Three-shaft numerical control deep hole drilling machine for processing multi-deep-hole workpiece

A deep hole drilling machine and workpiece technology, which is applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., to improve processing efficiency, ensure processing accuracy, and good positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

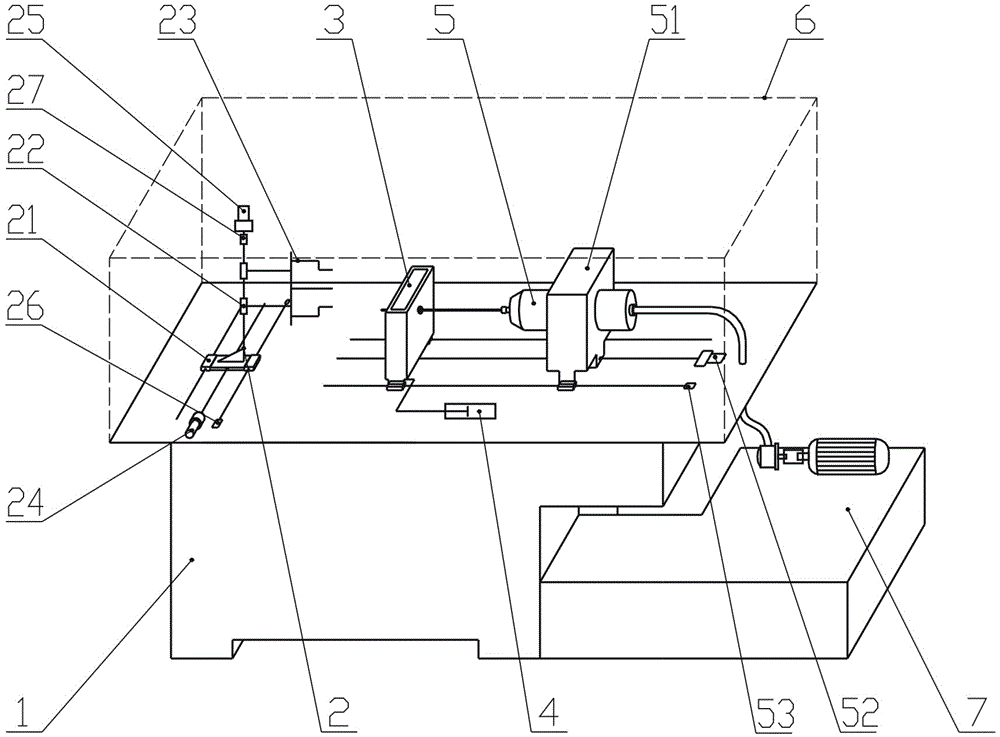

[0014] Such as figure 1 As shown, the present invention is composed of a bed base 1, a machine head 2, a chip receiving box 3, a cylinder 4, an electric spindle 5, a machine tool shield 6 and a filter cycle chip removal device 7. The filter cycle chip removal device 7 is externally connected to the bottom of the bed base 1; the machine head 2, the chip receiving box 3, and the electric spindle 5 are installed on the bed base 1 in sequence from left to right, and a machine guard 6 is provided on the outside . Machine head 2 is made up of forward and backward moving device 21, up and down moving device 22 and clamping device 23, forward and backward moving device 21 is controlled by forward and backward moving driving device 24, and up and down moving device 22 is controlled by up and down moving driving device 25. The chip receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com