Force-controlled electromagnetic permanent magnetic composite excitation vibration platform

A composite excitation and shaking table technology, applied in vibration testing, fluids utilizing vibration, measuring devices, etc., can solve the problems of inability to realize low frequency drive, many components and links, and inability to realize efficient direct drive and high reliability drive, etc. Achieve the effects of good rigidity, precise and controllable vibration displacement, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

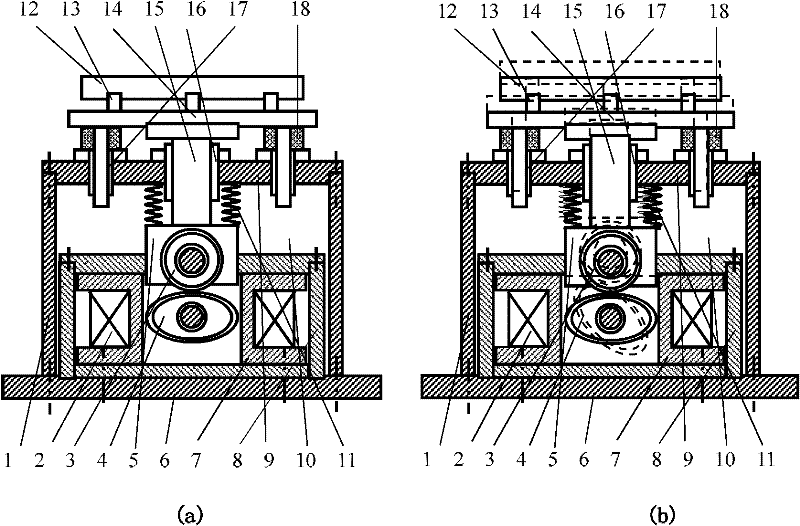

[0029] like figure 1 As shown, this embodiment includes: a casing 1, an electromagnetic coil 2, magnetic energy bodies 3, 4 and a load-carrying mechanism 5, wherein: the two magnetic energy bodies 3, 4 are respectively arranged up and down inside the casing 1 in the form of a horizontal axis of rotation and mutually Contact, the electromagnetic coil 2 is located inside the casing and faces the second magnetic energy body 4, and the loading mechanism 5 is movably arranged on the top of the casing 1 and is in contact with a magnetic energy body.

[0030] The housing 1 includes: a base 6, a rotating shaft support frame 7, a magnetic circuit inner frame 8 and an outer frame body 9, wherein: the outer frame body 9 is fixedly connected with the base 6, and the rotating shaft support frame 7 and the magnetic circuit are fixedly connected. The inner frame body 8 is respectively fixed and arranged in the outer frame body 9 of the fuselage and located inside and outside the electromagne...

Embodiment 2

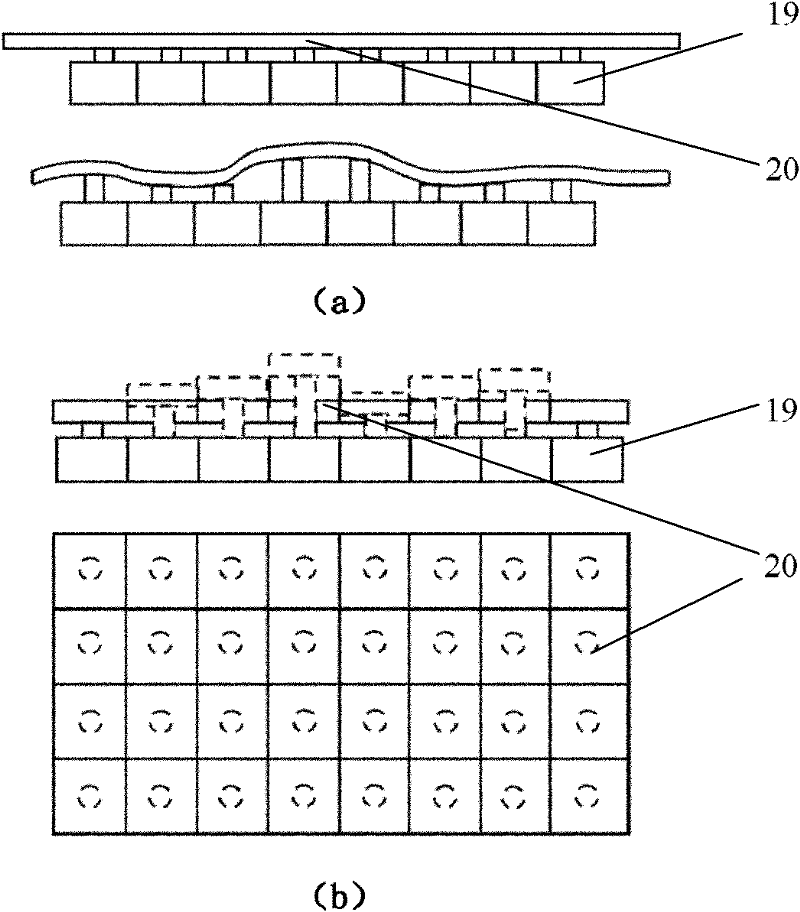

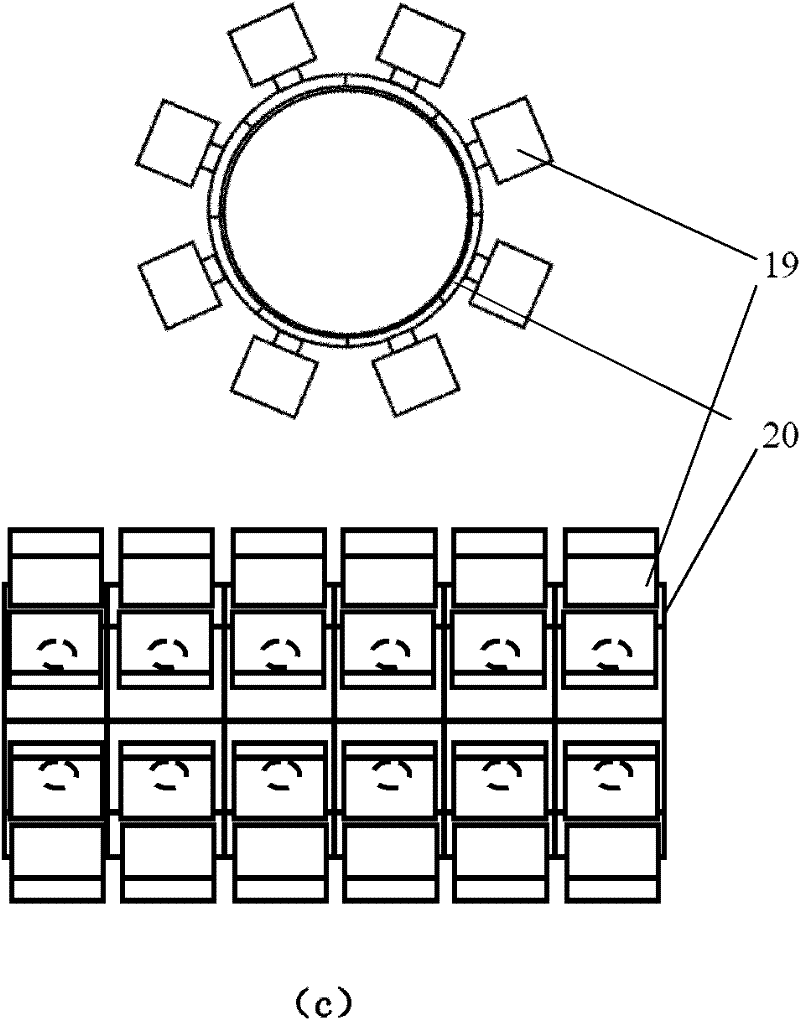

[0045] like figure 2 As shown, this embodiment excites the corresponding driven body or driven body array 20 by arranging the above-mentioned several force-controlled electromagnetic permanent magnetic composite excitation vibration tables 19 in a linear array, a plane array or a three-dimensional array. And independently control or connect or connect their electromagnetic coils in series to form a corresponding force-controlled electromagnetic-permanent-magnet composite excitation vibration system. This system can be used to simulate and realize anti-vibration and anti-external load experiments on large-scale facilities such as bridges with long "length". Test work, used to simulate and realize the anti-vibration and anti-external load experiments on vehicles and large buildings such as road surfaces, ocean waves, earthquakes, etc., or to simulate the realization of three-dimensional external loads on vehicles and large buildings Experimental test and research on resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com