Aircraft with changeable wing shape

An aircraft and wing technology, applied in the field of aircraft, can solve the problems of complex wing motion mechanism, high development cost, and low flight performance, and achieve the effects of reducing risk, reducing maintenance cost, and high flight quality

Inactive Publication Date: 2007-09-05

HARBIN INST OF TECH

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide an aircraft capable of changing the shape of the wing, which can solve the problems of complex wing motion mechanism, heavy weight, high development cost, difficult operation, and low flight performance in existing deformed wing aircraft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

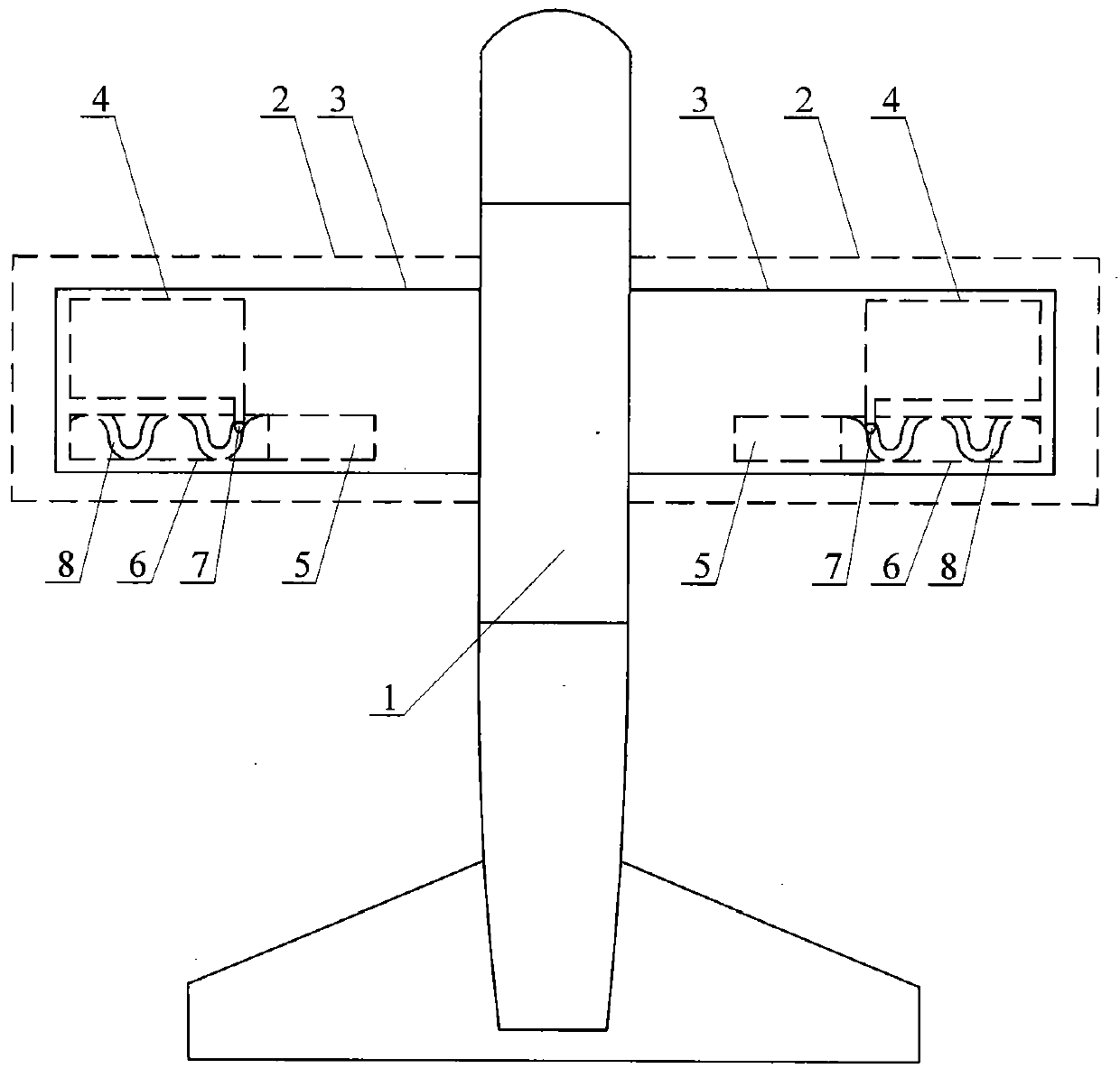

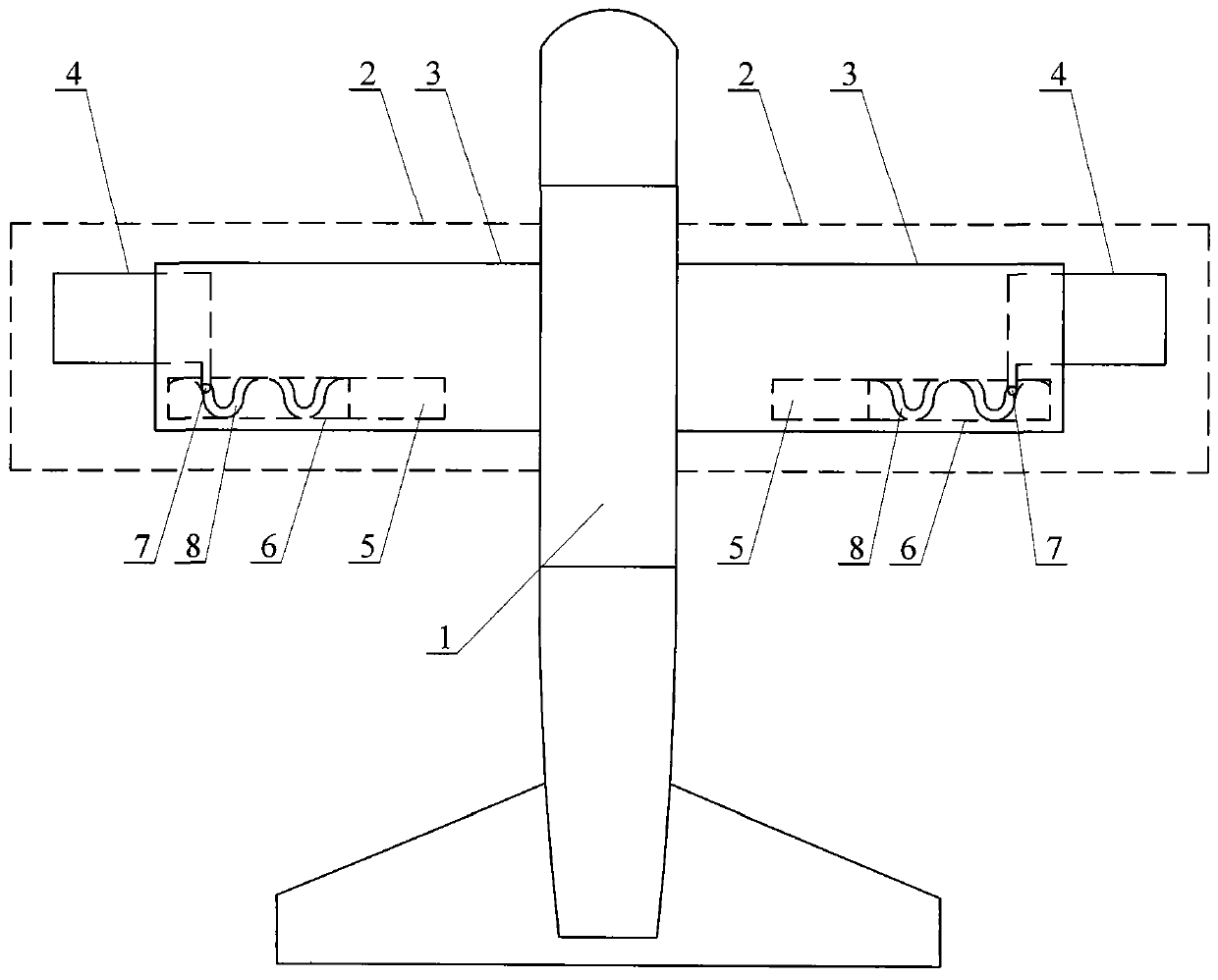

An airplane able to change the shape of wing is composed of an airplane body and two wings consisting of fixed wing with one end fixed to airplane body, slide wing installed in the skeleton of said fixed wing and with a roller moving in a spiral slot on a cylindrical body, and the cylindrical body and shape memory alloy bar, which are fixed to each other and installed in the skeleton of said fixed wing. Said shape memory alloy bar is used as the drive source for changing wing shape.

Description

technical field The invention relates to an aircraft. Background technique Wings are the main components of an aircraft that are reconfigurable in flight. Purposefully changing the shape of the wing in flight (such as wing sweep, changing the wingspan and camber, etc.) can effectively increase the flight performance of the wing. Among them, the effect of changing the wingspan and wing area is the most prominent. For example, an airplane usually requires a high aspect ratio and a large wing area when cruising, but a low aspect ratio and a small wing area are required for an airplane to fly at high speed. The small aspect ratio and large swept wings widely used in modern supersonic aircraft have small supersonic resistance, but the aerodynamic efficiency is low at low speeds, and the lift characteristics are not good. Wings would again degrade supersonic performance. The variable aspect ratio aircraft can solve the contradiction between high and low speed performance requ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B64C3/56

Inventor 冷劲松刘彦菊刘晓伟孙启健

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com