Batching machine with batching control system

A control system and batching machine technology, applied in mixers, mixer accessories, raw material supply devices for sale, etc., can solve the problems of cumbersome operation, waste of manpower and time, etc., to facilitate control operations, save manpower and time, improve protection and safety. The effect of the fault diagnosis function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

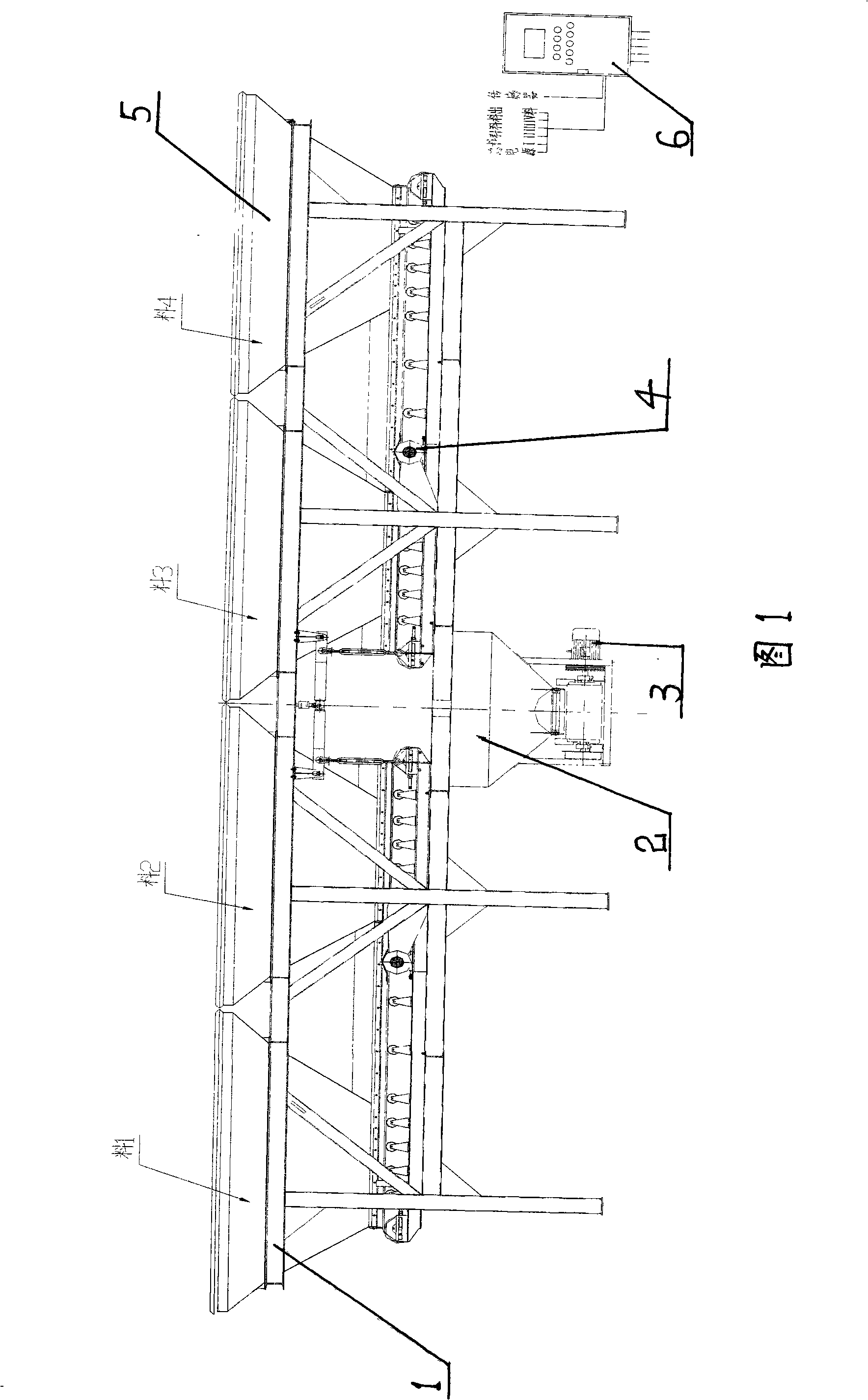

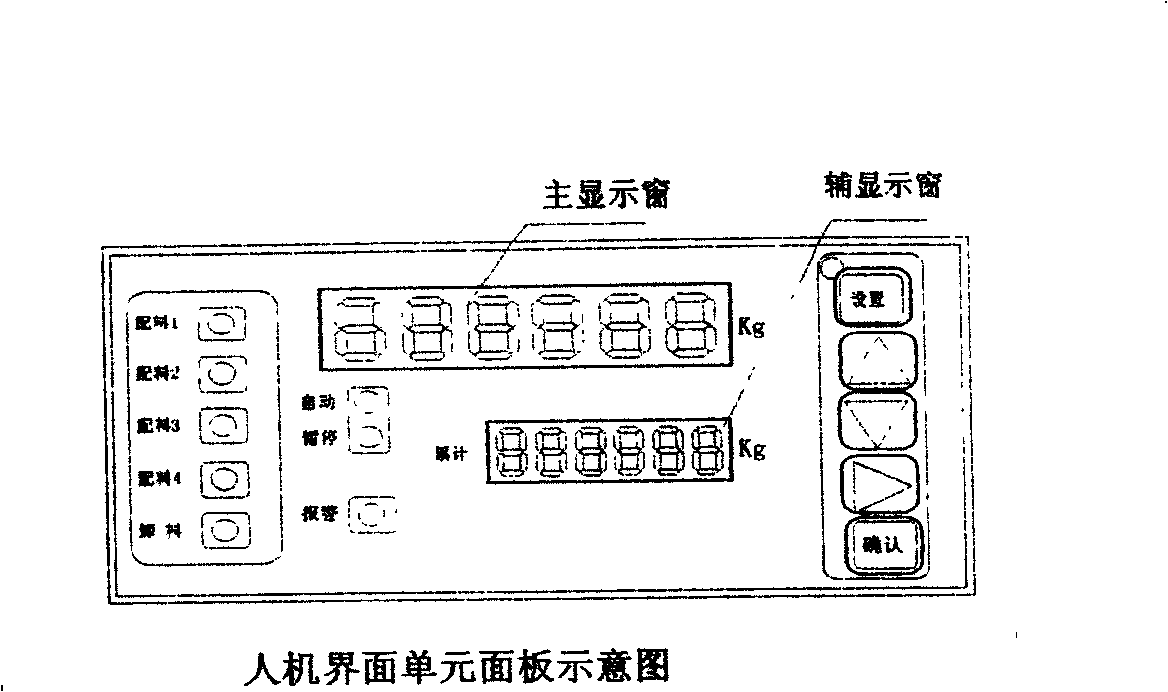

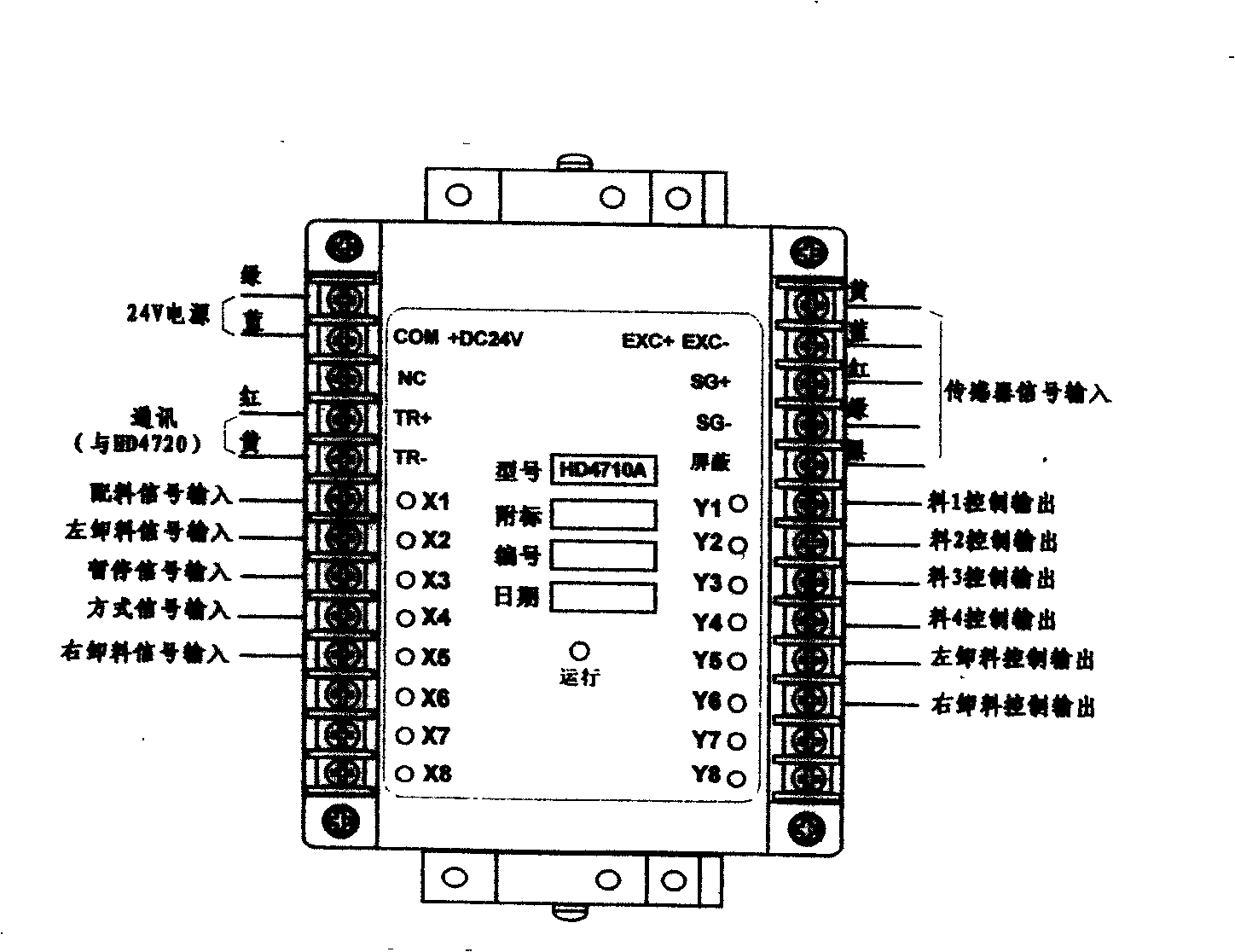

[0021]Embodiment: a batching machine with a batching control system, a number of hoppers 5 with a batching motor 4 are arranged on the body 1, and a weighing hopper 2 with a discharge motor 3 is characterized in that the batching controller is controlled and connected by each motor composed of a strong electric circuit. Among them, the batching controller mainly includes HD4720 display module and HD4710 measurement control module, HD4710 and HD4720 modules are connected through TR+ and TR- ports, and the load cell is connected with HD4710 module through shielded wire RVVP-0.5×4, shielded wire and sensor use plug JT1 is connected with the socket JZ1, the remote controller is connected with the HD4710 module with the plug JT2 and the socket JZ2, and the HD4720 module is connected with the manual mode buttons AN4, AN5, AN6, AN7, AN8 through the switch S, and the buttons AN4~AN8 are respectively passed through the relay 1J, 2J, 3J, 4J, 5J are connected to the contactors 1K, 2K, 3K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com