Patents

Literature

1185results about "Hand hammers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

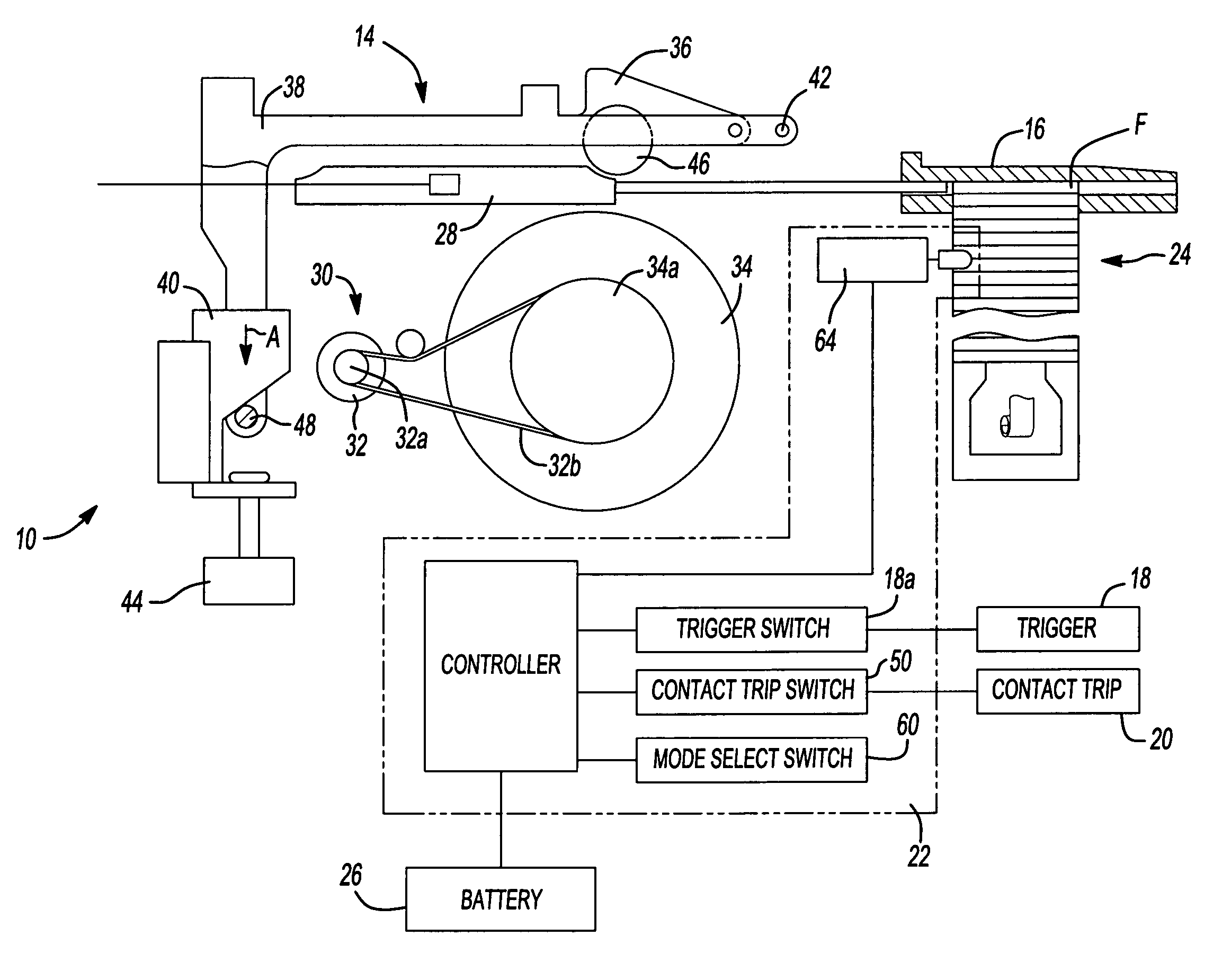

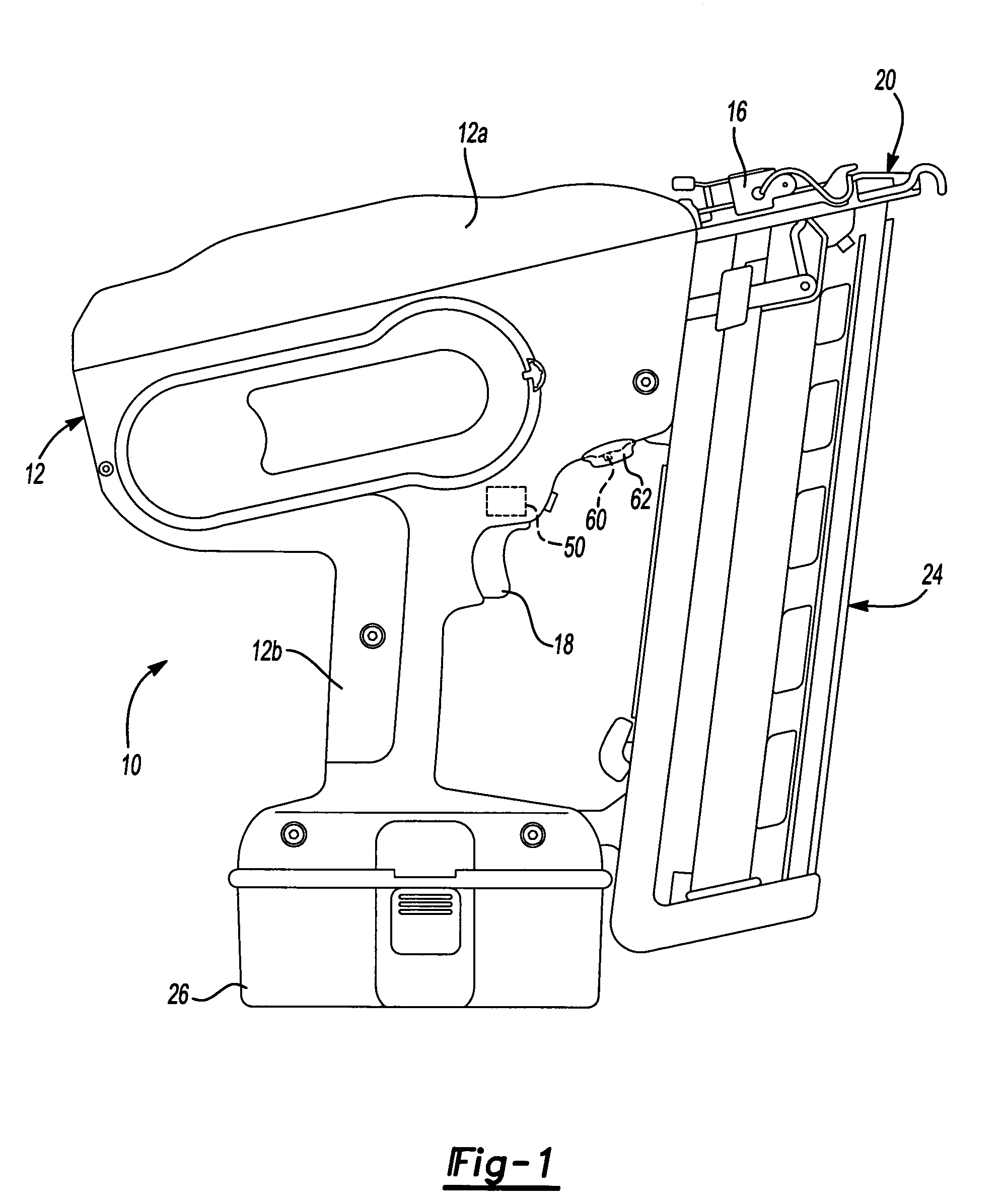

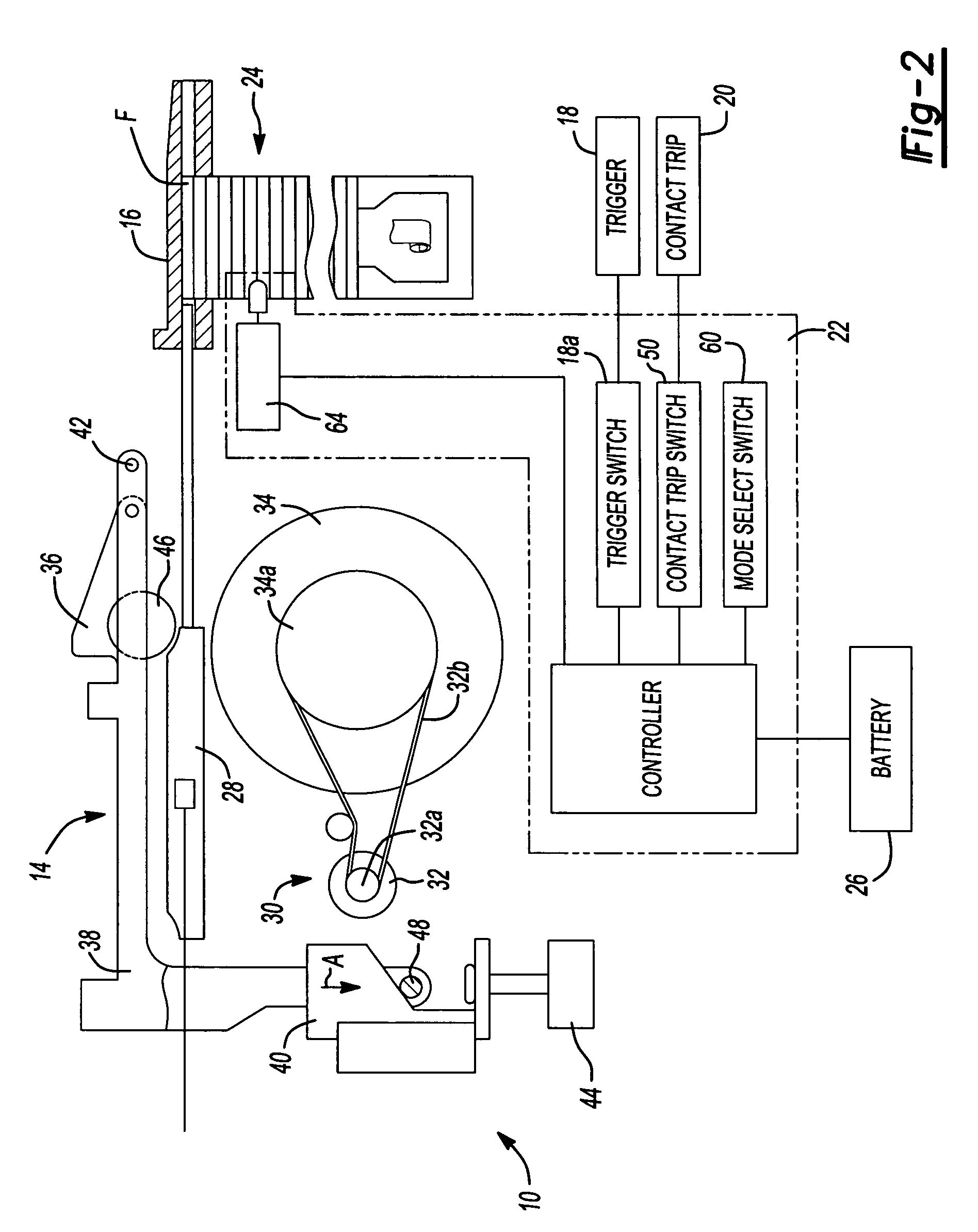

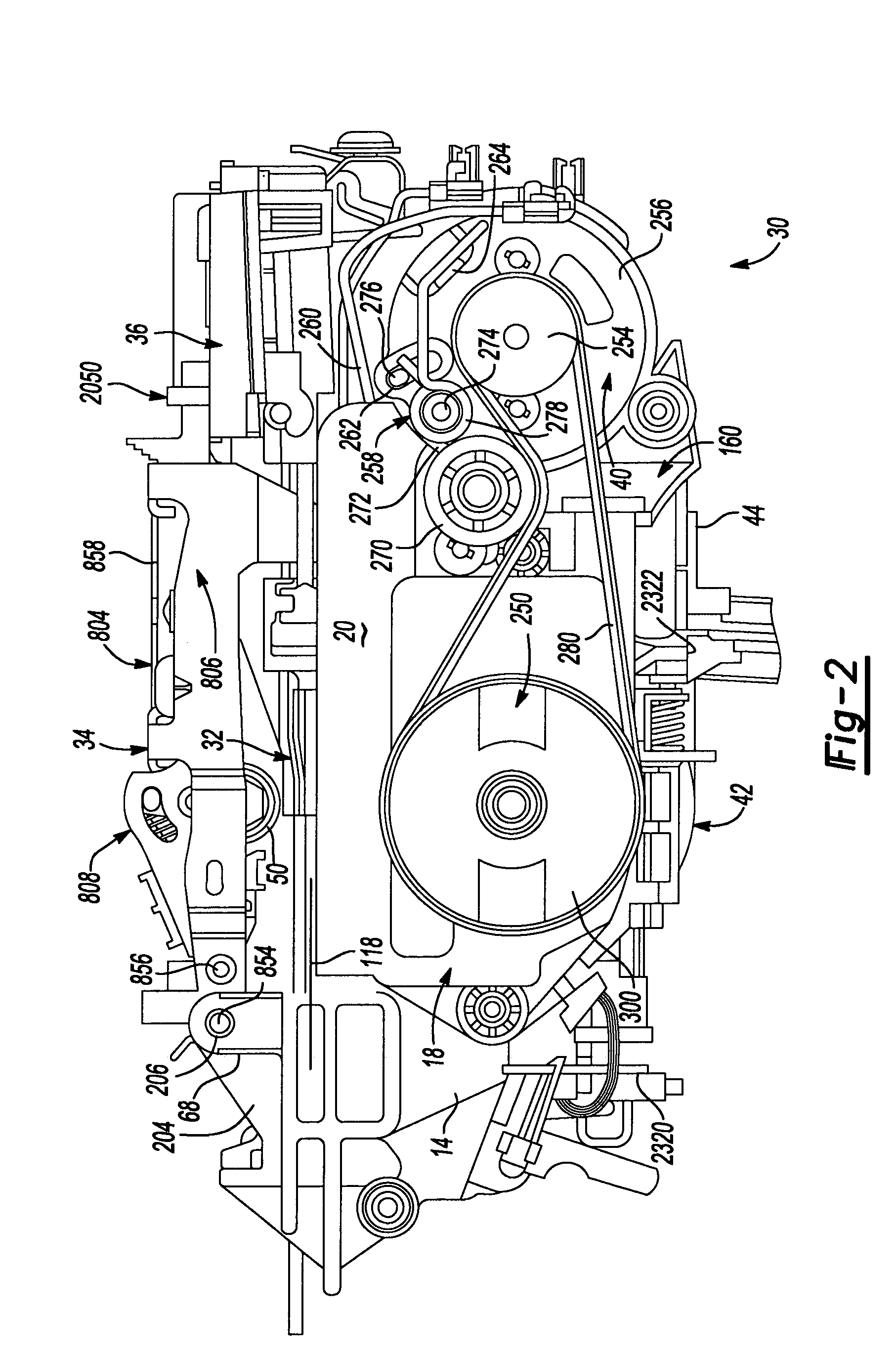

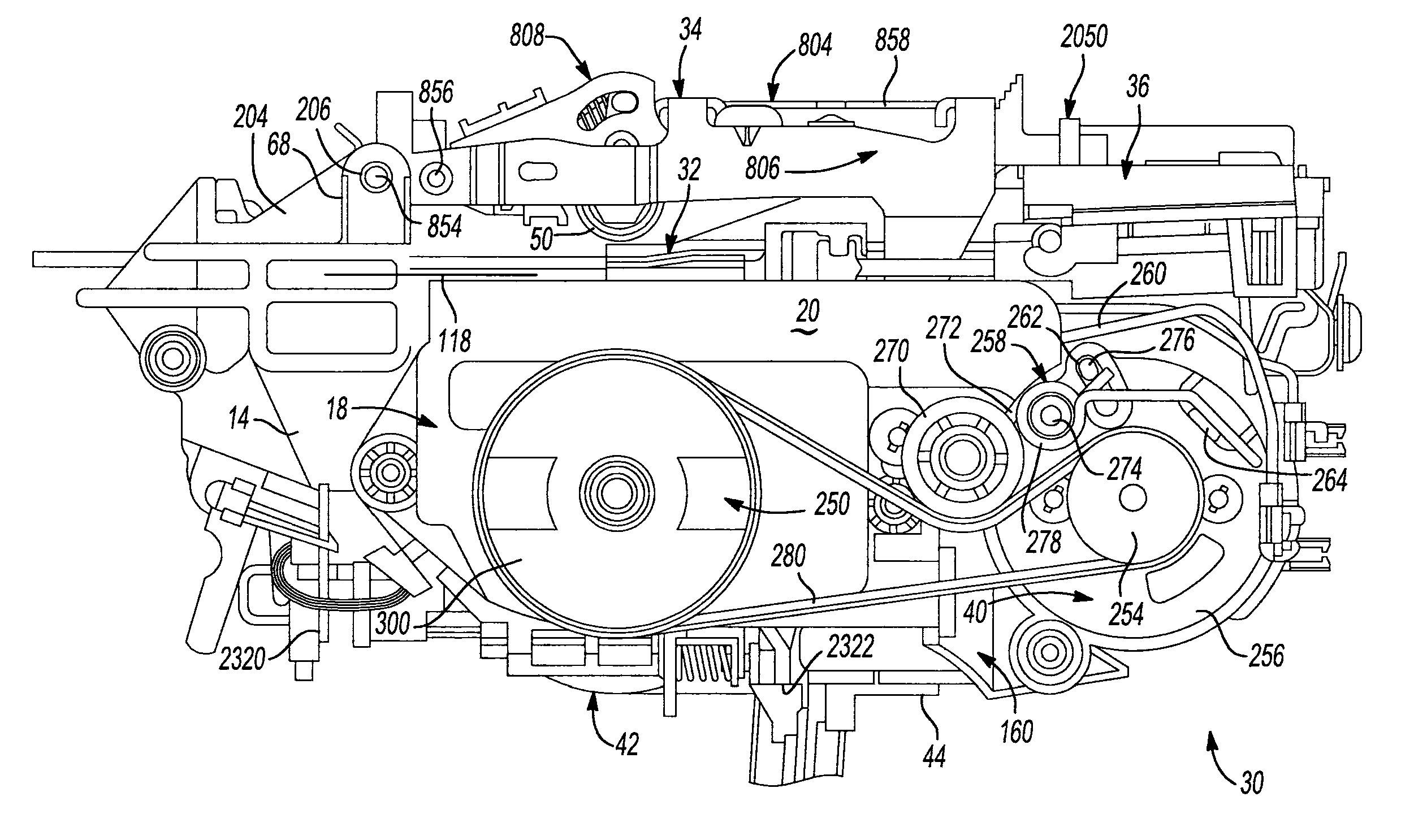

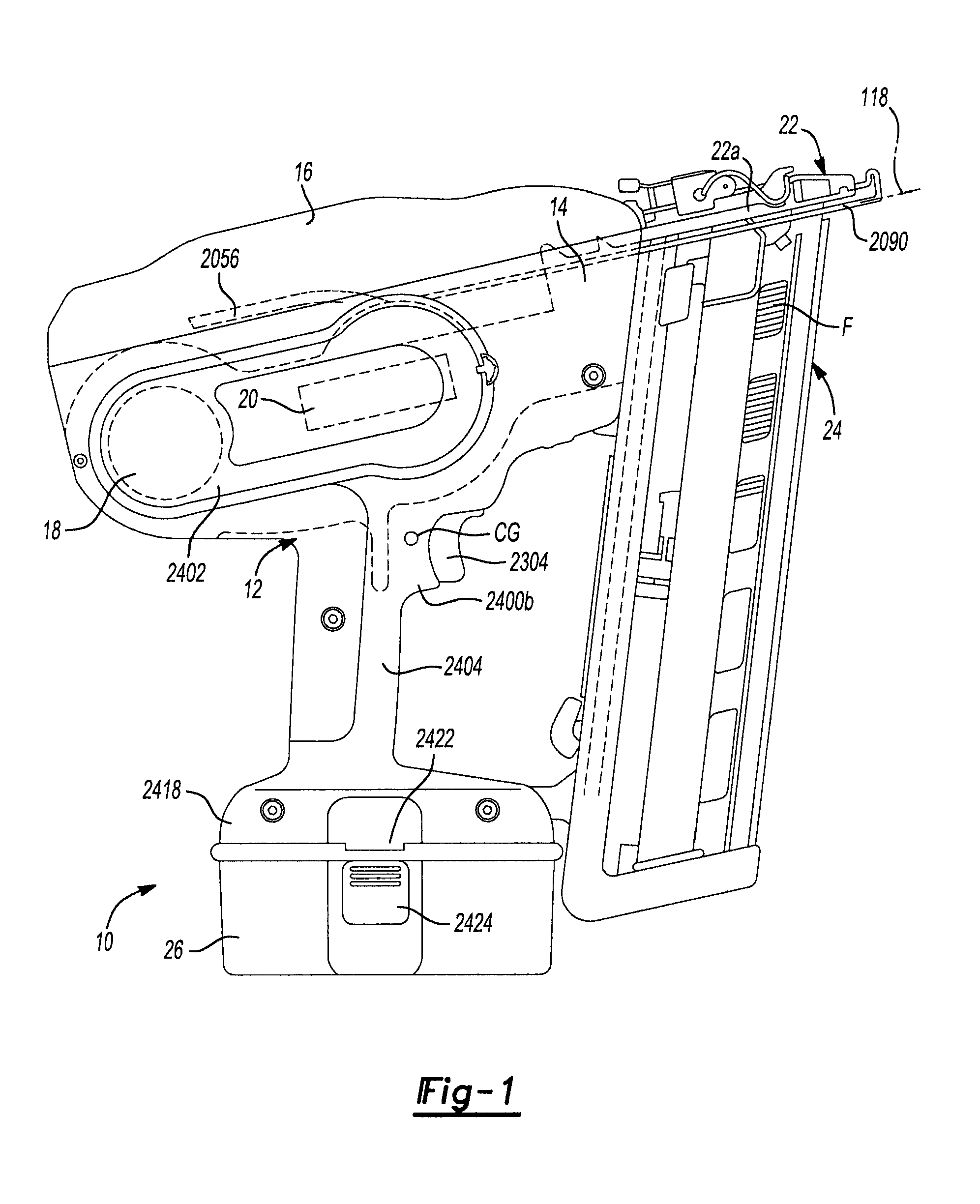

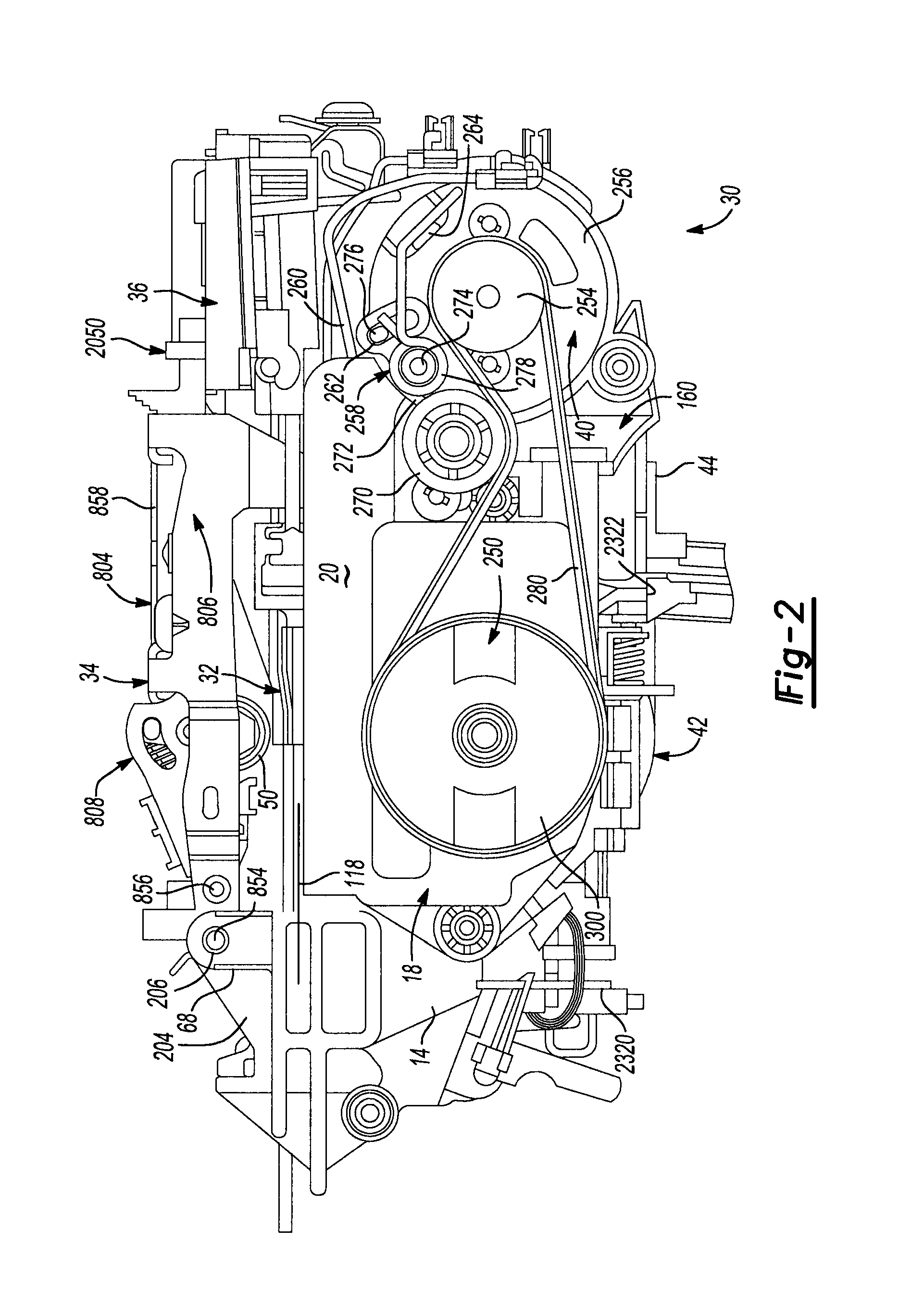

Method for controlling a power driver

A driving tool having a driver, a power source, a sensor and a controller. The power source selectively provides an input to the driver to cause the driver to translate along an axis. The sensor senses a condition in the power source that is indicative of a level of kinetic energy of an element in the power source and generates a sensor signal in response thereto. The controller is coupled to the power source and the sensor and is responsive to the sensor signal for deactivating the power source to inhibit the power source from providing the input to the driver when the level of kinetic energy of the element in the power source is below a predetermined threshold. A method for operating a driving tool is also provided.

Owner:BLACK & DECKER INC

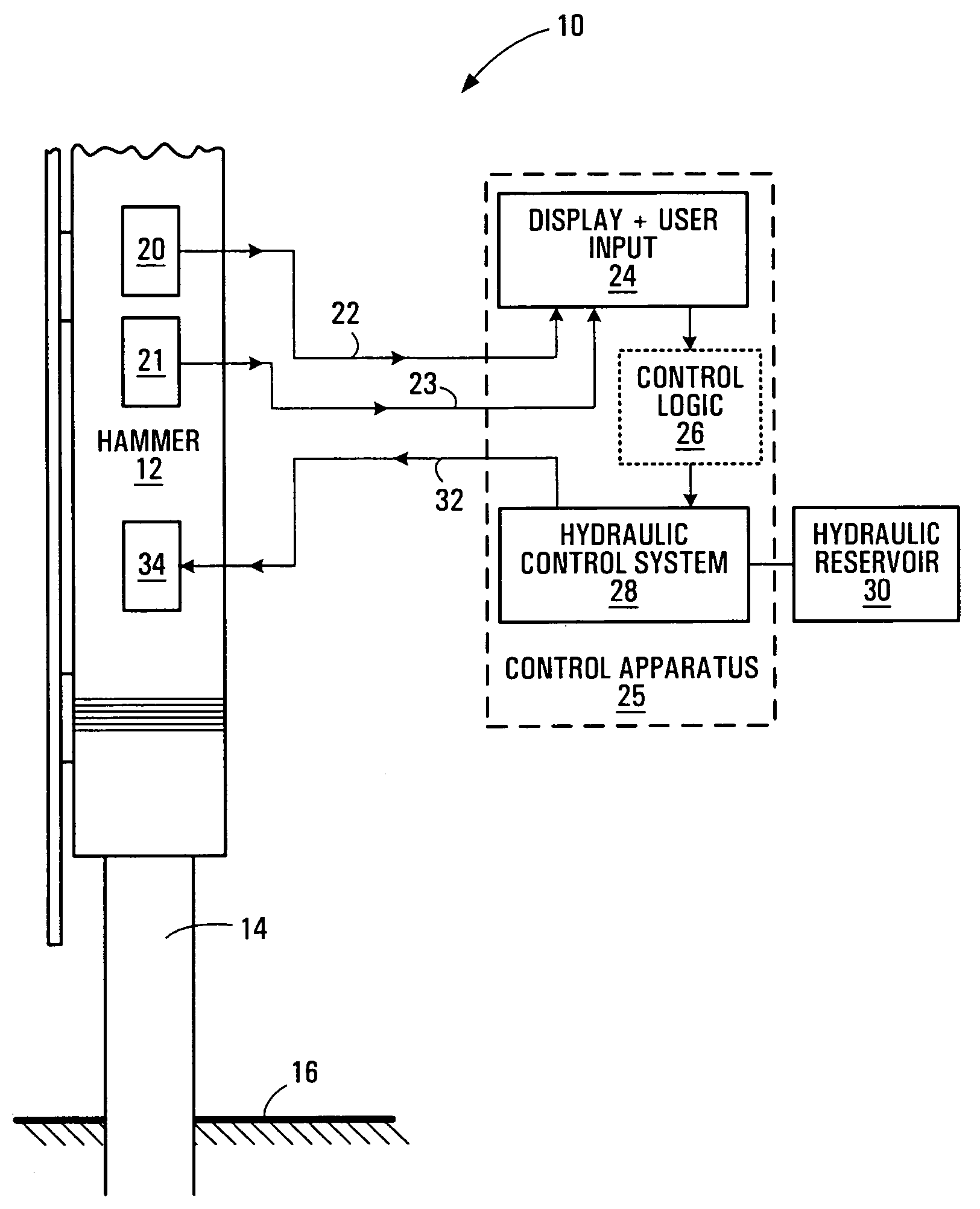

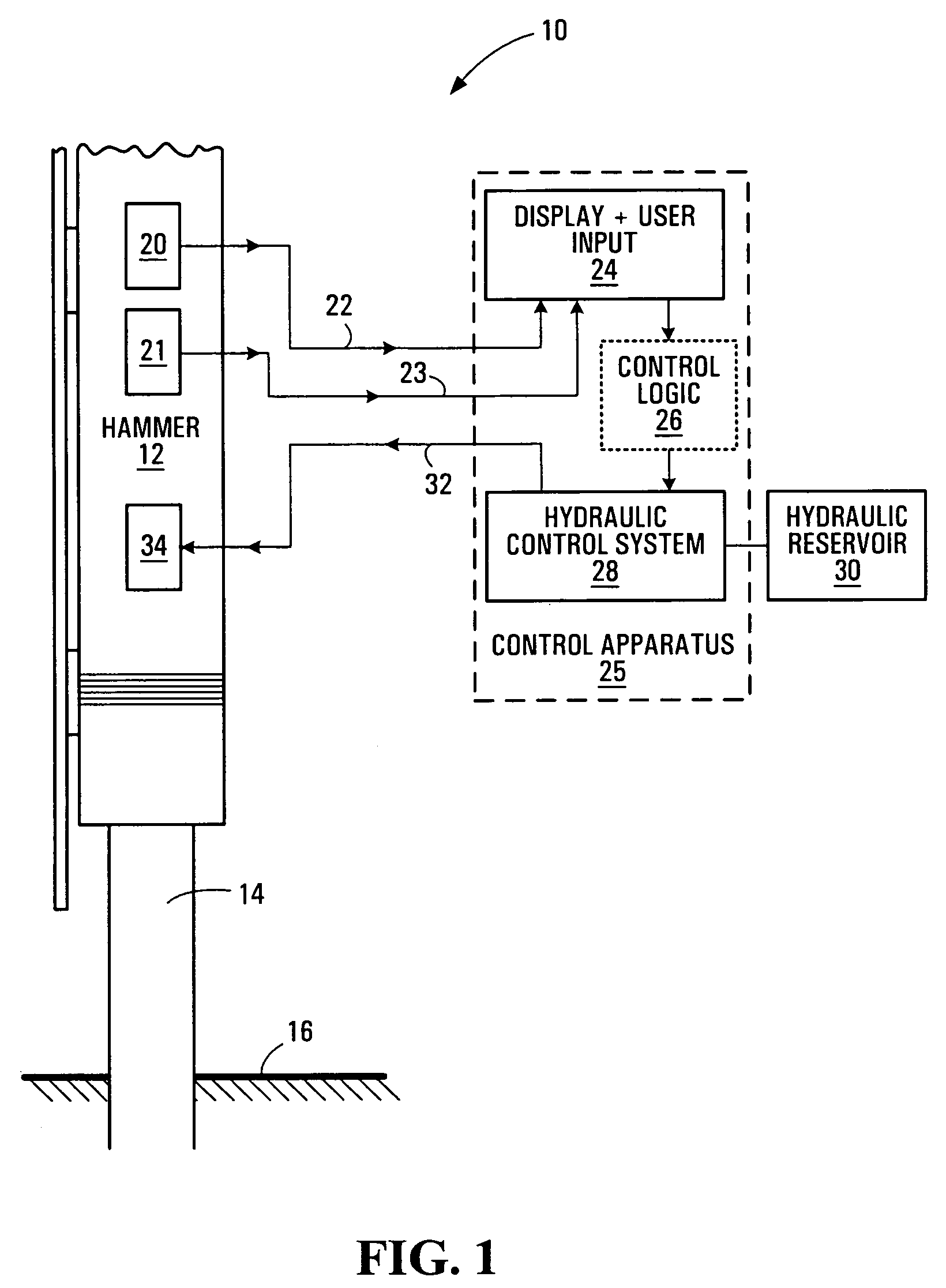

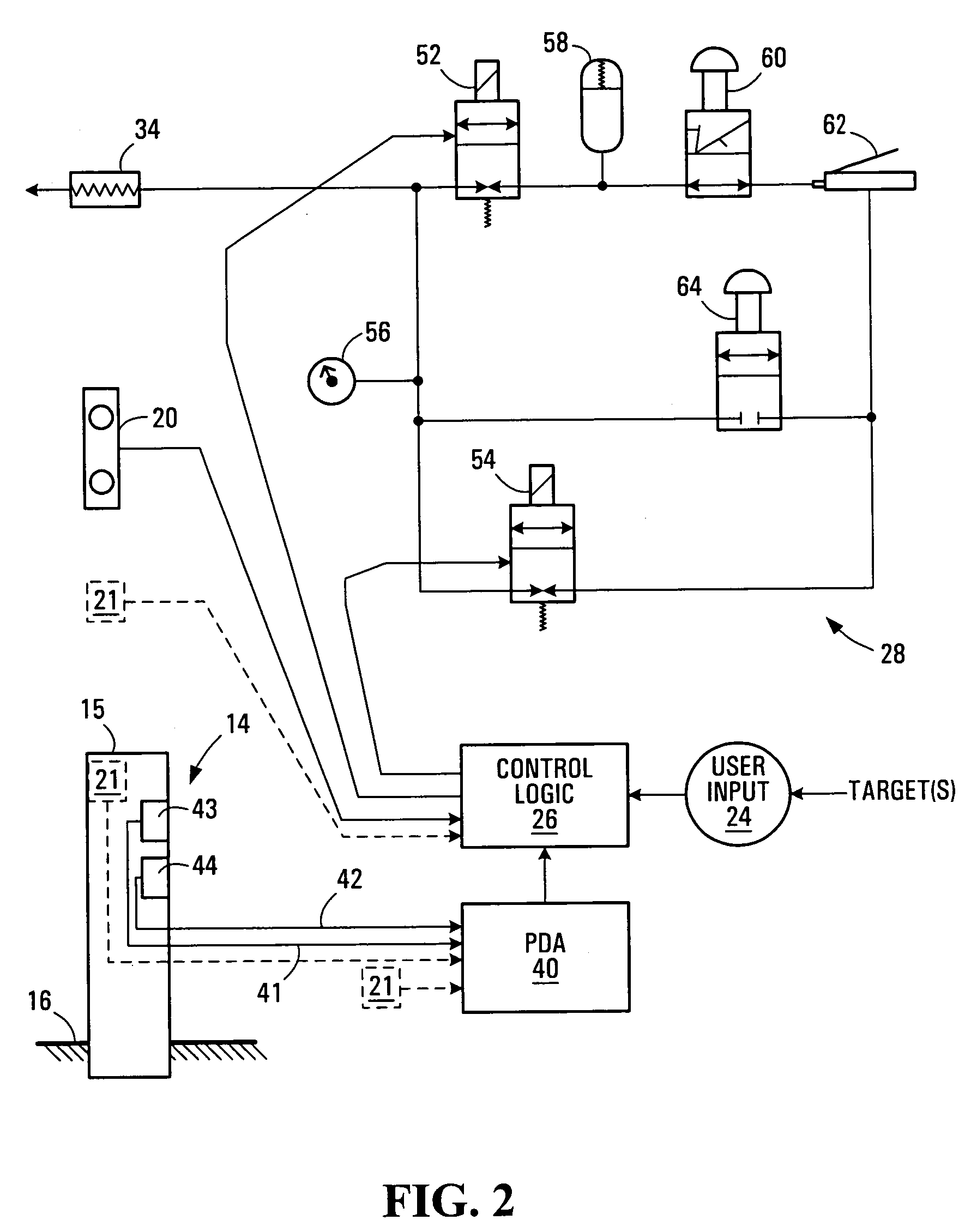

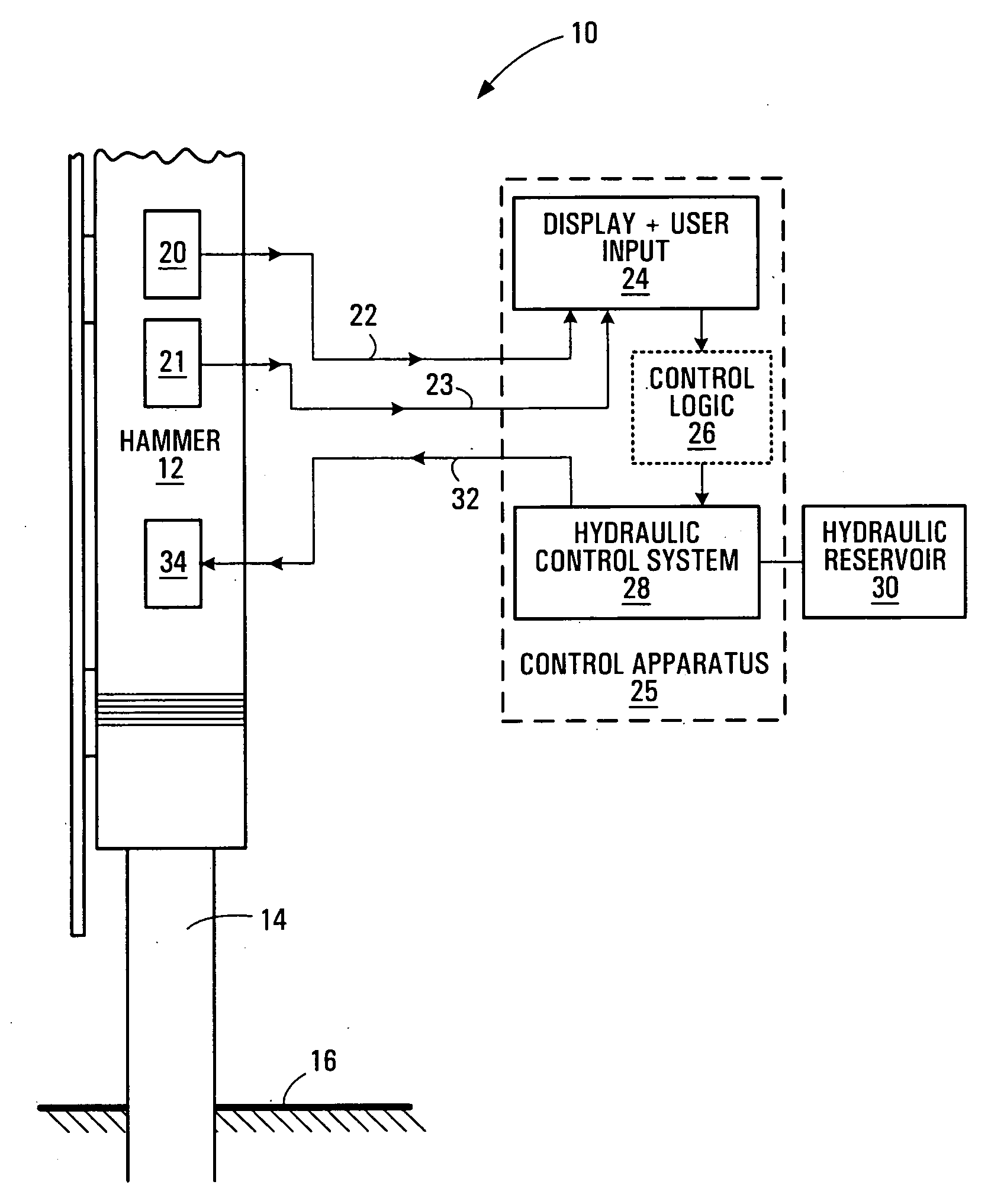

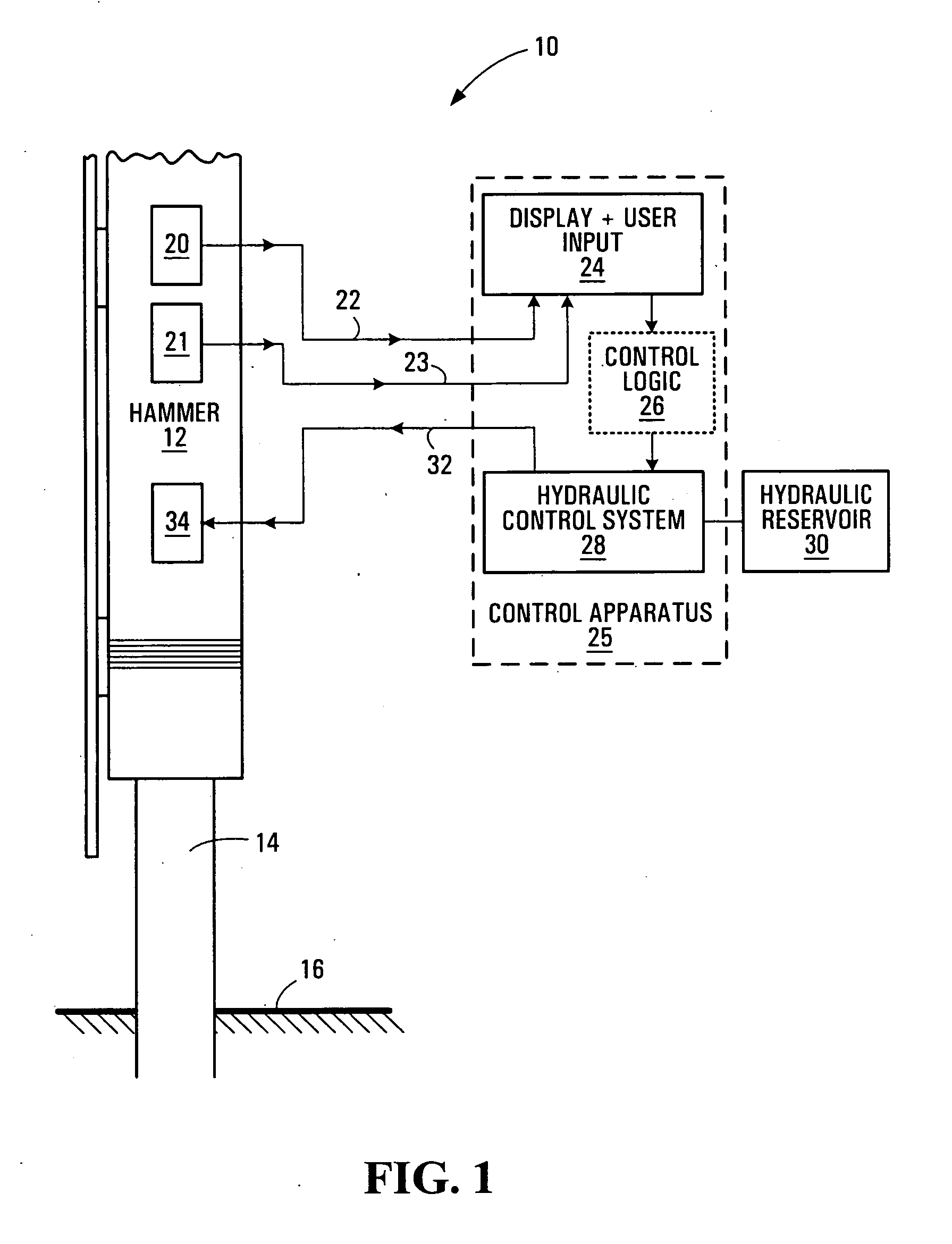

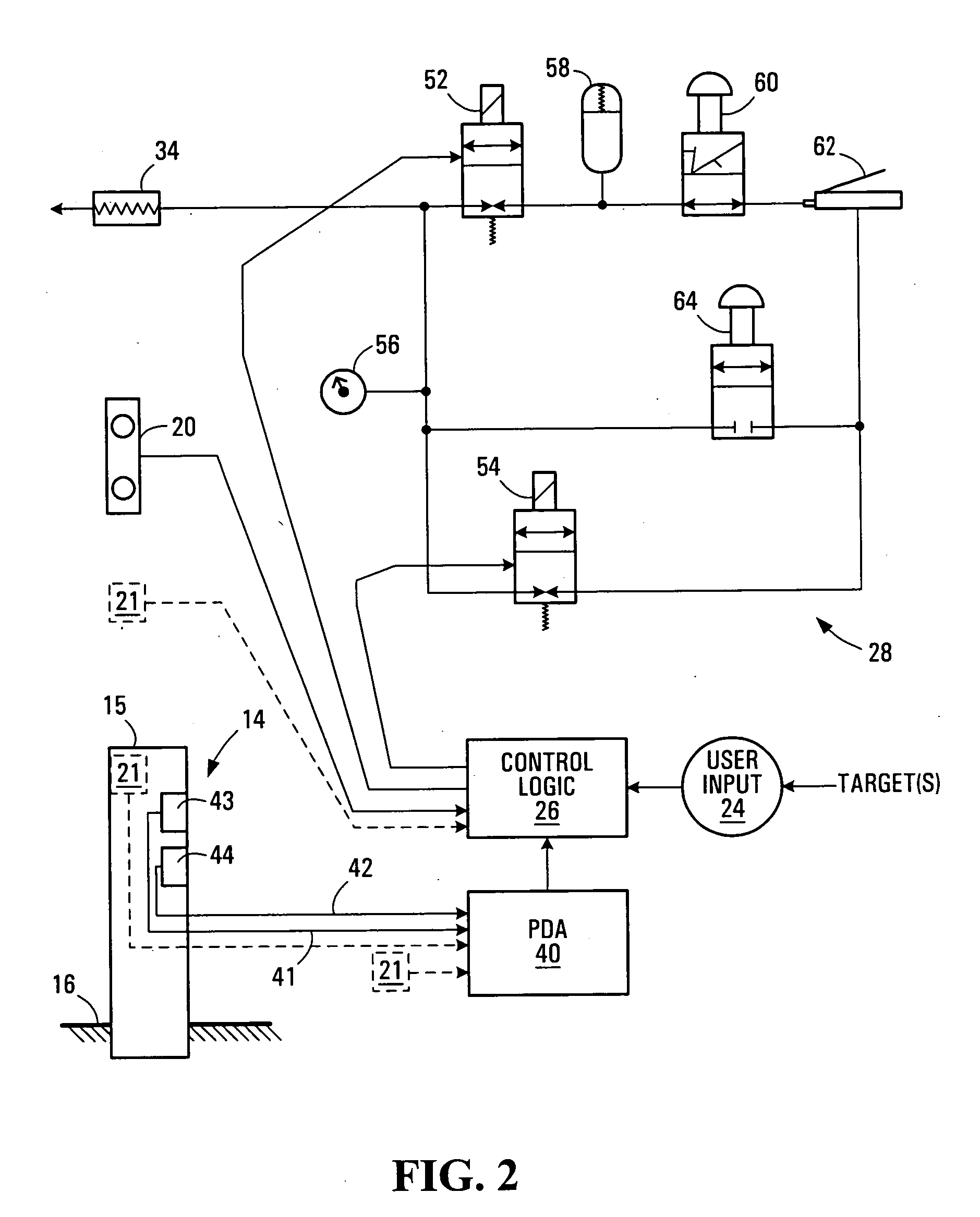

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

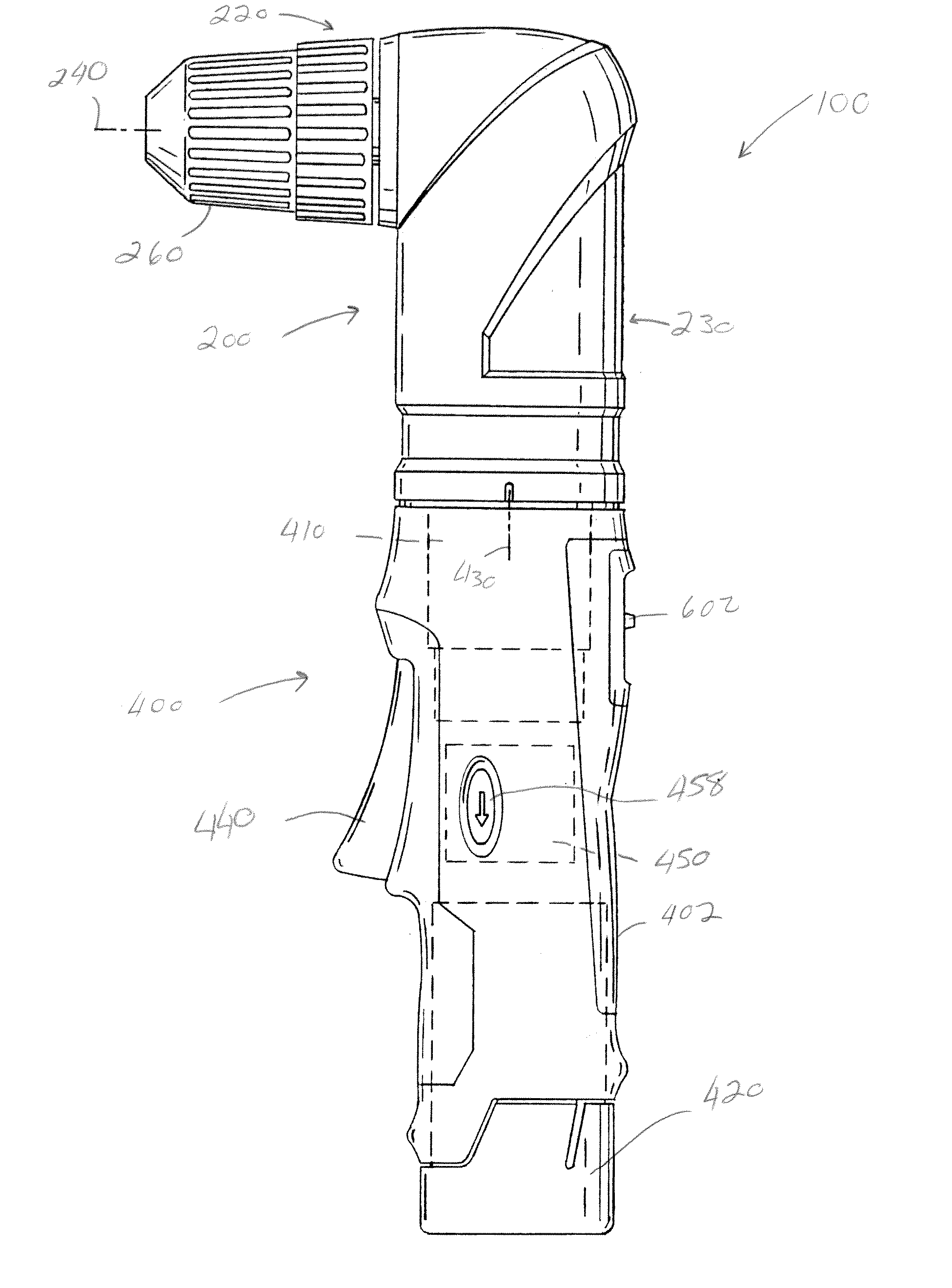

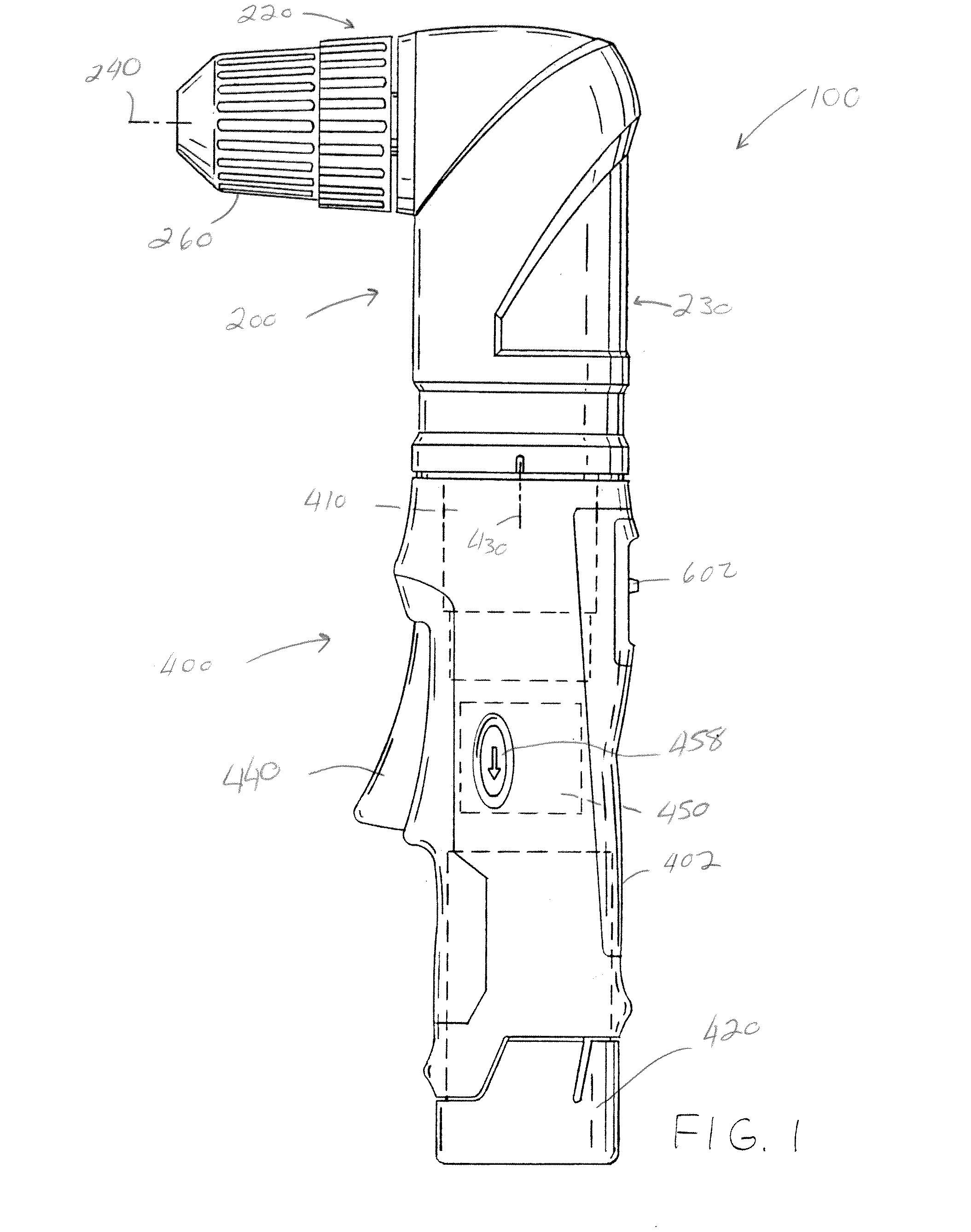

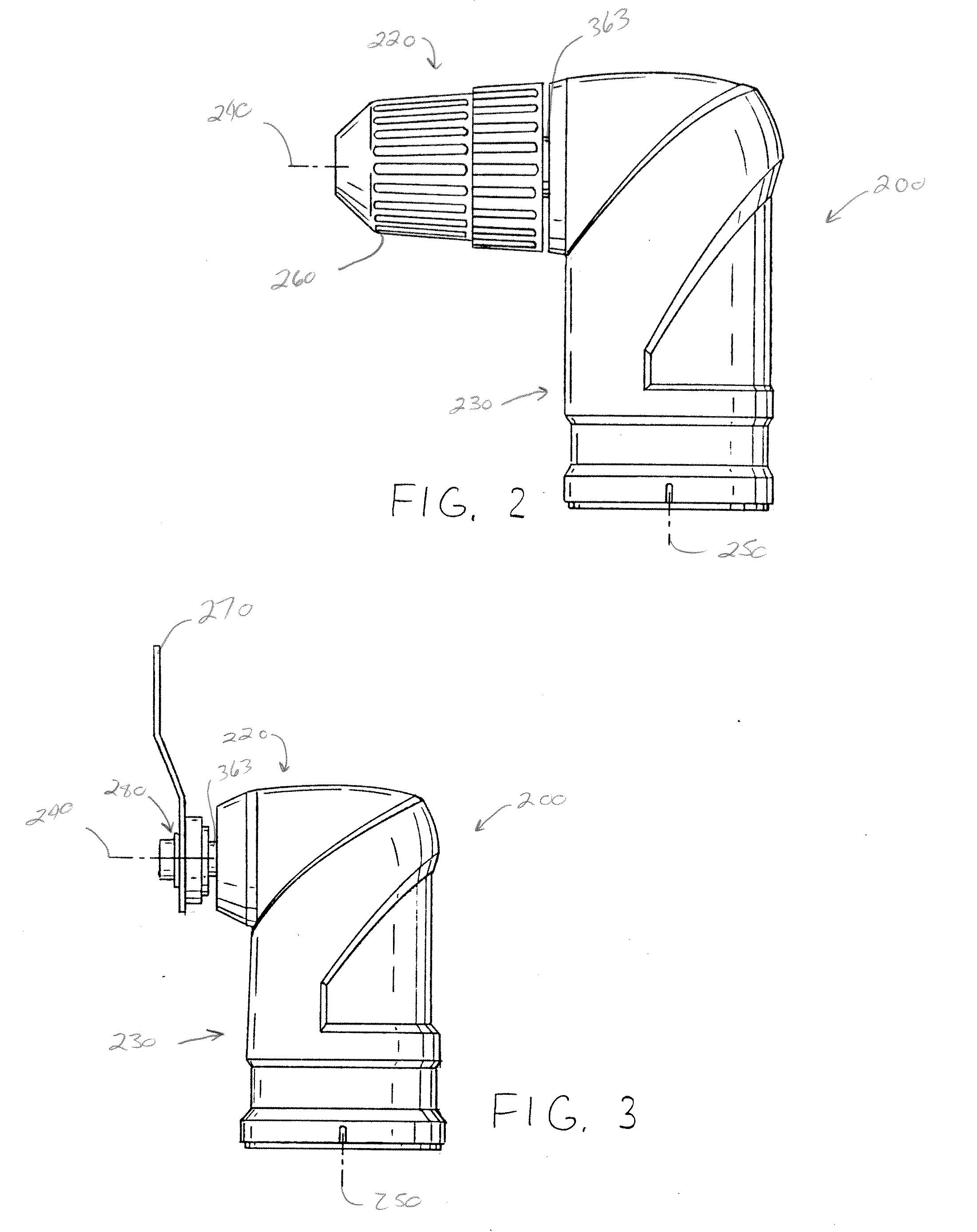

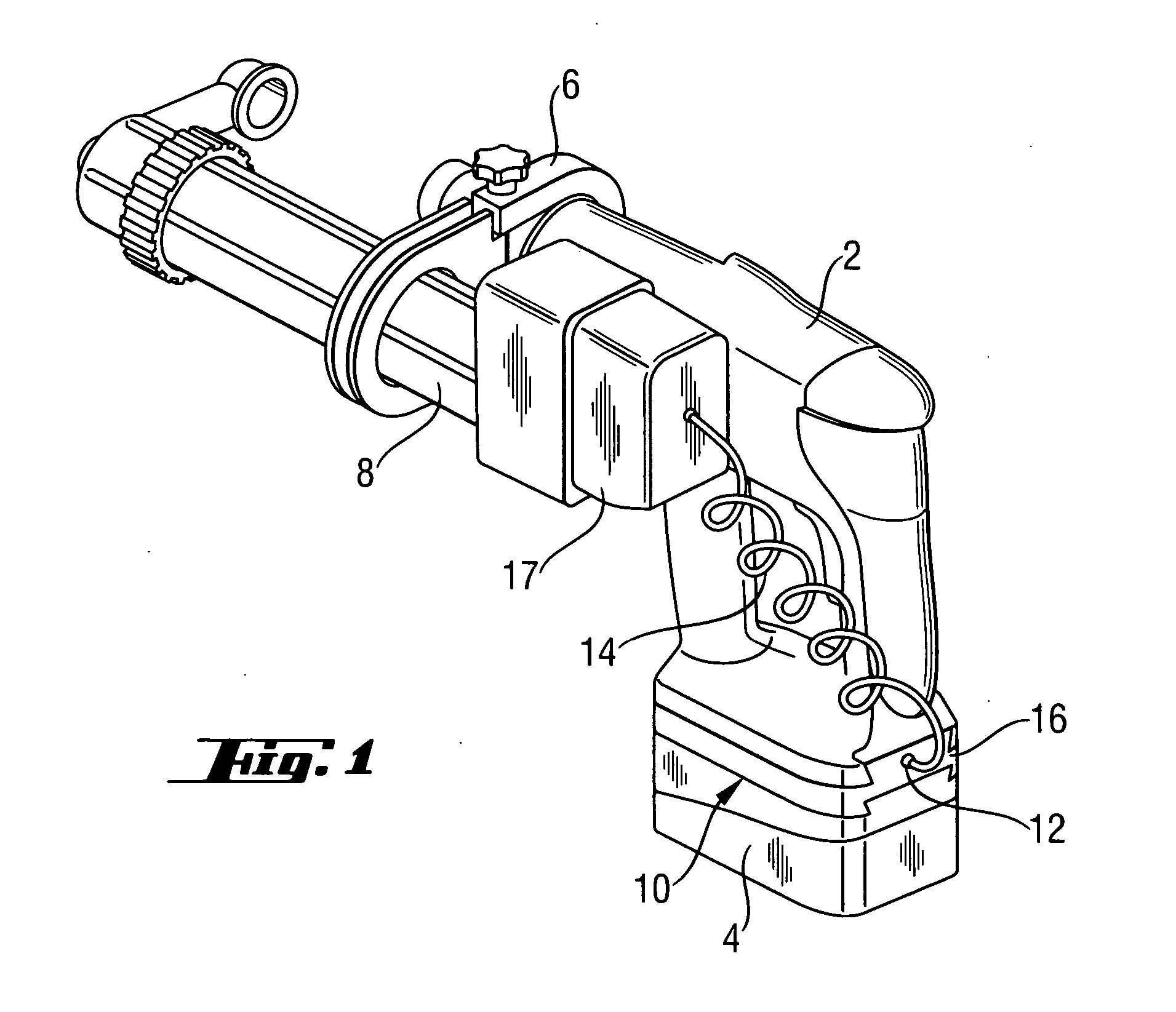

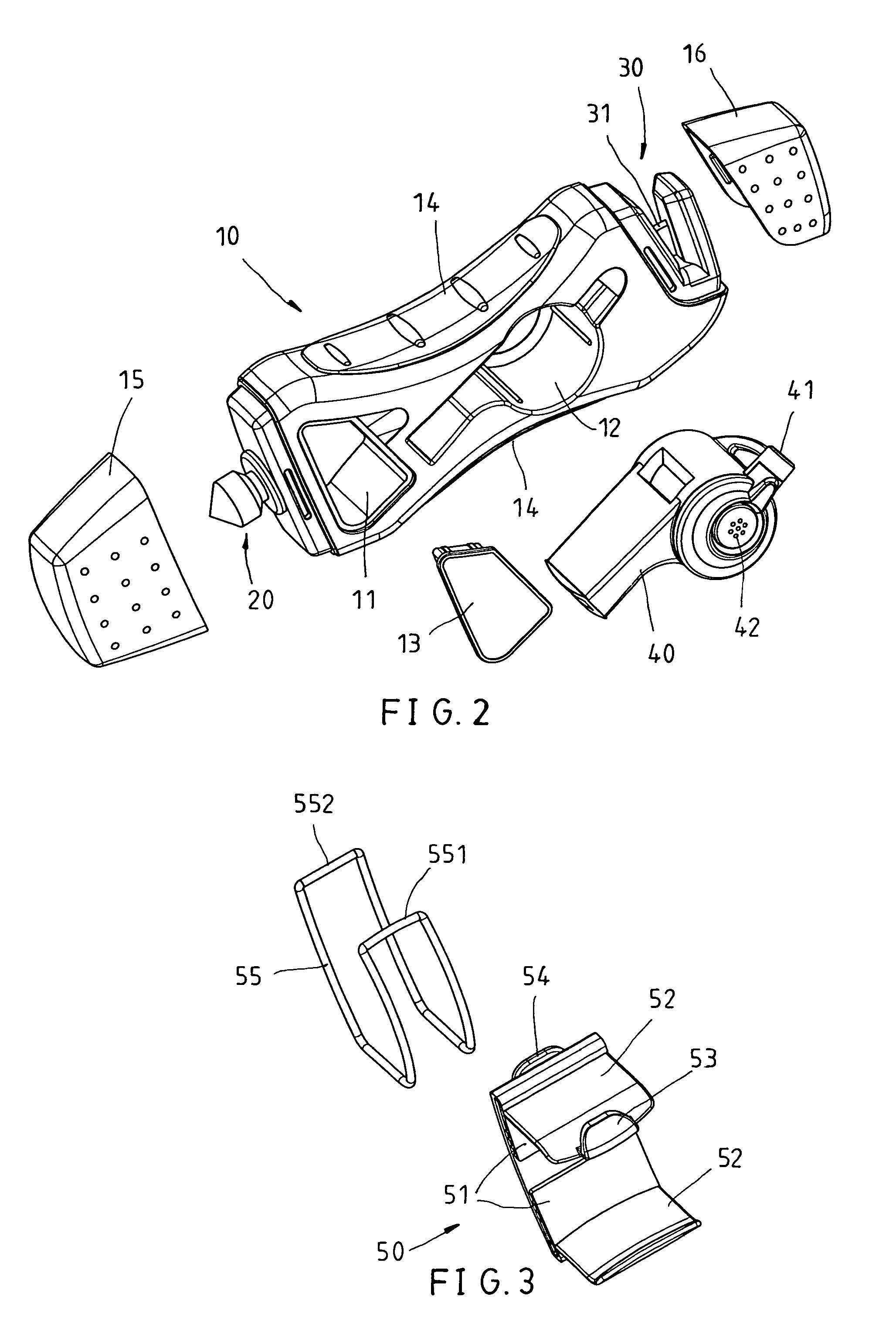

Multi-head power tool

InactiveUS20130008677A1Easy to installImprove versatilitySpannersPortable power-driven toolsHand heldEngineering

A handheld power tool that includes a base portion and one or more head portions that are designed to be removably connectable to the base portion. The base portion includes a base housing, an electric motor at least partially positioned in the base housing, a power supply removably connected to the housing, a top connection arrangement. The head portion includes a head housing, a first gear assembly, a second gear assembly, and a head connection arrangement. The first gear assembly has a first shaft that is rotatably positioned about a first longitudinal axis and a second gear assembly having a second shaft that is rotatable about a second longitudinal axis. The first and second longitudinal axis of the two gear assemblies are non-parallel to one another.

Owner:NINGBO HANPU TOOLS

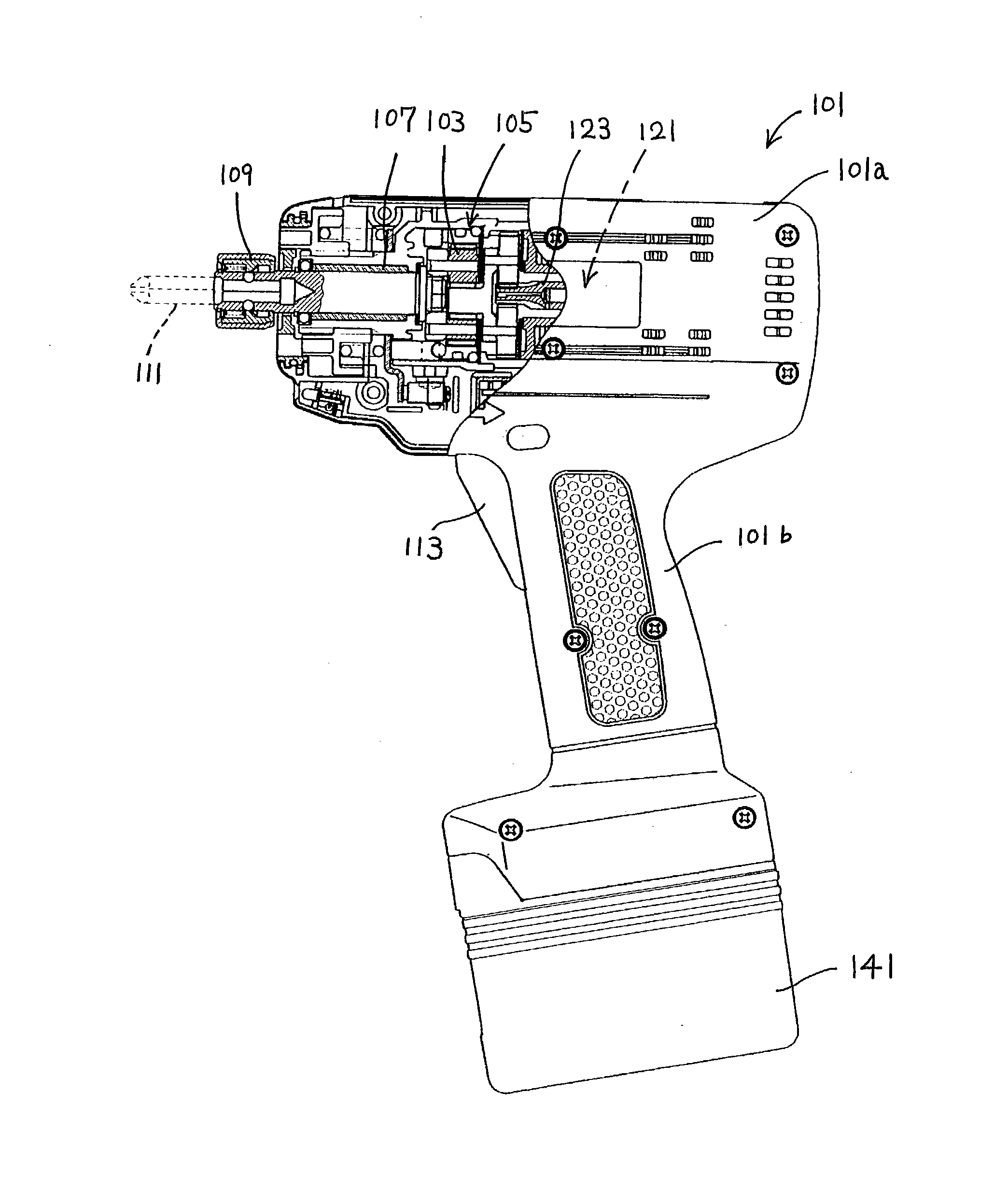

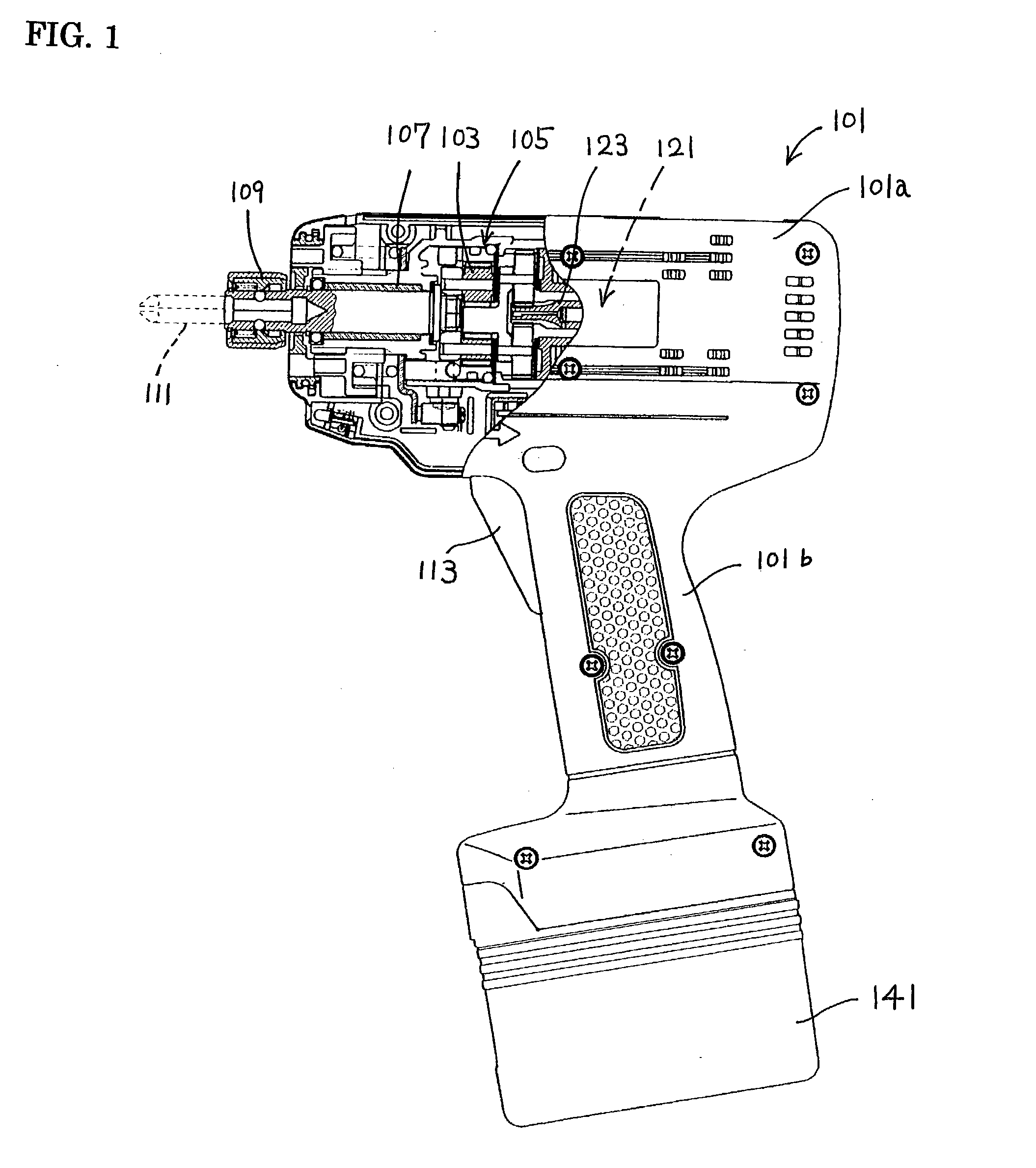

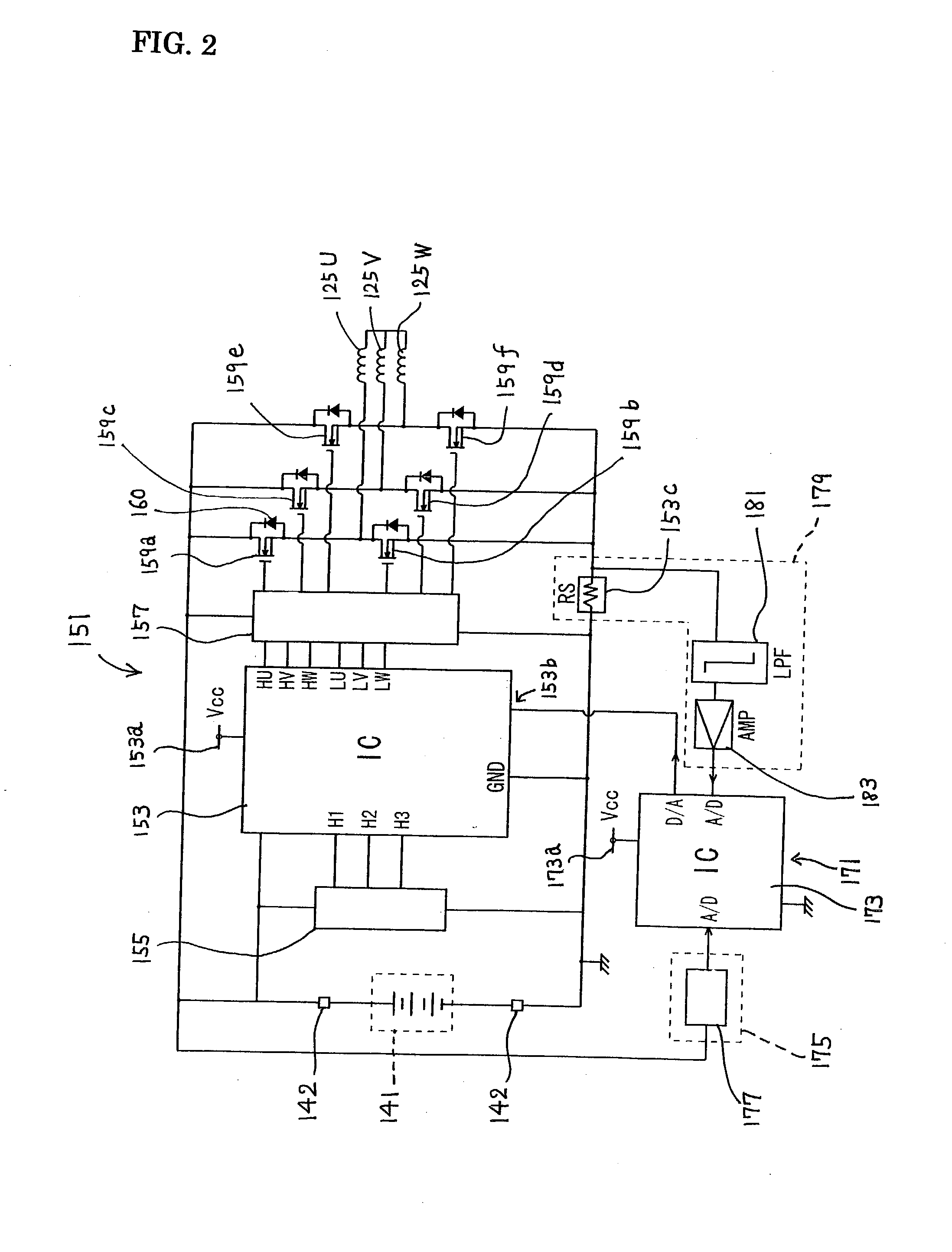

Power tool

It is an object of the present invention to provide a technique to increase efficiency of the output torque of the blushless motor to drive a power tool. A representative power tool may comprise a tool bit, a brushless motor to drive the tool bit, a battery to operate the brushless motor and a control device. The control device may operate the brushless motor by means of the battery. The control device may include an advance angle controlling section to control an advance angle of the brushless motor. According to the present teachings, the advance angle of the brushless motor may be determined based upon indexes that reflect working condition of the tool bit when the brushless motor is under the operation. By reflecting the working condition of the tool bit to the determination of the advance angle of the brushless motor, the brushless motor can be operated with higher efficiency under the various working condition such as a hard joint operation and a soft joint operation.

Owner:MAKITA CORP

Rotary impact tool

InactiveUS20050263305A1Guaranteed continuous performanceDerricks/mastsSpannersDrive shaftEngineering

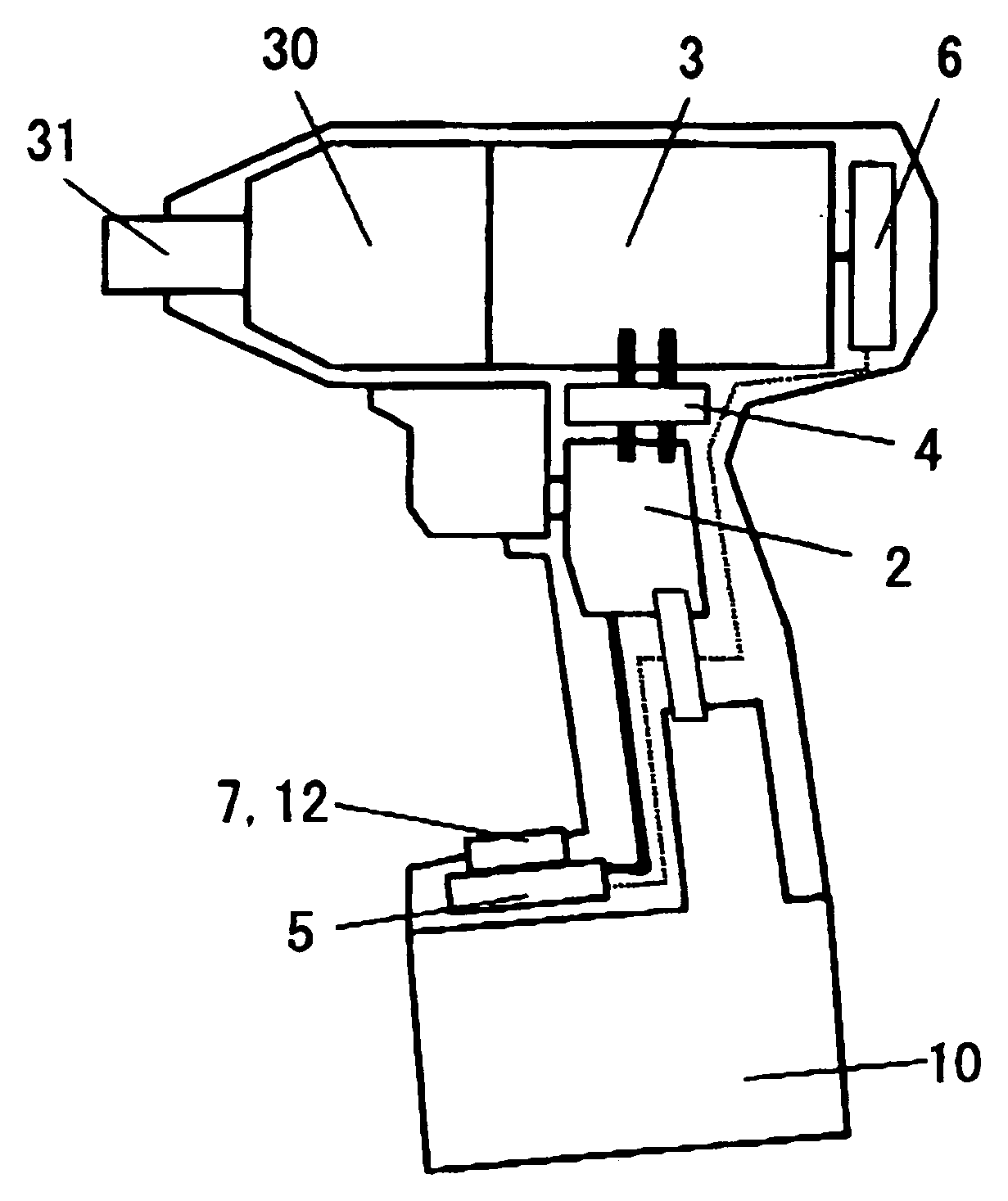

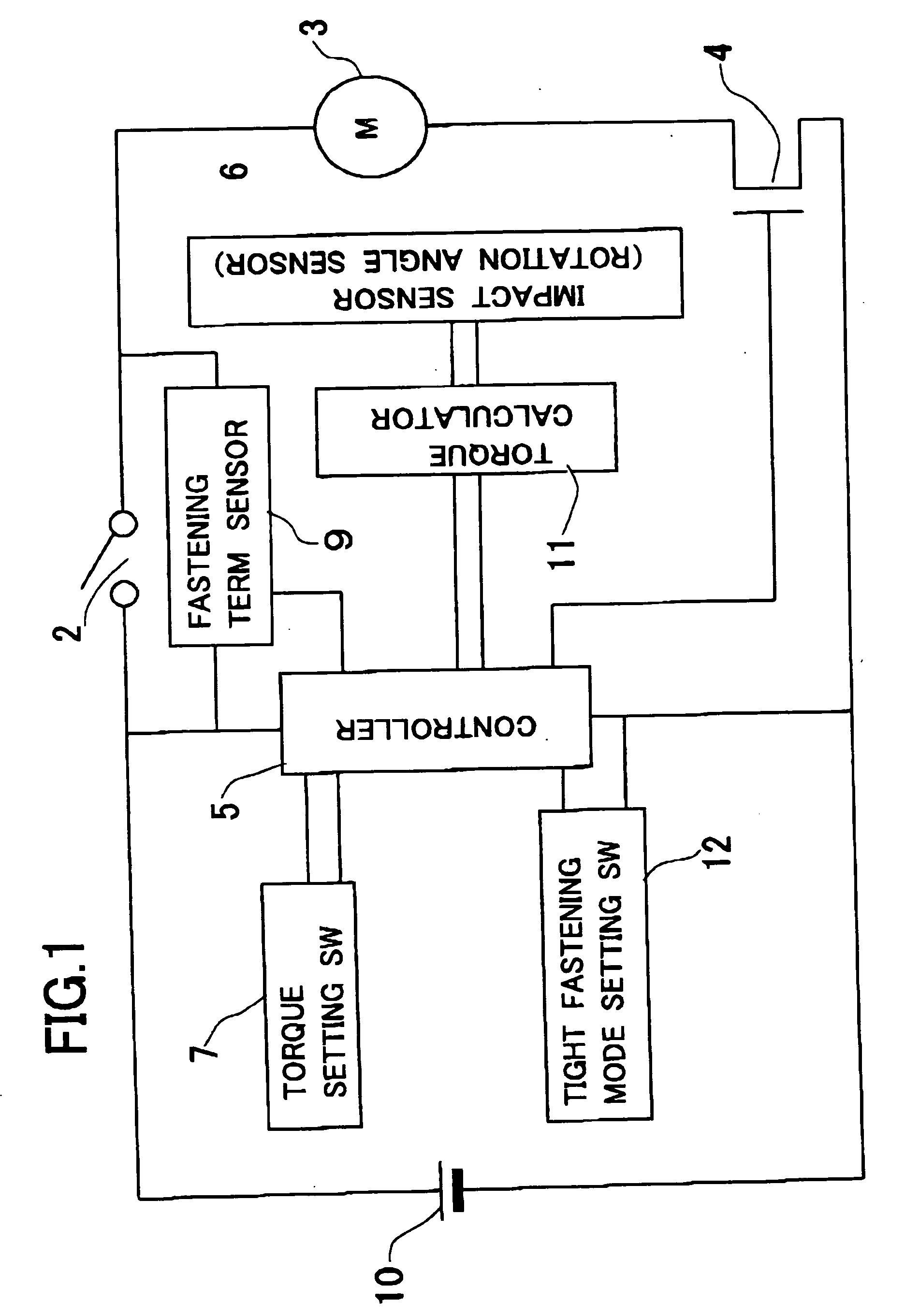

A rotary impact tool can be used continuously for fastening a plurality of fastening members such as screws, bolts or nuts in tight fastening mode. The rotary impact tool comprises a rotary driving mechanism including a motor for rotating a driving shaft, a hammer engaged with the driving shaft, an output shaft to which a driving force is applied by impact blow of the hammer, a main switch operated by a user for controlling fastening operation, and a controller for controlling on and off of the motor. The controller has a normal fastening mode and a tight fastening mode, and a tight fastening mode setting switch used for setting the tight fastening mode is further comprised. When the tight fastening mode setting switch is switched on, the controller continuously drives the rotary driving mechanism so as to perform tight fastening operation continuously.

Owner:MATSUSHITA ELECTRIC WORKS LTD

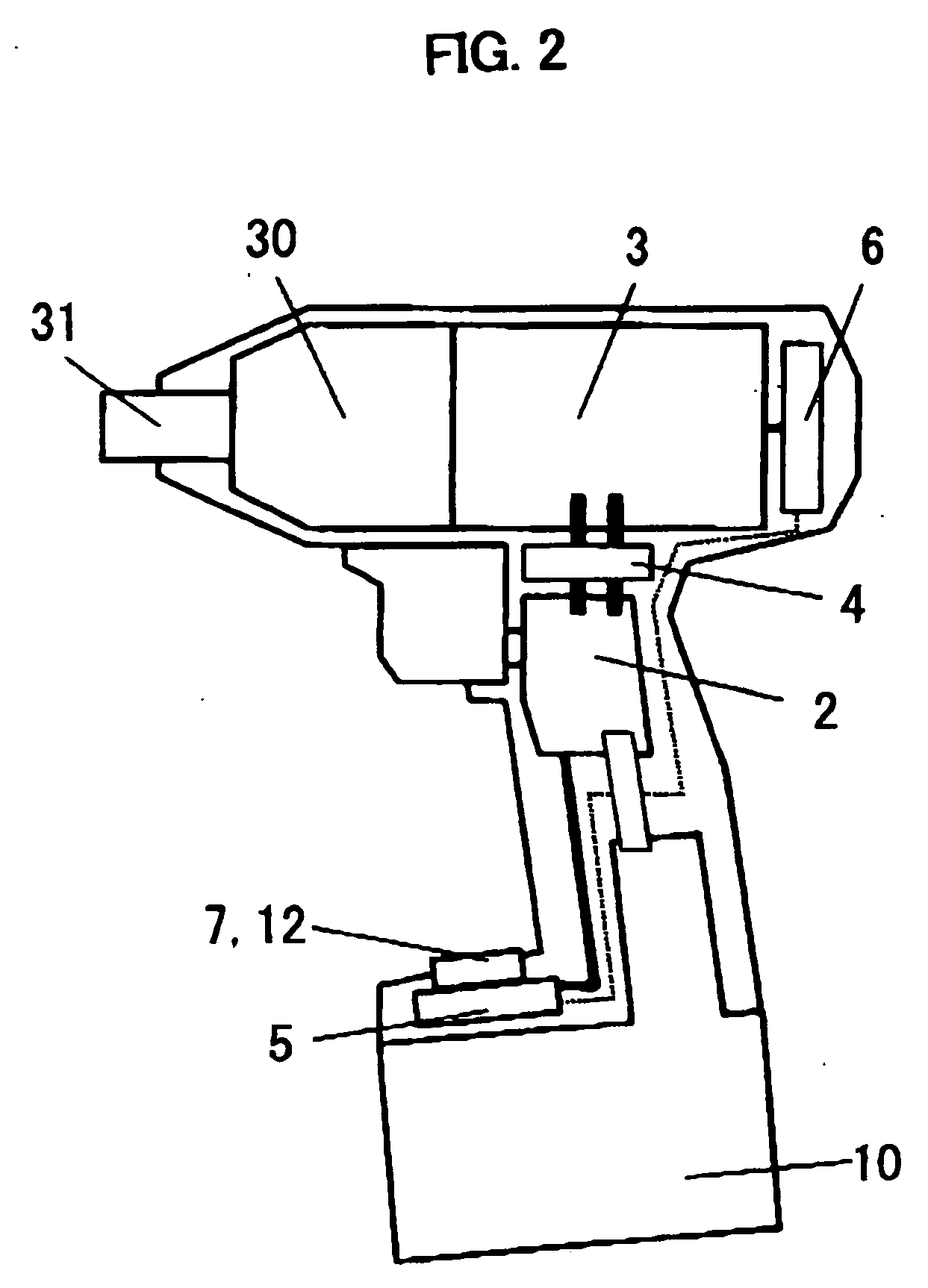

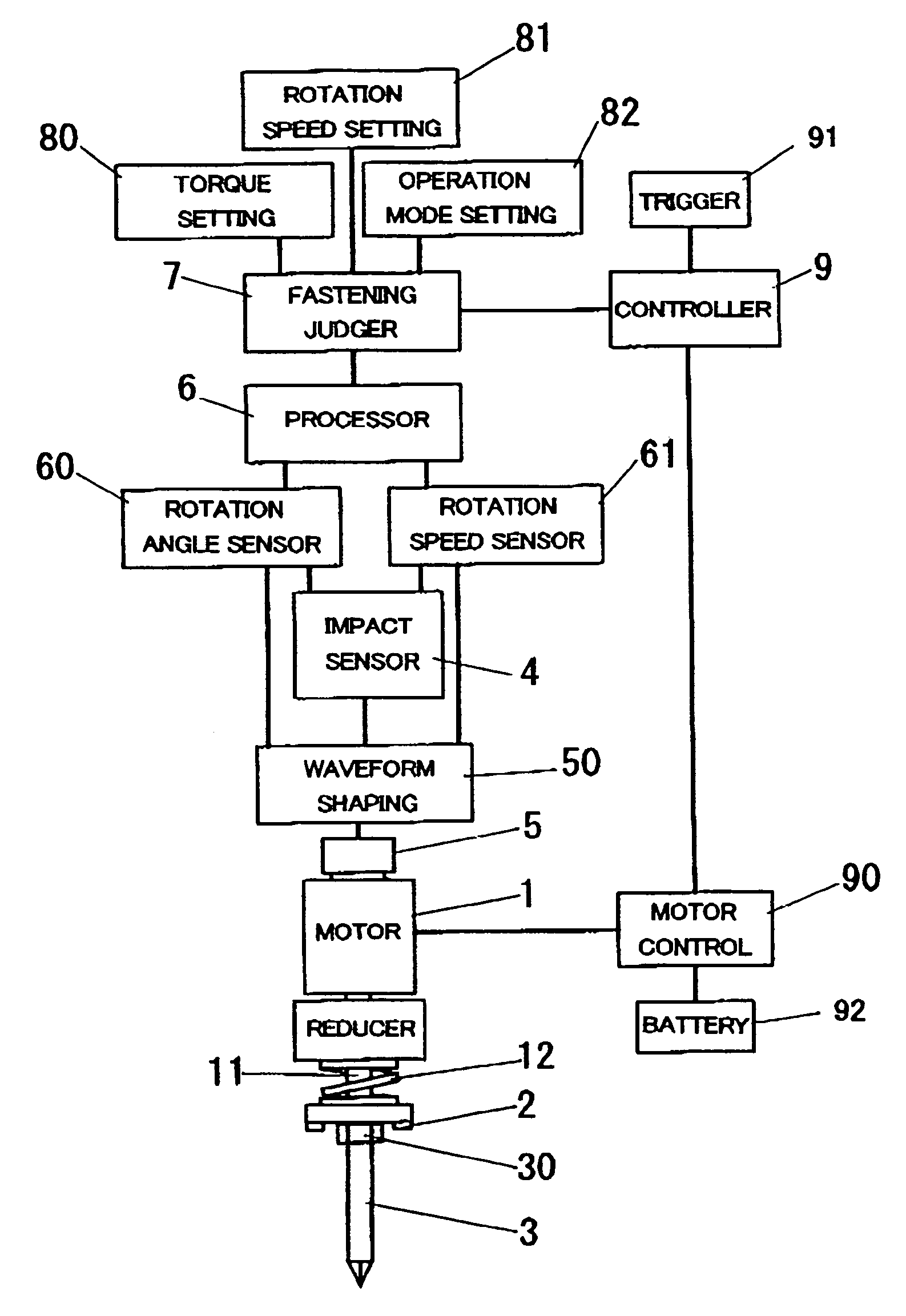

Rotary impact tool

ActiveUS7419013B2Low costReduce speedConstructionsReciprocating drilling machinesDrive shaftRotation velocity

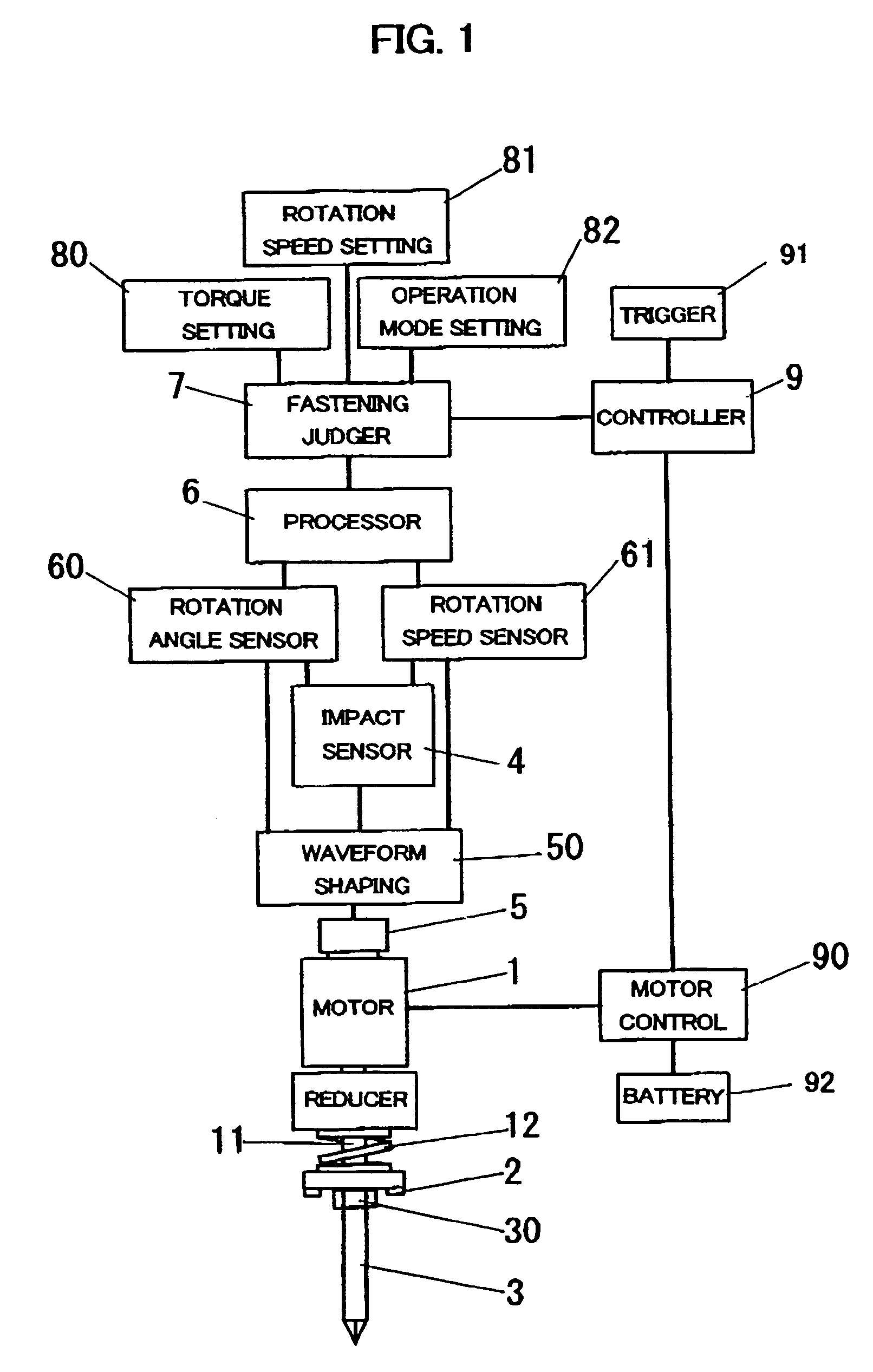

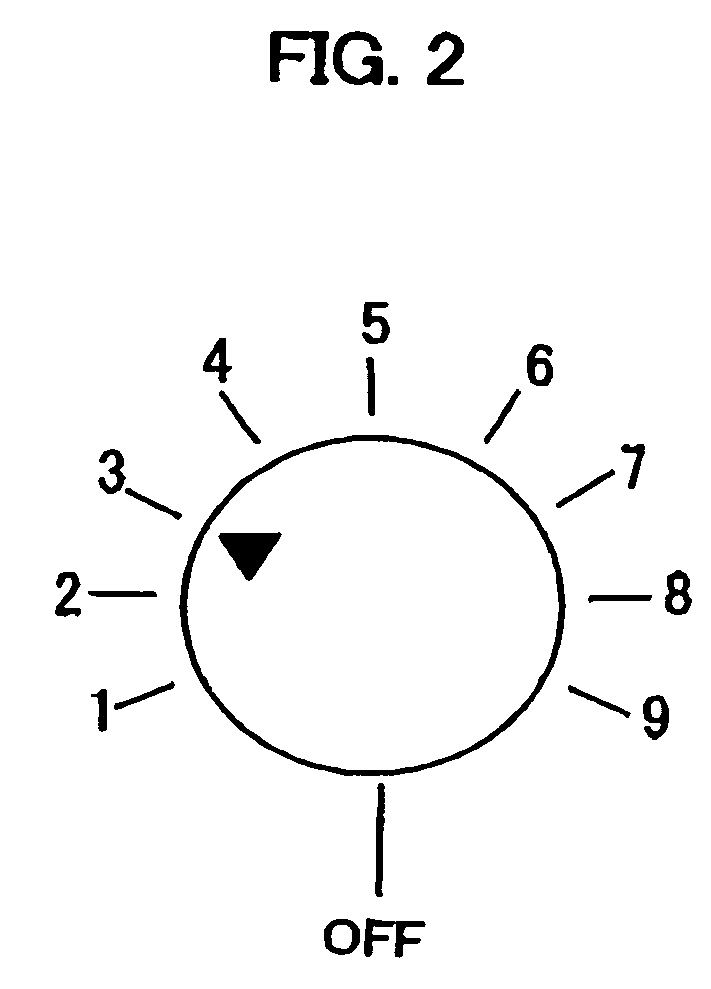

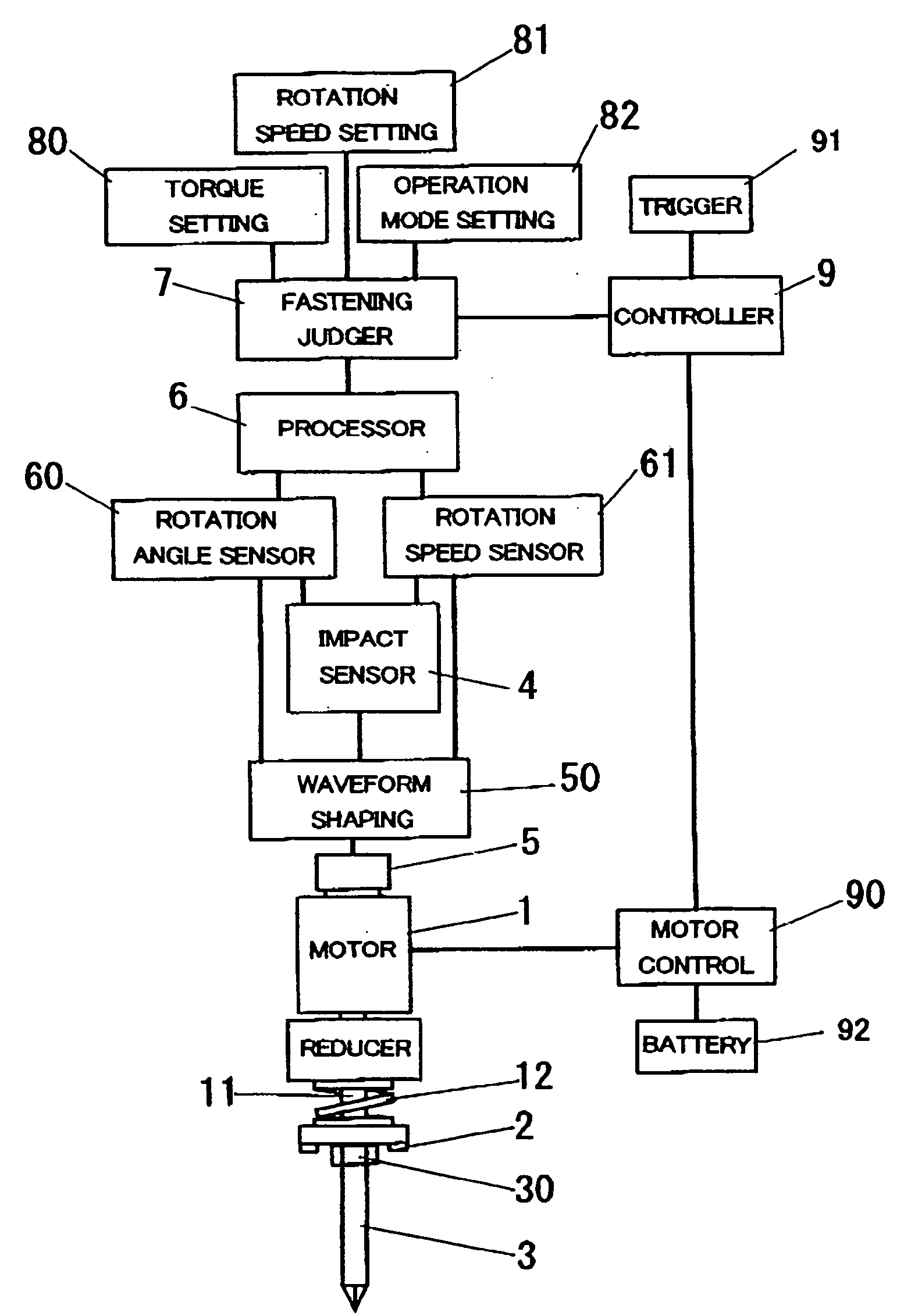

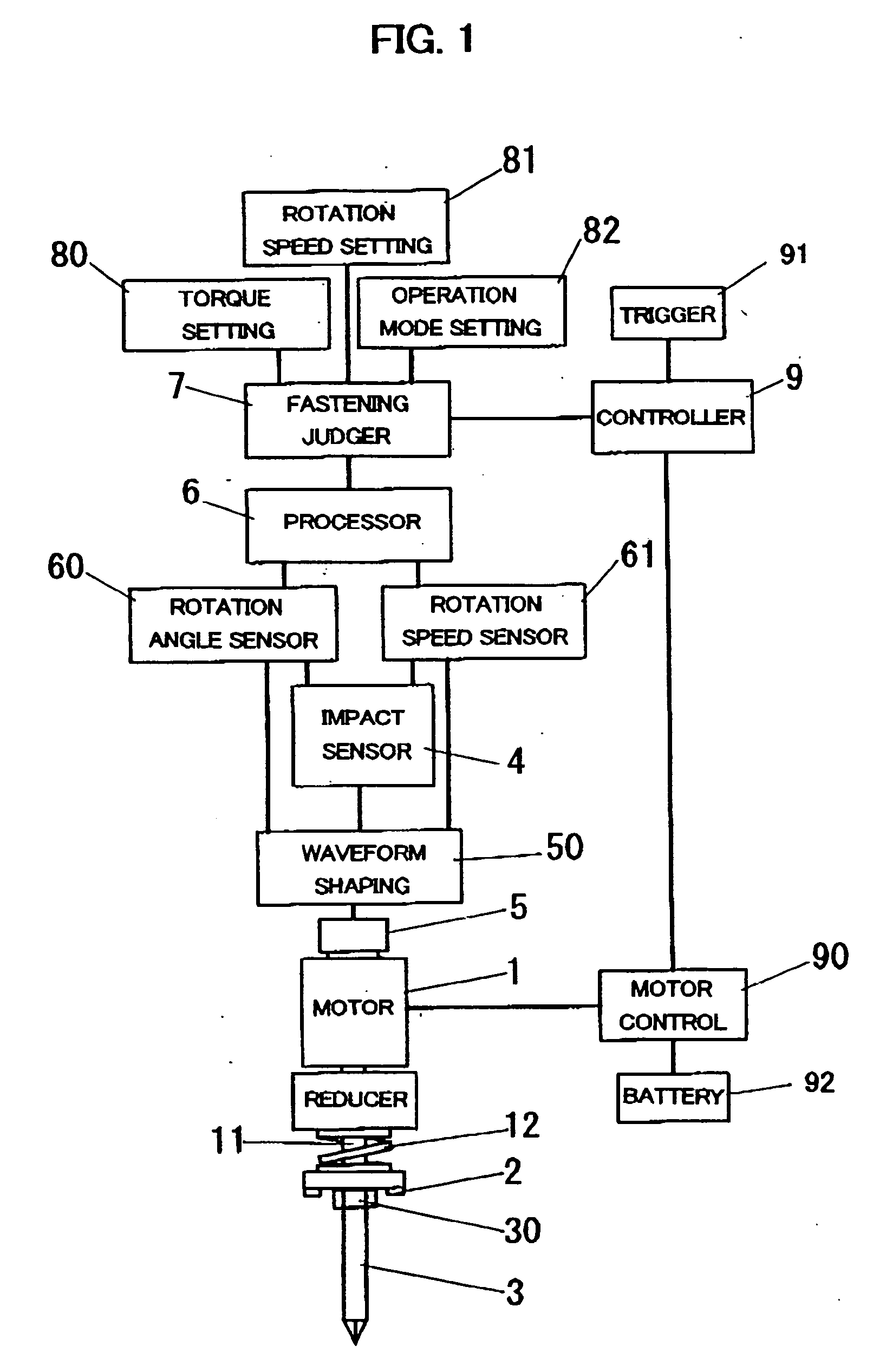

A rotary impact tool can be used in a work especially precision or finishing of fastening is important. The rotary impact tool comprises a rotary driving mechanism including a driving source for rotating a driving shaft, a hammer fixed on the driving shaft, an output shaft to which a driving force is applied by impact blow of the hammer, a torque setting unit used for setting a fastening torque, a processor for calculating fastening torque from impact blow of the hammer, a rotation speed setting unit used for setting rotation speed of the driving shaft, and a controller for rotating the driving shaft of the rotary driving mechanism in a rotation speed set in the rotation speed setting unit and for stopping rotation of the driving shaft of the rotary driving mechanism when the fastening torque calculated in the processor becomes equal to or larger than a reference value of fastening torque previously set in the torque setting unit.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Rotary impact tool

ActiveUS20050263304A1Low costReduce speedReciprocating drilling machinesConstructionsDrive shaftControl theory

A rotary impact tool can be used in a work especially precision or finishing of fastening is important. The rotary impact tool comprises a rotary driving mechanism including a driving source for rotating a driving shaft, a hammer fixed on the driving shaft, an output shaft to which a driving force is applied by impact blow of the hammer, a torque setting unit used for setting a fastening torque, a processor for calculating fastening torque from impact blow of the hammer, a rotation speed setting unit used for setting rotation speed of the driving shaft, and a controller for rotating the driving shaft of the rotary driving mechanism in a rotation speed set in the rotation speed setting unit and for stopping rotation of the driving shaft of the rotary driving mechanism when the fastening torque calculated in the processor becomes equal to or larger than a reference value of fastening torque previously set in the torque setting unit.

Owner:MATSUSHITA ELECTRIC WORKS LTD

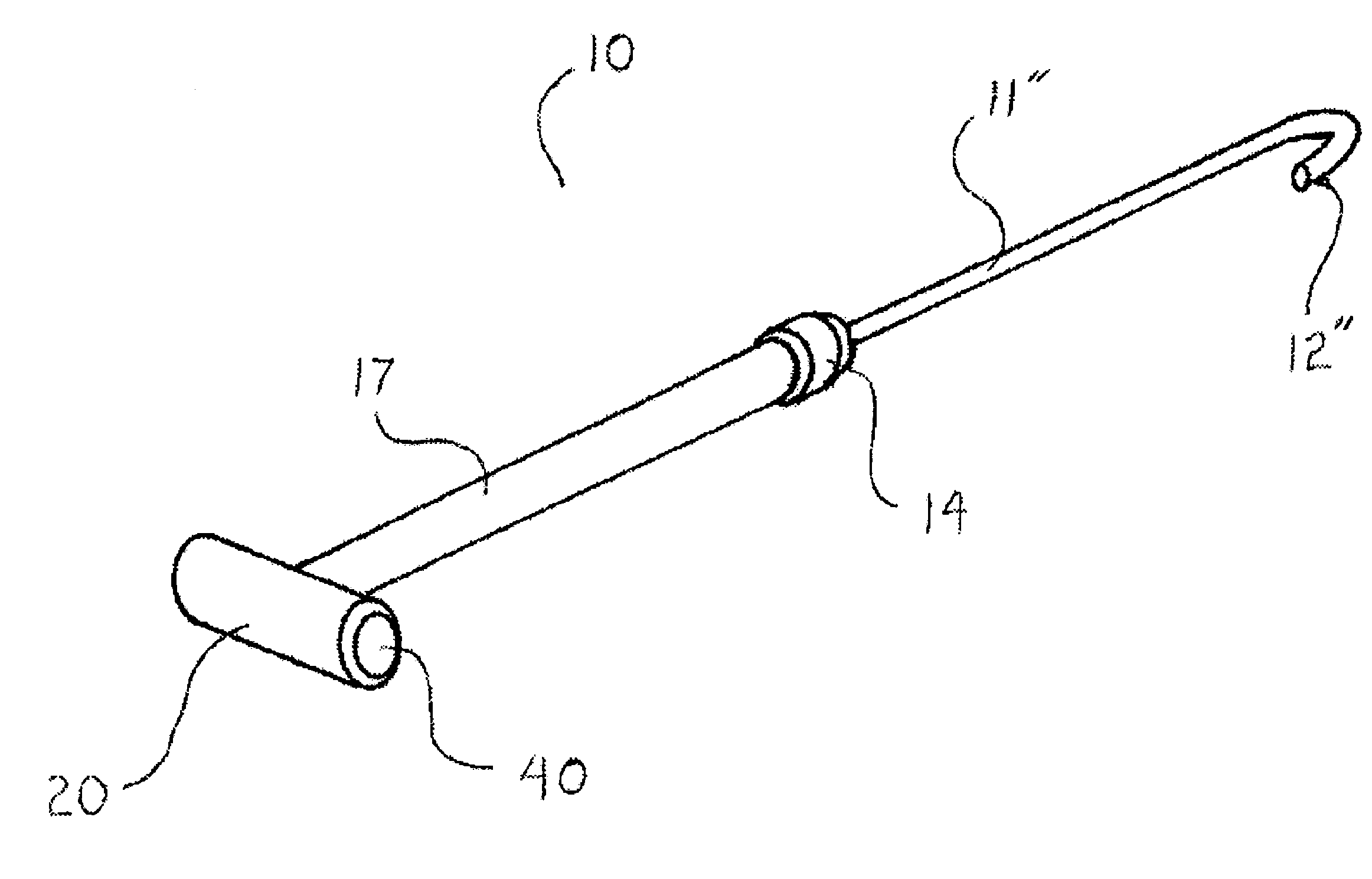

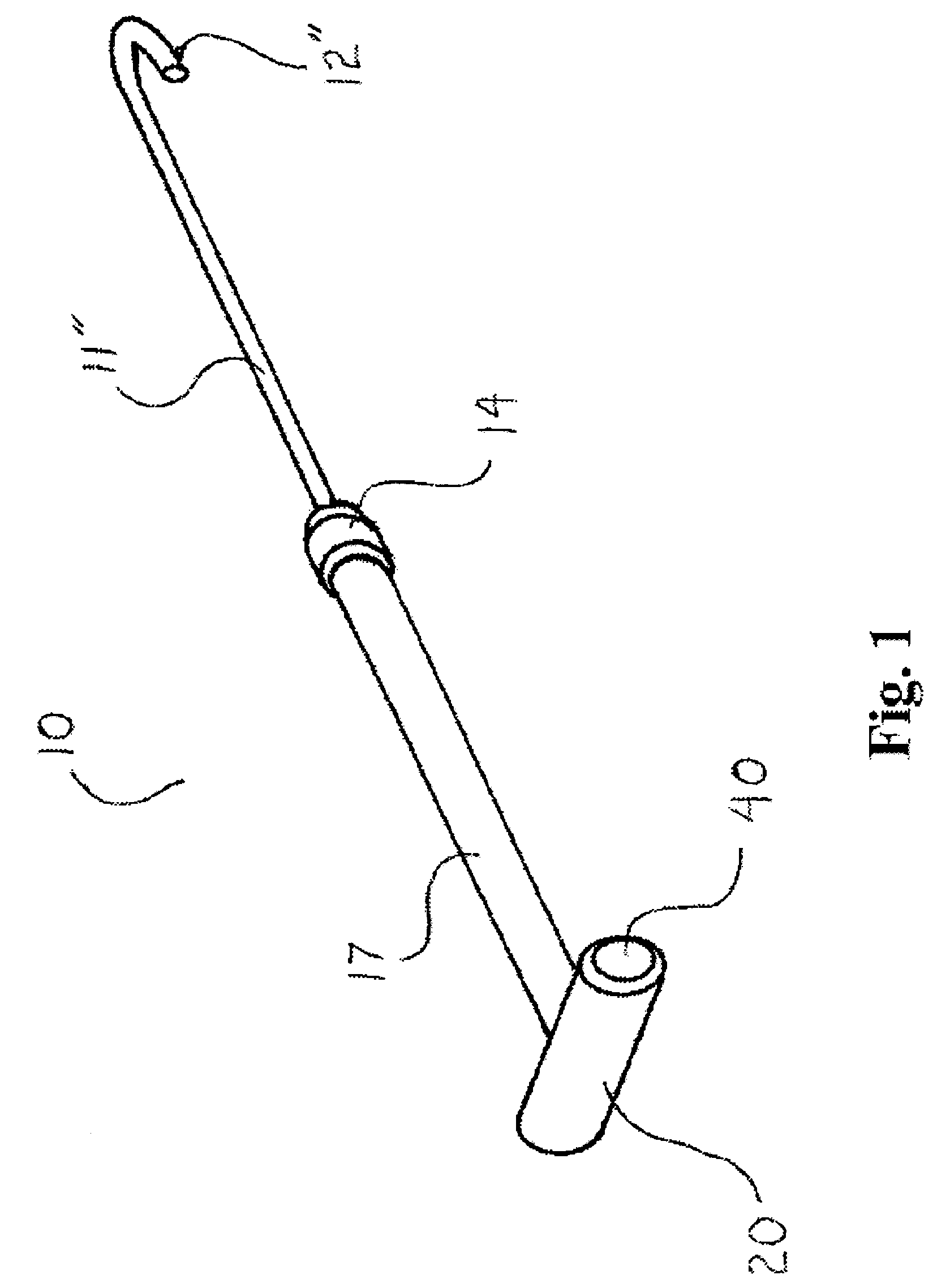

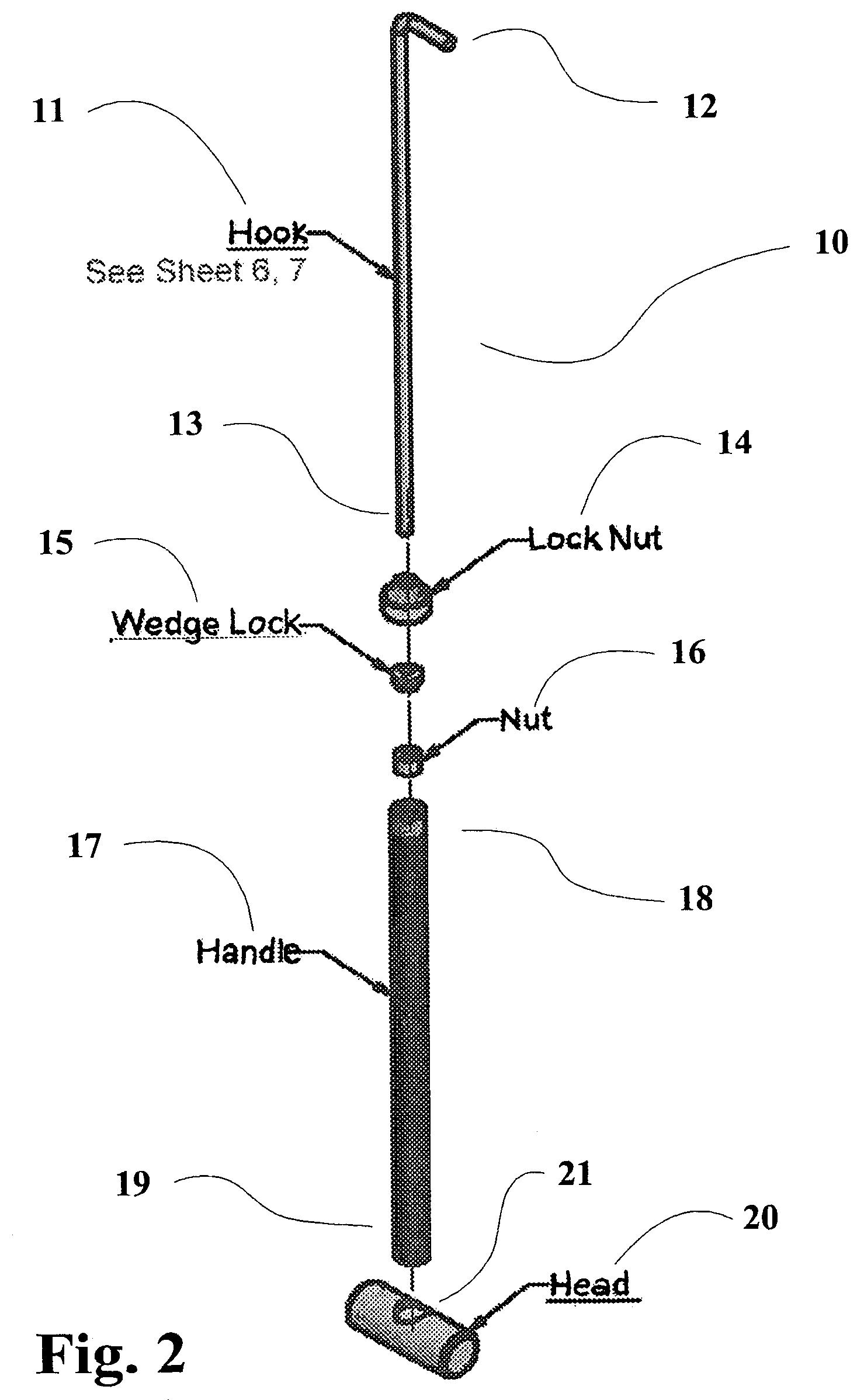

Multi-purpose trucker's power-puller tool

A multi-purpose trucker's power puller tool with a hook rod that slides in the bore of a handle, and a weighted head at an end of the handle. The weighted head provides momentum to the hooked end for yanking free stuck objects, such as a truck's fifth wheel pin. The slidable rod also allows the tool to be locked in extended or collapsed positions. The invention also allows interchangeable hook rods to be used, so that the tool may be adapted to different purposes, such as grabbing and pulling eyelets of truck load covers, or pulling chains.

Owner:HANSEN DENNIS

Surgical slap hammer

Owner:HUENE DONALD

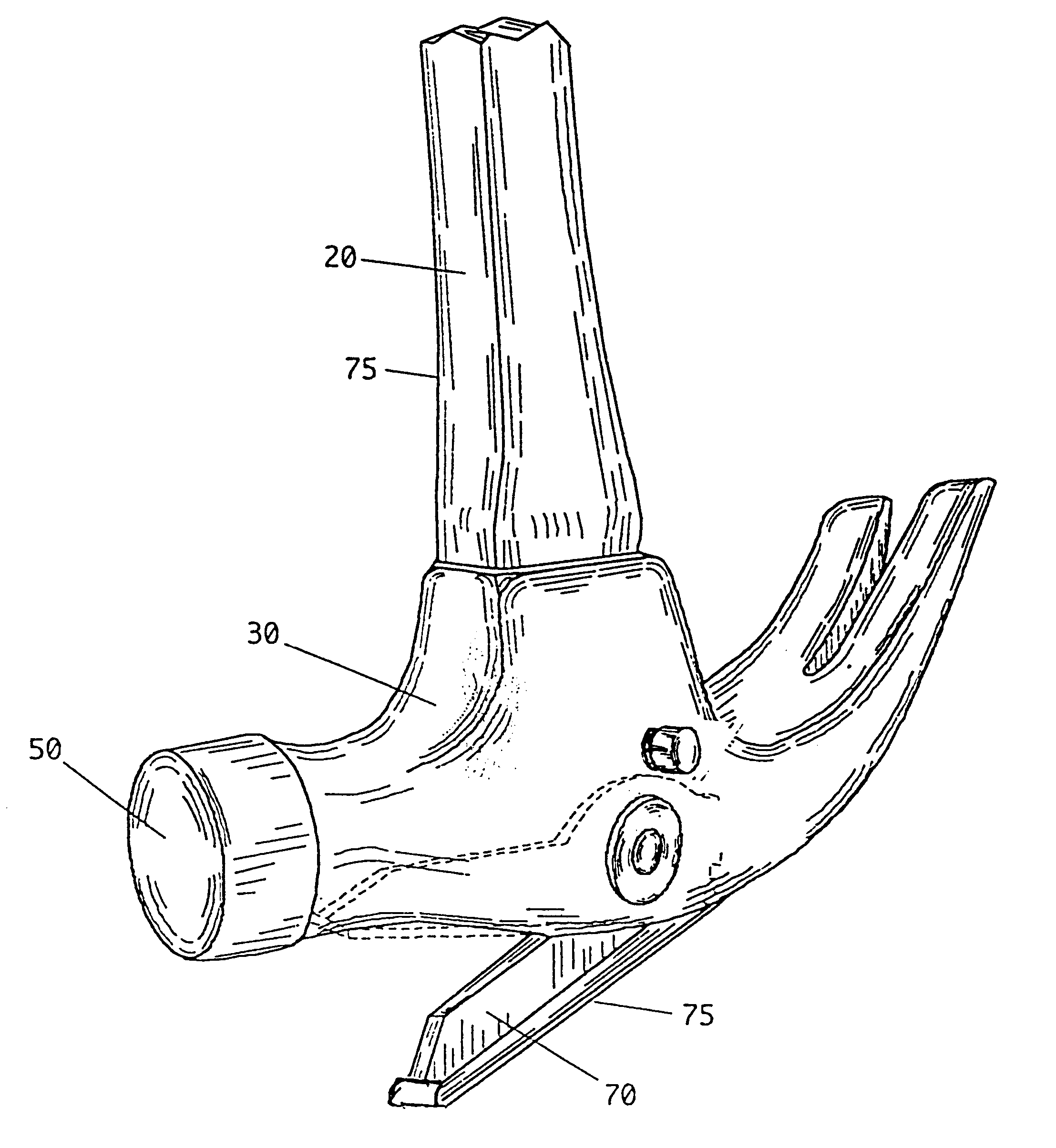

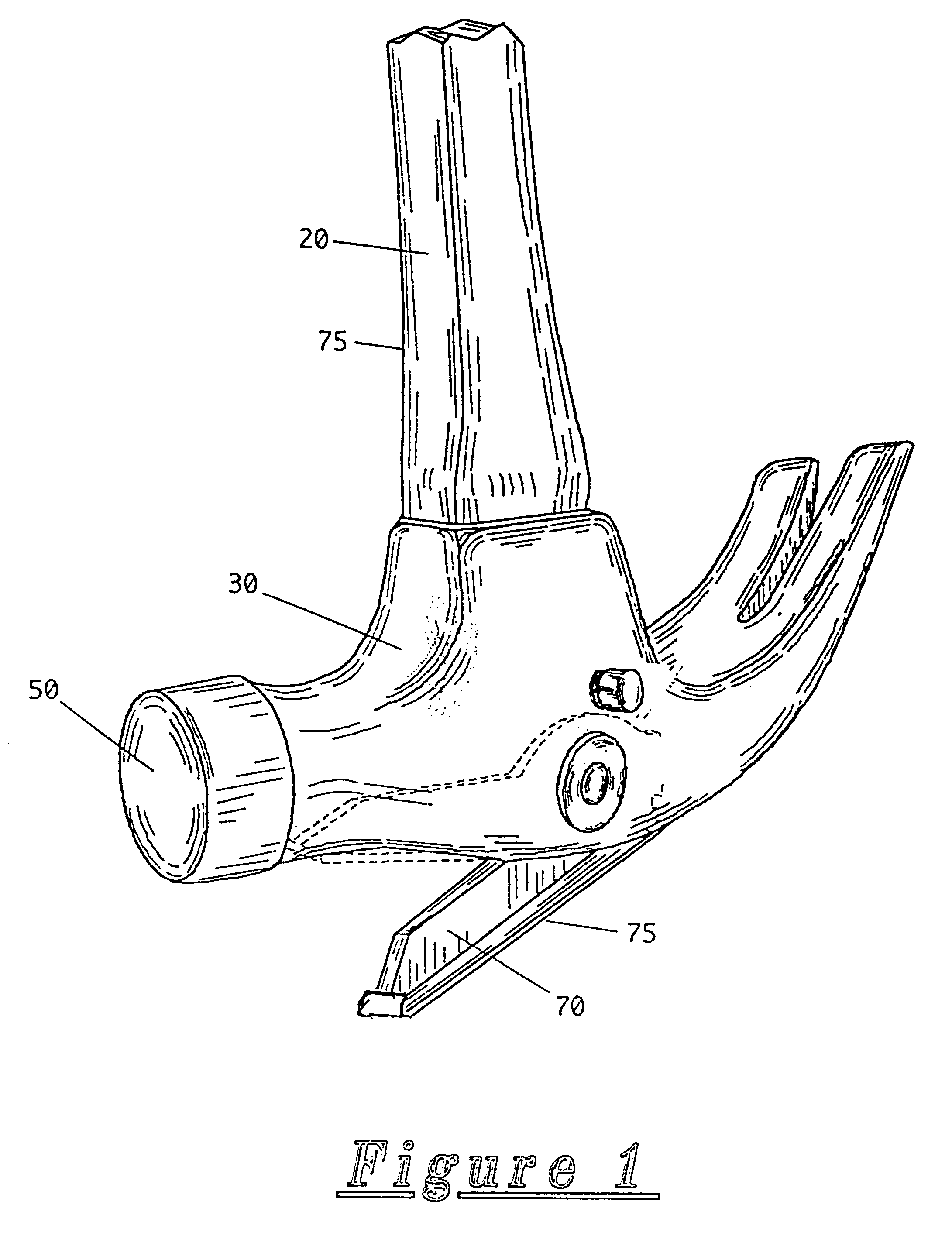

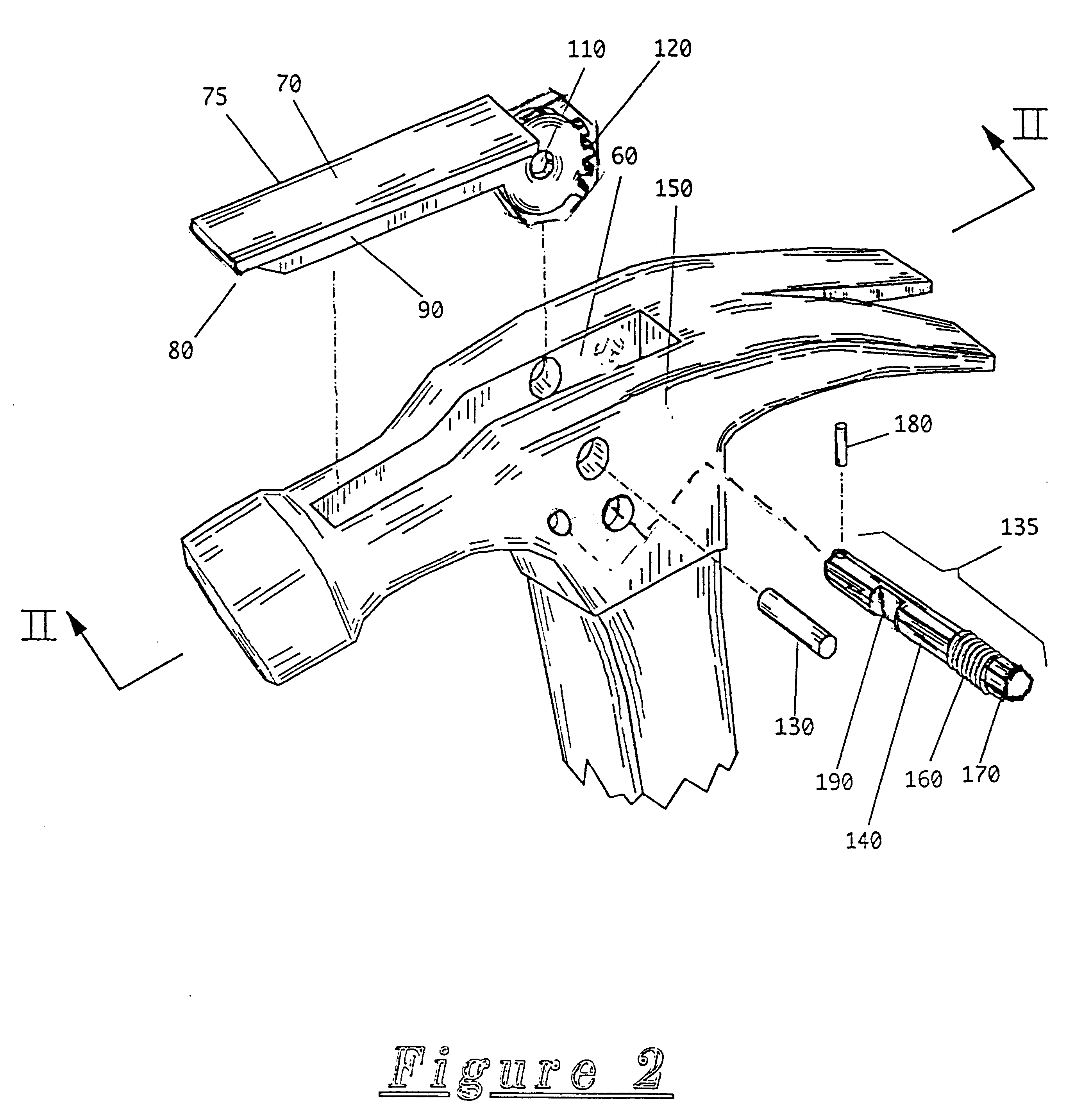

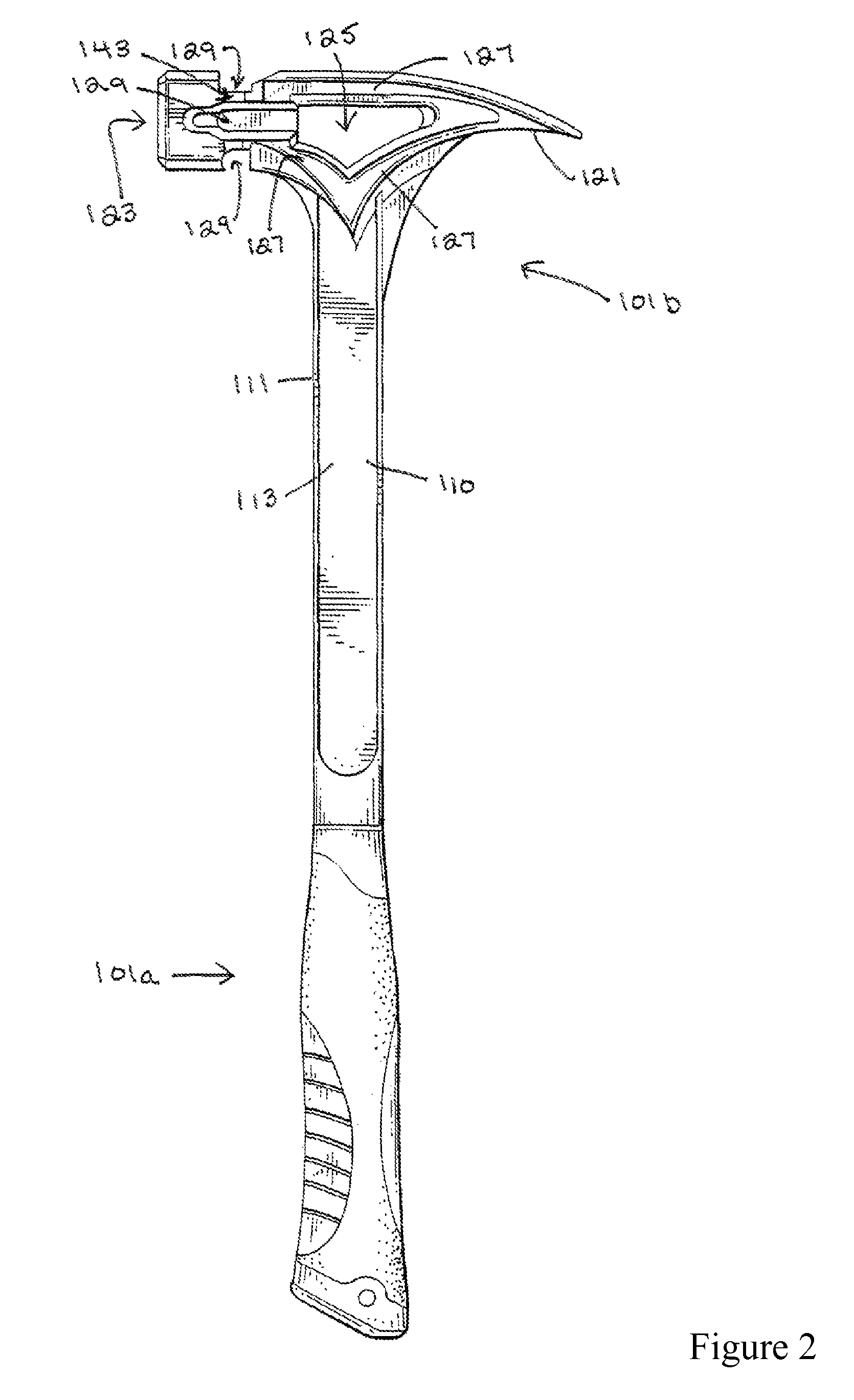

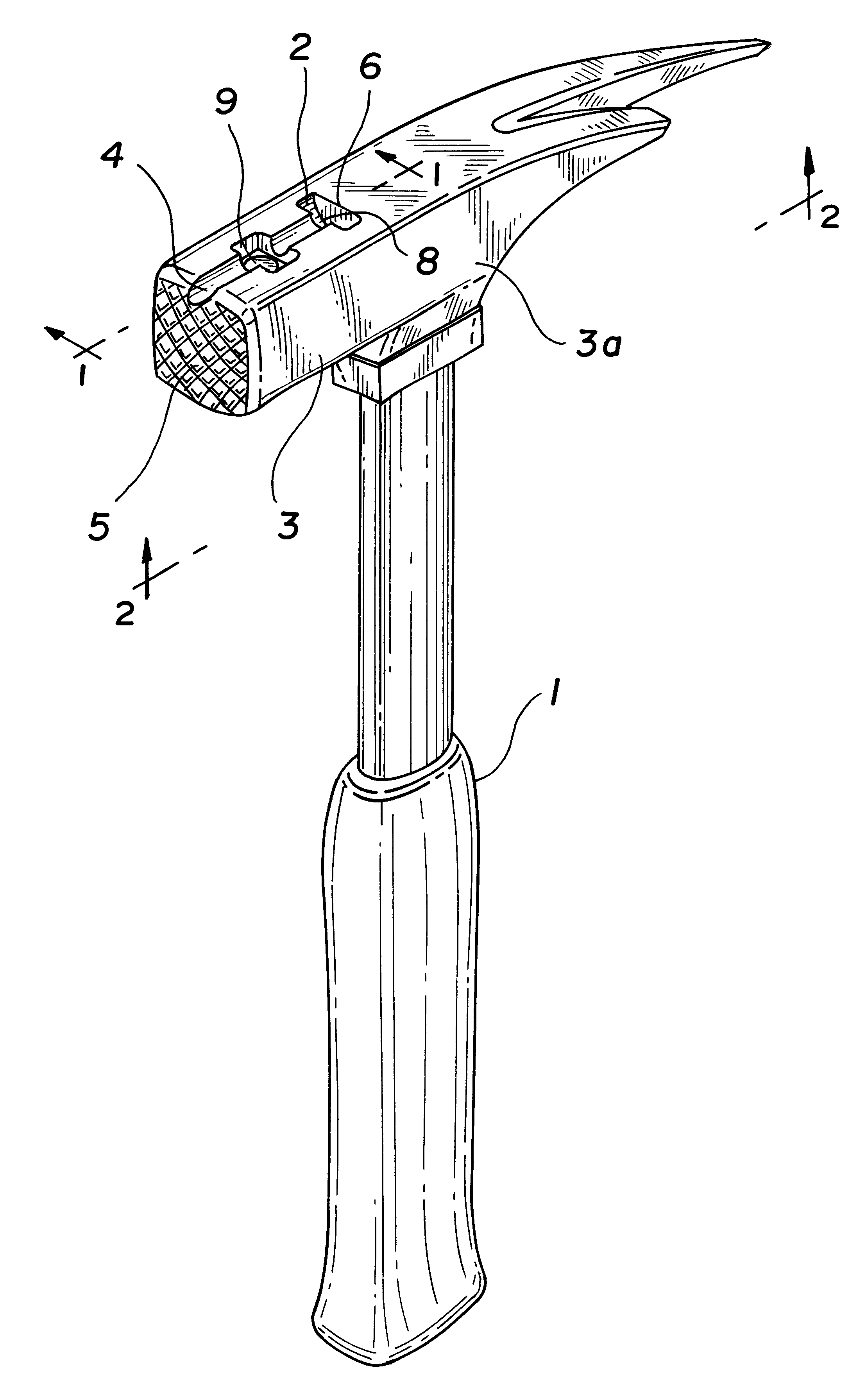

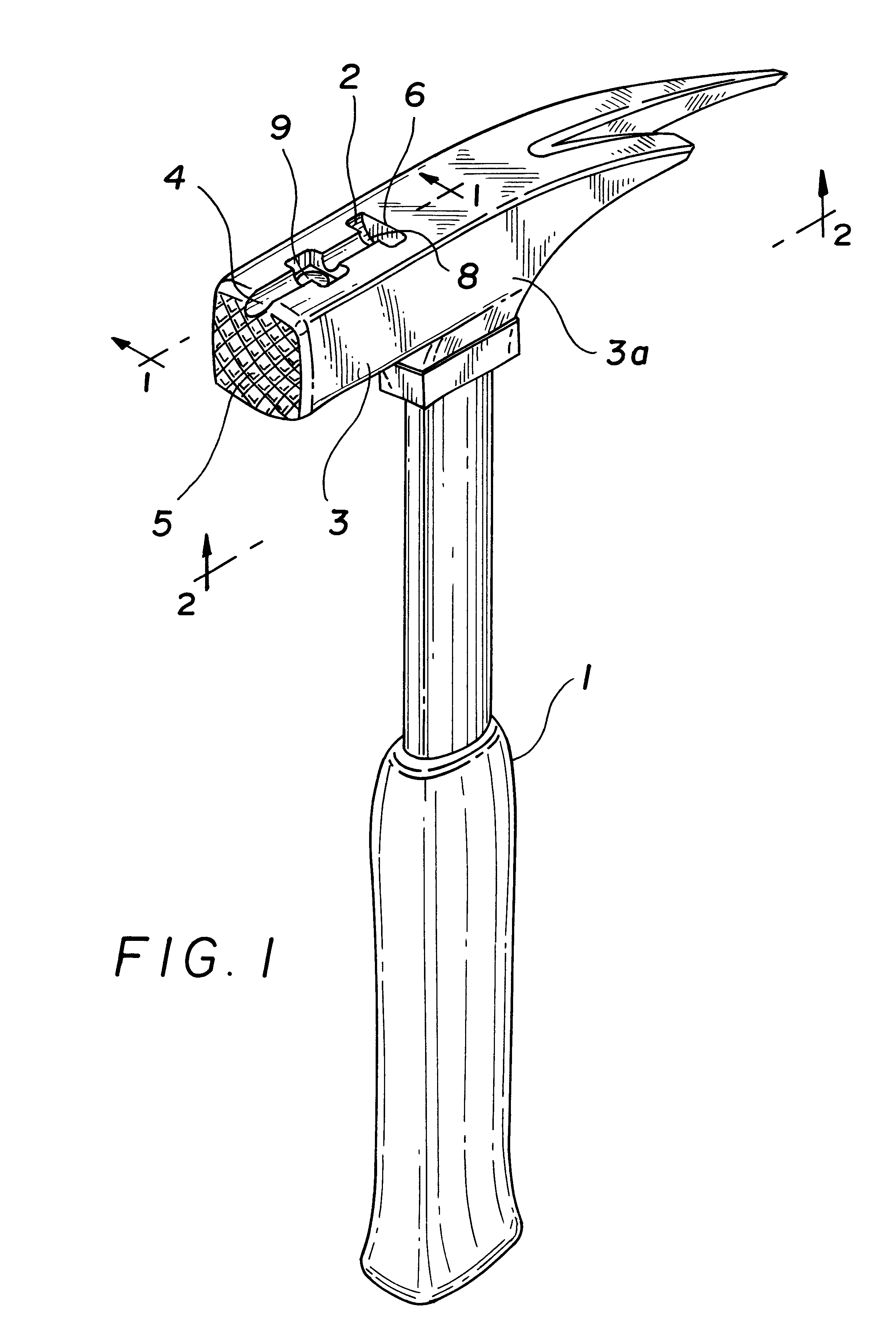

Hammer with integral lever mechanism

InactiveUS6279876B1Reduce the risk of injuryGood removal effectCrowbarsNail extractorsLong nailsNail removal

A hammer with integral lever mechanism is disclosed, comprised of a traditional handle and claw head. To increase leverage during nail removal and enable the user to remove longer nails with speed and ease, a lever is incorporated into the design of the device. The lever is T-shaped, and in its resting position is located inside of the head, so as to not interfere with use of the device when the lever is not needed. The lever can be rotated relative to the head by depressing a lever release button, to aid in nail removal . The lever is of ratchet style configuration, allowing the user to position the lever in a multitude of locations relative to the head, to assist in removing nails of various lengths. The lever is capable of being locked into position relative to the head at each of the lever's possible positions. A hand guard and finger grips permit the user to maintain a firm hold on the handle during use, thus reducing risk of injury. A retractable tape measure is incorporated into the design of the handle.

Owner:MASSIE ARNOLD

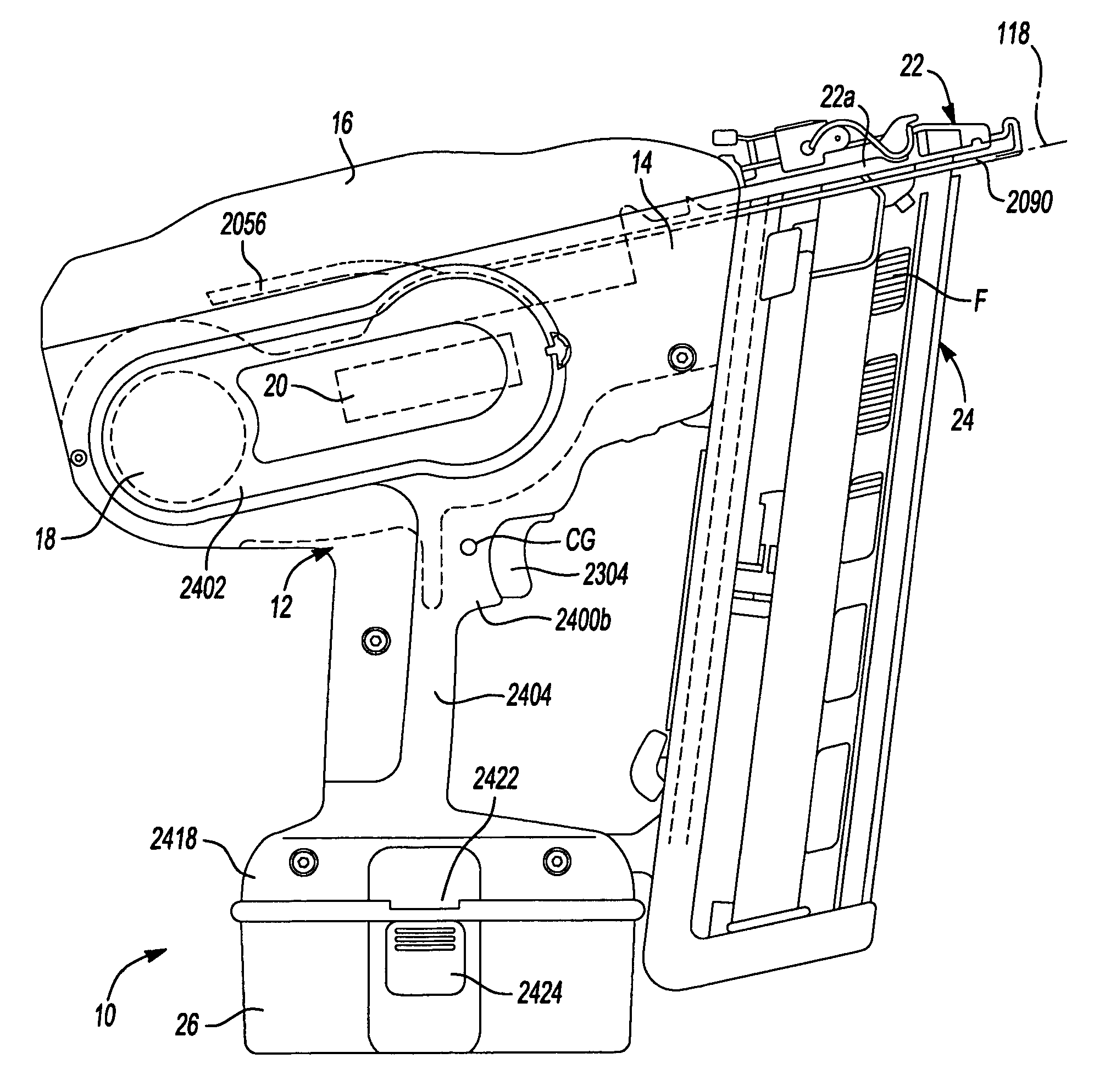

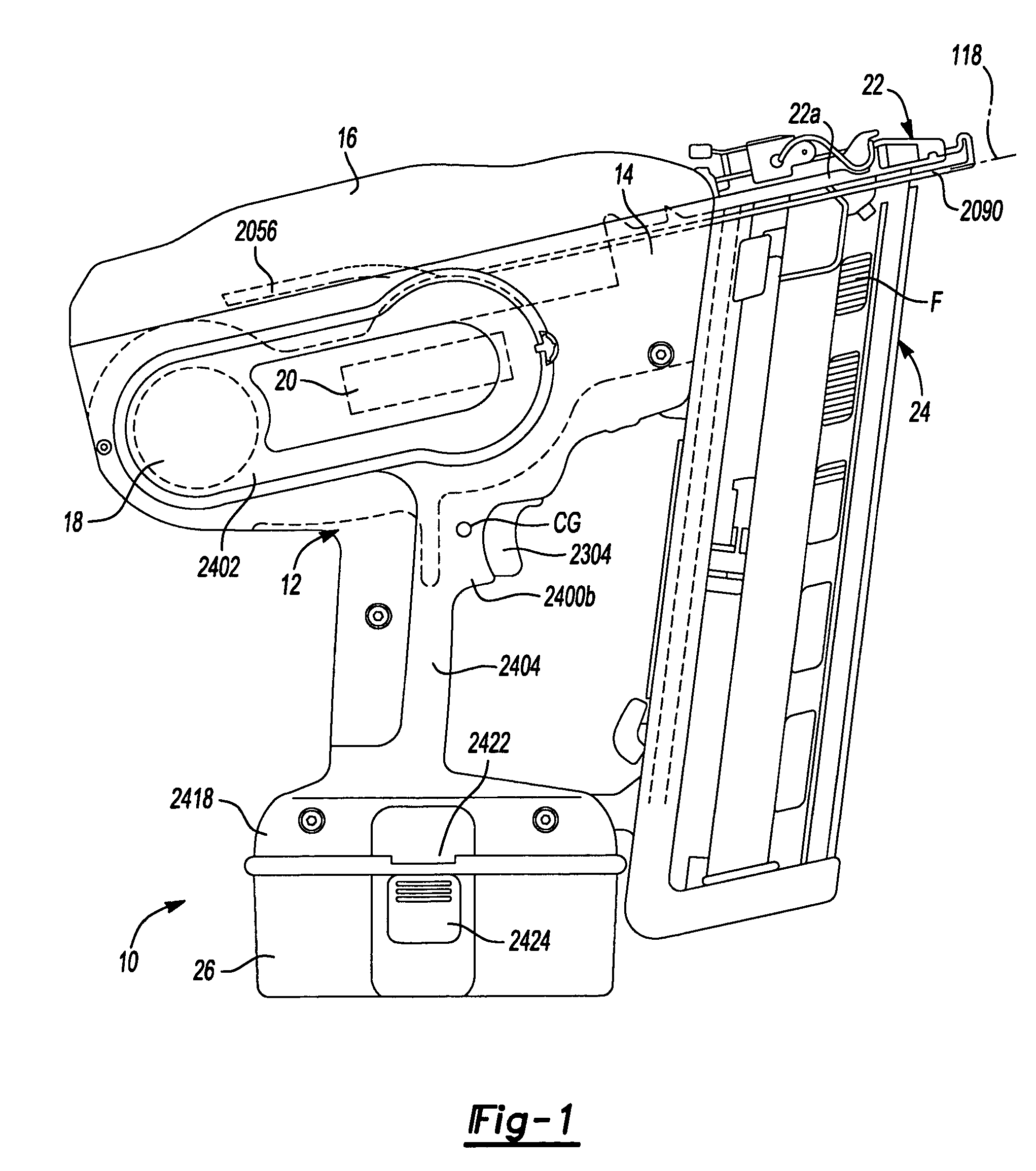

Activation arm assembly method

A method for assembling an activation arm assembly for a power tool, such as a fastening tool or nailer. The method includes the mounting of various components of the activation arm assembly on pivot pins and positioning of a pair of arm members to load a spring that biases one of the arm members relative to another of the arm members.

Owner:BLACK & DECKER INC

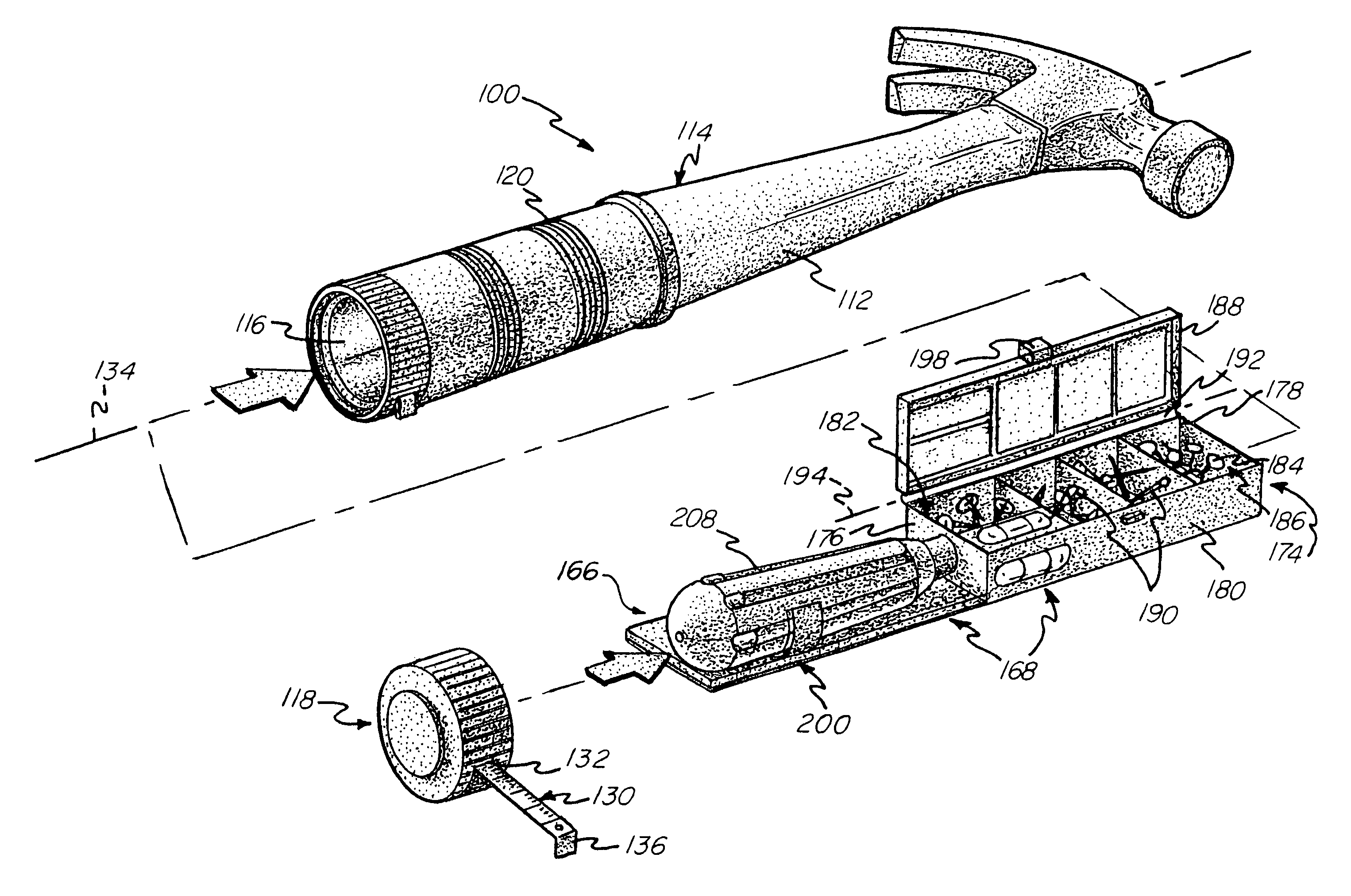

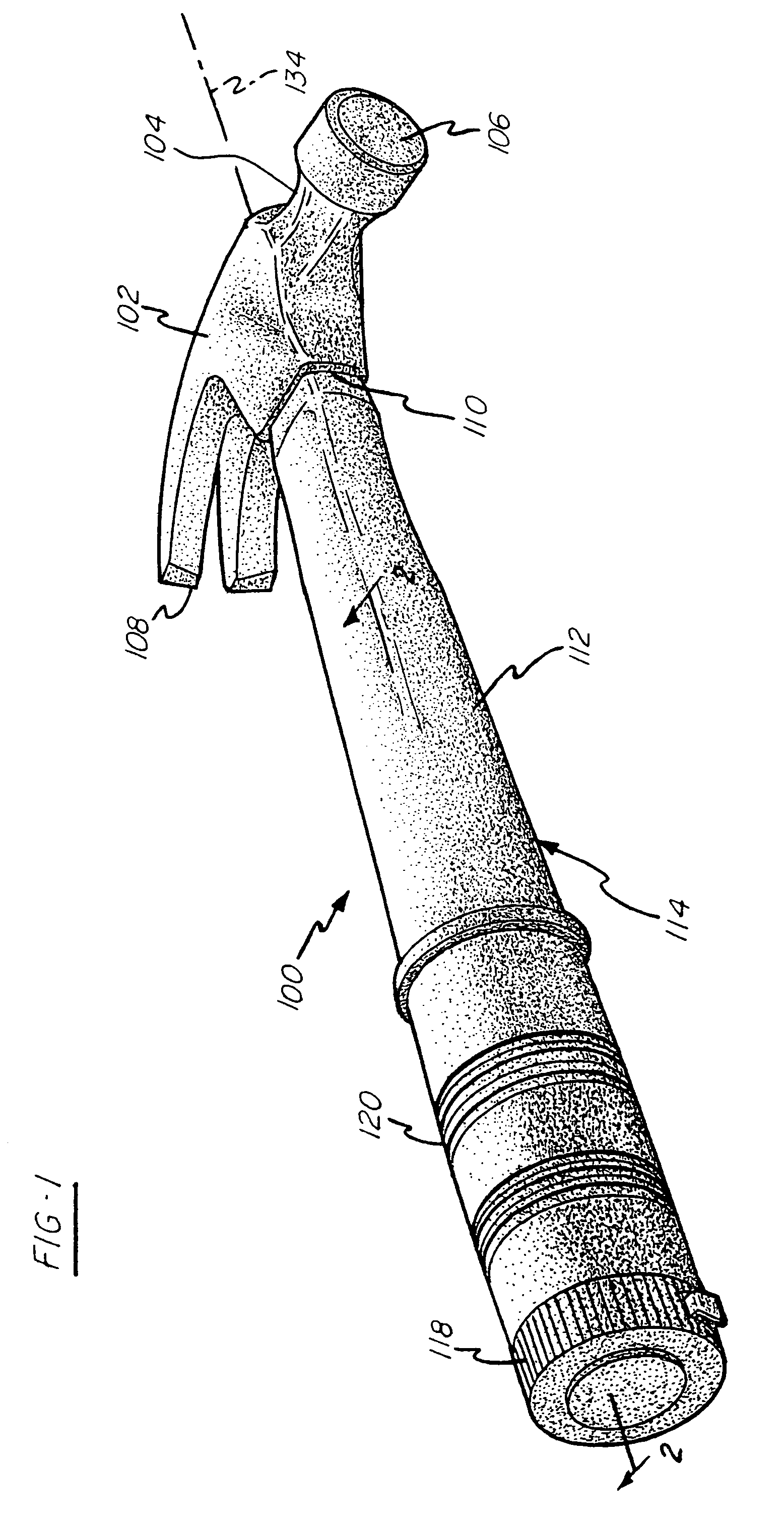

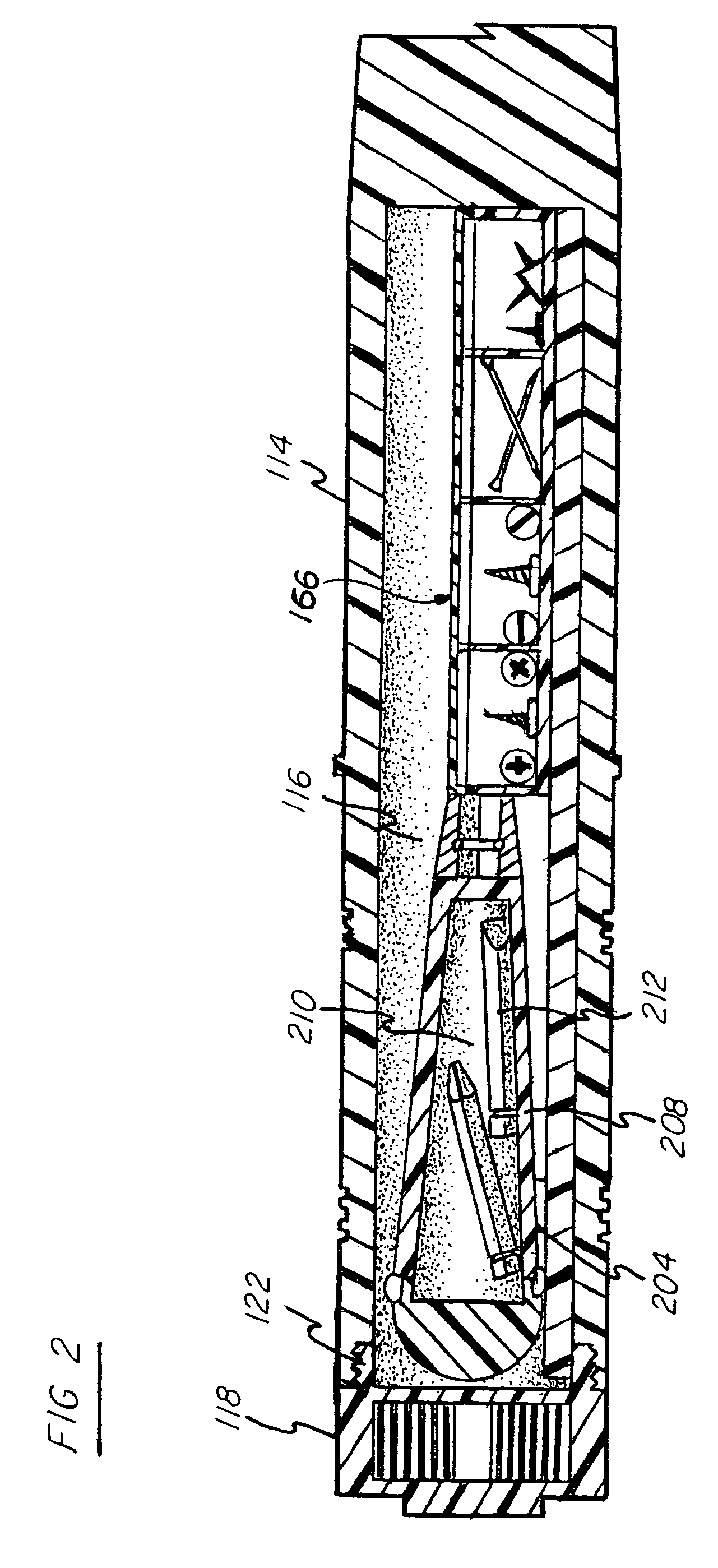

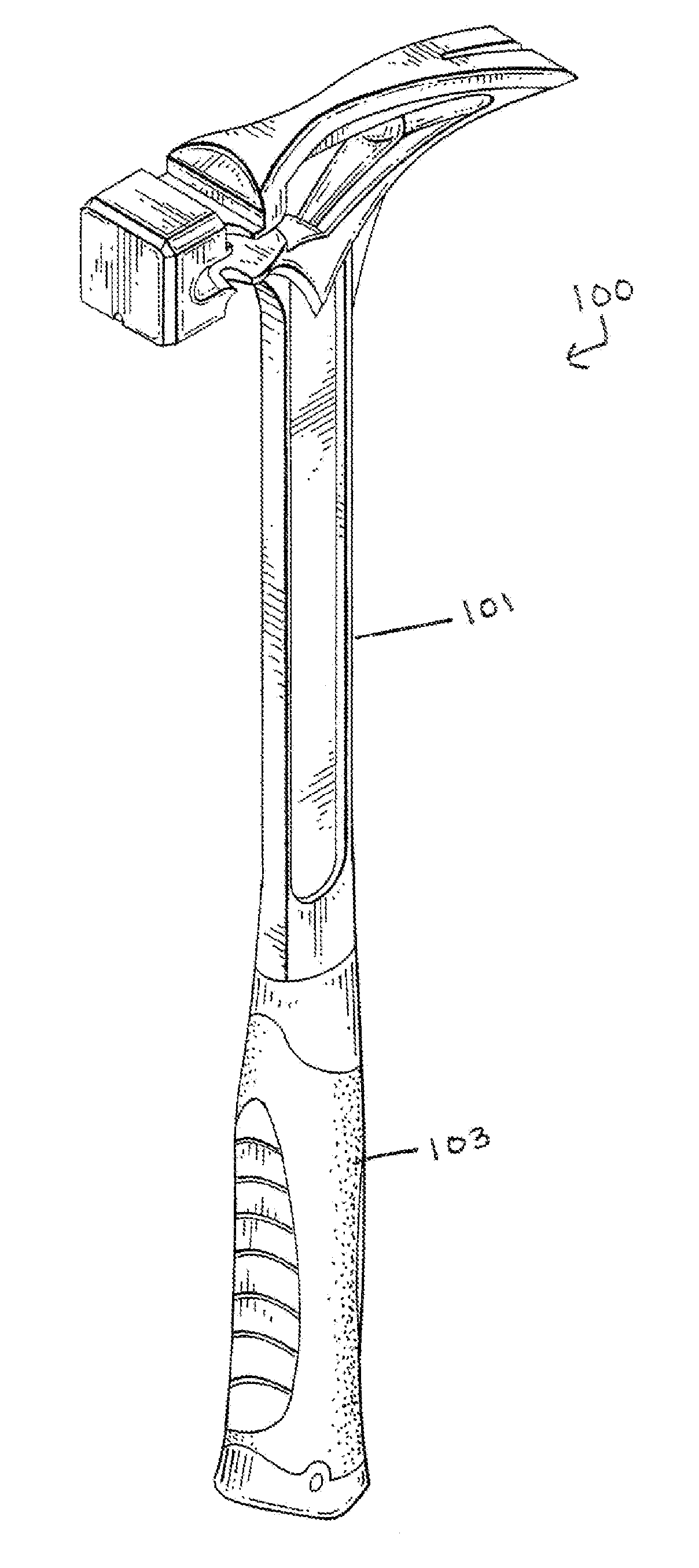

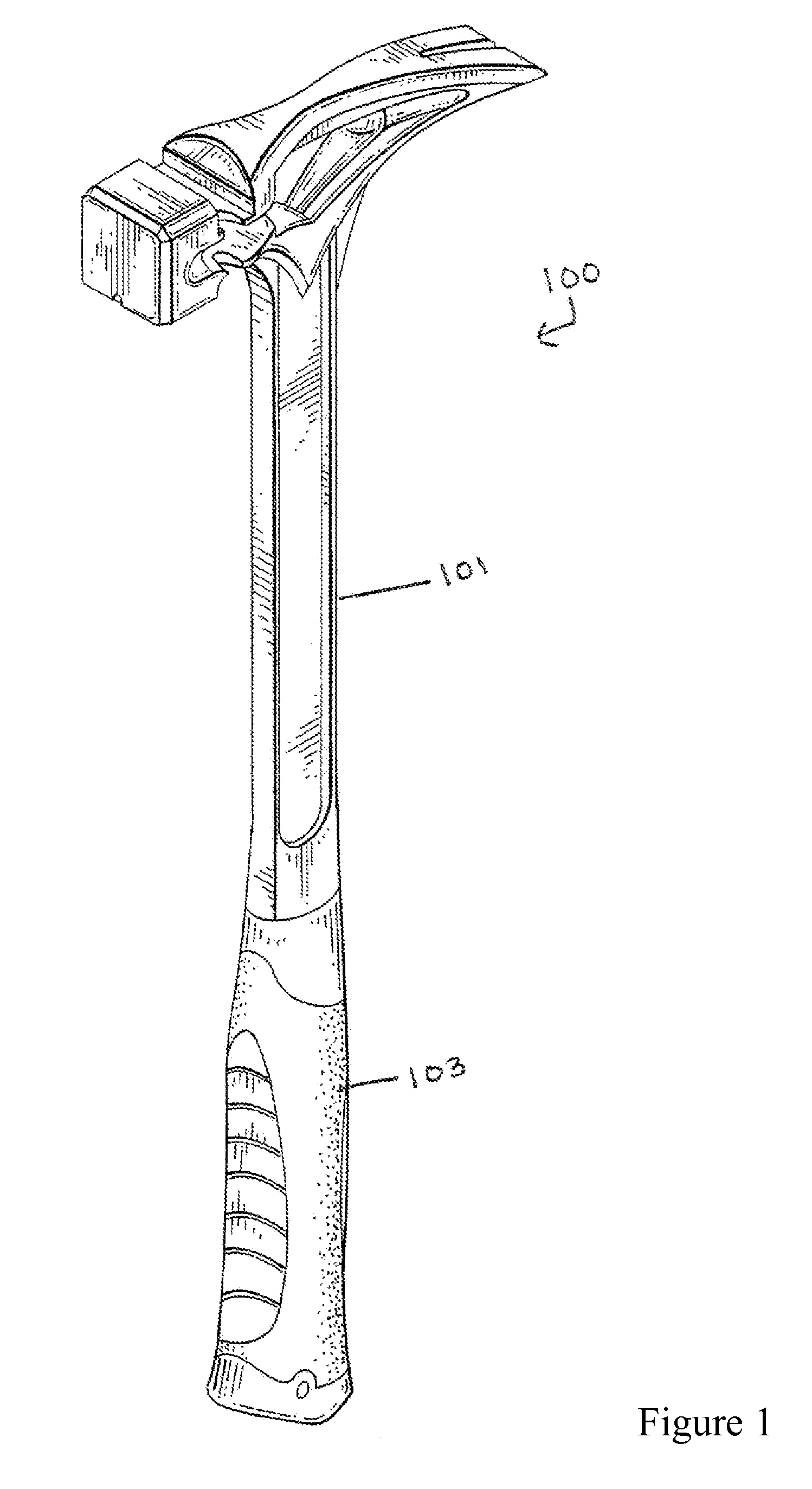

Hammer

InactiveUS7013516B1Easy to useEfficiently and conveniently holdsSpannersWrenchesEngineeringMechanical engineering

The present invention is directed to a hammer having a number of accessories including a storage cavity adapted to efficiently and conveniently hold tools, supplies, and the like and / or an additional number of accessories. The hammer comprises a hammer head having a front portion adapted for striking a nail or a tack, and a handle having a longitudinal extending cavity therein. A tray tailored to fit and slide within the longitudinal extending cavity is provided and is adapted to support a plurality of accessories.

Owner:READY TOOLS

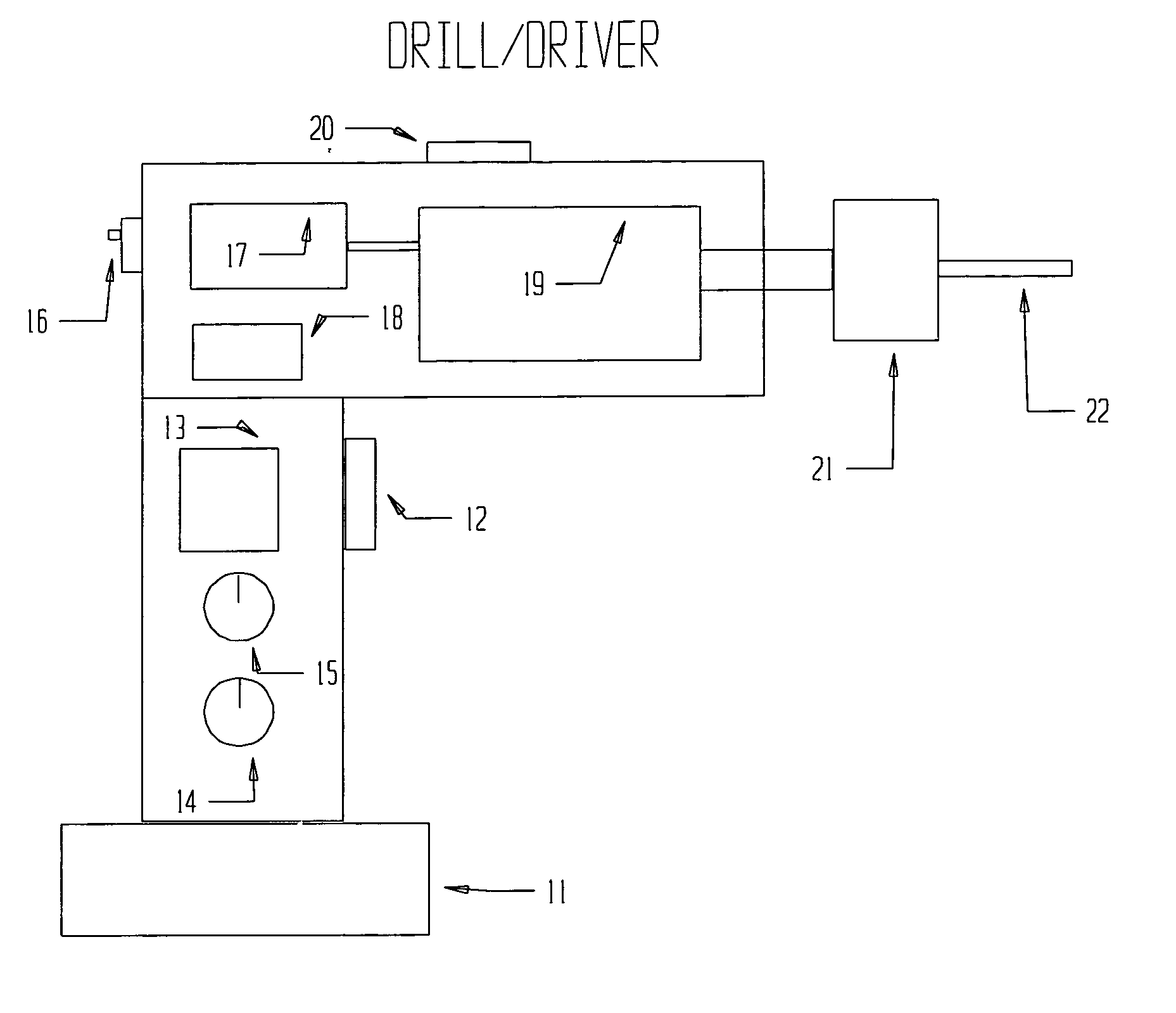

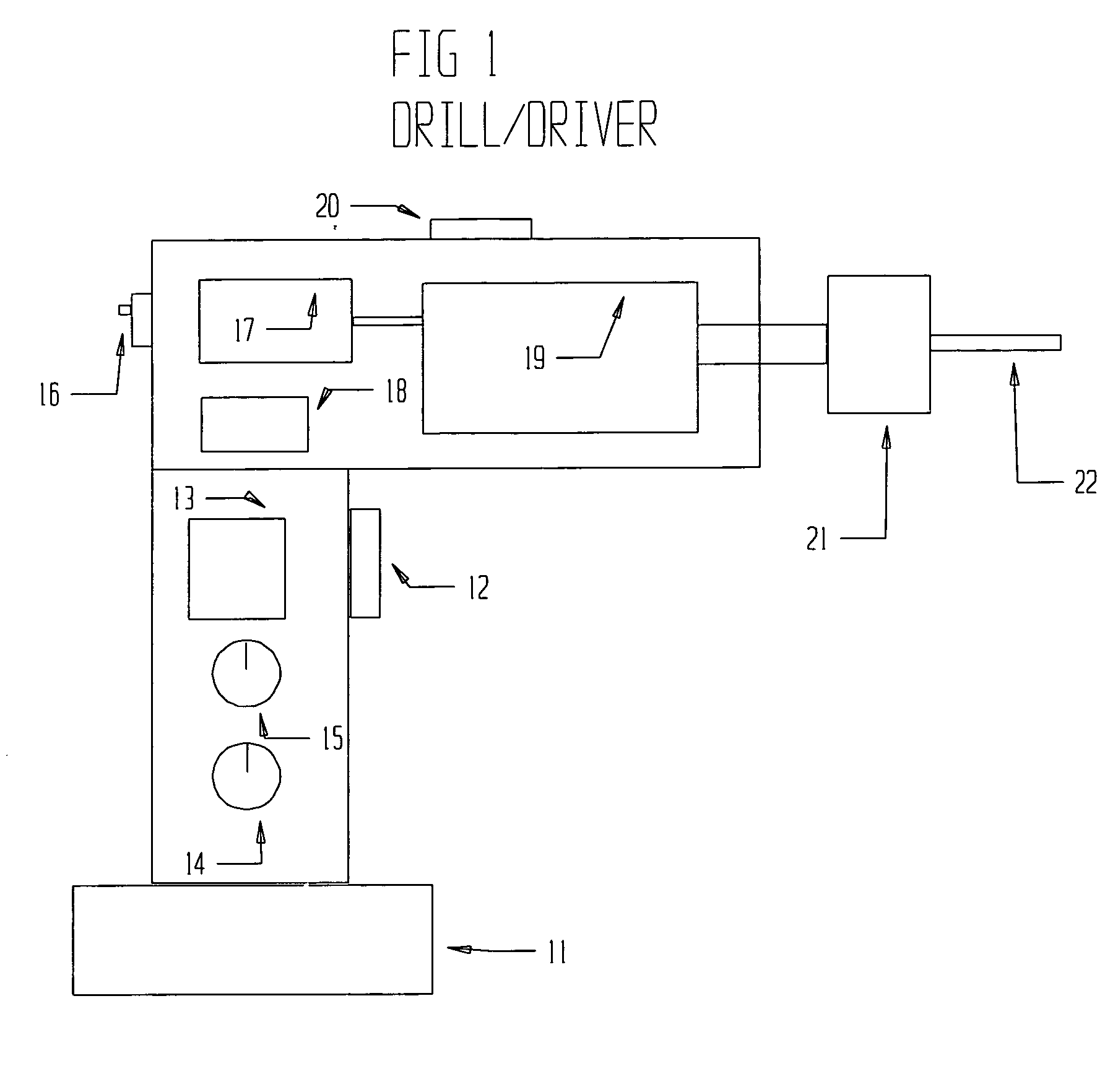

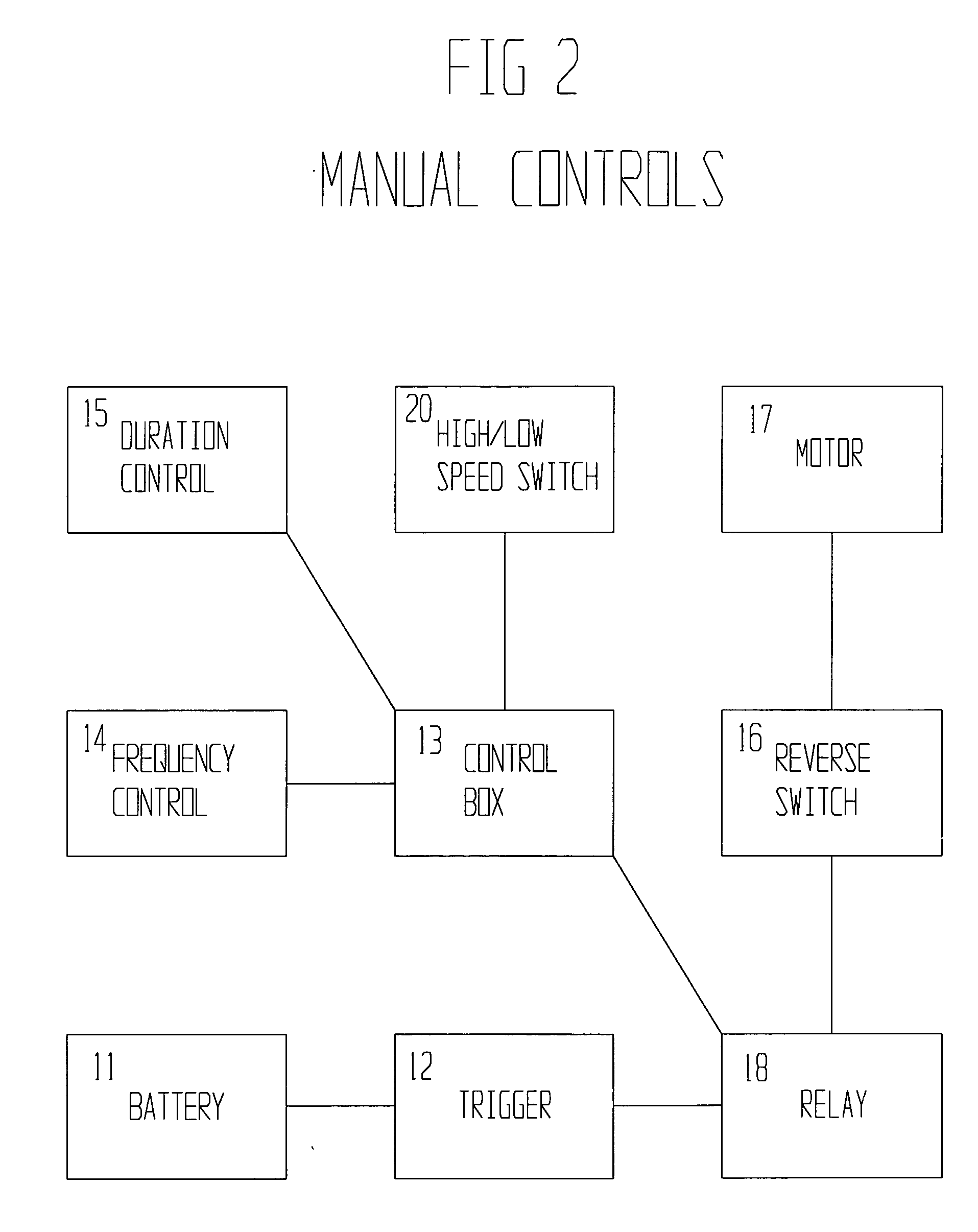

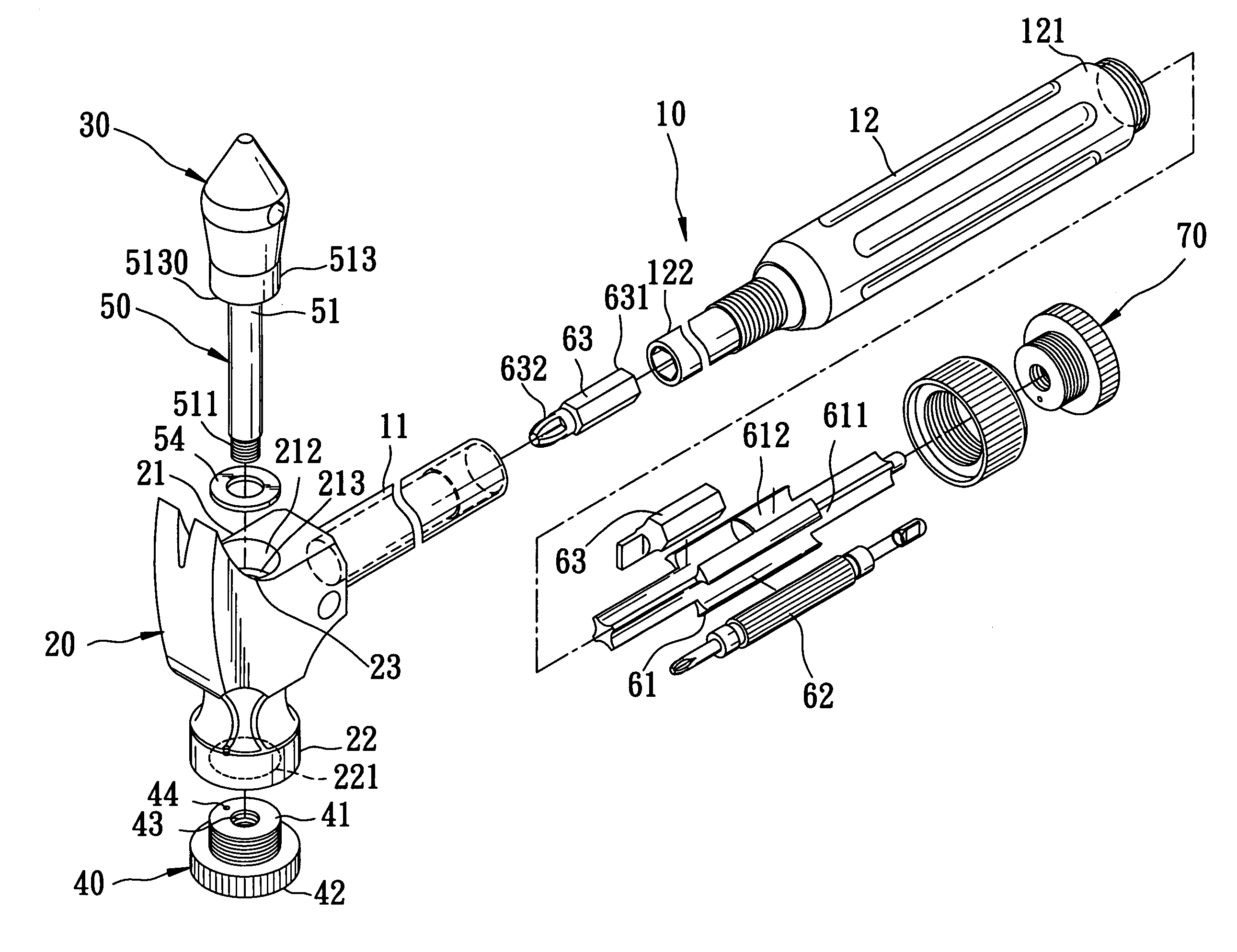

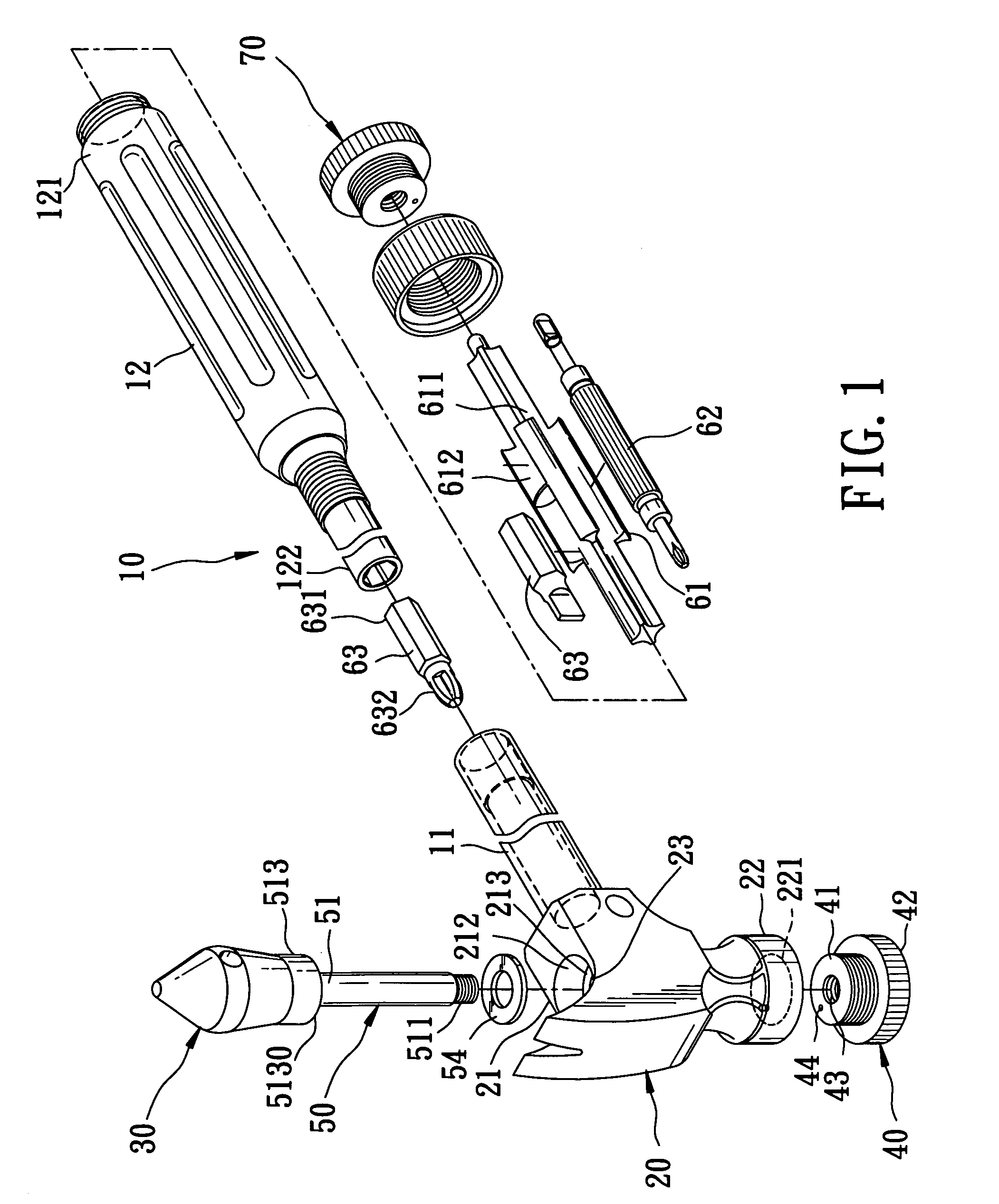

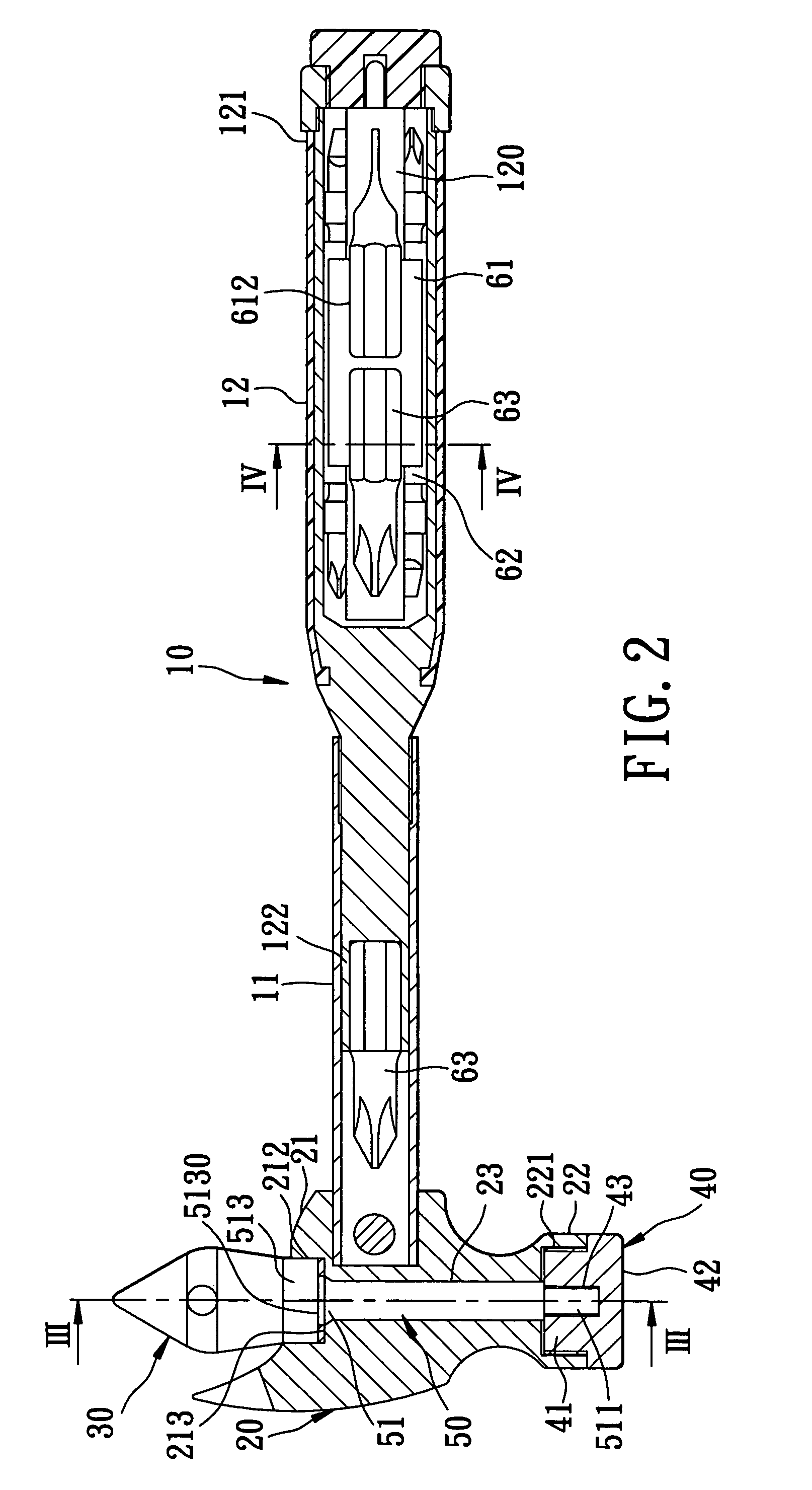

Pulsed rotation screw removal and insertion device

InactiveUS20050205274A1Reduce generationPrevent peelingDC motor speed/torque controlDerricks/mastsEngineeringInsertion device

A drill / driver (e.g. an electric drill) with a screwdriver bit attachment, and a method of controlling the drill / driver, are described. This method of control will greatly reduce the occurrence of stripped screw heads on most types of screws. By periodically stopping insertion of a screw and reversing direction of the screwdriver bit, the screwdriver bit will be reinserted fully back into the screw head. By ensuring the screwdriver bit is always fully inserted in the screw head, the stripping of a screw head will be prevented. This can be easily implemented on most types of powered screwdrivers including the most common device used for screw insertion on a construction job site, the cordless drill / driver.

Owner:BOGUE EDWARD M

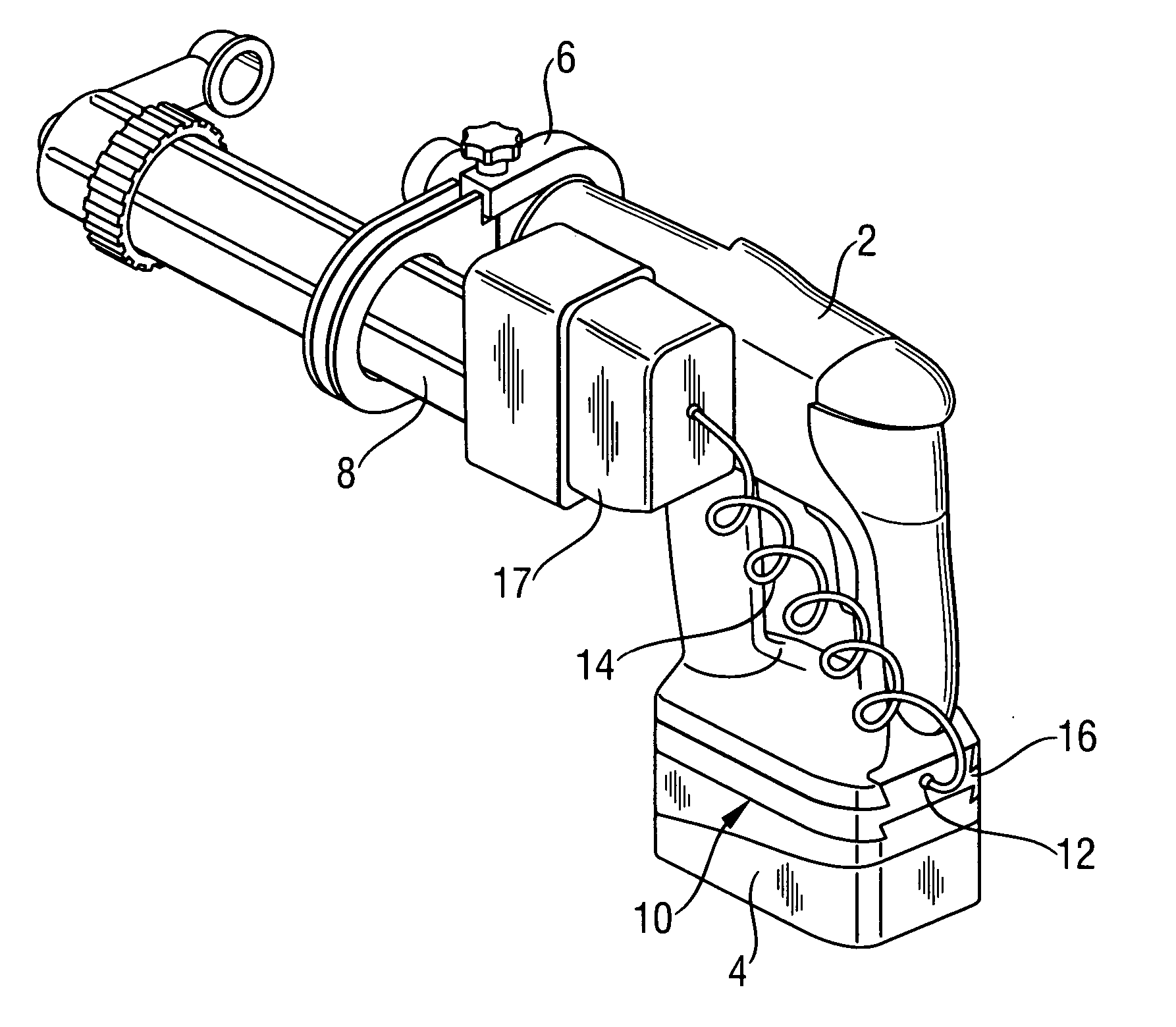

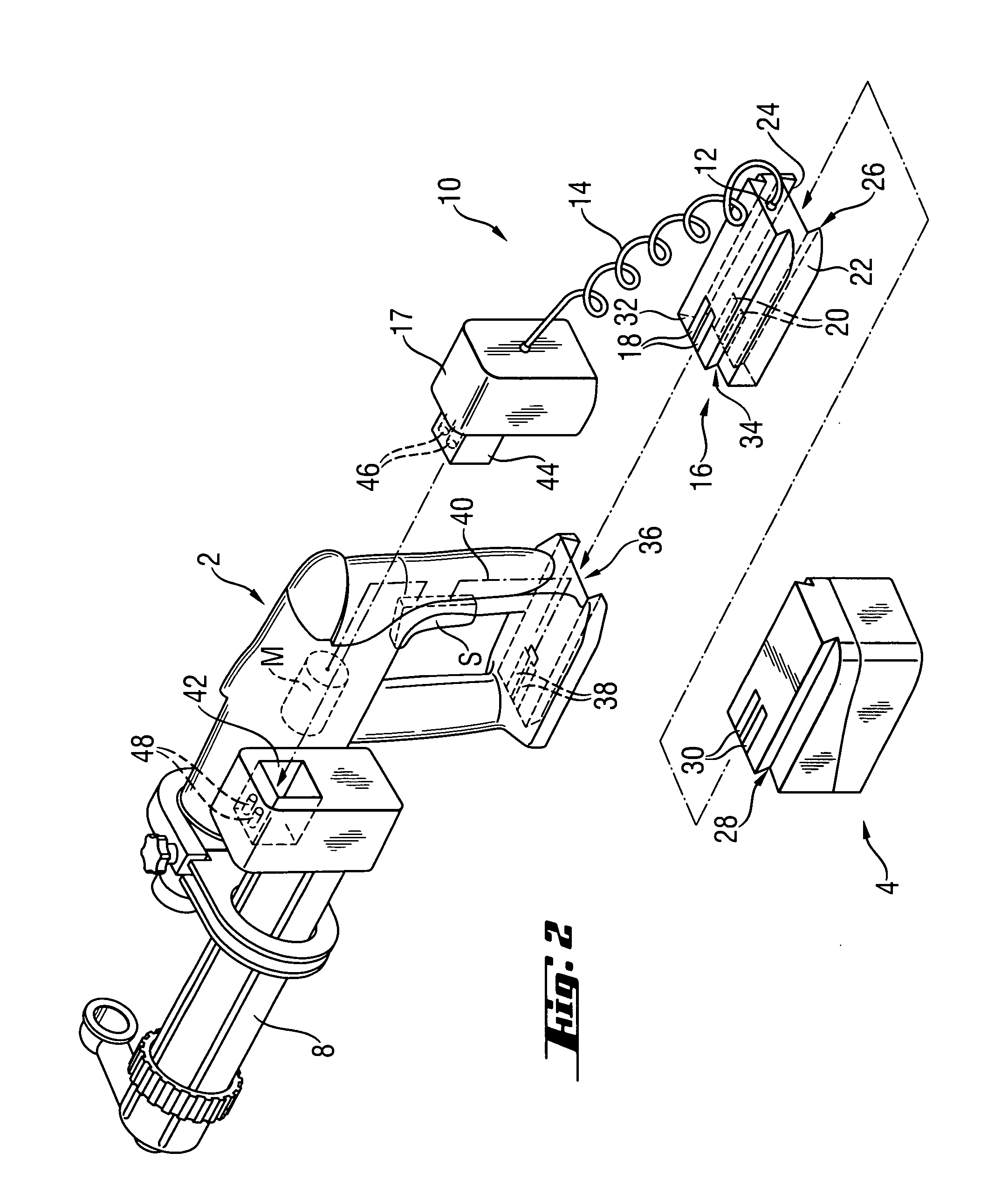

Electrical connection arrangement for hand-held tools with auxiliary devices

ActiveUS20050082920A1Easy to fixSimple wayCoupling device connectionsBatteries circuit arrangementsElectricityHand held

An electrical connection arrangement (10) for a battery pack-powered electrical hand-hand tool (2) has an adapter (16) which can be arranged at an electric hand-held tool (2) and which, for the electrical connection of the electric hand-held tool (2) to a battery pack (4), has an electric battery terminal (20) for the connection of the battery pack (4) and an electric hand-held tool terminal (18) for detachable connection of the electric hand-held tool and electrically connected with the battery terminal (20), and an auxiliary device terminal (12) for the electrical connection of the auxiliary device (8) with the battery pack, which auxiliary device terminal (12) can be detached from the auxiliary device (8) and is electrically connected to the battery terminal (20).

Owner:HILTI AG

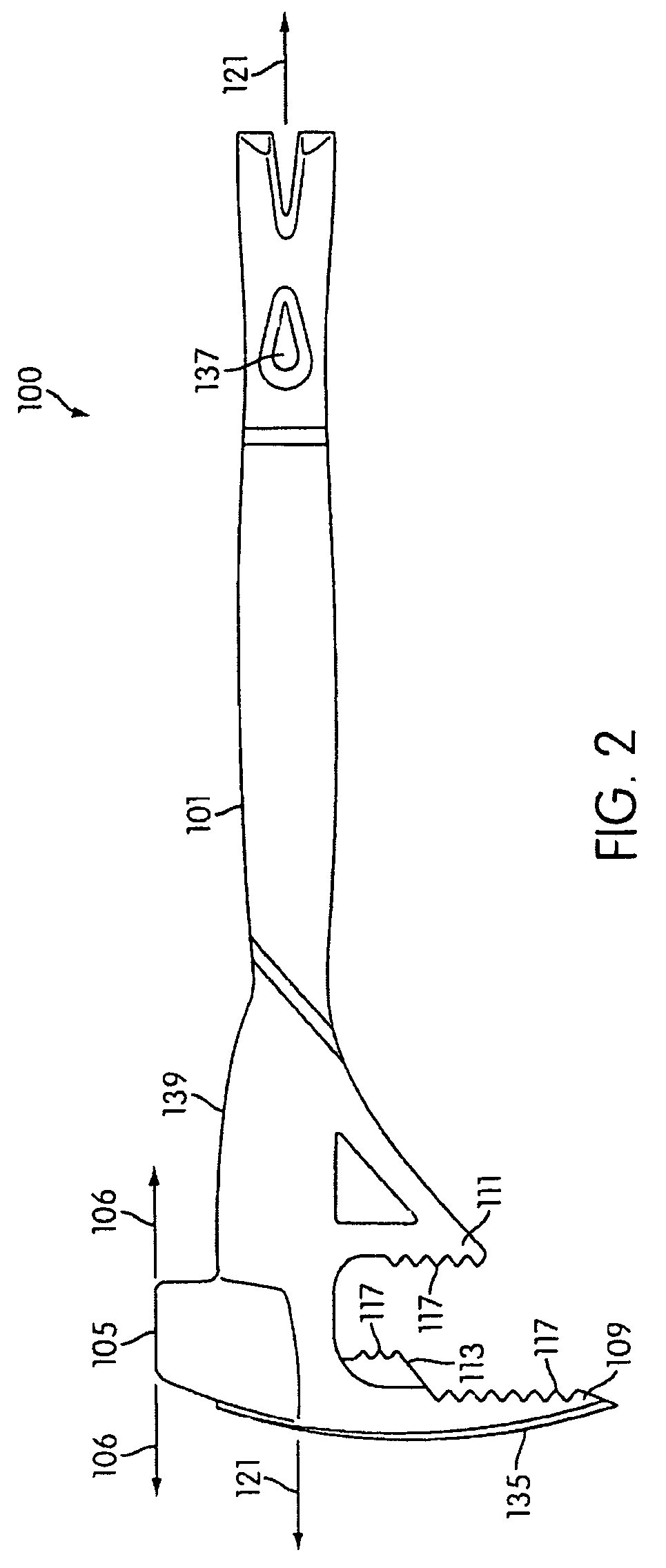

Striking tool

A hammer that that reduces vibration and provides advantageous balance and mass distribution having a handle portion comprising an I-shape sectional profile and a head comprising a cavity formed therethrough. The hammer may further comprise various nail or other fastener removal structures, such as a claw, slots, notches, or the like. The hammer may further include a nail-starter with magnetic nail retention.

Owner:POOLE HLDG

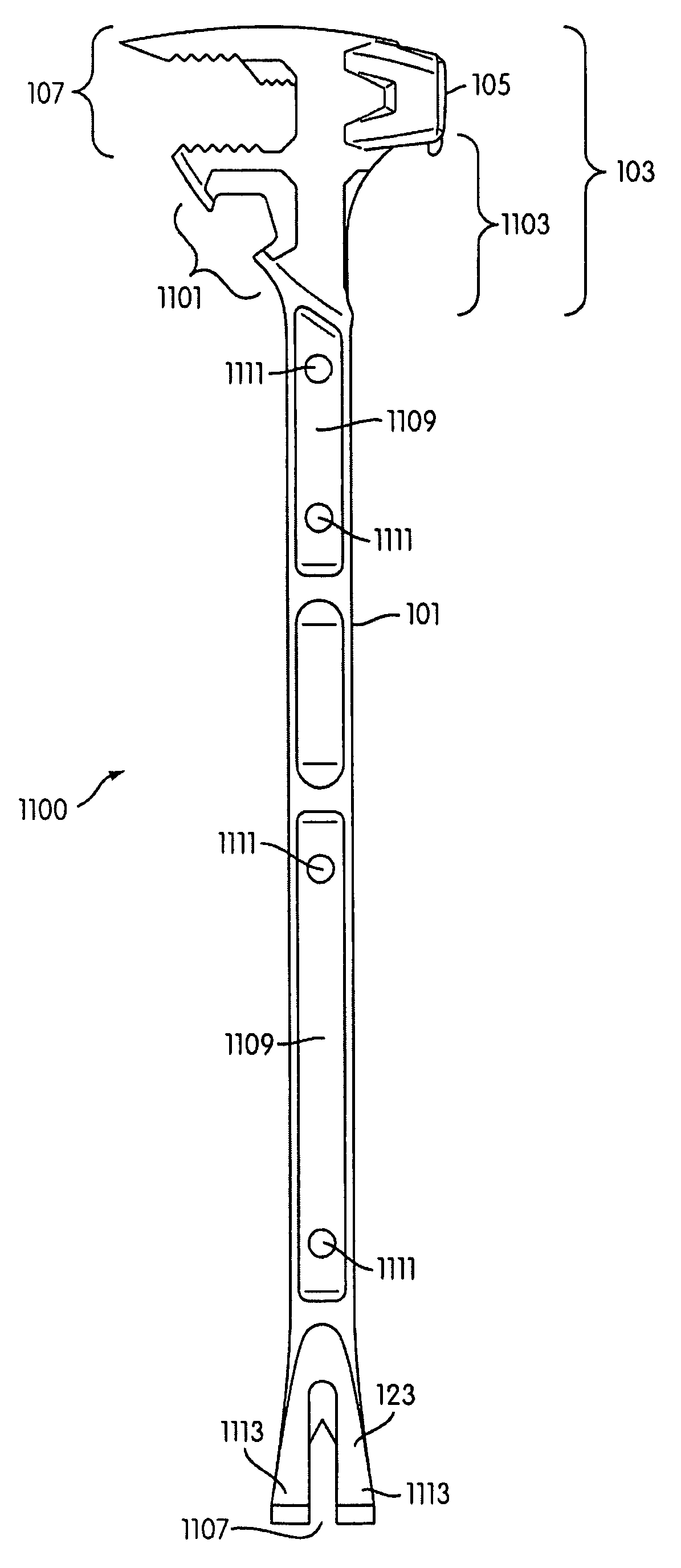

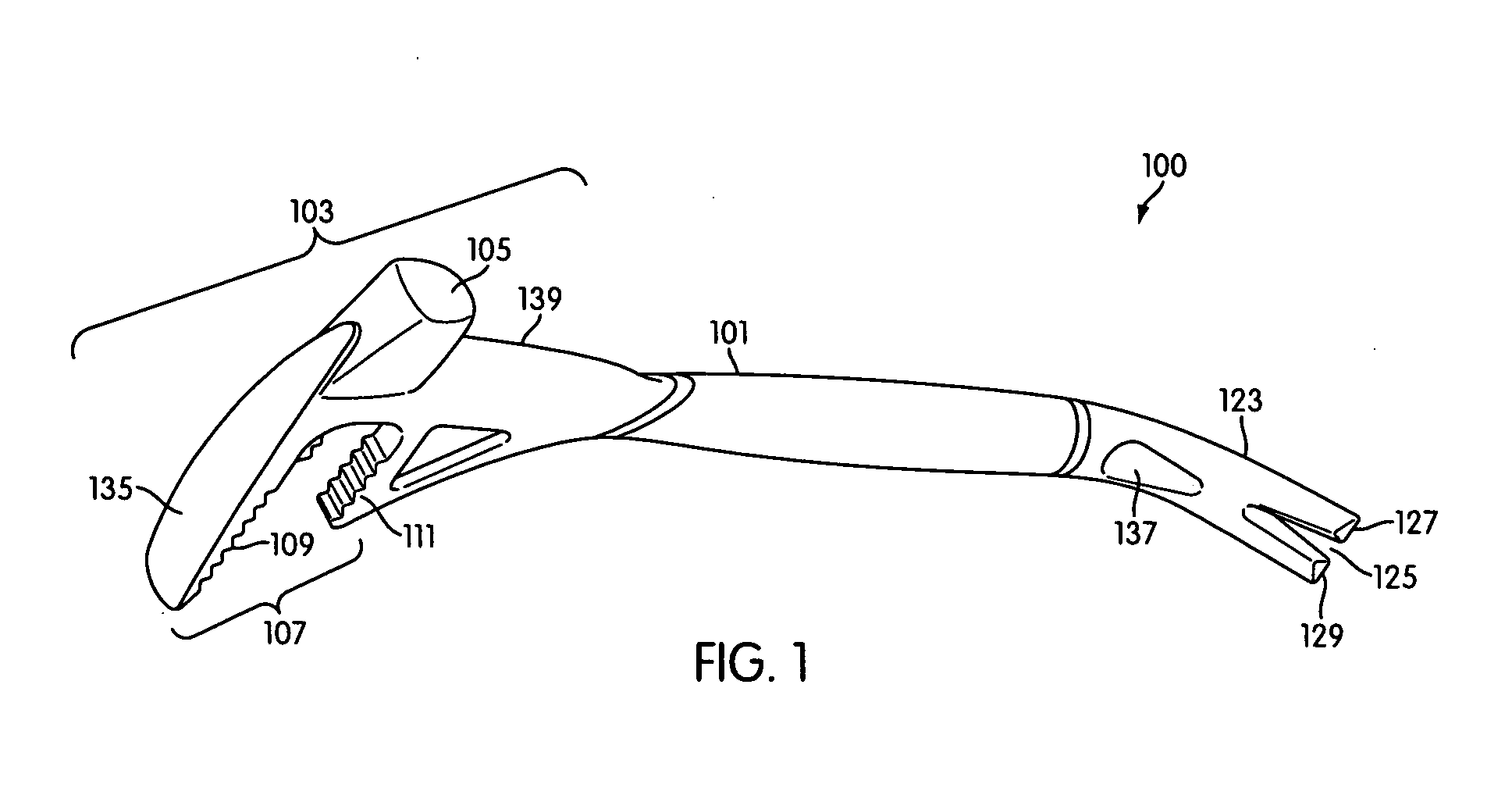

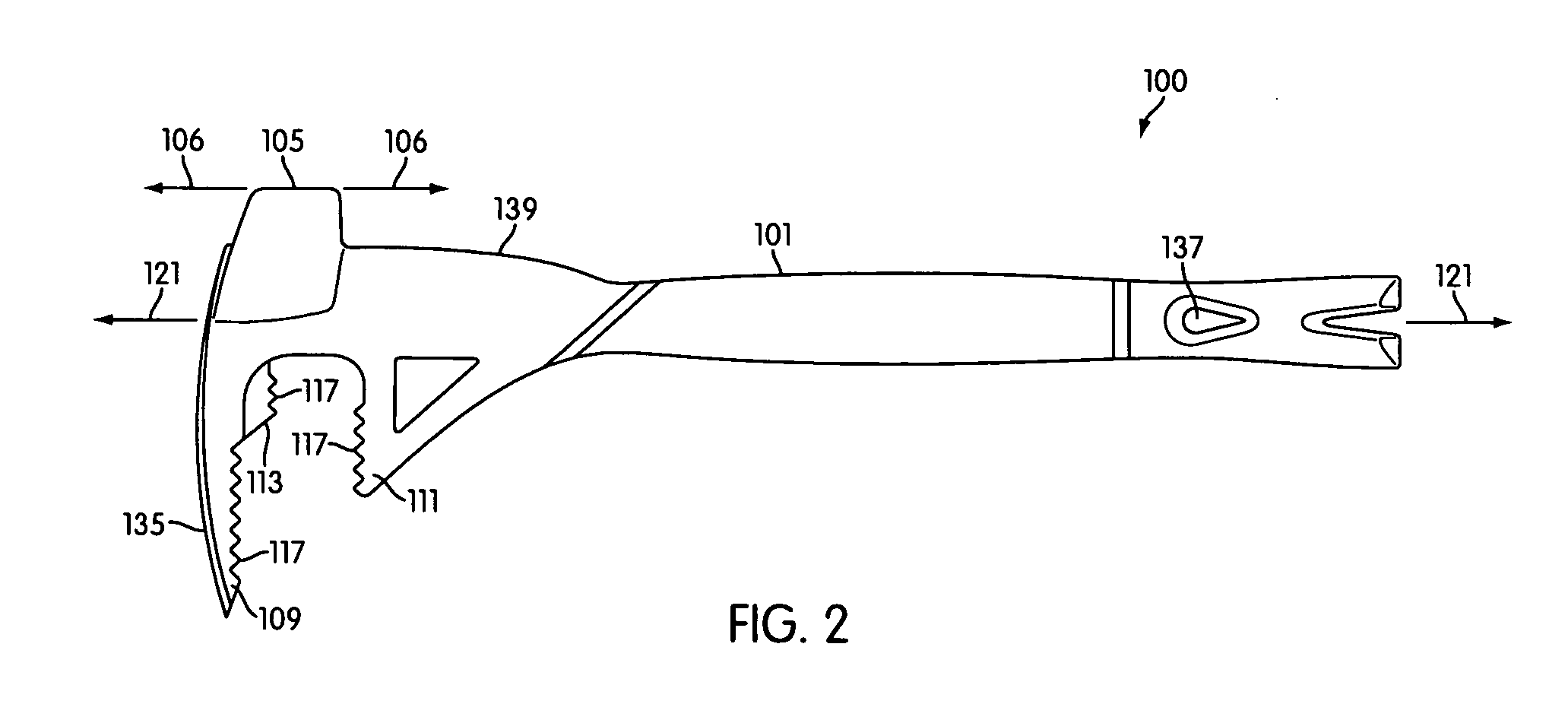

Demolition utility tool

The invention provides a demolition utility tool that can be used in many ways for the demolition of materials and / or for the manipulation of clamps valves, nuts, or other hardware. The tool includes a handle having a head at one end. The head has a longitudinal central plane that bisects the head, a strike contact face, and toothed, stepped grasping jaws that accommodate multiple sizes of material. The demolition tool may include a fixed wrench element and / or a spanner wrench element on the head. The demolition tool may also include a bent end pry bar at a second end of the handle that is offset 90 degrees from the longitudinal central plane of the tool head enabling full range of motion without interfering with other tool functions. The bent end pry bar may include a slot between located between its forked end for manipulating gas shut-off valves.

Owner:STANLEY WORKS THE

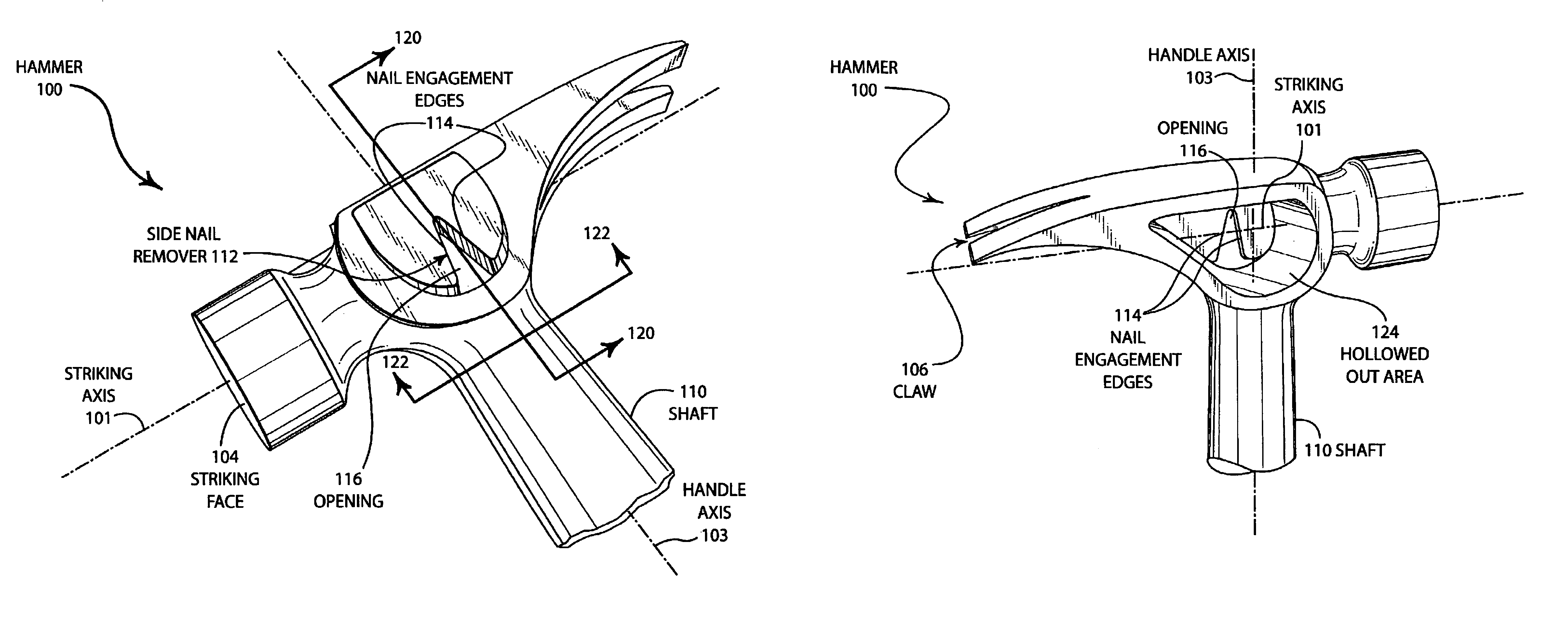

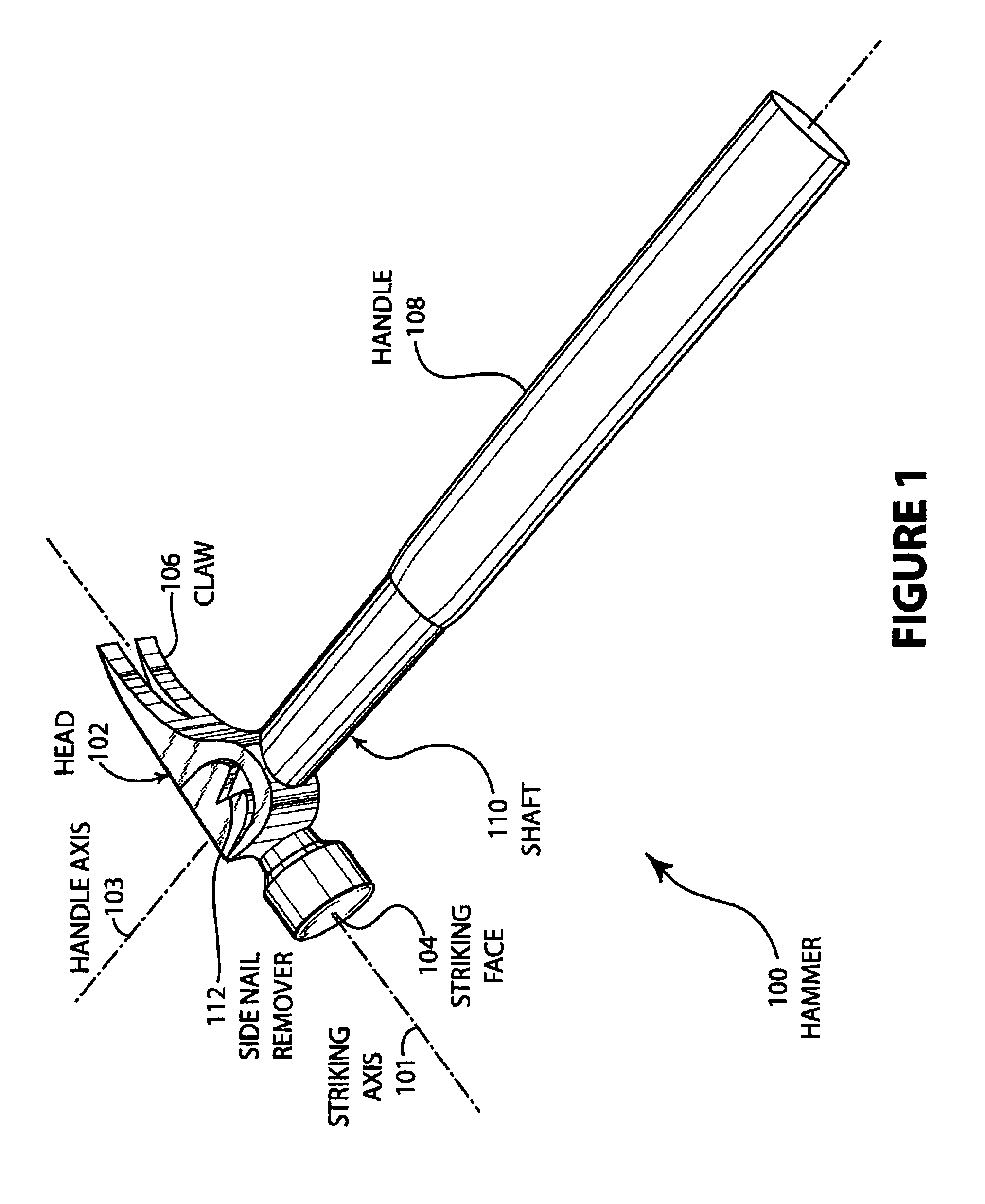

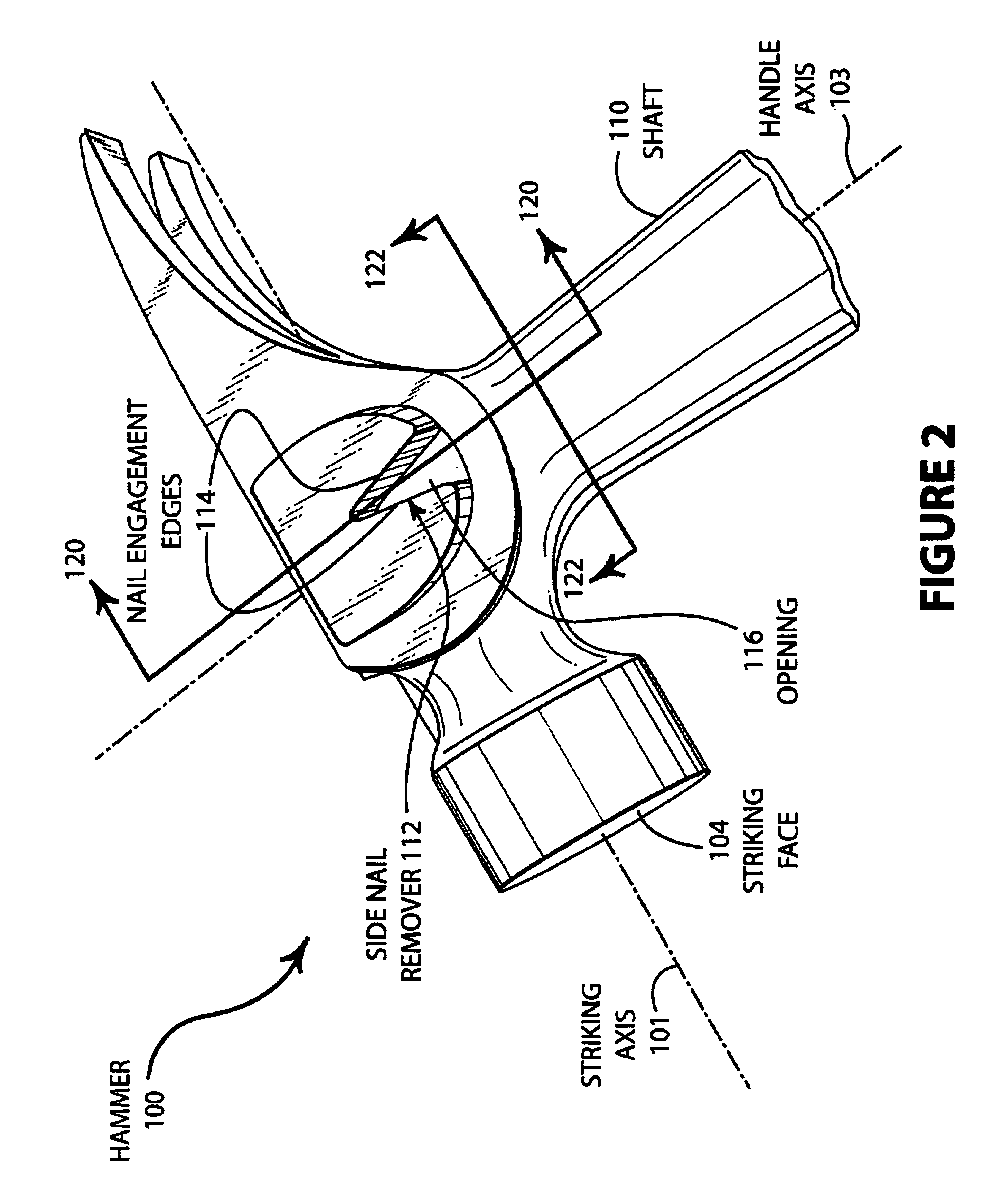

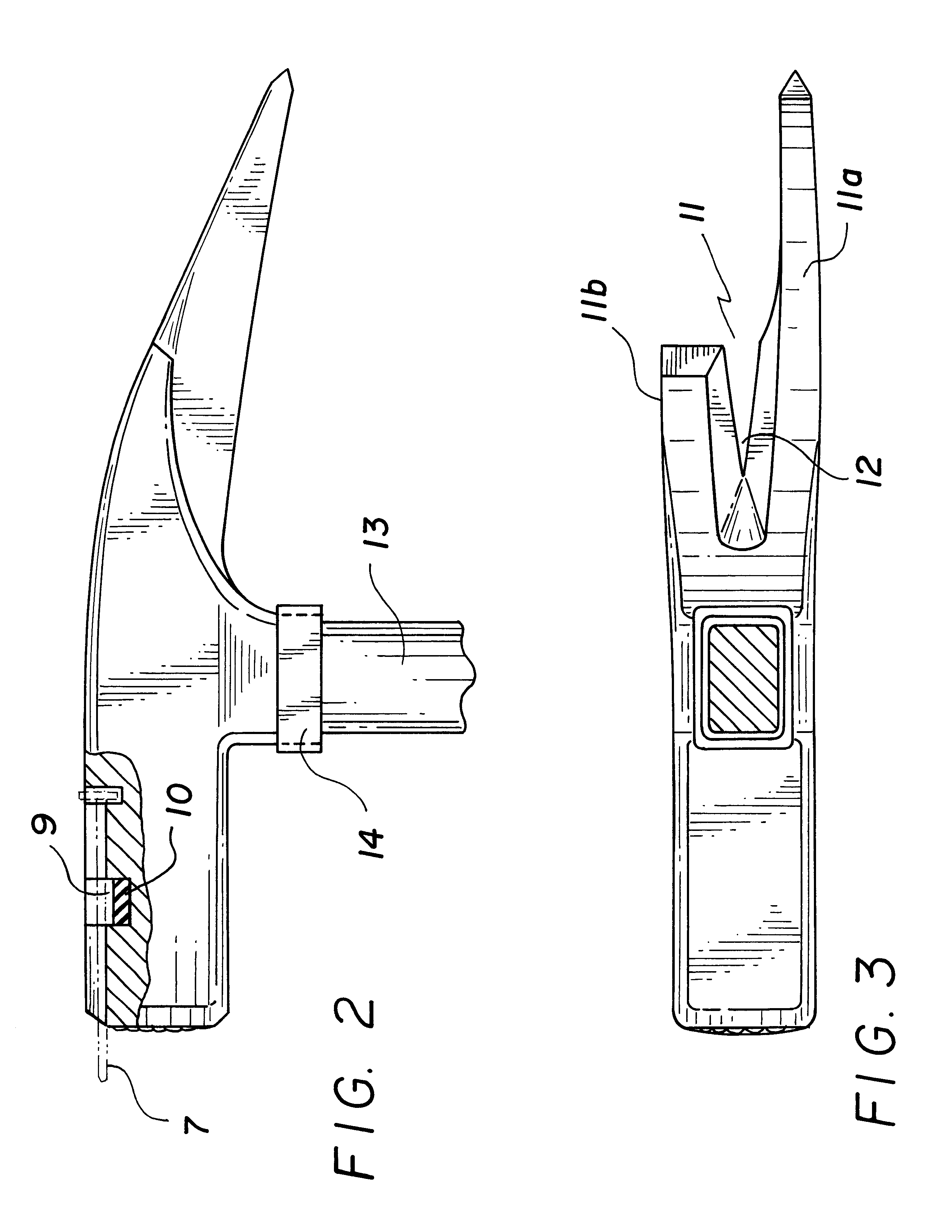

Side nail puller

ActiveUS6923432B1Simple and intuitive mannerSignificant complexityCrowbarsNail extractorsBiomedical engineeringFinger nail

A nail puller mounted on the side of the head of a hammer. The nail puller may be incorporated into a metal hammer head and consist of a groove mounted substantially in line with the handle of the hammer. The nail puller consists of a V-shaped opening suitable for engaging various sizes of nail heads or shanks. The nail puller is located on the side of the hammer, such that the nail is engaged when the hammer is laid nearly parallel to the work surface. The position of the nail puller gives the user nearly 180 degrees of rotation to remove the nail.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Pile driving control apparatus and pile driving system

ActiveUS20070074881A1Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl signal

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

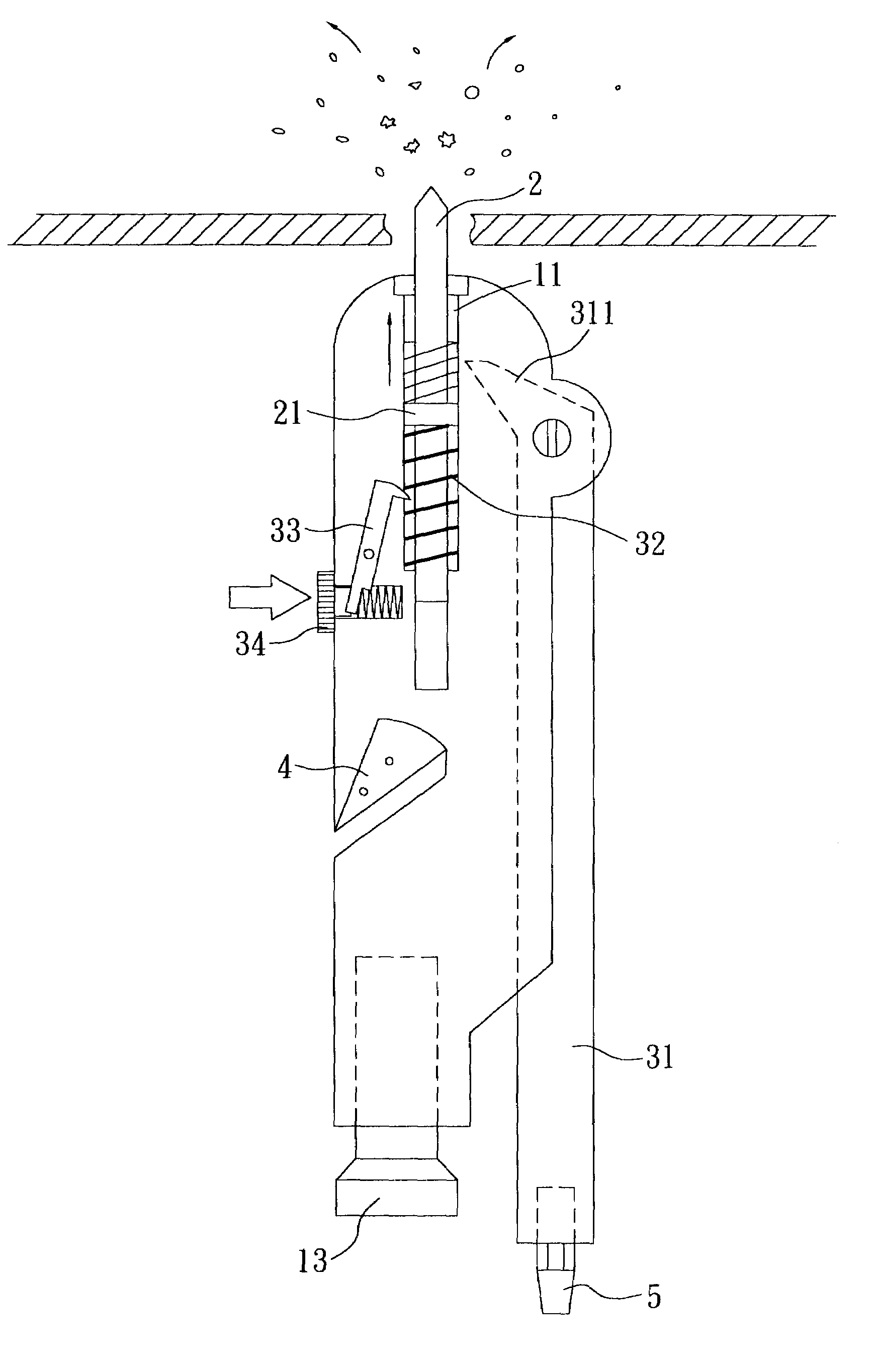

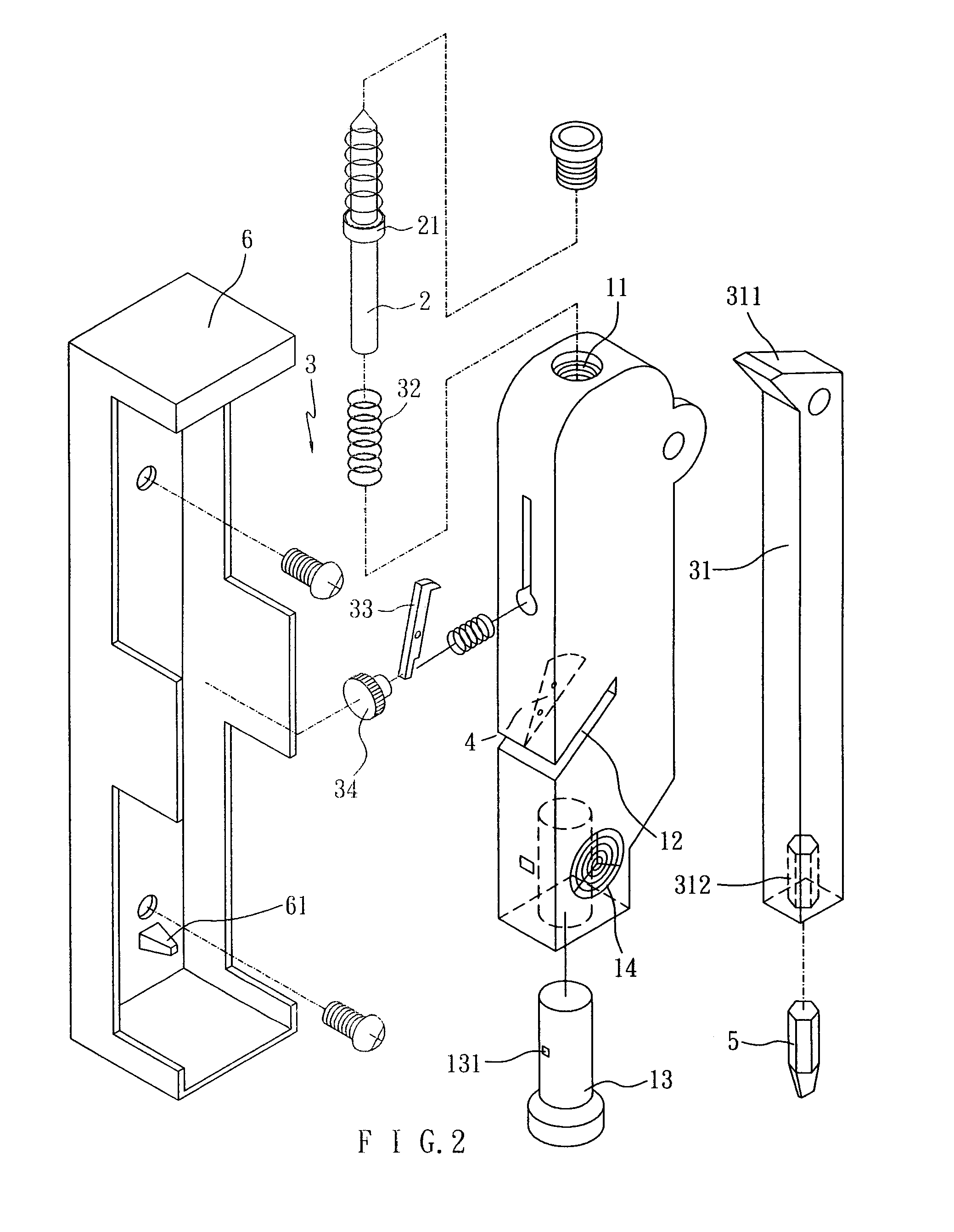

Windows-breaking emergency escape device

InactiveUS7028874B2Avoid injurySmall widthReciprocating drilling machinesConstructionsEngineeringPower apparatus

A windows-breaking emergency escape device including a main body, a hammer and a supplementary power apparatus, wherein the hammer and the supplementary power apparatus are installed on the main body. The front end of the hammer extrudes from the surface of the main body. The supplementary power apparatus will reserve enough power in advance to lessen an operating force and to release the reserved power to drive the hammer to break the car window when a car accident happened. Moreover, the main body of the device of the present invention includes a groove containing a cutter.

Owner:CLEAR DAWN

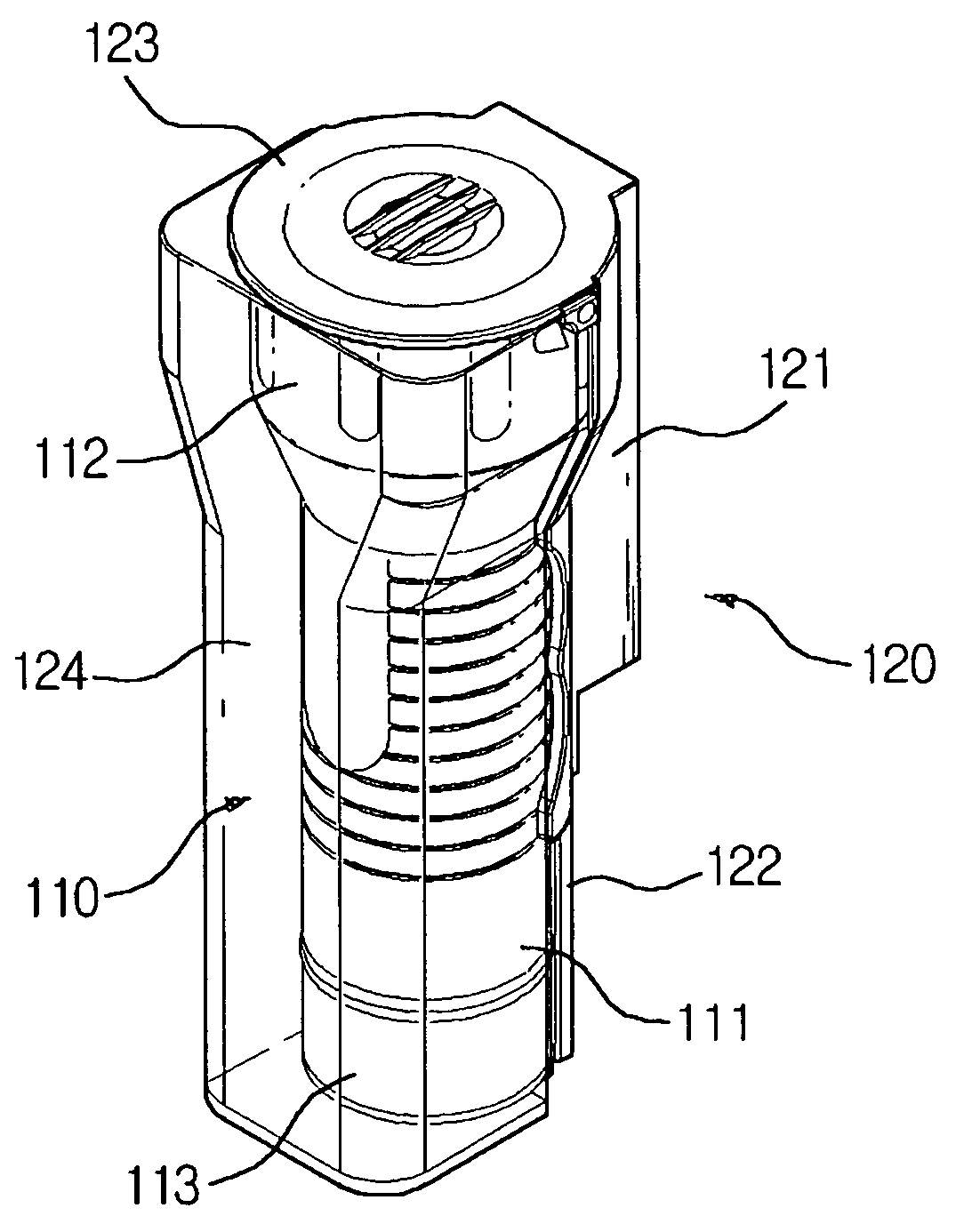

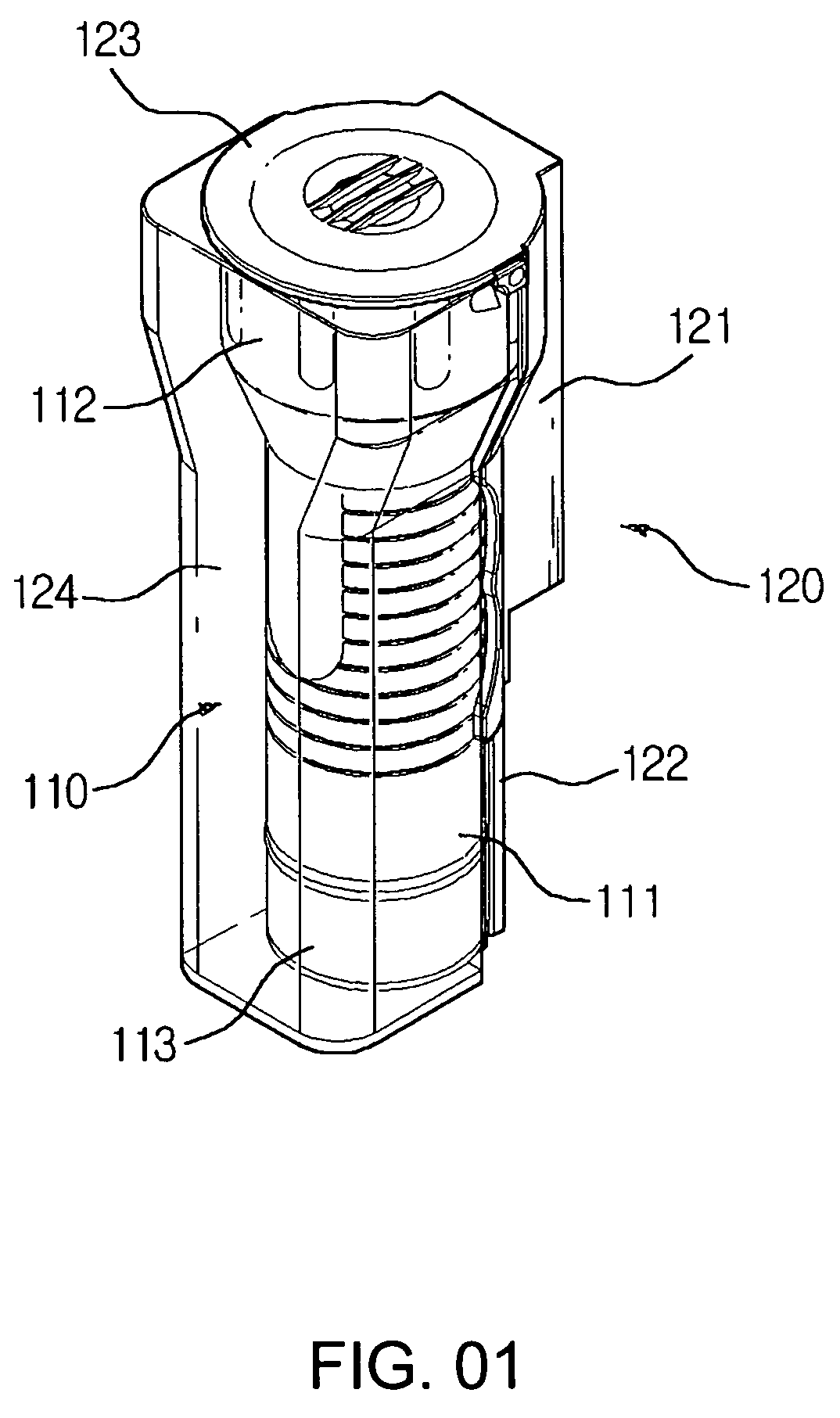

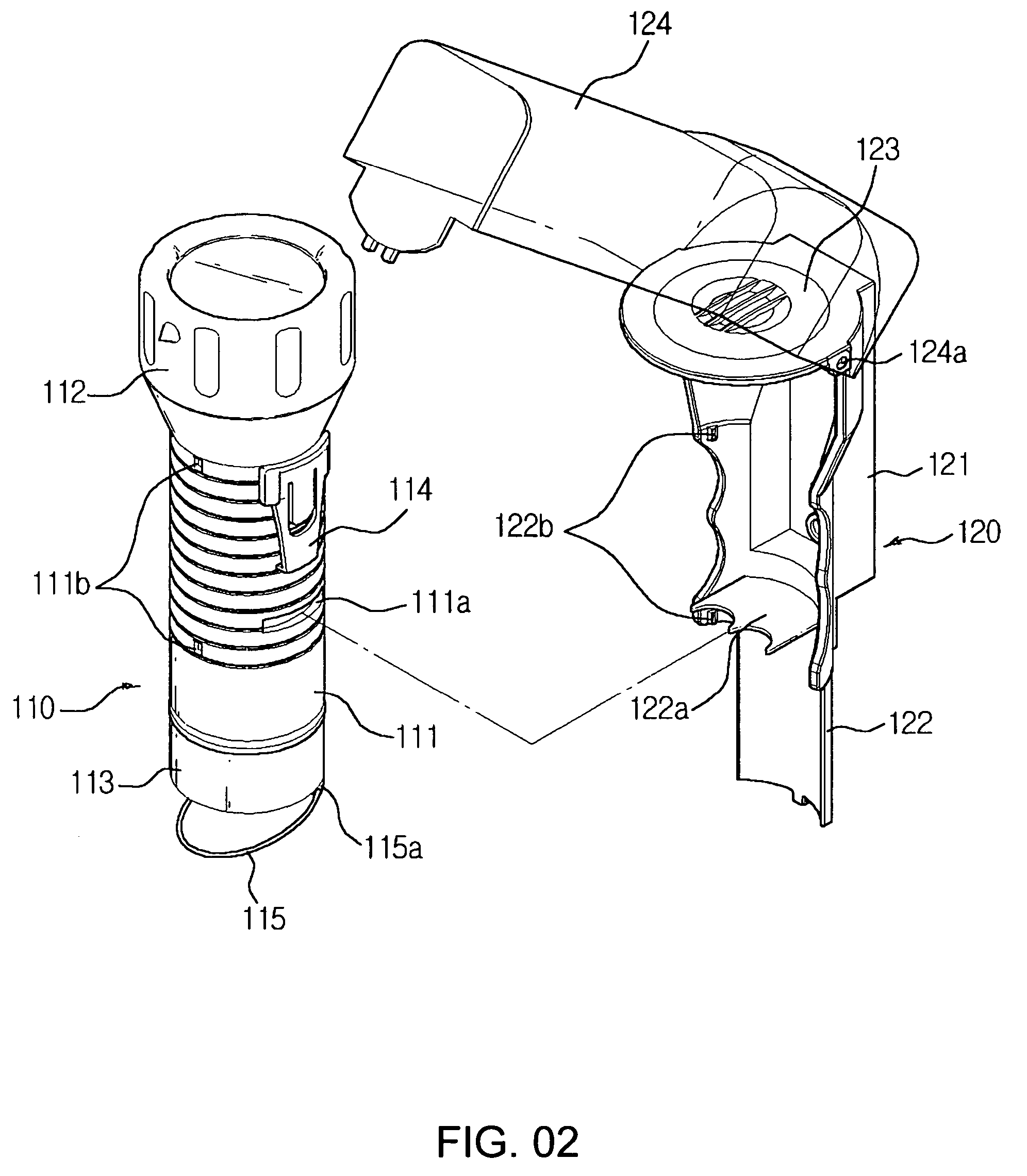

Emergency flashlight

InactiveUS7033042B2Easy to findCoupling device connectionsLighting support devicesEngineeringFlashlight

An emergency flashlight has a flashlight body, and a holder supporting the body. The body includes a receiving section that stores small batteries, an electric lighting section, and a lower covering section. The holder includes a holder body section fixed to a structure such as a wall, a support section extending from the holder body section, and a protecting section horizontally extending from the holder body section. A cap is pivotally supported by opposite ends of the support section through a hinge shaft. A transverse through slot is formed on the receiving section included in the flashlight body. A partition plate is placed on the support section of the holder in a location corresponding to the through slot, wherein the partition plate separates the battery circuit when the flashlight body is placed in the holder.

Owner:SAFELINE

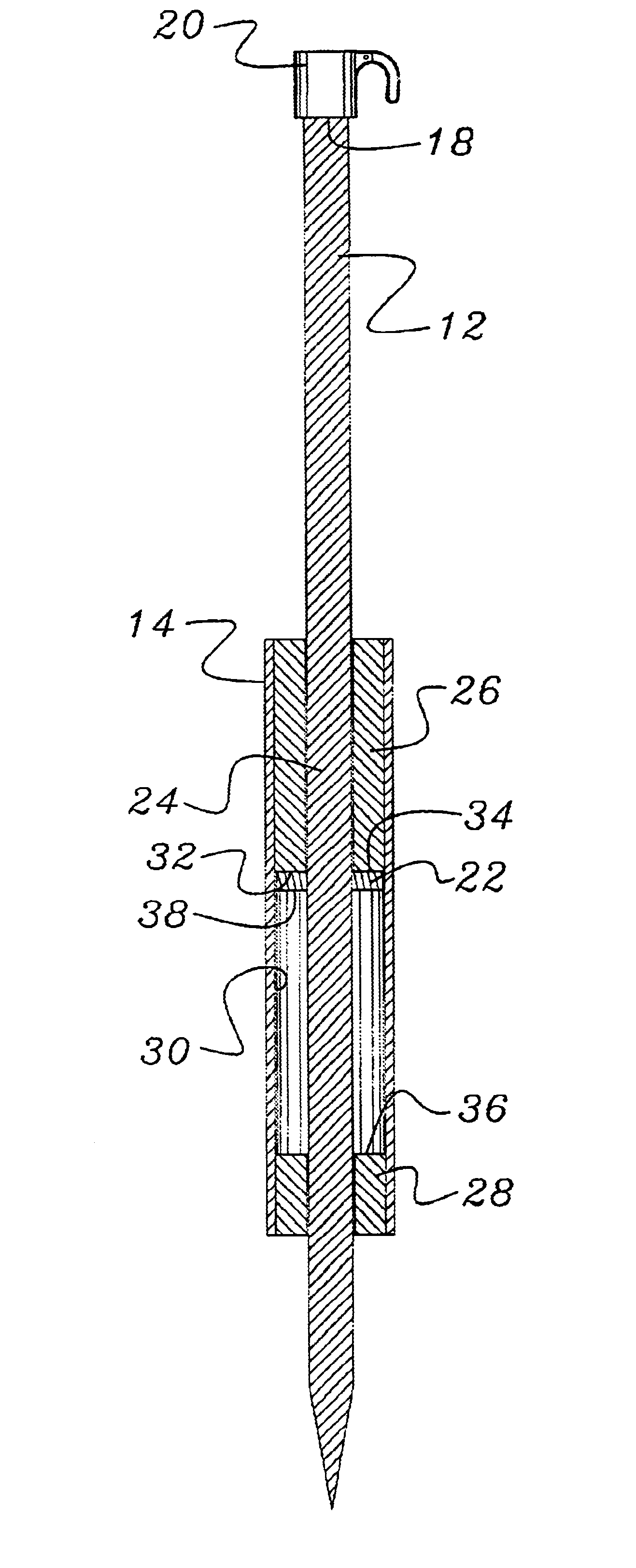

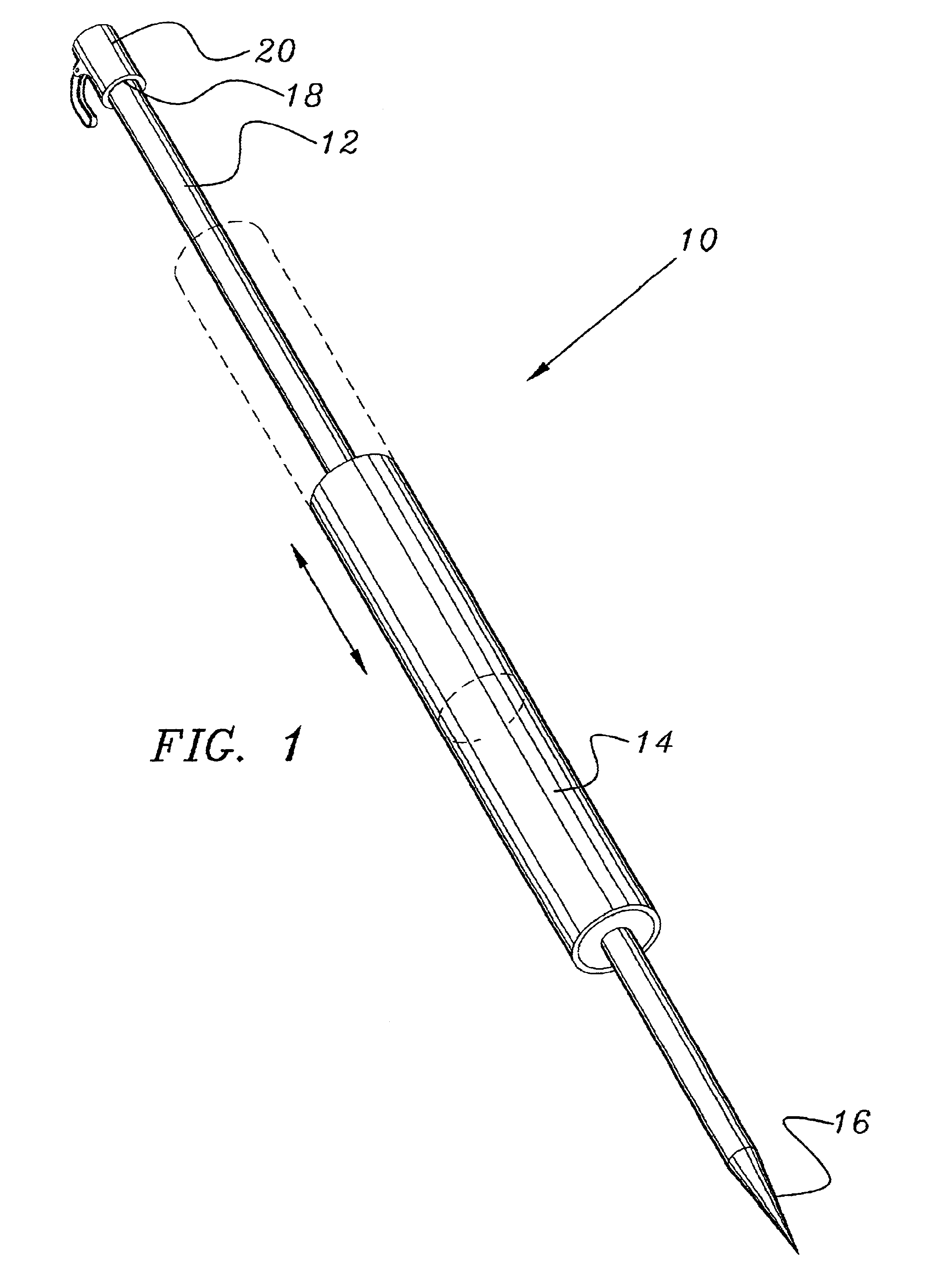

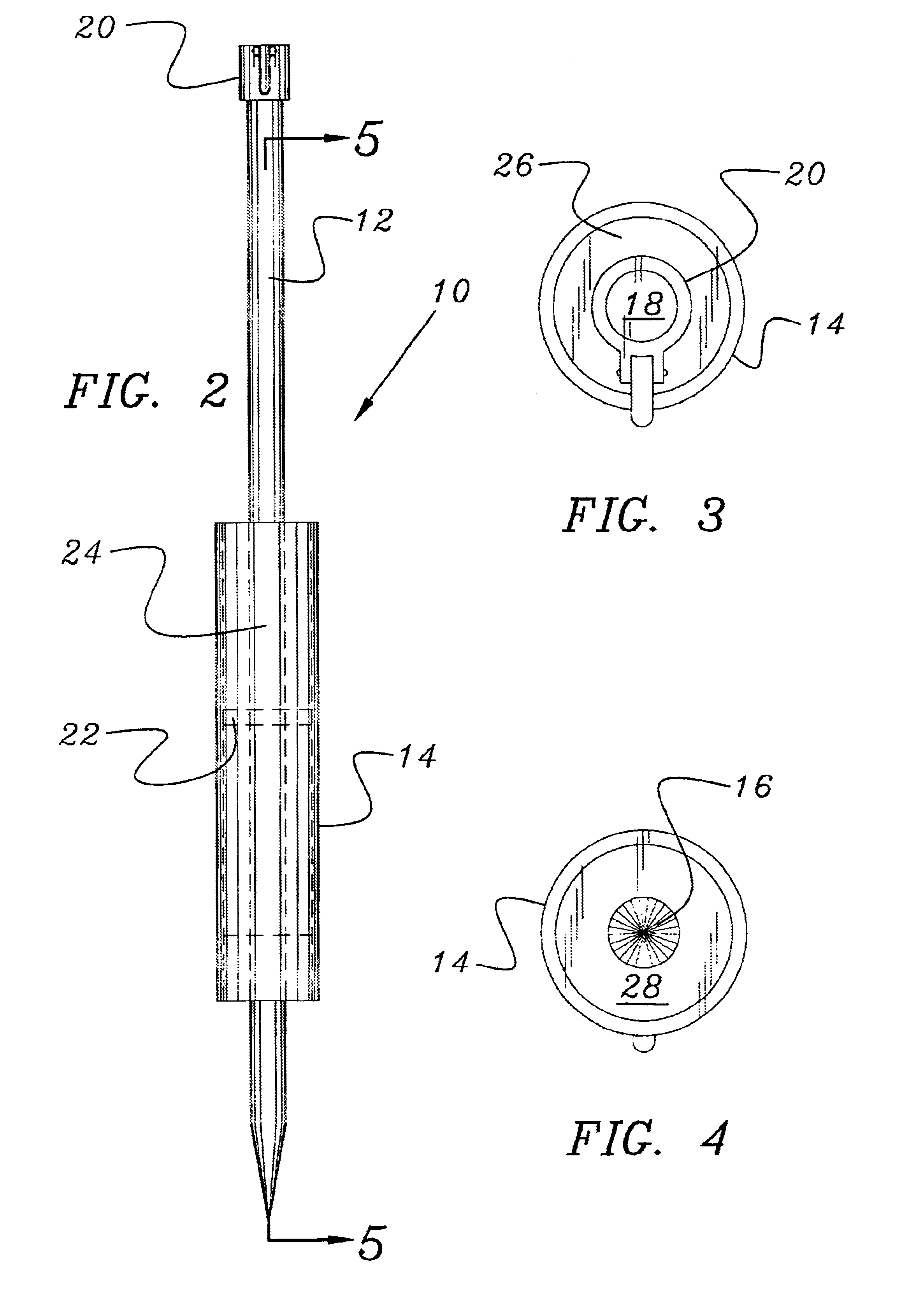

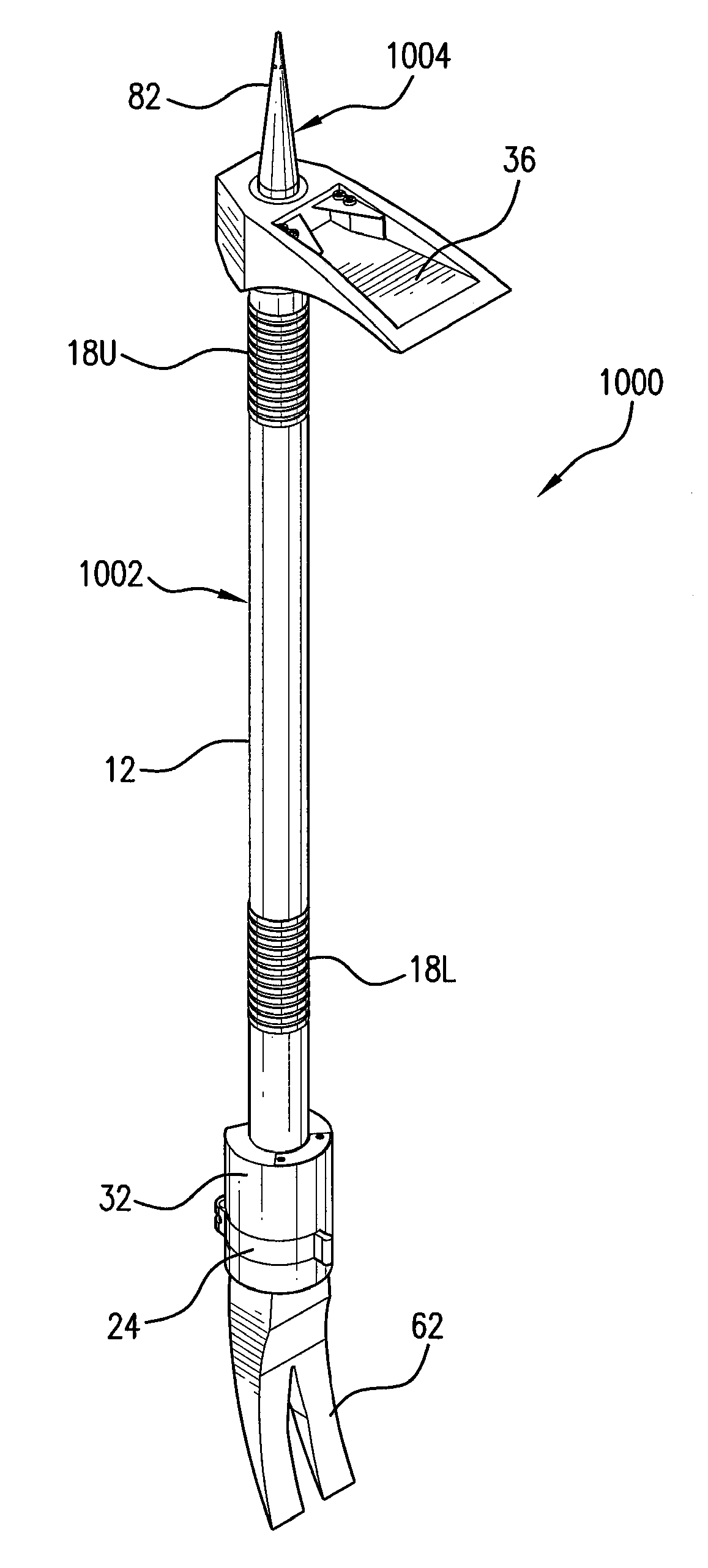

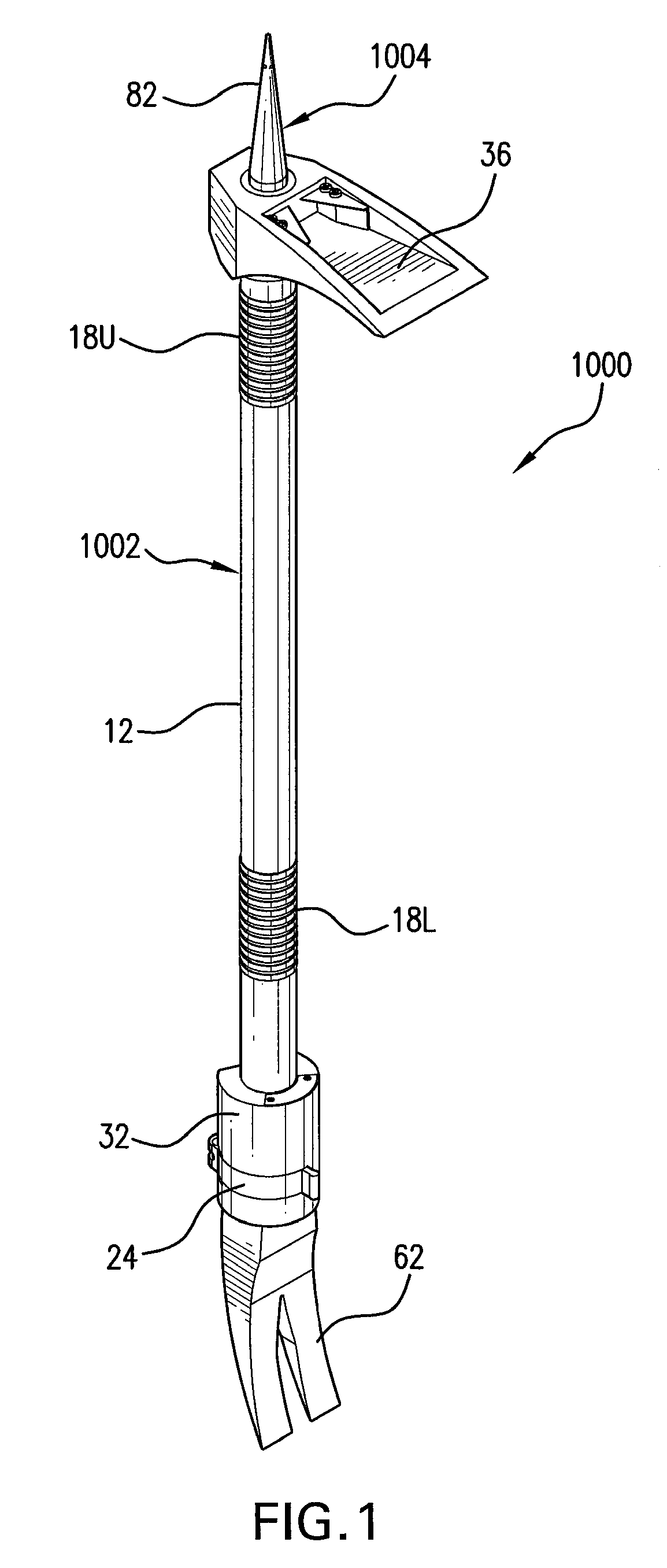

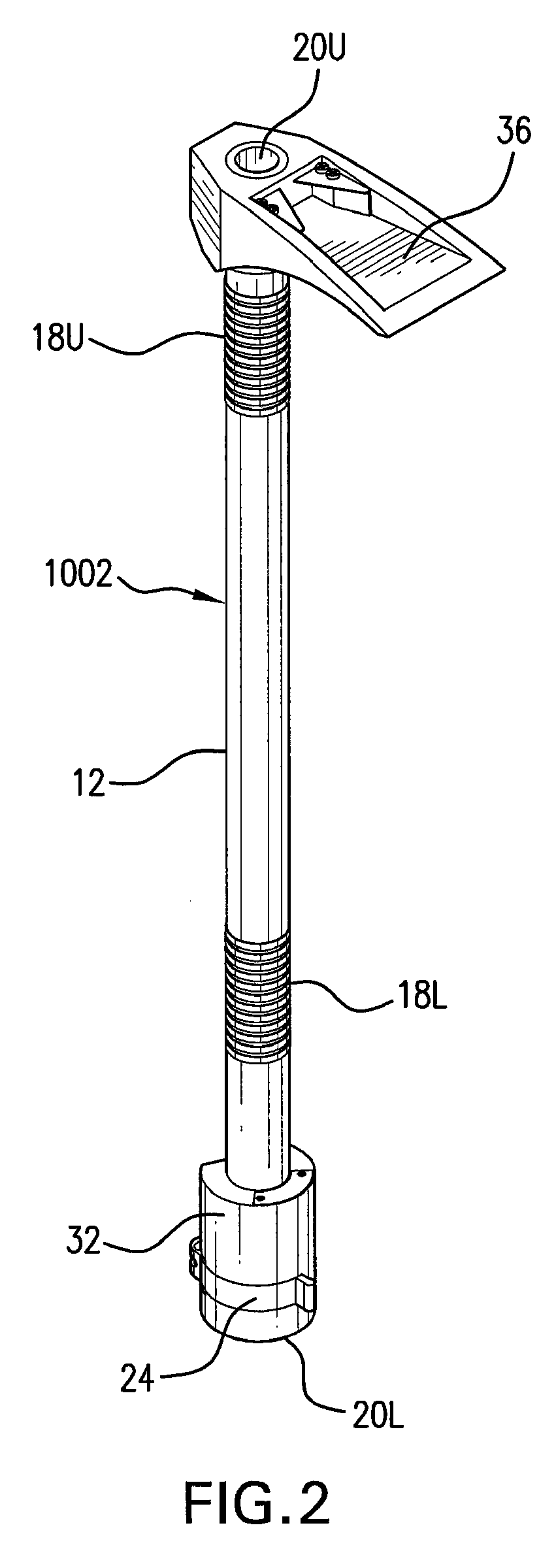

Hollow pole driver

InactiveUS6899187B1Avoid injuryNo pinching of the skin of the userEarth drilling toolsTents/canopiesLower limitMechanical engineering

A hollow pole has an open top end and a pointed bottom end; the open top end supports an additional pole. A ring member is permanently mounted about a mid-section of the hollow pole. A hammer sleeve having a length less than that of the hollow pole inserts over the hollow pole and around the ring member. A pair of weights are mounted within opposed ends of the hammer sleeve and surrounds the ring member. The ring member provides an upper and lower limit to the hammer sleeve. With the pointed bottom end of the hollow pole positioned on the ground, the hammer sleeve is pulled upward and slammed downward driving the pole into the ground. To remove the pole, the procedure is reversed whereby the hammer sleeve is slammed upwards away from the ground. The additional pole can support a plurality of different items, such as, for example, a beach umbrella or an attachment to a volley ball net.

Owner:TCB FLASH

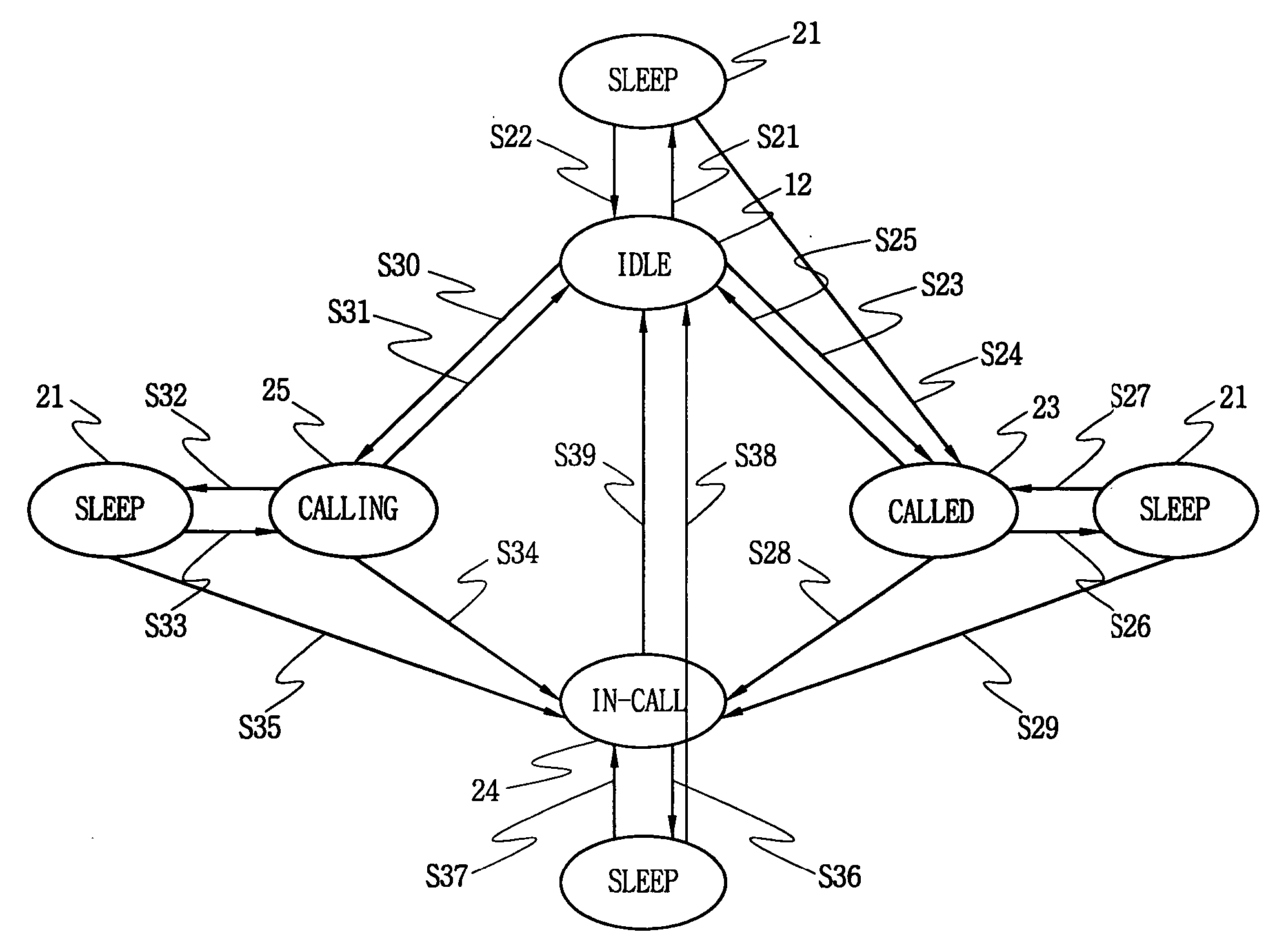

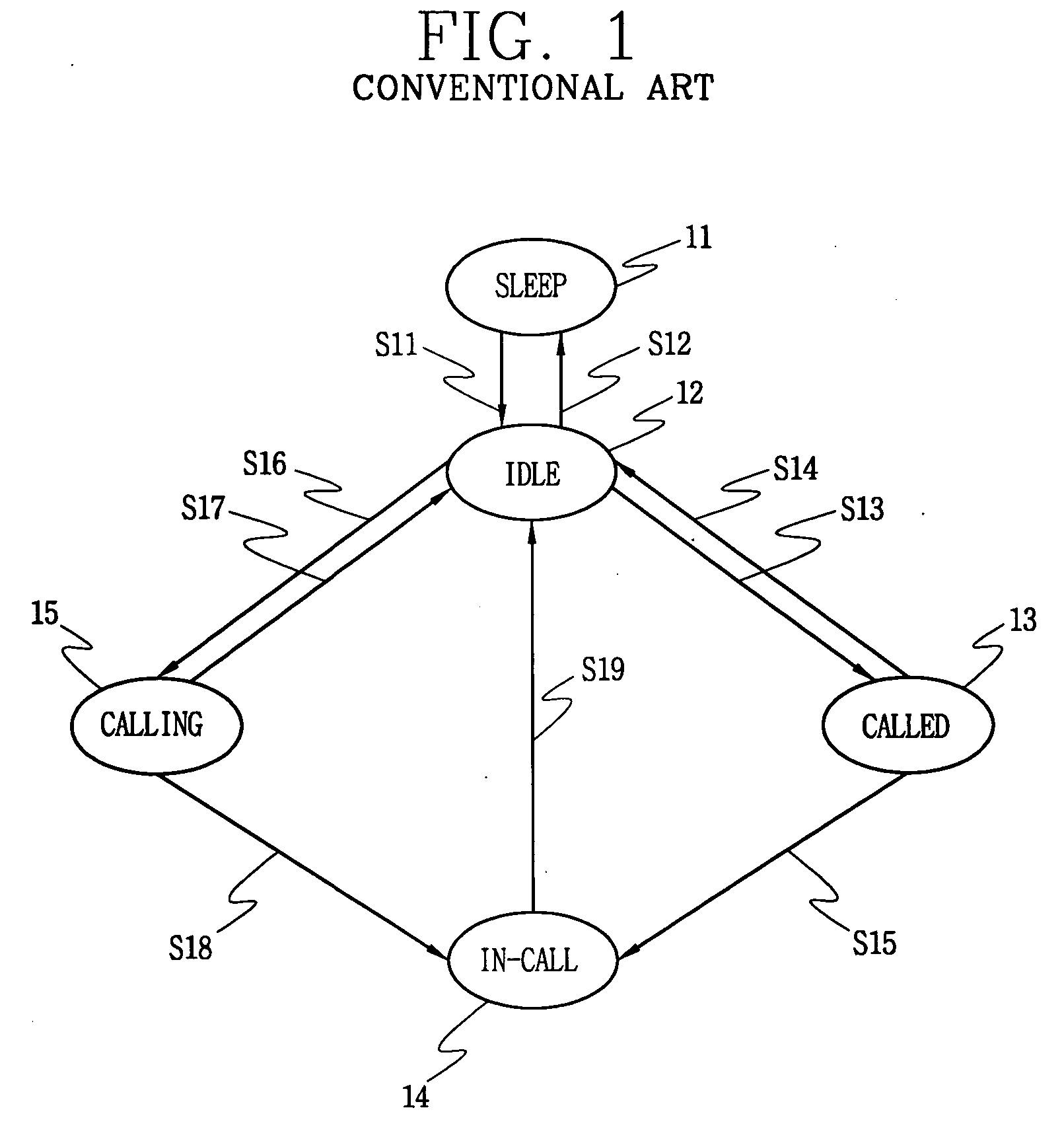

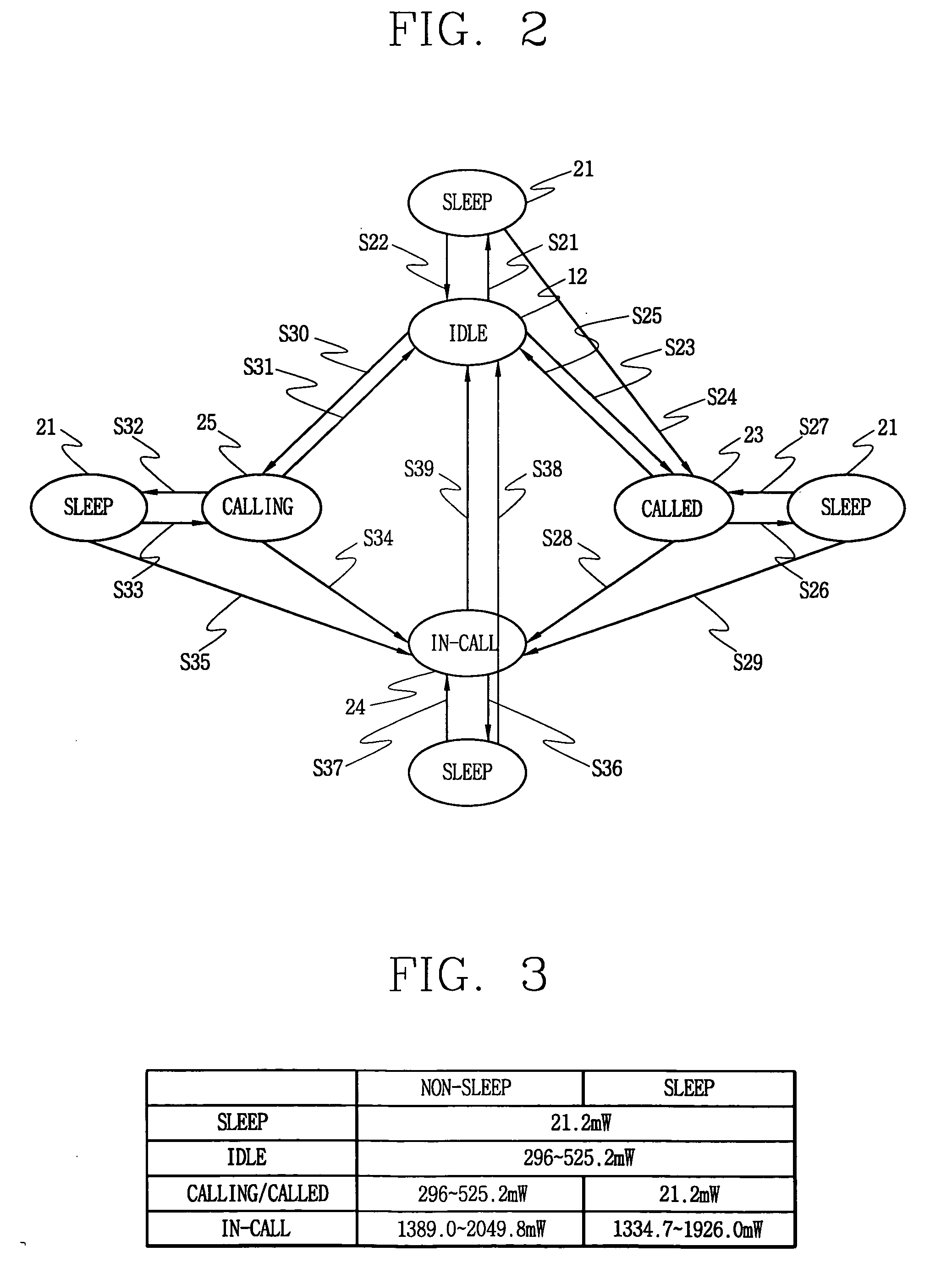

Power consumption control apparatus in personal digital assistant phone

ActiveUS20050210300A1Reduce power consumptionEnergy efficient ICTCurrent supply arrangementsUser inputEngineering

Owner:LG ELECTRONICS INC

Carpenter hammer

A hammerhead made of tool steel and having in combination a pair of asymmetric claws and a magnetic nail holder, the holder being in the form of a T-shaped notch and a permanent magnet having a very high field intensity as compared to the conventional permannet magnet.

Owner:KOTSCHNER JOSEF +1

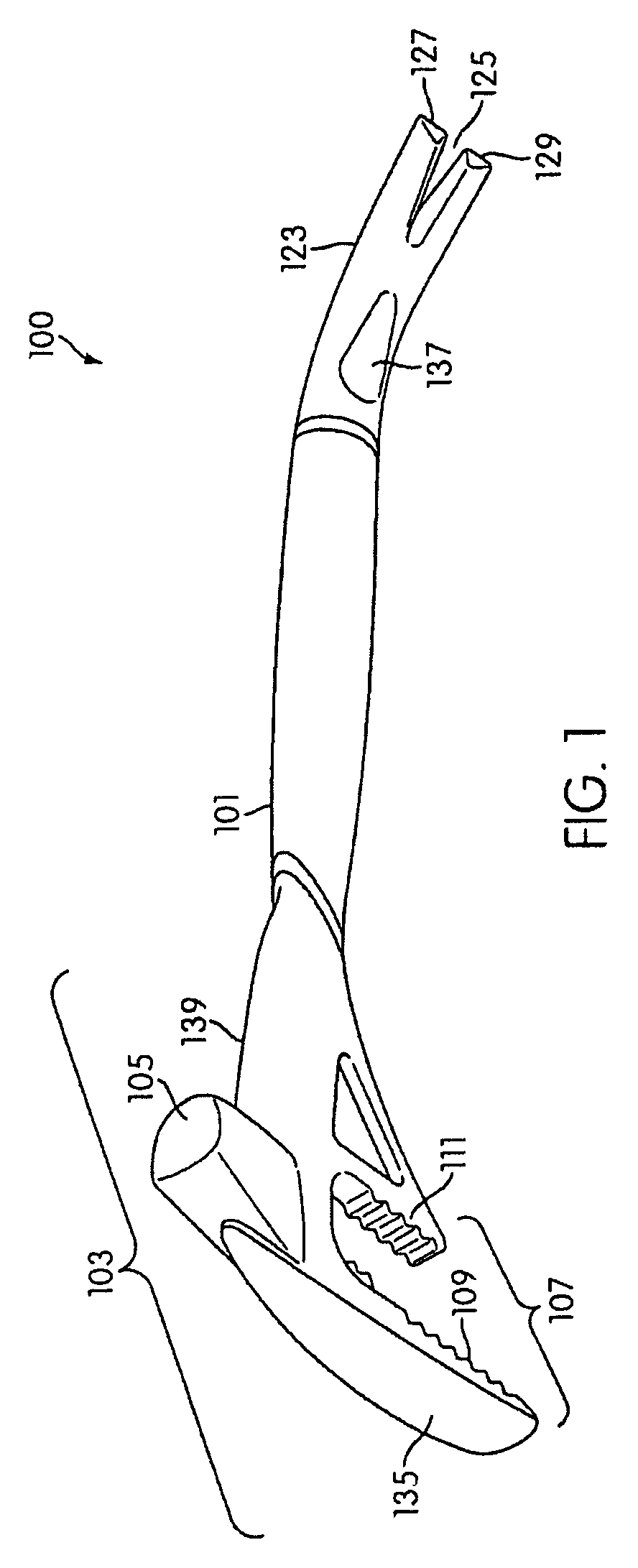

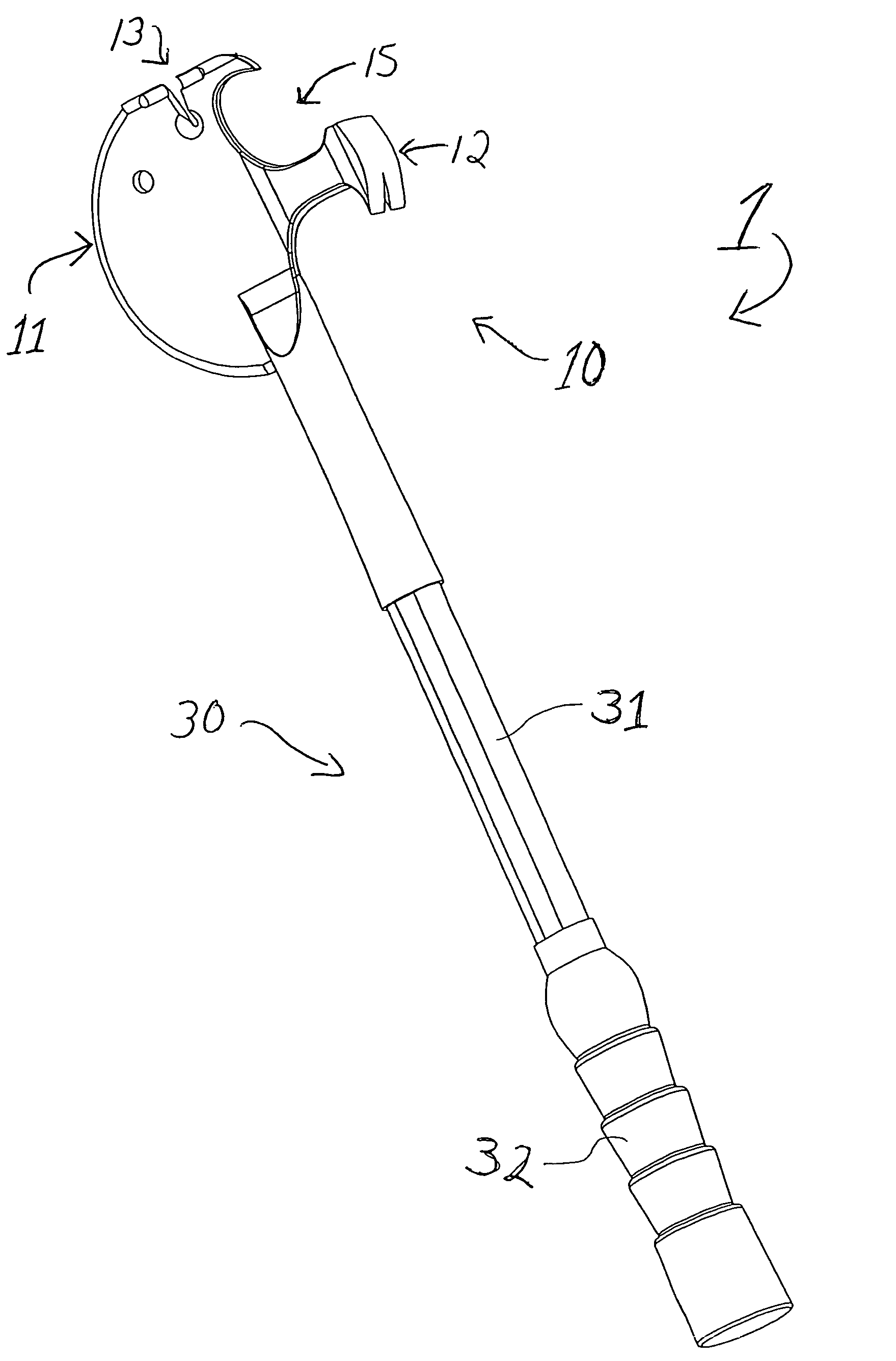

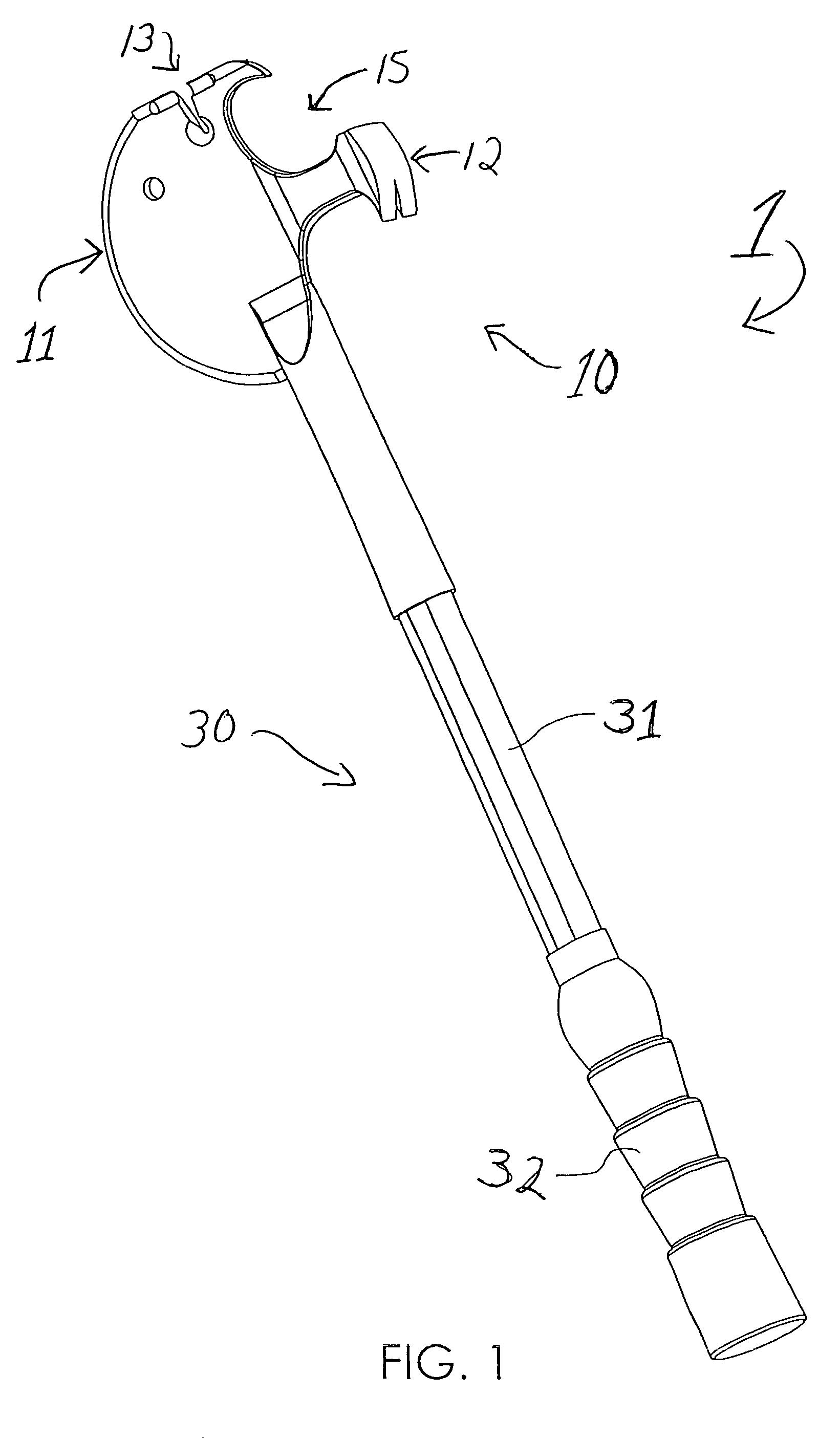

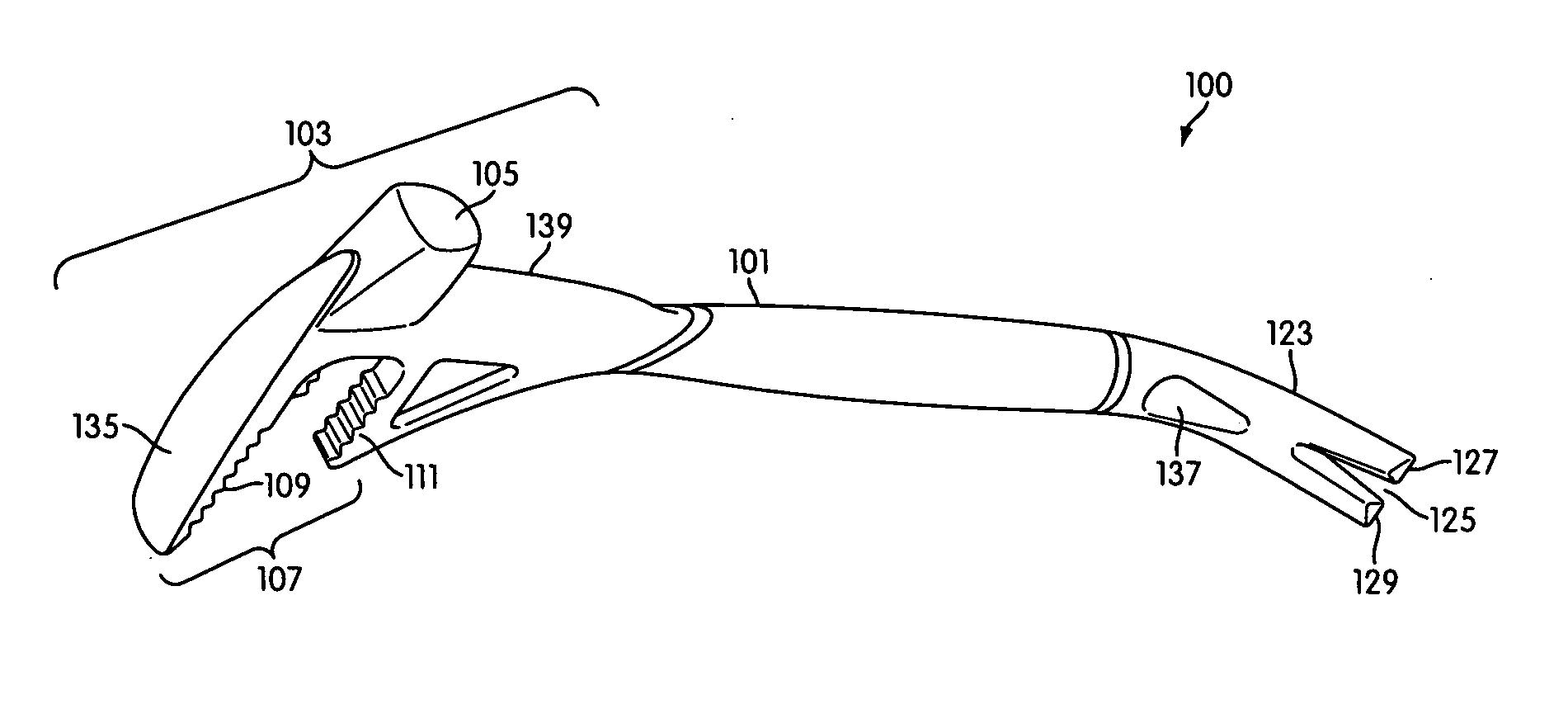

Multi-purpose tool

A multipurpose tool is designed to meet the particular needs of commercial truck drivers. Preferably, it has a unitary, single-piece head which includes a chopping tool, a hammering tool, and a prying-pivoting tool, and a nail and / or staple removal assembly. Preferably, there are no sharp edges that are capable of cutting a person's skin. There are multiple surfaces and edges that may be easily wedged underneath an object to pry, lift, or force the object either in a proximal direction toward the user or in a distal direction away from the user, or upwards off a floor or truck bed. It may perform a multitude of functions, such as removing objects embedded in tires, tightening tire chains, repairing pallets (with a hammer / nail remover), moving pallets, prying open frozen doors, chopping ice (for example, removing ice build-up on vehicle). The head of the tool is slightly tilted to facilitate use as a lever. Other users, such as ranchers or farmers, will find the tool useful for repairing wire fences, stretching wire, pulling staples, and performing other small repairs.

Owner:MIW ASSOC

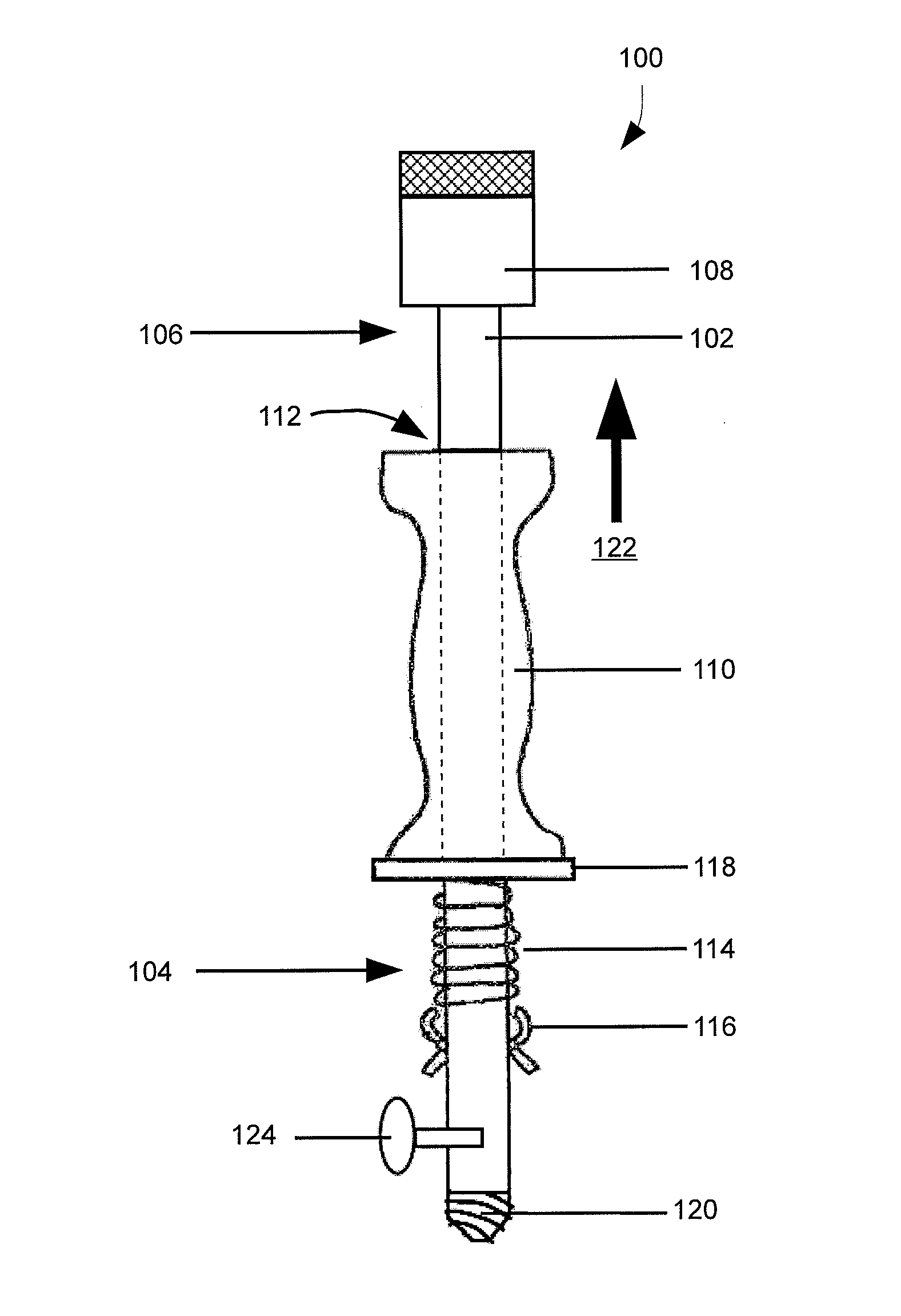

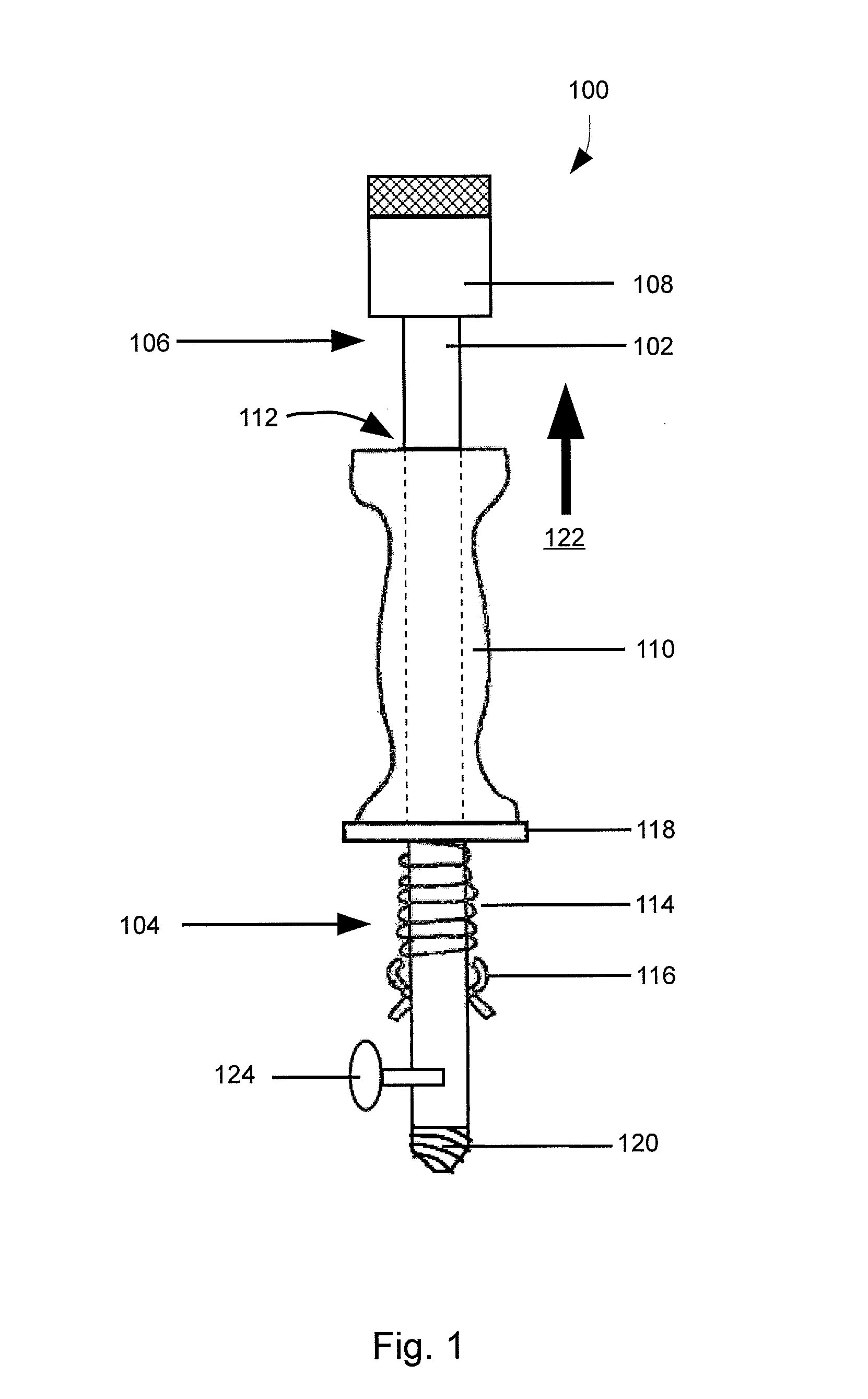

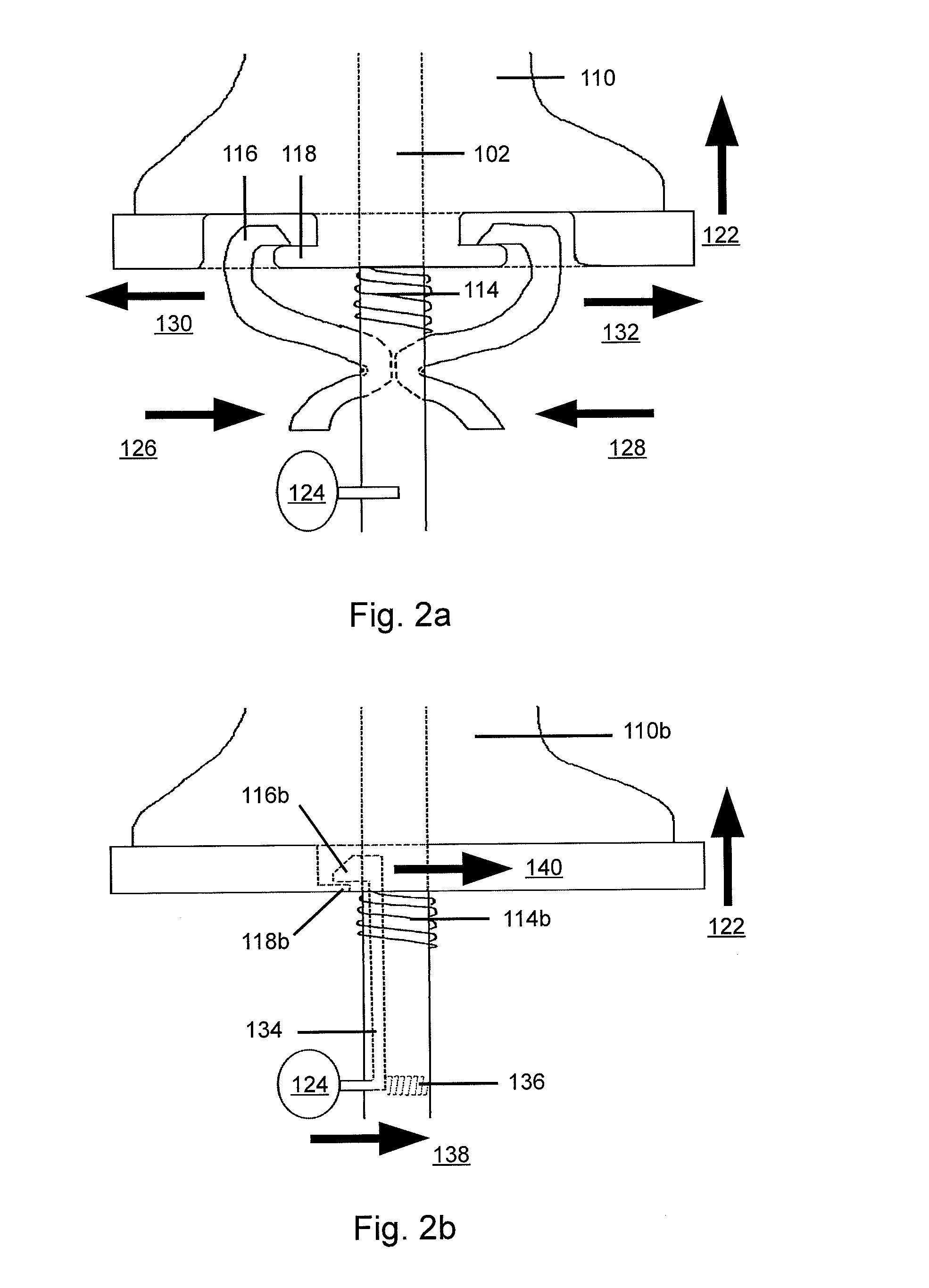

Solenoid positioning methodology

A method for calibrating a power tool having a roller, a driver and a solenoid. The solenoid has a body and a rod and is coupled to the roller so as to be capable of selectively advancing the roller toward the driver. The method includes: locating the roller onto a predetermined portion of the driver; moving the body of the solenoid in a first direction until the occurrence of a first predetermined condition, the first direction being in a direction that causes the roller to be driven toward the driver; after the occurrence of the first predetermined condition, moving the body of the solenoid in a second direction opposite the first direction until the occurrence of a second predetermined condition and thereafter securing the body of the solenoid to inhibit further movement of the body of the solenoid.

Owner:BLACK & DECKER INC

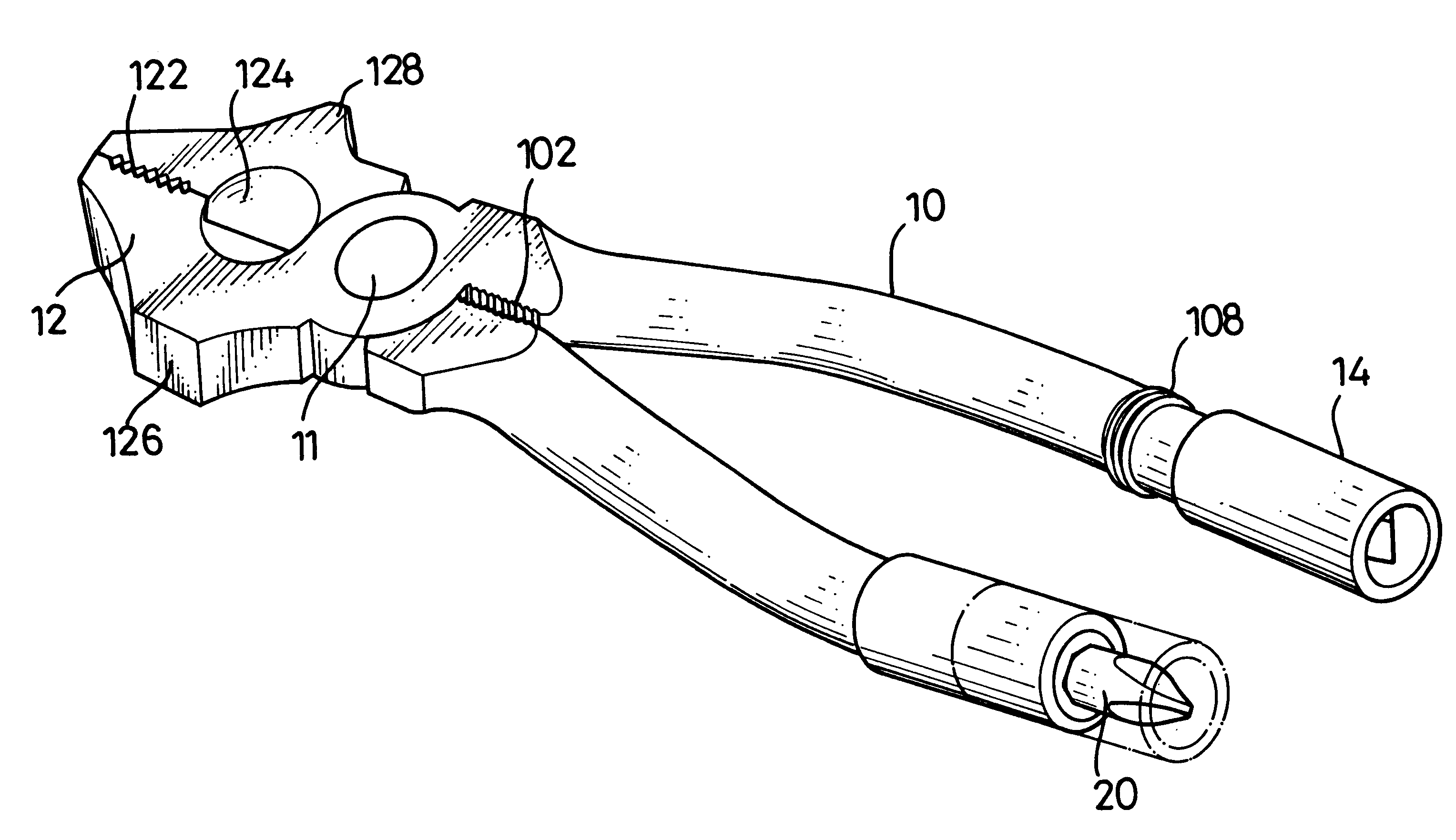

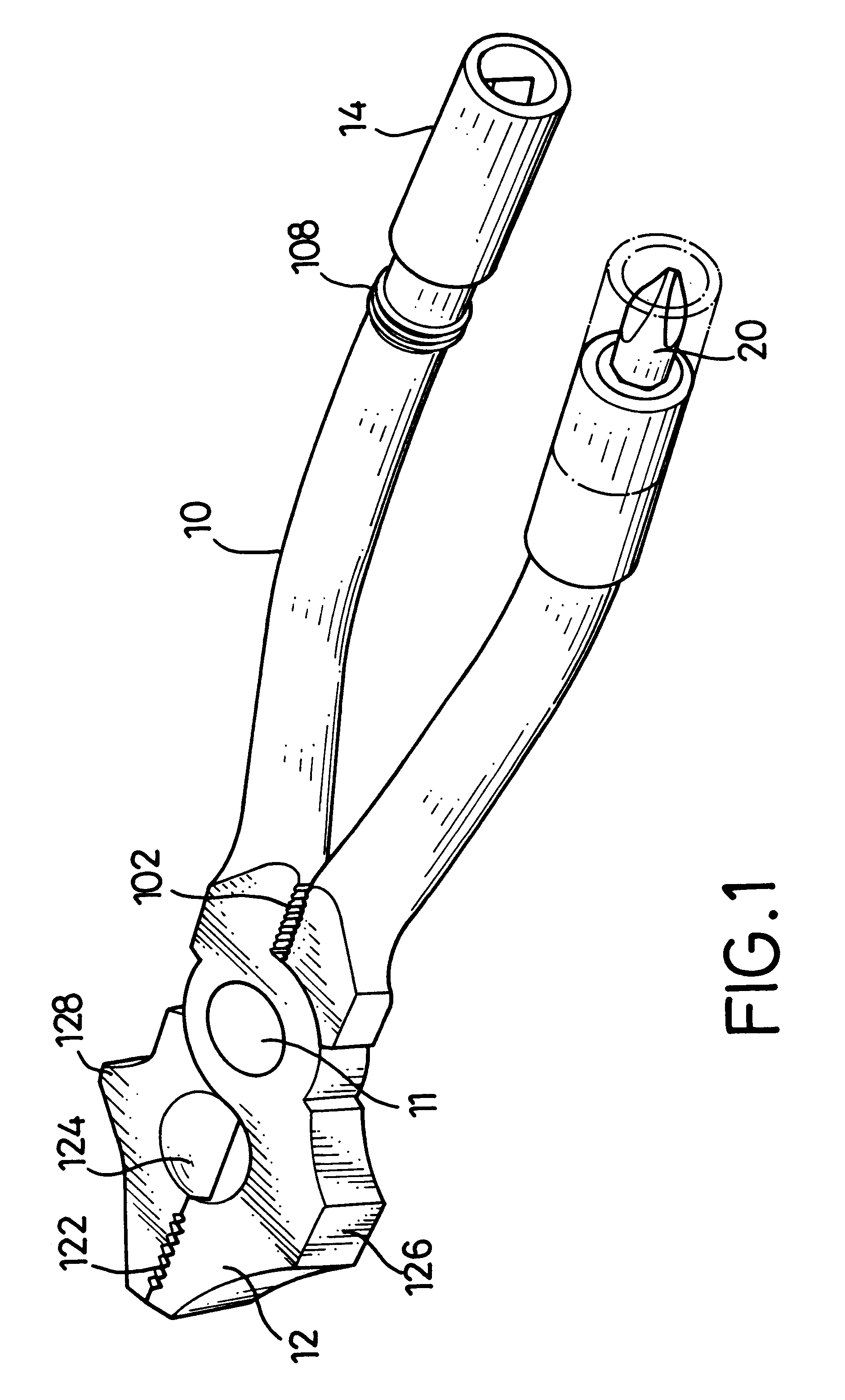

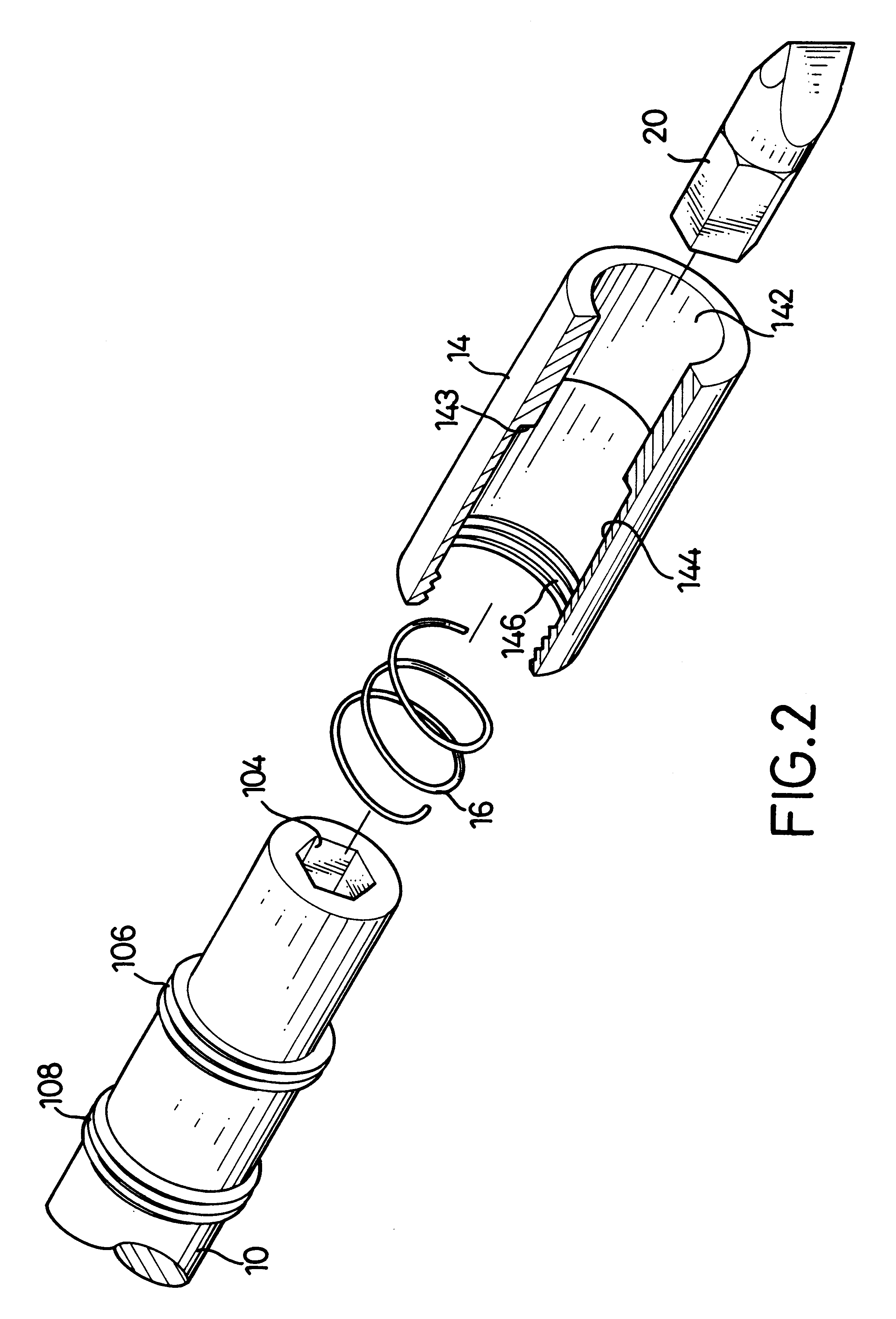

Pliers

A pair of pliers with multiple functions is disclosed. The pliers have a pair of shanks pivotally engaged with each other each having a jaw formed at one end thereof, a polygon hole defined in the other end to hold a tool head, a hammer formed on the outside of one of the jaws and a chisel formed on the other. In addition, teeth and a cutting edge are formed on the face of the corresponding jaws or shanks. Consequently, the pair of pliers can be used as a hammer, a chisel or a screwdriver. This can improve the flexibility of the pair of pliers.

Owner:YEH SHIH YUAN

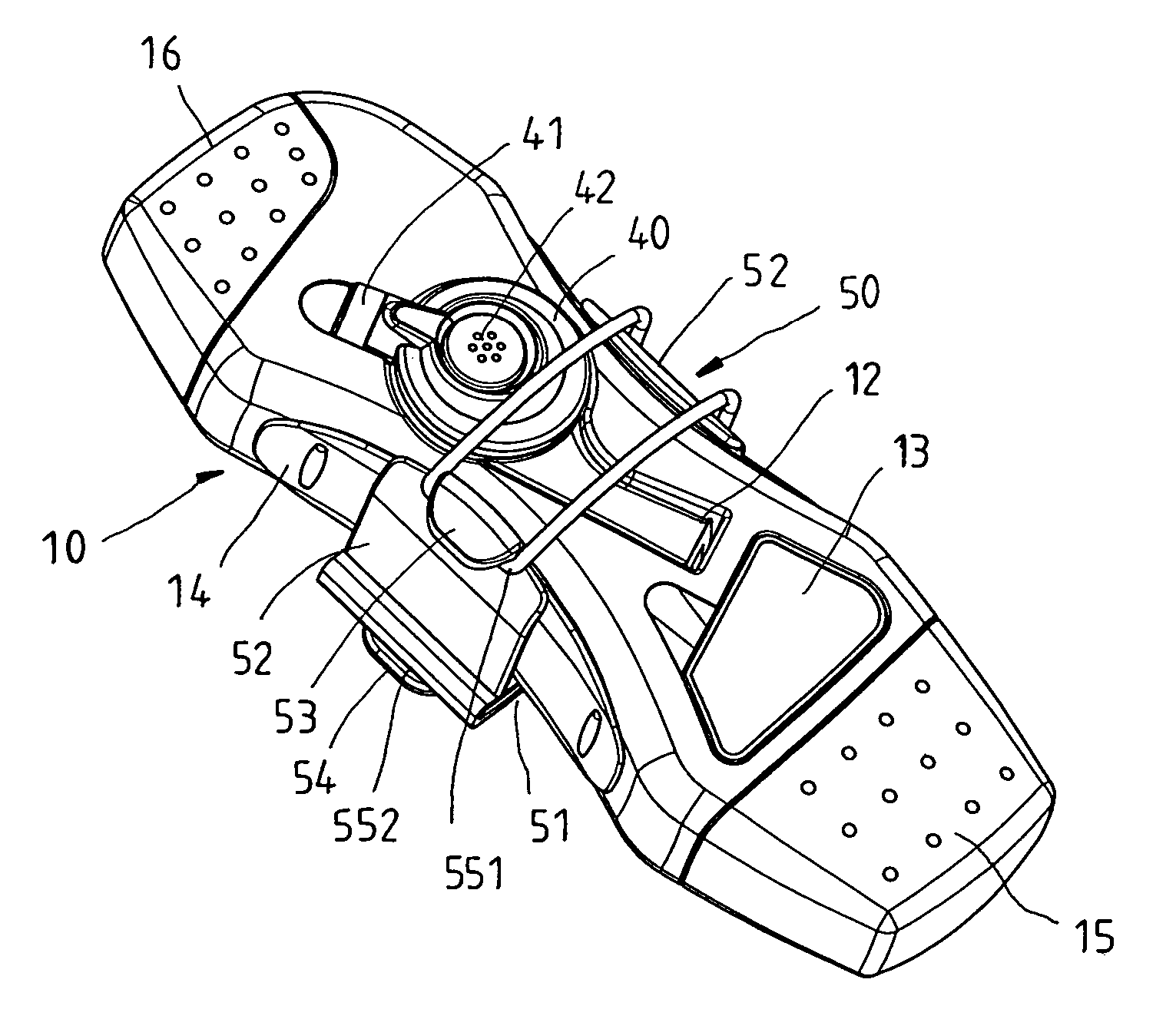

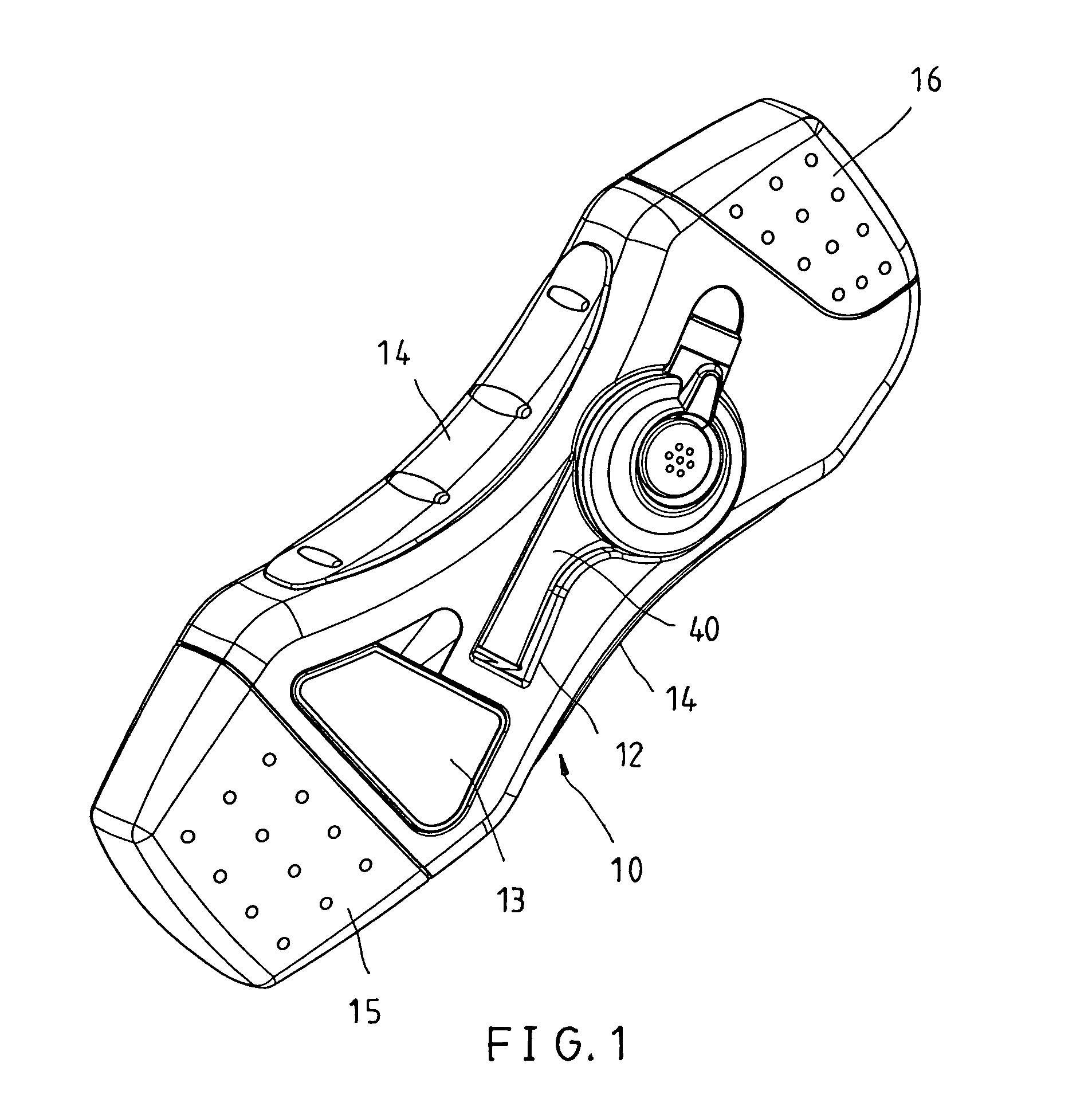

Emergency escape tool for vehicle

An emergency escape tool for helping people escaping from a vehicle while emergency has a member on which has a hole and a recess. The main member is provided with a hammer and a cutting device respectively at opposite ends thereof and two covers detachably mounted on the main member to shield the hammer and the cutting device. A whistle is received in the hole of the main member on which has a light emitting device. A clip and a holder are mounted on the main member to fasten the main member on a seat belt of the vehicle.

Owner:WANG LO PIN

Striking head-interchangeable hammer with a stress-distributable fastener

A striking head-interchangeable hammer includes a handle, a head body connected securely to the handle and formed with a through-hole and upper and lower bores, a striking body having a connecting portion that is received fittingly in the lower bore, and a stress-distributable fastener including a connecting rod that extends through the through-hole and the upper and lower bores in the head body to engage threadedly the striking body, and that is formed with an abutting flange received fittingly in the upper bore and anchored on and abutting against an abutting face of a bore-defining wall of the upper bore upon tightening of the connecting rod onto the striking body.

Owner:LIN MING HSUAN

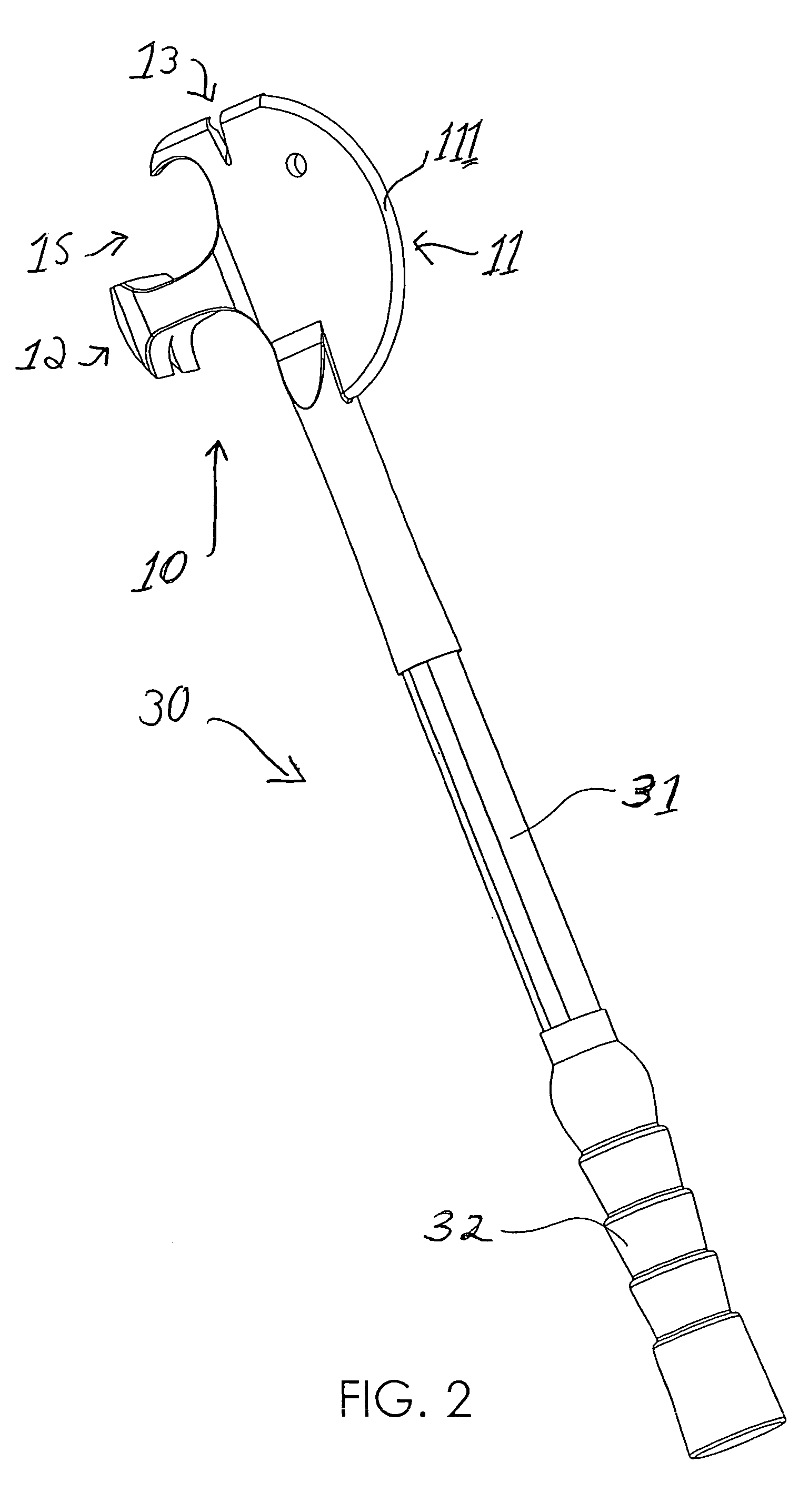

Multi-purpose firefighting tool

Owner:FIRE HARDWARE

Demolition tool

The invention provides a demolition tool that can be used in many ways for the demolition of construction materials or other materials. The demolition tool includes a handle having a head at one end. The head has a longitudinal central plane that bisects the head, a strike contact face, and toothed, stepped grasping jaws that accommodate multiple sizes of lumber or other material. The head may also include a blunt blade edge below the strike contact face for striking and demolishing material. The demolition tool includes a bent end pry bar at a second end of the handle. The bent end pry bar being offset 90 degrees from the longitudinal central plane of the tool head enabling full range of motion without interfering with other tool functions. The demolition tool may comprise a single piece of material and may be softer than tools used to strike it, but harder than materials which it is used to strike.

Owner:STANLEY WORKS THE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com