Spherical (spherical surface) mirror surface rolling lathe

A spherical and rolling technology, which is applied in the field of machine tools, can solve problems such as high assembly difficulty, limited precision, and low production efficiency, and achieve the effects of improved production efficiency and quality, high rotary machining accuracy, and simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

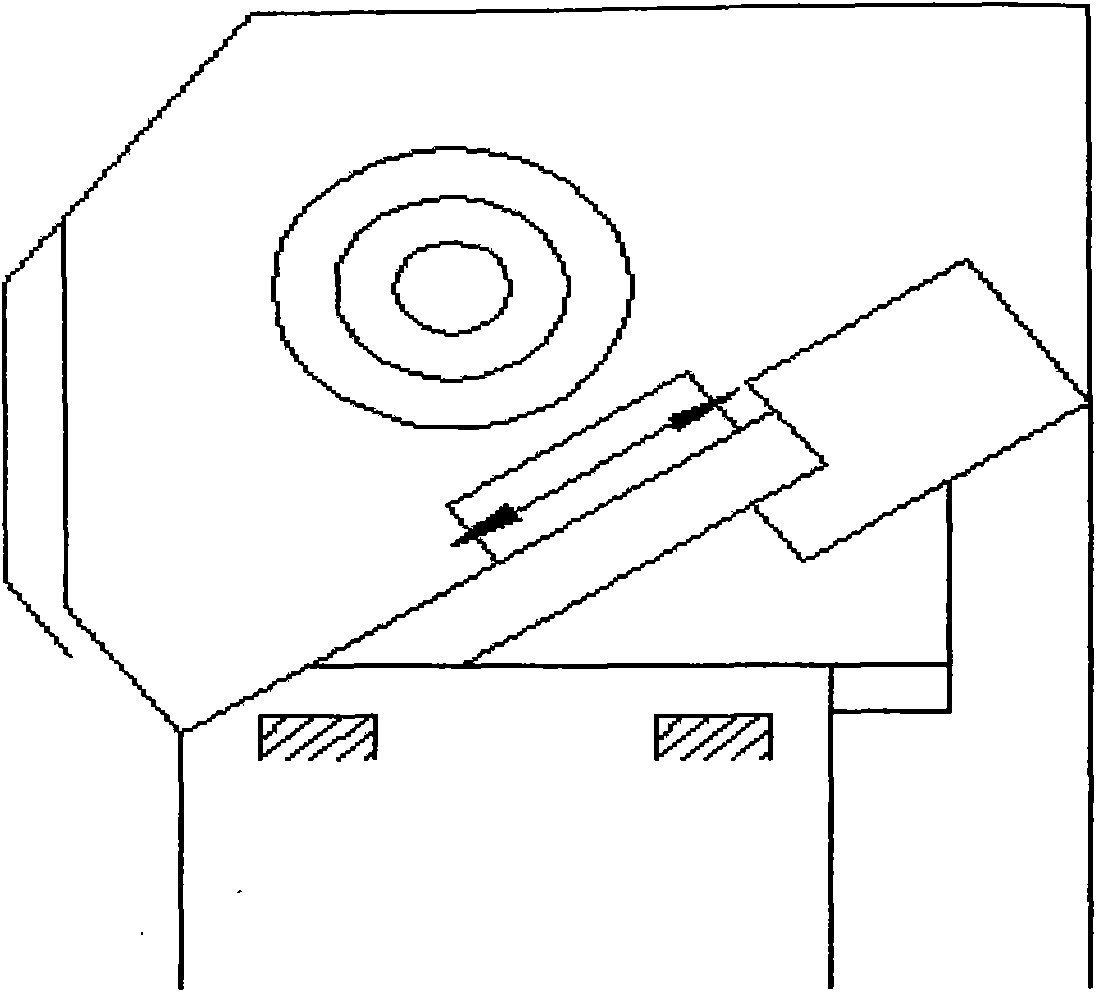

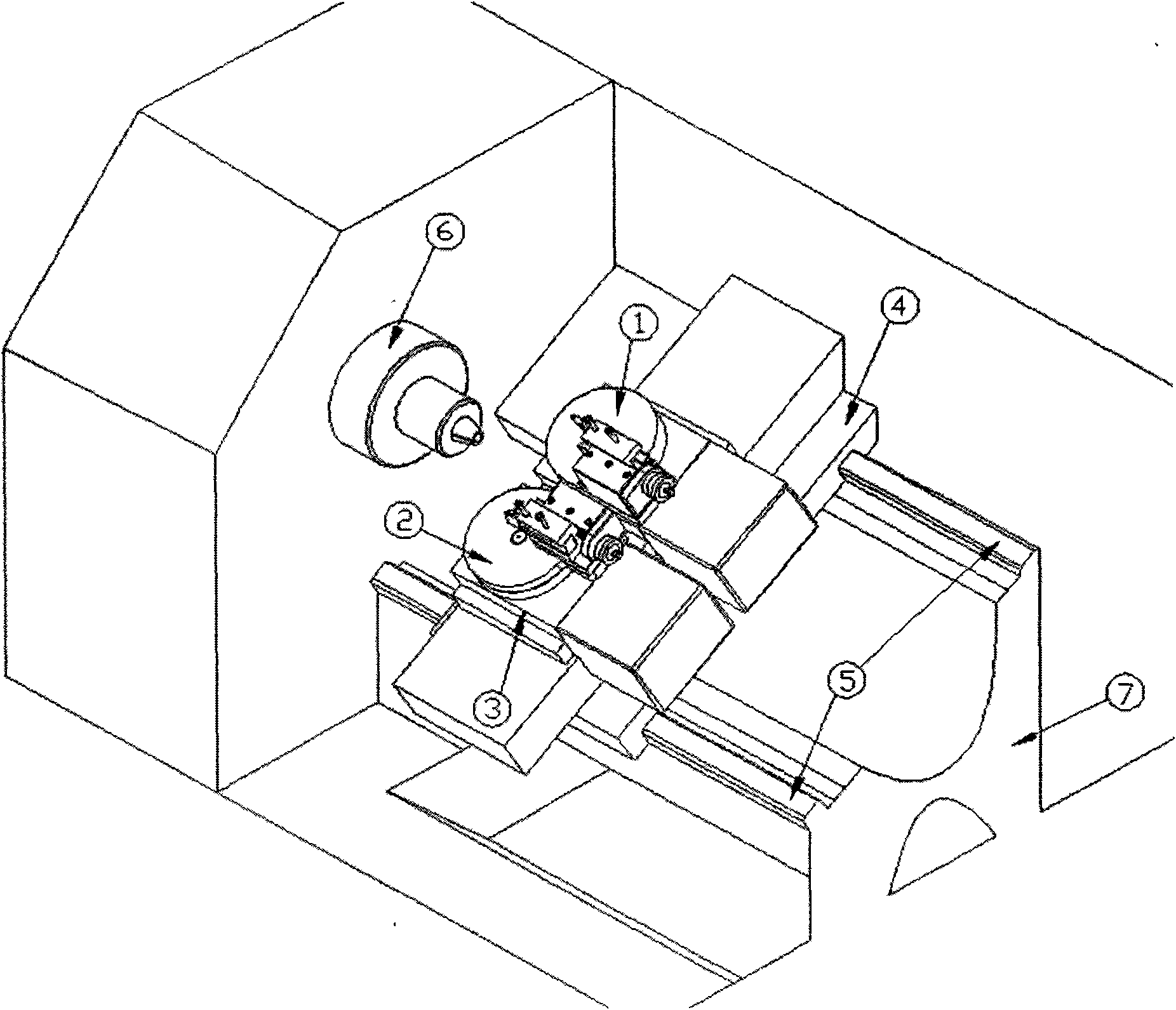

[0034] Such as figure 2 As shown, in the spherical (spherical) mirror surface rolling lathe described in the present invention, there are two mechanisms that adopt (1) (2) disc rotary knife rests that are connected and driven by synchronous belts, synchronous wheels and servo motors, and disc rotary knife inside the frame as image 3 shown.

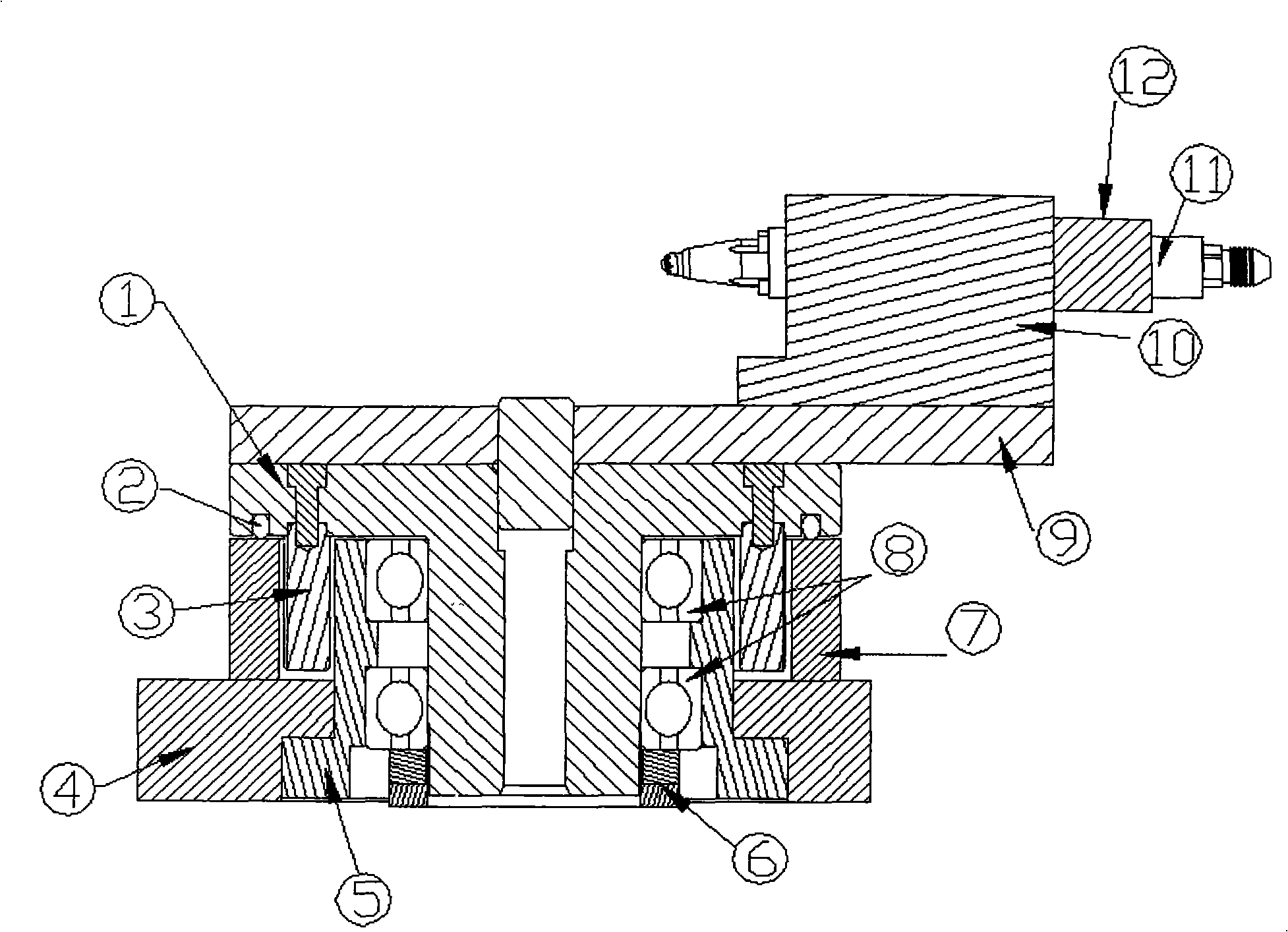

[0035] The power source of the disc rotary tool holder is as follows: Figure 5 As shown, after the (14) servo motor receives the operation command, it is transmitted to the (3) high-precision disc synchronous wheel through the coaxial (16) servo motor upper synchronous wheel and (13) toothed synchronous belt to drive the disc The moving part of the tool post moves around the arc path of the center of the (8) high-precision large-diameter conical push (pressure) force bearing, and the moving part of the disc to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com