Patents

Literature

1924results about "Mixing materials pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

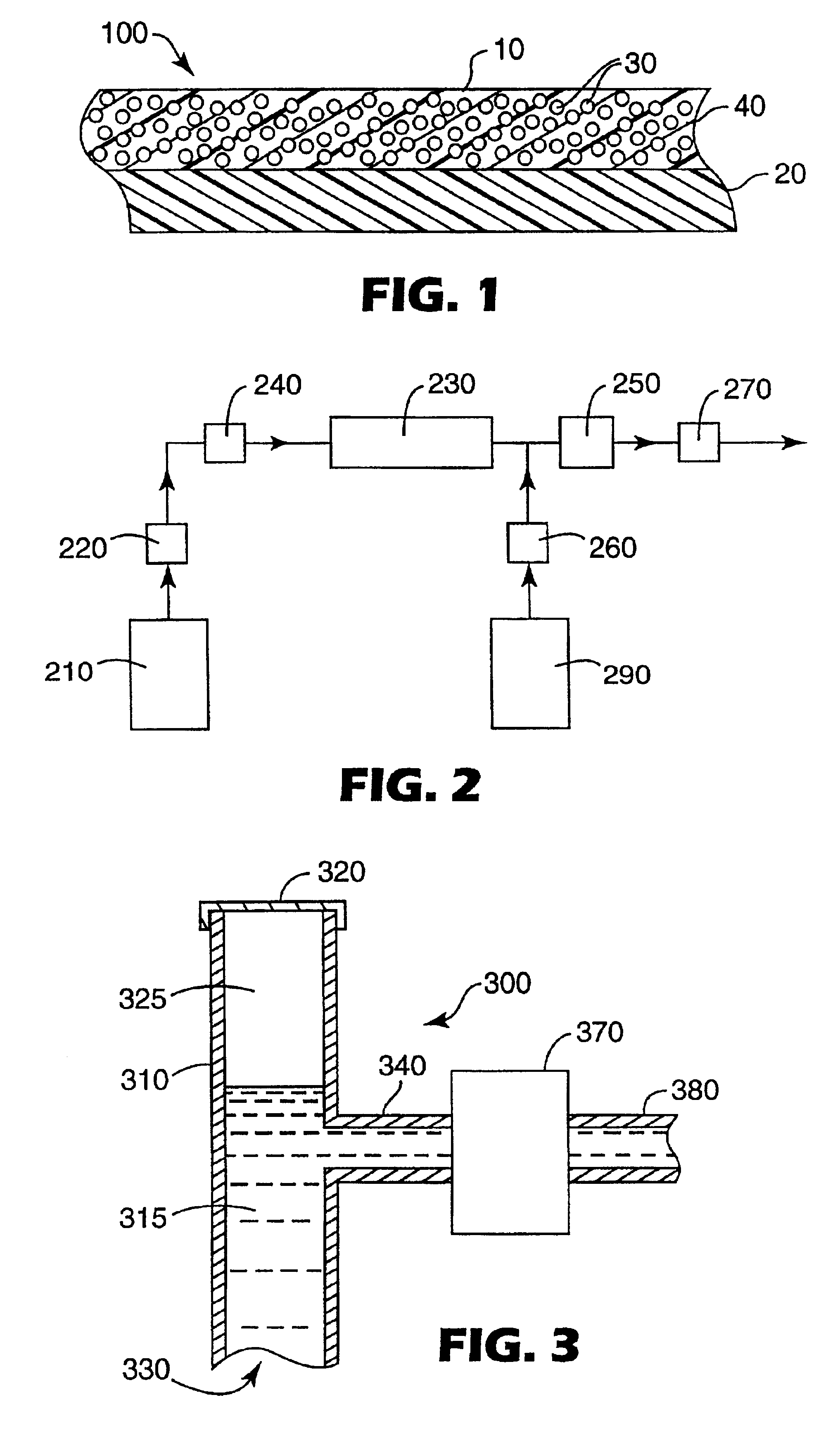

Microemulsion process and composition

ActiveUS20060057168A1Quality improvementCosmetic preparationsOrganic active ingredientsVegetable oilSilanes

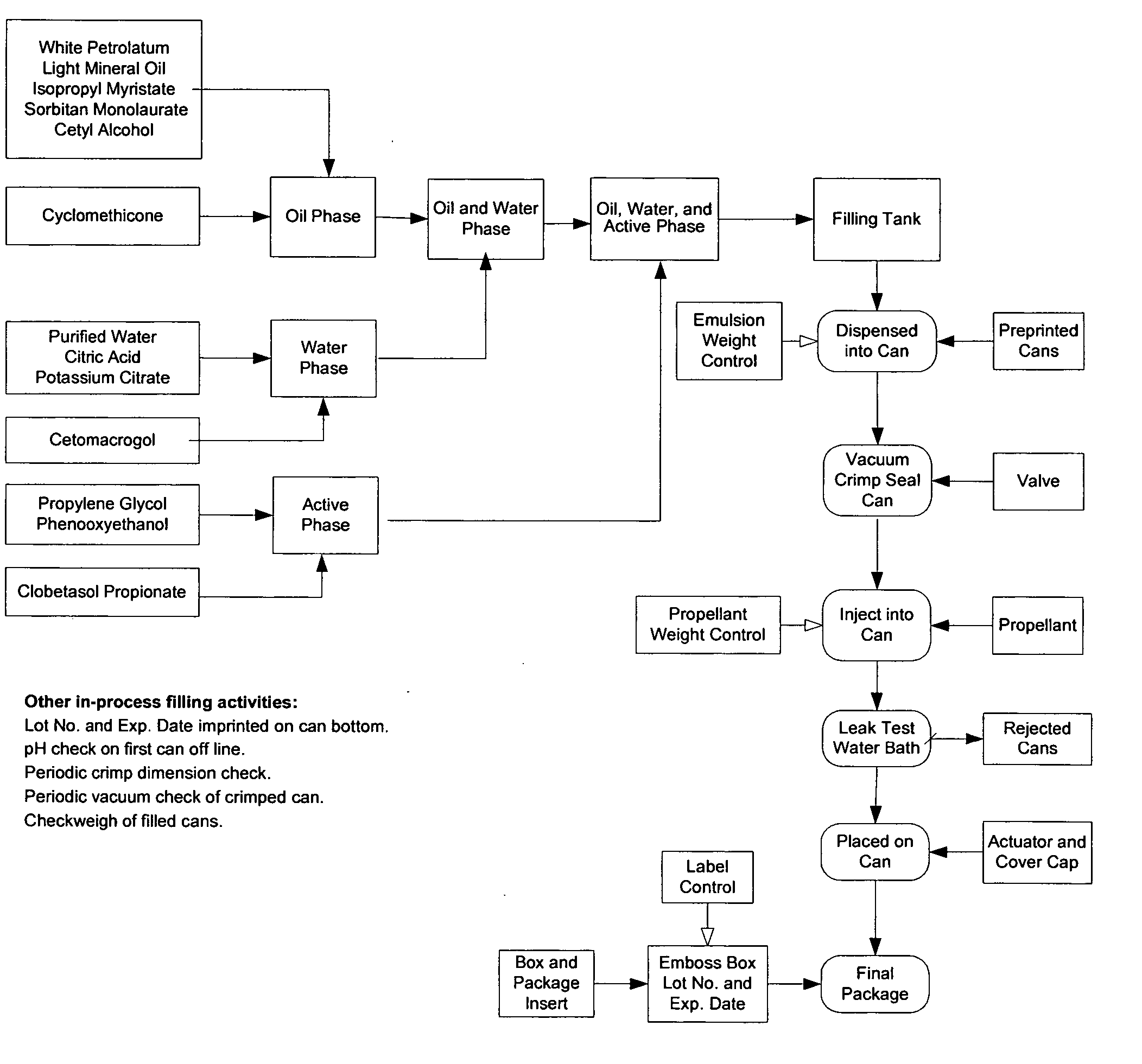

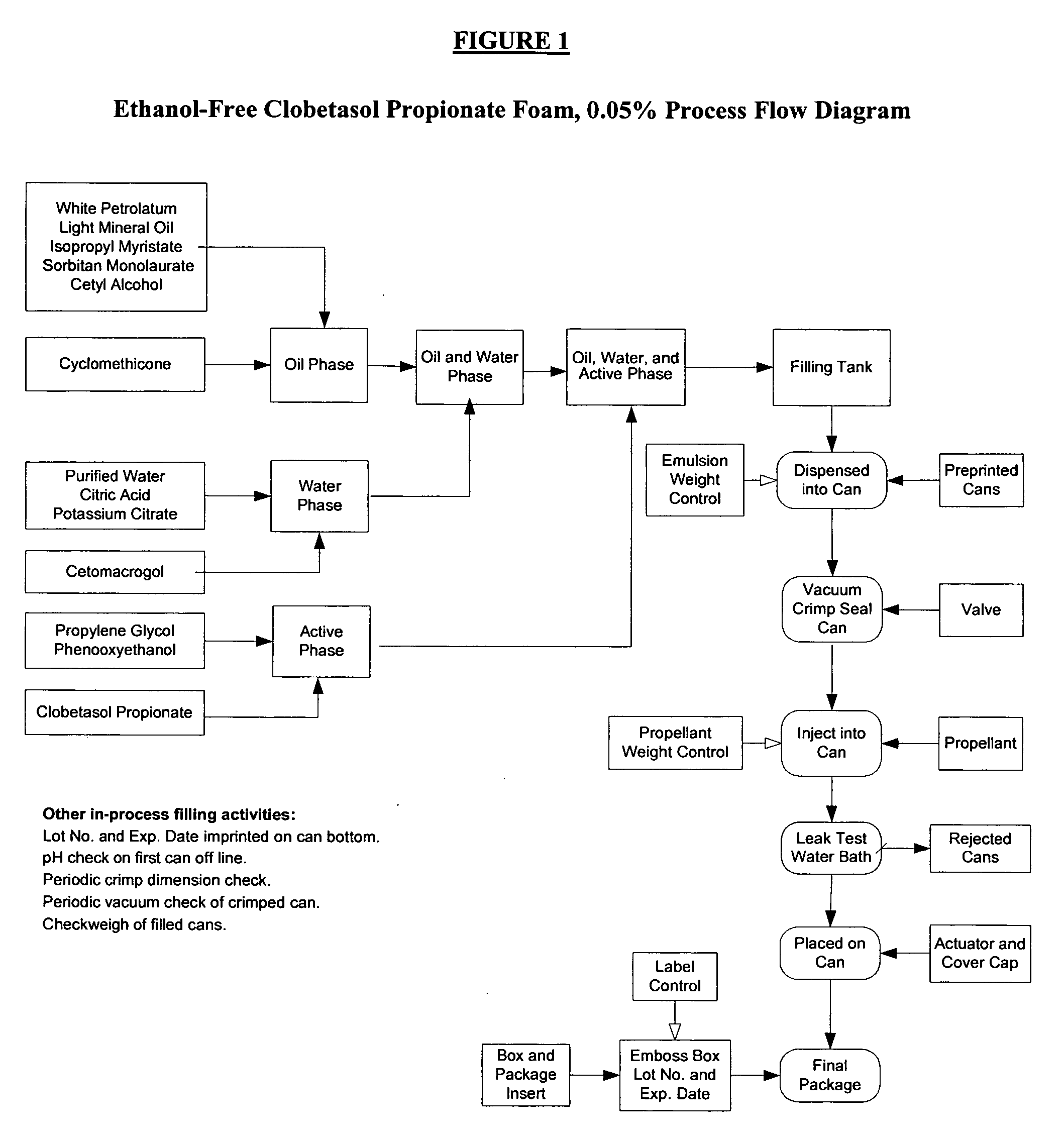

There is provided a process for the preparation of an oil in water (O / W) microemulsion or sub-micron emulsion composition for dermal delivery of at least one pharmaceutically active ingredient, the method including the steps of a) Admixing a first part including at least one of the group consisting of animal, mineral or vegetable oils, silanes, siloxanes, esters, fatty acids, fats, halogen compounds or alkoxylated alcohols; and one or more lipophilic surfactants, and a second part including water and at least one hydrophilic surfactant to achieve homogeneity, b) heating the mix of step a) to a phase assembly temperature in the range of 40-99° C., preferably 45-95° C., more preferably 65-85° C. with continuous mixing to obtain a microemulsion or sub-micron emulsion, c) allowing said microemulsion or sub-micron emulsion to cool, and d) adding a third part to said microemulsion or sub-micron emulsion at a temperature between 2° C. and said phase assembly temperature, said third part if necessary being premixed and heated until the components are dissolved and including at least one component selected from the group consisting of non-surfactant amphiphilic type compound, surfactant and water with the proviso that when the third part includes water it also includes a non-surfactant amphiphilic type compound and / or surfactant. The phase assembly temperature can be determined visually by the achievement of translucence in the composition or by measures such as conductivity which peaks and then is maintained at a plateau whilst phase assembly occurs. It has been found that whilst if a non-surfactant amphiphilic type compound such as the polyol is added together with the second part as would conventionally be the case, a microemulsion or sub-micron emulsion is not formed, by adding the so called third part, phase assembly occurs at a lower temperature than would be expected and moreover, this phase appears to assist in maintaining the microemulsion or sub-micron emulsion characteristics of the formulation during storage at normal temperatures.

Owner:STIEFEL WEST COAST

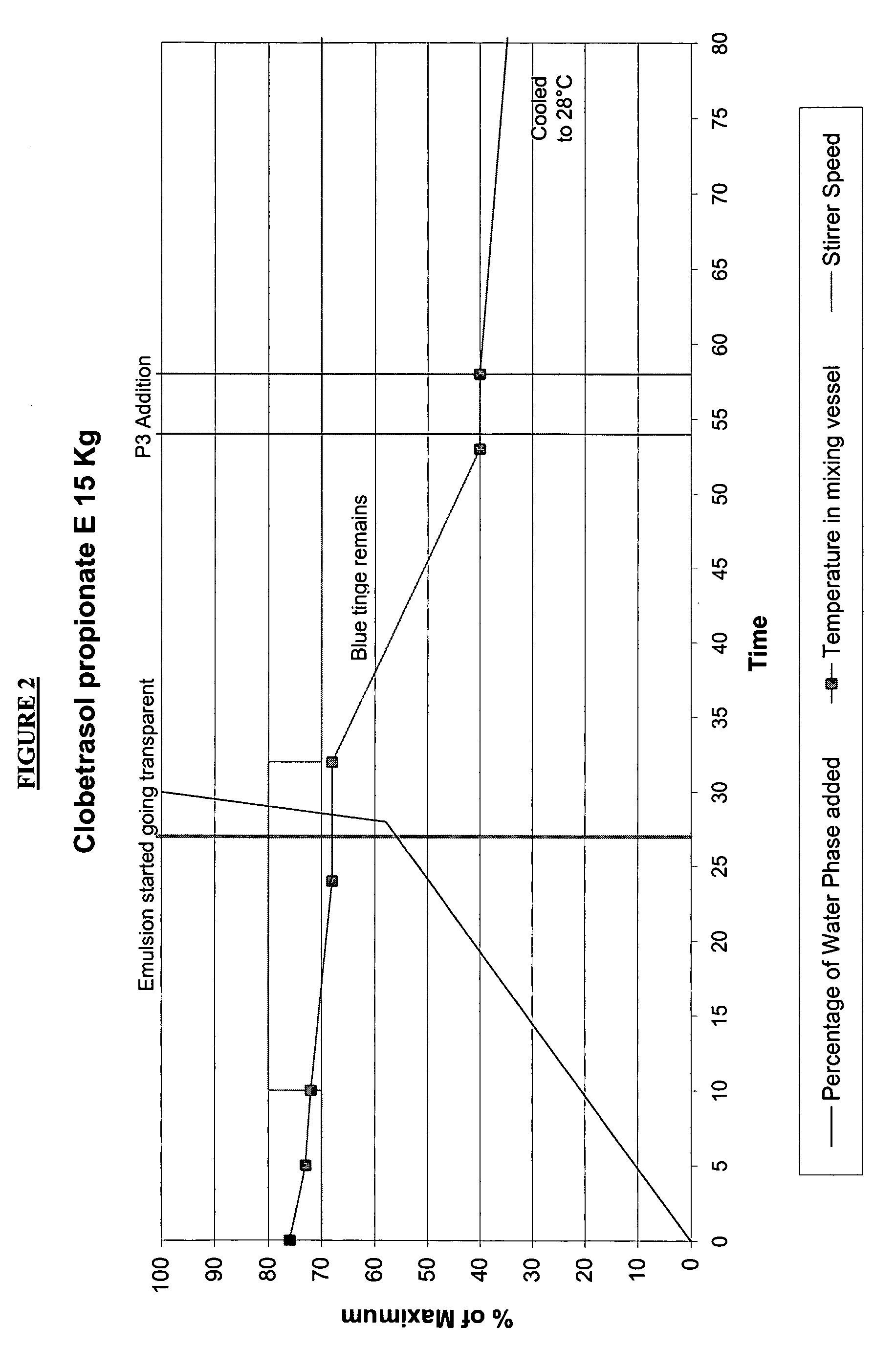

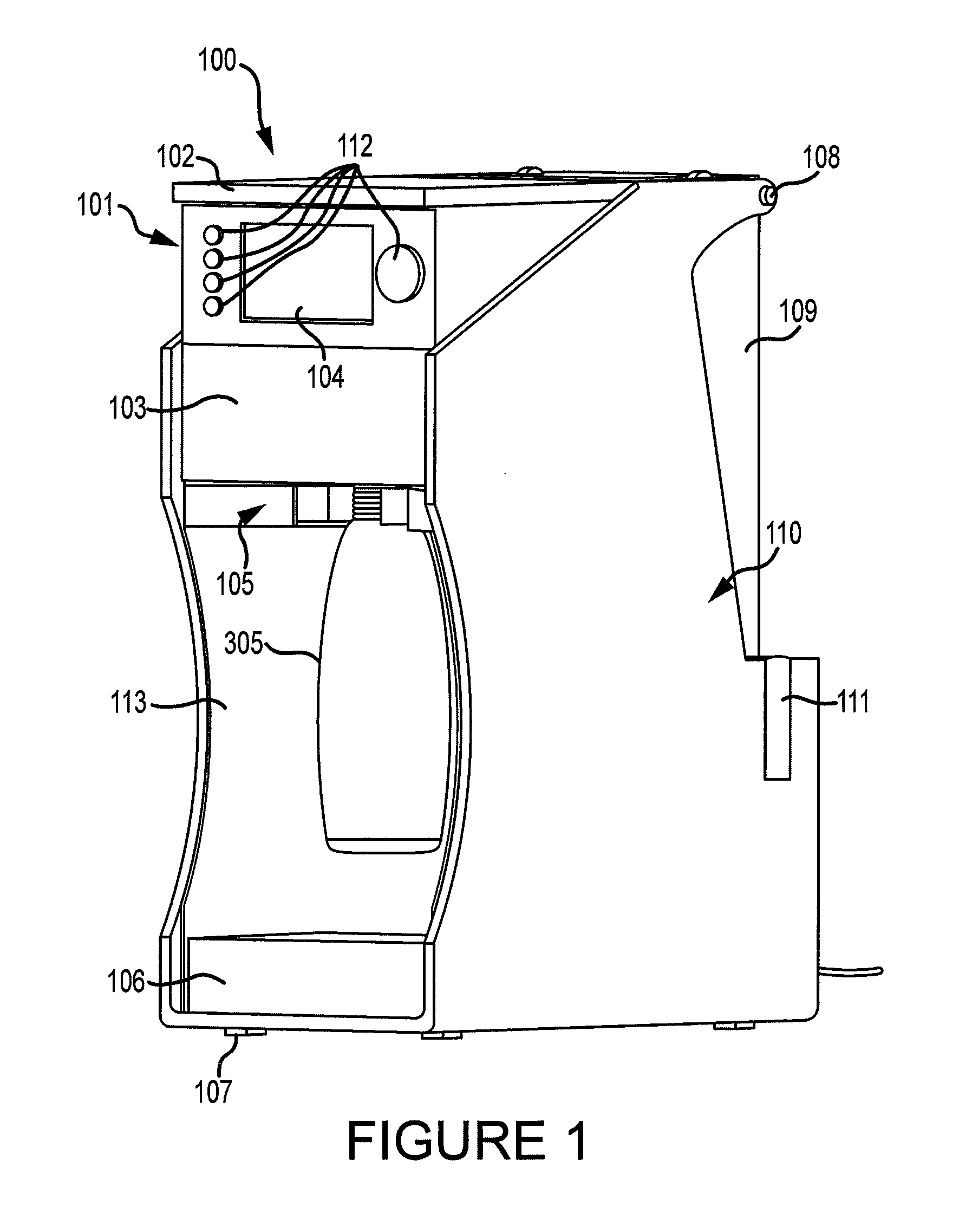

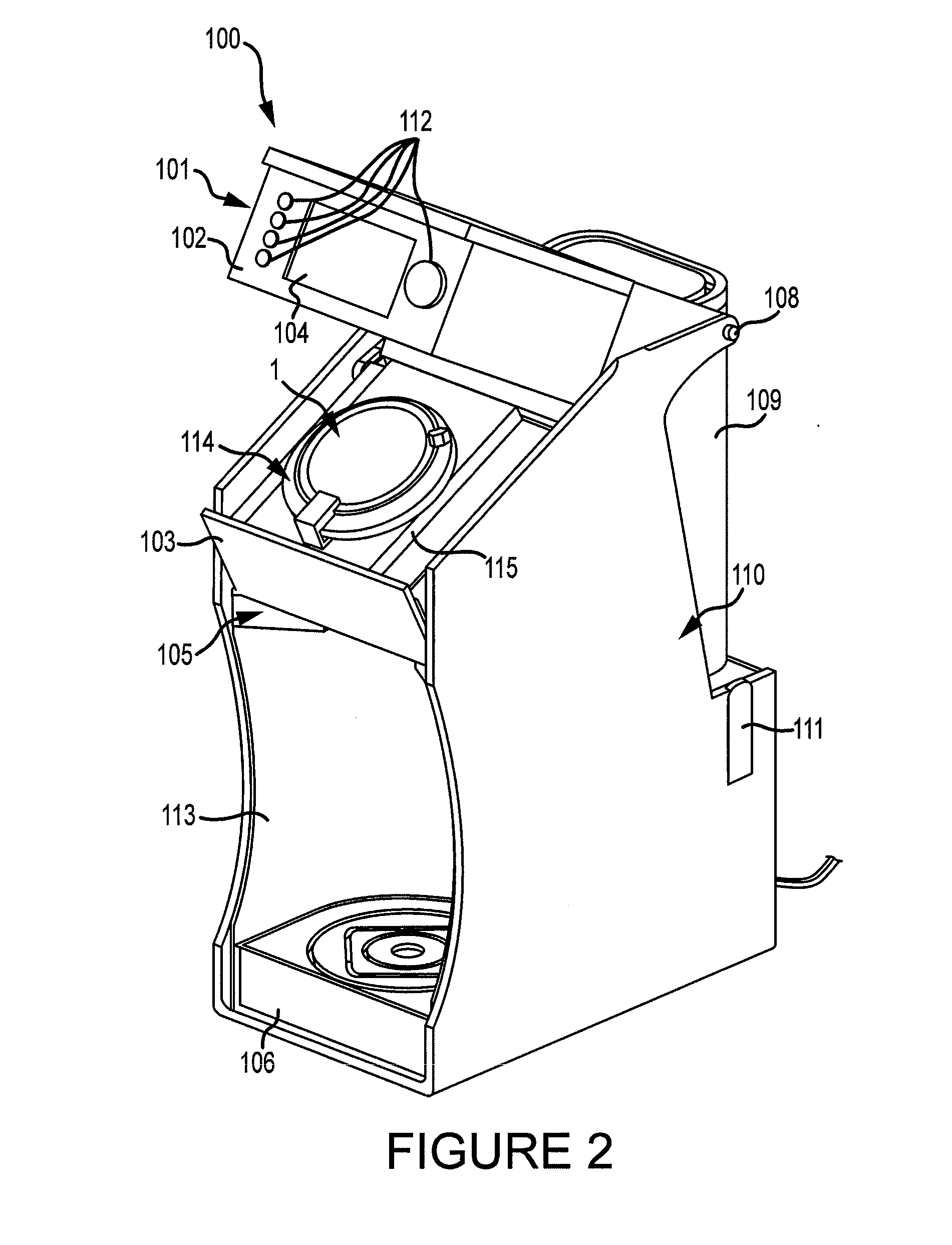

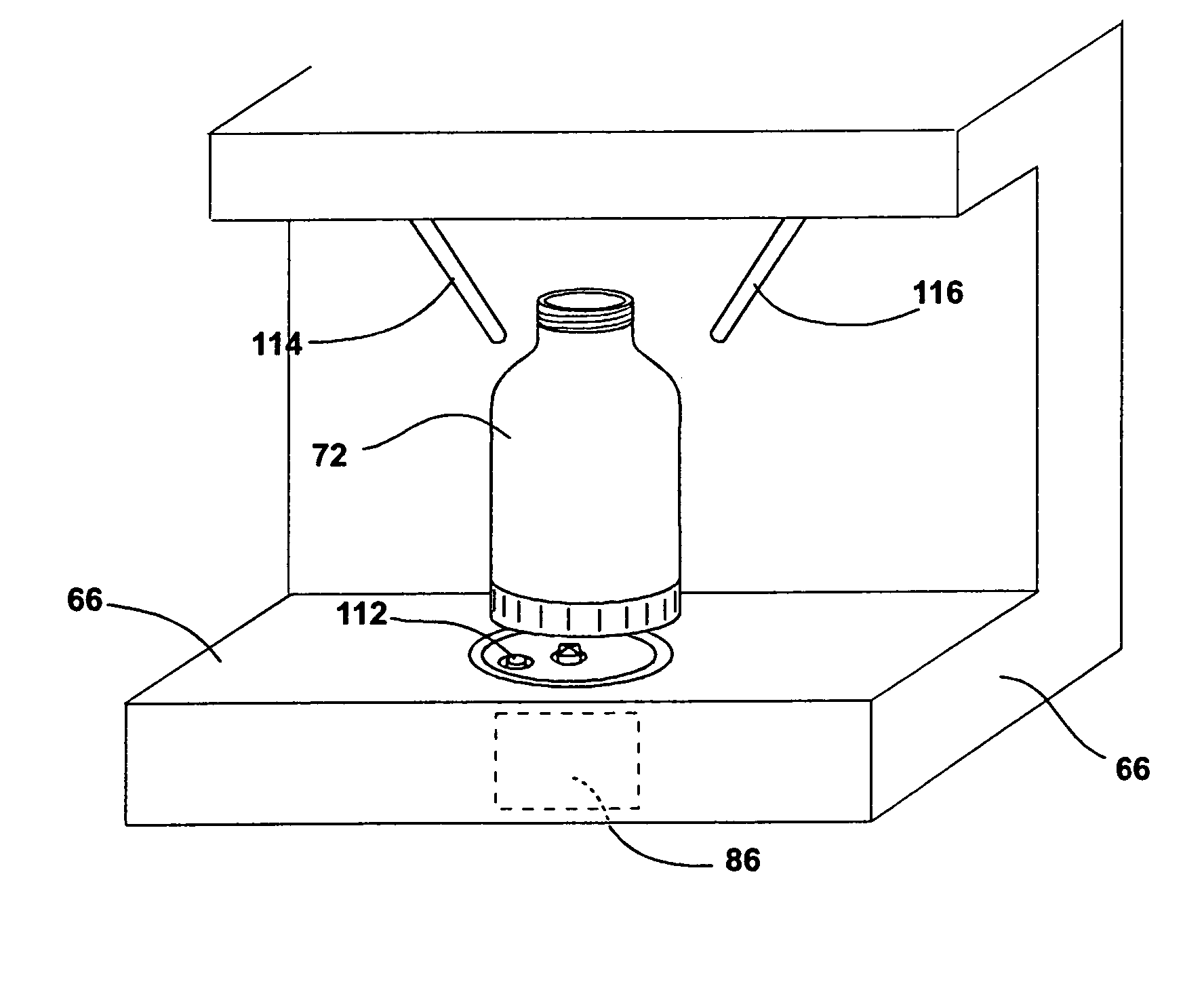

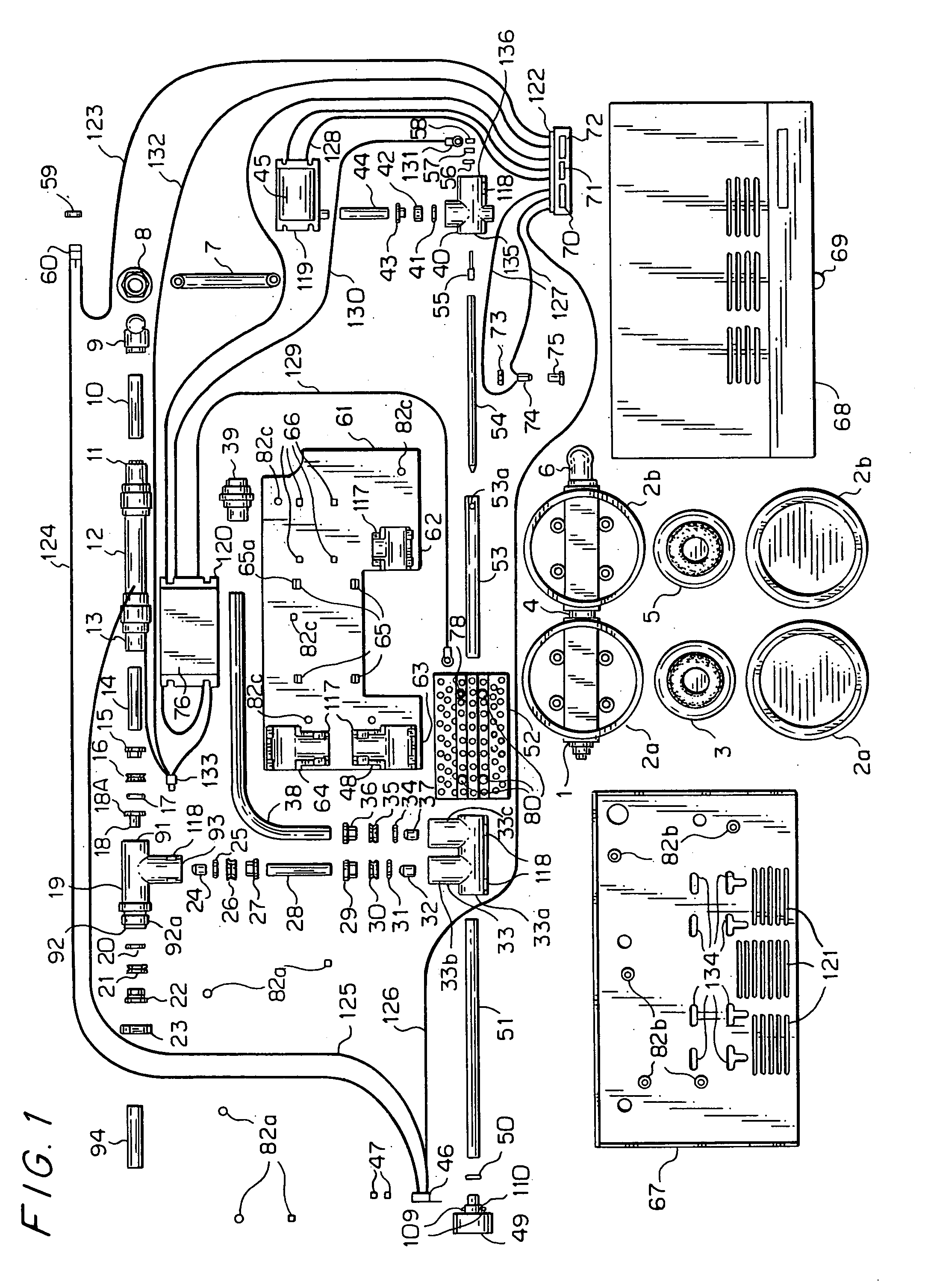

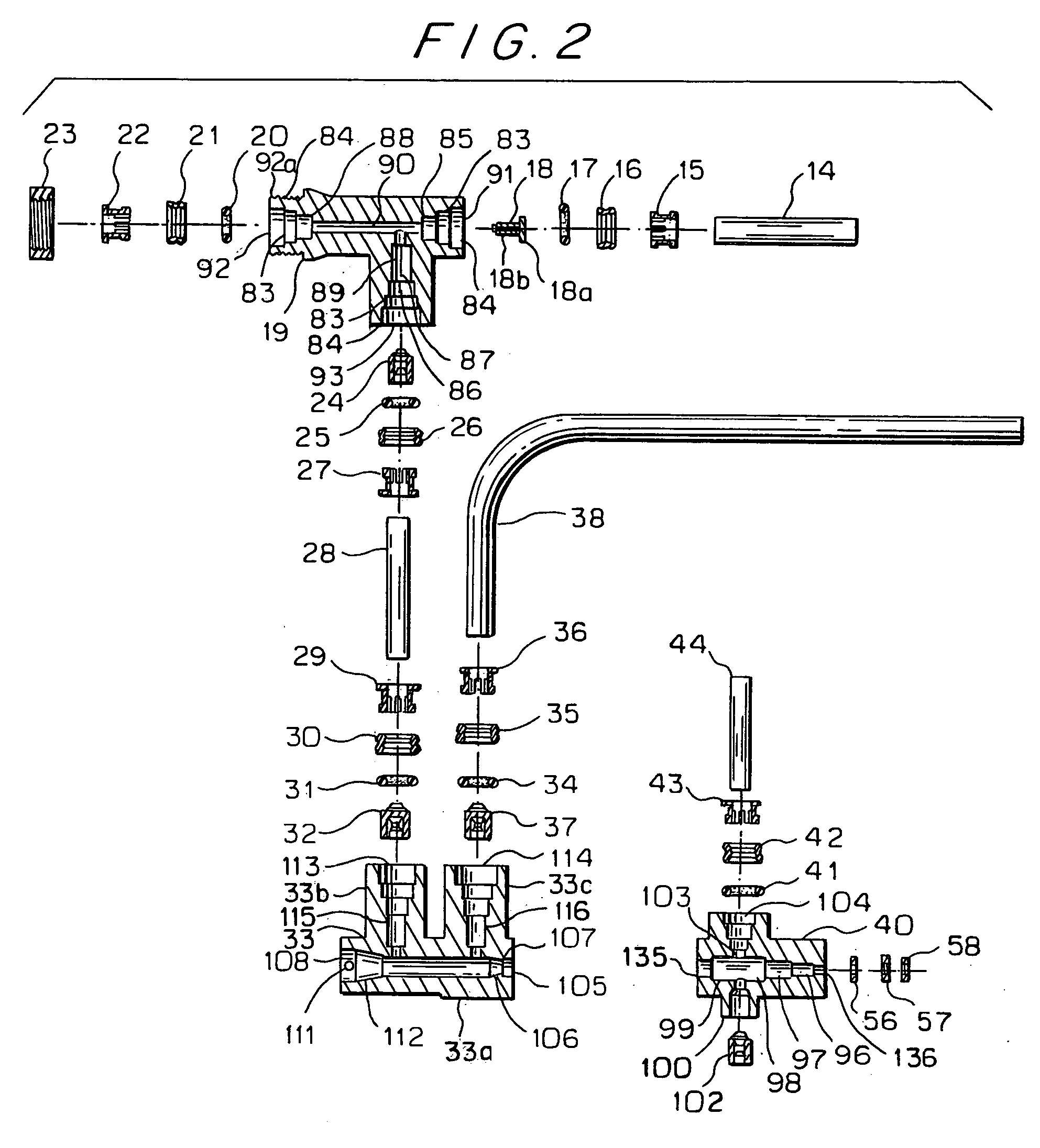

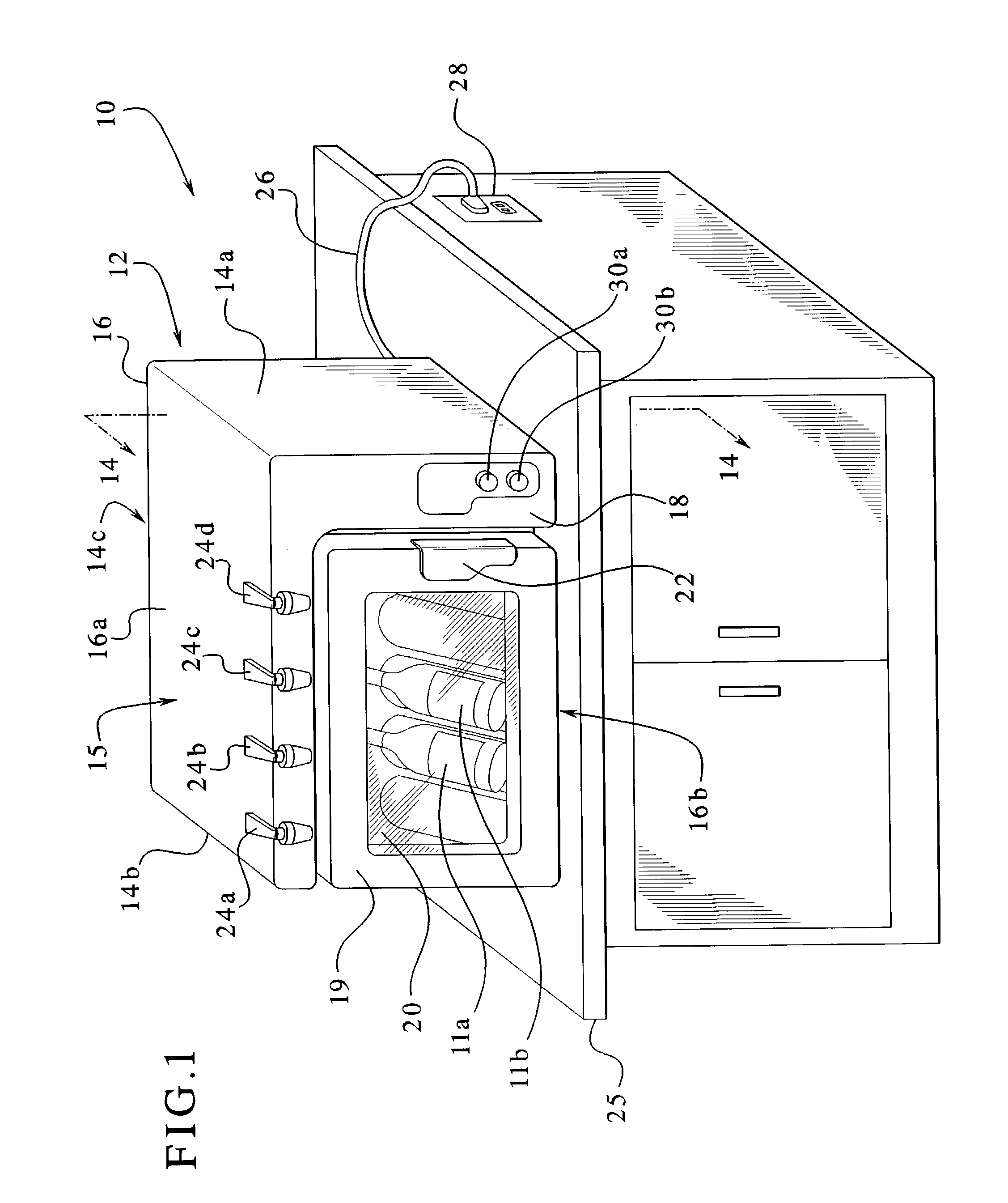

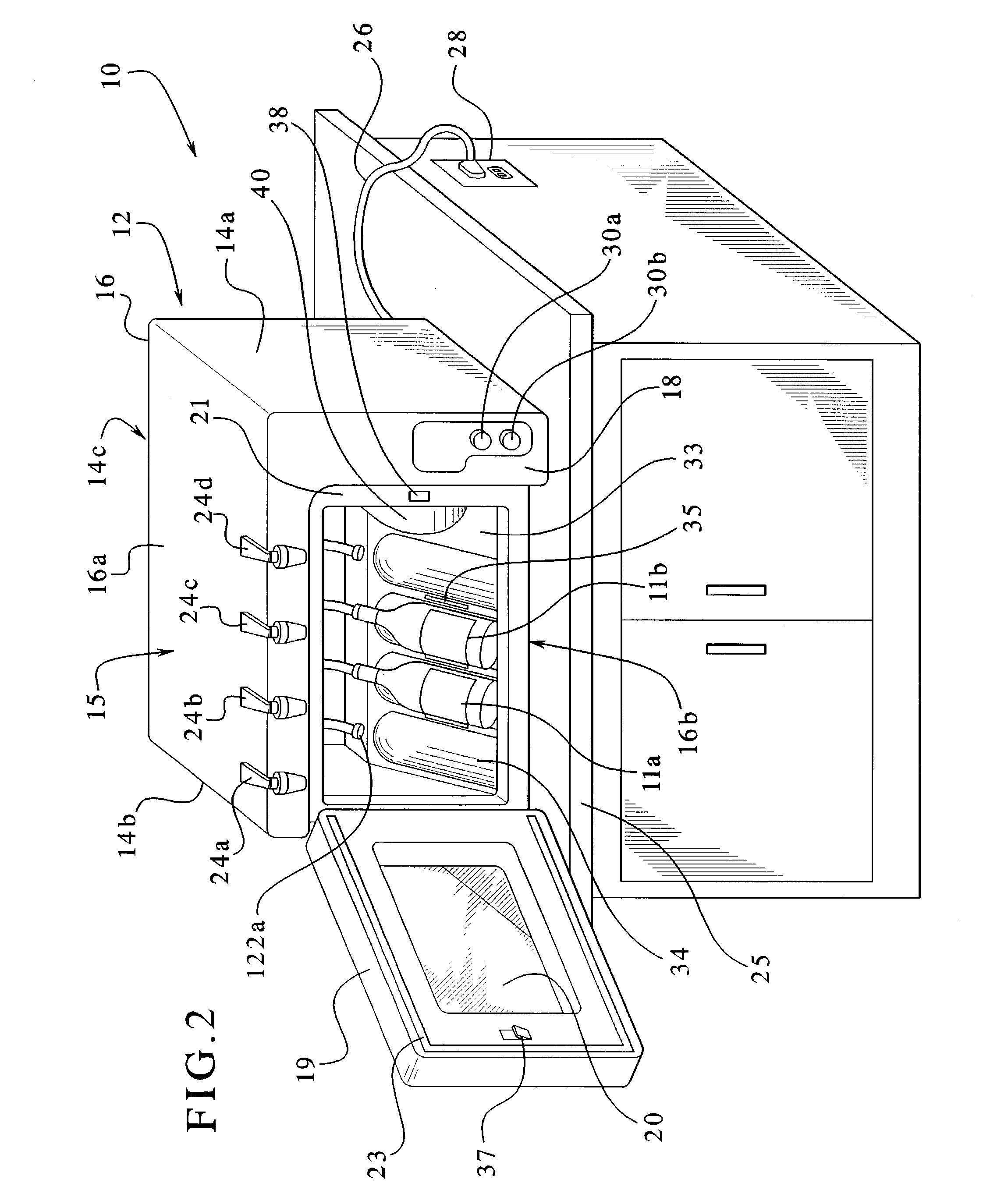

Apparatus and method for preparing a liquid mixture

A mixing apparatus, puncturing mechanism, and cartridge are disclosed. The mixing apparatus has a housing and a drawer with a recess. Corresponding cartridges may be inserted into the drawer and slid into the housing to facilitate mixing a liquid with contents of the cartridge. The liquid may originate from a reservoir in the mixing apparatus or a direct line. Also inside the housing of the mixing apparatus is the puncturing mechanism. The puncturing mechanism has a nozzle configured to puncture a lid of a cartridge and inject liquid to mix with the contents of the cartridge. The puncturing mechanism is further configured to drive an internal puncturing unit inside of the cartridge through a lower portion of the cartridge to allow liquid from the nozzle and contents of the cartridge to be dispensed into a receptacle.

Owner:FORMULANOW

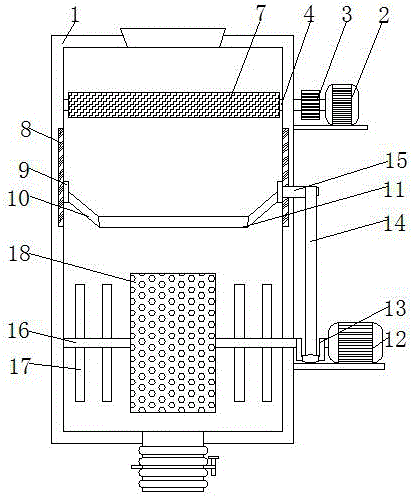

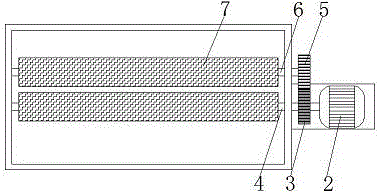

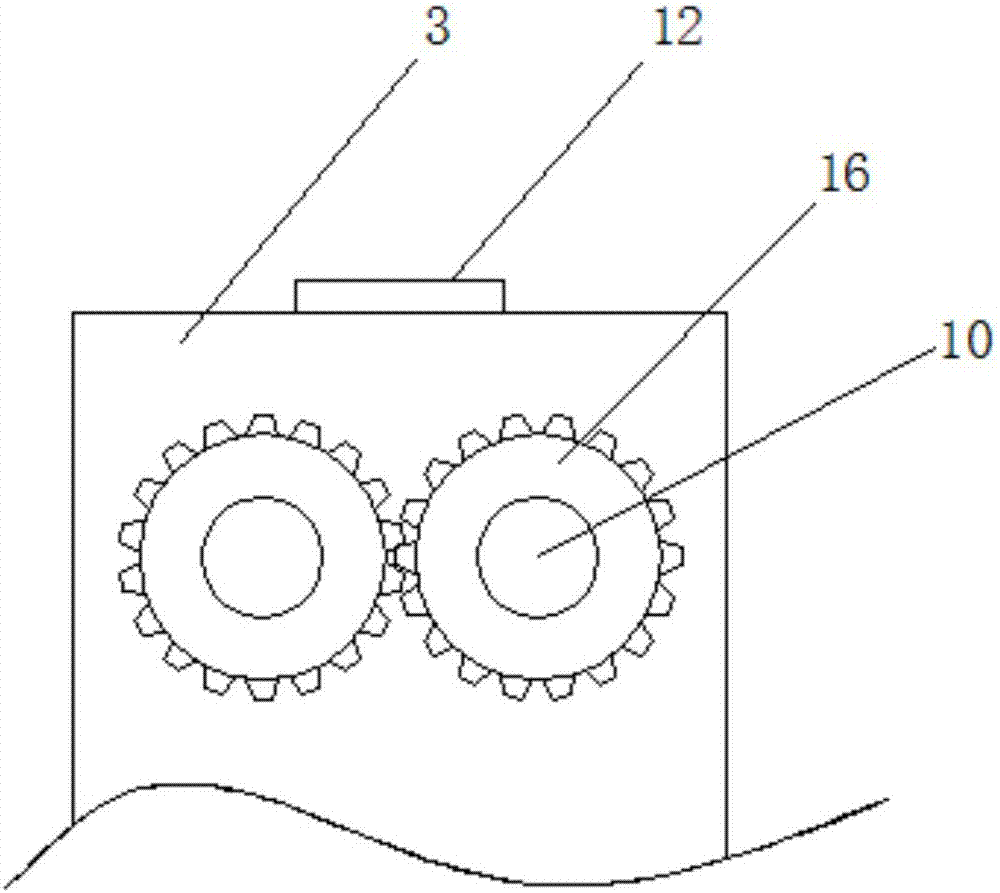

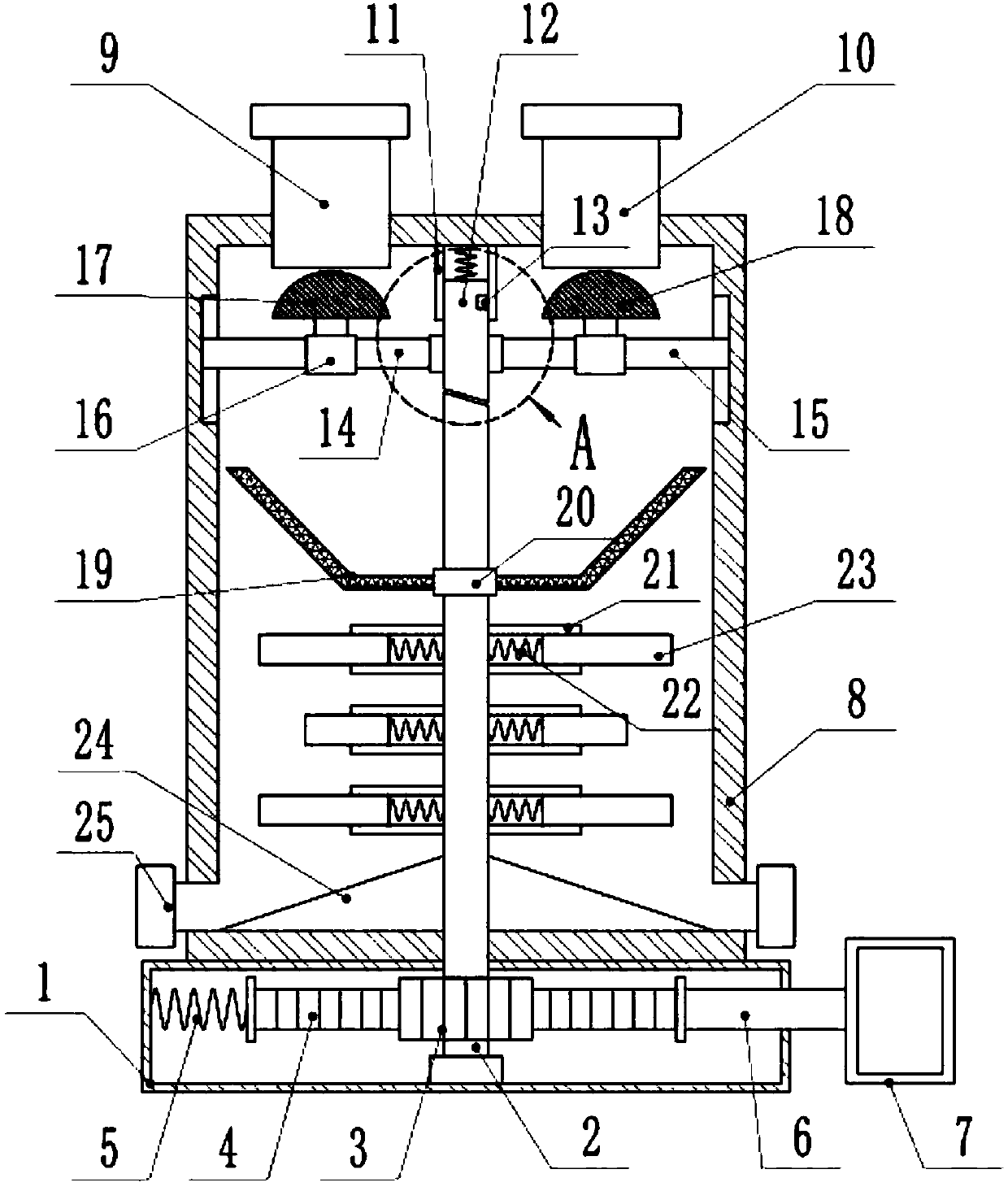

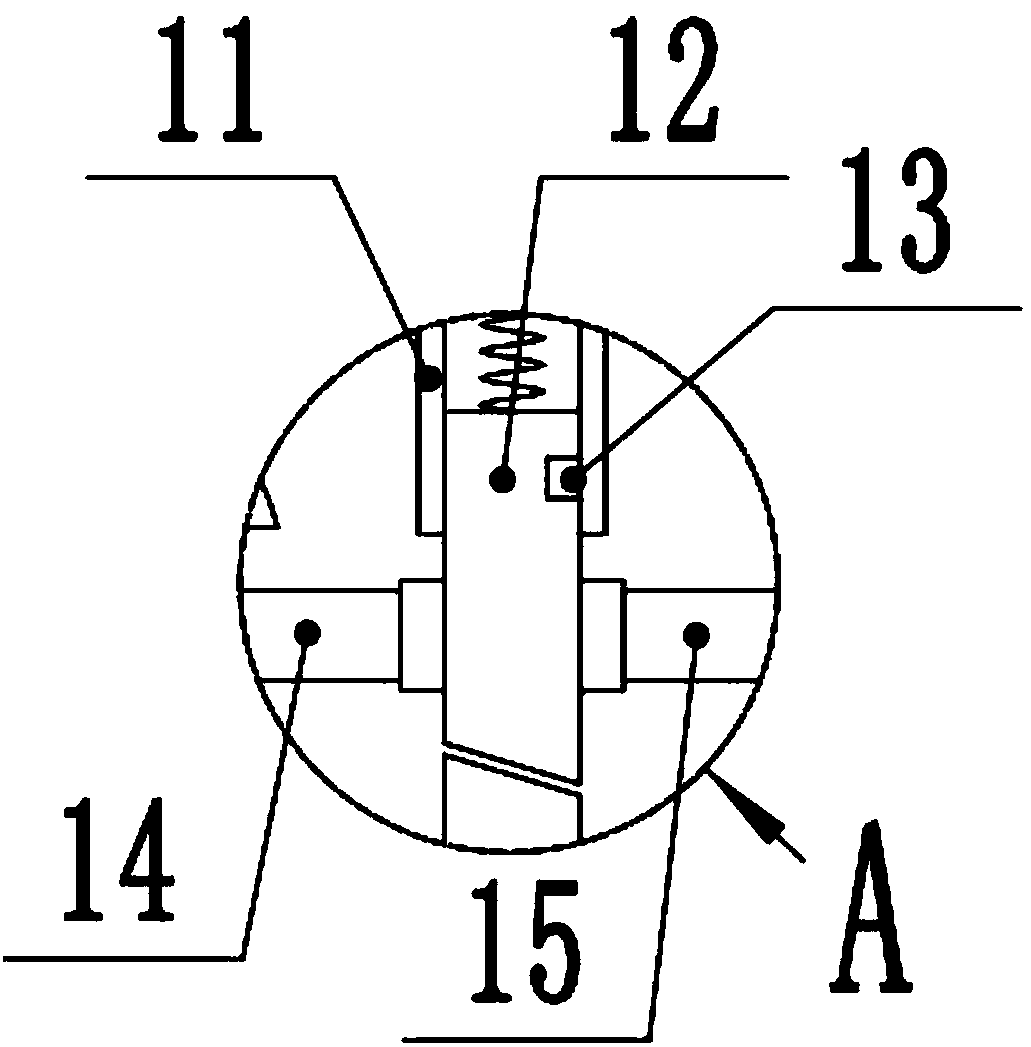

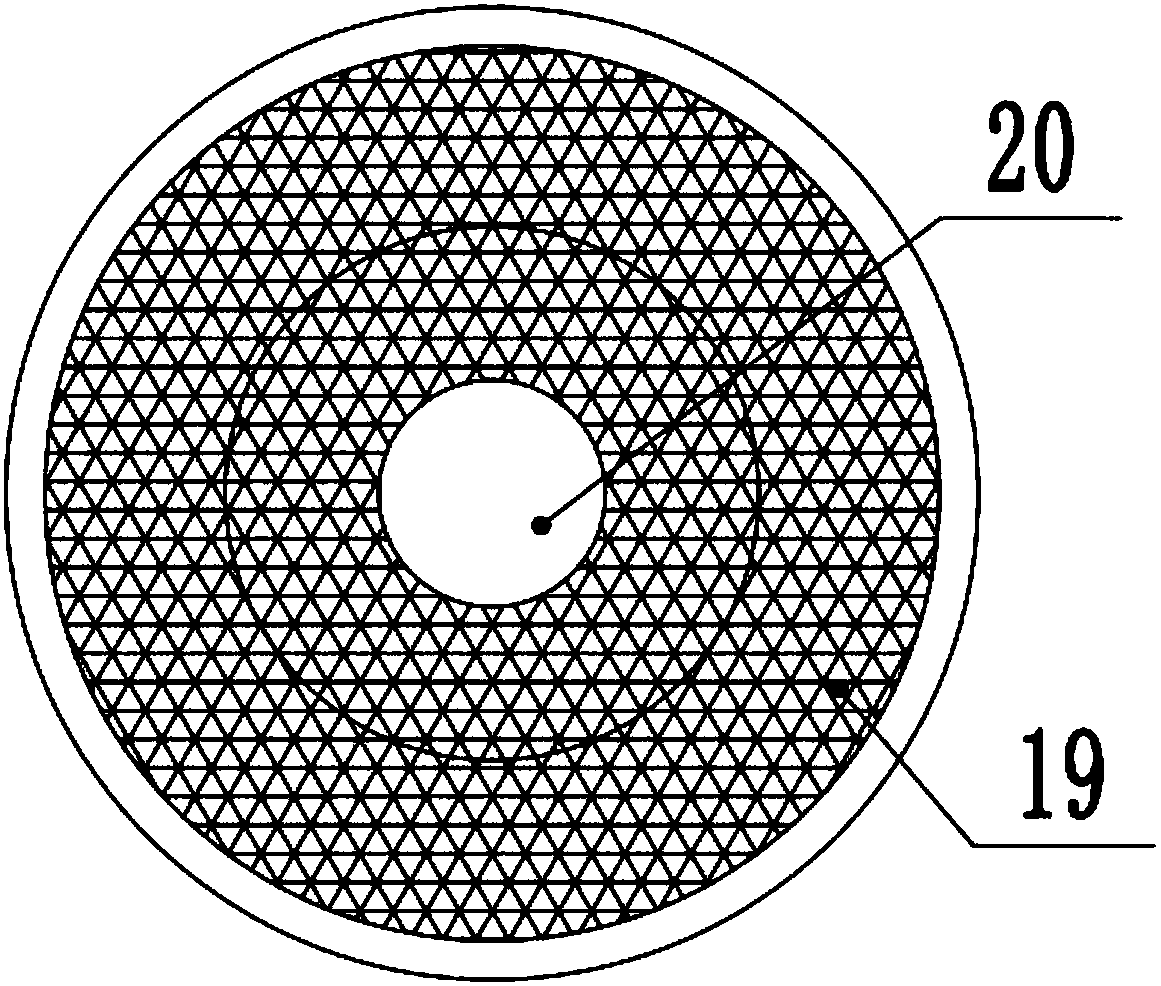

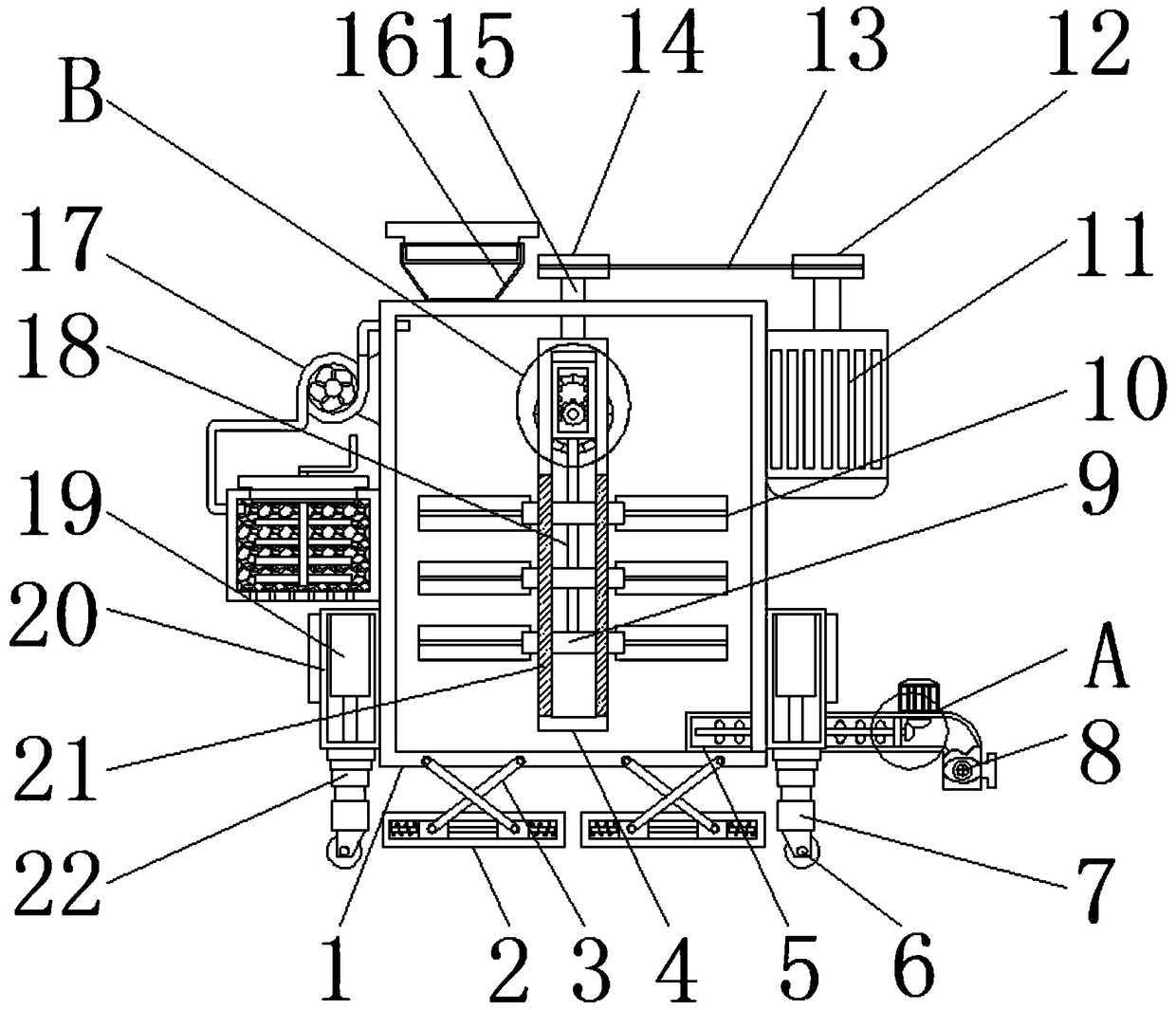

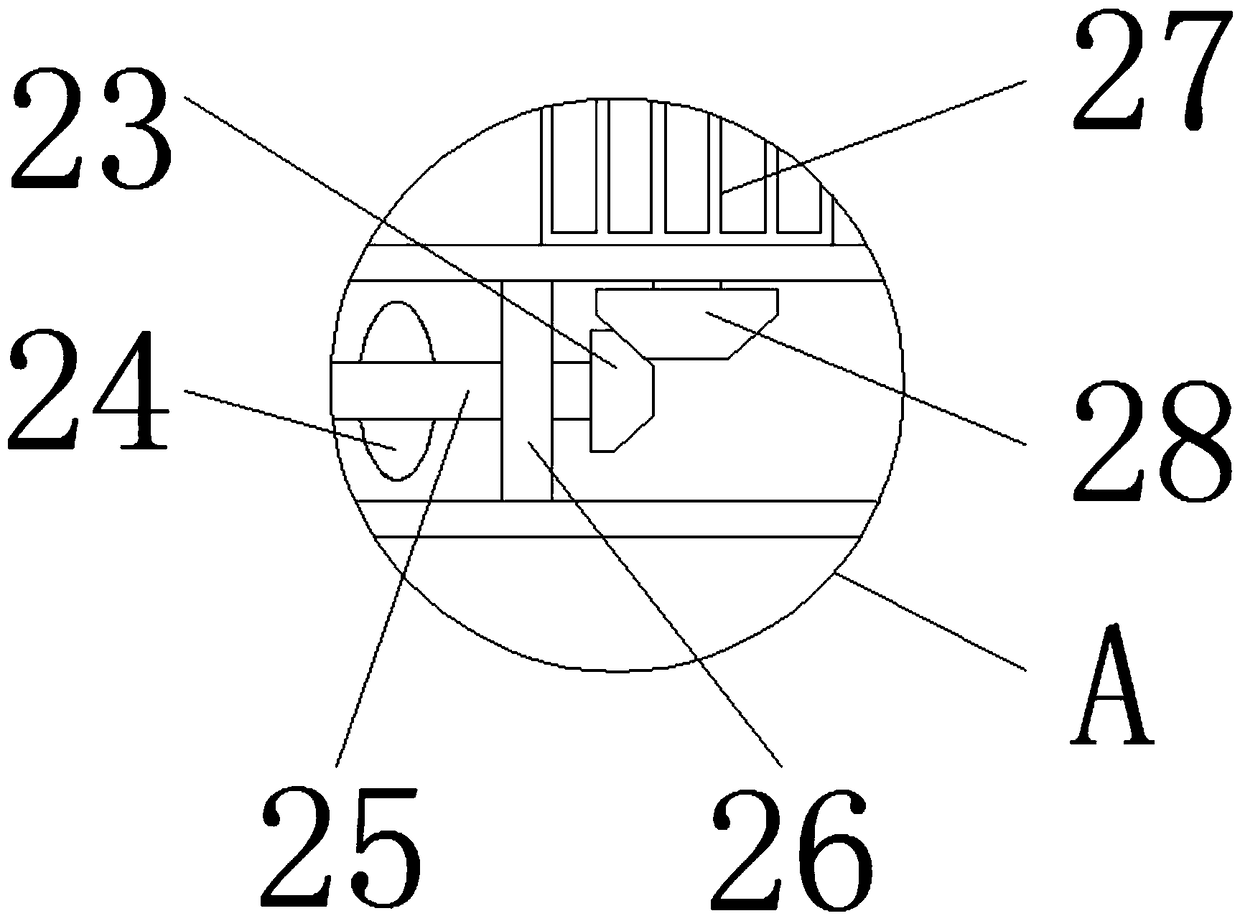

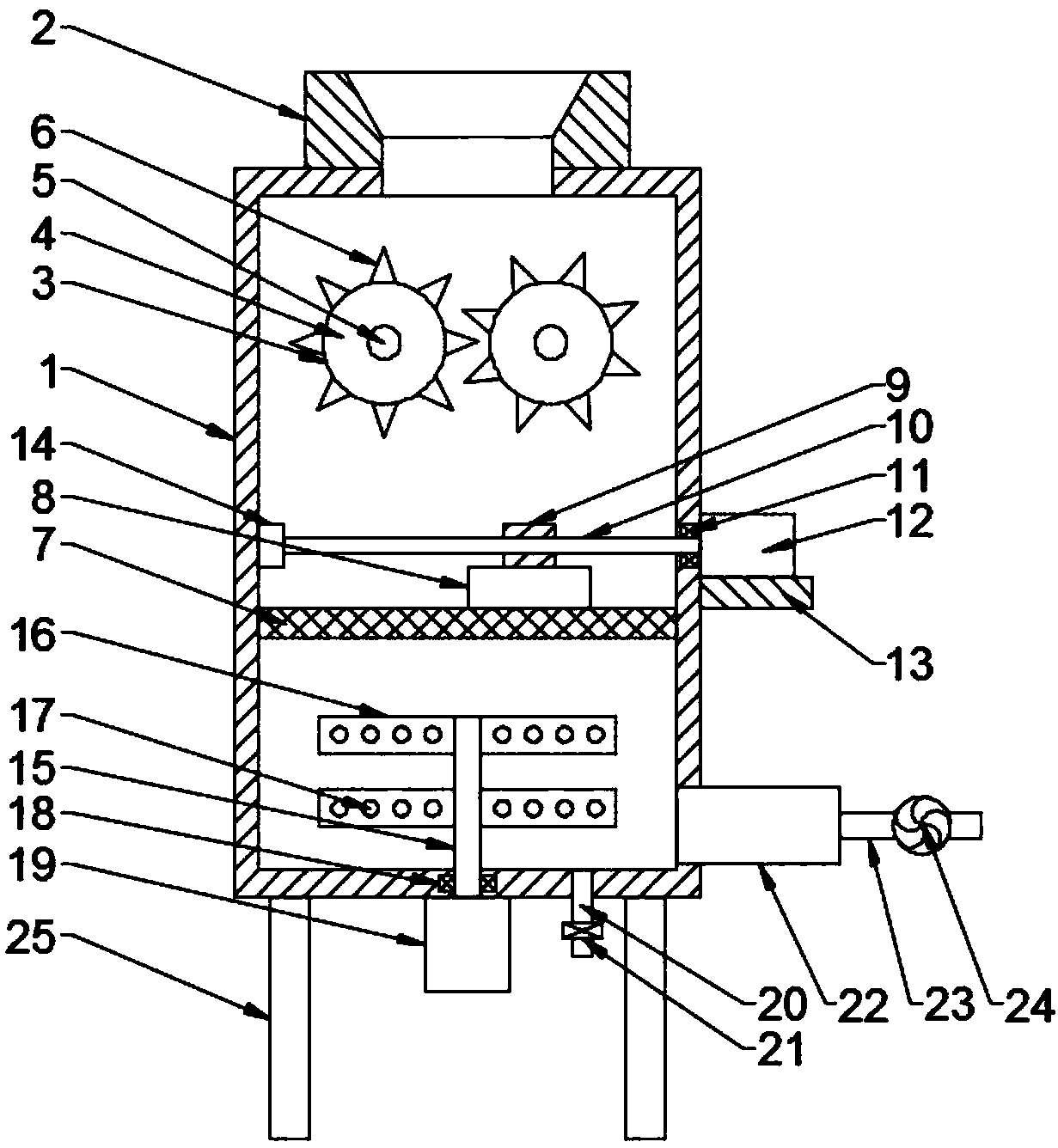

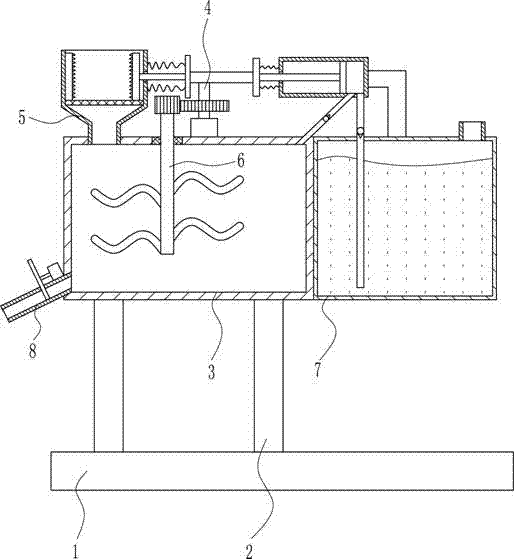

Chemical engineering raw material mixing and stirring device convenient for screening

The invention discloses a chemical engineering raw material mixing and stirring device convenient for screening. The device comprises a stirring box, the top of the stirring box is provided with a material inlet, the bottom of the stirring box is provided with a material outlet, one side of the stirring box is provided with a first motor through a carrier plate, the output end of the first motor is fixedly connected with the axle center of one side of a driving gear, the axle center, opposite to the first motor, of the driving gear is fixedly connected with one end of a driving rotating rod, and the other end of the driving rotating rod traverses through the stirring box, and is movably connected with the internal of the stirring box. A crushing roller is improved, teeth on the crushing roller can crush a chemical engineering raw material, the crushed chemical engineering raw material is screened under the cooperation of a filter screen frame, a stirring screen is improved, and the stirring screen can drive a stirring shaft and a stirring filter screen to simultaneously rotate through the rotating shaft and can stir the chemical engineering raw material in order to realize the screening and breaking effects in the stirring process.

Owner:洛阳毅兴石化电器仪表设备有限公司

Nanoparticles having a rutile-like crystalline phase and method of preparing same

Owner:3M INNOVATIVE PROPERTIES CO

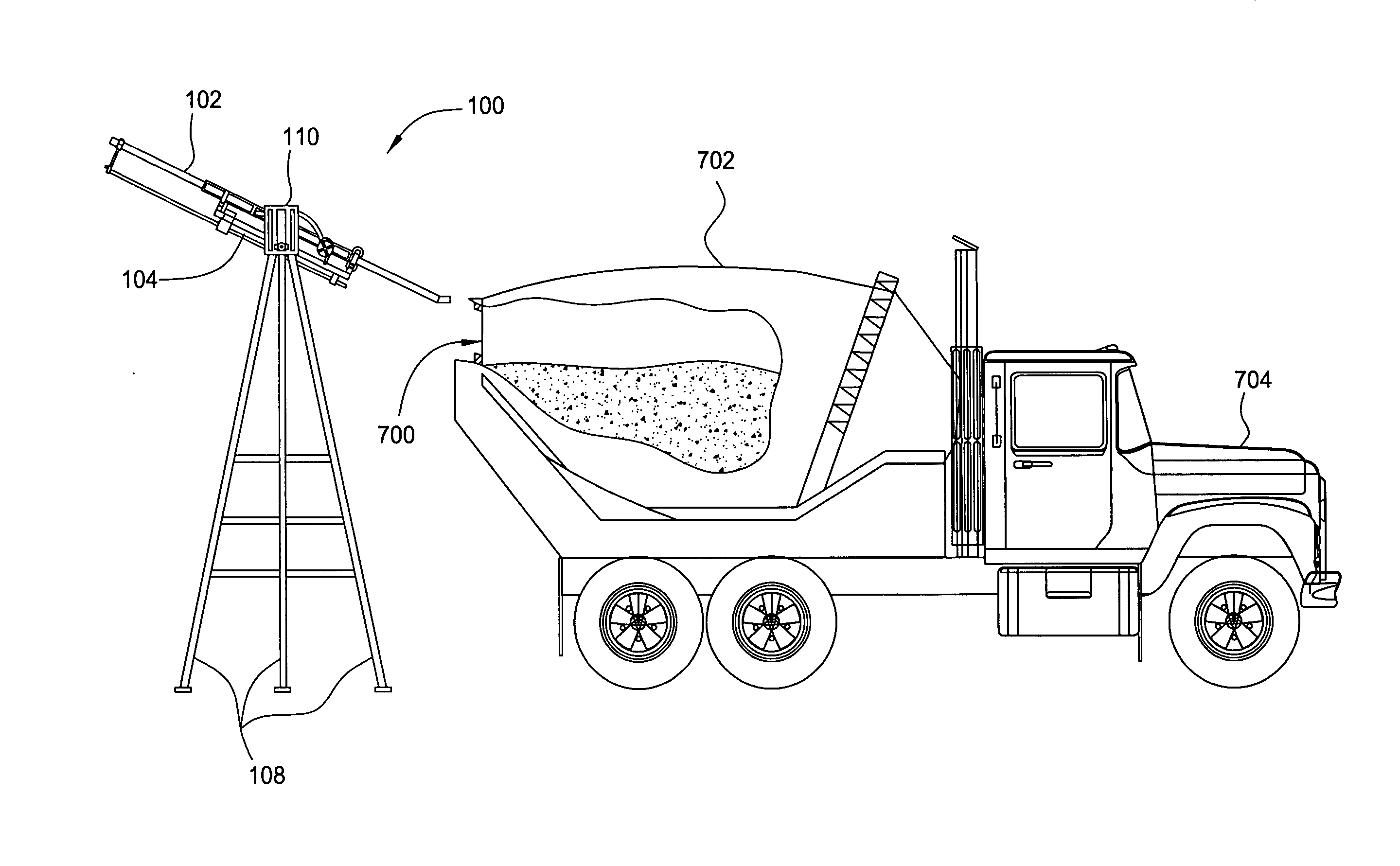

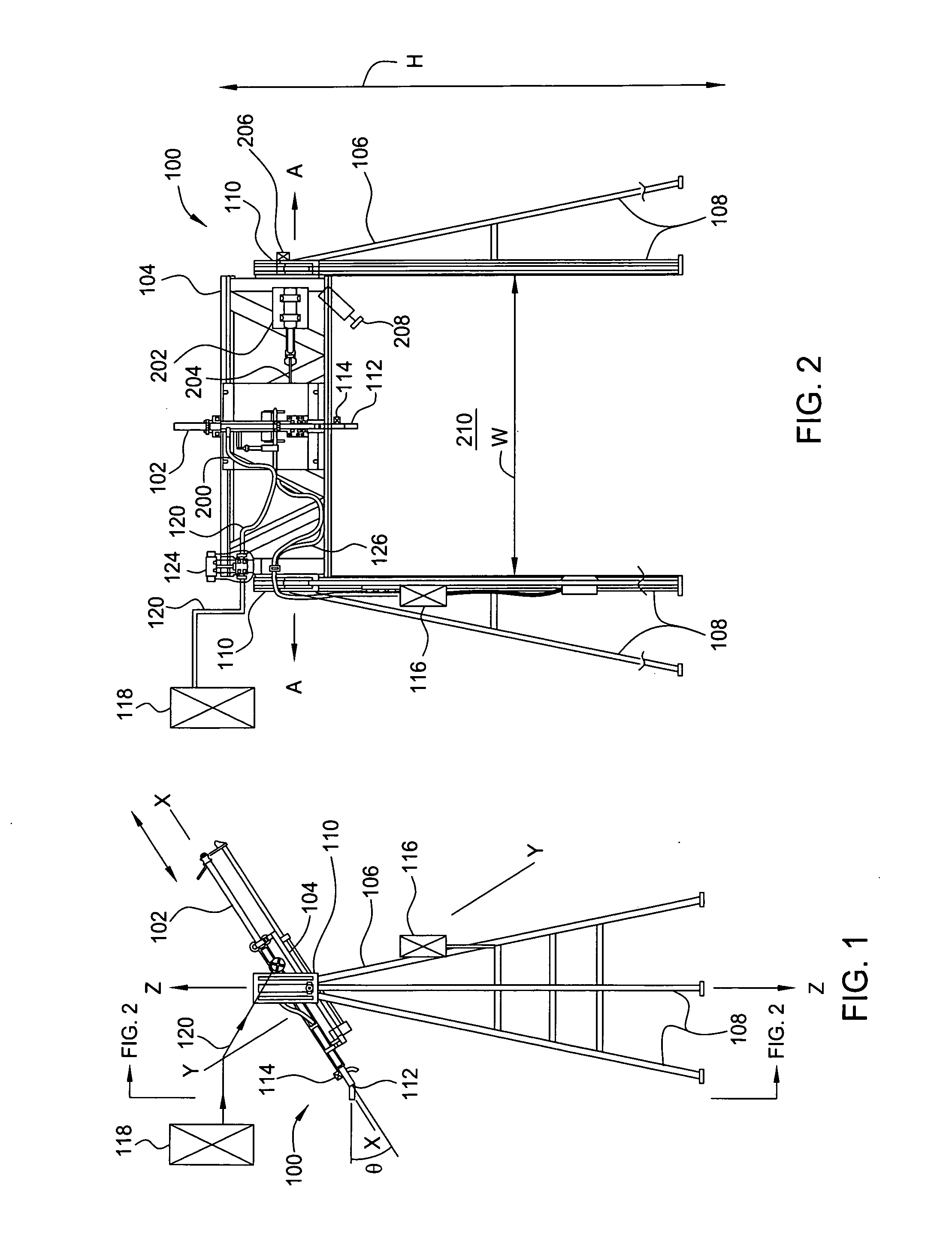

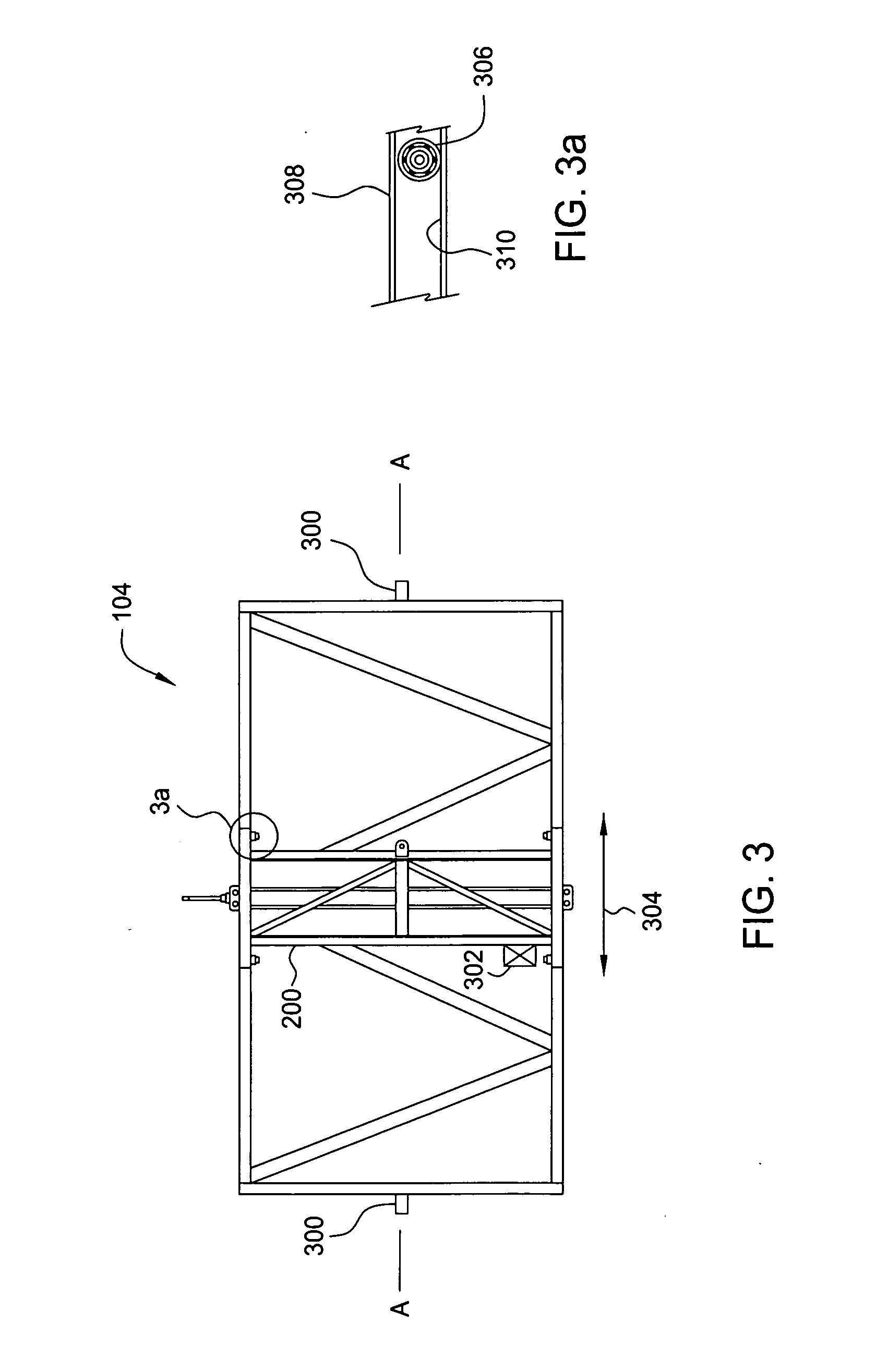

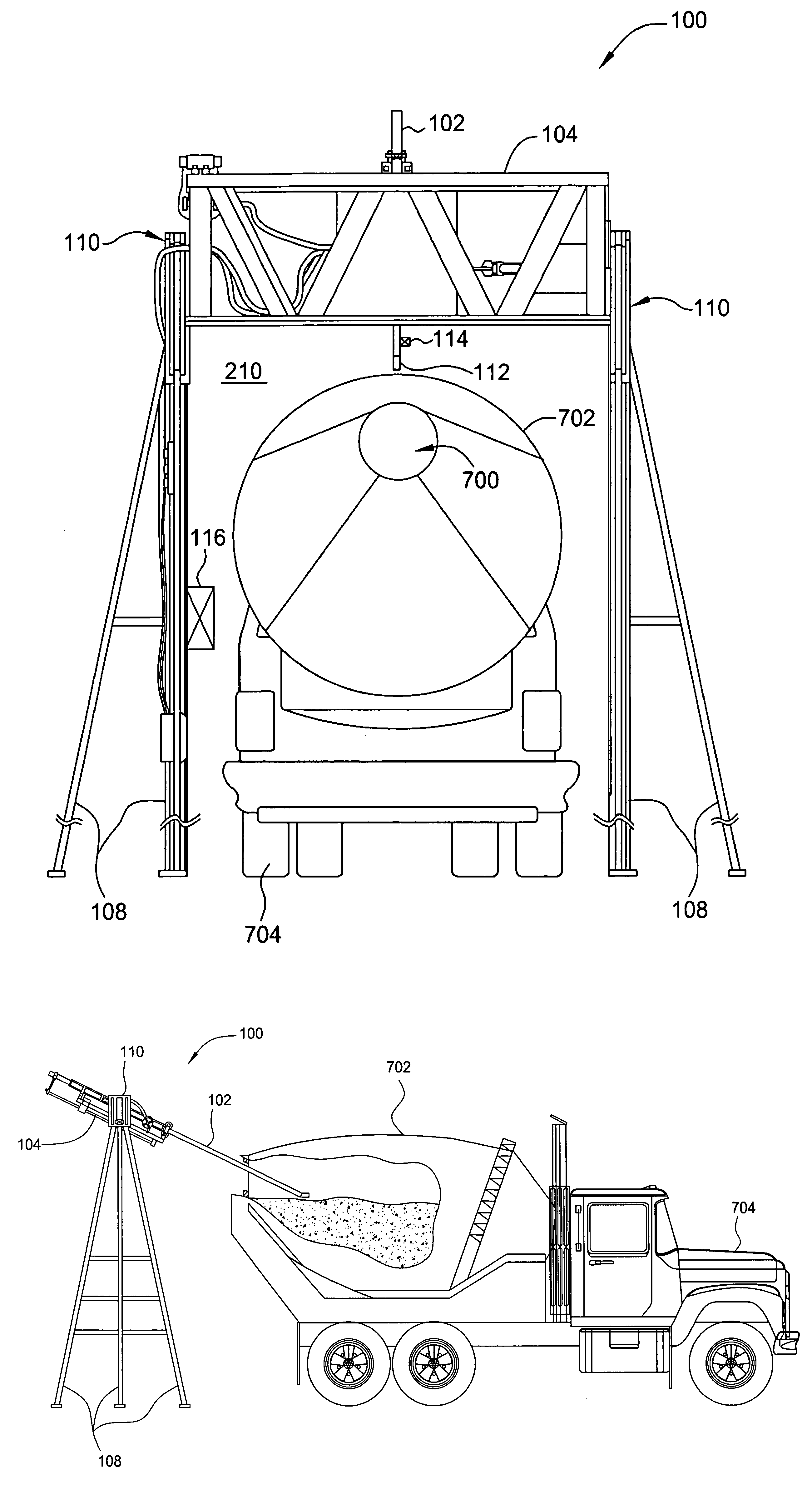

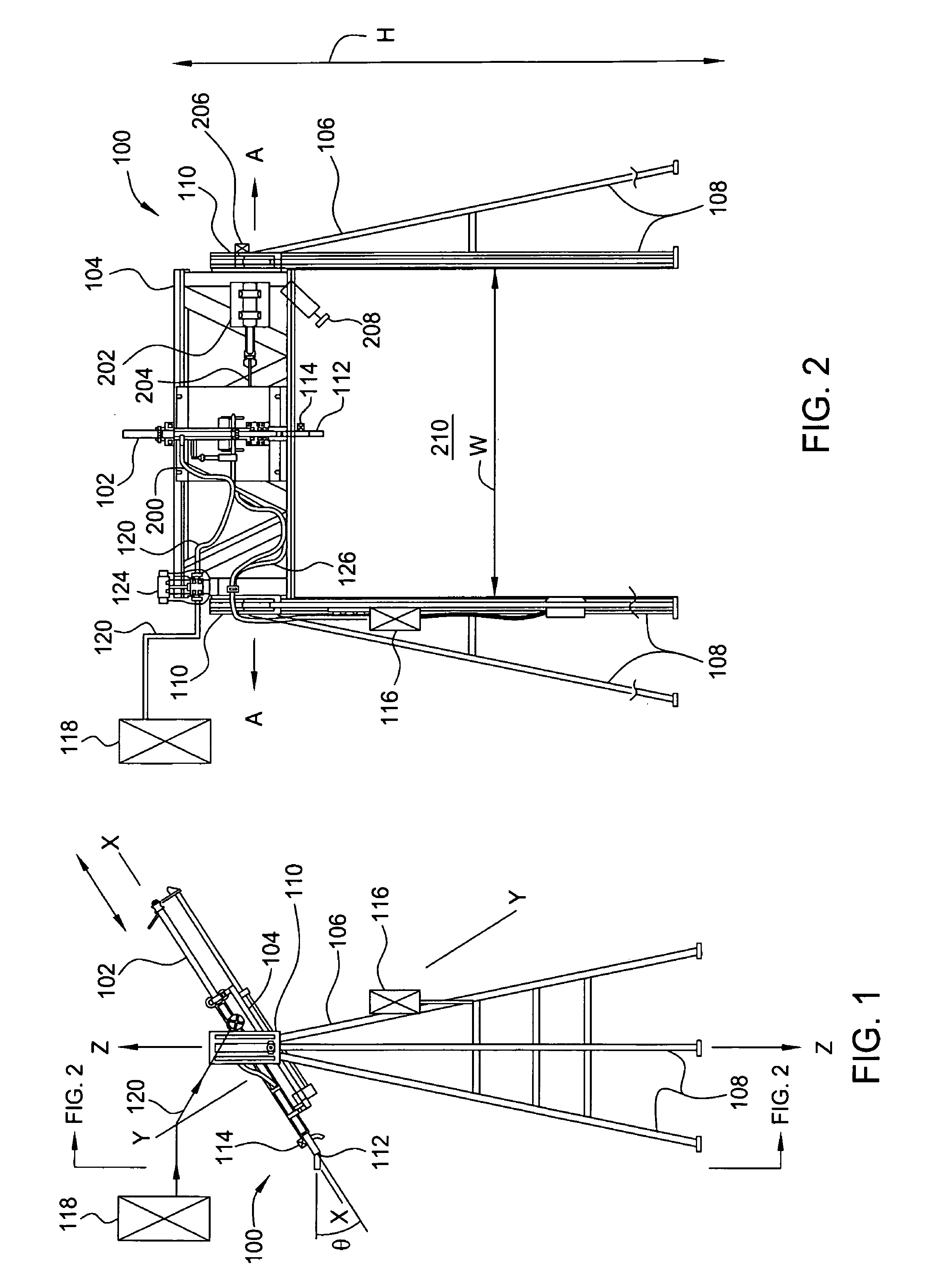

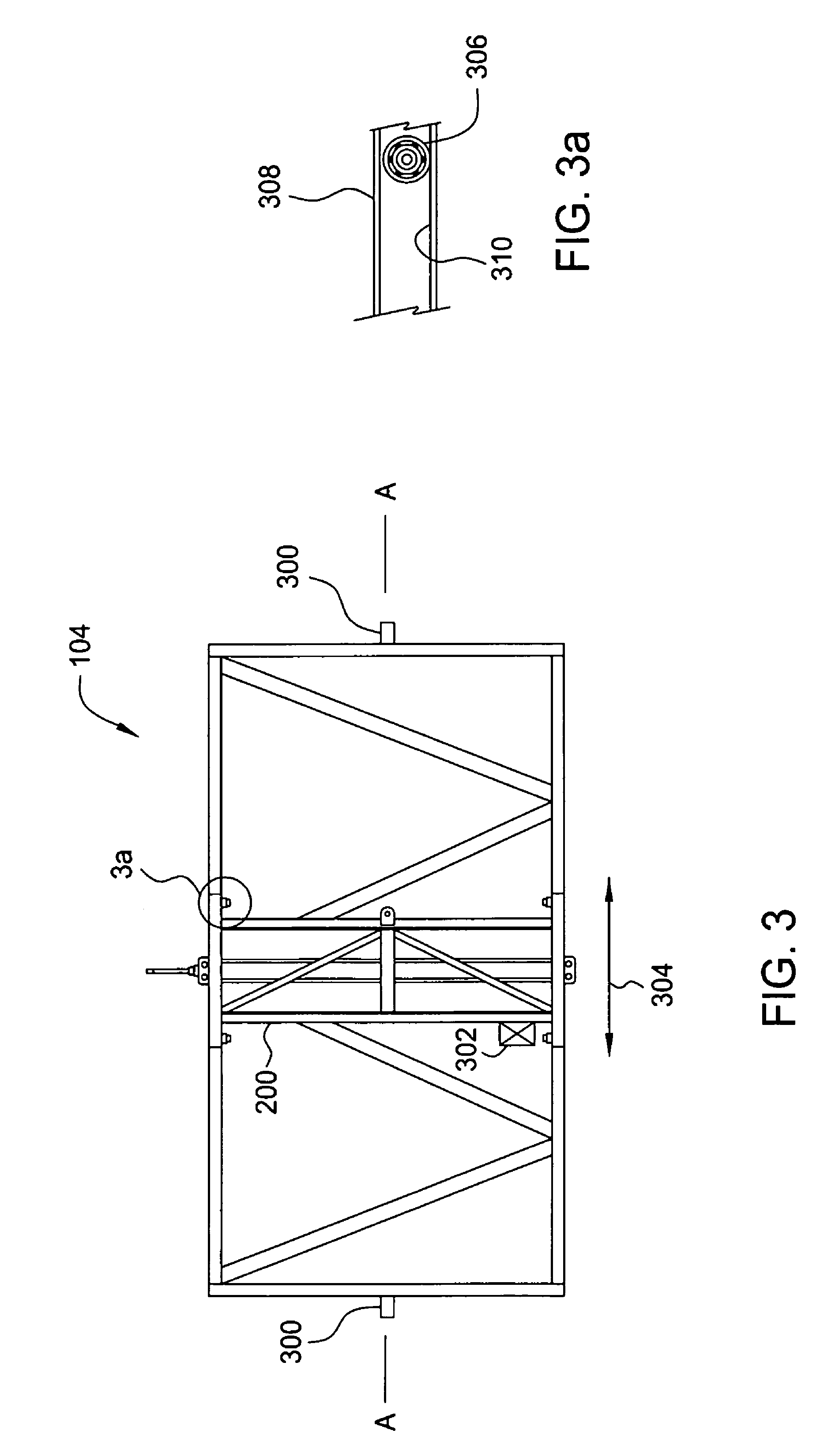

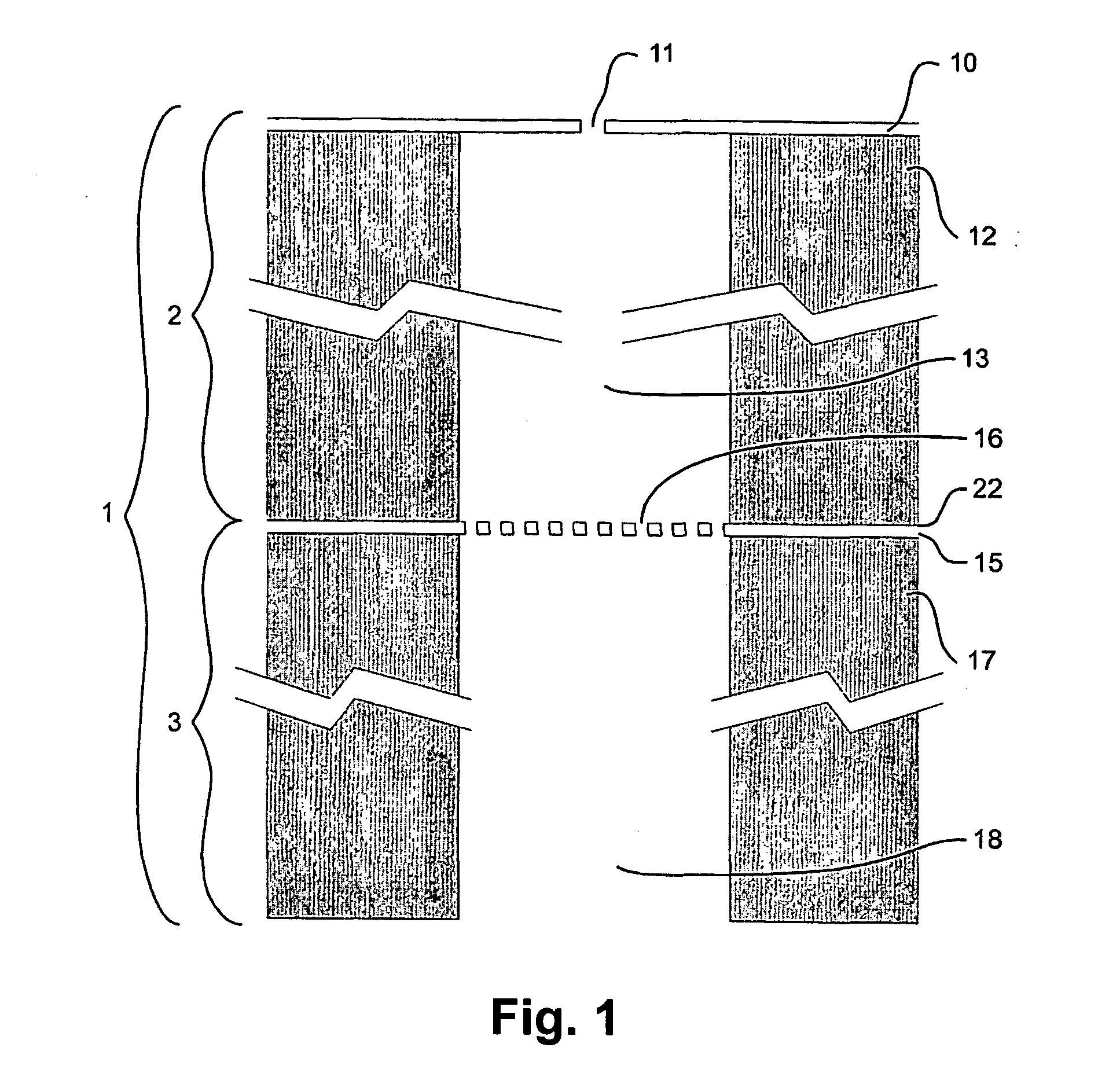

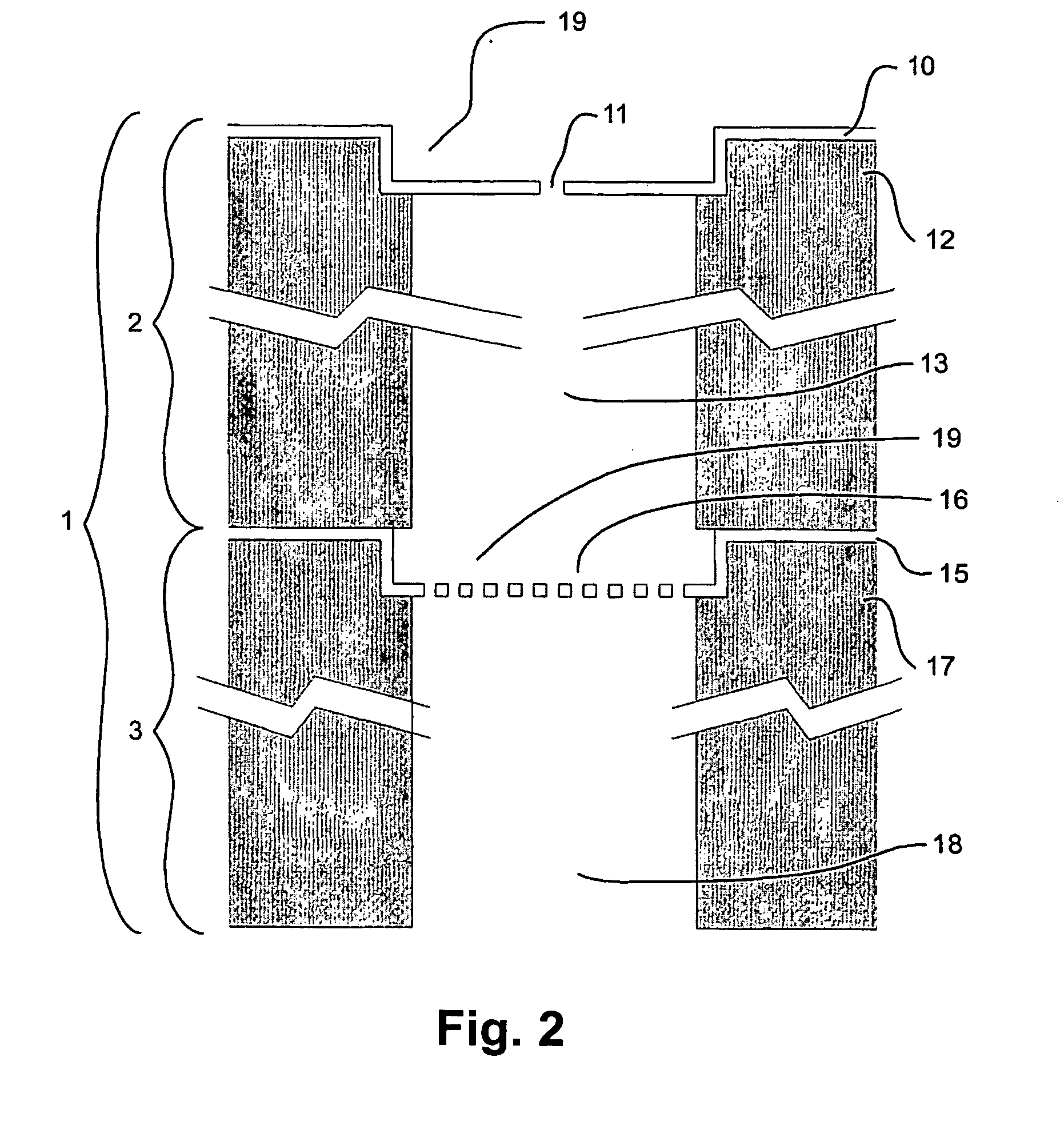

Concrete cooling injection unit and method of injecting a coolant into a concrete mixture

A method and apparatus for cooling a mixture with an injection system. The injection system is adjustable to accommodate the relative position and particular specifications of a given container (e.g., concrete mixer). In one embodiment, the injection system is operable to inject a coolant directly into the mixture while in the mixing process.

Owner:AIR LIQUIDE IND US LP

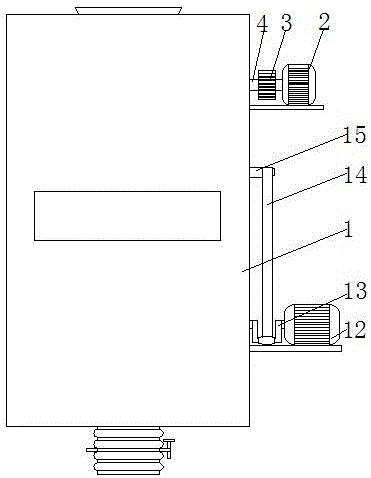

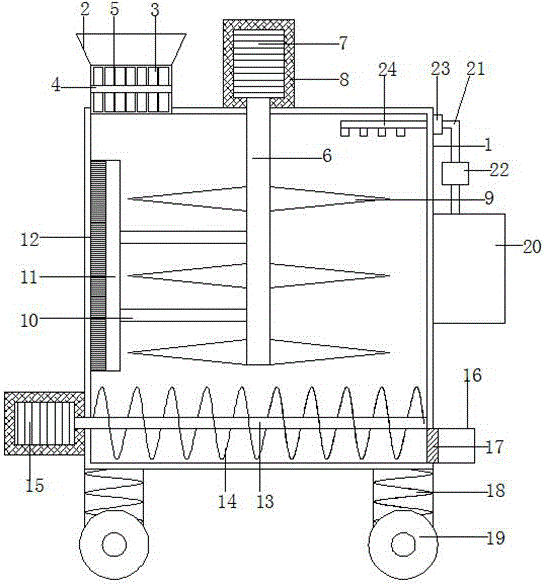

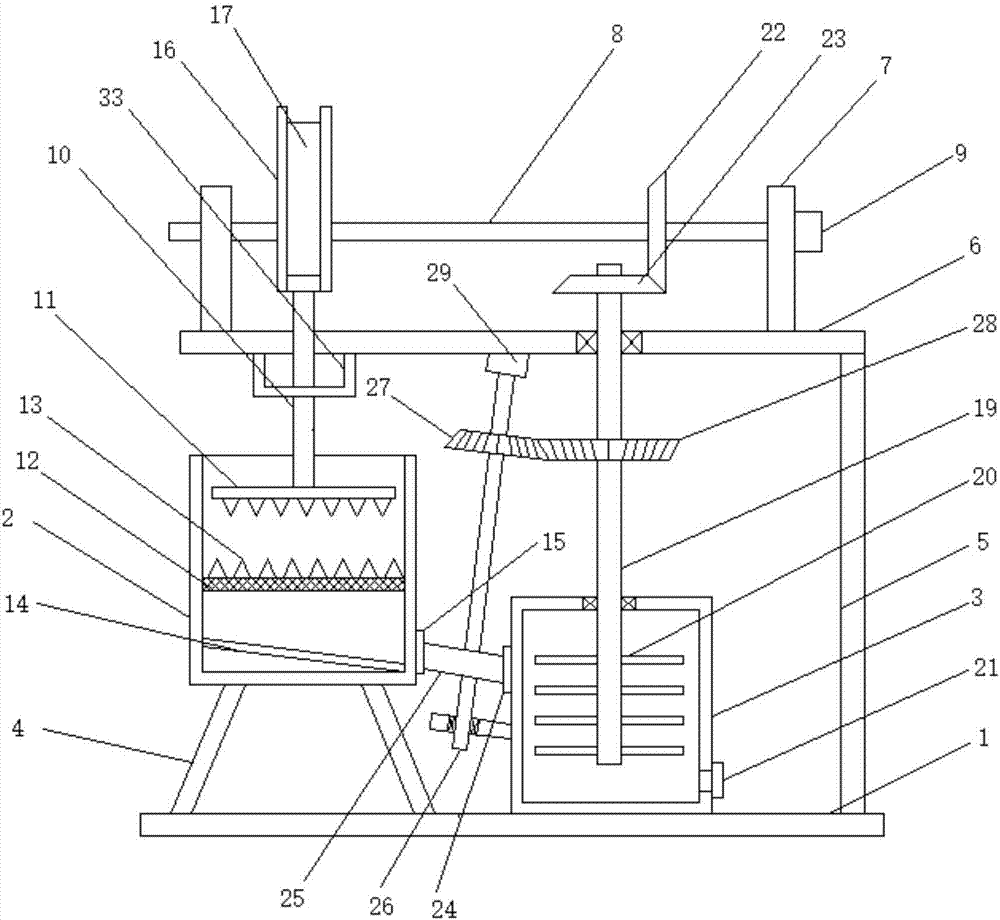

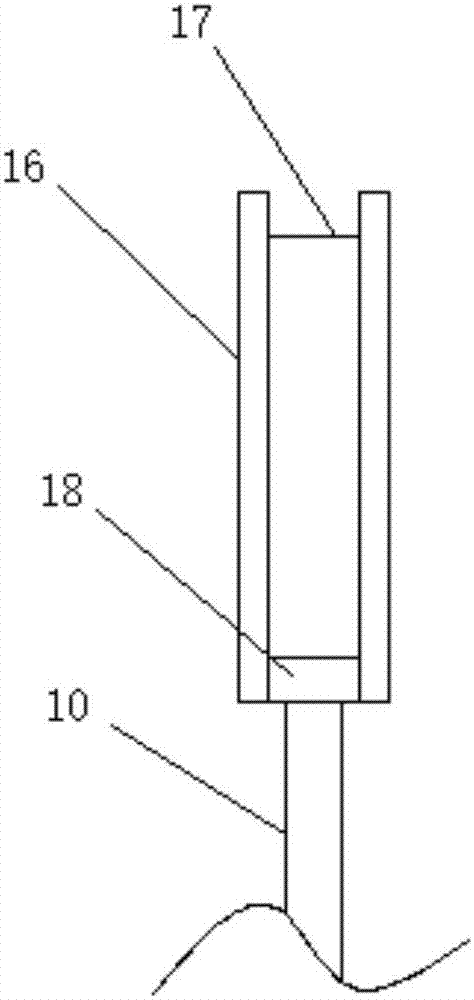

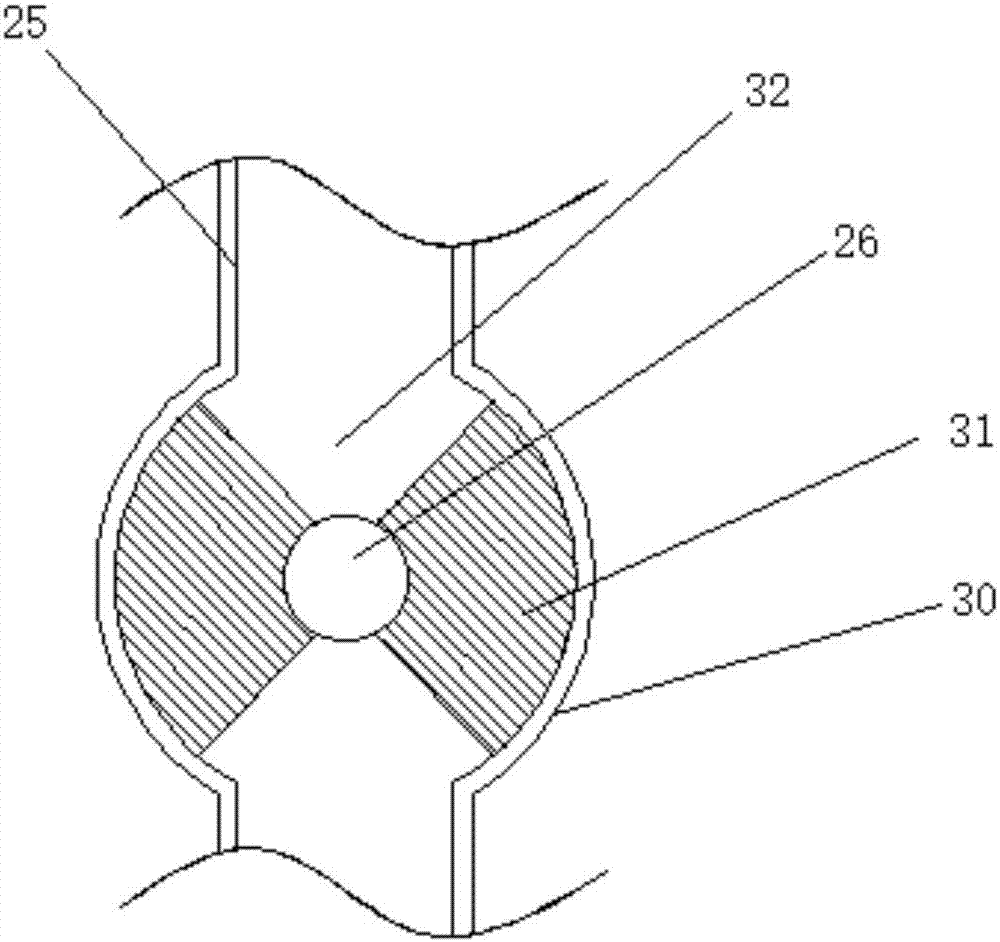

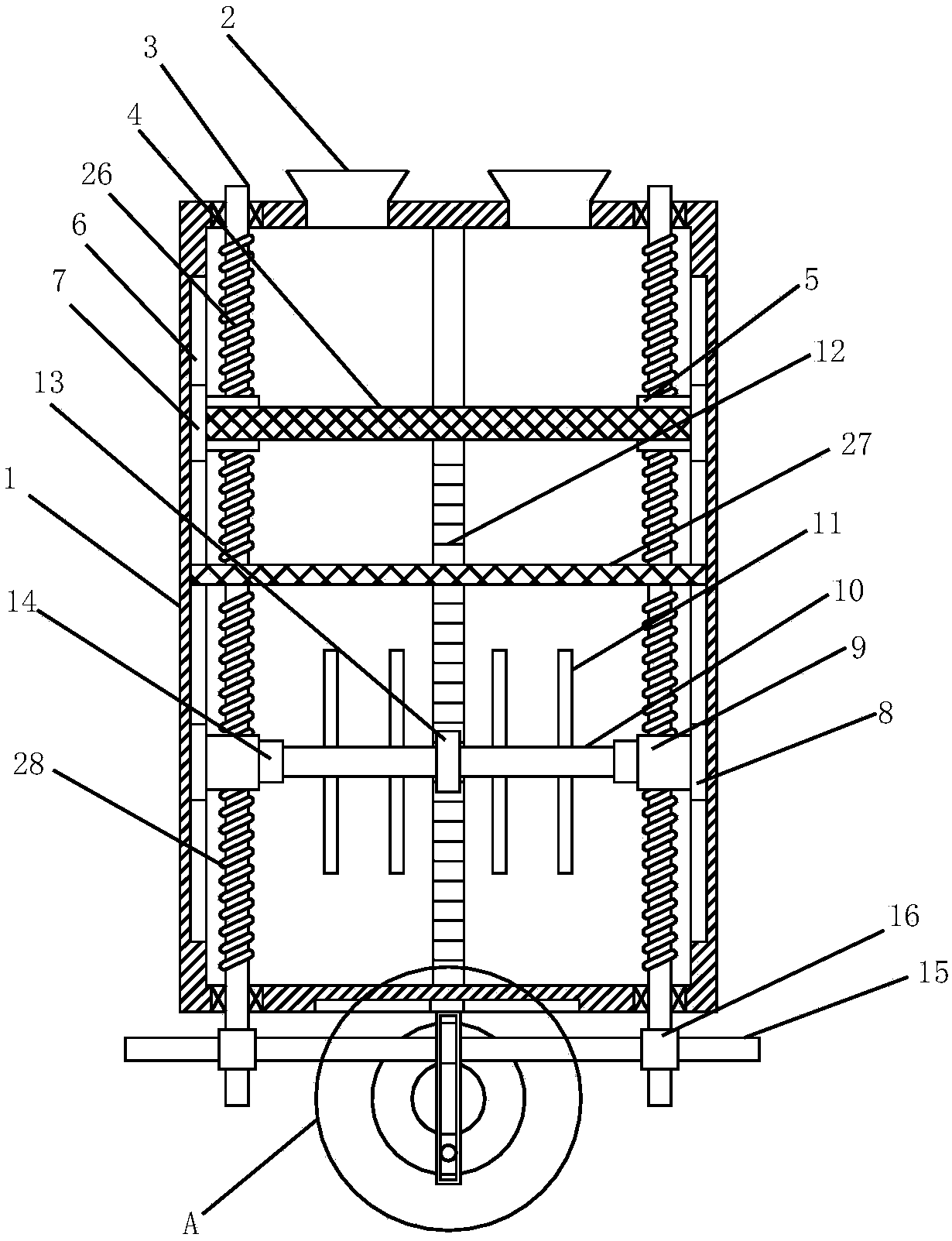

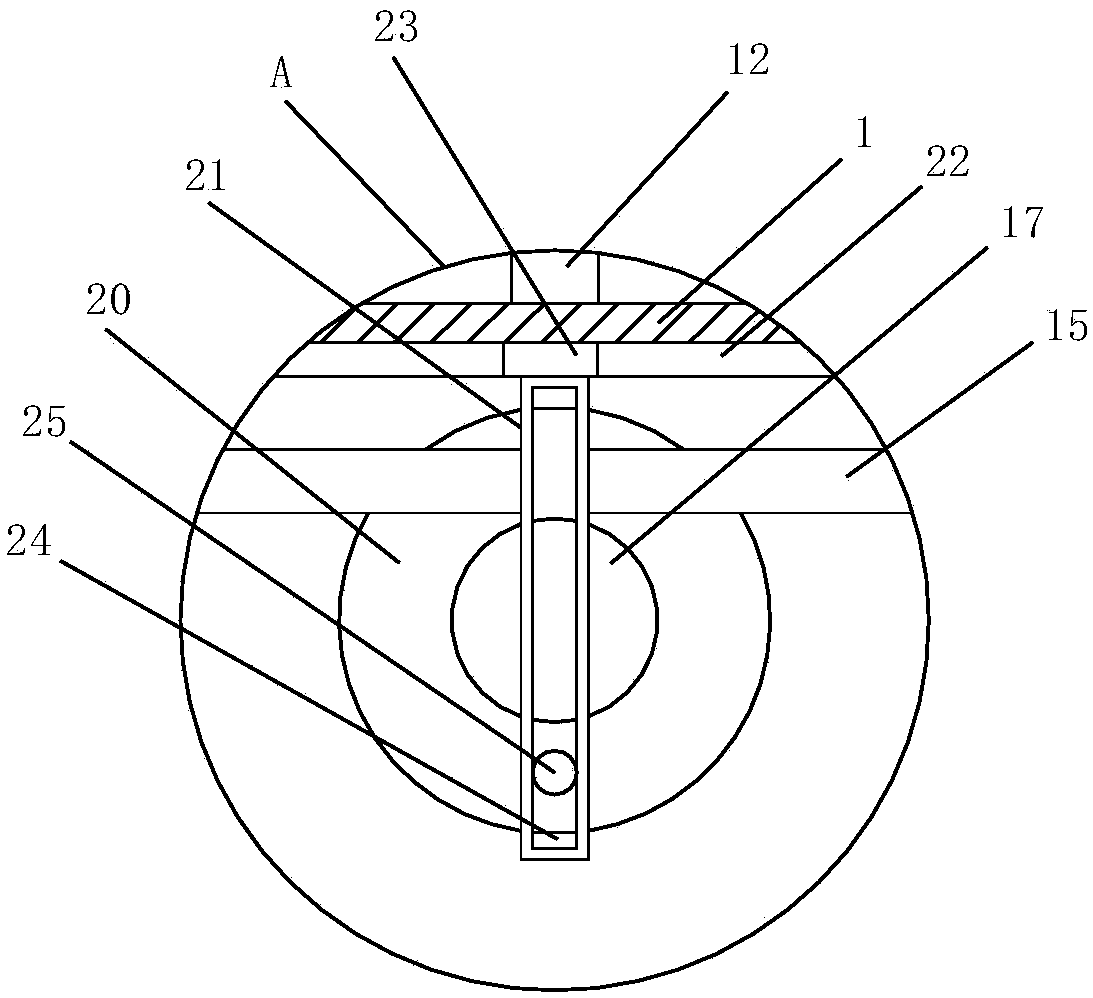

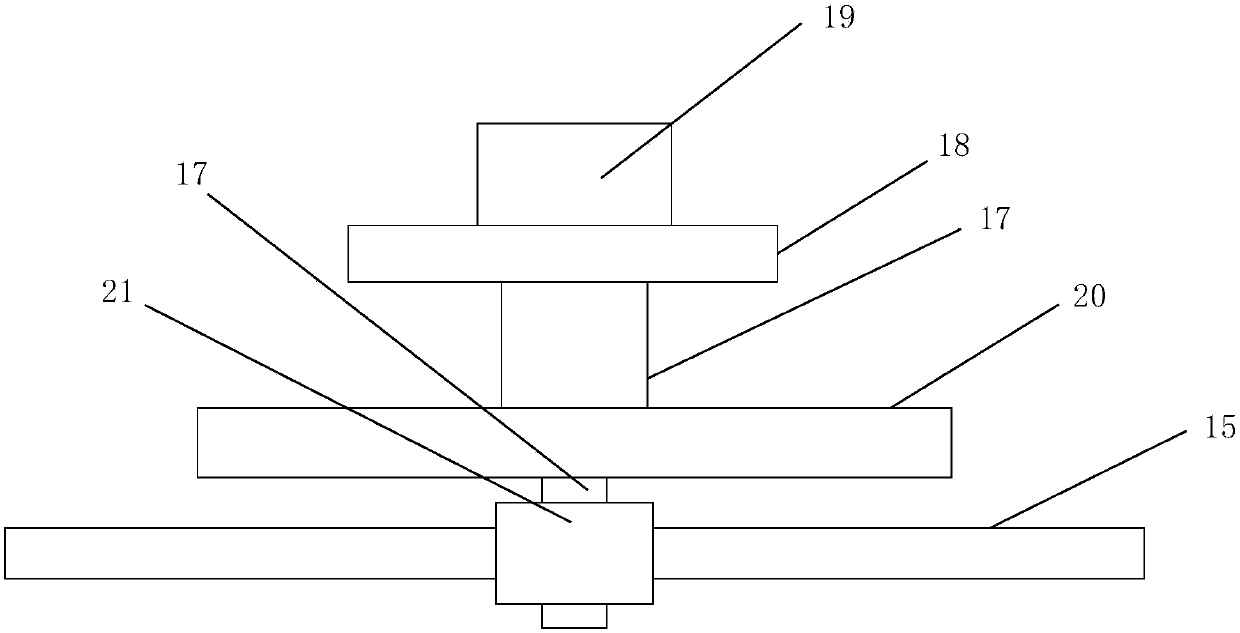

Livestock excrement treatment device used for animal husbandry

InactiveCN108014676AEasy to collect and processEasy to moveRotary stirring mixersTransportation and packagingLivestock manureEngineering

The present invention relates to treatment apparatus, and in particular relates to livestock excrement treatment apparatus used for animal husbandry. The technical problem to be solved by the presentinvention is to provide the livestock excrement treatment apparatus used for the animal husbandry, wherein the apparatus saves time and labor, has a fast crushing speed, can stir and mix the crushed excrement and fertilizer, does not need to perform stirring and mixing manually, and has high working efficiency. In order to solve the above technical problem, the present invention provides such thelivestock excrement treatment apparatus used for the animal husbandry: the apparatus includes a bottom plate, supporting legs, a collecting frame and the like; and the supporting legs are symmetrically installed on the left and right sides of the bottom of the bottom plate, a supporting plate is installed on the left side of the top of the bottom plate, and cross plates are symmetrically installedon the upper part of the right side surface of the supporting plate. The apparatus provided by the present invention can stir and mix the fertilizer and the excrement through a stirring device, and can make operators more convenient for collecting and treating the stirred fertilizer and excrement through a material unloading device, so that the effects of saving time and labor, having a fast crushing speed, and being capable of stirring and mixing the crushed excrement and fertilizer are achieved.

Owner:黄志东

Quantitative building coating particle crushing and mixing integrated device

InactiveCN107349813AWell mixedMix well with waterRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a quantitative building coating particle crushing and mixing integrated device. The device comprises a bottom plate, a stirring and mixing barrel and a crushing box, wherein a connecting channel is arranged between the stirring and mixing barrel and the crushing box, two parallel first cross shafts are arranged in the crushing box, crushing rollers are arranged on the two first cross shafts, the two first cross shafts are connected through meshing of drive gears, a second cross shaft is arranged in the connecting channel and sleeved with a sleeve, a transport barrel is arranged on the outer side wall of the sleeve, three collection tanks arranged at equal angles circularly are arranged on the side wall of the transport barrel, a stirring shaft is arranged in the stirring and mixing barrel, stirring rods are arranged on the stirring shaft, and a discharge port is formed in the side wall of the bottom of the stirring and mixing barrel. The device is simple in structure, quantitative and uniform in mixing, higher in working efficiency and easy to operate and higher in practicability and has the linkage performance, and the viscosity is proper after mixing.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

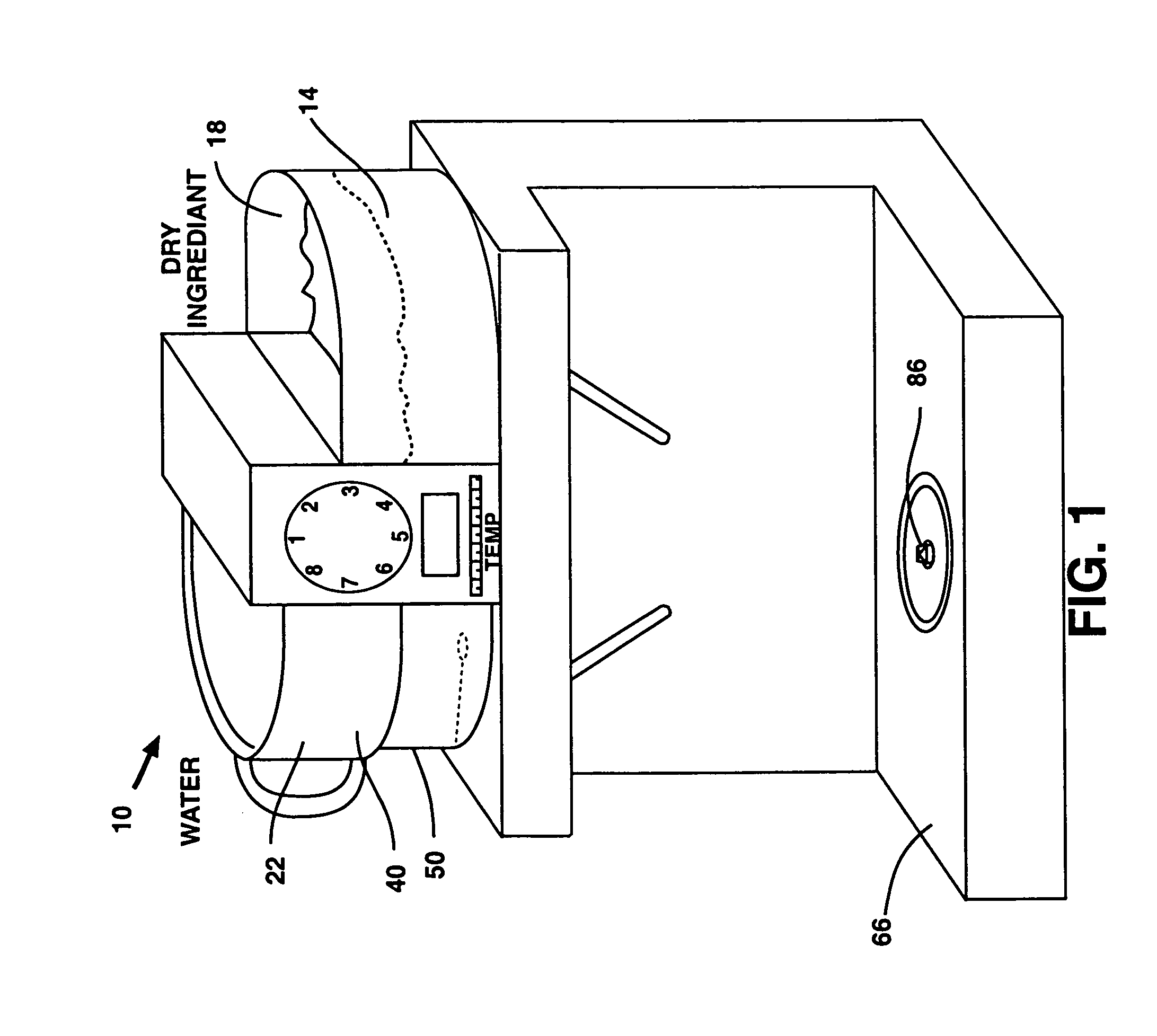

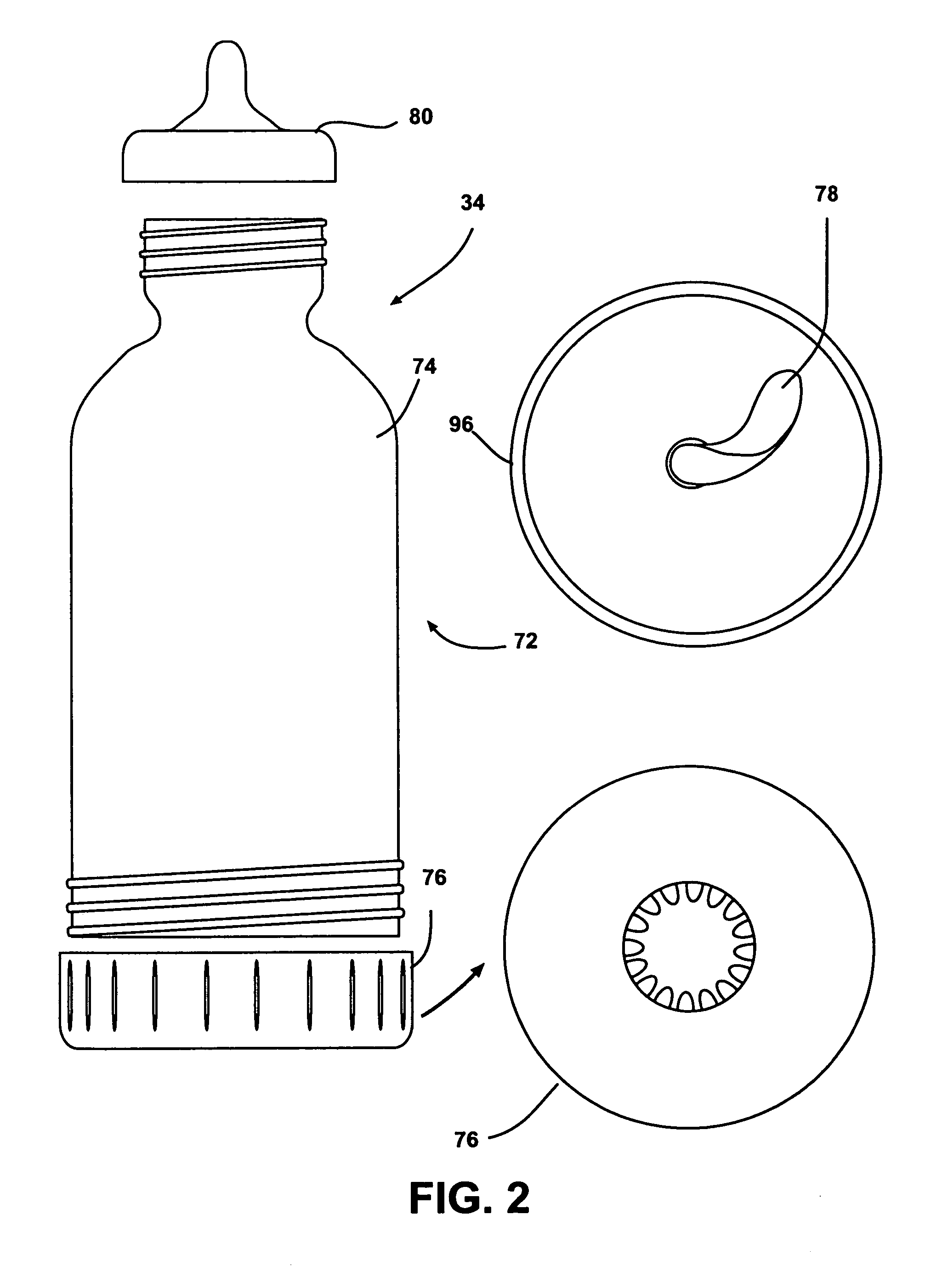

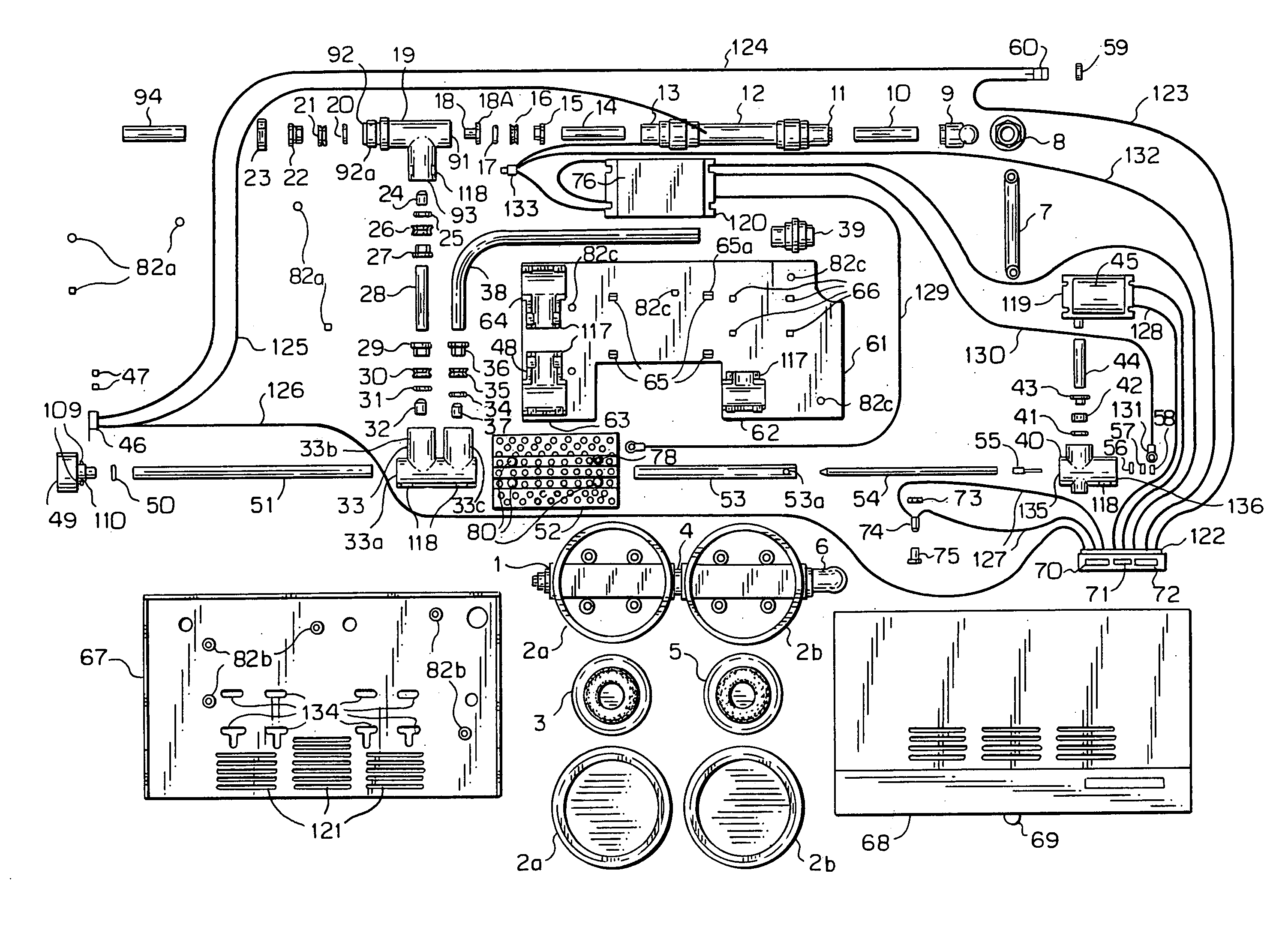

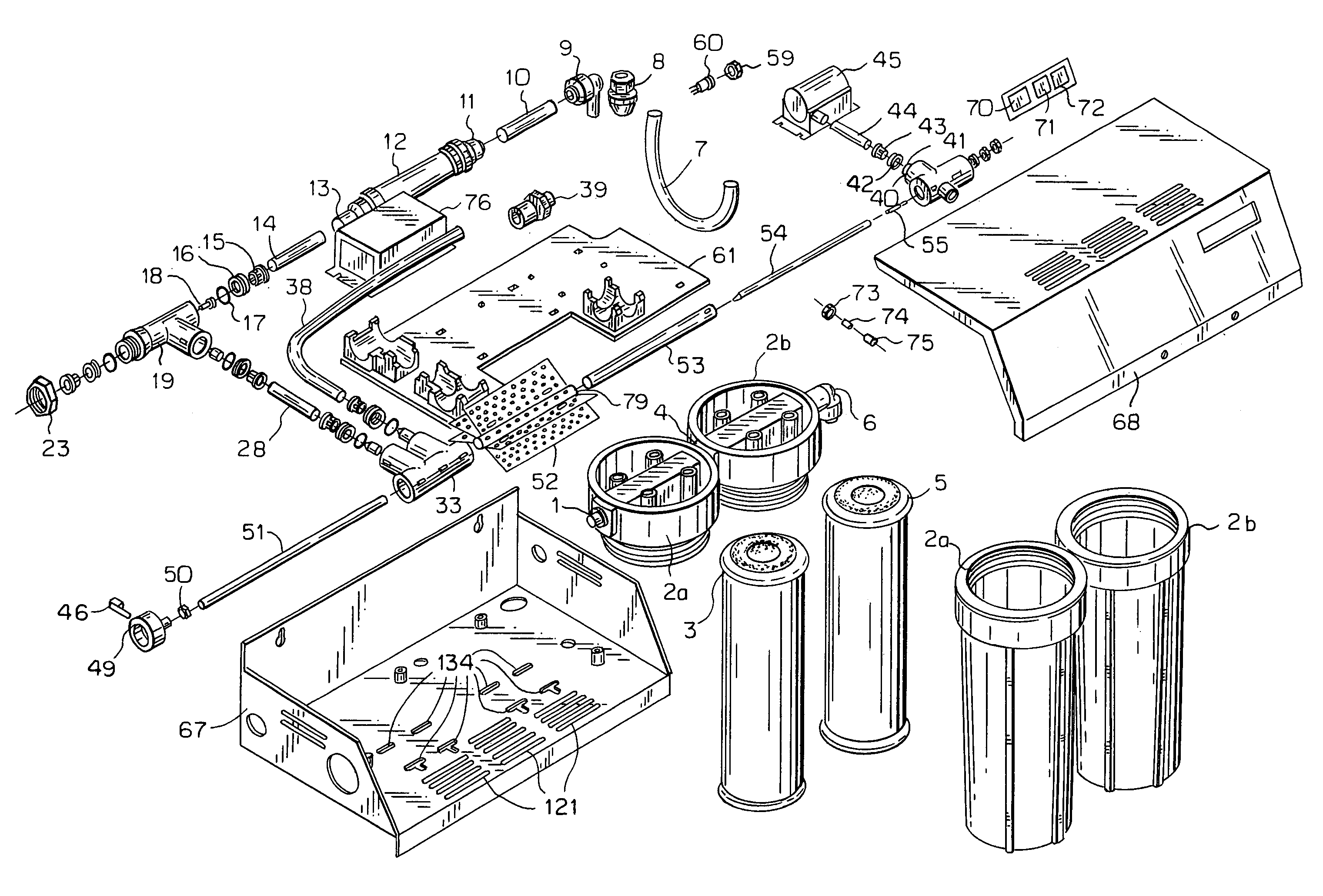

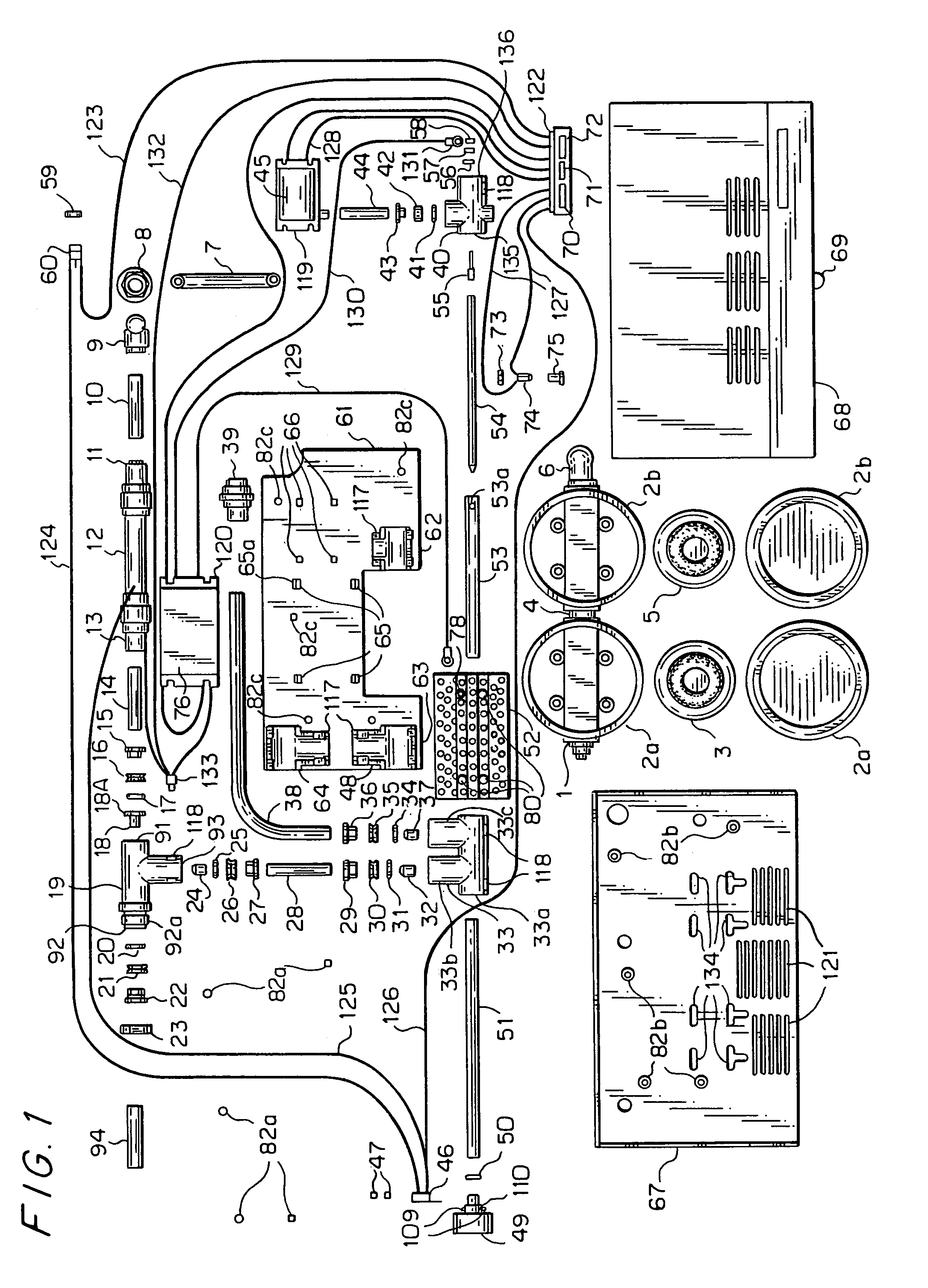

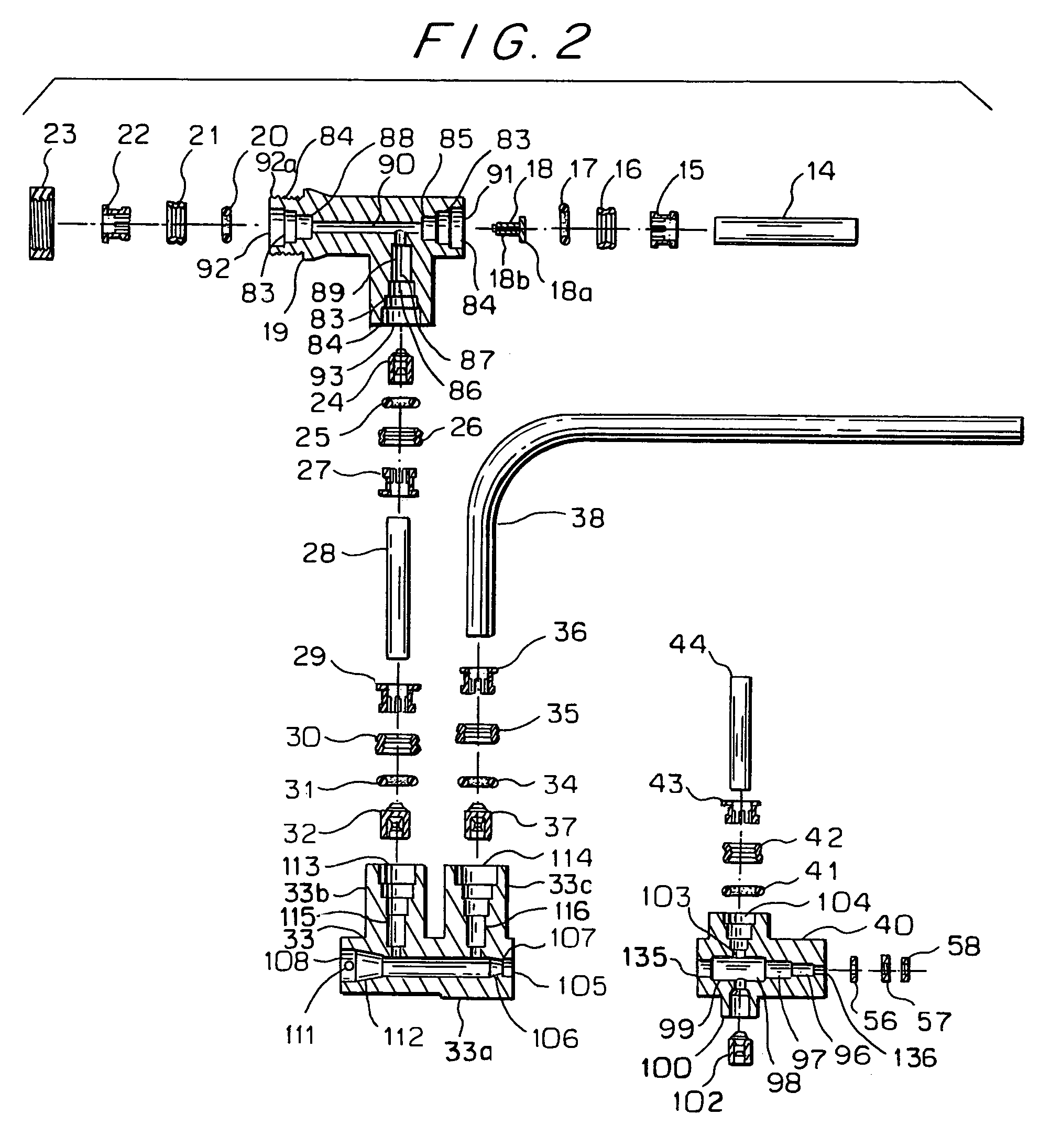

Formula mixing appliance

InactiveUS20060007781A1Quick fixTransportation and packagingHollow article cleaningAdditive ingredientBaby Formulas

An appliance for measuring and mixing dry ingredients such as baby formula with a liquid such as water, heating the water to a desired temperature, and mixing the two ingredients together in the appliance. The result is a liquid food, which is at a desired temperature for use by a consumer.

Owner:MARTIN ROBERTSON & BAIN LTD +1

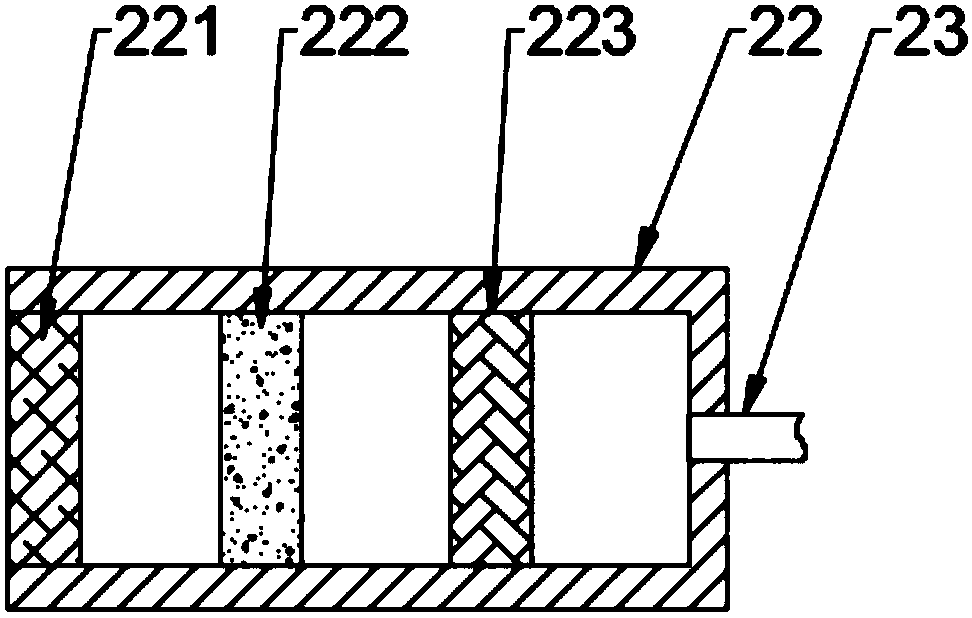

Environmental sanitizer and odor remover for purification of foods, surfaces, air and water with disposable ozone generation electrode, pressure/flow adaptable venturi injector and aqueous phase filter device

ActiveUS20050147546A1Reduce and eliminate ozone demandFlow mixersTransportation and packagingElectricityDielectric

A dielectric assembly for generating ozone includes a positive electrode, a negative electrode in operational proximity to the positive electrode, a dielectric in operational proximity to the positive and negative electrodes for generating the ozone, and a knob adapted to extend outside of a housing into which the dielectric assembly is to be placed. A system is also provided for sanitizing and deodorizing water, food, surfaces and air including a microbiological reduction filter device having an input connected to a water supply, a venturi injector disposed within a housing and connected to an output of the microbiological reduction filter device which generates ozone and mixes the generated ozone with the water, and an electrode assembly comprising a plurality of electrodes, a dielectric for generating the ozone, and a knob extending outside of the housing. The dielectric in a first embodiment and the entire dielectric assembly in a second embodiment can be removed from the housing and replaced in its entirety by the knob.

Owner:LONG RONALD BRUCE +1

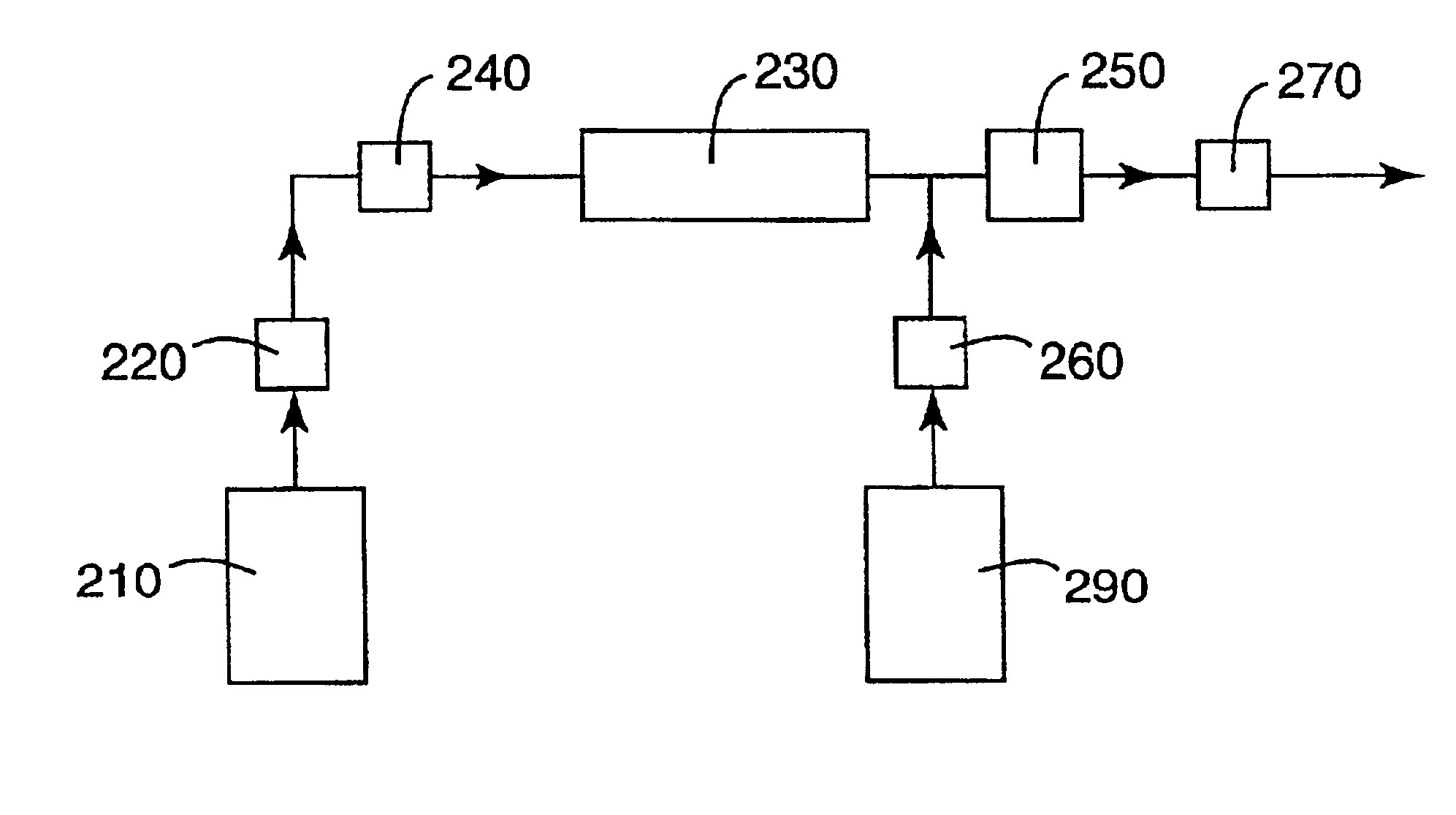

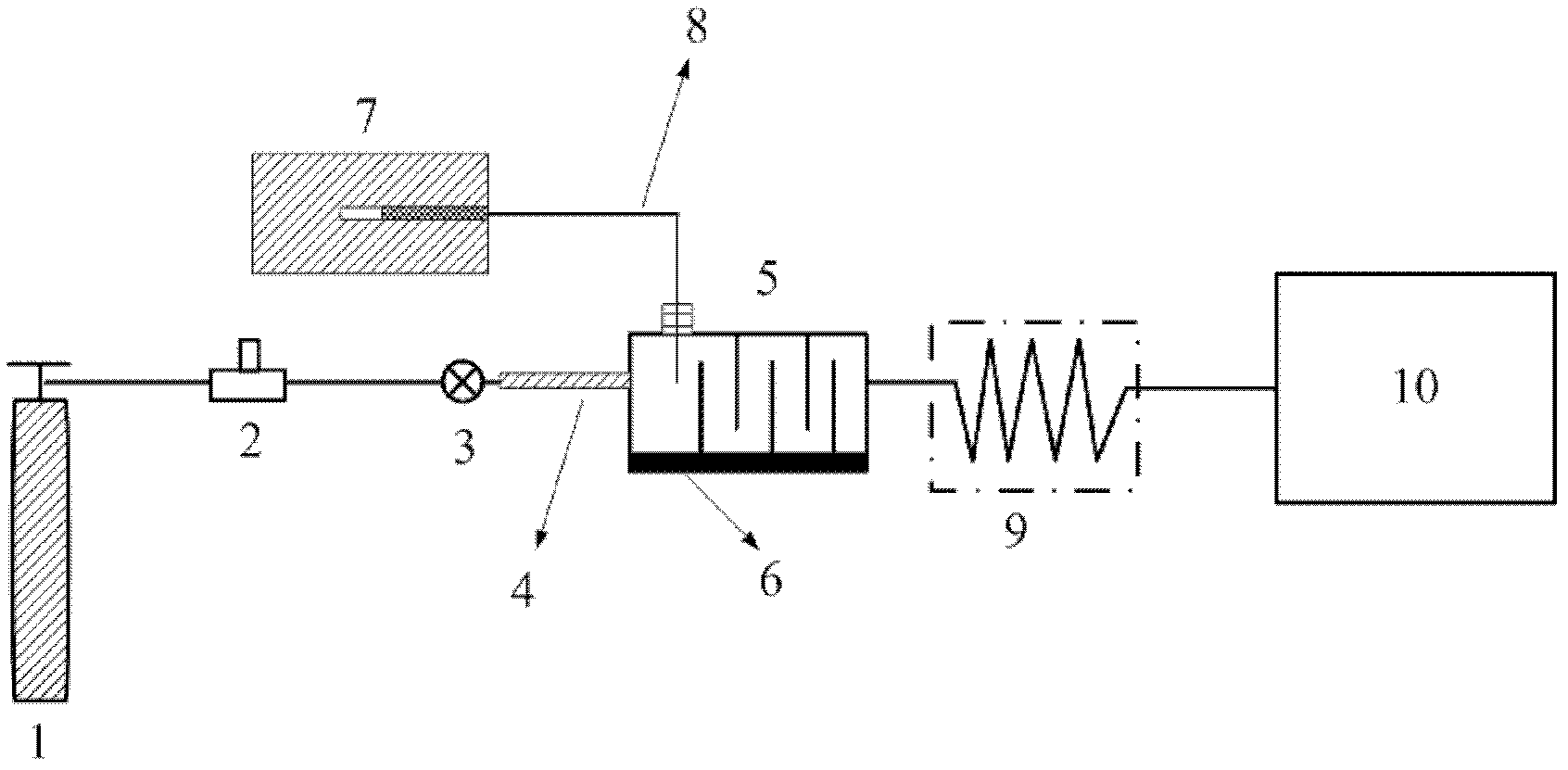

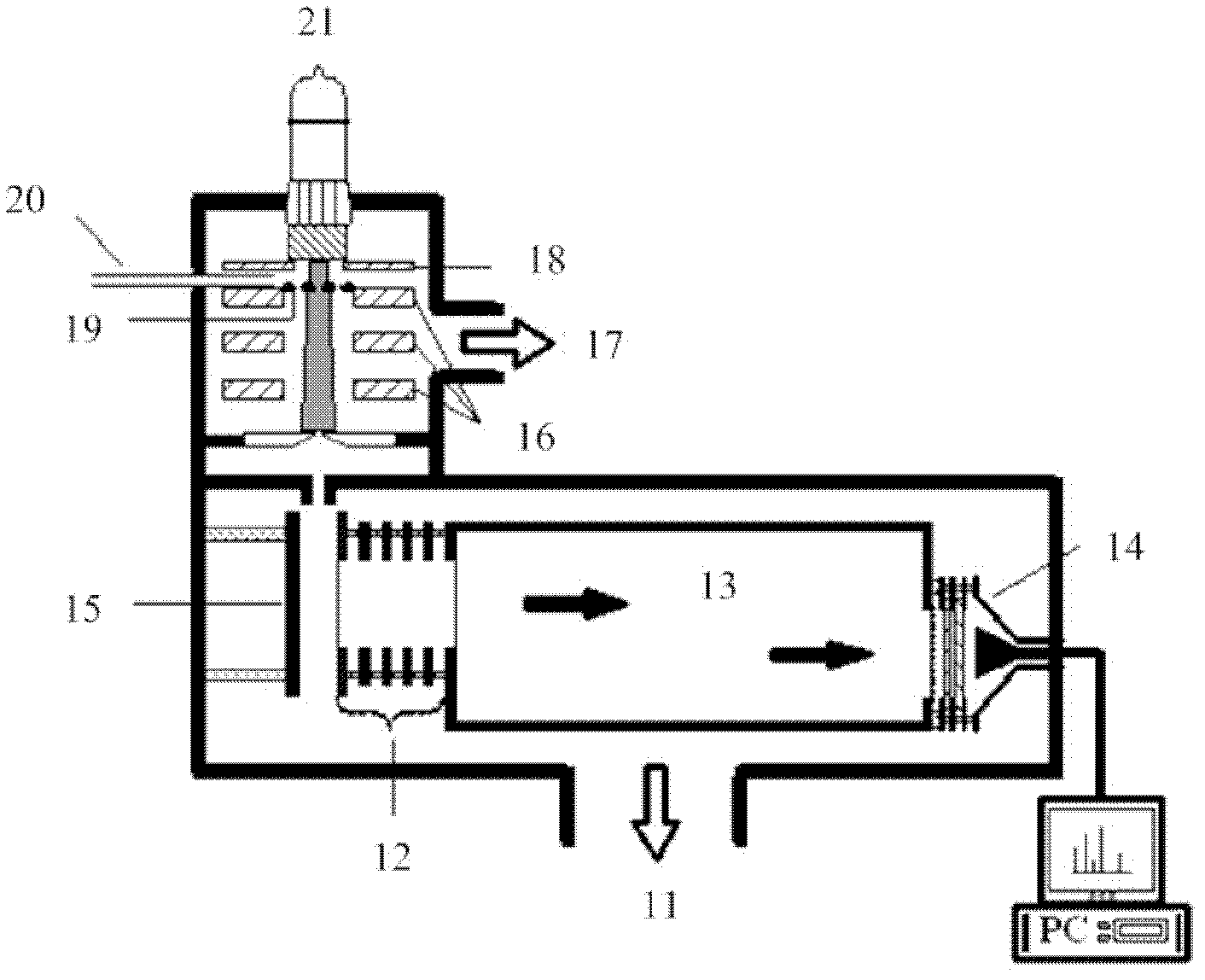

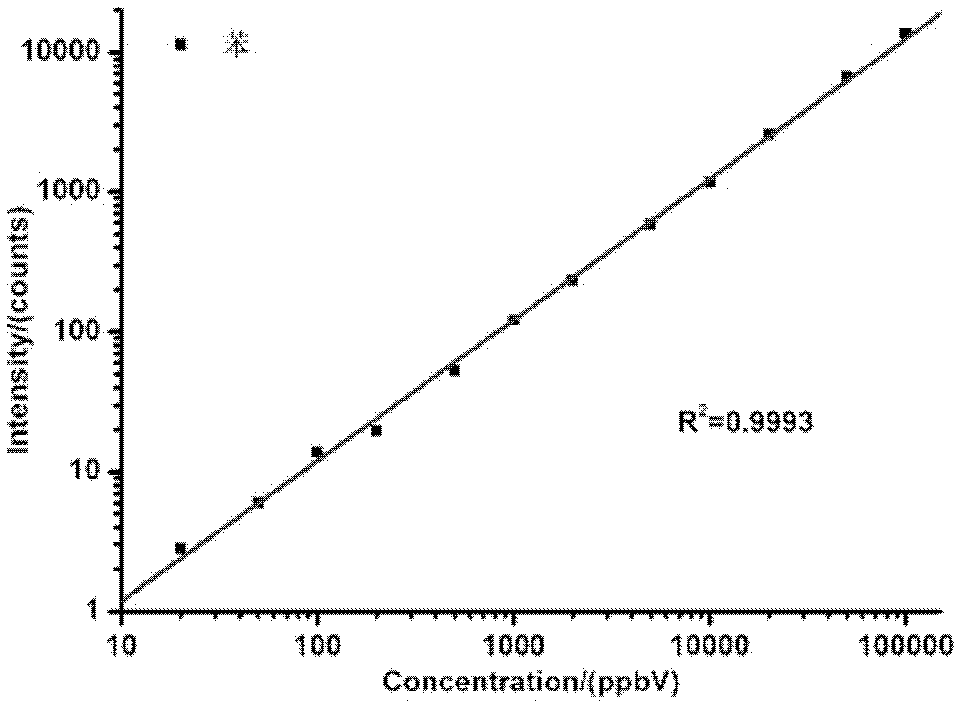

Solid phase and liquid phase compound dynamic gas preparation device and gas preparation method

InactiveCN103163007AEasy to operateShorten the timeComponent separationPreparing sample for investigationGas analysisFlow ratio

The invention provides a solid phase and liquid phase compound dynamic gas preparation device and a gas preparation method. The gas preparation system comprises a diluted gas supplying portion, a diluted gas preheating portion, a sample standard liquid micro-scale control sample injector, a gas mixing portion and a gas analysis device. According to the gas preparation method, diluted gas passes through the diluted preheating device and enters a liquid evaporating device in a certain flow, meanwhile sample standard liquid enters the liquid evaporating device to mix with the diluted gas, finally the mixed gas passes through the gas mixing portion for being mixed evenly, a part of gas enters the gas analysis device for analysis and other gas is exhausted as tail gas. The flow ratio of sample gas and the diluted gas can be effectively controlled due to change of flow of the micro-scale sample injector and flow of the diluted gas so that the mixed gas with different concentrations can be obtained without preparation of the sample standard liquid in all concentration points and preparation efficiency and accuracy of solid phase and liquid phase compound standard gas are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Concrete cooling injection unit and method of injecting a coolant into a concrete mixture

A method and apparatus for cooling a mixture with an injection system. The injection system is adjustable to accommodate the relative position and particular specifications of a given container (e.g., concrete mixer). In one embodiment, the injection system is operable to inject a coolant directly into the mixture while in the mixing process.

Owner:AIR LIQUIDE IND US LP

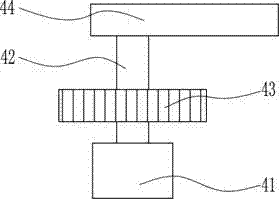

Anode slurry of high-rate lithium ion battery and fabrication method of anode slurry

ActiveCN103035924ASmall particle sizeLarge specific surface areaCell electrodesMixing materials pretreatmentHigh rateMass ratio

The invention discloses anode slurry of a high-rate lithium ion battery and a fabrication method of the anode slurry. The fabrication method comprises the steps of mixing a binder, a conductive agent and a lithium iron phosphate active substance uniformly at a mass ratio of 1:(0.8-1.2):(18-23) with a mixer at a rotating speed of 19-21r / min for 2-4h, adding the uniformly mixed raw materials into an air blowing oven for baking at 80-90 DEG C for 8-12h, turning off the air blowing oven, cooling the mixed raw materials naturally to below 45 DEG C for use, adding the raw materials into a stirring barrel containg NMP (N-Methyl Pyrrolidone) in three times, stirring with a planetary stirrer, controlling the solid content of the slurry to be 30%-40%, stirring for 5-10min at a low speed and 1-1.5h at a high speed when the mixed raw materials are added in the first time and the second time, stirring for 5-10min at the low speed and 2-3h at the high speed when the mixed raw materials are added in the third time, adding NMP to adjust viscosity, controlling the viscosity to be 5000-10000MPa*s, stirring at the low speed to conduct vacuum defoaming, and filtering the slurry with a screen with 200 meshes.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

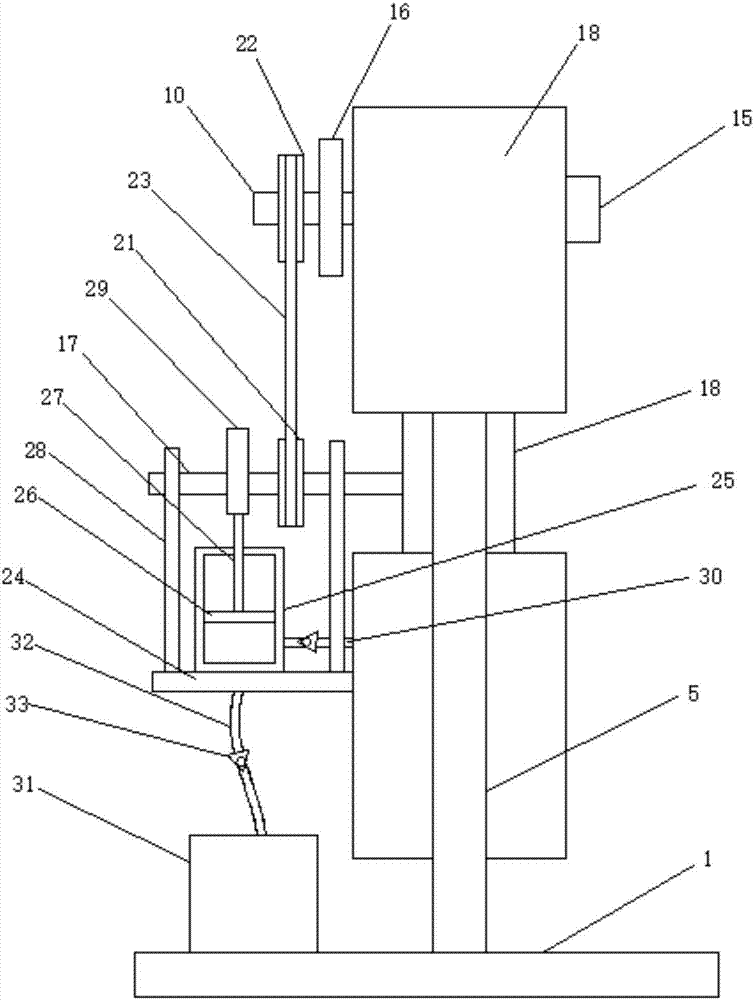

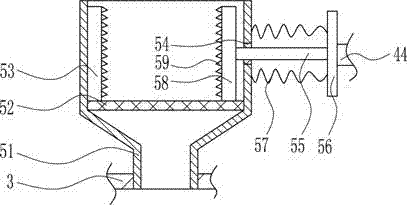

Equivalent liquid preparation mixing device for medicine factory

InactiveCN107596956AAvoid clogging pipesNovel structureRotary stirring mixersMixer accessoriesFiltrationEngineering

The invention discloses an equivalent liquid preparation mixing device for a medicine factory. The device comprises a base, a spindle, a mixing box, a plugging head A, a plugging head B, a filtrationbox and stirring blades, wherein the spindle is rotationally mounted in the base, the mixing box is arranged on an upper surface of the base, a clamping groove is welded and mounted on the inner wallof the top of the mixing box, a slope clamping block is glidingly mounted on the clamping groove, and the lower end surface of the slope clamping block is an inclined surface; multiple groups of sliding slots are also fixedly mounted on the spindle, and the stirring blades are glidingly mounted on the sliding slots. The device is novel in structure and can realize spaced type equivalent feeding during feeding of a liquid preparation, the condition that the reagent filtration speed is too slow due to excessive one-time feeding is effectively avoided, the rotating speed of the spindle can be adjusted by adjusting the pulling speed of the handle, centrifugal force is different due to different rotating speeds of the spindle, accordingly, the stirring ranges of the stirring blades are different, the mixing and stirring area is effectively adjusted, and the mixing effect is greatly improved.

Owner:广州林腾生物科技有限公司

Copper welding paste for automatic brazing and its preparing method

InactiveCN1586795AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaRare-earth elementOrganic solvent

The copper base welding paste for automatic brazing includes brazing material, brazing agent and paste forming material. The brazing material has Cu as main material and added alloy elements P, Sn, Ni, B, Ti, In and RE; the brazing agent consists of chemically synthesized intermediate polyboride M, potassium fluoroborate N and flux Q; and the paste forming material consists of mixture of polyisobutylene in different molecular weight and organic solvent. The copper base welding paste has good flowability, wetability and gap-filling performance, etc. and is suitable for industrial production.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

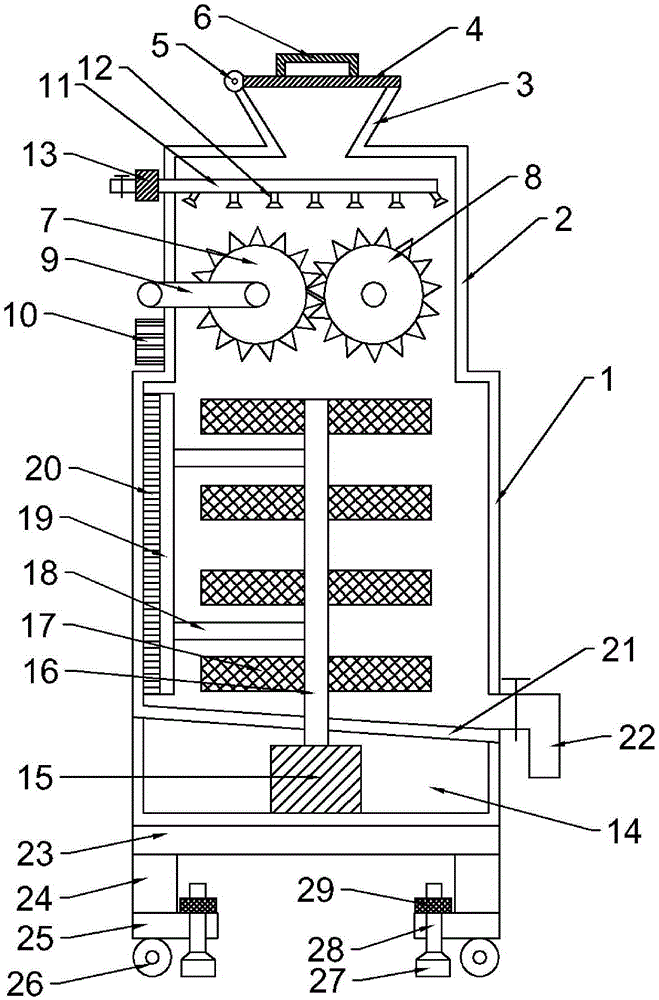

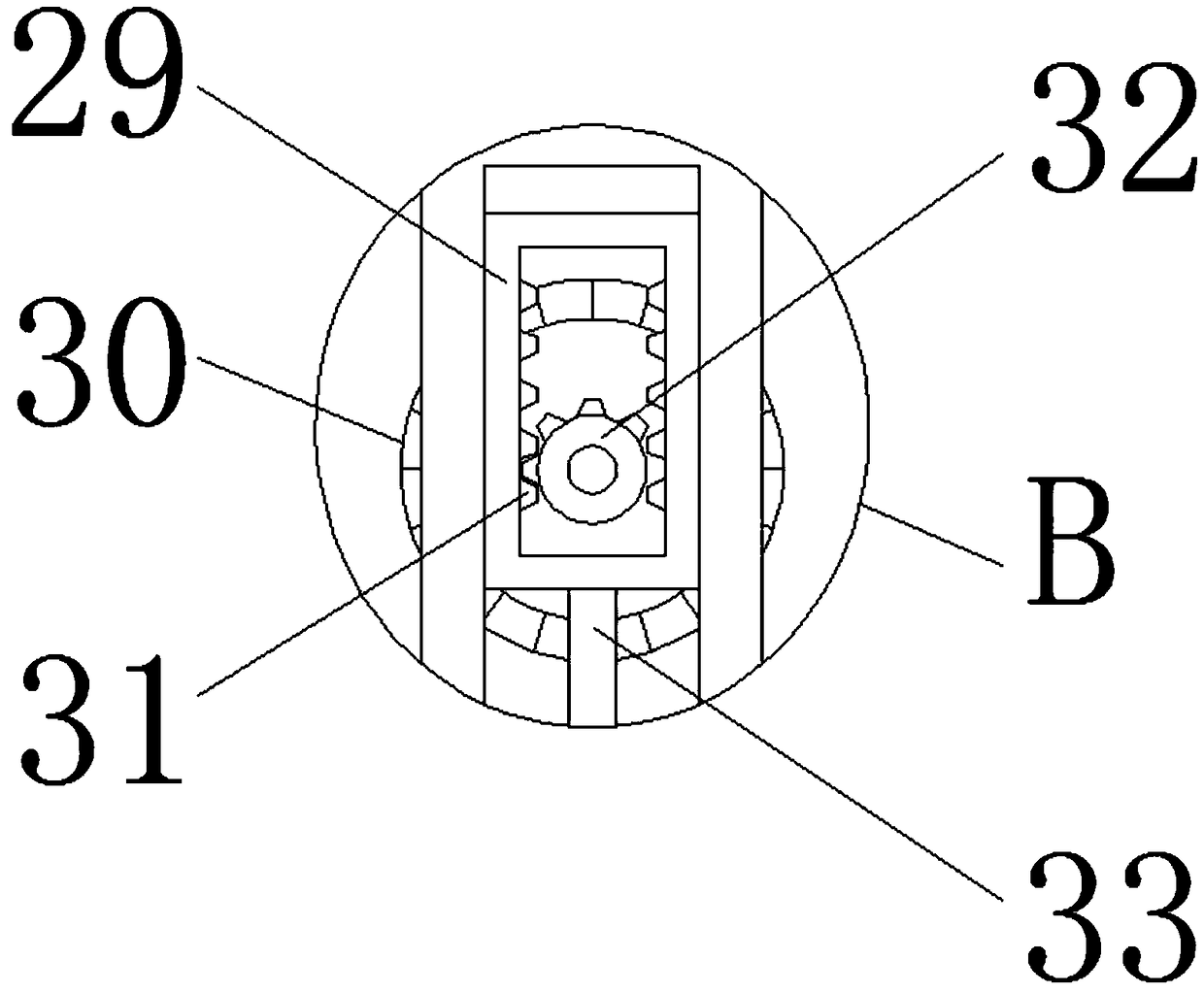

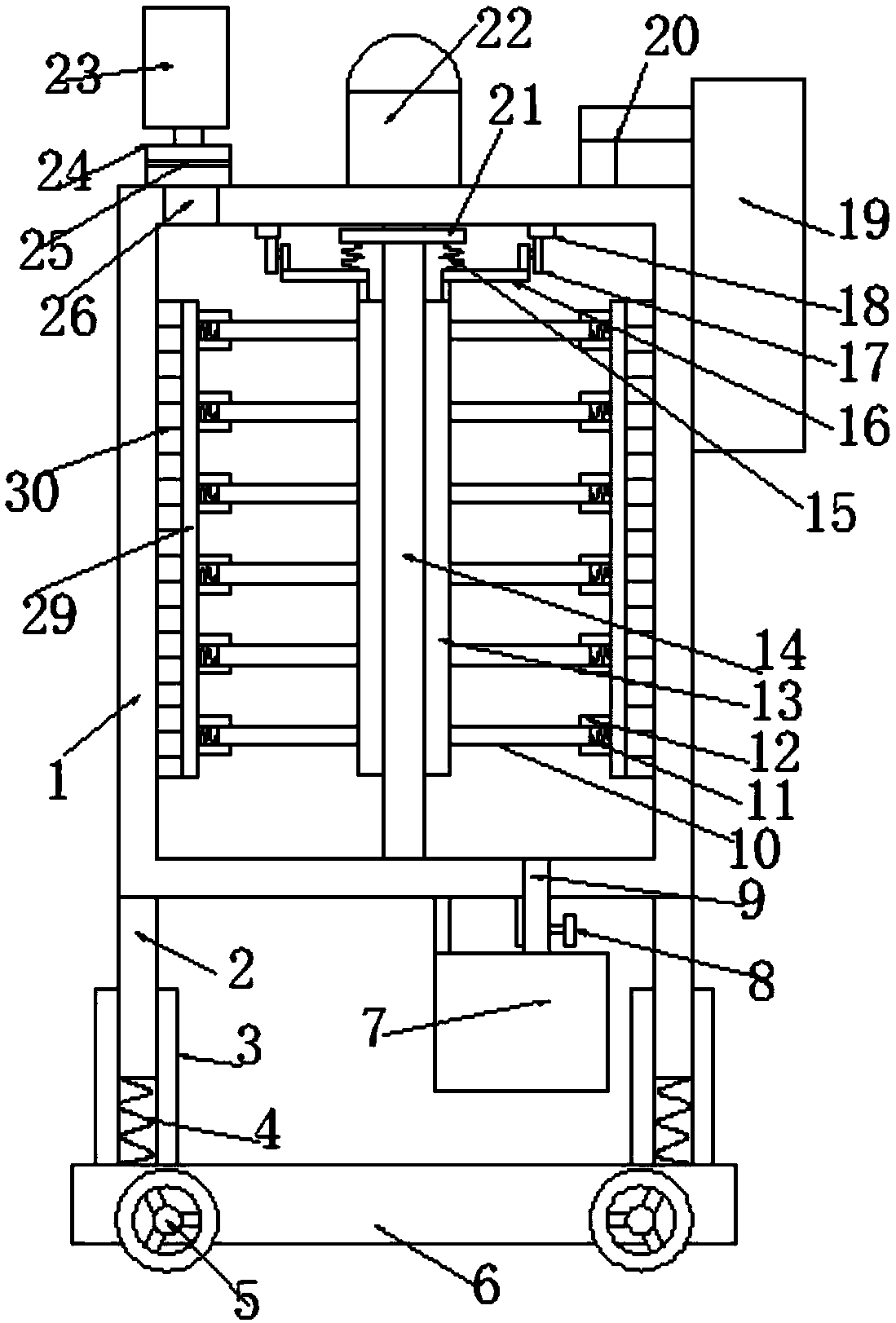

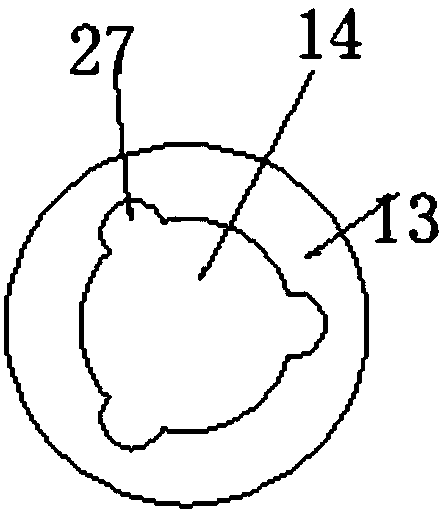

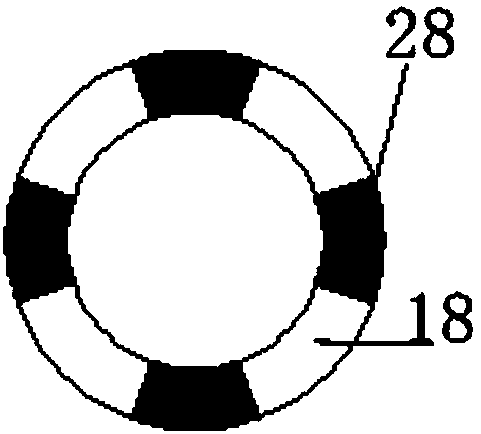

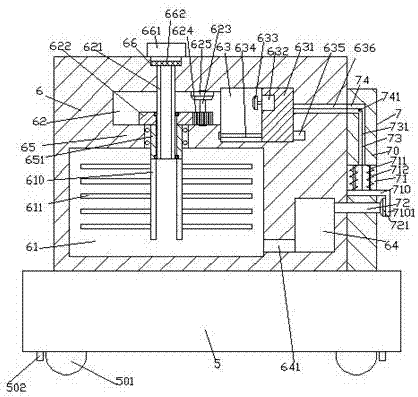

Mobile efficient stirrer

InactiveCN105268353AGuaranteed cleanlinessPrevent splashRotary stirring mixersMixer accessoriesArchitectural engineeringWater pipe

The invention discloses a mobile efficient stirrer. The mobile efficient stirrer comprises a stirring barrel, the upper end of the stirring barrel is connected with a crushing cavity, the upper side of the crushing cavity is connected with a feeding hopper, and the upper side of the feeding hopper is provided with an upper cover plate; the left side of the interior of the crushing cavity is provided with a drive crushing gear, and the right side of the drive crushing gear is provided with a driven crushing gear; the interior of the crushing cavity is provided with a cleaning water pipe, and the lower side of the cleaning water pipe is provided with cleaning spray heads; the lower side of the stirring barrel is provided with a stirrer body base, the interior of the stirring barrel is provided with a stirring shaft, the left side of the stirring shaft is provided with connecting rods, the right sides of the connecting rods are vertically provided with a connecting vertical plate, and the left side of the connecting vertical plate is connected with a scraping and cleaning brush; the bottom end of the stirrer body base is fixedly connected with a support base, the lower side of the support base is provided with support legs, the lower sides of the support legs are provided with bases, the lower sides of the bases are provided with support foots, the upper sides of the support foots are connected with screws, the screws penetrate through the base, and the upper sides of the screws are sleeved with bolts. According to the mobile efficient stirrer, the quality of stirred materials is improved, the stirring effect and efficiency are improved, and the practicability and convenience of the stirrer are improved.

Owner:嘉善远大新型墙体股份有限公司

High-efficiency agitation device for chemical production

InactiveCN106378029AQuality assuranceQuality improvementTransportation and packagingRotary stirring mixersHelical bladeIron removal

The invention discloses a high-efficiency agitation device for chemical production. The high-efficiency agitation device comprises an agitation barrel, wherein the left end of the upper side of the agitation barrel is provided with a material feeding hopper; the lower side of the material feeding hopper is connected with an iron removal cavity; an iron removal rotating shaft is horizontally arranged in the center of the interior of the iron removal cavity; the outer wall of the iron removal rotating shaft is provided with permanent magnet sheets in a longitudinal symmetry manner. By using a high-efficiency pre-crushed chemical material agitator, the iron removal can be carried out on a raw material of a chemical material; in an agitation process, the scraping and the washing can be carried out on the chemical material, which is adhered to an inner wall, by a scraping and washing hairbrush; the waste which is caused as the chemical material is adhered to the inner wall is avoided; the material discharge can be carried out when a helical blade positively rotates; the agitation and the mixing can be carried out on the chemical material at a bottom when the helical blade negatively rotates; the agitation effect and efficiency are improved; the automatic and quantitative water addition can be realized; the quality of the material is guaranteed; the effective shock absorption can be realized by a spring pillar; further, the movement is more convenient and quicker; the practicability and the convenience are high.

Owner:GUANGXI UNIV

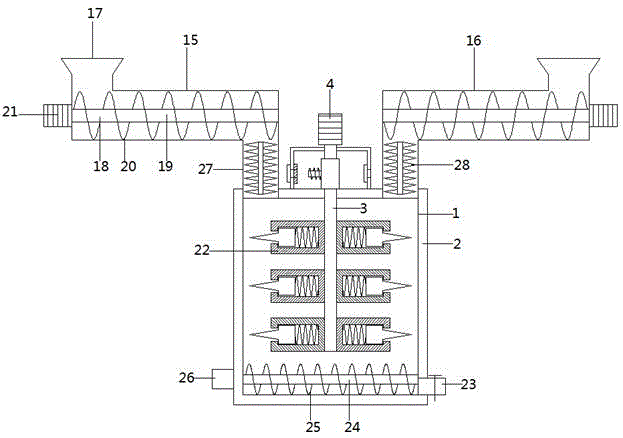

Efficient fertilizer mixer for agriculture

InactiveCN105536600AImprove mixing efficiencyQuality improvementRotary stirring mixersTransportation and packagingEngineeringMixing effect

The invention discloses an efficient fertilizer mixer for agriculture. The mixer comprises a mixer body, wherein feeding ports are formed in left and right ends of the upper surface of the mixer body; a first feeding barrel and a second feeding barrel are arranged at left and right ends of the upper side of the mixer body respectively; feeding ports of the first feeding barrel and the second feeding barrel are both connected with feeding hoppers; screw feeding mechanisms are horizontally arranged in inner axis positions of the first feeding barrel and the second feeding barrel; each screw feeding mechanism comprises a horizontal rotating shaft and a screw blade arranged on the outer wall of the rotating shaft, and the rotating shaft is electrically connected with a first motor. The efficient fertilizer mixer for agriculture can realize automatic feeding and discharging, the working efficiency of the mixer is greatly improved, fertilizer can be crushed before mixing, the quality of the fertilizer is improved, the mixing effect is good, full mixing can be realized, besides, stirring rotating shafts can be cooled, cooling can be performed without halt, the working efficiency of the mixer is improved, and the service life of the stirring rotating shafts is prolonged.

Owner:李秋琦

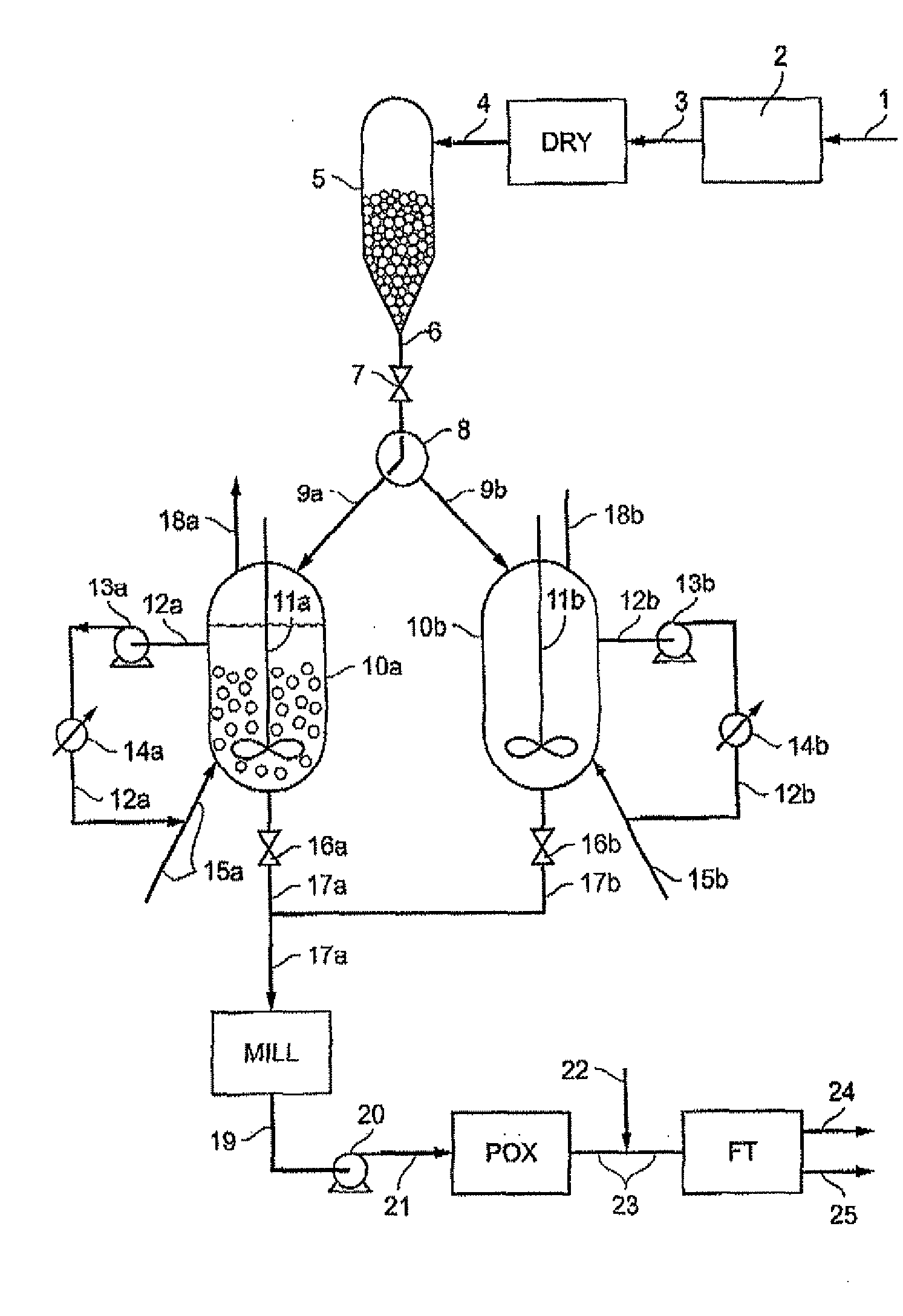

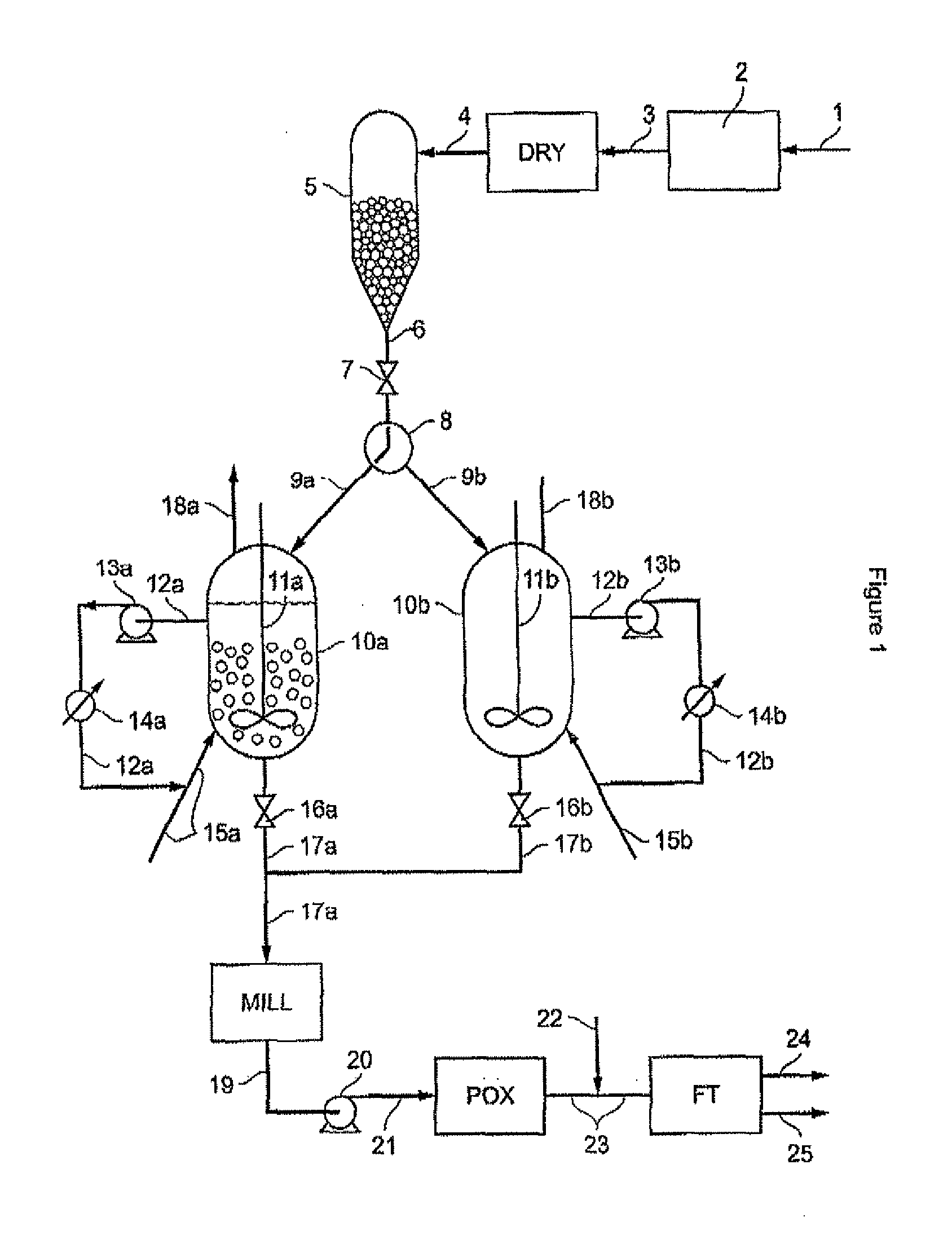

Process for converting biomass to produce synthesis gas

The process of the invention concerns a series of steps for preparing a solid lignocellulosic biomass type feed to supply a unit for gasification of that feed.The process employs at least one step for maturing the feed in the presence of a liquid hydrocarbon phase at a temperature in the range 250° C. to 320° C. for a residence time of at least 10 minutes, and milling the solid fragments which have thus been heat-treated in the presence of liquid hydrocarbon to obtain a suspension of solid in the divided form with a characteristic dimension of less than 150 micrometres.The invention also concerns a device for carrying out the process.

Owner:INST FR DU PETROLE

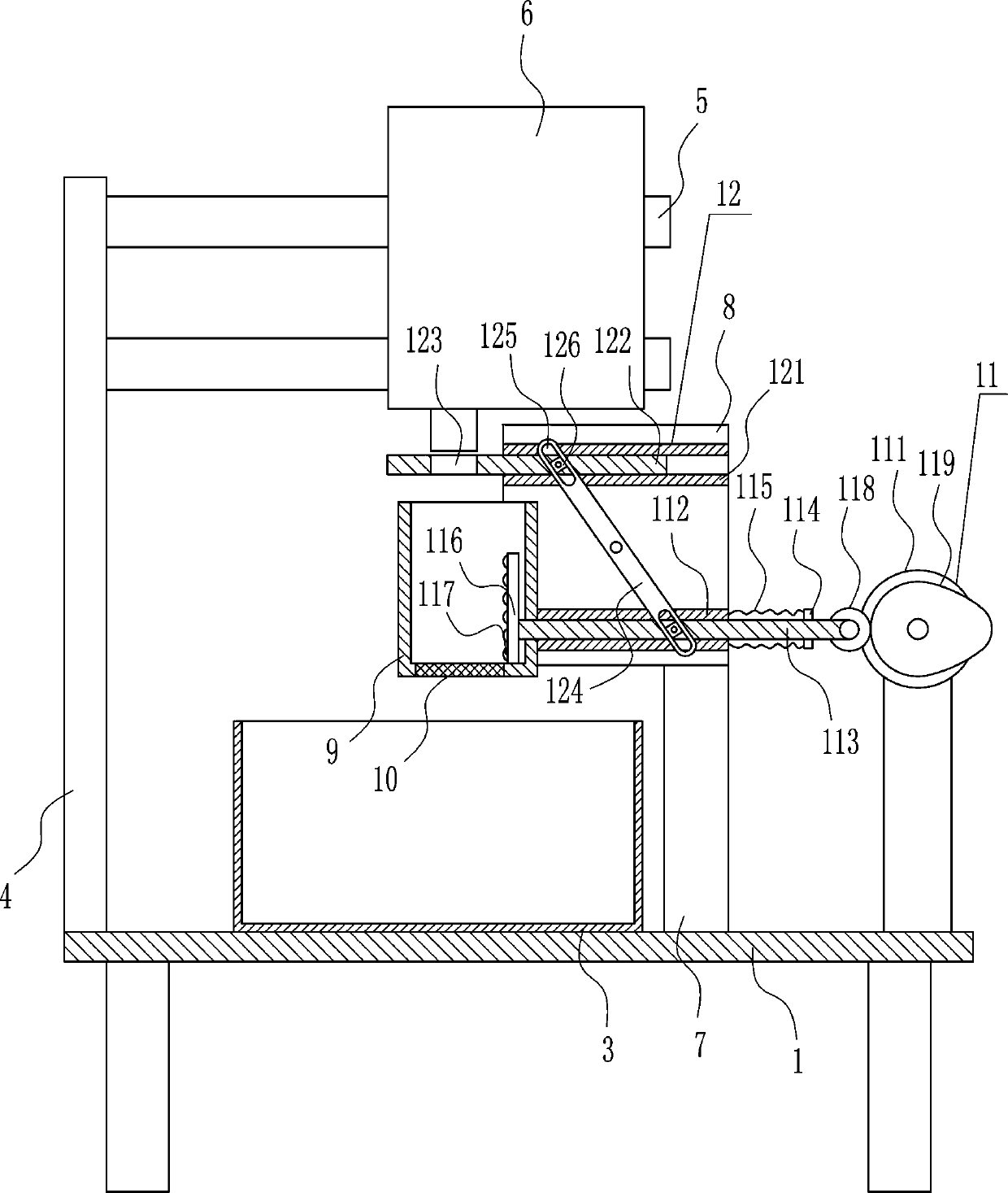

Extrusion mixing device for architectural coating

InactiveCN108905669AIncrease contact areaImprove mixing efficiencyGas treatmentShaking/oscillating/vibrating mixersGround contactHydraulic cylinder

The invention discloses an extrusion mixing device for an architectural coating. In the operation process, two hydraulic cylinders are respectively started to drive pressure bearing blocks to move downwards in order to drive universal wheels to contact with the ground until support frames are removed from the ground, so a whole bin body is moved to a suitable position and is used, and can be easily moved to a suitable position in the building construction process; the hydraulic cylinders are started to make the universal wheels removed from the ground until the support frames contact with theground; the telescopic sleeves act to make the whole pressure bearing blocks move upwards or downwards stably, so the stability is improved, and comfort is provided for a raw material adding operator;dampers can buffer shock generated in the stirring process to achieve continuous up-and-down moving extrusion in the stirring process in order to improve the stirring efficiency, and stirring is alsocarried out in the discharging process to improve the mixing efficiency, so the stability in the running process is improved, the internal peculiar smell of the bin body is removed, the no peculiar smell environment of the bin body is kept, comfort is provided for people's operating process, and the device is convenient for people to operate.

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

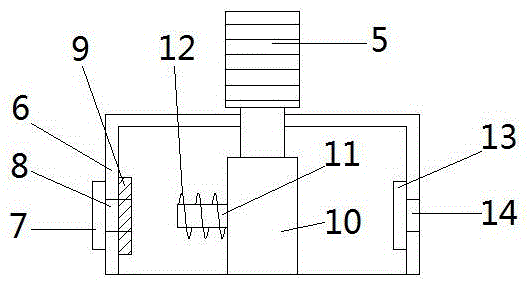

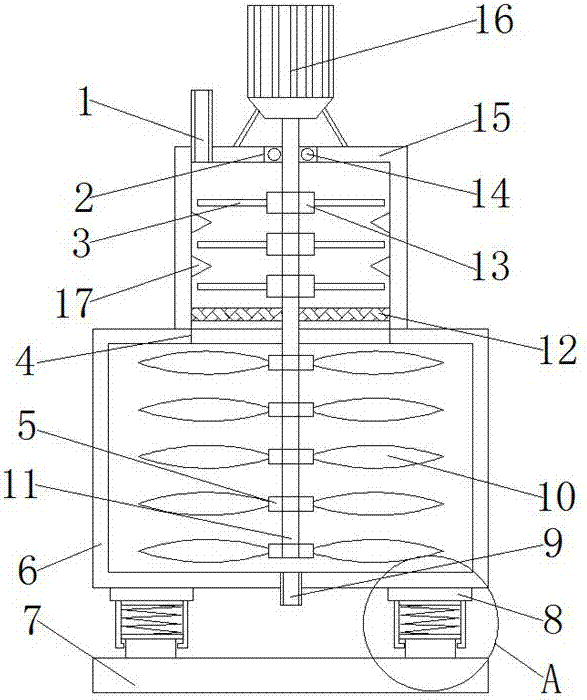

Extracting device for effective components in traditional Chinese medicine

InactiveCN108435036AImprove seismic performanceExtraction helpsShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringChinese herbology

The invention discloses an extracting device for effective components in traditional Chinese medicine. The extracting device comprises an extracting box, wherein a base is arranged under the extracting box; rollers are symmetrically arranged at the left side and right side of the base and are used for conveniently handling the device; support sleeves are symmetrically arranged at both sides of theupper end of the base; a support leg is glidingly arranged at the upper end of each support sleeve, and the upper end of each support leg is fixedly connected with the bottom part of the extracting box; a buffer spring is arranged in each support sleeve; each support sleeve is fixedly connected with the corresponding support leg through the corresponding buffer spring. The extracting device has the advantages that by arranging the buffer mechanism, the vibration-proof property is effectively improved; a material inlet is arranged at the left upper end of the extracting box, and a preheating box is arranged at the upper end, with the material inlet, of the extracting box; the structure is simple and reasonable, the handling is convenient, the buffer property is good, the material stirringeffect is improved, the cleaning effect on the inner wall of the extracting box is improved, and the practicality is strong.

Owner:张志航

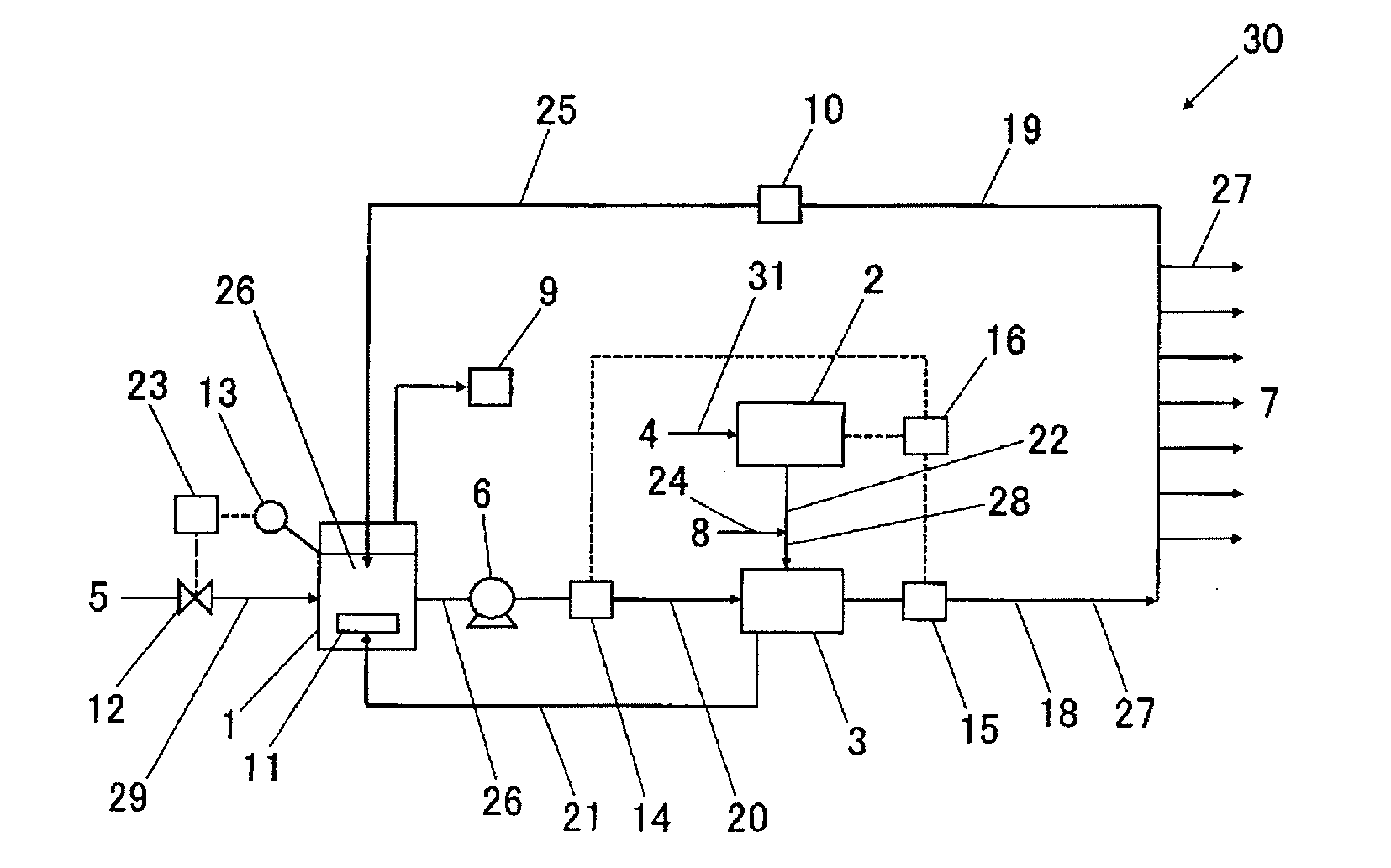

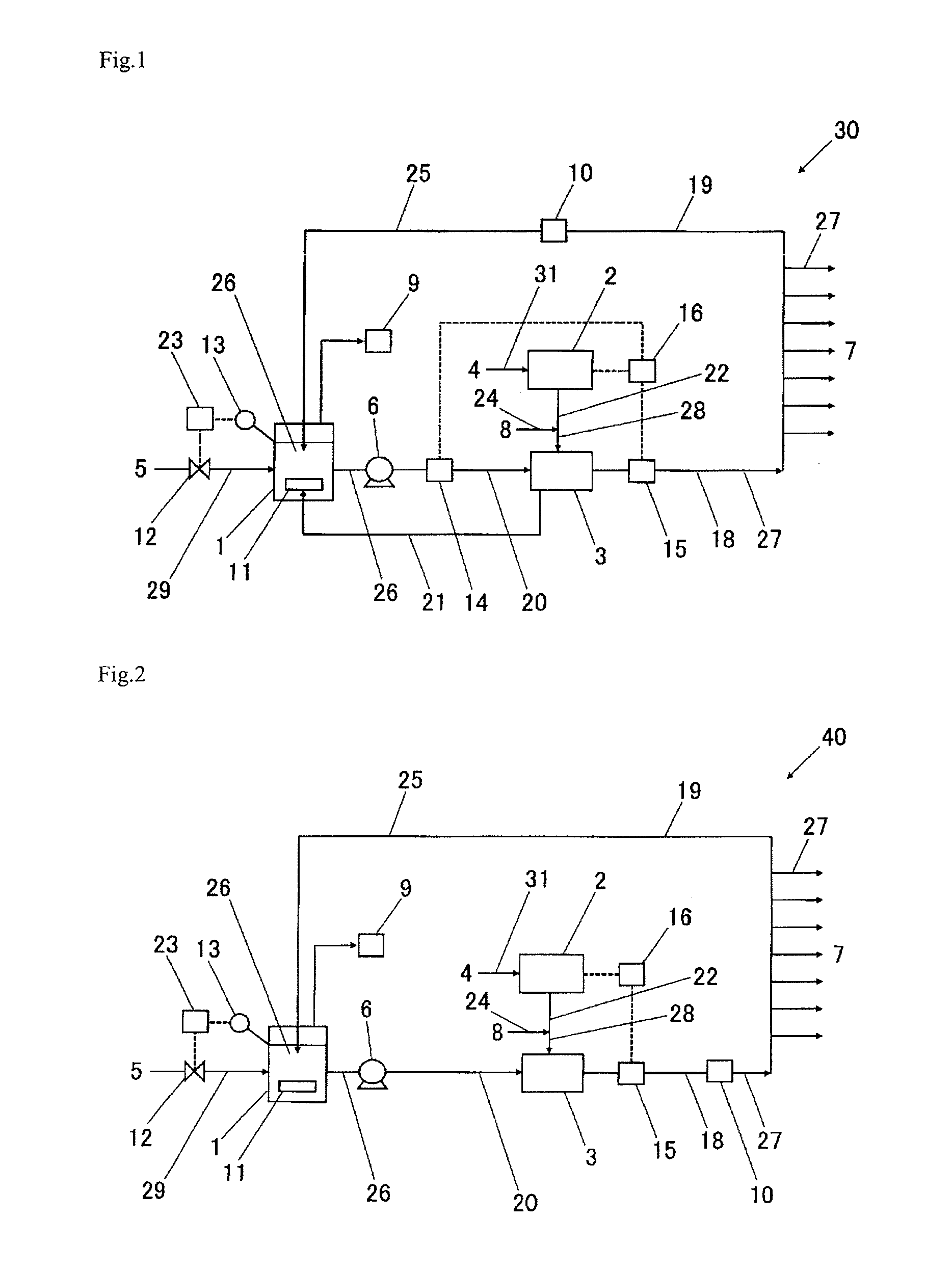

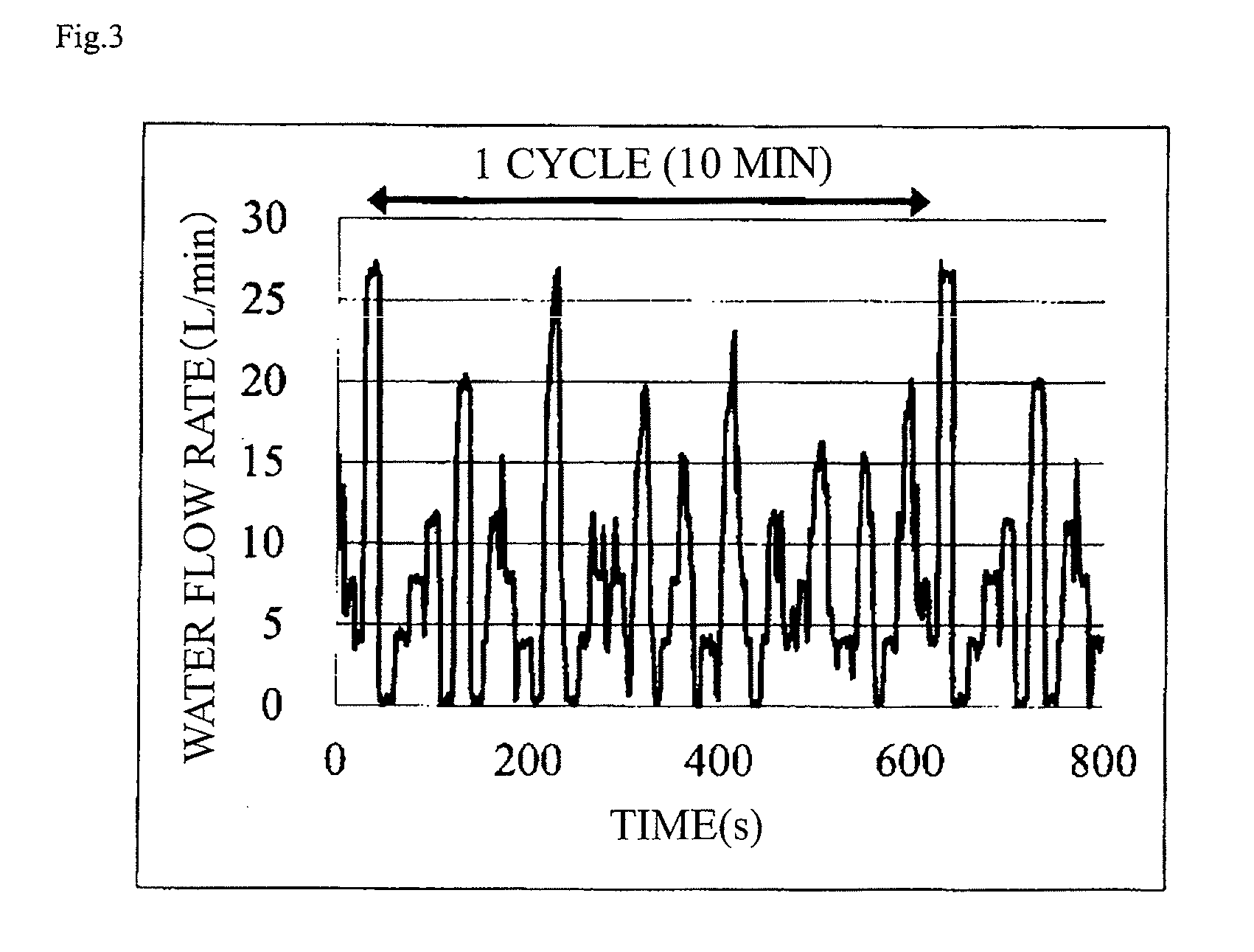

Ozone water supply method and ozone water supply device

ActiveUS20160361693A1Reduce and suppress accumulationWater treatment parameter controlFlow mixersWater useProduct gas

An ozonated water supply method includes: feeding dissolving water contained in a circulation tank to an ozonation device at a given feed rate while feeding ultrapure water to the circulation tank, and returning ozonated water that has not been used at a use point to the circulation tank, dissolving ozone in the dissolving water using the ozonation device to obtain ozonated water, and feeding the ozonated water to the use point; feeding oxygen gas having a nitrogen gas content of 0.01 vol % or less to a discharge-type ozone gas-producer, and feeding the resulting ozone-containing gas to the ozonation device; adjusting the feed rate of the ultrapure water to the circulation tank; and adjusting the dissolved ozone concentration in the ozonated water. The method can reduce or suppress the accumulation of nitric acid in the recirculation system when a discharge-type ozone gas-producer is used as the ozone gas-producer.

Owner:ORGANO CORP

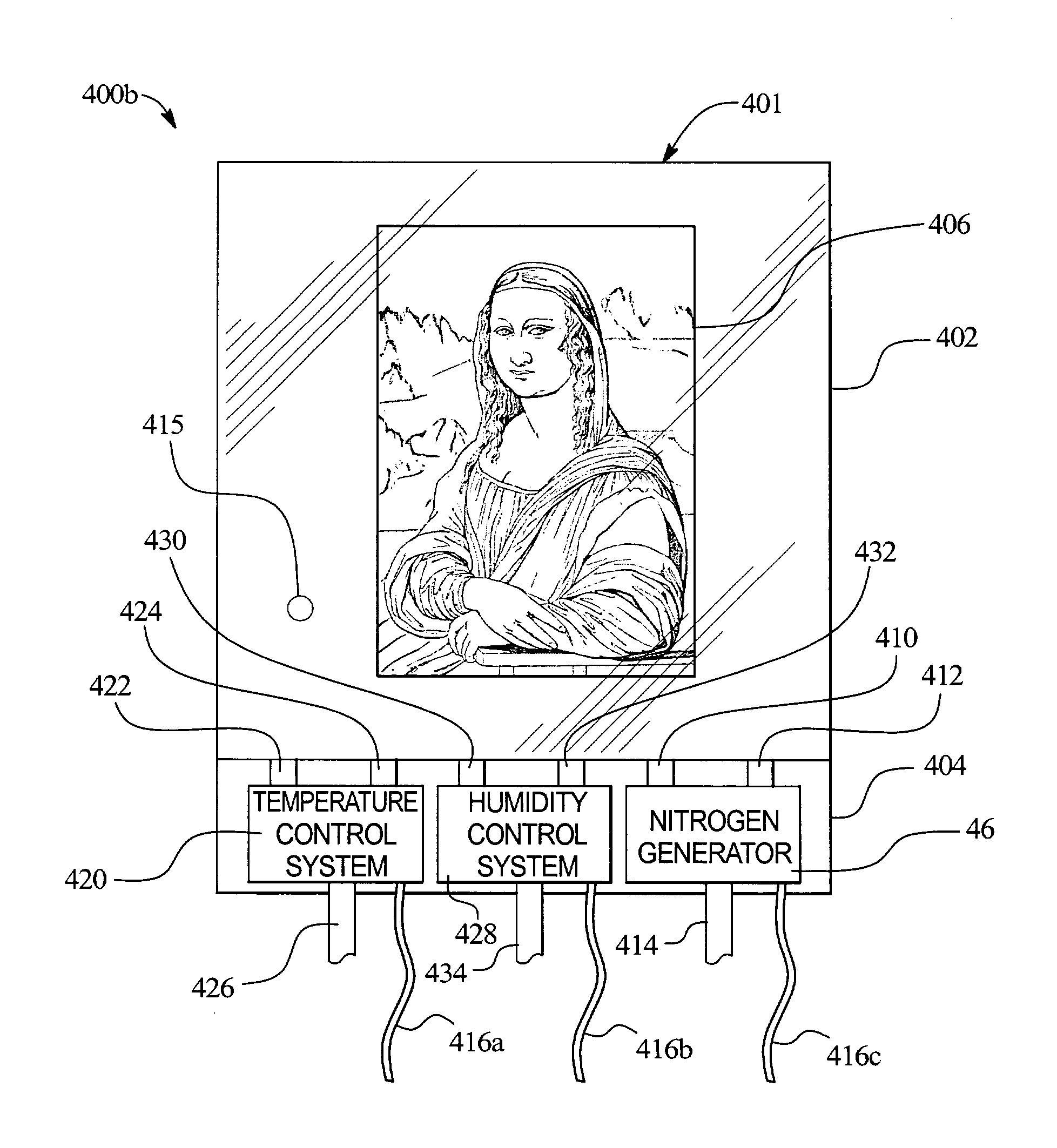

Apparatus and method for preserving collectible items

The present invention relates to an apparatus and method for preserving one or more collectible items. The apparatus includes a housing and a nitrogen generator. A nitrogen generator generates a nitrogen rich gas and supplies the nitrogen gas to the housing, which displaces the oxygen inside the housing to preserve the collectible item or items enclosed by the housing. The nitrogen rich gas significantly reduces the degradation of the collectible item due to the exposure of the item to oxygen in the air. In another embodiment, the apparatus further includes a temperature control system and a humidity control system to control the temperature and humidity inside the housing. This further aids in preserving a collectible item for relatively long periods of time by reducing the effects of the environment on the item.

Owner:VIN VALET

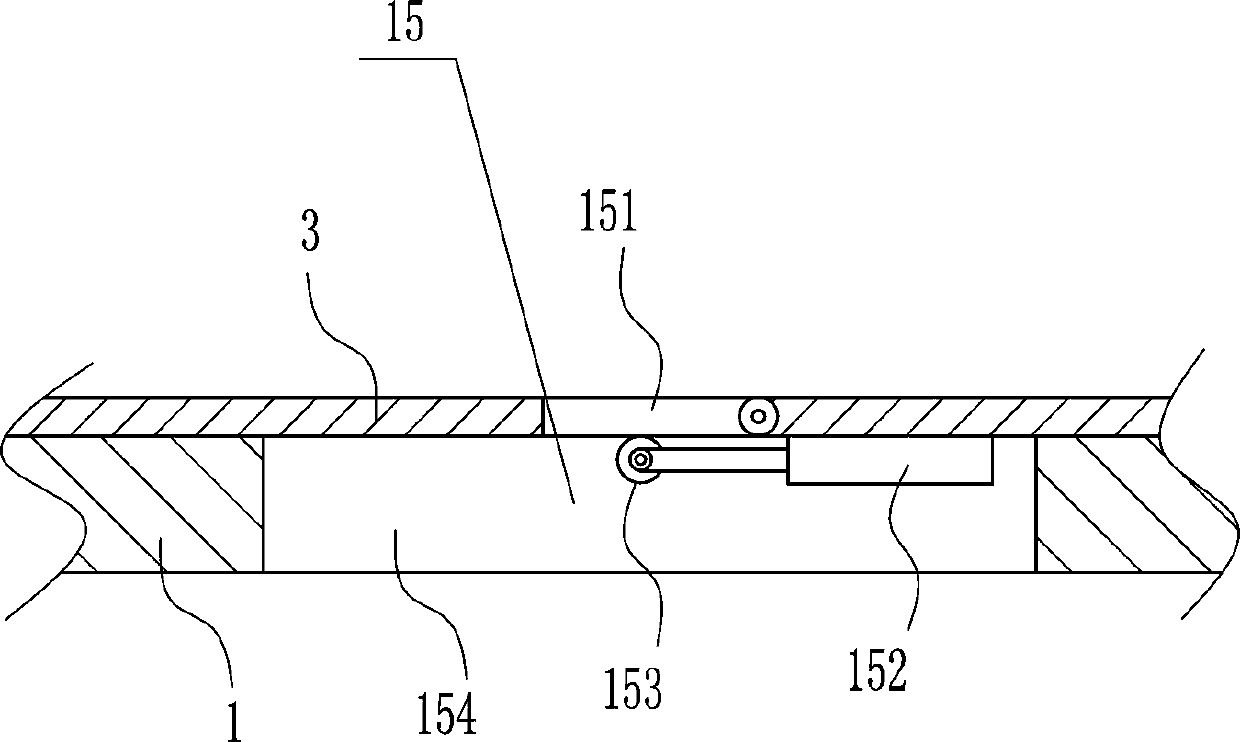

Cable device

InactiveCN107262436ATransfer manipulation implementationImprove mixing efficiencyRotary stirring mixersTransportation and packagingEngineeringElectric cables

The invention discloses a cable device. The cable device comprises a base body, a storage box arranged on the top of the base body, and a scouring device used for being connected with the storage box in a matched manner. The scouring device is fixedly arranged on the top of the part, on the right side of the storage box, of the base. A storage cavity is formed in the storage box. A first cavity is formed in the part, above the top of the storage cavity, of the storage box. A sinking groove is formed in the top face of the part, above the first cavity, of the storage box. A partition plate is arranged between the first cavity and the storage cavity and is internally connected with an up-down extending rotation shaft sleeve in a rotation fit manner. The rotation shaft sleeve is internally connected with an up-down extending supply pipe in a rotation fit manner. An extending part on the top of the supply pipe passes through the first cavity, then penetrates the part, between the first cavity and the sinking groove, of the storage box, and is fixedly connected, and the extending tail end at the bottom of the supply pipe stretches into the storage cavity. The cable device is simple in structure, convenient to operate, capable of achieving automatic operation and rapid scouring work and uniform in scouring, and meanwhile the service life is prolonged.

Owner:柯步勋

Shower gel production device based on natural tea and ginger raw material production technology

InactiveCN107551600AEasy extractionEasy to completeCosmetic preparationsRotary stirring mixersShower gelPulp and paper industry

The invention discloses a shower gel production device based on a natural tea and ginger raw material production technology. The shower gel production device comprises a kettle body, wherein the top end of the kettle body is connected with a feeding hopper in a penetrating way, a crushing roller group is arranged at the upper part of an inner cavity of the kettle body, a filter screen is arrangedin the middle of the inner cavity of the kettle body, a grinding disc is arranged at the top end of the filter screen, the top end of the grinding disc is fixedly connected with a moving block, a screw rod is embedded in the moving block, a stirring rod is arranged at the bottom of the inner cavity of the kettle body, a plurality of stirring blades are uniformly arranged at the stirring rod, a plurality of supporting legs are uniformly arranged at the bottom end of the kettle body, the bottom of one side end of the kettle body is connected with a filter cartridge in the penetrating way, the other end of the filter cartridge is connected with a drug discharging pipe in the penetrating way, and a water pump is arranged on the drug discharging pipe; according to the shower gel production device, through arranging the crushing roller group and the grinding disc, tea leaves and ginger blocks are respectively crushed and ground, so that the beneficial components in the tea leaves and the ginger blocks can be conveniently and fully extracted to improve the raw material utilization rate; the filter cartridge can completely remove fixed particles in a solution, so that the quality of the extracting solution is guaranteed, and the completion of subsequent procedures of the shower gel is facilitated.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

Nozzle device and nozzle for atomisation and/or filtration and methods for using the same

InactiveUS20050178862A1Low flow resistanceHigh work pressureTransportation and packagingUltrafiltrationAs elementEmulsion

Nozzle device and nozzle for atomization and / or filtration as well as methods for using the same. The nozzle and nozzle device for atomization, in particular a micro-machined reinforced nozzle plate, may produce small liquid droplets in air (spray) or into a liquid (emulsion) with a narrow droplet size distribution and make small air bubbles into a liquid (foam). A nozzle part for filtration as well as elements and methods to facilitate atomization and filtration are also disclosed.

Owner:MEDSPRAY

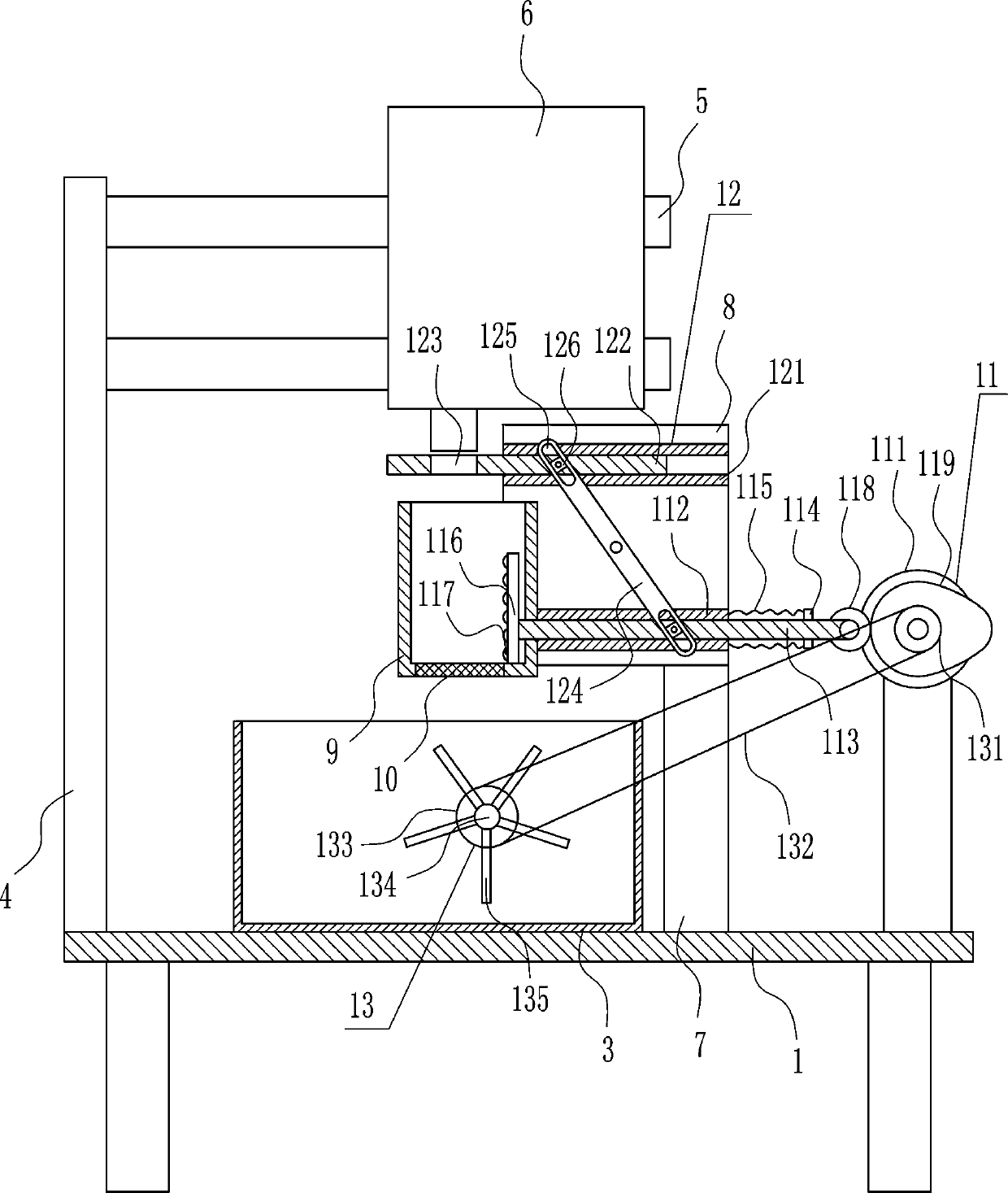

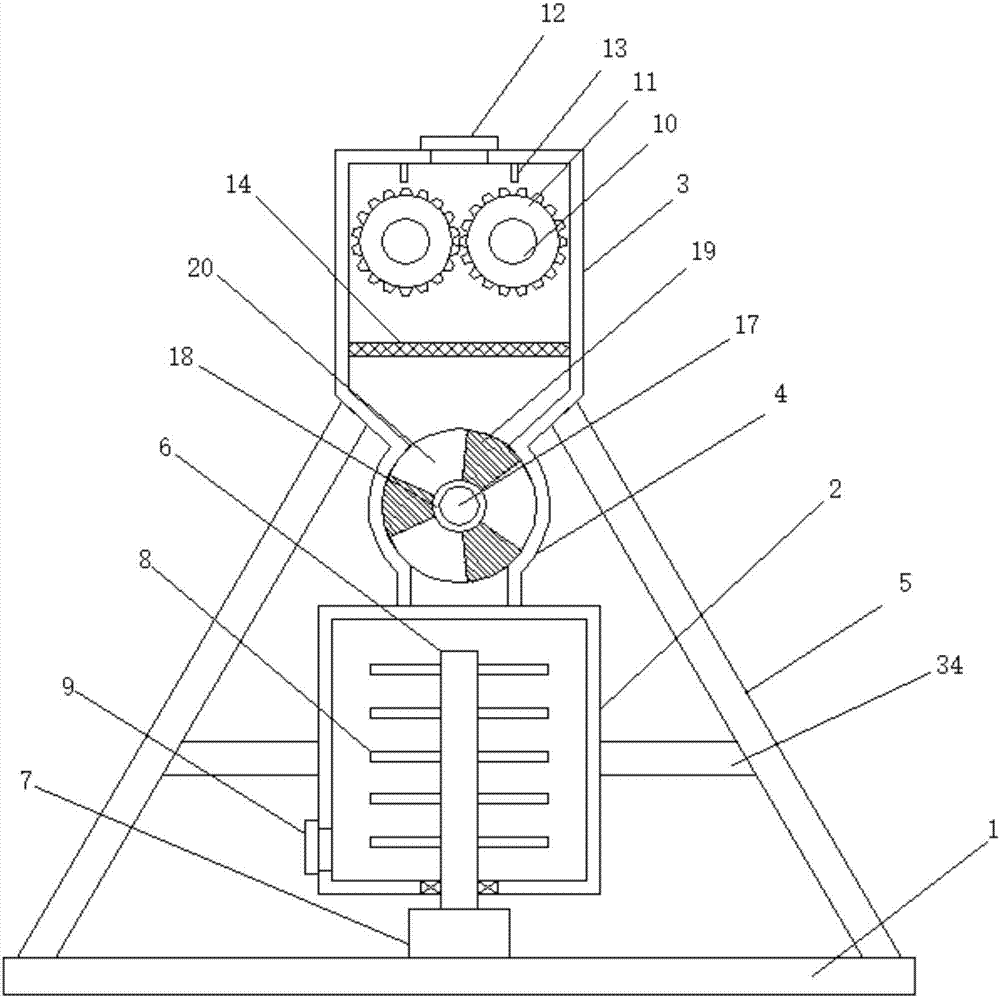

Quick agent adding device for sewage treatment tank

InactiveCN107185432AImprove stirring efficiencySave energyRotary stirring mixersTransportation and packagingSewage treatmentMixing tank

The invention relates to an adding device, in particular to a quick agent adding device for a sewage treatment tank. Technically, the invention aims to provide the quick agent adding device for a sewage treatment tank with the characteristics of high mixing efficiency and fast agent adding speed. In order to solve the technical problems, the invention provides a mining transportation device with sorting functions. The device comprises a base plate, brackets, a mixing tank, a driving mechanism, a dosing mechanism, a stirring mechanism, a water adding mechanism, a discharge mechanism and an otter board, the mixing tank is fixedly connected to the base plate through two brackets, the water adding mechanism is fixedly connected a side of the mixing tank, and the discharge mechanism is fixedly connected below a mixing tank end far from the water adding mechanism. According to the invention, through cooperation of the driving mechanism, the dosing mechanism, the stirring mechanism and the water adding mechanism, drugs can be stirred and mixed rapidly, and through the discharge mechanism, the agent can reach a better effect.

Owner:段建英

Integrated crushing, stirring and mixing device for construction coating particles

InactiveCN107442031AAvoid affecting useMix in timeTransportation and packagingMixer accessoriesDrive shaftArchitectural engineering

The invention discloses an integrated crushing, stirring and mixing device for construction coating particles, which comprises a bottom plate, a crushing groove and a mixing box, wherein a driving shaft is mounted on a support rack; one end of the driving shaft is connected with a driving motor arranged on the support rack; a vertical upward pressure rod is arranged at a port of the crushing groove; a crushing pressure plate is arranged at the lower end of the pressure rod; a sieve plate is arranged in the crushing groove; a material inlet is formed in a side wall, close to the crushing groove, of the top end of the mixing box, and connected with a material outlet by a material guide channel; a stirring shaft is arranged in the crushing groove; the upper end of the stirring shaft is connected with the driving shaft by a gear mechanism; a plurality of stirring and mixing rods arrayed in a circular ring manner are arranged at the lower end of the stirring shaft; and a discharge port is formed in a side wall of the bottom end of the mixing box. The device is simple in structure, higher in processing and production efficiency, better in linkage, stable in transmission, uniform and sufficient in mixing, easy and simple to operate and higher in practicability, and can simultaneously perform crushing and mixing.

Owner:林红英

Stirring rod moving type chemical raw material mixing device

InactiveCN107583544AAvoid cloggingAvoid influenceShaking/oscillating/vibrating mixersMixing materials pretreatmentCircular discDrive shaft

The invention discloses a stirring rod moving type chemical raw material mixing device. The chemical raw material mixing device comprises a mixing box body, wherein two rotating shafts are respectively arranged at two sides inside the mixing box body, the two rotating shafts are both provided with lower spiral sections, the two lower spiral sections are both provided with driving sleeves in spiraland matching connection with the corresponding lower spiral sections, a stirring shaft is arranged between the two driving sleeves, two ends of the stirring shaft are both provided with rotating sleeves in rotating connection with the two ends of the stirring shaft, the stirring shaft is provided with a plurality of stirring rods, a driving shaft is arranged at the lower side of the mixing box body, the other end of the driving shaft is provided with a rotating disc, a push vertical rod is arranged at one side of the end surface of the rotating disc, transverse racks vertical to two sides ofthe push vertical rod are arranged at two sides of the push vertical rod, and rotating gears meshed with the transverse racks are arranged at the lower ends of the rotating shafts. The chemical raw material mixing device has a simple structure, is convenient to operate, can mix raw materials uniformly and fully, has high linkage, is convenient to control and operate, has high efficiency, and has high practicability.

Owner:宁波市江北区伊人宝贸易有限公司

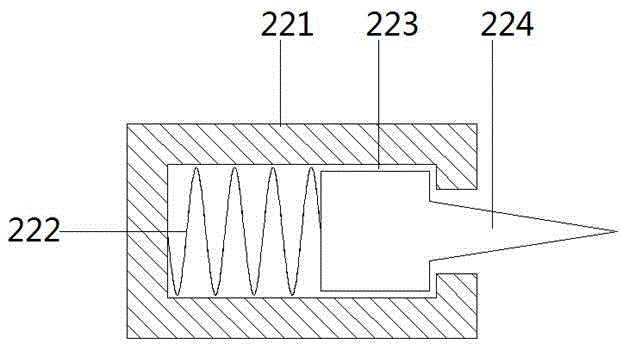

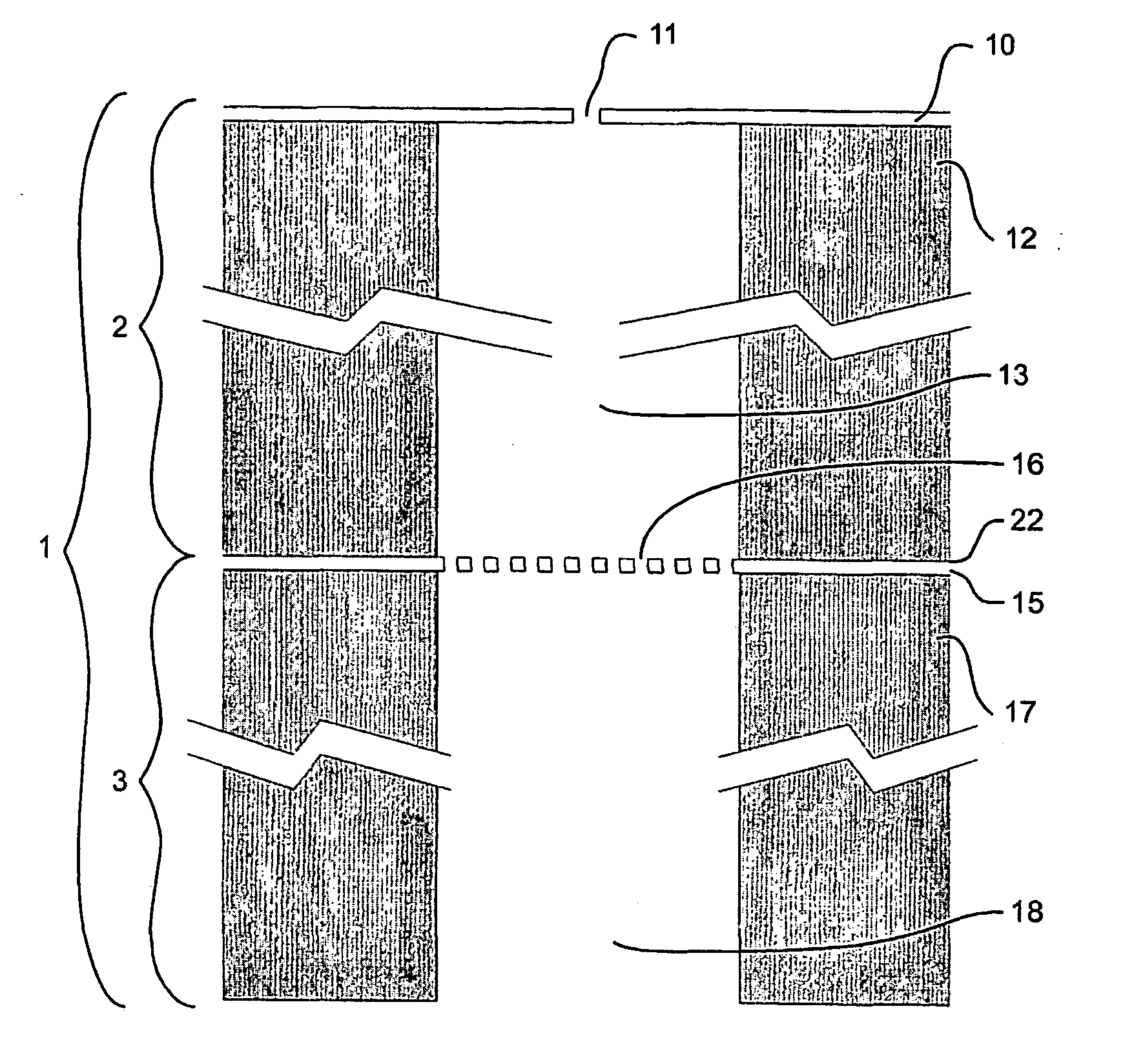

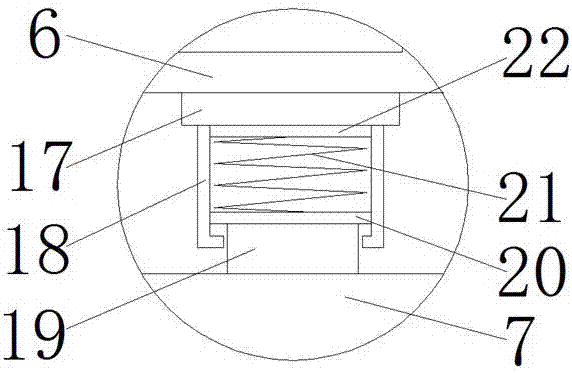

Slurry stirrer having pulverizing and vibration resisting functions

InactiveCN107051279AWith crushing functionWith anti-seismic functionRotary stirring mixersTransportation and packagingLoss rateSlurry

The invention provides a slurry stirrer having pulverizing and vibration resisting functions, and relates to the technical field of batteries. The slurry stirrer having pulverizing and vibration resisting functions comprises a slurry stirrer body, a pulverizing bin and a fixing base, the fixing base is located below the pulverizing bin, and the center of the top of the slurry stirrer body is fixedly connected with the pulverizing bin. The slurry stirrer having pulverizing and vibration resisting functions is provided with a second fixing sleeve, an auxiliary pulverizing block and a pulverizing blade, so that the slurry stirrer has the pulverizing function, the problem of the current slurry stirrer that the quality of the stirred product is poor as added materials are condensed to blocks after being placed for a long period of time is effectively solved, due to the arrangement of a damping cylinder, a spring, a bumper post and a movable plate, the slurry stirrer have the vibration resisting effect, and the problems that strong vibration of high-speed stirring on the ground surface affects the moods of staffs and surrounding residents and the loss rate of the slurry stirrer is also accelerated are effectively solved.

Owner:赵咪咪

Environmental sanitizer and odor remover for purification of foods, surfaces, air and water with disposable ozone generation electrode, pressure/flow adaptable venturi injector and aqueous phase filter device

ActiveUS7524466B2Reduce and eliminate ozone demandFlow mixersSpecific water treatment objectivesDielectricElectricity

Owner:LONG RONALD BRUCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com