Transmission system suitable for large-tonnage alternating current servo press

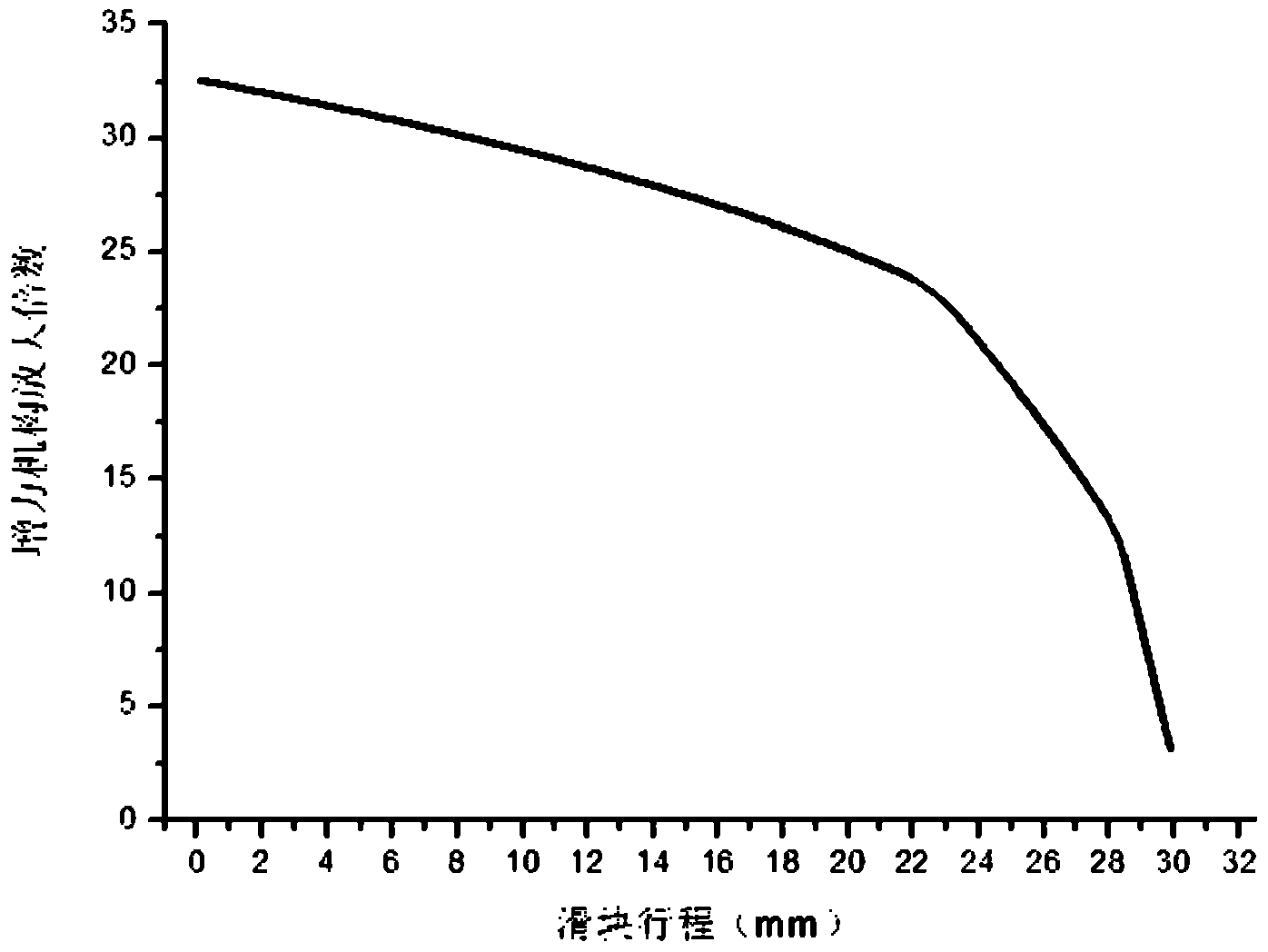

An AC servo and transmission system technology, applied in the field of transmission systems, can solve the problems of small initial boost effect, large terminal boost effect, and inconspicuous boost effect, so as to improve the boost effect and overcome the effective boost stroke Short, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

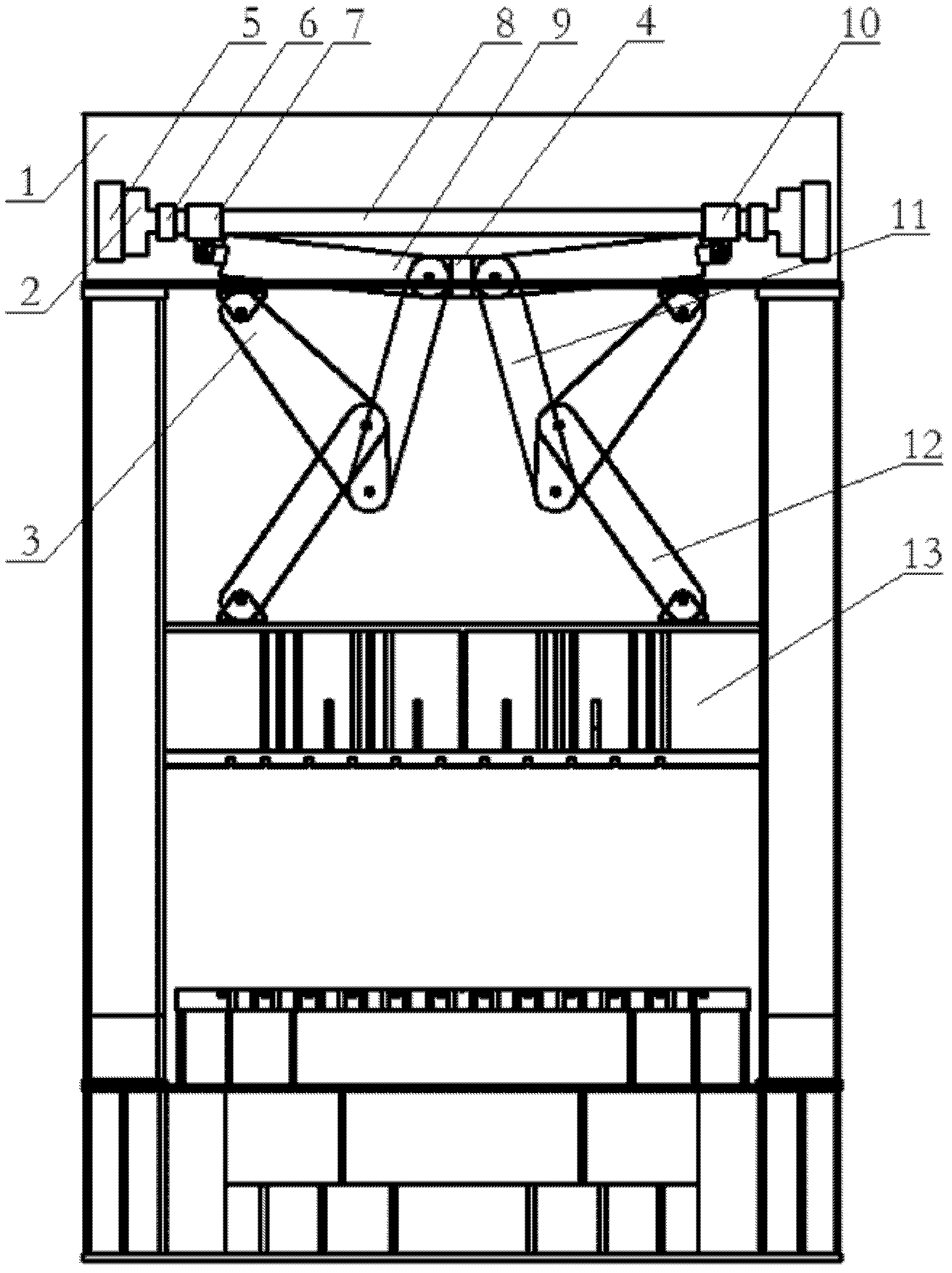

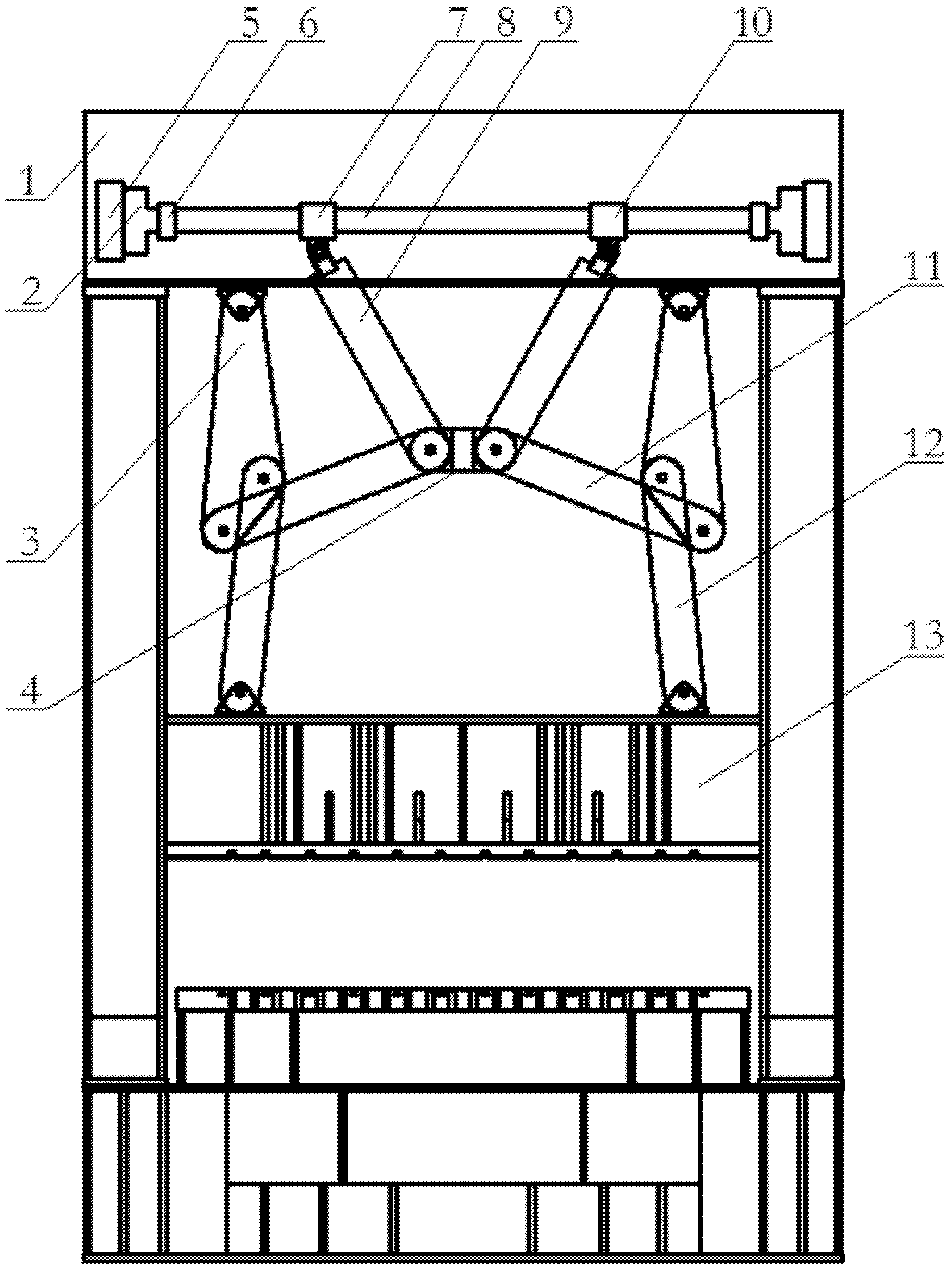

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , a transmission system suitable for large-tonnage AC servo presses, including a disc permanent magnet synchronous servo motor 5 and a planetary gear reducer 2, the disc permanent magnet synchronous servo motor 5 is symmetrically fixed on the upper beam 1, and the disc permanent magnet synchronous servo motor The magnetic synchronous servo motor 5 and the planetary gear reducer 2 are designed together to amplify the torque and form a first-level booster mechanism. The symmetrically placed disc permanent magnet synchronous servo motor 5 works at the same time, and the disc permanent magnet synchronous servo motor 5 The connection with the planetary gear reducer 2 can make the structure more compact, smaller in size, and save space. The symmetrically placed disc permanent magnet synchronous servo motor 5 works synchronously under the control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com