Quality monitoring system and method of tobacco primary process

A quality monitoring and silk-making technology, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of not being able to guide the silk-making production process well, and the control method of silk-making process parameters cannot objectively reflect the actual production status, etc. To achieve the effect of convenient homogeneous production analysis, reducing labor intensity and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

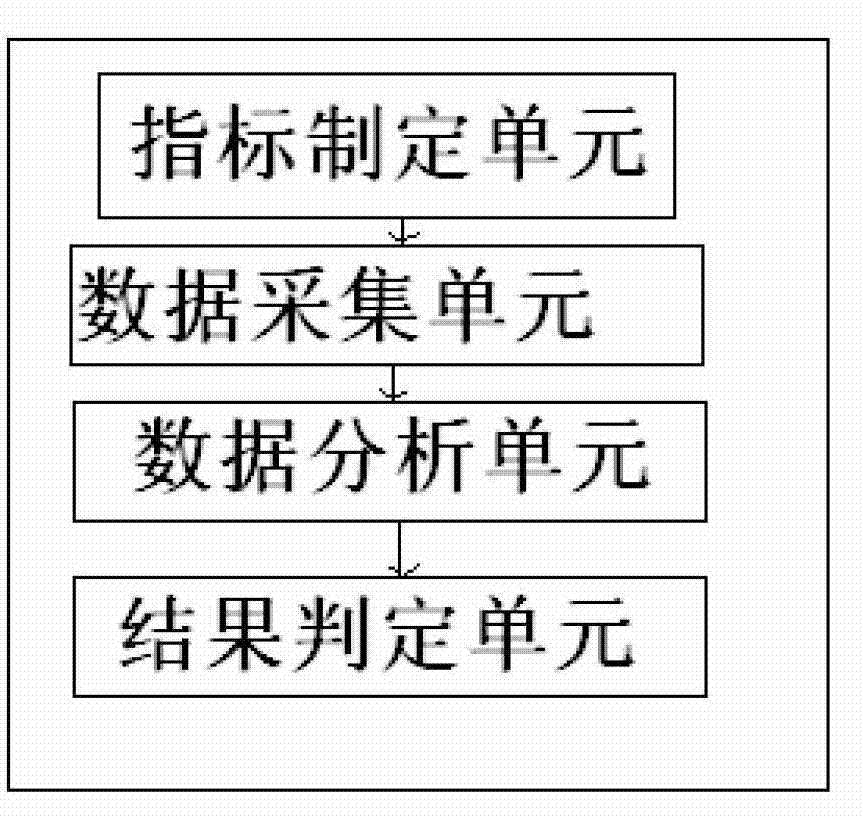

[0034] Silk-making process quality monitoring system of the present invention comprises

[0035] Index formulation unit: analyze the historical data in the central control data system, obtain the indicators that affect the quality of the silk-making process, formulate the benchmark value of each indicator, and set the upper limit and lower limit of the SPC control of the indicator;

[0036] The data acquisition unit sets the batches for tracking production, and collects the index values of the batches of products from the central control data system during the silk making process;

[0037] The data analysis unit analyzes the collected index value and compares it with the benchmark value of the index obtained in the step (1), when the collected index value exceeds the upper limit of the SPC control of the index or lower limit, alarm display;

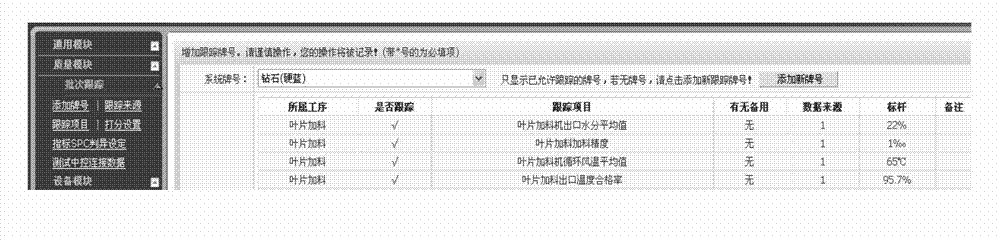

[0038] The result judging unit performs SPC judgment after the silk making process is completed, and forms the SPC judgment result. ...

Embodiment 2

[0045] On the basis of the silk-making process quality monitoring system described in Example 1, an evaluation unit is also included. After the production of the batch is completed, the batch is evaluated and the quality of the batch is quantified.

[0046] A kind of silk making process quality monitoring method described in the present embodiment, comprises the following steps:

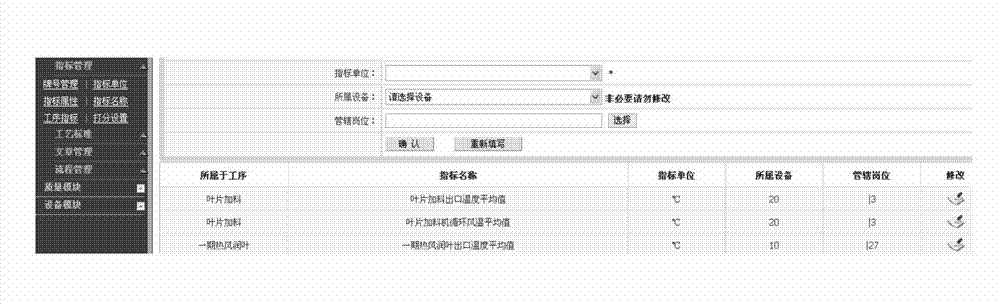

[0047] (1) Analyze the historical data of the past two years in the central control data system to obtain indicators that affect the quality of the silk-making process, such as figure 2 shown. At the same time, through preliminary screening, a large number of parameters irrelevant to batch quality are eliminated, reducing the subjectivity of data submitted by craftsmen and reducing the workload of staff. Then, according to the obtained indicators that affect the quality of the silk-making process, the benchmark value of each indicator is formulated, and the upper and lower limits of the SPC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com