Pressure high chord thickness ratio empty box bluff body streaming flow induced vibration test device

A technology of vibration test and empty box, which is applied in the vibration displacement, flow field test device, and the field of synchronous measurement of pulsating pressure on the wall surface of the blunt body, which can solve the problems of high delay, low precision and influence of linear displacement sensors, and achieve improvement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

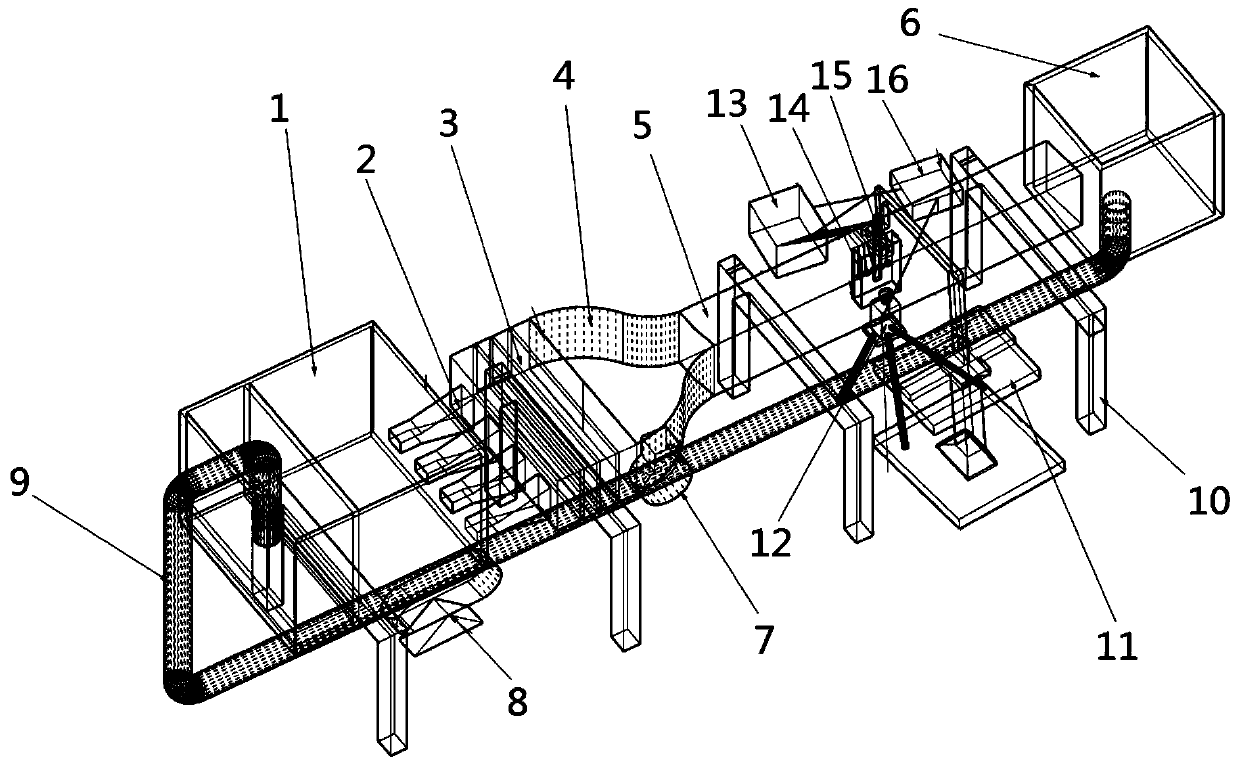

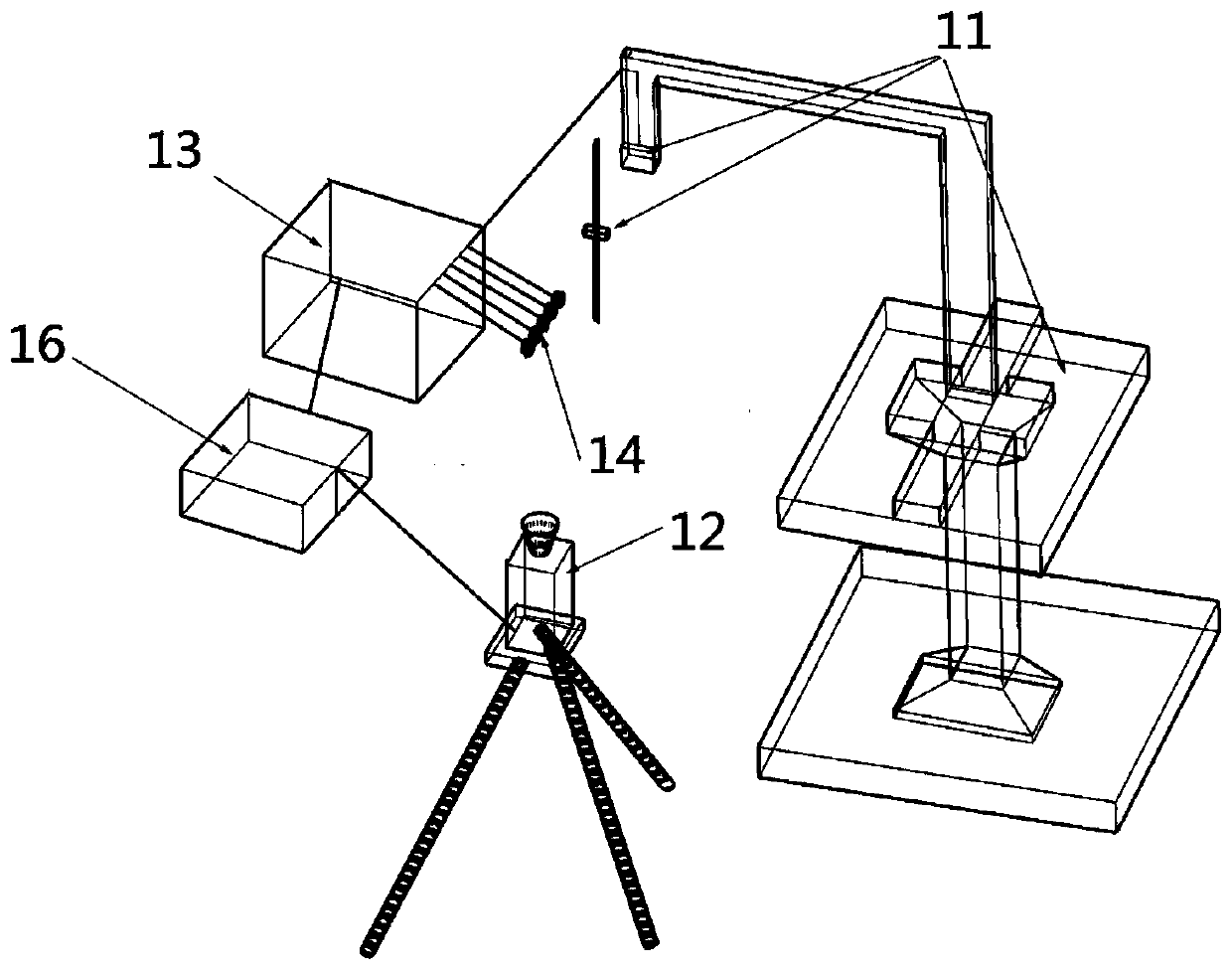

[0031] Embodiment: A test device for flow-induced vibration around a blunt body with pressure and high chord-thickness ratio, including a water circulation part and a test measurement part.

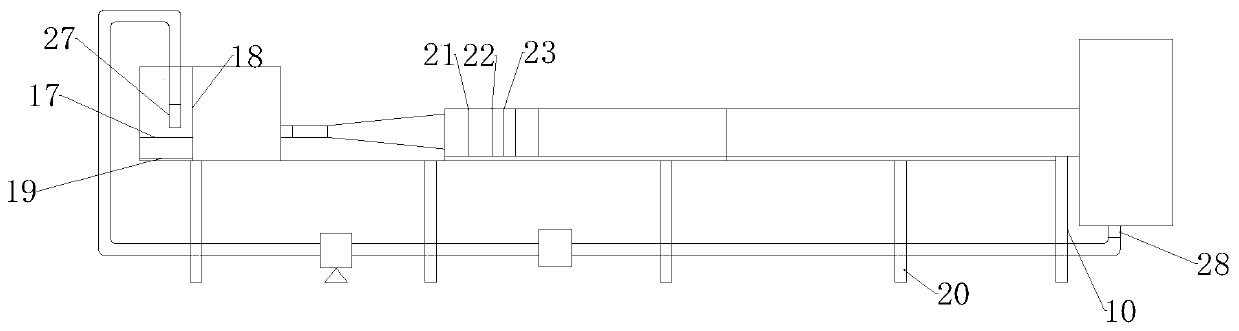

[0032] The water circulation part includes the water storage tank 1, the diffusion pipe group 2, the rectification section water tank 3, the contraction section water tank 4, the test section water tank 5 and the return water tank 6 connected in sequence, and the water storage tank 1 and the return water tank 6 are connected through the return pipe 9 , the return pipe 9 is provided with a water pump 8 and an electromagnetic flowmeter 7, the water flow in the return pipe 9 is measured by the electromagnetic flowmeter 7, and the flow rate of the water in the return pipe 9 is adjusted by changing the power of the water pump 8. The water flow in the water circulation part circulates under the action of the water pump 8 . Water storage tank 1, diffusion pipe group 2, rectification section wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com