Patents

Literature

150results about How to "Avoid correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

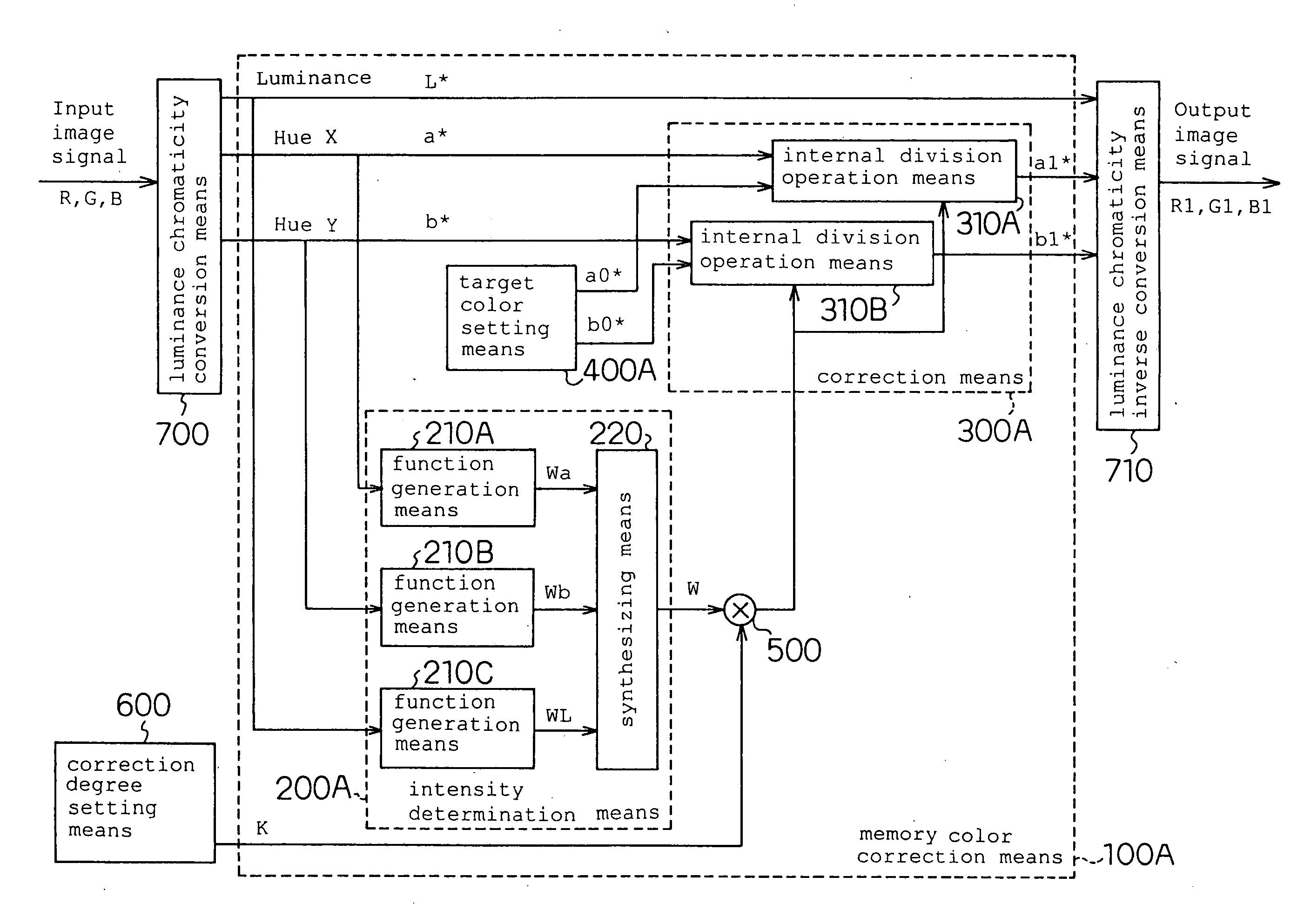

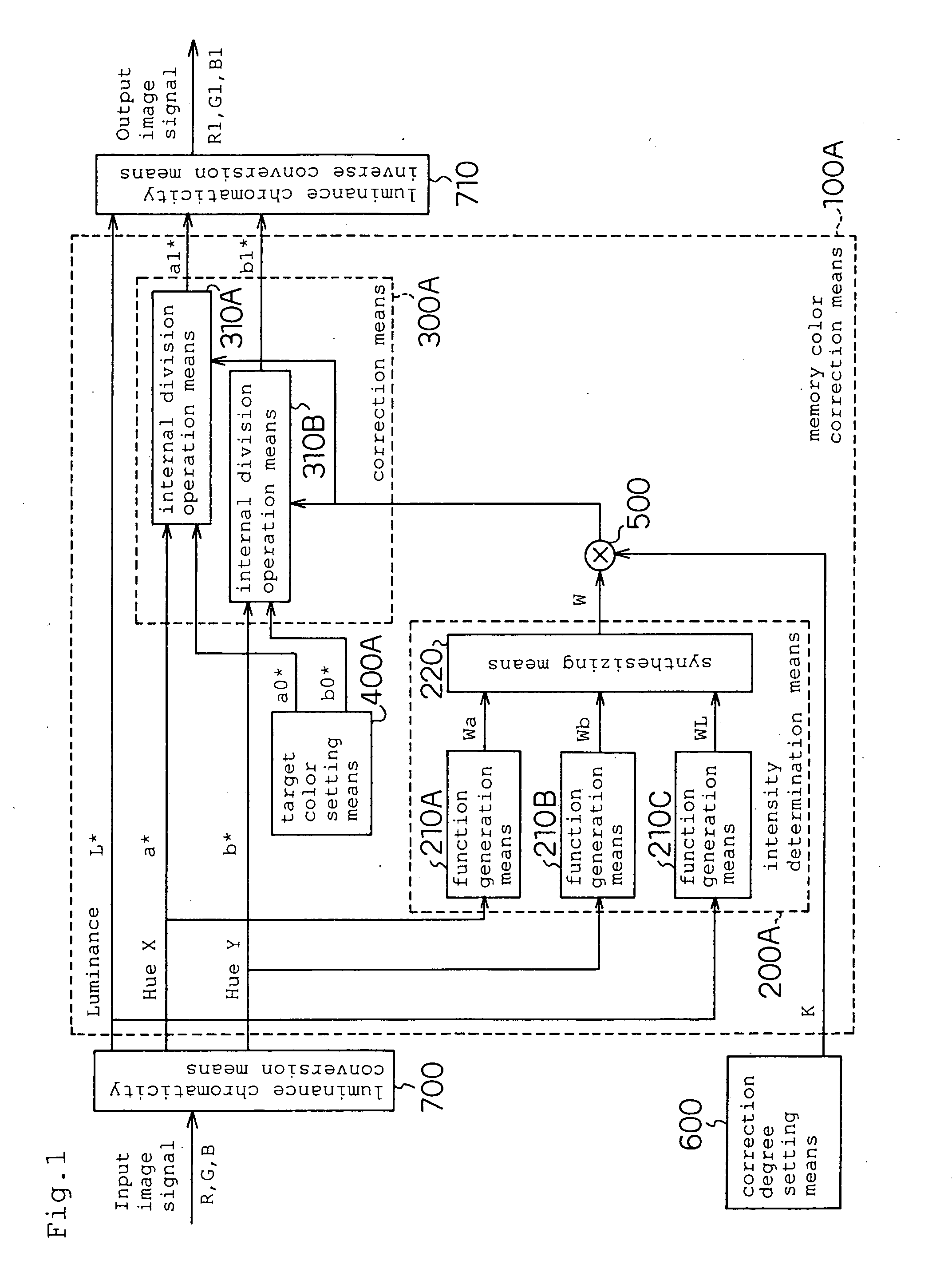

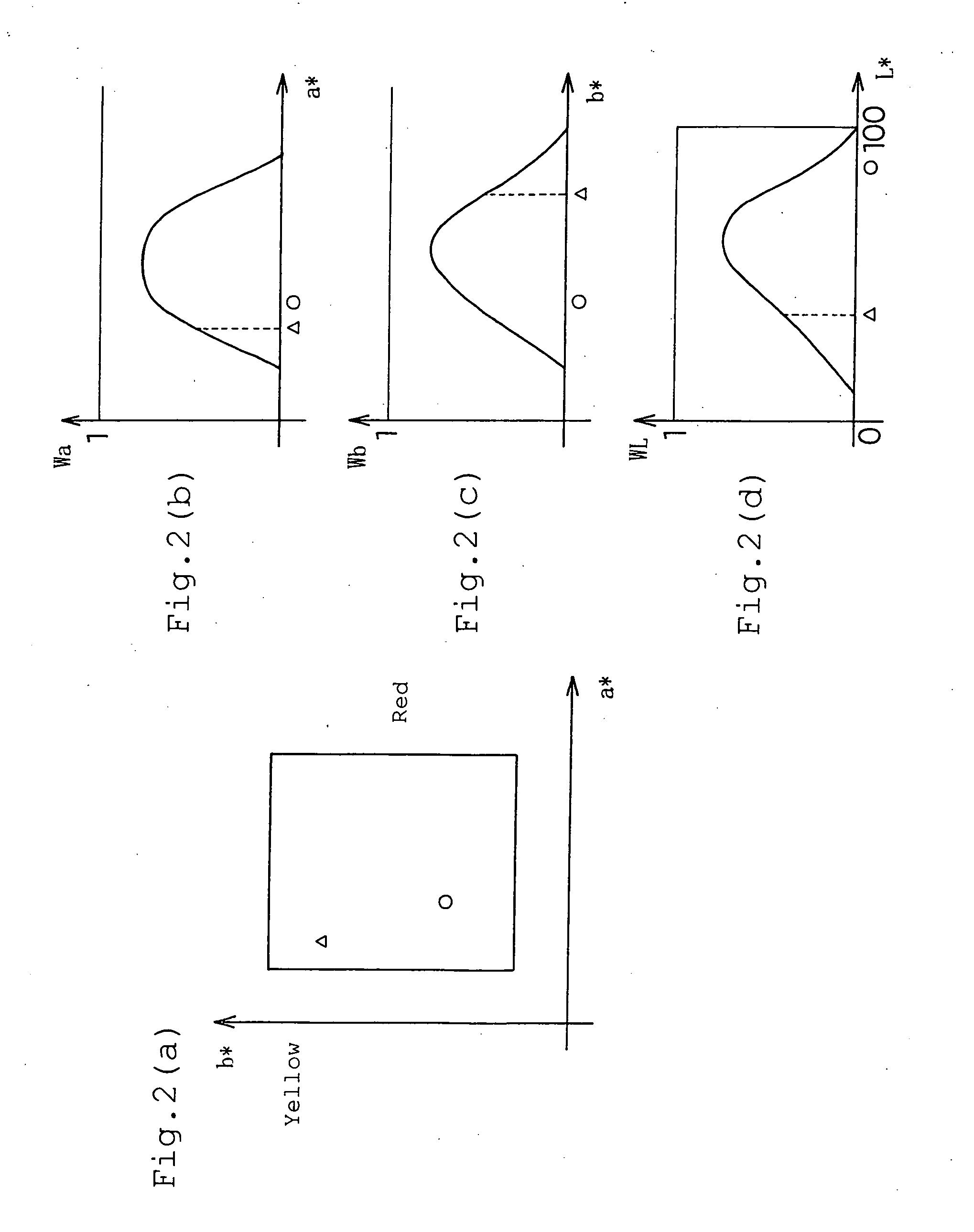

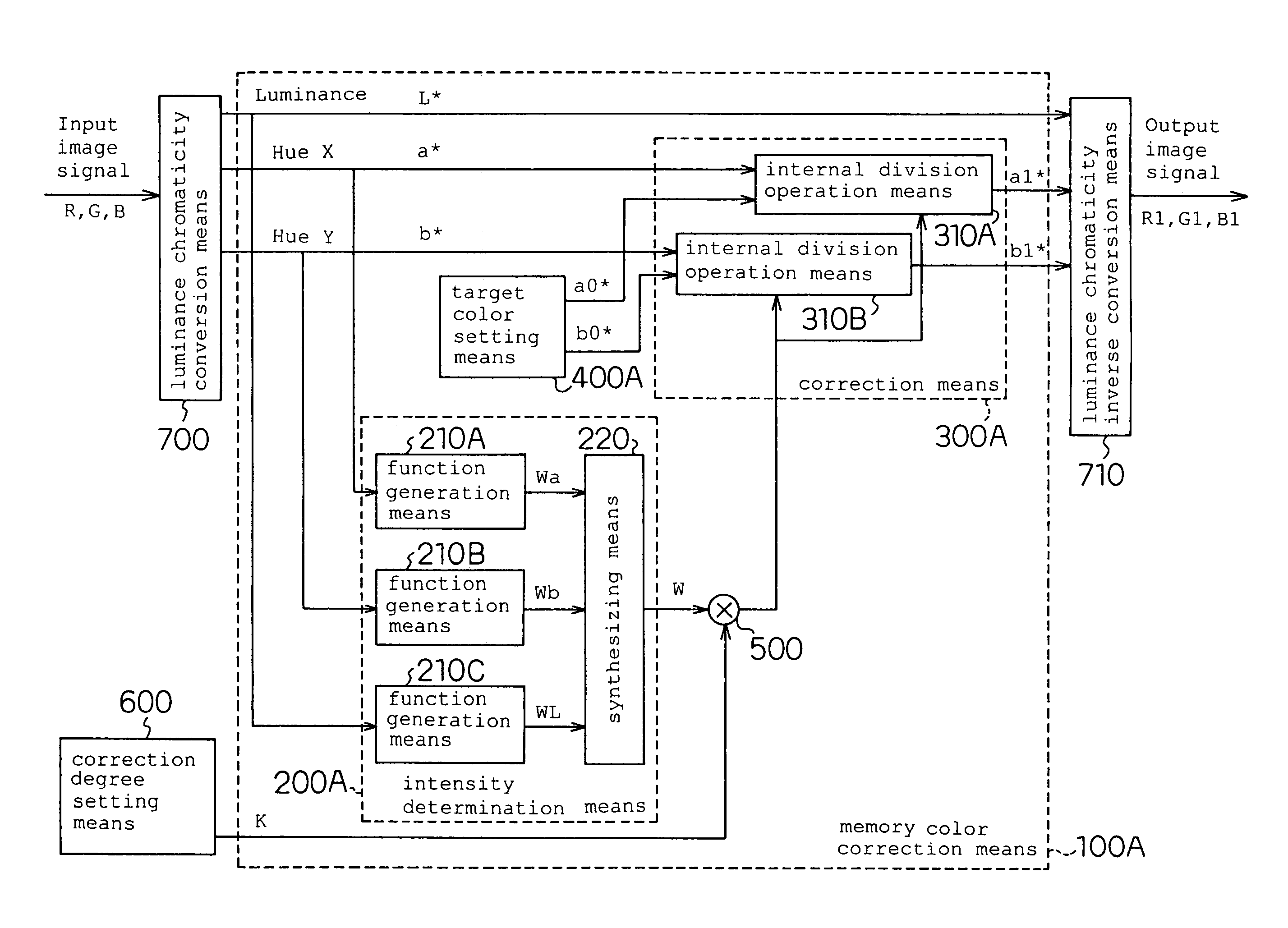

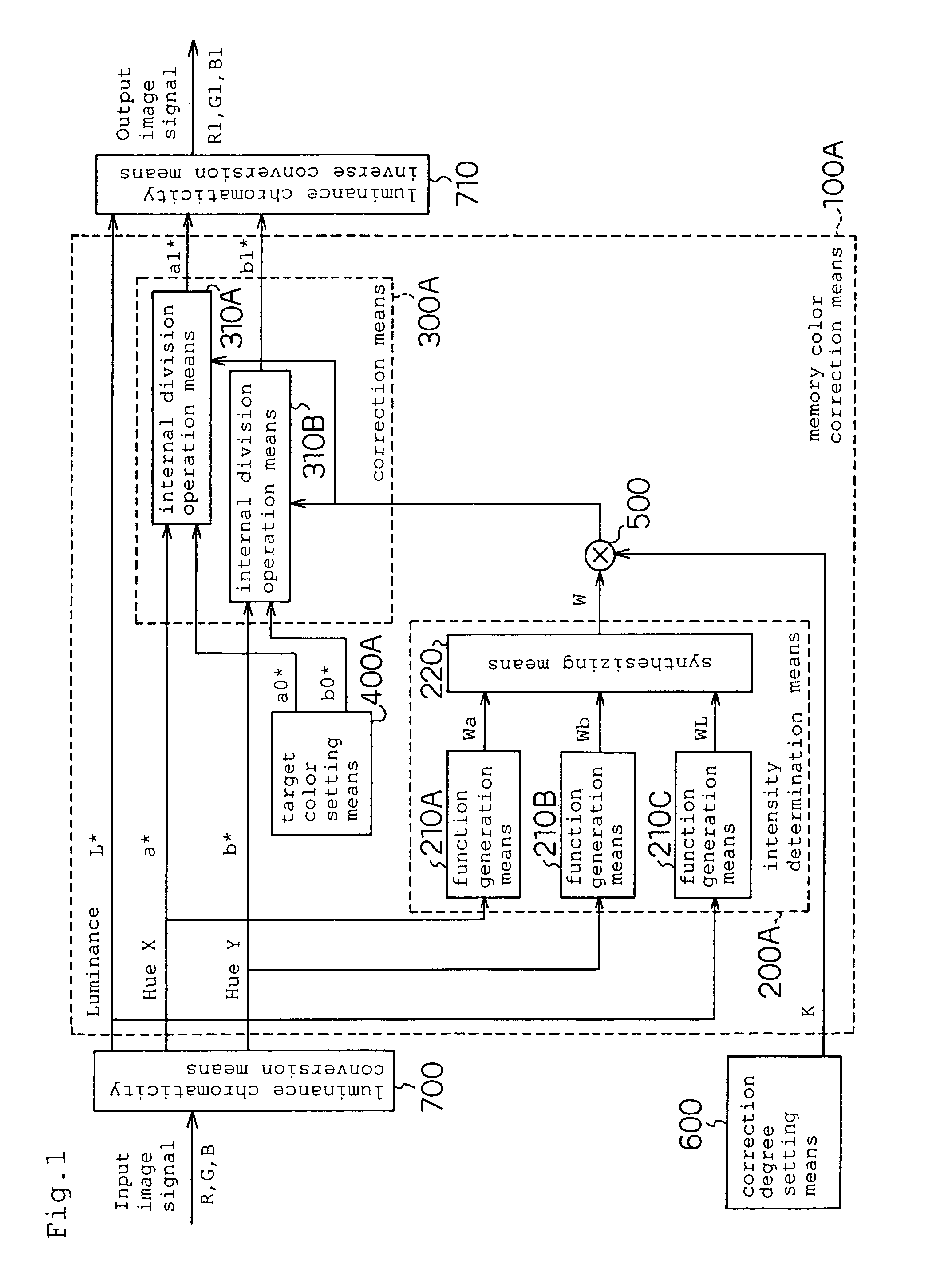

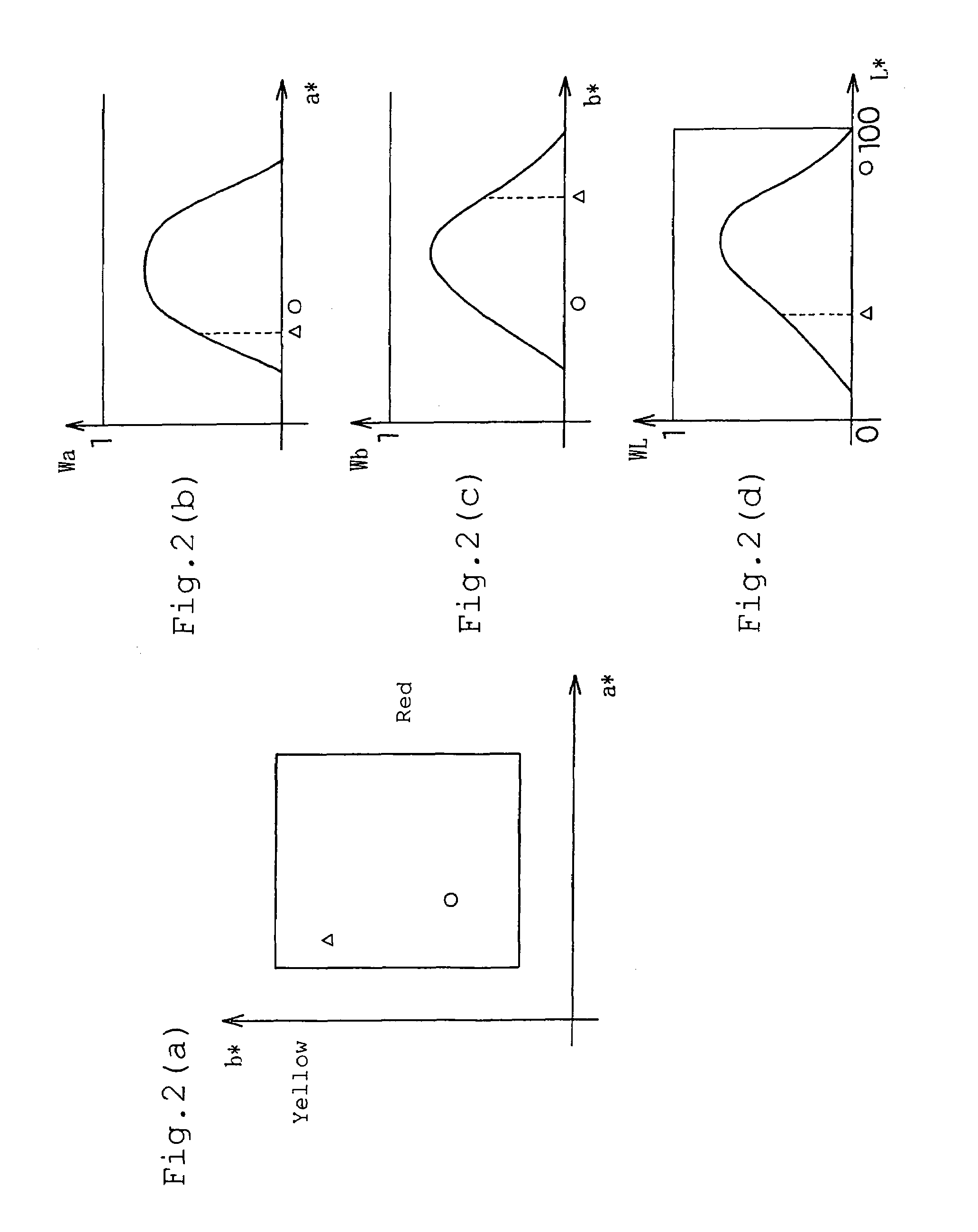

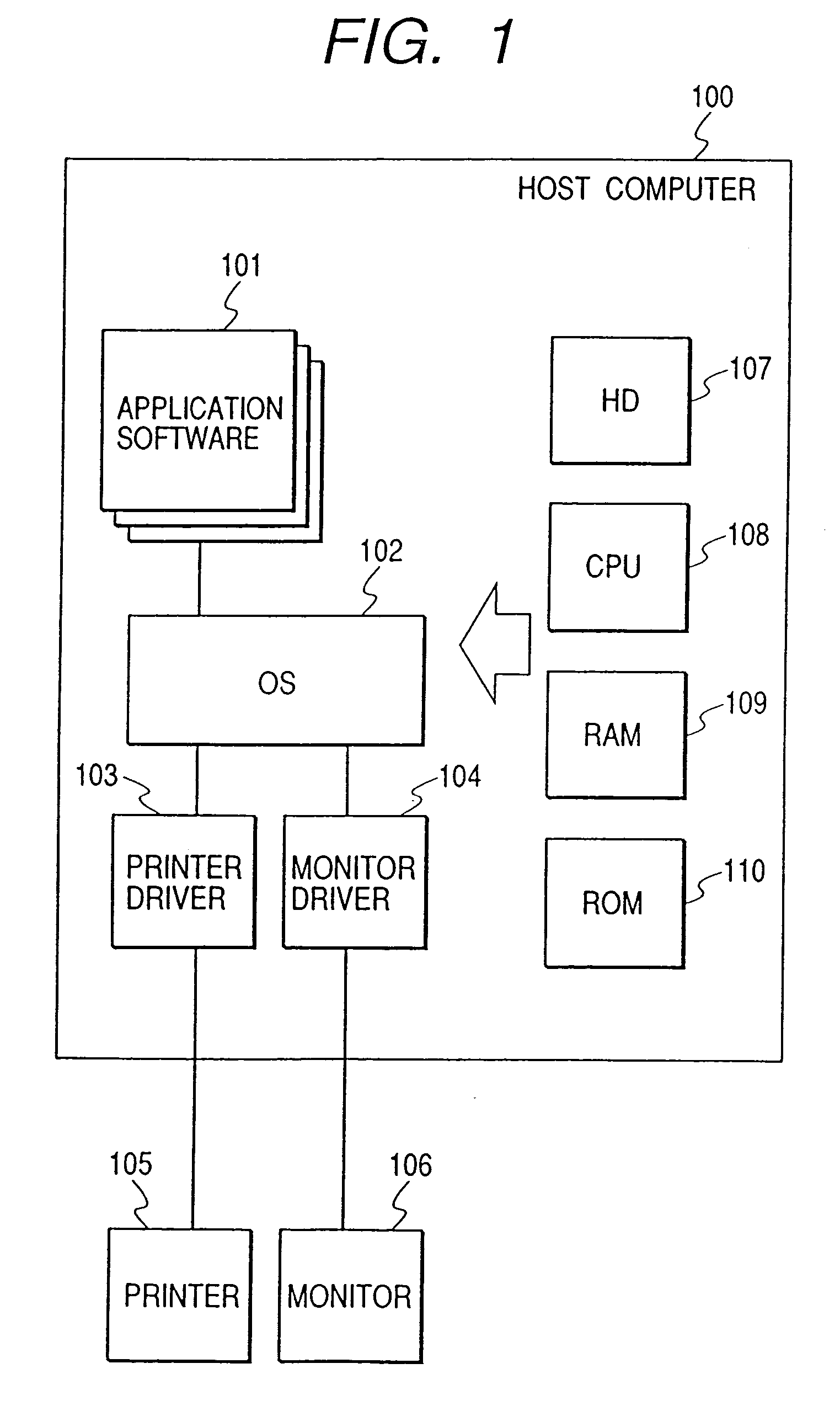

Image processing device

InactiveUS20060013478A1Avoid correctionImage enhancementDigitally marking record carriersImaging processingColor correction

An image processing apparatus of correcting the color of a specific range of a pixel signal for each pixel included in an input image signal, comprises an intensity determination means of generating a correction intensity that is small on the periphery of the color region of the specific range on the basis of two chromaticity signals excluding a luminance component and large in the vicinity of the nearly central portion of the range in the pixel signal, a target color setting means of setting a target color depending on which the pixel signal is corrected, a correction degree setting means of setting correction degree by also using information, other than pixel information, included in the pixel signal, and a correction means of making the image signal close to the target color depending on the correction intensity output from the intensity determination means and the correction degree output from the correction degree setting means.

Owner:GK BRIDGE 1

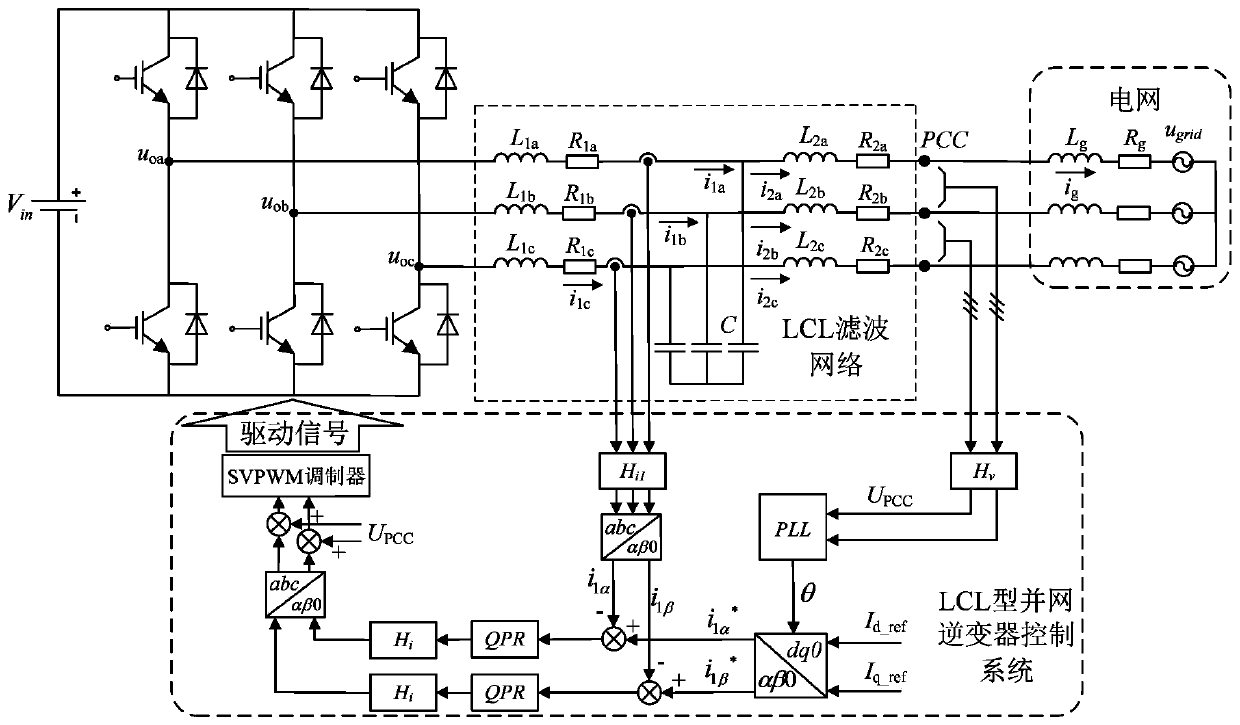

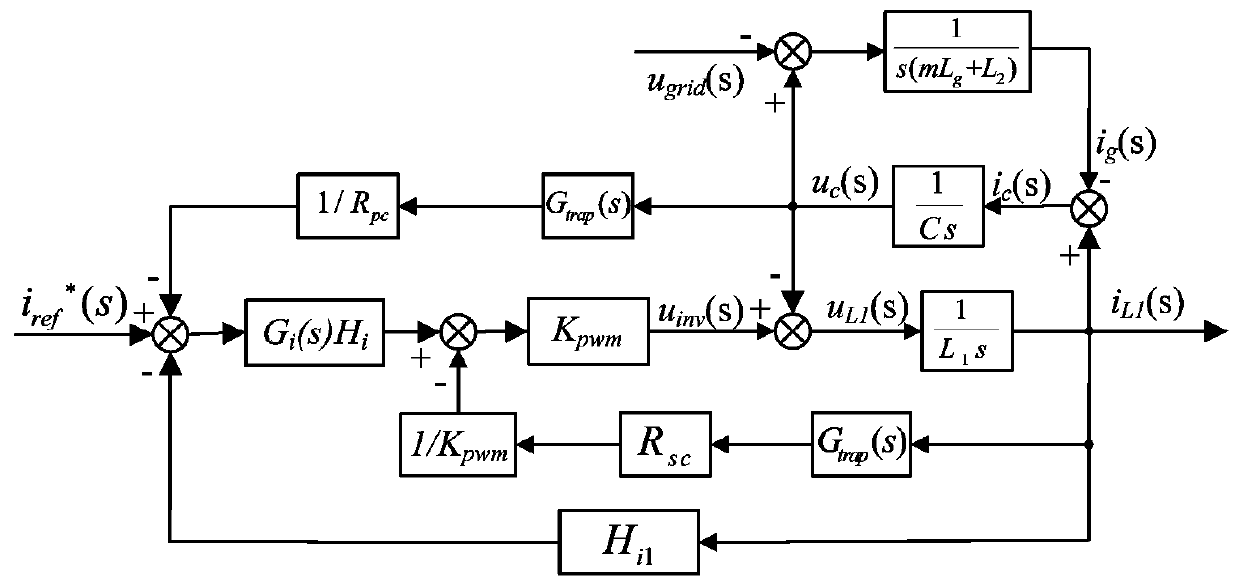

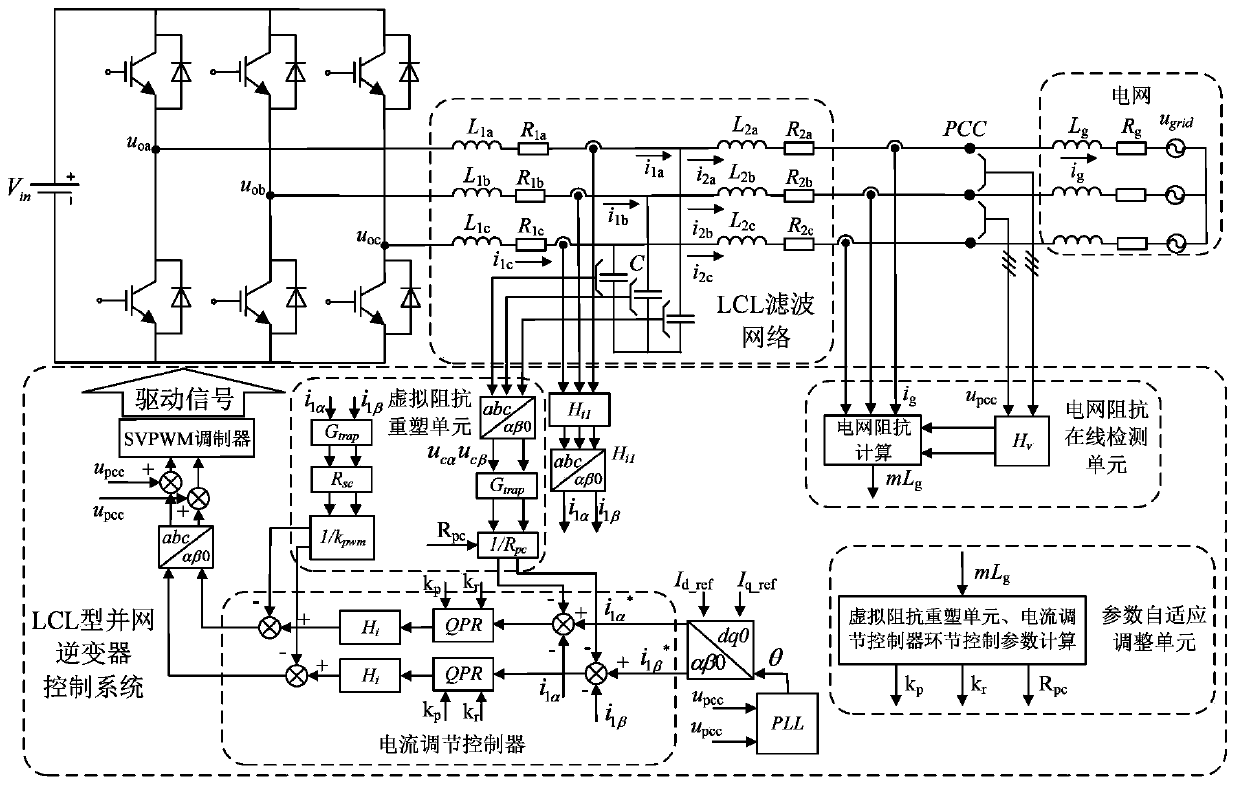

Multi-inverter micro-grid harmonic resonance suppression method based on adaptive virtual impedance remodeling

InactiveCN109698502AImprove output impedance characteristicsSuppression of series and parallel resonanceSingle network parallel feeding arrangementsHarmonic reduction arrangementGrid impedanceEngineering

On the basis of the inverter-side current feedback control strategy, the invention presents a multi-inverter micro-grid harmonic resonance suppression method based on adaptive virtual impedance remodeling. The method includes a virtual impedance remodeling unit, a parameter adaptive adjustment unit and a grid impedance online detection unit. The virtual impedance remodeling unit can improve the output impedance characteristics of grid-connected inverters and inject certain damping components into a micro-grid. The parameter adaptive adjustment unit adaptively adjusts the control parameters ofthe virtual impedance remodeling unit and a current regulating controller according to the impedance parameters of the grid to maintain the stability of the system. The grid impedance online detectionunit provides the equivalent impedance of the grid as the input of the parameter adaptive adjustment unit. The method improves the characteristics of the current loop, and enables inverters to maintain stability under various grid impedance conditions. The method can solve the problems of complex control system, fixed control parameters and low efficiency of the regulation process in the existingmulti-inverter micro-grid system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

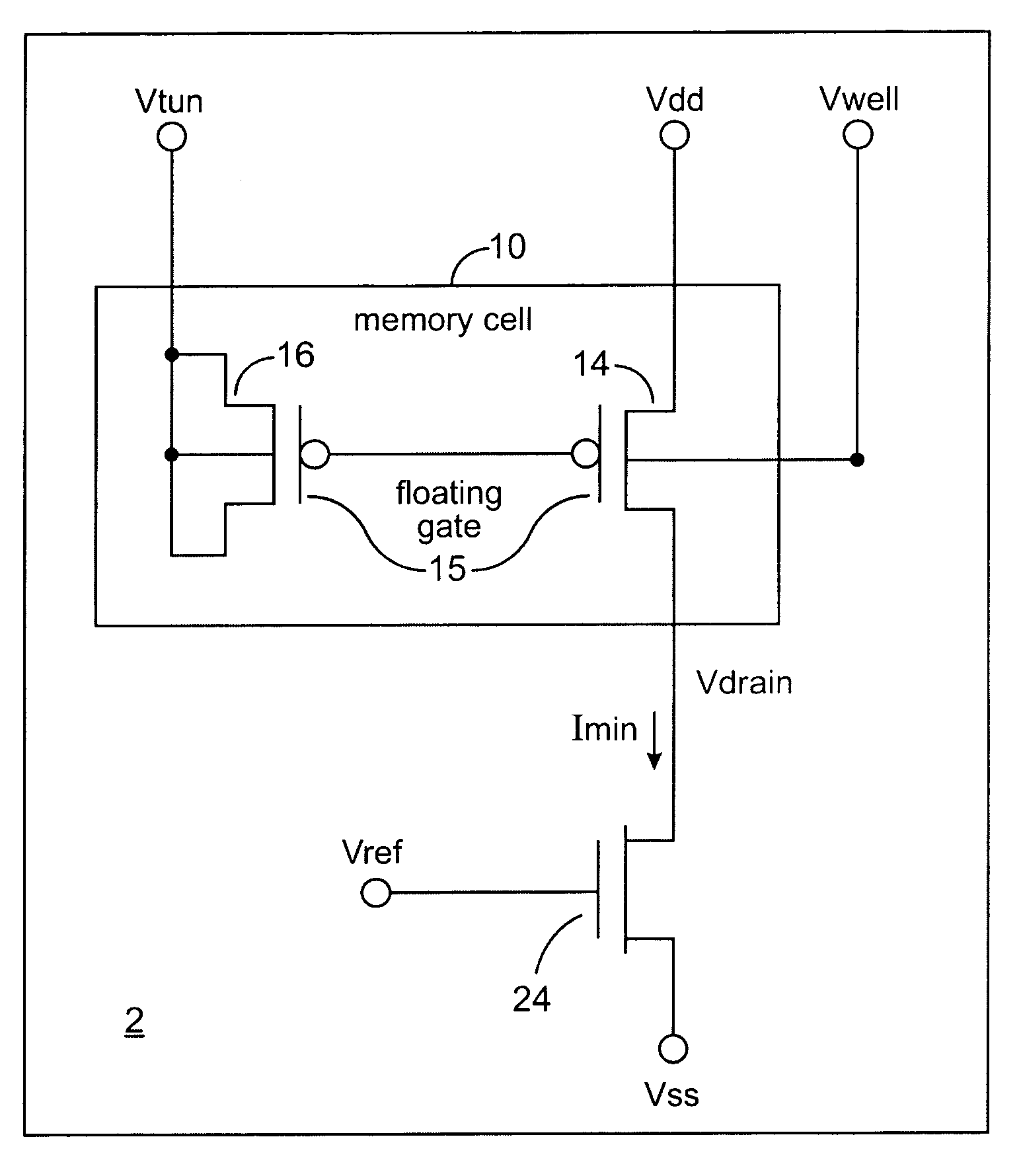

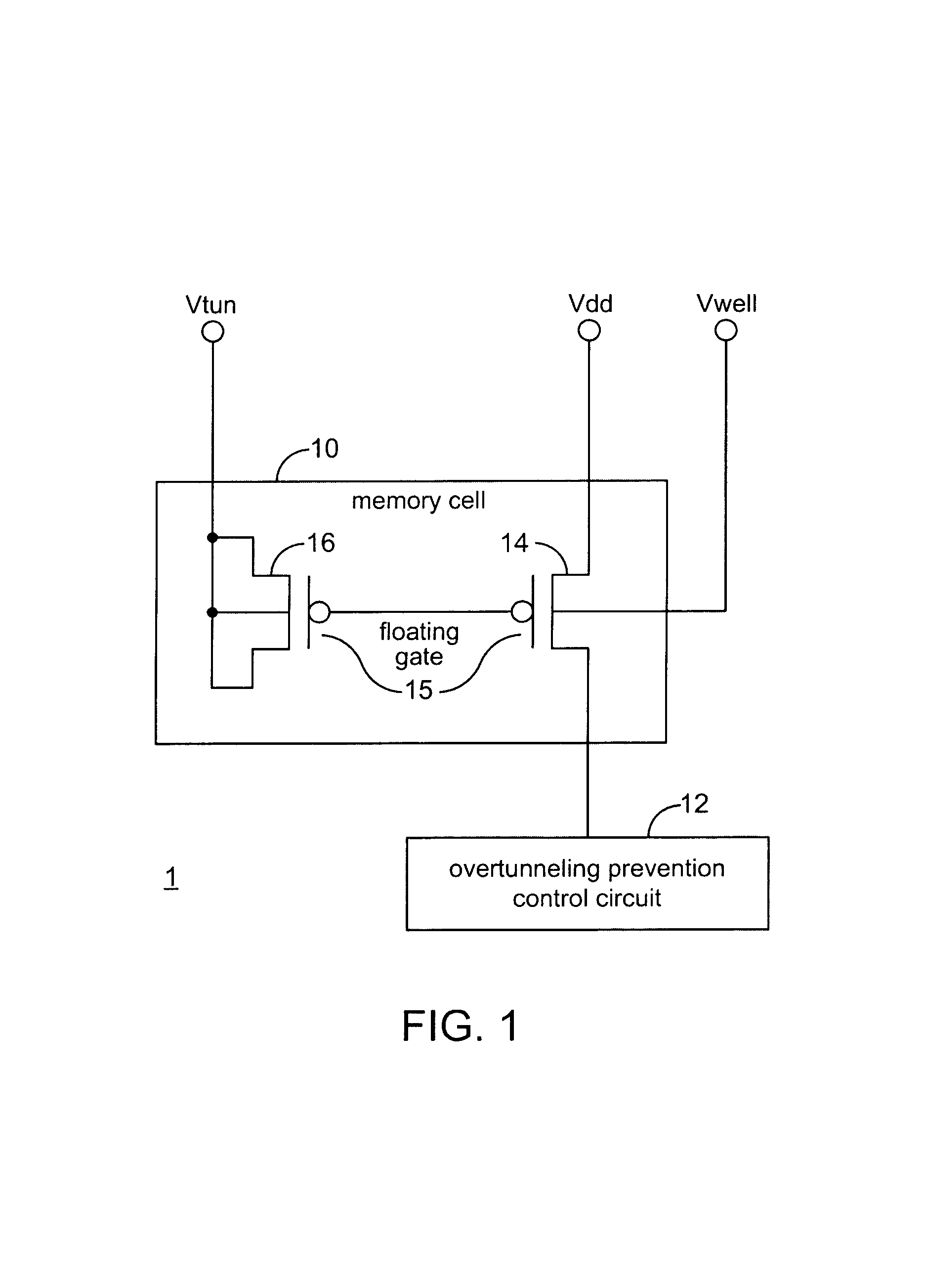

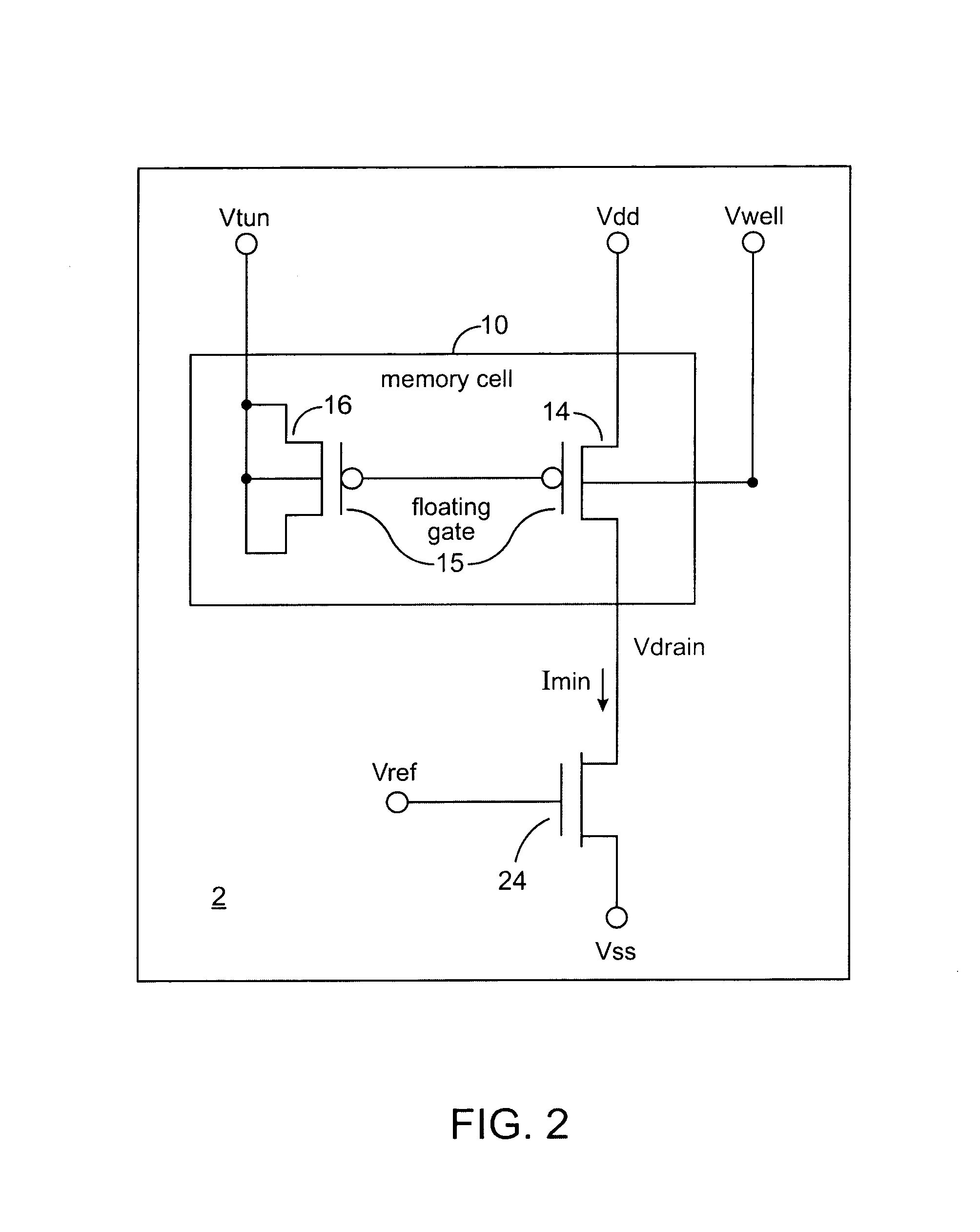

Counteracting overtunneling in nonvolatile memory cells using charge extraction control

InactiveUS7212446B2Avoid correctionPreventing overtunnelingSolid-state devicesRead-only memoriesHemt circuitsEngineering

Methods and apparatuses prevent overtunneling in nonvolatile floating gate memory (NVM) cells. An individual cell includes a circuit with a transistor that has a floating gate that stores charge, and a capacitor structure for extracting charge from the gate, such as by tunneling. A counteracting circuit prevents extracting charge from the floating gate beyond a threshold, therefore preventing overtunneling or correcting for it. In one embodiment, the counteracting circuit supplies electrons to the floating gate, to compensate for tunneling beyond a point. In another embodiment, the counteracting circuit includes a switch, and a sensor to trigger the switch when the appropriate threshold is reached. The switch may be arranged in any number of suitable ways, such as to prevent a high voltage from being applied to the capacitor structure, or to prevent a power supply from being applied to a terminal of the transistor or to a well of the transistor.

Owner:SYNOPSYS INC

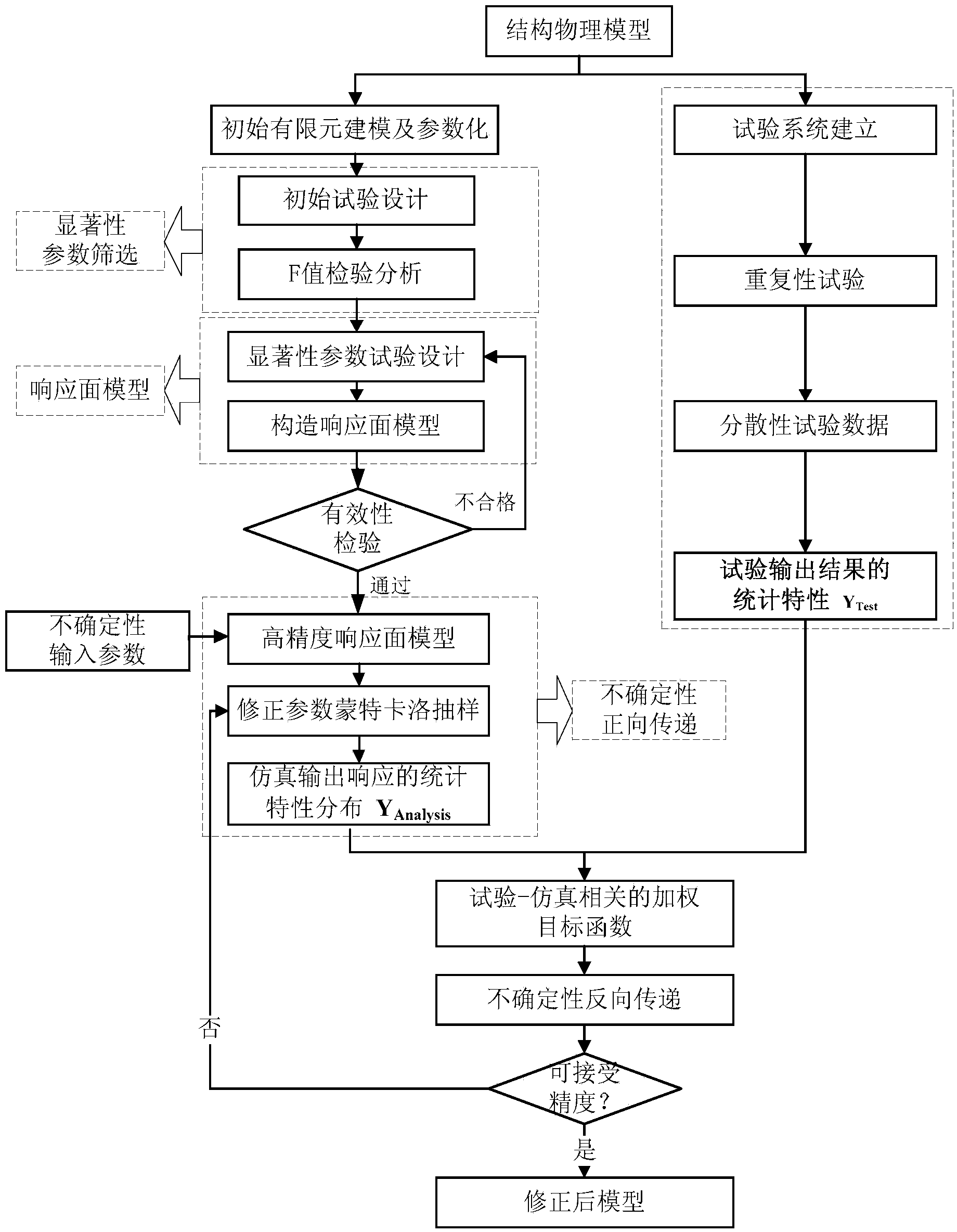

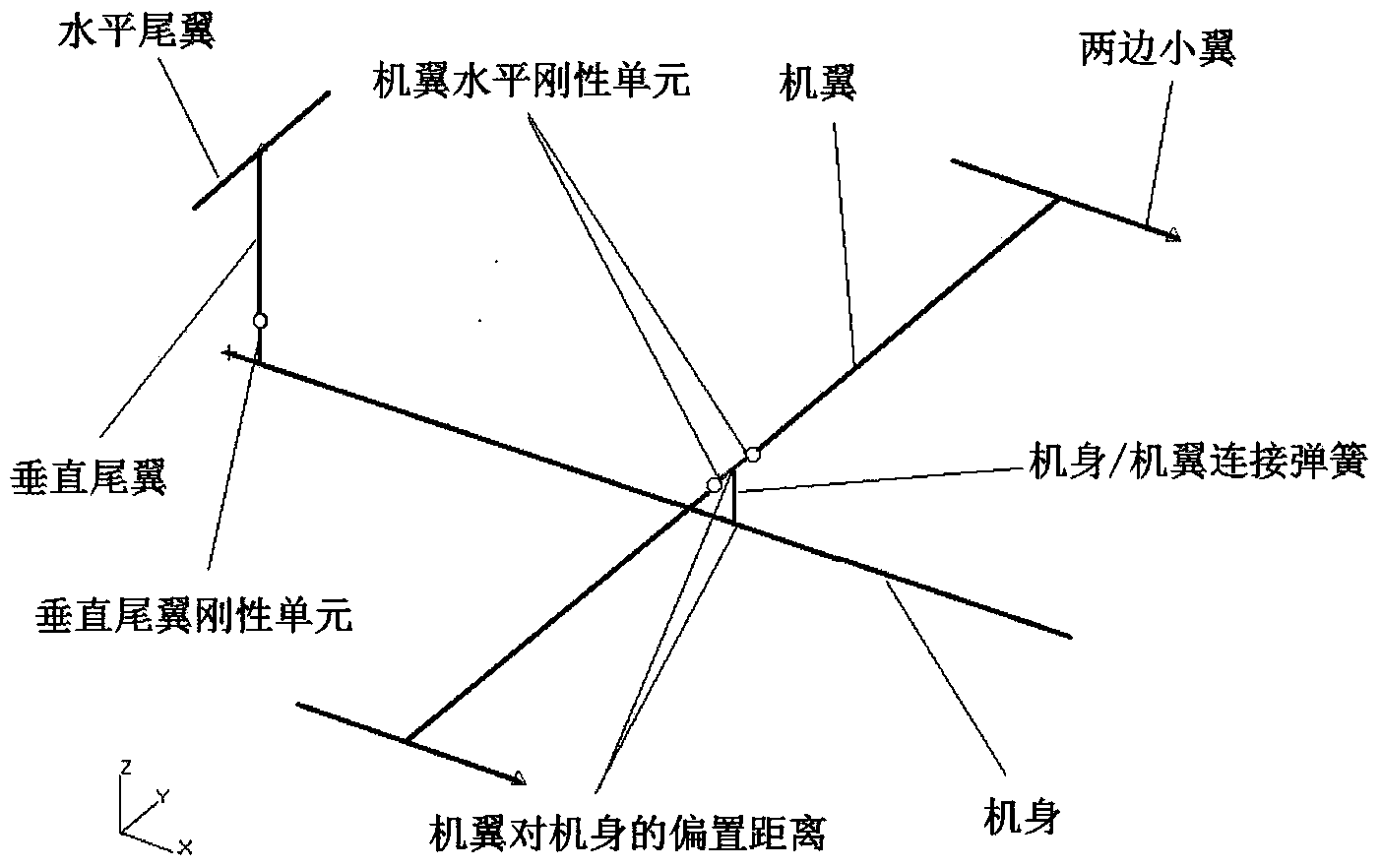

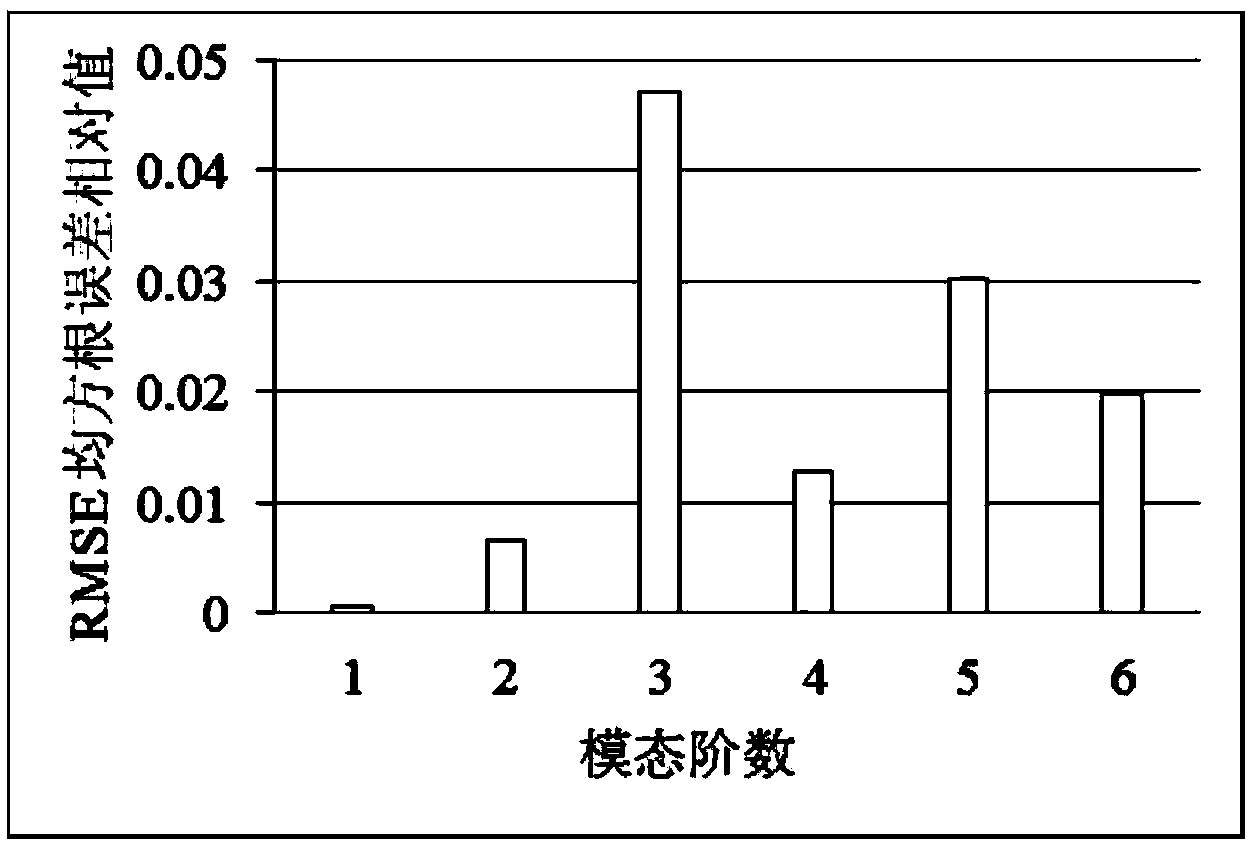

Structure finite element model correcting method based on multi-element uncertainty

InactiveCN103902785AReduce the numberAvoid correctionSpecial data processing applicationsApplicability domainElement model

A structure finite element model correcting method based on multi-element uncertainty comprises the following steps: (1) building an initialized parameterization equivalent finite element model in finite element software; (2) screening out significance parameters; (3) obtaining sample points, and constructing an incomplete variable high-order response surface model; (4) judging validity of the response surface model, if the validity of the response surface model meets the requirement, executing the next step, and if the validity of the response surface model does not meet the requirement, executing the step (3) again; (5) building a rapid random sampling analysis model with the combination of a high-order response surface and the Monte Carlo method, and conducting statistics on a mean value and a covariance matrix of simulation output responses; (6) conducting statistics on a mean value and a covariance matrix of test output results; (7) constructing a weighting objective function of the mean values and covariances of tests and simulation; (8) reversely estimating a mean value and a covariance matrix of input parameters; (9) judging whether the mean value and the covariance matrix of the input parameters meet correction accuracy or not, if yes, stopping iteration, and if not, executing the step (8) again. According to the structure finite element model correcting method, the calculated amount of the iteration is reduced, the application range is wide, and optimization of a large-scale parameter range is achieved.

Owner:BEIHANG UNIV

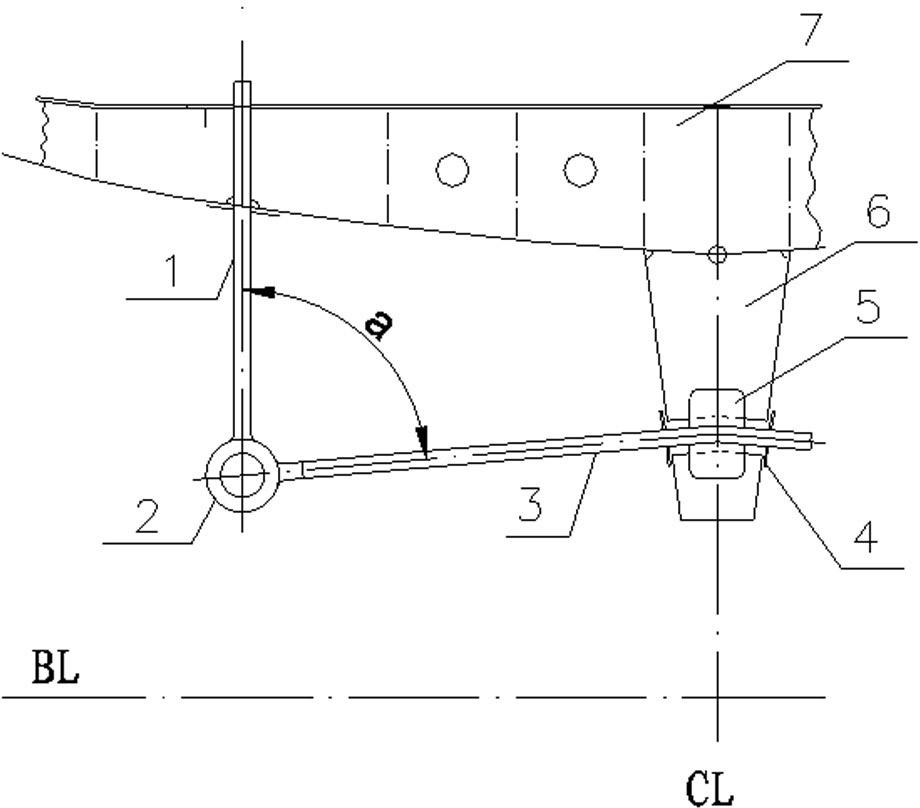

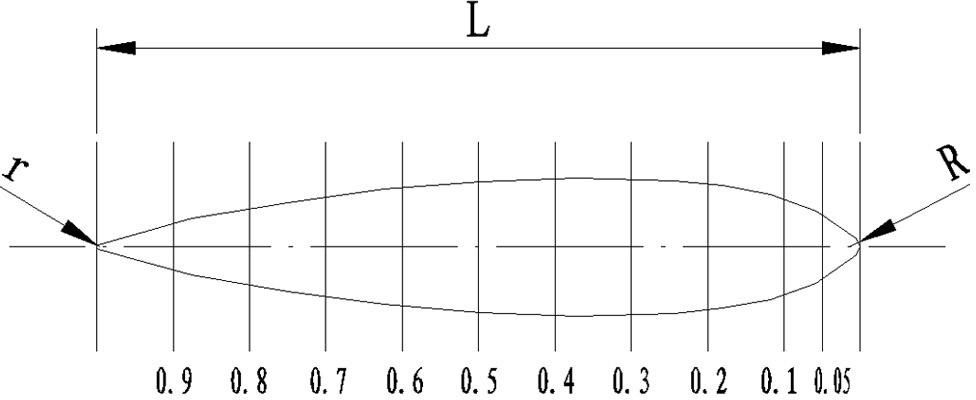

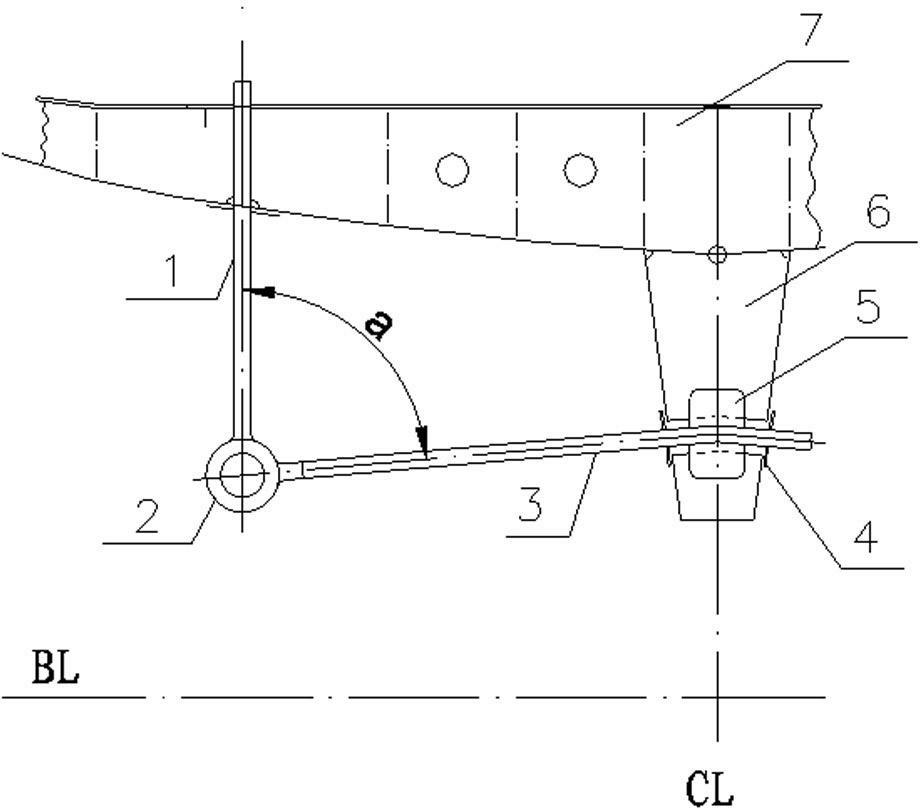

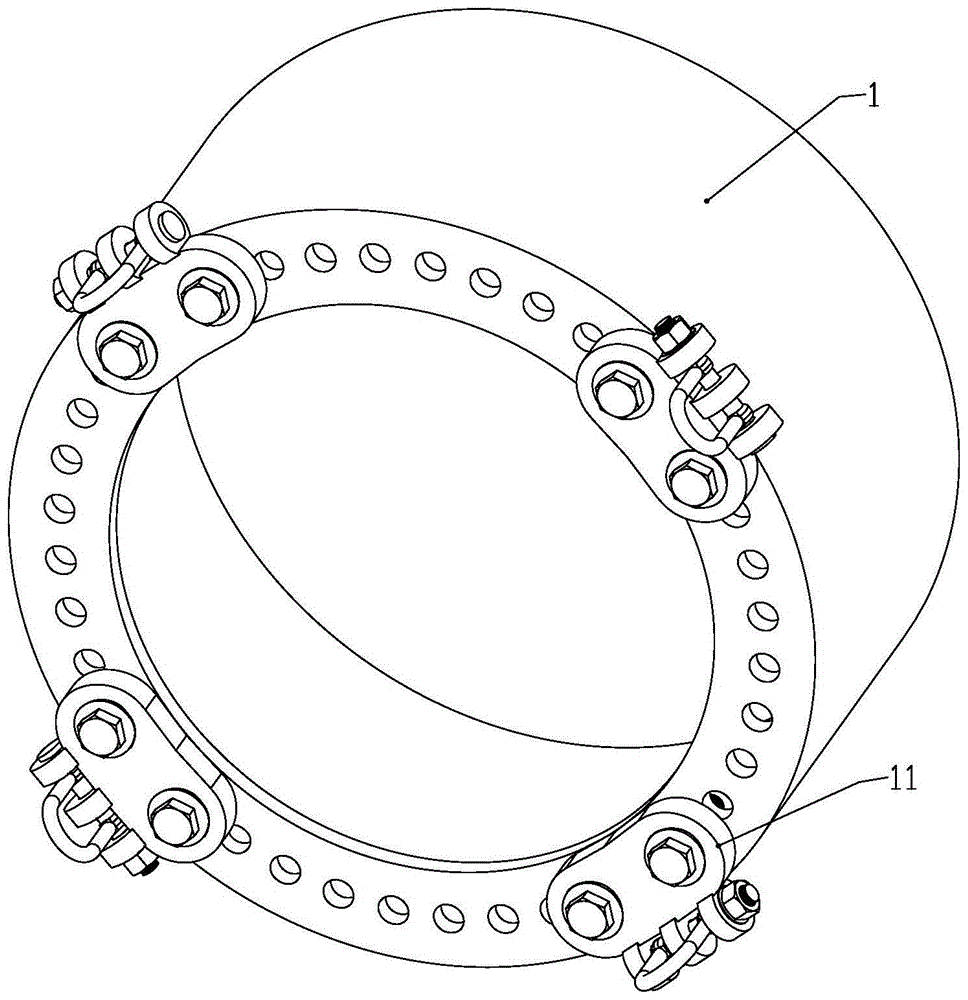

Assembly welding process for propeller shaft bracket

InactiveCN102303176AMixed flow and small forceAvoid correctionWelding/cutting auxillary devicesArc welding apparatusPropellerPore diameter

The invention relates to an assembly welding process for a propeller shaft bracket, and belongs to the technical field of ships. The process comprises the following steps of: before assembling a propeller shaft hub, performing a hydrostatic test of 0.2 MPa; correcting axes and pore diameters of front and rear end faces of the propeller shaft hub and sizes of four points on the left and right sides and upper and lower sides of the propeller shaft hub, and marking temporarily; cutting corresponding position holes on a bottom board and rib board of a ship body, and machining beveled edges of a supporting arm and the propeller shaft hub to perform point welding pre-positioning connection; allowing transverse arms in the horizontal direction to form an included angle alpha of 85 degrees with the supporting arm, splicing the supporting arm and the propeller shaft hub on a moulding bed in advance, and inserting into an open pore of the bottom board of the ship body to perform pre-welding positioning; after the supporting arm and the transverse arms are pre-positioned, welding and positioning the transverse arms and the propeller shaft hub according to a shafting bracing wire; and after welding, performing ultrasonic detection and magnetic particle detection on the propeller shaft bracket. The propeller shaft bracket assembled by the process is small in positional deviation and vibration quantity and low in noise, and the service life of the ships is prolonged greatly.

Owner:YANGFAN GROUP

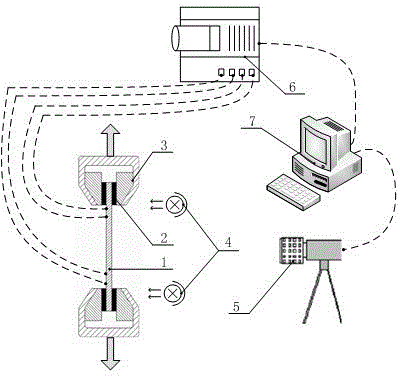

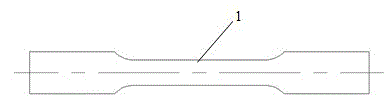

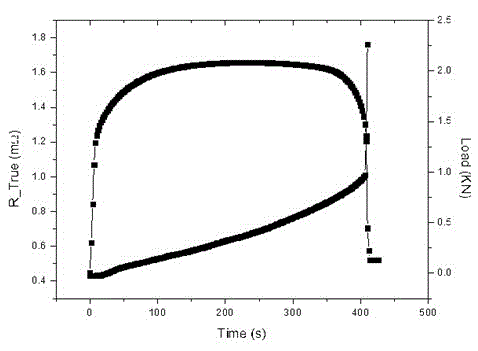

Device and method for measuring toughness damage evolution in process of metal uniaxial tension

ActiveCN103149086AEasy to buildOvercome the disadvantage of being unable to handle non-uniform strainStrength propertiesElectrical resistance and conductanceEvolution rule

The invention discloses a device and a method for measuring toughness damage evolution in process of metal uniaxial tension. The method includes a first step of utilizing a camera and a direct-current low-resistance tester to simultaneously record images and resistance of a sample in the stretching process, wherein the sample is sprayed with random free speckles, a second step of obtaining a strain field of the sample in the stretching process through a digital image correlation DIC) method, and a third step of combining strain increment and resistance increment of the sample in the stretching process to indirectly obtain a damage evolution rule in the stretching process.

Owner:SOUTH CHINA UNIV OF TECH

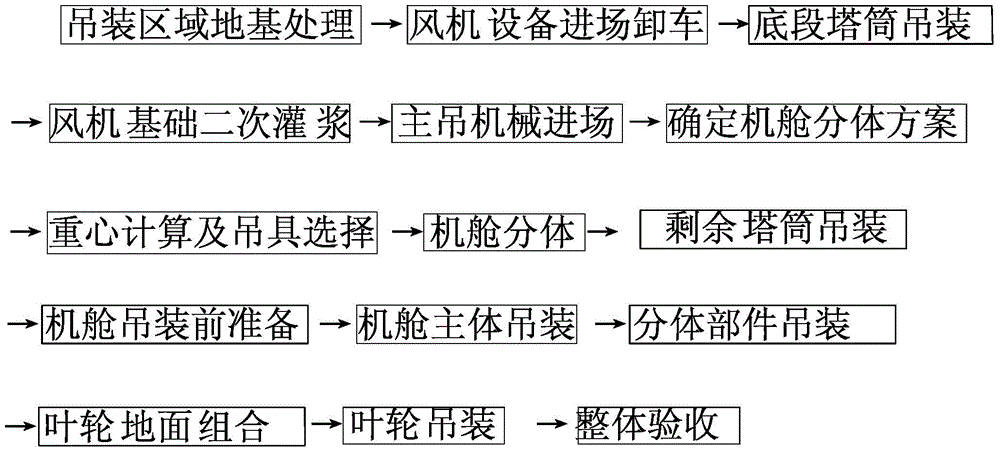

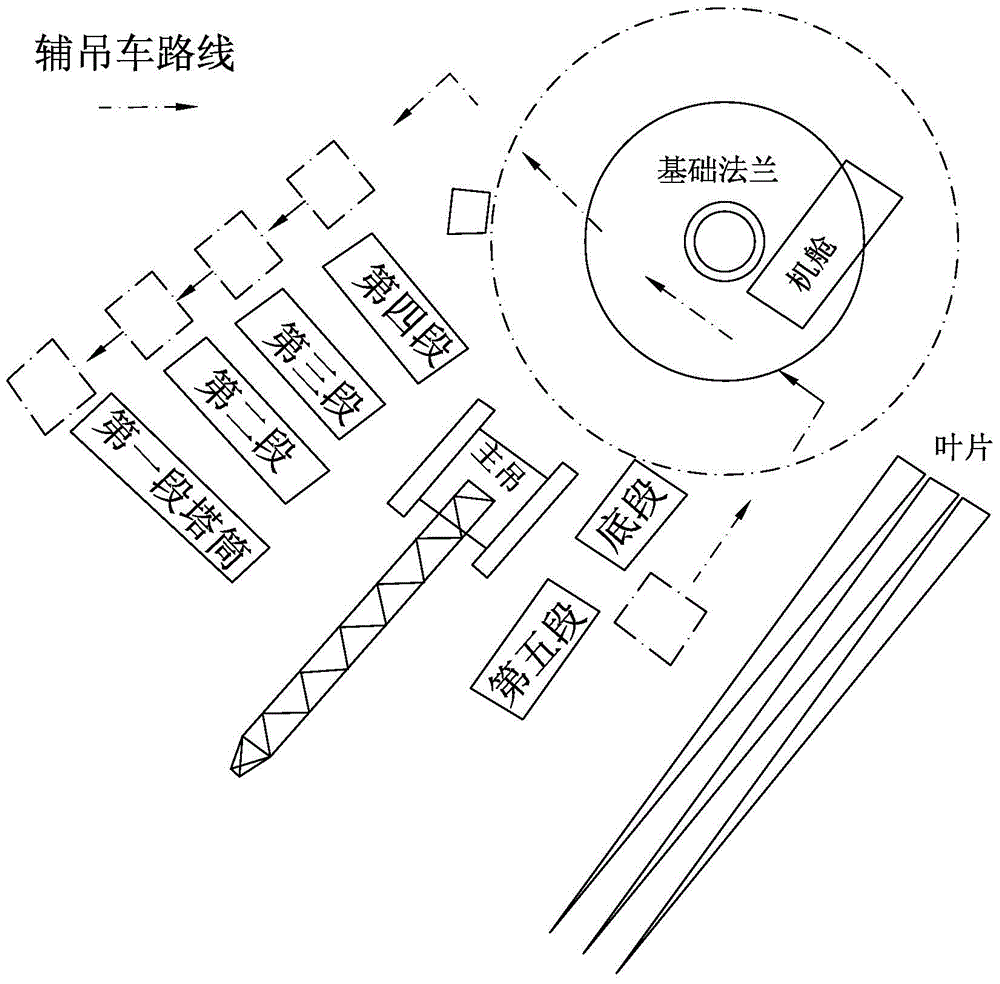

Split type hoisting method for 5MW land type wind generating set

ActiveCN105000462AReduce single lifting weightReduced mechanical lifting performance requirementsLoad-engaging elementsGravity centerEngineering

The invention discloses a split type hoisting method for a 5MW land type wind generating set. According to the method, a cabin is hoisted in a split mode, and split into a cabin body, a generator, a maintenance crane and a top housing according to the weight and the boundary dimension of all parts of the cabin and the hoisting capacity of a main hoisting machine; after the cabin is split, software is utilized for analyzing and recalculating the gravity center position to adjust the design of a hoisting sling, and therefore the level and the safety of cabin hoisting are ensured. The main hoisting machine is utilized for sequentially installing the cabin body and the generator in place and sequentially installing the maintenance crane and the top housing in place. According to a general scheme, a 1600t crawler crane is needed when a whole hoisting scheme is adopted for a 5MW fan, while by means of the implementation of the method, the construction requirement can be met by adopting a 1000t crawler crane, and therefore the construction cost is effectively saved.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

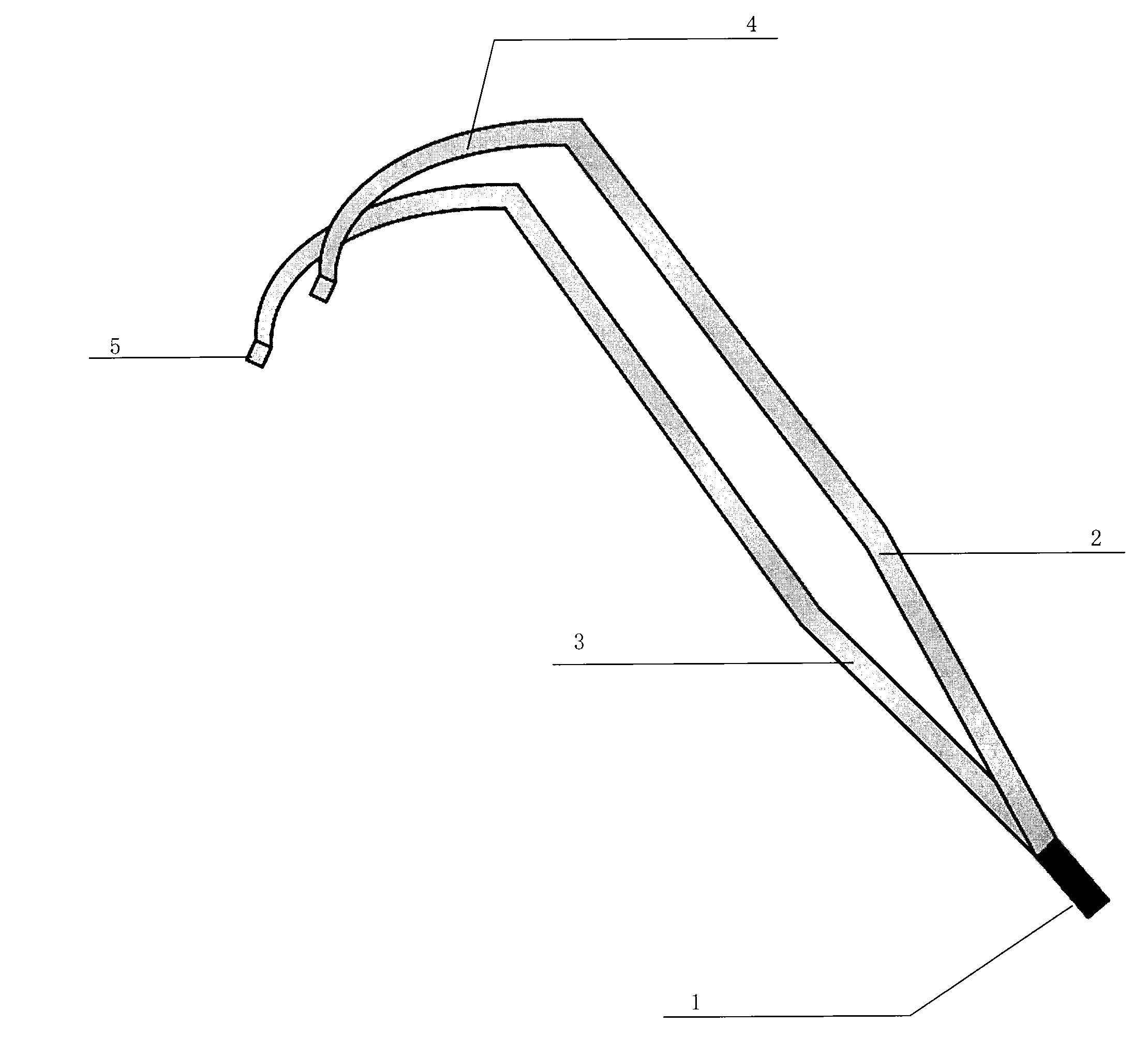

Nipper for clipping false eyelashes

The invention discloses a nipper for clipping false eyelashes. The nipper for clipping the false eyelashes comprises a nipper handle, an upper arm and a lower arm, and the upper arm and the lower arm are welded on the nipper handle in a certain angle. The upper arm and the lower arm are sheet metal bent inwards, and arc-shaped nipper heads are welded on the tail portions of the upper arm and the lower arm. A flat and straight head portion is manufactured on the tail portion of the nipper head. With the nipper for clipping the false eyelashes, the false eyelashes can be clipped so as to bend into shapes of eyelashes and be attached to the root portion of upper eyelashes, and therefore the false eyelashes can be natural. In addition, repeated position correction of the false eyelashes is avoided, and time for putting on makeup is saved. The flat and straight head portion at the tail portion of the nipper head can play the role of a common nipper at the same time, and therefore the nipper for clipping the false eyelashes is multifunctional.

Owner:陈在福

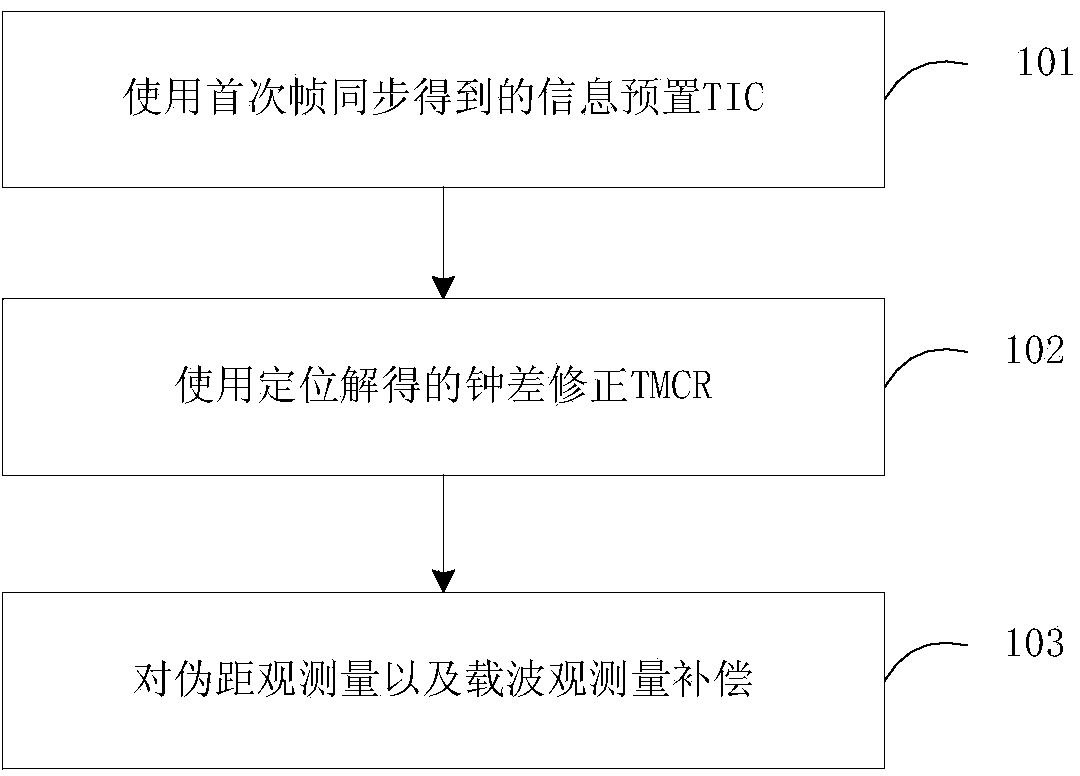

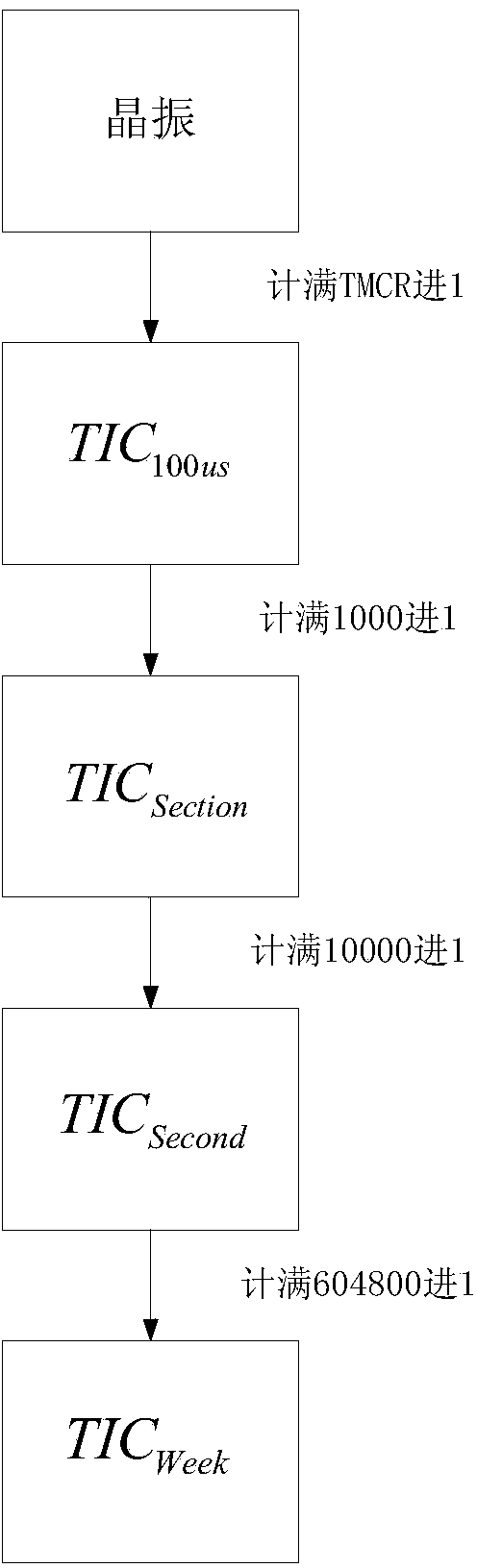

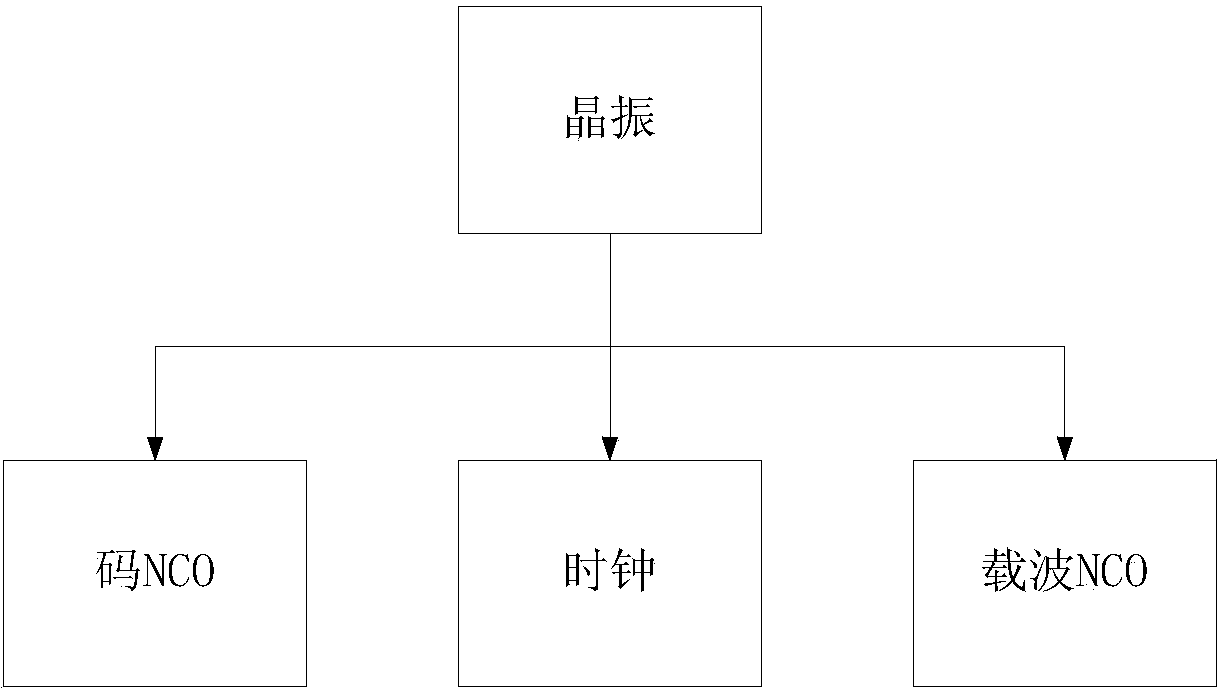

Satellite navigation receiver local time correction method and positioning method

ActiveCN103995268AReduce the impactImprove timing accuracySatellite radio beaconingCarrier signalCorrection method

The invention discloses a satellite navigation receiver local time correction method and positioning method. Due to the method, time service accuracy can be improved, meanwhile, the carrier phase and the pseudo observation quantity can be compensated for, a carrier phase smoothing filter is made to work normally, and positioning is achieved. After a receiver is powered on, TIC presetting is performed when frame synchronization occurs at the first-time, a TIC is firstly subjected to rough adjustment through the difference between GNSS time and local time of the receiver, then, the TIC is further subjected to fine adjustment by adjusting a TMCR value through clock correction of the receiver, and a receiver clock and a GNSS clock can be synchronous rapidly and accurately through the rough adjustment mode and the fine adjustment mode. According to the method, the carrier phase and the pseudo observation quantity are further compensated for, the defect of the hopping of the observation quantity extracting time moment caused by correction on a local TIC is overcome, and therefore the carrier phase can be accurately calculated, and the carrier phase smoothing filter can normally work.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Image processing device

InactiveUS7583403B2Avoid correctionImage enhancementDigitally marking record carriersImaging processingTime signal

An image processing apparatus of correcting the color of a specific range of a pixel signal for each pixel included in an input image signal, comprises an intensity determination means of generating a correction intensity that is small on the periphery of the color region of the specific range on the basis of two chromaticity signals excluding a luminance component and large in the vicinity of the nearly central portion of the range in the pixel signal, a target color setting means of setting a target color depending on which the pixel signal is corrected, a correction degree setting means of setting correction degree by also using information, other than pixel information, included in the pixel signal, and a correction means of making the image signal close to the target color depending on the correction intensity output from the intensity determination means and the correction degree output from the correction degree setting means.

Owner:GK BRIDGE 1

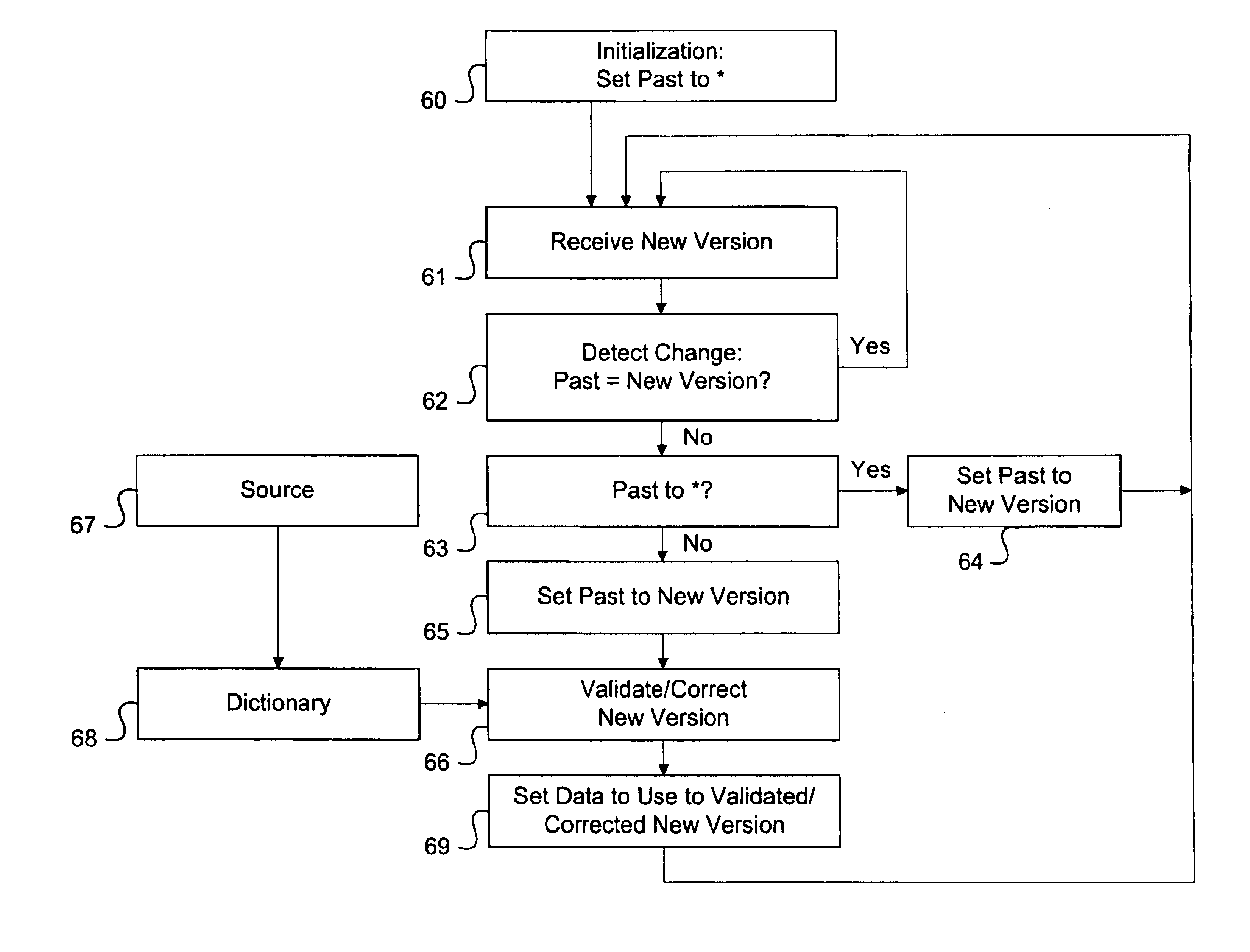

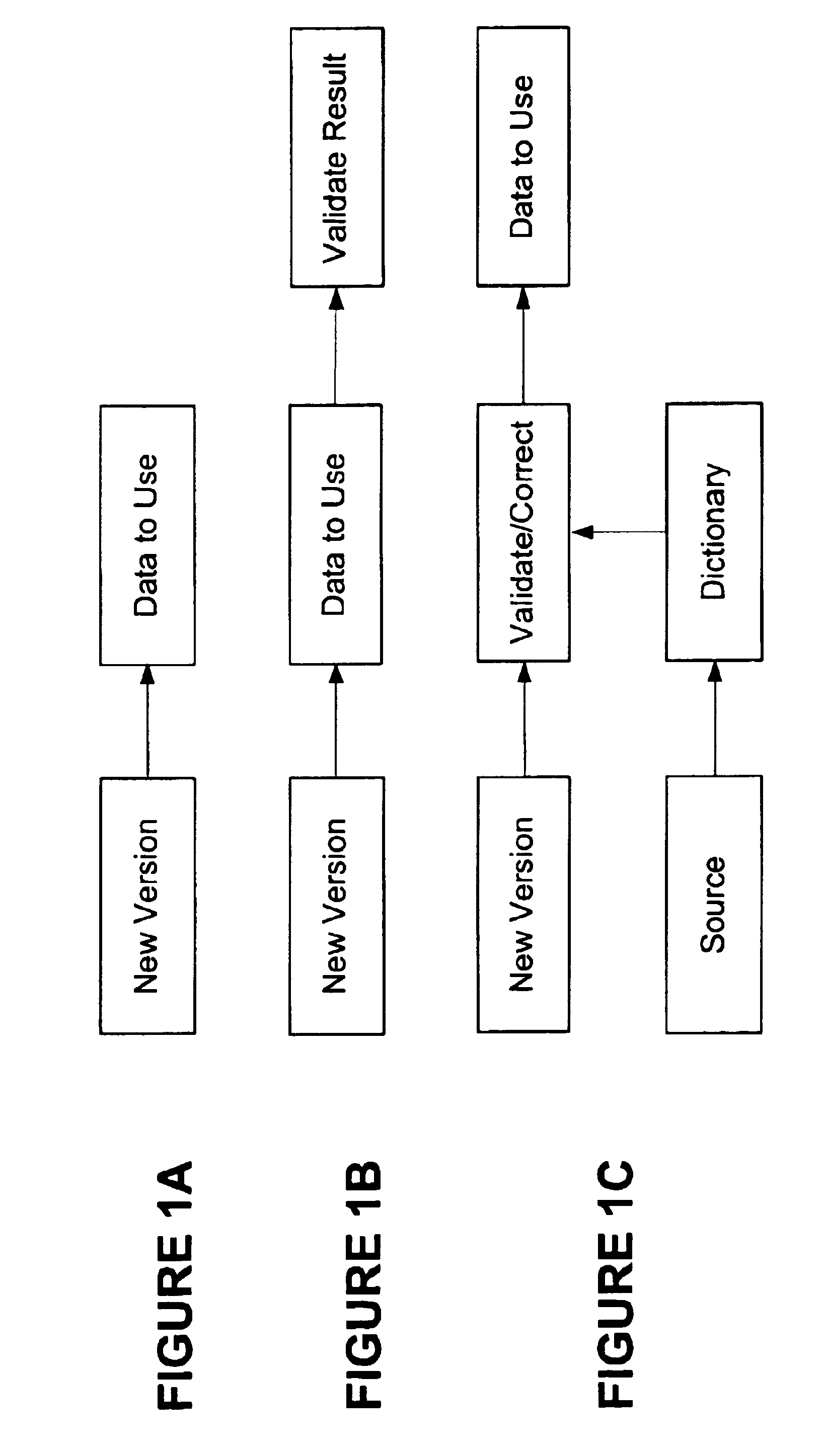

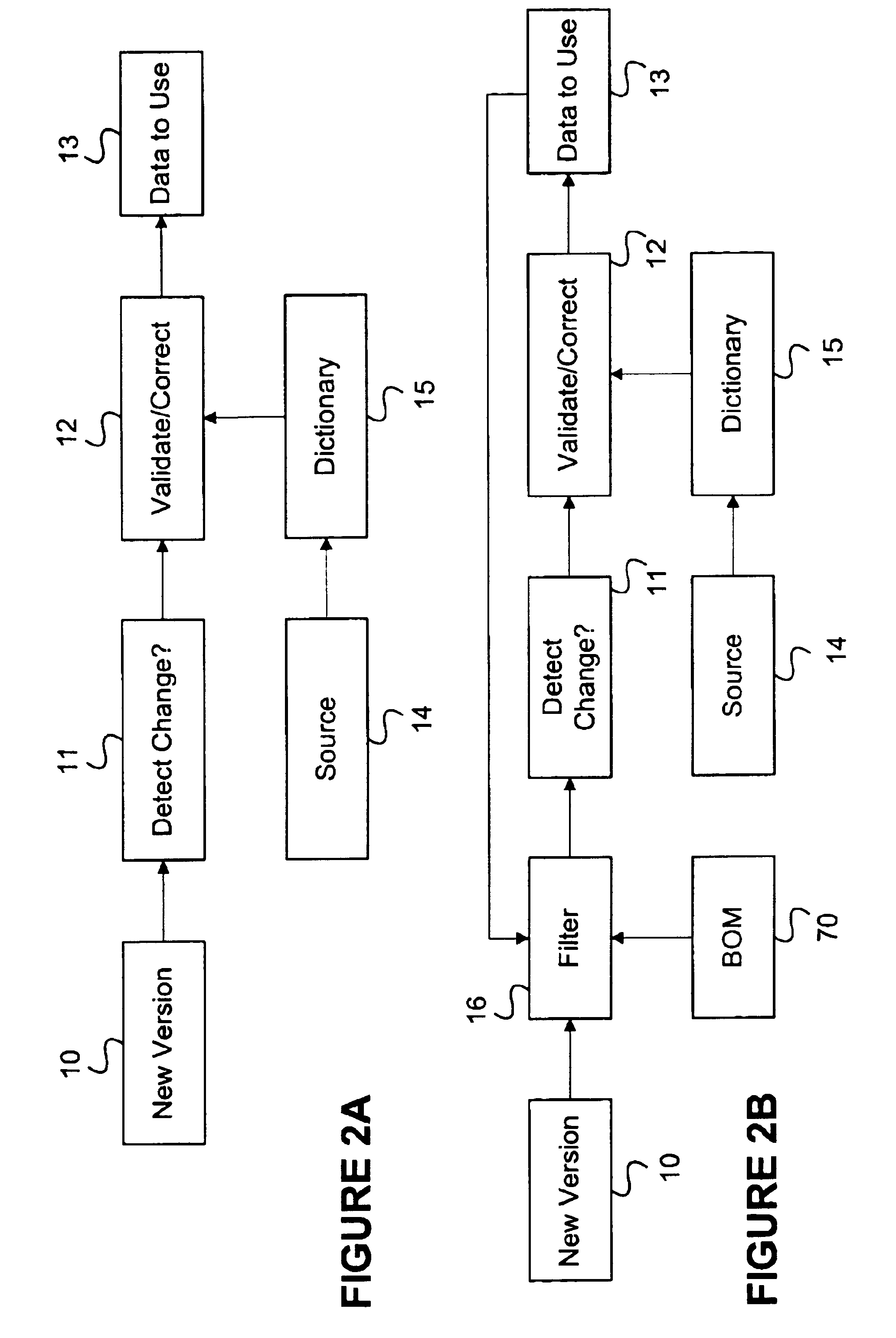

Systems and methods for organizing and validating data in documents

InactiveUS6954766B2Avoid unnecessary validationAvoid correctionResourcesMemory systemsDesign organizationDocument preparation

The invention relates to systems and methods to validate data in a design document transmitted over a computer network from a design organization to a contract manufacturer for manufacturing a product. The computer implemented system includes computer software for storing a past version of the design document, receiving and storing a new version of the design document, storing a dictionary, comparing the new version to the past version of the design document to detect a change in the data. If there is no change, the program stops. If there is a data change, the software sets the past version to the new version of the design document, and uses the dictionary to correct and validate the data that has changed between the past and new version which results in a design document with data to use for the contract manufacturer only.

Owner:JUMIPER NETWORKS INC

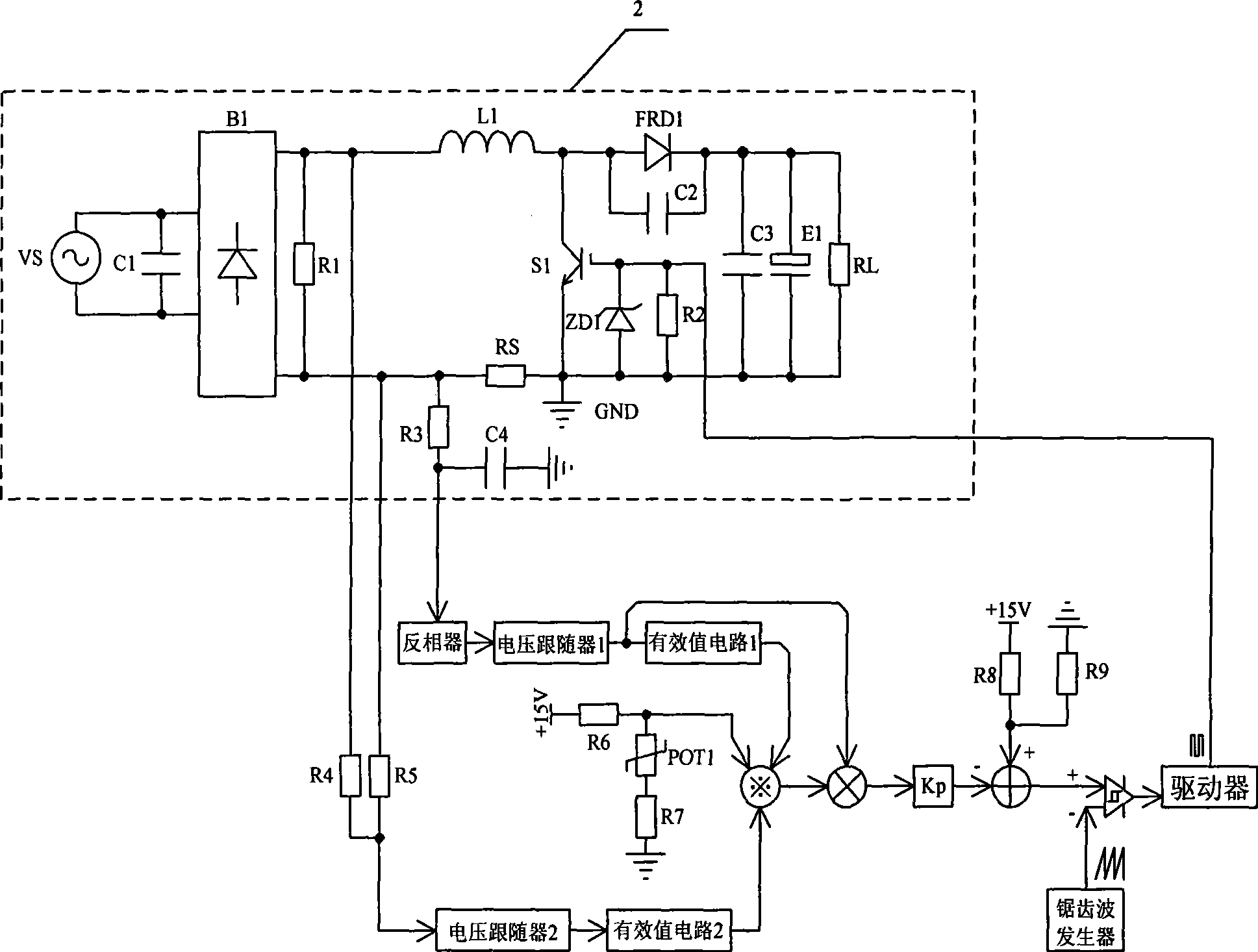

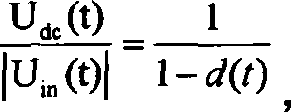

Single phase power factor correcting analog circuit without need of detecting DC output voltage

ActiveCN101499716AAvoid detectionAvoid correctionEfficient power electronics conversionReactive power adjustment/elimination/compensationElectrical resistance and conductanceControl signal

The invention provides a single-phase power factor correction analog circuit without the requirement of detecting the DC output voltage. The single-phase power factor correction analog circuit detects the transient current of the shunt resistance of a power circuit by a current detection circuit, then converts the transient current into a current effective value by a first effective value conversion circuit; meanwhile, an input voltage effective value gaining the circuit and an output DC voltage generation circuit respectively gain the input voltage effective value and the output DC voltage; then a calculation circuit calculates an input current regulation signal according to the voltage and current values output by all circuits; subsequently, a control signal forming circuit generates a control signal according to the input current regulation signal and the unit voltage generated by a unit voltage generation circuit; subsequently, a comparison circuit outputs corresponding PWM pulse sequences by comparing the carrier wave signal generated by a carrier wave signal generation circuit with the control signal; furthermore, the turn-on and turn-off of a power tube is driven by a driving circuit; therefore, the correction of the power is realized, meanwhile, the circuit can be effectively simplified as the DC output voltage is not required to be detected.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

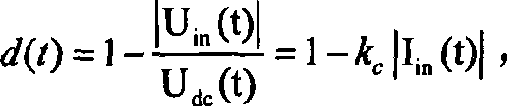

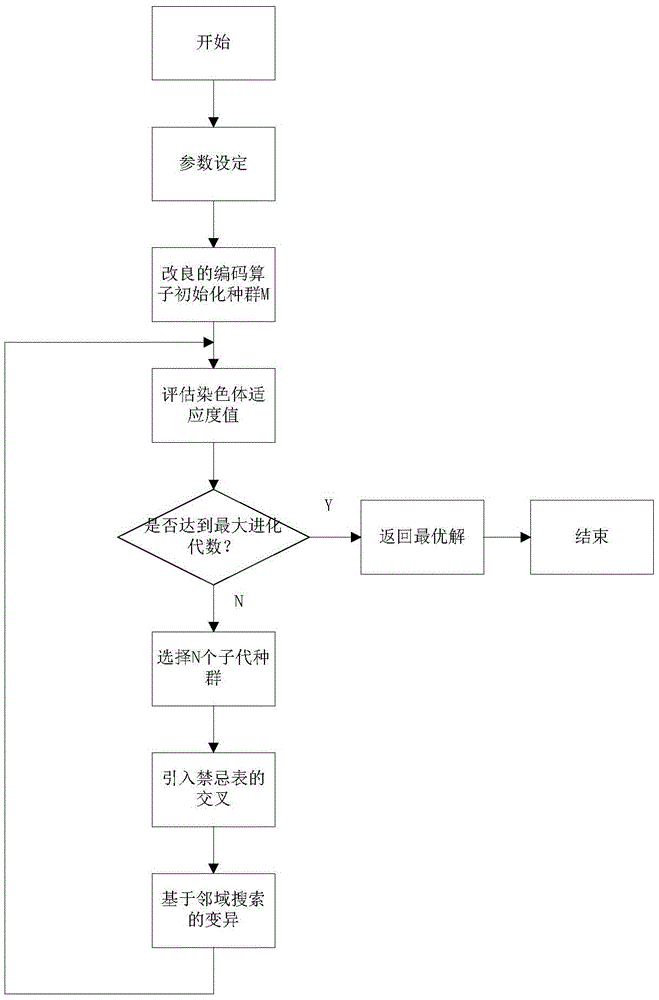

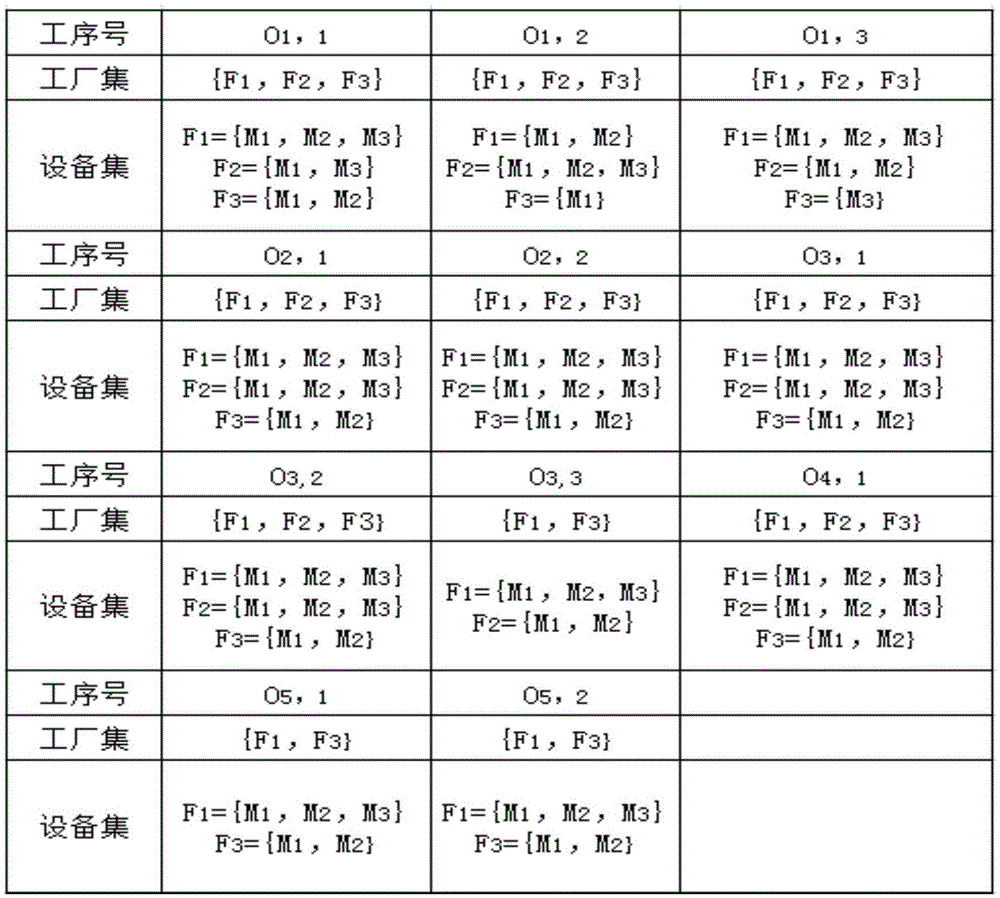

Genetic algorithm using improved coding method to solve distributed flexible job shop scheduling problem

InactiveCN106610652AFast convergenceImprove stabilityTotal factory controlProgramme total factory controlLocal optimumNeighborhood search

The invention provides a genetic algorithm using an improved coding method to solve a distributed flexible job shop scheduling problem. The algorithm is suitable for the field of flexible job shop scheduling. The distributed flexible job shop scheduling problem refers to production activities carried out in several factories and manufacturing units, contains the information of flexible job shop scheduling problems, and contains the selection of suitable factories and flexible manufacturing units. The allocation of specific workpieces to different factories produces different production scheduling, which affects a supply chain. The existing technology has little research on the problem. The invention proposes the genetic algorithm to solve the problem. A traditional genetic algorithm is easy to fall into local optimum and leads to premature convergence, and the coding method produces infeasible solution and other problems. According to the invention, the improved coding method based on probability is provided; the crossover of a tabu table is introduced; the problems are avoided based on the variation of neighborhood search; and the genetic algorithm takes into account the actual production situation, and has the characteristics of high practicability and the like.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

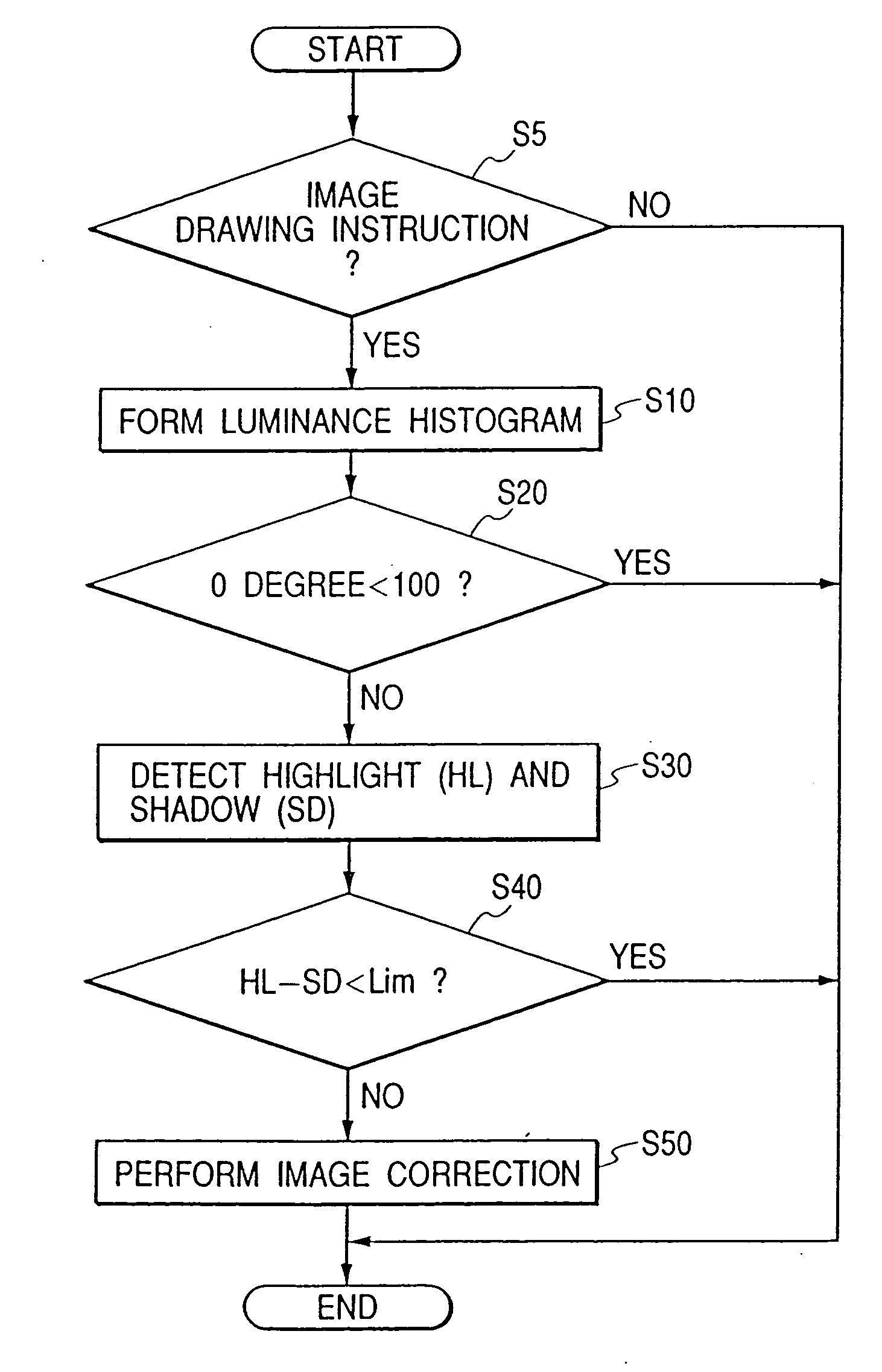

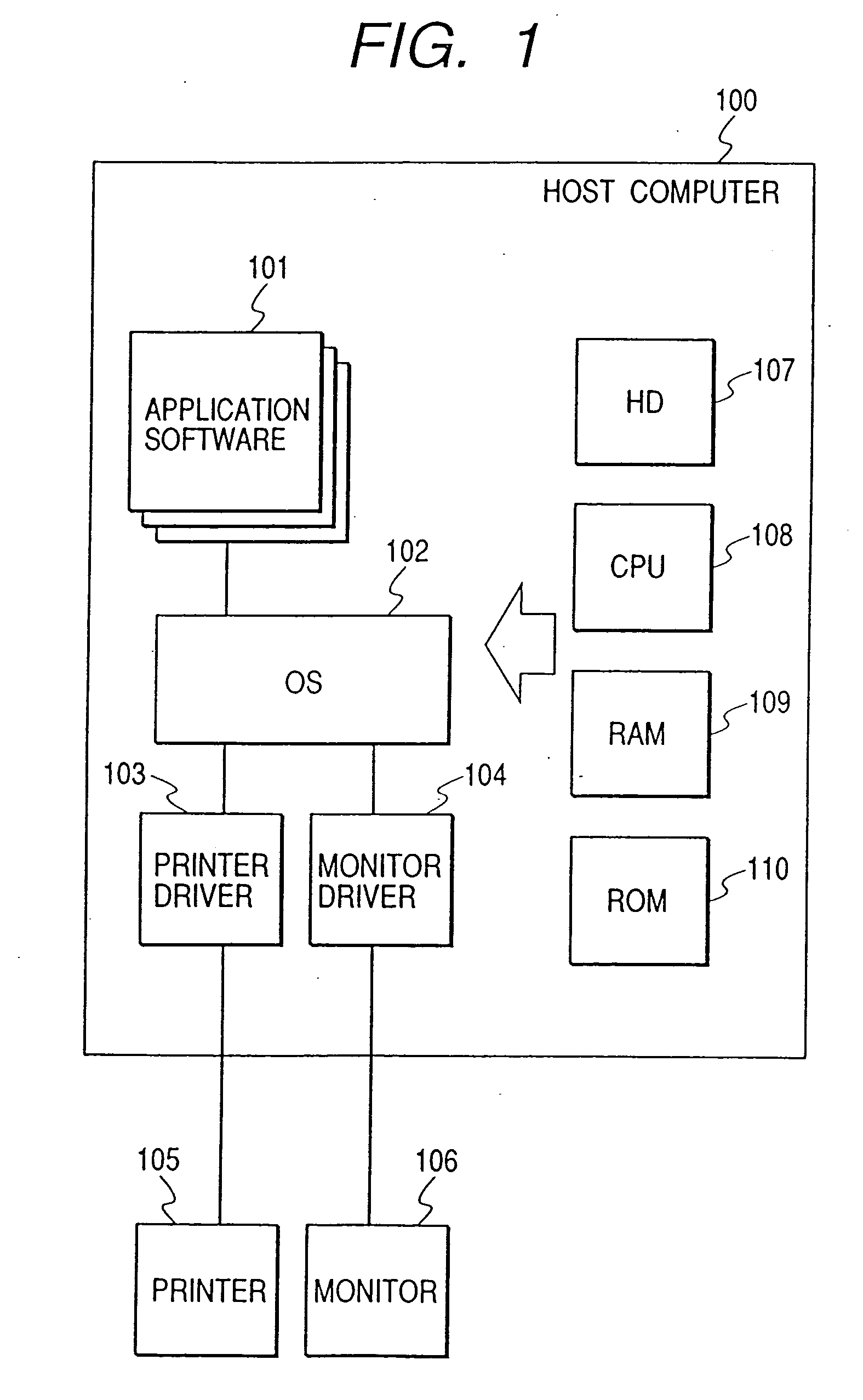

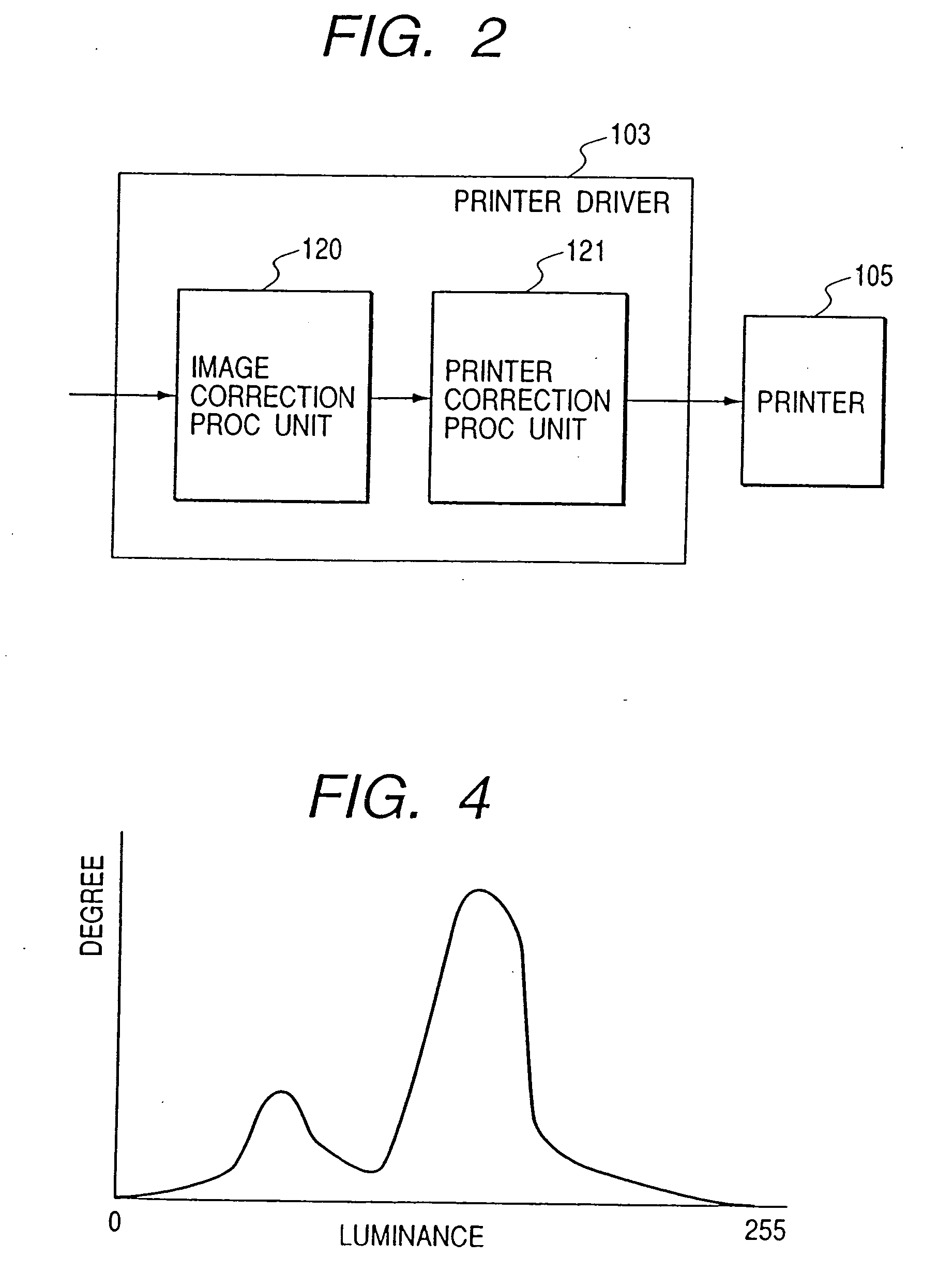

Image processing method and apparatus and storage medium

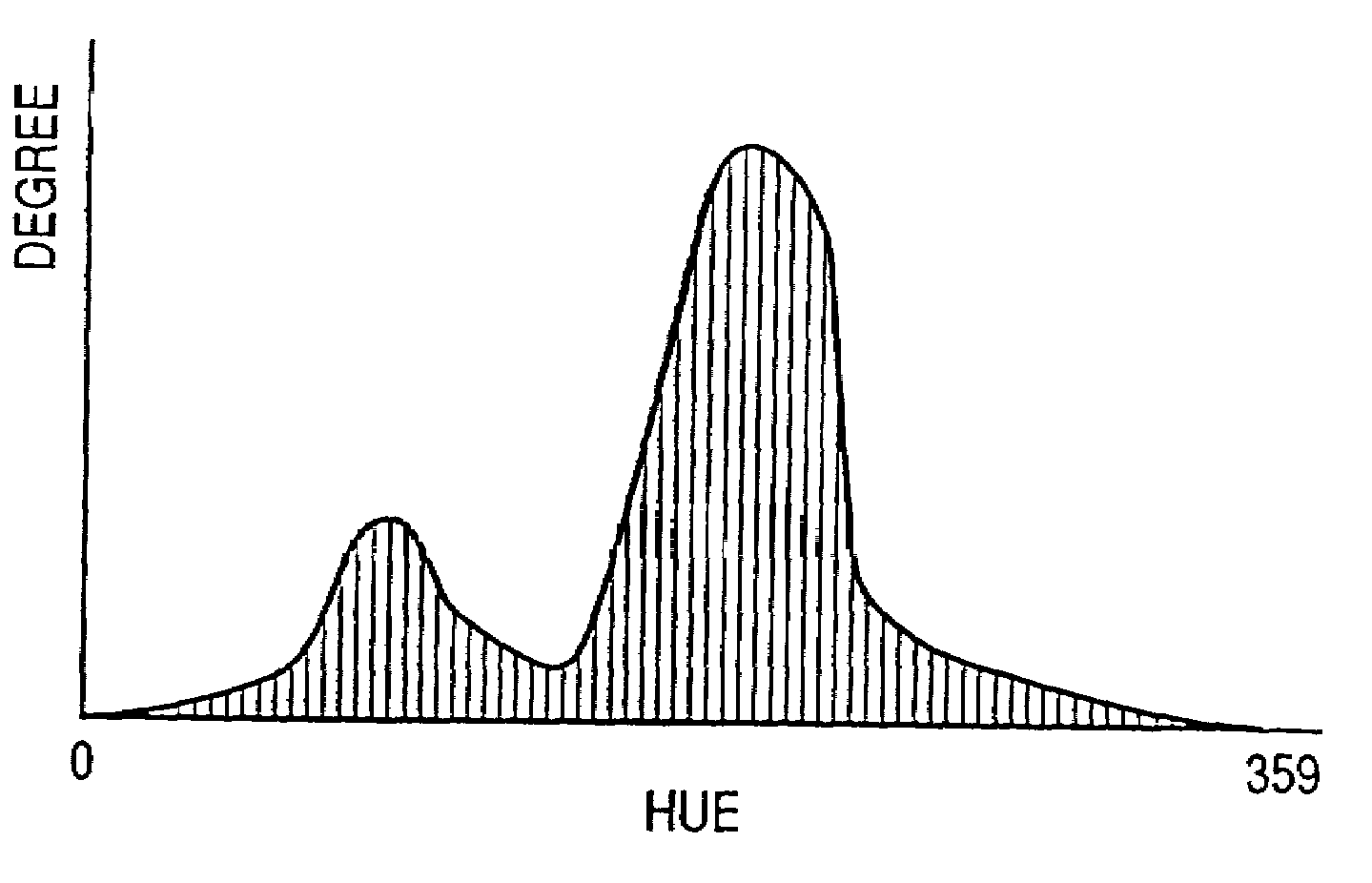

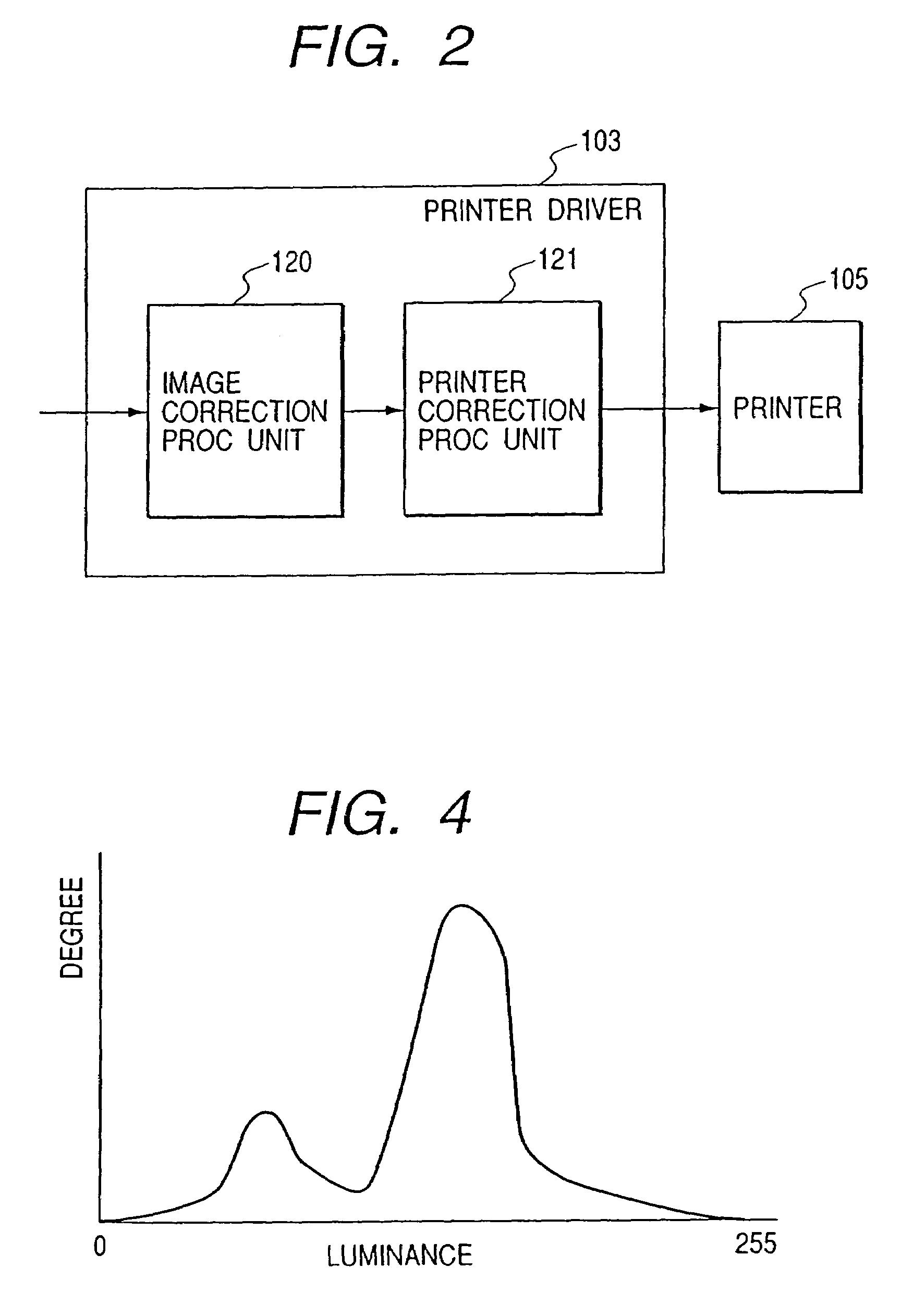

InactiveUS20040022434A1Easy to judgeAvoid correctionImage enhancementCharacter and pattern recognitionImaging processingImage correction

Software of a simple configuration checks whether an original image to be corrected is an image picture, and an image correction process based upon a formed histogram of the original image is not performed for an image different from the image picture. An image processing condition is set in accordance with the formed histogram to perform the image correction process for the original image. An image processing method judges from a shape of the formed histogram whether the original image is an image picture, and does not perform not perform the image correction process for the original image if it is judged that the original image is not an image picture.

Owner:CANON KK

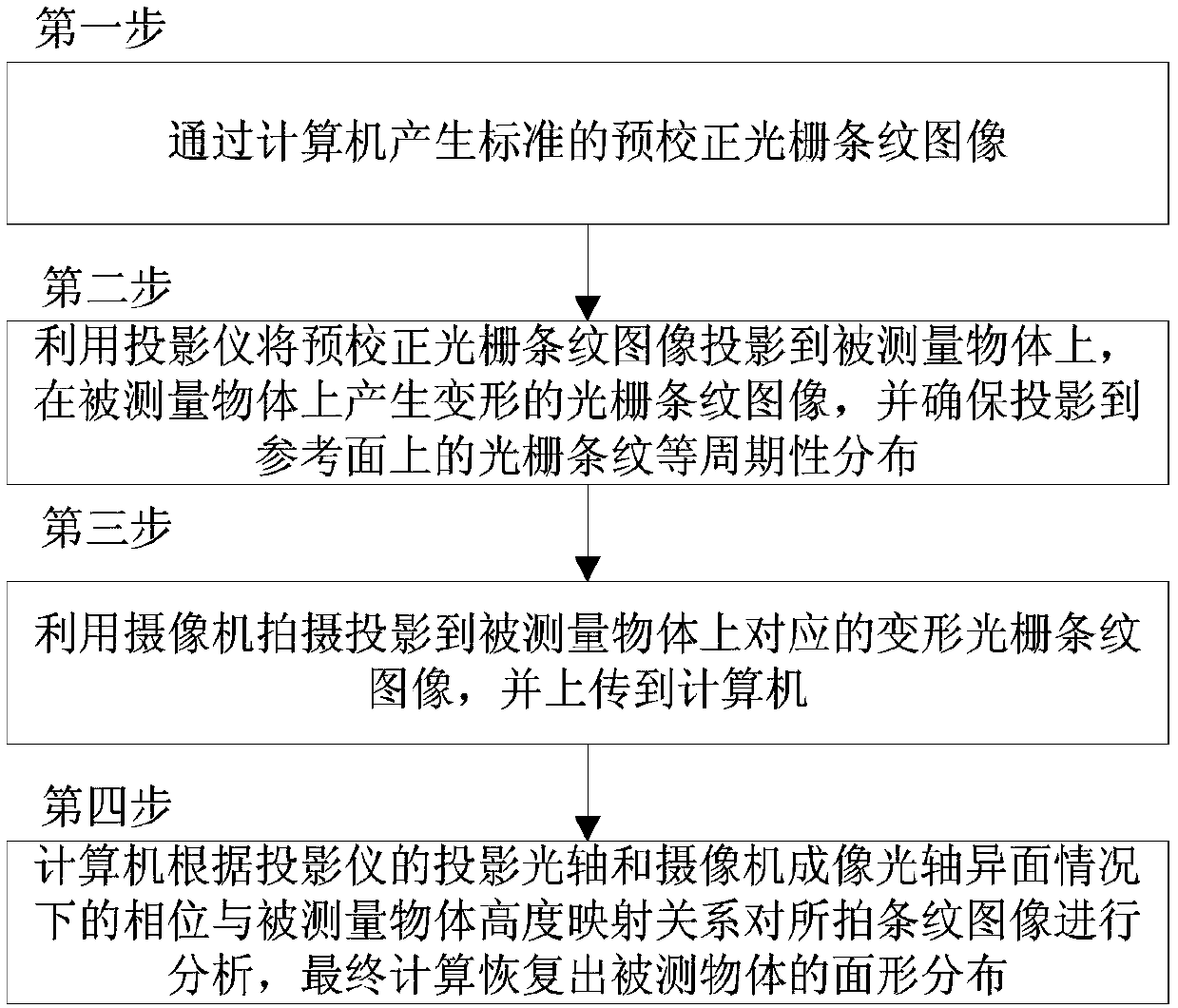

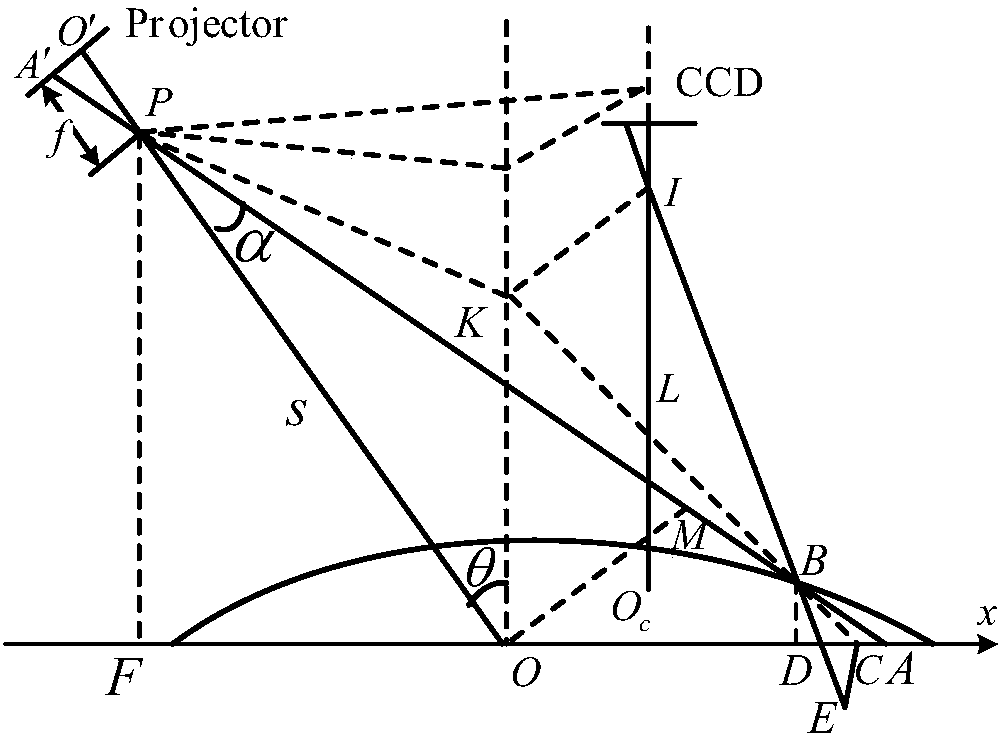

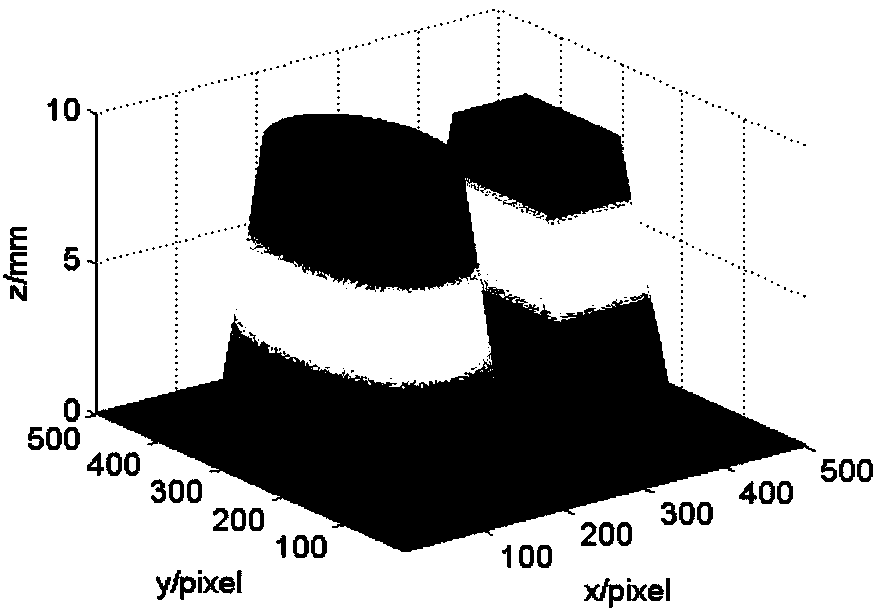

Three-dimensional surface shape measurement method based on precorrected grating projection

InactiveCN106017358AImprove Phase Measurement AccuracyEasy to buildUsing optical meansMapping algorithmOptical axis

The invention discloses a three-dimensional surface shape measurement method based on precorrected grating projection. The method includes the following steps that standard precorrected grating stripe images are generated through a computer; the precorrected grating stripe images are projected to a to-be-measured object through a projector, and it is guaranteed that grating stripes projected to a reference face are distributed in an equal-cycle mode; a camera shoots corresponding deformed grating stripe images projected to the to-be-measured object and uploads the images to the computer; the computer analyzes the shot stripe images according to the mapping relation between phases of a projection axis of the projector and an imaging optical axis of the camera on different surfaces condition and the height of the to-be-measured object, and finally the surface shape distribution of the to-be-measured object is calculated and recovered. By means of the three-dimensional surface shape measurement method, distribution of the projected grating stripes is improved, a phase-height mapping algorithm under the situation that the projection axis of the projector and the imaging optical axis of the camera are on different surfaces is derived, constraint conditions for system measurement are broadened, erection of a measurement system is easier, and high-precision measurement can be achieved.

Owner:HUAIYIN TEACHERS COLLEGE

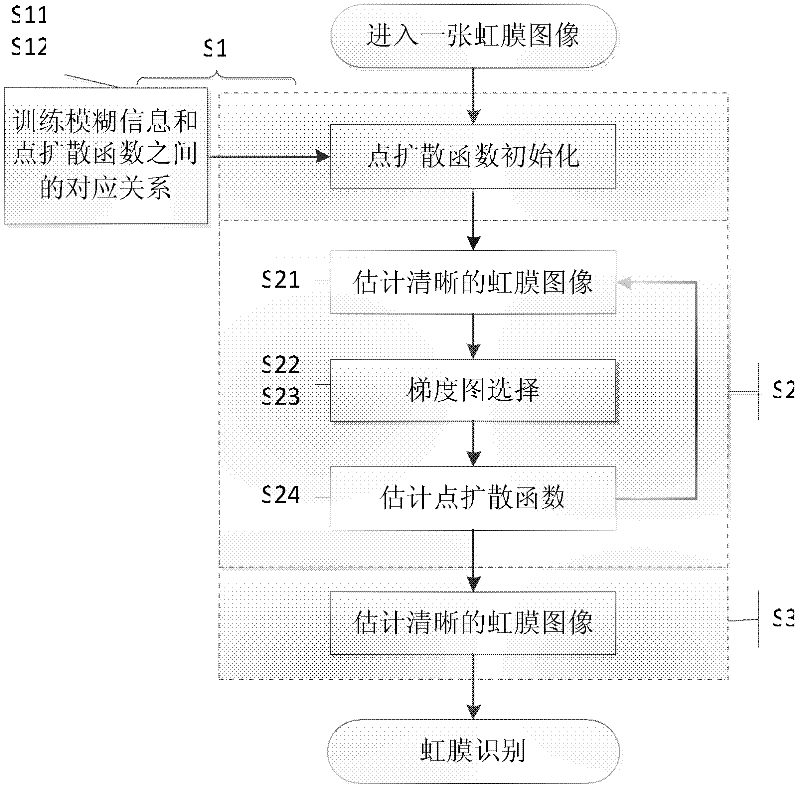

Method for deblurring iris image

ActiveCN102542535AImprove reliabilityImprove robustnessImage enhancementCharacter and pattern recognitionPoint spread functionIris image

The invention discloses a method for deblurring an iris image, which comprises the following steps of: a step S1, analyzing the input iris image, judging blur of the iris image belongs to defocus blur or motion blur and initializing according to a judging result to obtain a point spread function; a step S2, selecting the gradient of the input iris image so that the point spread function can be more effectively estimated on a selected gradient map, and further modifying the initialized point spread function on the basis of selected gradient information; and a step S3, on the basis of the modified point spread function, repairing the blurring iris image. According to the method, the adverse effect of the blurring iris image on the identification performance of a system can be effectively reduced, and the method can be widely applied to an iris identification system so as to improve the robustness and the reliability of the system and relax the requirement for a user.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

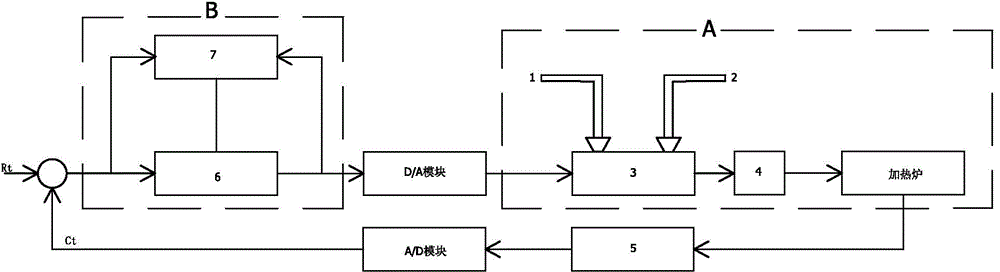

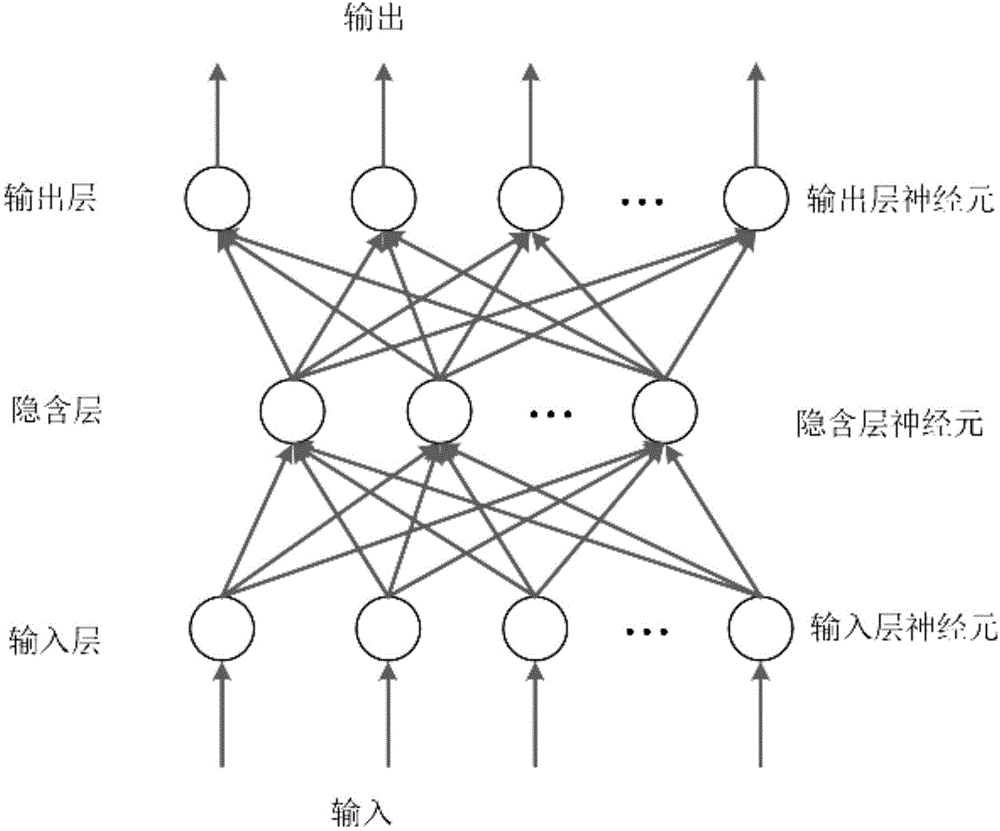

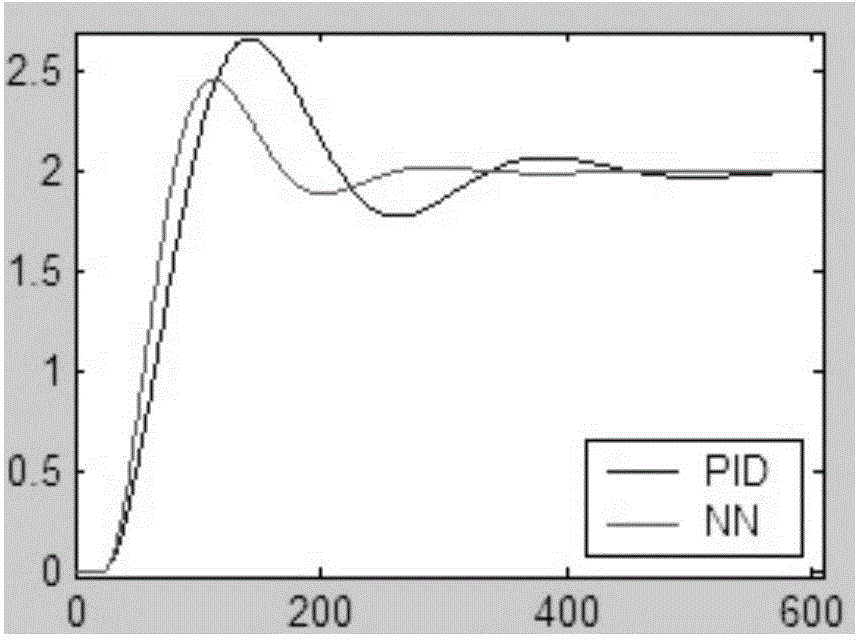

Aluminum rod heating furnace combustion temperature automation control device based on neural network

InactiveCN106292785ASmall overshootShort transition timeAuxillary controllers with auxillary heating devicesAutomatic controlHeating furnace

The invention discloses an aluminum rod heating furnace combustion temperature automation control device based on a neural network. The device contains a heating furnace combustion system and a temperature automation control electrical system. The temperature automation control electrical system contains a neural network control module. The neural network control module is connected to a PID controller. A neural network is divided into two portions of forward propagation and backward learning. The forward propagation of the neural network is used for outputting a proportion parameter Kp, an integration parameter Ki and a differential coefficient Kd in PID control. The backward learning of the neural network is used for adaptively adjusting a self network weight coefficient so that a PID control parameter correspondingly to one optimal control rule is output. In the invention, an aluminum rod heating furnace combustion temperature reaches a technological requirement, a rejection rate caused by a heating temperature change is reduced and work efficiency of aluminum rod pressing is increased, and adjusting time for the temperature to reach a stable state is reduced and energy consumption losses are decreased so that a purpose of reaching energy saving and emission reduction is achieved.

Owner:GUANGDONG XINGFA ALUMINUM +3

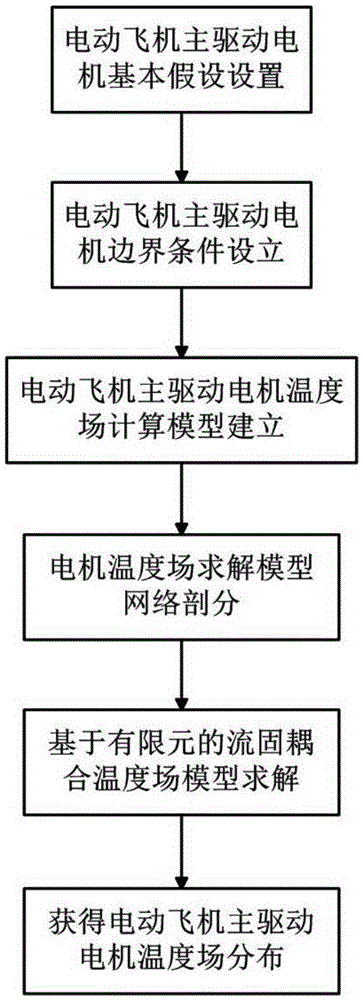

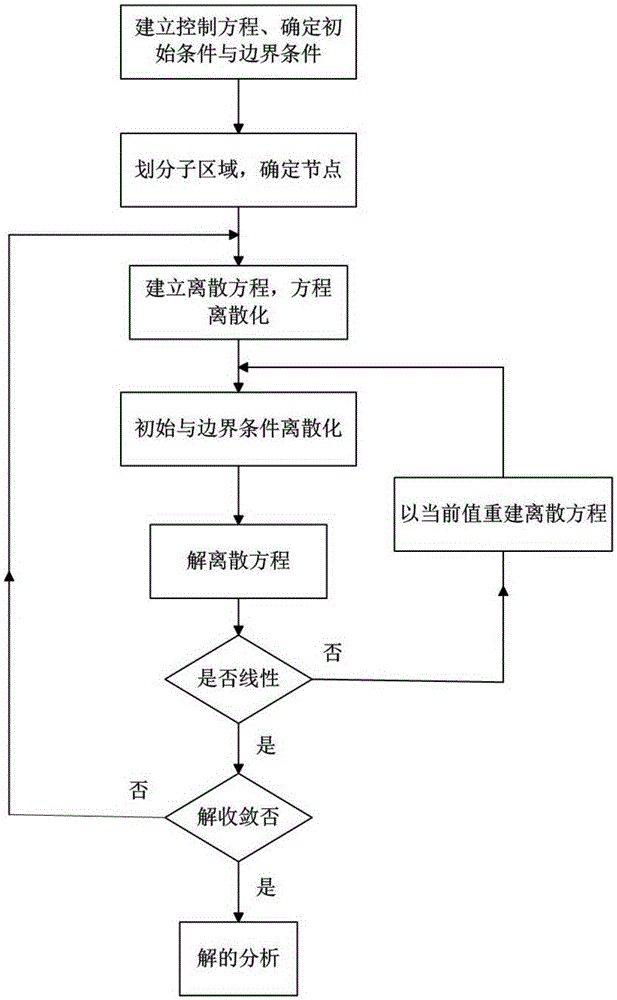

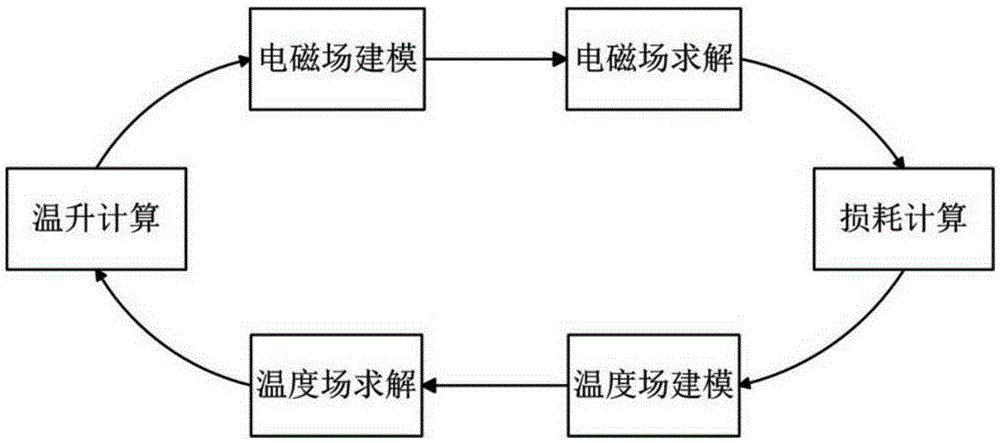

Method for calculating temperature field of main driving motor of electric aircraft

ActiveCN105354354AAvoid correctionHigh precisionDesign optimisation/simulationSpecial data processing applicationsMathematical modelElectric aircraft

The invention discloses a method for calculating a temperature field of a main driving motor of an electric aircraft. The method comprises: (1) in combination with a special structure of the main driving motor of the electric aircraft, setting a basic assumption of a solving process; (2) in combination with a practical working condition of the main driving motor of the electric aircraft, finishing the setting of boundary conditions of a fluid field and the temperature field; (3) establishing a mathematic model of the main driving motor of the electric aircraft; (4) establishing a physical model of the main driving motor of the electric aircraft, and finishing model network subdivision; and (5) based on a fluid-structure coupled differential equation, performing solving with a finite element numerical method to obtain temperature rise distribution of the main driving motor of the electric aircraft in different operation conditions. According to the method, the temperature field and the fluid field of the main driving motor of the electric aircraft are subjected to whole-field solving; the same mathematic model is adopted; and the method has the advantages of high solving speed, low iterative frequency and high calculation precision.

Owner:SHENYANG AEROSPACE UNIVERSITY

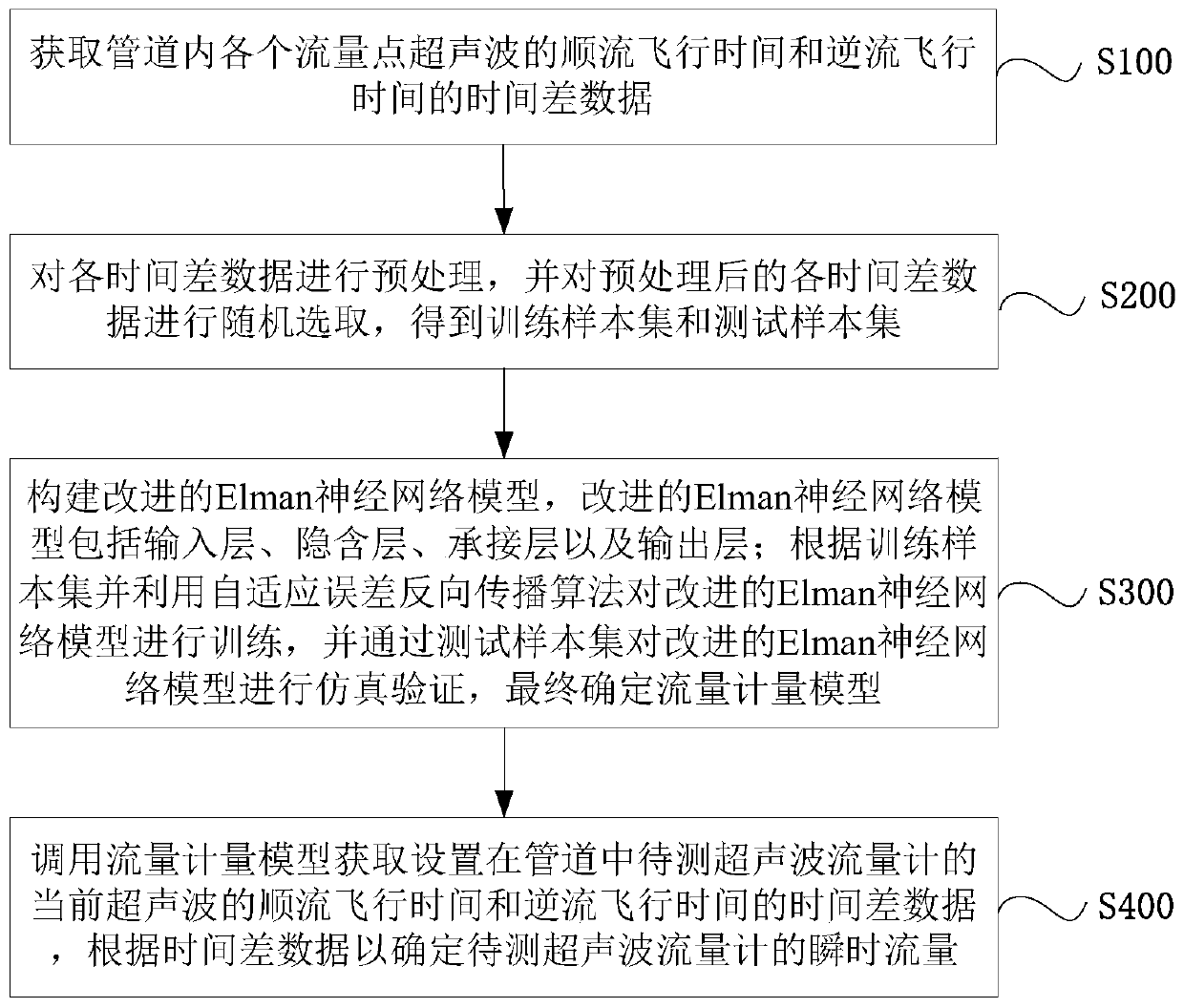

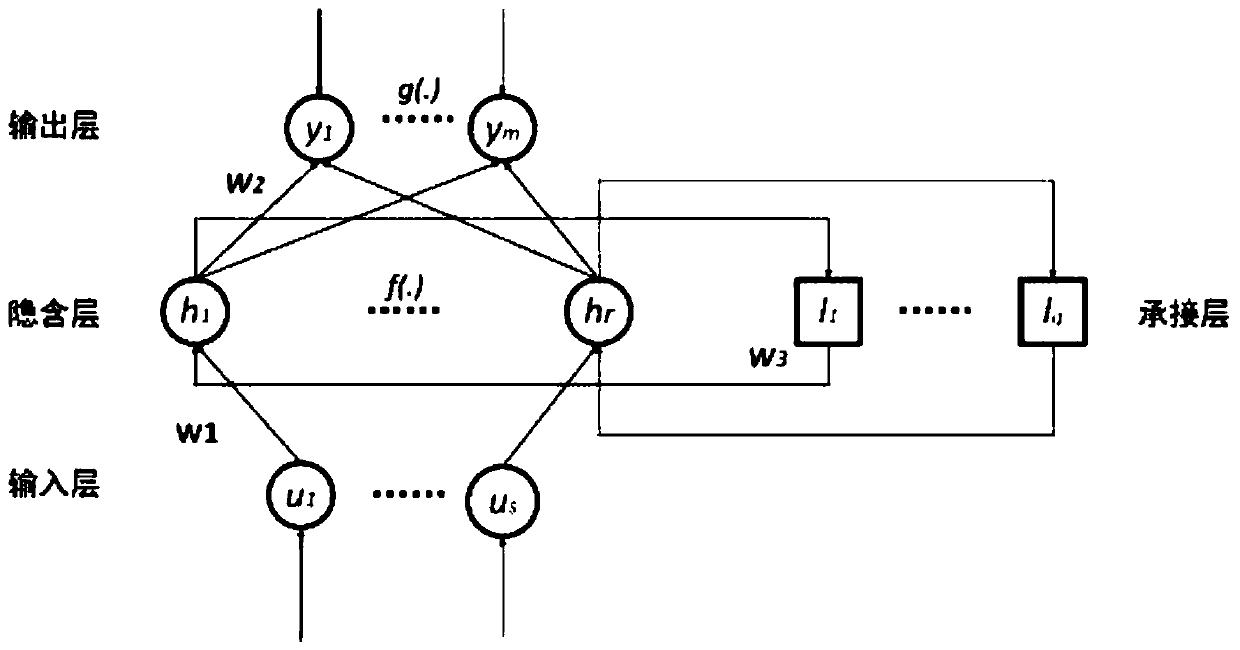

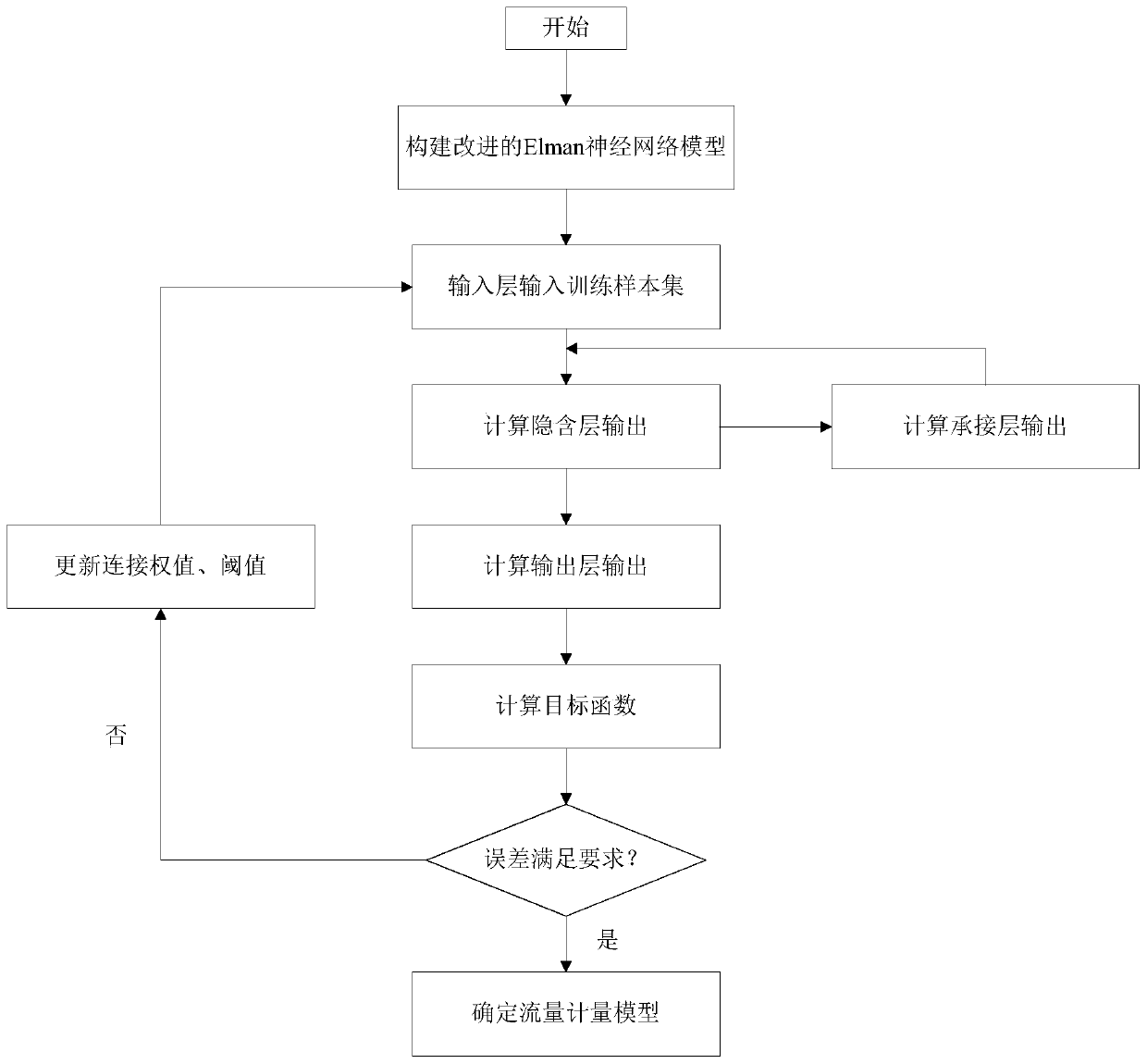

Metering method and system for flow of water meter based on improved Elman neural network

InactiveCN109724657AAvoid correctionAvoid errorsVolume/mass flow measurementNeural learning methodsAlgorithmTest sample

The invention discloses a metering method and system for flow of a water meter based on an improved Elman neural network. The method comprises acquiring time difference data of each flow point ultrasonic wave in a pipeline; performing random selection on the preprocessed time difference data to obtain a training sample set and a test sample set; constructing the improved Elman neural network model, training the improved Elman neural network model according to the training sample set and using an adaptive error inverse propagation algorithm, and performing simulation verification on the improved Elman neural network model through the test sample set to determine a flow metering model; and acquiring the time difference data of the current ultrasonic wave of a to-be-detected ultrasonic flowmeter by calling the flow metering model, and determining the instantaneous flow rate of the to-be-detected ultrasonic flowmeter according to the time difference data. According to the metering method and system for flow of the water meter based on the improved Elman neural network, the adaptive error inverse propagation algorithm is adopted for training, so that the specific convergence speed is high, thereby avoiding the problem that complex parameter correction and correction compensation are involved to reduce the metering error, and the measurement precision is high.

Owner:HANGZHOU LAISON TECH CO LTD

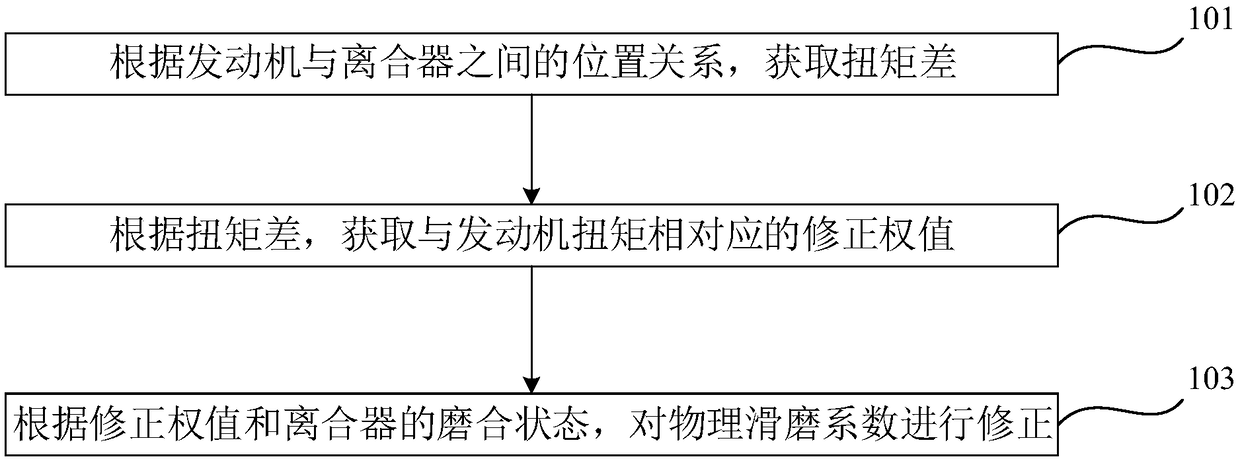

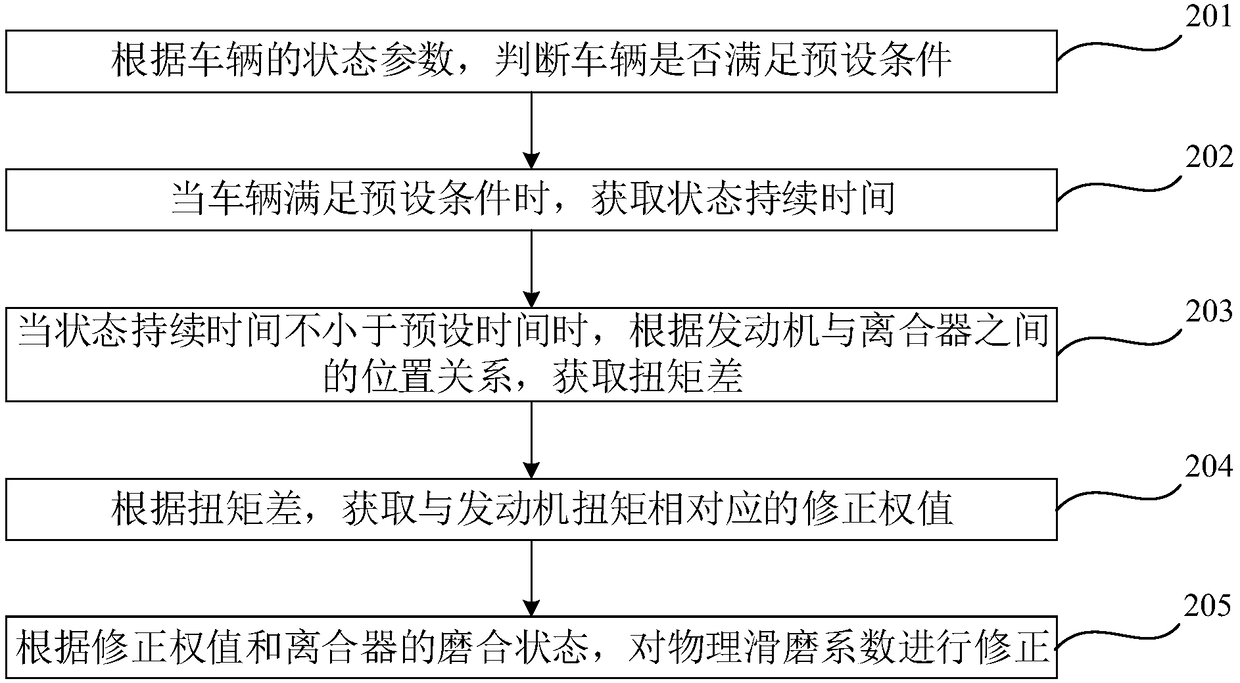

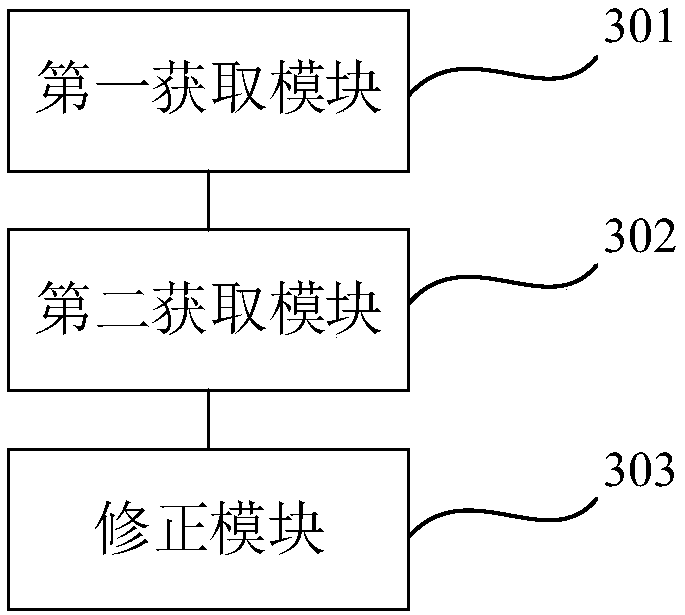

Clutch physical slip grinding coefficient correcting method and device

The invention provides a clutch physical slip grinding coefficient correcting method and device. The clutch physical slip grinding coefficient correcting method comprises the following steps that according to the position relation between an engine and a clutch, the torque difference is obtained, a correction weight corresponding to the torque of the engine is obtained according to the torque difference, and the physical slip grinding coefficient is corrected according to the correction weight and the grinding-in state of the clutch. According to the clutch physical slip grinding coefficient correcting method, through the position relation between the engine and the clutch, the torque difference is obtained by means of a mode corresponding to the position relation so that the torque difference can be obtained in real time, moreover, the correction weight corresponding to the torque of the engine can be obtained according to the torque difference, then the physical slip grinding coefficient is corrected according to the correction weight and the grinding-in state of the clutch, so that the situation that the physical slip grinding coefficient can be corrected only under the condition that the rotating speed difference interval is relatively small is avoided, the physical slip grinding coefficient can be corrected at any time, and comprehensiveness and flexibility of correcting the physical slip grinding coefficient are improved.

Owner:GREAT WALL MOTOR CO LTD

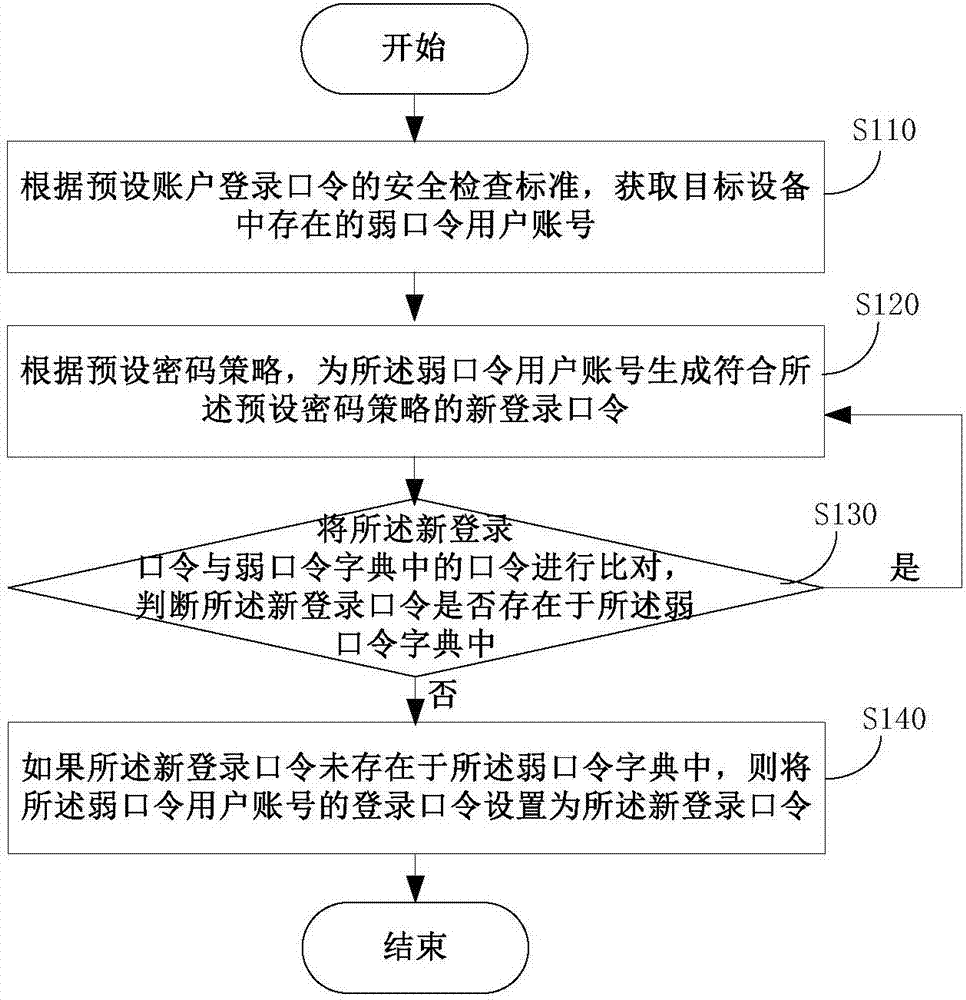

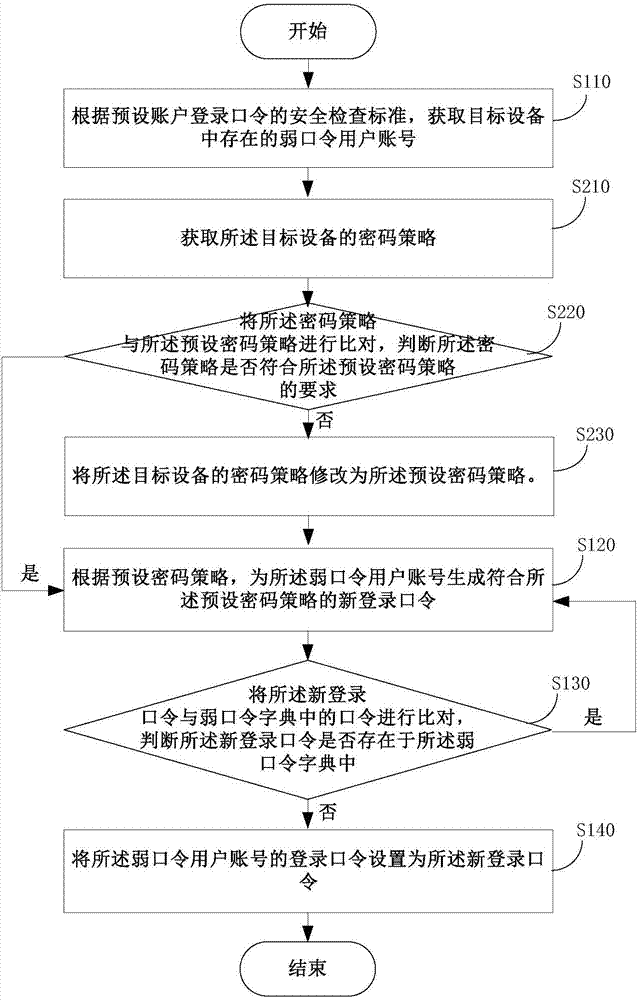

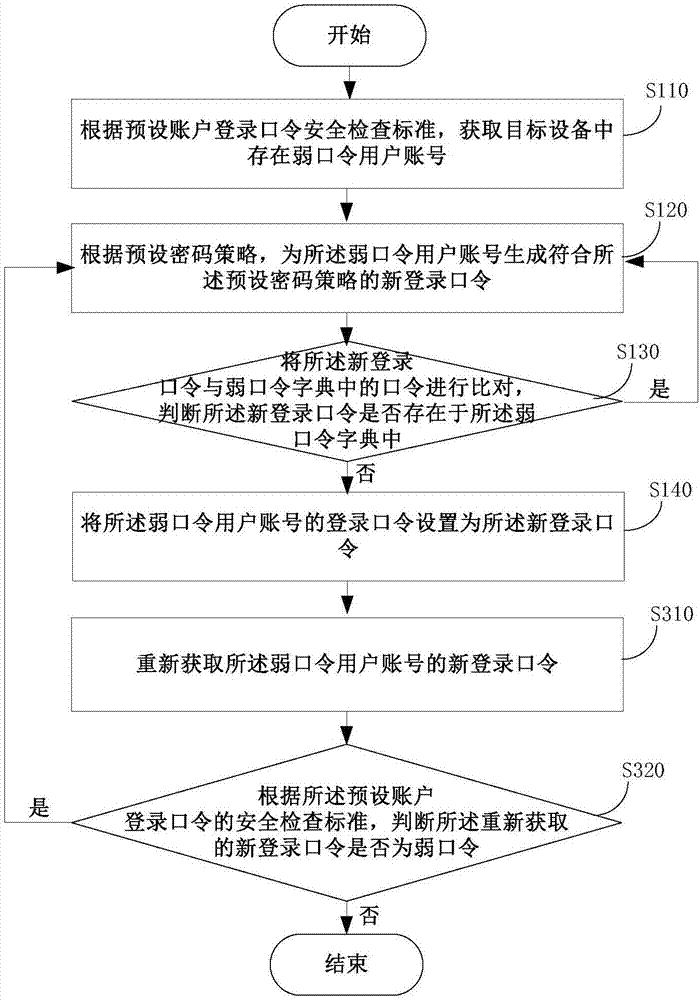

Method and device for managing device weak password

ActiveCN107196899AAccurate timingAvoid correctionTransmissionPassword policyApproaches of management

The invention discloses a method and a device for managing a device weak password. The method comprises steps: according to a preset account login password security check standard, a user account with a weak password in a target device is acquired; according to a preset password policy, a new login password meeting the preset password policy is generated for the user account with a weak password, weak password detection is carried out on the generated new login password, and if the new login password is not a weak password, the login password of the user account with the weak password is set to be the new login password. According to the method provided by the invention, weak password check and automatic repairing can be completed automatically, the work of a maintenance person can be lessened, the weak password in the device can be timely corrected, existence of a weak password in a network system is eliminated in a shortest time, and system data loss caused by a weak password and economic loss brought to an enterprise are further avoided.

Owner:ULTRAPOWER SOFTWARE +1

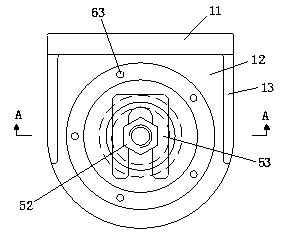

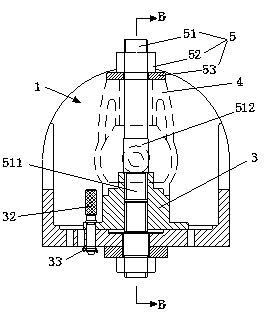

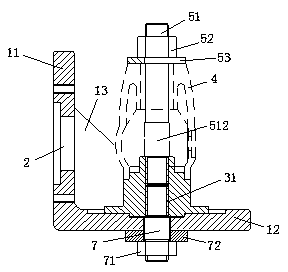

Tool used for machining blade holes of axial flow pump impeller body

ActiveCN103707106ASolving Concentricity ProblemsSolve the measurement datum problem of key dimensionsPositioning apparatusMetal-working holdersAxial-flow pumpImpeller

The invention relates to a tool used for machining blade holes of an axial flow pump impeller body. The tool comprises a rotary body fixed to a lathe spindle, wherein a scale dividing block is fixed on the rotary body, a fastening device used for fixing a workpiece on the scale dividing block is arranged above the scale dividing block, a first layer of positioning pin holes, a second layer of positioning pin holes and a third layer of positioning pine holes are formed in the outer side of the scale dividing block in the circumferential direction from inside to outside, and positioning pins matched with the positioning pin holes are arranged on the scale dividing block. According to the technical scheme, an installation method with the tool directly connected with a lathe is adopted, a rotating center in the direction same as the rotating direction of the lathe spindle is generated for each blade hole to be machined, and concentricity is achieved between the blade holes to be machined and the lathe spindle; by means of the cooperation between the scale dividing block and the rotary body and the utilization of a scale dividing mechanism, fast and accurate scale division is achieved easily when the blade holes rotate along with the scale dividing block during machining; a cylindrical section arranged on a pull rod enables the measuring basis of the critical dimension to be available during lathe machining.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

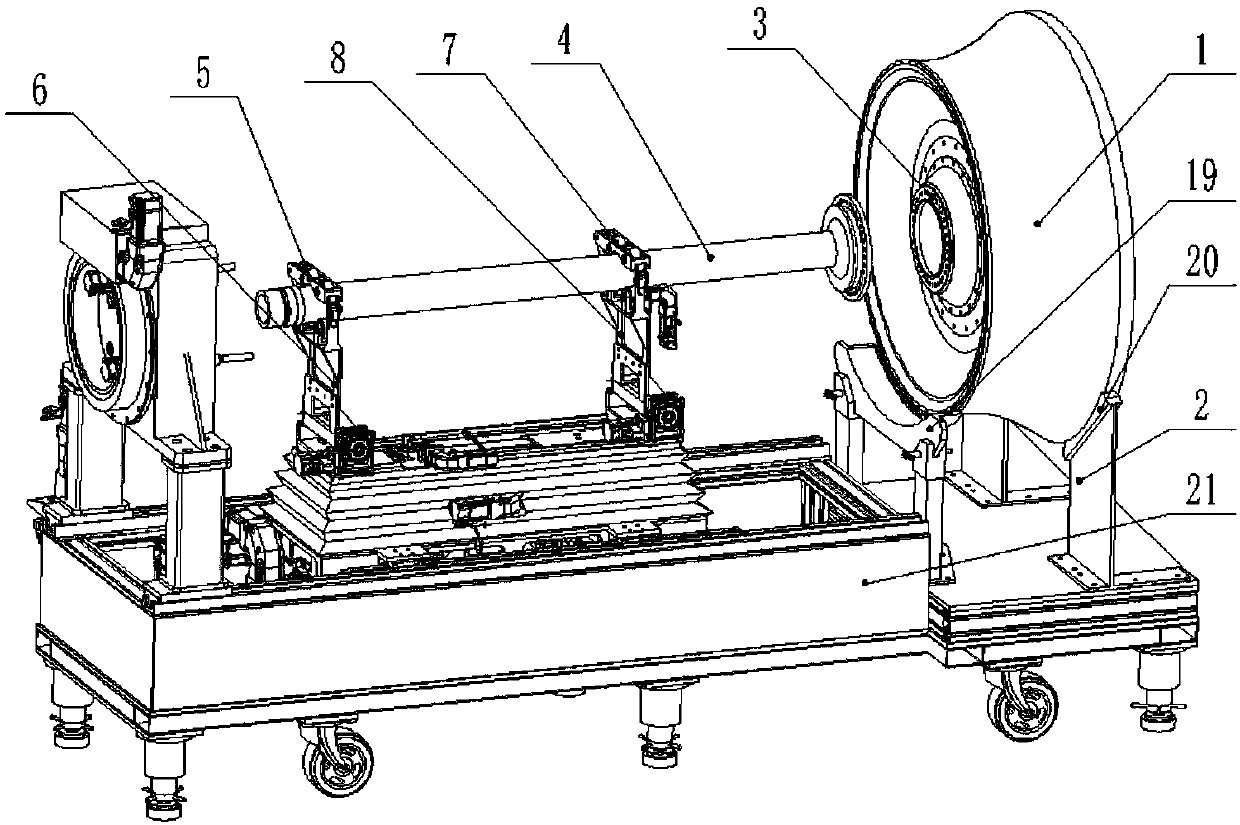

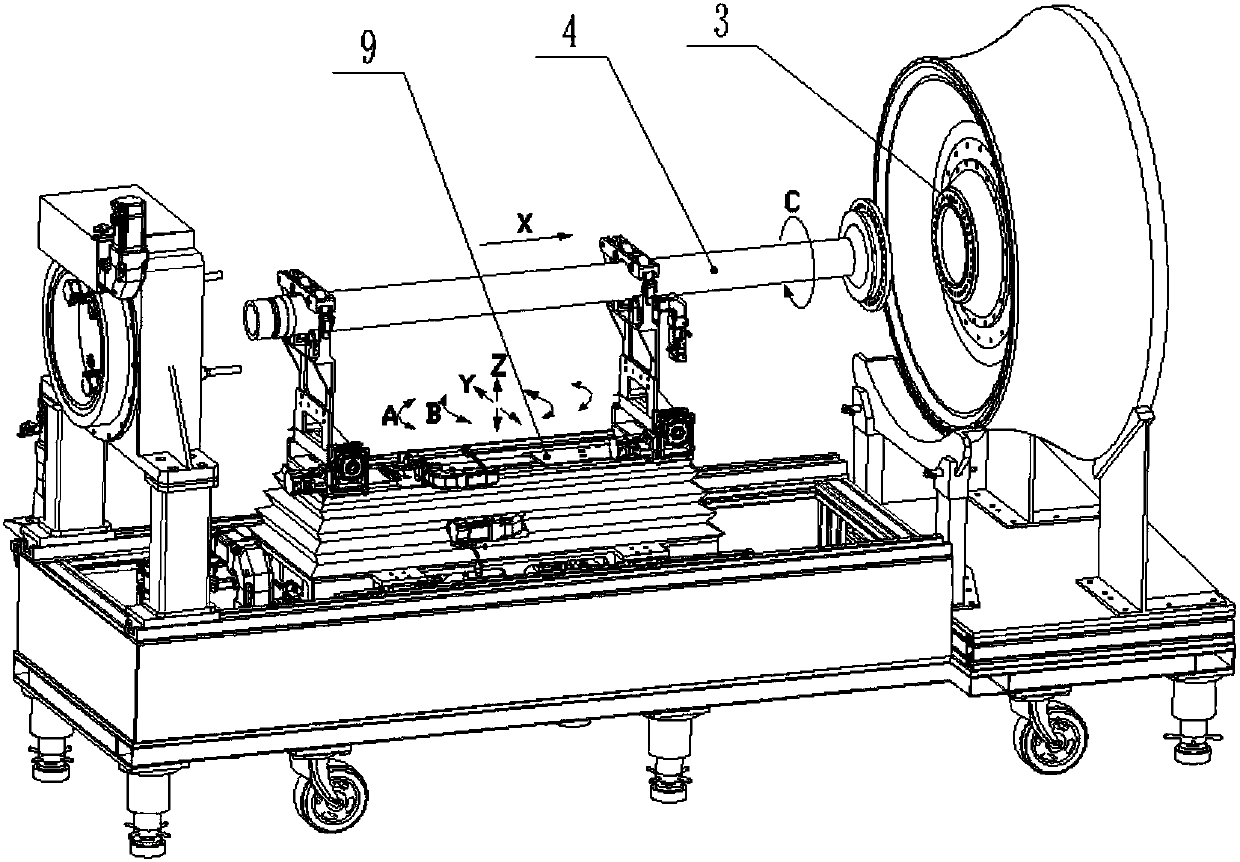

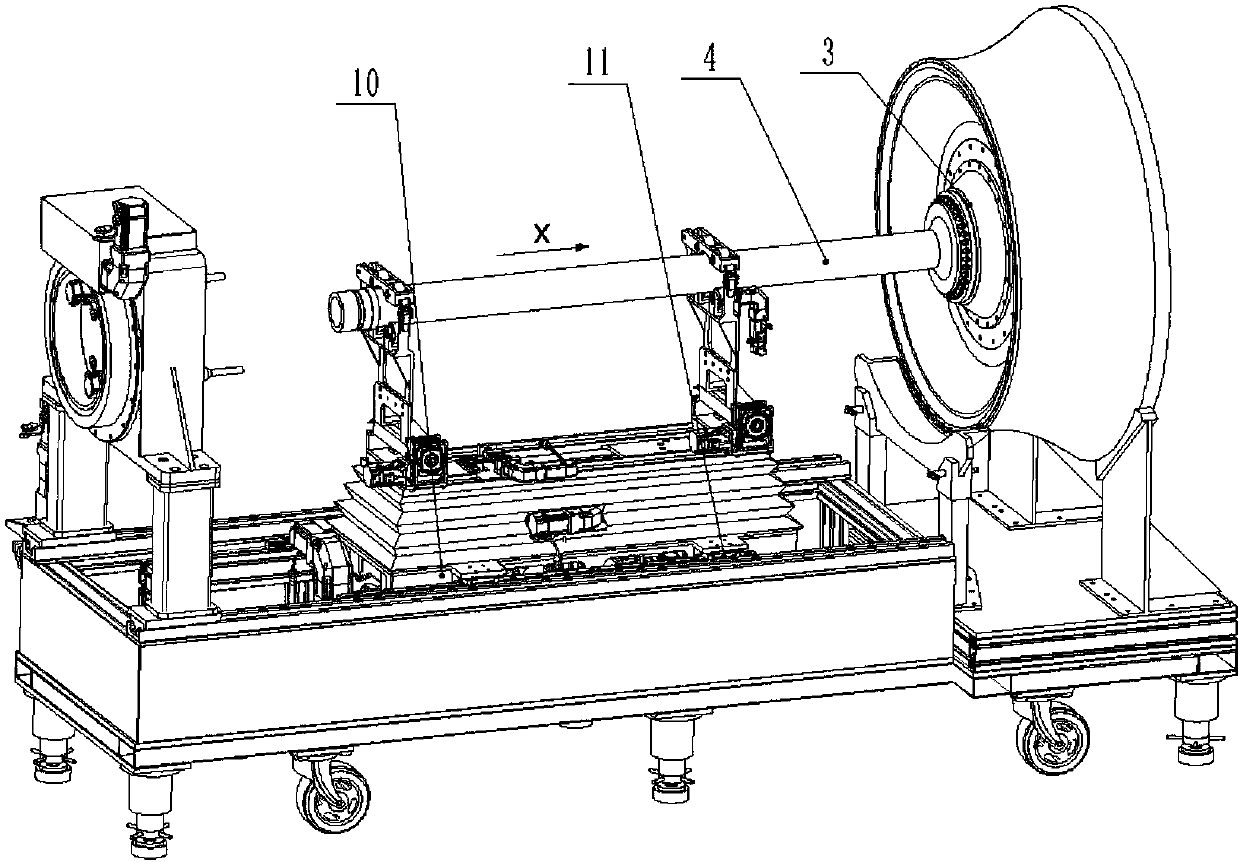

Assembling method for low-pressure turbine shaft-disc assembly of aero-engine

The invention discloses an assembling method for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembling method comprises the following steps that workpieces are installed, the position and the posture of a turbine shaft are adjusted; the turbine shaft butts joint and is pre-installed; an indexable tightening system is fed to a front end operation area; a tightening shaft is tightened; and the indexable tightening system returns back. According to the assembling method for the low-pressure turbine shaft-disc assembly of the aero-engine, an assembly mode that an axis of a low-pressure turbine shaft-disc is horizontal is adopted, the position and the posture of the low-pressure turbine shaft with the large length are adjusted precisely and advantageously in the butt-joint process, centering positioning alignment and end face correct close fitting of the turbine shaft relative to a connecting disc are achieved, and the butt-joint and assembling precision is improved;a turbine shaft position and posture adjusting table is applied, quantitative position and posture adjusting is conducted on the low-pressure turbine shaft through a mechanical way, experiential methods such as traditional manual hanger operating are replaced, manual repeated trial assembly and correction are avoided, the butt-joint efficiency is improved, and assembly consistency requirements ofassemblies are met; and the indexable tightening system is adopted, worker skill requirements and the labor intensity are reduced, and the tightening efficiency is improved.

Owner:DALIAN UNIV OF TECH

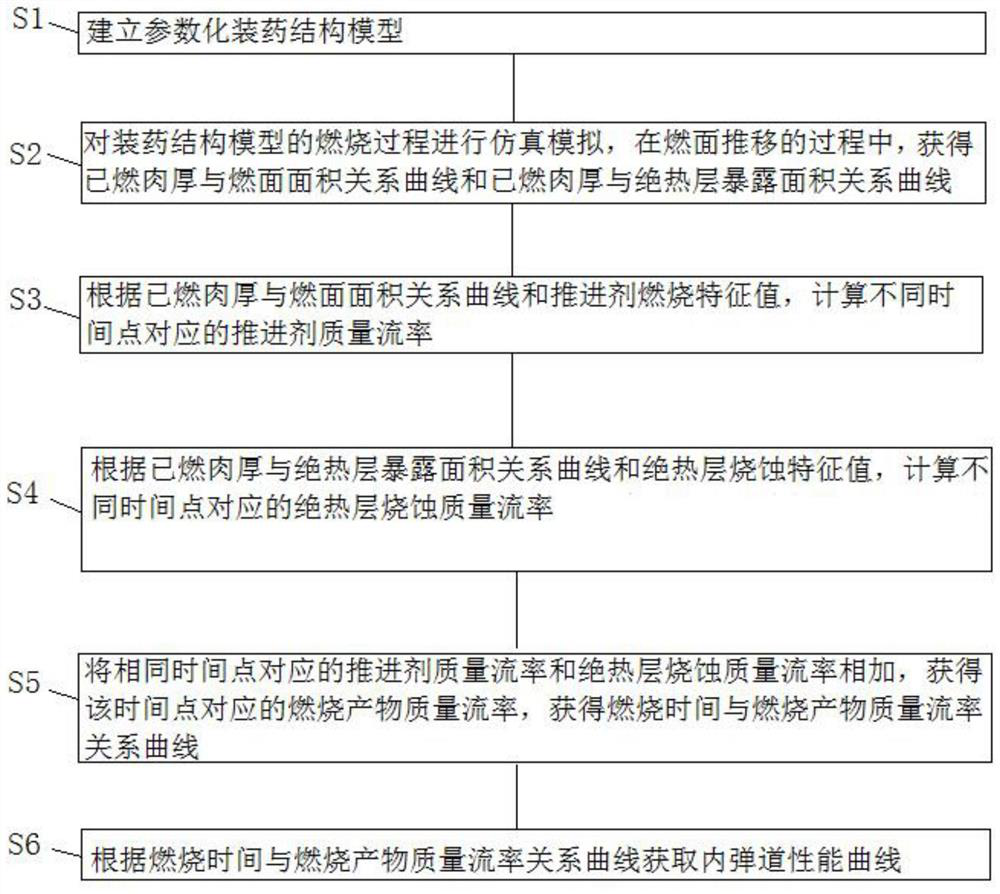

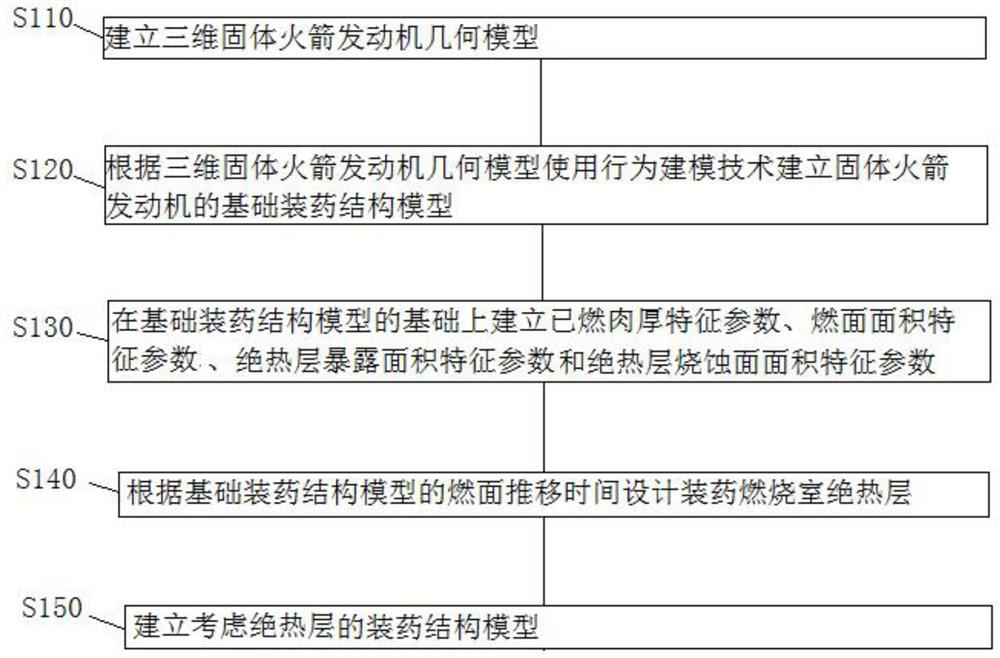

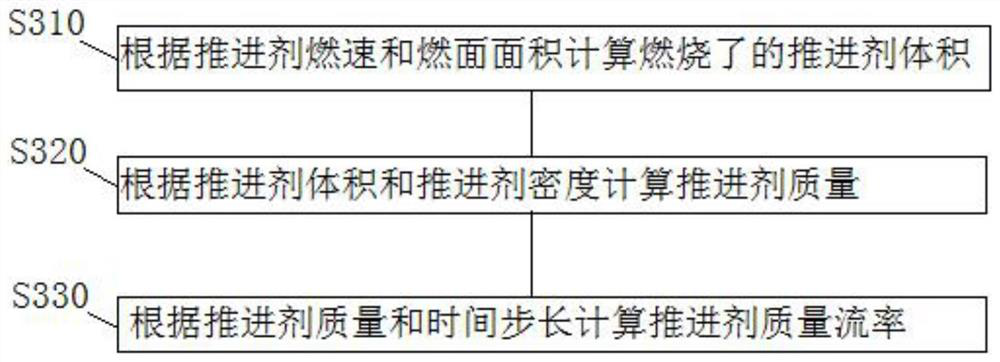

Method for predicting internal ballistic performance of solid rocket engine

ActiveCN111814348AHigh precisionAvoid correctionGeometric CADDesign optimisation/simulationThermodynamicsInsulation layer

The invention provides a method for predicting internal ballistic performance of a solid rocket engine. The method comprises the following steps of: establishing a parameterized charging structure model; carrying out analogue simulation on the combustion process of the charging structure model, and outputting a relation curve between combusted thickness and a combustion surface and a relation curve between the combusted thickness and the exposed area of a heat insulation layer; calculating propellant mass flow rates corresponding to different time points according to the relation curve of thecombusted thickness and the area of the combustion surface, calculating the ablation mass flow rates of the heat insulation layer corresponding to the different time points according to the relation curve of the combusted thickness and the exposure area of the heat insulation layer, adding the propellant mass flow rate and the ablation mass flow rate of the heat insulation layer corresponding to the same time point, and outputting the relation curve of time and combustion product mass flow rates; and obtaining an internal ballistic performance curve according to the relation curve of the combustion time and the combustion product mass flow rates. The method obviously improves the prediction precision of the internal ballistic performance in of solid rocket engine before a ignition test, optimizes the performance of the solid rocket engine, and reduces the development time and development cost.

Owner:广州中科宇航探索技术有限公司

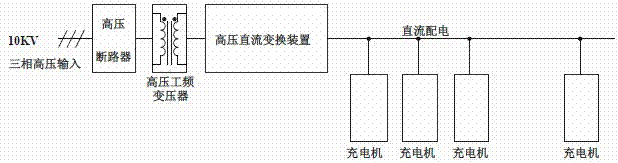

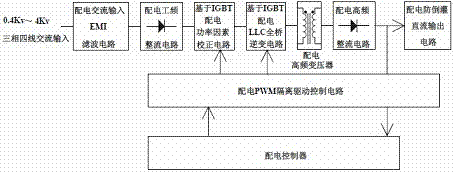

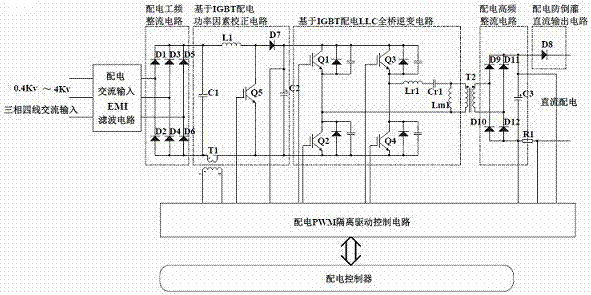

High withstand voltage IGBT DC power distribution based electric vehicle charging station

InactiveCN107069891ASolve the rectificationAvoid correctionCharging stationsMobile unit charging stationsTransformerPower factor

The invention discloses a high withstand voltage IGBT DC power distribution based electric vehicle charging station. The high withstand voltage IGBT DC power distribution based electric vehicle charging station comprises a high-voltage circuit breaker, a high-voltage power frequency transformer, a high-voltage DC conversion device and a charger. A three-phase high-voltage input voltage is connected with the high-voltage power frequency transformer through the high-voltage circuit breaker; the output end of the high-voltage power frequency transformer is connected with the high-voltage DC conversion device; and the high-voltage DC conversion device converts a three-phase high-voltage input AC power into a DC power and then supplies to DC power to the charger. By adoption of the high withstand voltage IGBT, the high-voltage DC conversion device realizes power factor correction, LLC full bridge inversion and a DC power distribution scheme of converting the three-phase high-voltage input AC power into the DC power and then supplying the DC power to the charger; and without power factor correction, the design of the DC charging module is simplified, the power density of the DC charging module is improved, the reliability of the charger is improved and the cost of the charger is reduced. In addition, the high withstand voltage IGBT DC power distribution based electric vehicle charging station increases the device IP protection level, improves the working reliability of the device in an outdoor malicious environment and prolongs the service life of the device.

Owner:GUANGDONG THOUSANDS OF CITIES & CHARGING STATIONS E VEHICLES OPERATING CO LTD

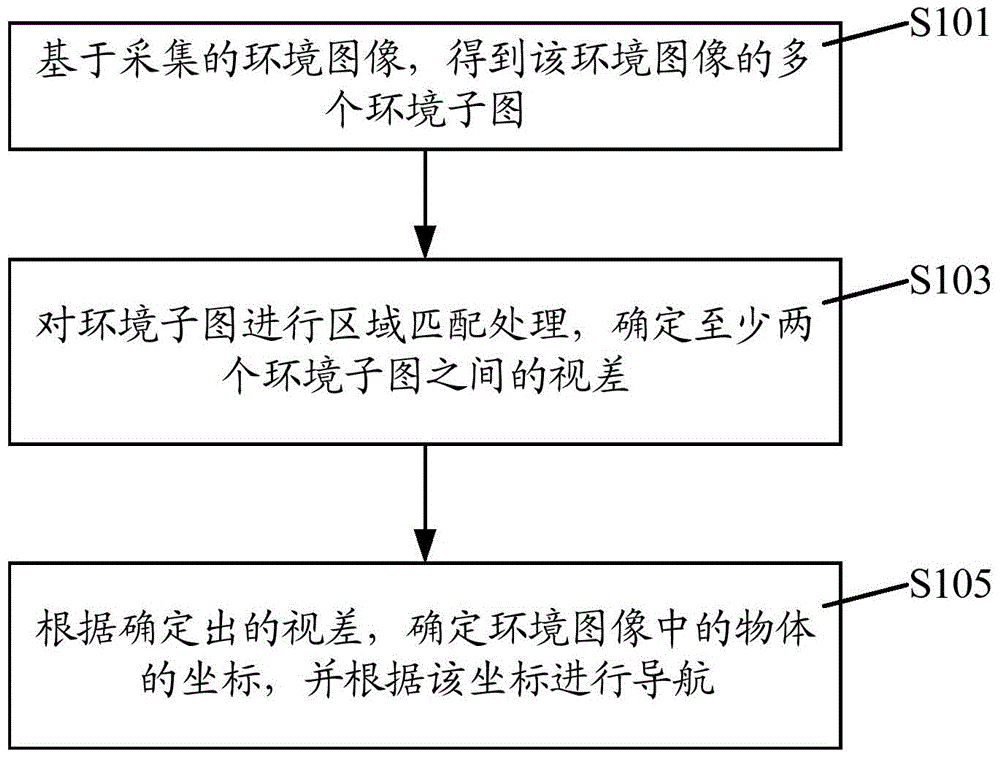

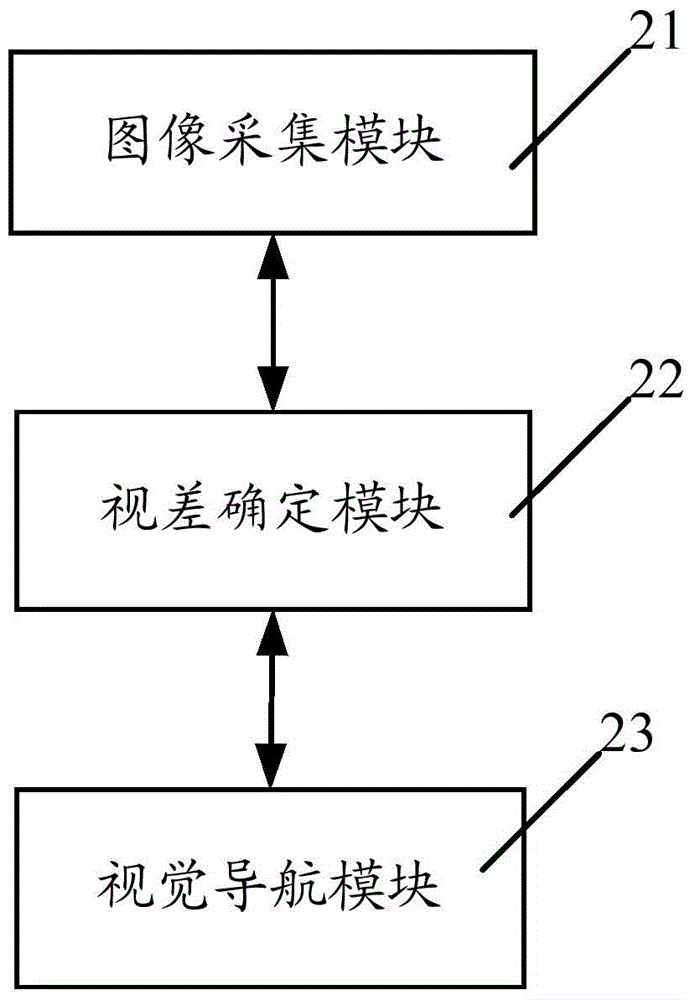

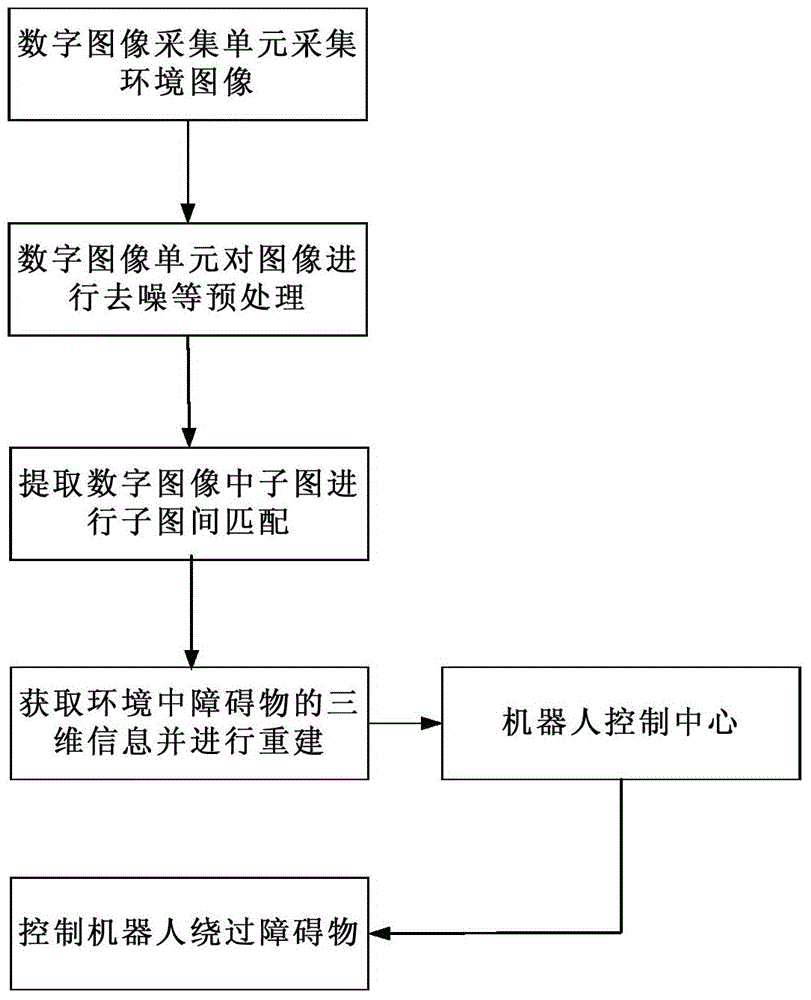

Visual navigation method and device and robot

A visual navigation method and device. The visual navigation method comprises: obtaining, on the basis of a captured environmental image, multiple environmental subimages of the environmental image; performing region matching on the environmental subimages and determining a parallax between at least two environmental subimages; and determining a coordinate of an object in the environmental image according to the determined parallax and performing navigation according to the coordinate. By capturing an environmental image using a camera, obtaining multiple environmental subimages by means of a micro lens array on the basis of the environmental image, and performing stereo matching and three-dimensional reconstruction according to the environmental subimages, the function of visual navigation is achieved; both horizontal parallax information and vertical parallax information of an object can be obtained, so that accuracy of navigation is effectively improved.

Owner:CHINA ACAD OF TELECOMM TECH

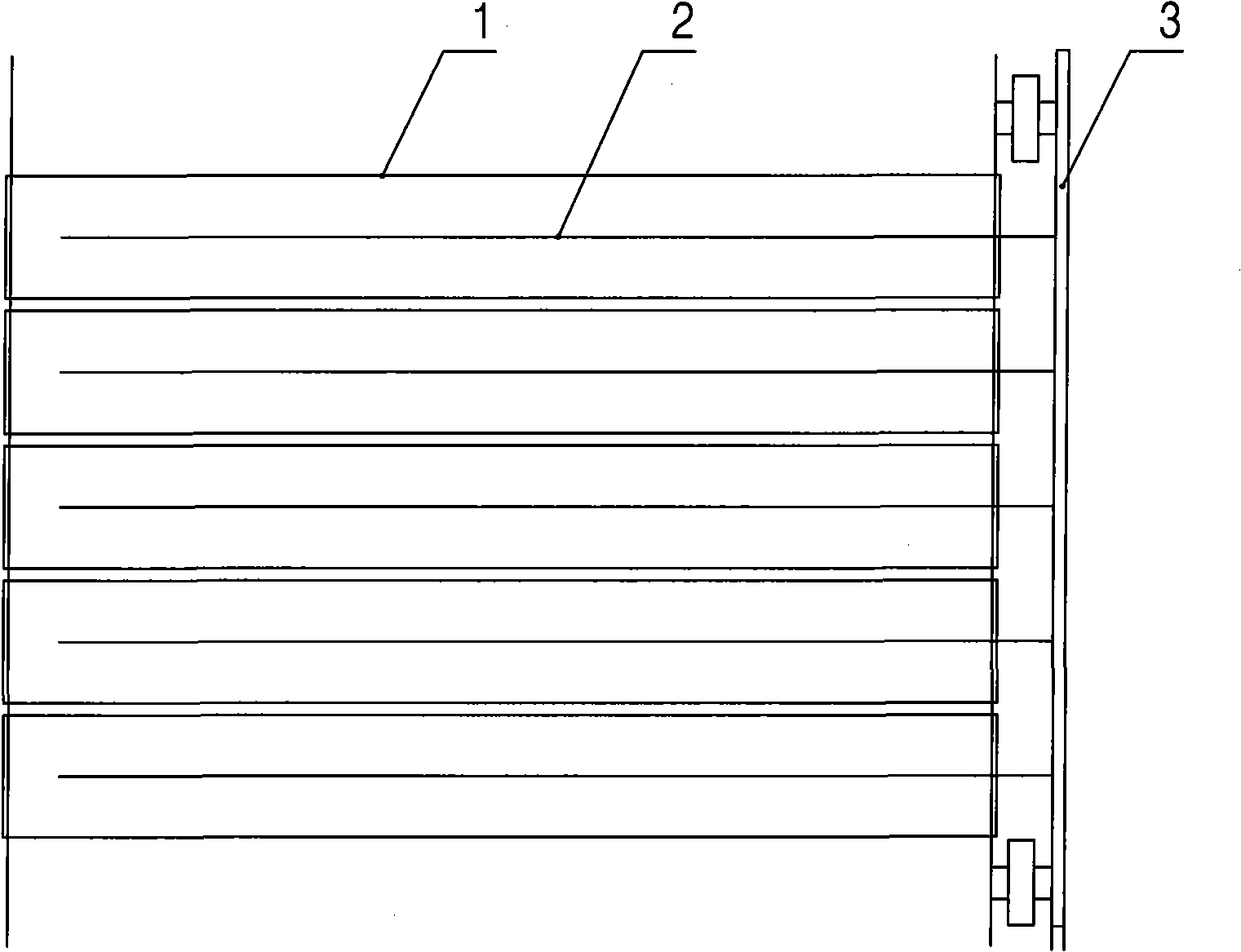

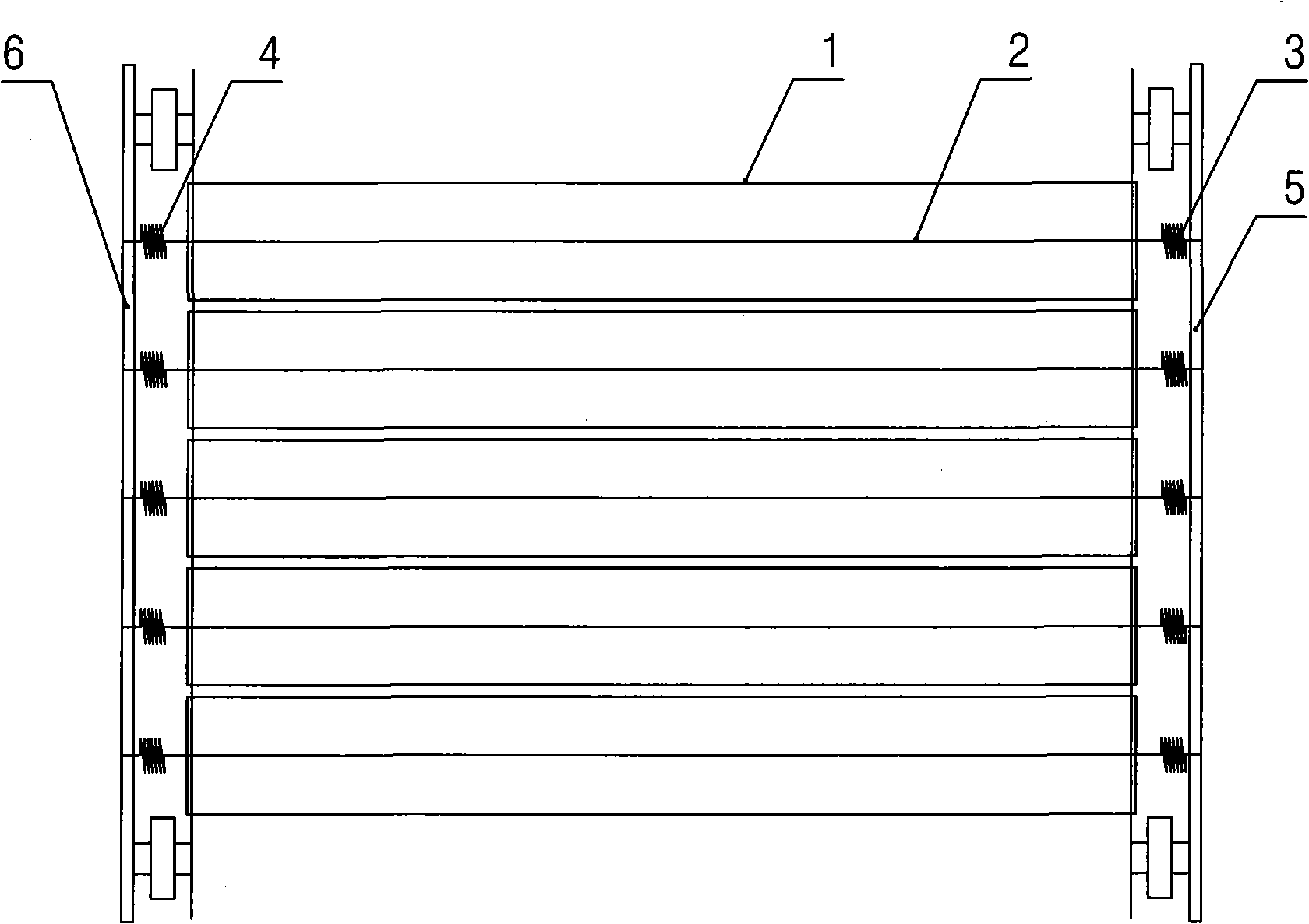

Mounting structure of wire electrode of honeycomb electric field

The invention discloses a wirelike electrode assembling structure of a honeycomb electric field, which enables a wirelike electrode to keep straight all the time, and comprises a wirelike electrode arranged in a tubular electrode, wherein, the two ends of the wirelike electrode are fastened on a pair of supports positioned on the two sides of the wirelike electrode through a pair of springs. The wirelike electrode assembling structure is characterized in that the wirelike electrode can be fastened on a pair of supports through a pair of springs, so the straightness of the wirelike electrode can be ensured, namely, the wirelike electrode cannot droop, thereby guaranteeing the reliable operation of the electrode of the honeycomb electric field, and also preventing the periodic correction carried out to the wirelike electrode and the correction carried out to the wirelike electrode after the cleaning process.

Owner:江苏保丽洁环境科技股份有限公司

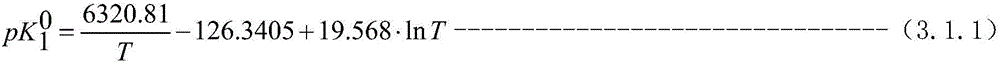

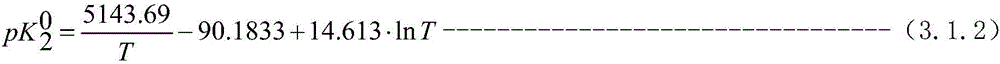

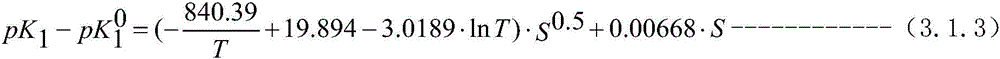

Detection method of pH value of coastal seawater

ActiveCN106093326AAvoid correctionAvoid the hassle of changing electrode tipsTesting waterSeawaterOrganic acid

The invention provides a detection method of the pH value of coastal seawater. The pH value of coastal seawater rich in organic matters is accurately detected by detecting a variety of physical and chemical parameters of the seawater. The detection method comprises the following steps: acquiring a seawater sample; detecting a variety of physical and chemical parameters of the seawater sample; calculating the dissociation constants of a variety of acids; and analyzing and calculating the alkalinity of each component. According to the method, contribution of organic acids in the seawater to alkalinity is taken into consideration; the rule of influence of organic acids in the coastal seawater on the pH value is obtained through study; deviations caused by negligence of organic acids in the process of detection of the pH value of seawater are avoided; and a novel method is provided for high-precision detection of the pH value of the coastal seawater.

Owner:OCEAN UNIV OF CHINA

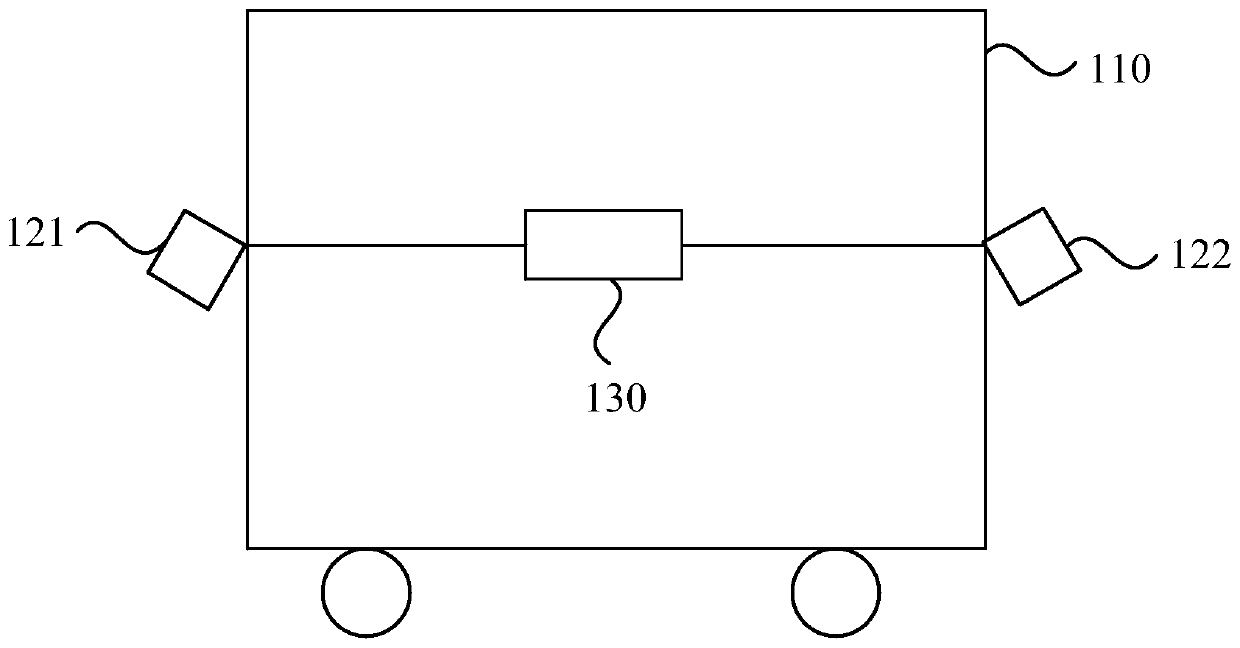

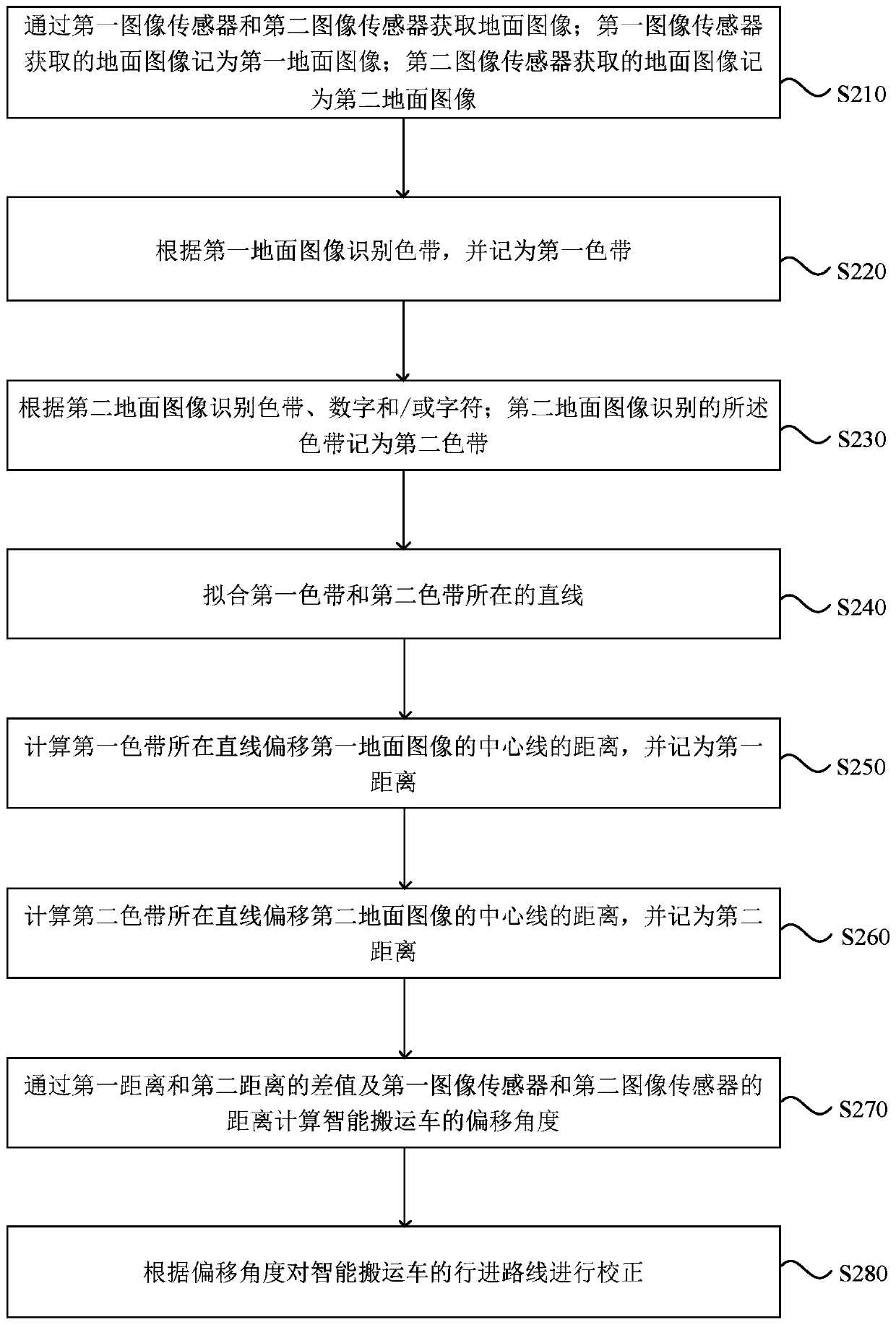

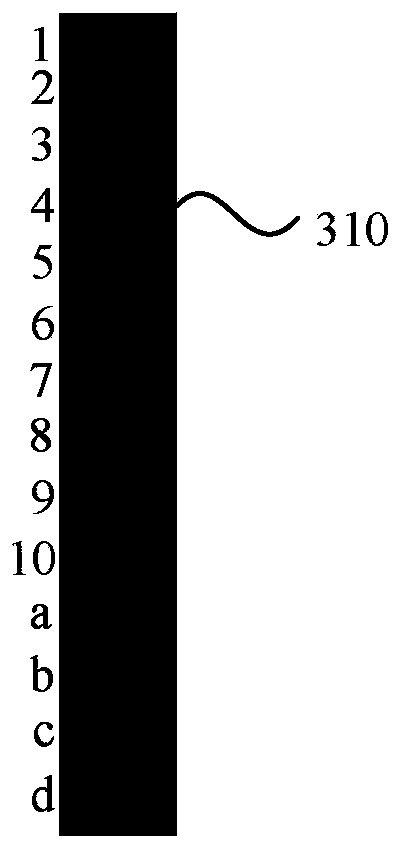

Intelligent carrier, navigation method and device thereof, equipment, and storage medium

InactiveCN110488833AAvoid correctionTelevision system detailsLifting devicesComputer scienceMarine navigation

The embodiment of the invention discloses an intelligent carrier, a navigation method and device thereof, equipment, and a storage medium. The intelligent carrier comprises a vehicle body, at least two image sensors and an operation processing unit are installed on the carrier body, the image sensors are used for acquiring ground images of a same advancing direction and an opposite advancing direction of the vehicle body and are connected with the operation processing unit. The operation processing unit is used for controlling the intelligent carrier based on the ground images obtained by theimage sensors. The plurality of image sensors collect the ground images at the same time, so that the processing speed is increased, whether the advancing route of the intelligent carrier deviates ornot can be determined, and the advancing route of the intelligent carrier is corrected.

Owner:国以贤智能科技(上海)股份有限公司

Image processing method and apparatus and storage medium

InactiveUS7146045B2Easy to judgeAvoid correctionImage enhancementCharacter and pattern recognitionImaging processingImage correction

Software of a simple configuration checks whether an original image to be corrected is an image picture, and an image correction process based upon a formed histogram of the original image is not performed for an image different from the image picture. An image processing condition is set in accordance with the formed histogram to perform the image correction process for the original image. An image processing method judges from a shape of the formed histogram whether the original image is an image picture, and does not perform not perform the image correction process for the original image if it is judged that the original image is not an image picture.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com