Patents

Literature

52results about How to "Improve batching accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

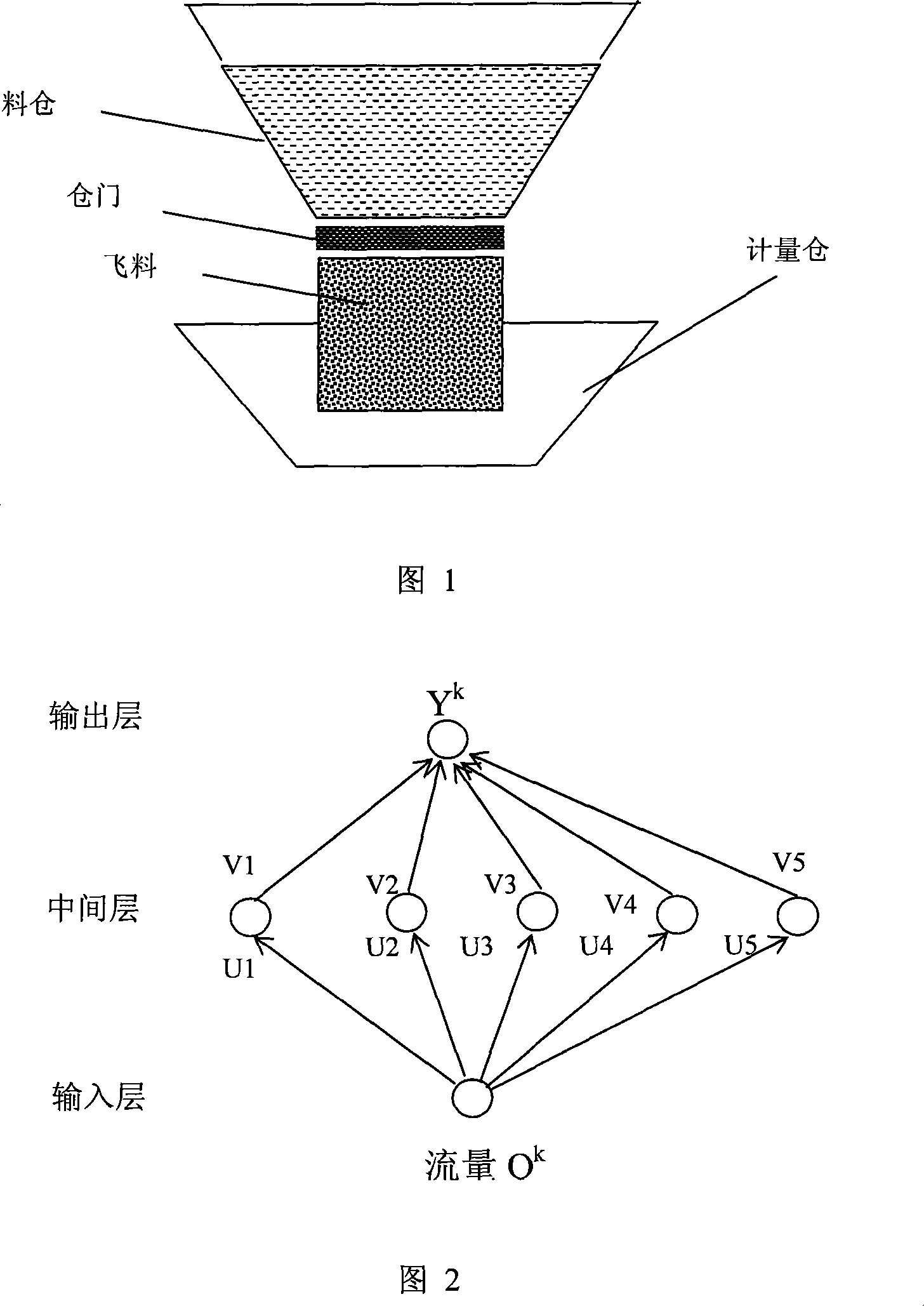

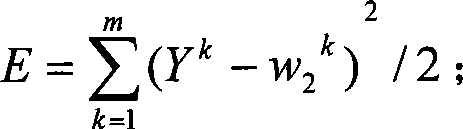

Robust control method for asphalt mixing plant batching error

InactiveCN101226377AImprove batching accuracyImprove control effectMixing operation control apparatusRoads maintainenceProcess dynamicsArtificial neural network model

The invention discloses a robust control method of burden error of pitch concrete stirring device, which comprises first building an input / output artificial neutral network model of three-layer structure, while the input layer has one neuron, the middle layer has five neurons and the output layer has one neuron, processing dynamic prediction and learning. The invention builds the non-linear model of flux and fly ash amount to be compared with a linear model of fixed parameters via continuous learning and adjustment, to adapt the change of external parameters, thereby effectively controlling the burden error of pitch mixture stirring device, reaching +-2% burden error as maximum and improving the burden accuracy of pitch mixture stirring device.

Owner:NANJING UNIV OF SCI & TECH +1

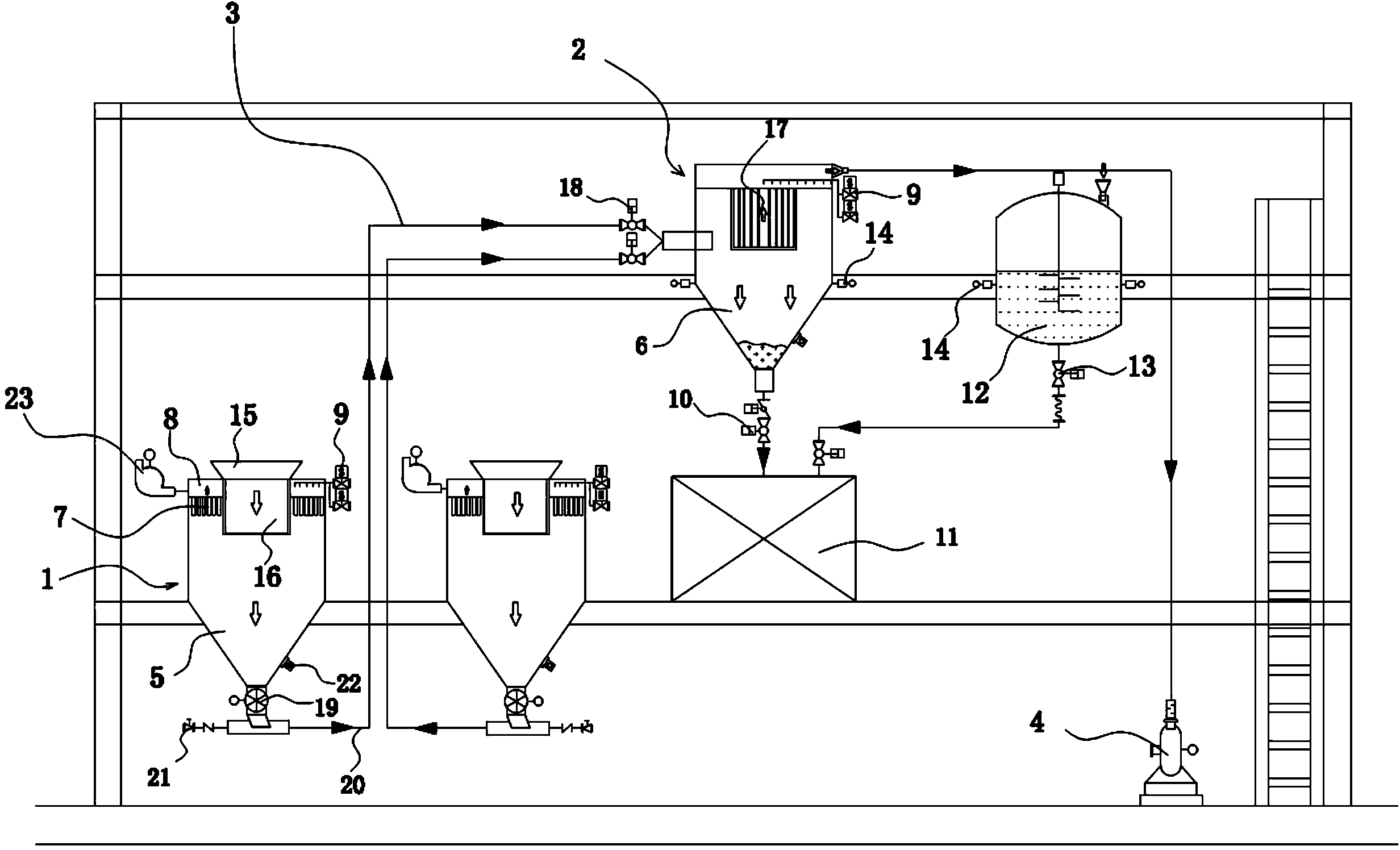

Automatic batching system

ActiveCN104028131AImprove batching accuracyIncrease productivityMixing methodsVacuum extractorBatch machine

An automatic batching system comprises a solid material conveying system and a liquid material conveying system; the solid material conveying system comprises a batching machine, a feeding machine and a vacuum conveying device; the vacuum conveying device comprises a vacuum conveying pipe and a vacuum extractor, a bin discharging hole of the batching machine is connected with a bin feeding hole of the feeding machine through a vacuum conveying pipe, a bin of the feeding machine is a closed cavity, the upper portion of the bin is spaced through a dedusting filter to form a vacuumized channel, and the vacuumized channel is communicated with the vacuum extractor through the vacuum conveying pipe; a bin discharging hole of the feeding machine is connected with a mixer feeding hole through a pneumatic butterfly valve; the liquid material conveying system comprises a liquid stirring kettle; a discharging hole of the stirring kettle is provided with an automatic ball valve and is connected with the mixer feeding hole through the automatic ball valve; the powder feeding machine and the stirring kettle are respectively provided with a weighing sensor. The full-automatic batching system is adopted, the automatic whole batching process and continuous batching are achieved, and the batching precision of raw materials is improved.

Owner:桐乡市京工树脂有限公司

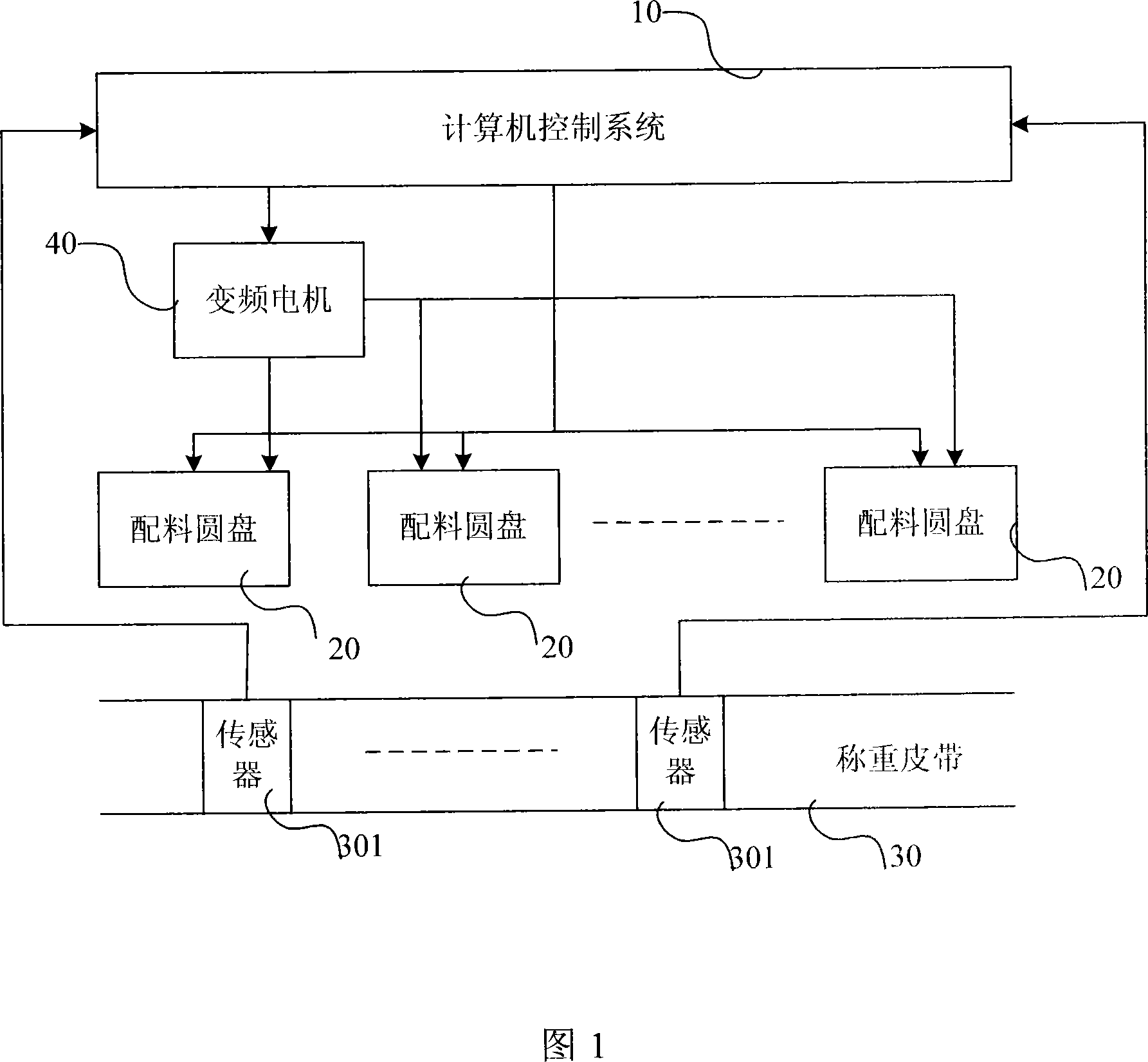

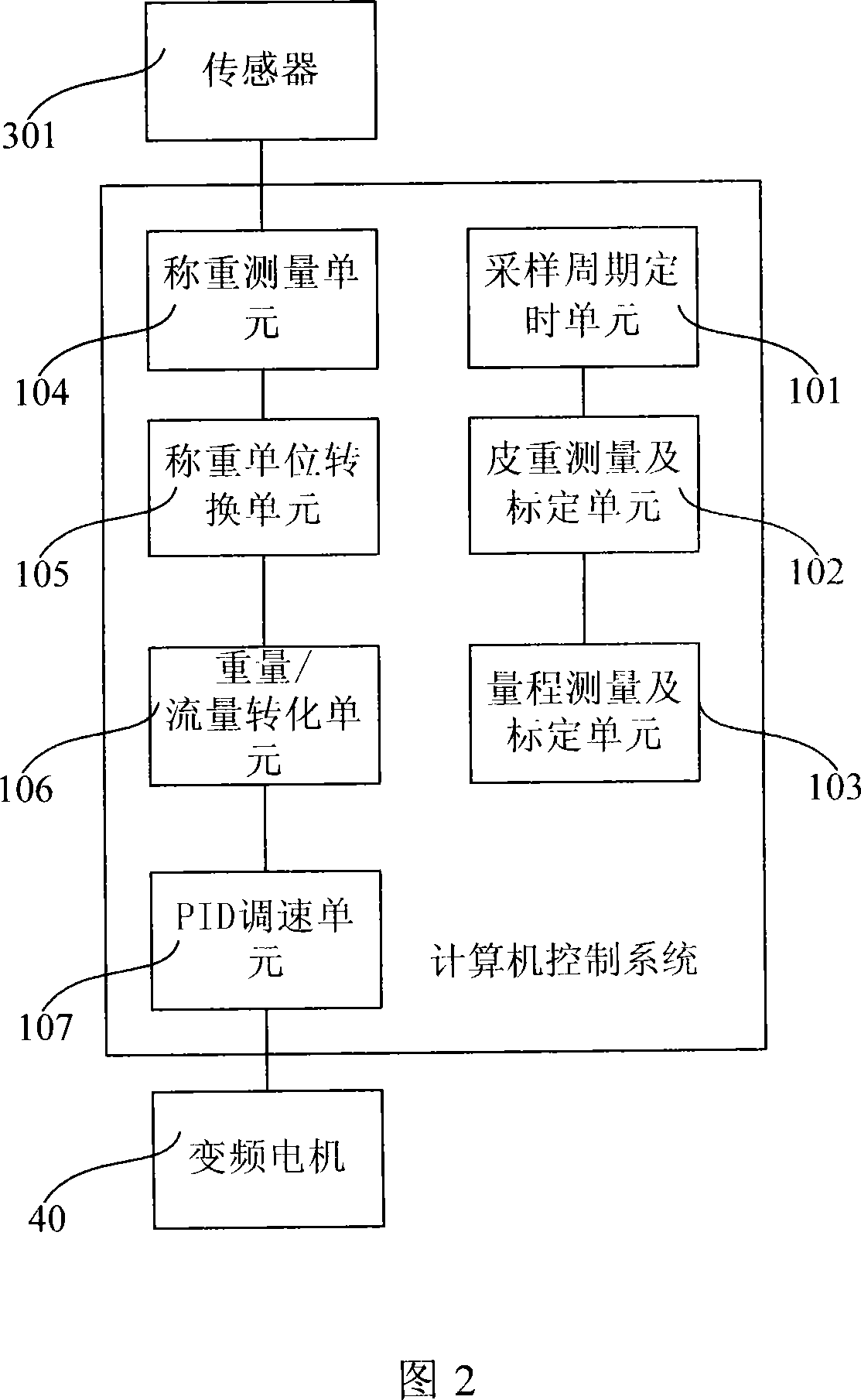

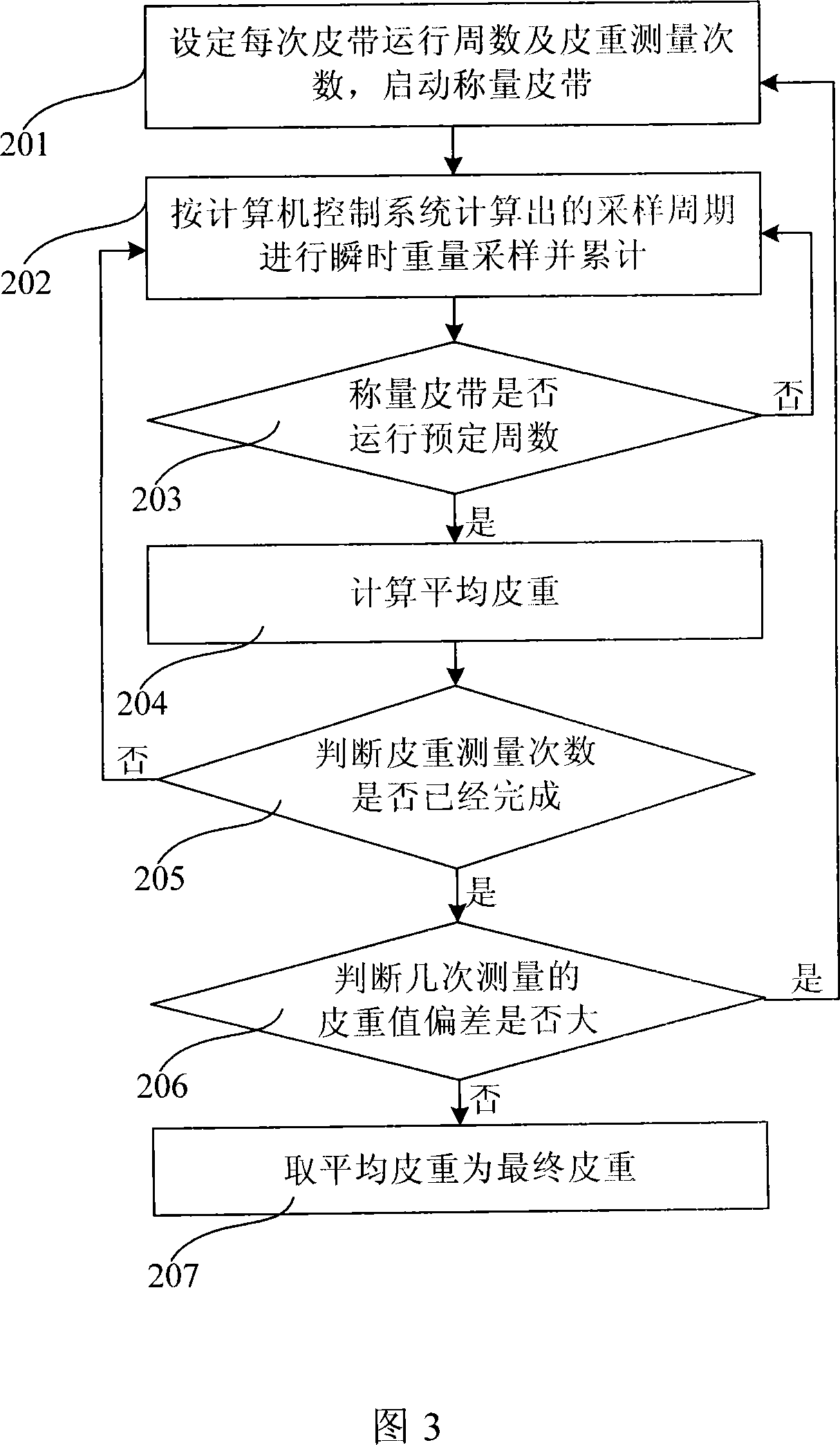

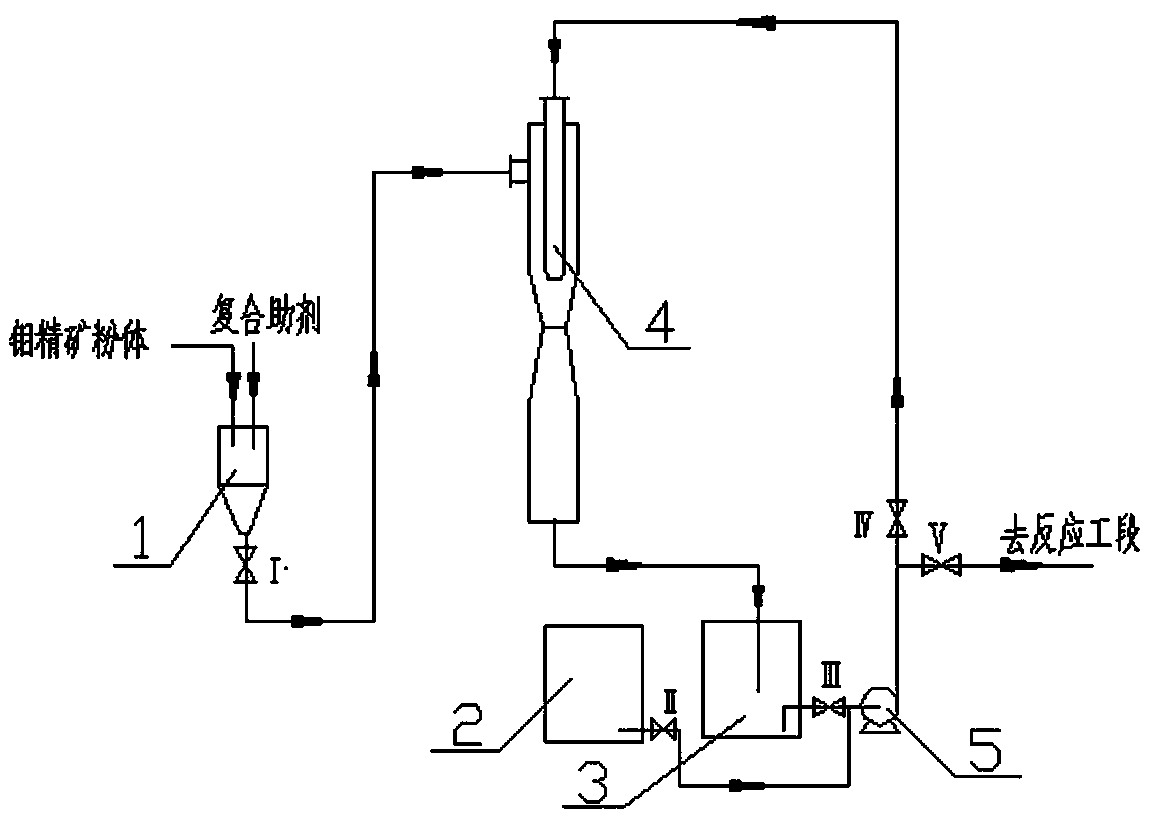

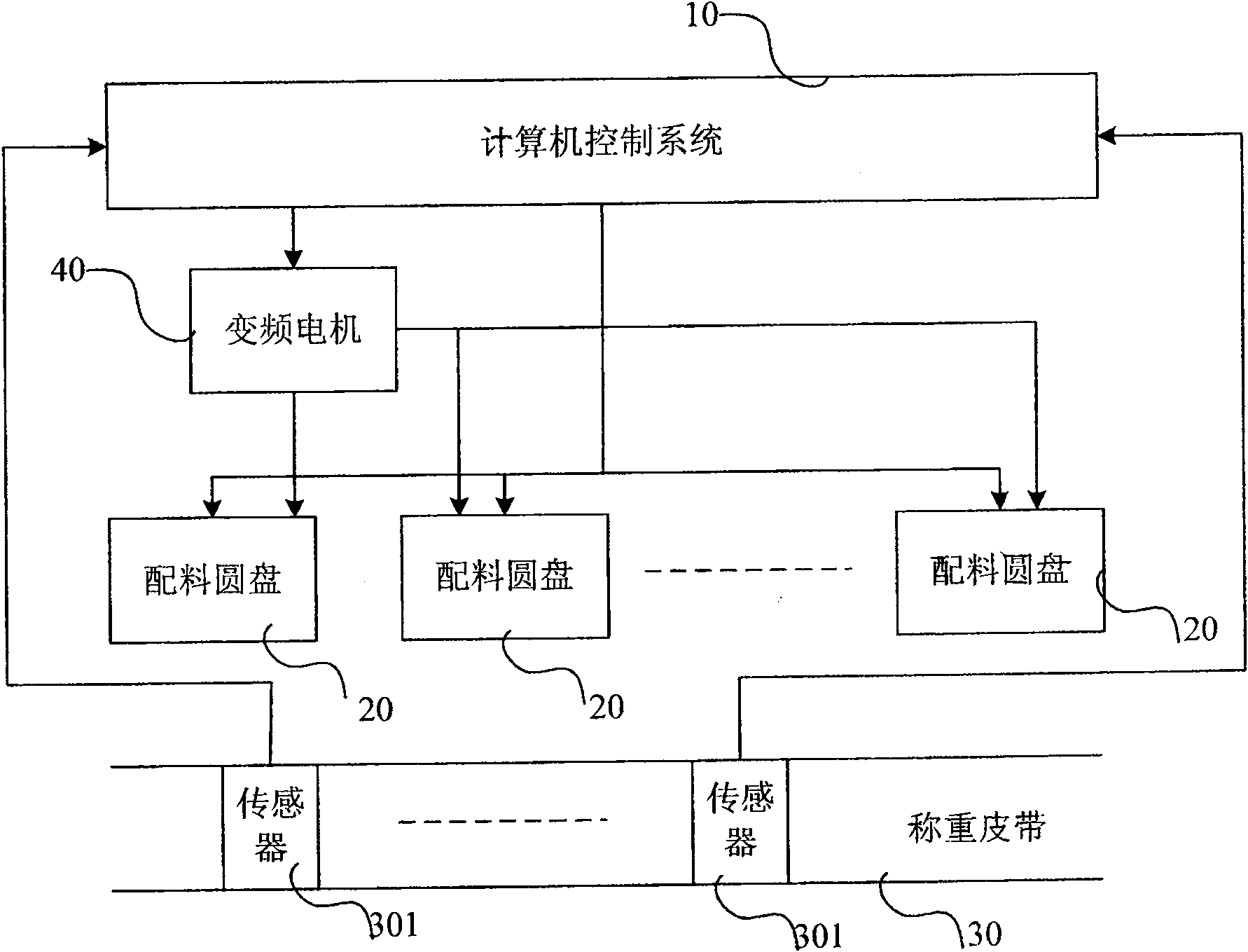

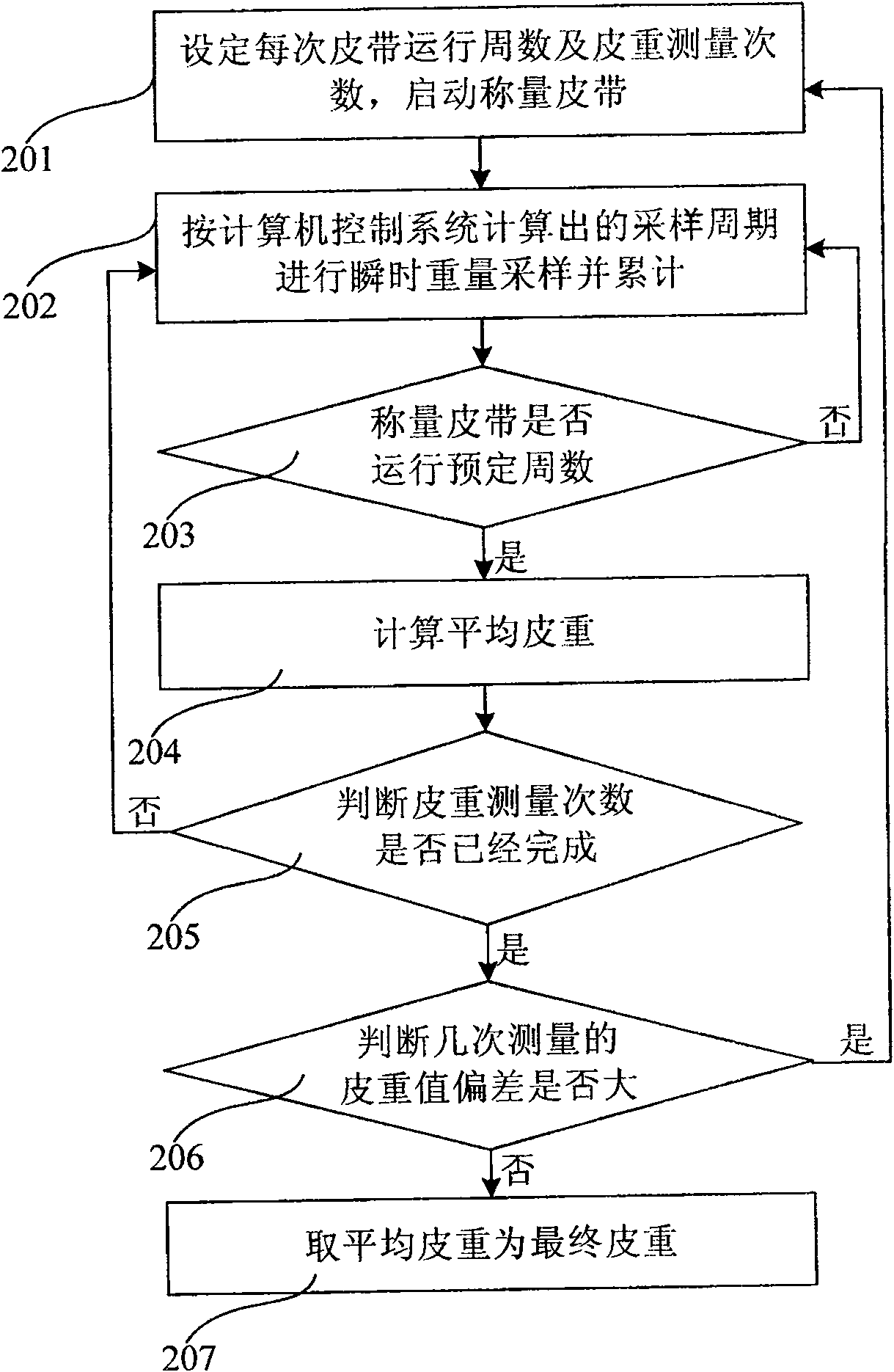

Dynamic batching digital control system and method

InactiveCN101249396AReduce construction costsAdvanced and reasonable digital control technologyMixer accessoriesRatio controlFrequency changerCircular disc

The invention discloses a dynamic dosing digital control system, which comprises a computer control system used for determining the total flow based on production plans, generating charger sheets automatically dosing ingredients, converting alternate current into direct current and obtaining the output frequency of a transducer; a dosing circular disc communicating and connected with the computer control system, which is used for giving ingredient flow according to the charger sheets; a weighing sensor arranged on a weighing belt and communicating with the computer control system, which is used for weighing the weight of ore dosed by the dosing circular disc and feeding the detected data back to the computer control system; a frequency conversion motor connected with and communicating with the computer control system and the dosing circular disc, which is used for regulating the speed according to the output frequency of the transducer obtained by the computer control system based on the detected data, and further regulating the rotation speed of the dosing circular disk. The invention further discloses a dynamic dosing digital control method. By adopting the control system and the control method, the construction cost and usage and maintenance cost are reduced, and the dosing precision is improved.

Owner:武钢集团有限公司

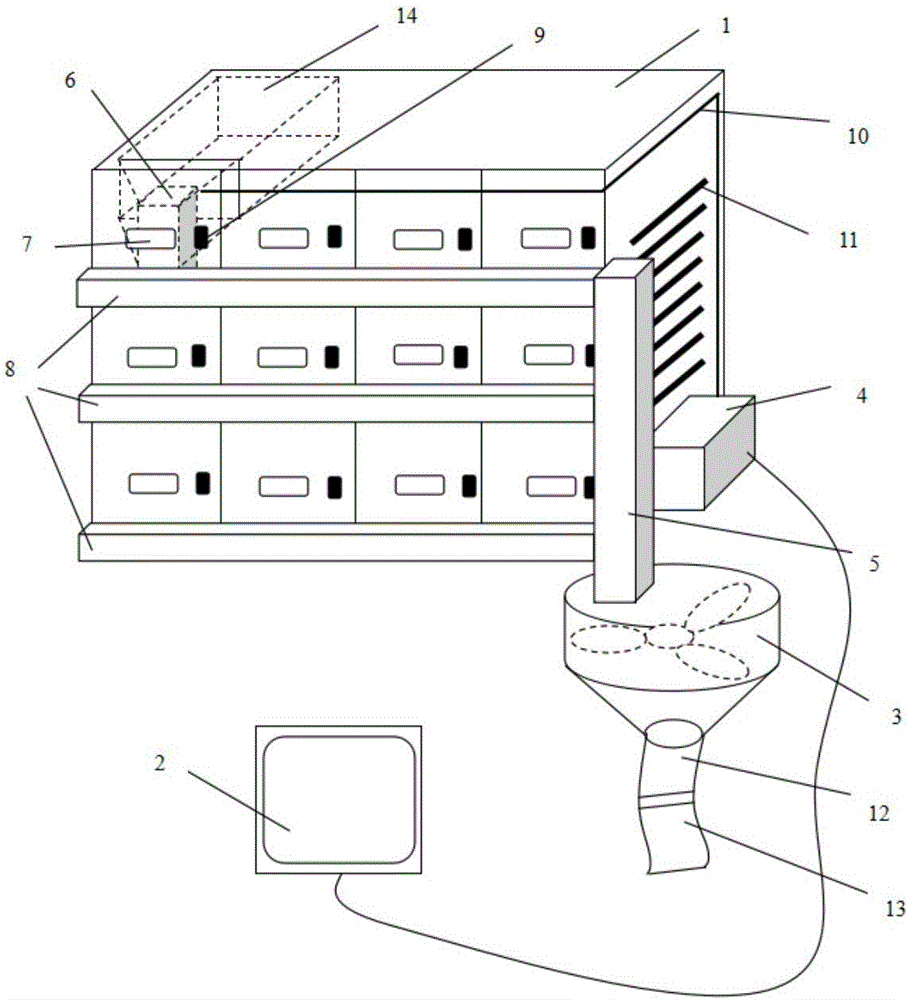

Intelligent automated traditional Chinese herbal medicine dispensing system

ActiveCN106709258AReduce dispensing timeReduce waiting time in lineRotating receptacle mixersTransportation and packagingControl systemMedical prescription

The invention discloses an intelligent automated traditional Chinese herbal medicine dispensing system. The system comprises a medicine containing system, a medicine extraction system and a control system. Starting from the prescription made by a doctor, the QR code identification technology and the computer input technology are used for the two-way information collection, a central processor of the control device is used to make the analysis to drive a medicine discharge switch and a weighing device in the medicine extraction device to generate a series of work responses, accumulation and instantaneous flow statistic are done, at last the medicine is mixed and then packed, the medicine discharge error is reduced, the mixing precision and the efficiency is enhanced. According to the intelligent automated traditional Chinese herbal medicine dispensing system, after the doctor gives out the prescription, what remains in the procedure is only pushing a button once, thus the medicine extraction time spent by the medical personnel is shortened, the queuing time of the patients is shortened, the cost is low, and therefore the system is applicable to the promotion and use.

Owner:WUTONG AROMA CHEM CO LTD

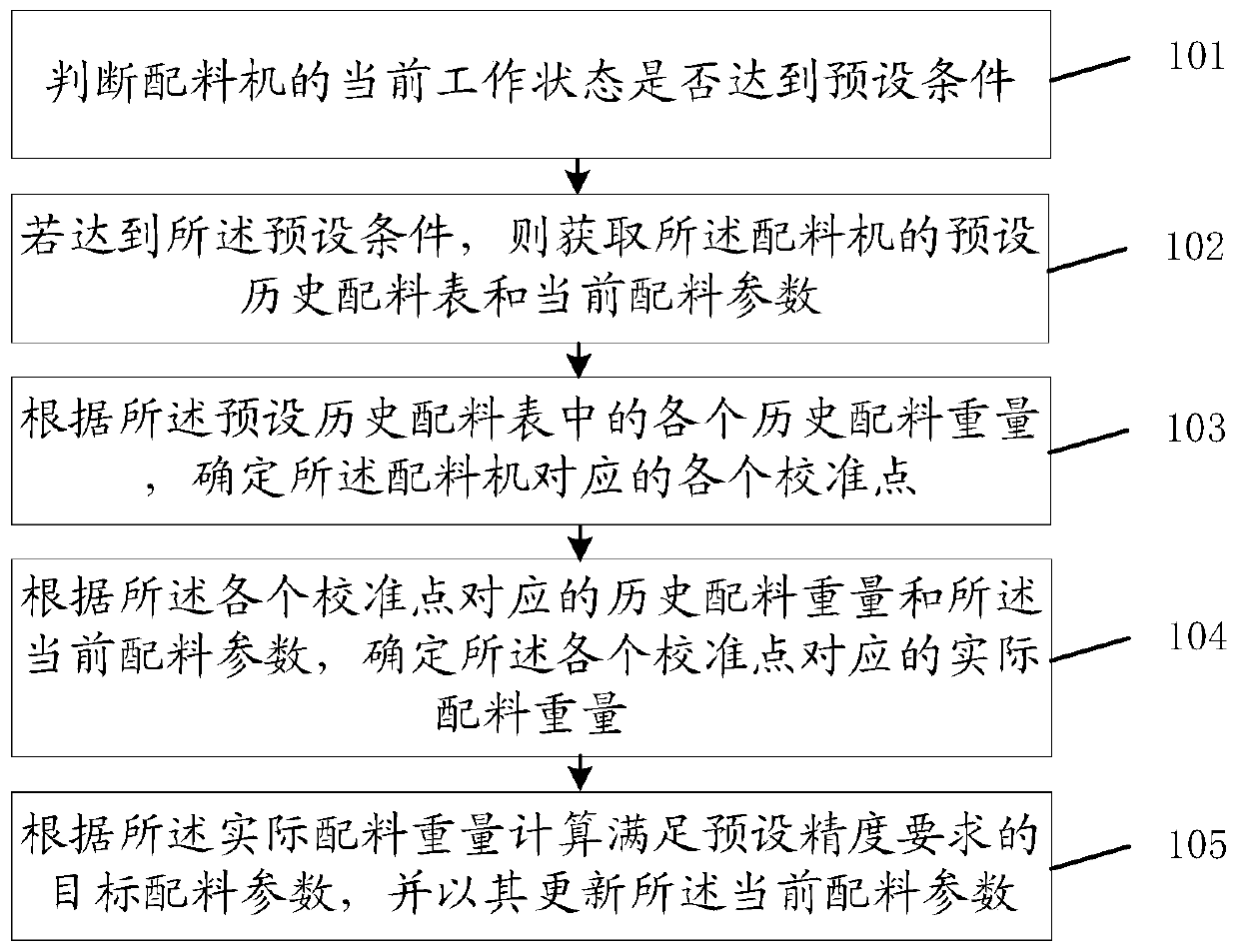

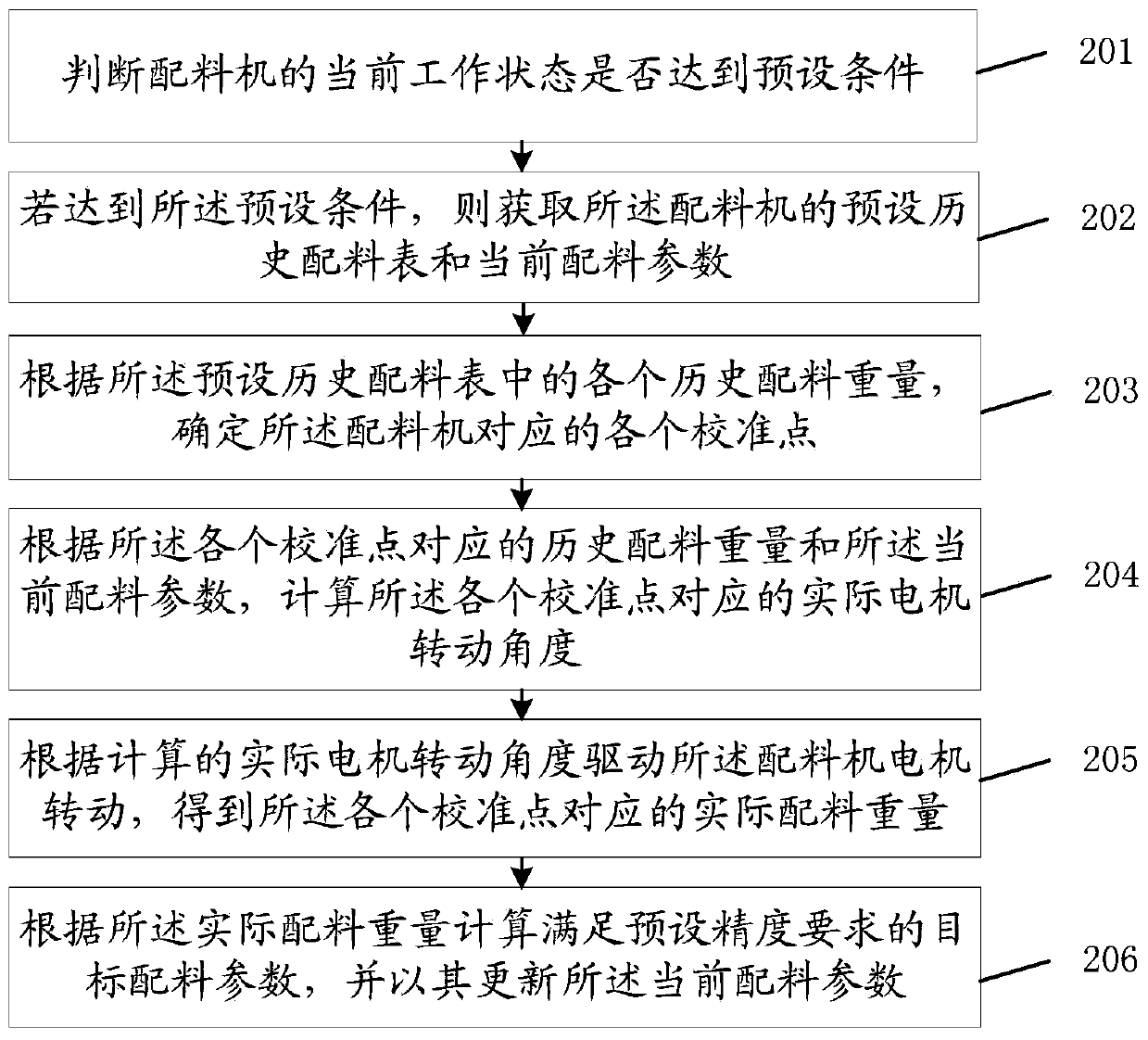

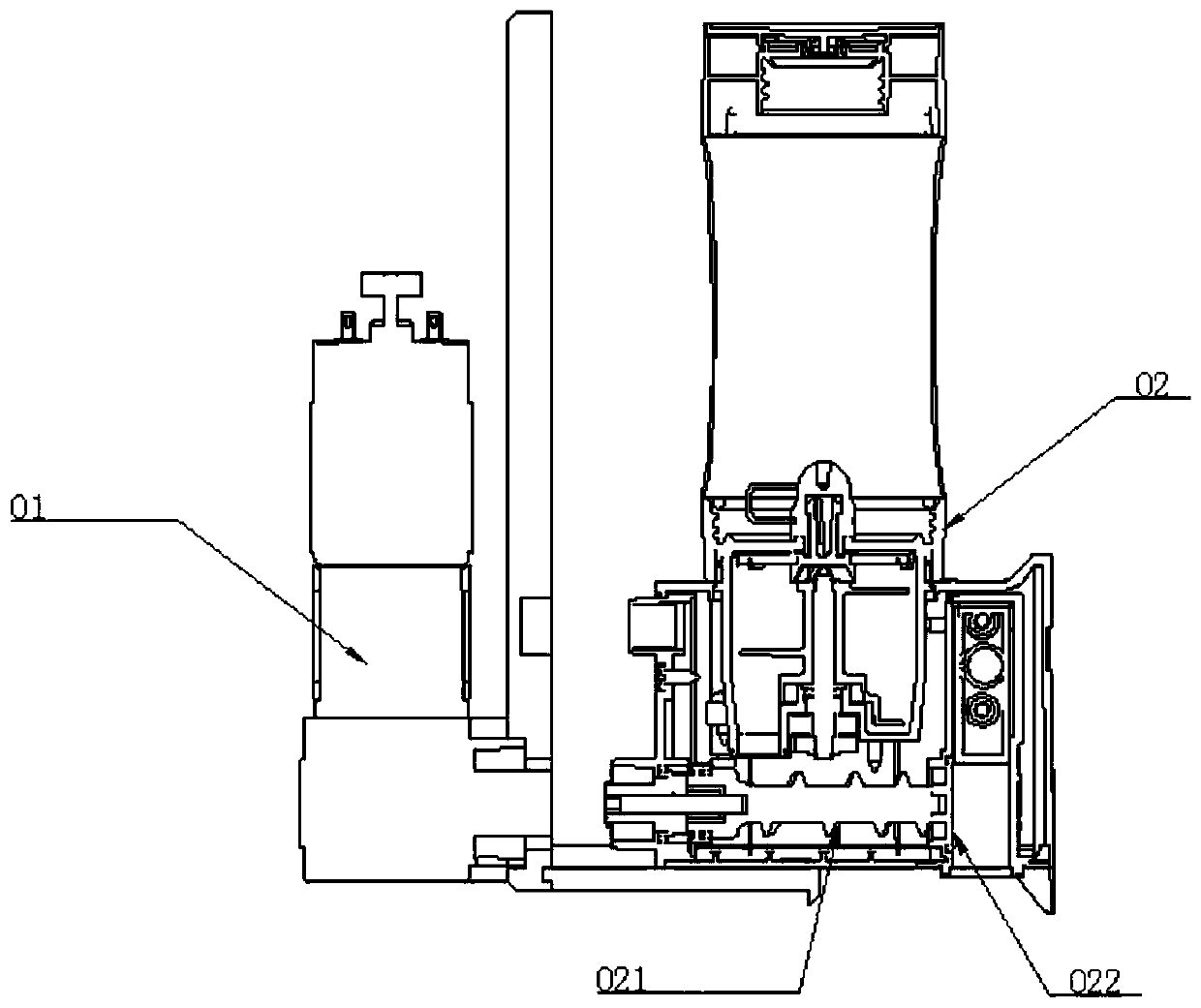

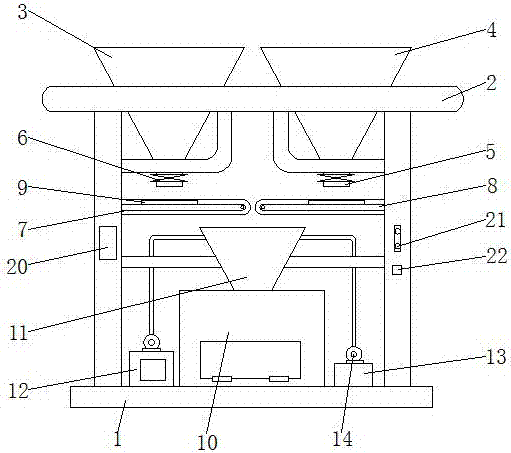

Calibration method for batching precision of batching machine, batching machine and computer equipment

PendingCN111581591AImprove batching accuracyMeet the needs of useCooking vesselsOther databases queryingSoftware engineeringBatch machine

The invention discloses a calibration method for batching precision of a batching machine, the batching machine and computer equipment, relates to the field of intelligent control, and mainly aims tocalibrate the batching precision of the batching machine in time, improve the batching precision of the batching machine and meet the requirements of users. The method comprises the following steps: judging whether the current working state of the batching machine reaches a preset condition or not; if the preset condition is met, obtaining a preset historical batching table and a current batchingparameter of the batching machine; determining each calibration point corresponding to the batching machine according to each historical batching weight in the preset historical batching table; determining the actual batching weight corresponding to each calibration point according to the historical batching weight corresponding to each calibration point and the current batching parameter; and according to the actual batching weight, calculating a target batching parameter meeting a preset precision requirement, and updating the current batching parameter by using the target batching parameter. The method is suitable for calibrating the batching precision of the batching machine.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Precise preparing device for food processing and production

ActiveCN107136548AImprove batching accuracyConvenient and accurate ingredientsMachines/enginesFood shapingEngineeringFood processing

The invention discloses a precise preparing device for food processing and production. The precise preparing device comprises a base, wherein a support frame is fixedly connected to the top of the base, a first feed hopper and a second feed hopper are sequentially arranged at the top of the support frame from left to right, material leakage pipes separately communicate with the bottom of the first feed hopper and the bottom of the second feed hopper, and an electromagnetic material leakage unit is arranged in the corresponding material leakage pipe; and a first electric conveyor belt is arranged on one side of the inner wall of the support frame and is located at the bottom of the first feed hopper. The invention relates to the technical field of food preparing facility. The precise preparing device for food processing and production can realize precise measurement on the food raw materials, so that the preparing precision of the food preparing device is greatly improved; a plurality of measurement funnels do not need to be mounted on the preparing equipment to measure and compound different food raw materials, so that personnel can precisely prepare the foods conveniently, and the preparing cost of the foods is saved.

Owner:HUNAN UNIV OF ARTS & SCI

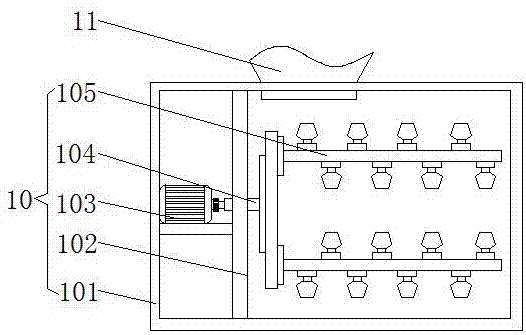

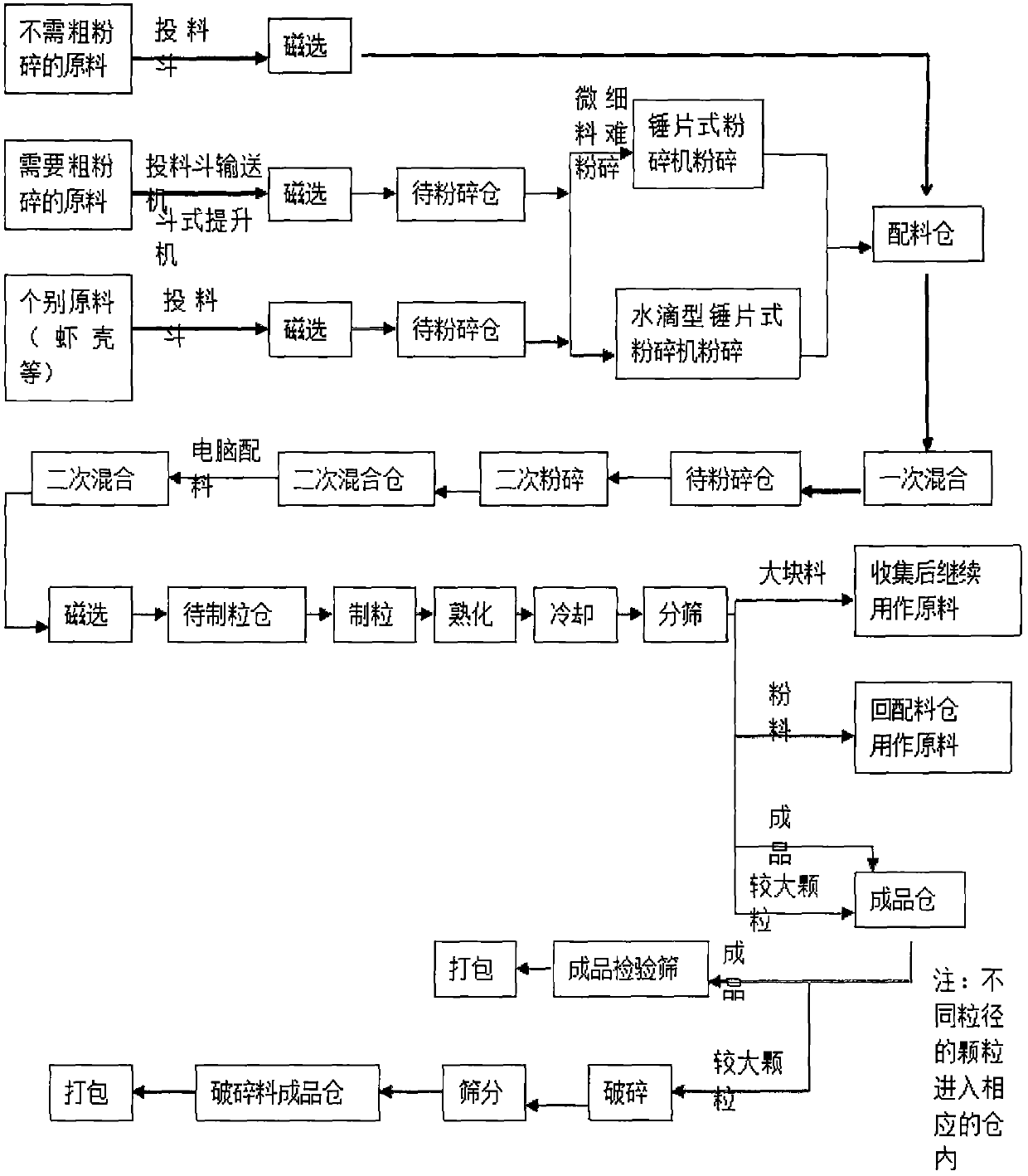

Production process method of aquatic feed

PendingCN110859248ASave construction investmentEasy to operateFeeding-stuffFood processingProcess engineeringBiology

The invention, which relates to the technical field of aquatic feed production, discloses a production process method of aquatic feed. The method comprises the following steps of raw material receiving and primary coarse crushing, primary batching and mixing, secondary crushing and secondary batching and mixing, granulation section execution, fish feed finished product treatment and packaging, shrimp feed finished product treatment and packaging, granule puffing section and finished product treatment. The production process method has the beneficial effects: the operation is convenient; various raw material varieties can be involved; the batching precision is high, the crushing fineness is fine, and the mixing uniformity requirement is high; the technological process can be simplified; with full utilization of functions of equipment, unnecessary equipment investment and plant construction investment can be saved; the construction period is shortened, the yield is increased, and the production cost is lowered; and the production line process can be used for producing 8 to 10 t / h of granular fish feed, 8 to 10 t / h of granular shrimp feed and 3.5 to 4.5 t / h of high-grade puffed aquatic feed at the same time.

Owner:唐山三发普林饲料有限公司

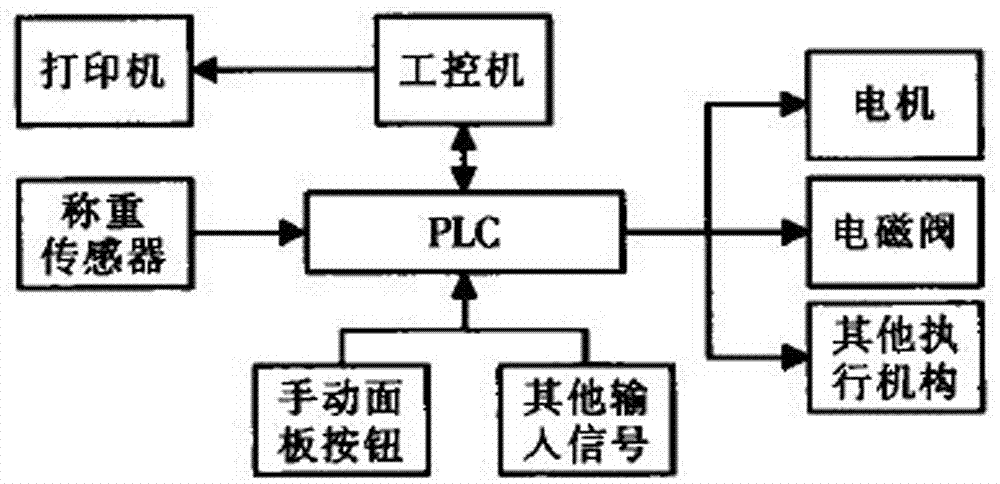

Intelligent control system for mixing plant

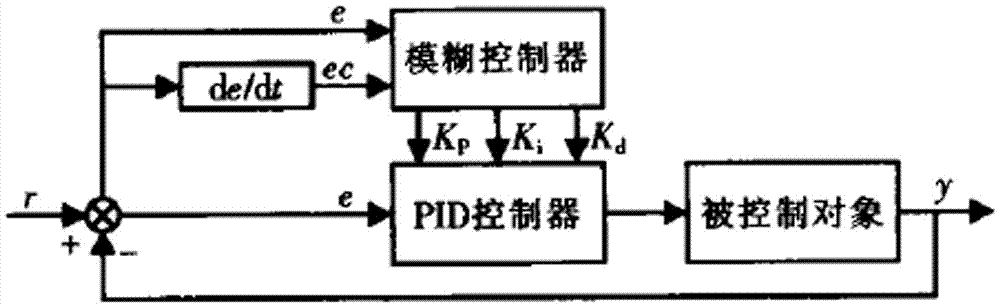

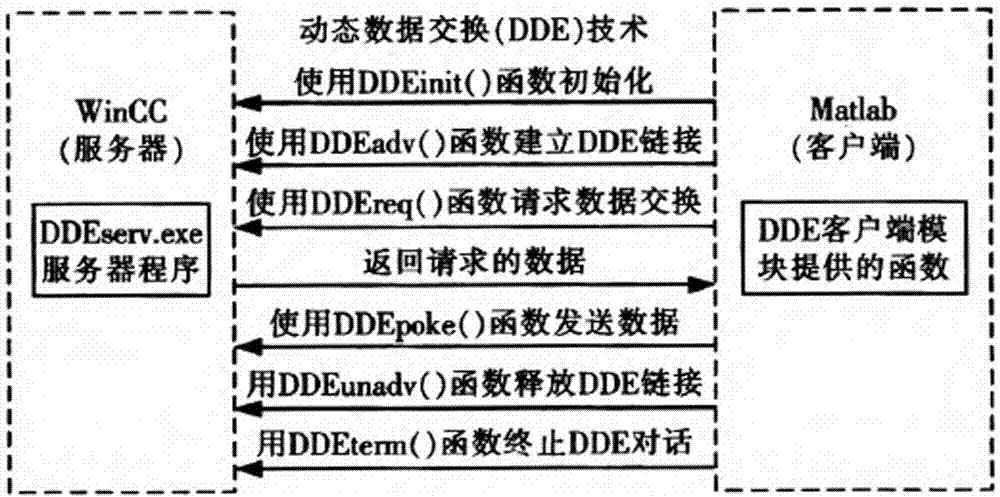

InactiveCN106863616ARealize dynamicImprove batching accuracyComputer controlSimulator controlHuman–machine interfaceAutomatic control

An intelligent control system for a mixing station is composed of a hardware system and a software system. Aiming at the production process and motion control process of the concrete mixing plant, the control mode combining upper and lower locomotive machines is adopted, and the composition principle of the system hardware, software design process and DDE communication program design method are analyzed in detail. The upper computer control system is developed with WinCC configuration monitoring software, which realizes the automatic control and data management of the mixing station site. Aiming at the problems of poor batching precision and low production efficiency, a fuzzy PID control method is proposed, and the accuracy of batching control is improved by online tuning of PID parameters. The field test shows that the intelligent control system of the mixing plant is stable and reliable. It has the advantages of low cost, friendly man-machine interface and high production efficiency, and can meet the requirements of the intelligent control system of the mixing station.

Owner:李福来

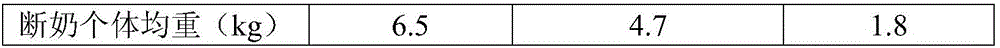

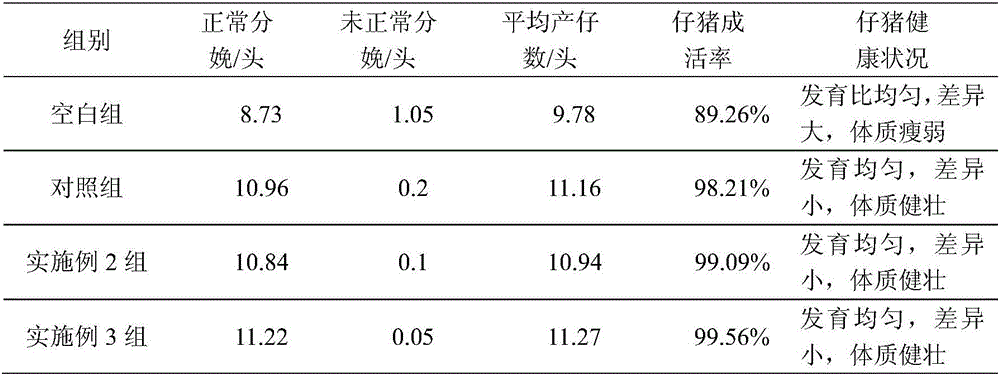

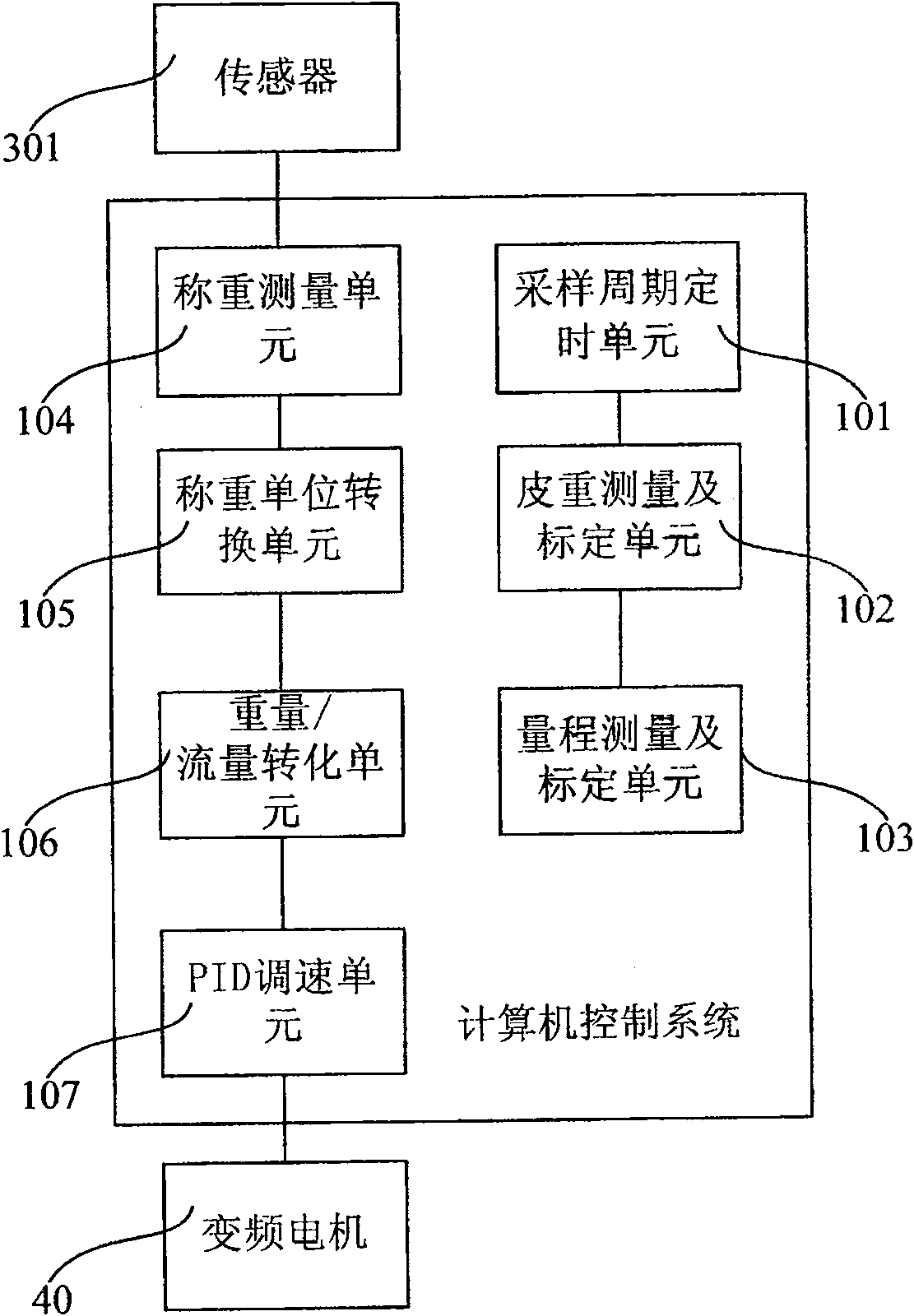

Lactating sow premixed feed for preventing and treating postpartum inflammation and preparation method thereof

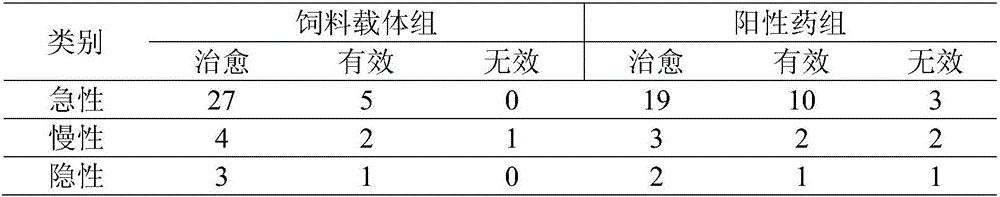

InactiveCN106578537AQuality assuranceGuaranteed stabilityAntipyreticFood processingDiseasePuerperal disorder

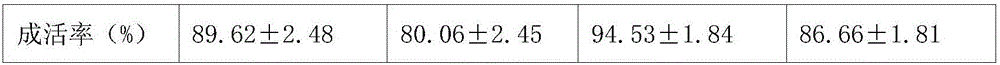

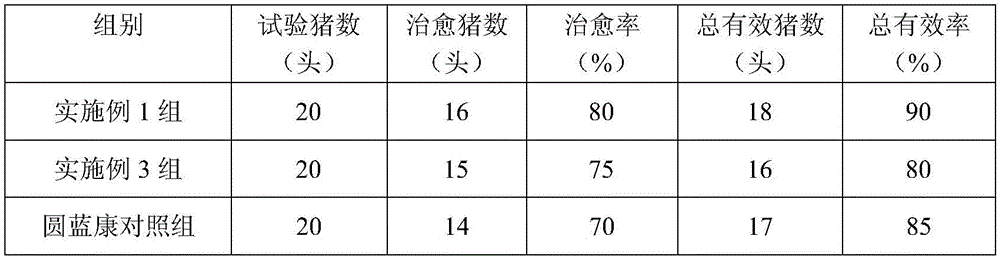

The invention relates to lactating sow premixed feed for preventing and treating postpartum inflammation and a preparation method thereof. The lactating sow premixed feed contains a nutrient additive, Chinese herbal medicine extract and a diluent. The premixed feed comprises 0.5-8% by weight of the raw medical materials and is prepared from 0.5-3 parts by weight of radix angelicae sinensis, 0.5-3 parts by weight of ligusticum wallichii, 1-4 parts by weight of herba houttuyniae and 0.5-3 parts by weight of cortex magnoliae officinalis through medicine extraction or direct crushing. The diluent is a mixture of zeolite powder and rice hull powder according to a weight ratio of 1: 1. The ingredients of the premixed feed are environmentally friendly raw materials. The used Chinese herbal medicine extract has functions of promoting blood circulation to restore menstrual flow, promoting circulation and removing dampness, clearing away heat and toxic materials, and eliminating carbuncle and expelling pus, has good treatment effects on sow postpartum hysteritis, has efficiency of 85% or more, promotes sow fast recovery, improves immunity, resists bacteria, diminishes inflammation and mainly treats postpartum diseases such as sow puerperal fever, postpartum inability to eat, hysteritis, mastitis, postpartum syndrome and lochiorrhea.

Owner:ZHONGYUEMINAN BEIJING TECH DEV CO LTD

Estrus and pregnancy promoting premixed feed for lactating sow and preparation method of estrus and pregnancy promoting premixed feed

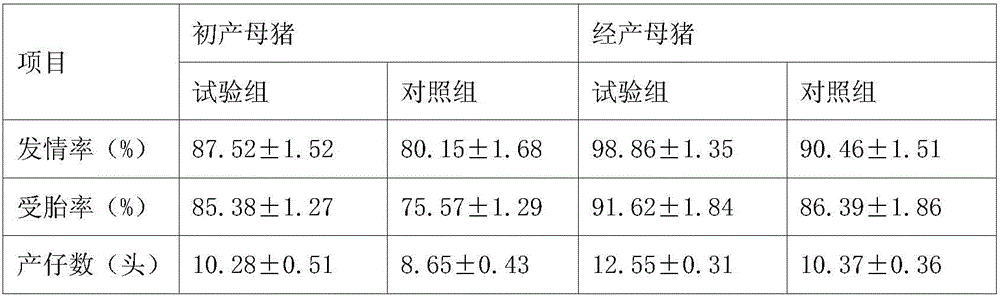

InactiveCN106666149AQuality assuranceGuaranteed stabilityFood processingAnimal feeding stuffMiscarriageLiver and kidney

The invention discloses an estrus and pregnancy promoting premixed feed for a lactating sow. The premixed feed contains a nutritional additive, a Chinese herbal medicinal additive and a diluent, wherein the amount of raw medicinal materials contained in the Chinese herbal medicinal additive is 0.5 to 8 percent of the weight of the premixed feed; the Chinese herbal medicinal additive is prepared from the following medicinal materials in parts by weight: 0.5 to 3 parts of semen allii tuberosi, 0.5 to 3 parts of rhizoma chuanxiong, 0.5 to 3 parts of Chinese angelica, 0.5 to 3 parts of cortex eucommiae and 0.5 to 3 parts of radix astragali seu hedysari. The product can meet vitamins, trace elements, amino acid and the like required by growth and development of sows at a lactation stage; the production efficiency is improved, and the immunity is enhanced; the added Chinese herbal medicinal additive has the functions of warming and reinforcing liver and kidney, regulating menstruation and preventing miscarriage, and the like, promotes estrus of the sows, and can be widely applied to estrus of sows suitable for mating and post-parturient sows; after use, the estrus and pregnancy promoting premixed feed is quick in result; after the estrus and pregnancy promoting premixed feed is fed for one week, the estrus is started; the number of production litters of the sows every year can be increased, and the yield of piglets is increased.

Owner:ZHONGYUEMINAN BEIJING TECH DEV CO LTD

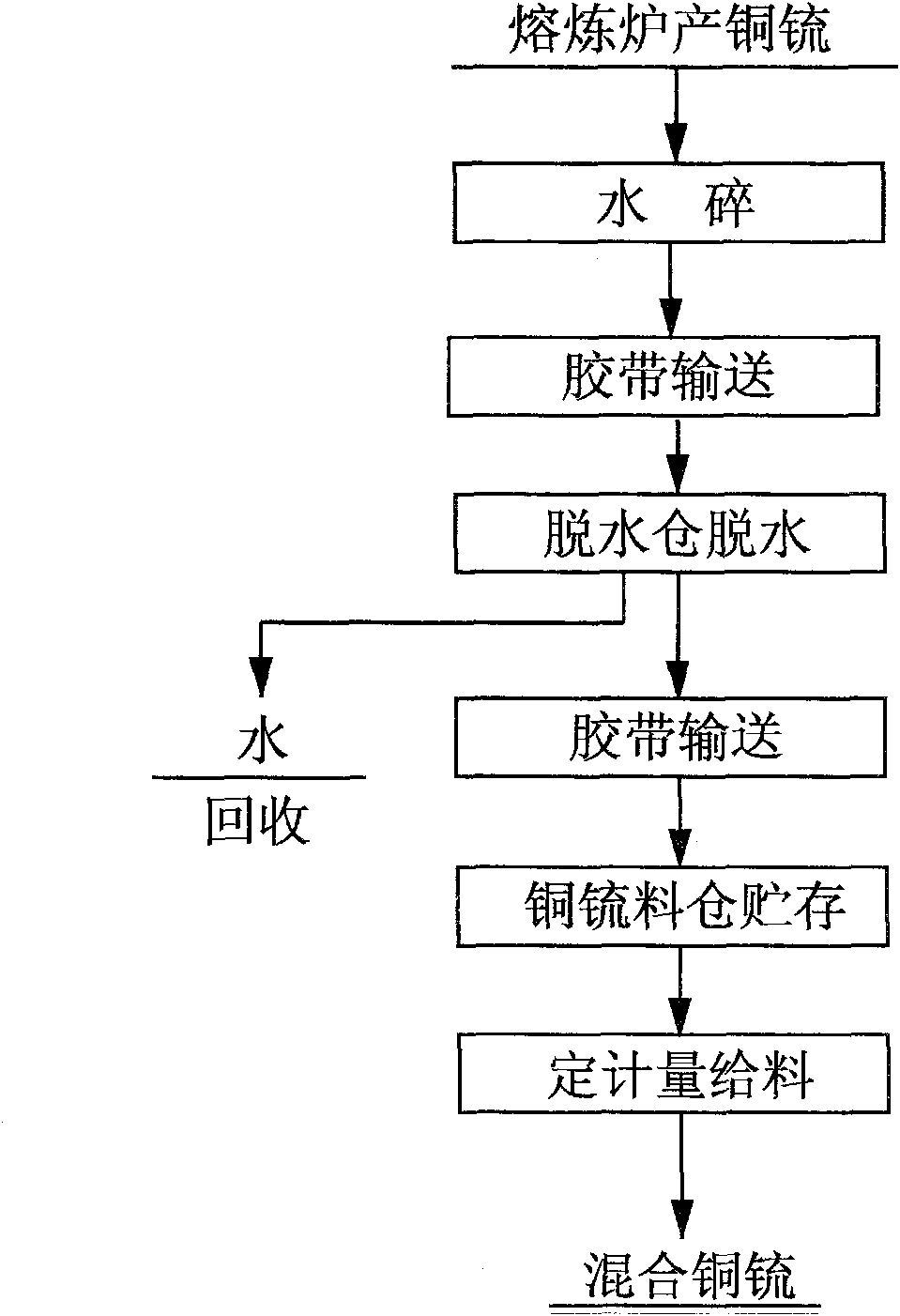

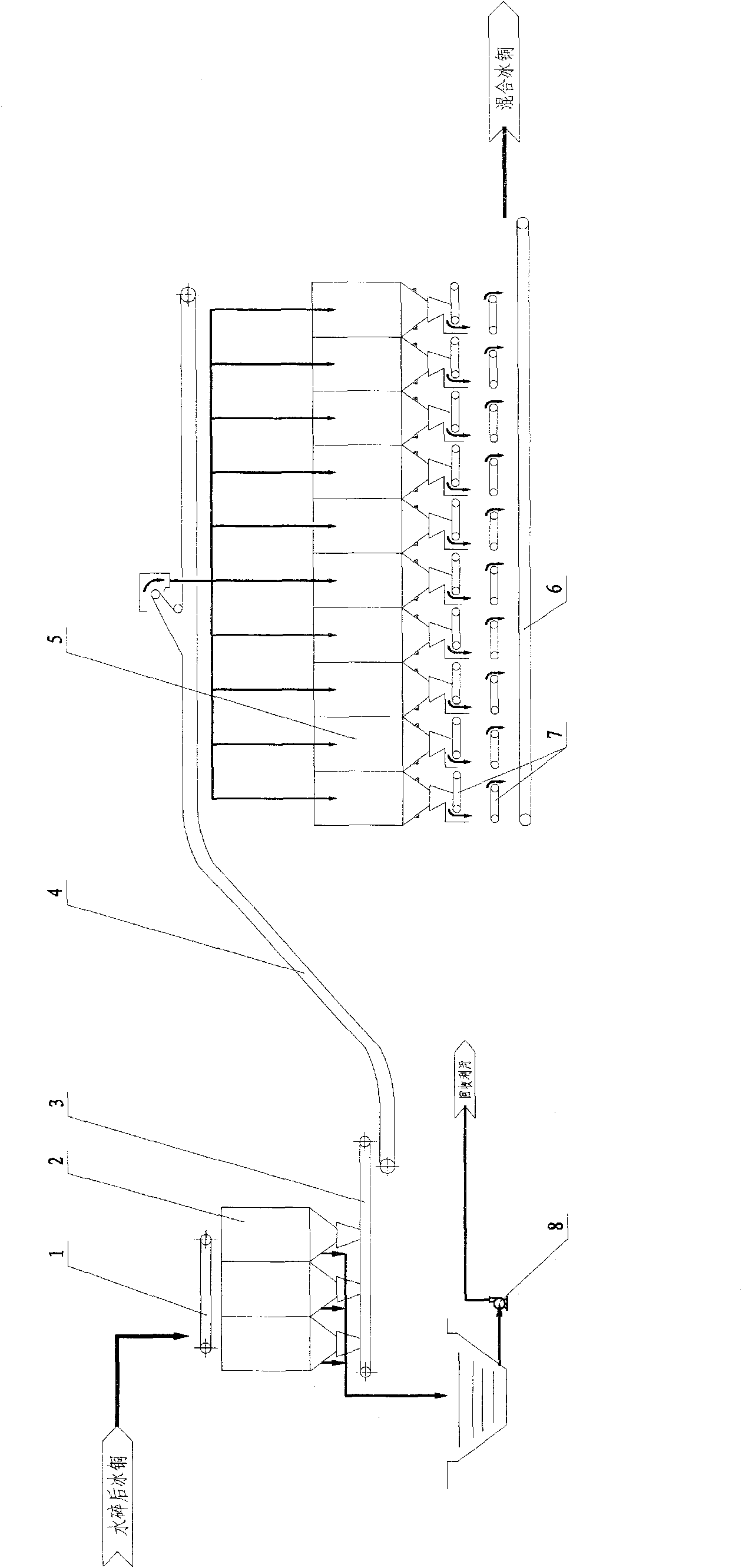

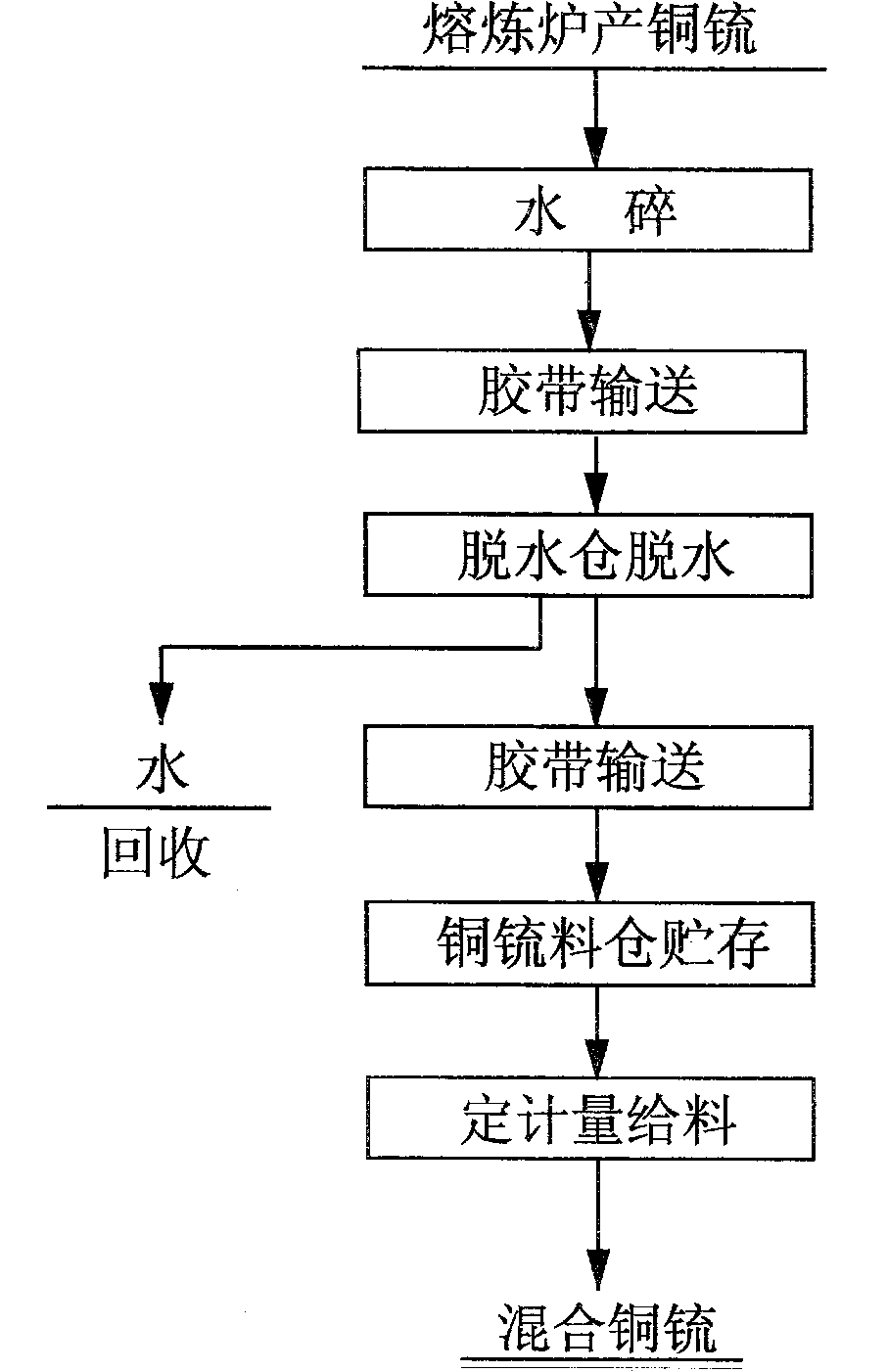

Copper matte processing method and device thereof

InactiveCN101880778AAvoid emissionsImprove the operating environmentRotary drum furnacesCrucible furnacesComputer control systemLiquid copper

The invention discloses a copper matte processing method. In the method, a liquid copper matte is granulated into solid copper matte particles, and then the method comprises the following steps of: 1) water removal, 2) differentiation and storage, 3) accurate measurement and 4) material mixing. The invention also discloses a processing device, which comprises at least two dewatering bins of which the lower parts are provided with water collectors, at least one storage bin and a belt conveyor, wherein the belt conveyor is controlled by a computer control system; the storage bin stores dehydrated copper mattes which have different grades and are produced by different melting of a smelting furnace respectively; and a fixed-measurement feeding belt arranged at each storage bin discharge port is controlled by the computer control system so as to control the copper matte feeding amount of each storage bin. The method can prevent surface water of the copper matte from natural flowing discharge and obviously improve the operating environment, and the device has a small floor area, comparatively low investment, stores the copper mattes with different grades of different smelting of the smelting furnace respectively, can accurately control the feeding amount of the storage bin, has high mixing accuracy, and is particularly suitable for a copper continuous converting process for processing raw material component fluctuations.

Owner:CHINA NERIN ENG

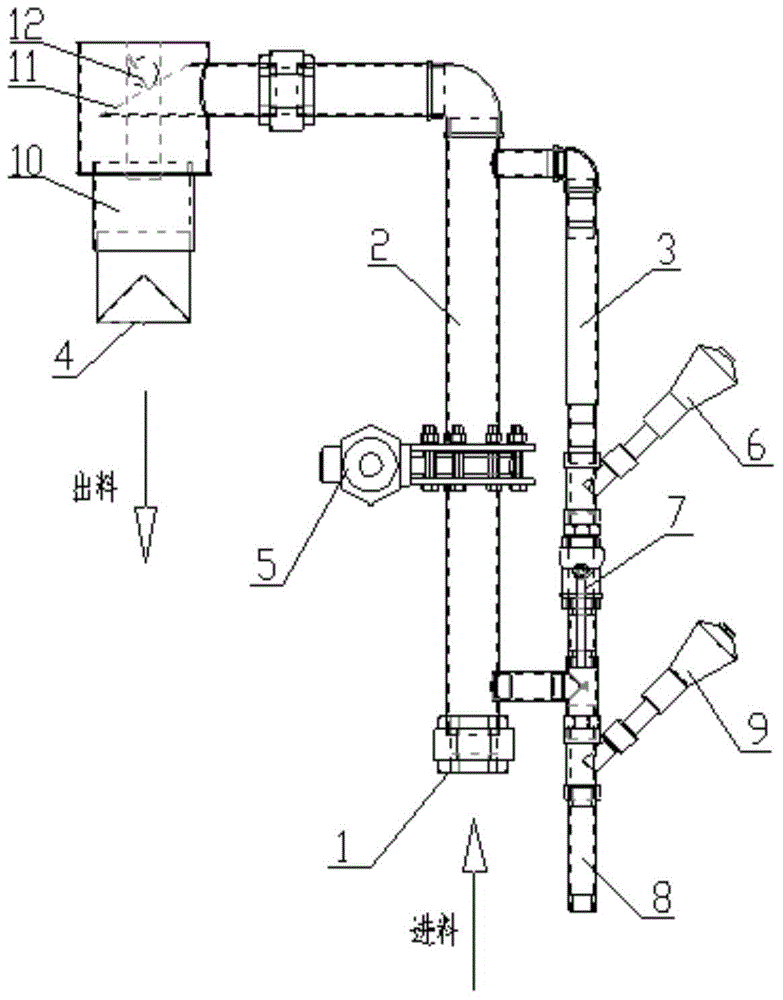

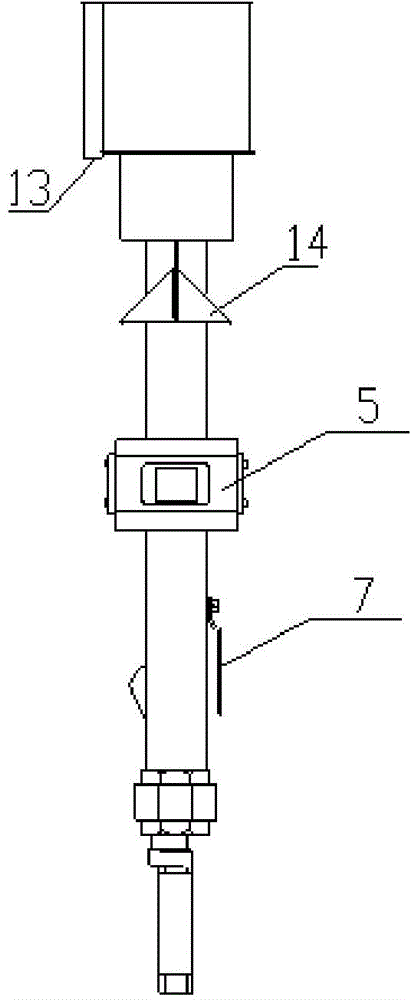

Valve-controlled batching system, mixing plant and valve-controlled batching method

ActiveCN104441251AImprove batching accuracyLiquid ingredients supply apparatusEngineeringButterfly valve

The invention relates to a valve-controlled batching system, a mixing plant and a valve-controlled batching method. The valve-controlled batching system comprises a feeding hole, a coarse batching pipeline, a precise batching pipeline and a discharge hole, wherein the coarse batching pipeline is connected with the precise batching pipeline in parallel; a coarse batching butterfly valve is arranged on the coarse batching pipeline; a precise batching angle seat valve is arranged on the precise batching pipeline; the mixing plant comprises the valve-controlled batching system; and the valve-controlled batching method comprises the following steps: firstly, carrying out coarse batching by virtue of the coarse batching pipeline; and then carrying out precise batching by virtue of the precise batching pipeline, wherein the coarse batching pipeline is connected with the precise batching pipeline in parallel; and switching between the coarse batching and the precise batching is achieved in the batching process through the coarse batching butterfly valve arranged on the coarse batching pipeline and the precise batching angle seat valve arranged on the precise batching pipeline. Through adding a precise batching flow on the basis of existing large-flow coarse batching, the batching precision of the valve-controlled batching system is relatively high.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

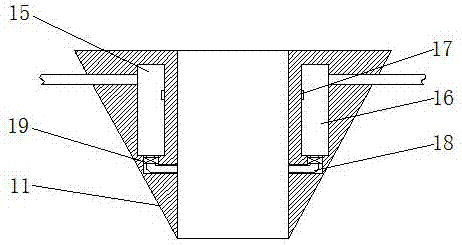

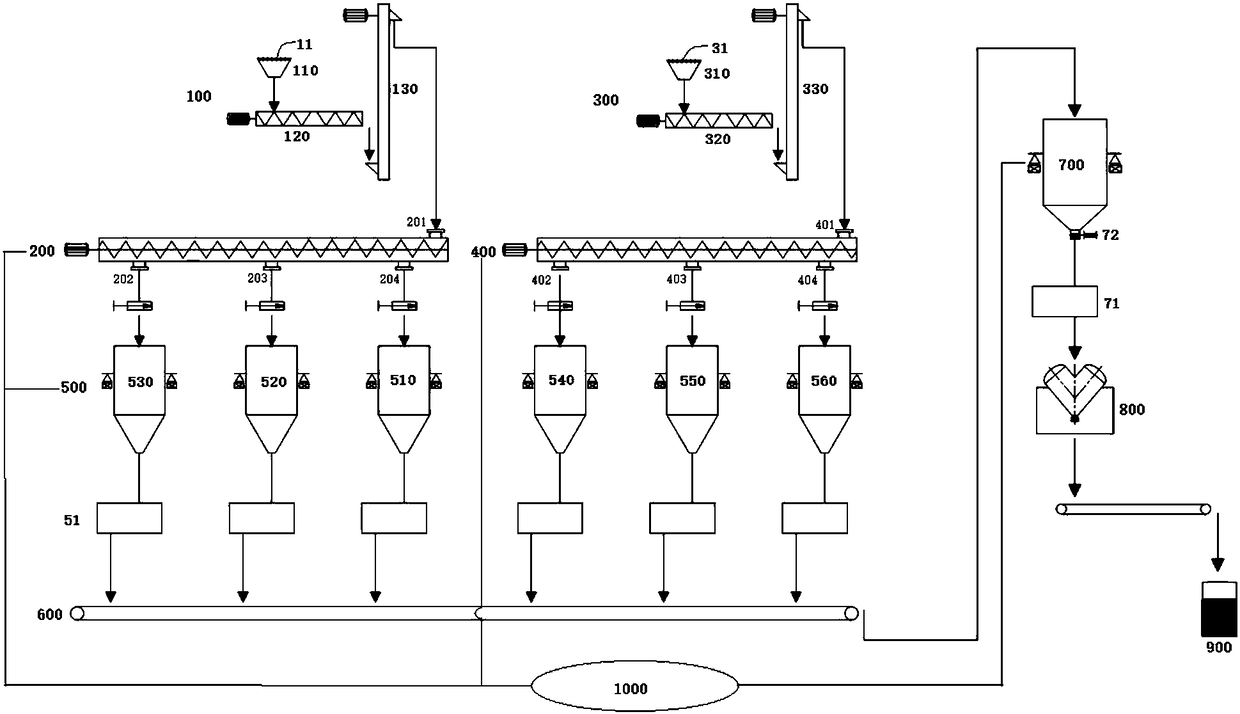

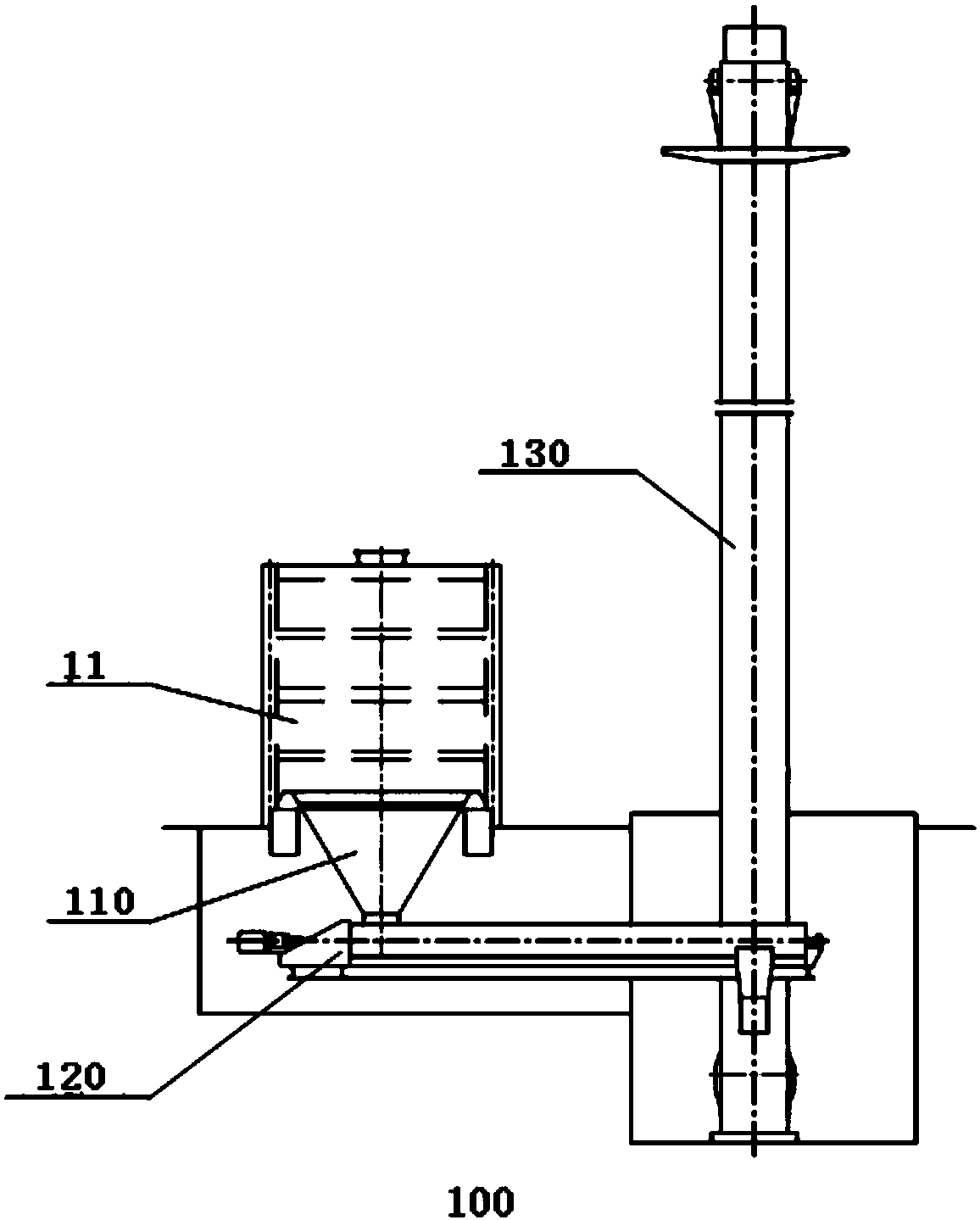

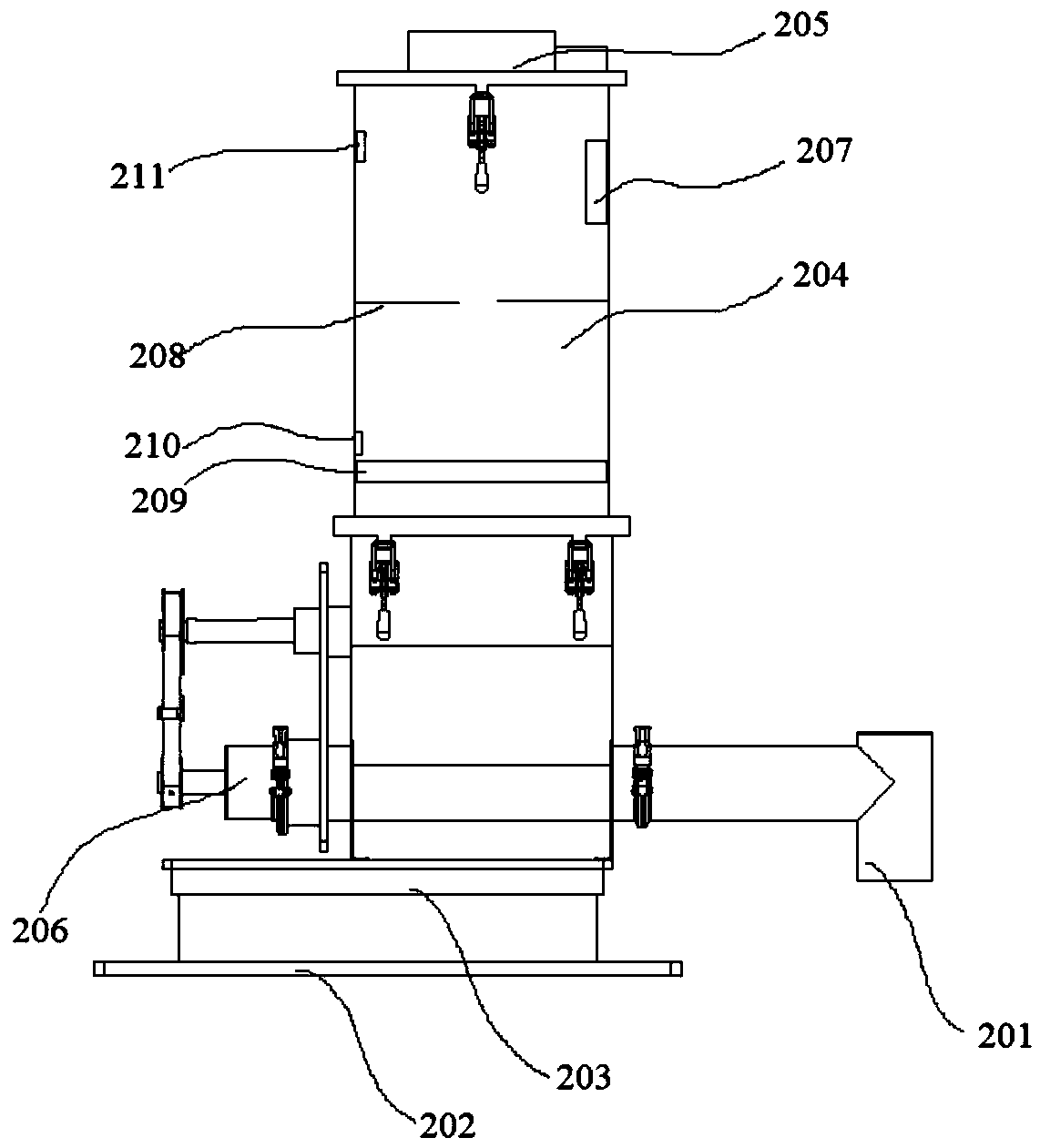

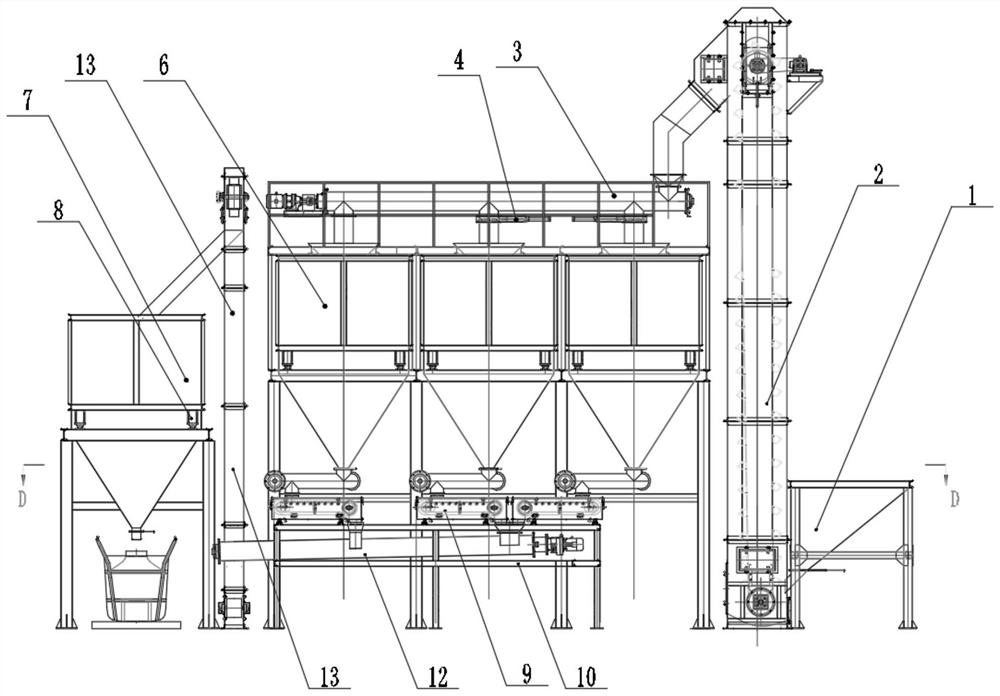

Ferromolybdenum smelting batching system

PendingCN108097157AImprove first-time yieldReduce manufacturing costDispersed particle filtrationMixing methodsFerrosiliconEngineering

The invention discloses a ferromolybdenum smelting batching system. The ferromolybdenum smelting batching system comprises a first charging unit comprising a first charging hopper, a first screw conveyor and a first bucket elevator, a first conveyor provided with a material inlet, a steel scrap outlet, an iron phosphate outlet and a lime outlet, a second charging unit comprising a second charginghopper, a second screw conveyor and a second bucket elevator, a second conveyor provided with a material inlet, an aluminum powder outlet, a ferrosilicon powder outlet and a molybdenum concentrate outlet; a material bin comprising a lime bin, an iron phosphate bin, a steel scrap bin, an aluminum powder bin, a ferrosilicon powder bin and a molybdenum concentrate bin, a belt conveyor connected withthe lime bin, the iron phosphate bin, the steel scrap bin, the aluminum powder bin, the ferrosilicon powder bin and the molybdenum concentrate bin, a buffering and metering bin connected with the beltconveyor, a mixer connected with the buffering and metering bin, a smelting furnace connected with the mixer, and a control unit connected with the first conveyor, the second conveyor, the material bin and the buffering and metering bin.

Owner:中国冶金科工股份有限公司 +1

Piglet premixed feed for relieving diarrhea with astringents and preparation method thereof

InactiveCN106615818AQuality assuranceGuaranteed stabilityFood processingAnimal feeding stuffMedicinal herbsFodder

The present invention relates to the field of compound premixed feeds and more particularly discloses a piglet premixed feed for relieving diarrhea with astringents and a preparation method thereof. The premixed feed contains a nutritional additive, a Chinese herbal medicinal additive and a diluent. Containing amount of raw medicinal materials in the Chinese herbal medicinal additive is 0.5-8% by weight of the premixed feed and the Chinese herbal medicinal additive is prepared by extracting or directly crushing the following medicinal materials in parts by weight: 0.5-3 parts of radix astragali, 0.5-3 parts of poria cocos, 0.5-2 parts of dandelions, 0.5-2 parts of herba portulacae, 0.5-2 parts of haws and 0.5-2 parts of fructus chebulae; and the diluent is a mixture of zeolite powder and rice husk powder at a weight ratio of 1:1. The product can meet the needed vitamins, trace elements, amino acids, etc., for piglets (15-30 kg) at a stage growth and development, improves production efficiency, relieves diarrhea with astringents of the piglets, and protects intestinal mucosa.

Owner:ZHONGYUEMINAN BEIJING TECH DEV CO LTD

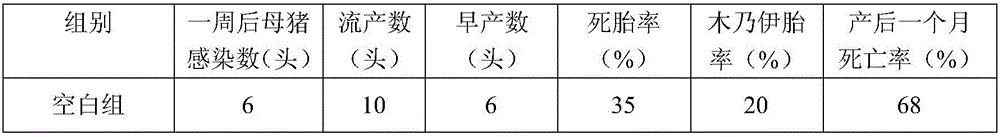

Miscarriage preventing premixed feed for pregnant sows and preparation method thereof

InactiveCN106578536AQuality assuranceGuaranteed stabilityFood processingAnimal feeding stuffDiseaseMedicinal herbs

The present invention relates to the field of compound premixed feeds and more particularly relates to a miscarriage preventing premixed feed for pregnant sows. The premixed feed comprises a nutritional additive, Chinese herbal medicinal additives and a diluent. The content of crude medicinal materials in the Chinese herbal medicinal additives is 0.5-8% by weight of the premixed feed and the Chinese herbal medicinal additives are prepared by an extraction preparation or a direct crushing of the medicinal materials in the following parts by weight: 0.5-3 parts of radix angelicae sinensis, 0.5-3 parts of rhizoma chuanxiong, 0.5-3 parts of rhizoma atractylodis macrocephalae, and 0.5-3 parts of cortex eucommiae. The diluent is a mixture of zeolite powder to rice hull powder at a weight ratio of 1:1. The product can meet the needed vitamins, trace elements, amino acids, etc. in the growth and development stages of the pregnant sows, improves production efficiency and enhances immunity. The added Chinese herbal medicinal additives have effects of preventing miscarriage and strengthening piglets, strengthening spleen and supplementing kidneys, and supplementing blood and securing exterior, can prevent miscarriage, prevents dead embryos, increases the litter sizes of the pregnant sows and the weight of the newborn piglets, increases the appetite and disease resistance of the sows, etc.

Owner:ZHONGYUEMINAN BEIJING TECH DEV CO LTD

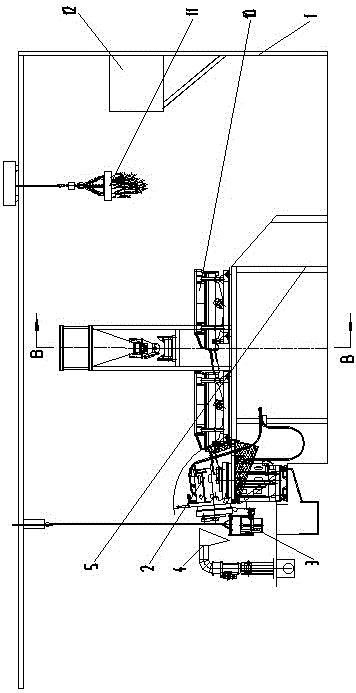

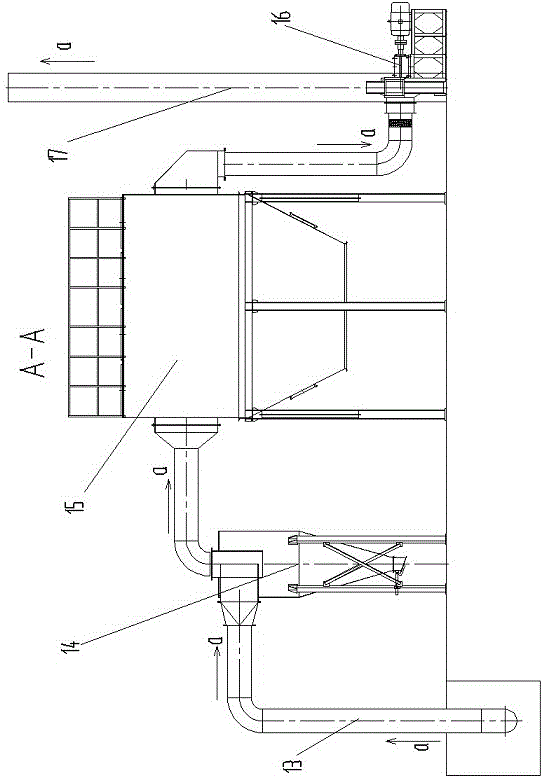

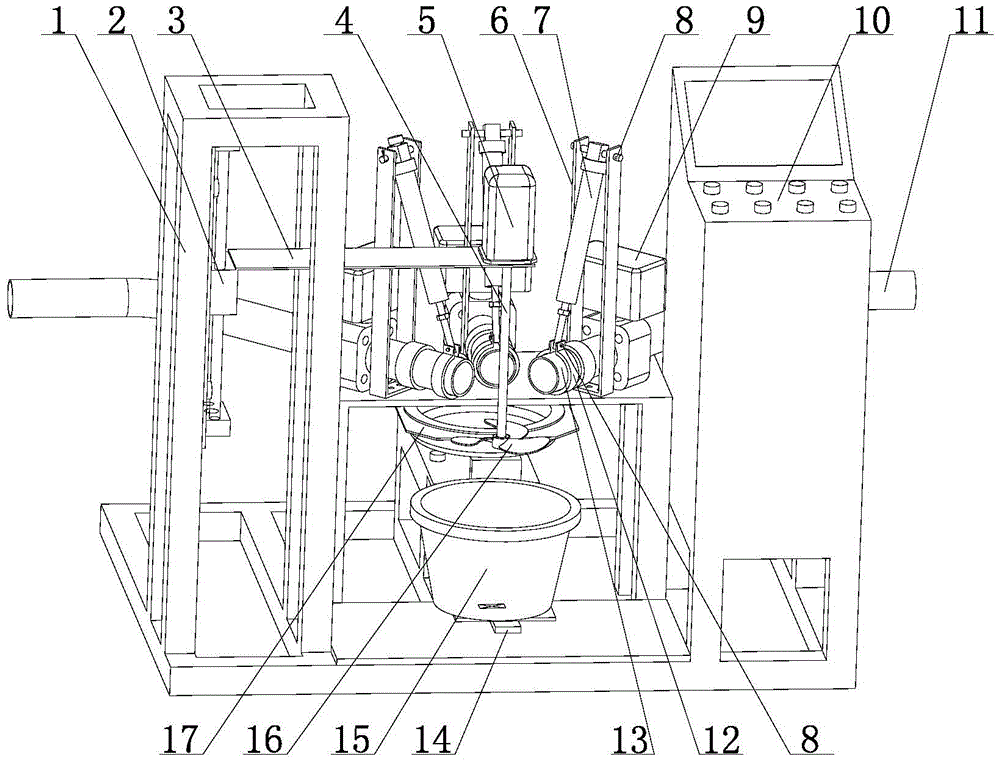

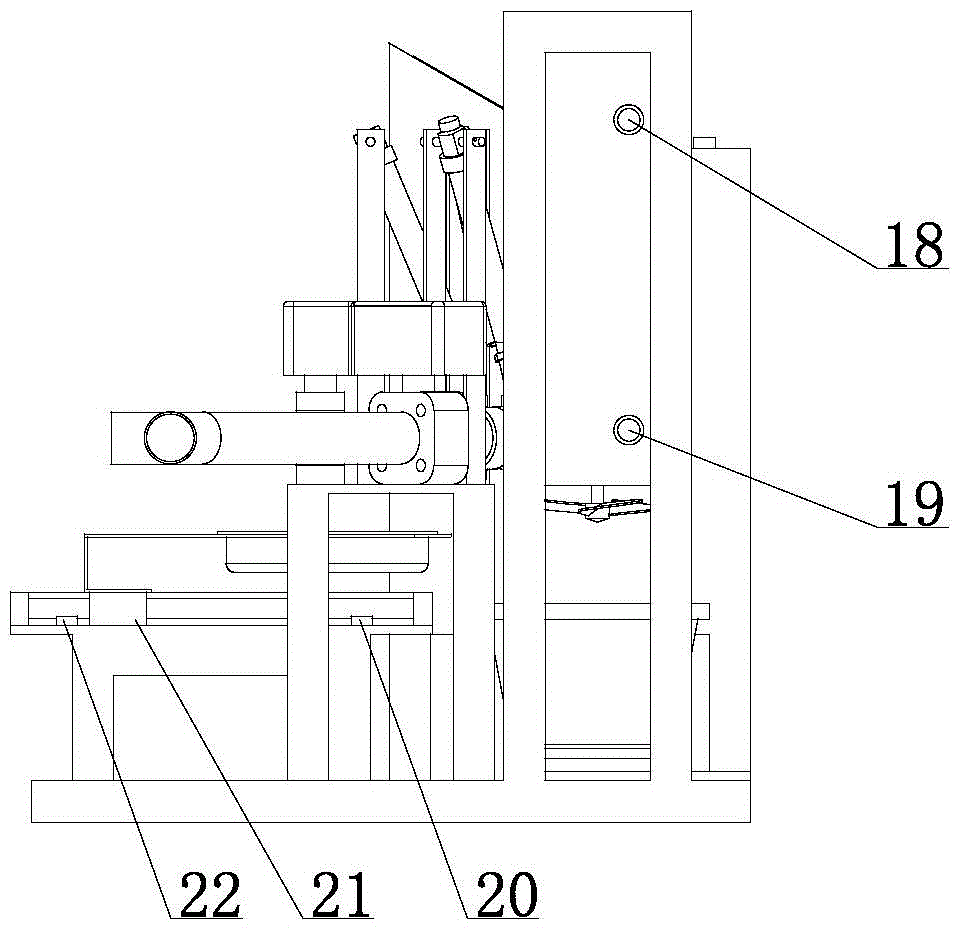

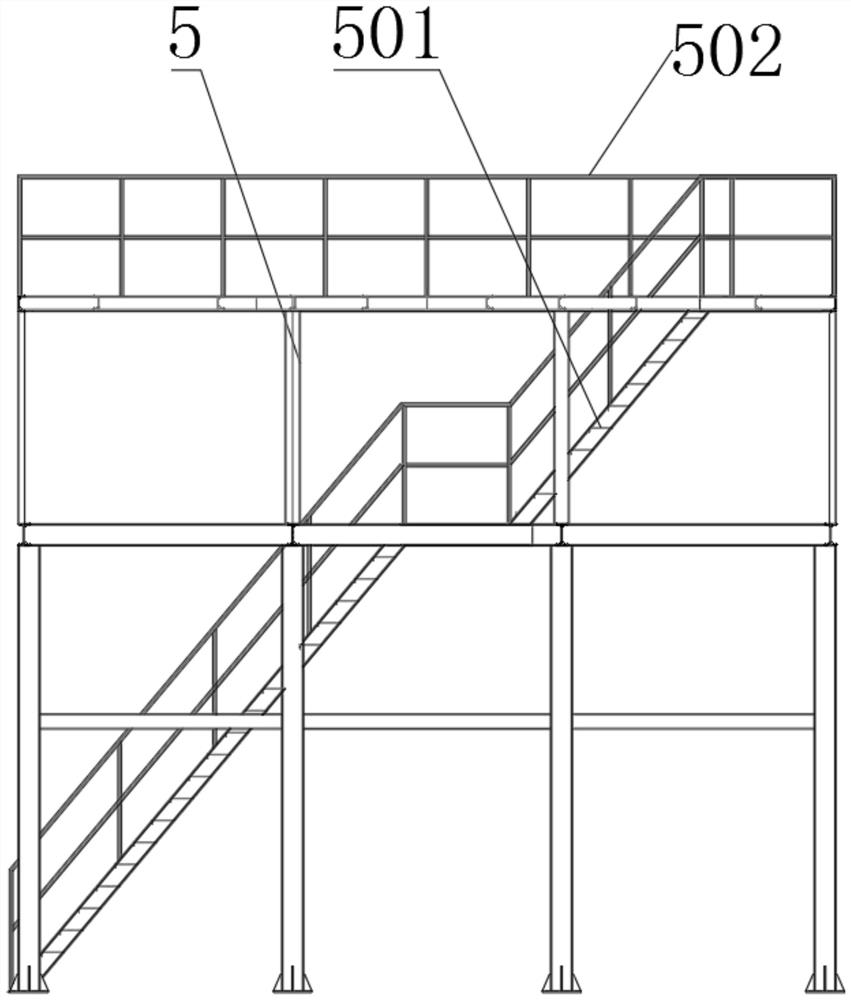

Automatic material feeding and blending, smoke prevention, dust control and emission reduction integrated system for electric furnace

ActiveCN105066709AIngredients with low error rateImprove batching accuracyCharge manipulationWaste heat treatmentIntegrated systemsEngineering

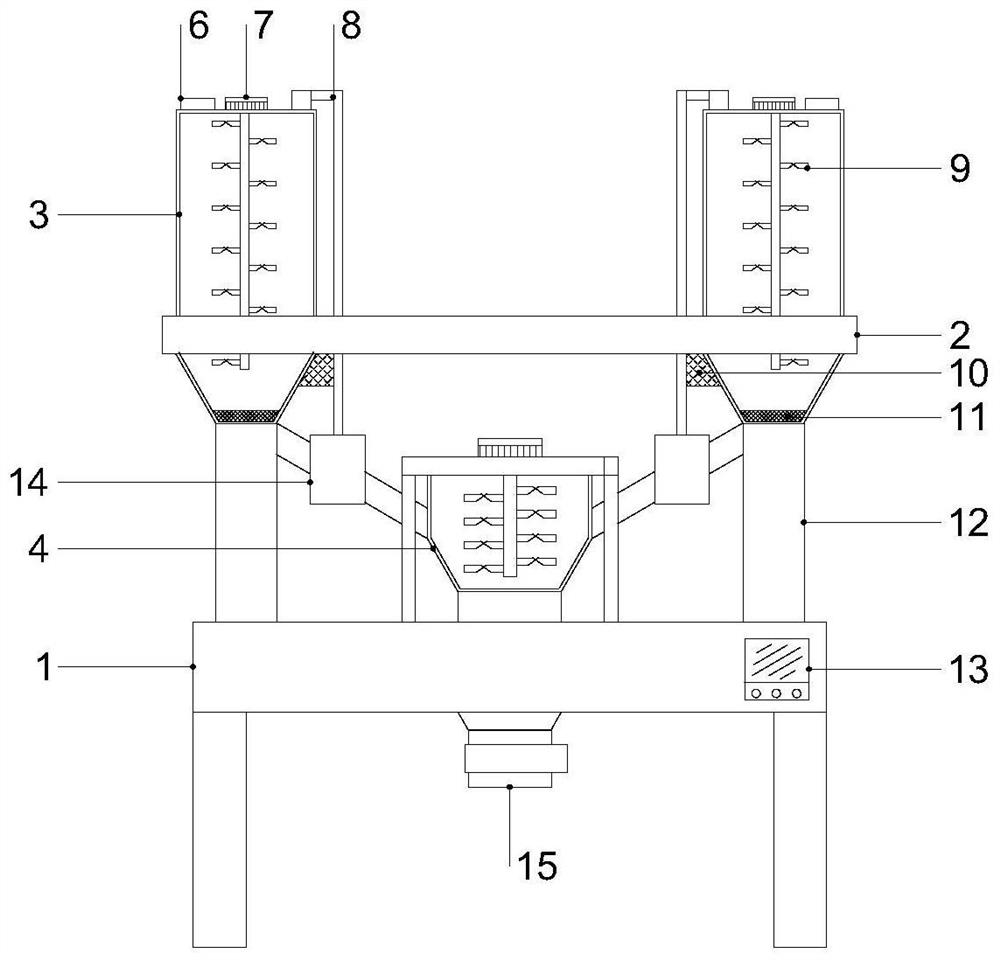

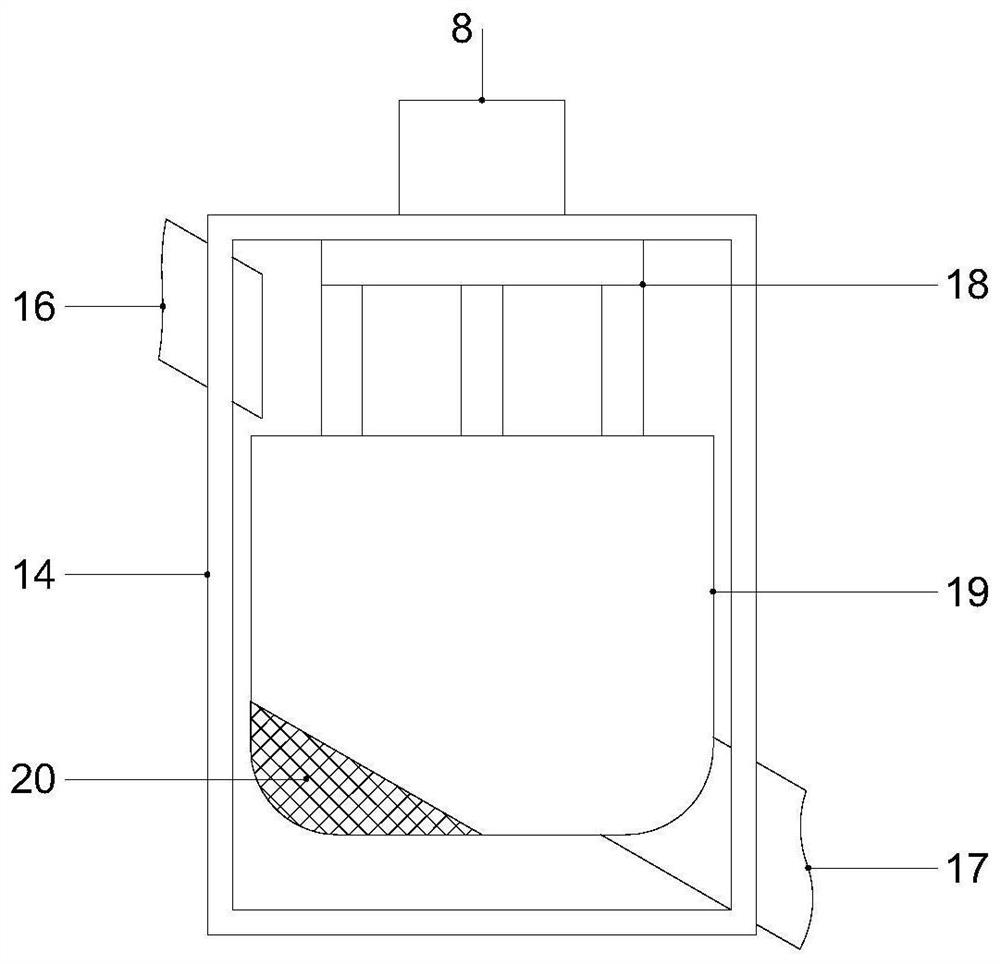

An automatic material feeding and blending, smoke prevention, dust control and emission reduction integrated system for an electric furnace is characterized by comprising a machine frame, the electric furnace installed on a lower platform of the machine frame, a balling bag which is close to the front side of the electric furnace and hung on a top platform of the machine frame, a balling smoke and dust trapping system next to the balling bag, a blending rack located on the back side of the electric furnace and installed on the lower platform of the machine frame, an alloy preparing overhead bin installed on the top of the blending rack, an electromagnetic vibrating feeder installed below the alloy preparing overhead bin, an alloy weighing hopper hung on the alloy preparing overhead bin, a bidirectional belt conveyer located below the alloy weighing hopper and installed on the blending rack, an electric furnace vibrating feeding trolley placed on the lower platform of the machine frame, a movable furnace rear automatic iron preparing device hung on the top platform of the machine frame, and a central integrated control system installed on the machine frame. The system is high in automation degree, capable of achieving smoke and dust removal, energy saving and emission reduction, relieving the labor intensity of staff and improving production efficiency, and capable of being widely applied to electric furnace smelting systems.

Owner:青岛中智达环保熔炼设备有限公司

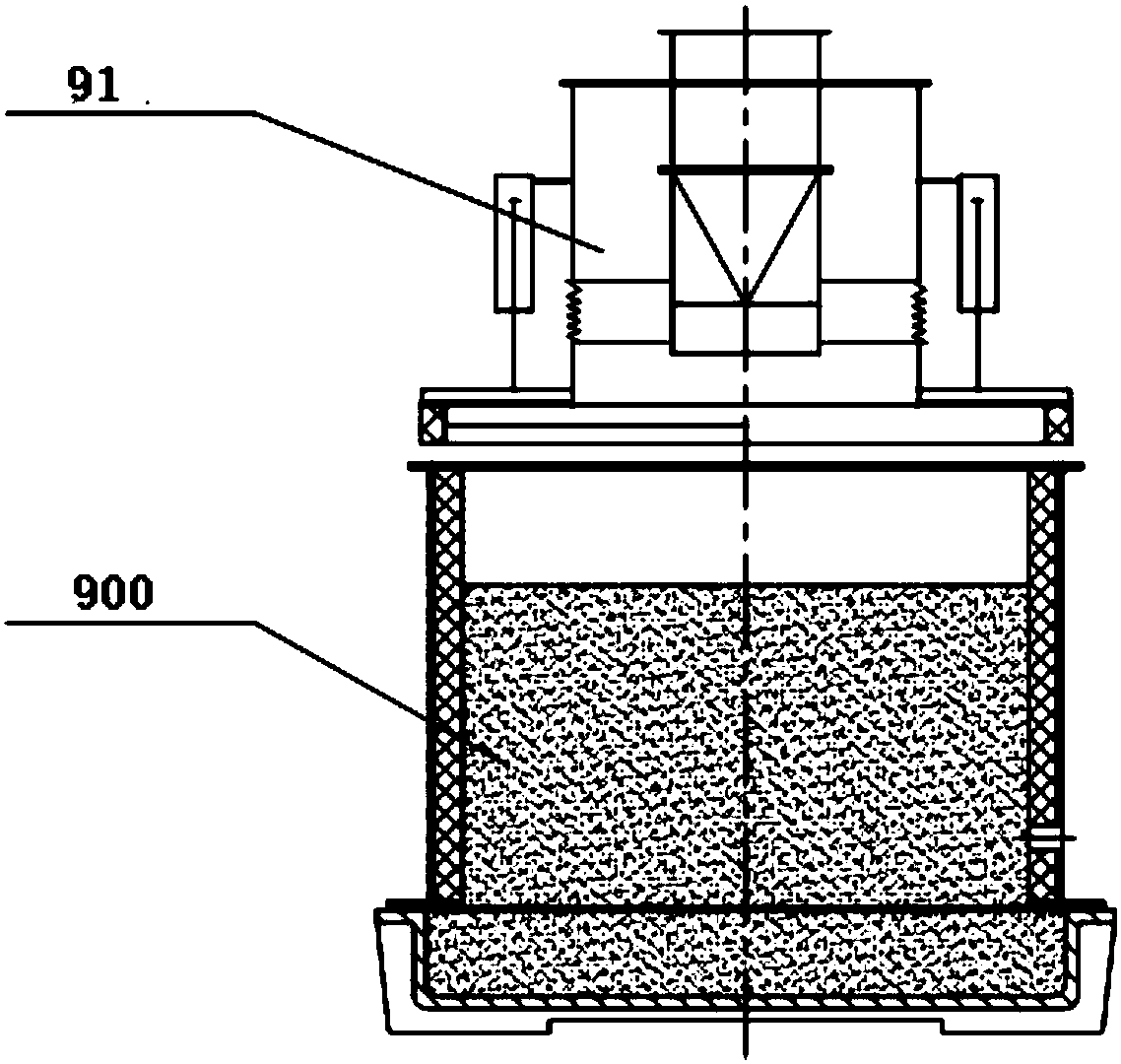

Composite material full-automatic preparation device

InactiveCN105727790AGuaranteed accuracyImprove batching accuracyRotary stirring mixersTransportation and packagingAutomatic controlMass measurement

The invention belongs to the technical field of material preparation, and in particular relates to a composite material full-automatic preparation device. The device comprises a frame and a mixer, a stirring mechanism and at least two groups of material conveyor pipes arranged on the frame; a material mass measurement device is arranged below the mixer, the stirring mechanism is arranged above the mixer, the stirring mechanism is connected with a lifting driving mechanism; each material conveyor pipe is installed with an automatic control valve, the tail end of each material conveyor pipe is connected with a hose along the material conveying direction, the discharge hole of each hose corresponds to the opening of the mixer, the corresponding hose is provided with a pulling lowering mechanism; and the material mass measuring device, the automatic control valve, the lifting driving mechanism and the pulling lowering mechanism are connected with the control system. The preparation device disclosed by the invention is high in automation degree, capable of realizing the sufficiently precise burdening of the composite material and the fast stirring, the problems that the manual operation efficiency is low, the labor intensity is large and the general automatic equipment is large in random error are solved.

Owner:SHANDONG UNIV OF TECH

Automatic small-size material blending equipment

PendingCN108745196AReduce manual labor intensityImprove the site environmentTransportation and packagingMixer accessoriesData inputWeightlessness

The invention discloses automatic small-size material blending equipment which comprises a plurality groups of allocation units, wherein each group of the allocation units consists of a plurality of independent weightlessness type allocation scales connected with a control device in a surrounding manner; a supply device comprises feeding stations which are correspondingly arranged above the weightlessness type allocation scales; the discharge holes of the feeding stations are communicated with inlet holes of the weightlessness type allocation scales; buckets of a collection conveying device are arranged on a roller conveyer belt, are conveyed on the roller conveyer belt, and are positioned below discharge holes of the weightlessness type allocation scales of each group of the allocation units through stoppers; first dust collection holes of dust collection devices are communicated with dust collection holes of the feeding stations; second dust collection holes are formed in the discharge holes of the weightlessness type allocation scales; a re-weighing labeling device rechecking platform data output end is connected with the data input end of the control device; a labeling machinedata input end is connected with the data output end of the control device. By adopting the blending equipment, the working intensity of operators can be alleviated, on-site environments can be improved, and allocation efficiency and precision can be improved.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

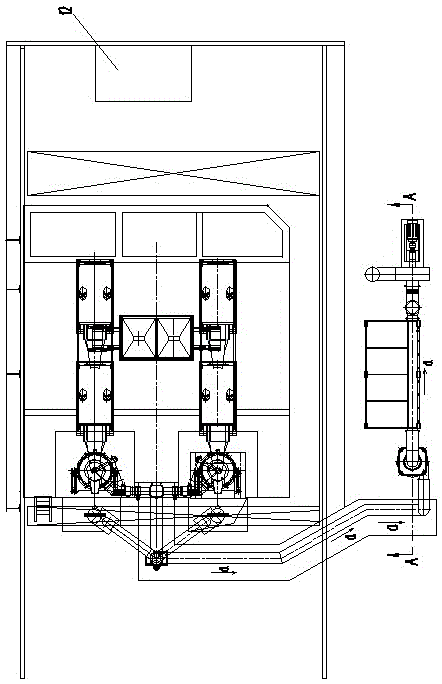

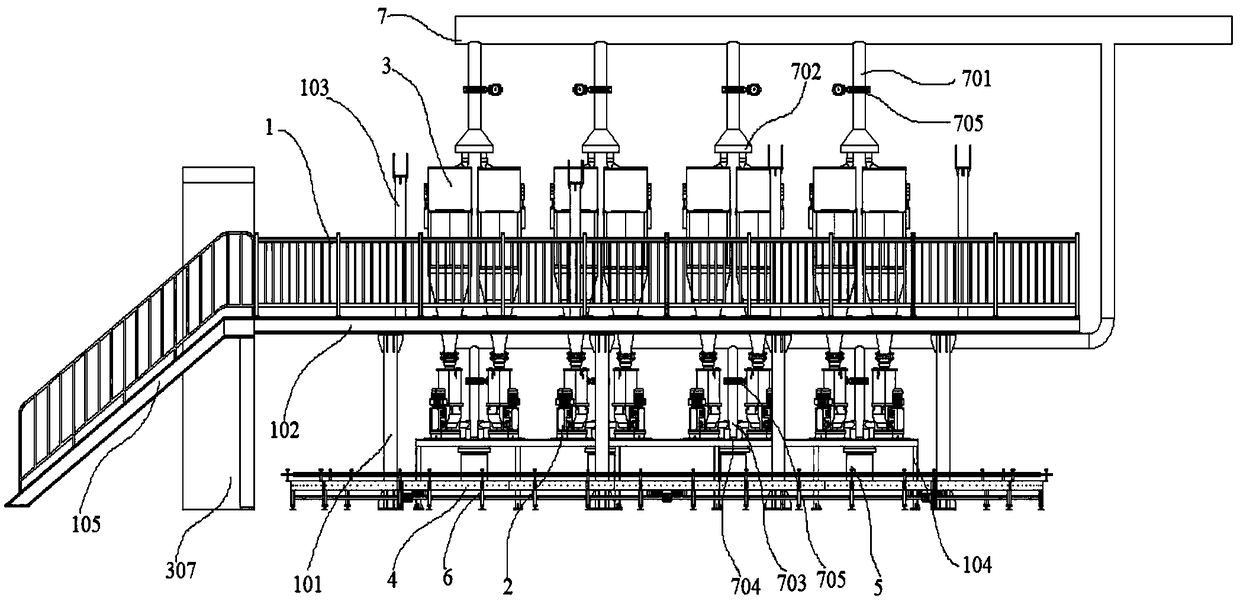

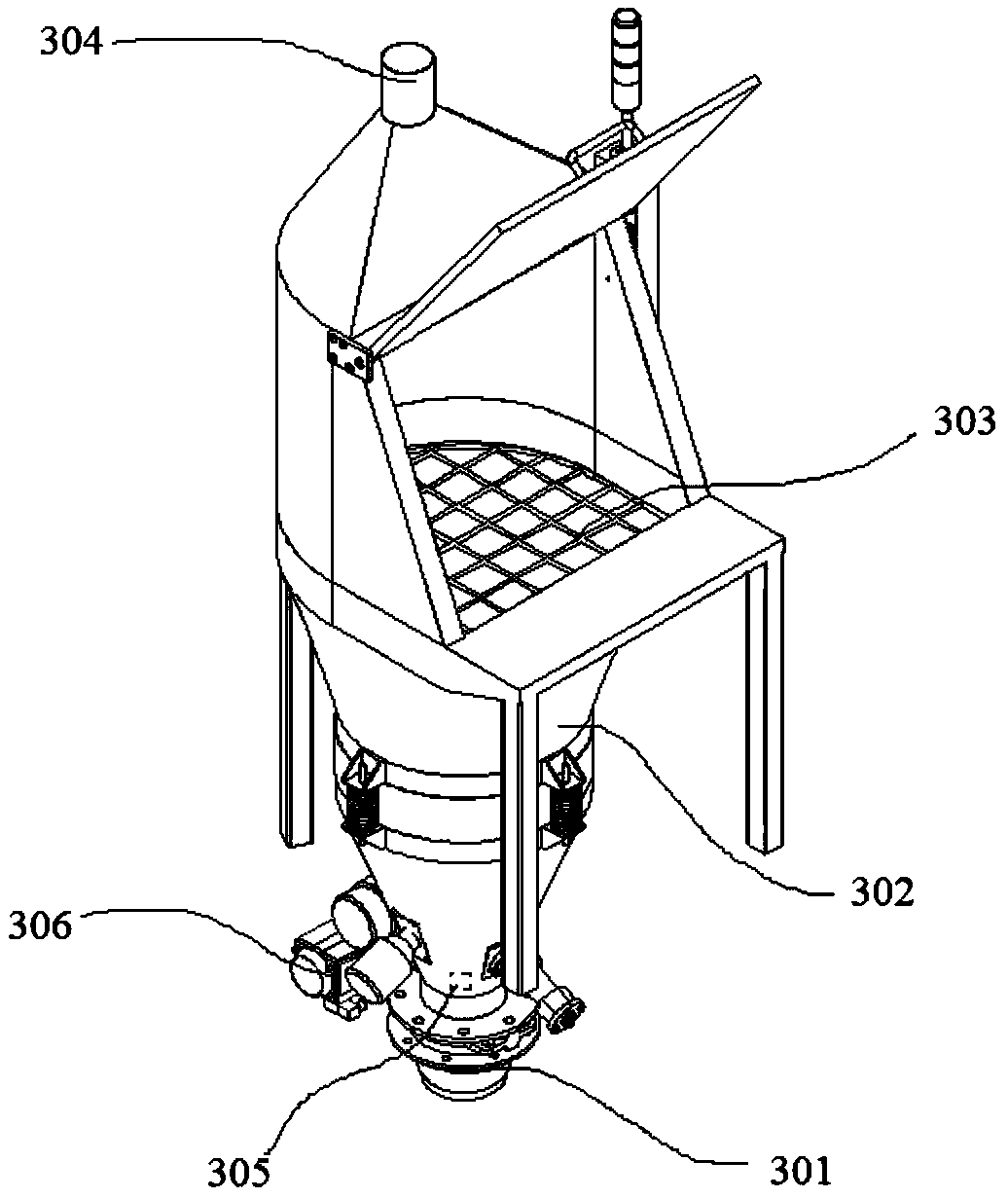

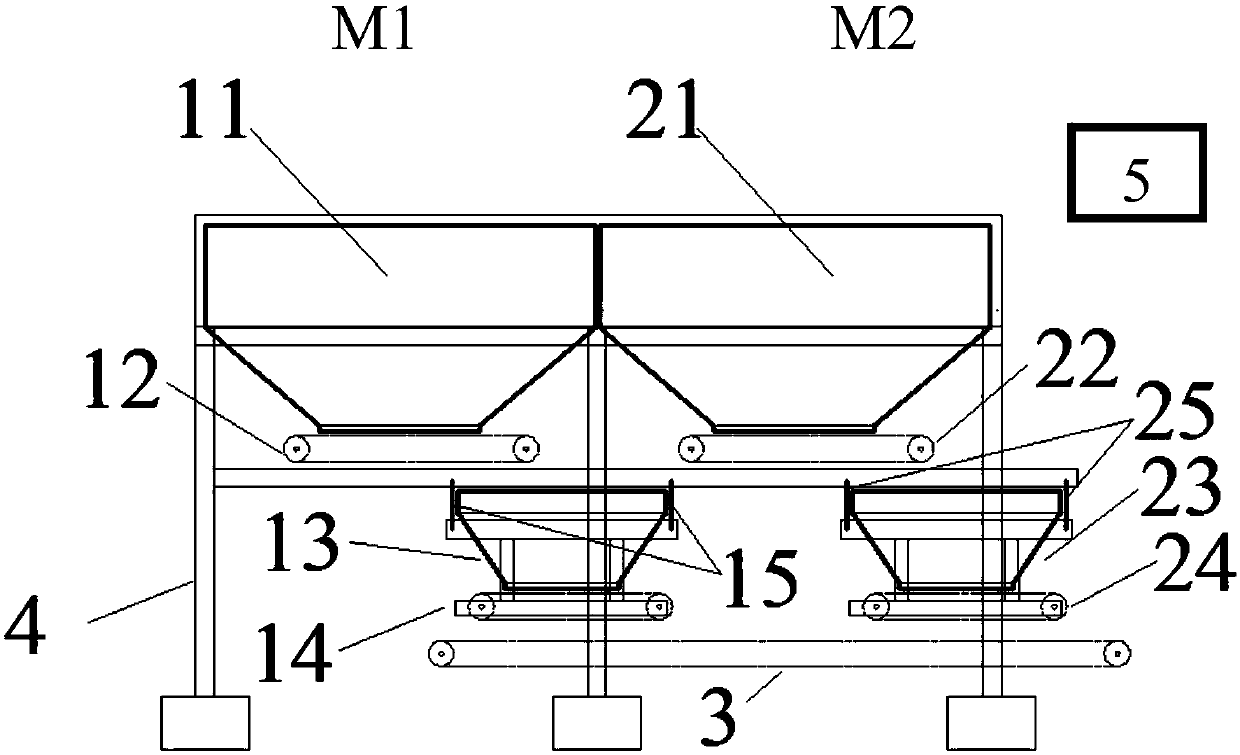

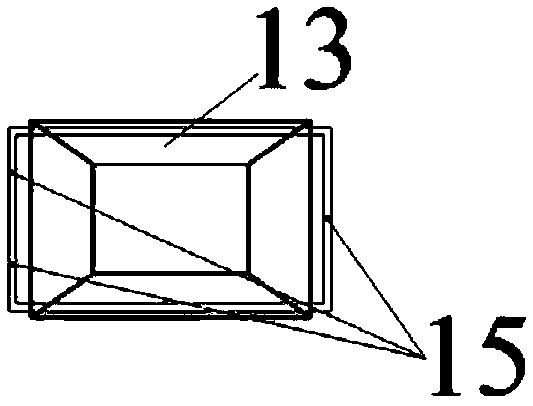

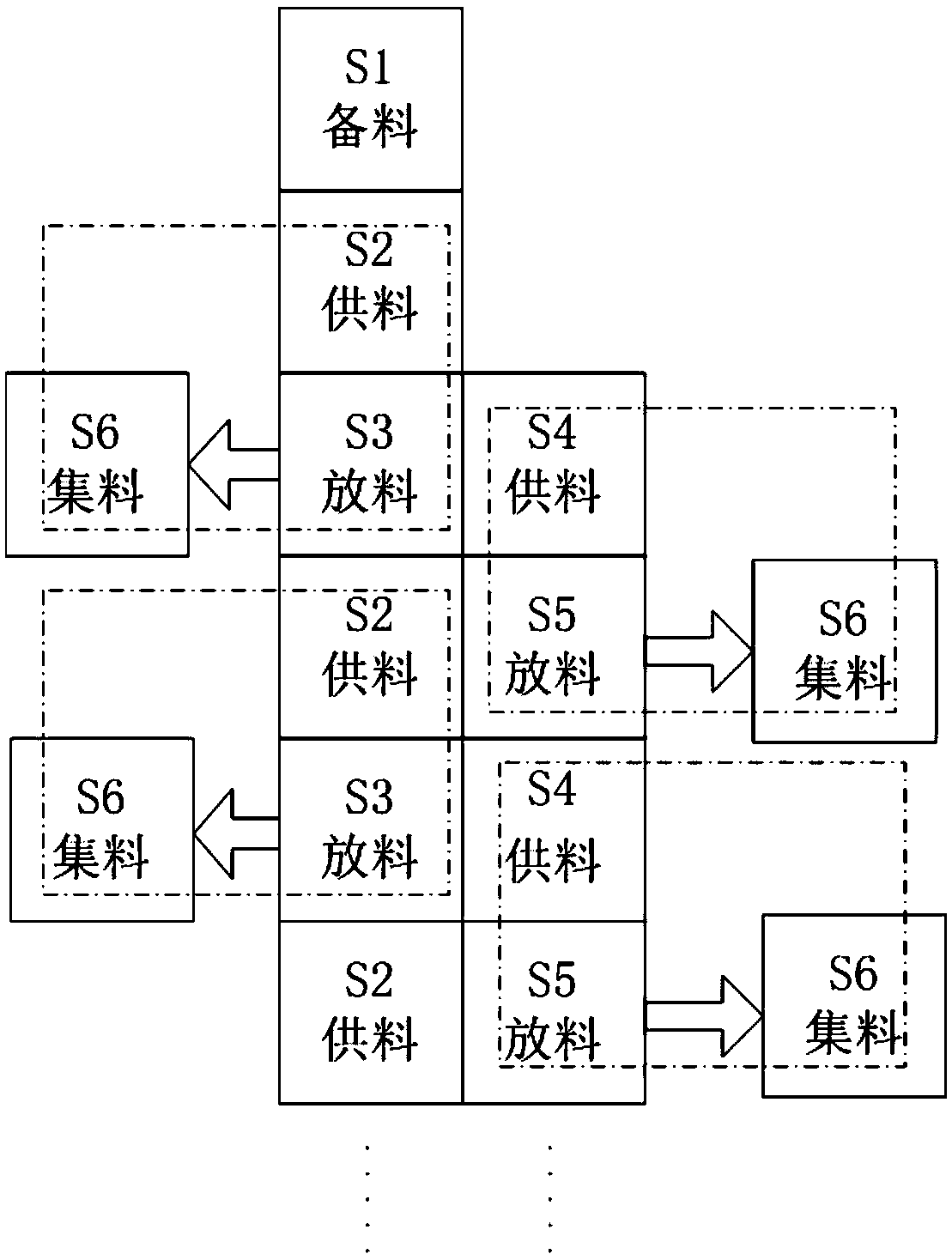

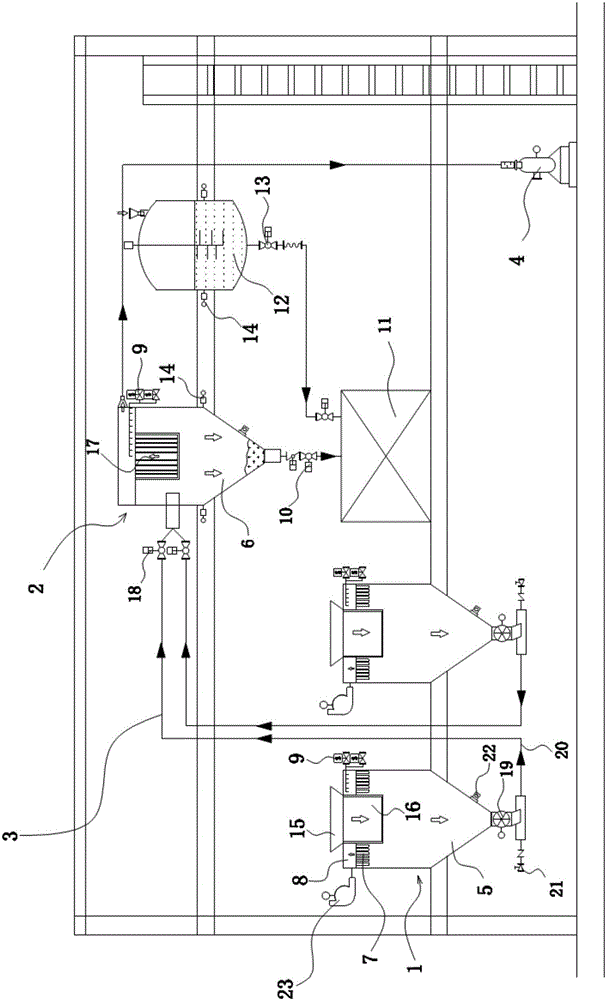

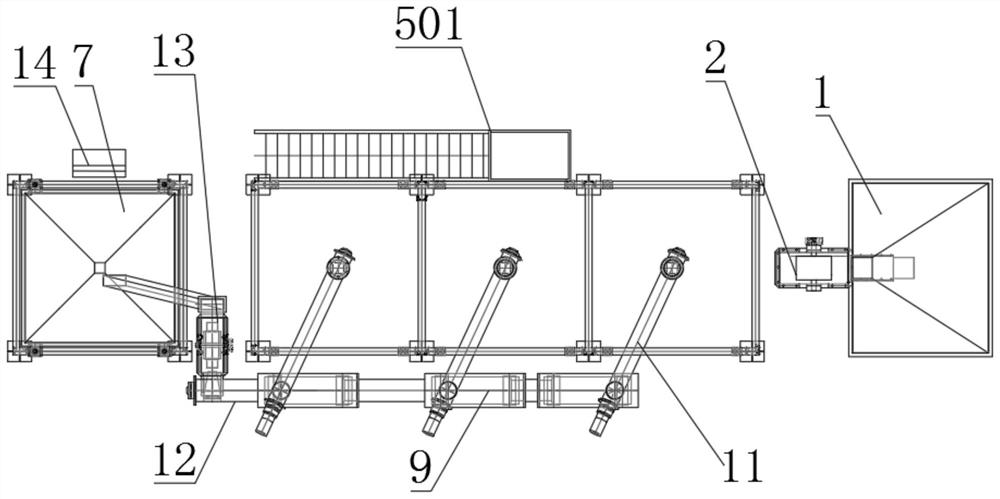

Aggregate preparing system of civil engineering materials

InactiveCN109591175AImprove batching accuracyIncrease productionFeeding arrangmentsAdditive ingredientContinuous feeding

The invention discloses an aggregate preparing system of civil engineering materials. The aggregate preparing system comprises a first preparing module, a second preparing module, a material collecting belt, a supporting framework and a controller, wherein the first preparing module comprises a first aggregate bin, a first feeding belt, a first weighing hopper and a first discharging belt; similarly, the second preparing module comprises a second aggregate bin, a second feeding belt, a second weighing hopper and a second discharging belt; the material collecting belt is located below the firstpreparing module and the second preparing module to collect aggregate ingredients from the first preparing module and the second preparing module; the supporting framework is used for supporting thefirst preparing module, the second preparing module and the material collecting belt; and the controller is used for controlling the first preparing module and the second preparing module to perform alternative discharging on the material collecting belt, so that high-precision weighing and continuous feeding can be realized.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +3

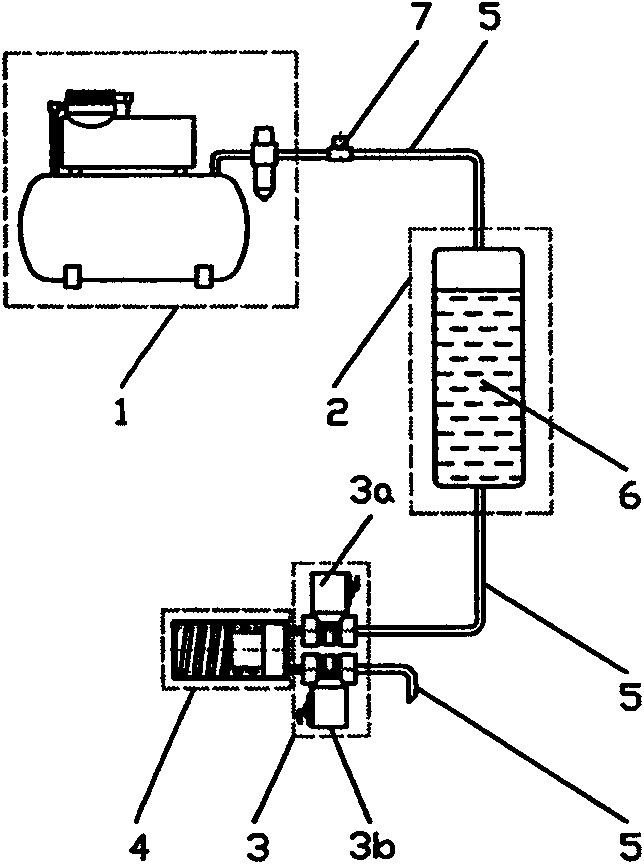

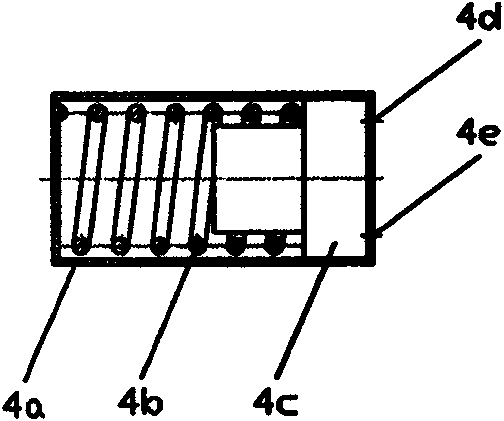

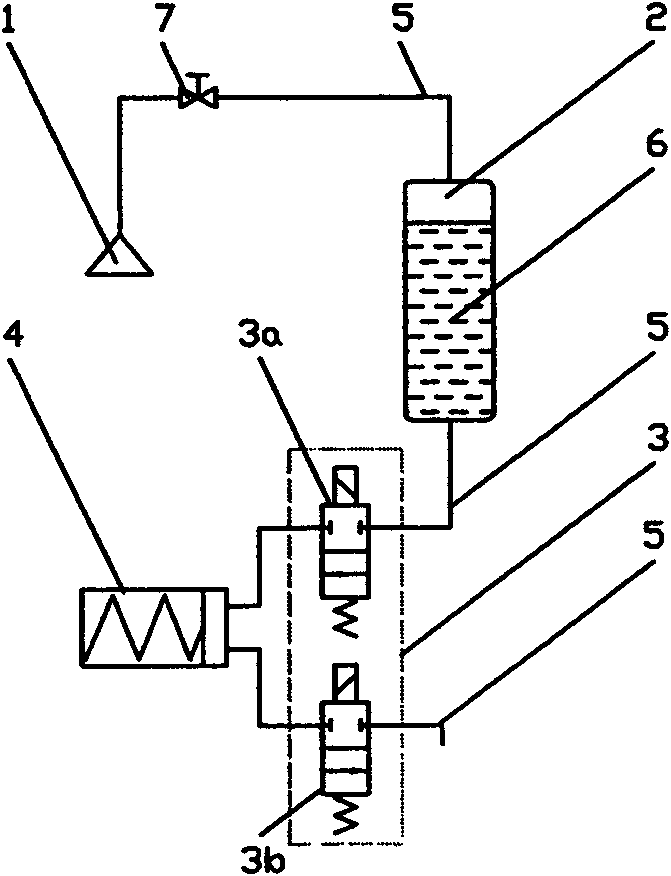

Quick metering and dispensing device and method thereof for liquid spices

InactiveCN101629839AImprove batching accuracyPrecise ingredientsMovable measuring chambersLiquid storage tankExhaust valve

The invention belongs to the field of liquid metering, and particularly relates to a quick metering and dispensing device and a method thereof for liquid spices. The quick metering and dispensing device for liquid spices is characterized in that an air exhaust opening of a compressed air source (1) is connected with an air inlet of a liquid storage tank (2) through a pipeline; a liquid exhaust opening of the liquid storage tank (2) is communicated with a liquid inlet of a liquid inlet valve (3a) of a control valve (3); a liquid exhaust opening of the liquid inlet valve (3a) is communicated with a liquid inlet (4d) of a metering cavity (4); a liquid exhaust opening (4e) of the metering cavity (4) is communicated with a liquid inlet of a liquid exhaust valve (3b) of the control valve (3); and a liquid exhaust opening of the liquid exhaust valve (3b) is communicated with outside through a pipeline.

Owner:杨斌

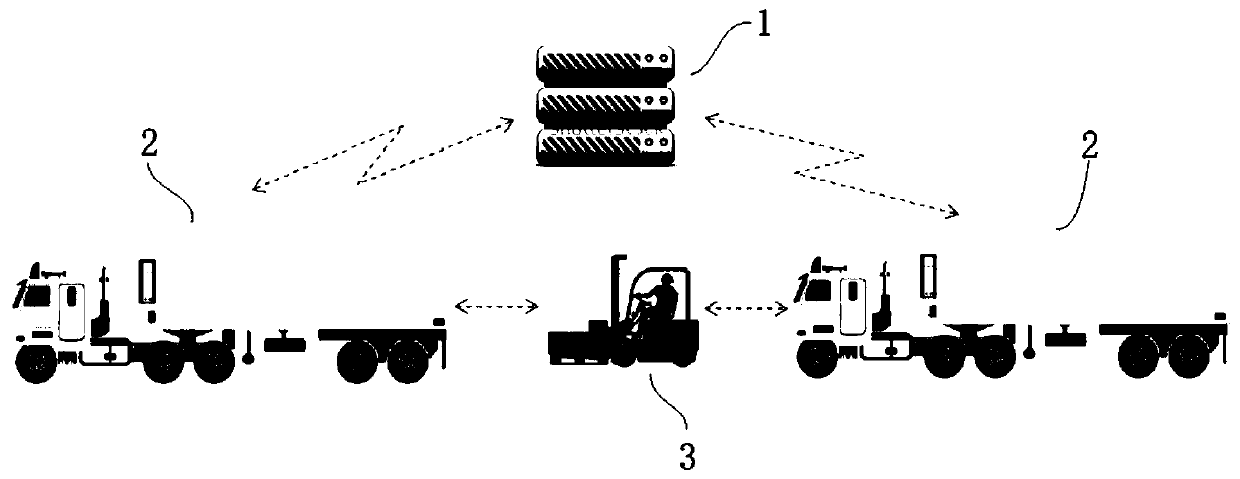

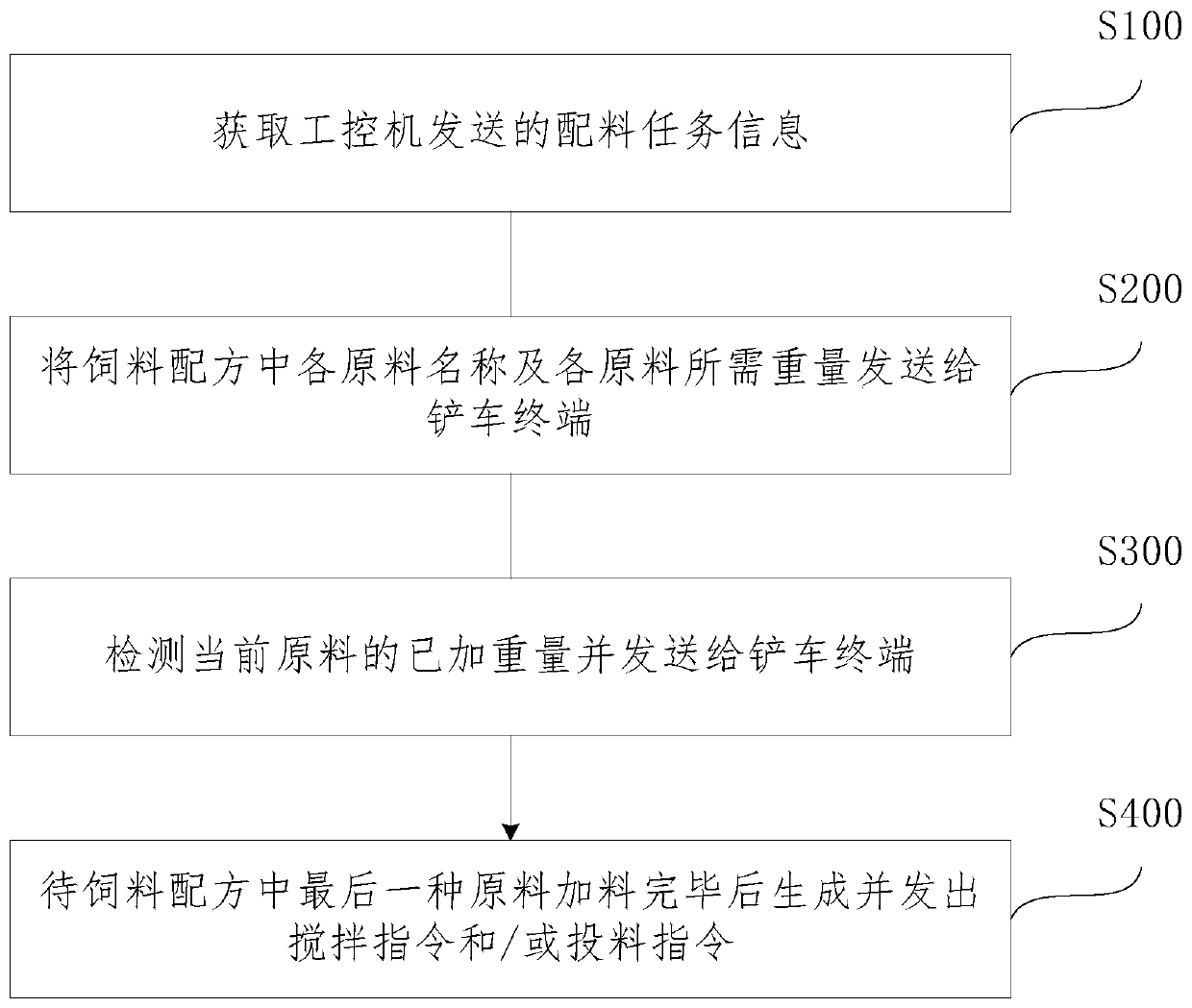

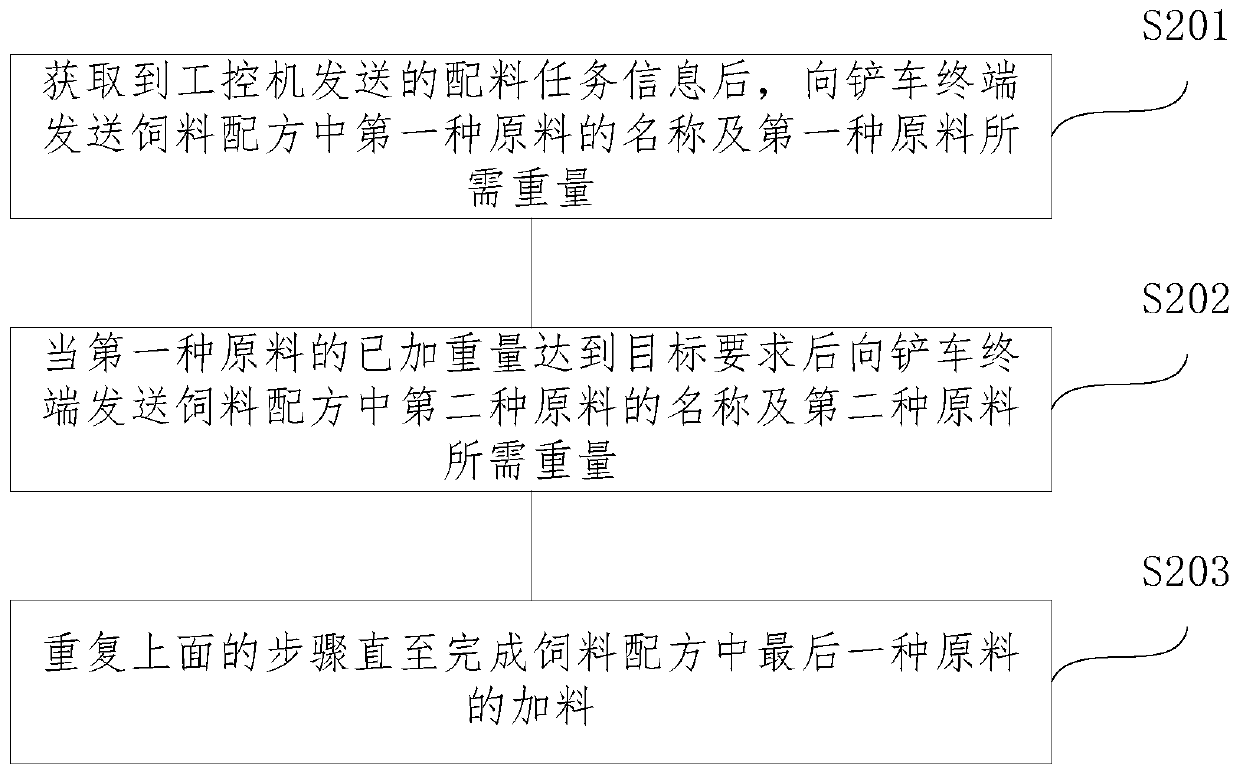

Feed batching process monitoring method and device, electronic equipment and storage medium

ActiveCN111123856AImprove batching accuracyImprove eating qualityTotal factory controlProgramme total factory controlMilk cow'sProcess engineering

The invention relates to the technical field of communication, in particular to a feed batching process monitoring method, a feed batching process monitoring device, electronic equipment and a storagemedium. The feed batching process monitoring method comprises the following steps of: acquiring batching task information sent by an industrial personal computer, wherein the batching task information comprises a feed formula, a feed weight and a delivery destination; transmitting names of all the raw materials in the feed formula and the required weight of the raw materials to a forklift terminal; detecting the added weight of the current raw materials and transmitting the added weight to the forklift terminal; and generating and sending a stirring instruction and / or a feeding instruction after the last raw material in the feed formula is fed. According to the feed batching process monitoring method, the task is transmitted to a mixer truck terminal by means of the industrial personal computer, then the mixer truck terminal can decompose the task to the forklift truck terminal, and the charging weight can be obtained in real time in the forklift truck charging process. Through adopting the monitoring method, the batching precision of the feed is improved, the feeding quality of dairy cows is improved, and then the milk production quality can be improved.

Owner:BEIJING SHOUNONG LIVESTOCK DEV

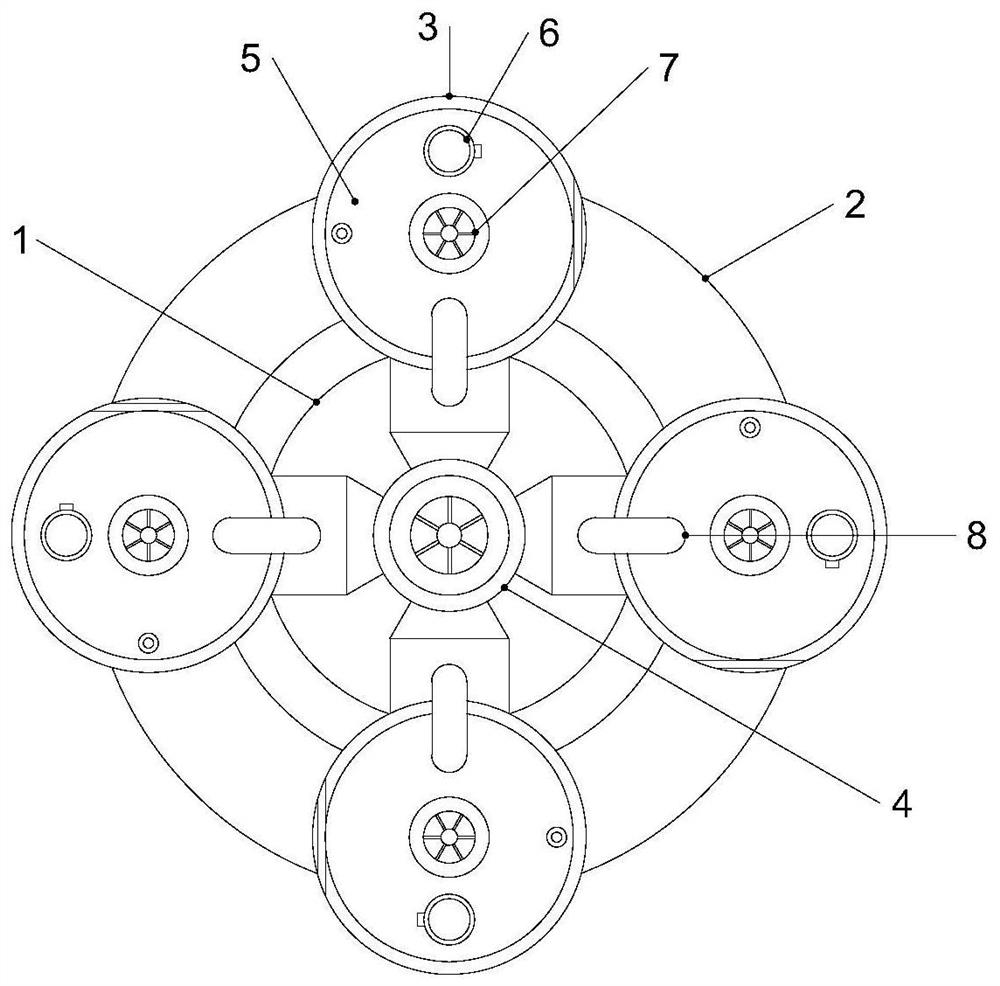

Quantitative batching device and method for producing and processing special refractory material

PendingCN112023811ALow costImprove batching accuracyRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention discloses a quantitative batching device and method for producing and processing a special refractory material. The quantitative batching device comprises a base; supporting columns arefixedly installed on the bottom end edge and the top end edge of the base; a controller is fixedly embedded in the front face of the base; a mixing barrel is fixedly installed in the center of the topend of the base; and the bottom end of the mixing barrel penetrates through the base and is provided with a discharging opening; raw material barrels are fixedly embedded in the edge of a fixing ring; raw material covers are arranged at the top ends of the raw material barrels and provided with feeding openings; a stirring motor and a return pipe; an air suction pump and a flow valve are installed at the bottom of each raw material barrel. The quantitative batching device and method for producing and processing the special refractory material have the advantages of simple and reasonable structure, novel design and easiness in operation; the multiple sets of raw material barrels are arranged to facilitate independent storage of all raw materials; a weighing box is arranged to facilitate accurate weighing of the raw materials and conveying of the raw materials into the mixing barrel for uniform stirring, and therefore, the butt joint blockage and caking phenomena of the raw material arereduced; and the device and method have high practical value.

Owner:连云港海蓝研磨材料有限公司

Premix feed capable of preventing and curing porcine reproductive and respiratory syndrome (PRRS) of pregnant sows, and preparation method of premix feed

InactiveCN106615660AQuality assuranceGuaranteed stabilityFood processingAnimal feeding stuffAnti stressDisease

The invention relates to premix feed capable of preventing and curing porcine reproductive and respiratory syndrome (PRRS) of pregnant sows. The premix feed is prepared from a nutrition additive, a Chinese herbal medicine additive and a diluent; the raw medicinal material content of the Chinese herbal medicine additive is 0.5-8% of the weight of the premix feed; the Chinese herbal medicine additive is prepared by extracting or directly grinding the following medicines in parts by weight: 0.5-3 parts of honeysuckle flower, 0.5-3 parts of herba houttuyniae, 0.5-3 parts of radix paeoniae rubra, 0.5-3 parts of radix astragali seu hedysari and 0.5-3 parts of cortex mori; the diluent is a mixture of zeolite powder and rice hull powder, wherein the weight ratio of the zeolite powder to the rice hull powder is equal to 1 to 1. The premix feed can meet vitamins, trace elements, amino acids and the like which are needed by staged growth and development of the pregnant sows, improves production efficiency and enhances immunity; the Chinese herbal medicine additive added into the premix feed has the functions of clearing away heat and toxic materials, eliminating carbuncle and removing pus, cooling blood and dispersing blood stasis, strengthening body resistance and dispelling evils, resisting bacteria and eliminating inflammation, and the like; therefore, the premix feed improves the body immunity, disease resistance and anti-stress ability of pigs, and has a remarkable effect for preventing and treating highly pathogenic PRRS.

Owner:ZHONGYUEMINAN BEIJING TECH DEV CO LTD

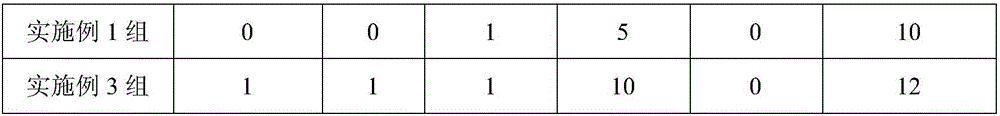

Jet flow self-suction molybdenum disulfide production batching and slurry mixing device

PendingCN110743407ASimple structureEasy to processFlow mixersTransportation and packagingEngineeringProcess engineering

The invention discloses a jet flow self-suction molybdenum disulfide production batching and slurry mixing device. The jet flow self-suction molybdenum disulfide production batching and slurry mixingdevice is characterized by comprising a powder bin, a hydrochloric acid storage tank, a slurry mixing tank, a jet pump and a slurry pump, wherein an outlet in the bottom of the powder bin is connectedwith a side inlet of the jet pump through a pipeline and a valve I; an outlet in the bottom of the jet pump is connected with an inlet of the slurry mixing tank through a pipeline; an outlet of the slurry mixing tank is connected with an inlet of the slurry pump 5 through a pipeline and a valve III; the outlet of the hydrochloric acid storage tank is connected with the inlet of the slurry pump through a pipeline and a valve II; one path of the outlet of the slurry pump communicates with an inlet in the top of the jet pump through a pipeline and a valve IV; and the other path of the outlet ofthe slurry pump communicates with a next reaction device through a pipeline and a valve V.

Owner:洛阳申雨钼业有限责任公司

Dynamic batching digital control system and method

InactiveCN100577272CReduce construction costsAdvanced and reasonable digital control technologyMixer accessoriesRatio controlFrequency changerCircular disc

The invention discloses a dynamic dosing digital control system, which comprises a computer control system used for determining the total flow based on production plans, generating charger sheets automatically dosing ingredients, converting alternate current into direct current and obtaining the output frequency of a transducer; a dosing circular disc communicating and connected with the computer control system, which is used for giving ingredient flow according to the charger sheets; a weighing sensor arranged on a weighing belt and communicating with the computer control system, which is used for weighing the weight of ore dosed by the dosing circular disc and feeding the detected data back to the computer control system; a frequency conversion motor connected with and communicating with the computer control system and the dosing circular disc, which is used for regulating the speed according to the output frequency of the transducer obtained by the computer control system based on the detected data, and further regulating the rotation speed of the dosing circular disk. The invention further discloses a dynamic dosing digital control method. By adopting the control system and the control method, the construction cost and usage and maintenance cost are reduced, and the dosing precision is improved.

Owner:武钢集团有限公司

Premixed feed processing technique

InactiveCN105685496AIncrease productivityImprove batching accuracyFood processingAnimal feeding stuffFeed processingCart

The invention relates to a premixed feed processing technique. Technique equipment are in vertical arrangement according to the flow, a mobile cleaning type feeding cart is used for feeding various raw materials into special batch bins, the raw materials are conveyed to batching scales via a tubular variable-pitch screw conveyor, one batching scale is used specially for one component, trace elements are directly put into a mixing machine after being batched with an electronic trace element batching scale manually and subjected to electronic scanning, a door of the mixing machine is opened after mixing uniformity reaches more than or equal to 95% to allow the premixed feed to fall into two finished product bins respectively, after the premixed feed is directly packed from lower packing openings of the two finished product bins, the premixed feed is conveyed to a finished product warehouse via a belt conveyor for storage, and productivity of the back-end conveyor is higher than that of the front-end conveyor by 5-10%. The premixed feed processing technique has the advantages that cross contamination is reduced, weighing accuracy is improved, traceability is realized, and product quality and production effectiveness are improved comprehensively.

Owner:储福娣

An automatic batching system

ActiveCN104028131BImprove batching accuracyIncrease productivityMixing methodsAutomatic balancing valvesVacuum extractor

An automatic batching system comprises a solid material conveying system and a liquid material conveying system; the solid material conveying system comprises a batching machine, a feeding machine and a vacuum conveying device; the vacuum conveying device comprises a vacuum conveying pipe and a vacuum extractor, a bin discharging hole of the batching machine is connected with a bin feeding hole of the feeding machine through a vacuum conveying pipe, a bin of the feeding machine is a closed cavity, the upper portion of the bin is spaced through a dedusting filter to form a vacuumized channel, and the vacuumized channel is communicated with the vacuum extractor through the vacuum conveying pipe; a bin discharging hole of the feeding machine is connected with a mixer feeding hole through a pneumatic butterfly valve; the liquid material conveying system comprises a liquid stirring kettle; a discharging hole of the stirring kettle is provided with an automatic ball valve and is connected with the mixer feeding hole through the automatic ball valve; the powder feeding machine and the stirring kettle are respectively provided with a weighing sensor. The full-automatic batching system is adopted, the automatic whole batching process and continuous batching are achieved, and the batching precision of raw materials is improved.

Owner:桐乡市京工树脂有限公司

Material automatic conveying, batching, metering and packaging system

PendingCN113650862AGood physical propertiesCompact structureRotary stirring mixersMixer accessoriesControl engineeringWorking environment

The invention discloses a material automatic conveying, batching, metering and packaging system. The system is compact in structure, is practical for a small-sized batching and packaging process, and is also expanded and analogized to large-sized process engineering needing batching. The system is high in batching precision and weighing precision, and meets a large-batch and continuous working environment. The system adapts to working environments with high environmental protection requirements, and the whole process can be operated in closed space. The system has the biggest advantages that the automation degree is high, the whole process is operated indoors, if the physical performance of materials is good and the previous and next working procedures and the process outside the system are smooth, the program of an electric appliance microcomputer control operation table can be set to be a fool mode of on-off one-key control, required metering specifications are input from the electric appliance microcomputer control operation table, discharging and packaging are carried out, the whole set of technological process is controlled by the electric appliance microcomputer control operation table, the defects that the occupied area of a working site is large and many participants are needed are overcome, the labor intensity is reduced, the working efficiency is improved, and the working environment is optimized.

Owner:湖南港建输送设备有限公司

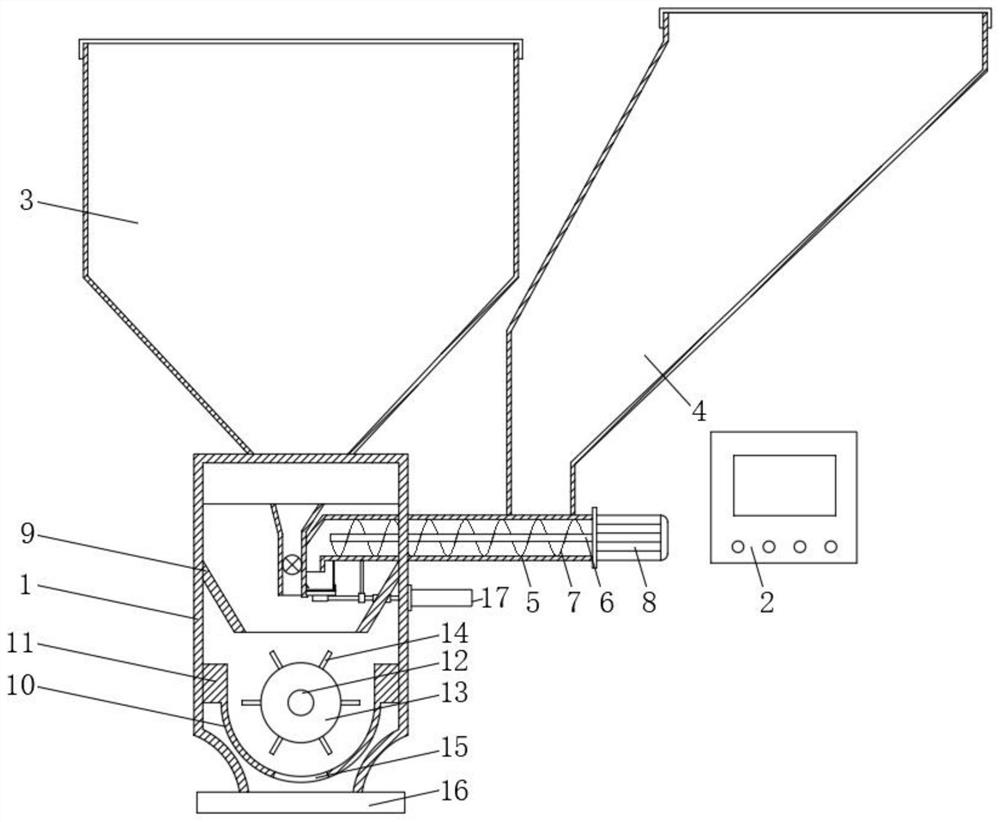

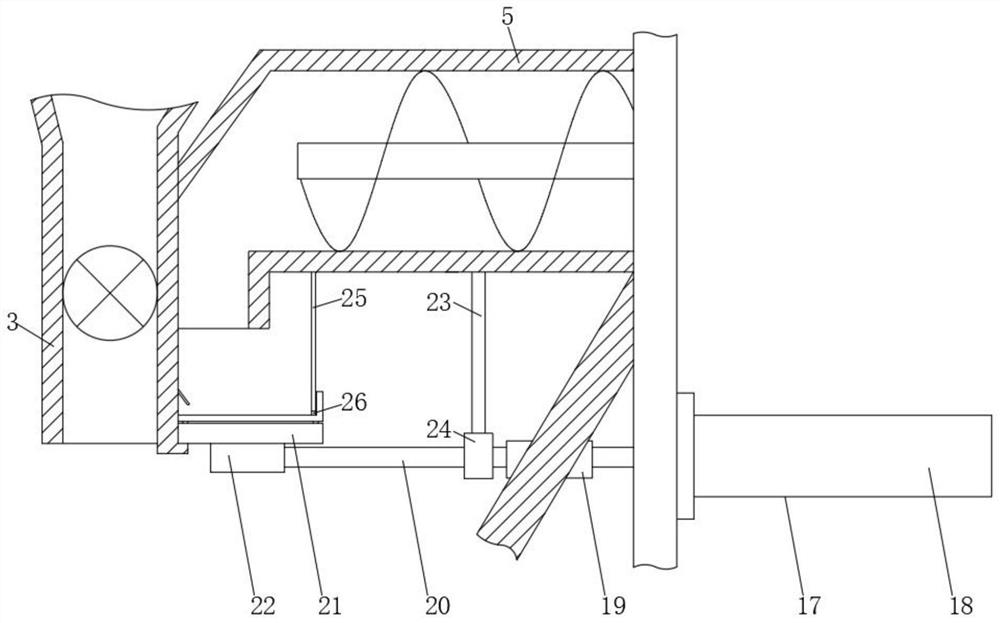

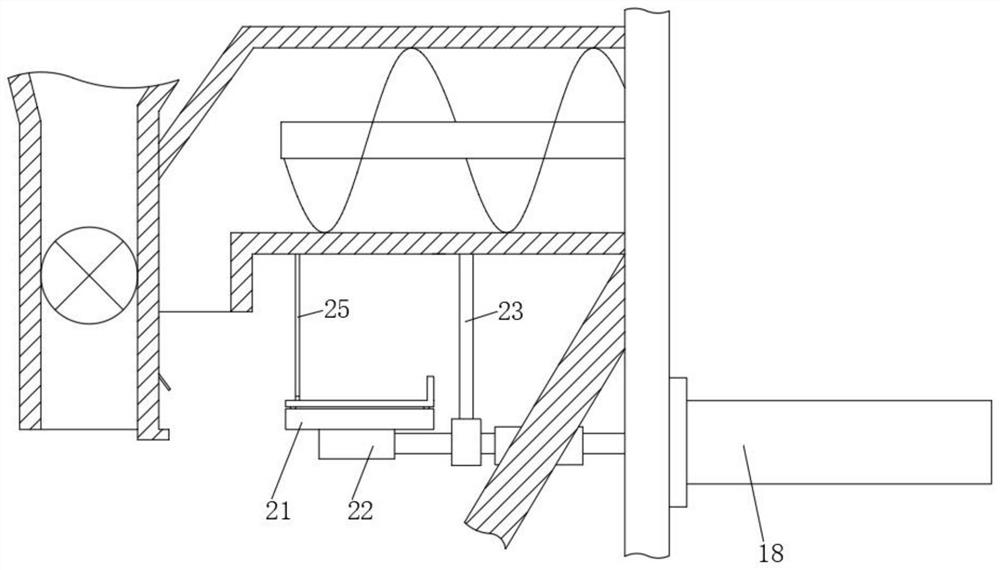

Weighing type color master machine and automatic correction method and application thereof

The invention discloses a weighing type color master machine and an automatic correction method and application thereof. The weighing type color master machine comprises a base and a control device, a main material barrel is fixedly installed on the upper portion of the base, a feeding barrel is fixedly installed on one side of the base, a shaft rod is rotatably installed in the feeding barrel, a spiral blade is fixedly installed outside the shaft rod, a stepping motor is fixedly installed at one end of the feeding barrel, and a color master barrel is fixedly installed on the upper portion of the feeding barrel. According to the weighing type color master machine, a color master batch pushing mode is changed into a stepping type material pushing mode through the stepping motor, and the color master batch pushed in a stepping mode each time can be weighed by a weighing platform, so that people can conveniently and clearly know the weight of the color master batch falling in the stepping mode each time; and the automatic correction of the weighing type color master machine can be effectively realized, so that the proportion of a main material to the color master batch is kept the same as a preset proportion, the batching precision is higher, and the use is facilitated.

Owner:深圳市奥酷曼智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com