Patents

Literature

416results about How to "Increase boost effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

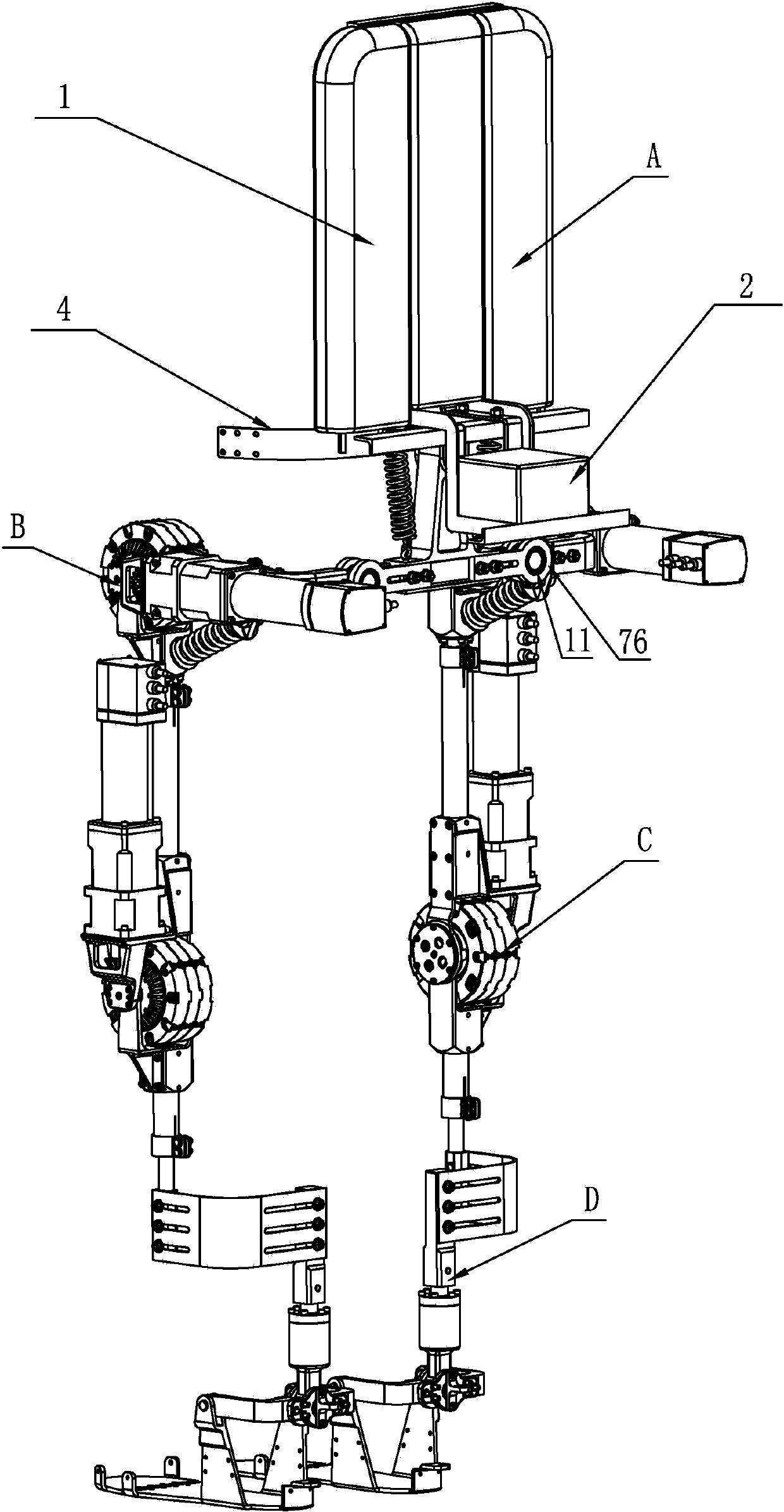

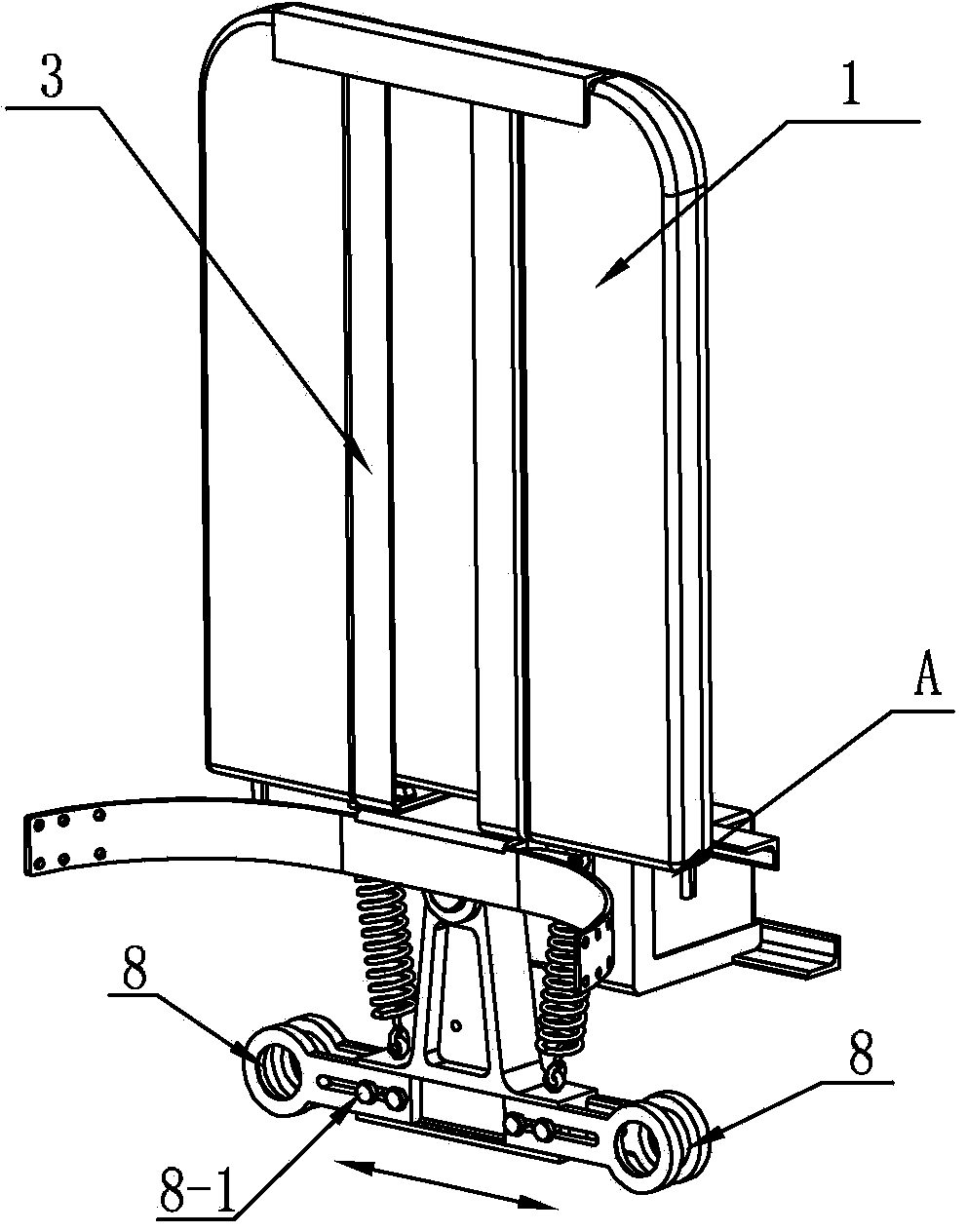

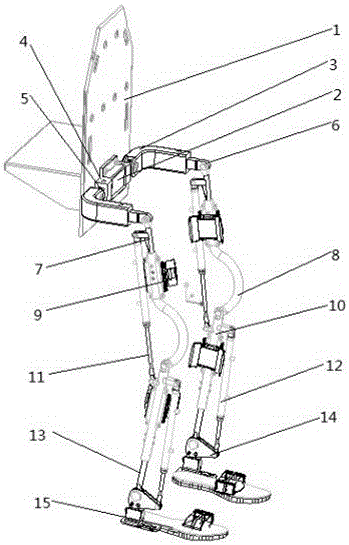

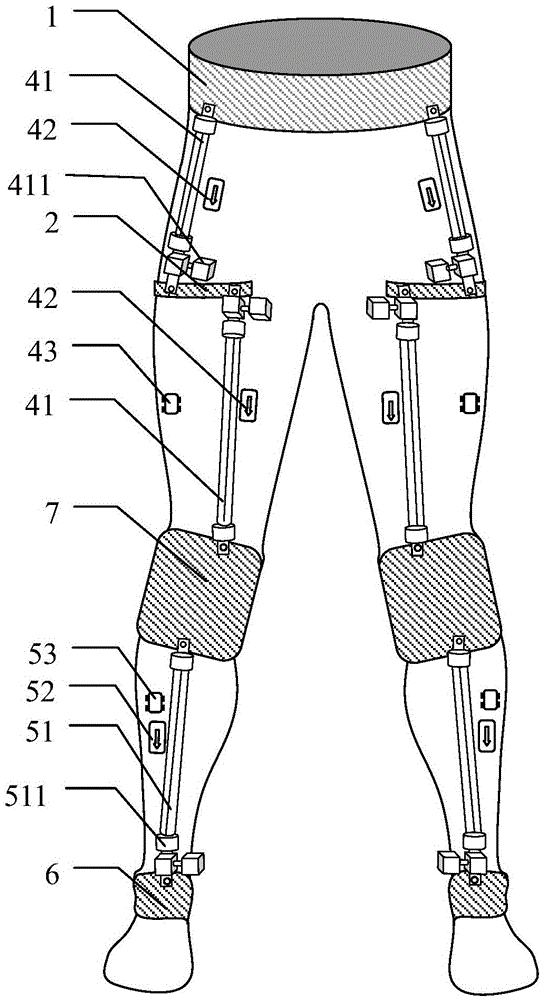

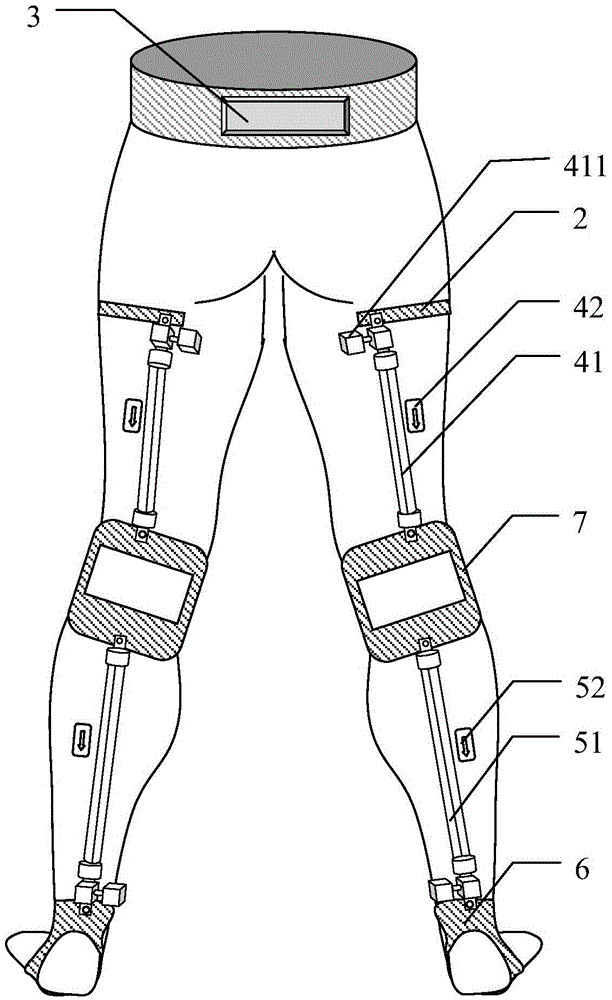

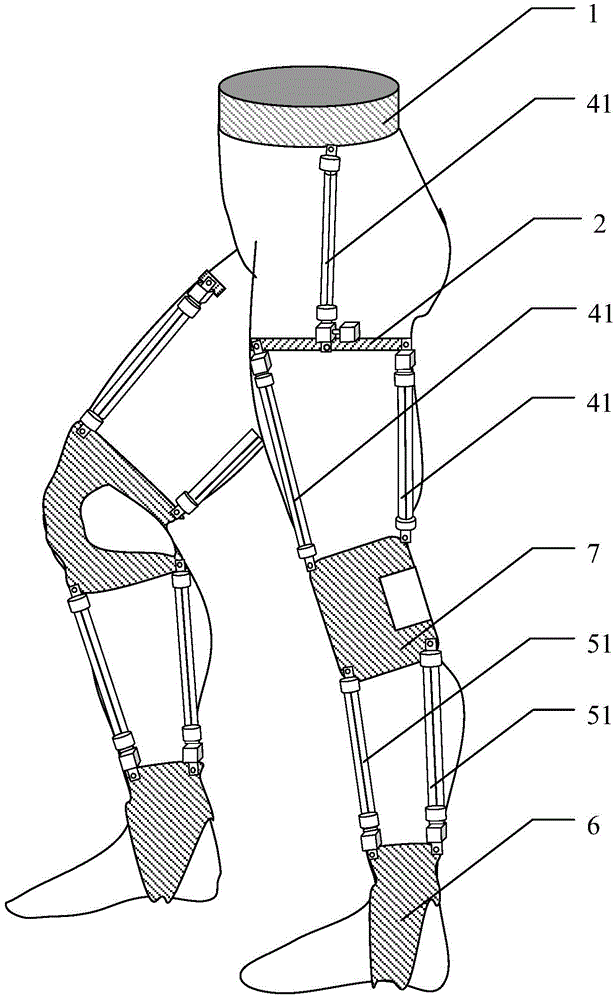

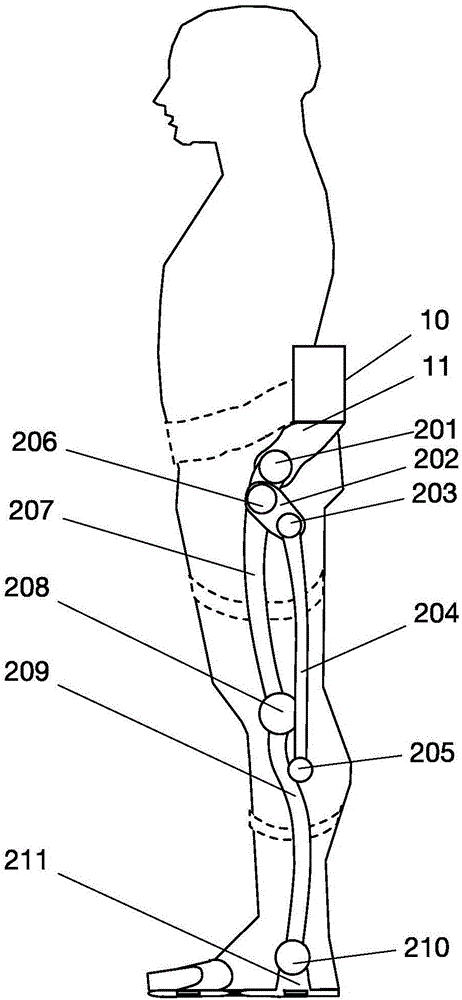

Human-simulated external skeleton robot assisting lower limbs

ActiveCN103610568ARealize the safety requirements of mechanical limitConvenient and accurate adjustment of telescopic lengthChiropractic devicesWalking aidsThighExoskeleton robot

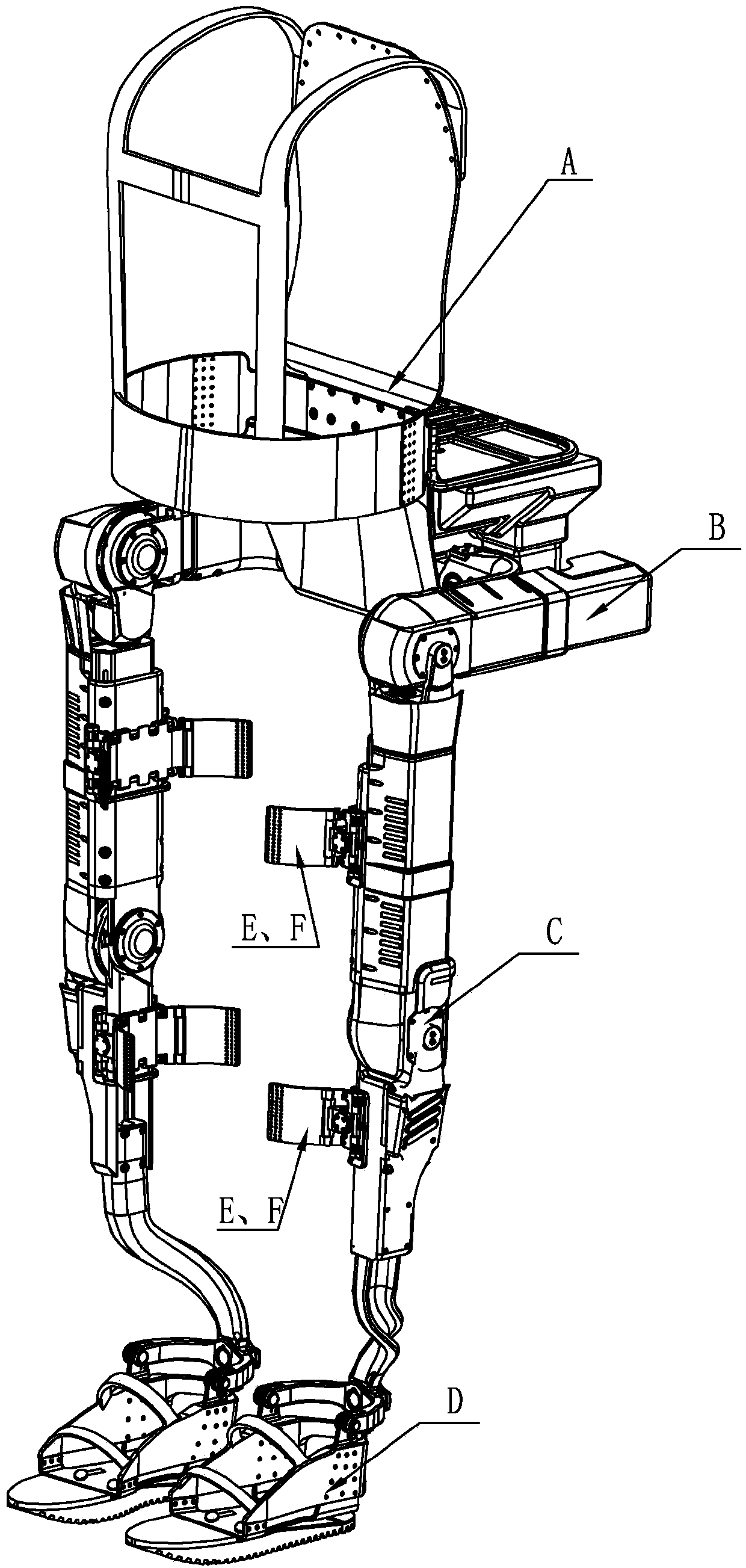

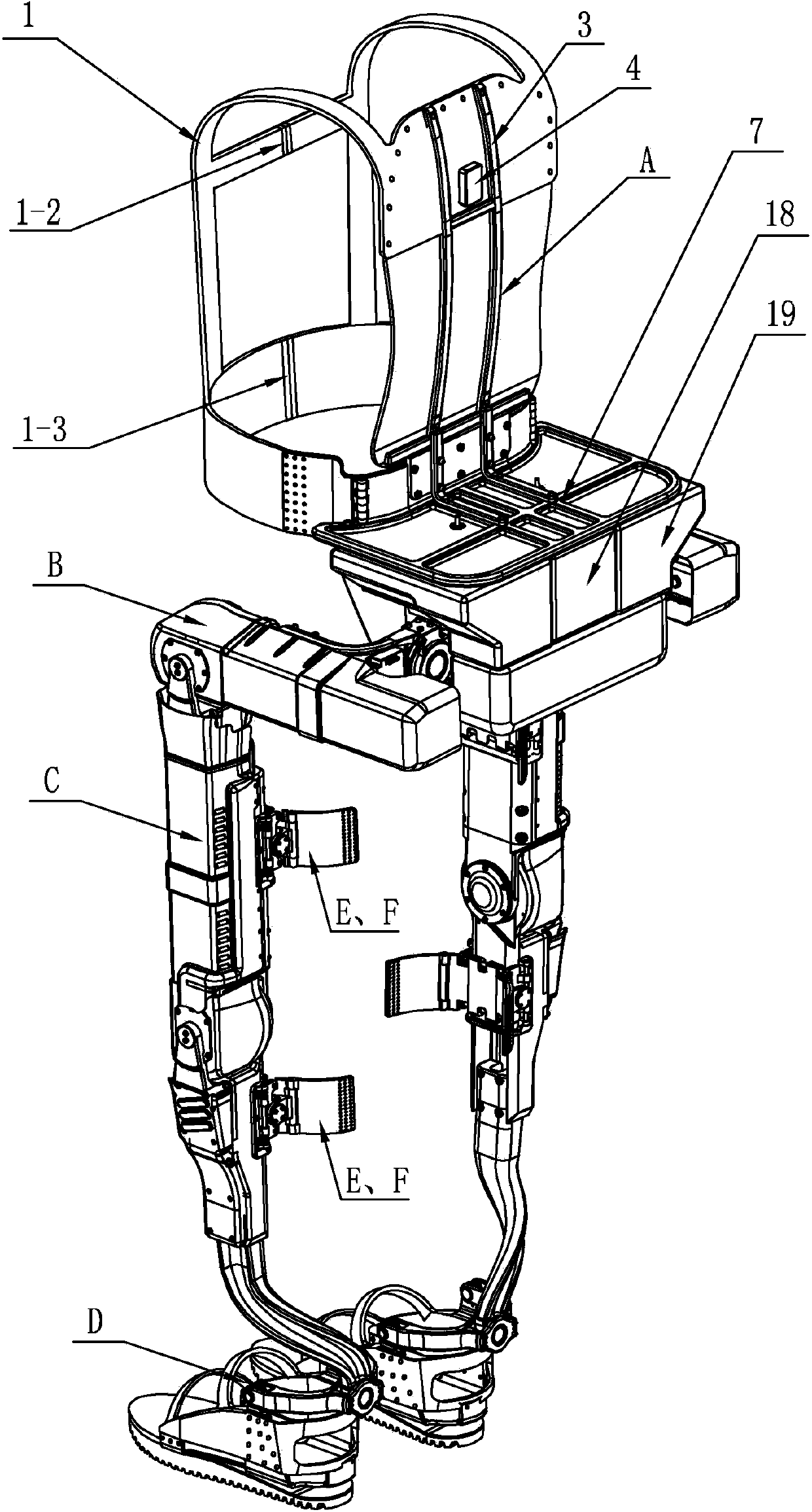

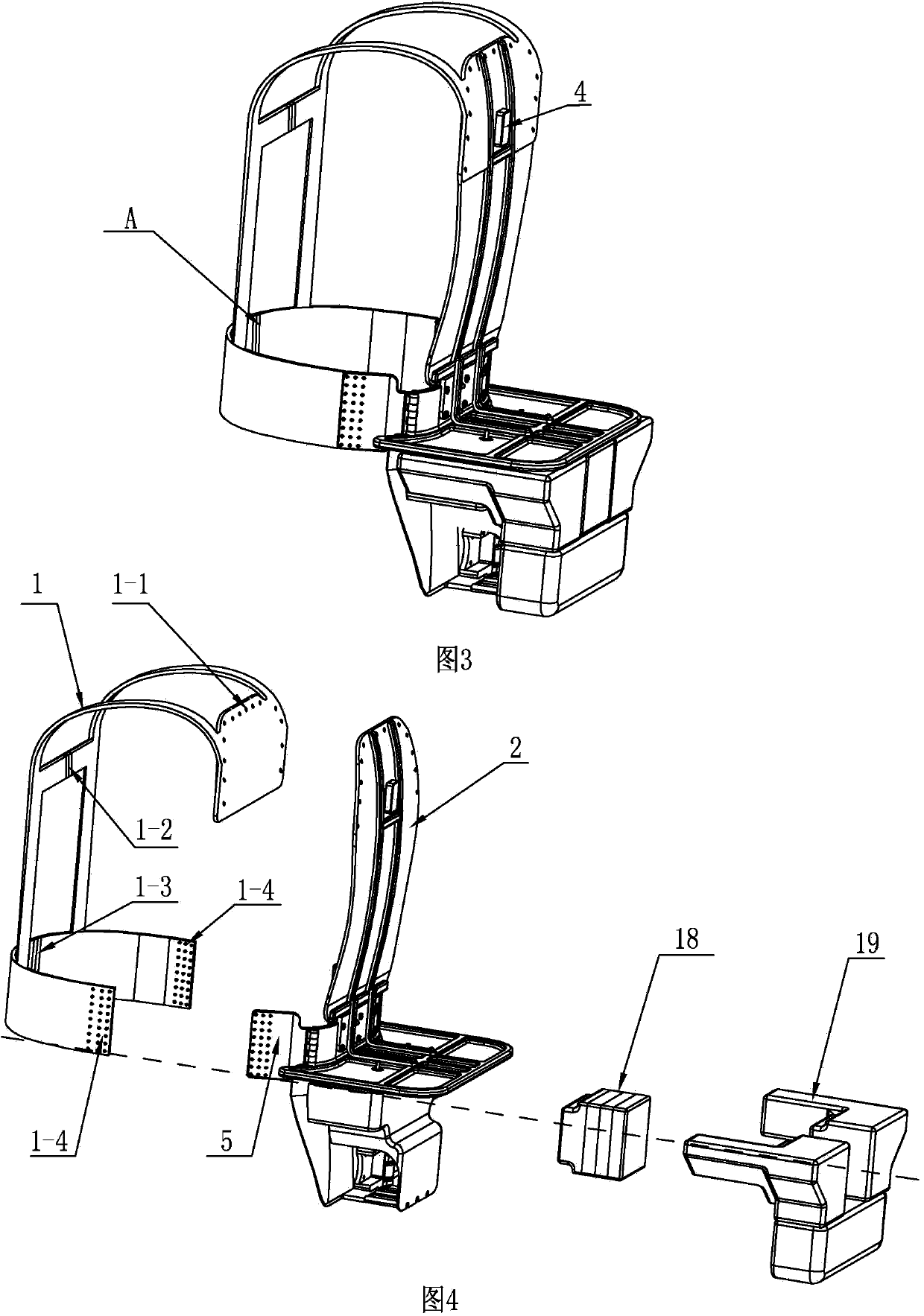

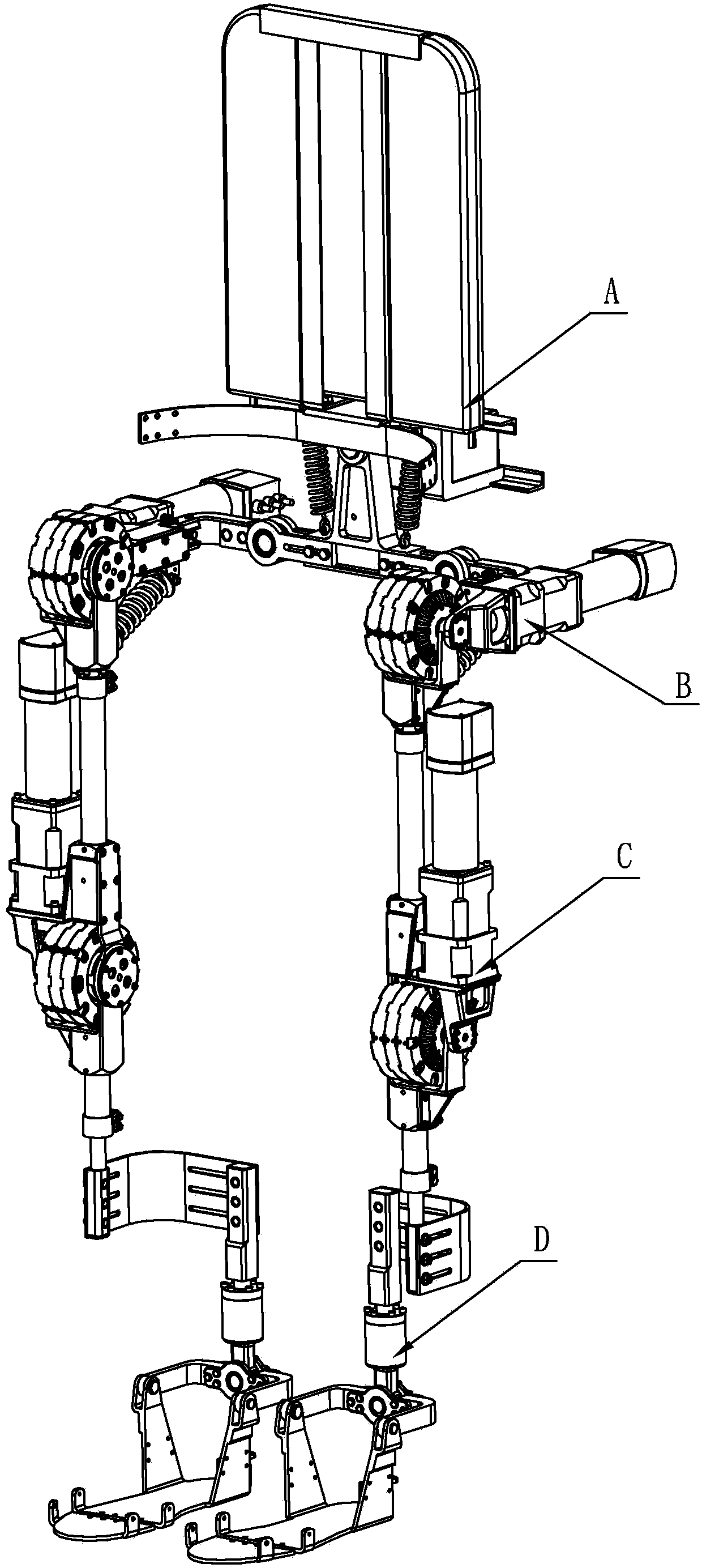

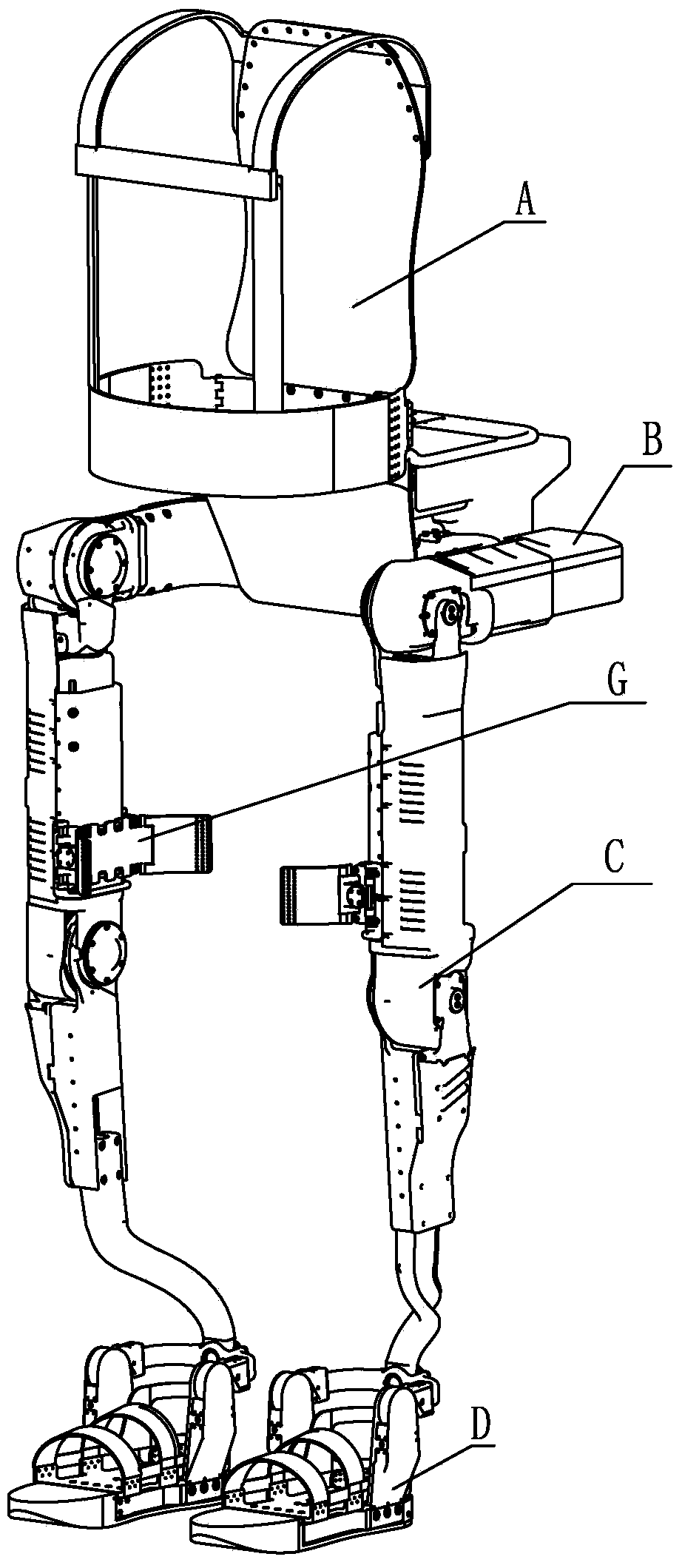

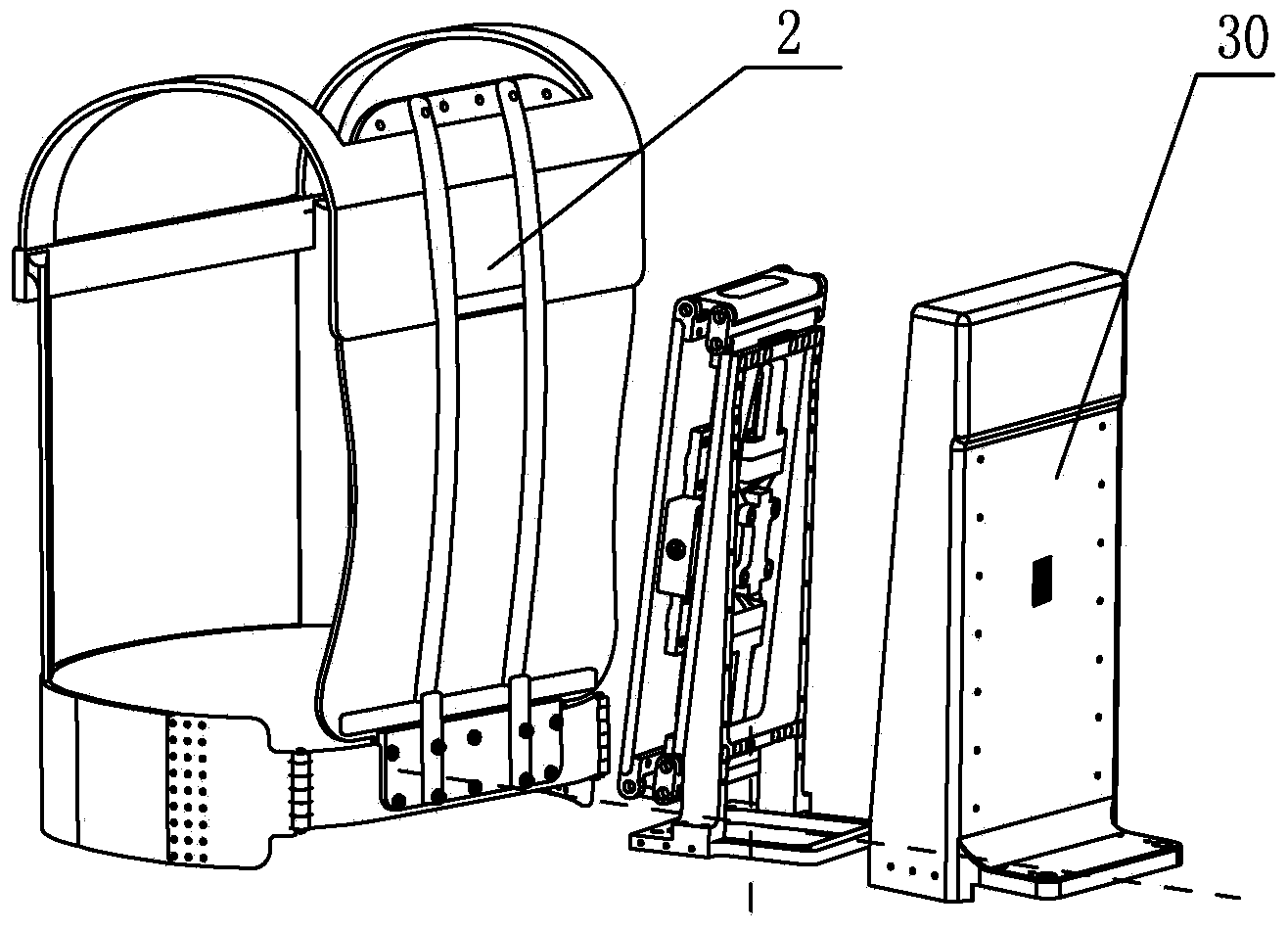

The invention relates to an external skeleton robot, in particular to a human-simulated external skeleton robot assisting the lower limbs. The human-simulated external skeleton robot assisting the lower limbs aims to solve the problems that an existing external skeleton robot is low in coupling degree of motion space and poor in wearing comfort, reliability and adaptation, and power needed by a motor is large. The human-simulated external skeleton robot assisting the lower limbs comprises an upper body back part, a left leg and a right leg. The left leg and the right leg respectively comprise a hip drive system, a knee drive system and a foot wearing system. A rear side connection board of the waist is in rotating connection with a load installation board. Each hip joint supporting board is provided with a first motor and a first reducer, wherein the first motor is provided with an encoder, and the output end of the first motor provided with the encoder is connected with the input end of the first reducer. Each hip joint connecting board can rotate in the vertical plane. Each thigh stretching board is in detachable connection with the corresponding hip joint connecting board. The output end of a main drive mechanism is connected with each crus connecting board. The lower surfaces of elastic boards are bonded with the upper surfaces of the rubber soles of the feet. The human-simulated external skeleton robot assisting the lower limbs can assist in walking.

Owner:HARBIN INST OF TECH

Portable energy-storage type external skeleton assisting robot

ActiveCN103610524AIntrusion Length AdjustmentEasy to disassemble and assembleArtificial legsThighExoskeleton robot

The invention relates to an external skeleton assisting robot, in particular to a portable energy-storage type external skeleton assisting robot. The problems that an existing lower limb external skeleton assisting robot worn on the human body is poor in assisting effect so that the loading capacity of the human body can be reduced, the wearing comfort for the human body is poor, the universality is poor, and the field environmental suitability is poor are solved. The portable energy-storage type external skeleton assisting robot comprises the upper body back, the left leg and the right leg, and the left leg and the right leg respectively comprise a hip driving system, a thigh driving system and a shank wearing system. A hip joint energy-storage mechanism comprises a connecting base, a stretching rod, a second spring and a stopping sheet, and a first bevel gear is meshed with a second bevel gear. Each hip driving system comprises a second motor with a coder, a second reducer, a third bevel gear, a fourth bevel gear, a thigh connecting rod, a knee joint support, a knee joint connecting plate, an angle sensor, a series connection elastic combination body, a knee joint gearbox body, a knee joint shaft and an end cover. The portable energy-storage type external skeleton assisting robot is suitable for being worn outdoors for walking assisting.

Owner:HARBIN INST OF TECH

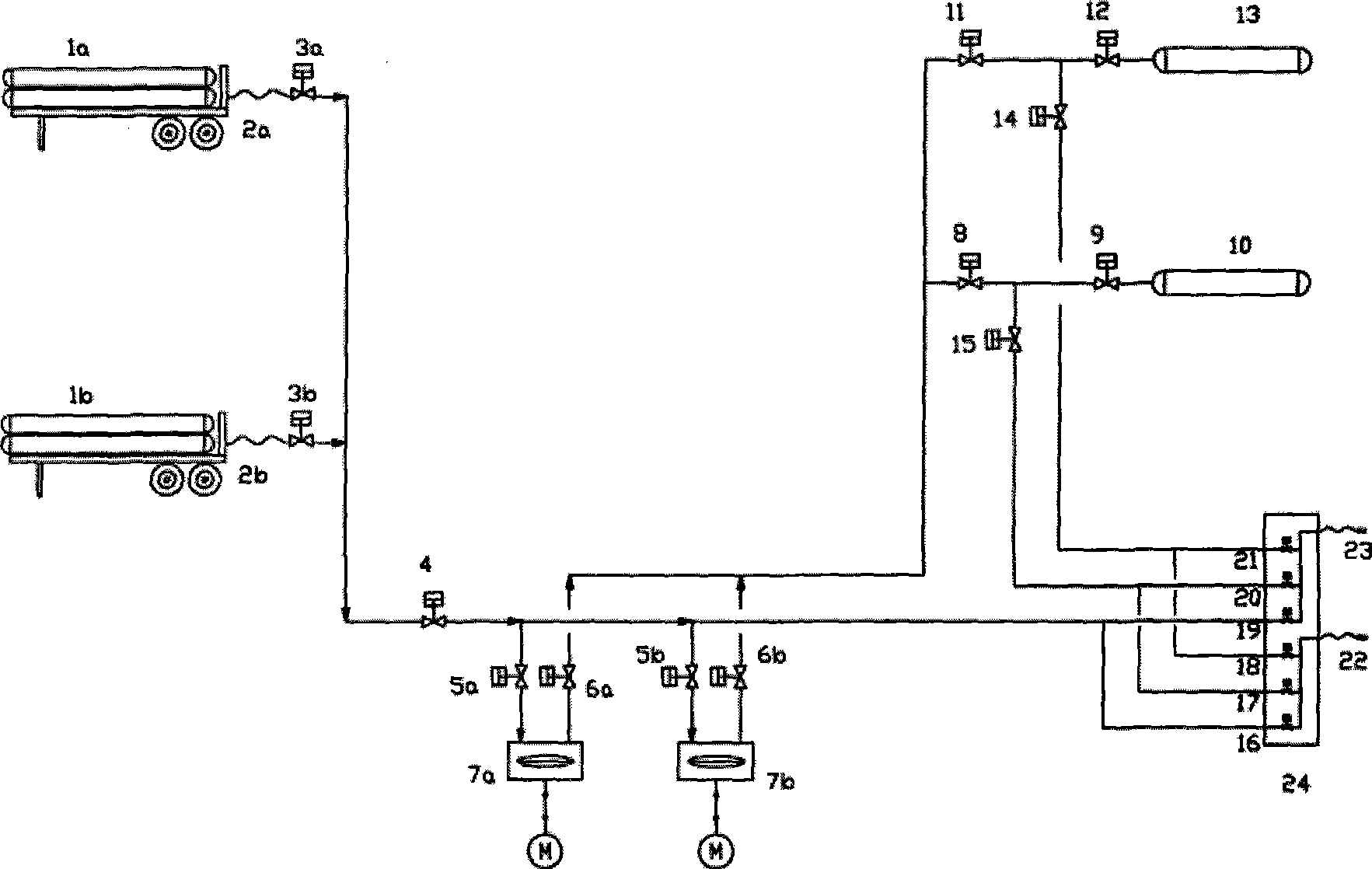

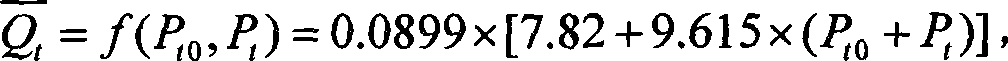

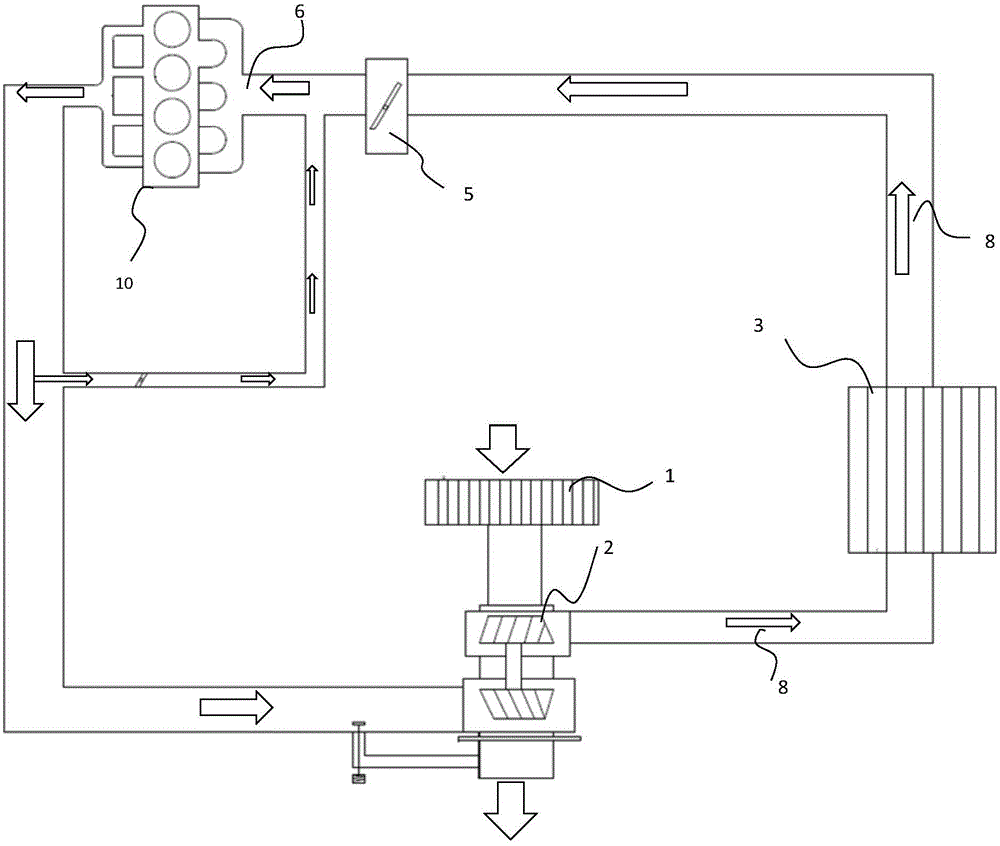

High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

ActiveCN101418907ASimplified hydrogen supply processLow investment costContainer filling under pressureHigh pressure hydrogenData acquisition

The invention provides a high-pressure hydrogen supply system for an external supplying type hydrogen filling station, which can fill hydrogen fuel for fuel cell powered vehicles. The hydrogen supply system mainly comprises a pipe bundle hydrogen conveying vehicle, a fixed high-pressure hydrogen storage tank group, a parallel multi-compressor pressurizing system, a high-pressure hydrogen filling system, and a data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system takes the pipe bundle hydrogen conveying vehicle as a part of a hydrogen storage container of the hydrogen filling station and makes the pipe bundle hydrogen conveying vehicle a first stage of the staged hydrogen storage container, adopts the pressurizing system consisting of multiple compressors which are connected in parallel, and introduces the data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system has the advantages of adjustable hydrogen storage volume, large operation flexibility, cost conservation, convenient maintenance, high service efficiency and so on.

Owner:TONGJI UNIV

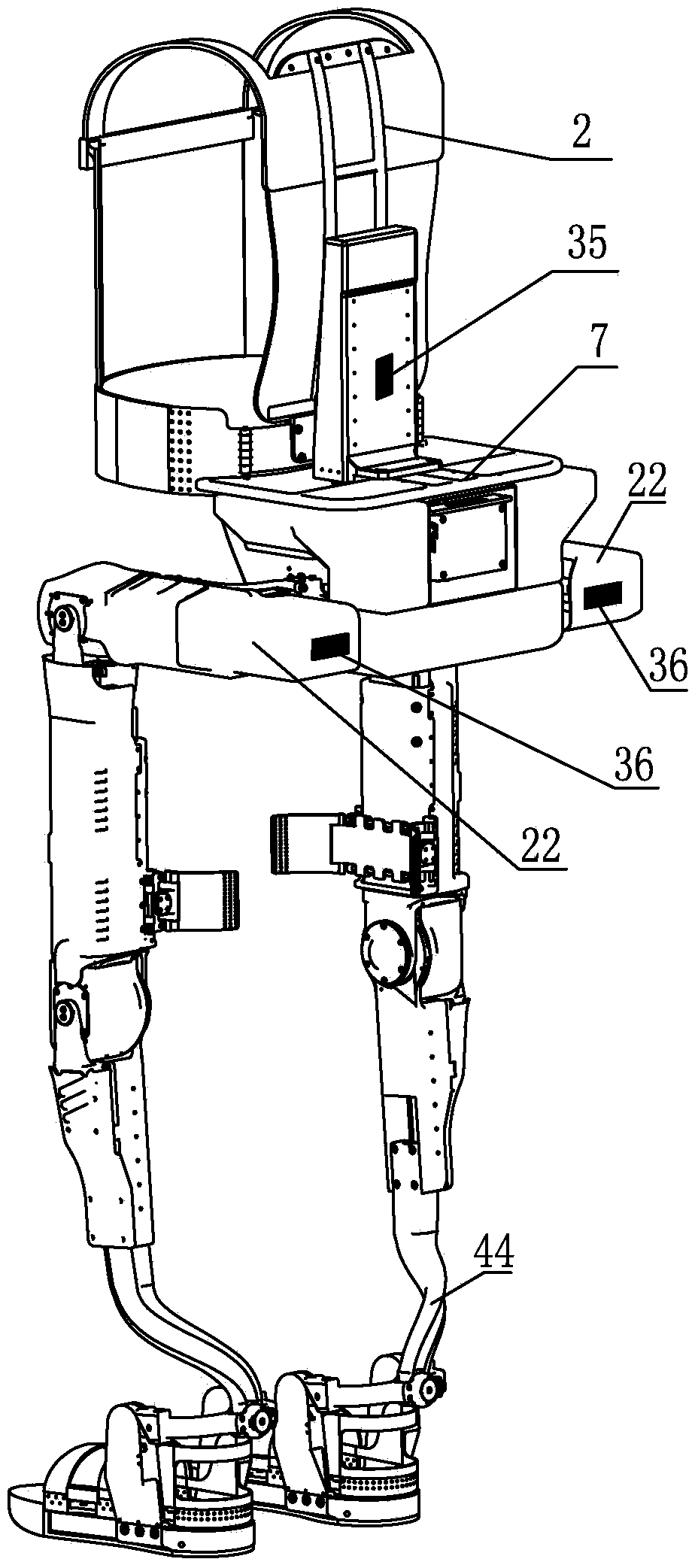

Exoskeleton robot system and kinematics extremity detection-based control method

The invention discloses an exoskeleton robot system and a kinematics extremity detection-based control method, and relates to an exoskeleton robot system and a control method to solve the problems that an accurate control effect cannot be achieved by the traditional electromyographic signal detection method for assisting in improving the walk of a human body, and man-machine interaction performance is low and an effective control method is lacked in the aspect of resisting self weight in the process of assisting in doing walk of the human body. The exoskeleton robot system comprises an upper body back, a left leg and a right leg; the left leg and the right leg respectively comprise a hip driving system, a knee driving system, a foot wearing system and a binding device; the exoskeleton robot system also comprises insole plates, a back detection shell, a nine-axis flight attitude measurement module, an industrial control computer, two thin film pressure sensors, two first angle sensors, two second angle sensors, two three-axis inclination sensors and three sets of three-dimensional contact force detection device. The exoskeleton robot system and the method are used for assisting in walking and performing detection and control of a moving posture of the human body.

Owner:HARBIN INST OF TECH

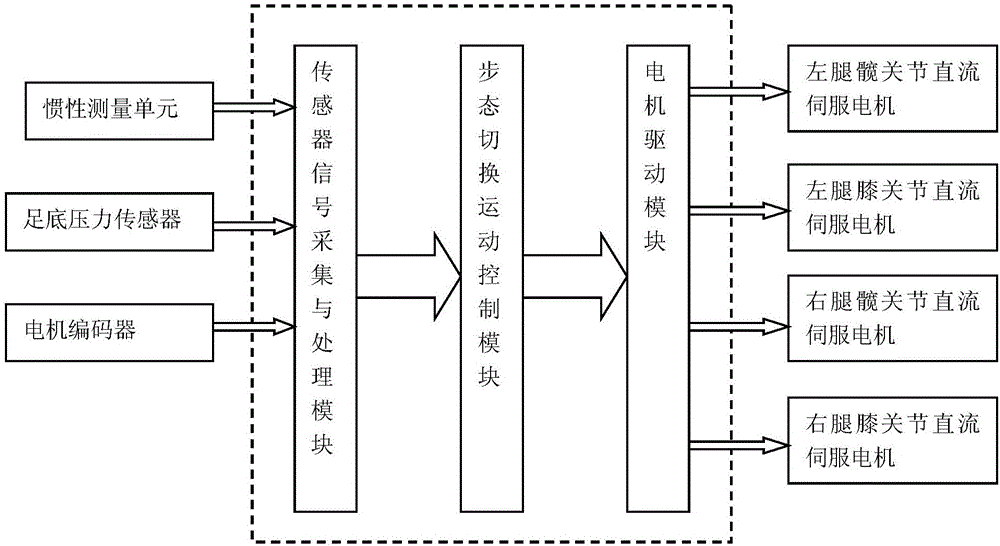

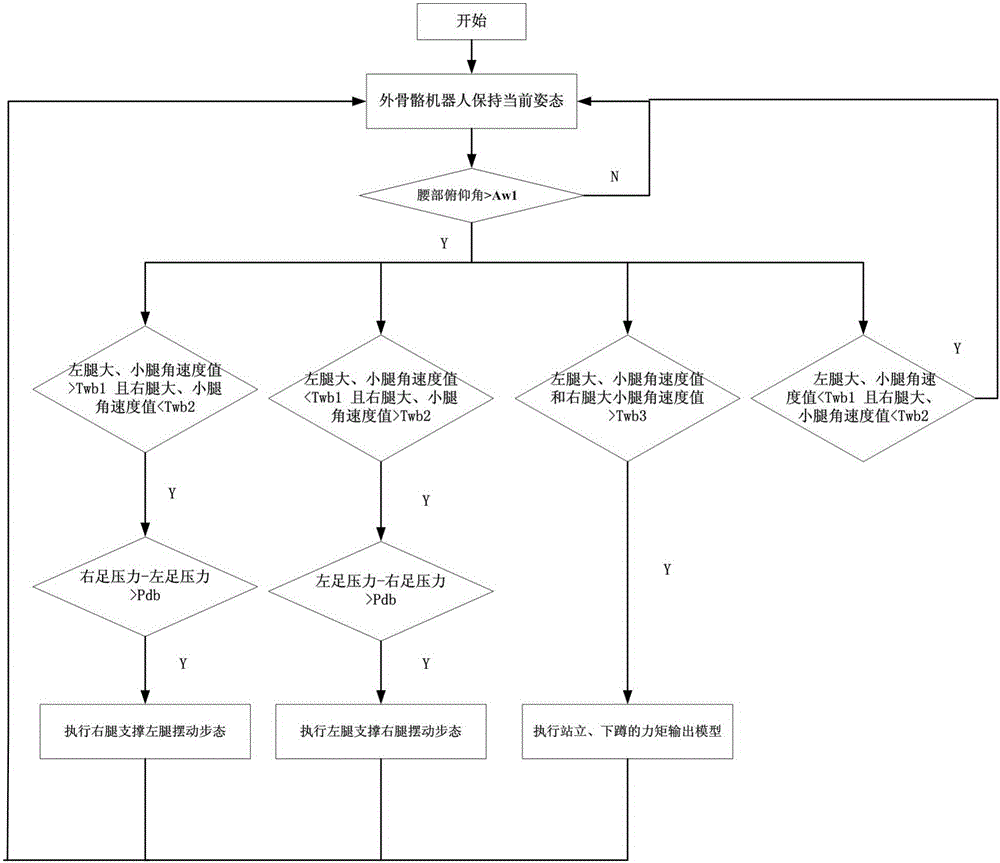

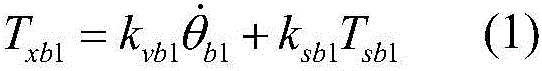

Multi-phase gait switching control system and control method for power-assisted exoskeleton robot

ActiveCN106325273AProtect personal safetyImprove work efficiencyProgramme-controlled manipulatorPosition/course control in two dimensionsExoskeleton robotMotor power

The invention discloses a multi-phase gait switching control system and control method for a power-assisted exoskeleton robot. The multi-phase gait switching control system is characterized in that the multi-phase gait switching control system includes a sensor module, a signal acquisition and processing module, a gait switching motion control module and a motor driving module; and sensors comprise inertial measurement units, plantar pressure sensors and motor encoders. With the multi-phase gait switching control system and control method for the power-assisted exoskeleton robot of the invention adopted, the output of lower hip joint and knee-joint motor power-assisted torque under various of phase gaits and smooth switching between the phase gaits can be planned under a condition that the exoskeleton robot bears a heavy object, and the coordination and flexibility of the movement of the limbs of the weight-bearing exoskeleton equipment can be realized.

Owner:江苏中科伟思智能机器人科技有限公司

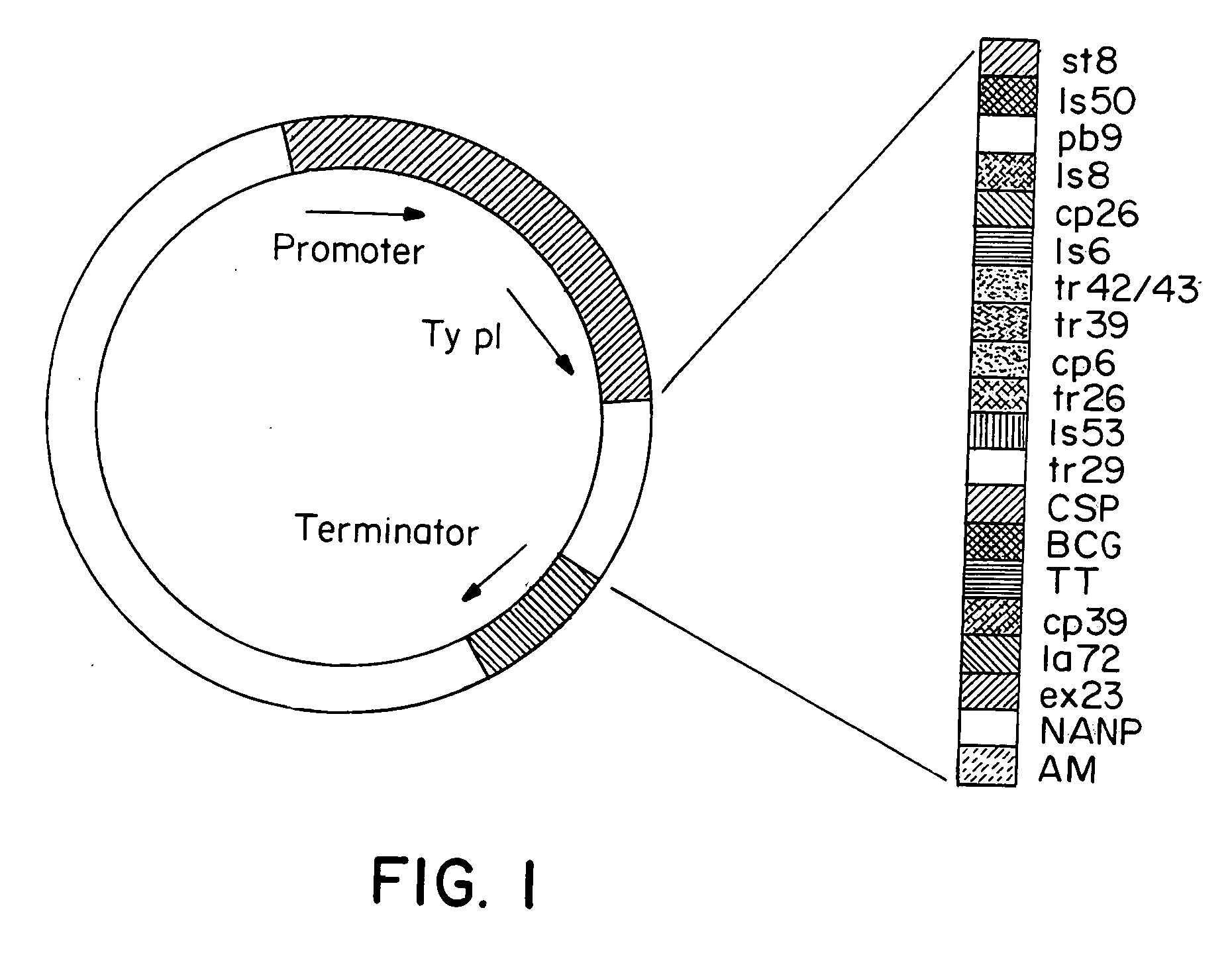

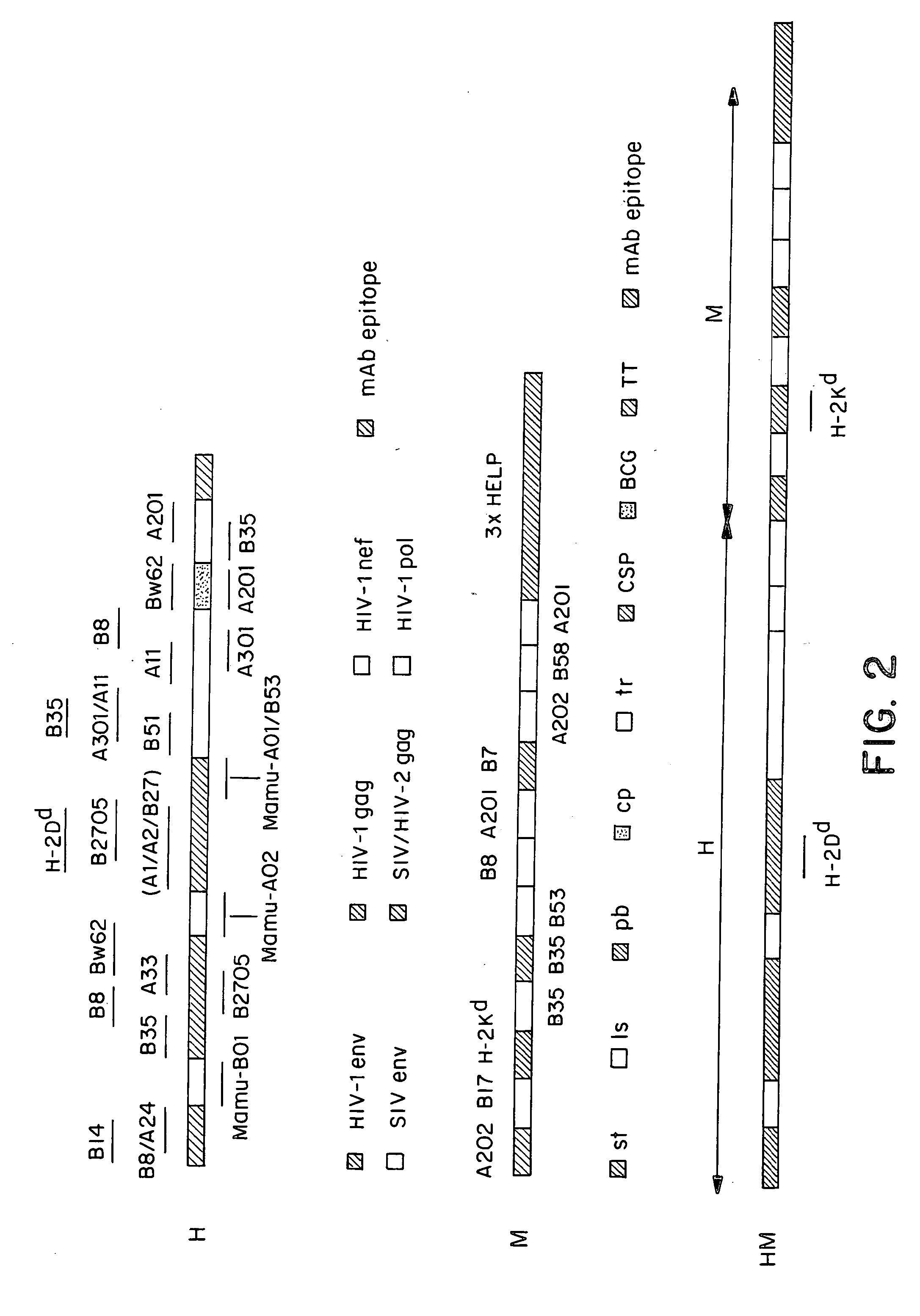

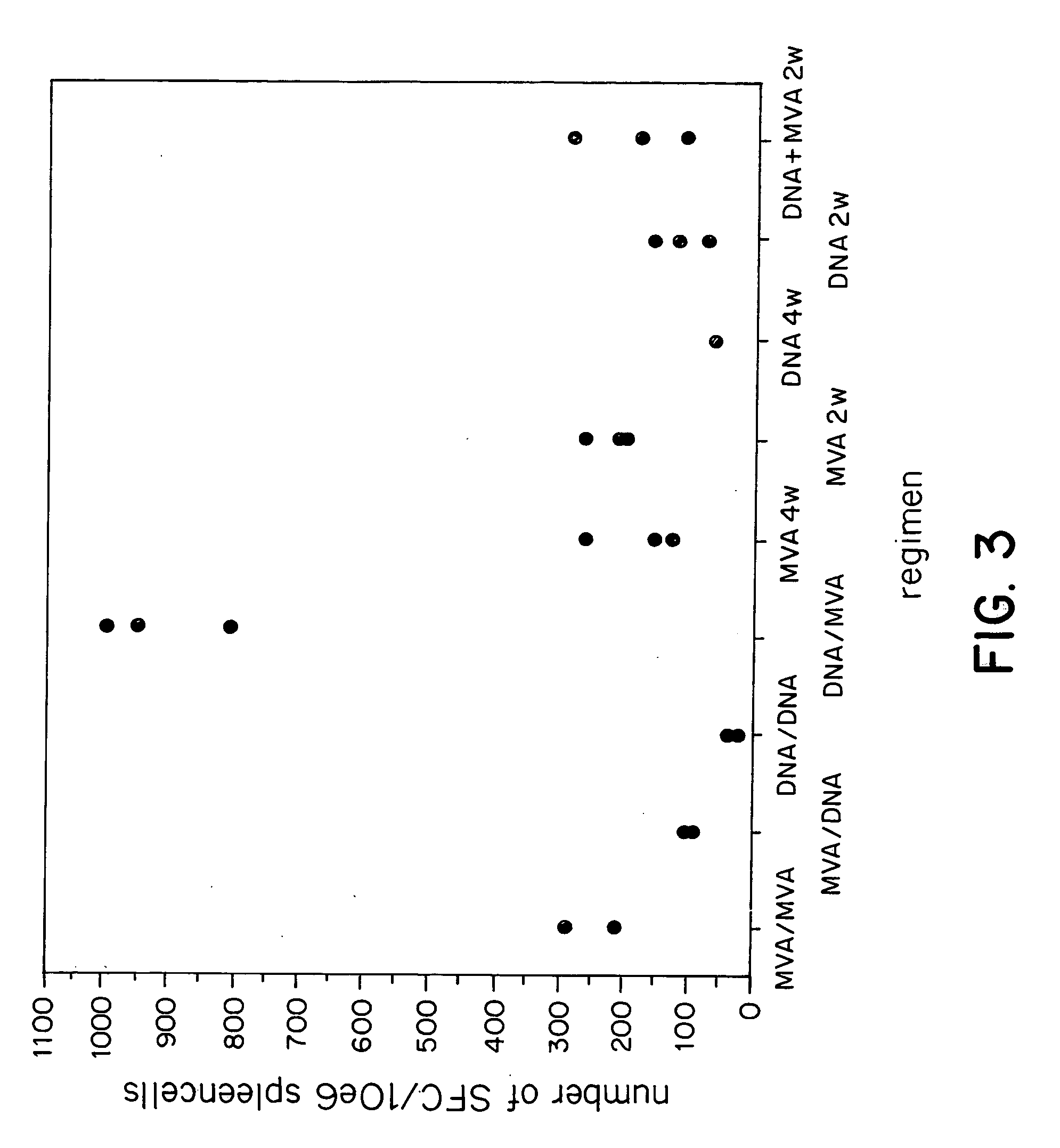

Methods and reagents for vaccination which generate a CD8 T cell immune response

New methods and reagents for vaccination are described which generate a CD8 T cell immune response against malarial and other antigens such as viral and tumour antigens. Novel vaccination regimes are described which employ a priming composition and a boosting composition, the boosting composition comprising a non-replicating or replication-impaired pox virus vector carrying at least one CD8 T cell epitope which is also present in the priming composition.

Owner:OXXON THERAPEUTICS LTD

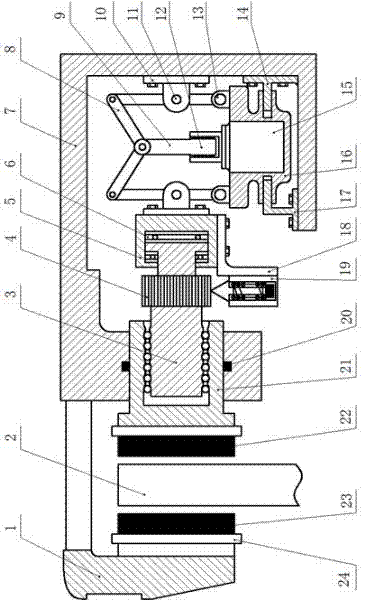

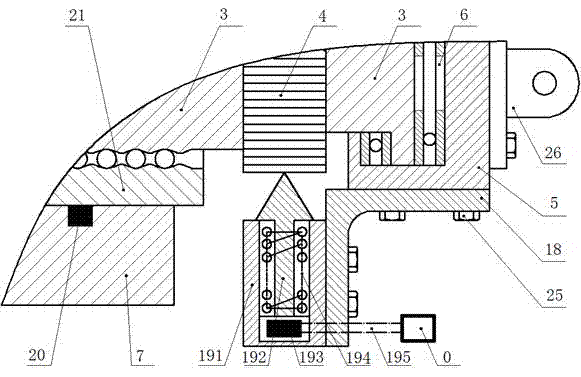

Automobile electromechanical brake

ActiveCN102518718AWith parking brakeIncrease boost effectBrake actuating mechanismsSlack adjustersEngineeringCalipers

The invention discloses an automobile electromechanical brake, which comprises a front floating caliper and a floating caliper block. The front floating caliper is connected with a front friction disc, the floating caliper block is connected with a back friction disc through a nut-piston, a brake disc is arranged between the front friction disc and the back friction disc, and the nut-piston is connected with a motor through a boosting linkage and is connected with a gap regulating mechanism. The motor pushes the back friction disc and the front friction disc to attach onto the brake disc by the boosting linkage, thereby realizing braking. The automobile electromechanical brake has a gap regulating function, and gaps among the brake disc and the friction discs can be regulated freely, so that constancy of the brake response speed of automobiles is guaranteed and braking performance is guaranteed further. The automobile electromechanical brake is fine in braking performance, simple in structure, convenient in installation, easy to maintain and low in energy consumption.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

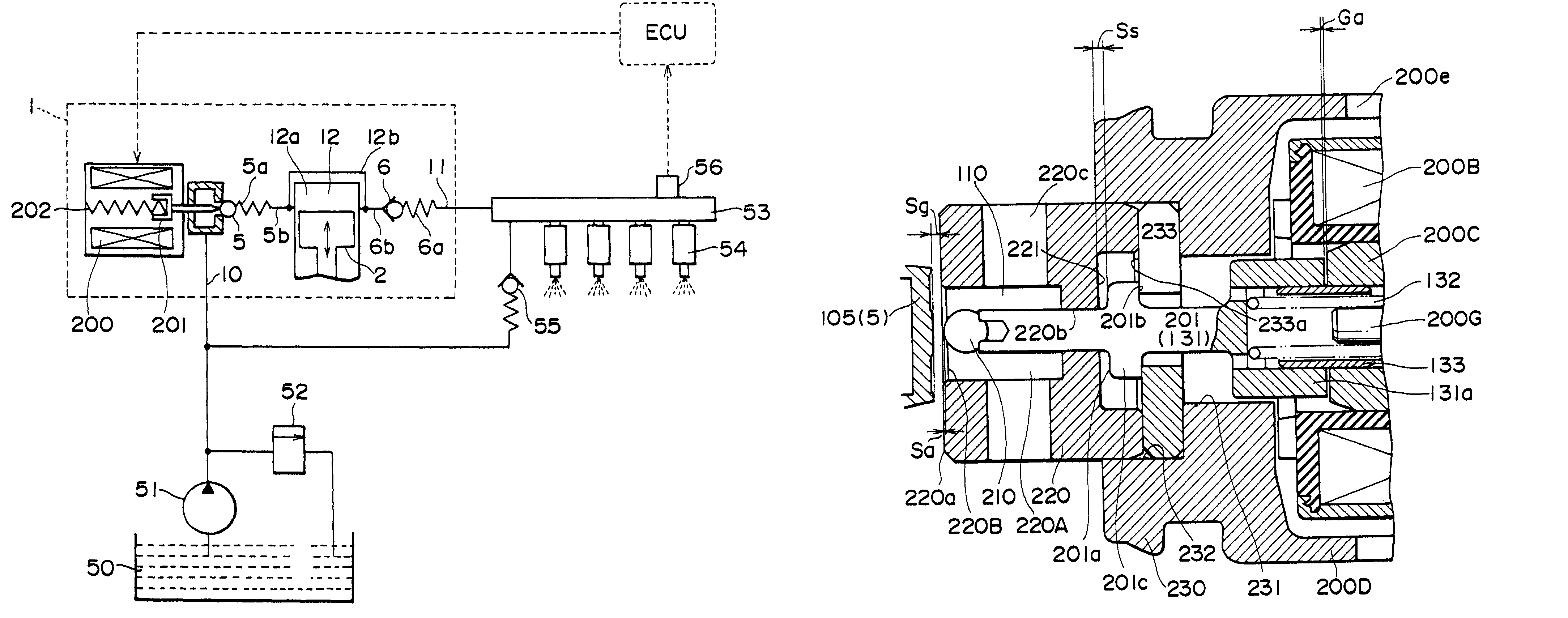

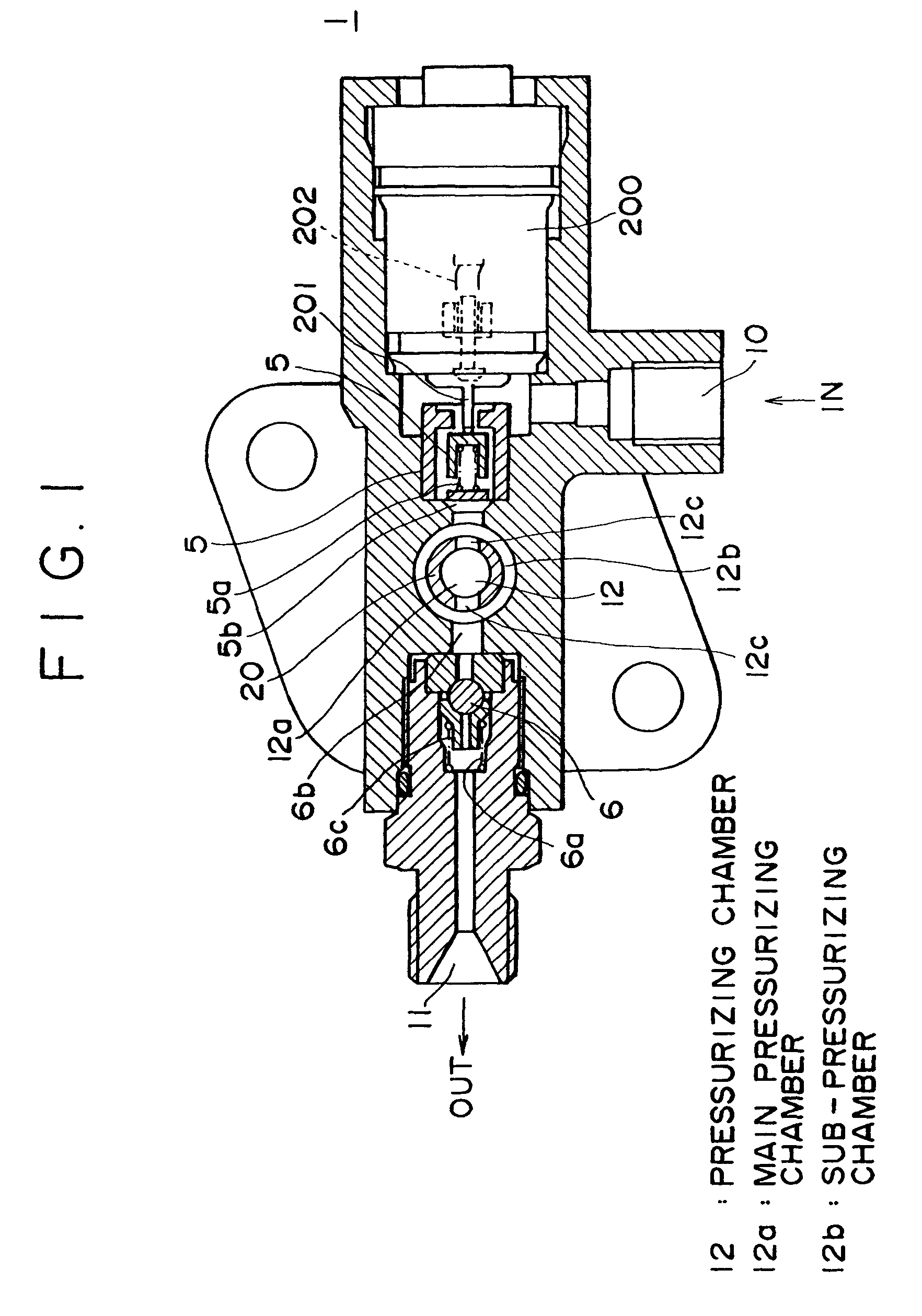

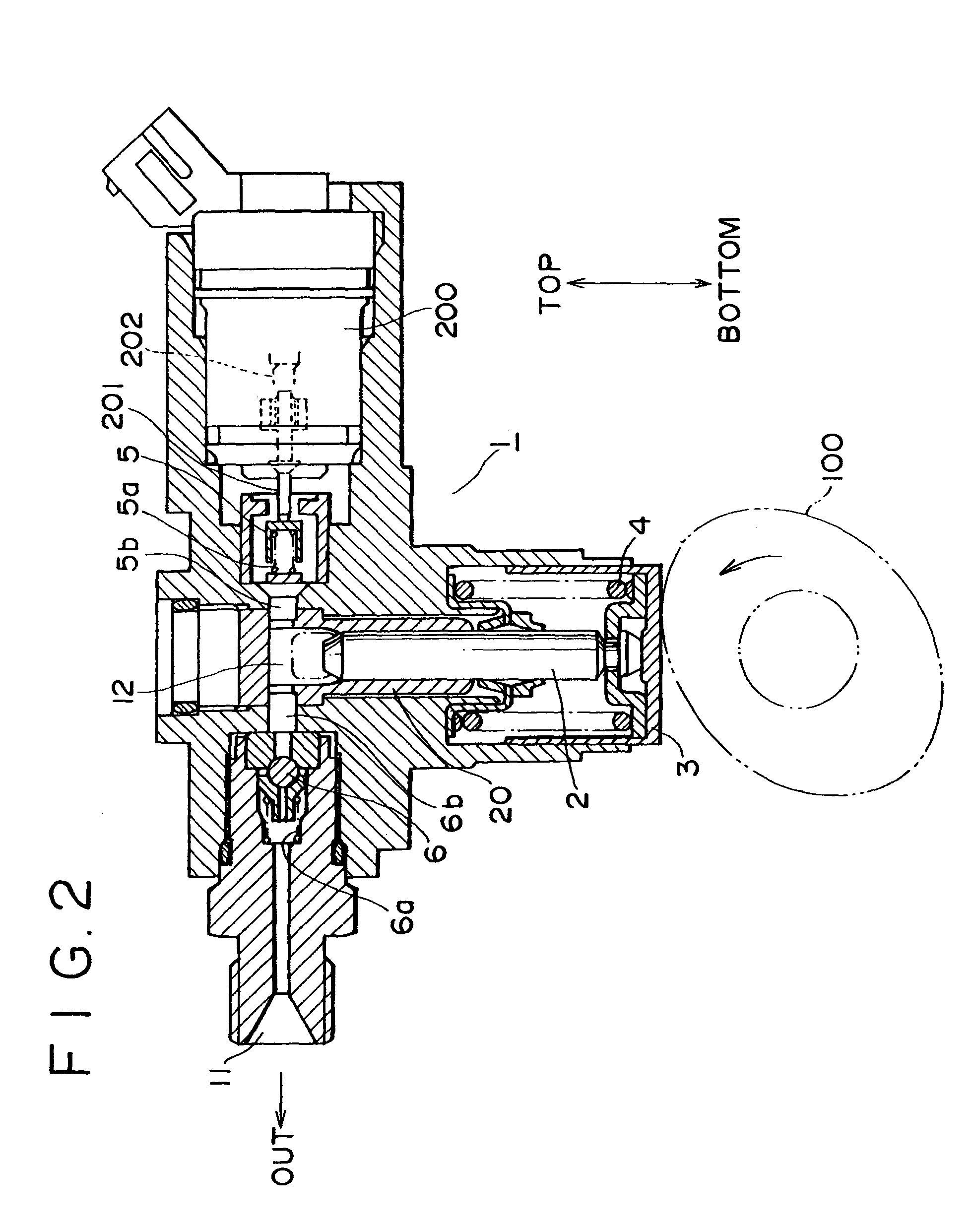

High pressure fuel supply pump for internal combustion engine

InactiveUS7540274B2Speed up the processAvoid oscillationPositive displacement pump componentsFuel injecting pumpsExternal combustion engineInlet valve

An intake valve automatically opened and closed by pressure of a pressuring chamber is provided in a fuel intake passage, the intake valve is pushed to open by a plunger of an electromagnetic plunger mechanism, pulling-in operating timing of the plunger is controlled according to the operating condition of an internal combustion engine, and opening time of the intake valve during compression stroke of a pump is controlled to make discharge flow-rate of high pressure fuel variable.

Owner:HITACHI AUTOMOTIVE SYST LTD

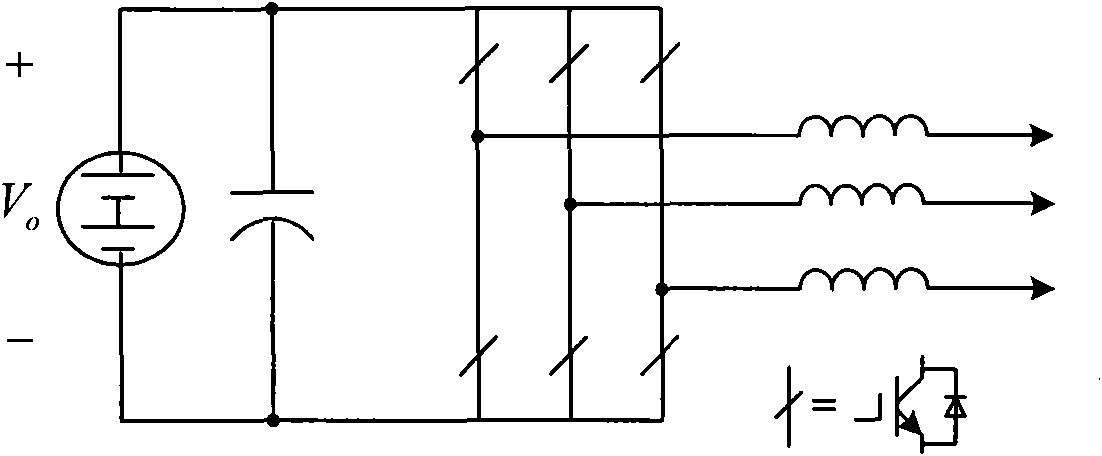

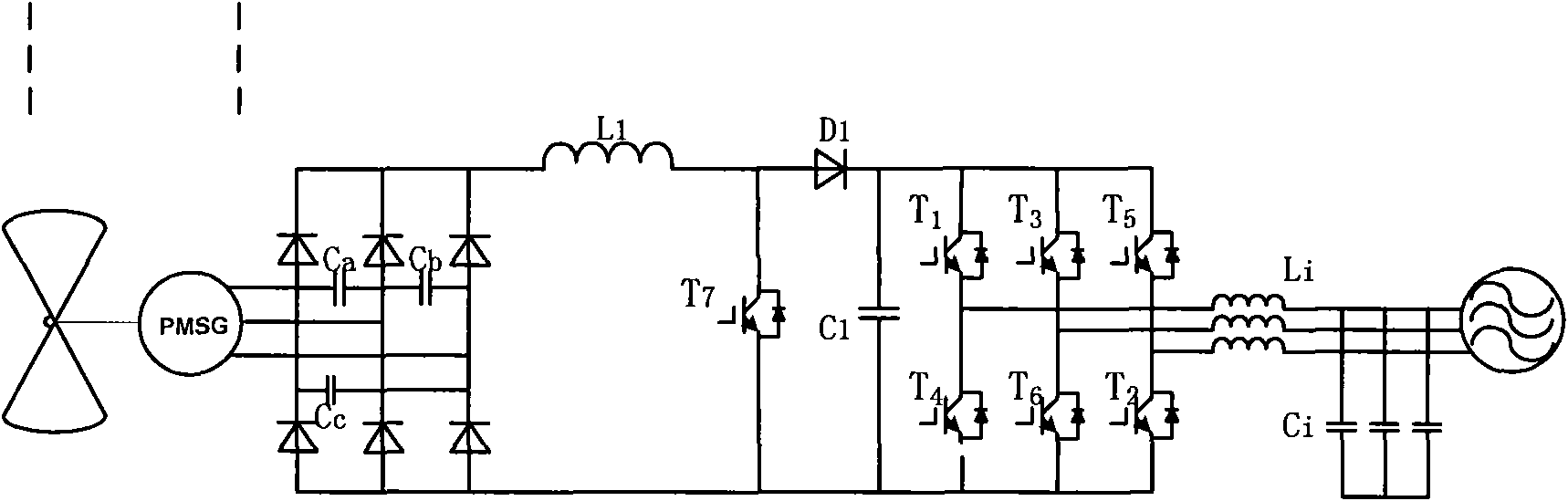

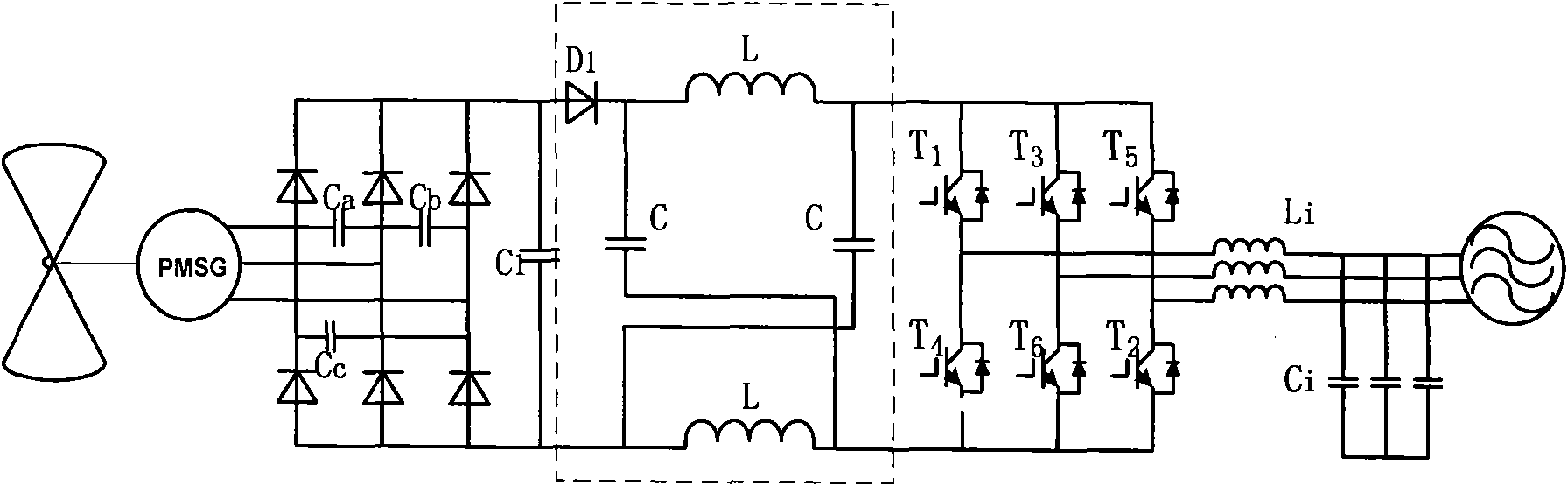

Monopole inverter capable of boosting voltage

InactiveCN101599710ARealize large voltage difference power transferAvoid output current waveform distortionSingle network parallel feeding arrangementsDc-ac conversion without reversalCapacitanceControl mode

The invention relates to a novel monopole inverting circuit capable of boosting voltage, and topology is shown in an attached figure. Besides a three-phase switch bridge (B) of the conventional voltage type inverter, the circuit is additionally provided with a tightly coupled inductor consisting of inductors (L1, L2), a capacitor (C), an interdiction diode (D) and a switch tube (T) for an energy feedback passage (can be removed if no energy is needed to feedback). The voltage boosting control mode of the circuit to an inverter direct current bus uses the state of the through zero vector of the upper and lower switch tubes emitted by the three-phase inverter bridge during zero vector to adjust the action time so as to realize the controllable promotion of direct current bus voltage of the input side of the inverter. The inductors (L1 and L2) are tightly coupled, when the inductors are in a state of through zero vector, the inverter is directly communicated, and a DC voltage source (Vs) charges a couple inductor (L1); and when the inductors are in a state of non-through zero vector, the inductors release energy to supply power to the direct current bus of the inverter (B); the voltage of the direct current bus of the inverter is obtained by lapping the voltage of the inductor (L2) and the voltage of the capacitor (C) so as to enable the voltage of the direct current bus of the inverter to be improved, so that the inverter voltage is boosted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

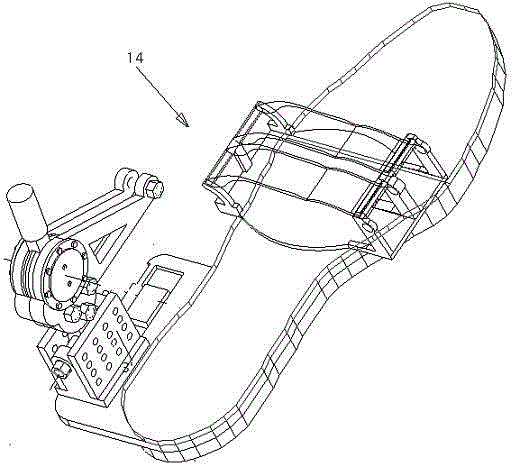

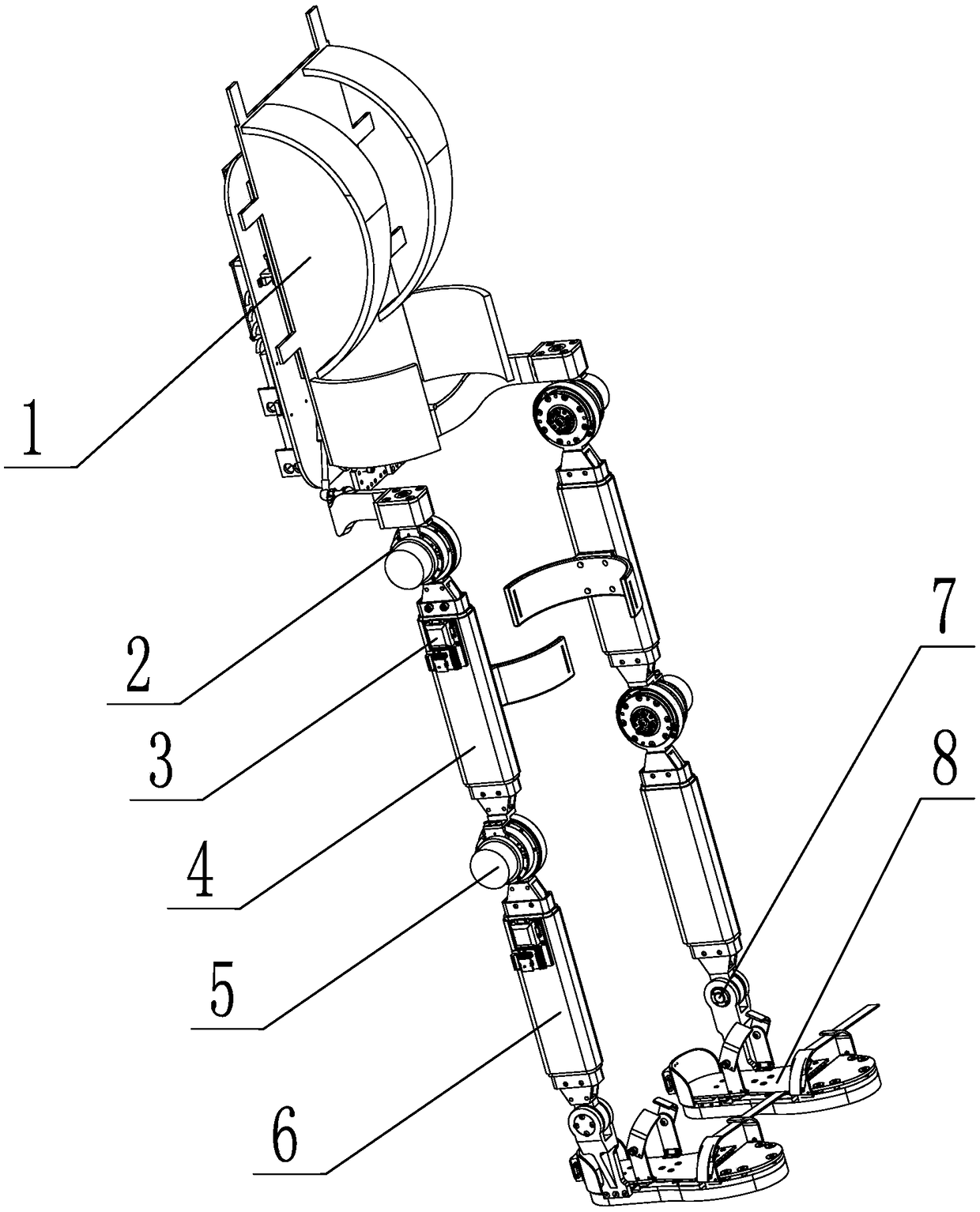

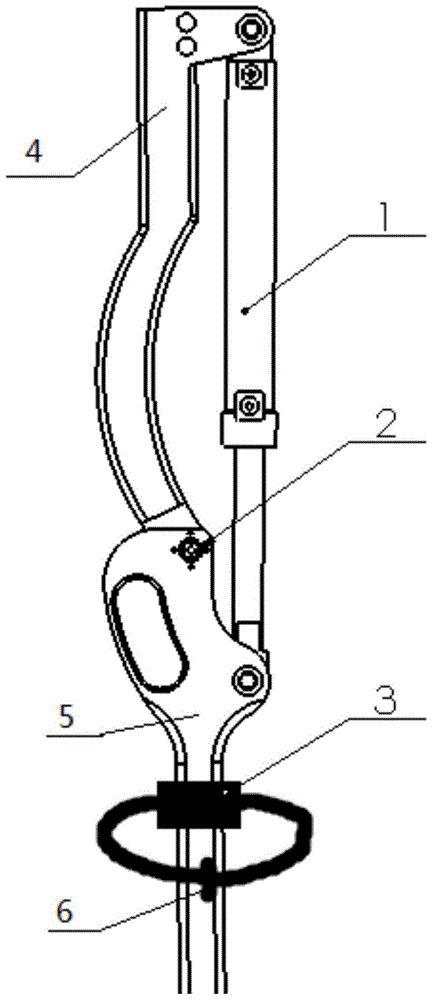

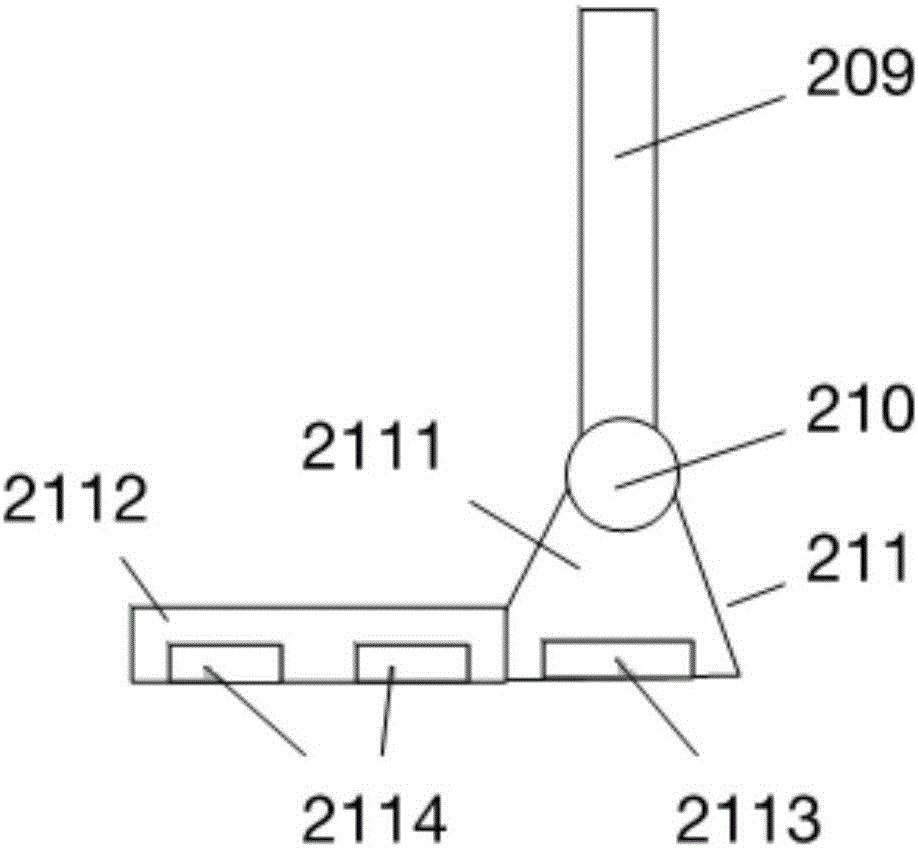

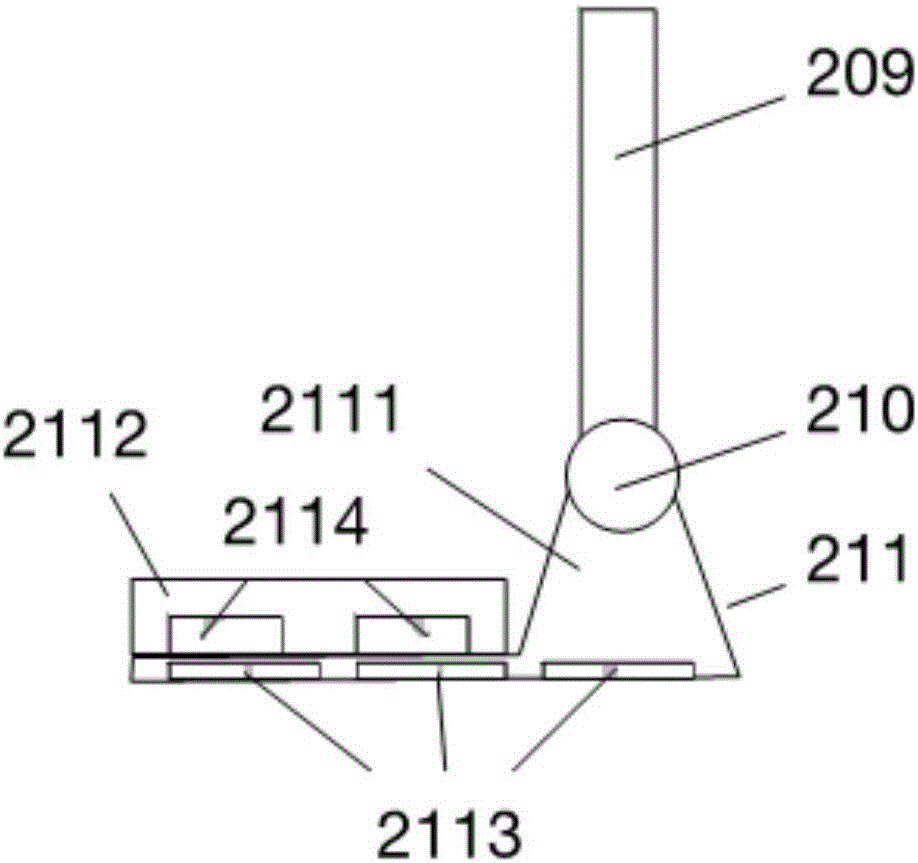

A foldable portable lower extremity exoskeleton

ActiveCN105686927AImprove weight capacityImprove adaptabilityChiropractic devicesWalking aidsThighEngineering

The invention provides a foldable portable lower extremity exoskeleton comprising a back frame (1) and thigh assemblies (17). Each thigh assembly (17) mainly consists of a thigh upper adjusting rod (7), a thigh lower adjusting rod (8), a binding device (9) and a thigh driving cylinder (11), wherein the thigh driving cylinder (11) is connected with the thigh upper adjusting rod (7), the thigh upper adjusting rod (7) is in inserted connection with the thigh lower adjusting rod (8); the binding device (9) is installed on the thigh upper adjusting rod (7); the thigh lower adjusting rod (8) is arc-shaped so that a shank upper adjusting rod (10) in a shank assembly (18) can be rotated and folded; the connecting portion between the thigh upper adjusting rod (7) and a hip joint assembly (16) can perform rotation around a vertical axis and can perform rotary swing around a frontal axis; the hip joint assembly (16) can perform rotary swing around a sagittal axis. The foldable portable lower extremity exoskeleton can be folded for transport, is small in size and is convenient to transport and deliver.

Owner:PLA UNIV OF SCI & TECH

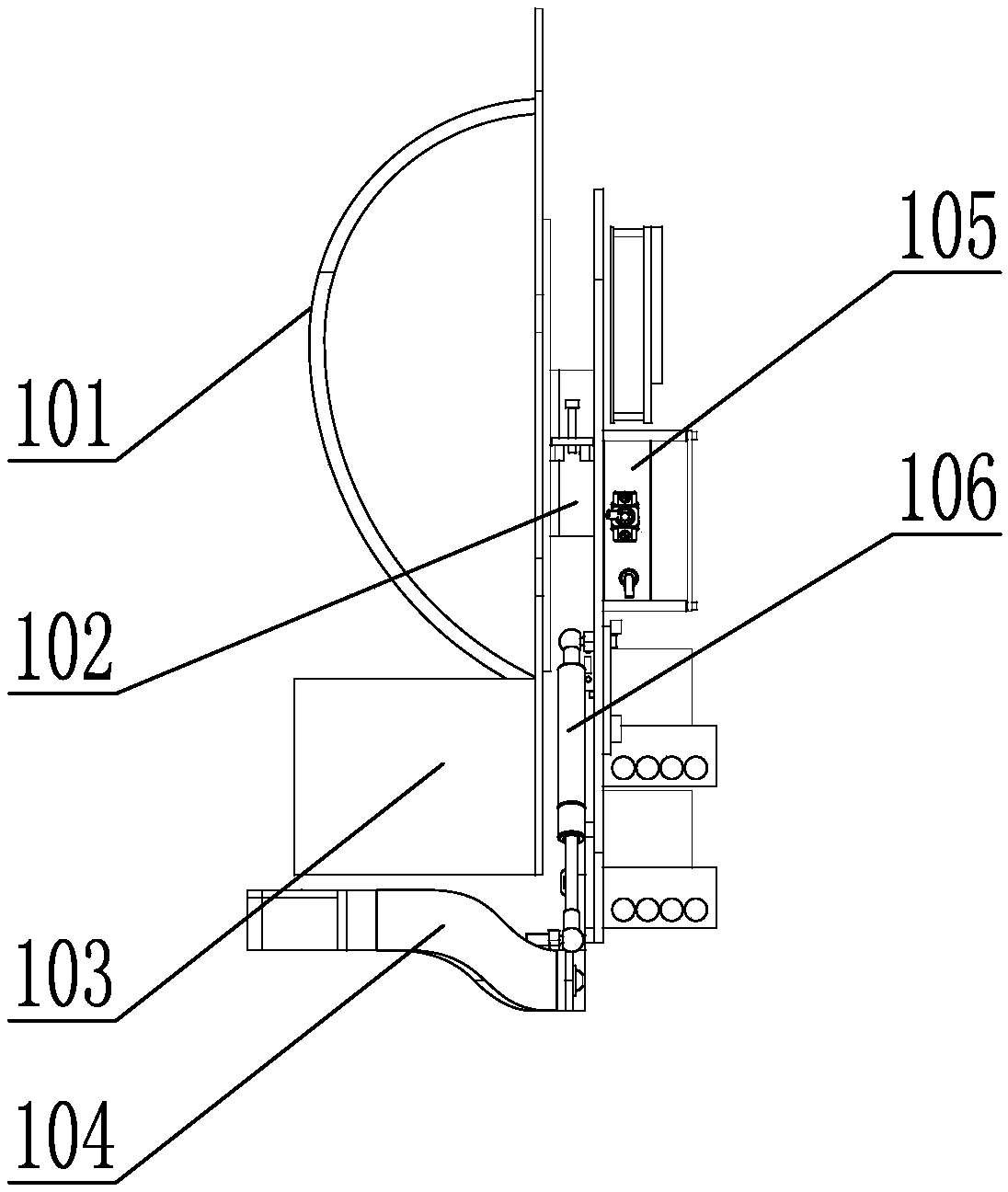

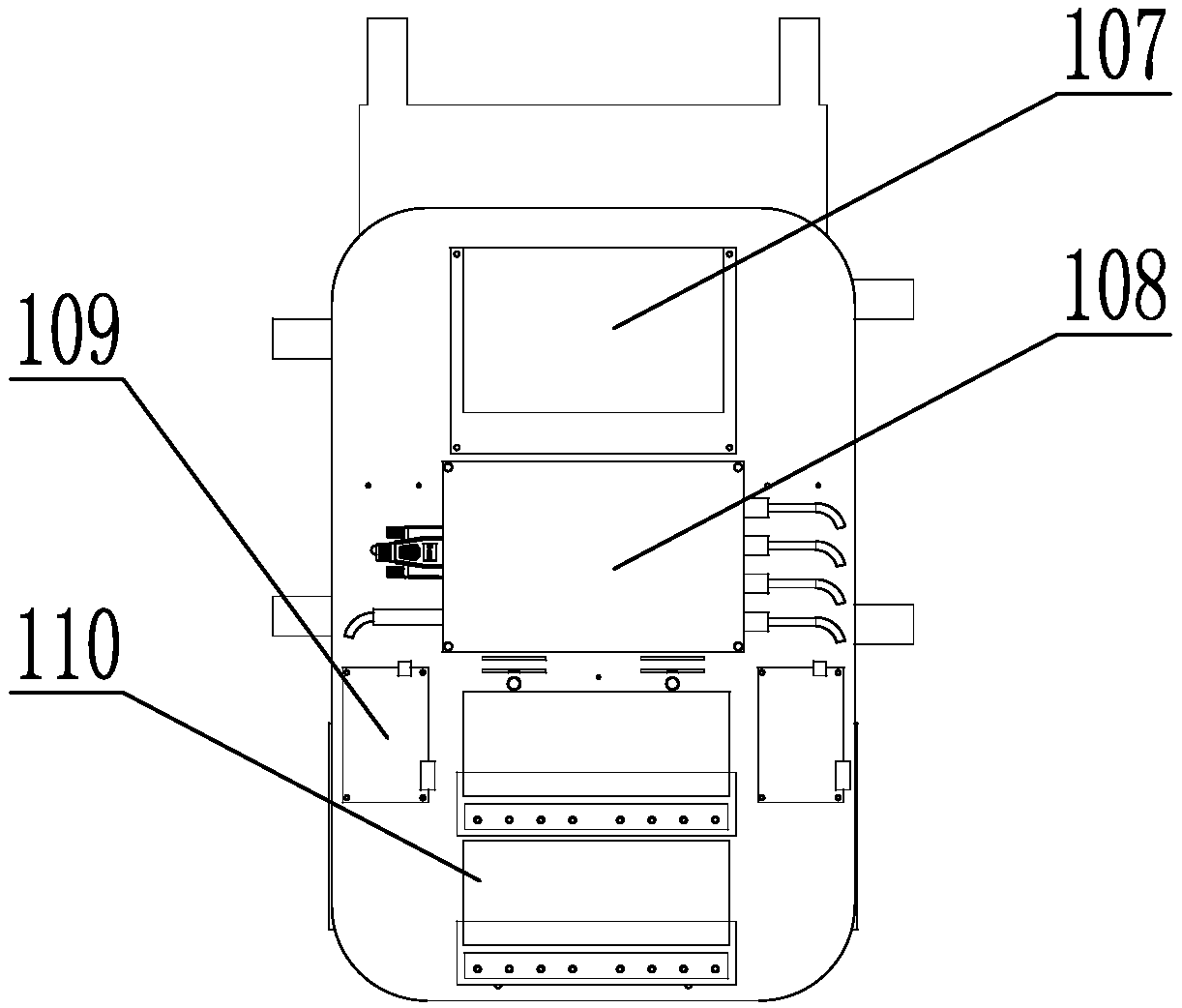

Lower limb exoskeleton robot system based on human-machine terminal interaction

The invention provides a lower limb exoskeleton robot system based on human-machine terminal interaction, and relates to a lower limb exoskeleton robot. The system solves the problems of poor adhesionbetween the lower limb exoskeleton and the human body, uncomfortable wearing, inaccurate human-computer interaction information, poor man-machine following effect and inconspicuous power assisting effect caused by the prior lower limb exoskeleton. A low part of that back frame is symmetrically provided with two hip joint bracket, one end of the hip joint support is rotatably connected with the back frame 1 through an adduction and abduction shaft, the free end of each hip joint bracket is rotatably connected to the corresponding hip joint through an internal and external hip rotation axis, Each hip joint is connected with a corresponding thigh rod through a hip flexion and extension shaft, an inertia unit is arranged at the upper part of each thigh rod, the lower part of each thigh rod isconnected with the upper end of the corresponding calf rod through a knee joint, one end of a pneumatic spring is connected with a back frame, and the other end of the pneumatic spring is connected with a corresponding hip joint bracket. The invention is used for a lower limb exoskeleton robot.

Owner:HARBIN INST OF TECH

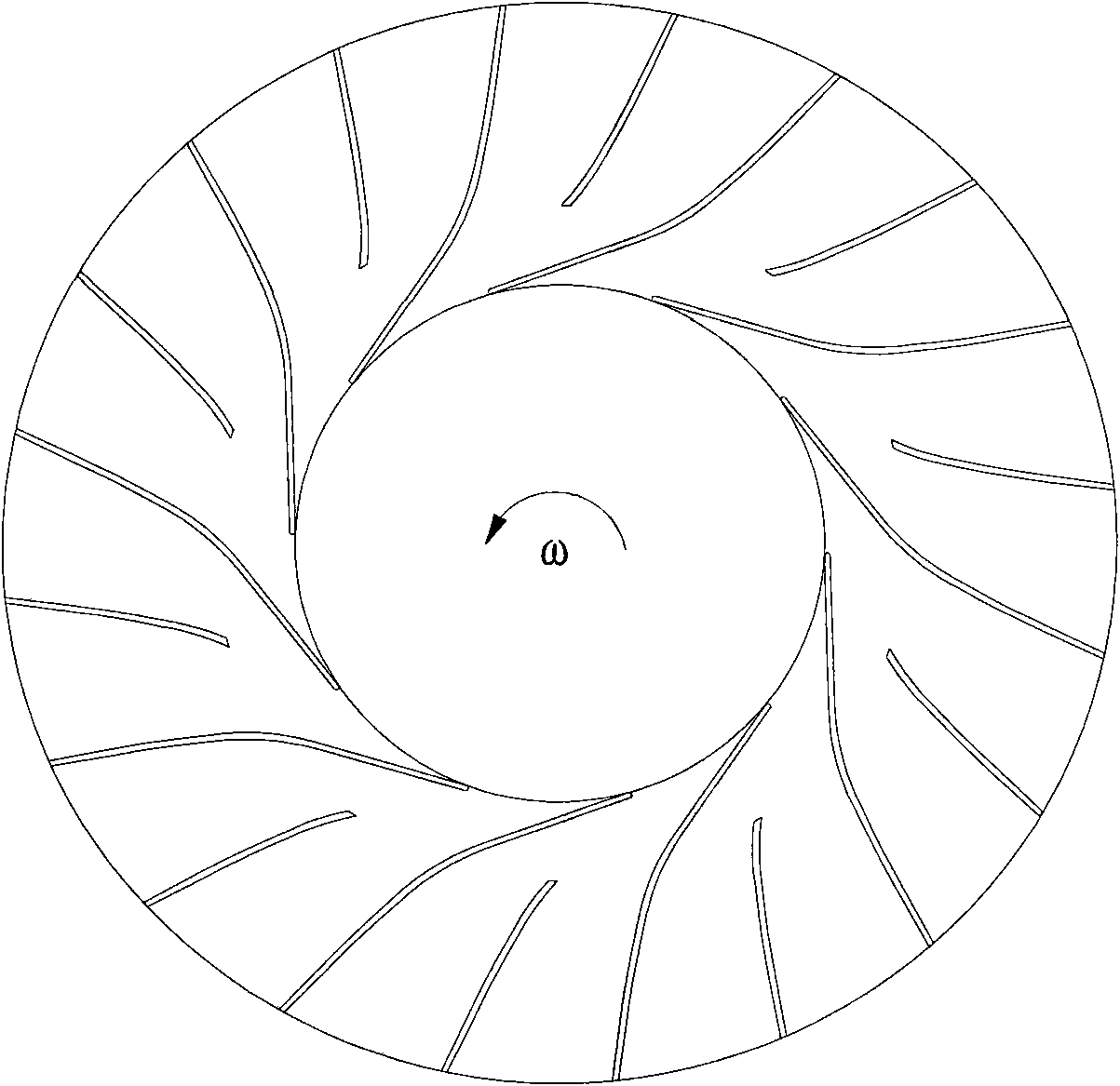

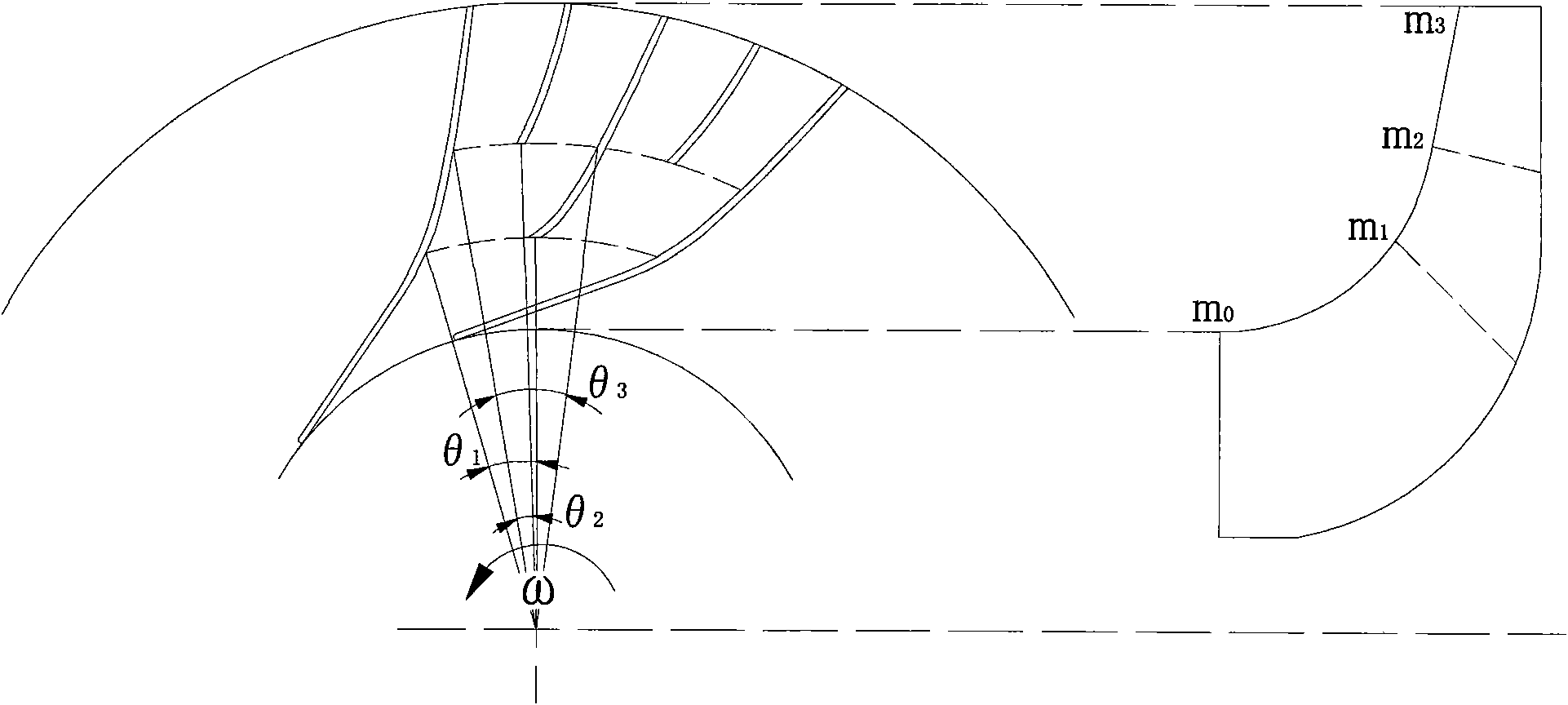

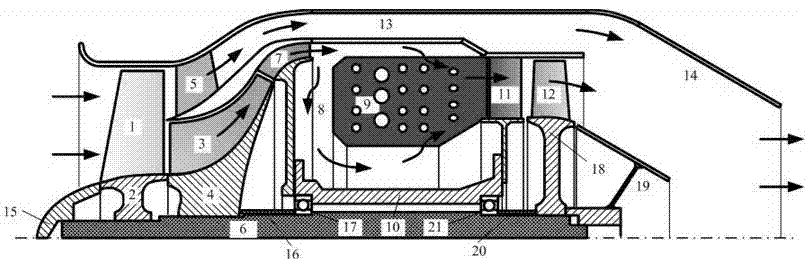

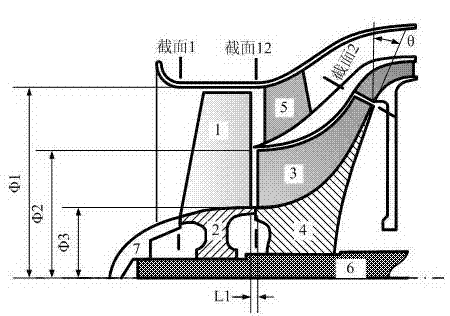

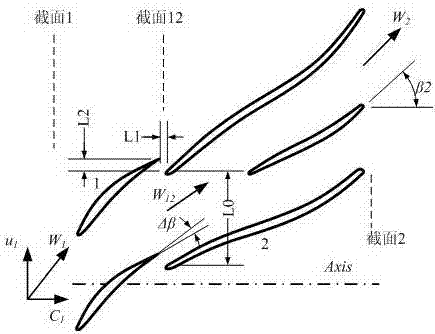

Secondary splitter blade type centrifugal impeller

InactiveCN101598138AImprove mobilityImprove flow efficiencyPump componentsPumpsImpellerAerodynamic load

The invention discloses a secondary splitter blade type centrifugal impeller, comprising a long blade extending from impeller inlet to impeller outlet. The suction surface of the long blade and the pressure surface of an adjacent long blade form a complete air flow passage; wherein a middle blade is arranged between the two long blades to form a primary splitter blade; the two sides of the middle blade are respectively provided with a short blade to form a secondary splitter blade; the inlet of the middle blade deflects toward the suction surface in the air flow passage; the inlet at the wheel disc side of the short blade deflects towards the suction surface in the air flow passage, and the inlet at the wheel cap of the short blade deflects towards one side of the pressure surface in the air flow passage; the number ratio of the long, middle and short blades is 1:1:2; and the long, middle and short blades are evenly distributed at the periphery of the outlet of the impeller. The centrifugal impeller of the invention gradually increases splitter blades, and can effectively allocate blade passage gas flow and blade aerodynamic load, improve flow uniformity at the impeller outlet and improve pressurizing capacity and steady operation range of the centrifugal impeller.

Owner:XI AN JIAOTONG UNIV

Myoelectricity-controlled exoskeleton assistant robot

InactiveCN105476822AIncrease contraction forceImprove athletic abilityDiagnosticsWalking aidsHuman bodyHigh energy

The invention discloses a myoelectricity-controlled exoskeleton assistant robot. The robot comprises an air source, a left leg, a right leg, a waist fixing device and a control device; the upper end of the left leg and the upper end of the right leg are fixed to the waist fixing device and symmetrically arranged on the two sides of the waist fixing device; the control device is fixed to the waist fixing device. The robot analyzes the movement demand of a wearer by collecting surface electromyogram signals of the legs to control pneumatic muscles to simulate the activity of muscles of a human body, and assists in movement of the wearer on the basis of fully understanding the movement intention of the wearer to avoid discomfort and even hurt caused by forced movement. The pneumatic muscles with low weight, a high energy conversion rate and good smoothness are used as actuators and directly installed between all joints of the human body to provide assistant power for the wearer. The robot is simple in structure, safe, smooth and fit for the physiological characteristics of the human body, and the comfort level is increased obviously.

Owner:HEBEI UNIV OF TECH

Rolling and cutting metal plate shearing machine

The present invention belongs to the field of metal plate shearing technology, and is especially hydraulic rolling and cutting metal plate shearing machine. The metal plate shearing machine includes hydraulic cylinders, one transmission mechanism and one shearing mechanism; and features two hydraulic cylinders hinged horizontally on the frame, two piston rods, two link rods, two push rod and the upper shearing edge holder hinged successively, and one guide rod hinged between the upper shearing edge holder and the frame. The present invention has the advantages of simplified mechanism, simple and reliable transmission system and greatly raised sheared section quality.

Owner:TAIYUAN HEAVY IND SCI & TECH +1

Single rotor minitype turbofan engine adopting axial flow oblique flow serial composite compressing system

ActiveCN103161608AIncrease the overall boost ratioImproved thermodynamic cyclePump installationsJet propulsion plantsImpellerCombustion chamber

The invention provides a single rotor minitype turbofan engine adopting an axial flow oblique flow serial composite compressing system. The structure of the single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system is that airflow of an outer duct of a turbofan engine and the airflow which enters into a combustor of an inner duct are both supplied by the axial flow oblique flow serial composite compressing system, the axial flow oblique flow serial composite compressing system adopts a combination of both an axial flow fan rotor and an oblique flow compressor rotor, and provides pressure boosting airflow for both the inner duct and the outer duct. The serial axial flow fan rotor is relative to the portion of the inner duct, and directly forms an oblique flow compressor impeller to a serial blade lattice form; a row of stator impellers is arranged on the axial flow fan rotor corresponding to the portion of the outer duct, the air flow is adjusted to the rear direction of the meridian plane through rectification deceleration, and flows into a turbofan engine outer duct bypass along the outer surface of an intermediary cartridge receiver. The single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system has the advantages of being capable of realizing to provide the pressure boosting airflow for the inner duct and the outer duct by the needs of the turbofan engine, lowering an oil consumption rate of the engine, improving windward side thrust of each unit of the engine, and effectively improving voyage and enhancing load when the single rotor minitype turbofan engine adopting the axial flow oblique flow serial composite compressing system is applied in carriers of unmanned planes, loitering munitions, and the like.

Owner:南京凌日星能源科技有限公司

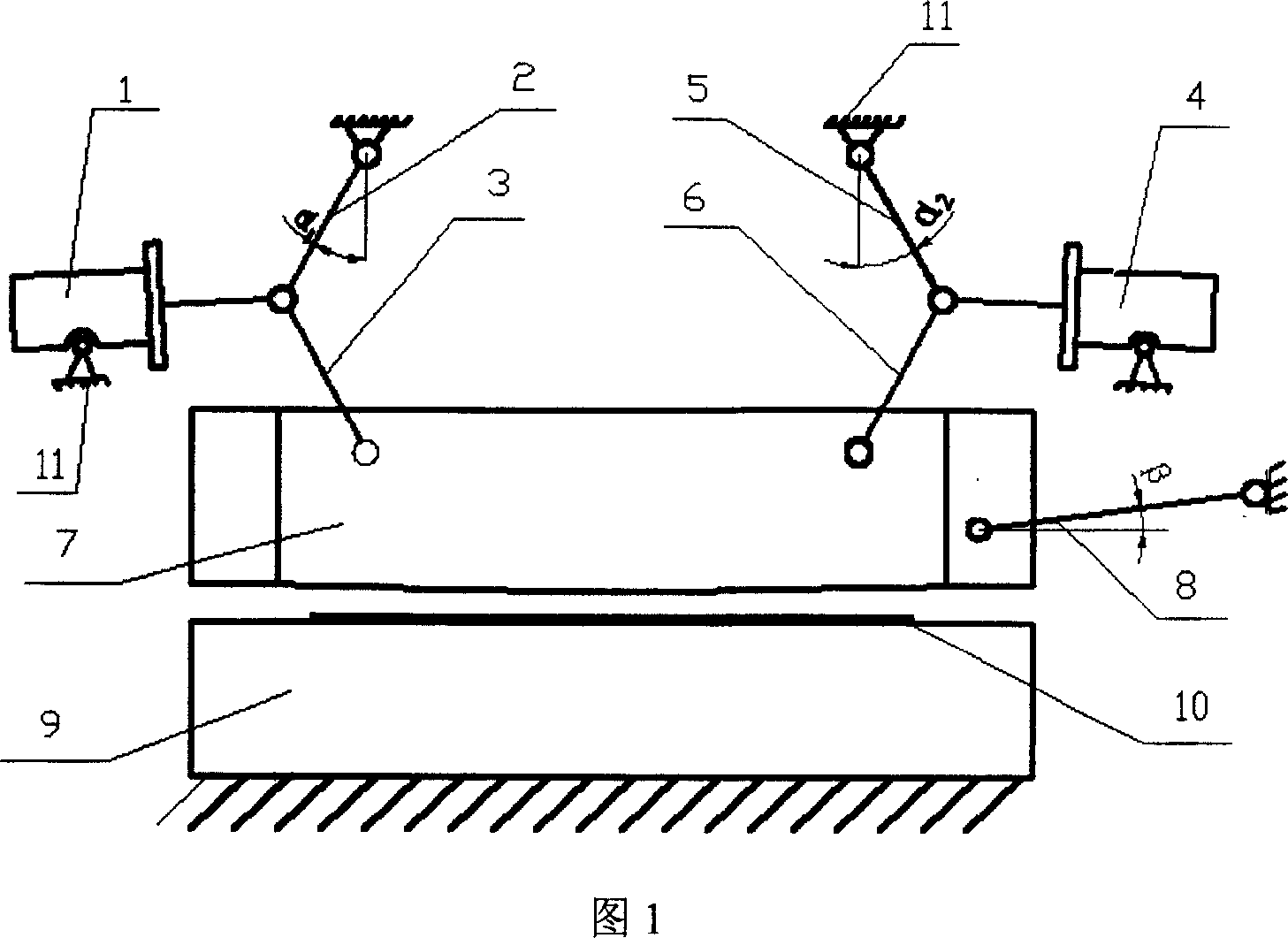

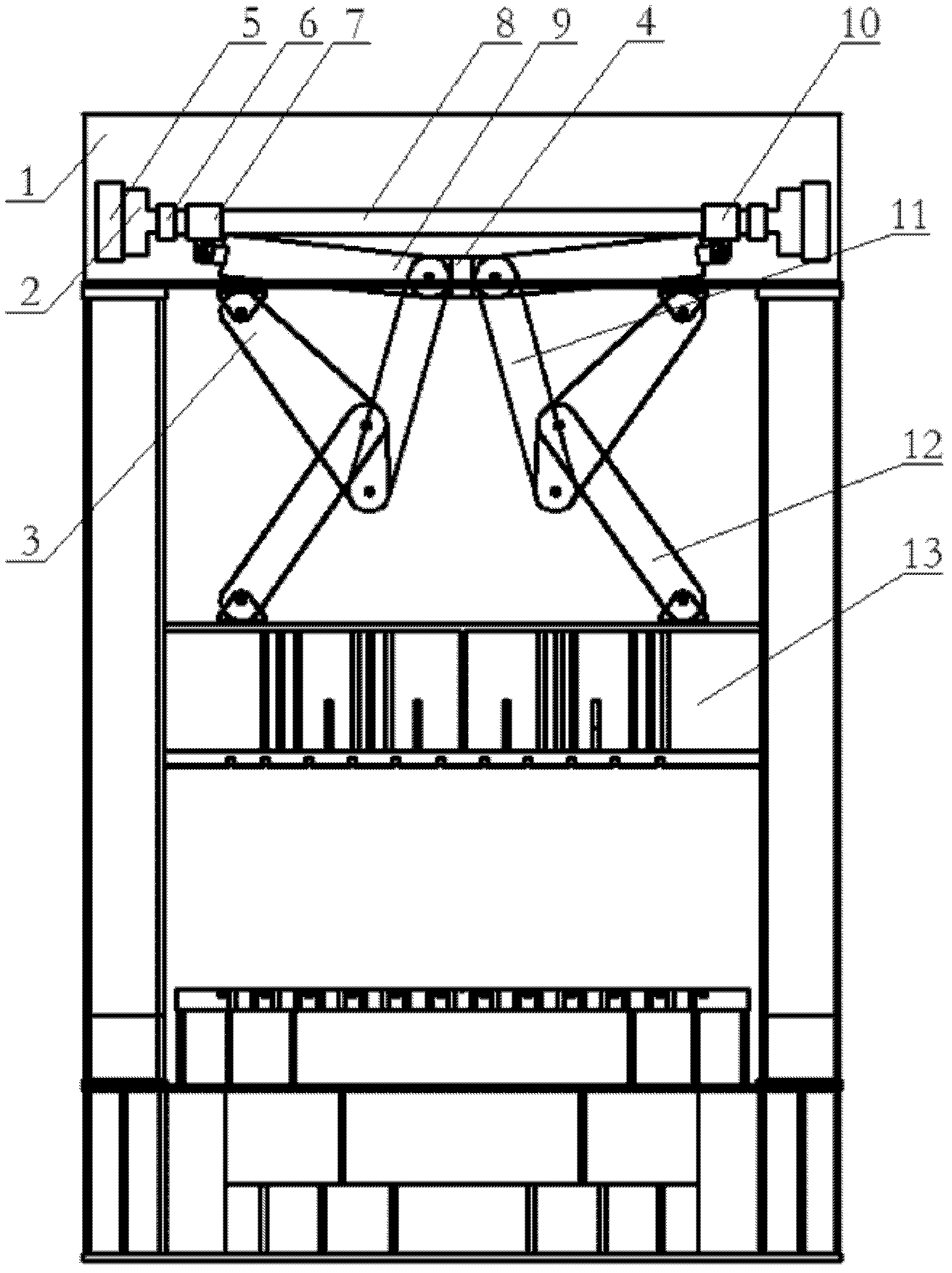

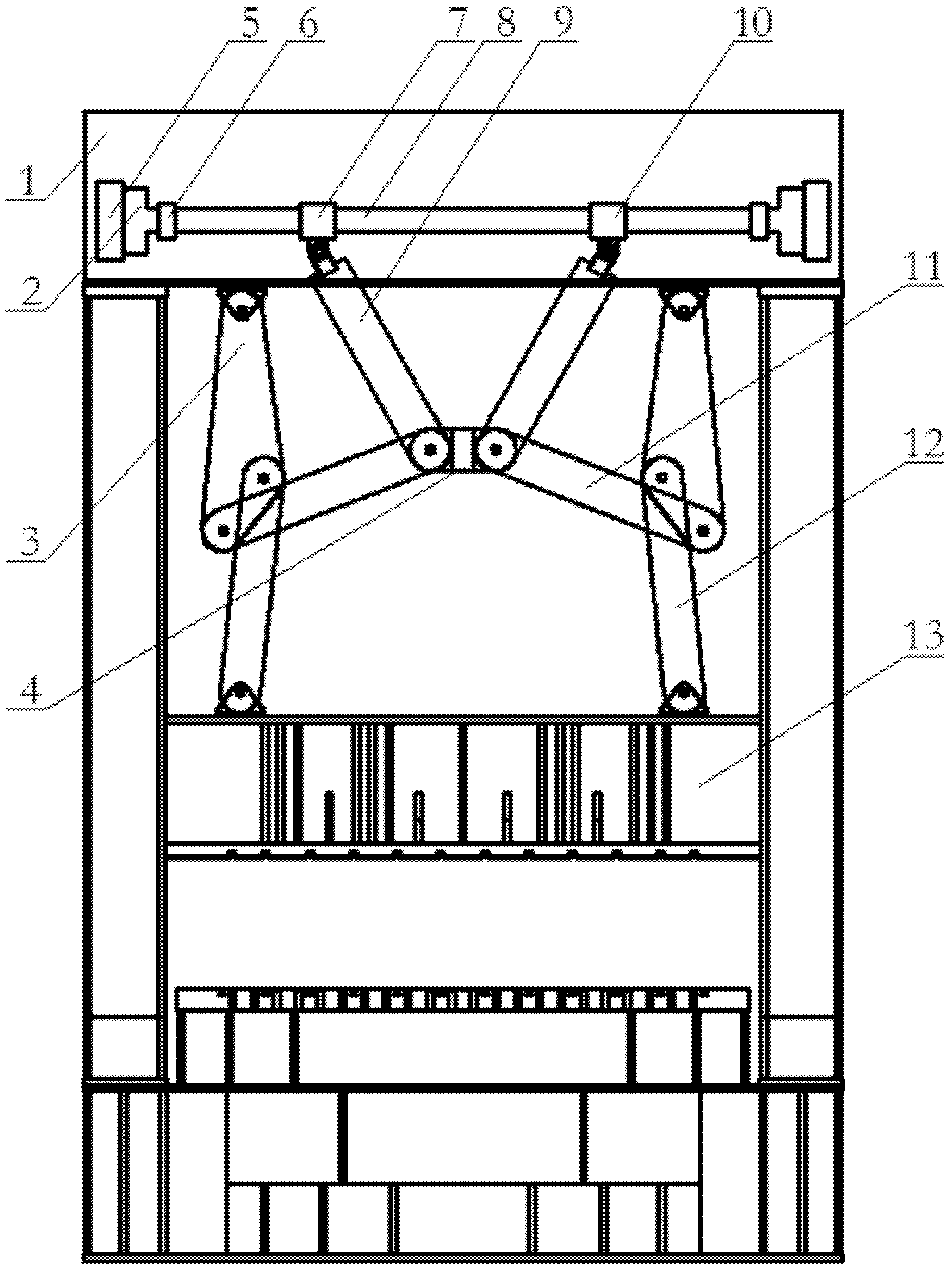

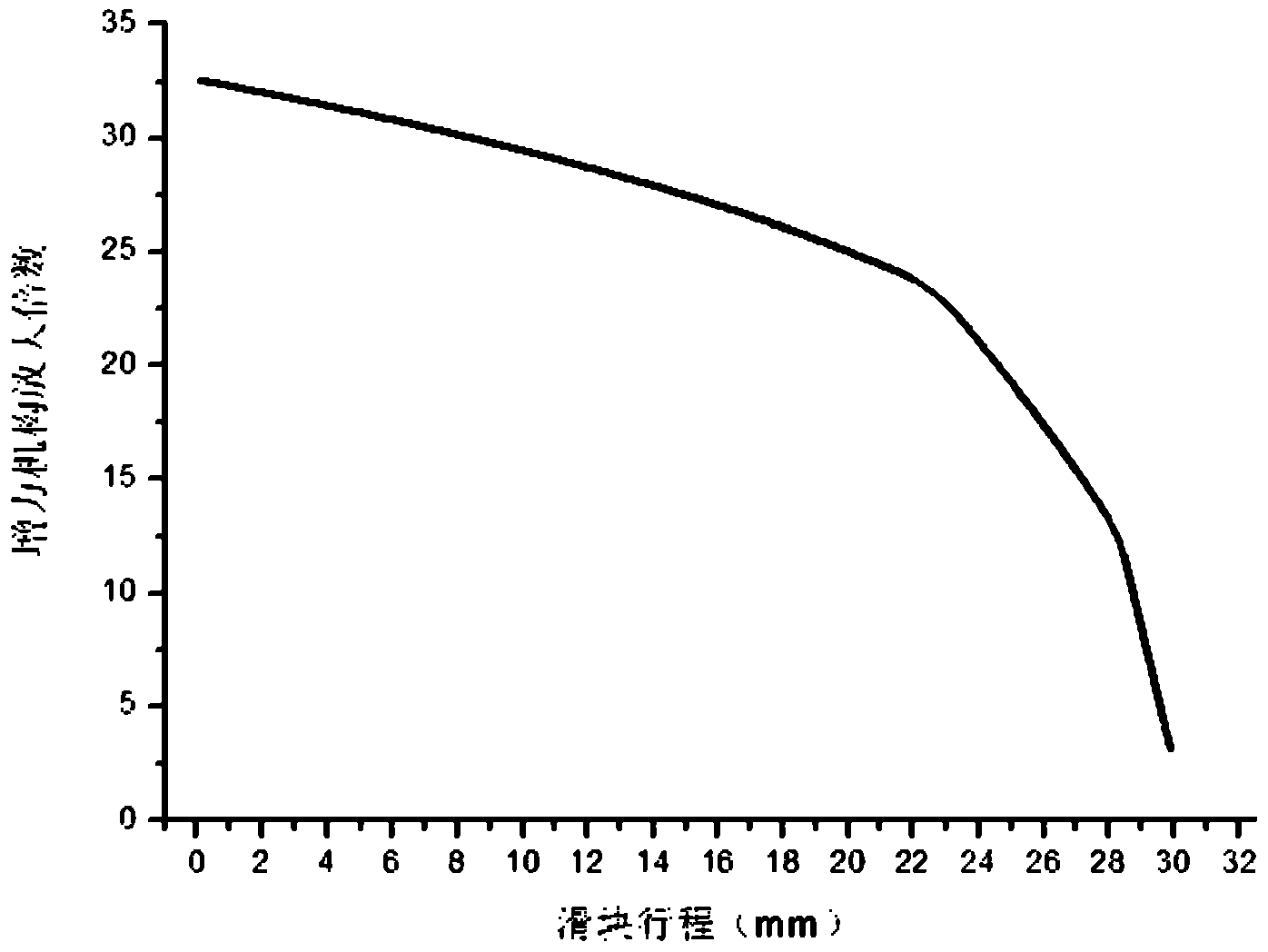

Transmission system suitable for large-tonnage alternating current servo press

ActiveCN102320153AOvercome the disadvantage of small magnificationLow powerGearingPressesThree levelBall screw

The invention discloses a transmission system suitable for a large-tonnage alternating current servo press. The output shaft of a disk-type permanent magnet synchronous servo motor and a planet gear speed reducer are made into integral structure; the screw of a driving mechanism and two nuts arranged on the nut form a ball screw structure; the screw is connected with the planet gear speed reducer; the left and the right of a top bar as well as the front and the back of the top bar are symmetrically provided with double toggle rod boosting mechanisms; a symmetrical oscillating rod input type boosting mechanism is arrange between the top bar and the double toggle rod boosting mechanisms; a three-level boosting mechanism causes the amplification multiple of the boosting mechanisms in the beginning stage to be above 15 times; and the amplification multiple is bigger and bigger along with the shaping process to lower the power of the disk-type permanent magnet synchronous servo motor. The transmission system can provide large amplification multiple and has the advantages of obvious boosting effect, large effective boosting travel, small integral structural size, big sliding block travel, quick virtual travel, high working efficiency, quick feeding, low shaping speed and the like, and unbalance loading is simultaneously eliminated.

Owner:XI AN JIAOTONG UNIV

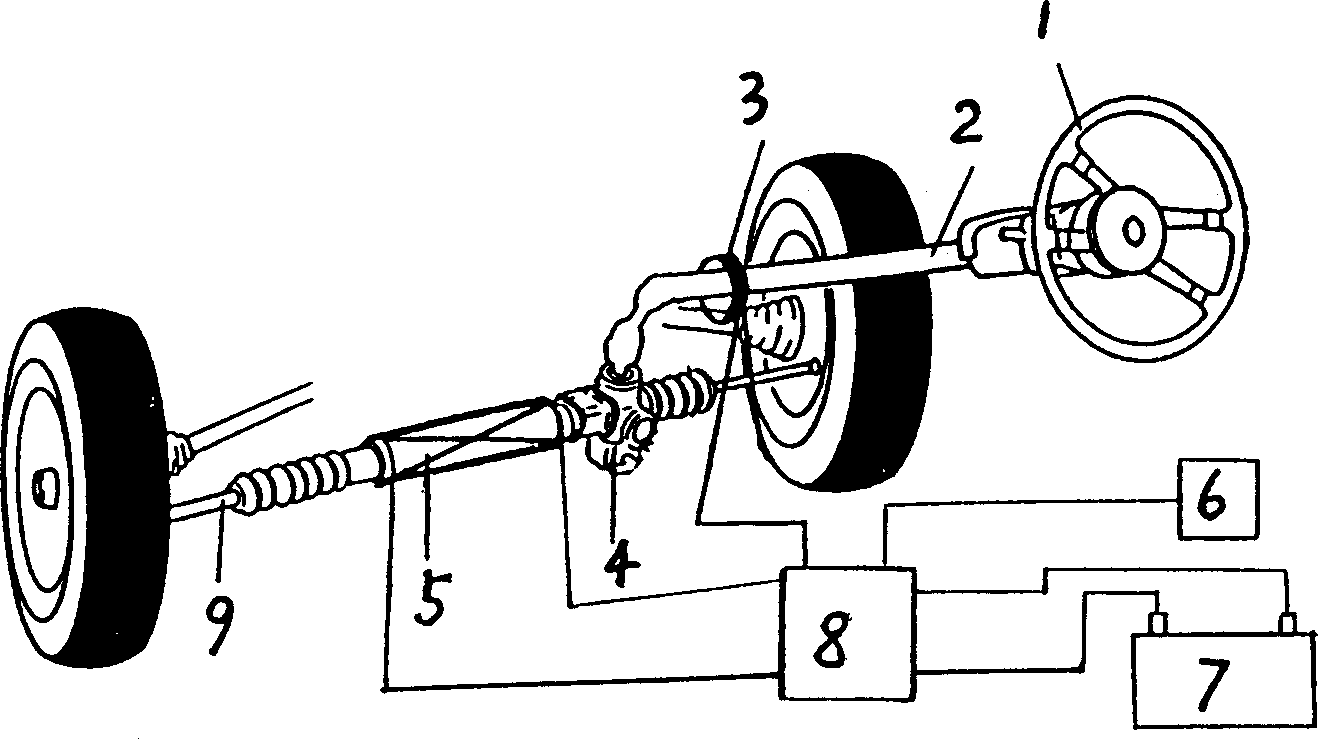

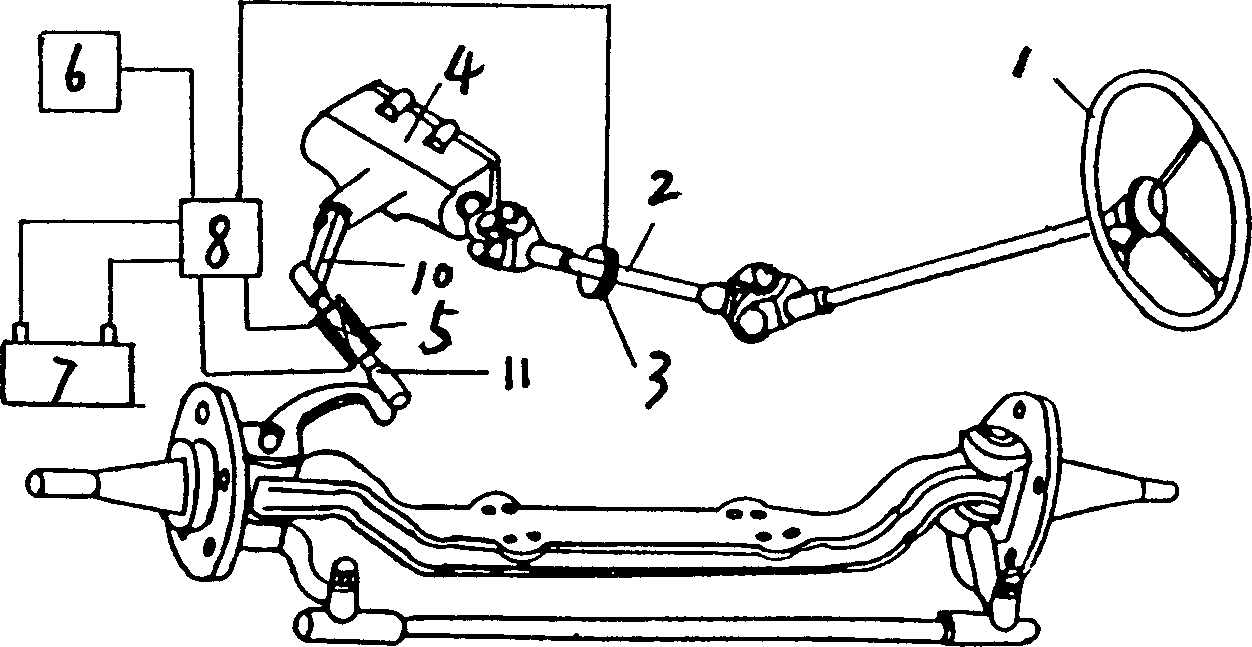

Electromagnetic steering booster of vehicle

InactiveCN1439560AAppropriate road feelSimple structureSteering linkagesAutomatic steering controlSteering wheelControl theory

An electromagnetic steering booster of car is composed of speed sensor, control module, power supply, and angle displacement sensor for steering wheel, and features that said control module is electrically connected to all others. Its advantages are simple structure, low cost, high reliability and saving energy.

Owner:WUHAN UNIV OF TECH

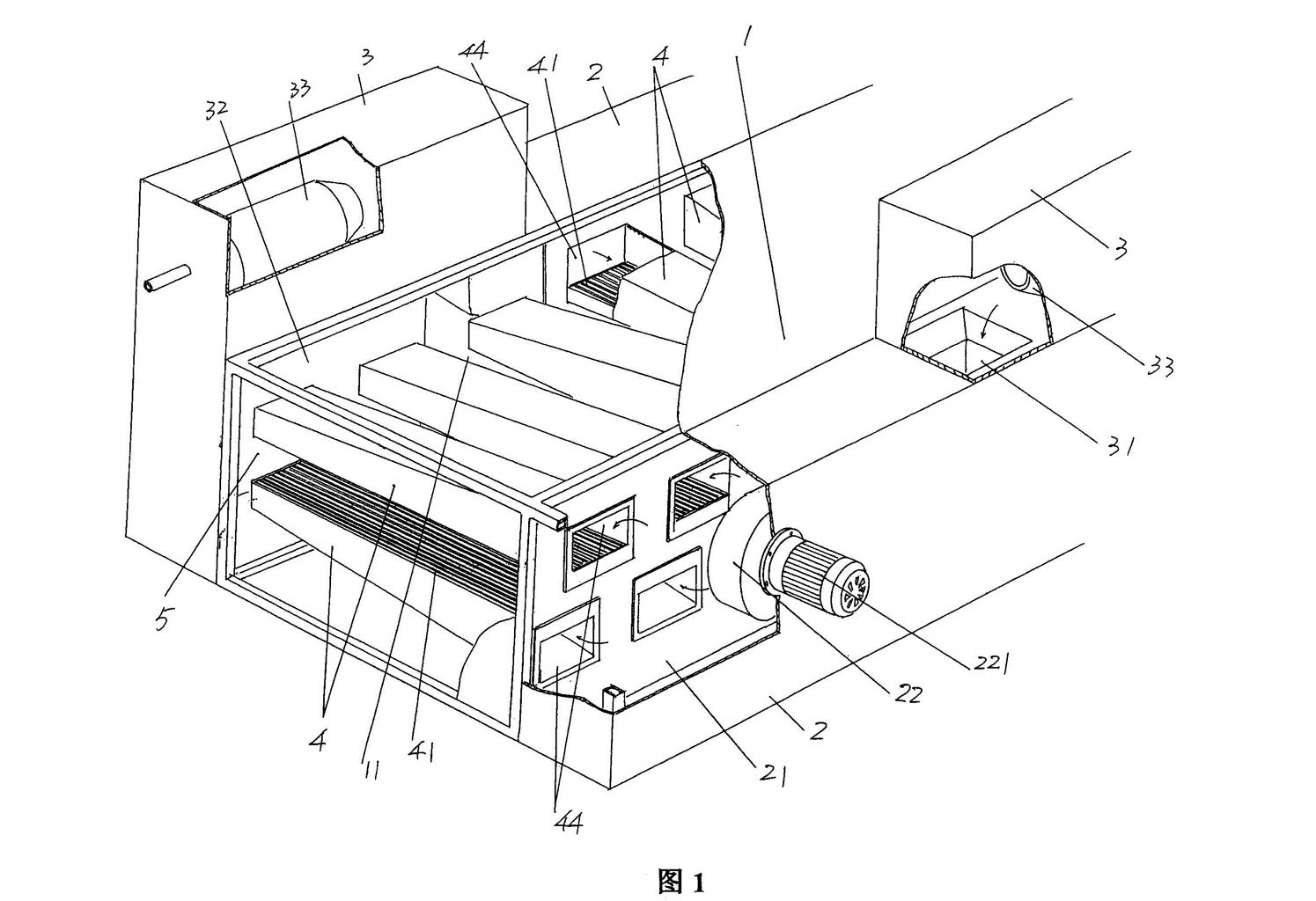

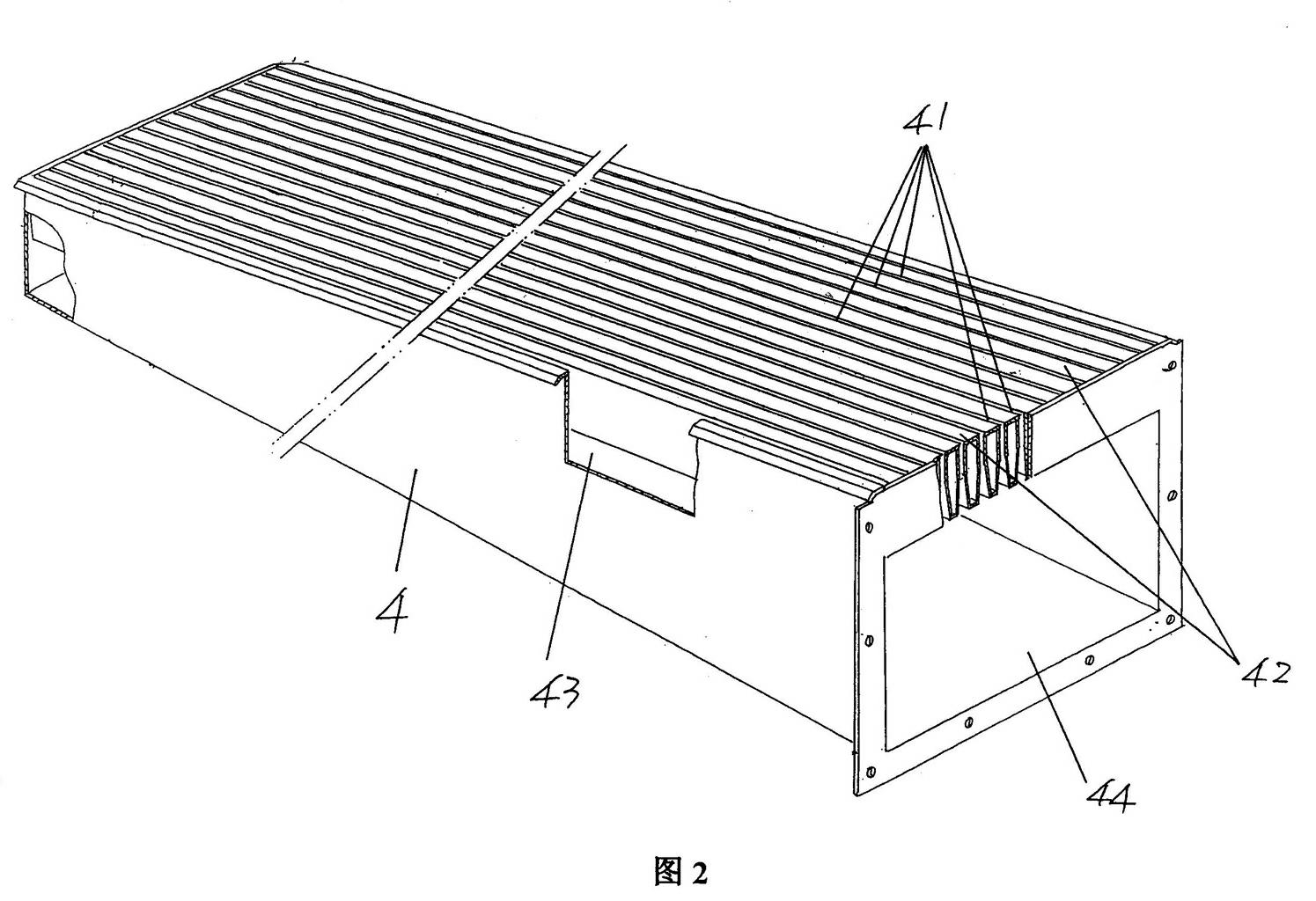

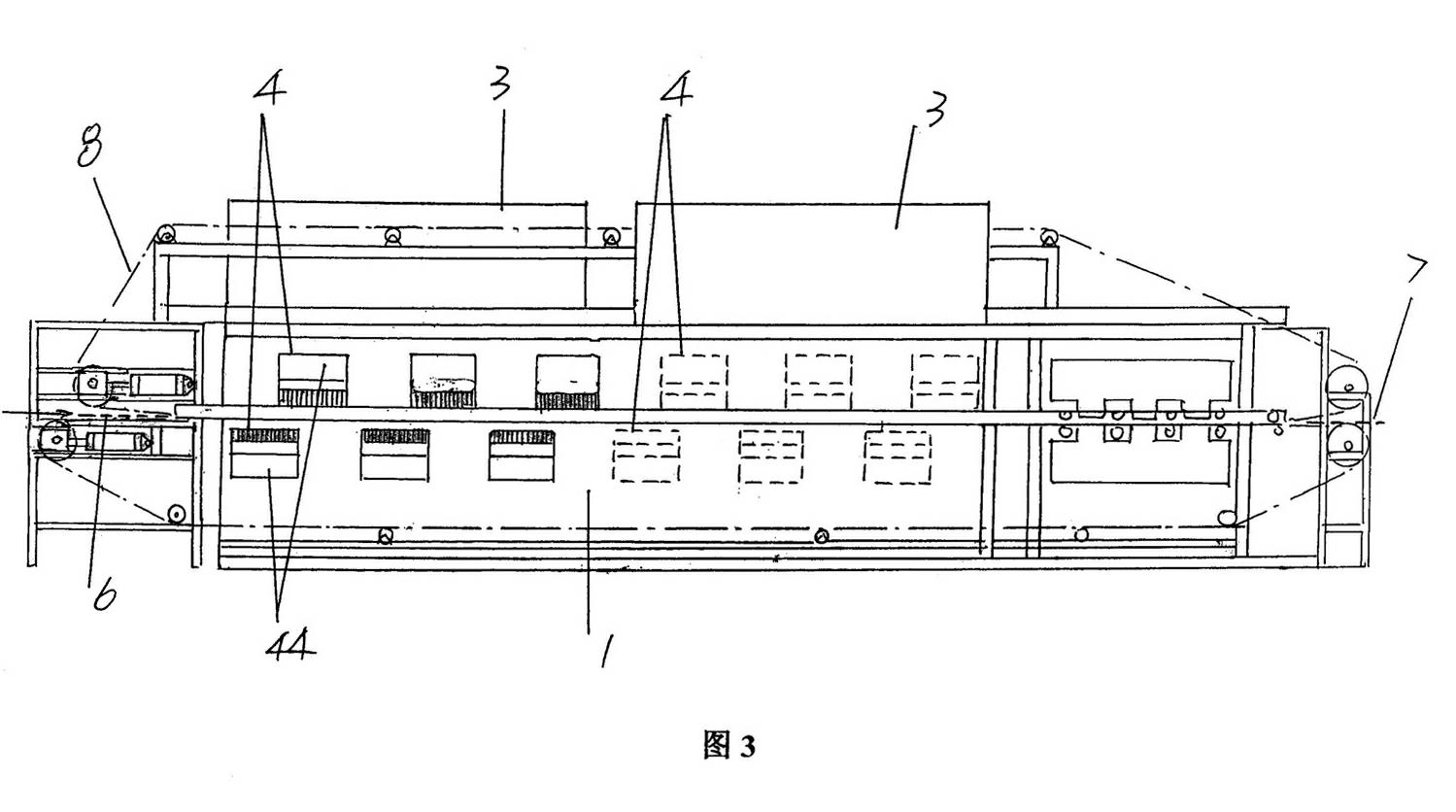

Hot air drying box

ActiveCN102384639AStrong penetrating powerReduce consumptionDrying gas arrangementsDrying machines with progressive movementsThermodynamicsNonwoven fabric

The invention relates to a hot air drying box, and belongs to the technical field of nonwoven machines. The hot air drying box comprises a box body, a hot air chamber and a combustion chamber which are arranged on two sides of the box body and are provided with fans, and two groups of hot air lead-out pipes which are arranged in a box body cavity. The hot air drying box is characterized in that each group comprises the same number of hot air lead-out pipes which are arranged at intervals to form upper and lower rows; a fabric guiding cavity is formed between the hot air lead-out pipes on the upper and lower rows; air outlet channels positioned on the hot air lead-out pipes on the upper row are downward, air outlet channels positioned on the hot air lead-out pipes on the lower row are upward, and the adjacent air outlet channels are partitioned by air flue partition pipes; each air flue partition pipe is contracted gradually towards the direction of pipe cavities of the hot air lead-out pipes and forms a structure of which the cross section is in a trapezoidal shape; and the widths of the air outlet channels are reduced towards the direction away from the pipe cavities from the pipe cavities. The hot air drying box has the advantages that an ideal hot drying effect can be achieved, the non-uniform heating phenomenon is avoided, large-thickness nonwoven fabrics or cotton fleeces are easy to penetrate, and the consumption of energy is reduced.

Owner:常熟市伟成非织造成套设备有限公司

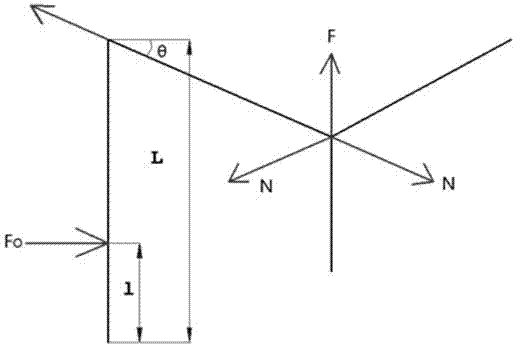

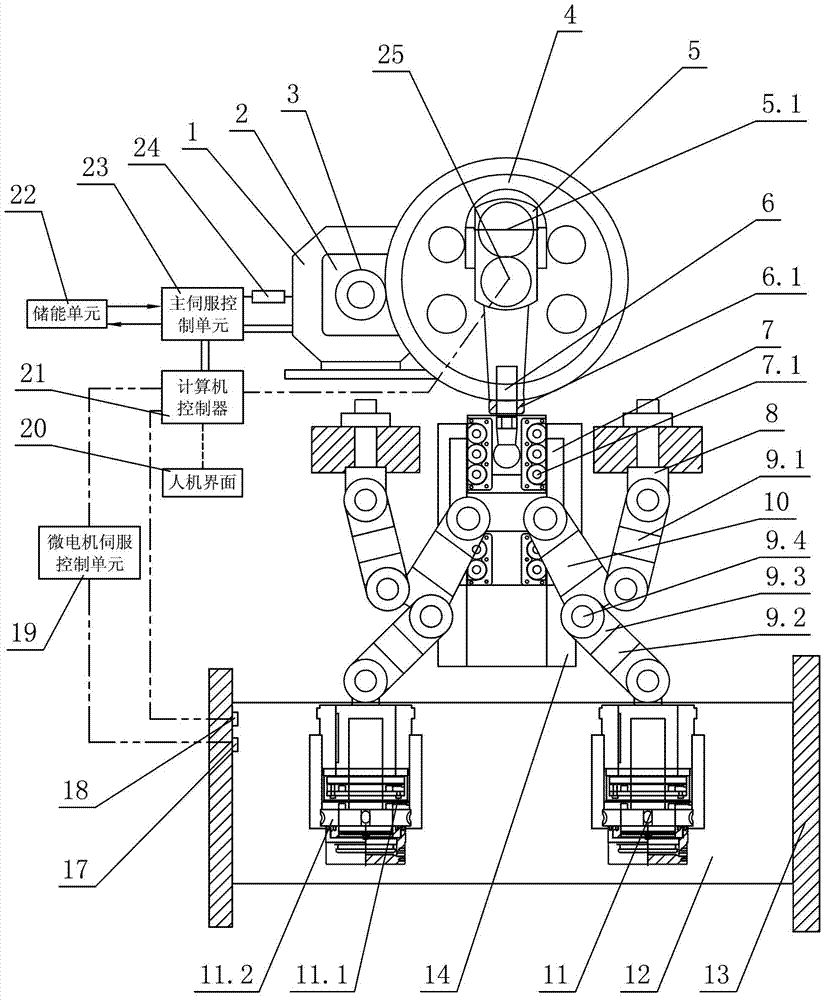

Multifunctional servo crank knuckle-lever press

A multifunctional servo crank knuckle-lever press comprises a servo motor, a crankshaft, a connecting rod, a ram, a sliding block body and a control system, wherein the servo motor is connected with the crankshaft through a speed-reducing mechanism in a driving mode, a crank of the crankshaft is connected with a rotary bearing at the upper end of the connecting rod, the lower end of the connecting rod is hinged to the center of the ram through a bulb screw rod, and the ram is hinged to a symmetrical knuckle lever structure. The symmetrical knuckle lever structure is composed of a triangular connecting rod, an upper knuckle lever and a lower knuckle lever, wherein three angle ends end of the triangular connecting rod are respectively provided with a pin hole, are large semicircular column bodies, and are hinged to semicircular square bearing bushes arranged on an upper knuckle lever and a lower knuckle lever through pin shafts, and the upper knuckle lever and the lower knuckle lever are hinged to an upper support of a machine body and a lower support of the sliding block body respectively. According to the multifunctional servo crank knuckle-lever press, the servo control system controls the servo motor to drive the sliding block to make vertical reciprocating motion operations, different punching curves are achieved through preset control programs according to different processes, and multifunctional punching operations such as blanking, silent punching, tensioning and fine press forming and stamping are carried out.

Owner:广东宏兴机械有限公司

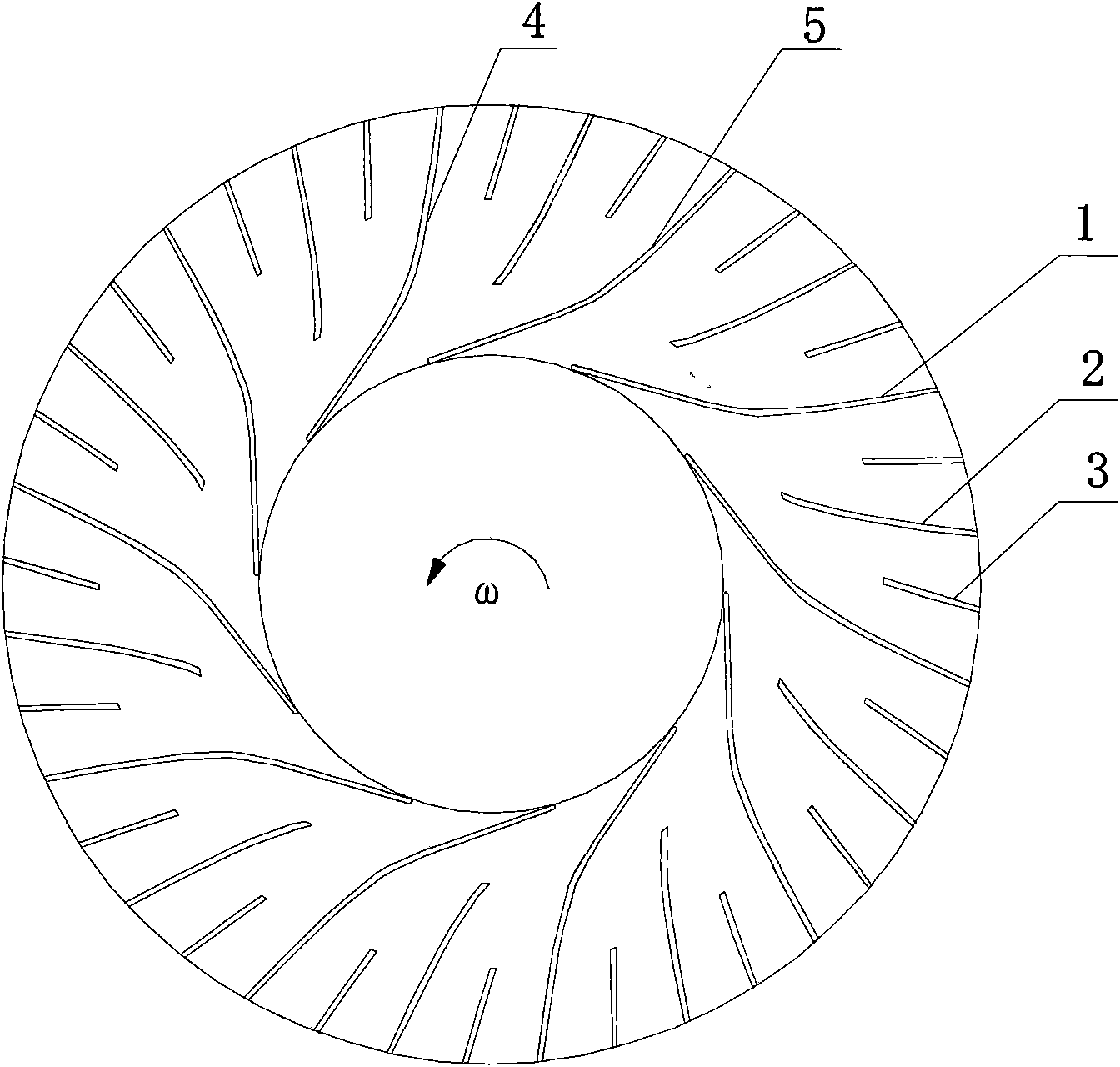

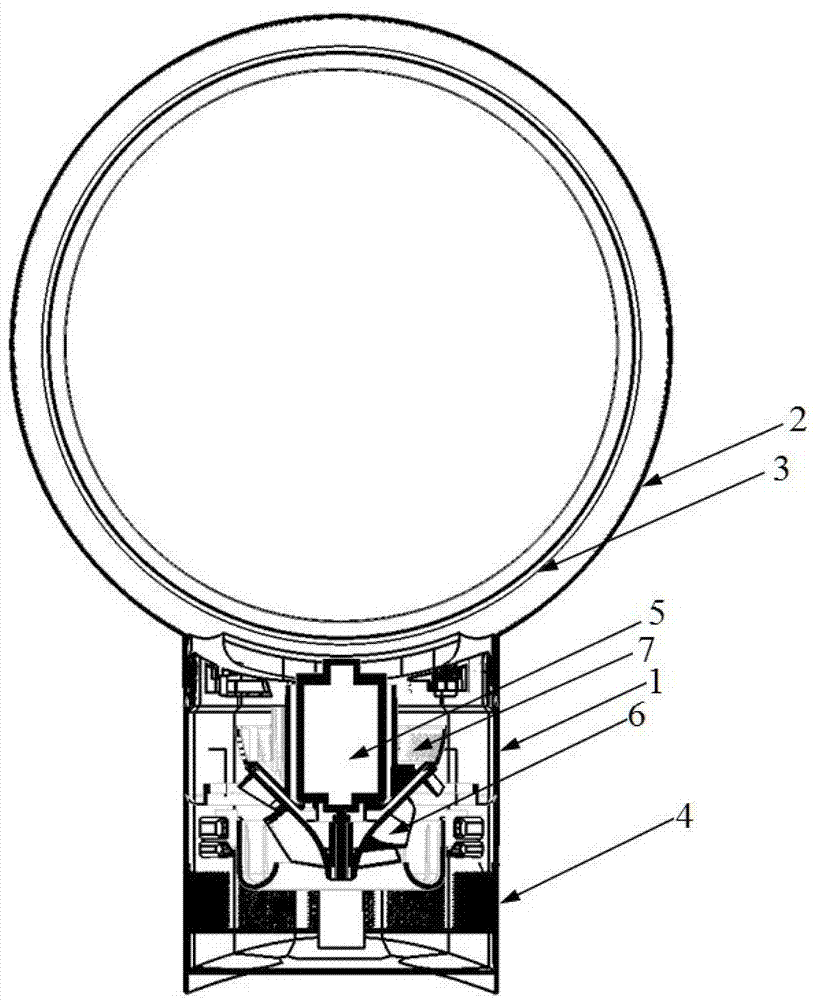

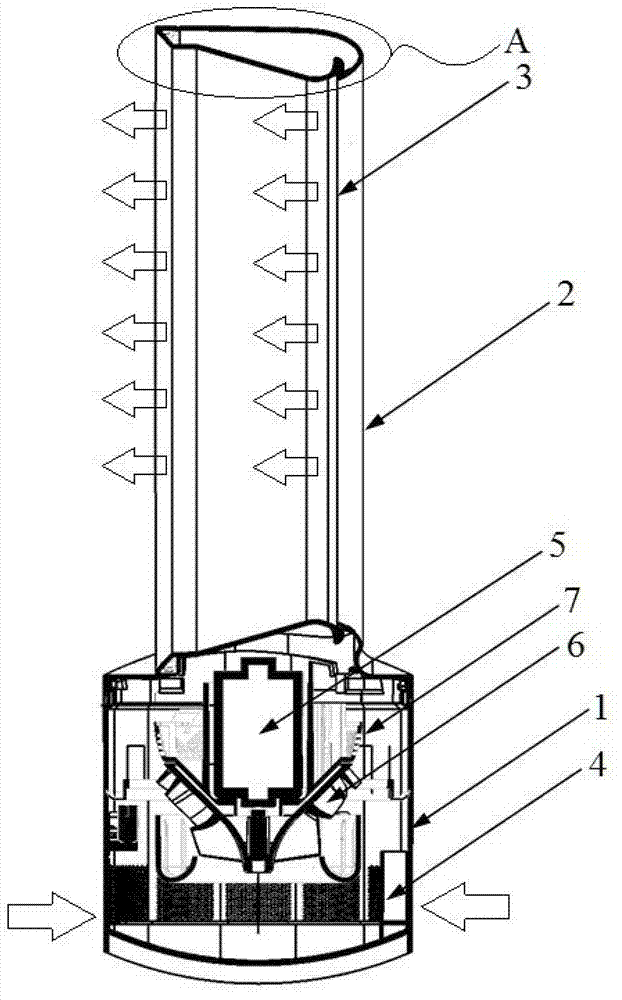

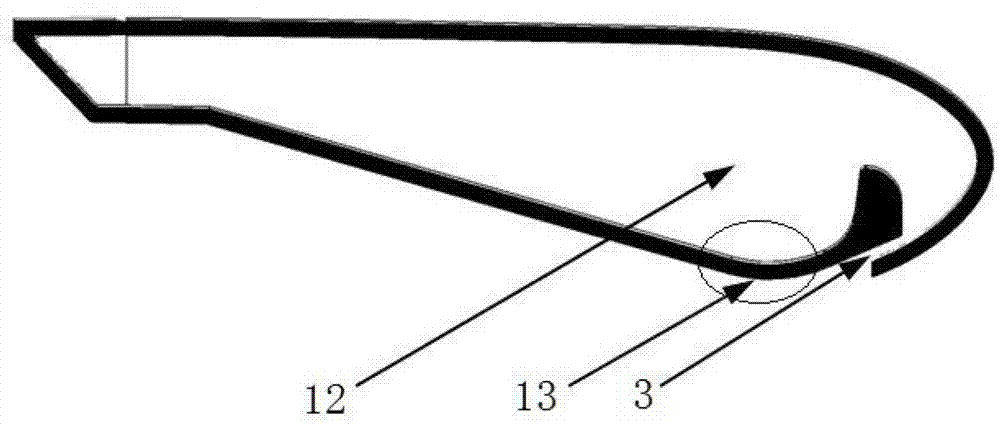

Bladeless fan turbine device with splitter blades

The invention discloses a bladeless fan turbine device with splitter blades. The bladeless fan turbine device with the splitter blades comprises a motor, a motor fixing device, a splitter blade turbine and an outer ring wall. A motor rotating shaft penetrates through the motor fixing device and is connected with the inner side of the inner ring wall of the splitter blade turbine. The inner side of the outer ring wall is sleeved on the splitter blade turbine. The splitter blade turbine comprises the inner ring wall, long blades and splitter blades, wherein the long blades are arranged in the peripheral direction of the inner ring wall, the splitter blades are located between every two adjacent long blades respectively and are distributed on the inner ring wall in the peripheral direction, the outlet diameters of the splitter blades equal those of the long blades, and the inlet diameters of the splitter blades differ from those of the long blades. The bladeless fan turbine device with the splitter blades is located in a bladeless fan base. Pressurizing ability and pressurizing efficiency of the bladeless fan turbine device with the splitter blades are effectively improved, service life of the bladeless fan turbine device with the splitter blades is prolonged, and therefore air-out amount of a bladeless fan is increased, operation stability is improved, noises of the bladeless fan are reduced, overall performance of the bladeless fan is improved, and the bladeless fan has the advantages of saving energy and protecting the environment.

Owner:ZHEJIANG SCI-TECH UNIV

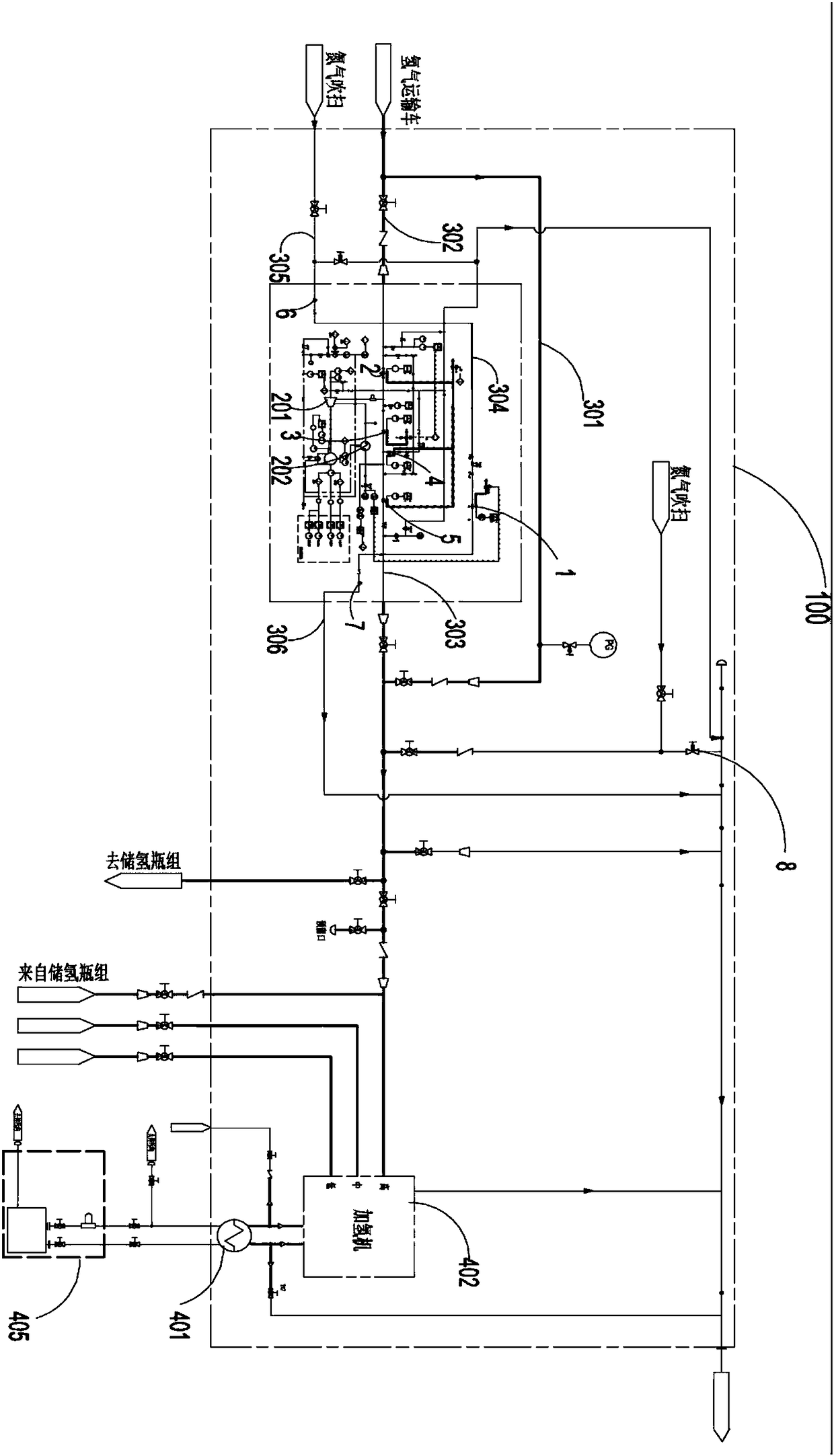

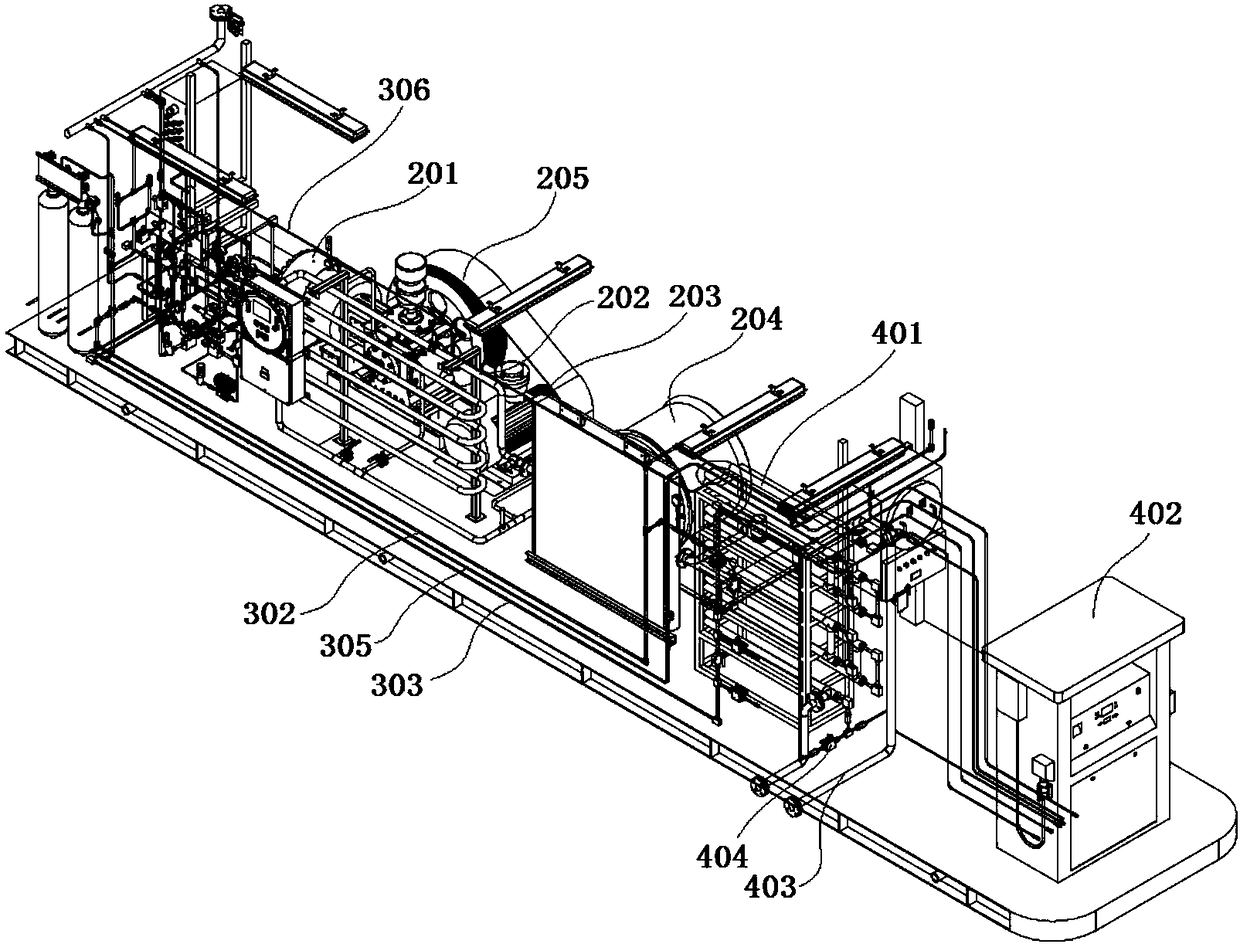

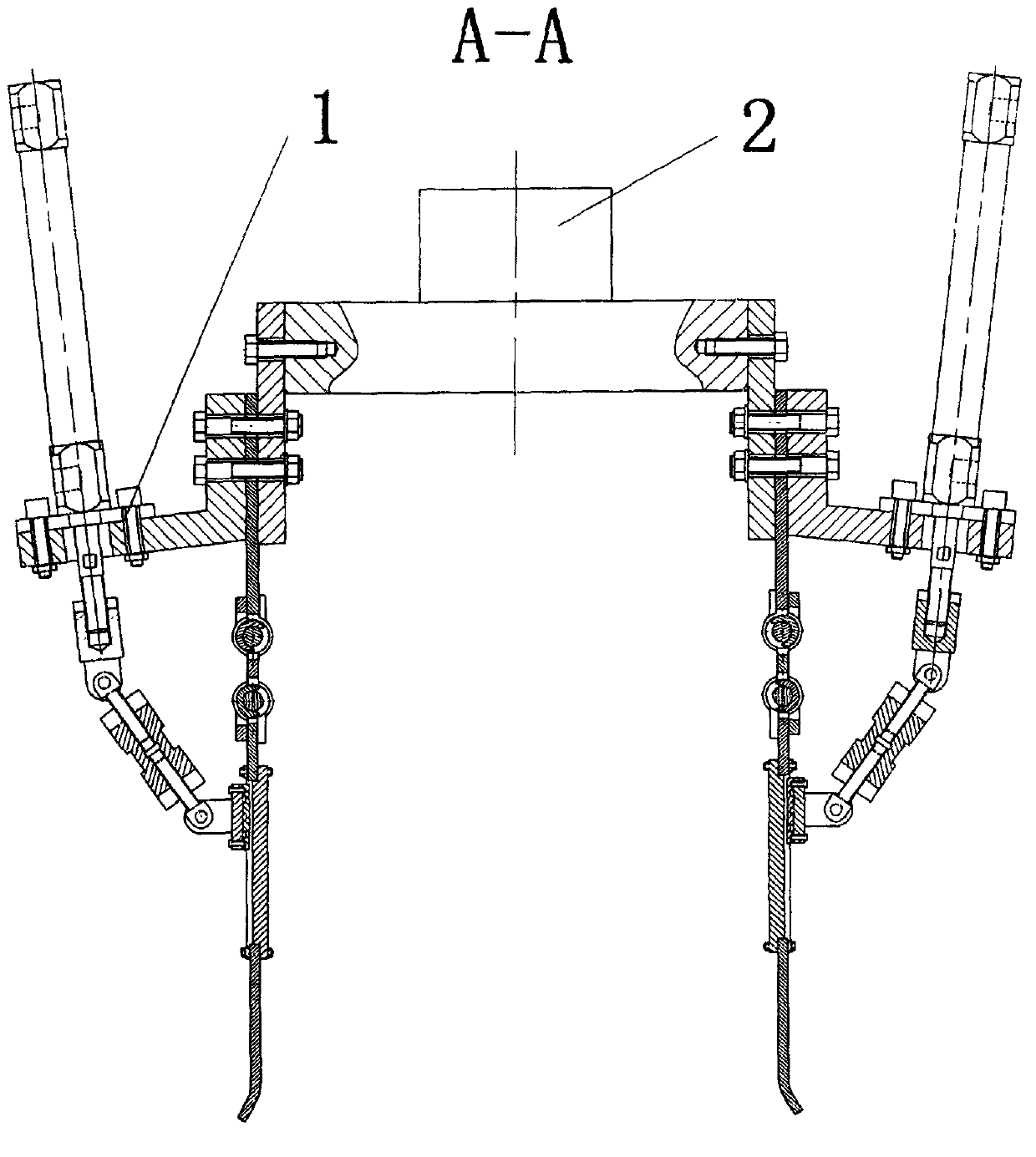

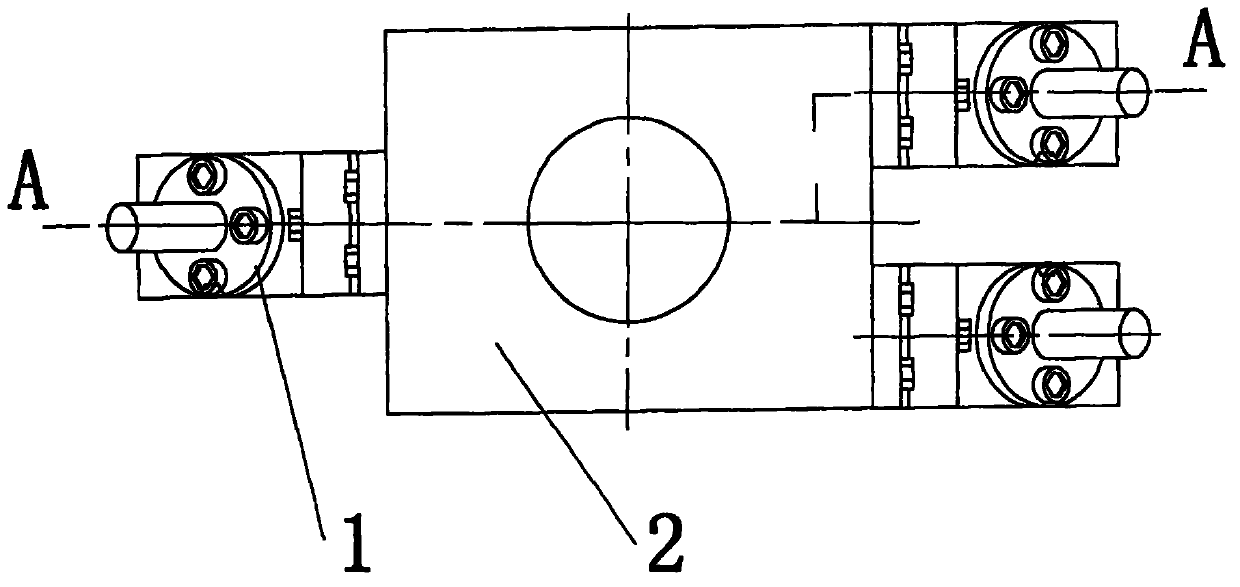

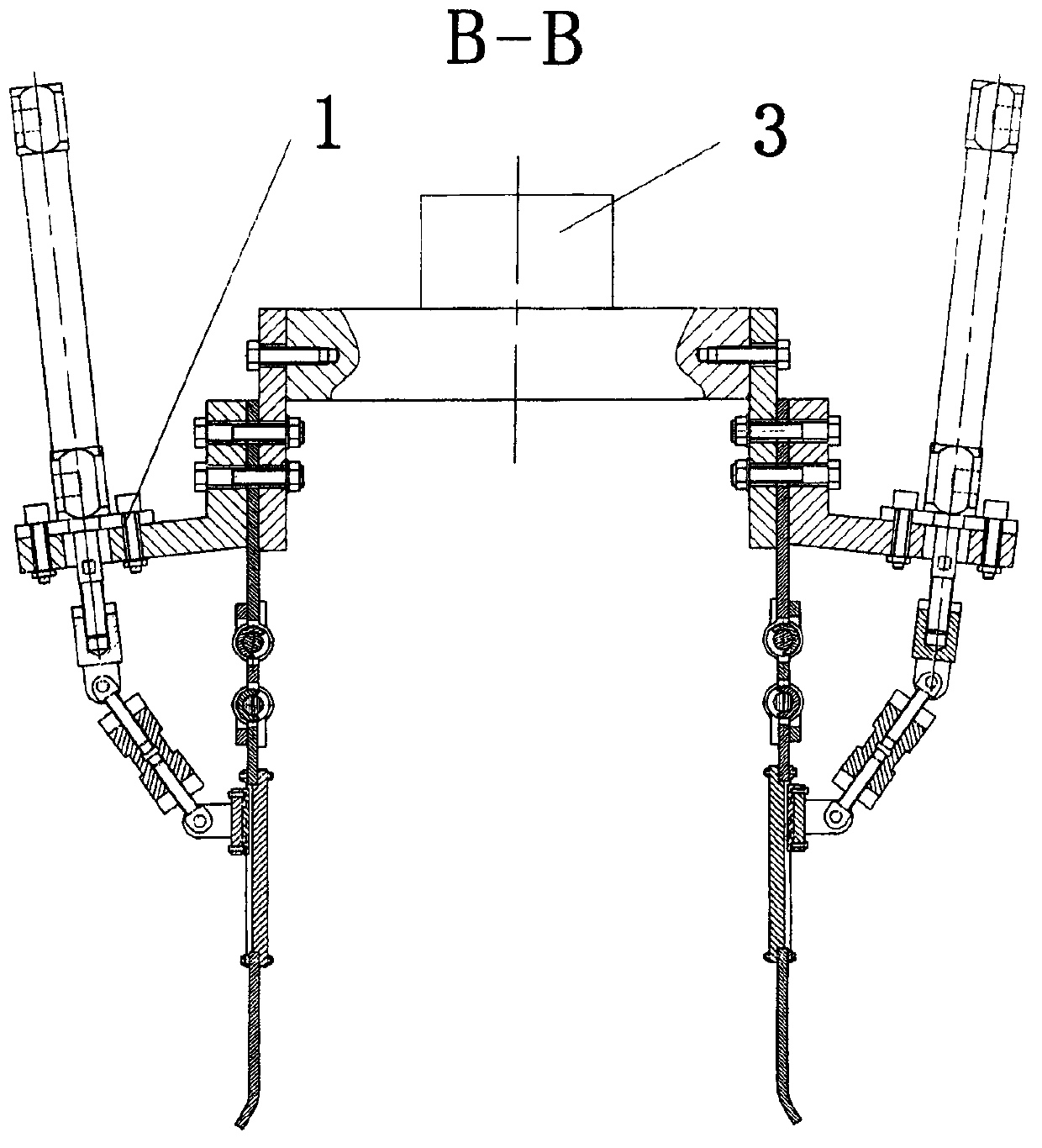

Hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and hydrogeneration method thereof

ActiveCN108361546ACompact structureSmall footprintVessel geometry/arrangement/sizeSecondary cellsProcess engineeringSmall footprint

The invention provides a hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and a hydrogenation method. The system comprises the following components arranged insidea skid-mounted shell: a pressurizing component, a hydrogen dispenser, a circulation loop and a controller, wherein a gas inlet of a diaphragm compressor in the pressurizing component is connected witha hydrogen inlet pipe, the end of the hydrogen inlet pipe is provided with an input end connected with a gas outlet of a hydrogen transporting truck, a gas outlet of the diaphragm compressor is connected with a hydrogen outlet pipe, and hydrogen in the hydrogen outlet pipe is cooled when flowing through a first cooling heat exchange element; a gas inlet pipeline of the hydrogen dispenser is connected with the hydrogen outlet pipe, and hydrogen in the gas inlet pipeline is cooled when flowing through a second cooling heat exchange element; one end of the circulation loop communicates with thehydrogen inlet pipe, and the other end of the circulation loop communicates with the hydrogen outlet pipe; and a first control valve, a second control valve and a third control valve which are used for controlling on and off of the pipelines are arranged on the hydrogen inlet pipe, the hydrogen outlet pipe and the circulation loop correspondingly, and are all connected with the controller. The whole hydrogeneration system is compact in structural arrangement, small in occupied area, and large in hydrogeneration capacity.

Owner:上海氢枫能源技术有限公司

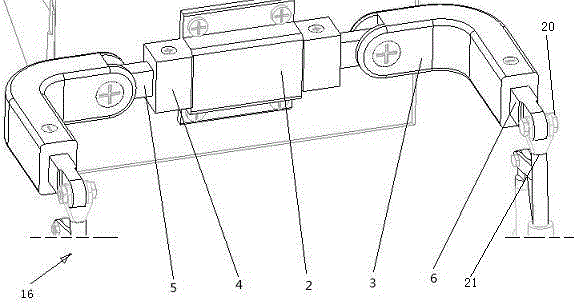

Self-locking boosting type flexible and smooth tail end gripper for serial connection loose hinge

ActiveCN104175325AKeep a safe gripSo as not to damageProgramme-controlled manipulatorGripping headsGrip forceSelf locking

The invention relates to a self-locking boosting type flexible and smooth tail end gripper for a serial connection loose hinge. The tail end gripper consists of a palm and three flexible fingers, wherein the palm is of two kinds of structures including a rectangular structure and a hexagonal structure, each flexible finger has the same structure and mainly consists of an inner guide air cylinder, a linear guide rail (which can also be a linear bearing) and the serial connection loose hinge, one torque spring is respectively arranged on a hinge mandrel of each serial connection loose hinge, the characteristic parameters and the pre-tightening angle of the torque springs are optimized and designed according to the characteristics of gripped objects, and the gripping force is generated through the driving of the air cylinder. The tail end gripper is applied to the gripping of fragile brittle objects or special-shape objects with variable shapes or sizes, belongs to the technical field of application of robots and mechatronics, is connected with a robot main body, and is particularly applicable to the fields of logistics and production such as gripping, sorting and packaging of food, farm products and light industrial products.

Owner:泰州市华驰不锈钢制品有限公司

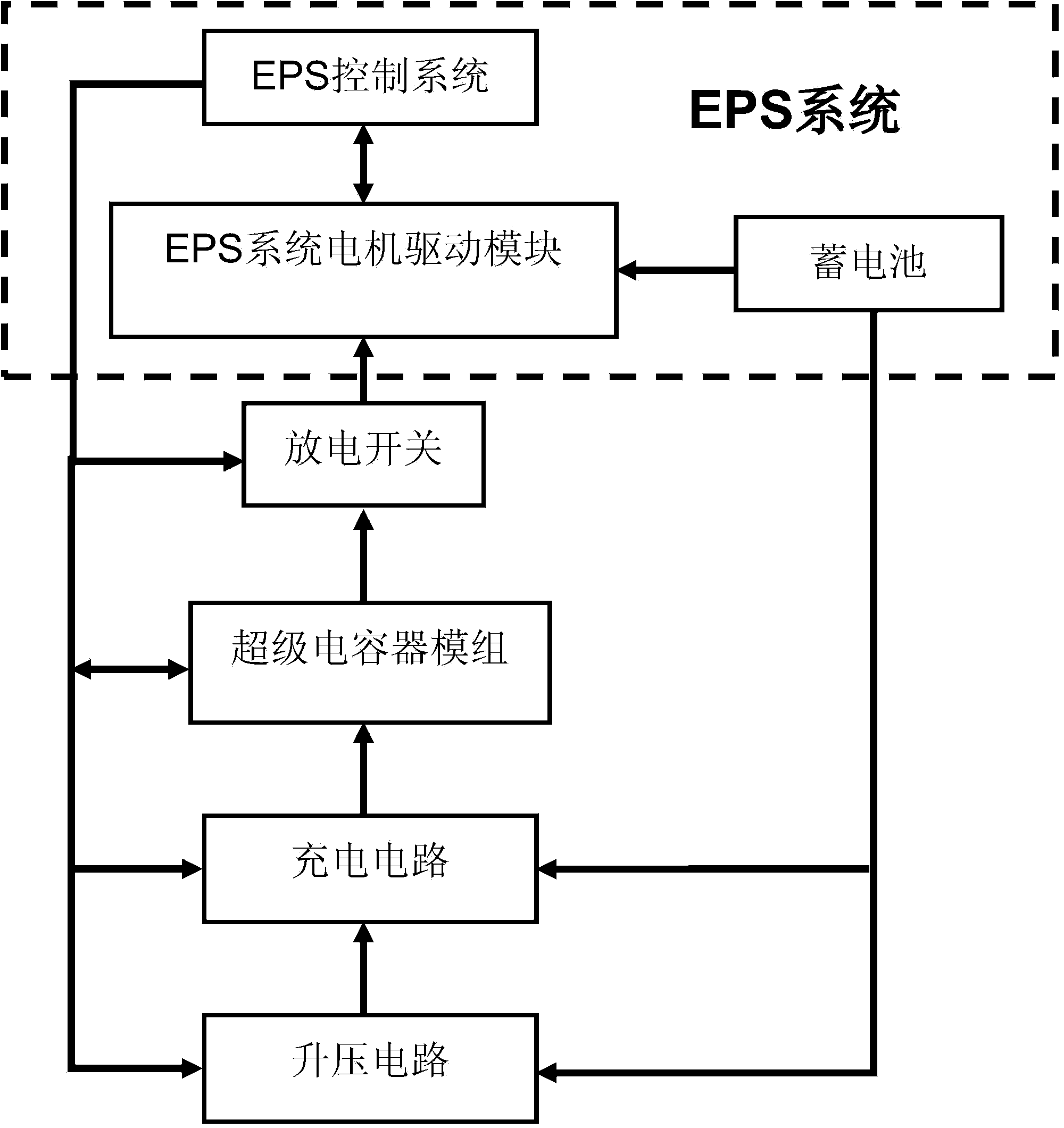

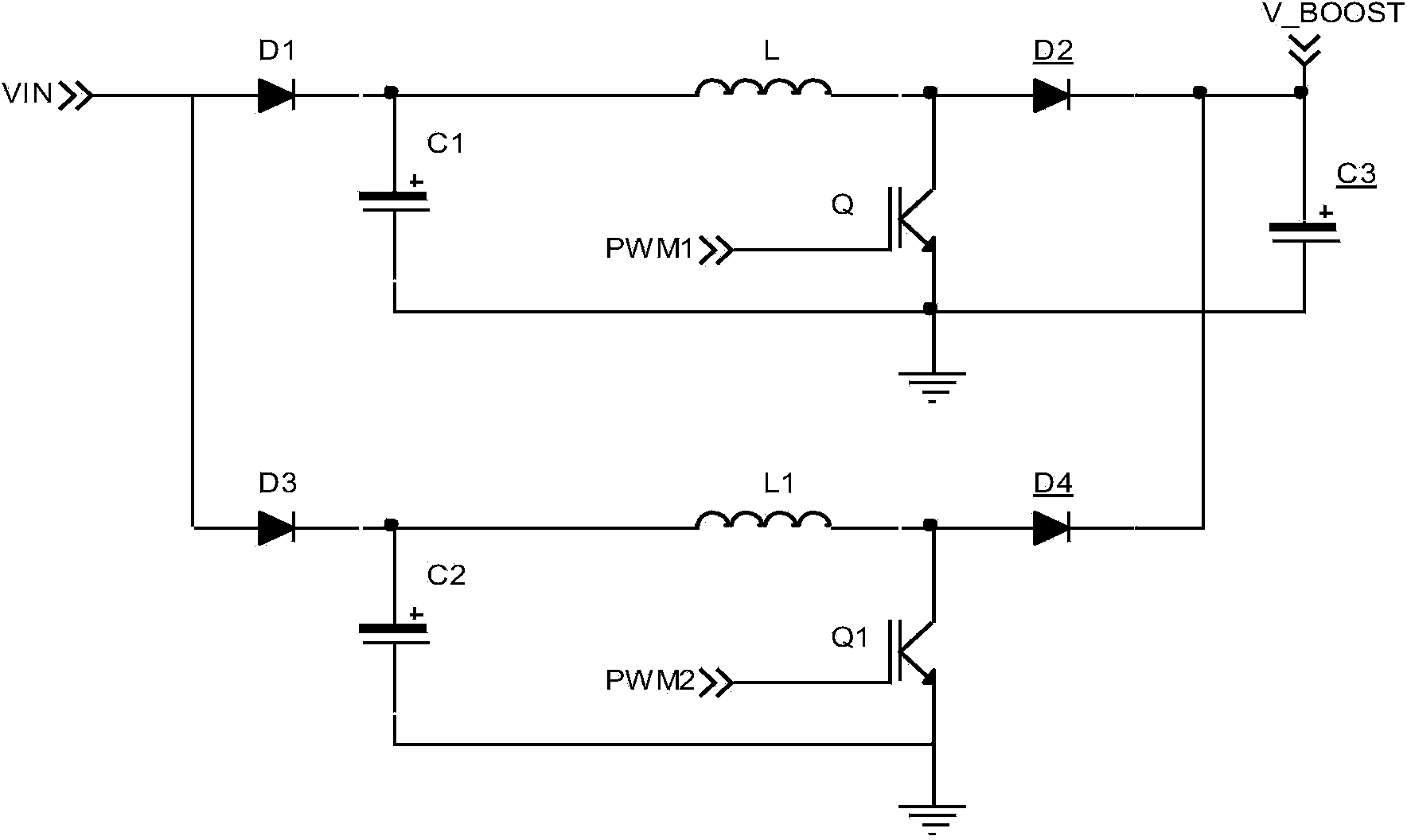

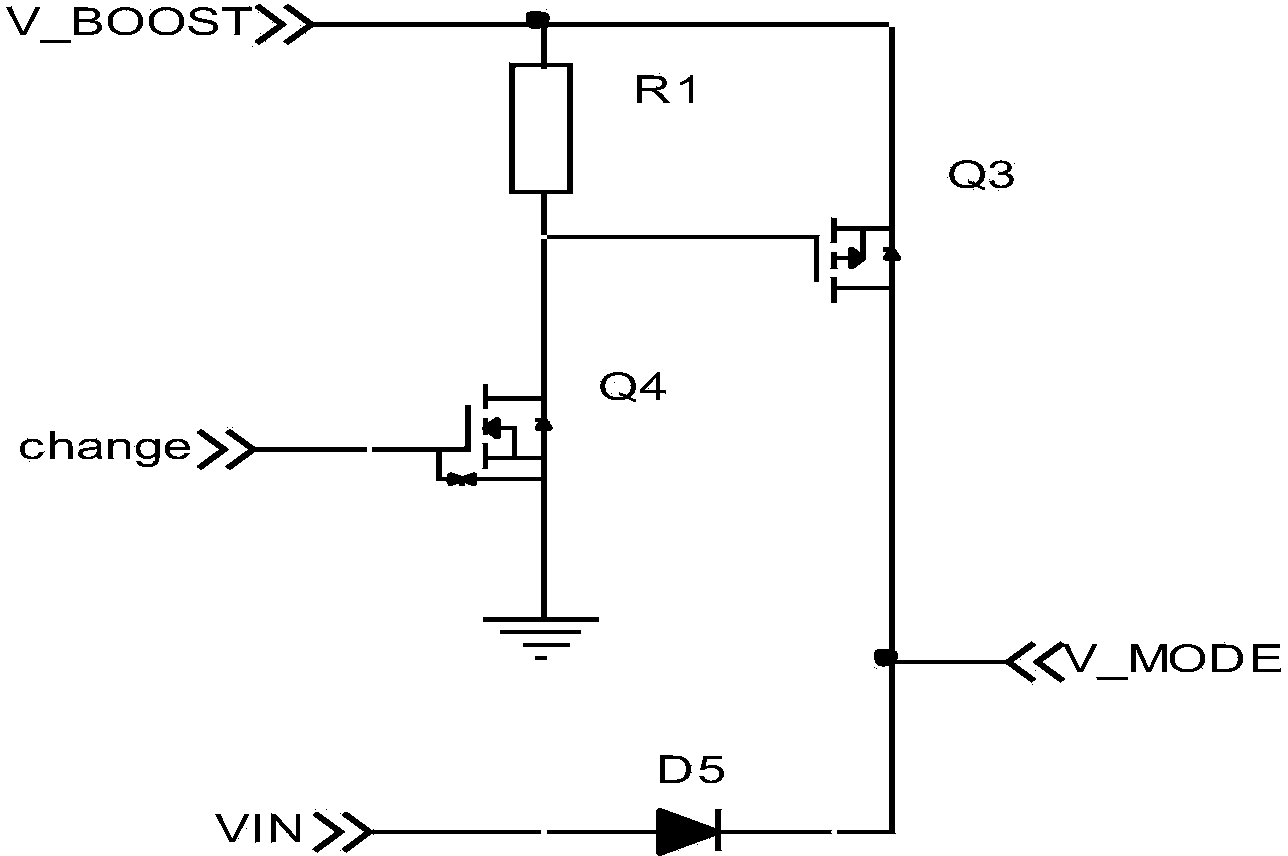

Power supply method for automotive electronic power-assisted steering system based on supercapacitor

ActiveCN103818329ABoost powerImprove boost effectBatteries circuit arrangementsElectric powerDriving safetyMotor drive

The invention discloses a power supply method for an automotive electronic power-assisted steering system based on a supercapacitor. The system comprises a discharging switch, a supercapacitor module, a charging circuit and a booster circuit; an accumulator has three electric signal outputs; a control signal end of an EPS (Electric Power Storage) control system is respectively bi-directionally communicated with signal ends of an EPS system motor driving module and the supercapacitor module; a control signal output end of the EPS control system is respectively communicated with control signal input ends of the discharging switch, the charging circuit and the booster circuit. Compared with the existing power supply method for a steering system, the power supply method has the advantages that the discharging switch is switched on and the supercapacitor module is connected after the detecting analysis is performed by the EPS control system when the steering is performed under a villainous road condition; the supercapacitor is matched with the accumulator for supplying enough driving current and increasing the assisting power, so that the purpose of improving the assisting effect is achieved; and the driving safety of a driver is effectively ensured.

Owner:AVX NEW ENERGY (CHENGDU) CO LTD

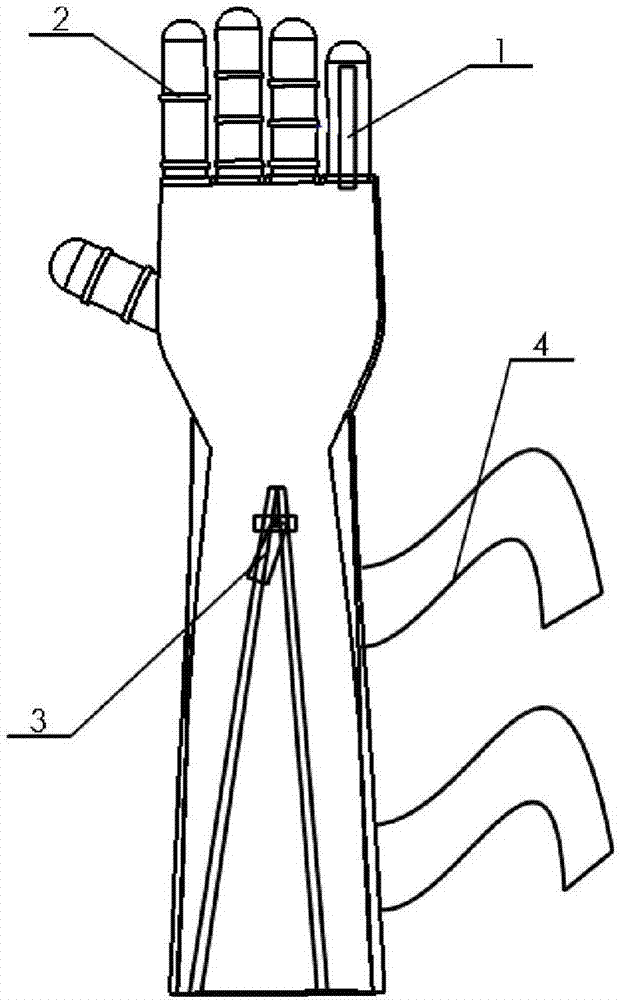

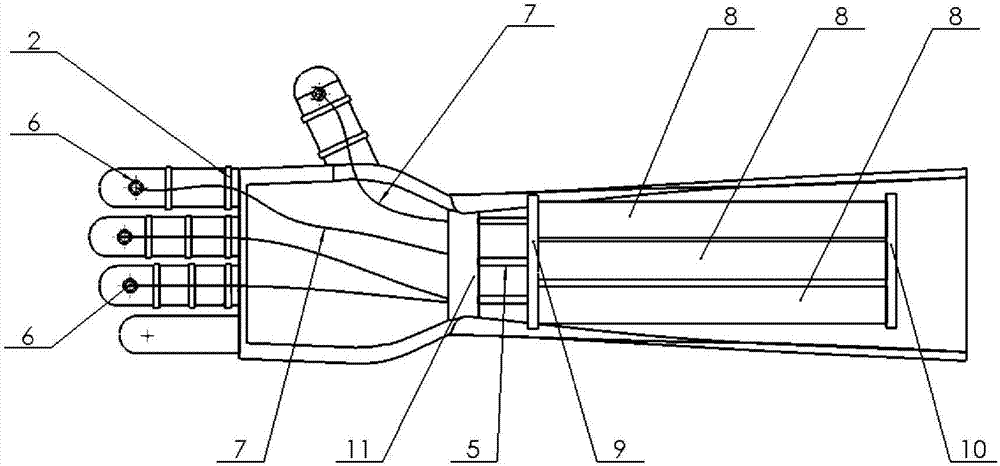

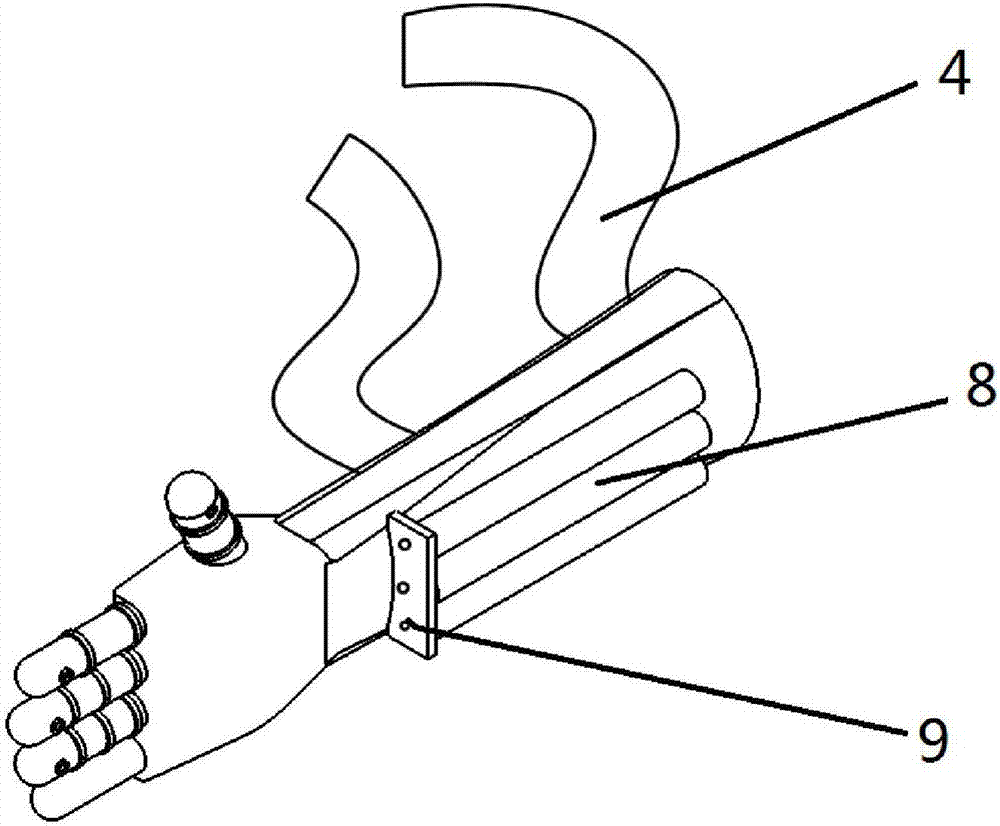

Portable wearable power-assisted glove

The invention provides a portable wearable power-assisted glove. The portable wearable power-assisted glove comprises a glove body, a bent sensor, a lead screw motor driving device, a steel wire transmission mechanism and a control mechanism. The motion intention of fingers of the human body is obtained by using the bent sensor, the forward rotation and the reverse rotation of a lead screw motor are controlled by the controller, and the bent sensor is tightly connected with a finger stall through a silica sol solution, so that the reading of the sensor is high in stability. According to the portable wearable power assist glove, a rope drive mode is adopted, a steel wire rope simulates a tendon transmission mode so as to drive the fingers to move, so that the glove has an obvious power-assisted effect, the motion form of the glove can be well unified with the hand motion of the human body, and the glove has wearable comfort. Moreover, the rope drive mode has drive flexibility and man-machine interaction safety. A minitype lead screw motor drive mode is adopted in the driving device, and the driving device has the advantages of being small in size, large in driving force, low in mass, high in integration level, simple in control and the like.

Owner:NORTHEASTERN UNIV LIAONING

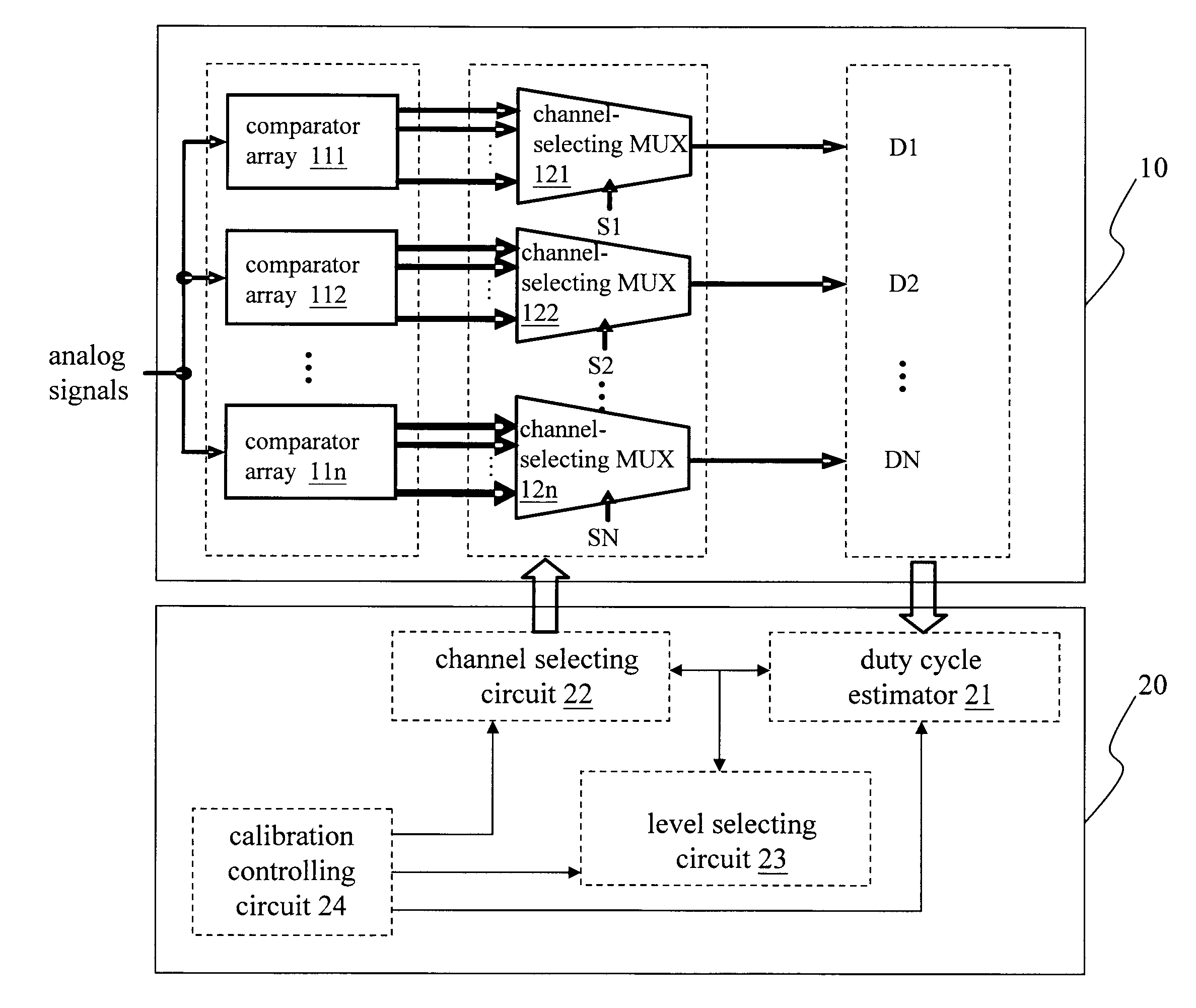

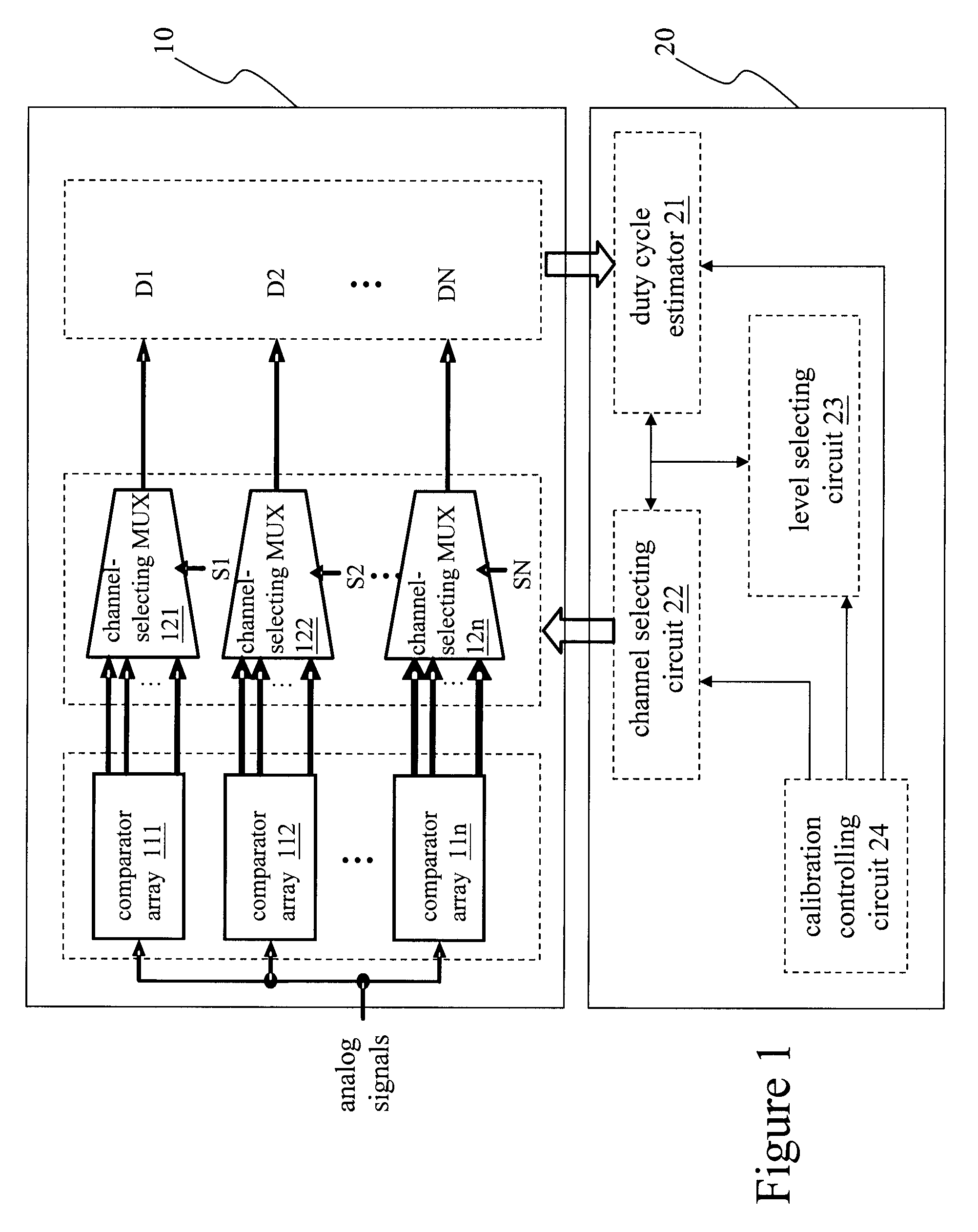

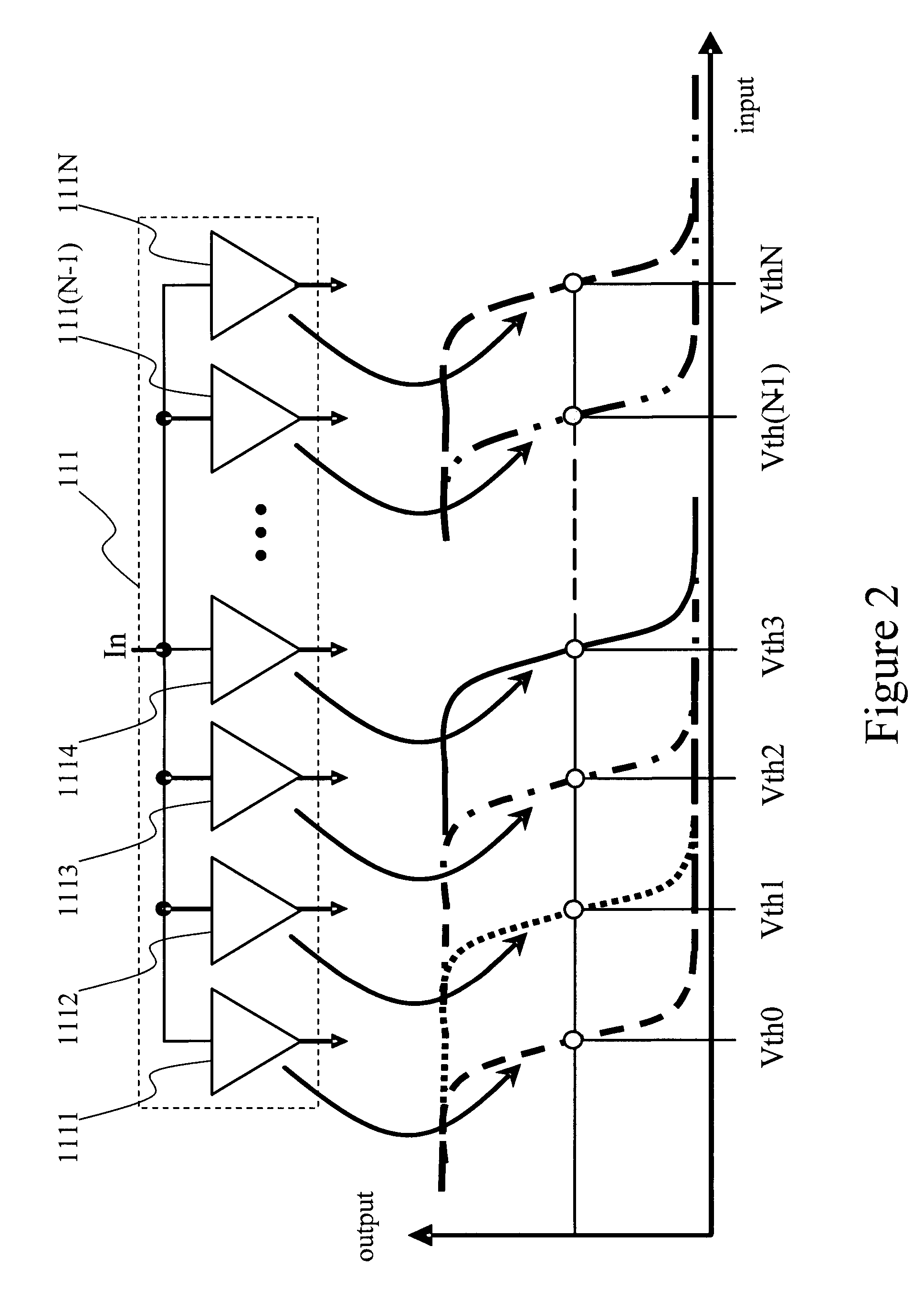

Self-calibrating high-speed analog-to-digital converter

ActiveUS7474239B2Low powerIncrease boost effectPower saving provisionsElectric signal transmission systemsMultiplexerAnalog-to-digital converter

In a precisely self-calibrating high-speed analog to digital converter the aspect ratios of tri-state inverters are adjusted to fine-tune threshold voltage as comparators. And the multiplexers composed of tri-state inverters amplify the signal from the output of comparators. Their switches of tri-state inverters may be properly controlled to select the optimal channels and reduce unnecessary power consumption. The calibration circuitry utilizes under-sampling to calculate the duty cycles of comparators, selecting the optimal comparators and channels. By the way, the invention may avoid process variation.

Owner:NAT CHIAO TUNG UNIV

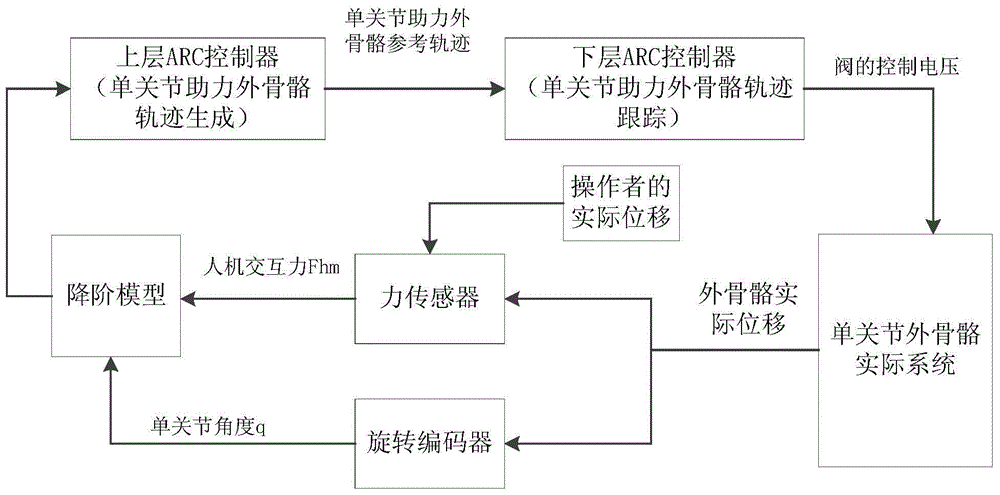

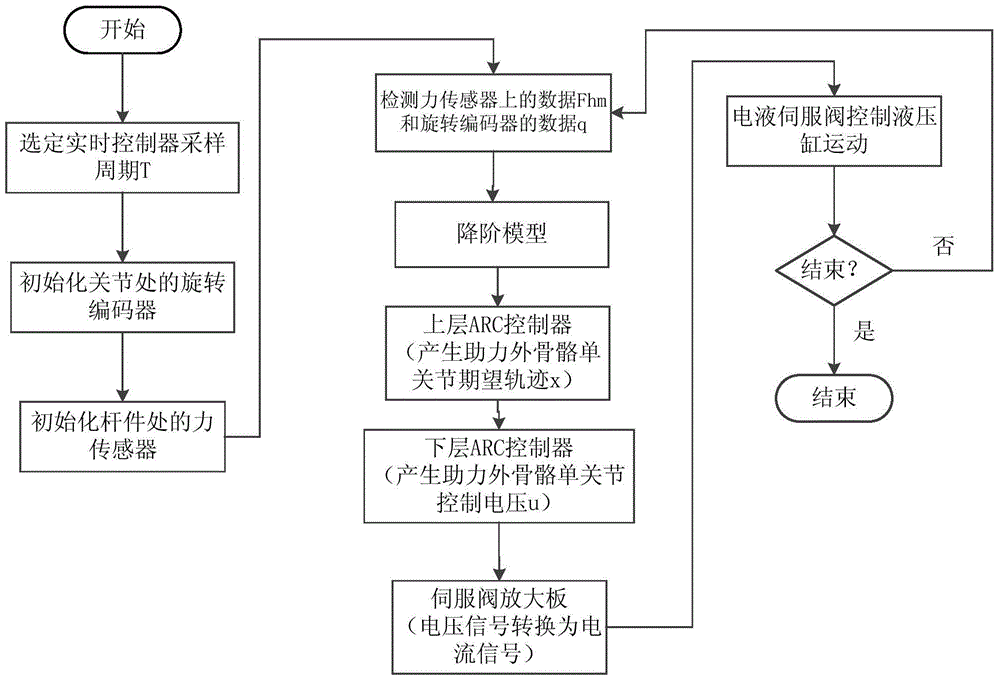

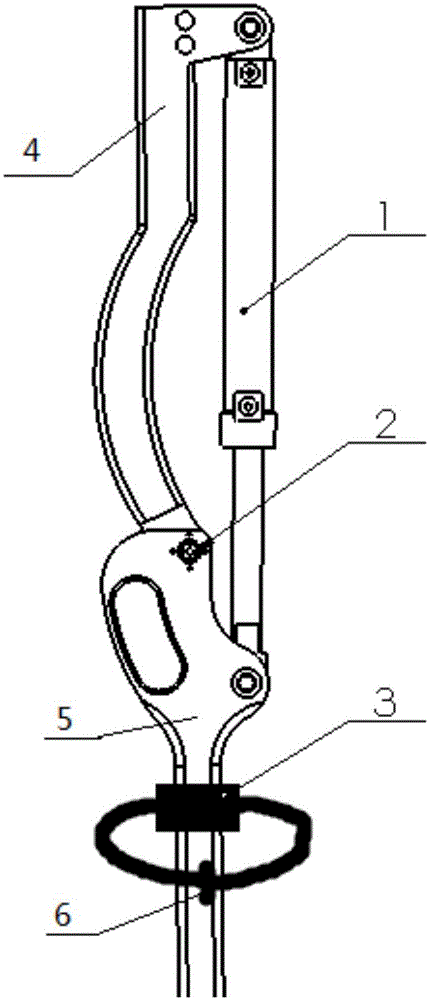

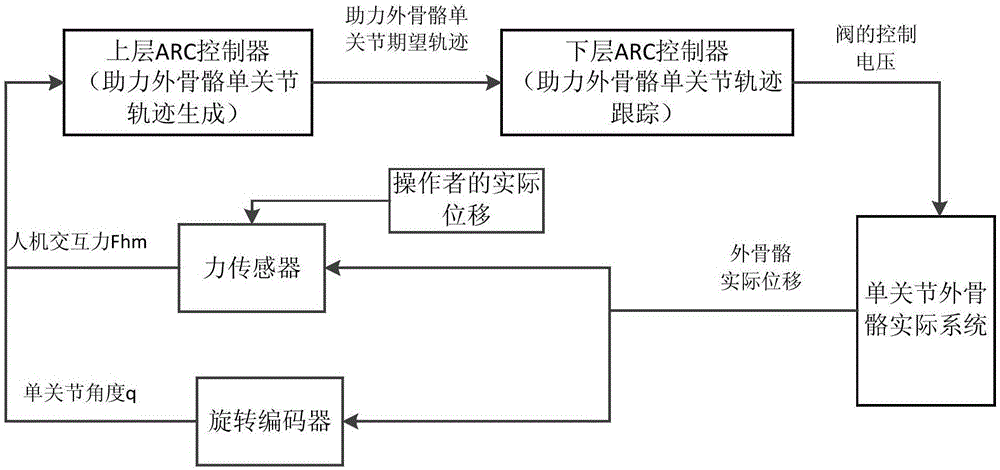

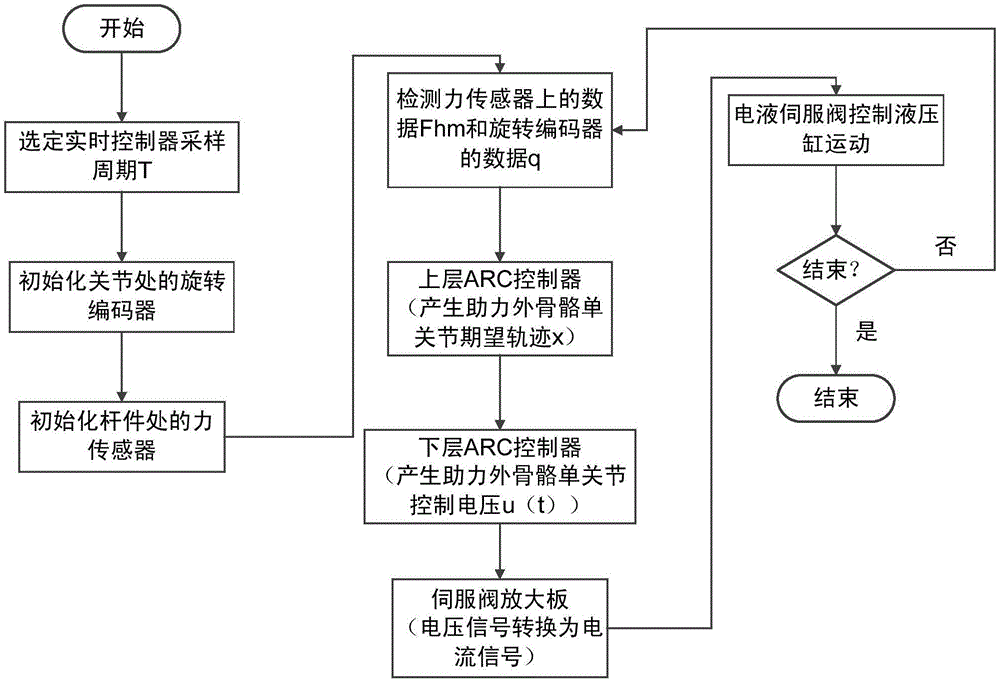

Reduced-order adaptive robust cascading force control method for single-joint powered exoskeleton

ActiveCN105108761AOvercoming the effects of uncertaintySimple designProgramme-controlled manipulatorSpecial data processing applicationsHydraulic cylinderPowered exoskeleton

The invention discloses a reduced-order adaptive robust cascading force control method for the single-joint powered exoskeleton. A reduced-order model is adopted by aiming at the power reinforcement and following problems of the single-joint powered exoskeleton driven by a hydraulic cylinder, errors caused by sensor precision problems are effectively eliminated, and controller design is simplified. The cascading force control method is adopted in the controller design, an upper-layer controller and a lower-layer controller are designed, a single-joint reference track is generated by the upper-layer controller, and the reference track is tracked through the lower-layer controller. When the powered exoskeleton bears weights, man-machine acting force is minimized to achieve power assistance and motion along with a person. The upper-layer controller and the lower-layer controller are designed through an adaptive robust control (ARC) algorithm, the influence of model nondeterminacy of the single-joint powered exoskeleton is effectively overcome, the good following and assisting effects of the powered exoskeleton to the motion of the person are achieved, and high application value is achieved.

Owner:ZHEJIANG UNIV +1

Light motion assisting device and control method thereof

ActiveCN106309081AIncrease contact areaAccurate detectionChiropractic devicesMuscle exercising devicesLoop controlControl signal

The invention relates to a light motion assisting device and a control method thereof. The light motion assisting device includes a power system, a control system and an execution mechanism; the execution mechanism includes a connection rod structure and a sensor group, which match and bear a lower limb of a human body; the sensor group includes a human body pressure monitoring system for monitoring the pressure acted on a foot of the human body, and a mechanical pressure monitoring system for monitoring the pressure acted on the connection rod structure, wherein the human body pressure monitoring system and the mechanical pressure monitoring system output signals to the control system respectively; the control system outputs a control signal to the power system; and the power system drives the connection rod structure to match the human body to move, and then a loop control system is formed. The actual load of the human body and the device assisting load can be measured timely, the changing trend of the pressured acted on the human body can be monitored timely, and the motion assisting device is controlled to do a control action; and all the states of motion of the human body can be included, and the motion assisting device can timely and rapidly make a response and cannot be triggered wrongly.

Owner:SHENZHEN CONCHIN TECH CO LTD

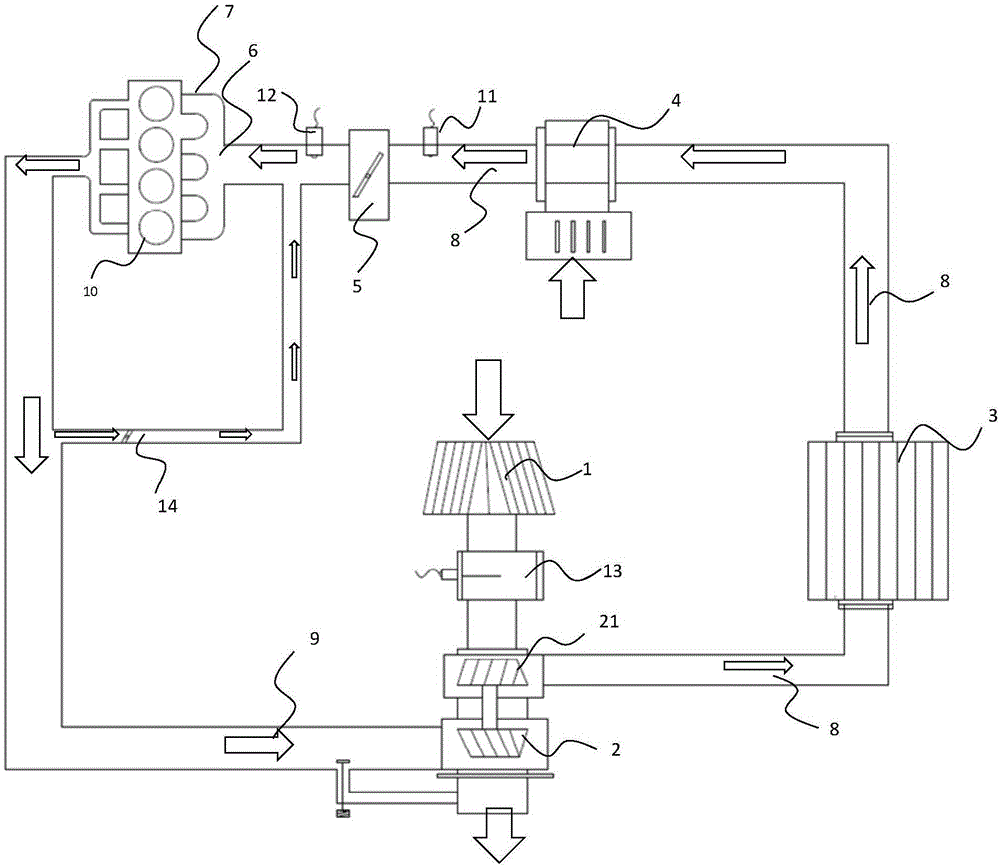

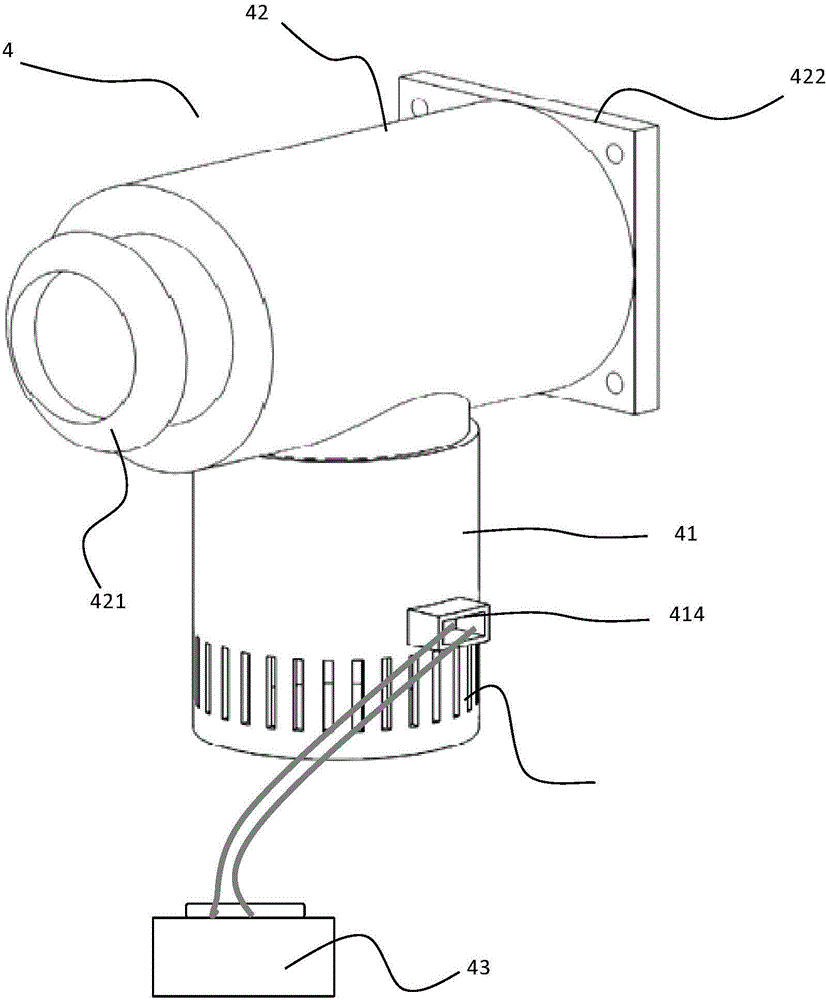

Engine and air inlet system thereof

ActiveCN105804896AIncrease boost effectSupercharge effect is goodMachines/enginesThermal treatment of fuelLow speedEngine efficiency

The invention discloses an engine and an air inlet system thereof. The air inlet system of the engine comprises an air inlet pipe, an air inlet manifold, an air inlet manifold header and an electric supercharger arranged on the air inlet pipe and located in front of the air inlet manifold header of the engine. The electric supercharger comprises a base, a motor arranged in the base, fan blades arranged in the base and a supercharging pipe communicated with the base through fluid. The base is provided with an air inlet, and the supercharging pipe is provided with an air outlet. The supercharging pipe is connected to the air inlet pipe in series and communicated with the air inlet pipe through fluid, and the motor can drive the fan blades to rotate, so that air flow flows in through the air inlet and flows out from the air outlet, and the air flow is mixed with air flowing in from the air inlet pipe to be sucked into an air cylinder of the engine together. By means of the engine and the air inlet system of the engine, emission can be effectively reduced, the efficiency of the engine is improved, the low-speed torque characteristics of the engine are improved, and engine surge is not caused.

Owner:SHANGHAI QINGCHE AUTOMOTIVE ENG CO LTD

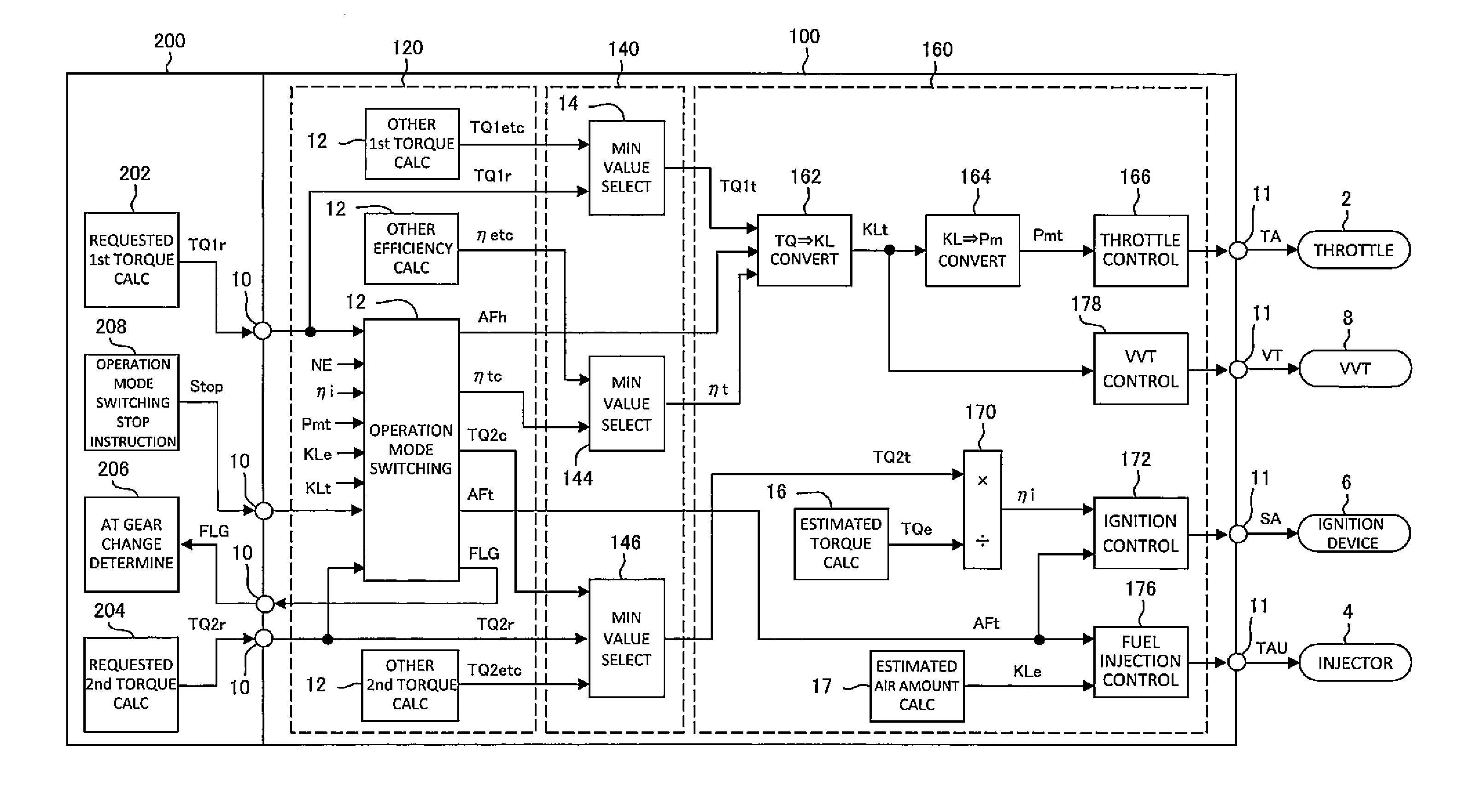

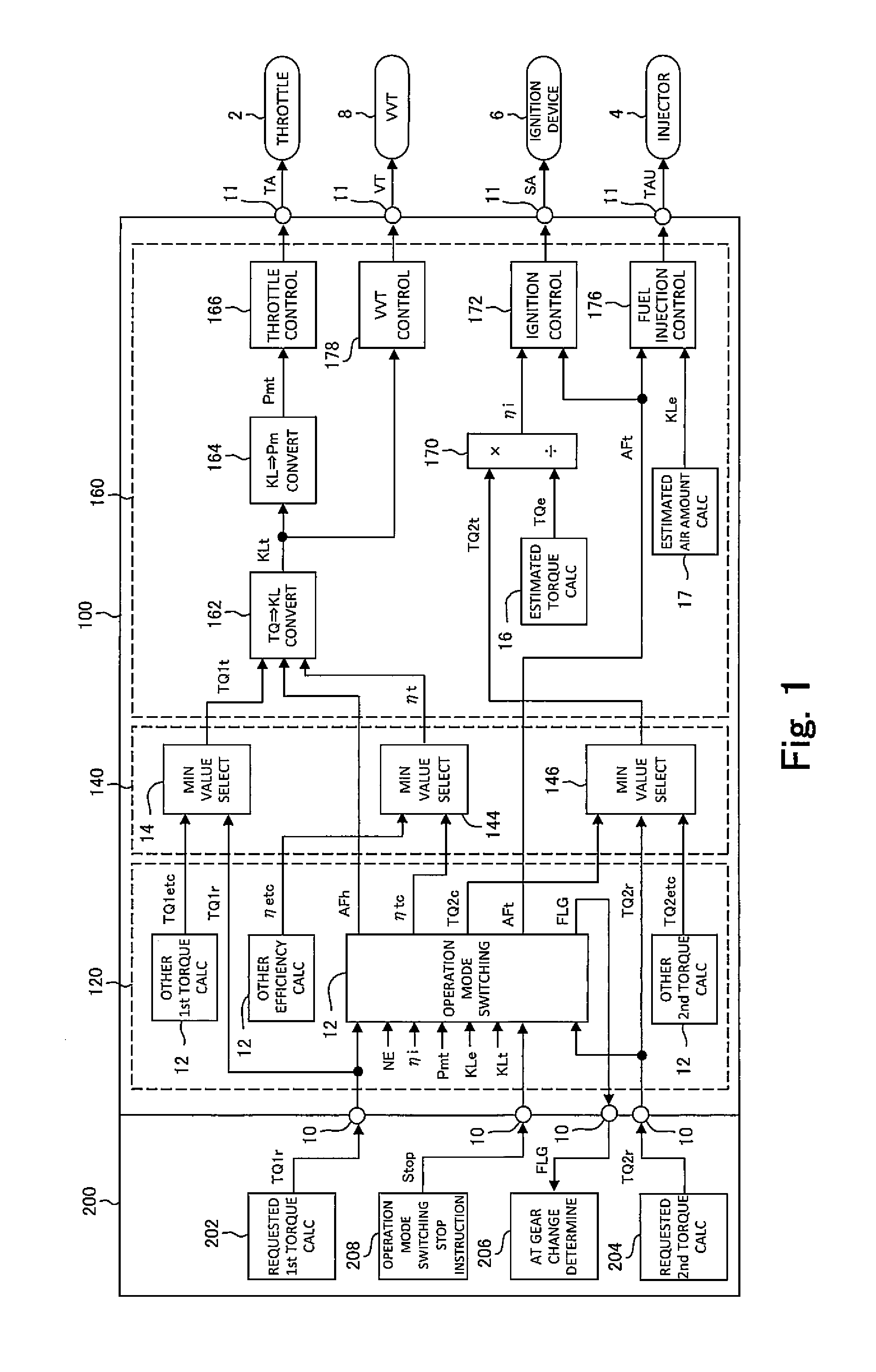

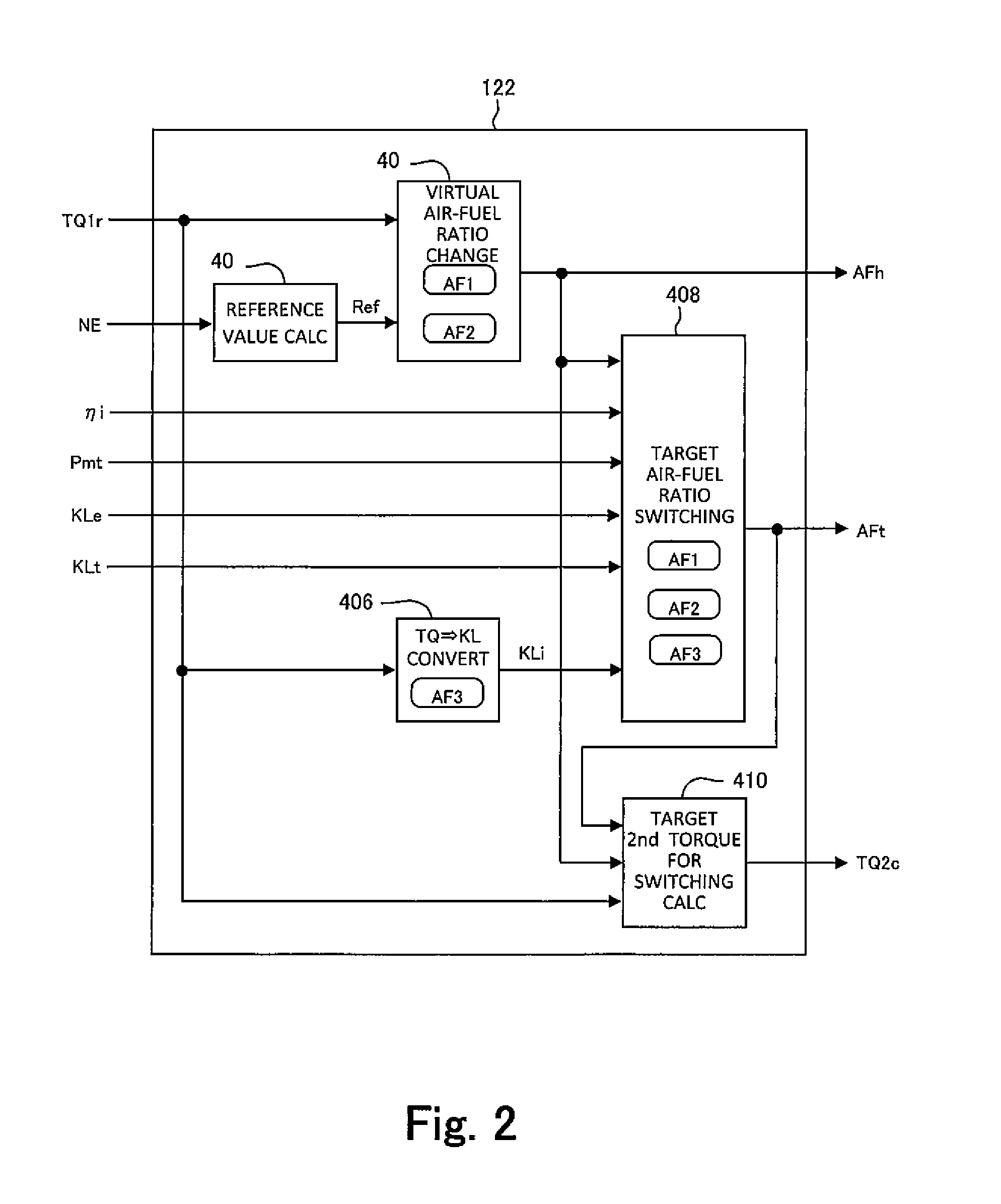

Control device for internal combustion engine with turbocharger

ActiveUS20160123246A1Quick upgradeFavorable responsiveness without generating fluctuations in the torqueElectrical controlInternal combustion piston enginesTurbochargerOperation mode

A target air amount for achieving a requested torque is back-calculated from the requested torque using a virtual air-fuel ratio. The virtual air-fuel ratio is changed from a first air-fuel ratio to a second air-fuel ratio in response to a condition for switching an operation mode being satisfied. After the virtual air-fuel ratio is changed, the target air-fuel ratio is maintained at the first air-fuel ratio until the ignition timing reaches a retardation limit. Subsequently, in response to the ignition timing reaching the retardation limit, the target air-fuel ratio is switched from the first air-fuel ratio to a third air-fuel ratio. After switching of the target air-fuel ratio, in response to a difference between the target air amount and an estimated air amount becoming equal to or less than a threshold value, the target air-fuel ratio is switched from the third air-fuel ratio to the second air-fuel ratio.

Owner:TOYOTA JIDOSHA KK

Adaptive robustness cascading force controlling method for single-joint powered exoskeleton

ActiveCN105137972AReduce volumeLight in massAdaptive controlPosition/course control in two dimensionsHydraulic cylinderPowered exoskeleton

The invention discloses an adaptive robustness cascading force controlling method for a single-joint powered exoskeleton. The cascading force controlling method is sued for aiming at problems of force increasing and force following in a hydraulic cylinder driven single-joint powered exoskeleton. An upper-layer controller and a lower-layer controller are arranged. A reference track of the single joint is generated through the upper-layer controller, and the lower-layer controller realizes tracking for the reference track. According to the adaptive robustness cascading force controlling method, when the powered exoskeleton bears a heavy object, a man-machine interaction force is minimized for realizing powering and movement along with a person. An adaptive robustness control algorithm (ARC) is used for designing the upper-layer controller and the lower-layer controller, thereby effectively an influence of uncertainty of a single-joint powered exoskeleton model, realizing a good following effect and a good powering effect of the powered exoskeleton to the motion of a person, and obtaining a relatively high application value.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com