Calibration method for batching precision of batching machine, batching machine and computer equipment

A calibration method and batching machine technology, applied in complex mathematical operations, special data processing applications, and other database retrieval, etc., can solve problems such as inconvenient use, low batching accuracy of batching machines, and failure to satisfy users, so as to meet the needs of use, The effect of improving the accuracy of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0040] As in the background technology, the size of the solid particles and the gap between the solid particles will change as time accumulates and the solid powder is exposed to moisture or after standing for a period of time, which will result in lower batching accuracy of the batching machine and cannot satisfy users. needs, it is not convenient for users to use.

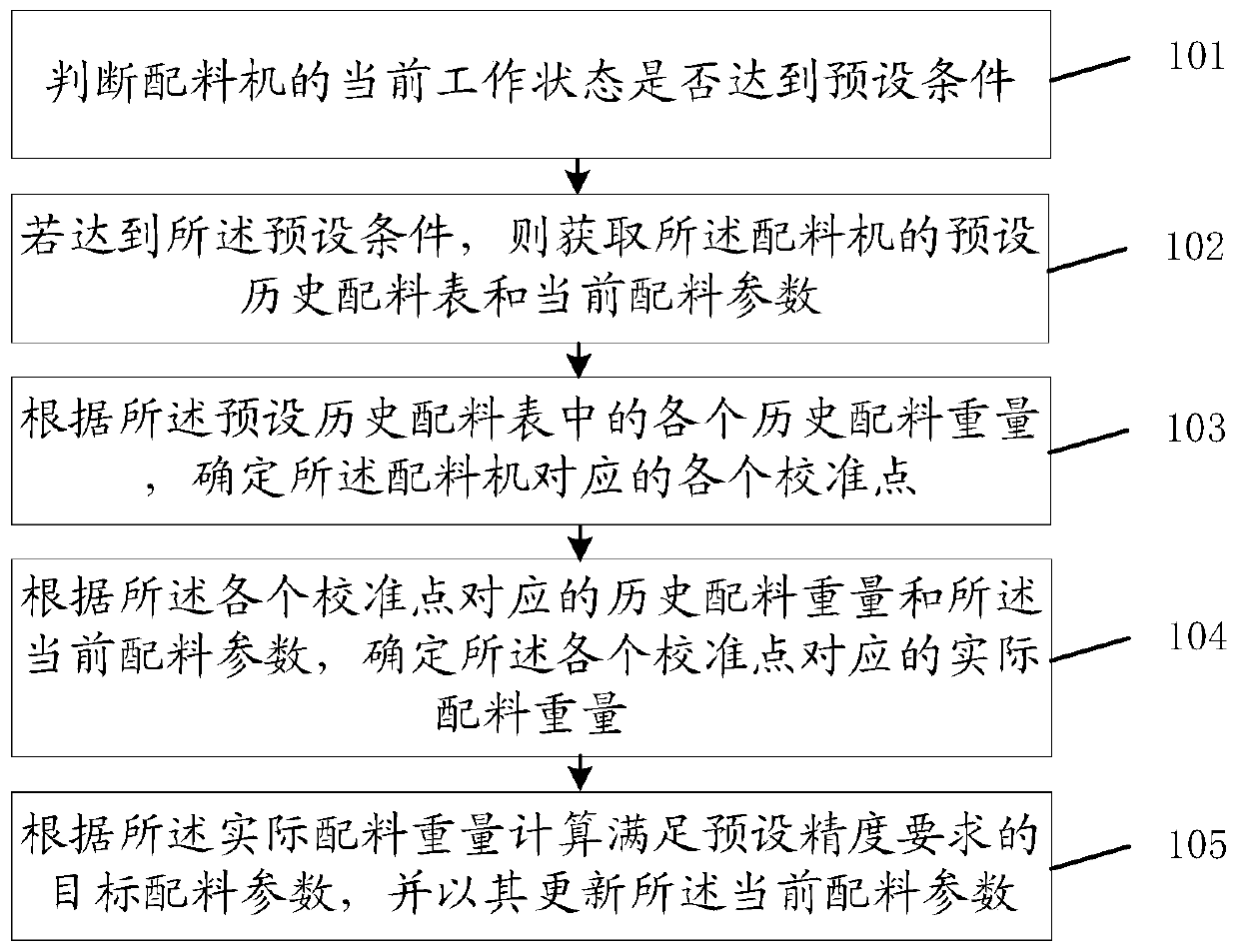

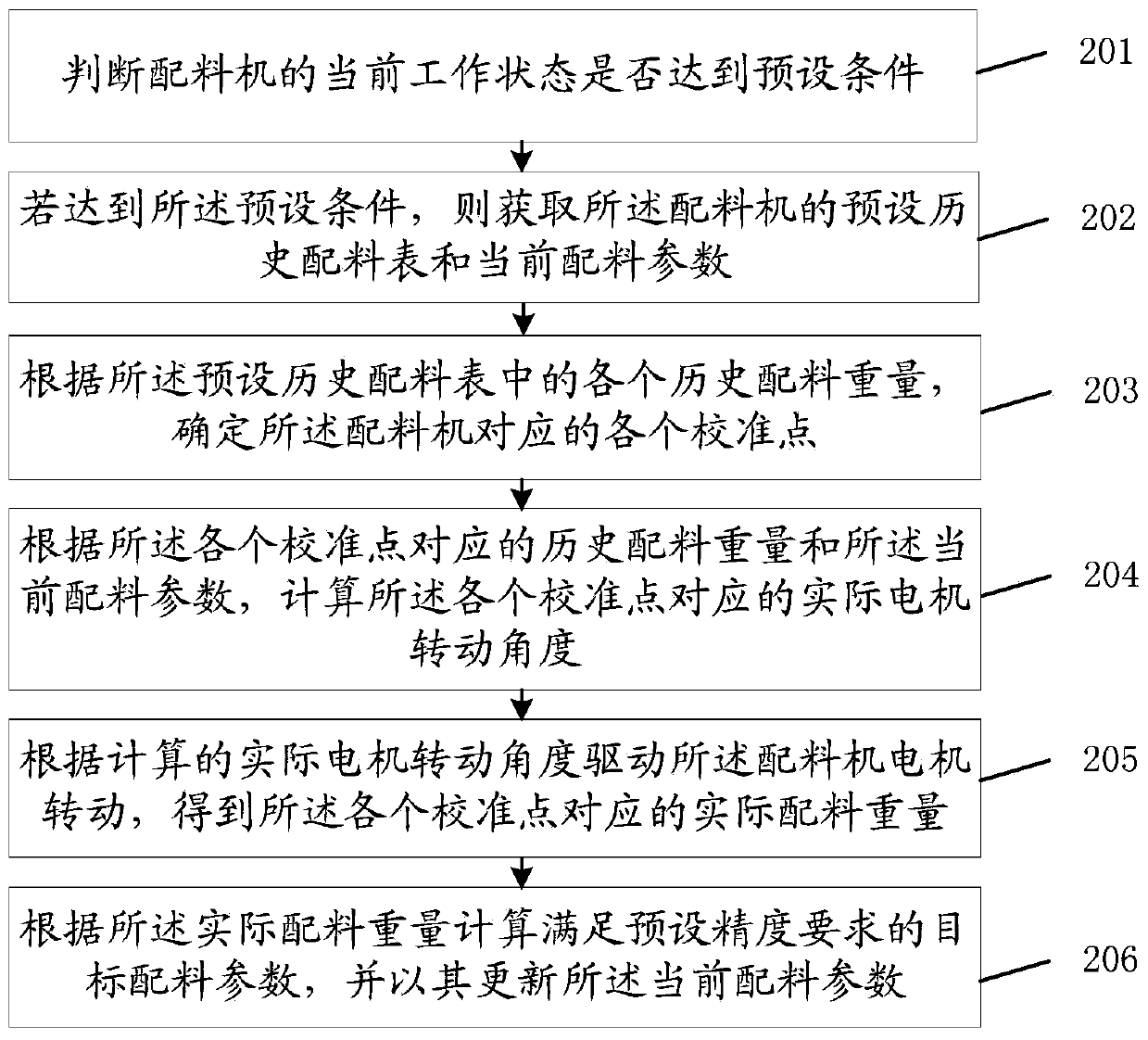

[0041] In order to solve the above problems, an embodiment of the present invention provides a method for calibrating the batching accuracy of the batching machine, such as figure 1 As shown, the method includes:

[0042] 101. Judging whether the current working state of the batching machine meets the preset condition.

[0043] For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com