Rolling control mechanism for minitype ornithopter

A technology of flapping-wing aircraft and control mechanism, which is applied in the field of rolling control mechanism, can solve problems such as the inability to realize the rolling operation of the flapping-wing aircraft, and achieve the effects of easy operation, strong reliability, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

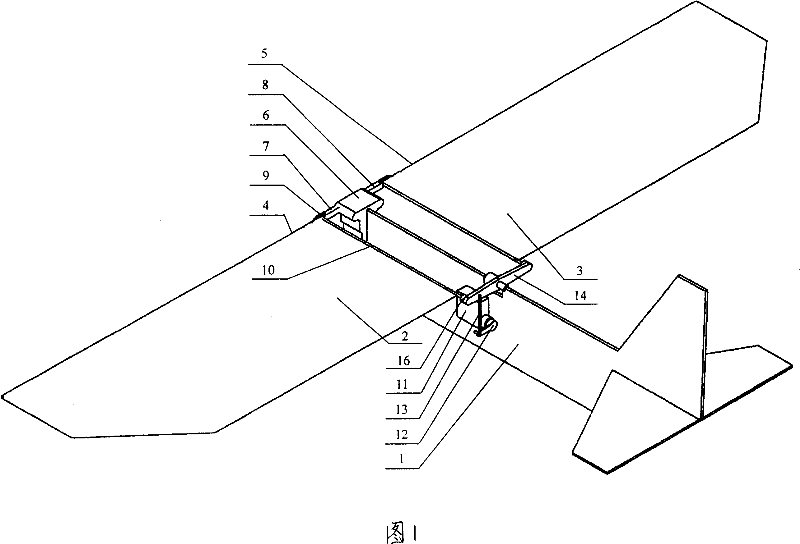

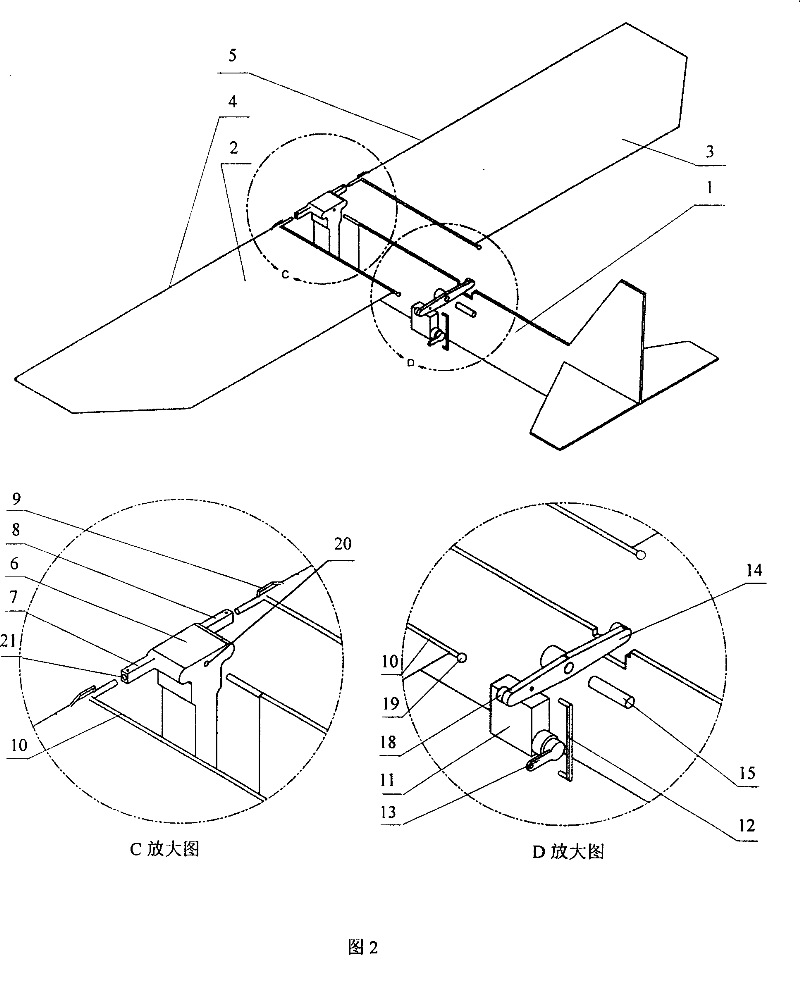

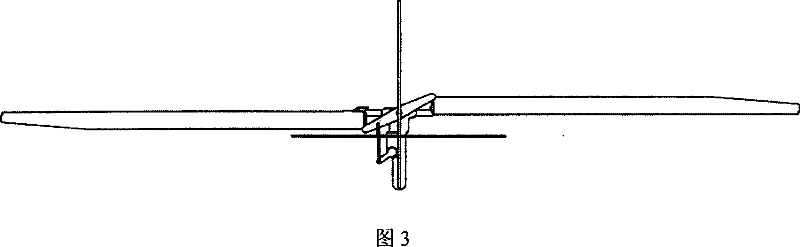

[0019] The present embodiment is a miniature flapping-wing aircraft of conventional layout, comprising fuselage 1, wing, wing flapping mechanism 6, rear bracket 14 and control steering gear 11 in order to support wing. During implementation:

[0020] The flapping mechanism 6 is located at the front end of the fuselage 1, and its upper surface and longitudinal section are T-shaped: a section of cantilever beams protrude from the front end of the upper surface panel to both sides, forming the left rocker arm 7 and right rocker arm of the flapping mechanism. arm 8, and on the end faces of the left rocker arm 7 and the right rocker arm 8, there are inner holes 21 assembled with the front main beam of the wing; font; there is a fuselage mounting hole 20 on the center line of the inner surface of the panel.

[0021] The front end of the fuselage 1 has a mounting pin, by which the front face of the fuselage 1 and the flapping mechanism 6 are fixedly fitted together;

[0022] The wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com