Patents

Literature

275results about How to "Reduce positional deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

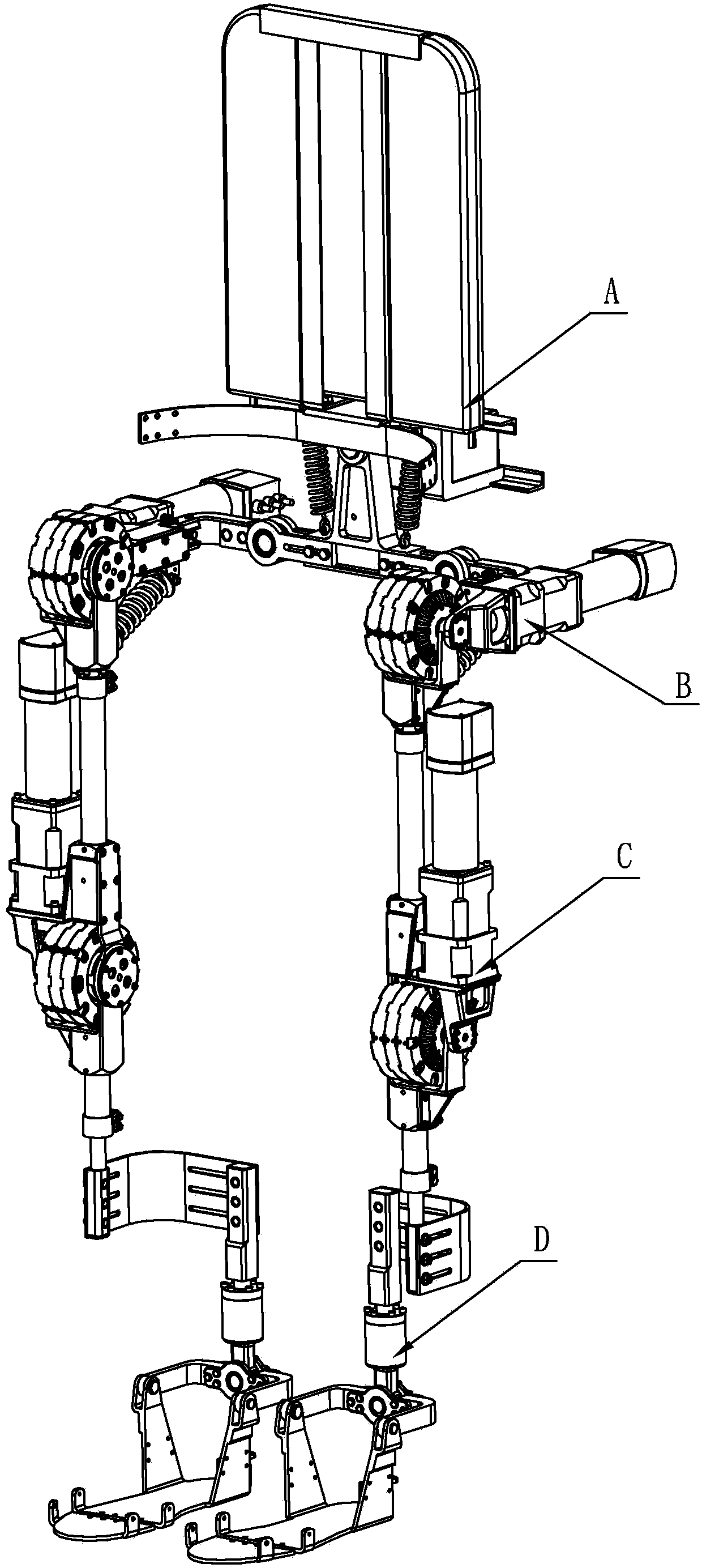

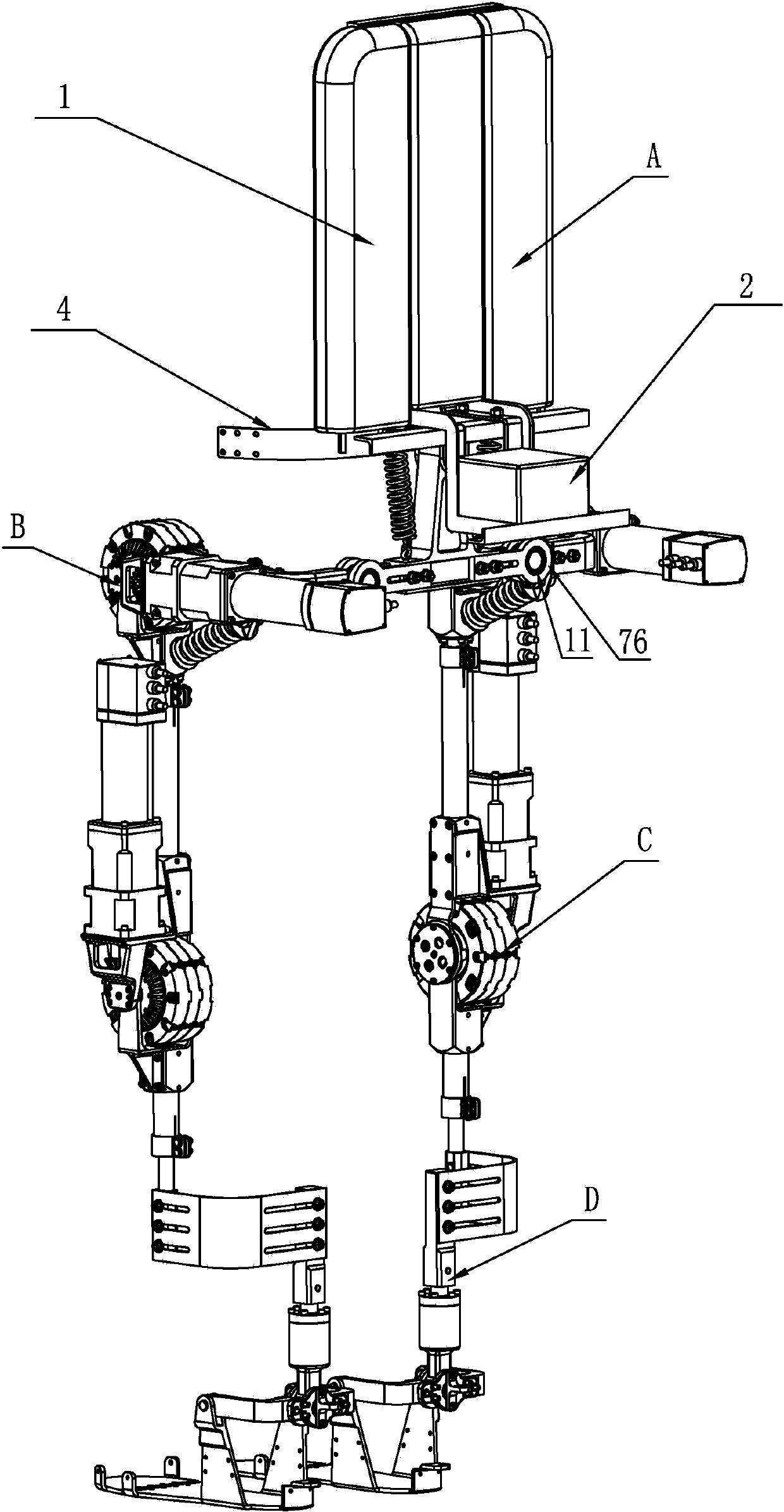

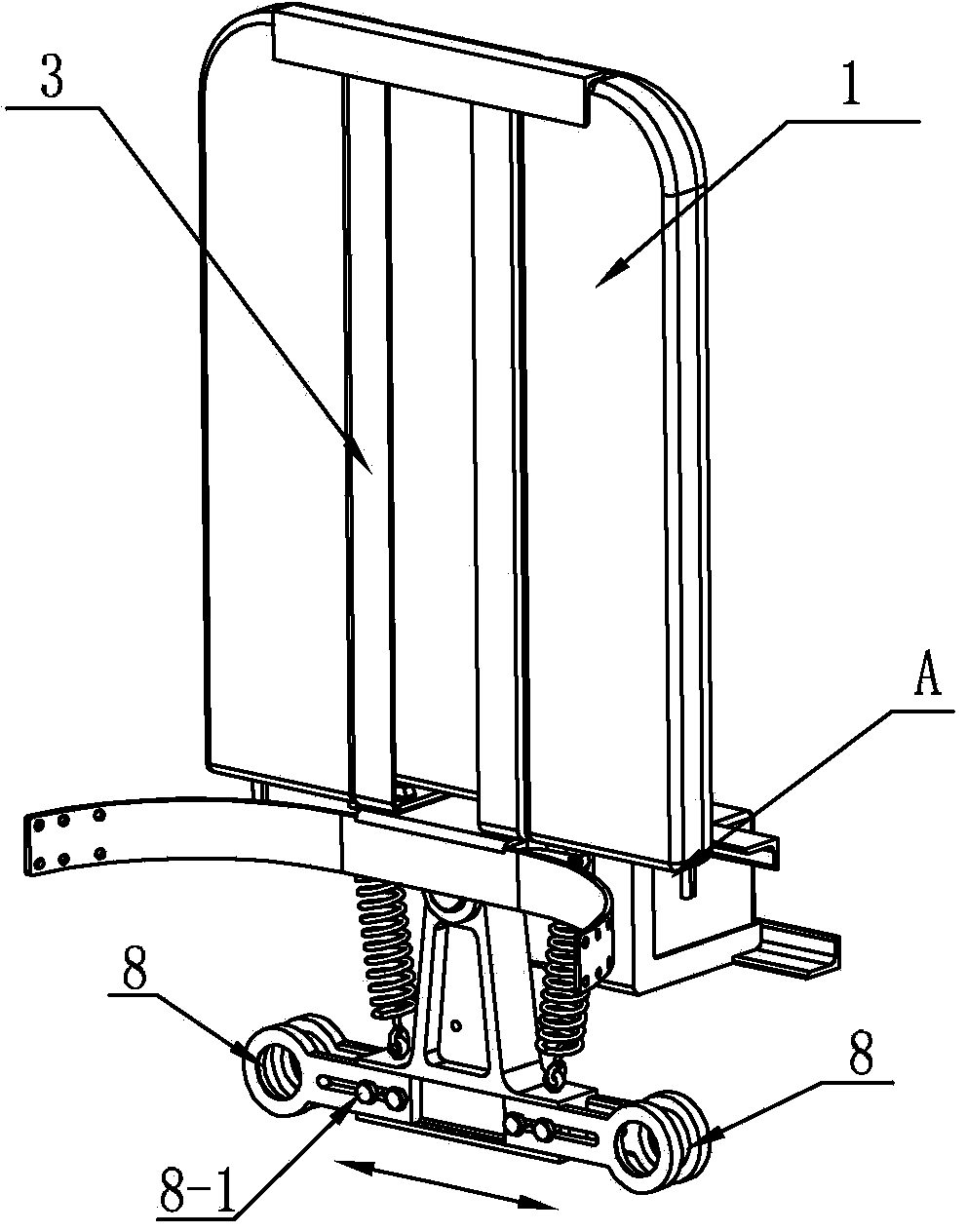

Portable energy-storage type external skeleton assisting robot

ActiveCN103610524AIntrusion Length AdjustmentEasy to disassemble and assembleArtificial legsThighExoskeleton robot

The invention relates to an external skeleton assisting robot, in particular to a portable energy-storage type external skeleton assisting robot. The problems that an existing lower limb external skeleton assisting robot worn on the human body is poor in assisting effect so that the loading capacity of the human body can be reduced, the wearing comfort for the human body is poor, the universality is poor, and the field environmental suitability is poor are solved. The portable energy-storage type external skeleton assisting robot comprises the upper body back, the left leg and the right leg, and the left leg and the right leg respectively comprise a hip driving system, a thigh driving system and a shank wearing system. A hip joint energy-storage mechanism comprises a connecting base, a stretching rod, a second spring and a stopping sheet, and a first bevel gear is meshed with a second bevel gear. Each hip driving system comprises a second motor with a coder, a second reducer, a third bevel gear, a fourth bevel gear, a thigh connecting rod, a knee joint support, a knee joint connecting plate, an angle sensor, a series connection elastic combination body, a knee joint gearbox body, a knee joint shaft and an end cover. The portable energy-storage type external skeleton assisting robot is suitable for being worn outdoors for walking assisting.

Owner:HARBIN INST OF TECH

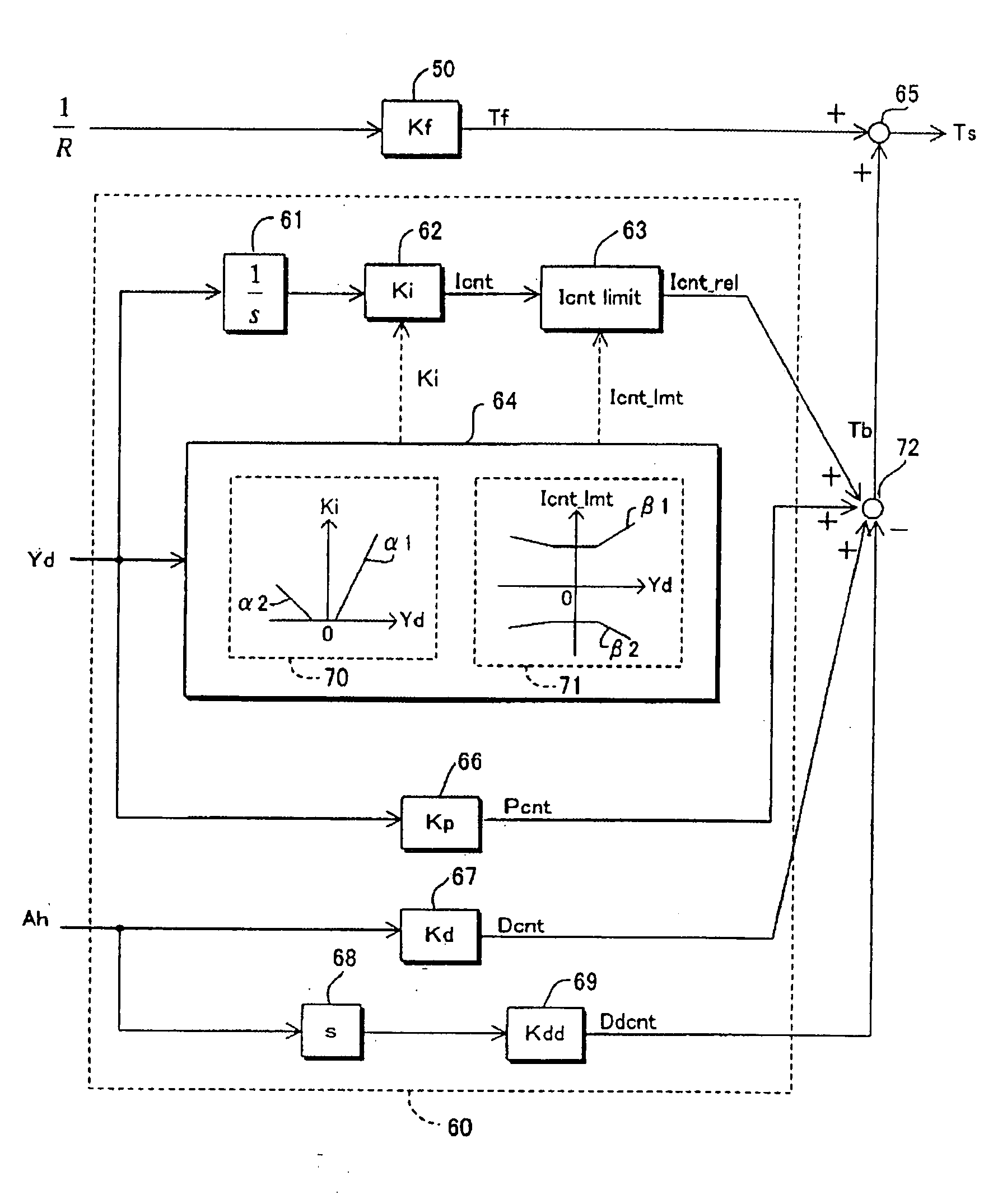

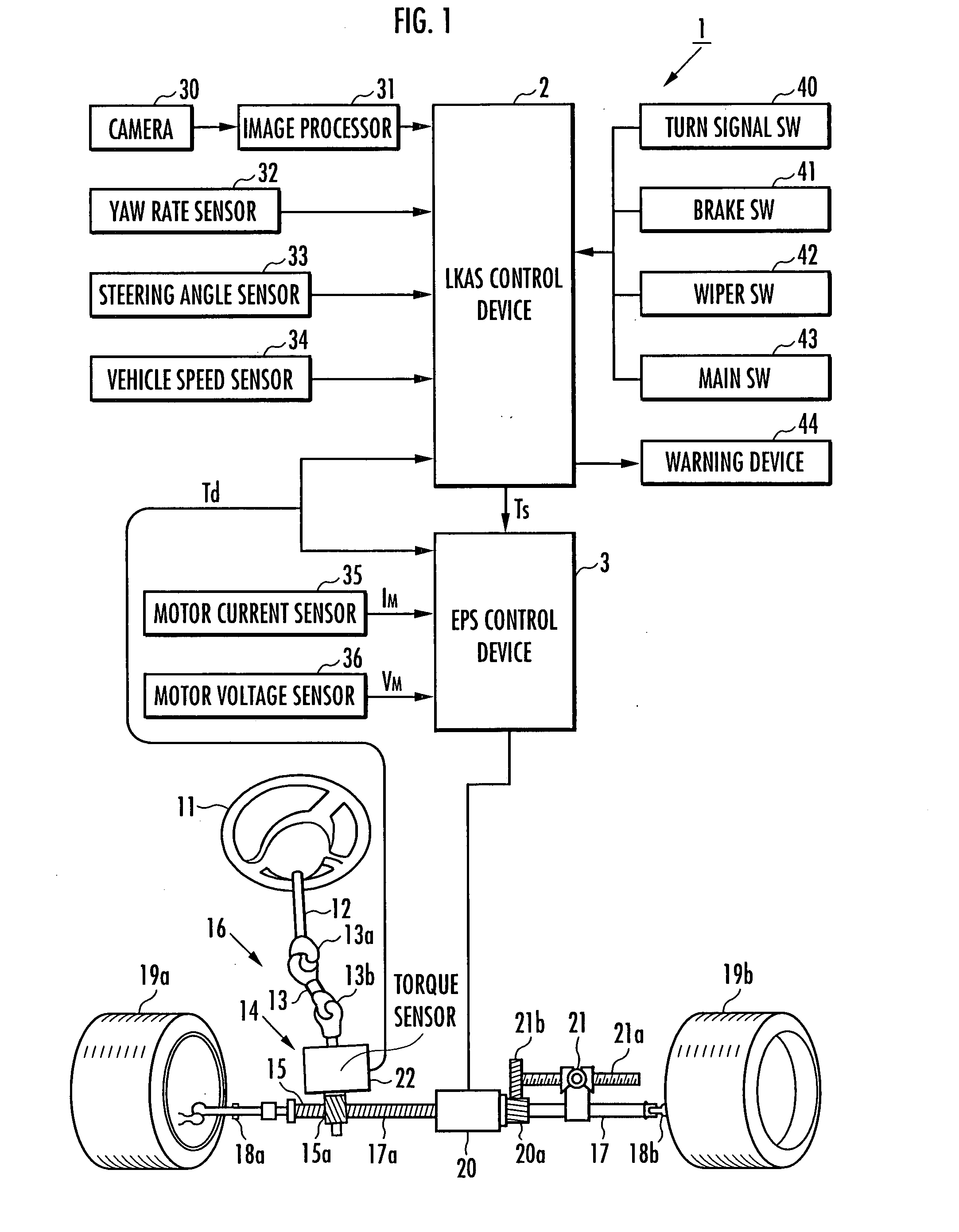

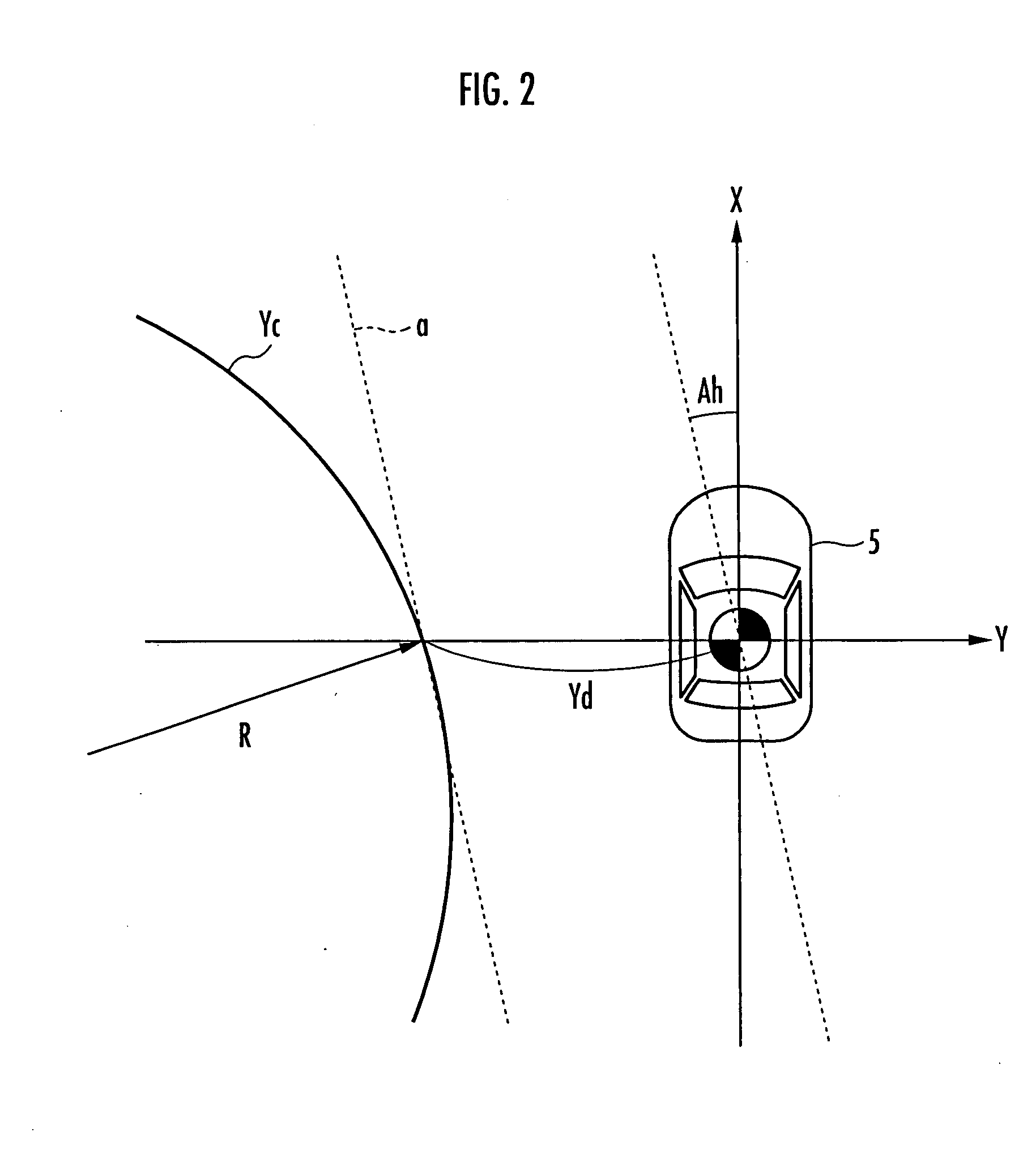

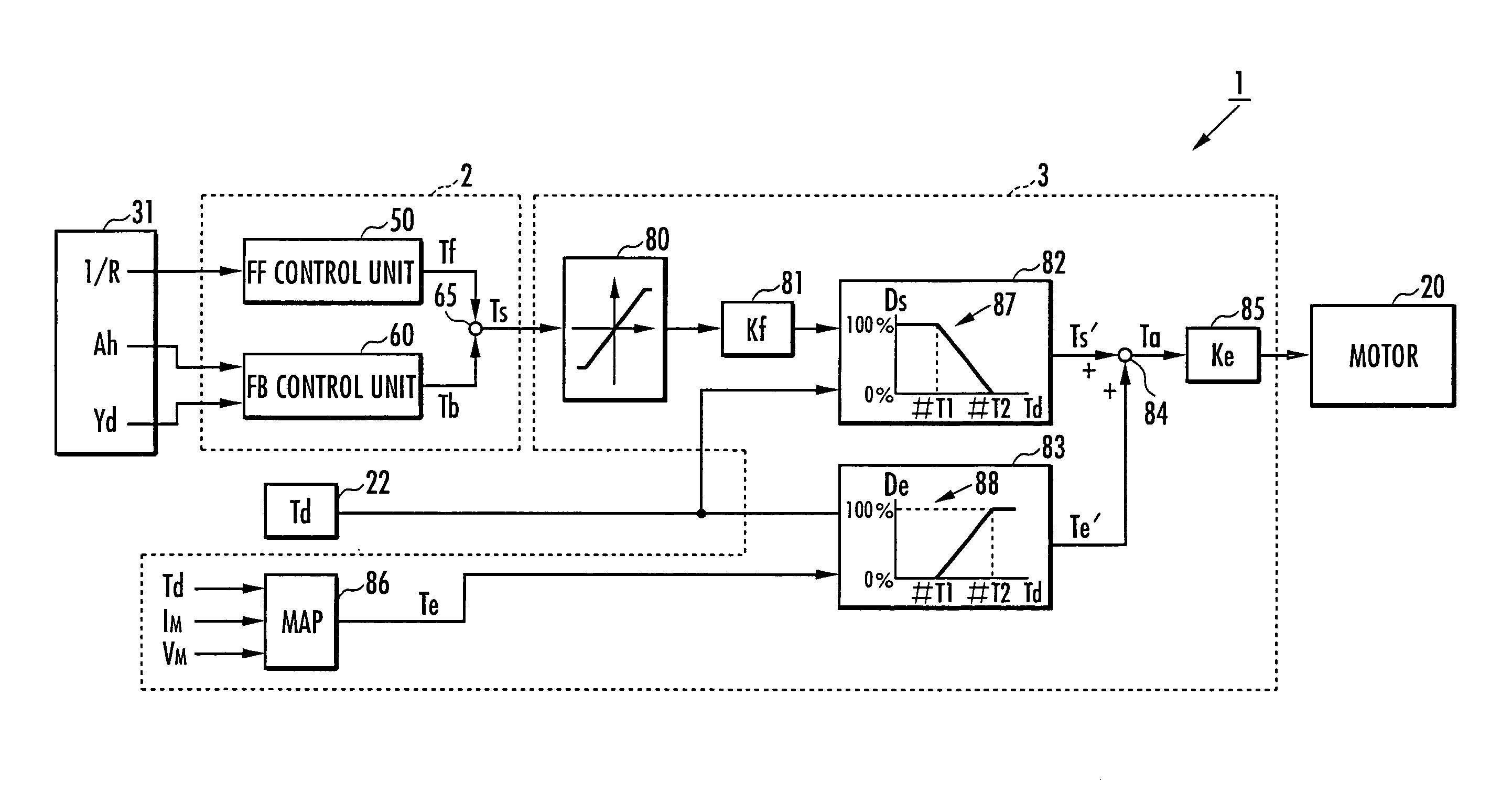

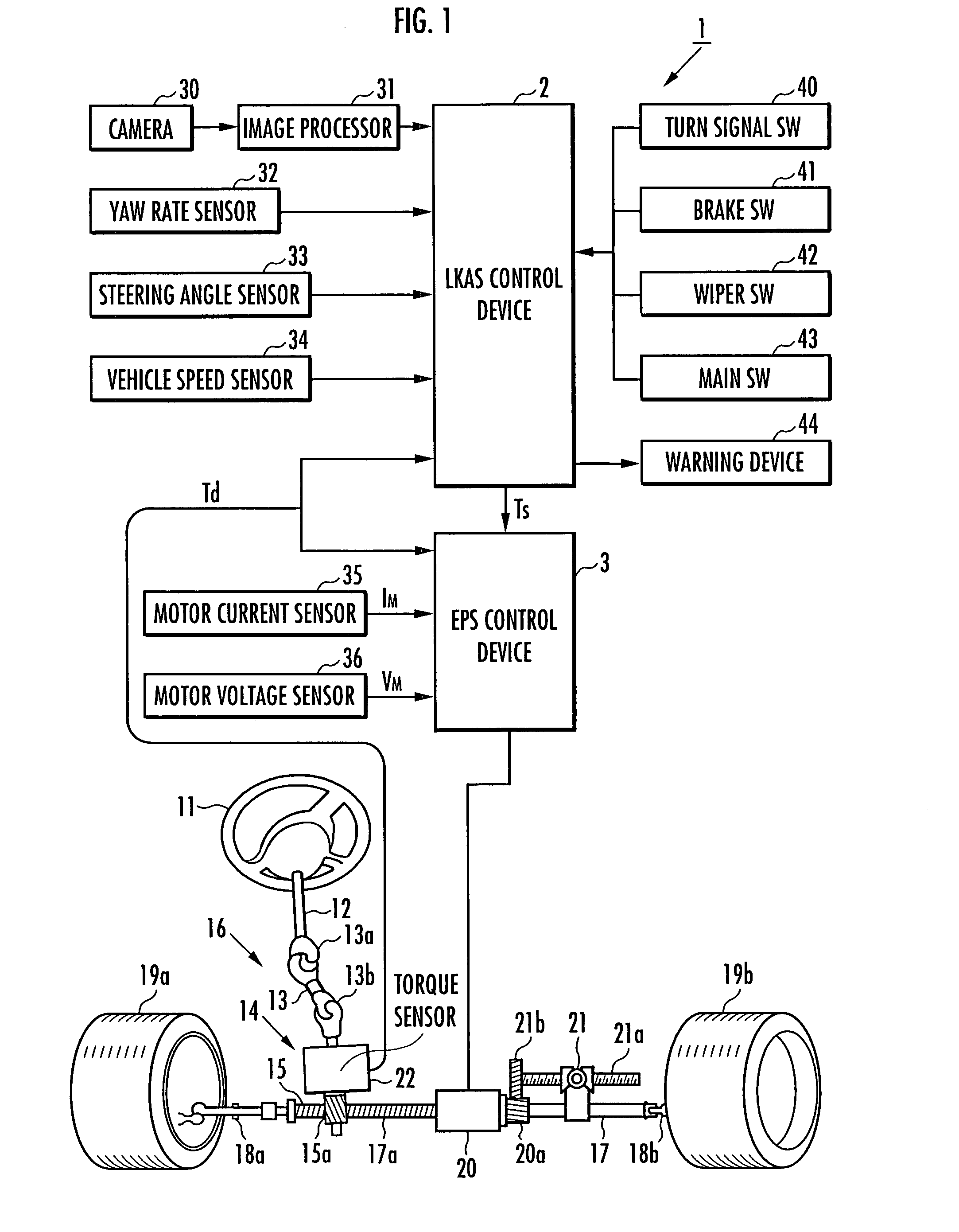

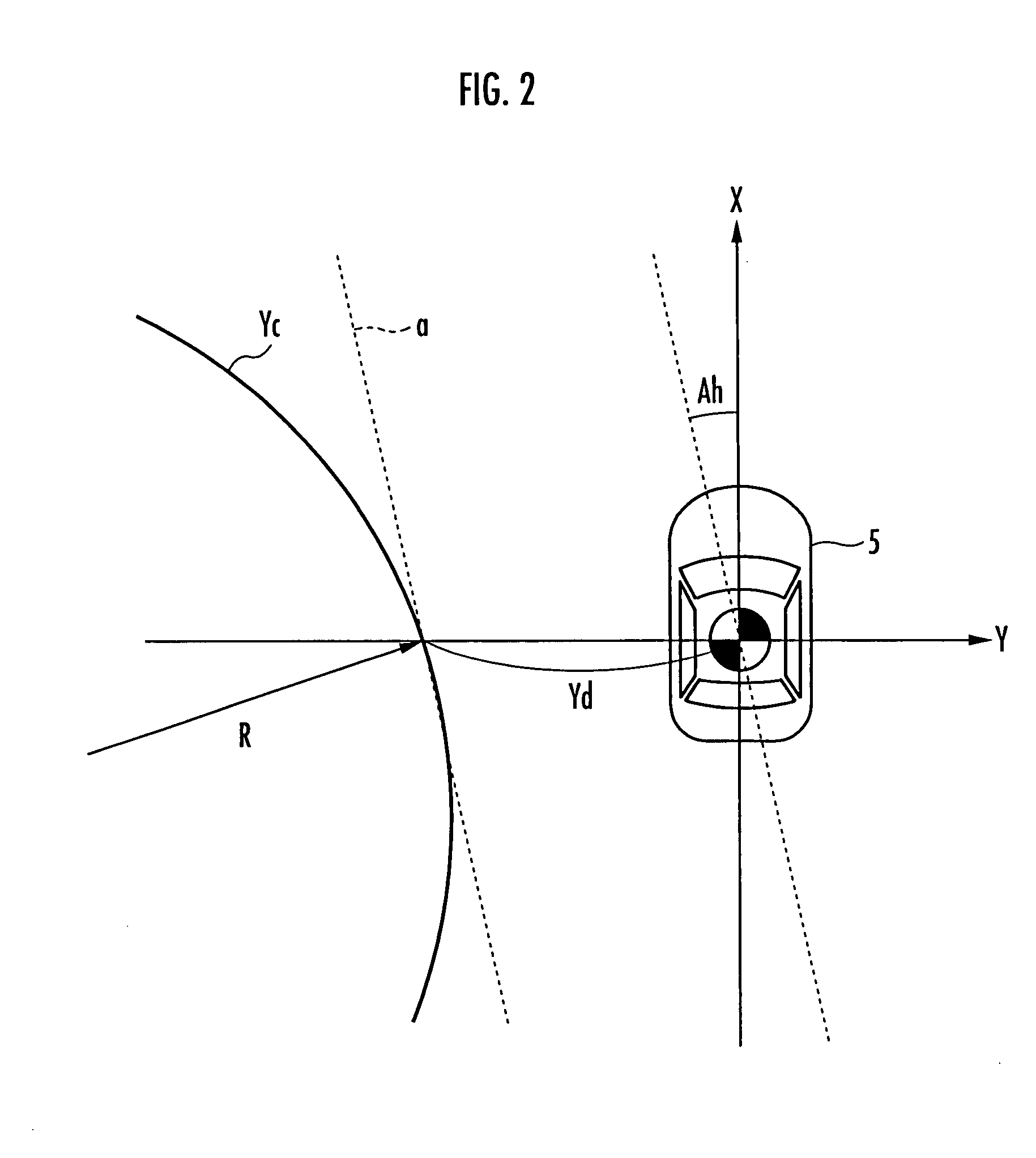

Steering Control Device for Vehicles

InactiveUS20090024278A1Prevent overshootAvoid phase delayDigital data processing detailsSteering initiationsAngular deviationSteering control

A vehicle steering control device which prevents overshoot or a phase delay of a vehicle position from a target position when an actuator of a steering mechanism is controlled so that an integral control reduces a positional deviation of a vehicle from the reference position of a traffic lane. An FB control unit (60) which calculates a corrected steering assist torque (Tb) of a motor so as to reduce a positional deviation (Yd) and an angular deviation (Ah) includes an integral element determination unit (64), which determines an integral gain (Ki), by which the positional deviation (Yd) is multiplied in an integral gain operation unit (62), according to the positional deviation (Yd) and which determines a limit value (Icnt_lmt) of an integral controlled variable (Icnt) according to the positional deviation (Yd), and an integral controlled variable limiting unit (63) which limits the integral controlled variable (Icnt) to within a range set by the limit value (Icnt_lmt) and outputs the current integral controlled variable (Icnt_rel).

Owner:HONDA MOTOR CO LTD

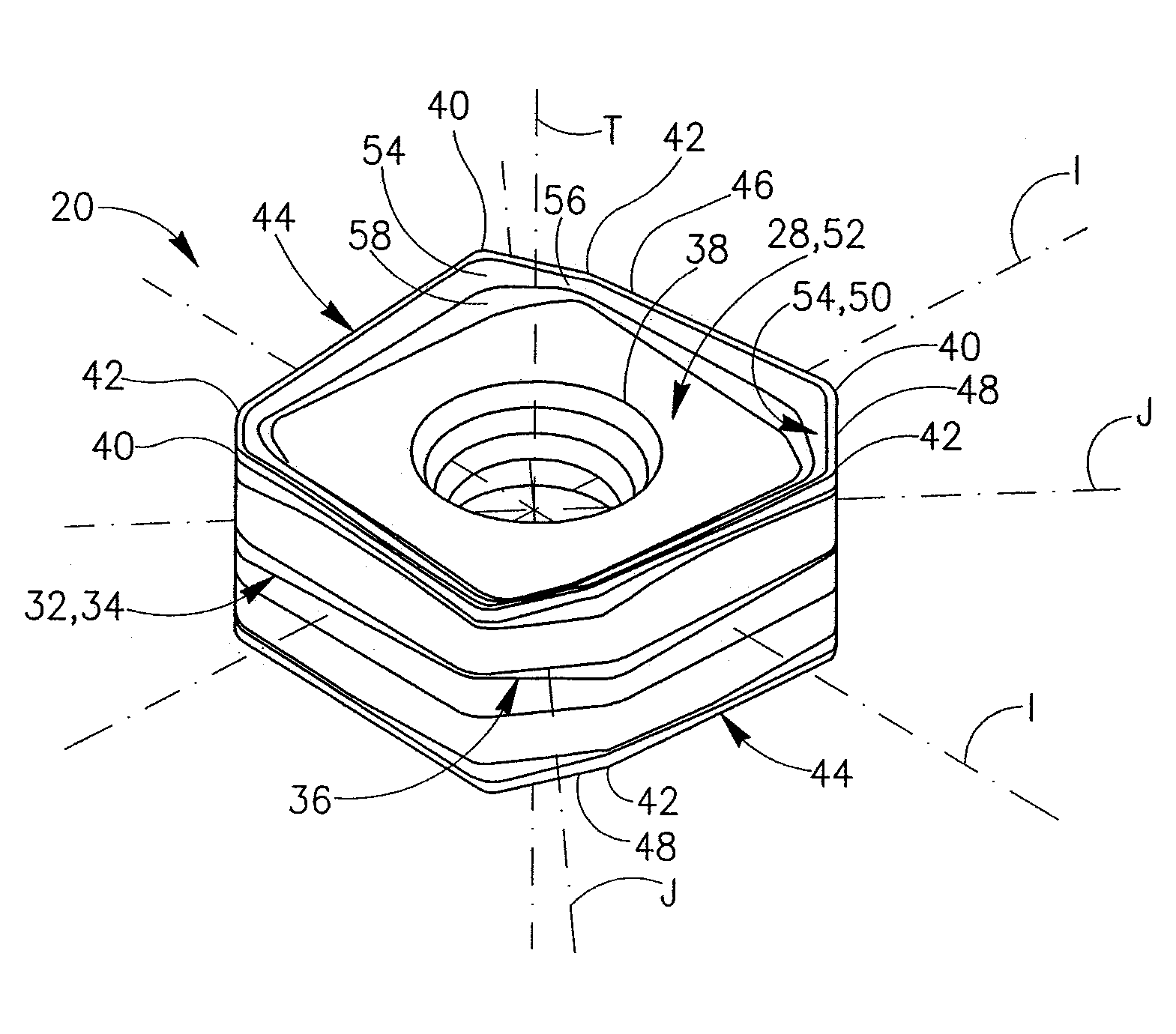

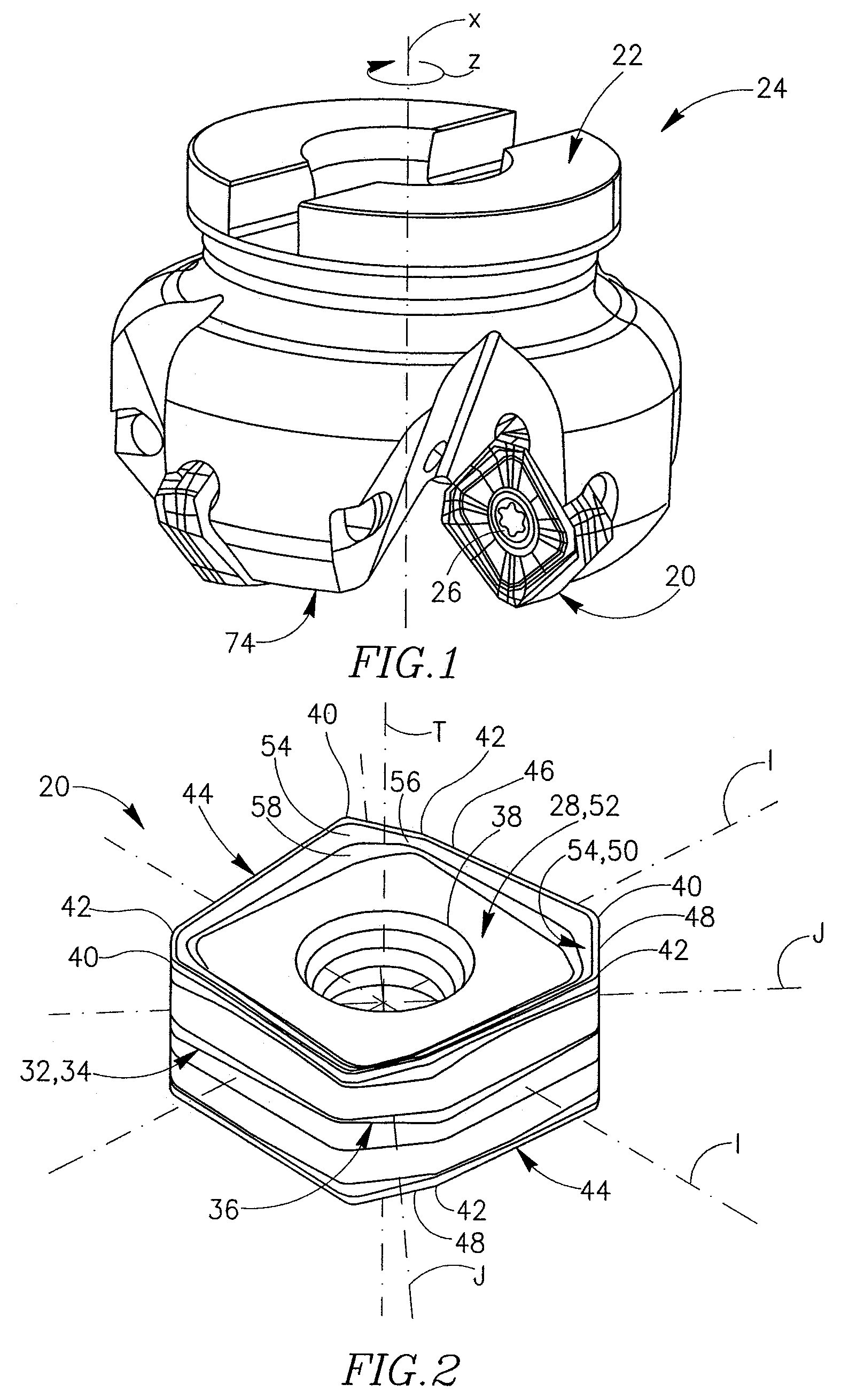

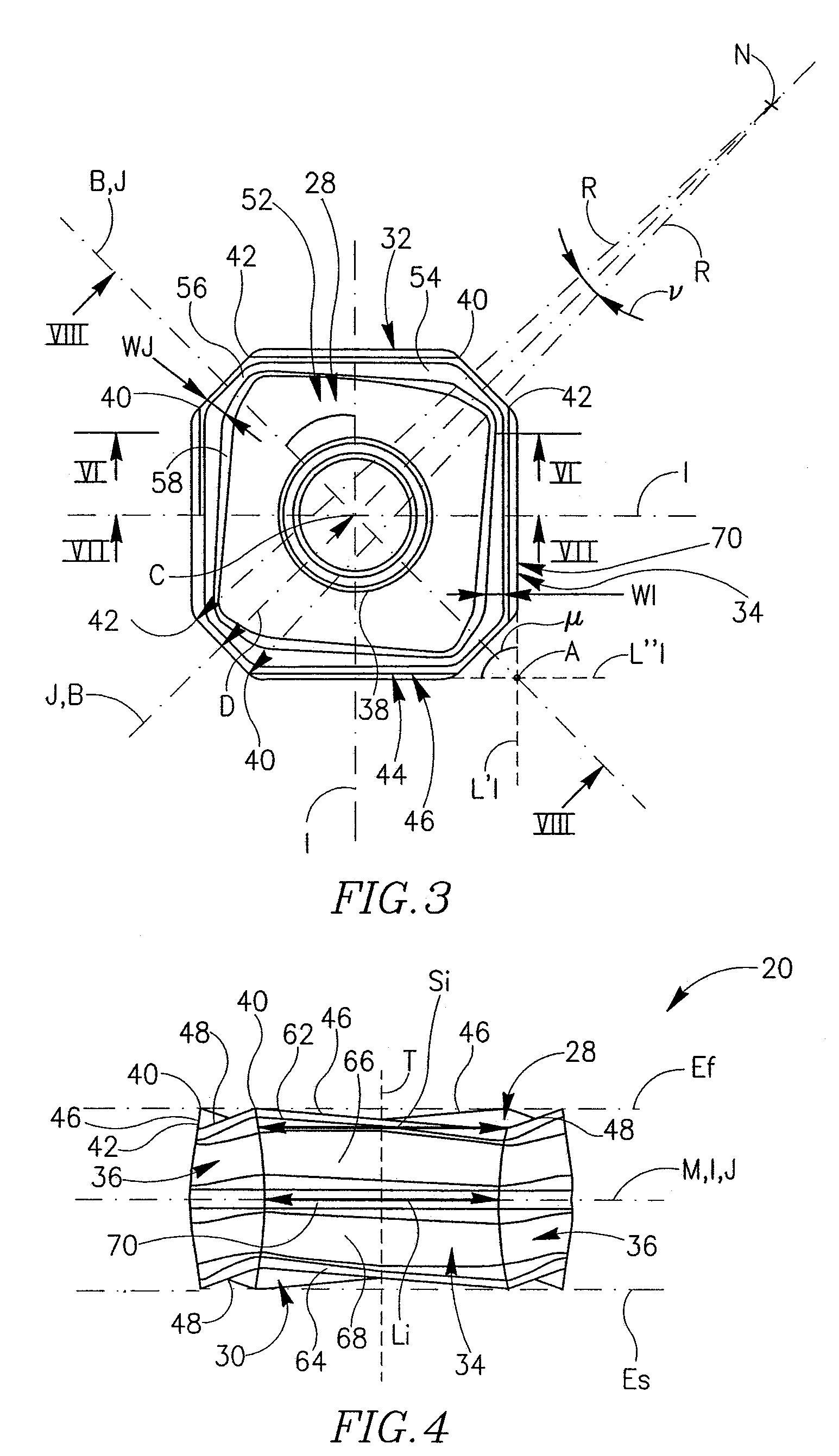

Cutting insert having cylindrically shaped side surface portions

ActiveUS7232279B2Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsEngineeringMechanical engineering

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

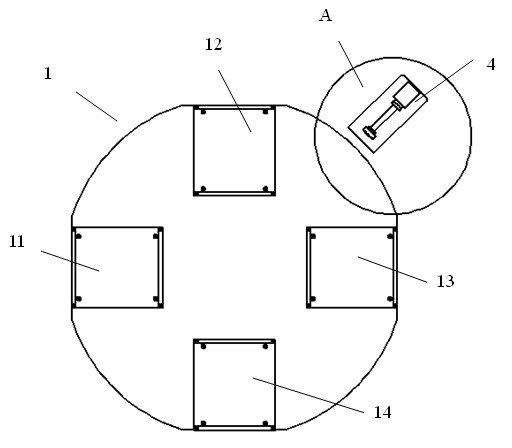

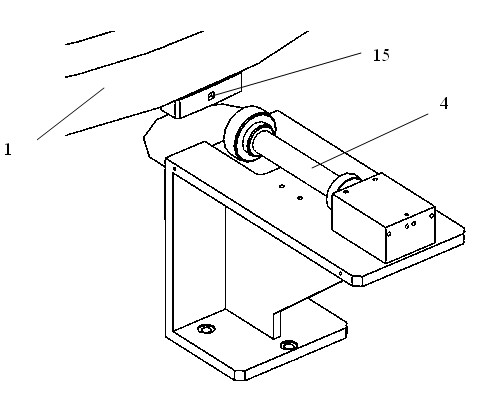

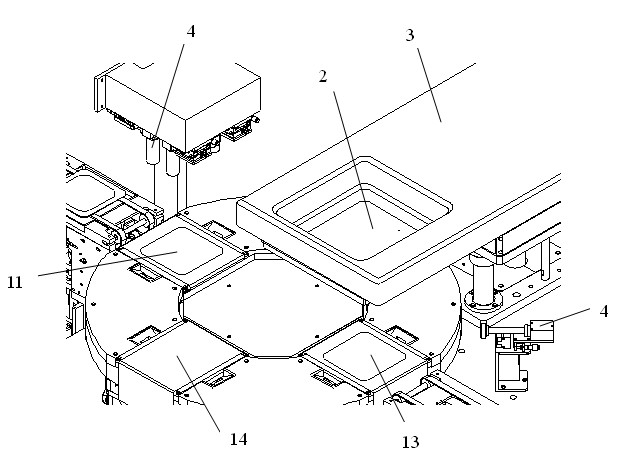

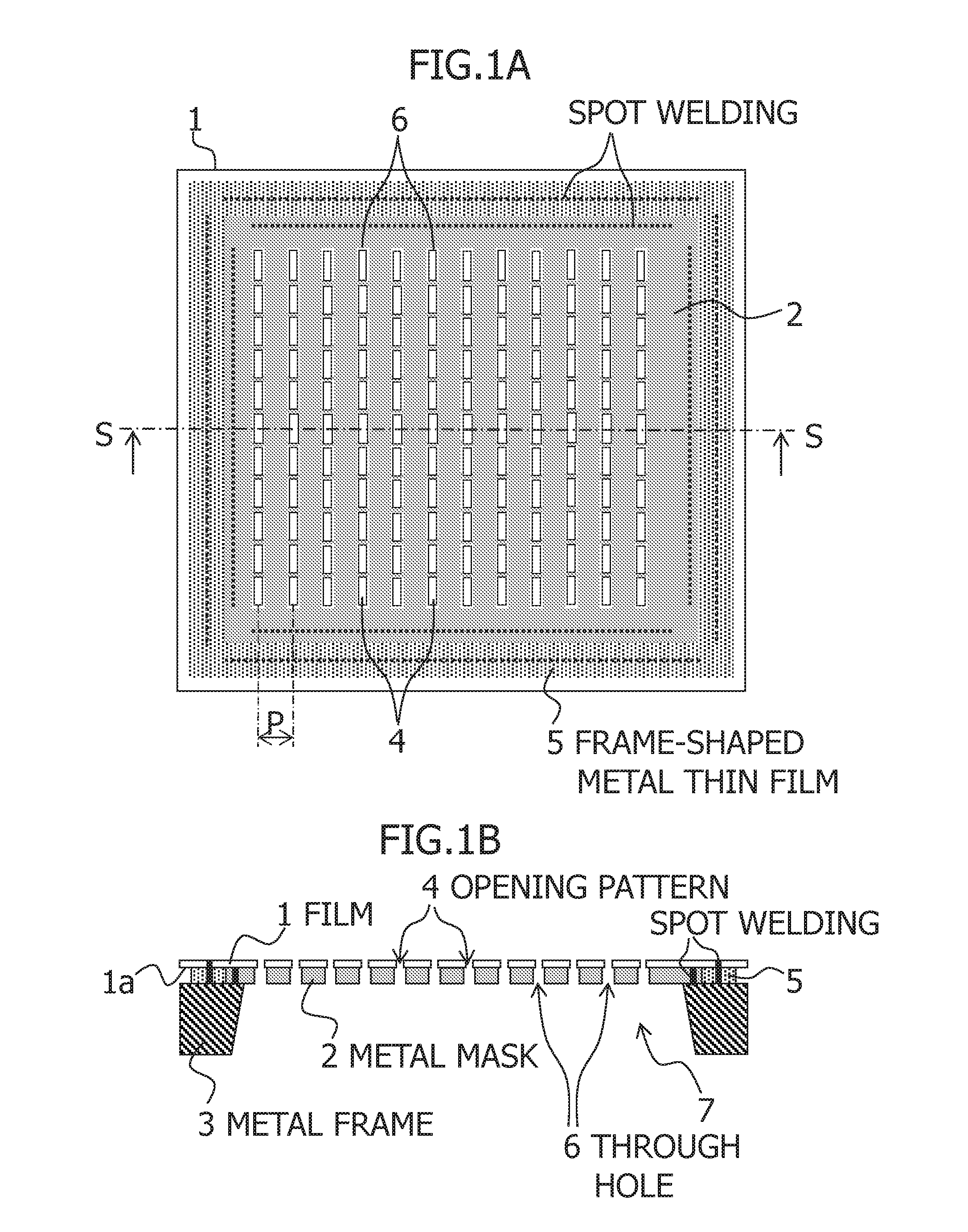

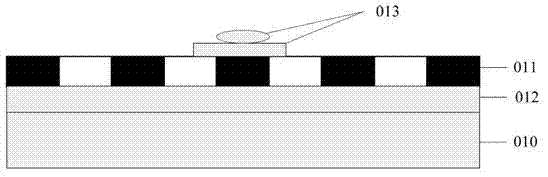

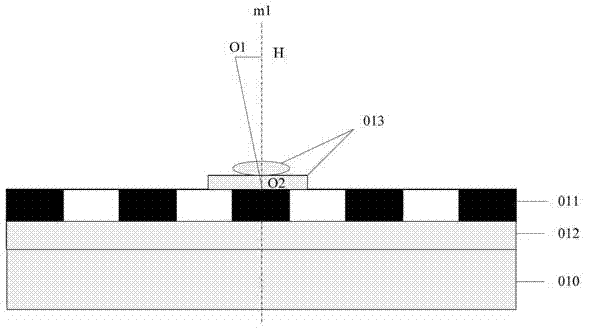

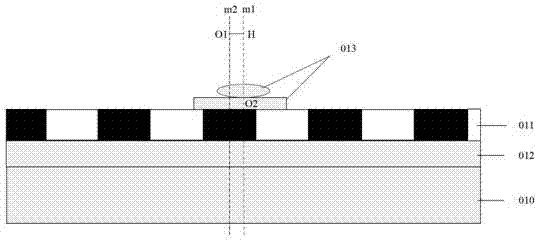

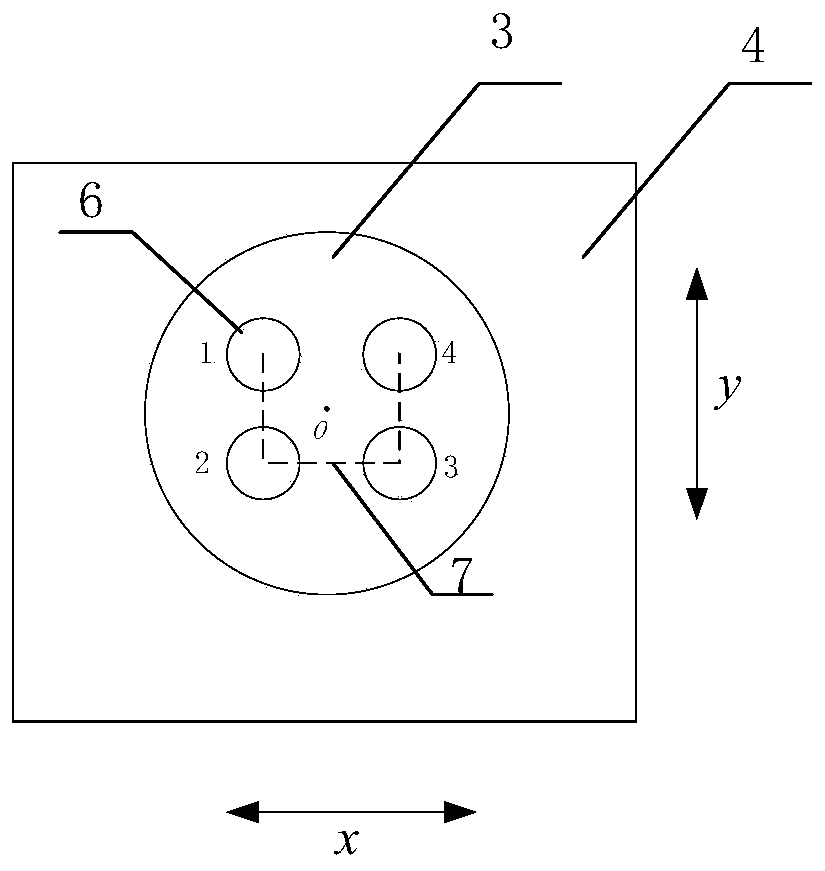

Printing deviation measuring method, printing method and printing device for solar cell plate

ActiveCN102001242AHigh precisionQuick position adjustmentScreen printersUsing optical meansEngineeringSolar cell

The invention relates to a printing deviation measuring method, a printing method and a printing device for a solar cell plate. The deviation measuring method comprises the following steps of: A. measuring the actual position P1' of the solar cell plate at a waiting station after plate feeding, and calculating the position deviation delta P1 of the solar cell plate according to a preset position P1 of the solar cell plate; B. measuring the actual position M' of one station of a rotating work table at the waiting station and the actual position N' of the rotating work table after the rotating work table rotates to a printing station, and calculating the position deviation delta M and delta N of the station respectively on the waiting station and the printing station by combining the actual positions M' and N' with the preset position M of the waiting station and the preset position N of the printing station; and C. calculating the integrated position deviation delta P of the solar cell plate according to the position deviations delta P1, delta M and delta N in the step A and the step B. The invention regulates the position of a printing screen of the printing device according to the integrated position deviation delta P so that the positions of the printing screen and the solar cell plate are sufficiently coincided, thereby outstandingly enhancing the accuracy of final printing.

Owner:SUZHOU MAXWELL TECH CO LTD

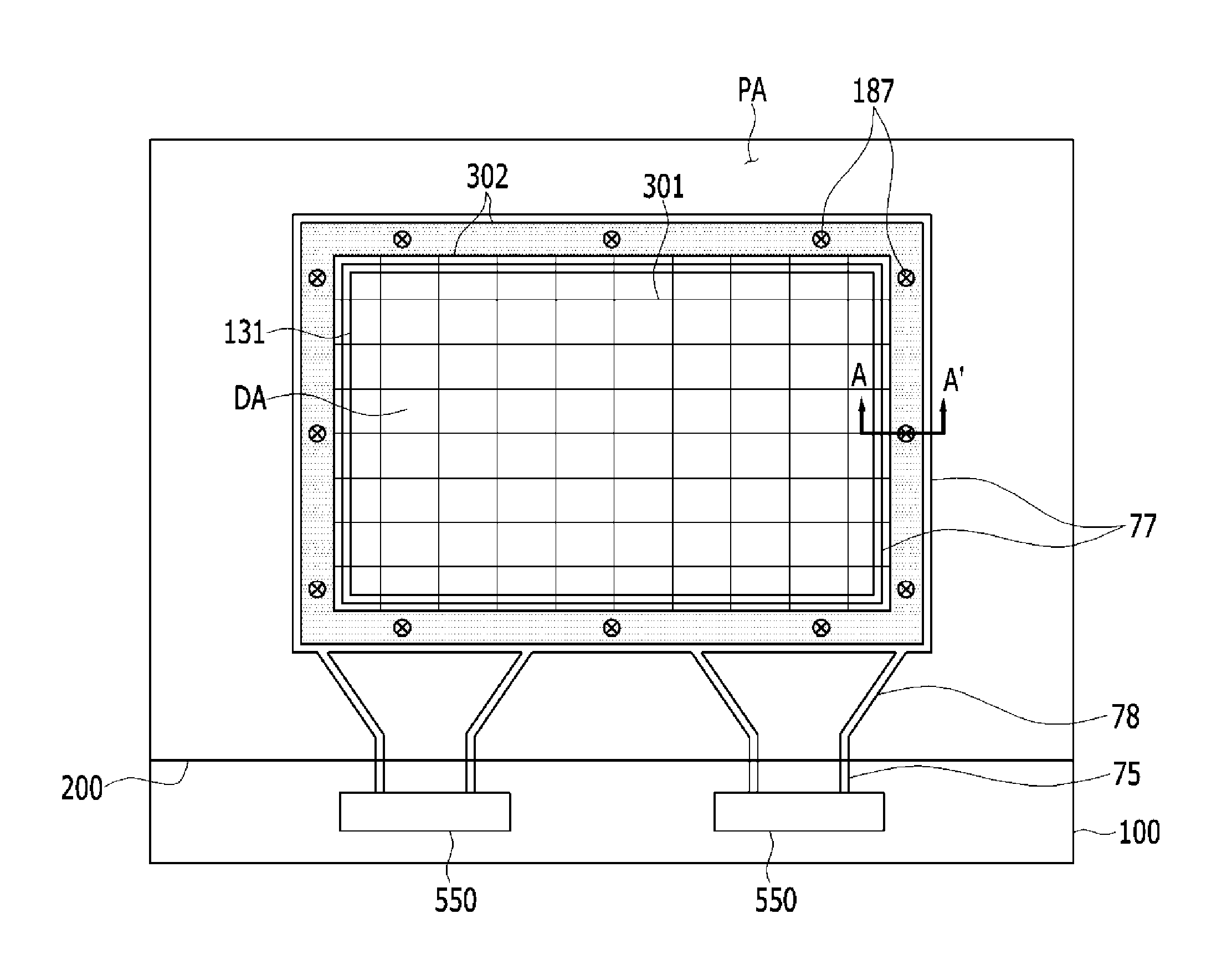

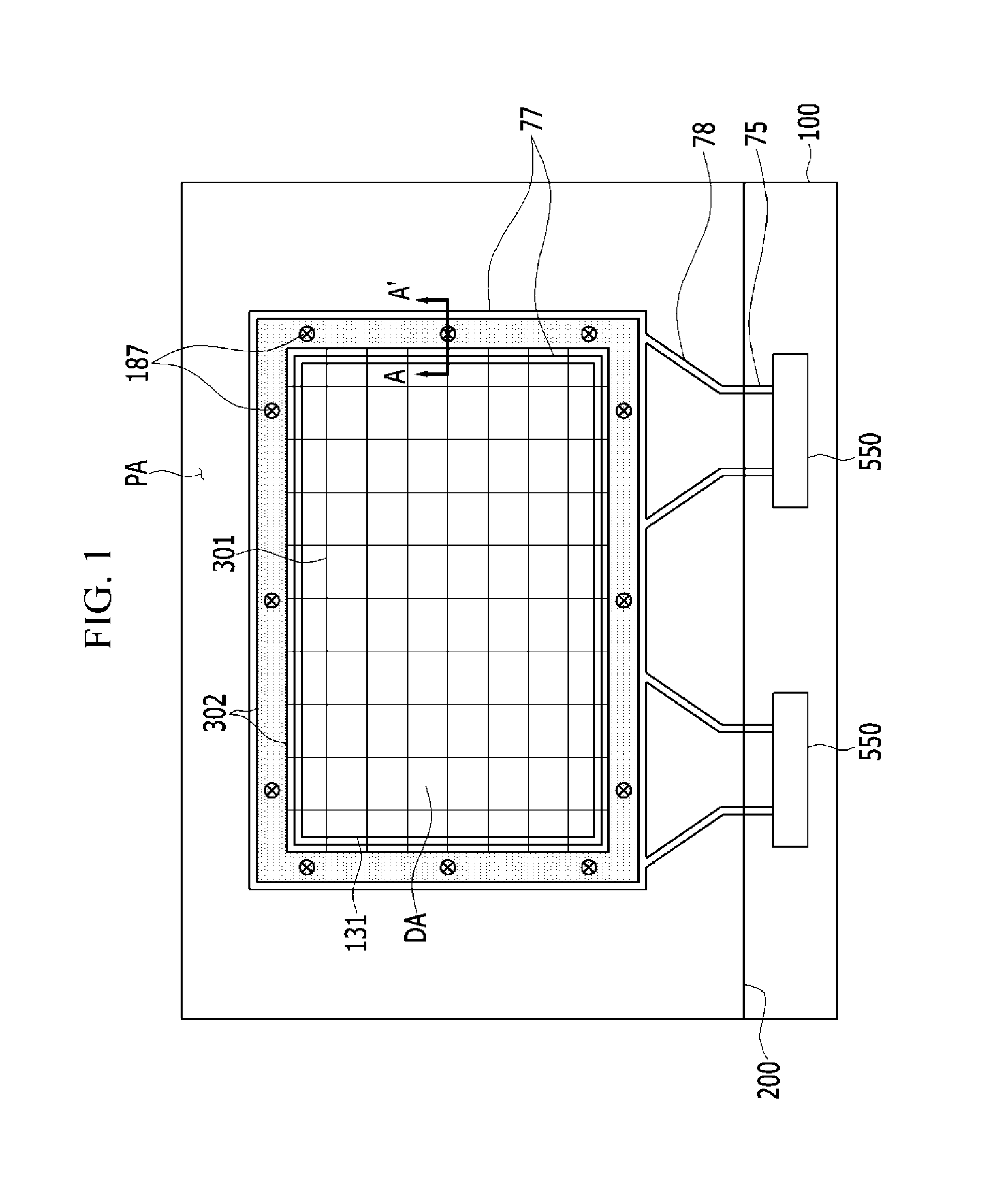

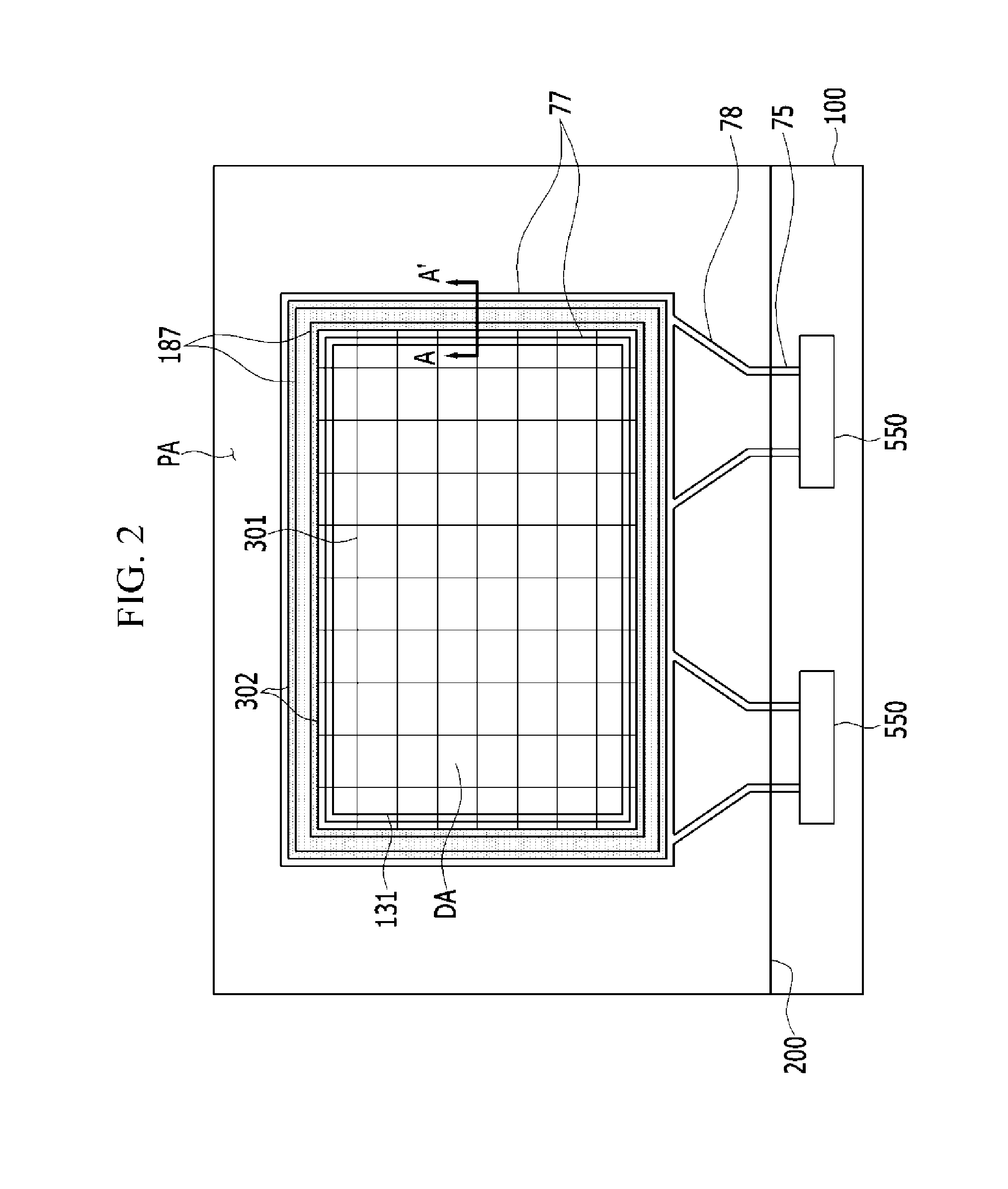

Display device

ActiveUS20140184964A1Reduce display defectsIncrease freedomStatic indicating devicesNon-linear opticsDisplay deviceEngineering

A display device including: a substrate including a display area in which pixels are positioned and a peripheral area around the display area; a common electrode and a pixel electrode that are positioned on the display area and overlapping with each other, with a first insulating layer disposed therebetween; a common voltage line positioned on or below the common electrode and contacting the common electrode; an edge common voltage line connected with the common voltage line and formed along an edge of the display area; and a first common voltage transfer line contacting the edge common voltage line in the peripheral area and configured to transfer a common voltage to the common voltage line.

Owner:SAMSUNG DISPLAY CO LTD

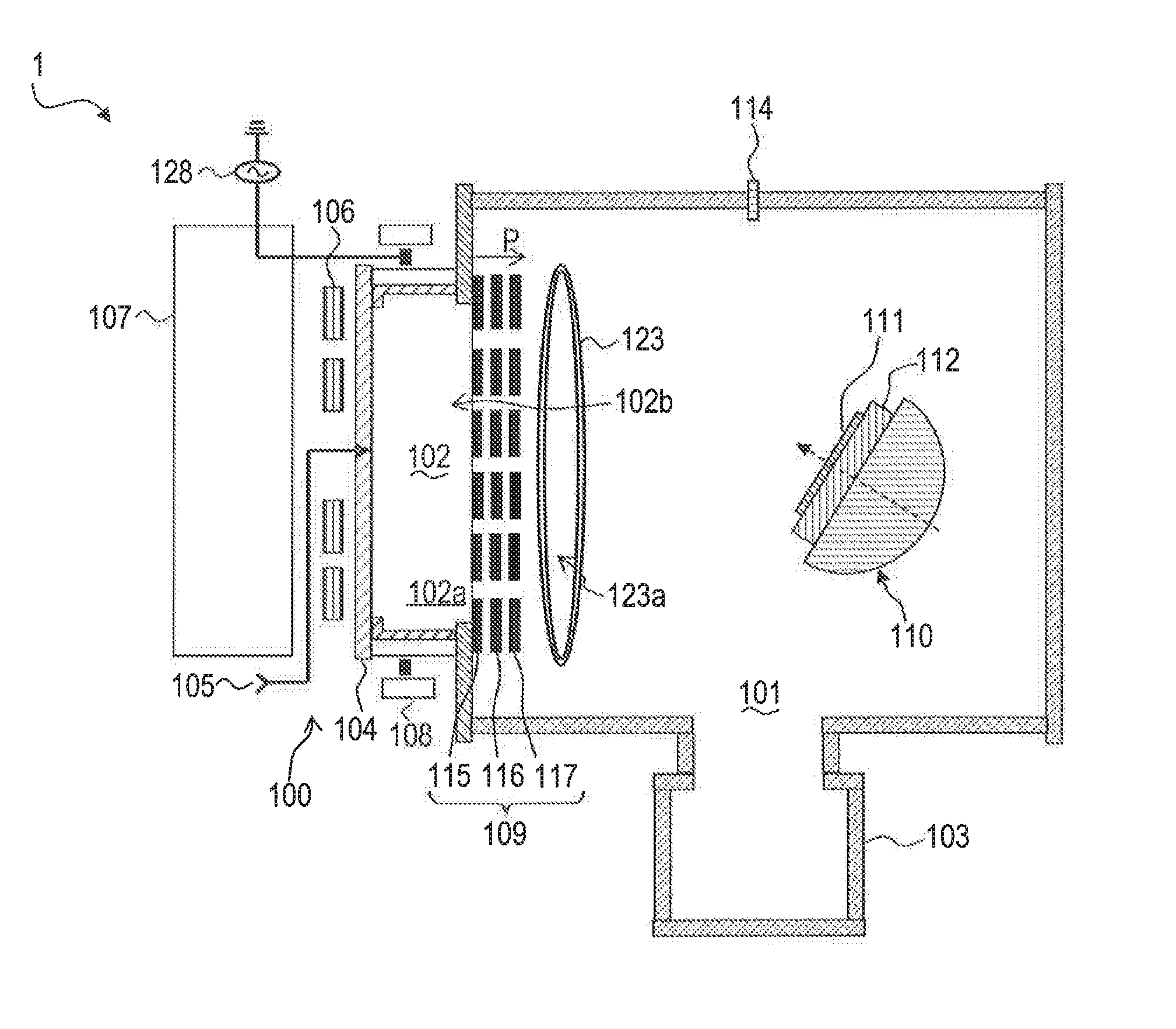

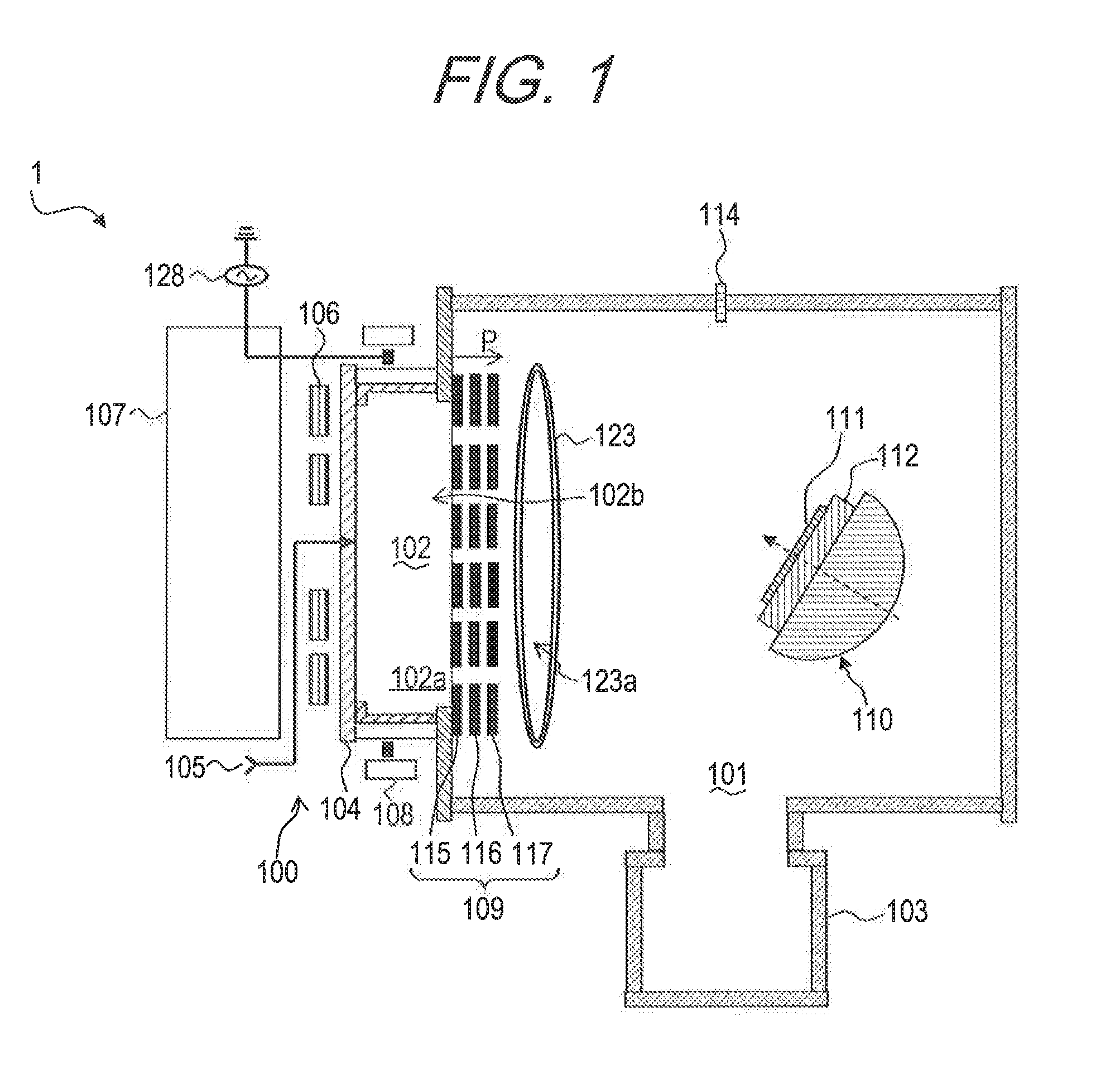

Ion beam etching apparatus and ion beam generator

InactiveUS20160351377A1Reduce the differenceIncrease in sizeElectric discharge tubesAtomic physicsIon beam etching

An ion beam etching apparatus includes: a processing chamber connected to the plasma generation chamber including an internal space; a plasma generating unit configured to generate plasma in the internal space; an extracting unit configured to extract ions from the plasma, from the internal space to the processing chamber, the extracting unit including first, second and a third electrodes, each of which has a plurality of ion passage holes; a first ring member provided closer to the plasma generation chamber; a second ring member provided closer to the processing chamber; a fixing member having one end and another end, the fixing member penetrating the first, second and third electrodes, and having the one end connected to the first ring member and the other end connected to the second ring member; and a heating unit configured to heat the third electrode from outside of the plasma generation chamber.

Owner:CANON ANELVA CORP

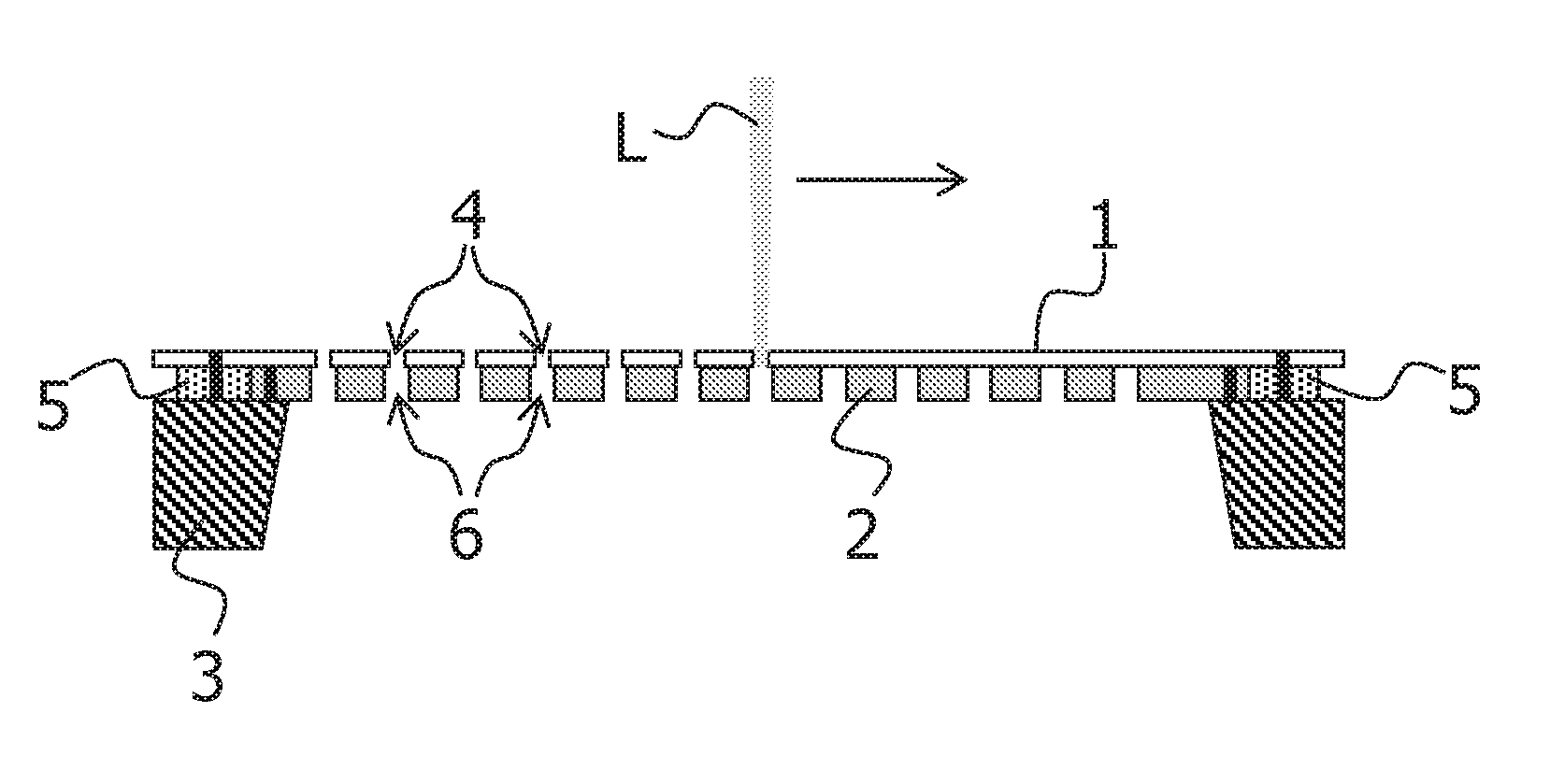

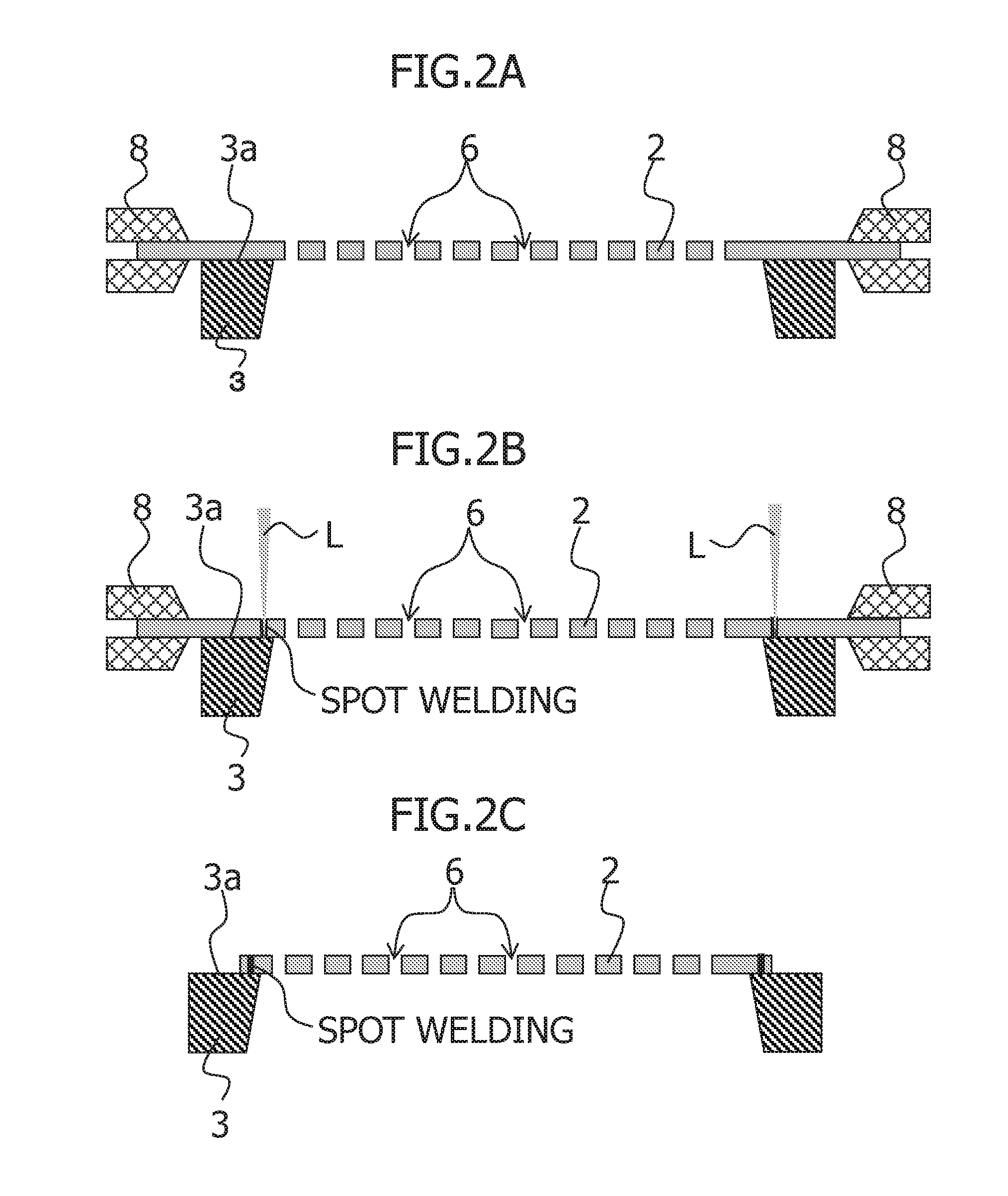

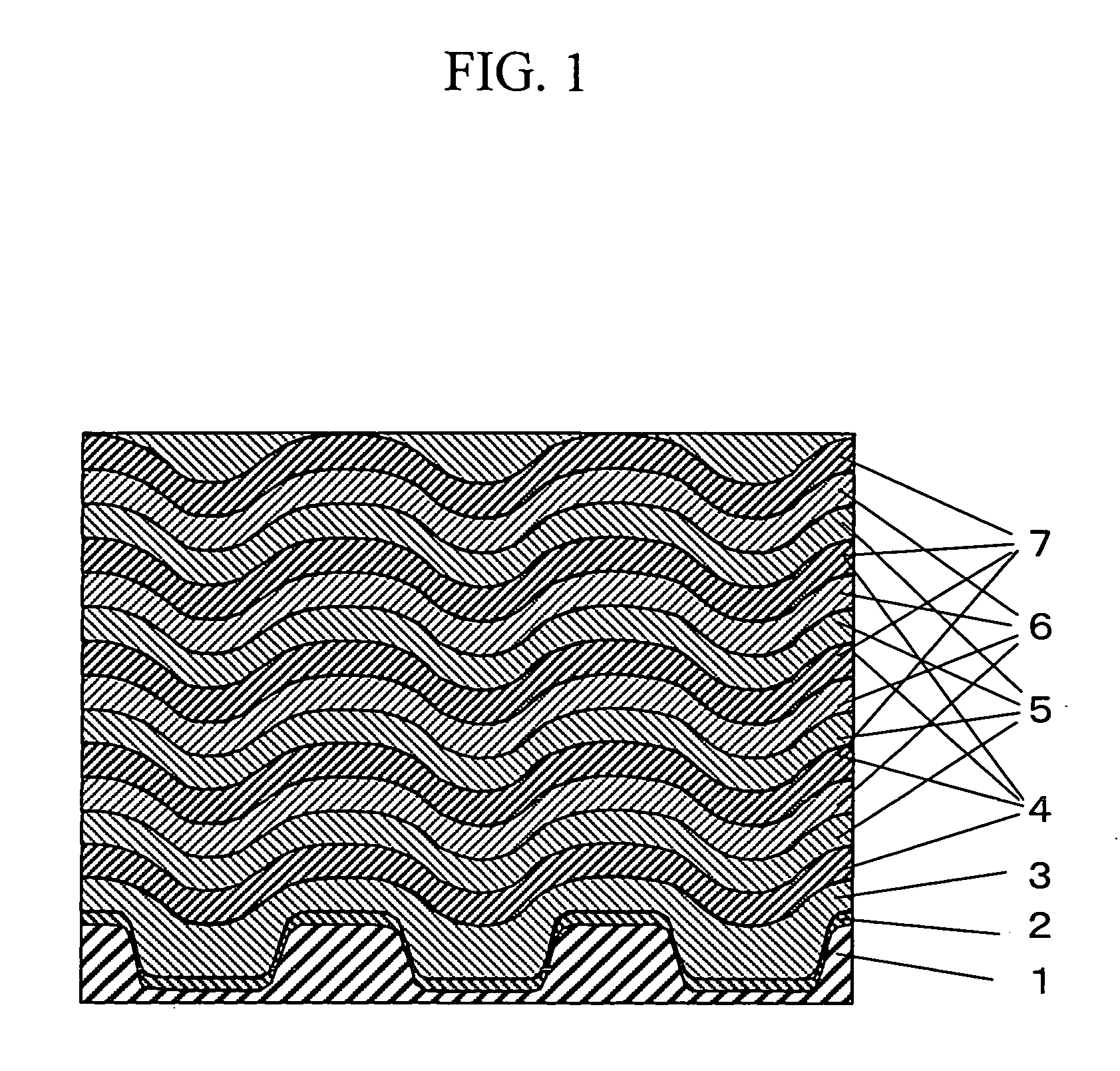

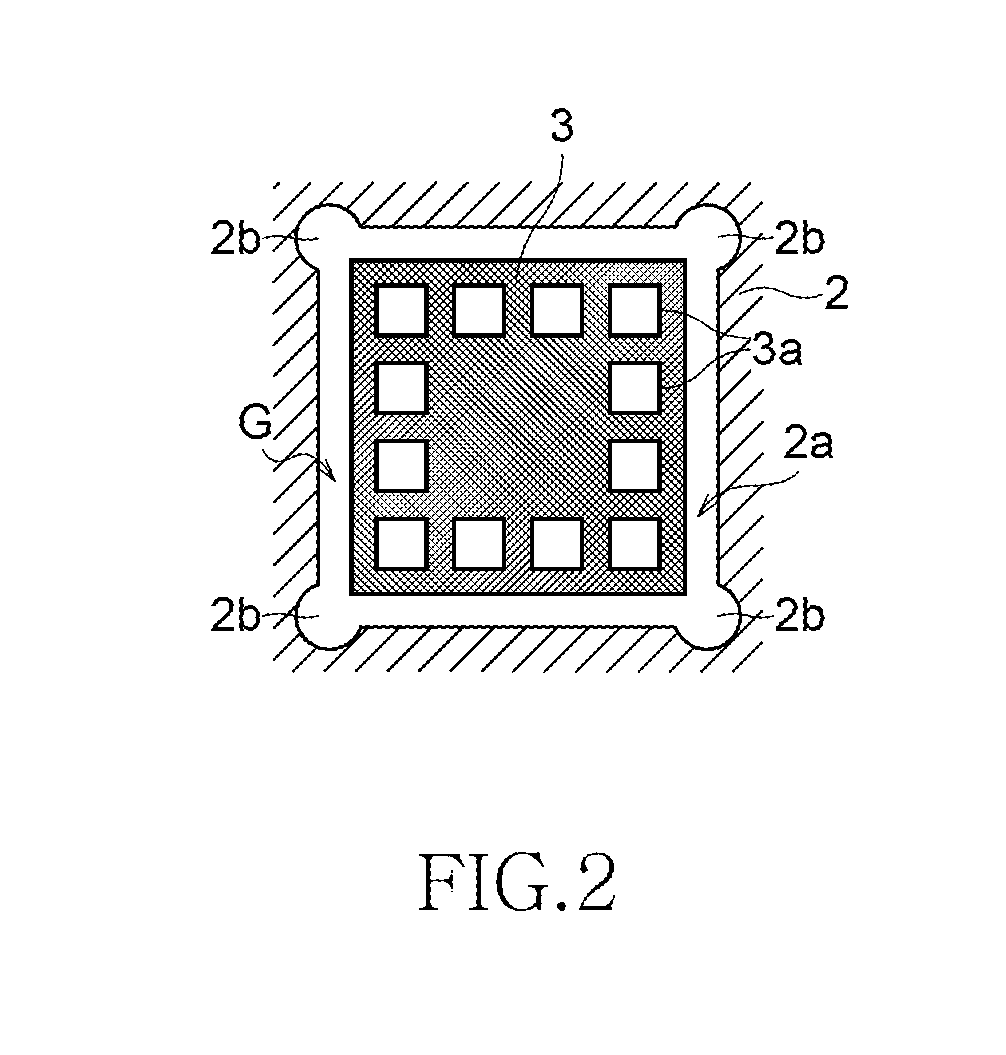

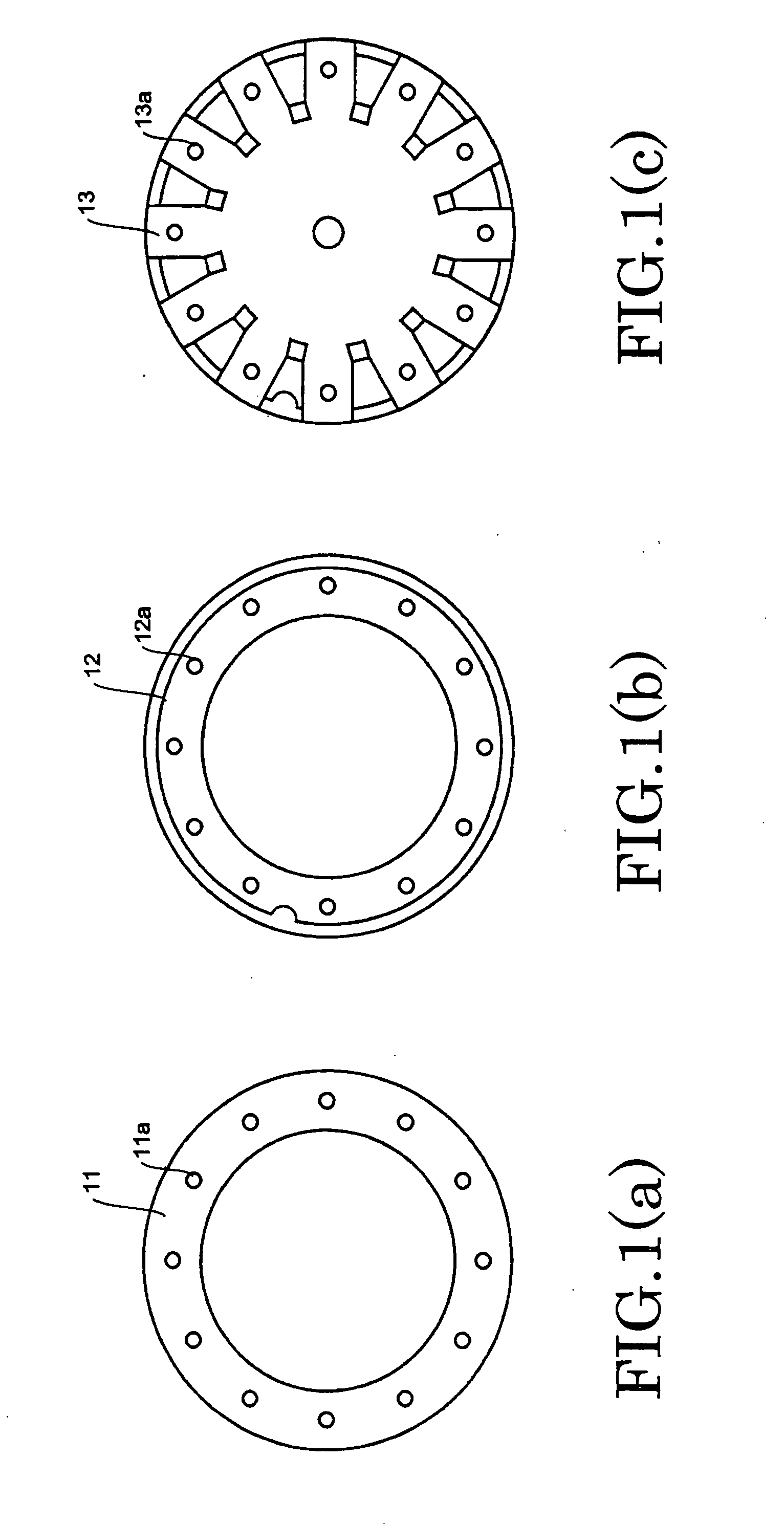

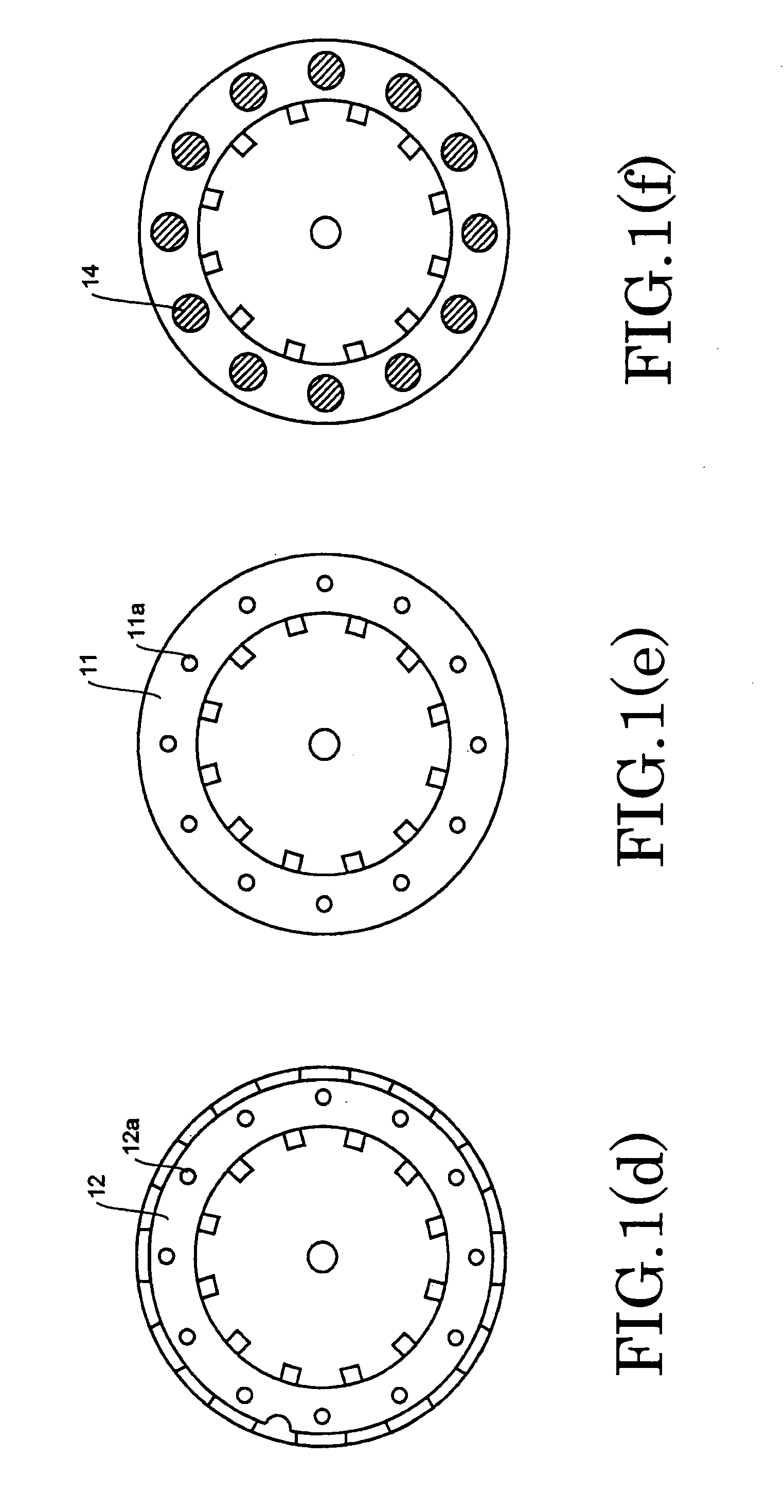

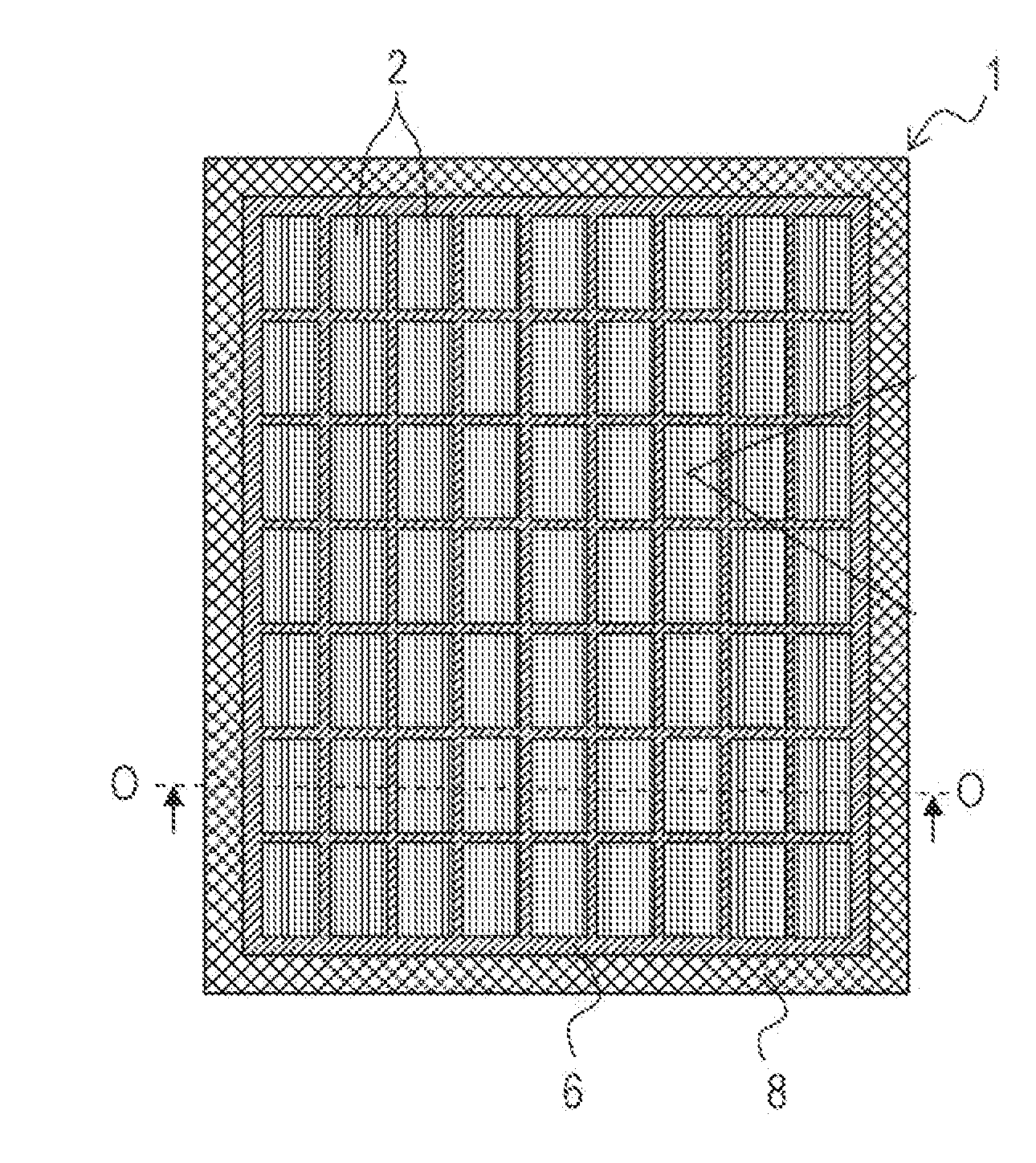

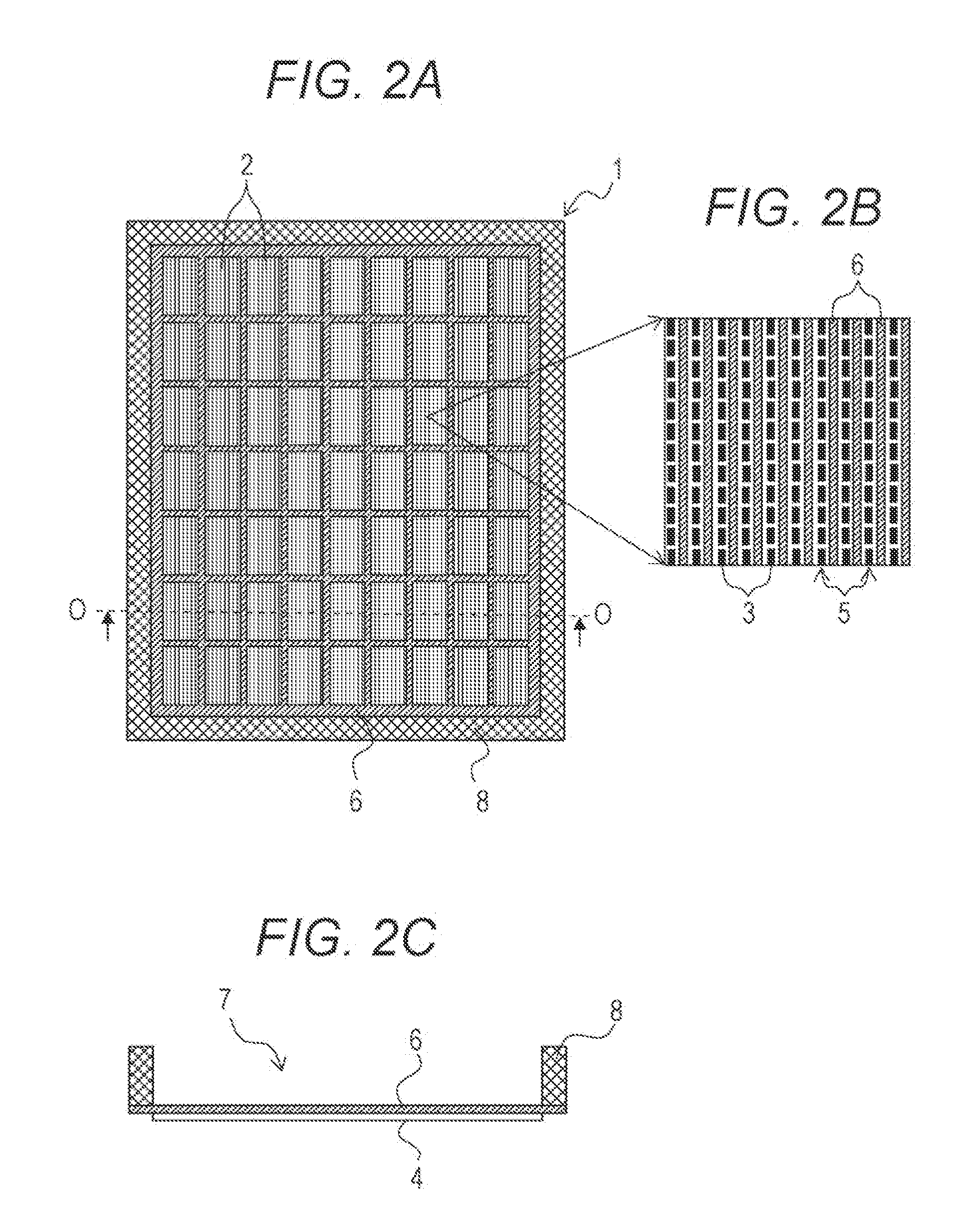

Deposition mask and method for producing deposition mask

ActiveUS20160115580A1High positioning accuracyReduce positional deviationVacuum evaporation coatingSputtering coatingEngineeringSpot welding

A deposition mask is provided. The deposition mask including: a resin film 1 in which penetrating opening patterns 4 are formed and a frame-shaped metal thin film 5 having an opening is provided on one face 1a of the film 1; a metal mask 2 provided at a position corresponding to the opening of the metal thin film 5 on one face 1a side of the film 1, the metal mask 2 being separated from and independent of the film 1, the metal mask 2 being provided with through holes 6; and a metal frame 3 positioned on one face 1a side of the film 1, the metal frame 3 supporting the film 1 and the metal mask 2 by spot-welding a portion of the metal thin film 5 and an edge region of the metal mask 2 to one end face 3a.

Owner:V TECH CO LTD

Three-dimensional display device and liquid crystal grating and control method thereof

InactiveCN103197474AGuaranteed 3D image display effectReduce positional deviationStatic indicating devicesSteroscopic systemsLiquid-crystal displayLiquid crystal

The invention discloses a three-dimensional display device and a liquid crystal grating and a control method thereof. The liquid crystal grating comprises a first substrate and a second substrate which are oppositely arranged, a liquid crystal layer located between the first substrate and the second substrate, a first substrate electrode located on the first substrate and facing to one surface of the liquid crystal layer and a second substrate electrode located on the second substrate and facing to one surface of the liquid crystal layer. The second substrate electrode comprises a plurality of parallel strip-shaped sub electrodes which are electrically insulated. When the liquid crystal grating performs displaying, a plurality of light-transmitting grating bars and light-shading grating bars which are distributed at intervals are formed, each light-transmitting grating bar comprises a plurality of sequentially adjacent sub electrodes, and each light-shading grating bar comprises a plurality of sequentially adjacent sub electrodes. The light-transmitting grating bars and the light-shading grating bars of the liquid crystal grating can be moved by controlling voltage of the sub electrodes of the second substrate electrode, the deviation of the center point position of the two eye connection line of a viewer and the position of a calibration grating bar is reduced, and the three-dimensional display effect is ensured.

Owner:TRULY SEMICON

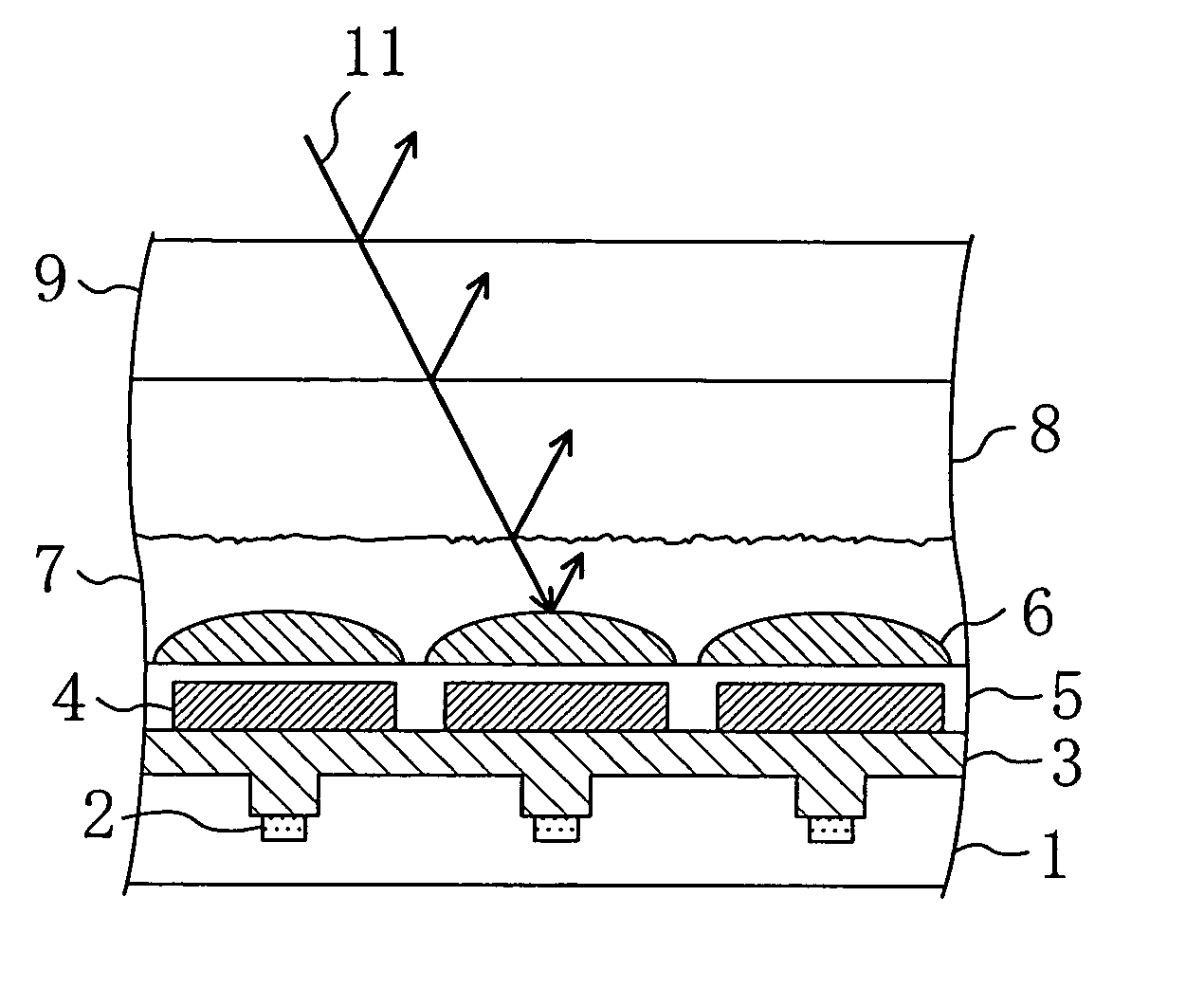

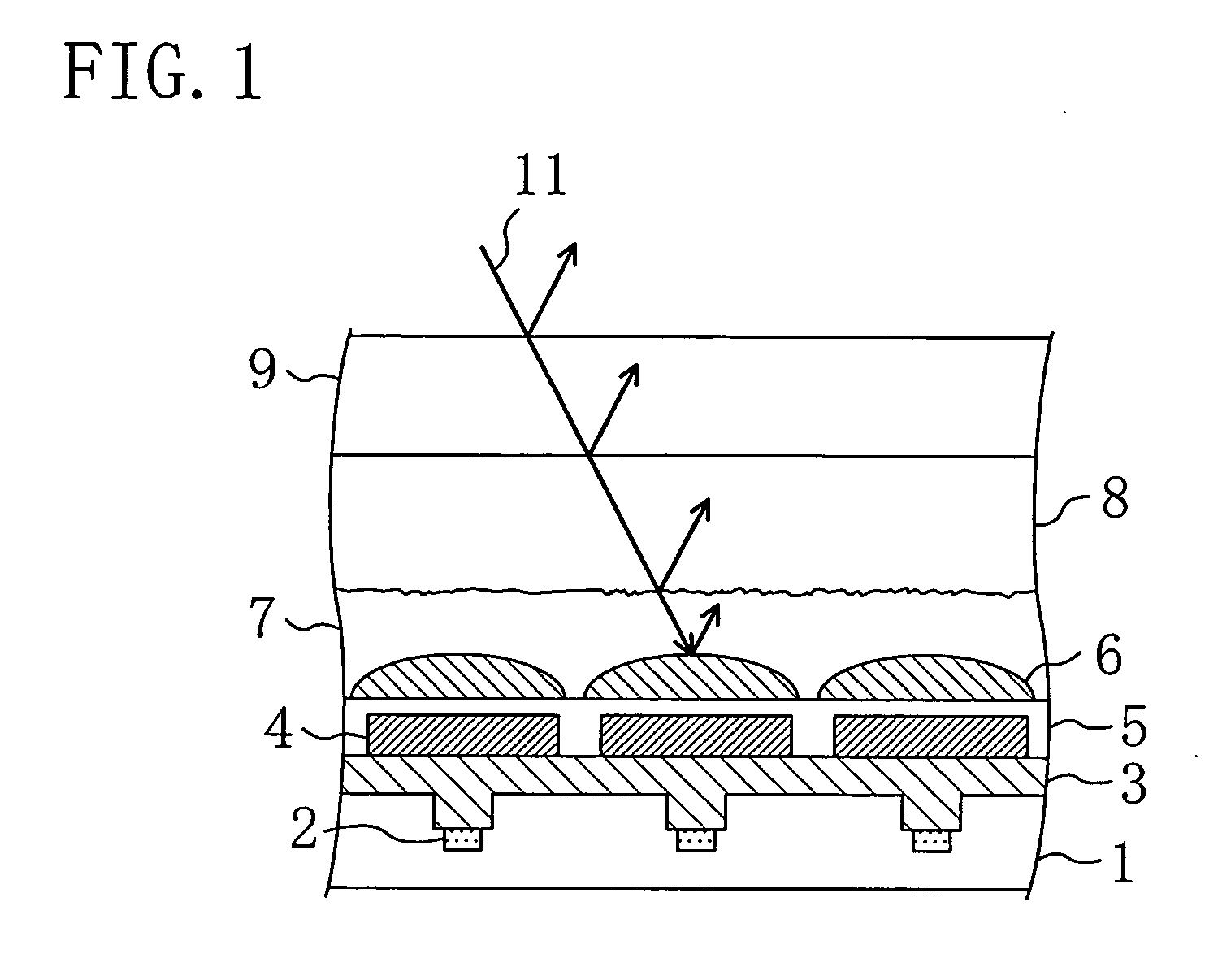

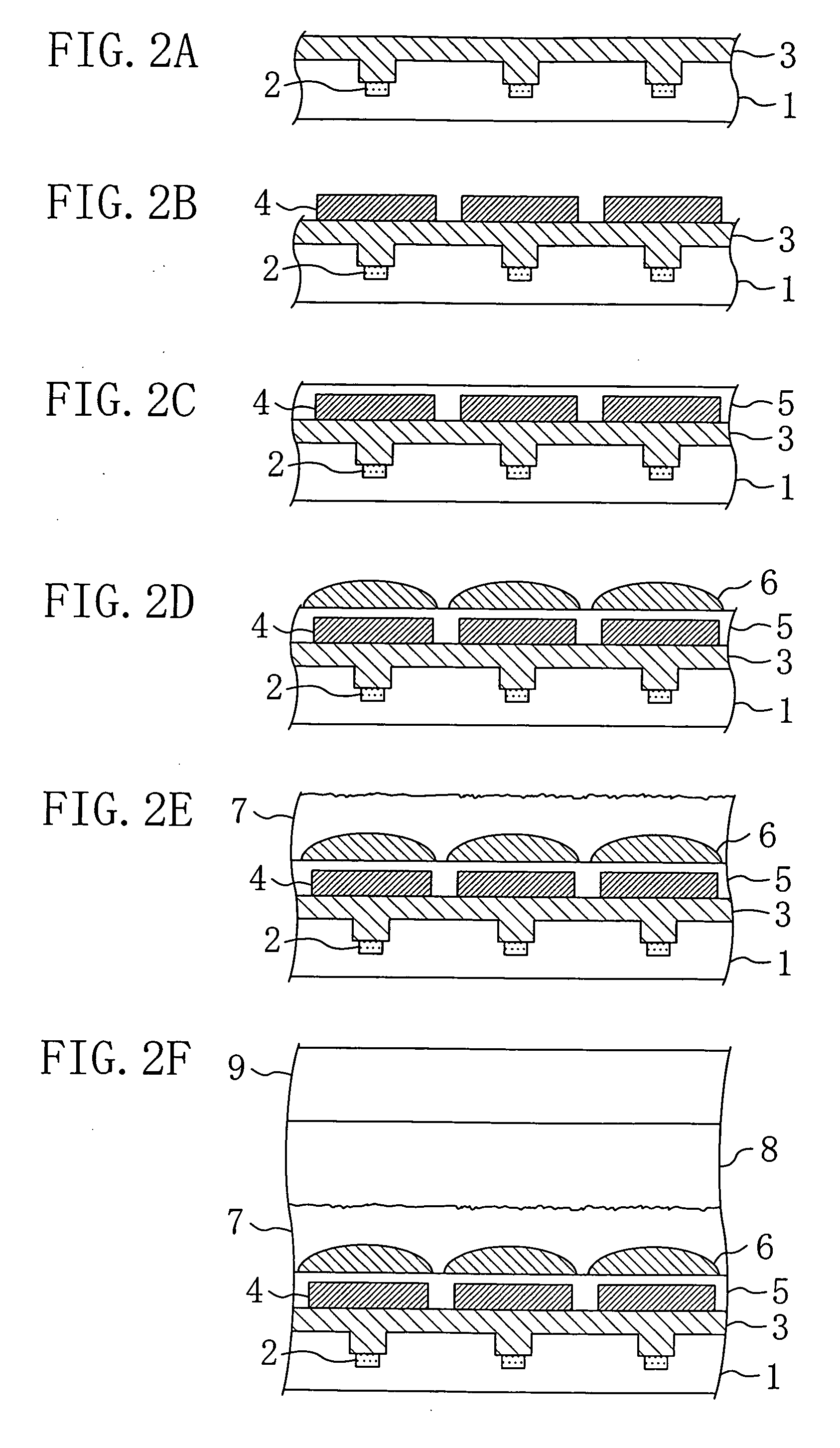

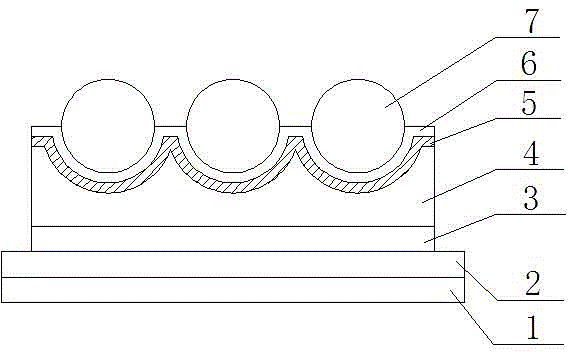

Solid-state image sensing device and method for fabricating the same

InactiveUS20070030380A1Improve G-sensitivityReduce the overall heightTelevision system detailsTelevision system scanning detailsFluorine containingImage sensing

A solid-state image sensing device comprises: a light receiving unit for receiving light; a microlens formed above the light receiving unit; a fluorine-containing resin material layer formed on the microlens; and a transparent substrate provided over the fluorine-containing resin material layer. A resin layer adheres the fluorine-containing resin material layer and the transparent substrate.

Owner:COLLABO INNOVATIONS INC

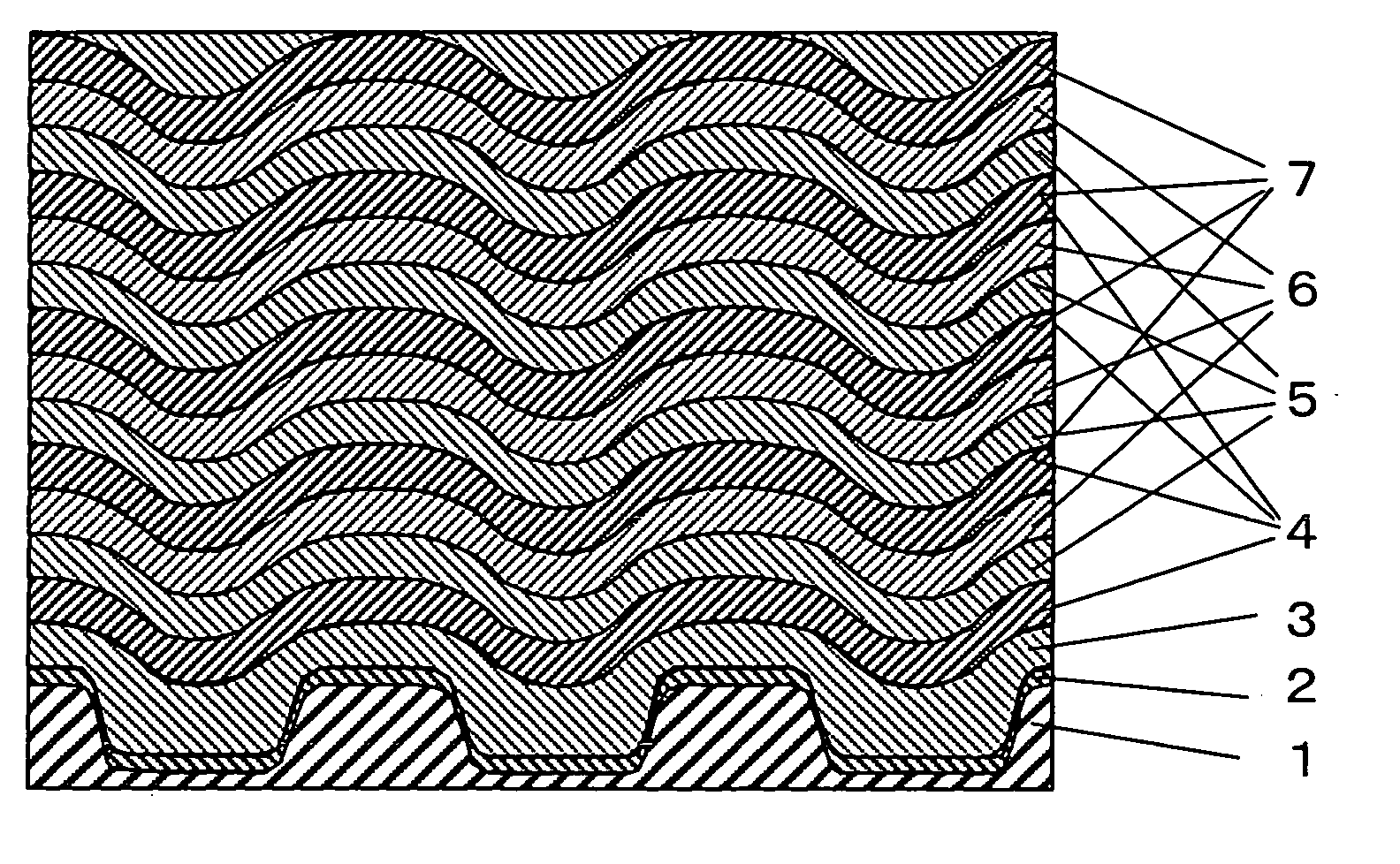

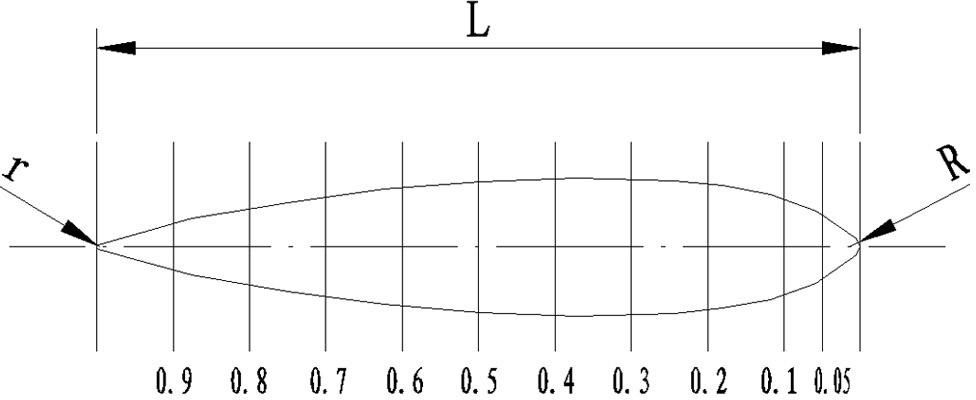

Information recording medium and manufacturing process

InactiveUS20050276211A1Ensure electrical connection reliabilityHigh speed recordingMechanical record carriersRecord information storageInformation layerOrganic film

An information recording medium and manufacturing method for high-speed and high density recording. An inorganic film is formed by sputtering while applying a bias voltage to shift the substrate voltage potential in the negative direction, or a laminated film is formed by applying energy after coating a substrate with an organic film, and the irregularities maintained even after the laminated film is formed, so that stable, high-capacity and high-speed recording can be attained by forming a multi-information-layer that still retains the irregularities.

Owner:HITACHT MAXELL LTD

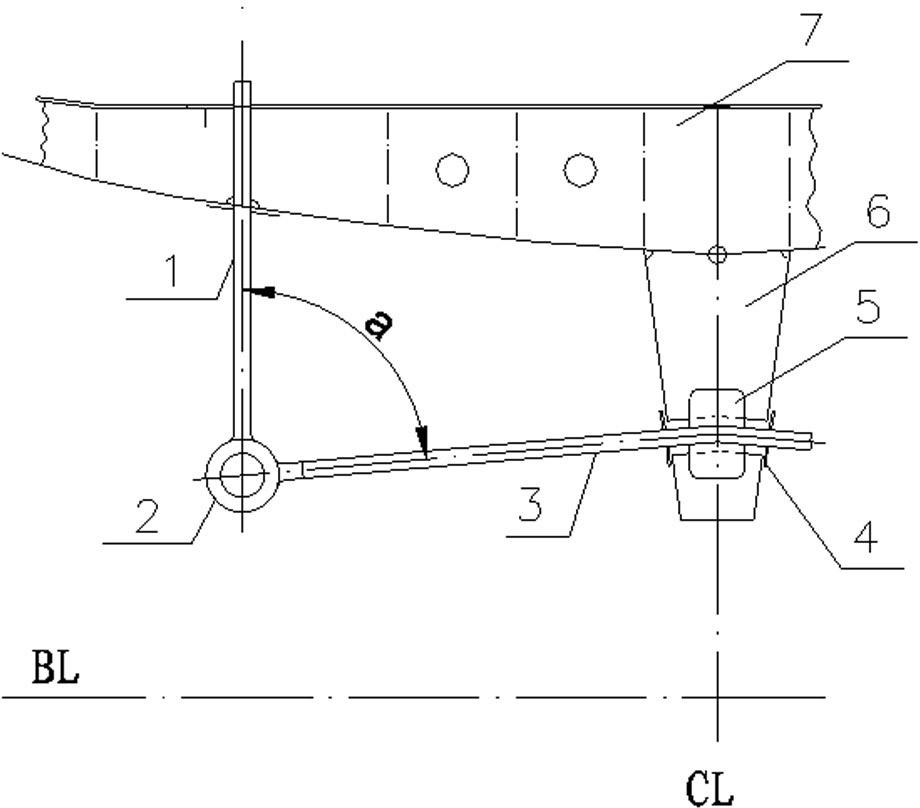

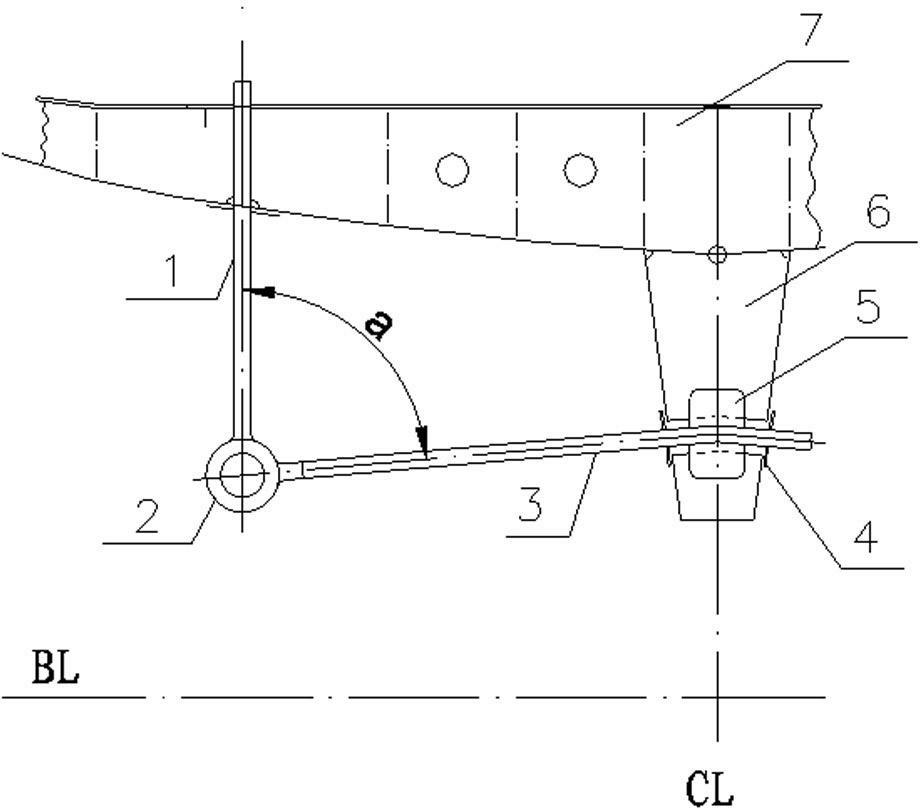

Assembly welding process for propeller shaft bracket

InactiveCN102303176AMixed flow and small forceAvoid correctionWelding/cutting auxillary devicesArc welding apparatusPropellerPore diameter

The invention relates to an assembly welding process for a propeller shaft bracket, and belongs to the technical field of ships. The process comprises the following steps of: before assembling a propeller shaft hub, performing a hydrostatic test of 0.2 MPa; correcting axes and pore diameters of front and rear end faces of the propeller shaft hub and sizes of four points on the left and right sides and upper and lower sides of the propeller shaft hub, and marking temporarily; cutting corresponding position holes on a bottom board and rib board of a ship body, and machining beveled edges of a supporting arm and the propeller shaft hub to perform point welding pre-positioning connection; allowing transverse arms in the horizontal direction to form an included angle alpha of 85 degrees with the supporting arm, splicing the supporting arm and the propeller shaft hub on a moulding bed in advance, and inserting into an open pore of the bottom board of the ship body to perform pre-welding positioning; after the supporting arm and the transverse arms are pre-positioned, welding and positioning the transverse arms and the propeller shaft hub according to a shafting bracing wire; and after welding, performing ultrasonic detection and magnetic particle detection on the propeller shaft bracket. The propeller shaft bracket assembled by the process is small in positional deviation and vibration quantity and low in noise, and the service life of the ships is prolonged greatly.

Owner:YANGFAN GROUP

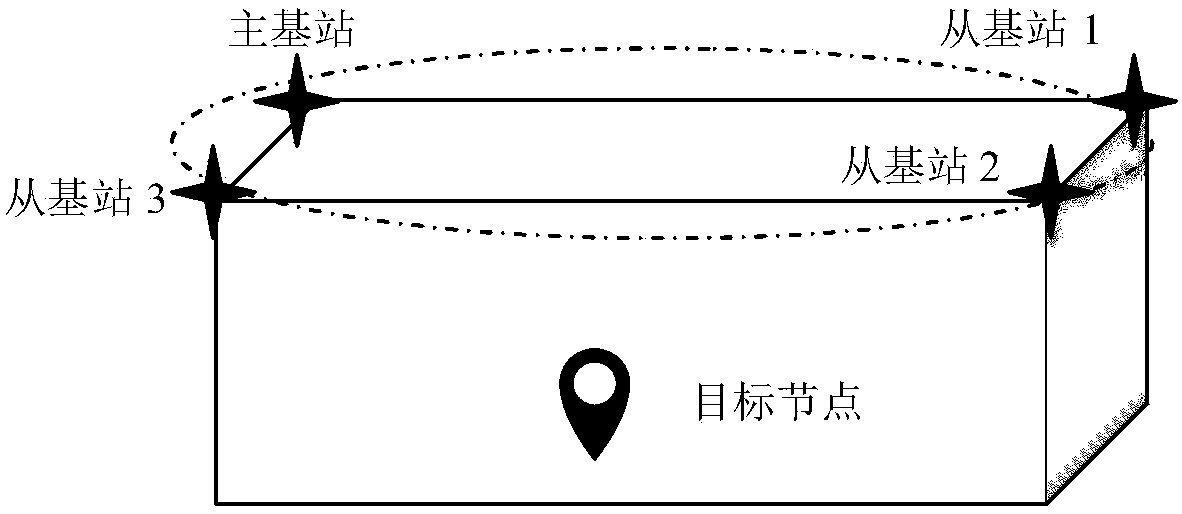

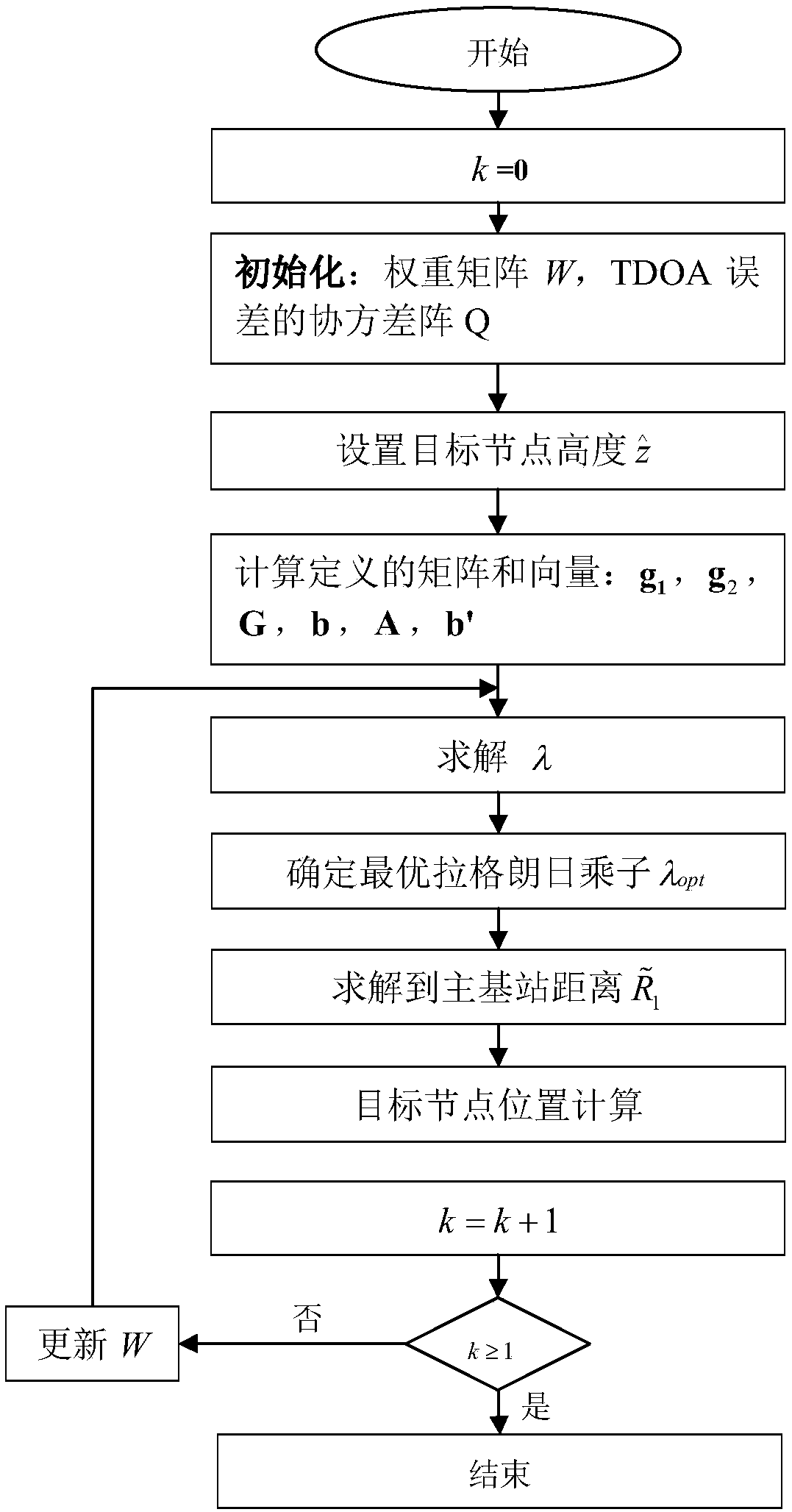

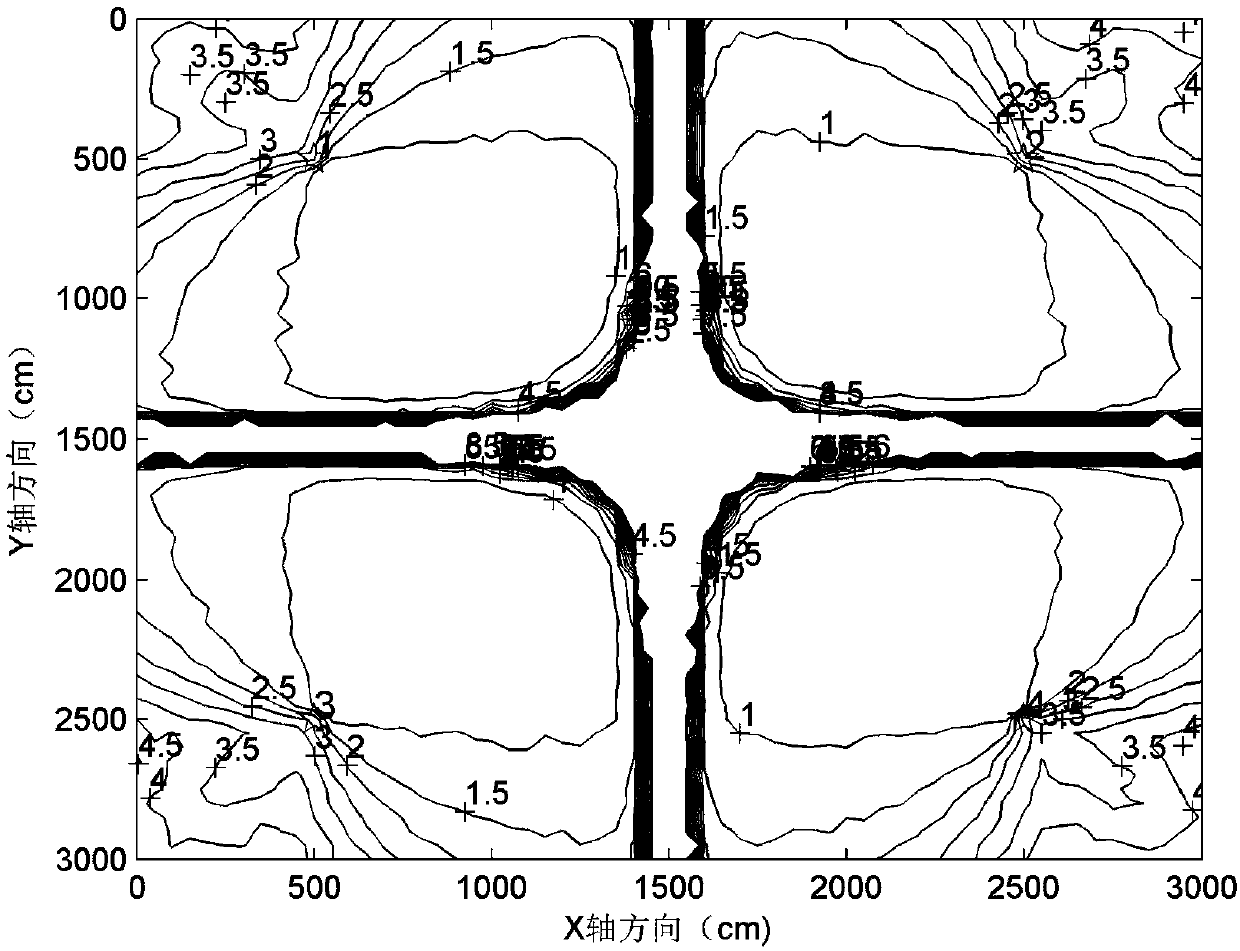

TDOA positioning method for indoor positioning based on height assisted correction

ActiveCN107371129AReduce positional deviationApplicable layout positioningPosition fixationWireless commuication servicesOriginal dataMaster station

The invention discloses a TDOA positioning method for indoor positioning based on height assisted correction, which includes the following steps: (1) setting M base stations including a master station in a three-dimensional indoor environment, and getting the time when a wireless signal of a target node arrives at each base station; (2) inputting the experience height of the target node or the measured height Z-(^) obtained by an auxiliary sensor, reading TOA original data of the base stations and the target node, calculating the difference between the arrival time of each slave base station and the arrival time of the master base station, and getting M-1 TDOA values through processing; and (3) calculating the position of the target node according to the position of a positioning base station and the arrival time difference of the target node. The method can reduce position deviation caused by the neglect of the height of the base stations in near-field indoor positioning, and is suitable for indoor positioning under circumferential distribution of base stations. Compared with the Chan positioning algorithm, the method is more suitable for near-field indoor positioning and indoor positioning under circumferential layout of base stations.

Owner:ZHENGZHOU LOCARIS ELECTRONICS TECH CO LTD

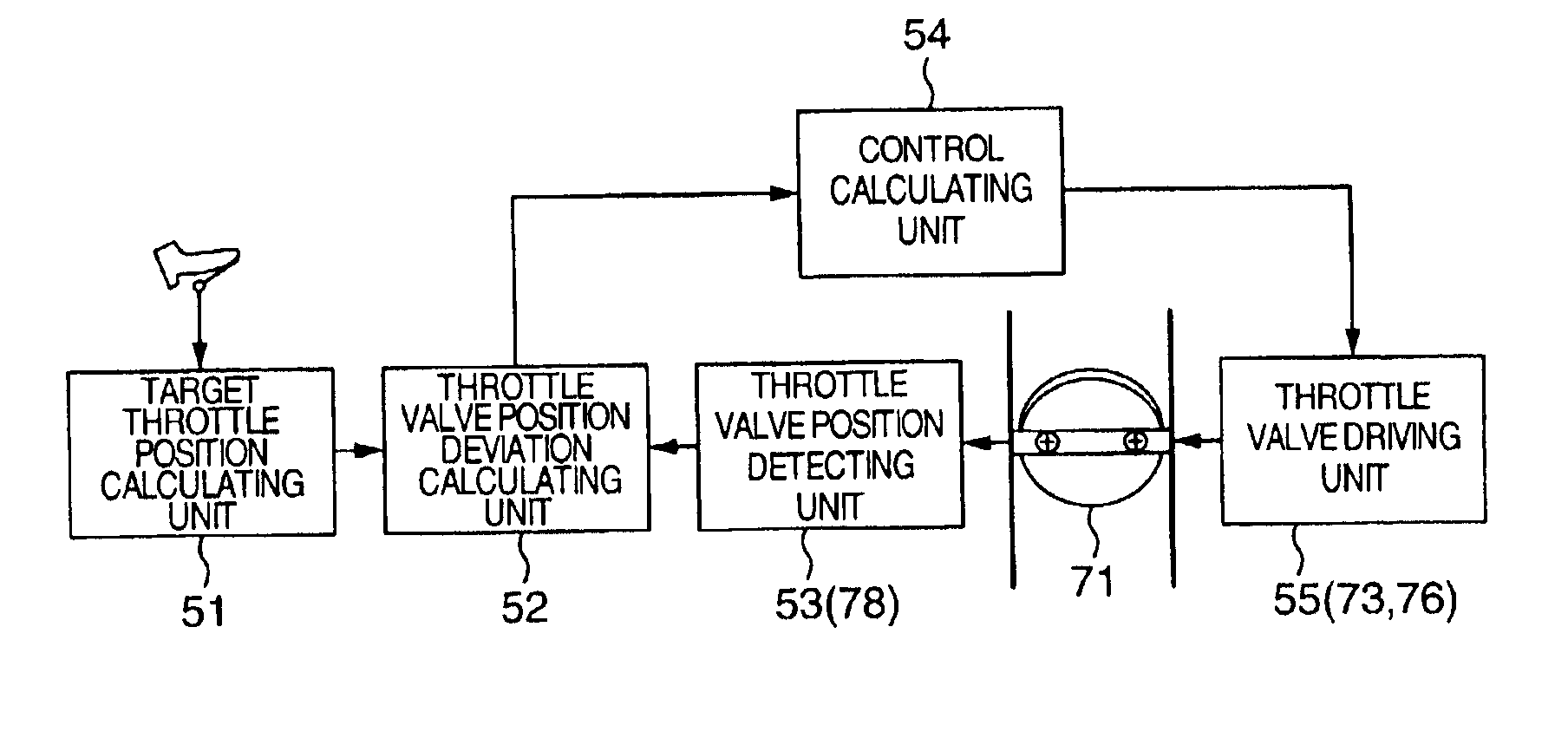

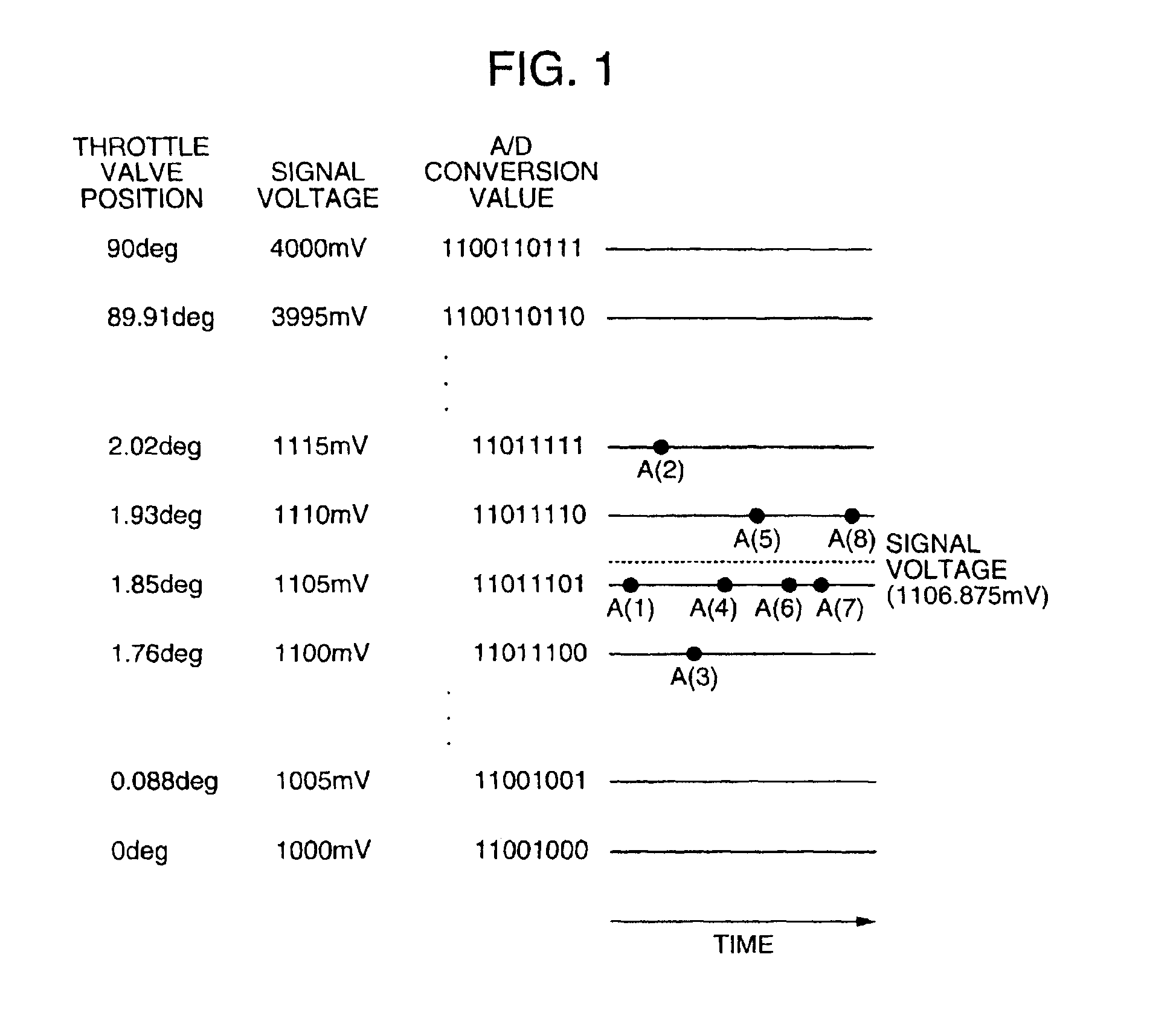

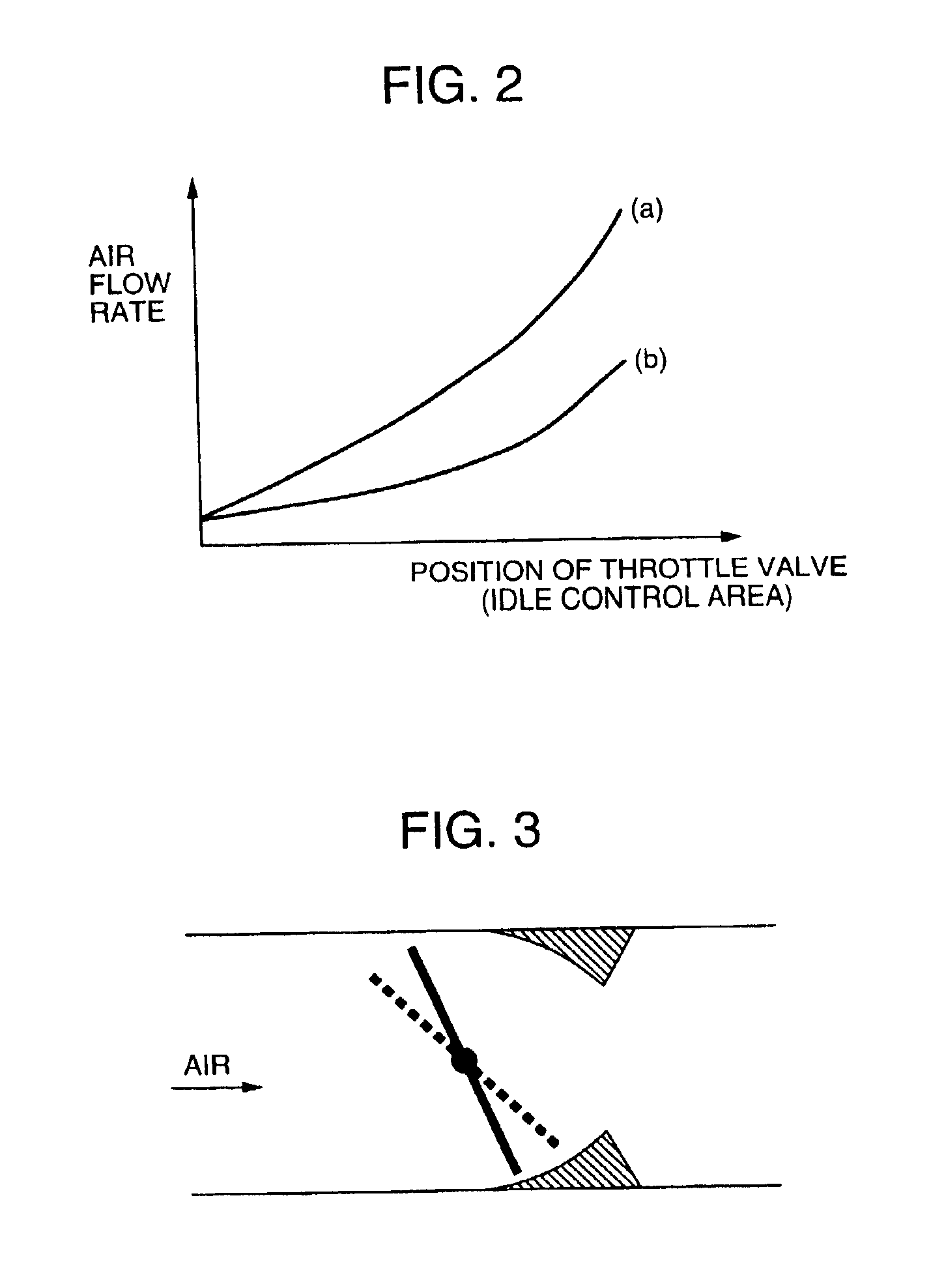

Method and apparatus for controlling motor drive type throttle valve

InactiveUS6874471B2Reduce positional deviationHigh resolutionElectrical controlMachines/enginesMotor driveThrottle

When the position of a throttle valve approaches a target value, an integration calculation of position control is stopped. When a deviation from the target value increases, the integration calculation is restarted. If an integration value includes no frictional amount, a motor output in which a motor and a spring are matched is set synchronously with a change in target value.

Owner:HITACHI LTD +1

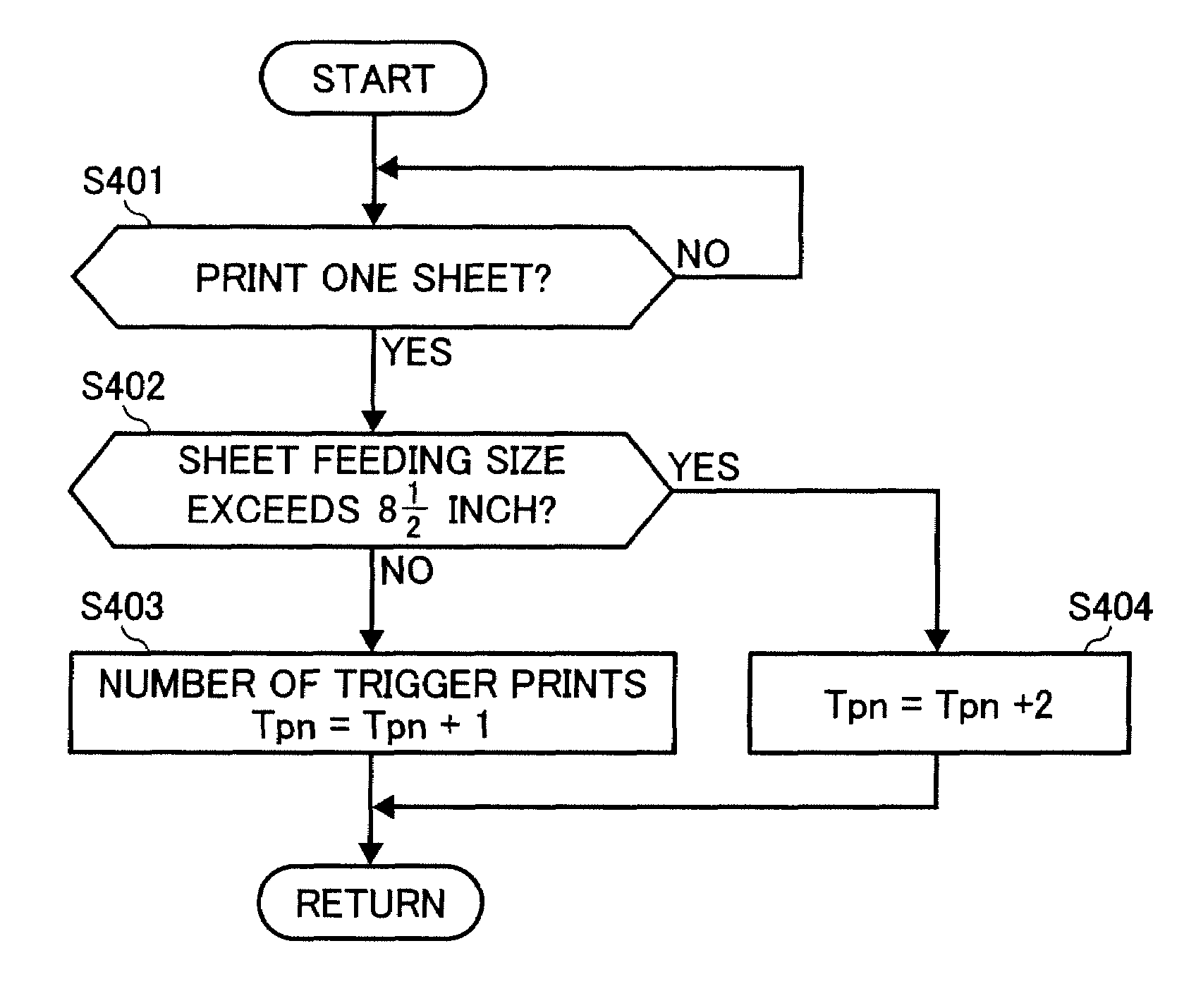

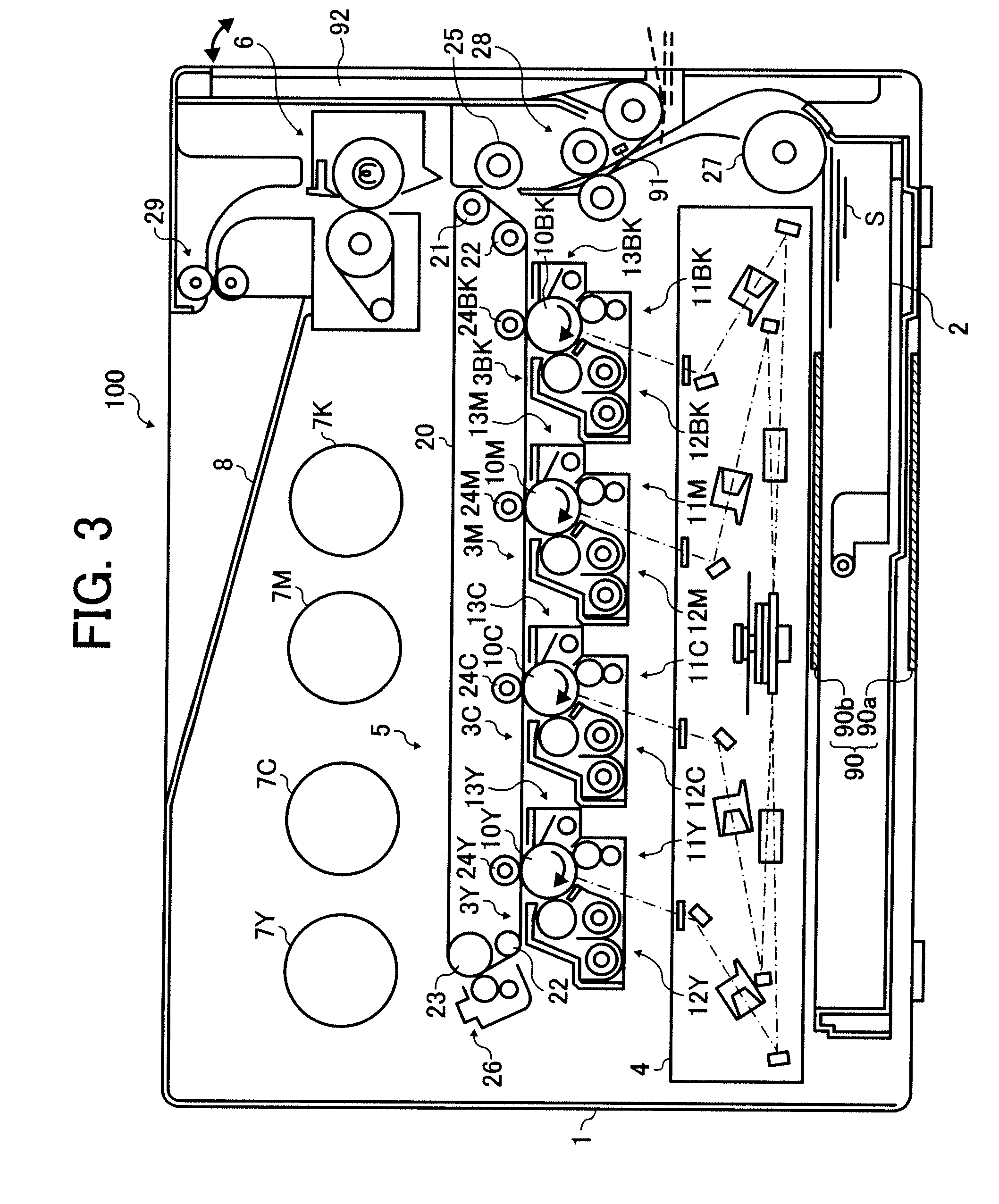

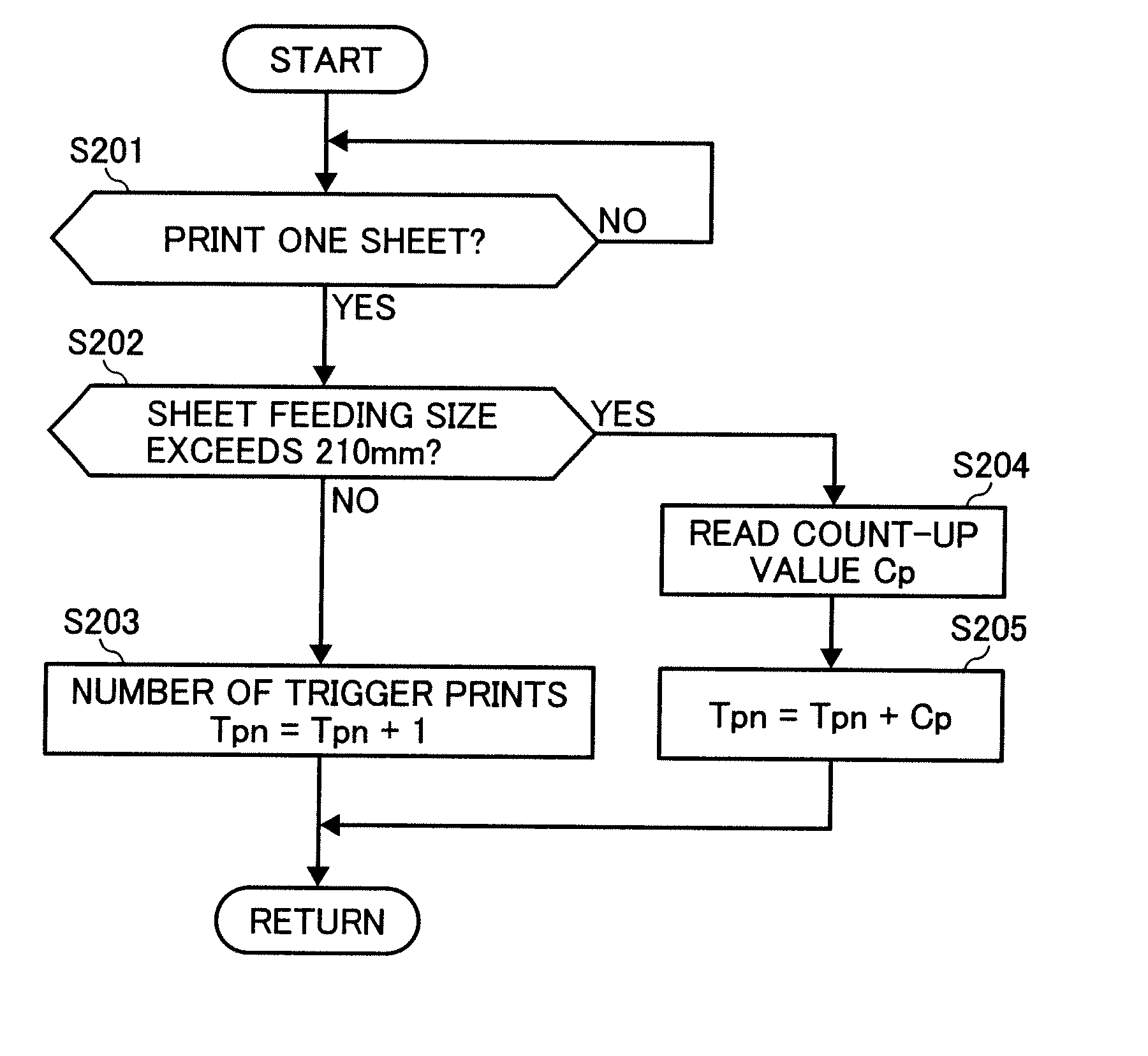

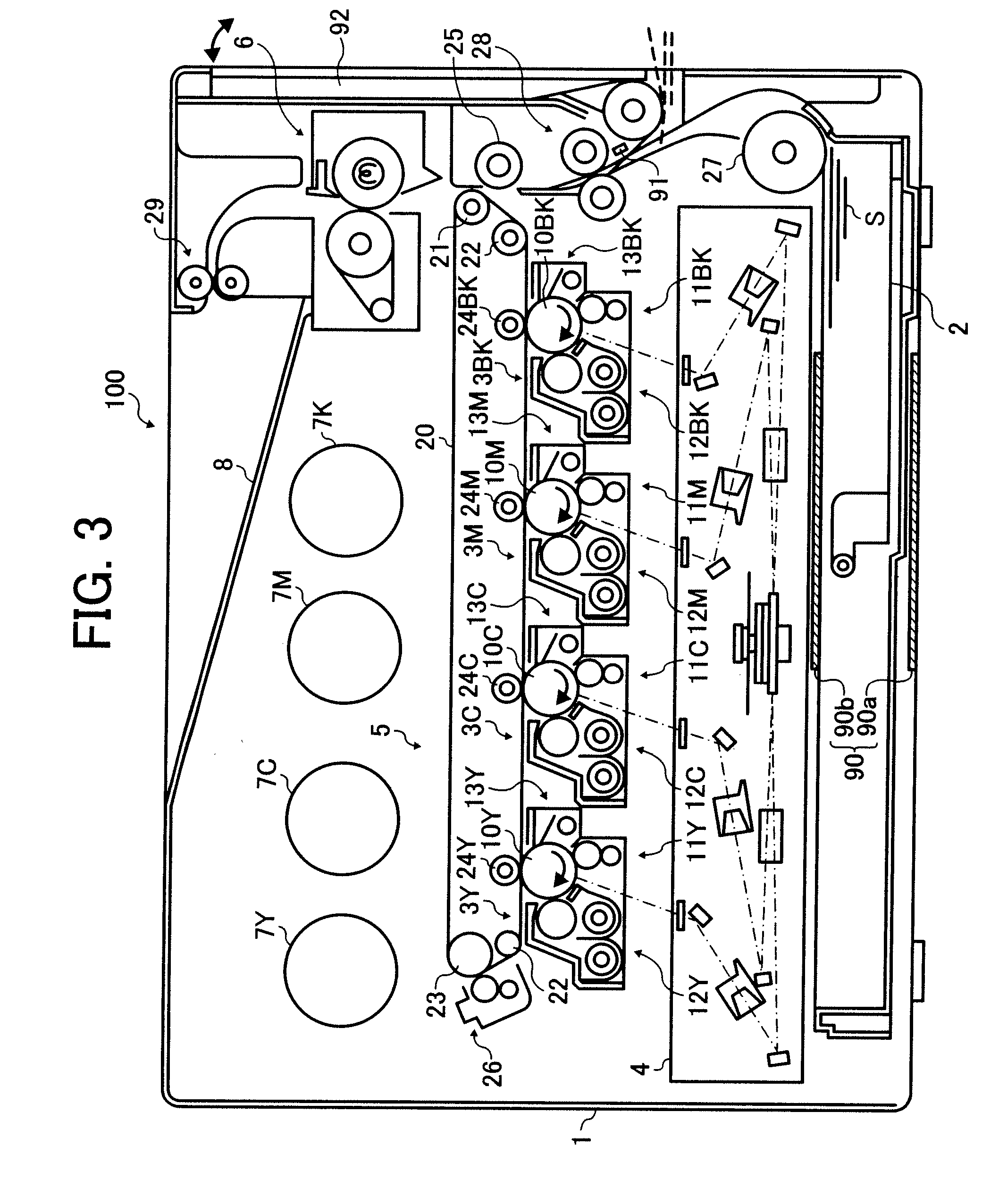

Method, apparatus, and program for image forming capable of effectively adjusting positional deviation

ActiveUS7630657B2Effective regulationQuality improvementElectrographic process apparatusImage detectionImage formation

An image forming apparatus, in which a program for carrying out an image forming method is provided, includes a transfer member to receive respective images formed on a plurality of image bearing members, an image detecting unit to detect the images conveyed on the transfer member, a paper length detecting unit to detect a length of a recording medium in a sheet travel direction, a counting unit to count the number of recording media and to change a count up value according to a detection result by the paper length detecting unit, and a control unit to control an image forming timing with respect to the image bearing members based on a detection timing of the image and to perform a positional deviation adjustment each time a counted value increases by a predetermined amount so as to reduce an amount of a positional deviation of the image.

Owner:RICOH KK

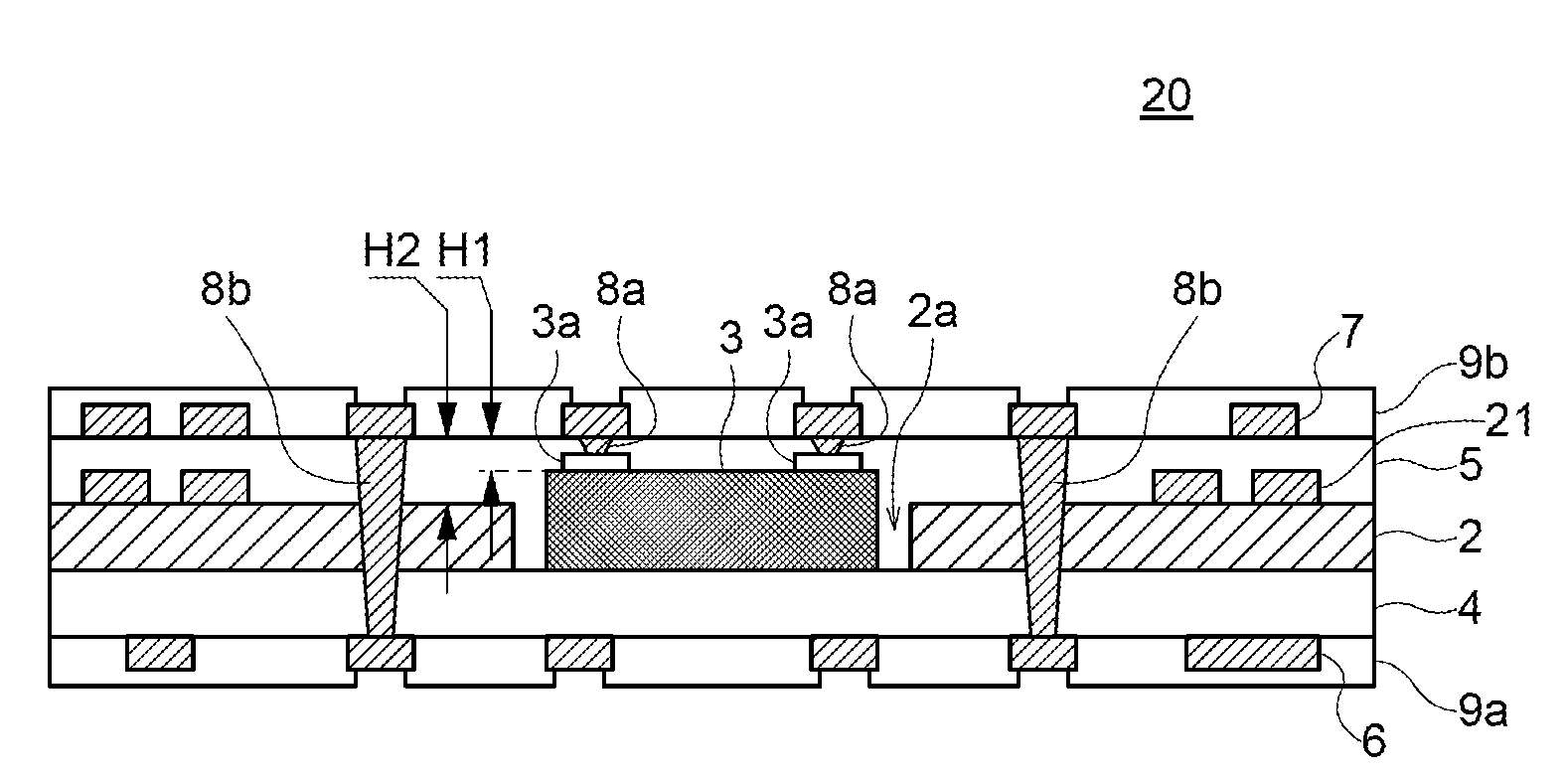

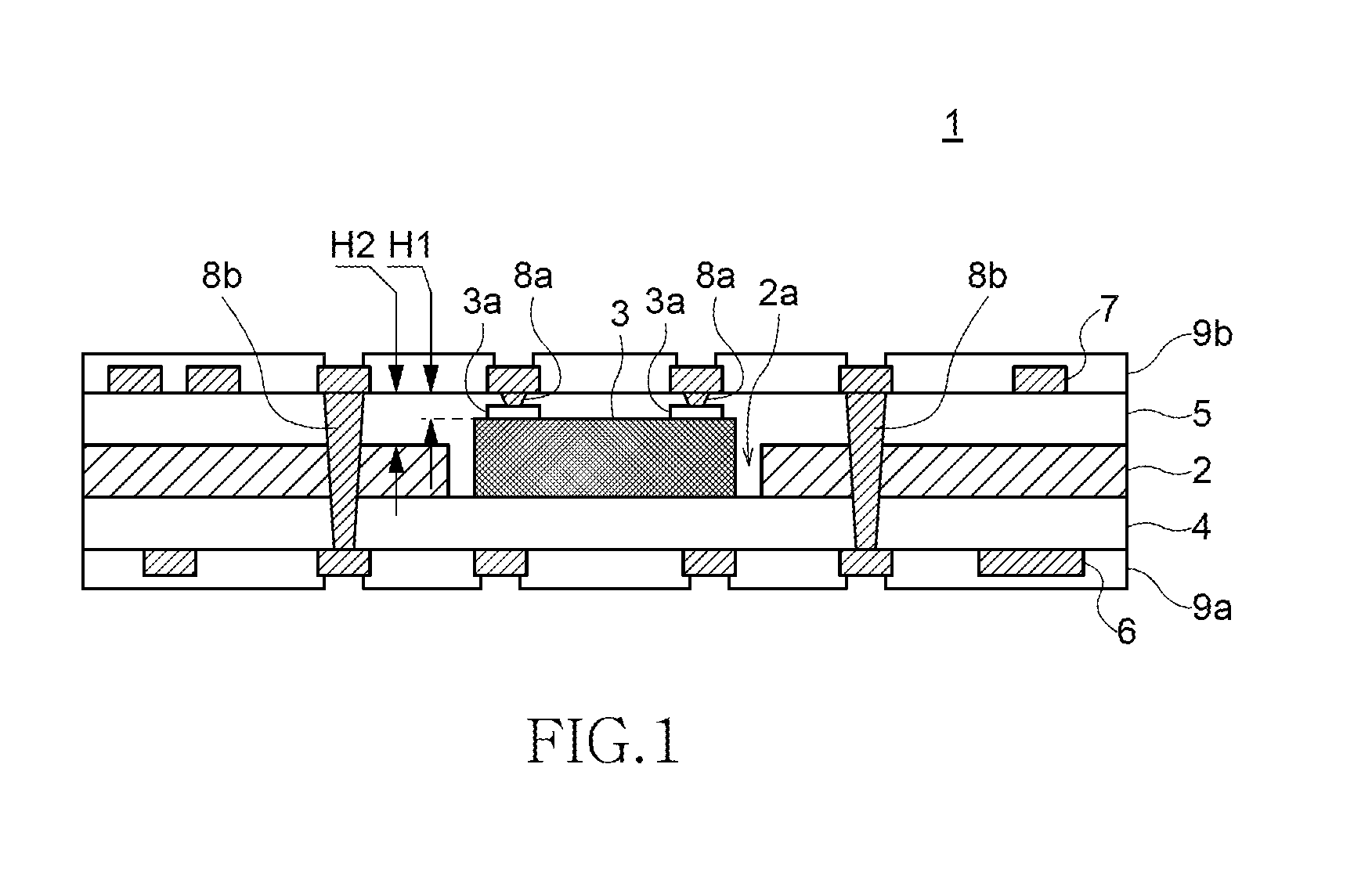

IC embedded substrate and method of manufacturing the same

ActiveUS20150145145A1High substrate strengthUniform thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineering

Disclosed herein is an IC embedded substrate that includes a core substrate having an opening, an IC chip provided in the opening, a lower insulating layer, and upper insulating layer. The IC chip and the core substrate is sandwiched between the lower insulating layer and the upper insulating layer. The upper insulating layer is formed in such a way as to fill a gap between a side surface of the IC chip and an inner peripheral surface of the opening of the core substrate. A first distance from the upper surface of the IC chip to an upper surface of the upper insulating layer is shorter than a second distance from the upper surface of the core substrate to the upper surface of the upper insulating layer.

Owner:TDK CORPARATION

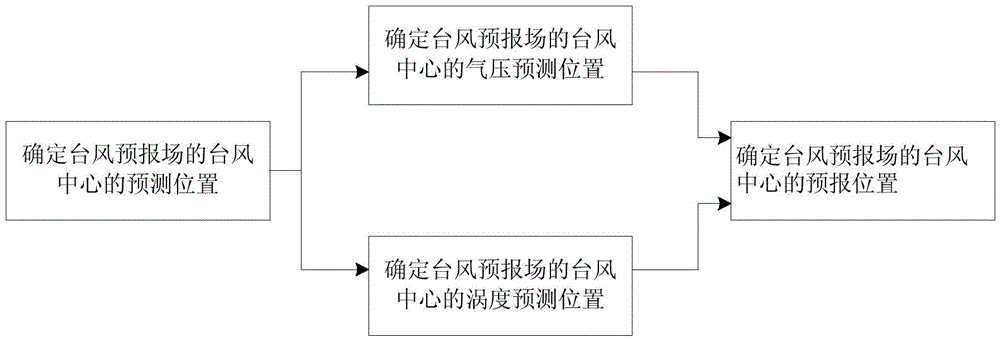

Method for extracting typhoon objective forecast information from numerical forecasting product

ActiveCN103955009AInterpolation fitImprove objective positioning accuracyWeather condition predictionWind fieldBusiness forecasting

The invention discloses a method for extracting typhoon objective forecast information from a numerical forecasting product. The method includes the steps of firstly, determining a forecasting position of a typhoon center of a typhoon forecast field; secondly, determining the air pressure forecasting position of the typhoon center of the typhoon forecast field according to a sea level pressure field, determining a vortex forecasting position of the typhoon center of the typhoon forecast field according to a 850 hPa vortex field, and determining the forecasting position of the typhoon center of the typhoon forecast field according to the vortex forecasting position of the typhoon center of the typhoon forecast field by comprehensively considering the 850 hPa vortex field, a 850 hPa wind field and the sea level pressure field of the typhoon forecast field; thirdly, extracting typhoon strength forecast information according to the forecasting position of the typhoon center of the typhoon forecast field. The method has the advantages that the forecasting position of the typhoon center can be automatically extracted, accuracy is high, and the typhoon strength forecast information can be more accurately extracted.

Owner:宁波市气象台

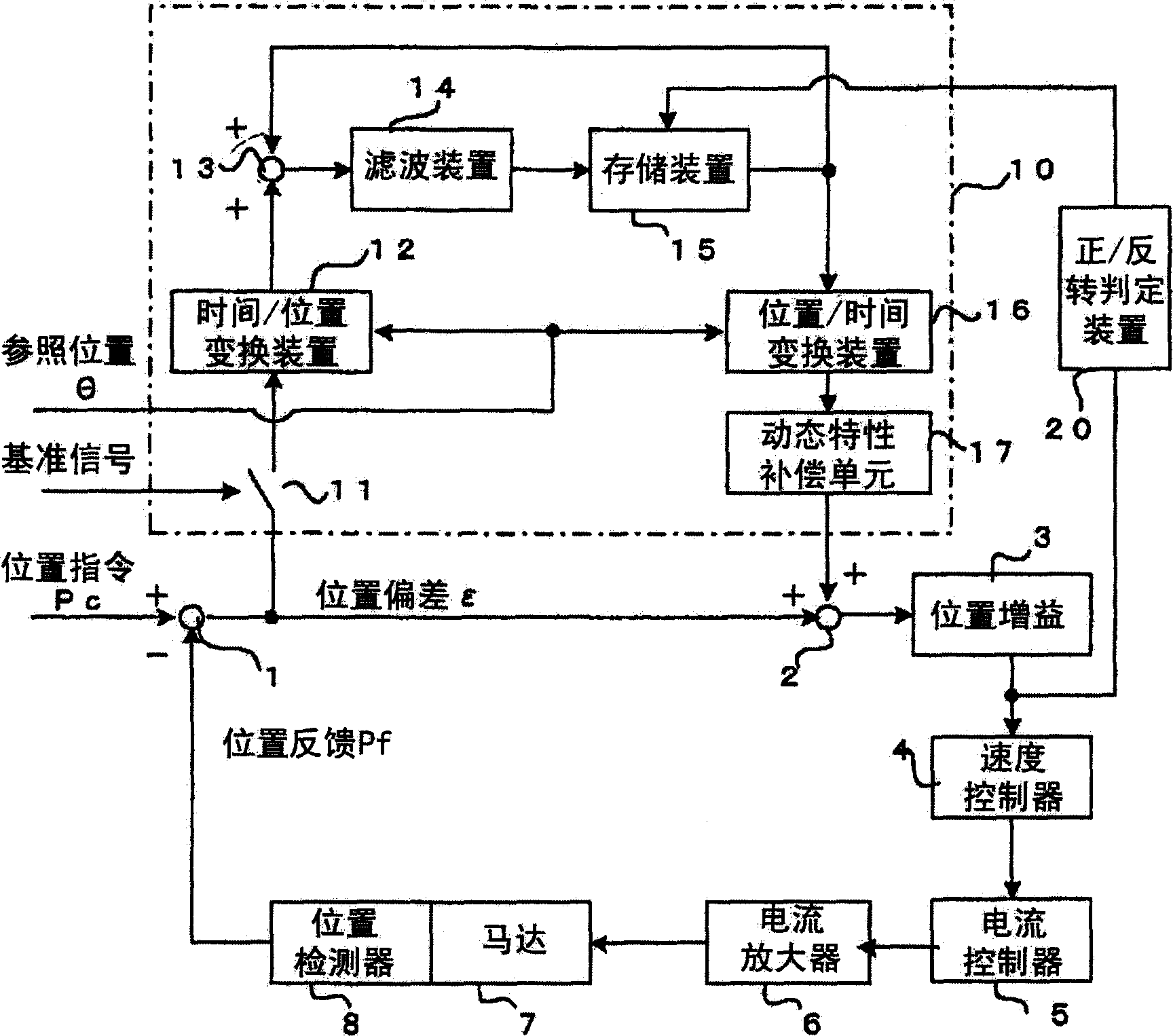

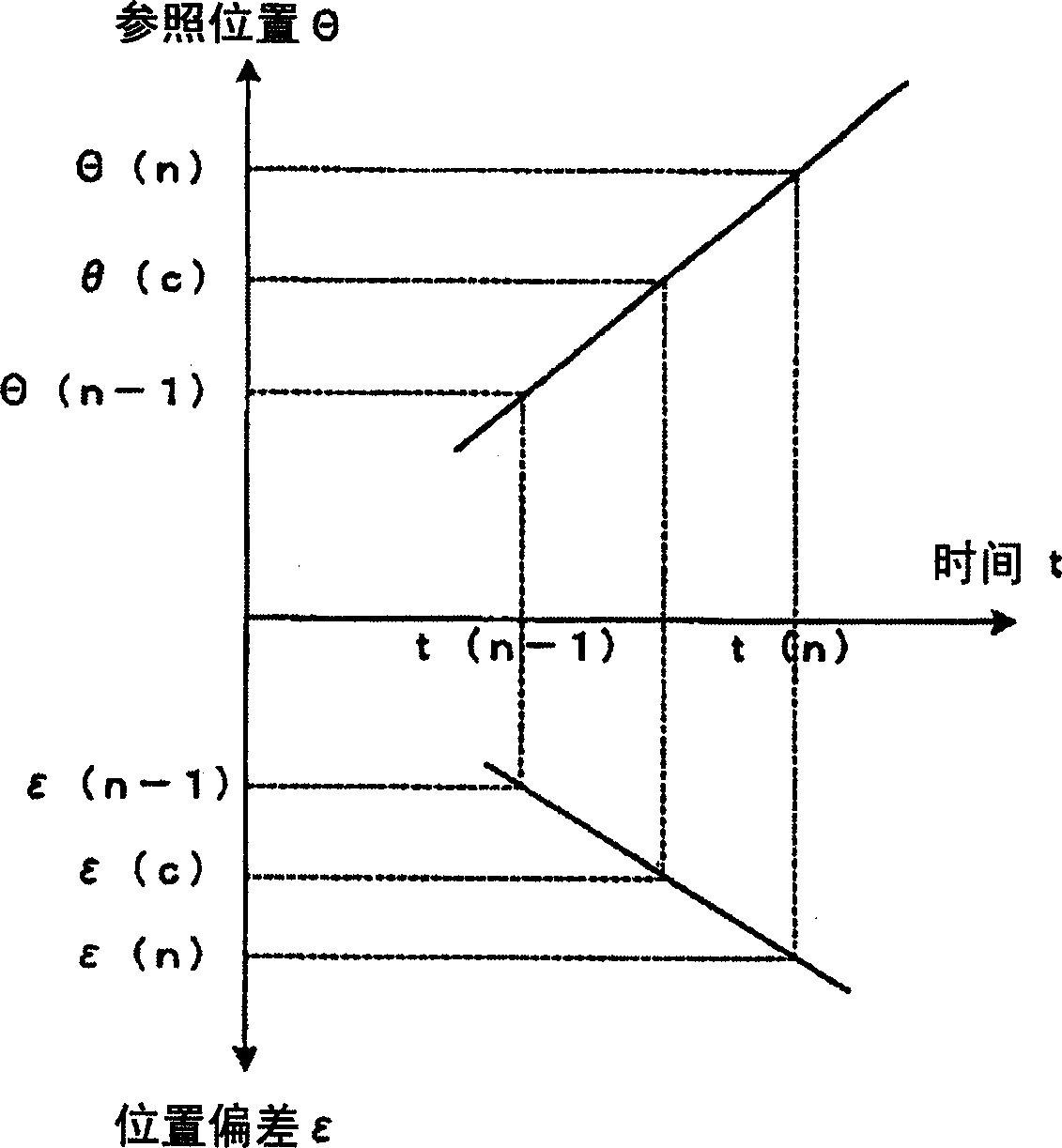

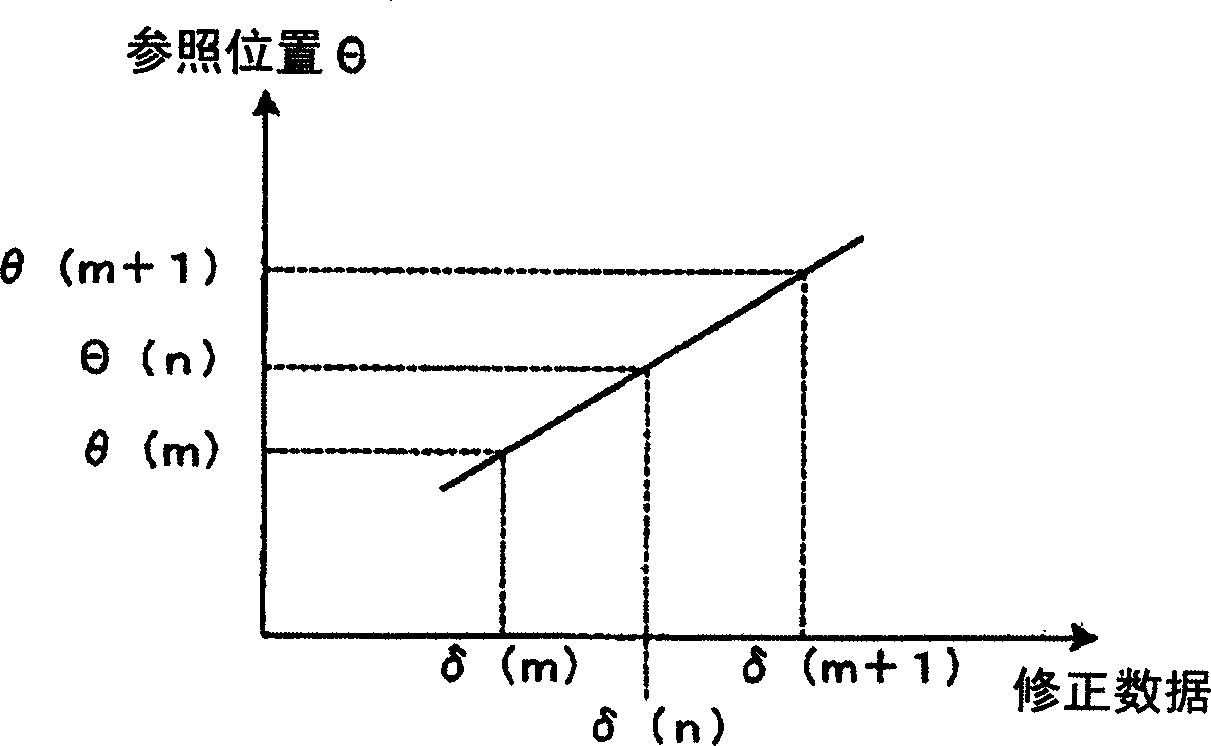

Servo motor drive control device

ActiveCN1523734AReduce positional deviationAutomatic control devicesComputer controlMotor driveControl engineering

Learning control is performed when carrying out processing by repeating operational instructions in a pattern cycle for a servo motor. Time / position converting means determines the positional deviation for a prescribed position with respect to a reference position from a positional deviation determined by sampling, and the reference position output in synchronization with the drive of the servo motor. Corresponding correction data stored in a memory means is added to the positional deviation, and then the result is subjected to filtering processing by means to update the correction data corresponding to the position. Position / time converting means then determines correction data for the current sampling time, on the basis of the correction data corresponding to the position as stored in the memory means, and the detected reference position. This correction data is processed by an element to compensate for dynamic properties, thereby deriving a correctional quantity, which is added to the positional deviation.

Owner:FANUC LTD

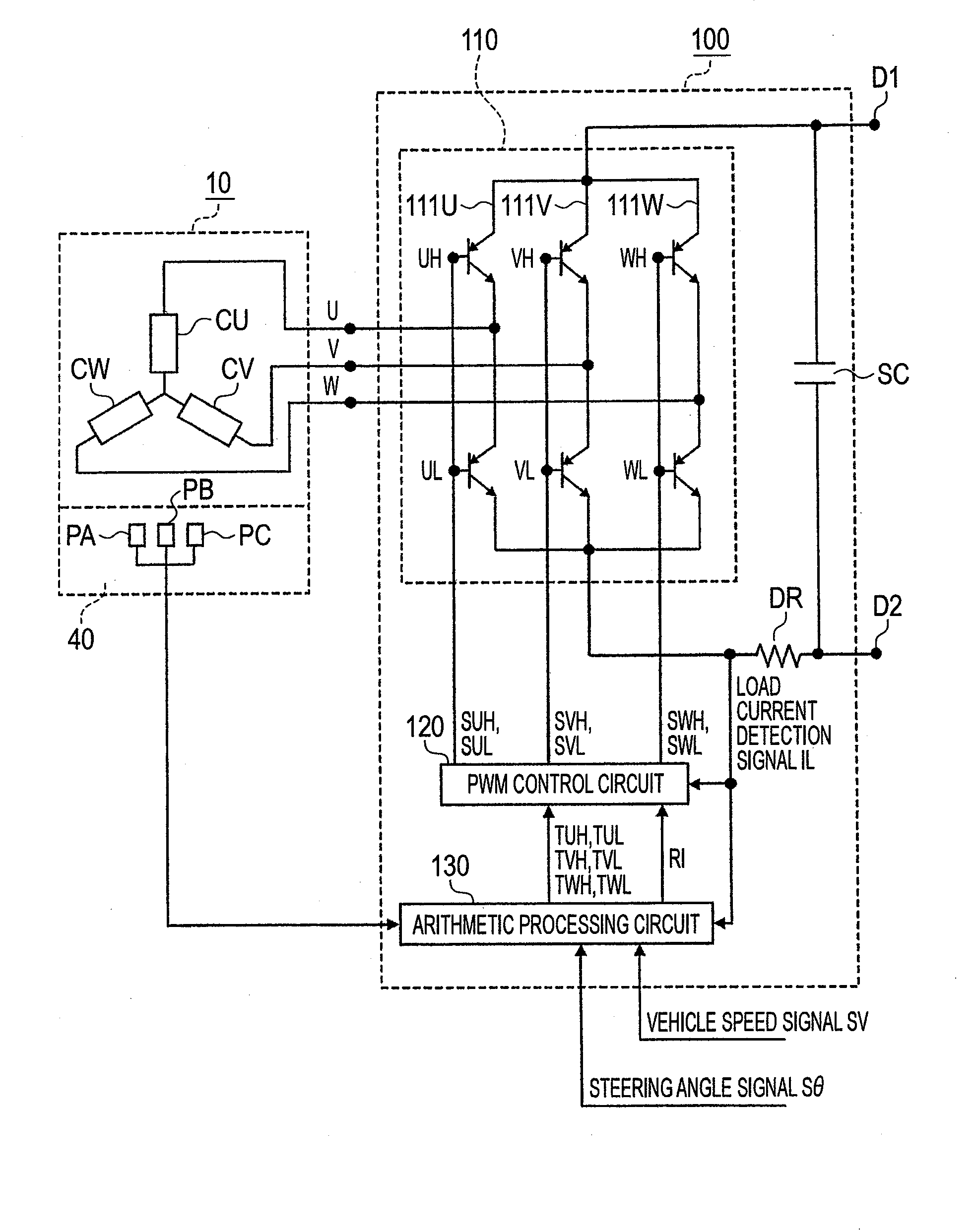

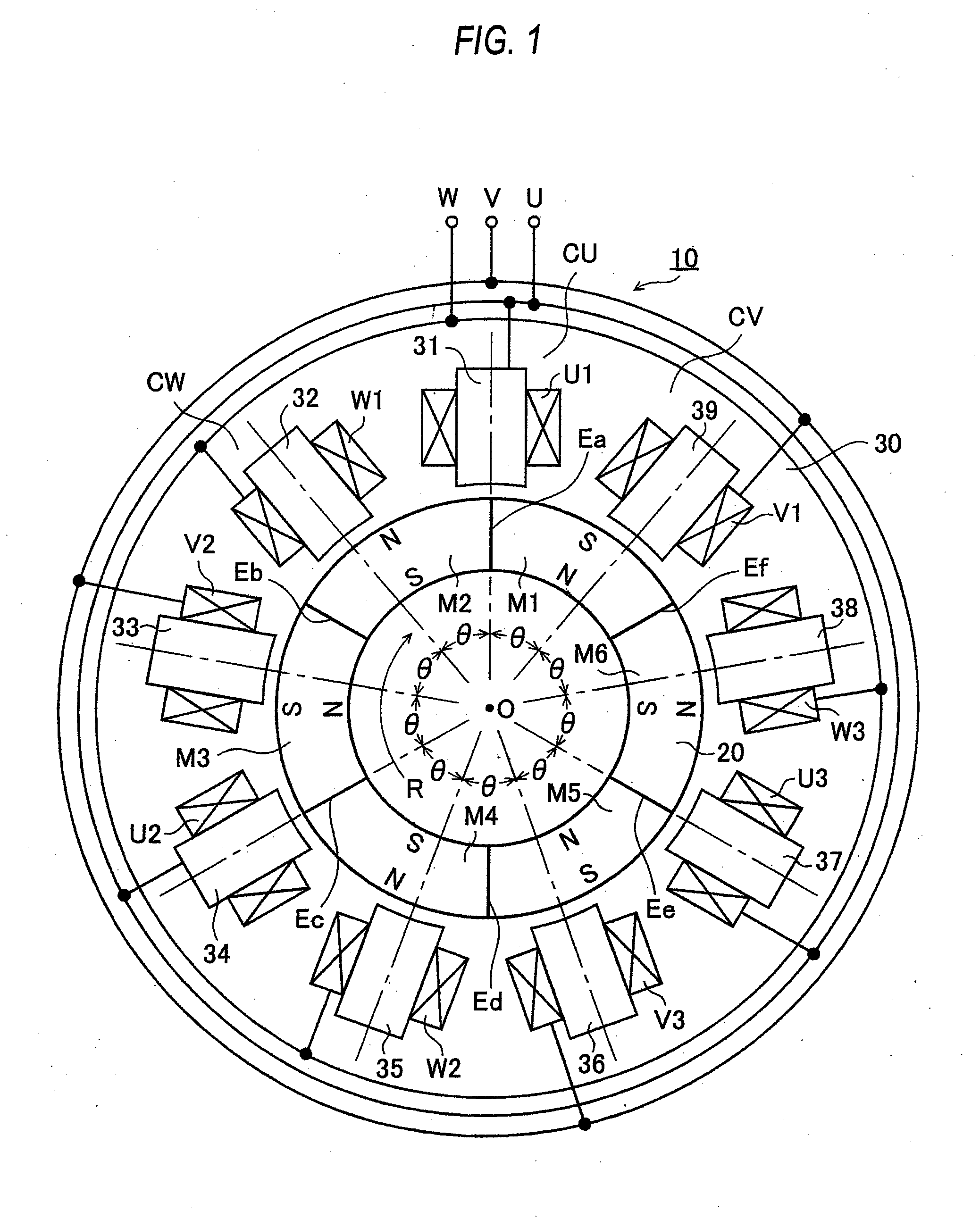

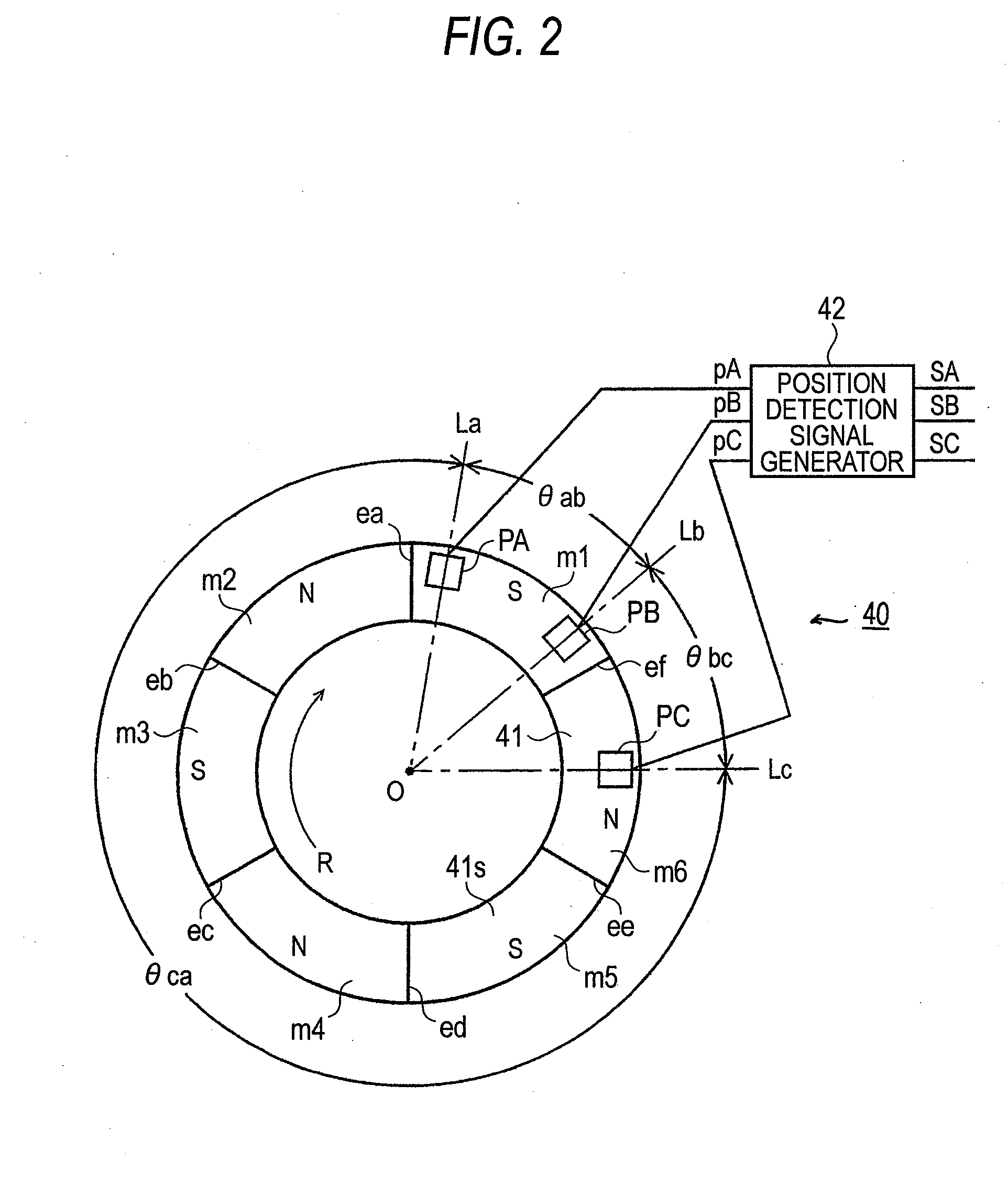

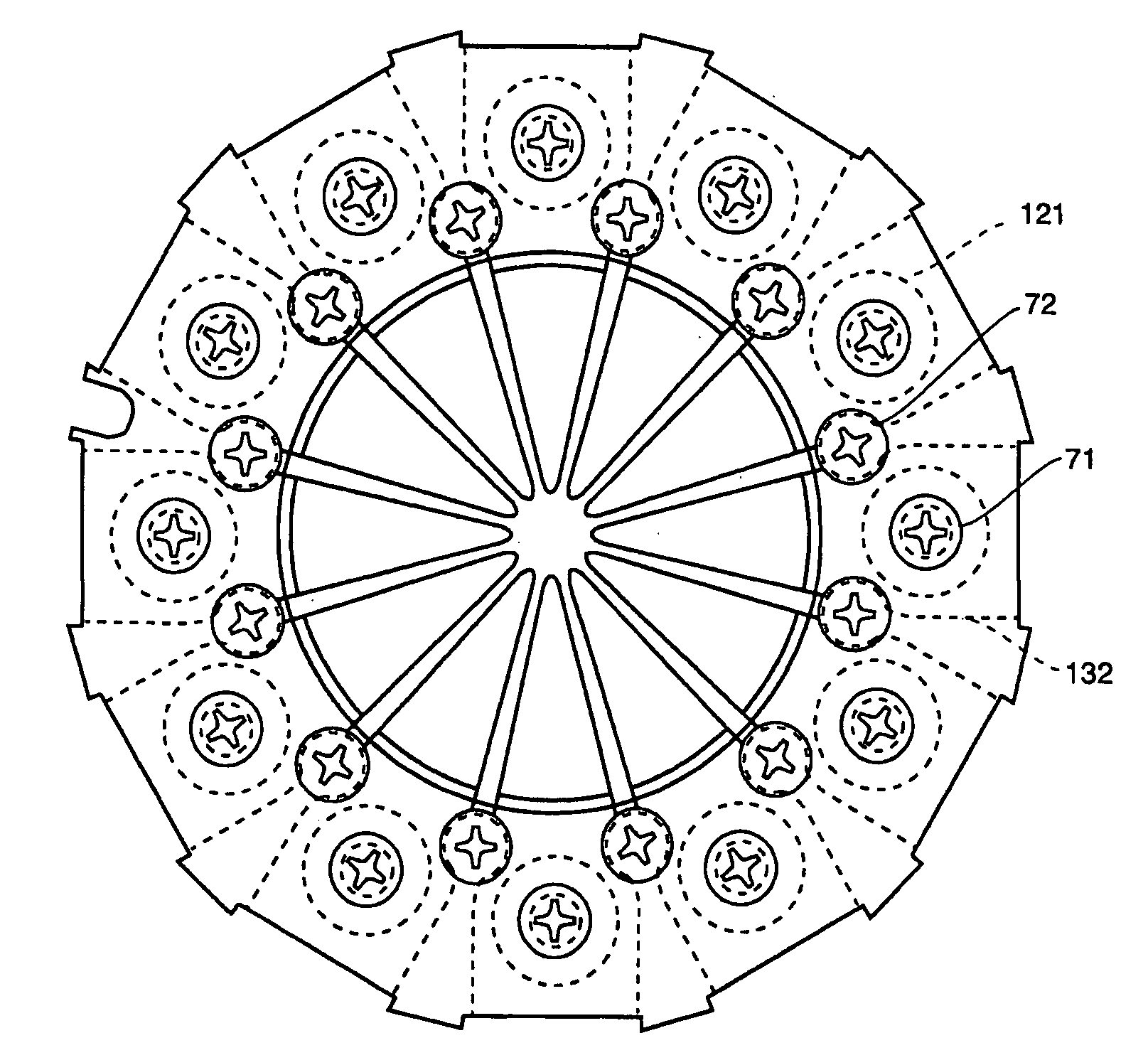

Control device for three-phase brushless motor

InactiveUS20090001912A1Decrease of deviationReduce positional deviationMotor/generator/converter stoppersAC motor controlThree-phasePosition sensor

A control apparatus for a three-phase brushless motor, in which a control circuit includes time interval calculation means (133 in FIG. 4). The time interval calculation means (133) is endowed with at least one time interval calculation mode. In the time interval calculation mode, pluralities of time intervals which correspond to an addition section obtained by adding up two or more Q continuous sections are calculated on the basis of two position detection signals which lie at both the ends of the addition section, among position detection signals successively generated. The control circuit determines pluralities of energization switching timings on the basis of the pluralities of time intervals. The control apparatus for the three-phase brushless motor can decrease the deviations of the energization switching timings attributed to the errors of the mounting positions of position sensors or to the errors of the magnetized positions of a rotor, without requiring any complicated adjustment.

Owner:MITSUBISHI ELECTRIC CORP

Multipole lens and method of fabricating same

InactiveUS20070278416A1Improve accuracyPrecise positioningElectric discharge tubesMaterial analysis by optical meansPhysicsMachining

There is disclosed a multipole lens that can be machined with improved accuracy. A method of fabricating this lens is also disclosed. The multipole lens has a blank material from which polar elements will be fabricated. The blank material is sandwiched vertically between two layers of filmy insulator. The blank material and the two layers of filmy insulator are sandwiched vertically between an upper ring and a lower ring. These members are provided with injection holes for injecting a curing agent. The injection holes of these members are aligned. The curing agent is injected into the holes and cured. Then, the blank material is machined by electric discharge machining to form the polar elements.

Owner:JEOL LTD

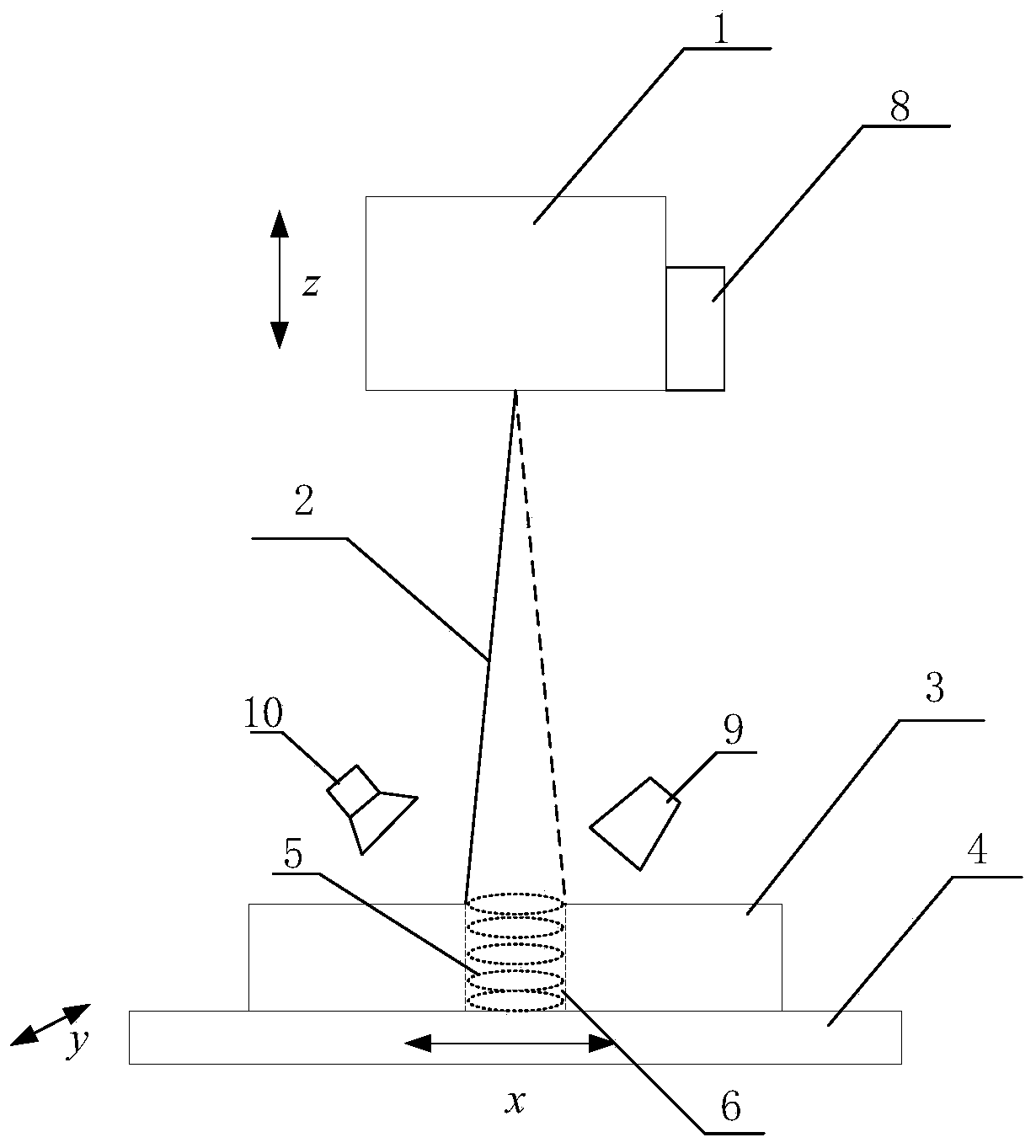

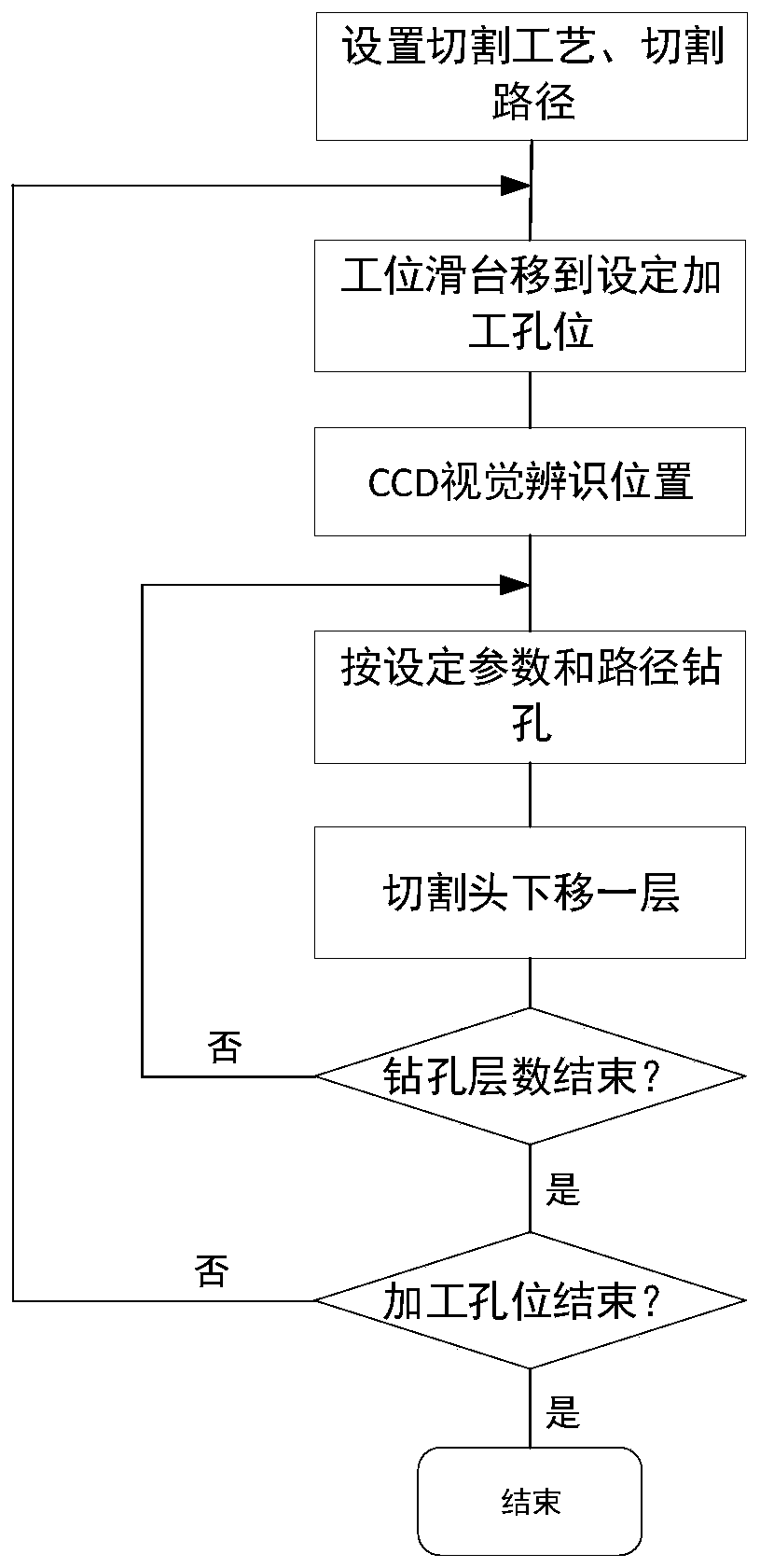

Ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method

InactiveCN111590197ANo damageSmooth edgesLaser beam welding apparatusPicosecond laserHeat-affected zone

The invention provides a ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method. The method comprises the steps that firstly a laser drilling route and a laser drilling technological parameter are arranged, during drilling, a station sliding table moves a hole to be drilled of a ceramic substrate to a drilling position, CCD vision identifies and positionsthe drilling position, and a galvanometer laser beam precisely drills the ceramic substrate layer by layer; meanwhile, smoke suction and protective gas are started, a cutting head automatically movesdown one layer of machining thickness for each layer machining until all the layers are machined; and then the station sliding table moves a workpiece to the next drilling position, repetition is carried out until all the holes in the ceramic substrate are drilled. According to the ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method, cutting edges of the ceramic substrate are smooth, the roundness is good, the taper is small, the fragmentation probability is low, nearly no heat affected zone exists, the edges are not yellowed, nearly no damage is caused to the ceramic substrate, and the yield is greatly improved.

Owner:苏州优快激光科技有限公司

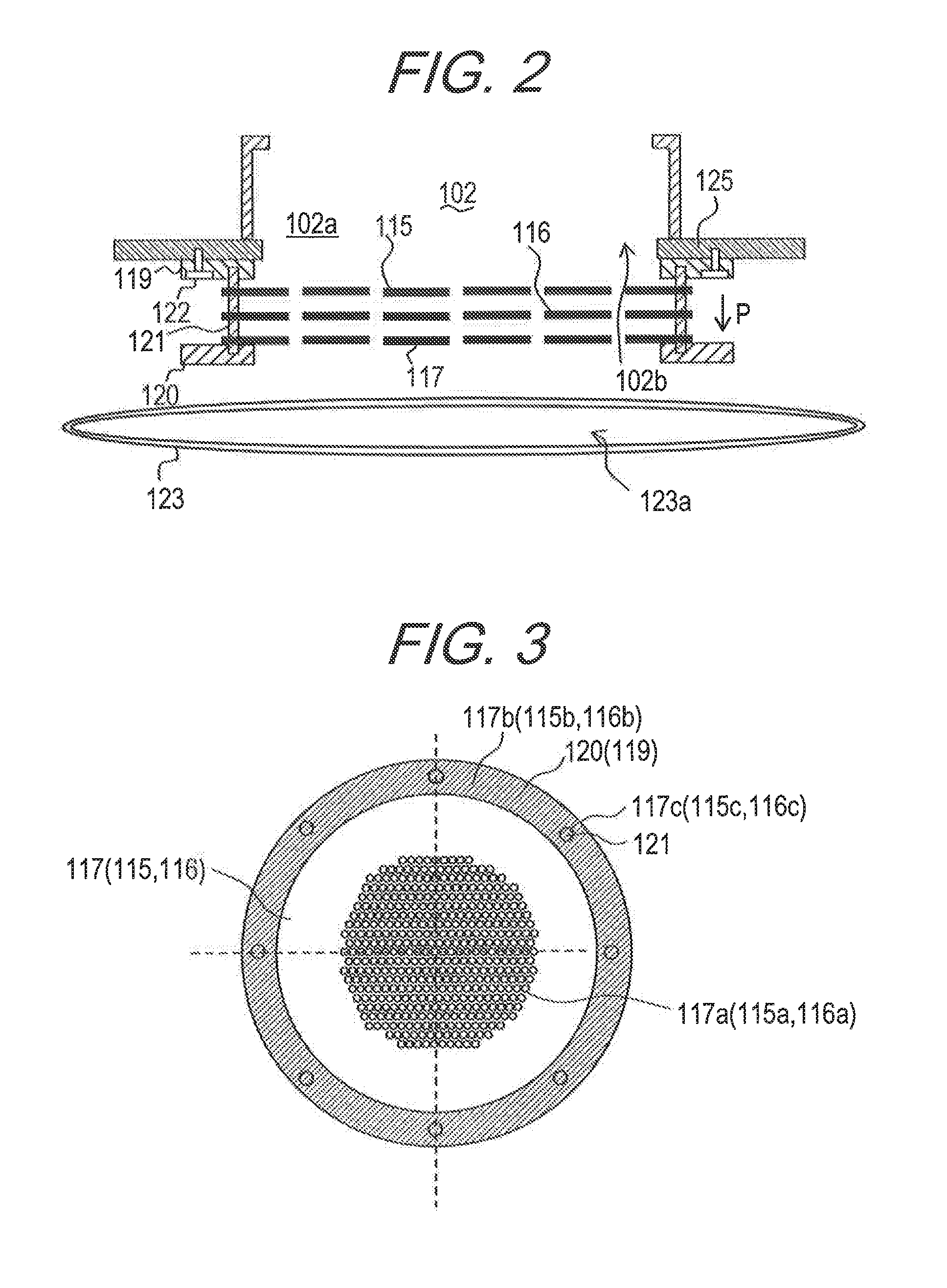

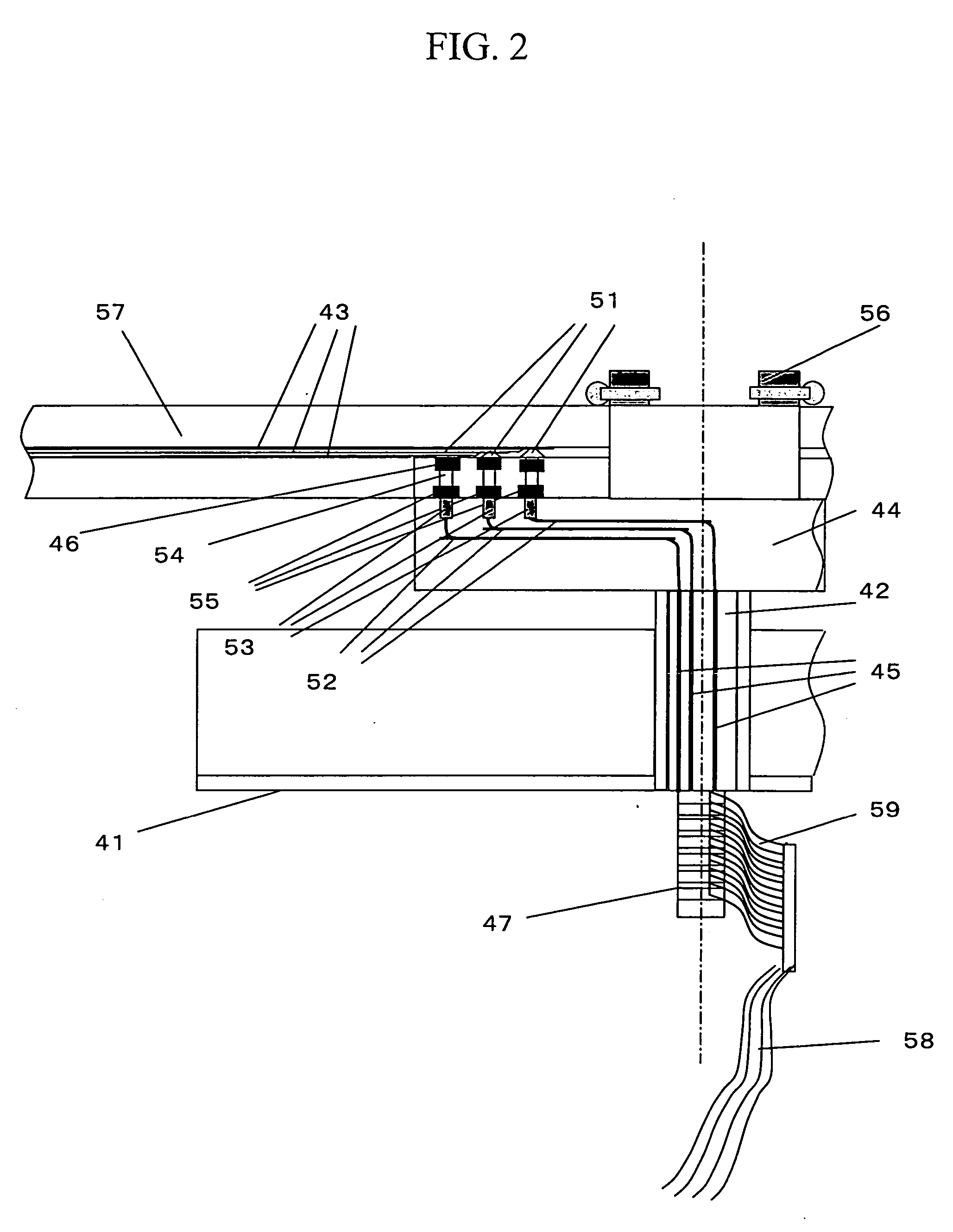

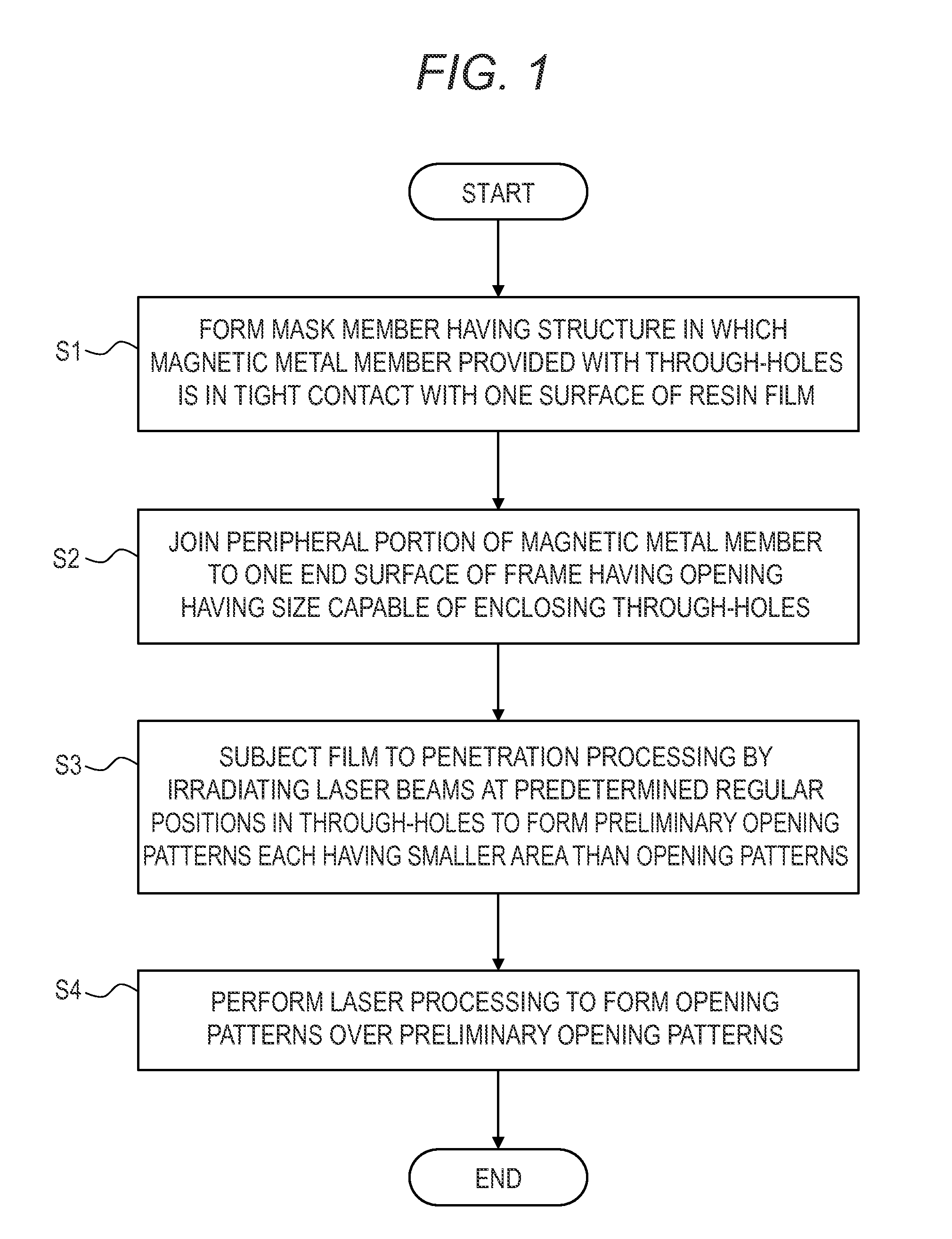

Deposition mask production method and laser processing apparatus

ActiveUS20150328662A1Reduce positional deviationHigh positioning accuracyRadiation applicationsVacuum evaporation coatingLaser processingLight beam

A method including: a first step of forming a mask member having a structure in which a magnetic metal member provided with through-holes is in tight contact with one surface of a film; a second step of forming a plurality of preliminary opening patterns by subjecting the film to penetration processing by irradiating laser beams at predetermined regular positions in the plurality of through-holes; and a third step of performing laser processing so as to form each opening pattern over the corresponding preliminary opening pattern, is provided.

Owner:V TECH CO LTD

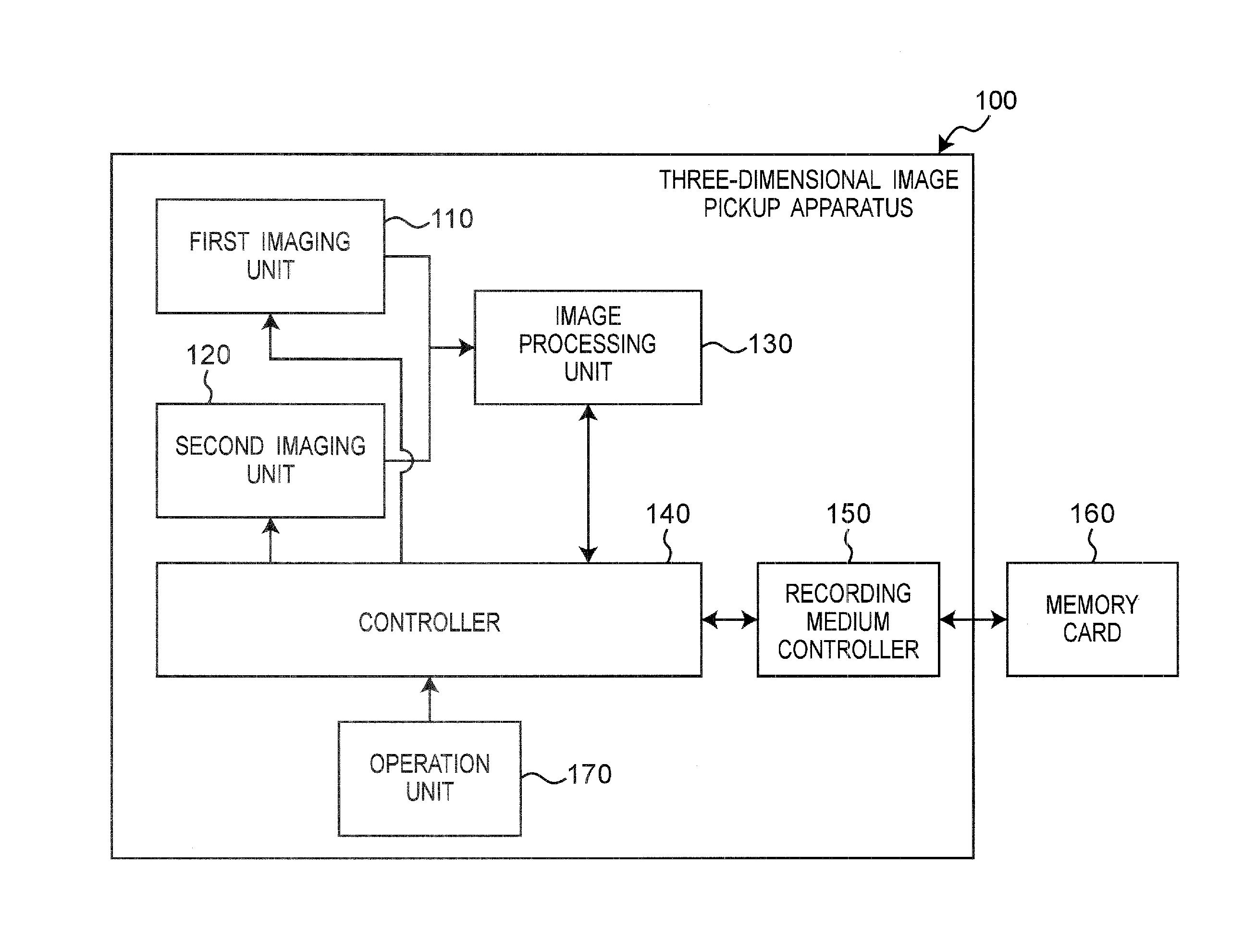

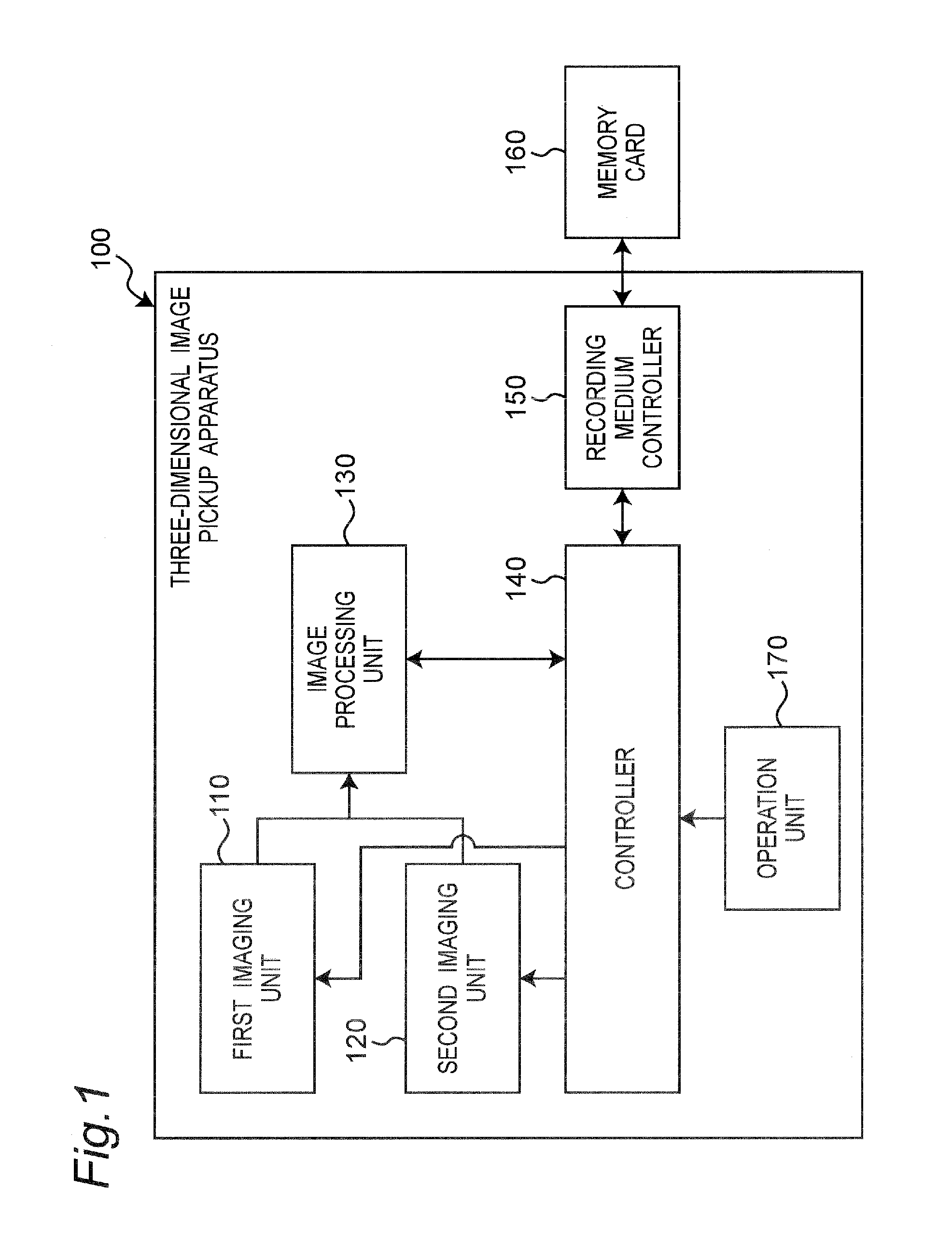

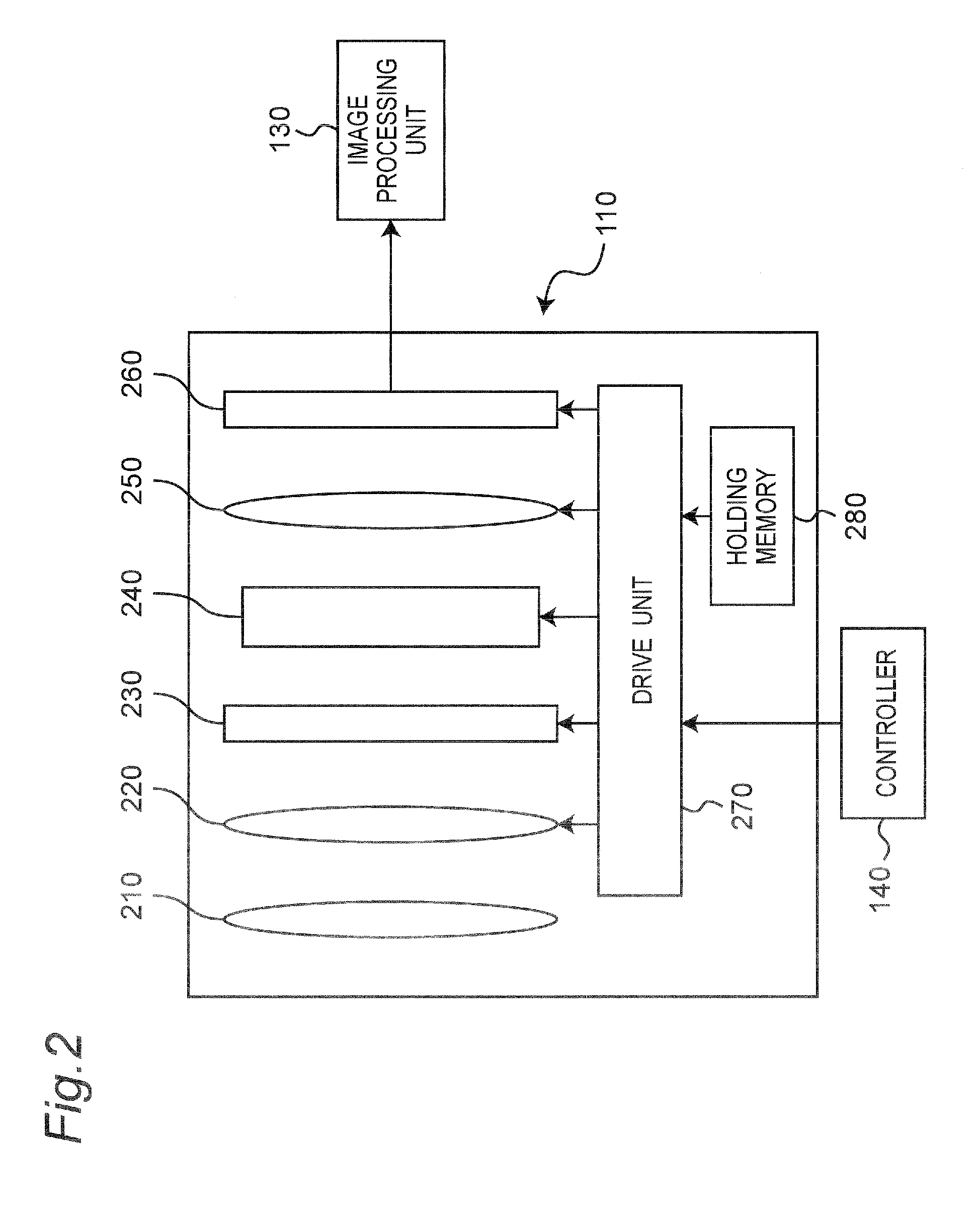

Three-dimensional image pickup apparatus and lens driving method of three-dimensional image pickup apparatus

InactiveUS20120019623A1Reduce positional deviationDispersion suppressionStereoscopic photographyMountings3d imageStereo image

A three-dimensional image pickup apparatus for capturing right and left images with a first imaging unit and a second imaging unit to generate a stereoscopic image is provided. In this three-dimensional image pickup apparatus, each of the first imaging unit and the second imaging unit includes a lens group including a zooming lens and a focusing lens, and a imaging device for converting an optical image from the lens group into an electrical signal, and the three-dimensional image pickup apparatus includes a driving controller operable to drive the zooming lens and the focusing lens of the first imaging unit and the second imaging unit, along a tracking curve showing a relationship of a position of the zooming lens and a position of the focusing lens, and the driving controller limits a range of moving the zooming lens and the focusing lens in either one of a first range and a second range, the first range ranges from a wide-angle end in the tracking curve to a inflection point at which the moving direction of the focusing lens is inverted, and the second range ranges from a telephoto end to the inflection point.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

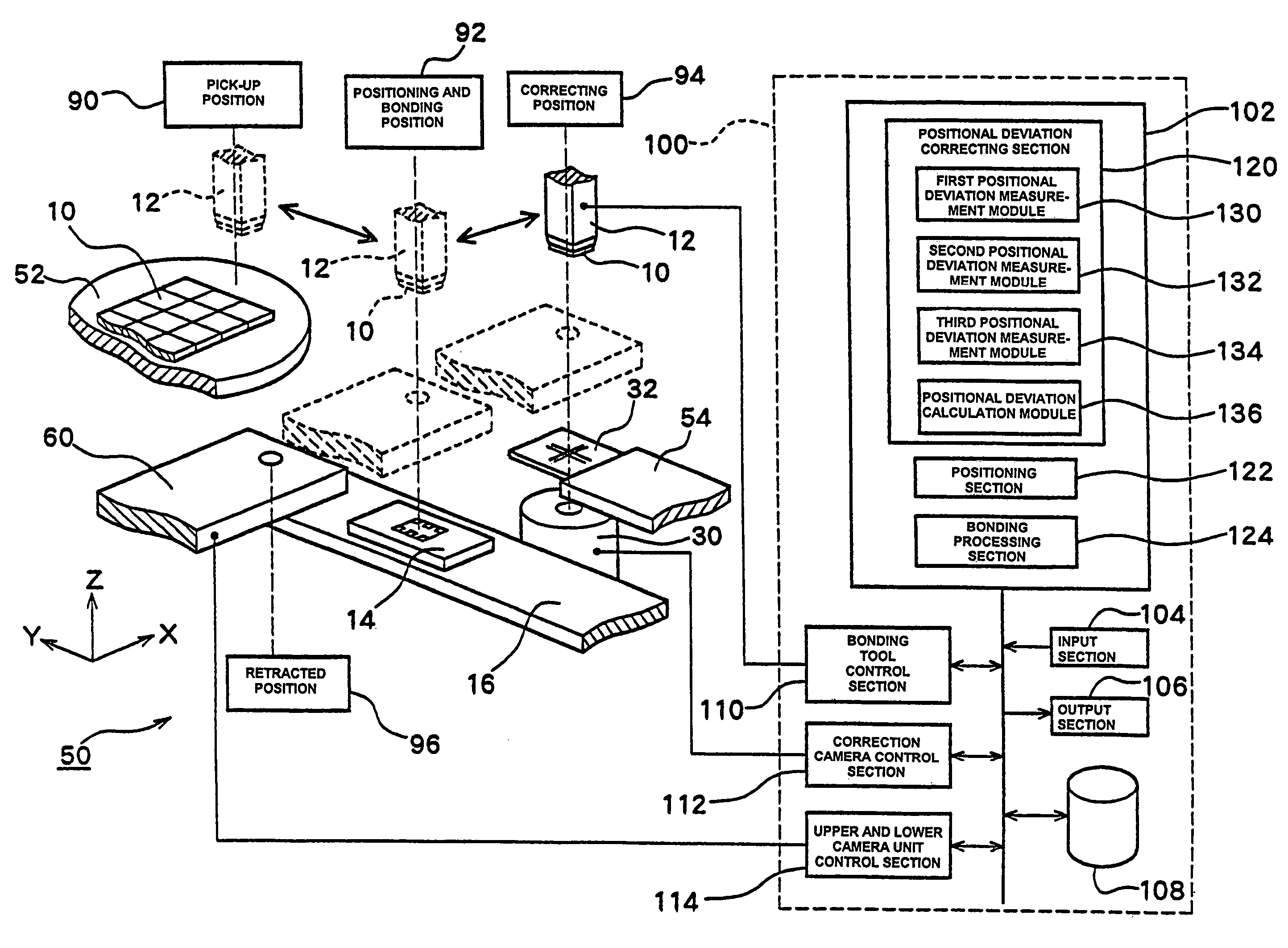

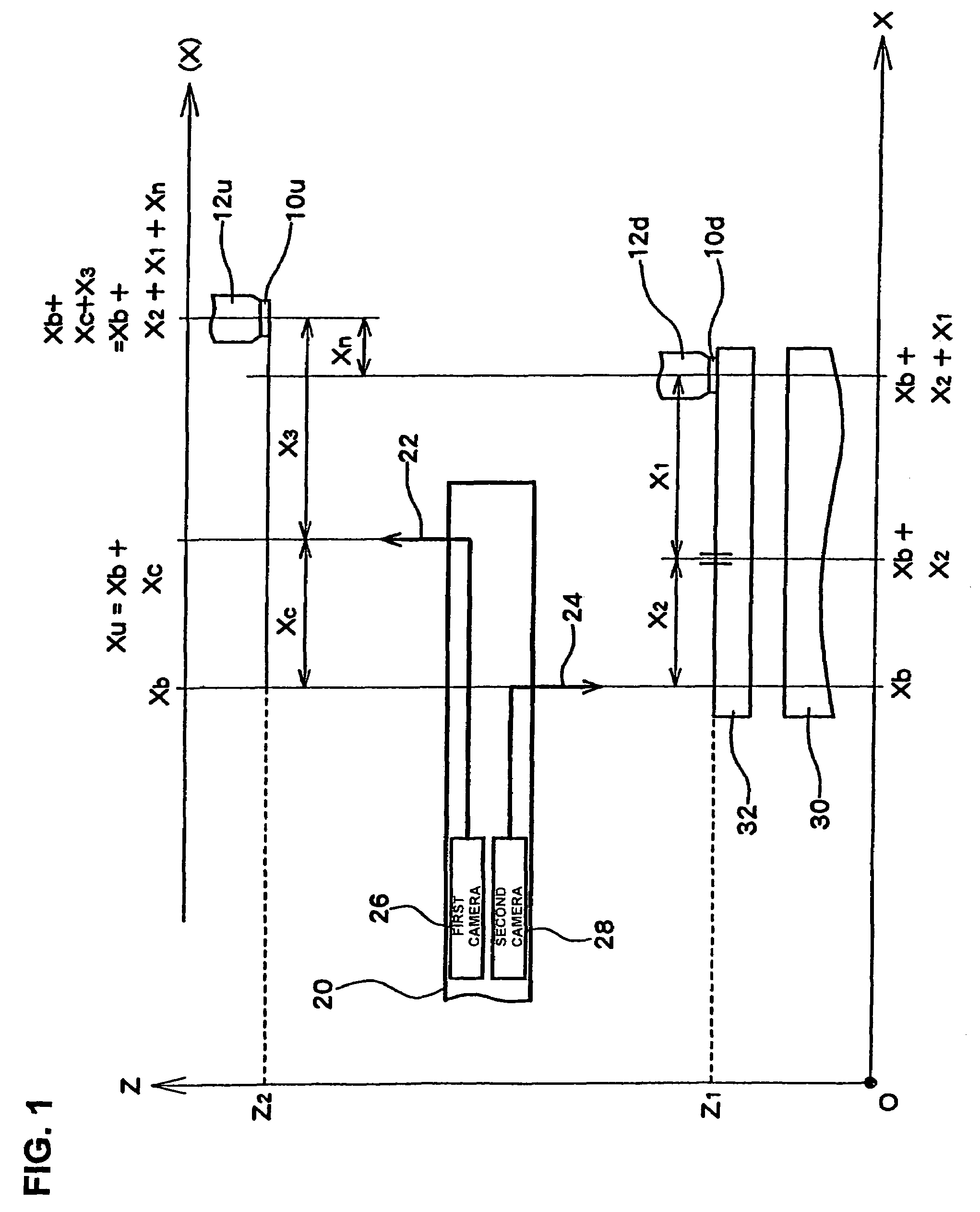

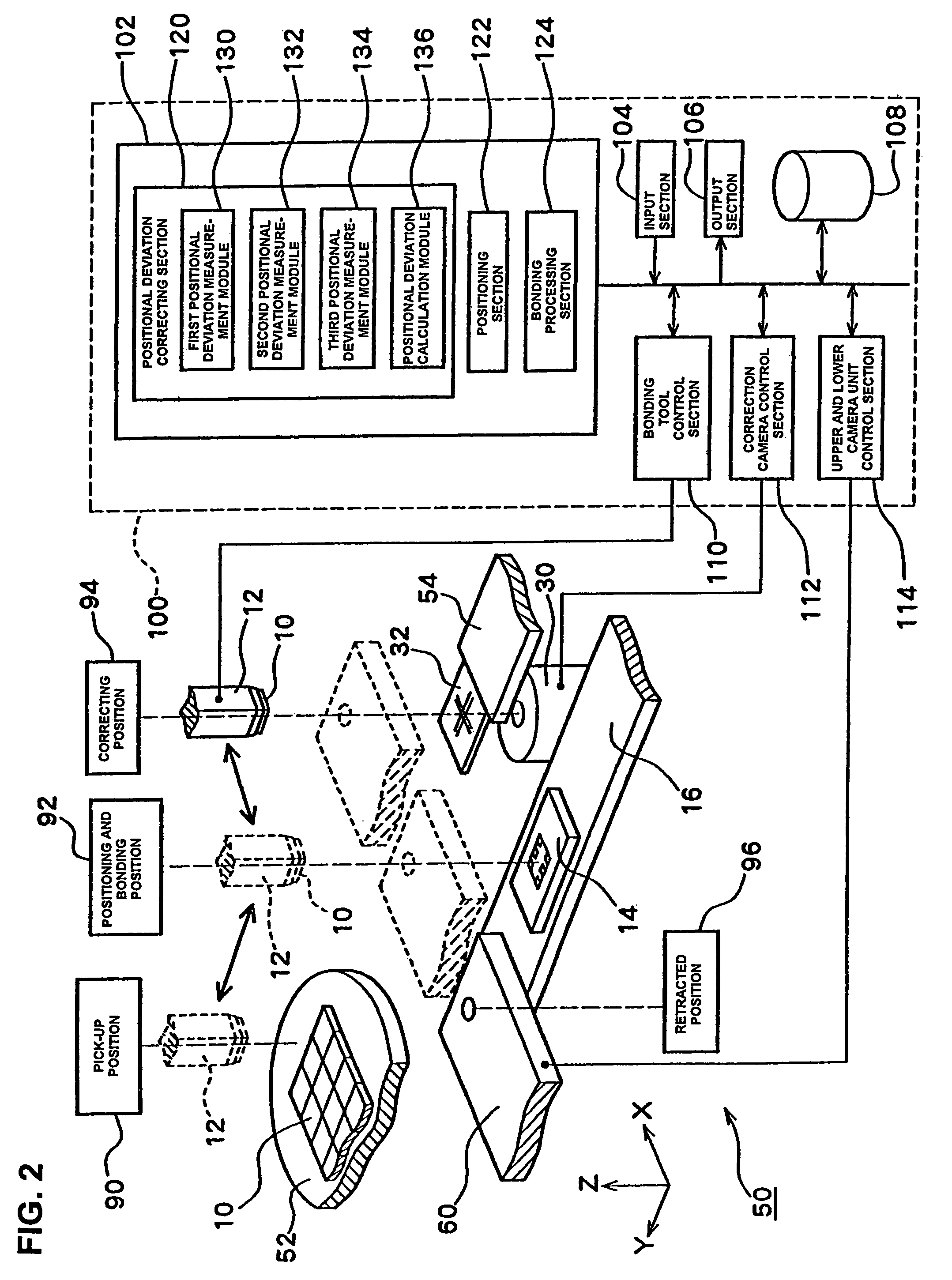

Bonding apparatus with position deviation correction

ActiveUS7044182B2Reduce positional deviationThe right amountControlling laminationSolid-state devicesEngineering

A bonding apparatus that makes correction ΔX=(Xn−Xc) in positioning of bonding tool and substrate where the imaging center of first camera shows deviation +Xc with respect to the imaging center of second camera, and deviation +Xn occurs when bonding tool moves from height Z1 to height Z2. A target is disposed at height Z1 in a correcting position, and a correction camera is disposed beneath the target. The correction amount ΔX=(Xn−Xc)=X3−(X2+X1) is determined based upon first positional deviation X1 which is the position of a chip 10d at height Z1 seen from the target, second positional deviation X2 which is the position of the target seen from the imaging center of the second camera, and third positional deviation X3 which is the position of the chip 10u at height Z2 seen from the imaging center of the first camera.

Owner:SHINKAWA CO LTD

Preparation technique for flame-retardant reflective warning tape

InactiveCN104101924AReduce consumptionReduce manufacturing costIlluminated signsOptical elementsMetal coatingFluorescence

The invention discloses a preparation technique for a flame-retardant reflective warning tape. The preparation technique for the flame-retardant reflective warning tape includes steps that (1) preparing gray cloth, to be specific, coating a fluorescent coating on a flame-retardant cloth base, and cutting into gray cloth with different widths for latter use; (2) implanting glass micro-beads; (3) preparing a focusing layer; (4) preparing a metal coating; (5) preparing a flame-retardant composite adhesive layer and a flame-retardant hot melt adhesive layer, to be specific, coating the flame-retardant composite adhesive layer on the metal coating, after drying the solvent, compounding with the flame-retardant hot melt adhesive film through hot ironing, after the composite adhesive is solidified completely, cutting into flame-retardant composite heat transfer films with different widths; (6) hot ironing to compound, to be specific, compounding the gray cloth of the step (1) with the flame-retardant composite heat transfer films of the step (5) through hot ironing, and peeling off a PE / PET composite film. The preparation technique for the flame-retardant reflective warning tape has advantages that the preparation technique consumes a little of raw materials, and the manufacturing cost is low; the edge of the composite reflective layer is clear and textured; an intermediate tape plays a role of reflecting light, and tapes at two sides play a role of fluorescent warning.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Method, apparatus, and program for image forming capable of effectively adjusting positional deviation

ActiveUS20070274746A1Effective regulationQuality improvementElectrographic process apparatusImage formationRecording media

An image forming apparatus, in which a program for carrying out an image forming method is provided, includes a transfer member to receive respective images formed on a plurality of image bearing members, an image detecting unit to detect the images conveyed on the transfer member, a paper length detecting unit to detect a length of a recording medium in a sheet travel direction, a counting unit to count the number of recording media and to change a count up value according to a detection result by the paper length detecting unit, and a control unit to control an image forming timing with respect to the image bearing members based on a detection timing of the image and to perform a positional deviation adjustment each time a counted value increases by a predetermined amount so as to reduce an amount of a positional deviation of the image.

Owner:RICOH KK

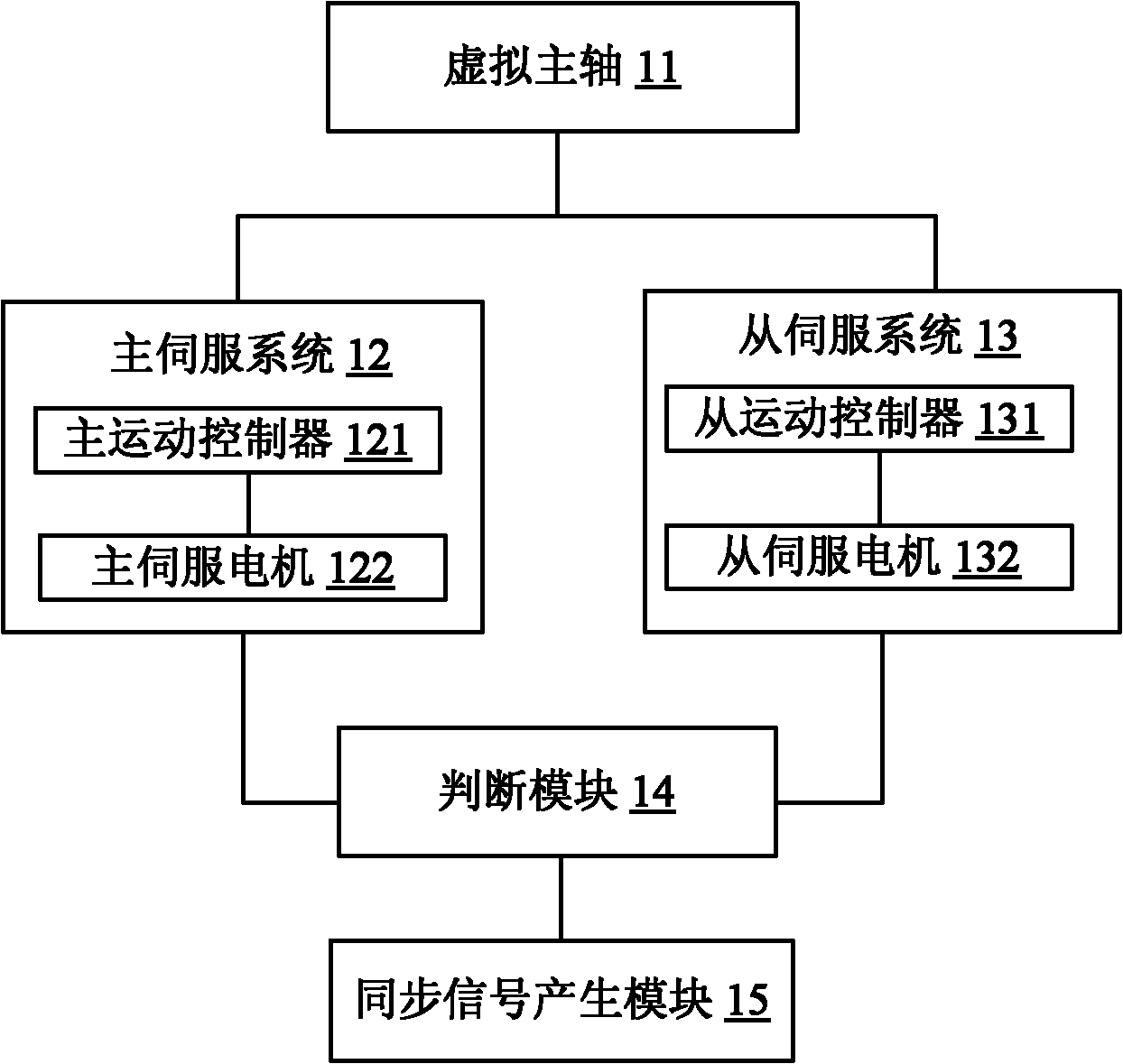

Method and device for generating master-salve servo system synchronous signals, and lamp detector

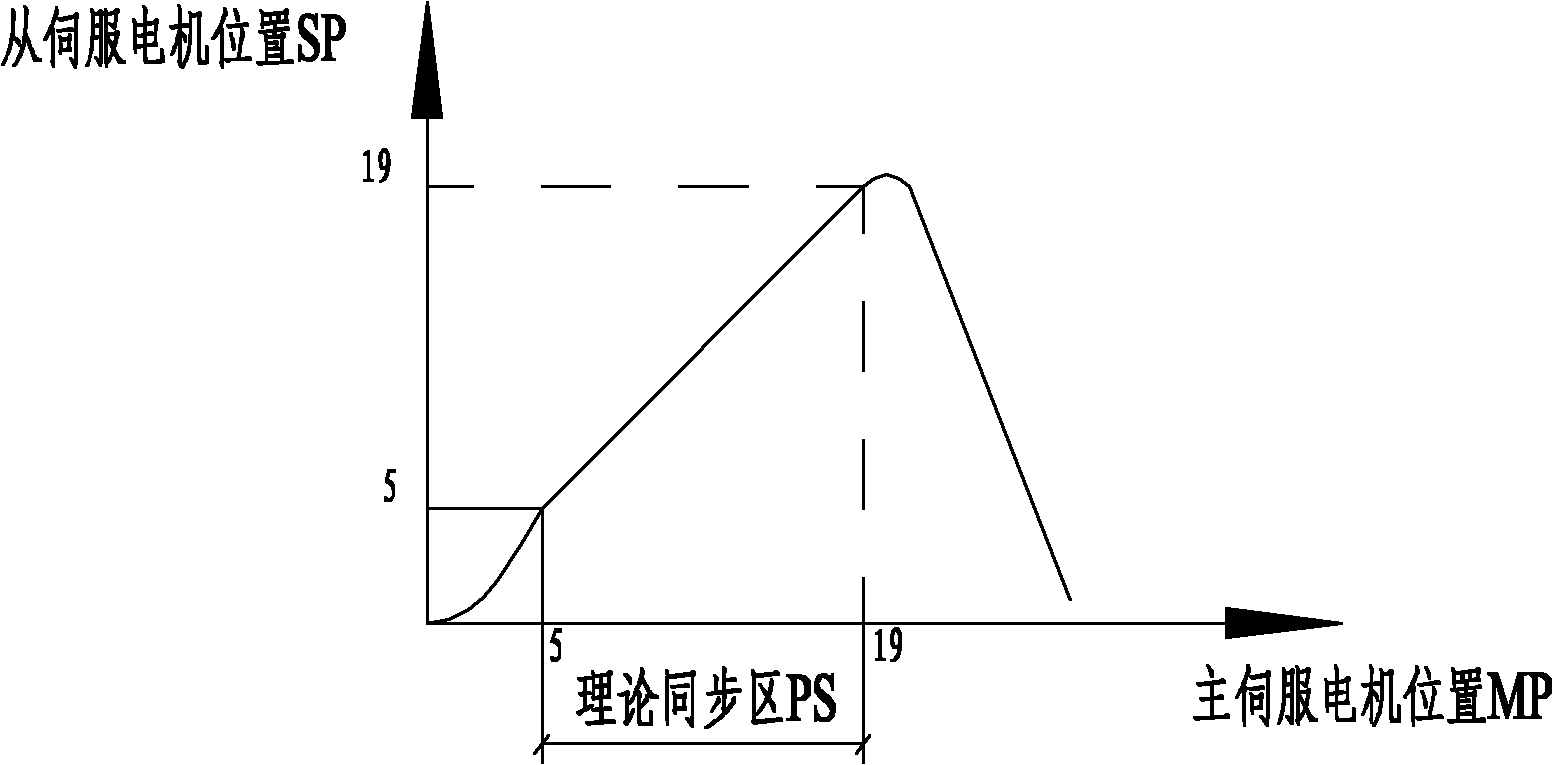

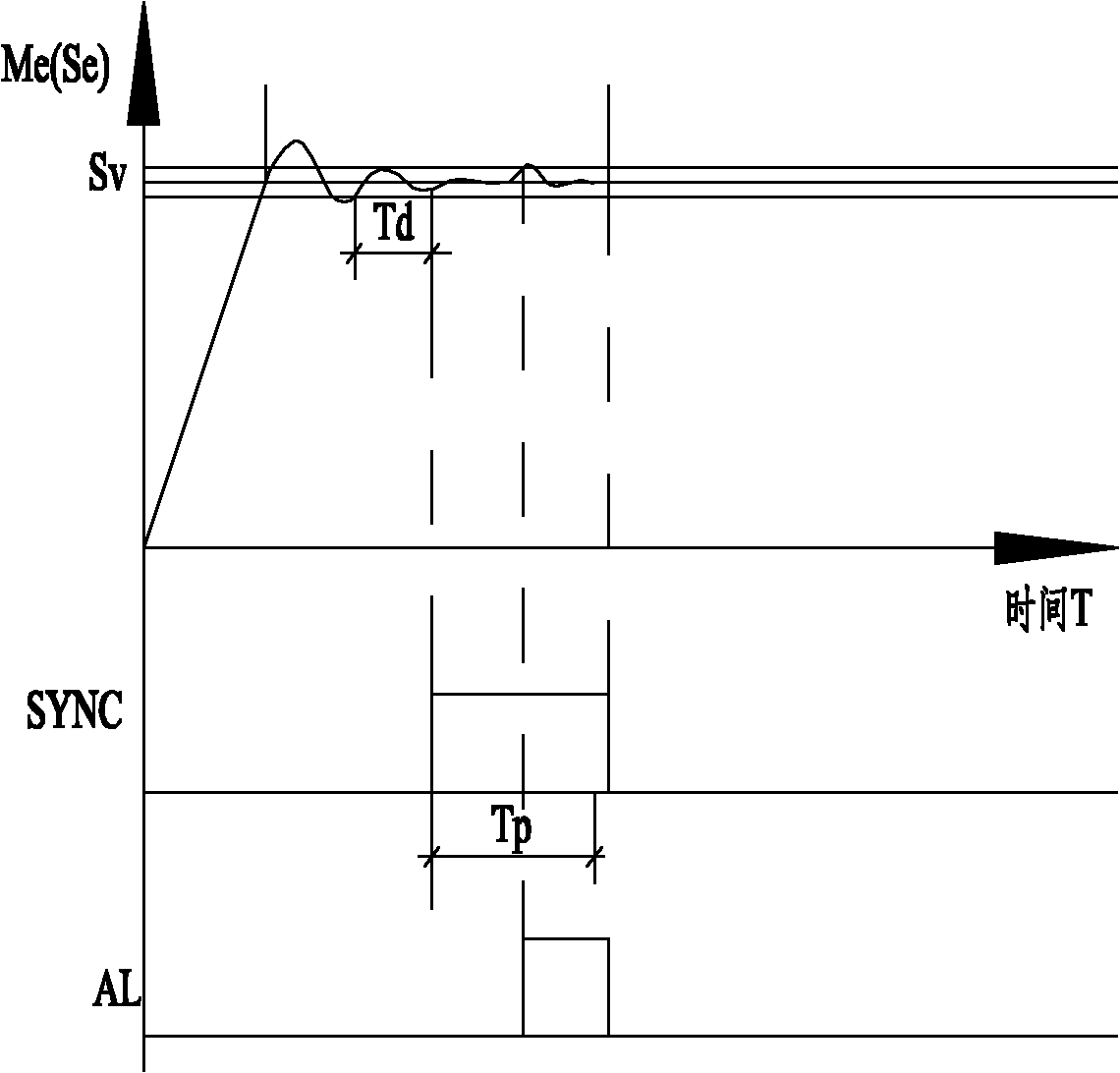

ActiveCN102176650AReduce positional deviationAchieve synchronizationOptically investigating flaws/contaminationMultiple dynamo-electric motors speed regulationComputer modulePosition error

The invention discloses a method and a device for generating master-salve servo system synchronous signals, and a lamp detector. The method for generating the master-salve servo system synchronous signals comprises the following steps that: a master servo system and a slave servo system receive control information sent by a virtual main shaft respectively; the master servo system and the slave servo system track the virtual main shaft according to the control information, and generate a master position following error and a slave position following error respectively; a judging module judges whether the master position following error and the slave position following error are in accordance with a predetermined condition; when the master position following error and the slave position following error are in accordance with the predetermined condition, a synchronous signal generating module generates the synchronous signals. By the invention, the position errors between the master and slave servo systems are small; the master and slave servo systems are synchronized; and the false inspection rate of the lamp detector is reduced.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

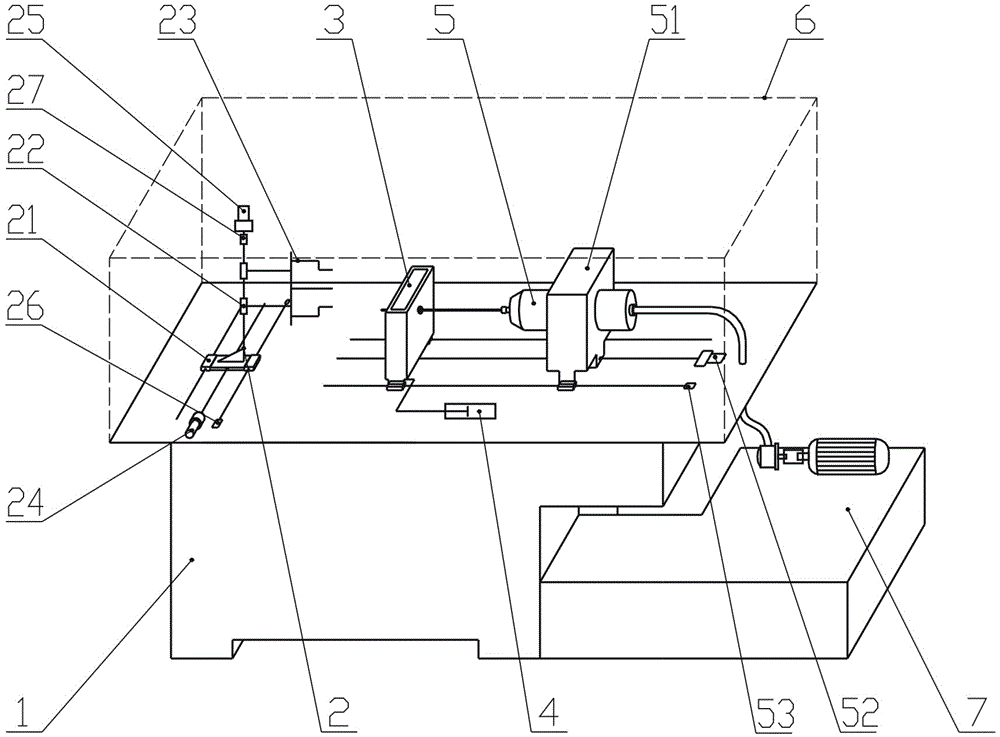

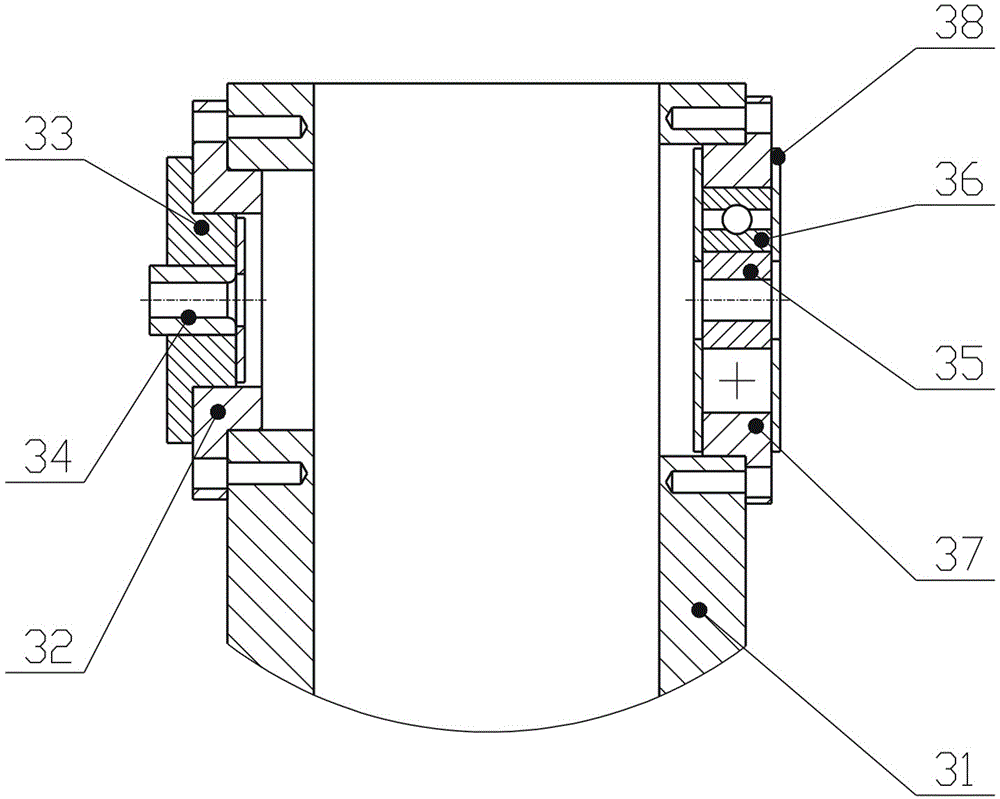

Three-shaft numerical control deep hole drilling machine for processing multi-deep-hole workpiece

InactiveCN102873367AEasy dischargeImprove processing efficiencyDrilling/boring measurement devicesMaintainance and safety accessoriesElectricityNumerical control

The invention relates to the field of numerical control processing equipment, and in particular relates to a three-shaft numerical control deep hole drilling machine for processing a multi-deep-hole workpiece. The three-shaft numerical control deep hole drilling machine comprises a base body of a machine body, a machine head part, a chip receiving box, an air cylinder pushing and guiding device, an electric main shaft, a machine tool shield and a filter circulation chip discharge device, wherein the filter circulation chip discharge device is externally connected below the base body of the machine body; the machine head part, the chip receiving box and the electric main shaft are sequentially installed on the base body of the machine body from left to right, and the machine tool shield is arranged outside the whole body of the machine head part, the chip receiving box, the electric main shaft and the base body of the machine body; the machine head part consists of a longitudinal moving device, a vertical moving device and a clamping device; the chip receiving box is connected with the air cylinder pushing and guiding device in parallel and can slide along the left-right direction of the base body of the machine body; and the electric main shaft is provided with a center hole which can be used for introducing water to cool the electric main shaft and is controlled by a left-right moving driving device to move left and right, and cooling liquid which is introduced in the center hole is supplied by a filter circulation device. The three-shaft numerical control deep hole drilling machine adopts three shafts to control, all hole stations can be processed through one-time clamping, the processing efficiency is high, the accuracy is good, and the three-shaft numerical control deep hole drilling machine is suitable for mass processing.

Owner:北京精雕精密机械制造有限公司

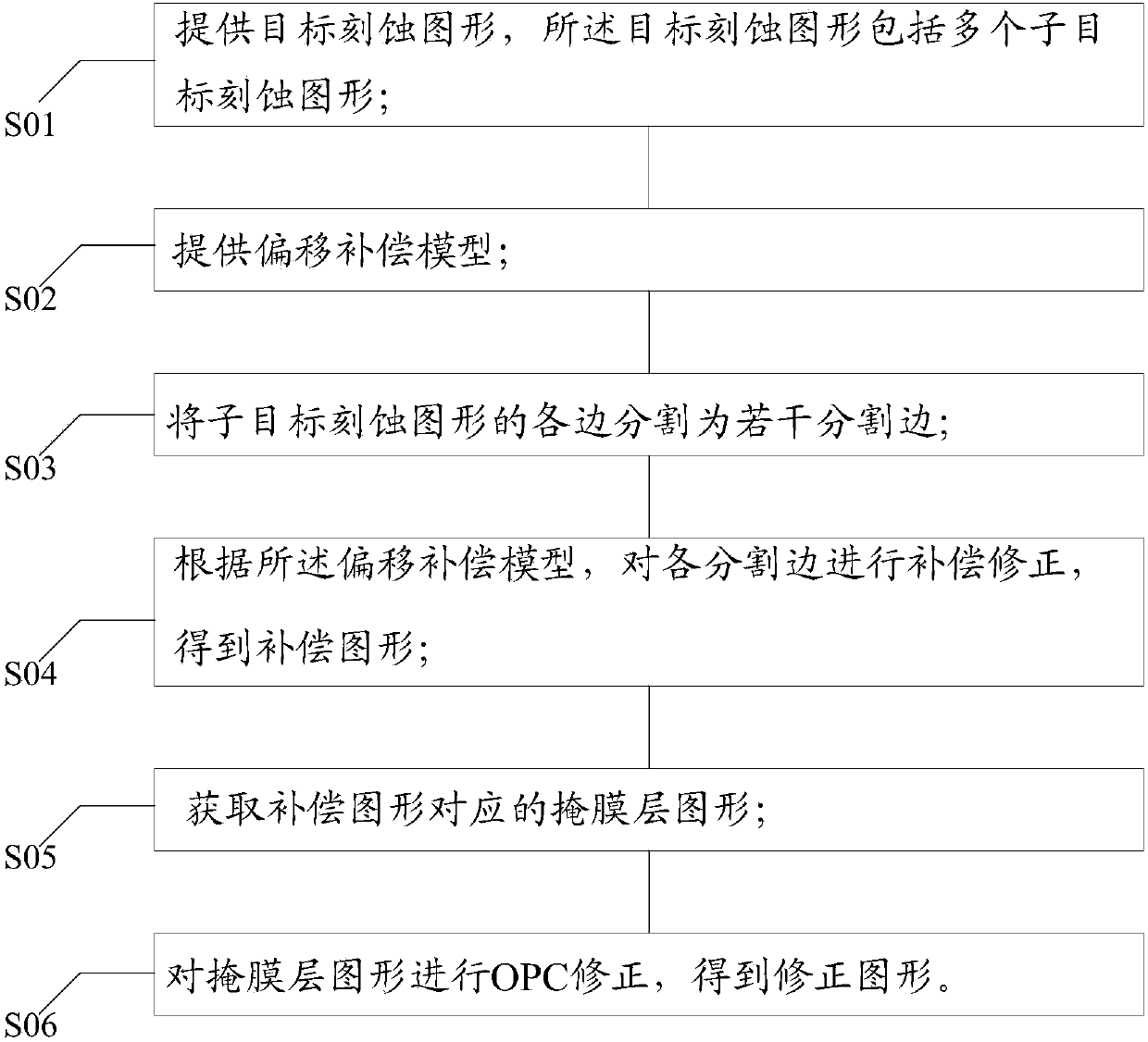

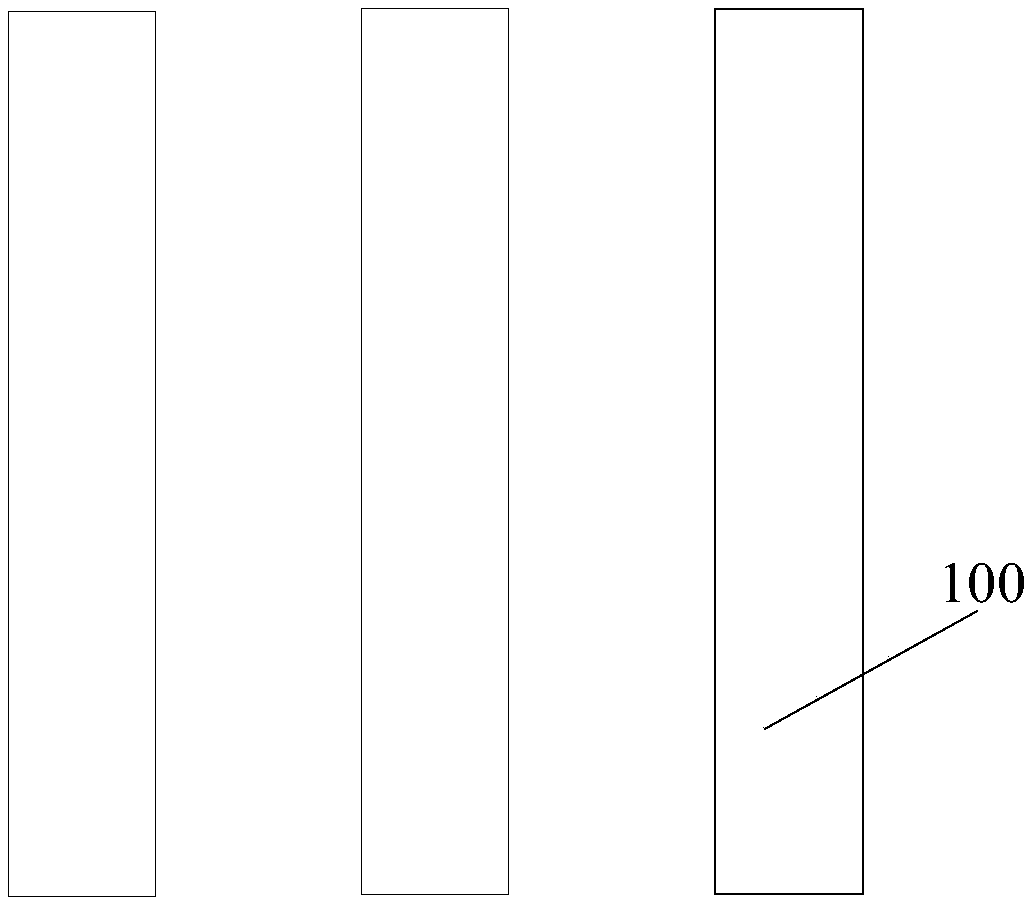

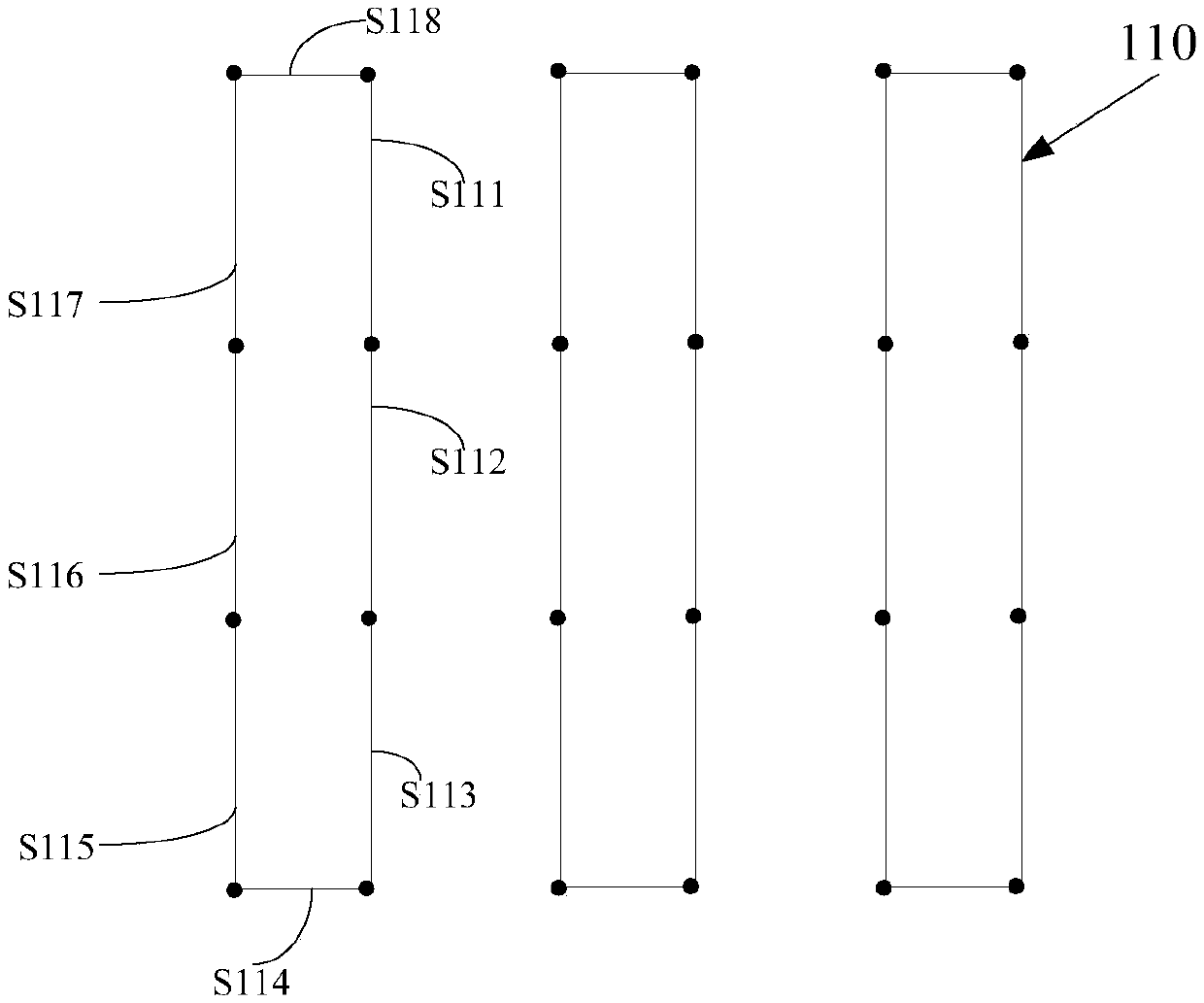

Optical proximity correction method and manufacturing method of mask

ActiveCN110119061AHigh precisionReduce positional deviationOriginals for photomechanical treatmentComputer scienceOptical proximity correction

The invention discloses an optical proximity correction method and a manufacturing method of a mask, and the method comprises the steps: providing a target etching pattern which comprises a pluralityof sub-target etching patterns; providing an offset compensation model; dividing each edge of the sub-target etching pattern into a plurality of segmentation edges; according to the offset compensation model, performing compensation correction on each segmentation edge to obtain a compensation graph; obtaining a mask layer graph corresponding to the compensation graph; and performing OPC correction on the mask layer pattern to obtain a corrected pattern. According to the optical proximity correction method, the correction precision is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Steering control device for vehicles

InactiveUS7894956B2Reduce positioningReduce positional deviationDigital data processing detailsSteering initiationsPower flowAngular deviation

Owner:HONDA MOTOR CO LTD

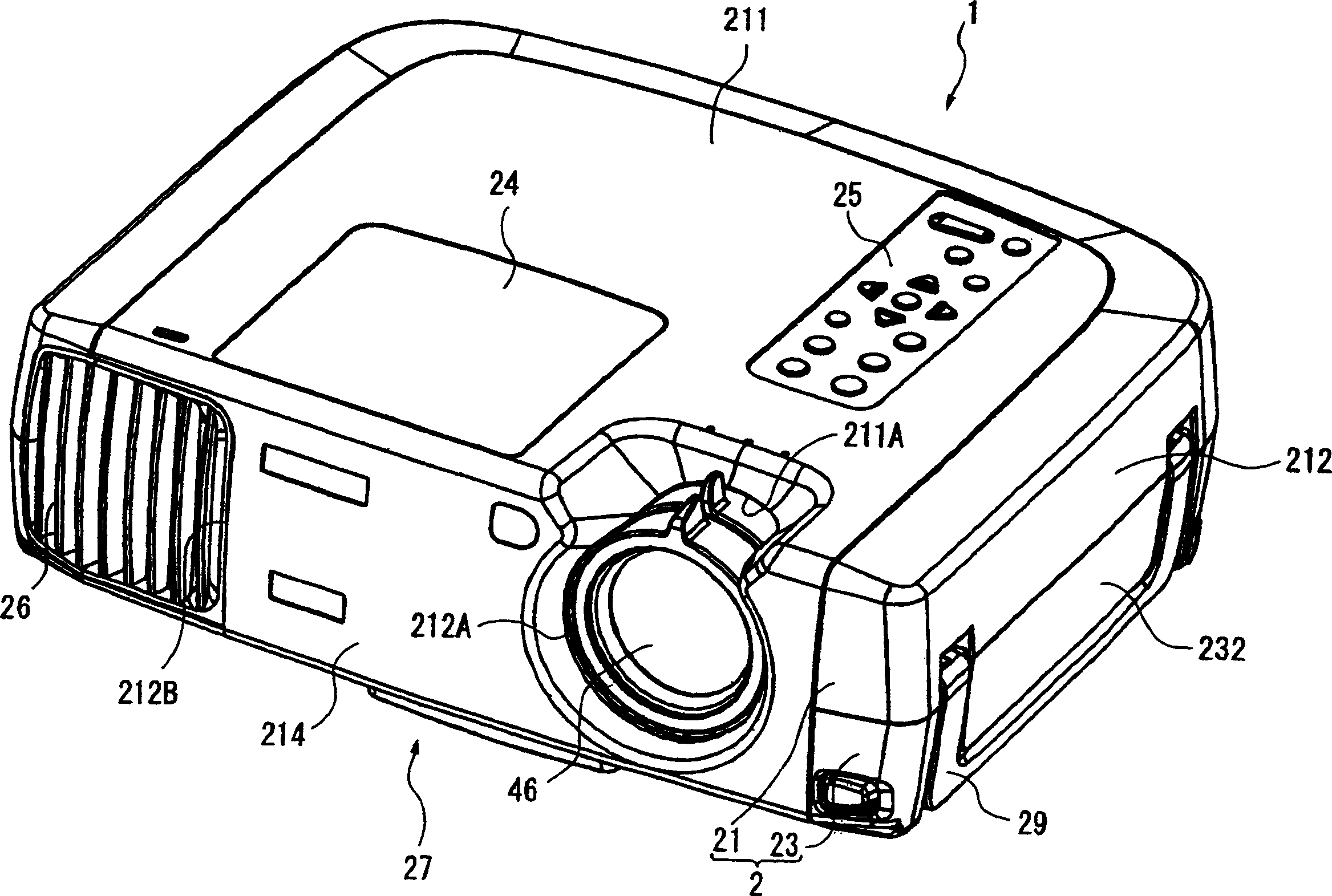

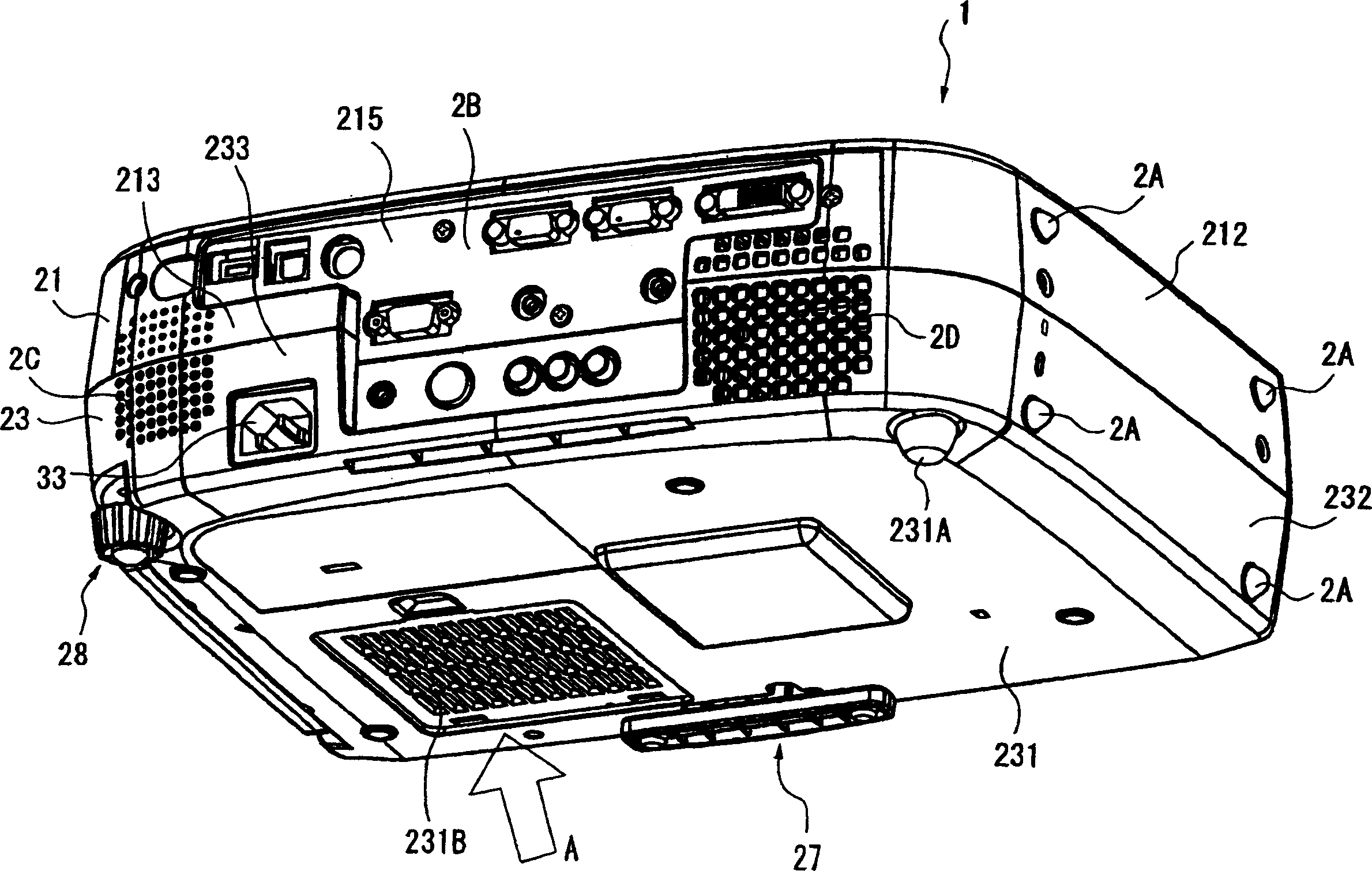

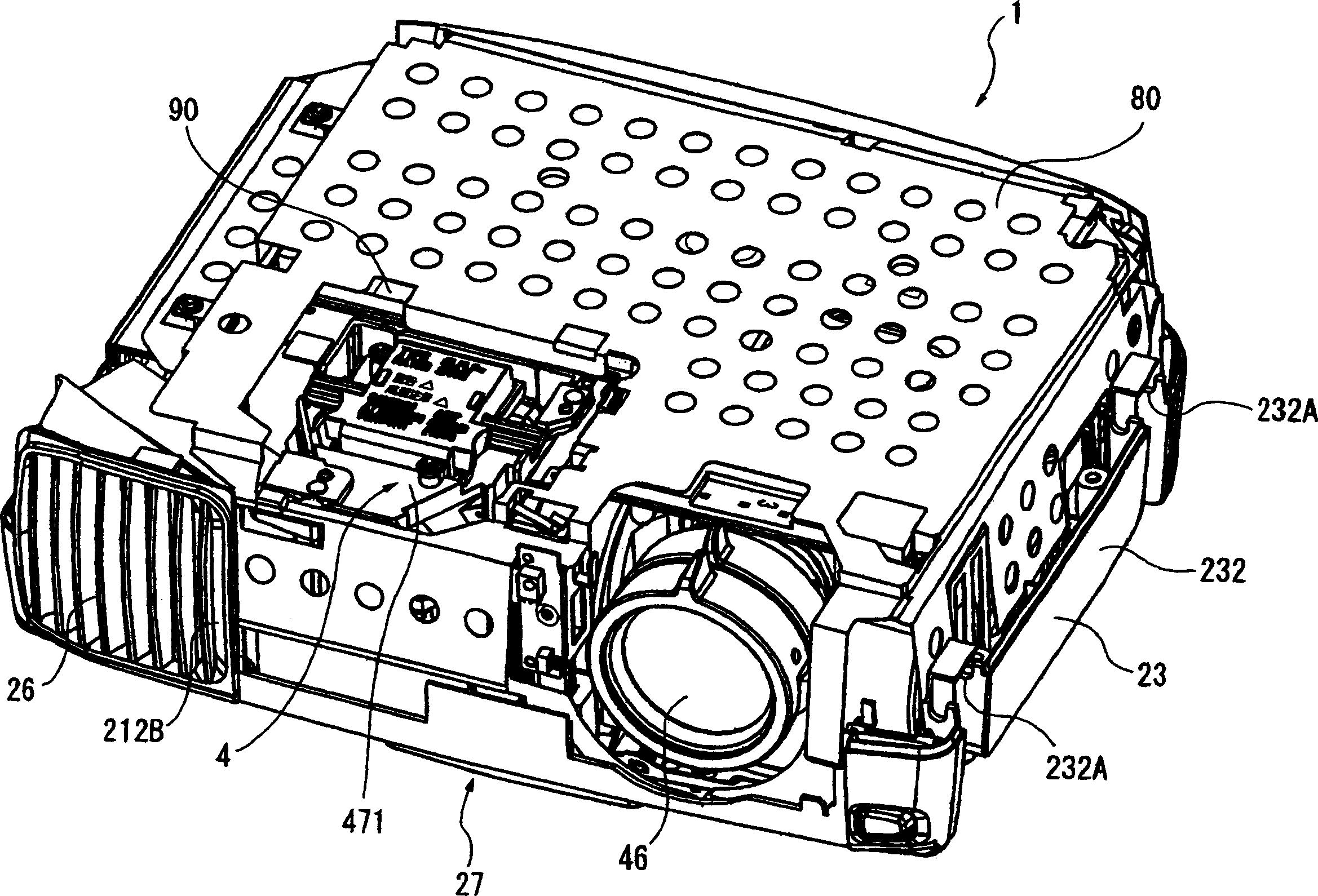

Optical device, mfg. method thereof and projector

InactiveCN1402054AMiniaturizationSimple structureTelevision system detailsProjectorsManufacturing cost reductionDichroic prism

The present invention provides an optical device that achieves reduction in size, reduction in manufacturing costs, improved image quality, and so forth, by simplification and the like of a panel in prisms (POP) structure wherein light-modulating devices and a color synthesizing optical element are integrally formed. A POP structure is configured wherein pins integrally formed with a holding member are inserted through holes formed in the four corners of holding frames storing the liquid crystal panelsso as to fix the holding frames and holding members by adhesion. End faces of holding members opposite to the pins are fixed by adhesion to the side faces of bases fixed on the upper and lower faces of a cross-dichroic prism.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com