Floating floor

A floor and deck technology, applied in the field of shock absorption and noise reduction, can solve the problems of inconvenient maintenance, long cycle and high cost, and achieve the effects of simple design, shortened shipbuilding cycle and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

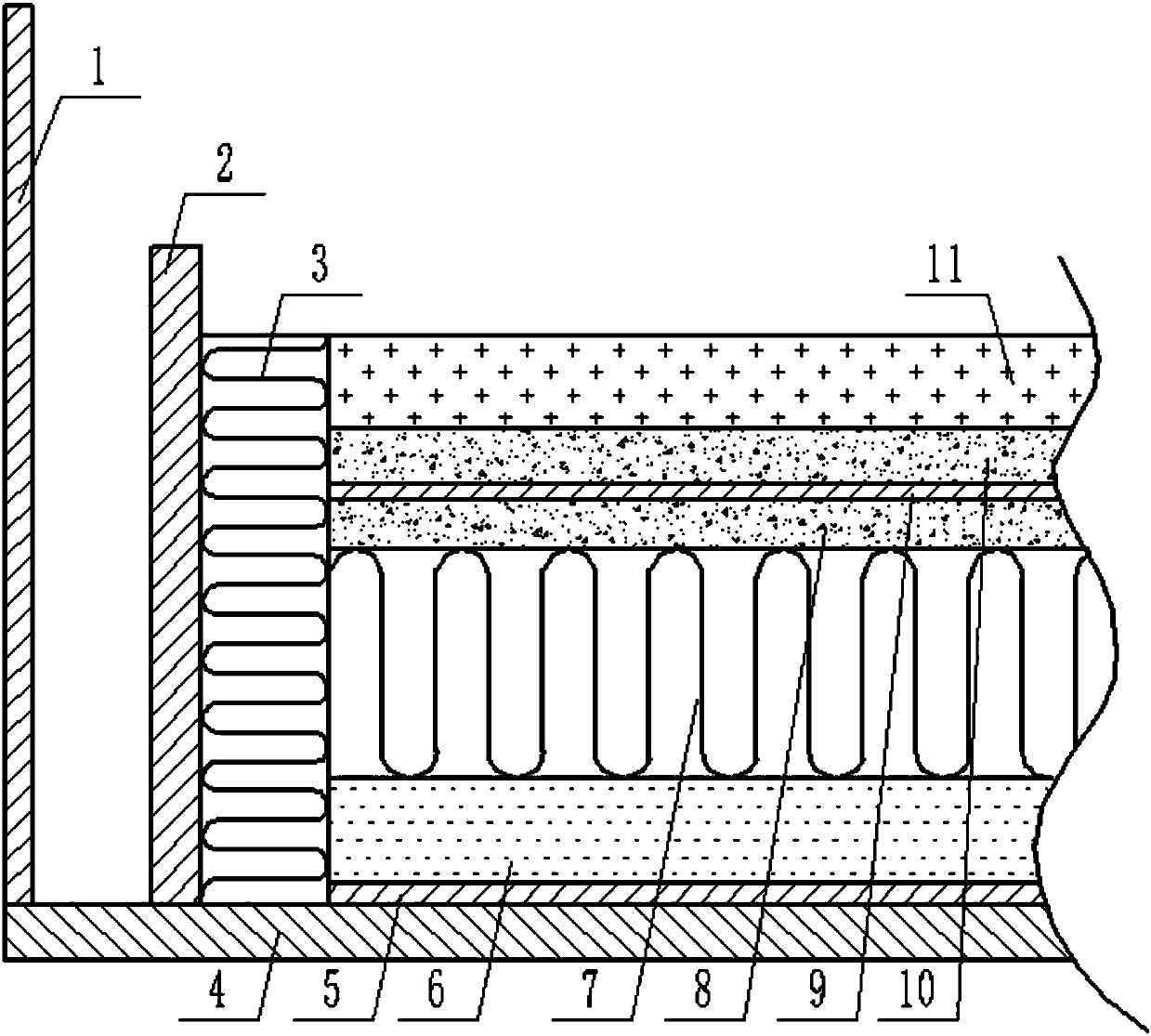

[0018] Combine below figure 1 This embodiment is described. The present invention relates to the technical field of shock absorption and noise reduction for ships, and more specifically, a floating floor, which includes a steel wall 1, a water-blocking flat steel 2, rock wool I3, a deck 4, a damping layer 5, Constraint layer 6, rock wool Ⅱ 7, galvanized steel Ⅰ 8, damping layer 9, galvanized steel Ⅱ 10 and base dressing 11, simple design, convenient construction, effectively shorten the shipbuilding cycle, and all technical indicators fully meet the ship's vibration and noise reduction, fire prevention Requirements for various indicators: the noise index of the crew cabin and working area is lower than the maximum allowable noise level, the vibration is lower than the maximum allowable vibration level, the comfort level can reach the first grade, and the surface material that meets the requirements of the SOLAS international convention is low. Flame spreading, according to the...

specific Embodiment approach 2

[0020] Combine below figure 1 This embodiment will be described. This embodiment will further describe the first embodiment, and the thickness of the damping layer 5 is 1 mm.

specific Embodiment approach 3

[0021] Combine below figure 1 This embodiment will be described. This embodiment will further describe the first embodiment. The thickness of the constrained layer 6 is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com