Semi-conductive shield material used for high-voltage direct-current cable and preparation method thereof

A high-voltage direct current, semi-conductive technology, applied in the field of cable materials, can solve the problems of less shielding materials for high-voltage direct current, cannot meet the production needs of high-voltage direct current cables, and space charge accumulation, etc., to achieve ultra-smooth interface, good heat resistance, The effect of reducing the amount of filler used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A semi-conductive shielding material for high-voltage DC cables, according to mass, comprising:

[0038] Base resin: 700g

[0039] Superconducting carbon black: 300g

[0040] Space charge inhibitor: 15g

[0041] Antioxidant: 10g

[0042] Lubricant: 20g

[0043] Cross-linking agent: 20g

[0044] Coupling agent: 5g

[0045] The melt index of the base resin is 4g / 10min, the mass content of acrylate is 27%, and the density is 0.926g / cm 3 ethylene-butyl acrylate copolymer.

[0046] The superconducting carbon black selected particle size is 15-20nm, specific surface area is 355m 2 / g, superconducting carbon black with an oil absorption of 480-510mL / 100g. .

[0047] The antioxidant used was Antioxidant 1010.

[0048] The lubricant used was silicone oil with a viscosity of 500.

[0049] The space charge inhibitors used are zeolites.

[0050] The crosslinking agent used was dicumyl peroxide (DCP).

[0051] The coupling agent used is KH550 silane coupling agent.

[0...

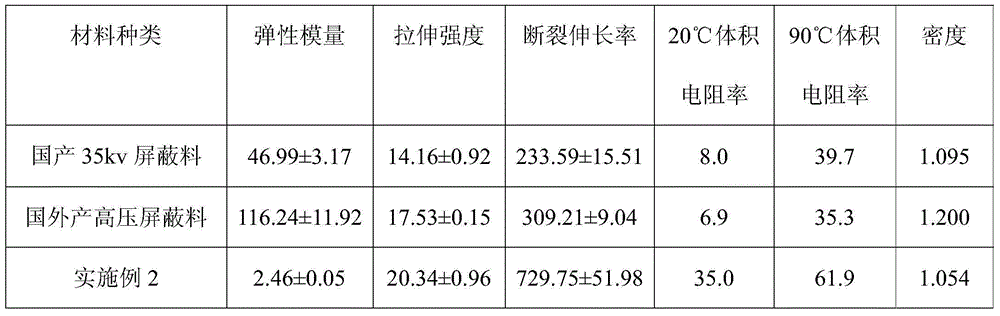

Embodiment 2

[0063] A semi-conductive shielding material for high-voltage DC cables, according to mass, comprising:

[0064] Base resin: 800g

[0065] Superconducting carbon black: 200g

[0066] Space charge inhibitor: 15g

[0067] Antioxidant: 10g

[0068] Lubricant: 20g

[0069] Cross-linking agent: 20g

[0070] Coupling agent: 5g

[0071] The melt index of the base resin is 4g / 10min, the mass content of acrylate is 27%, and the density is 0.926g / cm 3 ethylene-butyl acrylate copolymer.

[0072] The superconducting carbon black selected particle size is 15-20nm, specific surface area is 355m 2 / g, superconducting carbon black with an oil absorption of 480-510mL / 100g. .

[0073] The antioxidant used was Antioxidant 1010.

[0074] The lubricant used was silicone oil with a viscosity of 500.

[0075] The space charge inhibitors used are zeolites.

[0076] The crosslinking agent used was dicumyl peroxide (DCP).

[0077] The coupling agent used is KH550 silane coupling agent.

[...

Embodiment 3

[0090] A semi-conductive shielding material for high-voltage DC cables, comprising 60 parts of matrix resin, 40 parts of superconducting carbon black, 0.5 parts of space charge inhibitor, 2 parts of antioxidant, 2 parts of Lubricant, 0.5 part of crosslinking agent, 0.2 part of coupling agent, matrix resin is ethylene-ethyl acrylate copolymer.

[0091] The preparation method of the above-mentioned semi-conductive shielding material for high-voltage DC cables comprises the following steps:

[0092] 1) Weighing: In terms of parts by mass, weigh 60 parts of matrix resin, 40 parts of superconducting carbon black, 0.5 parts of space charge inhibitor, 2 parts of antioxidant, 2 parts of lubricant, 0.5 parts Cross-linking agent, 0.2 parts of coupling agent; matrix resin is ethylene-ethyl acrylate copolymer.

[0093] 2) Mixing to make a space charge suppression masterbatch: divide the coupling agent into two parts, the first part is 5% of the total mass of the coupling agent; first, mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com