Automatic small-size material blending equipment

A technology of automatic batching and equipment, applied in mixer accessories, mixed material pretreatment, mixer and other directions, can solve the problems of poor stability of small material production process, high personnel turnover rate, increase labor intensity of employees, etc., to improve the efficiency of material distribution and accuracy, improve the on-site environment, and reduce the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

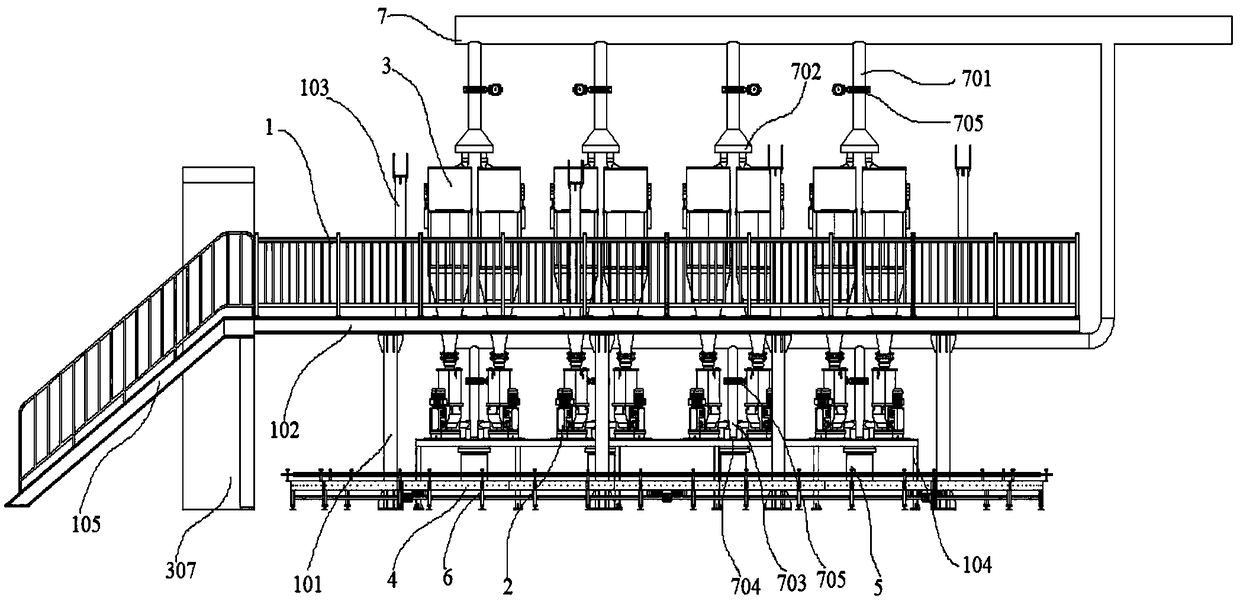

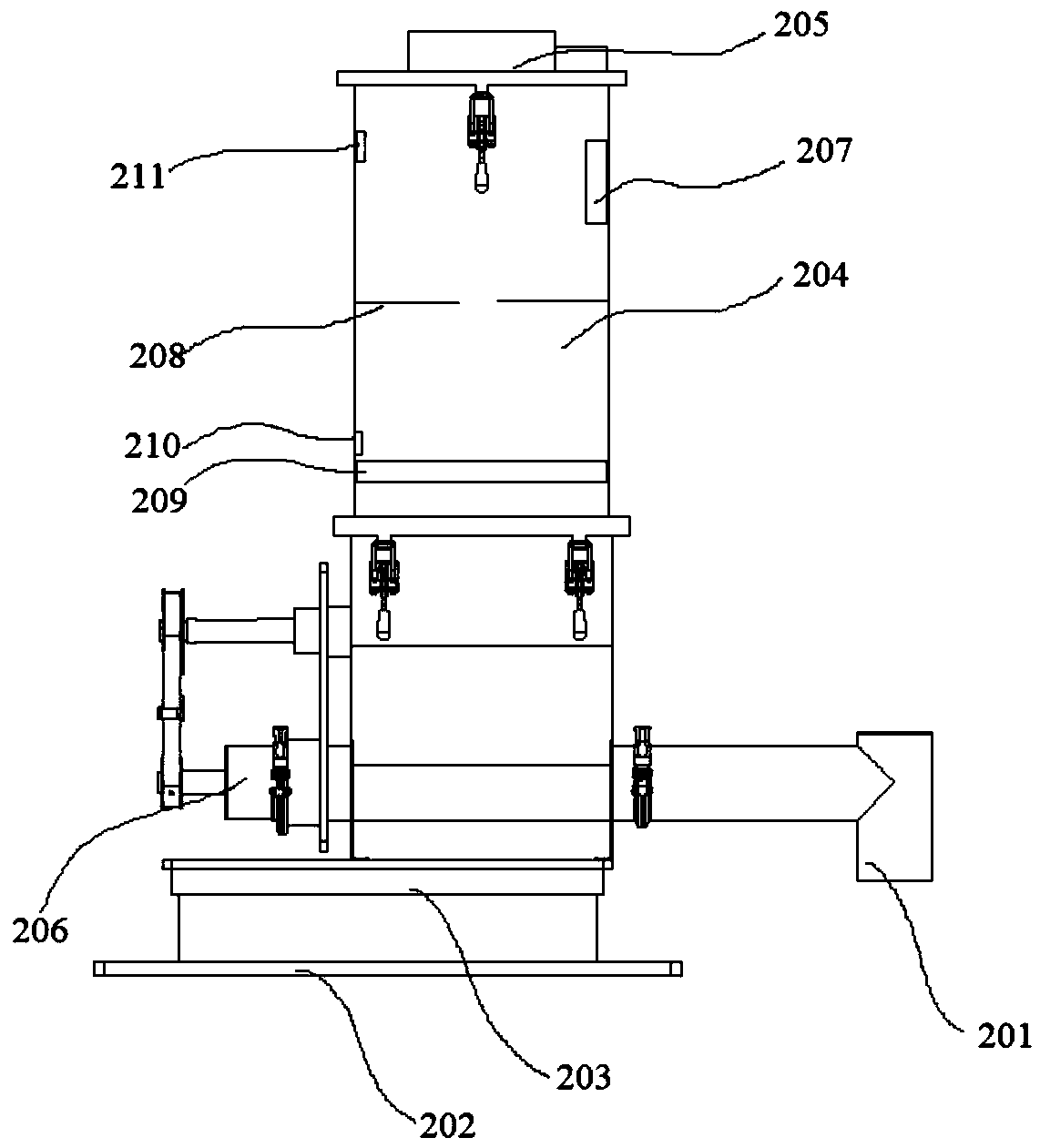

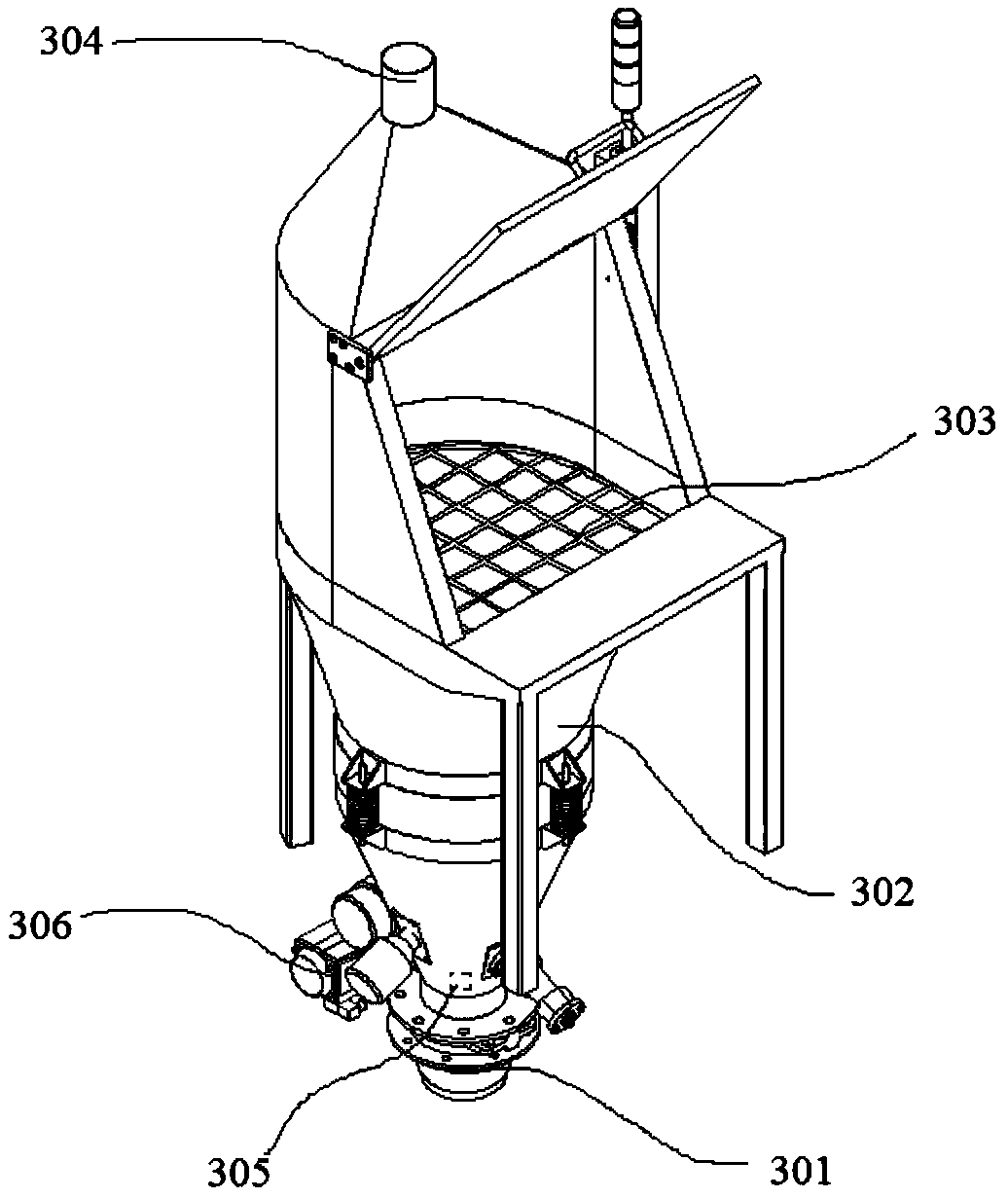

[0046] The invention discloses an automatic batching equipment for small materials. The support frame of this equipment comprises steel frame 1, and this steel frame comprises the support column 101 that is located on the ground, and this support column is provided with support platform 102, and support platform is provided with the suspender 103 that is fixedly connected with ceiling, in addition It includes a base 104 for supporting the following loss-in-weight weighing scale, the base 104 is positioned on the ground, and a staircase 105 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com