Patents

Literature

239results about How to "Lower vertical height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

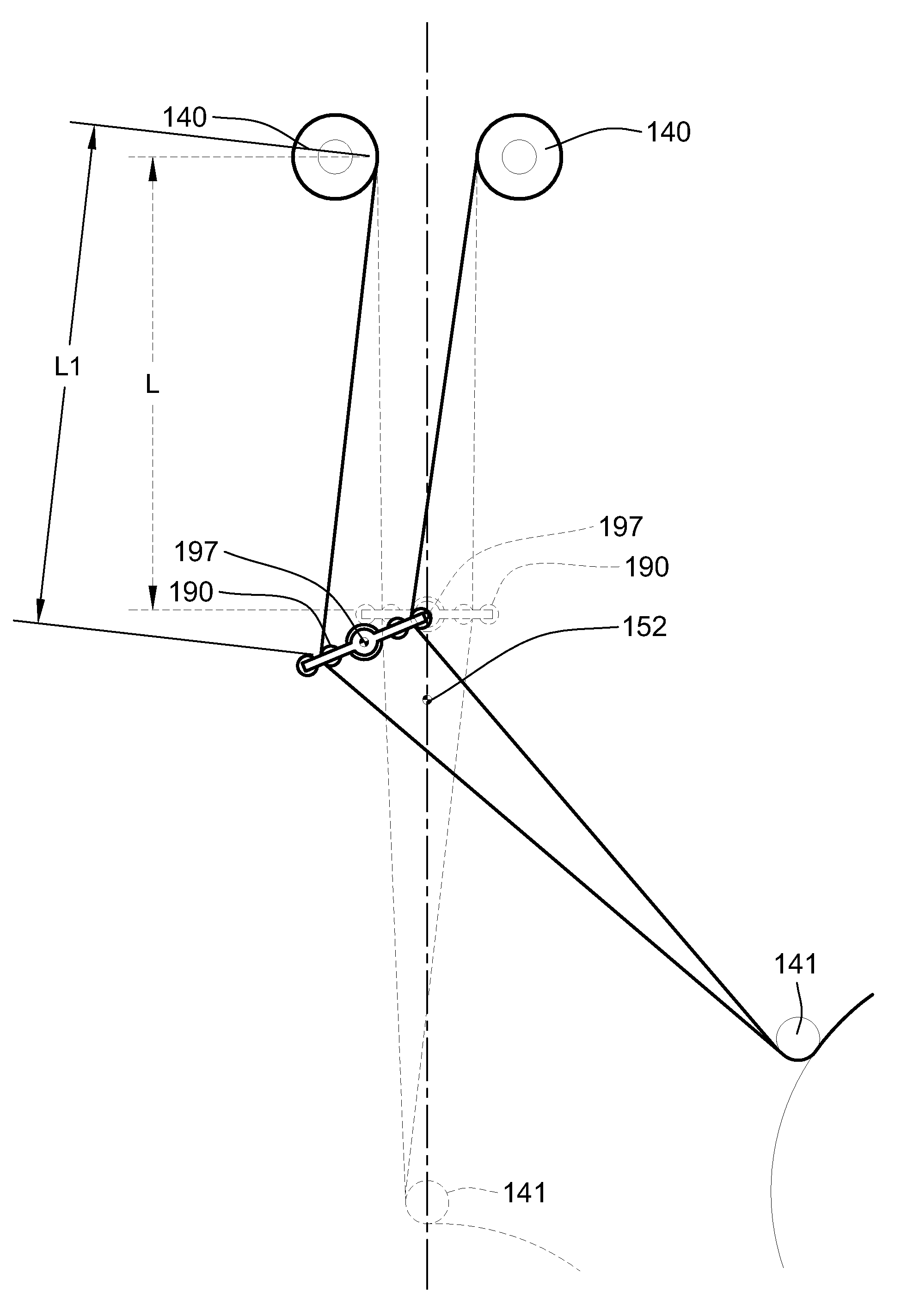

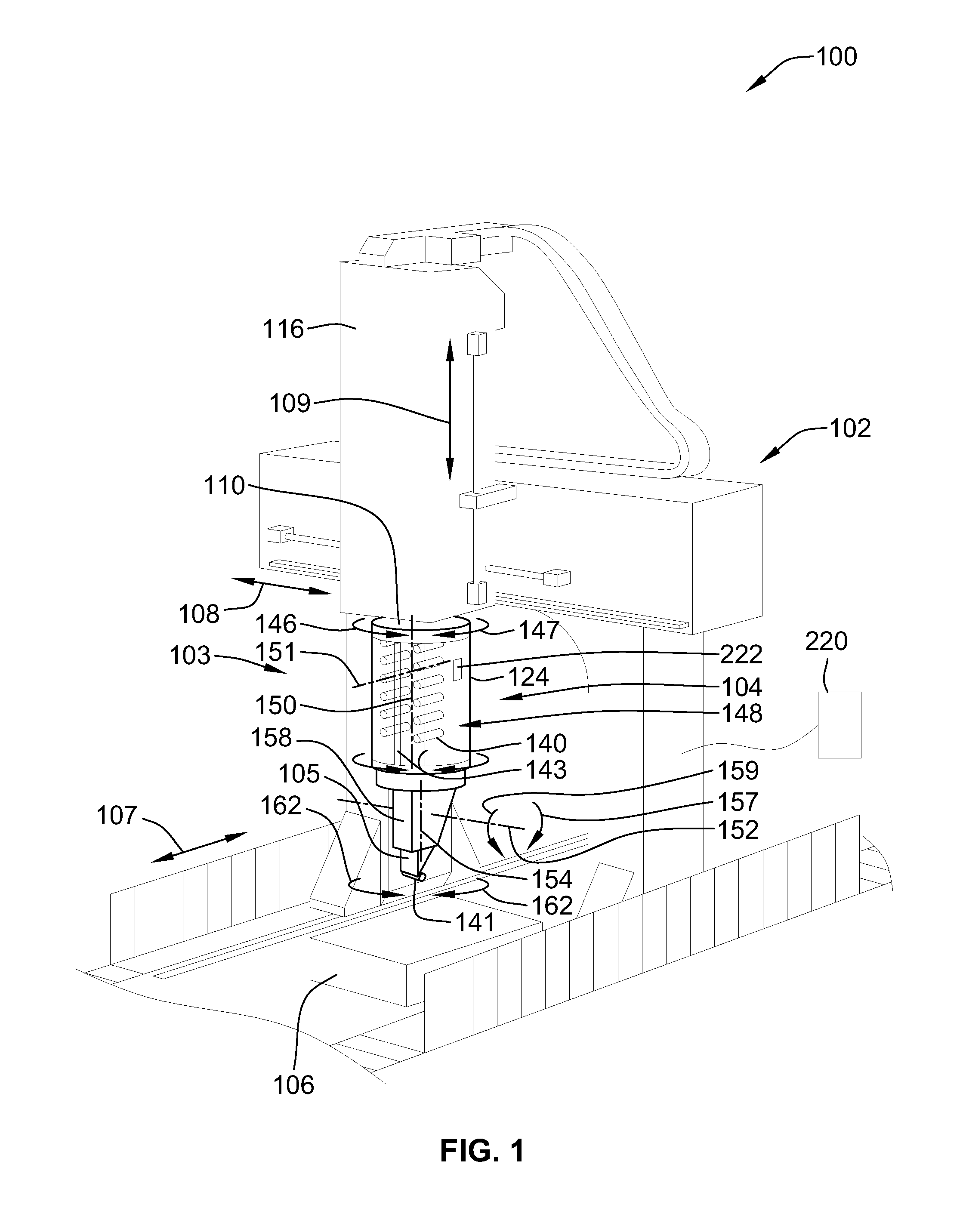

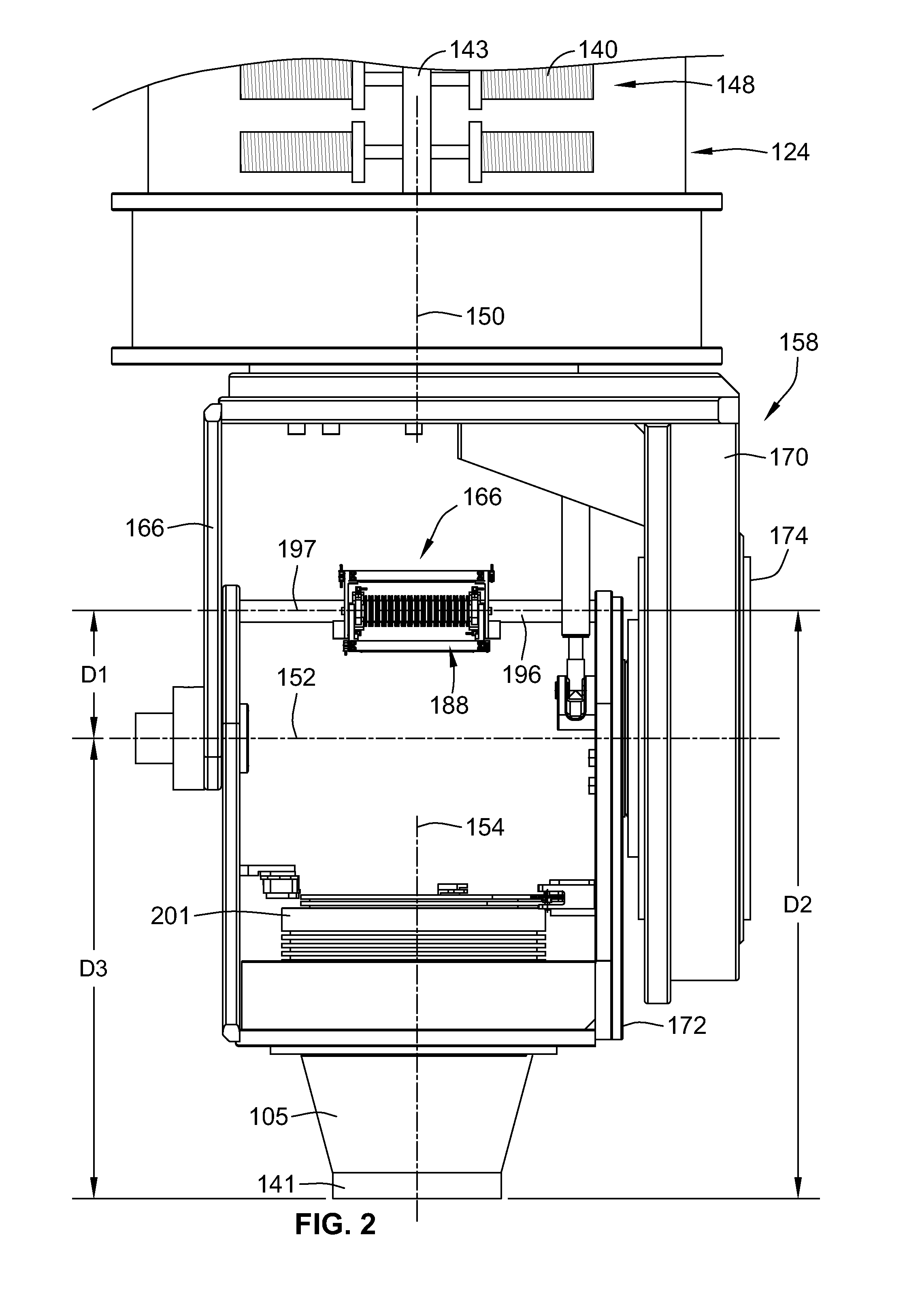

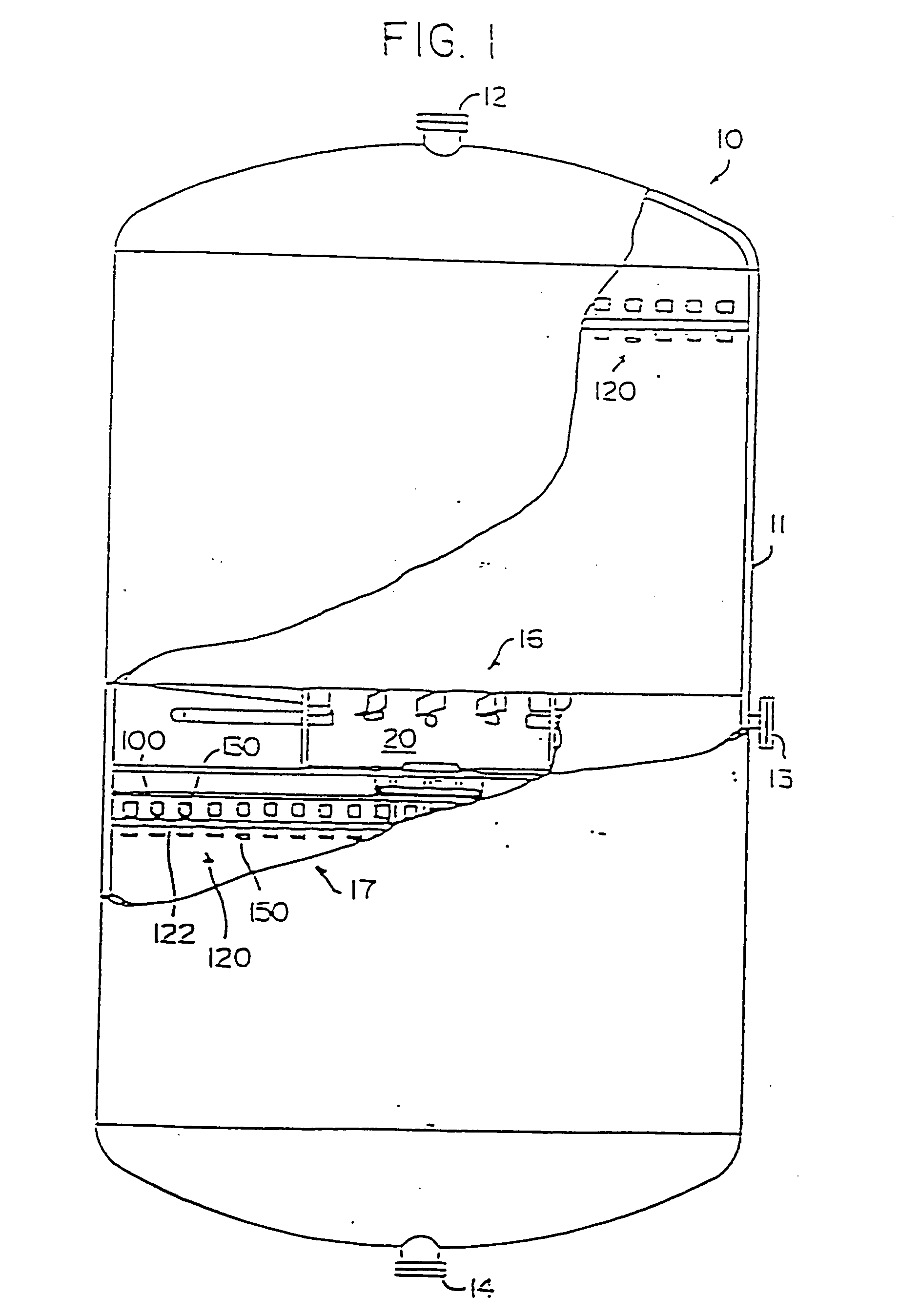

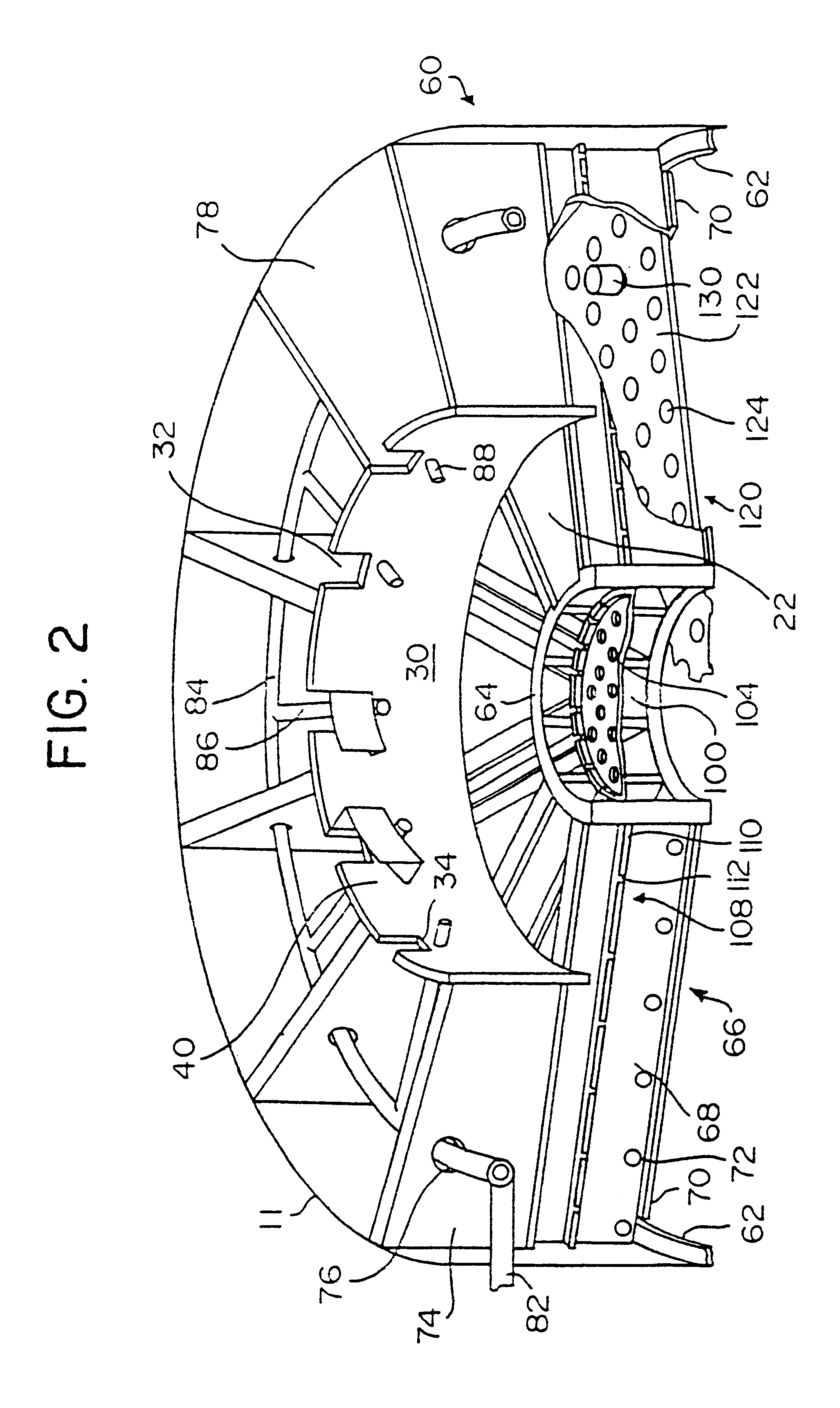

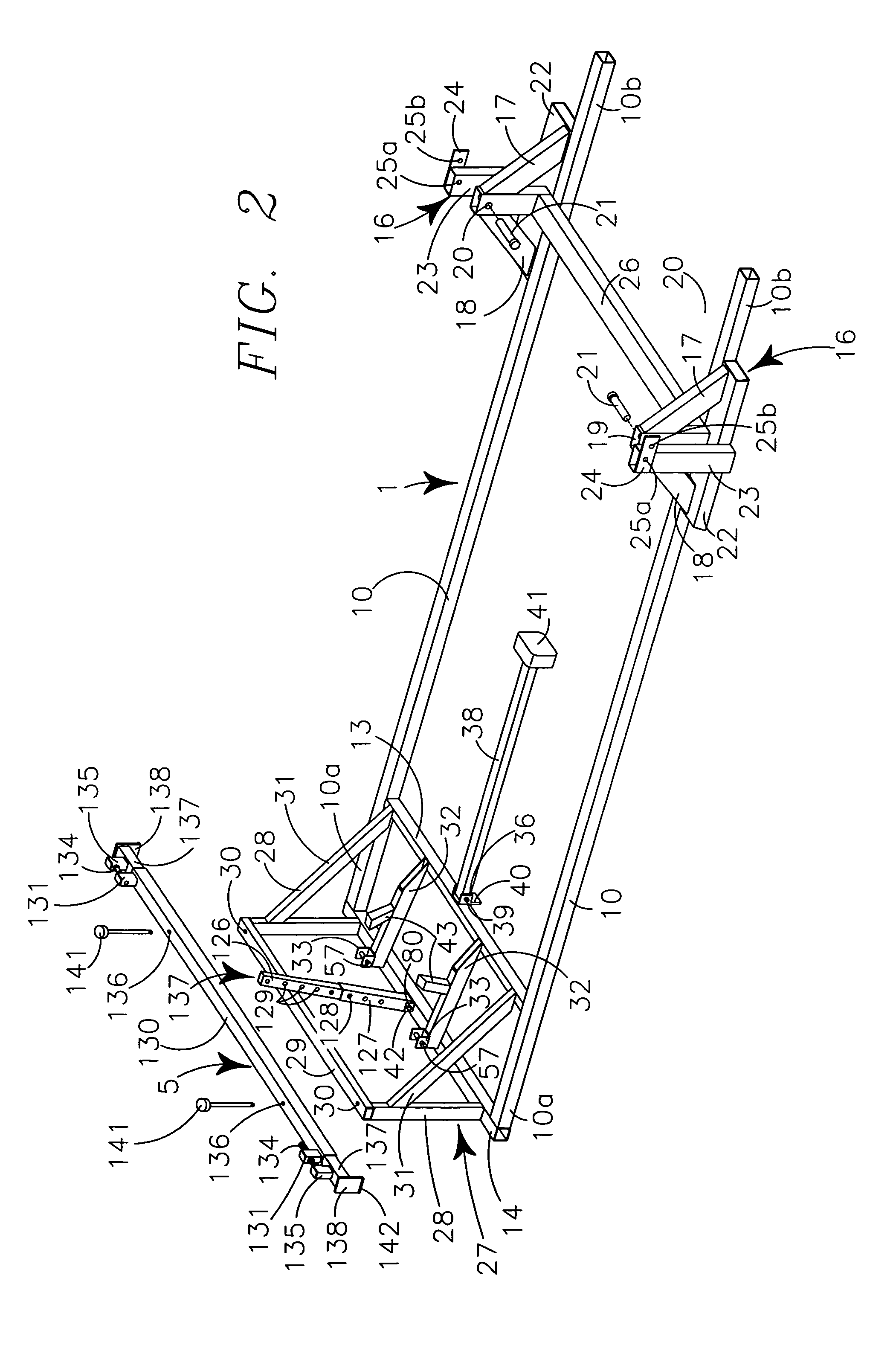

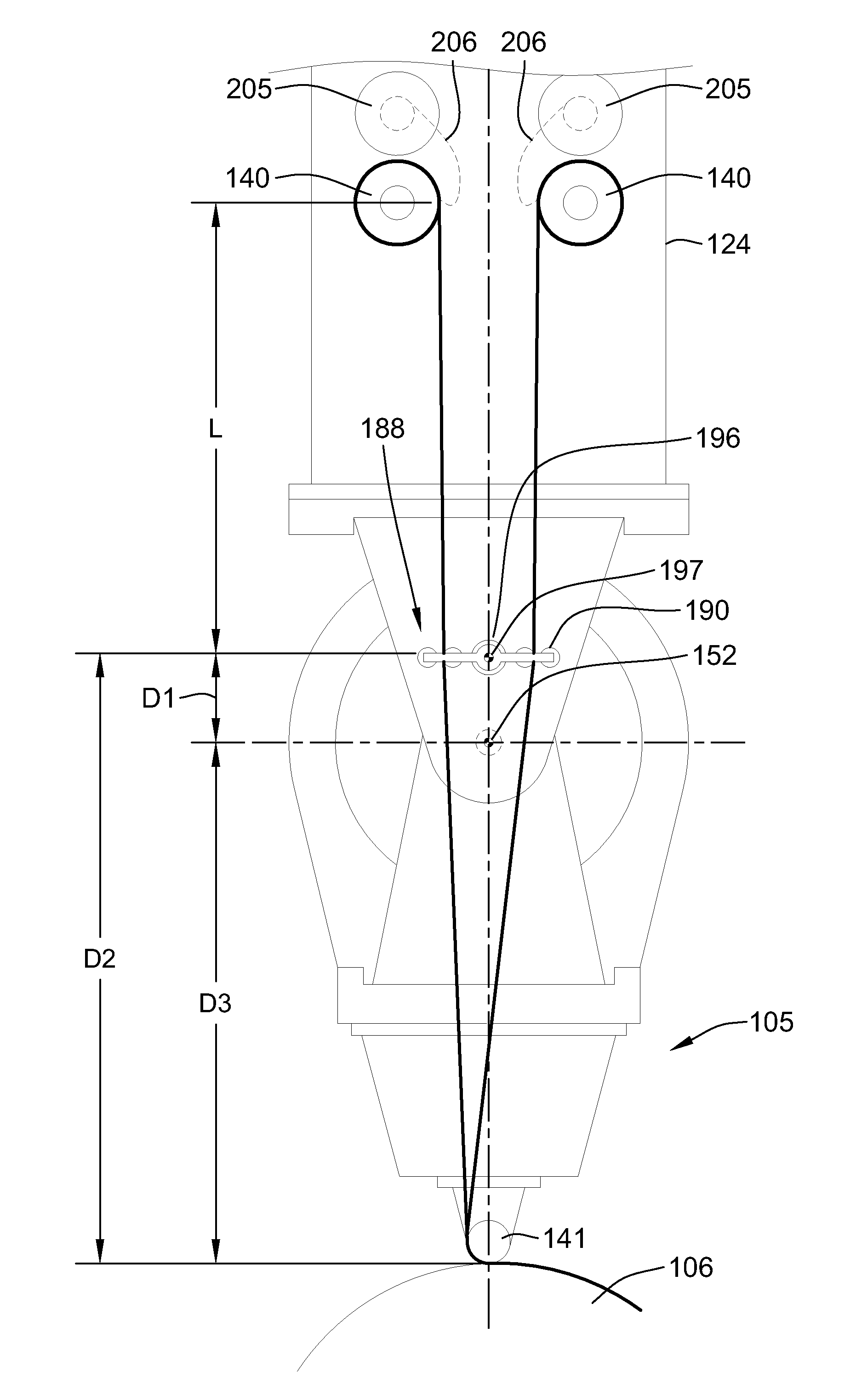

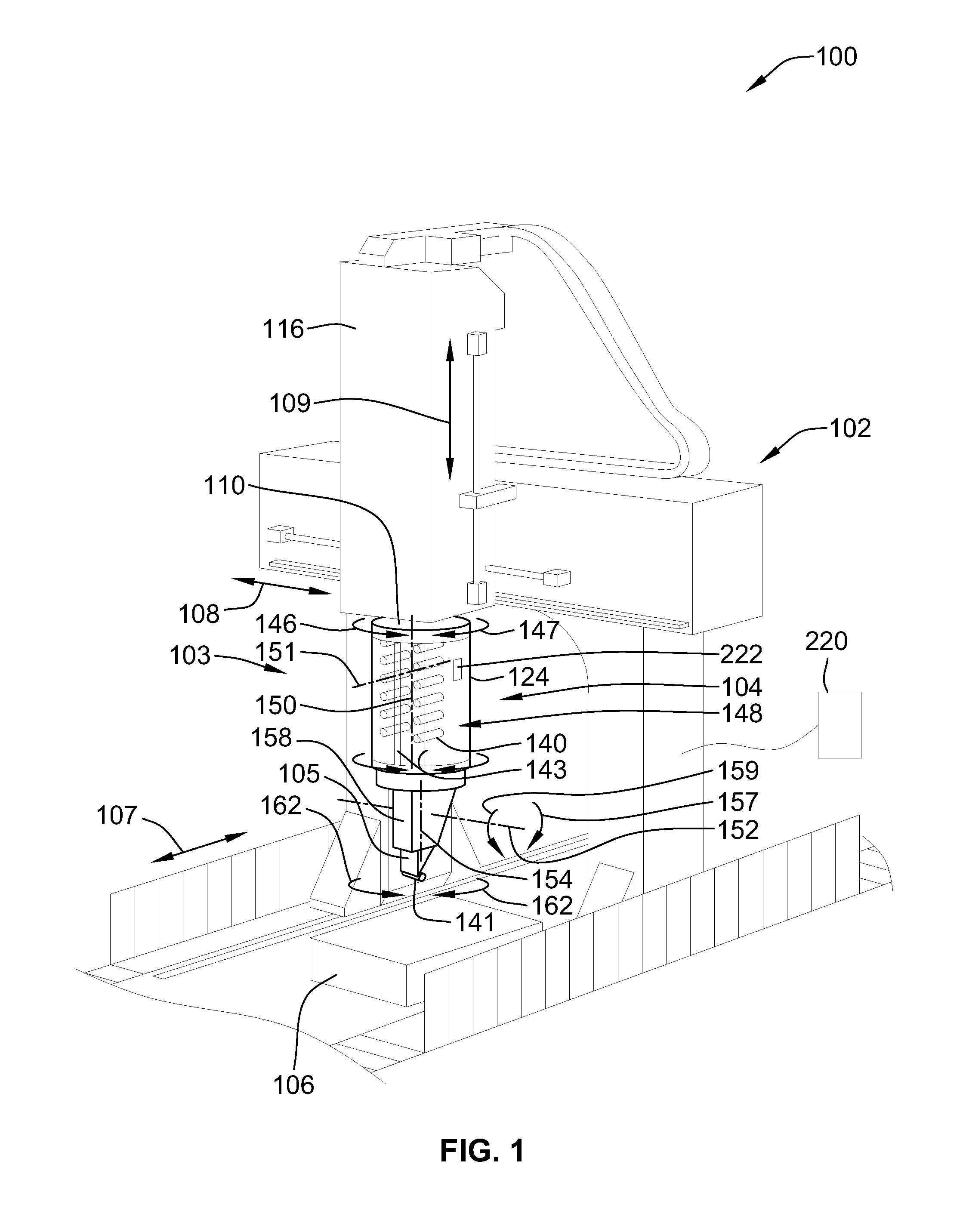

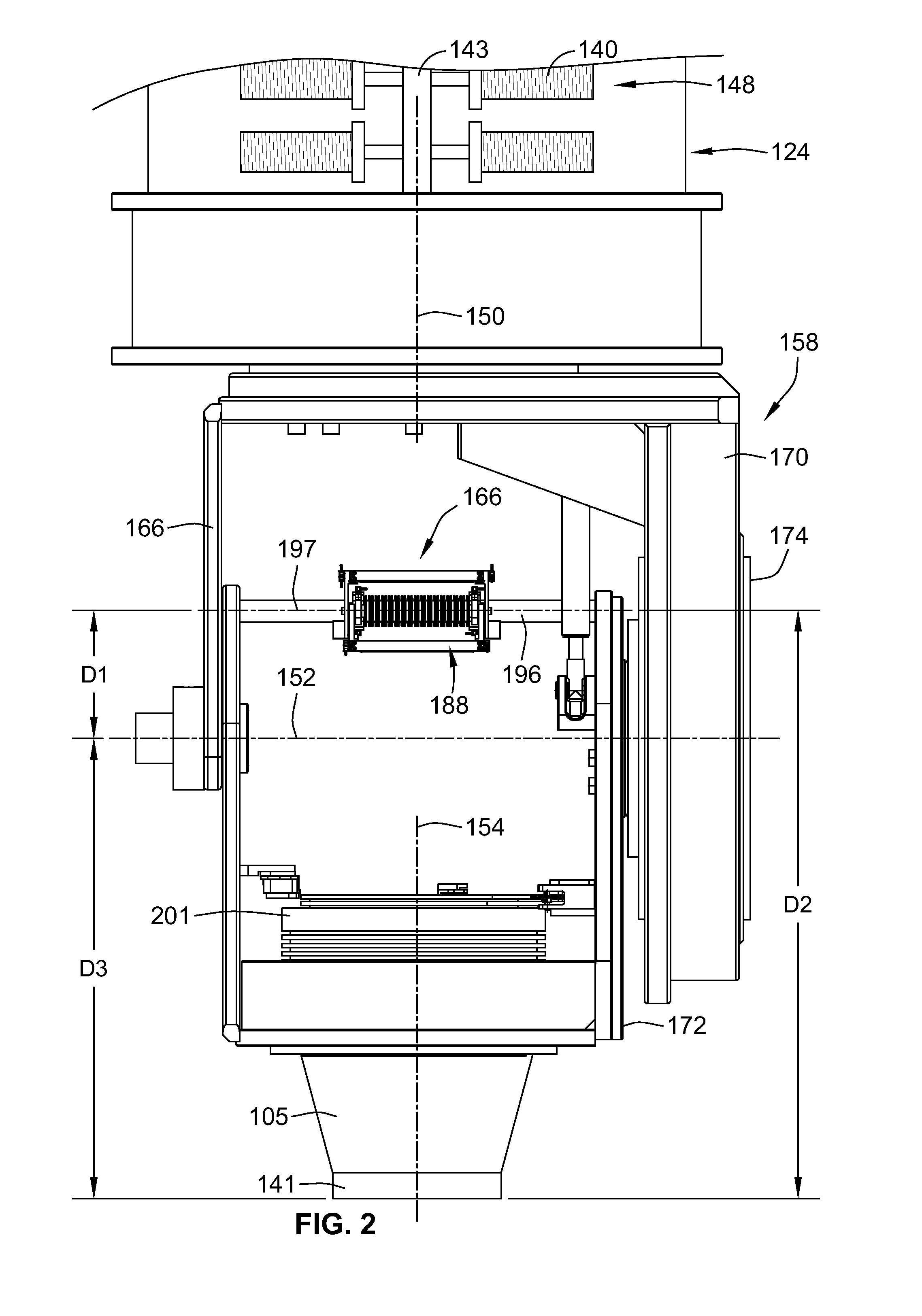

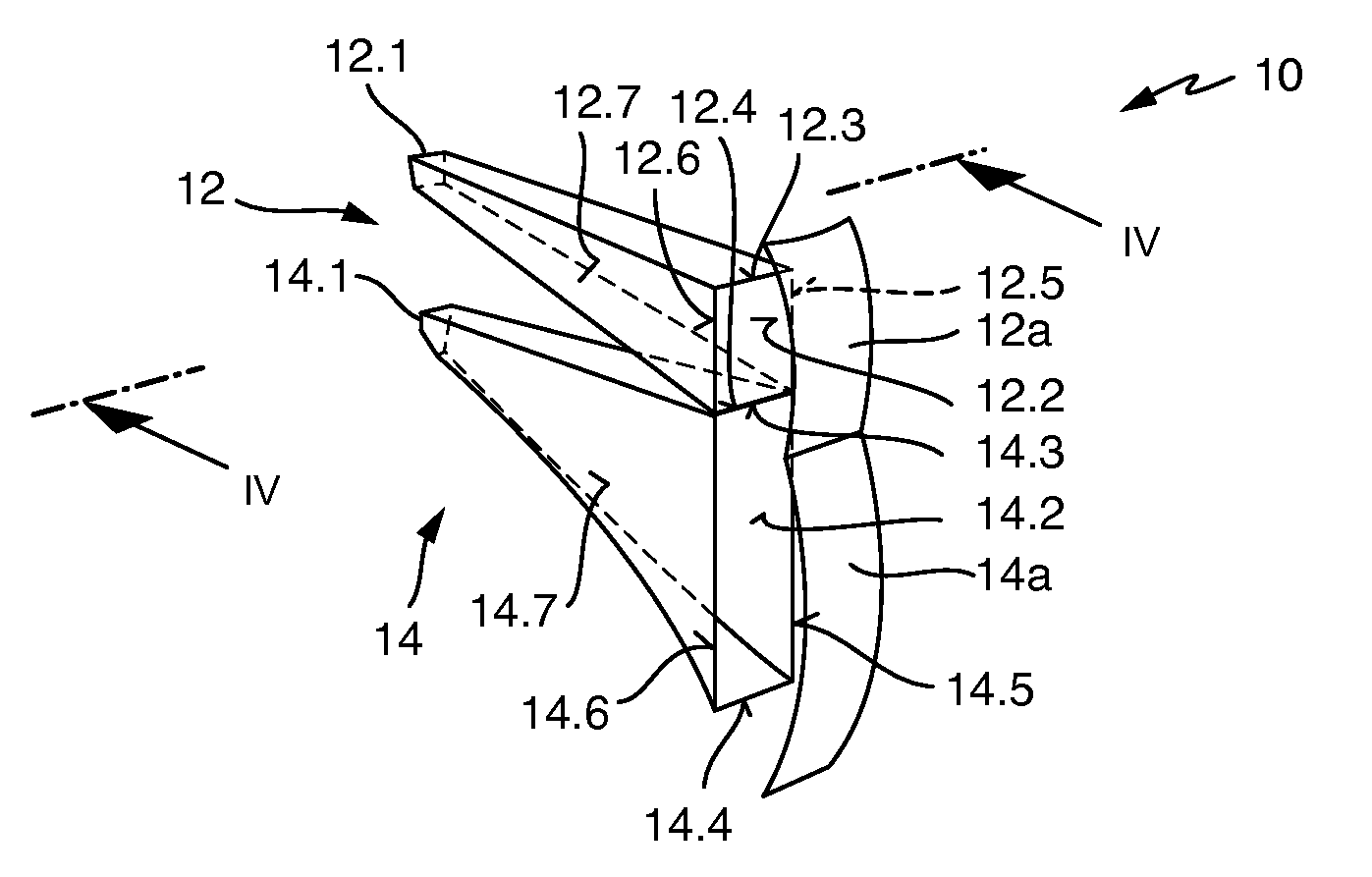

Fiber delivery apparatus and system having a creel and fiber placement head with polar axis of rotation

ActiveUS8534338B2Improve protectionReduce any negative affects on fiber towsEngine sealsLamination ancillary operationsFiberDegrees of freedom

A fiber placement system including positioner and a fiber delivery apparatus having a creel assembly and a fiber placement head is provided. The positioner moves the entire fiber delivery apparatus including the creel assembly and the fiber placement head via at least three linear degrees of freedom. The fiber delivery apparatus includes an articulating wrist for moving the fiber placement head relative to the creel assembly. The fiber placement apparatus is substantially free of linear degrees of freedom within the fiber tow paths between the spools and the fiber placement head. One or more rotational degrees of freedom may be provided along the tow path. In one embodiment, the interface between the fiber delivery apparatus and the positioner is laterally offset such that a portion of the creel axially overlaps with vertical ram of the positioner.

Owner:INGERSOLL MACHINE TOOLS

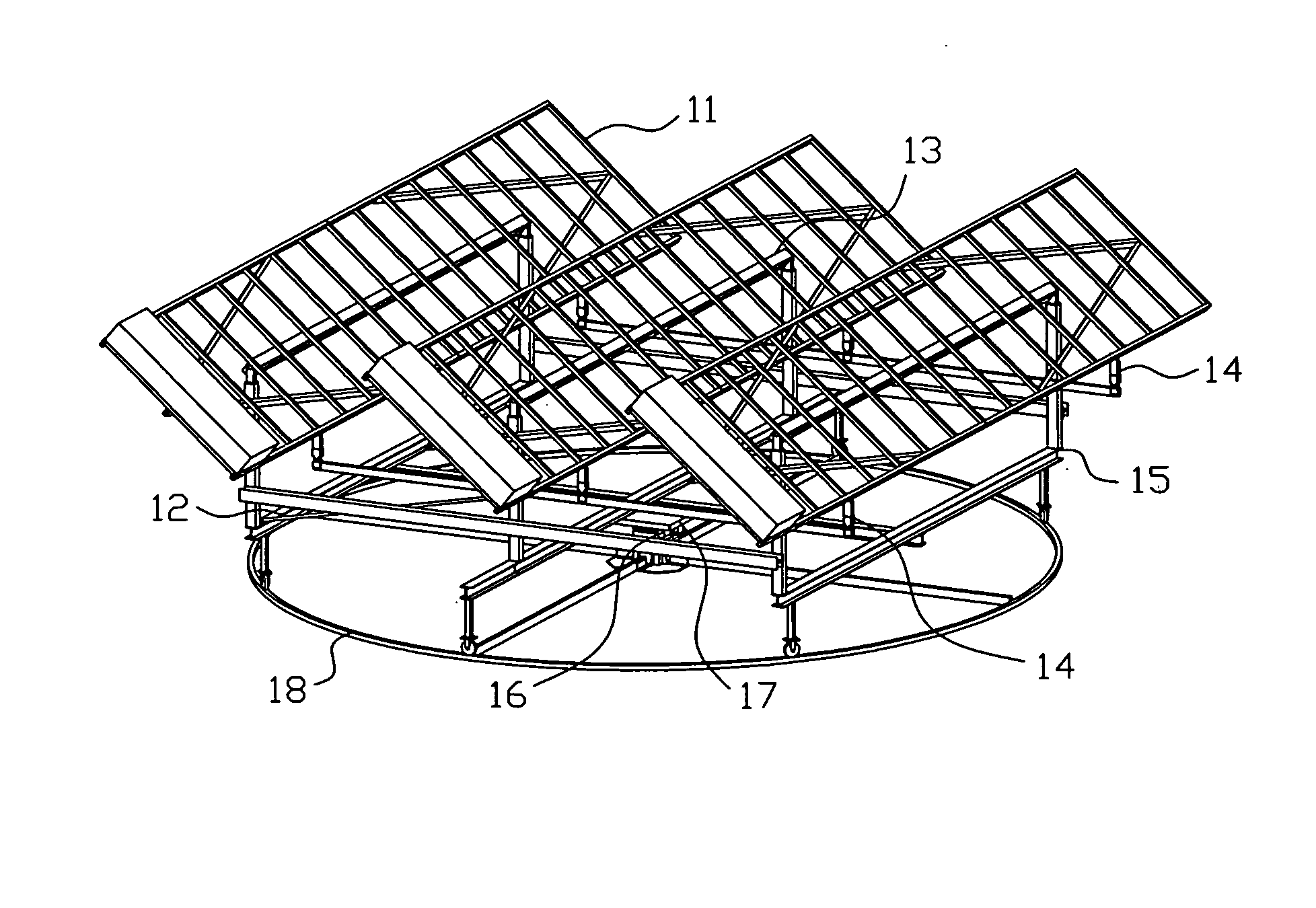

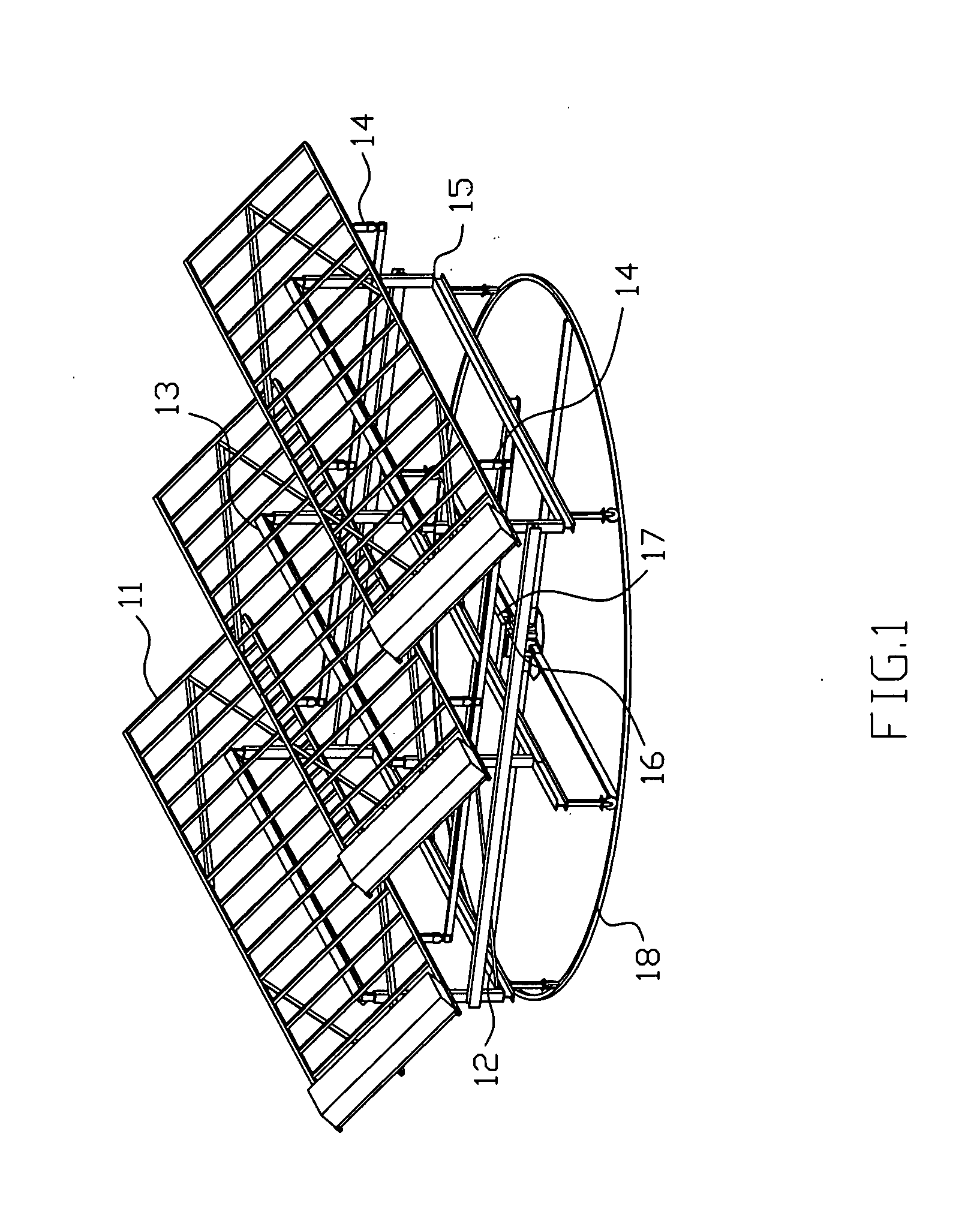

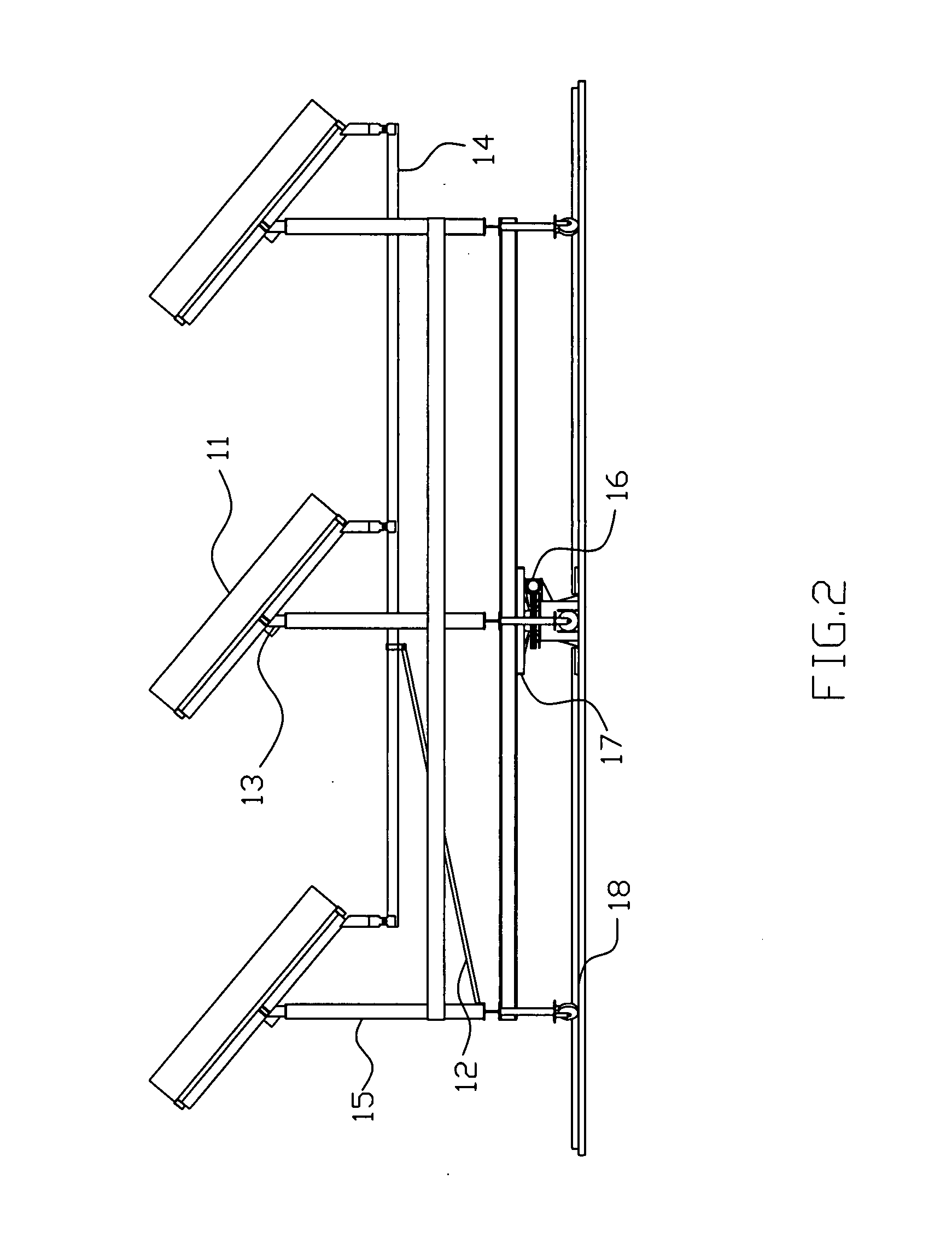

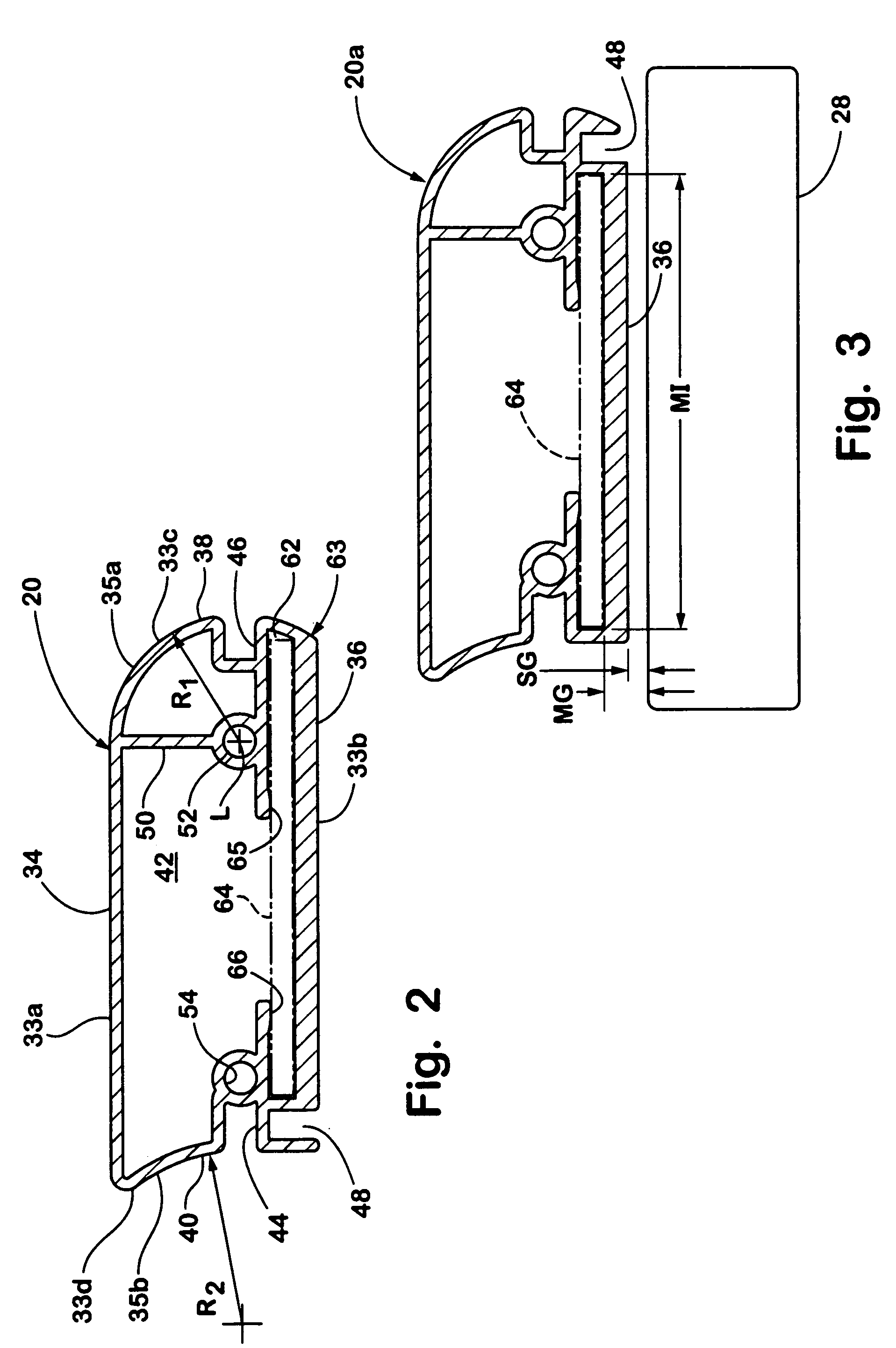

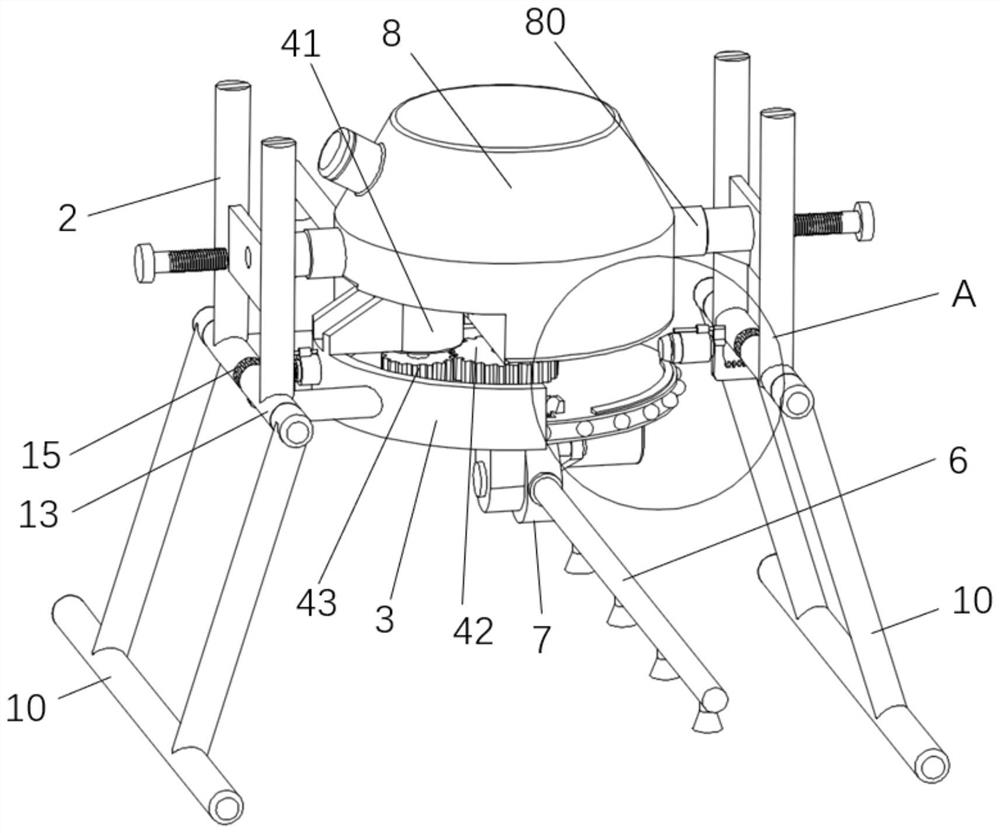

Solar tracker having louver frames

InactiveUS20090032089A1Lower vertical heightLow costPhotovoltaic supportsSolar heating energyLouverSolar tracker

A solar tracker does not need to stand high. The solar tracker has a strong structure and a stable center of gravity for tracking sunlight. Thus, the solar tracker does not need a foundation to be connected for standing upon. And the solar tracker is fit to be used on a bare ground or roof with a low cost.

Owner:INST NUCLEAR ENERGY RES ROCAEC

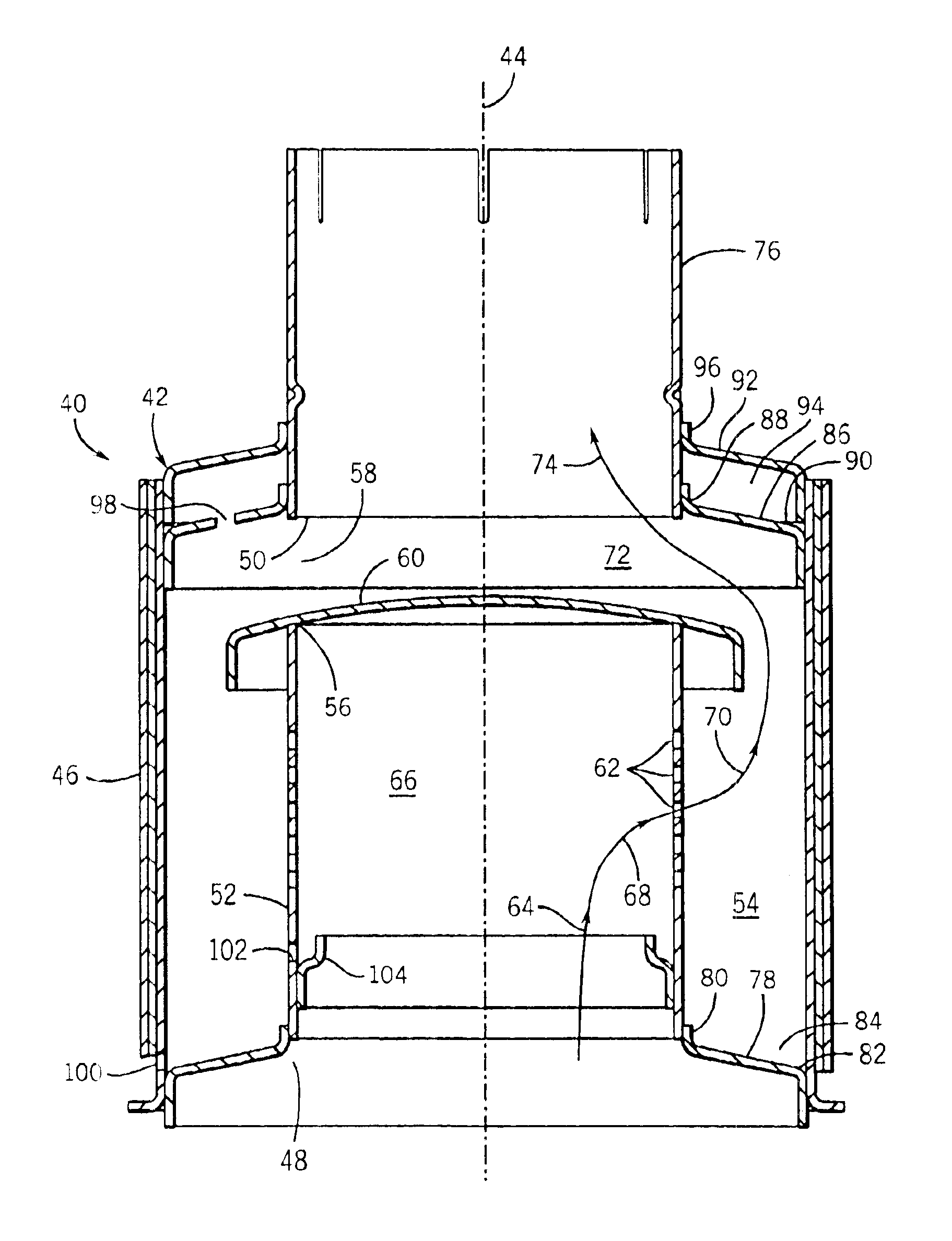

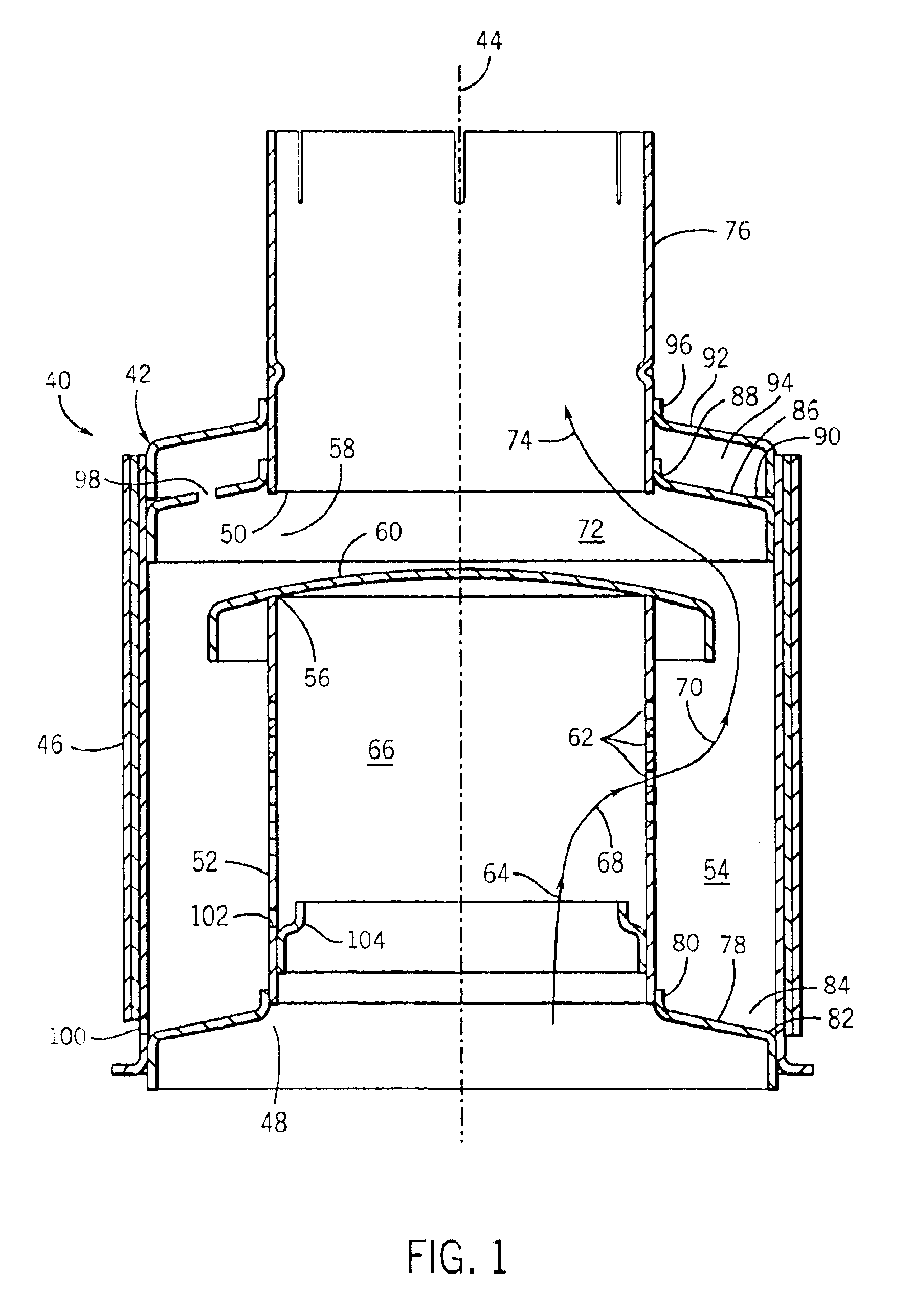

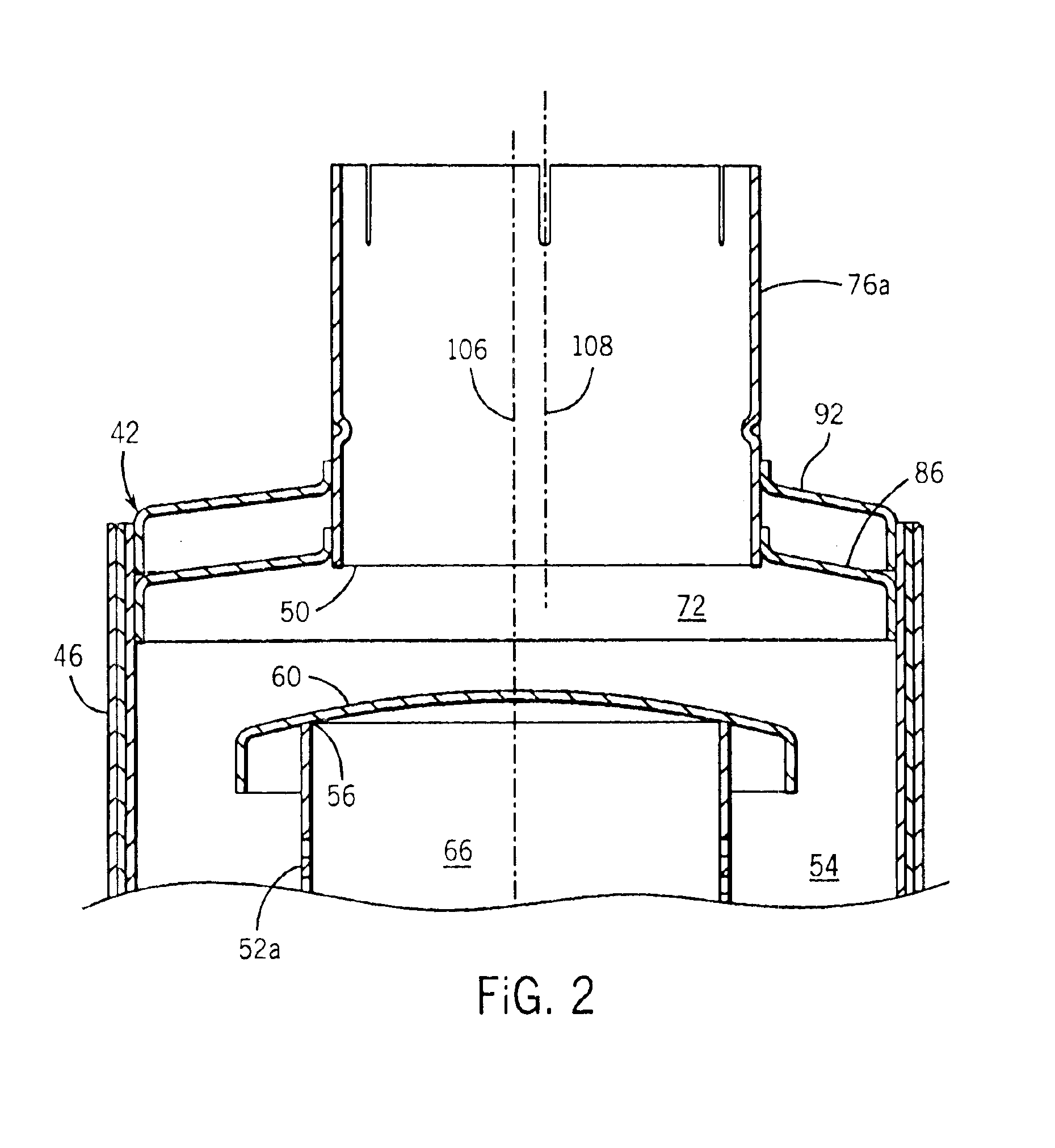

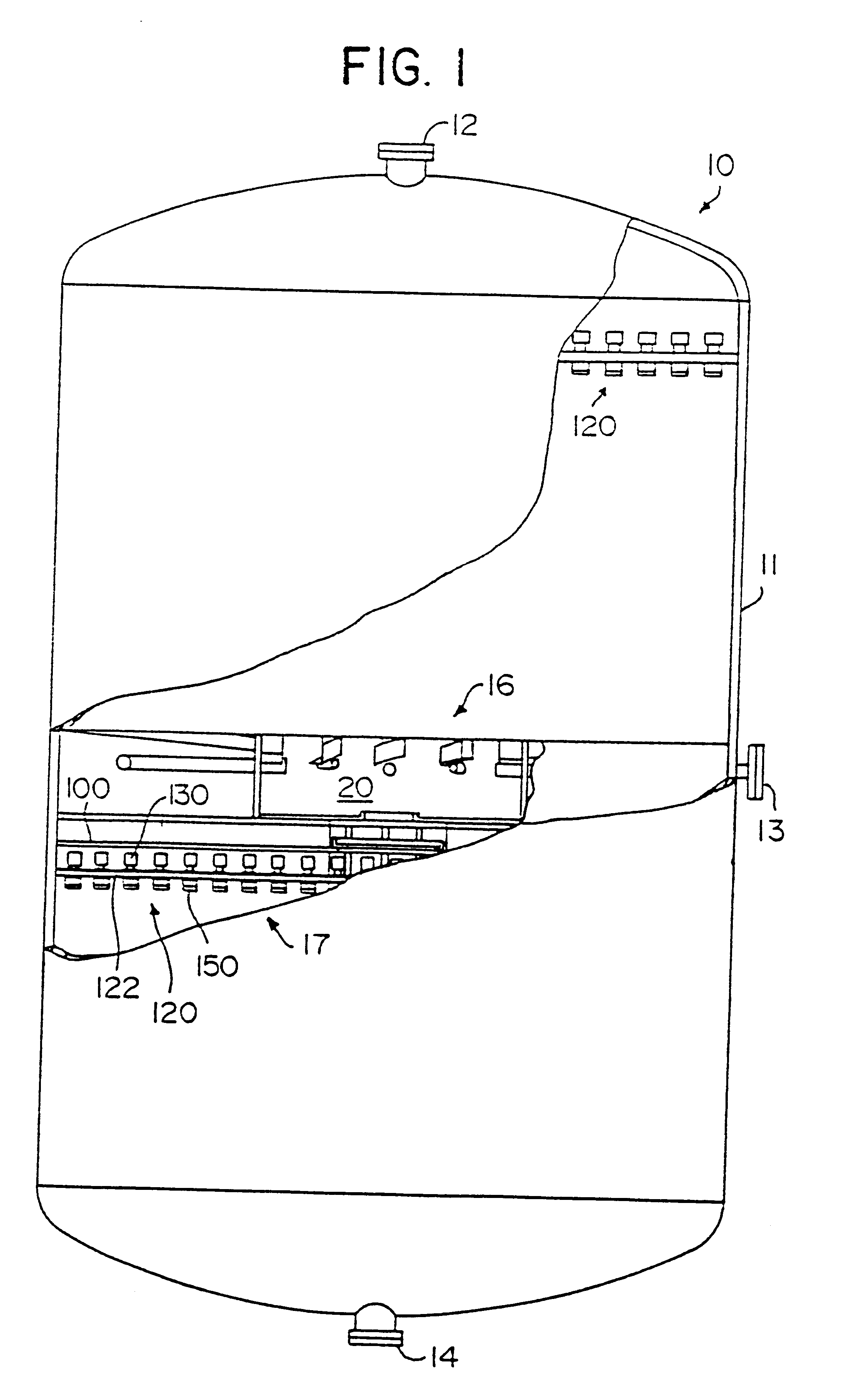

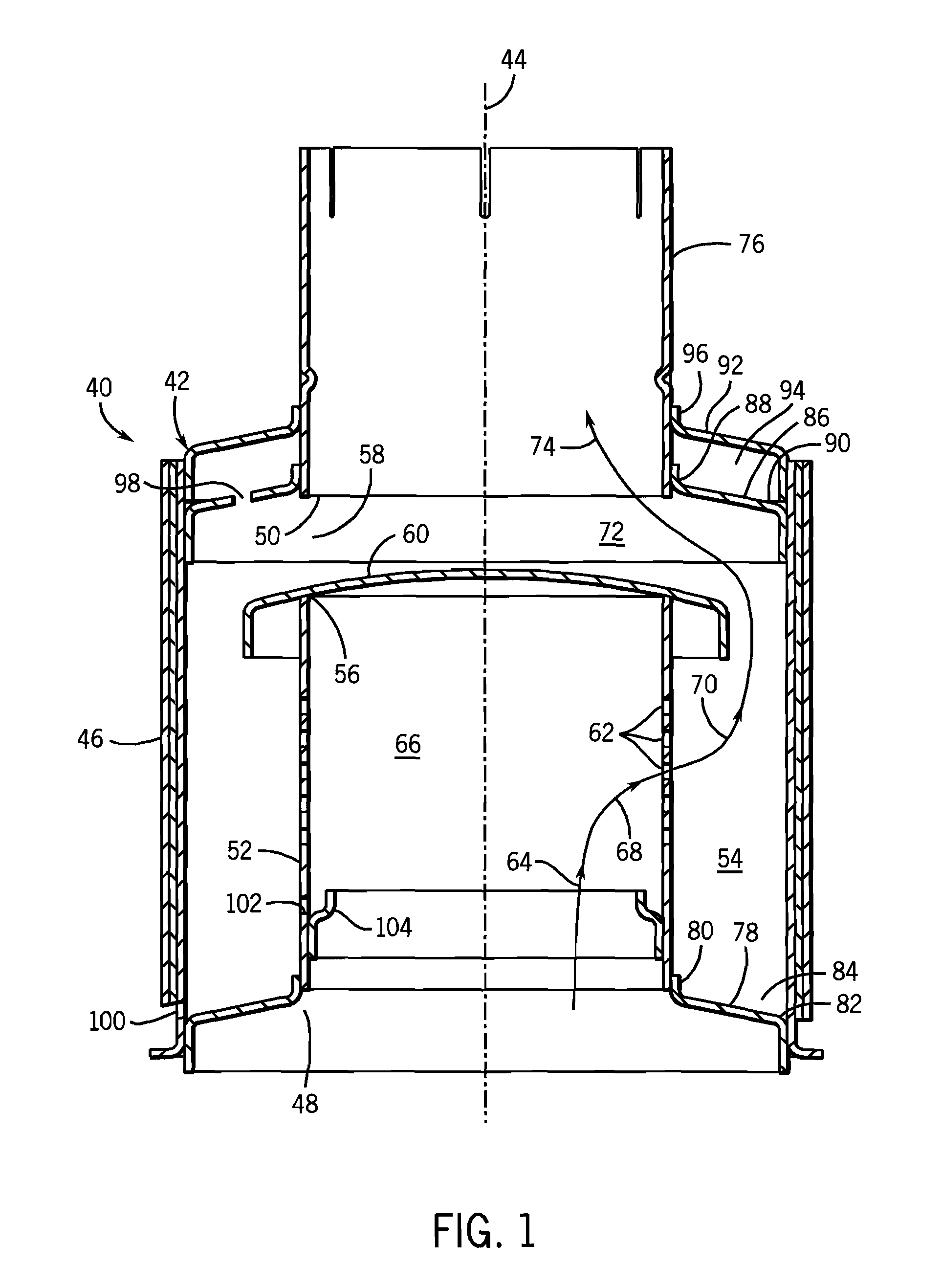

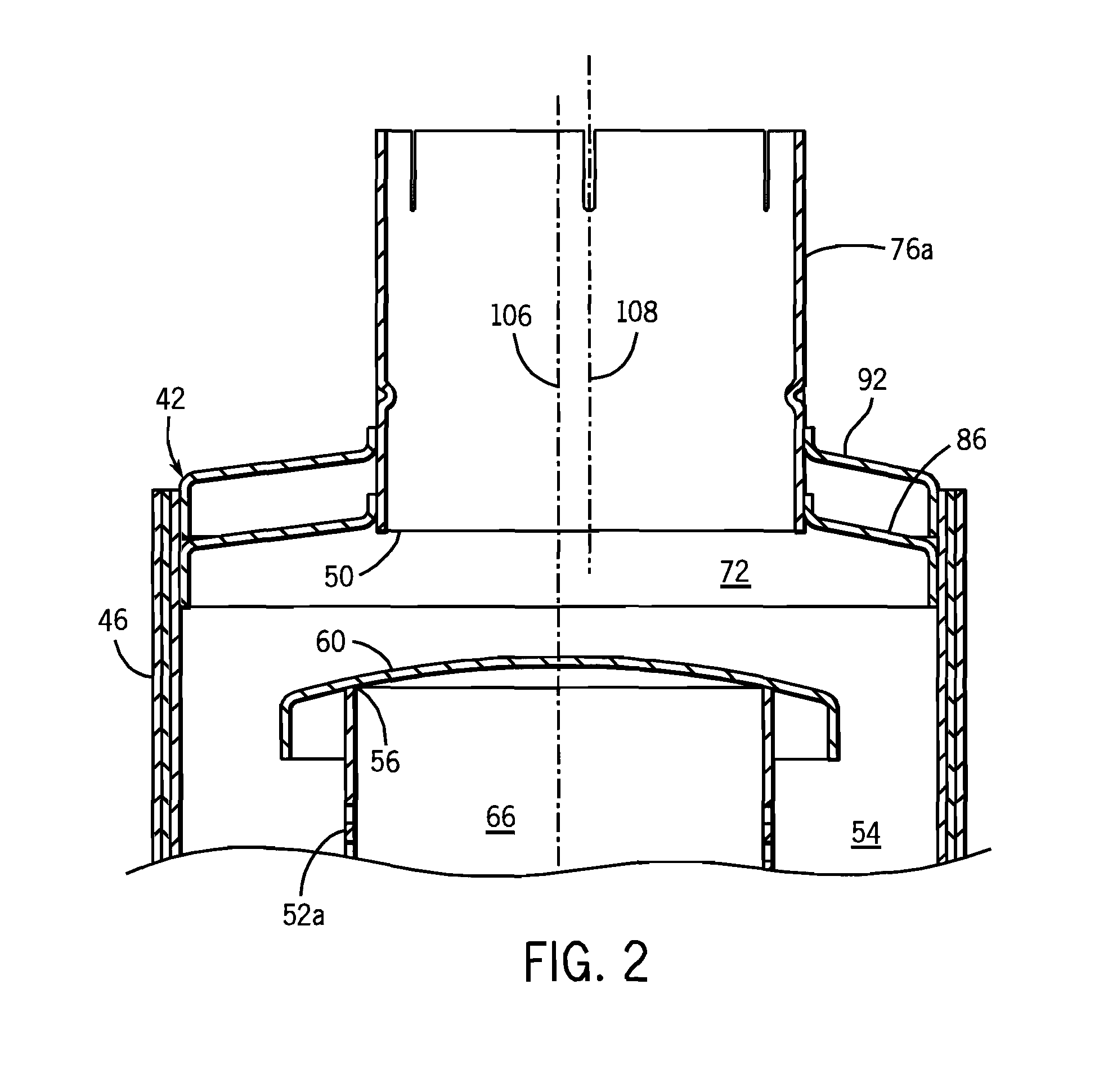

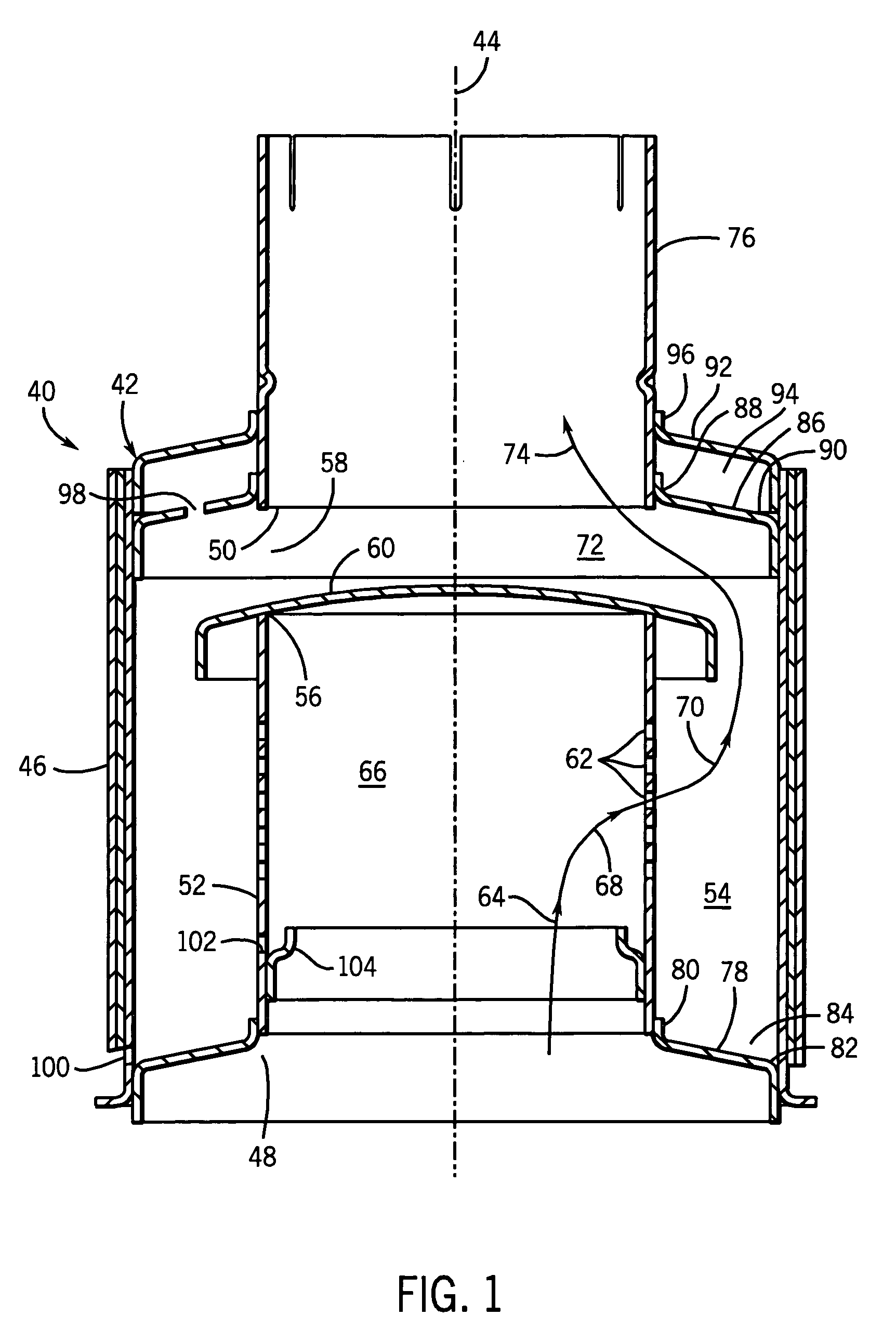

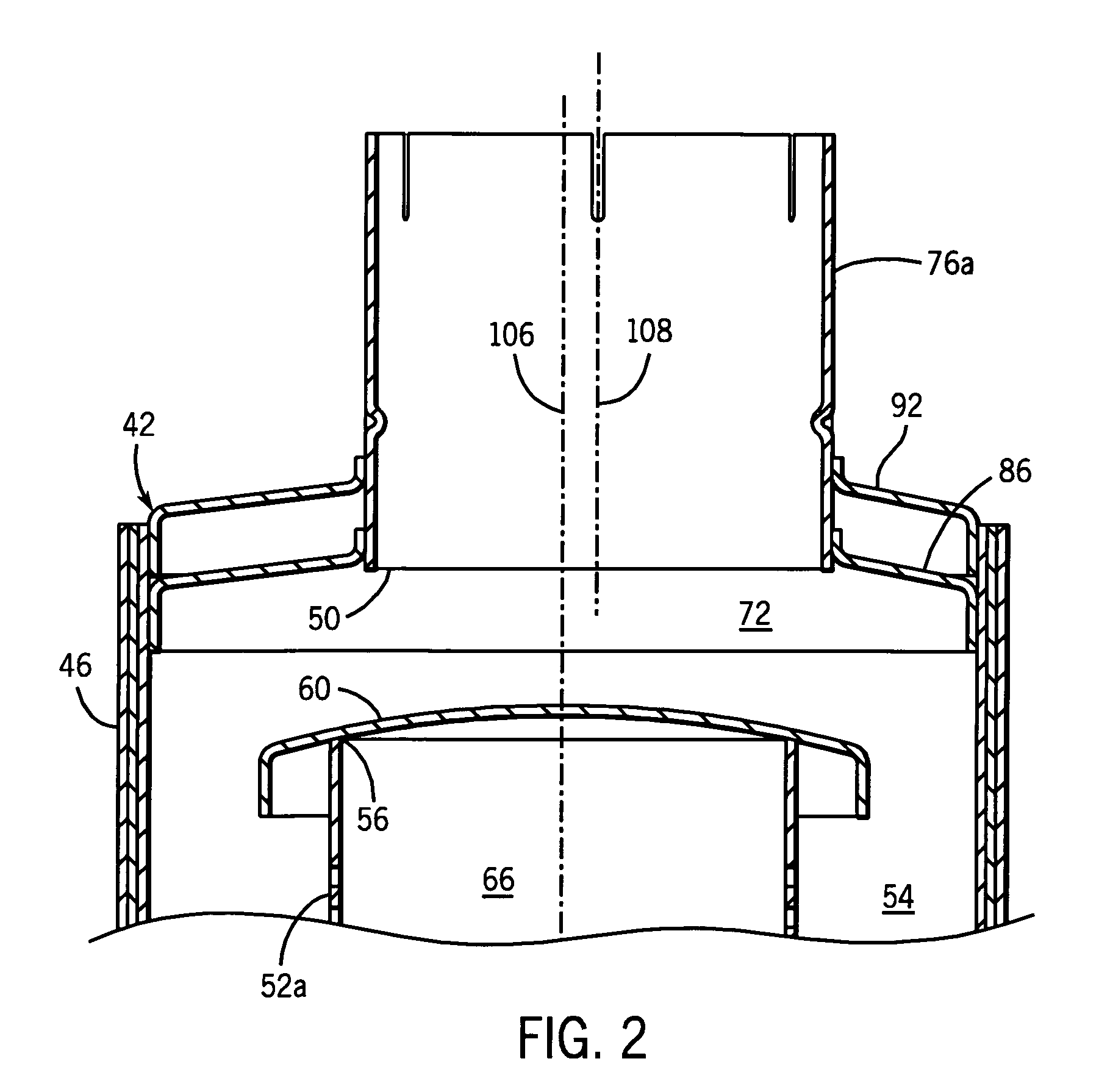

Compact, reduced backpressure, vertical exhaust water trap assembly

InactiveUS6868670B1Easy vehicle packagingReduce backpressureExhaust apparatusValve members for absorbing fluid energyWater trapEnvironmental engineering

An exhaust water trap assembly has separated and spaced exhaust tubes, and a dome cap blocking entry of water to protect an upstream catalytic converter or soot filter. A first tube extends axially upwardly into a housing, and a second tube is spaced vertically thereabove. The dome cap on the top end of the first tube blocks exhaust flow axially upwardly therepast and blocks entry of water axially downwardly therepast.

Owner:FLEETGUARD INC

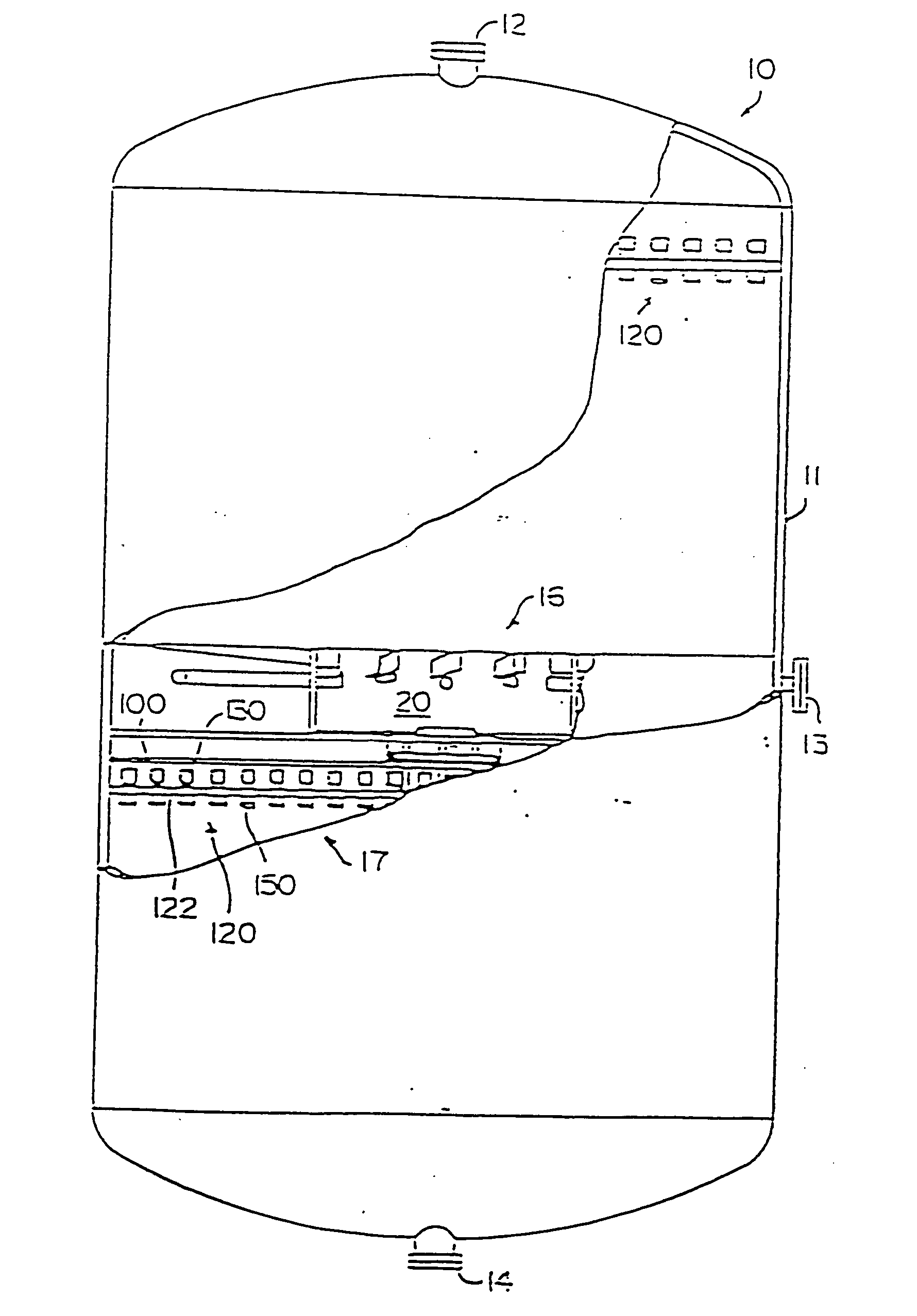

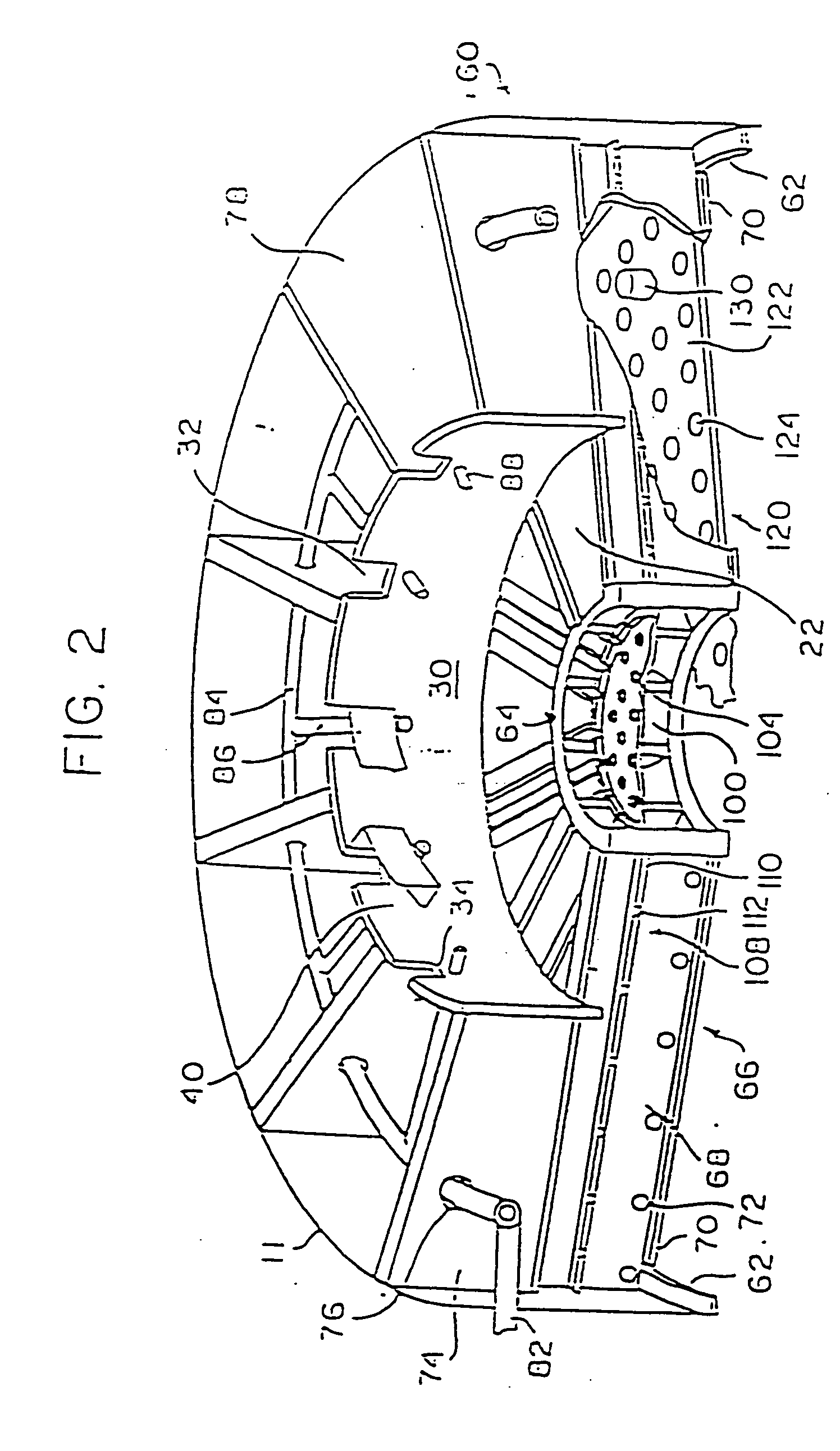

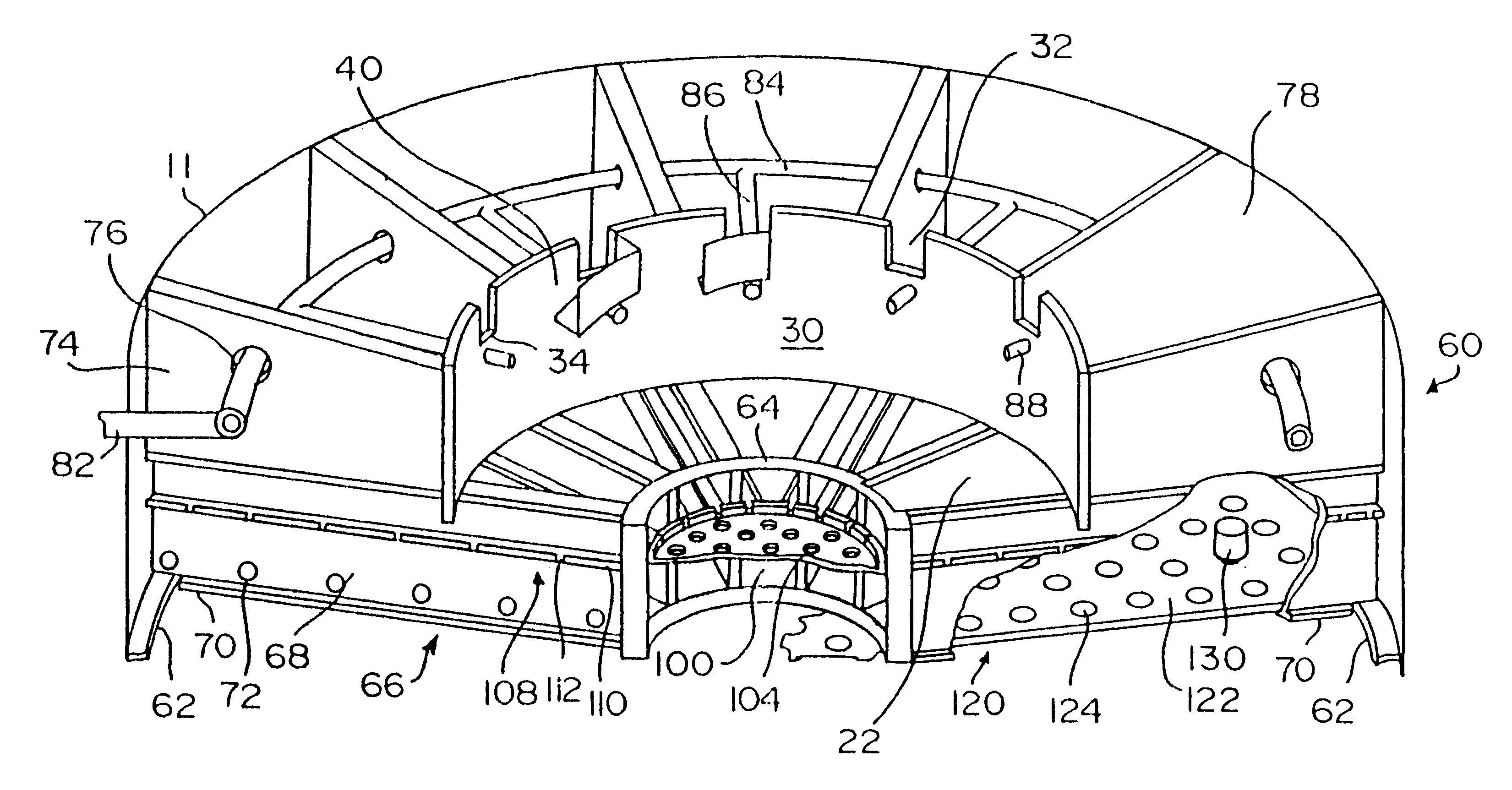

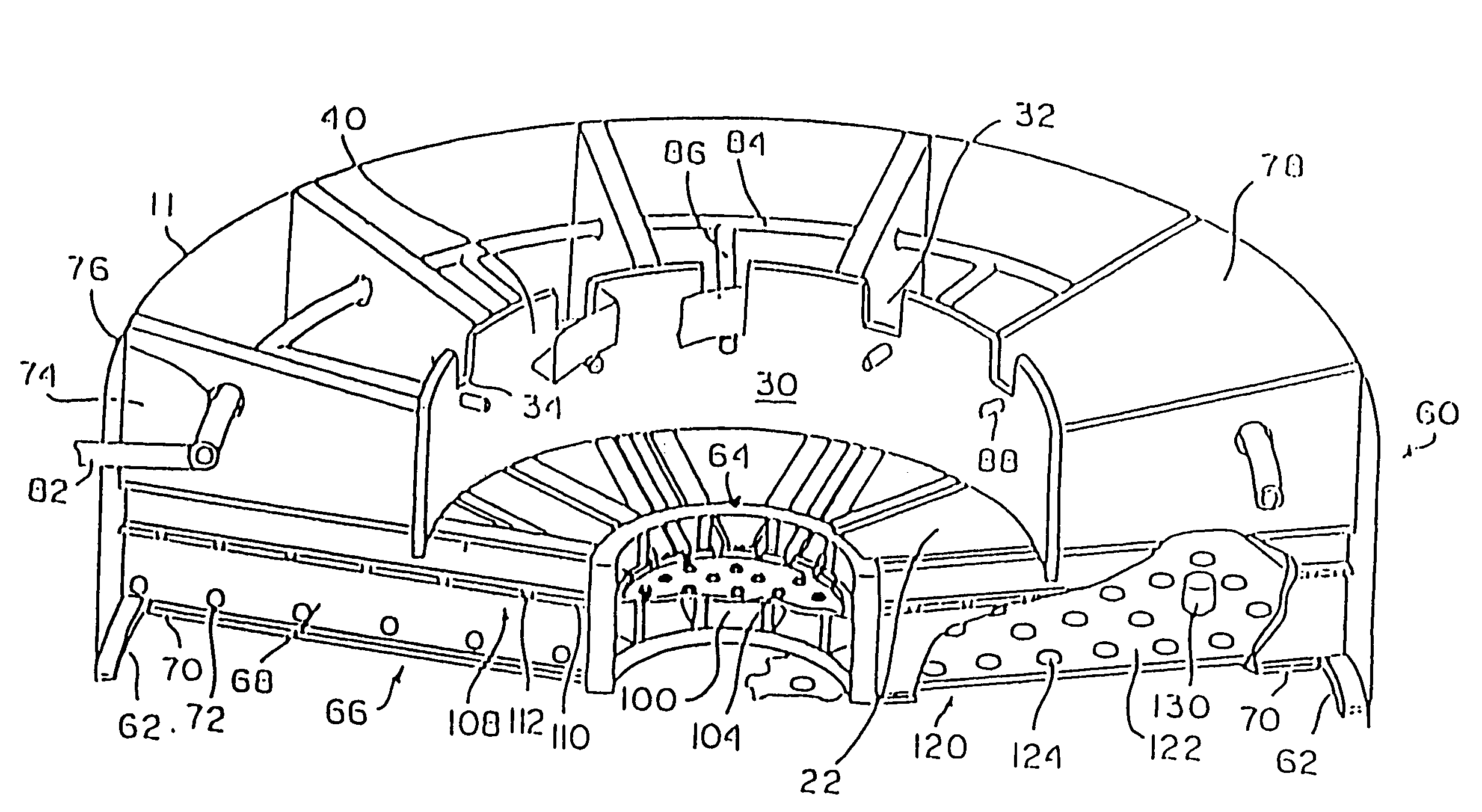

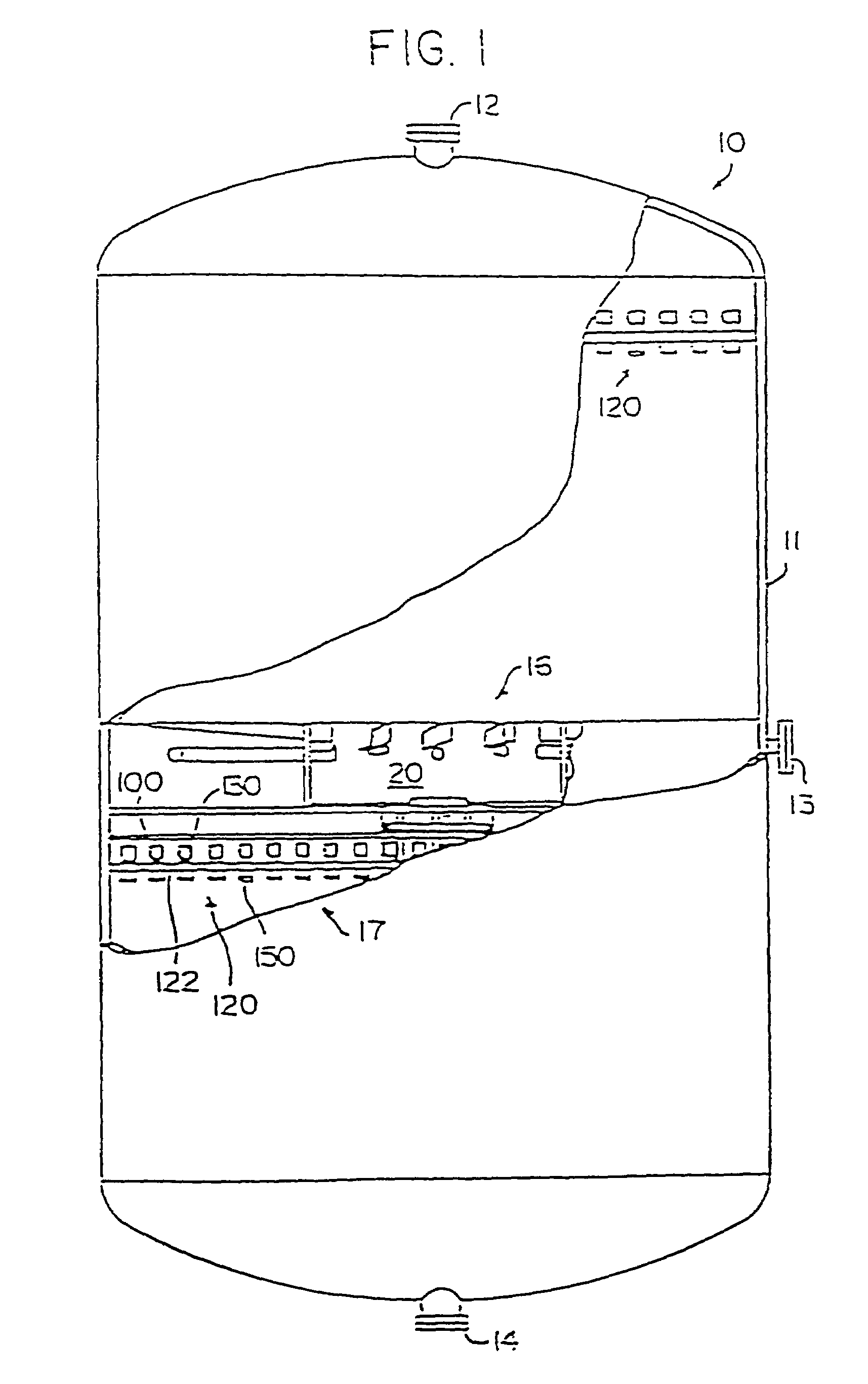

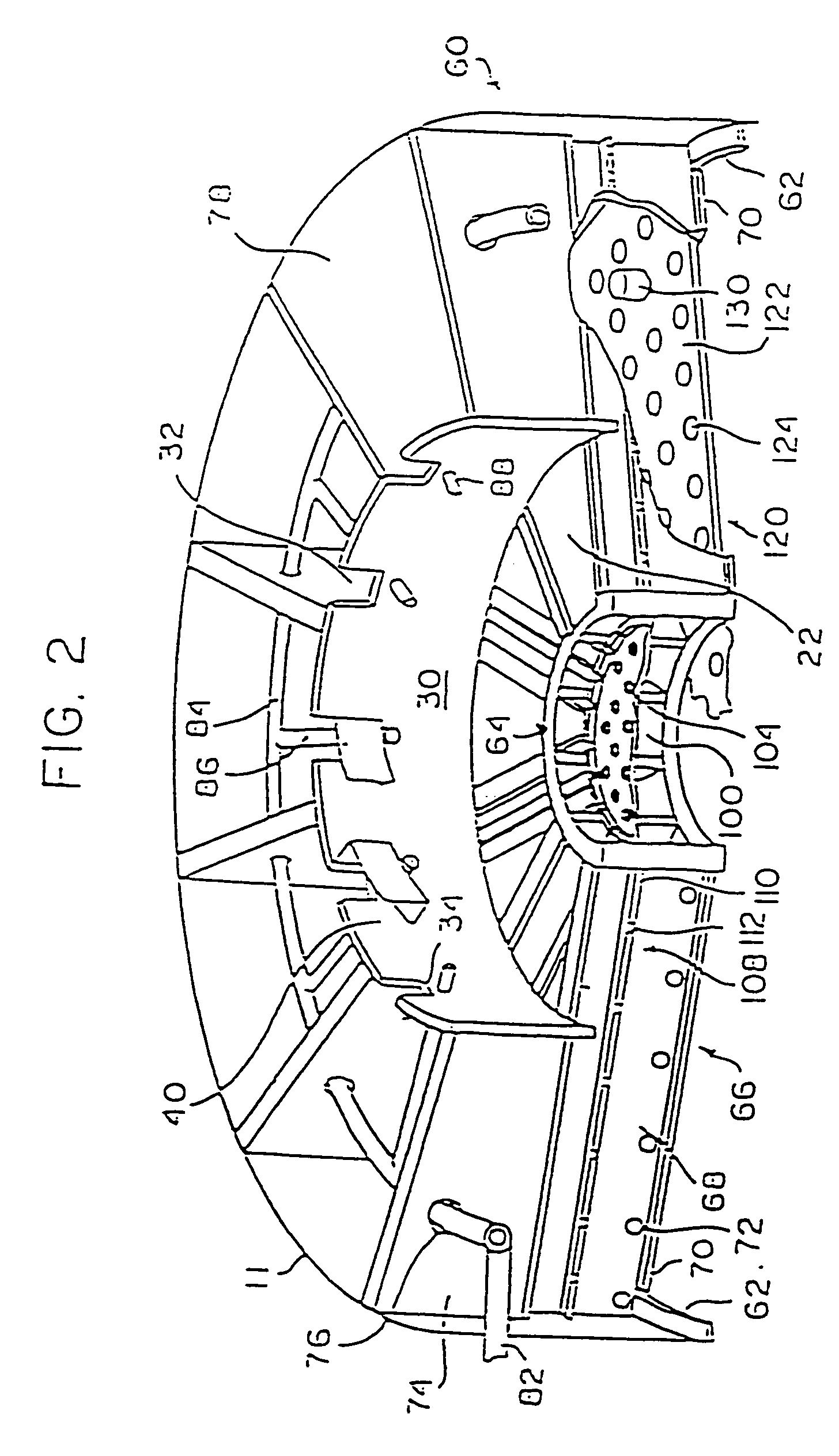

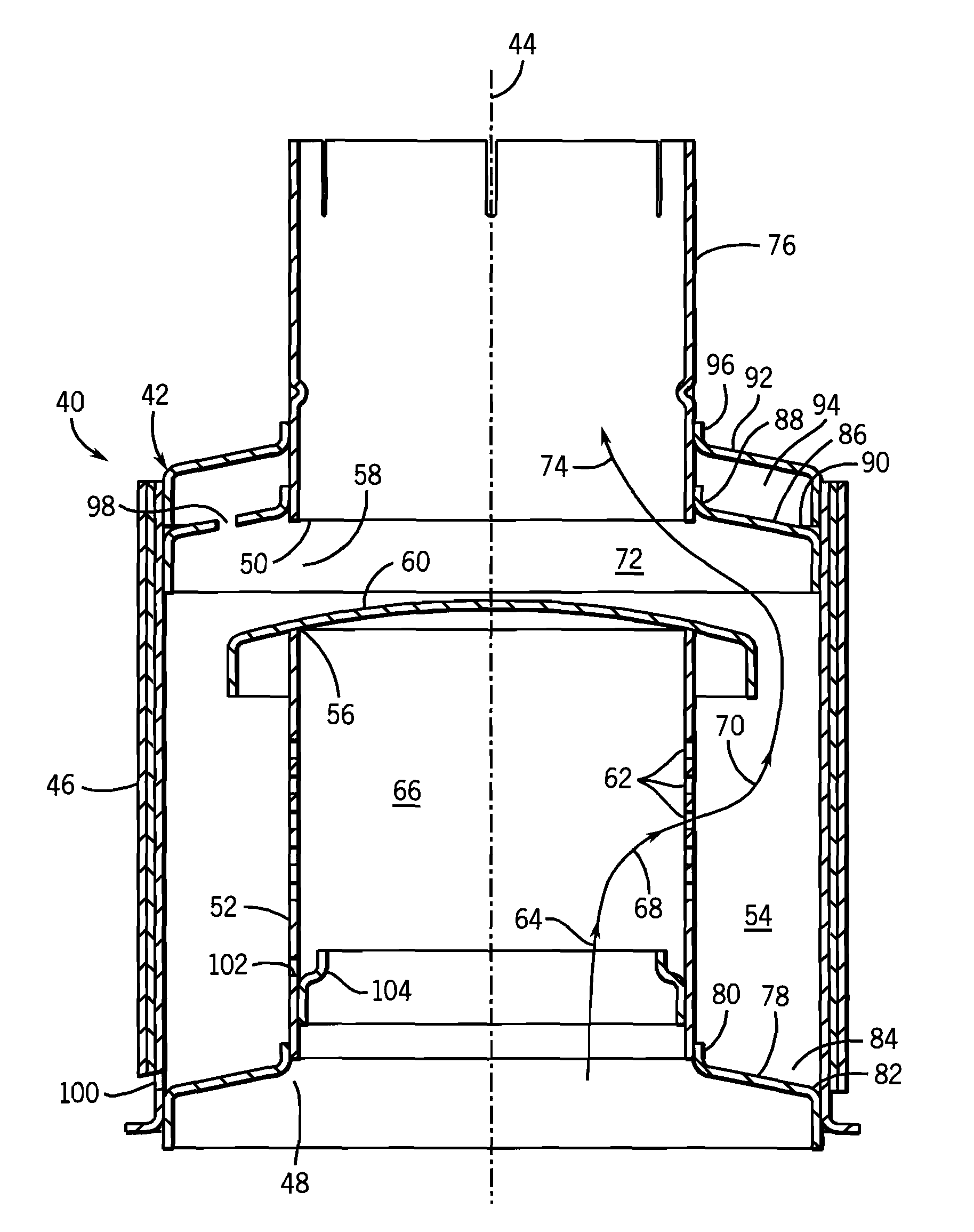

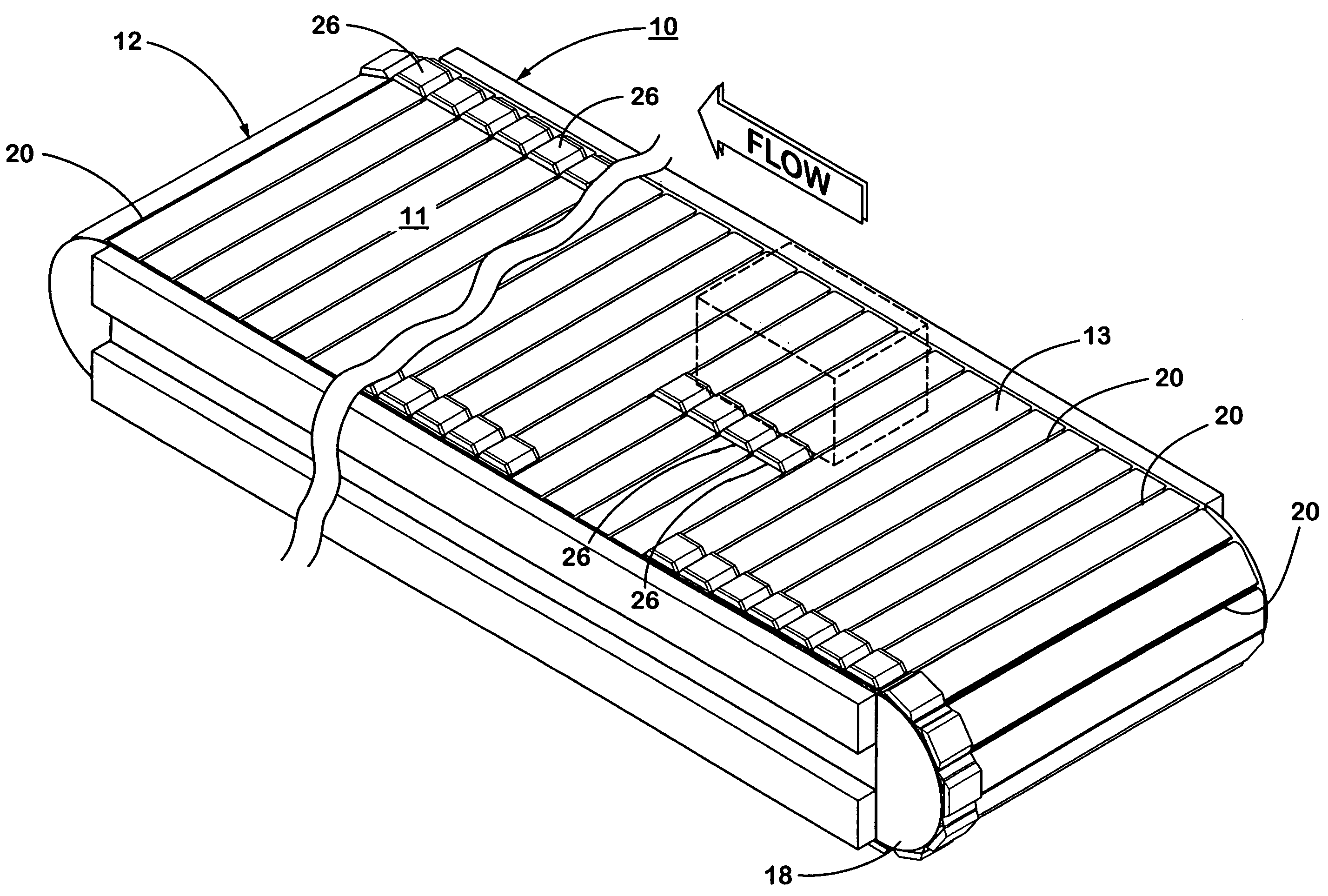

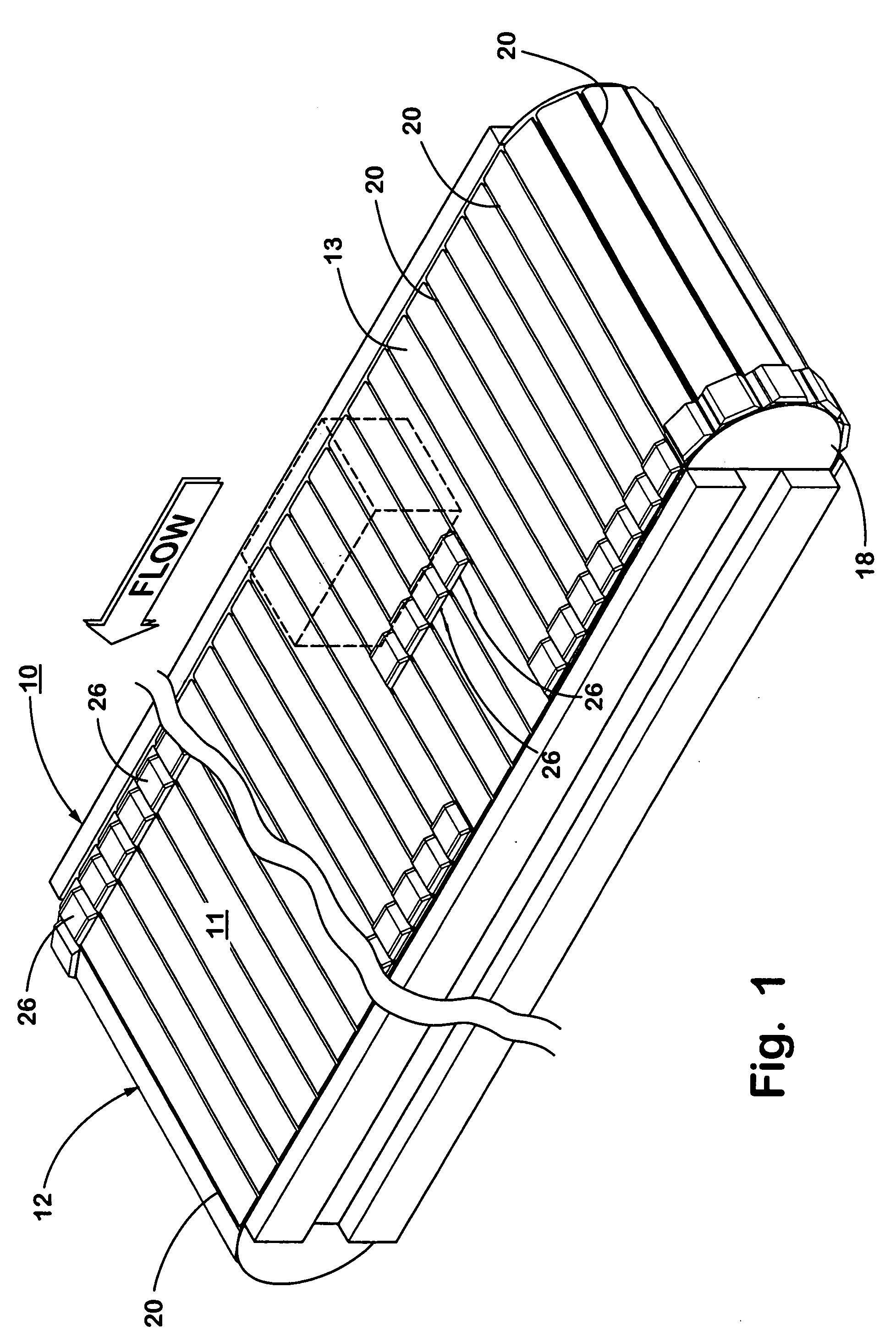

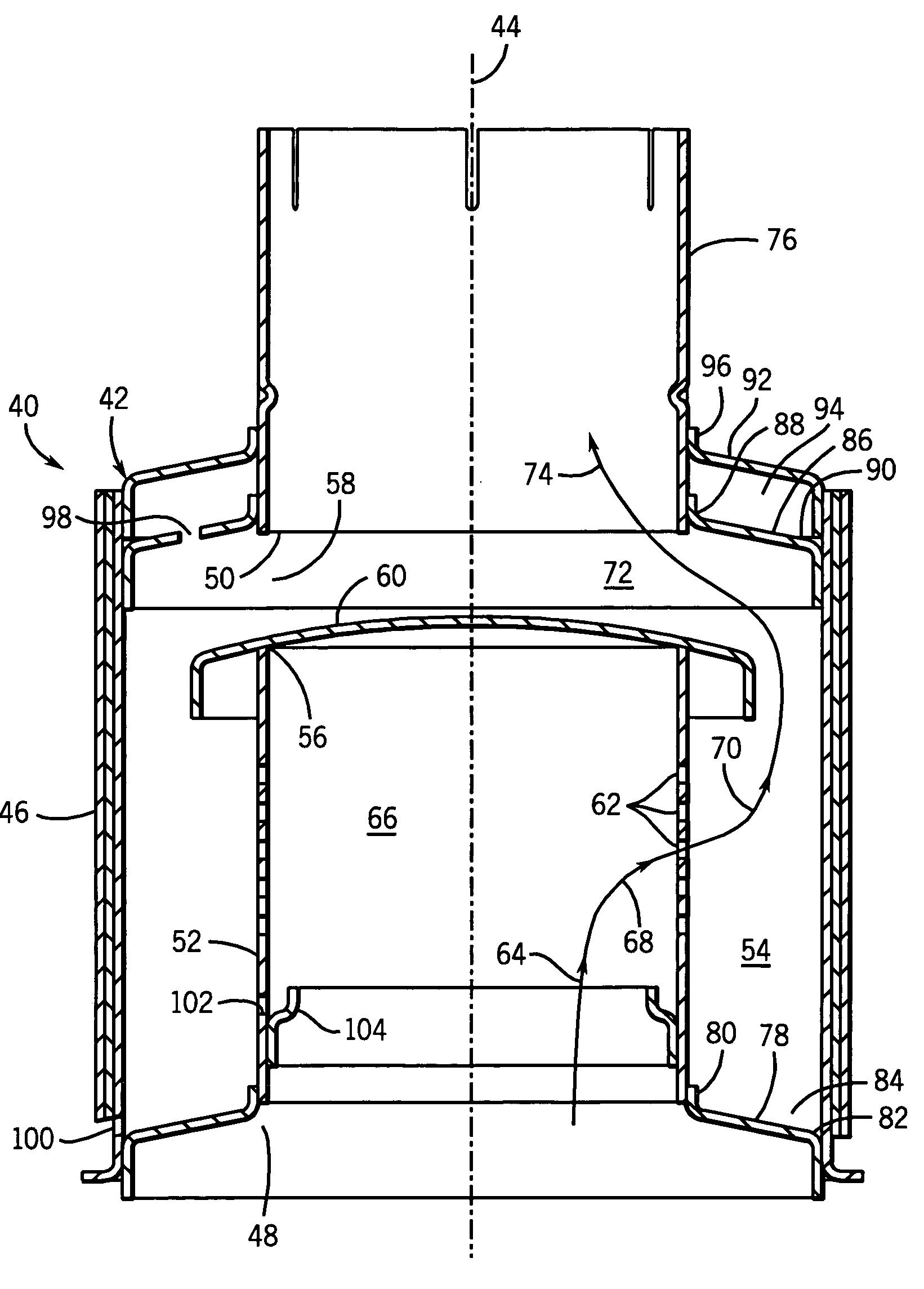

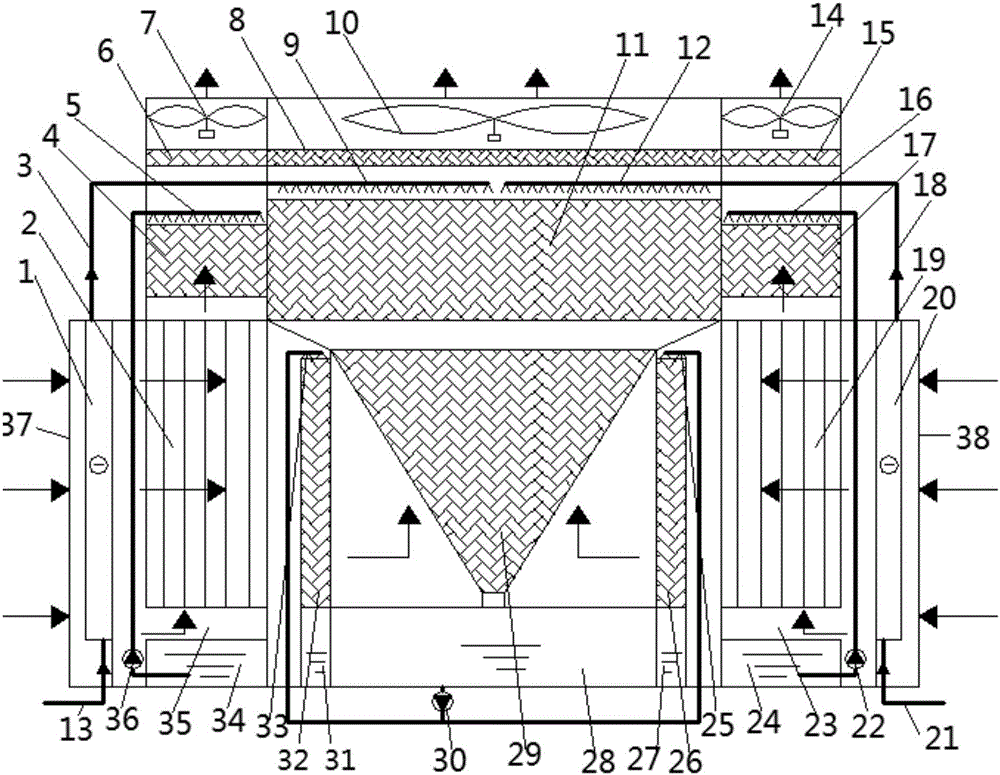

Reactordistribution apparatus and quench zone mixing apparatus

InactiveUS20050163682A1Reduce overall heightWide range of operationsFlow mixersUsing liquid separation agentDistribution systemEngineering

A quench zone mixing apparatus that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber, a rough distribution network, and a distribution apparatus. In the swirl chamber, reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber through an aperture to the rough distribution system where the fluids are radially distributed outward across the vessel to the distribution apparatus. The distribution apparatus includes a plate with a number of bubble caps and associated drip trays that multiply the liquid drip stream from the bubble caps to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps to provide a wider and more uniform liquid distribution below the plate. The distribution apparatus can be used in the reaction vessel without the swirl chamber and rough distribution system, e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS6338828B1Reduce overall heightWide range of operationsFlow mixersTransportation and packagingEngineeringFlange

A quench zone mixing apparatus is supported within a vessel of a reactor by a support structure that includes a concentric hub, which may be formed to act as a torsion tube, and at least a first set of radial beams extending radially outward from the hub and terminating at a support ring that is attached to the reactor vessel wall. In particular, the radial beams comprise a flange that supports the redistribution tray and a web of the beams preferably includes a plurality of openings to allow the passage of fluids across the vessel. In addition, the webs also carry the channels. The radial beams also support the mixing chamber and, in the area between the wall of the mixing chamber and the vessel wall, the radial beams may have a vertical height that slopes downward from the vessel wall to the mixing chamber wall.

Owner:FLUOR TECH CORP

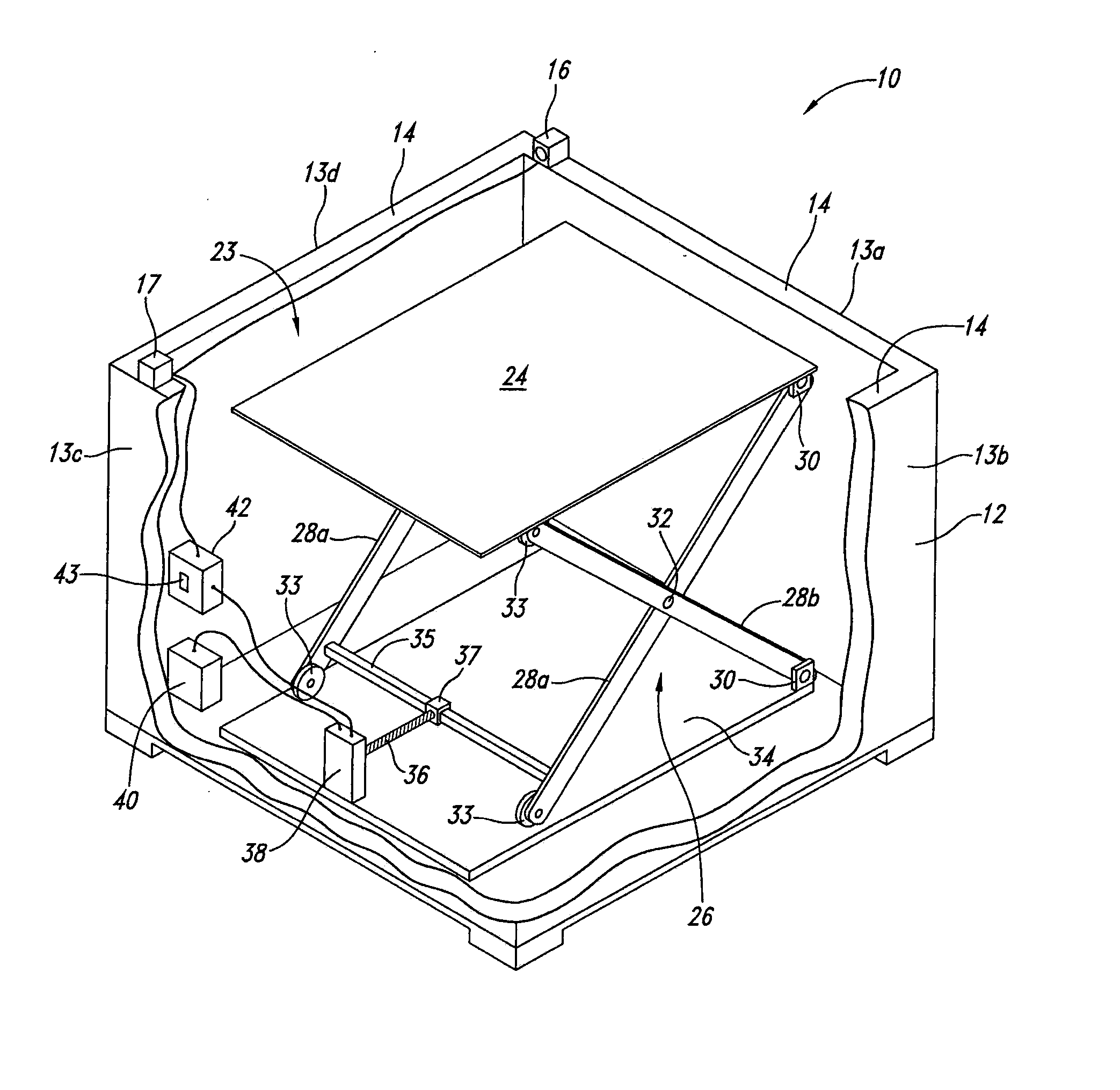

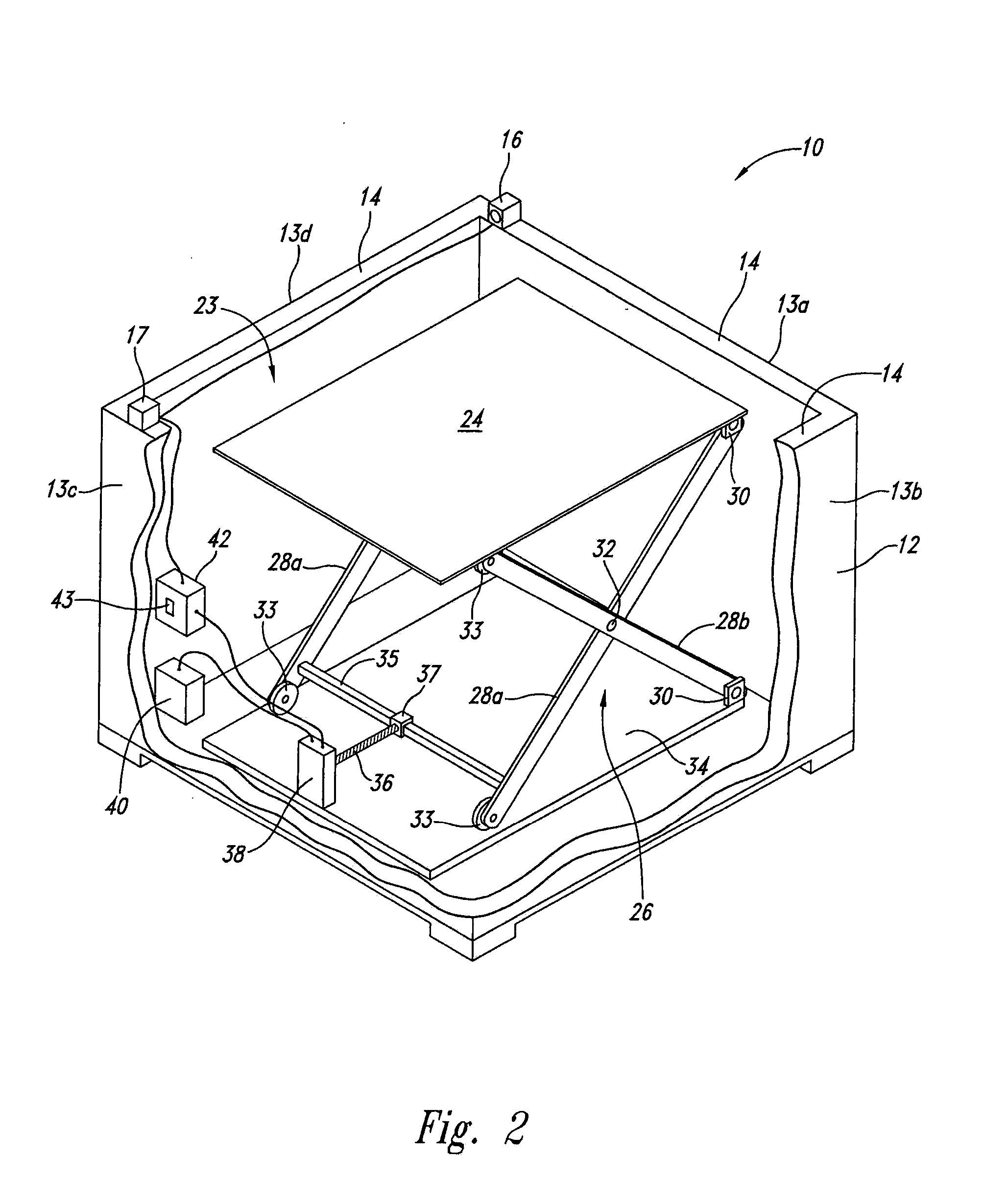

Self-adjusting goods display system and method

A self-adjusting goods display system maintains a proper shelf level for a display bin containing goods. An implementation has an open bin with side walls having top edges and a moveable shelf to receive a pile of goods. A light source and a light receiver are positioned on the top edges of opposing walls of the bin, and the light source generates light to be received by the light receiver. When the pile of goods is reduced so that the pile no longer obstructs the light from being received by the light receiver a signal indicates a need to raise the general level of the remaining pile contained in the bin. A controller receives the signal and controls operation of a motor to raise the height of the shelf until the remaining pile of the shelf again blocks the light, or the shelf is at a position of maximum height.

Owner:PACIFIC BIN CORP

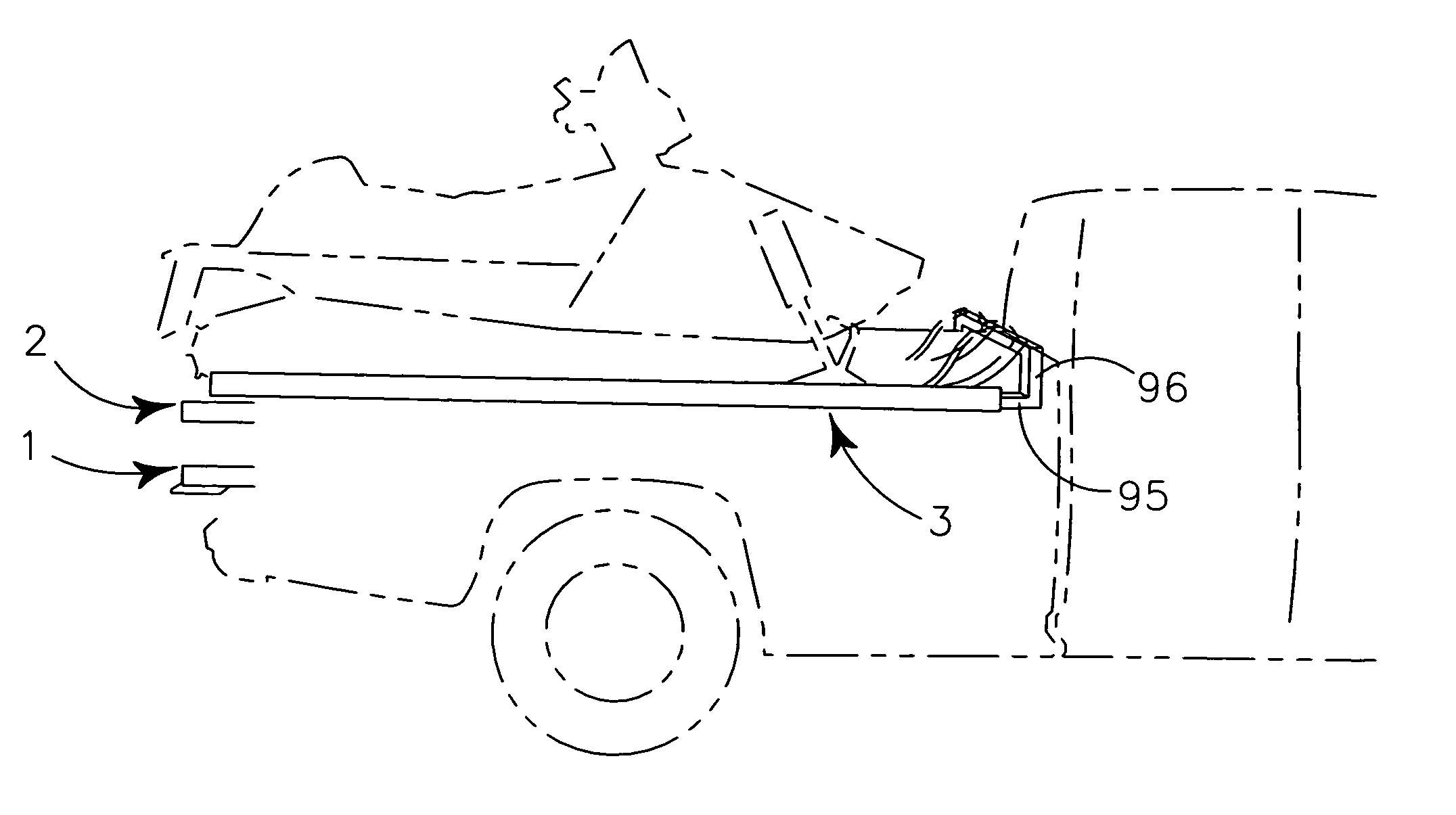

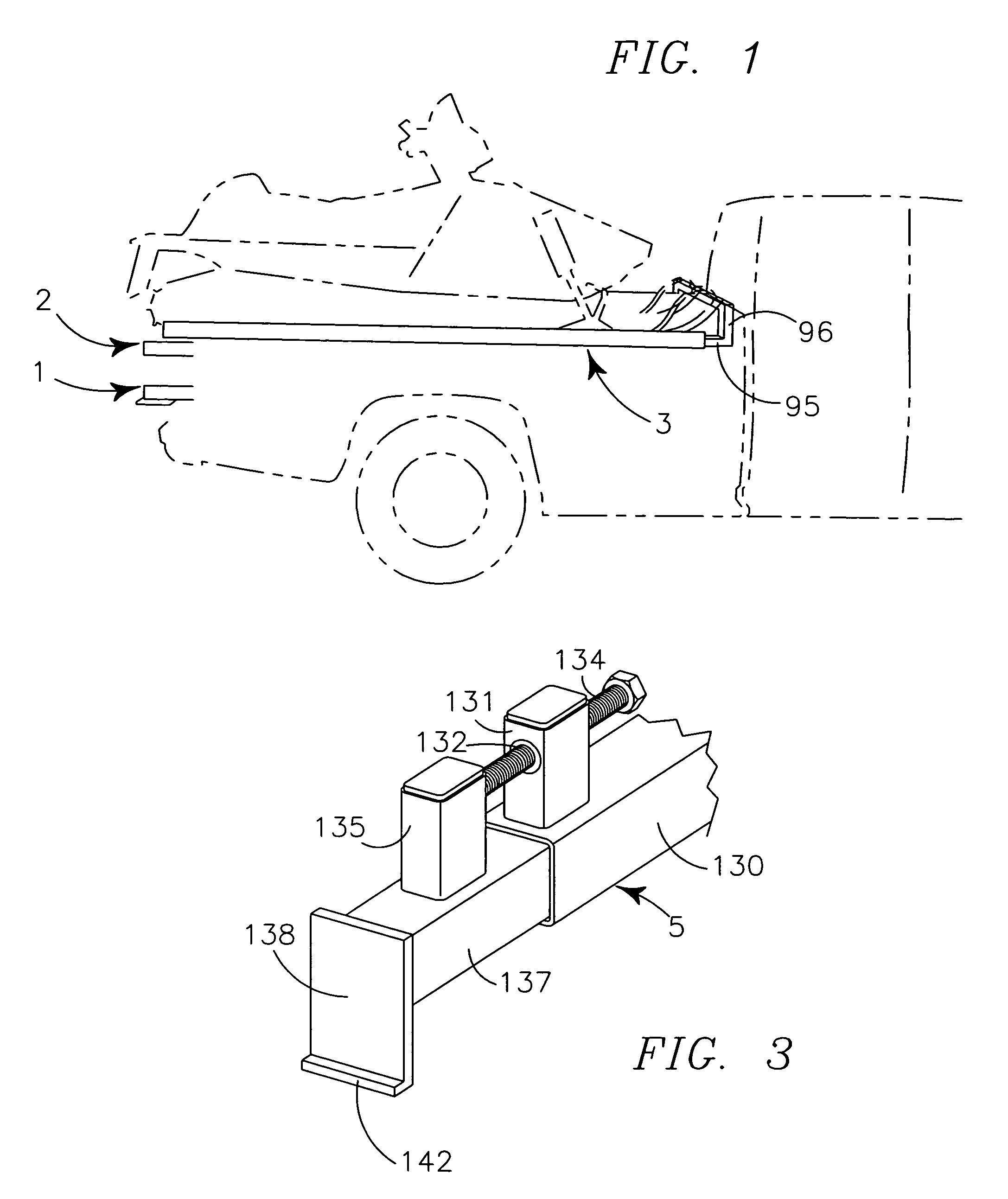

Recreational vehicle loading and transport platform for pickup trucks

InactiveUS6981835B1Reduce vertical heightReduce wind resistanceRefuse receptaclesLoading/unloading vehicle arrangmentPneumatic cylinderEngineering

A recreational vehicle loading and transport platform for pickups provides a base mountable in a pickup box to pivotally carry a transport platform below the upper edges of the pickup box. The transport platform carries outrigger assemblies laterally of and depending below the upper edge of the pickup box to support outer support structures of recreational vehicles straddling the pickup box sides. A pneumatic cylinder moves the forward end of the transport platform vertically to responsively tilt the transport platform for loading and unloading of recreational vehicles. A loading and unloading ramp is removably secured to the rear end of the transport platform to move between use and storage positions.

Owner:GROTH CALVIN DOUGLAS

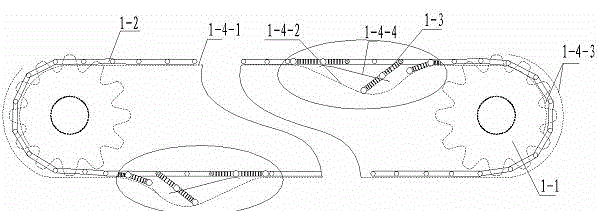

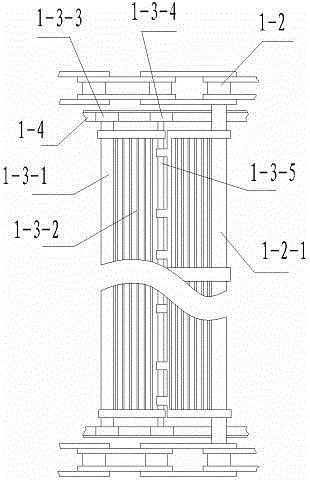

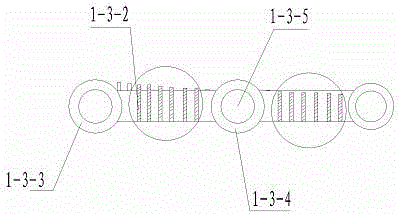

Chain plate conveying coal ball heat conduction oil dryer

ActiveCN104154728AUse diameter reductionImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsChain structureHeating effect

A chain plate conveying coal ball heat conduction oil dryer belongs to the field of drying equipment. The chain plate conveying coal ball heat conduction oil dryer comprises a heat insulation outer shell, a chain plate conveying mechanism, a feeding conveying belt, a discharging opening, a heating device and a waste heat using device. The chain plate conveying mechanism comprises a double-driving chain structure, a matched chain wheel, a bearing chain plate and a guiding sliding track. The bearing chain plate is a hollow-out structure formed by a frame and a grid bar and is located on a chain shaft in a hinge mode. The guiding sliding track is divided into an upper sliding track part and a lower sliding track part which have the same structure sequence. Each part is divided into a horizontal section, a V-shaped blanking section and an arc groove-shaped turning section which are connected in sequence. A falling zone corresponds to a lowering edge section of each V-shaped blanking section of the guiding sliding part. The heating device is connecting heat conduction oil furnace heat conduction calandrias which are distributed above and below a conveying interface formed by the bearing chain plate. An improved double-chain strip plate type conveyor is used, a high-efficiency heat conduction oil furnace is used as a heat source, a controllable heat conduction oil pipe composite layer distribution structure is used for improving the heating effect, and the effects of small space size, energy saving and environment protection are achieved.

Owner:HEBEI GOLD BANGZI BOILER

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS7674439B2Reduce overall heightWide range of operationsFlow mixersUsing liquid separation agentDistribution systemEngineering

A quench zone mixing apparatus that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber, a rough distribution network, and a distribution apparatus. In the swirl chamber, reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber through an aperture to the rough distribution system where the fluids are radially distributed outward across the vessel to the distribution apparatus. The distribution apparatus includes a plate with a number of bubble caps and associated drip trays that multiply the liquid drip stream from the bubble caps to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps to provide a wider and more uniform liquid distribution below the plate. The distribution apparatus can be used in the reaction vessel without the swirl chamber and rough distribution system, e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

Exhaust water trap

ActiveUS7347044B1Acceptable appearanceReduce back pressureInternal combustion piston enginesExhaust apparatusWater trapWater collection

A vertical exhaust water trap assembly has an outer housing and an internal housing or exhaust tube defining an annular water collection spaced therebetween bypassing a central exhaust flow area.

Owner:CUMMINS FILTRATION INC

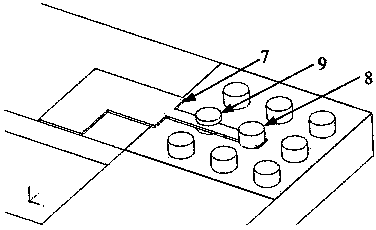

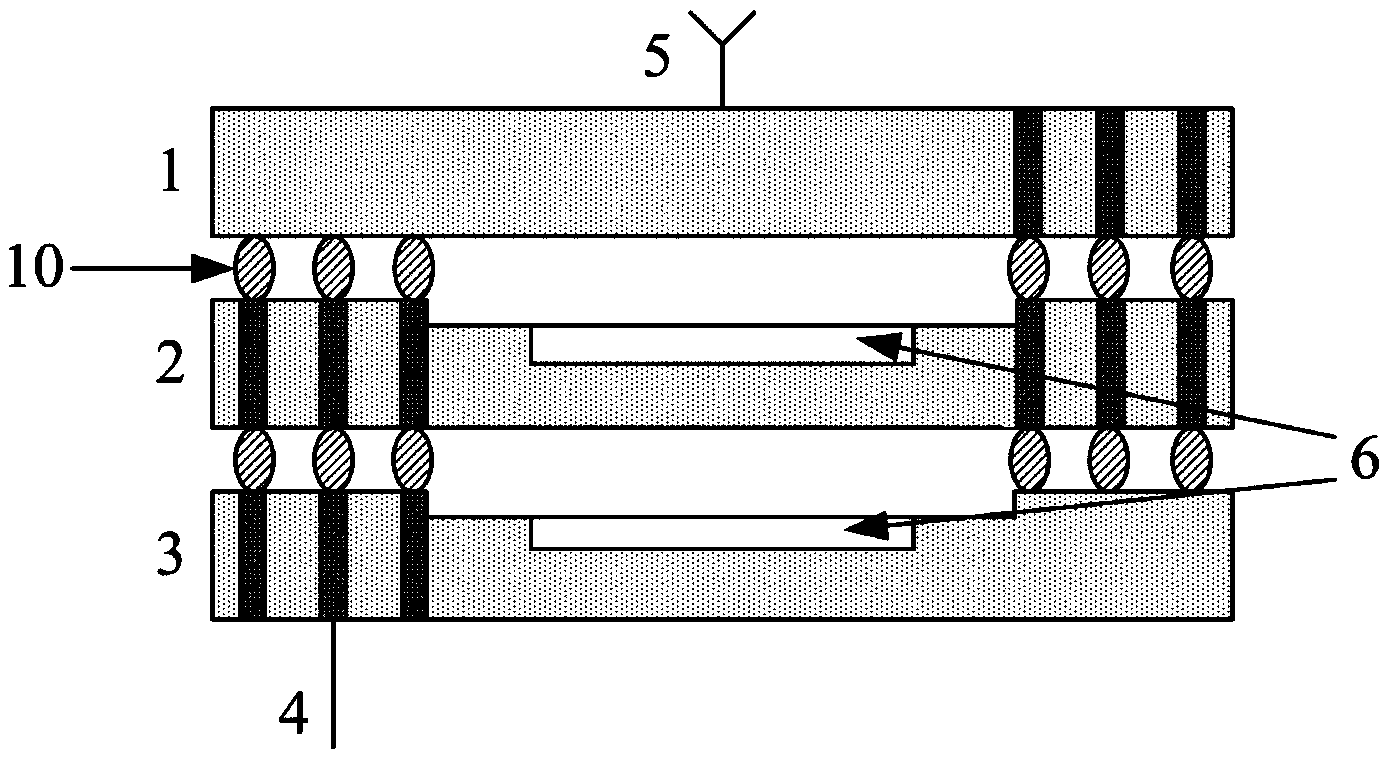

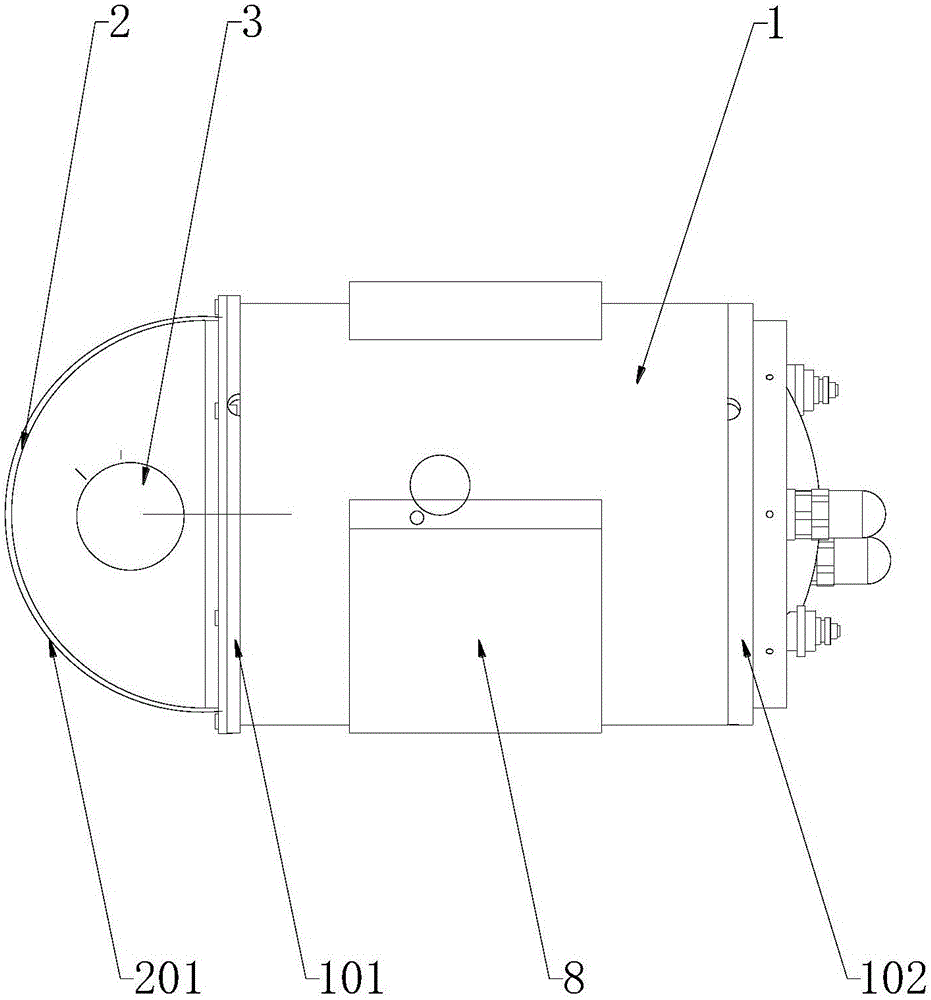

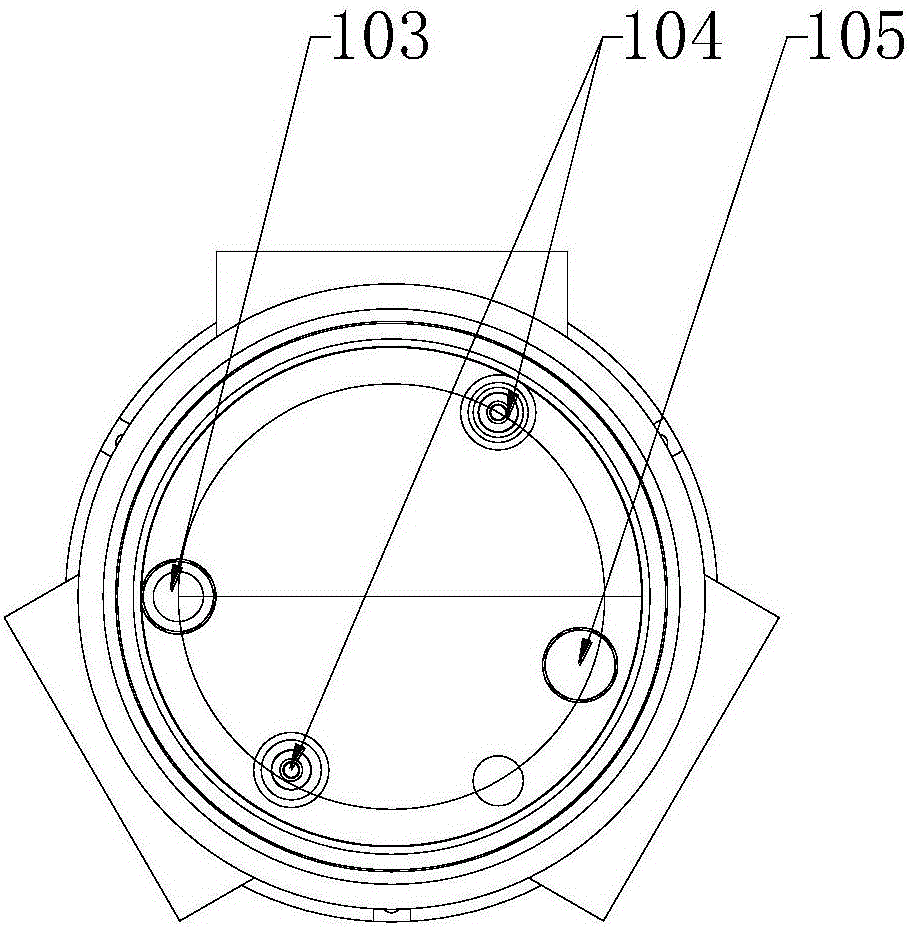

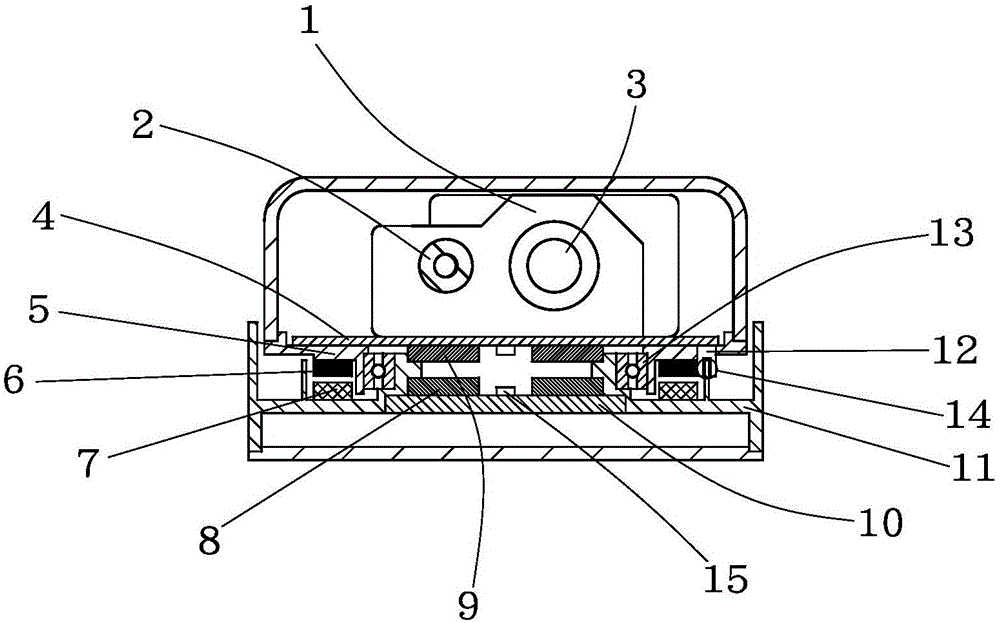

LTCC-based miniaturized tile type T/R assembly

The invention relates to an LTCC-based miniaturized tile type T / R assembly. By means of a conventional medium material, through reasonable layout of a microwave chip, a microwave transmission line and a control signal line, the miniaturized tile type T / R assembly which has a dimension of 9 mm * 9 mm * 4.3 mm, has high integration and facilitates conformation. The LTCC-based miniaturized tile type T / R assembly solves the problems of large dimension and difficulty in actual application and the like of a conventional T / R assembly, enables the T / R assembly to have higher integration, enables a current phased array to have the advantages of miniaturization, conformal to environment and the like, and satisfies the demands of special platforms such as a vehicular-mounted platform and the like.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

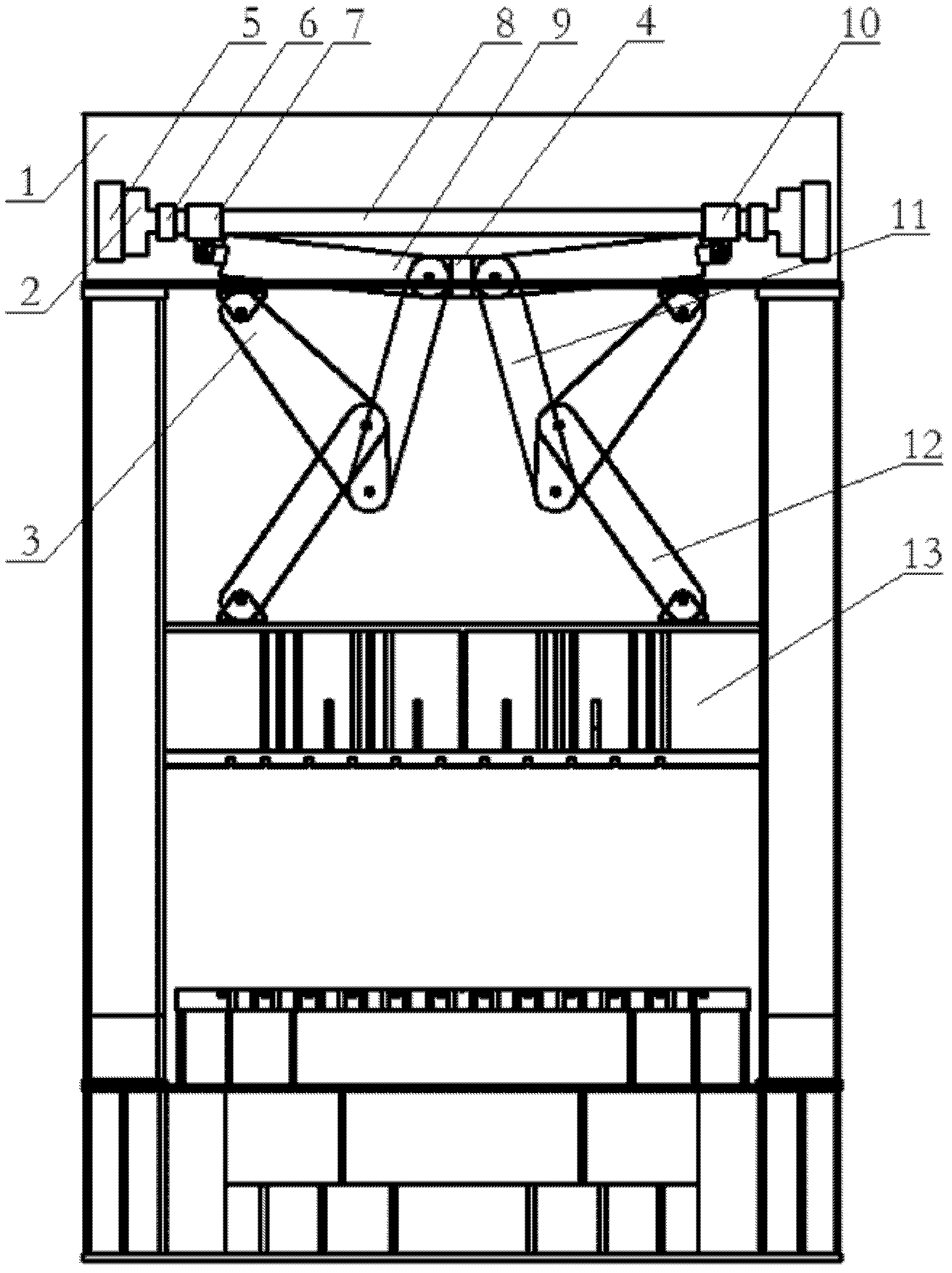

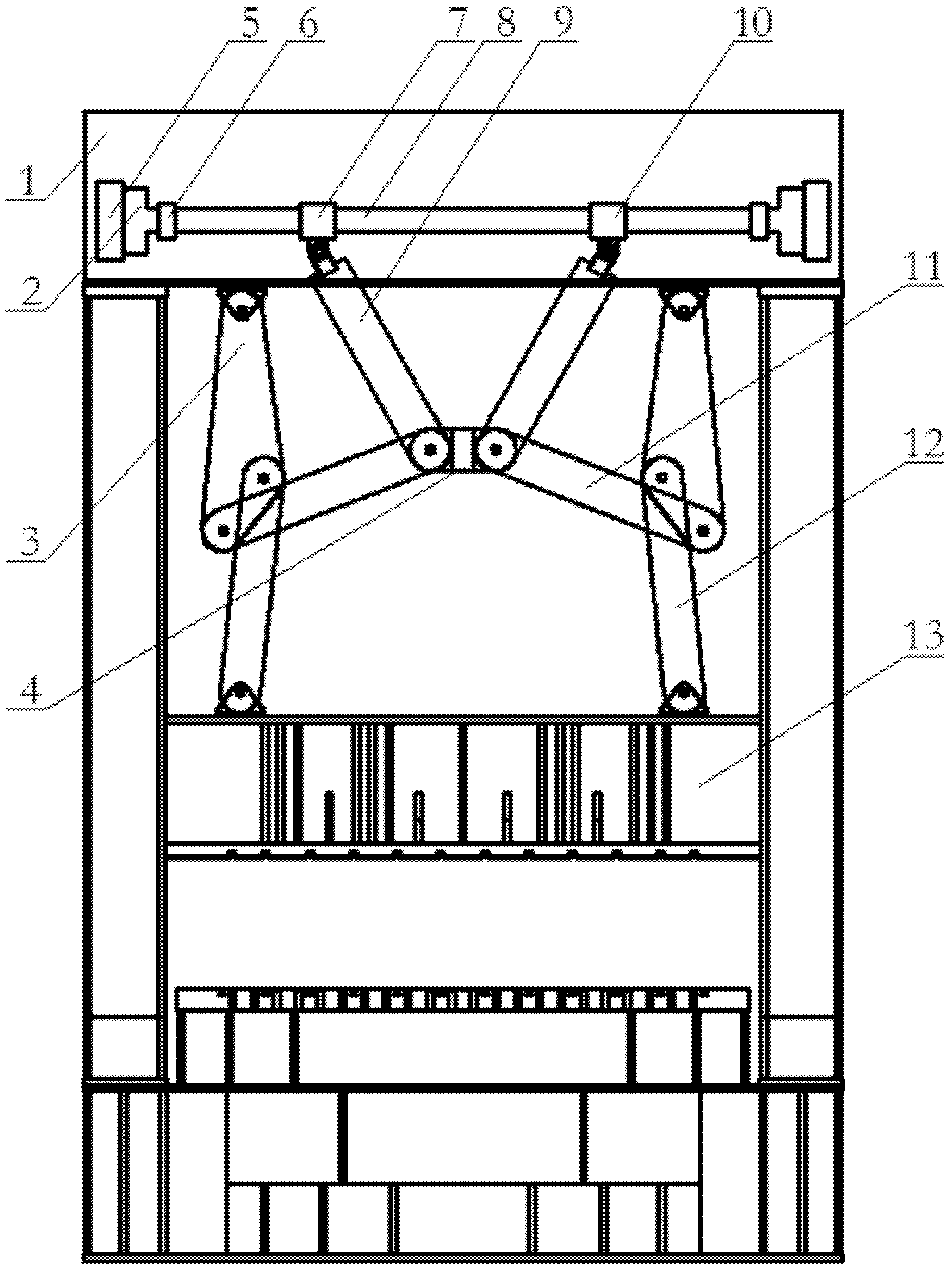

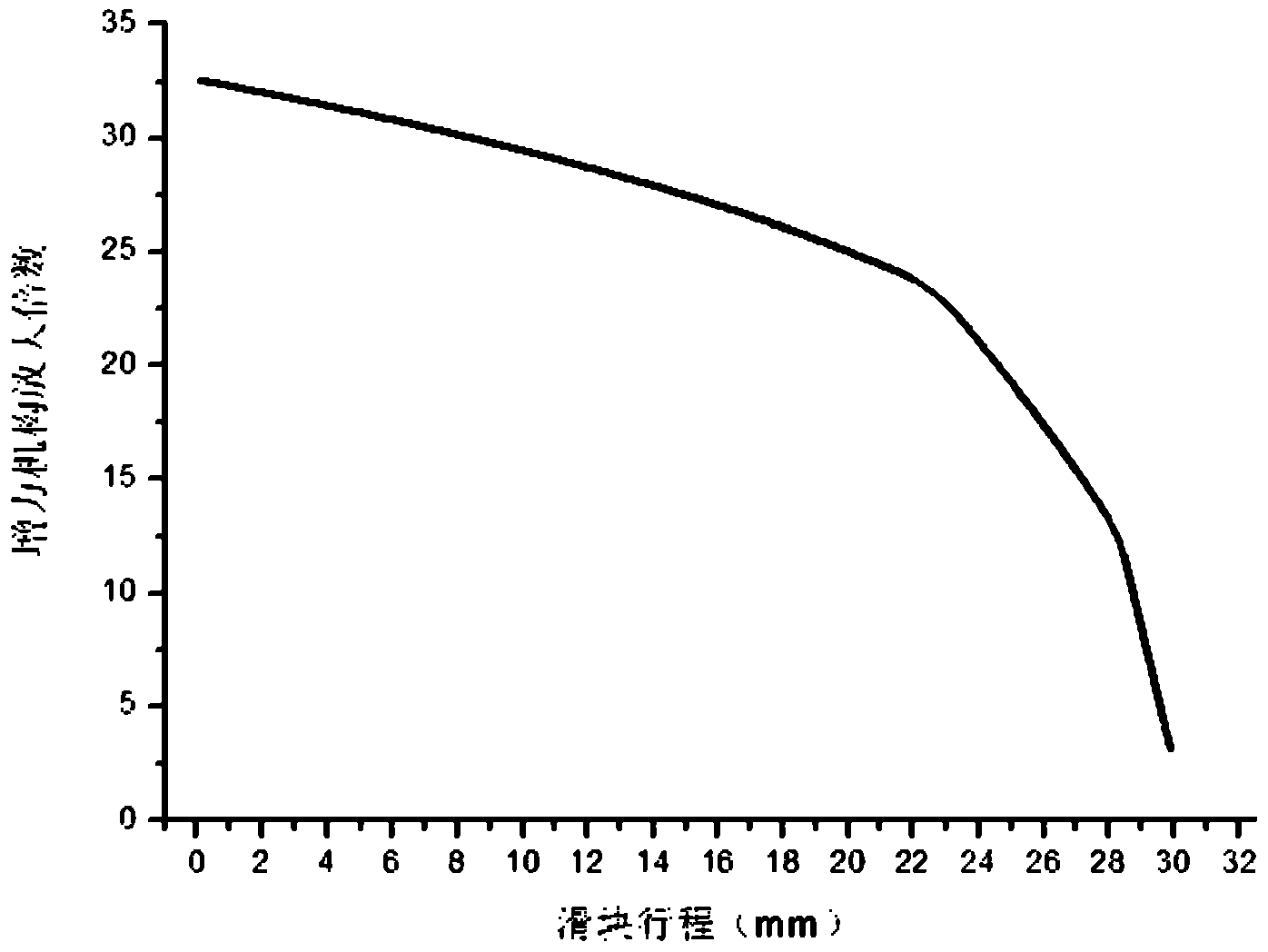

Transmission system suitable for large-tonnage alternating current servo press

ActiveCN102320153AOvercome the disadvantage of small magnificationLow powerGearingPressesThree levelBall screw

The invention discloses a transmission system suitable for a large-tonnage alternating current servo press. The output shaft of a disk-type permanent magnet synchronous servo motor and a planet gear speed reducer are made into integral structure; the screw of a driving mechanism and two nuts arranged on the nut form a ball screw structure; the screw is connected with the planet gear speed reducer; the left and the right of a top bar as well as the front and the back of the top bar are symmetrically provided with double toggle rod boosting mechanisms; a symmetrical oscillating rod input type boosting mechanism is arrange between the top bar and the double toggle rod boosting mechanisms; a three-level boosting mechanism causes the amplification multiple of the boosting mechanisms in the beginning stage to be above 15 times; and the amplification multiple is bigger and bigger along with the shaping process to lower the power of the disk-type permanent magnet synchronous servo motor. The transmission system can provide large amplification multiple and has the advantages of obvious boosting effect, large effective boosting travel, small integral structural size, big sliding block travel, quick virtual travel, high working efficiency, quick feeding, low shaping speed and the like, and unbalance loading is simultaneously eliminated.

Owner:XI AN JIAOTONG UNIV

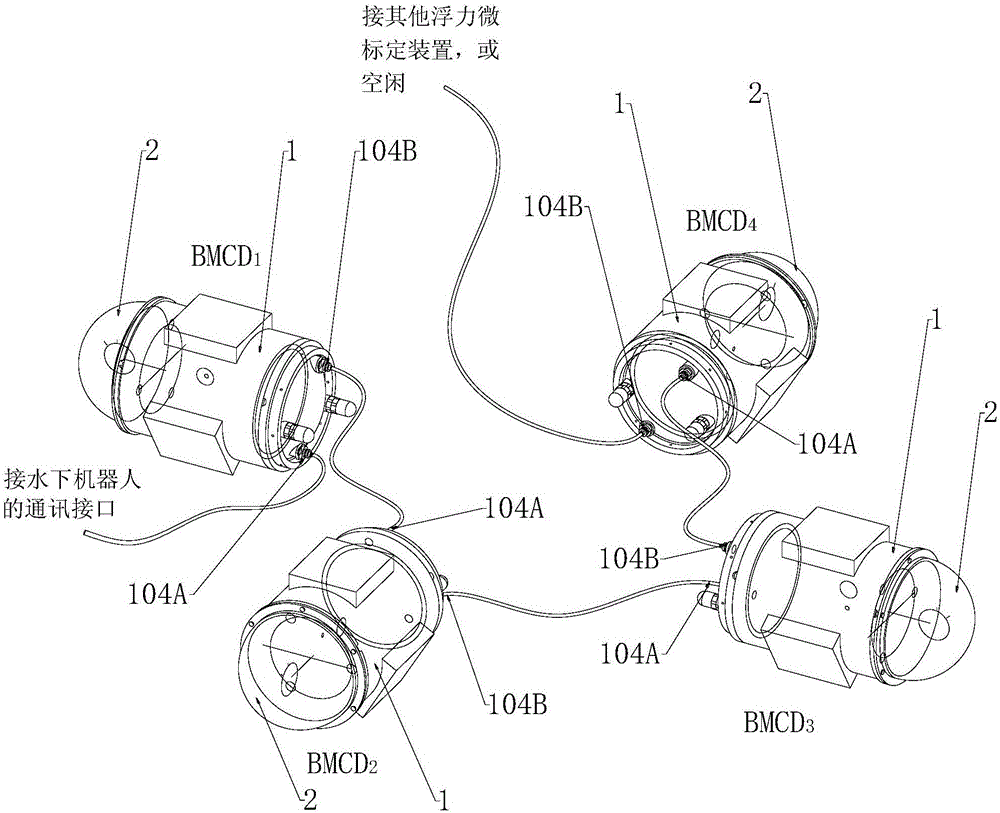

Self-adaptive buoyancy micro-calibrating collecting and distributing system for deep-sea underwater robot

ActiveCN106828835AAchieve mechanical adjustmentRealize regulationVessel safetyUnderwater equipmentEngineeringSelf adaptive

The invention discloses a self-adaptive buoyancy micro-calibrating collecting and distributing system for a deep-sea underwater robot. The self-adaptive buoyancy micro-calibrating collecting and distributing system comprises a plurality of self-adaptive buoyancy micro-calibrating devices, wherein each single self-adaptive buoyancy micro-calibrating device comprises a silo, an elastic balloon, a balloon swelling-shrinking mechanism, a power driving mechanism and a control module; the silos are watertight hollow cylinders; the power driving mechanisms are arranged in inner cavities of the silos; the elastic balloons are hemispheres, which are made from elastic materials, with hollow inner cavities, and are further connected with the front ends of the silos with watertight structures; the balloon swelling-shrinking mechanisms are arranged in the inner cavities of the elastic balloons; the balloon swelling-shrinking mechanisms are connected with the power driving mechanisms through telescopic connecting rods; the control modules arranged in the inner cavities of the silos drive and control the running of the power driving mechanisms. The self-adaptive buoyancy micro-calibrating collecting and distributing system is reasonable in design and compact in structure, and can be used for realizing the micro-calibration and the micro-adjustment of buoyancy.

Owner:天津海翼科技有限公司

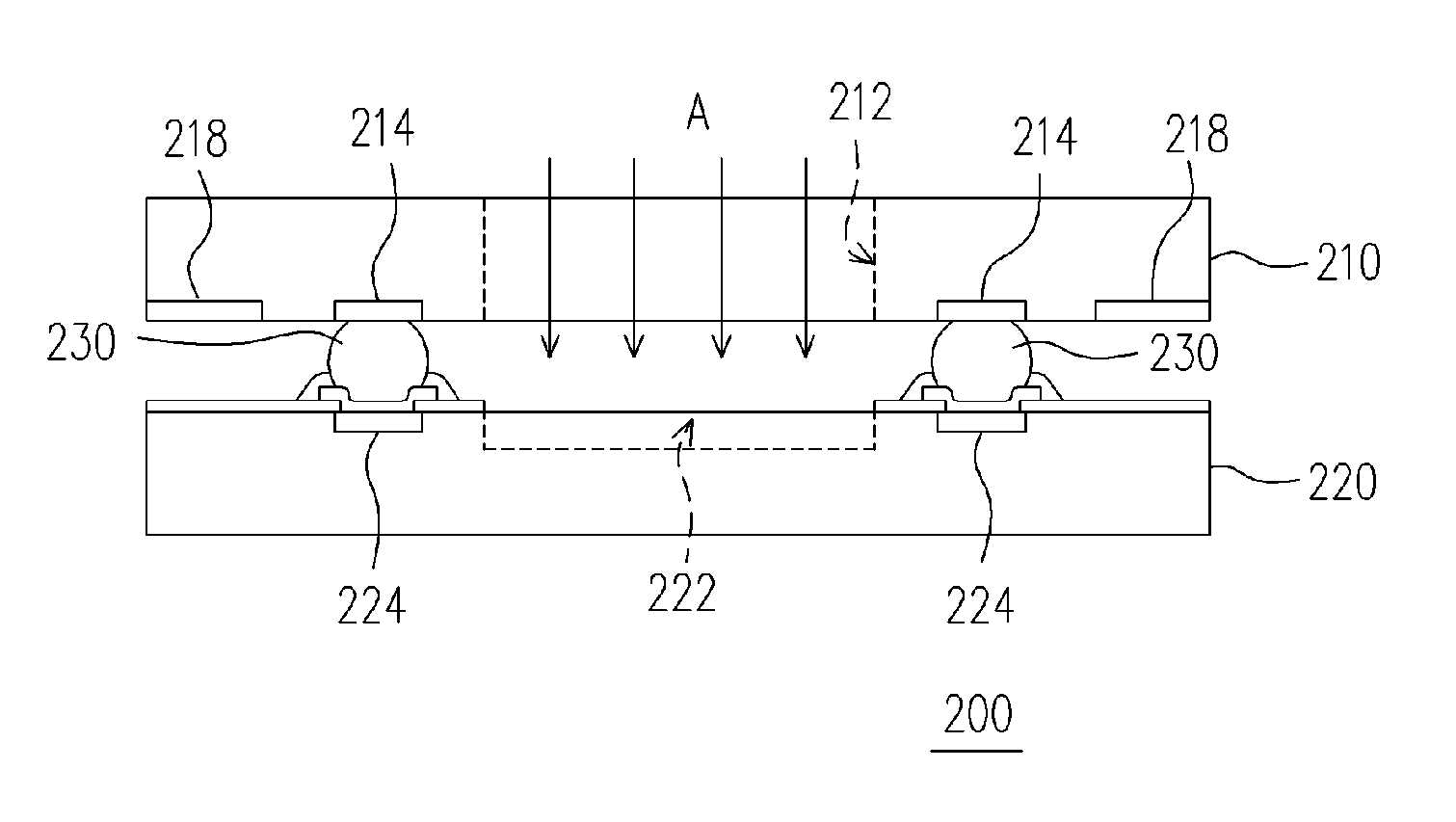

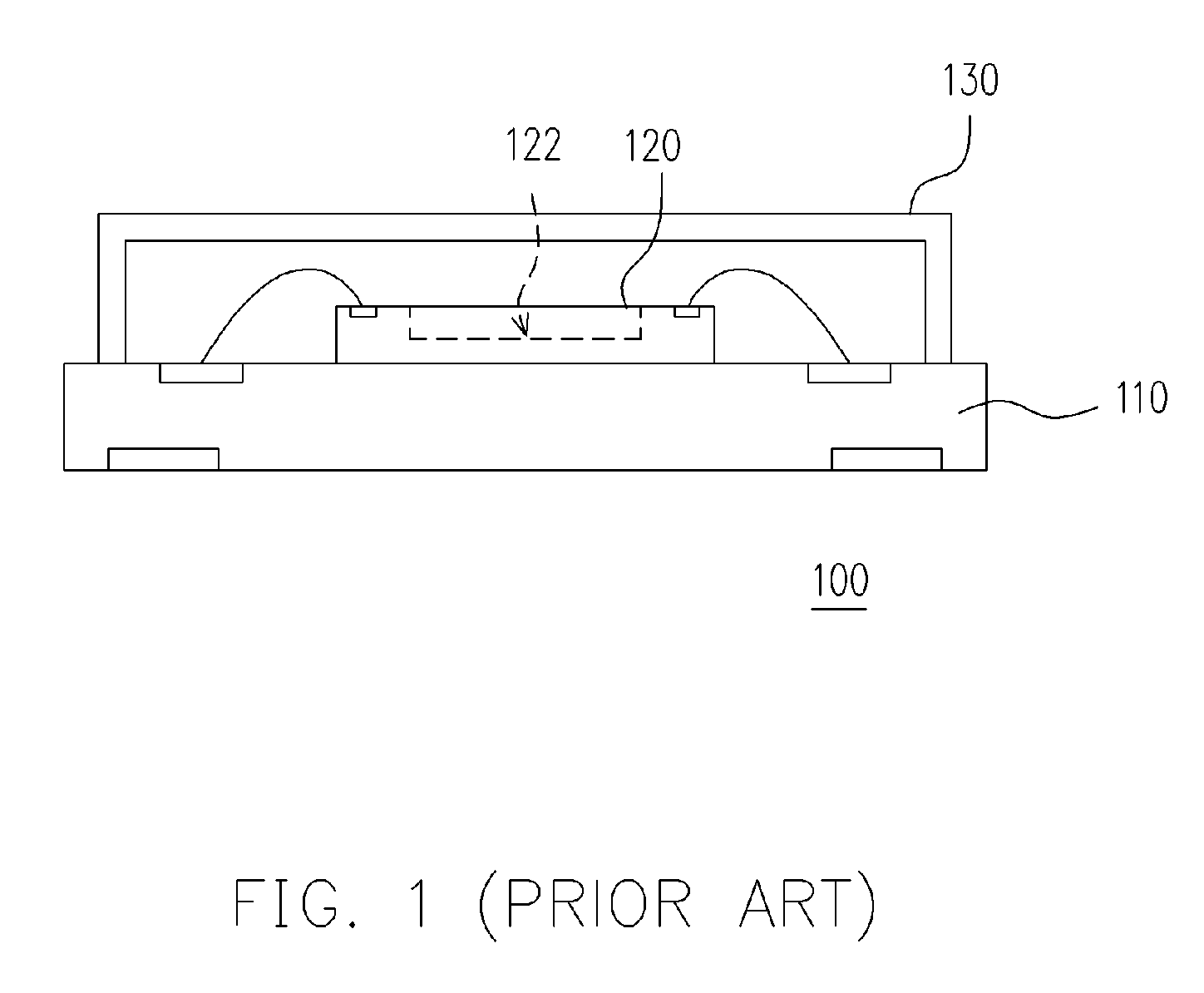

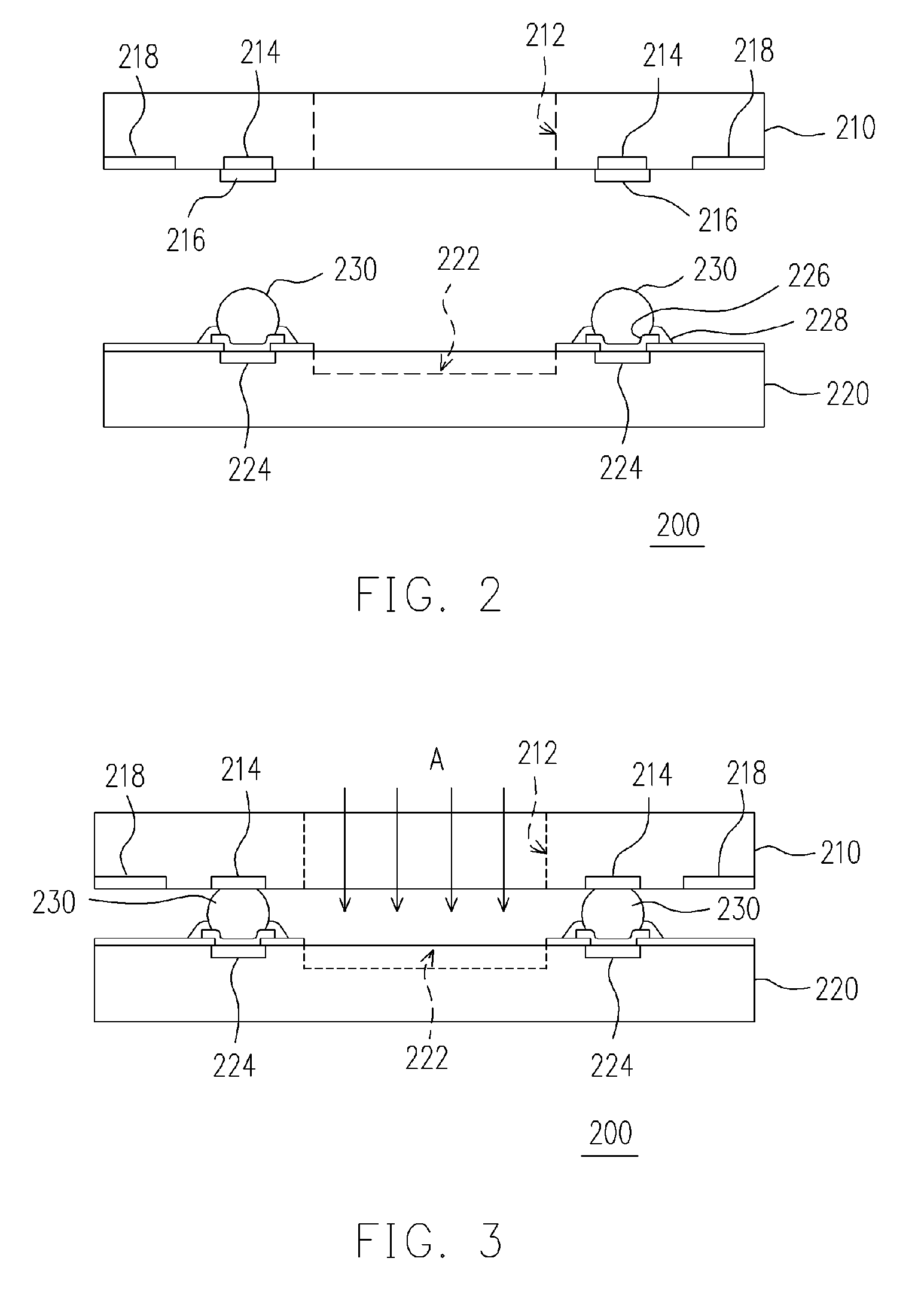

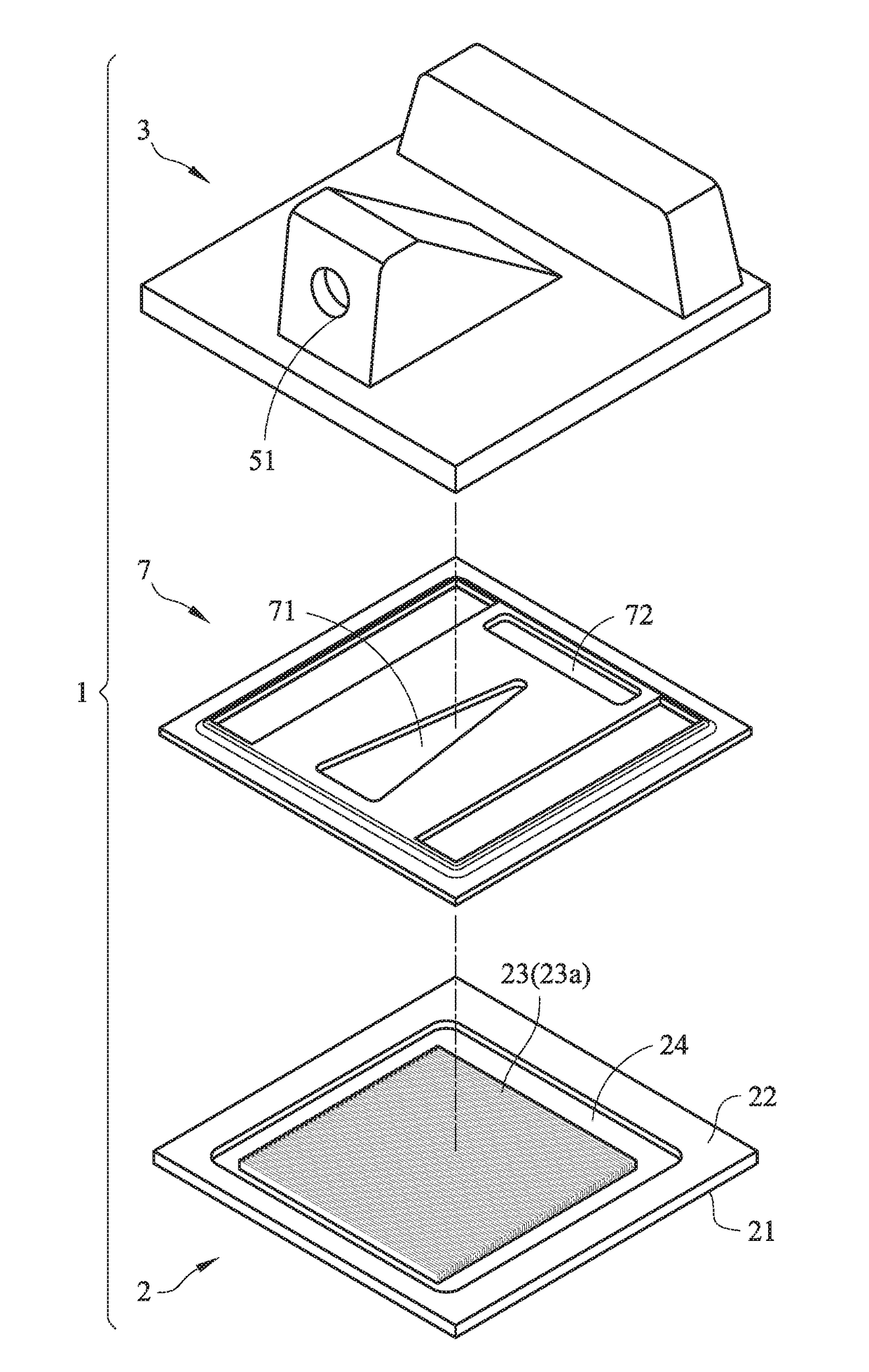

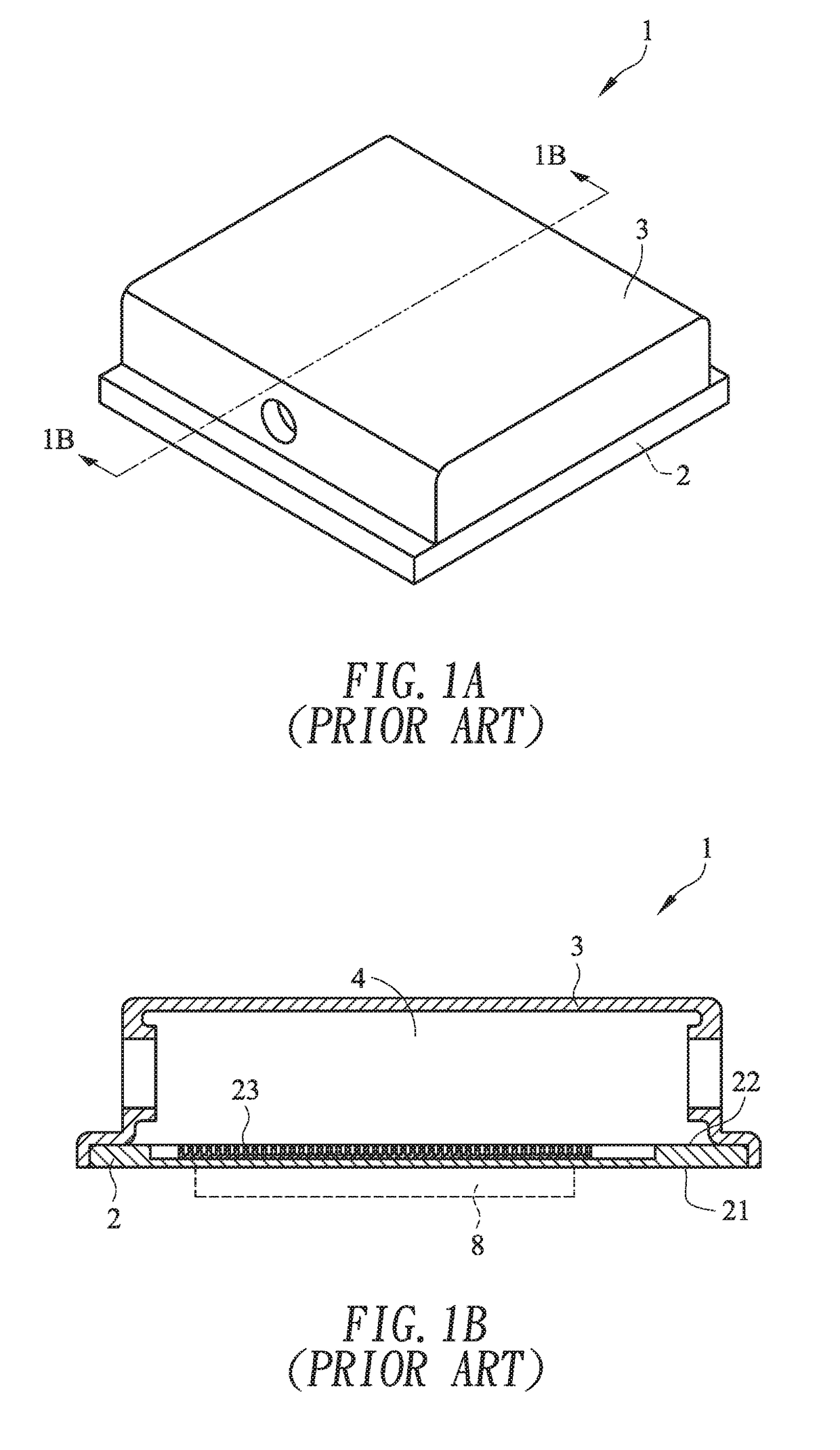

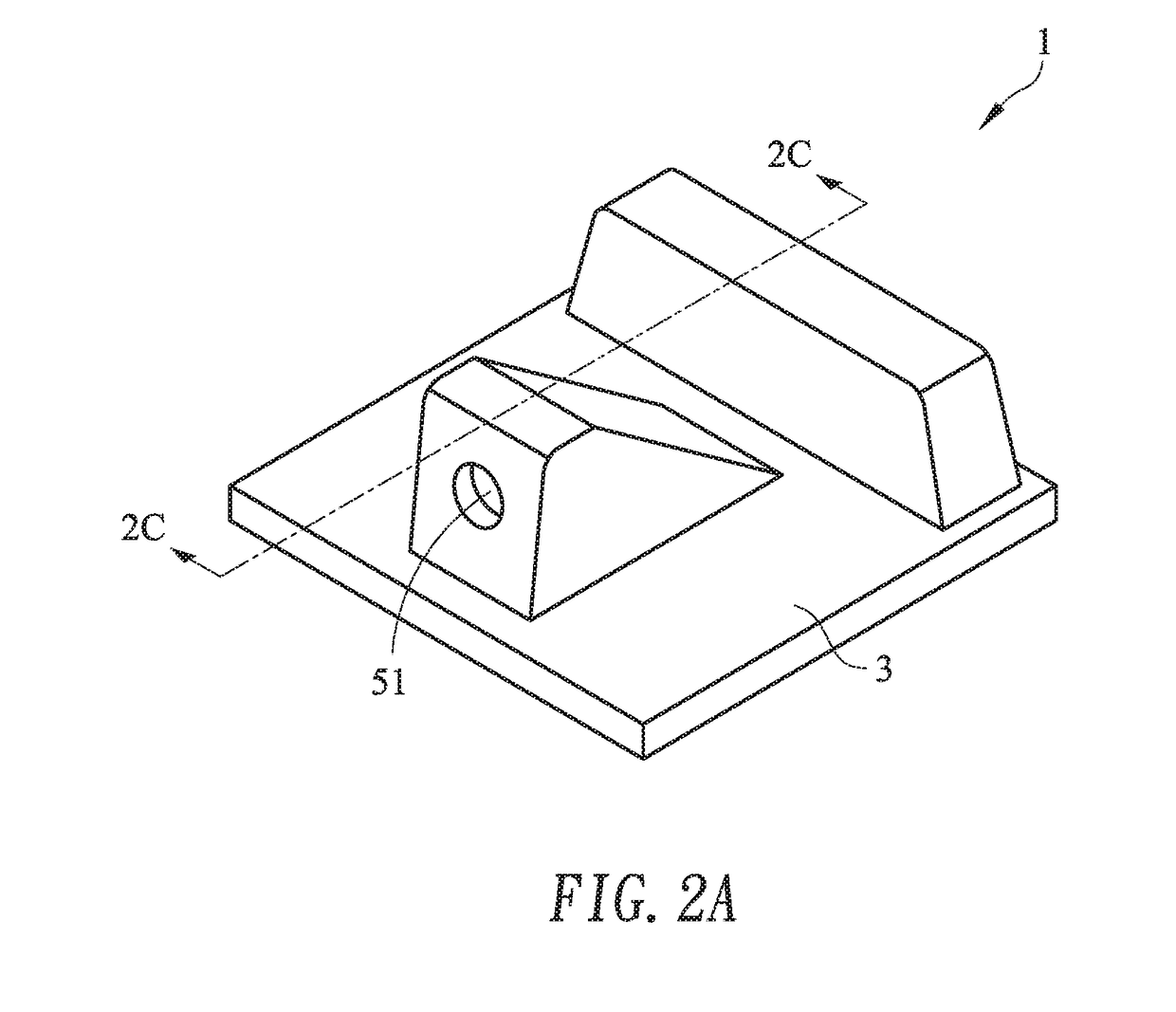

Photosensitive bonding package structure

InactiveUS20060060765A1Reduce areaReduce horizontal widthSolid-state devicesMaterial analysis by optical meansLight beamEngineering

A photosensitive bonding package structure mainly comprising a substrate, a photosensitive device and a plurality of bumps is provided. The substrate has a light incident area located near the central area of the substrate. The photosensitive device has a photosensitive area in a position corresponding to the light incident area so that the photosensitive device can receive a beam of incident light passing through the opening. In addition, the substrate has a plurality of inner contacts and corresponding outer contacts. Pads on the photosensitive device are connected to the inner contacts through bumps so that the electrical signals resulting from illuminating the photosensitive area is transmitted to the substrate.

Owner:ADVANCED SEMICON ENG INC

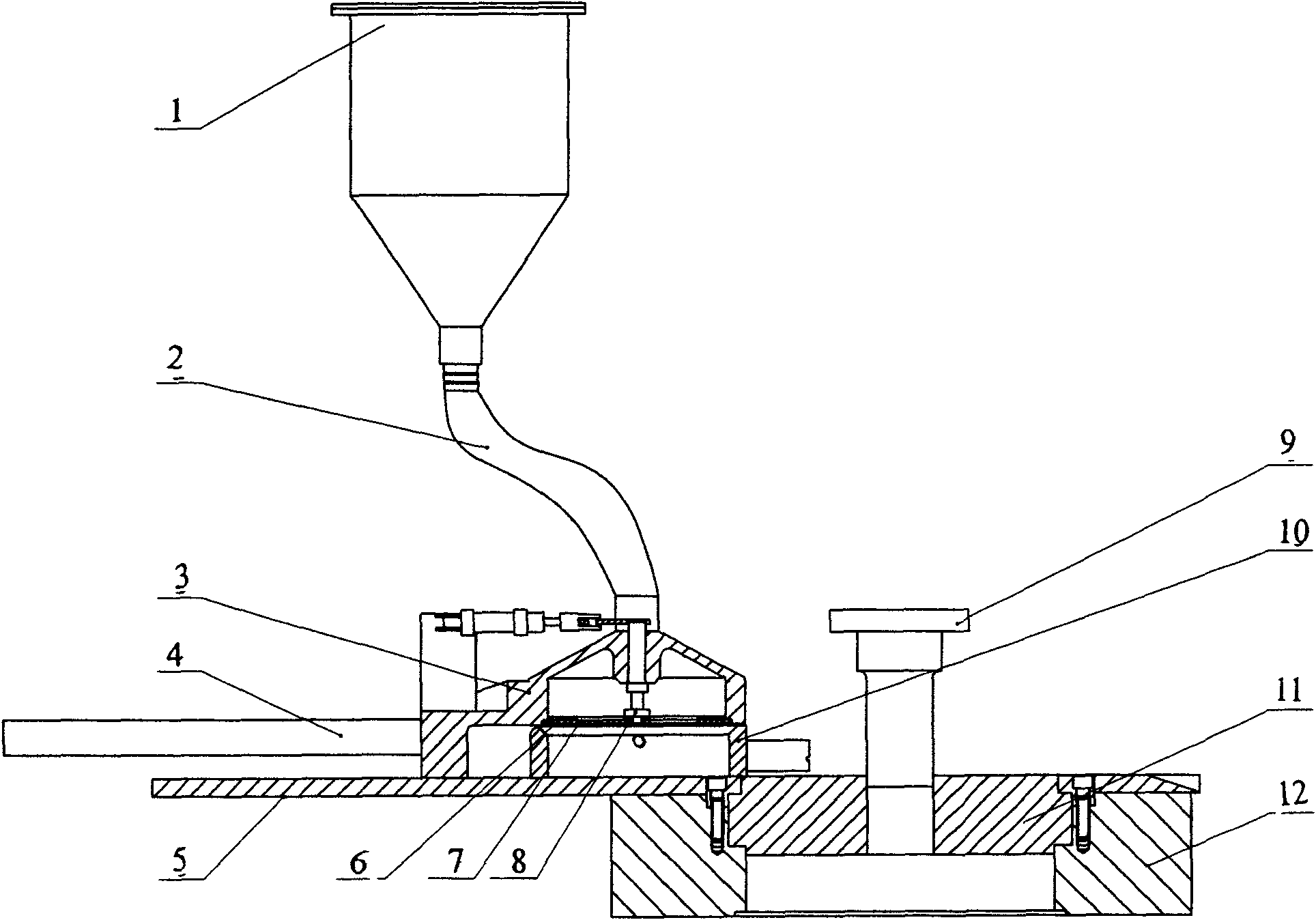

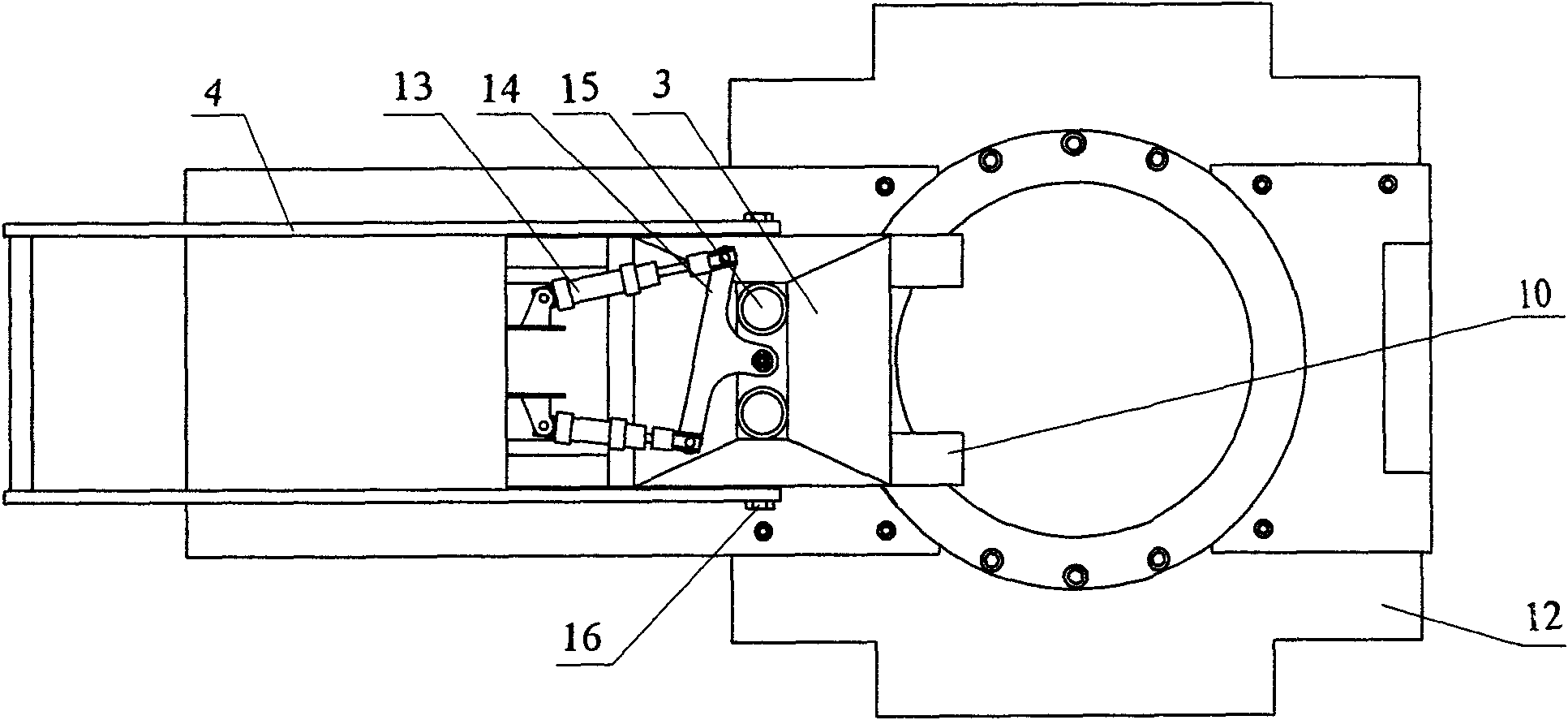

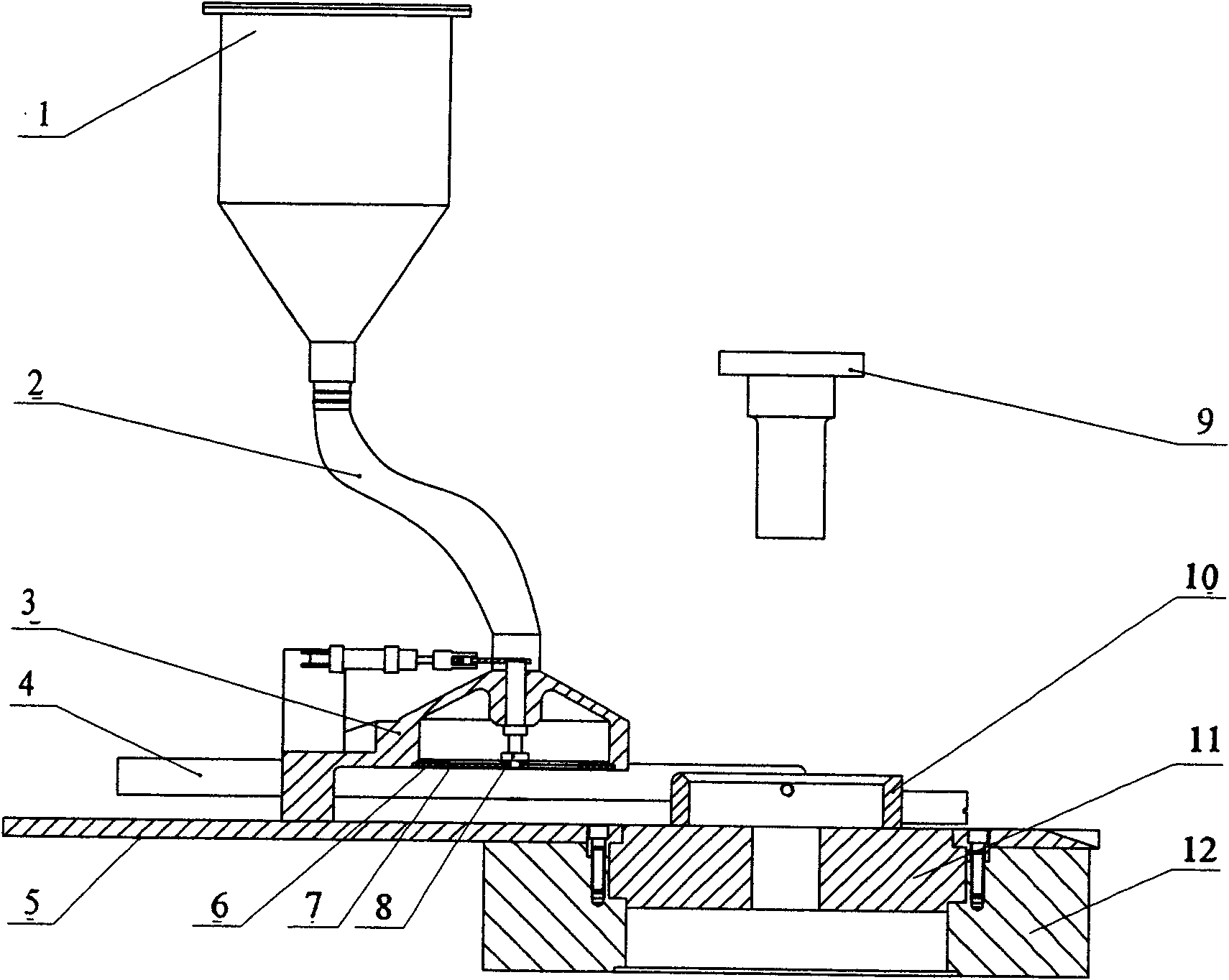

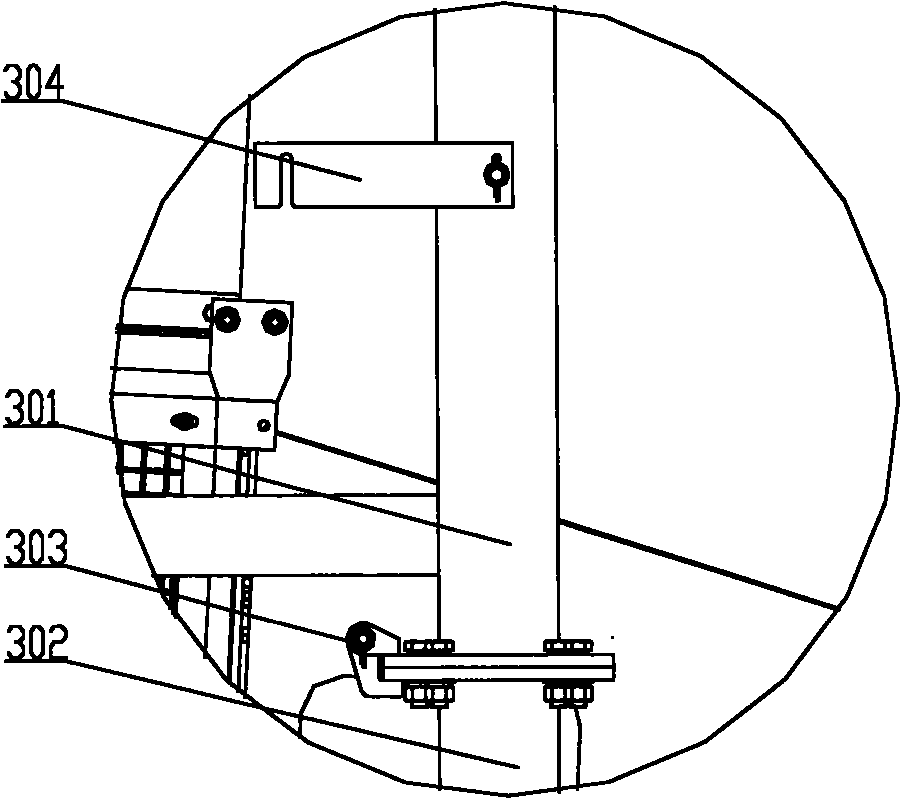

Controllable powder-feeding mechanism of power forming machine

ActiveCN102248161AReduce energy deliveredLower vertical heightPressesWhole bodyElectrical and Electronics engineering

The invention relates to a controllable powder-feeding mechanism of a power forming machine, comprising a whole body formed by connecting a powder-feeding bracket and a feeding hopper with a feeding inlet and a discharging valve, wherein the feeding hopper is formed by matching a charging hopper with a discharging hopper; the powder-feeding bracket and the discharging hopper are connected into a whole, a rotating shaft is installed on the discharging valve from the charging hopper, connected with a driving mechanism fixed on the charging hopper, driven by the driving mechanism to rotate and connected with a movable blade and matched with a stator blade fixed on the charging hopper. An integrated powder-feeding hopper is improved into a split type powder-feeding hopper consisting of the charging hopper and the discharging hopper, the integrated movement is changed into the movement that the discharging hopper is only pulled by the powder-feeding bracket, a stationary movement structureof the charging hopper ensures that a vertical height of the movement part of the powder-feeding mechanism is much lower than the integrated structure, therefore, the condition of collision or interference of the feeding hopper and a punch is thoroughly eradicated, the conveying energy of the powder-feeding bracket is greatly reduced, the operation is convenient, the powder-feeding speed is high and can be controlled, and the controllable powder-feeding mechanism has strong practicability.

Owner:宁波汇众粉末机械制造有限公司

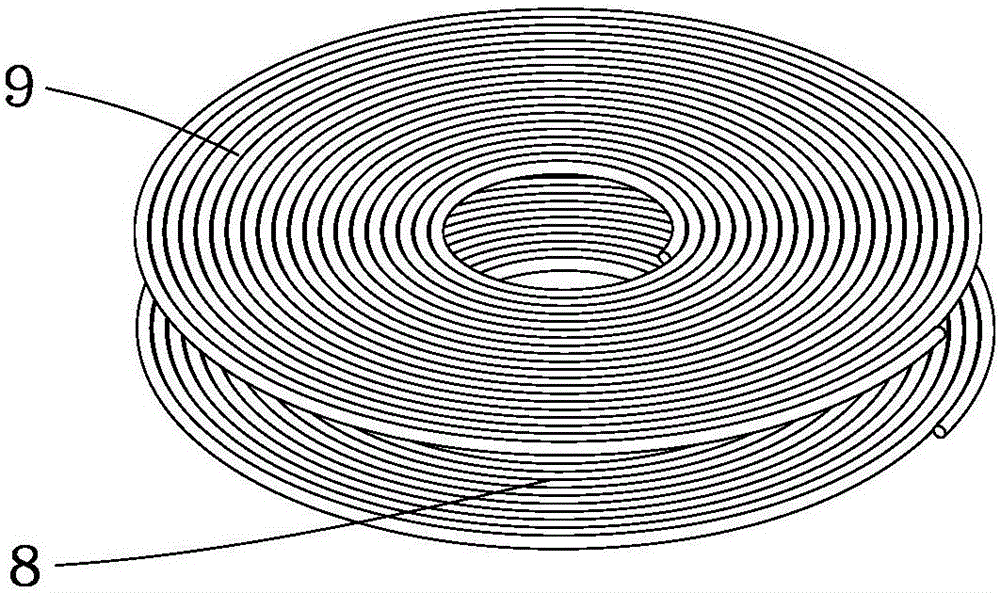

Laser scanning distance measuring device

ActiveCN105785383ALower vertical heightSmall footprintElectromagnetic wave reradiationLaser scanningStator

The invention provides a laser scanning distance measuring device. A rotation platform and a fixed platform are connected through a shaft bearing; rotors are installed on the rotation platform; stators are installed on the fixed platform; a drive transmitting circuit board is installed on the fixed platform; a receiving circuit board is installed on the rotation platform; a hollow transmitting coil is installed on the fixed platform; a magnetic isolating sheet is arranged between the hollow transmitting coil and the drive transmitting circuit board; a hollow receiving coil is installed on the rotation platform; a magnetic isolating sheet is arranged between the hollow receiving coil and the receiving circuit board. Compared with the prior art, the hollow transmitting coil and the hollow receiving coil are tiled in the direction vertical to the rotation shaft so that the vertical height of the laser scanning distance measuring device is shortened and therefore, the occupation volume of the whole structure of the laser scanning distance measuring device is reduced. In addition, when the vertical height of the overall device is reduced, the communication distance of spectrum diode for signal wireless transmission is reduced and therefore, the transmission speed of wireless signals is increased.

Owner:SHANGHAI SLAMTEC

Positive displacement shoe and slat sorter apparatus and method

InactiveUS20050167240A1Lower vertical heightIncrease the number ofConveyorsPackagingControl systemEngineering

A positive displacement sorter apparatus and method includes providing a plurality of slats being interconnected in an endless web, an upper run of the web defining a conveying surface, and a plurality of pusher shoes gliding along at least some of the slats to laterally displace articles on the conveying surface. A linear motor system is provided to propel the web and includes a plurality of linear motor secondaries at the slats and at least one primary for propelling the secondaries. A control system controls the primaries.

Owner:DEMATIC

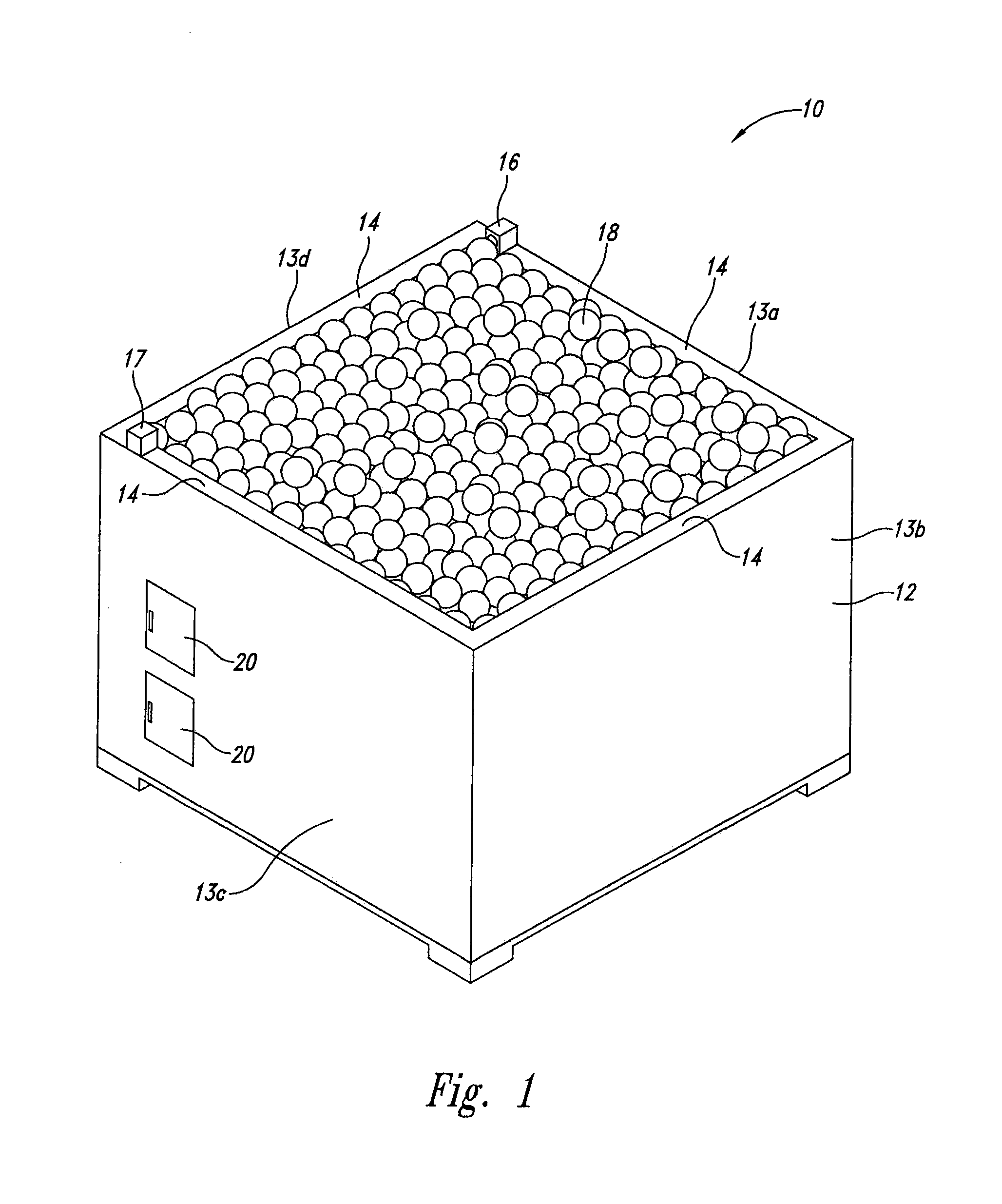

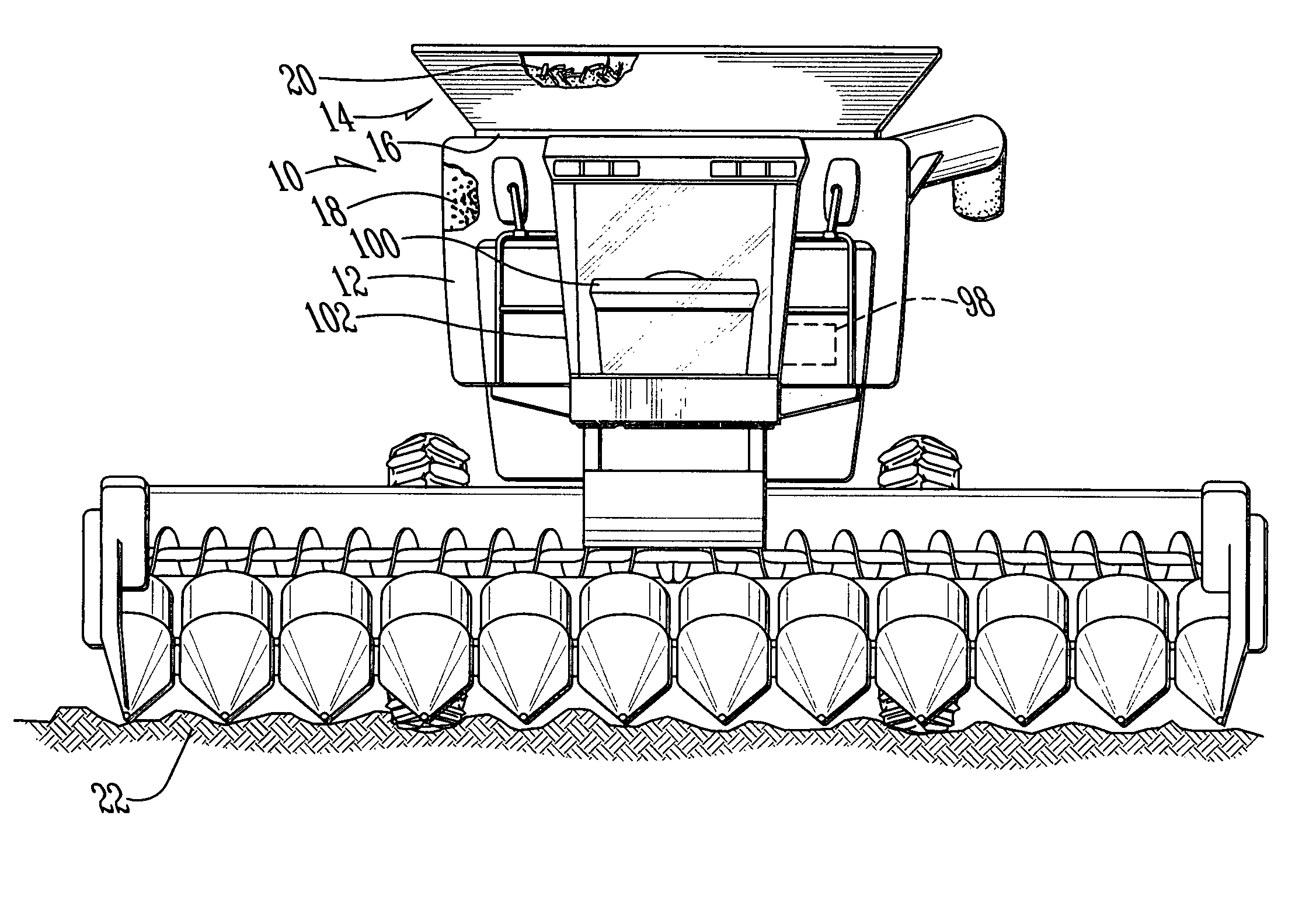

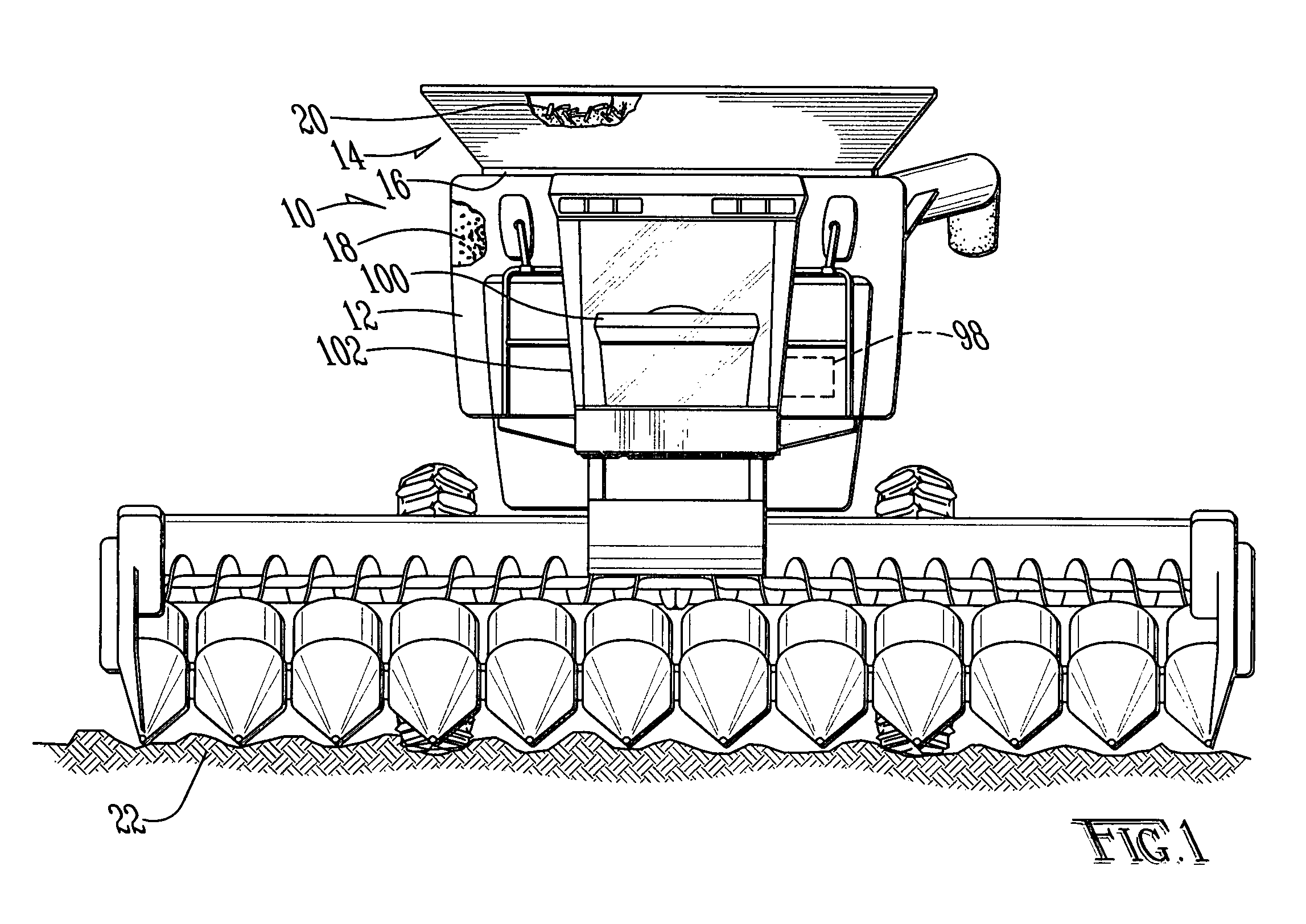

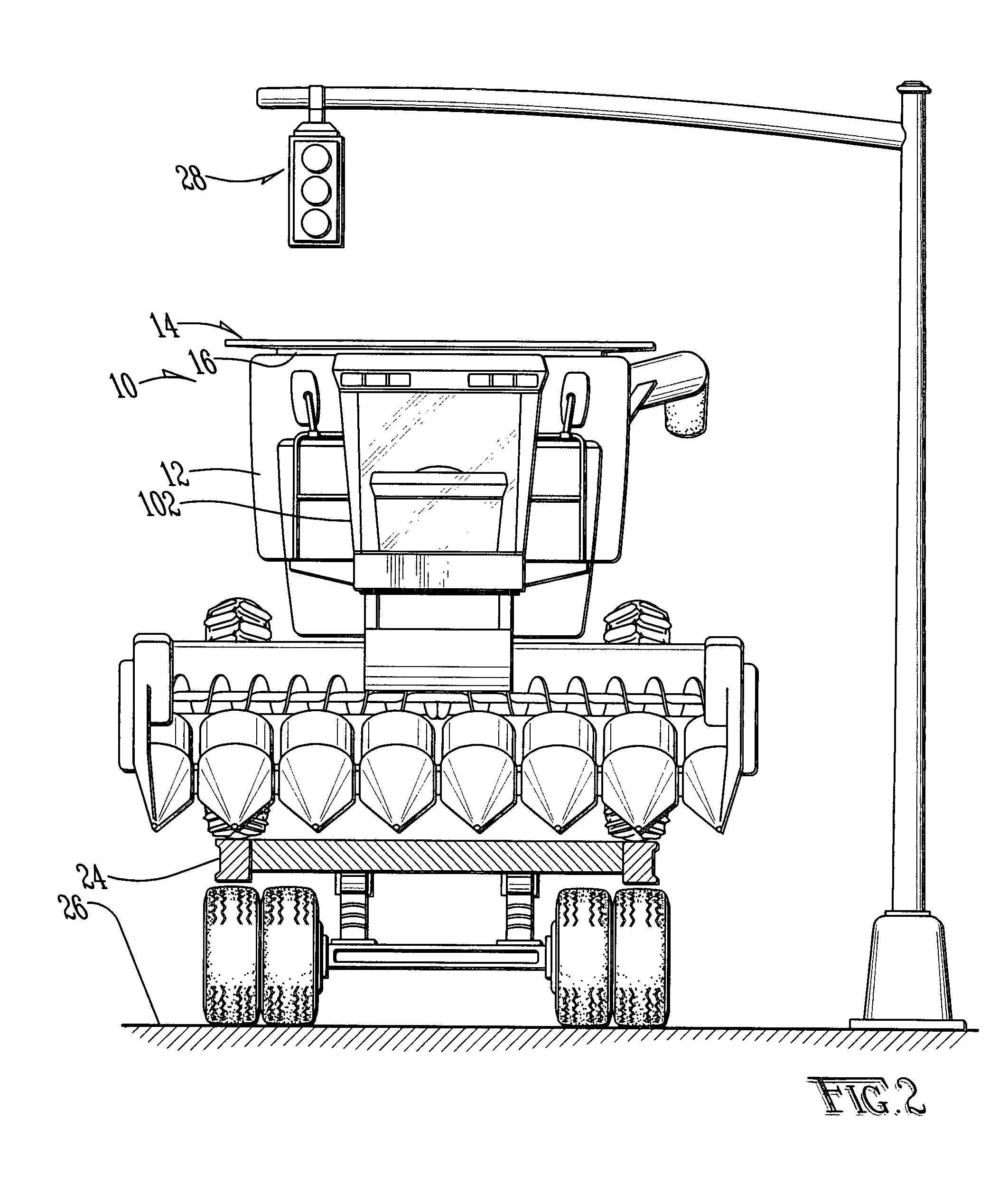

Collapsible storage bin

InactiveUS20080261672A1Reduce the overall heightIncrease capacityMowersLoading/unloading vehicle arrangmentEngineeringStreet light

An agricultural vehicle such as a combine is provided with a collapsible agricultural material storage bin. The bin may be collapsed to allow for decreased overall vertical height during transport to avoid contact with obstacles, such as overhead power lines and street lights. In the field, the agricultural material storage container may be expanded to increase the agricultural material holding capacity of the vehicle. The bin may be provided with an internal extension mechanism to increase the lifting power of the container to allow for the placement of a second container or other material thereabove. Alternatively, the container may be provided with an external lifting means to allow for unobstructed evacuation of the interior of the container.

Owner:COBCO MFG

Liquid-cooling heat dissipation device

InactiveUS20180213677A1Lower vertical heightIncrease heat dissipation structureSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

Owner:AURAS TECH

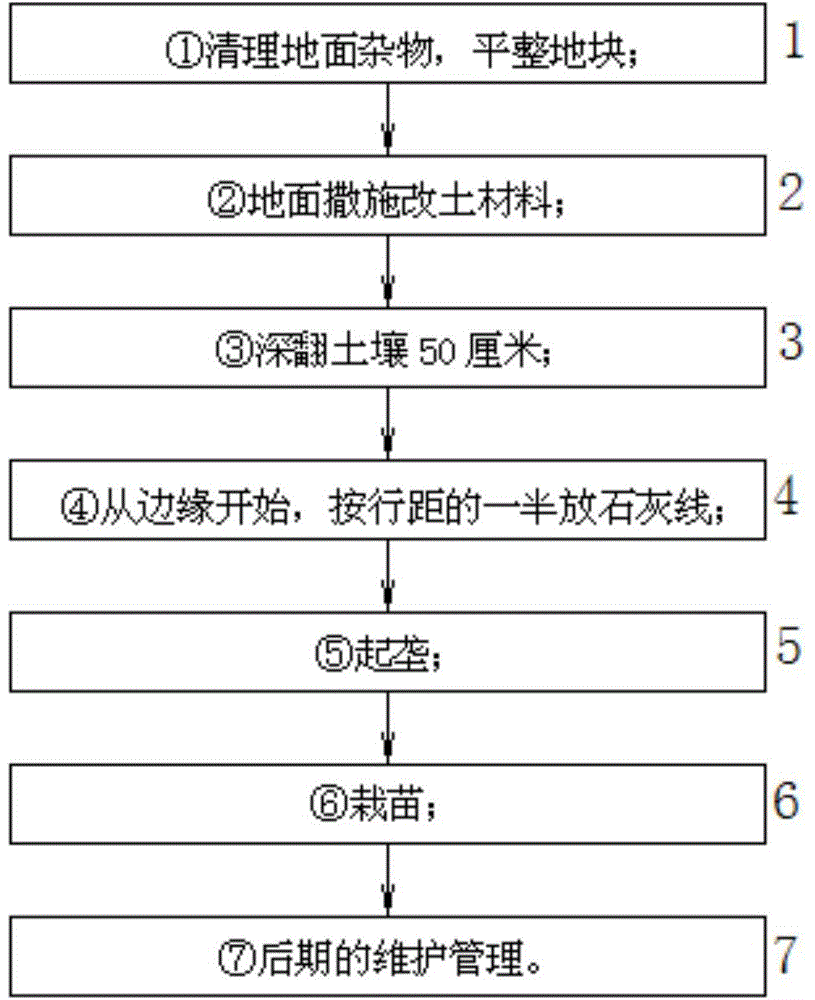

High-ridge cultivation method of high-yield and high-quality kiwifruit orchard establishment

ActiveCN104472293AReduce flood riskLower the water tableCultivating equipmentsForeign matterActinidia

The invention discloses a high-ridge cultivation method of high-yield and high-quality kiwifruit orchard establishment and relates to the field of kiwifruit orchard establishment and soil amelioration. The high-ridge cultivation method comprises the steps of (1) clearing away ground foreign matters and leveling the land parcel, (2) spreading a soil amelioration to the ground, (3) deeply turning up the soil by 50cm, (4) marking lime lines according to one half of a line spacing, starting from the edge, (5) ridging, (6) planting seedlings and (7) performing later maintenance and management. The high-ridge cultivation method of high-yield and high-quality kiwifruit orchard establishment has the following advantages: the soil layer is raised to reduce the risk that the root system suffers from water logging; the mellow soil of the original surface layer is gathered and piled up to facilitate rapid growth of the root system; coarse organic matters and organic fertilizers are added in the soil amelioration process to increase the organic substances and the permeability of the soil; the high-ridge cultivation method is suitable for a plurality of types of soil, in particular heavy soil of a high underground water level, and for sandy soil, the vertical height from the ridge top to the ridge bottom can be reduced appropriately.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

Vertical exhaust water trap assembly

InactiveUS7114330B1Easy vehicle packagingReduce back pressureExhaust apparatusValve members for absorbing fluid energyWater trapEnvironmental engineering

An exhaust water trap assembly has separated and spaced exhaust tubes, and a dome cap blocking entry of water to protect an upstream catalytic converter or soot filter. A first tube extends axially upwardly into a housing, and a second tube is spaced vertically thereabove. The dome cap on the top end of the first tube blocks exhaust flow axially upwardly therepast and blocks entry of water axially downwardly therepast.

Owner:CUMMINS FILTRATION INC

Fiber delivery apparatus and system having a creel and fiber placement head with polar axis of rotation

ActiveUS20120090788A1Improve protectionReduce any negative affects on fiber towsEngine sealsLamination ancillary operationsFiberMechanical engineering

A fiber placement system including positioner and a fiber delivery apparatus having a creel assembly and a fiber placement head is provided. The positioner moves the entire fiber delivery apparatus including the creel assembly and the fiber placement head via at least three linear degrees of freedom. The fiber delivery apparatus includes an articulating wrist for moving the fiber placement head relative to the creel assembly. The fiber placement apparatus is substantially free of linear degrees of freedom within the fiber tow paths between the spools and the fiber placement head. One or more rotational degrees of freedom may be provided along the tow path. In one embodiment, the interface between the fiber delivery apparatus and the positioner is laterally offset such that a portion of the creel axially overlaps with vertical ram of the positioner.

Owner:INGERSOLL MACHINE TOOLS

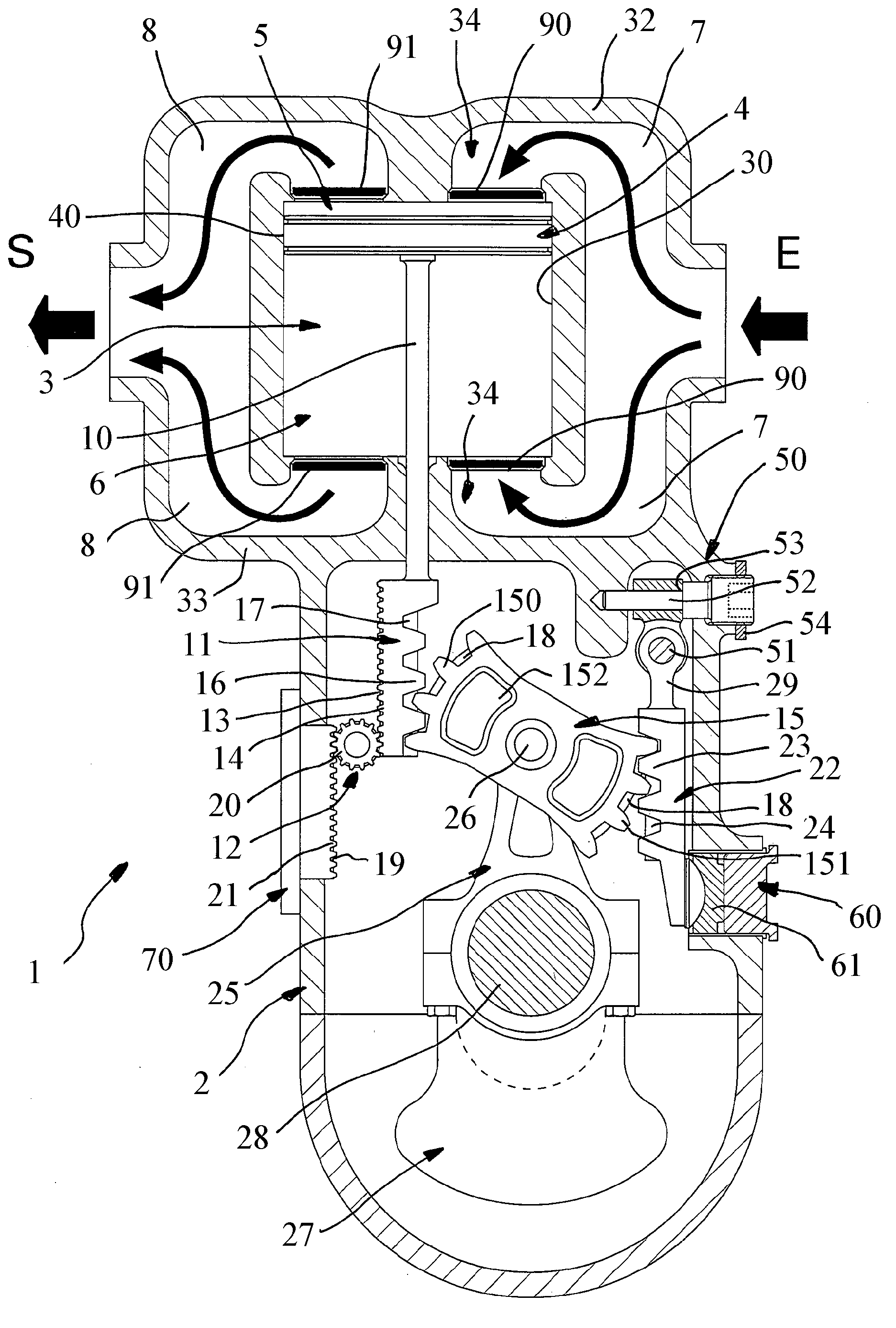

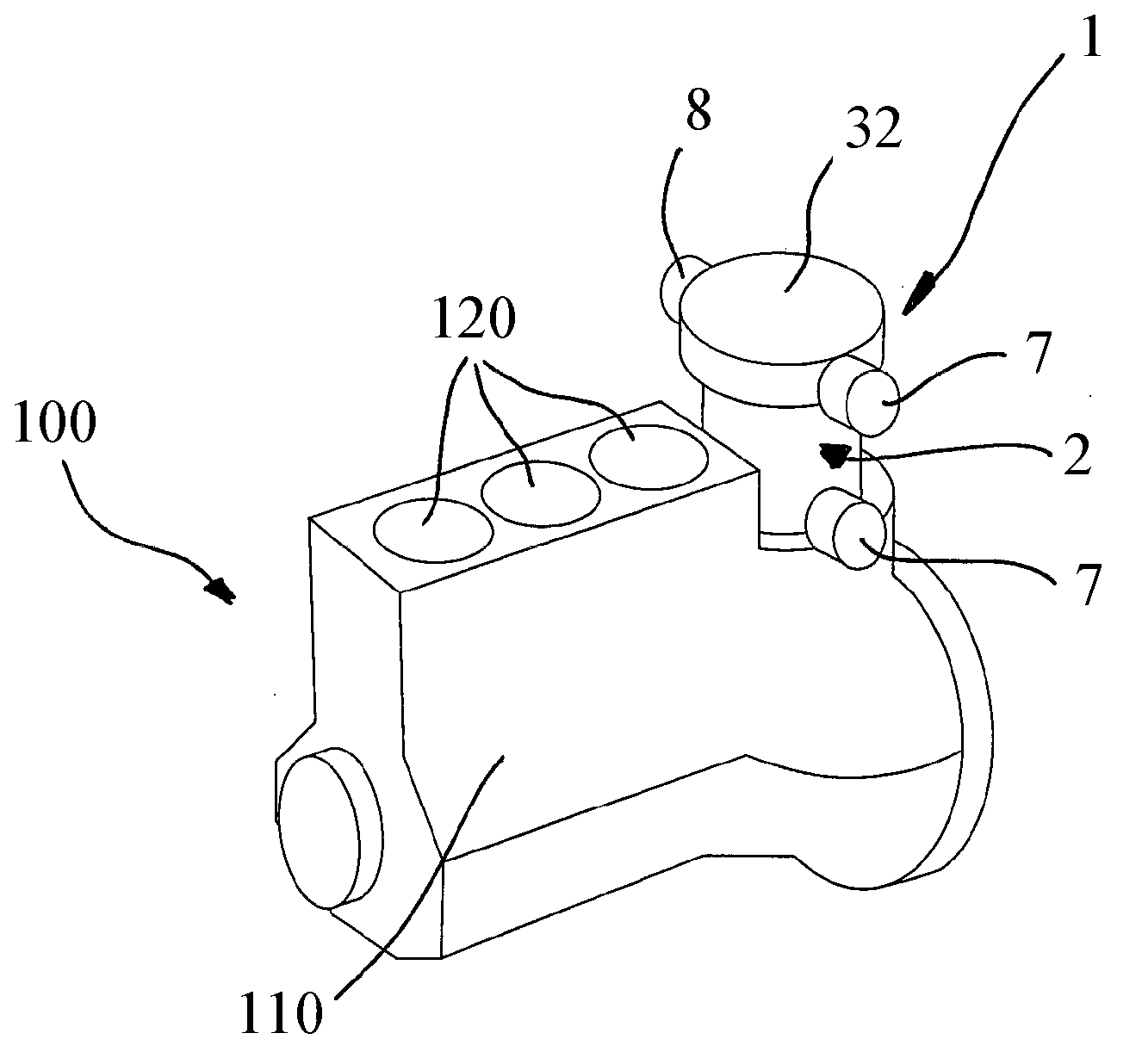

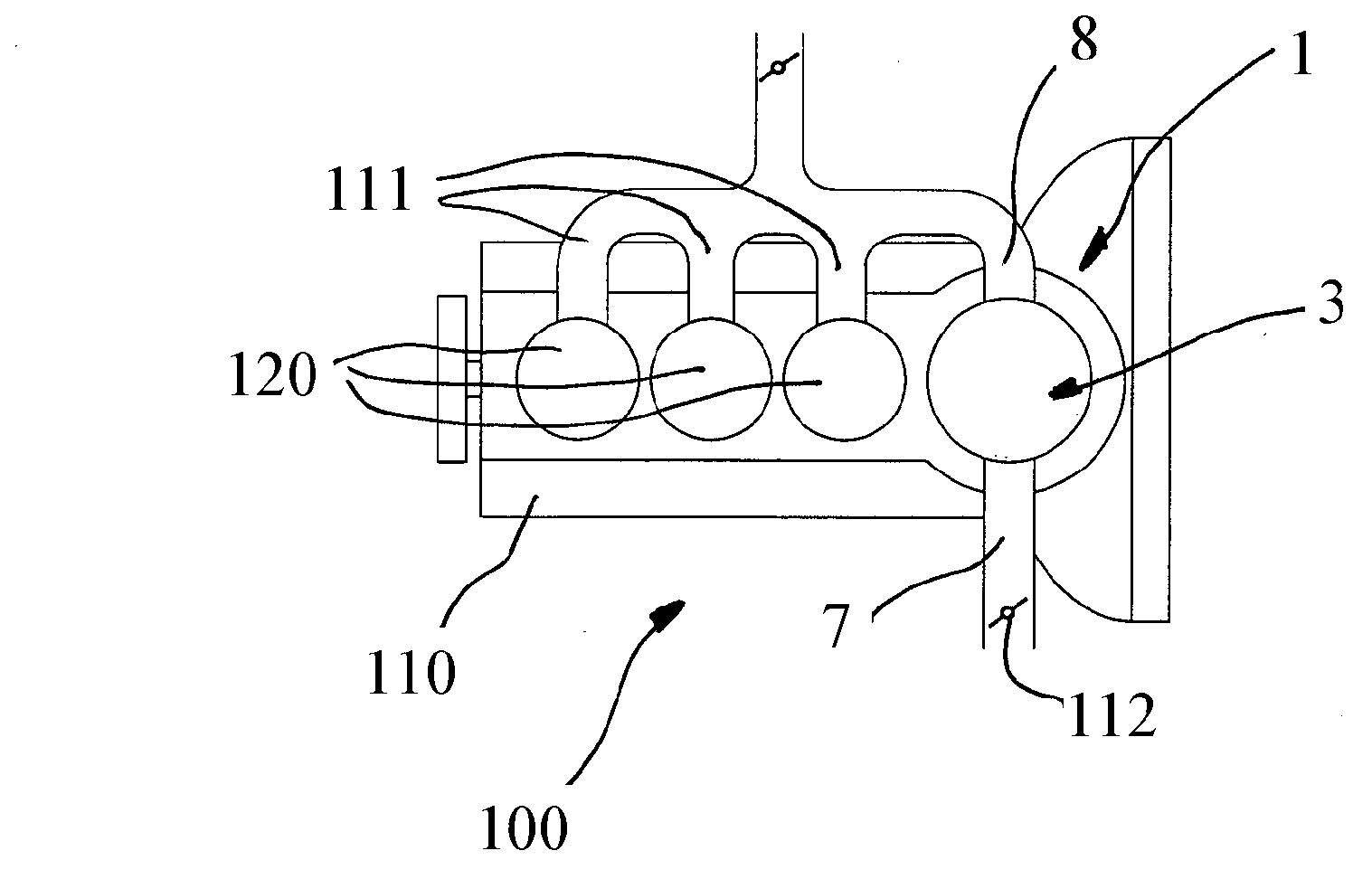

Double-acting piston compressor guided by a roller and driven by a gearwheel and racks

InactiveCN102859193ALower the altitudeLower vertical heightPositive displacement pump componentsCombustion enginesCrankshaftRack and pinion

The double-acting piston compressor (1) according to the present invention includes at least one cylinder (3) in which a double-acting piston (4) moves; said cylinder (3) and said piston (4) together define an upper chamber (5) and a lower chamber (6) each provided with at least one inlet port (7) and one delivery port (8), and each port comprises at least one valve (90, 91), and one link rod (10) connecting the double-acting piston (4) to a transmission member (11) engaging with a guide roller (12), on the one hand, and a gearwheel (15) on the other hand, at least one anchoring member (22) engages with the gearwheel (15); a connecting rod (25), to which the gearwheel (15) is pivotably connected by means of a pin (26) of said connecting rod (25), is connected to the crank (28) of a crankshaft (27) housed in bearings provided in the compressor housing (2).

Owner:维亚内·拉比

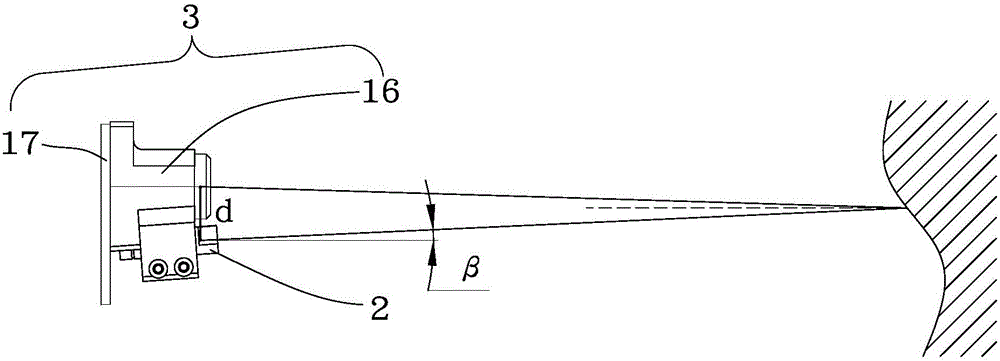

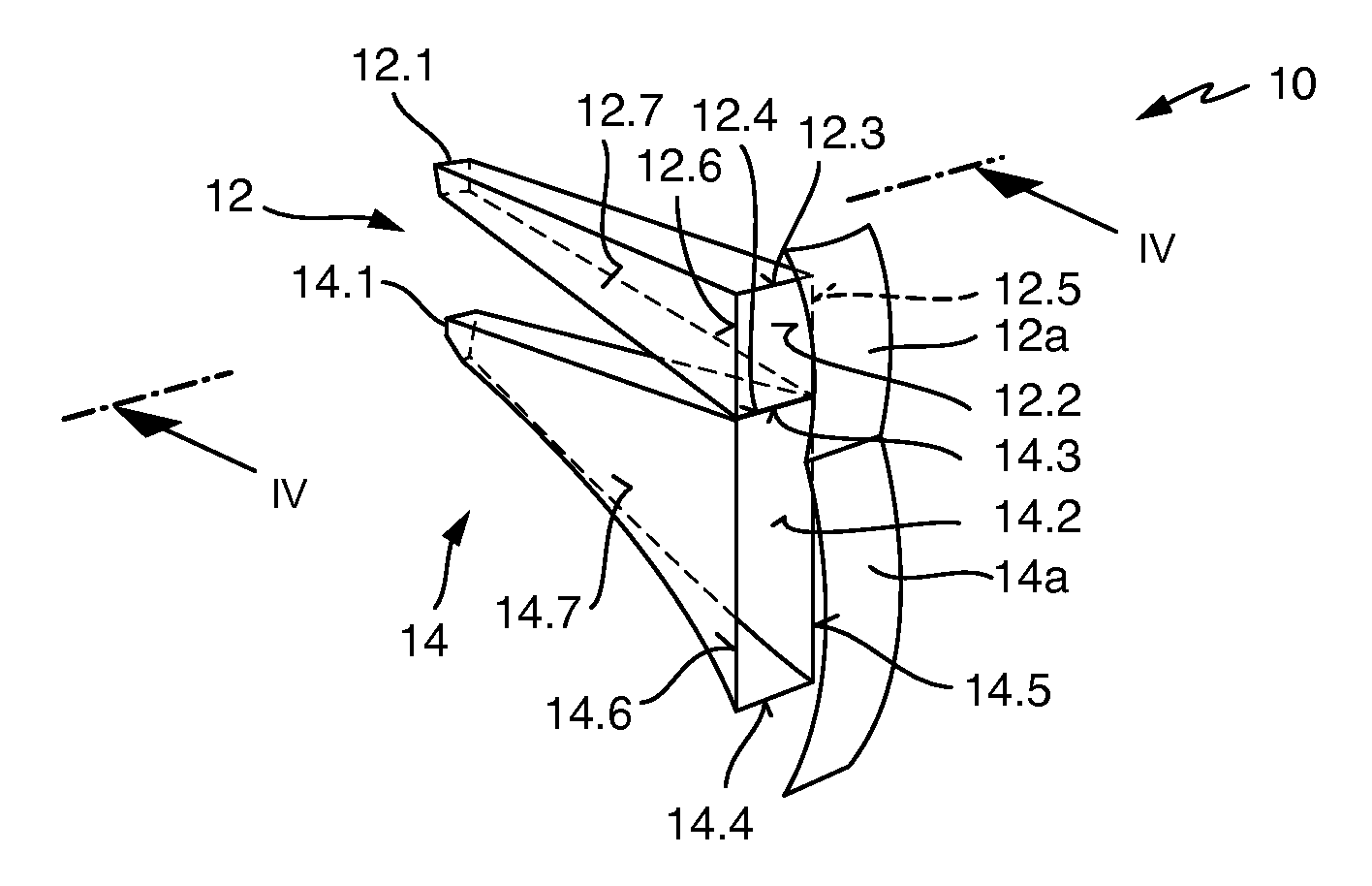

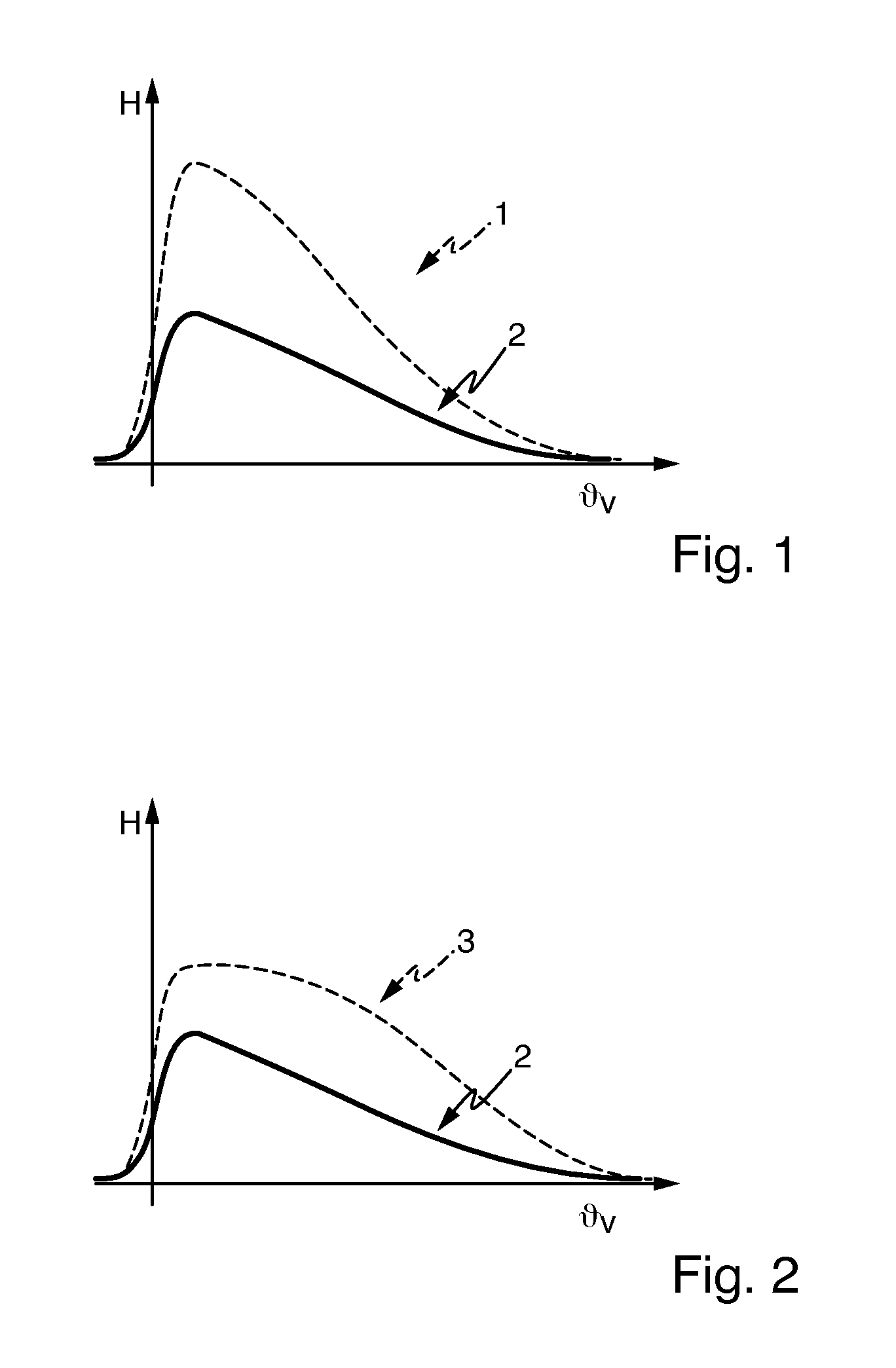

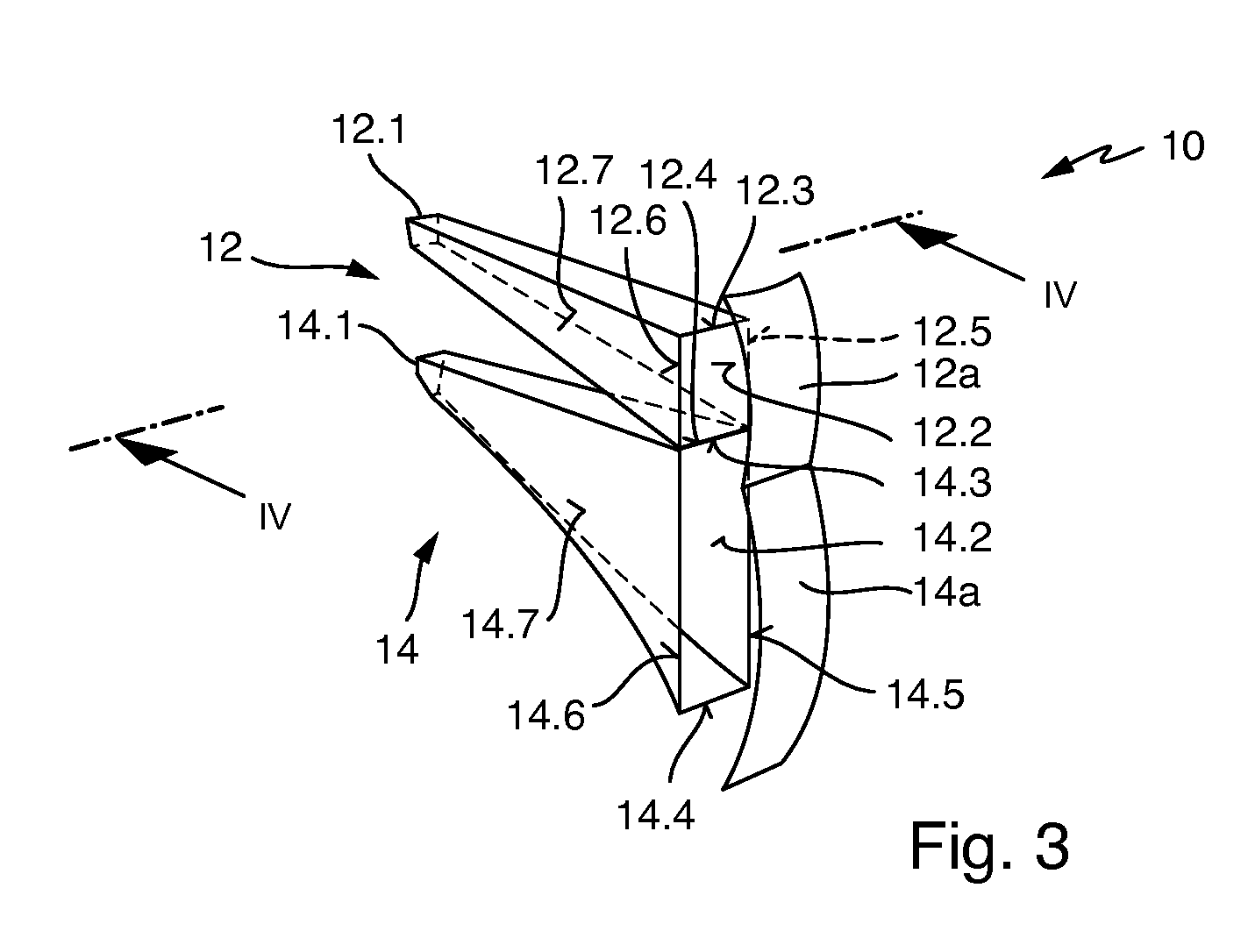

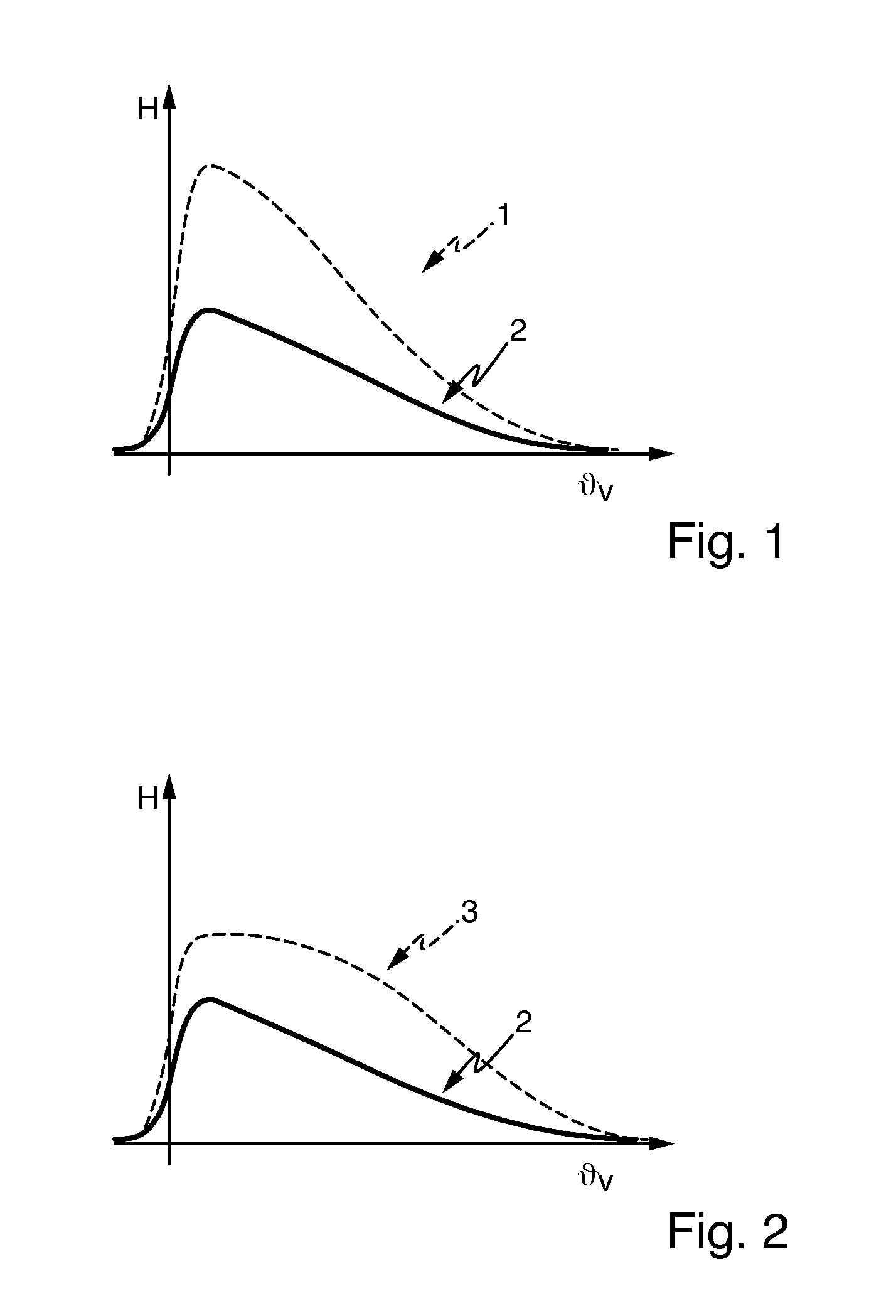

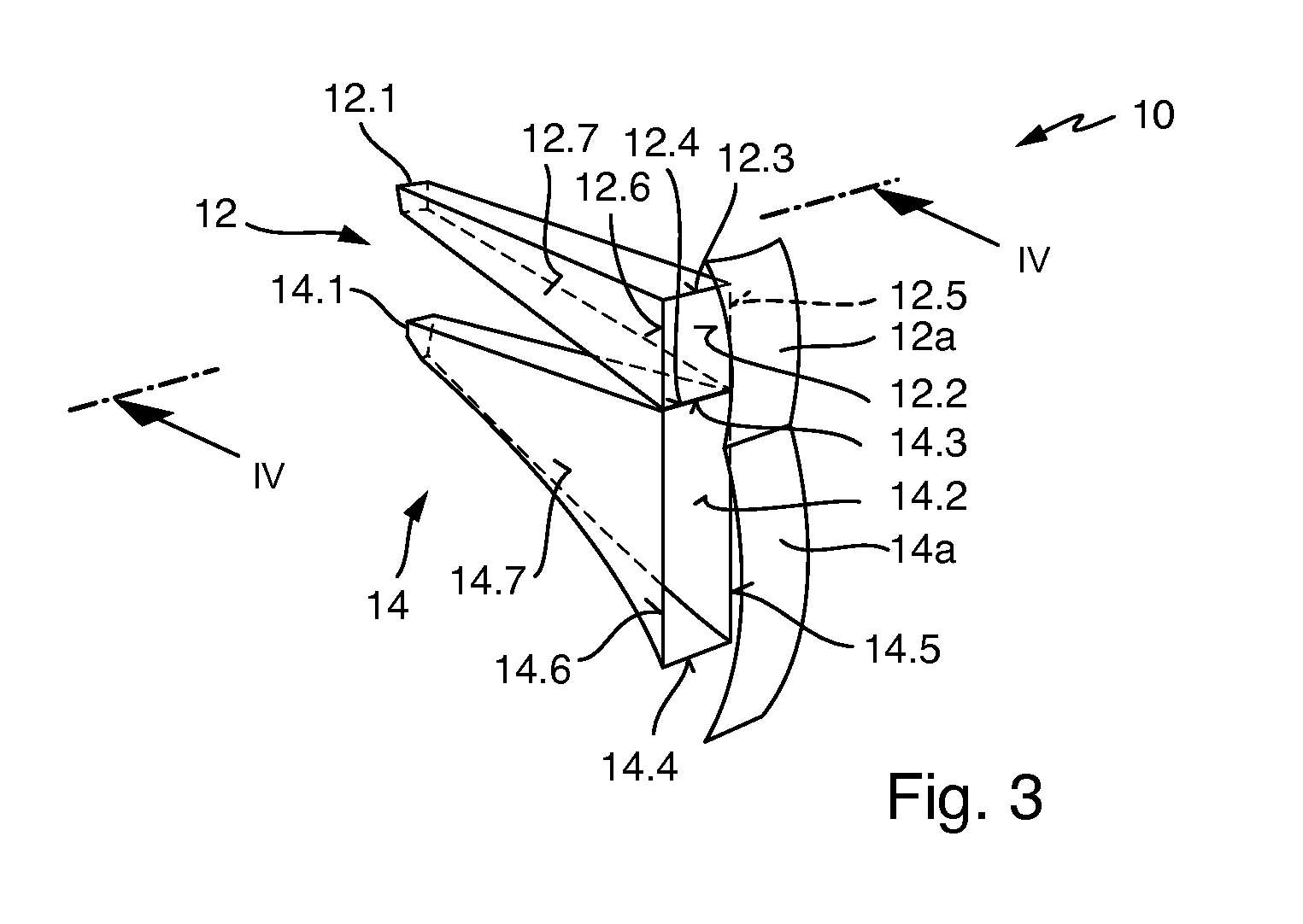

Light module for a motor vehicle headlamp, configured to generate a stripe-shaped light distribution

ActiveUS9046237B2Reduce intensityDecrease in luminosity)Vehicle headlampsVehicle lighting systemsMobile vehicleExit surface

A light module for a motor vehicle headlamp having an optical fiber configuration with at least one first optical fiber branch and one second optical fiber branch. Each of the two branches has a light exit surface each bordered by two narrow sides and disposed such that a narrow side of the first branch is disposed parallel and directly adjacent to a narrow side of the light exit surface of the second branch. Each branch exhibits two transport surfaces. The transport surfaces exhibit surface norms having a directional component, which faces more toward a first narrow side of the two narrow sides of the branch than toward a second narrow side of the two narrow sides of the branch, wherein the narrow sides lying directly adjacent and parallel to one another are a second narrow side of the first branch and a first narrow side of the second branch.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

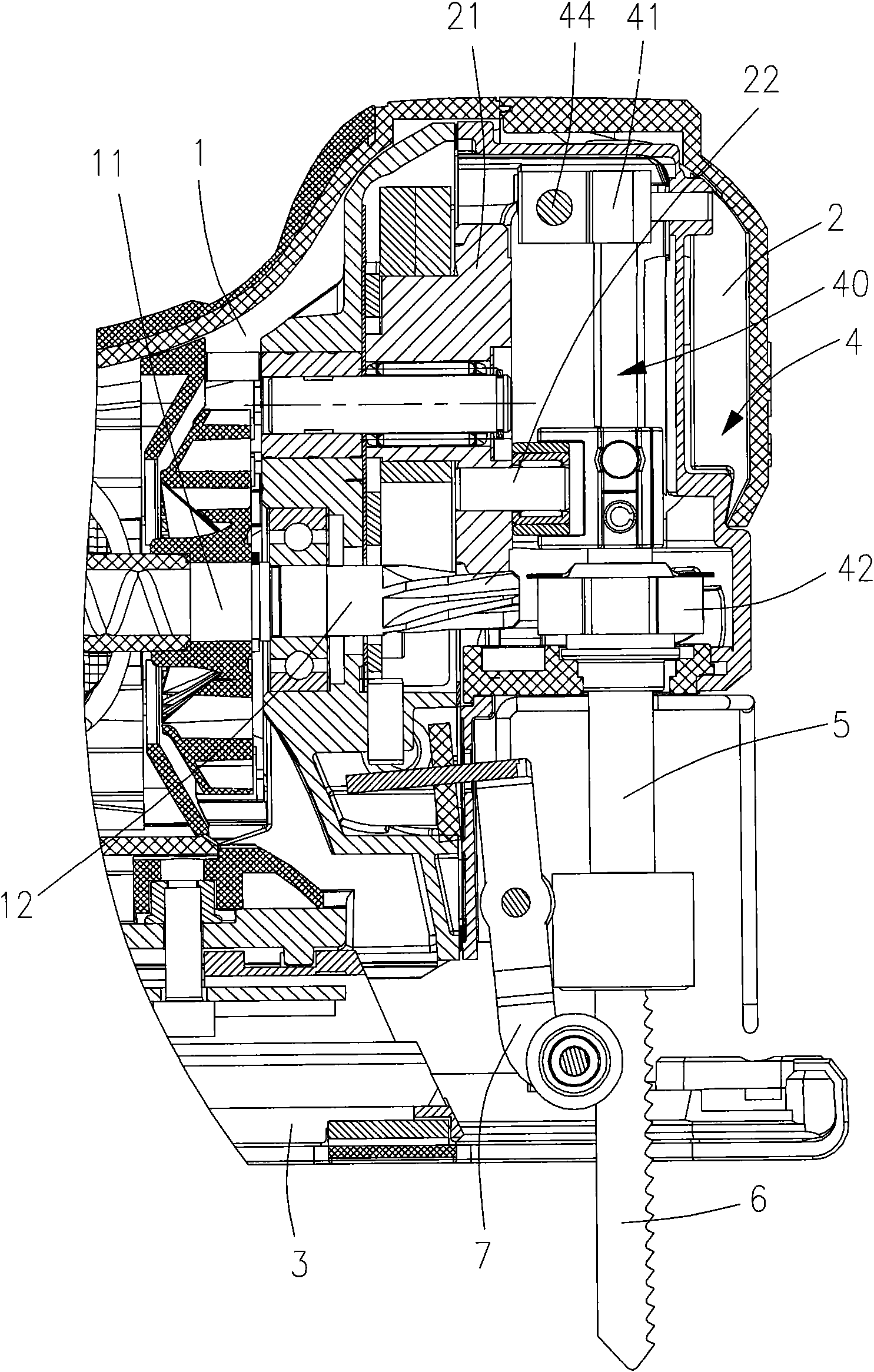

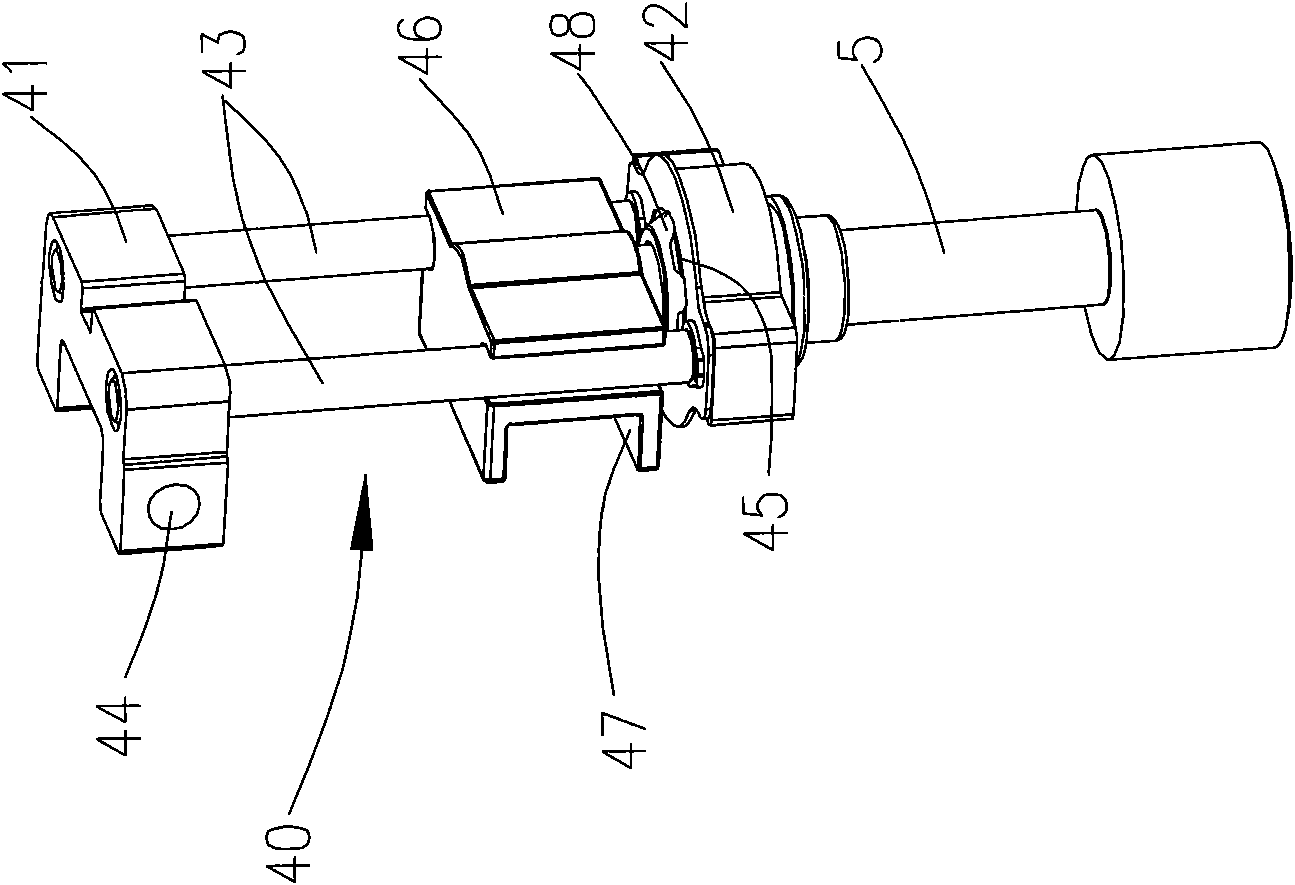

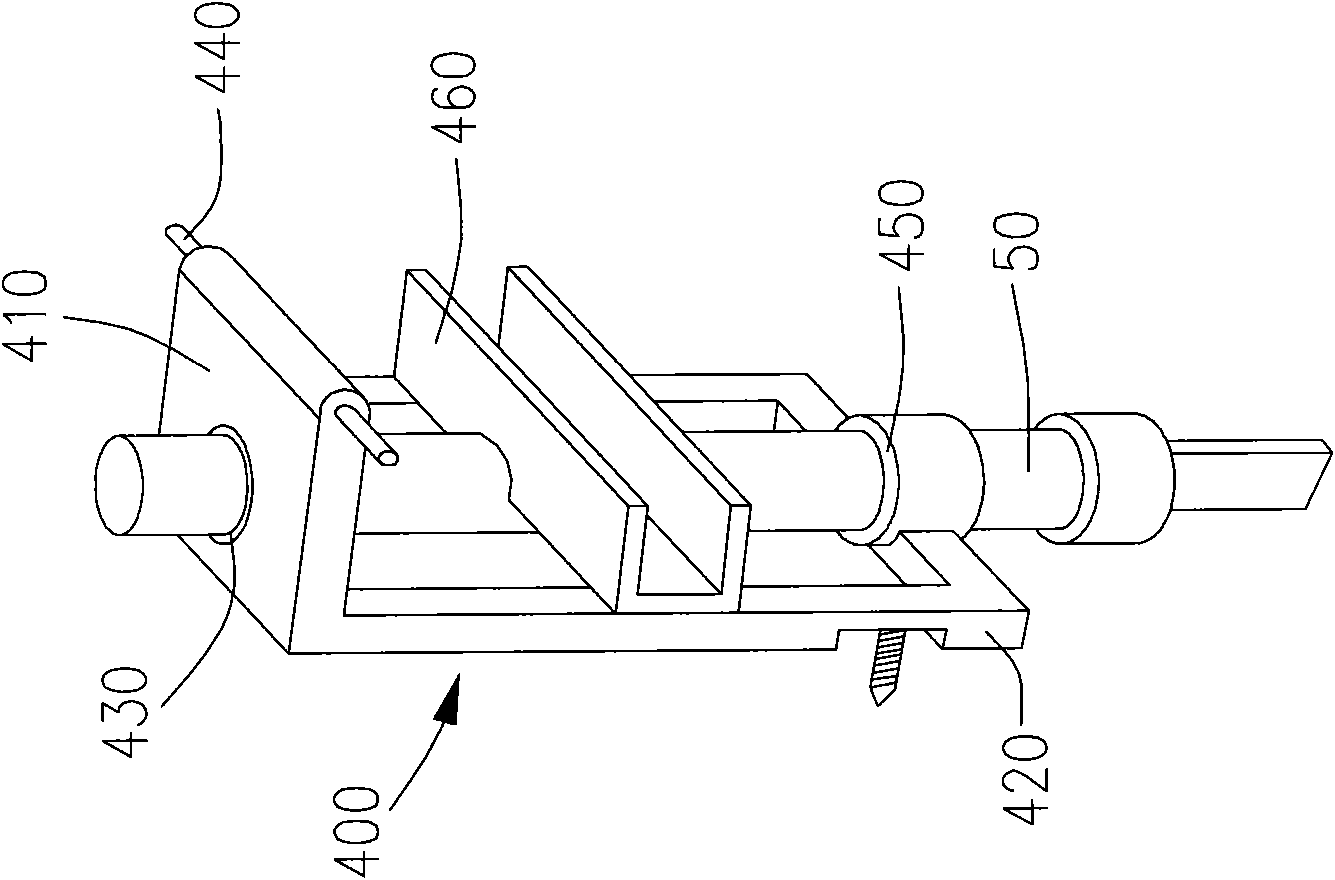

Reciprocating cutting tool

ActiveCN101596620ALower vertical heightMetal sawing devicesMechanical apparatusGear wheelReciprocating motion

The invention provides a reciprocating cutting tool, comprising a motor shell (1) and a reduction gearbox (2) connected with the motor shell (1), wherein a motor (11) is arranged in the motor shell (1); a reciprocating mechanism (4) is arranged in the reduction gearbox (2); the reciprocating mechanism (4) comprises a suspension (40) and a reciprocating rod (5) which is connected with the motor (11) through a reduction gear (21) and an eccentric shaft (22) and is driven by the motor (11); the suspension (40) comprises a top slab (41) and an underplate (42); the reciprocating rod (5) is only in movable connection with the underplate (42), and can not exceed the top plate (41) along the direction of reciprocating motion. The reciprocating rod can carry out guide-localization without depending on the top plate of the suspension, so the reciprocating rod can not extend out of the top plate of the suspension in a reciprocating moving process of the reciprocating rod so as to greatly reduce the vertical height of the reduction gearbox. Therefore, the vertical height of the reciprocating cutting tool is reduced, and the cutting tool is convenient for application.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

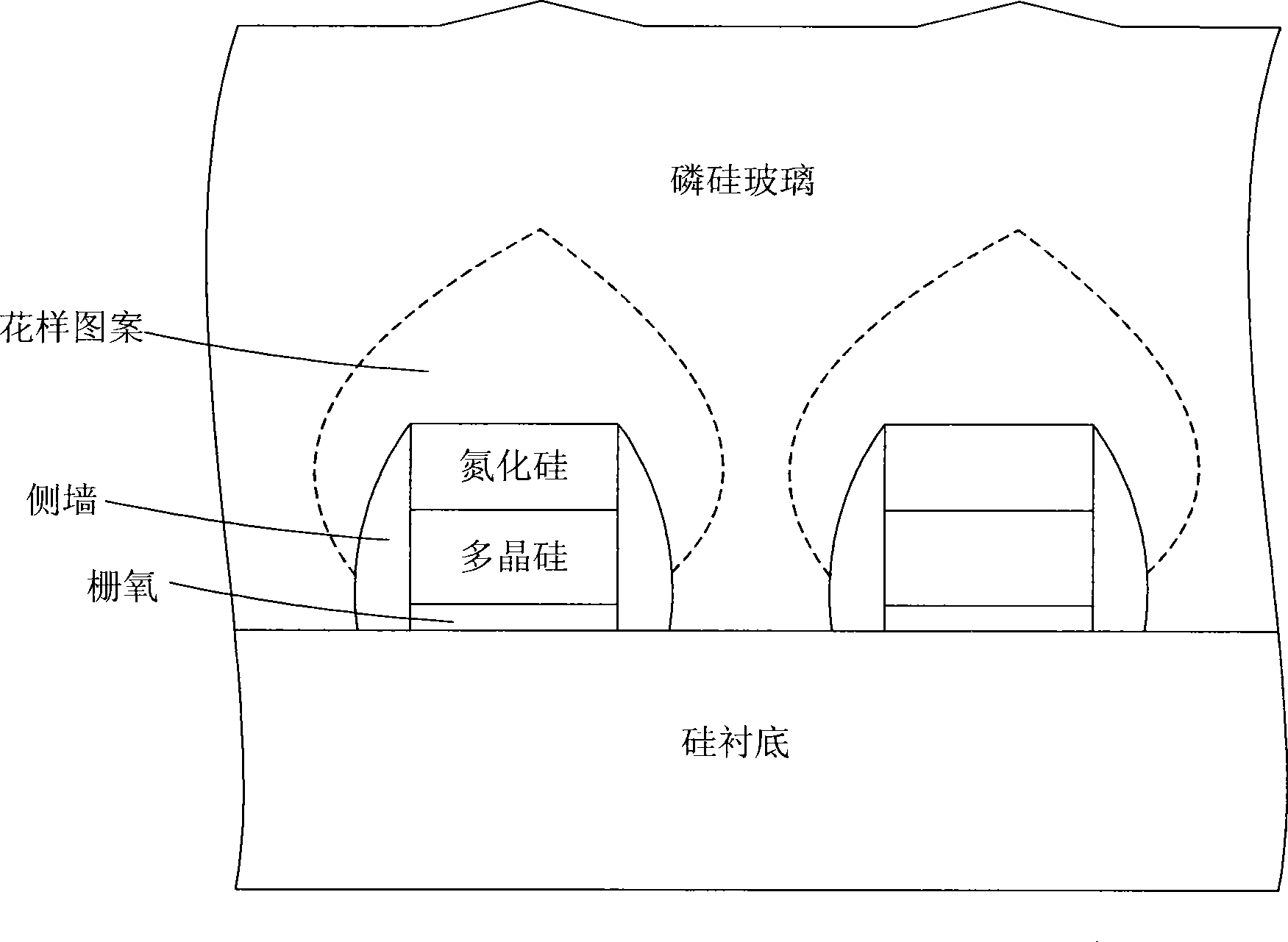

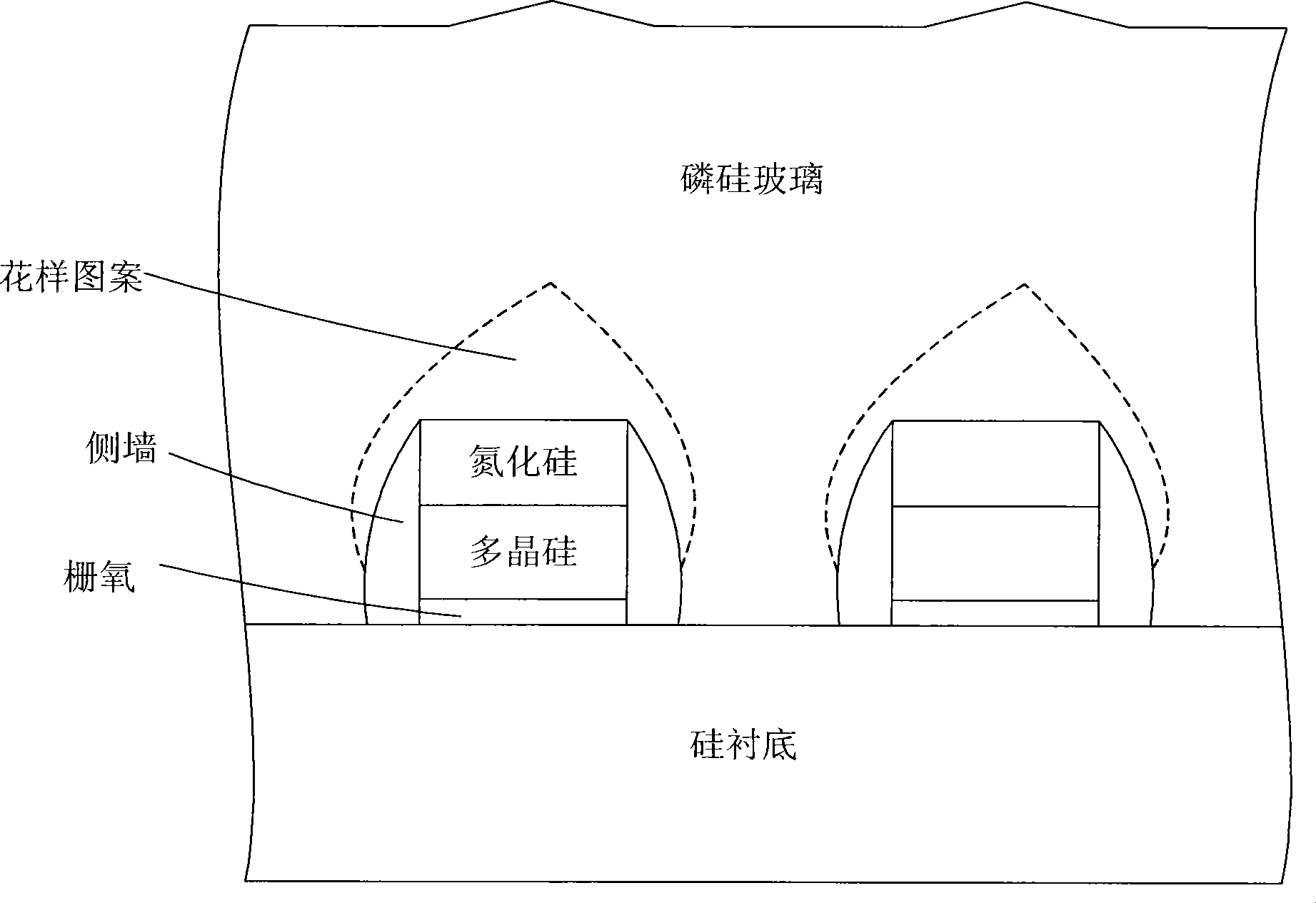

Method for preparing phosphorosilicate glass

The invention discloses a preparation method of phoshosilicate glass, which is characterized in that silane is used as reaction gas, high-density plasma deposition technology is utilized for preparation, and continuous deposition is carried out by using technological conditions of various multi-step deposition sputtering ratios in the process of deposition. During the first-step deposition, the deposition is carried out by using the technological condition of deposition sputtering ratio between 5.7 and 6.7; and then deposition is carried out by using the technological condition of deposition sputtering ratio less than 5.5 in the deposition steps. The preparation method can obviously reduce the horizontal width and vertical height of patterns in phoshosilicate glass layers and is suitable for semiconductor device manufacture.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Light module for a motor vehicle headlamp, configured to generate a stripe-shaped light distribution

ActiveUS20140198513A1Reduce intensityDecrease in luminosity)Vehicle headlampsVehicle lighting systemsExit surfaceHeadlamp

A light module for a motor vehicle headlamp having an optical fiber configuration with at least one first optical fiber branch and one second optical fiber branch. Each of the two branches has a light exit surface each bordered by two narrow sides and disposed such that a narrow side of the first branch is disposed parallel and directly adjacent to a narrow side of the light exit surface of the second branch. Each branch exhibits two transport surfaces. The transport surfaces exhibit surface norms having a directional component, which faces more toward a first narrow side of the two narrow sides of the branch than toward a second narrow side of the two narrow sides of the branch, wherein the narrow sides lying directly adjacent and parallel to one another are a second narrow side of the first branch and a first narrow side of the second branch.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

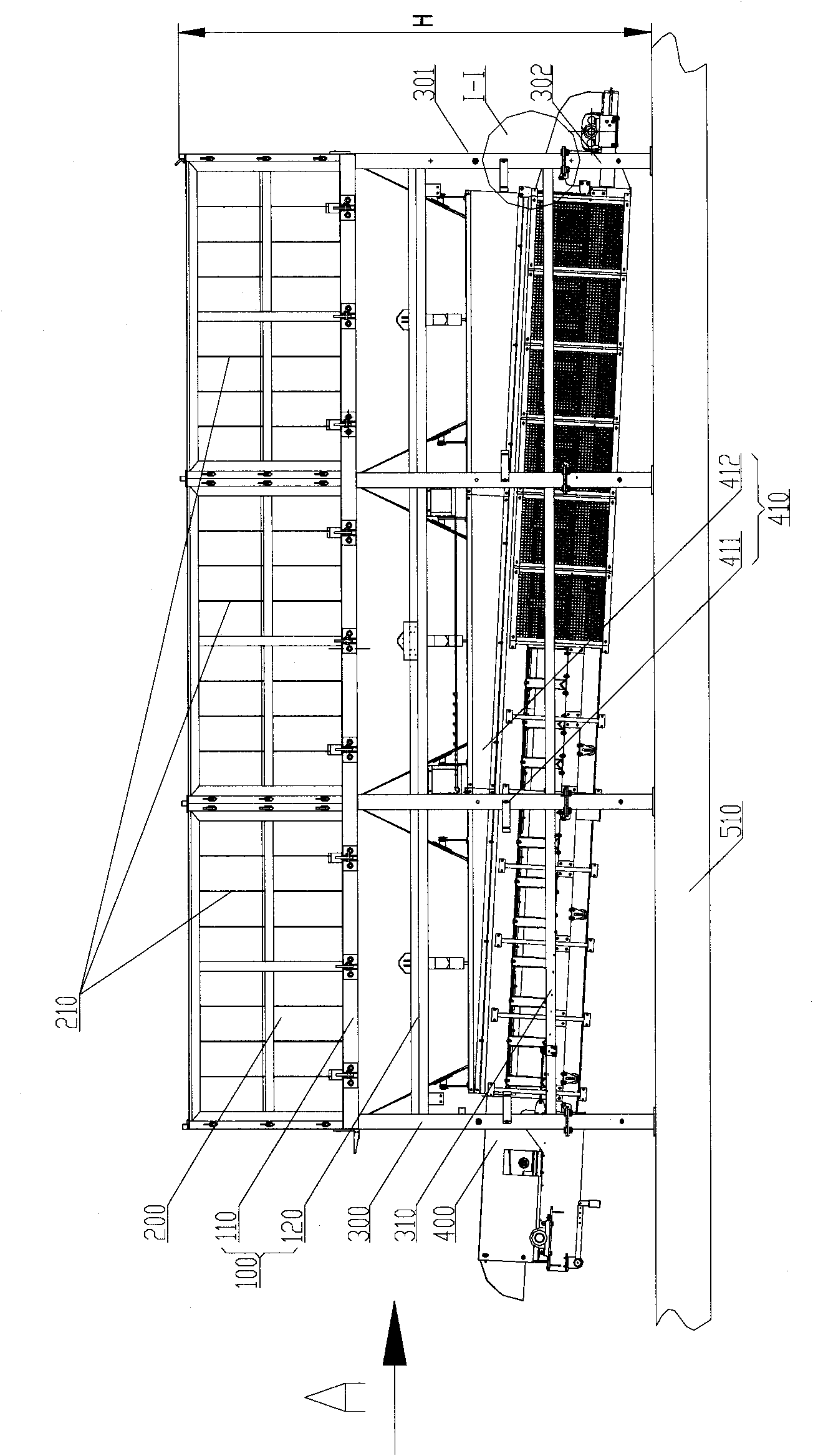

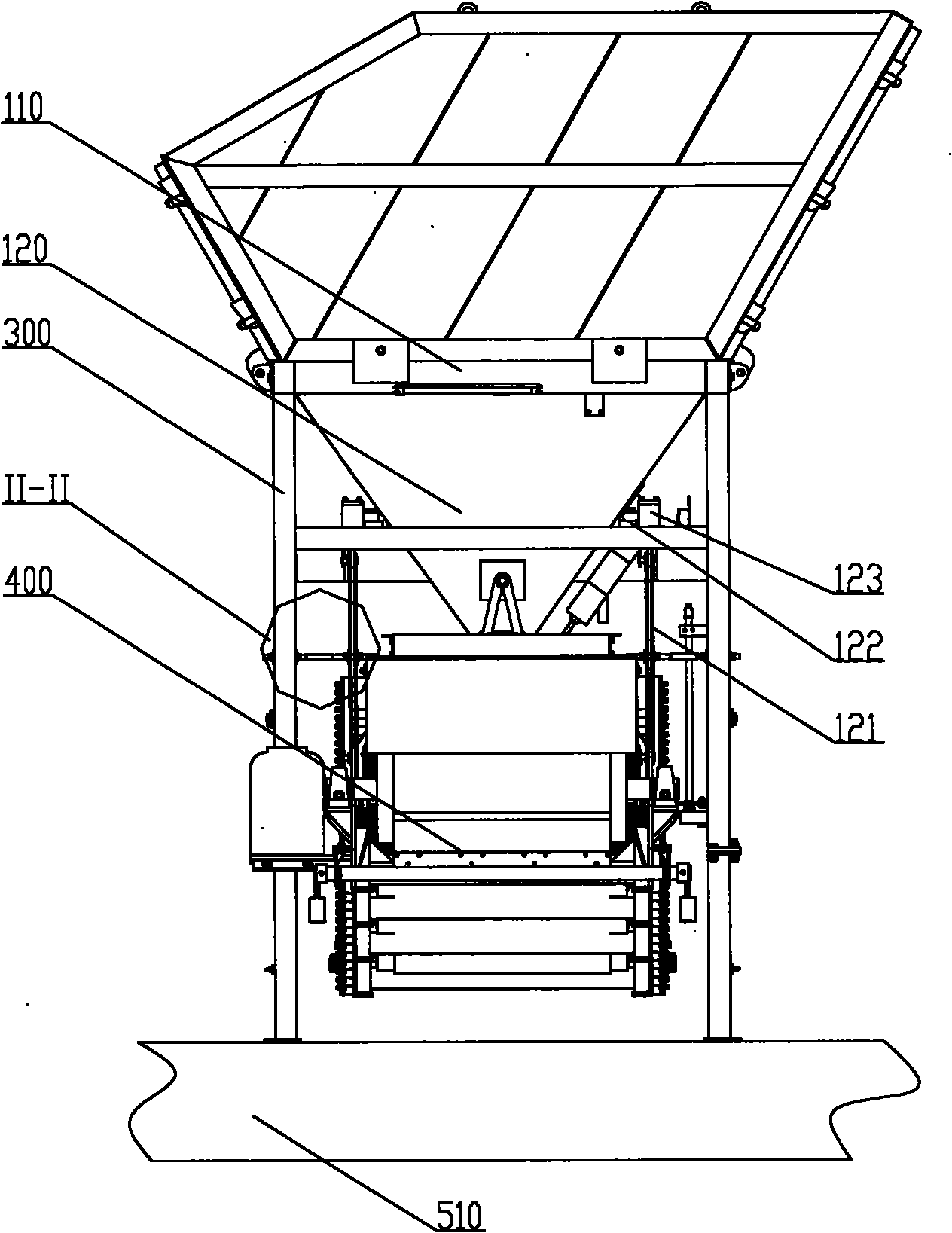

Mobile concrete mixing plant and batching machine thereof

ActiveCN101837612AGood transfer performanceReduced form factorSold ingredients supply apparatusMixing operation plantEngineeringBatch machine

The invention discloses a mobile concrete mixing plant and a batching machine thereof. The batching machine comprises a batching machine main body, a conveyor and a plurality of supporting legs, wherein the batching machine main body is supported on the preset base through the supporting legs. Compared with the prior art, the batching machine has a working state and a conveying state, wherein in the working state and the conveying state, the conveyor is suspended under the batching machine main body through suspending parts; when the working state is switched to be the conveying state, the vertical height of the supporting legs is reduced and the outline of the batching machine is reduced; in the conveying state, because the outline of the batching machine is smaller, the batching machinemain body does not need to be separated from the conveyor and materials do not need to be conveyed respectively before transfer and transportation and the batching machine has better transfer and transportation performance; and at the same time, in the working state, the batching machine has a bigger outline size so as to meet the requirement of the mobile concrete mixing plant on the preparationof concrete.

Owner:SANY HEAVY IND CO LTD (CN)

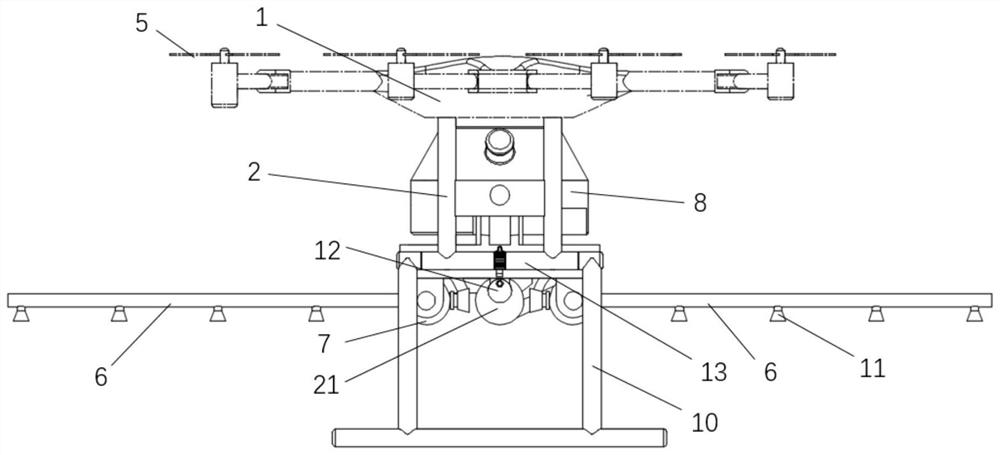

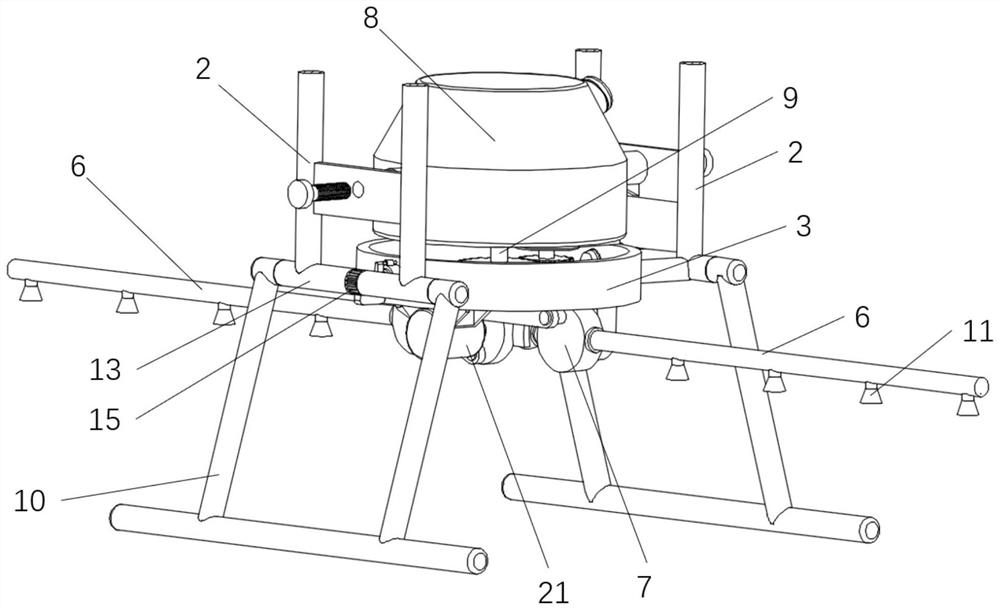

Unmanned aerial vehicle with close-range pesticide spraying function

ActiveCN111994281AImprove applicabilityReduce vertical heightInsect catchers and killersLaunching weaponsClose rangeAutomotive engineering

The invention discloses an unmanned aerial vehicle with a close-range pesticide spraying function. By arranging the angle adjusting device, the 90-degree rotation of the spraying rod is achieved suchthat a spraying head on the spraying rod can conduct pesticide spraying in the vertical direction, the applicability of the spraying rod is effectively improved, the pesticide spraying unmanned aerialvehicle can be suitable for horizontal pesticide spraying and vertical pesticide spraying, and the unmanned aerial vehicle can conduct close-range flying pesticide spraying between two rows of crops.Meanwhile, by arranging a folding device, supporting legs can be folded such that the vertical height of the unmanned aerial vehicle is reduced, and the unmanned aerial vehicle can perform close-range flying pesticide spraying; the angle adjusting device is combined to achieve the close-range pesticide spraying on the crops on the two sides, meanwhile, a rotatable rotating disc is combined, the low-altitude close-range rotary pesticide spraying can be conducted on the crops on the two sides, and the pesticide spraying efficiency of the crops and plants is effectively improved.

Owner:HAINAN NATURAL RUBBER IND GROUP +2

Multi-stage efficient evaporative cooling water-chilling unit

ActiveCN106123172AImprove stabilityImprove securityMechanical apparatusLighting and heating apparatusVertical tubeEngineering

The invention discloses a multi-stage efficient evaporative cooling water-chilling unit. The multi-stage efficient evaporative cooling water-chilling unit comprises a unit shell. A split packing type direct evaporative cooling unit is arranged in the center of the unit shell. A first packing-heat exchange tube combined evaporative cooling unit and a second packing-heat exchange tube combined evaporative cooling unit are arranged on the left side and the right side of the split packing type direct evaporative cooling unit correspondingly. An air inlet a is formed in the position, corresponding to the first packing-heat exchange tube combined evaporative cooling unit, of the side wall of the unit shell, and a high-temperature surface air cooler a is arranged between the first packing-heat exchange tube combined evaporative cooling unit and the air inlet a. An air inlet b is formed in the position, corresponding to the second packing-heat exchange tube combined evaporative cooling unit, of the side wall of the unit shell, and a high-temperature surface air cooler b is arranged between the second packing-heat exchange tube combined evaporative cooling unit and the air inlet b. Both the high-temperature surface air cooler a and the high-temperature surface air cooler b are connected with the split packing type direct evaporative cooling unit. The multi-stage efficient evaporative cooling water-chilling unit has the advantages that the height is small, the heat exchange efficiency of vertical tubes is high, the outlet water temperature is low, and the outlet water cleanliness is high.

Owner:安森(广州)环境能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com