Patents

Literature

217 results about "Batch machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

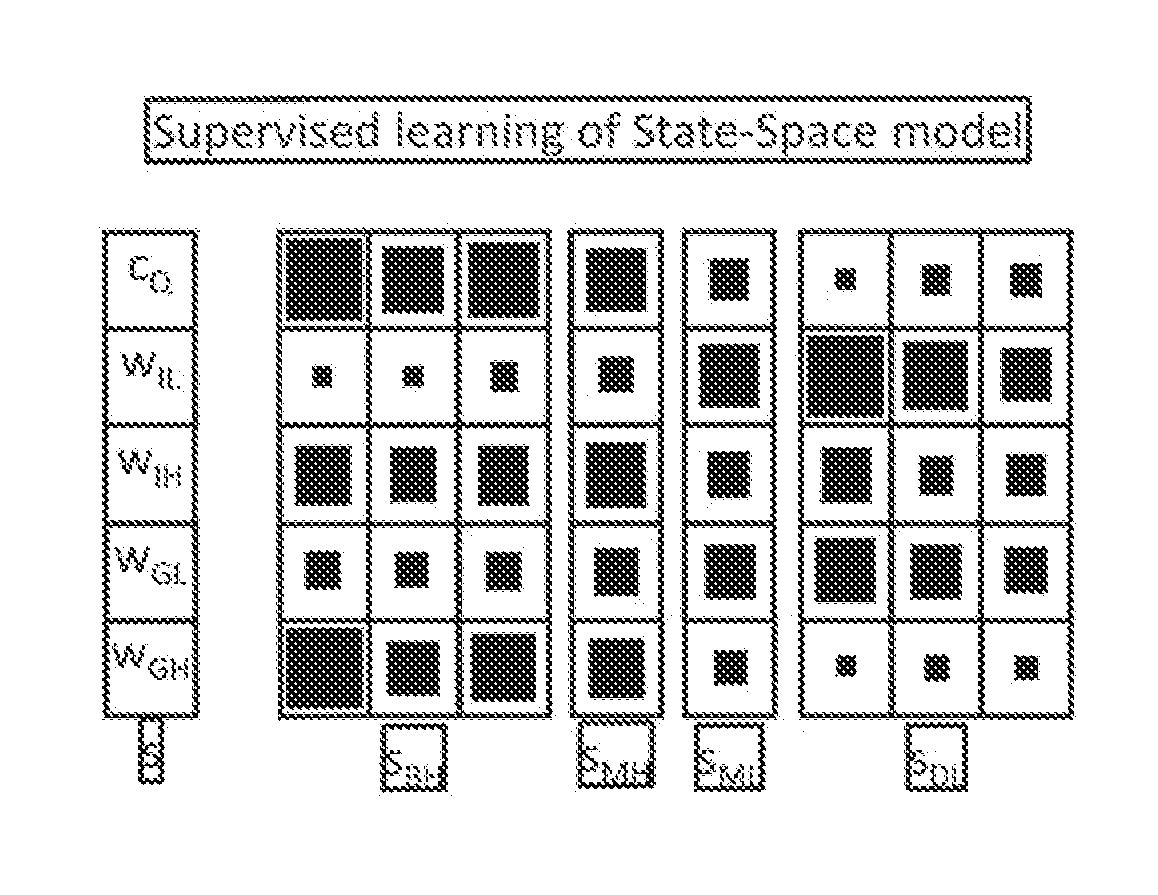

Machine-learning system for optimising the performance of a biometric system

ActiveUS20160063397A1Improve learning modeImprove learningDigital computer detailsBiostatisticsCommunication interfaceMachine learning

Owner:ACCENTURE GLOBAL SERVICES LTD

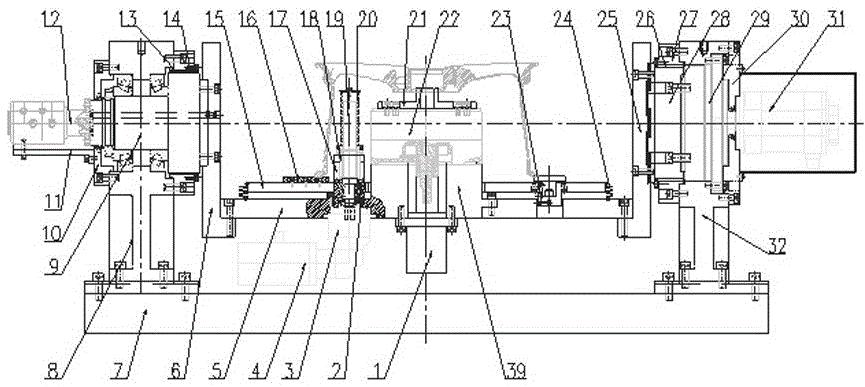

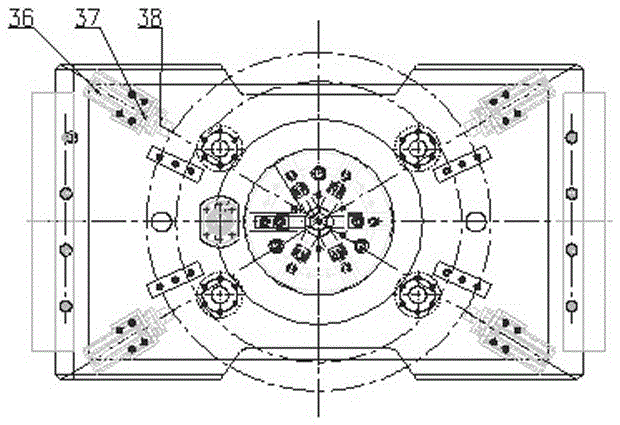

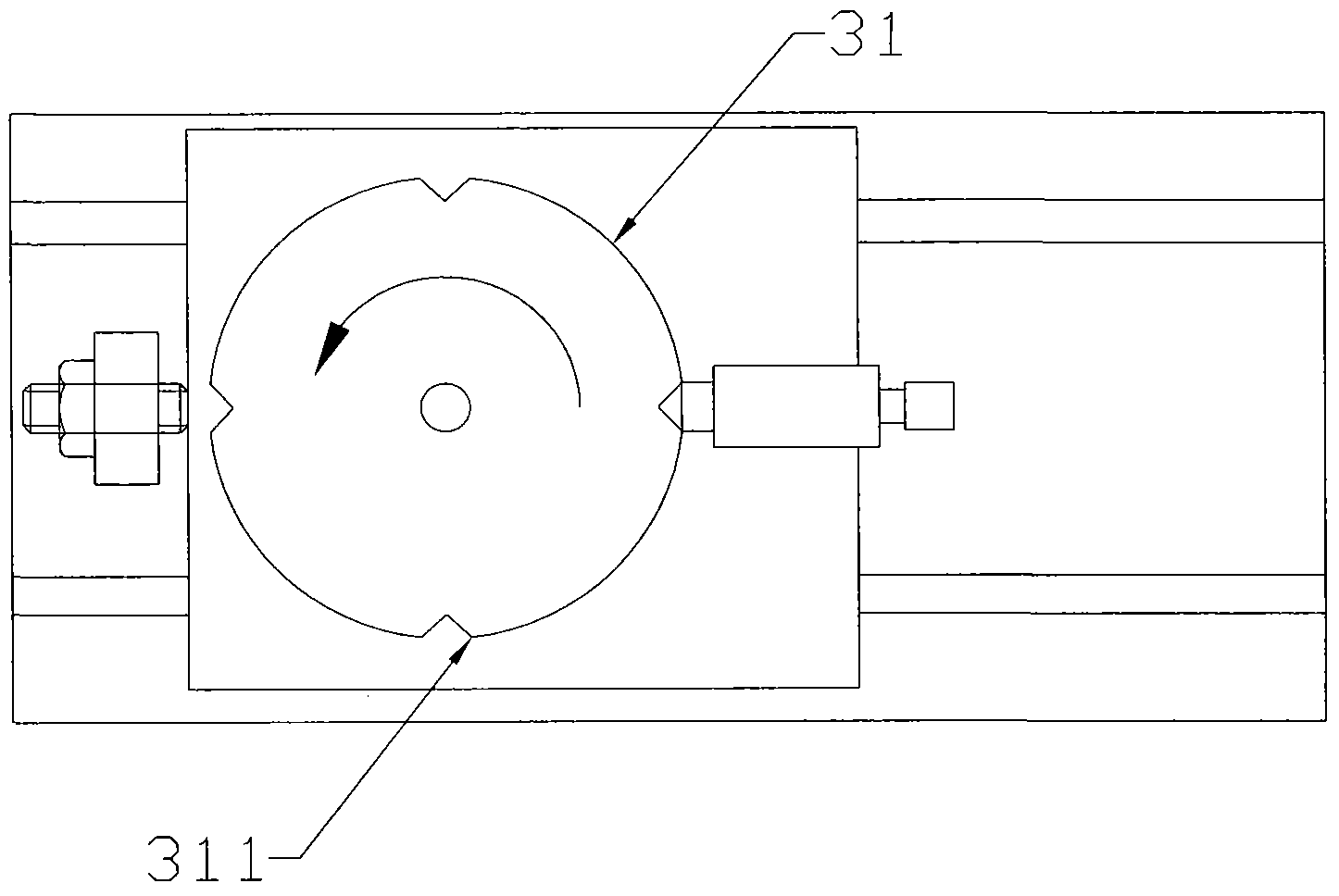

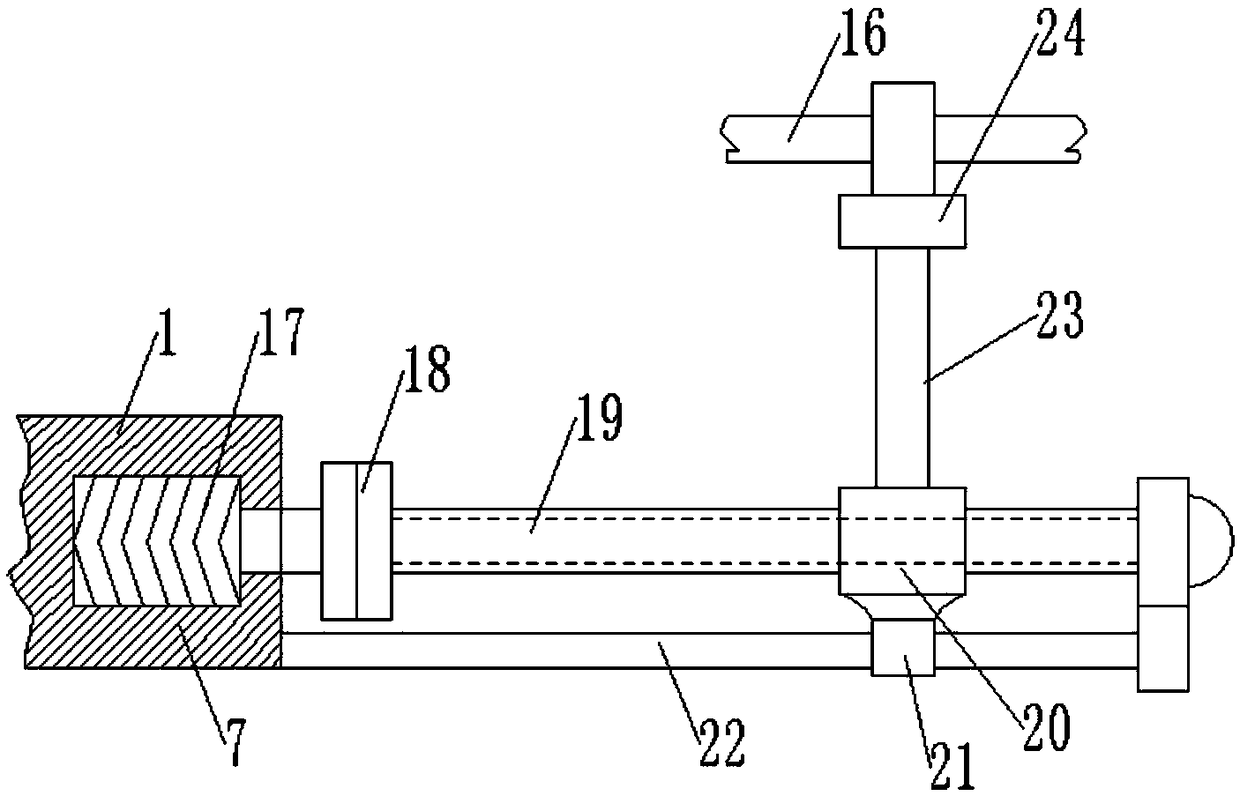

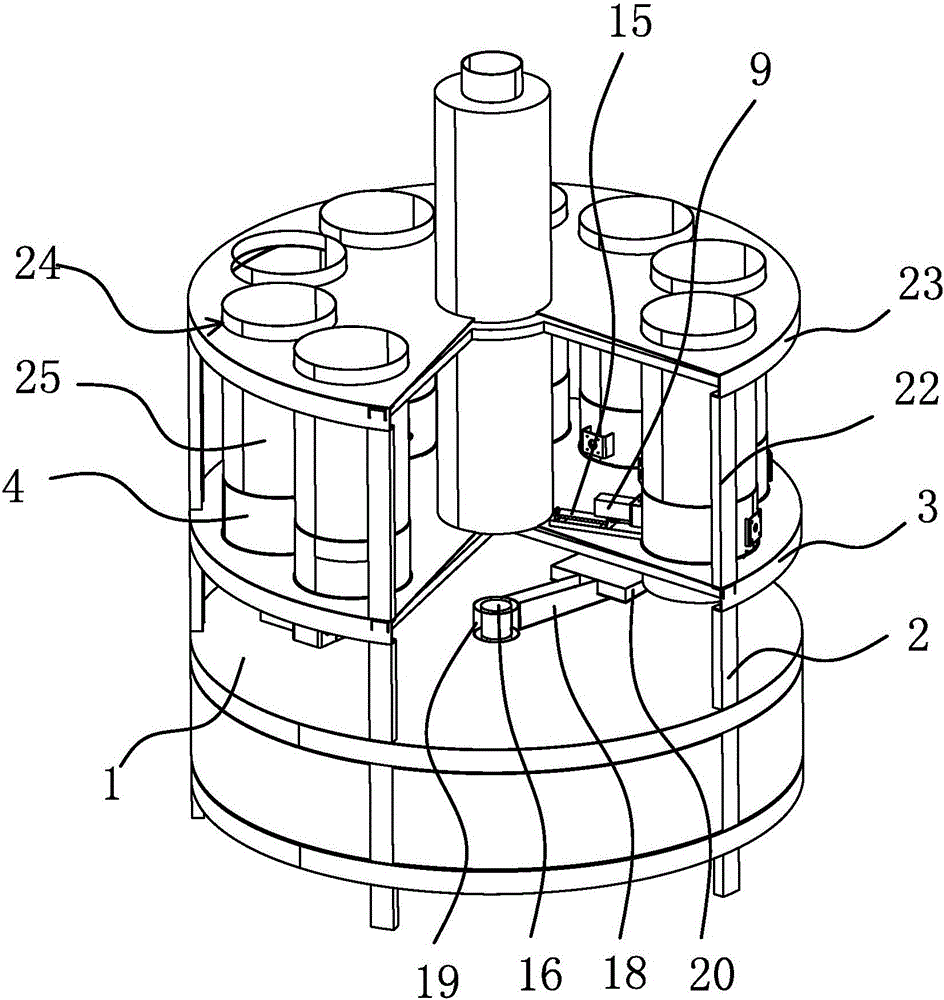

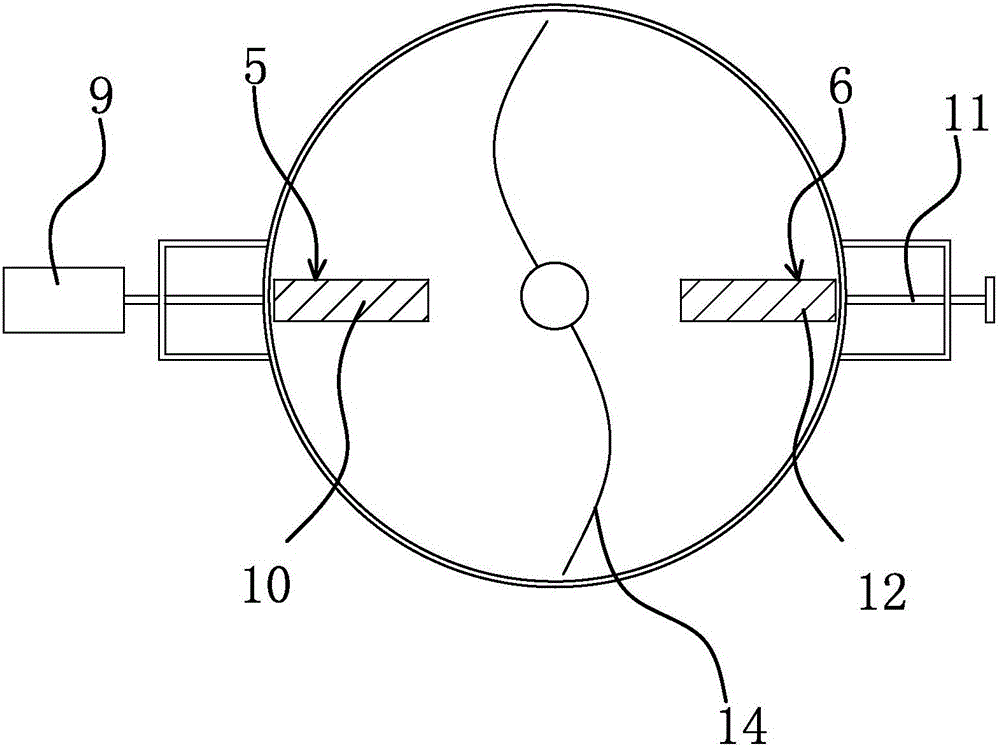

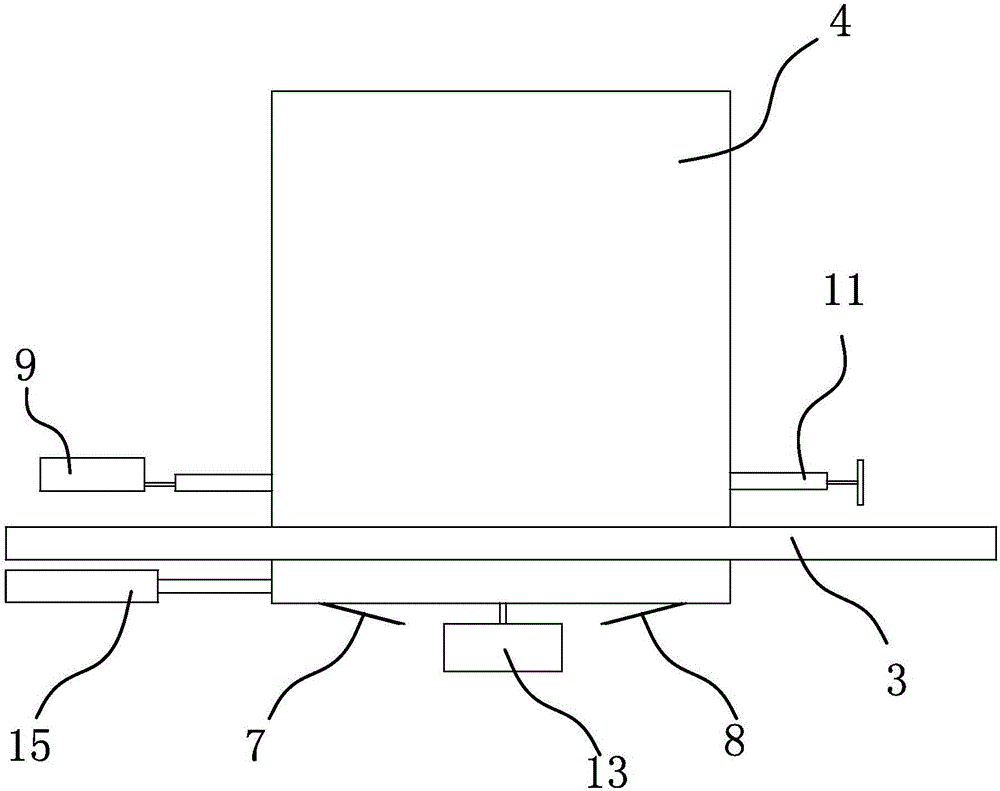

Wheel fixture

InactiveCN106624927AAdvanced technologyHigh degree of automationWorkpiecesExpansion mandrelsReduction driveBatch machine

The invention discloses a wheel fixture. When the wheel fixture is used, the wheel width is detected in the first place, a servo motor I drives a lead screw to rotate, a supporting block and a lifting plate are automatically adjusted to proper heights through nuts, a mechanical arm places a wheel above an end face block, an air tight device is pressed down, and an oil cylinder pulls a chuck so that a clamping jaw can tighten a wheel central hole in an expanding manner; meanwhile, four air cylinders make a clamping block tightly press the outer side of the wheel, and the wheel is completely positioned; at the moment, a wheel bolt hole can be drilled and machined; after machining is completed, a servo motor II makes a right shaft, a right ear plate and a turning-over part rotate by a certain angle through a speed reducer II; high-pressure oil is introduced into a cavity between a left expansion sleeve and a left end cover II and a cavity between a right expansion sleeve and a right end cover II, and the left expansion sleeve and the right expansion sleeve tightly lock a left shaft and the right shaft respectively. The wheel fixture is applicable to drilling machining of wheels of different outer circle diameters, different central hole diameters and different wheel width sizes and particularly applicable to mixed routing and automated batched machining production.

Owner:CITIC DICASTAL

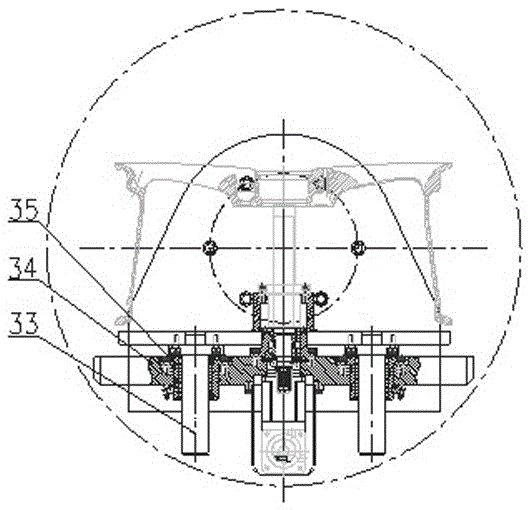

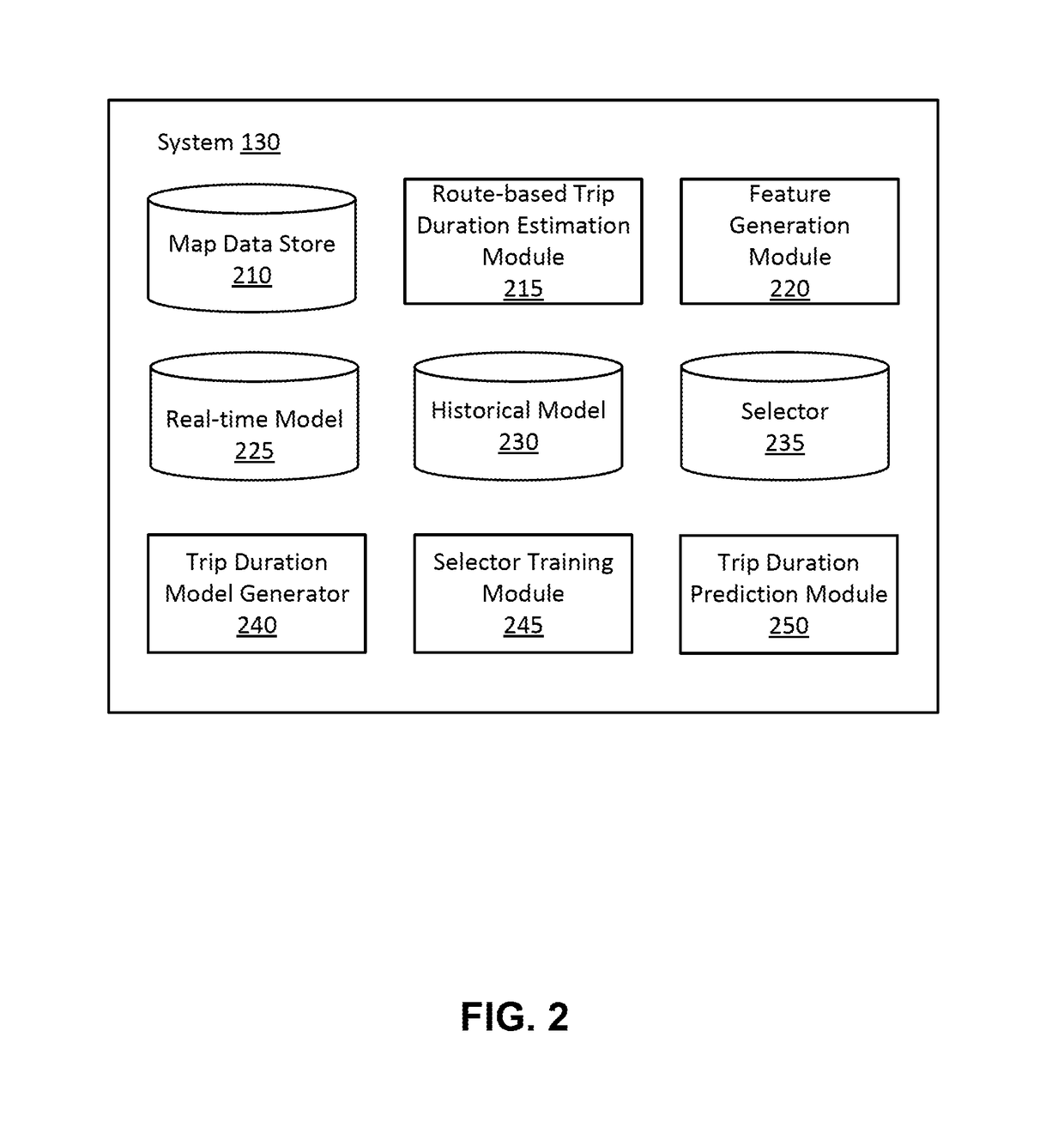

Generation of trip estimates using real-time data and historical data

ActiveUS10078337B1Accurately predict current trip durationInstruments for road network navigationPosition/course control in two dimensionsHistorical modelReal-time data

A system uses machine models to estimate trip durations or distance. The system trains a historical model to estimate trip duration using characteristics of past trips. The system trains a real-time model to estimate trip duration using characteristics of recently completed trips. The historical and real-time models may use different time windows of training data to predict estimates, and may be trained to predict an adjustment to an initial trip estimate. A selector model is trained to predict whether the historical model, the real-time model, or a combination of the historical and real-time models will more accurately estimate a trip duration, given features associated with a trip duration request, and the system accordingly uses the models to estimate a trip duration. In some embodiments, the real-time model and the selector may be trained using batch machine learning techniques which allow the models to incorporate new trip data as trips complete.

Owner:UBER TECH INC

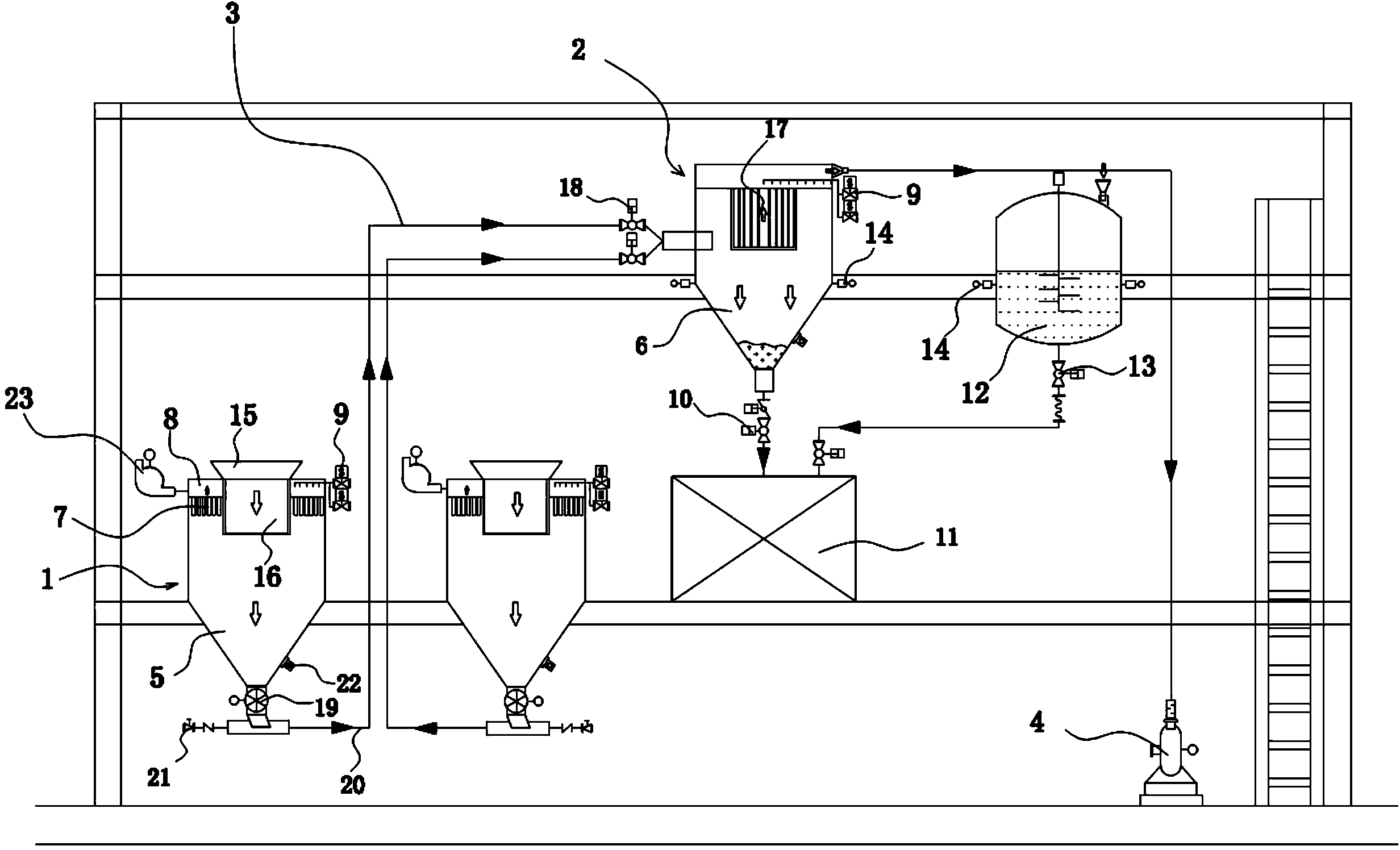

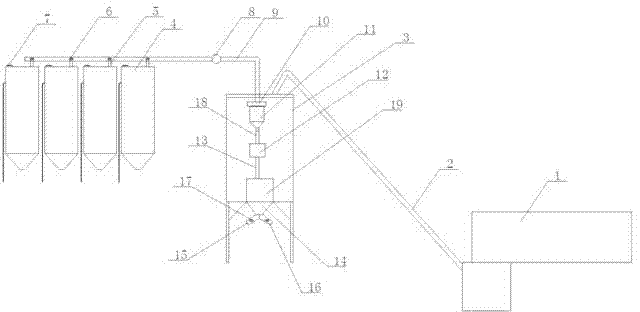

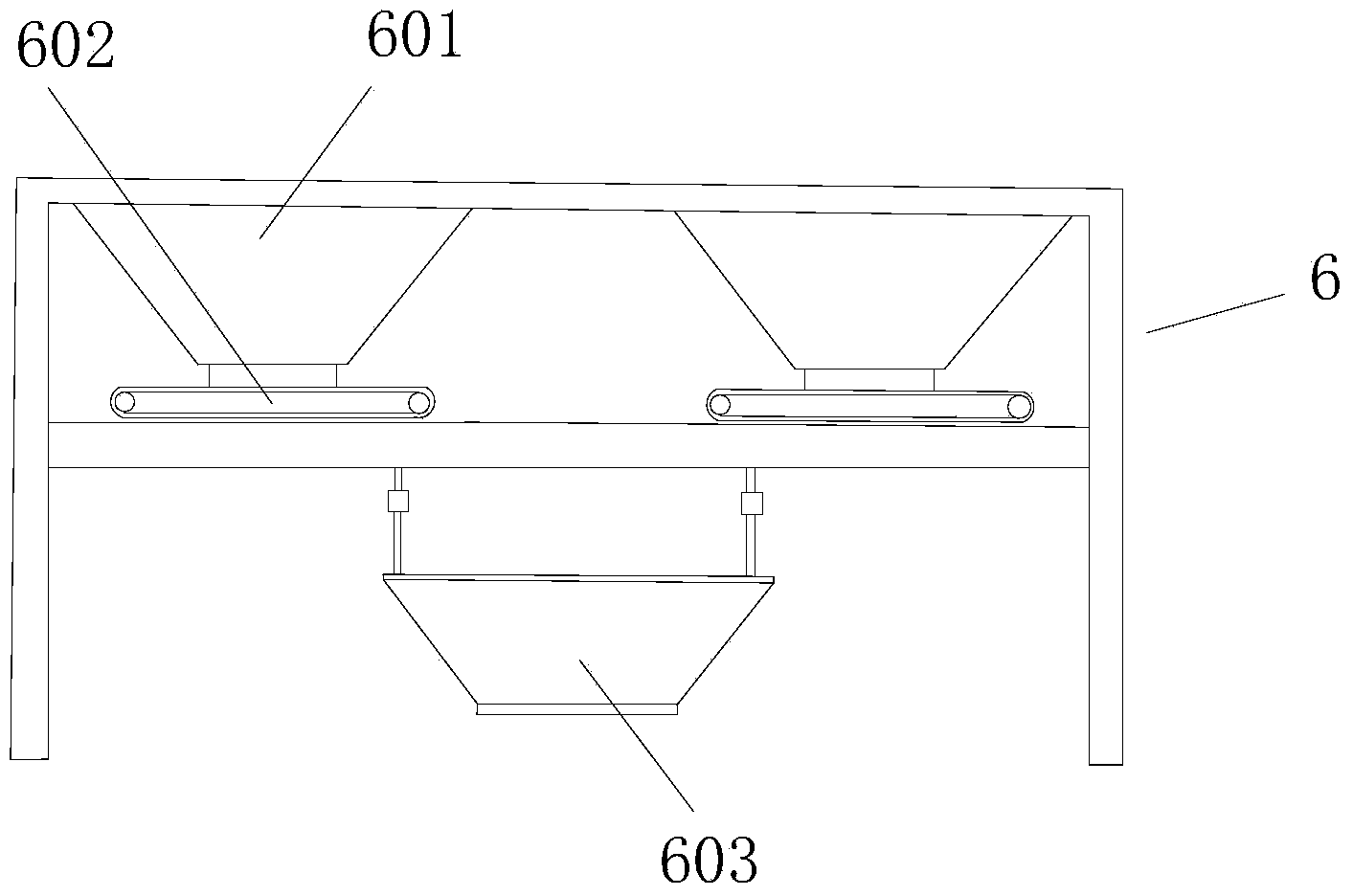

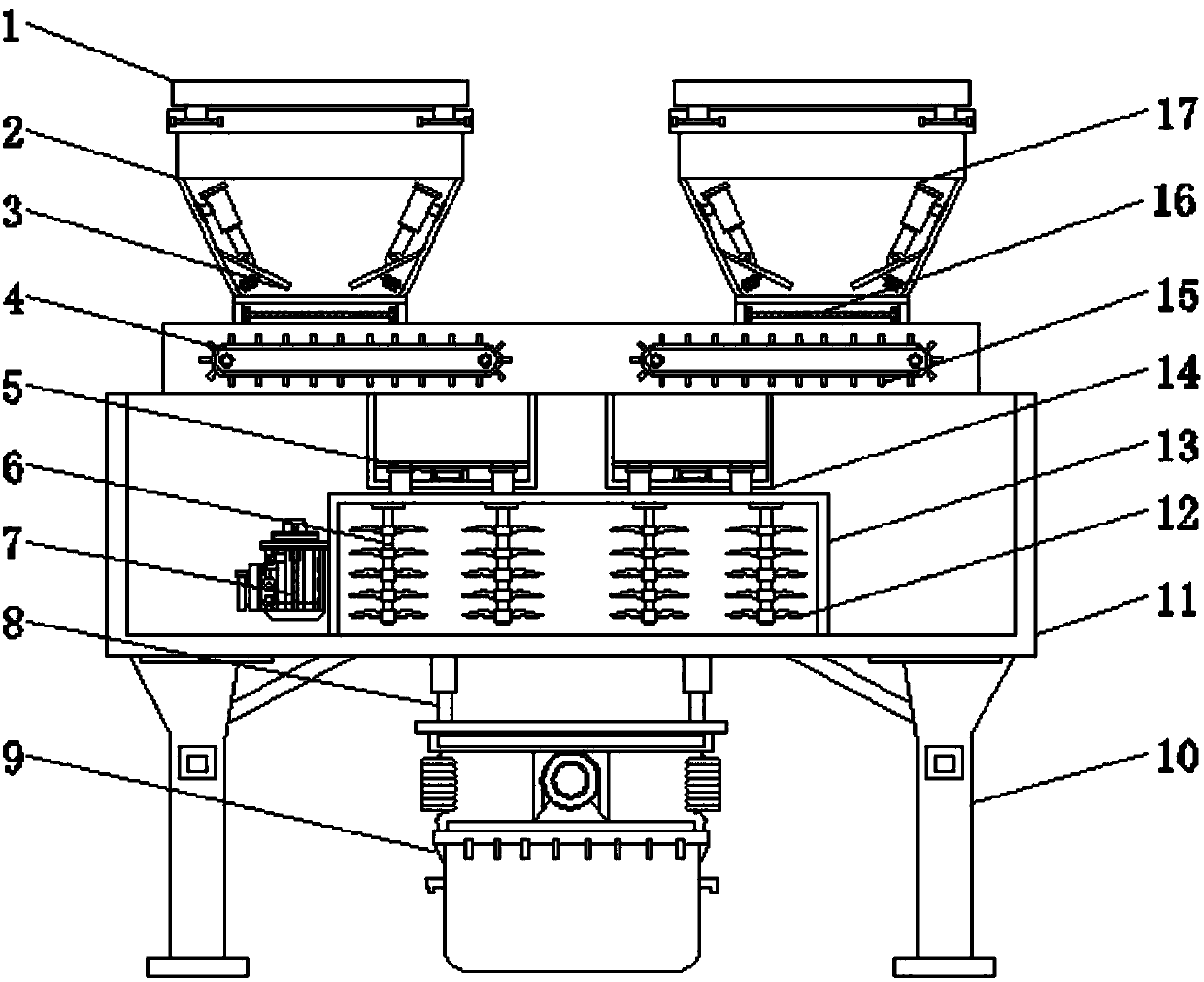

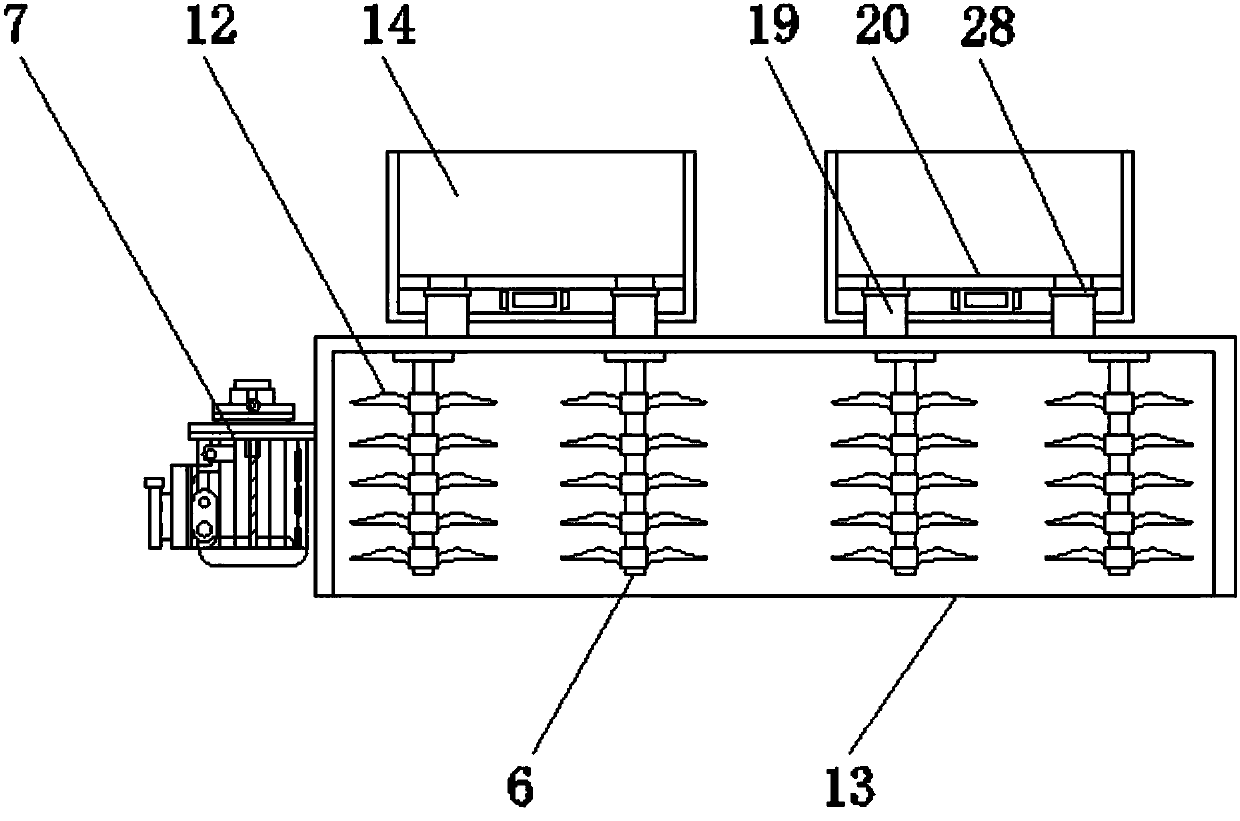

Automatic batching system

ActiveCN104028131AImprove batching accuracyIncrease productivityMixing methodsVacuum extractorBatch machine

An automatic batching system comprises a solid material conveying system and a liquid material conveying system; the solid material conveying system comprises a batching machine, a feeding machine and a vacuum conveying device; the vacuum conveying device comprises a vacuum conveying pipe and a vacuum extractor, a bin discharging hole of the batching machine is connected with a bin feeding hole of the feeding machine through a vacuum conveying pipe, a bin of the feeding machine is a closed cavity, the upper portion of the bin is spaced through a dedusting filter to form a vacuumized channel, and the vacuumized channel is communicated with the vacuum extractor through the vacuum conveying pipe; a bin discharging hole of the feeding machine is connected with a mixer feeding hole through a pneumatic butterfly valve; the liquid material conveying system comprises a liquid stirring kettle; a discharging hole of the stirring kettle is provided with an automatic ball valve and is connected with the mixer feeding hole through the automatic ball valve; the powder feeding machine and the stirring kettle are respectively provided with a weighing sensor. The full-automatic batching system is adopted, the automatic whole batching process and continuous batching are achieved, and the batching precision of raw materials is improved.

Owner:桐乡市京工树脂有限公司

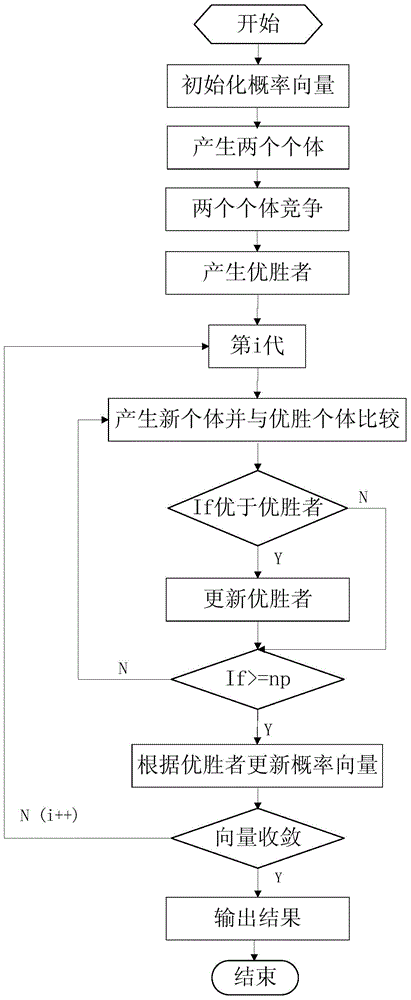

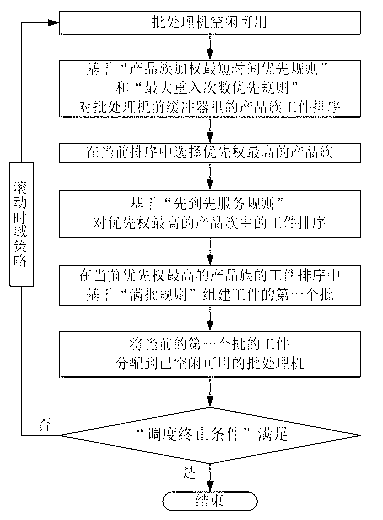

Optimal scheduling method of parallel batch processing machines

InactiveCN105320105AIncrease production capacityShorten the production cycleTotal factory controlProgramme total factory controlBatch processingOptimal scheduling

The present invention provides an optimal scheduling method of parallel batch processing machines. According to the characteristics of the batch scheduling problem, a probability model is established based on group batches of the workpieces; a corresponding individual sampling and probability update method is designed; the population generation of the compact genetic algorithm and the probability update mechanism are improved; and a novel intelligent algorithm for solving the batch scheduling problem is provided. On the premise of satisfying the batch switching-on production requirement of batch processing machines, the production is accelerated, and the production cycle is shortened. Through flexible parameter setting, different batch scheduling problems may be solved, different conditions, such as one machine / a plurality of machines, same arrival time / different arrival time, same size of workpieces and different sizes of workpieces, and limited capacity of the batch processing machines / unlimited capacity of the batch processing machines, are able to be flexibly combined, and the generality of the optimal scheduling method of parallel batch processing machines is high.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

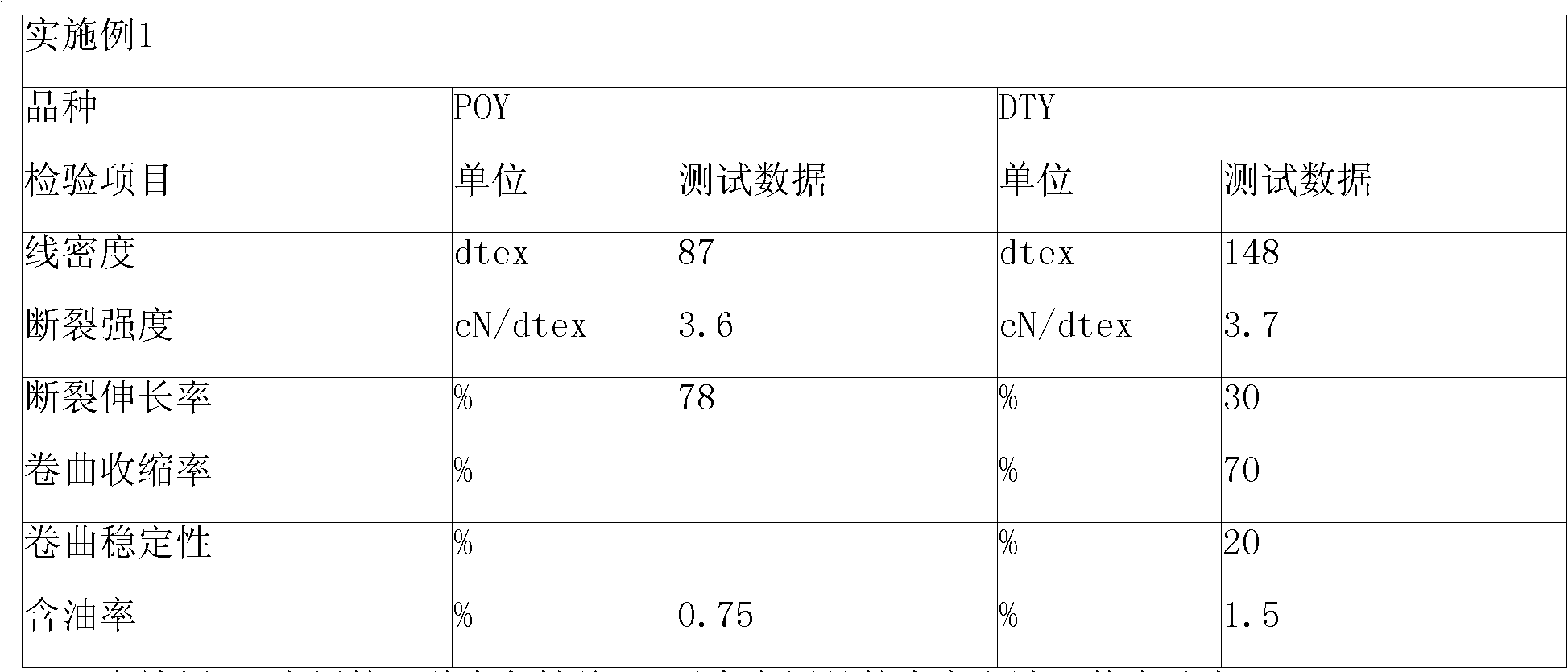

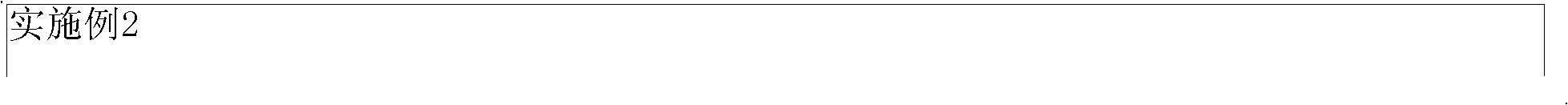

Production method for colored nylon DTY glove special-used silk

InactiveCN101671855AReduce processing costsAvoid pollutionMelt spinning methodsPigment addition to spinning solutionYarnFiber

The invention relates to a production method for nylon-6 fiber, in particular to a production method for colored nylon DTY glove special-used silk, which mainly solves technical problems that the existing technology can not be used for producing colored nylon, the existing other methods for manufacturing colored nylon has higher cost during dying, and causes environmental pollution, and the manufactured colored nylon has worse elasticity and shrink ability, is not suitable for manufacturing gloves and the like. The production method comprises the following steps: drying color master batches and then adding the color master batches into a color master batch machine, mixing, extruding and melting the color master batches and the nylon slices which are spun, injected, cooled, oiled and woundto form POY, adding the POY into an elasticizer for being elasticized to form grey yarn which is stretched and yarned by a roller, and then heated, cooled, false-twisted in sequence, and oiling and winding again after false-twisted strand silk is secondly rolled to obtain finished colored nylon DTY glove special-used silk.

Owner:ZHEJIANG MESBON CHEM FIBER

Method for batched server memory fault detection through IPMI tool

InactiveCN103970661ASuitable for configuration environmentEasy to implementSoftware testing/debuggingRedundant data error correctionMemory faultsBatch machine

The invention provides a method for batched server memory fault detection through an IPMI tool, and belongs to the field of fault detection. The method comprises the steps that recording and scanning bmc logs of all servers inside a network through the IPMI tool, analyzing machines with the memory problem from the result, conducting batched checking on the batched servers inside the network through a script, rapidly determining the machines with the memory ecc errors, and achieving memory batched checking of the batched machines. According to the method, the testing time is shortened, and working efficiency is improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

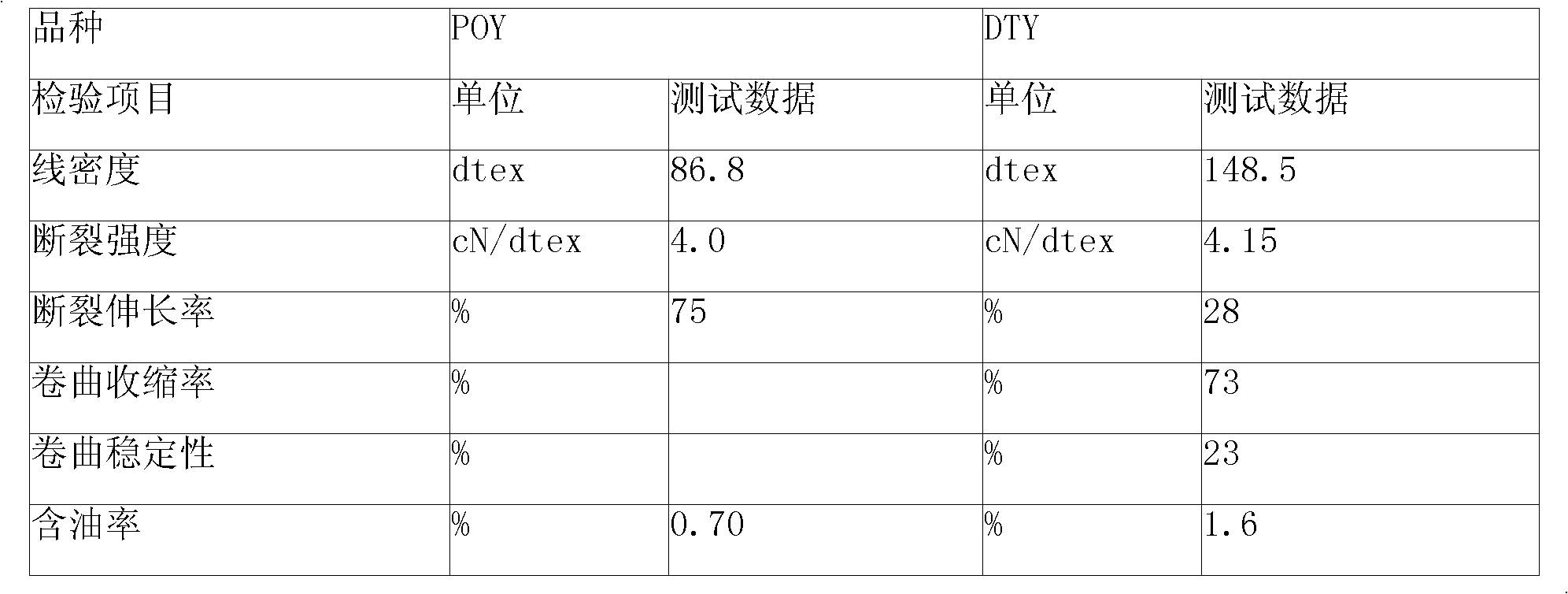

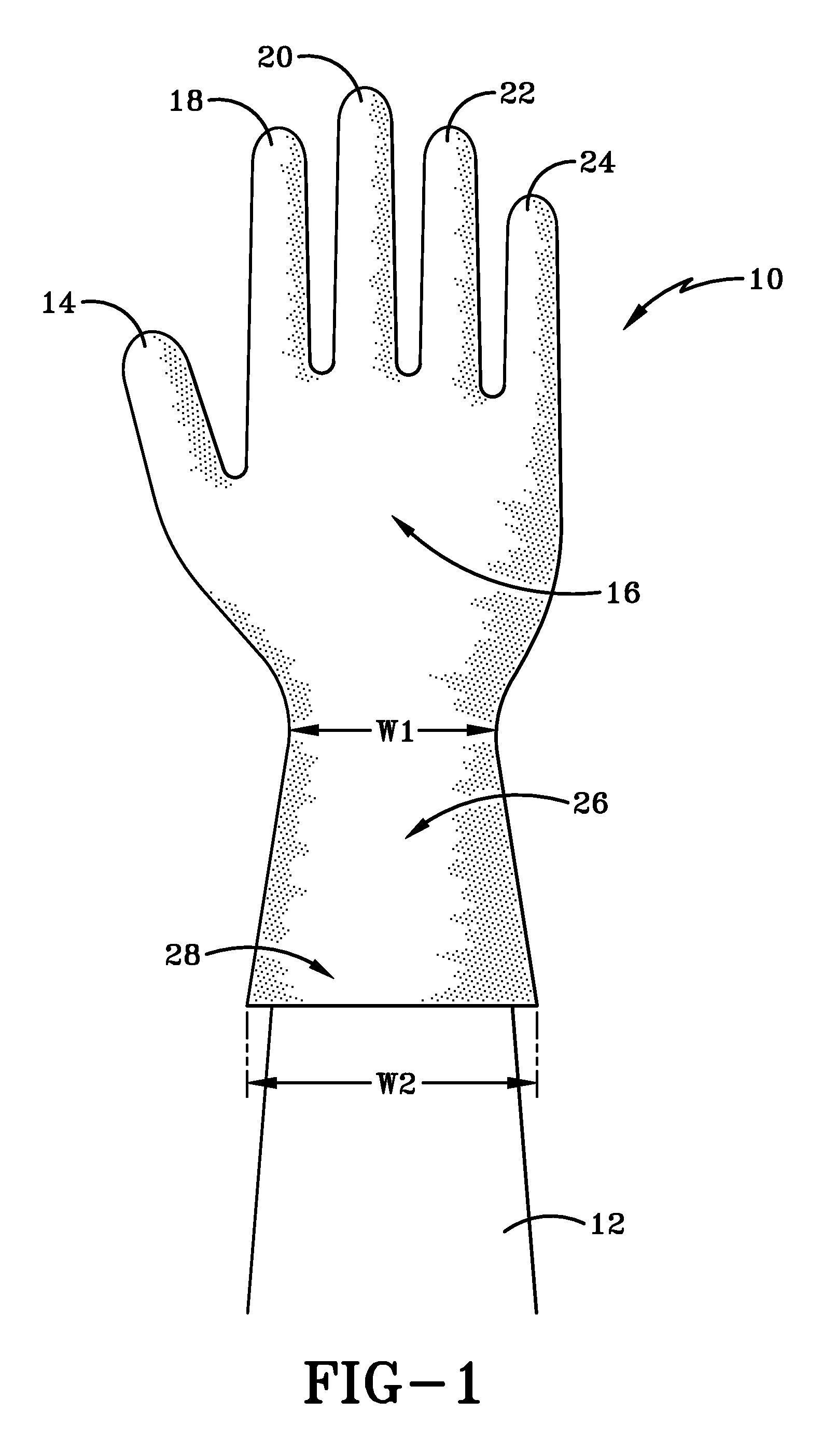

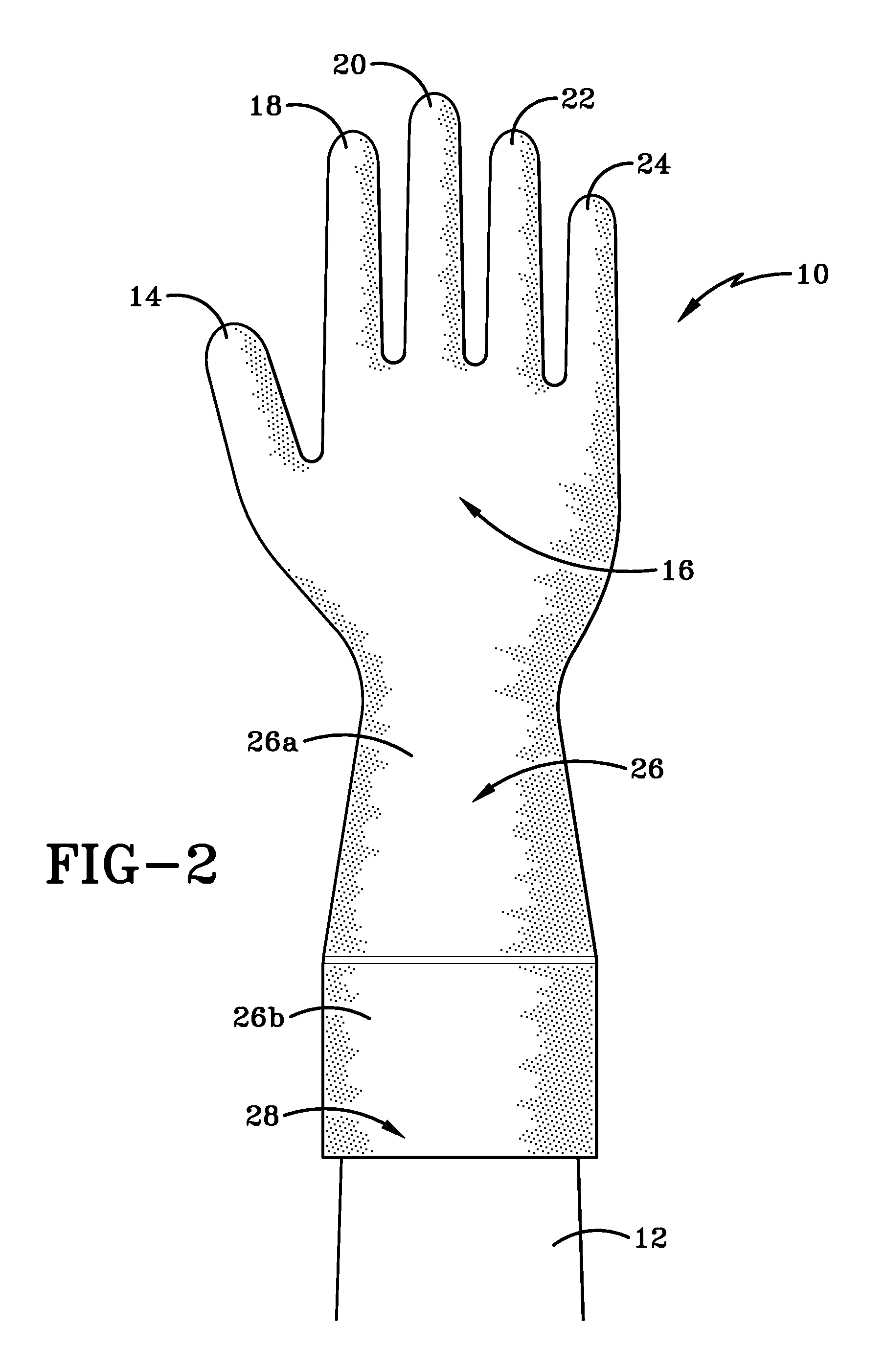

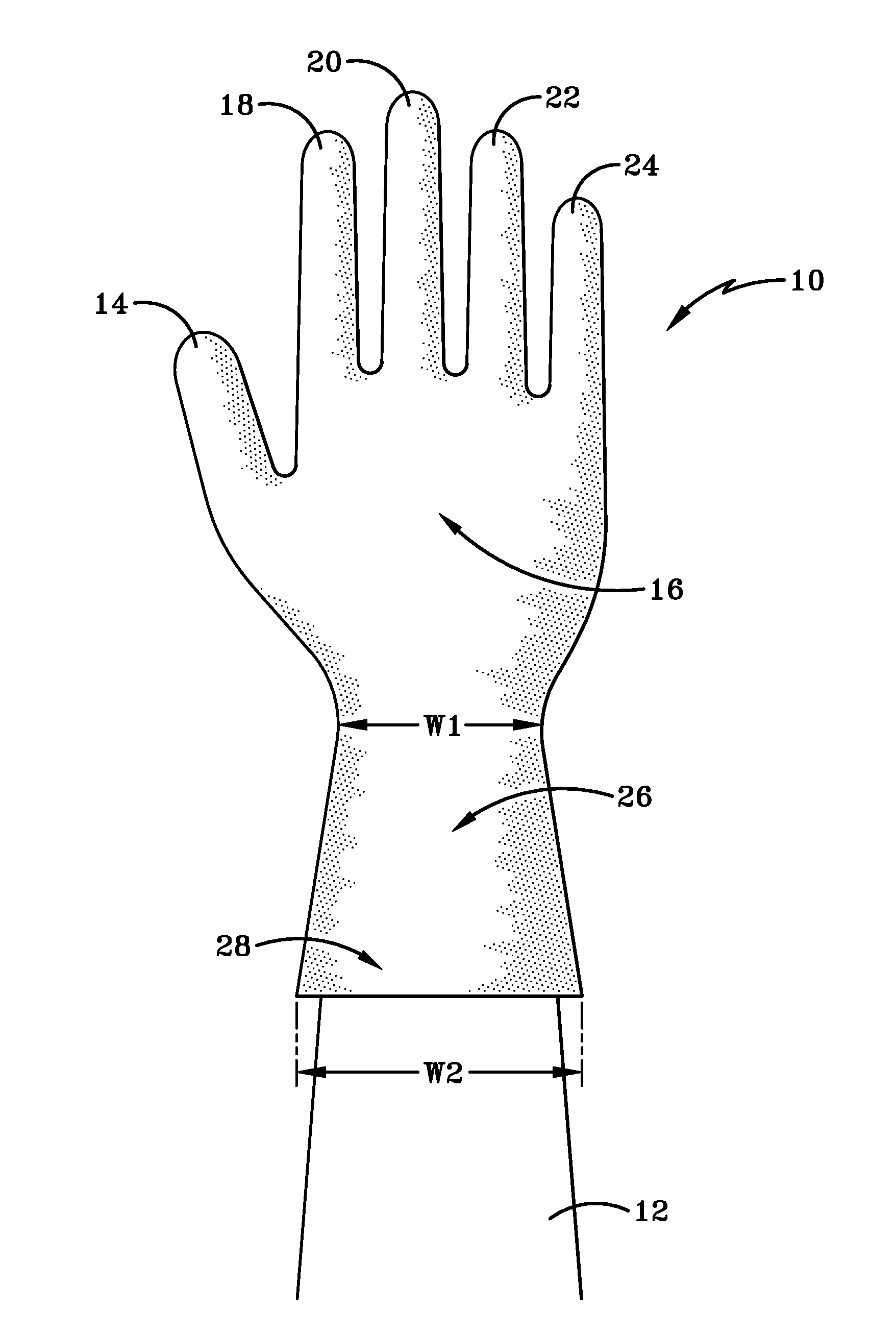

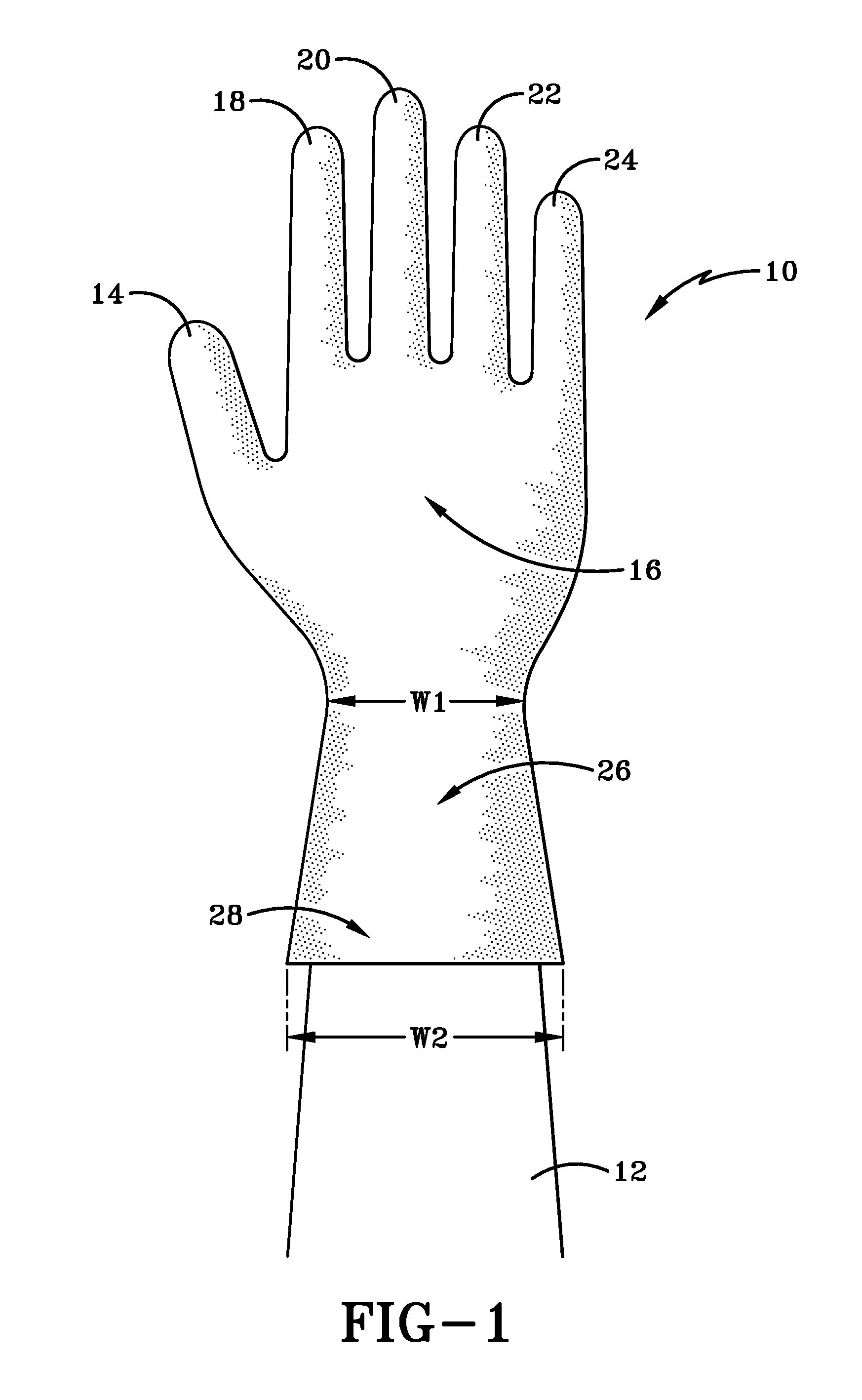

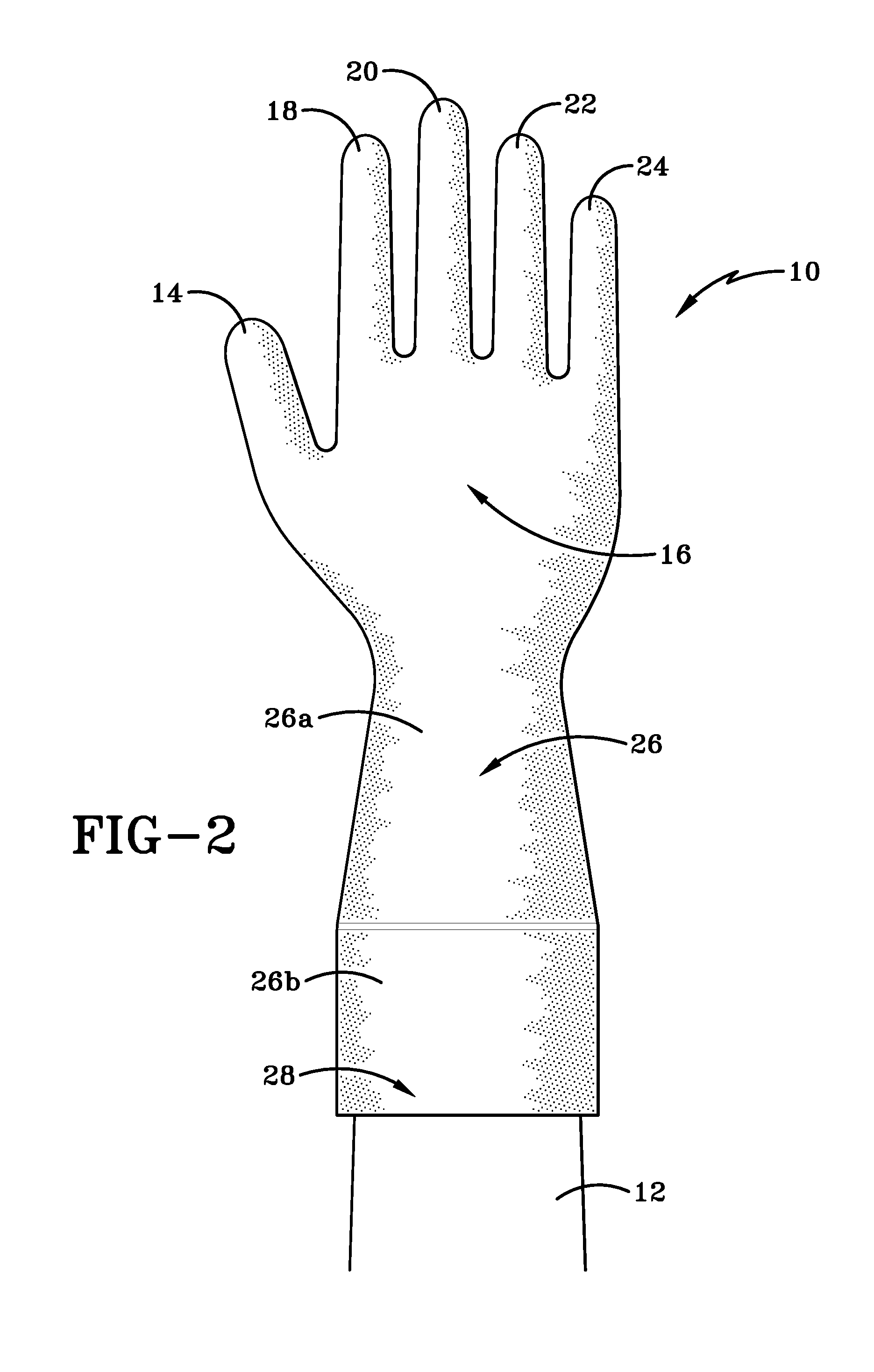

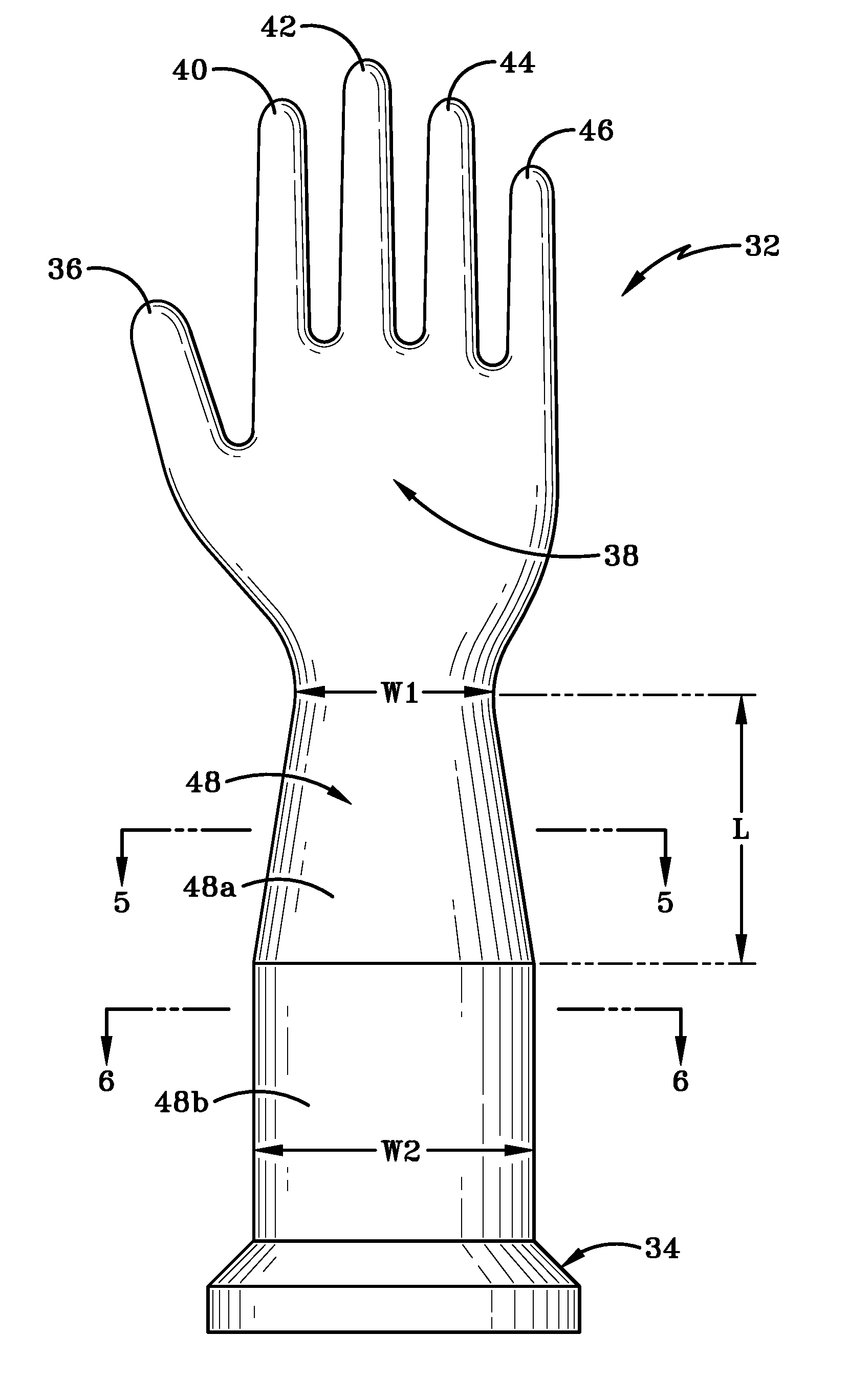

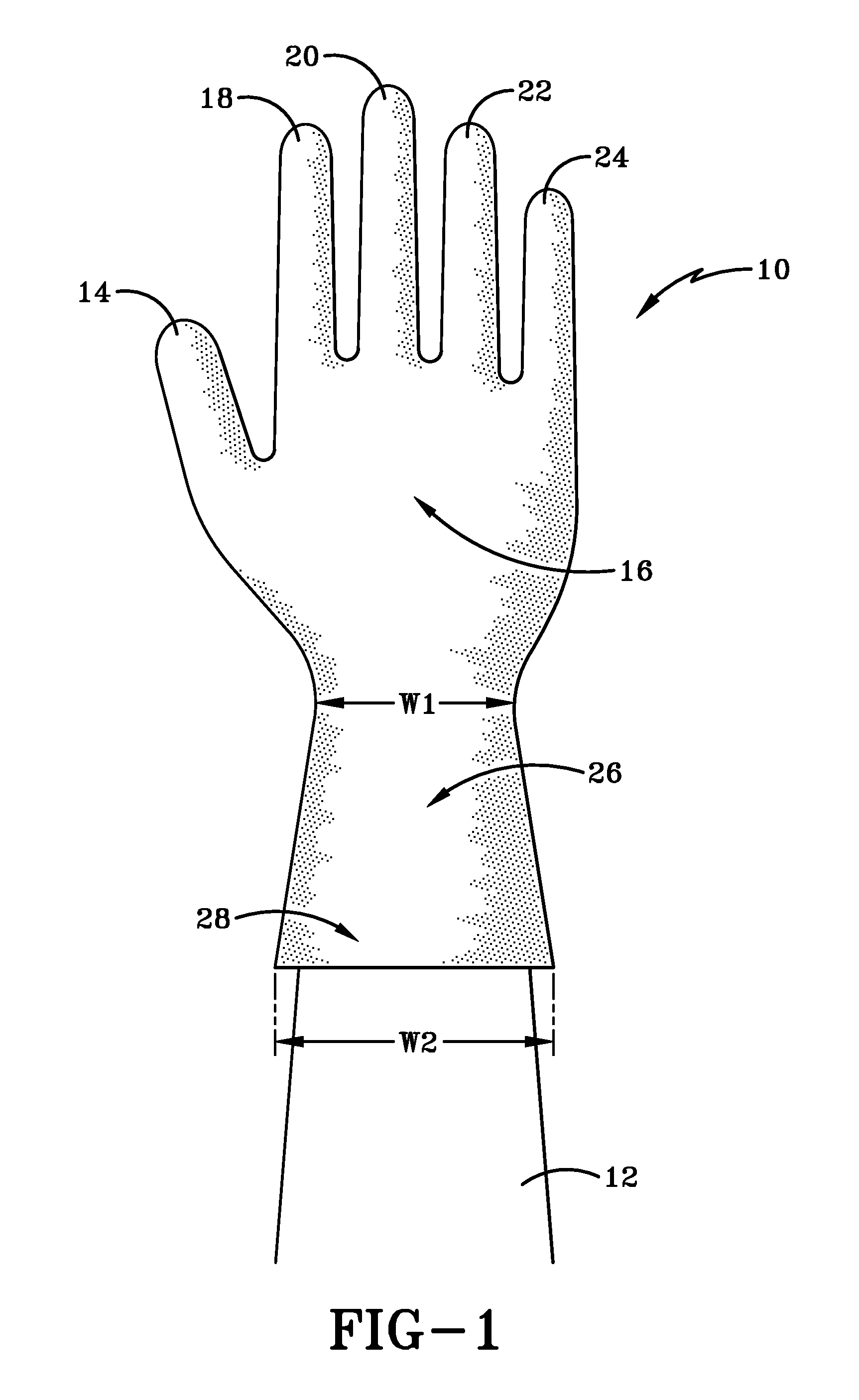

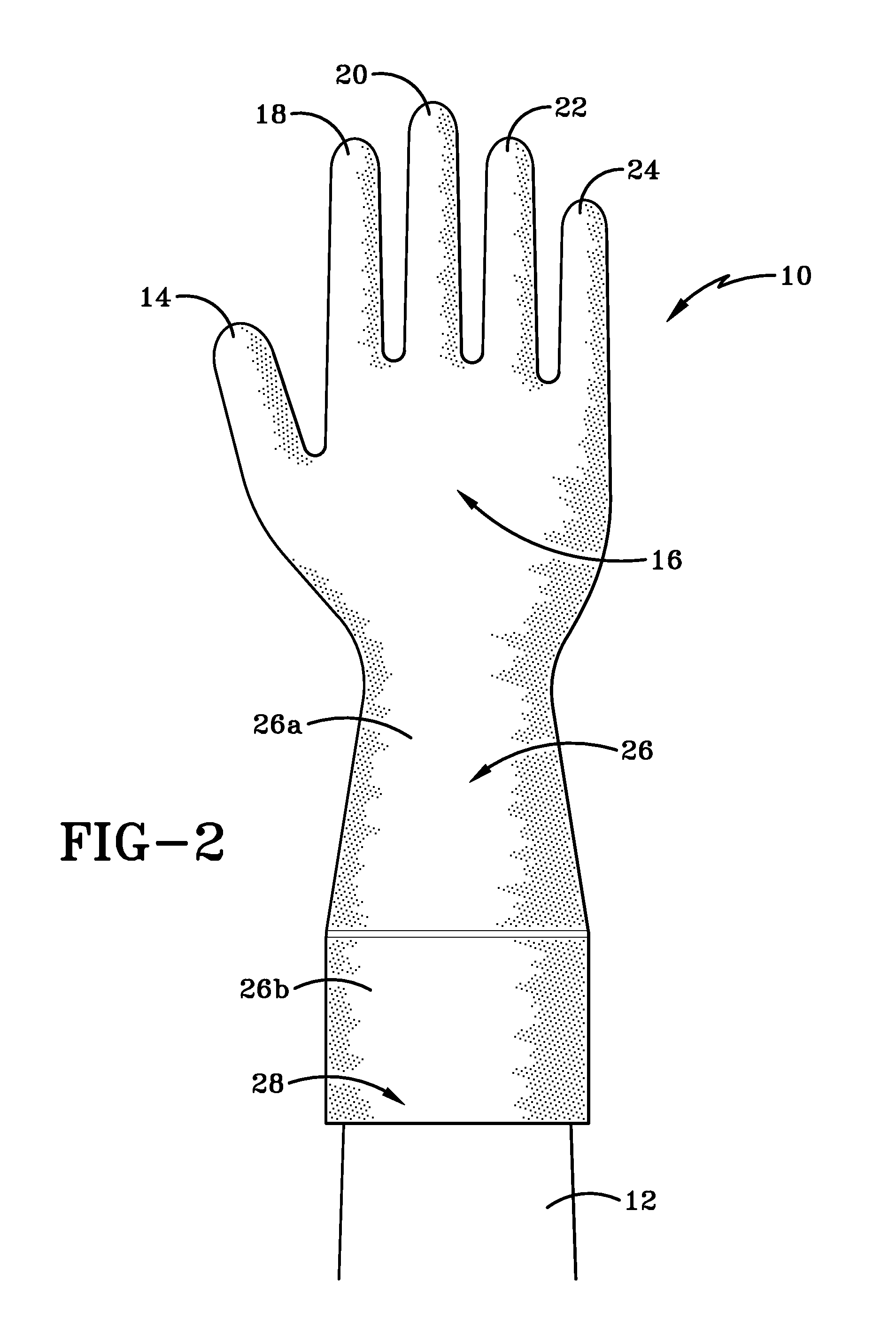

Method of fabricating a glove with a widened cuff area

An ambidextrous or hand specific glove with a widened cuff area to aid in donning or doffing the glove is disclosed, together with a former for fabricating the glove and a method of fabricating the same. The glove may further include a bead on the cuff to resist tearing when the glove is put on or taken off. The glove may be fabricated on a continuous, automated chain machine or a batch or semi-batch machine. While the cuff region on the former for fabricating the glove is elliptical in cross-section and is flared, the region of the former on which the end of the glove is fabricated is circular in cross-section and thus allows the beading process to be successfully undertaken.

Owner:SUMMIT GLOVE

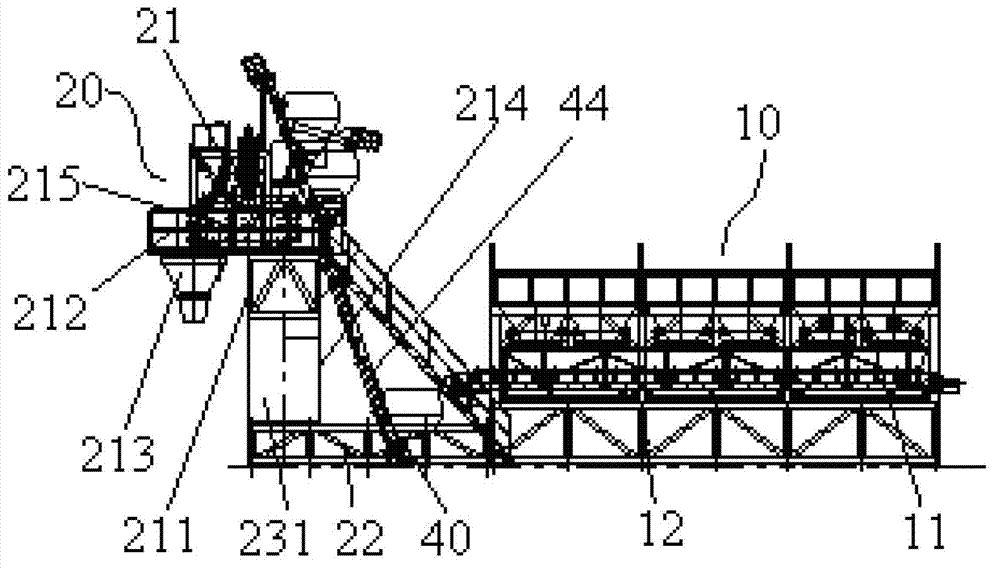

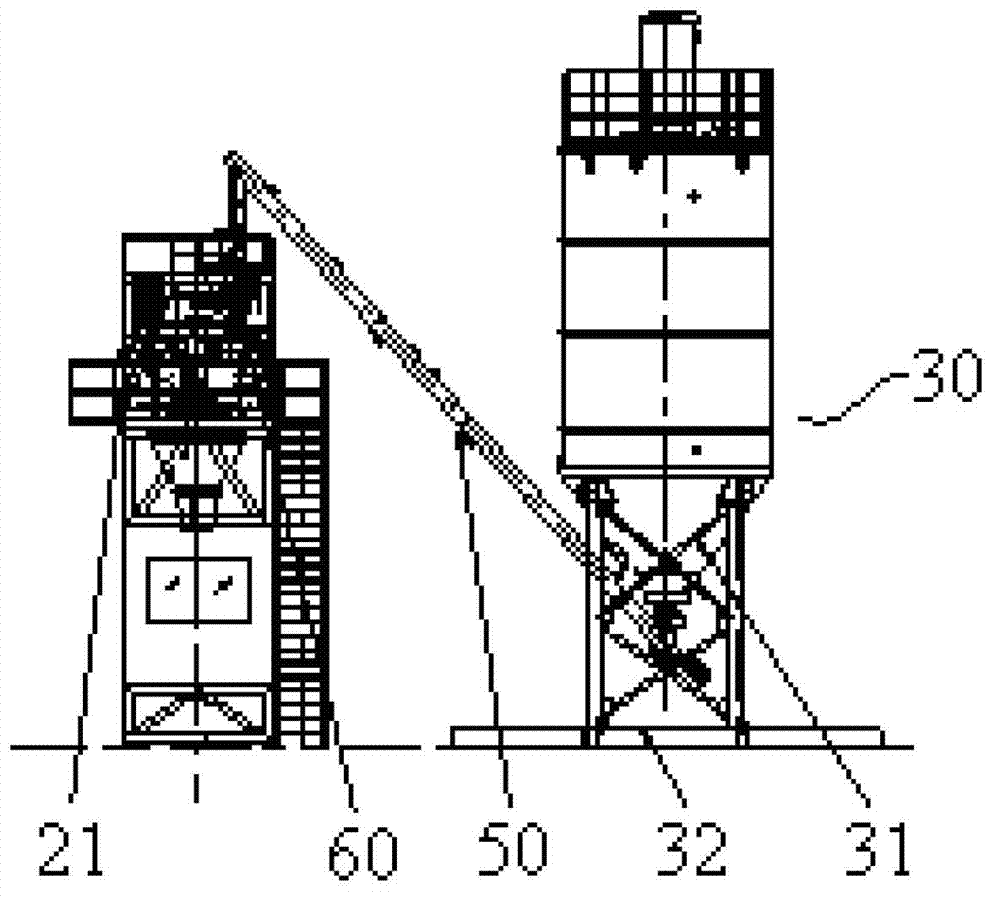

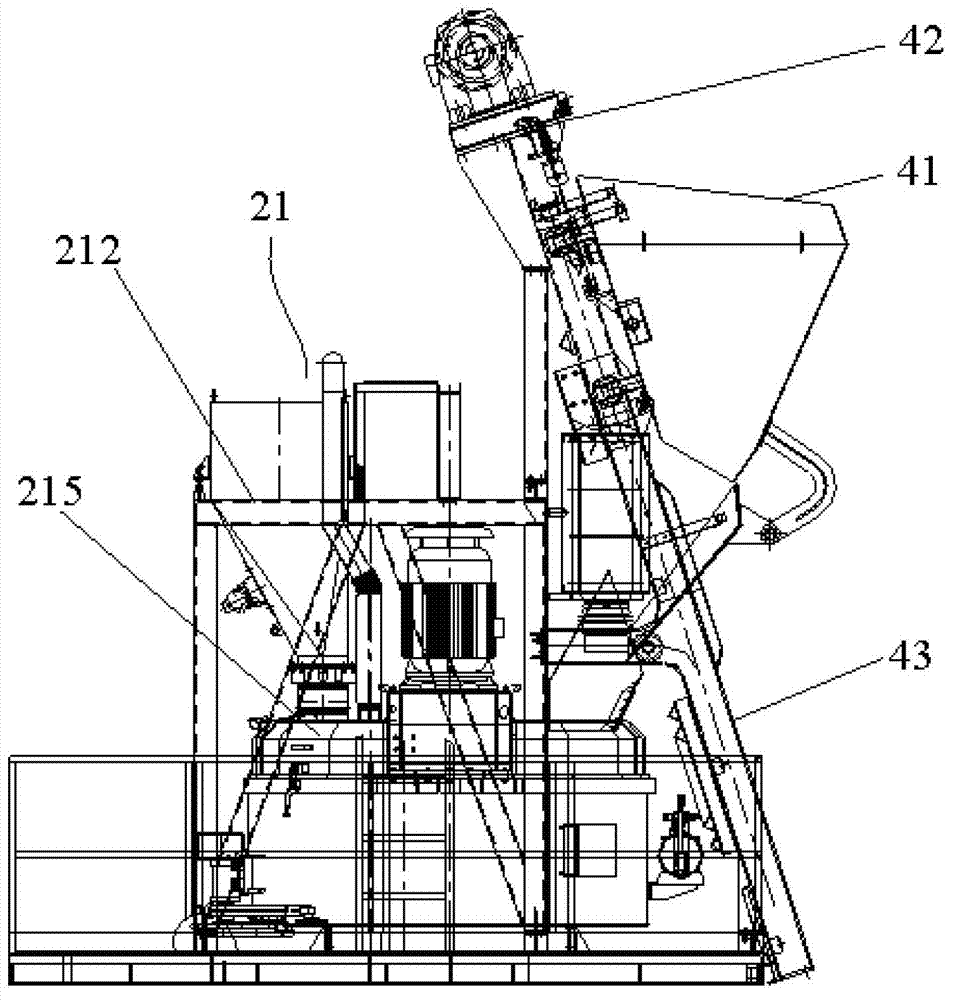

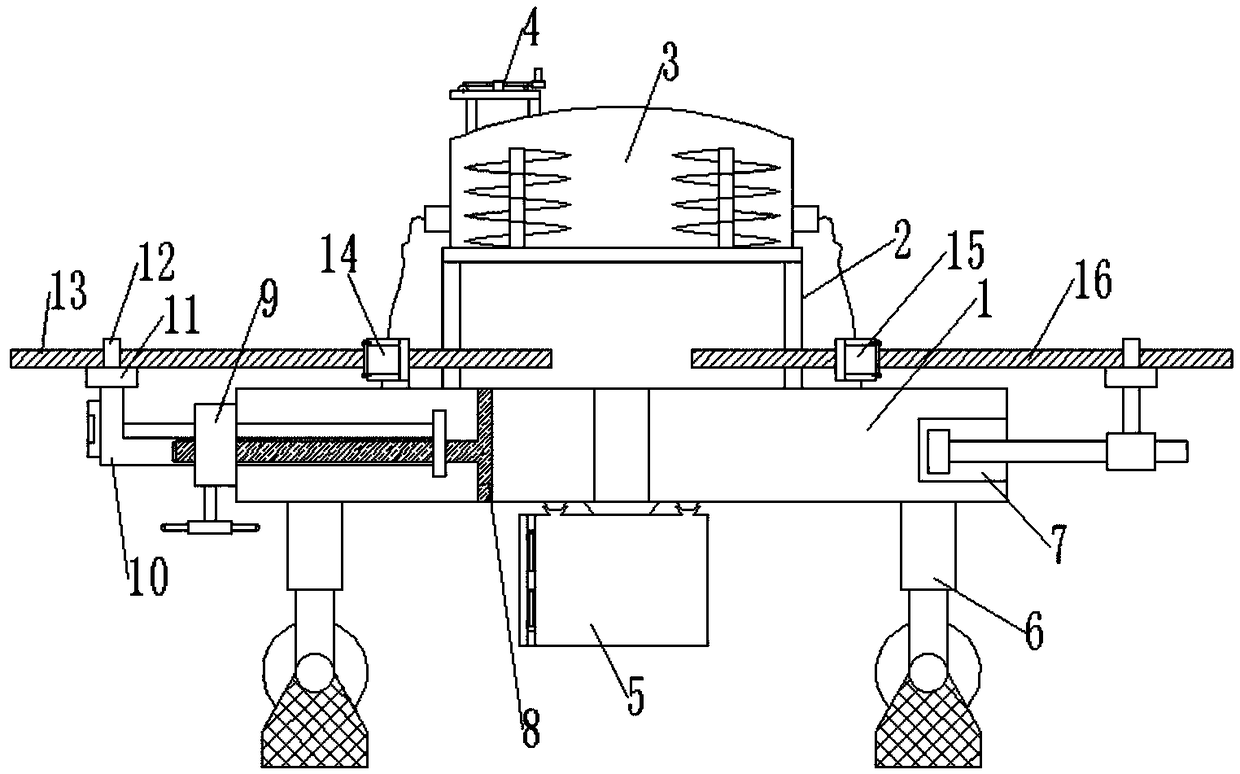

Mobile concrete mixing station

ActiveCN102873762AImprove assembly and disassembly efficiencyShorten the construction periodMixing operation plantBatch machineBuilding construction

The invention provides a mobile concrete mixing station. The mobile concrete mixing station comprises a batching system, a transporting system, a weighing system, a mixing system and a powder bin system, wherein the batching system comprises a batching machine and a batching machine base bracket; the mixing system comprises a main floor and a main floor base bracket; the powder bin system comprises a powder bin and a powder bin base bracket; the first end of the main floor is fixedly connected on the main floor base bracket; detachable connection is adopted between the batching machine and the batching machine base bracket, between the main floor and the main floor base bracket, and between the powder bin and the powder bin base bracket; and the second end of the main floor is suspended. According to the mobile concrete mixing station, the efficiency for mounting and dismounting each part of the concrete mixing station can be quickened, thereby reducing the construction period and construction cost.

Owner:ZOOMLION HEAVY IND CO LTD

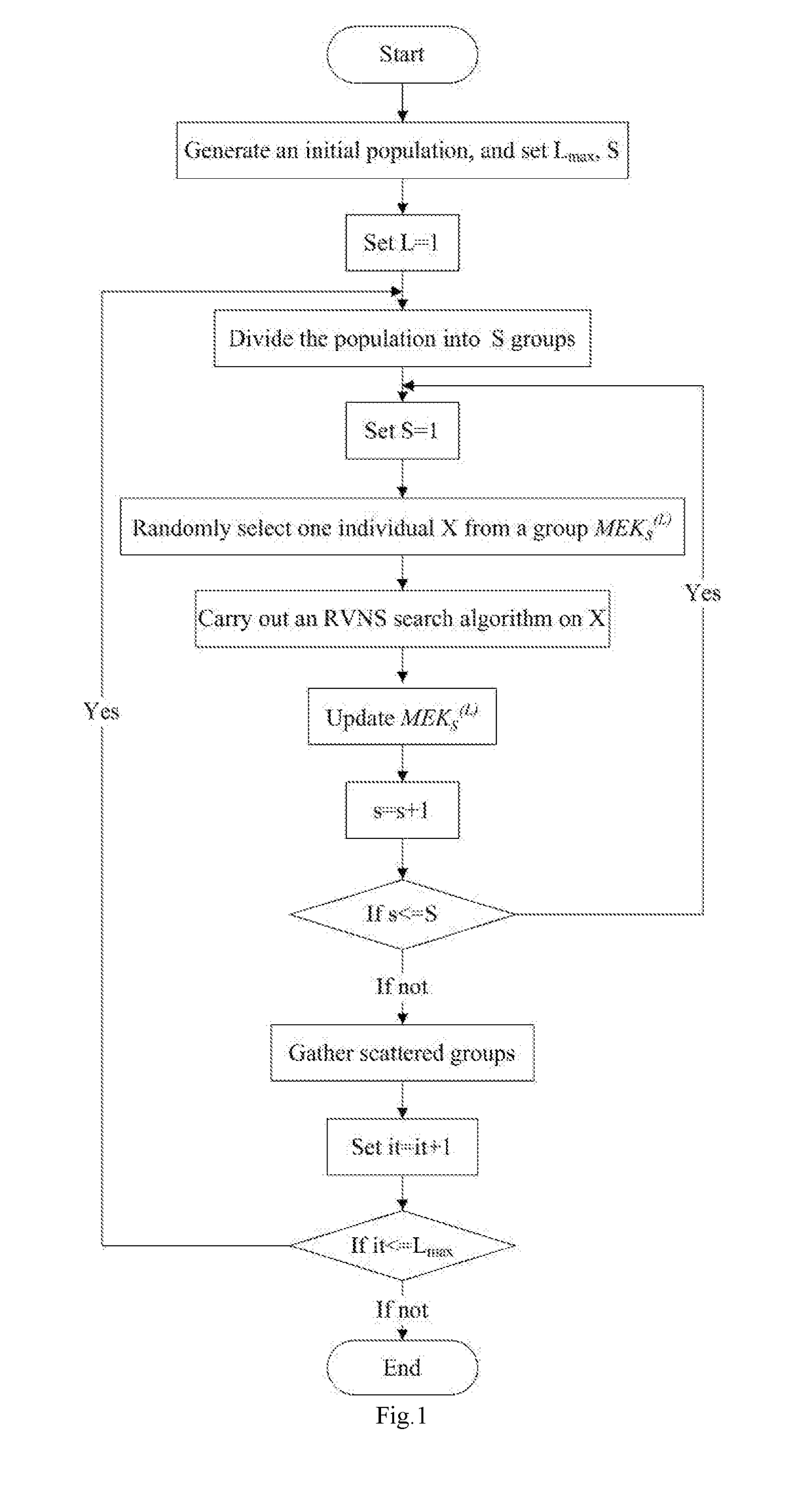

Method and system for scheduling parallel processing machines based on hybrid shuffled frog leaping algorithm and variable neighborhood search algorithm

ActiveUS20180356802A1Minimizing maximum completion timeImprove search procedureTotal factory controlAdaptive controlBatch processingMulti machine

A method and a system for scheduling parallel machines based on hybrid shuffled frog leaping algorithm and variable neighborhood search algorithm are provided to solve collaborative production and processing of jobs on a plurality of unrelated batch processing machines. The jobs are distributed to machines based on the normal processing time and deterioration situation of the jobs on different machines and are arranged. An effective multi-machine heuristic rule is designed according to the structural properties of an optimal solution for the single-machine problem, and the improved rule is applied to the improved shuffled frog leaping algorithm to solve this problem. The improvement strategy for the traditional shuffled frog leaping algorithm is to improve the local search procedure of the traditional frog leaping algorithm by introducing the variable neighborhood search algorithm. The convergence rate and optimization capacity of the original algorithm are thus improved.

Owner:HEFEI UNIV OF TECH

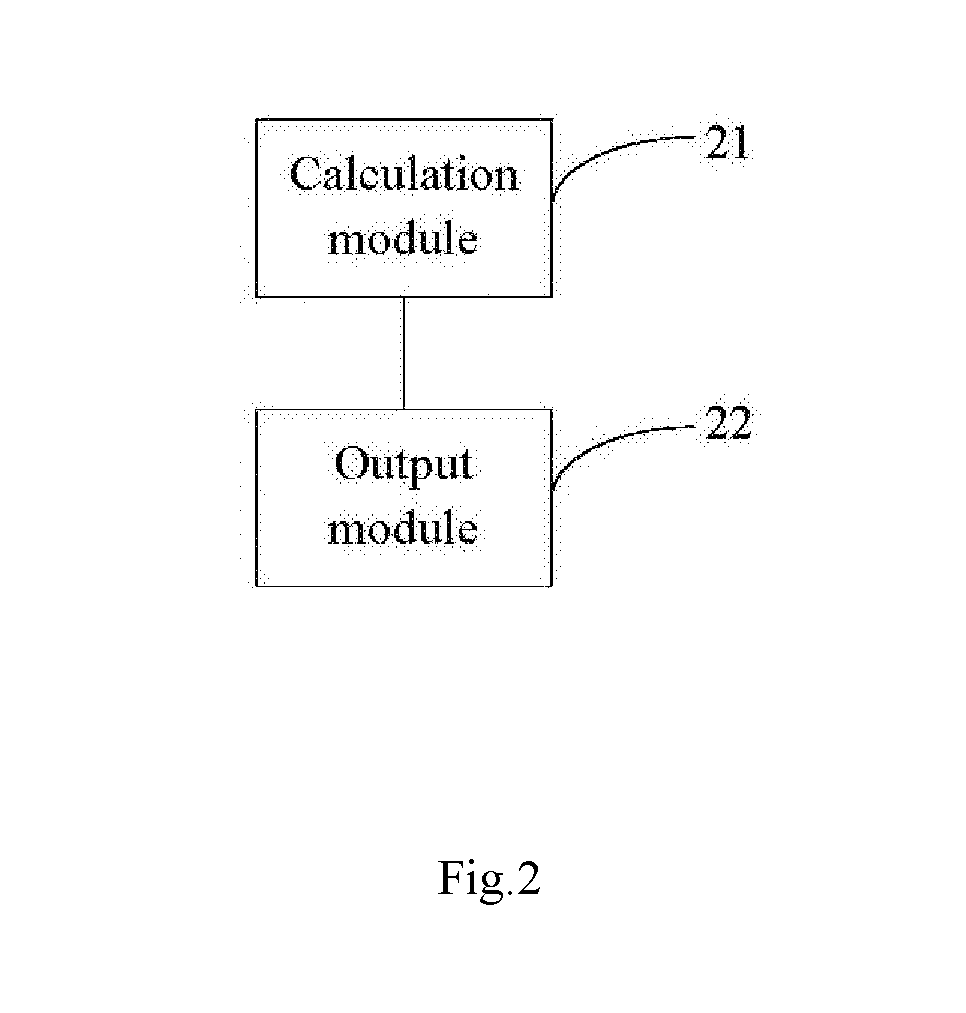

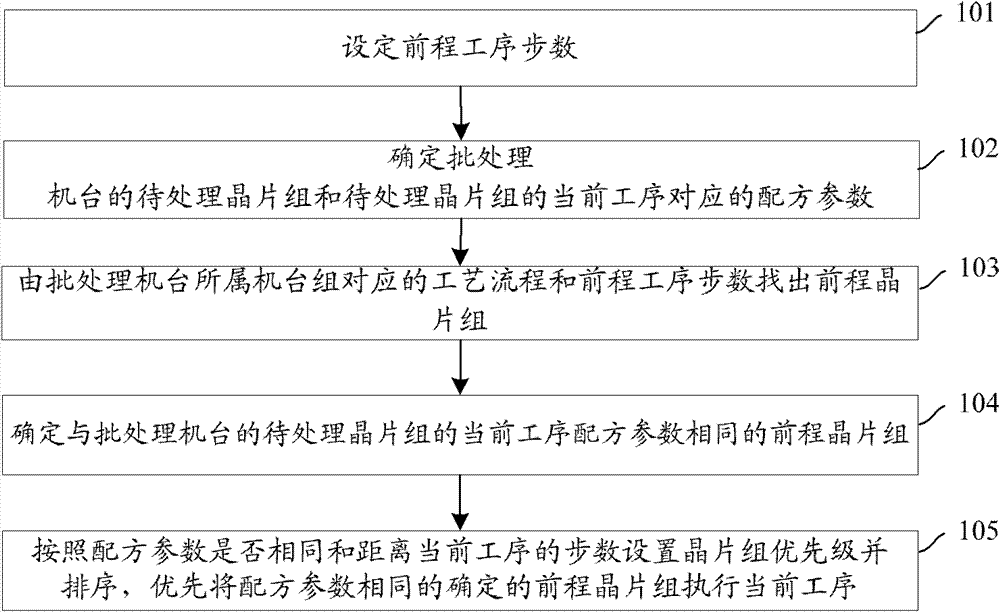

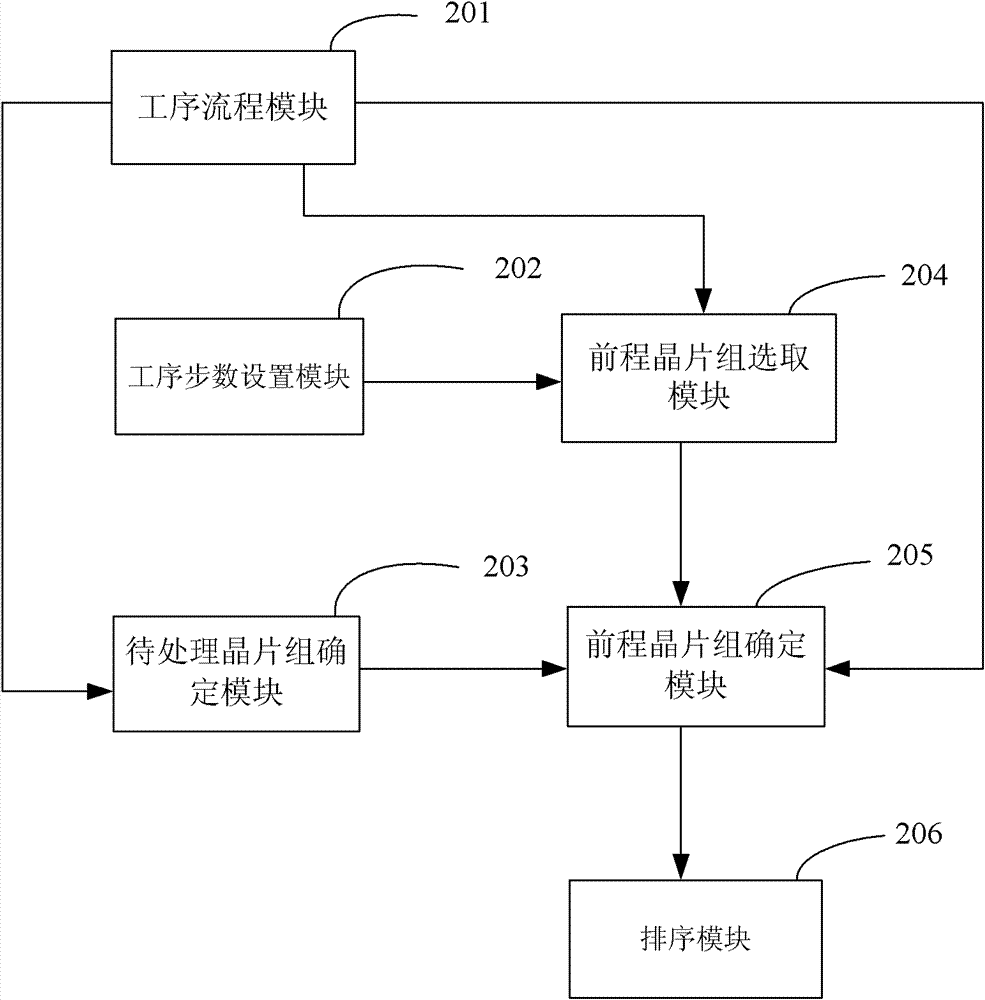

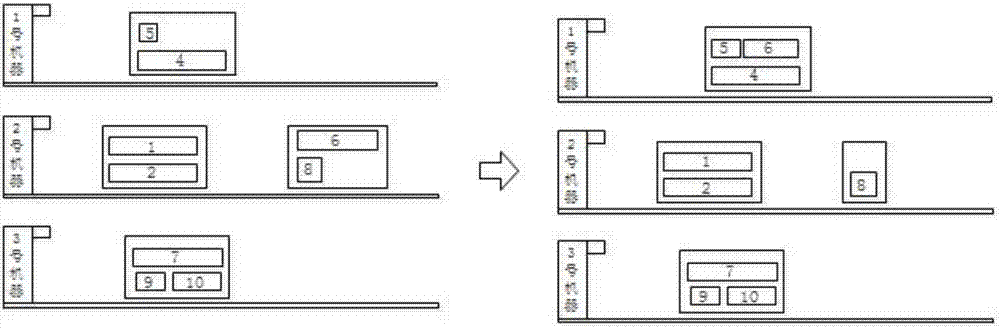

Method and device for dispatching to batch machine

ActiveCN102768941AAvoid the problem of lack of chipsets available for batch processingReduce waiting timeSemiconductor/solid-state device manufacturingBatch machineChipset

The invention provides a method and a device for dispatching to a batch machine. The method includes: by comparing the formulation parameter of each chipset in a performing process of a batch machine with the formulation parameter of a to-be-processed chipset of the batch machine, preferentially processing current processes of the chipsets with the same formulation parameter, and dispatching to the batch machine to enable the batch machine to obtain the chipsets as quickly as possible, wherein the chipsets can be batched together with the to-be-processed chipset. Therefore, waiting time for dispatching is shortened, accuracy and flexibility of dispatching are guaranteed, the problem that the batch machine cannot batch due to lacking of dispatching of the chipsets for batching is solved, and production efficiency is improved while cost for manufacturing semiconductors is saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

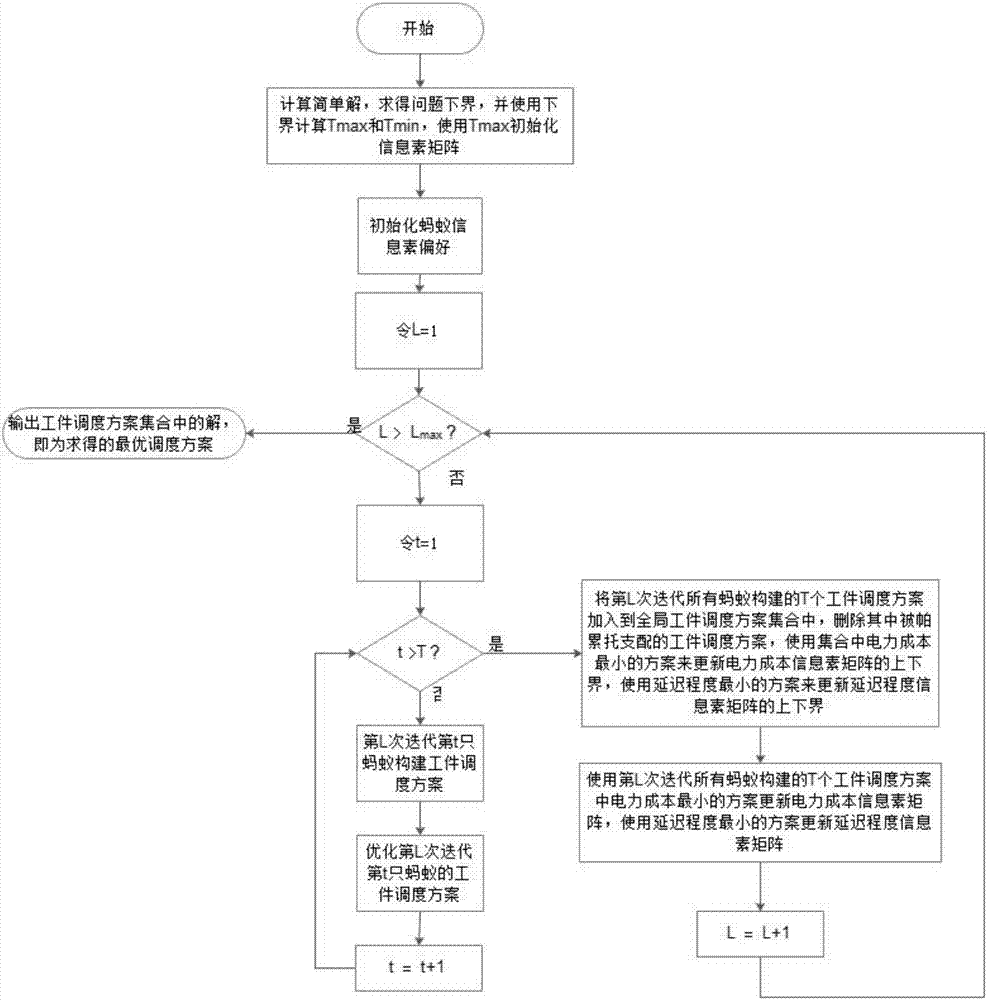

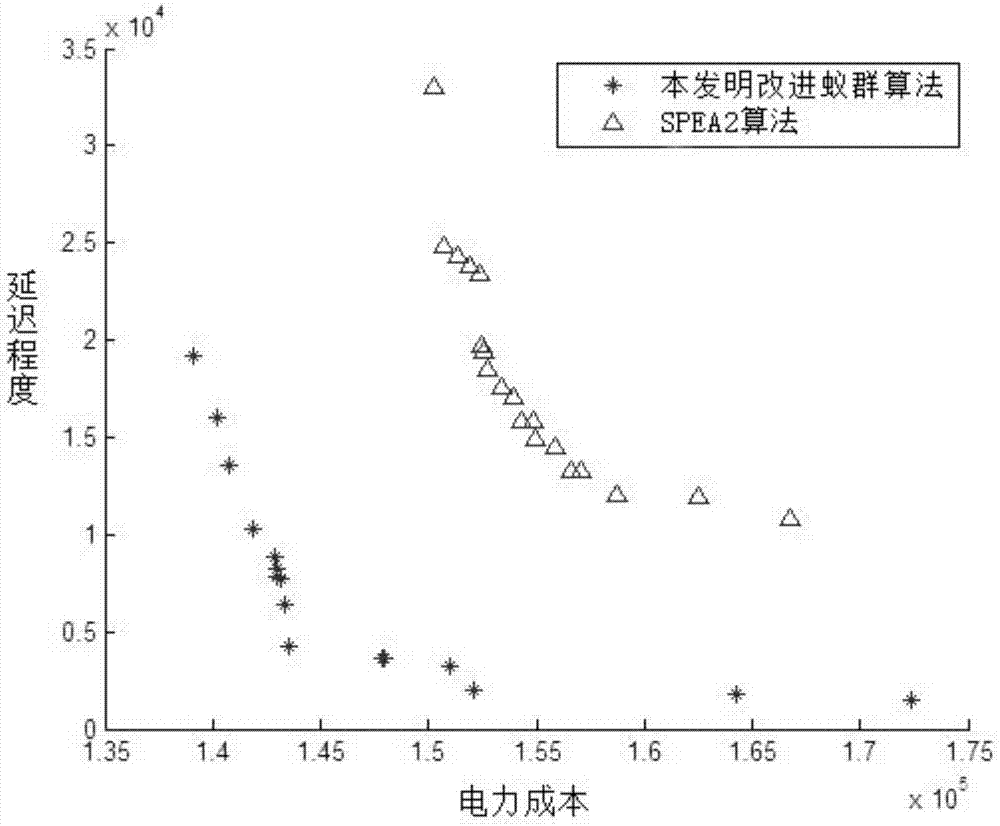

Multi-objective workpiece scheduling algorithm based on ant colony algorithm

ActiveCN106970604AEvenly distributedRich demandEnergy industryTotal factory controlElectricity priceProduction effect

The invention discloses a workpiece scheduling method based on an ant colony optimization algorithm. The workpiece scheduling method is characterized in that workpieces are effectively selected in the scheduling process through the workpiece characteristics by using a Pareto multi-objective method, and production is performed by preferentially using the low-electricity-price period so that two objectives of optimizing electric power cost A and delay degree B can be realized. A better workpiece scheduling scheme is calculated under the environment of the parallel batch processor of the background of industrial time-of-use electricity price so that the utilization rate of enterprise resources and the energy use efficiency can be maximized, optimization of cost control and the production effect of the enterprise production process can be achieved and the market competitiveness of the enterprise can be enhanced.

Owner:ANHUI UNIVERSITY

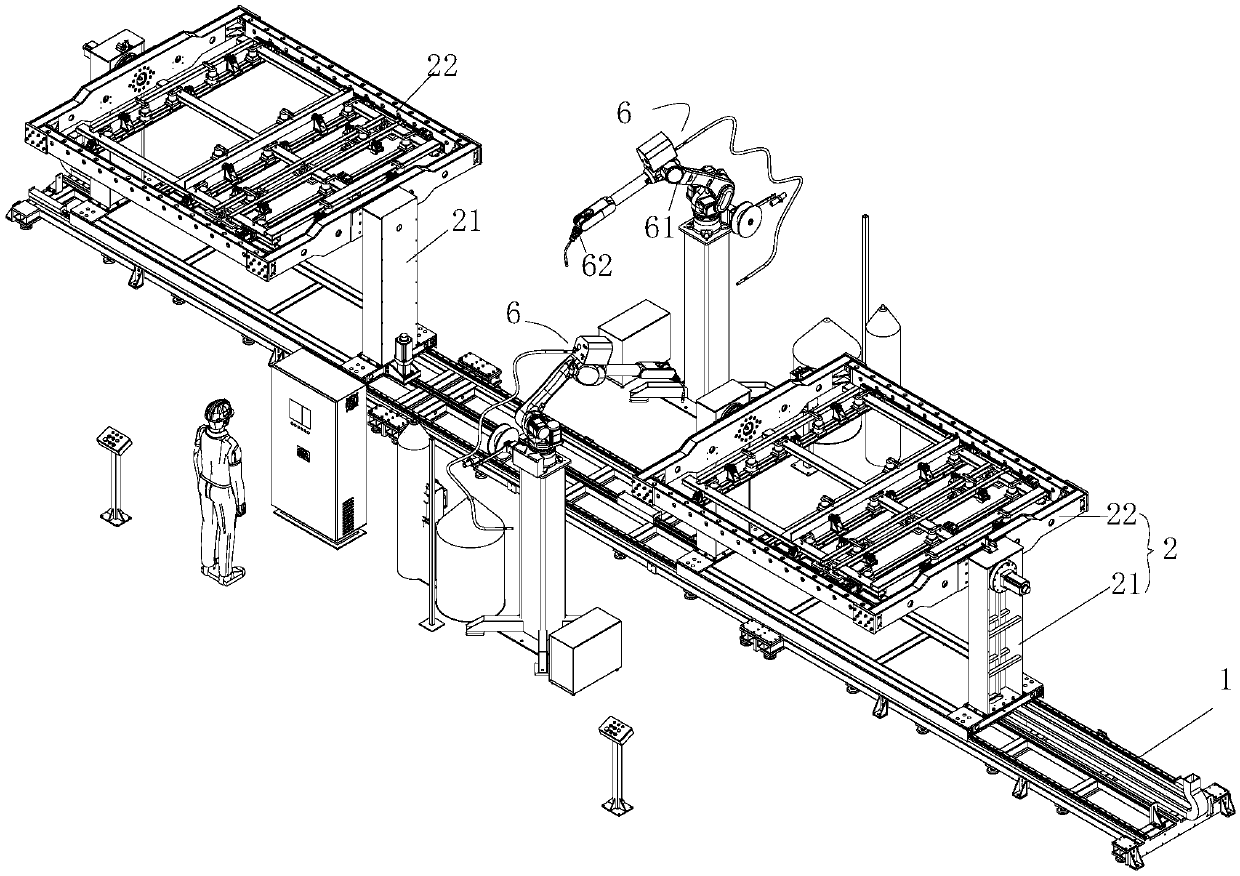

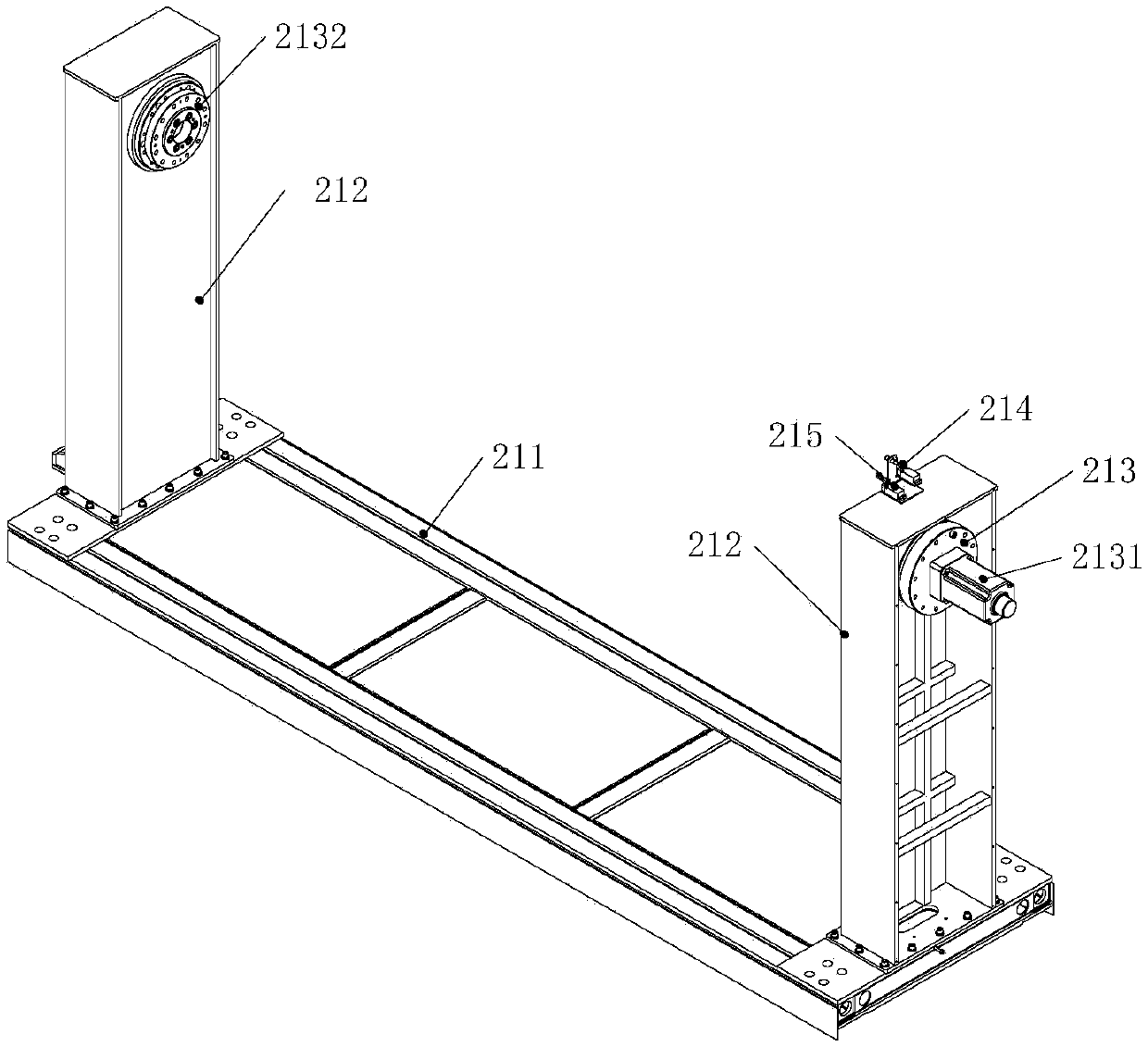

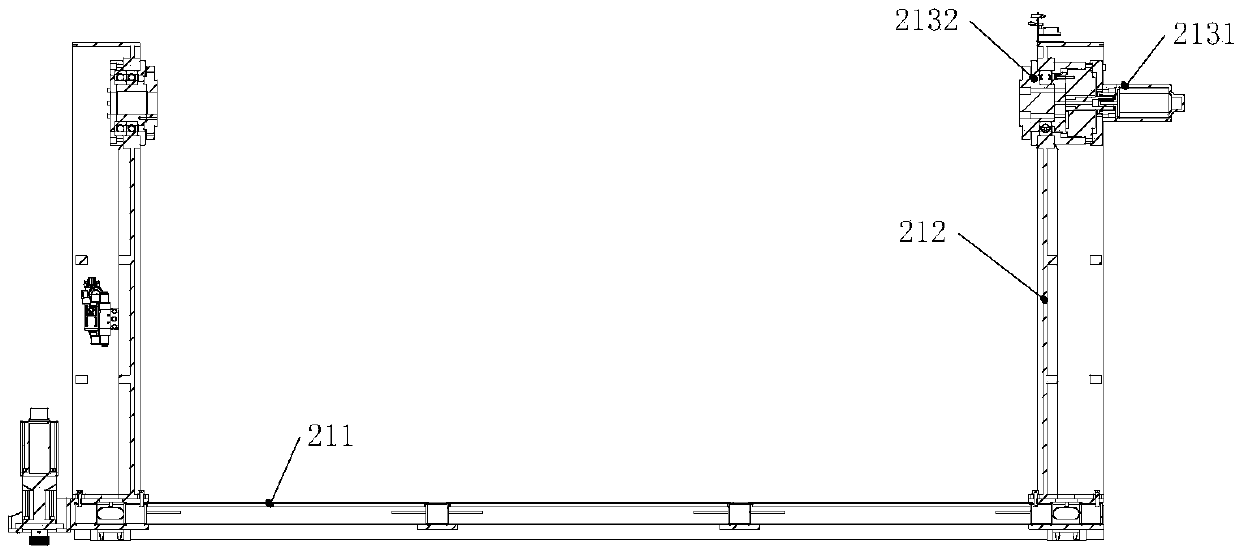

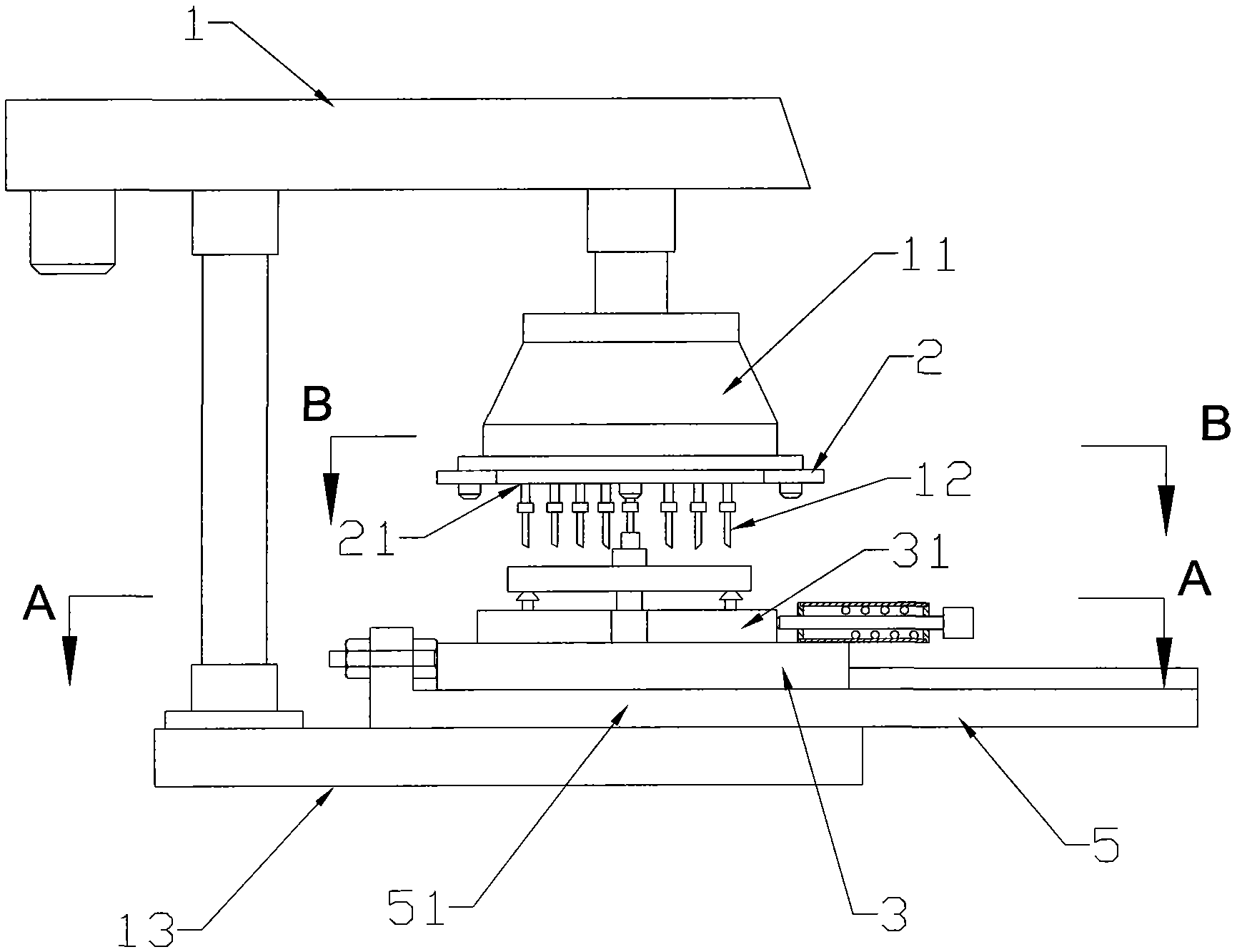

Automatic welding system for robots

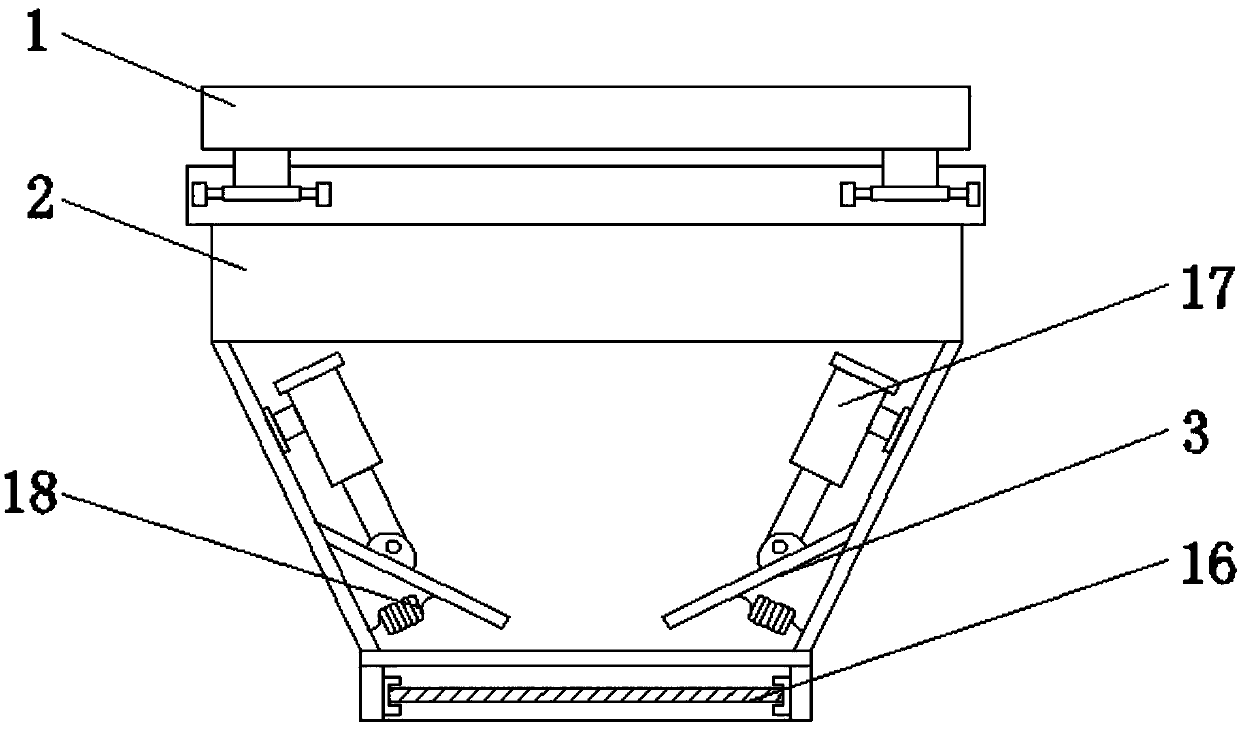

ActiveCN109623208AShorten the construction periodImprove versatilityWelding/cutting auxillary devicesAuxillary welding devicesBatch machineEngineering

The invention relates to an automatic welding system for robots. The system comprises a conveying rail; a loading station, a welding station and an unloading station are arranged along the conveying rail in sequence; overturning support mechanisms are slidingly mounted on the conveying rail; a driving device is arranged on the conveying rail, and drives the overturning support mechanisms to move to different stations along the conveying rail; the overturning support mechanisms comprise brackets, and flexible clamping assemblies rotationally mounted on the brackets; and the flexible clamping assemblies comprise frames, multiple cross beams slidingly arranged on the frames, and multiple fixtures for clamping profiles to be welded. Two or more overturning support mechanisms capable of movingto different stations along the conveying rail are provided; and the two overturning support mechanisms can synchronously perform different procedures, so that the large-batch machining efficiency ofworkpieces can be improved.

Owner:杭州固建机器人科技有限公司

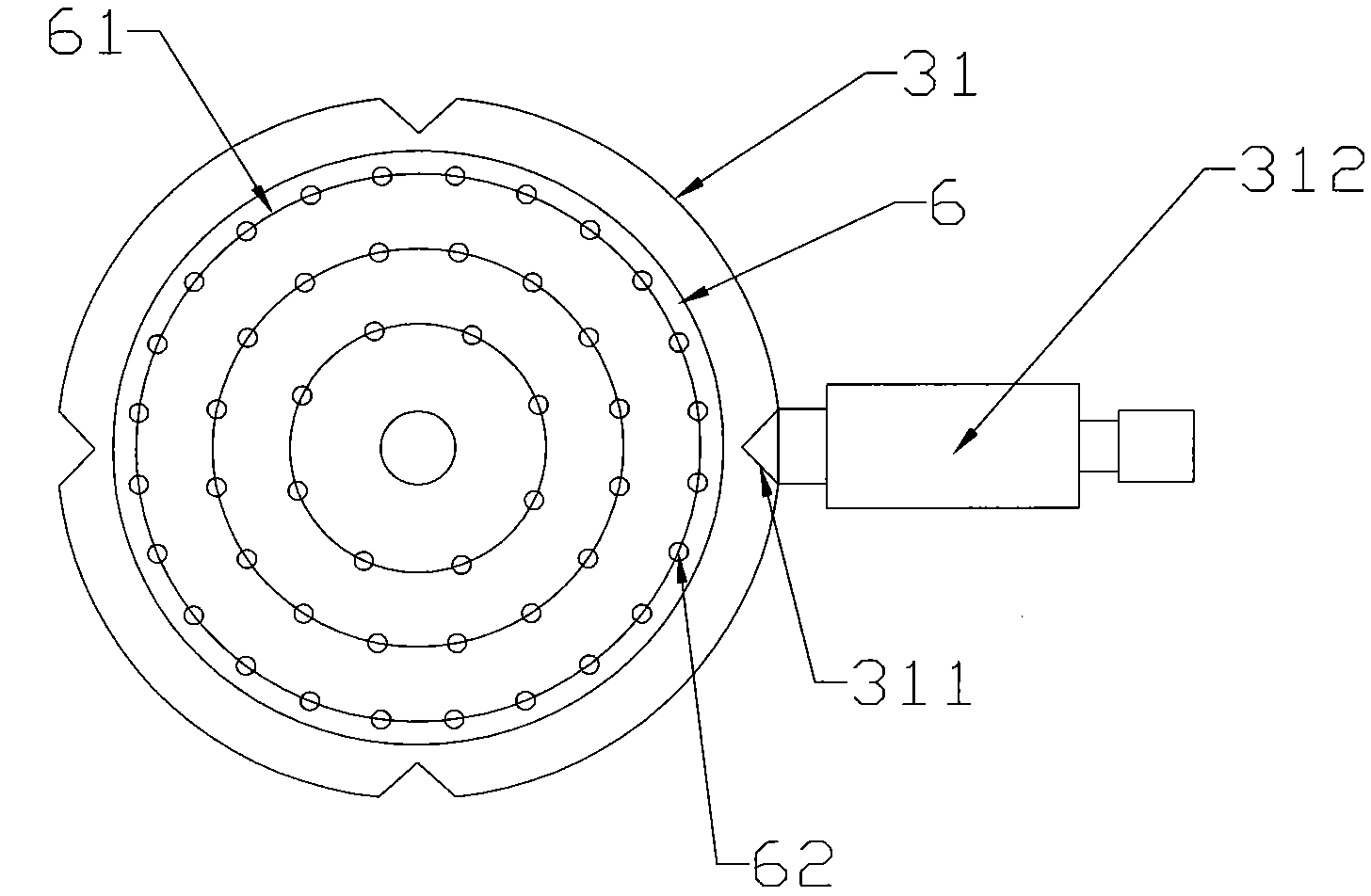

Batch machining device and machining technology for multiple holes uniformly formed in circumferences

InactiveCN103894645AImprove ergonomicsDrilling/boring measurement devicesPrecision positioning equipmentBatch machineStructural engineering

The invention discloses a batch machining device for multiple holes uniformly formed in circumferences. The batch machining device comprises a vertical hydraulic drilling machine, a base plate and an indexing fixture. The vertical hydraulic drilling machine is provided with a grouped drill bit assembly or grouped screw tap assembly with n drill bits or screw taps; bearing positioning holes are formed in the base plate, and the drill bits or screw taps are supported in the bearing positioning holes via bearings; the indexing fixture is provided with a turntable indexing plate; the bearing positioning holes are distributed on the central circumference of the drill base plate, the central circumference of the drill base plate and hole distribution circumferences are coaxial with one another and have equal diameters, each bearing positioning hole and one of circular holes or threaded holes in the hole distribution circumferences are coaxial with each other, and the circular holes or threaded holes are uniformly distributed on the hole distribution circumferences; the turntable indexing plate and the central circumference of the drill base plate are coaxial with each other, m indexing bolt openings are uniformly formed in the circumferential edge of the turntable indexing plate, the turntable indexing plate is divided into m intervals by radial lines which extend from the center of the turntable indexing plate to the indexing bolt openings, and the circular holes or threaded holes are uniformly distributed in the various intervals. The invention further discloses a batch machining technology for the multiple holes uniformly formed in the circumferences. The batch machining device and the batch machining technology have the advantages of simple structure and applicability to places where components with multiple holes, small diameters and short center distances are available.

Owner:梁满伦 +2

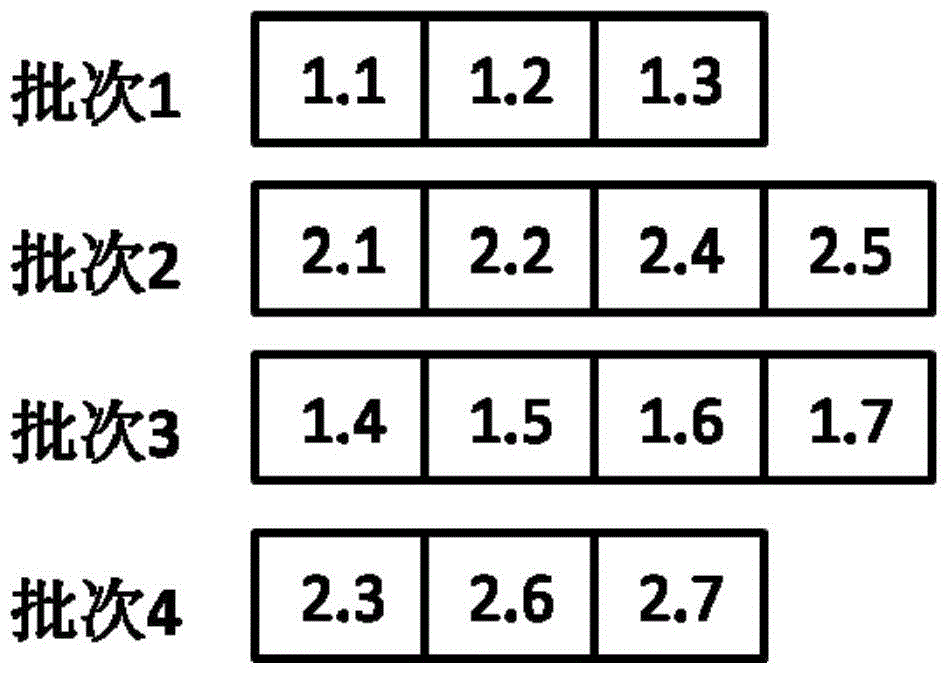

Batch scheduling method achieving minimum total completion time based on product family sorting

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

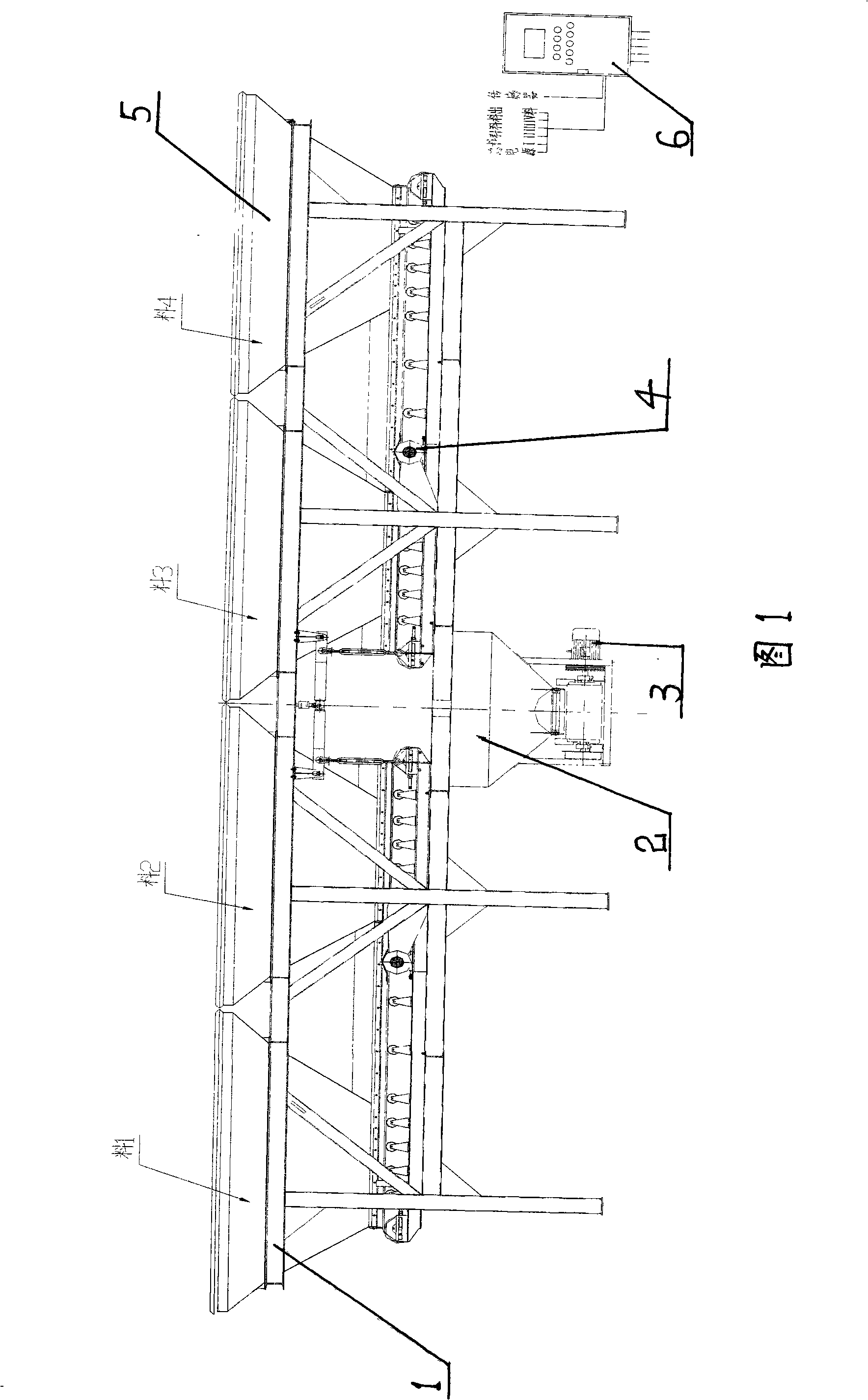

Concrete batching plant

ActiveCN103481378AAvoid emissionsAvoid pollutionDirt cleaningMixing operation plantBatch machinePollution

The invention relates to a concrete batching plant. The concrete batching plant comprises a batching machine, a hoisting machine, a main building of the batching plant, dust bins and a dust collecting system. The concrete batching plant has the beneficial effects that dust generated by the plurality of dust bins is recycled to a main batching machine for reutilization in a unified manner and is prevented from being discharged to outside air, pollution to the external environment is avoided, the energy consumption is effectively reduced and the cost is saved; and a first bin outlet and a second bin outlet are arranged at the lower part of an aggregate bin, the waiting time of a concrete tanker is effectively solved and the working efficiency is improved.

Owner:青岛磊鑫混凝土有限公司

Glove having a widened cuff and with finger regions that include a flexible hinge region

InactiveUS20160143379A1Bend their fingers and thumb easilyMaintain sensitivityGarment special featuresGlovesMedicineBatch machine

An ambidextrous or hand specific glove with a widened cuff area to aid in donning or doffing the glove is disclosed, together with a former for fabricating the glove and a method of fabricating the same. The glove may further include a bead on the cuff to resist tearing when the glove is put on or taken off. The glove may be fabricated on a continuous, automated chain machine or a batch or semi-batch machine. While the cuff region on the former for fabricating the glove is elliptical in cross-section and is flared, the region of the former on which the end of the glove is fabricated is circular in cross-section and thus allows the beading process to be successfully undertaken. The thumb region and finger regions of the glove may each be provided with a flexible hinge region that enables a user to more easily bend their thumb and fingers.

Owner:SUMMIT GLOVE

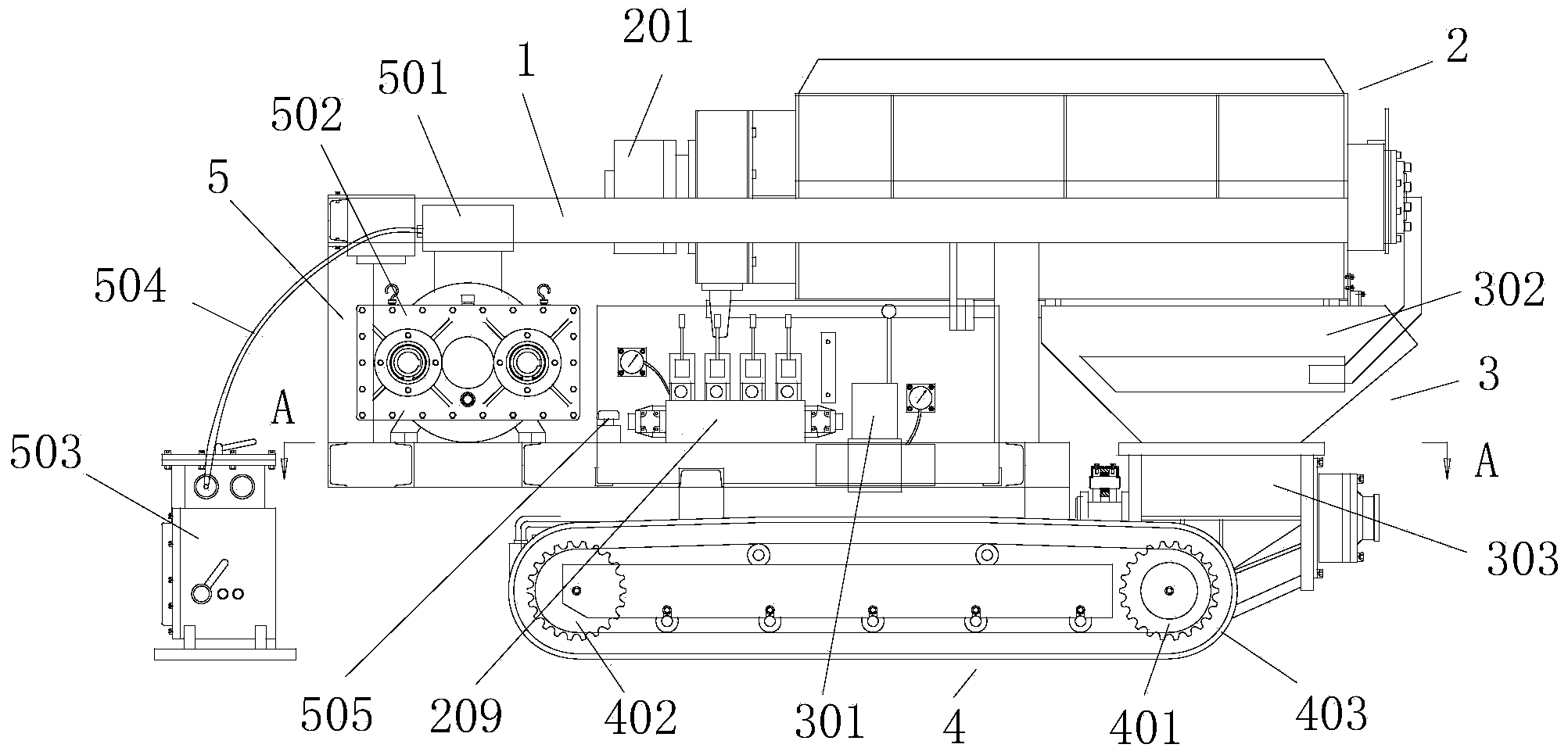

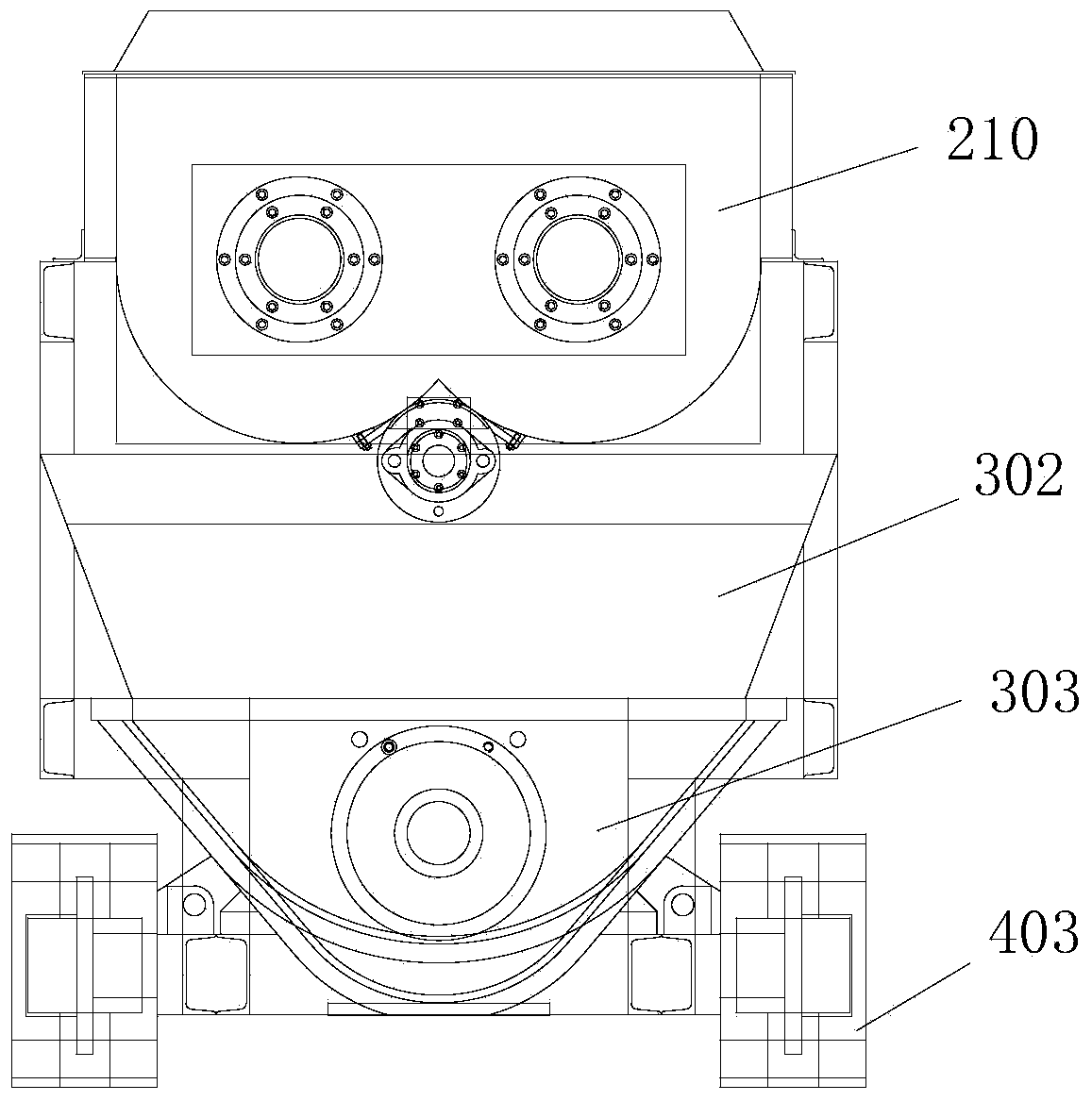

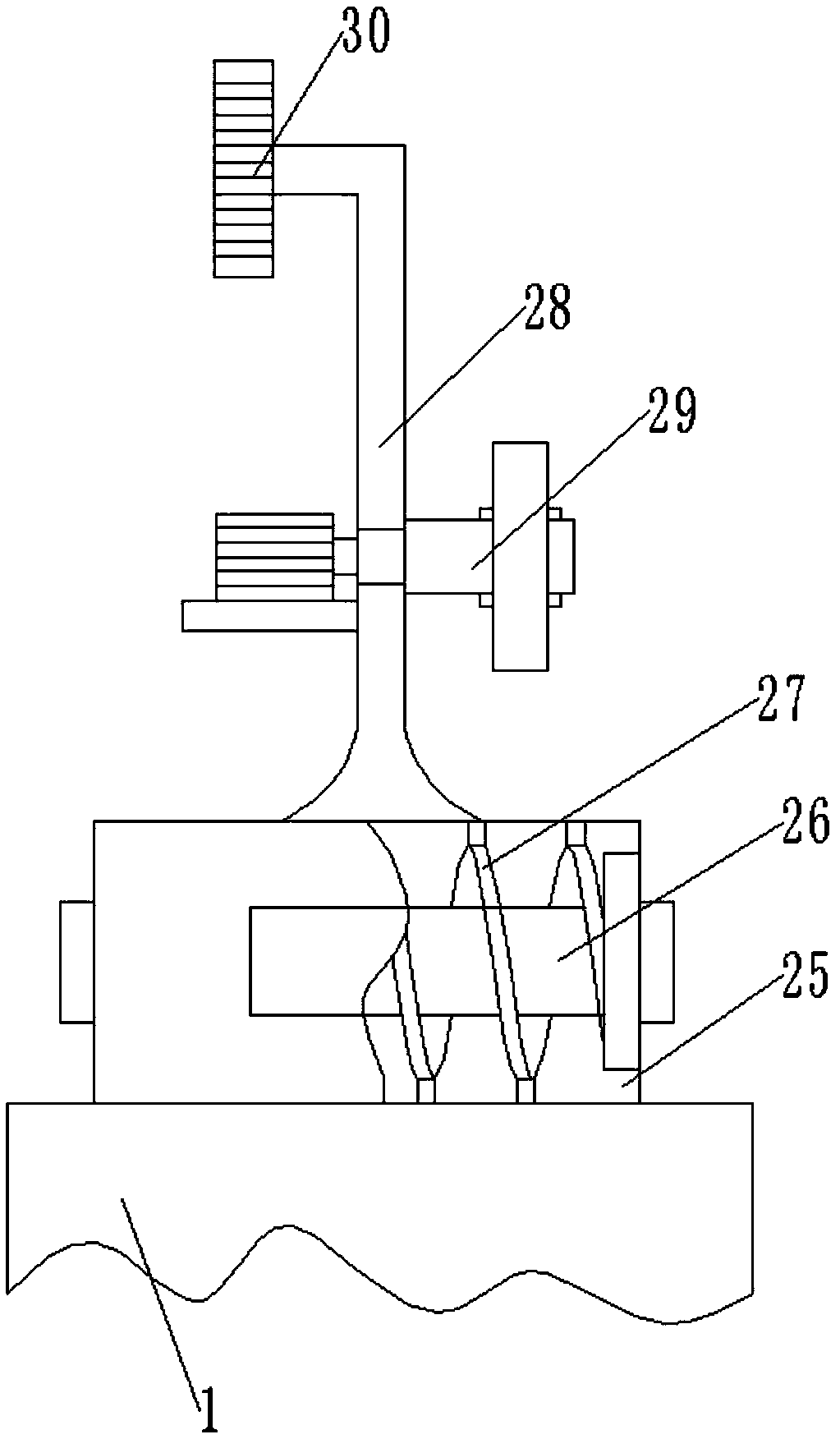

Concrete wet shotcreting equipment for roadway

ActiveCN104047615ASpeed up the progress of the projectShort mixing timeUnderground chambersCement mixing apparatusShotcreteBatch machine

The invention discloses concrete wet shotcreting equipment for a roadway. The concrete wet shotcreting equipment comprises a machine body, wherein a batching machine, a stirrer, a pumping mechanism and a power mechanism are arranged on the machine body; a walking mechanism is arranged below the machine body; the stirrer comprises a stirring cylinder and a stirring multi-path valve connected with the stirring cylinder; two parallel stirring shafts are arranged inside the stirring cylinder; the pumping mechanism comprises a wet shotcreting main valve block, a blanking copper and a wet shotcreting discharging copper communicated with the blanking copper; an S valve conveying pipeline is arranged inside the wet shotcreting discharging copper; one end of the S valve conveying pipeline is connected with a concrete conveying pump, and the other end of the S valve conveying pipeline is connected with a concrete wet shotcreting pipeline; a shower nozzle assembly is arranged at the tail end of the concrete wet shotcreting pipeline; the power mechanism comprises a mining anti-explosion motor and a transfer case; the transfer case is internally provided with a main pump and a secondary pump; the main pump is connected with the wet shotcreting main valve block; the secondary pump is connected with the stirring multi-path valve. With the adoption of the concrete wet shotcreting equipment provided by the invention, the functions of batching, stirring, discharging, wet shotcreting and walking can be realized. The concrete wet shotcreting equipment is particularly applicable to operations in underground engineering, shotcreting in the coal mine roadway and the like.

Owner:WIT LAB MINE EQUIP +1

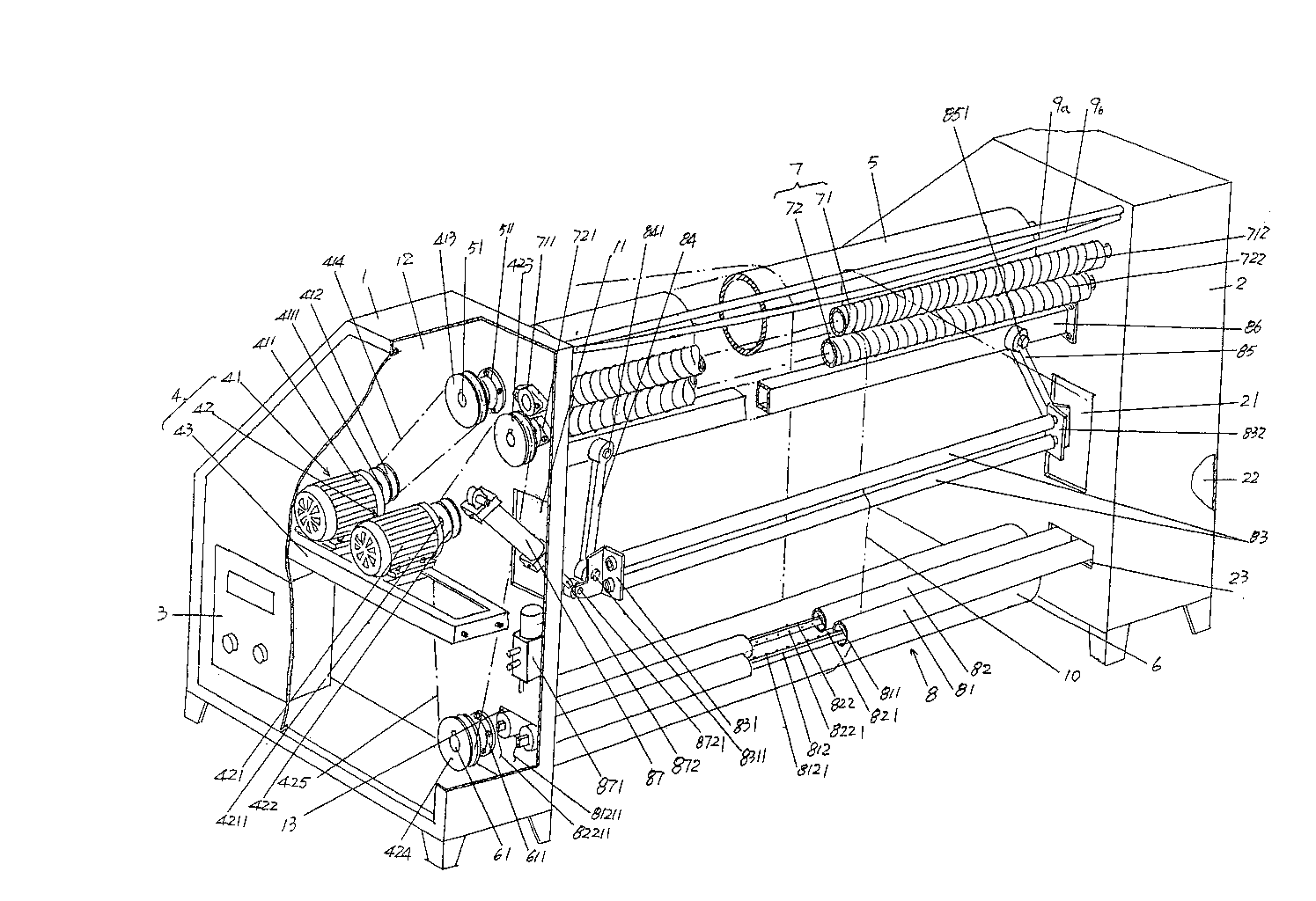

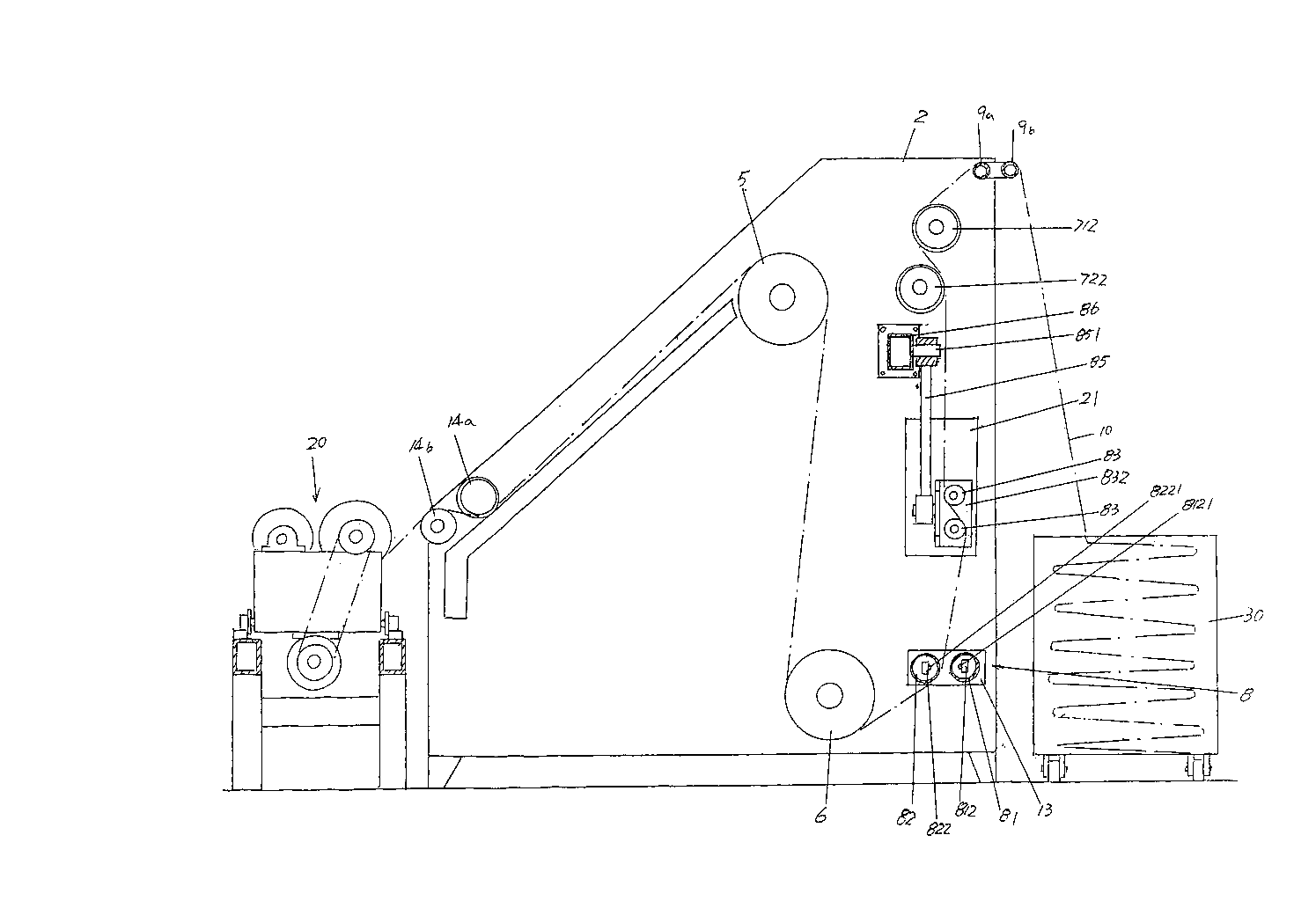

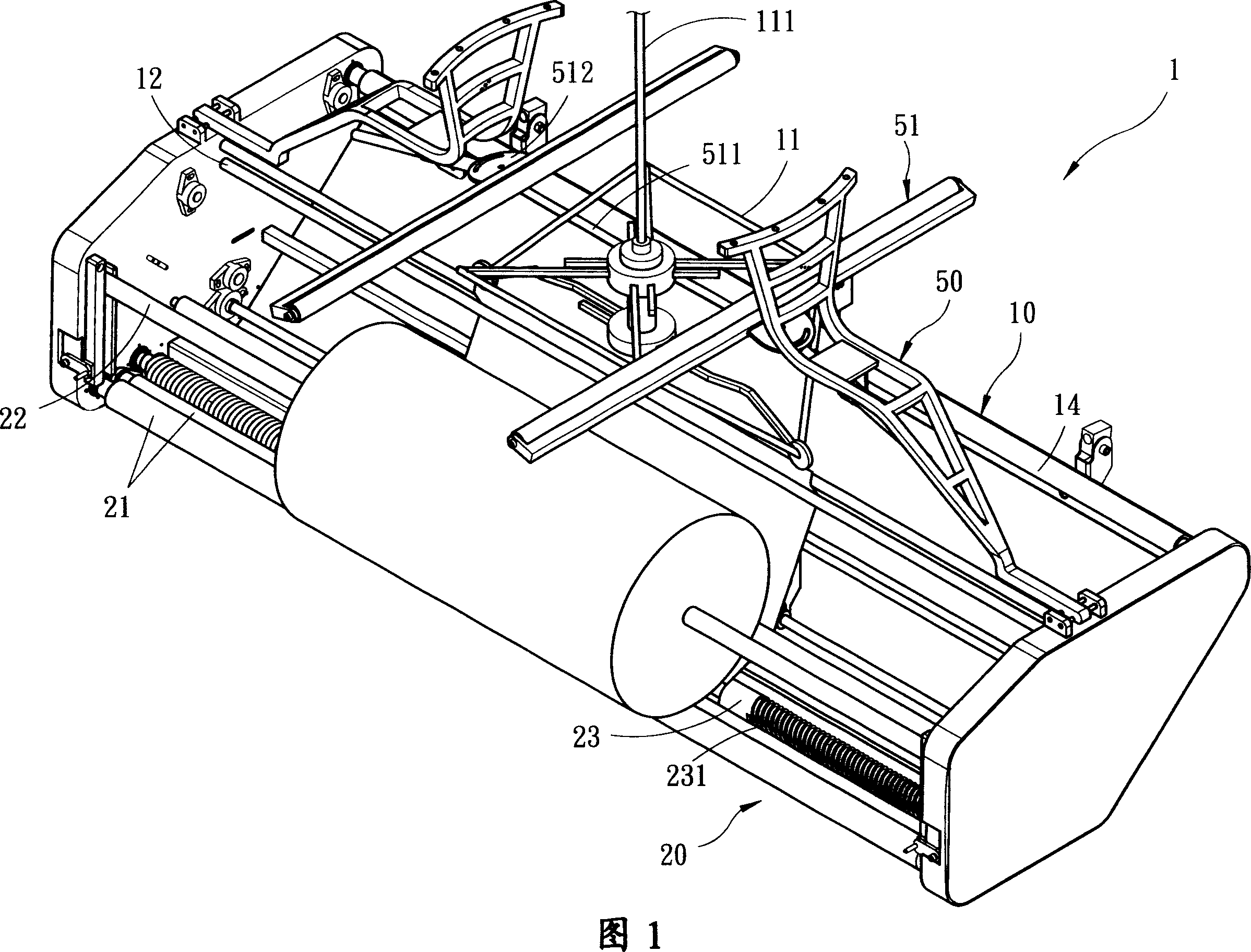

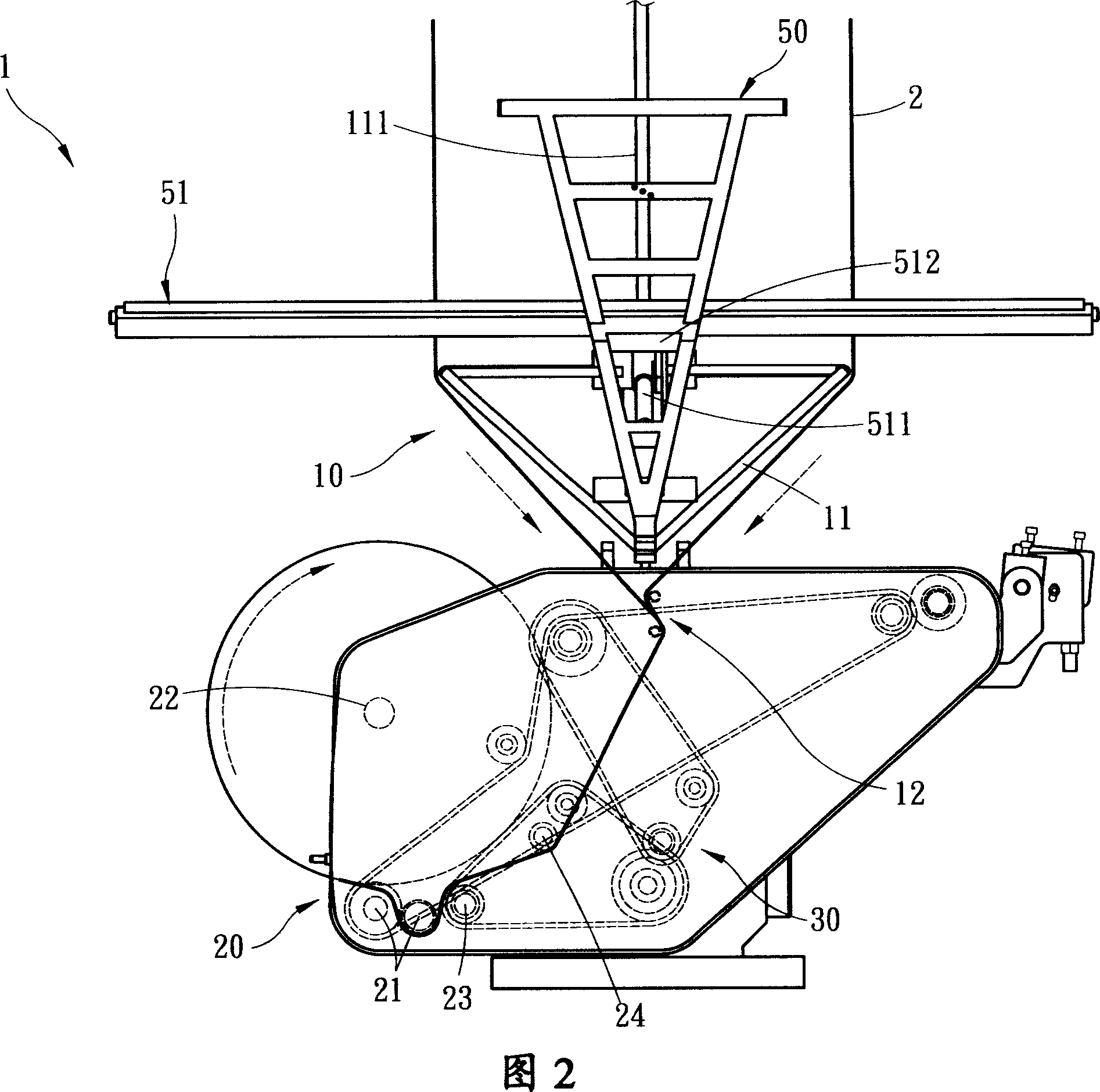

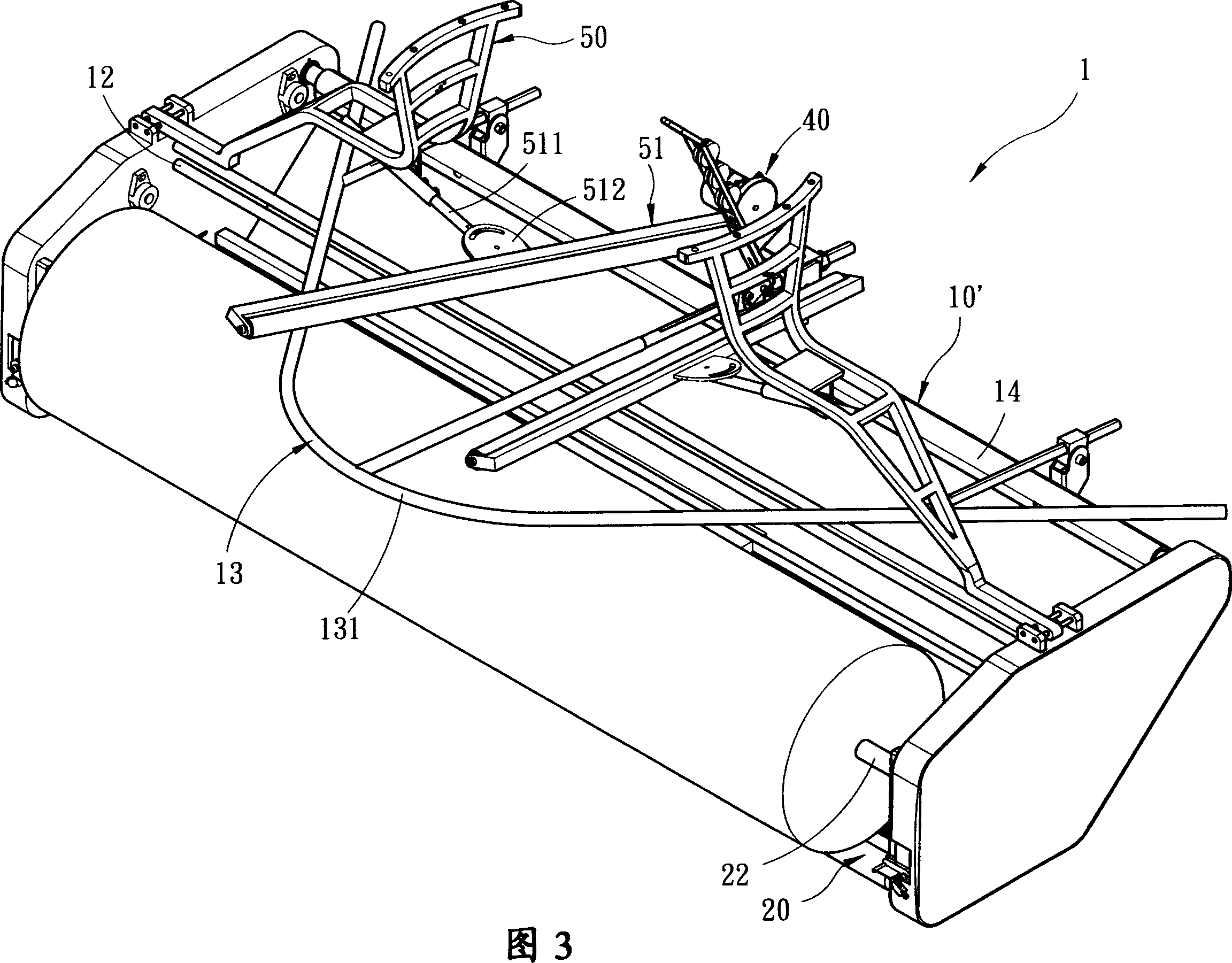

Batching machine with selvage flatting function

InactiveCN103264918AReduce labor intensityEnsure the quality of roll clothWebs handlingBatch machineEngineering

The invention relates to a batching machine with a selvage flatting function and belongs to the technical field of knitting textile machines. The batching machine with the selvage flatting function comprises a first rack wall plate, a second rack wall plate, an electric control box, a cloth guide roller driving mechanism and an upper cloth guide roller, wherein the first rack wall plate and the second rack wall plate are arranged in a face-to-face mode, the electric control box is arranged on the first rack wall plate or the second rack wall plate, the cloth guide roller driving mechanism is connected with the electric control box in an electrically-controlled mode, and the upper cloth guide roller is supported on the upper portion between the first rack wall plate and the second rack wall plate. The batching machine with the selvage flatting function is characterized in that the batching machine with the selvage flatting function further comprises a selvage flatting mechanism and a deviation-detecting and deviation-correcting mechanism, wherein the selvage flatting mechanism comprises a first cloth expansion roller and a second cloth expansion roller, one end of the first cloth expansion roller is supported on the first rack wall plate, the other end of the second cloth expansion roller is supported on the second rack wall plate, the deviation-detecting and deviation-correcting mechanism corresponds to the position below the second cloth expansion roller and is arranged between the first rack wall plate and the second rack wall plate, and the deviation-detecting and deviation-correcting mechanism is connected with the electric control box in an electrically-controlled mode. The batching machine with the selvage flatting function ensures batching quality, reduces labor intensity, and ensures the facts that two ends of a cloth roll formed of a winding drum shape are flush and free of gyroscopic effects.

Owner:常熟市龙略机电有限公司

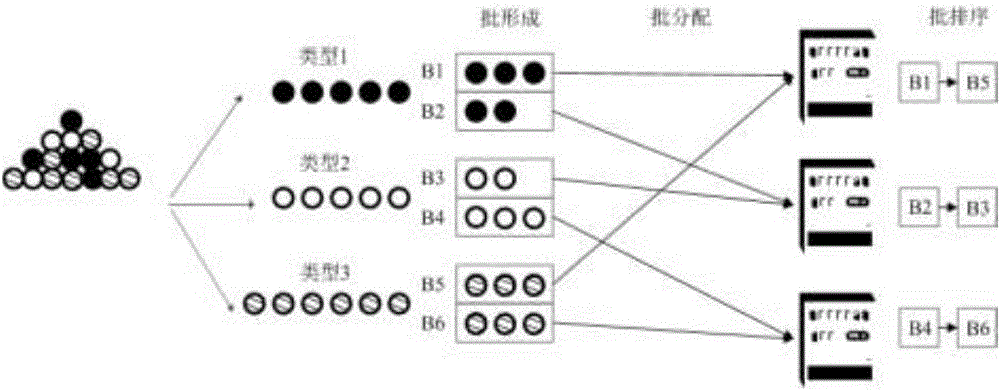

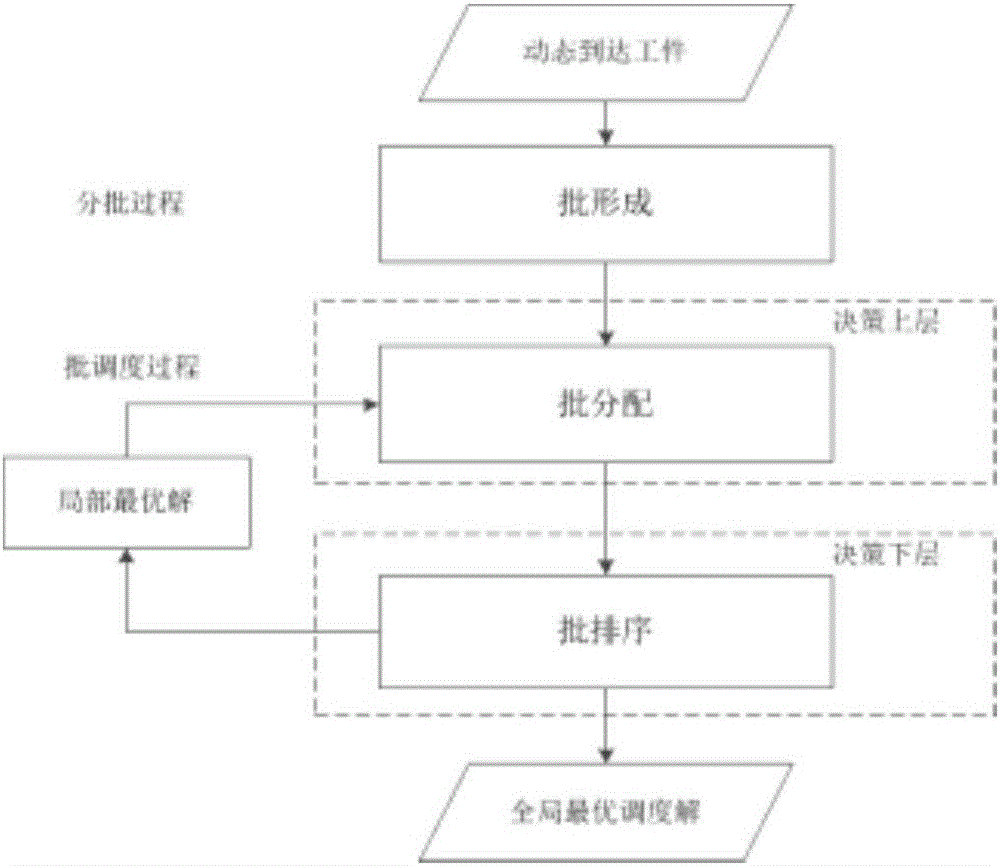

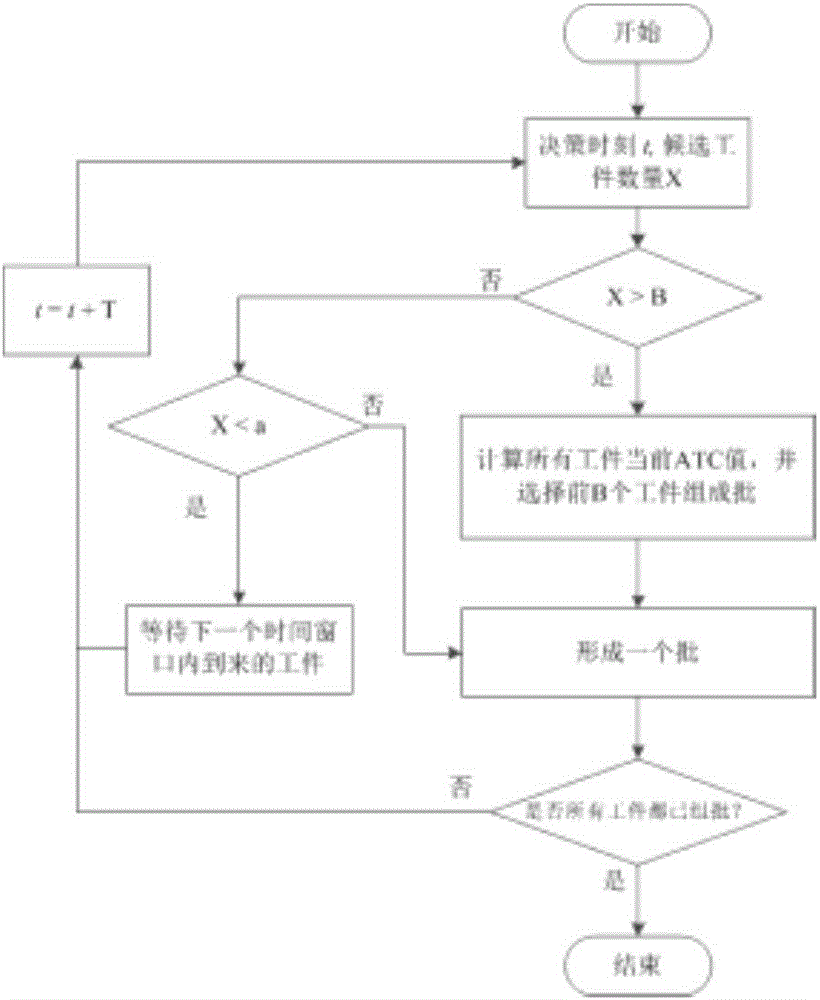

Fast evaluation method facing parallel batch processing machine dynamic scheduling

The invention discloses a fast evaluation method facing parallel batch processing machine dynamic scheduling. Firstly, based on an idea of decomposing a large complex problem into a plurality of sub problems, a batch processing machine scheduling problem is decomposed, when the processing emergency degree of a work piece is determined according to a designed priority rule and a group batching period is completed, a symbiotic evolution algorithm based on a new encoding mechanism is used to iteratively search a scheme of distributing an upper layer batch work piece to a parallel machine, and the optimal processing sequence of each processing machine of a lower layer is determined at the same time. Secondly, a key scheduling performance characteristic value is extracted, an agent model with predictive ability is subjected to off-line training, a prediction estimation value is used to carry out fast evaluation of the scheduling performance of a lower layer sub problem, and an upper layer sub problem is guided to be optimized and adjusted continuously. Finally, combined with estimation evaluation and true re-assessment strategy, the agent model is upgraded in an online way, the precision of a prediction effect is maintained, and the purpose of synchronously optimizing machine allocation and batch work piece ranking in a reasonable time range is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Method of fabricating a glove with a widened cuff area

An ambidextrous or hand specific glove with a widened cuff area to aid in donning or doffing the glove is disclosed, together with a former for fabricating the glove and a method of fabricating the same. The glove may further include a bead on the cuff to resist tearing when the glove is put on or taken off. The glove may be fabricated on a continuous, automated chain machine or a batch or semi-batch machine. While the cuff region on the former for fabricating the glove is elliptical in cross-section and is flared, the region of the former on which the end of the glove is fabricated is circular in cross-section and thus allows the beading process to be successfully undertaken.

Owner:SUMMIT GLOVE

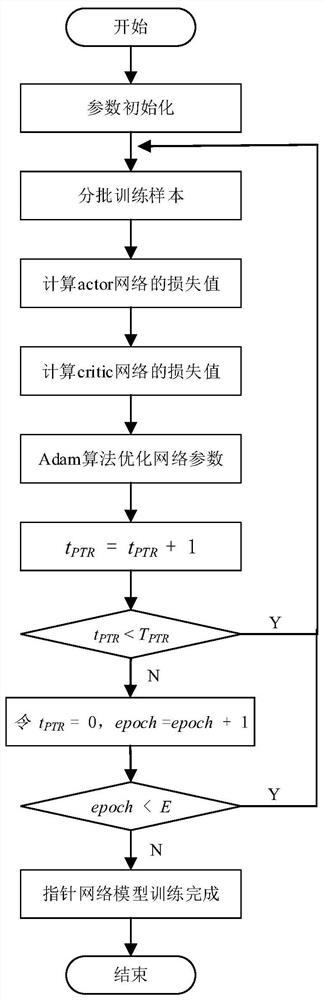

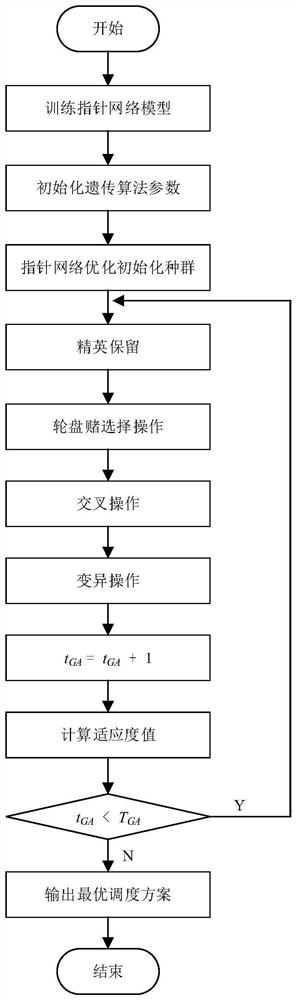

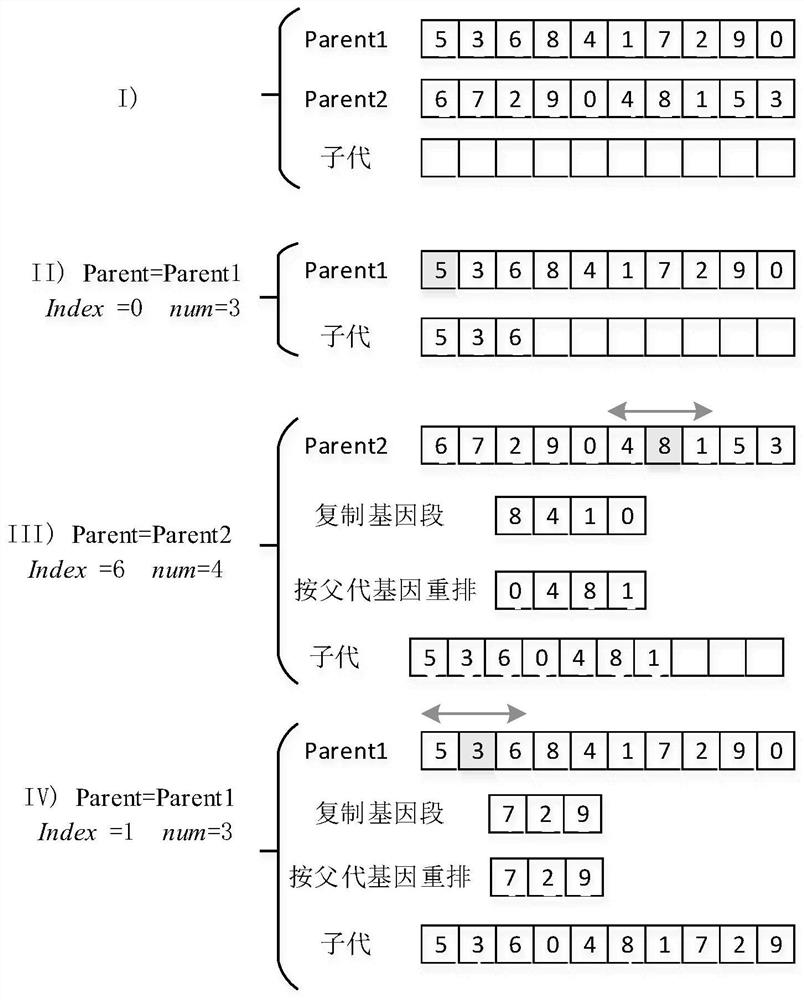

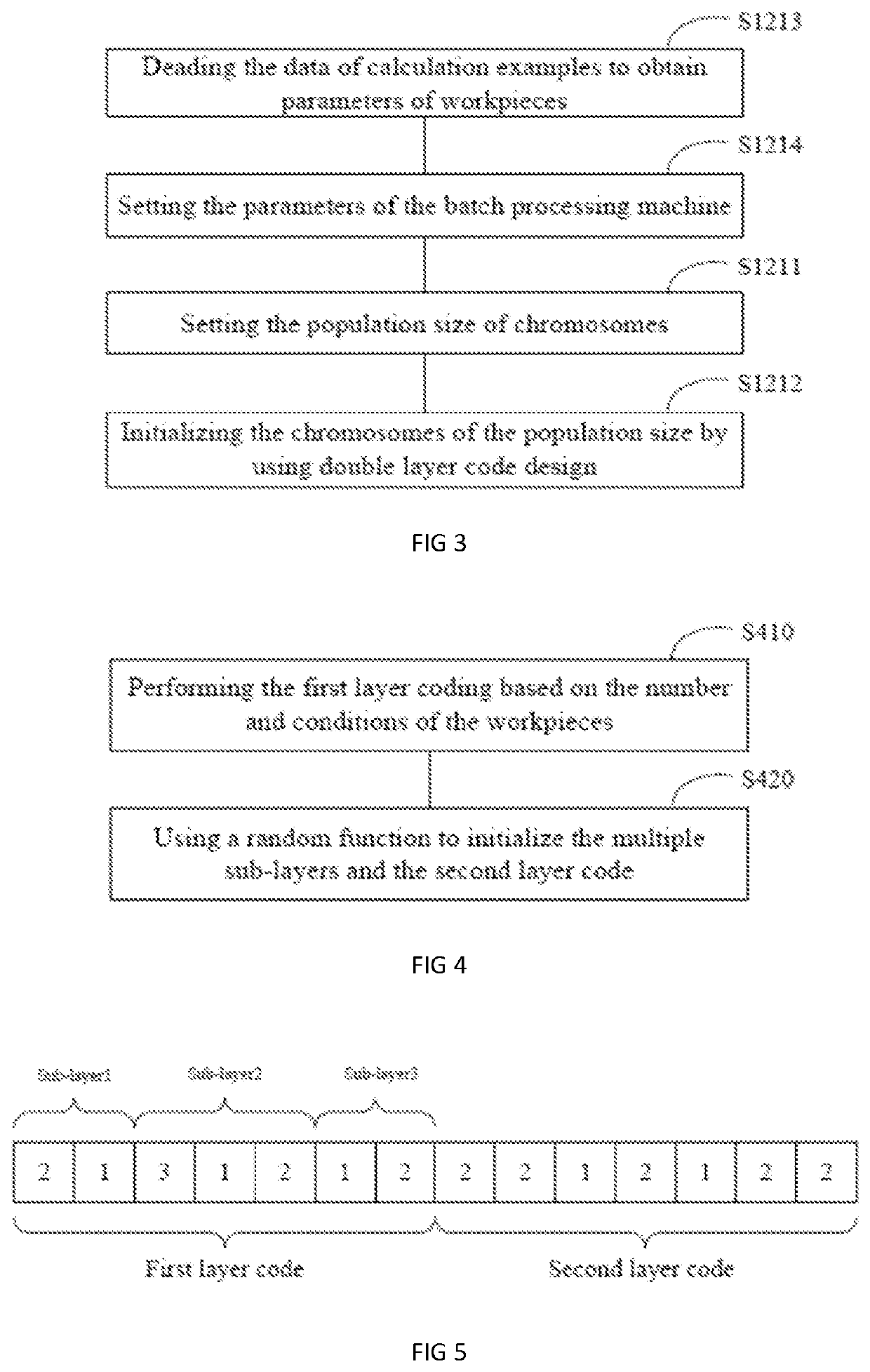

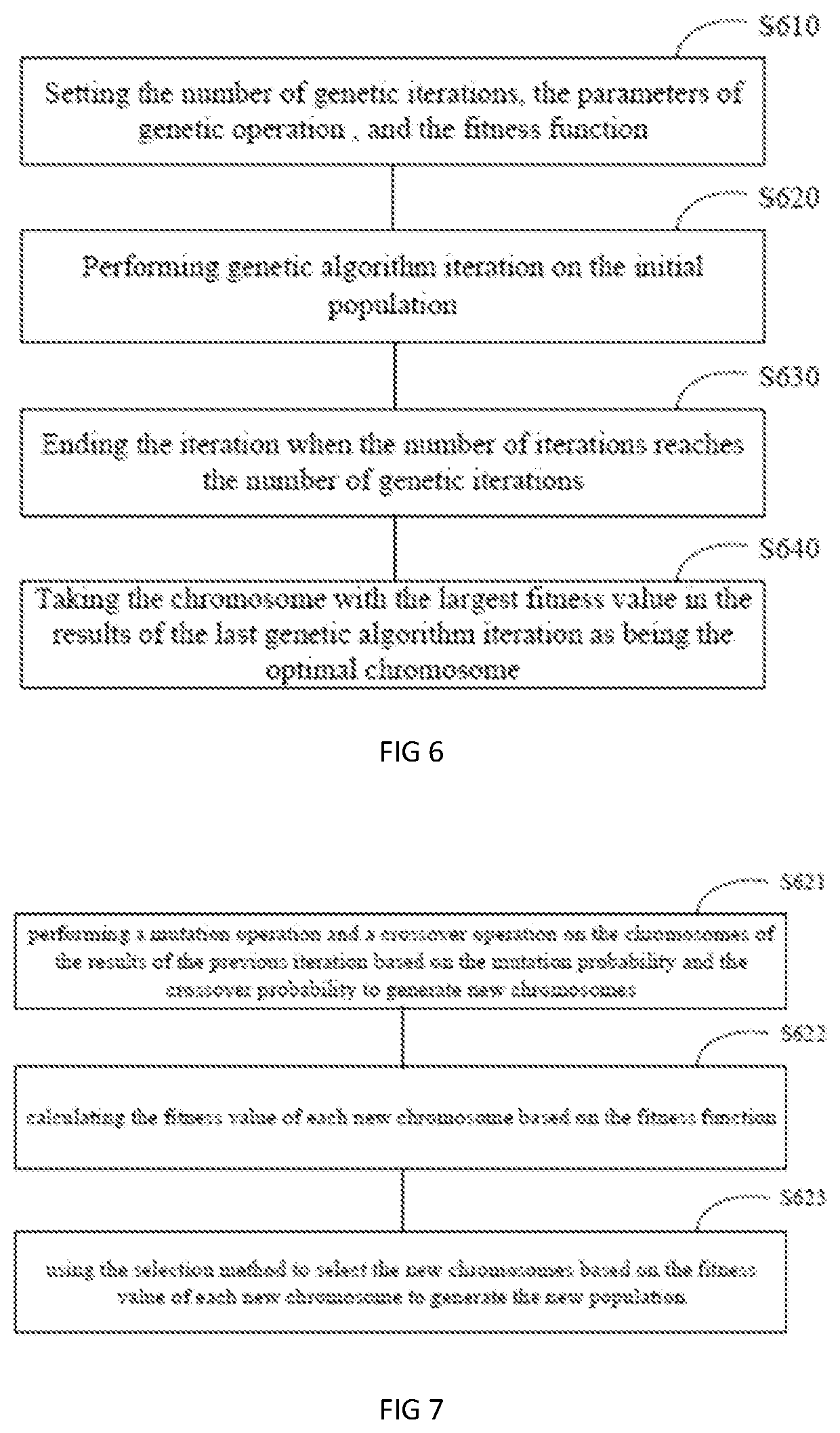

Batch scheduling optimization method based on deep reinforcement learning and genetic algorithm

ActiveCN112488315AQuality improvementImprove generalization abilityForecastingCharacter and pattern recognitionAlgorithmBatch machine

The invention belongs to the field of production and manufacturing scheduling, and discloses a batch scheduling optimization method based on deep reinforcement learning and a genetic algorithm, and the method comprises the steps: building a mathematic model of a difference workpiece batch scheduling problem; establishing a strategy model of the problem by adopting a pointer network; training a pointer network model by using an actor-critic algorithm; defining and initializing parameters of a genetic algorithm; optimizing the initial population of the genetic algorithm by using the trained pointer network; further optimizing the scheduling scheme by adopting a genetic algorithm; and the optimal scheme obtained by the genetic algorithm being used as a production scheme for processing workpieces by the batch processor. Compared with a traditional heuristic algorithm, the pointer network can obtain a better solution; in addition, in the crossover operation of the genetic algorithm, a novelcrossover mode is provided, and the performance of the scheme can be further improved by improving the optimization capability of the genetic algorithm on the basis of the scheduling scheme obtainedby the pointer network.

Owner:HEFEI UNIV OF TECH

Cloth rolling machine

The batching machine set in circular knitting machine for winding the endless fabric the circular knitting machine weaves. It may operates in either fabric slitting mode or no fabric slitting mode for different characteristics of fabric the circular knitting machine weaves, and these two operation modes are converted by making the fabric guider with mounted curved frame or fabric expanding frame so as to collect the fabric in one fabric collecting roll through different fabric winding locus. The present invention has easy conversion between two operation modes.

Owner:PAI LUNG MACHINERY MILL CO LTD

Reinforcing steel bar abut-joint device based on computer technology

InactiveCN108746963AAchieve flash butt weldingImprove welding qualityResistance welding apparatusNumerical controlSlag

The invention belongs to the technical field of numerical control machining, and particularly relates to a reinforcing steel bar abut-joint device based on the computer technology. The problems that the exquisite manual technology needs to be used for achieving welding of reinforcing steel bars, the reinforcing steel bars cannot be subject to batched machining under the condition that the reinforcing steel bar precise welding cannot be ensured, design structure is simple, the function is single, and use is not convenient are solved. The device comprises a fixed base, a fixed frame is welded tothe outer wall of the top of the fixed base, a transformer is connected to the outer wall of the top of the fixed frame through a bolt, and a knife switch is connected to the outer wall of one side of the top of the transformer through a wire. The device is suitable for welding of reinforcing steel bars of different specifications, welding slag of the reinforcing steel bars is collected, work environment of an operator is improved, manual assisting is reduced, the device is high in automation degree, the reinforcing steel bars can be ground in advance, rust stains on the surface of the reinforcing steel bars are removed, and the hollow phenomenon appearing in the interior during reinforcing steel bar welding is avoided.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Concrete batching machine for construction

The invention discloses a concrete batching machine for construction. The machine comprises a storage bin, a support stand column, a batching machine body and a mixing bin; the batching machine body is mounted at the top end of the support stand column; four hydraulic extension rods are vertically mounted in the center position of the bottom end of the batching machine body; a mounting frame is mounted at the bottom ends of the hydraulic extension rods; a metal screen is horizontally mounted at the top end in the mounting frame; a collecting barrel is mounted at the bottom end of the mountingframe; the mixing bin is mounted at the lower end in the batching machine body; and weighing bins are mounted at the positions, located on two sides of the top end of the mixing bin, in the batching machine body. The machine is provided with pressure sensors, the weighing bins and bearing plates, when materials fall onto the bearing plates in the weighing bins, the pressure sensors timely detect the weight of the materials, and transfer signals to a control system, so that people can know the weight of the added materials at any time, and the accurate concrete batching is guaranteed.

Owner:临沂朕玮建材有限公司

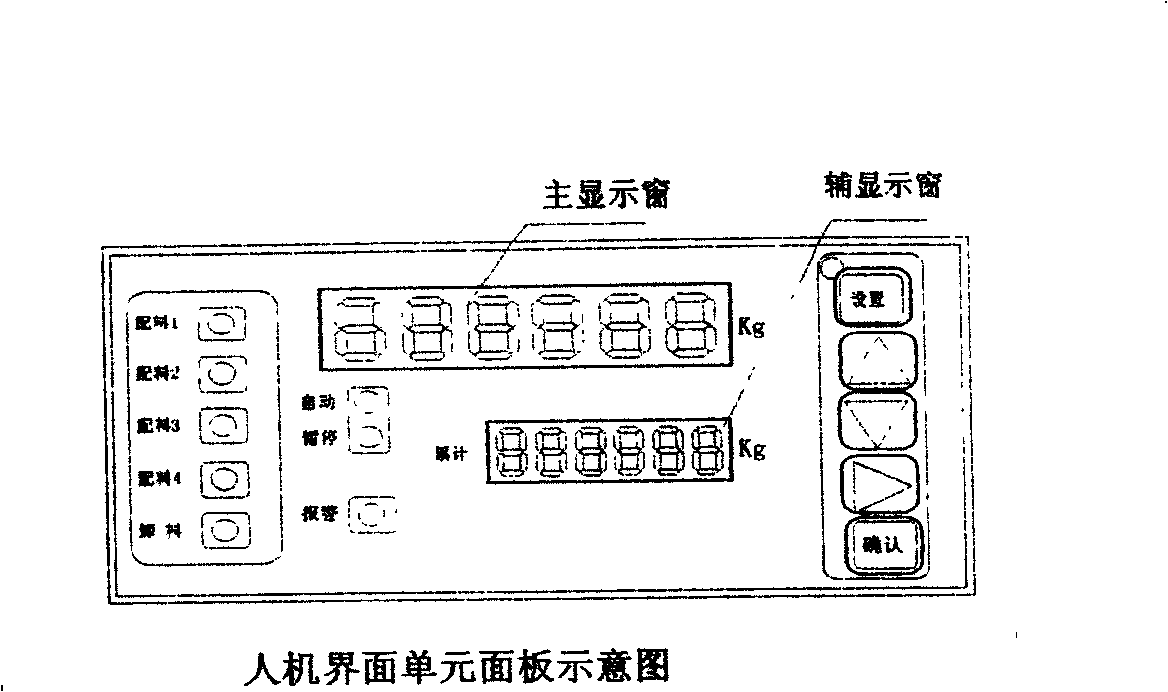

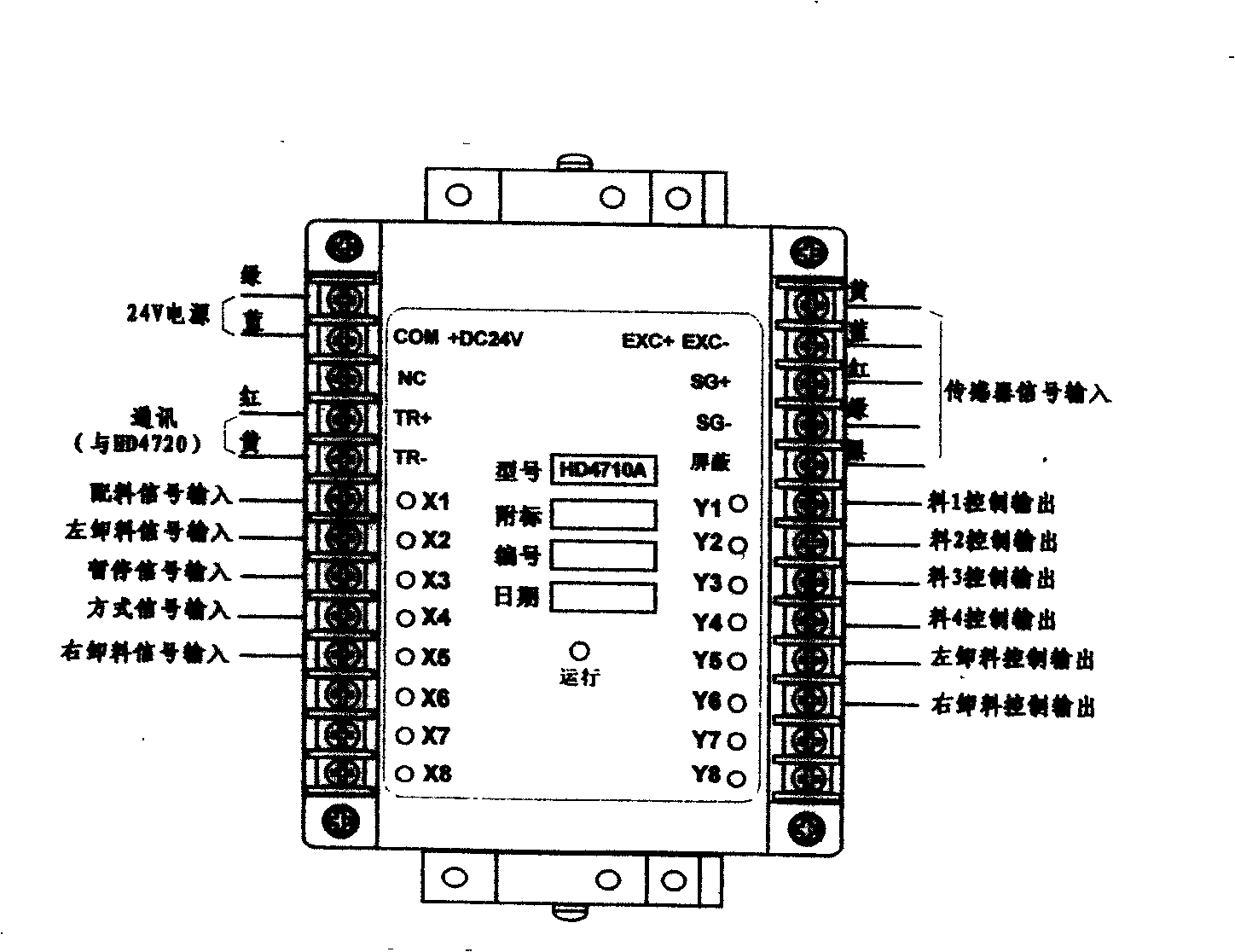

Batching machine with batching control system

InactiveCN101254631AEasy to storeEasy extractionMixer accessoriesSold ingredients supply apparatusControl systemElectric machinery

The invention relates to building material blending equipment, in particular to a material blending machine with blending control system, which is used for solving the problems of prior art such as complex operation and large consumption of labor force and time because materials are blended manually by a blending machine one by one. The technical scheme for solving the technical problems is that a blending controller is connected with a heavy current loop consisting of motors for controlling the heavy current loop. The equipment can be widely used for manufacture and use of material blending machine, and has the remarkable advantages of convenient control operation, reduced labor force and time, etc.

Owner:刘少杰

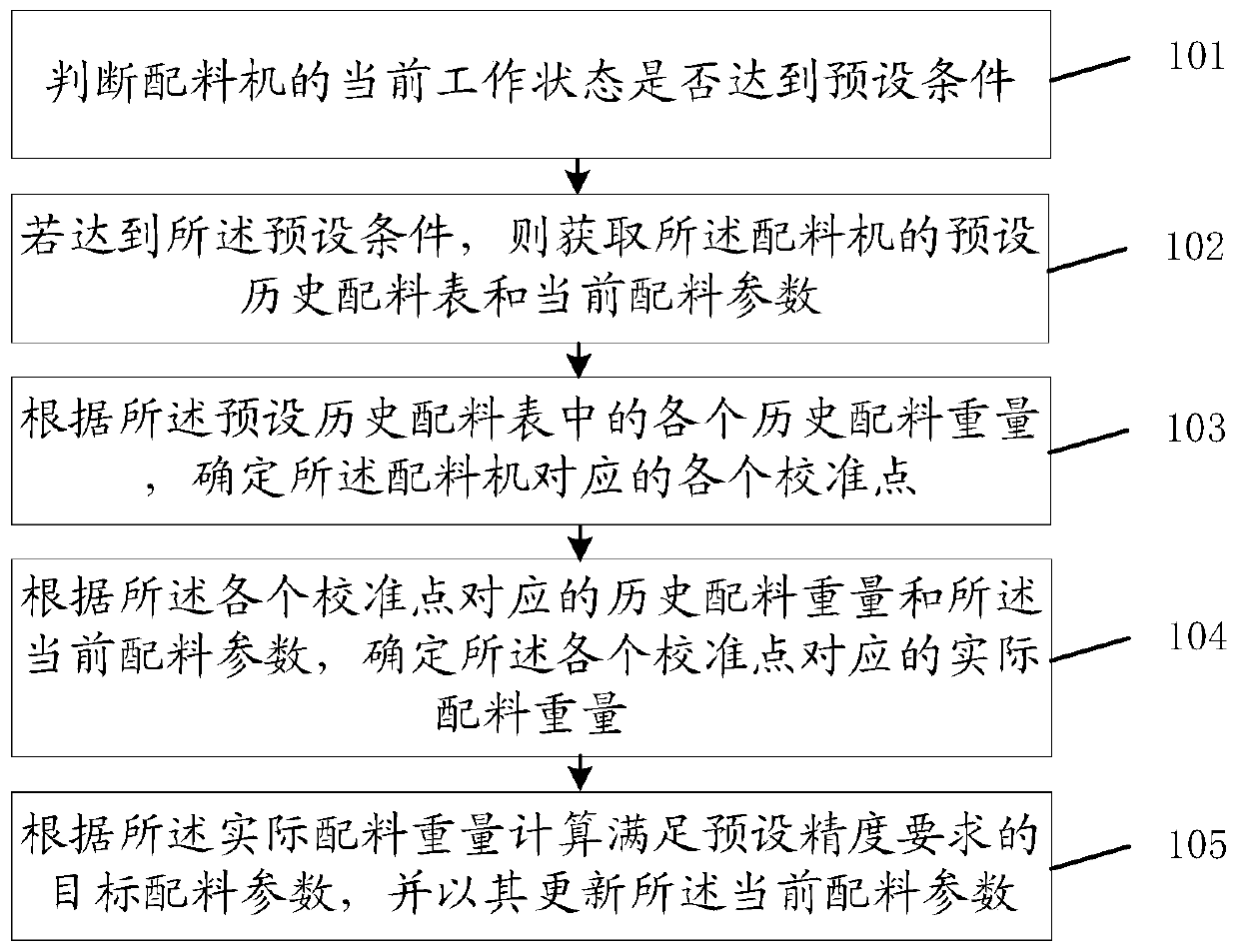

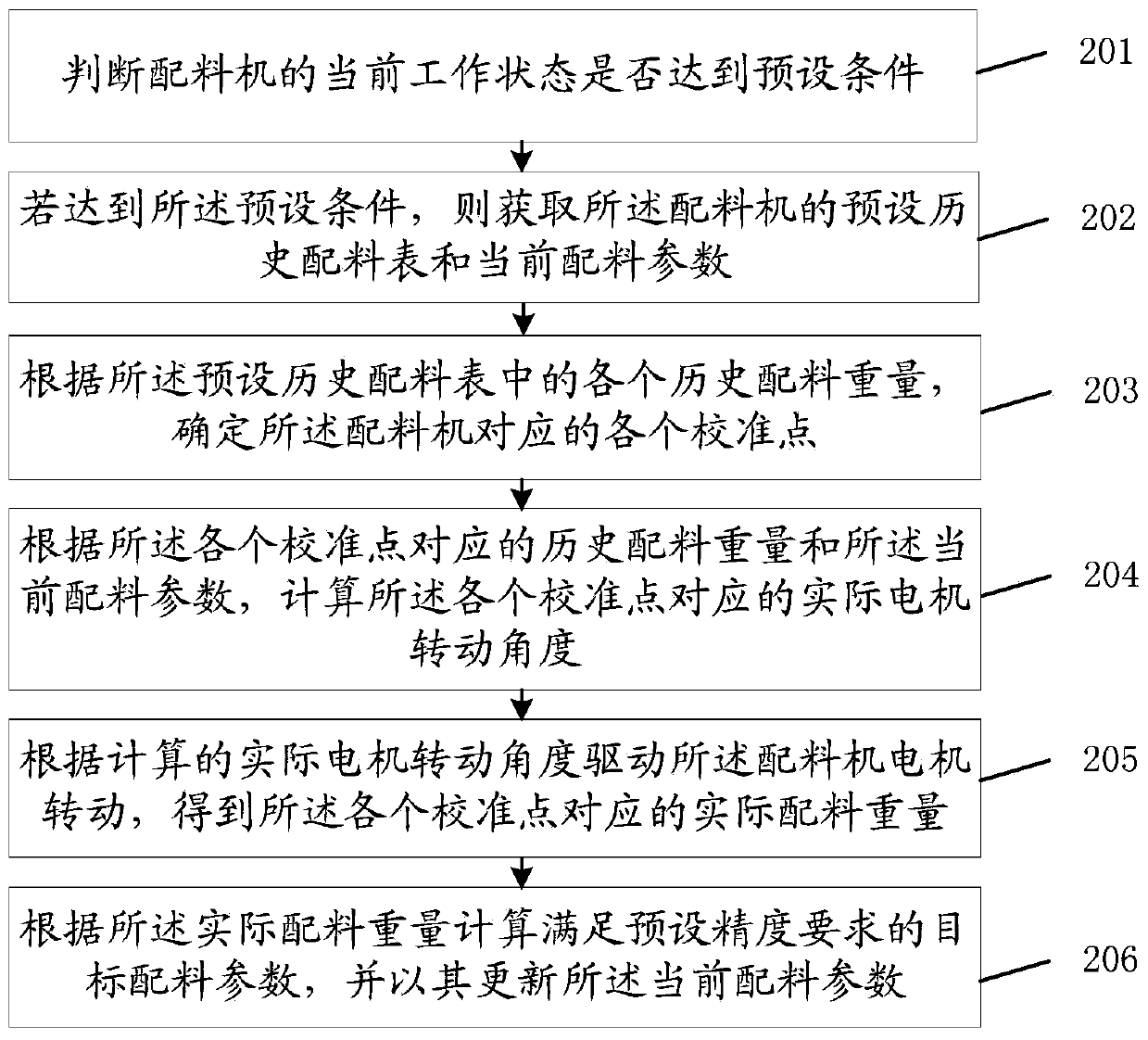

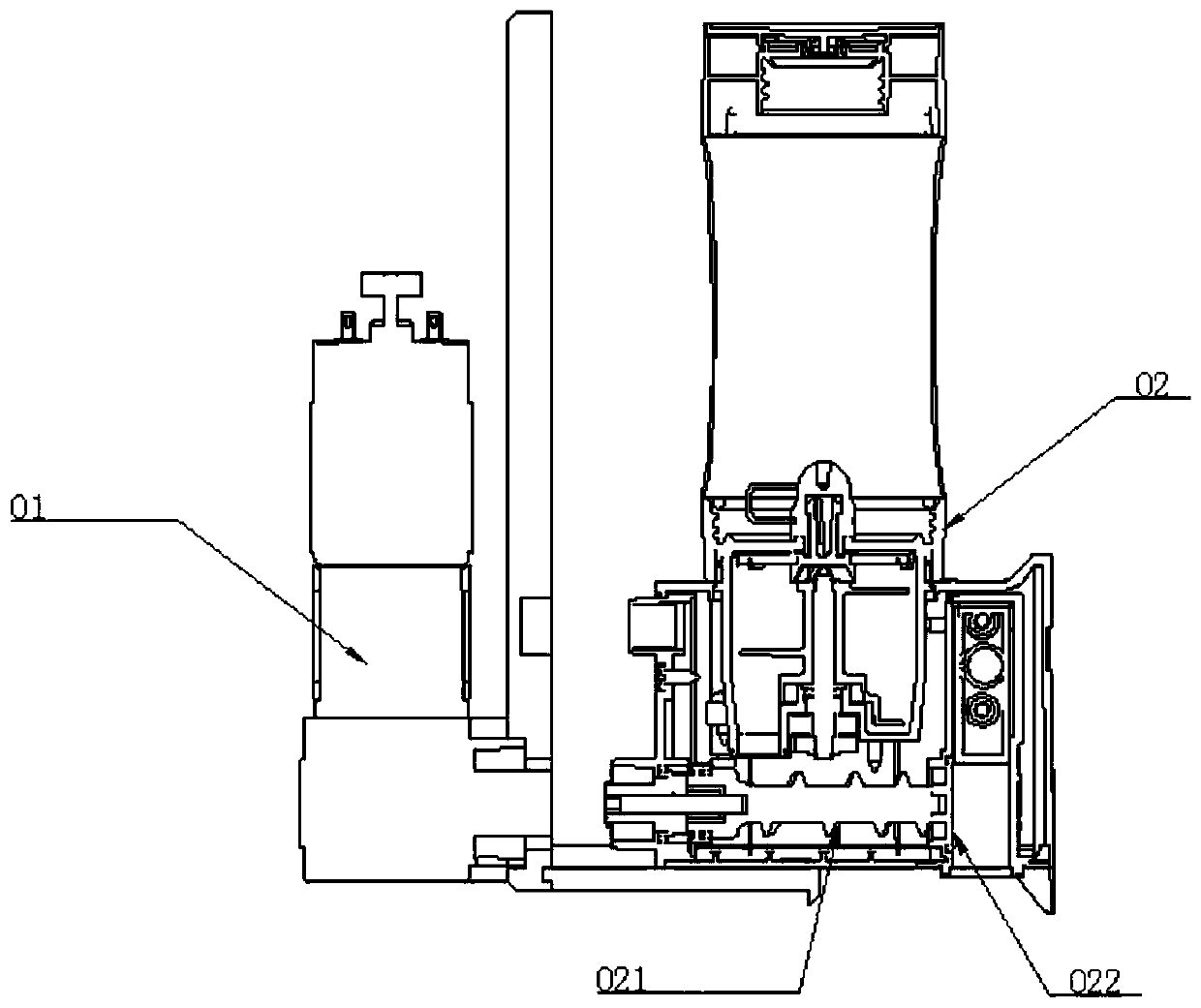

Calibration method for batching precision of batching machine, batching machine and computer equipment

PendingCN111581591AImprove batching accuracyMeet the needs of useCooking vesselsOther databases queryingSoftware engineeringBatch machine

The invention discloses a calibration method for batching precision of a batching machine, the batching machine and computer equipment, relates to the field of intelligent control, and mainly aims tocalibrate the batching precision of the batching machine in time, improve the batching precision of the batching machine and meet the requirements of users. The method comprises the following steps: judging whether the current working state of the batching machine reaches a preset condition or not; if the preset condition is met, obtaining a preset historical batching table and a current batchingparameter of the batching machine; determining each calibration point corresponding to the batching machine according to each historical batching weight in the preset historical batching table; determining the actual batching weight corresponding to each calibration point according to the historical batching weight corresponding to each calibration point and the current batching parameter; and according to the actual batching weight, calculating a target batching parameter meeting a preset precision requirement, and updating the current batching parameter by using the target batching parameter. The method is suitable for calibrating the batching precision of the batching machine.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Automatic batching machine

ActiveCN105799094ARealize the effect of positioning rotationSave time at workState of artBatch machine

The invention provides an automatic batching machine, belongs to the technical field of machinery, and solves the problem that in the prior art, the material distribution efficiency of an automatic batching machine is low. The automatic batching machine comprises a base, wherein a working plate is fixed to the base through a plurality of upright posts; an unloading space is formed between the base and the working plate; the unloading space is provided with a weighing mechanism capable of weighing a plurality of materials; a batching mechanism capable of weighing a plurality of materials for mixing is arranged on the working plate; the batching mechanism comprises a batching barrel arranged on the working plate; an unloading hole I and an unloading hole II are symmetrically formed in a bottom plate; a plug door I is arranged below the unloading hole I; an anti-sticking structure capable of preventing the materials in a barrel body from adhering to the unloading hole I is arranged in the unloading hole I; a plug door II is arranged below the unloading hole II; and an unloading structure capable of enabling the materials in the barrel body to fall off is arranged in the unloading hole II. The automatic batching machine has the advantage that the material distribution efficiency is high.

Owner:海宁红狮宝盛科技有限公司

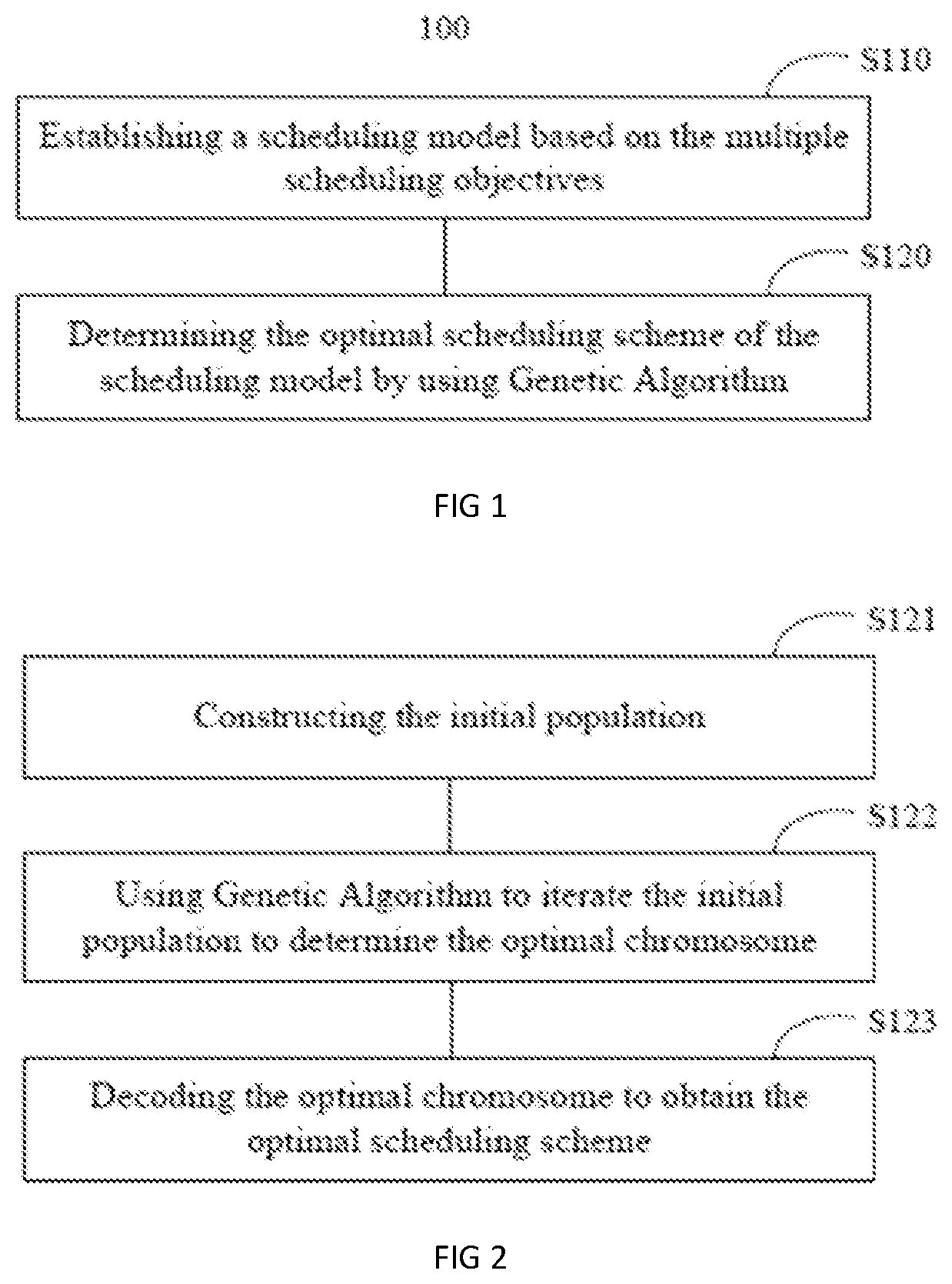

Scheduling method and device for batch processing machine

PendingUS20210335639A1Good effectReduced production cycle timeSemiconductor/solid-state device manufacturingResourcesBatch processingOptimal scheduling

The invention provides a scheduling method for batch processing machines, which is suitable for scheduling of workpieces on multiple batch processing machines in a manufacturing factory. The scheduling method for batch processing machines includes: establishing a scheduling model based on multiple scheduling objectives of the multiple batch processing machines and the workpieces, and the multiple scheduling objectives include meeting the delivery date of the workpieces, improving the capacity utilization rate and batch size of the batch processing machine, reducing the final production cycle time of the workpieces, and using Genetic Algorithm to determine the optimal scheduling scheme of the scheduling model.

Owner:SHANGHAI HUALI INTEGRATED CIRCUIT CORP

High-construction-performance polyurethane paint

The invention relates to a high-construction-performance polyurethane (PU) paint which is prepared by using main aggregates of alkyd resin, nitrocellulose, and a modified TDI curing agent. The paint has good construction performance. The paint is prepared from the components of: alkyd resin, nitrocellulose, titanium dioxide, talc, an organic solvent, a surfactant, a siccative, an anti-settling agent, and the modified TDI curing agent. With the components, the prepared PU paint has advantages of high surface drying speed. Under a natural environment, after 50min of natural drying, obtained materials can be fetched, and can be stacked and stored. The paint can be used for batched machine-stage on-line production, and provides good adhesive force for coated topcoat. During a drying early-stage, most of cross-linking reactions are fast. During a drying late-stage, the reactions are relatively slow, such that topcoats have certain dissolving capacity and good adhesive force for primers. A paint film has good flexibility and sealing ability, and is suitable for both soft and hard base materials. Especially, the paint film has good sealing ability for density boards, and assists in preventing oil-emitting or non-drying phenomena during a drying process. The paint provided by the invention is suitable for large-scale machine-stage productions of various solid wood furniture and board furniture.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com