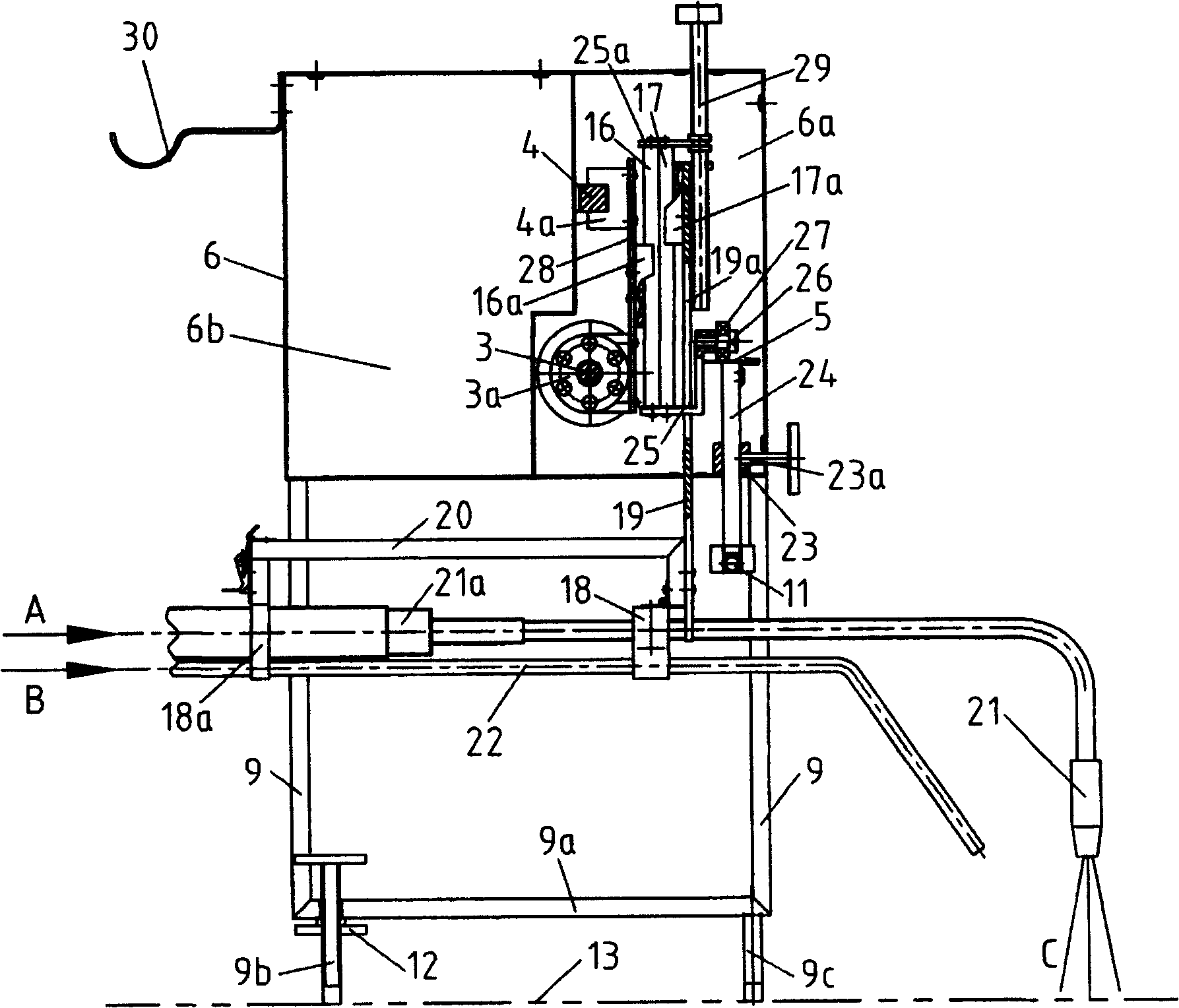

Idler wheel switch blade chain pulling device and manufacturing and installing technology of idler wheel switch blade chain pulling device

ActiveCN103523173AHigh precisionReduce workloadWaterborne vesselsWelding apparatusVertical planeIdler-wheel

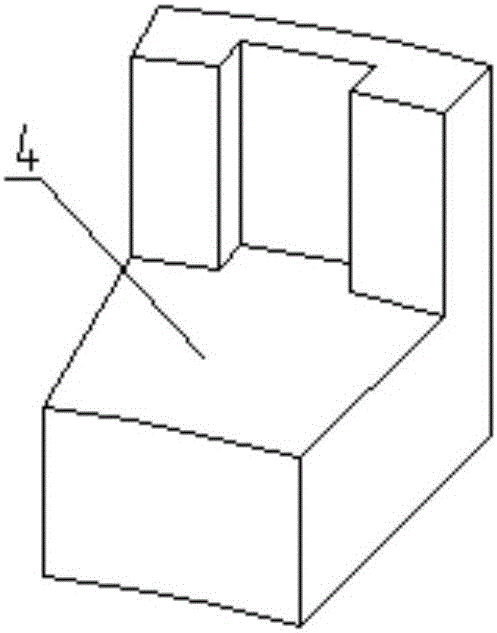

The invention discloses an idler wheel switch blade chain pulling device. A first bracket and a second bracket of the idler wheel switch blade chain pulling device are located on the vertical plane of the axial lead of an idler wheel, the upper end of the lateral side of a third bracket is located below a left lining, the upper end of the lateral side of a fourth bracket is located below a right lining, the lateral side of the first bracket and the lateral side of the third bracket are respectively connected with a left side plate of a body in a welded mode, and the lateral side of the second bracket and the lateral side of the fourth bracket are connected with a right side plate of the body in a welded mode. Parts of the idler wheel switch blade chain pulling device are assembled in place in an internal field according to designed sizes, the four brackets are welded on the body of the idler wheel switch blade chain pulling device, and one-step installation can be achieved when the idler wheel switch blade chain pulling device is installed on a slipway. According to the idler wheel switch blade chain pulling device, the four brackets are additionally installed, the dip angle alpha between the idler wheel switch blade chain pulling device and a deck is directly determined, the sizes of the parts of the idler wheel switch blade chain pulling device are directly determined at one time in the internal field, the manufacturing accuracy of the parts is improved, and the ship building cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

Method for rectifying cushion block for supporting asphalt tank, and measuring tool

PendingCN107796347AIncrease contactFully contactedMeasurement devicesEconomic benefitsStructural engineering

The invention provides a method for rectifying a cushion block for supporting an asphalt tank. The method comprises the following steps: marking at least one position at each of four corners of the first surface of the cushion block as a measuring point; placing the cushion block on the bottom of the asphalt tank, and maintaining the distance between the cushion block and the bottom plate of the asphalt tank at a basic value H1; placing measuring tools at respective measuring points, and obtaining, by the measuring tools, the vertical distances H2 between the cushion block and the bottom plateof the tank at respective measuring points; subtracting the basic value H1 from the measured vertical distances H2 to obtain the thicknesses H required to be machined at the corresponding positions on the cushion block; milling the four corners of the cushion block according to the thicknesses H and inspecting the quality of the milled cushion block. The method can rapidly inspect the cushion block for supporting the asphalt tank, improves the labor efficiency of workers, shortens shipbuilding period, improves the technical level of the construction of a asphalt ship, and can reduce the rejection rate of the cushion block, reduces cost loss, and creates economic benefits.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Portable semi-automatic processing machine of plate with curved surface

The invention relates to a portable semi-automatic processing machine for surface steel plate, belonging to ship and marine structure manufacturing and metal material heat processing forming fields. The portable semi-automatic processing machine for surface steel plate adopts small I shaft locating control mechanical transmission to accomplish work. Because of the organic combination of horizontal walk mechanism, manual height adjusting mechanism and automatic height adjusting mechanism it is provided with simple structure, small whole dimension, light weight, convenient motion by people, flexible operation, reliable work and high processing accuracy. It can satisfy various plates to be processed into demanded surfaces and it is especially suitable for field construction. It can improve the production efficiency and guarantee the production quality. If the equipment is used in shipyard, a key problem influencing production schedule for shipbuilding and it can provide the technology support for shortening shipbuilding period and improving shipbuilding total quantity.

Owner:DALIAN UNIV OF TECH

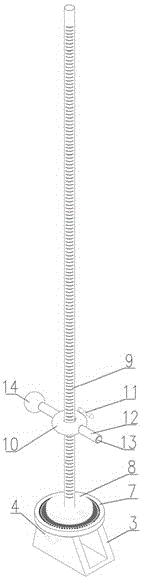

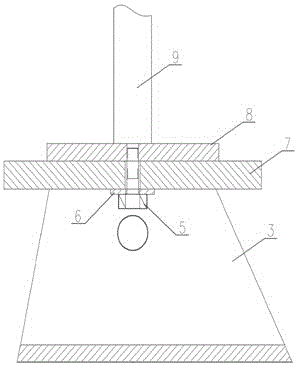

Pipe check platform instrument

ActiveCN105136032AReduce production errorsImprove working environmentUsing optical meansMeasurement deviceEngineering

The invention discloses a pipe check platform instrument, characterized by comprising a fixed mounting platform and a plurality of measurement mechanisms. The fixed mounting platform comprises a horizontal reference plate with an X graduation line and a Y graduation line, and a vertical reference plate perpendicular to the horizontal reference plate; the vertical plate is provided with connection apertures used for fixing installation flanges of a detected pipe. Each measurement mechanism comprises a scale column, and a base capable of being fixed to the horizontal reference plate; the base is provided with a panel; the scale column is provided with an infrared ray projector capable of sliding up and down along the scale column; the lower end of the scale column is fixedly provided with a rotary angle disc; the rotary angle disc is in connection with the panel, and can rotate relative to the panel.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

Ship shafting alignment technology with permanent magnet type journal-sticking shaft generator

ActiveCN108177727AGuaranteed installation qualityReduce construction costsVessel designingClassical mechanicsEngineering

The invention discloses a ship shafting alignment technology with a permanent magnet type journal-sticking shaft generator. The ship shafting alignment technology comprises the steps that S1, a theoretical value is calculated according to a shafting alignment calculation sheet; S2, a permanent magnet is temporarily removed from a rotor shaft of the permanent magnet type journal-sticking shaft generator, a shafting state at the time is adjusted to meet a shafting state without the permanent magnet on the shafting alignment calculation sheet firstly, and then the stator end position of the permanent magnet type journal-sticking shaft generator is adjusted, so that the centerline of the stator end is consistent with the centerline of the rotor shaft; and S3, the permanent magnet is mounted onthe rotor shaft, the stator end of the permanent magnet type journal-sticking shaft generator is finely adjusted, and the shafting state is made to meet the final shafting state on the shafting alignment calculation sheet. The mounting quality of a ship shafting is met, the construction cost of a shipyard is saved, and meanwhile, the shipbuilding cycle of the shipyard is reduced.

Owner:CSC JINLING SHIPYARD

Installation method of retractable azimuth auxiliary thruster

InactiveCN103963919BShorten the shipbuilding cycleImprove build qualityVessel partsAerospace engineeringPosition line

The invention discloses a method for installing a telescopic full-rotation auxiliary thruster. The method includes the following steps of firstly, fixing a ship body in a segmented mode, drawing out a midship line and a rib position line, and removing obstacles; secondly, hanging the thruster to the installation position so that the distance between the bottom of the thruster and the plane of a base at the installation position can range from 30 mm to 35 mm; thirdly, adjusting the levelness and perpendicularity of the thruster and fixing the thruster; fourthly, fixing a guide part so that the numerical value of a gap between a guide frame of the thruster and the guide part can be smaller than 1mm; fifthly, marking the installation position with a positioning mark, recording positioning data, and then hanging the thruster away; sixthly, installing accessories at the installation position; seventhly, hanging the thruster to the installation position again, and fixing the thruster according to the positioning data. According to the method, the segmented internal pre-assembly and two-time installation method is adopted, the ship manufacturing cycle is shortened, installation accuracy of the thruster is ensured, the use requirement of the thruster is met, and ship building quality is improved.

Owner:SHANGHAI SHIPYARD

Welding method for stainless steel

ActiveCN107953016AShorten the shipbuilding cycleReduce shipbuilding costsArc welding apparatusWeld seamElectric arc

The invention belongs to the field of welding, and relates to a welding method for stainless steel. The welding method comprises the following steps of: step I, forming a groove which is a double-Y-shaped groove; step II, checking whether a gap between welding root parts meets 0 or not, and checking whether a stainless steel jointed board is staggered or not; step III, checking and cleaning a welding bead, and coating the two sides of the welding bead by saturated limewater, and grinding and clearing a welding seam; step IV, welding, wherein the root parts of the double-Y-shaped groove are firstly welded, welding current of the root parts is controlled to be 430-460 A, electric-arc voltage is 30-32V, welding speed is 28-30m / h, and heat input is 1.48-1.98 KJ / mm; and welding the groove; andstep V, checking reverse molding, and performing sealing run. The welding method can effectively shorten a ship building period, reduces ship building cost, and reduces energy consumption.

Owner:南通象屿海洋装备有限责任公司

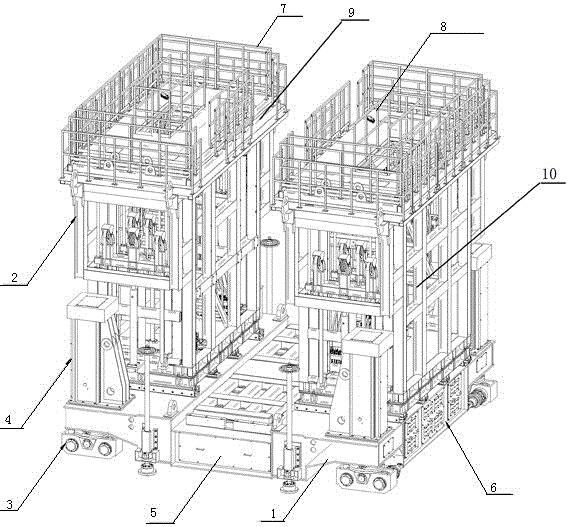

Combined type ship stern operating platform

The invention discloses a combined type ship stern operating platform which comprises main platforms (1), rudder blade workbenches (2), a control system (5), hydraulic systems (6), propeller workbenches (8), combined workbenches (9) and a device body (10), wherein the main platforms (1) are symmetrically arranged on the device body (10), and the main platforms (1) are of a trapezoidal structure; the control system (5) is arranged between the main platforms (1), the hydraulic systems (6) are fixedly arranged at the bottom ends of the main platforms (1), and the hydraulic systems (6) are matched with the control system (5); and the combined workbenches (9) are arranged on the main platforms (1), each combined workbench (9) comprises one rudder blade workbench (2) and one propeller workbench (8), and an included angle between each rudder blade workbench (2) and the corresponding propeller workbench (8) is 75-90 degrees. The combined type ship stern operating platform disclosed by the invention is low in labor intensity, short in crane occupation time, high in positioning accuracy and high in working efficiency, and each rudder blade workbench and the corresponding propeller workbench are combined into a whole.

Owner:徐秀阳

Installation method of outfitting parts

ActiveCN103661802BShorten the installation cycleTimely communication and dockingVessel partsManufacturing engineering

The invention discloses a method for installing outfitting parts. The method includes the step for installation in a ship and the step for installation outside the ship; the step for installation in the ship includes a whole assembling installing stage, a region installing stage and a system installing stage, according to the whole assembling installing stage, after two or more segments are assembled wholly, an outfitting installing stage is performed, in the stage, folding tubes which are assembled reversely in a segmented mode and outfitting parts between two folding tube segments are mainly installed in the stage; the step for installation outside the ship includes an assembling installing stage, a segmented installing stage, a unit assembling stage, in the assembling installing stage, some pipes and outfitting parts which can not be installed in segments after the segments are manufactured are taken into consideration, the segmented installing stage is also called a segmented advanced outfitting stage, the unit assembling stage belongs to the range of the advanced outfitting stage, a whole cabin area is divided into a plurality of units according to the arrangement characteristics of a cabin, and installation is performed in a fixed site. The method is performed in different stages, working efficiency is improved, and the installing period of the outfitting parts is shortened.

Owner:JIANGSU NEW TIMES SHIPBUILDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com