Rolling and cutting metal plate shearing machine

A roll-cutting, metal plate technology, applied in shearing devices, metal processing equipment, shearing machine equipment, etc., can solve the problems of large system, unstable force, poor section quality of sheared steel plates, etc., and achieve a simple transmission system. Reliable, simplified mechanism, improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

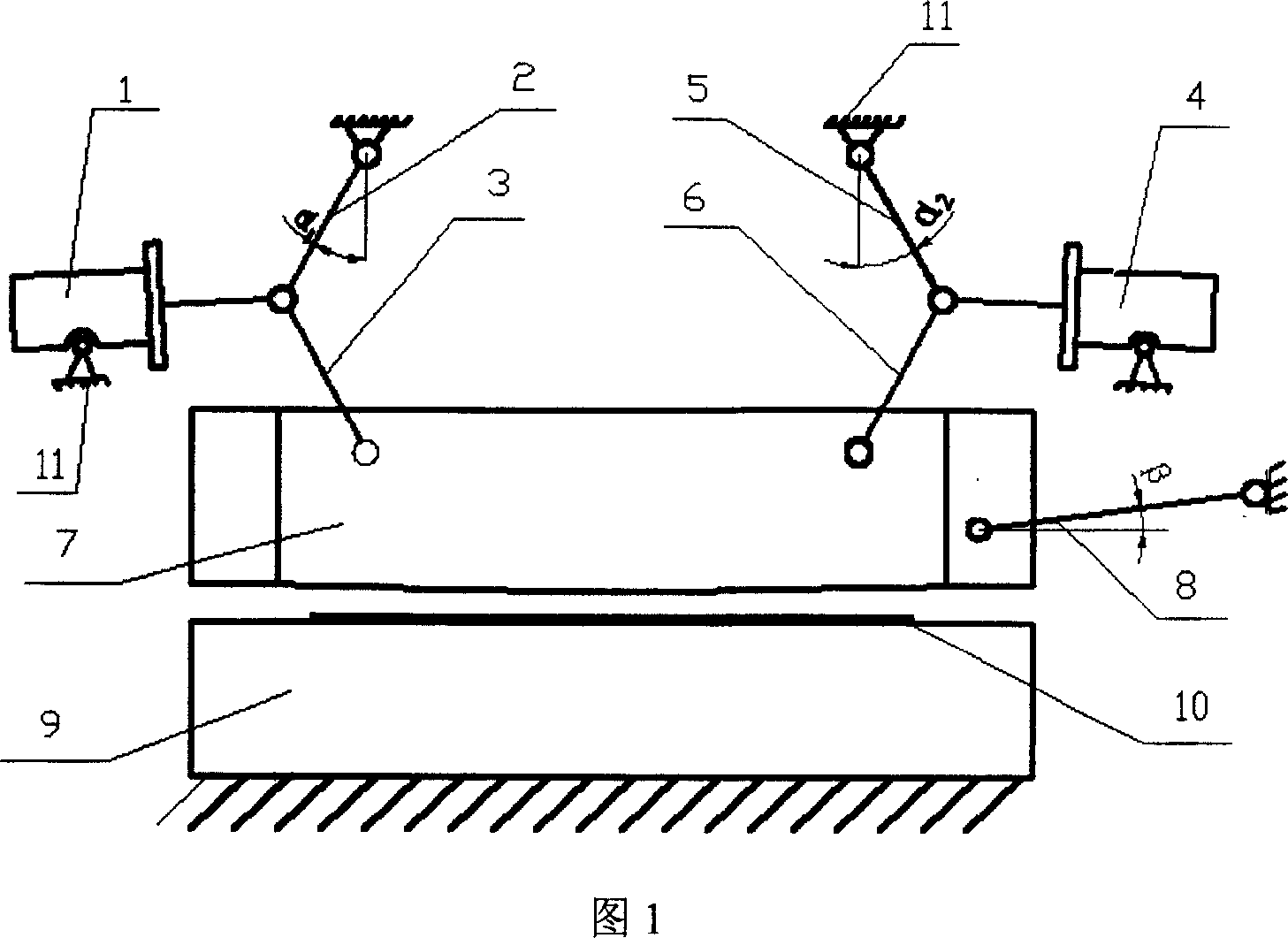

[0014] As shown in Figure 1, the hydraulic cylinders 1 and 4 are installed horizontally and hinged with pins on the frame 11 on the left and right sides above the upper shear blade holder 7, and the ends of the two piston rods pass through the pins. The shafts are respectively hinged with the push rods 2, 5 and the connecting rods 3, 6, and the other ends of the push rods 2, 5 are hinged with the frame 11 through pin shafts, and the included angles with the vertical line are respectively α 1 = -25° and α 2 =25°, the other end of the connecting rod 3,6 is hinged with the upper scissor frame 7 through the pin shaft, one end of the guide rod 8 is hinged with the upper scissor frame 7 through the pin shaft, and the other end is upwardly inclined to the frame 11 are hinged, and the angle with the horizontal line is β=5°. During production, starting the hydraulic cylinders 1 and 4 drives the movement of the connecting rods 3 and 6 and the push rods 2 and 5, which can drive the move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com