Patents

Literature

181results about How to "Reduce the amount of vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

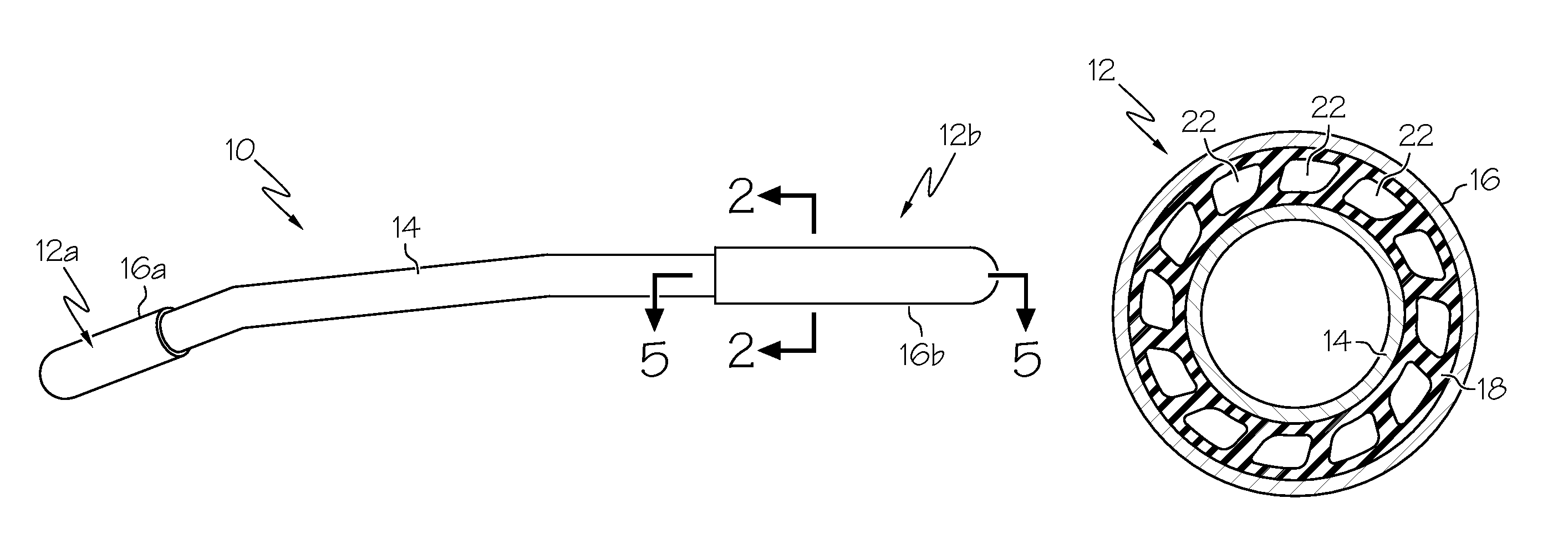

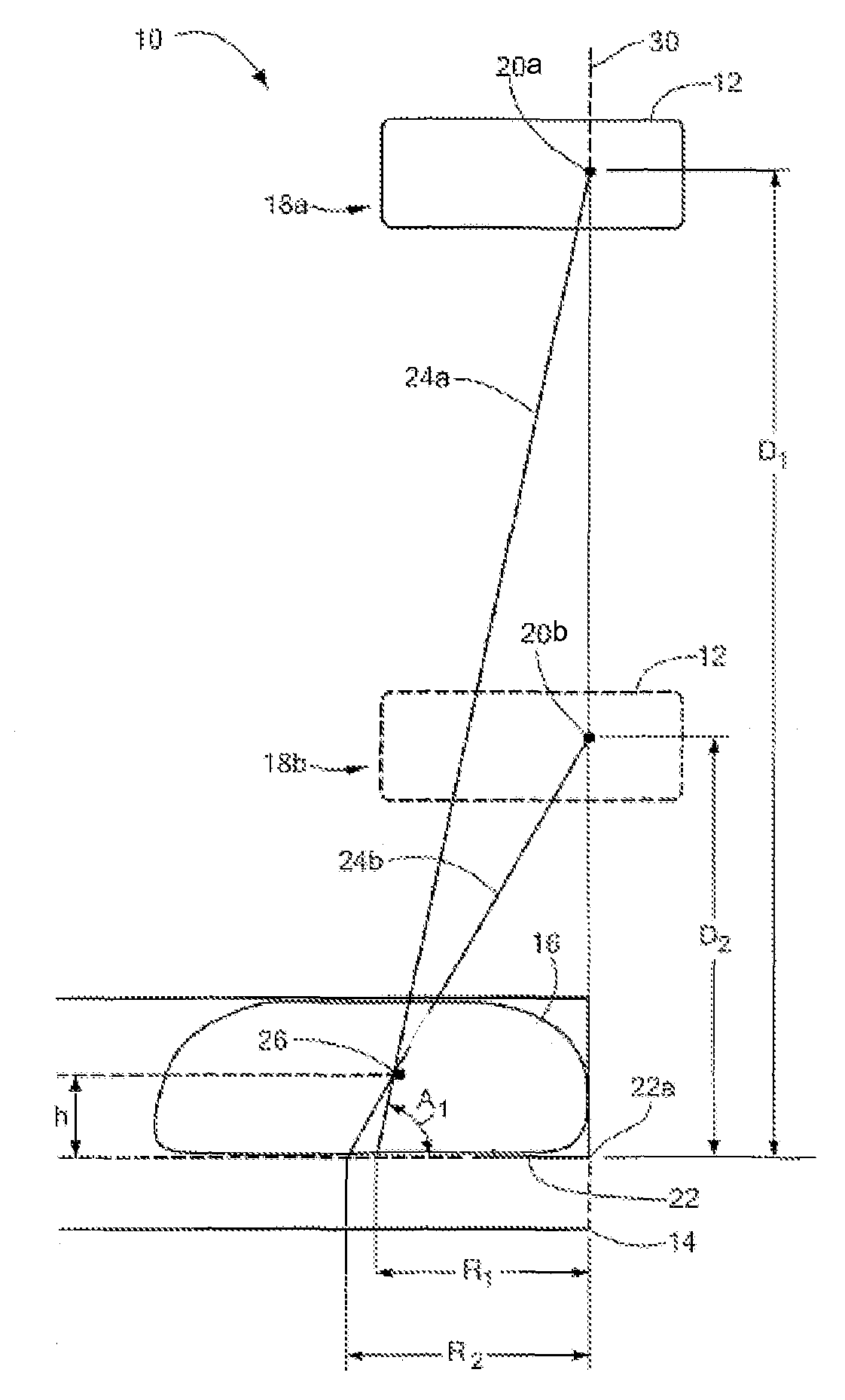

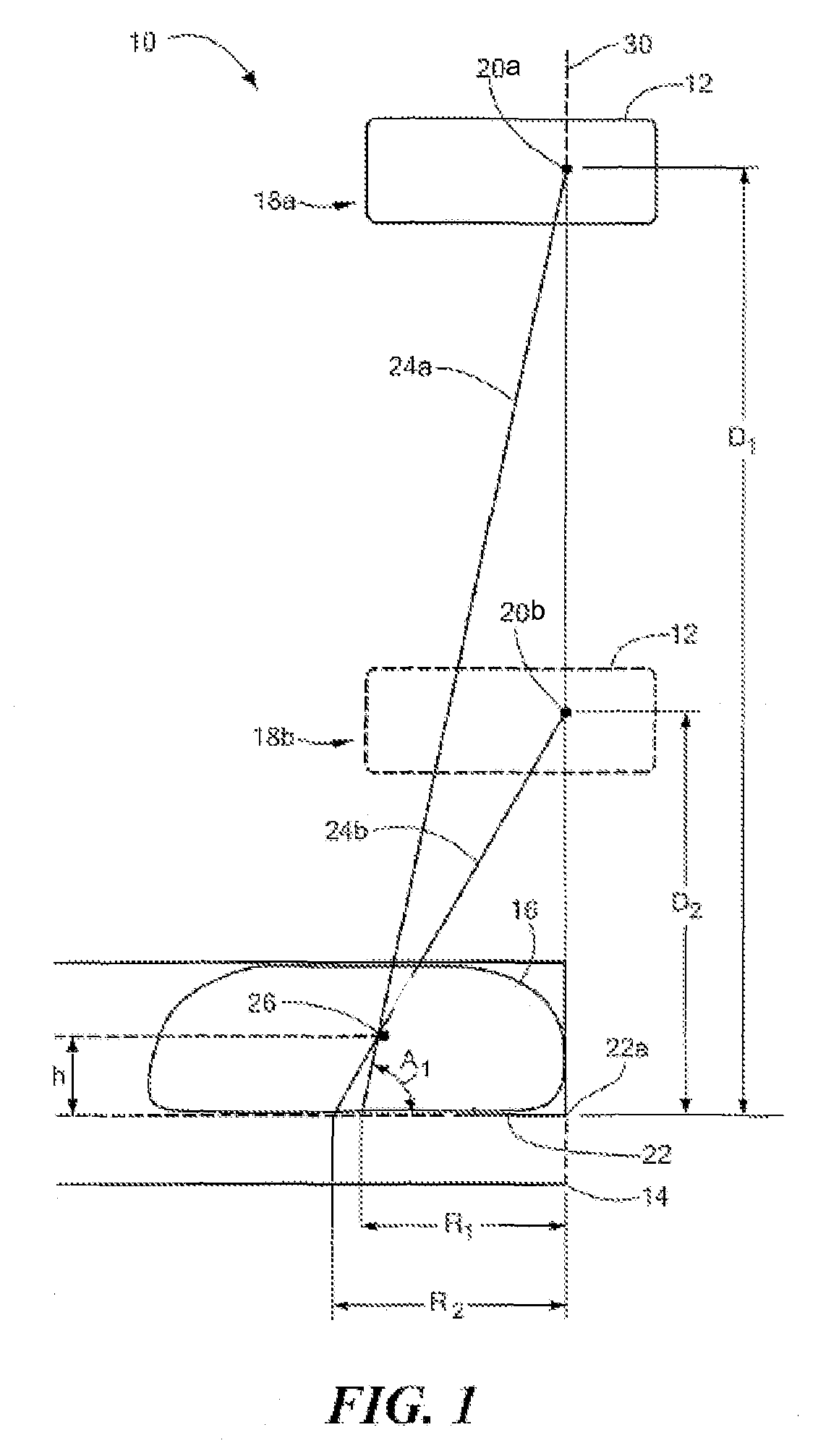

Imaging System and Related Techniques

InactiveUS20080285712A1Reduce the amount of vibrationReduce the amount requiredMaterial analysis using wave/particle radiationRadiation/particle handlingProjection imageComputer science

Owner:THE GENERAL HOSPITAL CORP

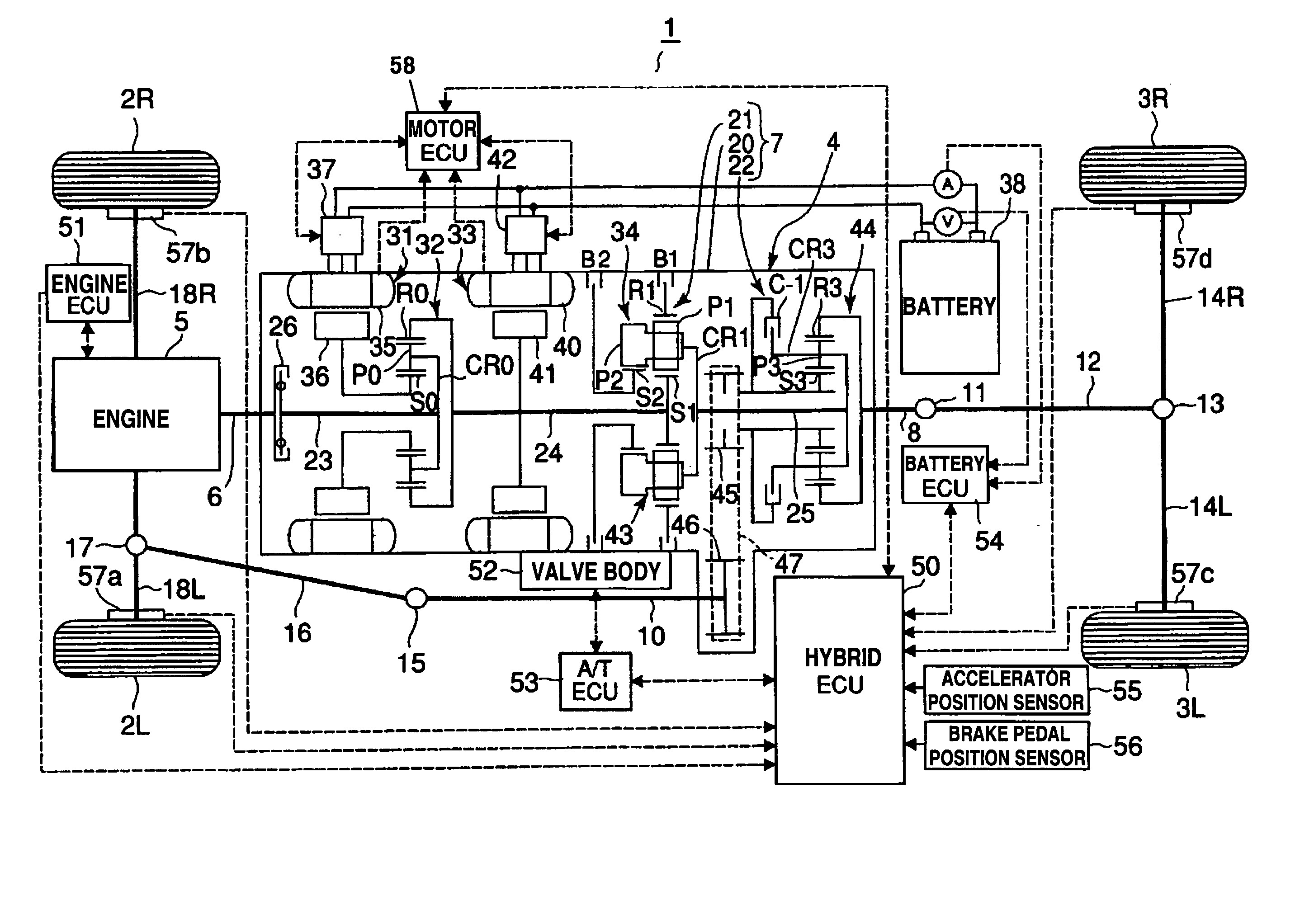

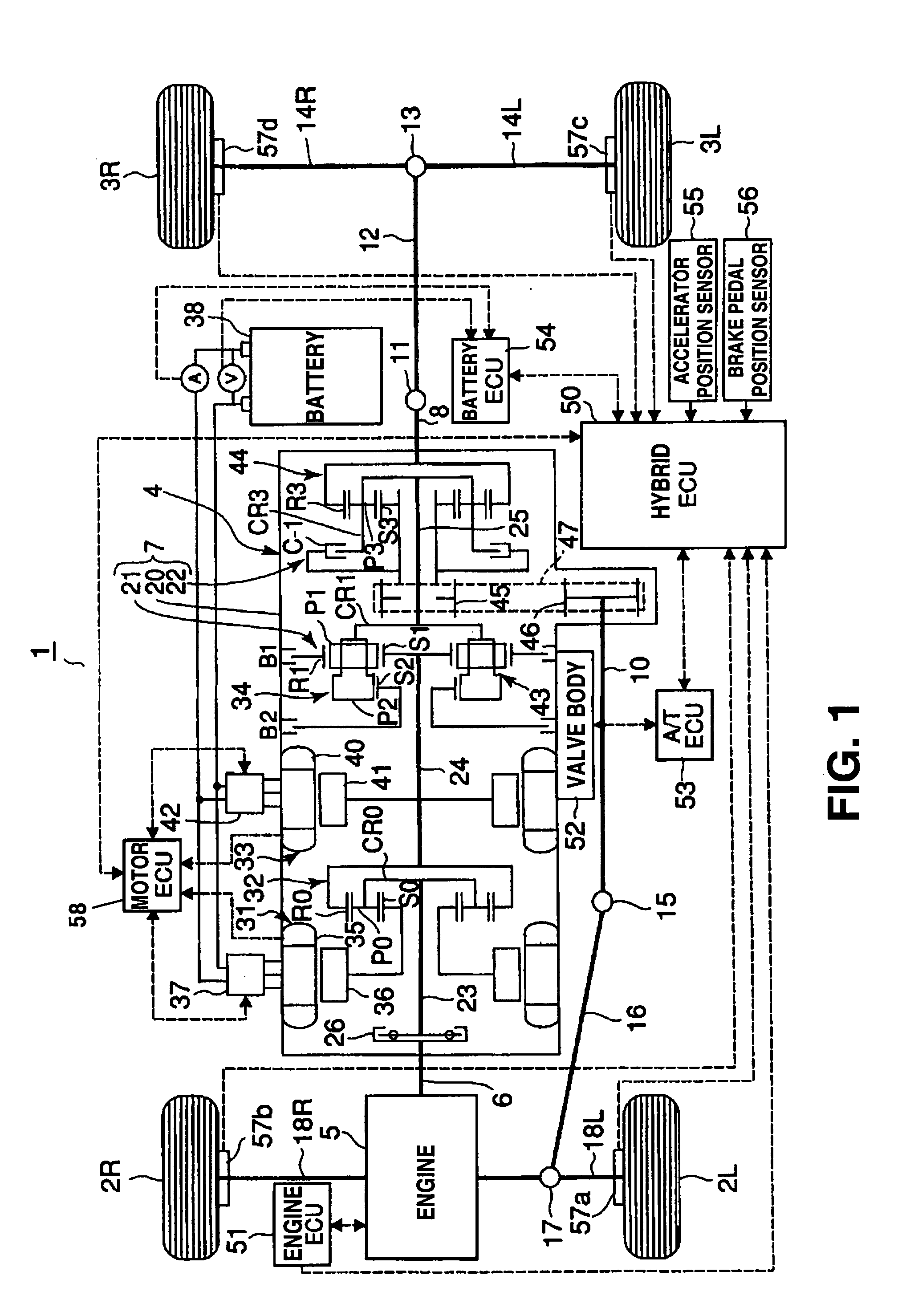

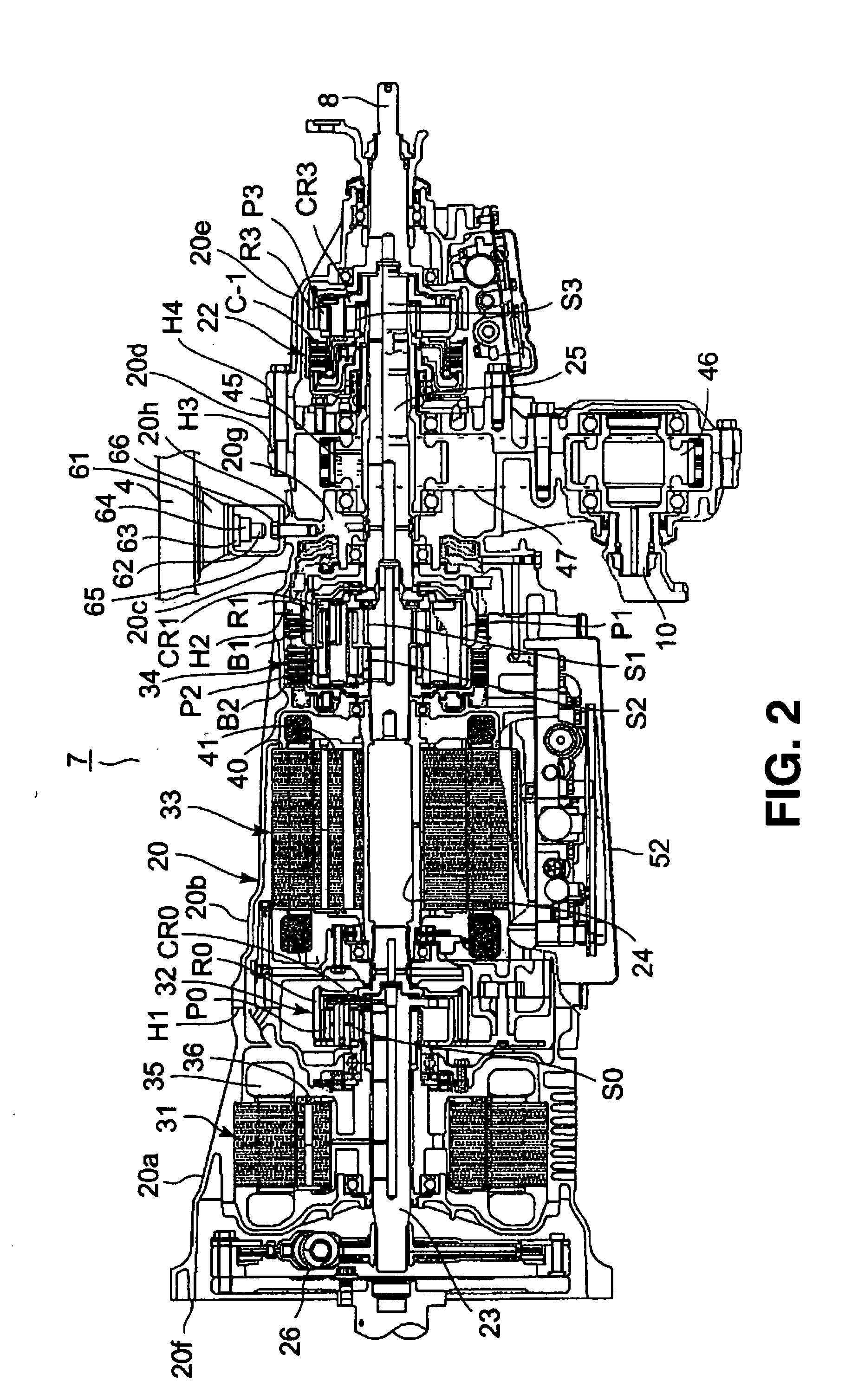

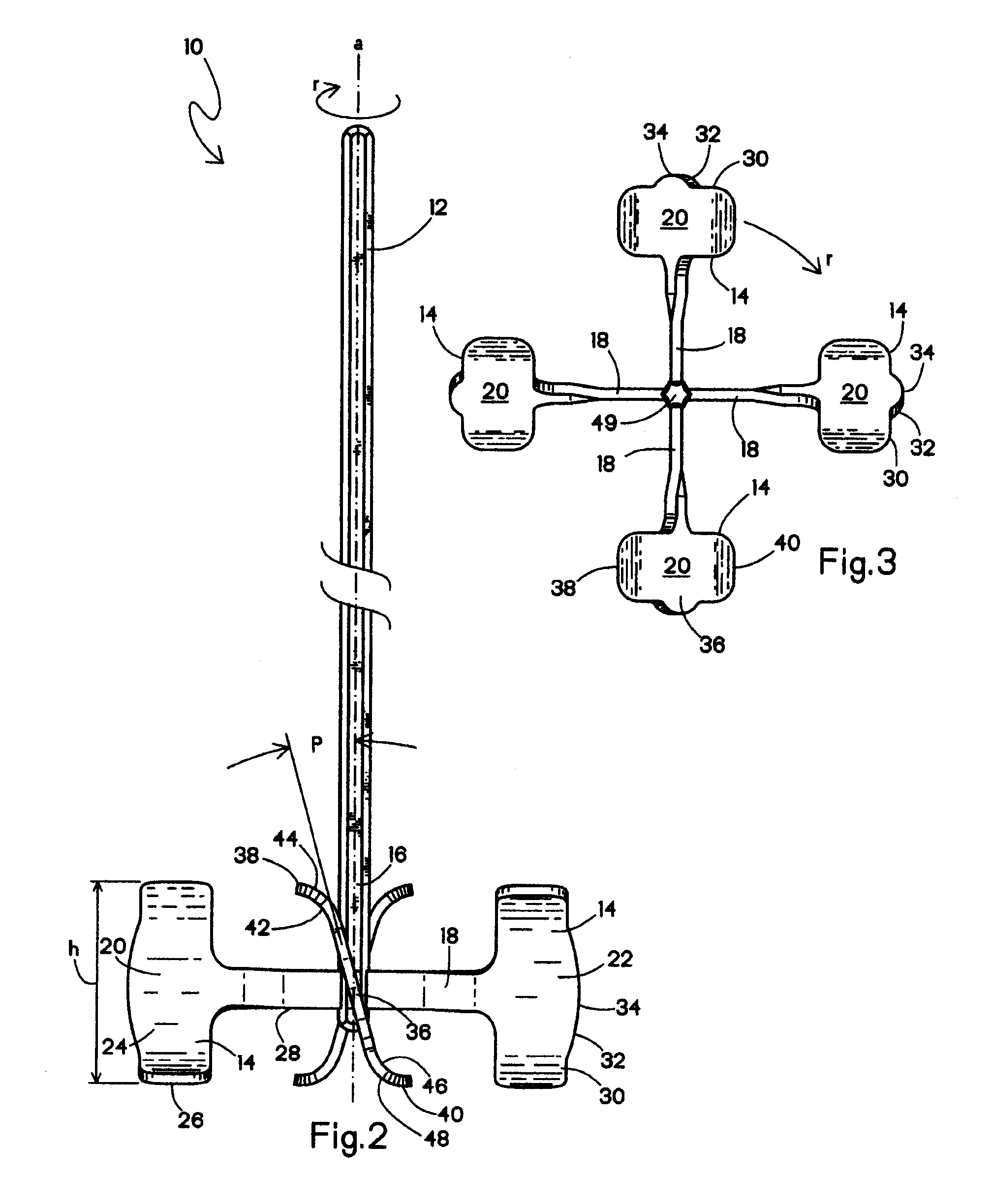

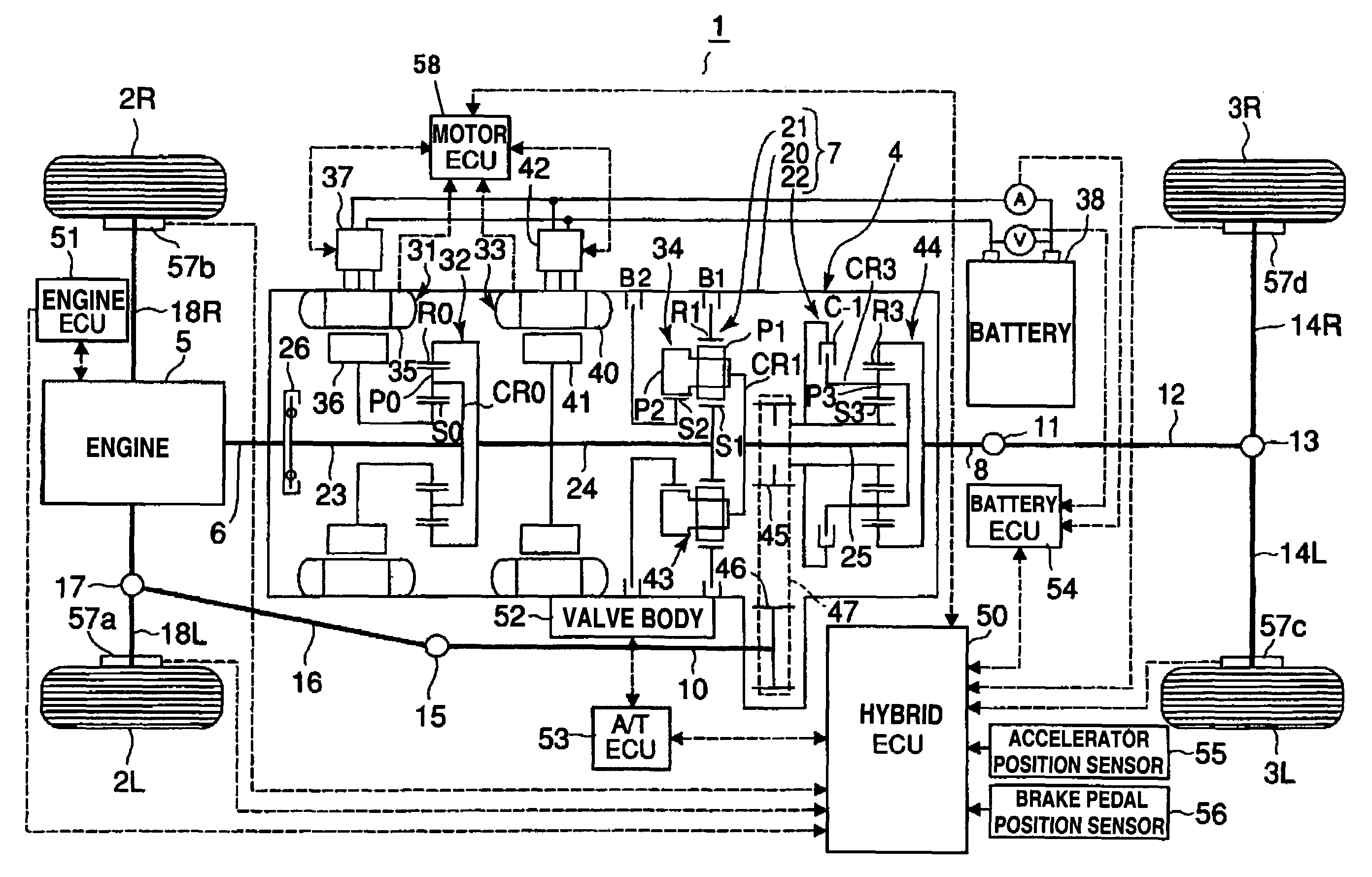

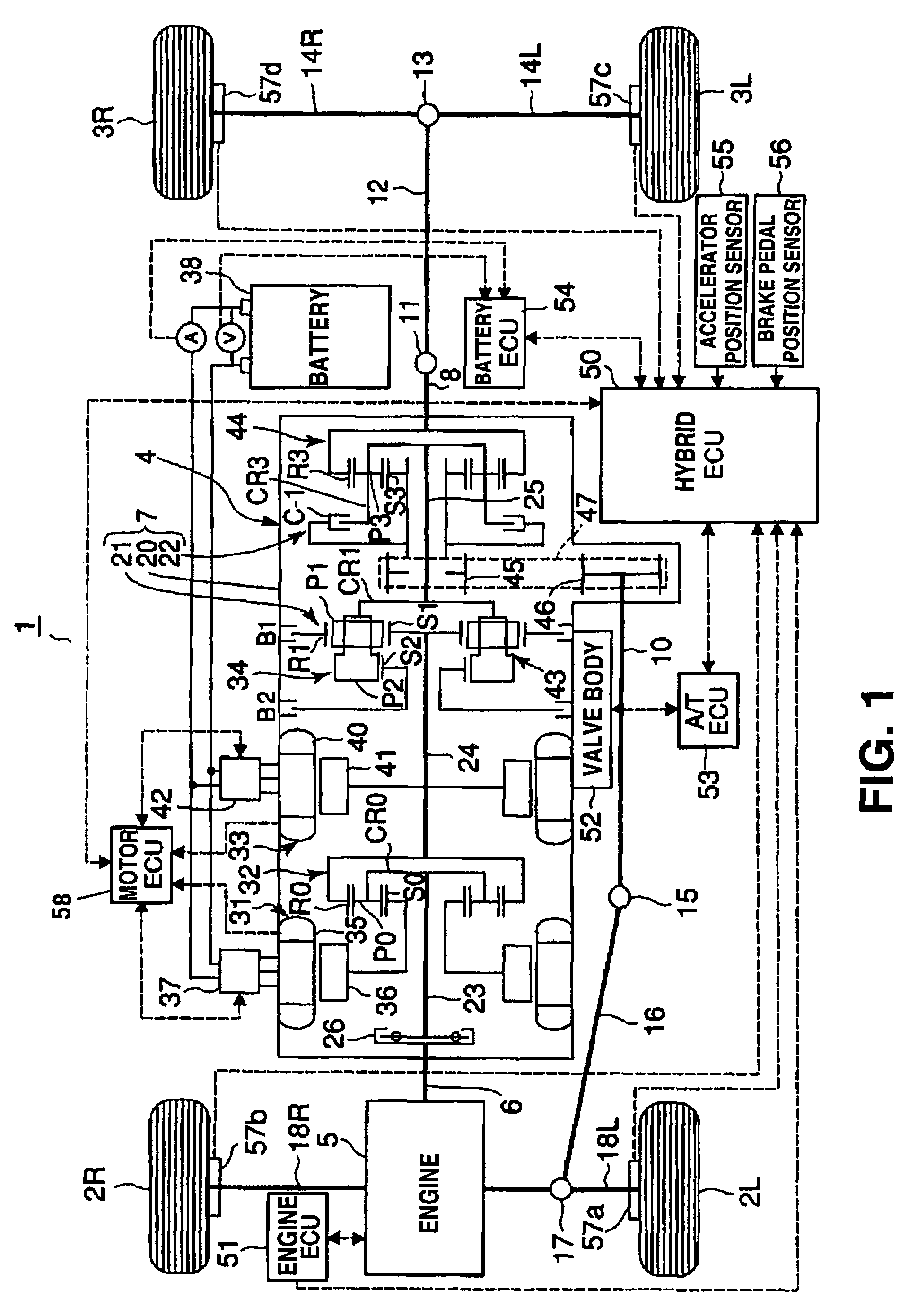

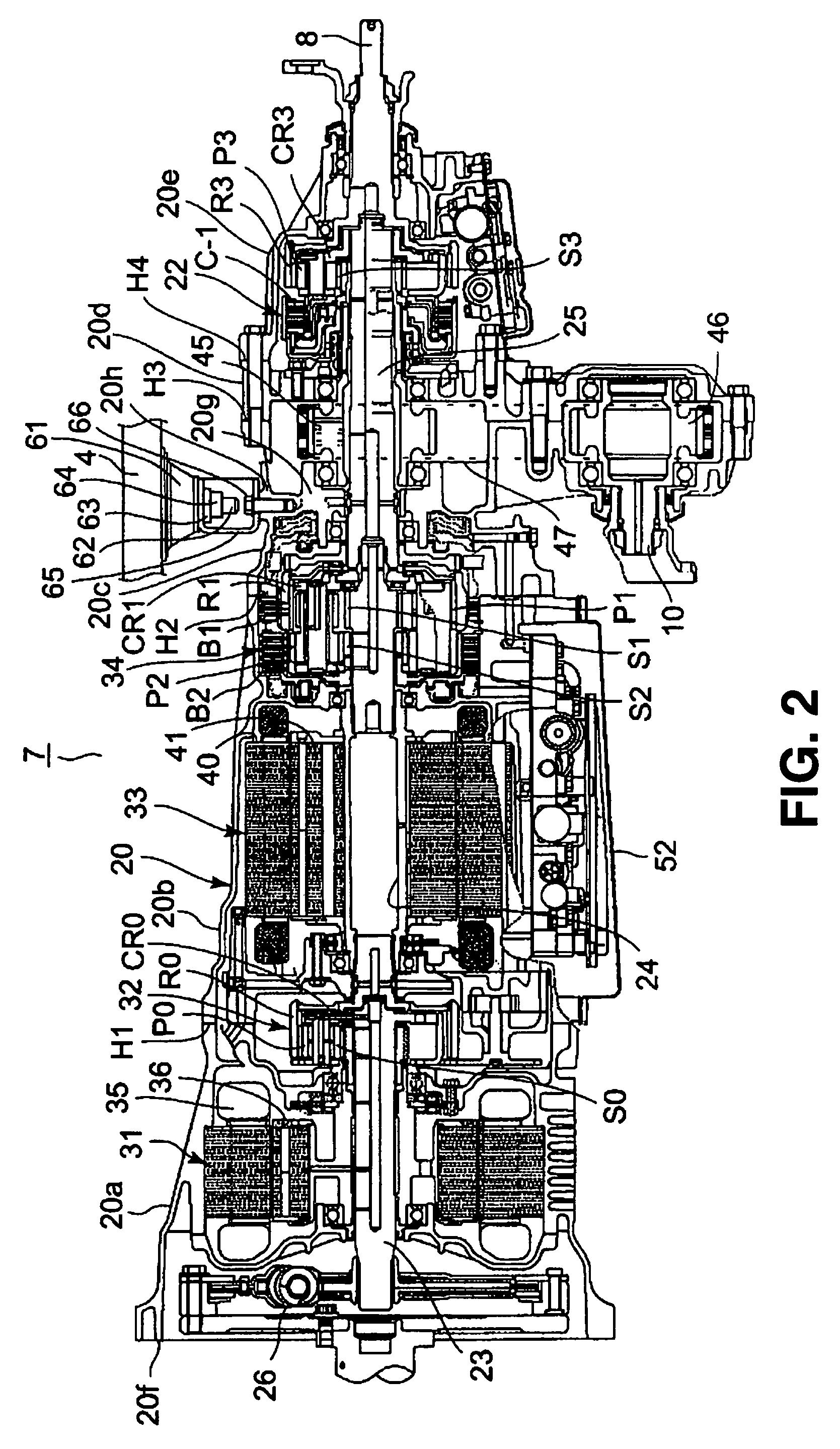

Hybrid drive unit and vehicle mounted therewith

ActiveUS20050115750A1Reduce amount of vibrationFeel goodHybrid vehiclesElectric propulsion mountingStructural elementHybrid drive

A hybrid drive unit includes a hybrid mechanism having at least one electric motor and a transfer that distributes driving force to front and rear wheels. The electric motor and the transfer are housed in a tubular shaped transmission case that extends in the front and rear directions of a vehicle. The hybrid drive unit is mounted on and supported by a second attachment coupled to an internal combustion engine and provided at a front end of the hybrid drive unit and a first attachment portion fixed to a vehicle body. The electric motor and the transfer that are heavy structural members of the hybrid drive unit are positioned separately to the front and rear of the first attachment portion that forms a boundary. By adopting this configuration, it is possible to reduce the amount of engine vibration that is transmitted to the vehicle body through the first attachment portion.

Owner:AISIN AW CO LTD +1

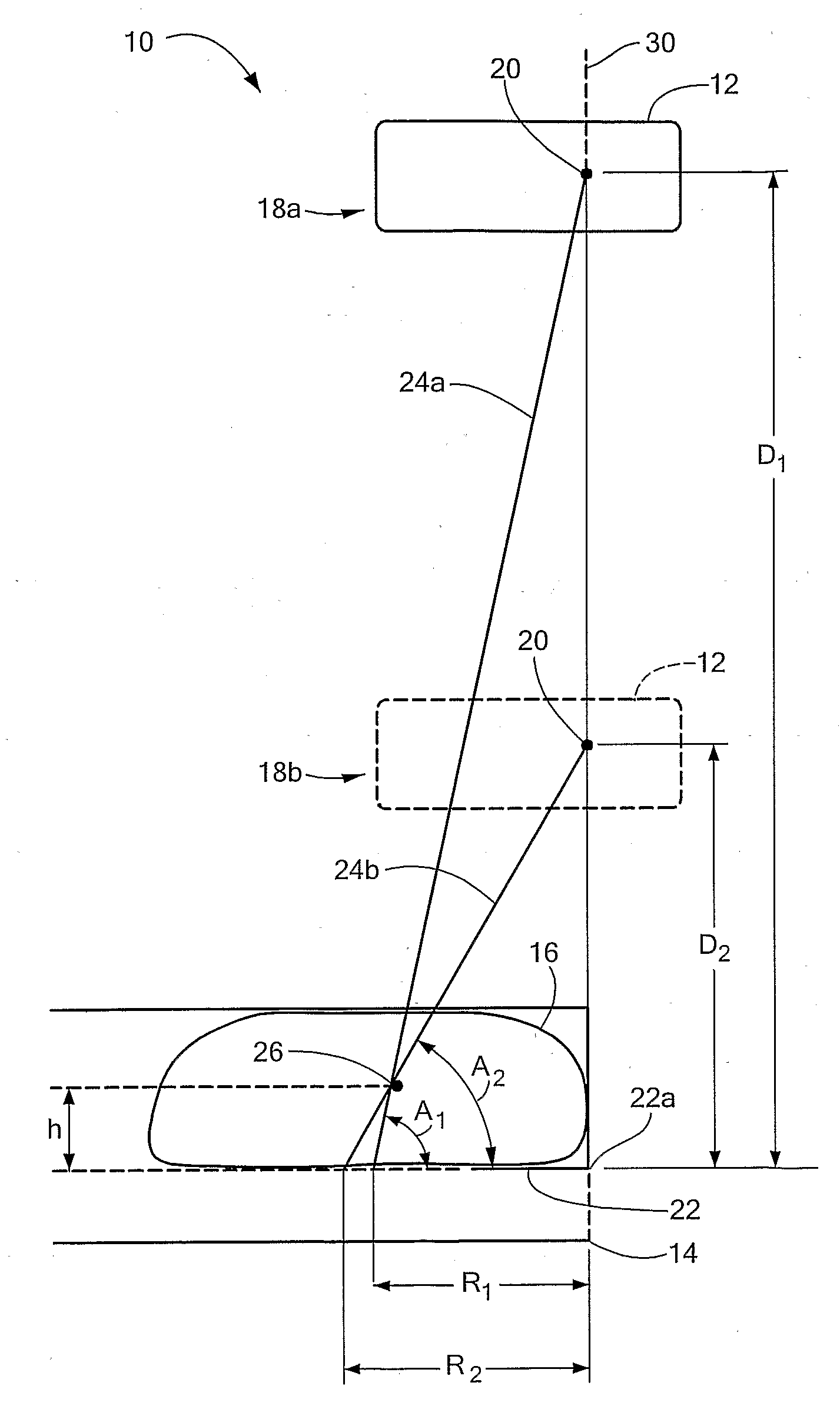

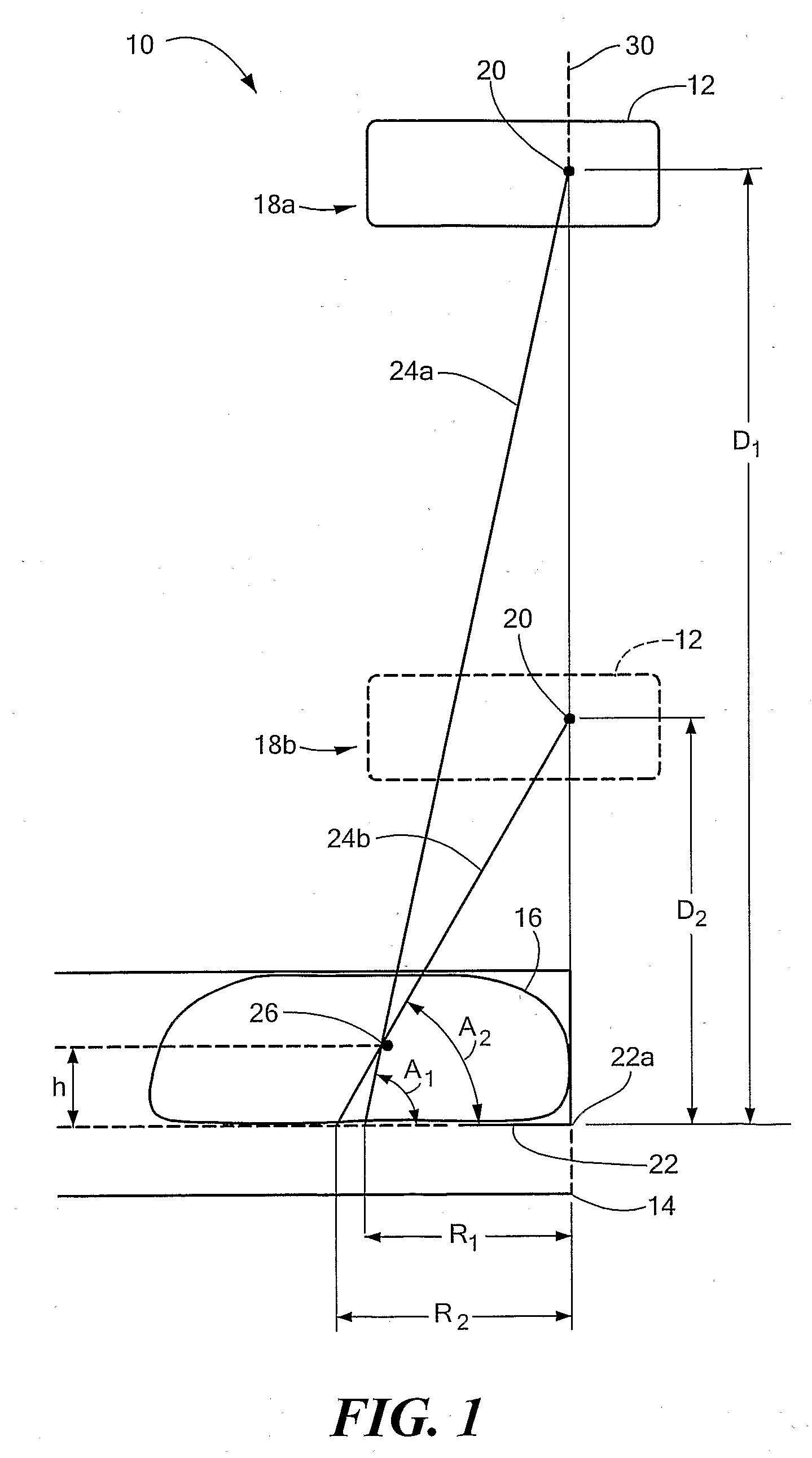

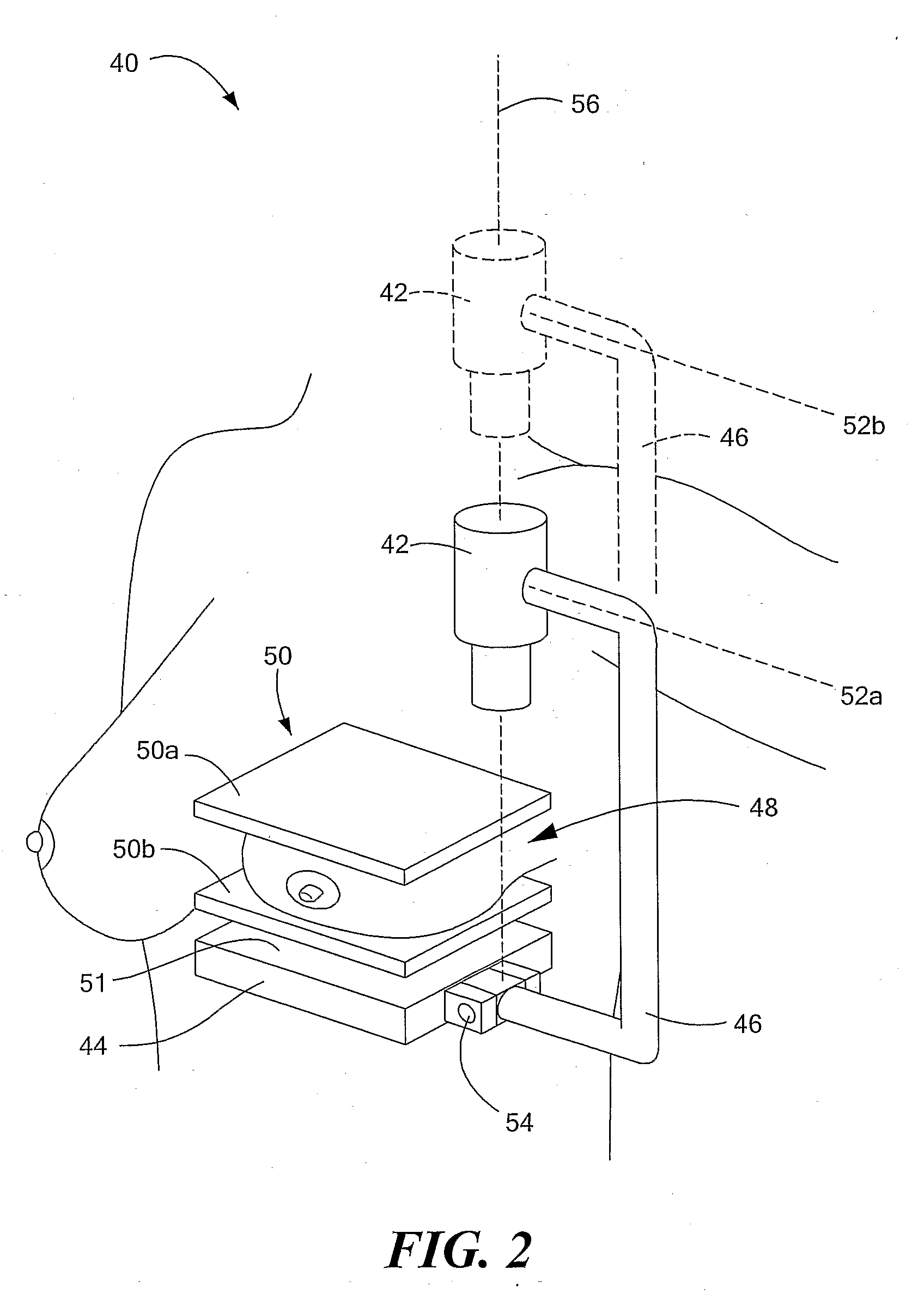

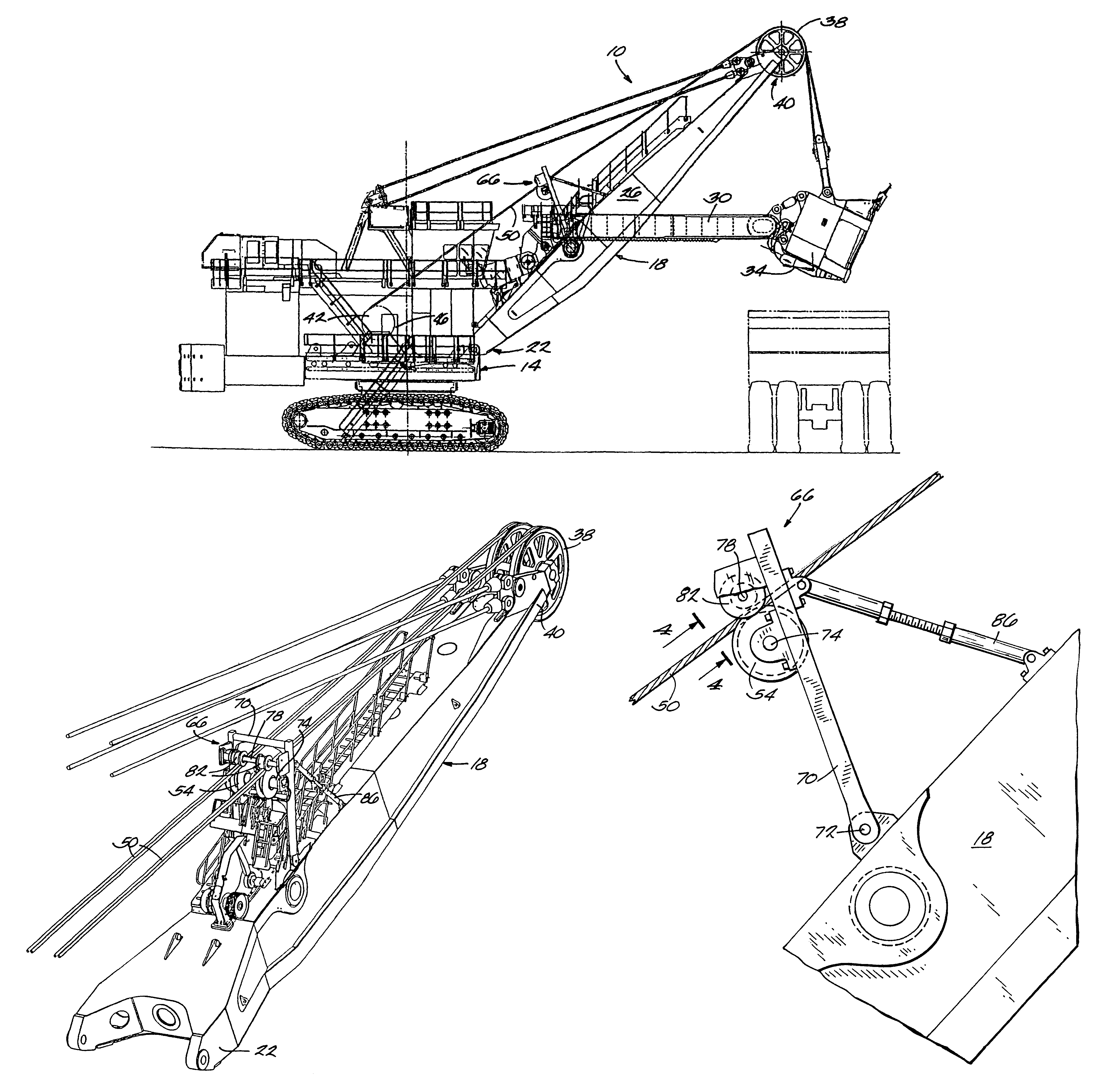

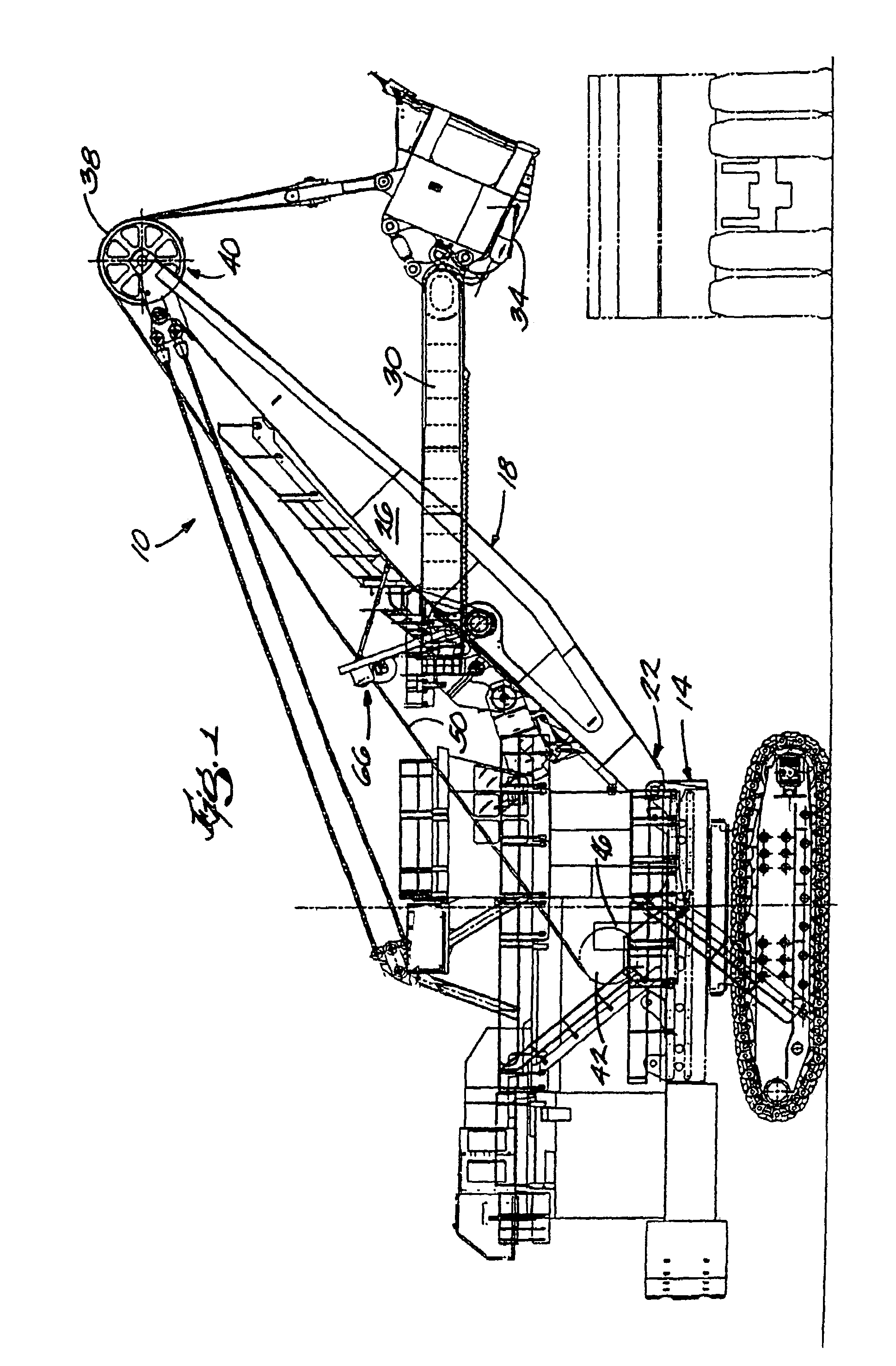

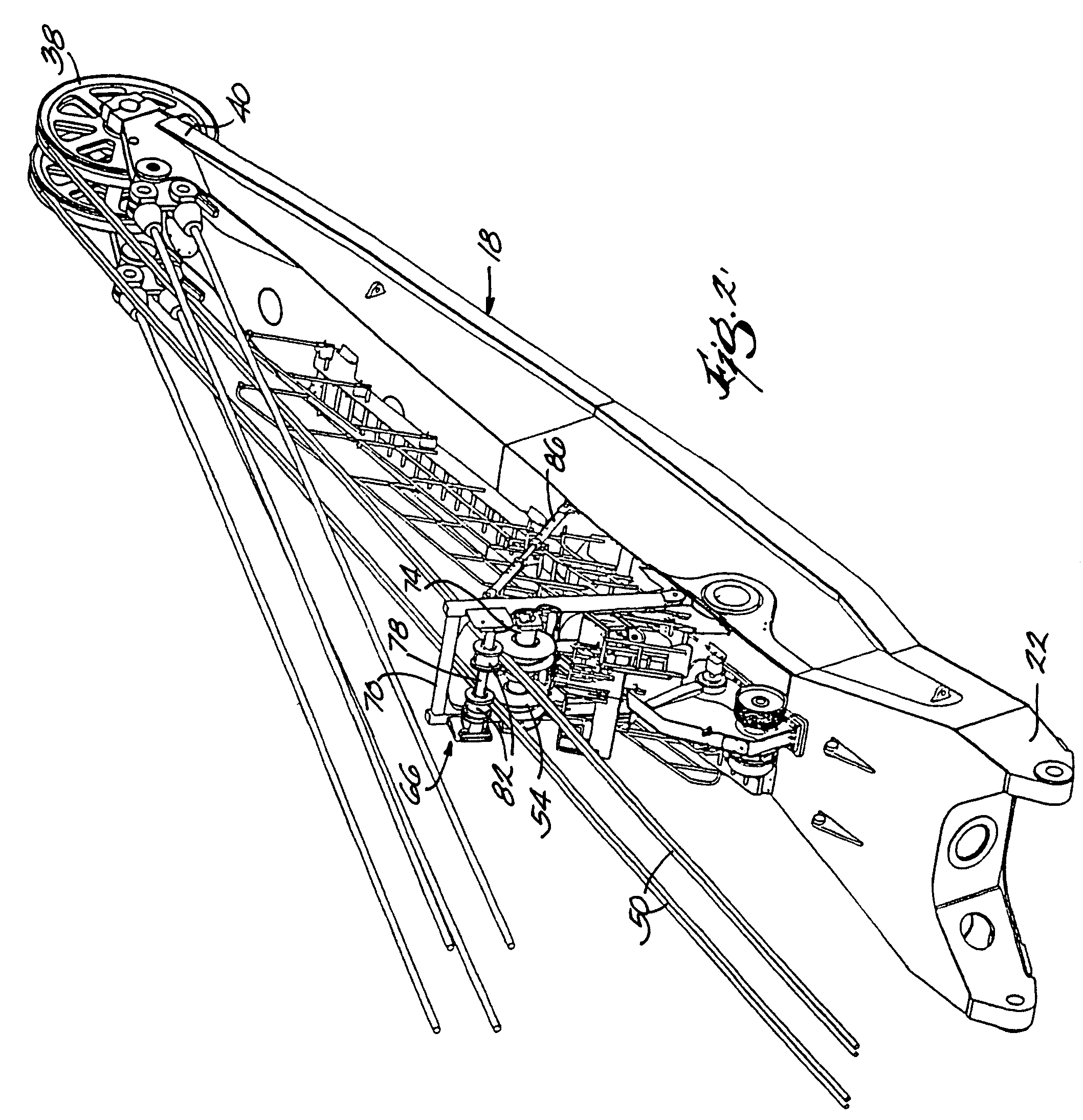

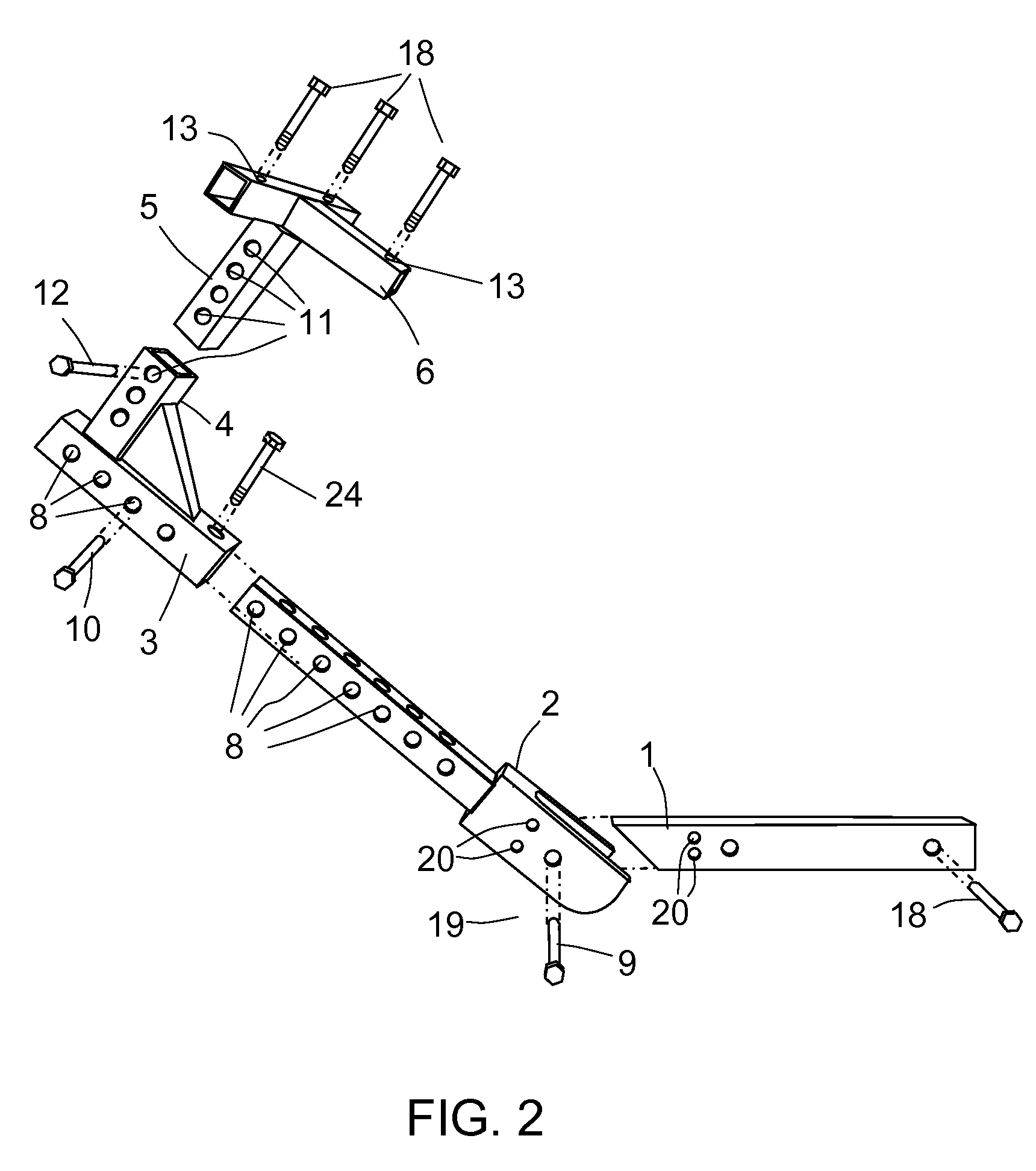

Auxiliary assembly for reducing unwanted movement of a hoist rope

ActiveUS7024806B2Reduce vibrationReduce bending stressMechanical machines/dredgersPortable liftingEngineeringAuxiliary system

An auxiliary hoist sheave assembly comprising a sheave support frame, a mechanism for mounting the sheave support frame to a boom, a lower sheave shaft mounted on the sheave support frame, and a grooved hoist sheave, rotatably supported by and slidable along the lower sheave shaft, the hoist sheave being in contact with a hoist rope, and the hoist sheave fleeting side to side along the lower sheave shaft as the hoist rope follows the hoist drum.

Owner:JOY GLOBAL SURFACE MINING INC

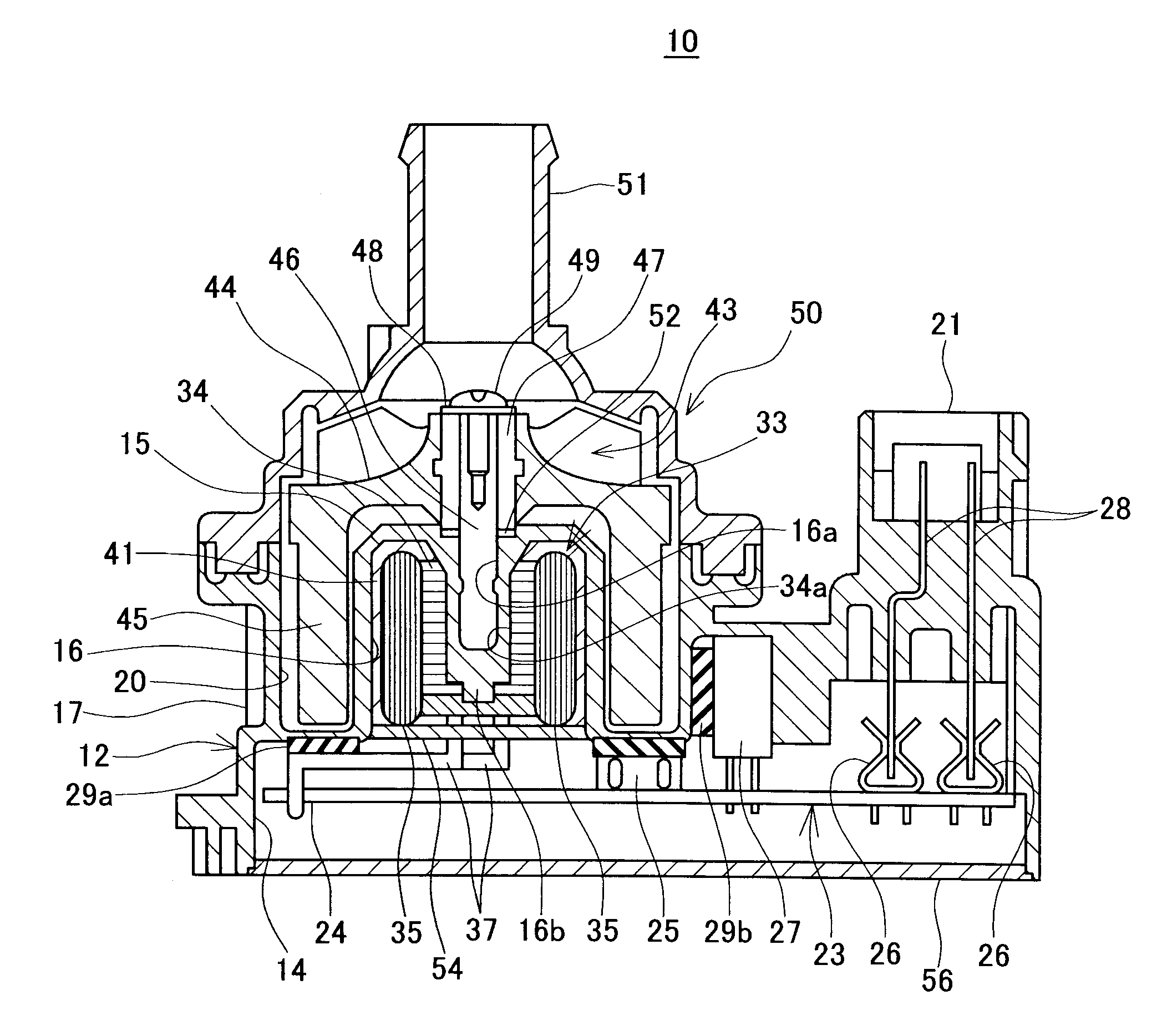

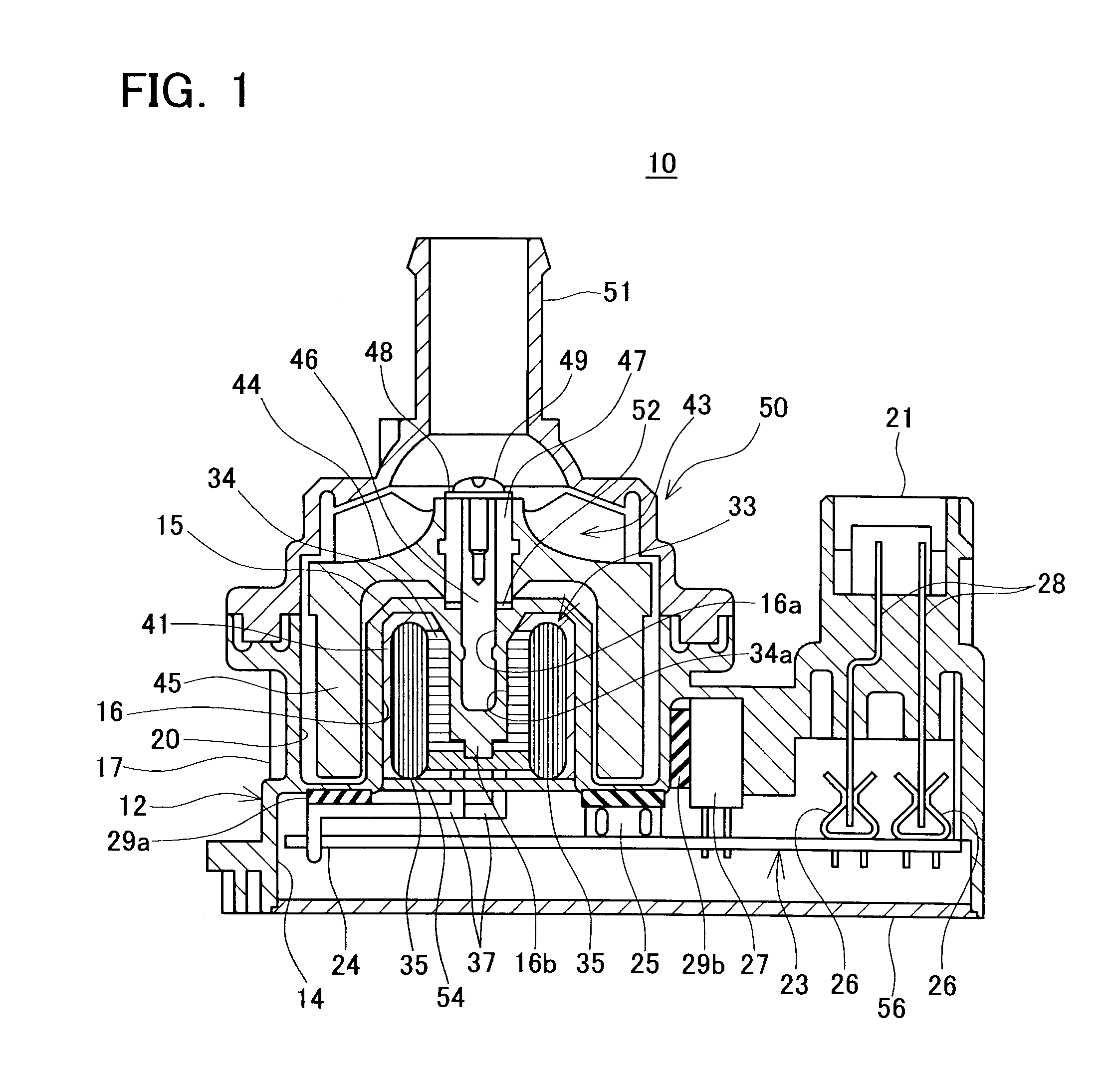

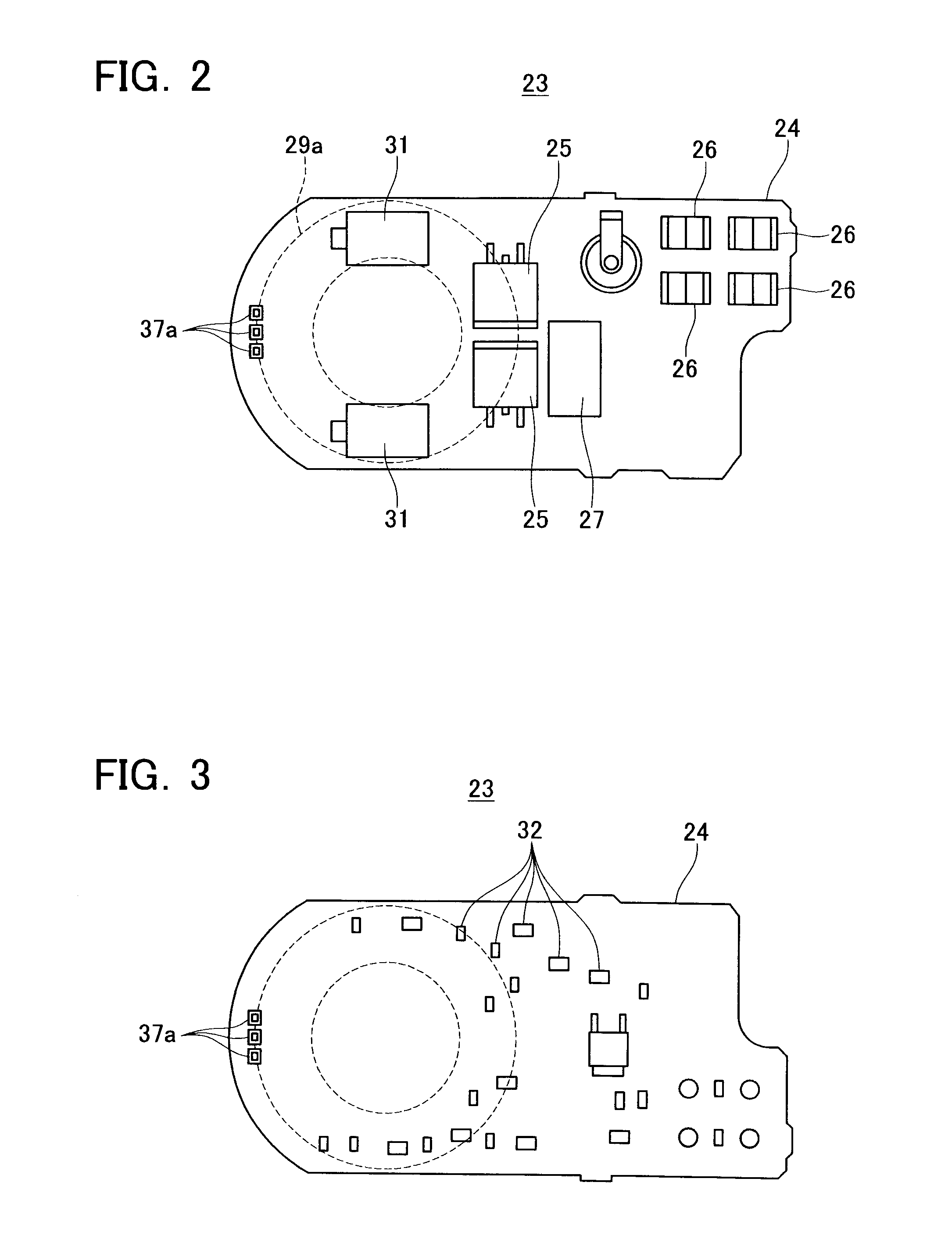

Fluid pump

InactiveUS20080118380A1Efficiently cooling semiconductor deviceReduce vibrationPump componentsPiston pumpsImpellerPump chamber

Fluid pump (10) comprises a casing provided with a partition separating a pump chamber and a housing chamber. Impeller (43) is disposed within the pump chamber. Stator (33), semiconductor device (25), terminal (37), and sheet member (29a) are disposed within the housing chamber. Terminal (37) electrically connects the semiconductor device to the stator. Sheet member (29a) may have rubber elasticity. Preferably, the sheet member has s a first plane surface, which makes contact in a planar manner with the semiconductor device, and a second plane surface which makes contact in a planar manner with the partition of the casing.

Owner:AISAN IND CO LTD

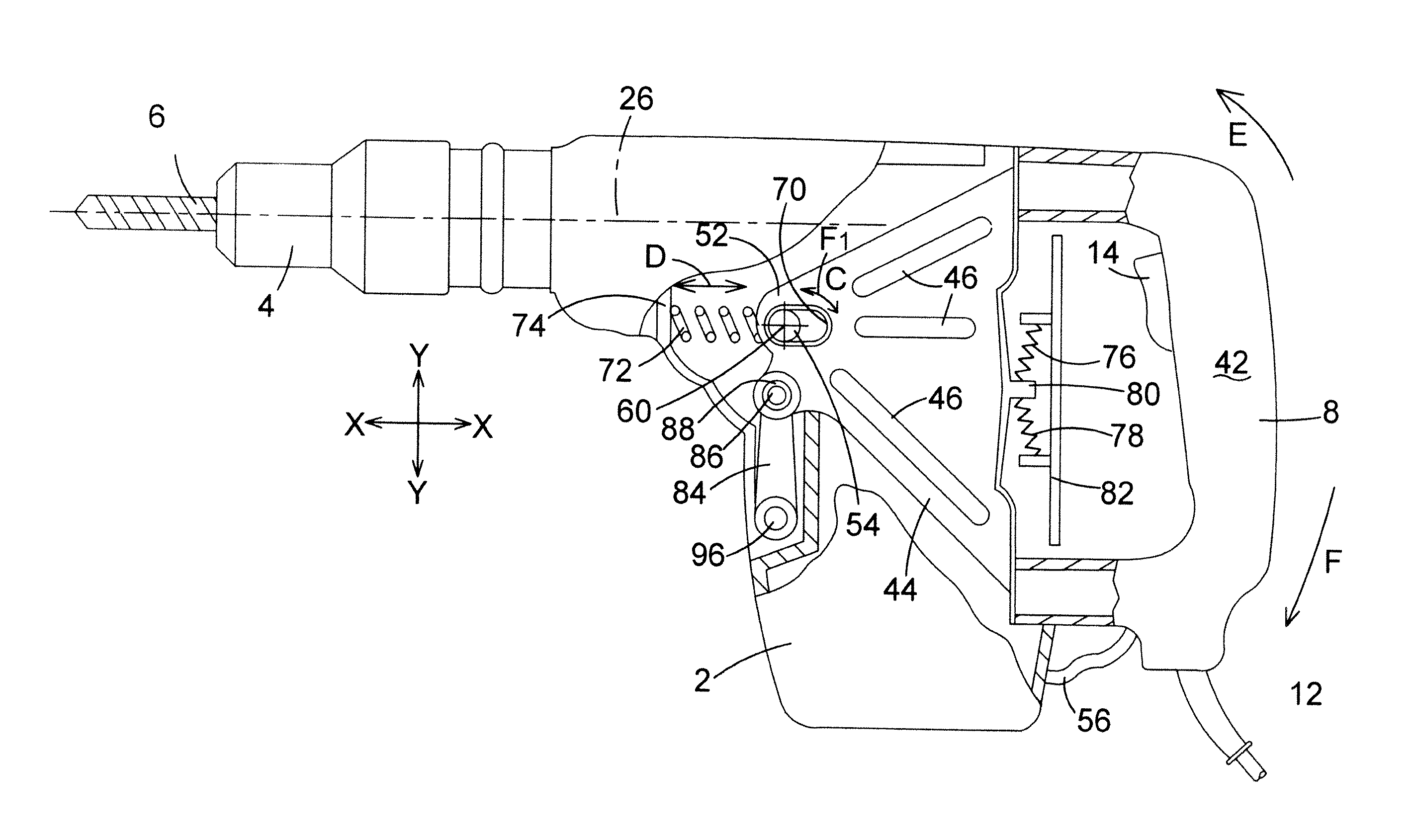

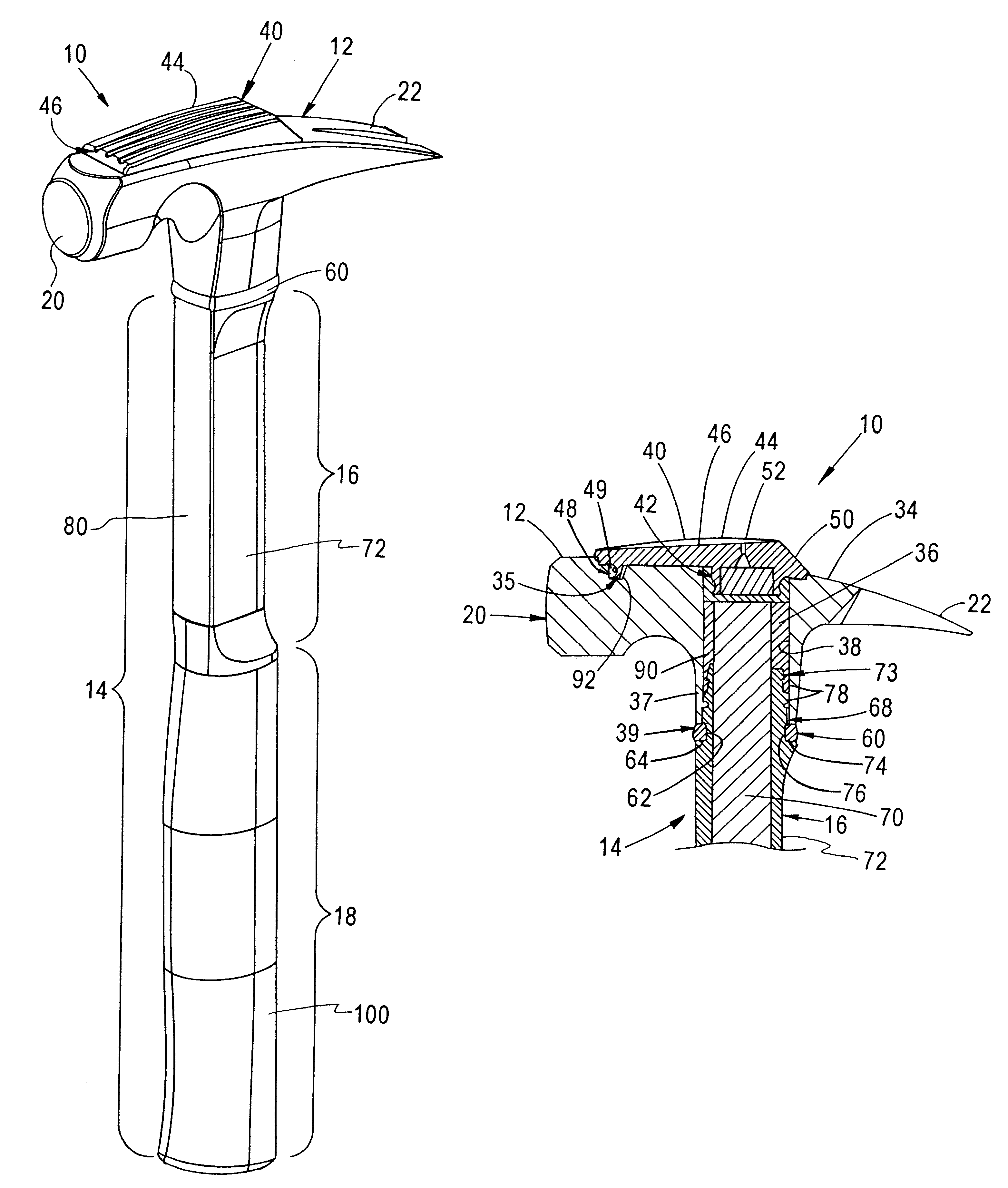

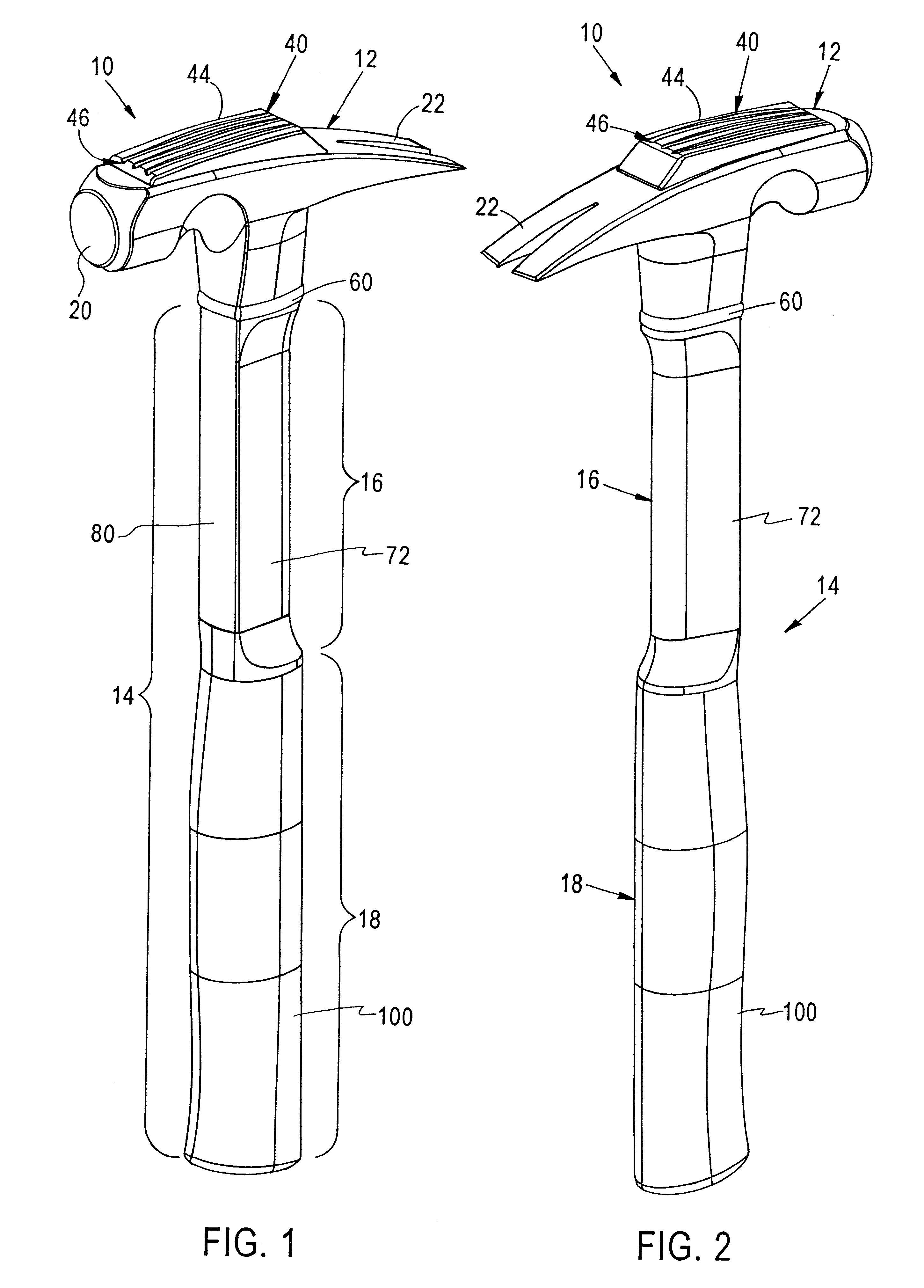

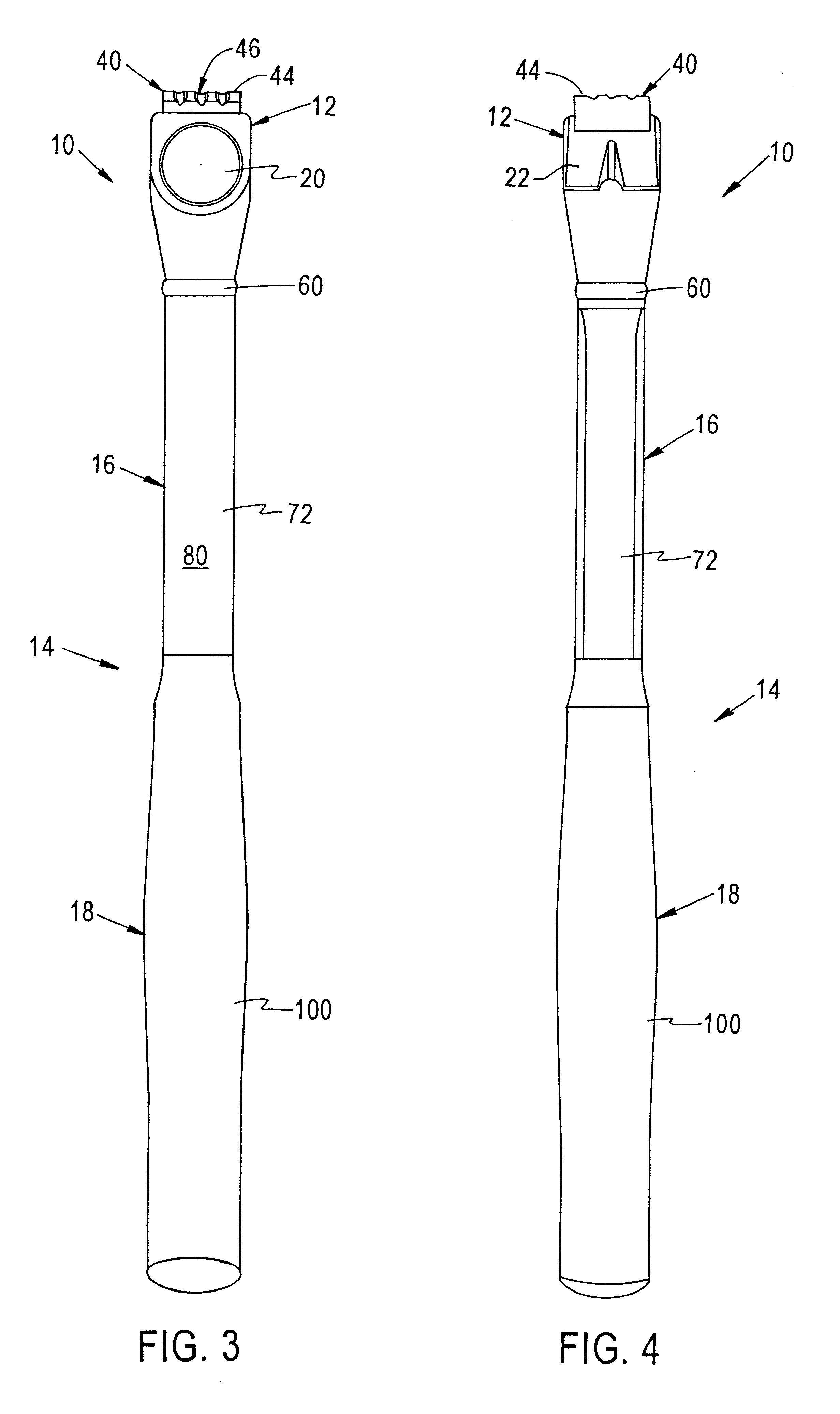

Hammer

InactiveUS7987921B2Reduce the amount requiredReduce the amount of vibrationDrilling rodsReciprocating drilling machinesGravity centerEngineering

Owner:BLACK & DECKER INC

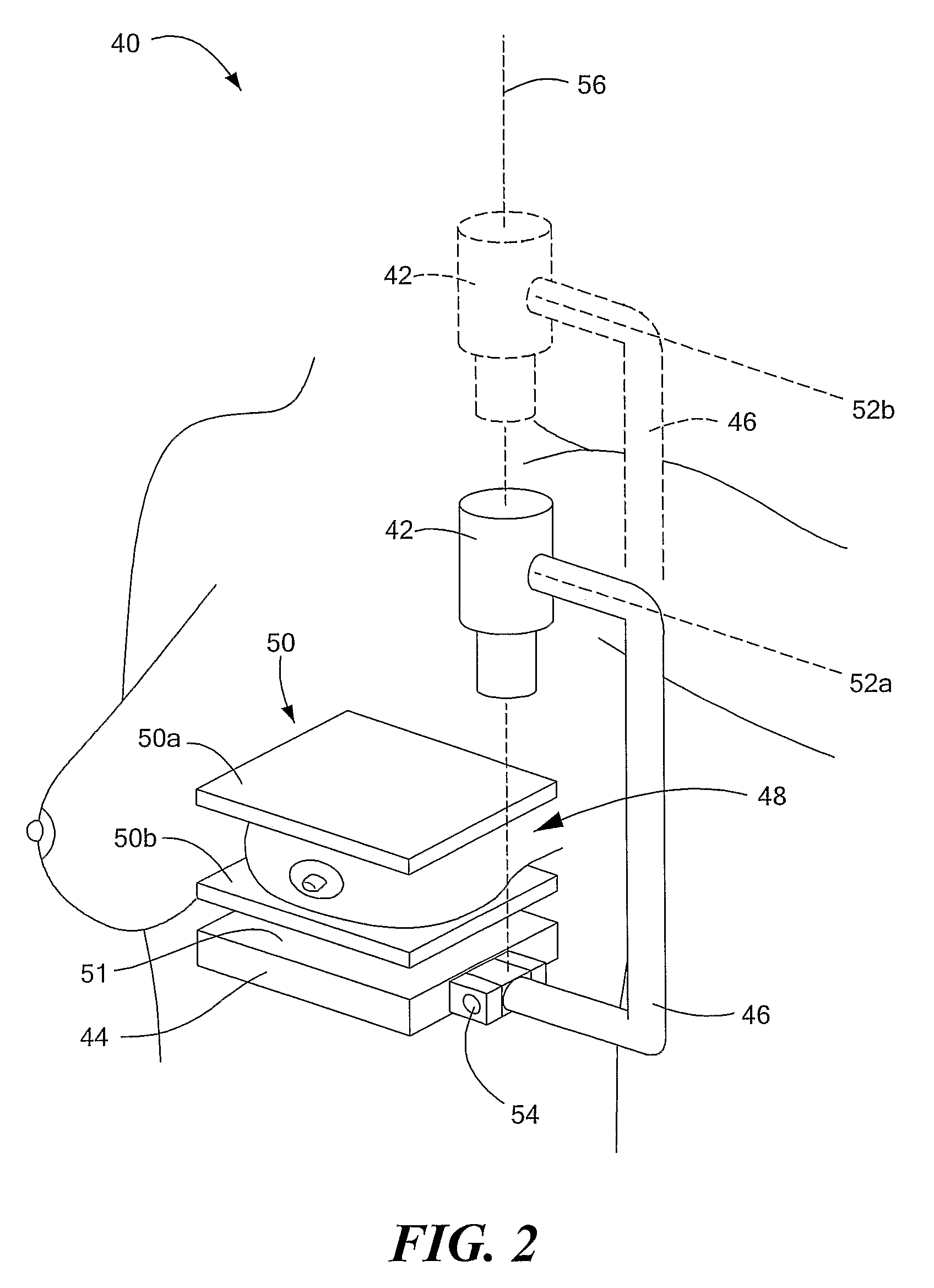

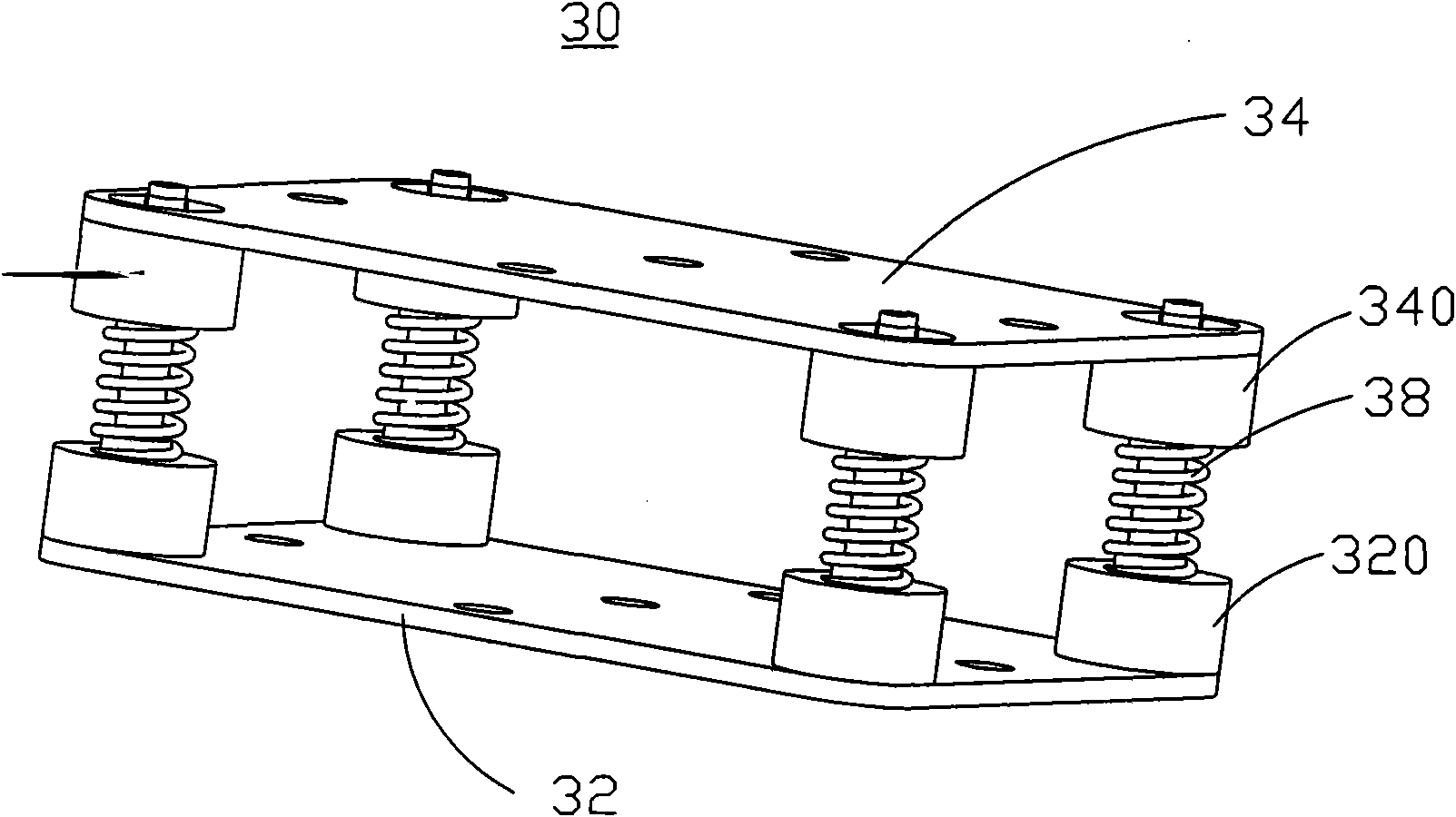

Lamp

InactiveCN101718419AGood vibration damping performanceExtended service lifeProtective devices for lightingEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

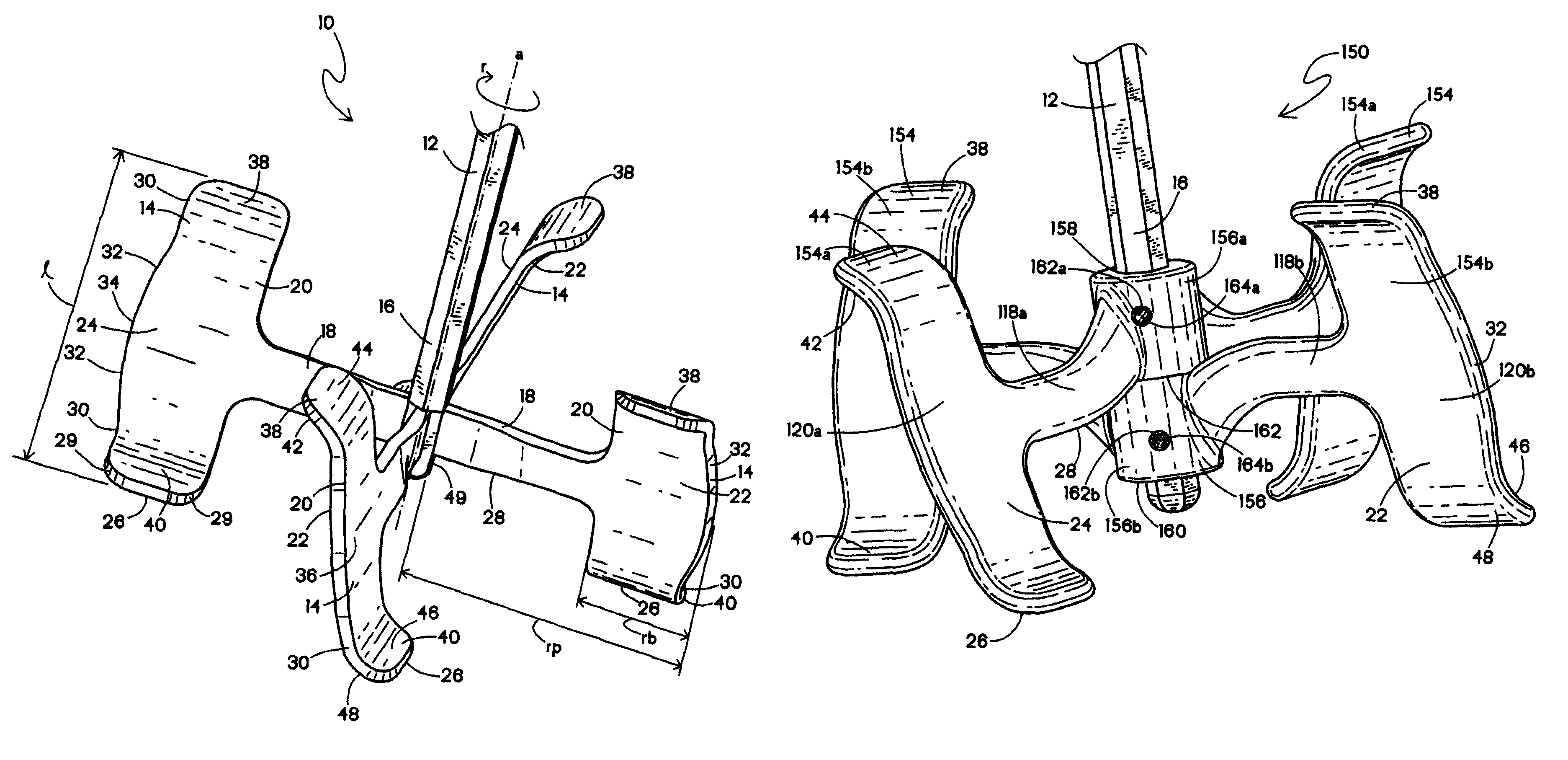

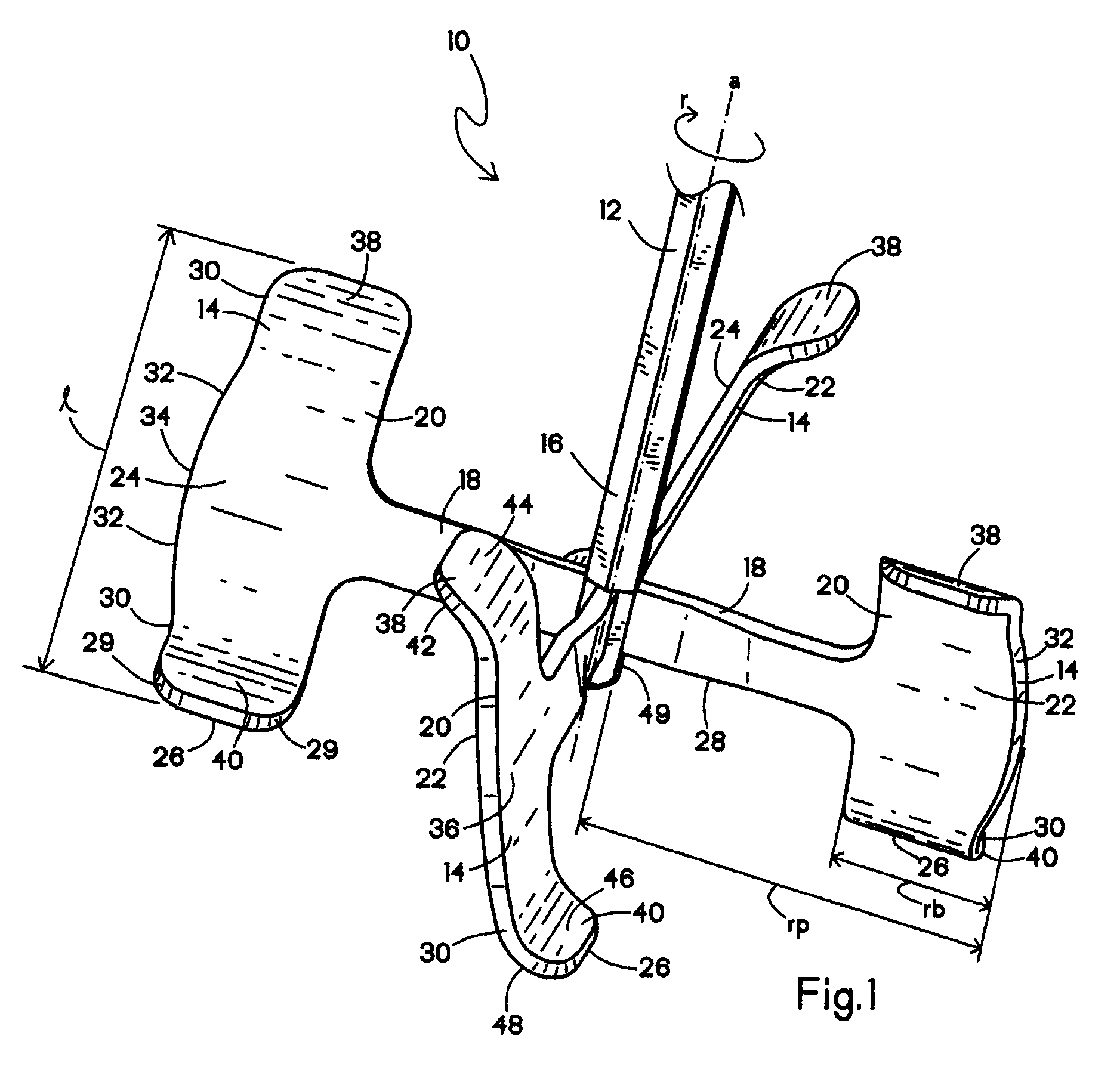

Shock absorption system for a striking tool

InactiveUS6363817B1Reduce the amount of vibrationComfortable gripHand hammersMetal-working hand toolsEngineeringMechanical engineering

A system for absorbing shock including a resilient member positioned between a portion of the head and a portion of the shaft of the tool. The resilient member dampens and absorbs vibration travelling from the head to the shaft and reverberations travelling through the tool. The system also includes a shock-absorbing member having an internal portion positioned within a cavity in the head of the tool and an external portion positioned on an upper surface of the head that dampens and absorbs vibration travelling within the head and reverberations travelling through the tool. The system further includes a bonding material filling spaces with the cavity and a channel within the head that further dampens and absorbs vibration travelling from the head to the shaft and reverberations travelling through the tool. The system includes a handle portion that has a soft elastomeric outer coating that provides a comfortable grip to the user and hinders vibration from travelling from the shaft to the hand of the user.

Owner:HELEN OF TROY LIMITED

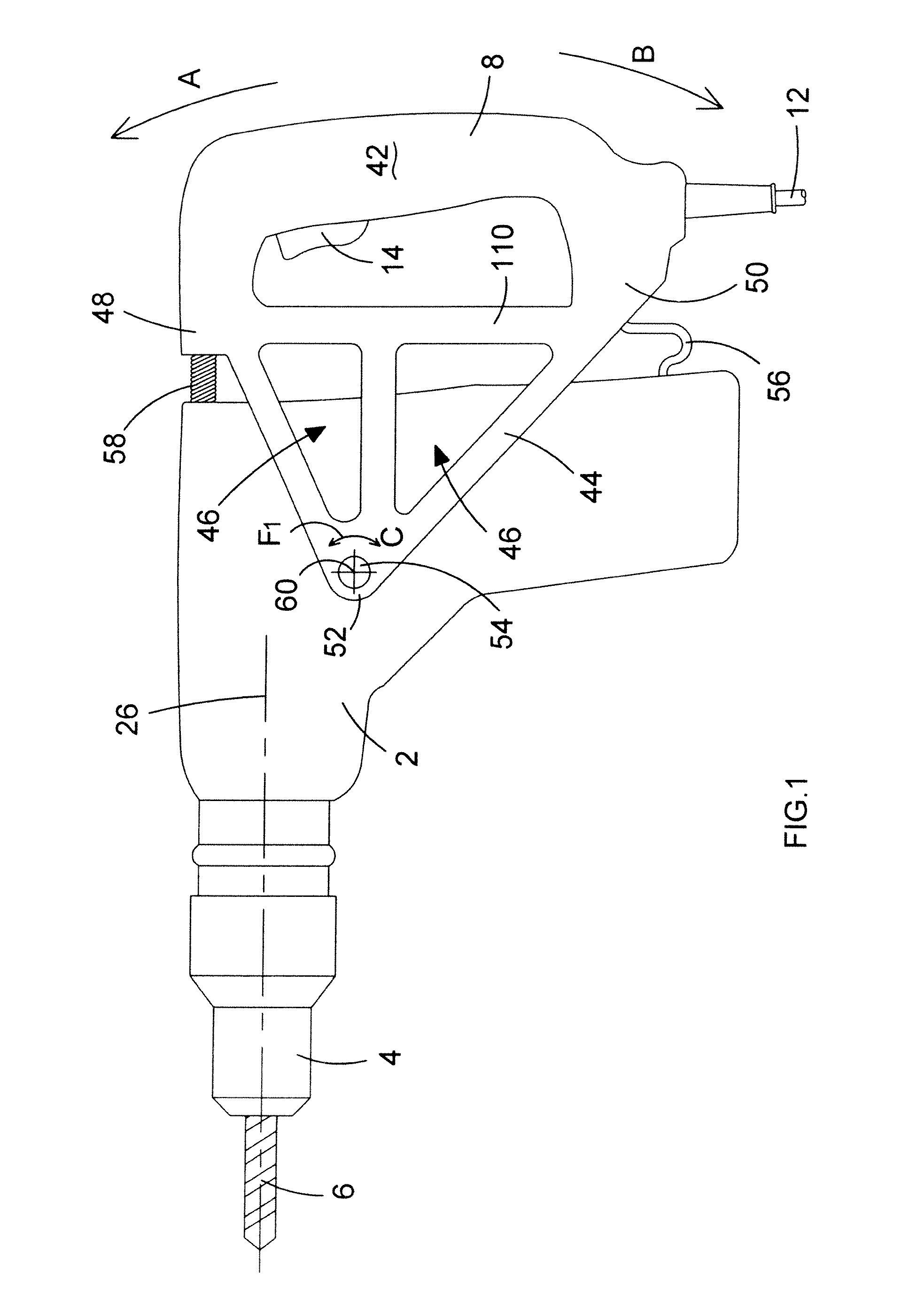

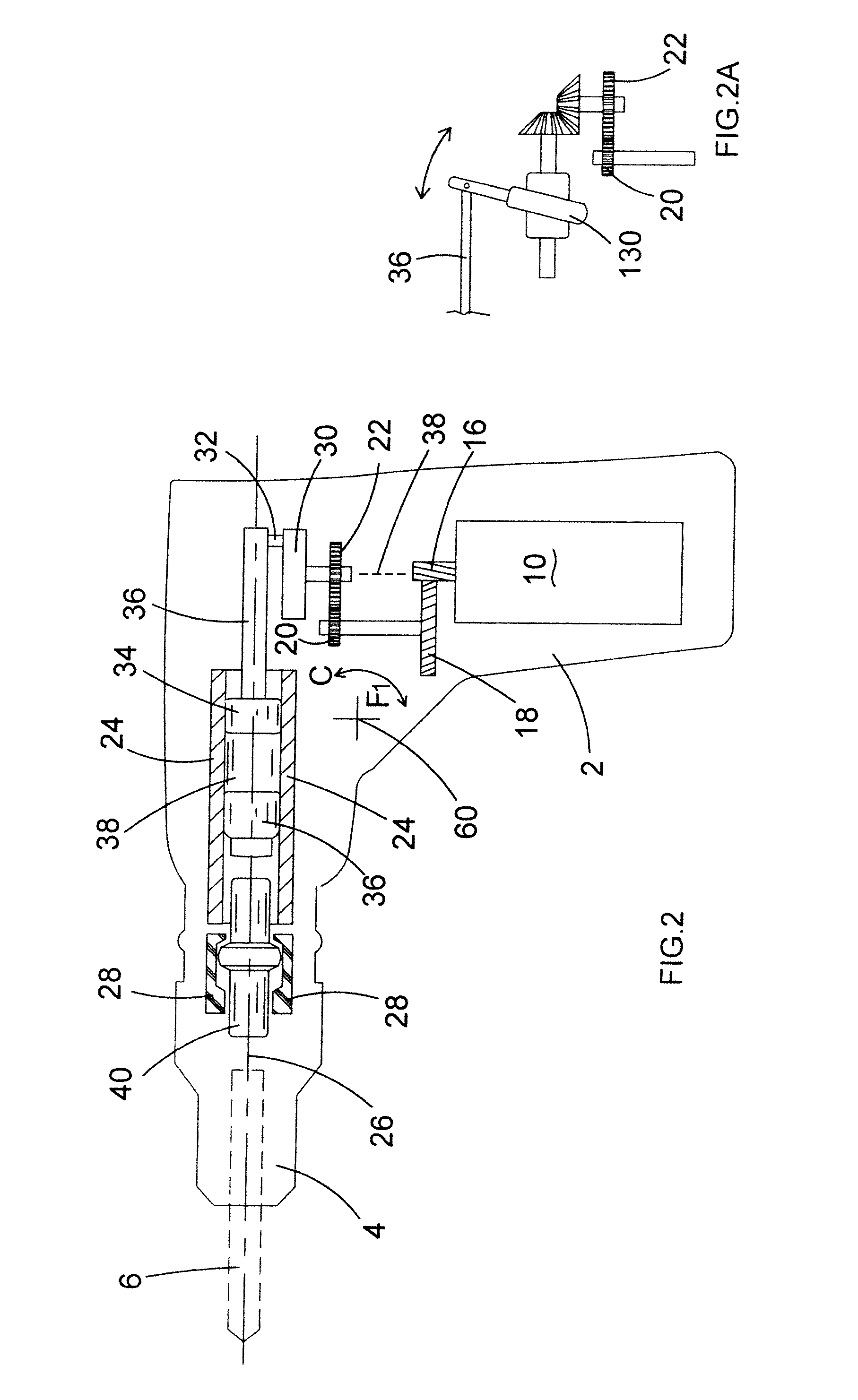

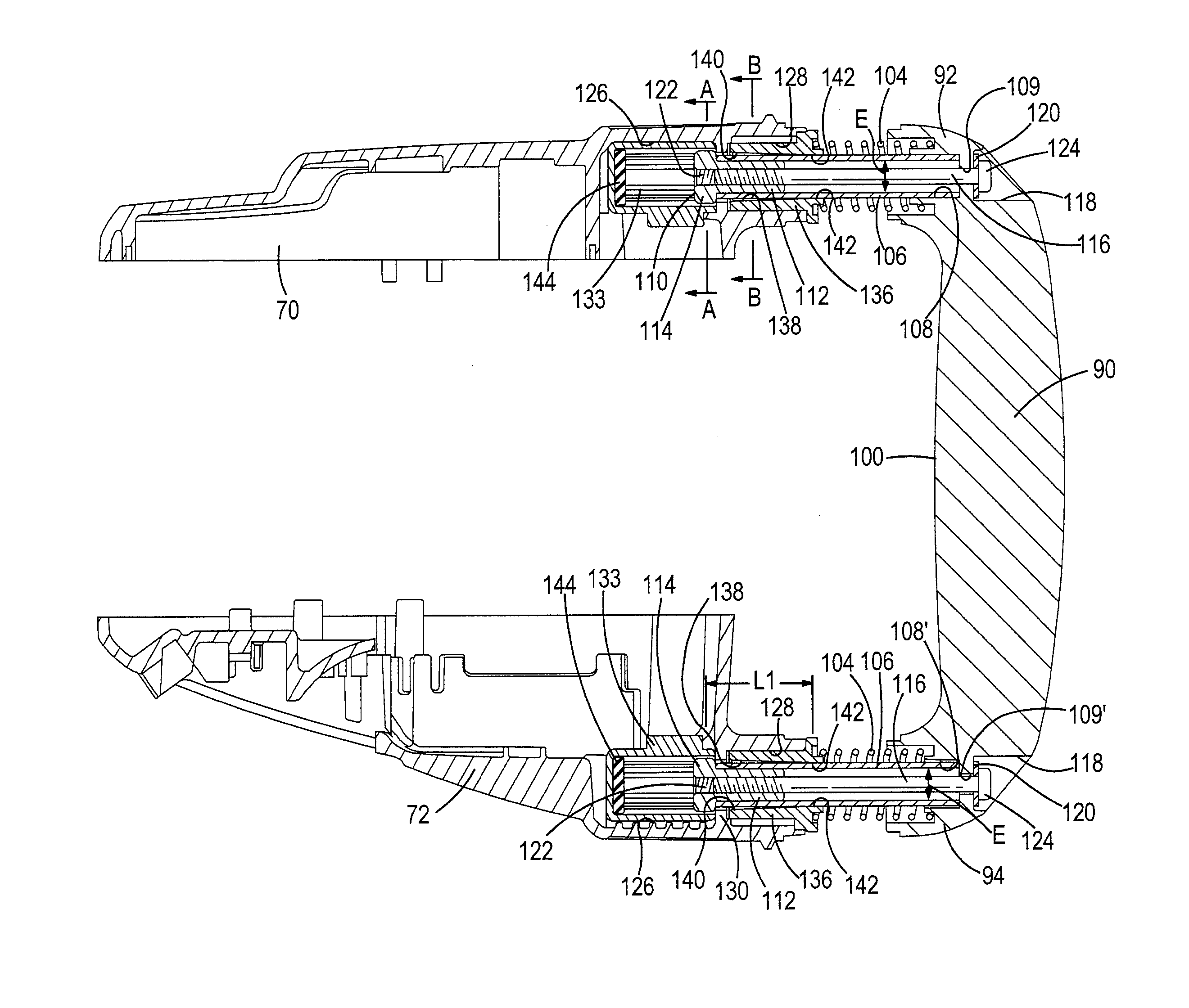

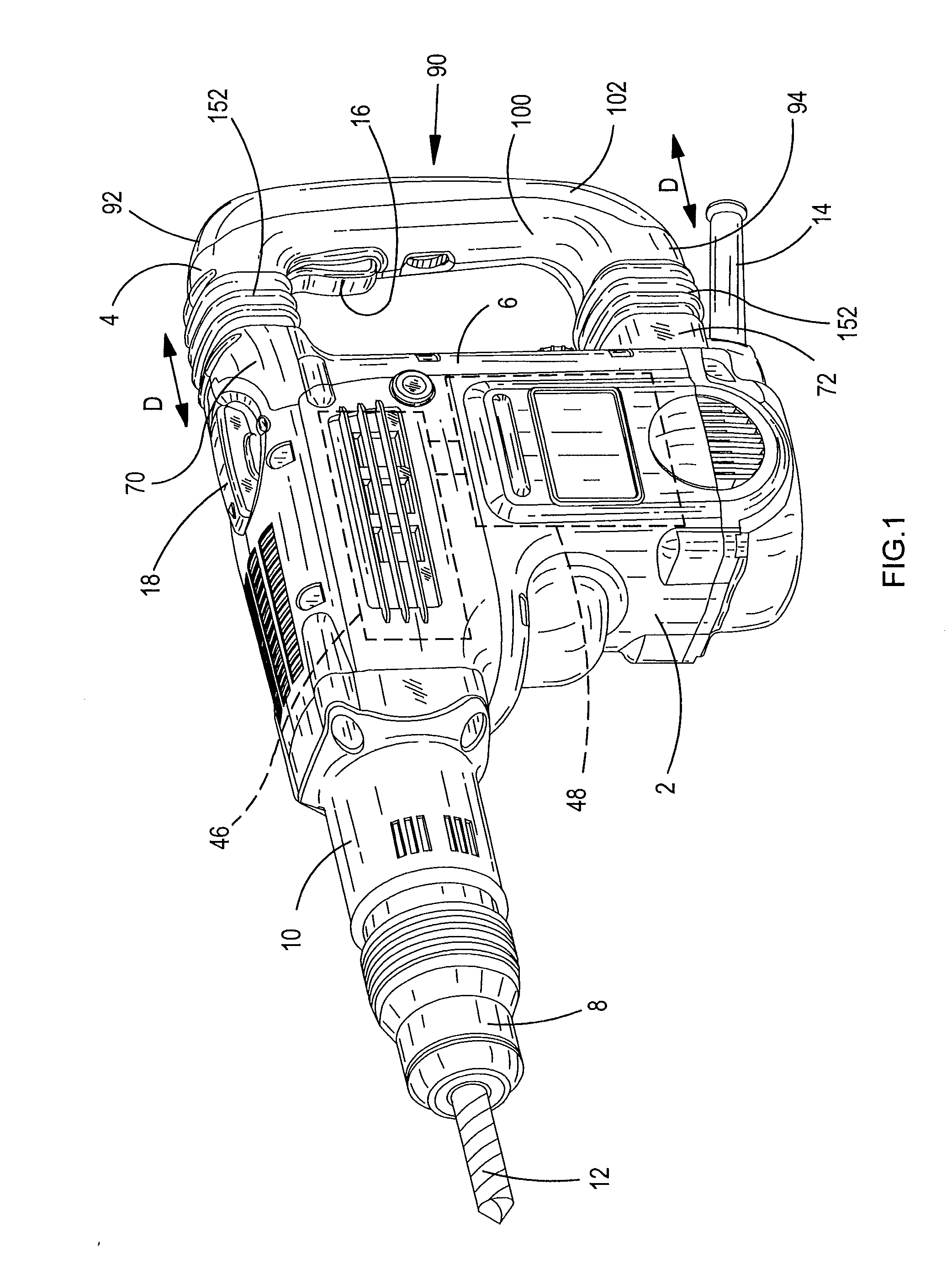

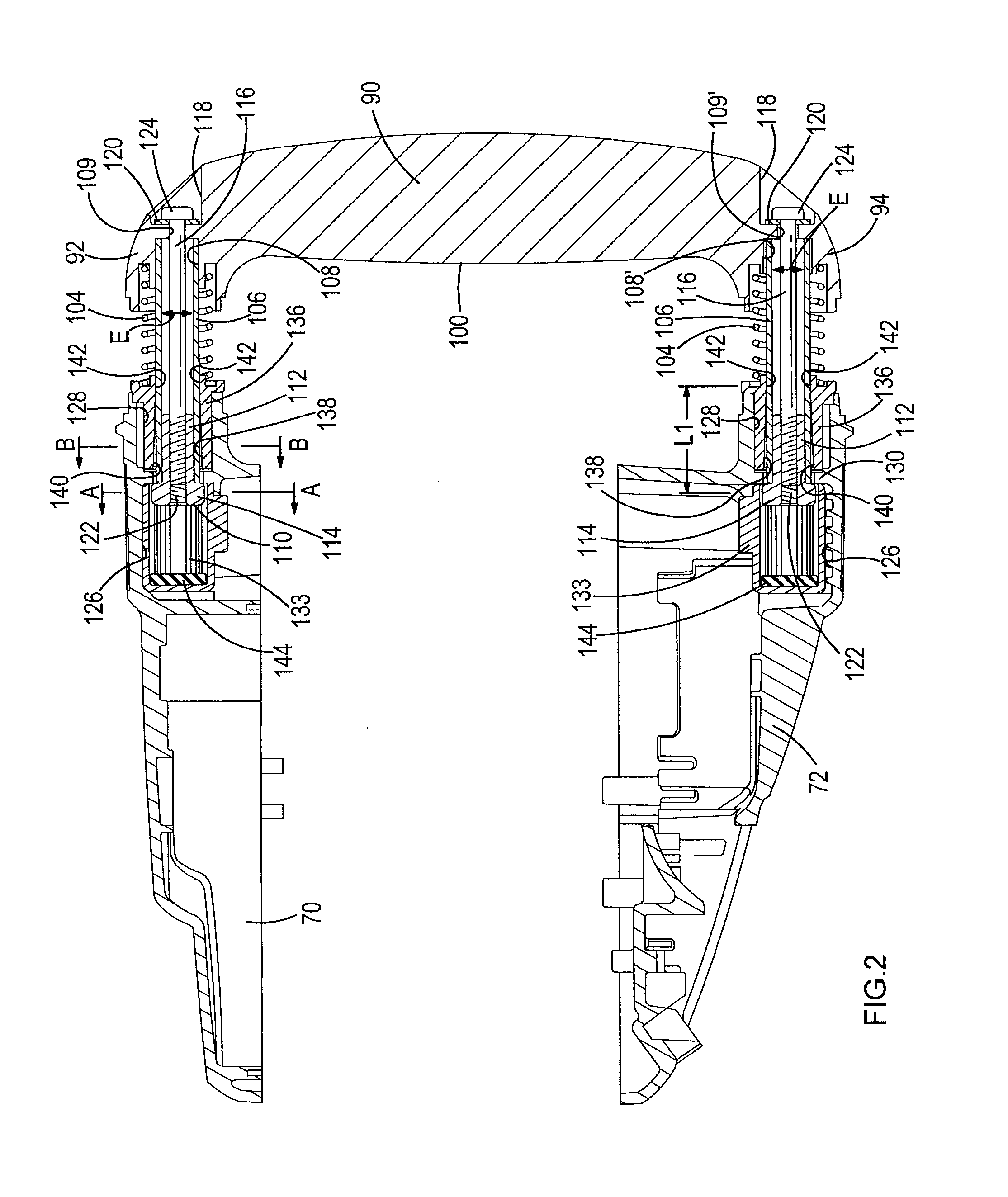

Hammer drill

ActiveUS20110127056A1Minimize impactReduce amountPortable percussive toolsMulti-purpose toolsEngineeringMovement control

A hammer drill comprising: a body 2 in which is mounted a motor 48 and a hammer mechanism 46 which is driven by the motor 48 when the motor 48 is activated; a tool holder 8 mounted on the front of the body 2 and which is capable of holding a cutting tool 12, the hammer mechanism 46, when driven by the motor 48, capable of imparting impacts to the cutting tool 12, when held by the tool holder 8; a rear handle 4, moveably mounted on to the rear of the body 2 via at least one movement control mechanism and which is capable of moving towards or away from the body 2; a biasing mechanism 104 which biases the rear handle 4 away from the body 2; wherein each movement control mechanism comprises: a first mount; a rod 106, having a longitudinal axis 107, rigidly connected at one of it ends to the first mount; a second mount which slidingly engages with the rod 106 at two distinct points only along its length to allow the rod 106 to slide relative to the second mount in a direction parallel to the longitudinal axis 107 whilst preventing the rod 106 from moving relative to second mount in a direction perpendicular to longitudinal axis 107; wherein one mount 70, 133, 136 is attached to the body 2 and the other mount 92 is attached to the rear handle 4.

Owner:BLACK & DECKER INC

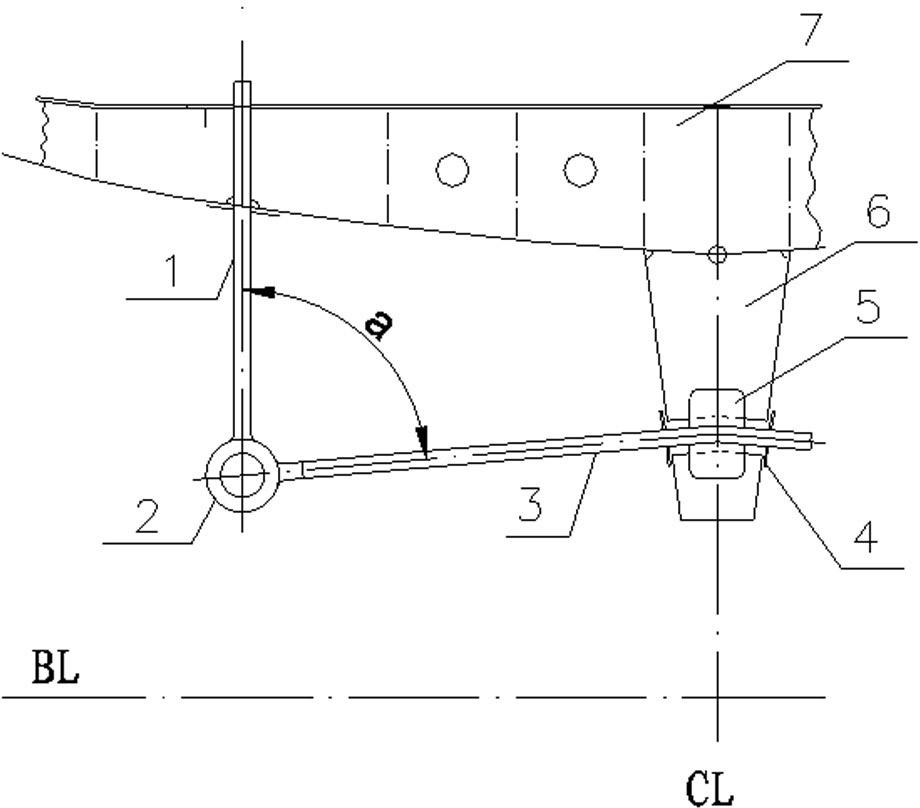

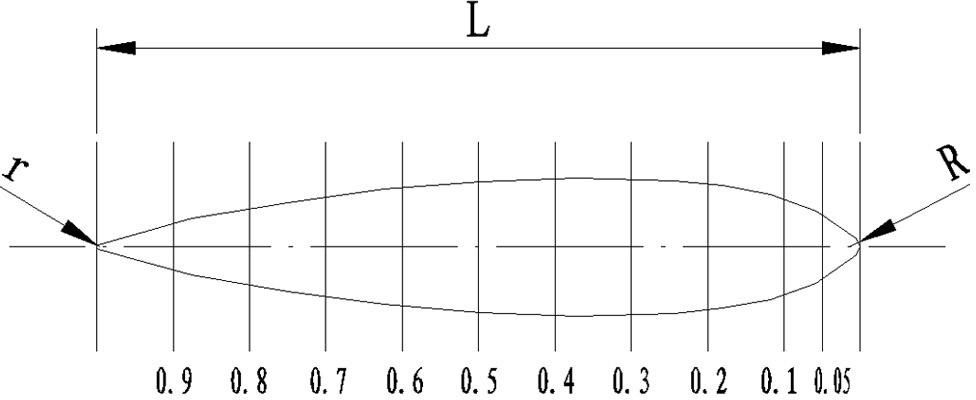

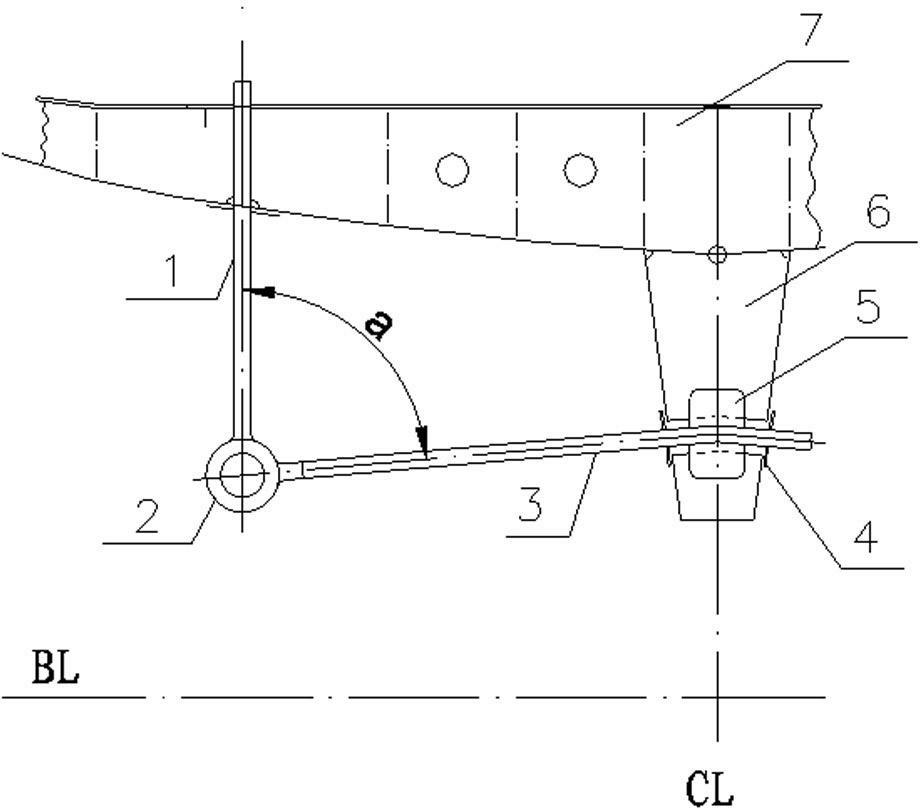

Assembly welding process for propeller shaft bracket

InactiveCN102303176AMixed flow and small forceAvoid correctionWelding/cutting auxillary devicesArc welding apparatusPropellerPore diameter

The invention relates to an assembly welding process for a propeller shaft bracket, and belongs to the technical field of ships. The process comprises the following steps of: before assembling a propeller shaft hub, performing a hydrostatic test of 0.2 MPa; correcting axes and pore diameters of front and rear end faces of the propeller shaft hub and sizes of four points on the left and right sides and upper and lower sides of the propeller shaft hub, and marking temporarily; cutting corresponding position holes on a bottom board and rib board of a ship body, and machining beveled edges of a supporting arm and the propeller shaft hub to perform point welding pre-positioning connection; allowing transverse arms in the horizontal direction to form an included angle alpha of 85 degrees with the supporting arm, splicing the supporting arm and the propeller shaft hub on a moulding bed in advance, and inserting into an open pore of the bottom board of the ship body to perform pre-welding positioning; after the supporting arm and the transverse arms are pre-positioned, welding and positioning the transverse arms and the propeller shaft hub according to a shafting bracing wire; and after welding, performing ultrasonic detection and magnetic particle detection on the propeller shaft bracket. The propeller shaft bracket assembled by the process is small in positional deviation and vibration quantity and low in noise, and the service life of the ships is prolonged greatly.

Owner:YANGFAN GROUP

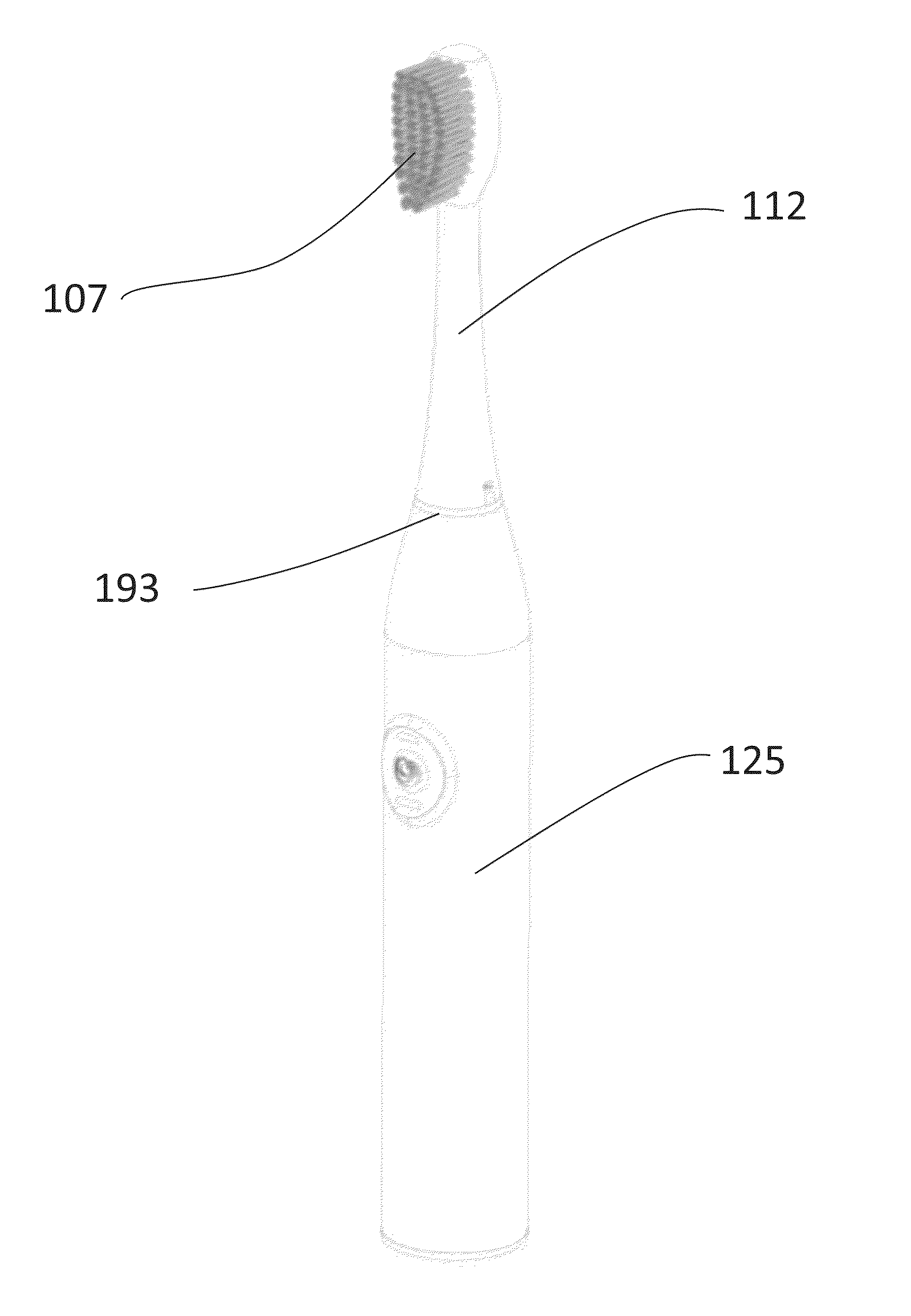

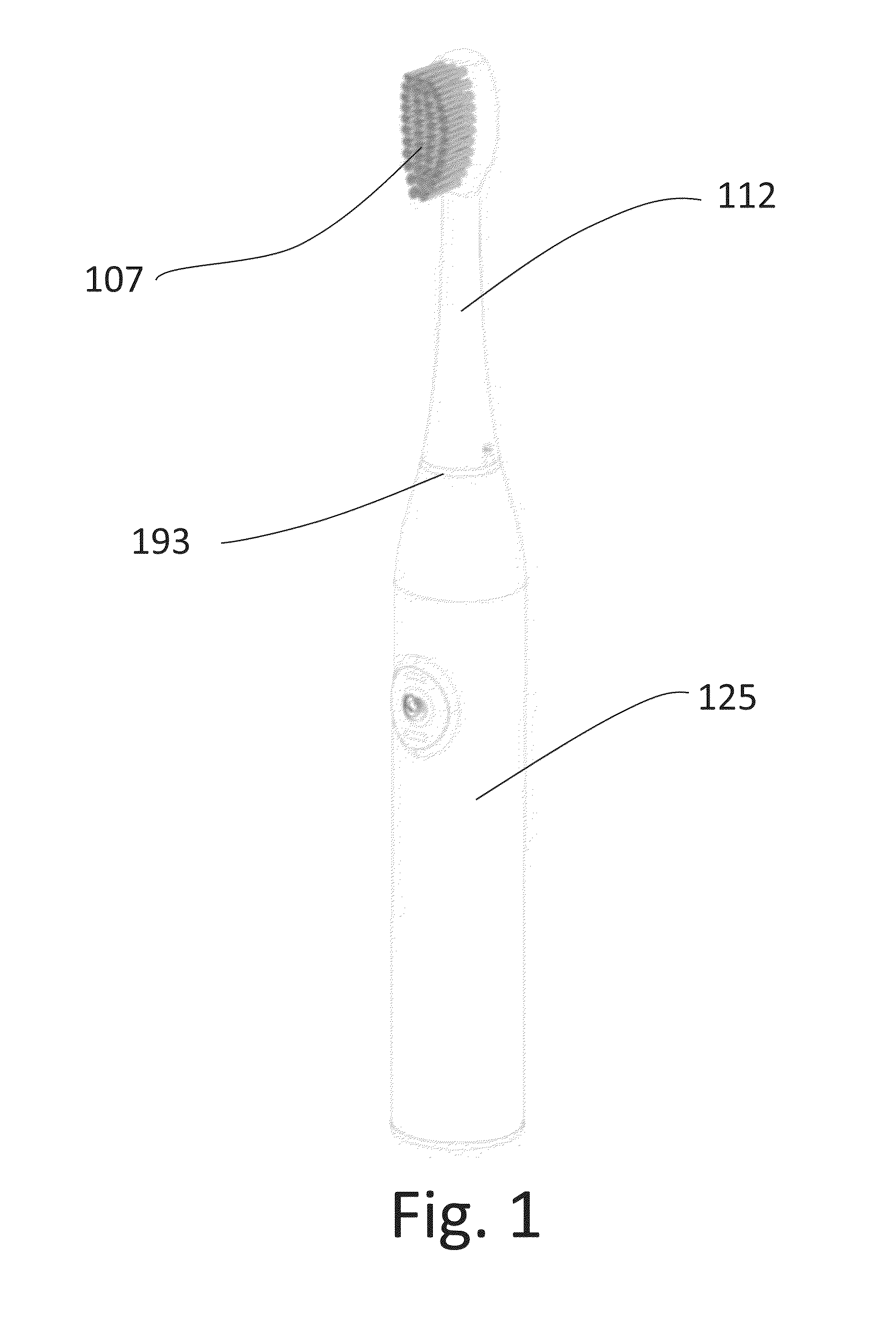

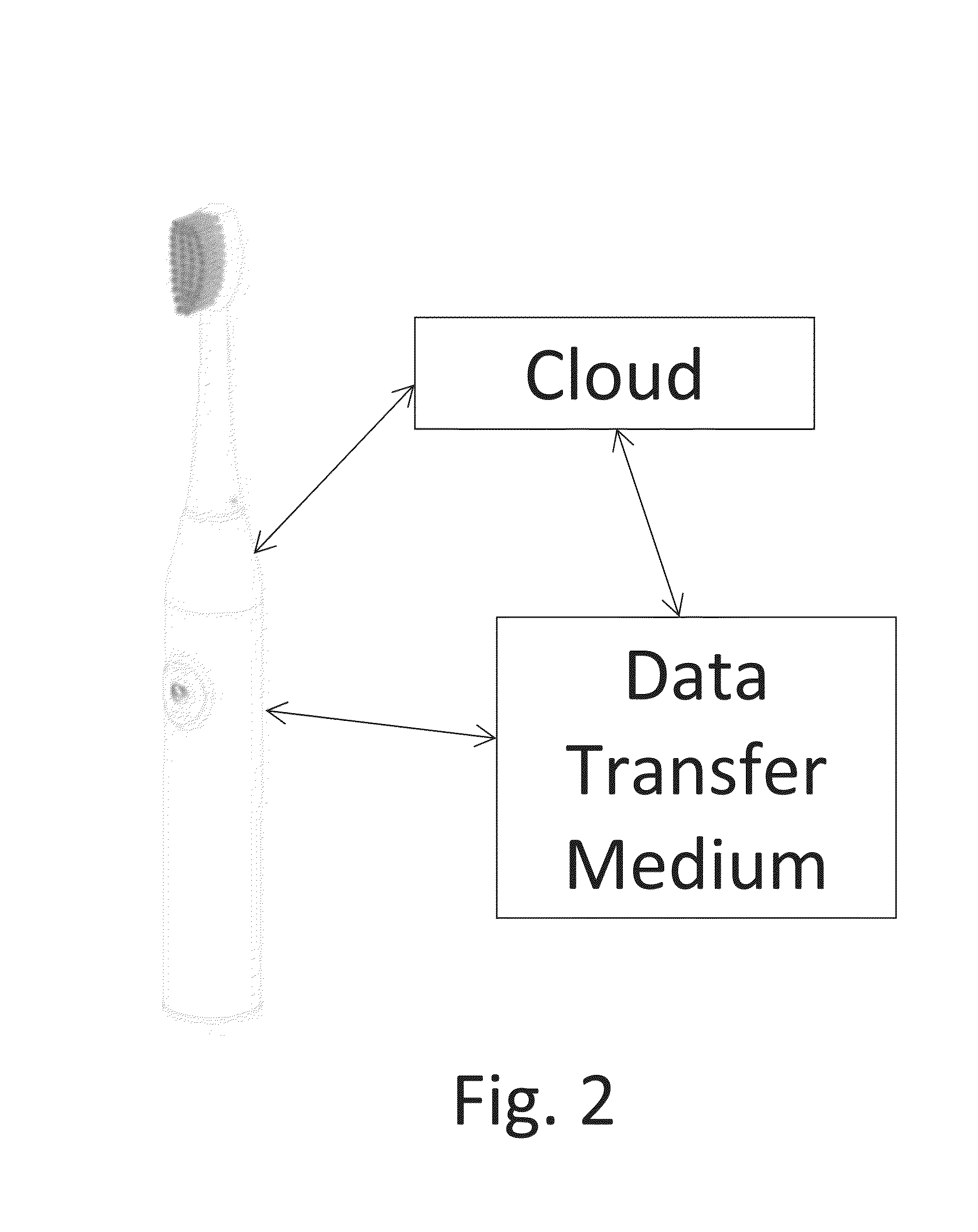

Data Transferring Powered Toothbrush

InactiveUS20140250612A1Reduce the amount of vibrationImprove vibrationCarpet cleanersBrush bodiesEngineeringOral health care

A data transferring powered toothbrush is provided for use during oral health care activities carried out daily by a user. A powered toothbrush is provided including an orientation sensor that provides data relating toothbrush usage to various positions within the oral cavity. Further, the toothbrush comprises a data extractor that provides a means for transferring the data from the toothbrush to an external medium for viewing and manipulation. Further still, the powered toothbrush is comprised in a system including a data transfer medium (i.e. “smartphone”) and the Cloud, which allows for data transfer between multiple external mediums from the powered toothbrush. The system further allows for passive participation in social games with awards and incentives. The system and powered toothbrush further provide for active participation in brushing games to encourage proper brushing techniques.

Owner:BEAM TECH

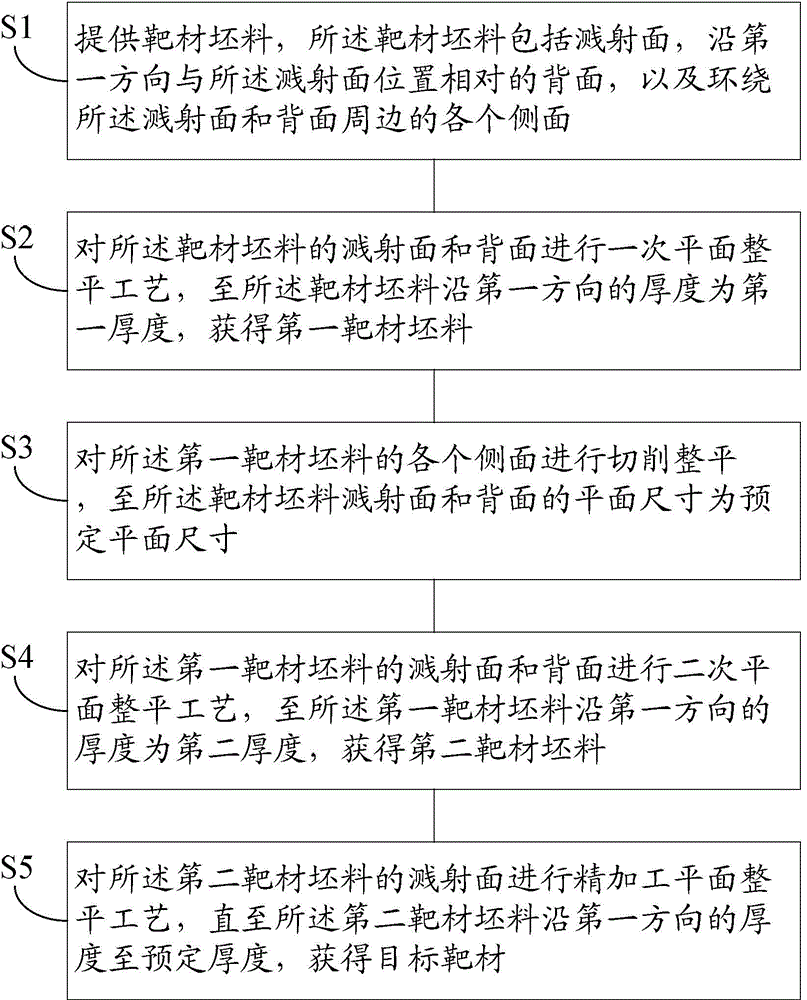

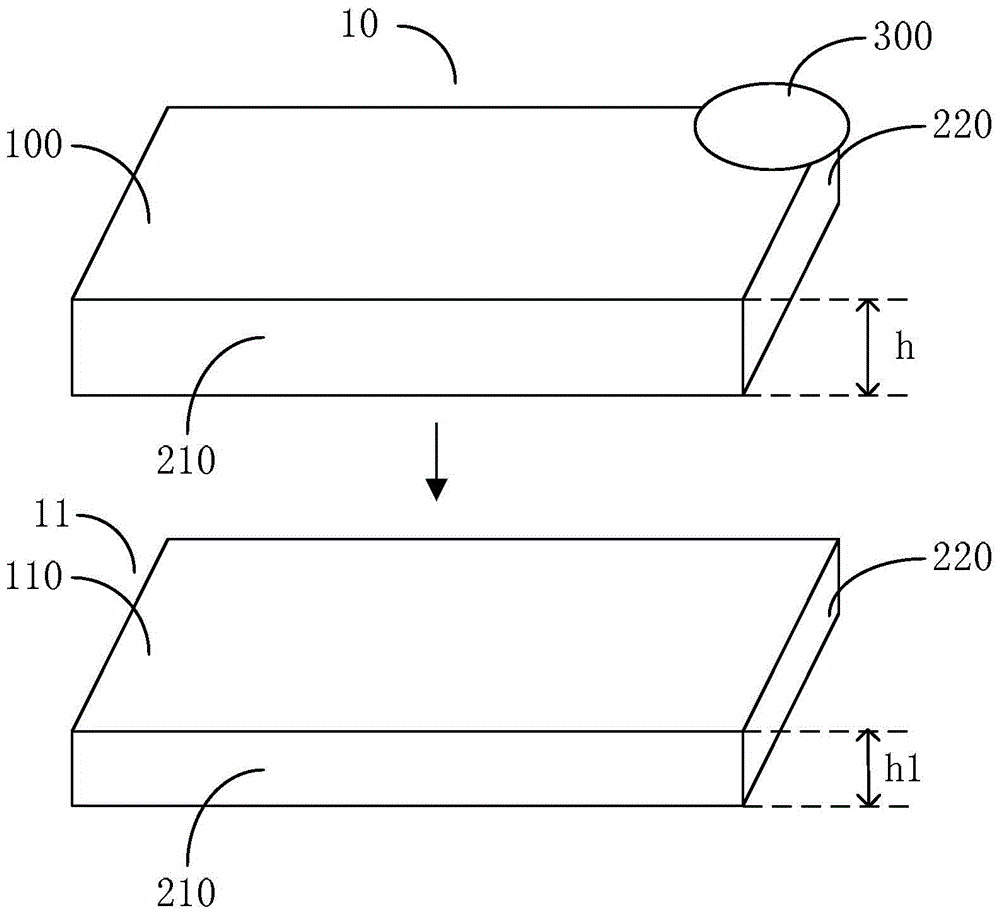

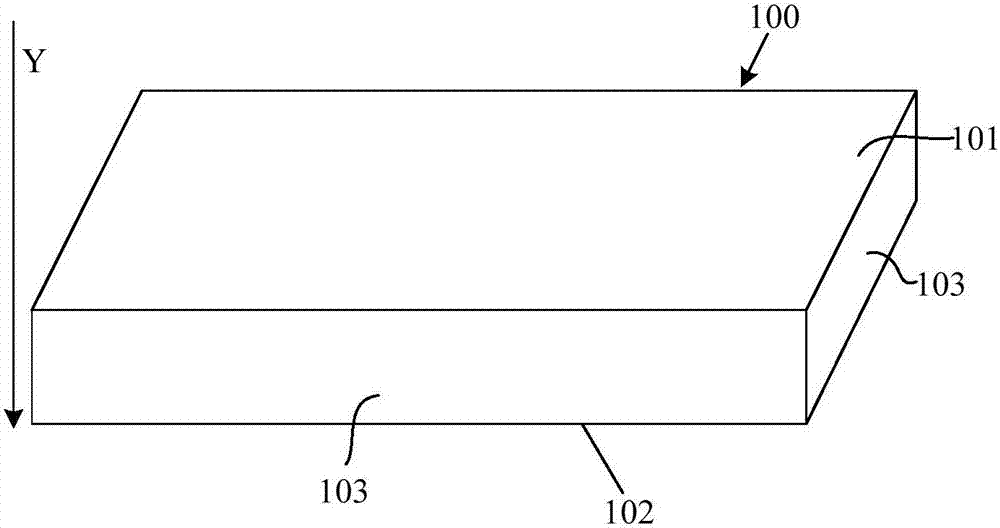

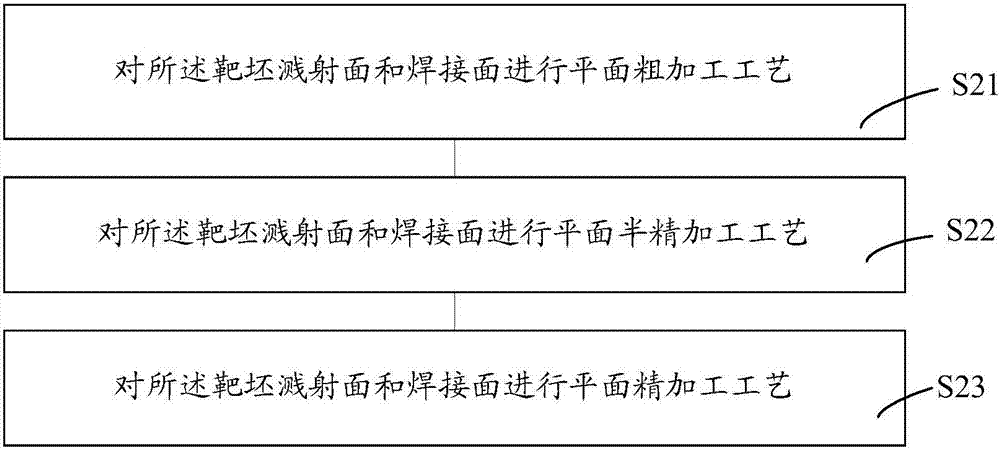

Machining method for target material

ActiveCN104561890AVibration reliefQuality improvementVacuum evaporation coatingSputtering coatingMachining processMaterials science

The invention relates to a machining method for a target material. The machining method for the target material comprises the following processing steps: levelling planes of a sputtering surface and the back face of a target material blank, and processing each side face of the target material blank so that thickness of the target material blank is the same as the predetermined thickness, and plane dimensions of the sputtering surface and back face of the target material blank are the same as the predetermined plane dimensions, wherein the levelling treatment process on the sputtering surface and back face of the target material blank comprises a primary plane levelling process and a secondary plane levelling process which are carried out on the sputtering surface and back face of the target material blank along the first direction and a finish machining plane levelling process carried out on the sputtering surface. By adopting the technical scheme, a multi-step levelling process is carried out on the sputtering surface or back face along the first direction, stress produced inside the target material and vibration produced to the target material by machining in a machining process can be effectively alleviated, so that the defects of deformation and the like can not be formed on the target material blank, quality of a machined target material is improved, and yield of the machined target materials is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

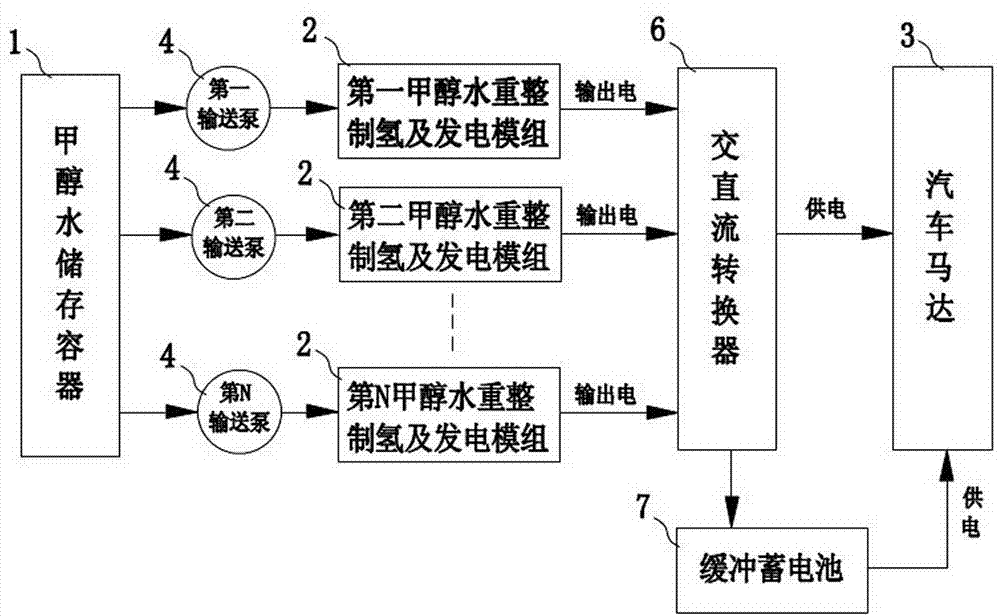

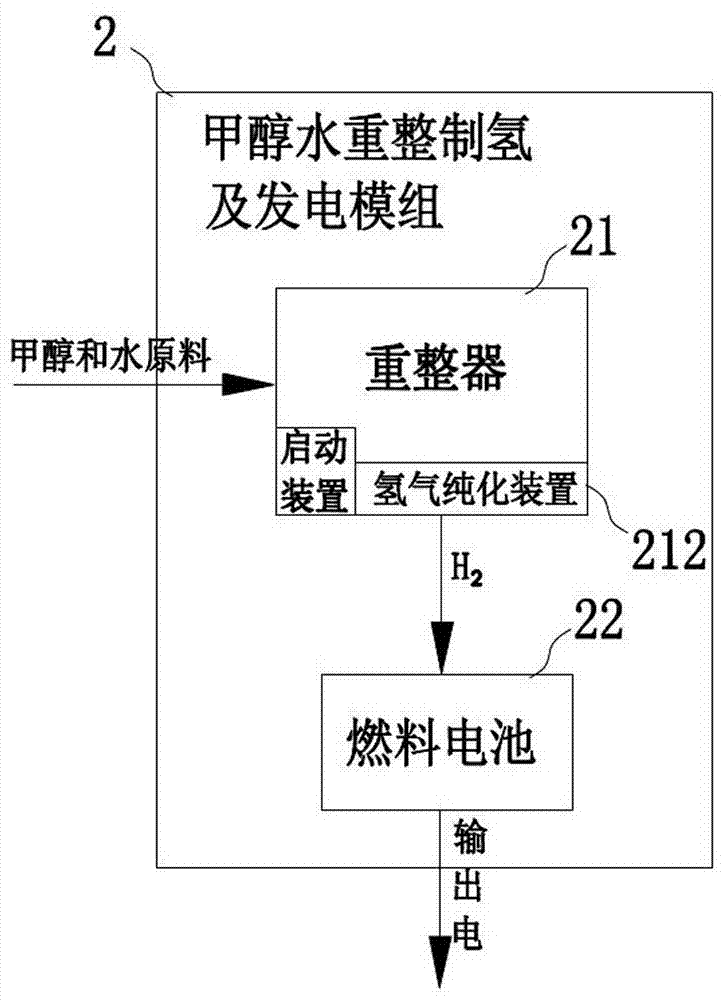

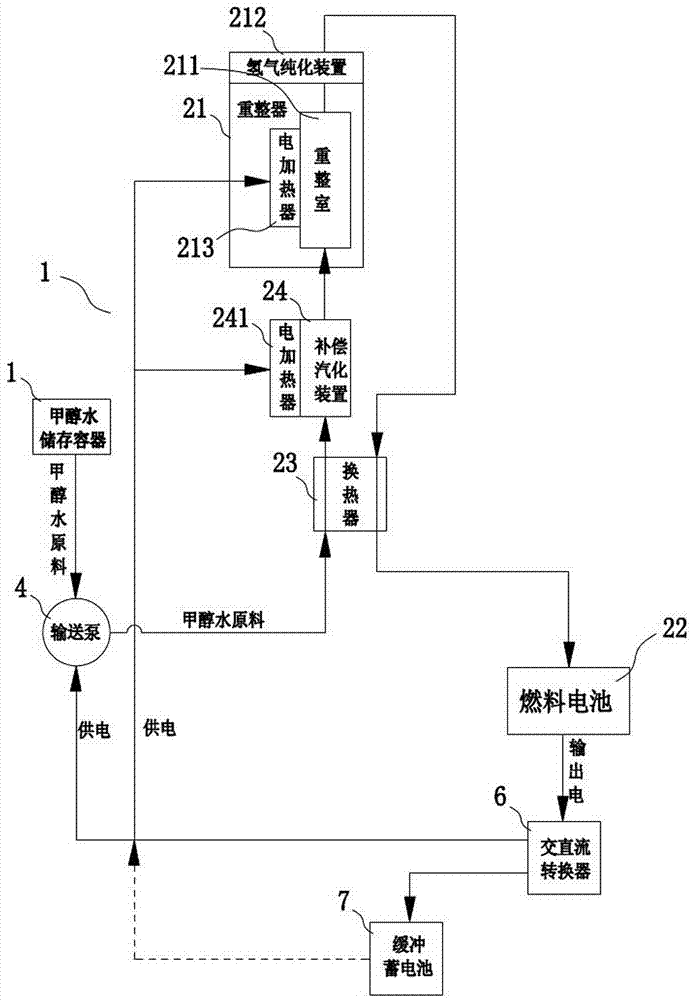

Multi-combination independent alcohol-water hydrogen generation fuel cell car

InactiveCN104752746AOverall small sizeSmall amount of hydrogen productionHydrogenFuel cell auxillariesMethanol waterAlcohol

The invention discloses a multi-combination independent alcohol-water hydrogen generation fuel cell car. The multi-combination independent alcohol-water hydrogen generation fuel cell car comprises a methanol water storage vessel, at least two groups of methanol water reforming hydrogen generation and power generation modules, a car motor and at least two conveying pumps, wherein the methanol water reforming hydrogen generation and power generation modules are integrated with a reforming device and a fuel cell, a reforming chamber and a hydrogen purifying device are arranged in the reforming device, the temperature in the reforming chamber is 300 to 570 DEG C, methanol and water have the reforming hydrogen generation reaction in the reforming chamber to prepare hydrogen-containing gas, the hydrogen-containing gas is purified by the hydrogen purifying device to obtain hydrogen, and obtained hydrogen is supplied to the fuel cell; the fuel cell is used for generating electric power which is used for powering the car motor; the car motor is used for driving a car axle to rotate so as to enable a car to run. According to the invention, the speed for converting methanol and water raw materials into hydrogen is high, the methanol conversion efficiency is high, the utilization rate of methanol is high, and the hydrogen-containing gas is easy to purify; the reforming device is easy to start, the stability is good, the vibration quantity is small, parameters such as the hydrogen generation temperature are sensitive to control, the safety is high, and the reliability is high.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

Controller, system and method used for active control of boom vibration

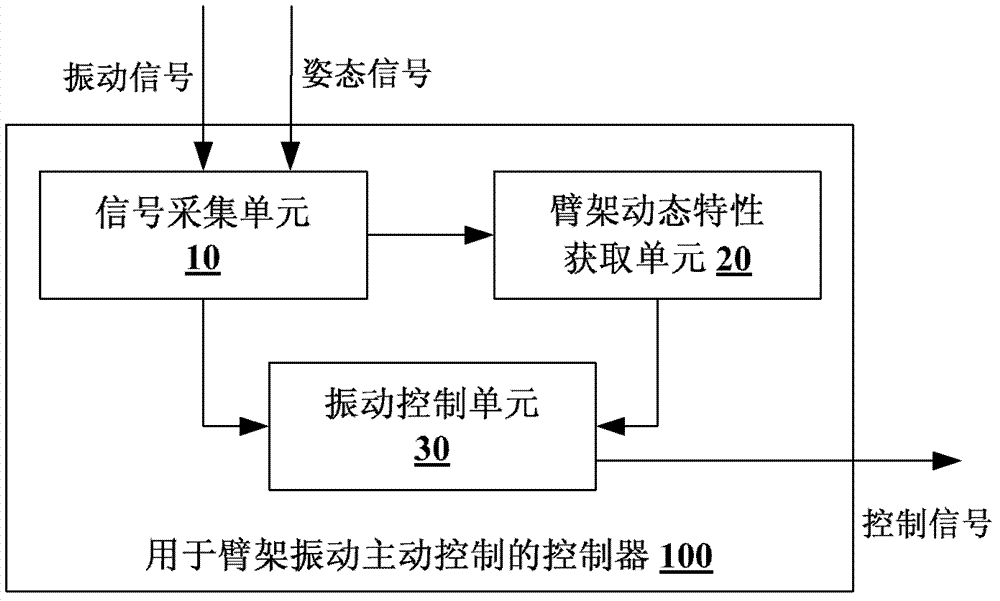

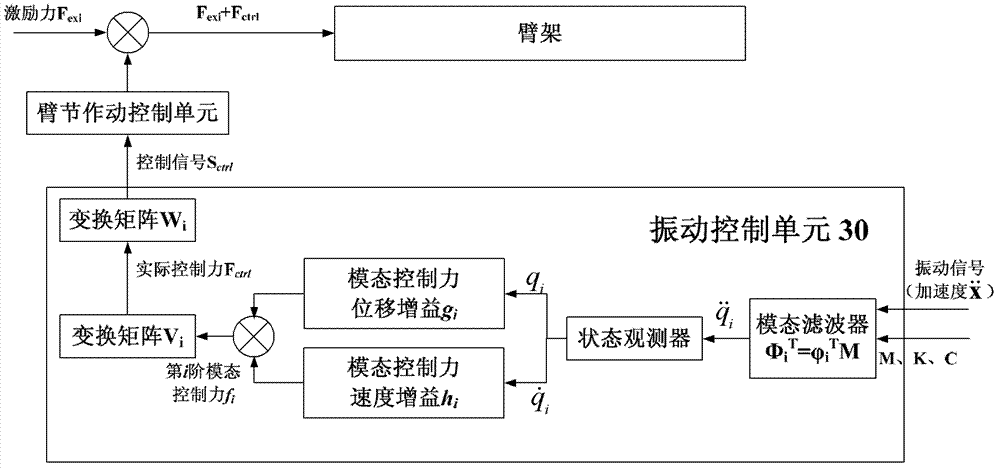

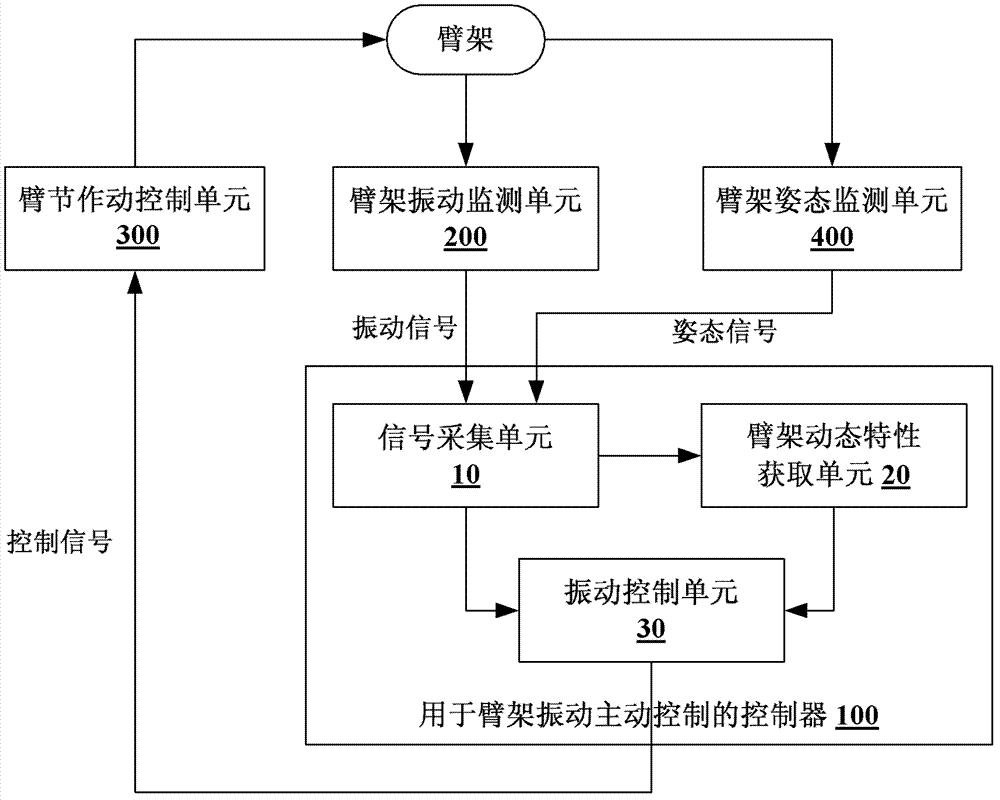

ActiveCN103092225AReduce the amount of vibrationActive vibration reduction is goodMechanical oscillations controlBuilding material handlingVibration controlControl signal

The invention discloses a controller, a system and a method used for the active control of boom vibration. The controller (100) comprises a signal collecting unit (10), wherein the signal collecting unit (10) is used for collecting the vibration signal of the boom vibration and the attitude signal of the boom attitude and converting the vibration signal and the attitude signal to the vibration data and the attitude data, a boom dynamic property obtaining unit (20) is used for obtaining the boom dynamic property corresponding to the attitude data converted by the signal collecting unit (10), and a vibration controlling unit (30) is used for calculating the controlling signal according to the vibration data and the boom dynamic property, and outputting the controlling signal to the actuating and controlling unit of the boom section. By means of adopting the attitude signal, the device obtains the dynamic property of the boom under the current attitude, combines the vibration signal and figures out the controlling signal to control the actuating and controlling unit of the boom section, thereby achieving the goal of better active vibration reduction.

Owner:ZOOMLION HEAVY IND CO LTD

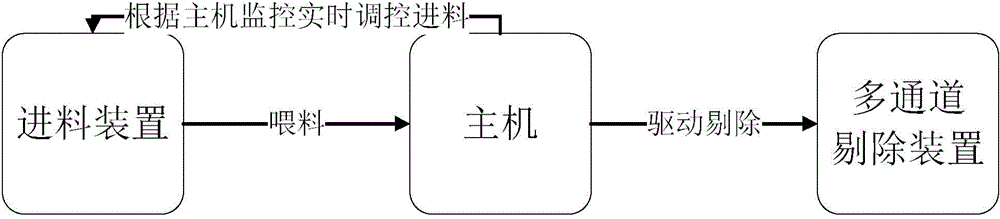

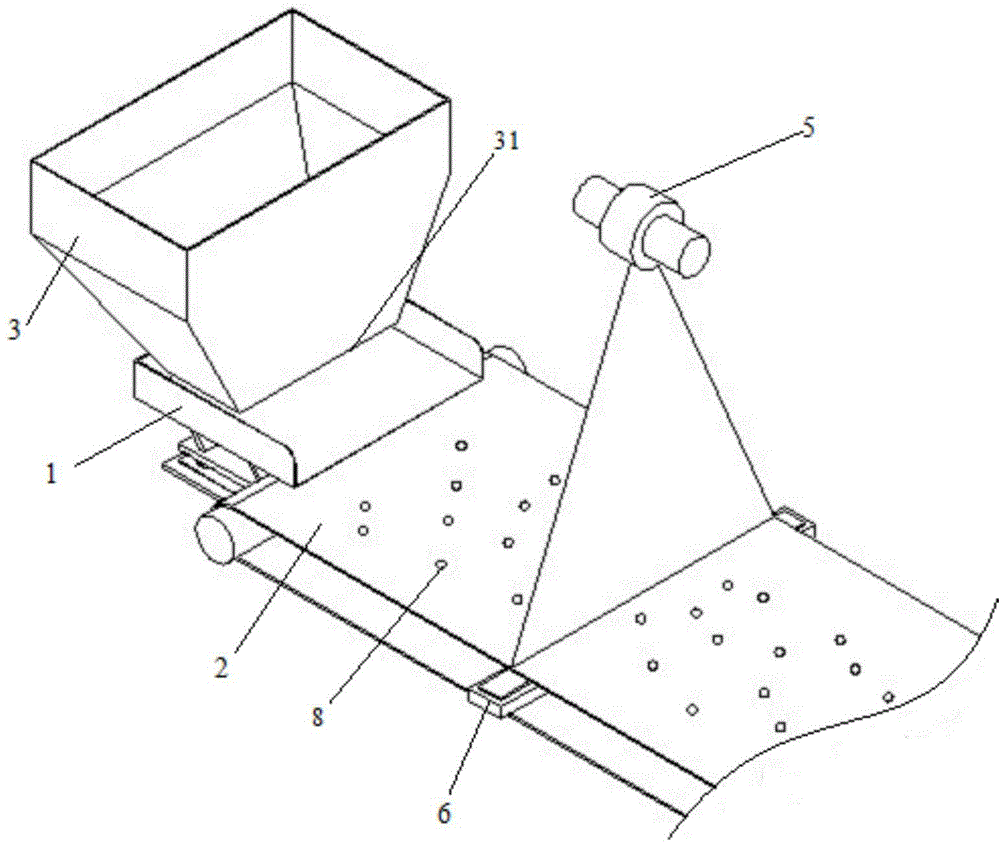

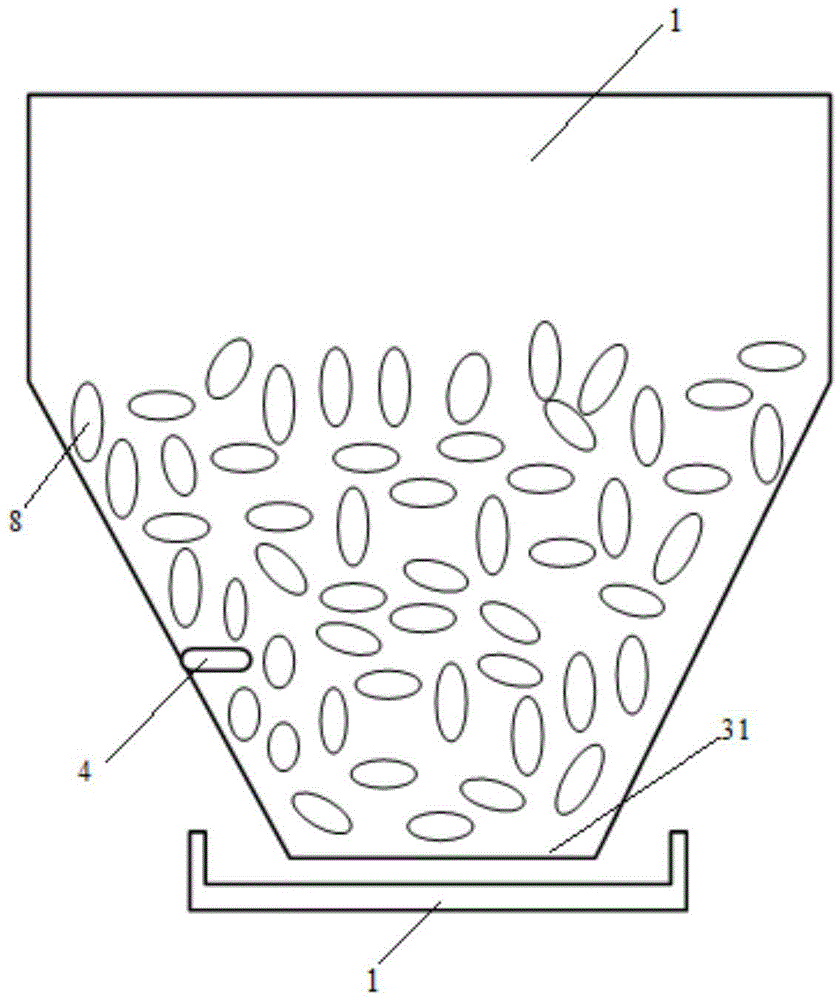

Automatic feeding adjustment module and method, device and bulk foreign body detection mechanism thereof

ActiveCN104085667ASpread evenlyReduce the amount of vibrationConveyor partsMaterial analysis by transmitting radiationForeign matterEngineering

The invention provides an automatic feeding adjustment module and a method, device and bulk foreign body detection mechanism of the automatic feeding adjustment module. A discharging port of a hopper is located above a conveying belt, and materials are evenly laid on the conveying belt through vibration of a vibrator. A first sensor detects the material level of the materials in the hopper. Rays are emitted from a radiation source to the materials on the conveying belt, and a second sensor collects the rays which penetrate through the conveying belt and the materials. A processor forms a corresponding target image according to the rays collected by the second sensor, in addition, when the material level is not smaller than a first preset material level value, the vibrator is turned on, and data analysis thread is started, wherein the duty ratio R of the target image is calculated, the vibration magnitude of the vibrator is increased if the duty ratio R is smaller than a first preset duty ratio threshold, the vibration magnitude of the vibrator is decreased if the duty ratio R is larger than a second preset duty ratio threshold, or else, the current vibration magnitude of the vibrator is kept unchanged, and the second preset duty ratio threshold is larger than the first preset duty ratio threshold.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

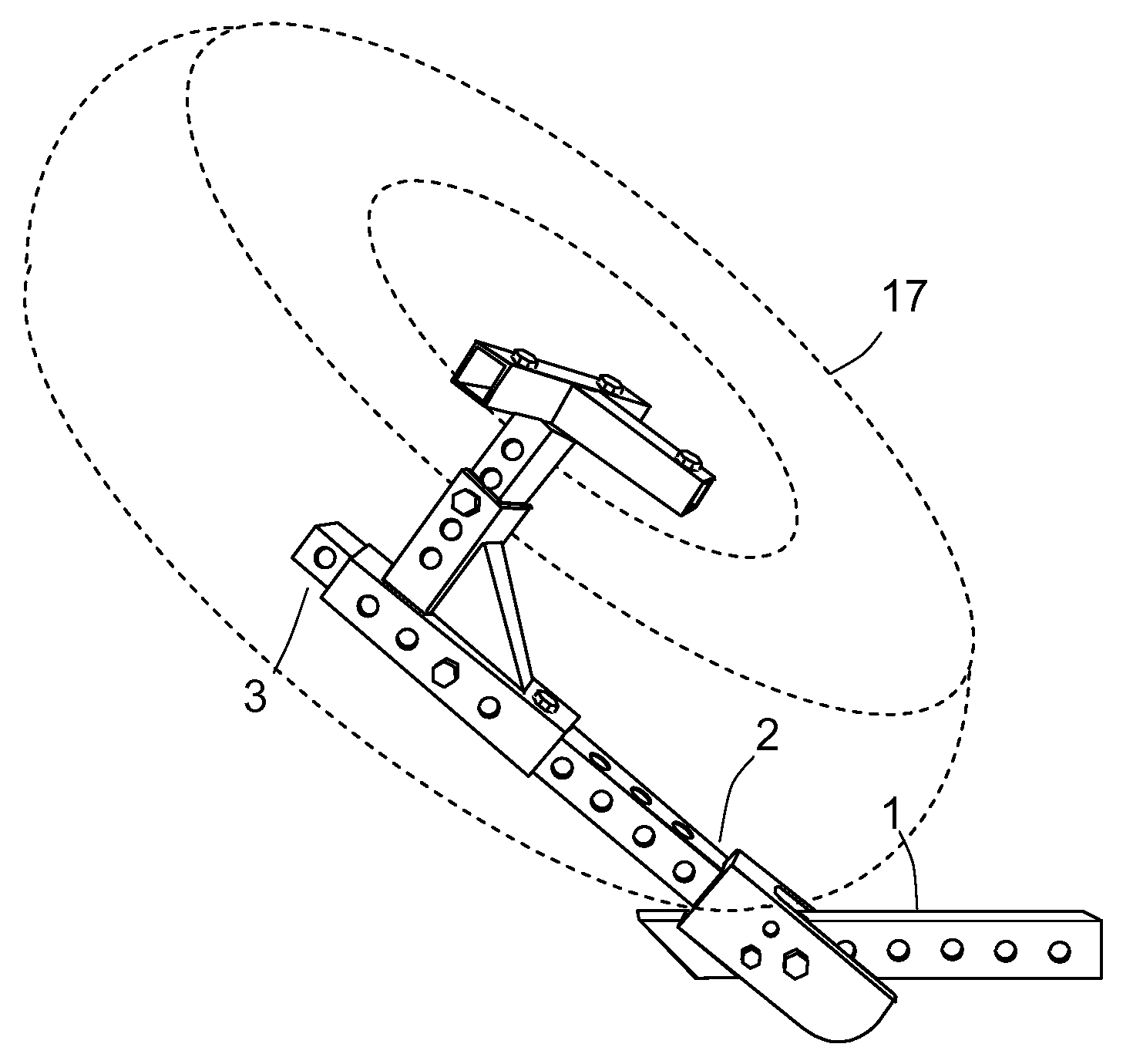

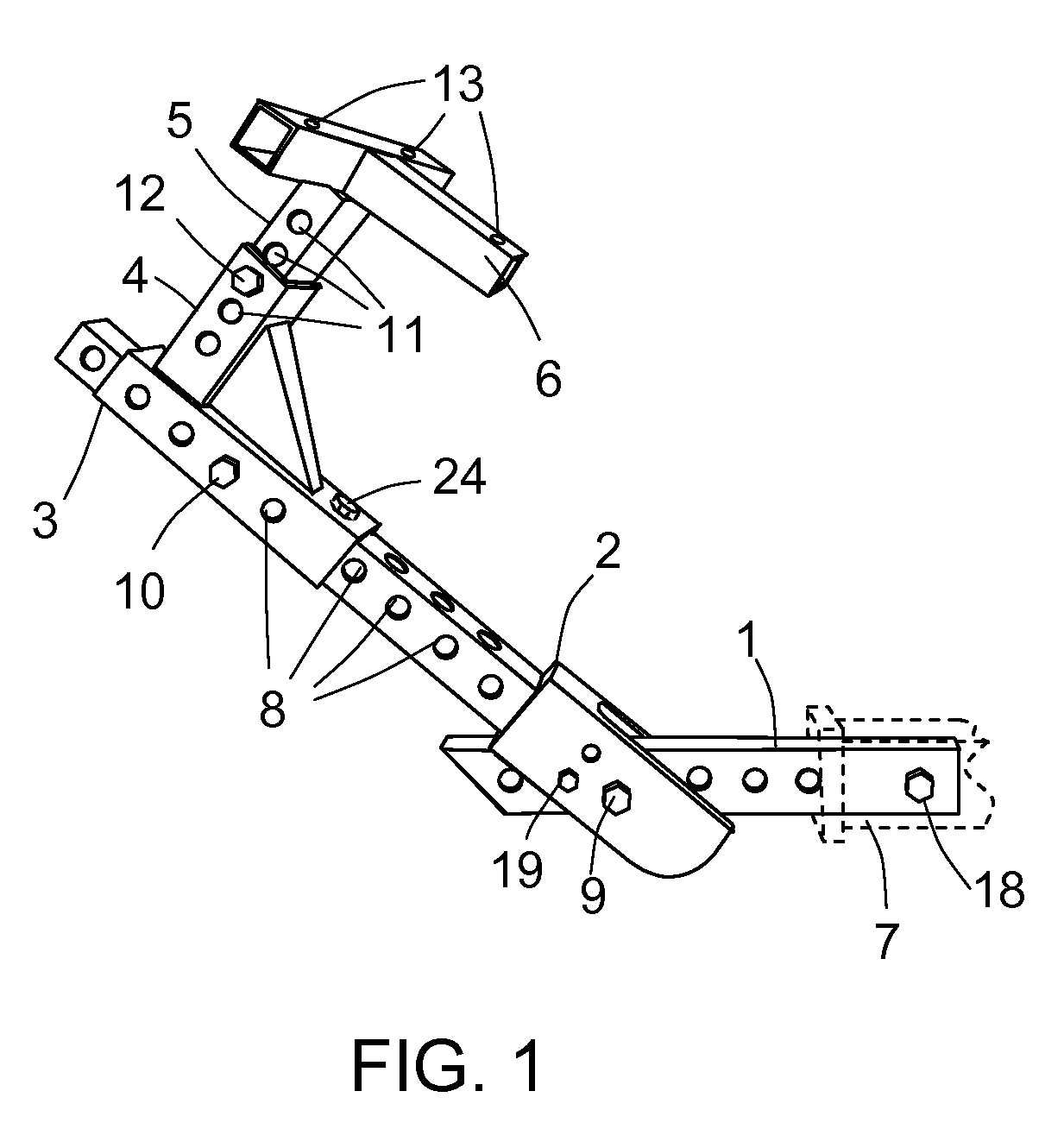

Spare tire carrier for all-terrain vehicles

InactiveUS8251265B2Reduce the amount requiredMinimizing flexibilitySupplementary fittingsArticle supporting devicesEngineeringSpare tire

A spare tire carrier that preserves the vehicle approach angle. The carrier comprises a hitch anchor configured to be mounted on a vehicle towing hitch; a fork having tines affixed to the back end of the hitch anchor by means of a hinge; a sleeve slidingly mounted on the fork's handle; a lower shoulder bar essentially perpendicularly mounted onto the sleeve; an upper shoulder bar slidingly mounted on the lower shoulder bar and a rim holder affixed to the upper shoulder bar. The device is constructed of telescoping bars that can be slidingly adjusted and kept in place by pins. This design allows the shape of the device to be modified and to accommodate a diversity of tire sizes. This invention can also be used as a jack by positioning the rim holder on the ground as a fulcrum and using the device as a lever to lift a car.

Owner:GRUDEK MICHAEL A

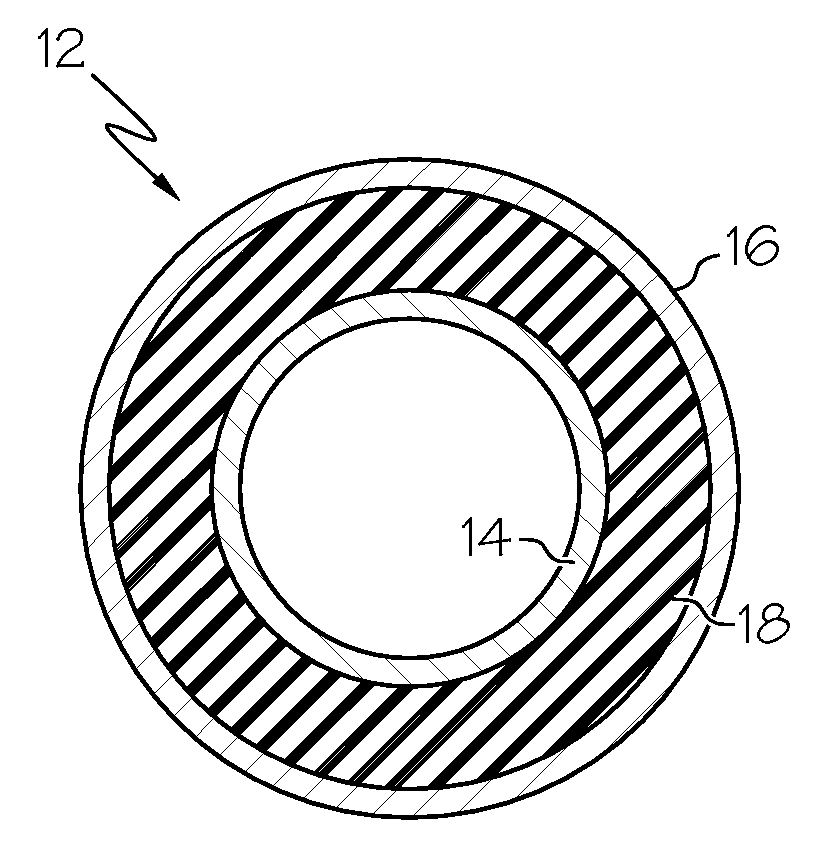

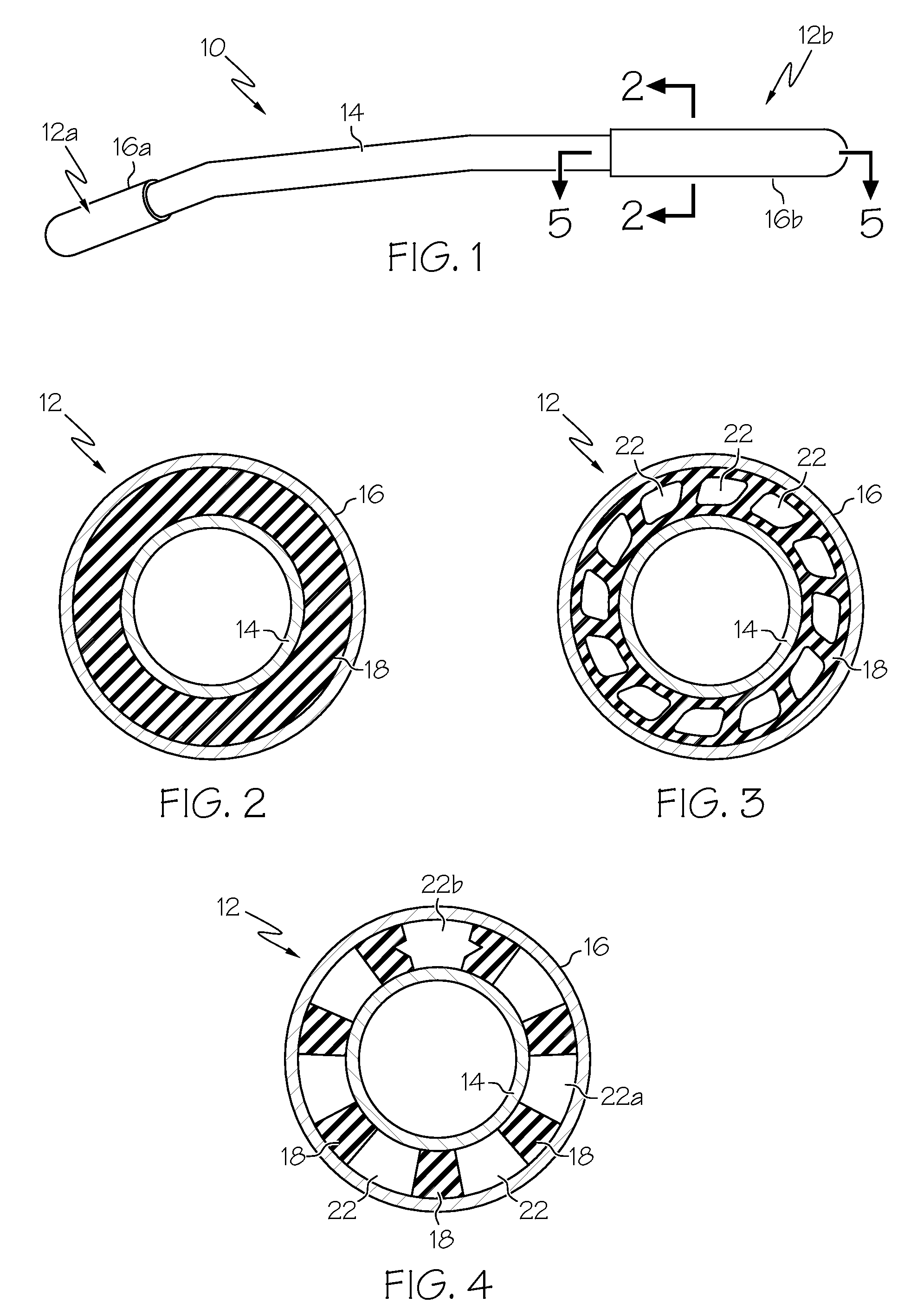

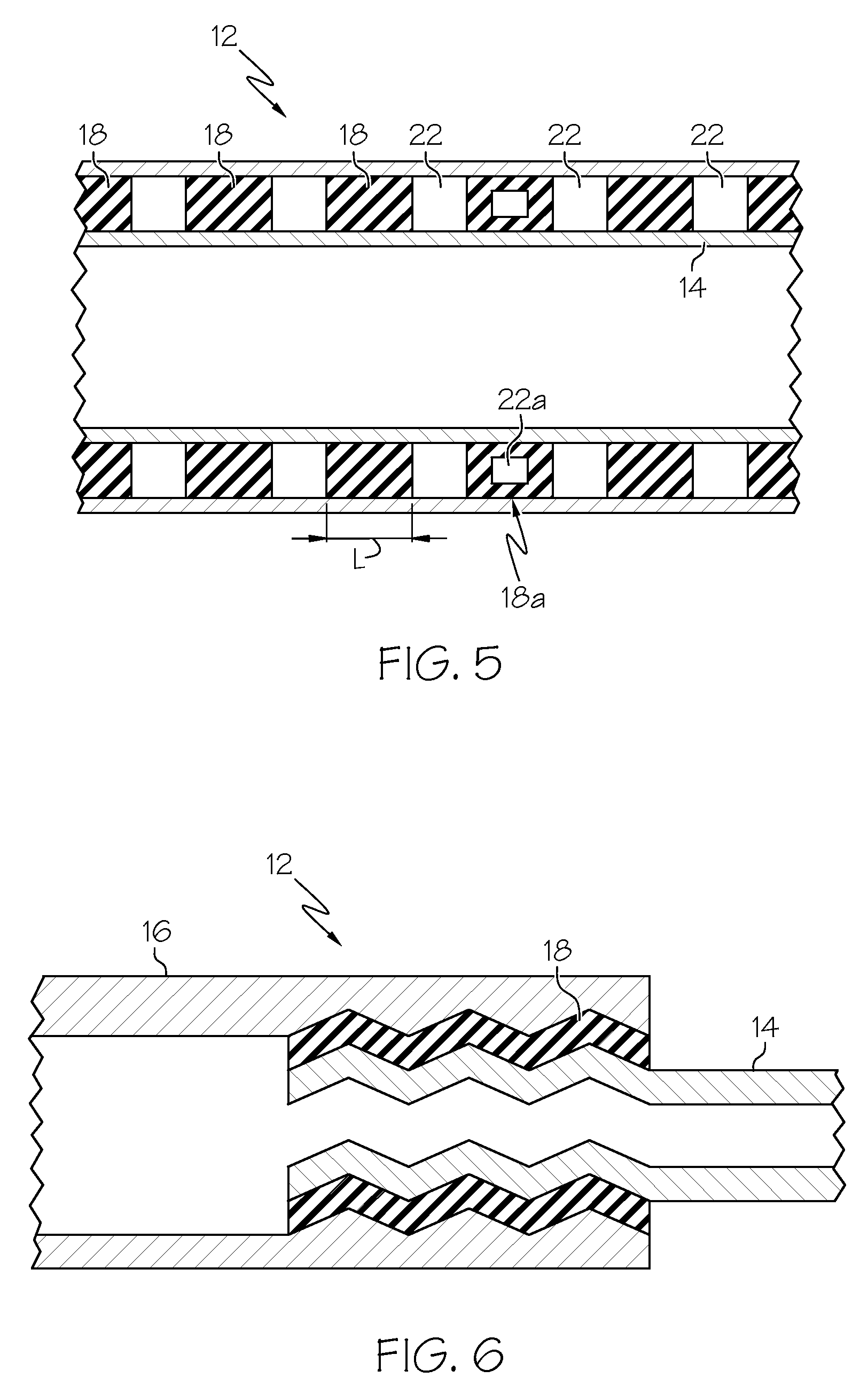

Coaxial tube damper

ActiveUS8038133B2Reduce the amount of vibrationPortable framesPortable percussive toolsEngineeringMechanical engineering

Owner:MCP IP

Imaging system and related techniques

InactiveUS7885378B2Reduce the amount of vibrationReduce the amount requiredMaterial analysis using wave/particle radiationRadiation/particle handlingProjection image

Owner:THE GENERAL HOSPITAL CORP

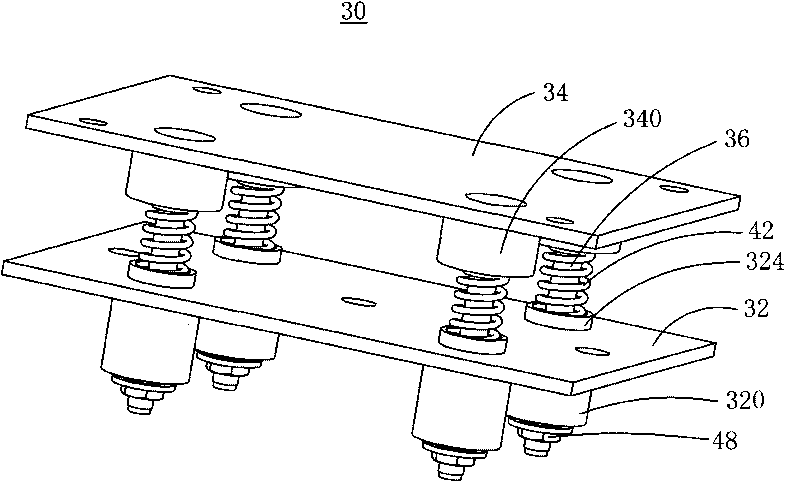

Lamp

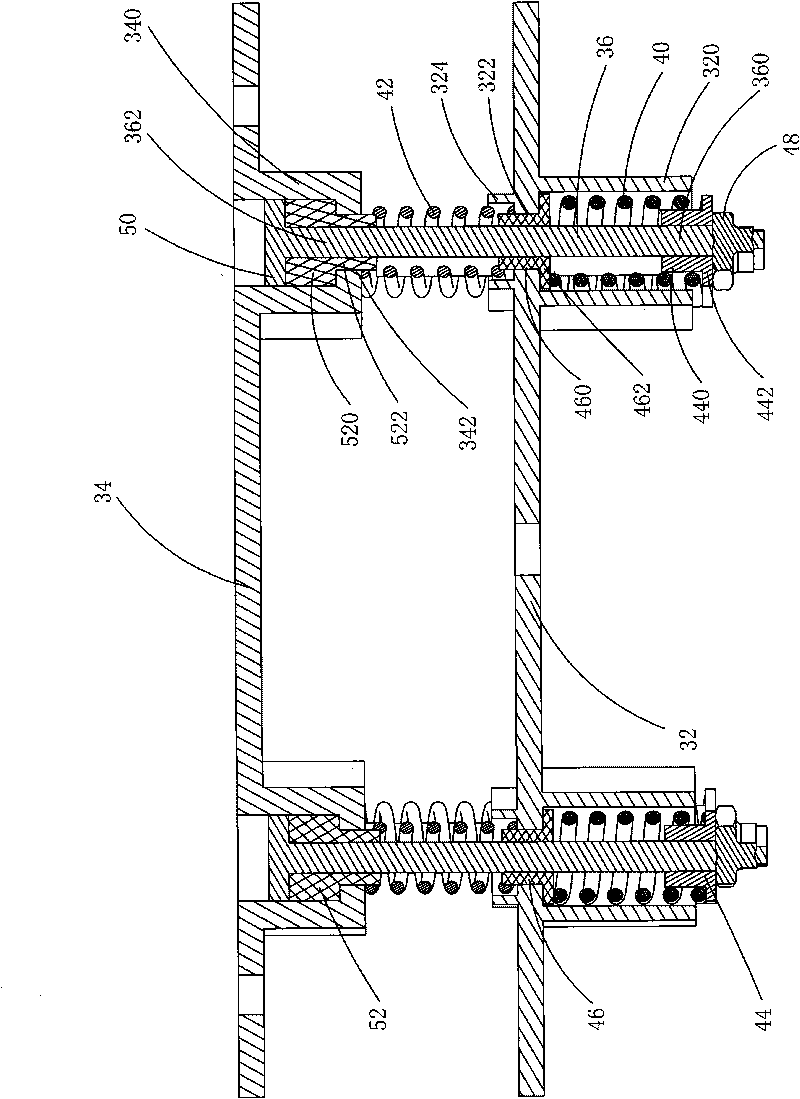

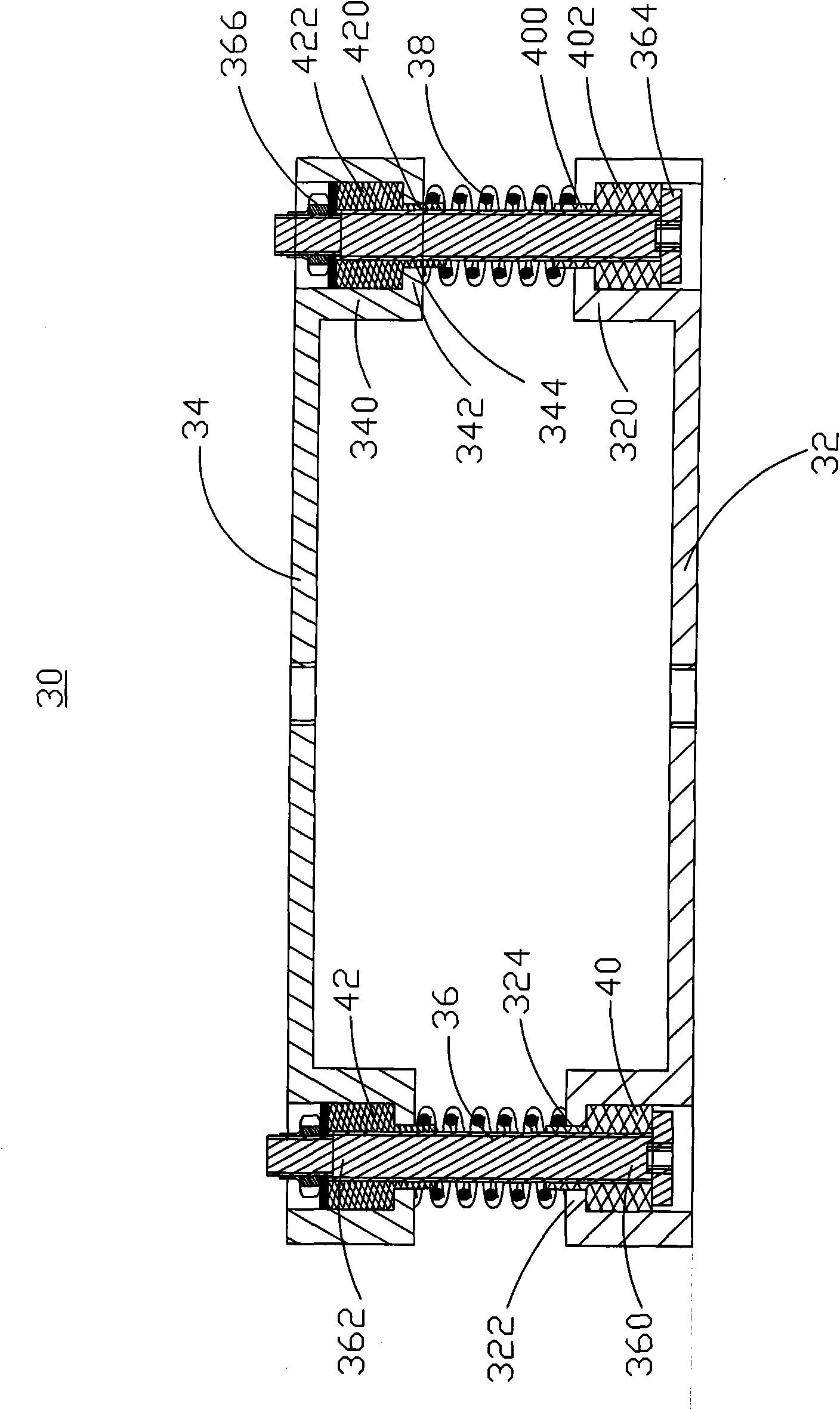

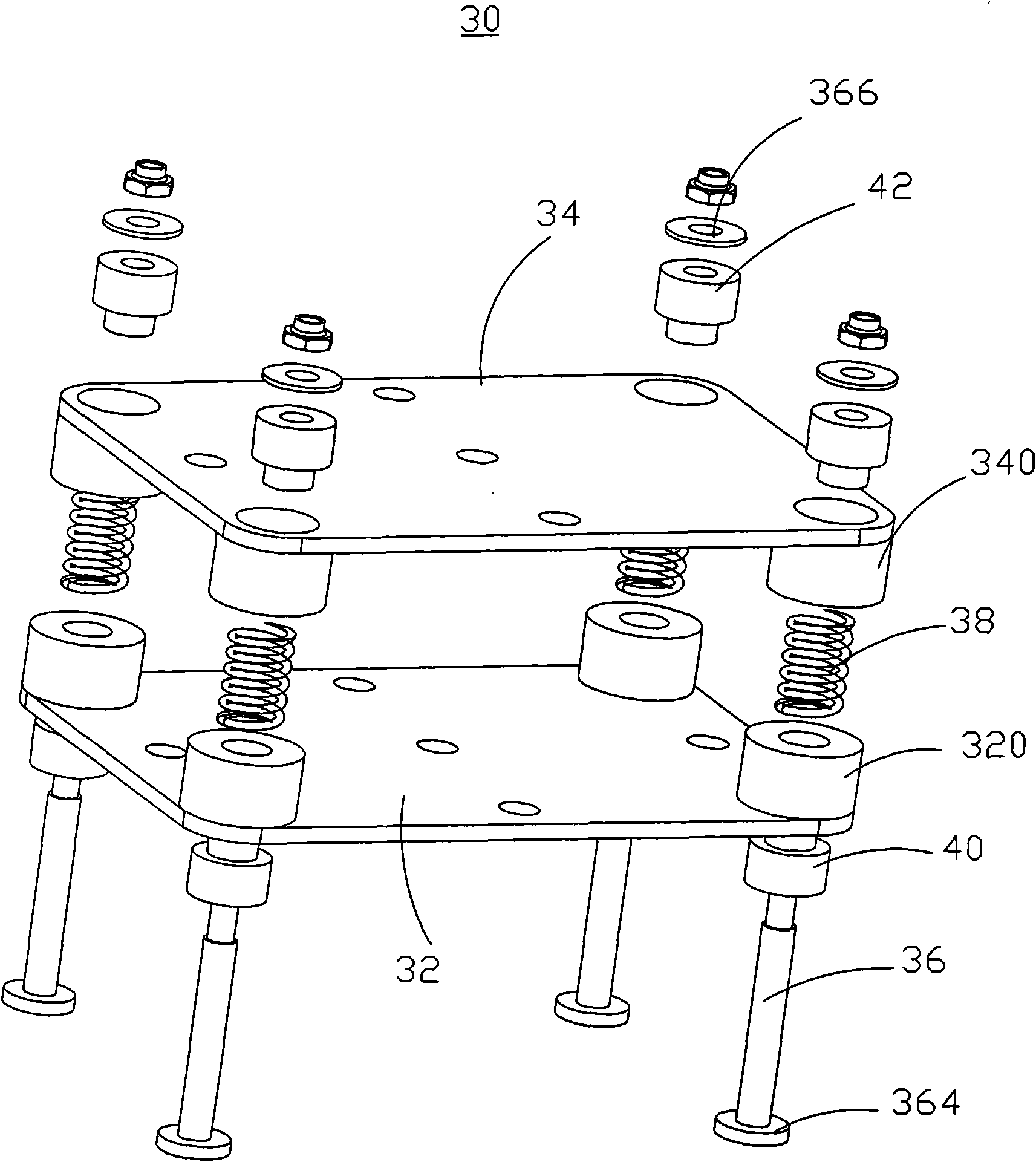

InactiveCN101852346AExtended service lifeReduce the amount of vibrationProtective devices for lightingElectric lightingEngineeringMechanical engineering

The invention relates to a lamp comprising a lamp body and a vibration damper connected with the lamp body. The vibration damper comprises a first installation board, a second installation board, a connecting rod, a spring, a first vibration absorbing sleeve and a second vibration absorbing sleeve, wherein the spring is clamped between the first installation board and the second installation board; a first sleeve barrel for containing the first vibration absorbing sleeve is formed by extending on the first installation board, and a second sleeve barrel for containing the second vibration absorbing sleeve is formed by extending on the second installation board; the connecting rod is provided with opposite first end and second end, the first end of the connecting rod protrudes the first sleeve barrel and limits the first vibration absorbing sleeve in the first sleeve barrel, and the second end of the connecting rod protrudes the second sleeve barrel and limits the second vibration absorbing sleeve in the second sleeve barrel. The lamp has the advantages of better vibration damping performance and longer service life.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Mixer having S-shaped paddles for mixing viscous materials

ActiveUS7887230B2Reduce the amount of vibrationPossibility of contaminationRotary stirring mixersTransportation and packagingEngineeringAxial distance

Owner:UNITED STATES GYPSUM CO

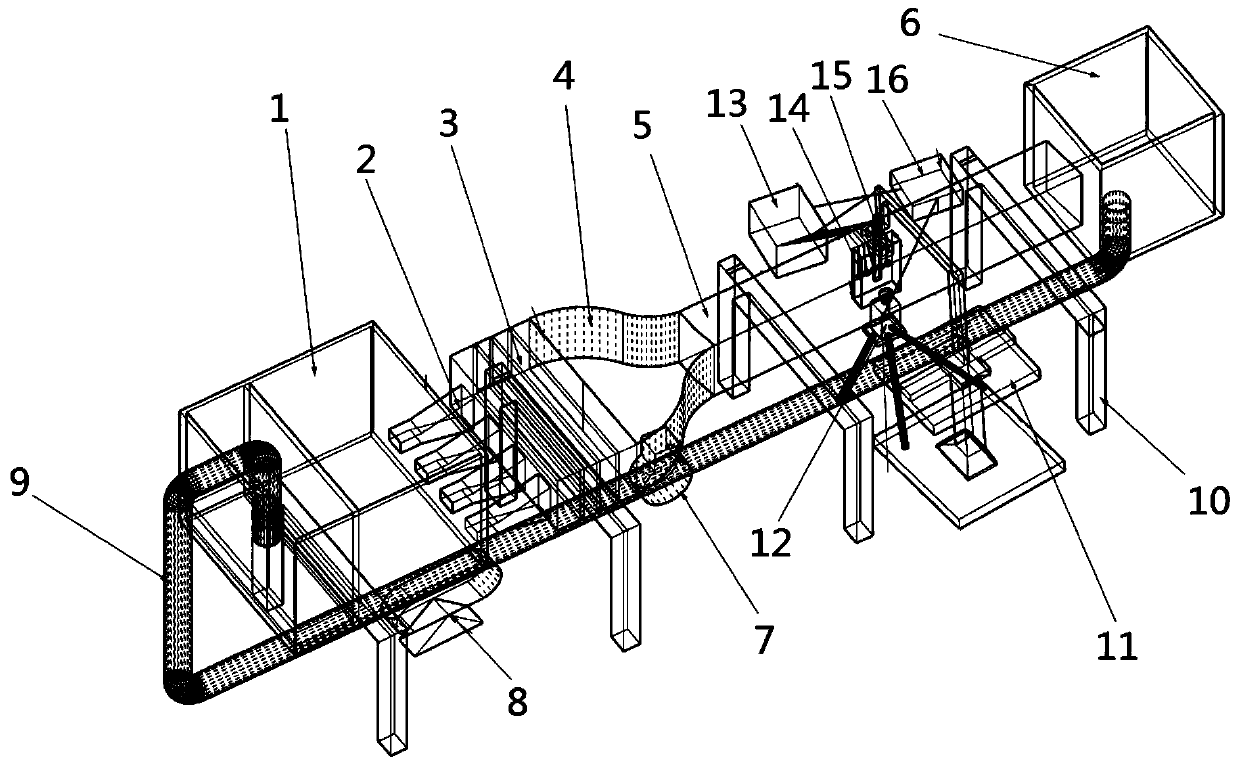

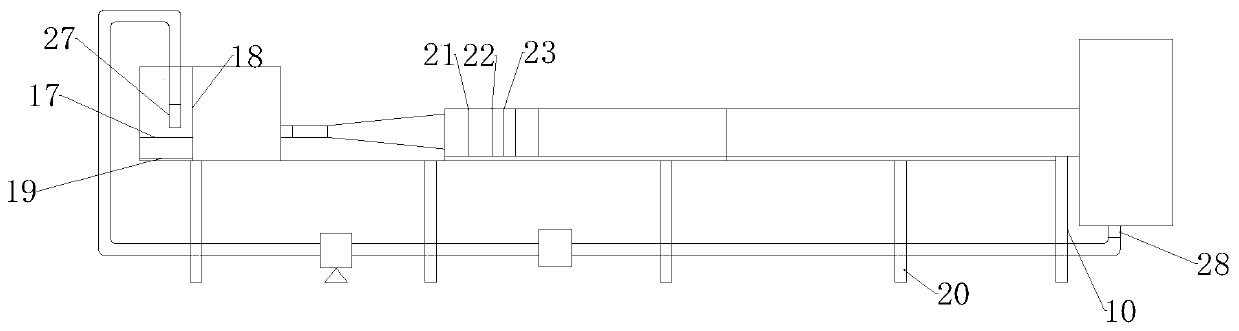

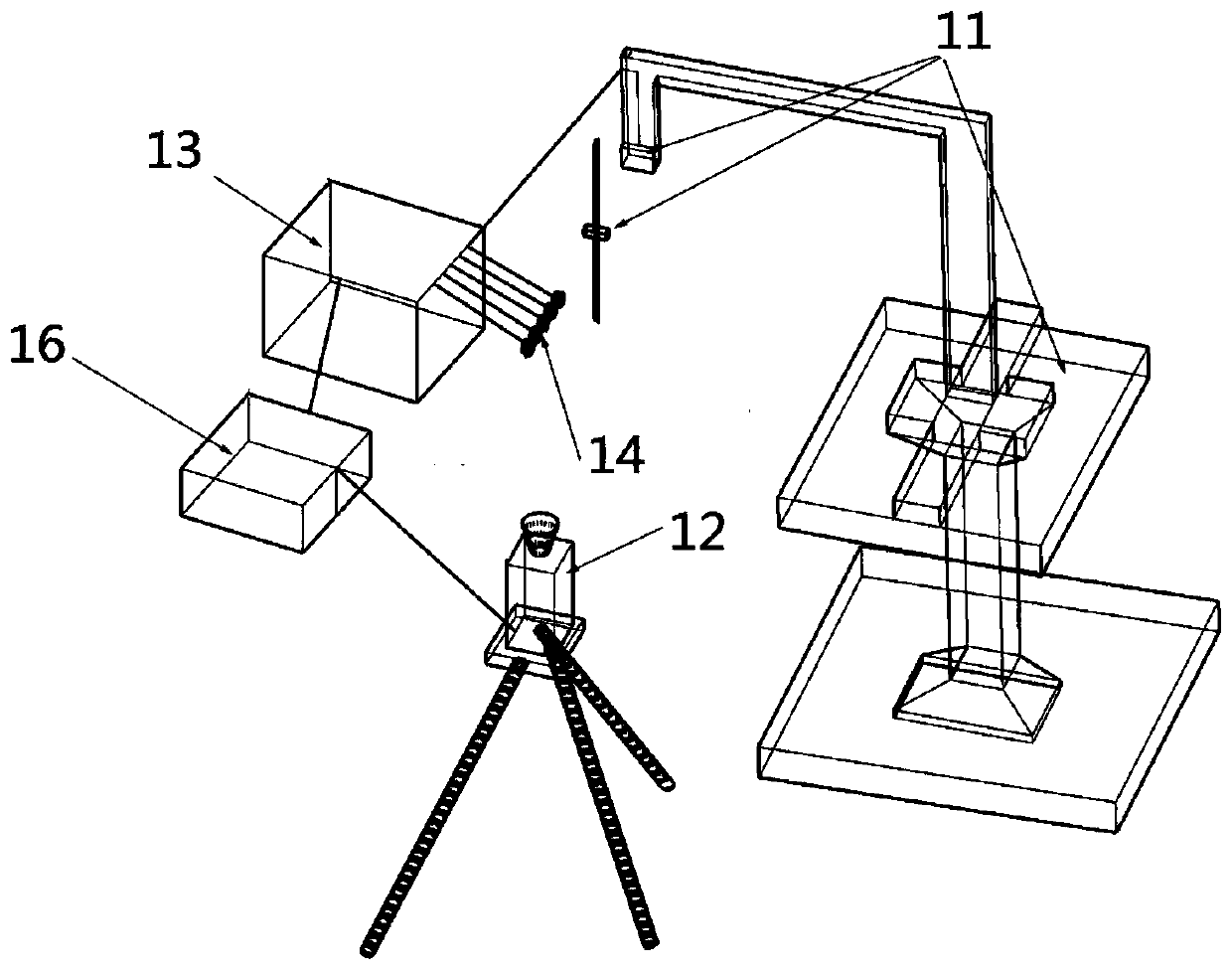

Pressure high chord thickness ratio empty box bluff body streaming flow induced vibration test device

ActiveCN111537190AHigh precisionImprove uniformitySubsonic/sonic/ultrasonic wave measurementHydrodynamic testingTest measurementSensor array

The invention discloses a pressure high chord thickness ratio empty box bluff body streaming flow induced vibration test device. An empty box is arranged in a test section water tank, the empty box isof a cuboid, cylinder or irregular structure with openings in the top end and the bottom end, and holes consistent in size and shape are formed in the portion, corresponding to the opening area in the top end of the empty box, of a top plate of the test section water tank; a test measurement part is arranged outside the test section water tank, and comprises a vibration displacement measurement system, a micro pulsating pressure sensor array, a PIV system, a multifunctional dynamic measurement instrument and a synchronous clock; oscillating bar vibration signals obtained by the vibration displacement measurement system and water flow pulsating pressure change signals detected by the micro pulsating pressure sensor array are transmitted to the multifunctional dynamic measuring instrument respectively and recorded, and signals of the multifunctional dynamic measurement instrument and the PIV system are synchronized through the synchronous clock. The device has the advantages of both contact measurement and non-contact measurement, and improves the precision of vibration displacement measurement while not interfering with a flow field.

Owner:NANJING HYDRAULIC RES INST

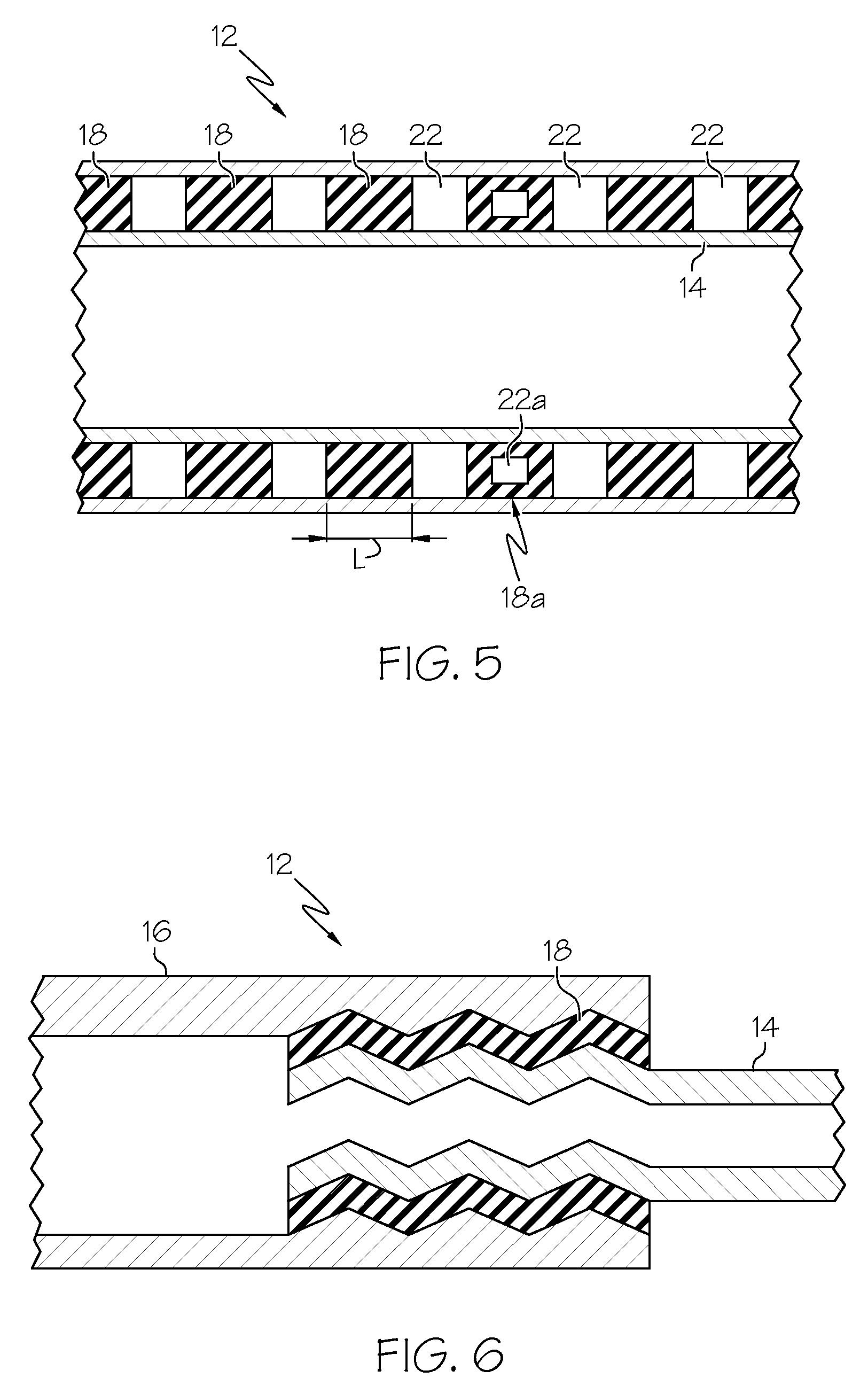

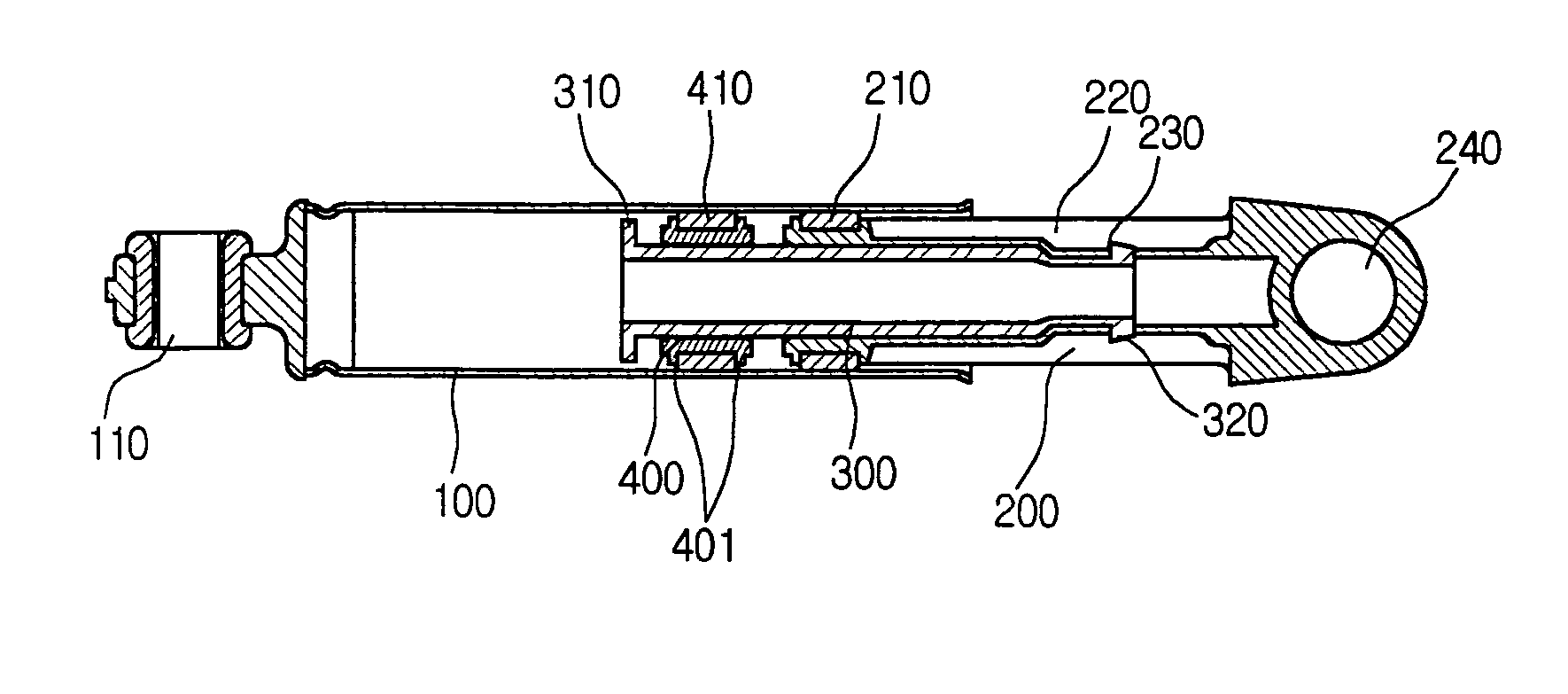

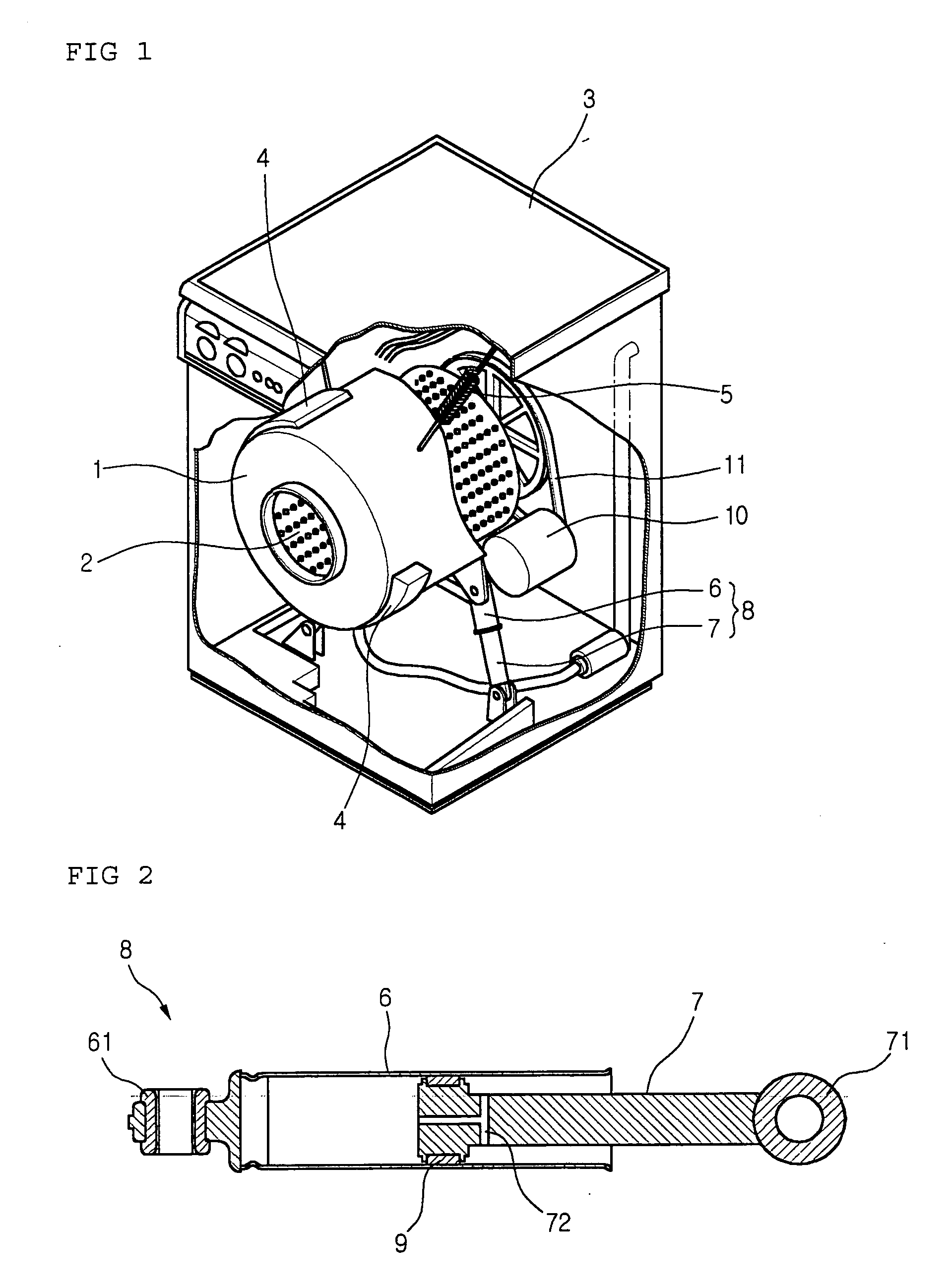

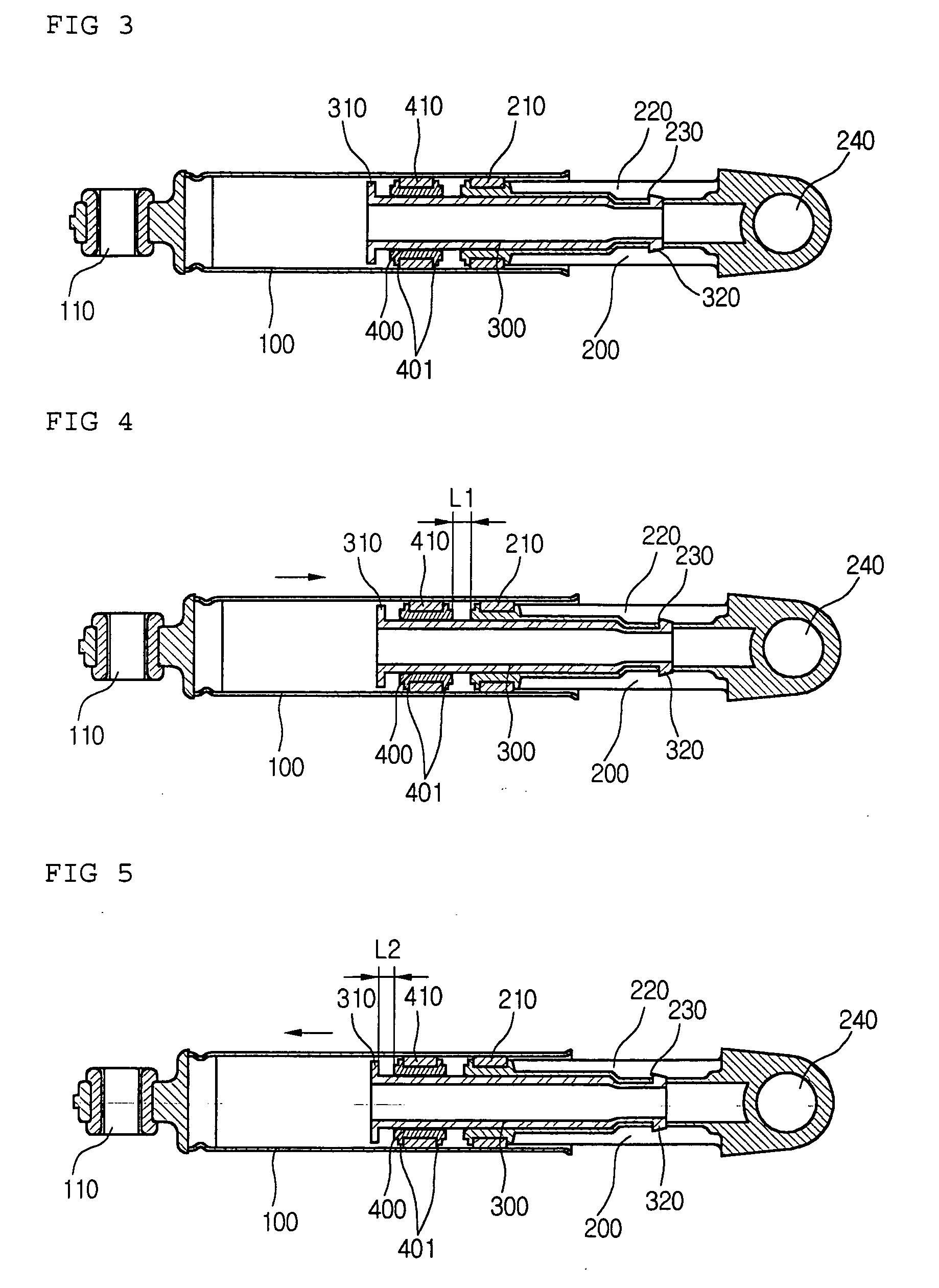

Damper in a washing machine and fabricating method of the same

ActiveUS20050224303A1Reduce the amount of vibrationAvoid damageLiquid resistance brakesSpringsEngineeringPiston

A damper for a washing machine includes: a cylinder; a piston body having one end inserted into the cylinder; a first friction member interposed in a contact surface between the piston body and the cylinder; an extension bar extended from an inserted portion of the piston body, the extension bar having a circumferential stopper at the extended portion; a friction ring formed between the circumferential stopper and the first friction member; and a second friction member formed on an outer circumferential surface of the friction ring to contact with an inner surface of the cylinder.

Owner:LG ELECTRONICS INC

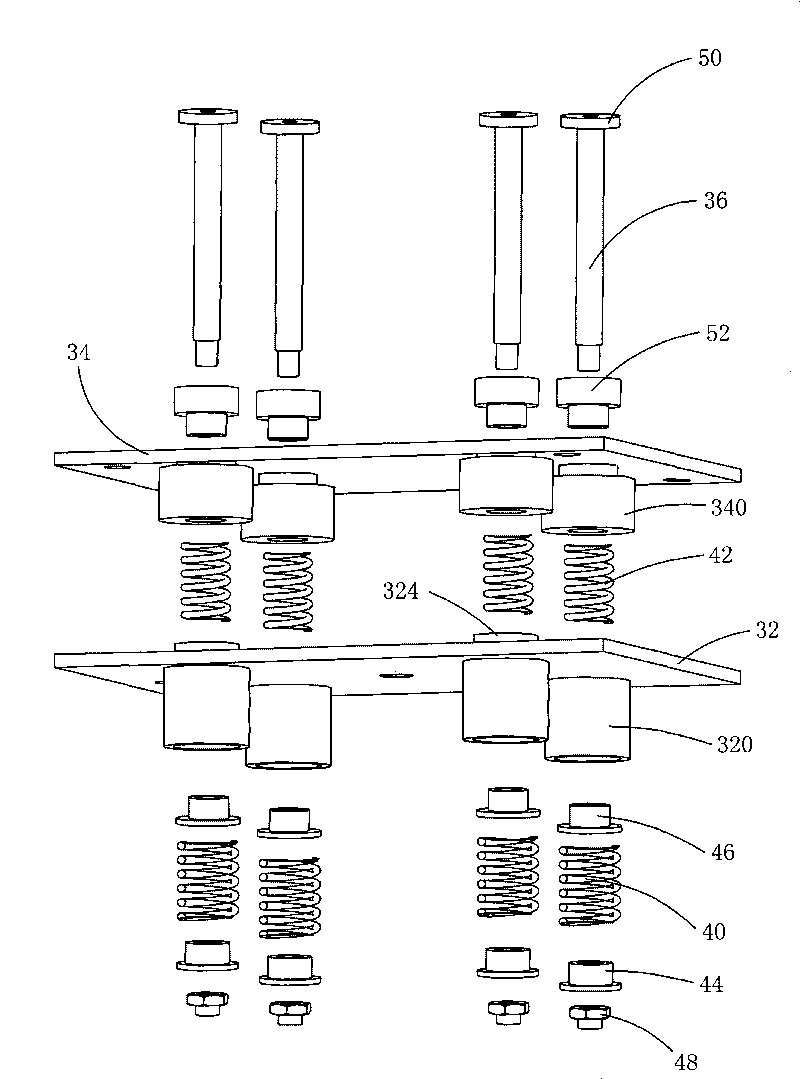

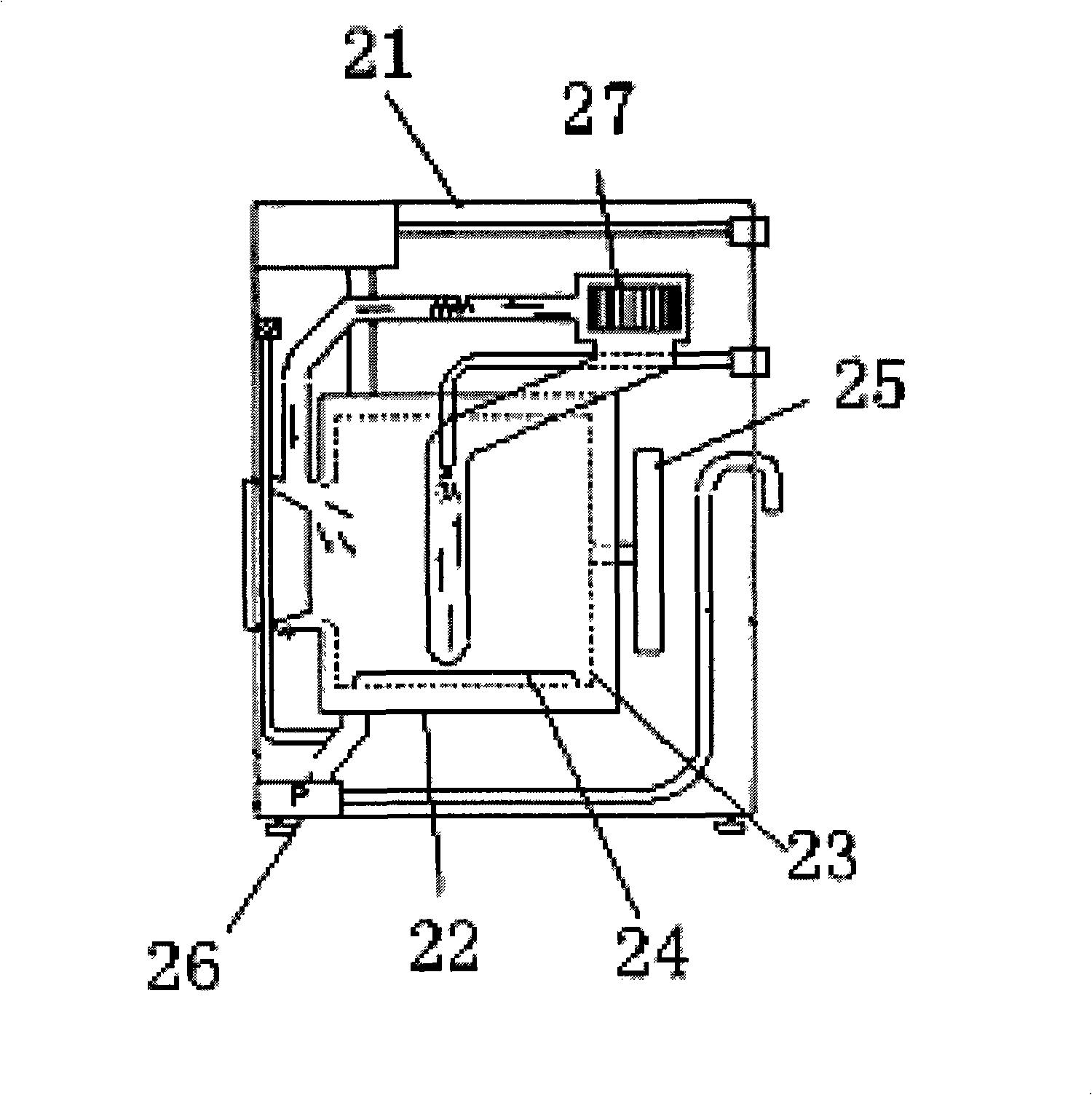

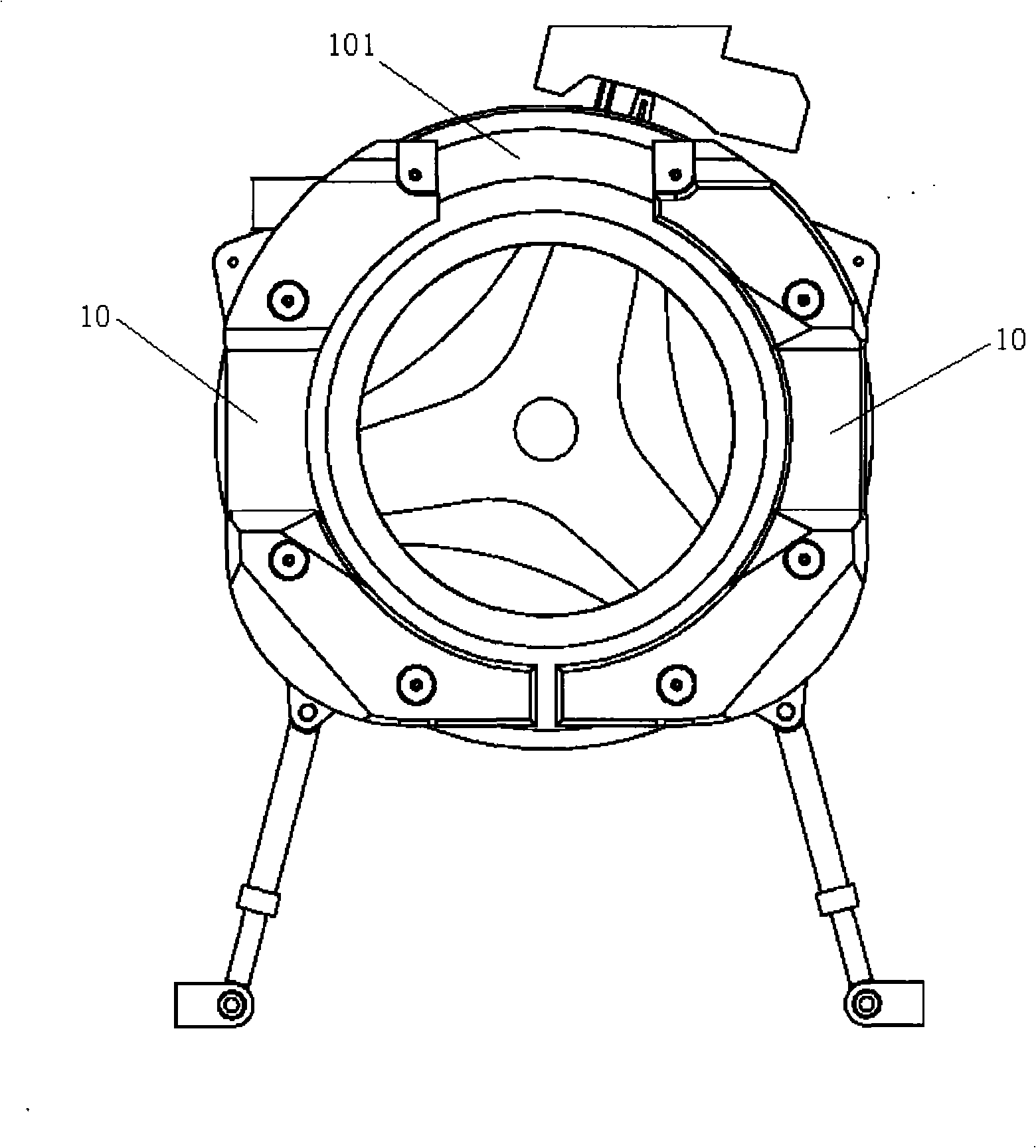

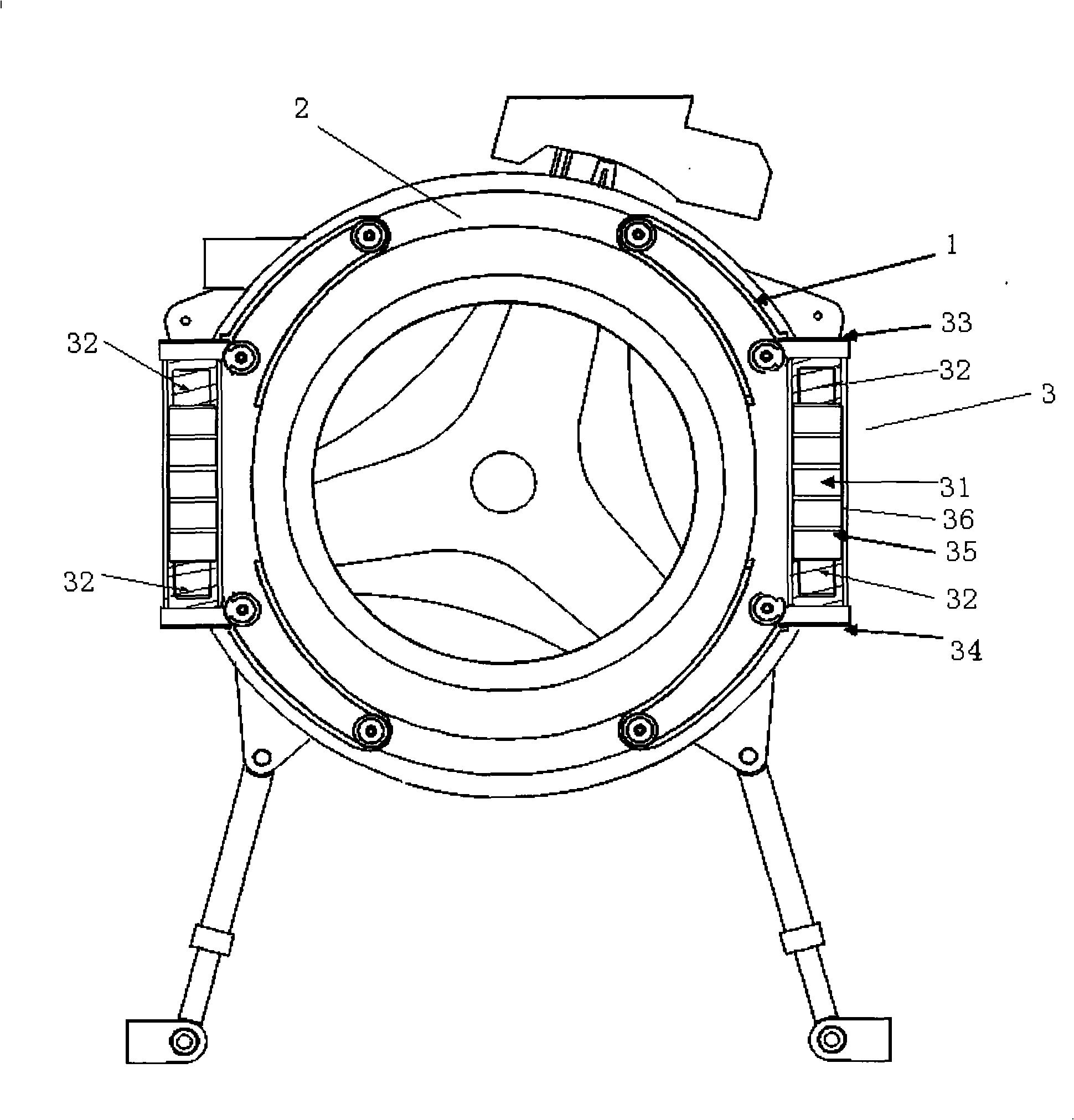

Dynamic shock-absorbing device for drum washing machine

InactiveCN101492876AControl the amount of vibrationReduce the amount of vibrationOther washing machinesTextiles and paperVibration absorptionDynamic Vibration Absorber

The invention discloses a dynamic vibration absorption device for a tumbling-cylinder washing machine, comprising balancing weights and dynamic vibration absorbers, two balancing weights are respectively arranged at left and right sides of the outer drum of the tumbling-cylinder washing machine, two dynamic vibration absorbers for absorbing the vibration of the tumbling-cylinder washing machine are respectively arranged at the balancing weights at left and right sides. The dynamic vibration absorbers are used for transferring the energy of a vibration system and absorbing the vibration of the tumbling-cylinder washing machine. The dynamic vibration absorber comprises a vibrator, springs, an upper cover plate and a lower cover plate, the upper cover plate and the lower cover plate are arranged on the balancing weights, both ends of the vibrator are provided with springs, the vibrator is mounted on the upper cover plate and the lower cover plate via the springs arranged at the two ends. The invention is in no need of the balancing weights with large mass, can effectively control the vibration amount of the entire drum and absorb the vibration of the washing machine. The invention is adapted to a variety of tumbling-cylinder washing machines.

Owner:NANJING LG PANDA APPLIANCES

Macromolecule self-glue rubber for preventing automobile tire flat and manufacturing method thereof

InactiveCN103849284AWidely used valueReduce the amount of vibrationRosin coatingsFoaming agentThermoplastic elastomer

The invention relates to macromolecule self-glue rubber for preventing automobile tire flat, comprises the following components in parts by mass (using 100 part by mass of thermoplastic elastomer as the standard): 100 parts of thermoplastic elastomer, 130-140 parts of tackifier, 100-110 parts of plasticizer, 5-5.5 parts of antiaging agent and / or antioxidant, 2-3 parts of foaming agent and 10-12 parts of filler. The macromolecule self-seal rubber after hot-melting is sprayed on the inner wall of the tire by using the automobile tire rubber sprayer, a layer of macromolecule self-seal rubber with thickness of more than 3.5mm is sprayed on all of the inner wall or partial crown type body of the tire by using the automobile tire rubber sprayer without performing any traumatic processing on the inner wall of the tire and only performing cleaning and drying treatment on the inner wall of the tire to remove the release agent, that is, the normal automobile tire is upgraded to realize that the tire can normally work within low temperature of minus 40 DEG C to high temperature 120 DEG C, and has the bullet-proof, leak-proof and puncture-proof performances; and the invention further discloses a manufacturing method of the macromolecule self-seal rubber.

Owner:LUOYANG JUNTENG ENERGY TECH

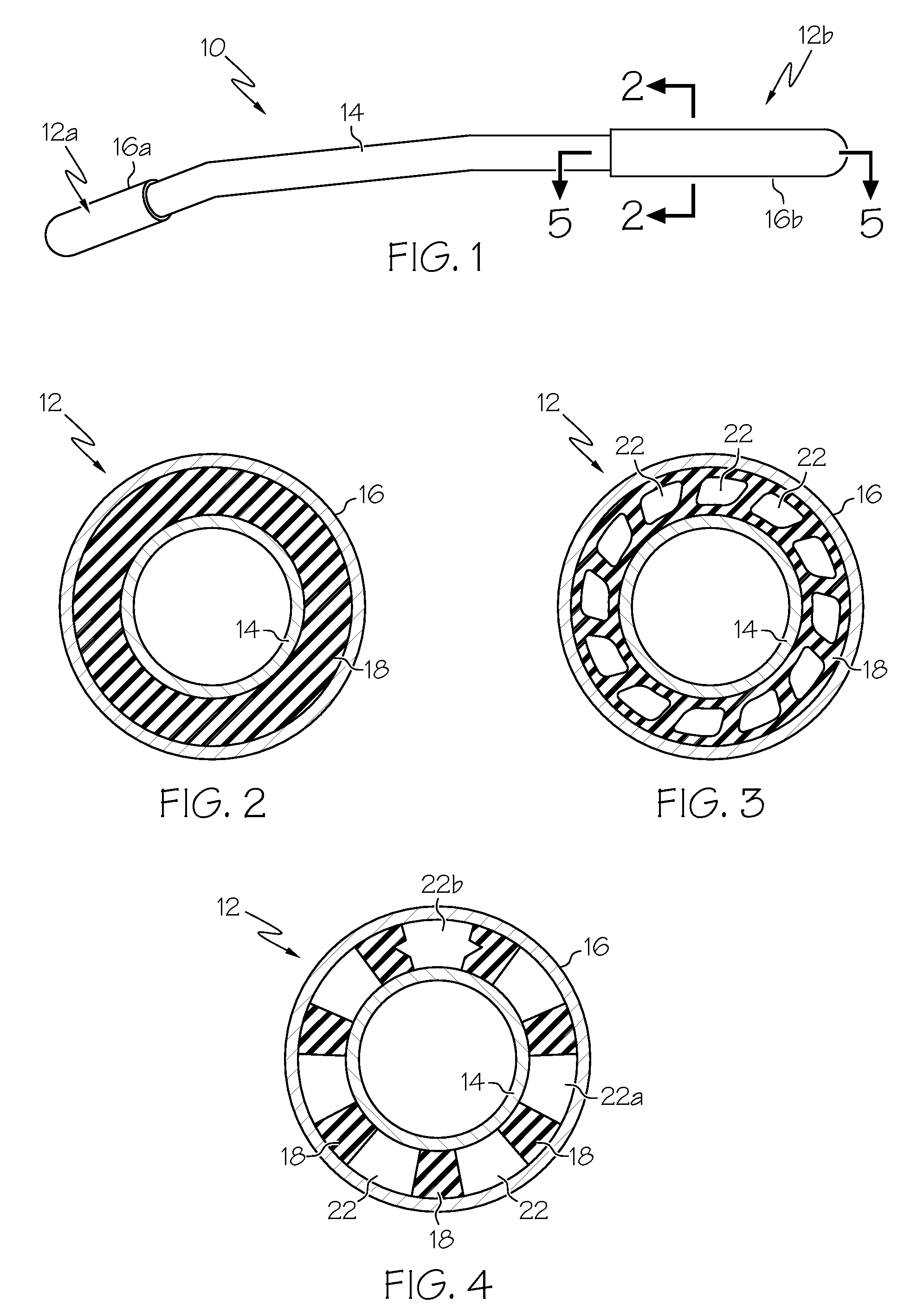

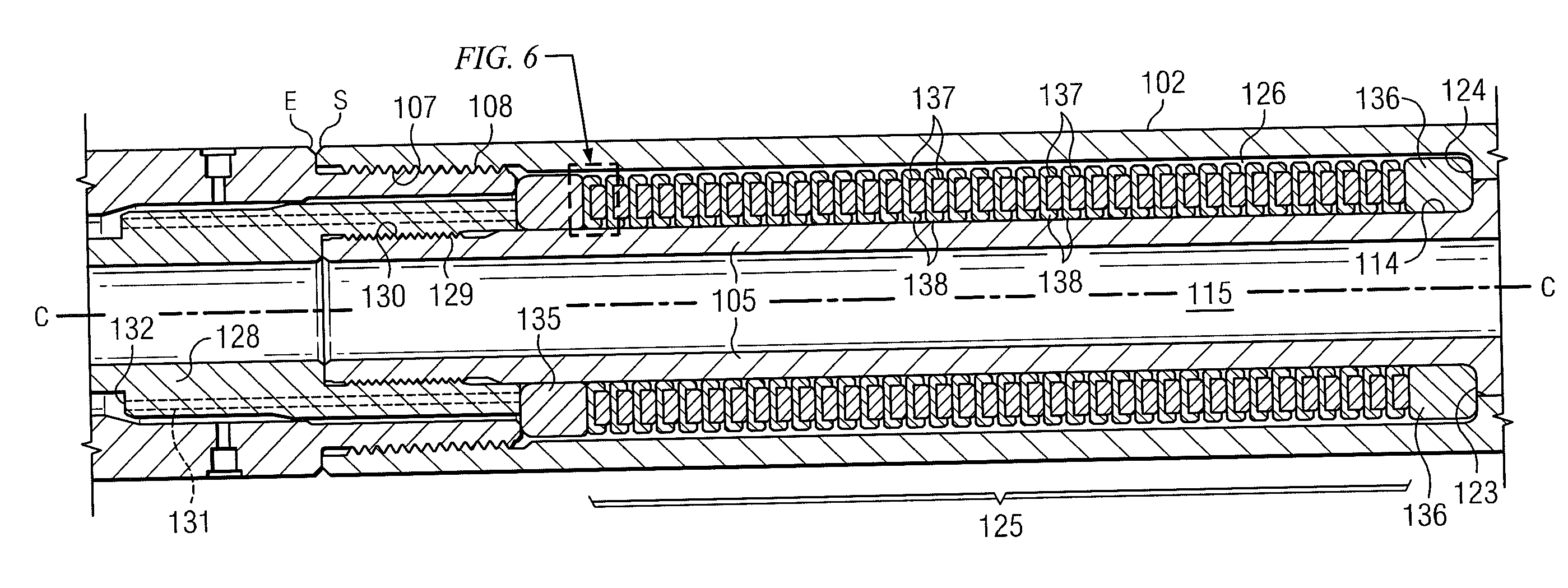

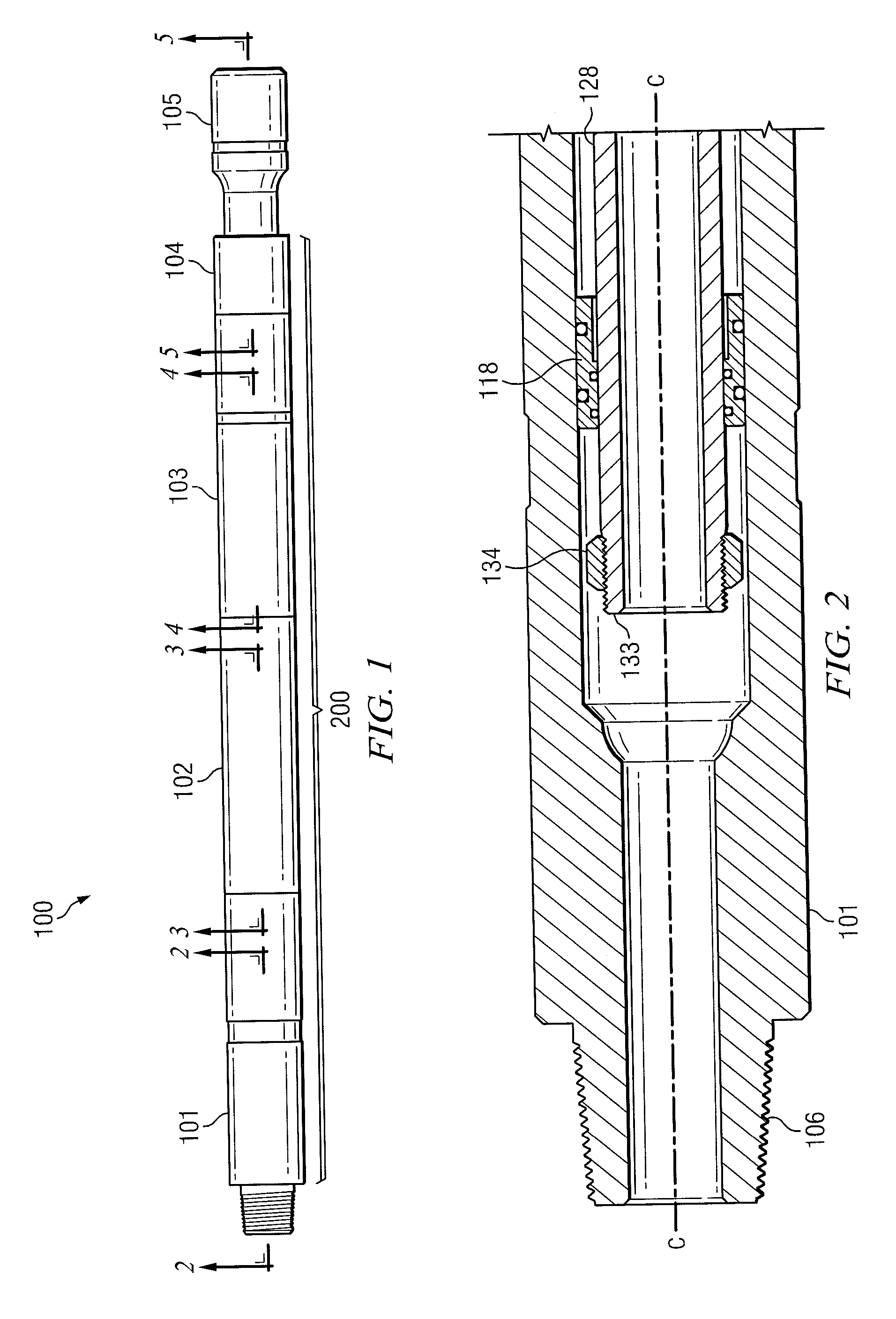

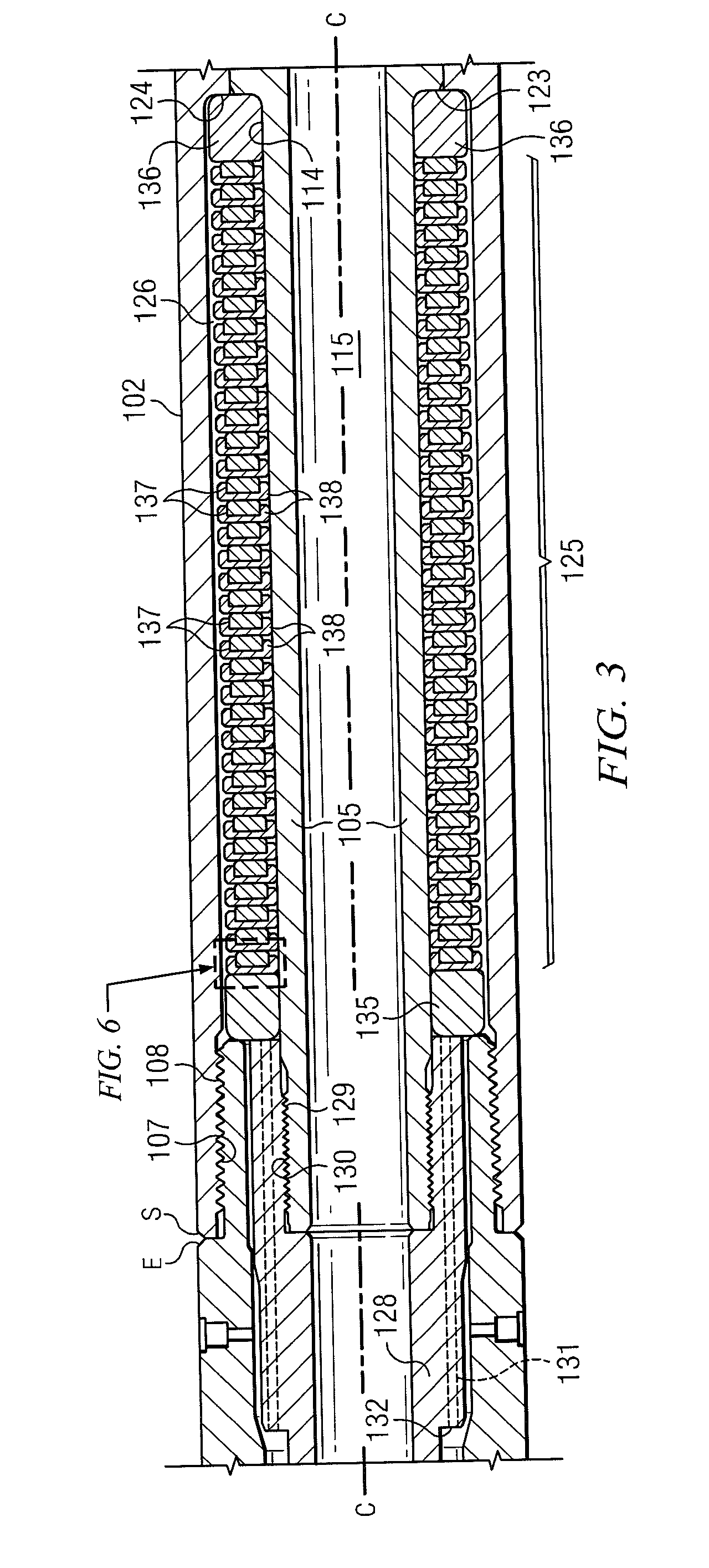

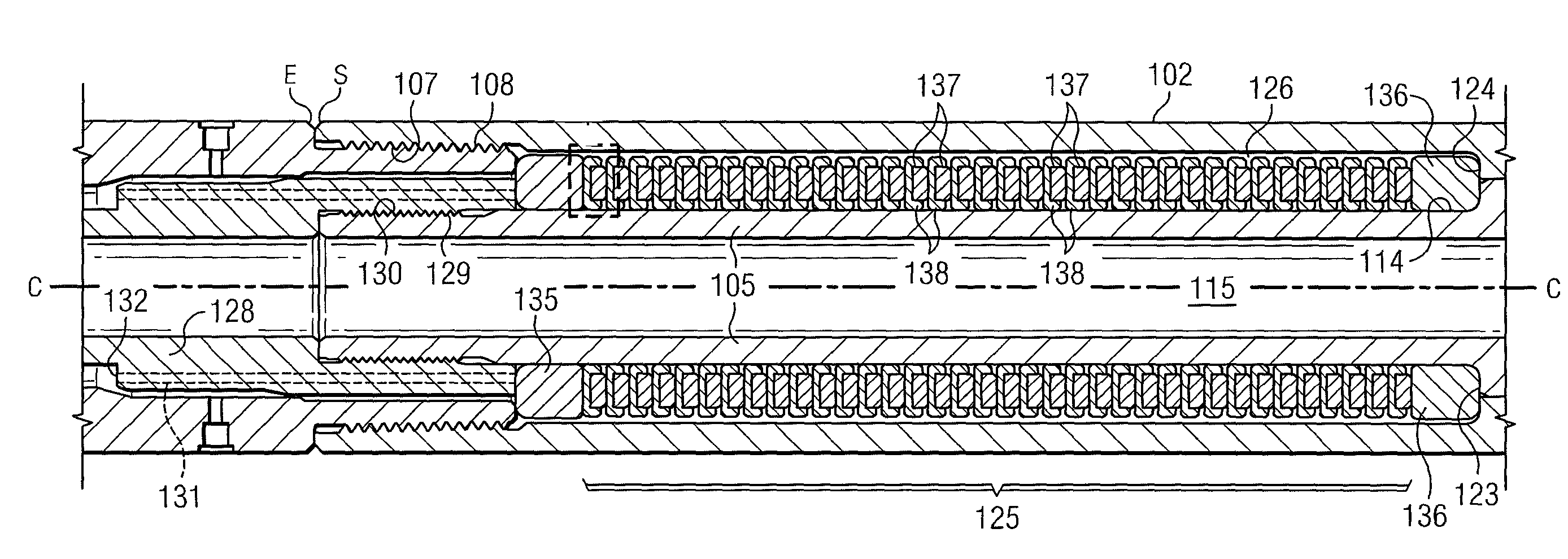

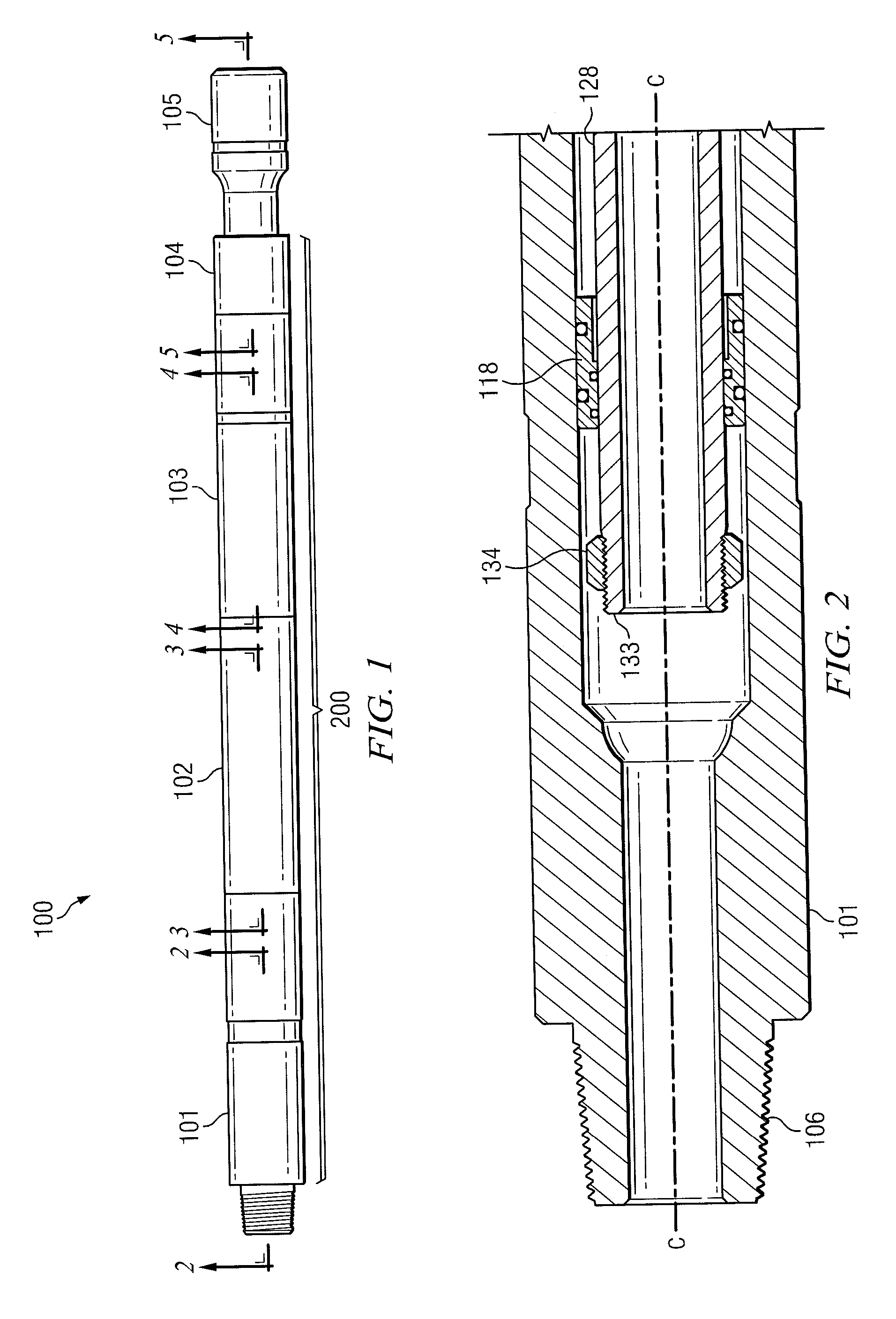

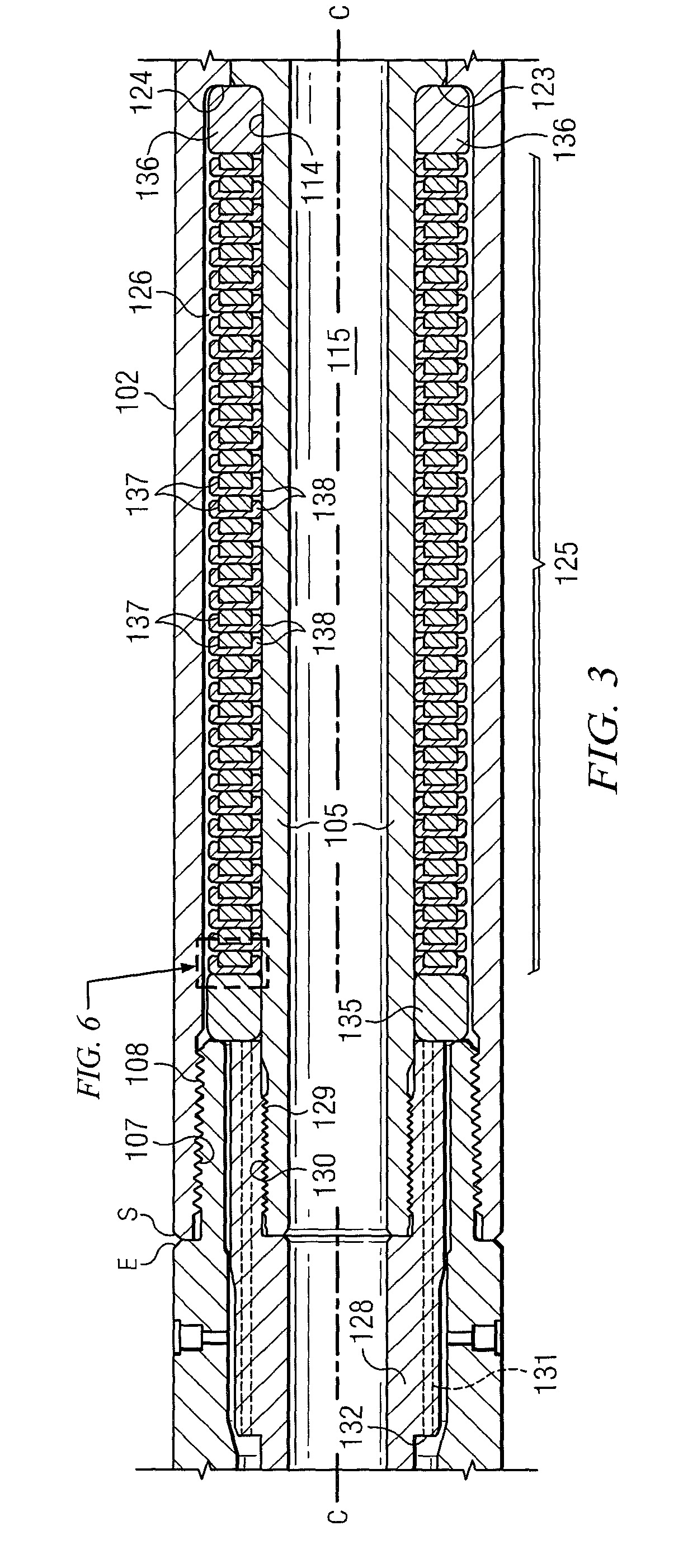

Downhole Vibration Dampener

ActiveUS20100181111A1Reduce vibrationReduce the amount of vibrationDrilling rodsDirectional drillingEngineeringLubricant

A down hole vibration dampener is disclosed that uses a set of polyurethane rings and steel support rings to create a shock absorber within the drill string to reduce the amount of vibration in the drill string. A splined mandrel extends longitudinally within a hollow cylindrical housing. A seal structure present between the exterior of the mandrel and the interior of the housing forms a lubricant receiving chamber. The series of polyurethane and steel rings are located in the lubricant chamber and are compressible longitudinally to absorb vibration and shock loads.

Owner:RIVAL DOWNHOLE TOOLS LC

Coaxial Tube Damper

ActiveUS20090072455A1Reduce amountReduce the amount of vibrationPortable framesPortable percussive toolsEngineeringMechanical engineering

Owner:MCP IP

Hybrid drive unit and vehicle mounted therewith

ActiveUS7350603B2Feel goodTransmission easilyHybrid vehiclesElectric propulsion mountingHybrid driveStructural element

A hybrid drive unit includes a hybrid mechanism having at least one electric motor and a transfer that distributes driving force to front and rear wheels. The electric motor and the transfer are housed in a tubular shaped transmission case that extends in the front and rear directions of a vehicle. The hybrid drive unit is mounted on and supported by a second attachment coupled to an internal combustion engine and provided at a front end of the hybrid drive unit and a first attachment portion fixed to a vehicle body. The electric motor and the transfer that are heavy structural members of the hybrid drive unit are positioned separately to the front and rear of the first attachment portion that forms a boundary. By adopting this configuration, it is possible to reduce the amount of engine vibration that is transmitted to the vehicle body through the first attachment portion.

Owner:AISIN AW CO LTD +1

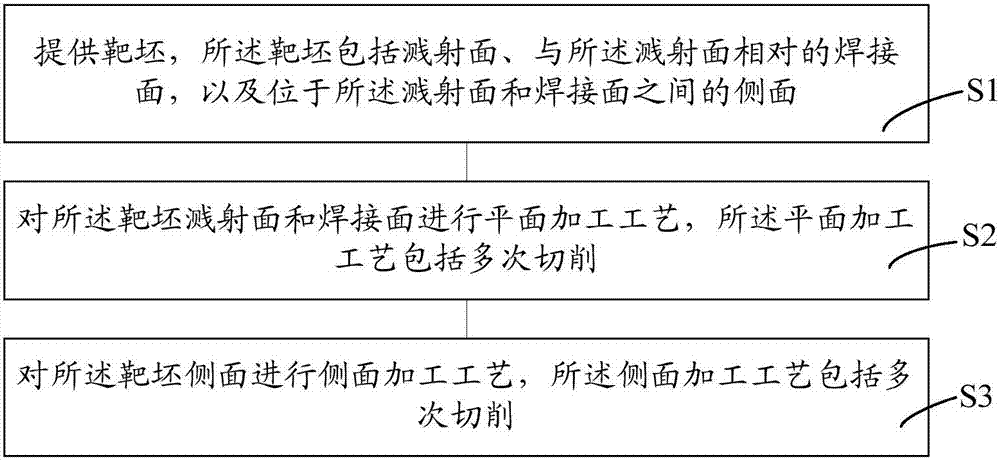

Machining method of target material

InactiveCN107570964AReduce cutting forceReduce releaseVacuum evaporation coatingSputtering coatingEngineeringCutting force

The invention provides a machining method of target material. The method comprises the following steps: providing a target blank comprising a sputtering surface, a welding surface opposite to the sputtering surface and a side surface located between the sputtering surface and the welding surface; performing plane machining operation on the sputtering surface of the target blank; and performing side-surface machining operation on the side surface of the target blank, wherein the plane machining operation and the side-surface machining operation both comprise cutting multiple times. During the plane machining operation and the side-surface machining operation, both the plane machining operation and the side-surface machining operation comprise cutting multiple times. The cutting frequency isincreased such that feeding amount and engagement of each cut are correspondingly reduced. Compared with the scheme with fewer cutting frequency, the machining method of target material can reduce cutting force of a tool to the target material during machining so that release of internal stress in the interior of the target material is minimized, thereby reducing the deformation degree of the target material. Additionally, reduction in cutting force can help vibration amount during machining of the target material, which further improves machining quality of the target material.

Owner:合肥江丰电子材料有限公司

Downhole vibration dampener

ActiveUS8205691B2Reduce vibrationReduce the amount of vibrationDrilling rodsDirectional drillingEngineeringLubricant

A down hole vibration dampener is disclosed that uses a set of polyurethane rings and steel support rings to create a shock absorber within the drill string to reduce the amount of vibration in the drill string. A splined mandrel extends longitudinally within a hollow cylindrical housing. A seal structure present between the exterior of the mandrel and the interior of the housing forms a lubricant receiving chamber. The series of polyurethane and steel rings are located in the lubricant chamber and are compressible longitudinally to absorb vibration and shock loads.

Owner:RIVAL DOWNHOLE TOOLS LC

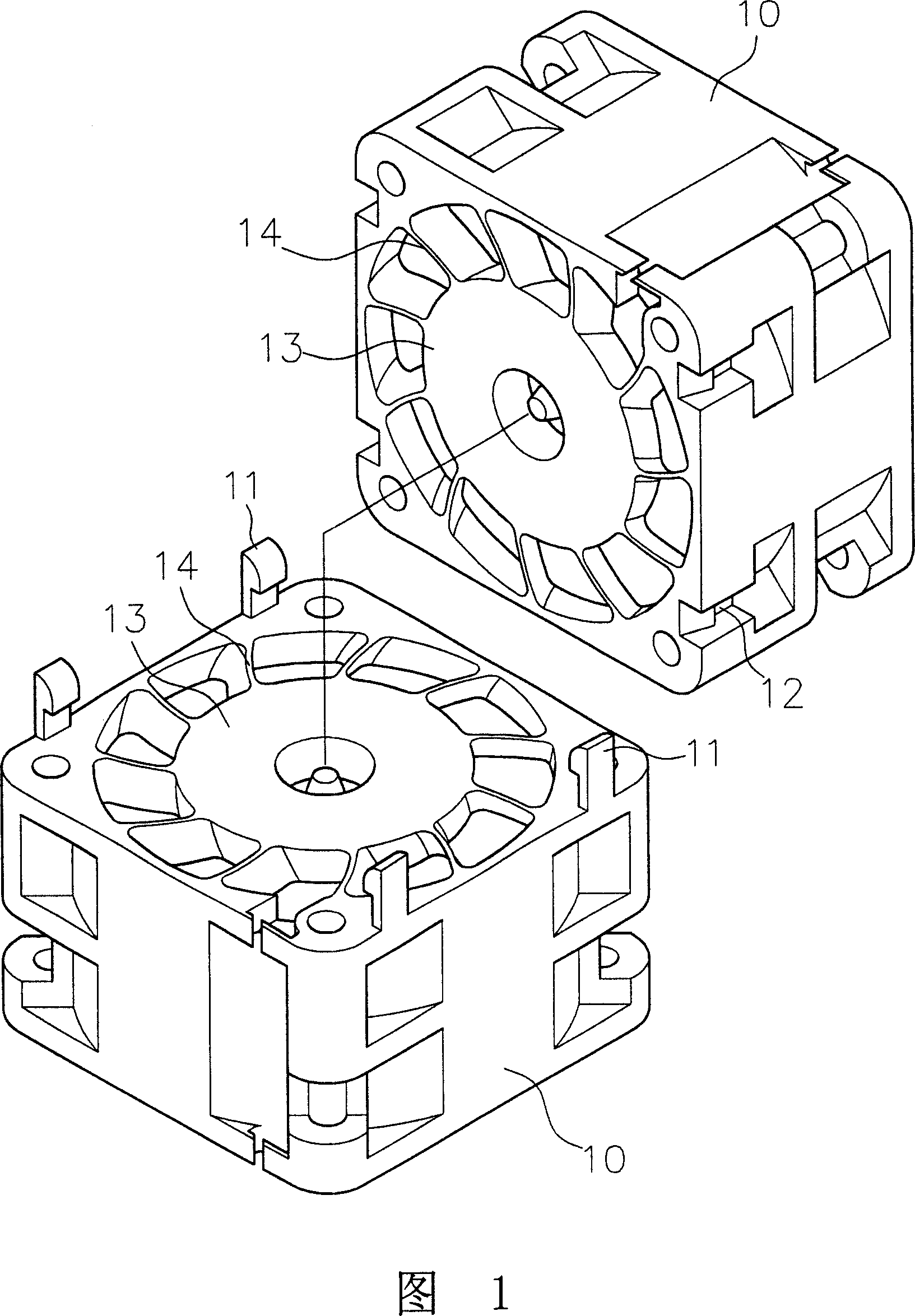

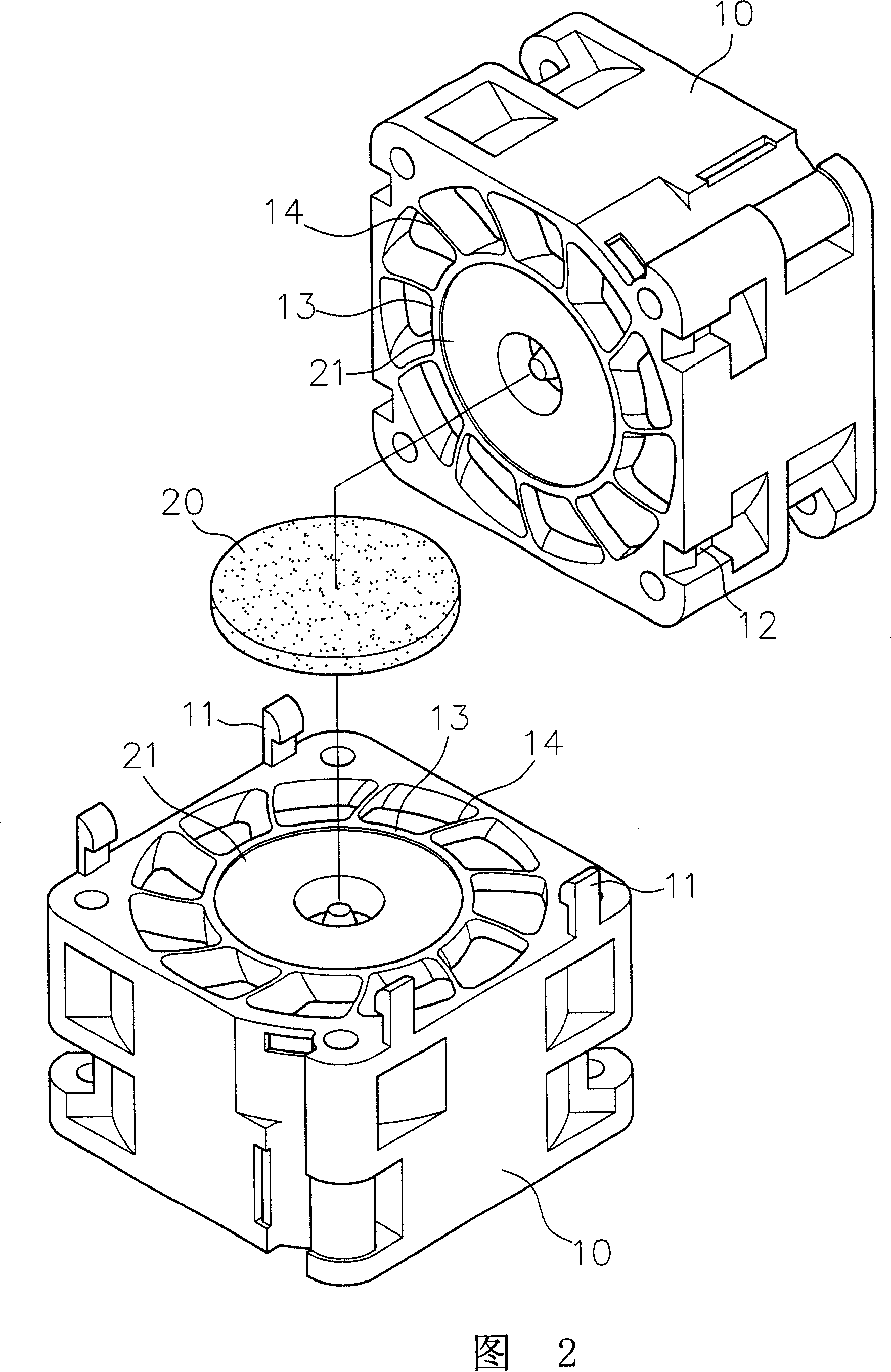

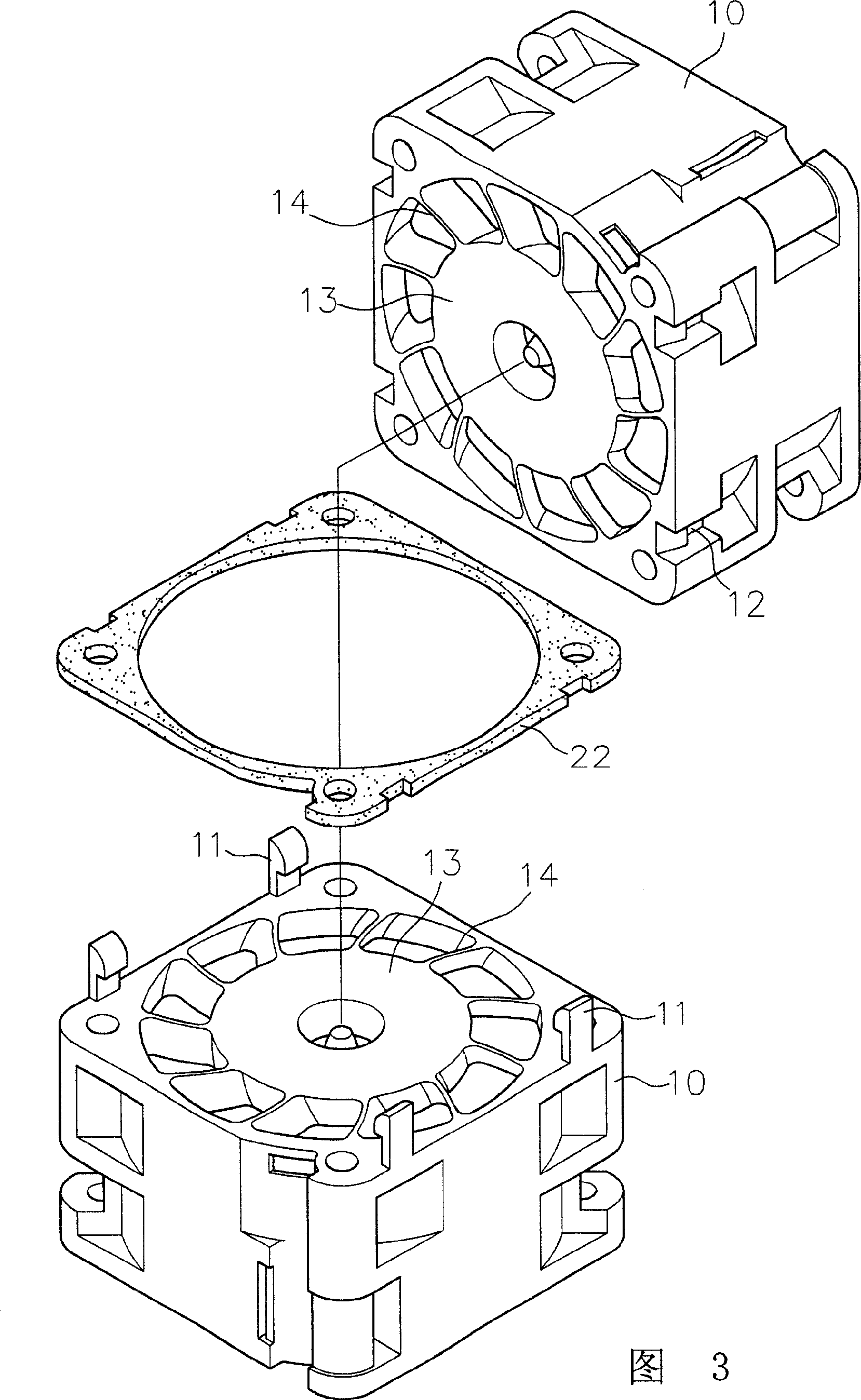

Vibration-proof structure of series fan

InactiveCN101117969AReduce the fundamental frequency of vibrationAvoid interactionPump componentsPump installationsImpellerEngineering

The present invention relates to a vibration reducing structure of a series connected fan. The series connected fan at least comprises two fan frames, a vibration reducing component is arranged between the surfaces at the vibration reducing combination of the fan frames, and the vibration reducing component must be made of elastic material of vibration absorbing and vibration damping. When the impeller rotators inside the fan frame run, the base frequency of the vibration of the two fan rotators can be damped and absorbed by the vibration reducing component of the present invention, thereby avoiding serious resonance effect and the vibration noise caused by mutual affect, and maintaining the optimum effect and the service life of the system.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

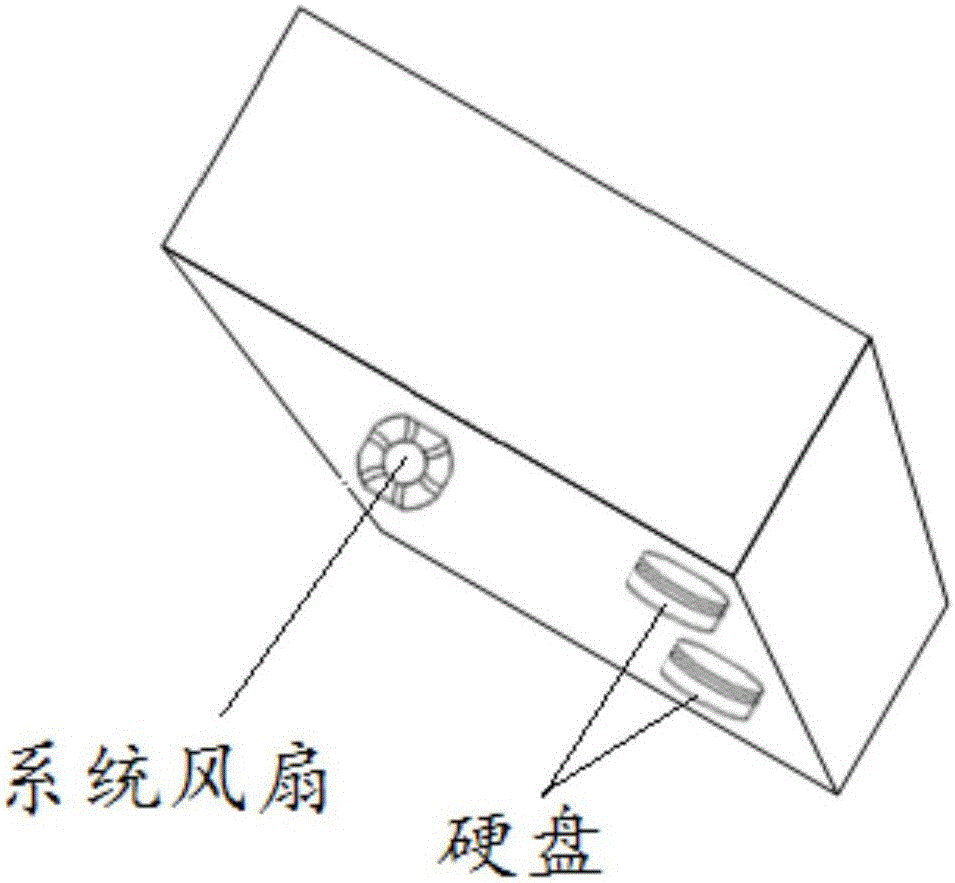

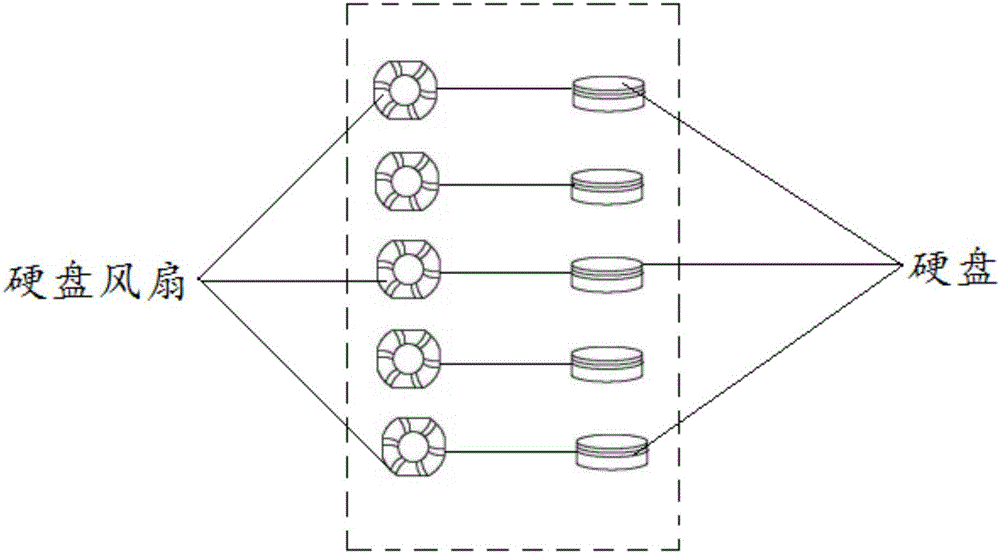

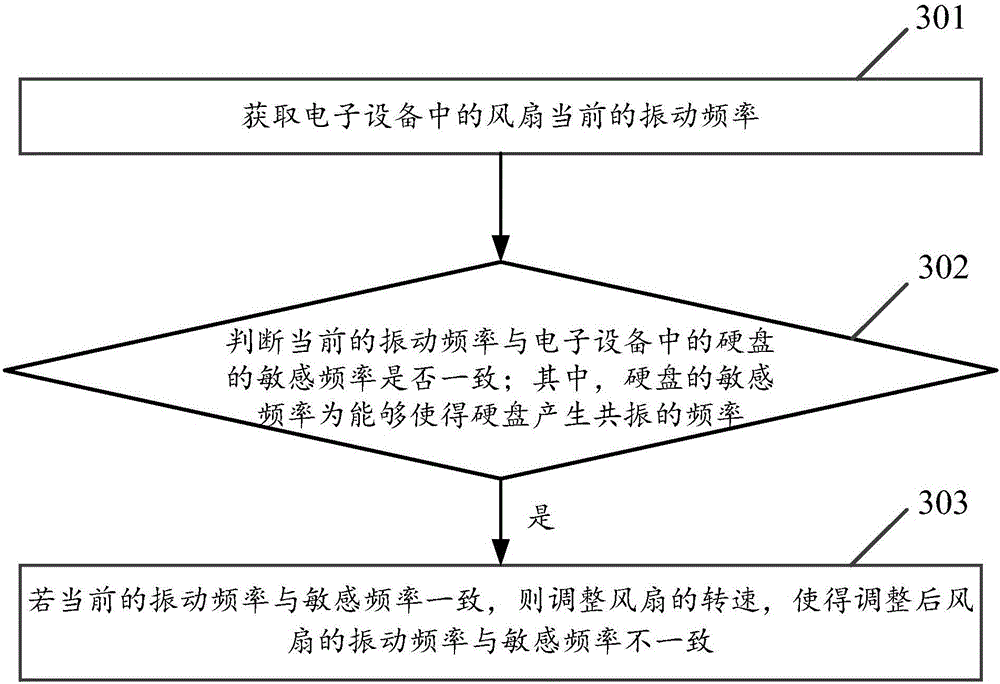

Method for adjusting rotating speed of fan and electronic device

ActiveCN106194807AReduce the amount of vibrationAvoid resonanceEngine controlPump controlResonanceComputer engineering

The invention discloses a method for adjusting the rotating speed of a fan and an electronic device. The method and the electronic device are used for solving the technical problem that the performance of a hard disk is reduced due to the too large quantity of vibration transmitted by the fan to the hard disk. The method includes the steps that the current vibration frequency of the fan in the electronic device is obtained; whether the current vibration frequency is consistent with the sensitive frequency of the hard disk in the electronic device or not is judged; the sensitive frequency of the hard disk is the frequency for the hard disk to generate resonance; and if the current vibration frequency is consistent with the sensitive frequency, the rotating speed of the fan is adjusted, and the vibration frequency of the fan is not consistent with the sensitive frequency after adjustment.

Owner:LENOVO (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com