Material automatic conveying, batching, metering and packaging system

An automatic conveying and packaging system technology, which is applied in the fields of metering, packaging systems, batching, and automatic material conveying. It can solve the problems of difficult environmental protection, inconvenience and easy reconstruction, and large space required to achieve compact structure, improvement of large footprint, and The effect of high weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

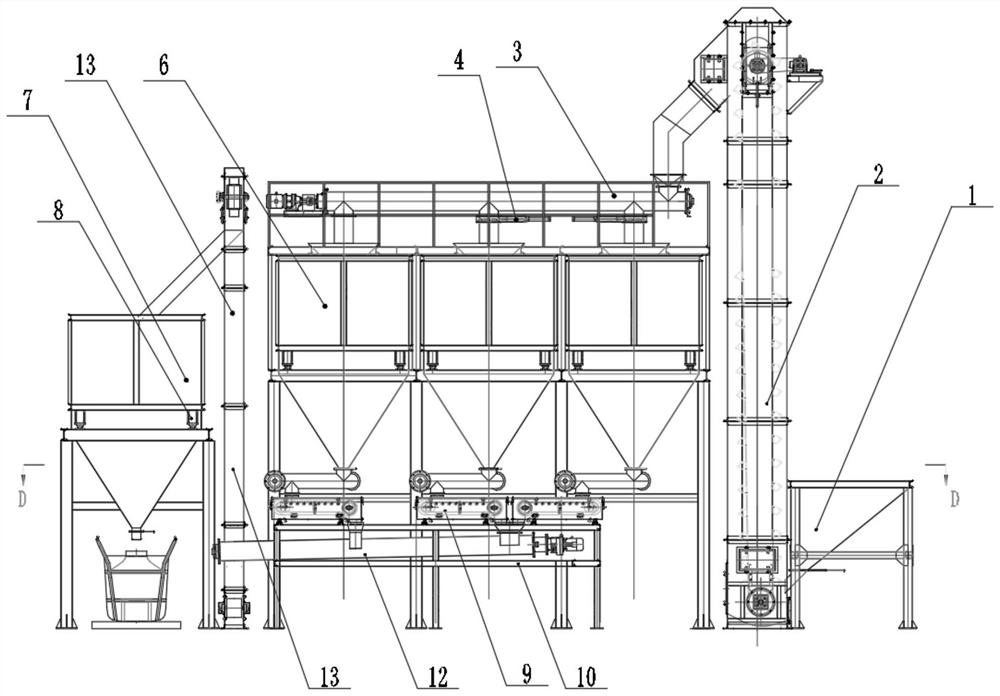

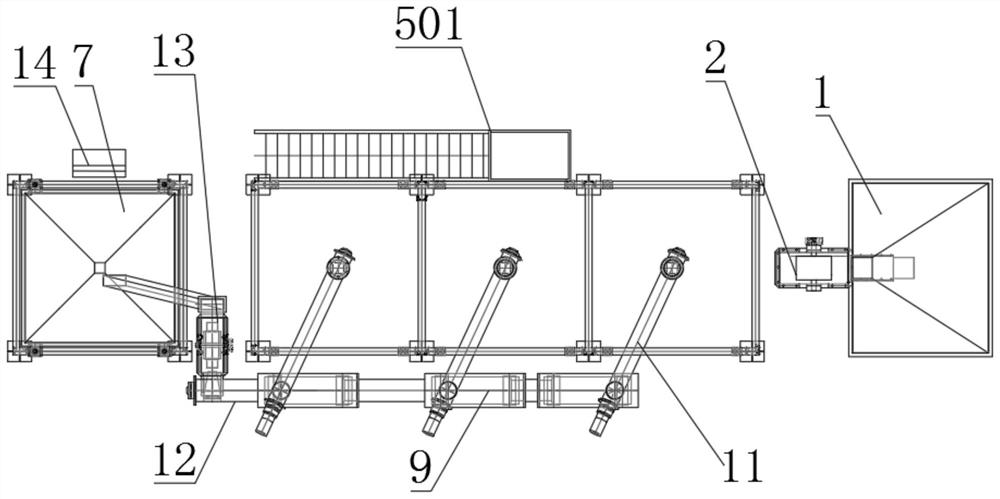

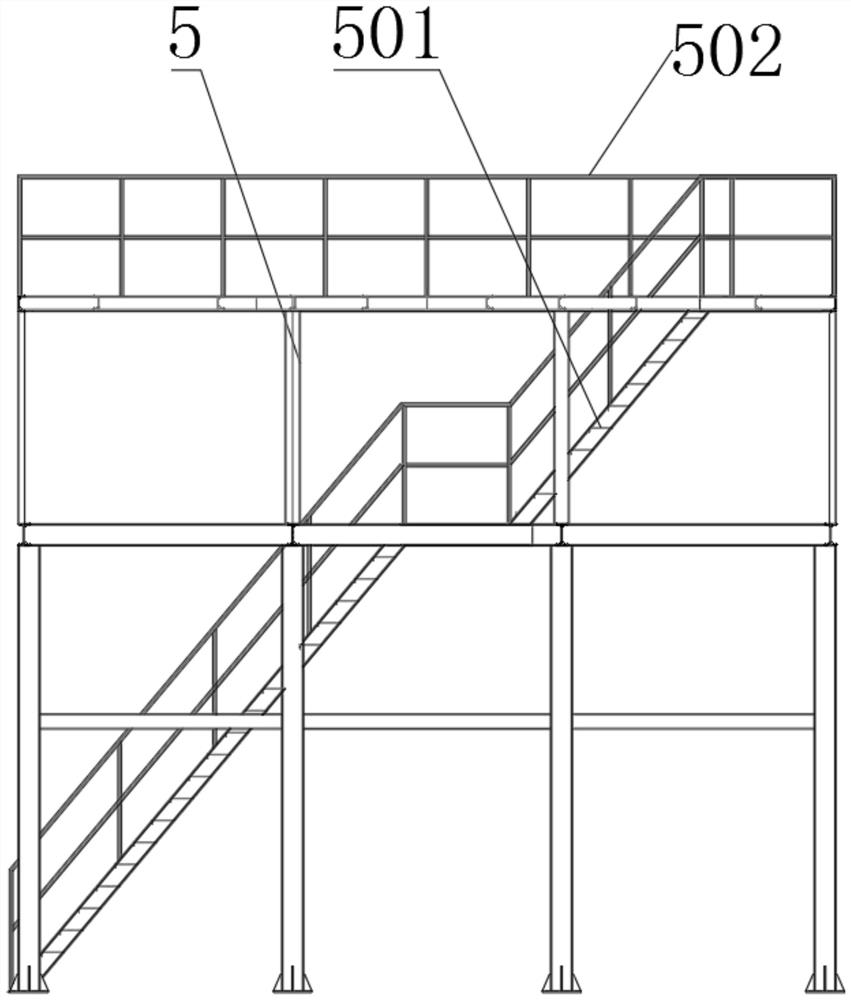

[0032] Such as Figure 1 to Figure 6 As shown, a specific embodiment of a material automatic conveying, batching, metering, and packaging system described in the present invention includes: a tubular screw conveyor 3, a silo platform 5, a square batching silo 6, and a square storage silo 7. Electronic belt scale 9, bin bottom frequency conversion screw feeder 11, mixing and stirring screw conveyor 12 and electrical microcomputer control console 14, the tubular screw conveyor 3 is connected with a first bucket type conveyor for feeding Elevator 2, a storage funnel 1 for adding materials is installed at the lower end of the first bucket elevator 2, and several square batching bins are installed below the tubular screw conveyor 3 6. A pneumatic valve 4 for on-off control is installed at the connection between the tubular screw conveyor 3 and the square batching bin 6, and the bin for discharging is installed under the square batching bin 6 Bottom frequency conversion screw feede...

Embodiment 2

[0040] Such as Figure 1 to Figure 6 As shown, a specific embodiment of a material automatic conveying, batching, metering, and packaging system described in the present invention includes: a tubular screw conveyor 3, a silo platform 5, a square batching silo 6, and a square storage silo 7. Electronic belt scale 9, bin bottom frequency conversion screw feeder 11, mixing and stirring screw conveyor 12 and electrical microcomputer control console 14, the tubular screw conveyor 3 is connected with a first bucket type conveyor for feeding Elevator 2, a storage funnel 1 for adding materials is installed at the lower end of the first bucket elevator 2, and several square batching bins are installed below the tubular screw conveyor 3 6. A pneumatic valve 4 for on-off control is installed at the connection between the tubular screw conveyor 3 and the square batching bin 6, and the bin for discharging is installed under the square batching bin 6 Bottom frequency conversion screw feede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com